Patents

Literature

192results about How to "Address reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

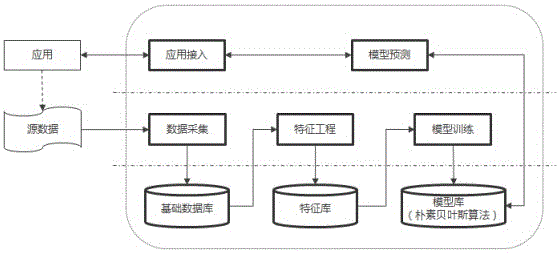

Real-time recommendation system and method of financial products of banks based on Naive Bayesian classification

InactiveCN106600369AImprove experienceIncrease stickinessMathematical modelsFinanceData setData mining

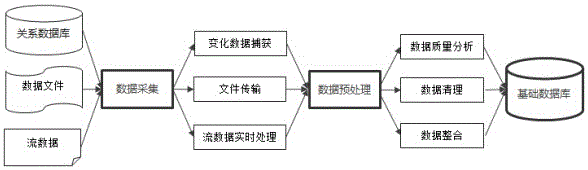

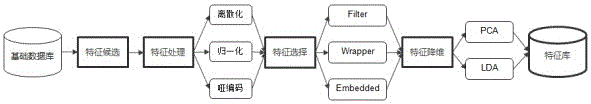

The invention discloses a real-time recommendation system and method of financial products of banks based on Naive Bayesian classification wherein the method comprises: acquiring the data of a bank business system, a peripheral system, and an internet / mobile internet; processing and storing the data in a basic database; conducting characteristic processing to the data attributes of the customers in a certain area; converting for data characteristics to develop a characteristic database; classifying the data in the characteristic database as a training data set and a verification data set which are used respectively for the training and estimating of a Naive Bayesian classification algorithm model; obtaining a model base after several times of iteration; identifying the characteristics of customers and in combination with the Naive Bayesian classification algorithm model base, matching the customers with the financial products they are mostly likely to purchase in real time; and recommending to the customers the financial products that are forecasted and matched by the models. The recommendation system and method of the invention are capable of helping customers to find out suitable products, therefore, increasing the user experience and the bonding effect of the customers to the financial products, lifting up the transferring rate of the products and making the bank more competitive.

Owner:广东奡风科技股份有限公司

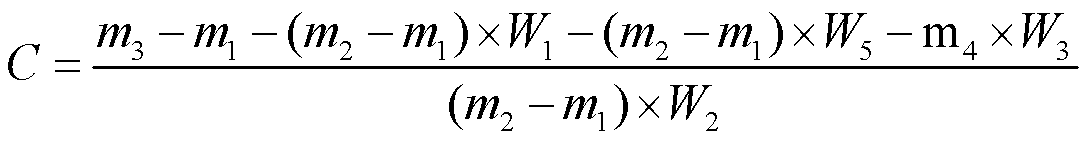

Method for preparing ginseng polysaccharide

The invention refers to a preparation method of ginseng polysaccharide. The method includes the following step: extract it from the ginseng or the marc of the ginseng decocted, filtrate, concentrate and deposit the extracting solution, get the precipitate after centrifugence and dry it with low temperature to get the crude product of ginseng polysaccharide. We get the polysaccharide product after the ginseng polysaccharide goes through the boiling, depositing, filtration, trash extraction, frost thawing, getting rid of the protein and getting the supernatant and the supernatant passes through the concentration with low pressure and drying with low temperature. We can make it into all kinds of forms of prepared drugs after the ginseng polysaccharide passes through the experiments in pharmaceutics. The invention effectively increases the quality of the ginseng polysaccharide injection, fully exerts the immunoloregulation function of the ginseng polysaccharide, increases the anti tumor effect of chemotherapy medicament and is used to reduce the side effect caused by the knubbly radiotherapy and chemotherapy as well as adjuvant for curing the tumor.

Owner:JILIN SIHUAN PHARM CO LTD

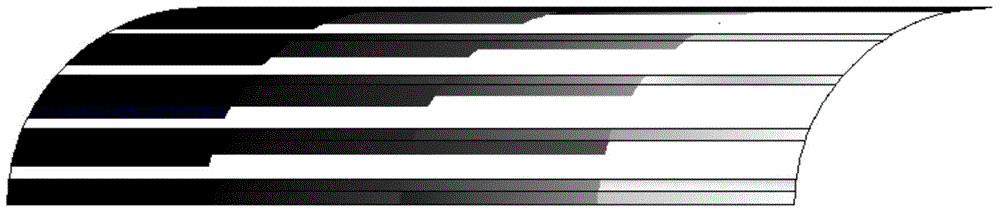

Copolyester with low melting point and synthesis method thereof

InactiveCN101735437AAddress reactivityFix stability issuesFlexible coversWrappersPolymer scienceSynthesis methods

The invention discloses polyester with an extensive amorphous region. The components of terephthalic acid, m-phthalic acid and dihydric alcohol and a dihydroxy compound with an ether bond are used as basic raw materials, an acid component contains 10-30 percent by mol of m-phthalic acid and 70-90 percent by mol of terephthalic acid, total acid and total alcohol are prepared into uniform slurry inthe mol ratio of 1.05:2.0, and the polyester which does not have an obvious melting peak under a DSC (differential scanning calorimetry) and has the extensive amorphous region and low melting point is generated by the reactions of esterification and polycondensation. The method can utilize a traditional semicontinuous and continuous polyester production line to realize industrialized production. The polyester produced by utilizing the method provided by the invention is used for preparing a packaging film, a sheet, a hot melt adhesive and the like. The invention is especially suitable for being prepared into a thermal contraction film used for a packaging purpose or a tag purpose so as to replace a polyvinyl chloride (PVC) thermal contraction film used in the market at present.

Owner:ZHONGFU GUANGHAN CHEM IND

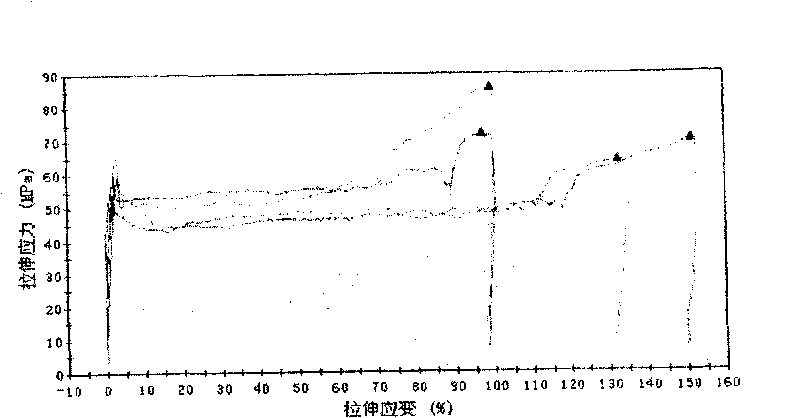

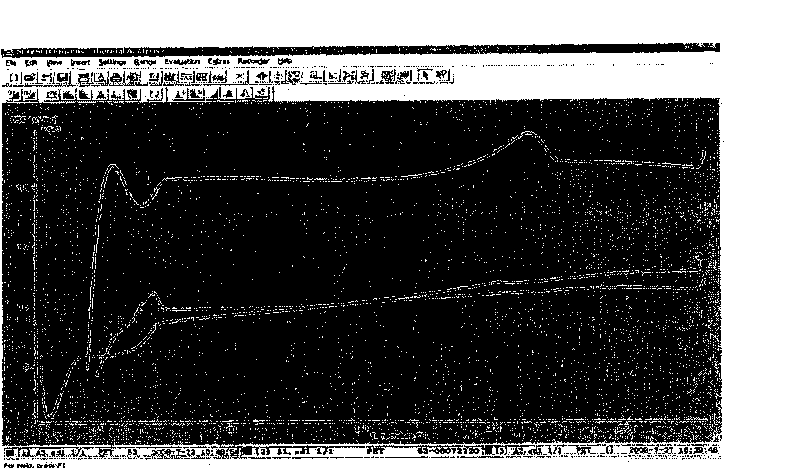

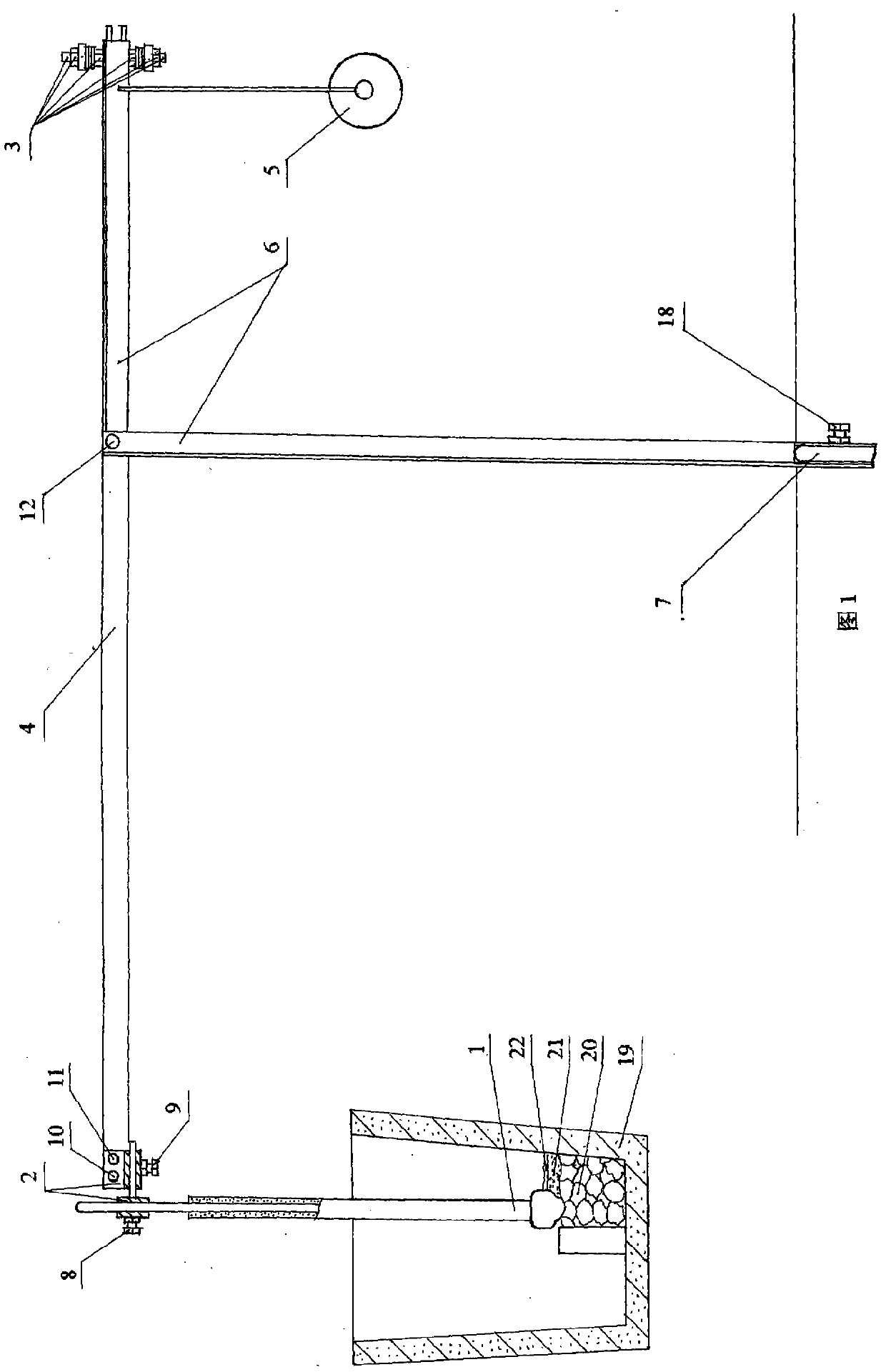

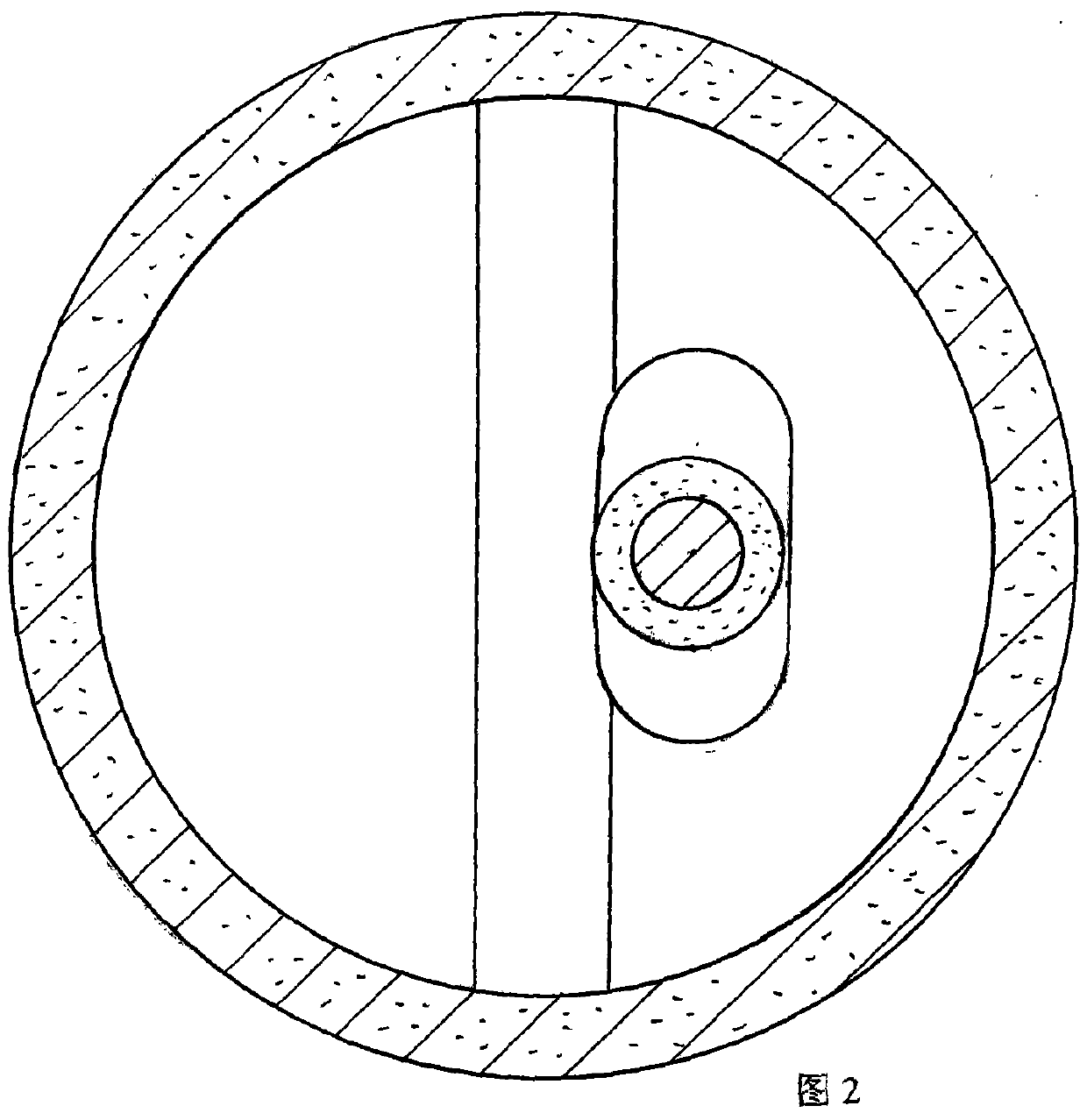

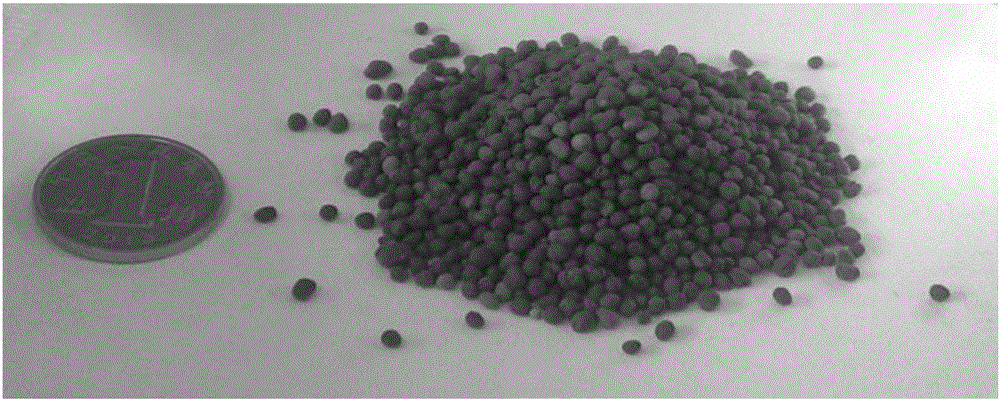

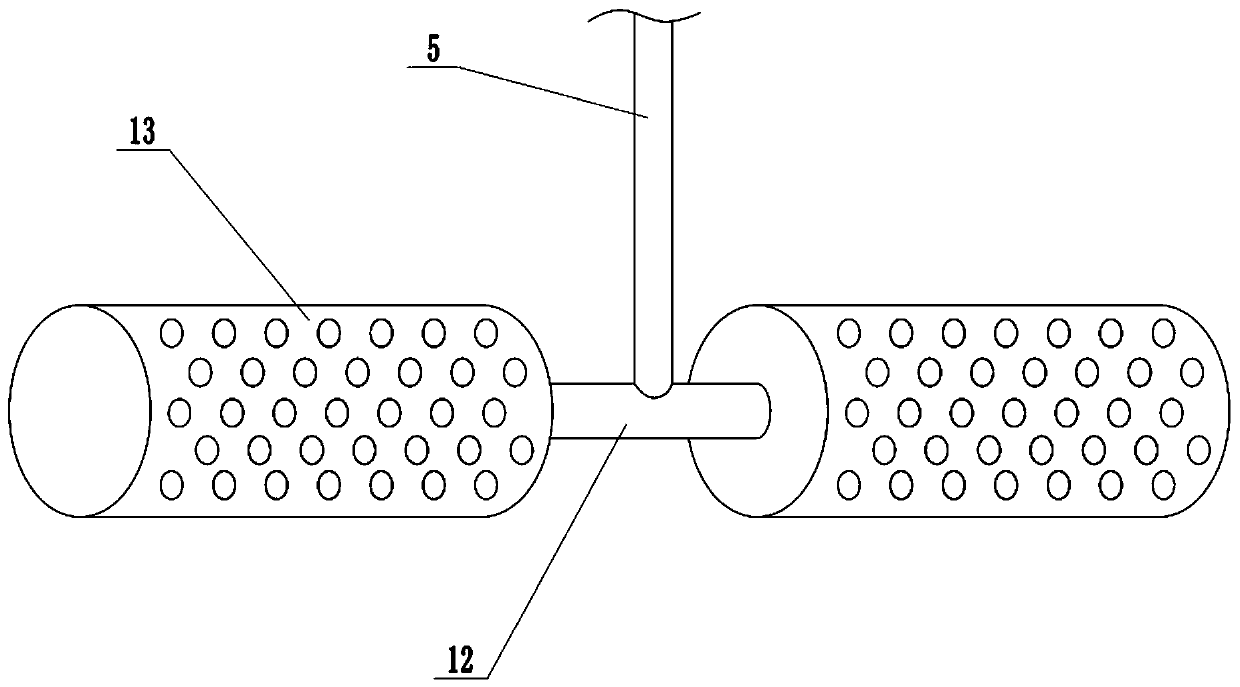

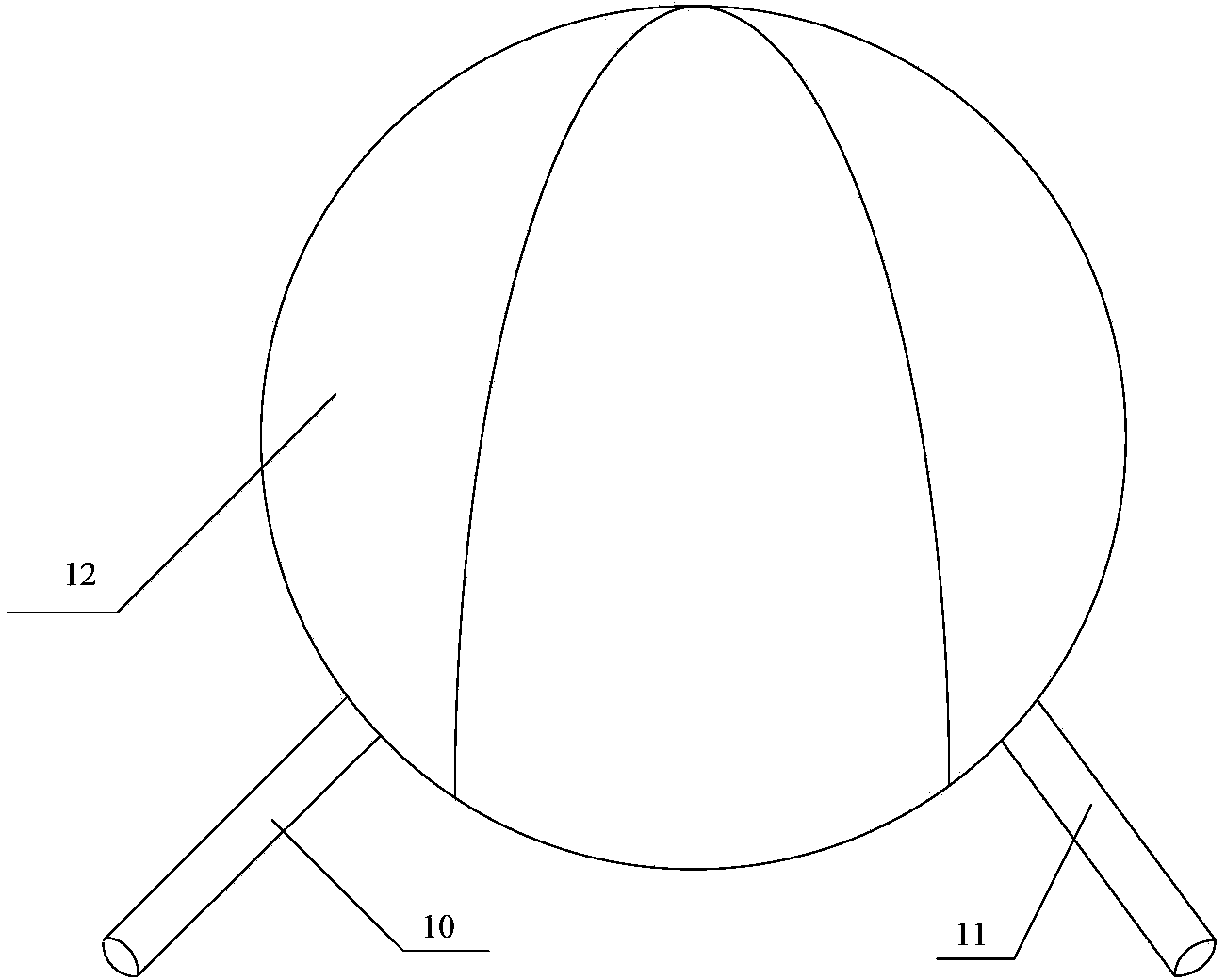

Spheroidizing treater and process

InactiveCN101029367AIncrease Mg contentCancel the secondary smelting processDuctile ironUltimate tensile strength

A spheroidizing treater for producing spheroidal graphite cast iron is carried out by adjusting bearing rod head and dam seam and controlling iron-water and nodulizer contact. It adopts waste-heat one-step method and controls spheroidizing reactive time and strength; the spheroidizing agent consists of Mg<=20%, RE<=3% and Si<=65%. It's simple, cheap and can be used for large-scale continuous production.

