Patents

Literature

97results about How to "Increase assembly flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

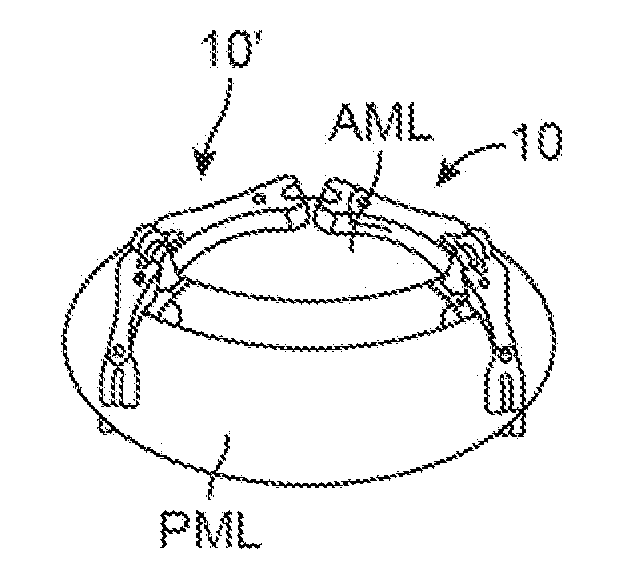

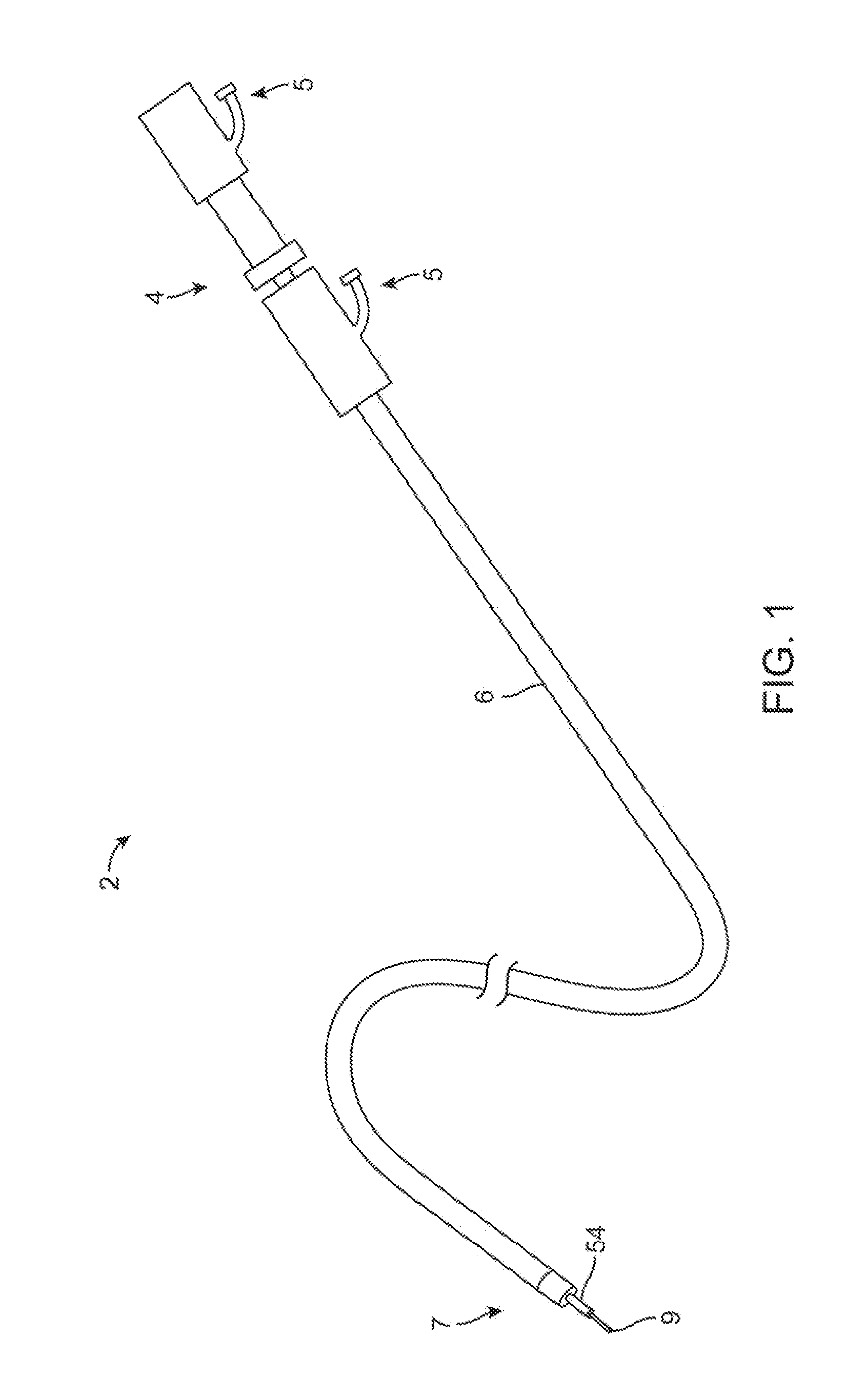

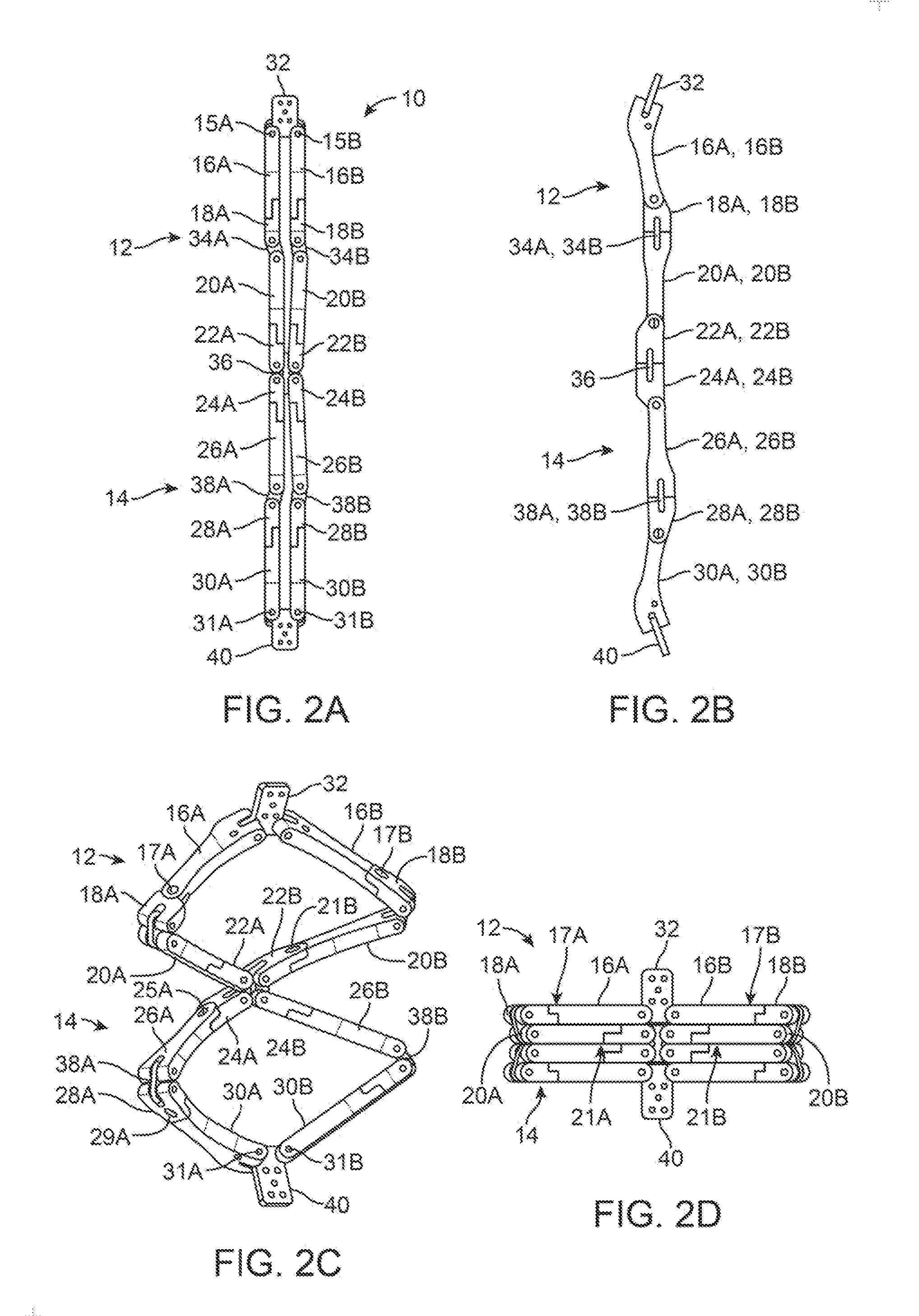

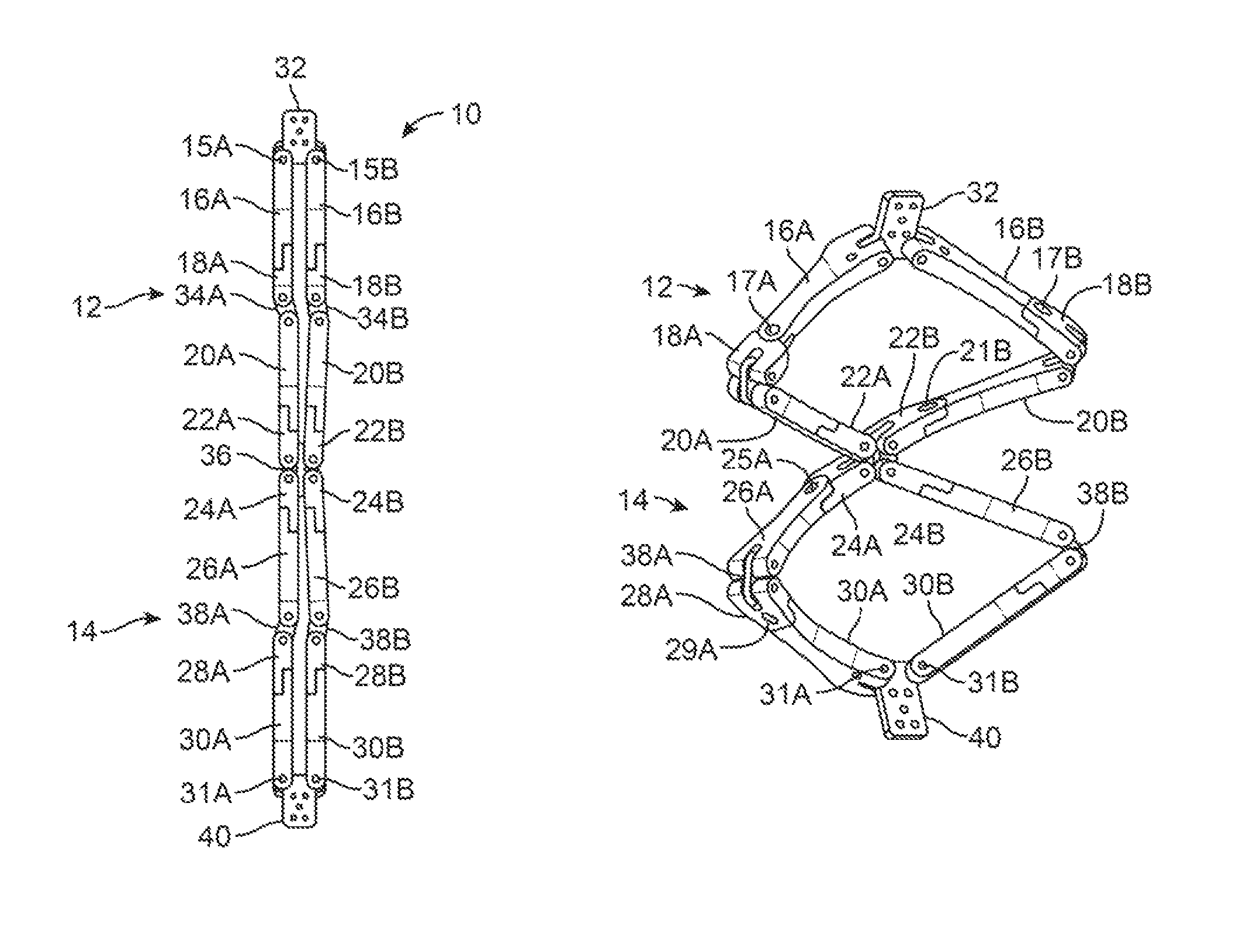

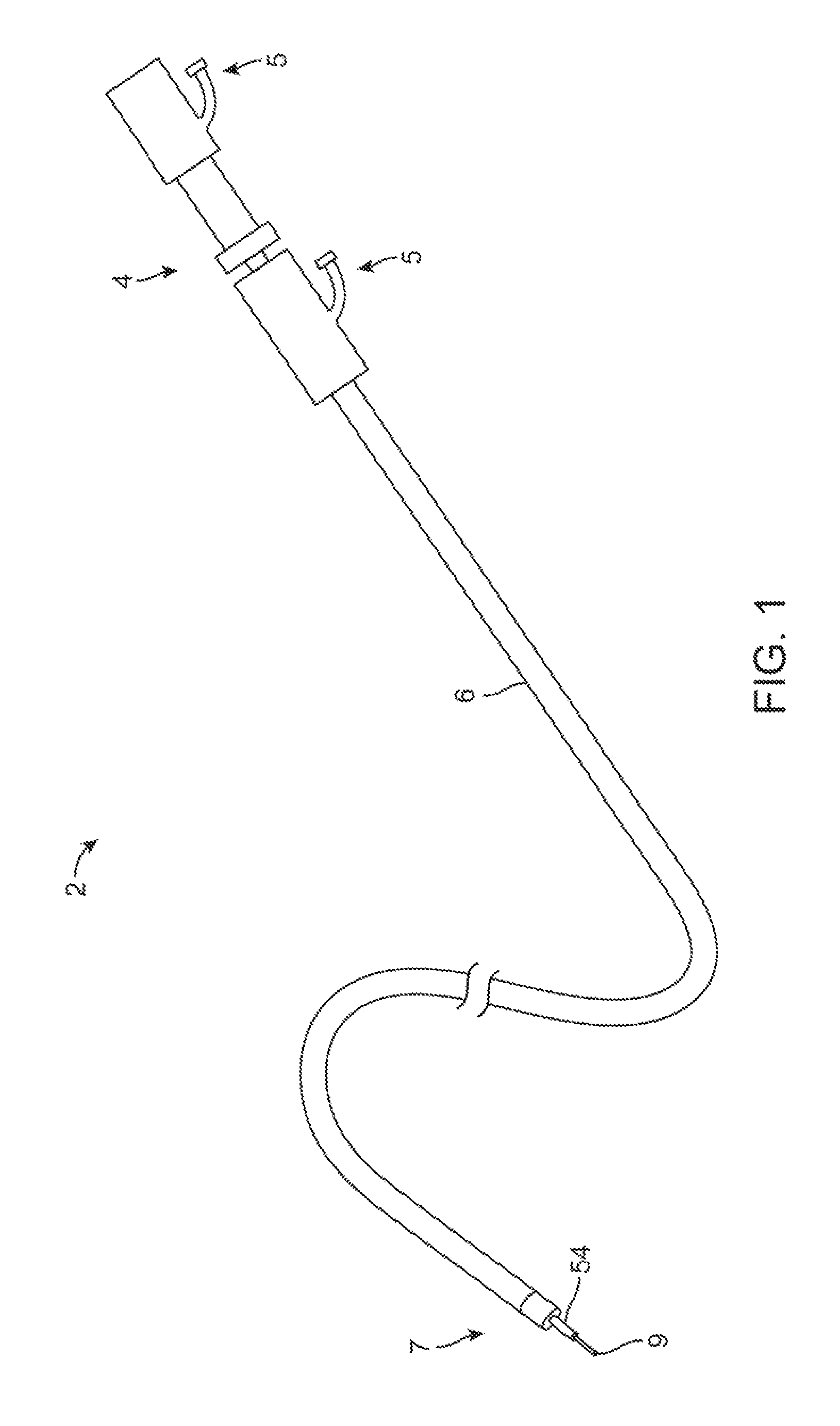

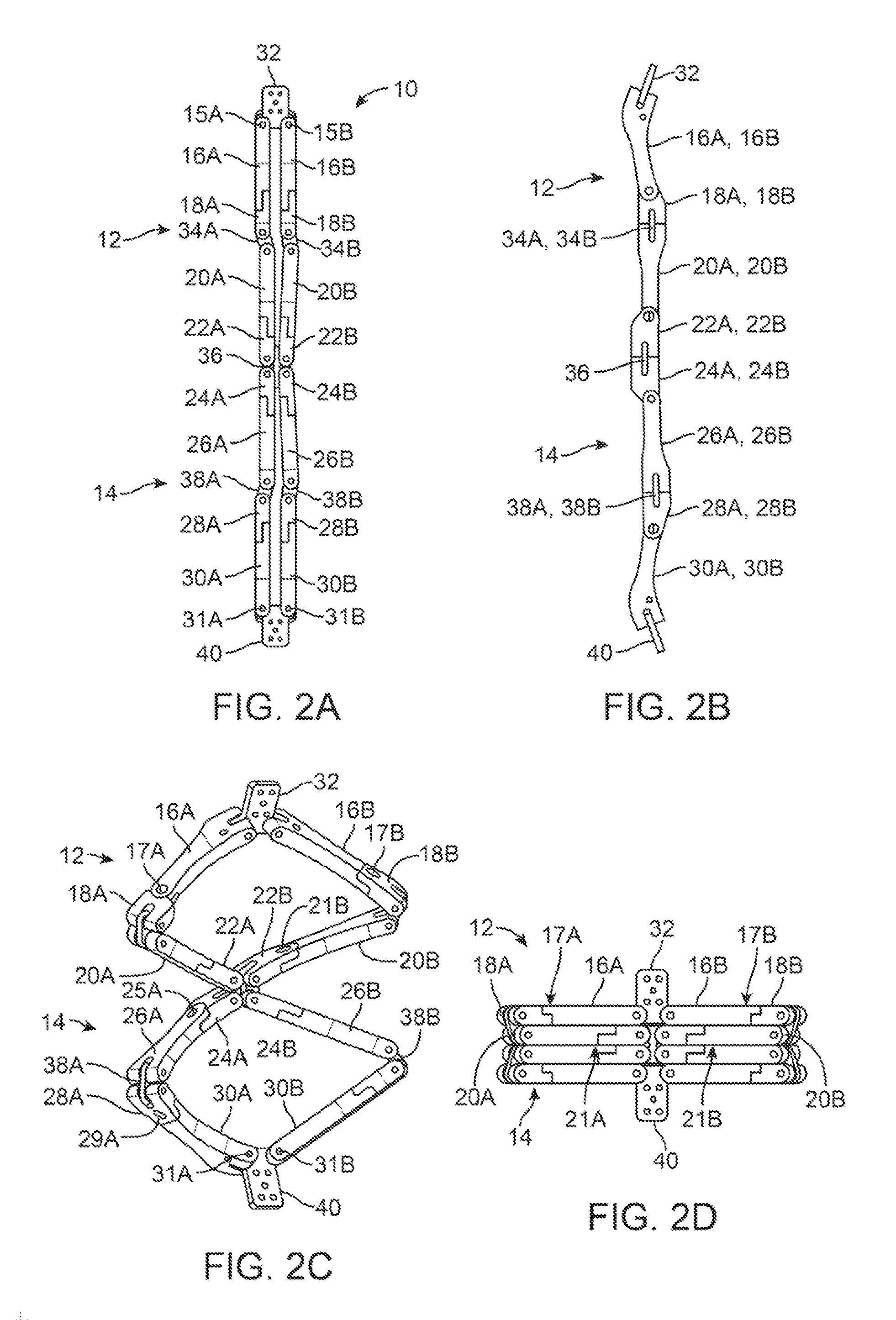

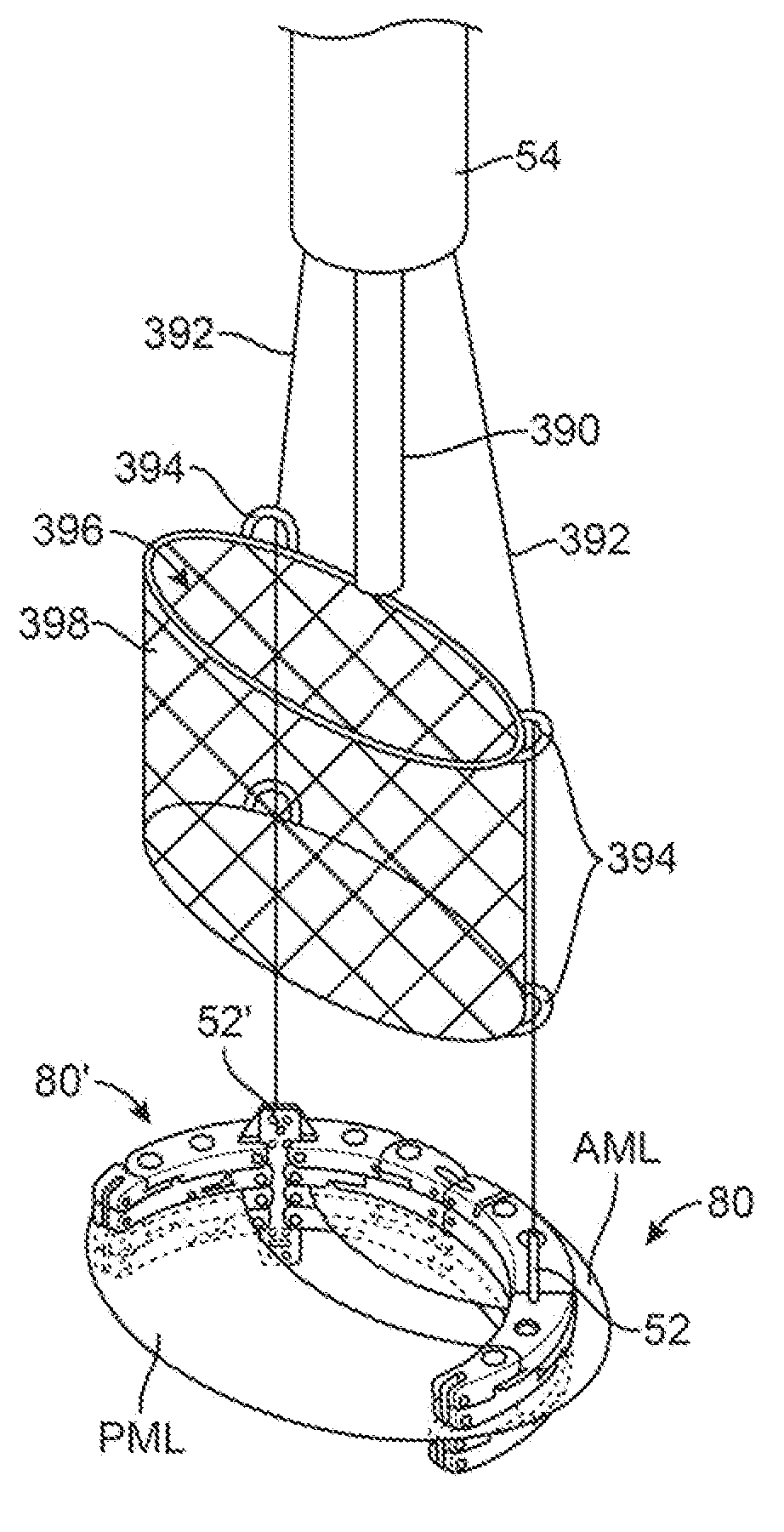

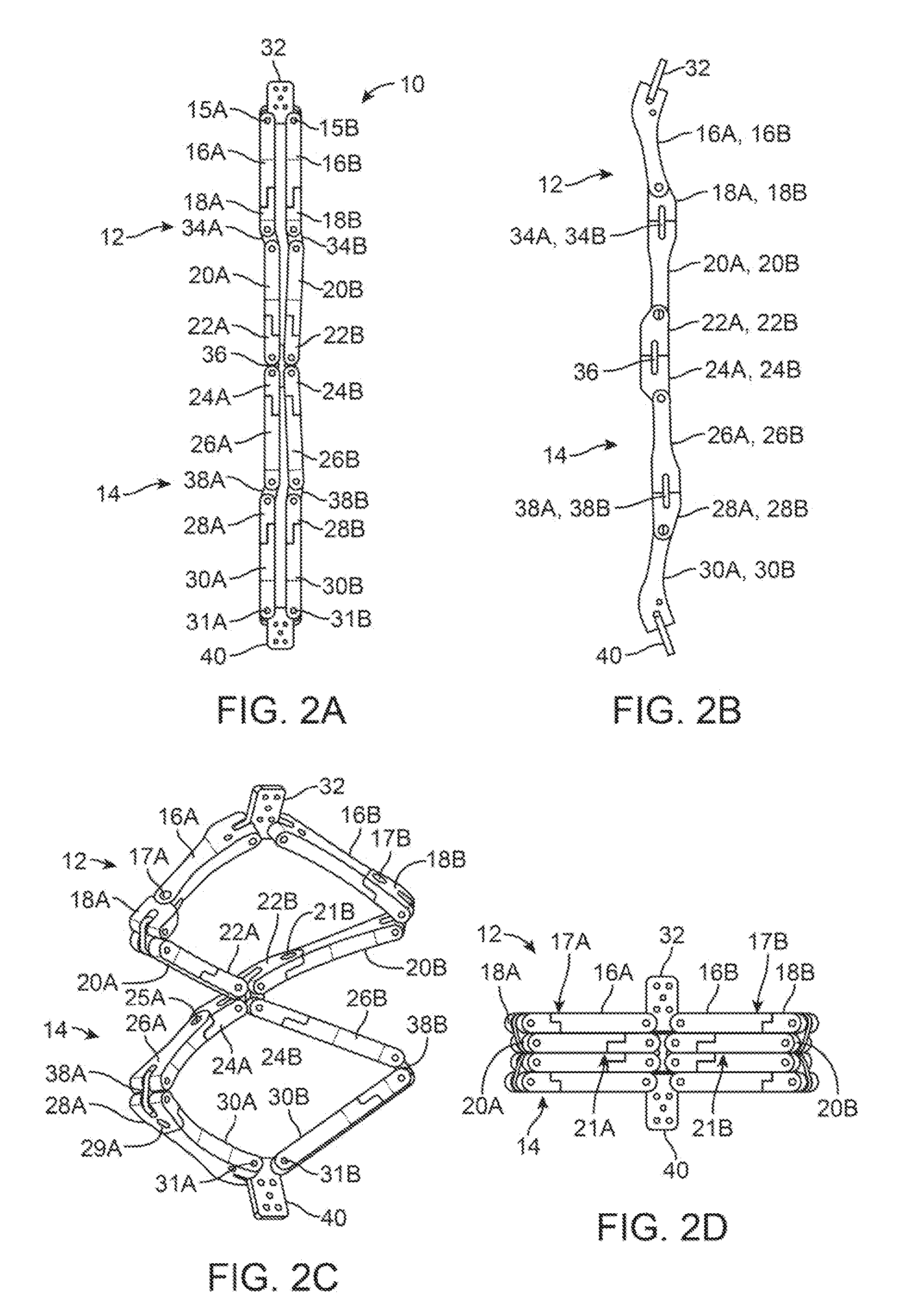

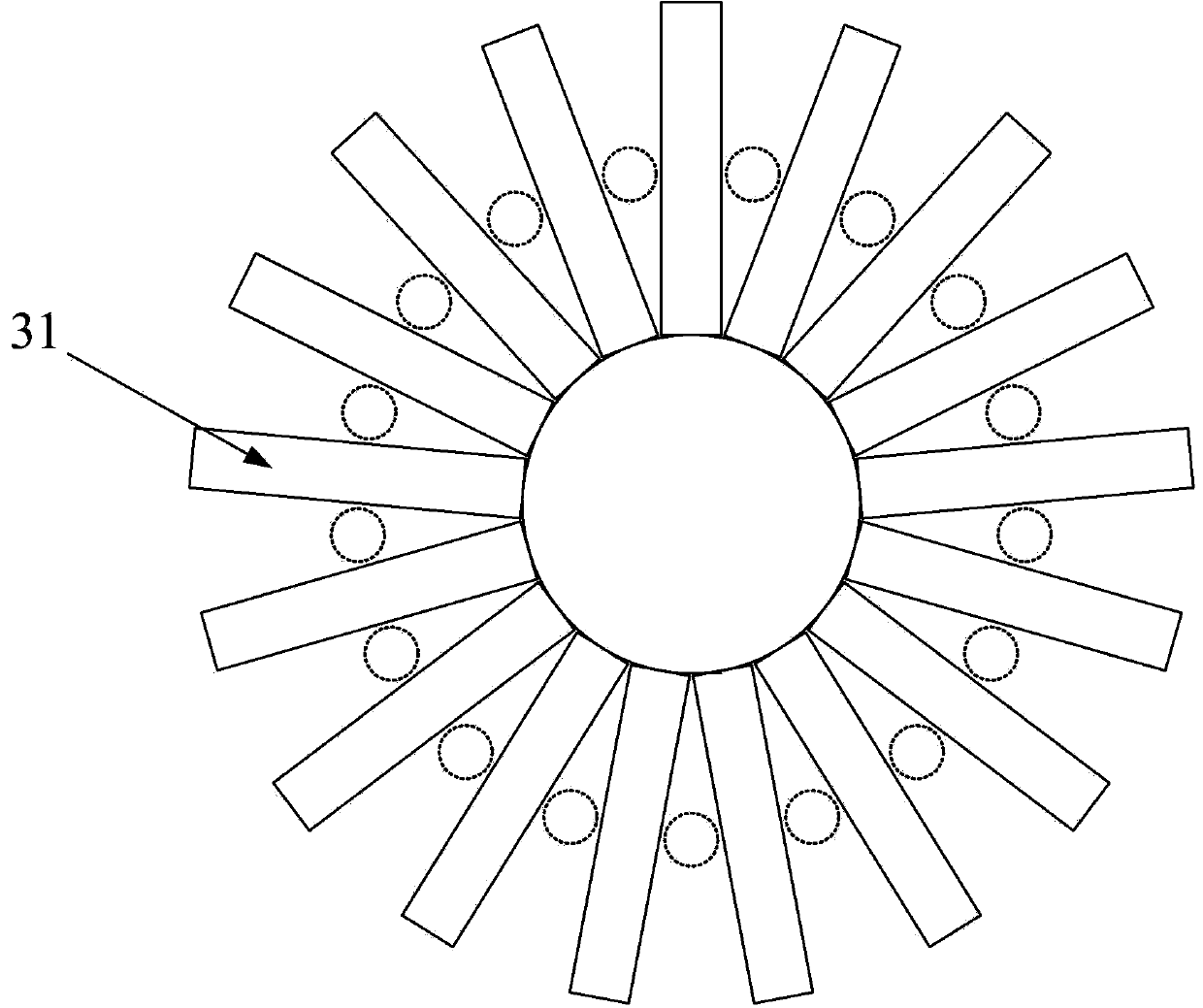

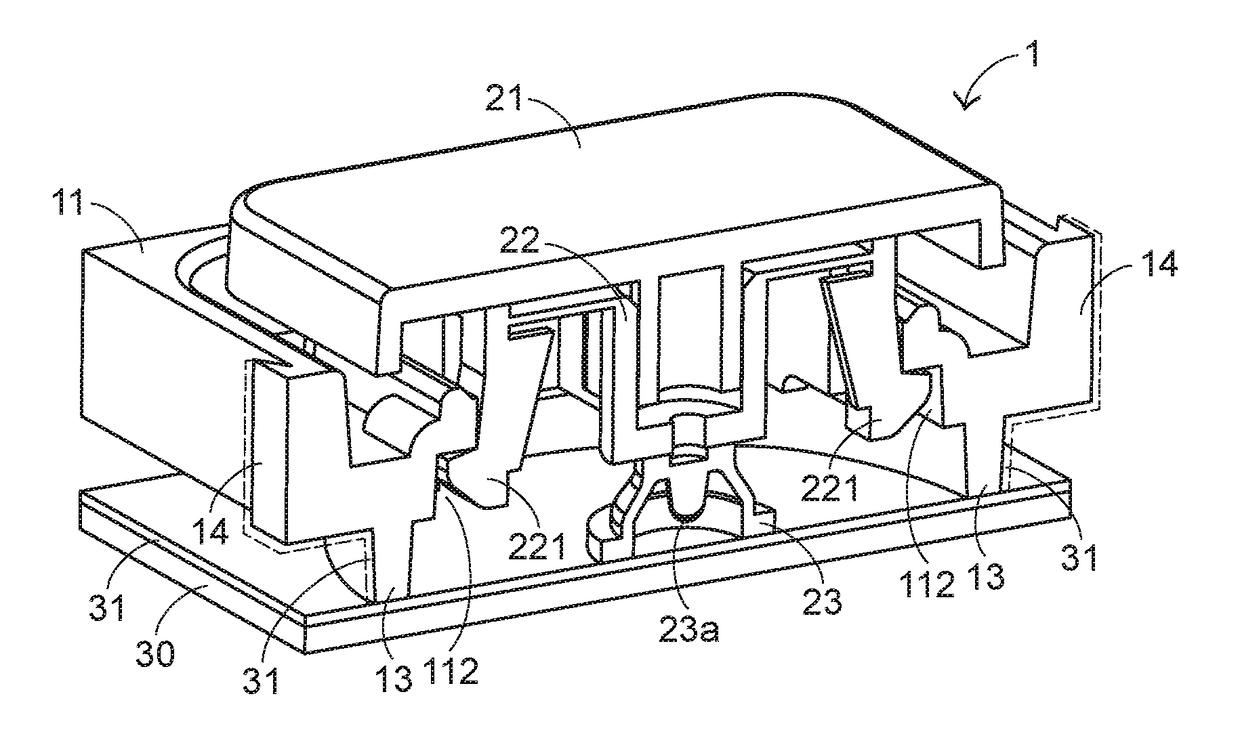

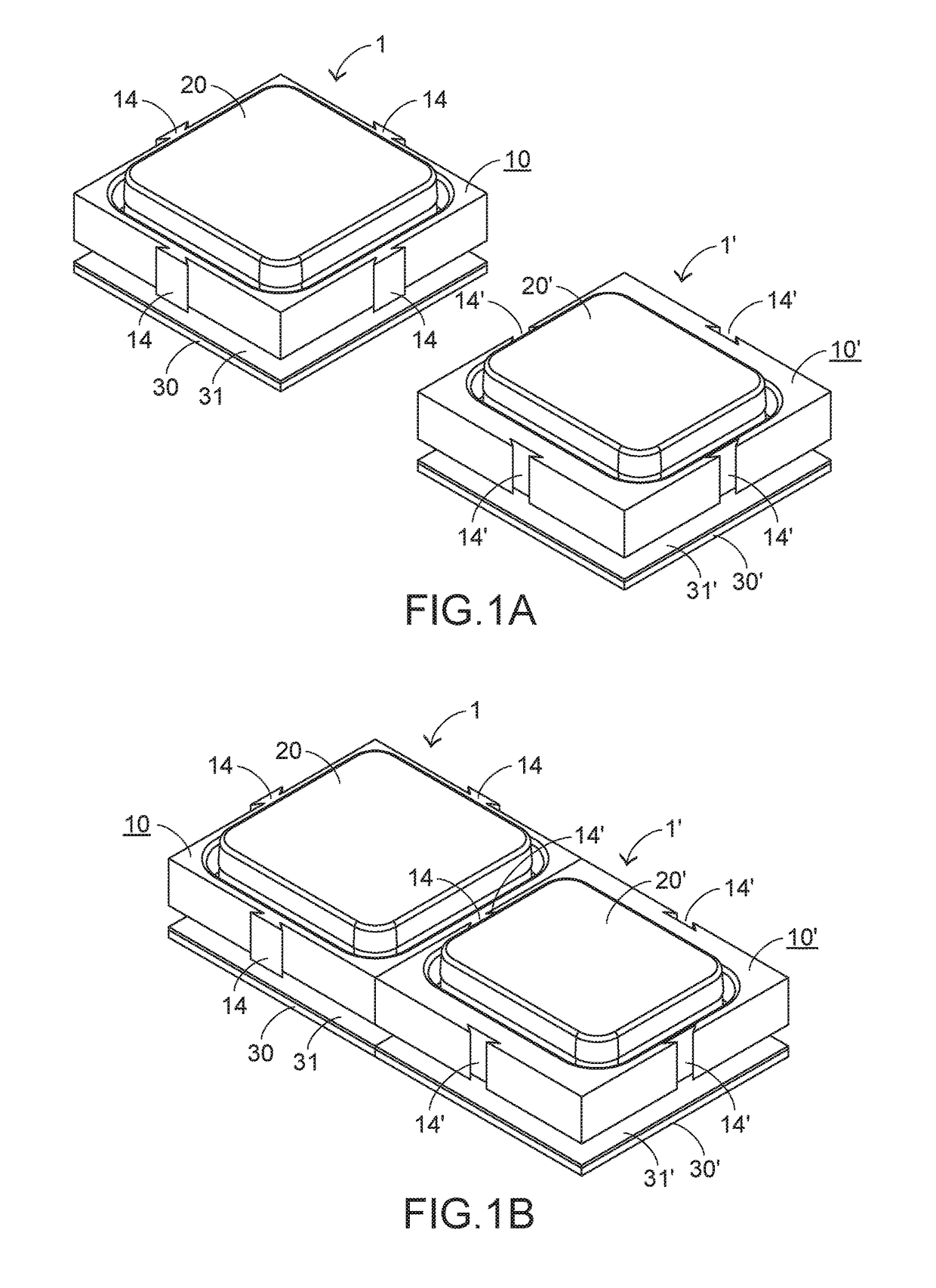

System for mitral valve repair and replacement

ActiveUS20120165930A1Increase flexibilityIncrease assembly flexibilityBone implantAnnuloplasty ringsProsthesisCatheter

Systems for mitral valve repair are disclosed where one or more mitral valve interventional devices may be advanced intravascularly into the heart of a patient and deployed upon or along the mitral valve to stabilize the valve leaflets. The interventional device may also facilitate the placement or anchoring of a prosthetic mitral valve implant. The interventional device may generally comprise a distal set of arms pivotably and / or rotating coupled to a proximal set of arms which are also pivotably and / or rotating coupled. The distal set of arms may be advanced past the catheter opening to a subannular position (e.g., below the mitral valve) and reconfigured from a low-profile delivery configuration to a deployed securement configuration. The proximal arm members may then be deployed such that the distal and proximal arm members may grip the leaflets between the two sets of arms to stabilize the leaflets.

Owner:TWELVE

System for mitral valve repair and replacement

ActiveUS9421098B2Increase flexibilityIncrease assembly flexibilityAnnuloplasty ringsProsthesisCatheter

