Patents

Literature

617 results about "Thermal contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal contraction is the "shrinking" of substances as they cool. Changes in temperature change the physical properties of substances- each substance does this on a different level, but with changes in temperature, substances either expand or contract.

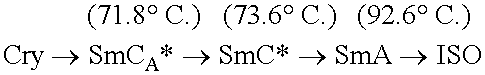

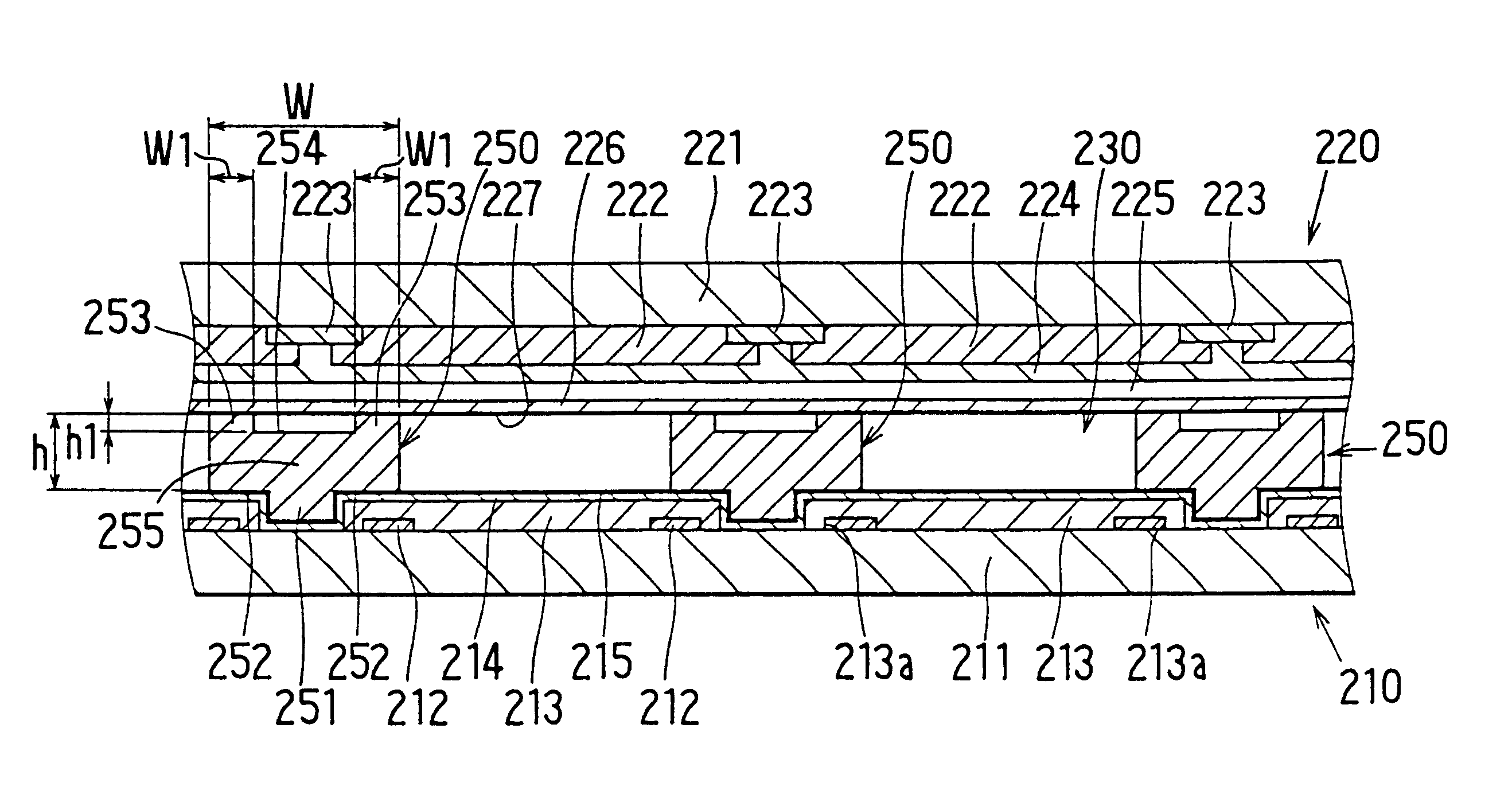

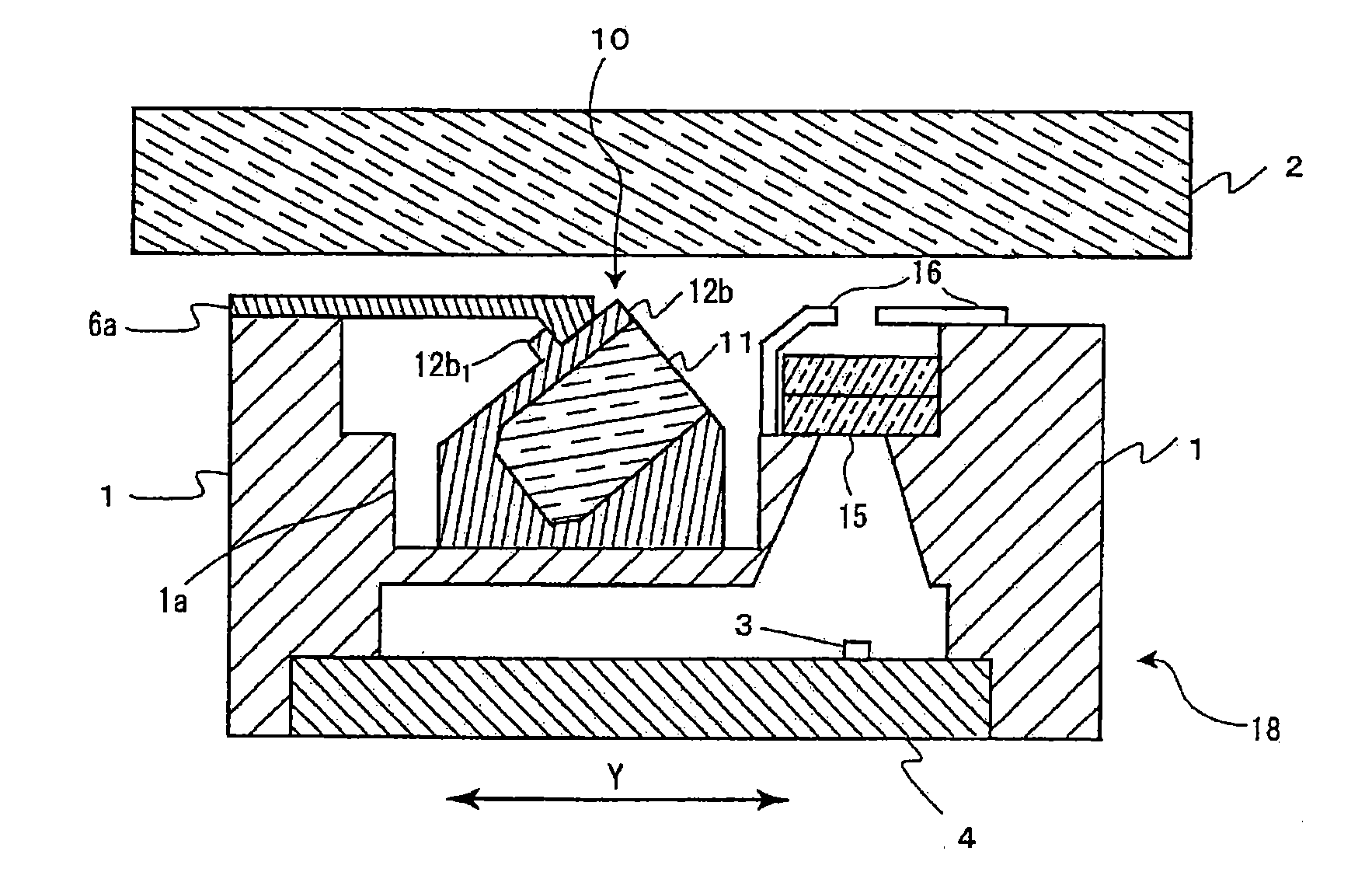

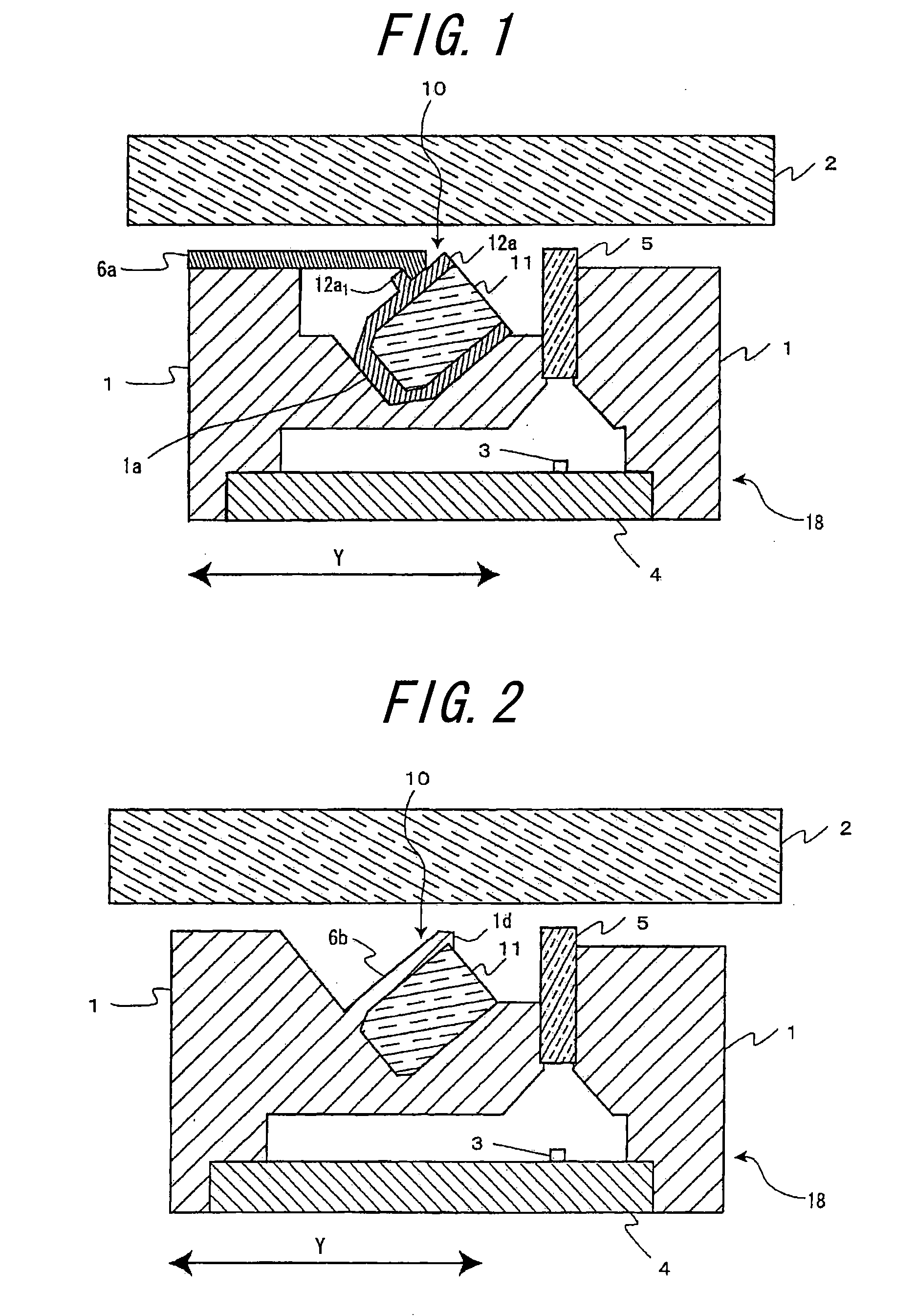

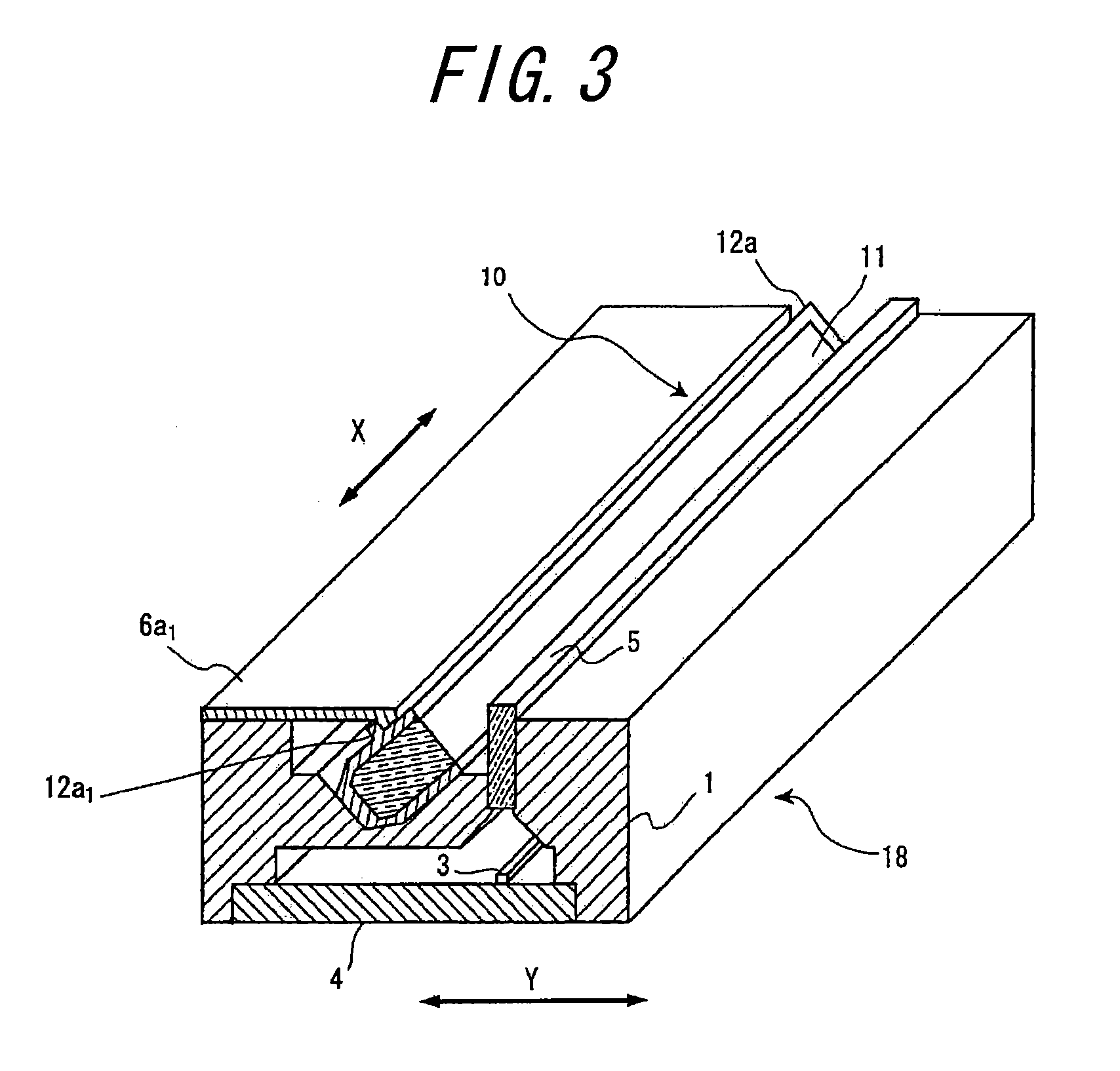

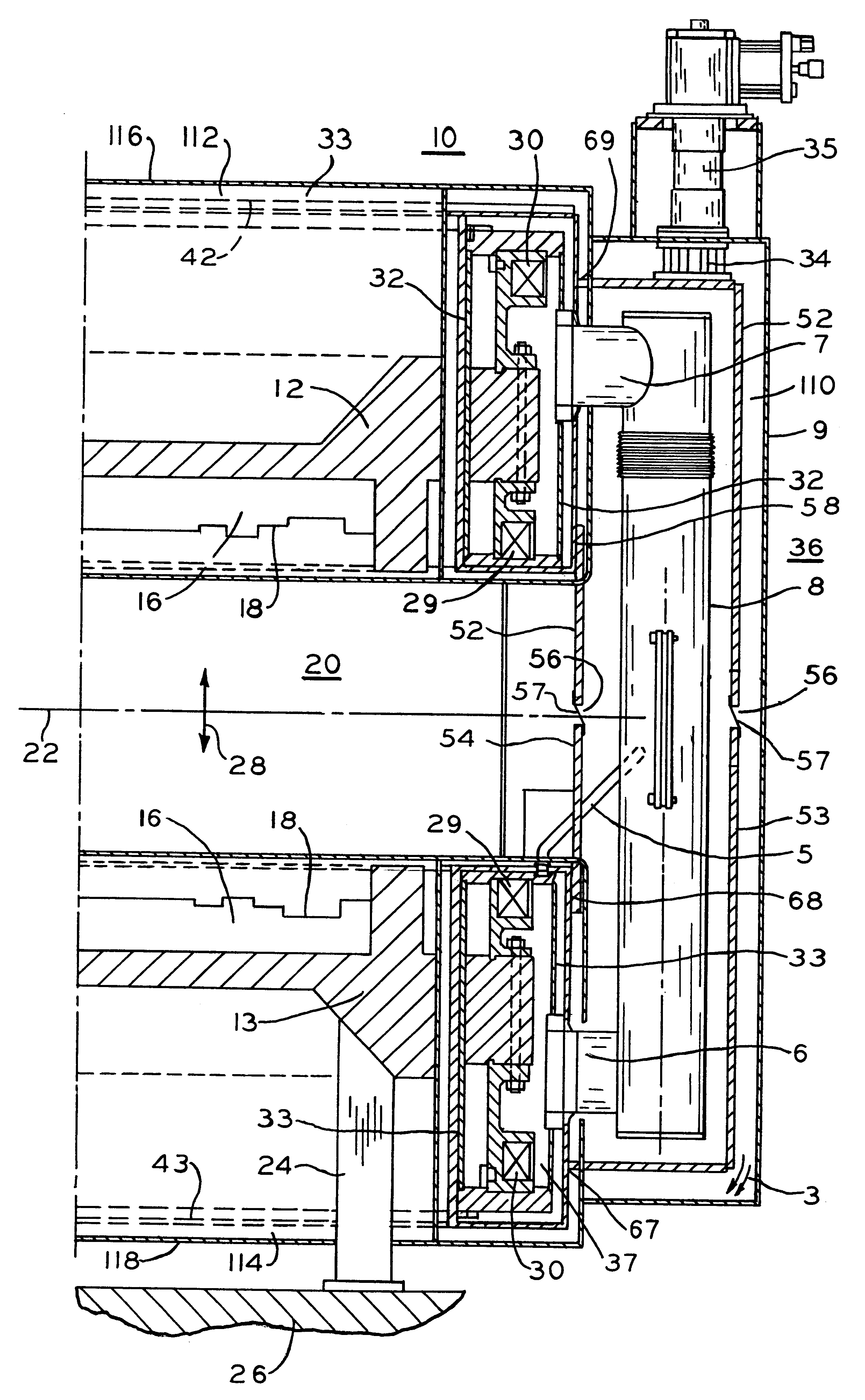

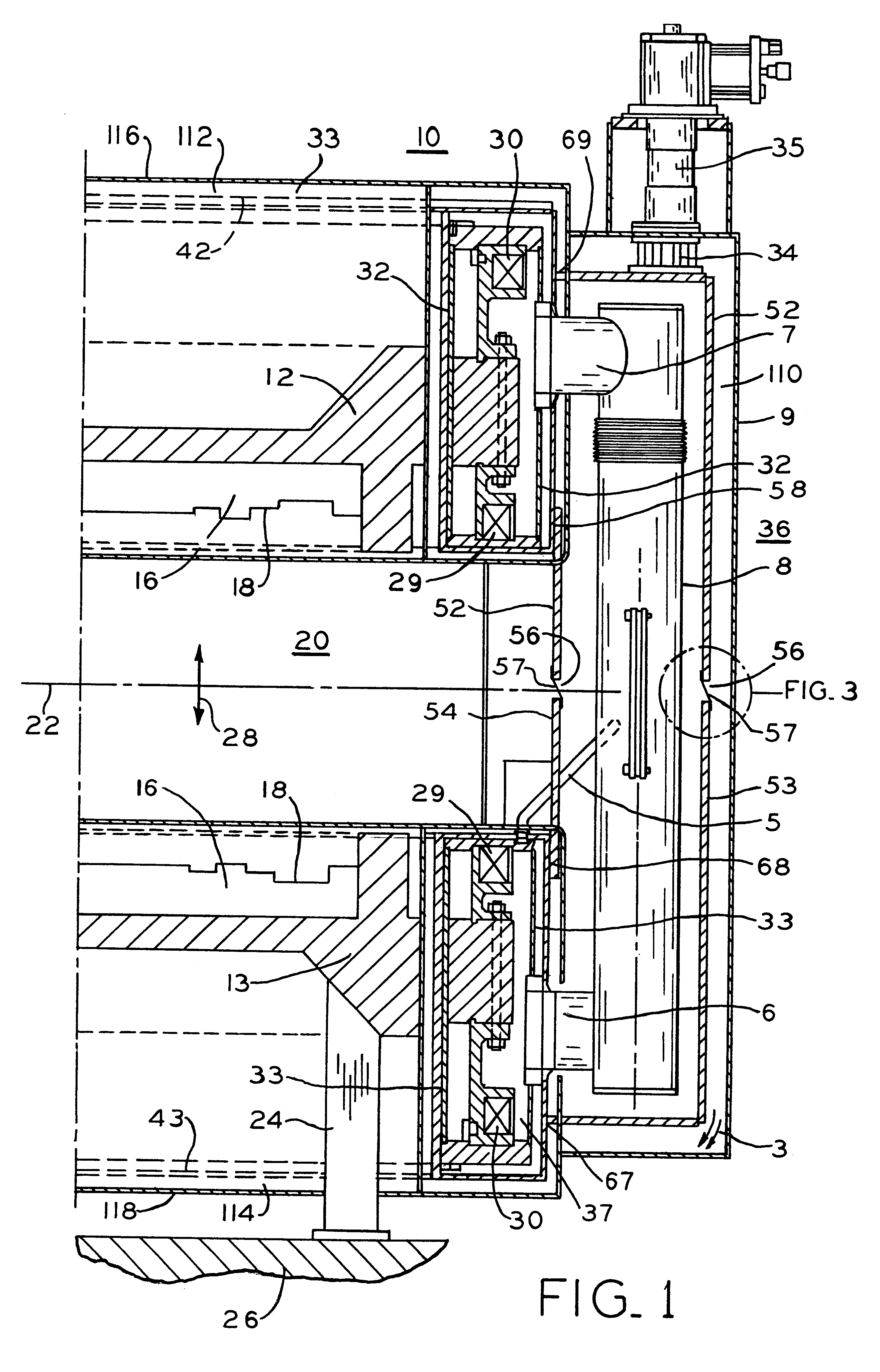

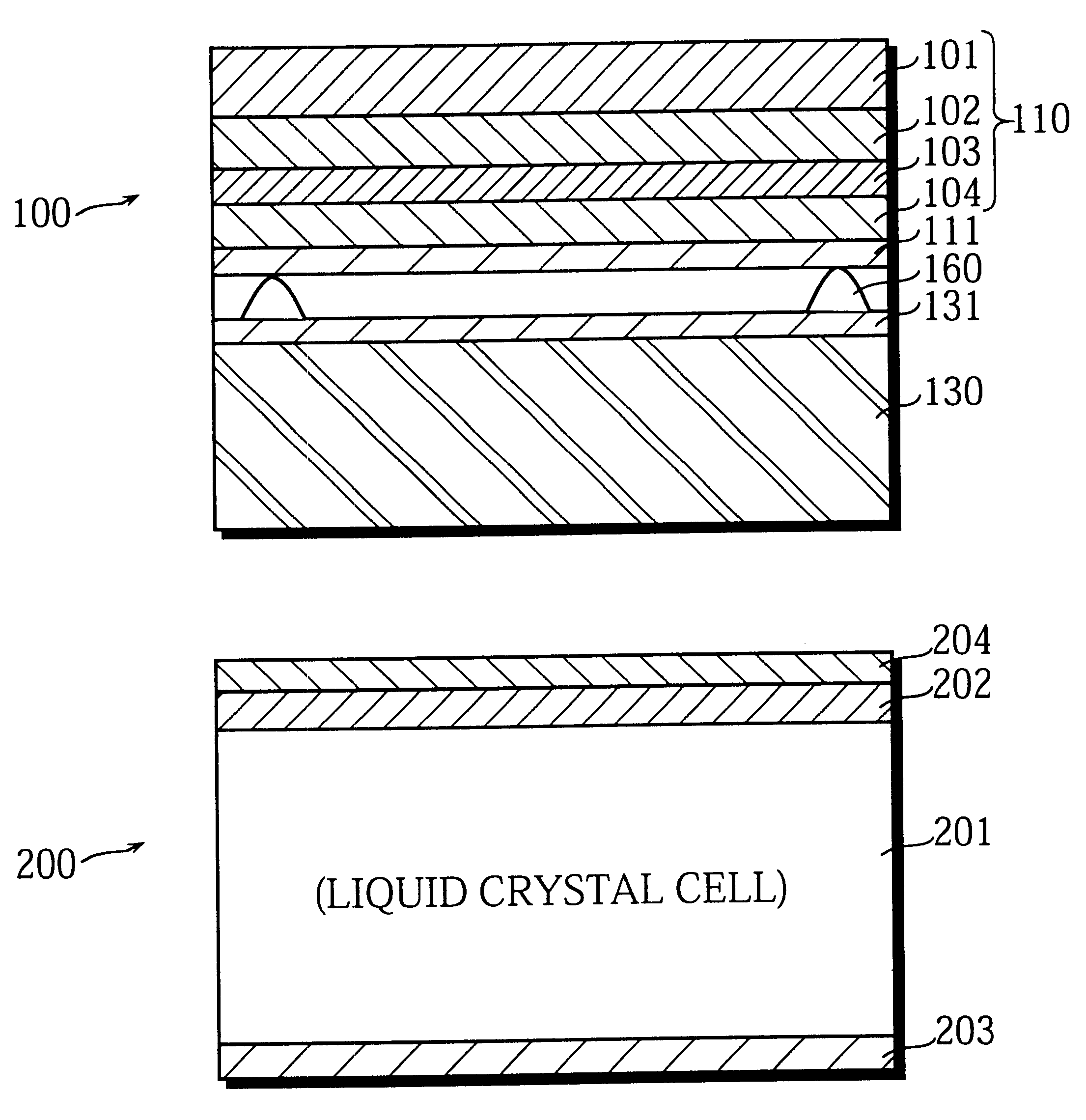

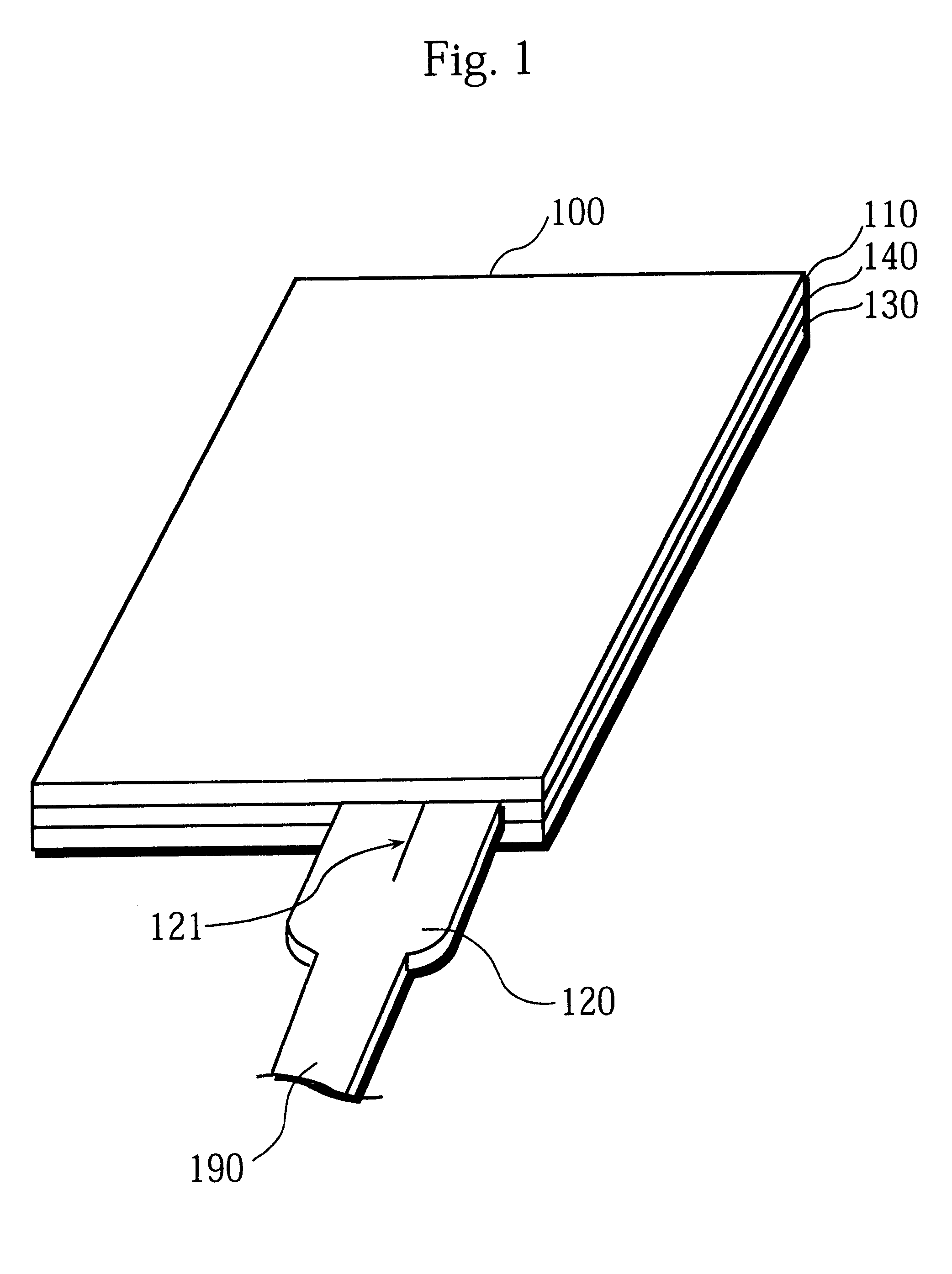

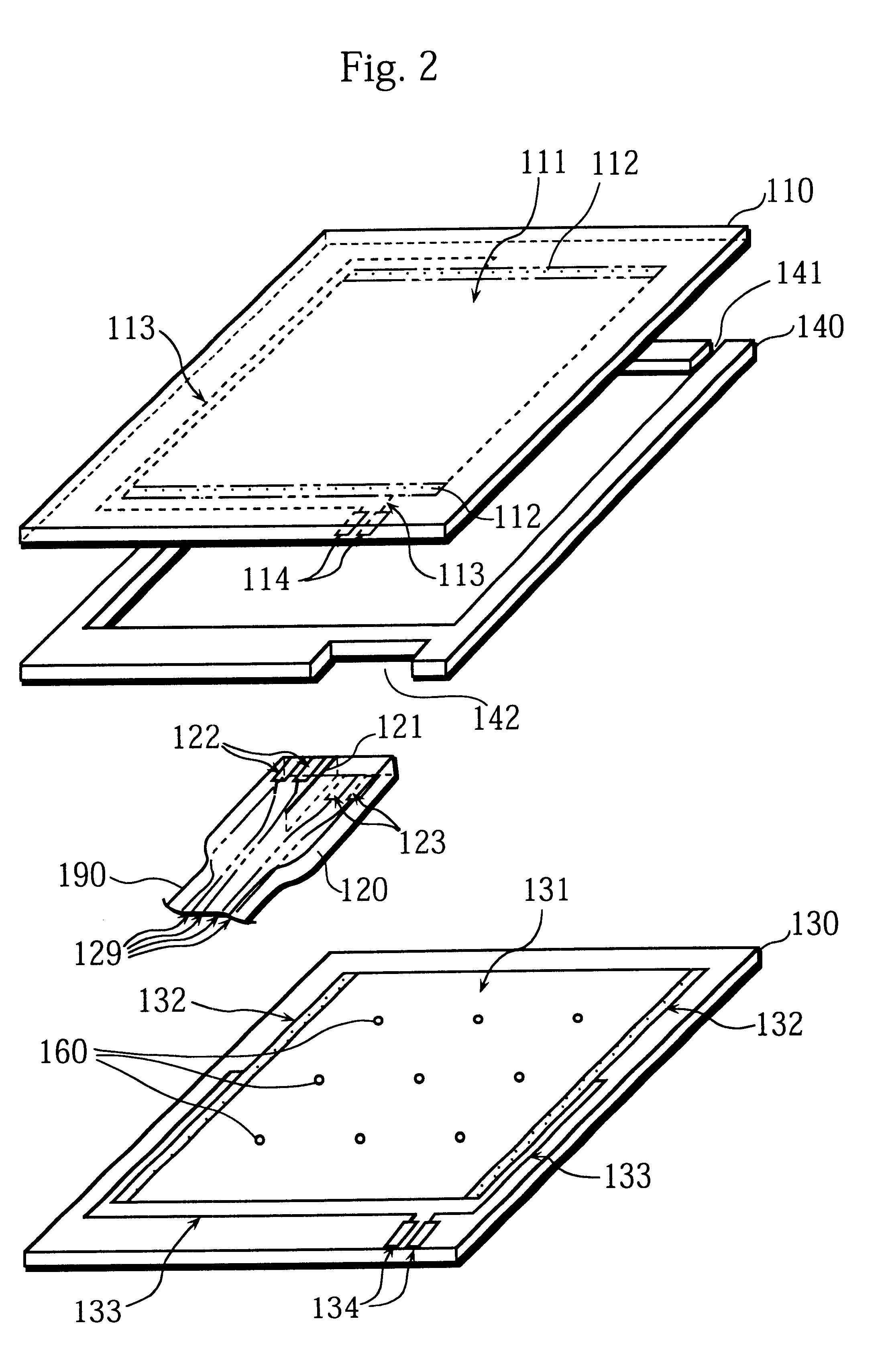

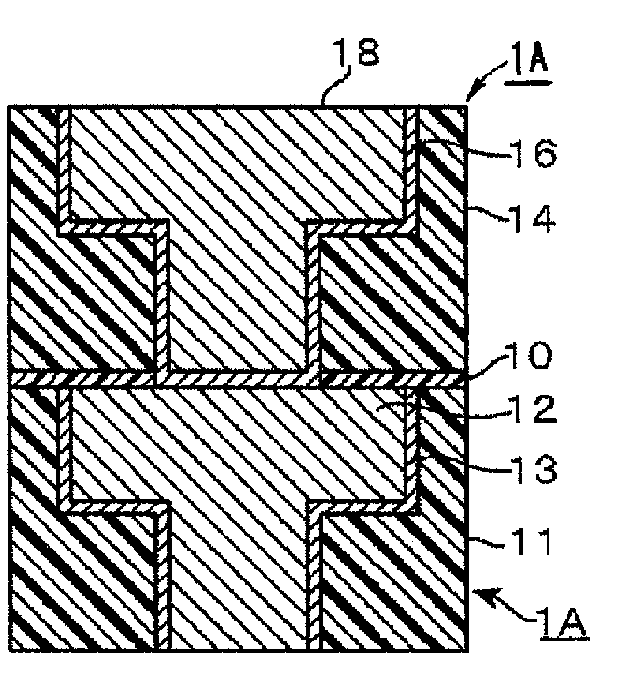

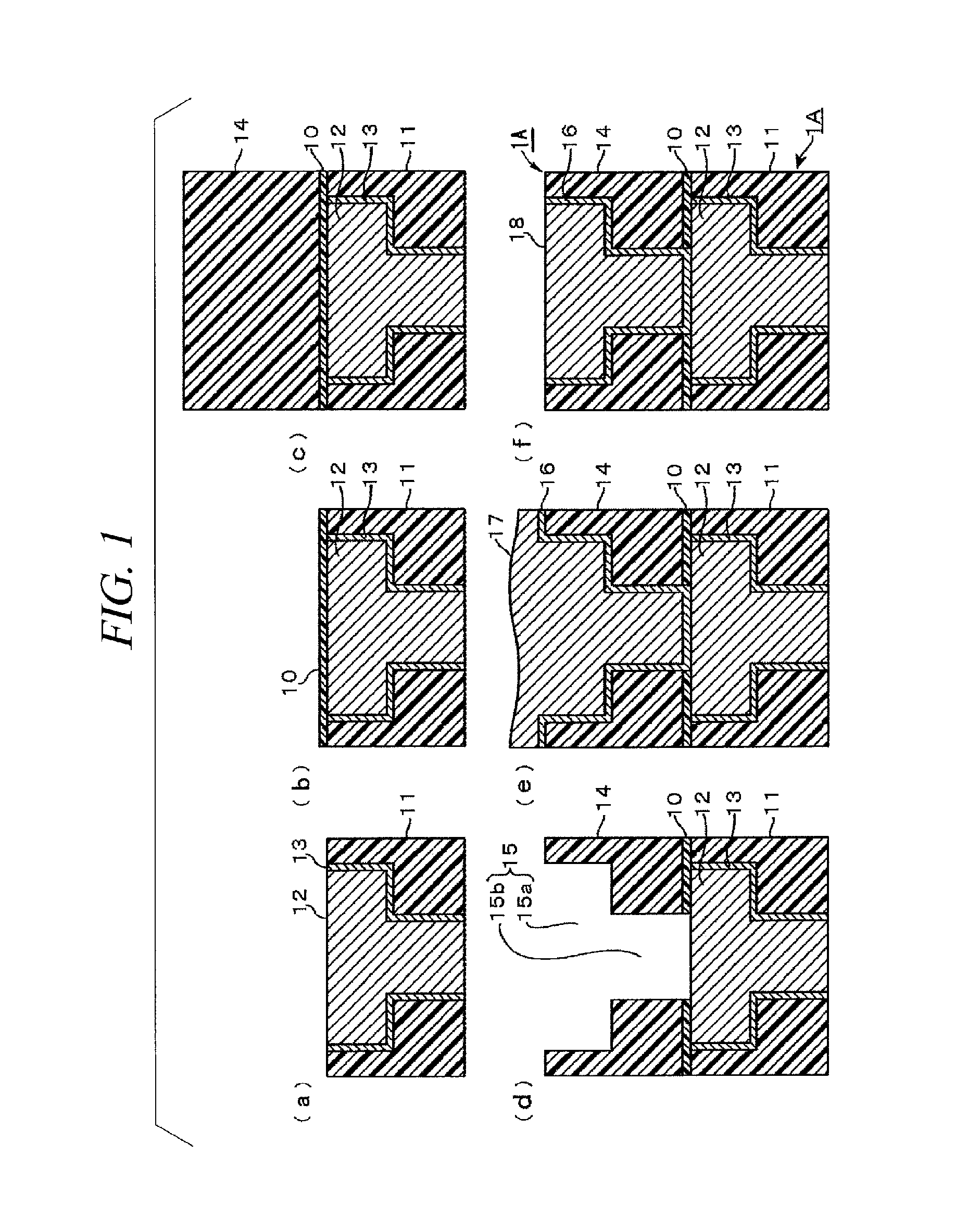

Non-uniformly-rigid barrier wall spacers used to correct problems caused by thermal contraction of smectic liquid crystal material

InactiveUS6337730B1Relieve stressRelieve pressureLiquid crystal compositionsStatic indicating devicesRoom temperatureEngineering

According to this liquid crystal cell, a vacuum to be established between two electrode substrates as a result of the volume shrinkage of a liquid crystal having a high viscosity at the room temperature can be damped by communicating between two of a plurality of filling portions formed between two electrode substrates by a plurality of barrier walls through the intervening barrier walls. An anti-ferroelectric liquid crystal (AFLC) is used as the liquid crystal. The liquid crystal cell has a lower electrode substrate and an upper electrode substrate, between which a smectic liquid crystal is disposed together with a plurality of barrier walls on the inner side of a band seal. Each barrier wall has through holes to communicate between the two filling portions located on the two sides of the barrier walls.

