Patents

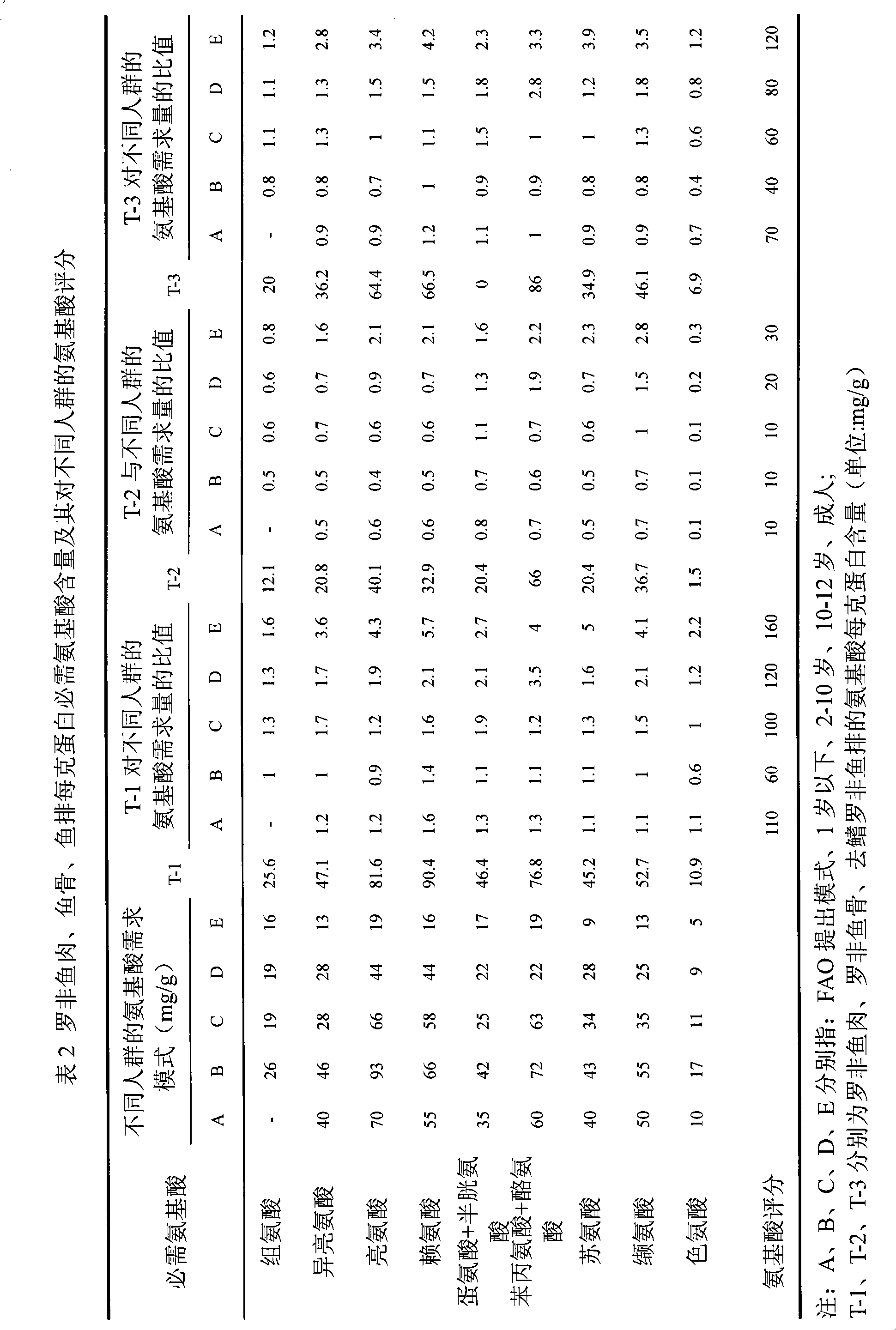

Literature

717results about How to "Short holding time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

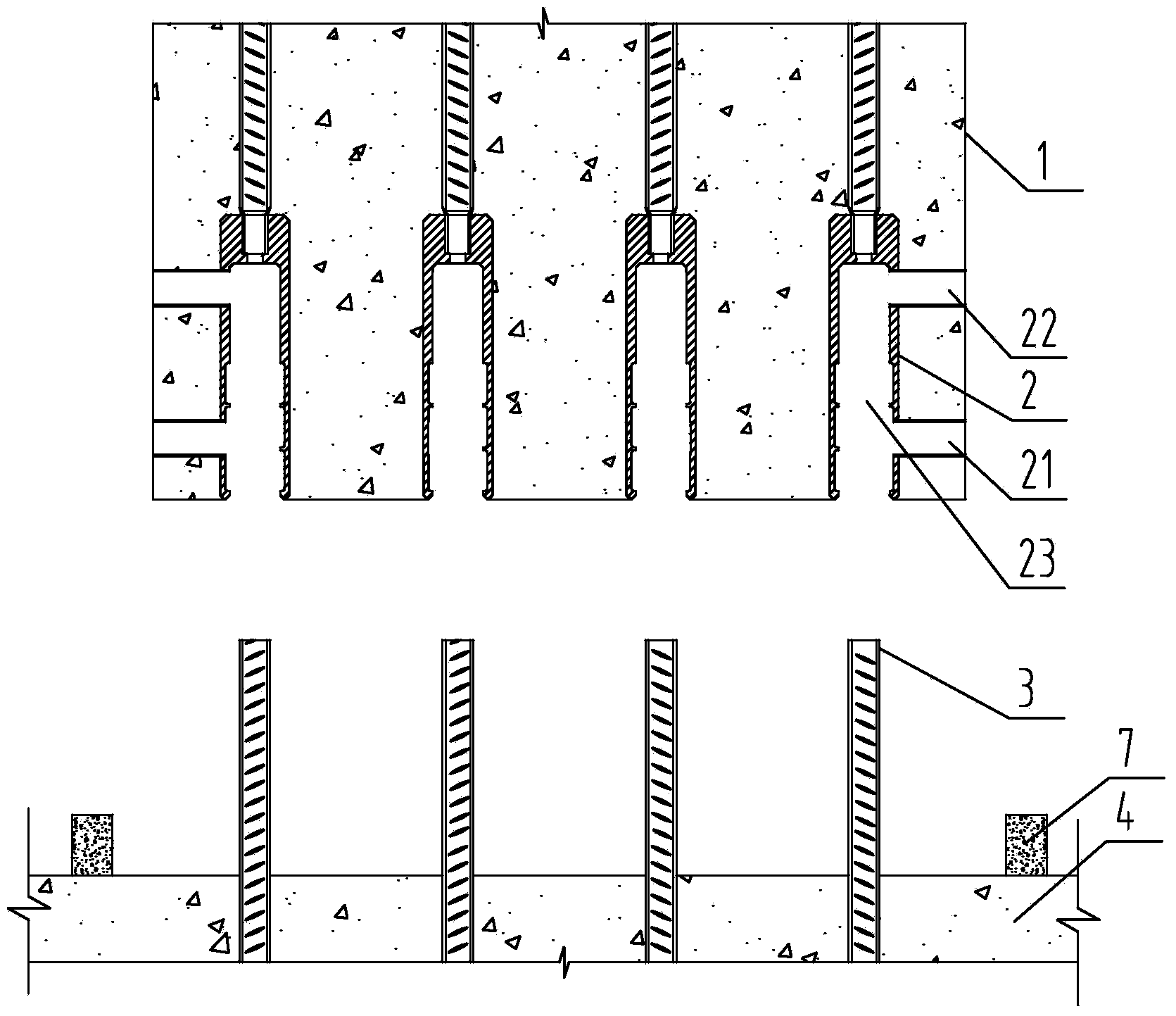

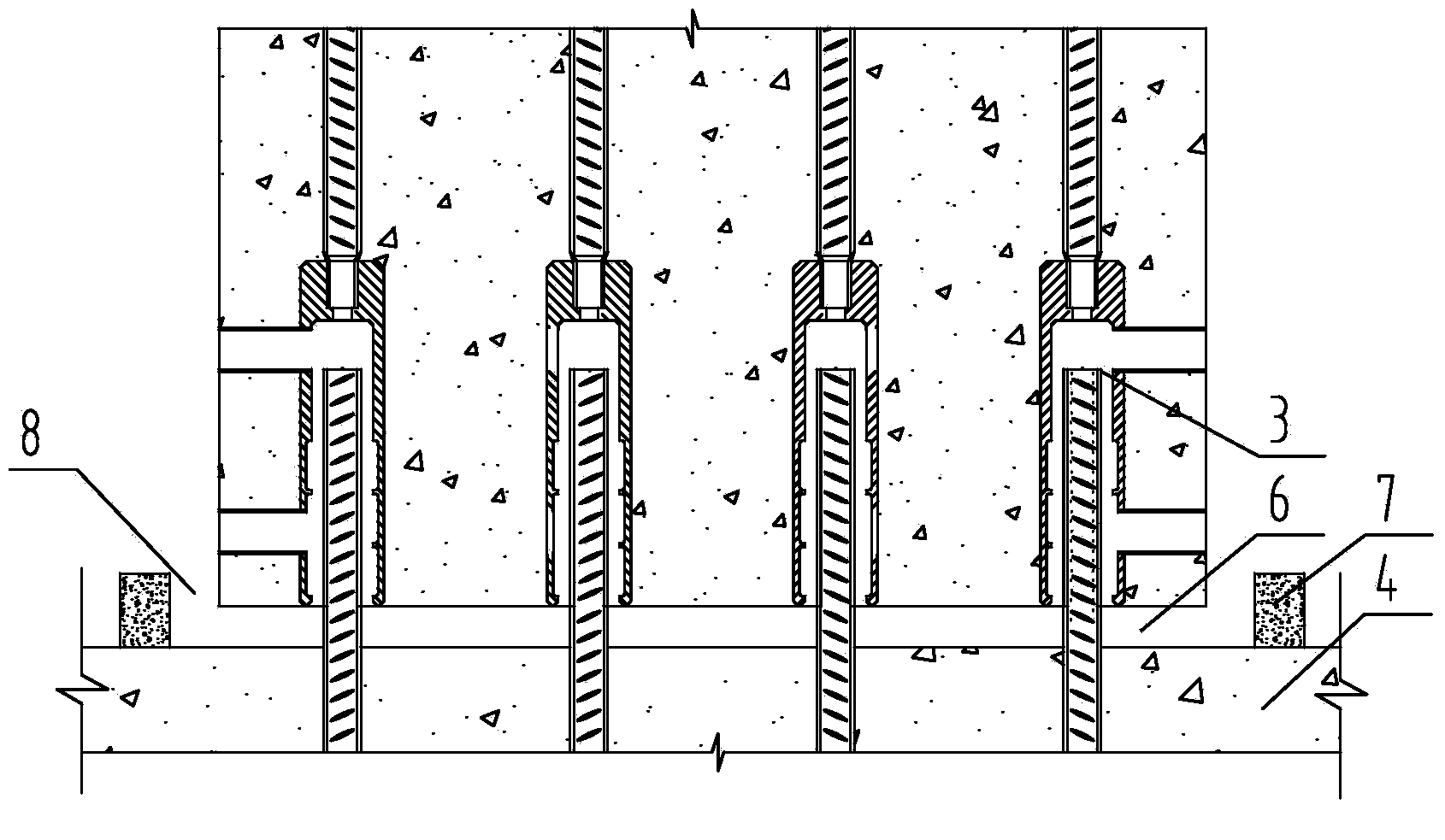

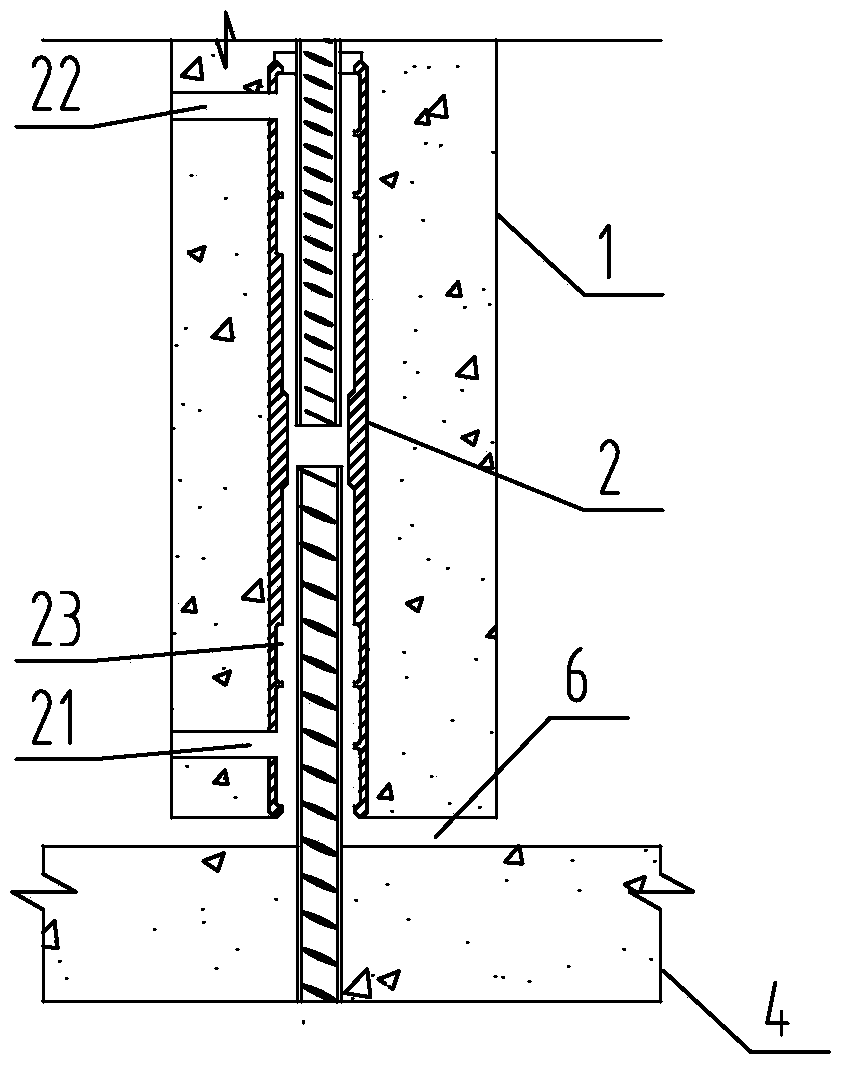

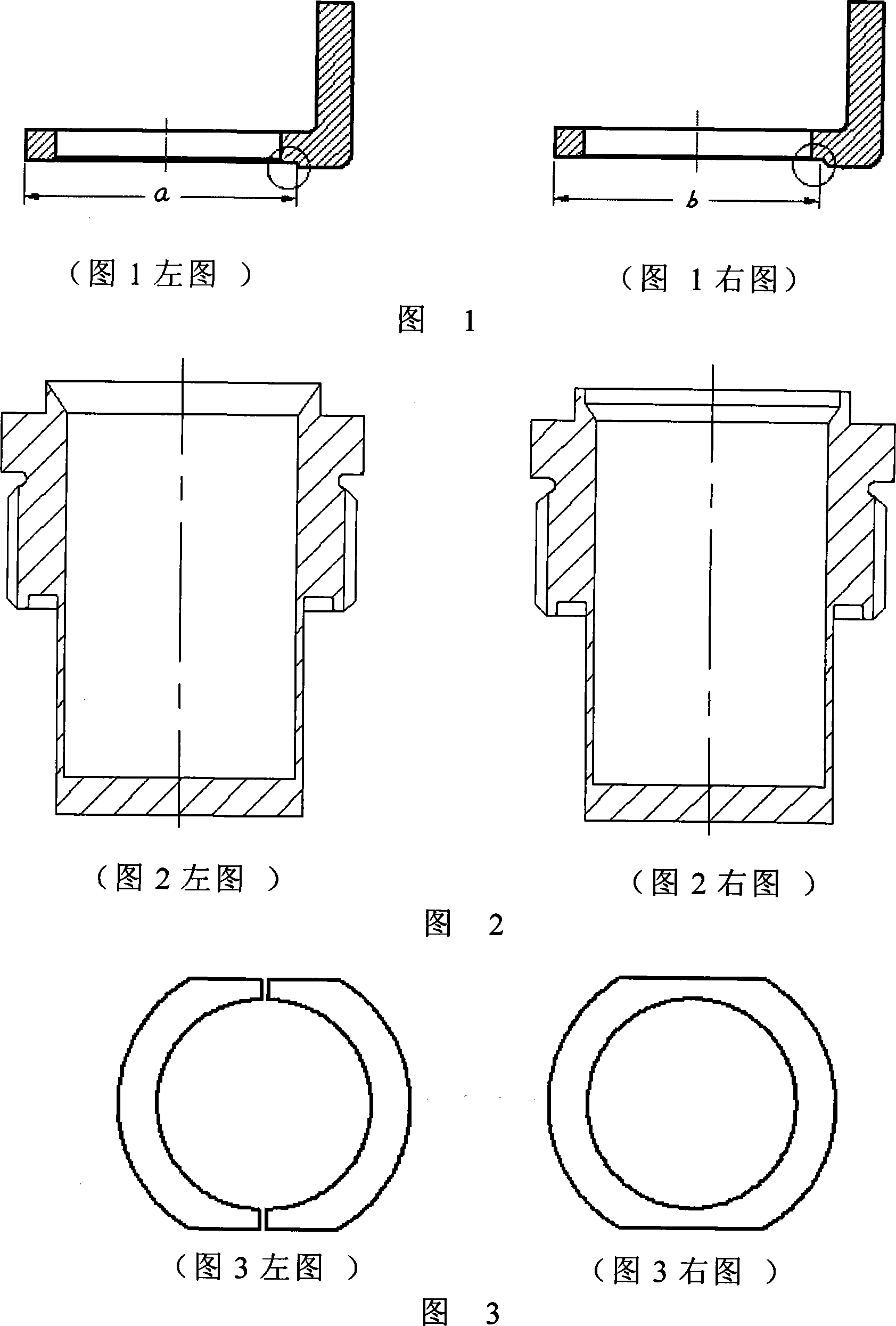

Grouting connection construction method

ActiveCN104314314AFast constructionImprove efficiencyBuilding reinforcementsBuilding material handlingRebarPrecast concrete

The invention discloses a grouting connection construction method which is used for connecting vertical reinforcements of an assembled concrete structure. The grouting connection construction method includes the steps: firstly, embedding a plurality of grouting connection devices at one end of a precast concrete unit to be connected in advance; secondly, lifting the precast concrete unit and then manufacturing a grouting box dam; thirdly, grouting horizontal gaps and then grouting the grouting connection devices. The grouting connection devices are connected with connection reinforcements extending out of a lower unit. Plugging grouting of the horizontal gaps and grouting of the grouting connection devices can be performed within the same day, so that the mounting efficiency of the precast concrete unit is greatly improved, the grouting connection construction method can be implemented in a subzero temperature environment even in winter, construction difficulty is reduced, and working efficiency is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

