Patents

Literature

443results about How to "Press evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

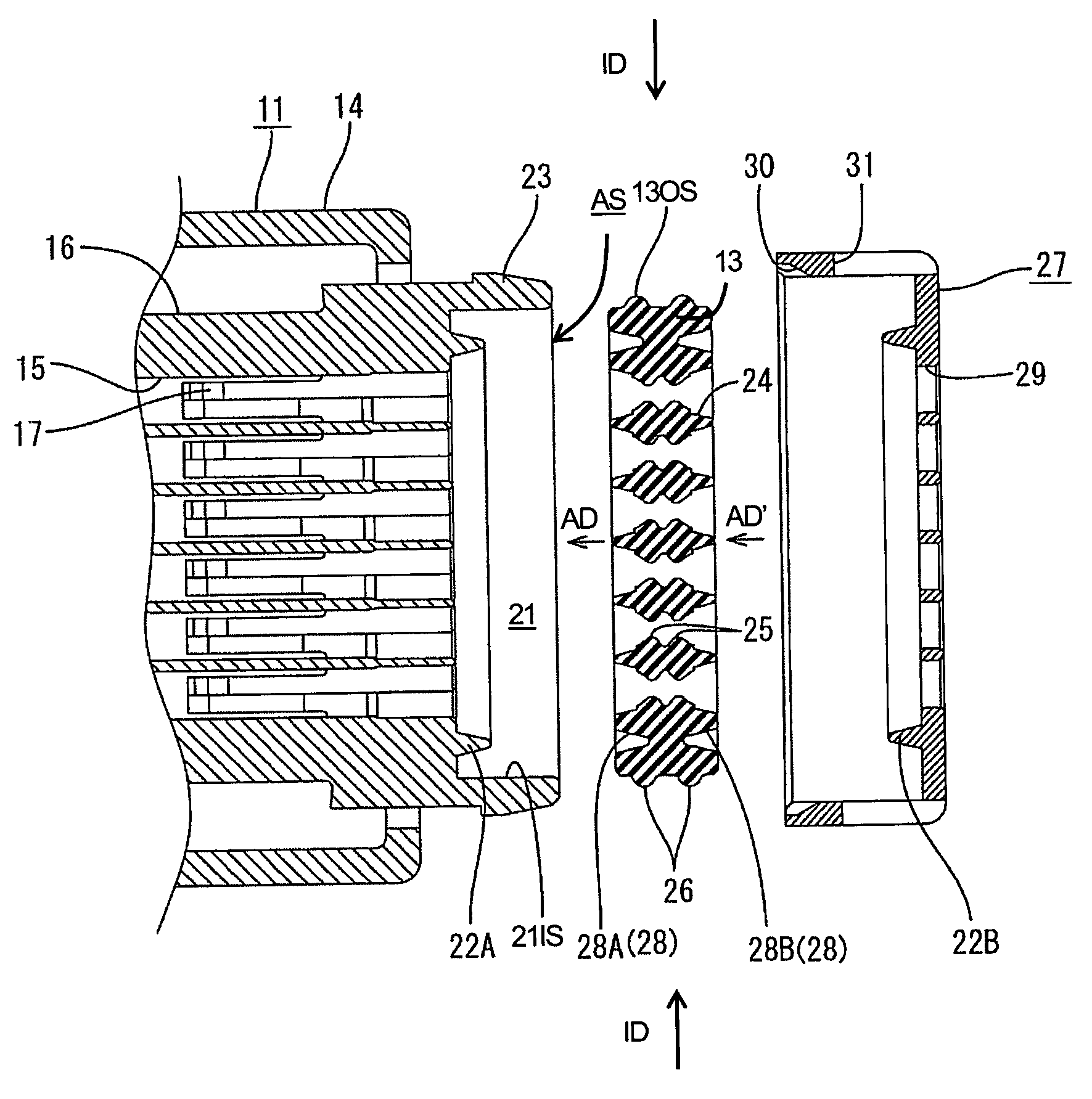

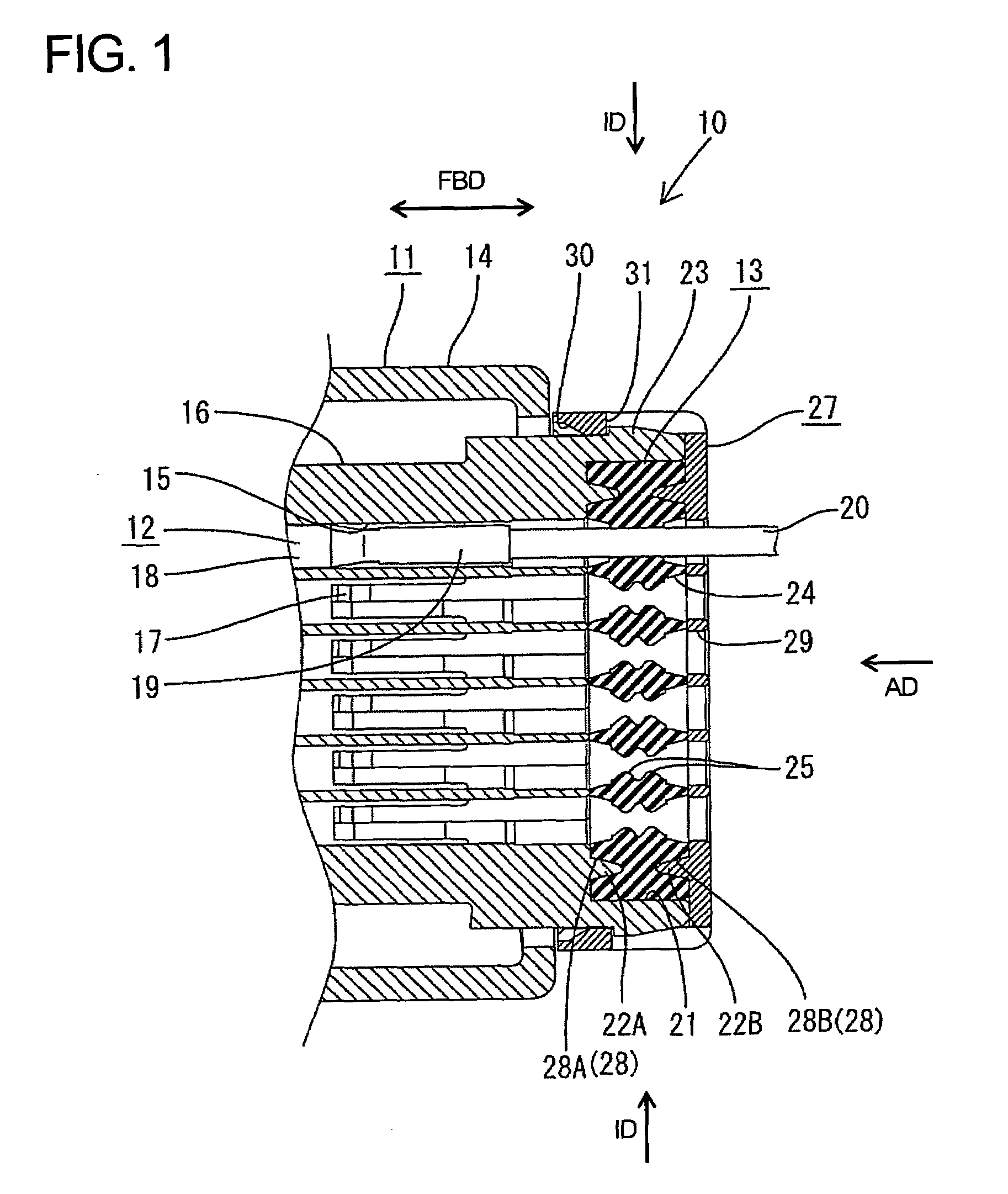

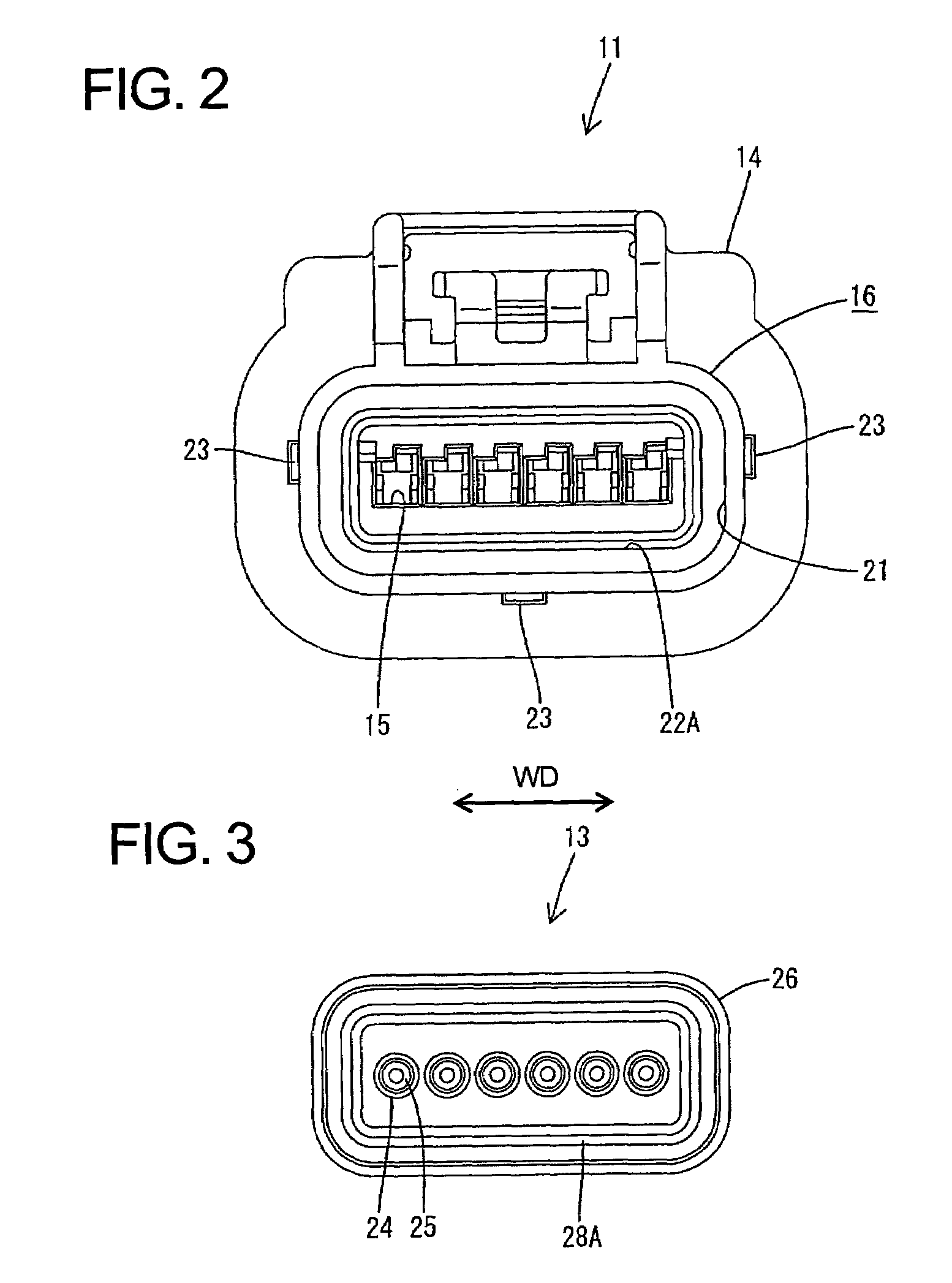

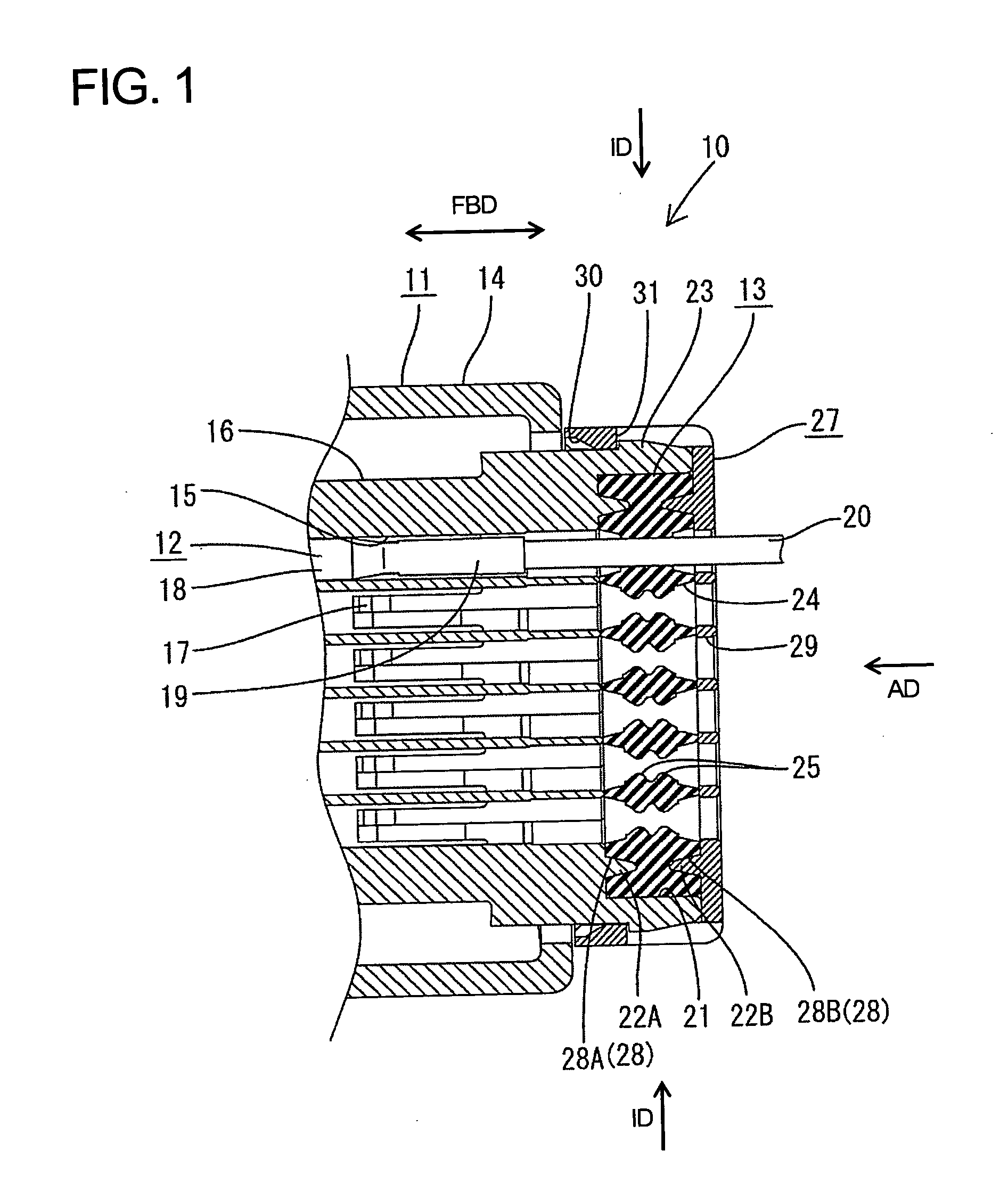

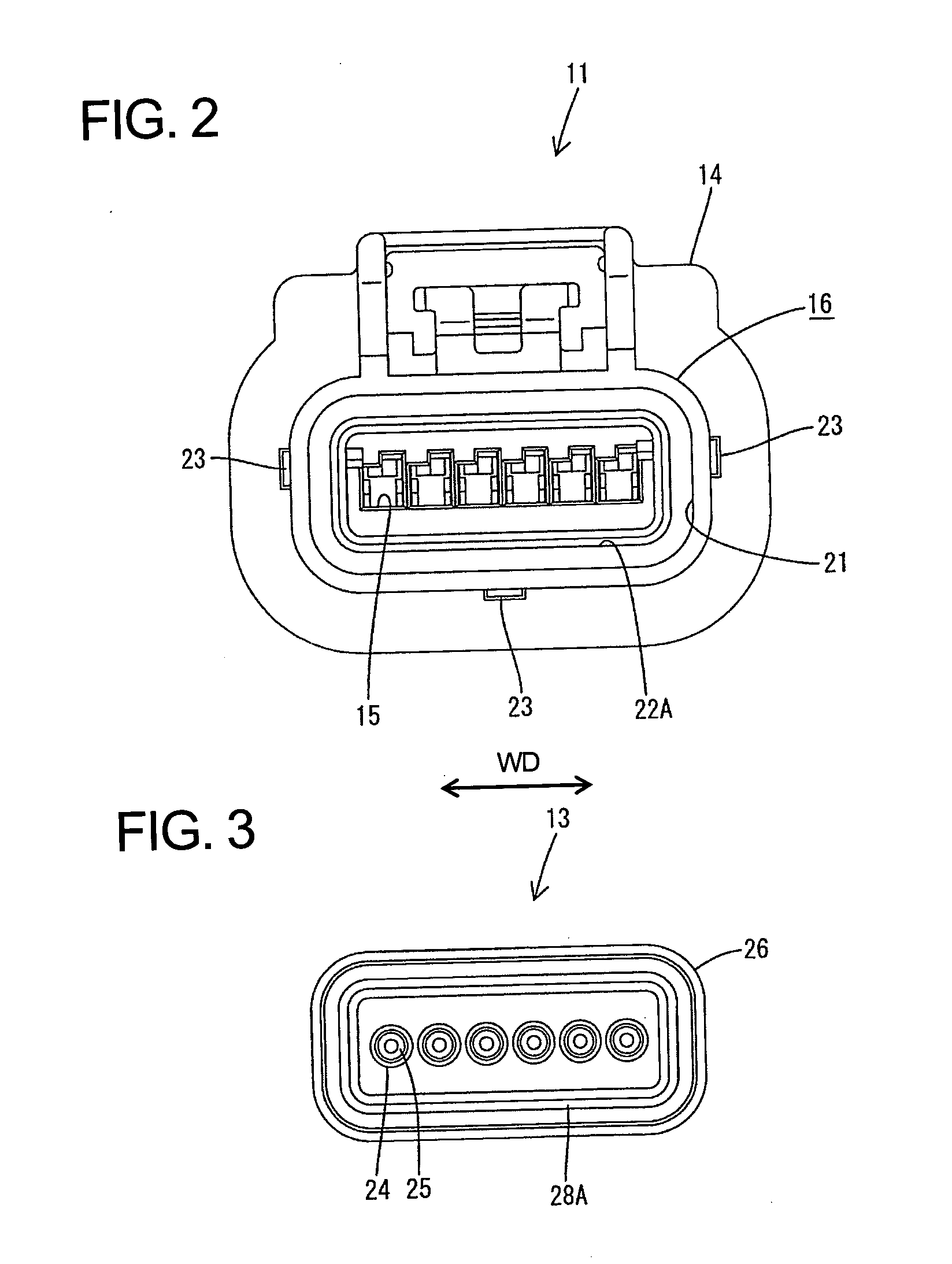

Waterlight connector

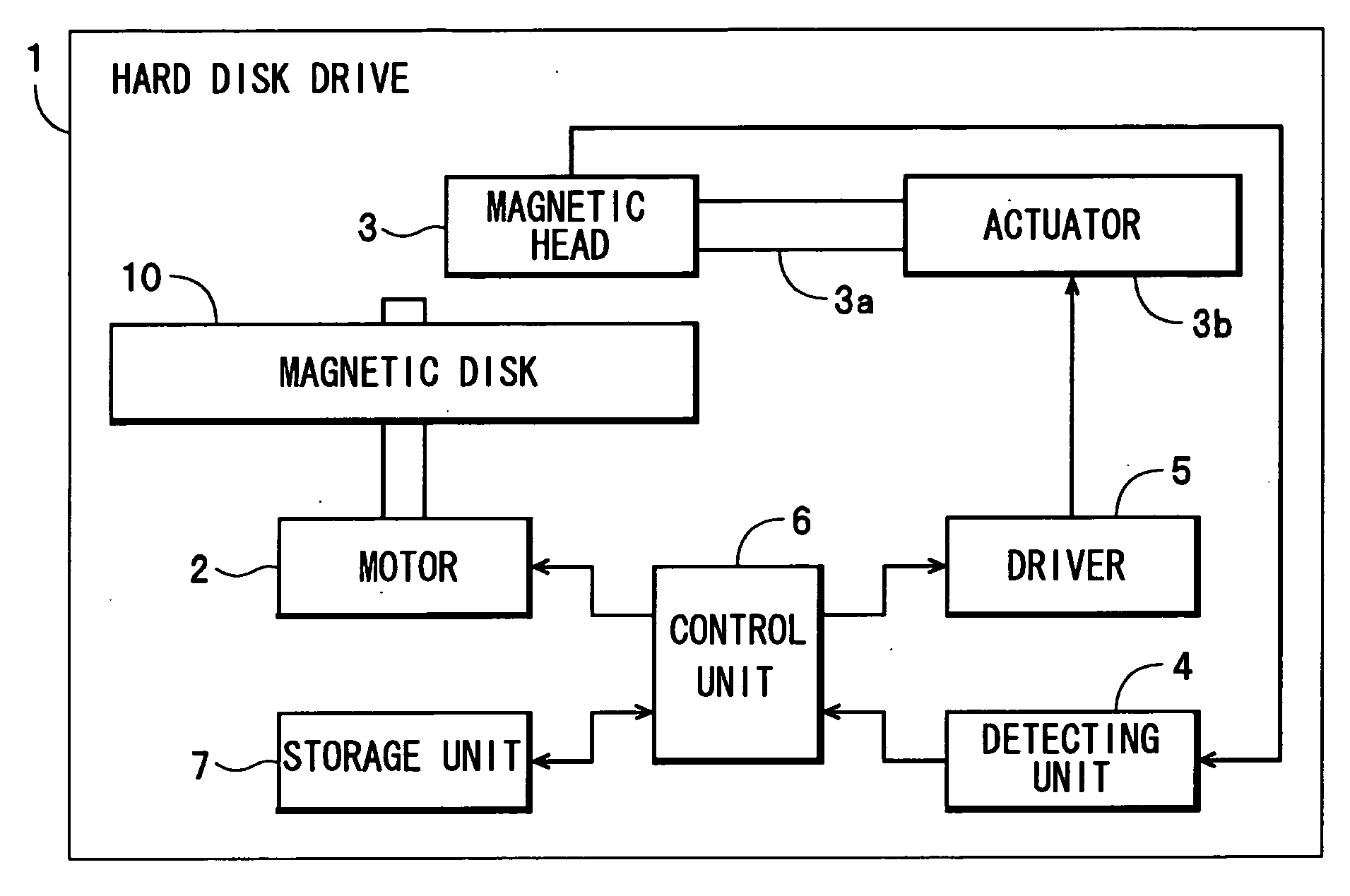

InactiveUS7156698B2Efficient insertionEasy to insertSecuring/insulating coupling contact membersEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