Owner:河北贝广电力设备有限公司

Magnetic resonance imaging nanometer drug carrier, and nanometer drug loading system and preparation method thereof

ActiveCN107715121AOvercoming selectivityOvercome toxic and side effectsOrganic active ingredientsEmulsion deliverySide effectTherapeutic effect

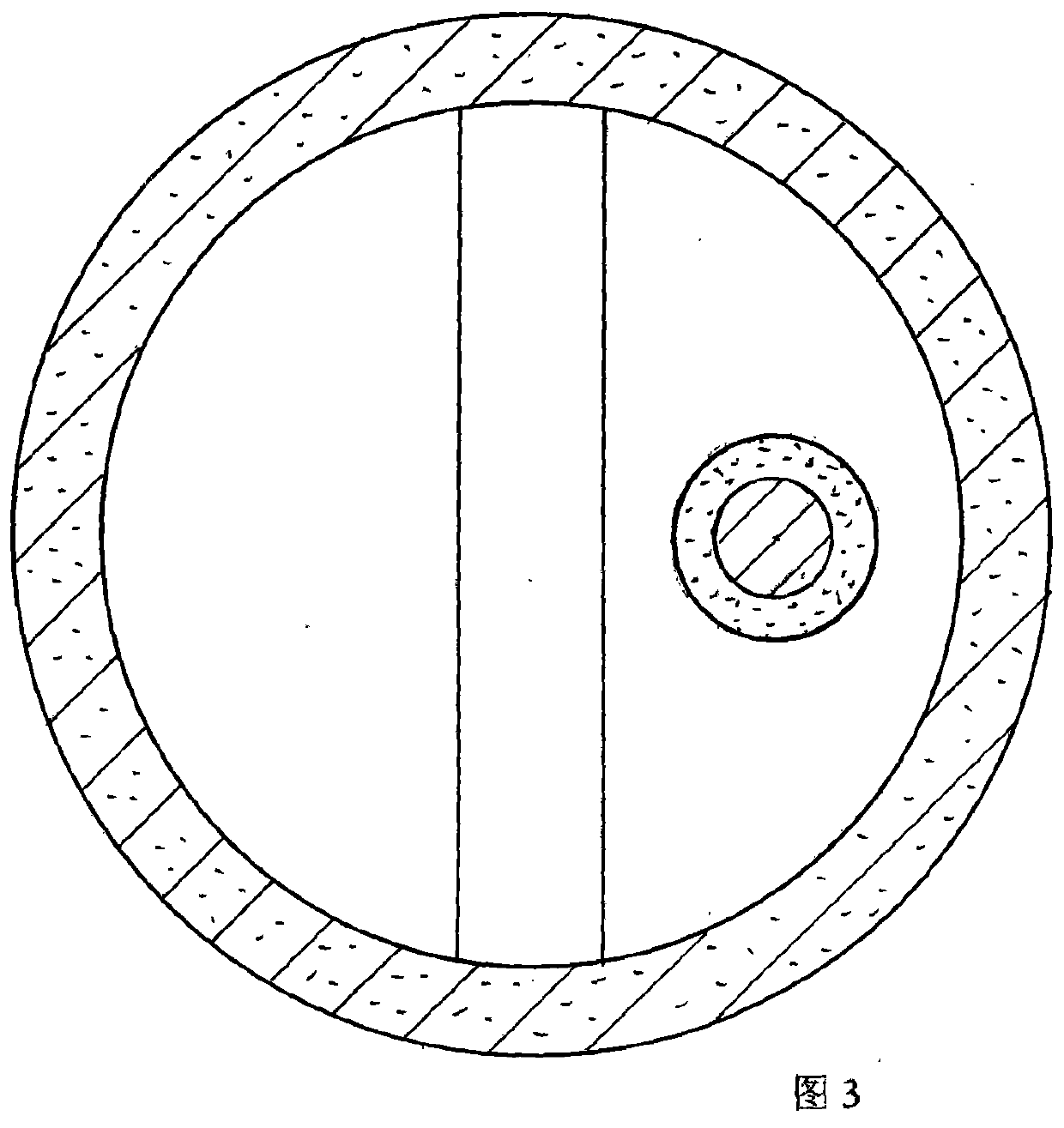

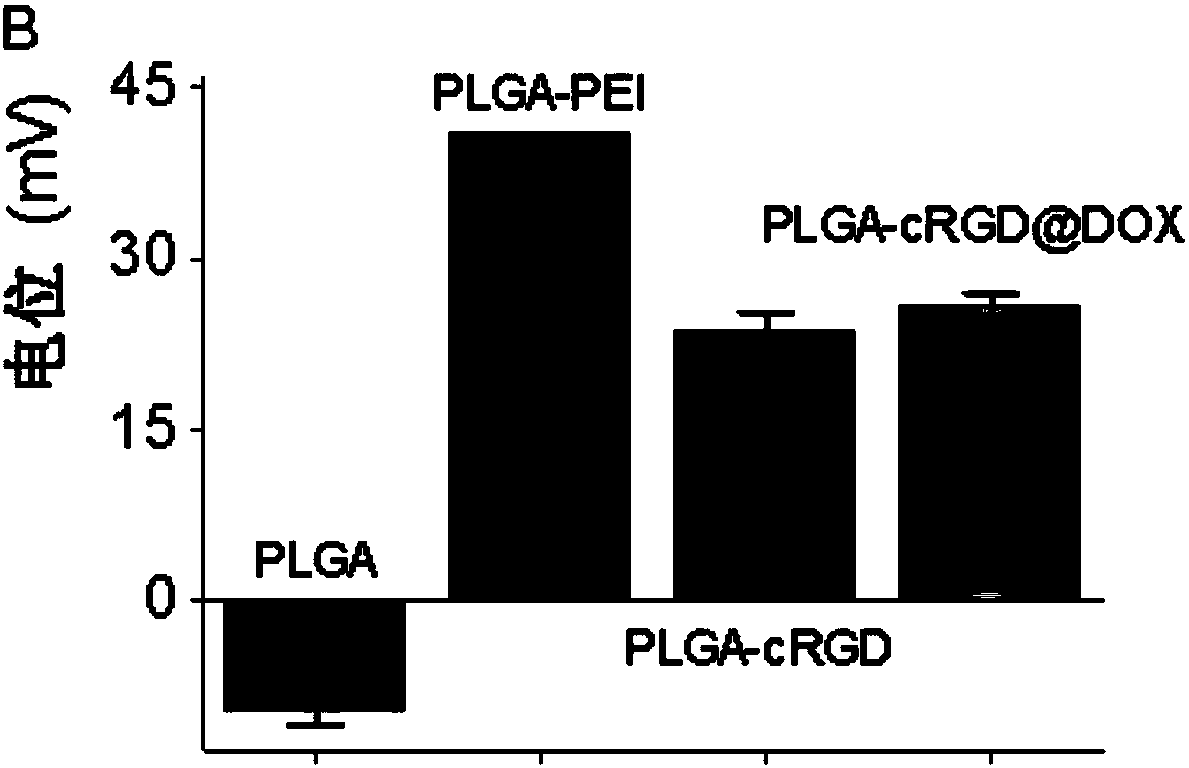

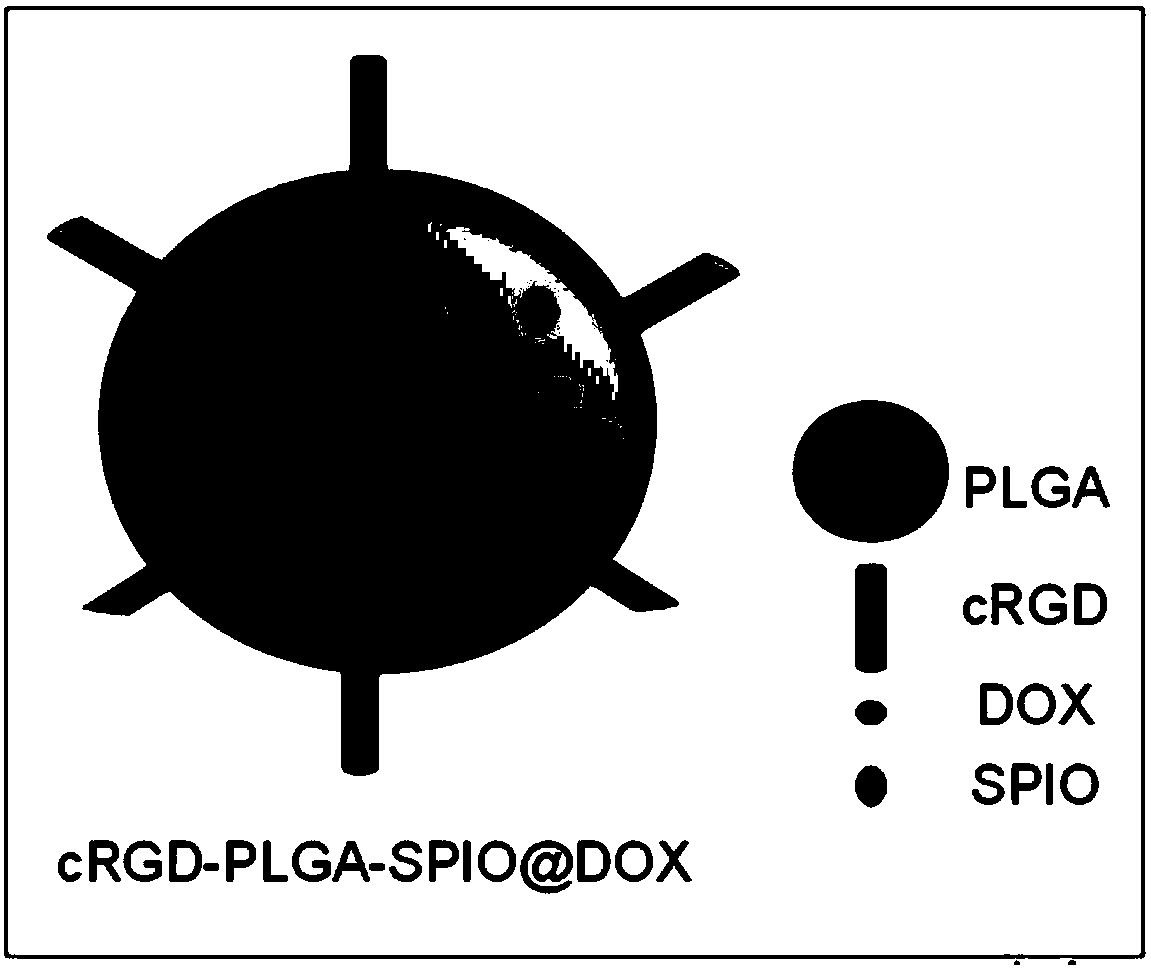

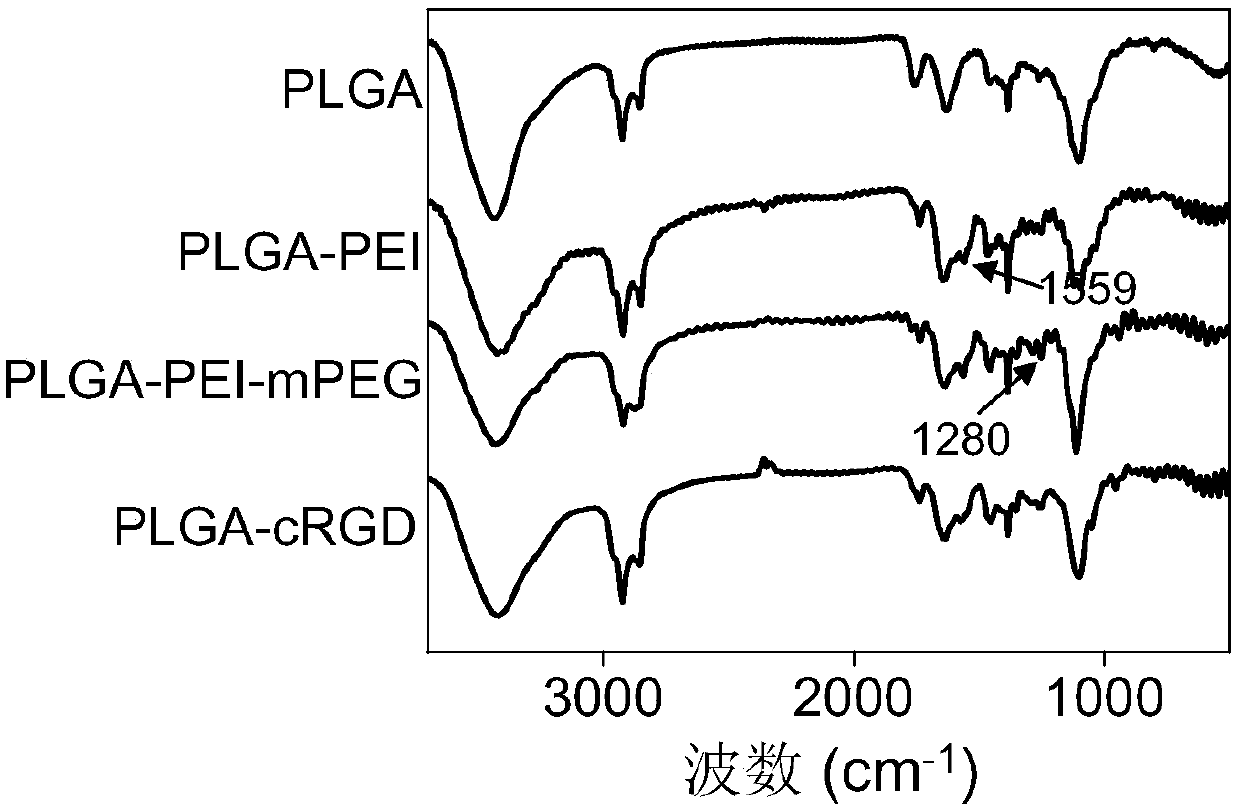

The invention discloses a magnetic resonance imaging nanometer drug carrier, and a nanometer drug loading system and a preparation method thereof. The magnetic resonance imaging nanometer drug carrieris a triblock polymer nanoparticle, wherein the triblock polymer is PLGA-PEI-PEG, and has active groups on the surface, and the active groups comprise amino, hydroxyl and carboxyl. According to the present invention, the drug carrier can efficiently load a nuclear magnetic resonance imaging drug and an antitumor drug to make the antitumor drug specifically reach the tumor lesion site, such that the nuclear magnetic resonance positioning of the superparamagnetic ferroferric oxide nanoparticle at the tumor region can be achieved while the high-selectivity and low-toxicity treatment effect can be achieved, and the disadvantages of poor selectivity, strong toxic-side effect, easy drug-resistance generation and the like of the traditional cytotoxic drugs can be overcome; and the preparation method is simple and is easy to perform, the prepared triblock polymer nanoparticle can be stably stored in the aqueous solution so as to be easily stored, and various functional groups exist on the surface of the particle, such that the prepared triblock polymer nanoparticle can be easily subjected to surface modification or surface functionalization.

Owner:JINAN UNIVERSITY

Intelligent device and method for remedying mis-operation of accelerator of vehicle

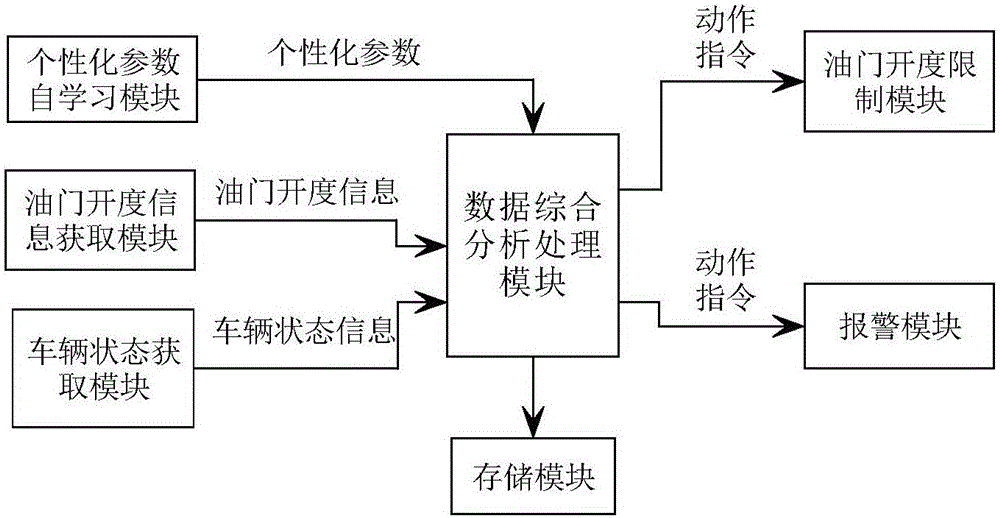

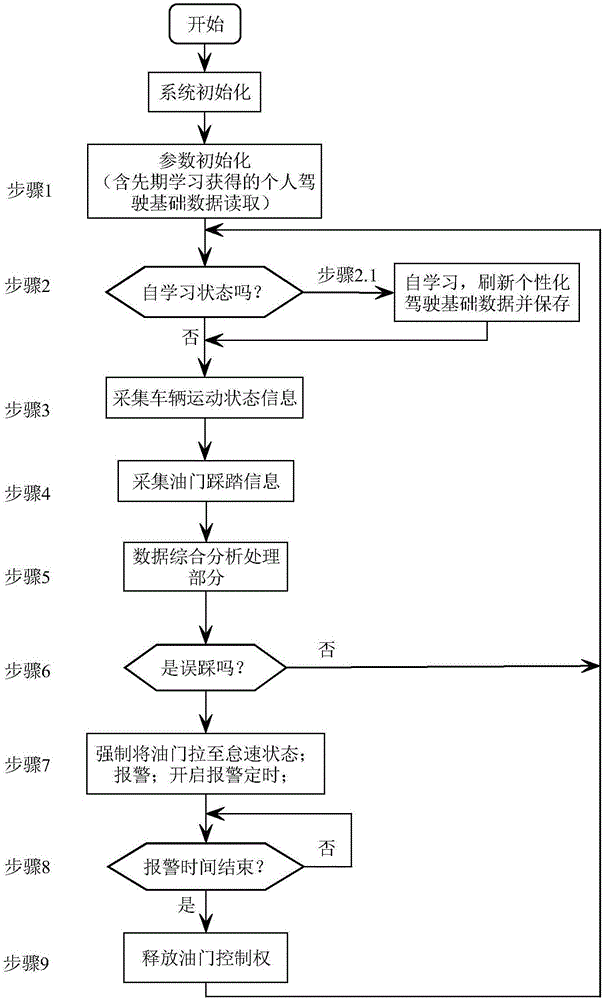

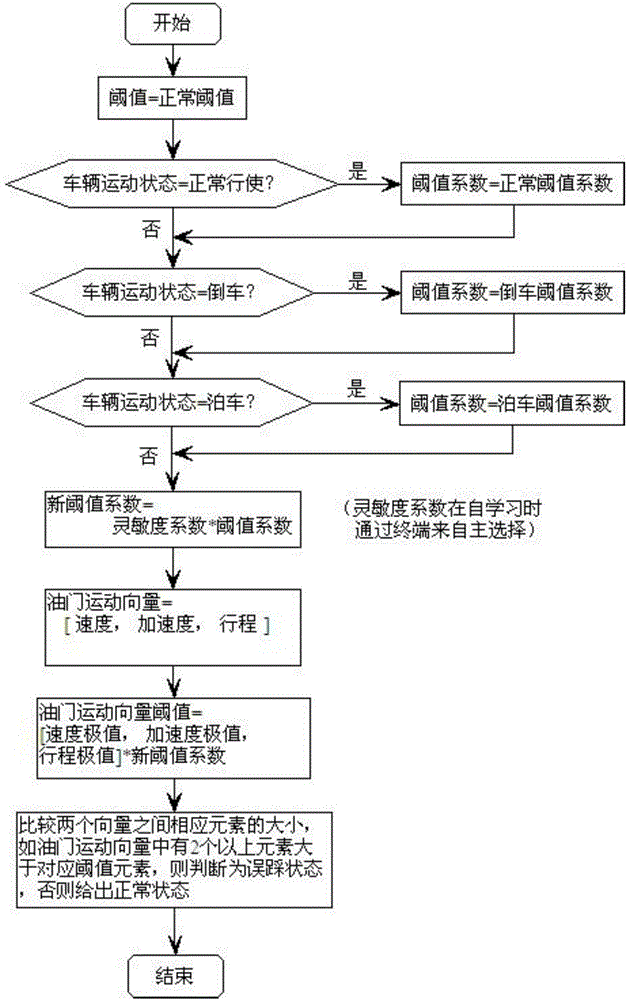

ActiveCN105128663AAddress driving habitsAddress reactivitySignalling/lighting devicesPropulsion unit arrangementsPersonalizationHabit

The invention discloses an intelligent device and an intelligent method for remedying mis-operation of an accelerator of a vehicle. The device includes a personalized parameter self-learning module, an accelerator opening information acquisition module, a data synthetic analysis processing module, and an accelerator opening limit module, wherein signal output ends of the personalized parameter self-learning module and the accelerator opening information acquisition module are connected to a signal input end of the data synthetic analysis processing module. According to the invention, the device can obtain an adaptive function by self-learning; the problem that the misjudgment is caused by individual difference in driving habits and reaction capacity of drivers can be solved, and the problem that the vehicles have differentiation requirements for threshold values under different motion states can be solved, so that the recognition rate of accelerator mis-operation is greatly improved.