Owner:DENSO CORP

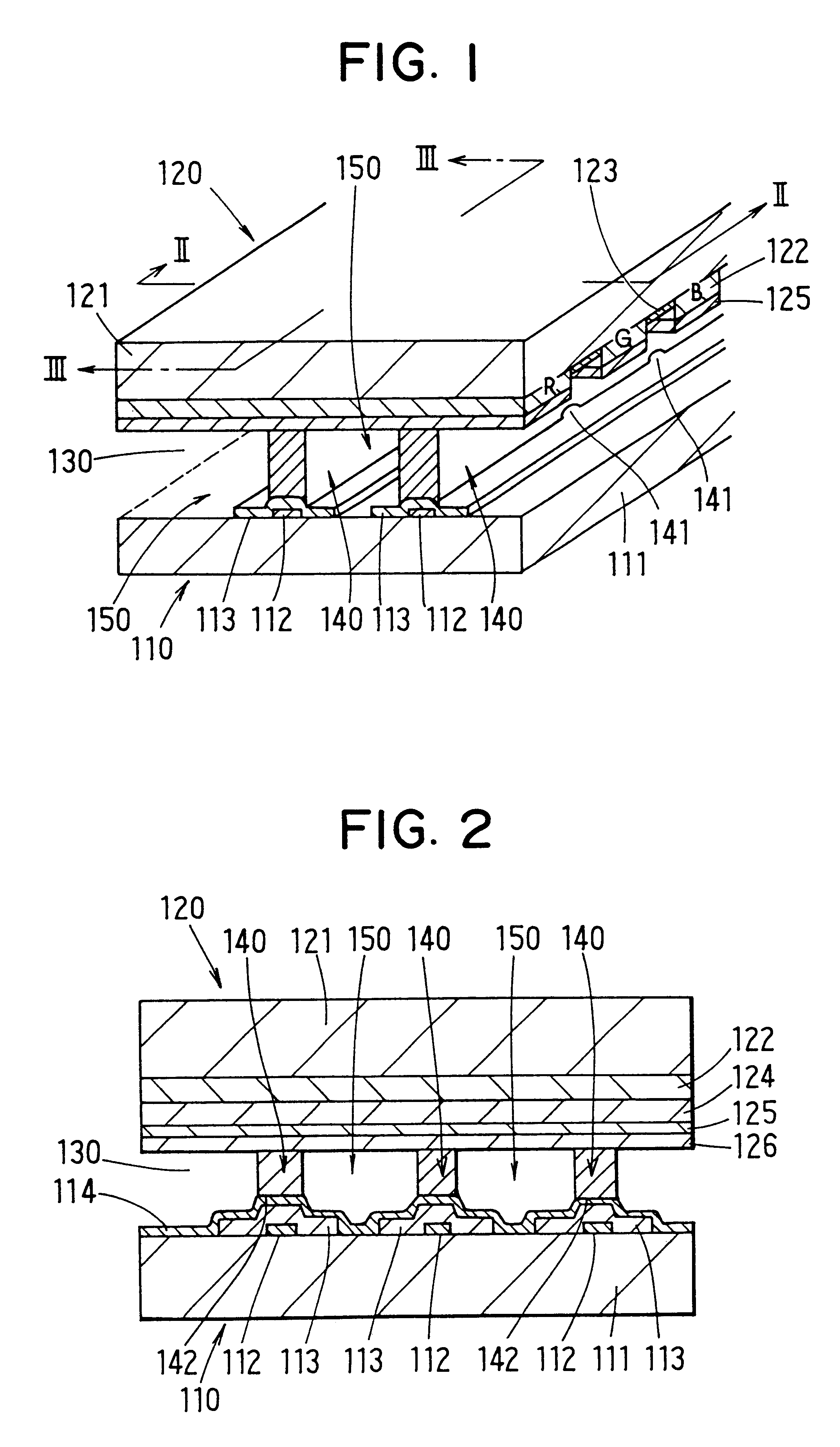

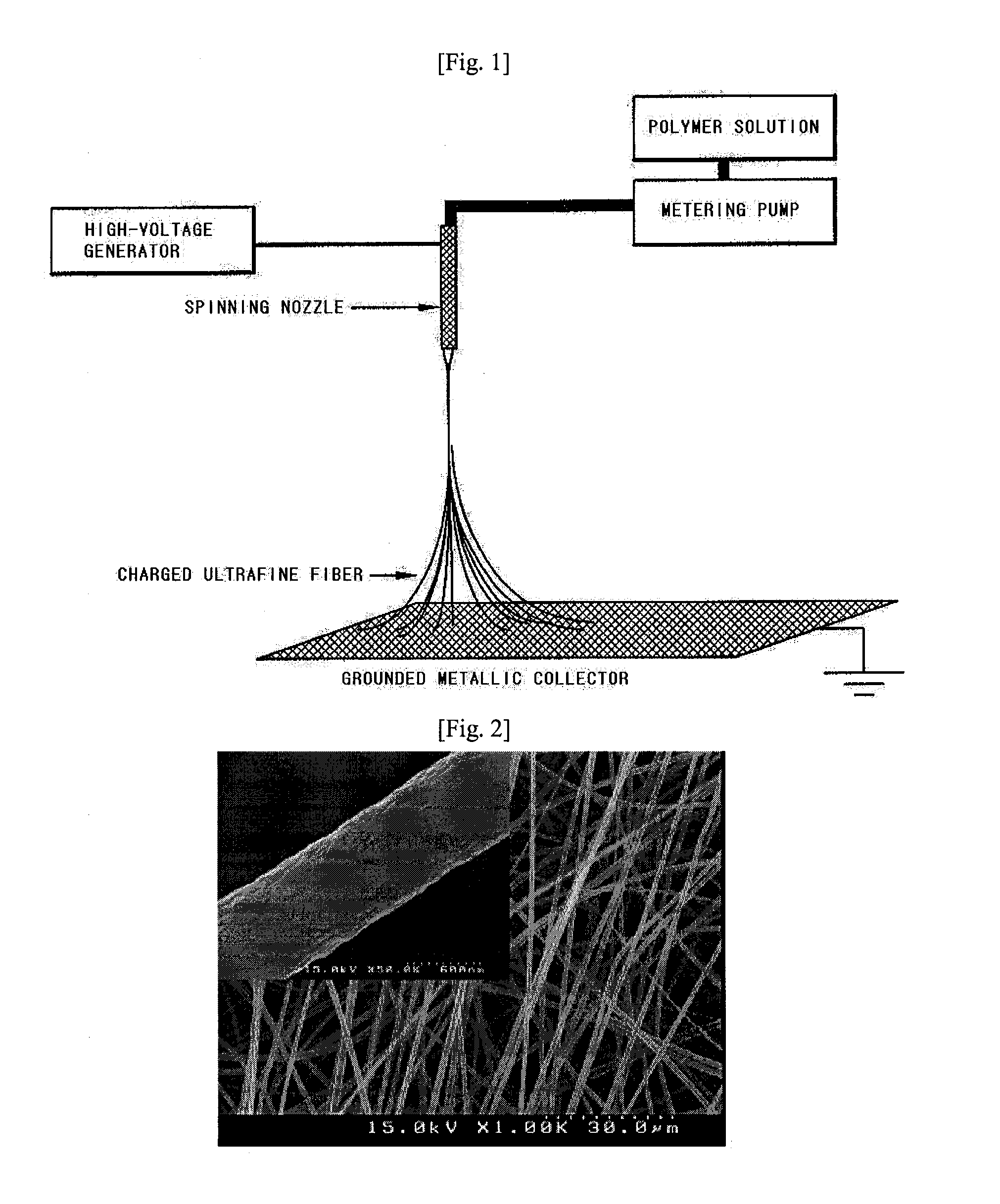

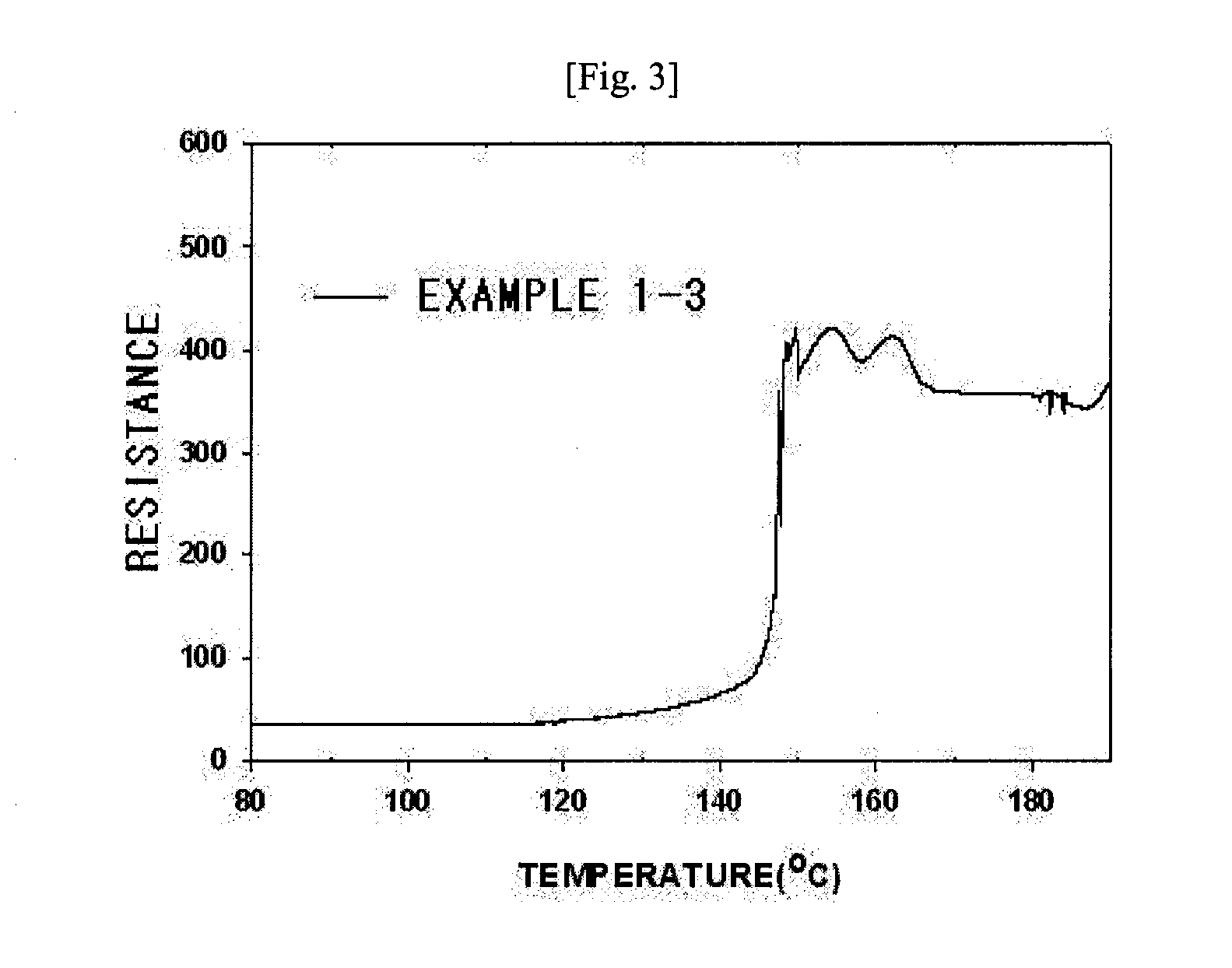

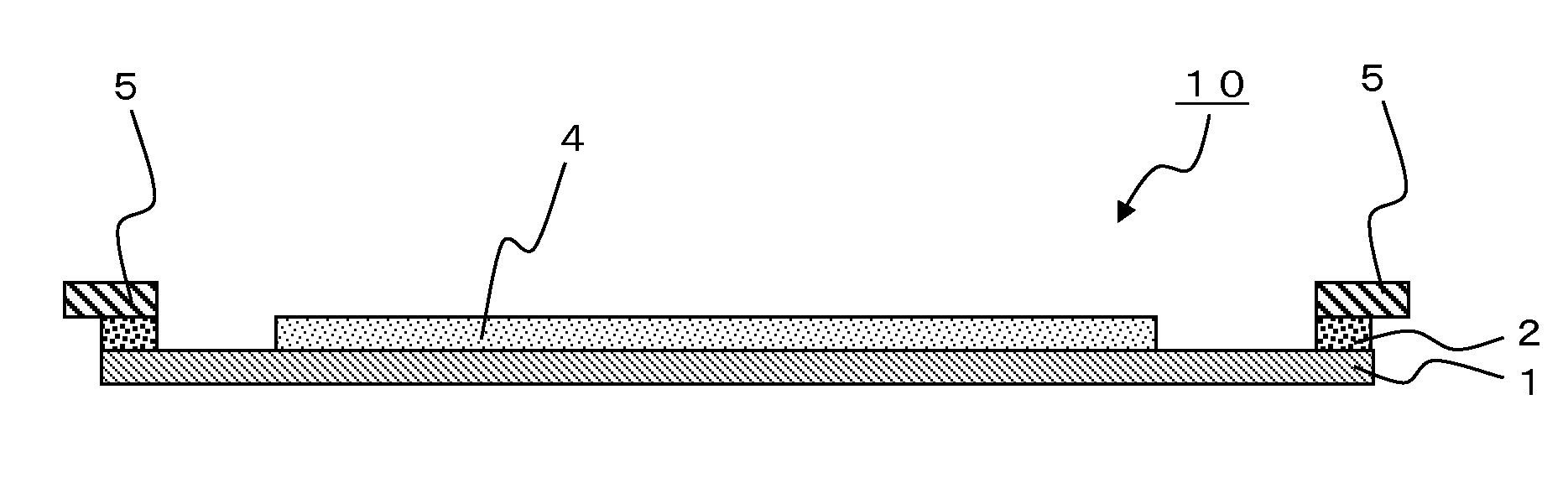

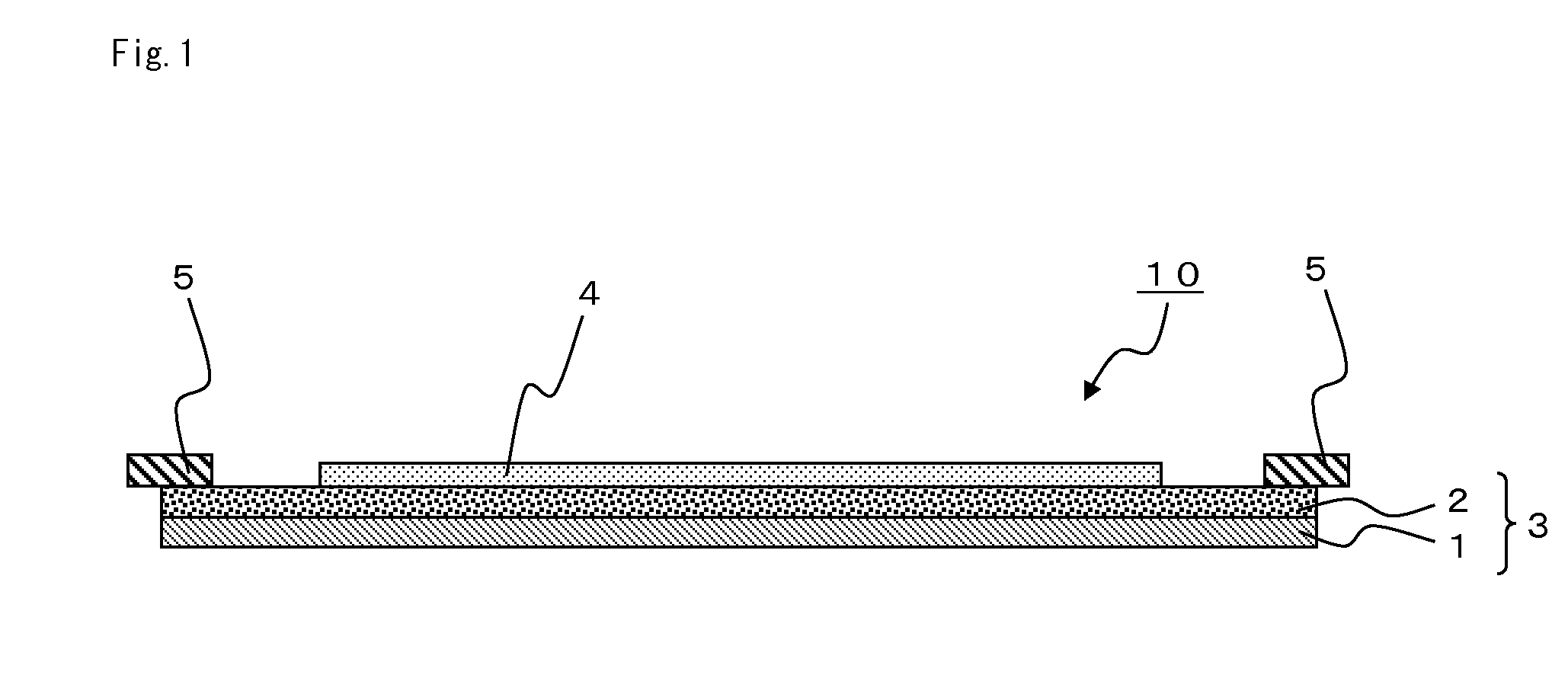

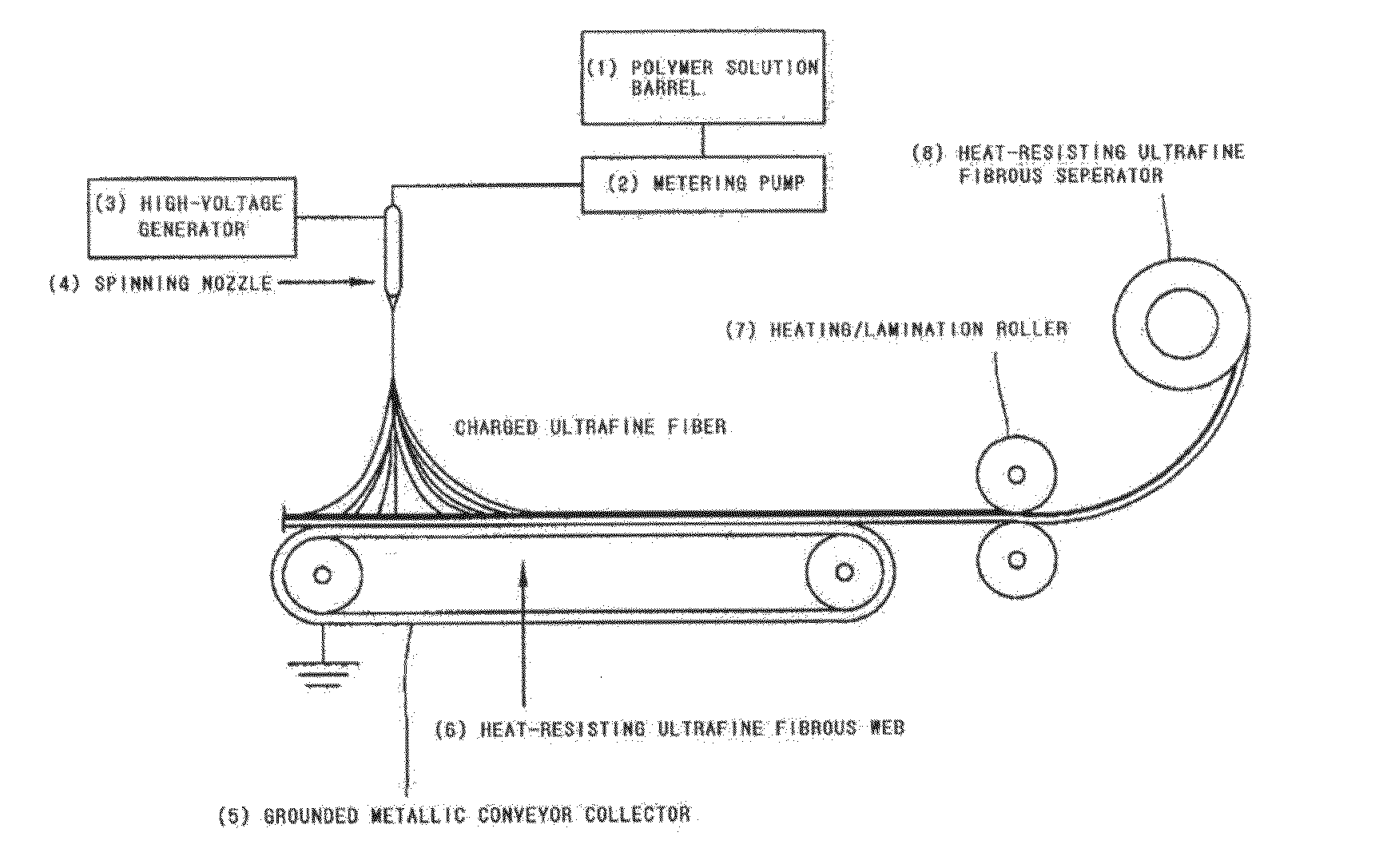

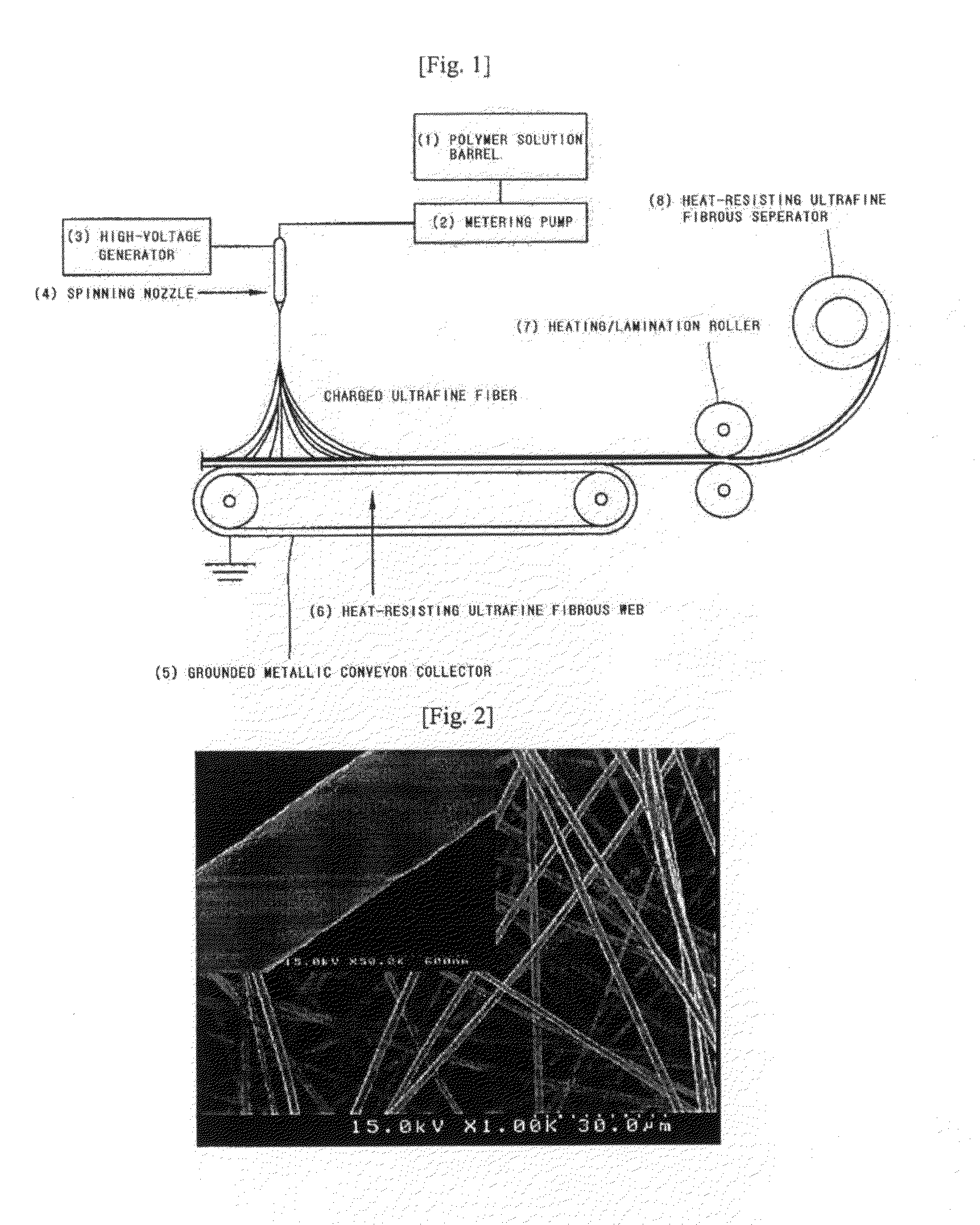

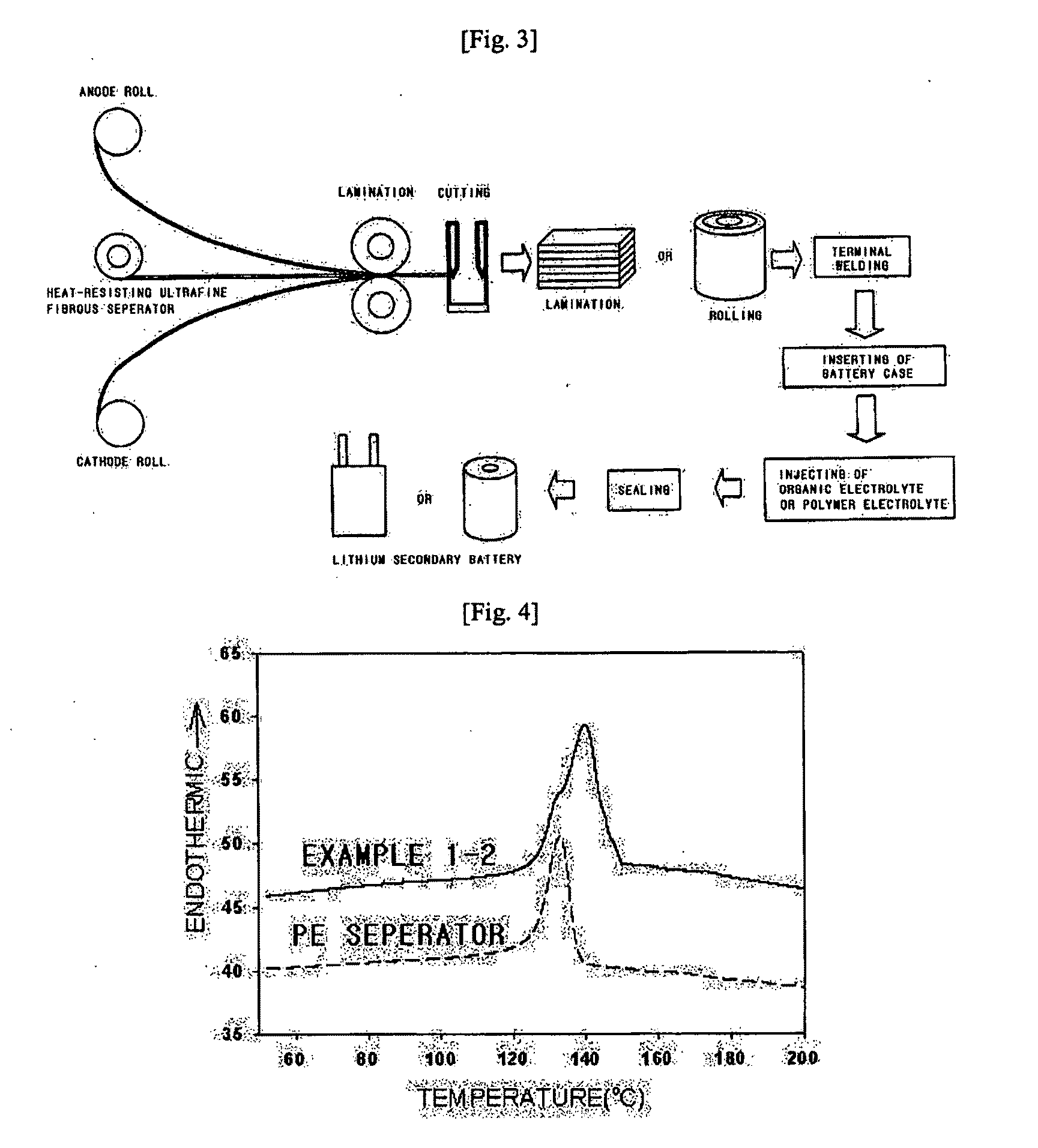

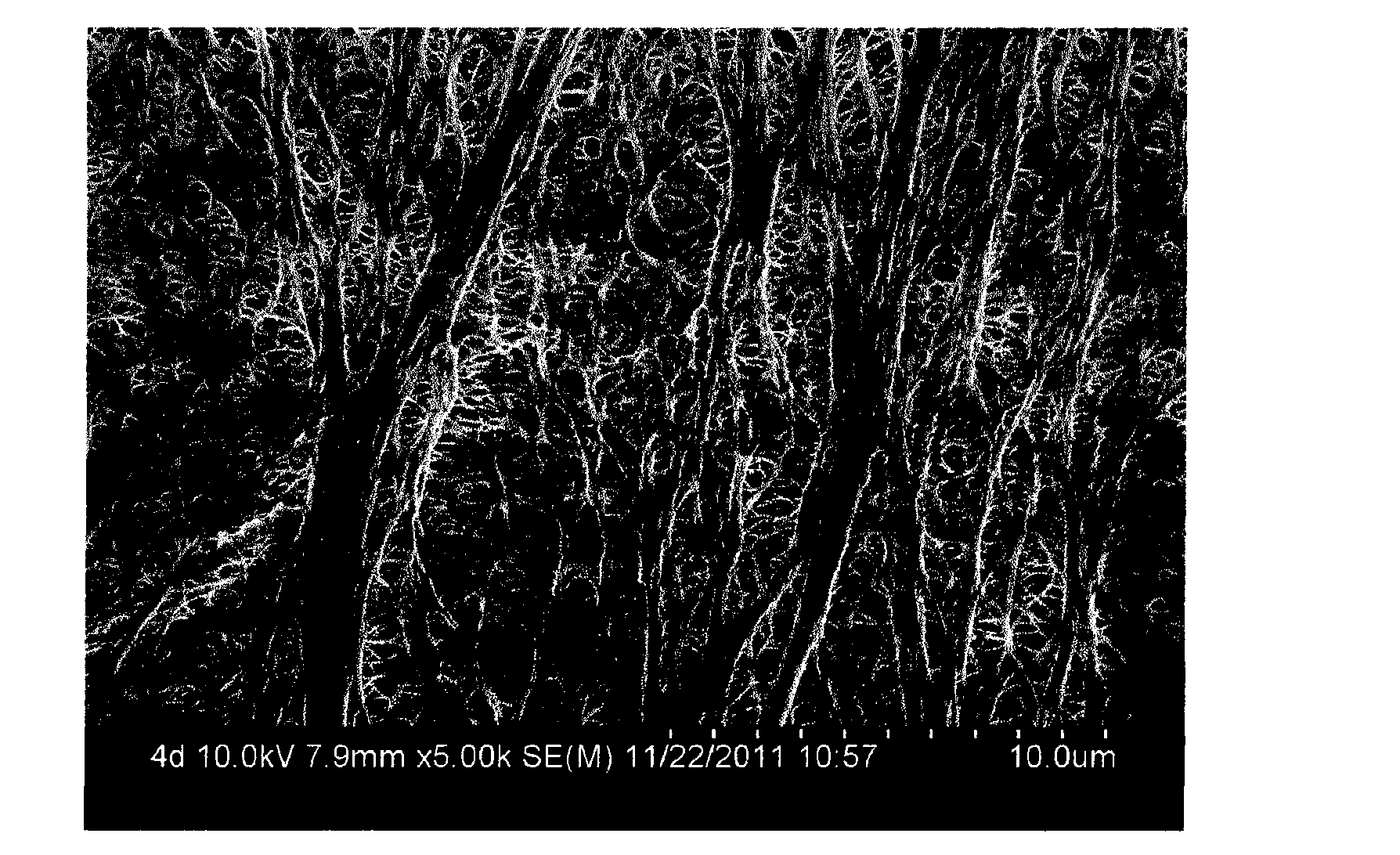

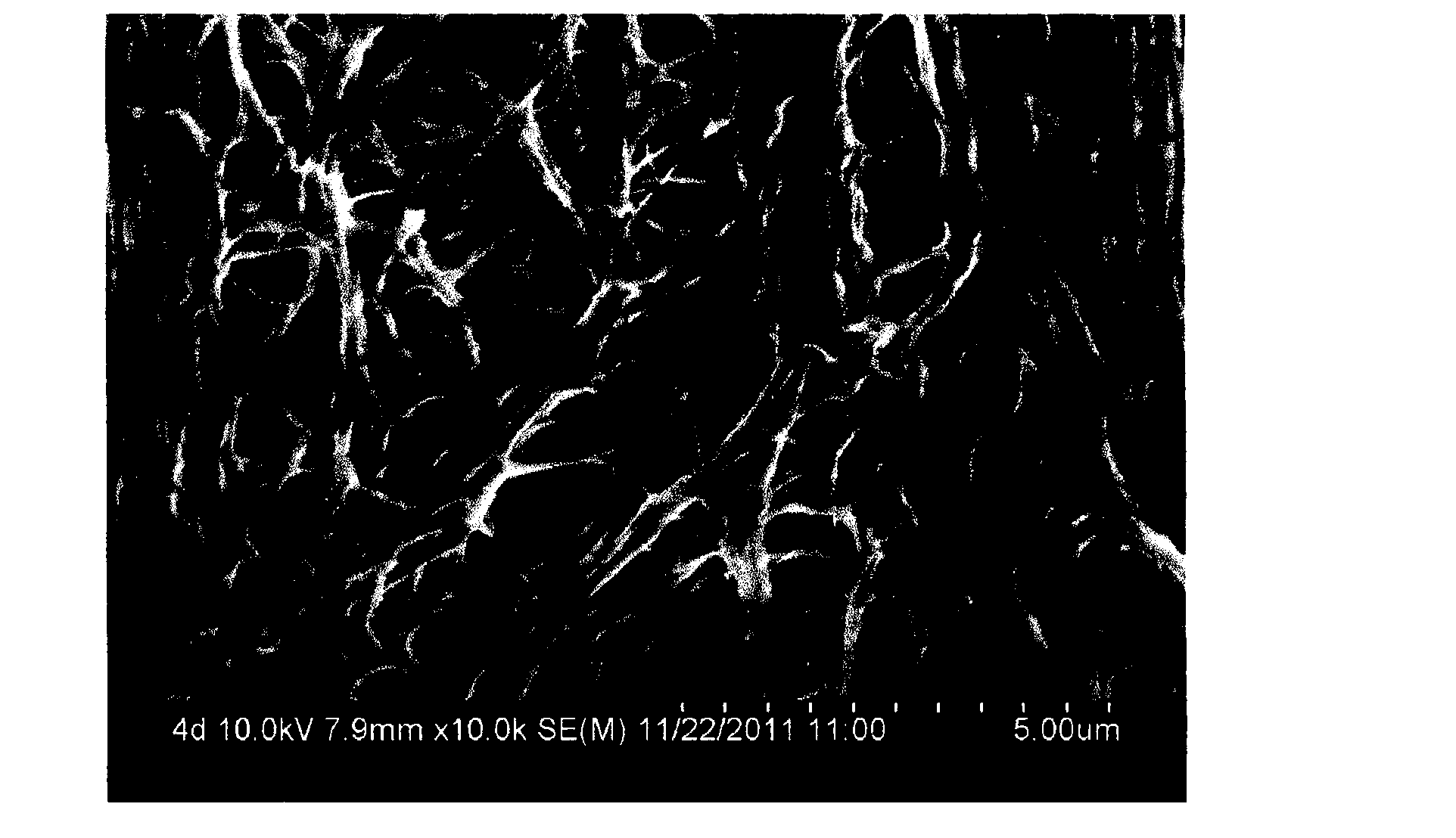

Heat resisting separator having ultrafine fibrous layer and secondary battery having the same

InactiveUS20100304205A1High suppression characteristicsImprove ionic conductivityHybrid capacitor separatorsProtecting/adjusting hybrid/EDL capacitorPolyolefinFuel cells

A polyolefin separator having an heat-resistant ultrafine fibrous layer and a secondary battery using the same, in which the separator has a shutdown function, low thermal contraction characteristics, thermal endurance, excellent ionic conductivity, excellent cycling characteristics at the time of battery construction, and excellent adhesion with an electrode. The present N invention adopts a very simple and easy process to form an ultrafine fibrous layer through an electrospinning process, and at the same time, to remove solvent and to form pores. Accordingly, the separator of the present invention is useful particularly for electrochemical devices used in a hybrid electric automobile, an electric automobile, and a fuel cell automobile, requiring high thermal endurance and thermal stability.

Owner:KOREA INST OF SCI & TECH

Dicing Sheet with Protective Film Forming Layer and Chip Fabrication Method

ActiveUS20140295646A1Improve printing accuracyWell formedLayered productsSemiconductor/solid-state device detailsTectorial membraneThermal contraction

A dicing sheet with a protective film forming layer has a substrate film, an adhesive layer, and a protective film forming layer, and at a minimum, the adhesive layer is formed in an area surrounding the protective film forming layer in a planar view, and the substrate film has the following characteristics (a)-(c): (a) the melting point either exceeds 130° C. or the film has no melting point; (b) the thermal contraction rate under conditions of heating at 130° C. for two hours is from −5 to +5%, and (c) the degree of elongation-to-break in the MD direction and the CD direction is at least 100%, and the stress at 25% is no more than 100 MPa.