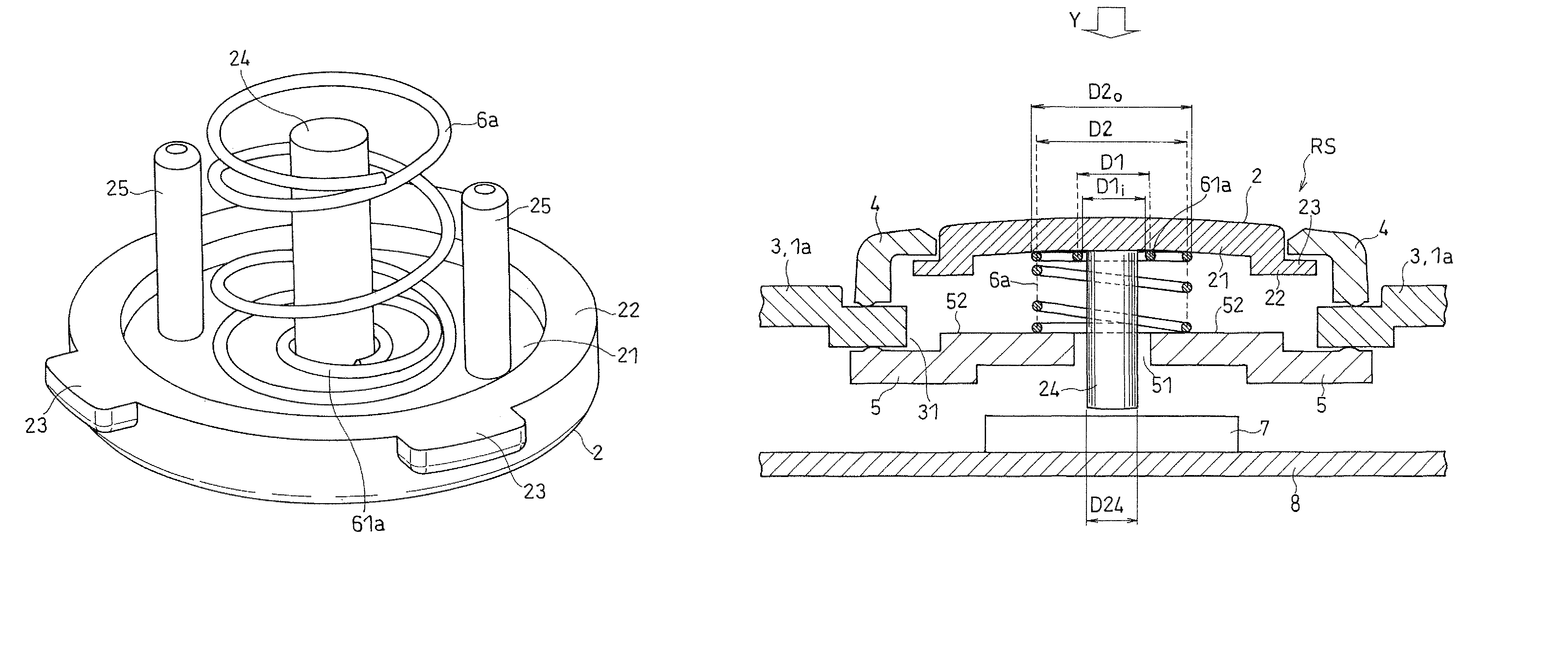

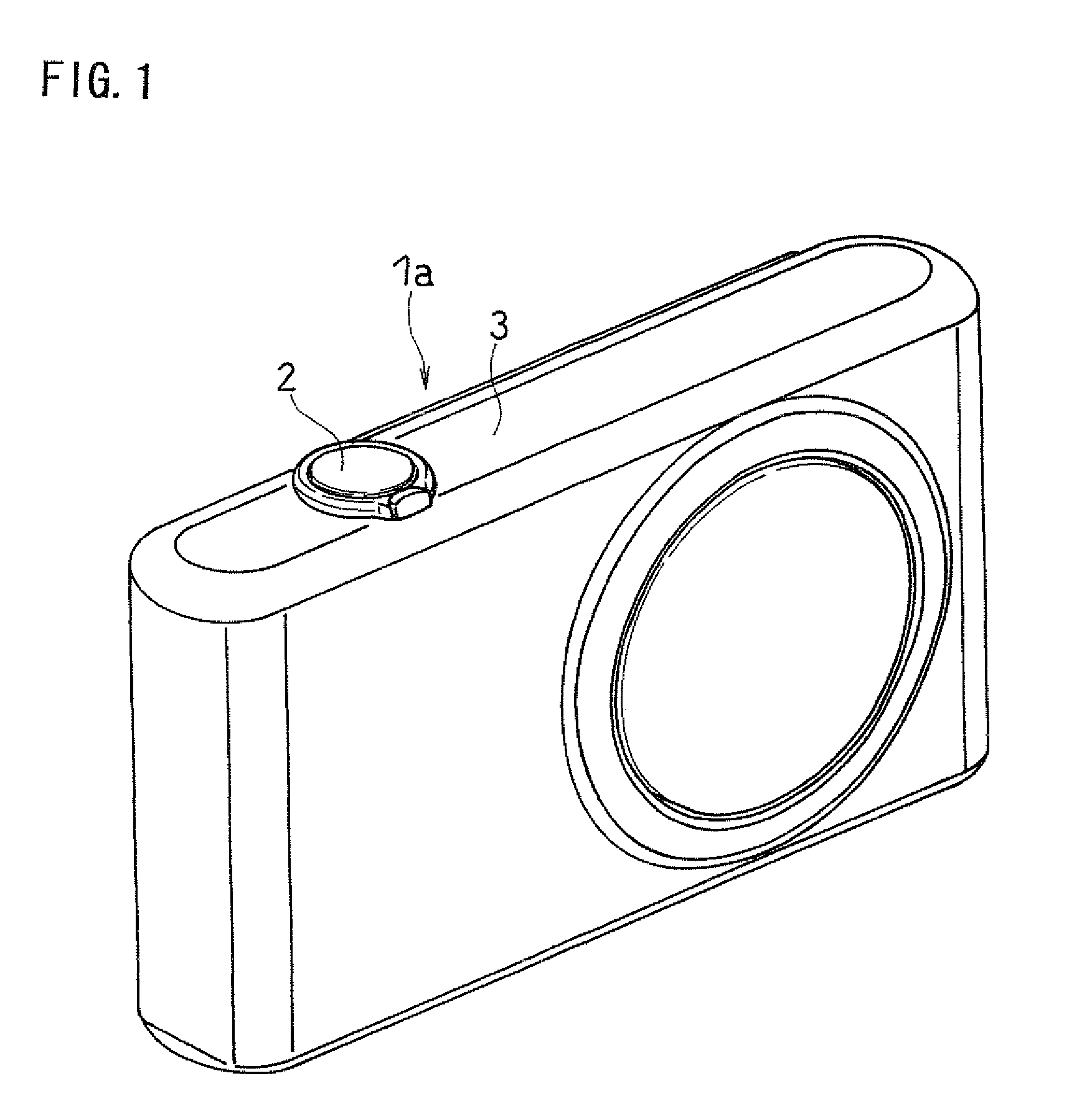

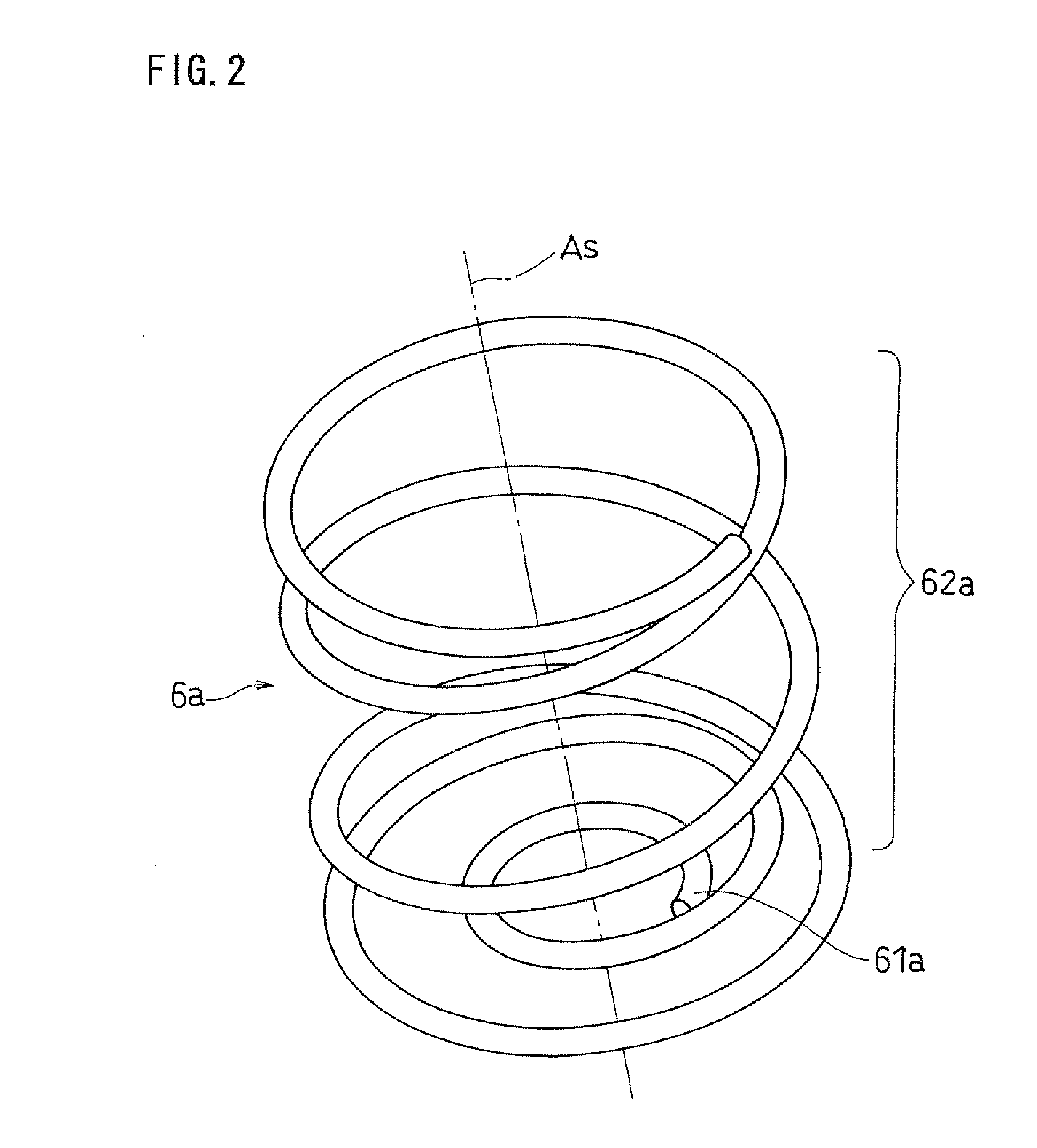

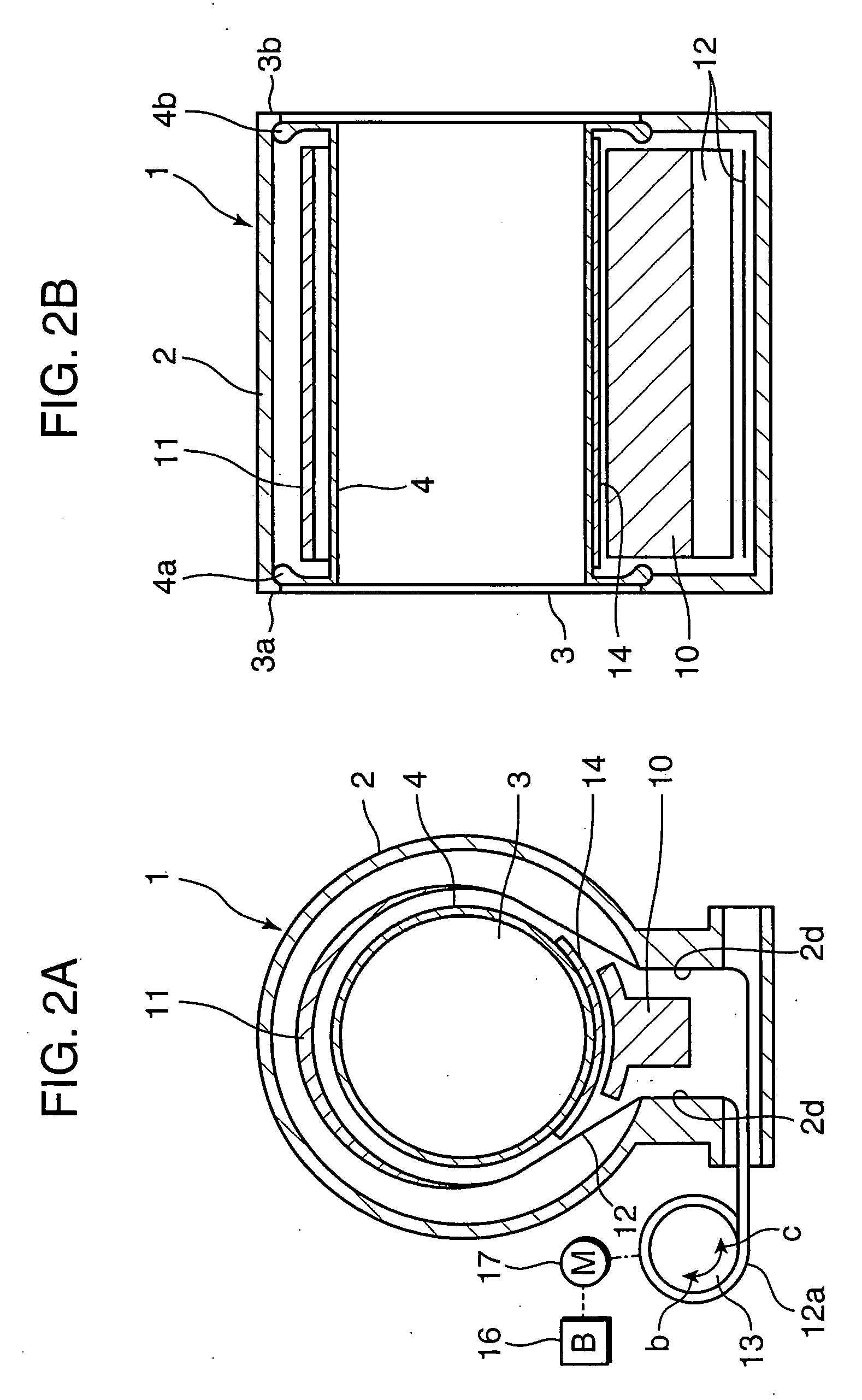

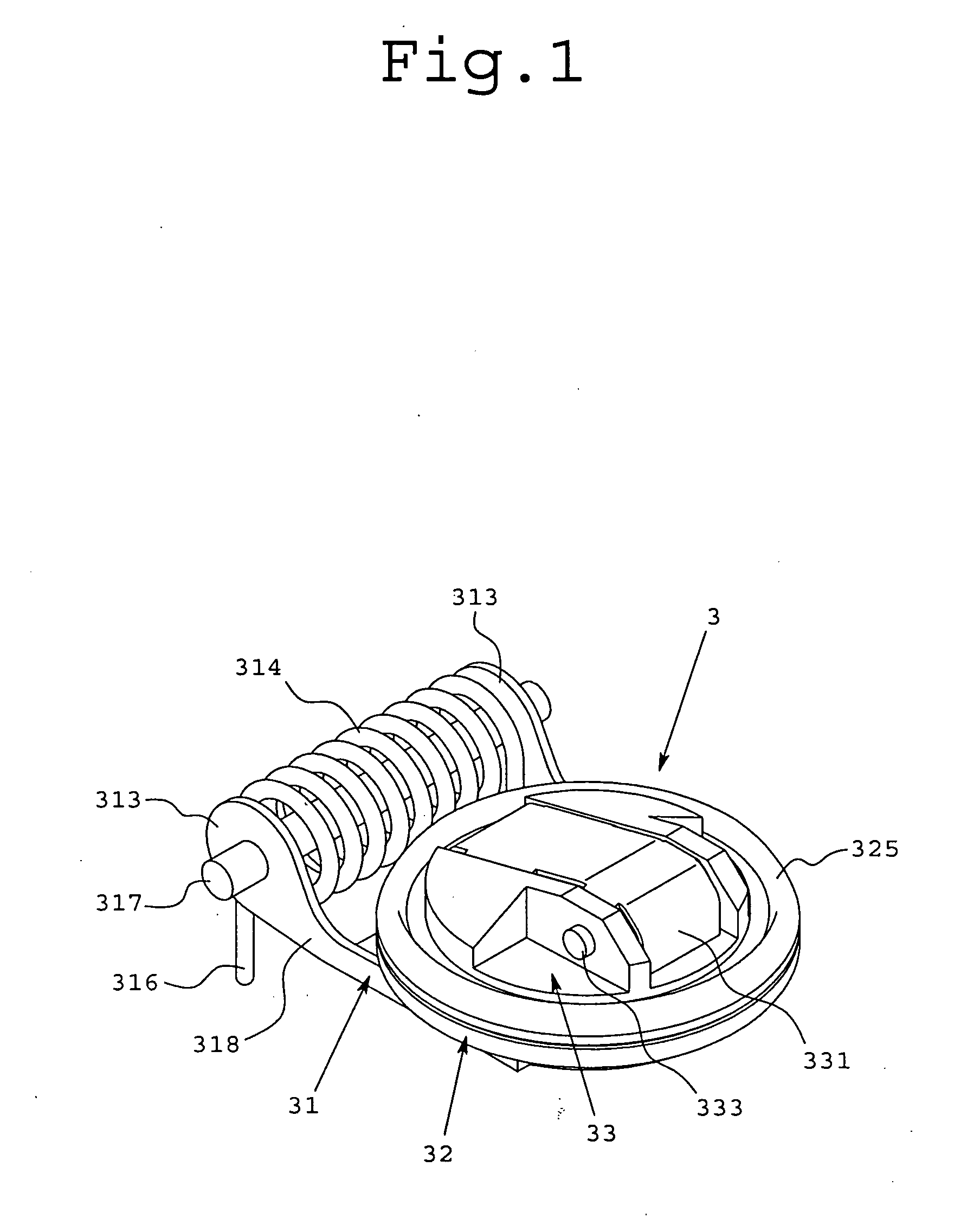

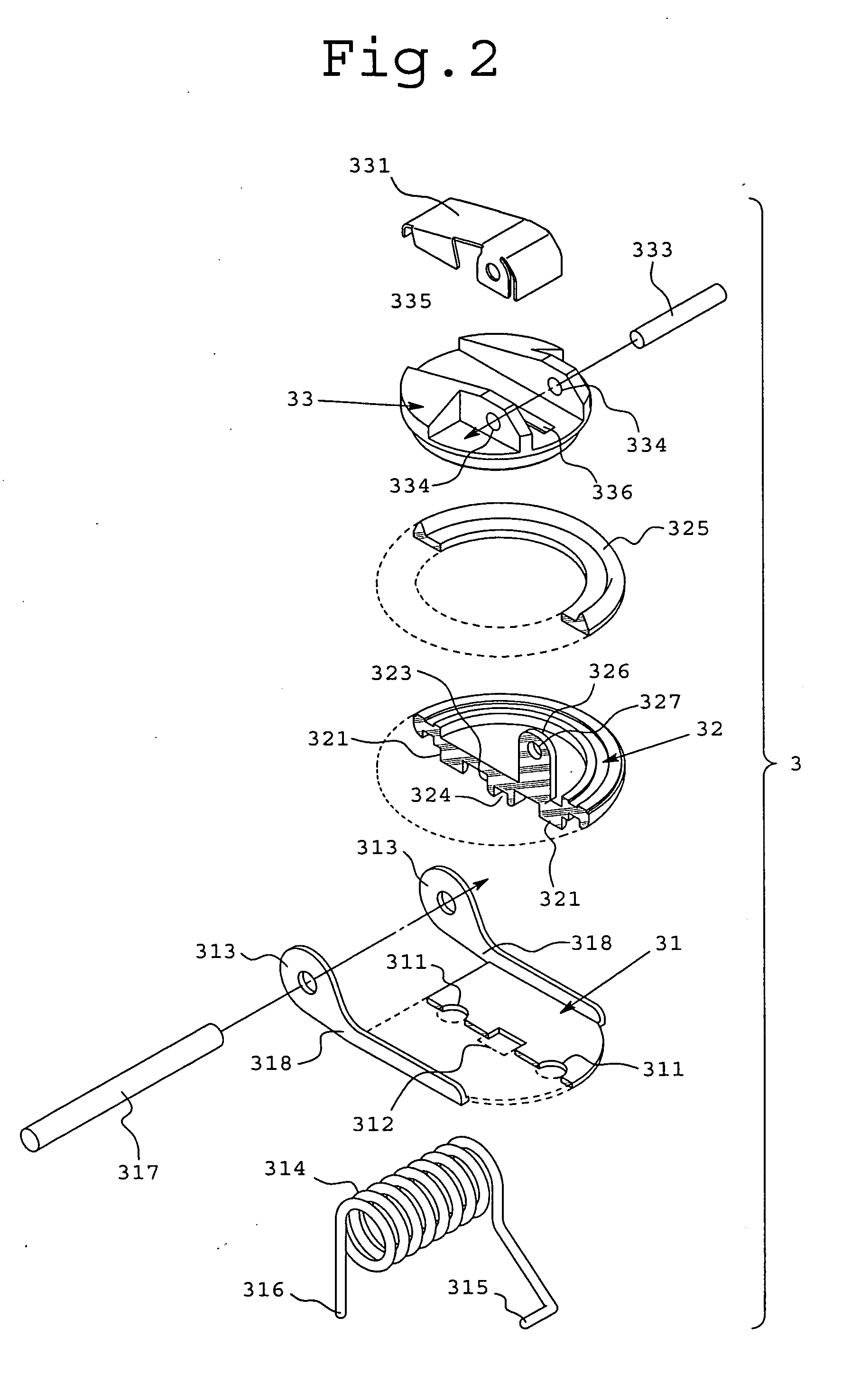

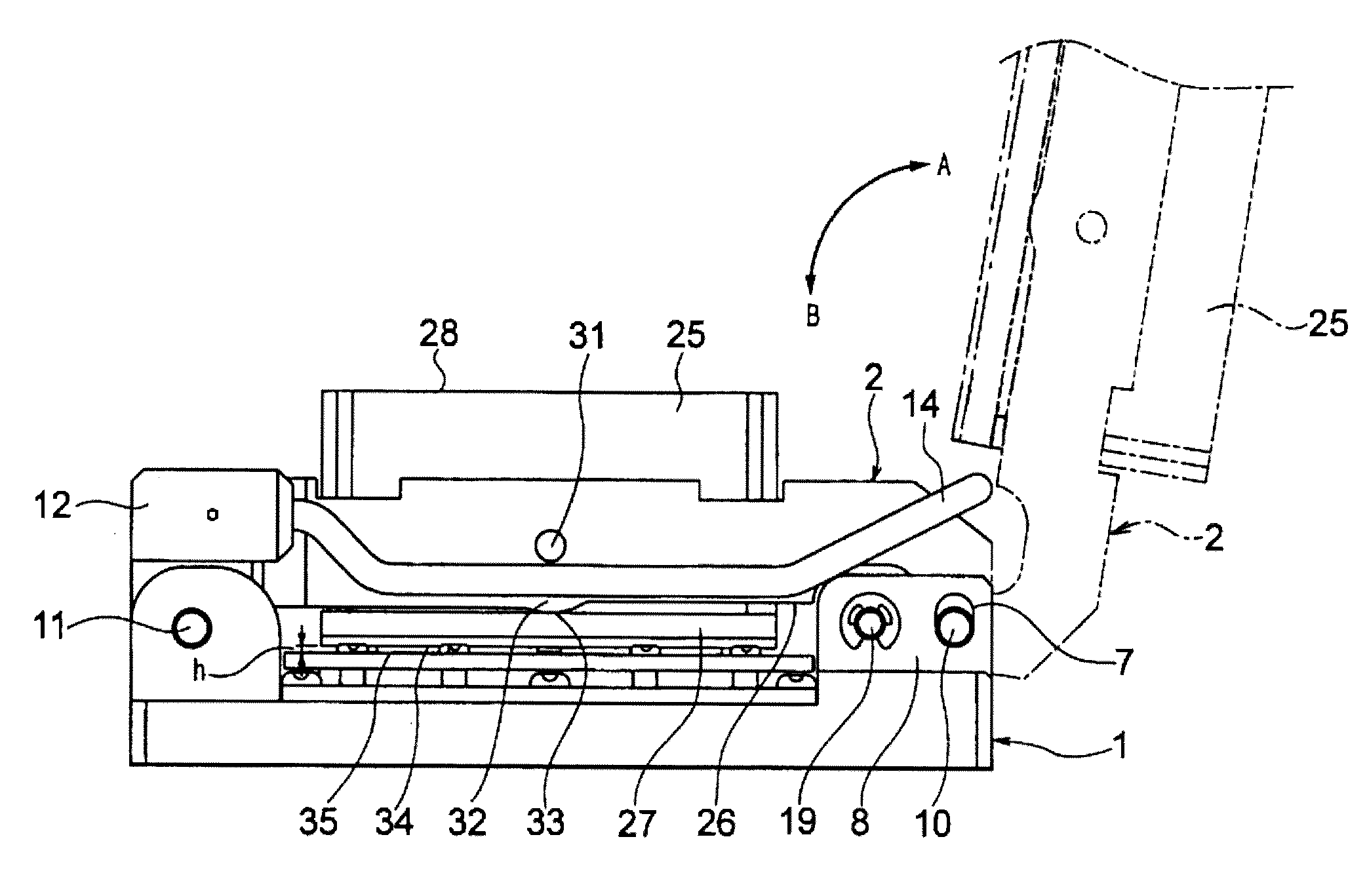

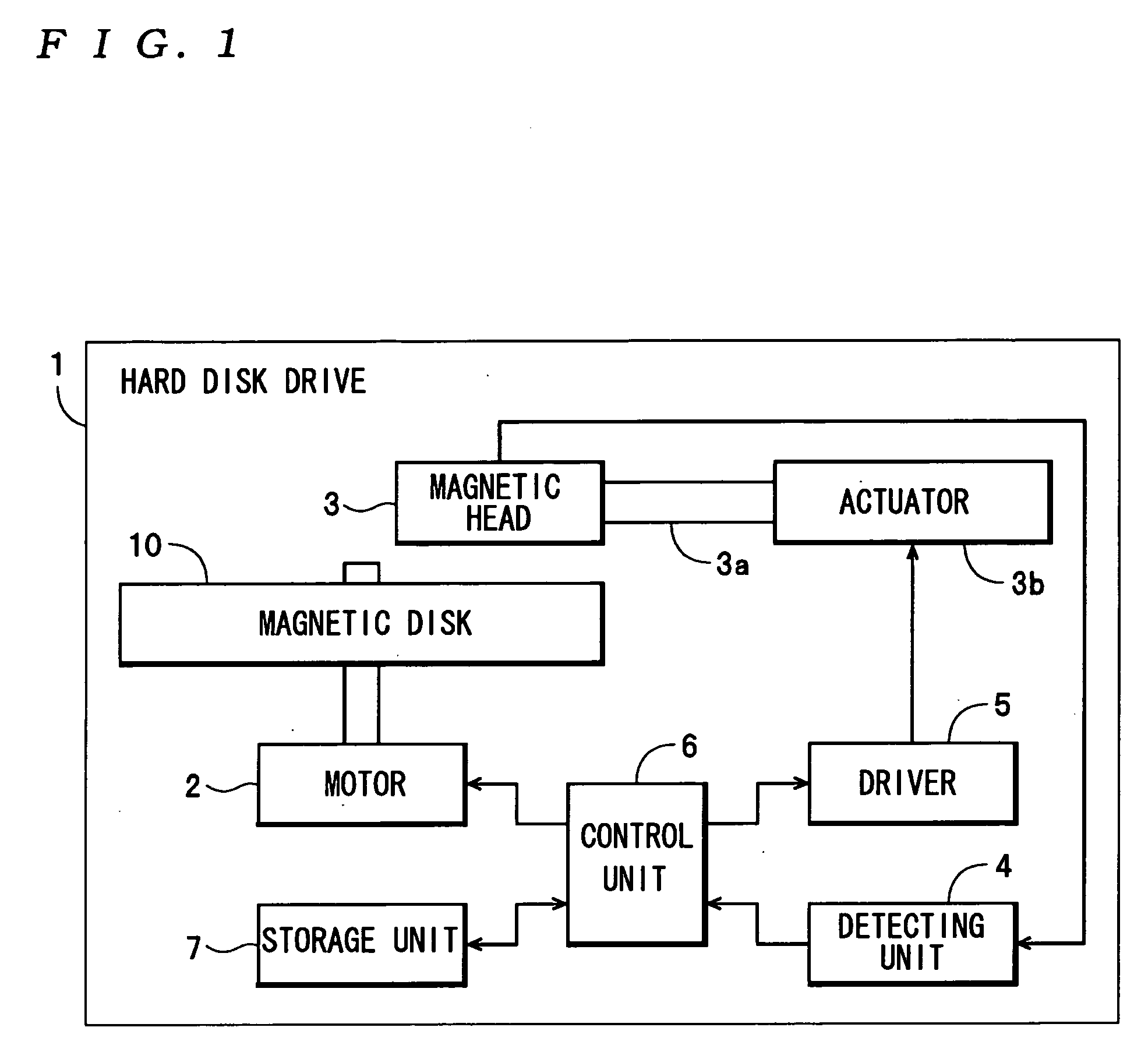

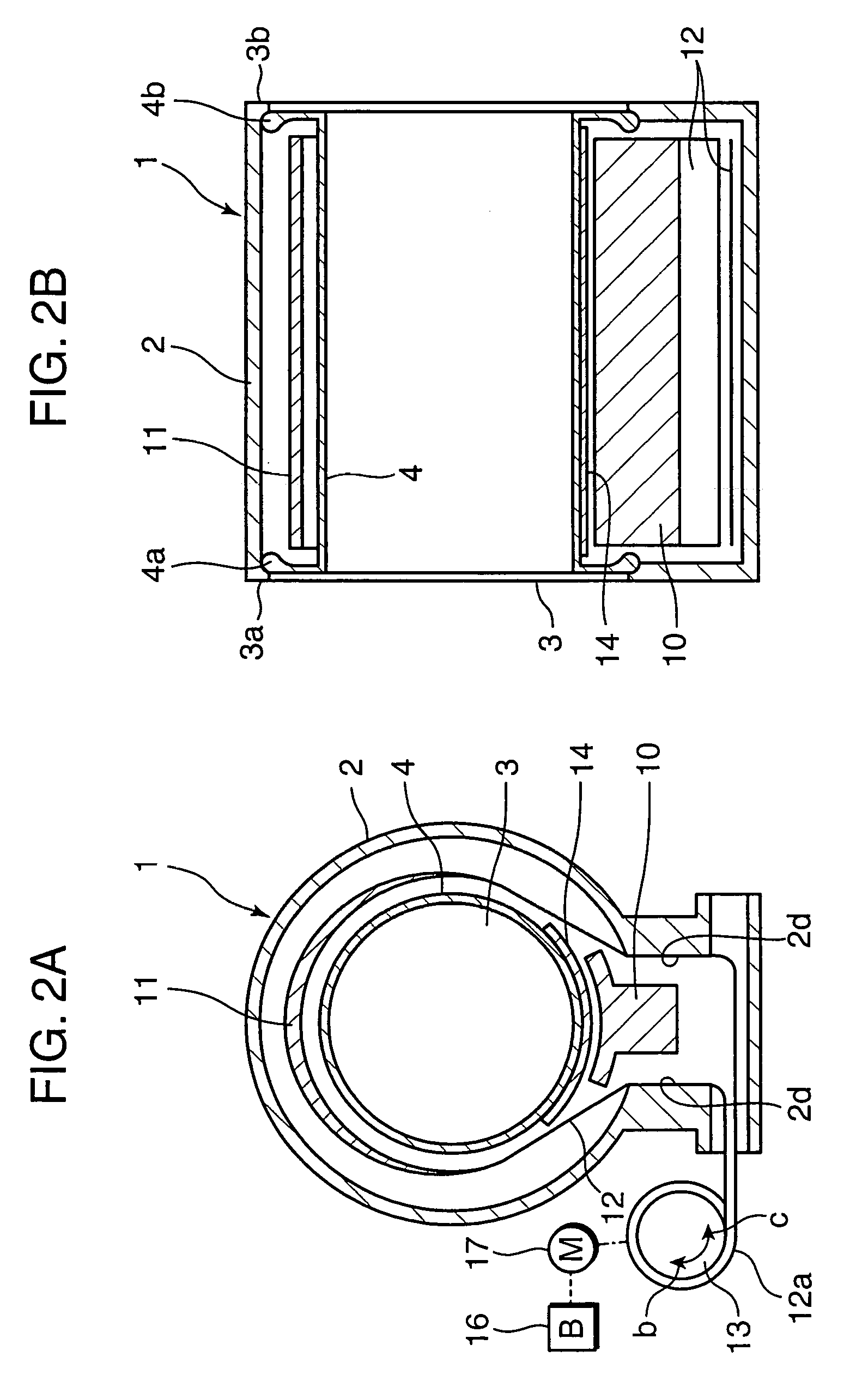

Coil spring structure of shutter button camera device and button structure of electronic device

InactiveUS7929859B2Press evenlyThe method is simple and reliableMultiple spring combinationsCamera body detailsCoil springElectronic equipment

In a camera device 1a with a shutter button 2 for transmitting an externally-applied pressing force to a switch 7, a boss 24 has a first end attached to the shutter button 2, and a second end opposed to the switch 7, a coil spring 6a has a first winding portion 61a and a second winding portion 62a, which are respectively wound into first and second shapes about a common central axis As, the second shape includes the first winding portion 61a, and the second end of the boss 24 is inserted into the first winding portion 61a.