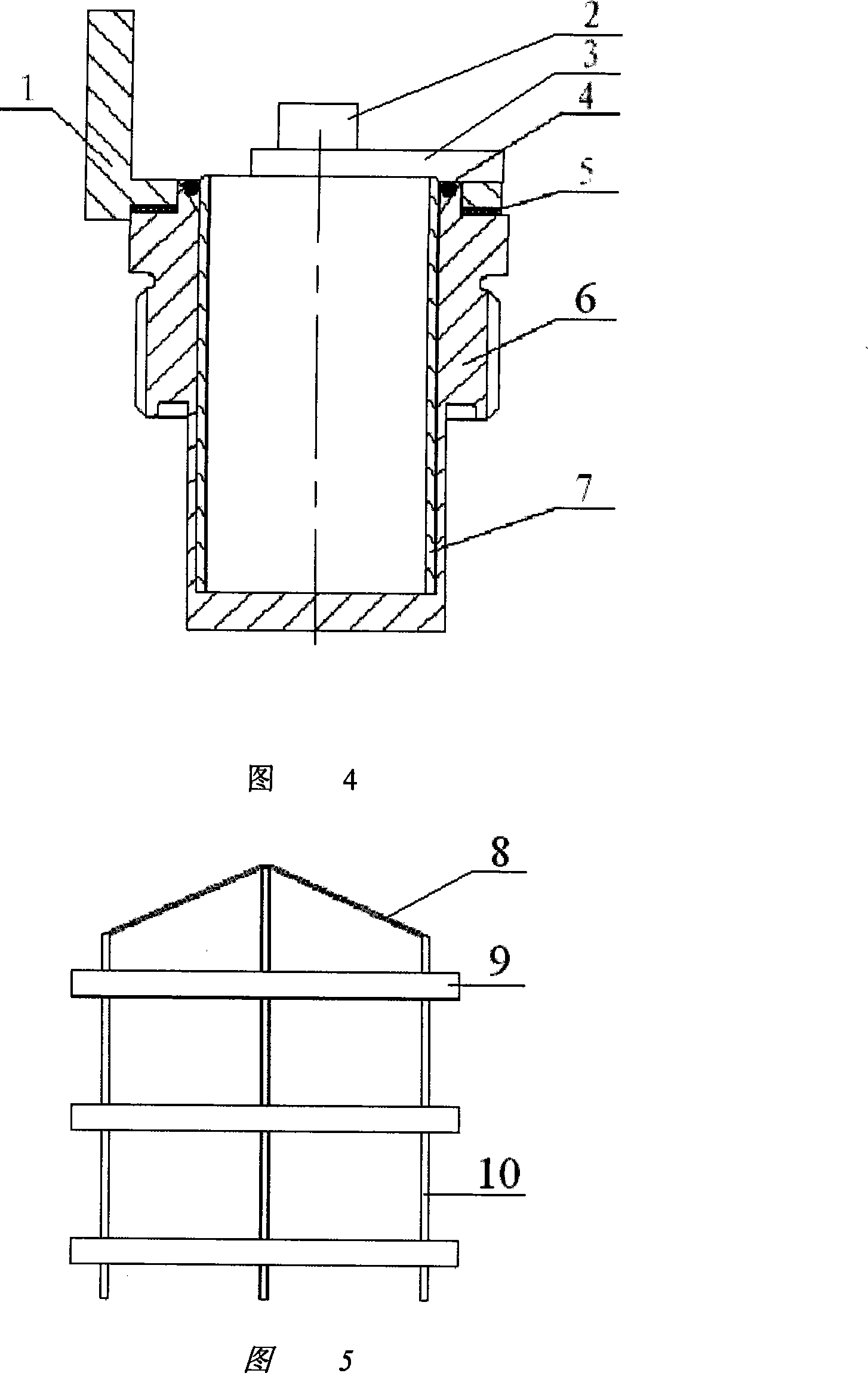

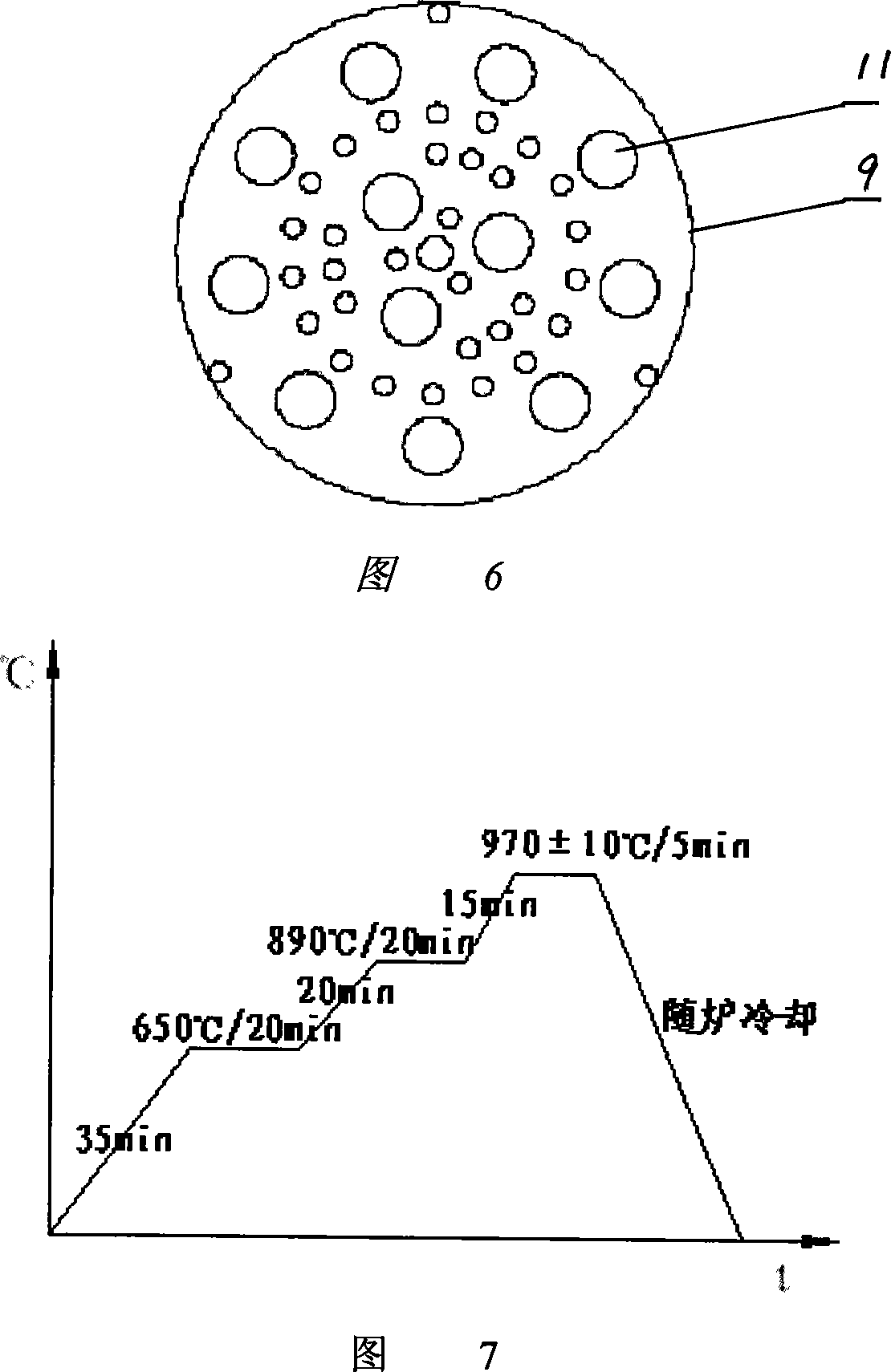

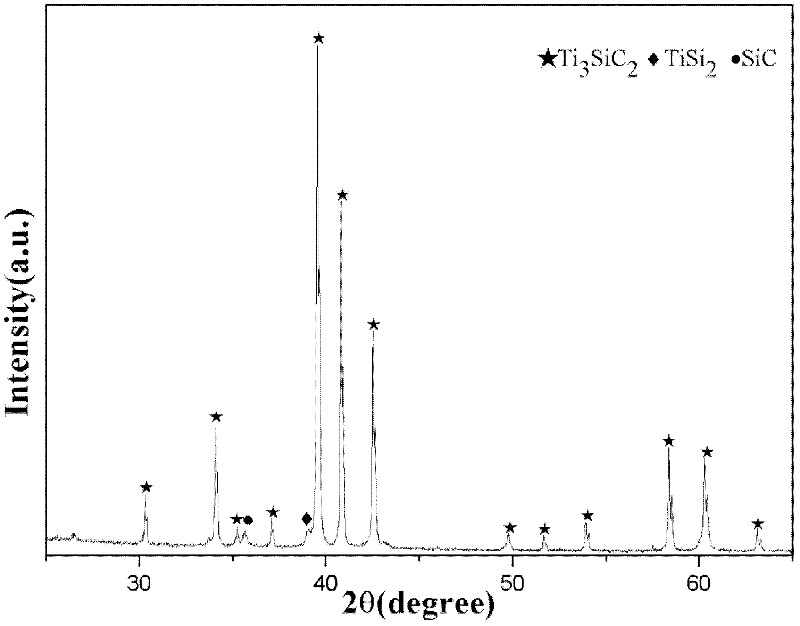

Copper and stainless steel dissimilar metal water adapter vacuum brazing technology method

ActiveCN101200013AThe method is simple and reliableIncrease productivitySoldering apparatusWelding/soldering/cutting articlesDissimilar metalBrazing

The invention discloses a vacuum brazing technology method between copper and stainless steel dissimilar metal water connector, comprising processing each part of the water connectior, controling the processing precision and component assembly clearance; washing the part of water connectior; assembling water connections and putting in special fixture. Put the fixture in vacuum brazing furnace and carry out braze welding according to the following brazing technology: 1) take 35 minutes to make the furnace temperature to rise to 650 DEG C at a uniform speed; 2) continue to preserve heat for 20 minutes; 3) rise the furnace temperature at a uniform speed to 890 DEG C in 20minutes; 4) continue to preserve the heat for 20 minutes; 5) then rise the furnace temperature to 970 DEG C+-10 DEG C at a uniform speed in 15 minutes; 6) Continue to preserve heat for 5 minutes; 7) then stop heating and cool naturally; 8) on the next day take out the water connector from the fixture; 9) carry out the acceptance test by using the ultrasonic automatic testing device. The technical problem that the annular gap of the water connector is not fully filled and can be corroded is solved; the invention has the advantages of reliable method and high production efficiency, and can effectively improve the qualified rate of the products.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

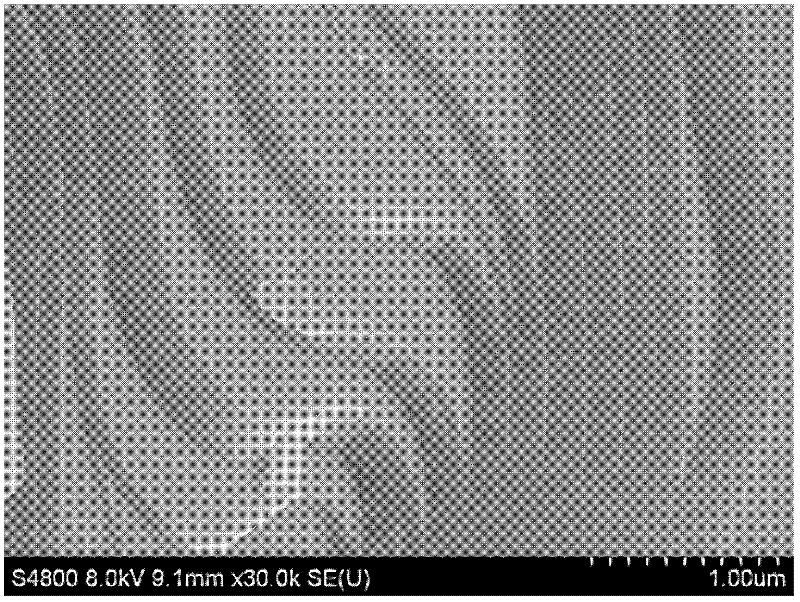

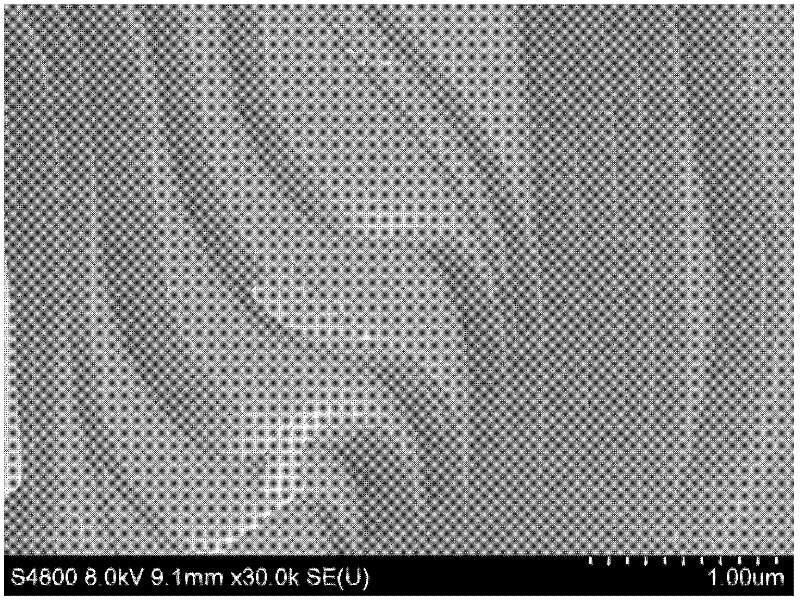

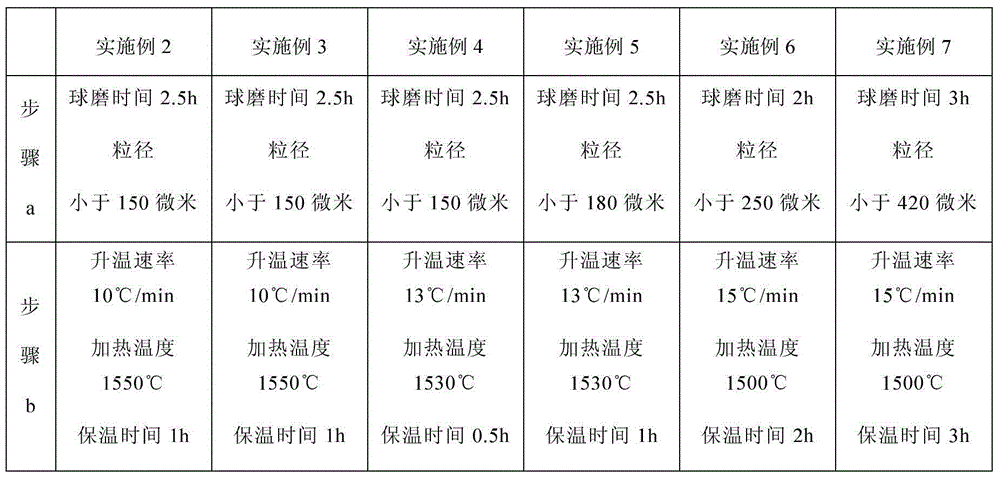

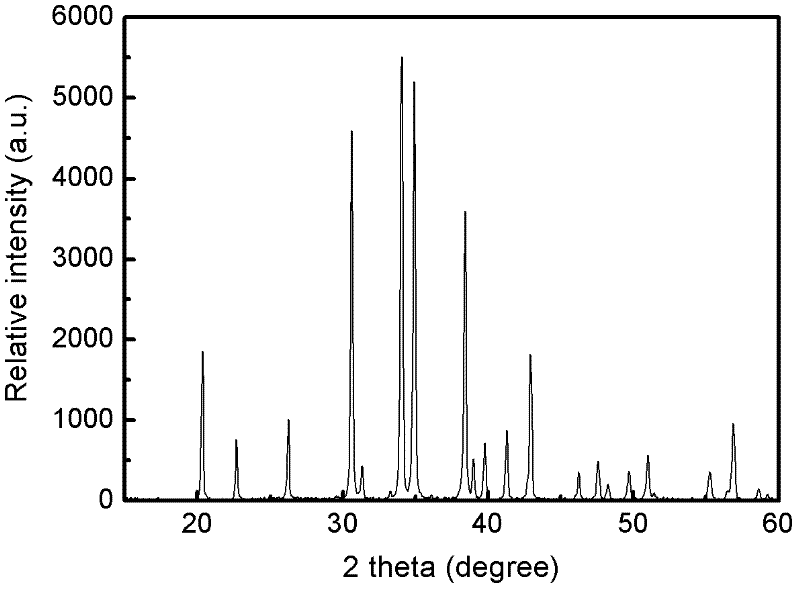

Method for preparing high-purity MAX-phase ceramic powder

InactiveCN102633505AHigh activityUniform distribution of temperature fieldChemical measurementBall mill

The invention discloses a method for preparing high-purity MAX-phase ceramic powder. The method includes approximately weighing raw materials according to stoichiometric ratios of various elements in a chemical formula of a MAX-phase ceramic material at first; then uniformly mixing the raw materials by the aid of a ball mill, placing mixture of the raw materials in a mold and prepressing the mixture to obtain a prepressed intermediate body; and finally placing the prepressed intermediate body into a special microwave oven, controlling the temperature rise rate by means of adjusting the microwave power in inertial atmosphere, increasing the temperature to a sintering temperature, keeping heat for a certain period, realizing furnace cooling to the room temperature, and grinding the mixture to obtain the MAX-phase ceramic powder with high purity, an excellent shape and a unique layered structure. The method for preparing the MAX-phase ceramic powder is speedy, efficient, energy-saving and environment-friendly and is low in cost and easy to realize large-scale production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

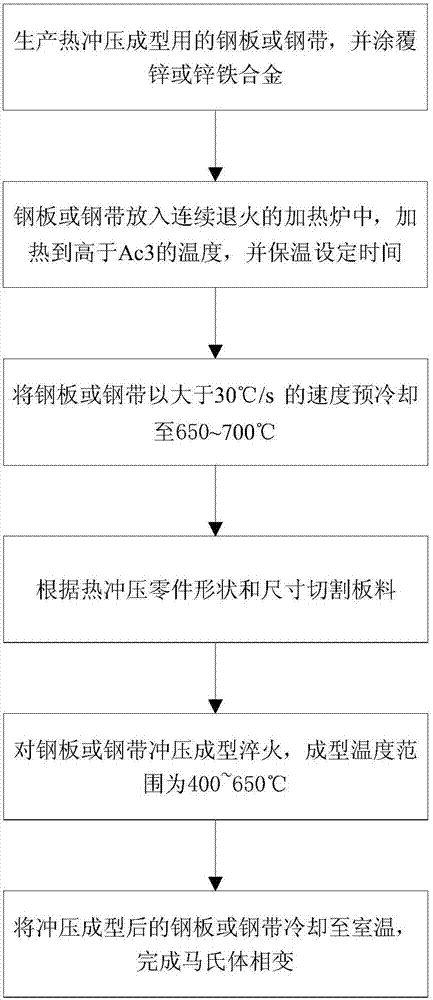

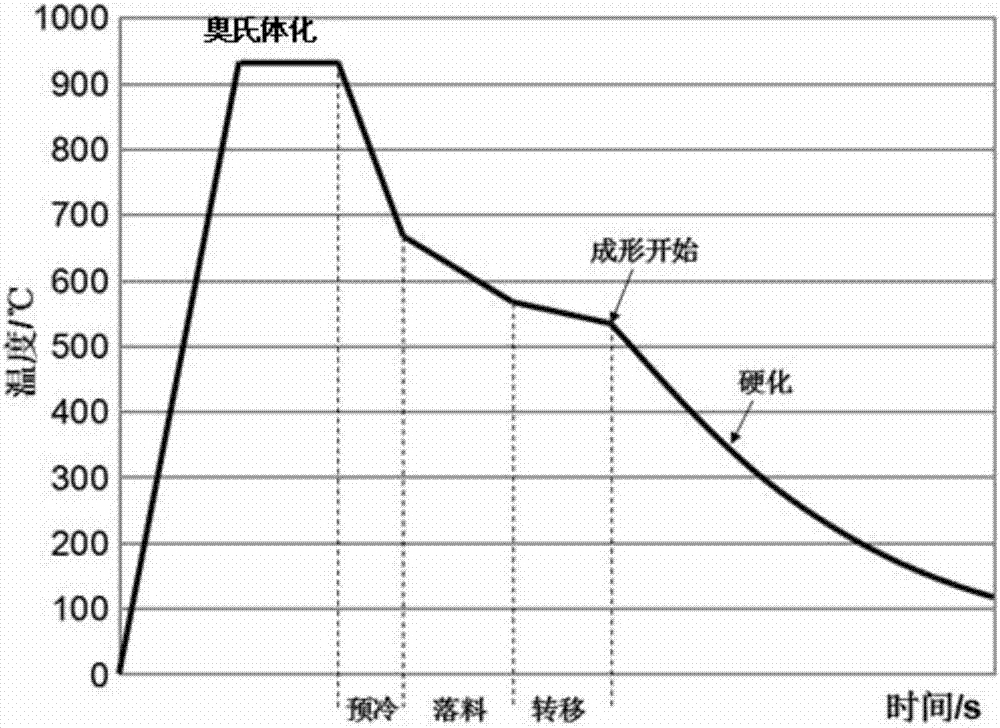

Hot-stamping forming method for zinc plating steel plate or steel strip

ActiveCN107127238ALow heating temperatureShort holding timeShaping toolsHot-dipping/immersion processesHot stampingSheet steel

The invention relates to a hot-stamping forming method for a zinc plating steel plate or a steel strip. According to the hot-stamping forming method, the steel plate or the steel strip is conveyed into a vertical heating annealing furnace, the temperature is kept for a certain time, the steel plate is completely austenitized, a pre-cooling device is used when the steel plate leaves the annealing furnace, the steel plate is cooled to 650-700 DEG C at the cooling rate higher than 30 DEG C / s, then blanking is performed according to the part shape and size, then the steel plate is quickly transferred into a mold for hot-stamping forming, the steel plate is hardened at the speed higher than 30 DEG C / s, and the hot-stamping forming temperature is kept between 400 DEG C and 650 DEG C. Base plate cracks caused by partial stress and liquid metal embrittlement (LME) can be avoided, and the method is used for solving the problem that the base plate cracks cannot be avoided for existing zinc-based hot-stamping formed steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method for lithium-based glass ceramic for dental prosthesis

The embodiment of the invention discloses a preparation method for lithium-based glass ceramic for dental prosthesis. The preparation method comprises: filling glass powder which is prepared in advance into a die, wherein the grain size of the glass powder is less than 50 microns; and pressing and moulding the powder under 50-500 Mpa to obtain a lithium-based glass ceramic blank; putting the lithium-based glass ceramic blank into a heating device to raise the temperature to 500-600 DEG C for first-time sintering at a temperature raising rate of 1-30 DEG C / min, wherein the insulating time of the first-time sintering is 10-120 minutes; and carrying out furnace cooling to prepare the lithium-based glass ceramic. Compared with lithium disilicate glass ceramic prepared in the prior art, the lithium-based glass ceramic prepared by the technical scheme is relatively low in strength, low in hardness, better in processability, more easy to mould and suitable for a processing room and a chair-side repairing system.

