Production equipment and process for large-diameter biaxial-stretching PVC pipe fitting

A PVC pipe, two-way stretching technology, applied in the direction of tubular objects, household appliances, other household appliances, etc., can solve the problems of late biaxially stretched pipes, discontinuous production methods, unstable product performance, etc., and achieve enhanced axial mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

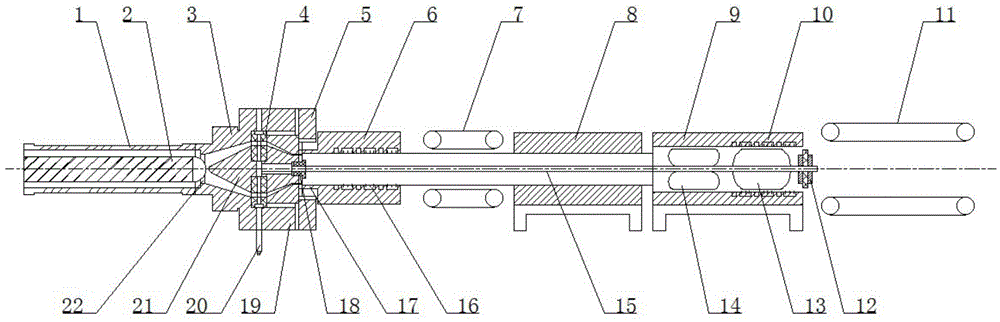

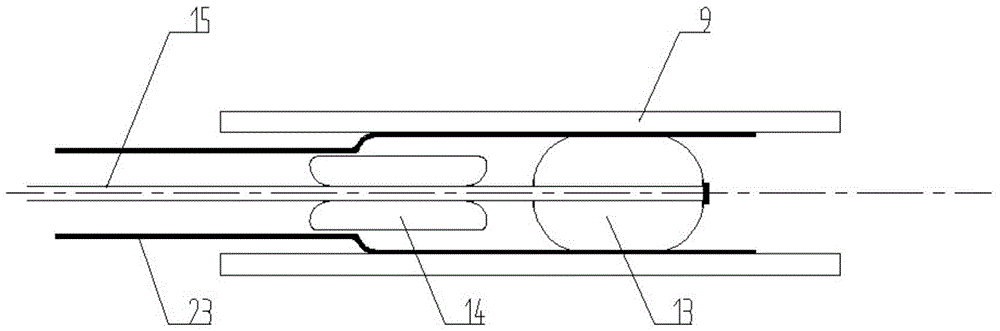

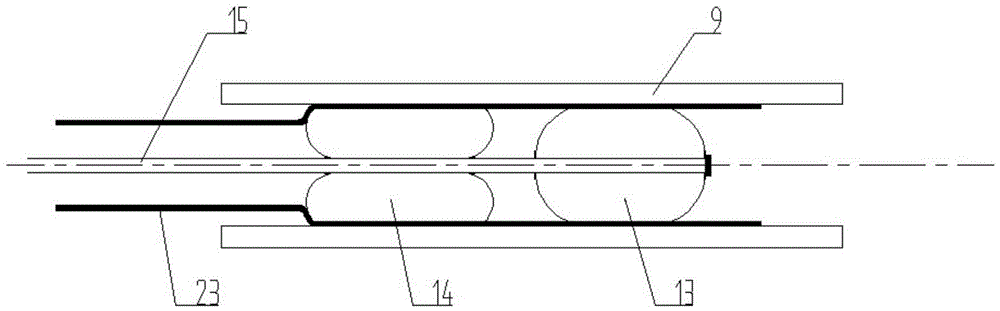

[0026] The present invention relates to the production equipment and process of a large-diameter biaxially stretched PVC pipe of the present invention, the equipment such as figure 1As shown, it mainly includes a conical twin-screw extruder 1, an extruder head 3, a vacuum sizing device A6, a first traction device 7, a reheating device 8, a stretching and expanding forming device 9, and a vacuum sizing device B10, the second traction device 11, these devices are arranged in a straight line in turn to form a production line. The conical twin-screw extruder 1 has an extruder screw 2, and the extruder head 3 is a pipe forming head. Usually, the extruder head 3 passes the melt from the twin-screw extruder 1 through its internal splitter cone. Shaped into a tubular tube blank, the extrusion head 3 has a die 17, a mandrel and a die pressing plate 5, the die pressing plate 5 fixes the die on the extrusion head 3, and the die pressing plate and the extrusion head pass through Bolts ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com