Owner:PANASONIC CORP

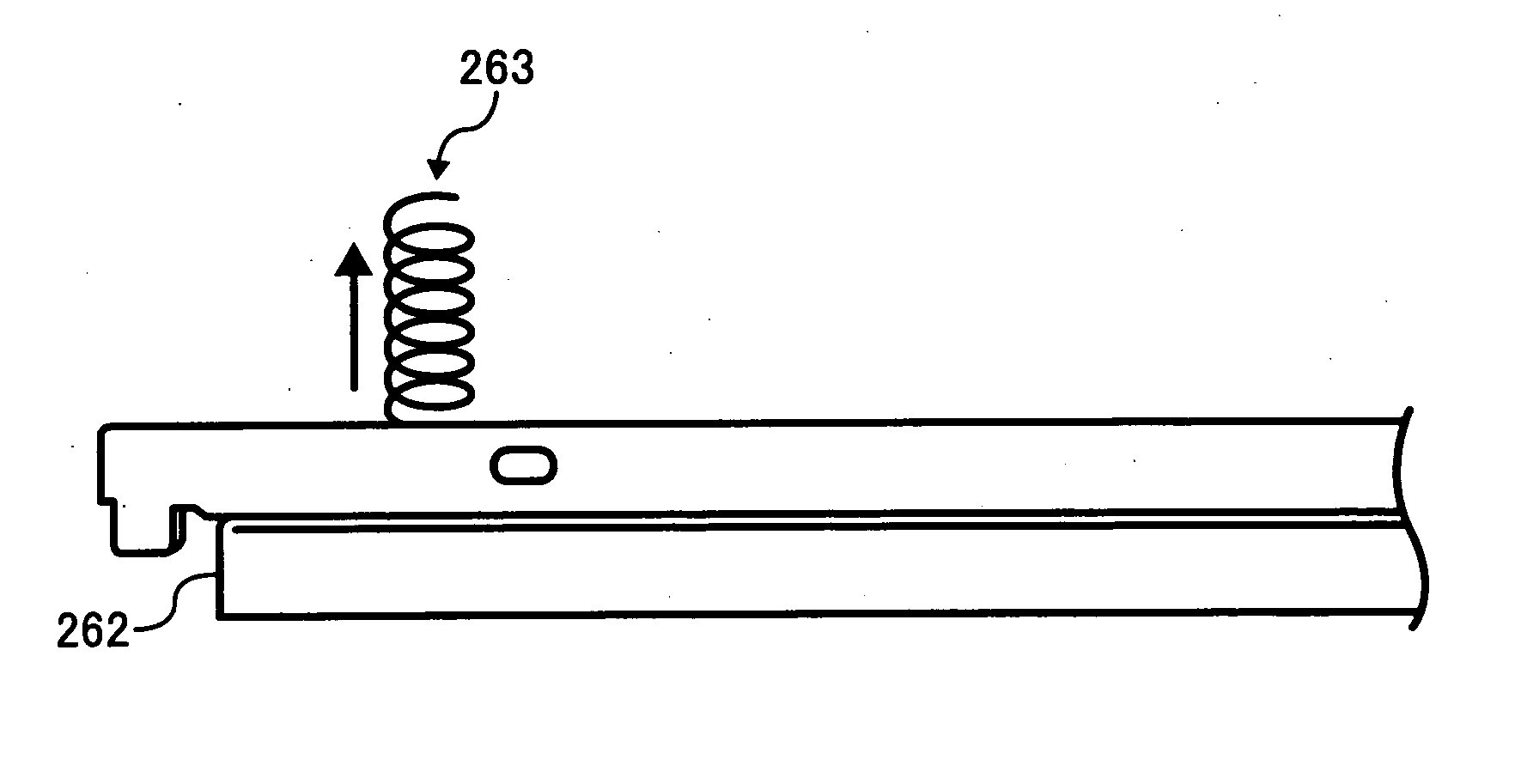

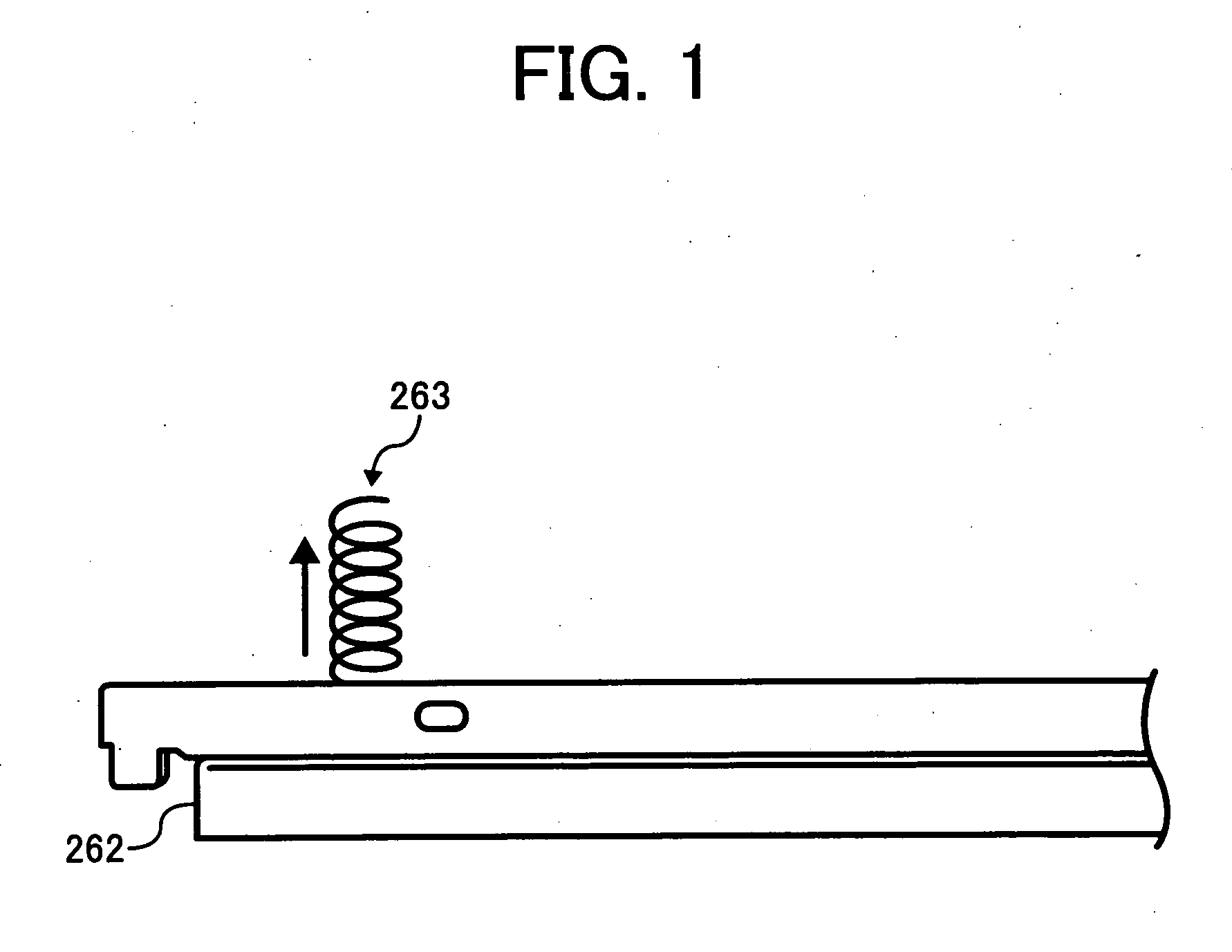

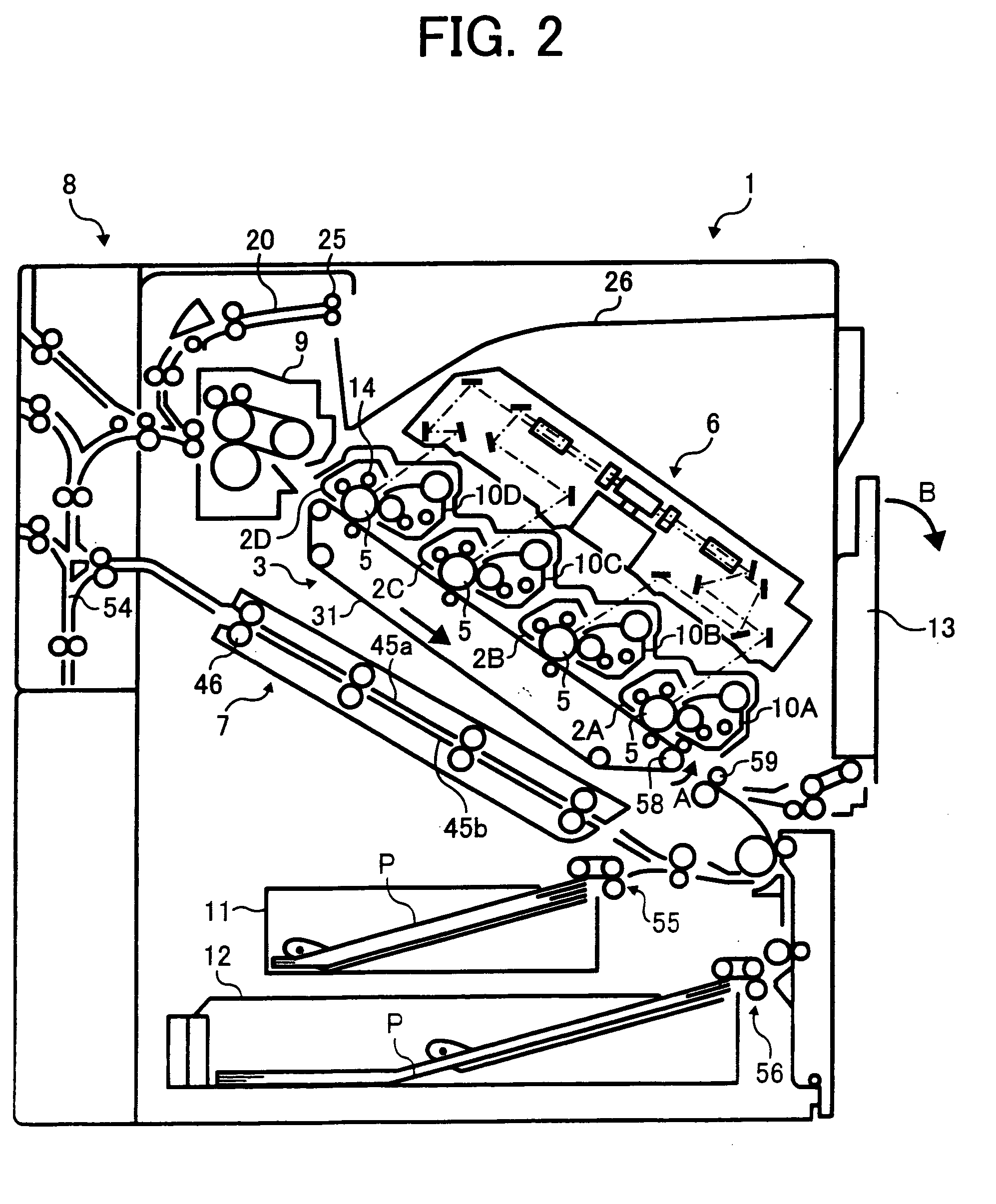

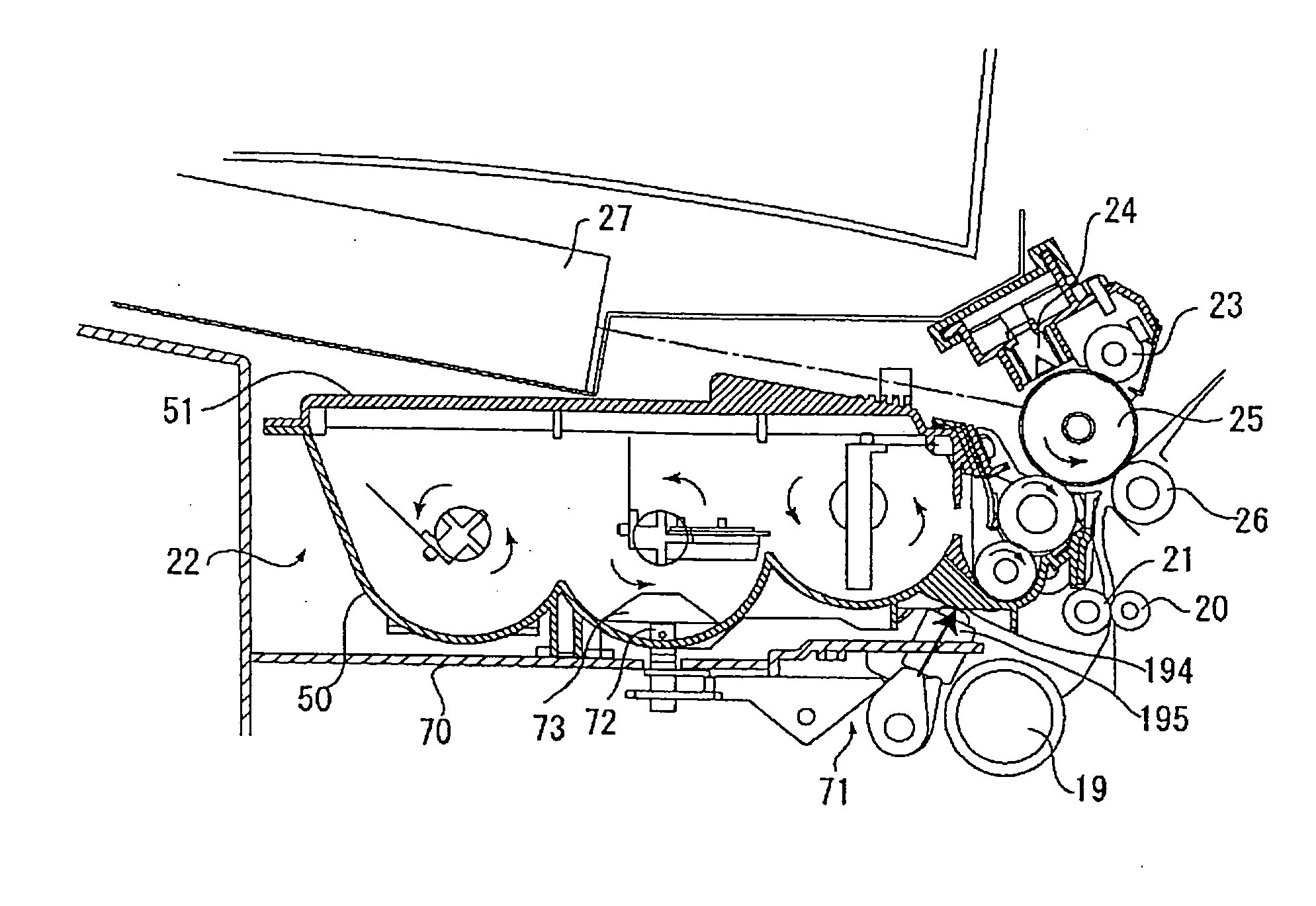

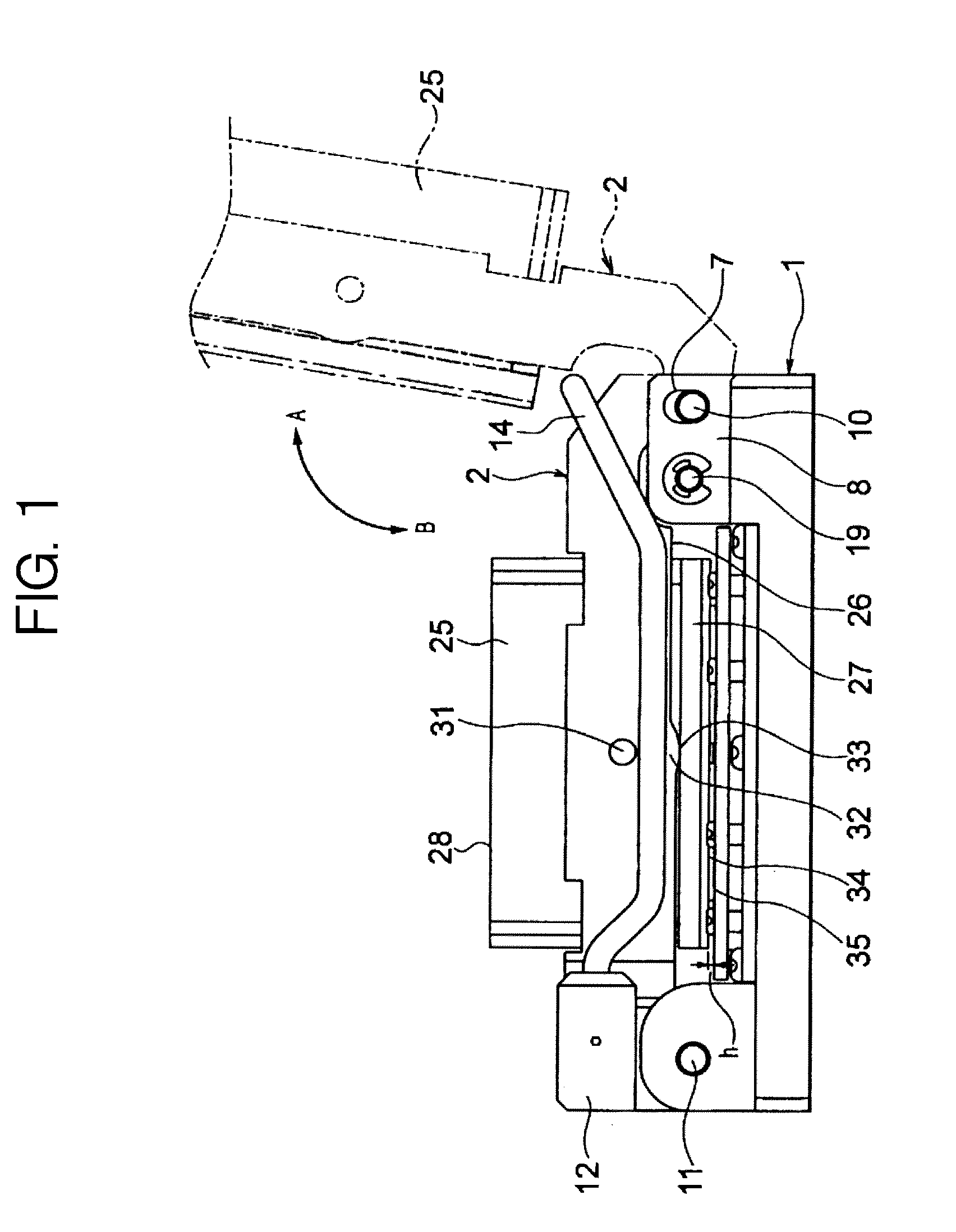

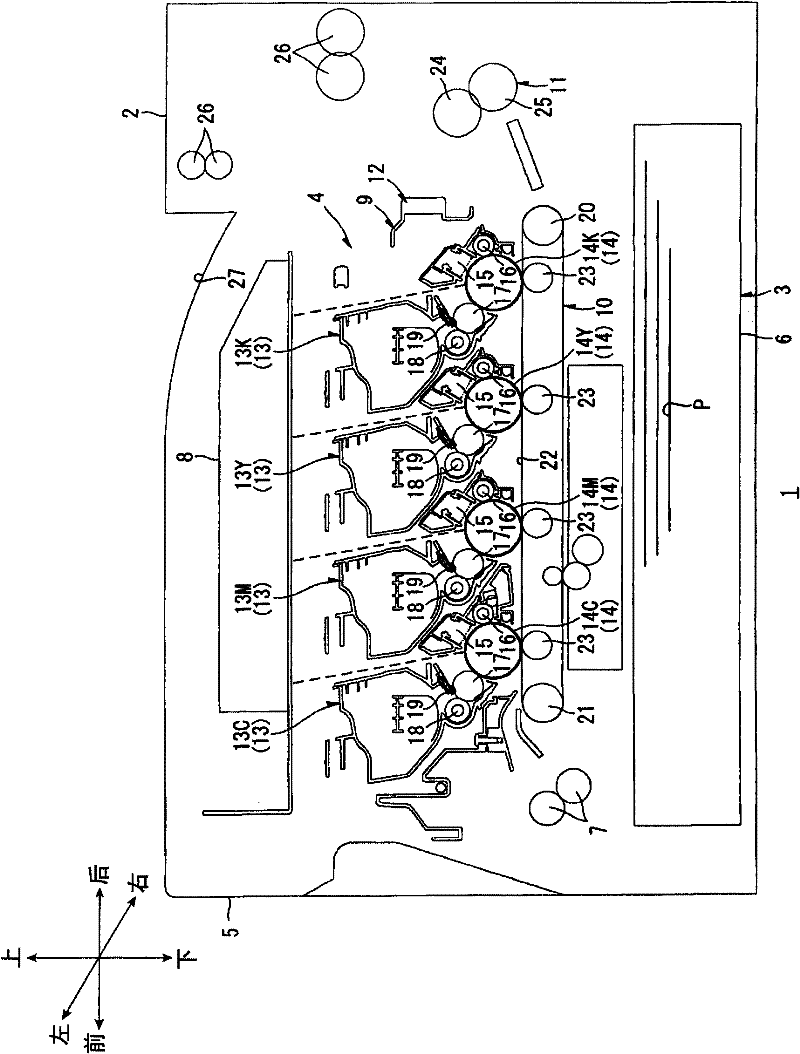

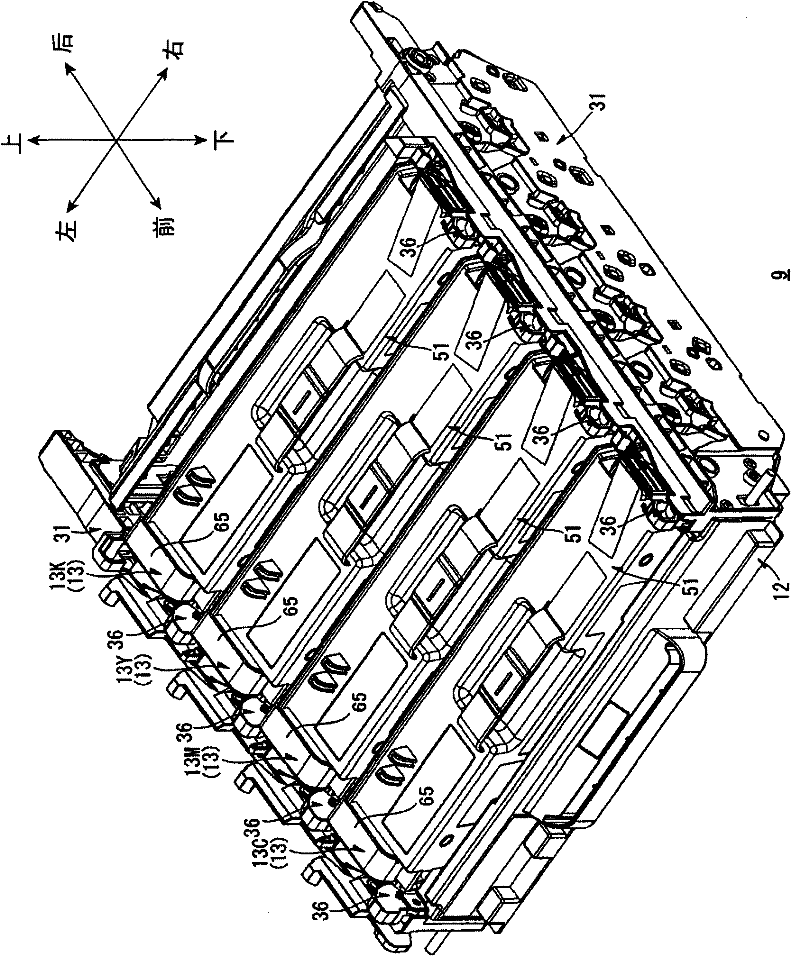

Lubricant supply device, image forming apparatus, and pressing device

ActiveUS20070068738A1Small amountSmall amount of changeElectrographic process apparatusRail lubricationEngineeringLubricant

A lubricant supply device includes a solid lubricant, a supply member contacting and rubbing the solid lubricant and thereby scraping a lubricant off the solid lubricant and supplying the lubricant to a lubricant supplying target, and a pressing mechanism pressing the solid lubricant against the supply member. The pressing mechanism includes a biasing device, and a plurality of pressing members receiving a biasing force of the biasing device and thereby pressing places of the solid lubricant at symmetrical positions with respect to a center of a contact part of the solid lubricant contacting the supply member, respectively.