Owner:SHENZHEN UPCERA DENTAL TECH

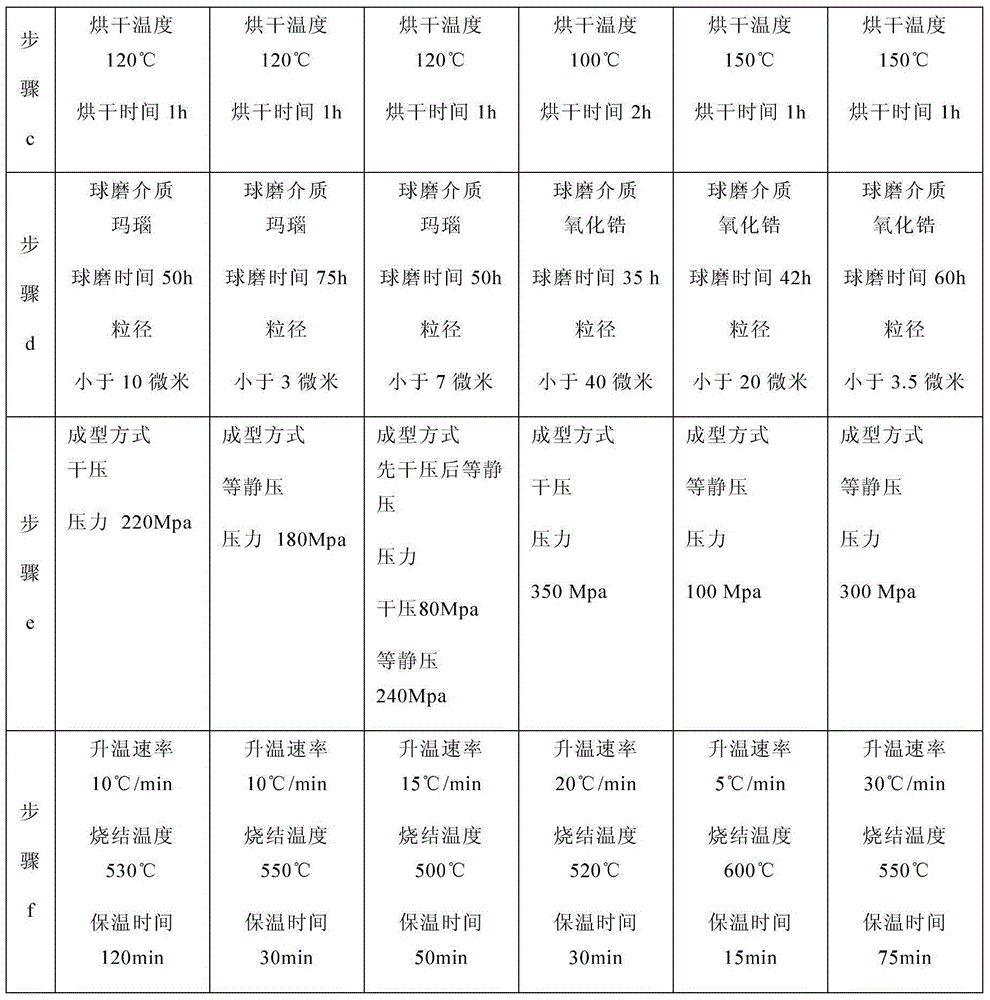

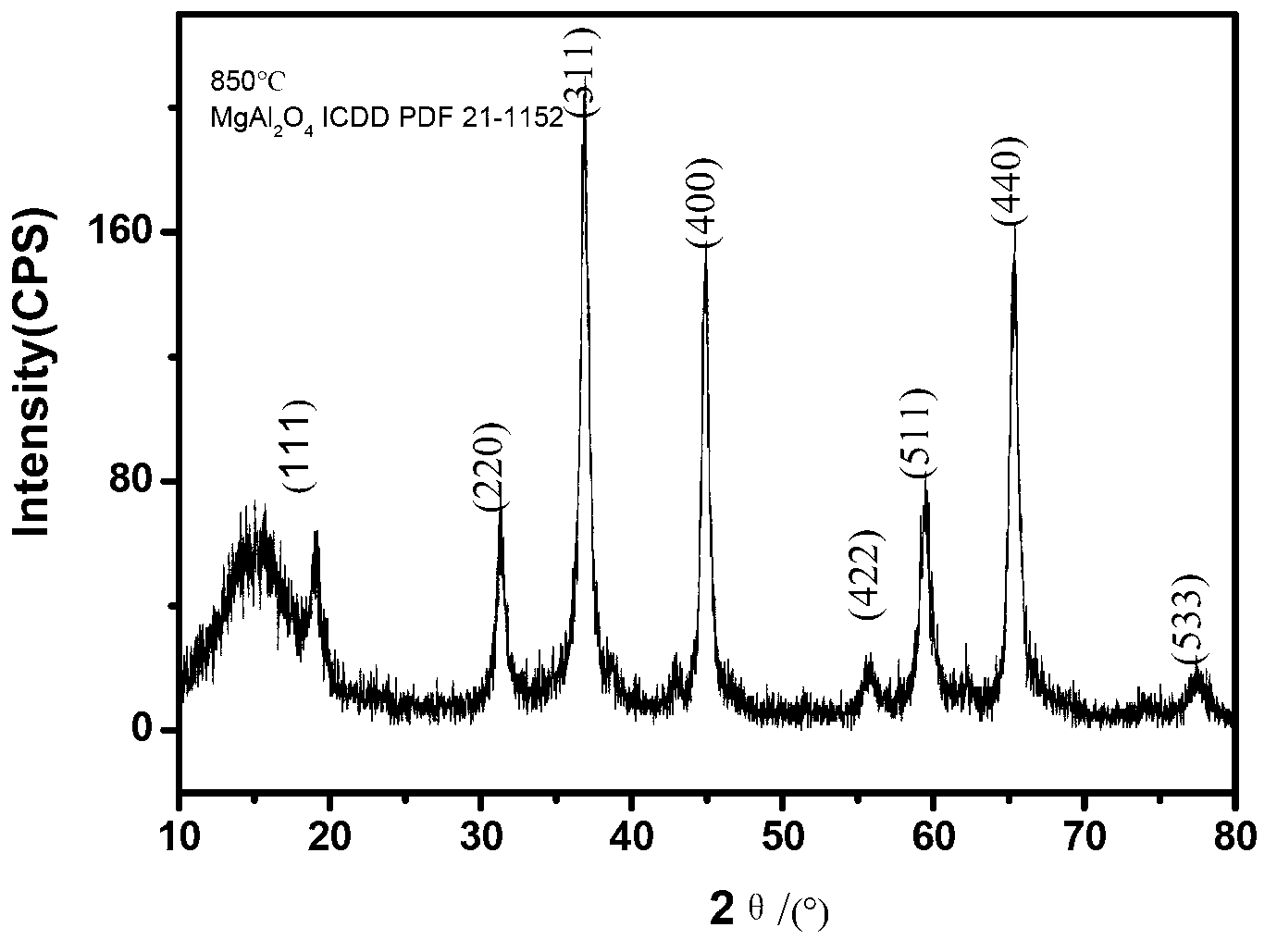

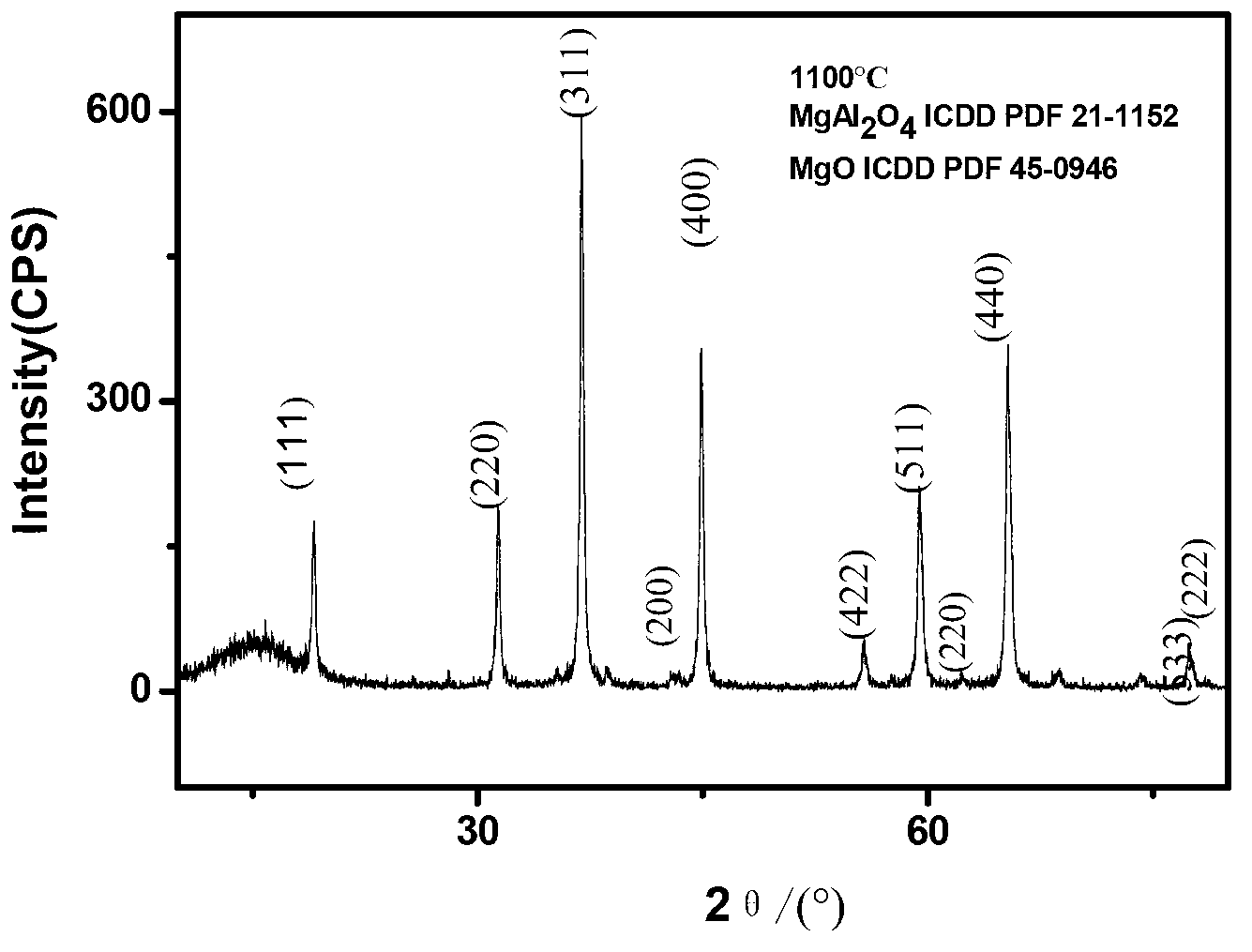

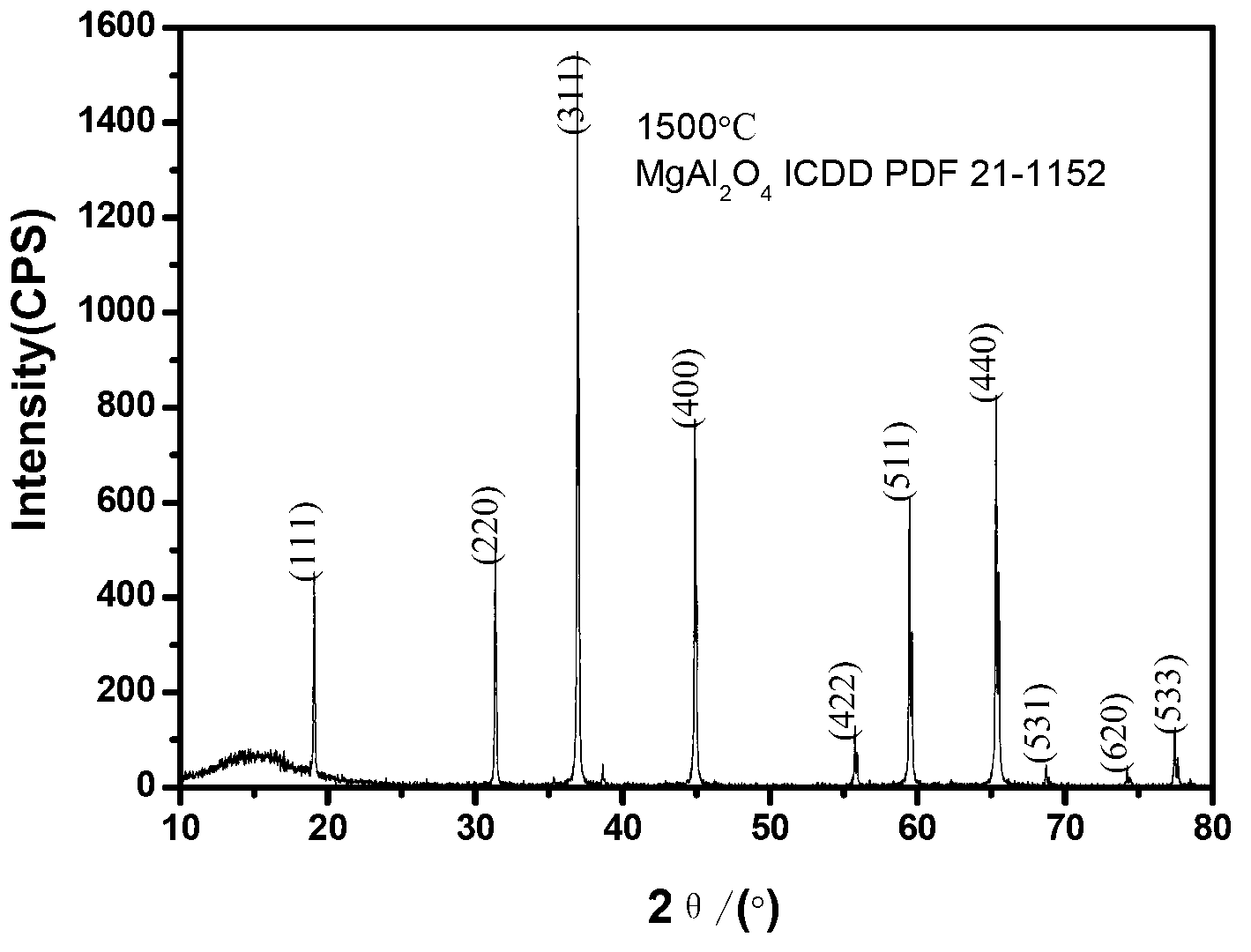

High purity nano-scale magnesium-aluminum spinel synthesis method

InactiveCN102936022ALower sintering temperatureHigh purityAluminium oxides/hydroxidesThermal insulationSpinel

The present invention discloses a high purity nano-scale magnesium-aluminum spinel synthesis method, which comprises the following steps: 1) uniformly mixing light burning magnesium oxide and boehmite according to an amount ratio of MgO to Al2O3 of 1:1, and carrying out ball milling and drying molding to obtain a billet sample sheet; and 2) pre-burning the billet sample sheet for 1 h at a temperature of 500 DEG C, then heating to a temperature of 850-1500 DEG C, carrying out thermal insulation for 2-3 h, and cooling to a room temperature to obtain the high purity nano-scale magnesium-aluminum spinel. According to the present invention, the raw material combination is the light burning magnesium oxide and the boehmite, a sintering reaction activity of the newborn gamma-Al2O3 obtained after boehmite pre-burning is greater than a sintering reaction activity of the general gamma-Al2O3, and the nano-scale material has a huge specific surface area and surface activity so as to reduce a sintering temperature of the magnesium-aluminum spinel, shorten a thermal insulation time, and reduce energy consumption, wherein the sintered spinel content can be up to 97.9%; and the method is applicable for industrial production, and meets requirements of energy saving and emission reduction.

Owner:HENAN UNIV OF SCI & TECH

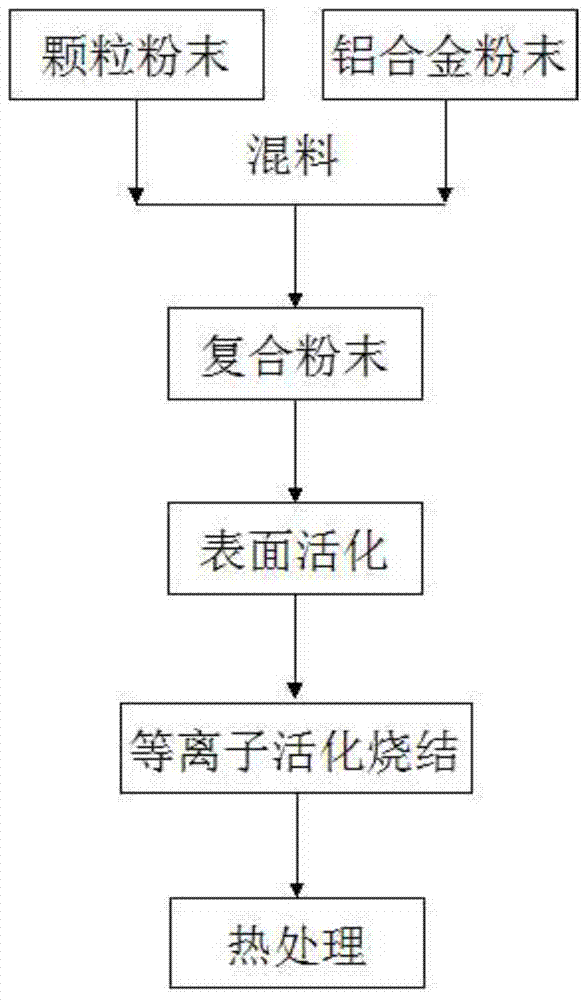

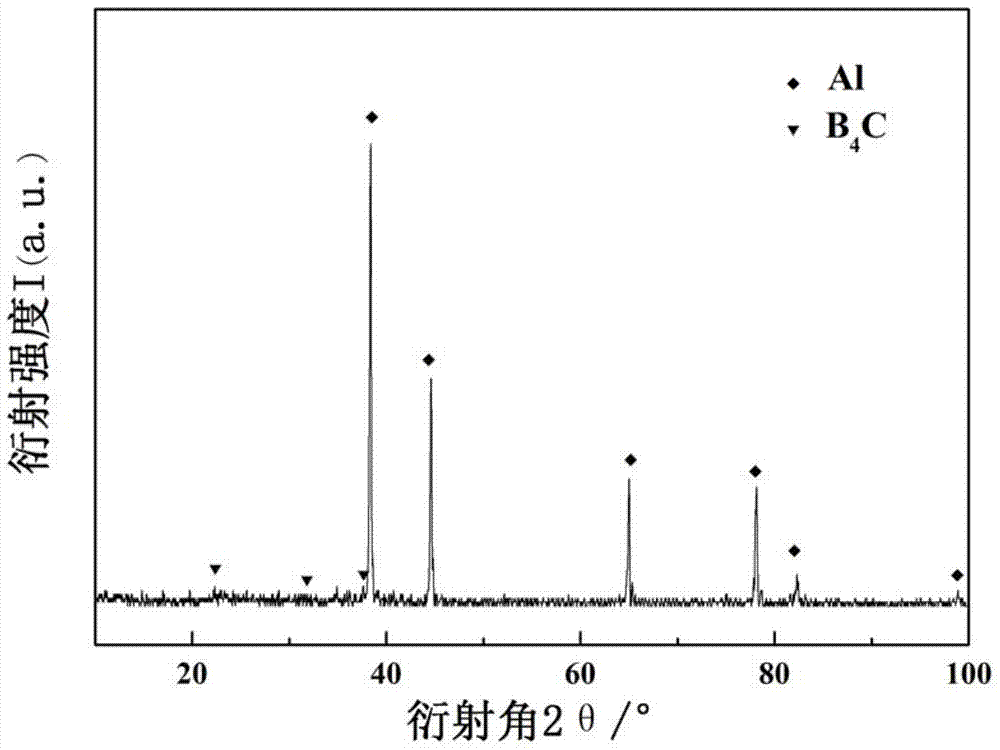

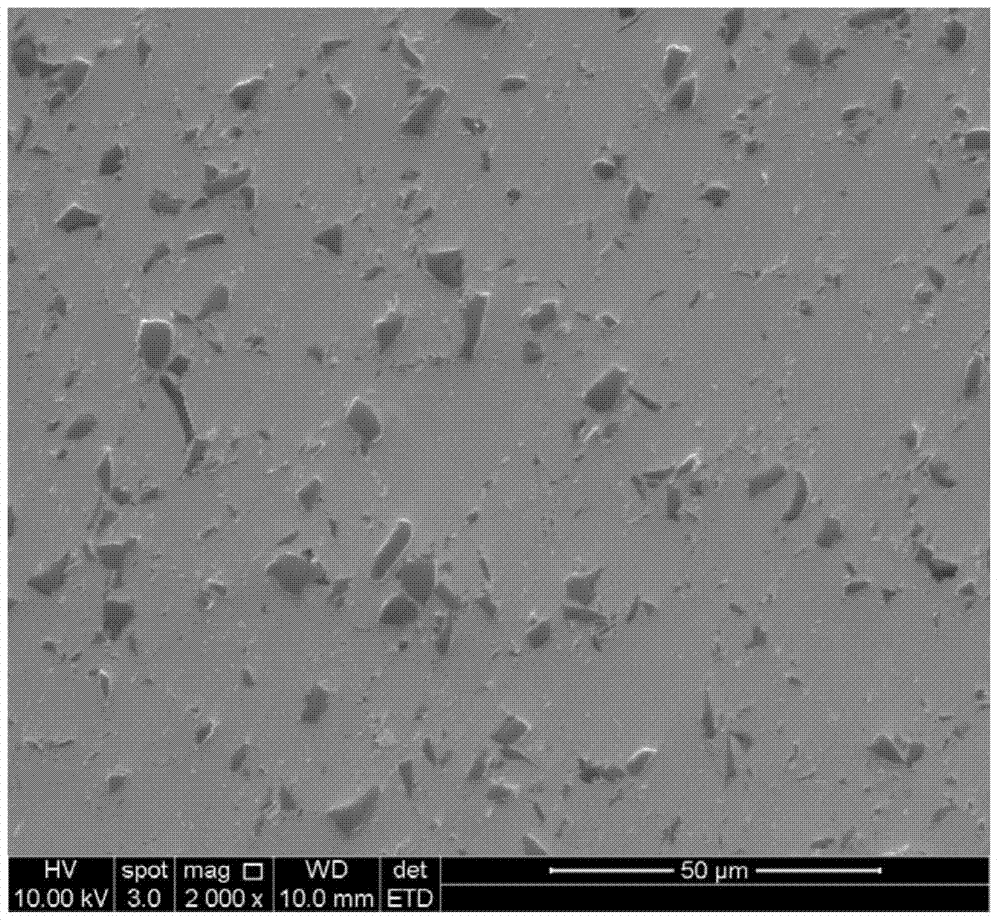

Preparation method of boron carbide particle enhanced aluminum-based composite material

The invention relates to the technical fields of aluminum-based composite materials and preparation thereof, in particular to a boron carbide particle enhanced aluminum-based composite material and a preparation method thereof. According to the composite material, aluminum alloy is used as a matrix; the mass percentage of boron carbide used as a wild phase is 2.5 to 30%; the boron carbide particles are distributed in the matrix uniformly. The specific preparation method comprises the following steps: mixing boron carbide powder and aluminum alloy powder; performing surface activation, plasma activated sintering and heat treatment to prepare a sintering test sample close to full density. The aluminum-based composite material prepared by the method has low sintering temperature, high density, small crystal particles and an excellent mechanical property, is simple to operate and high in controllability, and is a lightweight high-performance aluminum-based composite material.

Owner:WUHAN UNIV OF TECH

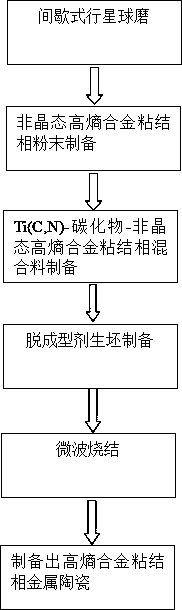

Preparation method for Ti(C,N)-based cermet with high-entropy alloy bonder phase

ActiveCN109022990AGood for maintaining relative contentKeep the relative contentWear resistantHigh entropy alloys

The invention discloses a preparation method for a Ti(C,N)-based cermet with a high-entropy alloy binder phase. The preparation method is characterized in that firstly, an amorphous high-entropy alloybinder phase powder with Co:Ni:Fe:Cu:Mn = 1:1:1:1:(0.3-1) is prepared by using an intermittent planetary ball mill; then, the amorphous high-entropy alloy binder phase powder is mixed with a hard phase powder by using a drum-type ball mill, and the prepared mixture is still in an amorphous state; lastly, microwave sintering at 1400-1450 DEG C is performed to allow the amorphous high-entropy alloybonder phase in the cermet to be crystallized, a transition process from the amorphous state to the crystalline state and the hysteretic element diffusion effect of the high-entropy alloy restrain the dissolution of the hard phase into the binder phase, and the binder phase of the cermet is the single-phase high-entropy alloy with a face-centered cubic structure; and thus, the cermet with the high-entropy alloy bonder phase is prepared. The preparation method overcomes the problem that during the existing preparation process of a cermet with a high-entropy alloy binder phase, a Ti(C,N) hard phase dissolves in a bonder phase, so that the relative content decreases and the grains of the hard phase are prone to abnormal growth, and finally insufficient mechanical properties of a hard alloy are caused. The preparation method can be used in cutting tools, wear-resistant parts and other fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Nanometer composite powder zinc impregnation processing method

ActiveCN1730727AMeeting Corrosion Protection NeedsDoes not affect mechanical propertiesHeat inorganic powder coatingCooling downZinc

The invention provides a process for nanometer composite powder zinc impregnation processing method, which comprises metal member pretreatment, powder zinc impregnation processing and metal member post-treatment. The powder zinc impregnation processing comprises formulation of nano composite powder zinc impregnation agent, a zinc impregnation procedure and a cooling down separation process.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +4

Manufacturing technology of hot work die steel forge piece

ActiveCN107686878AReduce contentOligodendrite segregationMetal-working apparatusSolution treatmentManufacturing technology

The invention relates to a manufacturing technology of a hot work die steel forge piece. The manufacturing technology comprises the steps including forging, high-temperature normalization, high-temperature tempering, ultrafine solution treatment, spheroidizing and sampling inspection. Through the procedures and related heat treatment, chemical components in the hot work die steel forge piece tendto be consistent, the structure inheritance is effectively cut off, and accordingly the purposes of refining grains and homogenizing structures are achieved. After spheroidizing, a spherical pearlitewith fine-particle-shaped carbide evenly distributed on a ferrite base body is obtained. An excellent organization structure is provided for final heat treatment.