Systems for mitral valve repair are disclosed where one or more mitral valve interventional devices may be advanced intravascularly into the heart of a patient and deployed upon or along the mitral valve to stabilize the valve leaflets. The interventional device may also facilitate the placement or anchoring of a prosthetic mitral valve implant. The interventional device may generally comprise a distal set of arms pivotably and / or rotating coupled to a proximal set of arms which are also pivotably and / or rotating coupled. The distal set of arms may be advanced past the catheter opening to a subannular position (e.g., below the mitral valve) and reconfigured from a low-profile delivery configuration to a deployed securement configuration. The proximal arm members may then be deployed such that the distal and proximal arm members may grip the leaflets between the two sets of arms to stabilize the leaflets.

Owner:TWELVE

System for mitral valve repair and replacement

ActiveUS20160324640A1Increase flexibilityIncrease assembly flexibilityAnnuloplasty ringsProsthesisMitral valve leaflet

Systems for mitral valve repair are disclosed where one or more mitral valve interventional devices may be advanced intravascularly into the heart of a patient and deployed upon or along the mitral valve to stabilize the valve leaflets. The interventional device may also facilitate the placement or anchoring of a prosthetic mitral valve implant. The interventional device may generally comprise a distal set of arms pivotably and / or rotating coupled to a proximal set of arms which are also pivotably and / or rotating coupled. The distal set of arms may be advanced past the catheter opening to a subannular position (e.g., below the mitral valve) and reconfigured from a low-profile delivery configuration to a deployed securement configuration. The proximal arm members may then be deployed such that the distal and proximal arm members may grip the leaflets between the two sets of arms to stabilize the leaflets.