Owner:LINTEC CORP

Heat resisting ultrafine fibrous separator and secondary battery using the same

ActiveUS20100233523A1Simple and easy processLow thermal contractionCell seperators/membranes/diaphragms/spacersFinal product manufactureFiberPolymer science

A heat-resisting ultrafine fibrous separator of the present invention is prepared by an electrospinning process, formed of ultrafine fibers of heat-resisting polymer resin having a melting point more than 1800 C or not having the melting point, or ultrafine fibers of polymer resin capable of swelling in an electrolyte, together with the ultrafine fibers of heat-resisting polymer resin. Also, polyolefine fine particles providing a shutdown function are dispersed in the heat-resisting resin or the polymer resin capable of swelling in the electrolyte. The heat-resisting ultrafine fibrous separator of the present invention has the shutdown function, low thermal contraction, thermal endurance, excellent ionic conductivity and excellent adhesive property with an electrode, so a battery having excellent cycling characteristics, and having high-energy density and high capacity can be prepared.

Owner:KOREA INST OF SCI & TECH

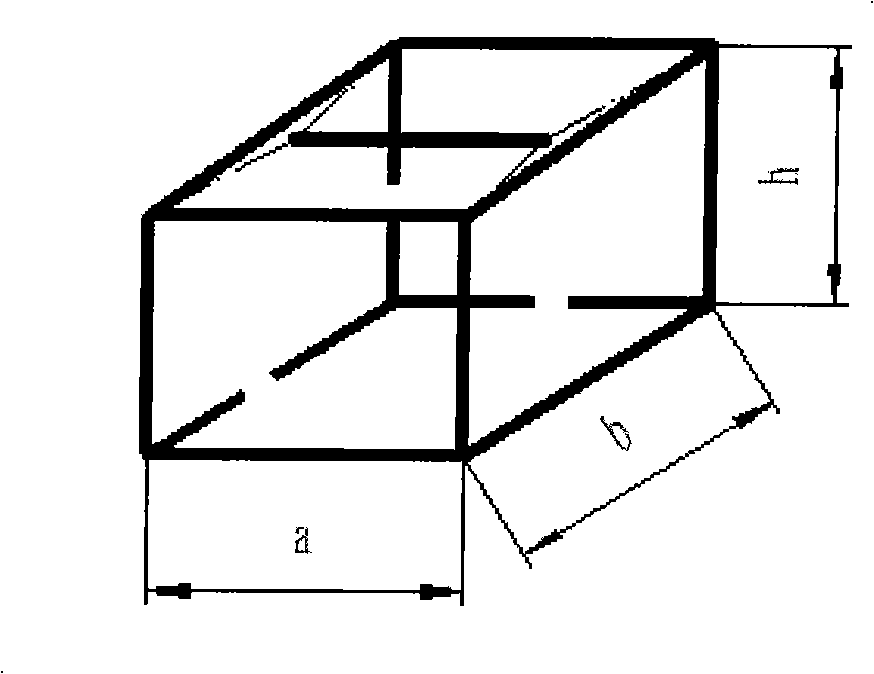

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

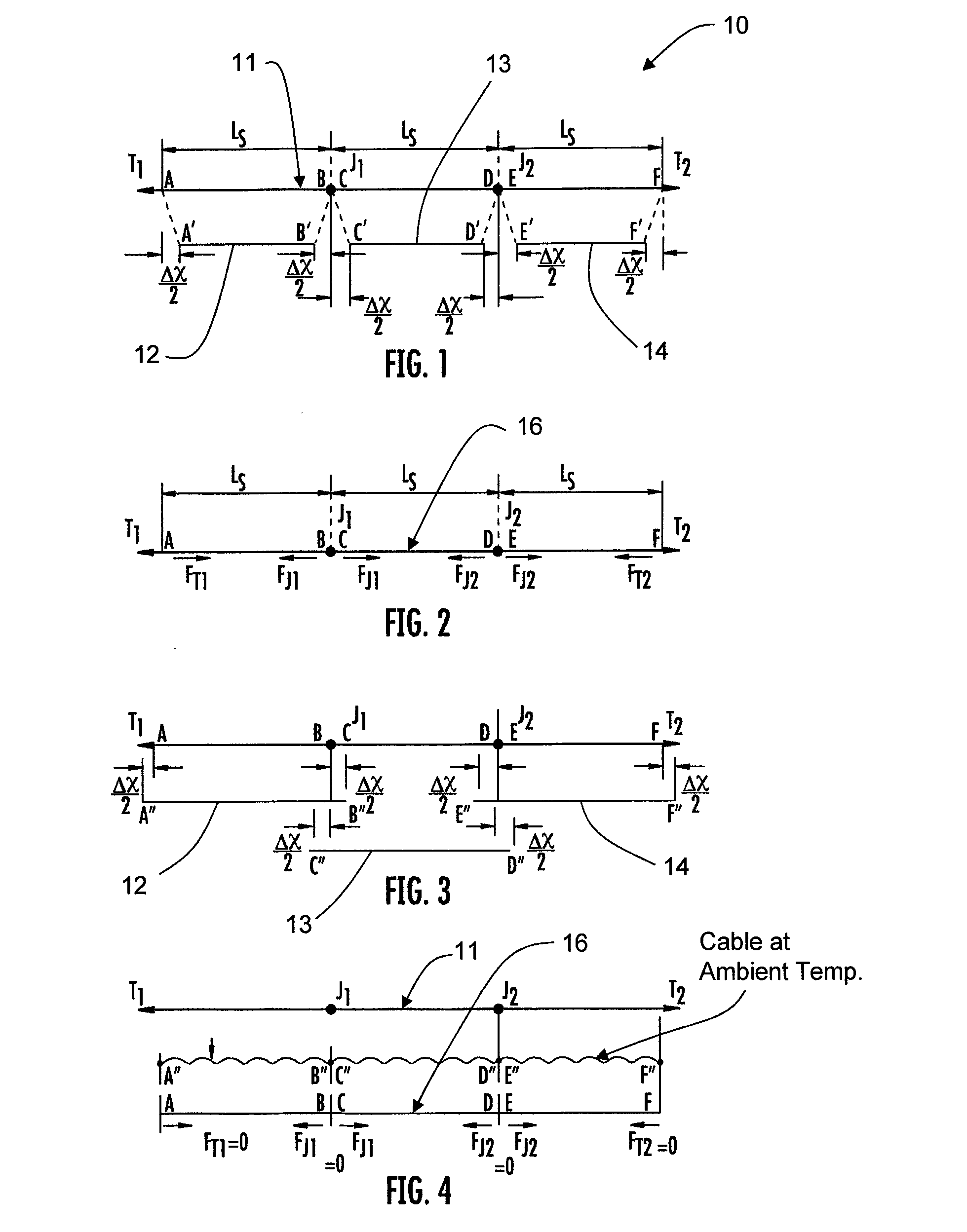

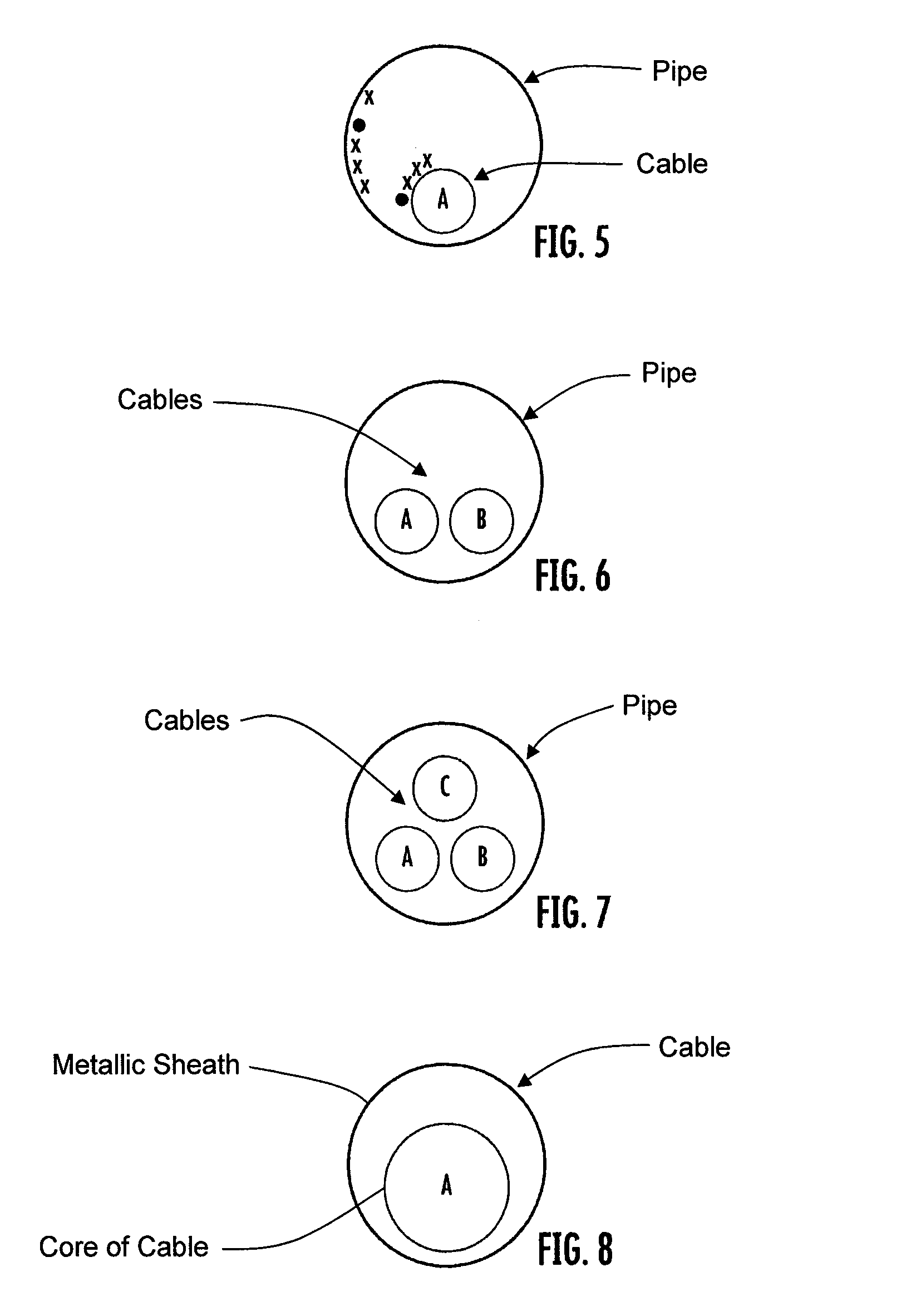

Thermal contraction compensation for superconducting and cryo-resistive cables

InactiveUS20100285968A1Eliminate and reduce magnitude of thermomechanicalSuperconductors/hyperconductorsApparatus for feeding conductors/cablesEngineeringThermal contraction

A method of compensating for thermal contraction of superconducting and cryo-resistive cables. The method includes the steps of determining a compensation length for a cable such that when the cable is subjected to an operating temperature, the cable is in or near a stress-free state, and installing the cable into a pipe such that portions of the cable extend outwardly past ends of the pipe. The method further includes the steps of marking each end of the cable such that the determined compensation length is visibly shown, forcing the cable into the pipe at an ambient installation temperature such that a cable pattern is formed therein, and maintaining the cable in the pipe to prevent the cable from being pushed out of the pipe.