Owner:山西同航特钢有限公司

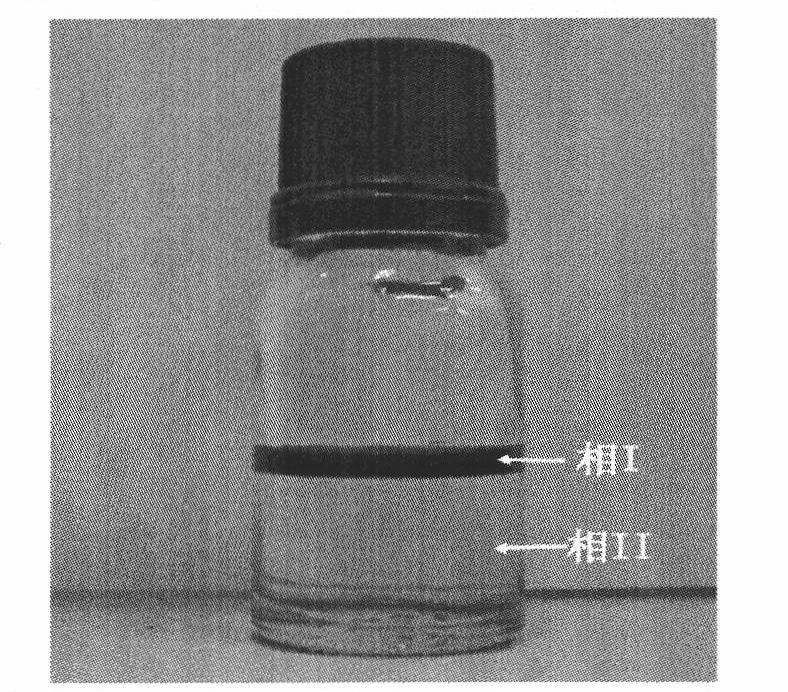

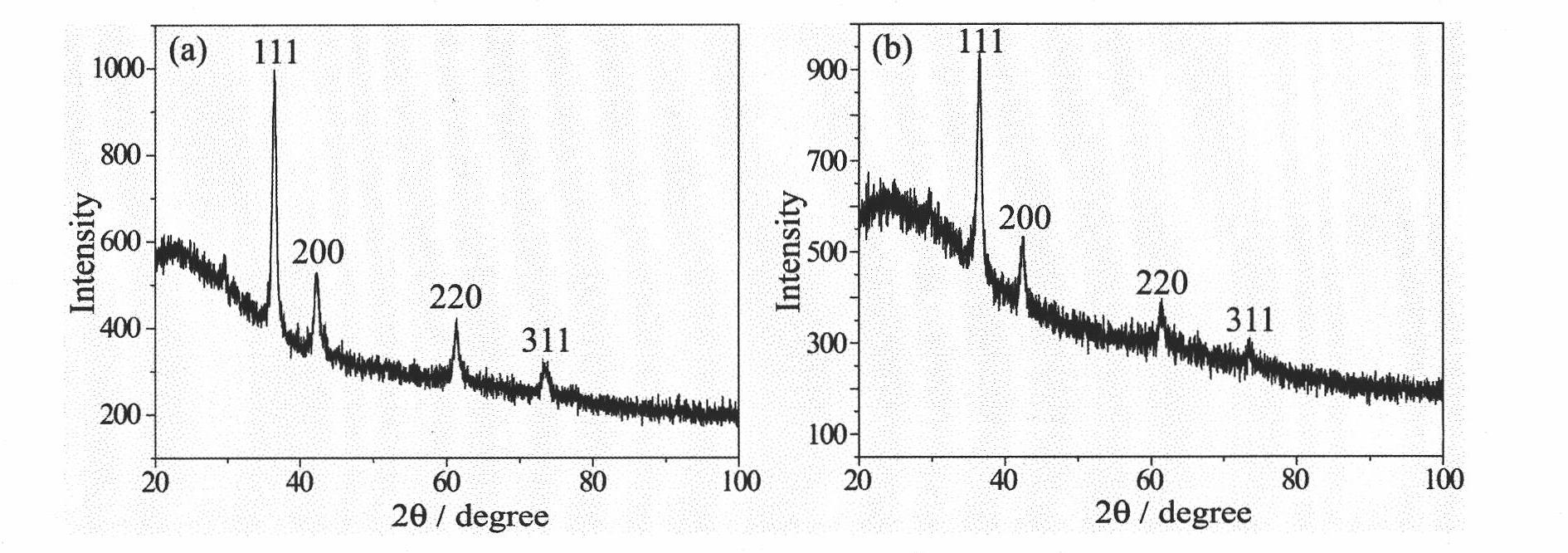

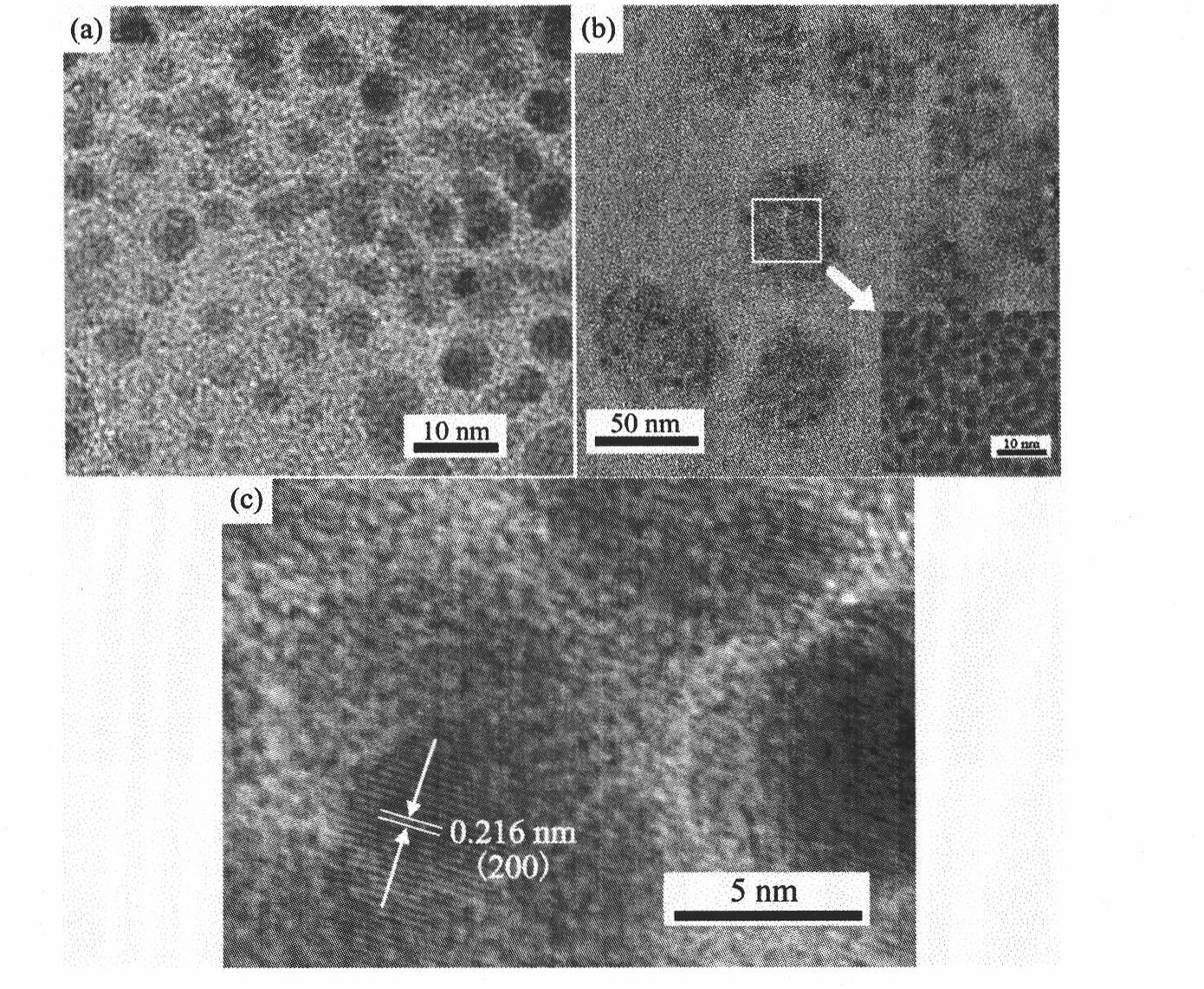

Cu2O ultra-fine nano-particles and self-assembly nanospheres as well as preparation method thereof

InactiveCN101805011AGood sustained releaseSlow release method, convenient to control the whole reaction processNanostructure manufactureCopper oxides/halidesMicrosphereUltra fine

The invention discloses Cu2O ultra-fine nano-particles and self-assembly nanospheres as well as a preparation method thereof, relating to the preparation method of the nano-particles. A whole reaction mixed liquid is divided into two phases through regulating the proportion of each substance in a reaction system, wherein one phase contains metal salt while the other phase contains a reducing agent. The metal salt is released to the phase containing the reducing agent, and contacted with the reducing agent at a part close to the interface of two phases to carry out reduction reaction, and the release action and a protecting agent in the reaction system commonly act in the whole reaction system so as to achieve the aim of controlling the appearances and the sizes of the product Cu2O ultra-fine nano-particles. The Cu2O ultra-fine nano-particles can be prepared by using the release method; if the reaction mixed liquid containing the Cu2O ultra-fine nano-particles continuously keeps the temperature for certain time at certain temperature, Cu2O self-assembly nanospheres with larger particle sizes formed by self-assembling the Cu2O ultra-fine nano-particles are prepared due to the Ostwald maturating action.

Owner:XIAMEN UNIV

Method for manufacturing high-hardness and high-abrasion-resistant pre-bending machine lower die

ActiveCN102581145ALarge heat treatment deformationHigh hardnessShaping toolsManufactured materialEngineering

The invention discloses a method for manufacturing a high-hardness and high-abrasion-resistant pre-bending machine lower die, which belongs to the technical field of machining methods for pre-bending machine lower dies. The method includes steps of (1), preparing raw materials of the pre-bending machine lower die; (2), annealing a forged blank; (3), primarily machining the forged blank; (4), conditioning the pre-bending machine lower die, quenching the pre-bending machine lower die by water or oil after the pre-bending machine lower die is kept at the temperature ranging from 830 DEG C to 850 DEG C for 3 hours, and then tempering the pre-bending machine lower die under the condition of the temperature ranging from 680 DEG C to 700 DEG C; (5), realizing deep processing of the pre-bending machine lower die; and (6), realizing heat treatment of the pre-bending machine lower die, dipping an arc surface R of the pre-bending machine lower die into quenching media for cooling at first during quenching, and then dipping the complete pre-bending machine lower die into the quenching media after the arc surface R is cooled in the quenching media for 4 minutes to 6 minutes. The raw materials of the forged blank include from 1.70 to 2.2% of Cr. The pre-bending machine lower die is low in final deformation, high in hardness and fine in abrasion resistance, and does not crack during the heat treatment, and the surface cannot sink even if the pre-bending machine lower die bears extremely high pressure during usage.

Owner:马鞍山博新高科产业服务有限公司

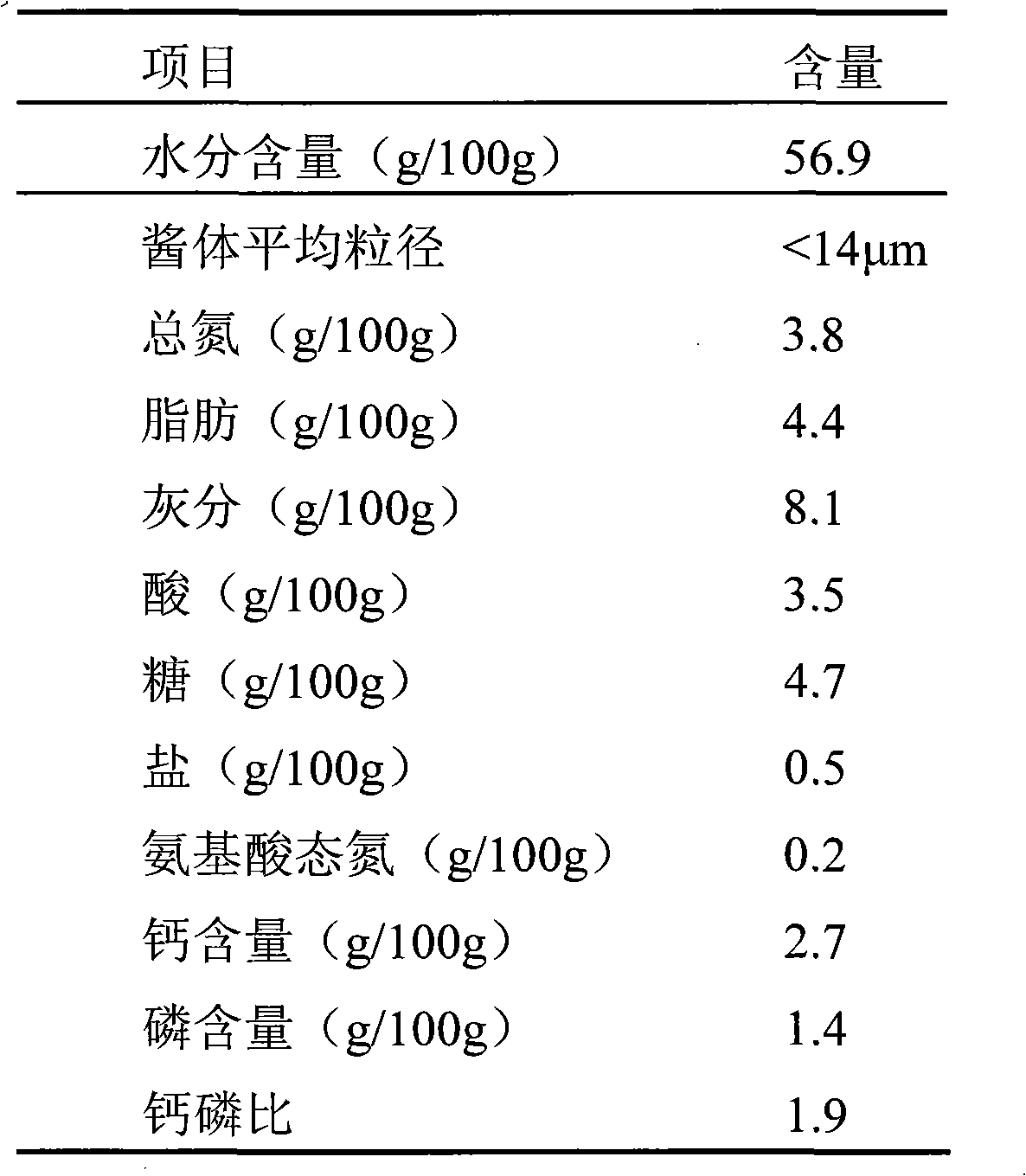

Fine and smooth tilapia mossambica bone and fish sauce and preparation method thereof

InactiveCN101919527AImprove softening effectShort holding timeFood preparationBiotechnologyMeat paste

The invention discloses a fine and smooth tilapia mossambica bone and fish sauce and a preparation method thereof. The preparation method comprises: taking tilapia mossambica processing leftovers fish fillet as raw material, and cleaning and mincing for standby; adding acetum into the minced raw material, and carrying out high-pressure cooking; after cooking and softening process, separating cooking liquid, and smashing solid bone and fish blocks by a meat grinder; then, mixing with the cooking liquid; adding clean water accounting for 50-100% of total weight of cooking liquid to adjust the denseness of size; then carrying out rubbing processing on the colloid; ensuring that colloid cycling time is 3-7 minutes; after degassing processing, processing material by a high-pressure microfluidics nanometer homogenizer at the pressure of 60-120MPa to obtain fine and smooth tilapia mossambica bone and fish pulp; and condensing and seasoning the fine and smooth tilapia mossambica bone and fishpulp to obtain the tilapia mossambica bone and fish sauce of different flavours. The invention can fully utilize the nutrition constituent of fish fillet raw material, has high processing speed and small average particle diameter of products and can meet the requirements of fine and smooth taste.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of transparent yttria ceramics with high optical quality

The invention relates to a preparation method of transparent yttria ceramics with high optical quality, which belongs to the field of preparation of transparent ceramics. The preparation method comprises the following steps: adding anhydrous ethanol to the mixture of commercial high-purity Y2O3 powder serving as a raw material, ZrO2 serving as a sintering additive and zirconia balls serving as a grinding medium, and carrying out mixing and ball milling for 3-30 hours; adding a crylic acid salt dispersant in the powder to prepare water-based slurry of Y2O3, and adopting a porous resin mold or porous alumina ceramic mold to achieve slip casting; and finally, carrying out pressureless sintering in a vacuum or hydrogen atmosphere furnace to obtain the transparent yttria ceramics with high optical quality. The transmission rate of the Y2O3 transparent ceramics with thickness of 2mm is up to 81.3% at the wavelength of 1100nm. The invention has the advantages of simple process, low cost and no pollution, and is easy to control, and the transparent yttria ceramics with high optical quality can be prepared at lower sintering temperature in shorter holding time.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Novel titanium alloy partitioned beta heat treatment process

ActiveCN102851627AGuaranteed uniformityPrecise control of primary alpha phase contentTitaniumTitanium alloy

The invention discloses an accuracy control-based novel titanium alloy partitioned beta heat treatment process. The process includes: first subjecting alpha+beta area forged alpha type and alpha-beta type titanium alloys to preheating at Tbeta-(20DEG C-40DEG C), calculating the heat preservation time according to t(min)=eta*delta max, with the delta max being the largest section thickness of a forged piece and the heating coefficient eta ranging from 0.5 to 0.8; then raising the temperature to (Tbeta-5DEG C)-(Tbeta+5DEG C) along with a furnace, and calculating the heat preservation time t(min) according to the above calculation formula, with the heating coefficient eta ranging from 0.2 to 0.6; and then raising the temperature to (Tbeta+5DEG C)-(Tbeta+30DEG C) along with the furnace again, and calculating the heat preservation time t(min) according to the above calculation formula, with the heating coefficient eta ranging from 0.2 to 0.5; and subjecting the forged piece discharged from the furnace to air cooling or cooling at certain cooling rate. The process is suitable for heat treatment of large, complex, variable section alpha type and alpha-beta type titanium alloy forged pieces, so that required high comprehensive performance lamellar structures with high ductility, high toughness and low fatigue crack propagation ability can be obtained, thus meeting the requirements of airplane and aero-engine manufacturing for large and complex variable section forged pieces or parts with uniform structure performance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

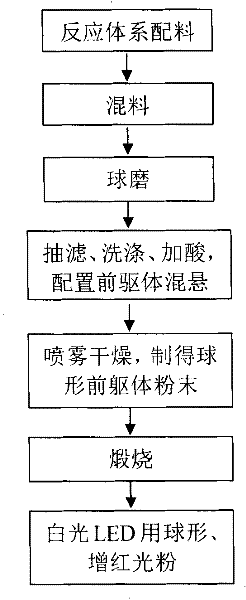

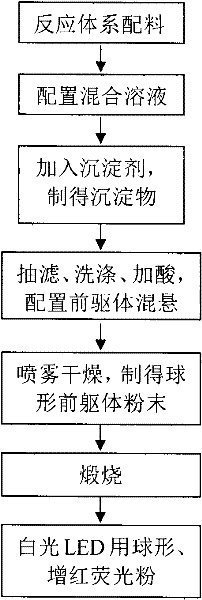

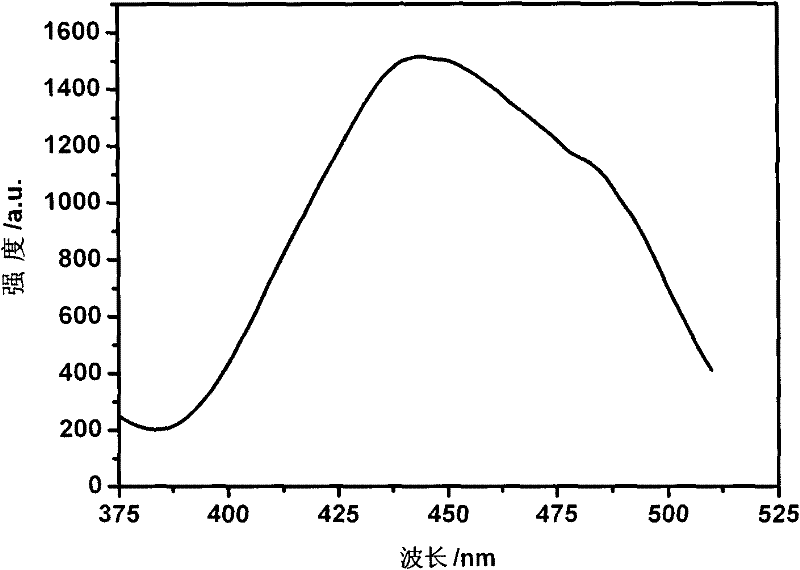

Ball-shaped red-enhanced phosphor used in white light LED, and preparation method thereof

InactiveCN102220131AIncrease productivityCalcination temperature is lowEnergy efficient lightingLuminescent compositionsChemical reactionStructural formula

The invention relates to ball-shaped red-enhanced phosphor used in white light LEDs, and a preparation method thereof. The structural formula of the phosphor is: YxREyMzCemAl5-nAnO12, wherein RE is at least one among Tb, Gd, Sm, Yb, La, and Lu; M is at least one among Mg, Ba, Ca, and Sr; A is at least one among Ga, Cu, Zn, Ni, Ge, and Si; 1.8<x<3; 0<=y<=0.8; 0<=z<=0.2; 0<m<=0.2; 2.9<x+y+z+m<3.1; 0<=n<=0.5; and 0<y+z+n<1. The preparation method is that: proper amounts of Y salt, RE salt, M salt, Ce salt, Al salt and A salt are weighed according to the stoichiometric ratio of the elements in the structural formula; the salts are well-mixed with a proper amount of surfactant; a precursor is then prepared with a mechanical solid-phase reaction method or a coprecipitation method; the mixture is processd through vacuum-filtrating and washing; a certain amount of volatile acid is added to the mixture, such that a suspension liquid is prepared; the suspension liquid is then produced into ball-shaped precursor power through spray drying; the ball-shaped precursor power is processed through pre-sintering, and then calcined under a reductive atmosphere, such that target phosphor is obtained. The phosphor provided by the present invention is ball-shaped. Red shifts occur in the emitted wavelength of the phosphor. The phosphor has good color rendering property, and can be effectively excited by blue-light chips.