Owner:HANGZHOU WEIEN ELECTRONICS SCI & TECH CO LTD

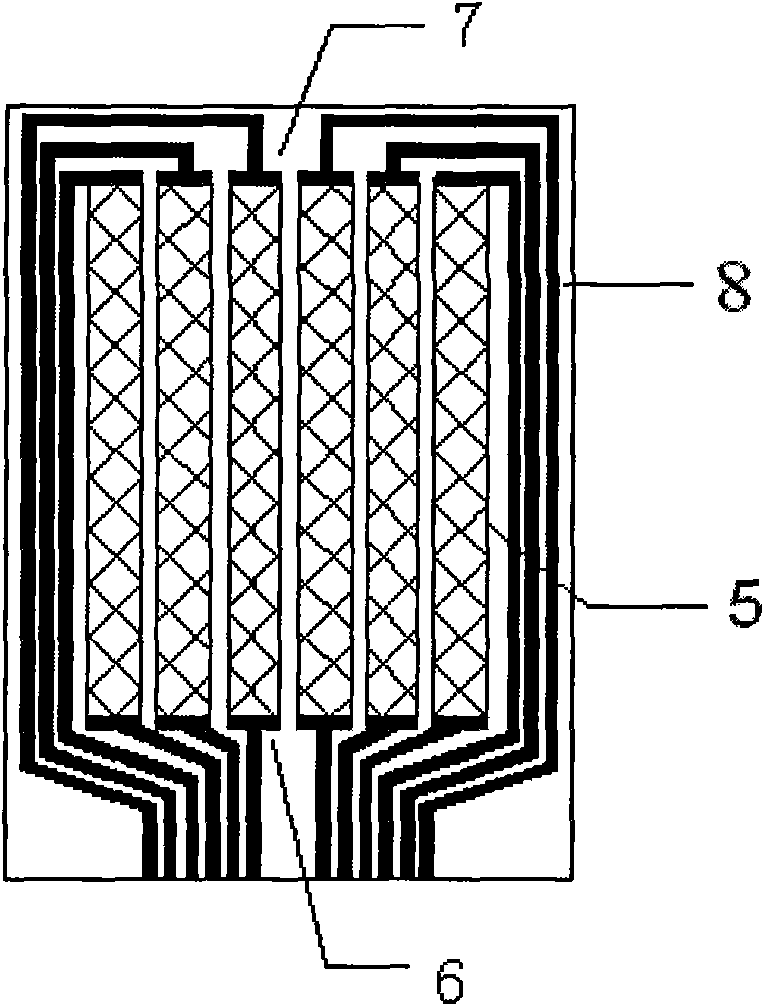

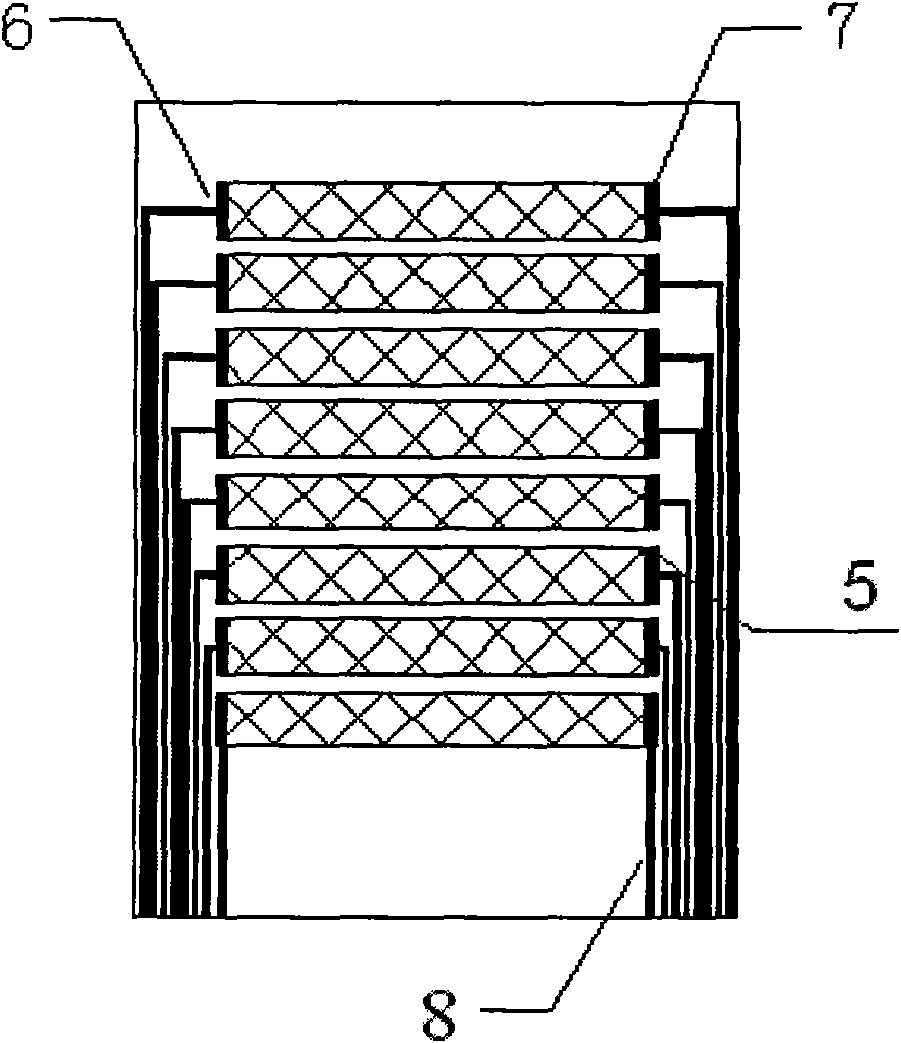

Projected capacitive touch screen

InactiveCN101571778AReduce scan timeImprove signal-to-noise ratioInput/output processes for data processingHigh volume manufacturingTouchscreen

The invention relates to a projected capacitive touch screen, which can greatly shorten scanning time and improve signal-to-noise ratio, and has accurate touch and sensitive response. The projected capacitive touch screen comprises a conductive layer covered on a substrate, the conductive layer comprises electrode strips, and each electrode strip is connected with more than two conducting wires which are connected with an external circuit. As a preferable mode, two ends of each electrode strip are connected with a conducting wire respectively. The substrate can be made of known various materials, preferably, the substrate is a membrane. By the projected capacitive touch screen, the problem that the face resistance value is overlarge when an ITO conductive layer uses the membrane as the substrate at present is well solved, the problems that the touch of the projected capacitive touch screen of an ITO membrane structure is inaccurate and the response is not sensitive are effectively solved, the dependency on raw materials is reduced, the material selection range of the projected capacitive touch screen of the ITO membrane structure is enlarged, and the projected capacitive touch screen of the membrane structure is feasible to be produced on a large scale.

Owner:NANJING WALLY ELECTRONICS TECH

Condensation polymerization method for preparing hydroxylated acid condensation polymer

The invention provides a condensation polymerization process for preparing hydroxylated acid condensation polymer, characterized in that hydroxylated acid or hydroxylated acid oligomer are subject to molten condensation polymerization reaction or molten / solid phase condensation polymerization reaction at the presence of ionic liquid catalytic action. The obtained hydroxylated acid condensation polymer contains no metallic elements.

Owner:ZHEJIANG UNIV

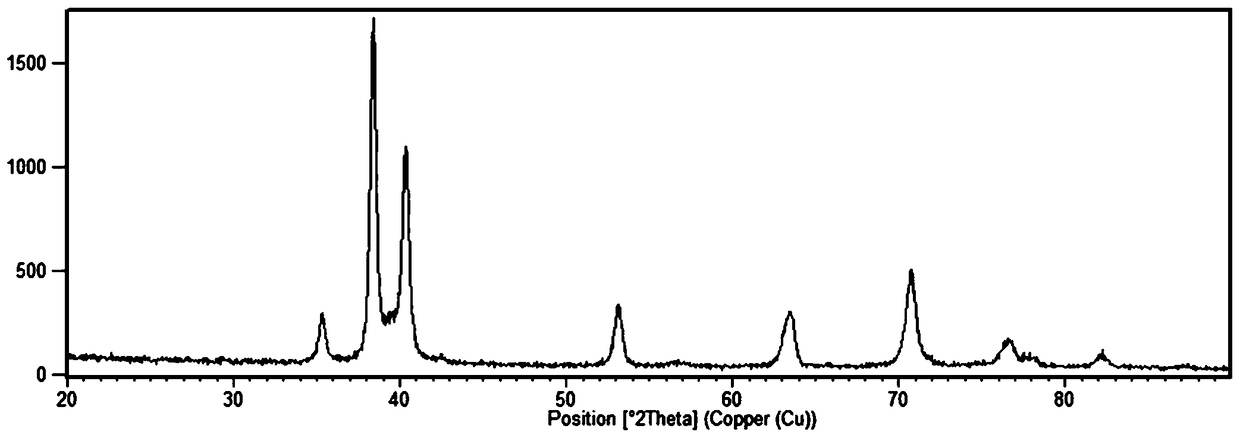

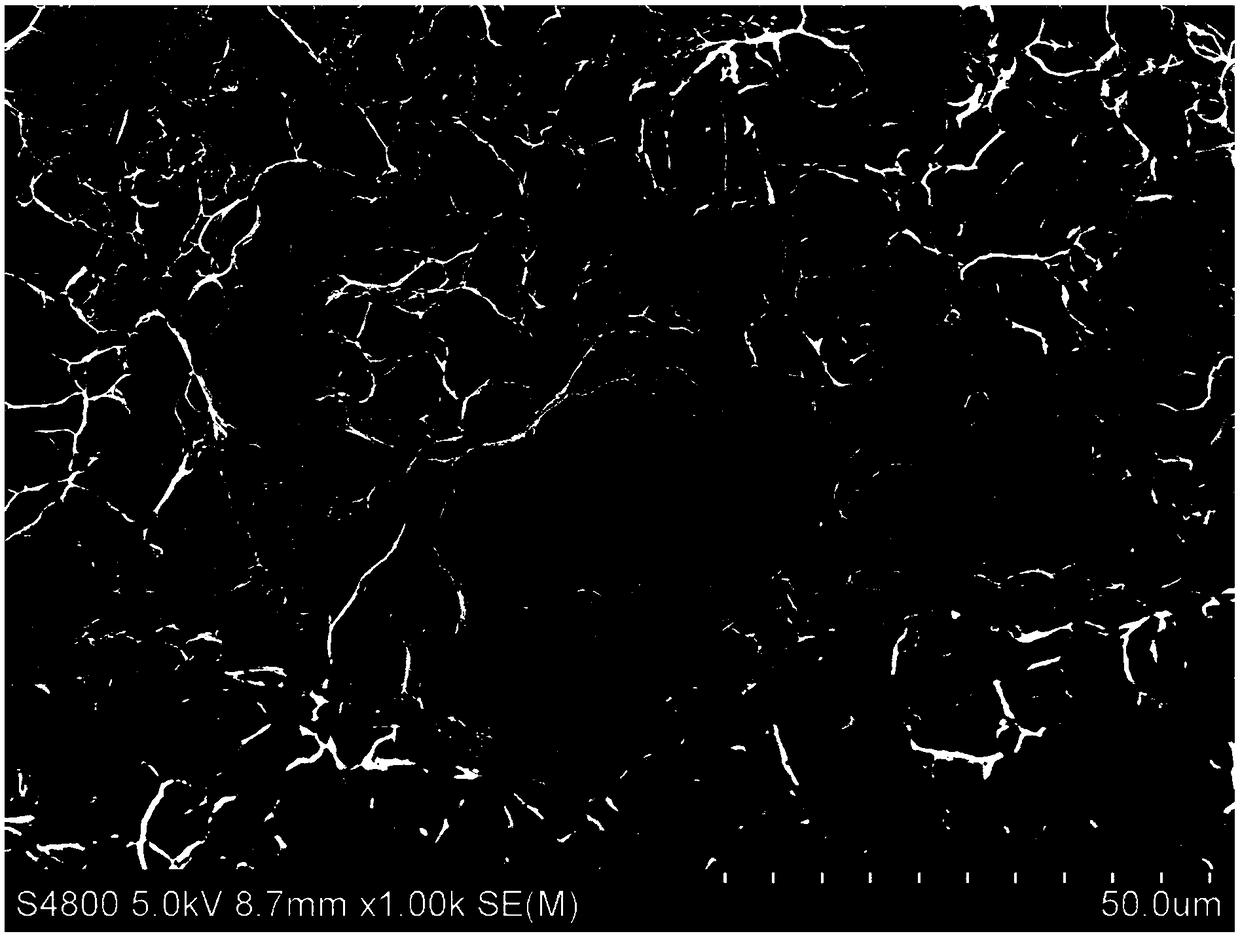

Preparation method of TiB nano-reinforced titanium-based composite material

The invention relates to a preparation method of a TiB nano-reinforced titanium-based composite material, and belongs to the field of metal-based composite materials. According to the method, the composite material is prepared through ball milling, spark plasma sintering and hot rolling. The original powder is prepared through ball milling, the advantages that the sintering efficiency of the discharge plasma is high, and the external pressure and the sintering atmosphere can be controlled are utilized, so that under the low sintering temperature and the high pressure, and on the premise that the TiB2 particles and the surrounding titanium or titanium alloy matrix do not generate in-situ reaction, a sintering block body with high compactness is prepared; and finally, the TiB2 particles in the sintered block body are subjected to in-situ reaction with the surrounding titanium or titanium alloy matrix through hot rolling to form whiskers, and meanwhile, the crystal grains of the matrix are deformed, the porosity in the structure is reduced, and the strength and the plasticity of the composite material are improved. The TiB nano crystal whisker generated in situ in the method is cleanin surface and is uniformly distributed in a matrix and free of agglomeration, has good interface bonding and lattice relationship with the titanium matrix, and can effectively refine matrix crystal grains.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

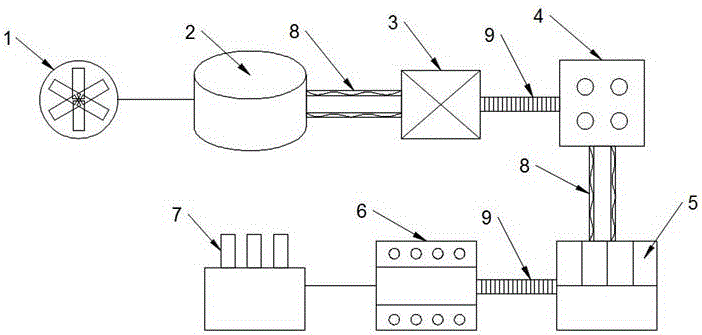

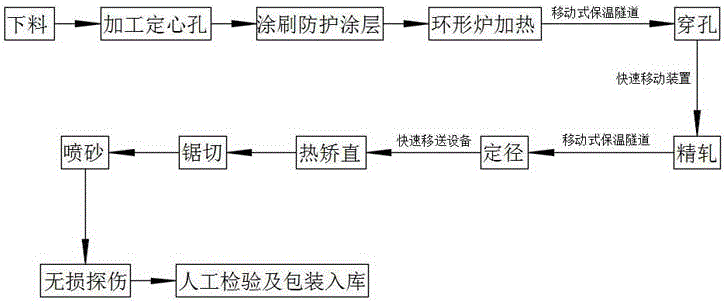

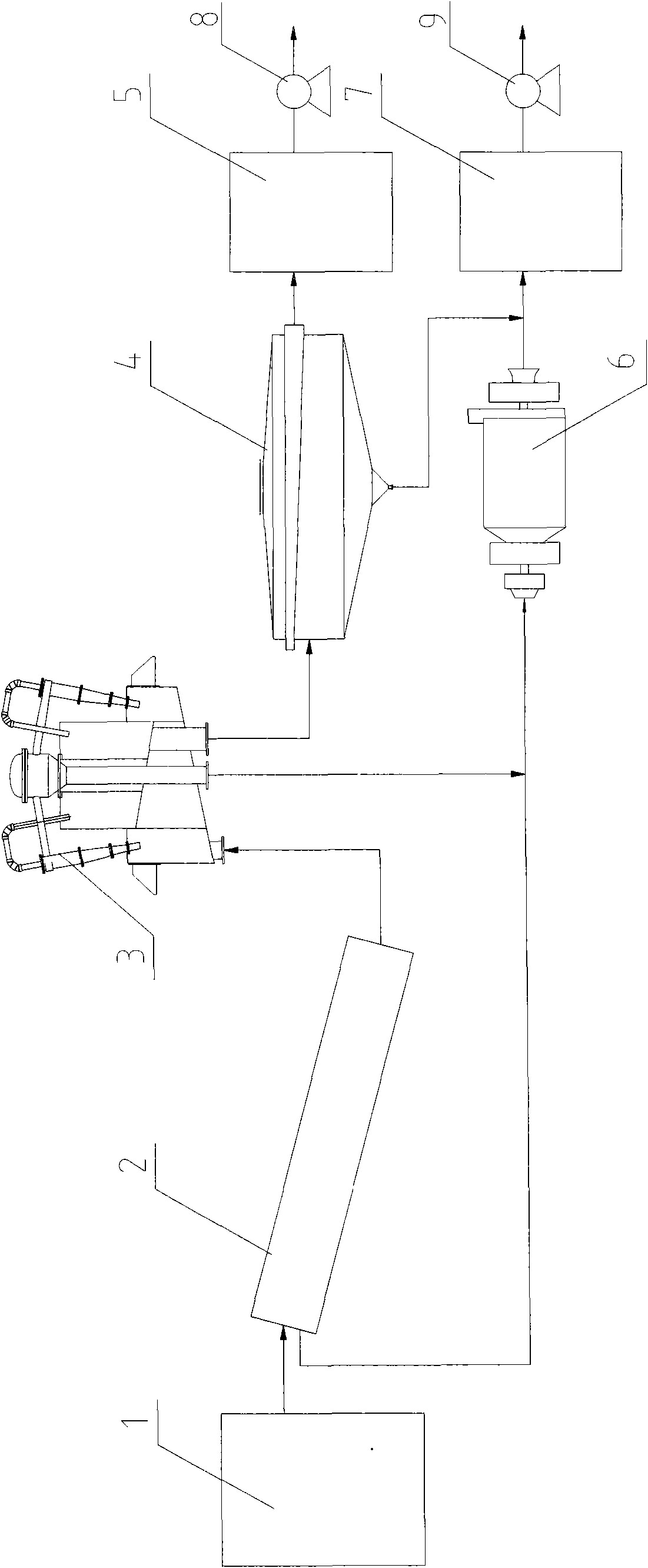

Hot-processing production system for titanium and titanium alloy seamless tube, product prepared on basis of system and manufacture method for product

The invention relates to a hot-processing production system for a titanium and titanium alloy seamless tube, a seamless tube prepared by using the hot-processing production system and a hot-processing production method for the seamless tube, and belongs to the technical field of titanium and titanium alloy seamless tube production. By improving various units and all kinds of auxiliary equipment, particularly, reselecting materials of parts and heating and rolling working modes thereof, thus the equipment precision is improved and the stability of the system is controlled, and a rolling process is enabled to be more stable, thereby ensuring that the quality and size of the inner and outer surfaces of the seamless tube are stable. On such basis, according to the hot-processing production method, various working procedures are arranged reasonably and efficiently, and a tube blank is coated with a protective layer before heating, so that the problem that the tube blank reacts with oxygen and nitrogen and absorbs hydrogen is well solved, the defect of exceeding standards does not occur in the tube blank and a foundation is laid for subsequent rolling.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