Owner:ELECTRIC POWER RES INST INC

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

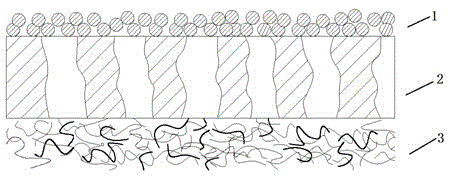

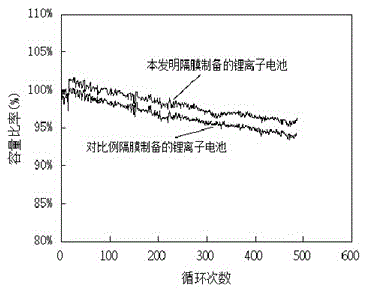

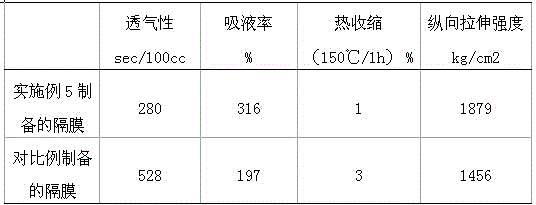

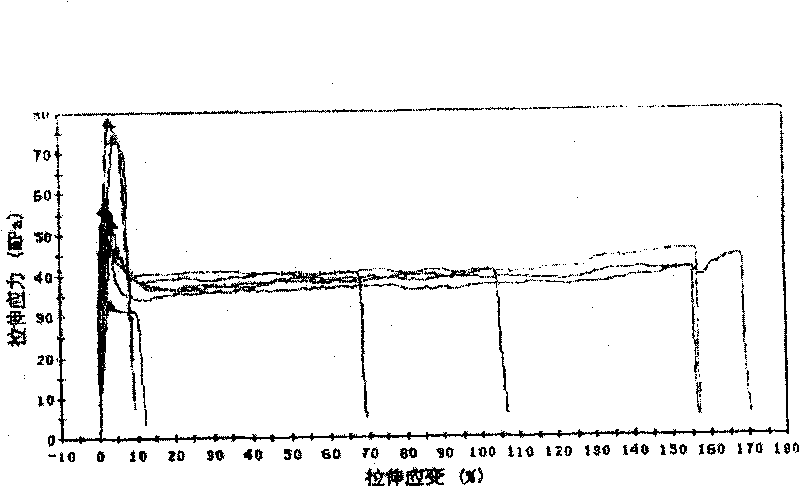

Composite coating lithium-ion battery separator and preparation method thereof

ActiveCN105552284AImprove thermal performanceImprove mechanical propertiesCell component detailsWater basedPole piece

The invention relates to a composite coating lithium-ion battery separator. The composite coating lithium-ion battery separator is composed of a base film, an aramid fiber coating coated on one side of the base film and a PVDF coating coated on the other side of the base film; the aramid fiber coating is obtained by an aramid fiber sizing agent after coating, soaking and drying, and the thickness of the coating is 0.5-4 microns; the PVDF coating is obtained by a water-based PVDF sizing agent after coating and drying, and the thickness of the coating is 0.1-2 microns. The invention also provides a preparation method of the separator. According to the composite coating lithium-ion battery separator and the preparation method thereof, the separator has the characteristics that the aramid fiber coating is good in thermal performance and mechanical performance and the PVDF coating has good wettability and liquid retention property for electrolytes, can effectively adhere batteries and pole pieces and is little in environmental pollution, and is beneficial for preparing lithium-ion batteries with longer cycle life and higher safety. Tests indicate that the separator has good air permeability, liquid absorption rate, thermal contraction and tensile strength, so that the cycle life of the batteries can be obviously prolonged by using the lithium-ion batteries prepared by the separator.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

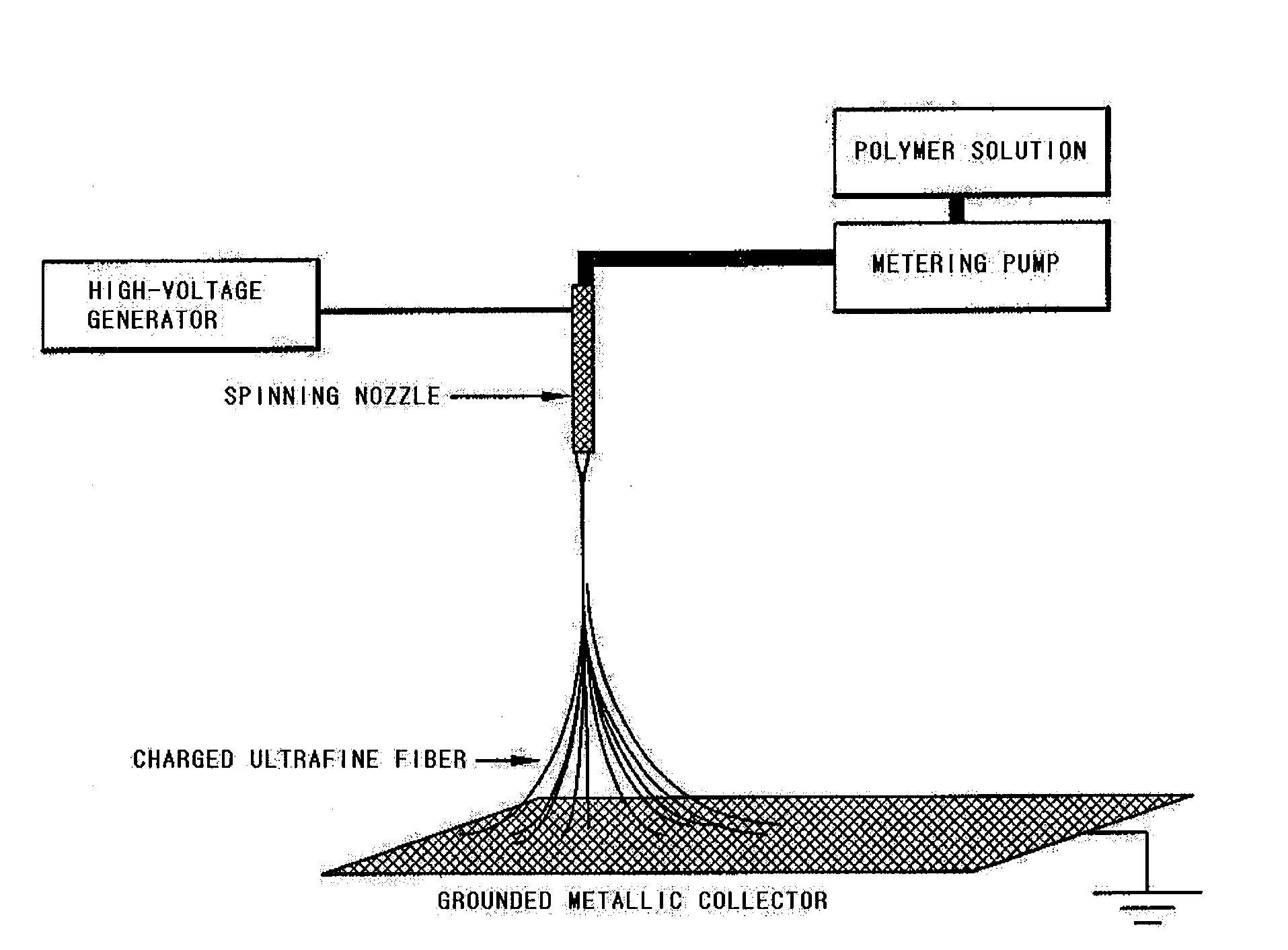

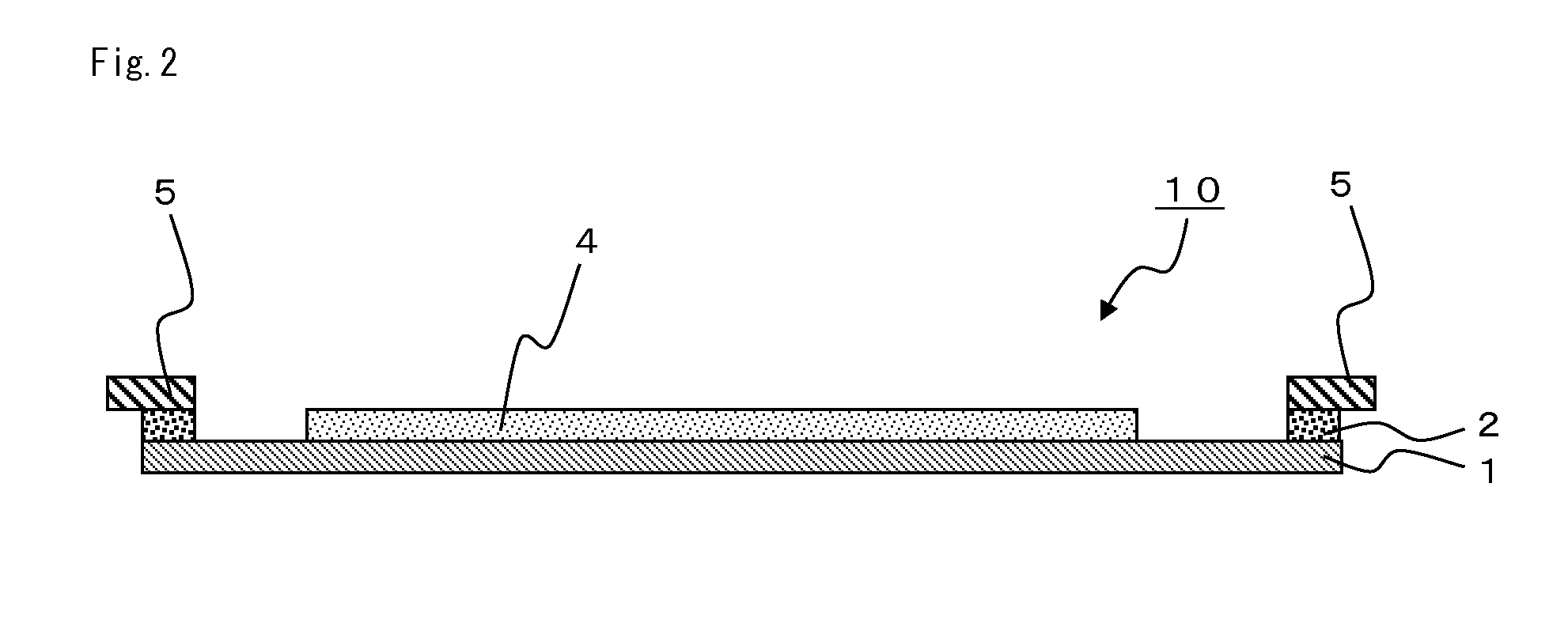

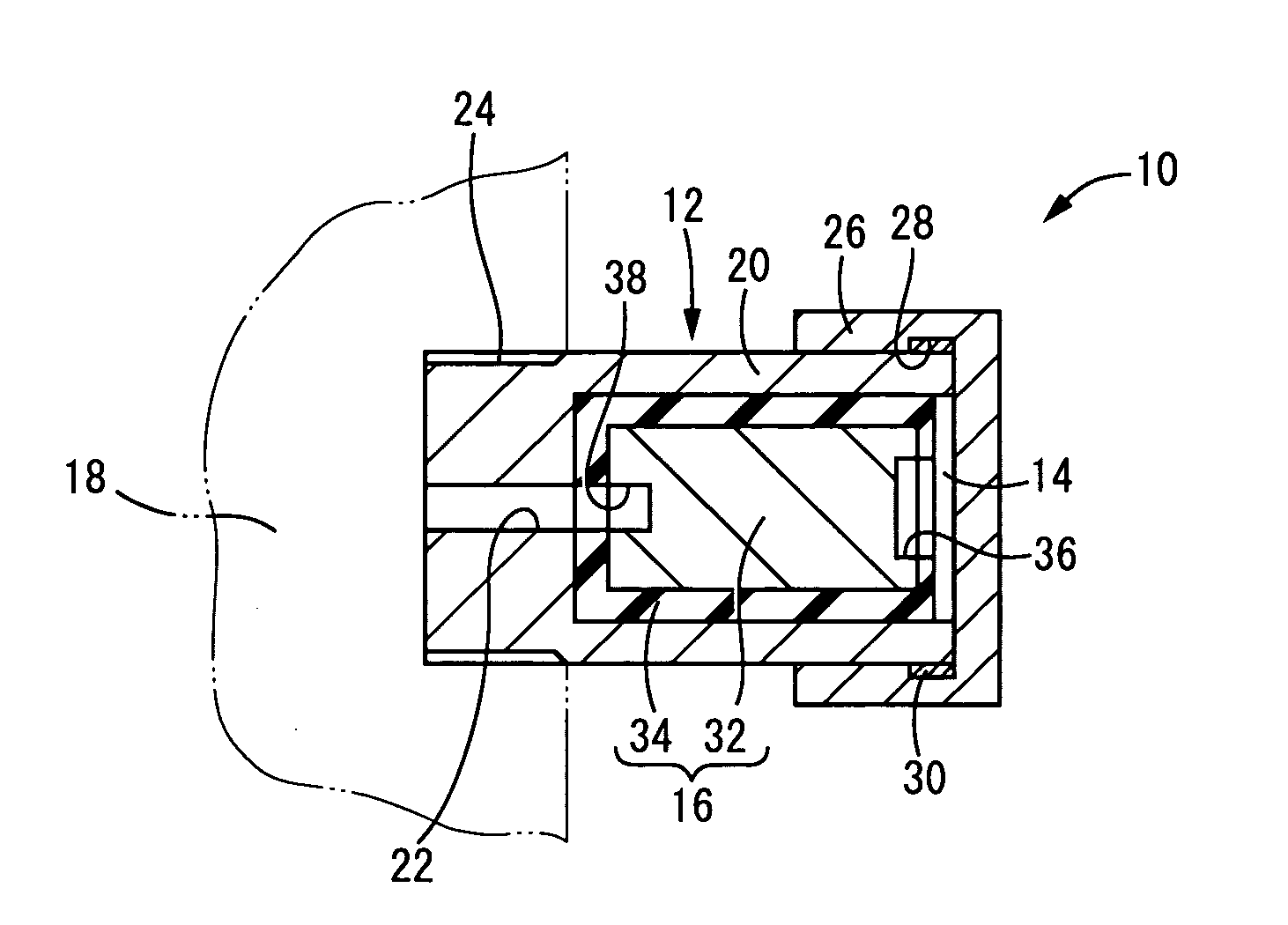

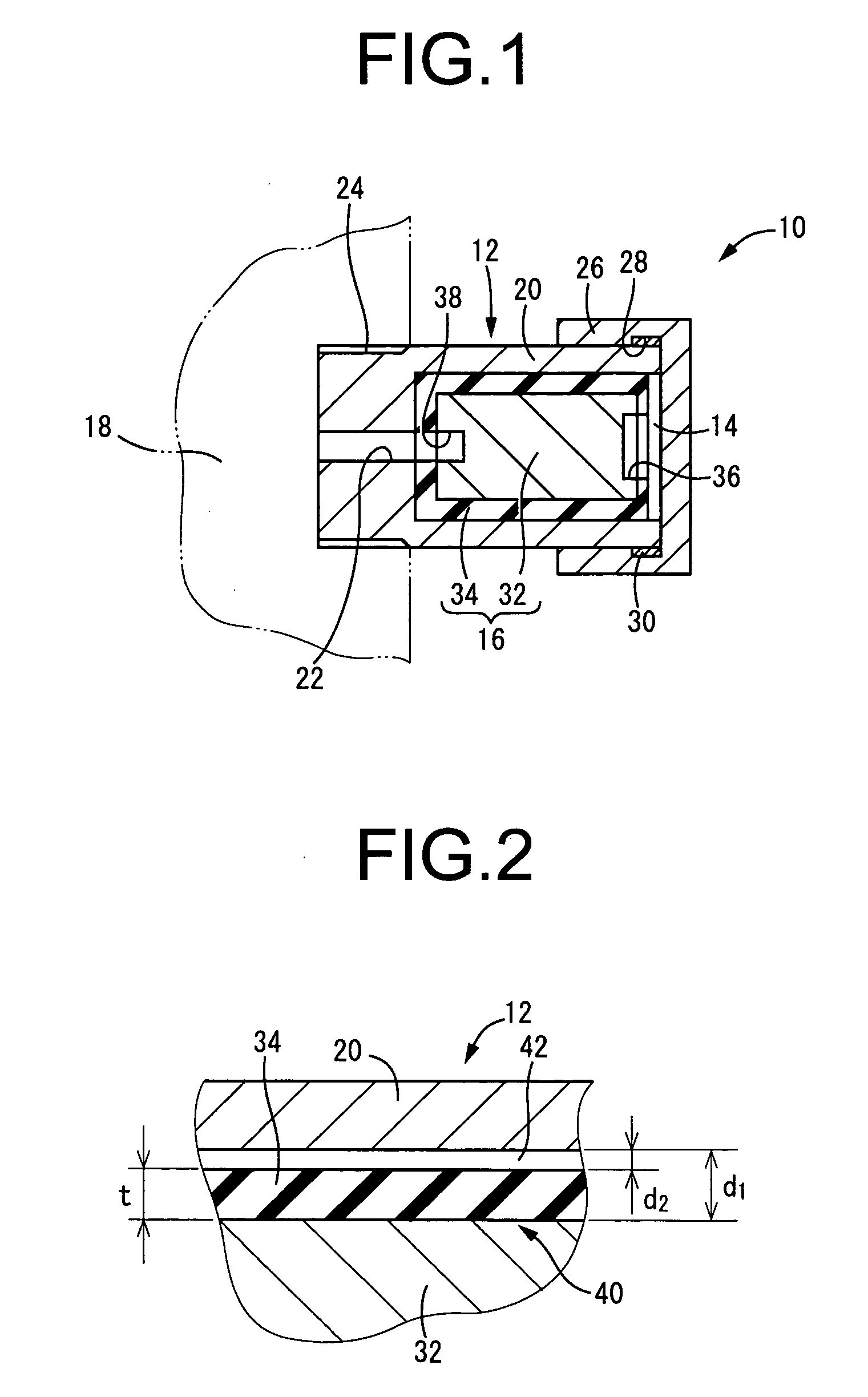

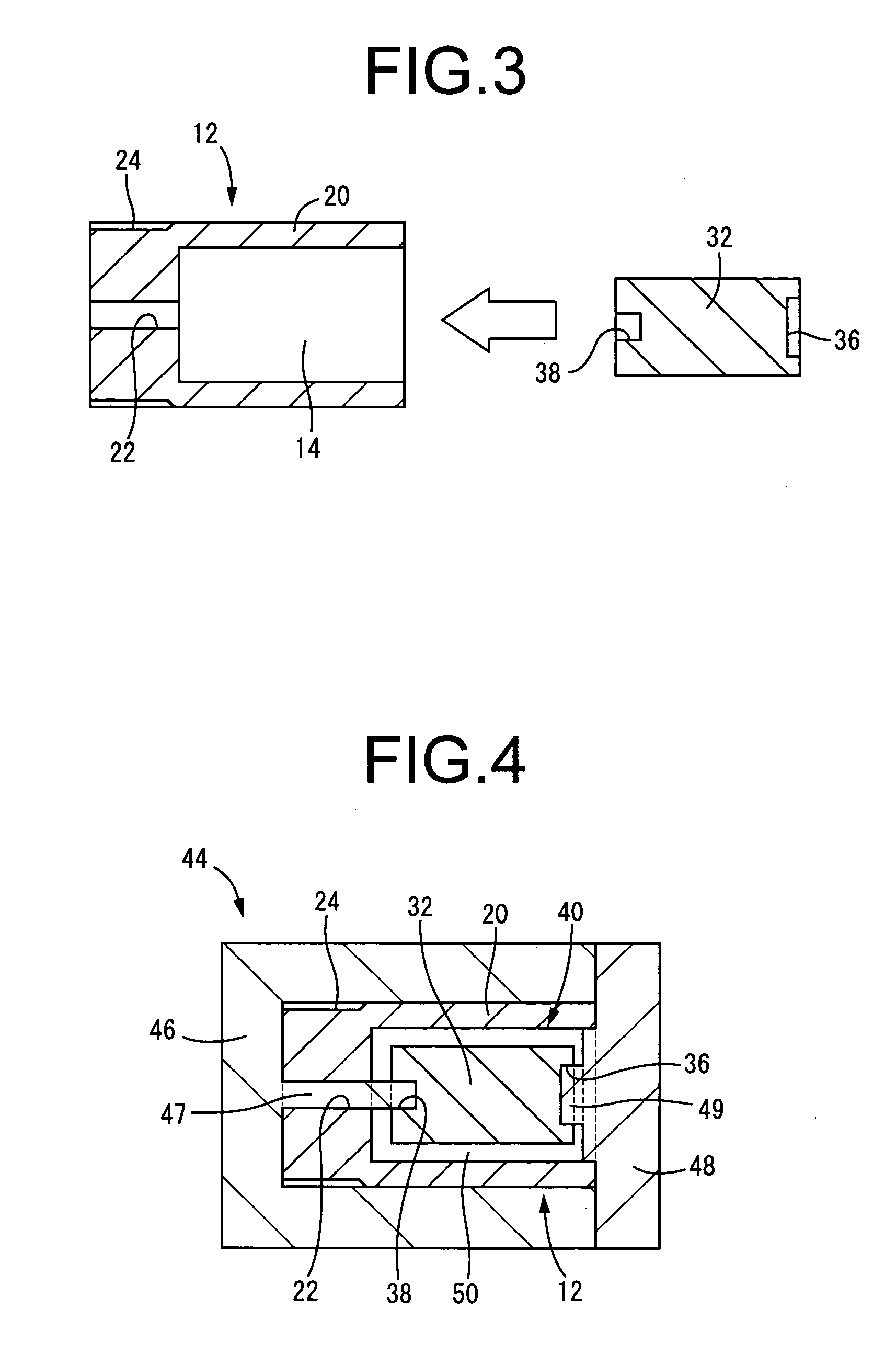

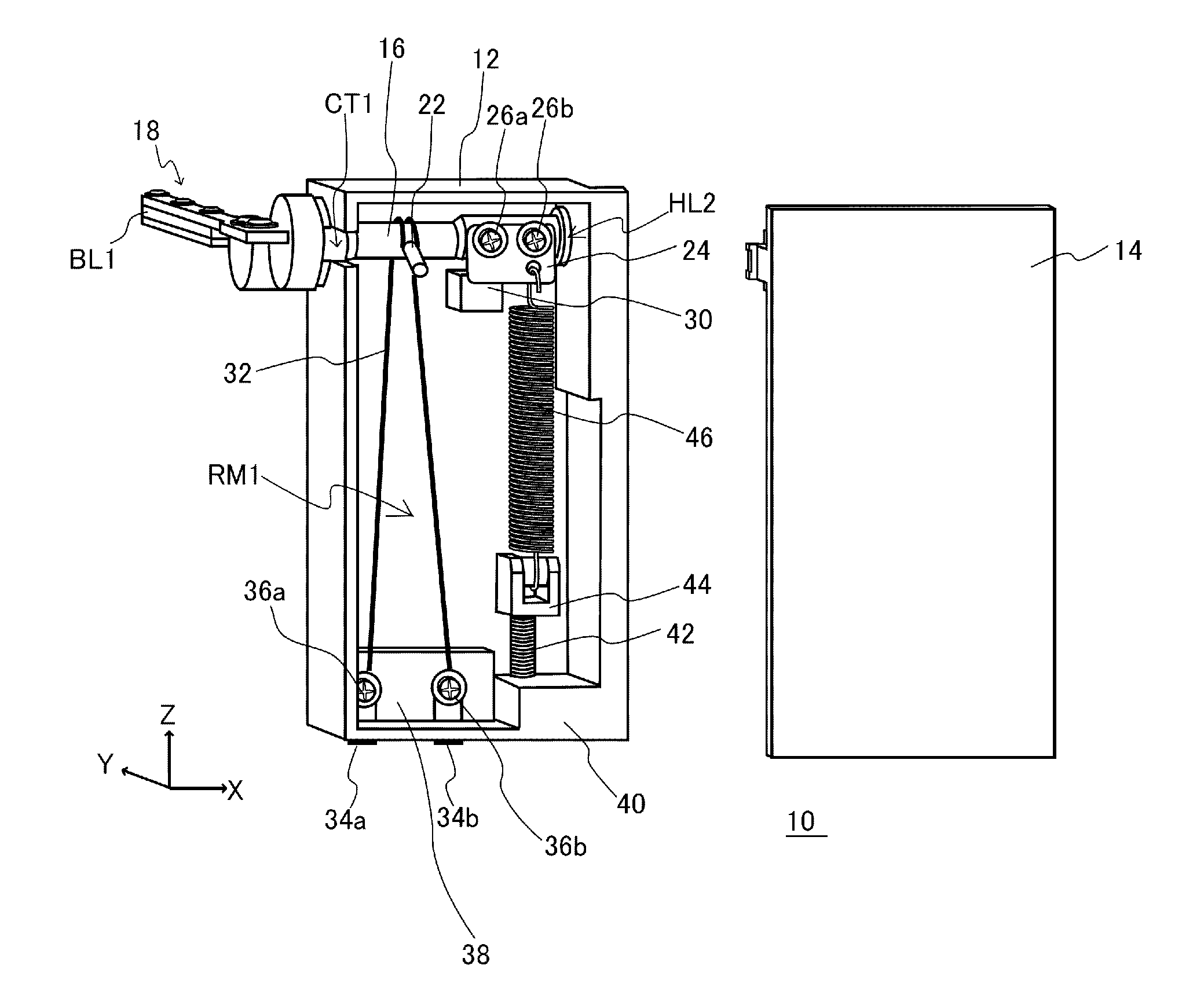

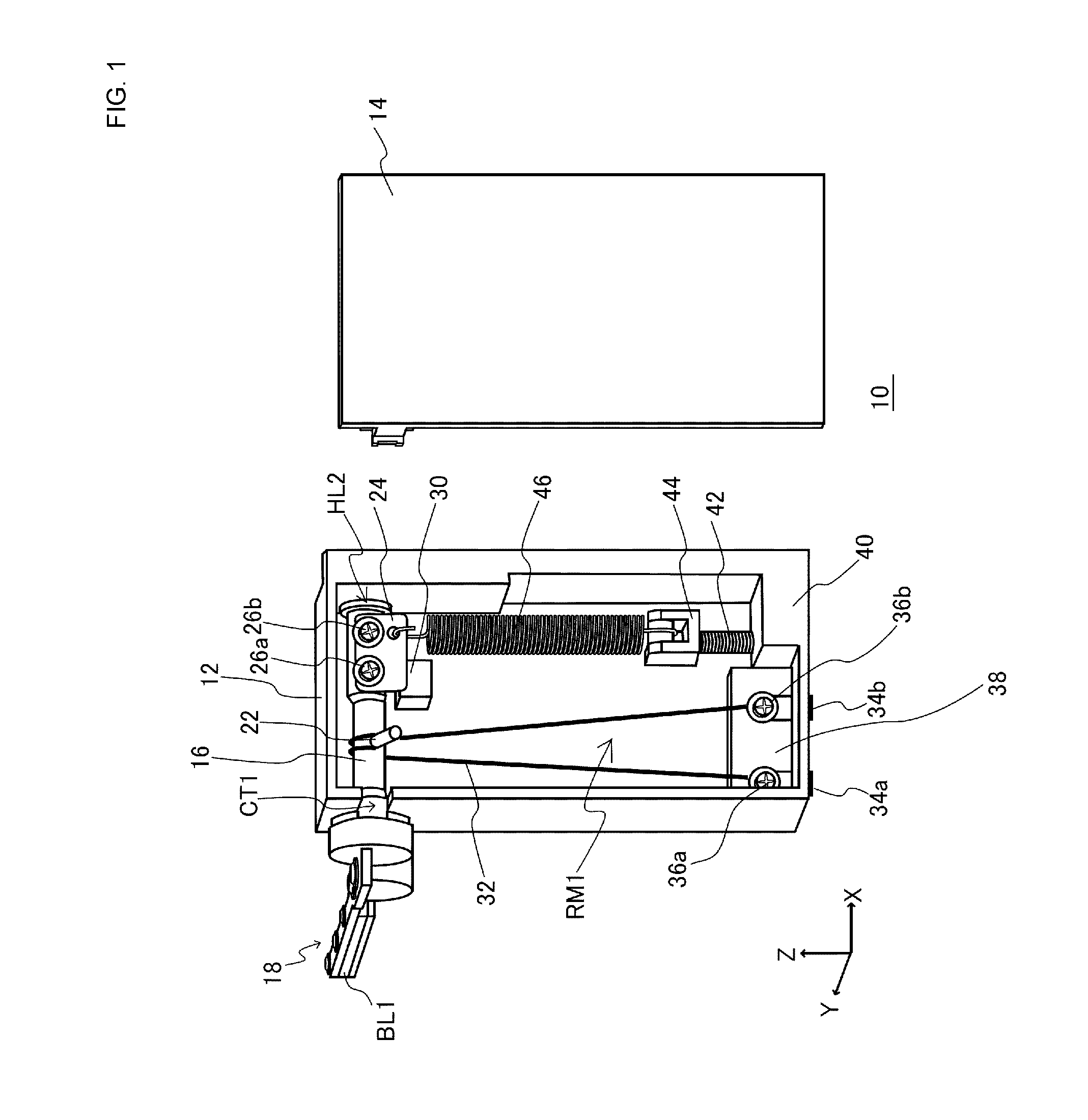

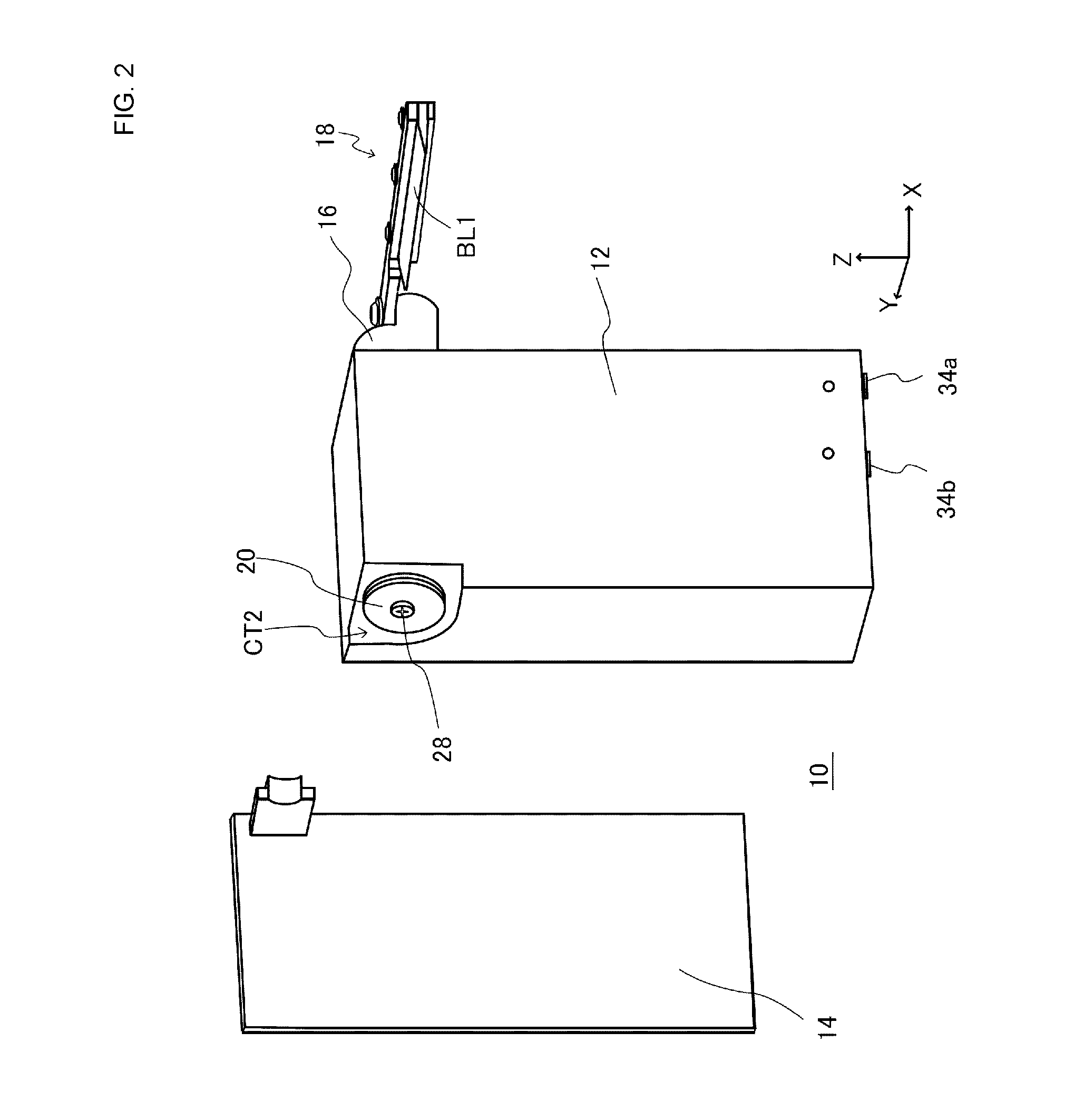

Image sensor, image reading device and production method of image sensor

InactiveUS20090294630A1Reduce warpageEasy to changeSolid-state devicesMaterial analysis by optical meansOptoelectronicsThermal expansion

An image sensor and a manufacturing method thereof are provided, so that the warp or the distortion is not caused even if there is the thermal expansion difference or the thermal contraction difference in the longitudinal direction between the linear illuminating device and the frame. The image sensor comprises a linear illuminating device for illuminating an original; a light-receiving element array for receiving reflected light from the original; a lens array for focusing the original on the light-receiving element array; a frame for containing the linear illuminating device, the lens array, and the light-receiving element array; and a resilient retaining portion for pressing the linear illuminating device, which is mounted in the frame, into the frame.