Owner:CHONGQING UNIV OF ARTS & SCI +1

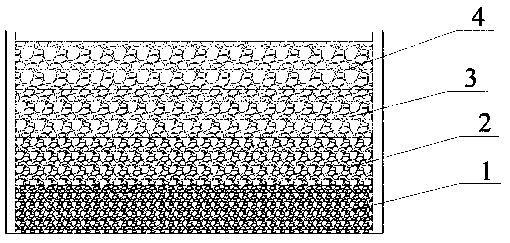

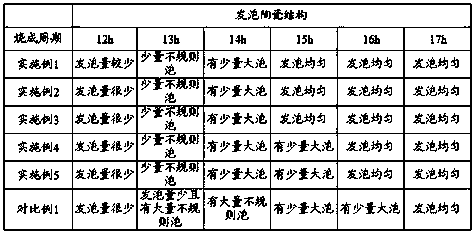

Process for producing foamed ceramic through layered material preparation and allocation and foamed ceramic material

ActiveCN109053214AShorten the production cycleEasy to passFeeding arrangmentsCeramic materials productionMaterials preparationFoaming agent

The invention discloses a process for producing foamed ceramic through layered material preparation and allocation and belongs to the field of materials. According to the process, multiple foamed ceramic granule materials of different oxidant contents and granularities are adopted to produce a foamed ceramic material through layered material preparation and allocation. Due to the adoption of oxidants, a foaming agent in a ceramic raw material can be promoted to be oxidized to generate gases; due to the adoption of a setup mode of small lower-layer granule particle sizes, high oxidant contents,large upper-layer granule particle sizes and low oxidant contents, channels are provided for low-temperature gas exhaust, and the low-temperature gas exhaust time can be shortened; moreover, the setup mode is beneficial to heat conduction, uneven foams caused by temperature gradients can be made up, the heating velocity in a foaming combustion period can be increased, the foaming temperature keeping time is shortened, and furthermore the production period of the whole foamed ceramic material can be shortened; the foamed ceramic material is prepared from the foamed ceramic produced through layered material preparation and allocation, and is high in quality, small in defect, short in production period and applicable to on-scale production.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD +2

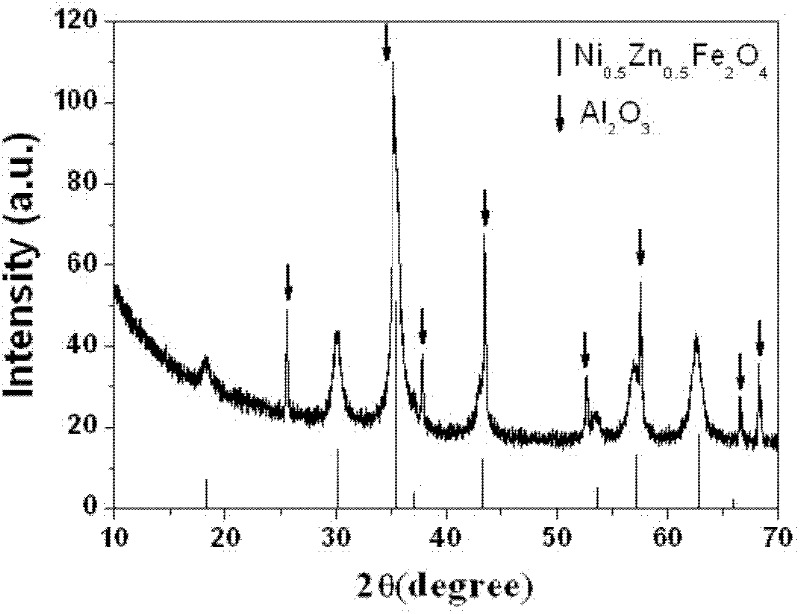

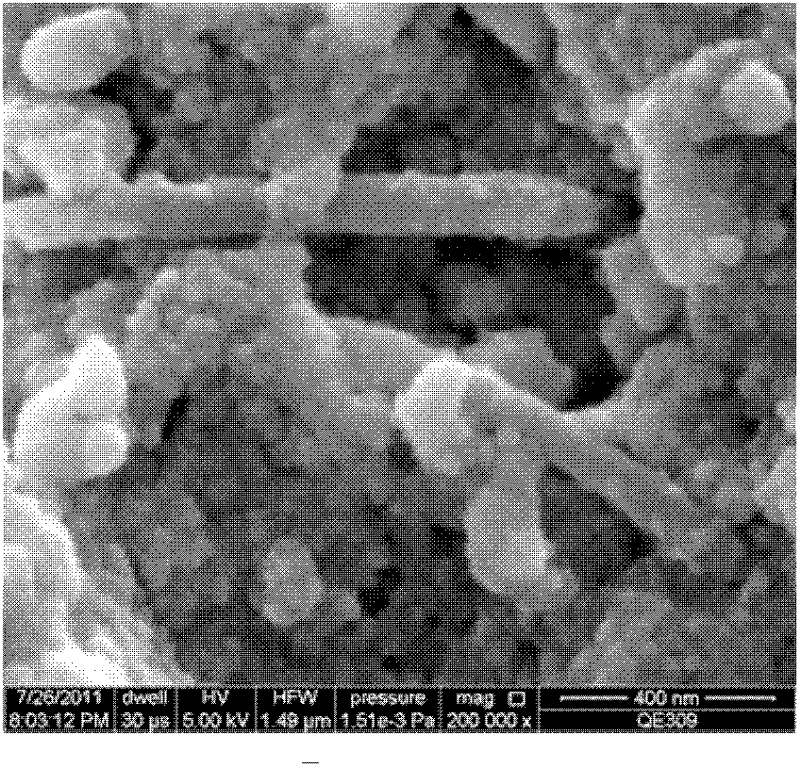

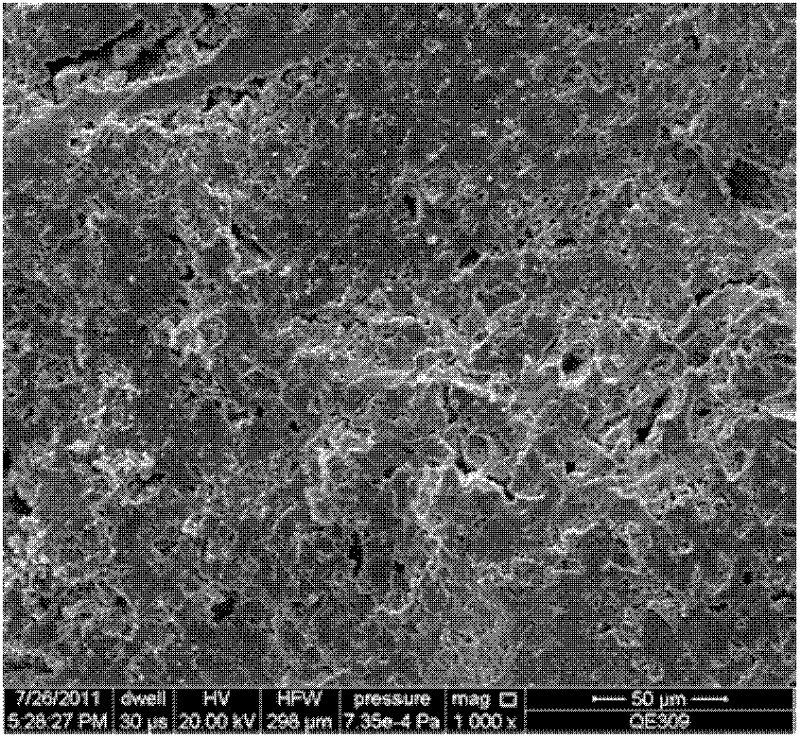

Ferrite-based ceramic composite material as well as preparation method and application thereof

ActiveCN102390989AMeet low temperature requirementsRealize the structureCeramic compositeStructure and function

The invention discloses a ferrite-based ceramic composite material as well as a preparation method and application thereof. The composite material is composed of ferrite, a carbon nanotube and a ceramic material, wherein the ferrite and the ceramic material are cladded on the tube wall of the carbon nanotube, and the ceramic material is one or several kinds of aluminum oxide, aluminum nitride, and silicon nitride. The three phases of materials, namely, the ferrite, the carbon nanotube and the ceramic, are compounded to make the advantages and disadvantages of all phases of materials complementary, so that the electrical conductance of the composite material is increased, the impedance matching performance of the composite material is improved, the wave absorption performance of the composite material is made adjustable, the structure and function integration of the ferrite-based ceramic material is realized, and thus, the application range of the composite material in the high-tech field is expanded. In addition, the powder of the composite material is prepared by adopting a coprecipitation hydrothermal method and is further prepared into a block material by adopting a microwave sintering method, and the ferrite-based ceramic composite material has the advantages that all phases are dispersed uniformly, the densification degree of the sintered material is high, the production cost is low, and the large-scale industrialization is easy to realize.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

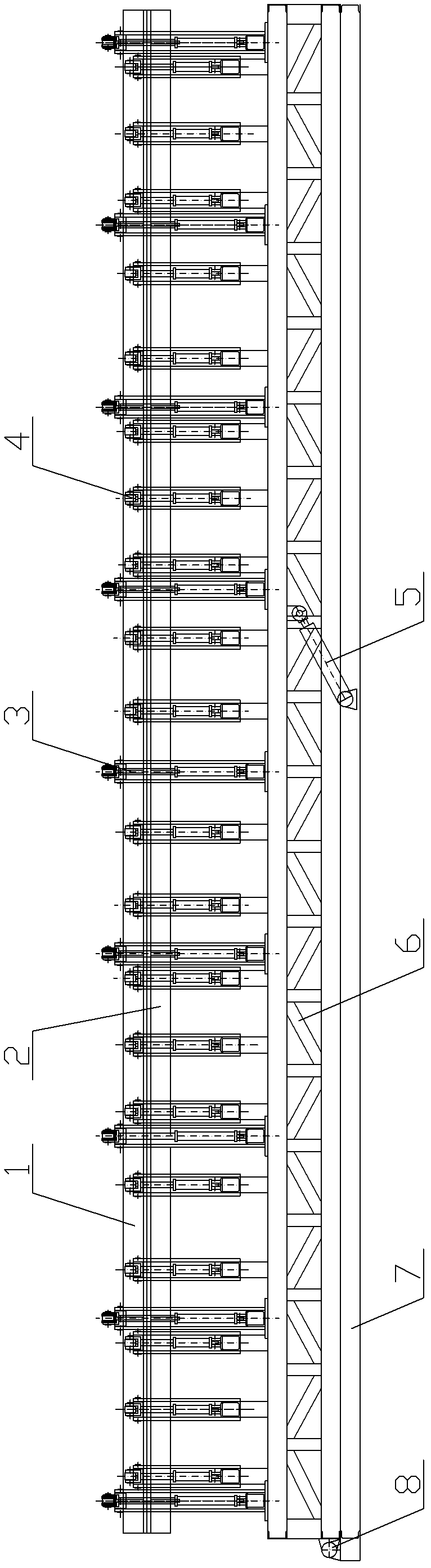

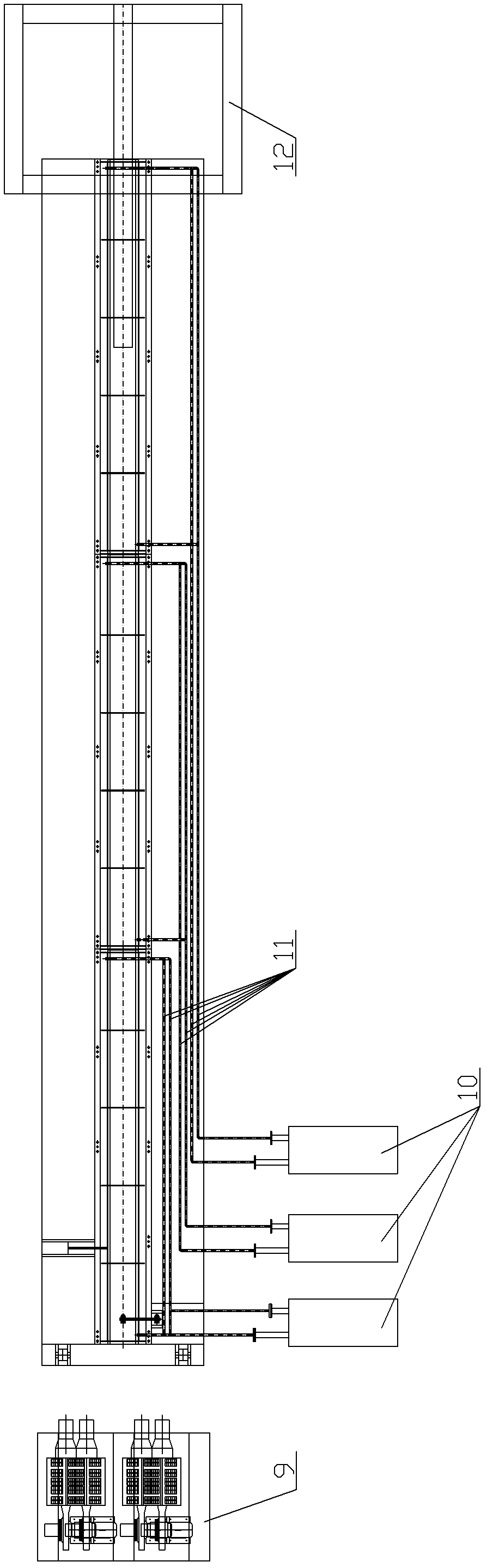

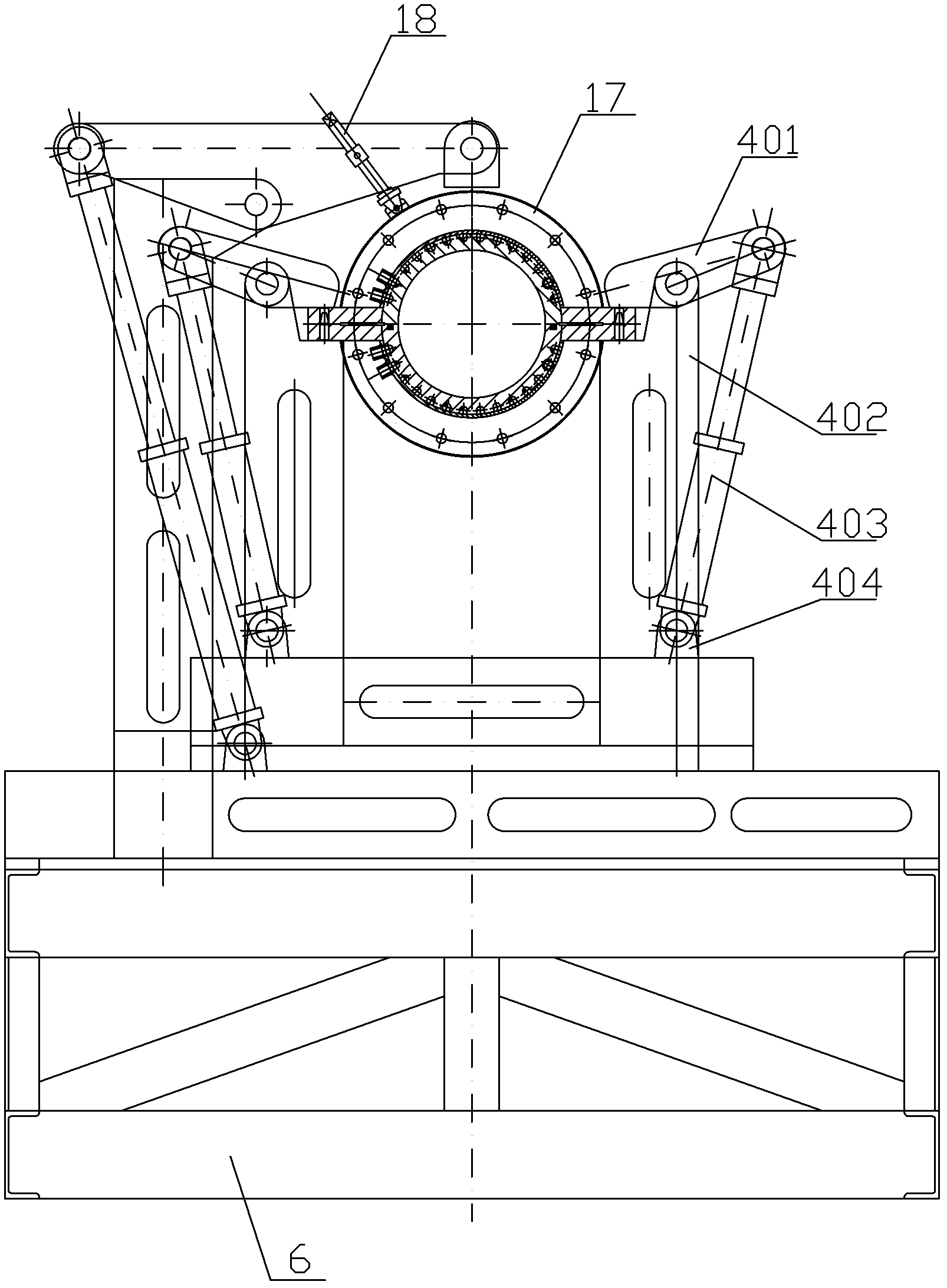

Deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device

The invention discloses a deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device. A subsection machining and integral assembly mode is adopted in a die, heating temperature control devices are arranged corresponding to subsection assemblies in subsections, and heating oil passages are arranged opposite; a positioning structure and a sealing structure arearranged in the parting surface of the die; and the die is provided with a die opening device, a die closing and an inclination device controlled by a hydraulic system. The device realizes mechanicaloperation of casting molding of a product, and has practical structure and strong operability; by adopting subsection machining in the die, the machining difficulty and the machining cost are reduced, and the machining precision and the machining quality are improved; and meanwhile, three sets of heating devices are used corresponding to three sections of assemblies, so that the heating temperature difference is reduced, the quality of the cast product is improved, automatic control of the temperature of the casting die can be realized, the heat insulation time of the polyurethane heat insulation layer in the die is shortened, and the service efficiency of the casting die is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

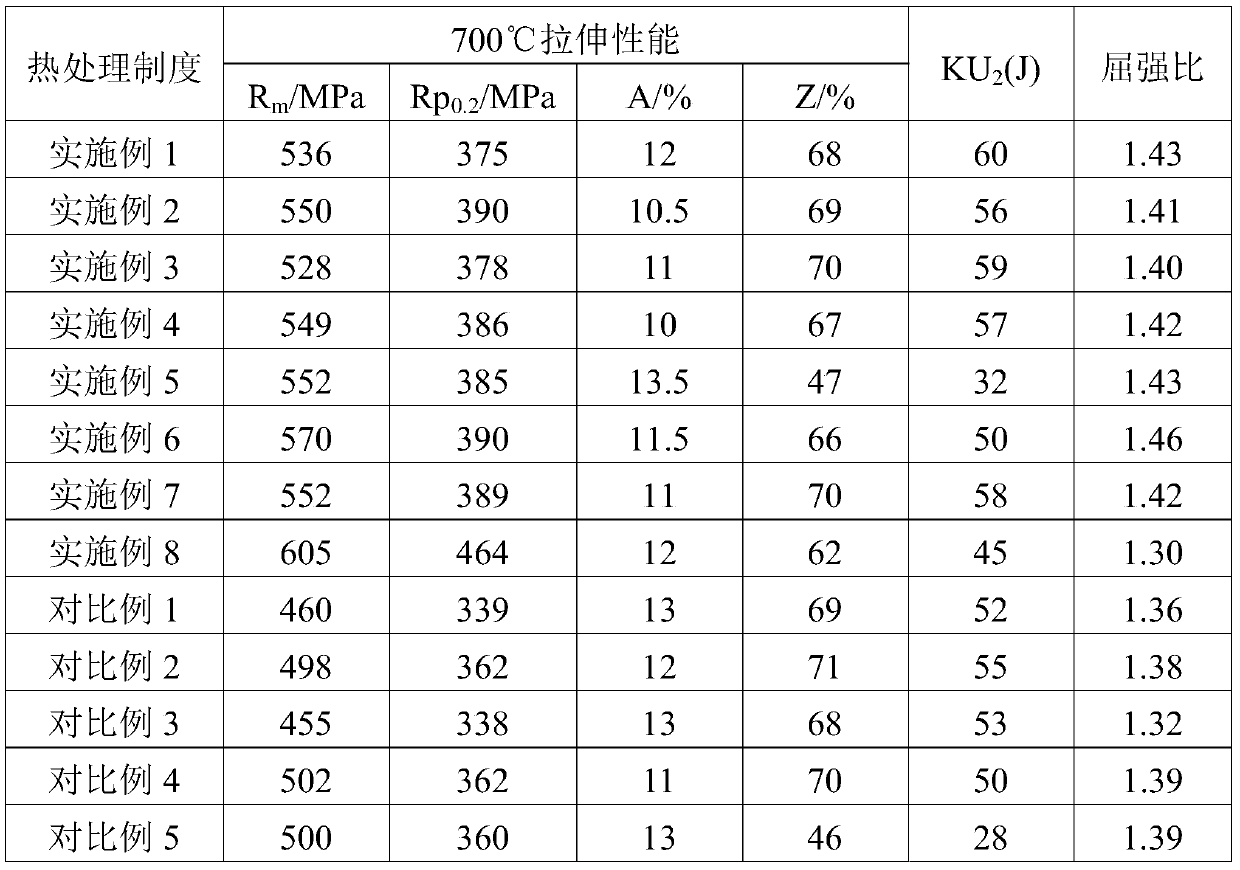

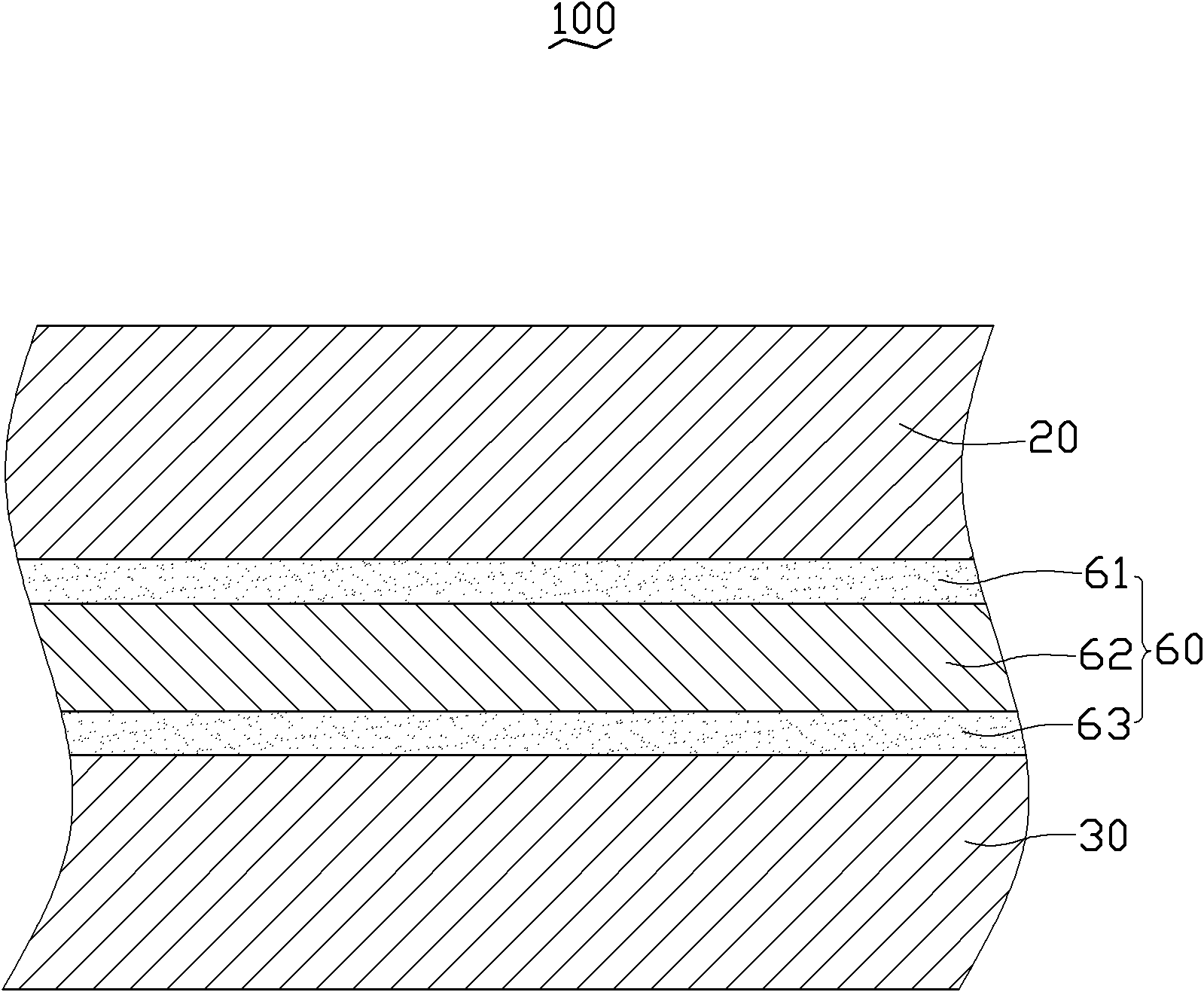

Hot-work die steel and heat treatment method thereof

ActiveCN110438310AShort austenitizing timeFine austenite grainsIncreasing energy efficiencyQuenchingHot work

The invention relates to the field of metal material heat treatment, in particular to hot-work die steel and a heat treatment method thereof. The heat treatment method comprises the following steps of1), heating the die steel at rate of 80-180 DEG C / min to 1100D EG C-1300 DEG C, and carrying out heat preservation for 3-10 minutes; 2), quenching the die steel after heat preservation in a quenchingmedium; and 3), tempering the quenched die steel. According to the method, the obtained hot-work die steel grains are not coarsening, the carbides are more dispersed and distributed, the tempering stability is good, the high temperature strength at the same hardness after processing is greatly improved, the thermal fatigue performance of the die steel is improved, after the heat treatment is performed to the same hardness, the impact toughness of the die steel after the new process is slightly higher than that of the traditional process, the method greatly shortens the heating and heat preservation time in the quenching process, and can achieve the effects of saving time and cost for small-batch and small-sized products.