Owner:RICOH KK

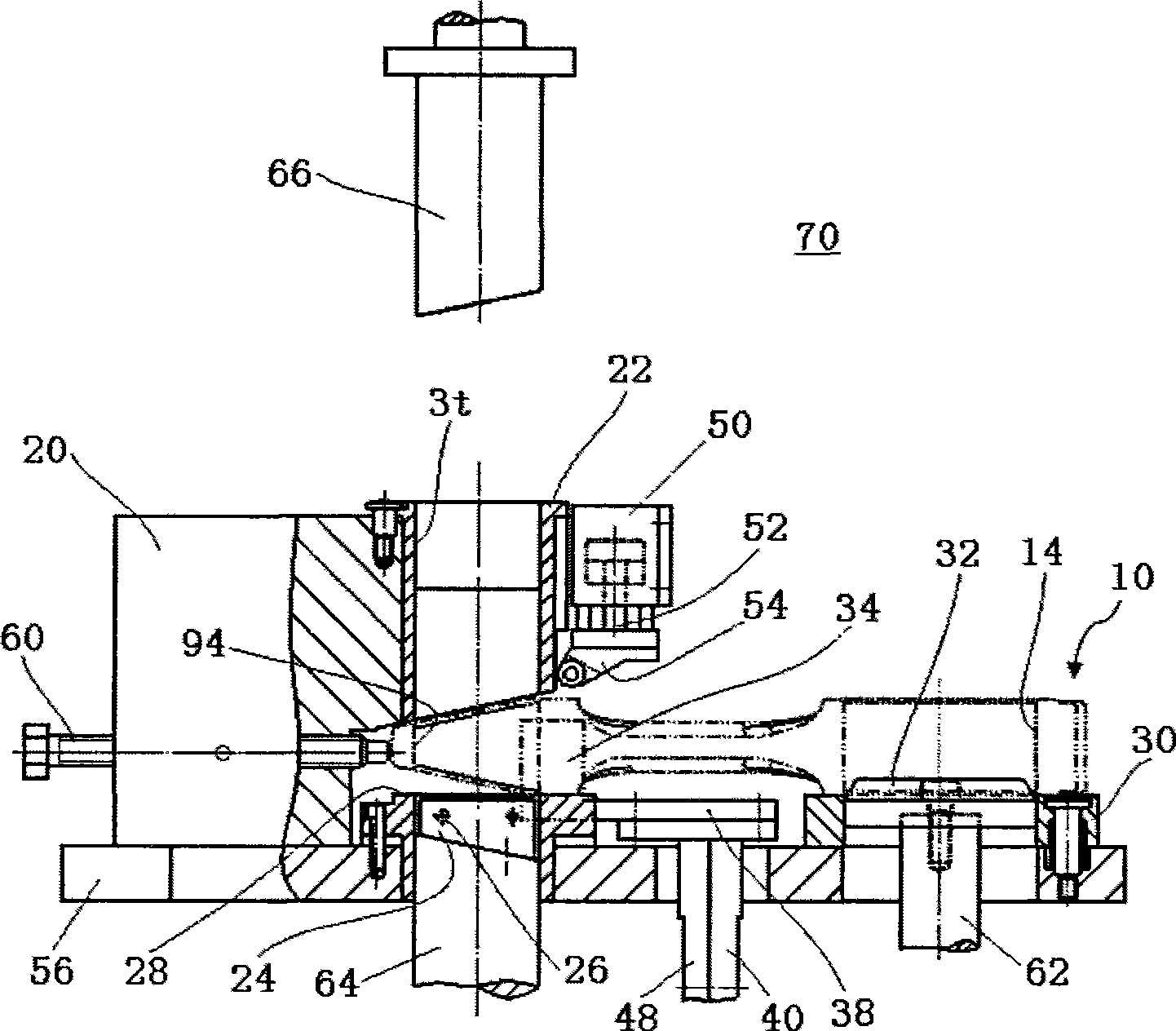

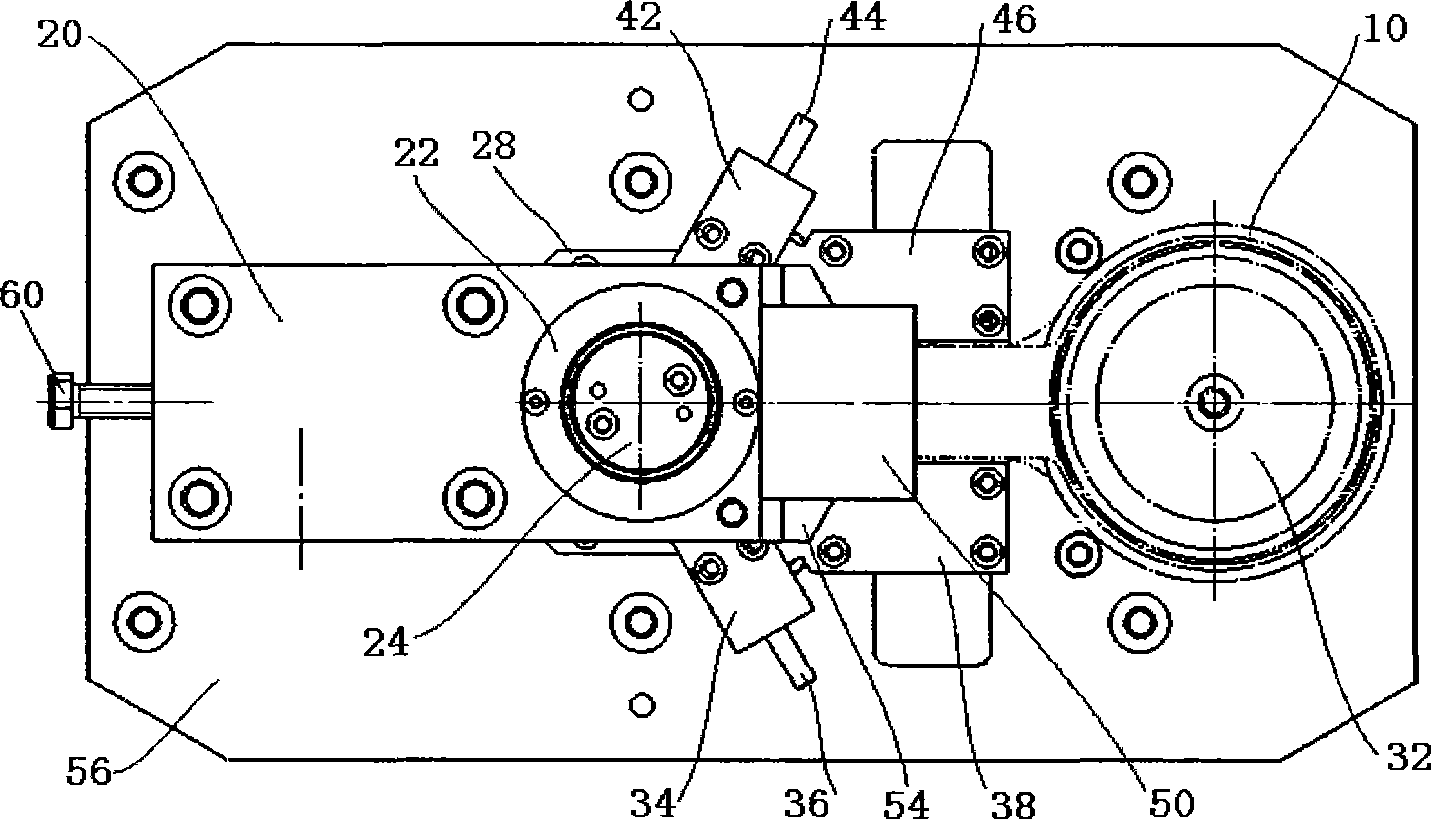

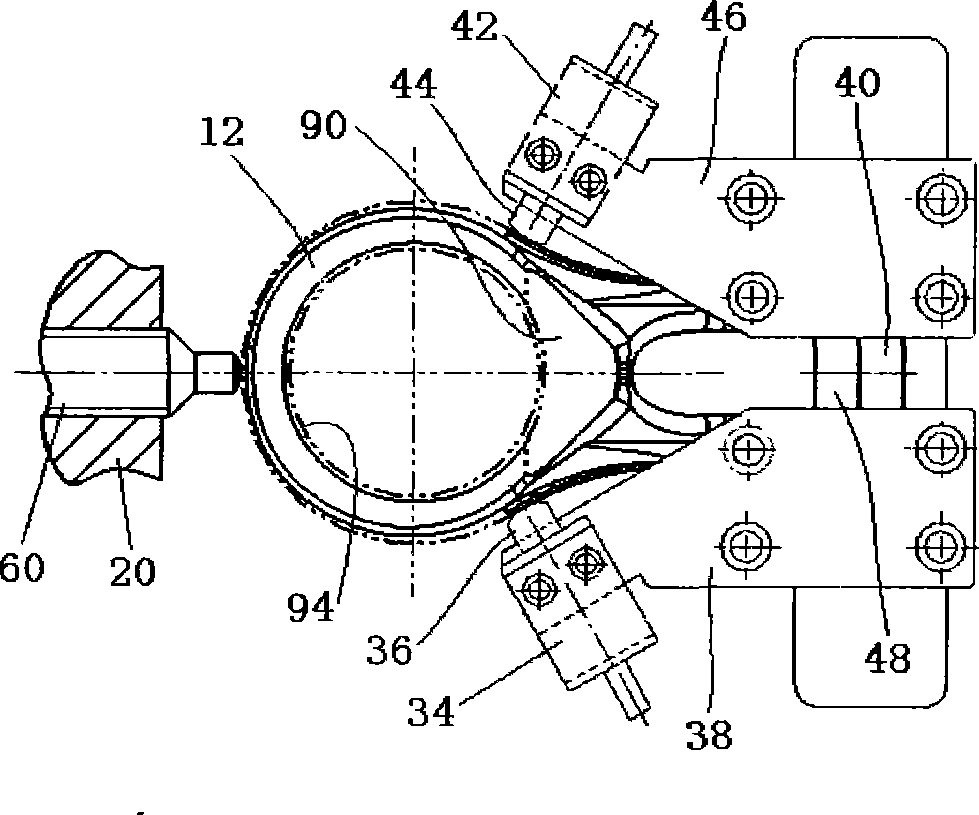

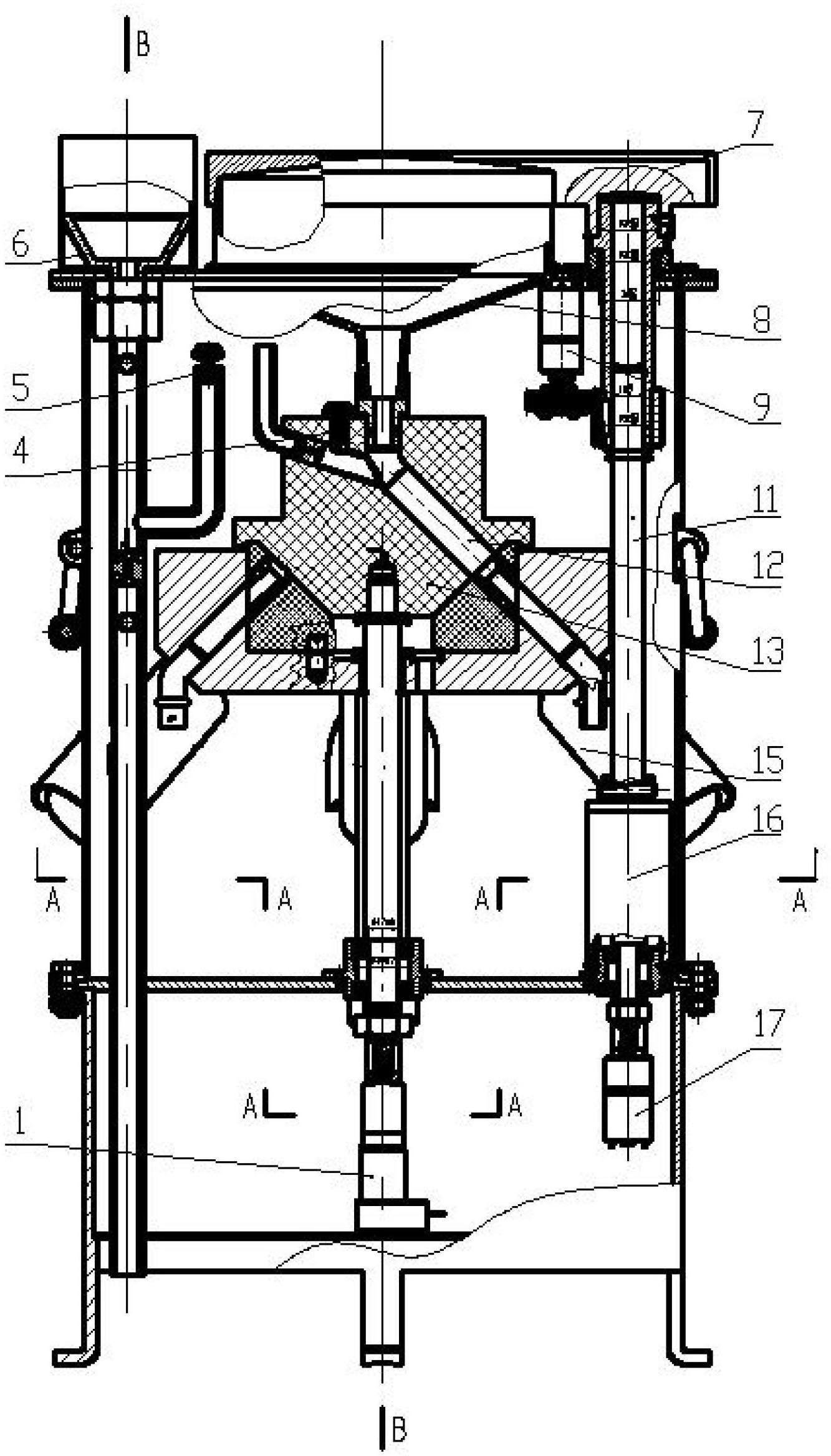

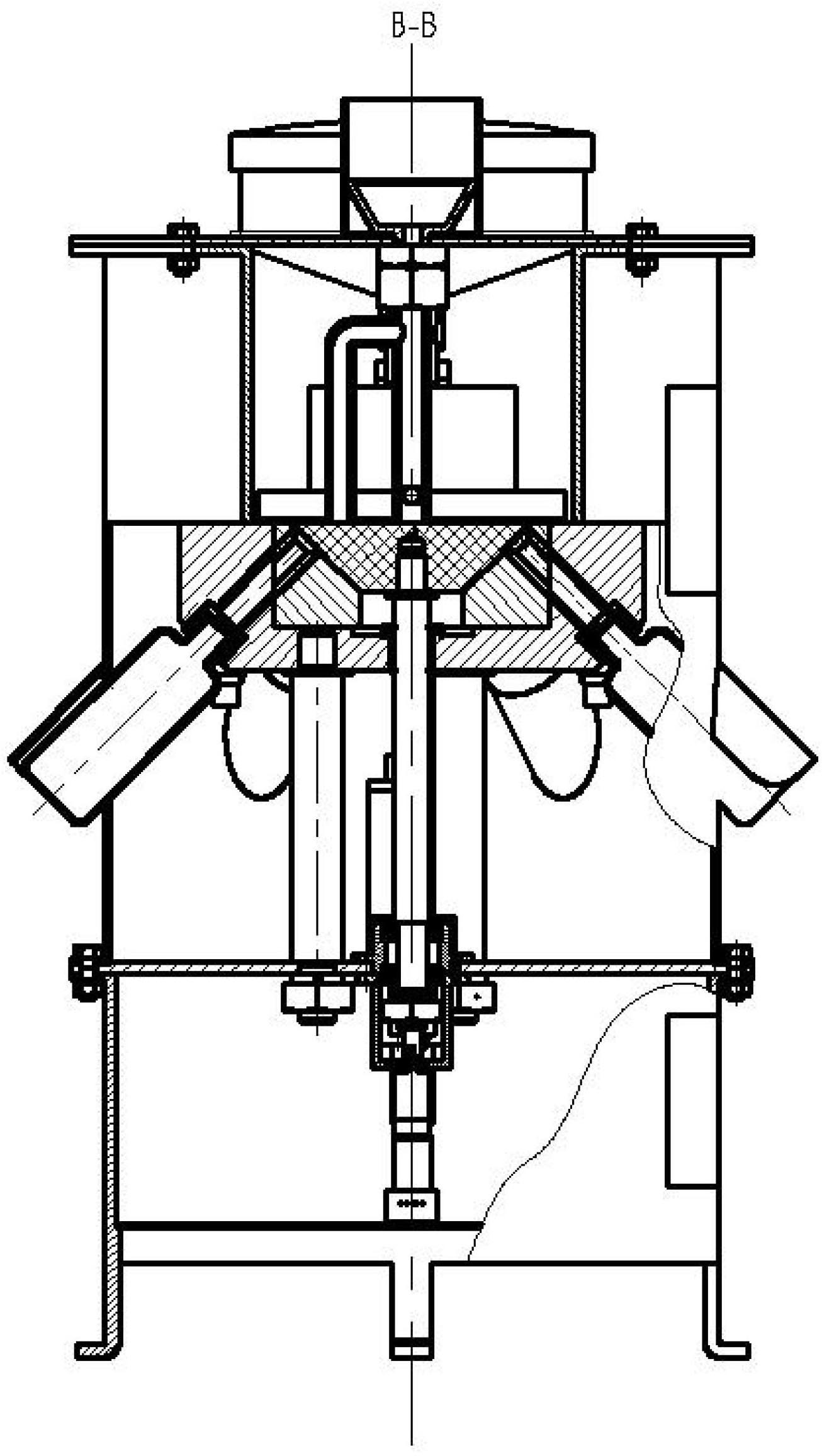

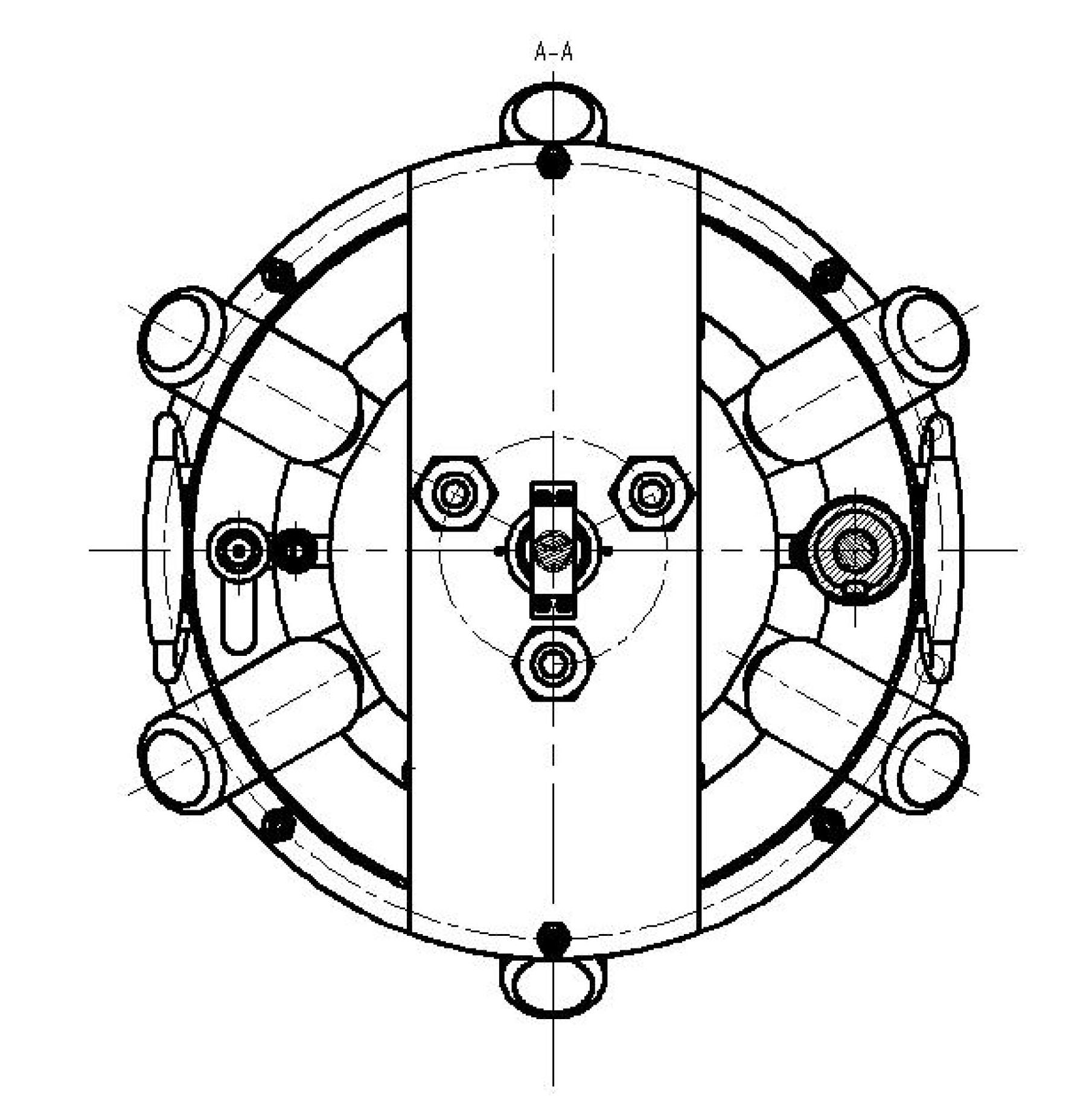

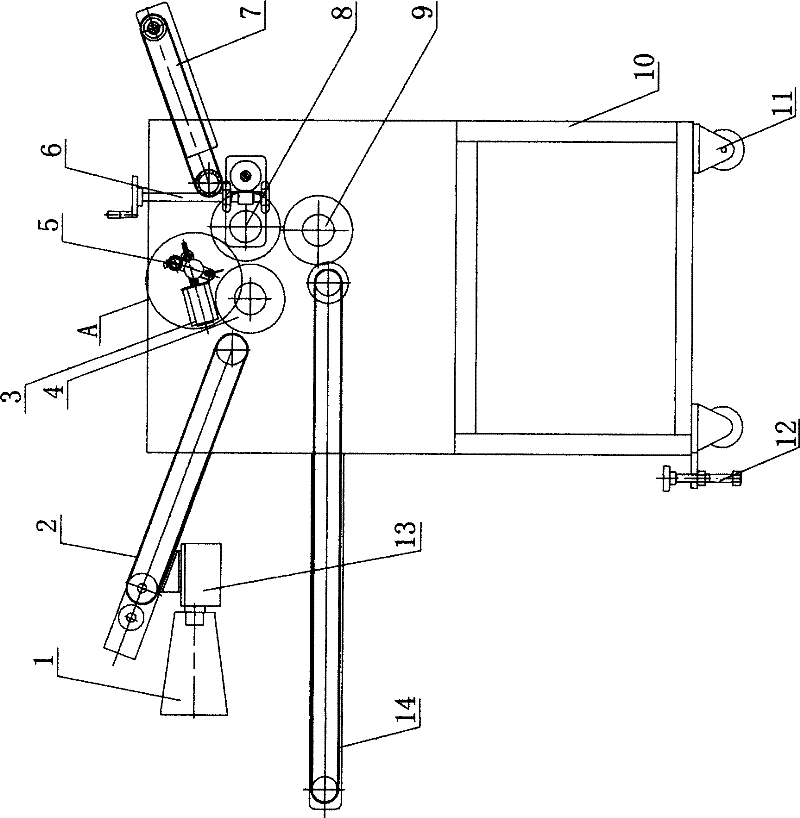

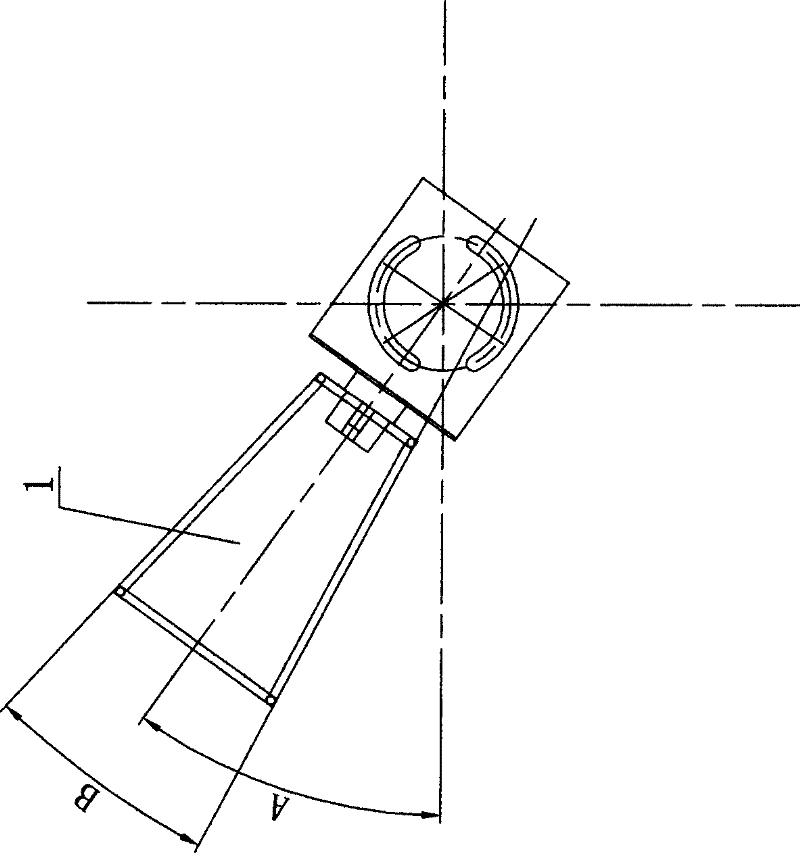

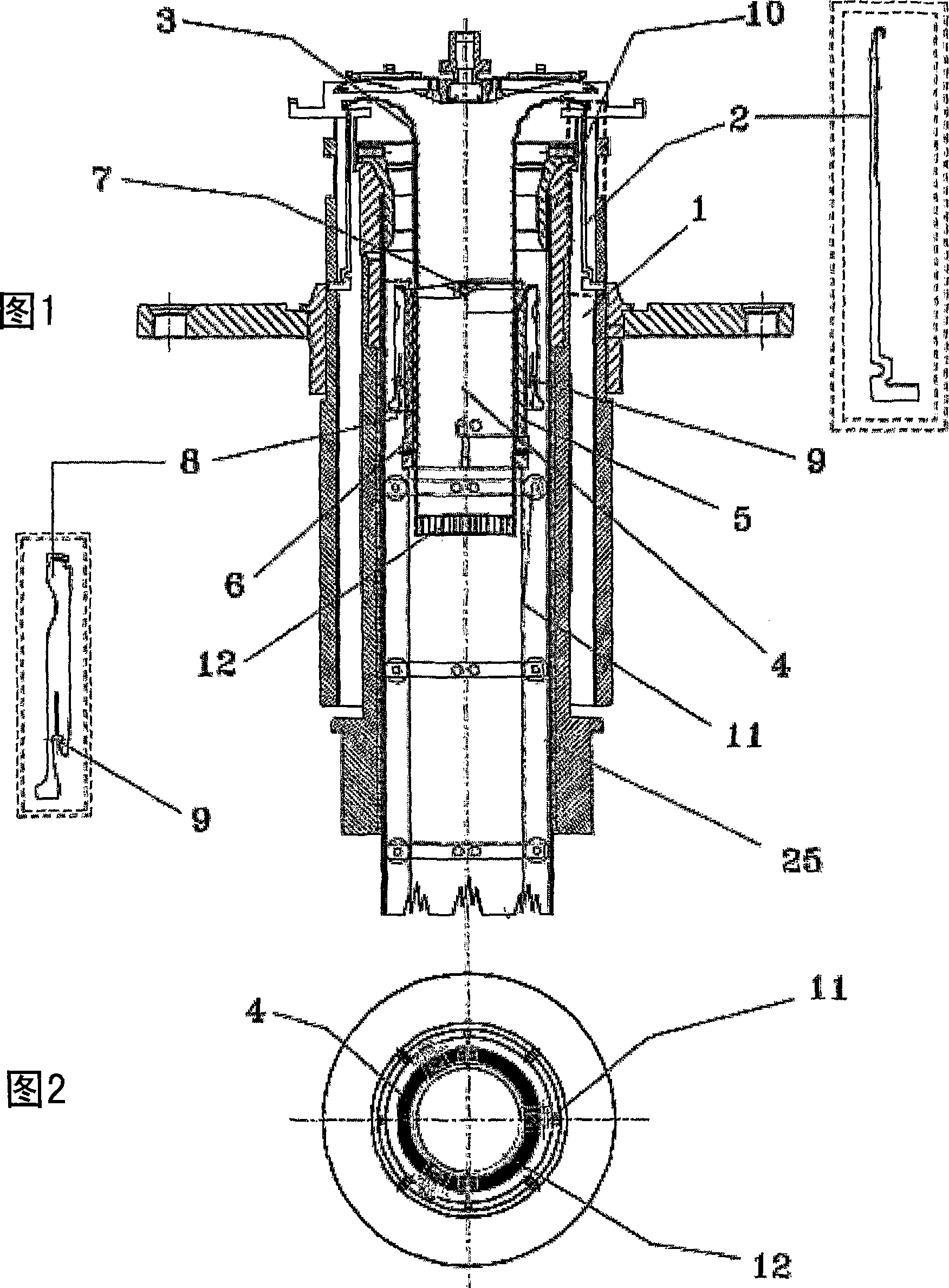

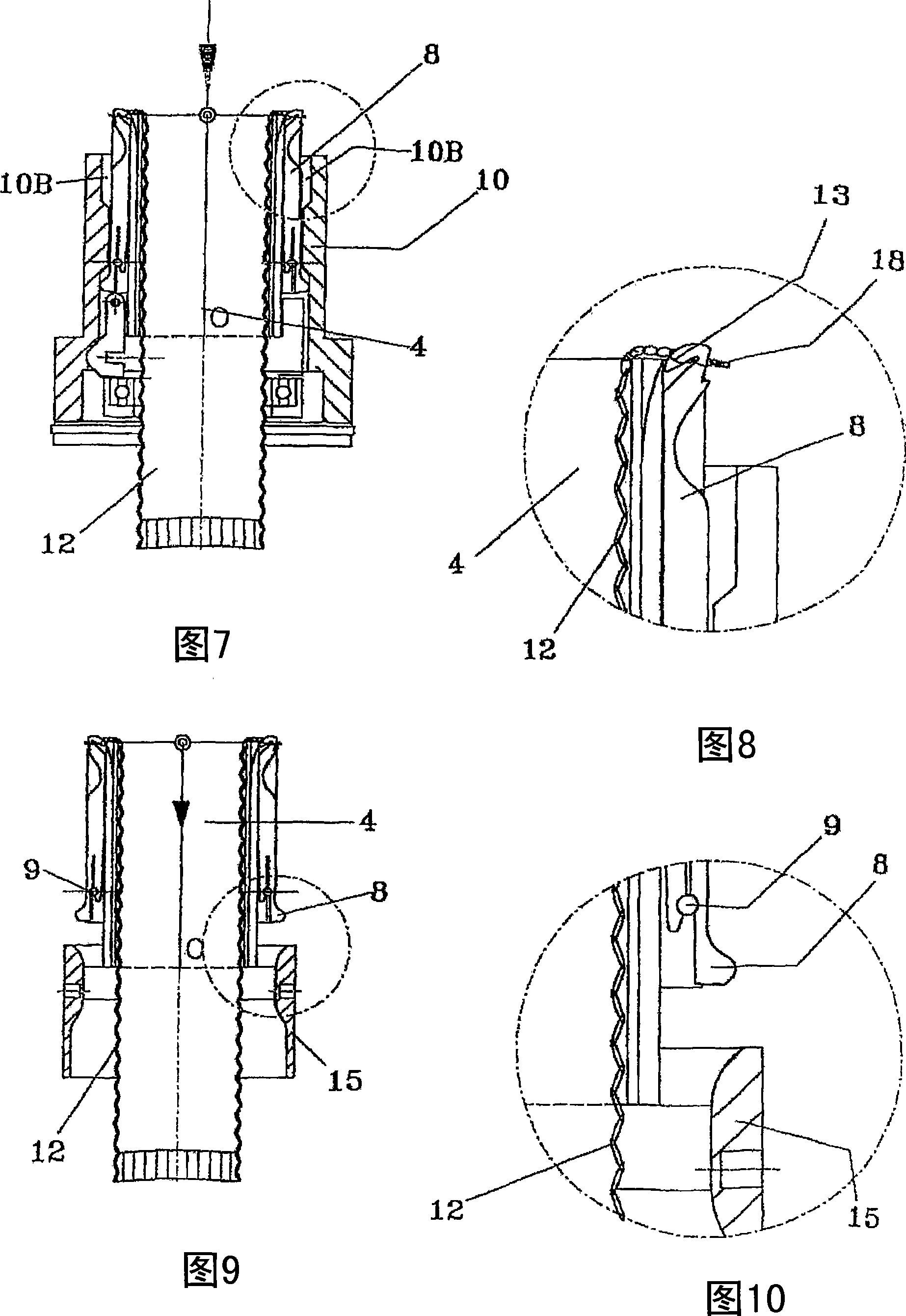

Connecting rod bushing press-loading device and method

InactiveCN101362286APress evenlyPress in evenly and ideallyMetal working apparatusEngineeringDriven element

The invention discloses a connecting rod bushing pressing device and a pressing method thereof. The device is used for pressing a wedge-shaped bushing into a pin hole at one end of a connecting rod, and comprises a horizontal connecting rod positioning mechanism used for the horizontal positioning of the connecting rod relative to the worktable plane, a clamping maintaining mechanism used for vertical positioning relative to the worktable plane, and a pressing head mechanism acting on the wedge-shaped bushing. The pressing head mechanism comprises an upper pressing head and a lower pressing head which are arranged oppositely and a driving element connected with the upper pressing head and the lower pressing head, the upper pressing head and the lower pressing head are coaxially arranged with the pin hole of the connecting rod, the opposite working end surfaces of the upper pressing head and the lower pressing head are bevel surfaces, and are respectively fitted with the upper bevel surface and the lower bevel surface of the wedge-shaped bushing. A positioning element for positioning the wedge-shaped bushing is arranged on the working end surface of the lower pressing head, the wedge-shaped bushing is sheathed on the positioning element, the upper pressing head and the lower pressing head tightly clamp the upper bevel surface and the lower bevel surface of the wedge-shaped bushing under the function of the driving element, and then the wedge-shaped bushing is pressed into the pin hole of the connecting rod. The moment of force generated during the pressing process in the prior art is eliminated, therefore, the wedge-shaped bushing can be pressed uniformly and ideally.

Owner:广东四会实力连杆有限公司

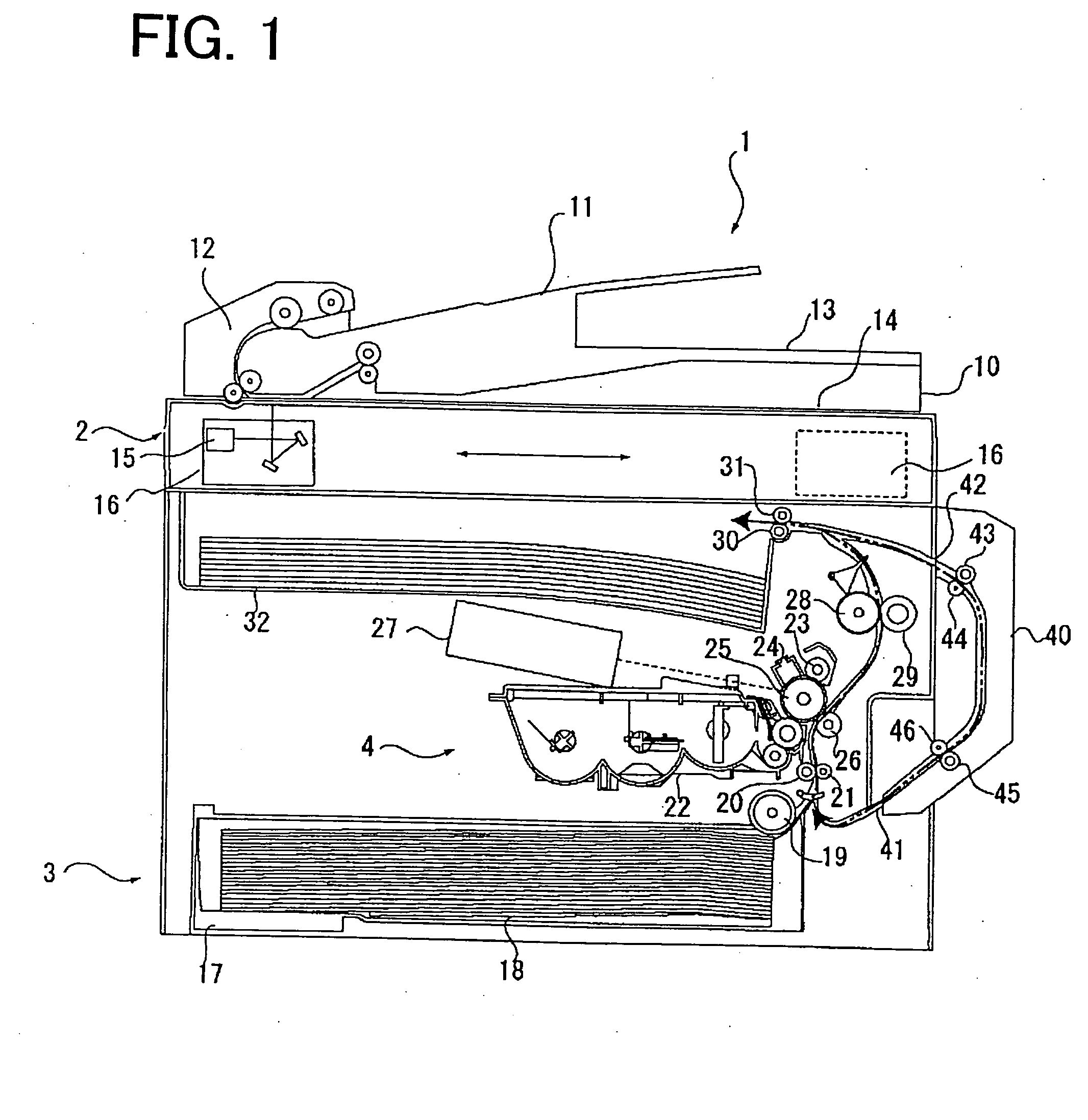

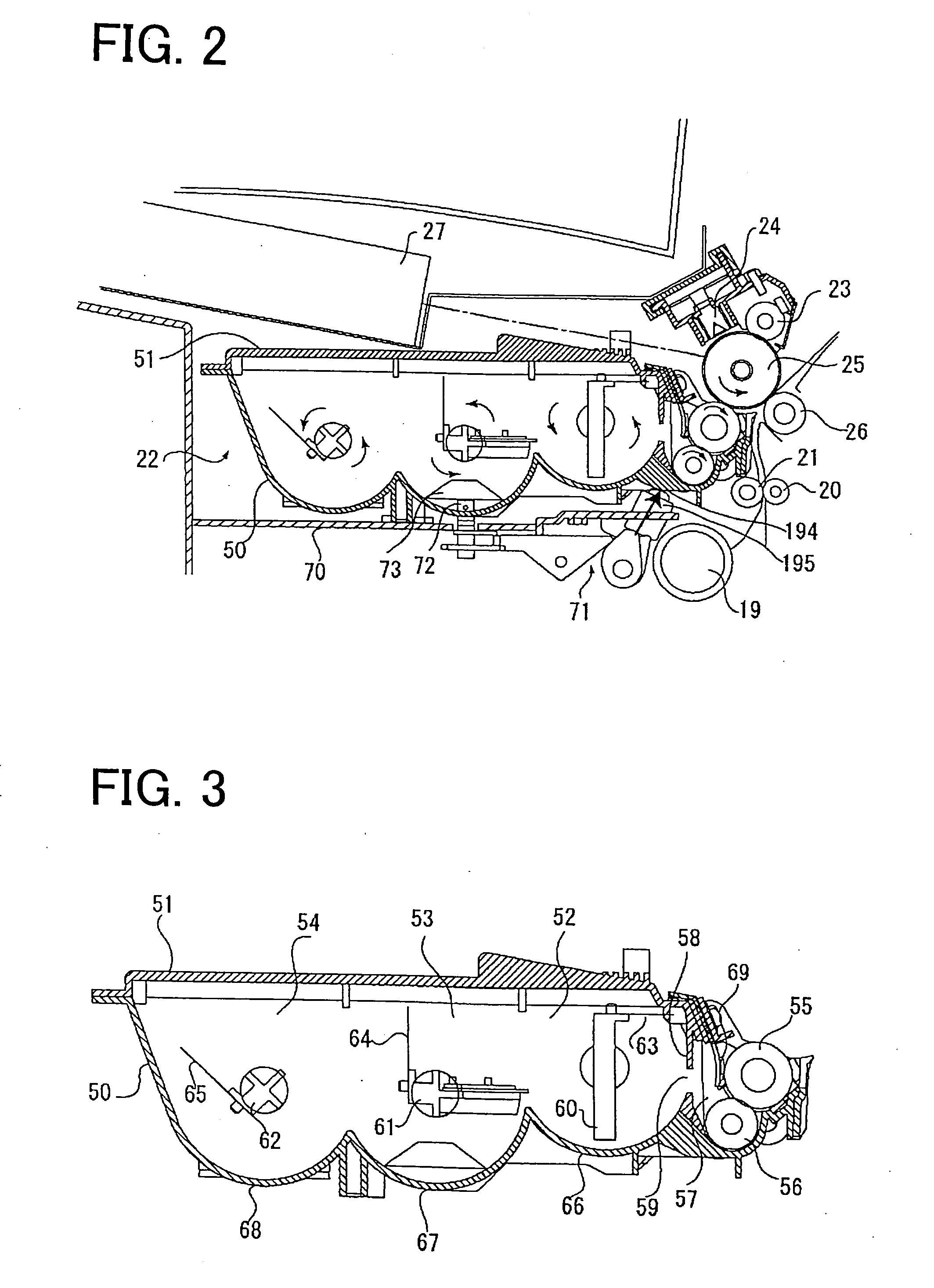

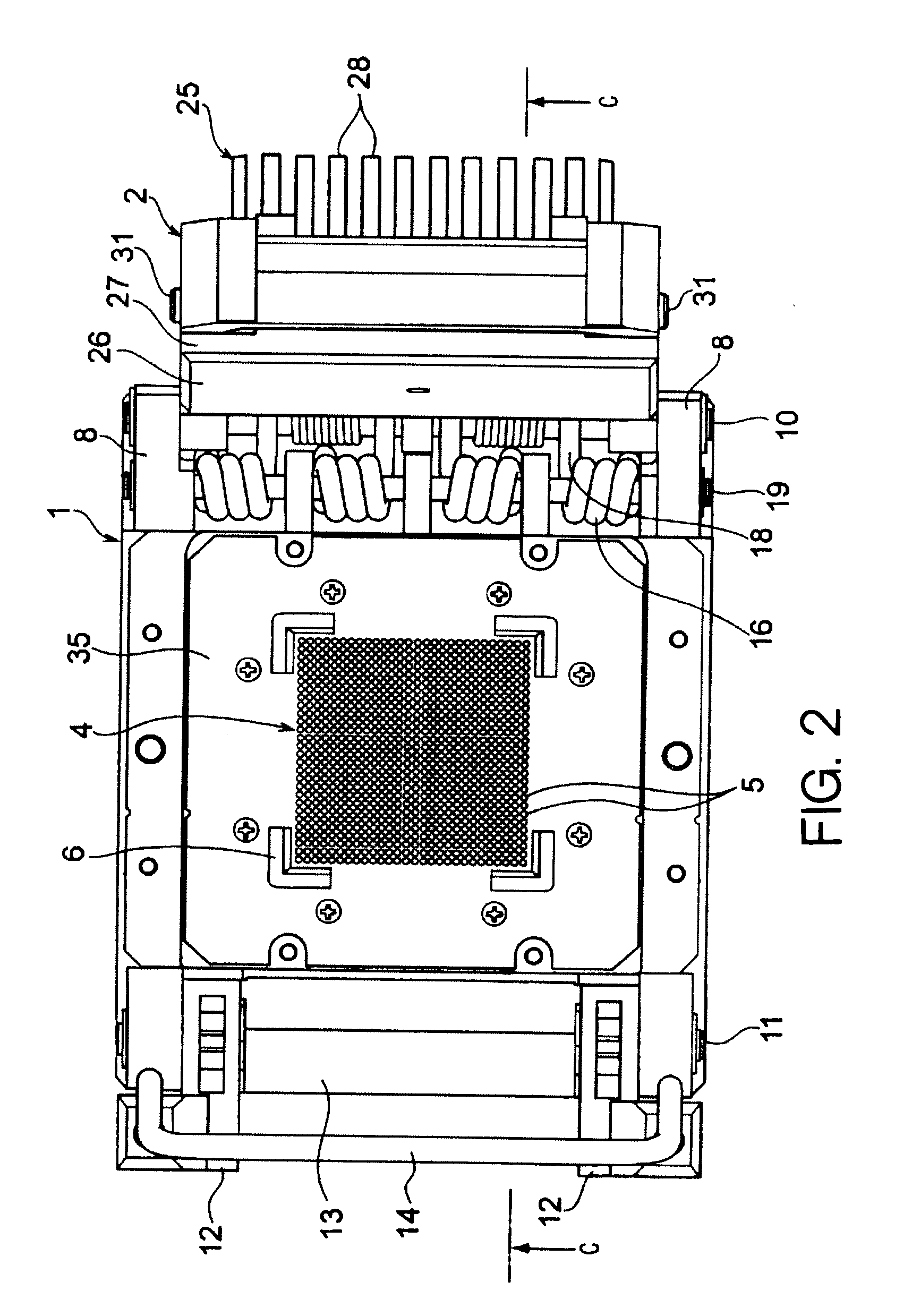

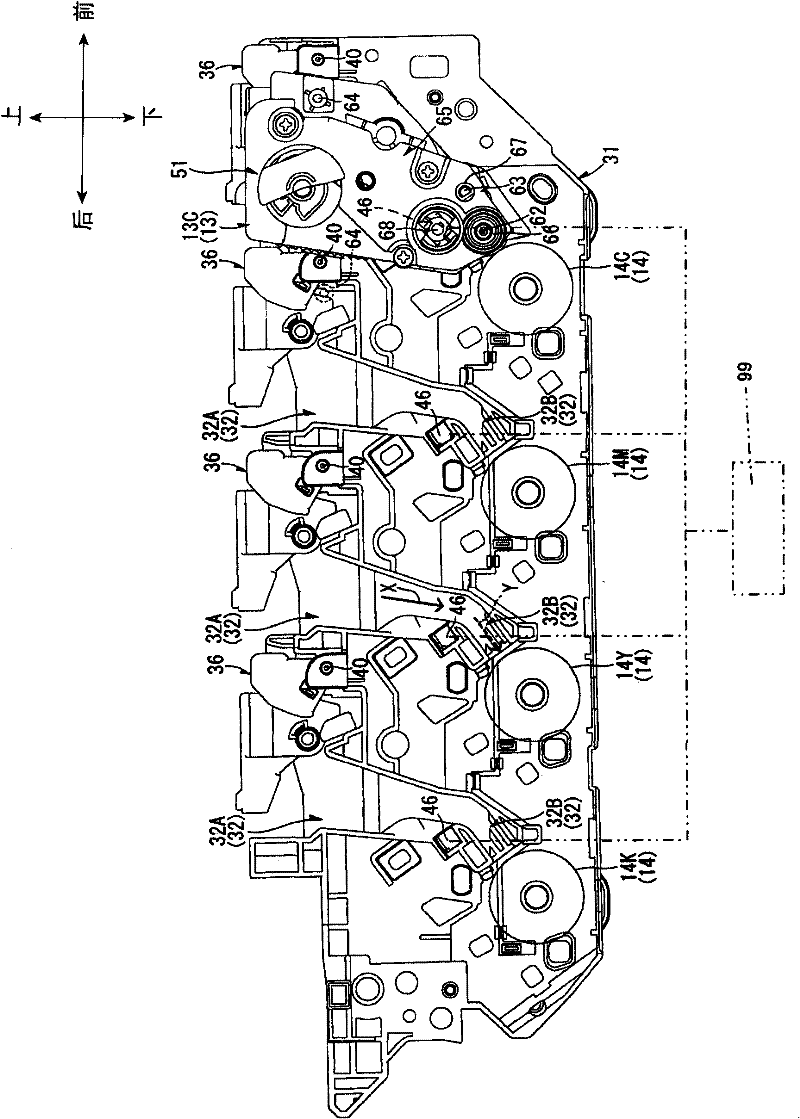

Image forming device

InactiveUS20050047825A1Made preciselyEasy to operateElectrographic process apparatusLatent imageImage formation

An image forming device includes an electrostatic latent image carrier on which an electrostatic latent image is formed, a main frame which supports the electrostatic latent image carrier, and a developing unit which is inserted removably in the main frame. The developing unit includes a developer carrier which supplies a developer to the electrostatic latent image carrier and a replenish chamber which replenishes the developer to the developer carrier. The image forming device also includes a pressing body which is provided on the main frame and is slidable in a direction along a straight line orthogonal to a rotational center shaft of the electrostatic latent image carrier and a rotational center shaft of the developer carrier, and an operating unit which operates the pressing body to press a bottom surface of the developing unit by sliding the pressing body in a direction of the straight line and to hold the pressing body so that the developer carrier is maintained under a state making contact with the electrostatic latent image carrier.