Owner:NIPPON SHEET GLASS CO LTD

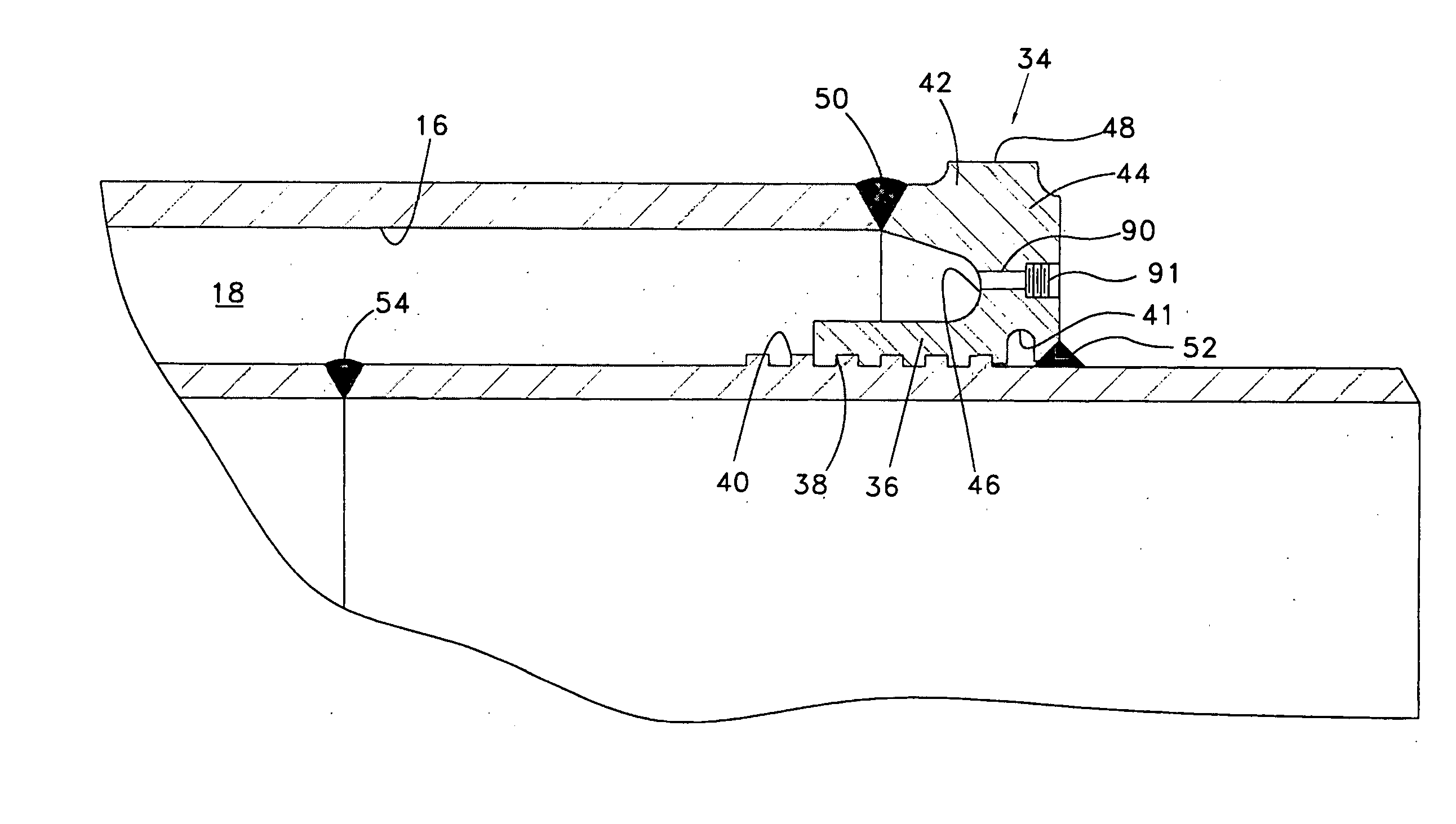

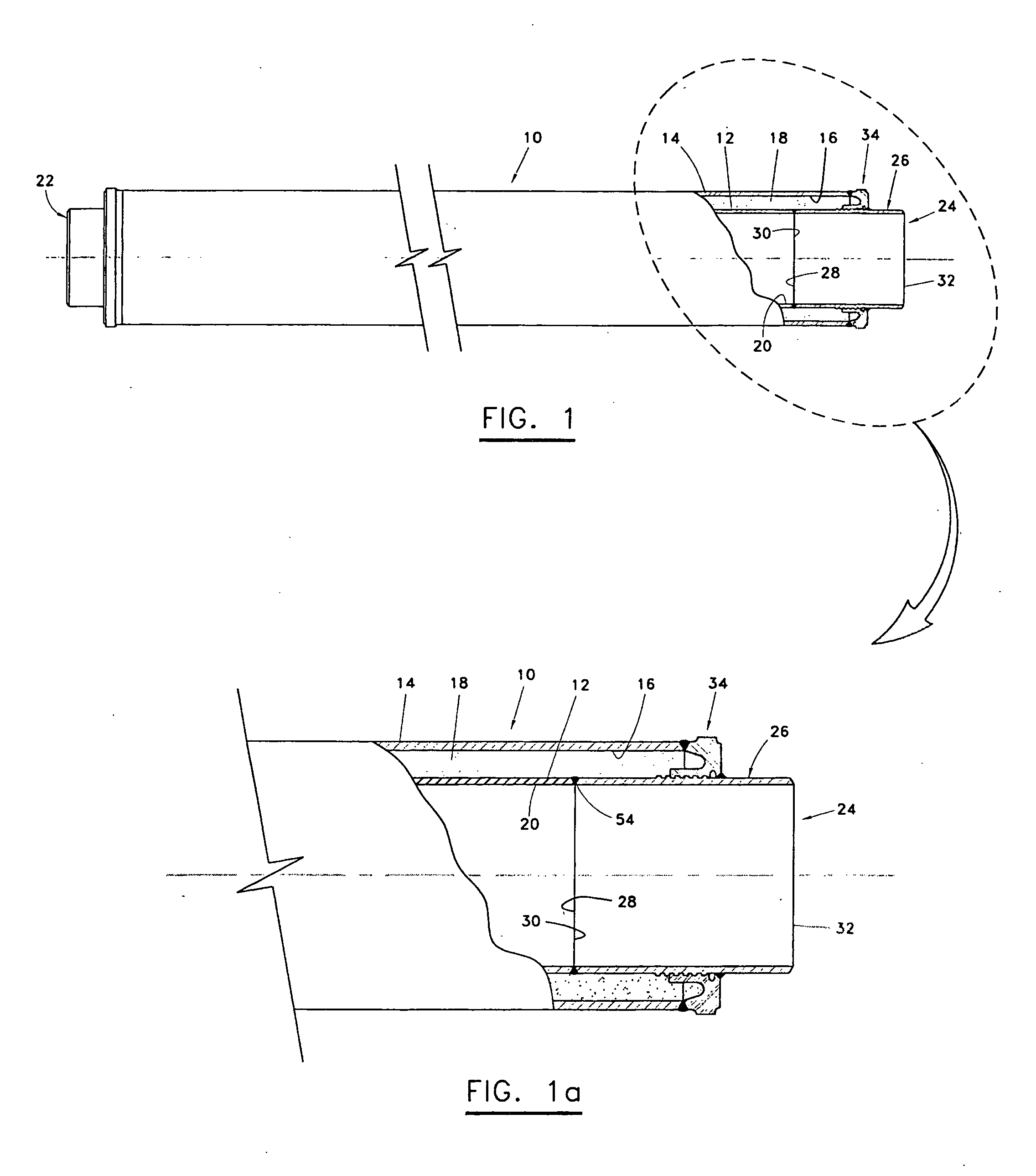

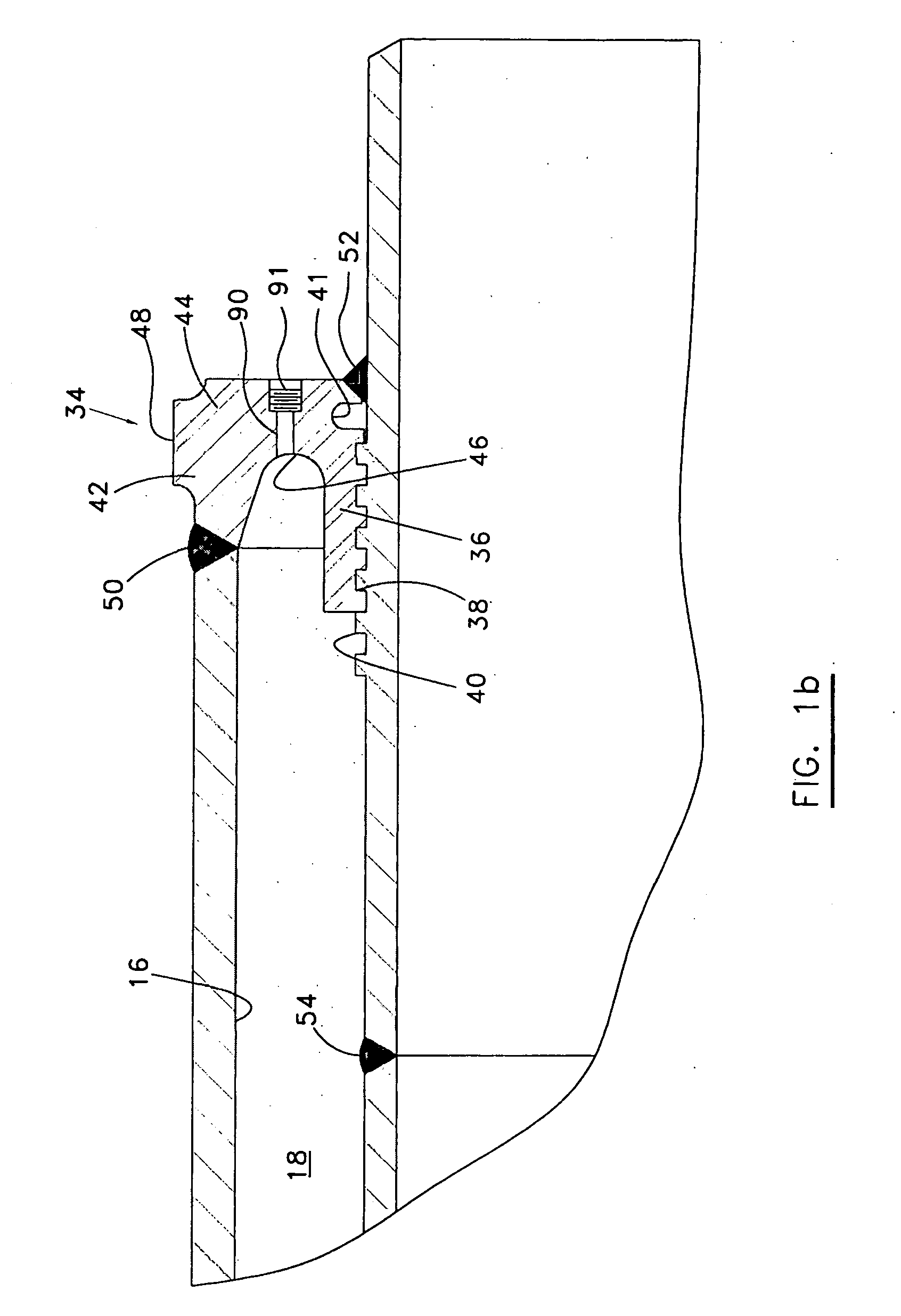

Dual-walled piping system and methods

InactiveUS20050212285A1Improved load transfer controlRelieve pressurePipe supportsThermal insulationCompound (substance)Axial force

Dual-walled piping segments and pipelines are described that use an annular bulkhead to secure the jacket pipe radially outside of the carrier pipe near the axial ends of the piping segment. Pup joints are welded to each end of the carrier pipe, and the bulkheads are welded to the pup joints. The bulkheads have a number of features that provide improved load path control for axial forces induced by temperature differentials. There is a mechanical load-sharing interlock mechanism provided between the bulkhead and the interior pup joint and field joint closure joints designed to transmit stress loading to a plurality of ridges or threads, that may be enhanced by thermal contraction, and preclude axial movement between the jacket pipe and pup joint. A number of methods are described for creating the load-sharing interlock. Additionally, the bulkhead has a generally arcuate cross-section that defines an interior channel. The arcuate cross-section allows the bulkhead to be somewhat flexible to absorb axial and radial loading while reducing the available heat transfer rate. The bulkhead also contains several ports for pressure equalization and plugged ports for the pressure-thermal-chemical conditioning of the annular spaces.

Owner:OPE INT

Superconducting magnet split cryostat interconnect assembly

InactiveUS6289681B1High strengthReduce thermal resistanceMagnetic measurementsGas handling applicationsElectricitySuperconducting Coils

A multi purpose interconnect assembly between upper and lower helium vessels in a recondensing superconducting magnet to provide isothermal connections to extend the ride-through period, and to provide for helium liquid and gas passage, electrical interconnections, and to accommodate differential thermal contraction and expansion.

Owner:GENERAL ELECTRIC CO

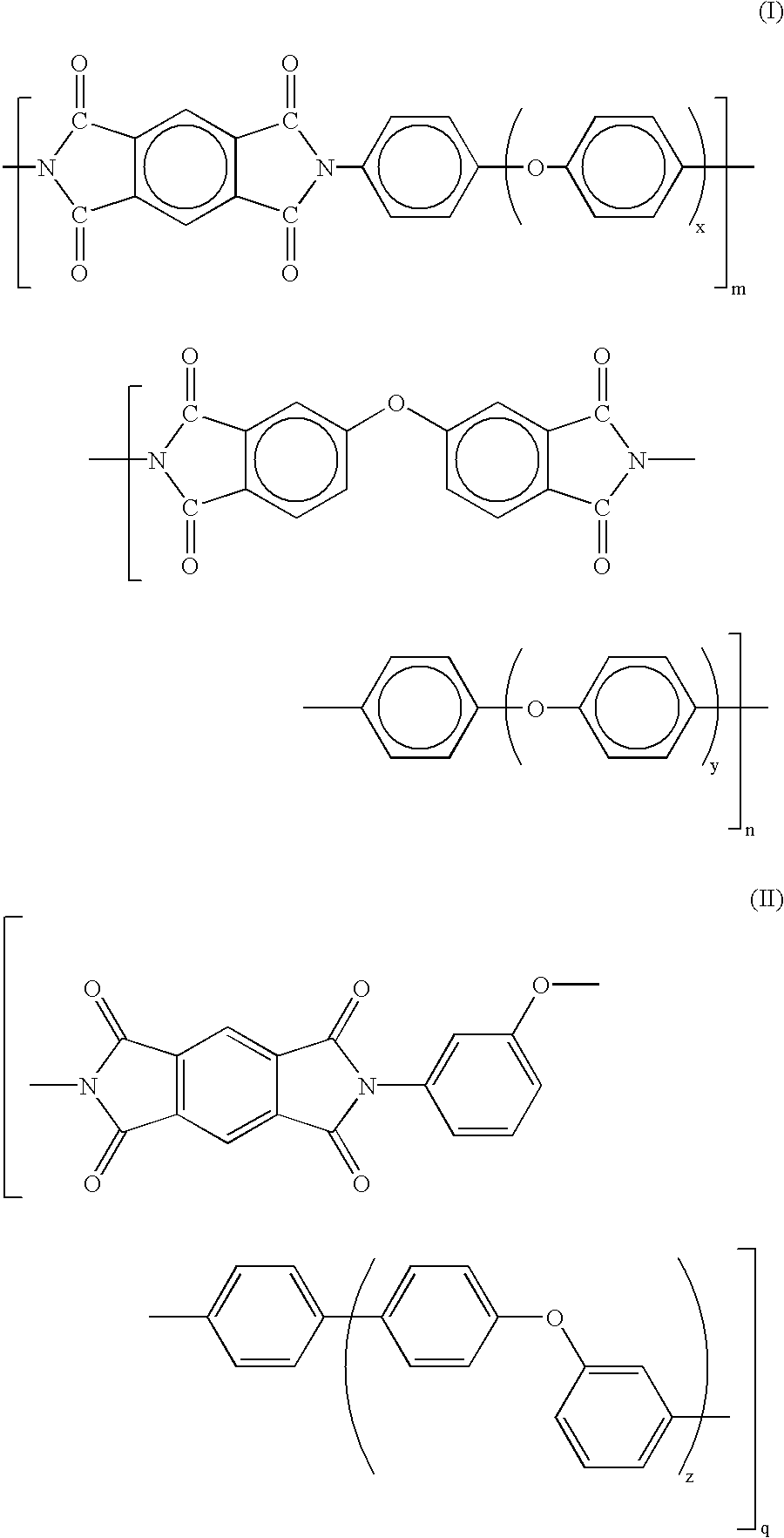

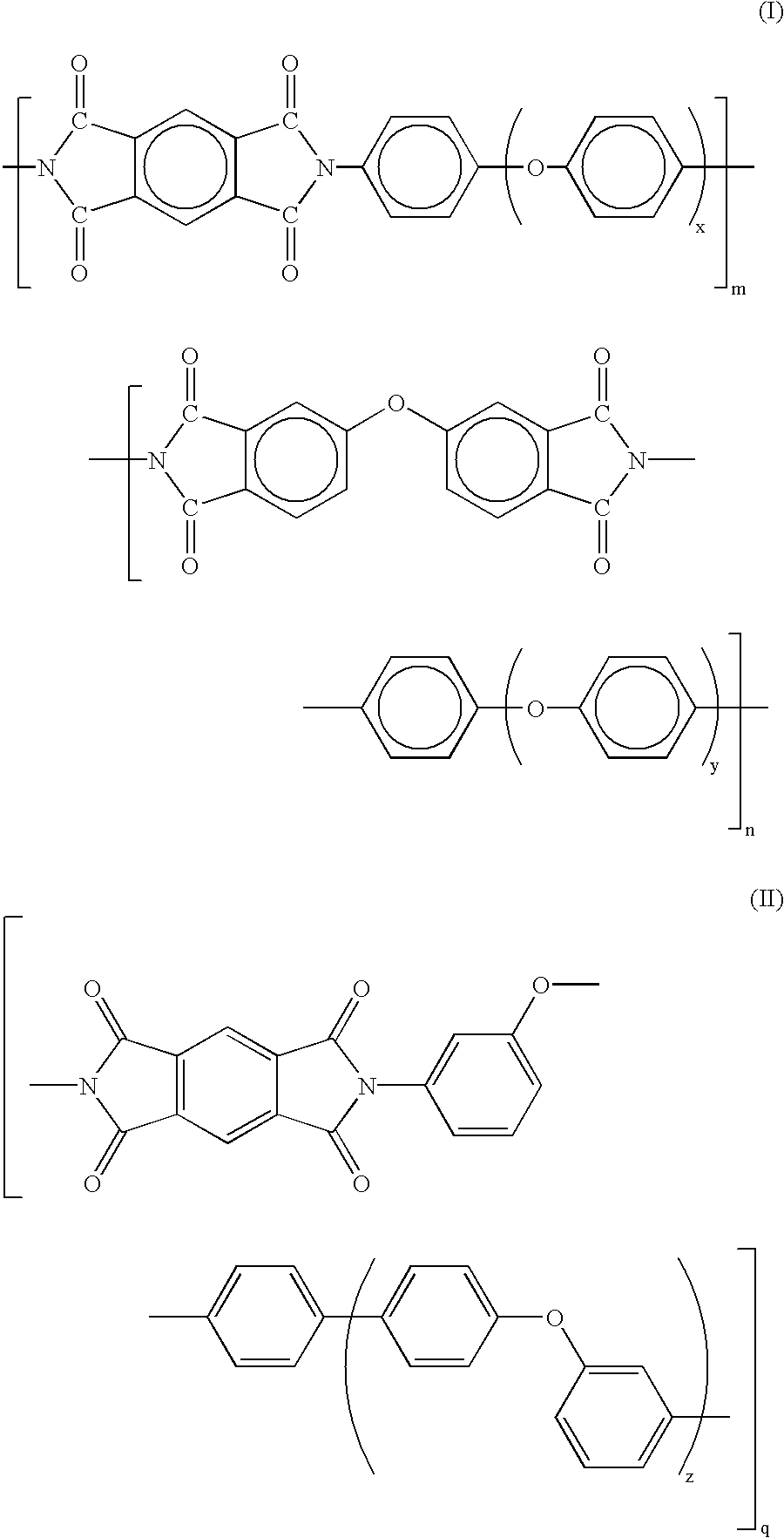

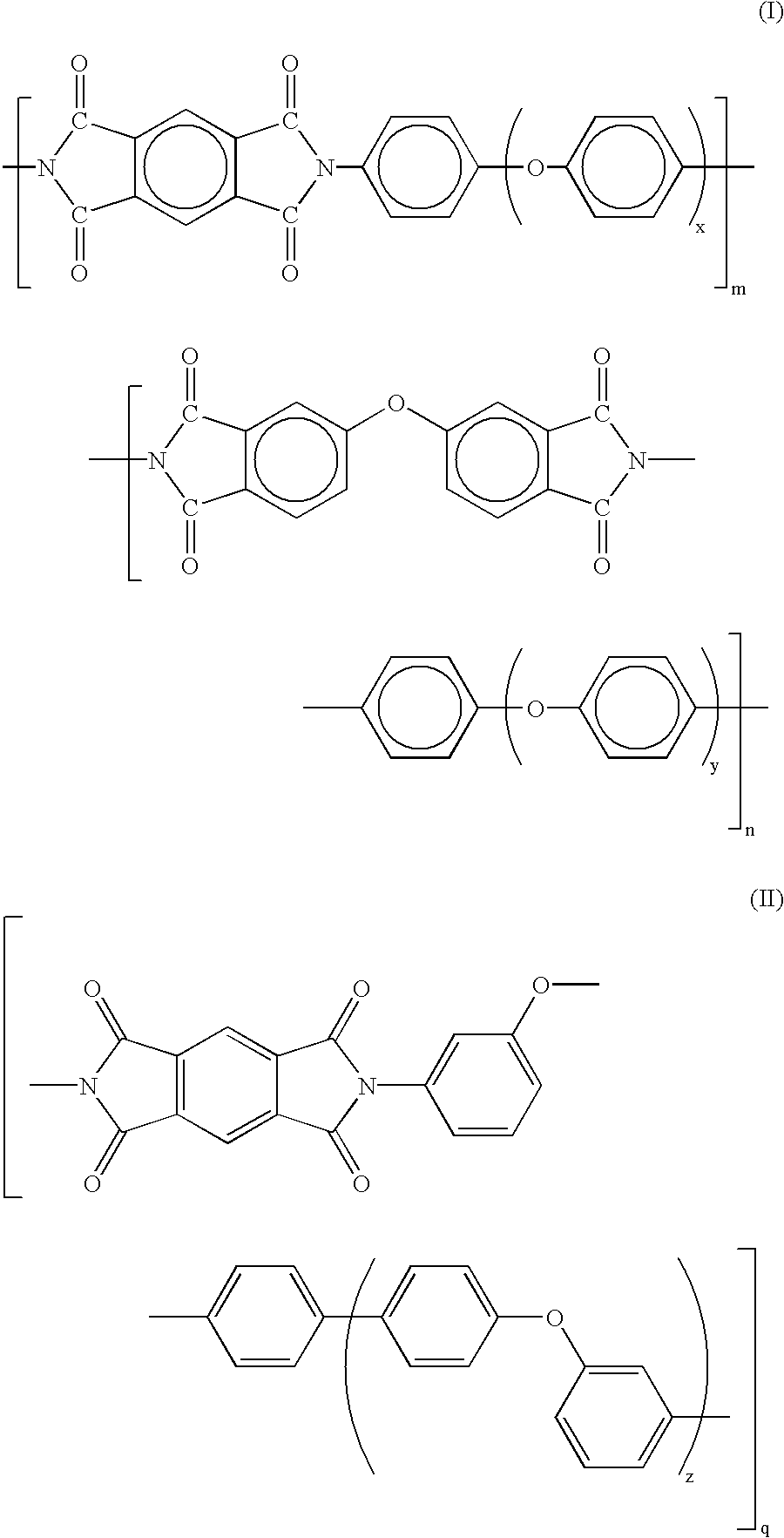

Simplified flexible electrostatographic imaging member belt

InactiveUS6660441B2Simple materialSimple material structureElectrographic process apparatusCorona dischargeVitrificationTransport layer

An electrostatographic imaging member having a substrate support material which eliminates the need for an anticurl backing layer, a substrate support layer and a charge transport layer having a thermal contraction coefficient difference in the range of from -2x10<->5 / ° C. to about +2x10<->5 / ° C. a substrate support material having a Glass Transition Temperature (Tg) of at least 100° C., wherein the substrate support material is not susceptible to attack from the charge transport layer coating solution solvent and wherein the substrate support material is represented by the two structural formulas below:wherein m, n, and q represent the degree of polymerization having a number from 10 to 300; and x, y, and z are integers; with x and y from 2 to 10 and z from 1 to 10. An electrostatographic imaging member containing this substrate support layer.

Owner:XEROX CORP

Glare-resistant touch panel

InactiveUS6559834B1Increase awarenessOutward bulge of the touch panel is effectively suppressedTransmission systemsCathode-ray tube indicatorsContraction rateLength wave

A touch panel is constructed of a top sheet member having a resistive membrane on its inner surface and a base sheet member having a resistive membrane on its inner surface, the top and base sheet members facing each other with dot spacers being located in between. The top sheet member is formed by laminating a bulge-resistant film, a polarizing plate, a quarter wavelength plate, and a light isotropic film in this order from above. A PET film which is not heat-treated so as to have a higher thermal contraction rate than the other members of the top sheet member underneath such as the polarizing plate, is used as the bulge-resistant film. Since the bulge-resistant film contracts more than the polarizing plate under a high ambient temperature, after the ambient temperature returns to normal, the bulge-resistant film does not become slack against the polarizing plate. Accordingly, the top sheet member can be kept from bulging outward.