Owner:UNIV OF SCI & TECH BEIJING

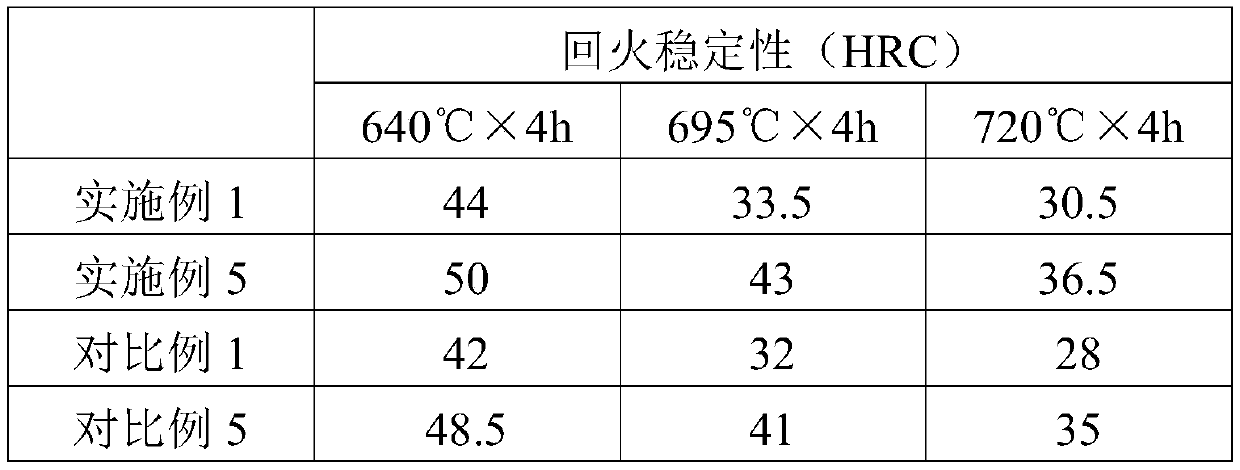

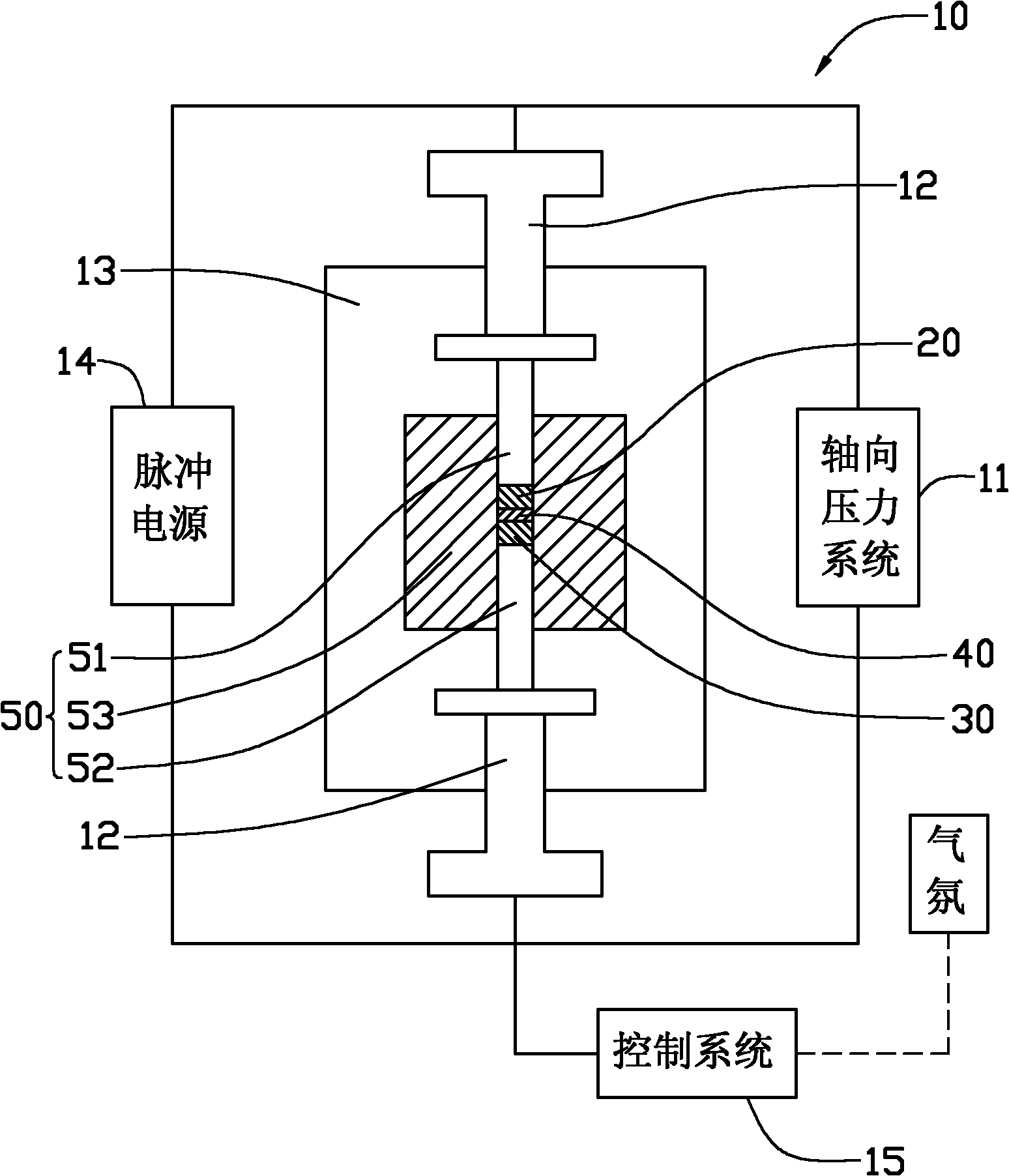

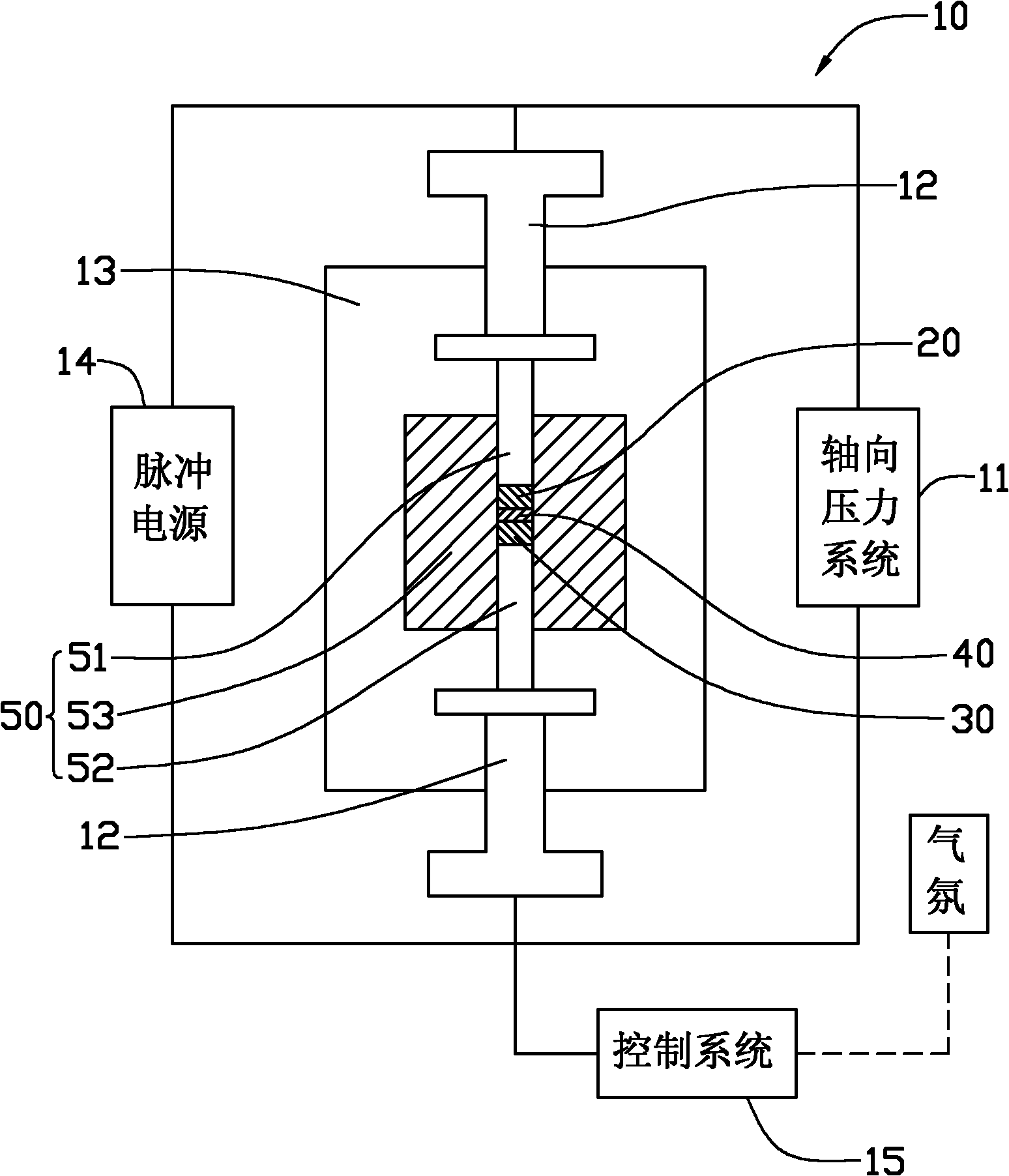

Connection method for carbon steel and zirconium oxide ceramic and connecting piece manufactured thereby

ActiveCN102335792AIncreased shear strengthShort holding timePlasma welding apparatusWelding/soldering/cutting articlesAxial pressureCarbon steel

