PH-responsive controlled release pesticide microcapsule suspension and preparation method thereof

A technology of microcapsule suspension and controlled-release pesticide, which is applied in the direction of botany equipment and methods, applications, biocides, etc., can solve the problems of uneven drug effect, achieve stable quality, simple and efficient preparation process, and solve the problem of easy clustering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 14

[0034] Embodiment 1 40% acetochlor microcapsule suspension

[0035] (1) Weigh 40g of acetochlor, 4g of toluene diisocyanate, 14g of polyurethane soft segment PEA-1000, 2g of dimethylolpropionic acid (DMPA), 0.5g of silicone defoamer, 6g of calcium lignosulfonate, 2g sodium benzoate, 5g glycerol, 2g xanthan gum and the water of surplus (total 100g), standby;

[0036] (2) Preparation of polyurethane prepolymer: Feed toluene diisocyanate and polyurethane soft segment PEA-1000 under anhydrous and oxygen-free conditions, stir and cure at 80°C for 5 hours, and react to obtain polyurethane prepolymer;

[0037] (3) Prepare the dispersed phase: mix the weighed acetochlor and the polyurethane soft segment prepolymer, stir evenly at 50° C., and prepare the dispersed phase;

[0038] (4) Prepare the continuous phase: mix and stir the weighed calcium lignosulfonate, dimethylolpropionic acid, silicone defoamer and water evenly to prepare the continuous phase;

[0039] (5) Preparation of micr...

Embodiment 2

[0045] The amount of dimethylolpropionic acid in embodiment 1 is adjusted to 3g, and other operating steps and technical parameters are the same as in embodiment 1.

Embodiment 3

[0047] The amount of dimethylolpropionic acid in embodiment 1 is adjusted to 5g, and other operating steps and technical parameters are the same as in embodiment 1.

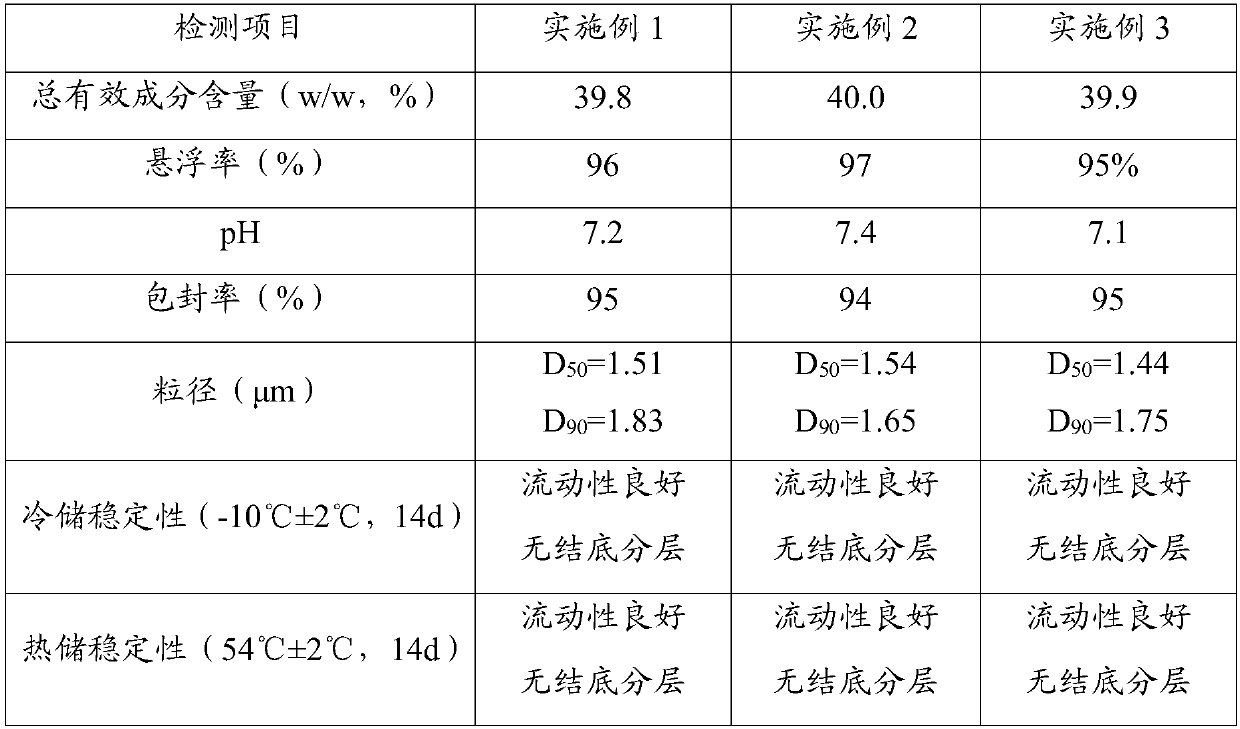

[0048] The performance indicators of the microcapsule suspension prepared in Examples 1-3 were tested respectively, and the test results are shown in Table 1.