Owner:TWELVE INC

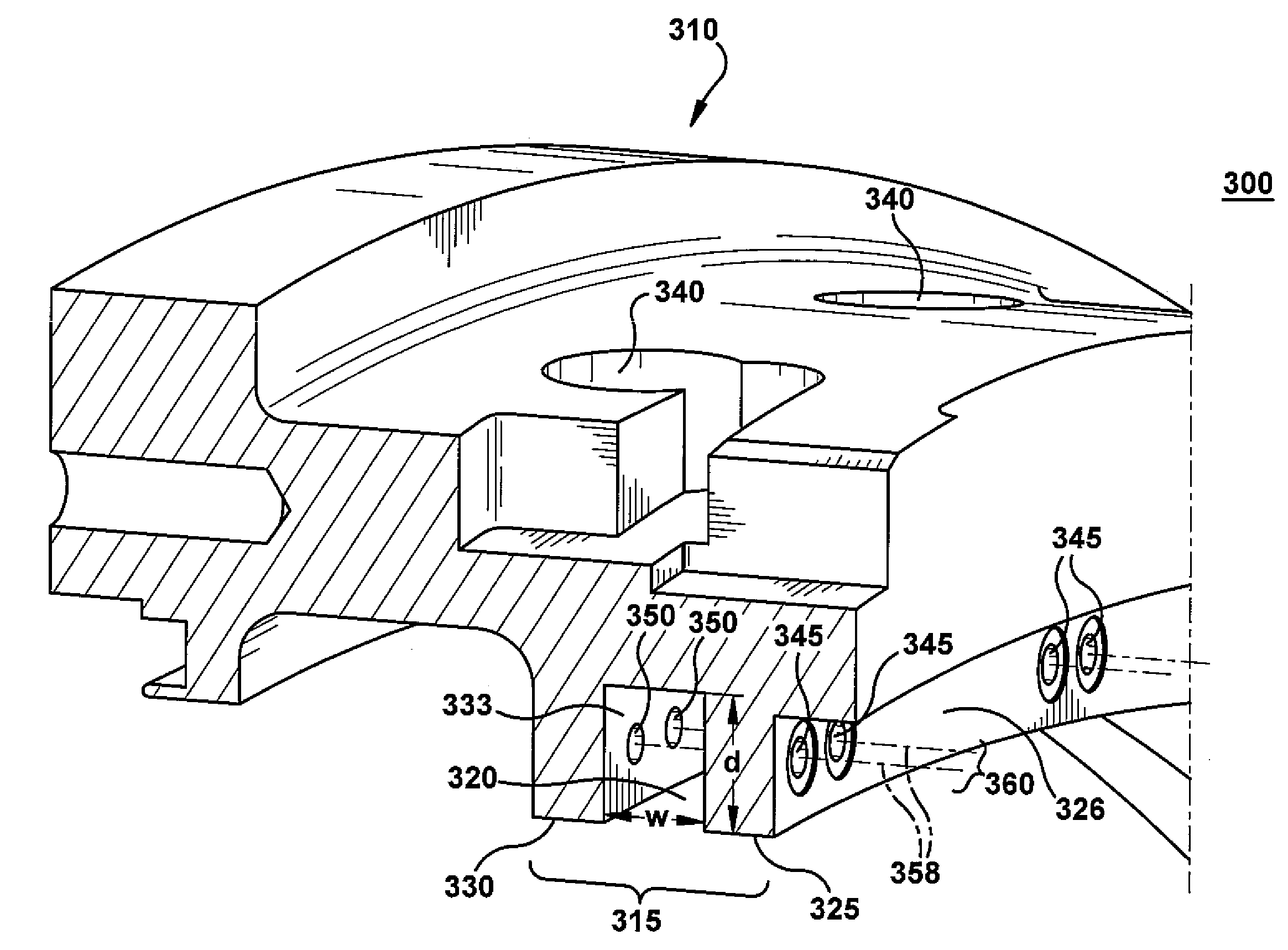

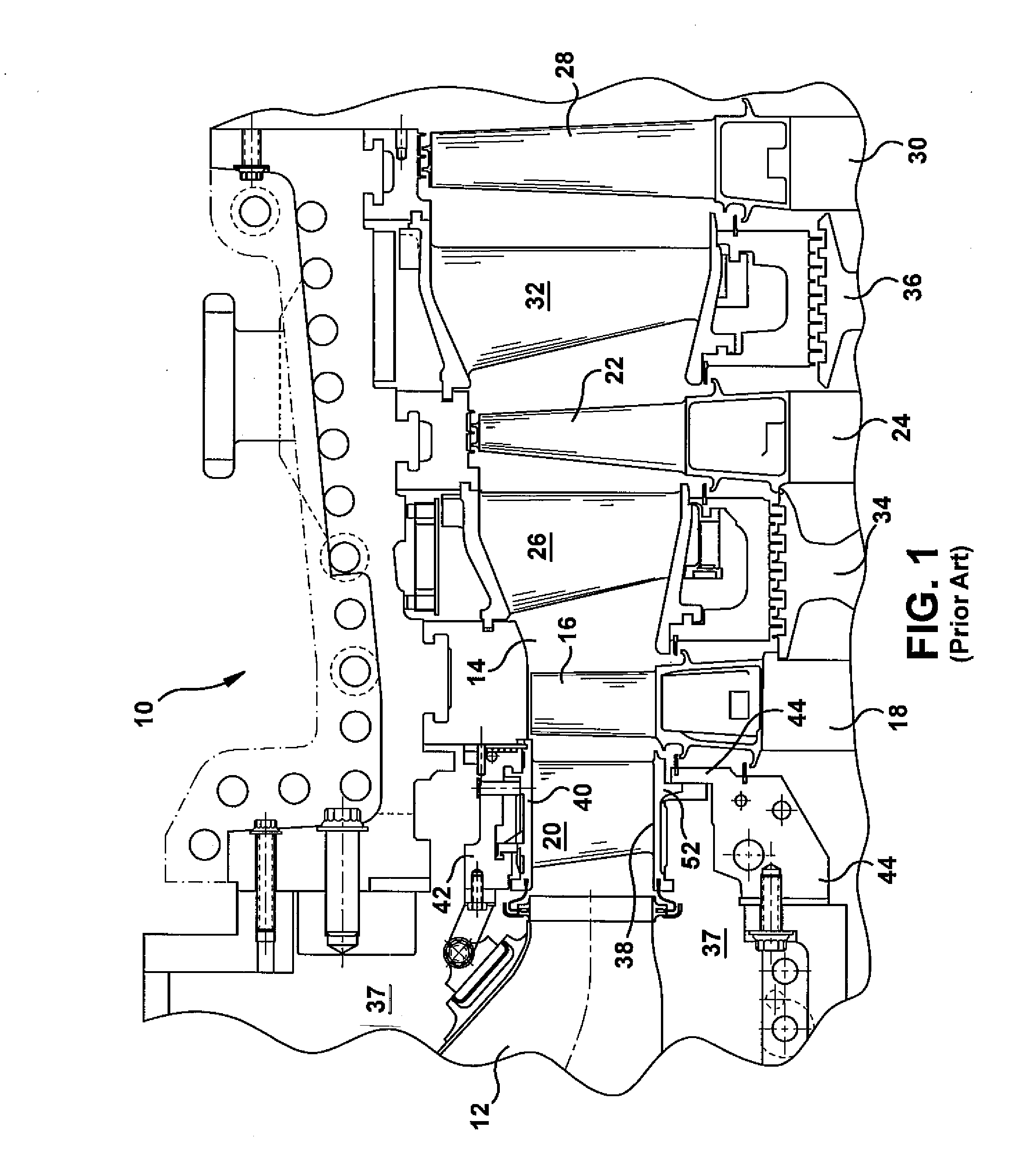

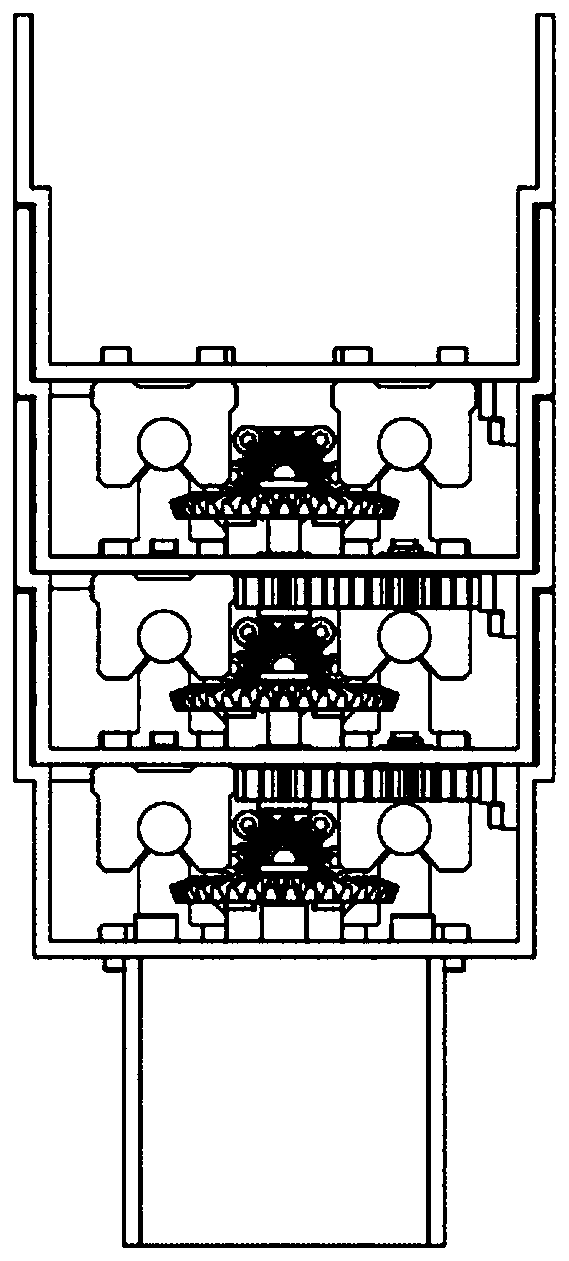

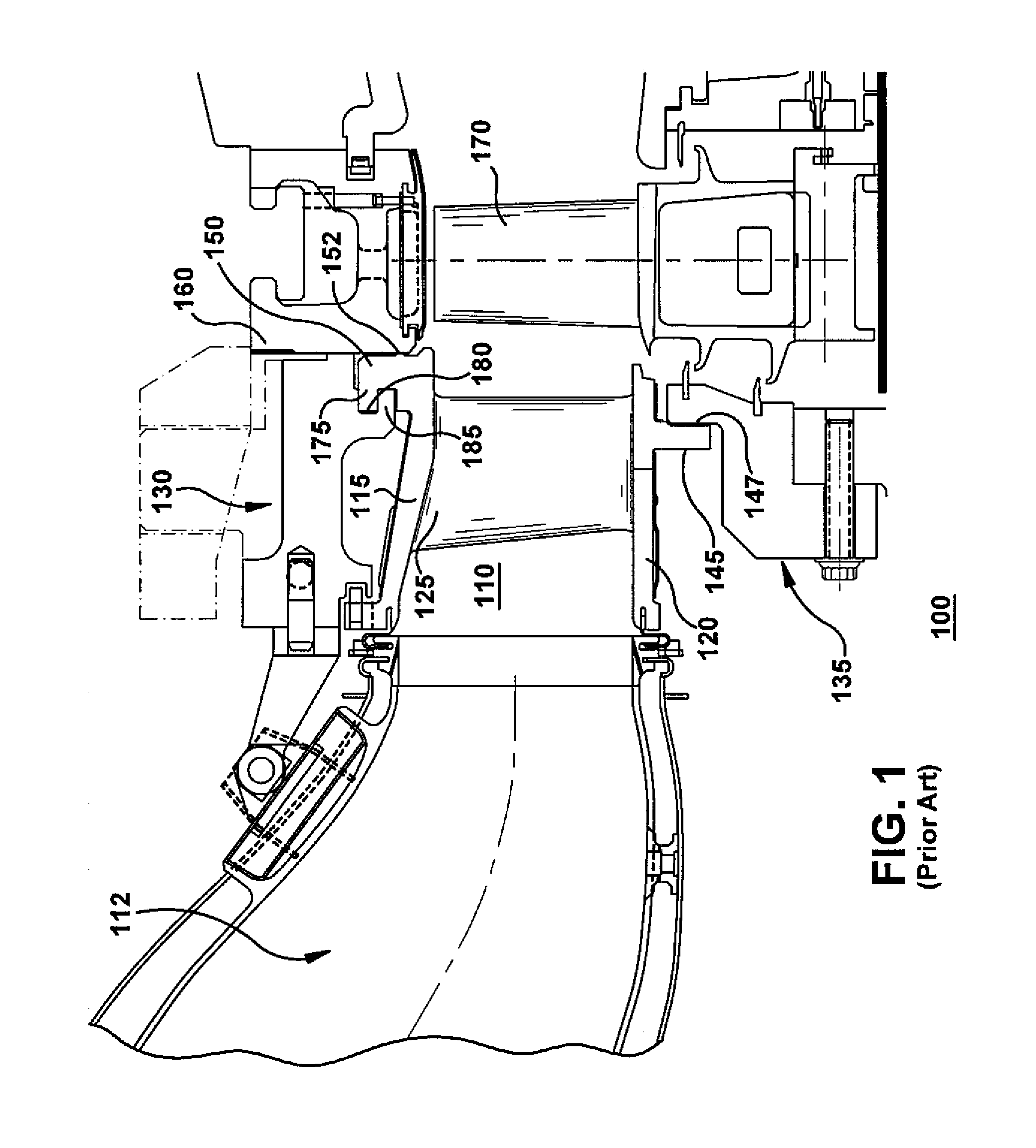

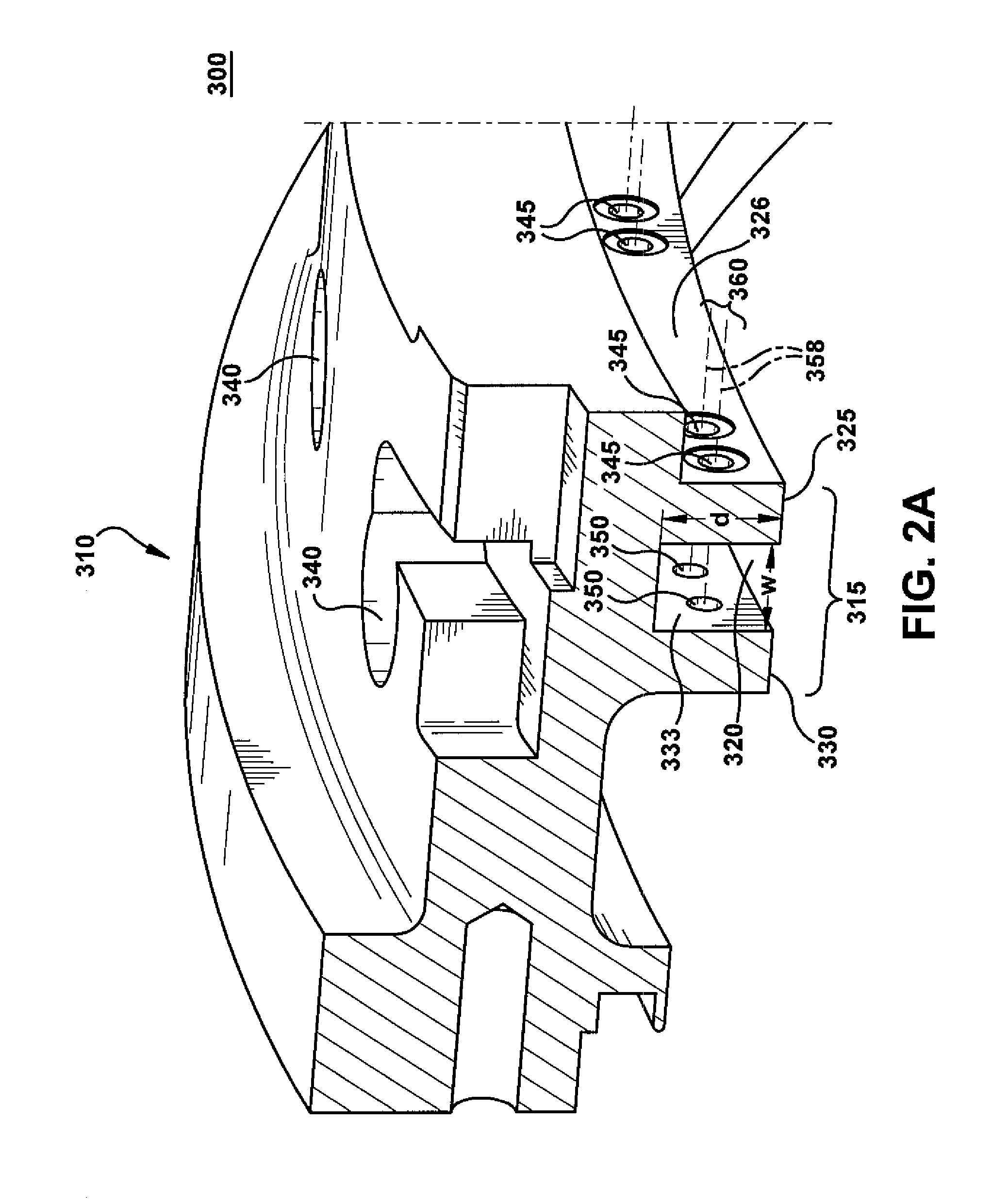

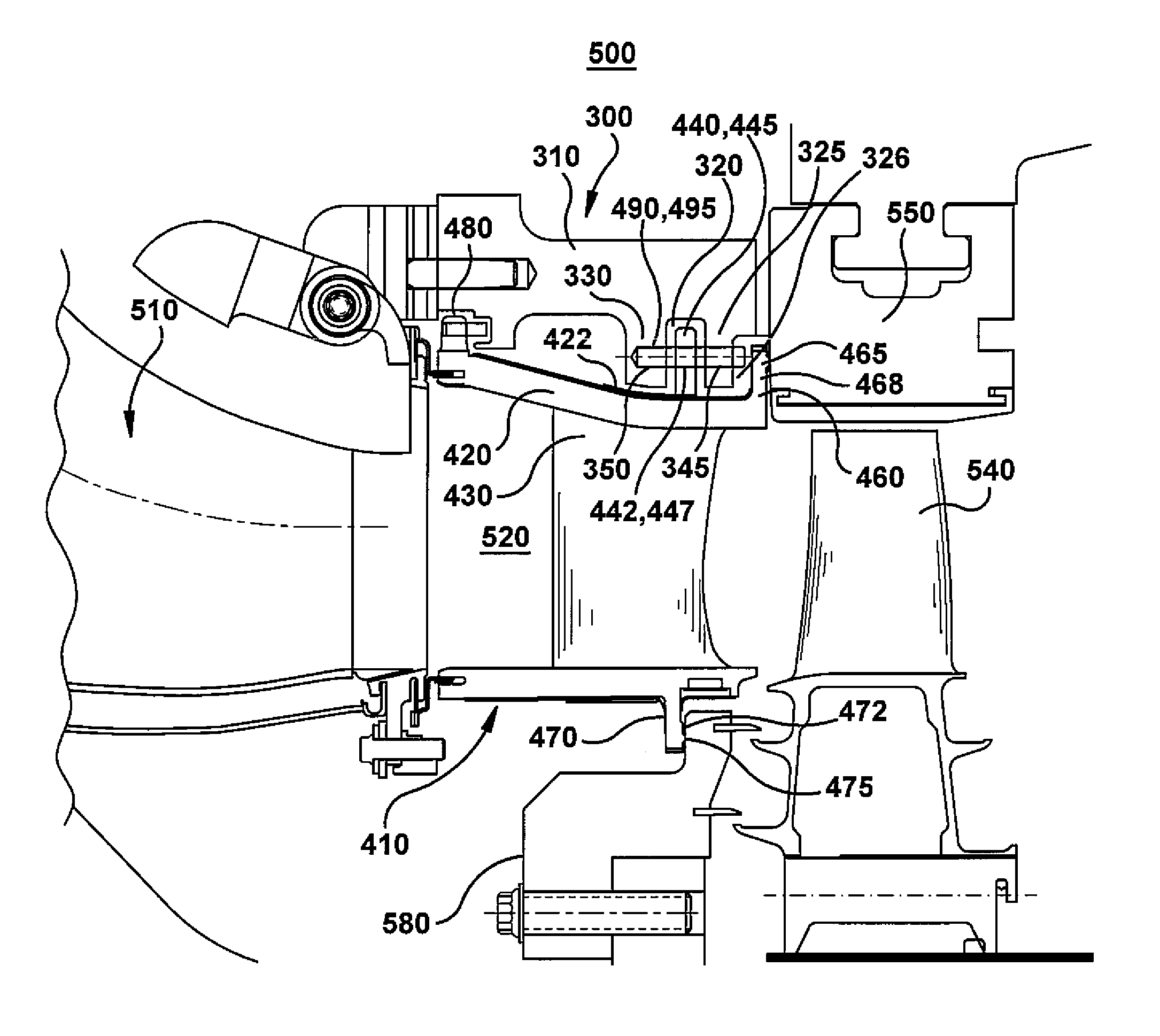

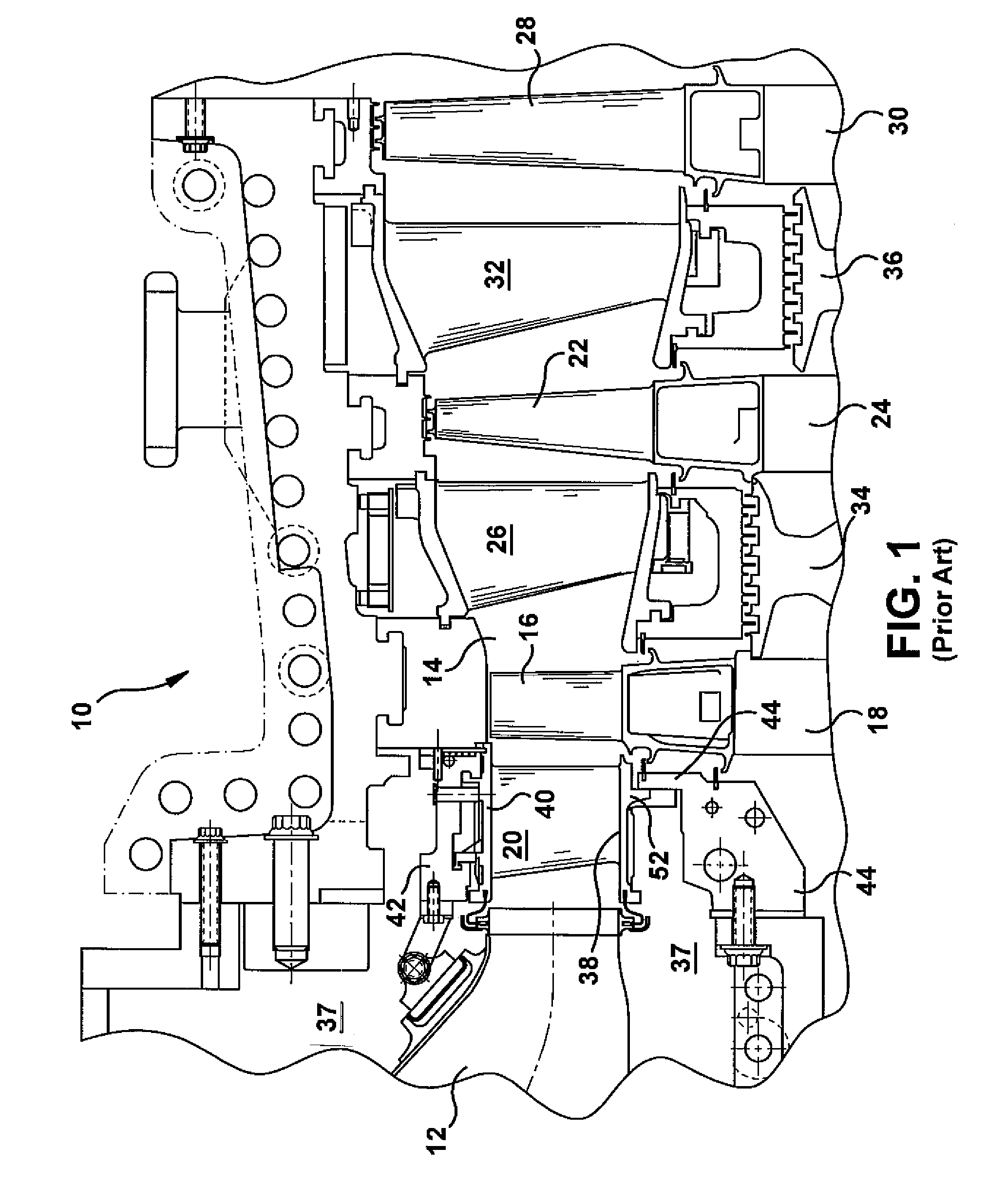

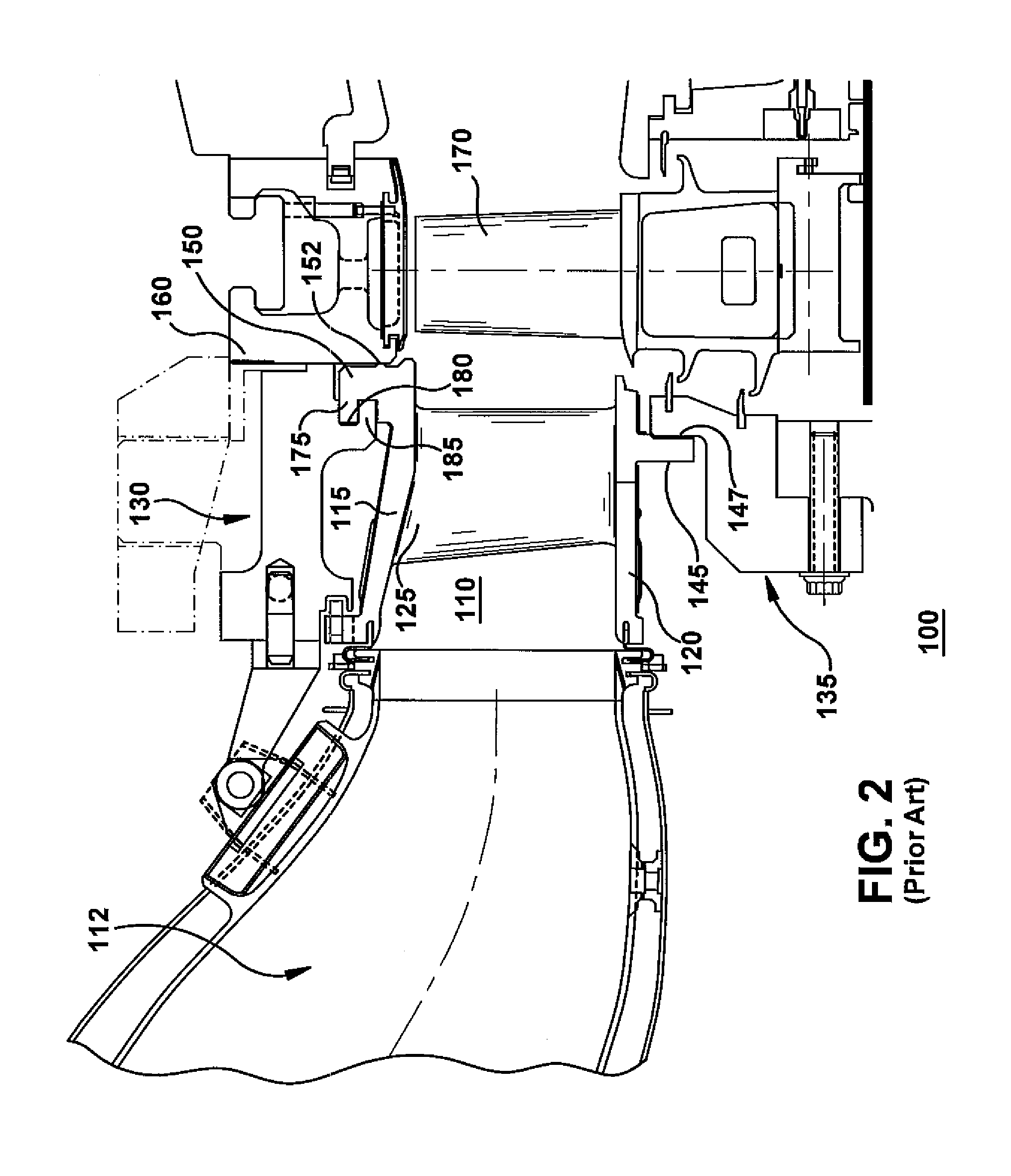

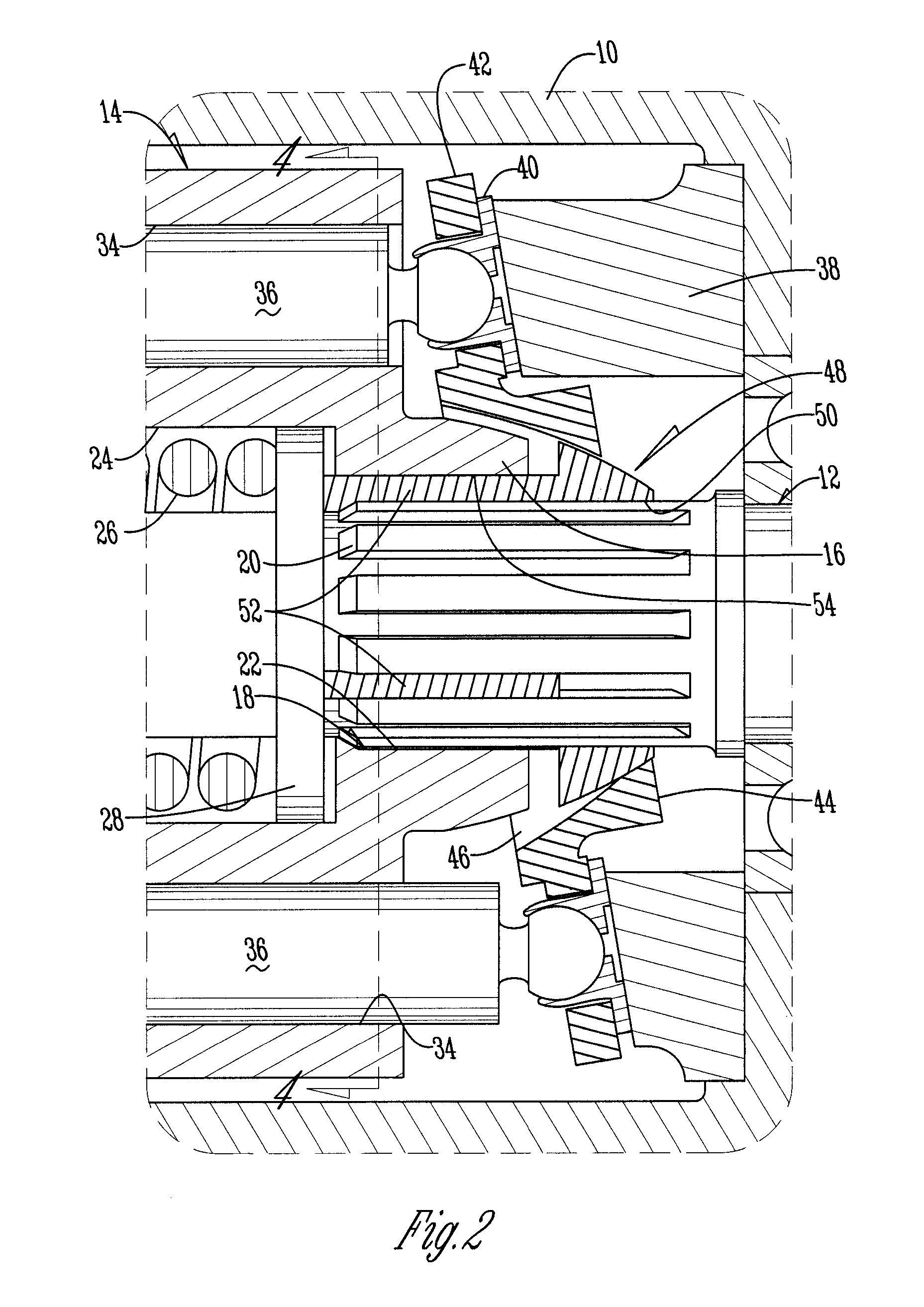

Outer Sidewall Retention Scheme For A Singlet First Stage Nozzle

InactiveUS20090038311A1Improve sealingImprove insulation performancePump componentsGas turbine plantsEngineeringGas turbines

An outer sidewall retention scheme for a singlet first stage nozzle of a gas turbine. The retention scheme includes a circumferential retaining ring with a main body and a pair of circumferential retaining lands projecting inward radially. A circumferential annular retaining groove is formed between the pair of circumferential retaining lands. A first lug and a second lug mounted on an outer face of the outer sidewall of each nozzle are adapted to fit within the circumferential annular retaining groove of the retaining ring and are supported radially and circumferentially by a first retaining pin and a second retaining pin, each pin passing though the circumferential retaining lands. Each nozzle further includes a chordal hinge rail and seal on the outer sidewall and a chordal hinge rail and seal on the inner sidewall providing axial support for the nozzle.