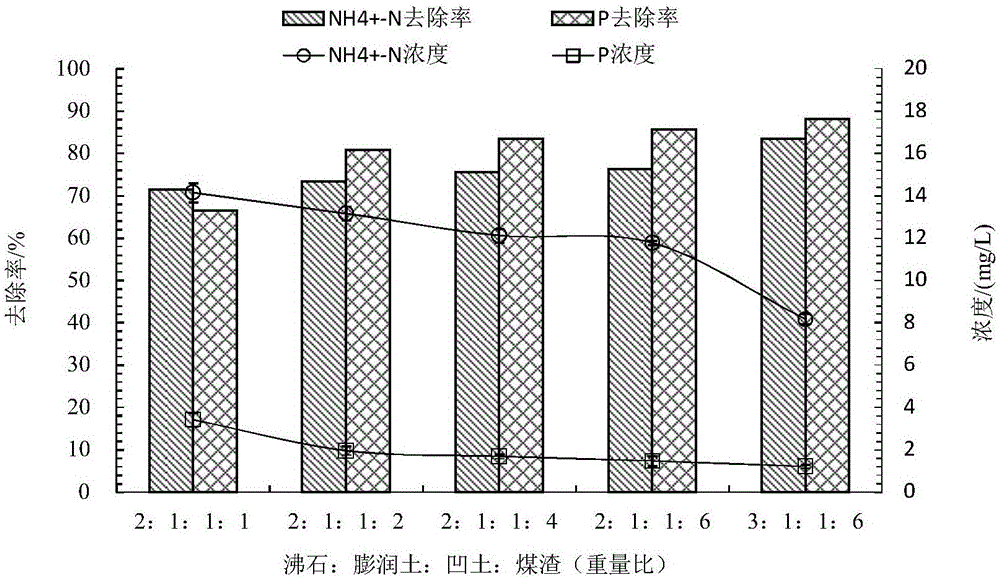

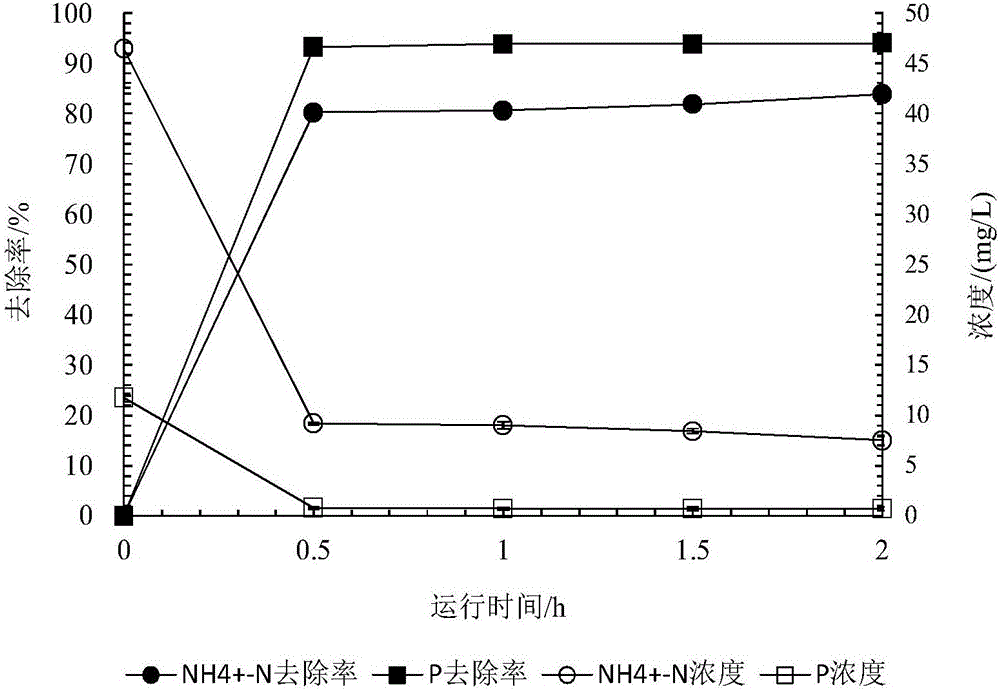

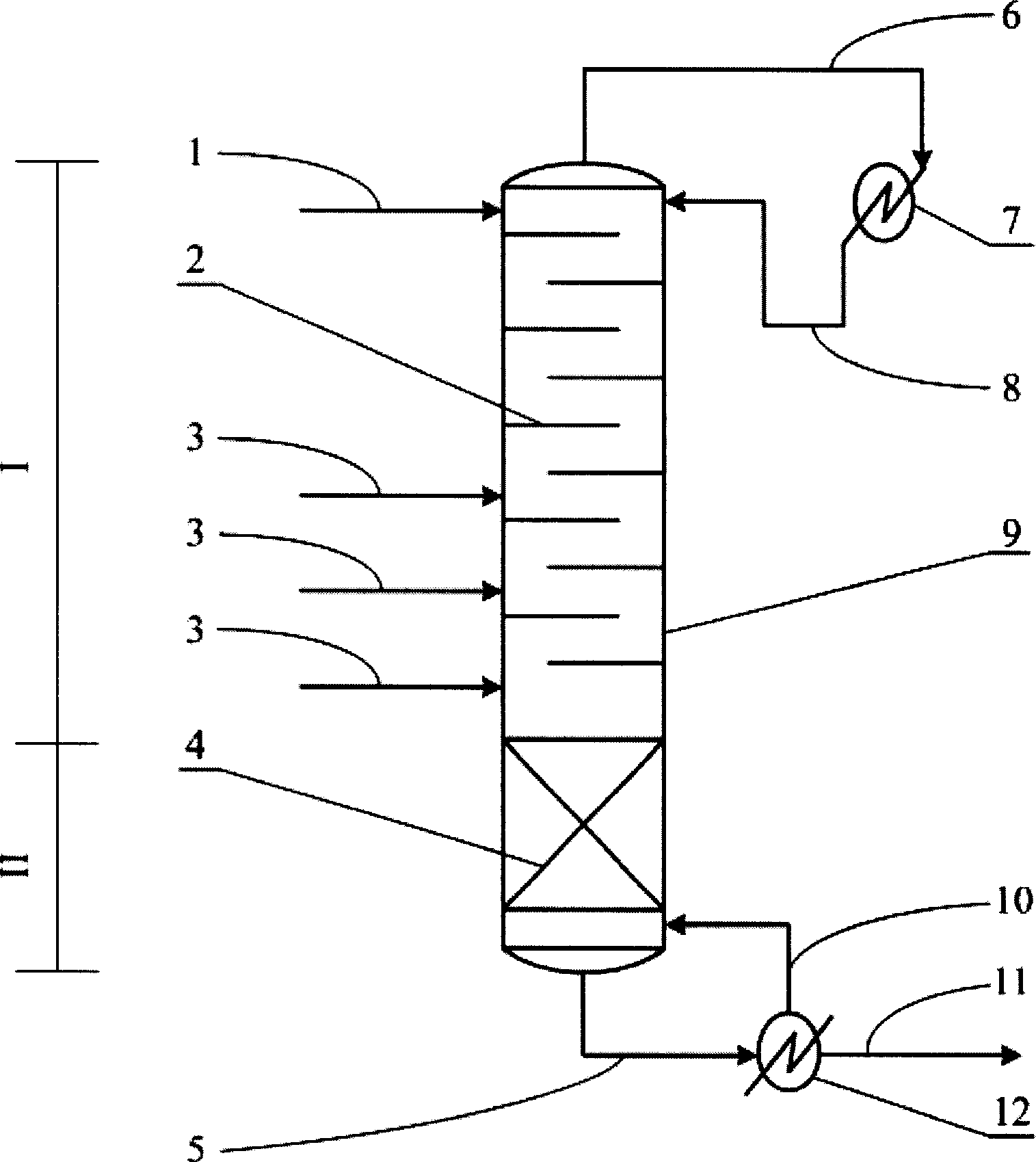

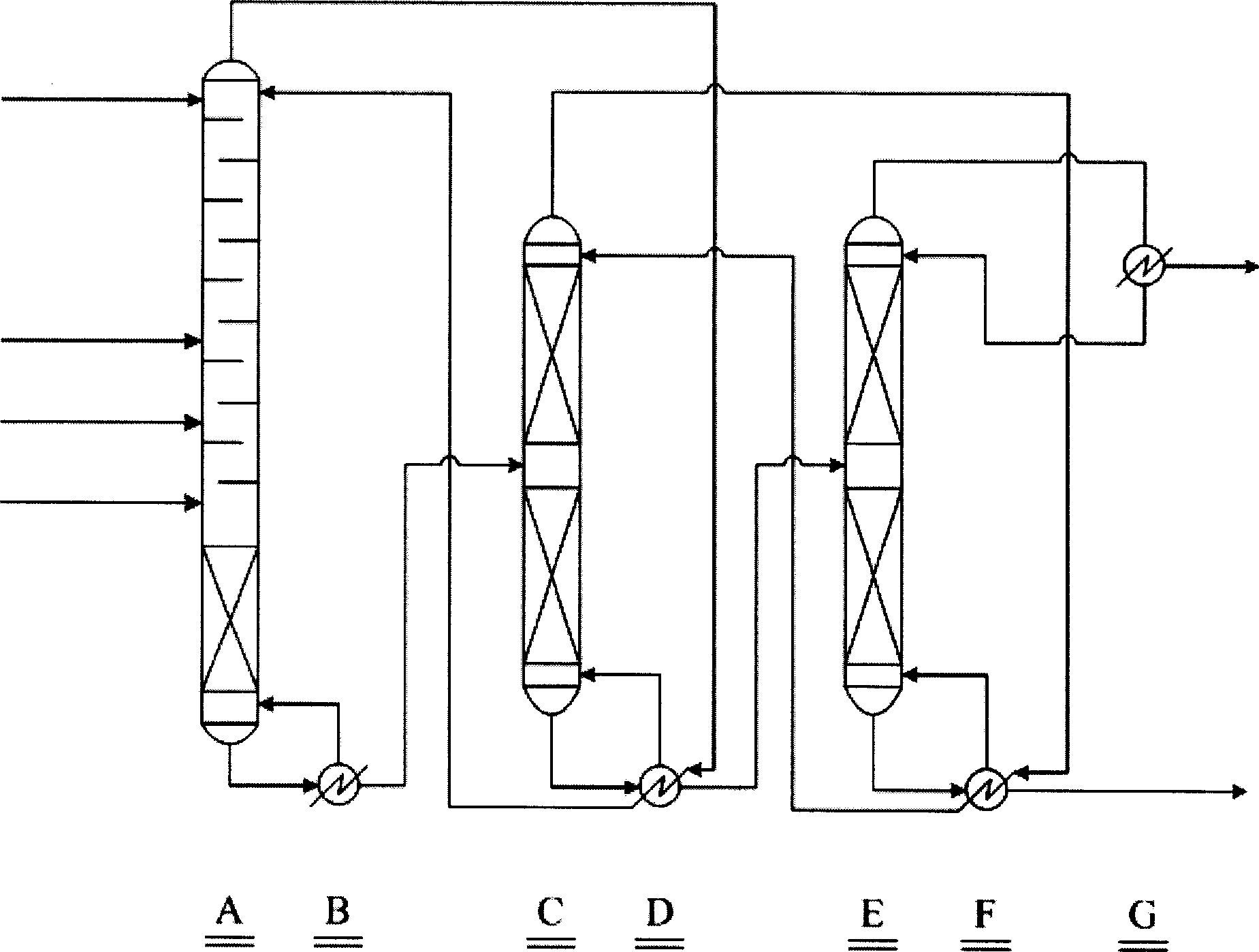

Composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and method for preparing composite reaction medium

ActiveCN106396134ASync removalEfficient removalWater contaminantsWater/sewage treatmentSodium BentoniteInstability

The invention discloses a composite reaction medium for removing nitrogen and phosphorus from underground water permeable reactive barriers and a method for preparing the composite reaction medium. The composite reaction medium comprises, by weight, 1.0-3.0 parts of zeolite, 0.7-1.3 parts of bentonite, 0.5-1.5 parts of attapulgite and 1.0-6.0 parts of coal cinder. The zeolite, the bentonite, the attapulgite and the coal cinder are sintered to obtain the composite reaction medium. The composite reaction medium and the method have the advantages that the nitrogen and the phosphorus can be synchronously, efficiently and quickly removed by the composite reaction medium, the composite reaction medium can be used as a biological carrier, accordingly, shortcomings of instability of biological phosphorus removal, large quantity of mud due to chemical phosphorus removal and the like can be overcome, and detour flow of water at the fronts of the barriers and the like can be prevented.

Owner:FOODSTUFF INST BEIJING

Method for producing glycol by epoxy ethane hydration

The present invention relates to epoxy ethane hydrating process to produce glycol. Unlike available technology, which needs several towers or several reactors and several reaction steps, the process of the present invention has the epoxy ethane hydrating reaction and the separation of glycol completed simultaneously in the reacting and rectifying tower, and thus has greatly simplified technological process, greatly lowered material / water ratio and epoxy ethane consumption, less side reactions and obviously raised glycol selectivity. The present invention has the features of low production cost and high glycol selectivity, and may be used in industrial production.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Preparation method of polybutylene succinate

The invention provides a preparation method of polybutylene succinate. The preparation method of the polybutylene succinate takes mono-methyl succinate and 1, 4-butanediol as monomers, adopts an efficient compound catalyst system and comprises the following steps: reacting to obtain a PBS (polybutylene succinate) oligomer first and then performing polycondensation reaction to obtain a PBS polymer with a high molecular weight and good color and luster. Through the adoption of the preparation method, on one hand, the problems that in the conventional technology that succinic acid and the 1, 4-butanediol are taken as monomers to prepare the PBS, the speed rate of esterification reaction is low, the succinic acid cannot react completely, and the amount of a generated byproduct tetrahydrofuran is high can be solved; on the other hand, the acidicity of the mono-methyl succinate is less than that of the succinic acid, so that corrosion to equipment is reduced, and thus the maintenance cost of the equipment is reduced and greater contribution is made to industrial production; in addition, a chain extender is not used, the application range of PBS degradable plastic in the field of food packaging can be further expanded.

Owner:TANGSHAN XUYANG CHEM IND CO LTD

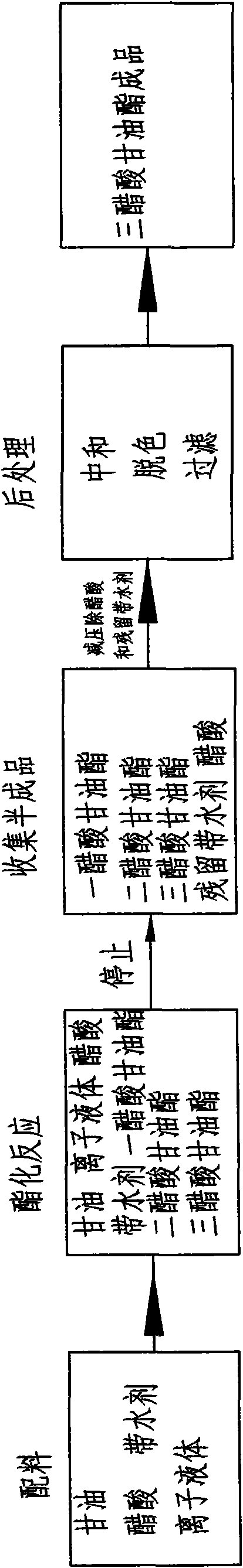

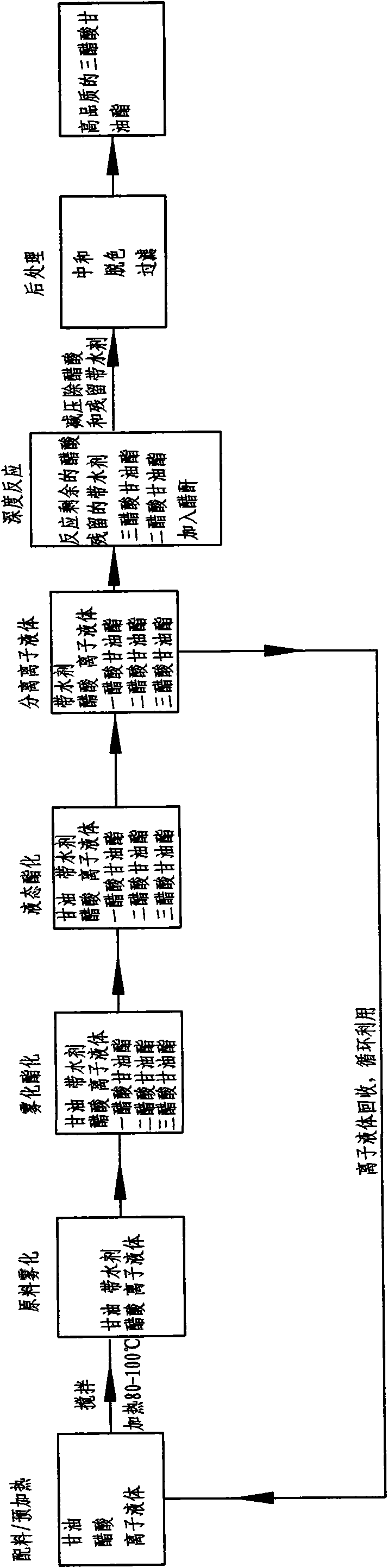

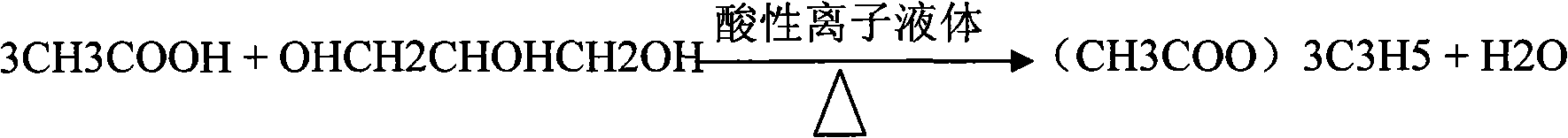

Method for producing glyceryl triacetate by atomizing raw materials

ActiveCN101613275AIncrease contentGood chromaOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The invention discloses a method for producing glyceryl triacetate by atomizing raw materials. The production method can help shorten esterification reaction time and improve product yield, quality and chroma. The objective is achieved in virtue of the following technical scheme: mixing glycerol and acetic acid at a mol ratio of 1:6-9; adding a proper amount of a liquid catalyst and an entrainer,stirring and preheating to 80-100 DEG C; atomizing the mixture to allow the mixture to be subject to esterification reaction at 100-120 DEG C for 1-2h to obtain a liquid mixture containing 98-99% of glyceryl triacetate; adding 1-1.5% of acetic anhydride to the obtained liquid mixture for deep esterification reaction at the temperature of 90-110 DEG C for 10-20min to obtain a semi-finished product; removing the entrainer and the acetic acid, neutralizing, decoloring and filtering to obtain the glyceryl triacetate finished product.

Owner:云南玉溪环腾科工贸有限公司

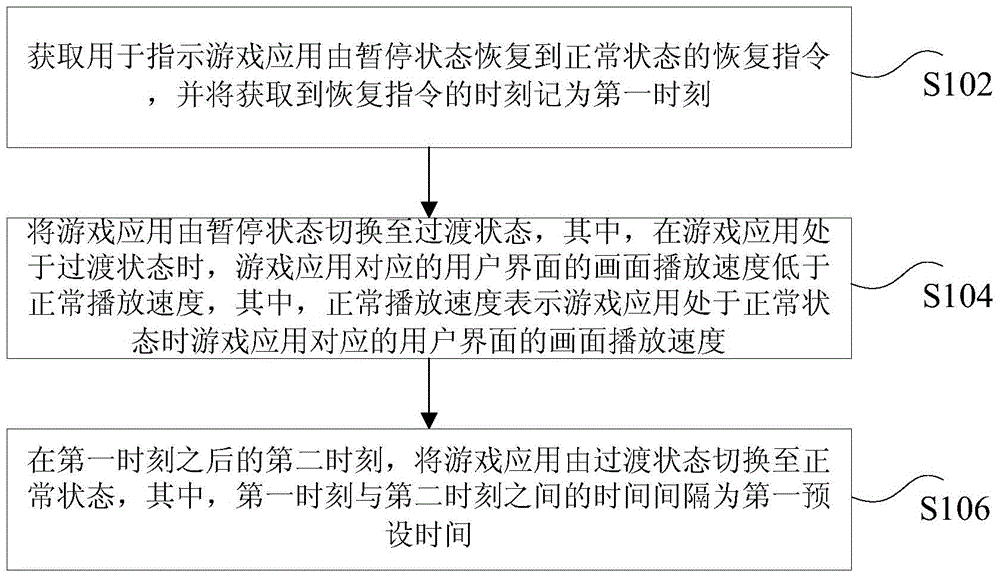

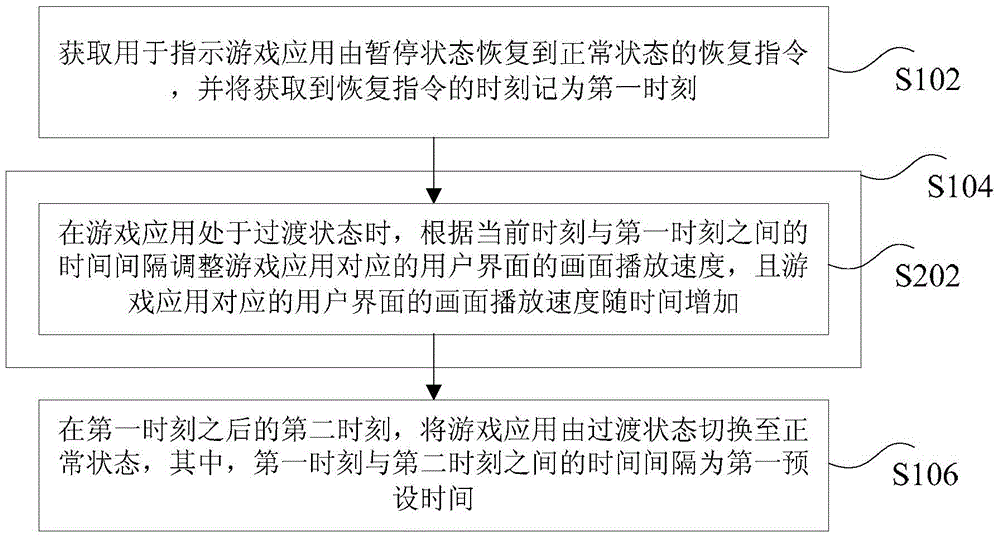

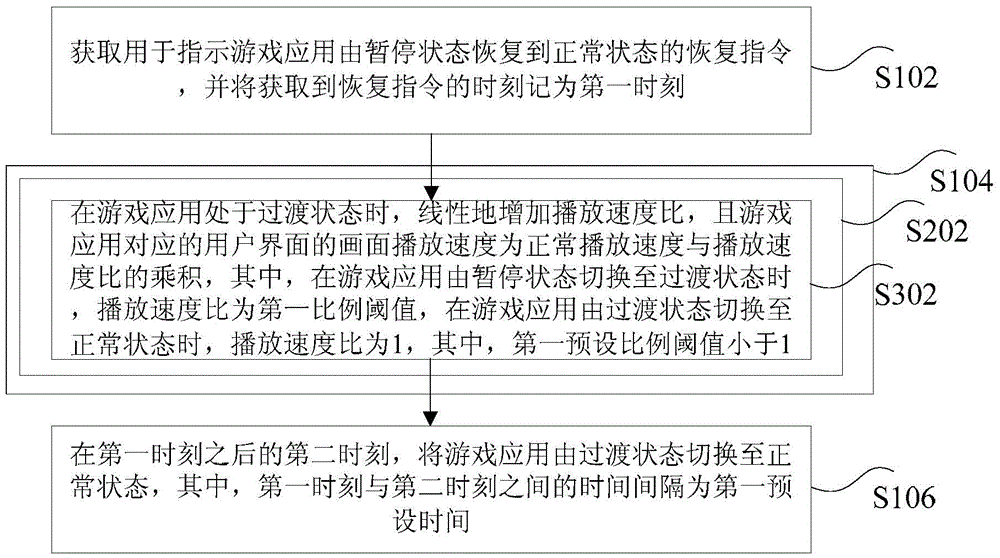

Frame playing method and client end for game application

ActiveCN104461718AAddress reactivityImprove user experienceProgram initiation/switchingVideo gamesHuman–computer interactionUser interface

The invention discloses a frame playing method and client end for a game application. The method comprises the steps that a recover instruction for indicating that the game application recovers to a normal state from a halted state is obtained, and the moment when the recover instruction is obtained is marked as a first moment; the game application is switched to a transition state from the halted state, and when the game application is in the transition state, the playing speed of the frame of the corresponding user interface of the game application is lower than a normal playing speed, wherein the normal playing speed represents the playing speed of the frame of the corresponding user interface of the game application when the game application is in the normal state; at a second moment after the first moment, the game application is switched to the normal state from the transition state, wherein the time interval between the first moment and the second moment is first preset time. The frame playing method and client end for the game application solve the technical problem that after the game application is recovered from the halted state, the playing speed of the frame of the user interface is increased suddenly and a game user can hardly respond timely.