Owner:MURATA MASCH LTD

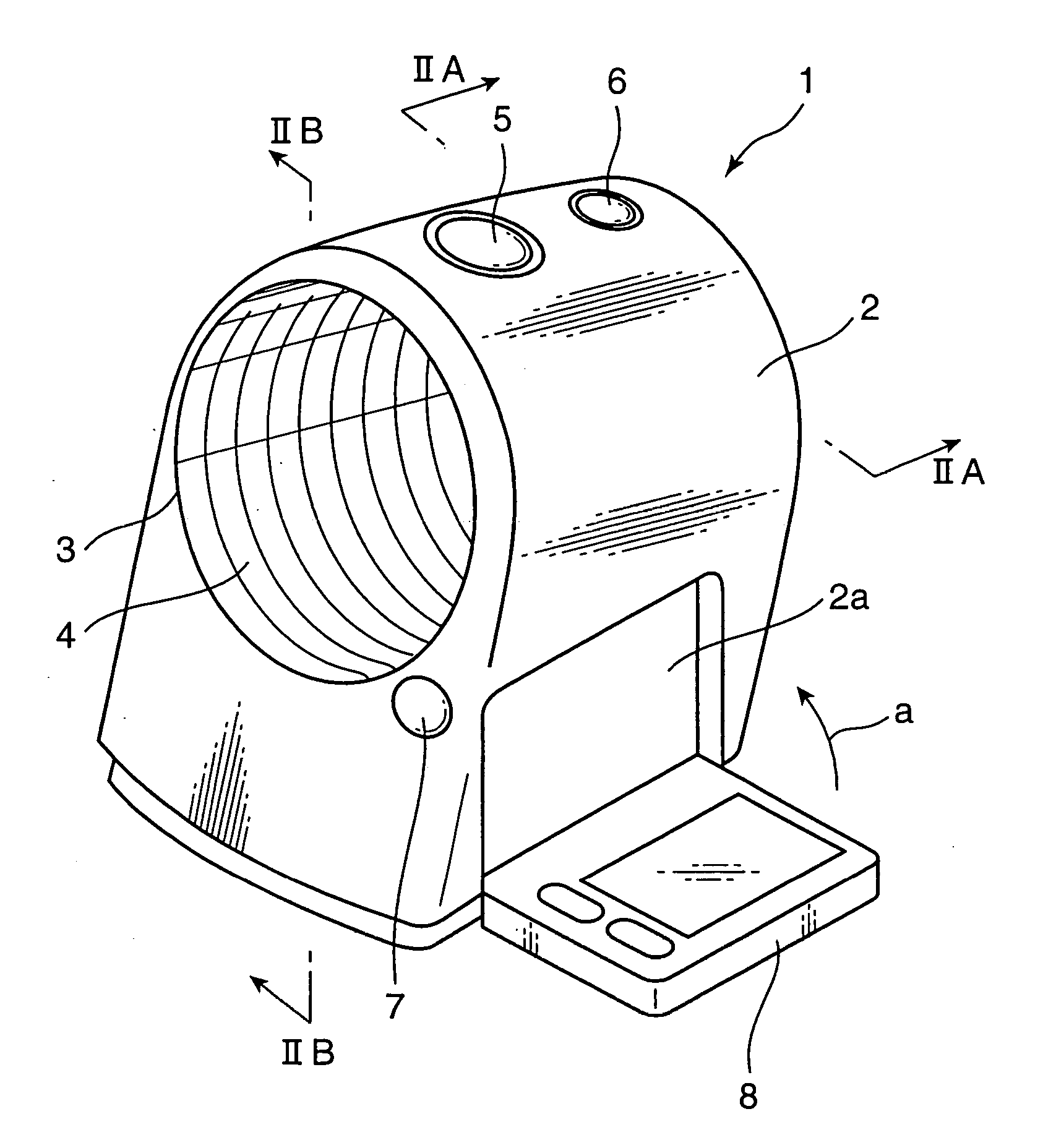

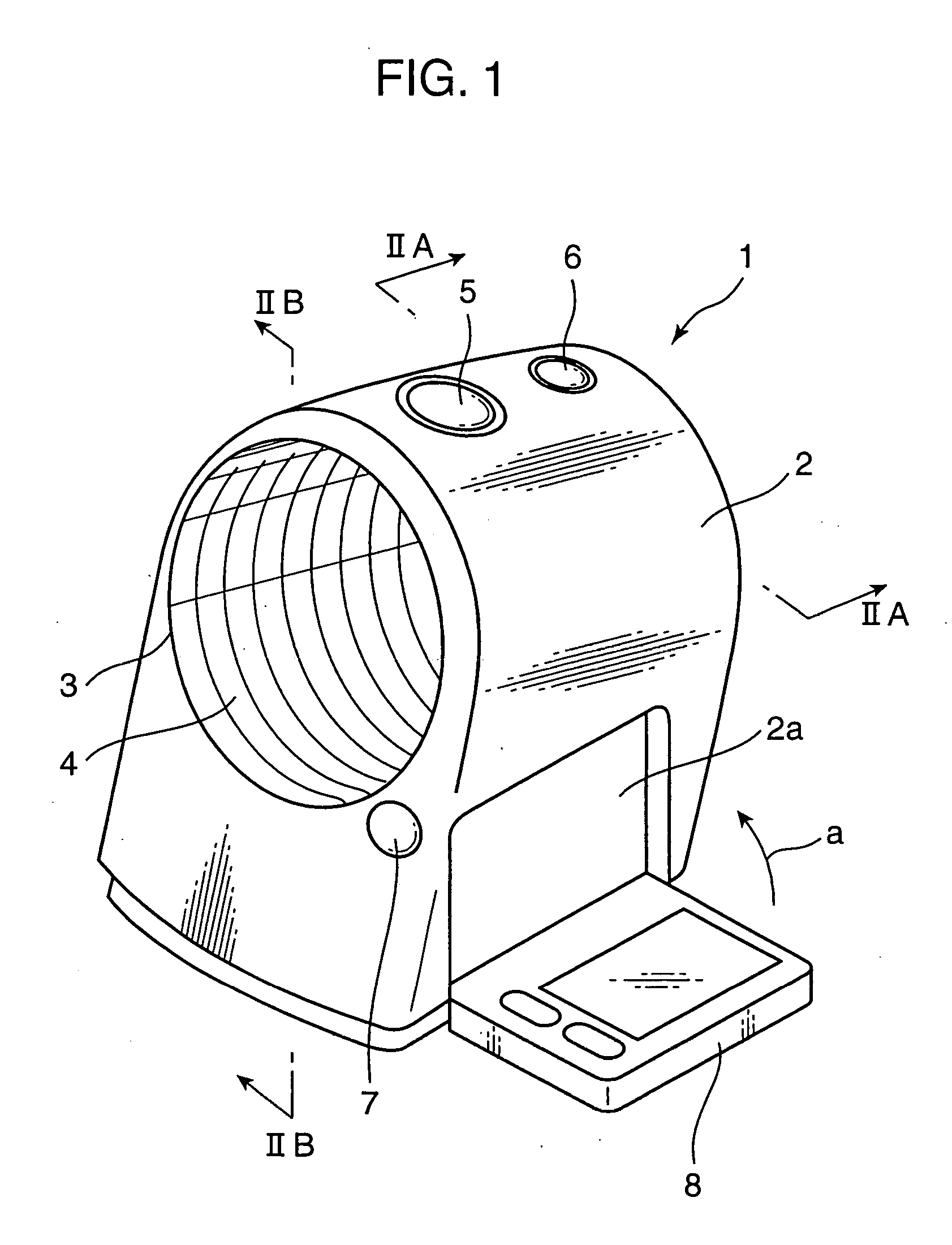

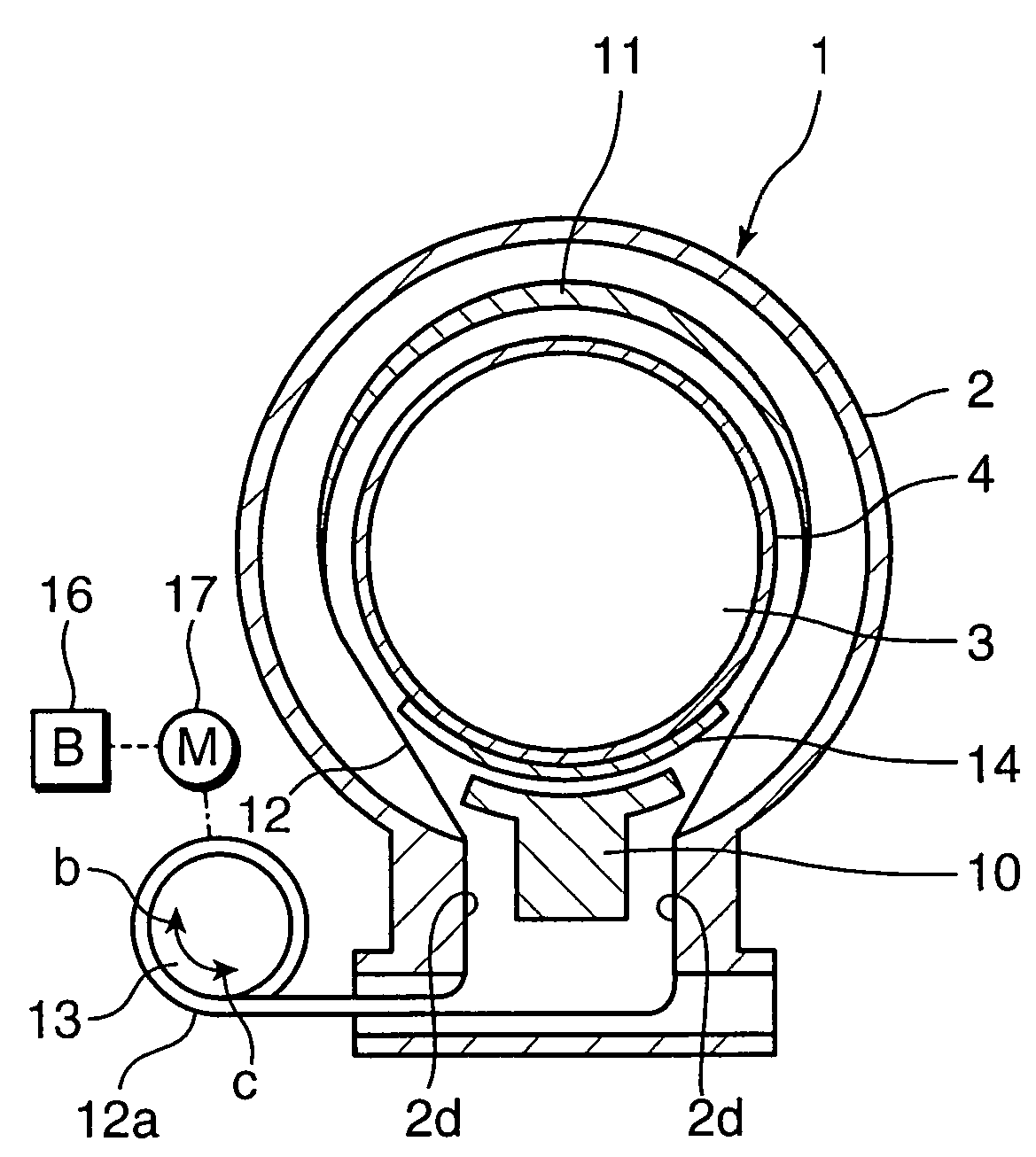

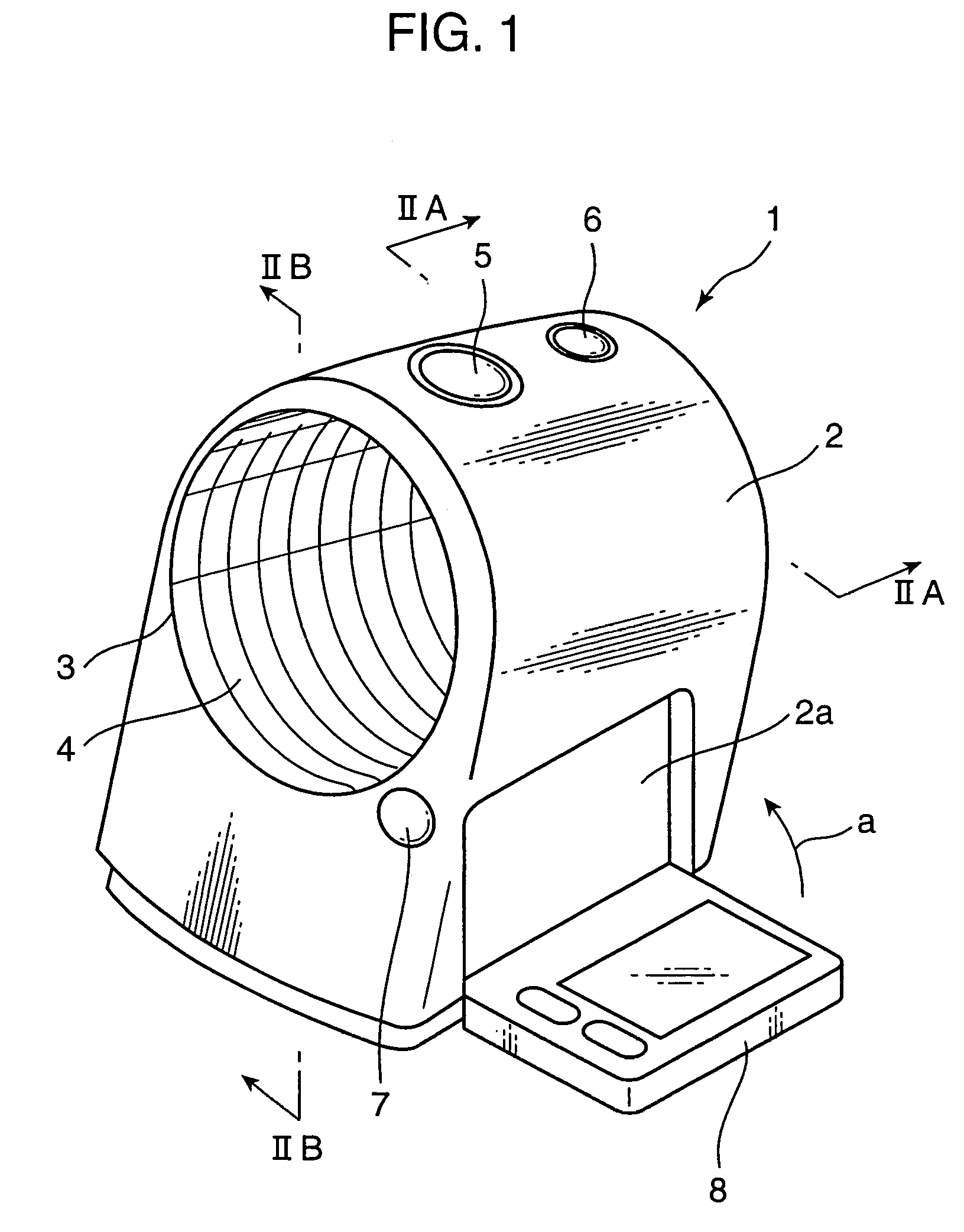

Blood pressure monitor

ActiveUS20050187485A1Reduce power consumptionPress evenlyEvaluation of blood vesselsCatheterBlood pressure monitorsEmergency medicine

A blood pressure monitor is provided with a box-shaped housing having openings formed in left and right side walls, a cuff transversely arranged in the housing and including an arm entrance and an arm exit at the opposite left and right ends corresponding to the openings. The cuff is formed with a blood flow blocking bag in a specified area. The opposite ends of the cuff is taken up by a cuff take-up drum such that the blood flow blocking bag extends along the outer circumferential surface of the inserted arm at the time of a measurement and a compressed air is supplied to the blood flow blocking bag to block the blood flow. The blood pressure monitor is further provided with at least one of a fastening force adjusting construction for adjusting a force of the cuff to evenly fasten the arm or the like of the measurer, a construction for preventing the epidermis part of the arm from getting in the cuff, a construction for suppressing the consumption of an electric power, and a construction for fixing a measuring position.

Owner:MATSUSHITA ELECTRIC WORKS LTD

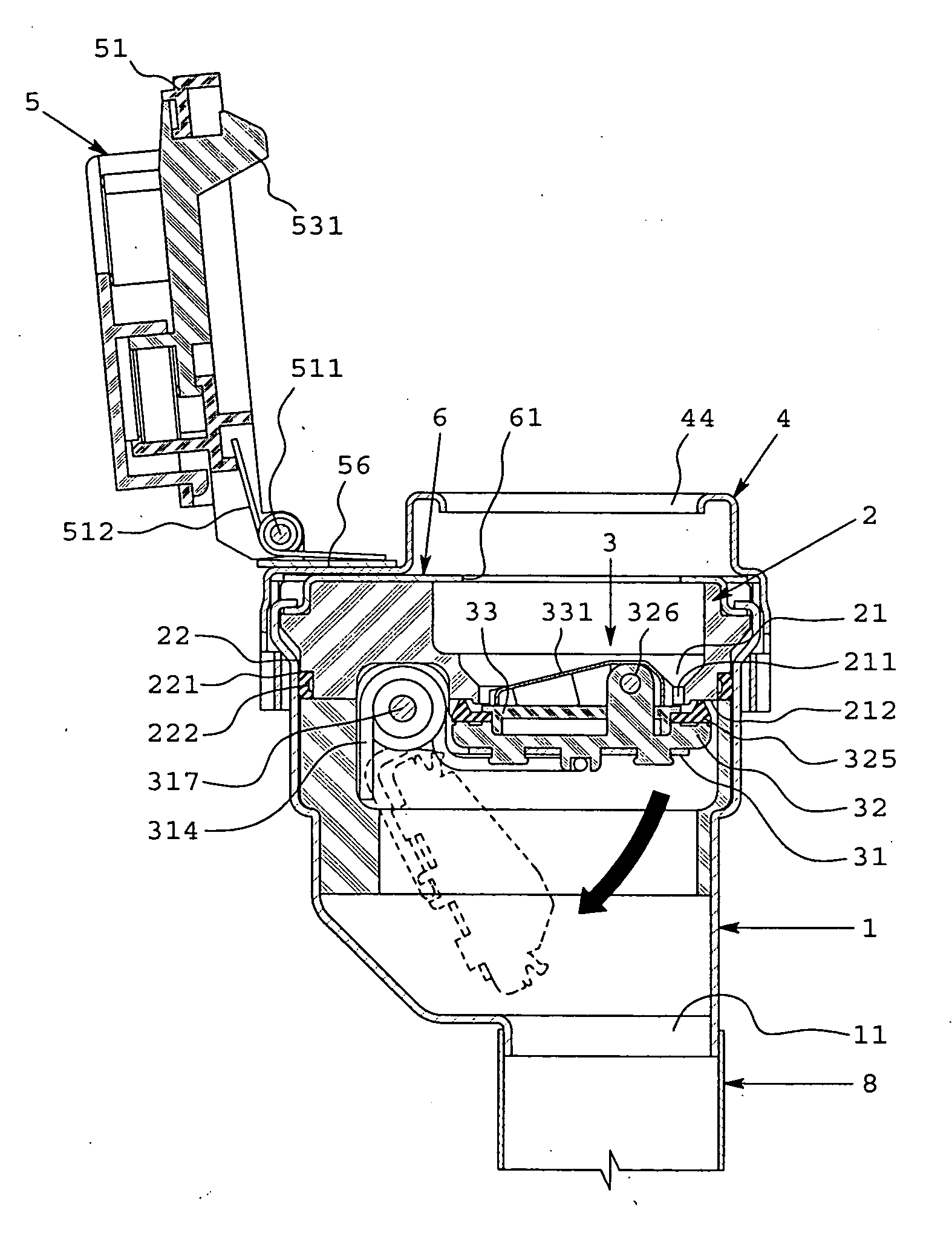

Fuel filler port closing apparatus

InactiveUS20100012223A1Stably and reliably pressingImprove sealingSolid materialClosures to prevent refillingNozzle

According to a fuel filler port closing apparatus of the present invention, an opening 44 of a filler neck or an opening 211 of a nozzle guide 21 is securely and reliably sealed, even when a seal packing 325 sags, bends or deflects. Such a reliable sealing is realized by a characteristic flapper 3 comprising a rotation plate 31 rotates and flaps, and a seal plate 32 having the seal packing 325 moving freely to up and down direction with respect to the rotation plate 31.

Owner:ASTEER

Spicy bean curd snack food

InactiveCN104642559AGreat tasteUniform tasteCheese manufactureFood scienceNutritive valuesSnack food

The invention discloses a spicy bean curd snack food, which is prepared from the following raw materials in parts by weight: 30,000 parts of bean curd, and spicy accessories including 500-700 parts of red oil, 80-120 parts of chilli powder, 30 parts of beef essential oil, 80-120 parts of cumin powder, 100 parts of thirteen spices, 30 parts of sesame oil essence and 30,000 parts of brine. The preparation method comprises the following steps: selecting the raw materials; pulping; boiling; curdling; shaping; baking; marinating; stirring; packaging; sterilizing; cleaning; airing; and warehousing. The invention aims at providing the spicy bean curd snack food which is spicy, good in taste, high in nutritive value and long in storage time.

Owner:XINHUANG XIAOFEINIU FOOD

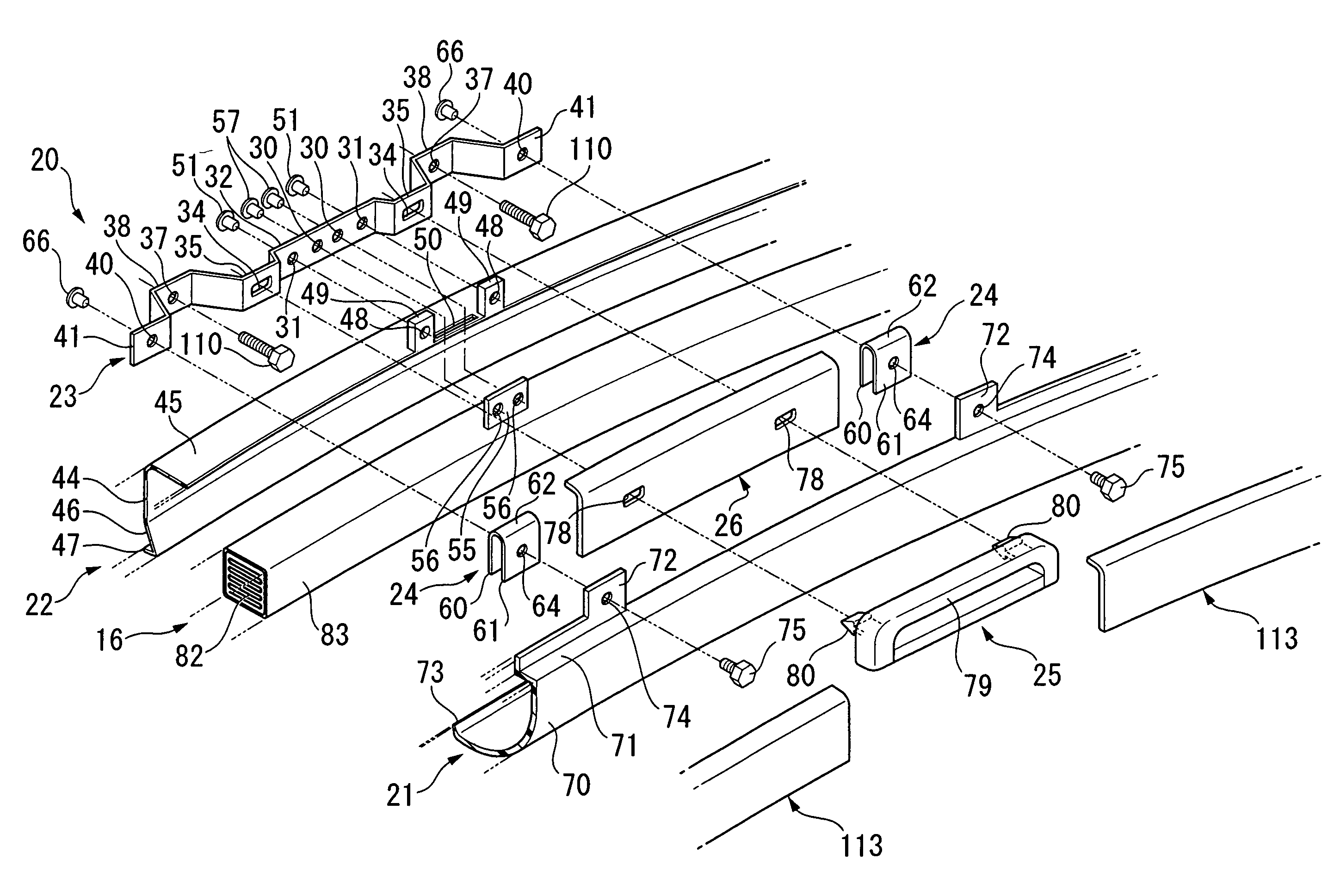

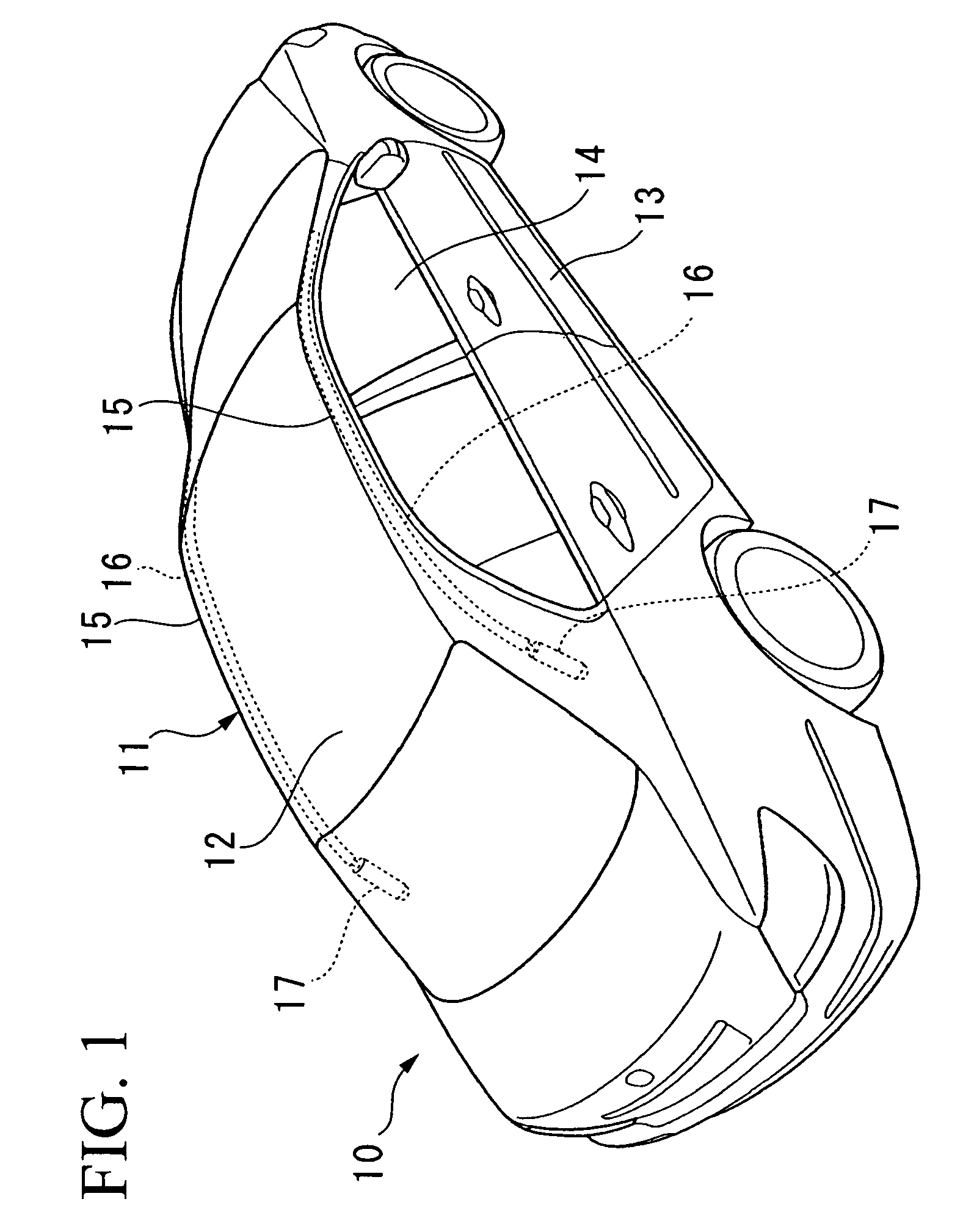

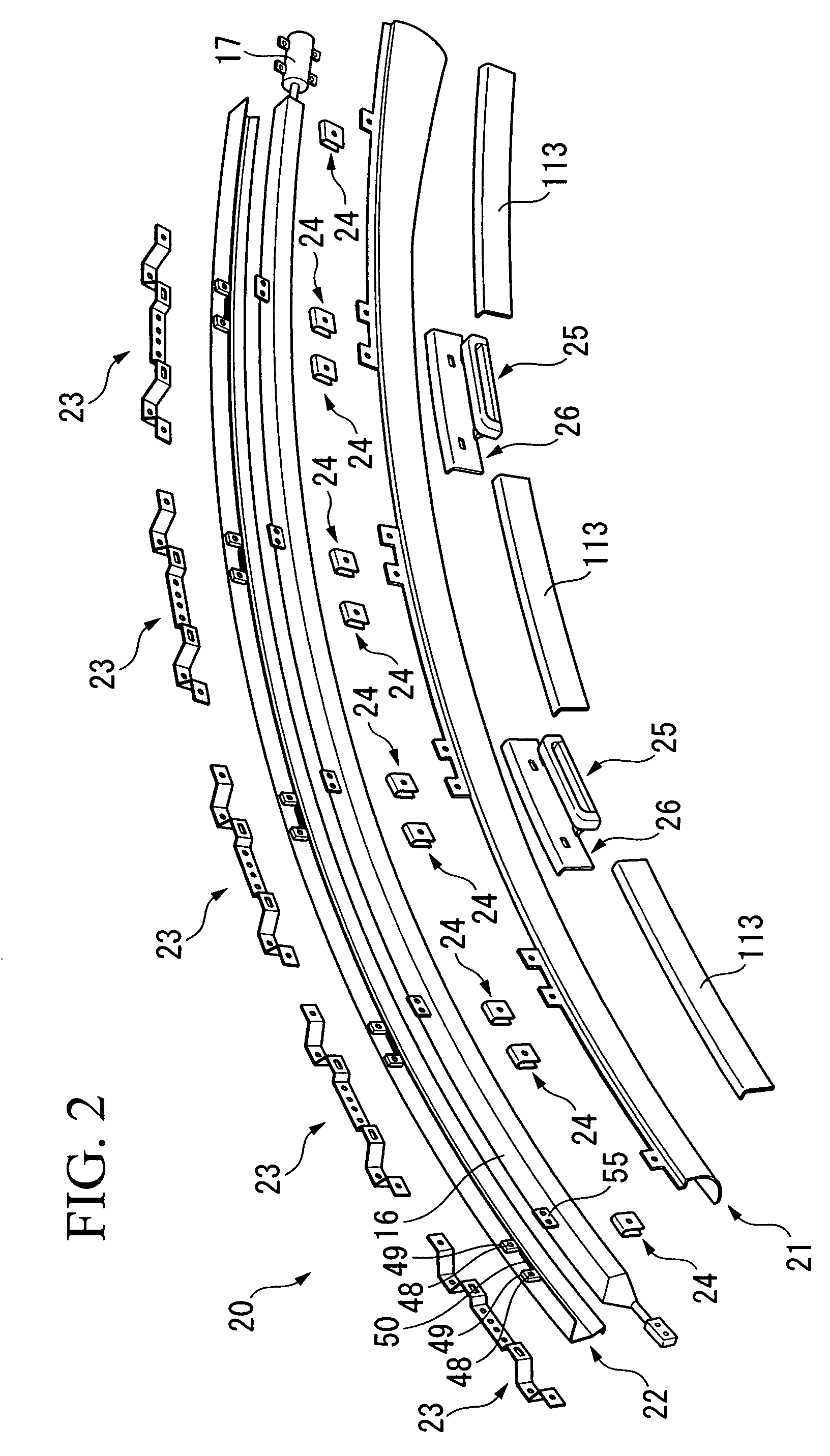

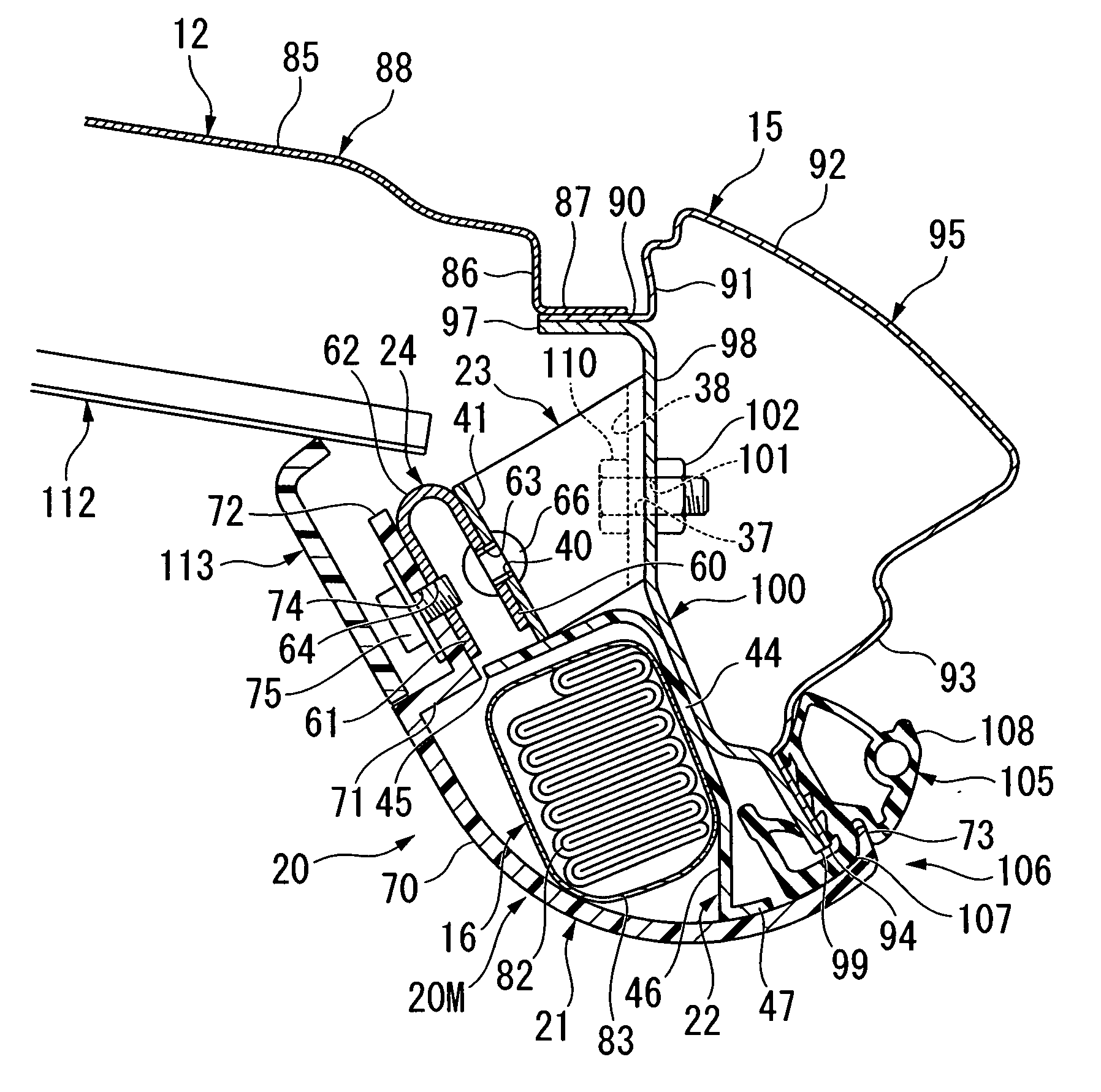

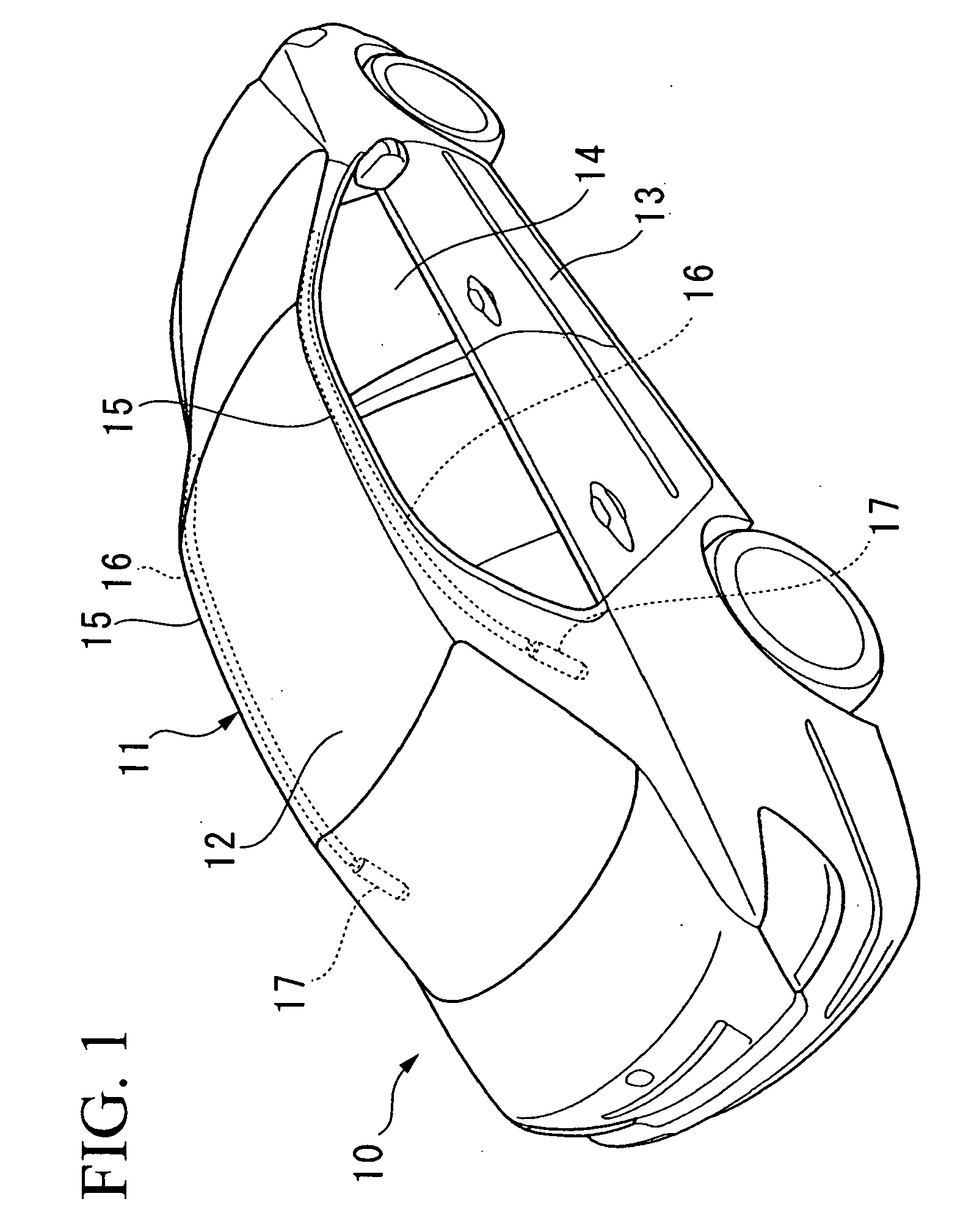

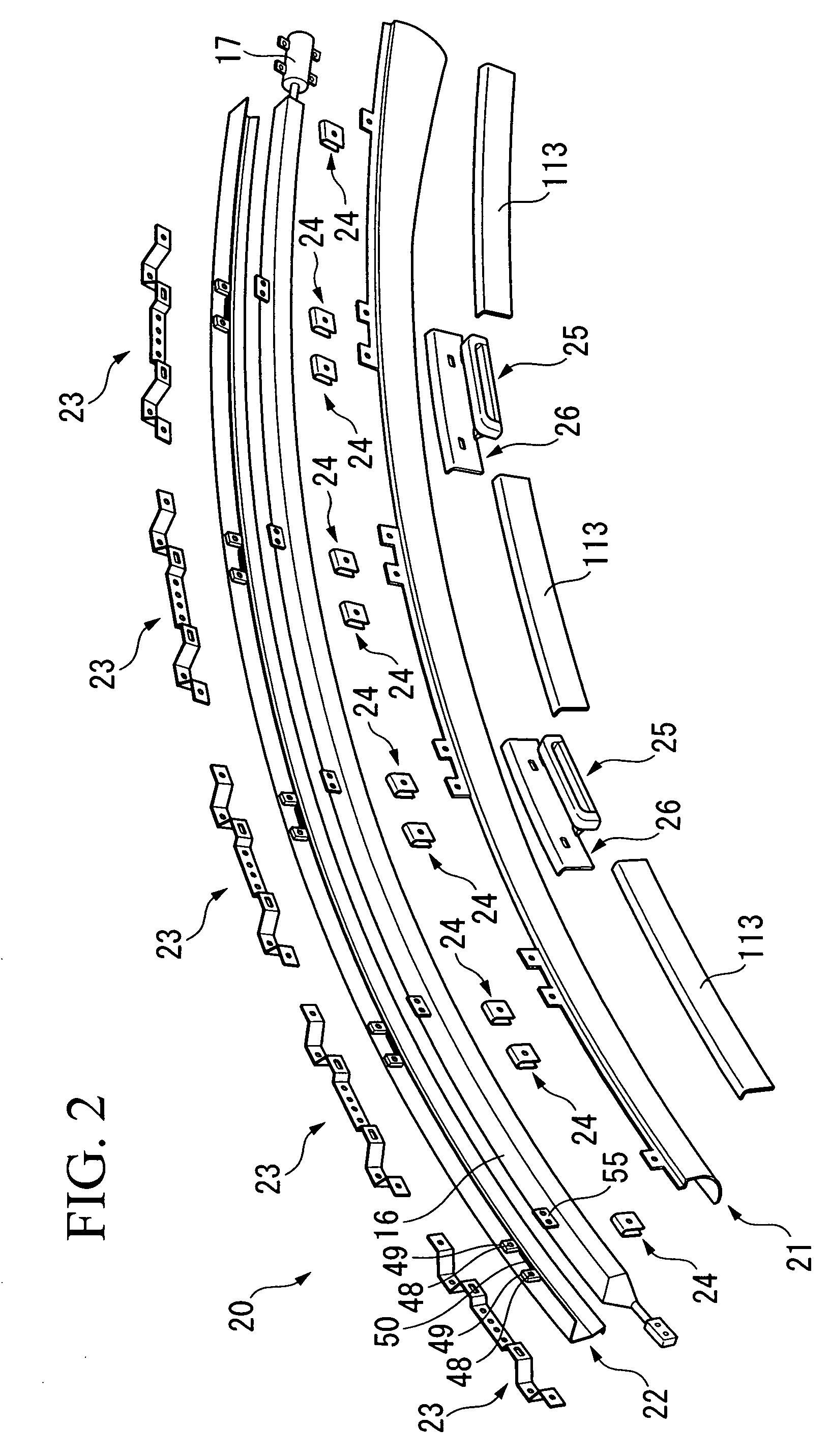

Curtain-type airbag apparatus and airbag module

InactiveUS7735857B2Press evenlyArrangement flexibility can be highPedestrian/occupant safety arrangementEngineeringAirbag