Owner:GENERAL ELECTRIC CO

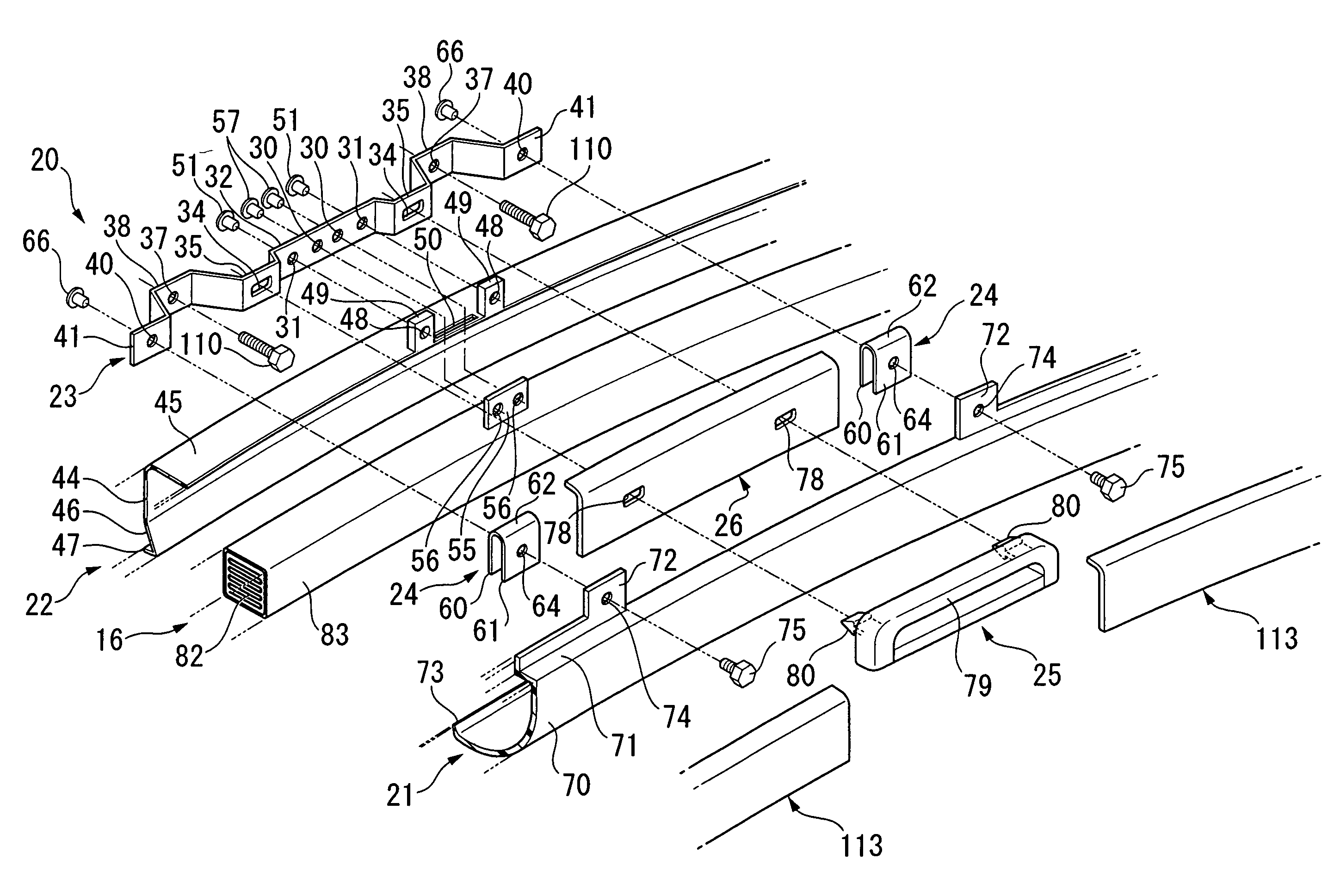

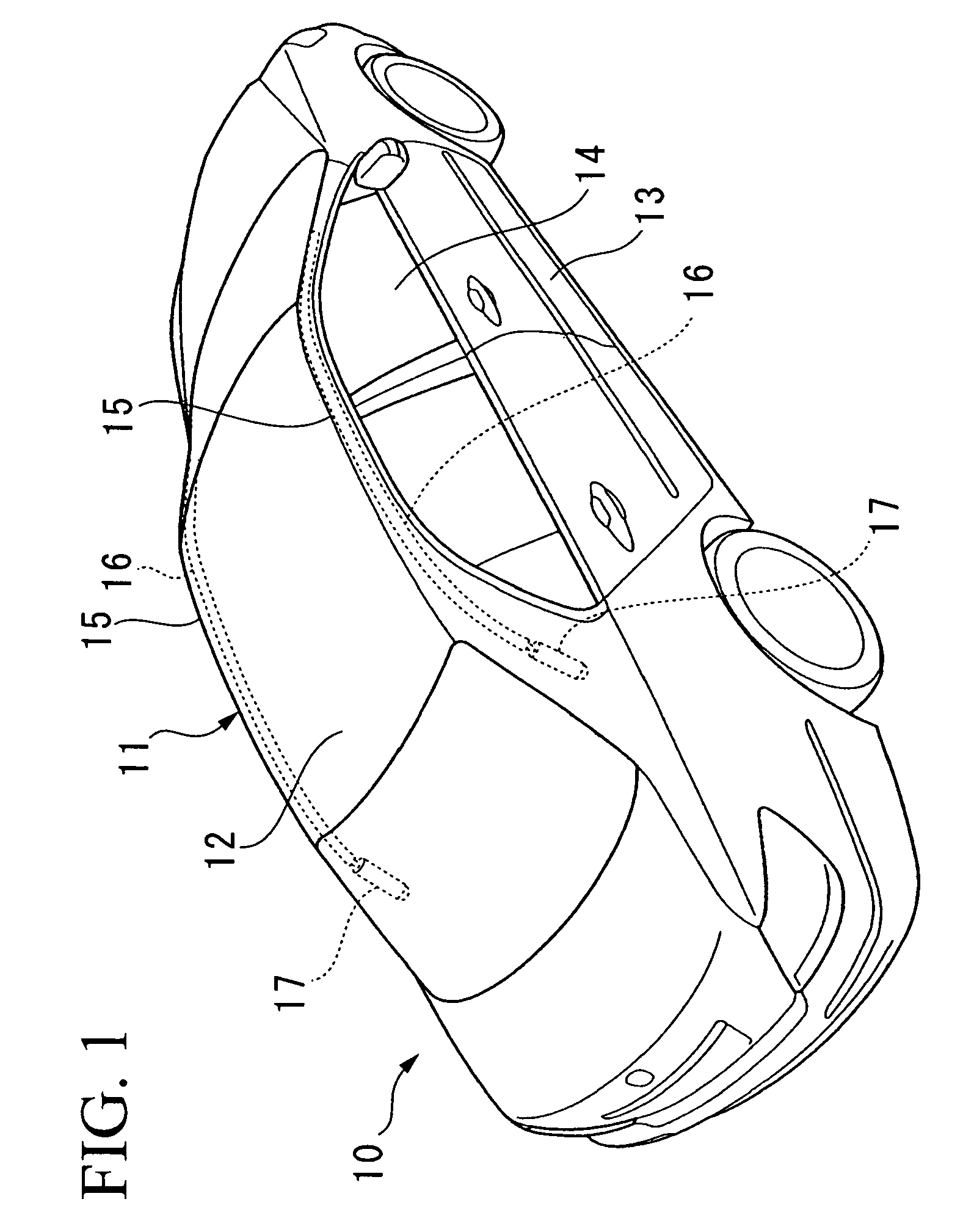

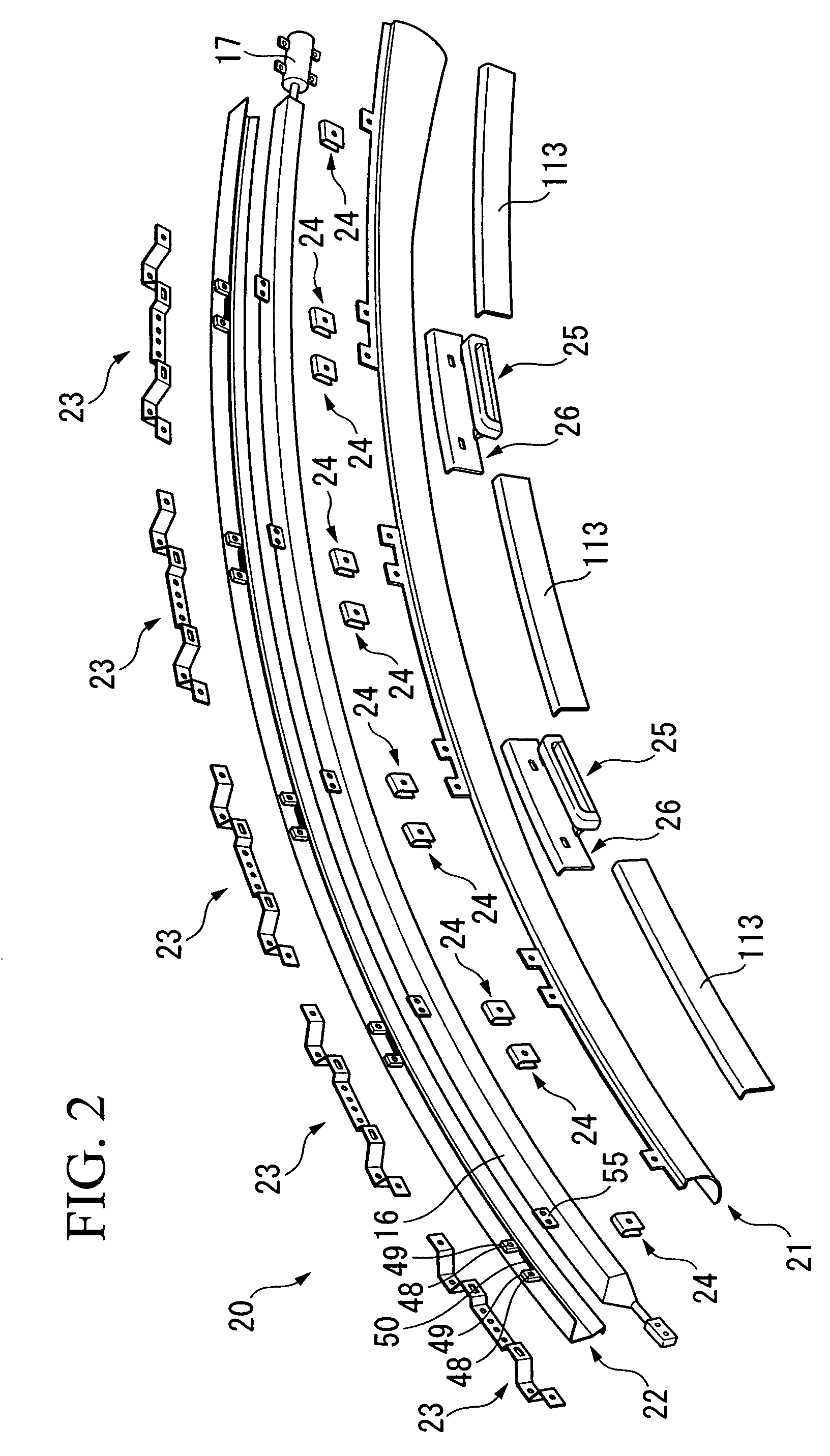

Curtain-type airbag apparatus and airbag module

InactiveUS7735857B2Press evenlyArrangement flexibility can be highPedestrian/occupant safety arrangementEngineeringAirbag

Owner:HONDA MOTOR CO LTD

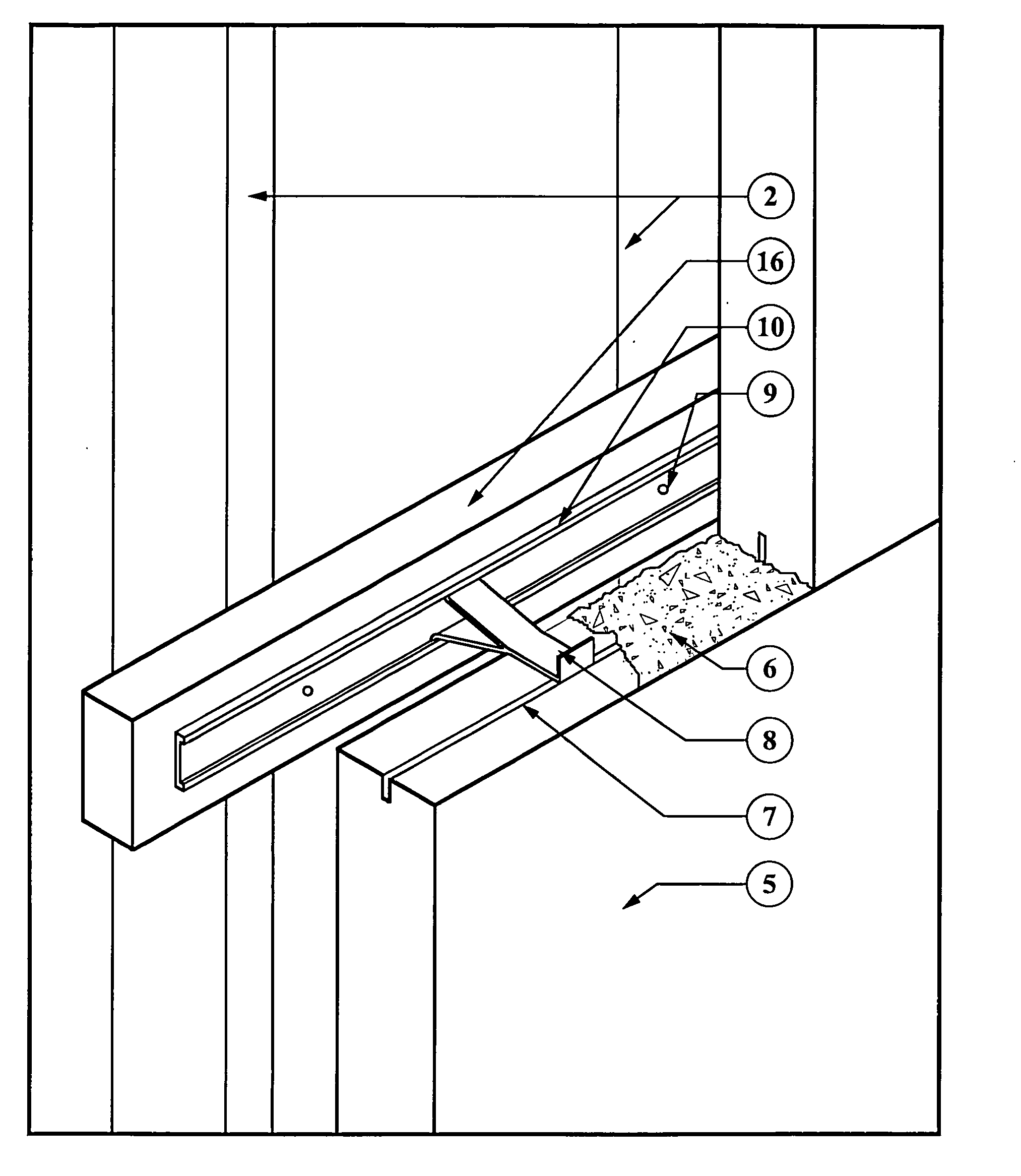

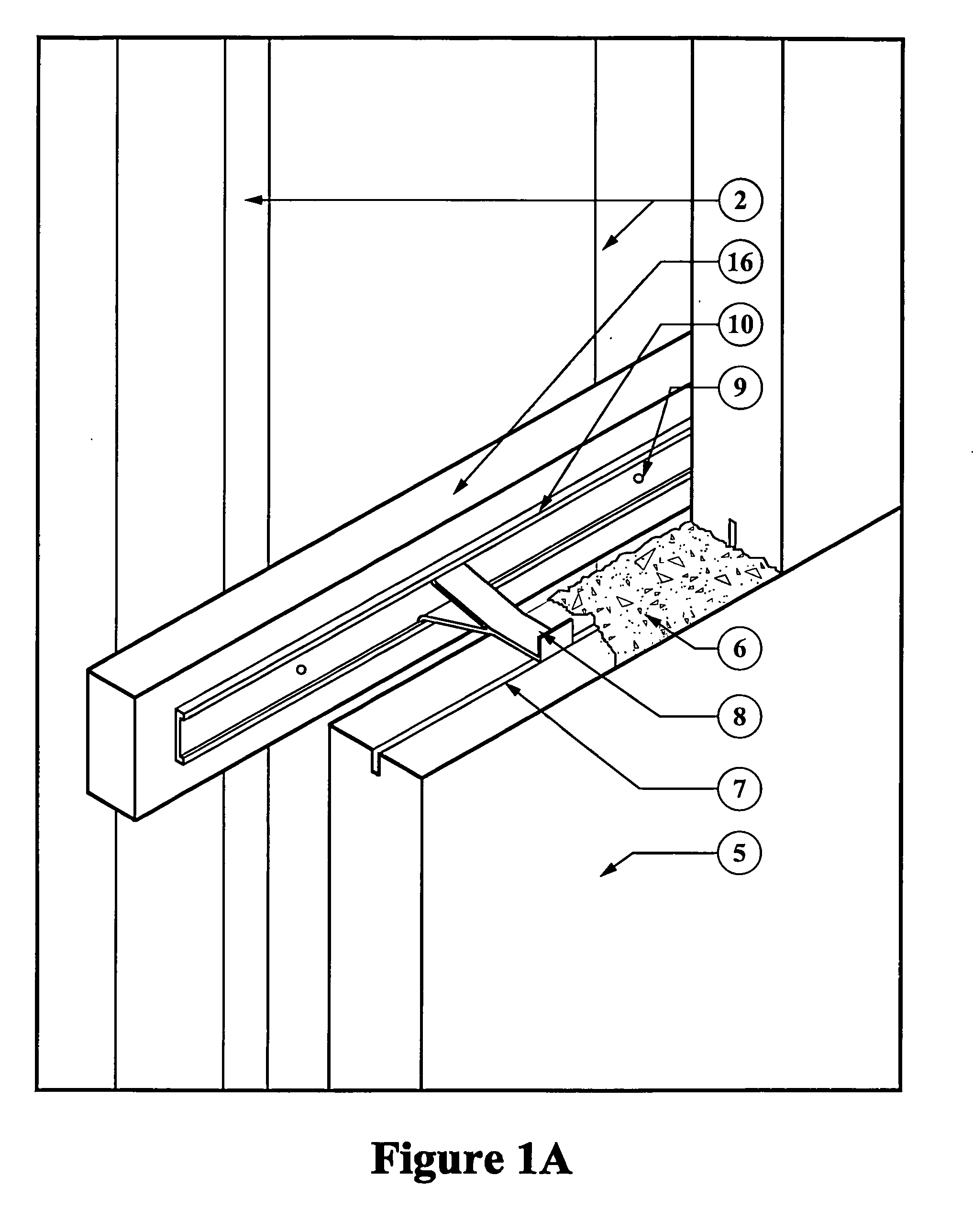

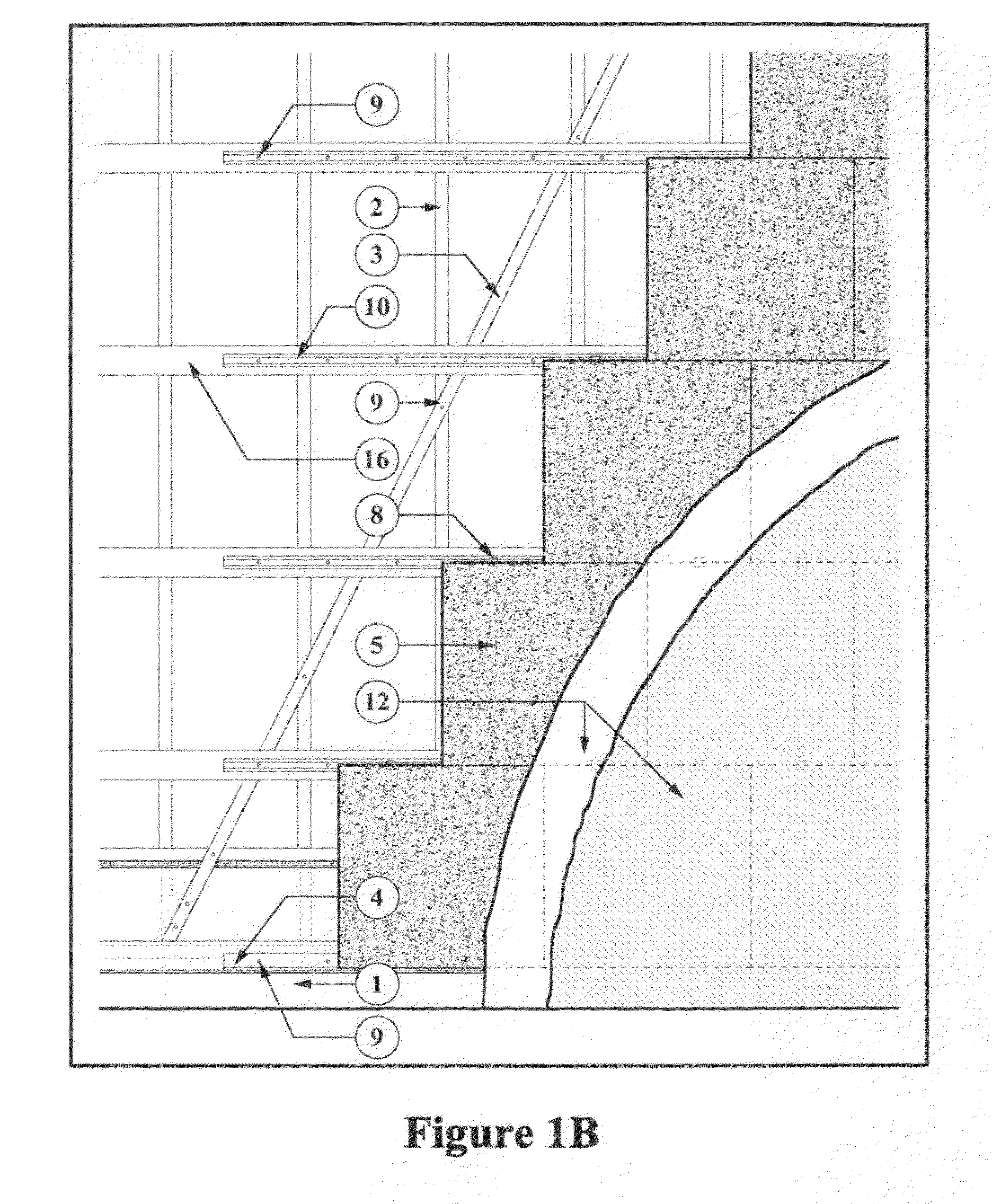

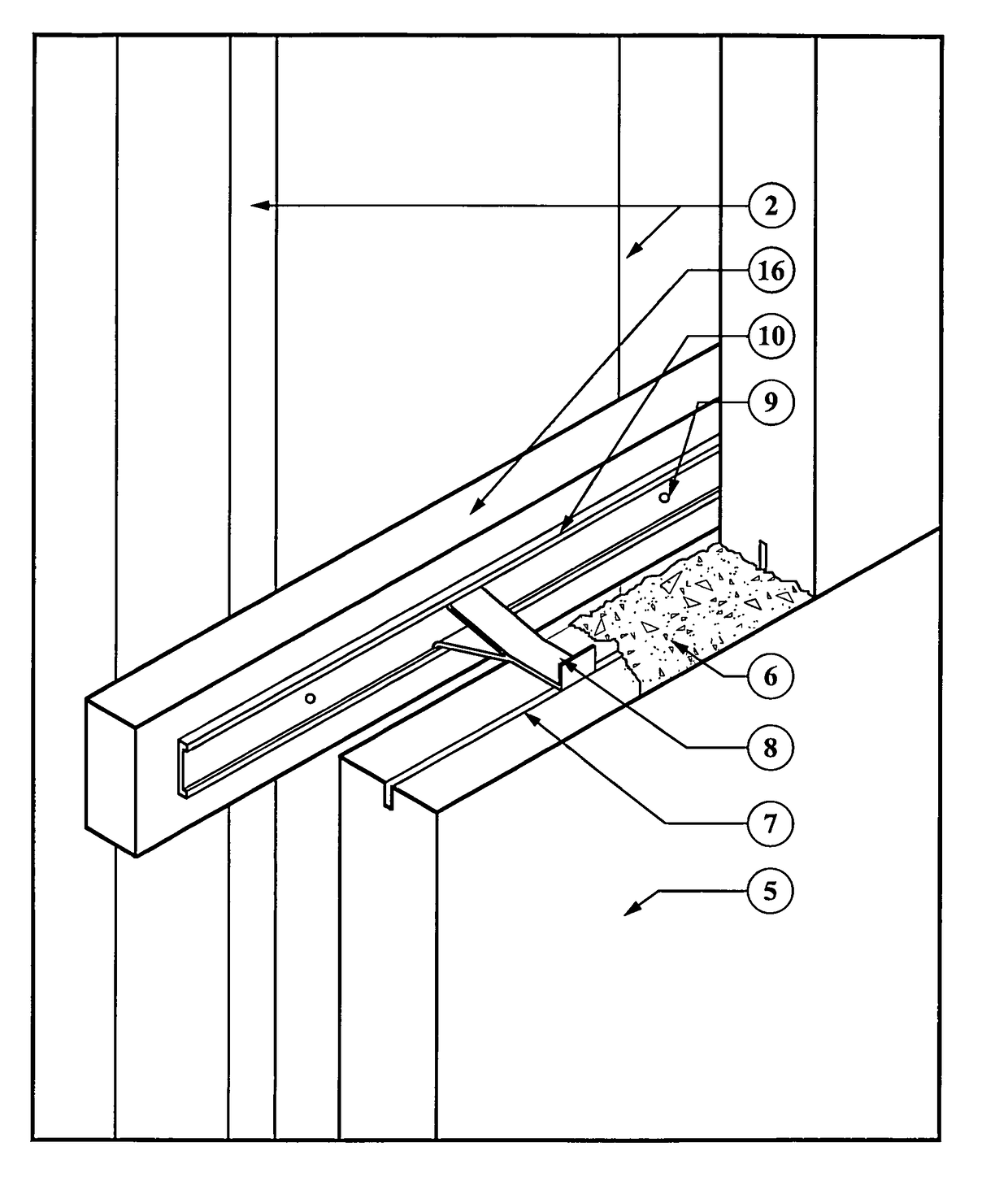

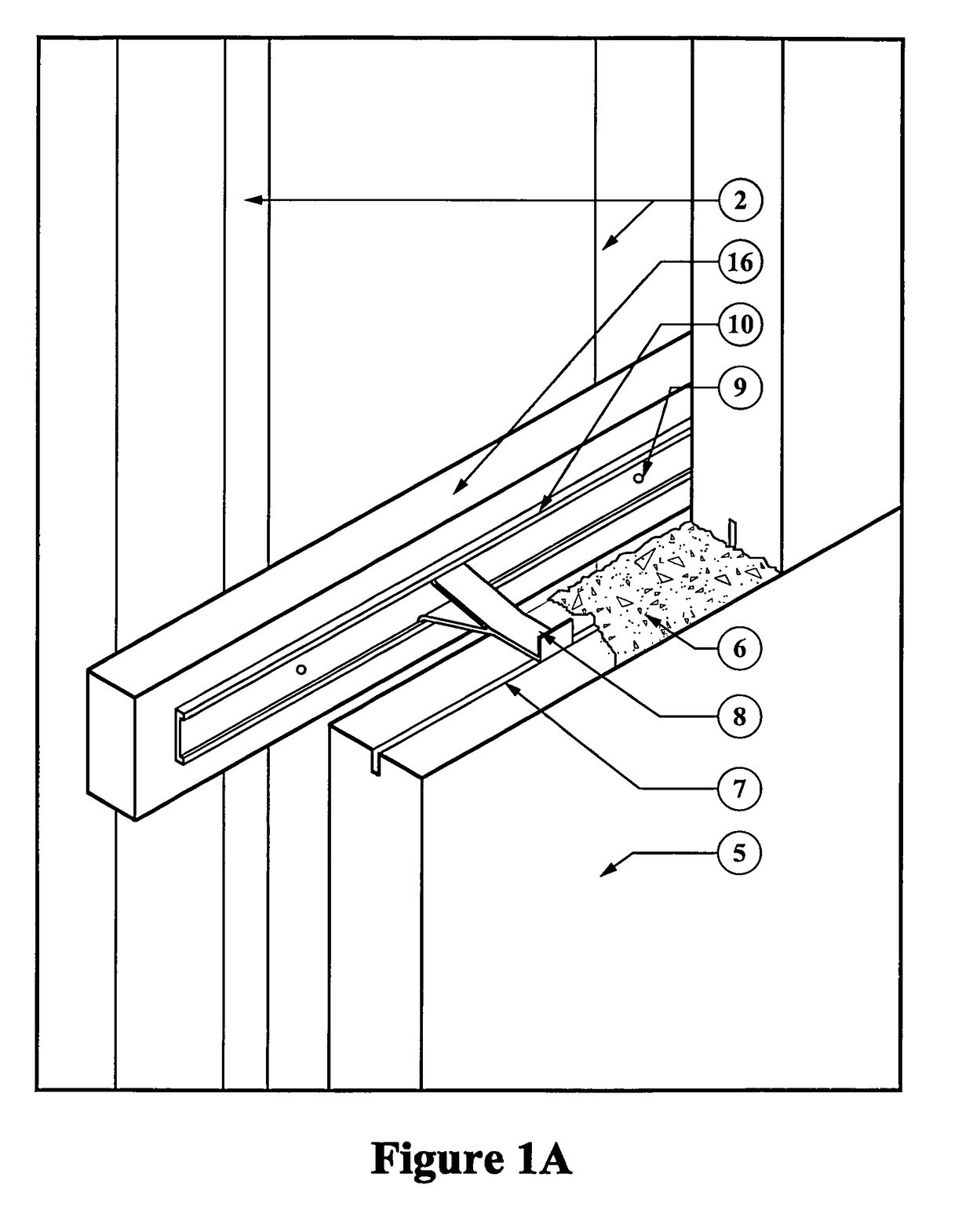

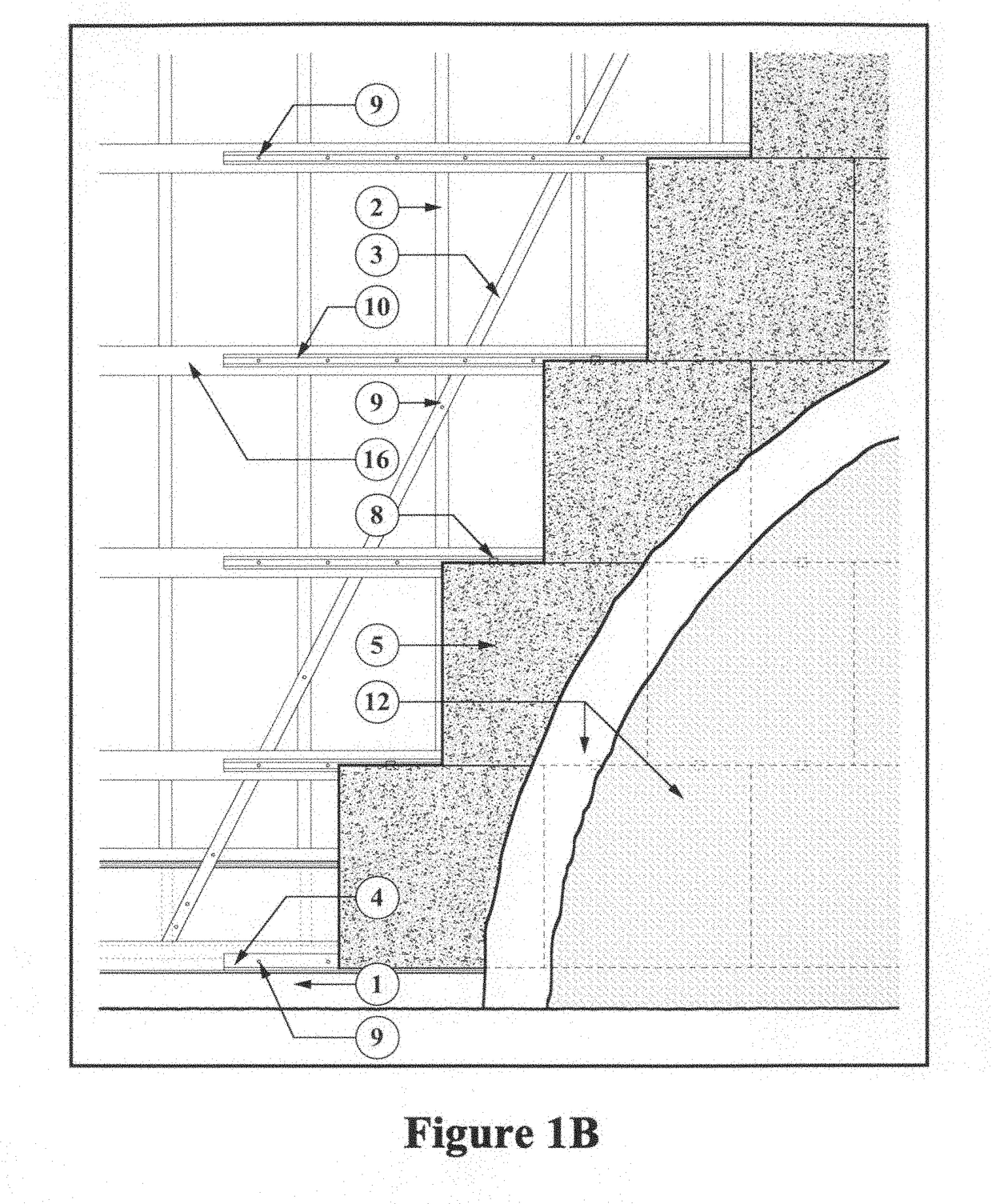

Wall construction method using injected urethane foam between the wall and autoclaved concrete (AAC) blocks