[0049] Table 1

[0050]

[0051]

[0052] As can be seen from the above table, the microcapsule suspensions prepared in Examples 1, 2, and 3 have good stability.

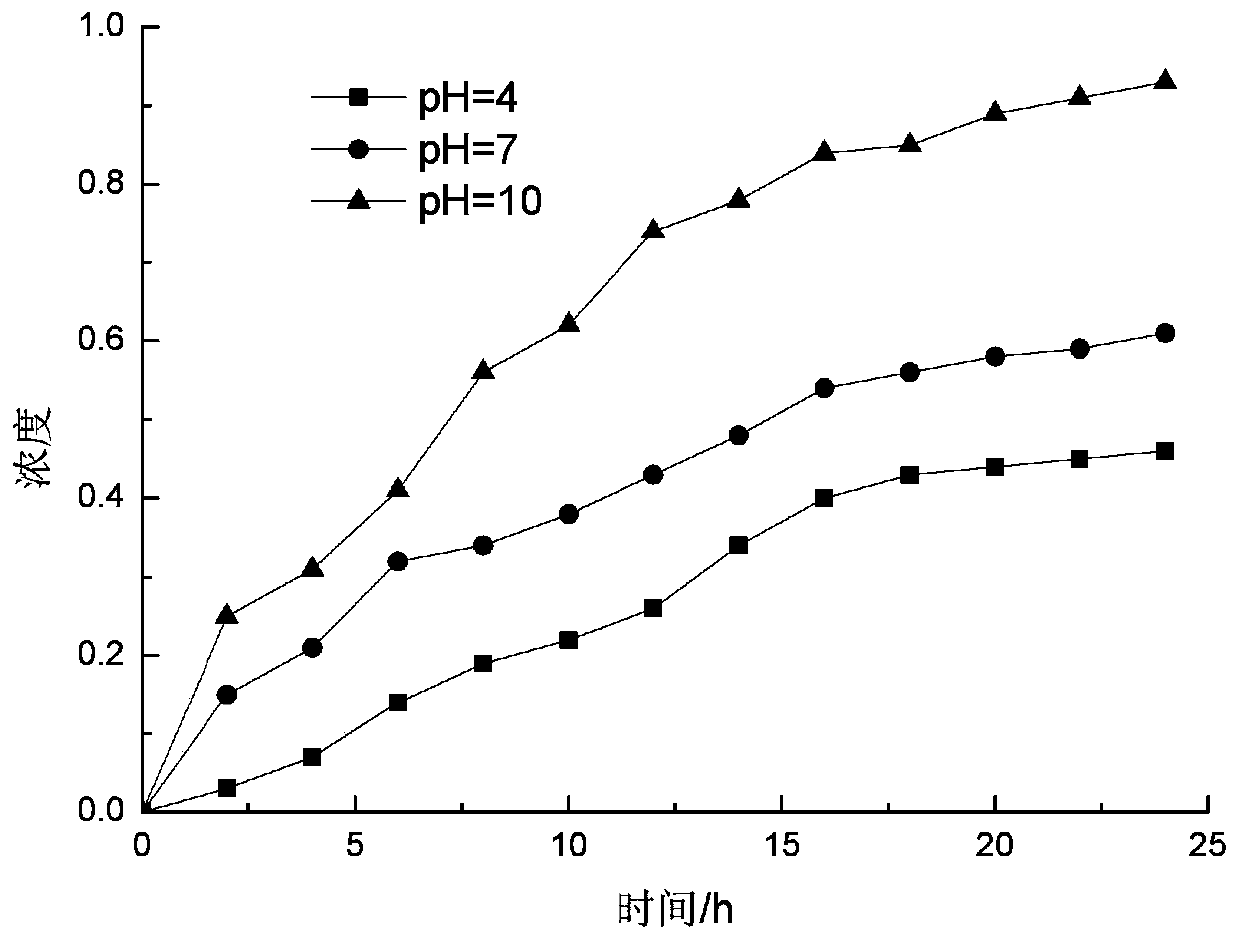

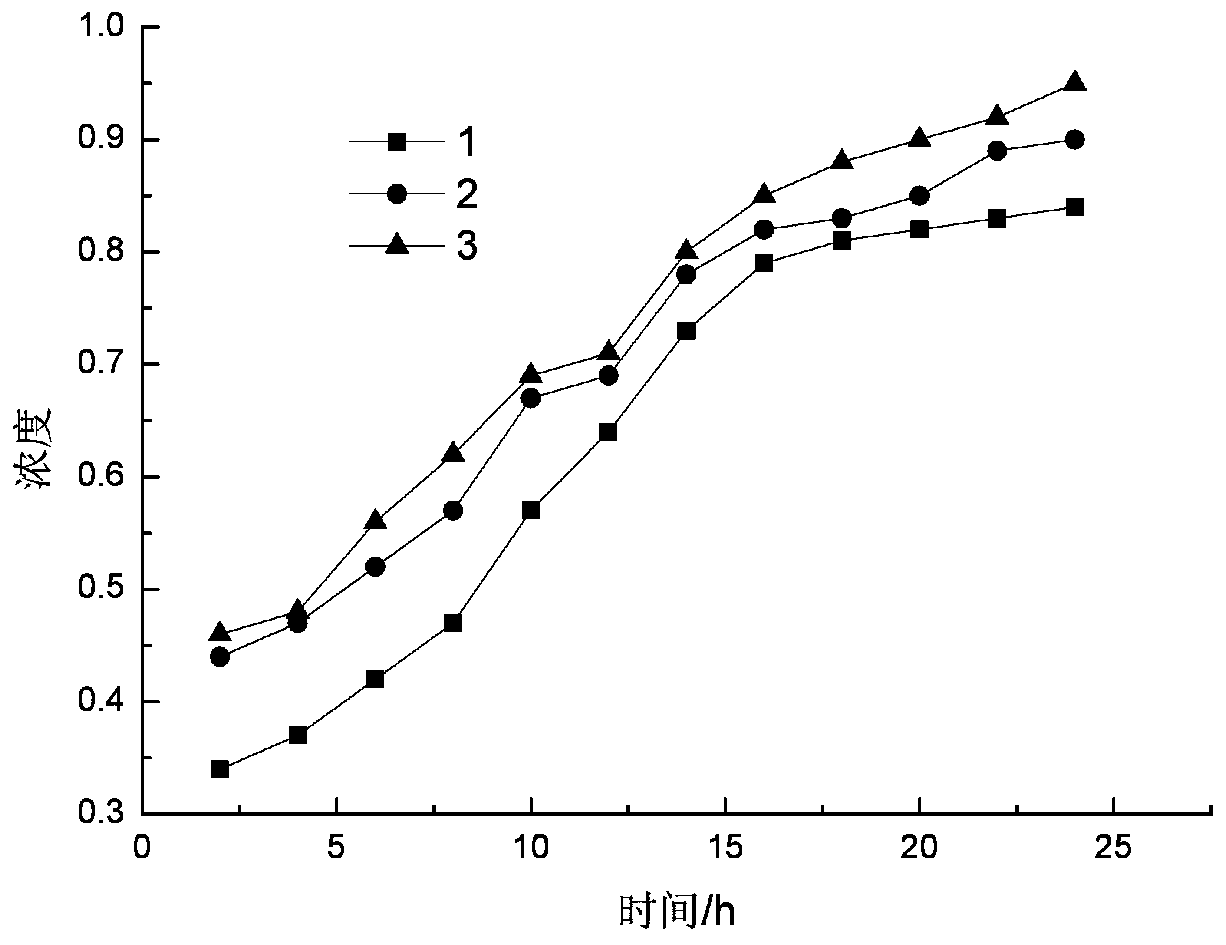

[0053] Further, test the release rate of the microcapsule suspension prepared in Example 1-3 at pH 10, weigh 1 g of the microcapsule suspension in Example 1-3, put it into a dialysis bag, and place it at pH 10 In a 50ml conical flask of buffered aqueous solution, at regular intervals (t), pipette 1mL sample solution with a pipette gun, measure its absorbance by ultraviolet spectroscopy, and add an equal amount of buffered aqueous solution to the conical flask, and compare the buffered aq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com