Owner:TENCENT TECH (SHENZHEN) CO LTD

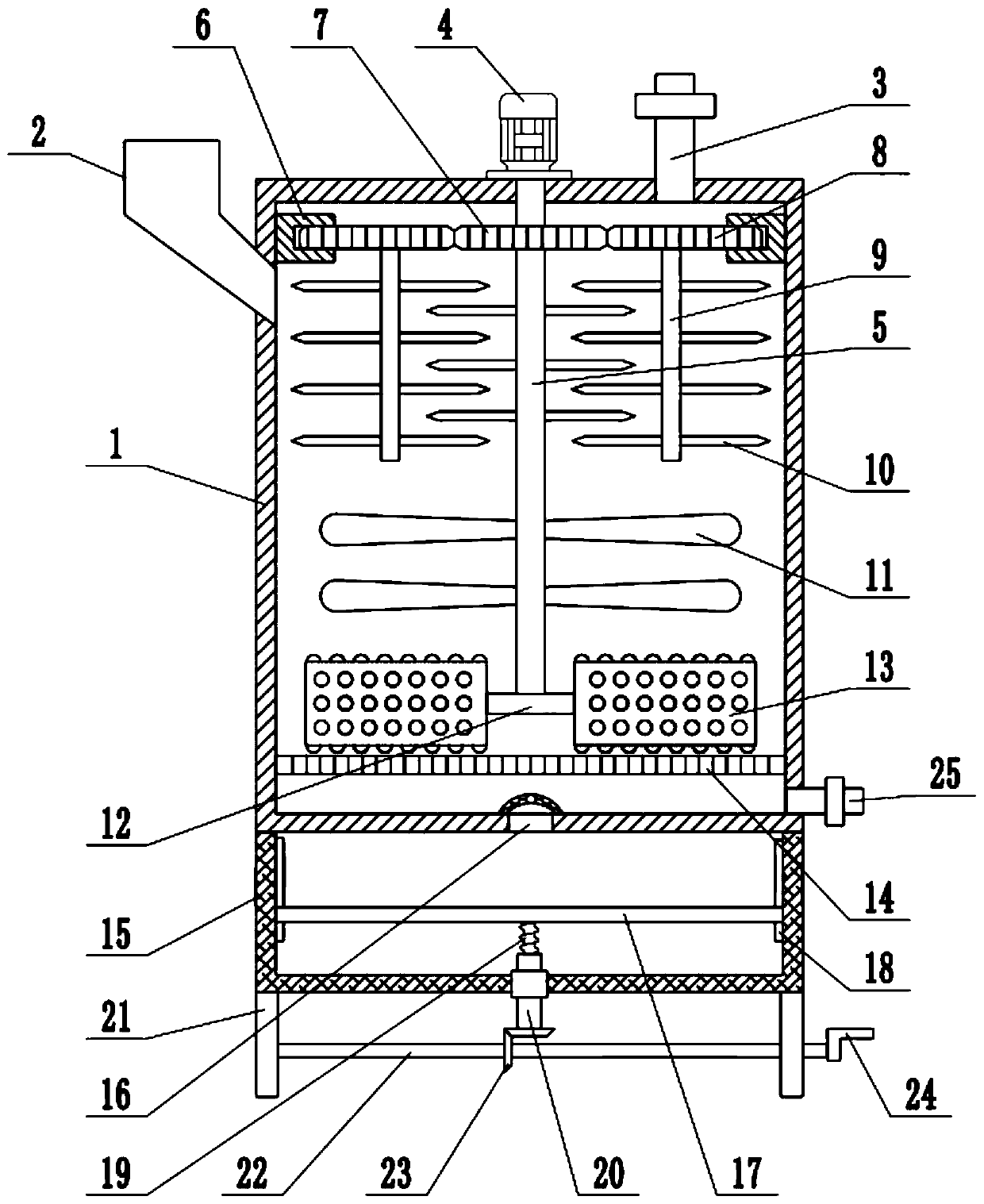

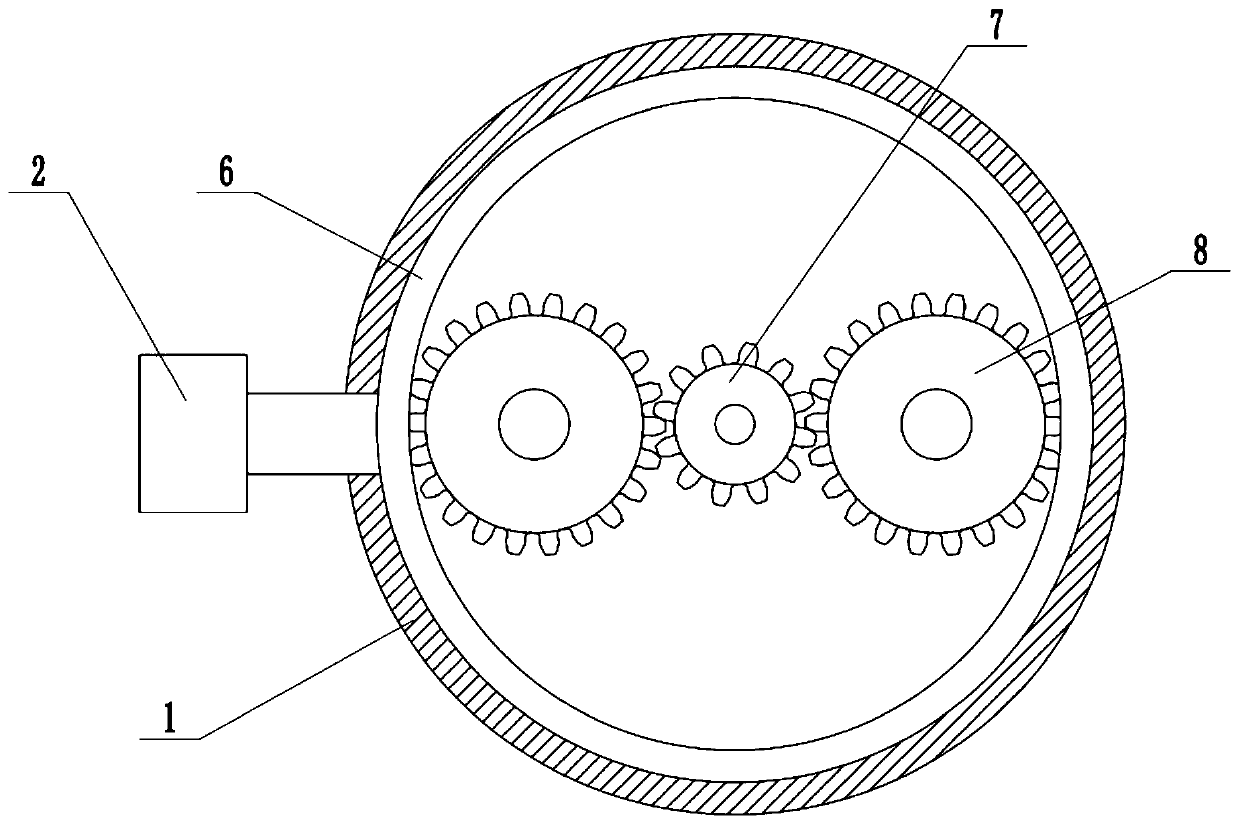

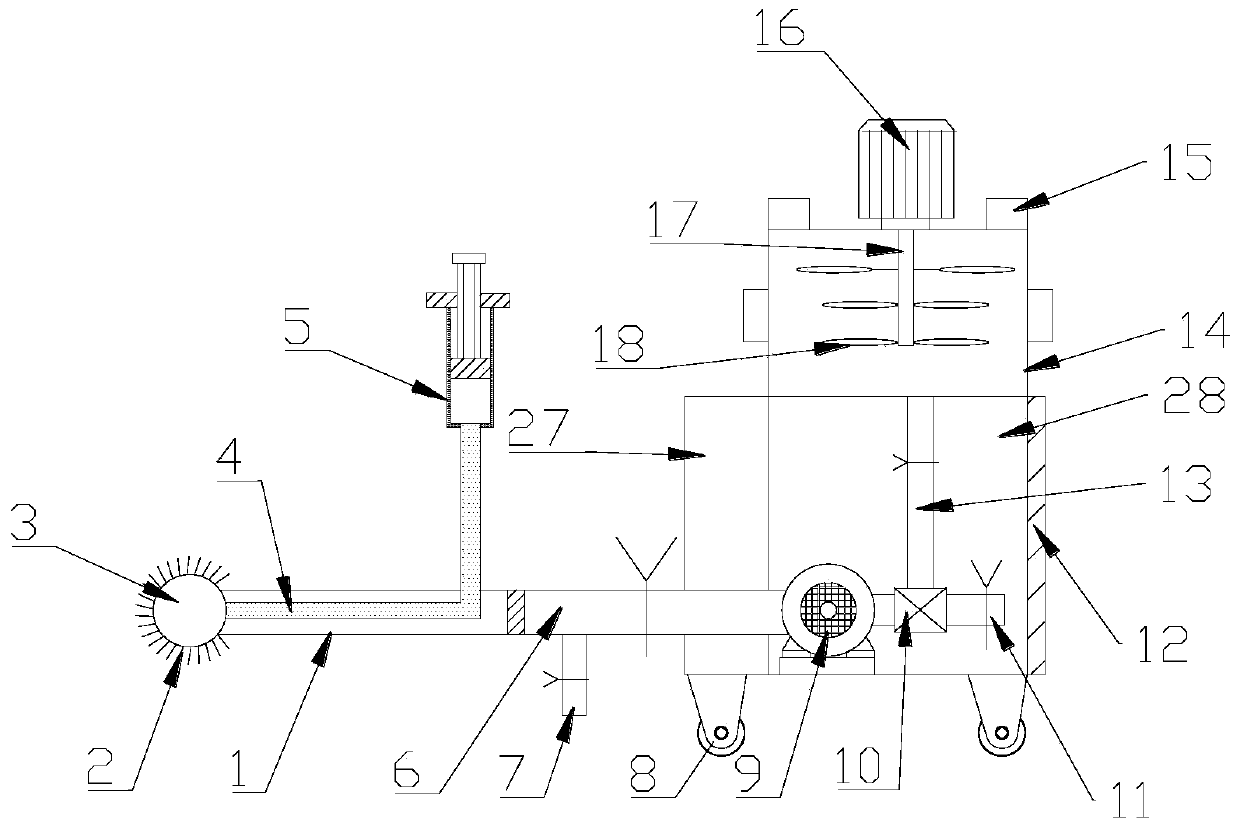

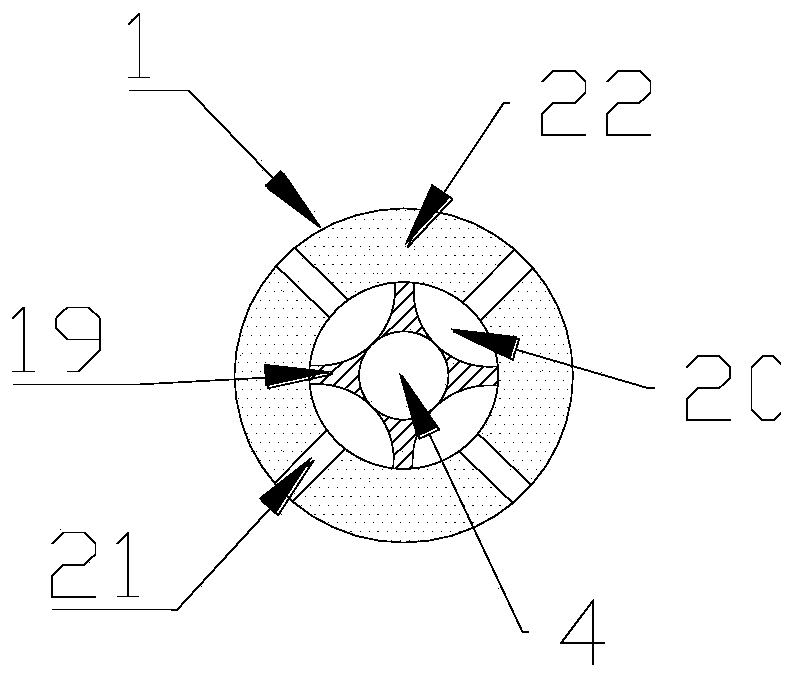

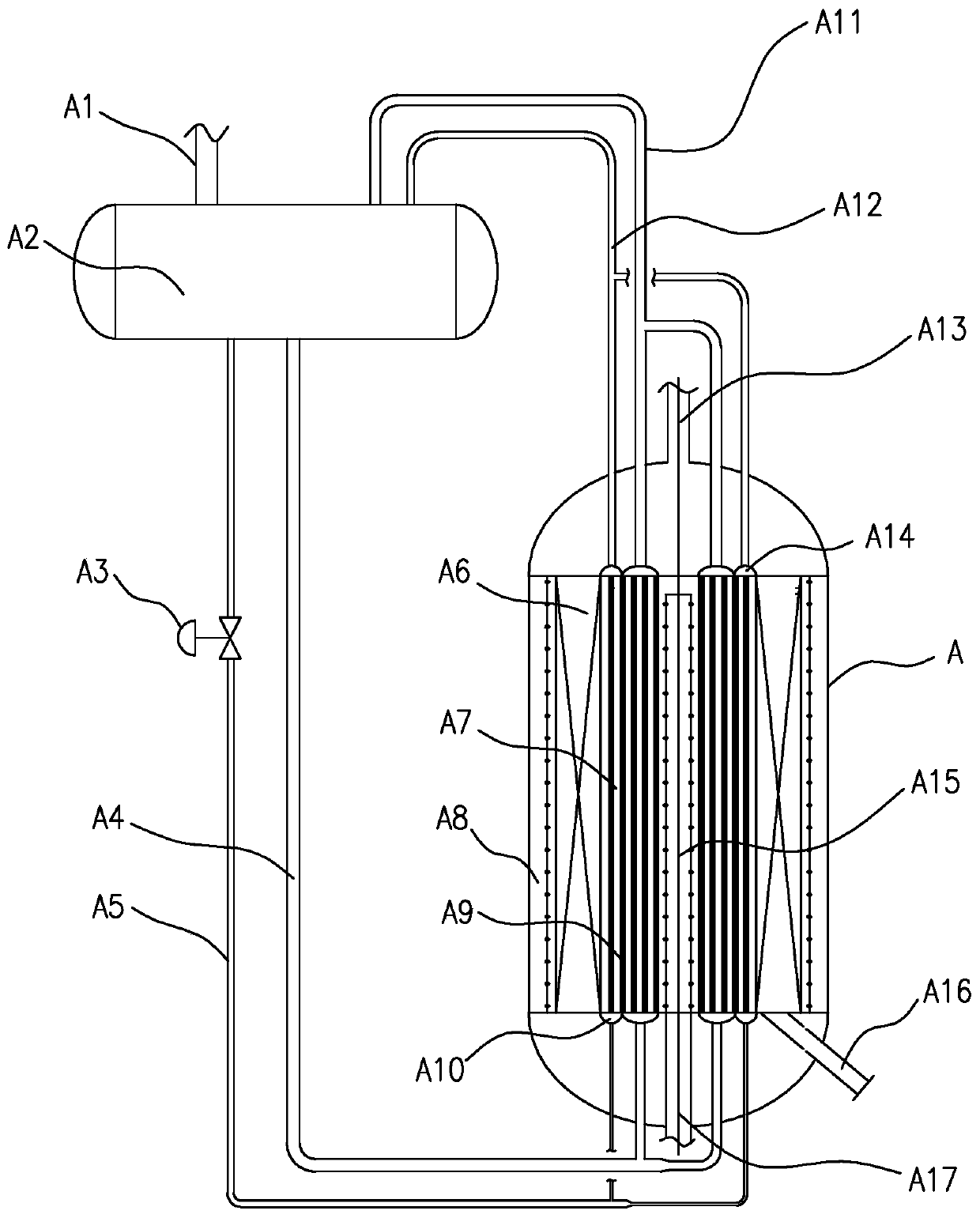

Solid-liquid reaction still beneficial for interrupting reaction process

InactiveCN110314633AIncrease contact areaWell mixedChemical/physical/physico-chemical stationary reactorsGrain treatmentsChemical reactionGear wheel

The invention relates to the field of chemical equipment, in particular to a solid-liquid reaction still beneficial for interrupting the reaction process. The solid-liquid reaction still comprises a still body, a motor, a driving shaft and a sieve plate. The top of the still body is fixedly connected with the motor. The shaft extending end of the motor is fixedly connected with the driving shaft.A gear ring is installed in the still body. A driving gear sleeves the driving shaft. A driven gear is installed between the driving gear and the gear ring. A pulverizing shaft is fixedly connected with the lower surface of the driven gear. A grinding device is installed at the lower end of the driving shaft. A liquid level adjusting device is installed at the bottom of the still body. Solid reactants are pulverized by pulverizing blades, and the contact area between the solid reactants and liquid reactants is increased; the liquid reactants are stirred by stirring blades, and chemical reaction is facilitated; the solid reactants are crushed by a crushing roller, and the contact area between the solid reactants and the liquid reactants is further increased; by arranging the liquid level adjusting device, the chemical reaction process can be interrupted at any time according to actual demands.

Owner:李云

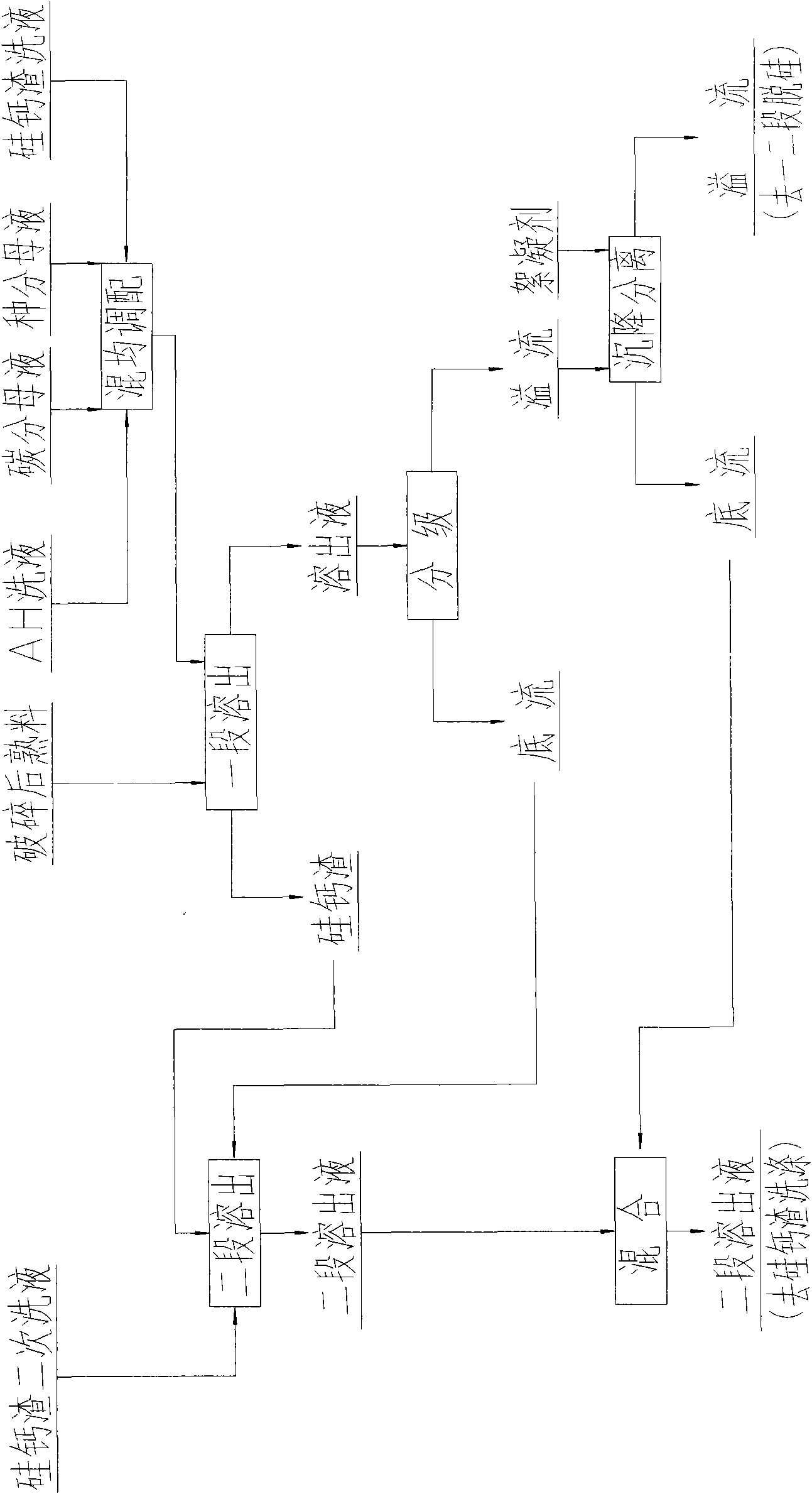

Method and device for quickly dissolving alumina out of sintered clinker of high-alumina fly ash

InactiveCN101628725AAddress reactivityHigh dissolution rateSolid waste disposalAluminium oxides/hydroxidesSlagDecomposition

The invention provides a method and a device for quickly dissolving alumina out of sintered clinkers of high-alumina fly ash. The device comprises a surge tank, a cylindrical dissolving device, a water-whirling device, a settling tank, a crude liquid tank, a rod mill, a two-stage dissolved slurry tank, a crude liquid pump and a two-stage dissolved slurry pump. The method comprises the following processes: Al(OH)3 washing liquor obtained by filtering spent liquor from seed precipitation, silicon and calcium slag washing liquor and finished products and partial spent liquor from carbonization precipitation are blended into adjustment liquid to be transported into the cylindrical dissolving device together with the sintered clinkers of the fly ash to undergo countercurrent dissolving, the overflow enters the water-whirling device, the overflow from the water-whirling device enters the settling tank to be further flocculated, settled and separated, and then the overflow enters the crude liquid tank to be pumped to the conventional process of desiliconizing; base flow from a cyclone, secondary silicon and calcium slag washing liquor and return sand in the cylindrical dissolving device enter the rod mill to undergo two-stage dissolving, and the two-stage dissolved grout and the base flow from the settling tank are transported to the process of silicon and calcium slag washing. The invention can solve the problems of long dissolving time, severe secondary decomposition reaction of dicalcium silicate and the like in the dissolving process for extracting aluminium from fly ash.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

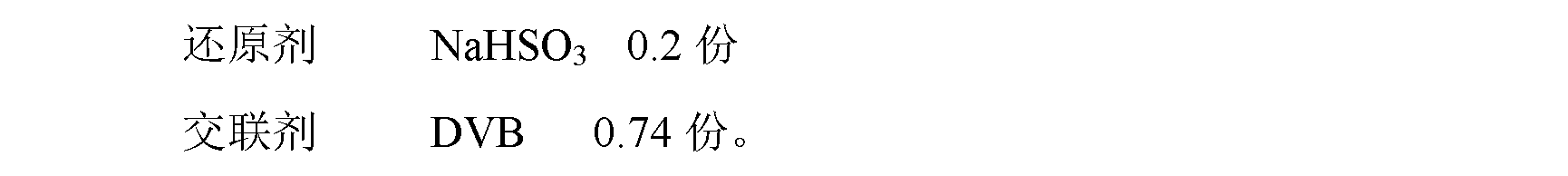

Method for preparing ASA (Acrylonitrile-Styrene-Acrylate) copolymer latex by using water-solubility redox initiator at low temperature

The invention discloses a method for preparing ASA (Acrylonitrile-Styrene-Acrylate) copolymer latex by using a water-solubility redox initiator at low temperature. The method comprises unit processes of preparing polyacrylate seeds, preparing a polyacrylate core, preparing an ASA resin shell and post processing. The water-solubility initiator adopted by the method can initiate polymerization at a lowest temperature of 35 DEG C and reach a high conversion rate. The method has the characteristics of good repeatability, warm reaction condition, low energy consumption, easiness in operation and low price of raw materials, so that the industrial implementation is facilitated.

Owner:HEFEI UNIV OF TECH

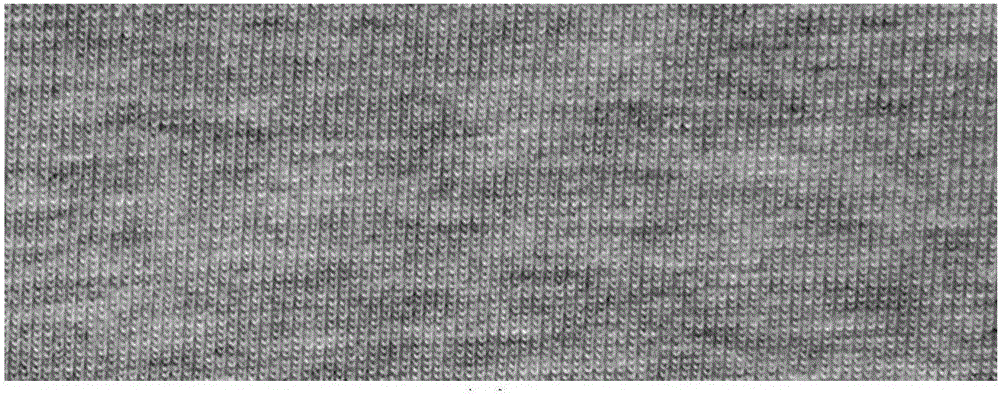

One-step-method differential dyeing process for cellulosic fiber textile

InactiveCN106638035AAddress reactivitySolve problems such as large inventorySucessive textile treatmentsDyeing processYarnTextile printer

The invention relates to the technical fields of textile printing and dyeing and particularly relates to a one-step-method differential dyeing process for a cellulosic fiber textile. The one-step-method differential dyeing process comprises the following specific processes: preparing a cellulosic fiber modified working solution, adding the cellulosic fiber modified working solution into a dyeing machine; heating the modified working solution in the dyeing solution to 60-80 DEG C, and maintaining the temperature; carrying out water washing, neutralization and dehydration, and drying for later use; mixing with unprocessed fibers, and spinning; weaving into textiles of different structures; preparing a scouring and bleaching working solution, adding the scouring and bleaching working solution into an overflow dyeing machine; putting the textiles into the overflow dyeing machine; heating the scouring and bleaching working solution in the overflow dyeing machine to 80-98 DEG C, and maintaining the temperature; carrying out water washing and dehydration, and drying for later use; dyeing the textiles; and carrying out normal-temperature dyeing, liquid discharging, water washing, soaping, water washing and dehydration for later use. Compared with the prior art, the one-step-method differential dyeing process has the advantages that a cellulosic fiber cationization theory and a process are researched and applied to loosened fibers, graft fibers and common fibers are blended, spun and woven, and then a white-texture flower yarn-patterned fabric is prepared by virtue of a one-step method.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

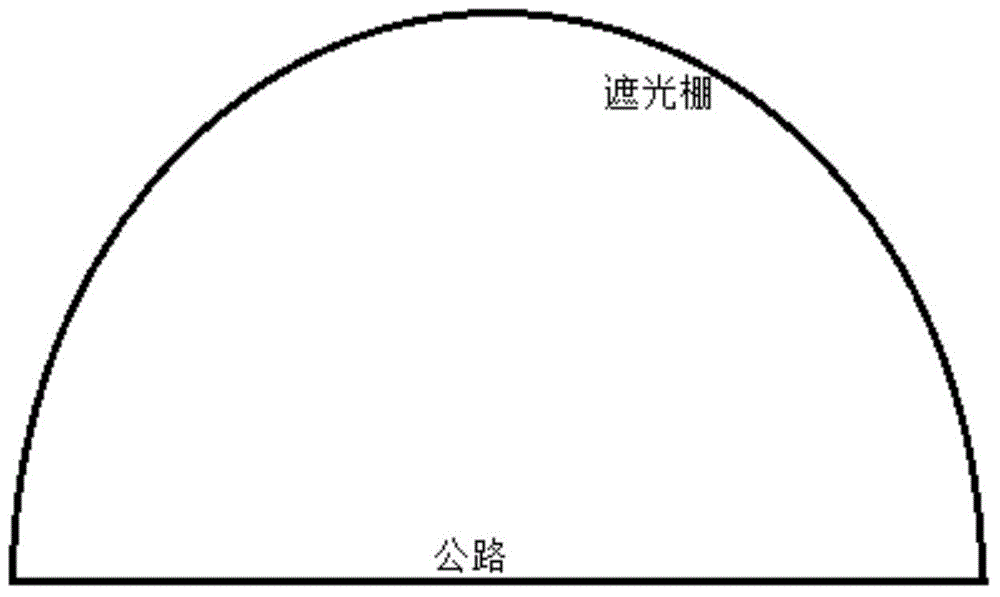

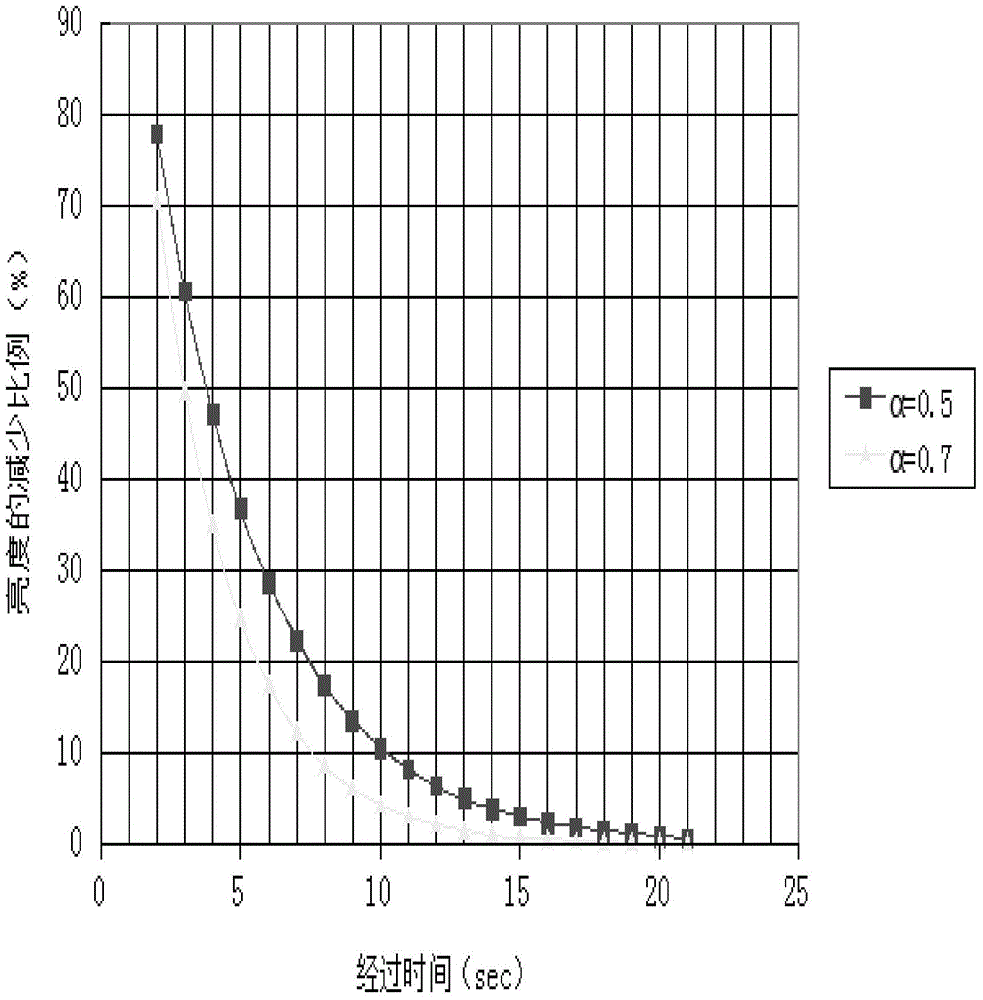

Method for achieving illumination of highway tunnel without artificial light source

ActiveCN104864355AAddress reactivitySolve the problem of too much fluctuation of illuminanceMechanical apparatusPoint-like light sourcePhysicsTransmittance

The invention discloses a method for achieving illumination of a highway tunnel without an artificial light source. The method is characterized by including the steps that no artificial light source is arranged in the whole highway tunnel, a sunshade with the segmented transition light transmittances is arranged outside a tunnel portal, and a hollow-out portion is arranged on the sunshade; the illumination problem in the tunnel is solved through the sunshade and reflecting signs in the tunnel. The danger level is reduced to the largest extent according to the eye adaptation time and economic conditions, the light-transmitting material and the light-transmitting area of a safety area are designed to gradually change according to the illumination transition rate which the eyes can adapt to naturally, so that a driver drives a car comfortably, and the method is the embodiment that highways are designed in the people-oriented principle. The method can be adaptive to long-sized highway tunnels at various areas, especially long-sized highway tunnels with large illumination changes, and has the advantages that the structure is simple, arrangement is convenient, and the use effect is good.