InactiveUS20150240483A1Limit waterLimit vapor infiltrationWallsHeat proofingArchitectural engineeringFraming (construction)

The present invention provides novel wall construction systems and materials for residential and commercial construction that incorporate grooved lightweight building material units (e.g., blocks, panels, and the like), a plurality of connection devices, a track system, and (injected) polyurethane structural foam. The wall construction system comprises building material units married to a building frame with a plurality of connection devices (e.g., clip fasteners) slidingly retained in a track system that is attached to the building's structural (e.g., load-bearing) framing. The building material units are joined to each other with a suitable binding agent. The cavity between the frame and the building material units is injected with an insulating structural polyurethane foam. The exterior of the wall is finished with a waterproof applied finish such as cementitious stucco. The interior of the wall is amenable to standard finish options.

Owner:BRETON SYST LLC

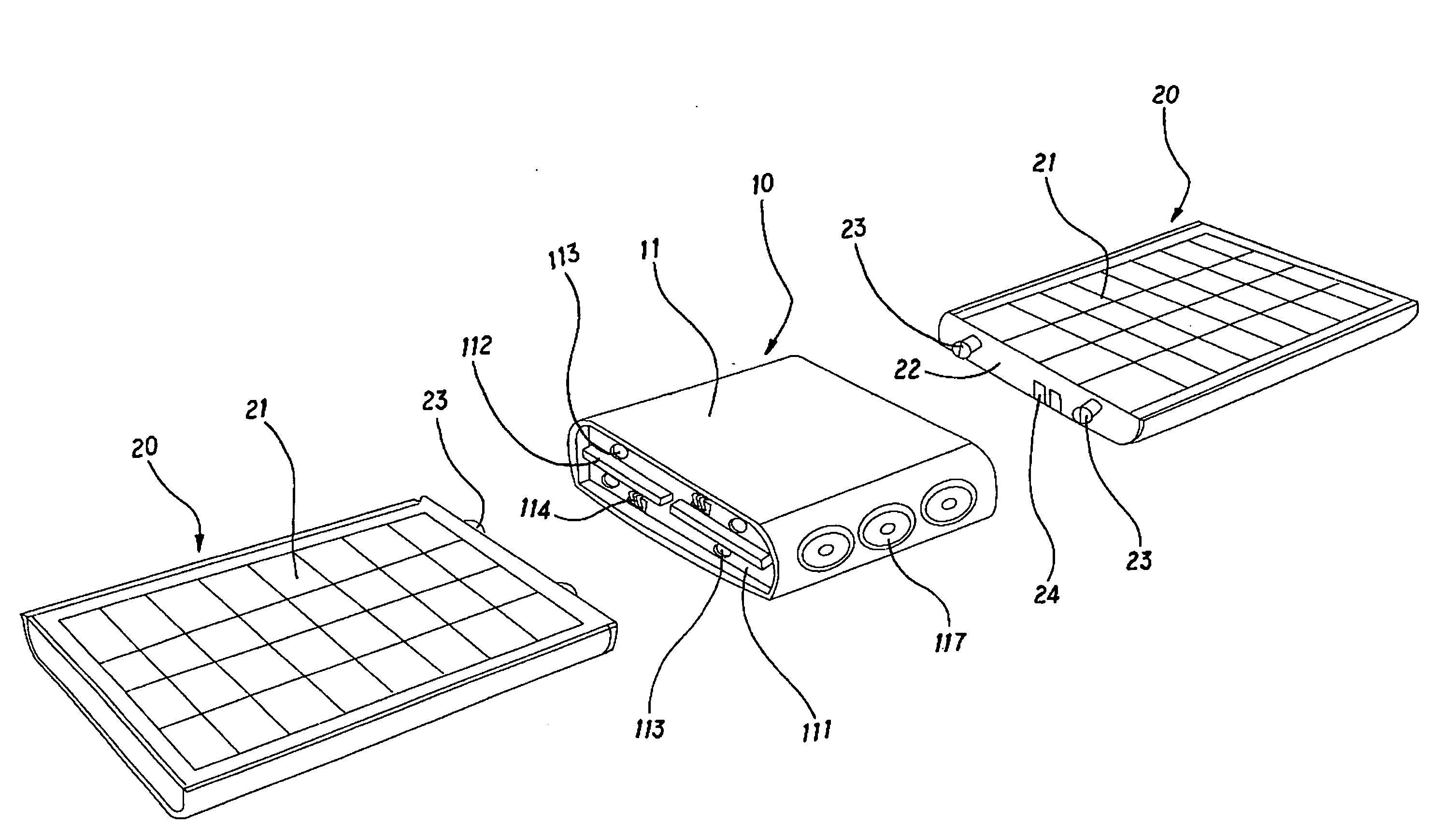

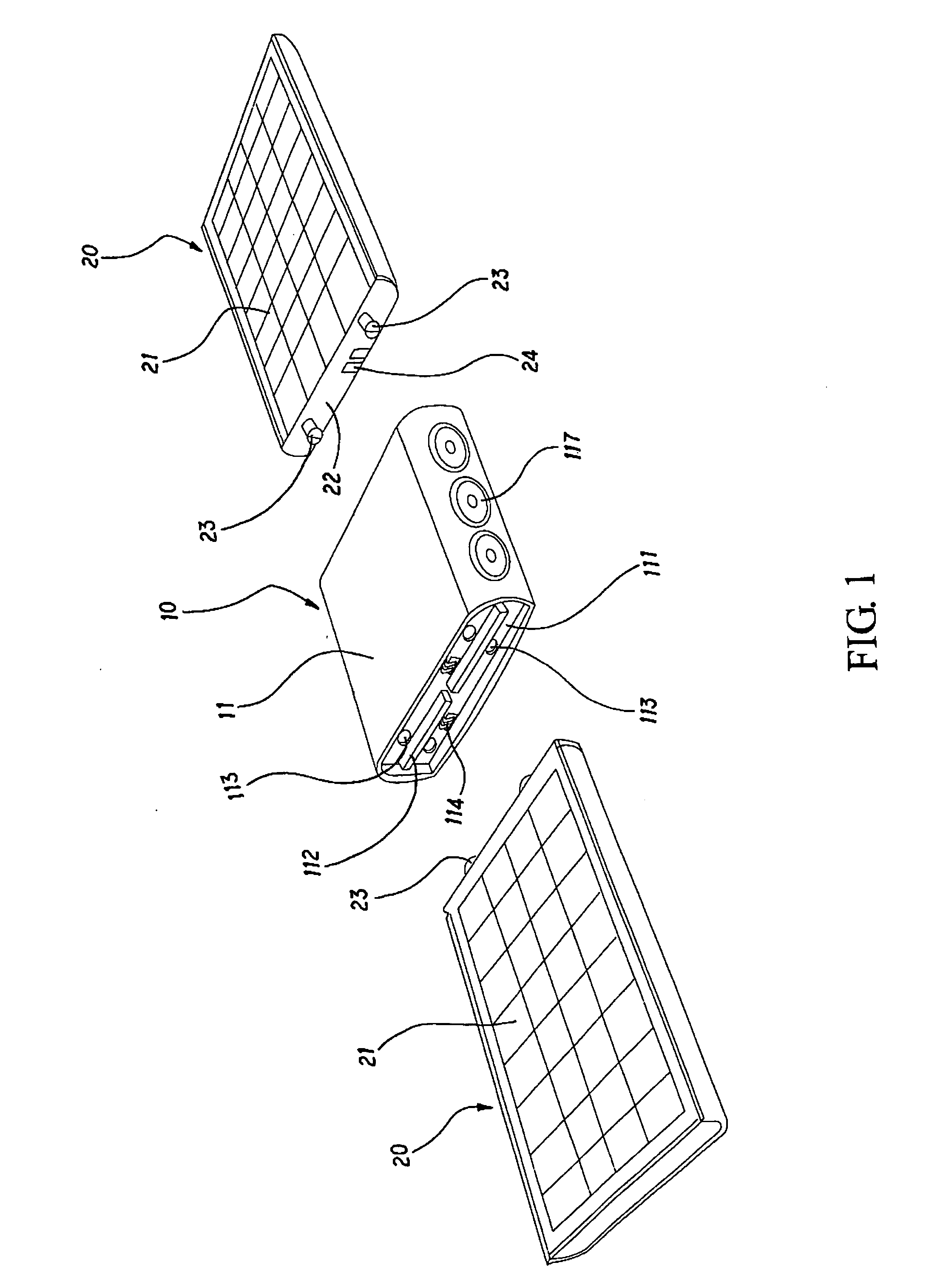

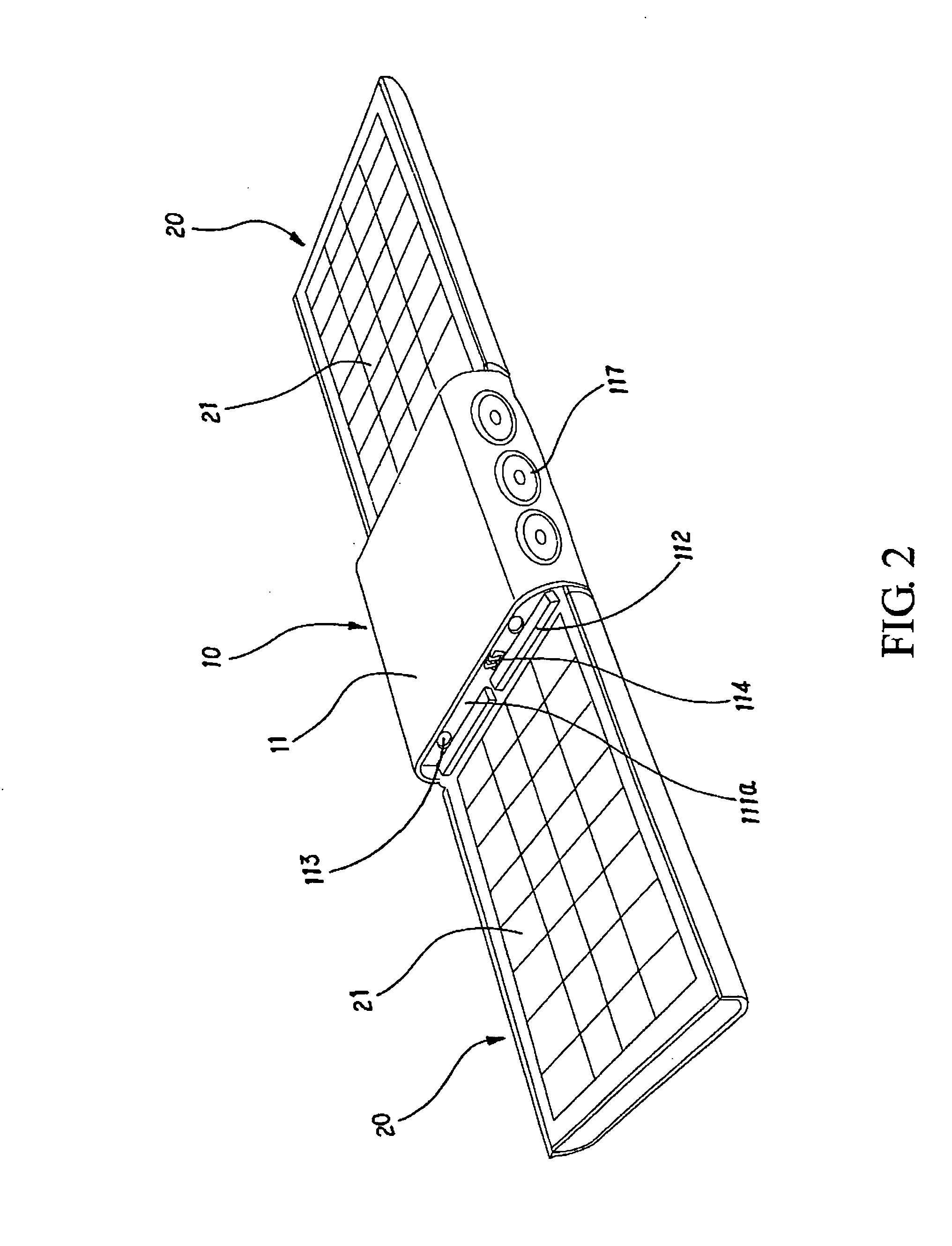

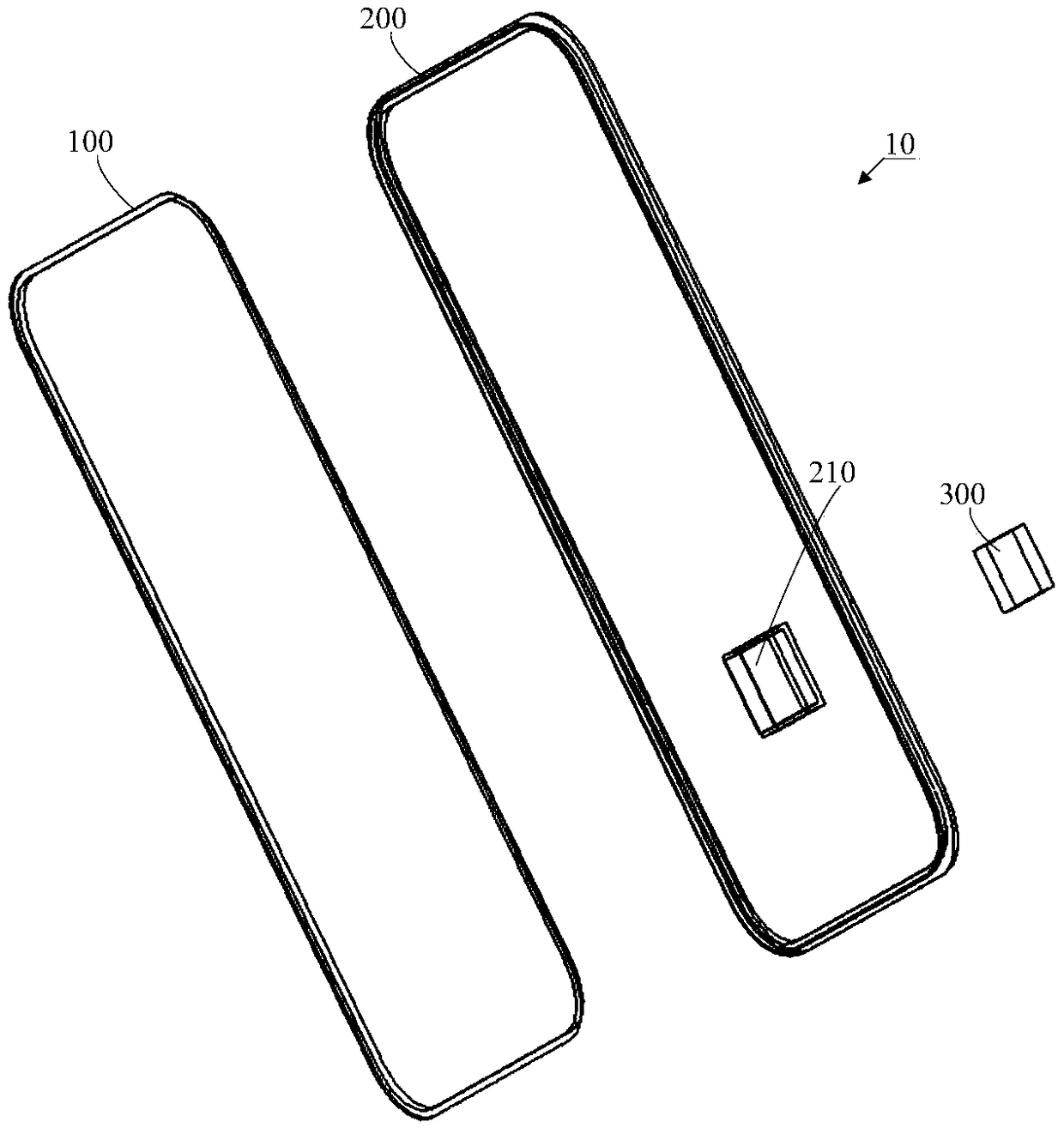

Solar charger

InactiveUS20090140689A1Reduce manufacturing costReduce processing costsBatteries circuit arrangementsSecondary cells charging/dischargingElectricityElectric power system

A solar charger primarily comprises a main body and at least one solar panel wherein the main body and the solar panel are respectively an independent modulized component. In addition, one edge of the solar panel can be detachably attached to one adjacent edge of the main body. Since contacts are respectively provided on the adjacent edges of the solar panel and the main body, the two components are electrically connected when they are assembled together so as to store an electric power transformed from a light energy in a rechargeable battery in the main body for providing the electric power to charge electronic devices later. Thereupon, the present invention facilitates manufacturing as well as processing and reduces time consumption of fabricating.