Owner:GUNZE LTD +1

Thermal anti-oxidation radiation resistance polyolefine thermal contraction material and preparation method thereof

A thermal anti-oxidation radiation resistance polyolefine thermal contraction material, comprising the following components by weight part: linear low density polyethylene 100-150 part, ethylene copolymer 30-80 part, polyolefine elastomer 20-40 part, cross-link sensibilizer 1-3 part, composite antioxidant 1-10 part, light stabilizer 1-5 part, halogen-containing fire retardant 20-60 part and antimony trioxide 10-30 part. The material is not only used in the nuclear island of the nuclear power station, but also widely used in the fields with higher material performance requirement such as navigation, shipping, nuclear submarine or the like.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

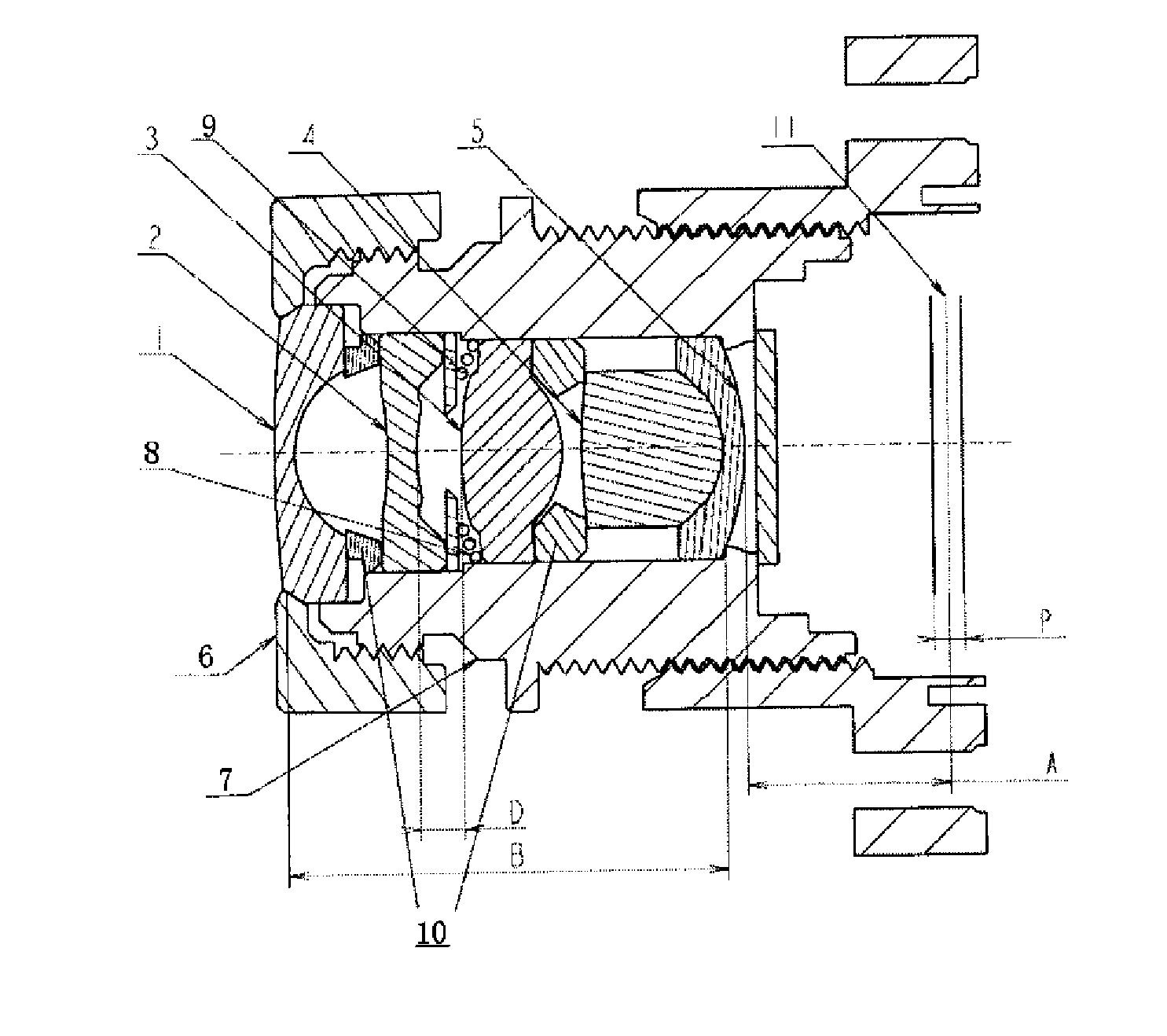

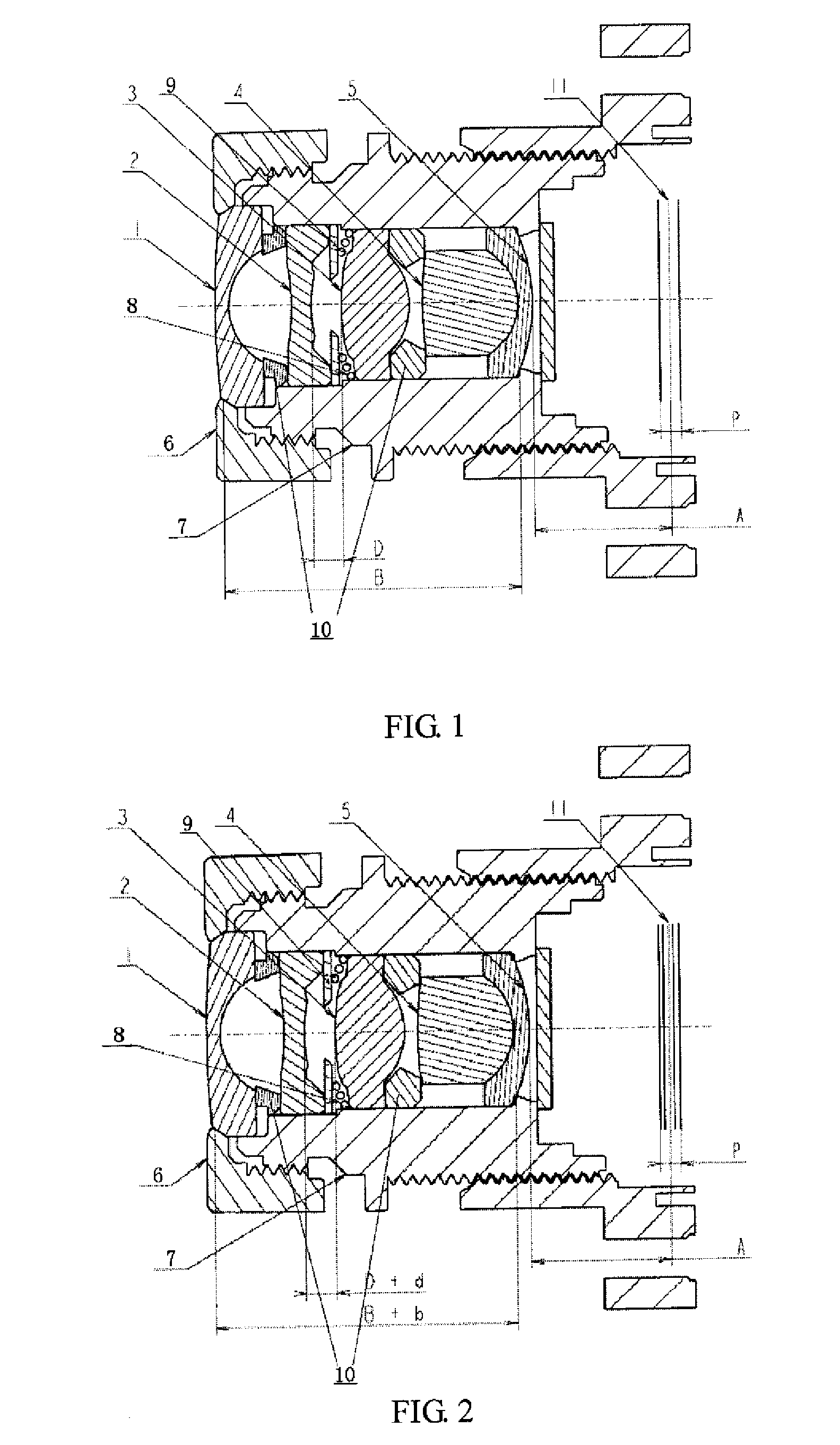

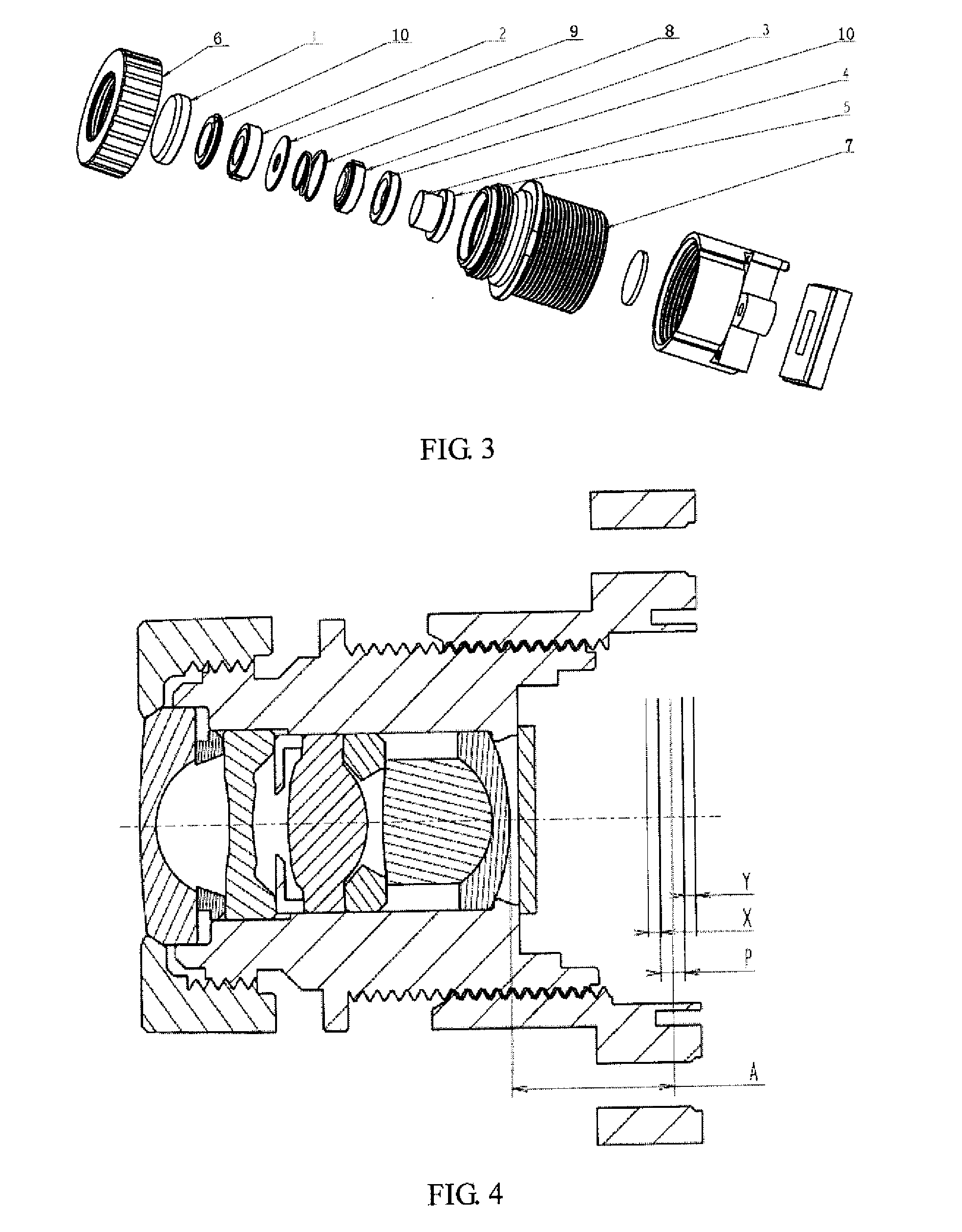

Lens Barrel

InactiveUS20140340771A1Small and low-costVariation in the focal position of the lens barrel is suppressedMountingsCamera lensOptical axis

The present invention provides a lens barrel applicable to digital cameras, image pickup devices and cell phones. The lens barrel is small, low-cost and high-performance, and can suppress, by means of a simple mechanism provided in the lens barrel, a variation in the focal position of the lens barrel caused by the change in temperature. The lens barrel comprises a lens group consisting of a plurality of lenses and a lens chamber for holding the lens group. An elastic member is provided between a set of adjacent lenses of the lens group, for urging the set of adjacent lenses in an optical axis direction of the lenses. The space between the set of lenses is increased or decreased by the elastic member, which causes a back focus of the lens barrel to move in a direction opposite to the direction in which the focal position of the lens barrel varies due to thermal expansion or thermal contraction of the lens group and the lens chamber and the change of refractive index of the lens group resulting from a temperature change. Hence, by increasing or decreasing the space in the optical axis direction between the lenses at both ends of the elastic member, the variation in the focal position of the lens barrel is suppressed.

Owner:JCD GUANG ZHOU OPTICAL

Polyethylene based composite material microporous diaphragm with hot-pressing adhesive characteristic

InactiveCN103178227AInhibit heat shrinkageImprove securityMembranesSemi-permeable membranesPolymer scienceWhole body

The invention relates to a polyethylene based composite material microporous diaphragm with a hot-pressing adhesive characteristic. According to the polyethylene based composite material microporous diaphragm, ethylene propylene monomer and polyisobutene rubbers with medium molecular weights are adopted to modify high-crystallinity high-density polyethylene, and fatty series dibasic acid ester of which the flashing point is more than 210DEG C is adopted as a process solvent and a pore forming agent of a diaphragm to obtain the diaphragm with the hot-pressing adhesive characteristic. The diaphragm with the hot-pressing adhesive characteristic and a positive pole piece are adhered into a whole body after hot-pressing lamination, so that the thermal contraction of the diaphragm is inhibited. The composite material diaphragm has high strength and high-temperature resistance, and can be applied to lithium ion power batteries with high safety and long cycle lives.

Owner:TIANJIN DG MEMBRANE

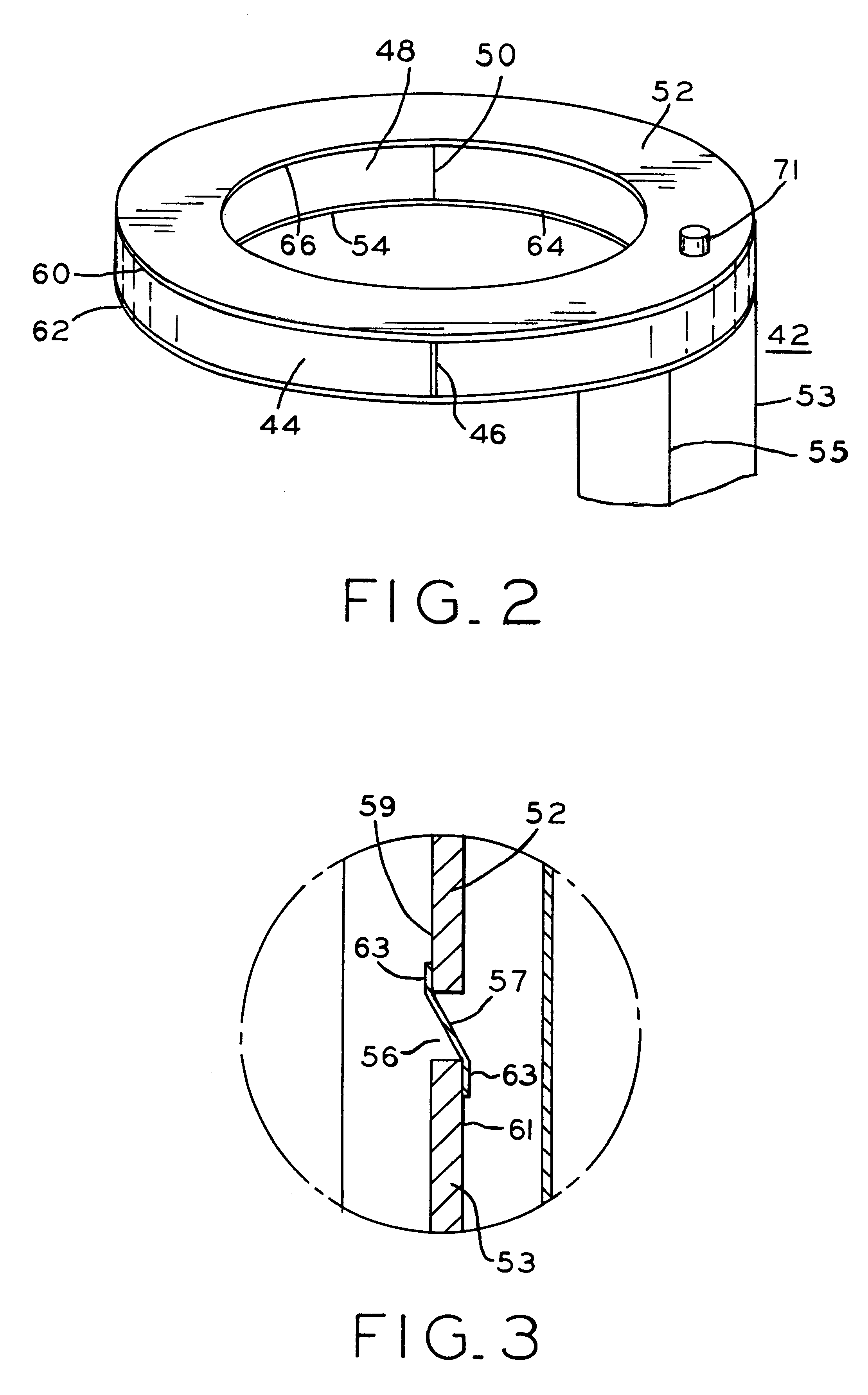

Vibration-damping device for vehicles and method of manufacturing the same

InactiveUS20050253317A1Novel structureReduce exerciseMachine framesNon-rotating vibration suppressionRubber materialVulcanization

A vehicle vibration-damping device including a rigid housing and an independent mass member housed in the housing and having a metallic mass of circular shape in section and a rubber elastic body layer adhered to the metallic mass. A distance of a gap between opposing surfaces of the housing and the metallic mass in the radial direction, with the housing and metallic mass disposed coaxially, is set to between 0.5 and 2 mm. The rubber elastic body layer is formed around an entire outer peripheral surface of the metallic mass by a vulcanization molding of a rubber material filling the gap, and thermal contraction is used both to cause the rubber elastic body layer to peel from the housing and to cause it to adhere onto the outer peripheral surface of the metallic mass to thereby fabricate a small gap of no more than 0.1 mm. A method of manufacturing the same is also disclosed.

Owner:SUMITOMO RIKO CO LTD

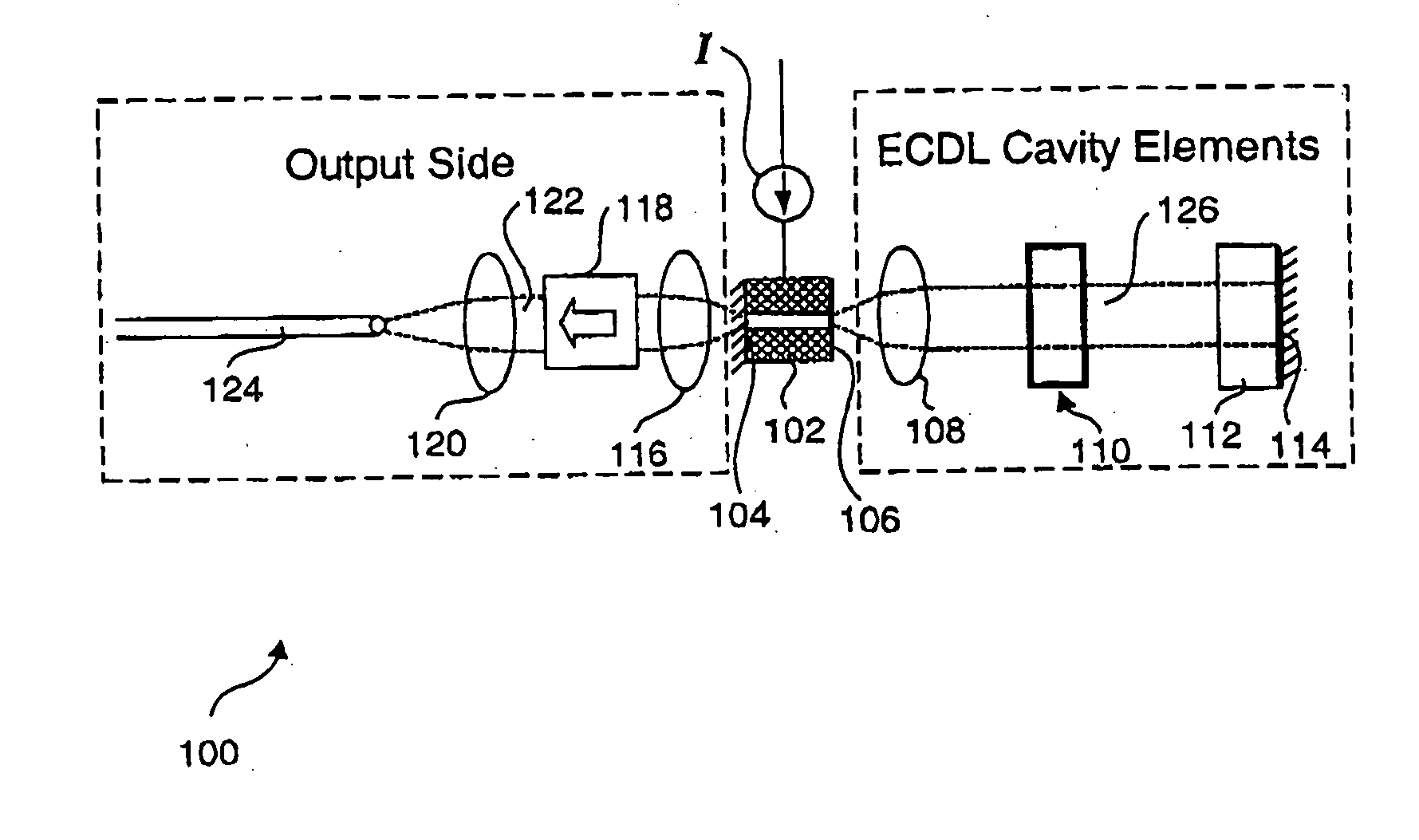

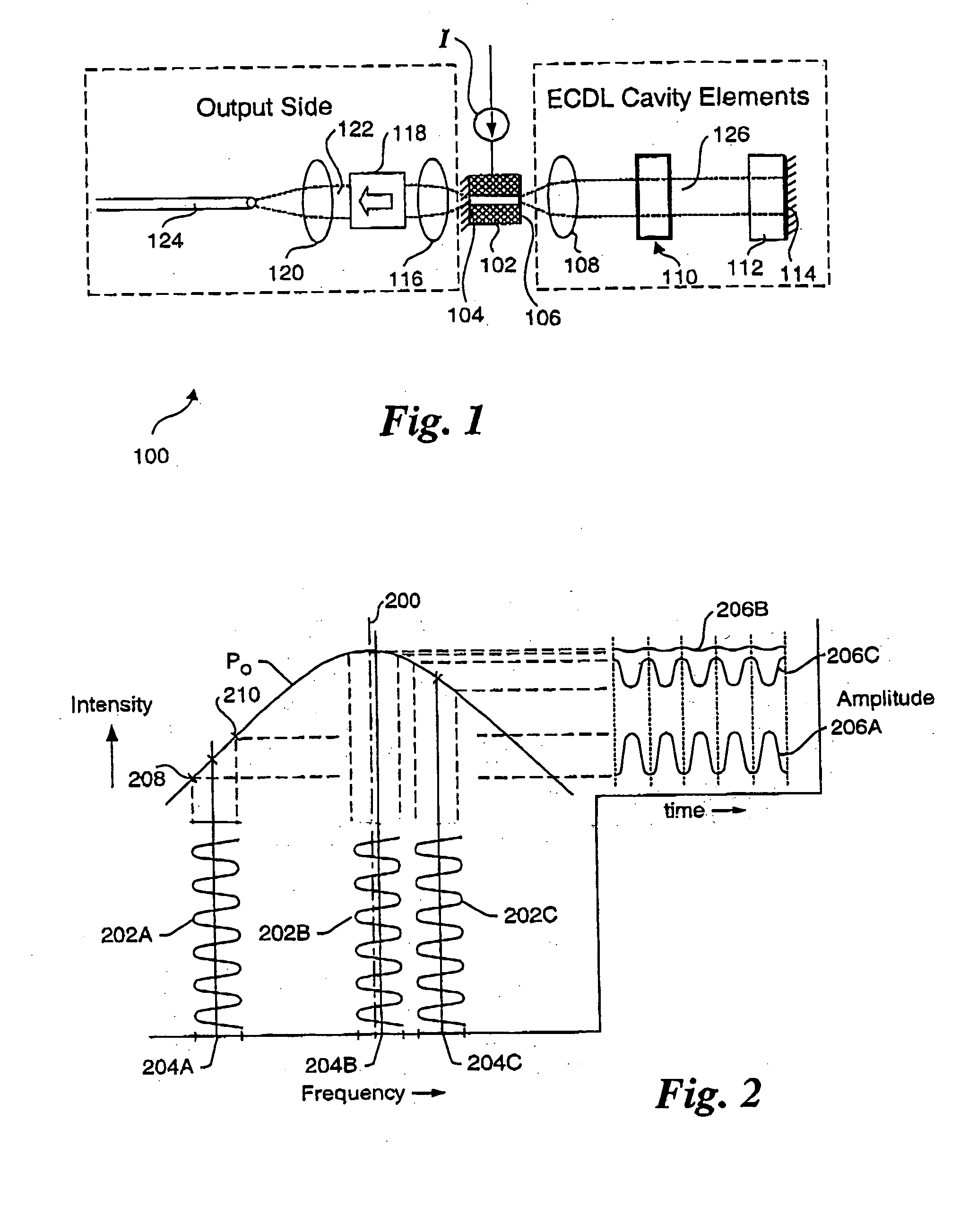

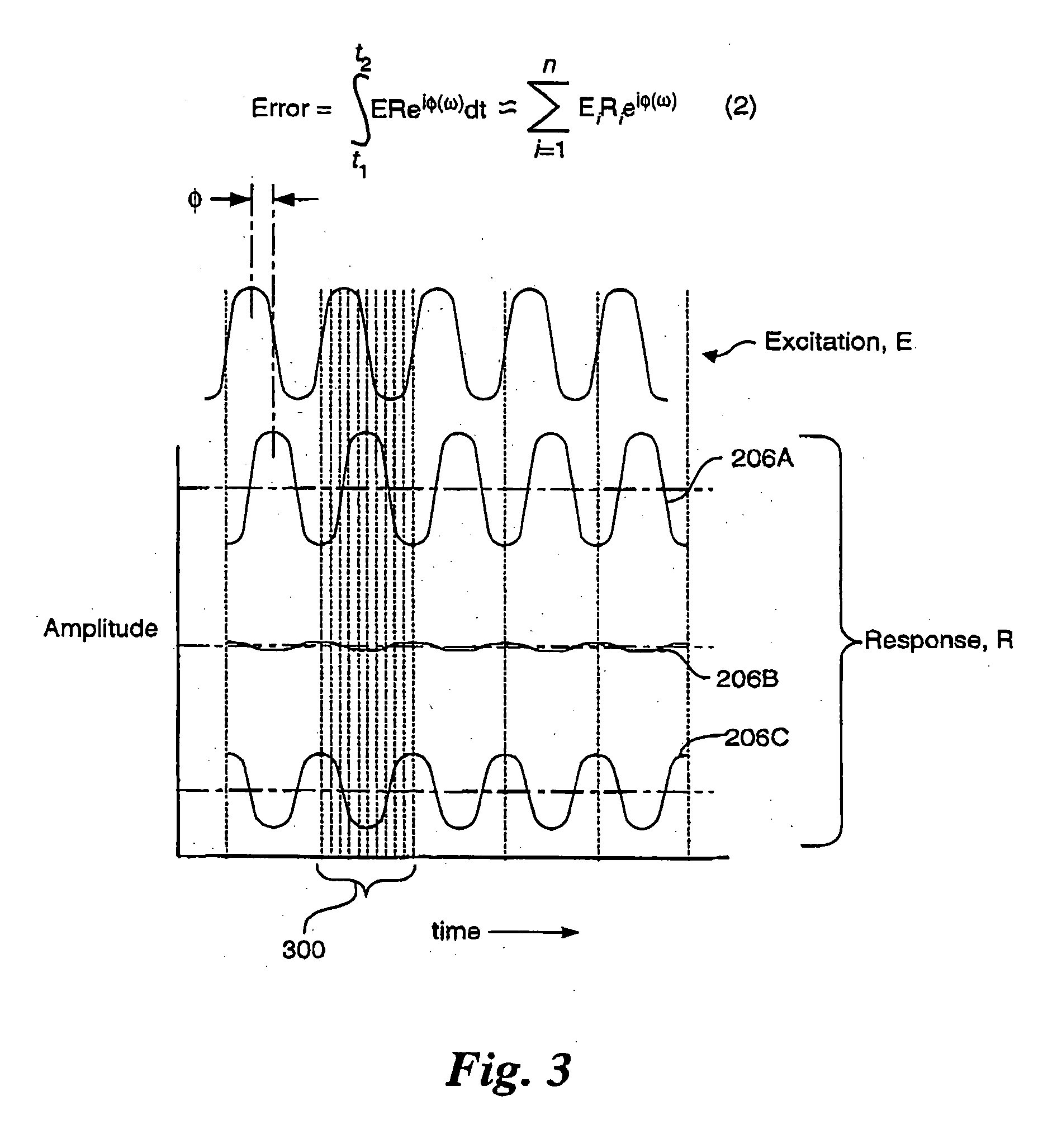

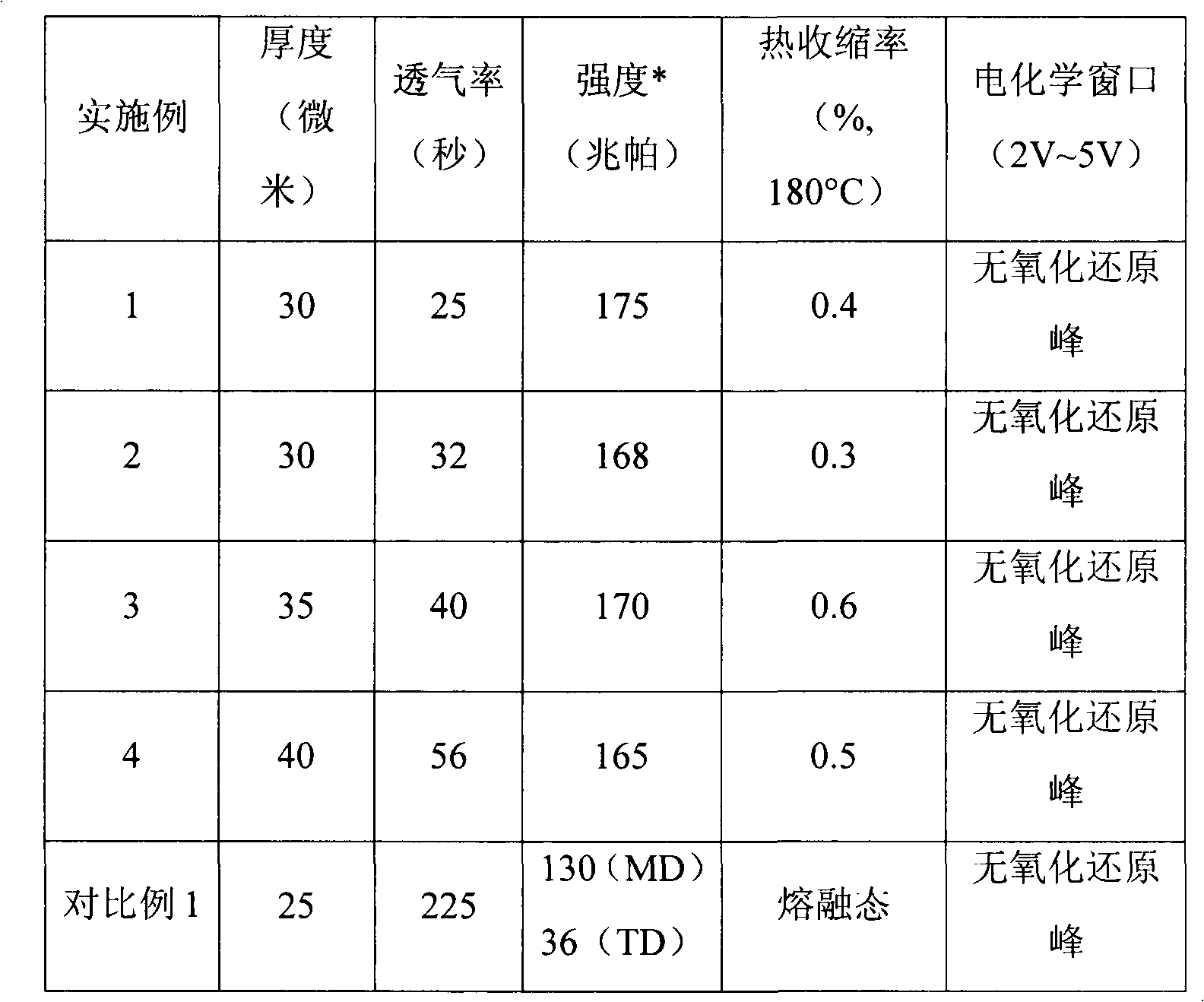

Multiple input/output ECDL cavity length and filter temperature control

InactiveUS20050123008A1Laser optical resonator constructionOptical resonator shape and constructionThermal contractionEngineering

A servo or control technique and apparatus for an external cavity diode laser (ECDL) are described. Coarse tuning adjustments for the ECDL may be performed by varying the temperature of tunable filters. Fine tuning adjustments may be performed varying the temperature of the ECDL sled (base) to vary the length of the cavity via thermal contraction and expansion. A controller comprises a coupler matrix that mathematically relates multiple control signal inputs for varying the temperatures of the tunable filters and sled to produce multiple outputs used to control, for example, thermal-electric cooler (TEC) elements associated with the tunable filters and sled.