Owner:HONDA MOTOR CO LTD

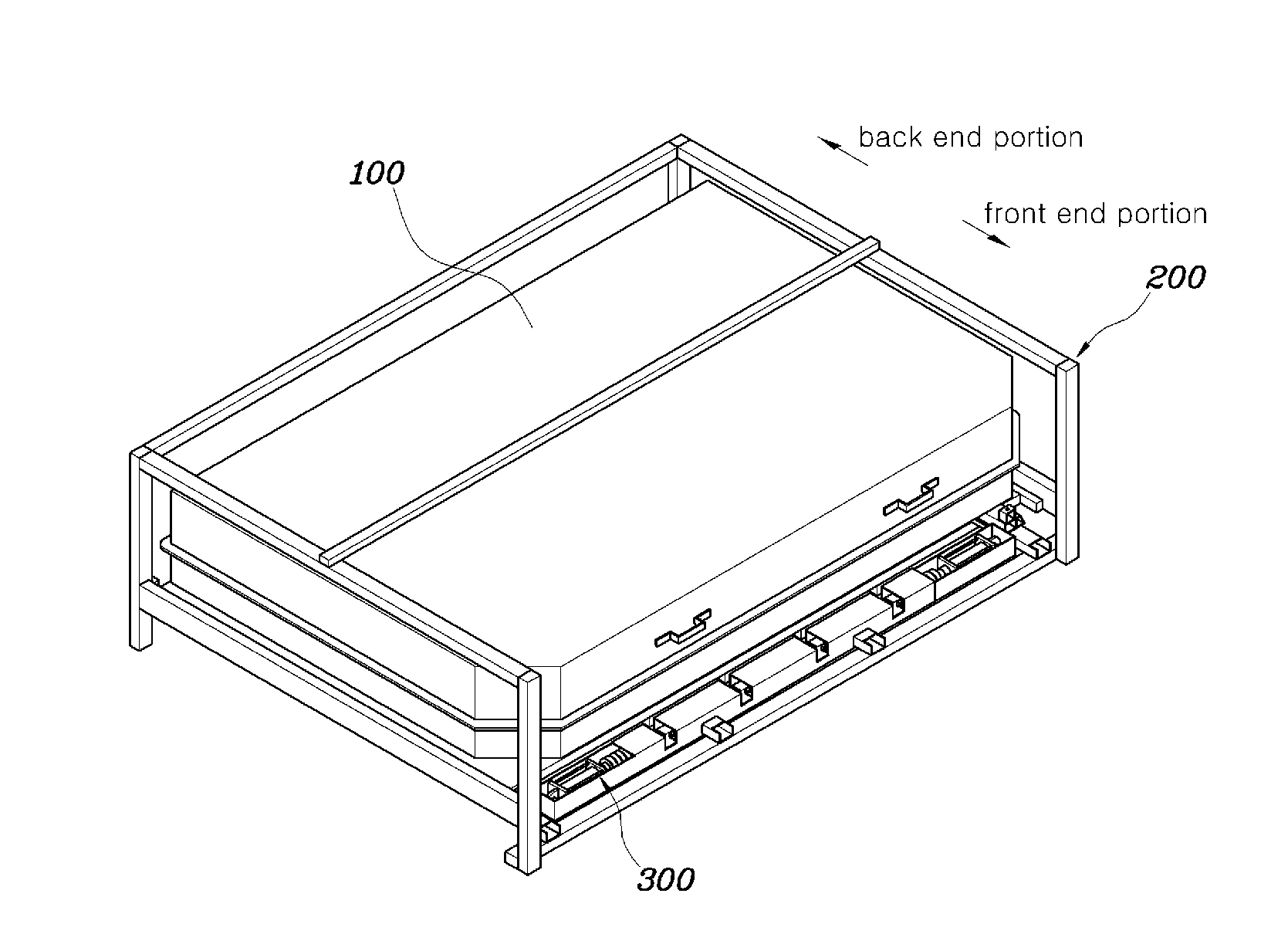

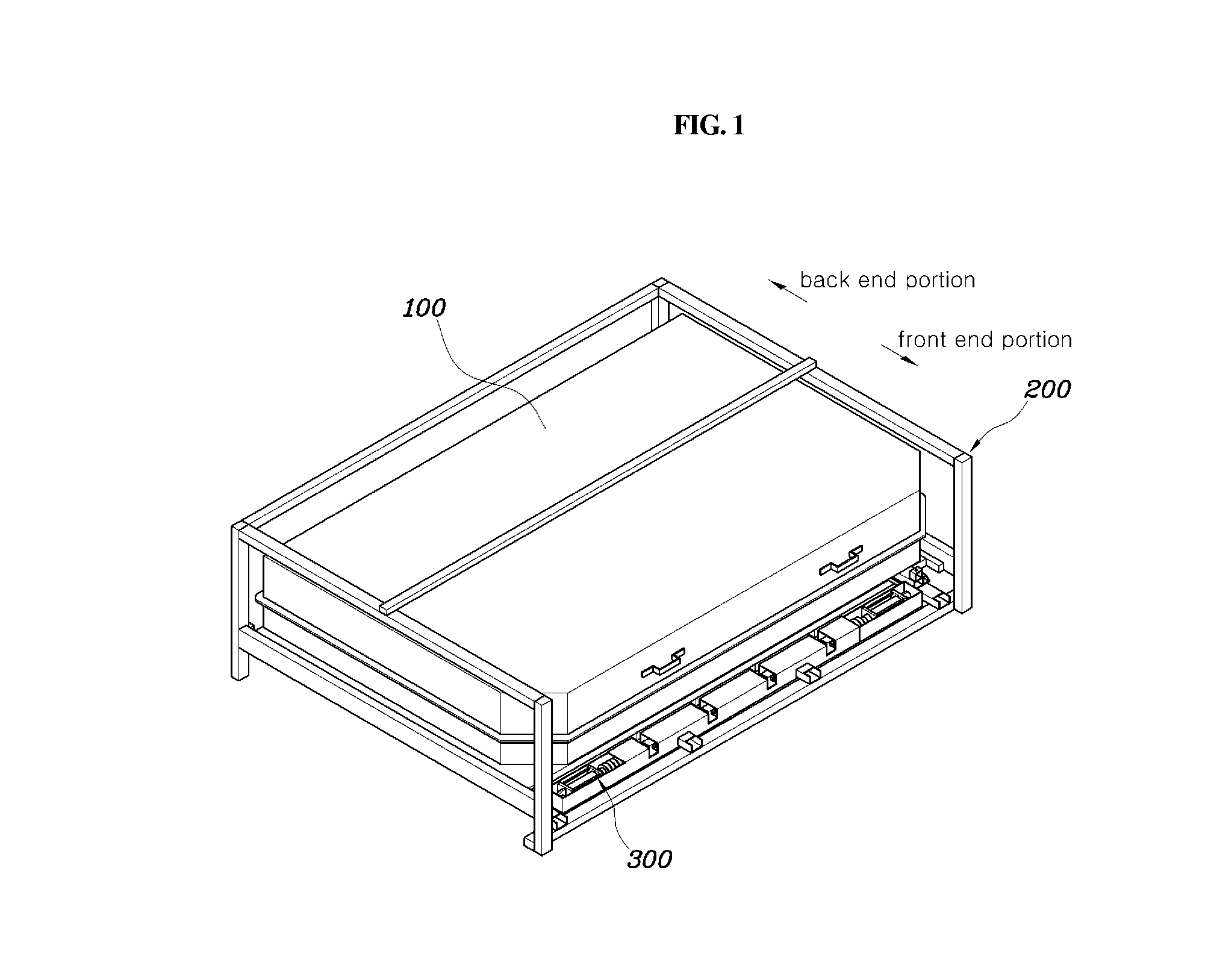

Battery pack holding apparatus

ActiveUS20150114733A1Press evenlyLess forceElectric propulsion mountingPropulsion by batteries/cellsHigh voltage batteryHigh pressure

A battery pack holding apparatus is disclosed that includes a high-voltage battery pack for a vehicle that has a protrusion at the front end, and a battery pack holder that is installed within a vehicle body and has a front end opening into which the high-voltage battery pack slides into. In addition, a fixed rail is disposed at a front end of the battery pack holder and a moving portion which slides in a width direction of the battery pack holder and along the fixed rail and has a contact portion that comes into contact with the protrusion of the high-voltage battery pack when the high-voltage battery pack slides when the high-voltage battery pack is in the battery pack holder. Further, an elastic portion is disposed in the moving portion to press the contact portion toward the protrusion.

Owner:HYUNDAI MOTOR CO LTD

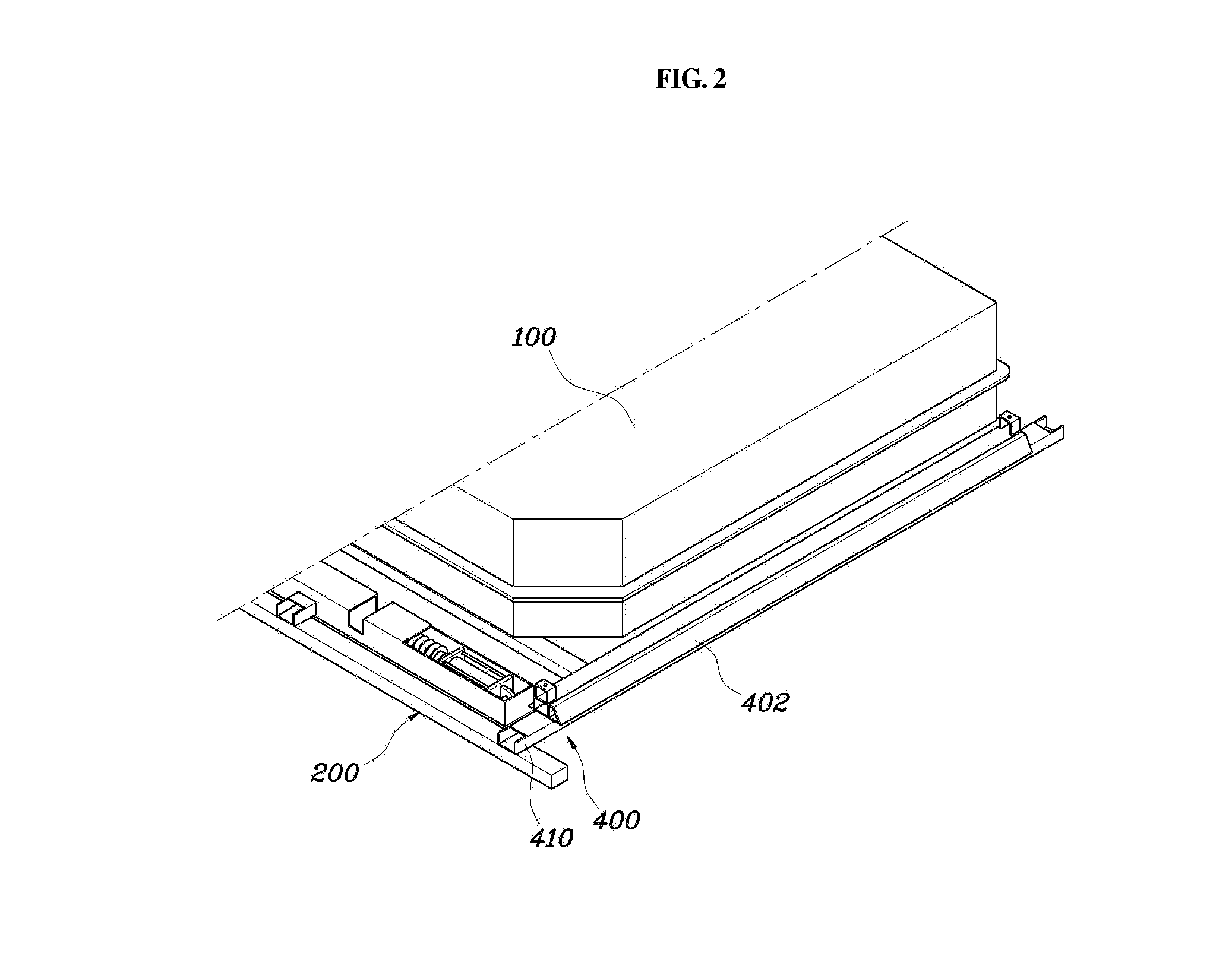

Metal and ceramic bonding agent and preparation method of metal and ceramic bonding agent, CBN grinding wheel and manufacturing method of CBN grinding wheel

ActiveCN105349868AImprove sharpnessGood self-sharpeningAbrasion apparatusGrinding devicesSurface roughnessGrinding wheel

The invention discloses a metal and ceramic bonding agent and a preparation method of the metal and ceramic bonding agent, a CBN grinding wheel and a manufacturing method of the CBN grinding wheel. The metal and ceramic bonding agent is composed of, by mass fraction, 75%-92% of ceramic and 8%-25% of metal. The ceramic is composed of, by mass fraction, 40%-65% of SiO2, 8%-35% of B2O3, 6%-20% of Al2O3, 5%-18% of Na2O5, 0.5%-5% of CaO, 3%-10% K2O, 0.5%-2% of MgO and 2%-6% of TiO2. The metal is composed of, by mass fraction, 55%-80% of Cu, 15%-30% of Sn and 5%-20% of Ni. The metal and ceramic bonding agent can be used as a CBN grinding wheel bonding agent and overcomes the defects that in the grinding process of the ceramic CBN grinding wheel, the surface roughness of a workpiece is large, chatter marks are generated easily, and impact resistance is poor.

Owner:白鸽磨料磨具有限公司

Electrical component socket

ActiveUS20100261371A1Simple structureImprove dissipation performanceEngagement/disengagement of coupling partsElectrical measurement instrument detailsEngineeringMechanical engineering

Owner:ENPLAS CORP

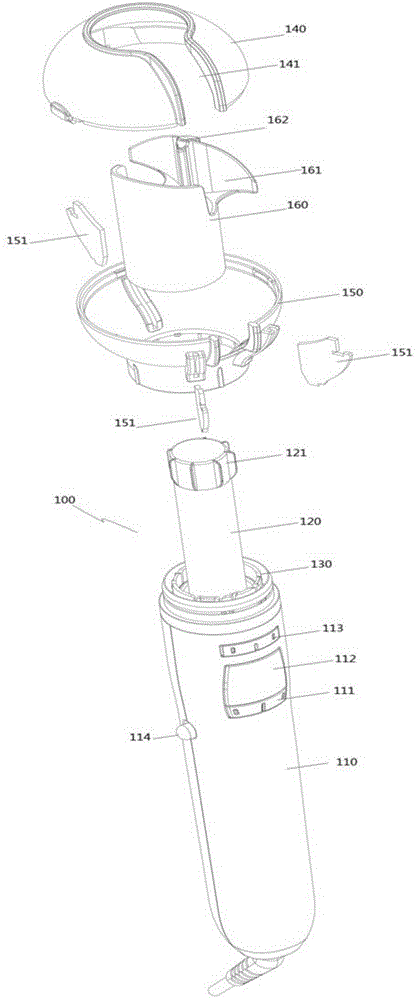

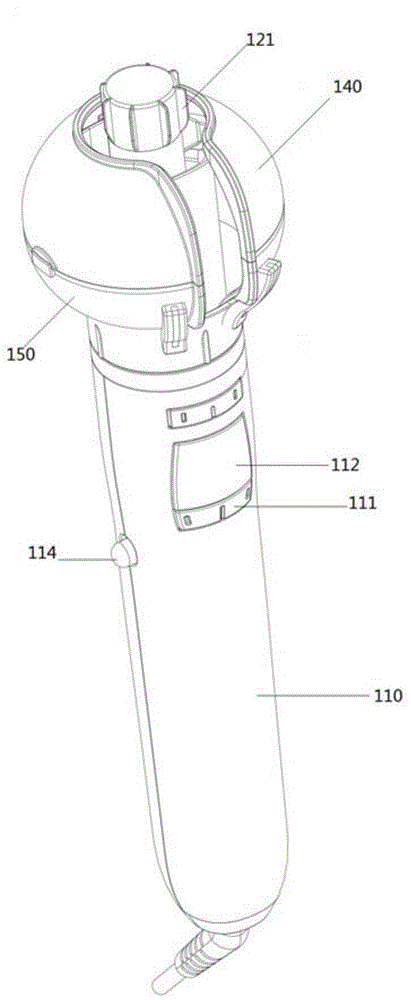

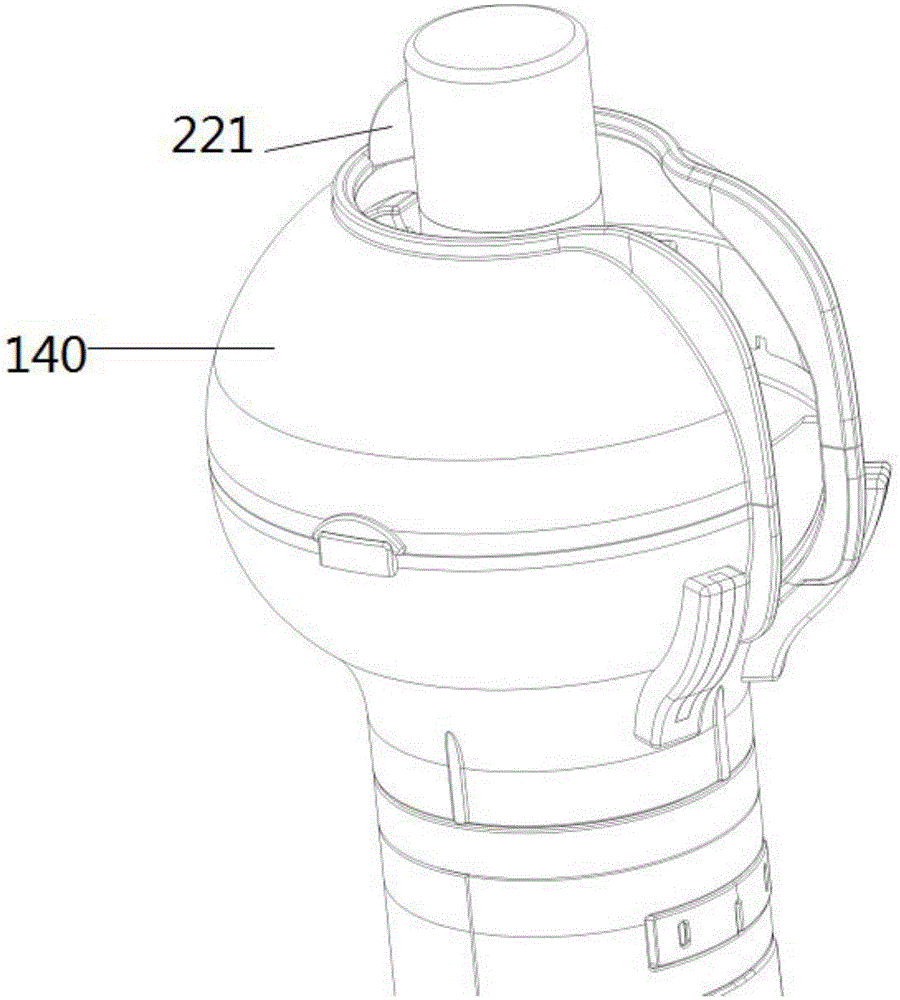

Curly hair styling device

Owner:SUN LUEN ELECTRICAL MFG

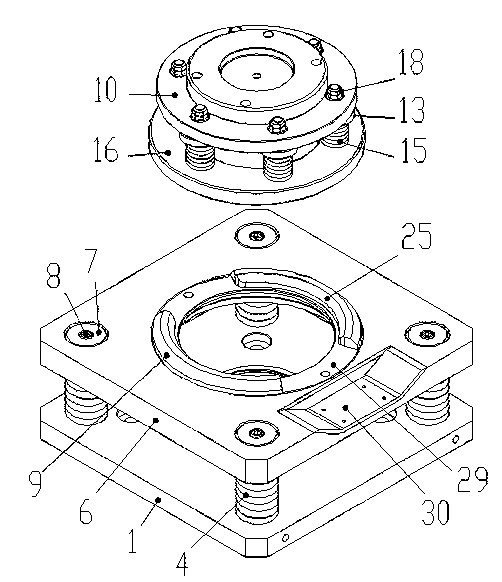

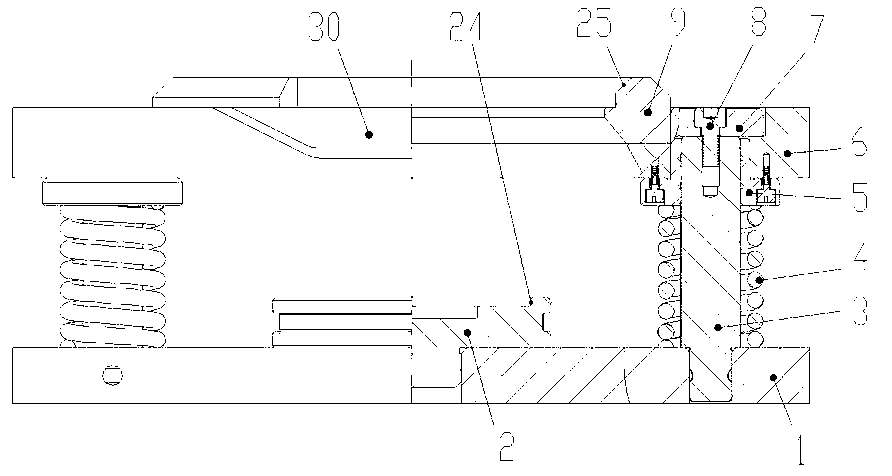

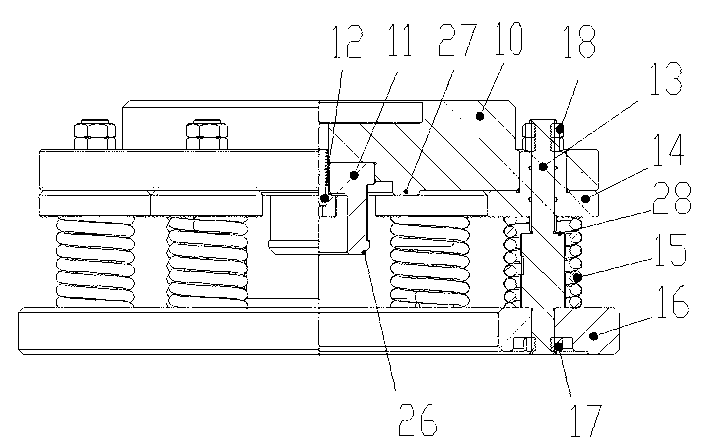

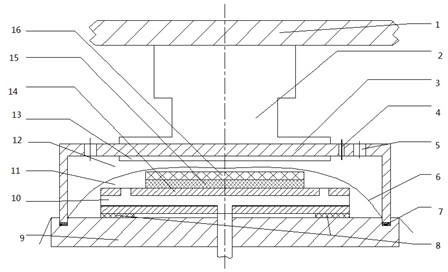

Press mounting device for one-time mounting of differential bearing of forklift

ActiveCN103240581ARealize the function of turning overPress evenlyMetal working apparatusEngineeringHydraulic press

The invention relates to a press mounting device for one-time mounting of a differential bearing of a forklift. The press mounting device comprises an upper platen mechanism and a lower seat mechanism, wherein the upper platen mechanism comprises a vertically corresponding upper base plate, an upper floating platen and more than three upper guide shafts, and the upper platen mechanism is divided into a fixed press head and a floating press head; and the lower seat mechanism comprises a vertically corresponding lower floating base plate, a lower base plate and more than three lower guide shafts, and the lower seat mechanism is divided into a fixed support and a floating support. The press mounting device can finish all press mounting operation of a differential assembly in one working stroke of a hydraulic press; and simultaneously, the press mounting device is provided with a turnover function of the differential assembly with the human assistance.

Owner:ANHUI HELI CO LTD

Curtain-type airbag apparatus and airbag module

InactiveUS20070296185A1Improve design flexibilityIncrease assembly flexibilityPedestrian/occupant safety arrangementEngineeringAirbag

This curtain-type airbag apparatus is provided with: an airbag which is arranged along a top edge of a vehicle body and develops in a curtain-shape manner along an inside of a window; and an inner cover which covers a vehicle interior side of the airbag. The inner cover is supported by the vehicle body via a hinge member having a reversed U-shape.

Owner:HONDA MOTOR CO LTD

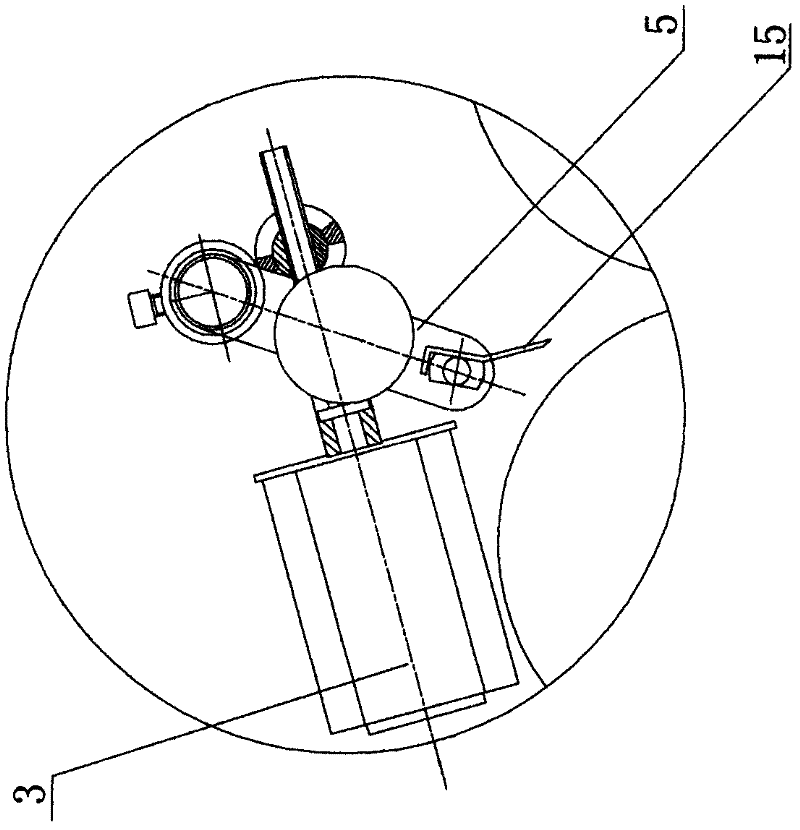

Automatic precipitation sampler

The invention aims to provide an automatic precipitation sampler which comprises a sampling bottle, a sampling bottle sensor, a pressure sensor, a detection funnel, a rain collection funnel, a cover, a rotary motor, a lifting rod, a lifting rod motor and a water injection mechanism, wherein the lifting rod is mounted below the cover; the lifting rod motor drives the lifting rod so that the cover moves up and down; the rotary motor is connected with the cover and drives the cover to rotate; the cover covers the rain collection funnel; the rain collection funnel is communicated with the water injection mechanism; the sampling bottle is arranged by corresponding to the water injection mechanism; the sampling bottle sensor is mounted on the water injection mechanism to detect whether the sampling bottle is full of water or not; the detection funnel is arranged beside the rain collection funnel; a pipeline blocking rainwater is connected below the detection funnel; a bypass pipe is mounted on the pipeline; and the pressure sensor is mounted on the bypass pipe. The automatic precipitation sampler provided by the invention can automatically collect rainwater in precipitation and automatically stop sampling after the rain stops; and after the collection, the precipitation automatic sampler can store the sample perfectly and record the precipitation-related data.

Owner:HARBIN ENG UNIV

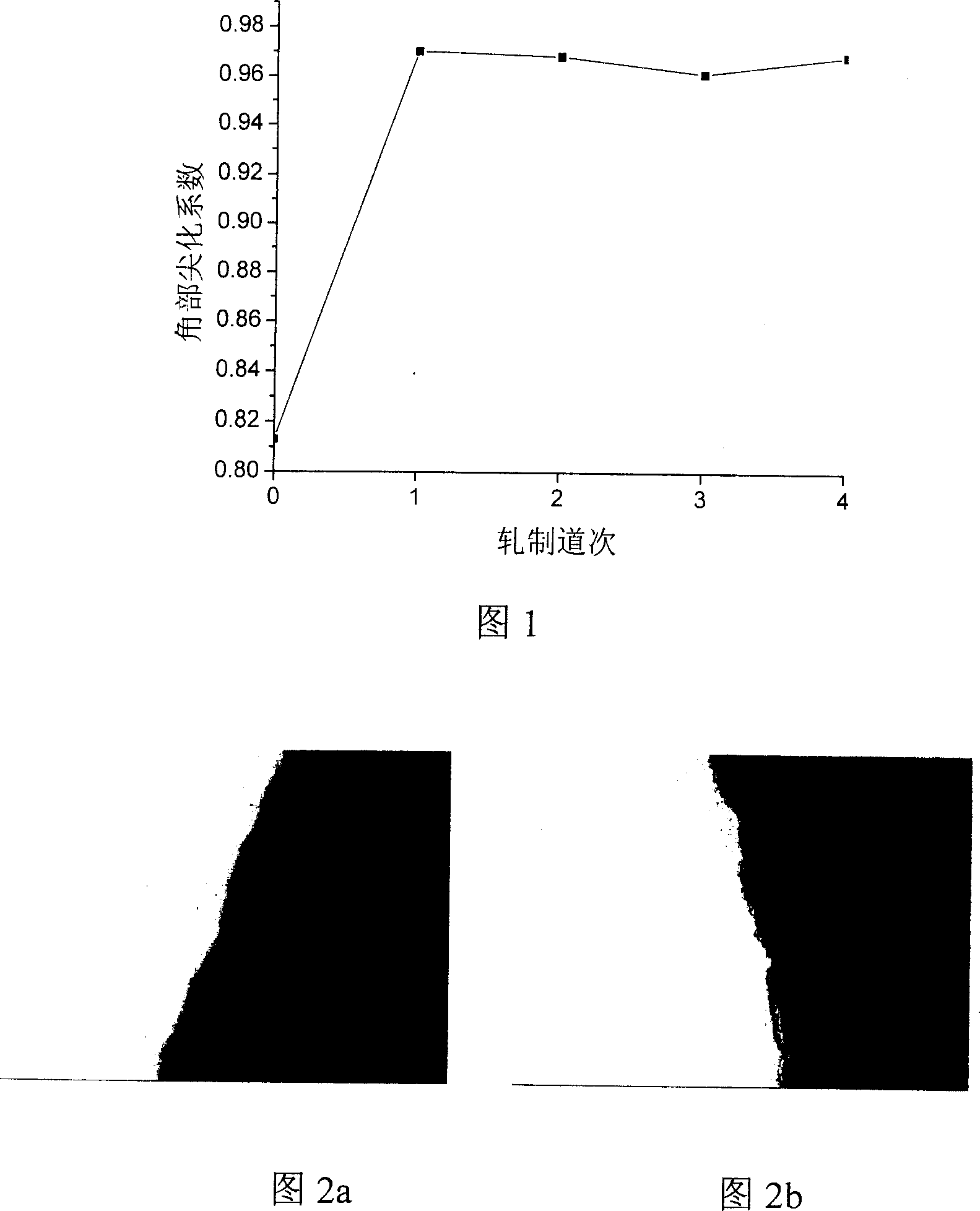

Non-groove rolling method for high speed wire bar intermediate rolling train

InactiveCN101152654AImprove work rateImprove productivityRoll force/gap control deviceTemperature control deviceReduction rateWire rod

The invention discloses a non-groove rolling method for high speed wire rod roughing mill group and mainly solves rolling technical problem of the high speed wire rod roughing mill group. The non-groove rolling method comprises two pass non-groove rolling, four pass non-groove rolling or six pass non-groove rolling; the ratio of height and width of the rolling component is 0.90 to 1.58, reduction rate of pass is 15 percent to 45 percent, rolling temperature is 1000 celsius degree to 1100 celsius degree, the adaptation range of blank is 120*120mm to 180*180mm, and the absolute spread coefficient range is 0.25 to 0.45. The invention adopts a pass-free flat roller to replace a rough rolling pass roller of the prior art and realizes non-groove rolling of the high speed wire rod roughing mill group. The invention aims to provide the non-groove rolling method for the high speed wire rod roughing mill group adopting the flat roller to replace the rough pass roller, meanwhile, decreasing production cost, improving product quality and productivity of the mill and expanding the adaptation range of blank.