Owner:LEE VINCENT

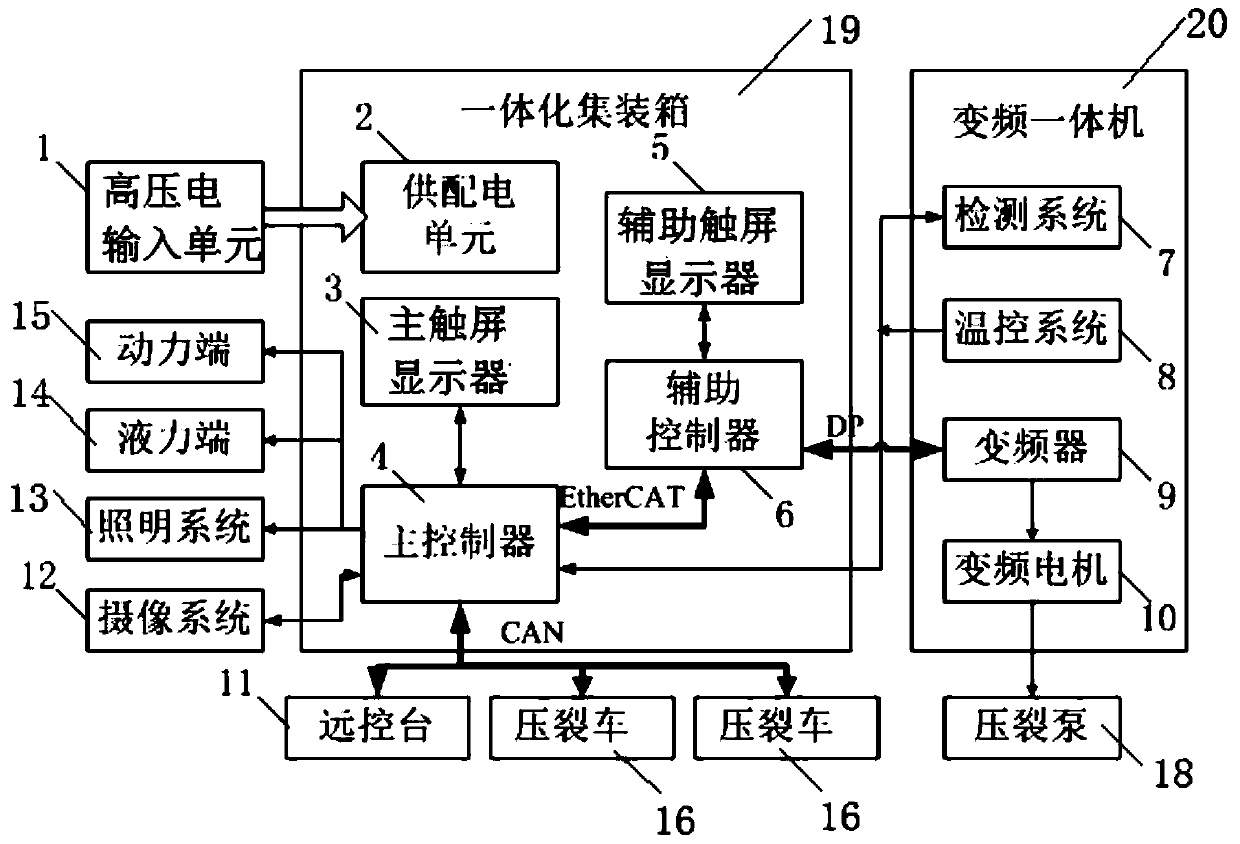

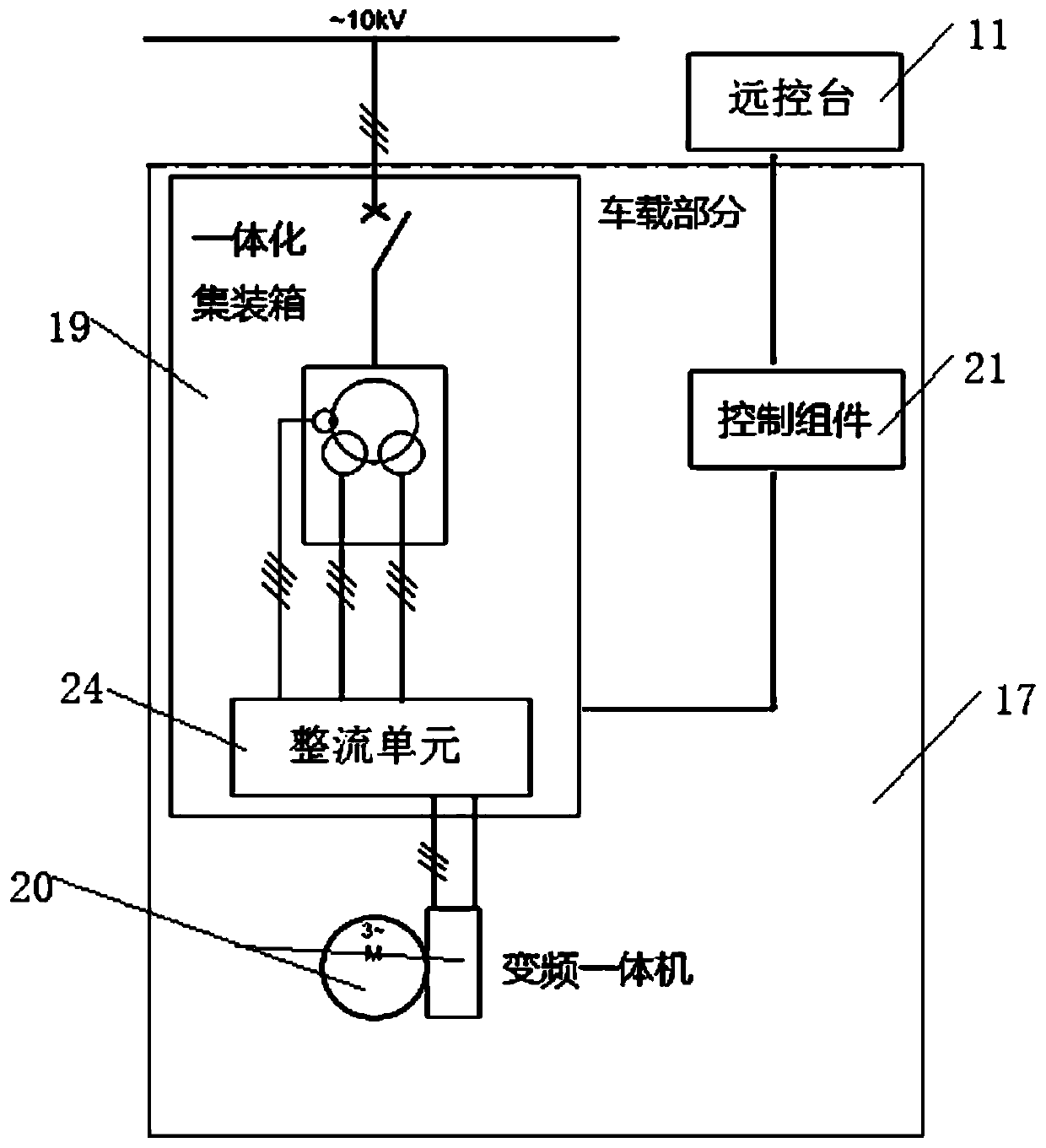

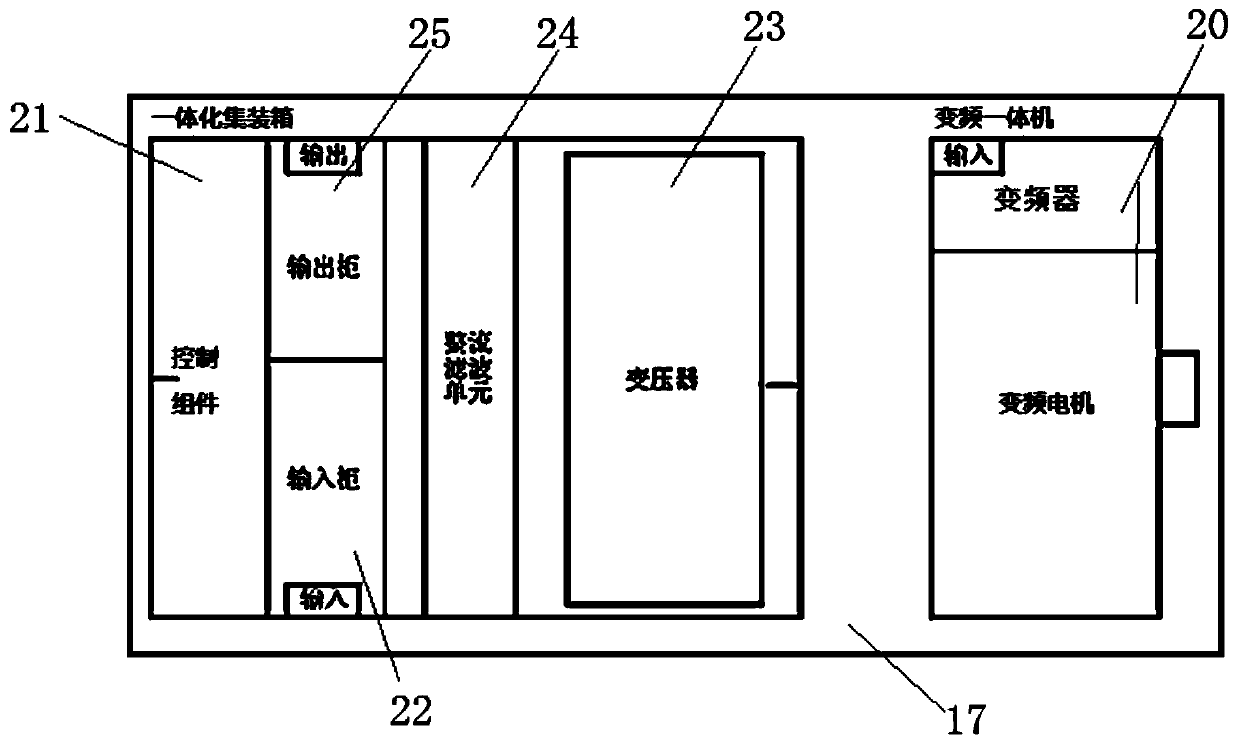

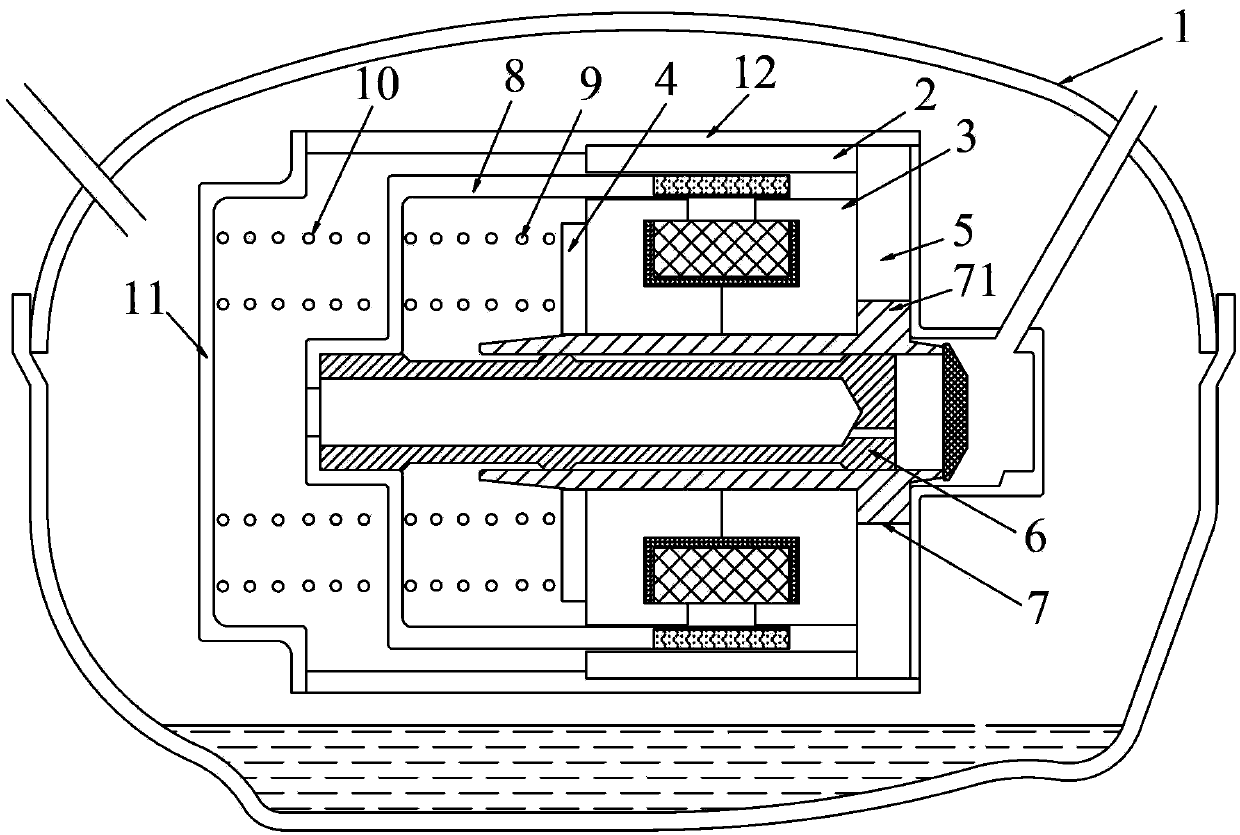

Integrated variable frequency fracturing pumping device control system and control method

ActiveCN110107490AAchieving a modular designCompact installation spaceFluid removalPump controlFrequency changerTouchscreen

The invention discloses an integrated variable frequency fracturing pumping device control system and control method. The integrated variable frequency fracturing pumping device control system comprises a high voltage electric input unit, an integrated container, and a variable frequency integrated machine; the integrated container comprises a power supply and distribution unit connected with a high voltage circuit breaker, the power supply and distribution unit is connected with and provides power for a main touch screen display, a main controller, an auxiliary controller, an auxiliary touchscreen display, and the variable frequency integrated machine correspondingly, and the main controller is connected with a remote control station and a camera system correspondingly; the main controller is further connected with the fluid end and the power end of a fracturing pump and an illuminating system; the main controller is further connected with a fracturing truck; the variable frequency integrated machine comprises a detection system, a temperature control system, and a frequency converter, wherein the detection system and the temperature control system are connected with the main controller correspondingly, the frequency converter is connected with the auxiliary controller, the frequency converter is connected with a variable frequency motor, and the variable frequency converteris connected with the fracturing pump. According to the integrated variable frequency fracturing pumping device control system and control method, the whole control system is divided into two independent modules, the structure adopts an integrated modular design, the mounting space is compact, maintenance is convenient, and assembly is flexible.

Owner:BAOJI PETROLEUM MASCH CO LTD +2

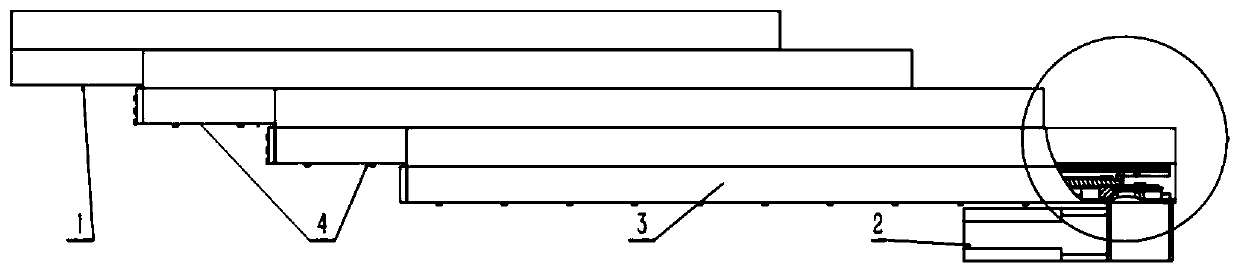

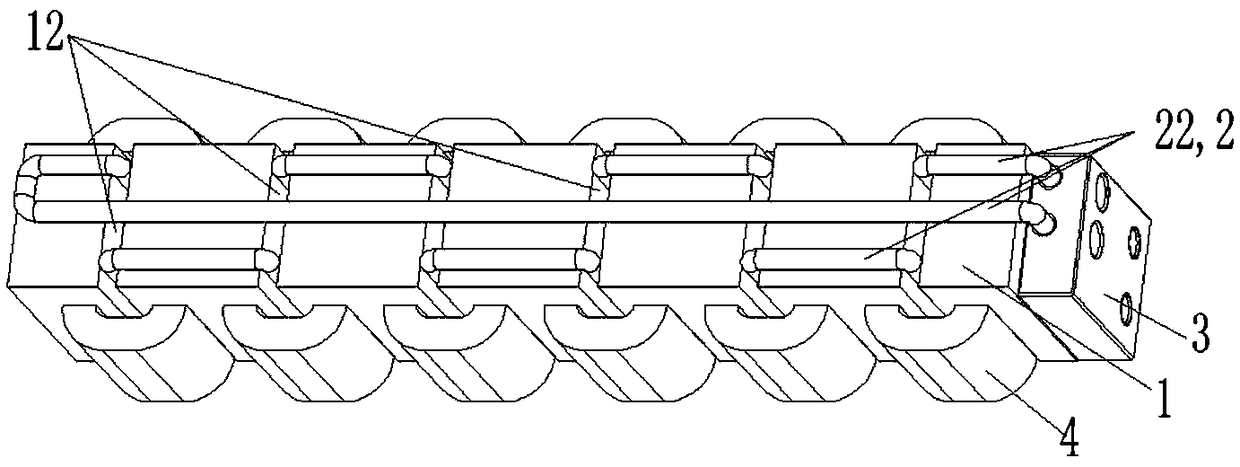

Lead screw drive based multistage synchronous telescopic boom

The invention discloses a lead screw drive based multistage synchronous telescopic boom. A bearing section is connected with a guide rail slide block and a lead screw nut fixed base of a last-stage telescopic middle section; a current-stage telescopic middle section is connected to a guide rail slide block and a lead screw nut fixed base of a previous-stage telescopic middle section or a first-stage telescopic drive section; a motor of the first-stage telescopic drive section drives a large bevel gear to be engaged with a small bevel gear for transmitting rotation onto a lead screw; the lead screw drives a lead screw nut and a first-stage telescopic middle section to move; a large plane transmission gear of the first-stage telescopic middle section is engaged with a rack of the first-stagetelescopic drive section to rotate; the large plane transmission gear is engaged with a small plane transmission gear to perform reversing and speed changing; the small plane transmission gear and the large bevel gear rotate coaxially; the large bevel gear is engaged with the small bevel gear for transmitting rotation to the lead screw; and the lead screw drives a next-stage telescopic middle section or the bearing section to move. The lead screw drive based multistage synchronous telescopic boom has the advantages of being synchronous and quick in extension and retraction, good in rigidity,high in transmission efficiency, high in precision, capable of expanding at any stage, good in self-locking performance, and the like.

Owner:BEIHANG UNIV

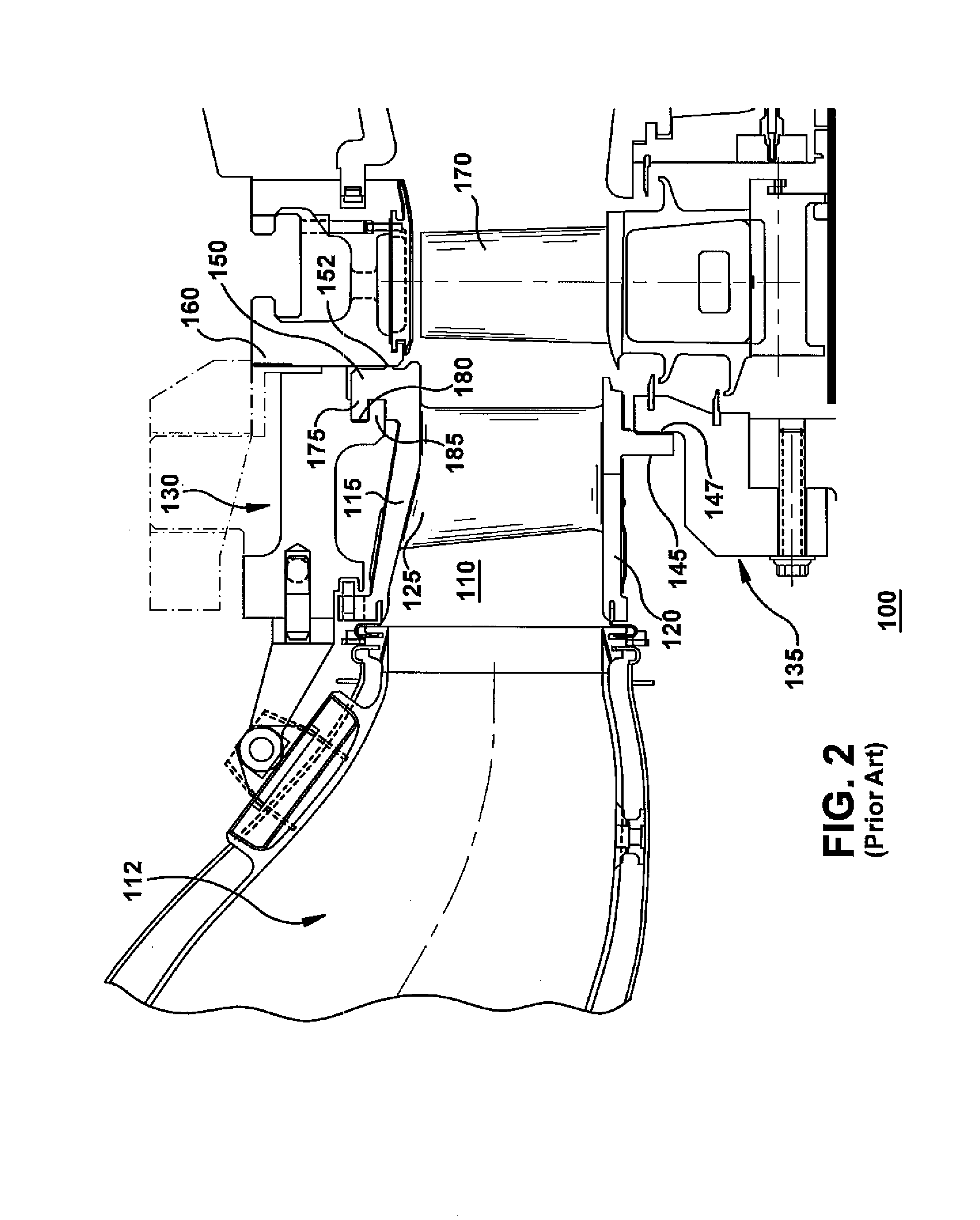

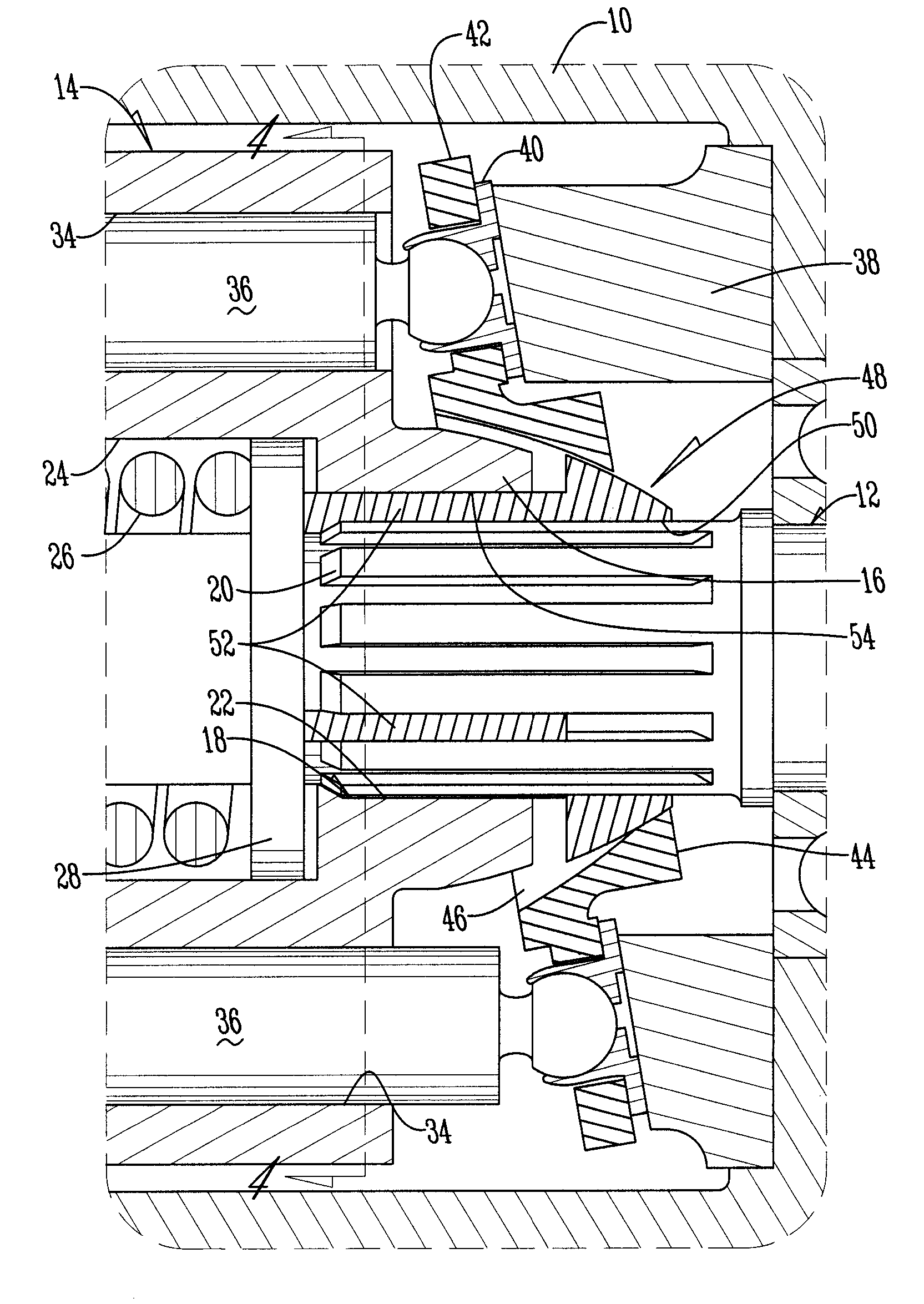

Fully contained retention pin for a turbine nozzle

InactiveUS20090110479A1Improve sealingImprove insulation performanceEngine manufacturePump componentsNozzle throatTurbine

A retention pin for fastening retaining lugs of an outer sidewall, of a turbine nozzle, within a groove between a forward land and an aft land of a retaining ring. The retention pins fit through coaxial holes in the lug and the lands, securing the radial and circumferential location of the nozzles as well as allowing transitional motion. While maintaining limited contact with both the nozzles and the retaining ring they significantly reduce conductive heat transfer from the nozzle to the retaining ring. By positioning the nozzles, they also set the desired nozzle throat areas for targeted turbine performance. The pins have been designed such that the nozzle cannot disengage within the assembly due to the pin backing out of its nominal axial position, and the pin will not fail due to low cycle fatigue, creep, or yielding, all of which prevent nozzle fallout.

