Copper and stainless steel dissimilar metal water adapter vacuum brazing technology method

A technology of dissimilar metals and brazing technology, applied in metal processing equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of large differences in melting point, thermal conductivity and linear expansion coefficient, etc., and achieve reliable and improved methods The effect of high product qualification rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Embodiment: The vacuum brazing process for a water joint of copper and stainless steel dissimilar metals includes the following steps:

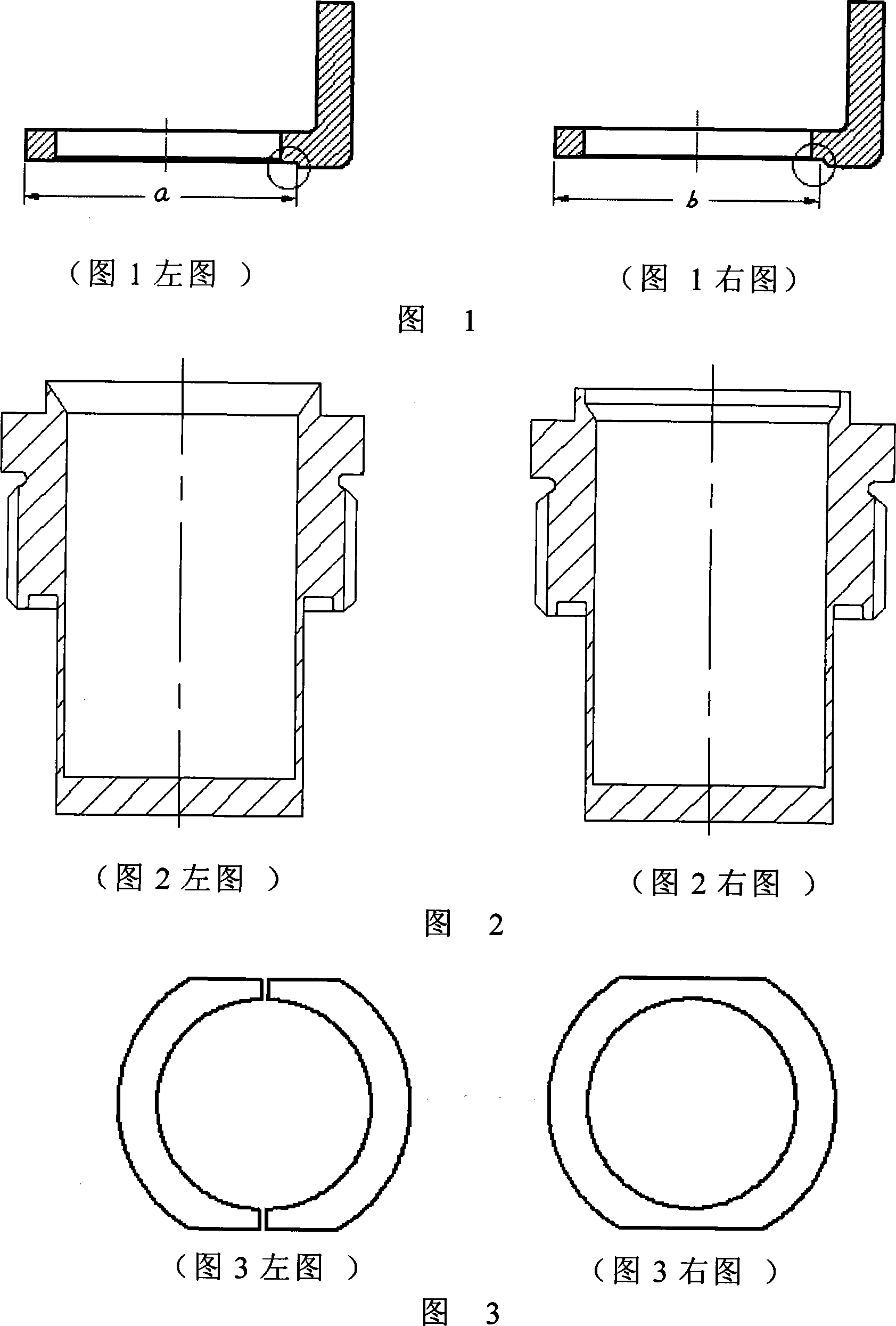

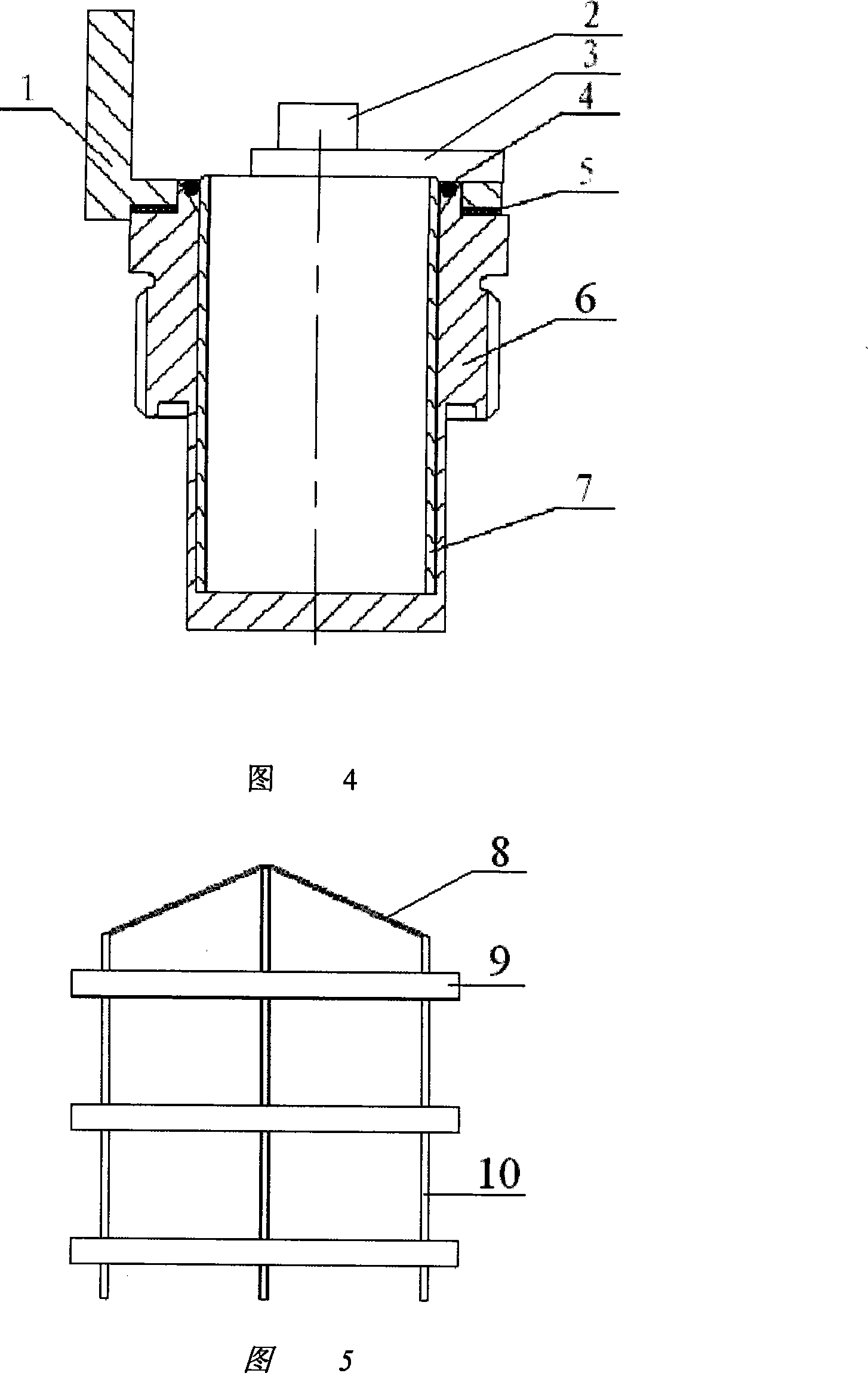

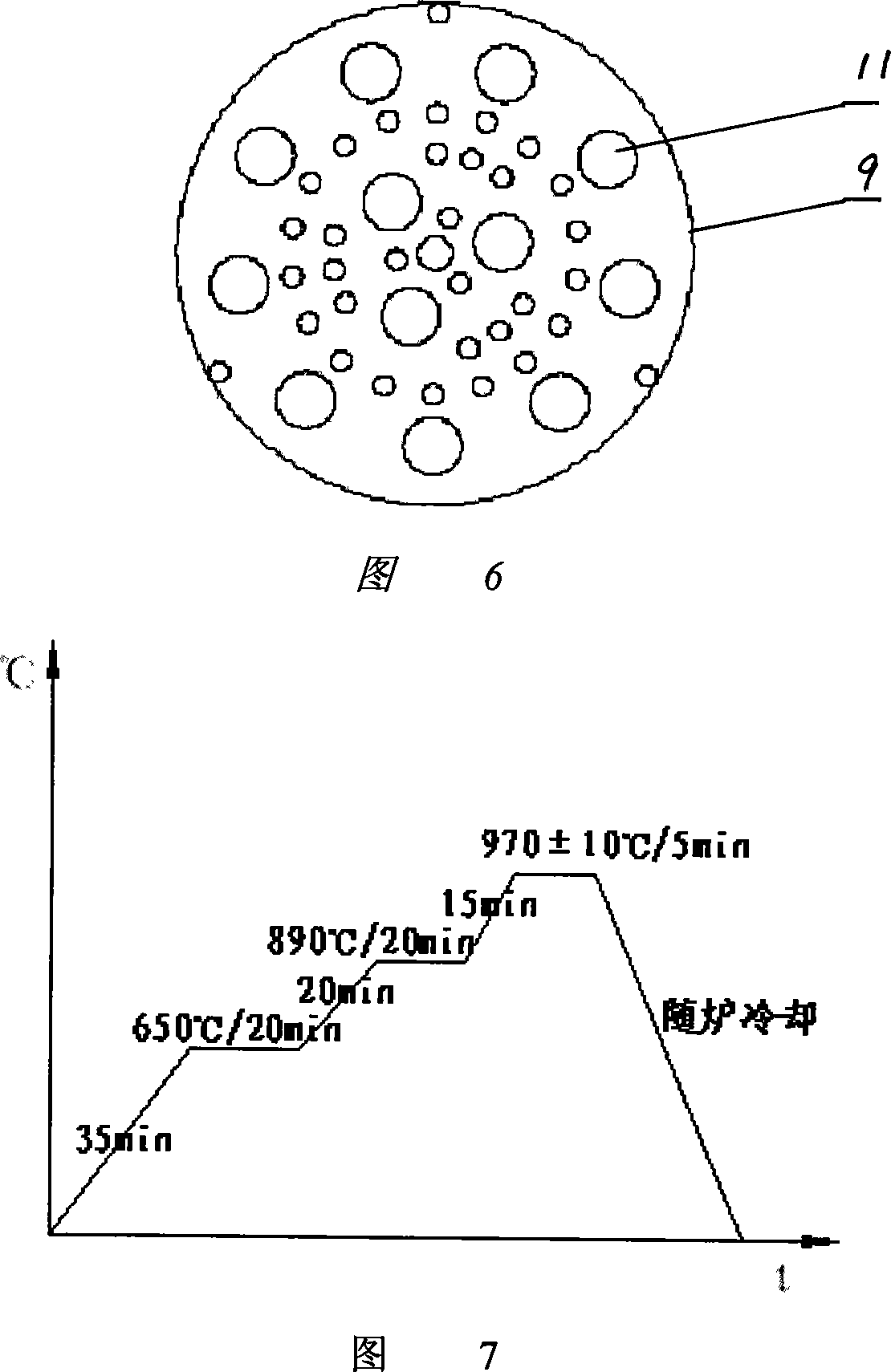

[0037] The first step is to process the various parts of the water joint, including the copper L support, the copper lining pipe, and the stainless steel water tank to control the processing accuracy and the assembly gap of related components. Taking into account the difference in melting point, thermal conductivity and linear expansion coefficient of copper and stainless steel vacuum brazing, when making stainless steel water tank and copper lined pipe, ensure that the assembly gap (diameter difference) is 0.04mm-0.14mm; processing copper When the L support and the stainless steel water box, ensure that the diameter of the inner hole of the L support matches the outer diameter of the top of the water box, and ensure the flatness of the horizontal mating surface, so that it is in close contact with the foil-shaped silver copper palladium s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com