Owner:BAOSHAN IRON & STEEL CO LTD +1

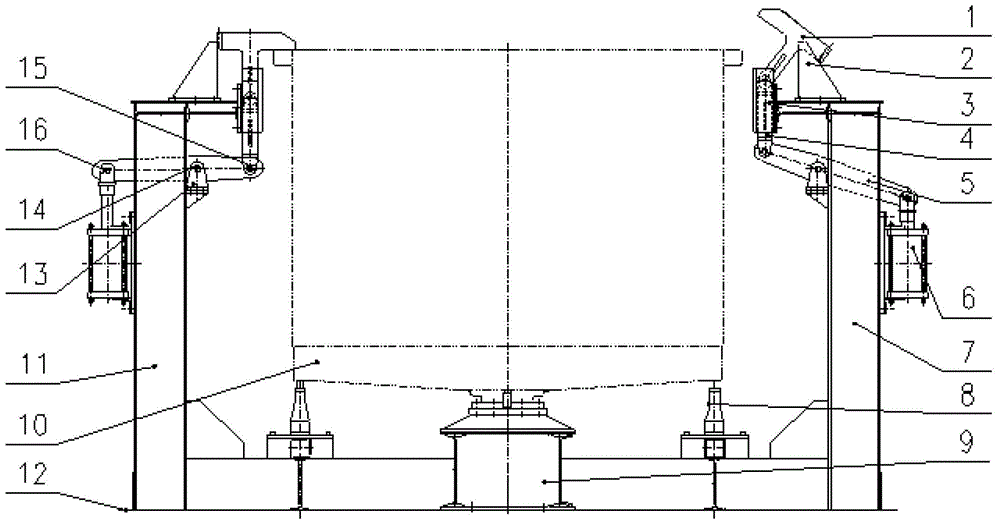

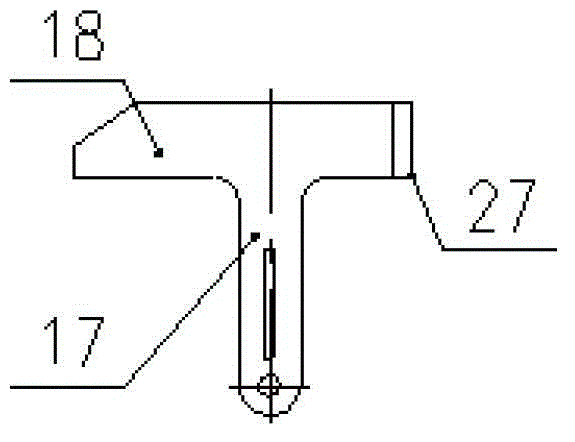

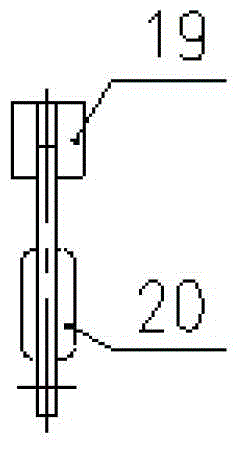

Pressing tool for assembling truck body

ActiveCN102744547AHigh strengthOpen smoothlyWelding/cutting auxillary devicesAuxillary welding devicesTruckPiston rod

The invention discloses a pressing tool for assembling a truck body. The pressing tool comprises an upright device, a pressing hook, a jack device and a workpiece locating device, wherein the upright device comprises uprights and bases, which are positioned on the two sides; the top ends of the uprights are provided with anti-rebound devices; guide devices and lug seats are arranged on the inner sides of the uprights; cylinders are arranged on the outer sides of the uprights; connecting devices matched with the guide devices are arranged on the inner sides of the guide devices; upper ends of the connecting devices are hinged with pressing hooks; pin holes and pin shafts I are arranged on the lug seats; the pin holes are matched with the pin shafts I; force amplifying levers, which rotate relative to the pin shafts I, are arranged on the pin shafts I; upper long circular holes and lower long circular holes are respectively formed in two ends of the force amplifying levers, wherein the upper long circular holes are hinged with connecting holes at lower ends of the connecting devices by pin shafts II; the lower long circular holes are hinged with connecting holes on end part joints of cylinder piston rods by pin shafts III; jack devices and workpiece locating devices are arranged on the inner sides of lower ends of the uprights; and the bases of the uprights, bottom surfaces of the jack devices and bottom surfaces of the workpiece locating devices are respectively connected with foundation embedded plates.

Owner:CRRC SHANDONG CO LTD

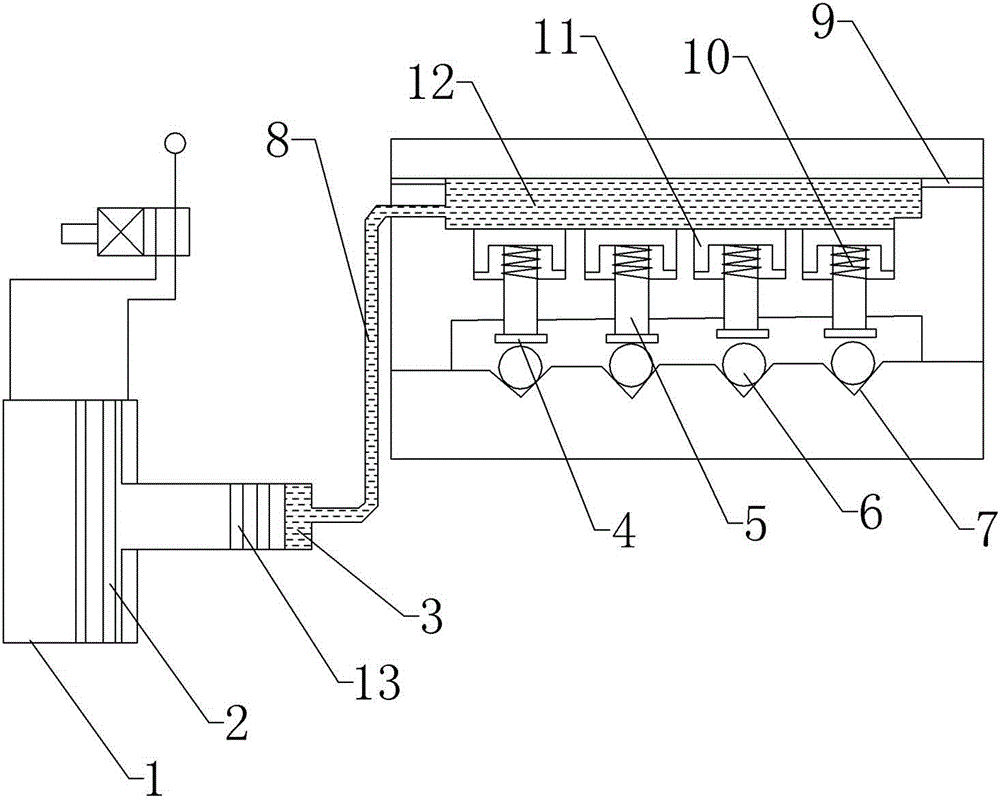

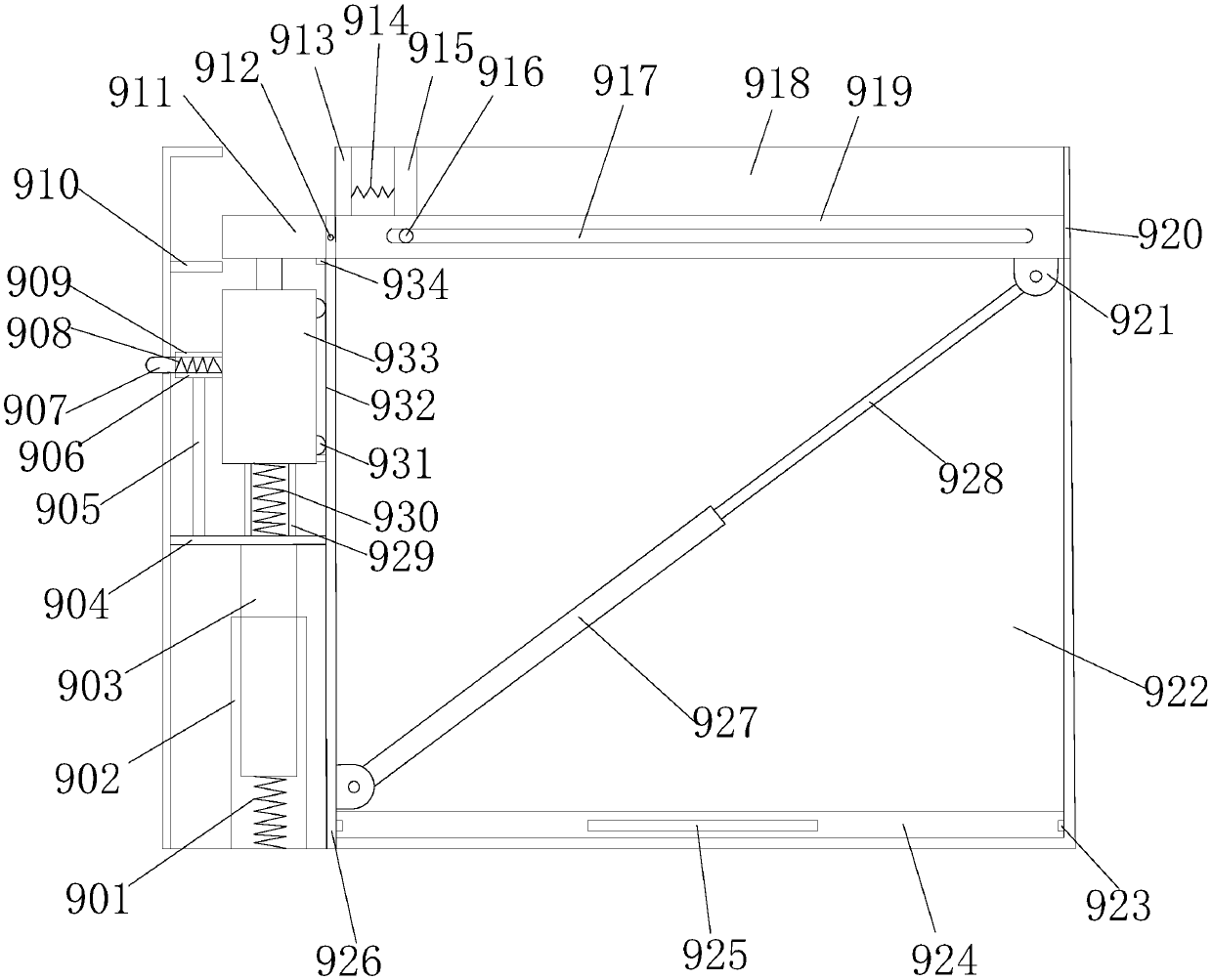

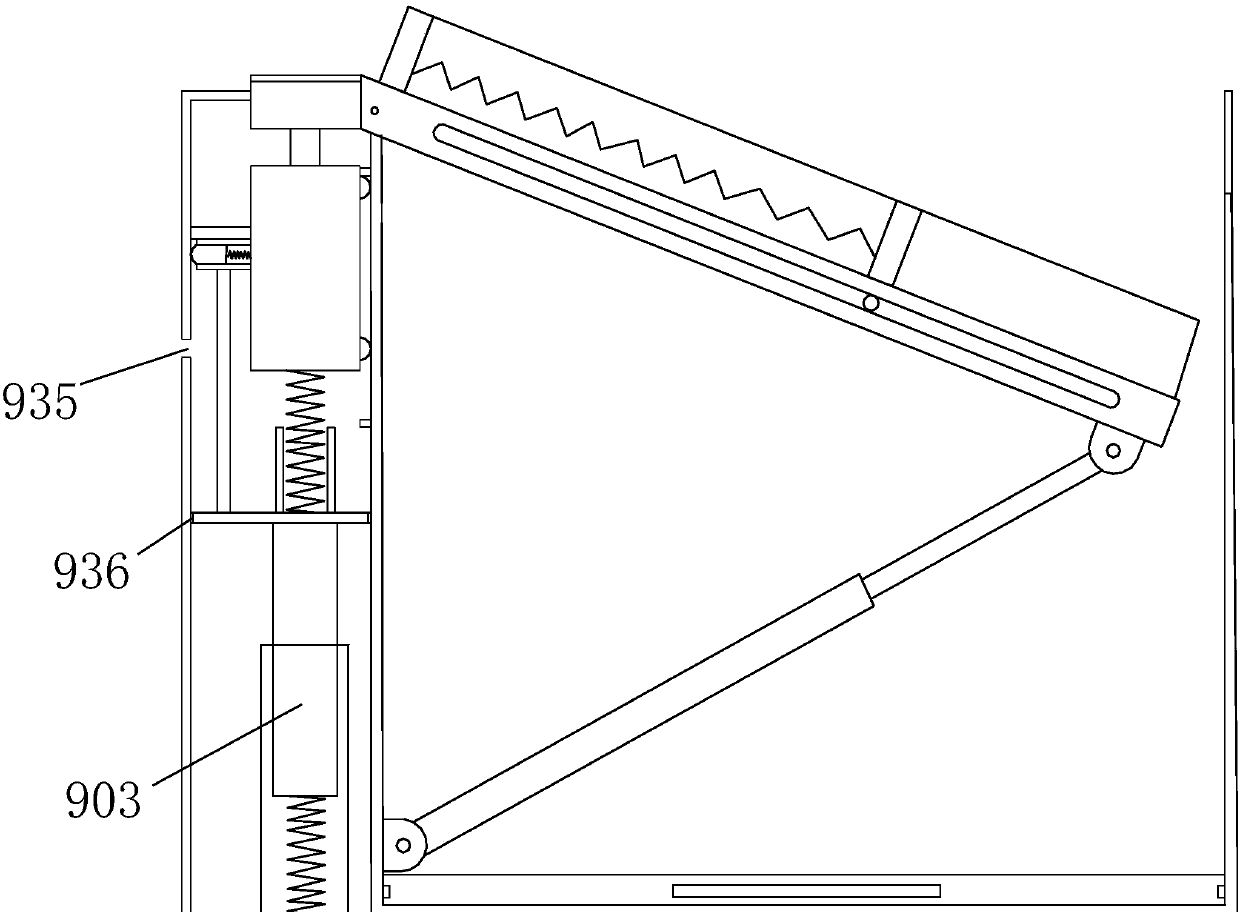

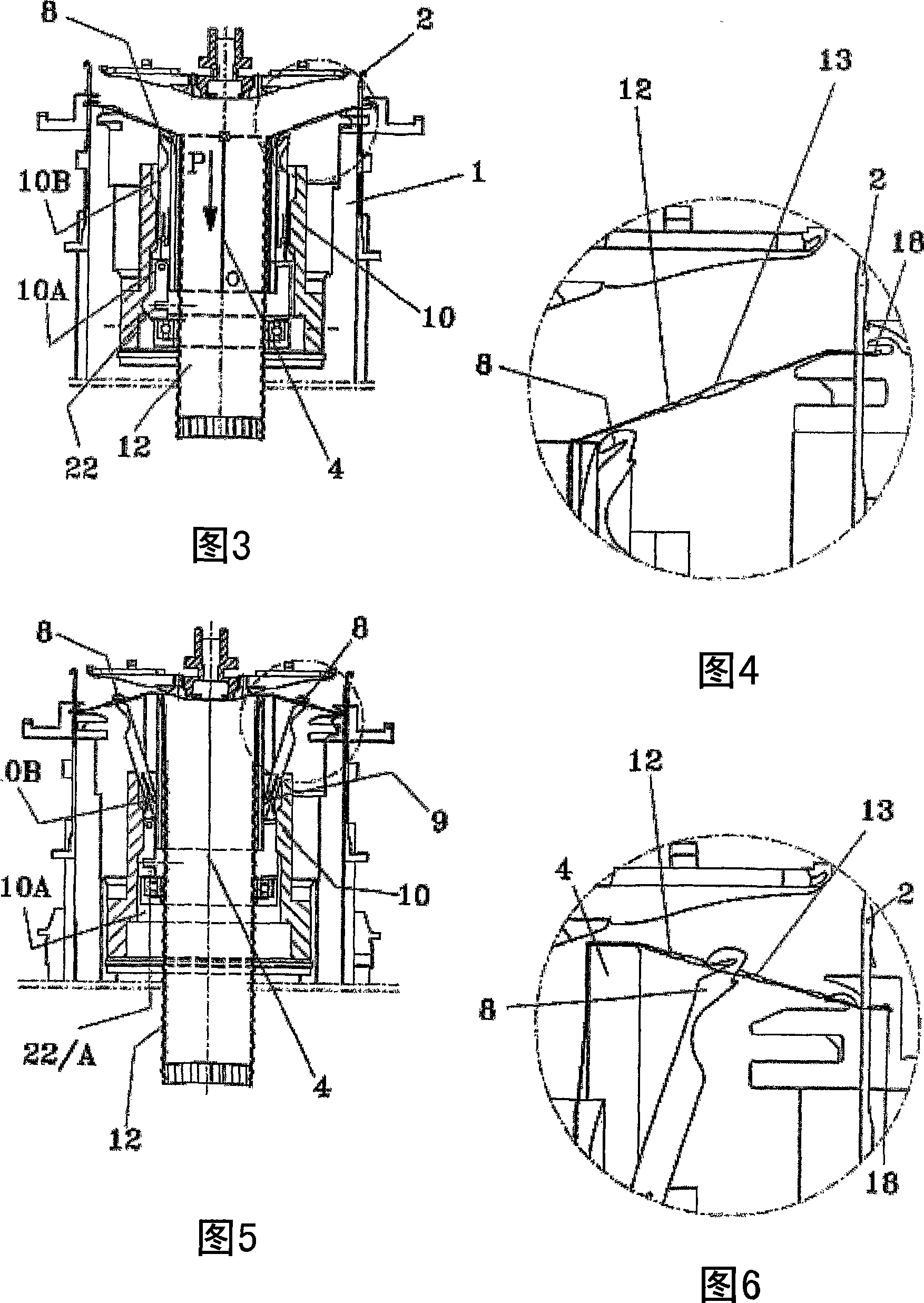

Multi-station balanced pressing mechanism for gas-liquid conversion cylinder

InactiveCN105179358ASame pressing forcePress evenlyFluid-pressure actuatorsPositioning apparatusEngineeringMechanical engineering

The invention discloses a multi-station balanced pressing mechanism for a gas-liquid conversion cylinder. The multi-station balanced pressing mechanism can guarantee the balanced press force of all stations and comprises a cylinder. The cylinder is controlled by an electromagnetic valve to be ventilated or not. A first sealing pad is arranged in the cylinder and divides the cylinder into a left cavity and a right cavity. The right cavity is provided with a pipe cavity protruding outwards. A second sealing pad is arranged in the pipe cavity and used for separating the pipe cavity and an oil cavity of an oil cylinder. The right side of the oil cylinder is communicated with an oil chamber through a pipeline. Four piston cavities are arranged side by side at the lower portion of the oil chamber at equal intervals. Pistons capable of moving axially along the piston cavities are arranged in the piston cavities and provided with sealing rings for preventing hydraulic oil from seeping downwards. The lower ends of the pistons are connected with piston rods. The diameters of all the piston rods are the same. Reset springs are arranged on the peripheries of the piston rods. Pressing boards are arranged at the lower ends of the piston rods.

Owner:CHONGQING YUKUNLONG METALLURGICAL MATERIAL CO LTD

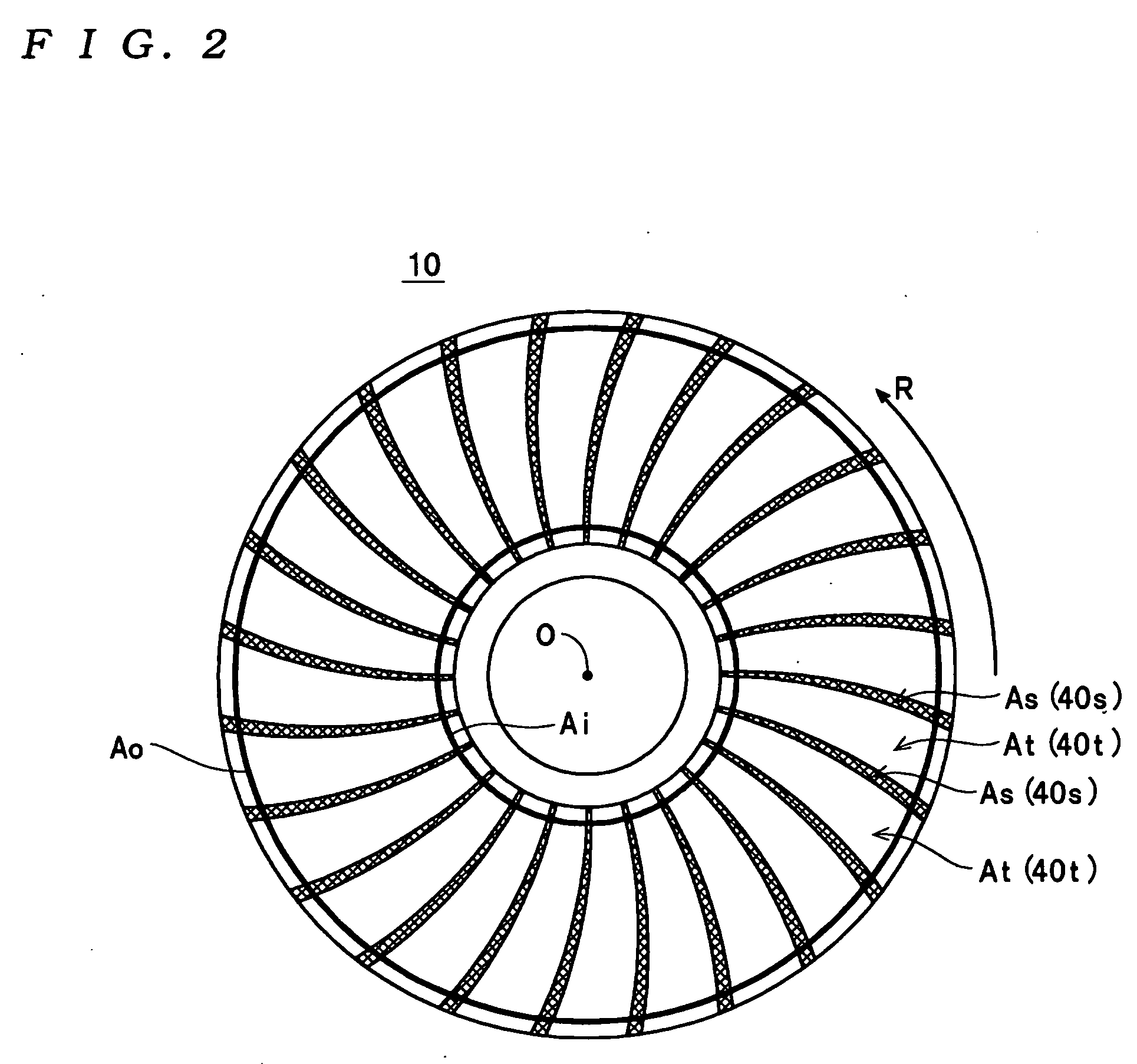

Magnetic recording medium, recording/reproducing apparatus, and stamper

InactiveUS20060198052A1Reliable readEvenly layeredCarrier storage meansNanoinformaticsMaximum diameterEngineering

On a magnetic recording medium, a servo pattern is formed in a servo pattern region on at least one surface of a substrate by a concave / convex pattern including a convex part, at least protruding end part of which is formed of magnetic material, and a concave part. The servo pattern region includes an address pattern region and a burst pattern region, wherein the convex part is formed in the servo pattern region so that a larger of an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the address pattern region and an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the burst pattern region is an inscribed circle with a largest diameter out of inscribed circles on an open surface of the concave part formed in the servo pattern region.

Owner:TDK CORPARATION

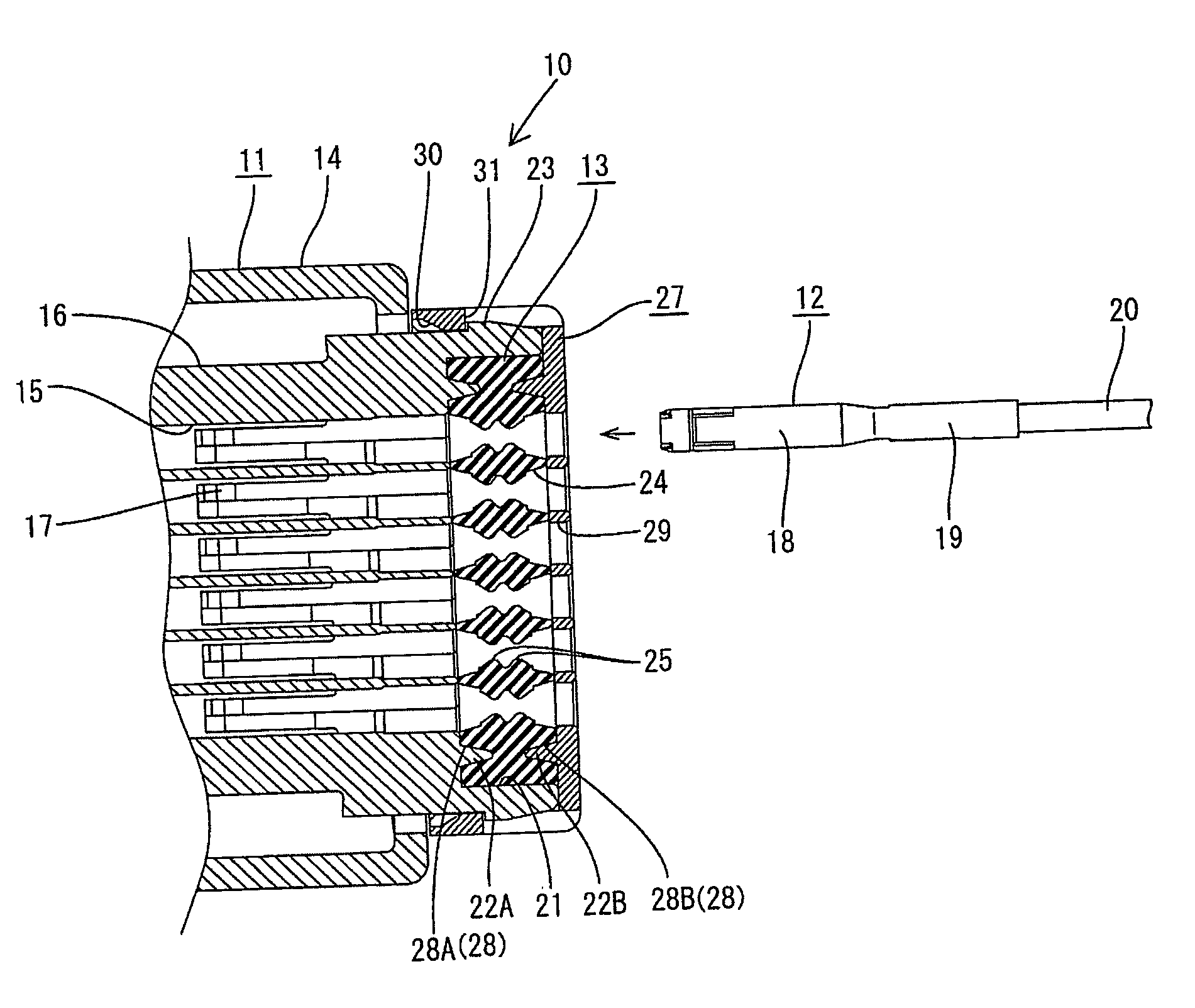

Watertight connector

InactiveUS20060040553A1Efficient insertionEasy to insertSecuring/insulating coupling contact membersEngineeringMechanical engineering

Resilient deformation of a rubber plug (13) can be absorbed by a housing-side groove (28A) and a holder-side groove (28B) formed to surround all wire insertion holes (24), thereby preventing the displacements of the wire insertion holes (24). Thus, a reduction in operability at the time of inserting female terminal fittings (12) and wires (20) through the rubber plug (13) can be avoided. Further, a housing-side pressing portion (22A) and a holder-side pressing portion (22B) are pressed into the housing-side groove (28A) and the holder-side groove (28B) over the entire periphery to press the rubber plug (13) into contact with the inner surface of an accommodation recess (21), sealability between a housing (11) and the rubber plug (13) can be ensured.

Owner:SUMITOMO WIRING SYST LTD

Numerical control noodle maker

ActiveCN102396577APress evenlyRealize automatic folding and flippingDough-sheeters/rolling-machines/rolling-pinsMechanical engineeringNumerical control

The invention discloses a numerical control noodle maker, which comprises a frame, wherein one side of the frame is provided with an upper conveying belt and a lower conveying belt; the other side of the frame is provided with a noodle outputting conveying belt; the upper conveying belt is positioned above the lower conveying belt, and inclines upwards; a noodle overturning roller is arranged below the upper conveying belt; an upper roll wheel, a lower roll wheel and an adjustable roll wheel are arranged on the frame close to the upper conveying belt, the lower conveying belt and the noodle outputting conveying belt respectively; and a noodle guiding device capable of oscillating leftwards and rightwards is arranged above the upper roll wheel and the adjustable roll wheel. The invention has the beneficial effects: (1) automatic folding and overturning of noodles are realized, so that the noodles can be pressed more uniformly; (2) by controlling the oscillating position of the noodle guiding device, circular pressing or outputting of the noodles is realized; (3) the noodle outputting conveying belt can be used for outputting pressed noodles out of the noodle maker towards the noddle feeding direction; (4) the noodle maker is convenient to move; and (5) the bottom of the frame is provided with adjustable support legs, so that the noodle maker is convenient to adjust to a horizontal position.

Owner:SHANDONG YINYING COOKING MACHINERY

Blood pressure monitor

ActiveUS7207944B2Press evenlyReduce power consumptionEvaluation of blood vesselsCatheterBlood pressure monitorsEmergency medicine

Owner:MATSUSHITA ELECTRIC WORKS LTD

Developer cartridge

In a developer cartridge, the base portion is fixed to an outer surface of the one side of the frame, and extends from one end thereof to another end thereof in a second direction orthogonal to the first direction. The first extending portion extends from one end thereof to another end thereof in the first direction. The one end of the first extending portion is connected to another end of the base portion. The second extending portion extends from one end thereof to another end thereof in a direction opposite to the second direction. The one end of the second extending portion is connected to another end of the first extending portion. The input portion is connected to another end of the second extending portion and inputs electrical power from an external device. The electrode is deformable such that a distance between the base portion and the second extending portion becomes smaller.

Owner:BROTHER KOGYO KK

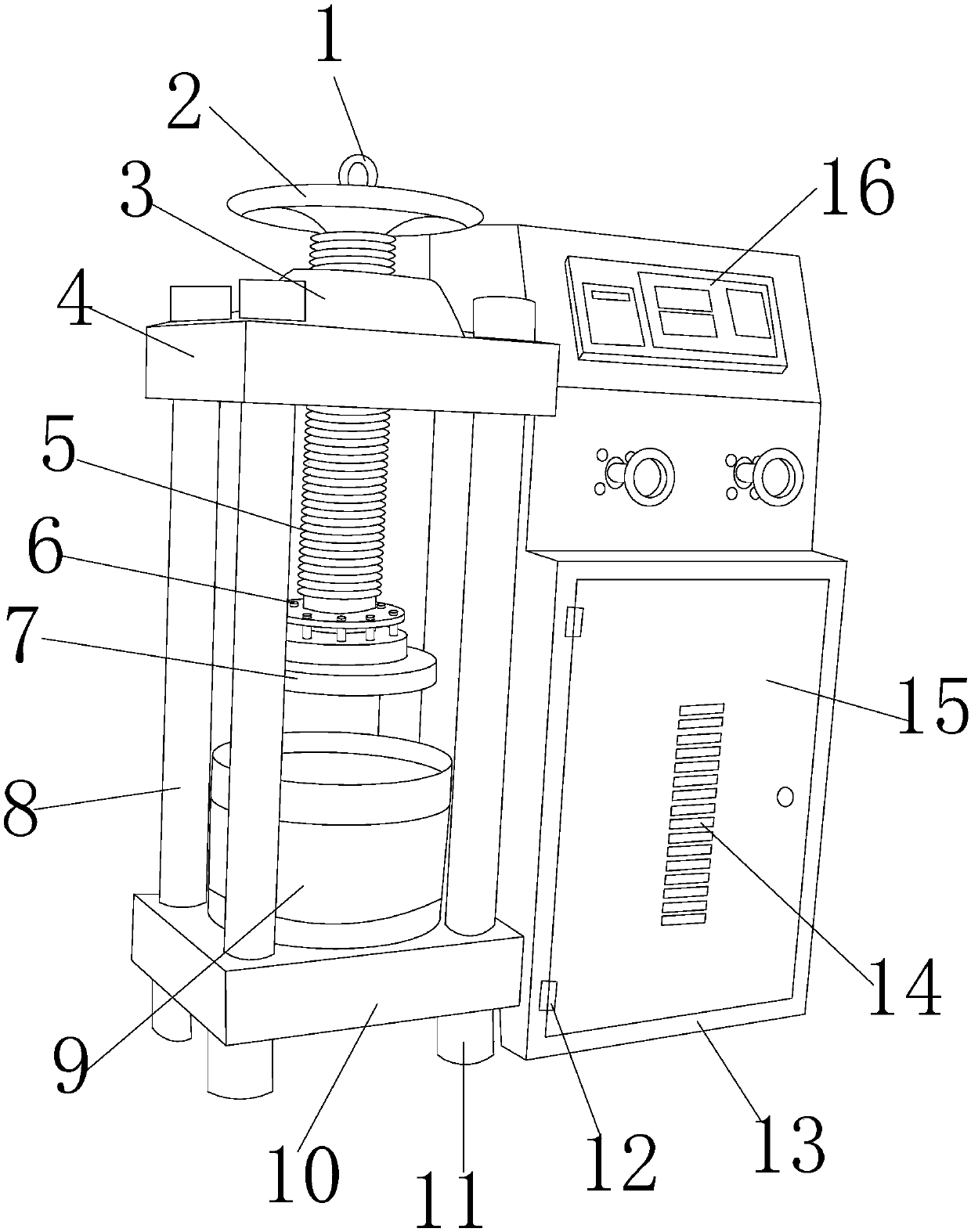

Concrete pressure testing device

ActiveCN107702981AReduce coefficient of frictionMove fastMaterial strength using tensile/compressive forcesGratingEngineering

The invention discloses a concrete pressure testing device. The concrete pressure testing device comprises a lifting ring, a rotary hand wheel, a hand wheel limiting top block, an upper mounting seat,an adjustment lead screw, a pressure sensor, an extrusion plate, an upright post, an automatic soil clearing device, a lower mounting seat, a leg support, symmetric hinges, a machine body, heat dissipation gratings, a door sheet and an operation panel, wherein the bottom of the front of the machine body is hinged and connected with the door sheet by virtue of the symmetric hinges, two or more symmetric hinges are arranged and are located on the same vertical surface, and the heat dissipation gratings are uniformly laid in the middle of the door sheet at equal intervals. The concrete pressuretesting device disclosed by the invention has the advantages that the automatic soil cleaning device is arranged, an automatic soil cleaning function is realized, after concrete is crushed, automaticcleaning operation on test block residues on a pressure-bearing plate can be easily and conveniently realized, harm caused by splashing of the test block residues on human body is effectively avoided,and the phenomenon that hands are scratched as the test block residues are manually cleaned is avoided.