Owner:深圳市伊比精密科技有限公司

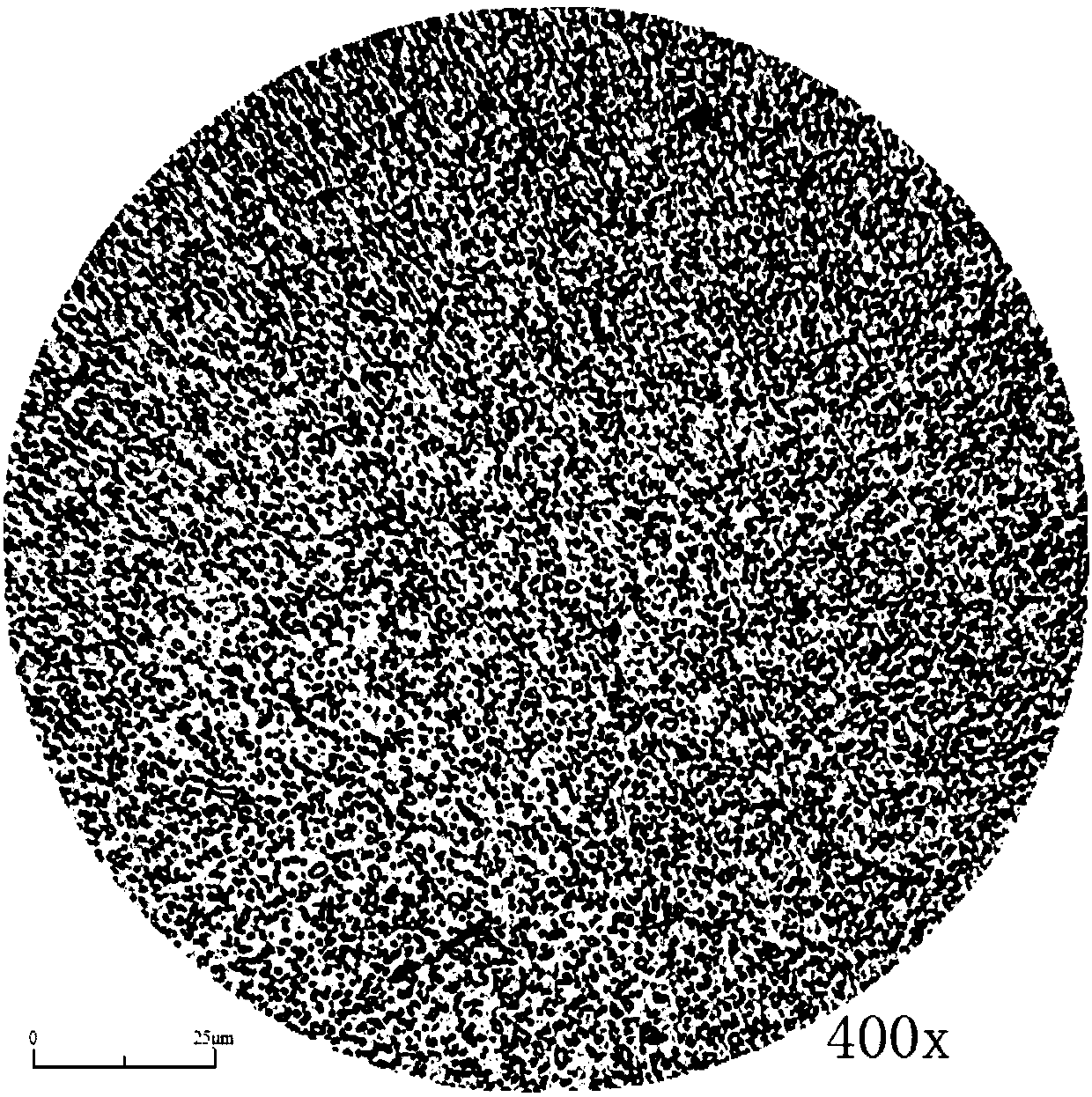

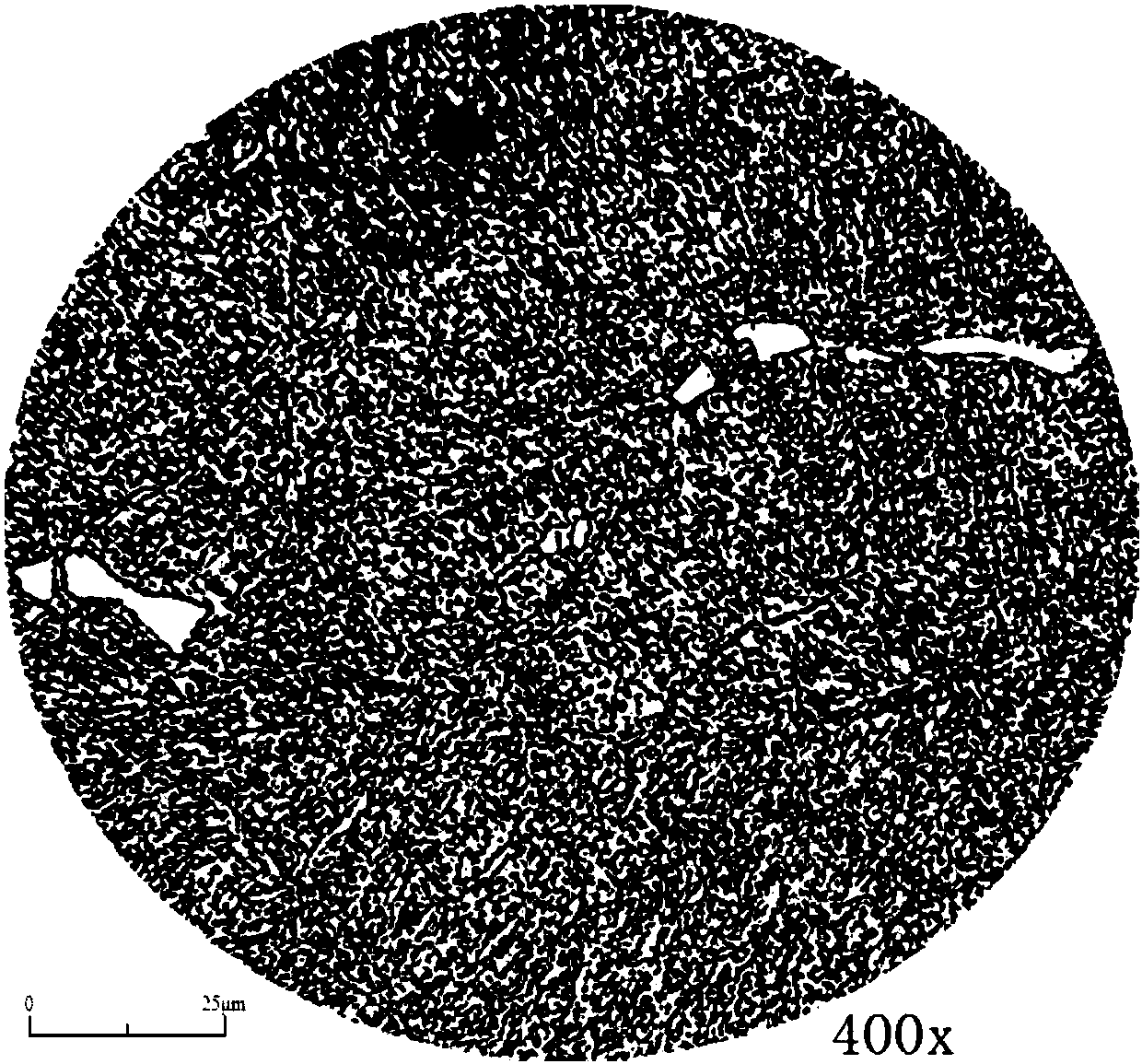

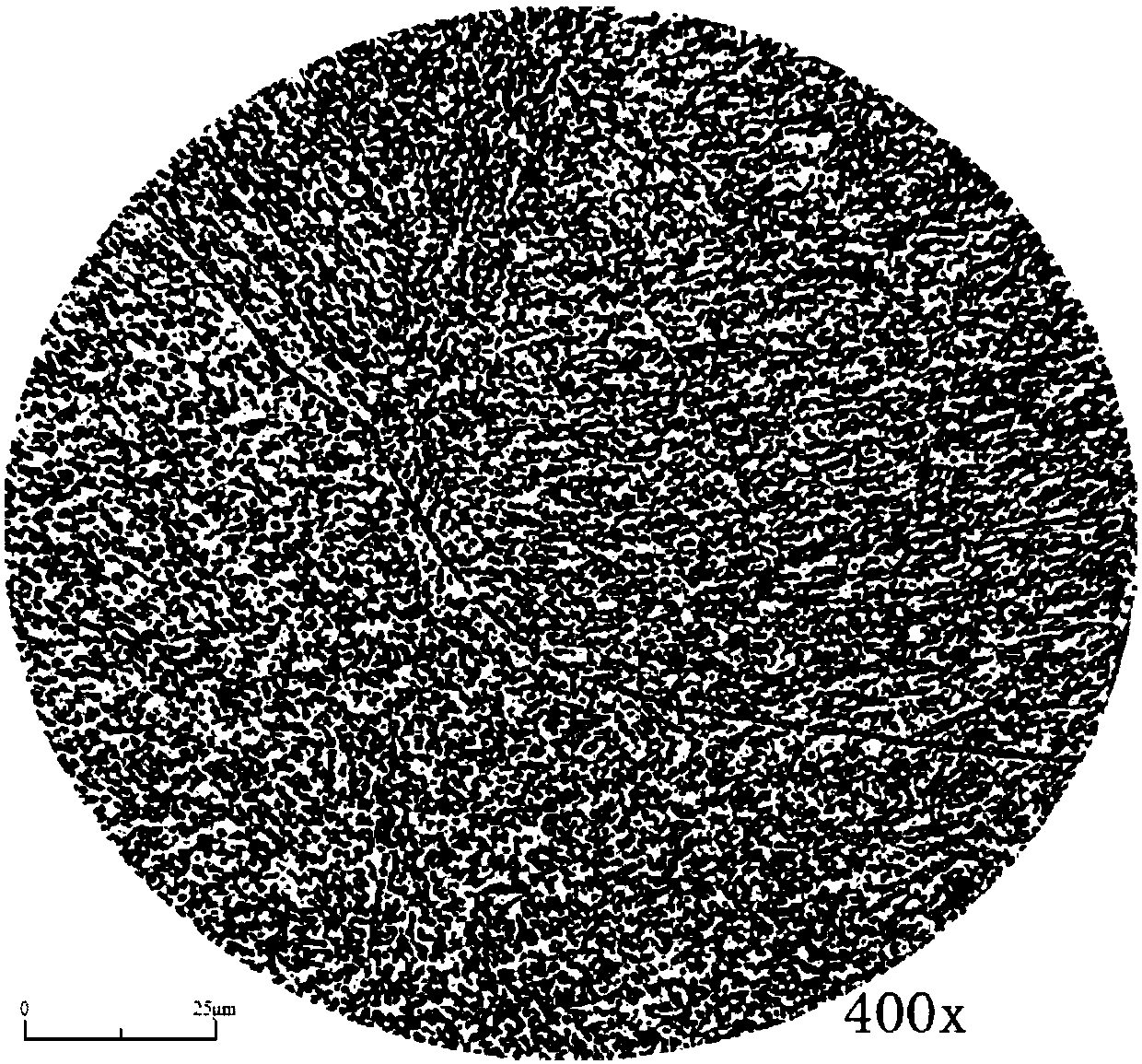

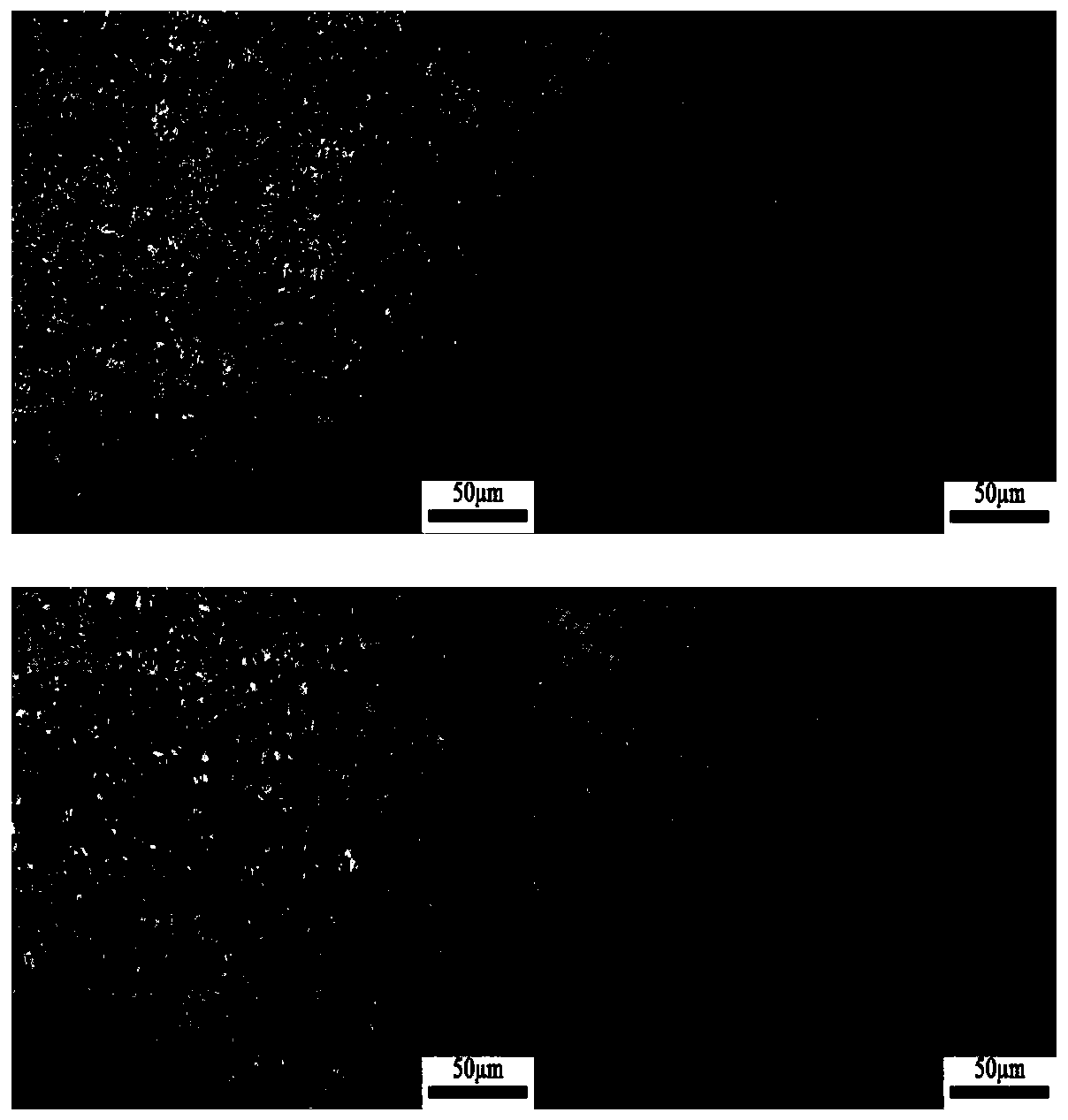

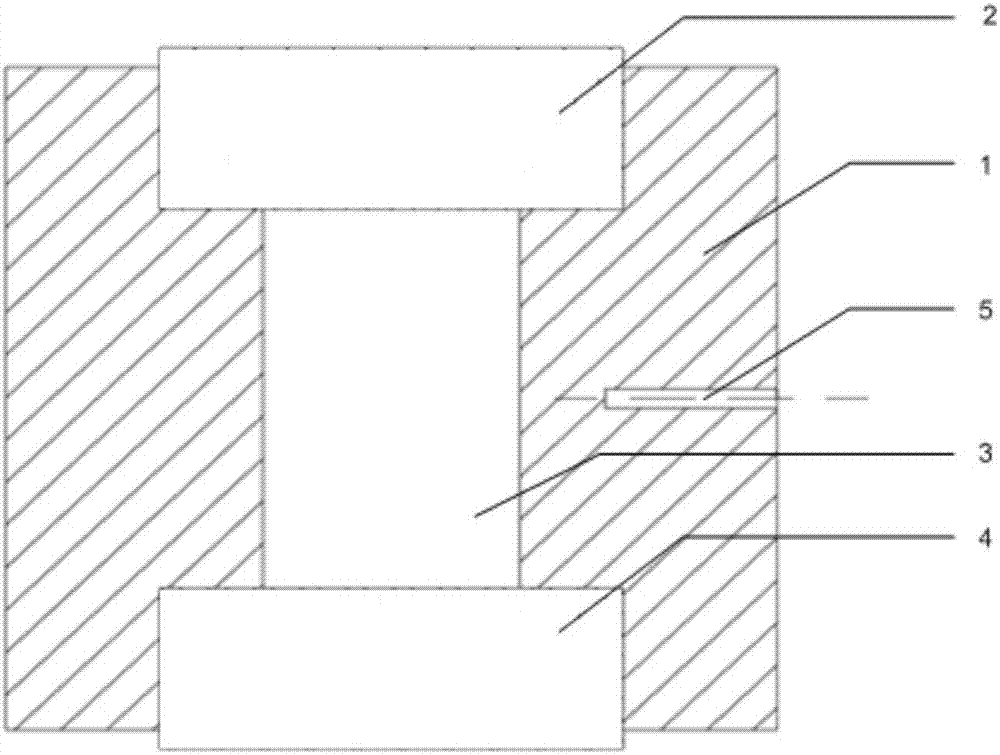

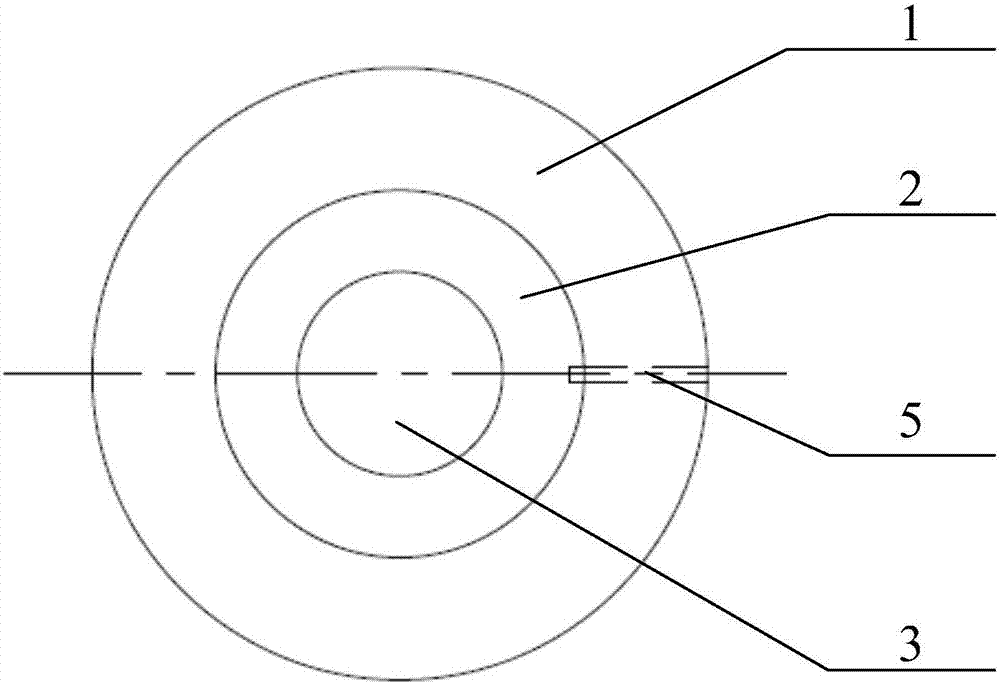

Al2O3/Ti(C,N) composite ceramic tool material and microwave sintering process thereof

The invention discloses an Al2O3 / Ti(C,N) composite ceramic tool material and a microwave sintering process thereof. The Al2O3 / Ti(C,N) composite ceramic tool material is prepared from, by mass, 61%-70% of alumina (Al2O3), 25%-35% of titanium carbonitride (Ti(C,N)), 2%-6% of nickel (Ni) and 1%-3% of molybdenum (Mo). Ceramic tool materials are sintered in a microwave sintering furnace with nitrogen as protection atmosphere through the characteristics that whole microwaves can conduct non-gradient heating, material compactness is promoted and environment friendliness is achieved, wherein the frequency of the microwave sintering furnace is 2.45 GHz. The prepared tool material is uniform in microstructure and small in crystalline grain, has high density, high fracture toughness and high harness, and the performance of the prepared tool material meets the use requirement of tools; meanwhile, the sintering process is advanced, the production efficiency is high, cost is low, large-scale production can be easily conducted, and popularization value is achieved.

Owner:NANJING UNIV OF SCI & TECH

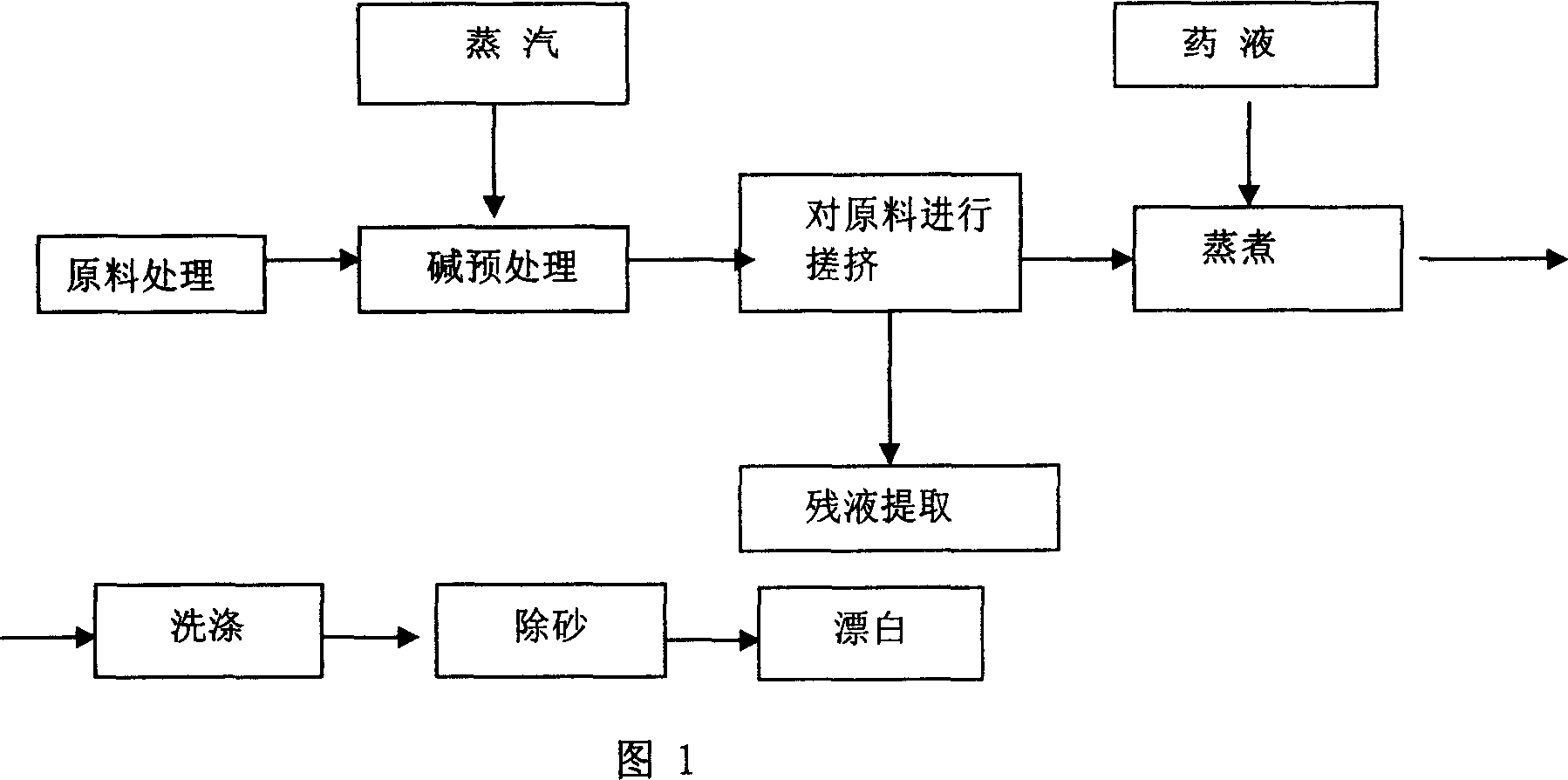

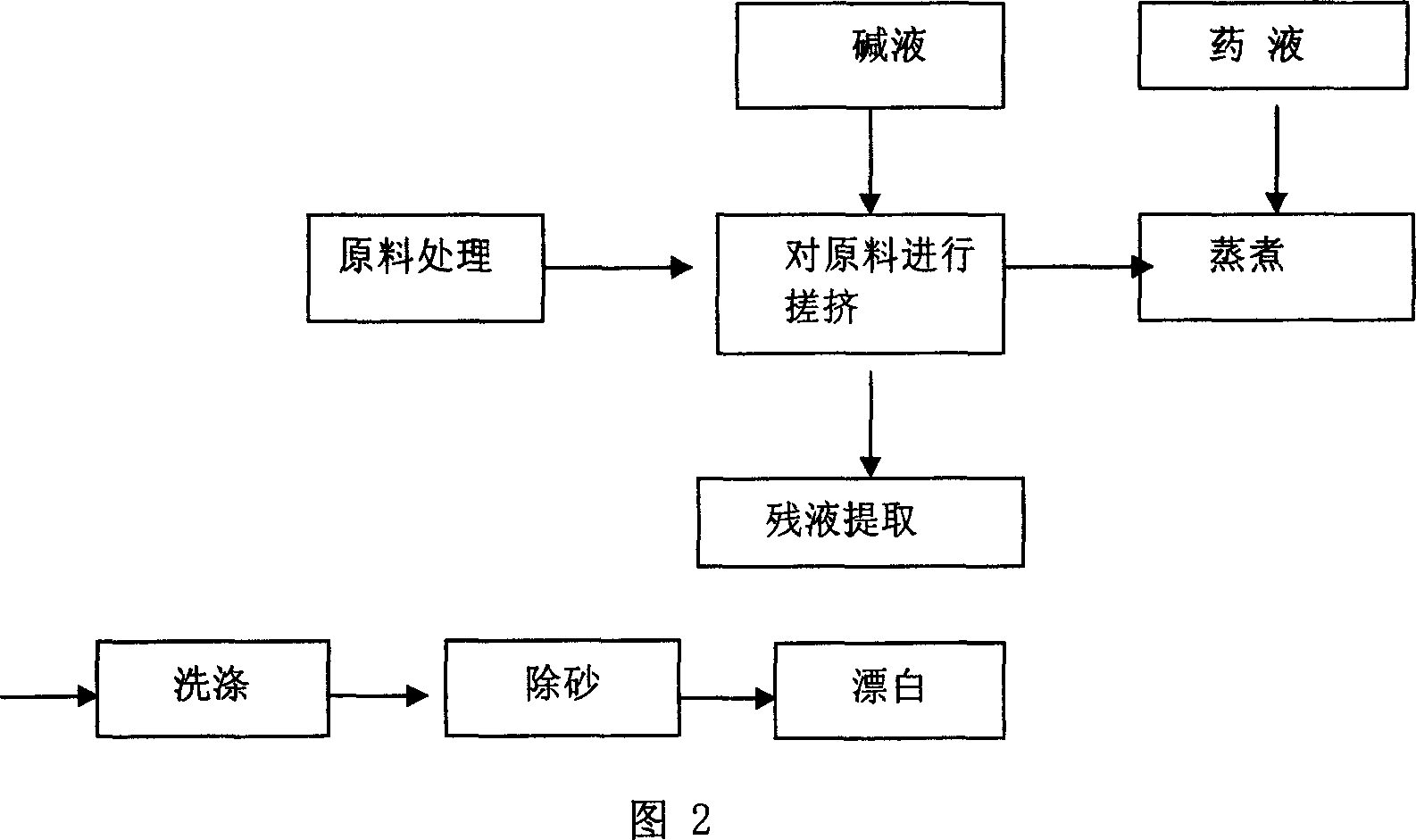

Method for producing chemical fiber pomace with fiber as raw material

InactiveCN1974922APerformance activationImprove impregnation effectCellulosic pulp after-treatmentDigestersBlack liquorPlant fibre

The present invention relates to a method for producing chemical fibre pulp by using plant fibre as raw material. Said method includes the following several steps: raw material treatment, making the treated raw material undergo the processes of rubbing and extruding, cooking, washing, removing sand and bleaching treatment. It is characterized by that in the preparation process of said chemical fibre pulp a screw extruding machine and a rubbing-extruding machine are adopted.

Owner:湖南吉湘生物科技有限公司

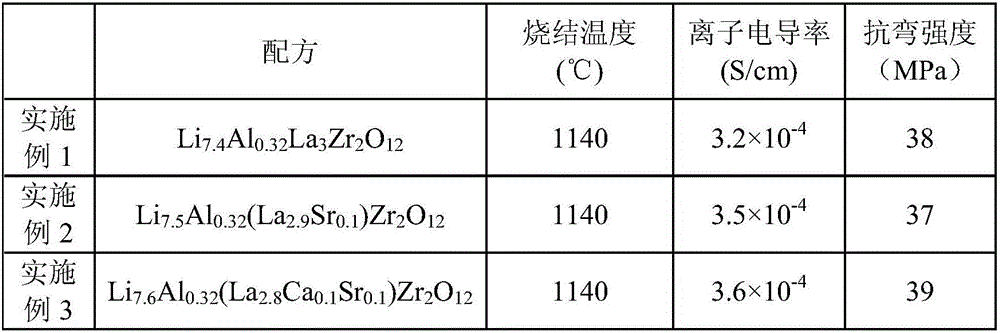

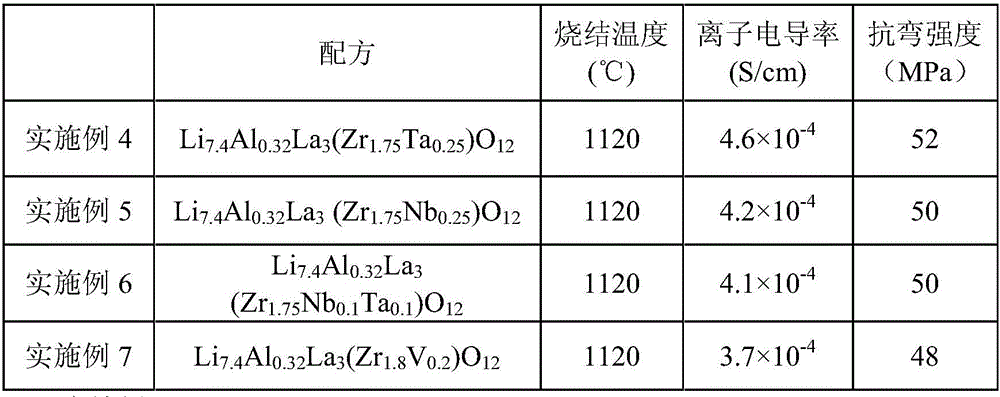

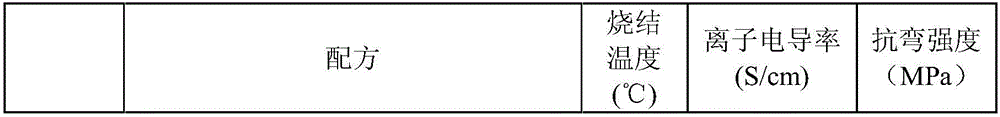

Solid electrolyte material and preparation method thereof

ActiveCN106129463AImprove machinabilityReduce volatilitySolid electrolytesSecondary cellsLithiumChemical composition

The invention relates to a solid electrolyte material and a preparation method thereof. The chemical composition is Li<6+x>Al<y>(La<z>A<3-z>)(Zr<n>G<2-n>)O<12+alpha>wt% D, wherein A is selected from at least one of Ca, Sr, Y and Ba; G is selected from at least one of Ti, Nb, Ta, Sb and V; D is selected from at least one of SiO2, Bi2O3, B2O3, CeO2, ZnO, CuO, MnO2, Co2O3 and SnO2; x is smaller than or equal to 2 and greater than or equal to 0; y is smaller than or equal to 1 and greater than or equal to 0; z is smaller than or equal to 3 and greater than or equal to 2; n is smaller than or equal to 2 and greater than or equal to 1; and alpha is smaller than or equal to 3 and greater than or equal to 0. The safety problems that a lithium-ion liquid battery leaks liquid and is flammable, explosive and the like are solved; battery miniaturization and product shape diversification are facilitated; the process route is simple; massive production is easily to implement; a sample is low in sintering temperature and short in heat preservation time; volatilization of lithium ions is reduced; and the sintering cost is greatly reduced.