Owner:CHANGAN UNIV

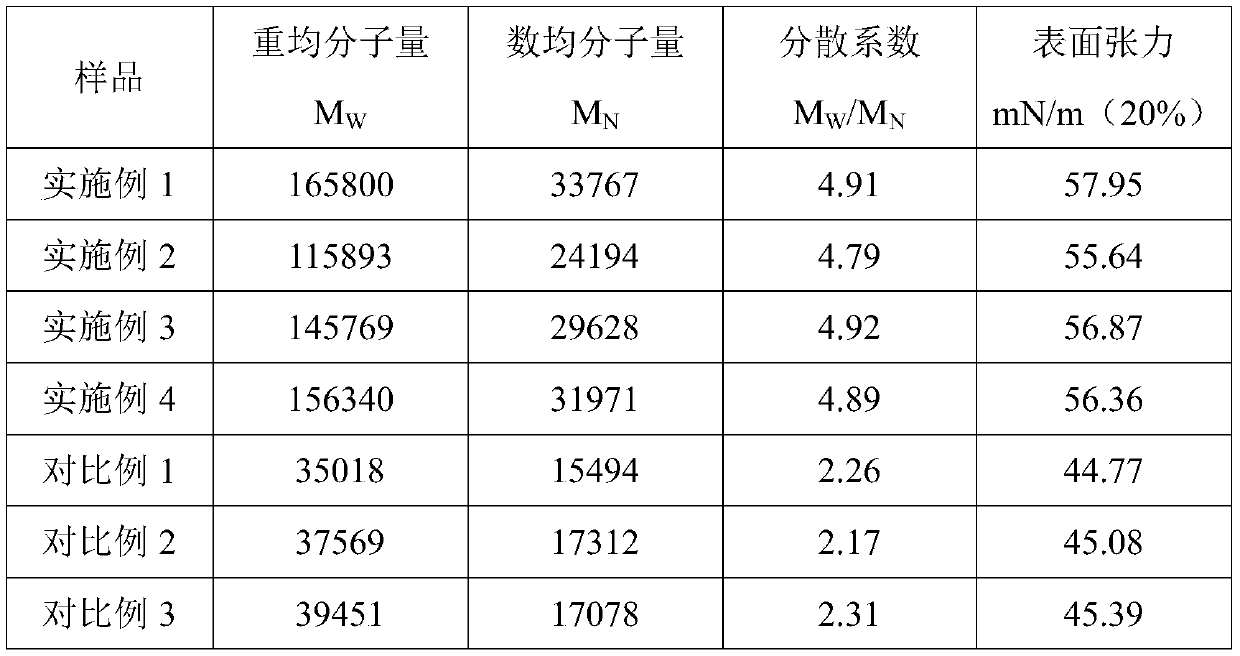

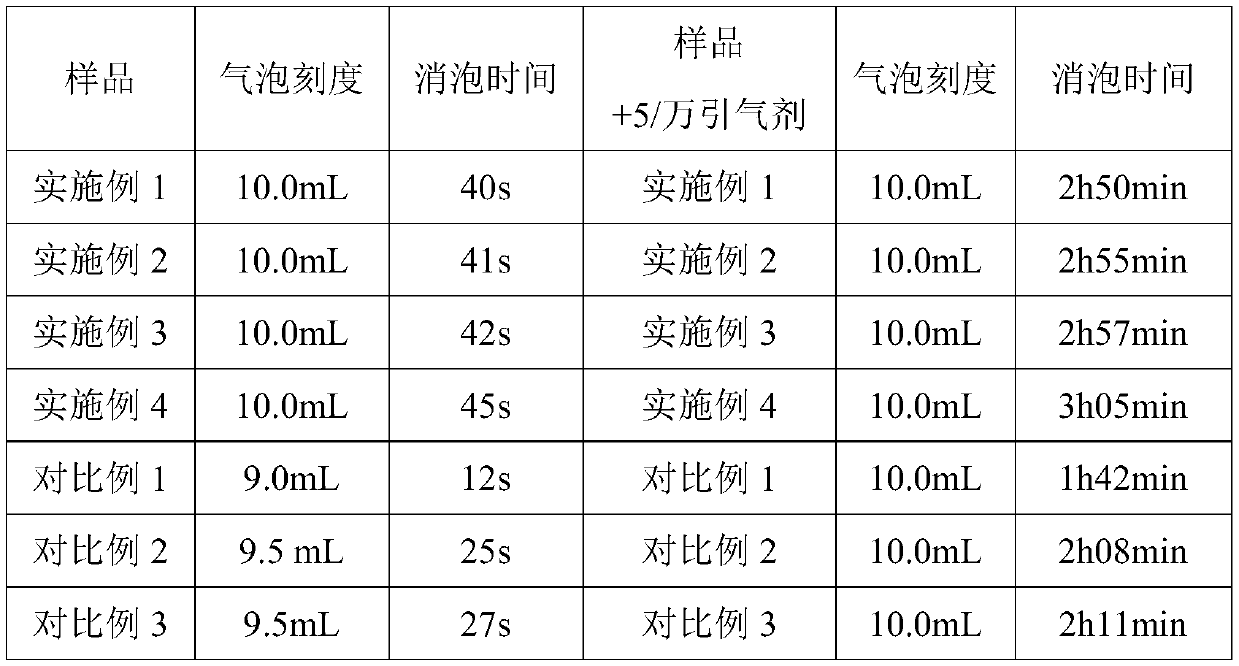

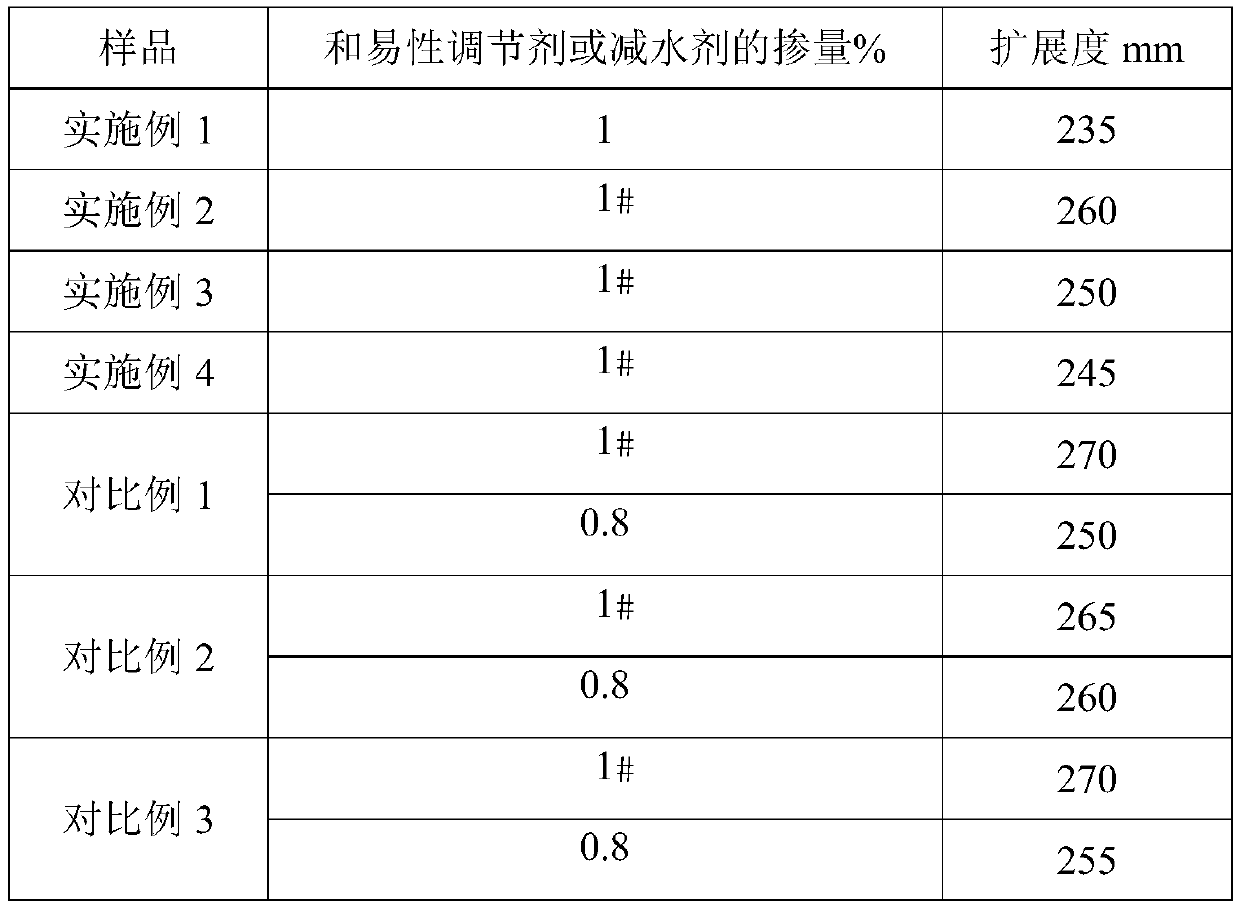

Concrete workability regulator and preparation method thereof

ActiveCN109880020AImprove workabilityWill not cause excessive air contentPotassium dichromateMacromonomer

The invention discloses a concrete workability regulator and a preparation method thereof. The concrete workability regulator comprises the following components: an unsaturated polyether macromonomer,an unsaturated ester monomer, a chain transfer agent, a strong oxidant and a hydrophilic modifier, wherein the molar ratio of the unsaturated polyether macromonomer to the unsaturated ester monomer to the hydrophilic modifier is (0.5-1.5):(0-0.2):(1.65-5.3); the addition amounts of the chain transfer agent and the strong oxidant respectively account for 0.17-0.67% and 0.25-1% of the mass of the unsaturated polyether macromonomer; and the chain transfer agent is a chain transfer agent with reducibility, and the strong oxidant is at least one of potassium permanganate and potassium dichromate.The concrete workability regulator is prepared by polymerizing the chain transfer agent with weak reducibility and the strong oxidant under the condition of no external heat source, the molecular weight of the concrete workability regulator is larger, the concrete workability regulator has thickening and water retention effects, the workability of concrete is improved, and the gas content of the concrete cannot exceed the standard.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Pediatric negative pressure gastric lavage device for pediatrician

PendingCN109999250ASolve real-timeAddress reactivityCannulasEnemata/irrigatorsGastric lavage kitGastric lavage

The invention discloses a pediatric negative pressure gastric lavage device for a pediatrician, and relates to the field of medical instruments. The gastric lavage device comprises a medicine supply box, a stirring box and a motor. The output end of the motor is connected with a stirring shaft, multiple sets of stirring paddles are evenly arranged on the stirring shaft, a liquid sucking pump is arranged in the medicine supply box, the input end of the liquid sucking pump is communicated with a discharge pipe and a feed pipe through tee joints respectively, the discharge pipe is communicated with the lower end of the stirring box, the output end of the liquid sucking pump is communicated with a gastric lavage pipe, an airbag is arranged at the end, away from the liquid sucking pump, of thegastric lavage pipe, the airbag is communicated with an inflating pipe, the other end of the inflating pipe is communicated with an inflating mechanism, and multiple sets of brushes are evenly arranged on the airbag. In order to solve the problems that most gastric lavage devices cannot configure gastric lavage liquid medicine or sample and collect gastric juice reactants in real time according tothe conditions of patients, the gastric lavage liquid medicine is configured in real time according to the conditions of the patients through the stirring box, the gastric juice reactants of the child patients are sampled and collected in real time through the feed pipe for chemical laboratory analysis, and the device has broad application prospects.

Owner:泗水县人民医院

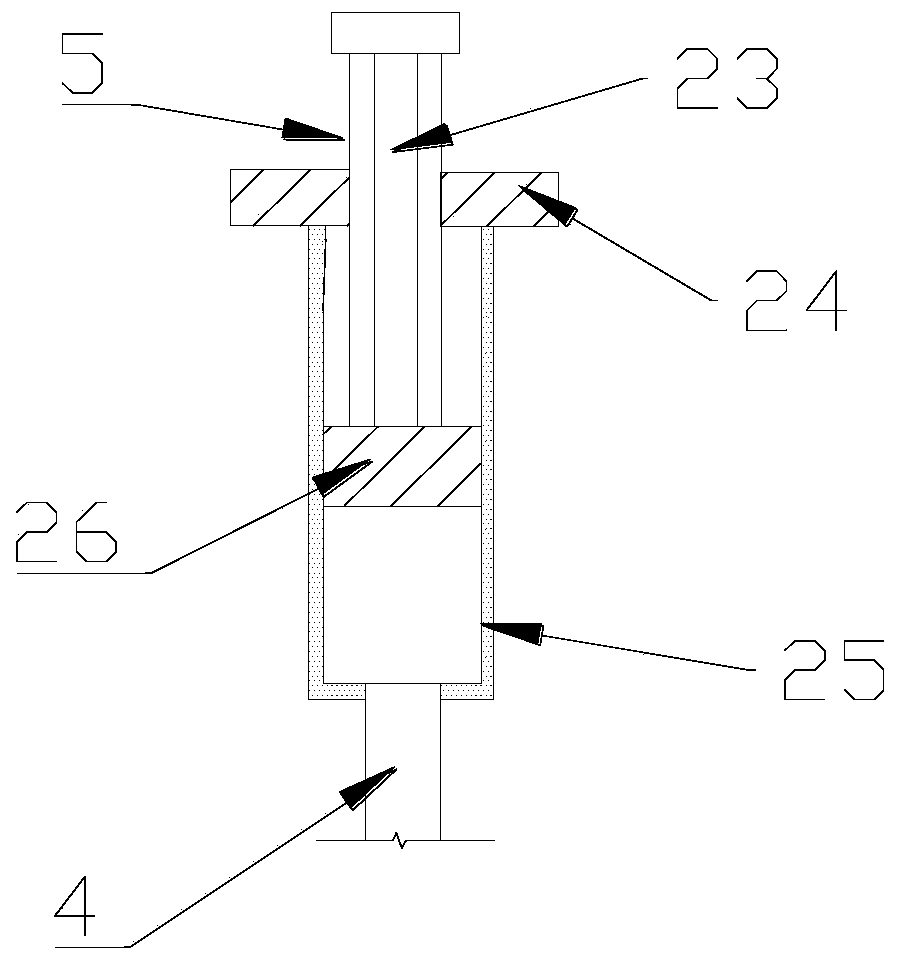

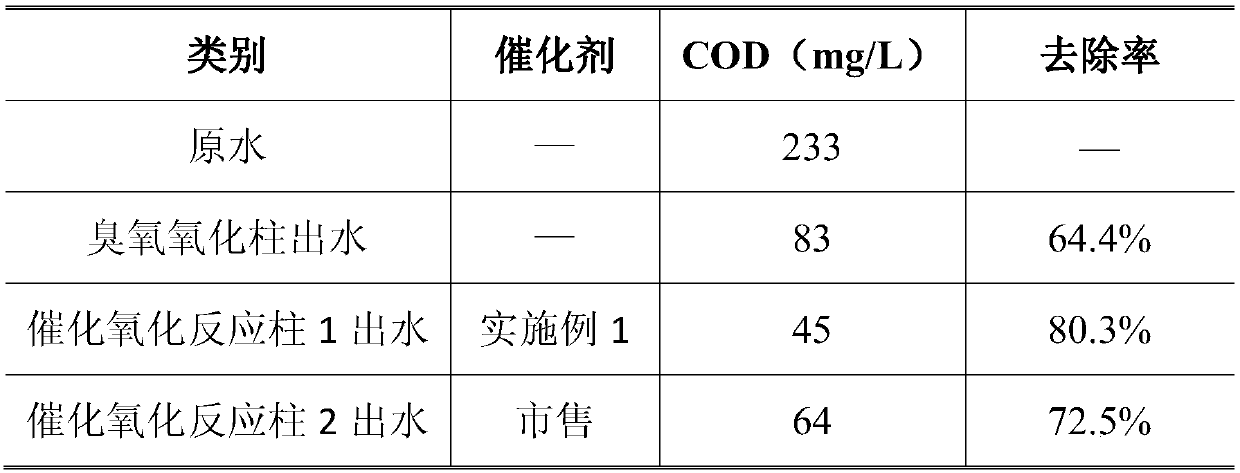

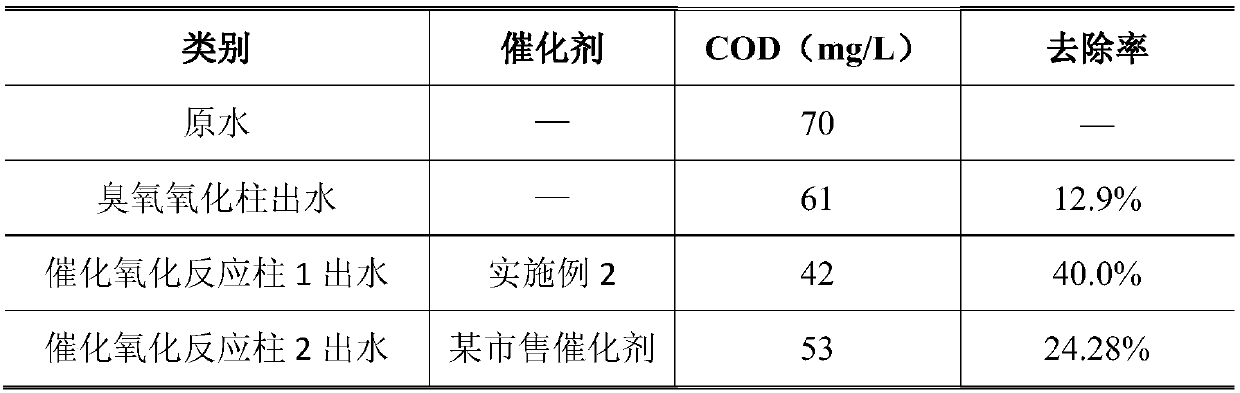

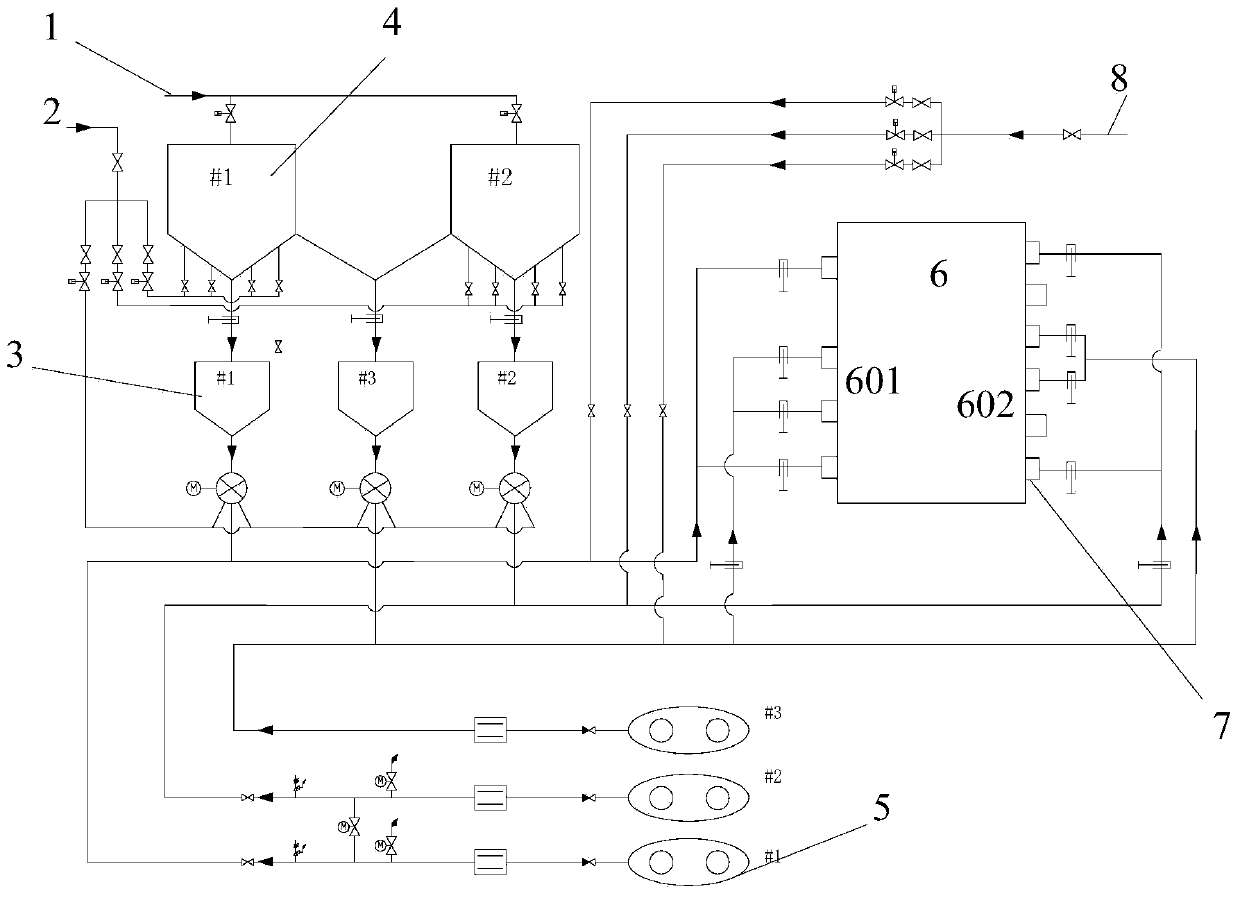

Catalyst used for ozone catalyzing and oxidizing treatment of hard-to-degrade waste and preparation method and application thereof

ActiveCN109647431AIncrease profitAddress reactivityWater contaminantsCatalyst activation/preparationOrganic matterOxidative treatment

The invention relates to the field of hard-to-degrade waste water treatment, provides a catalyst and a preparation method and application thereof, and particularly relates to a heterogenous catalyst used for the ozone catalyzing and oxidizing treatment of hard-to-degrade waste and a preparation method and application thereof. According to the catalyst, active aluminum oxide is taken as a carrier,transition metal is loaded on the carrier by adopting an impregnation-hydrothermal method, and the catalyst is obtained after drying and sintering. The catalyst has the advantages that a large numberof hydroxyl radicals can be generated when the catalyst is used for degrading the hard-to-degrade waste water to oxidize hard-to-degrade organic matters, and the catalyst is an efficient heterogenouscatalyst with higher catalytic activity, simple preparation technology and low cost.

