Method and device for quickly dissolving alumina out of sintered clinker of high-alumina fly ash

A high-alumina fly ash, alumina technology, applied in the removal of alumina/aluminum hydroxide, solid waste, etc., can solve the problems of long dissolution time, secondary reaction of dicalcium silicate decomposition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

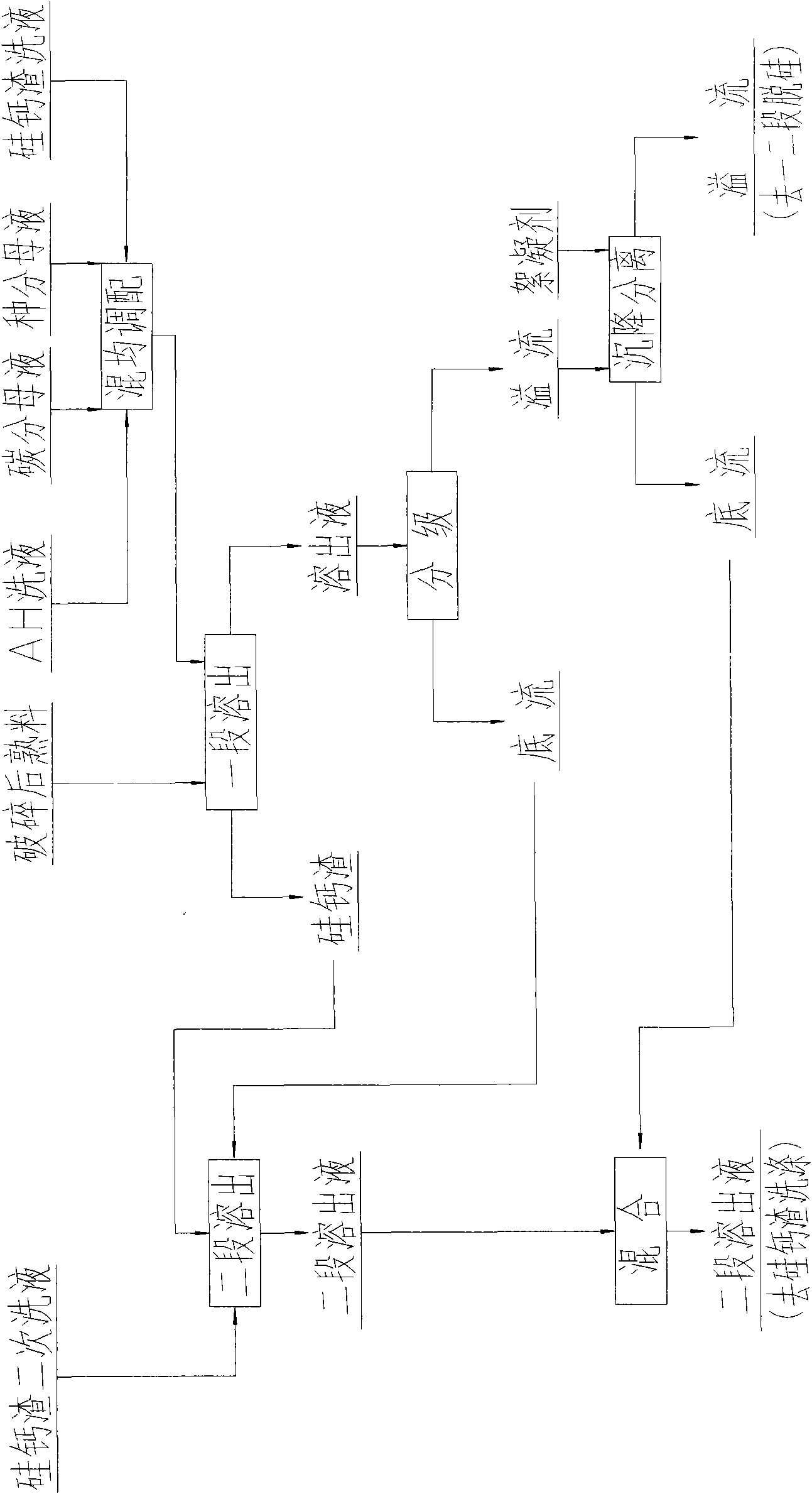

[0032] The process is as follows.

[0033] The four Al-containing 2 o 3 Mix with NaOH solution in the preparation tank to prepare the adjustment solution. These four kinds of solutions are: all the seeds are filtered from the mother liquor, all the silicon-calcium slag washings are washed, and all the finished products are filtered from Al(OH) 3 Part of the carbon mother liquor from the washing liquid and the evaporation tank tank area, the amount of the part of the carbon mother liquor used is 30% of the total amount of the carbon mother liquor.

[0034] Among them, the Al in the mother liquor separated from the seed filtration 2 o 3 : 68.69g / l, NaOH: 135.19g / l;

[0035] Al in silicon calcium slag washing liquid from silicon calcium slag washing 2 o 3 : 48.30g / l, NaOH: 47.99g / l;

[0036] Al(OH) from finished product filtration 3 Al in washing solution 2 o 3 : 17.56g / l, NaOH: 35.39g / l;

[0037] Part of the carbon from the evaporator tank area is divided into Al in ...

Embodiment 2

[0051] The process is as follows.

[0052] The four Al-containing 2 o 3 Mix with NaOH solution in the preparation tank to prepare the adjustment solution. These four kinds of solutions are: all the seeds are filtered from the mother liquor, all the silicon-calcium slag washings are washed, and all the finished products are filtered from Al(OH) 3 Part of the carbon mother liquor from the washing liquid and the evaporation tank tank area, the amount of the part of the carbon mother liquor used is 35% of the total amount of the carbon mother liquor.

[0053] Among them, the Al in the mother liquor separated from the seed filtration 2 o 3 : 69.32g / l, NaOH: 139.20g / l;

[0054] Al in silicon calcium slag washing liquid from silicon calcium slag washing 2 o 3 : 49.68g / l, NaOH: 49.55g / l;

[0055] Al(OH) from finished product filtration 3 Al in washing solution 2 o 3 : 19.25g / l, NaOH: 39.33g / l;

[0056] Part of the carbon from the evaporator tank area is divided into Al in ...

Embodiment 3

[0070] The process is as follows.

[0071] The four Al-containing 2 o 3 Mix with NaOH solution in the preparation tank to prepare the adjustment solution. These four kinds of solutions are: all the seeds are filtered from the mother liquor, all the silicon-calcium slag washings are washed, and all the finished products are filtered from Al(OH) 3 Part of the carbon mother liquor from the washing liquid and the evaporation tank tank area, the amount of the part of the carbon mother liquor used is 25% of the total amount of the carbon mother liquor.

[0072] Among them, the Al in the mother liquor separated from the seed filtration 2 o 3 : 65.57g / l, NaOH: 130.36g / l;

[0073] Al in silicon calcium slag washing liquid from silicon calcium slag washing 2 o 3 : 45.85g / l, NaOH: 45.63g / l;

[0074] Al(OH) from finished product filtration 3 Al in washing solution 2 o 3 : 15.11g / l, NaOH: 30.39g / l;

[0075] Part of the carbon from the evaporator tank area is divided into Al in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com