Owner:GENERAL ELECTRIC CO

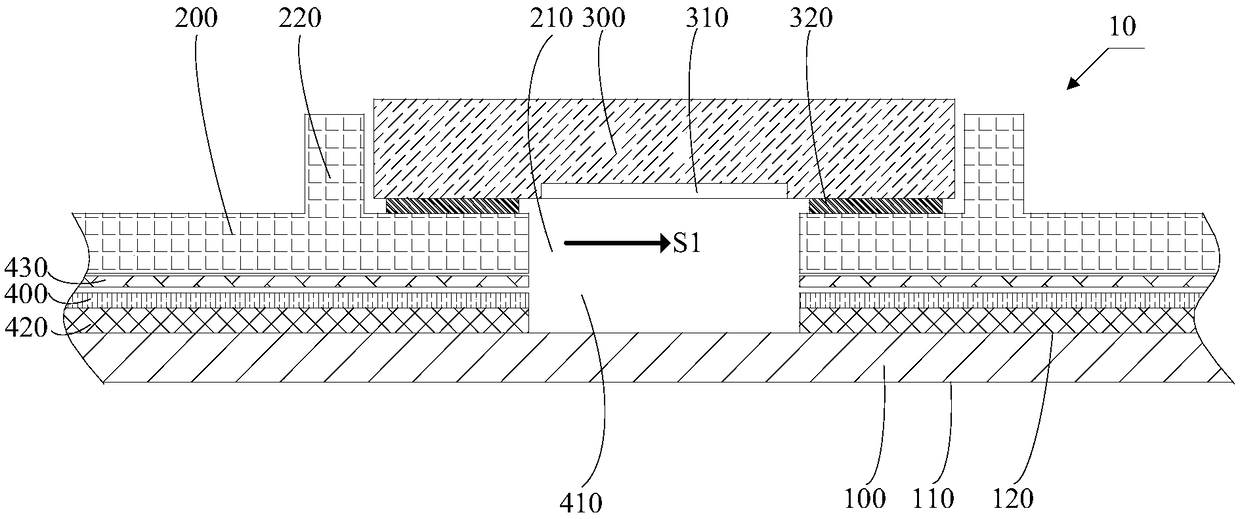

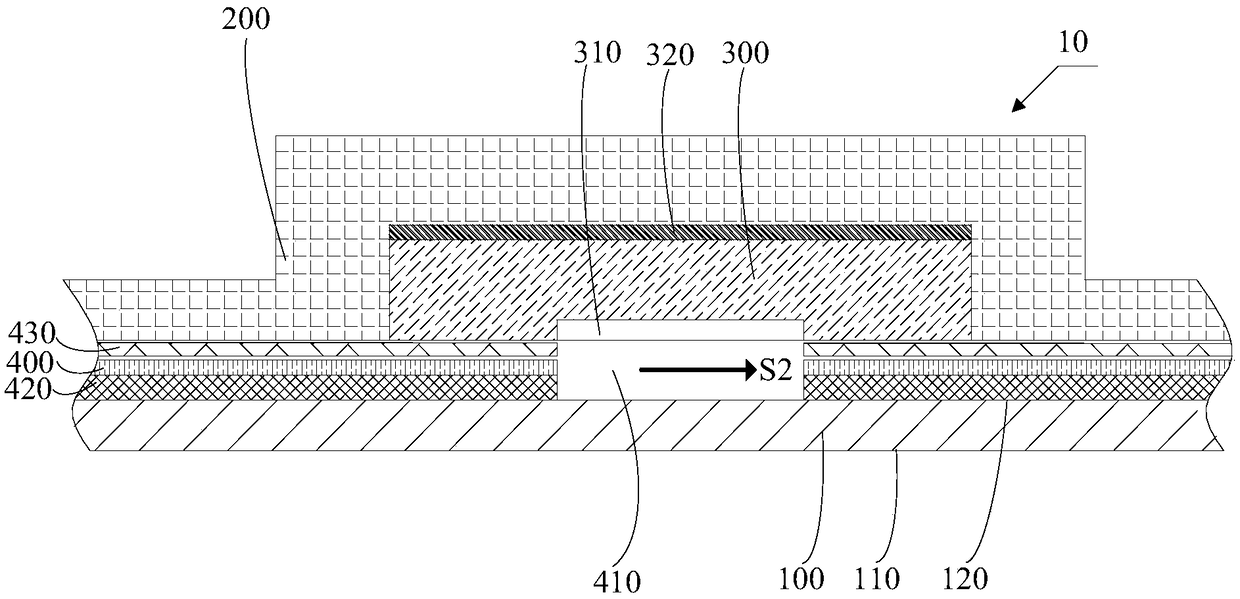

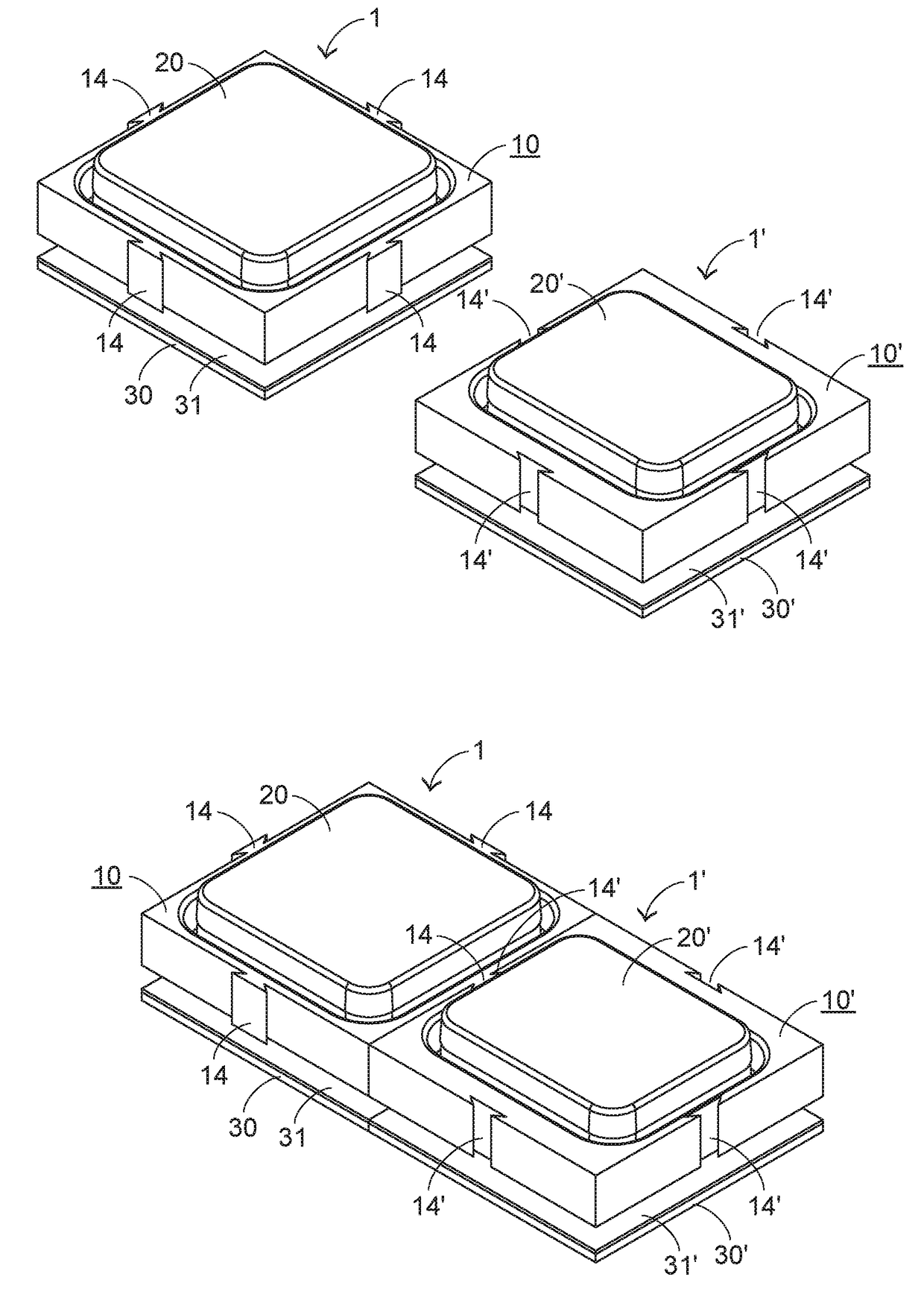

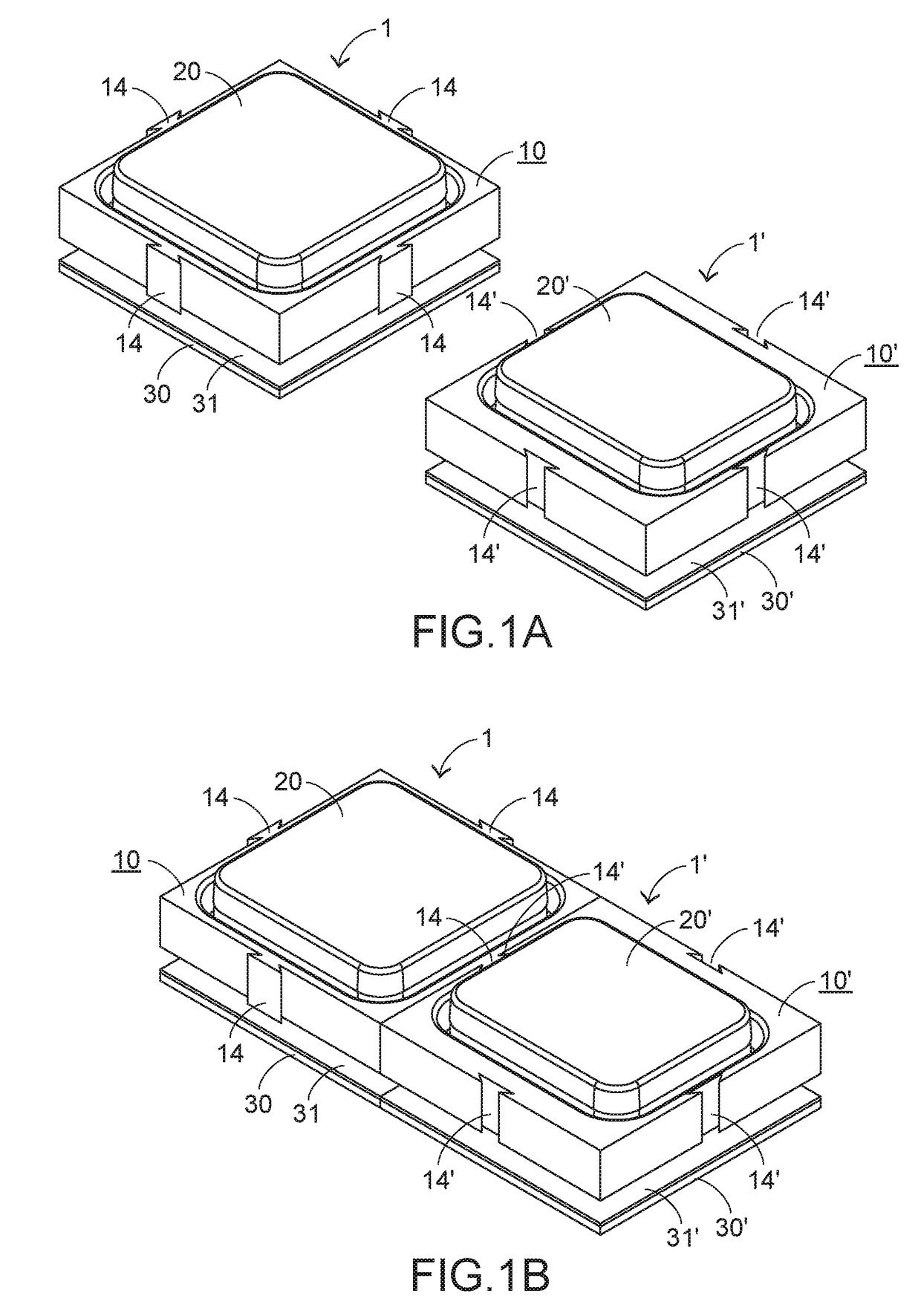

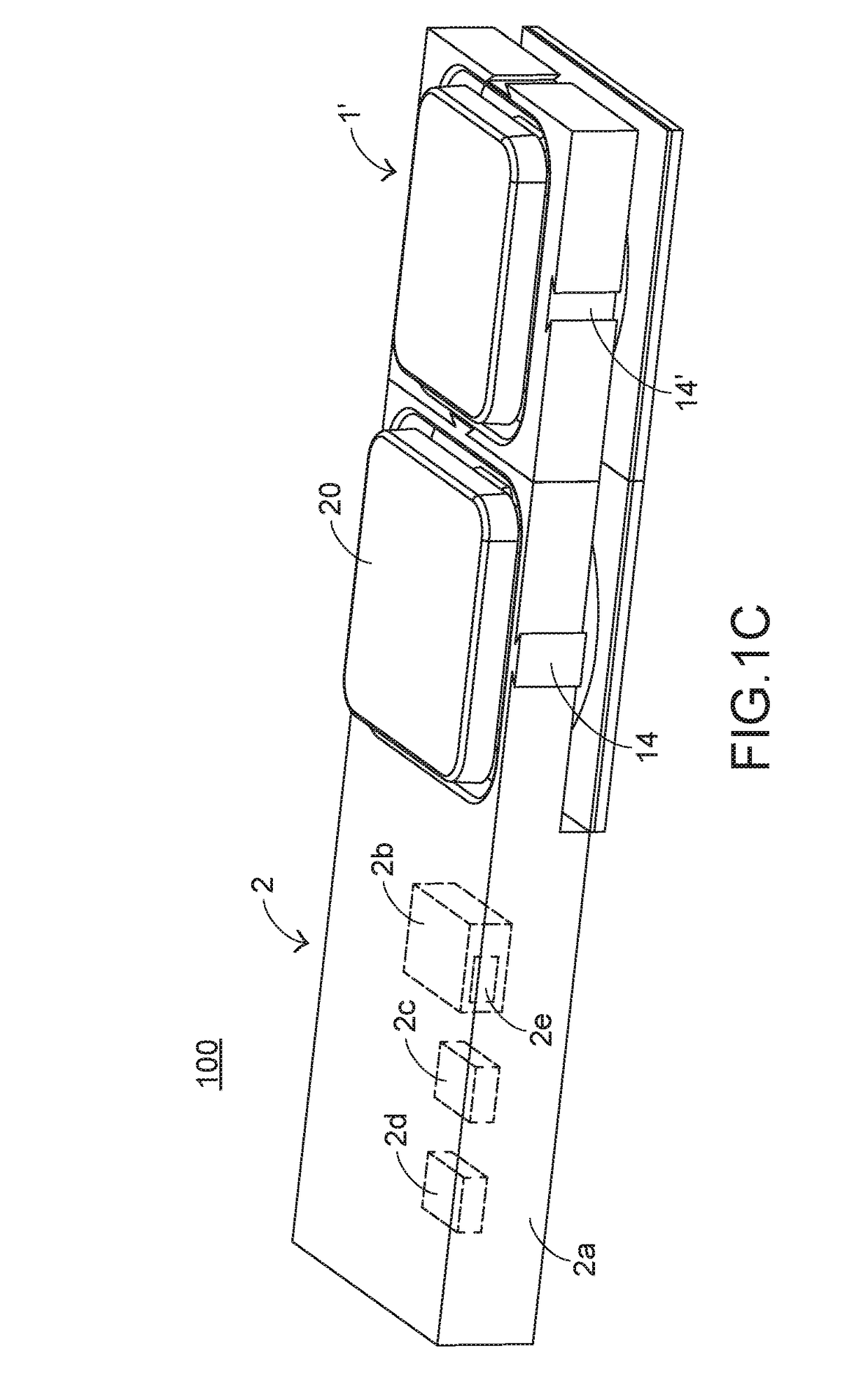

Display module and electronic device

InactiveCN108734119AIncrease assembly flexibilityEasy maintenancePrint image acquisitionIdentification meansComputer scienceElectronic equipment

Owner:VIVO MOBILE COMM CO LTD

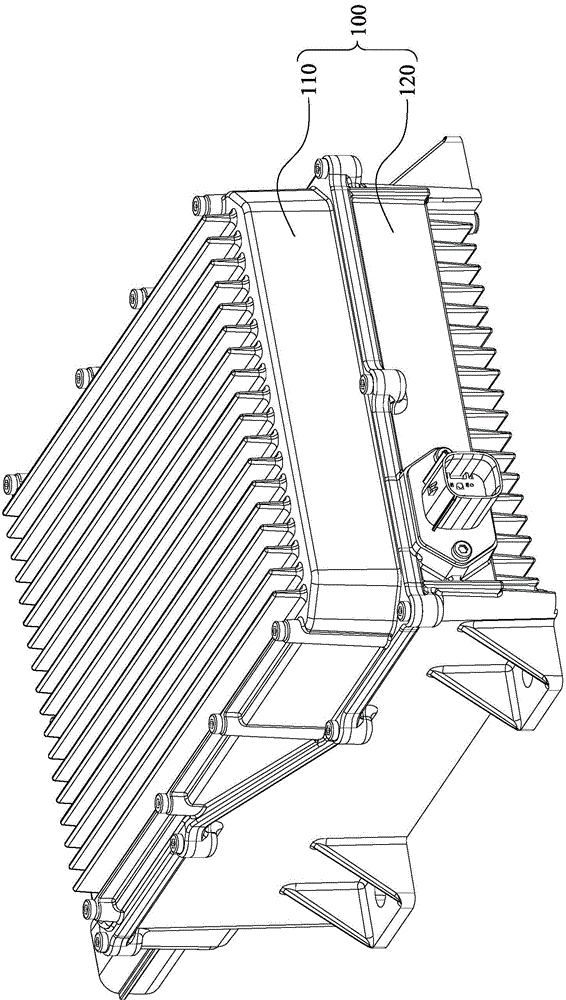

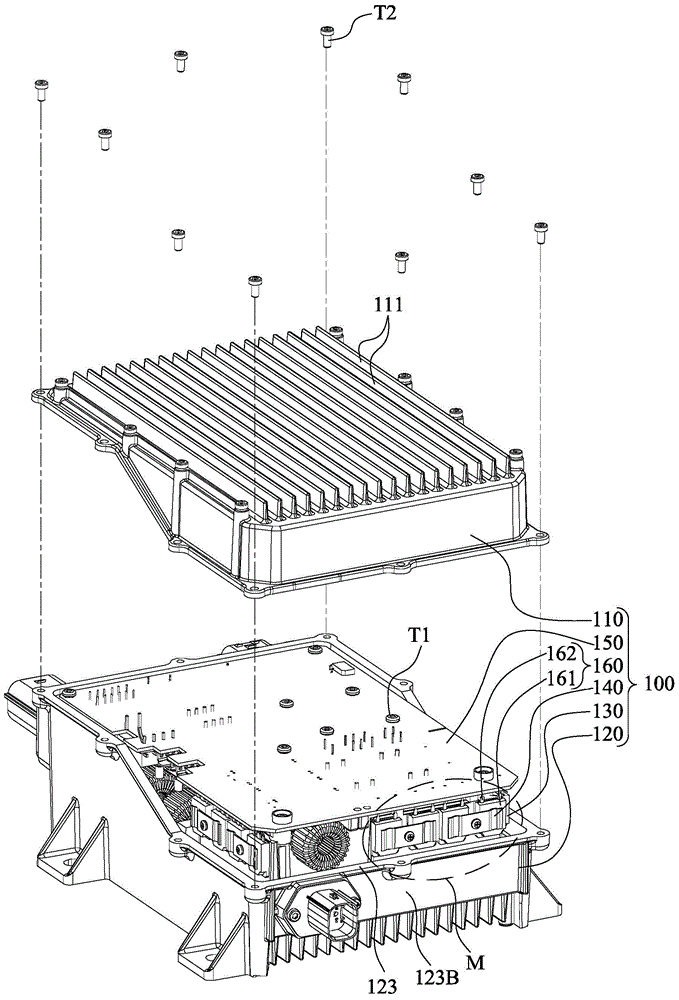

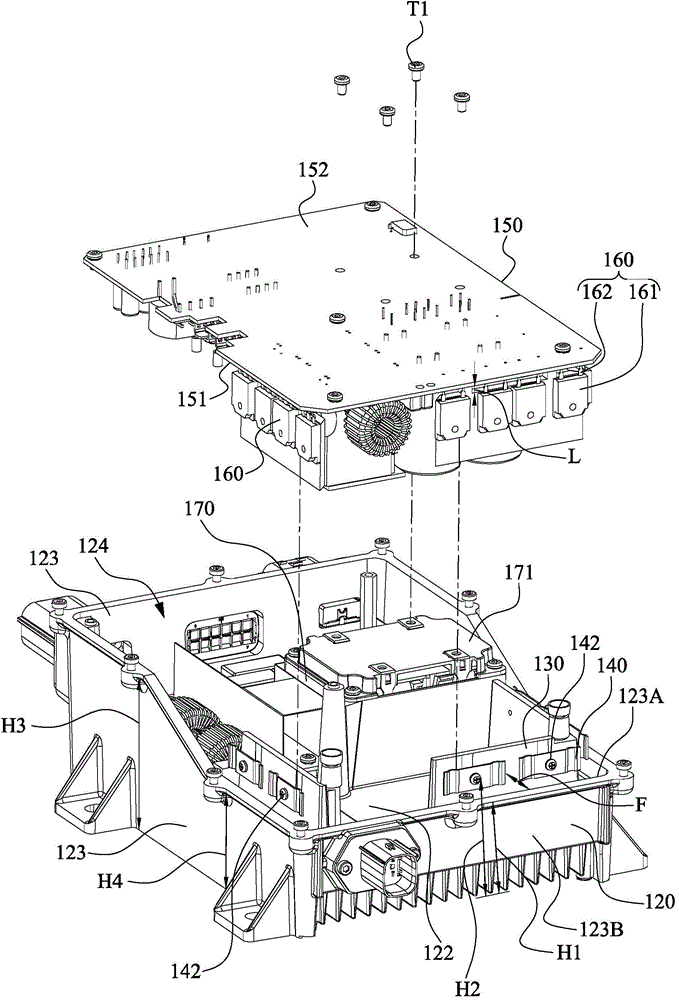

Electronic device and assembling method thereof

ActiveCN104684337AImprove cooling effectReduced risk of thermal failureElectrodynamic brake systemsSemiconductor/solid-state device detailsElectricityEngineering

An electronic device includes a bottom case, an accommodation unit, an electromagnetic induction module, a heat-dissipating component, an elastic clip, a printed wiring board, and an electronic component. The accommodation unit is disposed on the bottom case. At least one portion of the electromagnetic induction module is disposed in the accommodation unit. The heat-dissipating component is disposed on the bottom case and is positioned separately from the accommodation unit. The elastic clip is partially mounted on the heat-dissipating component. The printed wiring board has a first surface and a second surface, and the first surface faces the accommodation unit. The electronic component includes a main body and pin feet. The pin feet are electrically connected to the printed wiring board, and the main body is clamped between the heat-dissipating component and the elastic clip.