Owner:渤海水业股份有限公司 +1

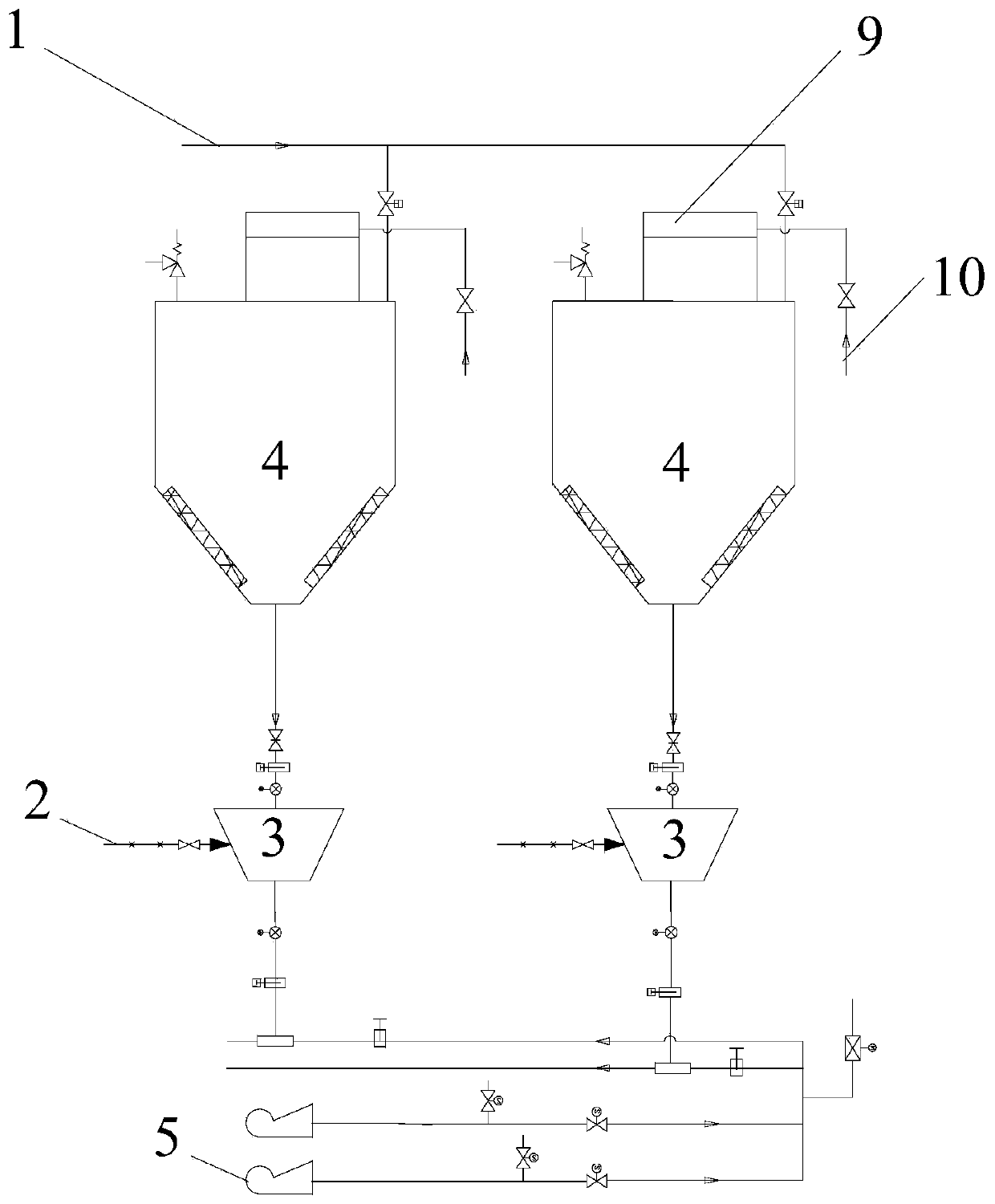

Acetylene sludge desulfurization method and equipment for coal-fired boiler

ActiveCN104190243ASolve shed blockageSolve for uniformityAir supply regulationDispersed particle separationSludgeHearth

The invention belongs to the field of flue gas purification and provides an acetylene sludge desulfurization method for a coal-fired boiler. The method comprises the following steps: (1) drying the acetylene sludge until the moisture content is less than 2 percent; and (2) blowing the acetylene sludge into a hearth of the coal-fired boiler by using a Roots blower, wherein the blowing position is a bend at a secondary air inlet below front and rear walls of the hearth, and four blowing points are distributed on the front wall and another four blowing points are distributed on the rear wall. The main component of the acetylene sludge is Ca(OH)2, calcium element contained in industrial waste residues remained in acetylene gas generated by adding water into calcium carbide can be reacted with SO2 in flue gas in a CaO form, SO2 emission is reduced, and desulfurization in a circulating fluidized bed boiler is realized. However, the acetylene sludge delivery and blockage problem and the problems such as feeding non-uniformity, incomplete reaction and large desulfurization indicator fluctuation in the circulating fluidized bed boiler are not solved. According to the invention, the problems of blockage, feeding non-uniformity, incomplete reaction and large desulfurization indicator fluctuation in the acetylene sludge delivery process are solved.

Owner:内蒙古君正化工有限责任公司

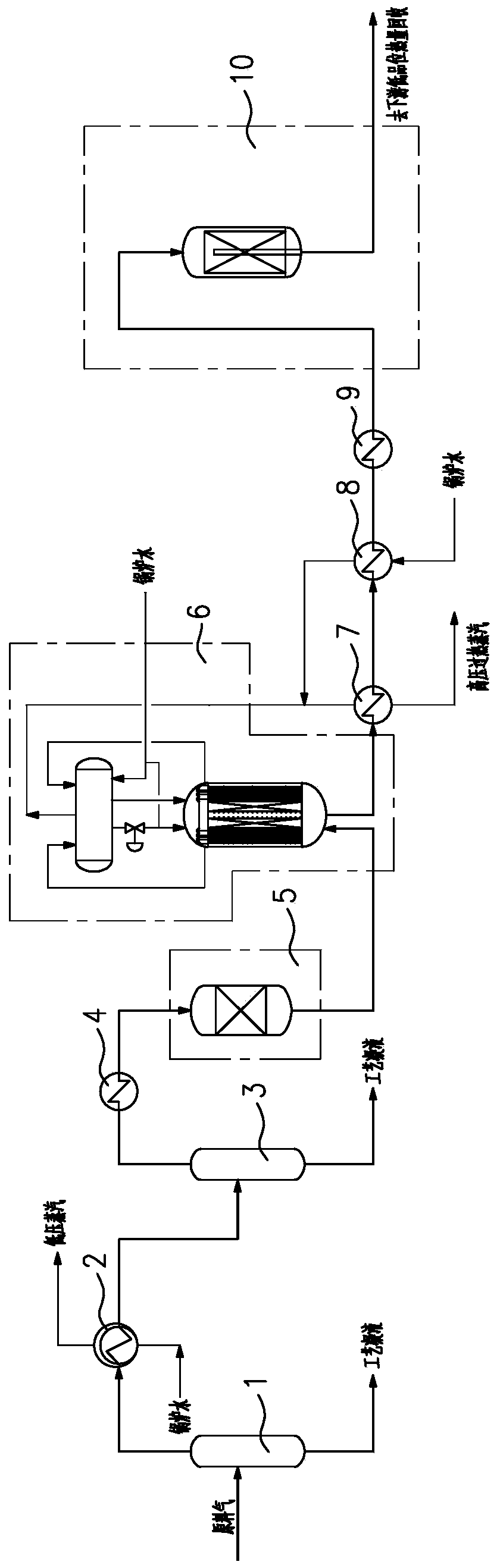

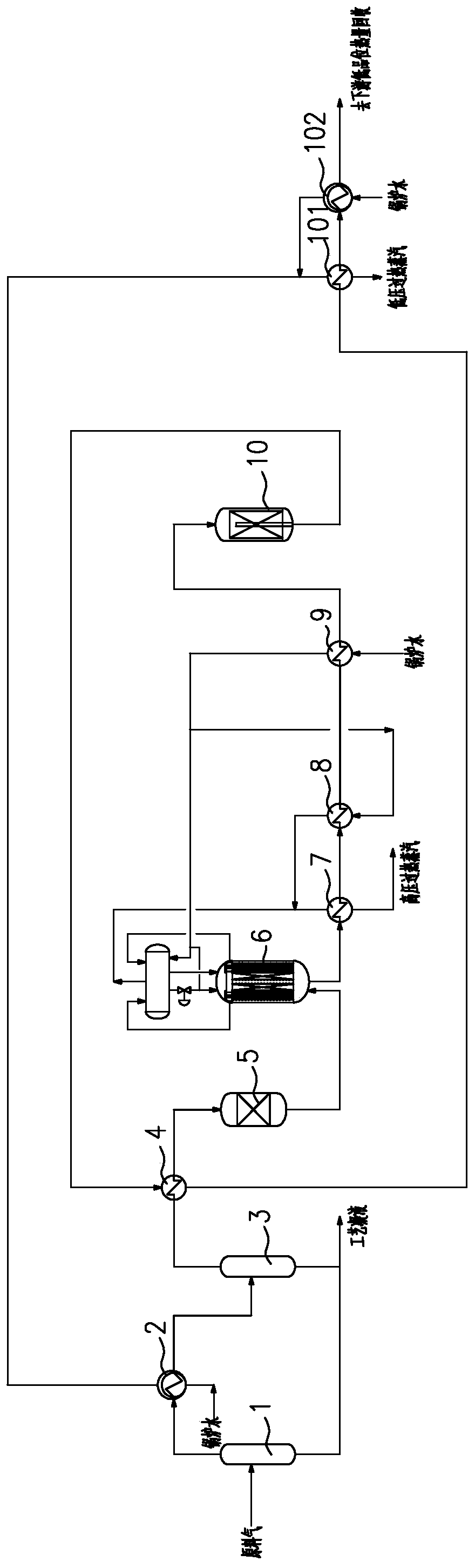

High-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis

ActiveCN110550602AAddress reactivitySolve the problem of difficult temperature controlHydrogenEnergy inputHigh concentrationHigh carbon

The invention relates to a high-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis. The application range is wide, and raw materials with the volume content of a carbon monoxide dry basis being 30-90% and with the volume ratio of water / extra-dry gas being 0.1-1.6 are adopted; the technological process is short, the number of equipment is small, control is easy, and the investment and operation costs are low; by arranging a controllable semi-isothermy saturated steam generation system with a control valve, the temperature of shift gas can be quickly and effectively adjusted, the steam generating pressure is not affected, the problems that a gas conversion reaction of the raw materials with the high carbon monoxide content is prone to overtemperature and difficult temperature control are solved, the grade of byproduct saturated steam is increased to the largest extent, and the yield of low-pressure saturated steam with low utilization value is decreased; high-pressure saturated steam can be overheated, arranging of an external overheating furnace or heat combination with other devices is not needed, and thus the investment and operation difficulty is lowered; and as for the working condition that the temperature needs to be increased at the terminal stage of a catalyst, only the opening degree of the control valve needs to be appropriately adjusted, and thus operation is convenient.

Owner:SINOPEC NINGBO ENG +2

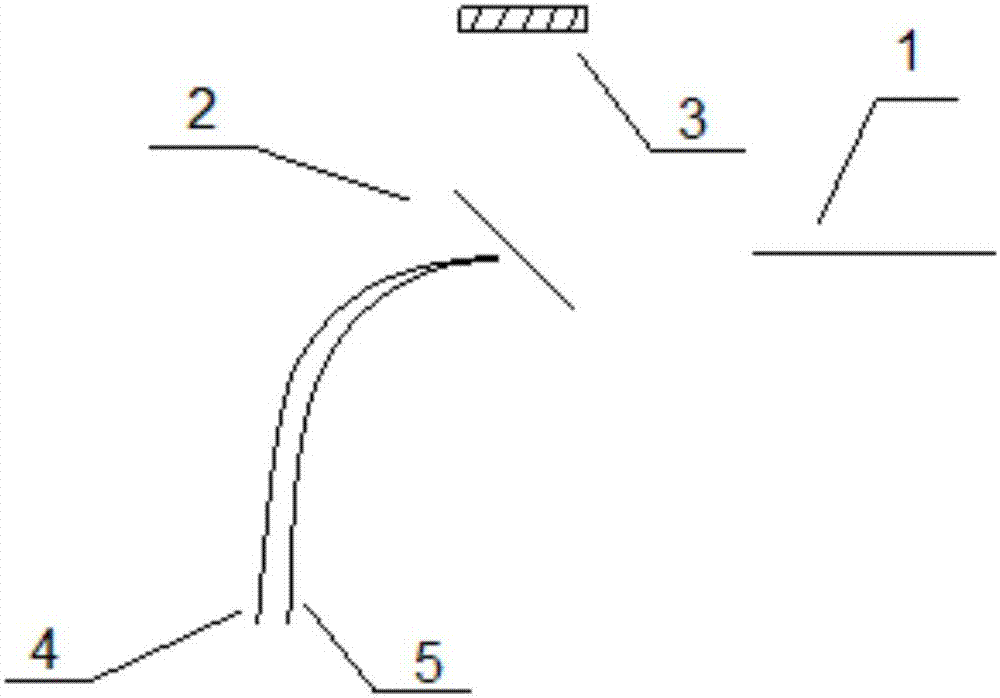

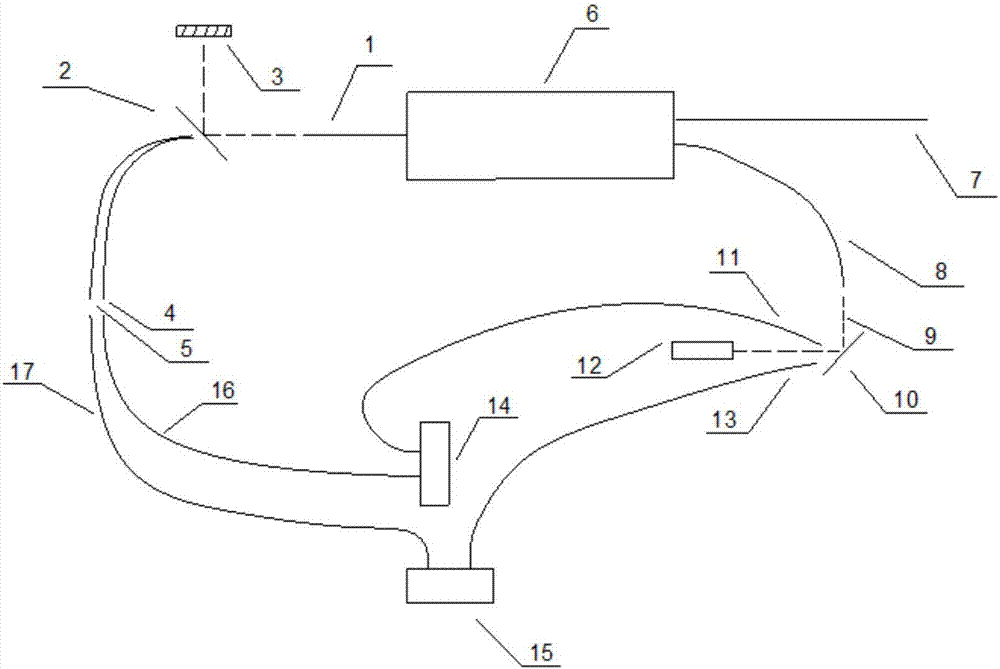

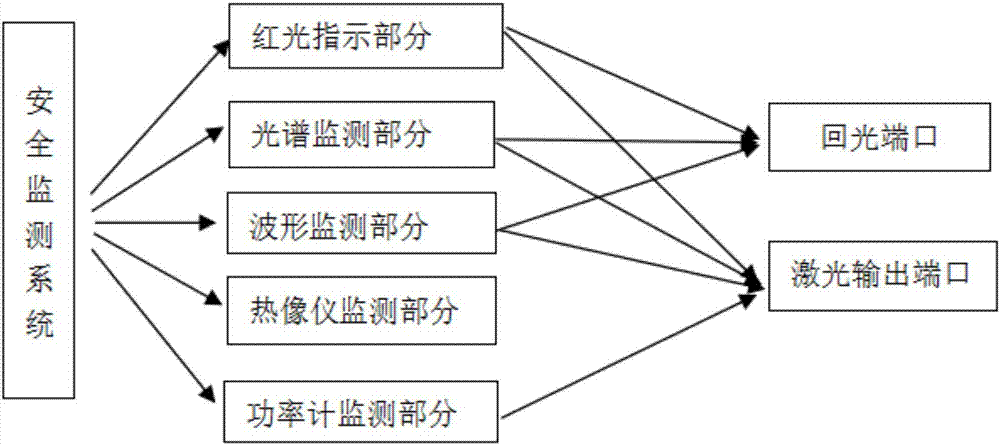

High-power fiber laser safety monitoring method and device

ActiveCN107219063AMonitor working statusSimple working conditionTesting optical propertiesMonitoring systemEngineering

A high-power fiber laser safety monitoring method comprises the following steps of: S1, establishing a monitoring channel for monitoring an output terminal and the light returning terminal of a forward combiner (usually the suspending arm of the combiner); S2, establishing a monitoring system that comprises a red light indicating part, a spectrum monitoring part, a waveform monitoring part, a thermal imager monitoring part and a power meter monitoring part; and S3 establishing a monitoring index for establishing the indexes of a fiber laser in normal operation, the indexes including a static index and a dynamic index.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