Owner:INTEL CORP

Cellulose/polymer fiber composite diaphragm material for lithium secondary battery and preparation method thereof

InactiveCN102522515AImprove heat resistanceGood chemical stabilityCell component detailsCelluloseFiber

The invention provides a cellulose / polymer fiber composite material for a lithium secondary battery and a preparation method thereof. The composite material is prepared by papermaking structural fibers of celluloses and superfine polymer fibers through a wet paper making technology, wherein the celluloses are obtained by beating cellulose raw materials of a wood pulp or a jute pulp, a cotton pulp and the like and have microfibrillar structures. The composite material prepared through the preparation method of the invention has the characteristics of small thermal contraction, high thermal stability and good mechanical performance and can satisfy diaphragm requirements of a nonaqueous electrolyte energy storage device; and additionally, the composite material which partially adopts renewable celluloses as the raw material has the advantages of low cost, simple process and environmental protection.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Copolyester with low melting point and synthesis method thereof

InactiveCN101735437AAddress reactivityFix stability issuesFlexible coversWrappersPolymer scienceSynthesis methods

The invention discloses polyester with an extensive amorphous region. The components of terephthalic acid, m-phthalic acid and dihydric alcohol and a dihydroxy compound with an ether bond are used as basic raw materials, an acid component contains 10-30 percent by mol of m-phthalic acid and 70-90 percent by mol of terephthalic acid, total acid and total alcohol are prepared into uniform slurry inthe mol ratio of 1.05:2.0, and the polyester which does not have an obvious melting peak under a DSC (differential scanning calorimetry) and has the extensive amorphous region and low melting point is generated by the reactions of esterification and polycondensation. The method can utilize a traditional semicontinuous and continuous polyester production line to realize industrialized production. The polyester produced by utilizing the method provided by the invention is used for preparing a packaging film, a sheet, a hot melt adhesive and the like. The invention is especially suitable for being prepared into a thermal contraction film used for a packaging purpose or a tag purpose so as to replace a polyvinyl chloride (PVC) thermal contraction film used in the market at present.

Owner:ZHONGFU GUANGHAN CHEM IND

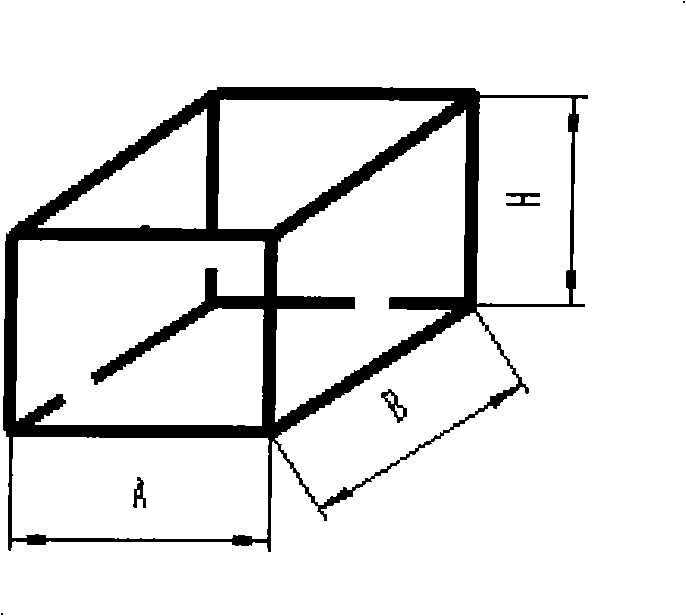

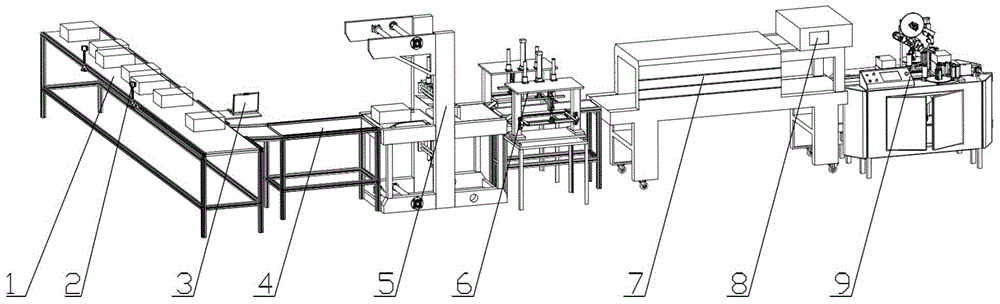

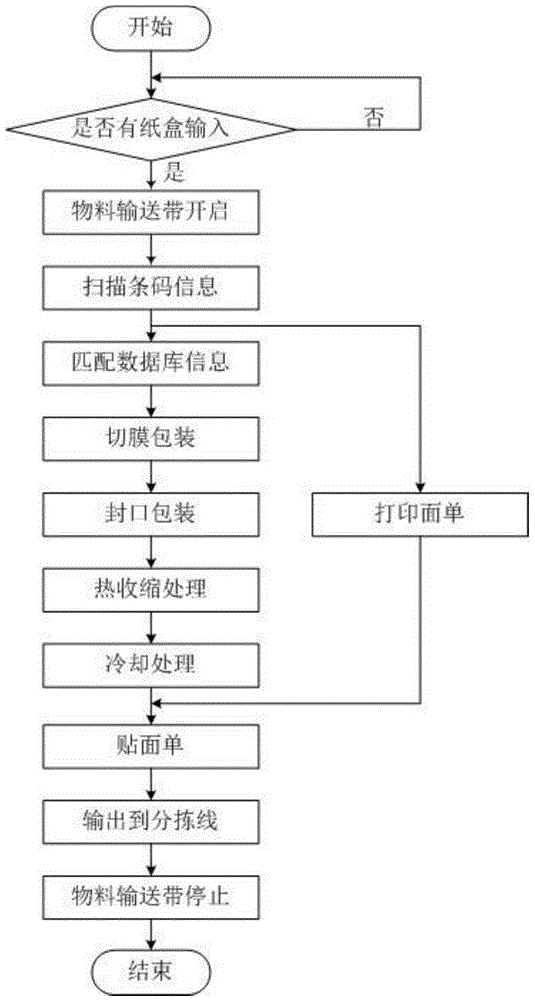

Novel automatic packing system and automatic packing method applied for electronic commerce and express delivery logistics industry

InactiveCN104890913AFully automatedReduce labor costsWrappers shrinkageConveyor wrappingLogistics managementPersonal computer

The invention provides a novel automatic packing system and a novel automatic packing method applied for electronic commerce and express delivery logistics industry. The packing system and the packing method are mainly provided for packing of paper boxes in electronic commerce and express delivery logistics industry. The packing system comprises a material conveyer belt, an industrial personal computer, a printer, a PLC, an infrared sensor, a film cutting machine, a sealing machine, a hot wind box, a cooling mechanism and a list pasting mechanism. The automatic packing method comprises steps of using transparent PE films as packing materials; scanning codes of paper boxes; matching information; sealing and packing four edges of each of the paper box; and performing thermal contraction, cooling and list pasting processes. Thus, automatic packing of the paper boxes is finished.

Owner:JIANGNAN UNIV

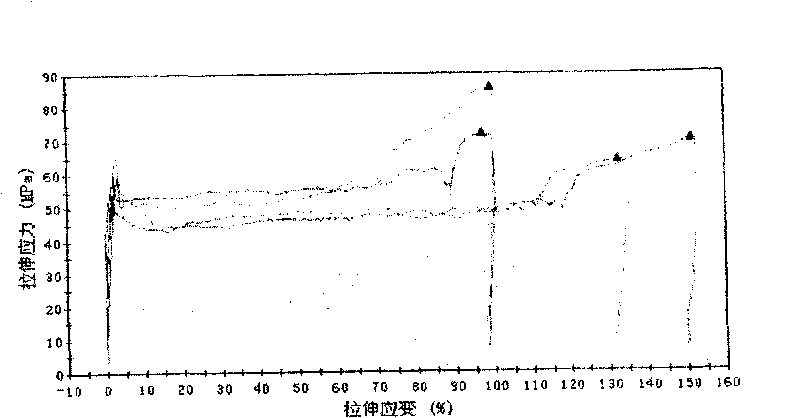

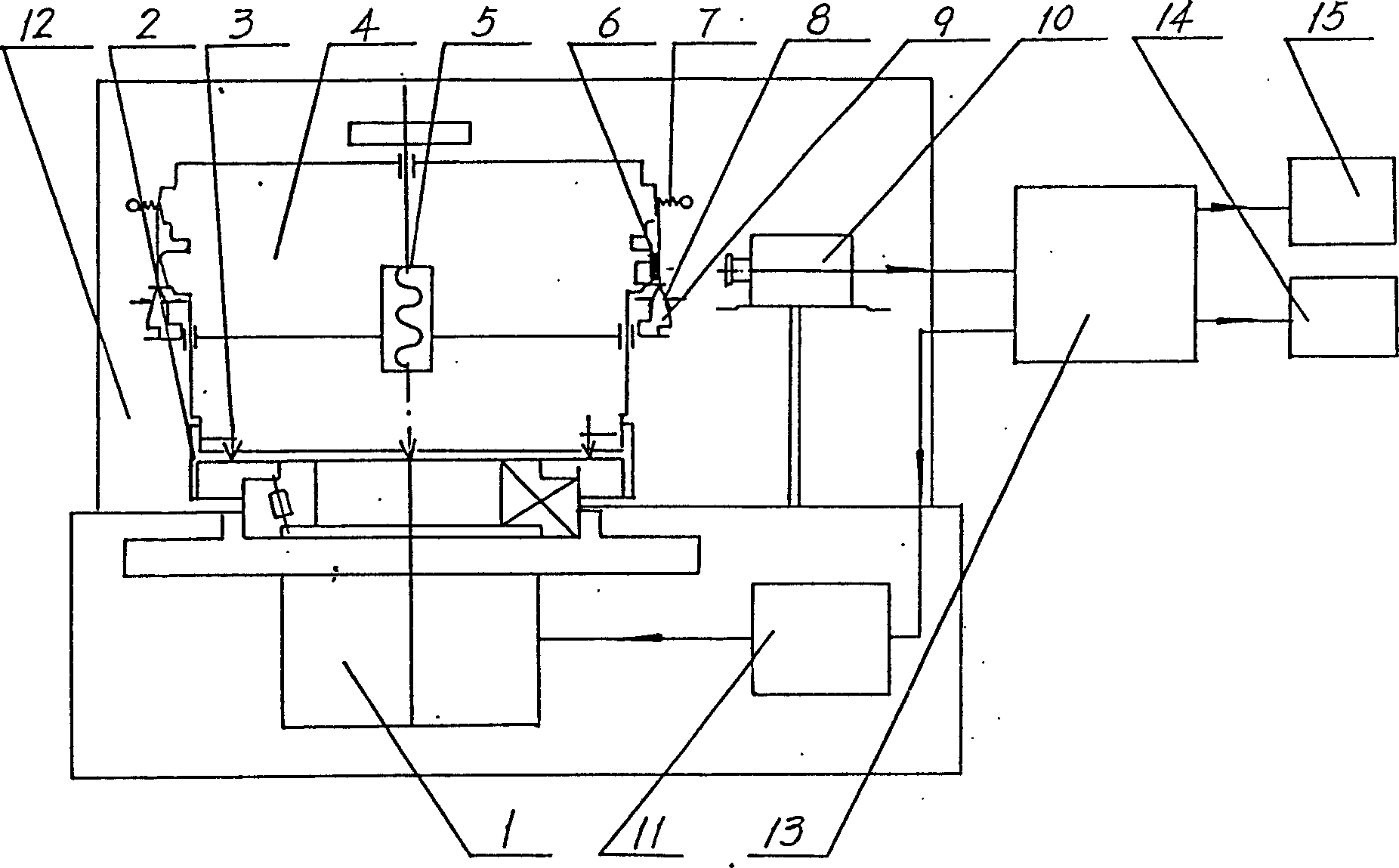

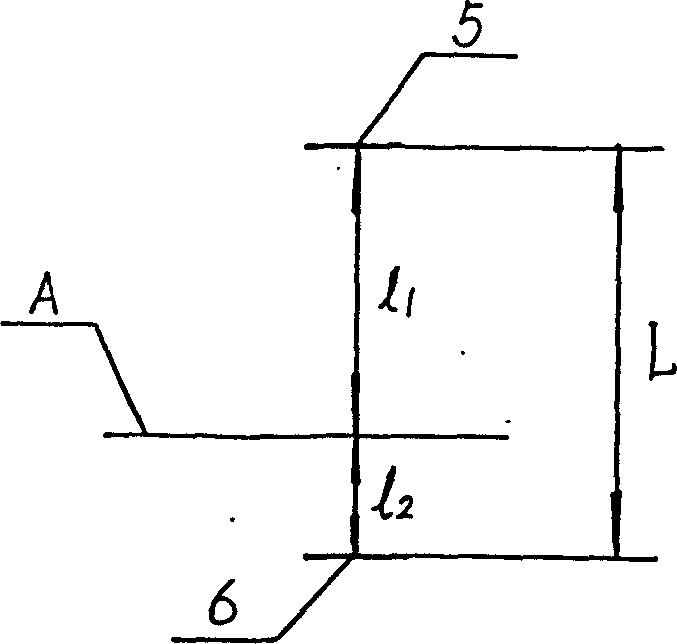

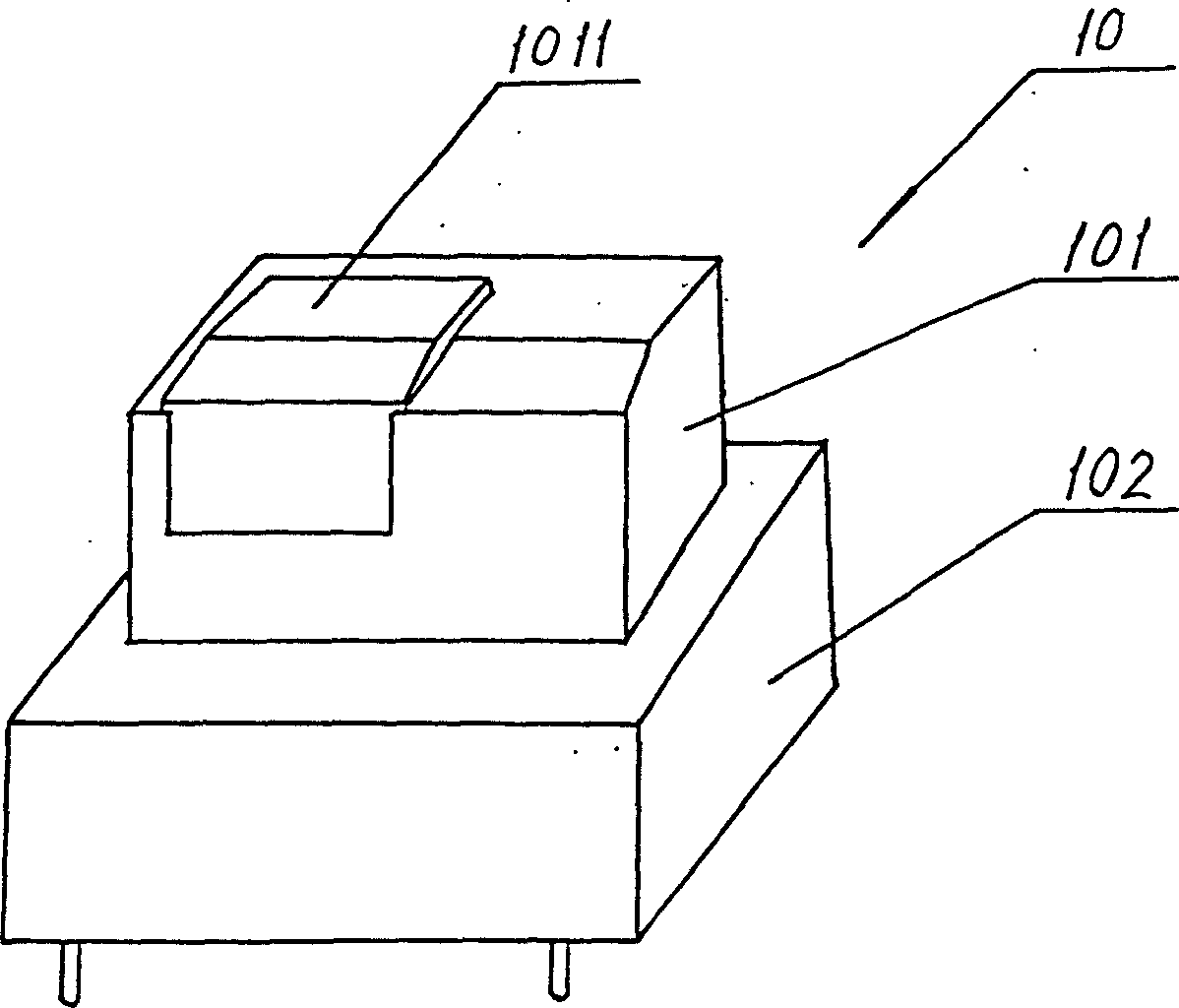

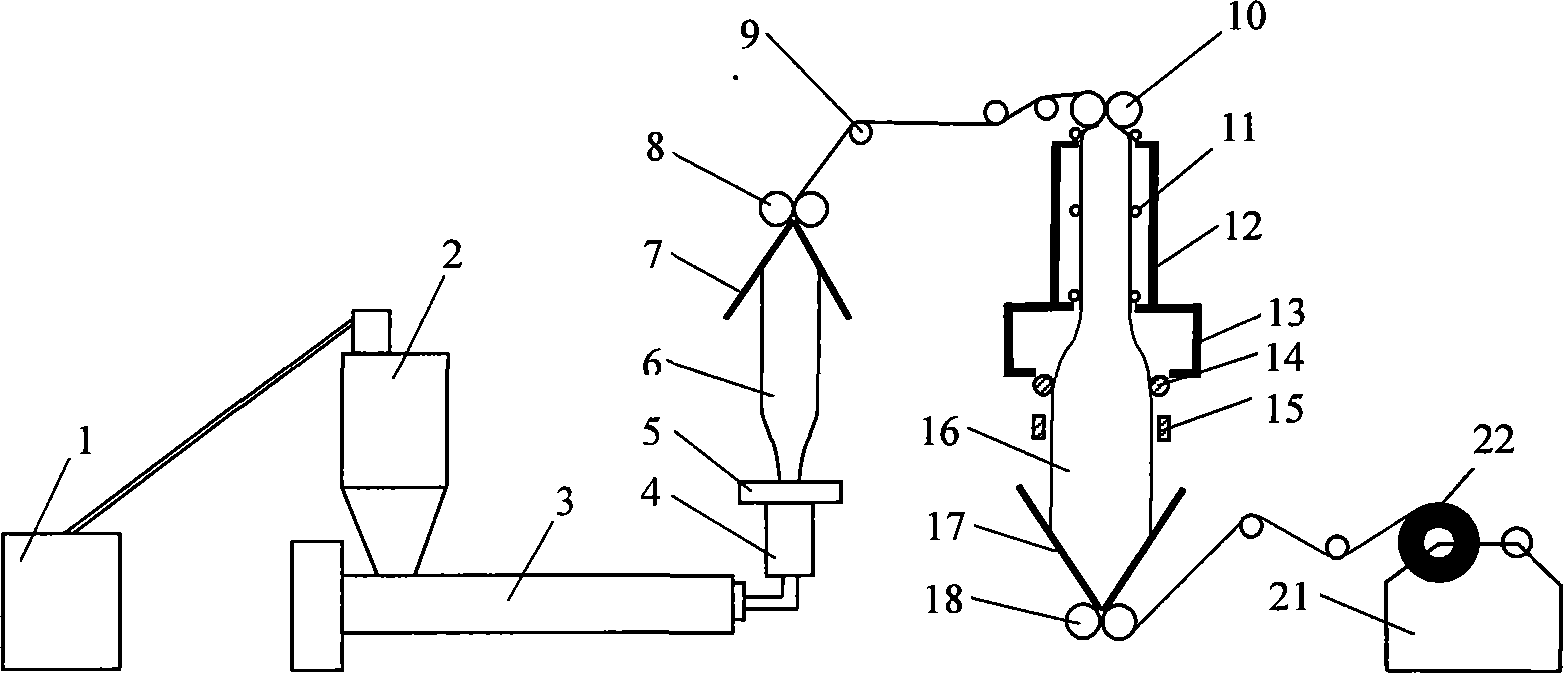

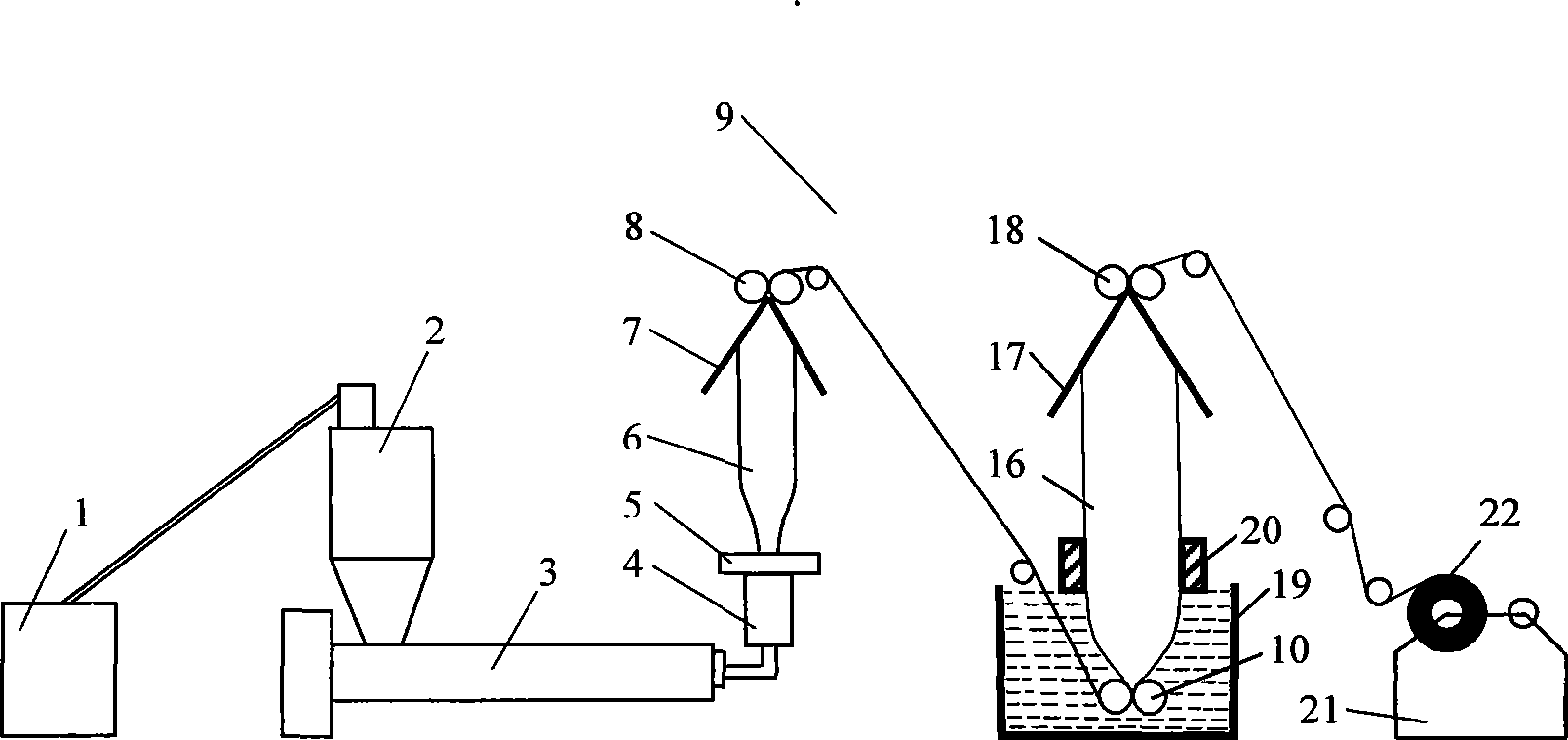

Image testing method for chemical fibre thermal contraction rate and testing apparatus thereof

InactiveCN1609603AImprove test accuracyStable structureTextile testingUsing optical meansMeasuring instrumentSingle fiber

The present invention belongs to the field of textile measuring instrument, and is one kind image test method and apparatus for the heat shrinkage of chemical fiber. The measuring method includes taking images of single fiber samples hung to cylindrical frame with CCD camera to obtain the length change before and after heating, and calculating in computer the heat shrinkage of chemical fiber. The measuring apparatus includes stepped motor, turntable, positioning pin, sample cylinder, elevator, metering calibration block, upper spring clamp, lower tensile clamp, holding circular ring, CCD camera, pulse distributor, casing, computer, display and printer. The present invention has the advantages of reliable test result, high precision, simple instrument structure and low fault rate.