Owner:徐州鼎博混凝土制品有限公司

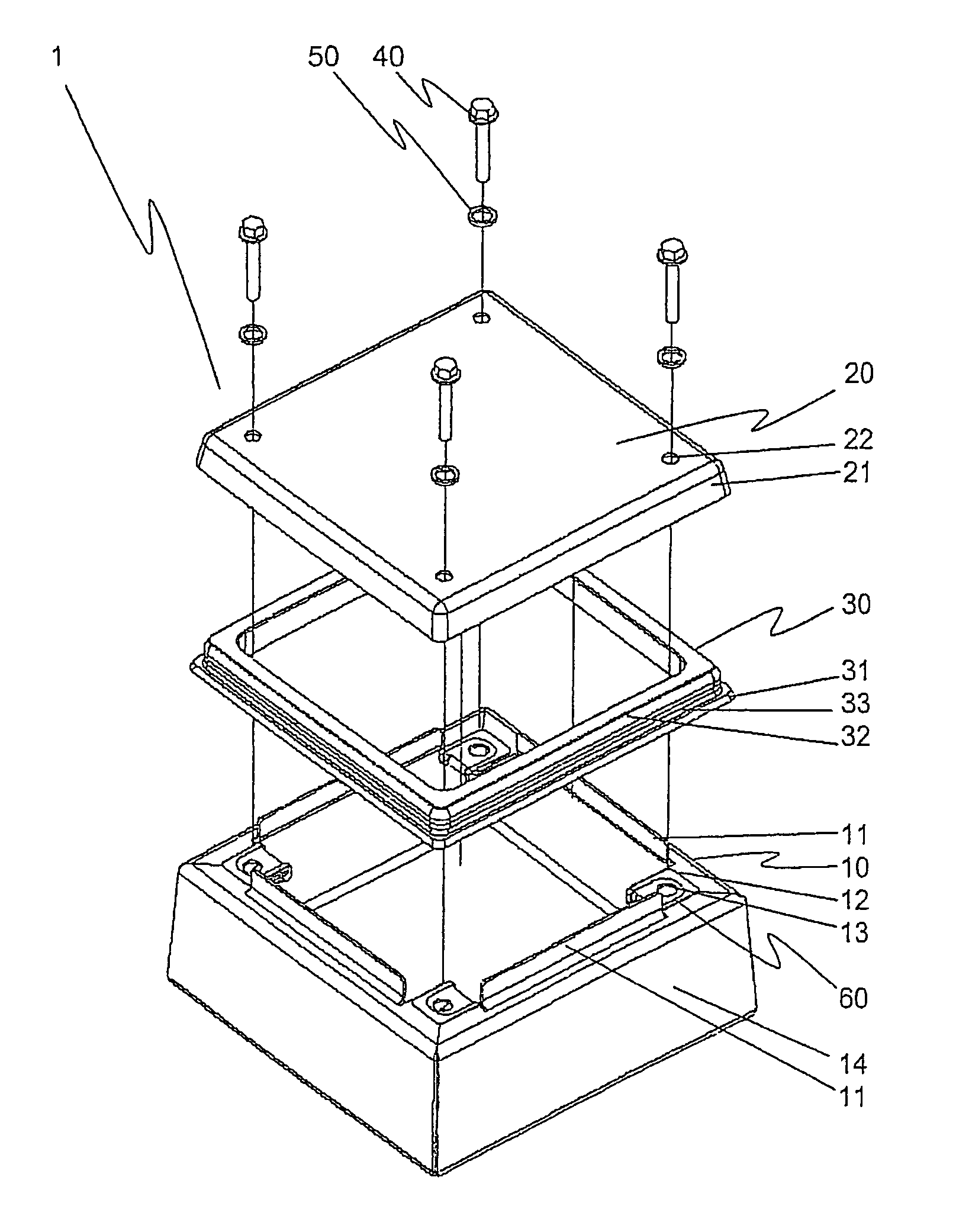

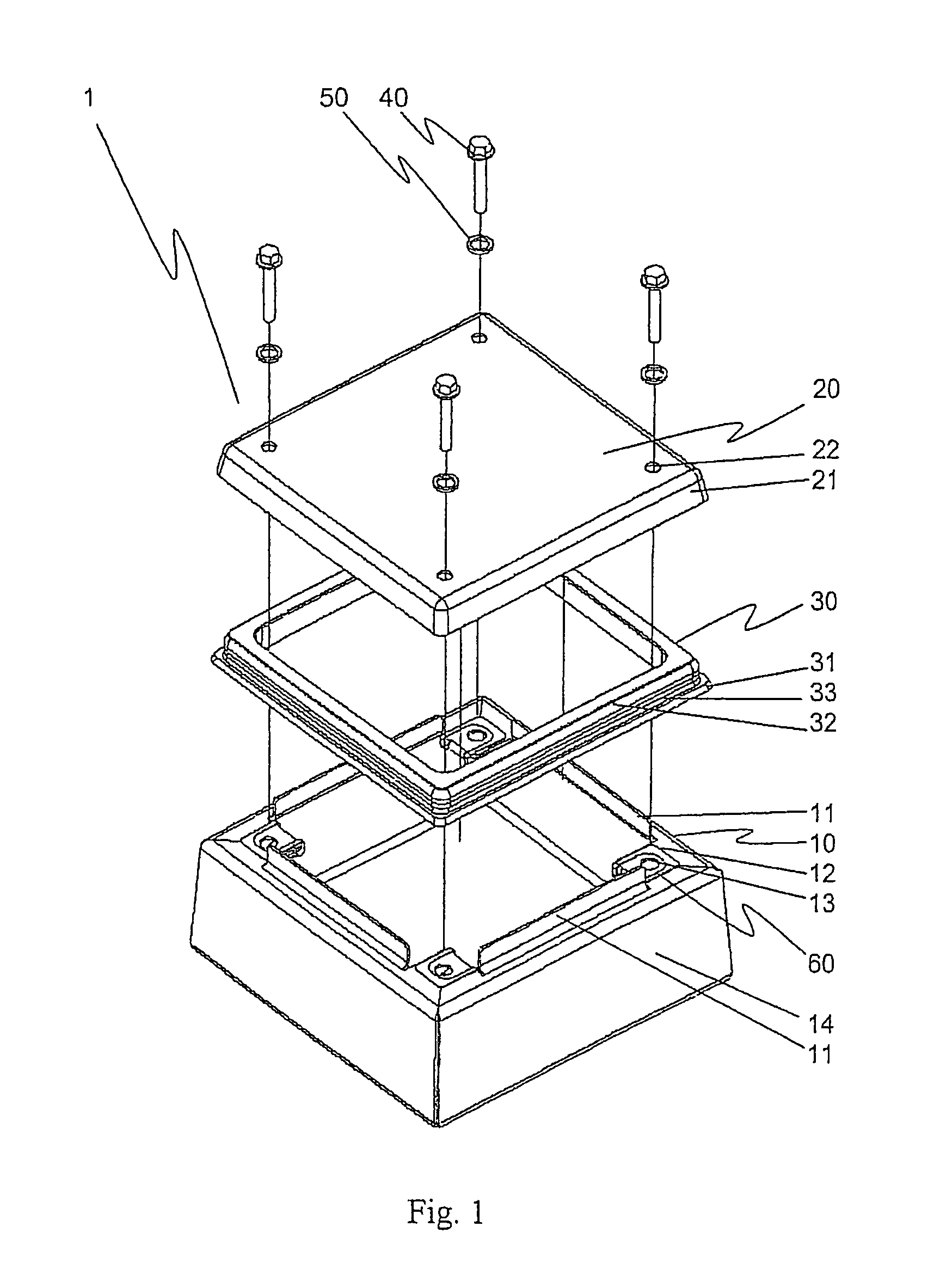

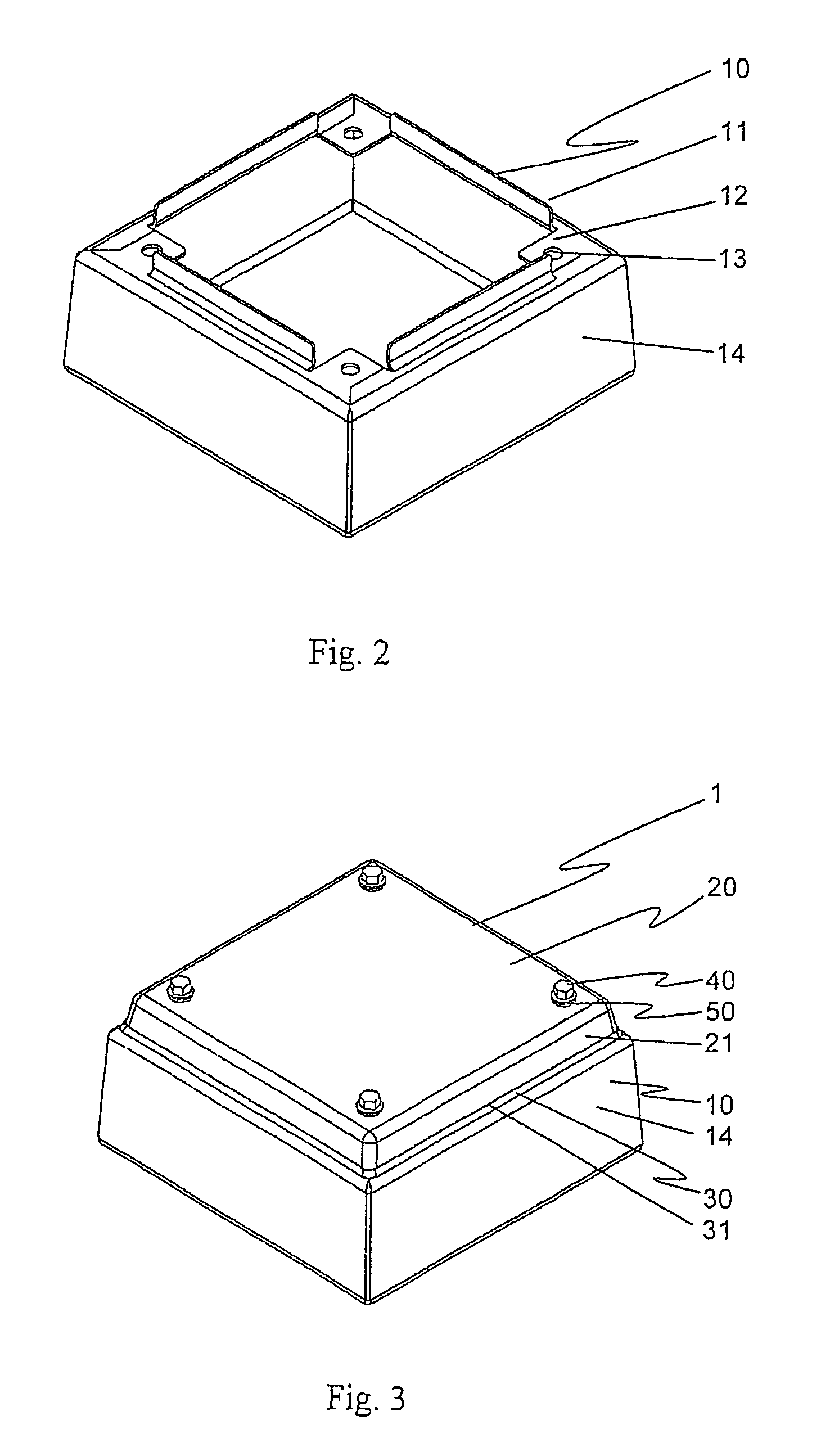

Housing

ActiveUS8492651B2Easy to cleanHigher hygienic demandsInstallation of lighting conductorsCouplings bases/casesBiochemical engineeringElectrical switching

A housing is used to accommodate electrical switching components. The housing includes a housing body, a cover, and a seal between the housing body and the cover. The cover is fastened to the housing body using fastening elements. A smooth transition is formed between the side parts of the housing body and the cover on the housing side having the seal. Thus a particularly easy to clean housing can be provided, wherein the housing meets the exceptional hygienic requirements that exist, for example, in the field of the food industry or in medical fields. In the housing as descried, soiling can no longer collect on the housing.

Owner:RITTALWERK RUDOLF LOH GMBH & CO KG

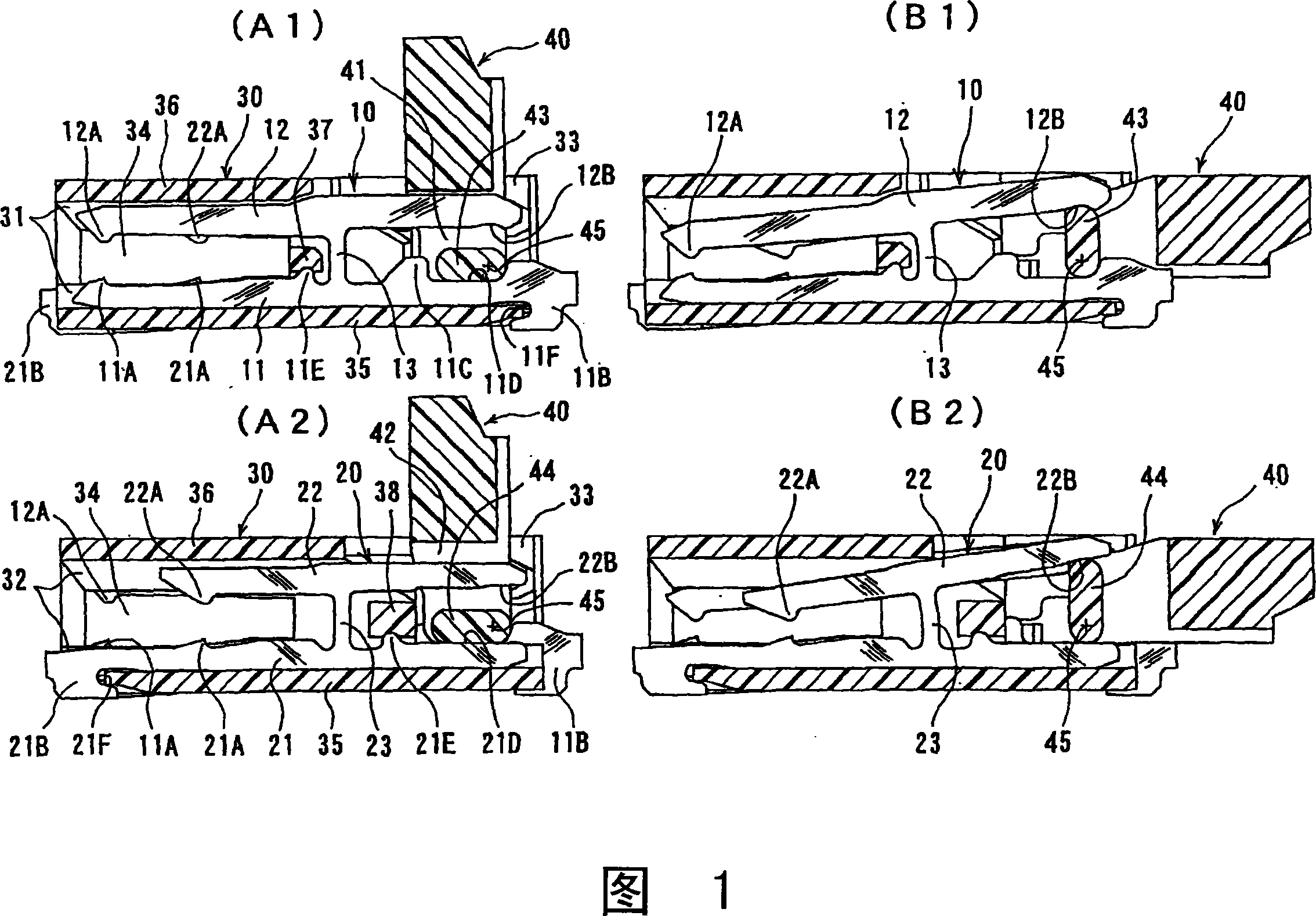

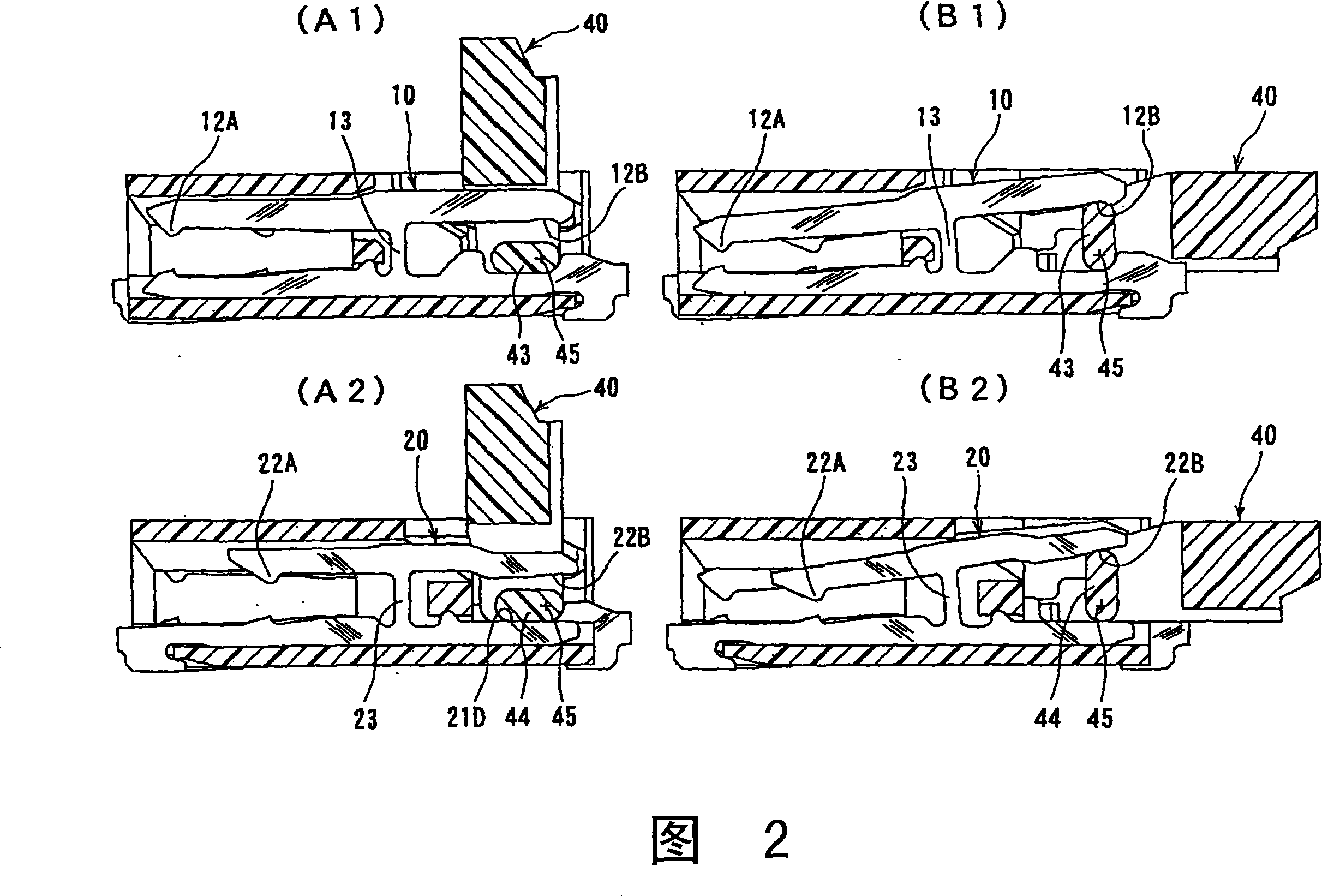

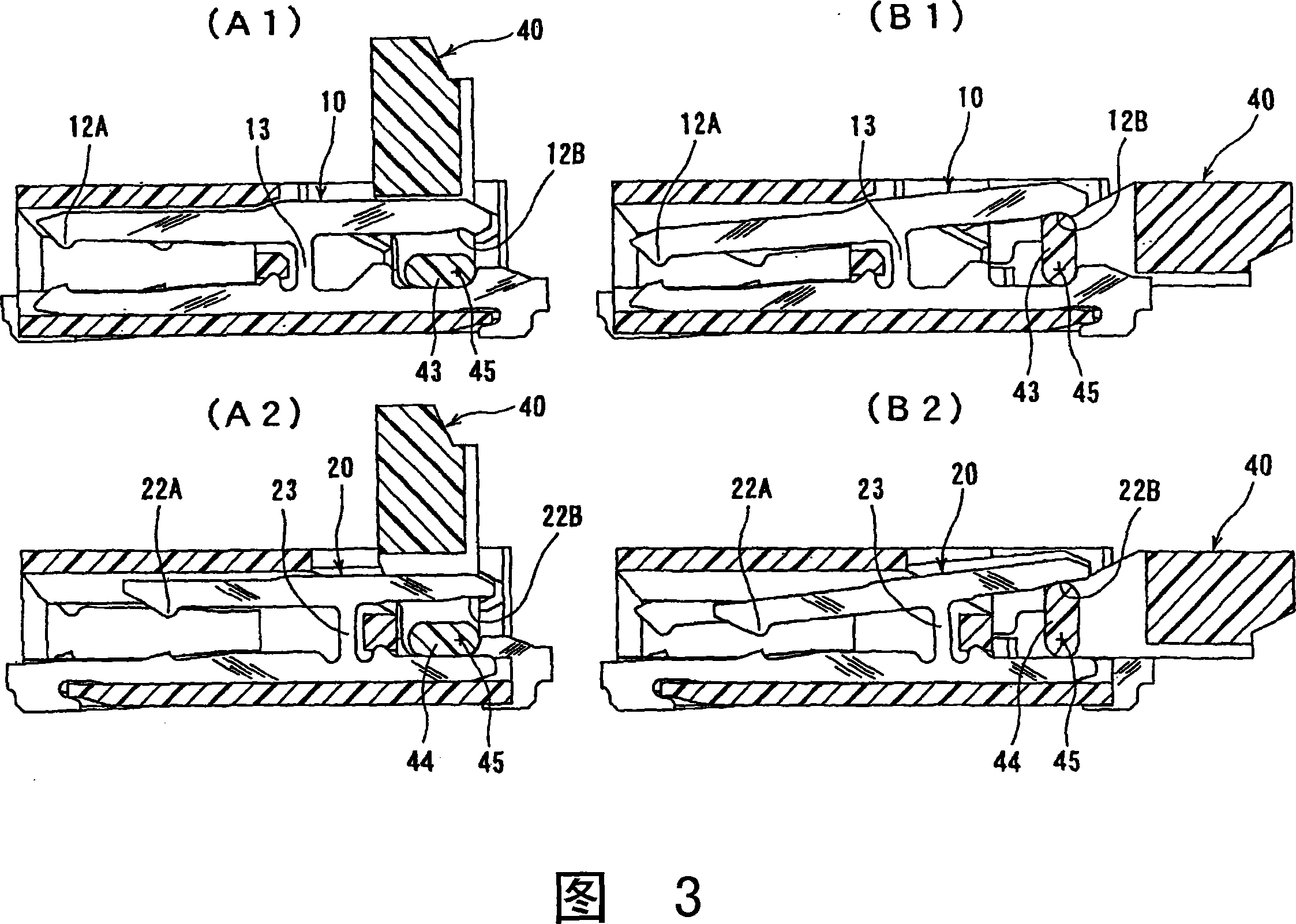

Electrical connector for flat conductor

ActiveCN101202387AExpand the compression areaPress evenlyContact member manufacturingCoupling device detailsElectrical conductorEngineering

A connector for a flat conductor includes a terminal (10) maintaining a flat plane shape and having a fixed arm portion (11) and a movable arm portion (12) extending in a same direction. The fixed arm portion and the movabie arm portion are connected through a joining portion (13) at an intermediate portion thereof in a longitudinal direction thereof. A housing (30) securely holds the fixed arm portion. The movable arm portion has a press portion (12A) on one end thereof in a longitudinal direction thereof and a pressed portion (12B) on the other end thereof. A cam portion (43) of a pressure member presses the pressed portion to displace the pressed portion when the pressure member moves in a specific direction. When the pressed portion is displaced within the plane, the movable arm portion is displaced around the joining portion as a lever to displace the press portion, so that the press portion presses the fiat conductor.

Owner:HIROSE ELECTRIC GROUP

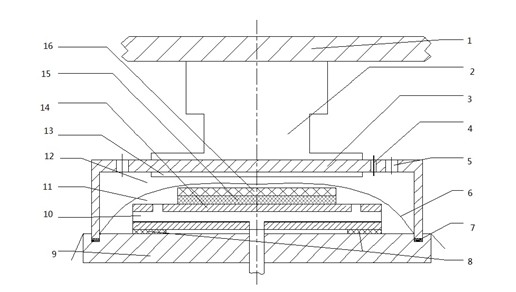

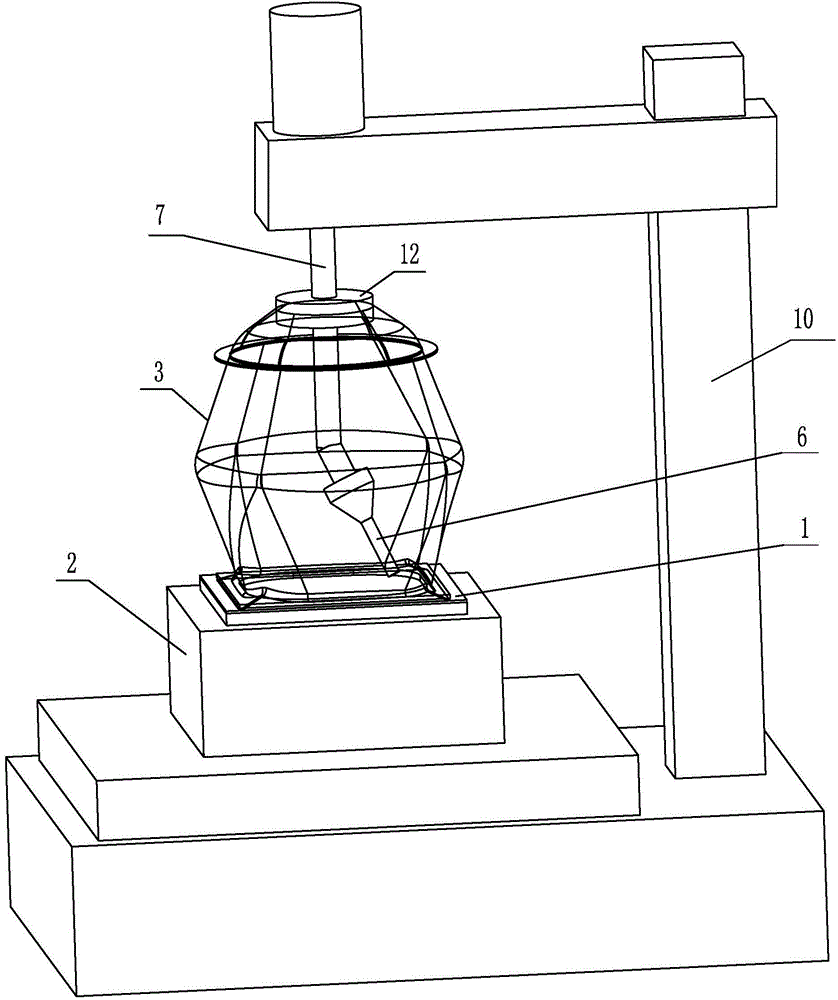

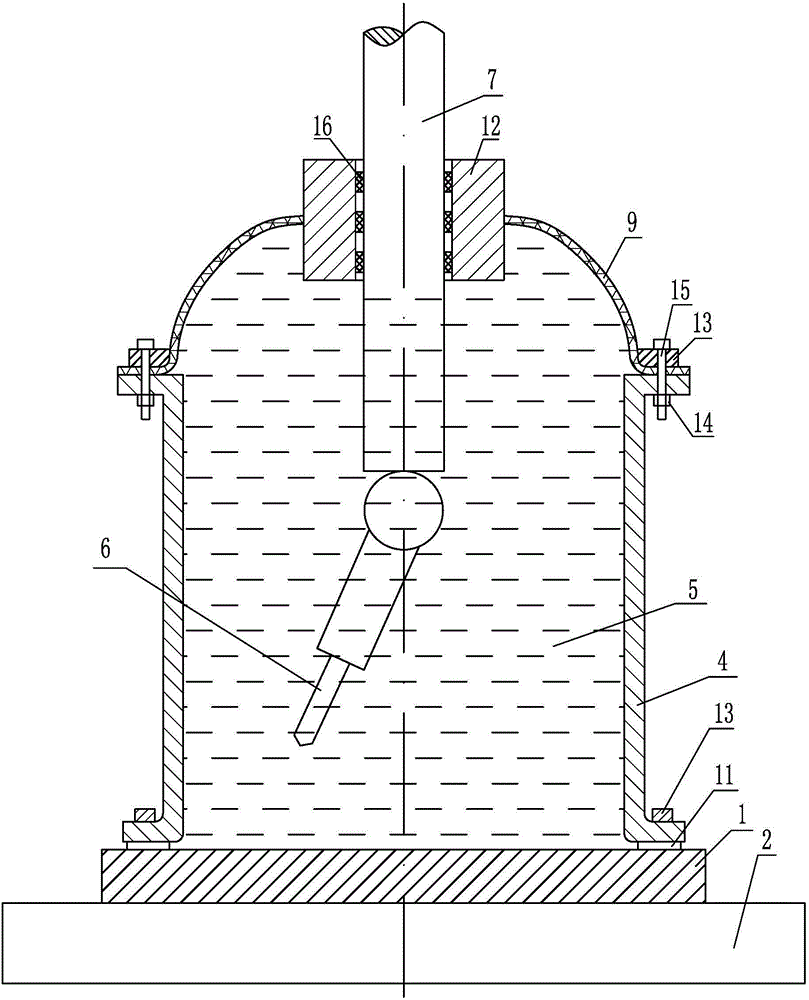

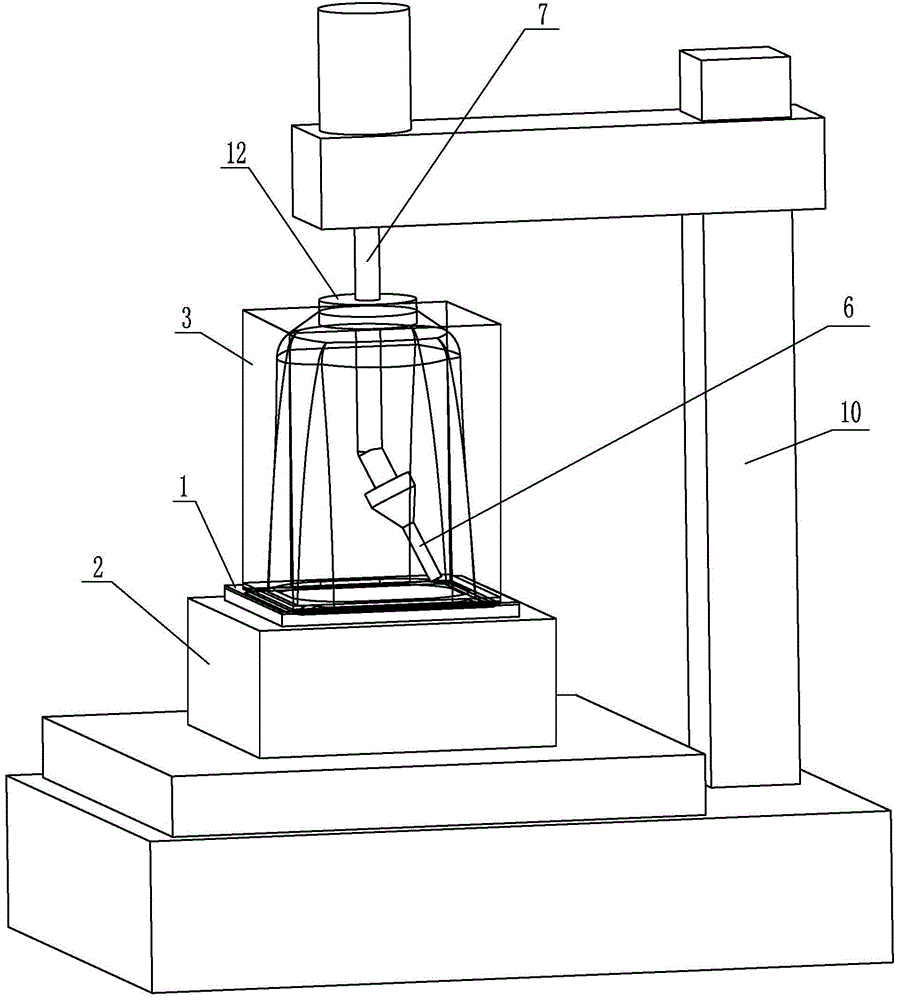

Nano hot stamping device

The invention discloses a nano hot stamping device which comprises a mould (16), a blank (15), a heating plate (14), a base (9) and a cavity (3), wherein the cavity (3) and the base (9) are movably sealed to form an enclosed space; the mould (16), the blank (15) and the heating plate (14) are closed in the enclosed space; a film (6) is also arranged in the cavity (3); the film (6) is fixed on a sealing contact surface of the cavity (3) and the base (9), and the enclosed space formed by the cavity and the base is divided into a pressure cavity (12) and a vacuum cavity (11); the pressure cavity (12) is communicated with an air inlet channel (5); and the vacuum cavity (11) is communicated with an air exhaust channel (10). According to the invention, a nano stamping die core is balanced and uniform and is pressed into a stamping base plate in a mode of being vertical to the surface; and the product is stable in quality, simple in structure and convenient to operate.

Owner:SUZHOU GUANGDUO MICRO NANO DEVICE

Integrated system for the close-down of the stocking on circular machines for tubular semifinished production in stitch and the device relative to it

InactiveCN101501259AImprove productivityProduction time synchronizationCircular knitting machinesWork in processEngineering

The invention provides a system and a method in the production of stitch tubular products for the closing of the seam of the point of a tubular stitch product. The system consists of a circular knitting machine with a cylinder of needles; a tacking-on device with a rim of holding crooks; and a stapler arranged on the outside of the cylinder of needles and used to carry out the closing of the point. Characteristically according to an aspect of the invention is that the tacking-on device includes a body substantially circulate subdivided in two substantially specular portions, wherein each of them is equipped with a semi-arc of holding crooks. The specular portions are hinged around to the overturn axis which is substantially diametral, so as to obtain the overturning of a portion on the other and therefore to bring a semi-arc of oppositely holding crooks with the semi-arc of opposite holding crooks. In this arrangement the tacking- on device can allow the closing by the stitching or looping of the point, for example placing the stapler below the circular machine, in a position in which the tacking-on device is placed after having taken and extracted the tubular stitch product to sew from the circular machine.

Owner:NTA INC +1

Pressure-assistant thin-wall blank precise processing method

ActiveCN104889763APress evenlyReliable compressionWork clamping meansPositioning apparatusThin walledEngineering

The invention discloses a pressure-assistant thin-wall blank precise processing method, relating to a precise processing method of a thin-wall blank and solving the problem that the shape and size precision of the final part cannot be guaranteed as an existing cutting processing method and device cannot avoid complex deformation or movement of large-size thin-wall blank during the cutting process. The method comprises the main steps of: step 1, placing a to-be-cut blank on a support molding bed and positioning the blank; step 2, placing a pressure medium cavity on the to-be-processed blank; step 3, filling a medium with the pressure medium cavity; step 4, cutting the to-be-cut blank by utilizing a cutting tool placed inside the pressure medium cavity to obtain a finally needed part; step 5, removing pressure in the pressure medium cavity, moving away the cutting tool and the pressure medium cavity and taking the part out. The pressure-assistant thin-wall blank precise processing method is used for precise processing of the thin-wall blank.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com