One-step-method differential dyeing process for cellulosic fiber textile

A cellulose fiber, differentiated technology, applied in the field of textile printing and dyeing, can solve the problems of slow market response, high inventory pressure, and many semi-finished products, and achieve the effect of solving slow market response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

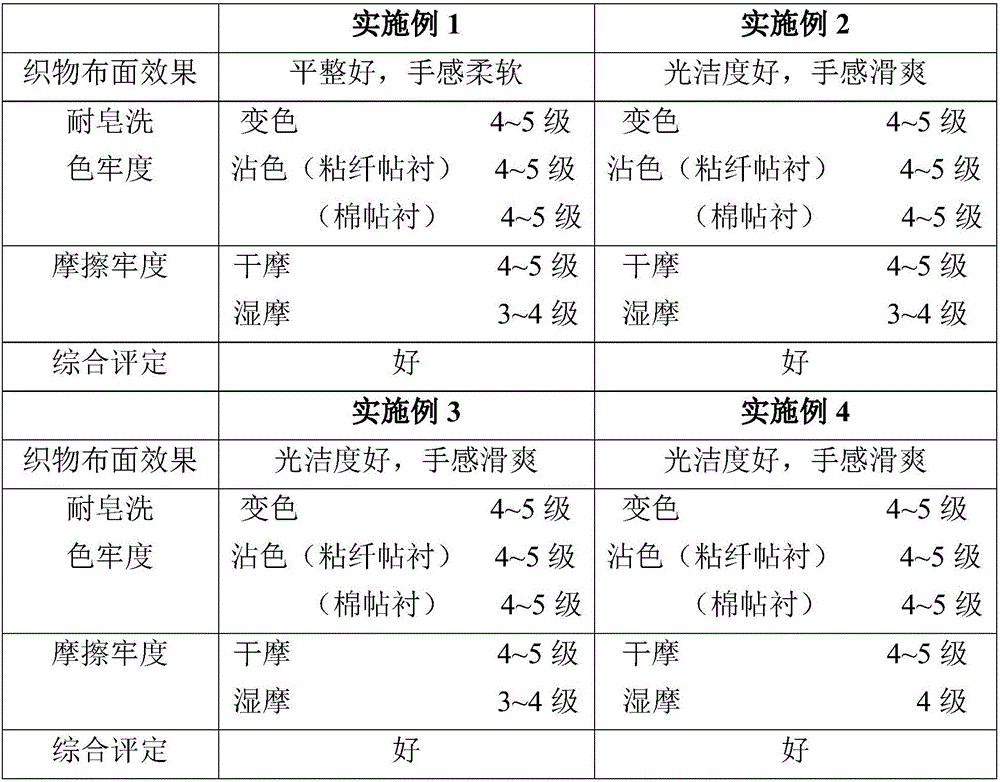

Embodiment 1

[0028] Raw material: raw cotton, grade 2.

[0029] Production requirements: One-step production of pure cotton knitted fabrics in the style of floral yarn with violet white background.

[0030] The production steps are as follows:

[0031] 1. Cotton fiber modification:

[0032] (a) prepare cotton fiber modification working liquid, add in the bulk fiber dyeing machine;

[0033] (b) Dosing cotton fiber into the dyeing machine, the weight ratio of cotton fiber to modified working fluid is 1:10;

[0034] (c) The temperature of the modified working fluid in the dyeing machine is raised to 80°C, and the holding time is 40 minutes;

[0035] (d) washing the modified cotton fibers with water, neutralizing, dehydrating, and drying for later use.

[0036] Among them, the formula of the modified working fluid: the olefin type quaternary ammonium salt modifier is 20g / L; the penetrant fatty alcohol polyoxyethylene ether is 1g / L; the caustic soda is 4g / L.

[0037] 2. Spin the modified c...

Embodiment 2

[0048] Raw material: viscose staple fiber, the specification is 1.4D×35mm.

[0049] Production requirements: One-step production of viscose knitted fabrics in the style of orange and white floral yarn.

[0050] The production steps are as follows:

[0051] 1. Modification of viscose fiber:

[0052] (a) prepare viscose fiber modified working fluid, add in the bulk fiber dyeing machine;

[0053] (b) Dosing viscose fiber into the dyeing machine, the weight ratio of viscose fiber to modified working solution is 1:7;

[0054] (c) The temperature of the modified working fluid in the dyeing machine is raised to 70°C, and the holding time is 60 minutes;

[0055] (d) washing the modified viscose fiber with water, neutralizing, dehydrating, and drying for later use.

[0056] Among them, the formula of the modified working fluid: Glytac reagent is 15g / L; penetrant sodium secondary alkyl sulfonate is 0.5g / L; caustic soda is 3g / L.

[0057] 2. The modified viscose fiber is mixed with t...

Embodiment 3

[0068] Raw material: Modal staple fiber, the specification is 1.0D×38mm.

[0069] Production requirements: One-step production of modal knitted fabrics in the style of bright blue floral yarn on a white background.

[0070] The production steps are as follows:

[0071] 1. Modal fiber modification:

[0072] (a) prepare Modal fiber modified working fluid, add in the bulk fiber dyeing machine;

[0073] (b) Dosing modal fiber in the dyeing machine, the weight ratio of modal fiber to modified working solution is 1:15;

[0074] (c) The temperature of the modified working fluid in the dyeing machine is raised to 80°C, and the holding time is 30 minutes;

[0075] (d) washing the modified modal fiber with water, neutralizing, dehydrating, and drying for later use.

[0076] Among them, the formula of the modified working fluid: the quaternary ammonium salt modifier is 30g / L; the penetrant fatty alcohol polyoxyethylene ether is 0.5g / L; the caustic soda is 5g / L.

[0077] 2. Spin the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com