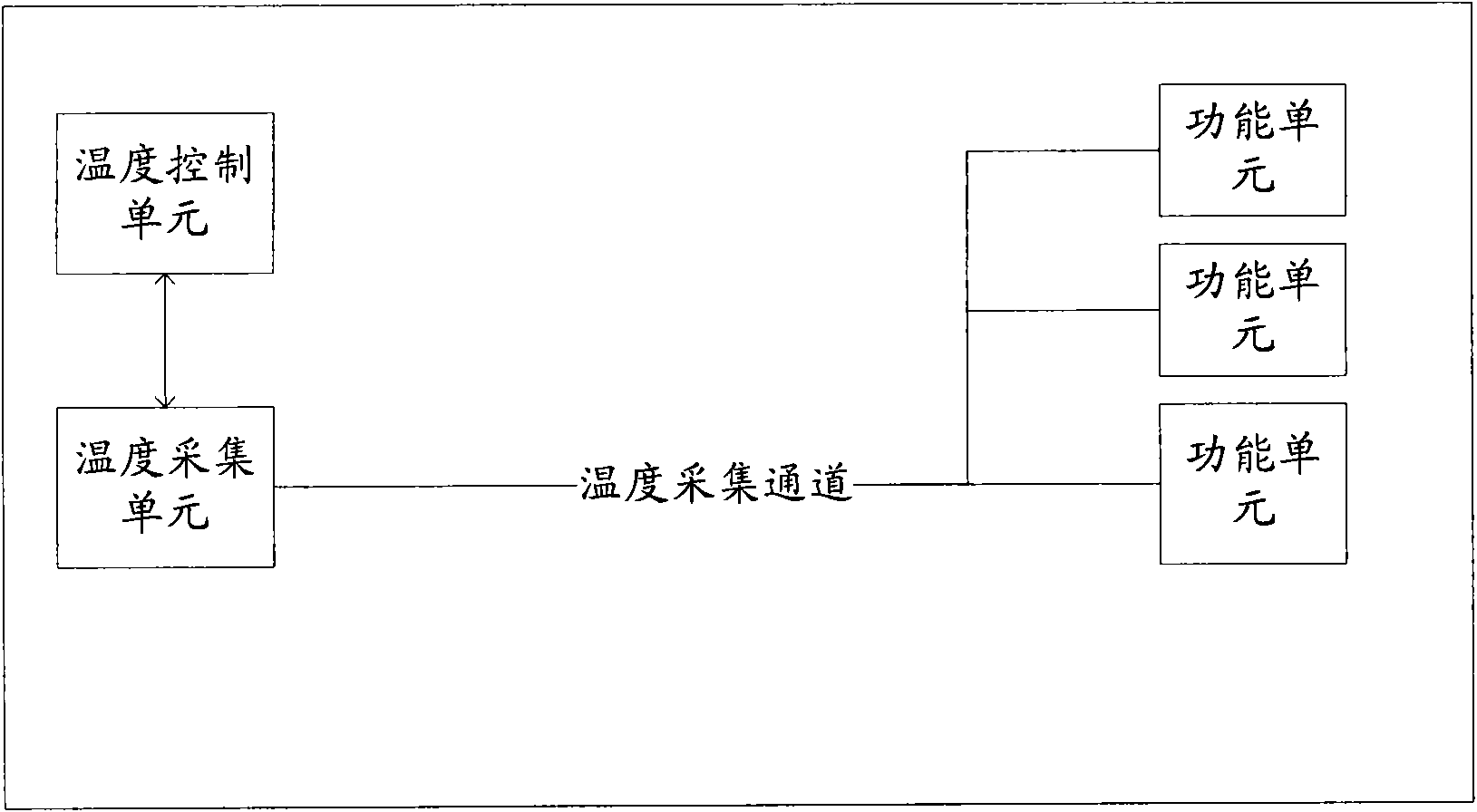

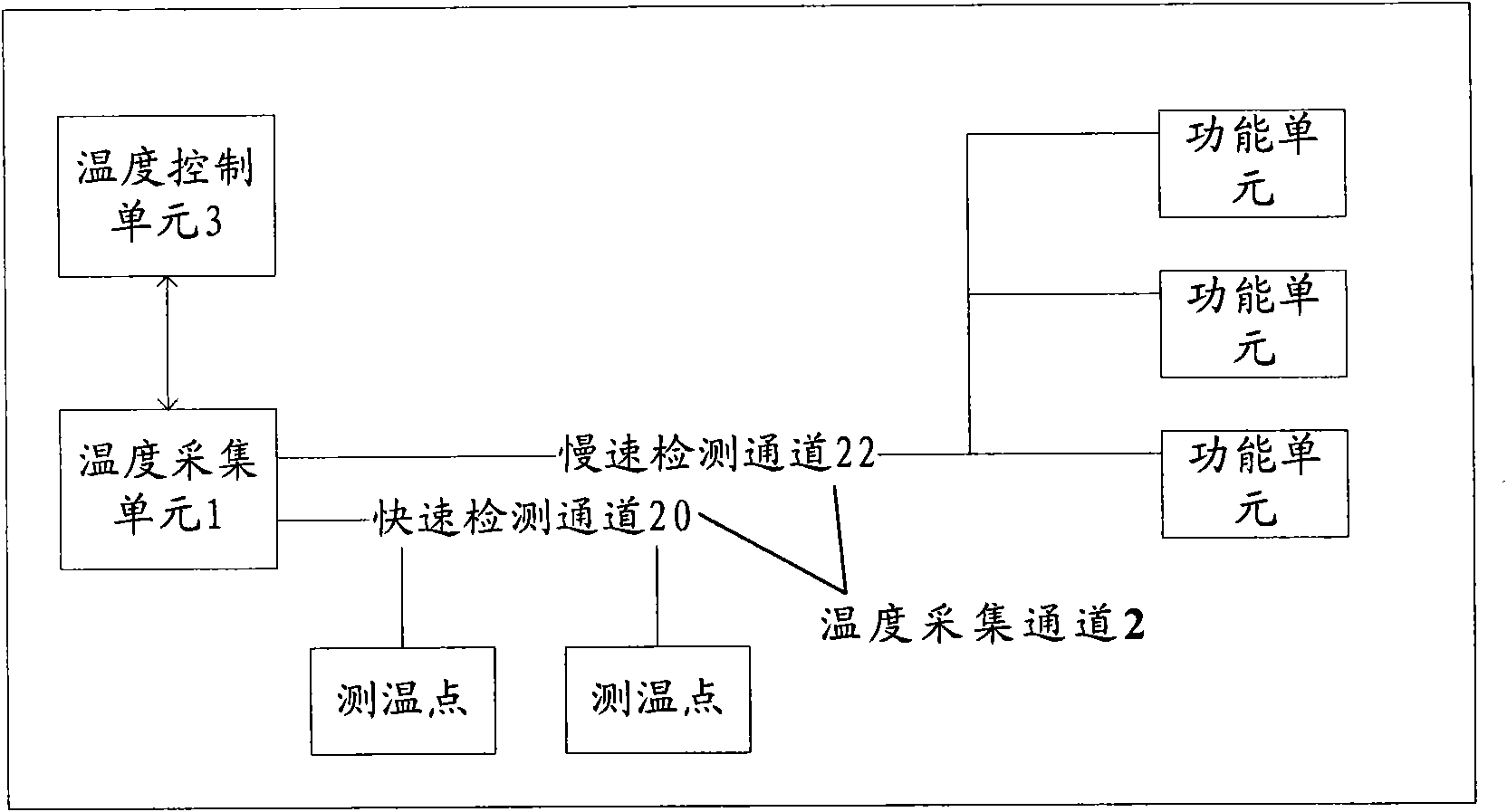

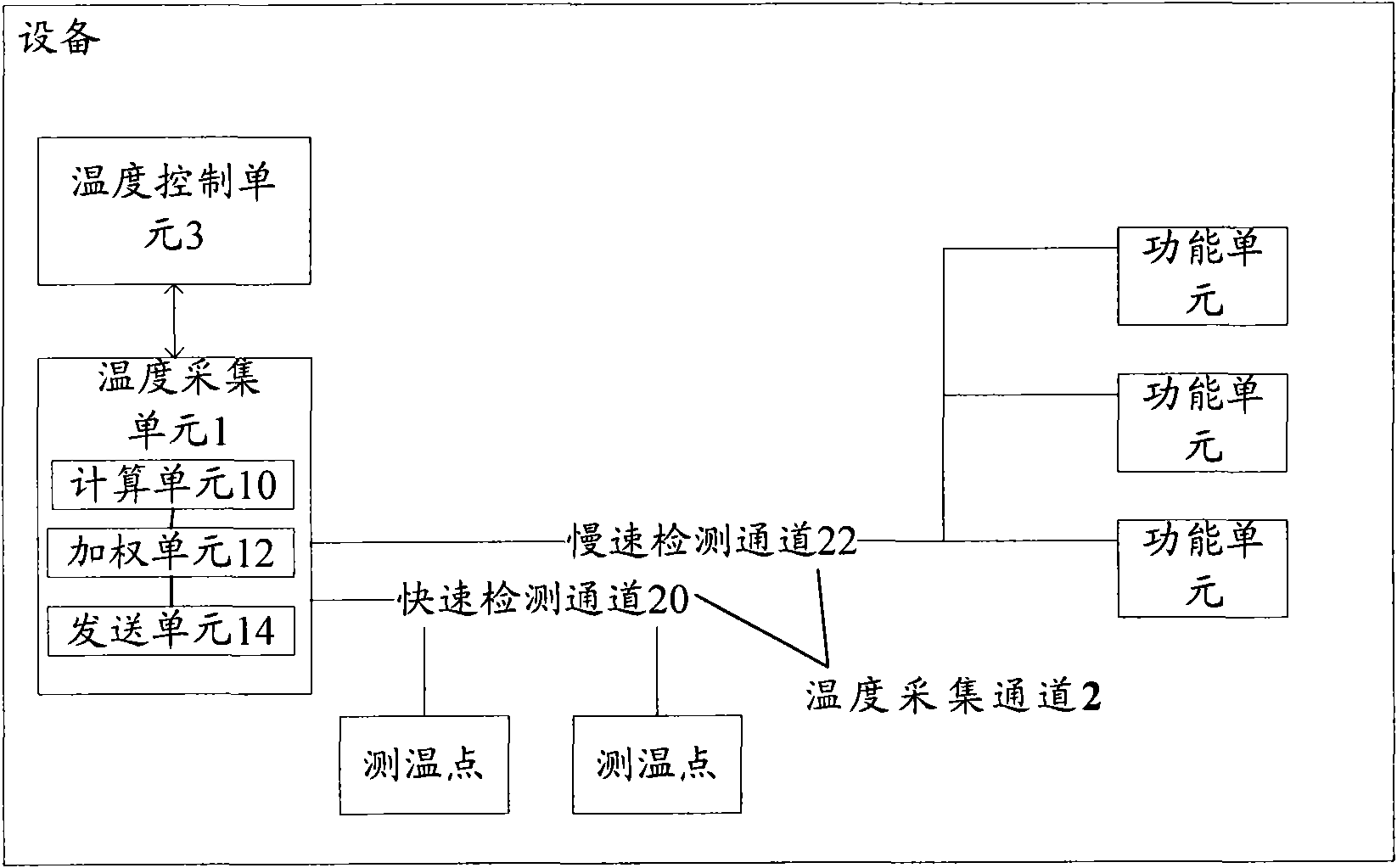

Temperature acquisition control device and method

ActiveCN101598949AAddress reactivityTimelinessThermometer detailsThermometer testing/calibrationTemperature controlEngineering

The invention discloses a temperature acquisition control device and a temperature acquisition control method. The device comprises a temperature acquisition unit, a temperature acquisition channel and a temperature control unit, wherein the temperature acquisition channel comprises a quick detection channel and a slow detection channel, wherein the quick detection channel is connected with a temperature measuring point of equipment controlled by the device, and is used for acquiring the temperature of the temperature measuring point of the equipment in a first preset cycle; the slow detection channel is connected with a functional unit of the equipment, and is used for acquiring the temperature of the functional unit in a second preset cycle; the second cycle is greater than the first cycle; the temperature acquisition unit is used for acquiring the temperature of the temperature measuring point and the temperature of the functional unit, which are acquired by the temperature acquisition channel; and the temperature control unit is used for controlling the temperature of the equipment according to difference of the temperature of the functional unit and the temperature of the temperature measuring point at the same moment. The technical proposal can reduce the occupation of system resources on the premise of timely acquiring the temperature of the equipment.

Owner:ZTE CORP

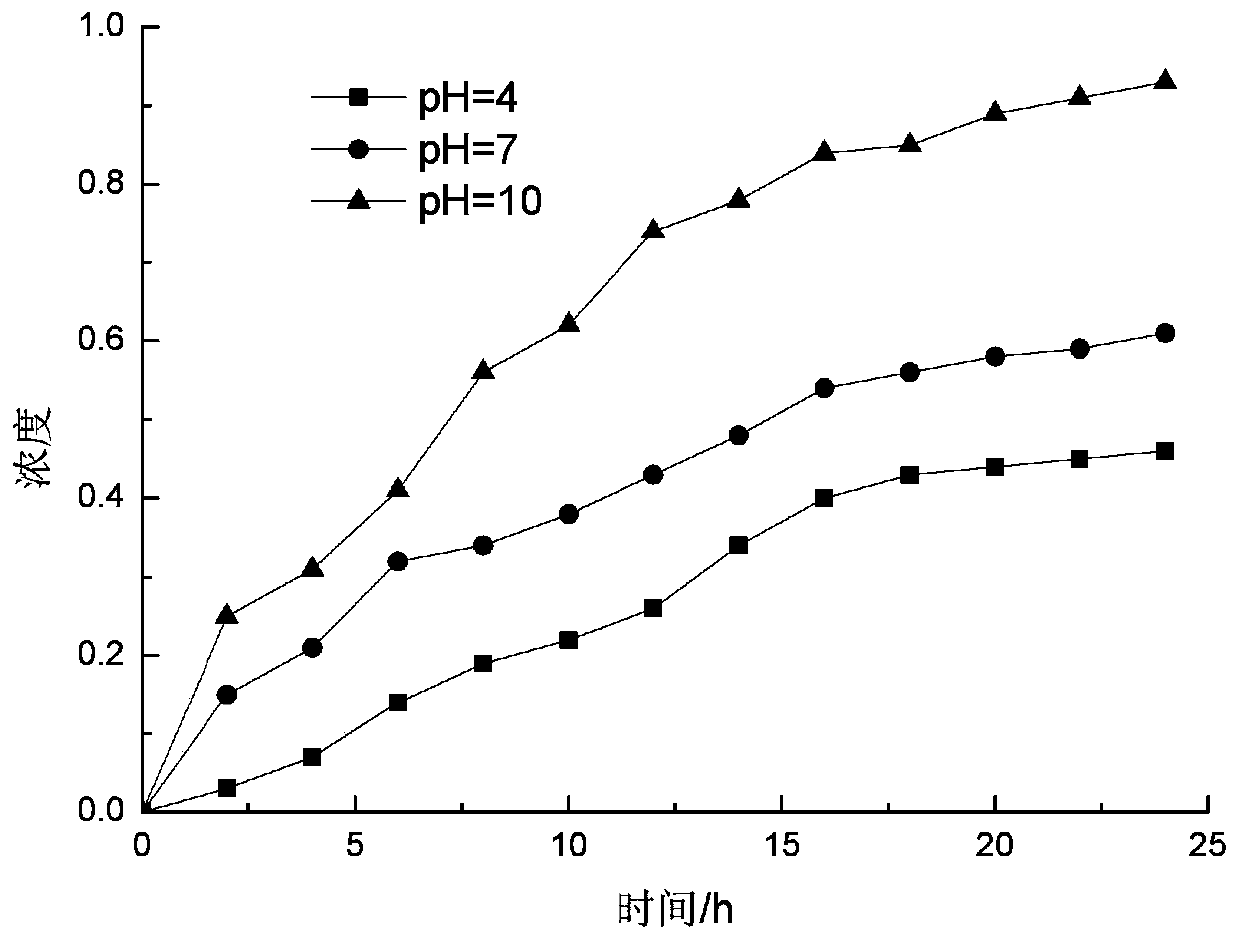

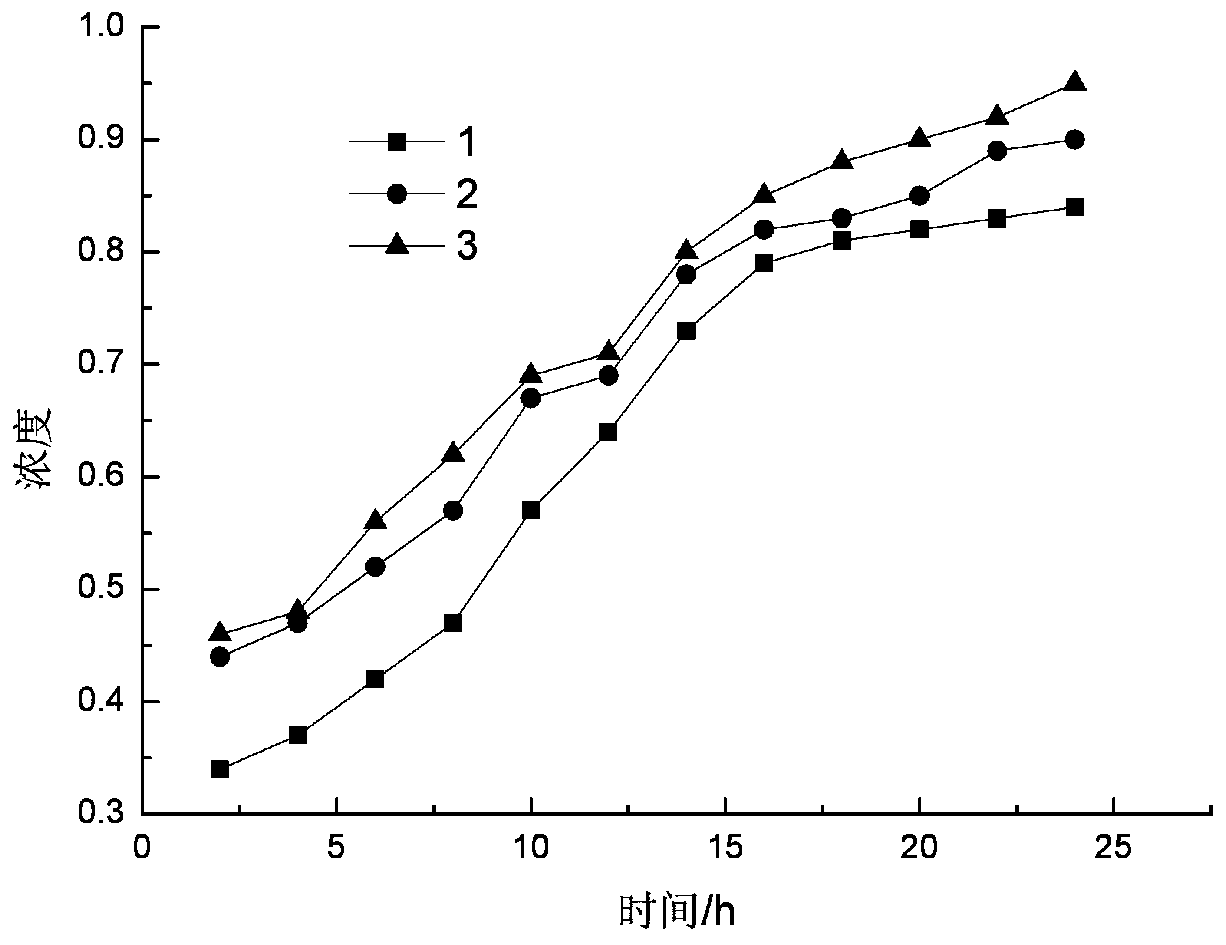

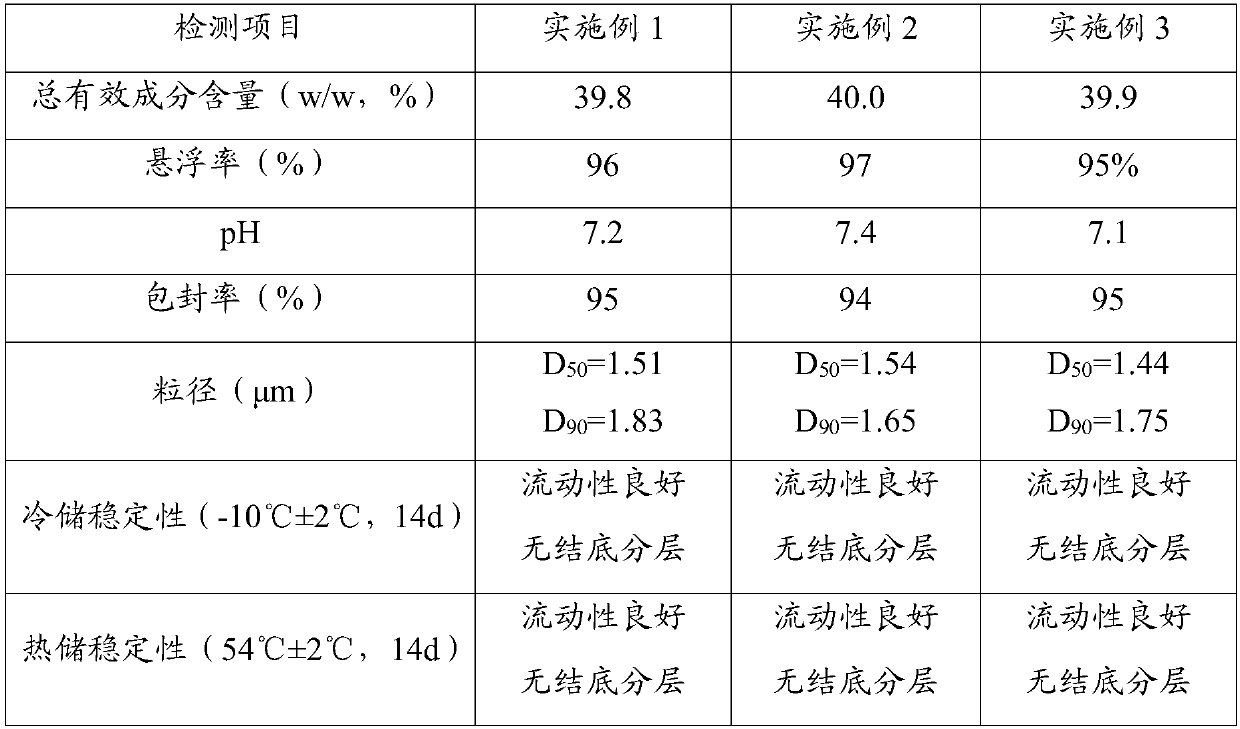

PH-responsive controlled release pesticide microcapsule suspension and preparation method thereof

InactiveCN109691444AWell mixedSolve the problem of easy violenceBiocideAnimal repellantsControl releasePreservative

The invention discloses a pH-responsive controlled release pesticide microcapsule suspension. The pH-responsive controlled release pesticide microcapsule suspension comprises 1-55 wt% of a capsule core effective component, 2-25 wt% of a capsule material, 0-15 wt% of a capsule core solvent, 2-6 wt% of a dispersant, 0.5-1 wt% of a defoamer, 0.5-2 wt% of a preservative, 3-5 wt% of an antifreeze agent, 0.1-2 wt% of a thickener, and the balance of water, and the capsule material is polyurethane obtained by crosslinking and curing isocyanate, a polyurethane soft segment and a carboxyl group-containing chain extender, and a weight ratio of the isocyanate to the polyurethane soft segment to the carboxyl group-containing chain extender is (10-20):(20-85):(4-30). The invention also discloses a preparation method of the pH-responsive controlled release pesticide microcapsule suspension. The pH-responsive controlled release pesticide microcapsule suspension prepared in the invention has the advantages of simple preparation process, stable quality, high efficiency, and realization of adjustment of the release rate according to different pH values.

Owner:江苏精禾界面科技有限公司 +1

Application of sinomenine or pharmaceutically acceptable salt thereof as medicament for preventing and treating pulmonary interstitial fibrosis

ActiveCN102579445AAvoid generatingAvoid developmentOrganic active ingredientsAntipyreticHydroxyprolineAdjuvant

The invention relates to application of sinomenine as a medicament for preventing and treating pulmonary interstitial fibrosis. The medicament is prepared by sinomenine or pharmaceutically acceptable salt thereof and other adjuvants, wherein sinomenine or pharmaceutically acceptable salt thereof serves as an activating agent. The routes of administration of the medicament include intravenous drip, intramuscular injection, oral administration, transdermal absorption, atomization inhalation and bronchoalveolar lavage. Experiments show that sinomenine does not have obvious difference with the dexamethasone control group in the effect on inhibiting formation of bleomycin-induced pulmonary fibrosis in mice and prove that sinomenine can alleviate pulmonary alveolitis and fibrosis degrees of themice with bleomycin-induced pulmonary fibrosis and the mechanisms are probably realized by inhibiting expressions of TGF (transforming growth factor)-beta1 and alpha-SMA (smooth muscle actin) and thecontent of HYP (hydroxyproline).

Owner:李蕴麟

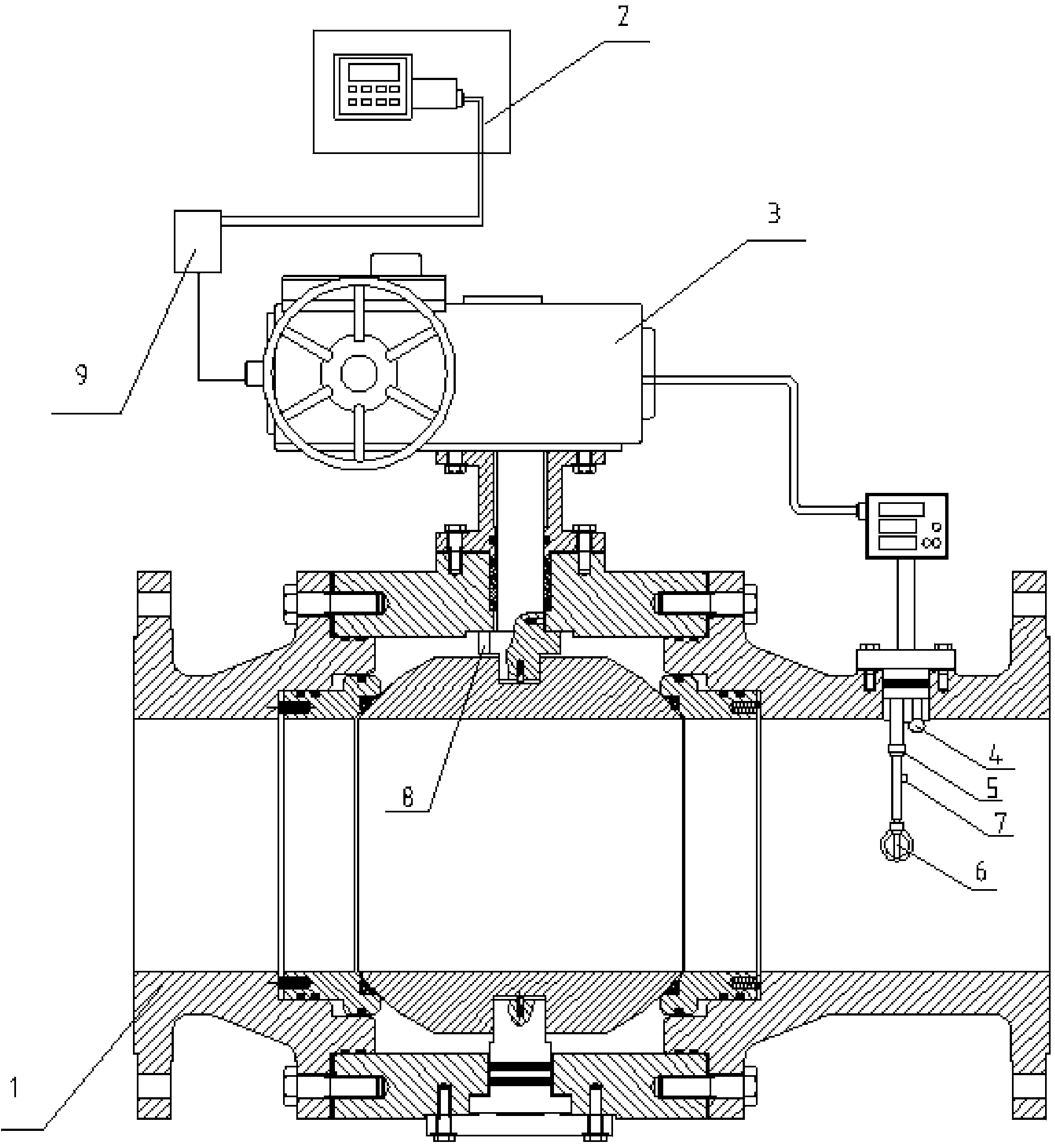

Valve remote-control system

InactiveCN104035419AFix security issuesAddress reactivityTotal factory controlProgramme total factory controlCondition monitoringSignal acquisition

The invention discloses a valve remote-control system. The valve remote-control system comprises a valve, an upper computer used for a valve remote operation and state monitoring, and arranged outside the valve, a micro-control system used for controlling the upper computer, and a drive mechanism arranged on the valve and used for controlling the valve, an electric power carrier communication module used for communicating with the upper computer and the micro-control system, and electrically connected with the upper computer and the micro-control system, and a signal acquisition module used for detecting the state of the valve, and electrically connected with the micro-control system, wherein the micro-control system is used for controlling the signal acquisition module to acquire the state of the valve after receiving the instruction sent by the upper computer, and sending an instruction for controlling the valve drive mechanism according to the state of the valve. The valve remote-control system disclosed by the invention is automatic in management, high in safety, fast in reaction speed, and saving in labour cost. In addition, the flexibility of the valve remote-control system is improved in case of a low external temperature.

Owner:BEIJING EXCELLENCE LIYA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com