Owner:淄博佳润纺织有限公司

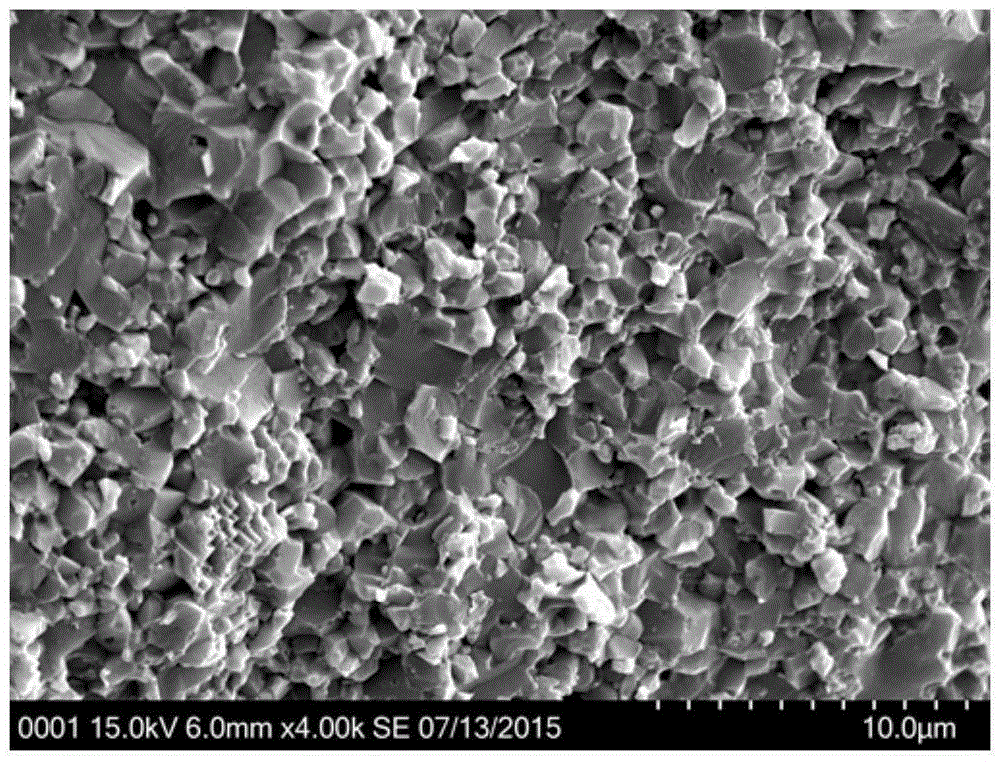

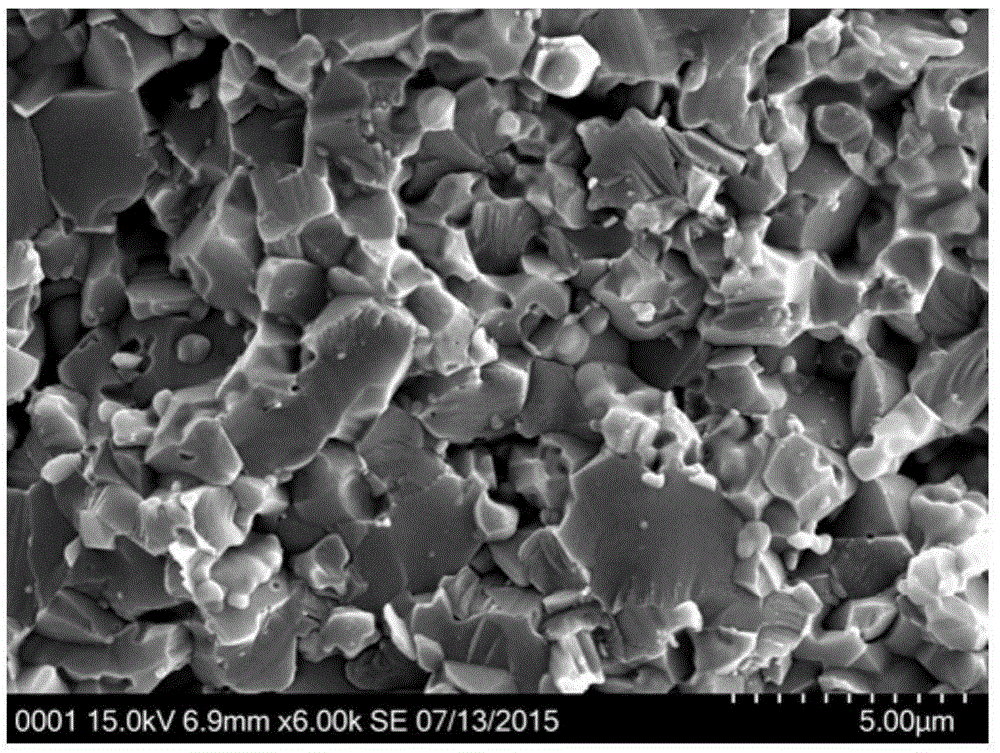

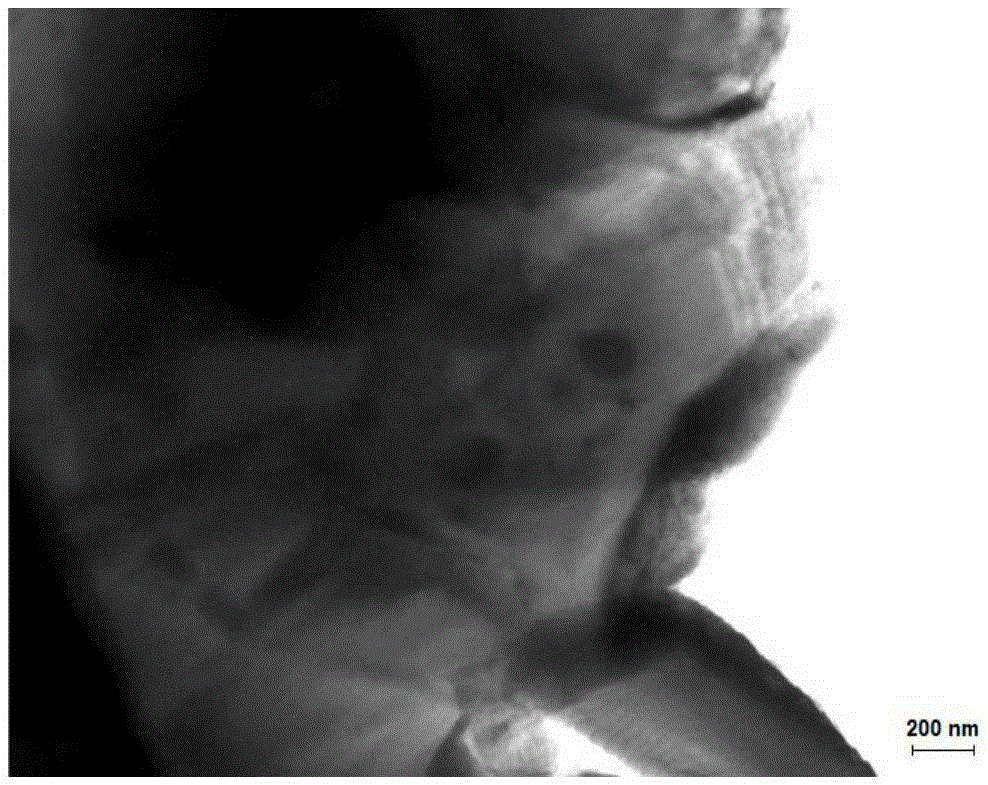

Superfine multi-component composite ceramic powder and preparation method thereof

The invention provides a preparation method of superfine multi-component composite ceramic powder. The preparation method comprises the following steps: (A) mixing a Ti source, an M source and a carbon source, and carrying out high-energy ball milling to obtain activated nano-crystalline raw material powder; and (B) subjecting the prepared activated nano-crystalline raw material powder to a carbothermal reduction reaction, so as to obtain the superfine multi-component composite ceramic powder. According to the preparation method provided by the invention, raw materials are pretreated by utilizing the ball milling operation, thereby obtaining the uniformly-mixed activated nano-crystalline raw material powder; meanwhile, the technical characteristics of spark plasma sintering are sufficiently utilized; compared with a conventional carbothermal reduction reaction, the carbothermal reduction reaction involved in the invention has the advantages that the temperature rise rate is very high, the synthesis temperature is relatively low, the heat preservation period is very short, and a powder product of which the particle size is relatively small can be easier to obtain; and the ball milling operation and the spark plasma sintering operation are ingeniously combined, thereby improving the raw material reaction driving force and diffusivity, enhancing the component reactivity, greatly lowering the synthesis temperature, and shortening the reaction period.

Owner:HAINAN UNIVERSITY

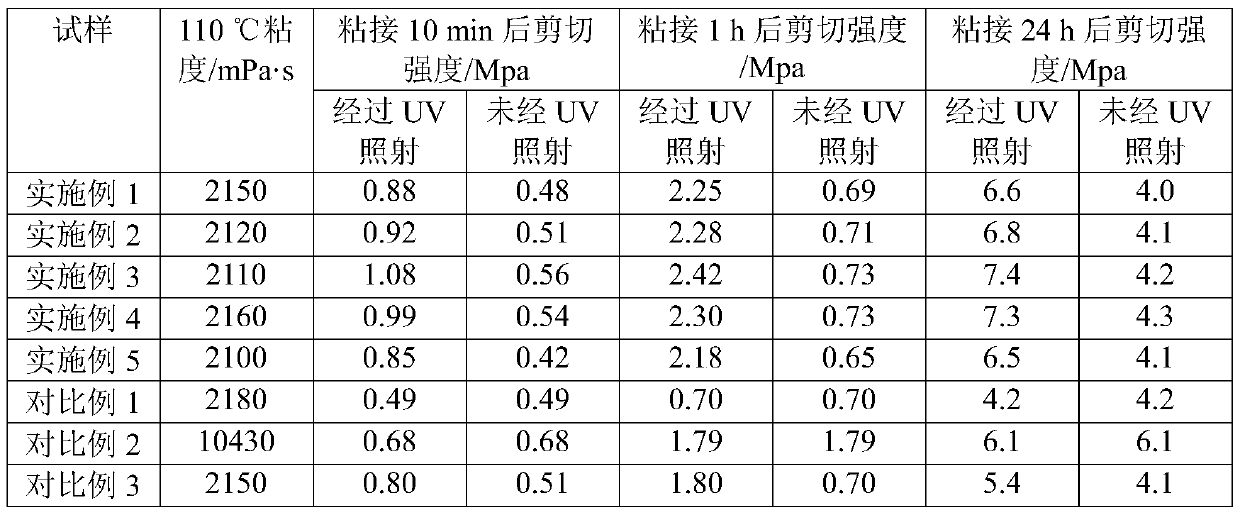

Low viscosity UV/moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

ActiveCN109705794ALow viscosityStrong initial adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention relates to a low viscosity UV / moisture dual-curing polyurethane hot melt adhesive and a preparation method thereof, belonging to the technical field of photocuring adhesives. The low viscosity UV / moisture dual-curing polyurethane hot melt adhesive comprises the following components in parts by weight: 95-97 parts of UV / moisture dual-curing polyester polyether polyurethane, 1-3 partsof free radical photoinitiator, 0.25-2 parts of cationic photoinitiator, 0.25-1 part of photosensitizer, 0.06-0.35 part of polyurethane catalyst, 0.01-0.02 part of water reducing agent, and 0.05-0.2 part of antioxidant. The hot melt adhesive can be used for the bonding of opaque substrates. The viscosity of the adhesive at the sizing temperature 110 DEG C is in the range of 2000-2500 mPa.s, the viscosity is low, the construction is convenient, the initial viscosity is strong, the positioning is fast, the holding time is shortened, even the holding pressure is not needed. The hot melt adhesivedoes not contain small molecular active diluent and is environmentally friendly. The preparation process is simple, easy to operate and suitable for industrial production.

Owner:重庆中科力泰高分子材料有限公司

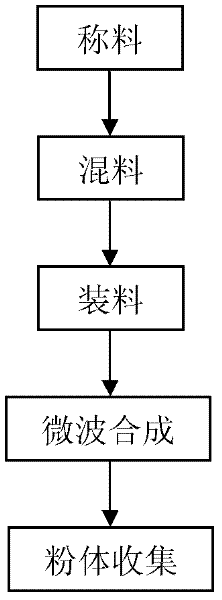

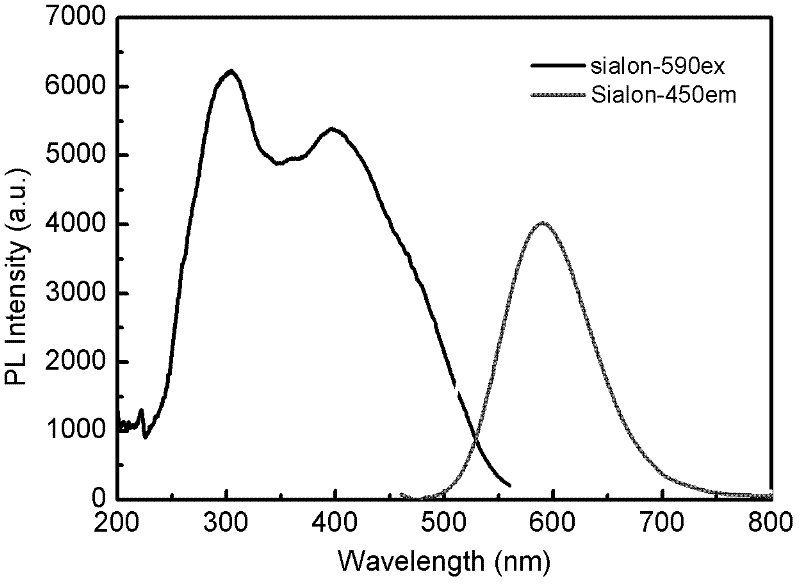

A kind of preparation method of nitride/oxynitride fluorescent powder for white light LED

InactiveCN102260500AUniform distribution of temperature fieldReduce temperature gradientElectroluminescent light sourcesGas discharge lamp usagePolymer scienceHigh pressure

Provided is a method for preparing a nitride / oxynitride fluorescent powder used by a white LED. The raw material is weighted according to the chemometry of each element in the chemical formula of a nitride / oxynitride fluorescent powder and loaded into a sagger made of a wave-transparent material after being mixed uniformly, then the sagger is placed into a professional microwave oven, in a fixed gas atmosphere, and the fluorescent powder is obtained by adjusting the microwave power to control the warming rate, heating to the resultant temperature, and finally cooling and grinding. As compared to methods in the prior art, the method is performed under normal pressure, reducing the resultant temperature, shortening the production period, and greatly reducing the production costs; and the fluorescent powder obtained has good crystallinity, fine grain size, a narrow granularity distribution range, good grain dispersibility, and a regular shape.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

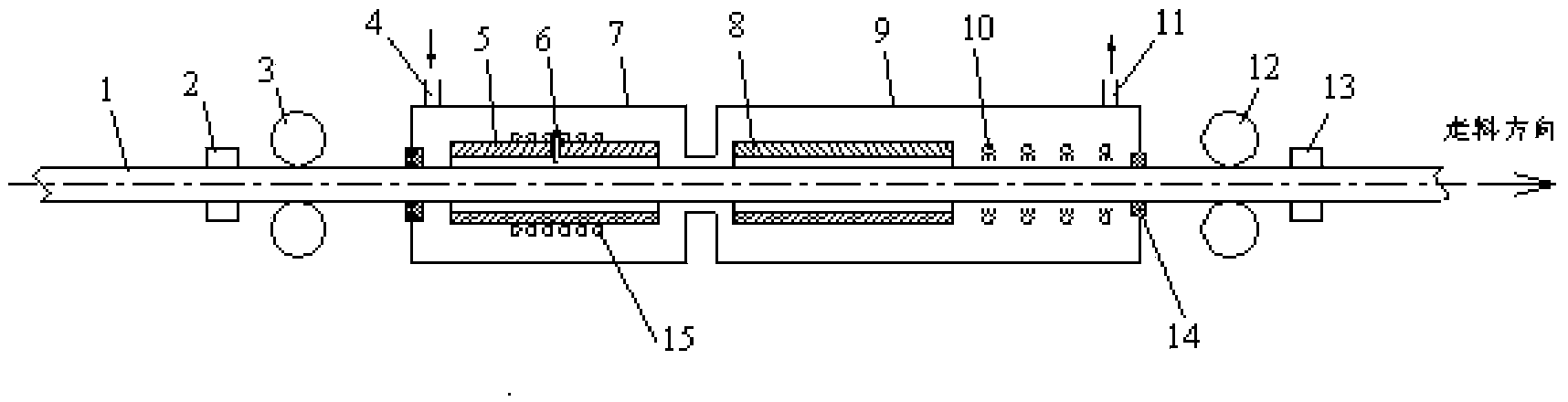

Copper-clad aluminium composite flat cable induction continuous annealing equipment and process using equipment

ActiveCN103710522AControl thicknessImprove performanceFurnace typesIncreasing energy efficiencyHeating timeContinuous annealing

The invention relates to induction heating continuous annealing equipment meeting the characteristics of a copper-clad aluminium composite electrical flat cable and a process using the equipment. The equipment mainly comprises a guide device, a drive device, a temperature measuring device, an induction heating system, a heat preserving section, a cooling section and a gas protective system. The equipment is characterized in that an induction heating power source adopts a frequency on the high side of an intermediate frequency so as to increase the rate of the induction heating, shorten the heating time and control the interface layer thickness; the cross section of an induction heating coil is of a flat shape similar to the shape of the cross section of the copper-clad aluminium flat cable so as to benefit the uniform distribution of temperature and the shortening of the heating time and control the interface layer thickness; a ceramic tube with a certain length and the heat preserving section are arranged to ensure that the temperature is uniform during the heating and enough time is provided to finish the recrystallization of a copper layer and an aluminium core; the forced cooling section is arranged to ensure that the temperature of the annealed flat cable can be rapidly reduced to below 150 DEG C and the copper-aluminium interface layer thickness is controlled at 2-3 micrometers. The invention further provides an annealing process using the annealing equipment.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing sucralose-6-ester by utilizing phase transfer catalyst to catalyze and chloridize

ActiveCN102417526AIncrease reaction rateReduce generationEsterified saccharide compoundsSugar derivativesSucroseDecomposition

Owner:HUBEI YITAI PHARMA

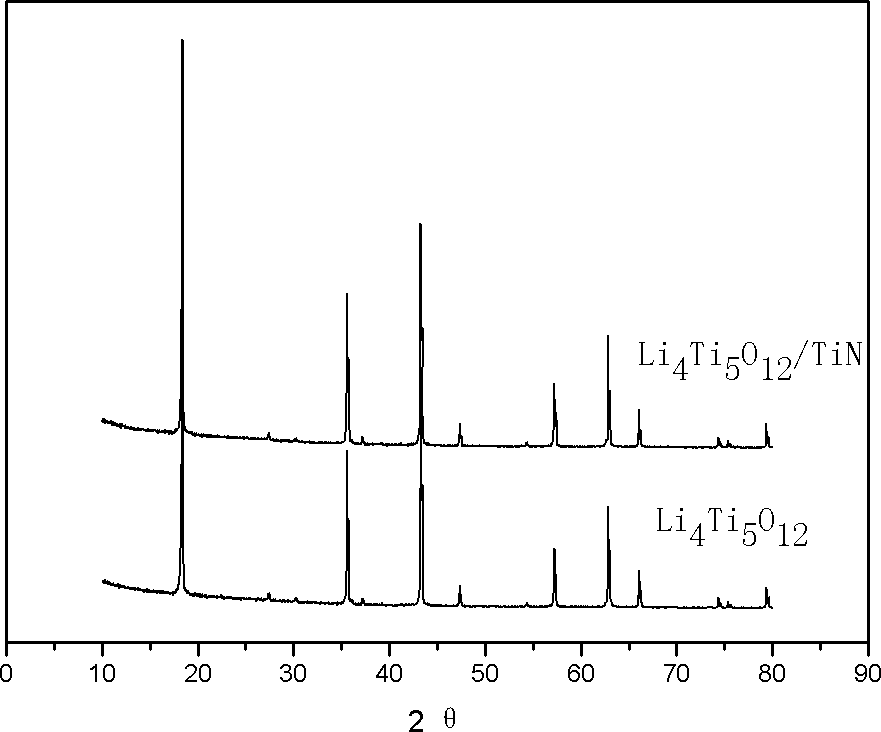

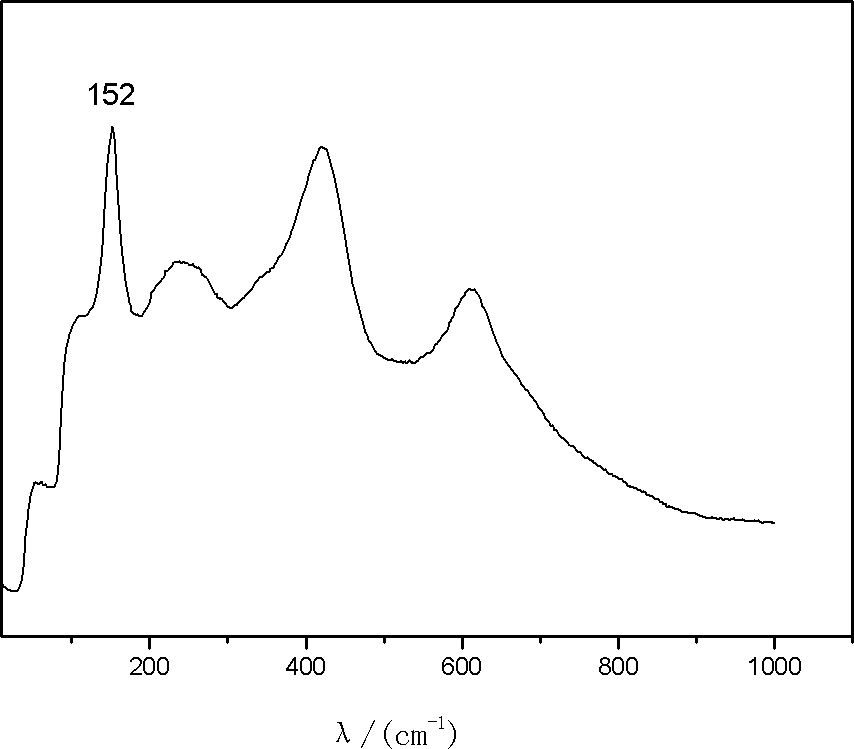

Anode material for lithium ion battery and preparation method thereof

InactiveCN102354748AImprove conductivityImprove high current charge and discharge performanceCell electrodesTitanium compoundsLithium electrodeLithium battery

The invention discloses a preparation method of an anode material for a lithium ion battery, which comprises the following steps of: mixing titanium dioxide with lithium carbonate to be ball-milled evenly, carrying out heat preservation for 10-180 minutes at the temperature of 750-850 DEG C and cooling to obtain lithium titanate; and mixing the lithium titanate with a solid-state nitrogen source compound to be calcined with the protection of protective gas, and obtaining the anode material for the lithium ion battery after reaction. In the step of preparing the lithium titanate, the time for heat preservation of raw materials at high temperature is greatly shortened, the aggregation of material particles caused by long-time ignition is avoided, the particle size of the lithium titanate is greatly reduced, and the modification area of TiN after the lithium titanate is nitrided is increased, so that the conductivity performance of the prepared anode material for the lithium ion battery is improved. In addition, due to the reduction of the particle size of the lithium titanate, the migration distance of lithium ions in a charge-discharge process of the lithium ion battery is reduced, and thus the large current charge-discharge performance of the anode material for the lithium ion battery is improved.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com