Owner:SHANGHAI LIPU APPLIED SCI TECH INST

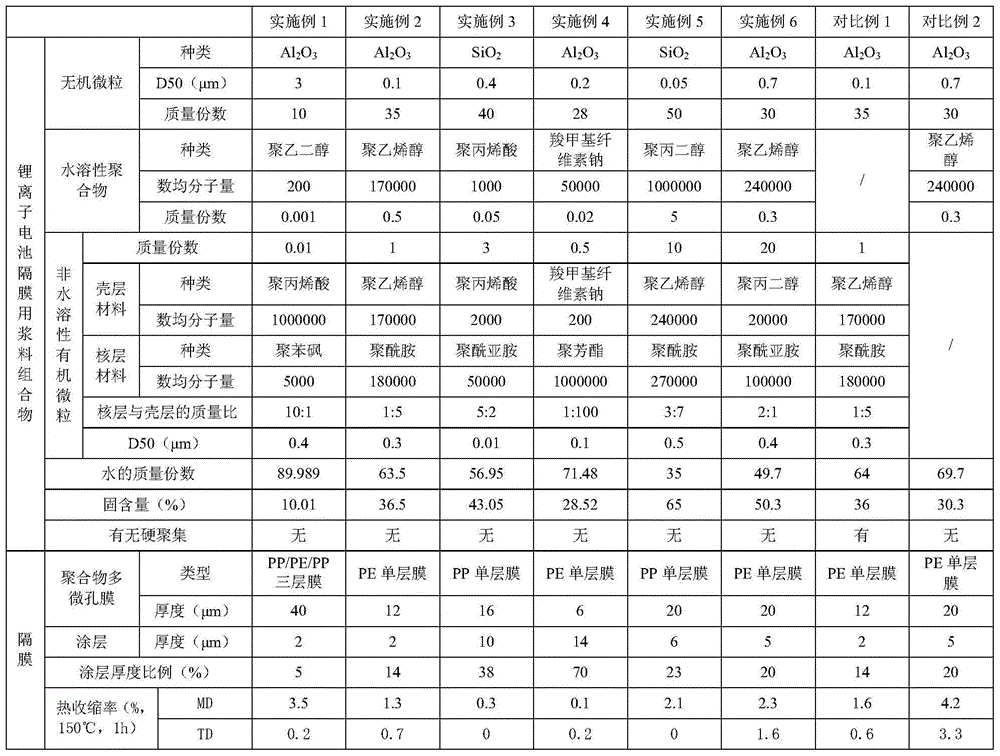

Slurry composition and lithium ion battery diaphragm containing same

ActiveCN105273444AImprove reliabilityEvenly dispersedCell component detailsCoatingsElectrical batterySlurry

The invention relates to a slurry composition and a lithium ion battery diaphragm containing the same. The slurry composition contains inorganic micro-particles, a water soluble polymer, non-water soluble organic micro-particles and water, wherein the water soluble polymer is used as a dispersant and is uniformly adsorbed on the surface of the inorganic micro-particles, so that the inorganic micro-particles are uniformly and stably dispersed in water, and an aqueous dispersion liquid of the inorganic micro-particles is obtained; the non-water soluble organic micro-particles have a core-shell structure, and the non-water soluble polymer as a core-layer material is uniformly dispersed in water due to the presence of a shell-layer material; the aqueous dispersion liquid of the inorganic micro-particles and the non-water soluble organic micro-particles are mixed uniformly, and the prepared slurry composition is used in the lithium ion battery diaphragm; through coating modification of the diaphragm, the heat resistant performance of the lithium ion battery diaphragm is improved, safety problems such as short circuit caused by thermal contraction of the diaphragm are reduced, and the reliability of a lithium ion battery is improved significantly.

Owner:乐凯胶片股份有限公司 +1

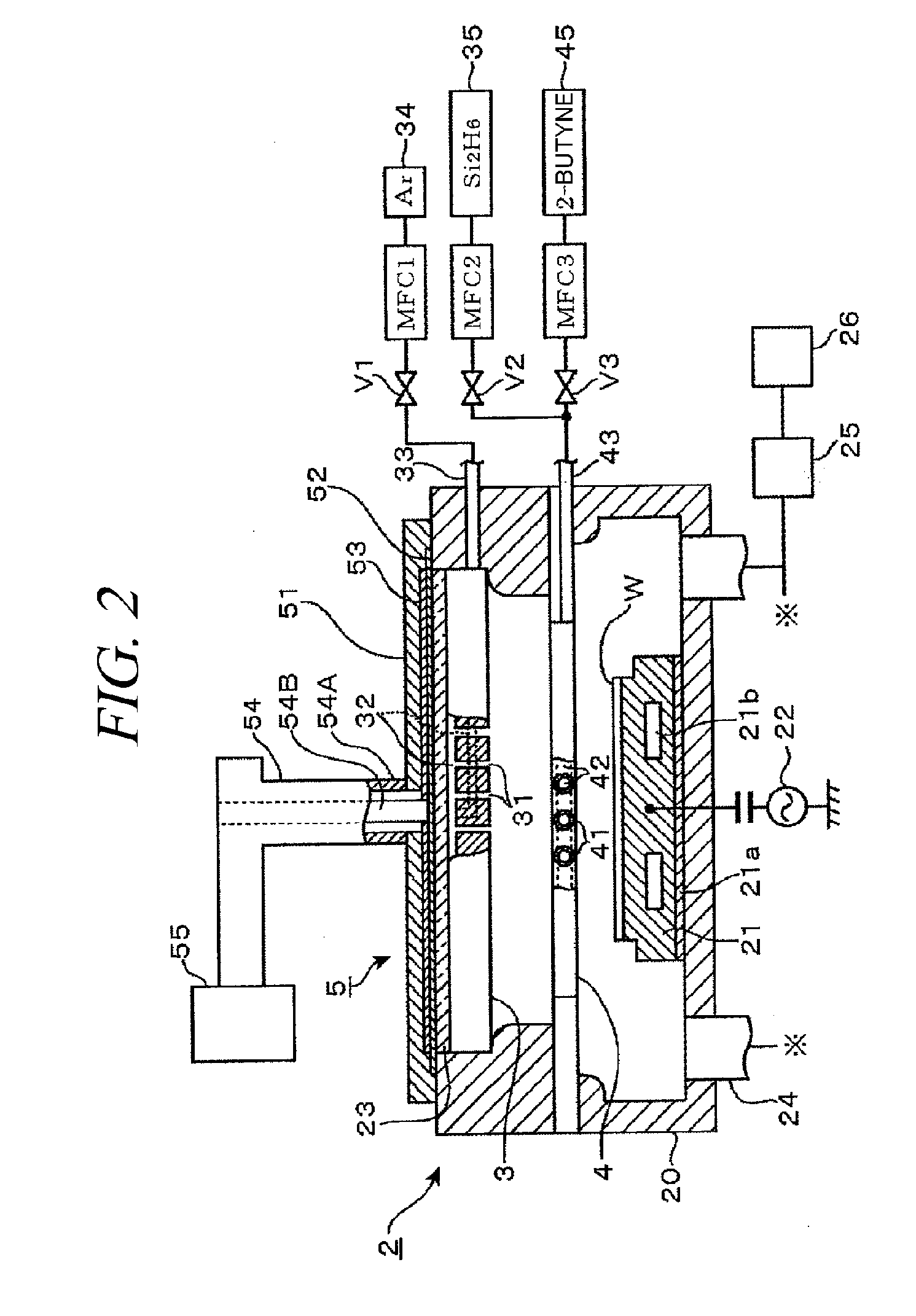

Amorphous carbon film, semiconductor device, film forming method, film forming apparatus and storage medium

InactiveUS20100032838A1Inhibited DiffusionSemiconductor/solid-state device detailsSolid-state devicesDielectric permittivityThermal contraction

Provided is an amorphous carbon film having a high elastic modulus and a low thermal contraction rate with a suppressed low dielectric constant, a semiconductor device including the amorphous carbon film and a technology for forming the amorphous carbon film. Since the amorphous carbon film is formed by controlling an additive amount of Si (silicon) during film formation, it is possible to form the amorphous carbon film having a high elastic modulus and a low thermal contraction rate with a suppressed dielectric constant as low as 3.3 or less. Accordingly, when the amorphous carbon film is used as a film in the semiconductor device, troubles such as a film peeling can be suppressed.

Owner:TOKYO ELECTRON LTD

Road surface crack sealing and mending tape and preparation and construction process thereof

The invention relates to a road surface crack sealing and mending tape and a preparation and construction process thereof. The road surface crack sealing and mending tape is mainly used for processing thermal contraction cracks and partial structural cracks. The raw material formula of the road surface crack sealing and mending tapeis as follows: 50-70g of petroleum asphalt, 6-8g of 1301SBS, 8-10g of methyl methacrylate, 10-15g of butyl acrylate, 5-8g of acroleic acid, 1-2g of styrene, 10-15g of calcium carbonate, 3-5g of softening agent, 2-3g of polyester fiber, 3-4g of tackifying resin, 0.6-0.88g of benzoyl peroxide (BPO), 10-20mg of antioxidant and 24-32g of mixed solvent. The road surface crack sealing and mending tape has excellent high and low temperature resistance, the glass transition temperature can reach below minus 25 DEG C, the high-temperature flowing temperature can reach more than 180 DEG C, the breaking elongation can reach 300-400%, the peel strength can reach 3-5MPa, the road surface crack sealing and mending tape can perform the autohesion at the temperature above 10 DEG C, and the road surface crack sealing and mending tape and the road surface can be formed into a whole by the rolling compaction of wheels after the crack is bonded, thereby achieving favorable crack sealing effect. The invention can actually mend the road surface crack at a very high efficiency, thereby greatly improving the service performance of the road surface and prolonging the service life of the road surface. The invention can be simultaneously used for fast mending the cracks in asphalt and cement concrete road surfaces, and has the advantages of good mending quality and low cost.

Owner:SHANGHAI UNIV

Double-bubble blown film moulding method for producing polyester thermal contraction film

The invention relates to a double bubble blow-molding film molding method of polyester heat-shrinkable film, belonging to the processing field of polymer materials. Polyester material is fed into a single-screw extrusion machine to carry out plasticizing extrusion after being dried, and a first film bubble is obtained after being blew by a blowing mould ram head, the first bubble is formed into a first bubble double-bending film through a first gable and a first pull roll, and secondary blowing is carried out to obtain a second film bubble for quenching molding after secondary heating is carried out to be in elastomeric state between Tg and Tf (Tg being a vitrification temperature, and Tf being a fusion temperature) through a second pull roll and a heating device, a second bubble double-blending film is formed through a second gable and a third pull roll and lastly taken up to obtain the polyester heat-shrinkable film. Compared with the existing flat film stretching method, the invention has the characteristics of small equipment investment, easy regulation for product standard and strong flexibility, and is applied to heat-shrinkable extension type label or goods package of containers.

Owner:BEIJING UNIV OF CHEM TECH +1

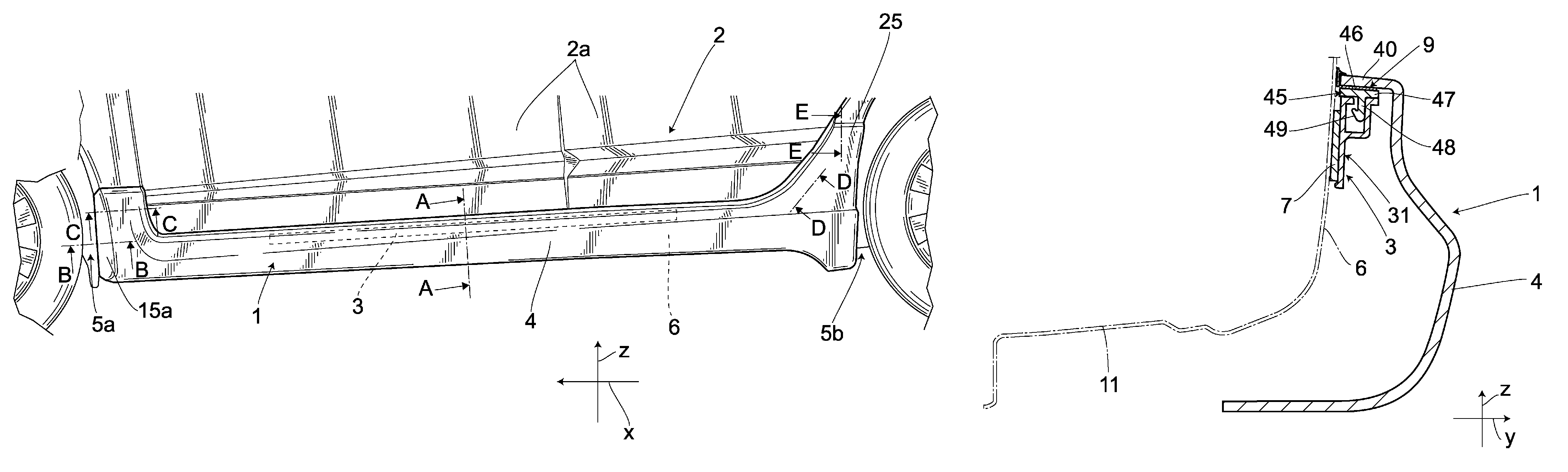

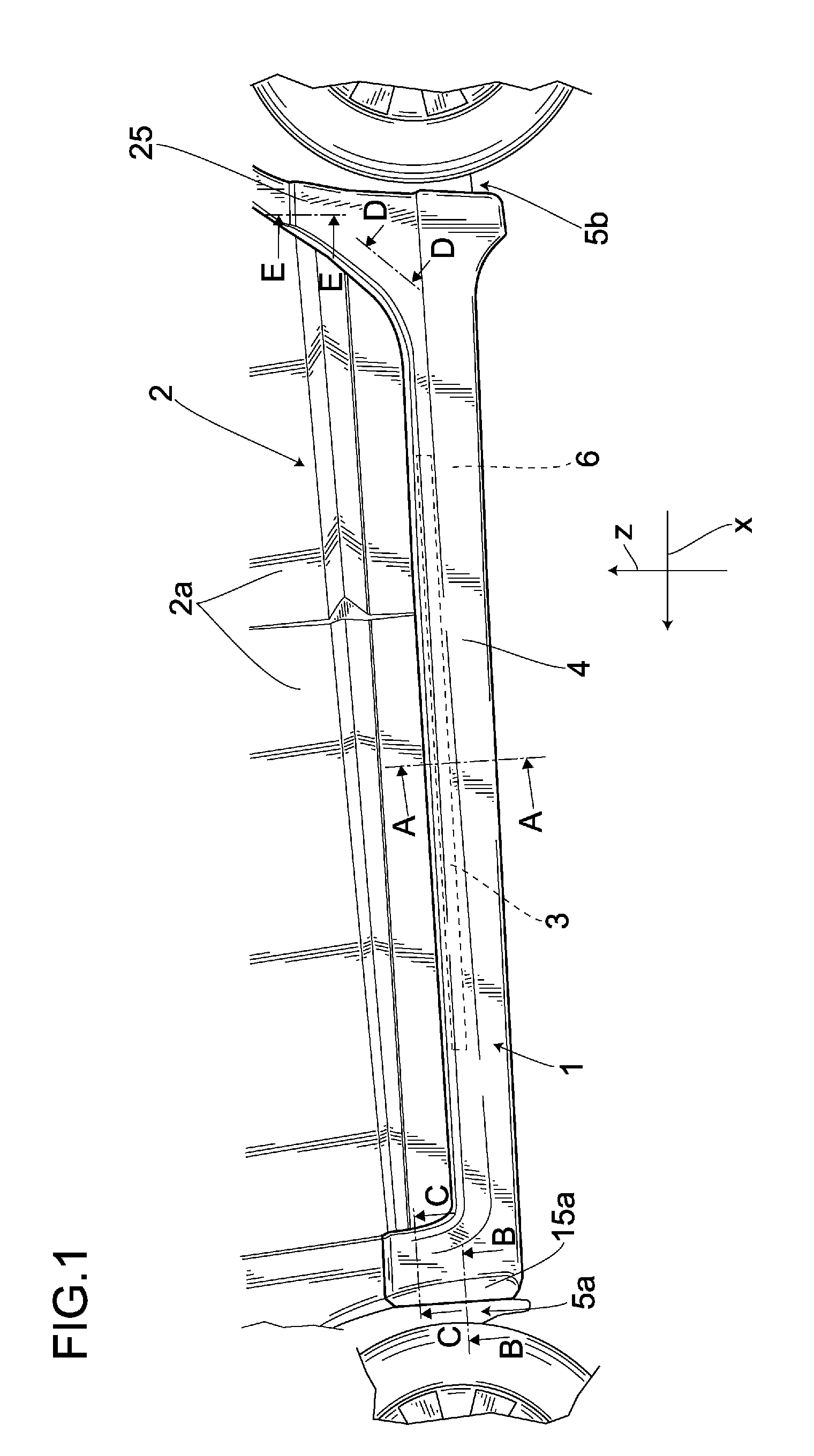

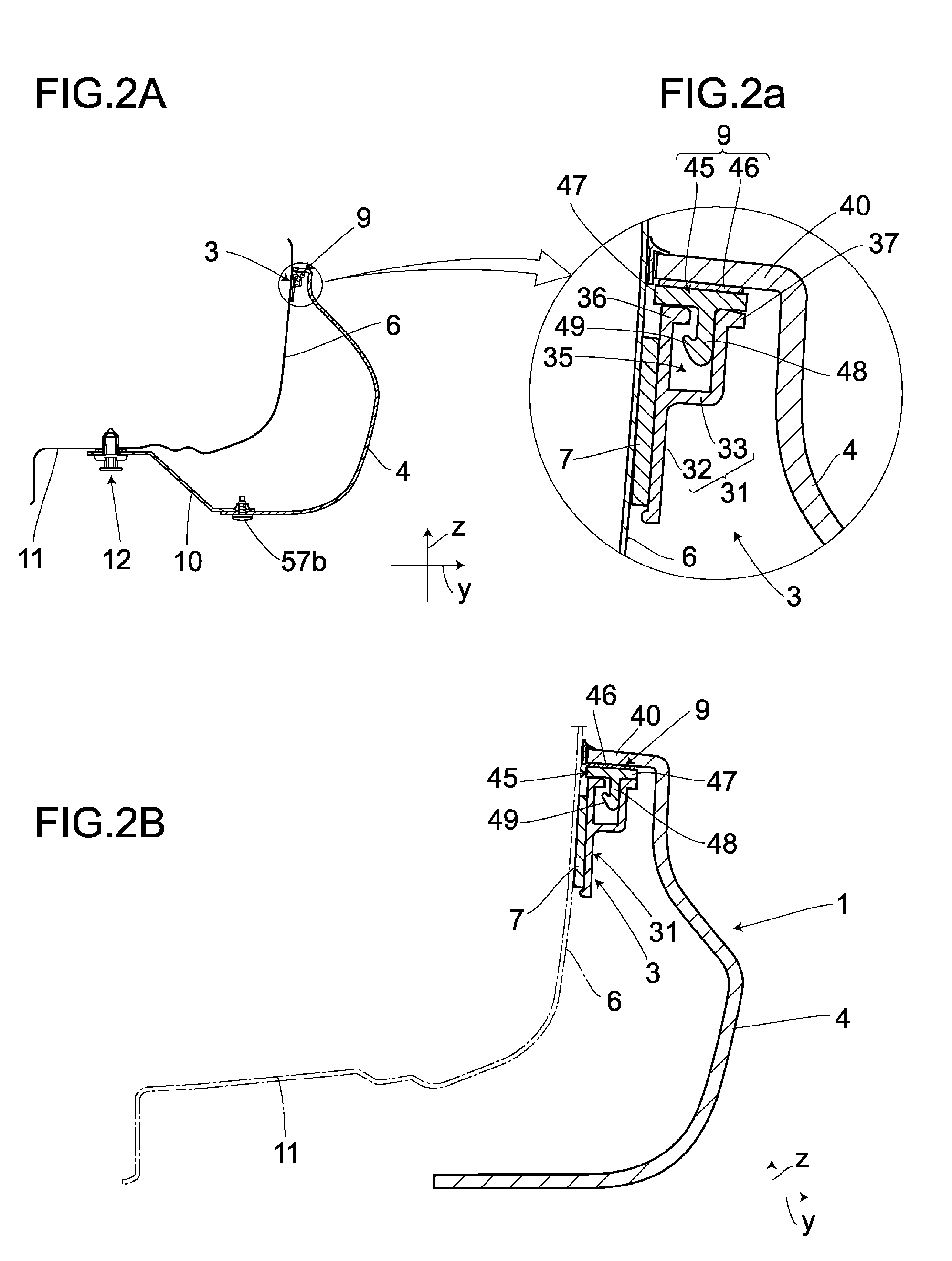

Side under spoiler mounting structure

ActiveUS8083285B2Easy to installMaintain abilityVehicle seatsCandle holdersThermal expansionEngineering

Because a vehicle lower portion 6 and a bracket 3 have an equal level of thermal expansion or thermal contraction, a bonded surface of the bracket 3 can be prevented from losing the bond with the vehicle lower portion 6 due to any deformation difference that might be caused if they have different thermal expansion coefficients. A side under spoiler 4 can be kept supported on the bracket 3 even if the side under spoiler 4 thermally expands or thermally contracts, and hence the side under spoiler 4 made of a different material from that of a vehicle body 2 can be more securely mounted on the vehicle body 2. The bracket 3 and the side under spoiler 4 after mounted can maintain their ability to be joined to the vehicle body 2 for a long term.

Owner:HONDA ACCESS CORP

Polyester thermal contraction film with balanced thermal contraction performance and production method thereof

The invention discloses a polyester thermal contraction film with balanced thermal contraction performance and production method thereof, the film is of three-layer construction: a top layer, a core layer and a bottom layer, wherein the component of the core layer is polyethylene terephthalate; the top layer and the bottom layer comprise parent material 15-25% wt and copolymerized modified polyester. The vertical, horizontal thermal contractions of the film are balanced and the vertical thermal contraction is about 65% and the horizontal thermal contraction is about 70% at 90-100DEG C; the vertical, horizontal tensile strengths are 240-260MPa. The process is mature with very strong operability, especially suitable for two-step tensile polyester film production line.

Owner:ANHUI GUOFENG PLASTIC

Driving device

InactiveUS20160315564A1Stably displacing objectSimple structureMachines/enginesVehicle cleaningRotational axisShape-memory alloy

A rotary shaft supported by a housing so as to be capable of rotating in a forward rotation direction and a reverse rotation direction. A shape-memory alloy member having a wire-like shape urges, by thermally contracting, the rotary shaft by applying an external force in the forward rotation direction. A bias spring urges the rotary shaft by applying an external force in the reverse rotation direction. A wiper is displaced along with rotation of the rotary shaft. The shape-memory alloy member is arranged such that, when a thermal contraction force is divided into a first partial thermal contraction force in the forward rotation direction and a second partial thermal contraction force in a length direction of the rotary shaft, the first partial thermal contraction force is larger than the second partial thermal contraction force.

Owner:MURATA MFG CO LTD

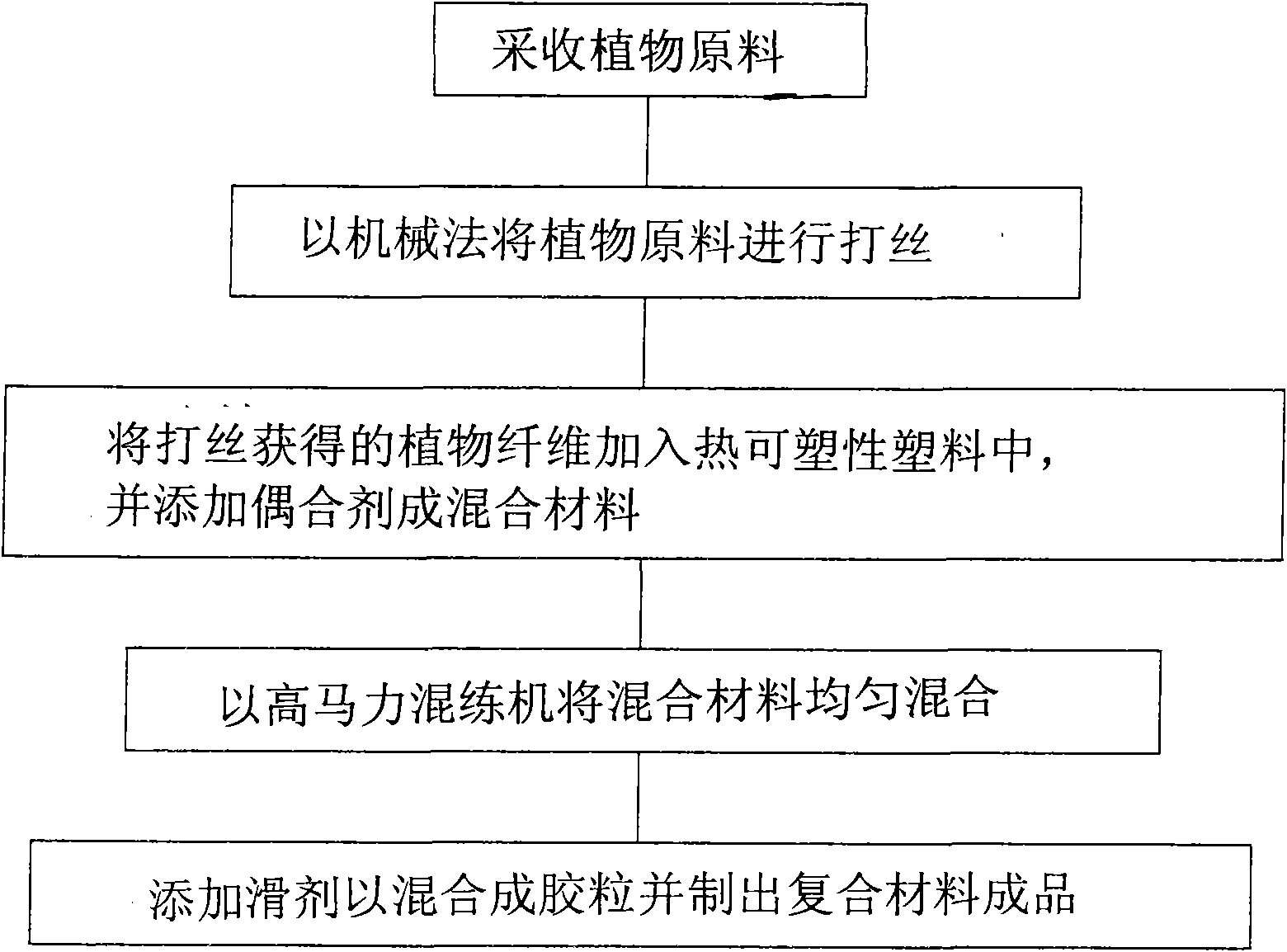

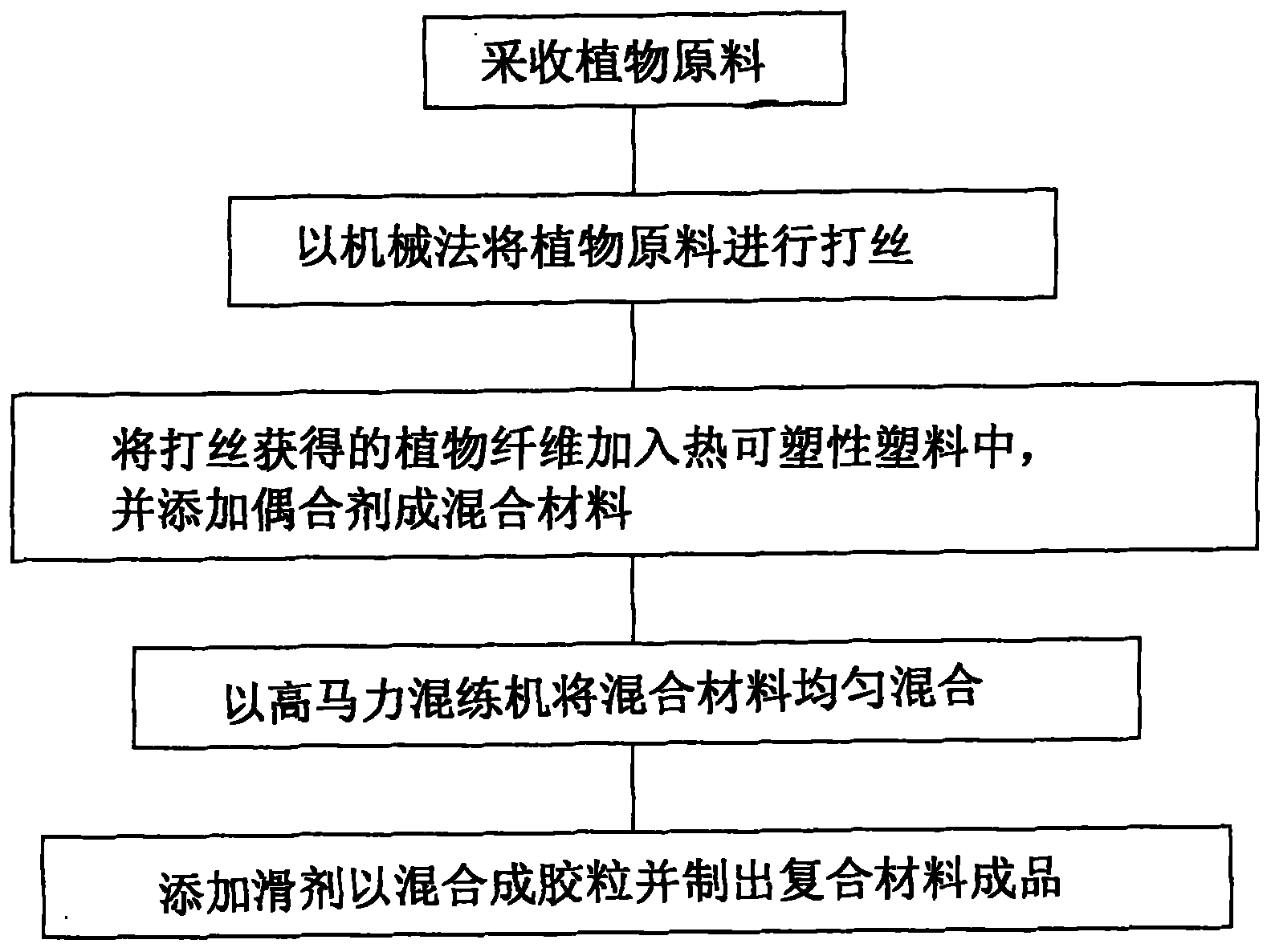

Preparation process of plant fiber composite materials

InactiveCN101781472AImprove flexural strengthReduce weightMechanical fibre separationManufacturing cost reductionFiber

The invention provides a preparation process of plant fiber composite materials, which comprises the following steps: collecting plant raw materials; using a mechanical method for cutting the plant raw materials into threads; adding the plant fiber obtained after the thread cutting into thermoplastic plastics and adding coupling agents to obtain mixed materials; using a high-horsepower calendaring machine for uniformly mixing the mixed materials; and adding lubricating agents to be mixed into colloidal particles and preparing finished products of composite materials. Because of the plant fiber composite materials, the prepared finished products have the characteristics of high bending resistance intensity, weight reduction, difficult thermal distortion, small thermal contraction force, manufacture cost reduction and the like.

Owner:詹德威

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com