Owner:DELTA ELECTRONICS SHANGHAI CO LTD

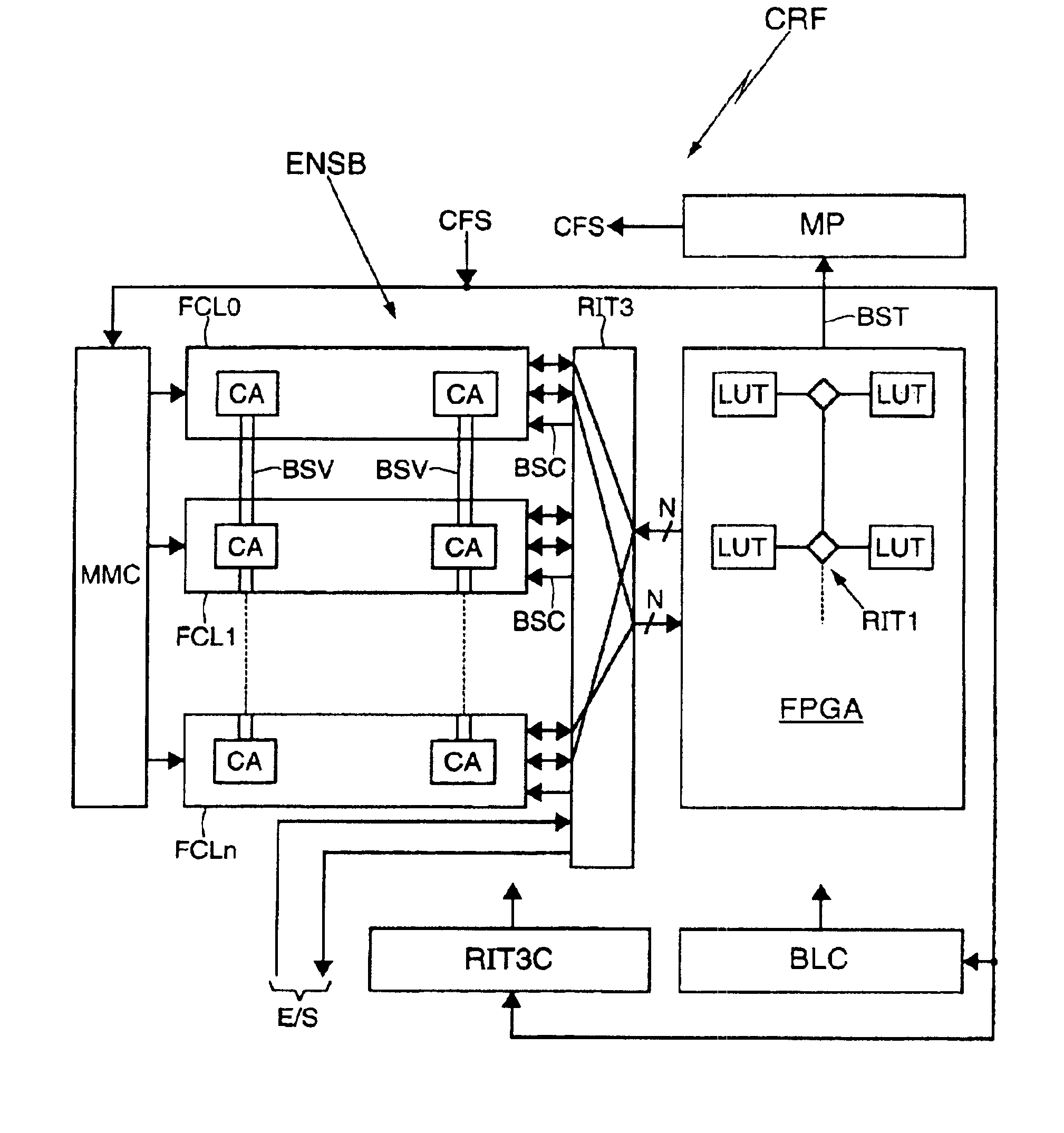

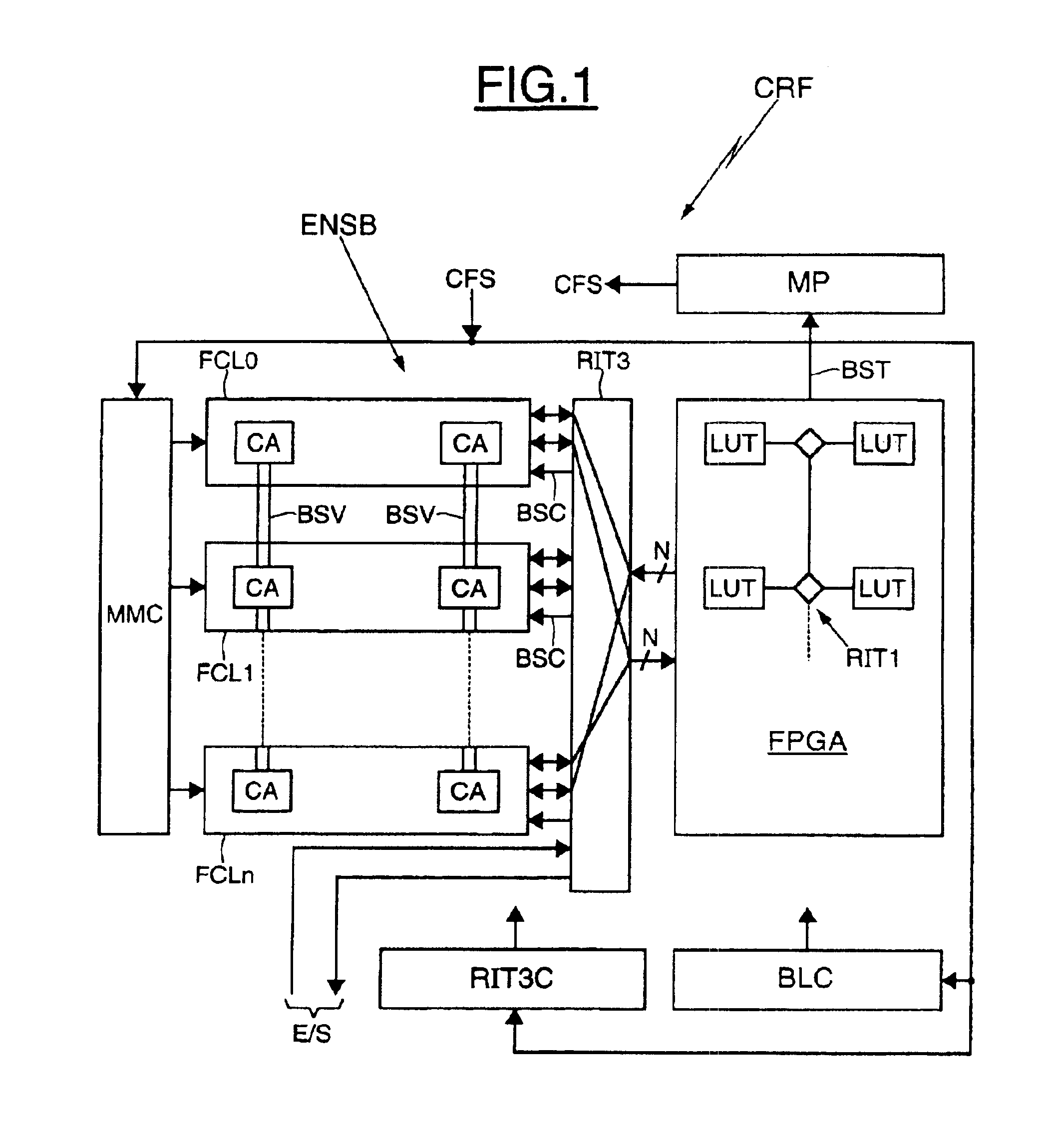

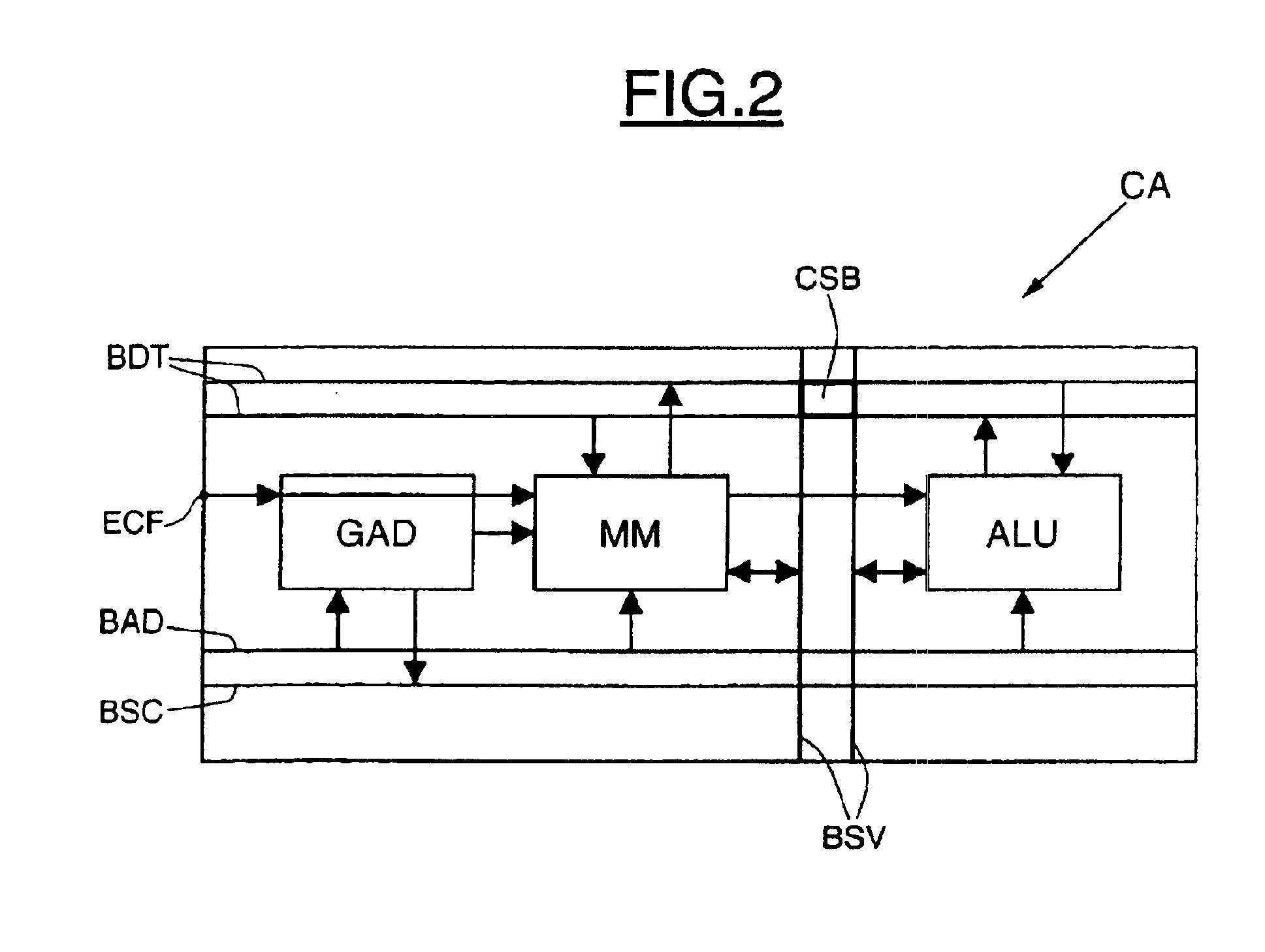

Configurable electronic device with mixed granularity

ActiveUS6960936B2Reduce consumptionImprove efficiencyEnergy efficient ICTSolid-state devicesNetwork linkGranularity

The configurable electronic device comprises a configurable electronic device includes at least one configurable basic assembly. The basic assembly includes a programmable circuit having a plurality of programmable elements, and a first configurable interconnection network for mutually connecting the programmable circuits. A plurality of configurable arithmetic cells are mutually connected by a second configurable interconnection network. A third configurable interconnection network links the programmable circuit and the configurable arithmetic cells. A control bus is between the programmable circuit and the configurable arithmetic cells, and also extends within the configurable arithmetic cells.

Owner:STMICROELECTRONICS SRL

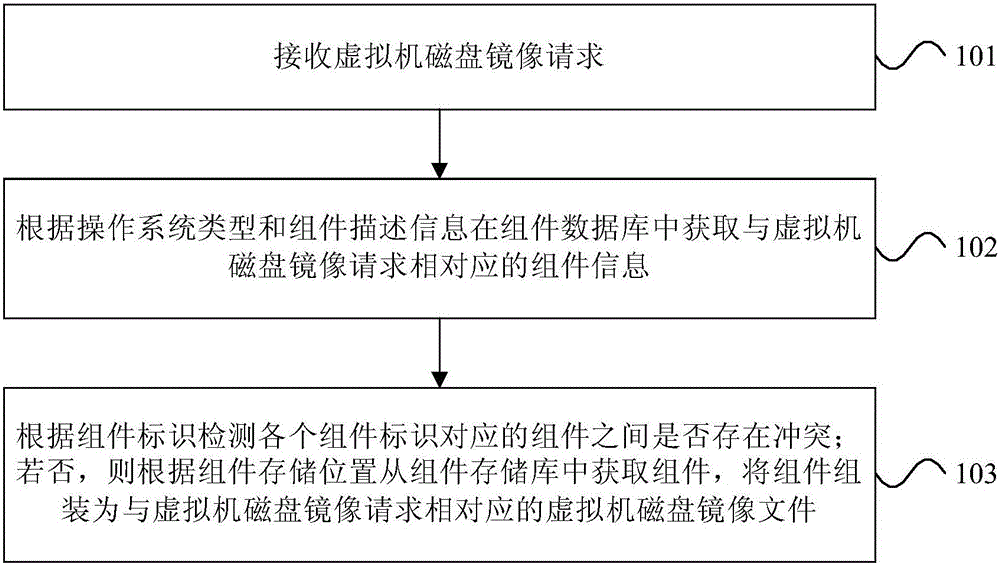

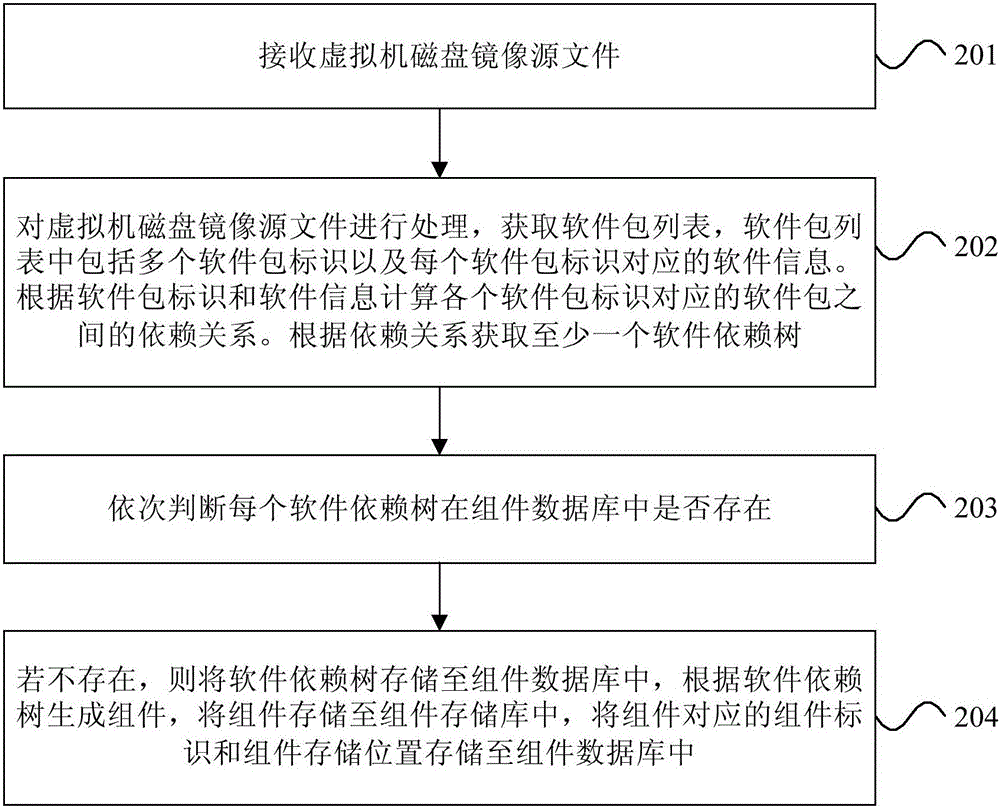

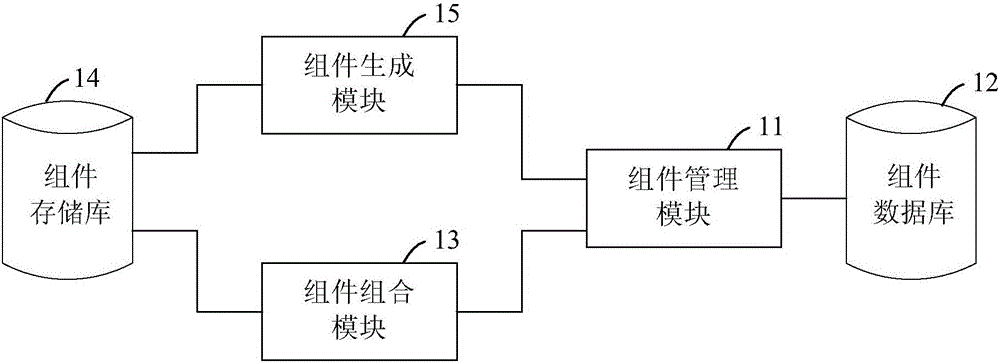

Quick modularized assembling method, device and system of virtual machine disk mirror image

ActiveCN105955674AIncrease assembly flexibilitySave storage spaceInput/output to record carriersFile access structuresMirror imageVirtual machine

The invention provides a quick modularized assembling method, device and system of a virtual machine disk mirror image. The quick modularized assembling method of the virtual machine disk mirror image comprises the following steps: receiving a virtual machine disk mirror image request; according to the type of an operating system and assembly description information, obtaining assembly information corresponding to the virtual machine disk mirror image request in an assembly database; according to an assembly identifier, detecting whether an assembly corresponding to each assembly identifier has a conflict or not; and if the assembly corresponding to each assembly identifier does not have the conflict, obtaining the assembly from an assembly memory pool according to an assembly storage position, and assembling the assembly into a virtual machine disk mirror image file corresponding to the virtual machine disk mirror image request. The quick modularized assembling method of the virtual machine disk mirror image can assembly the virtual machine disk mirror image in an assembly form, saves the file storage space, and improves the assembling flexibility of the virtual machine disk mirror image.

Owner:BEIHANG UNIV

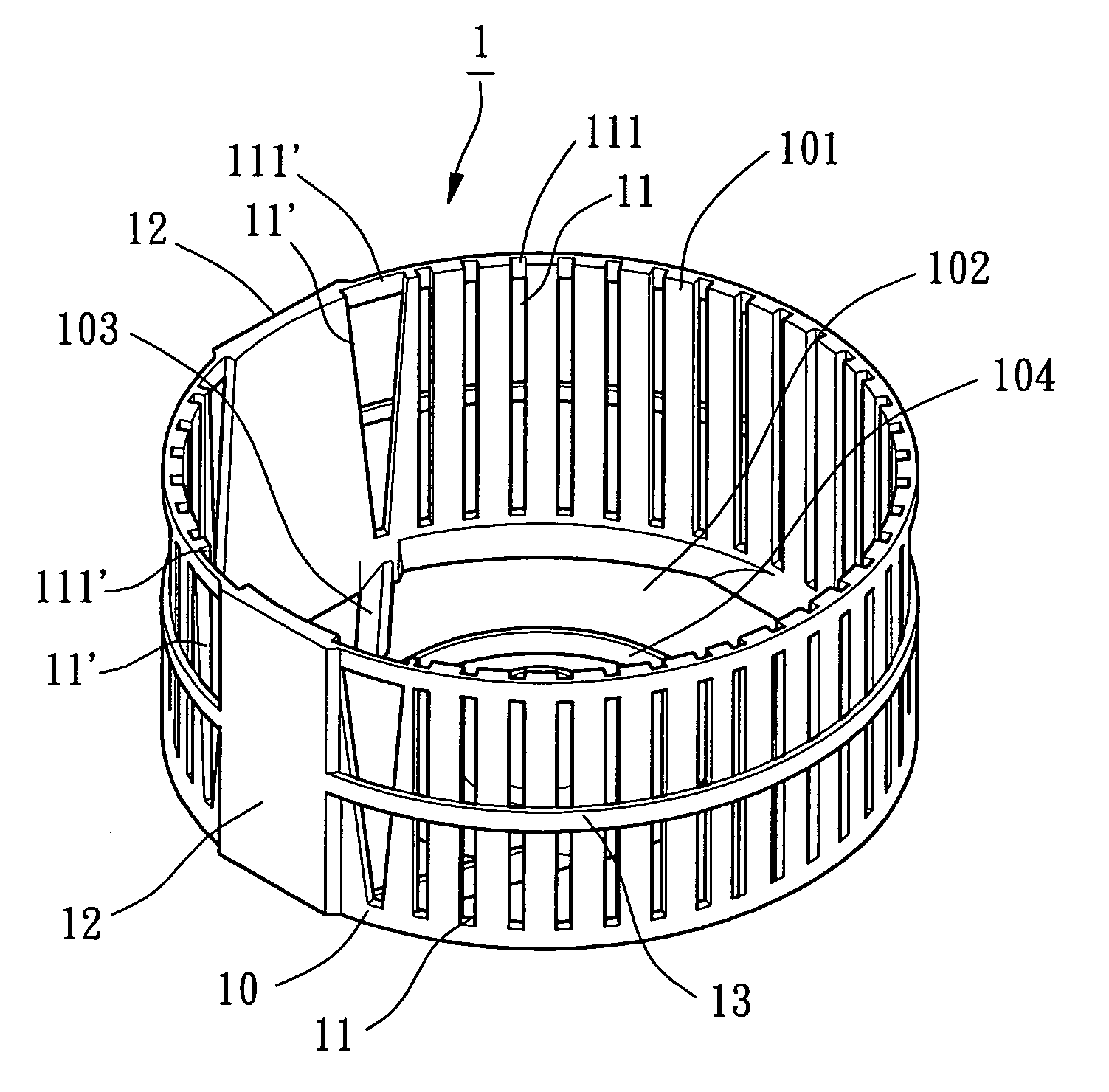

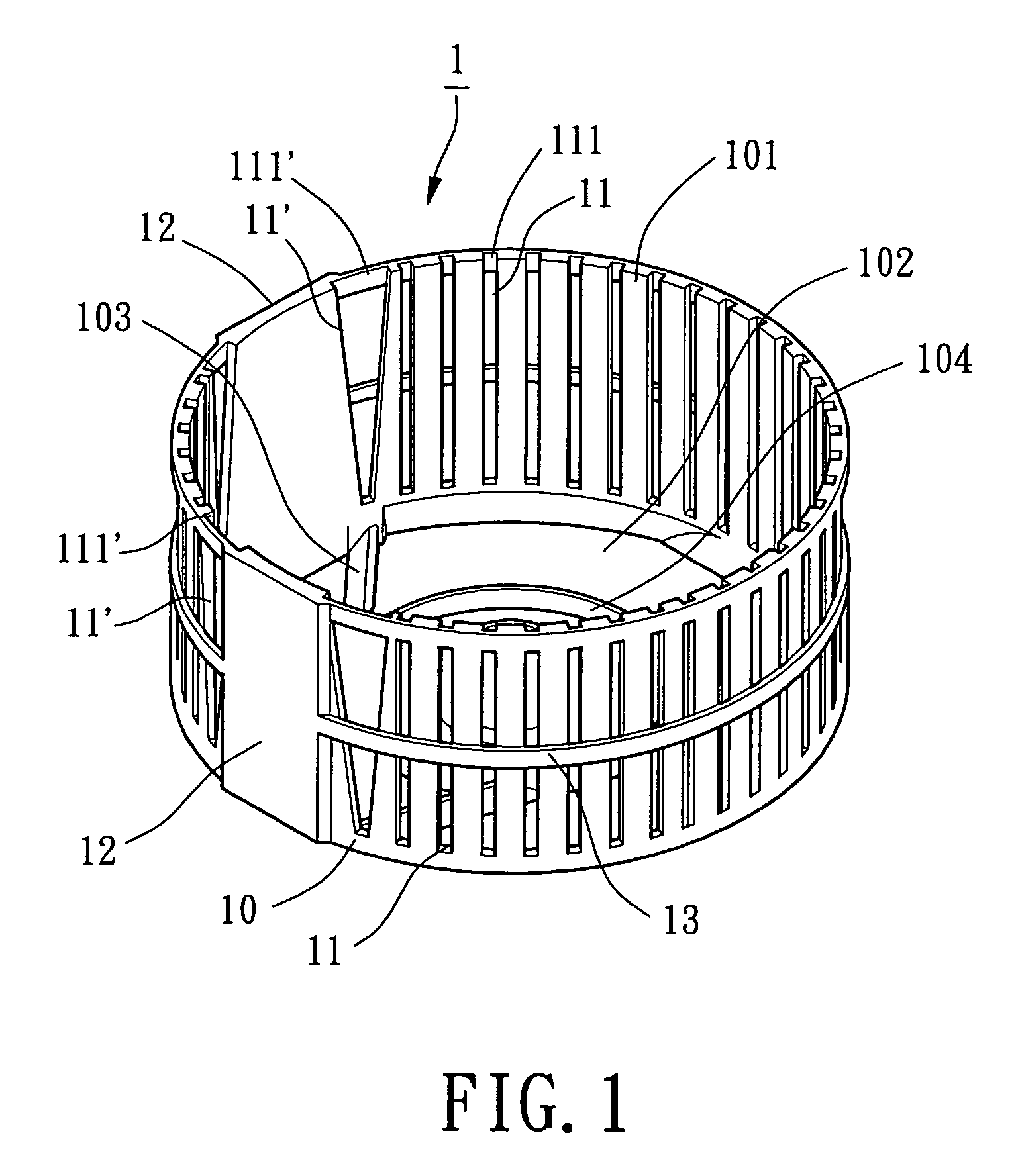

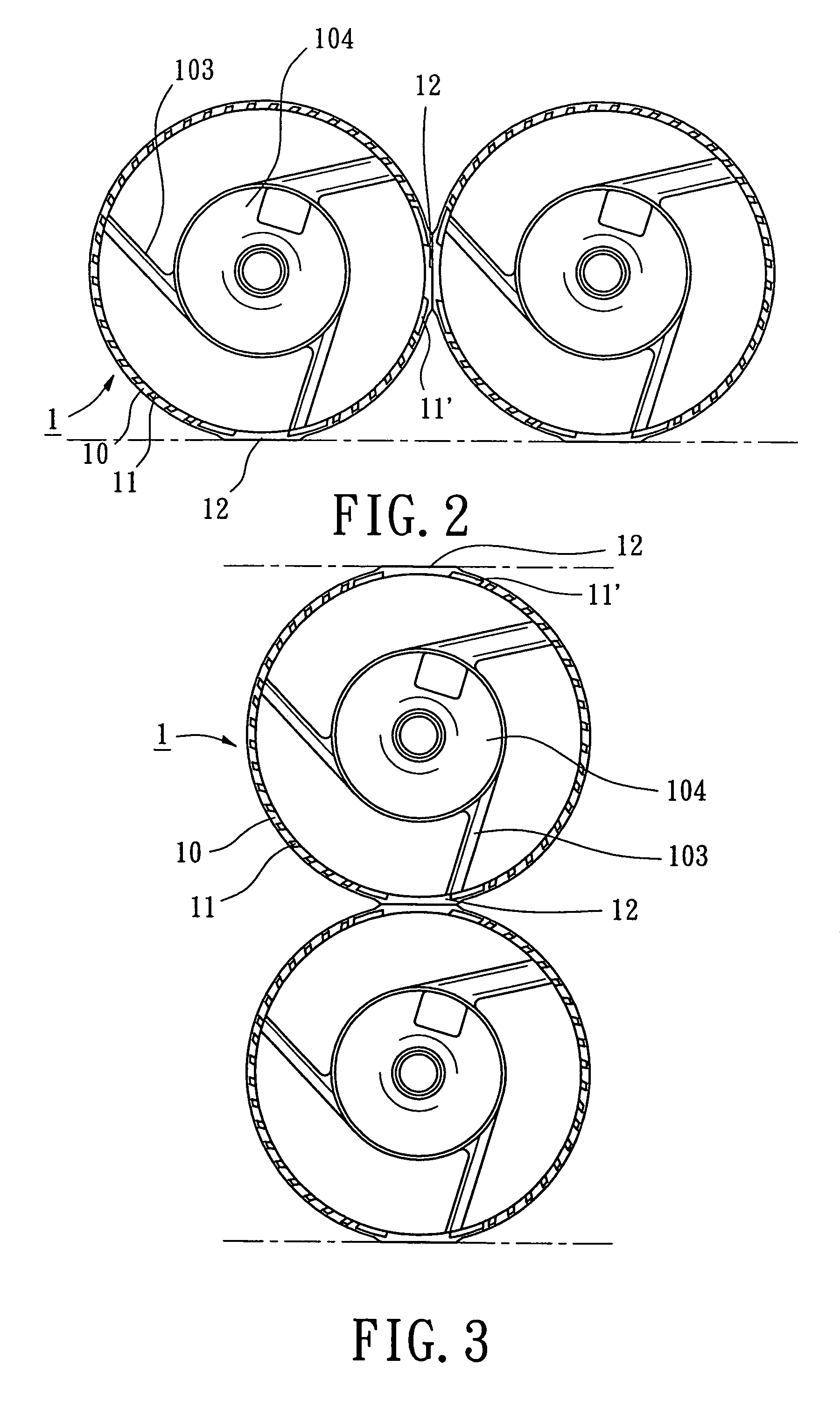

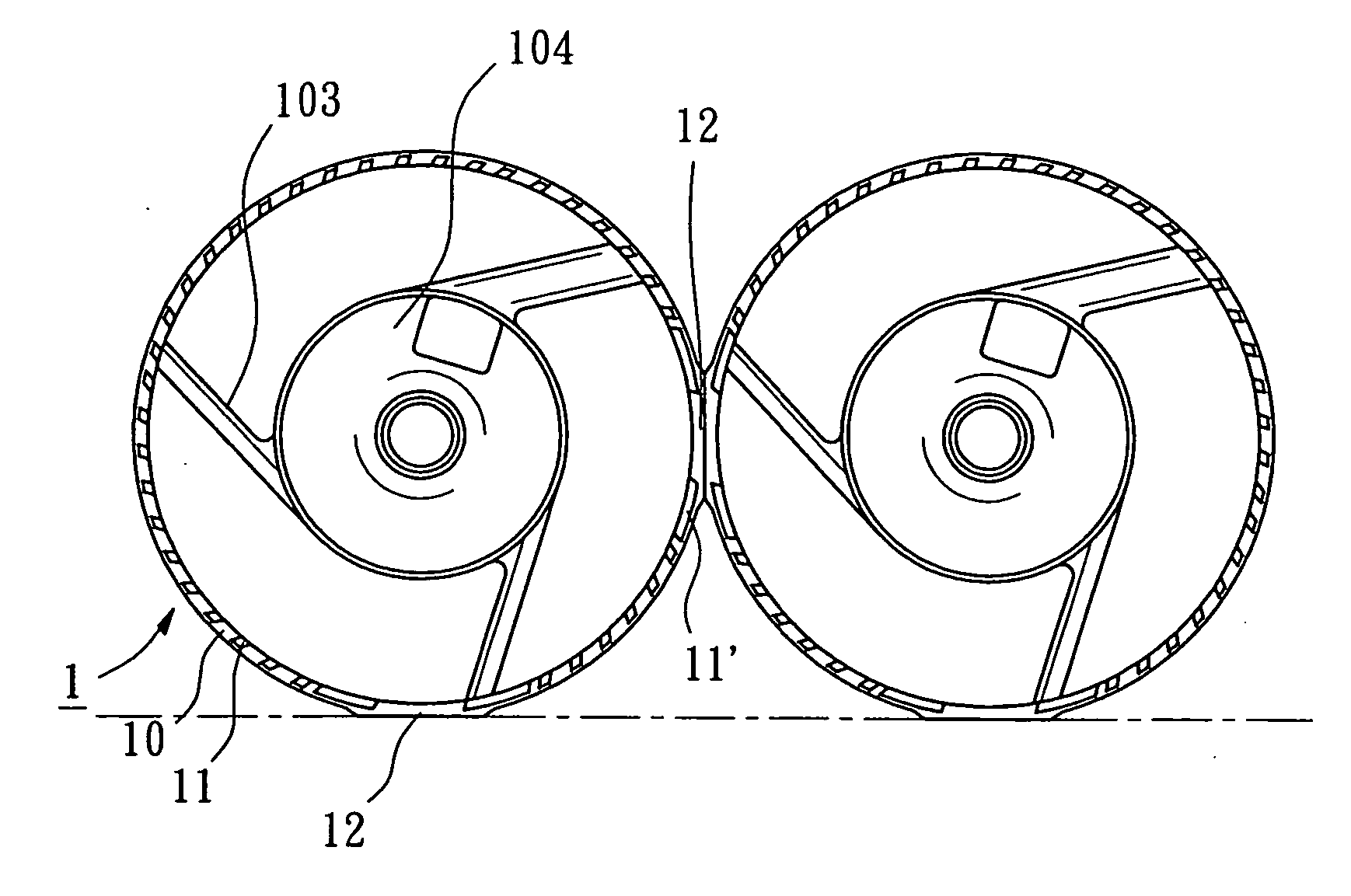

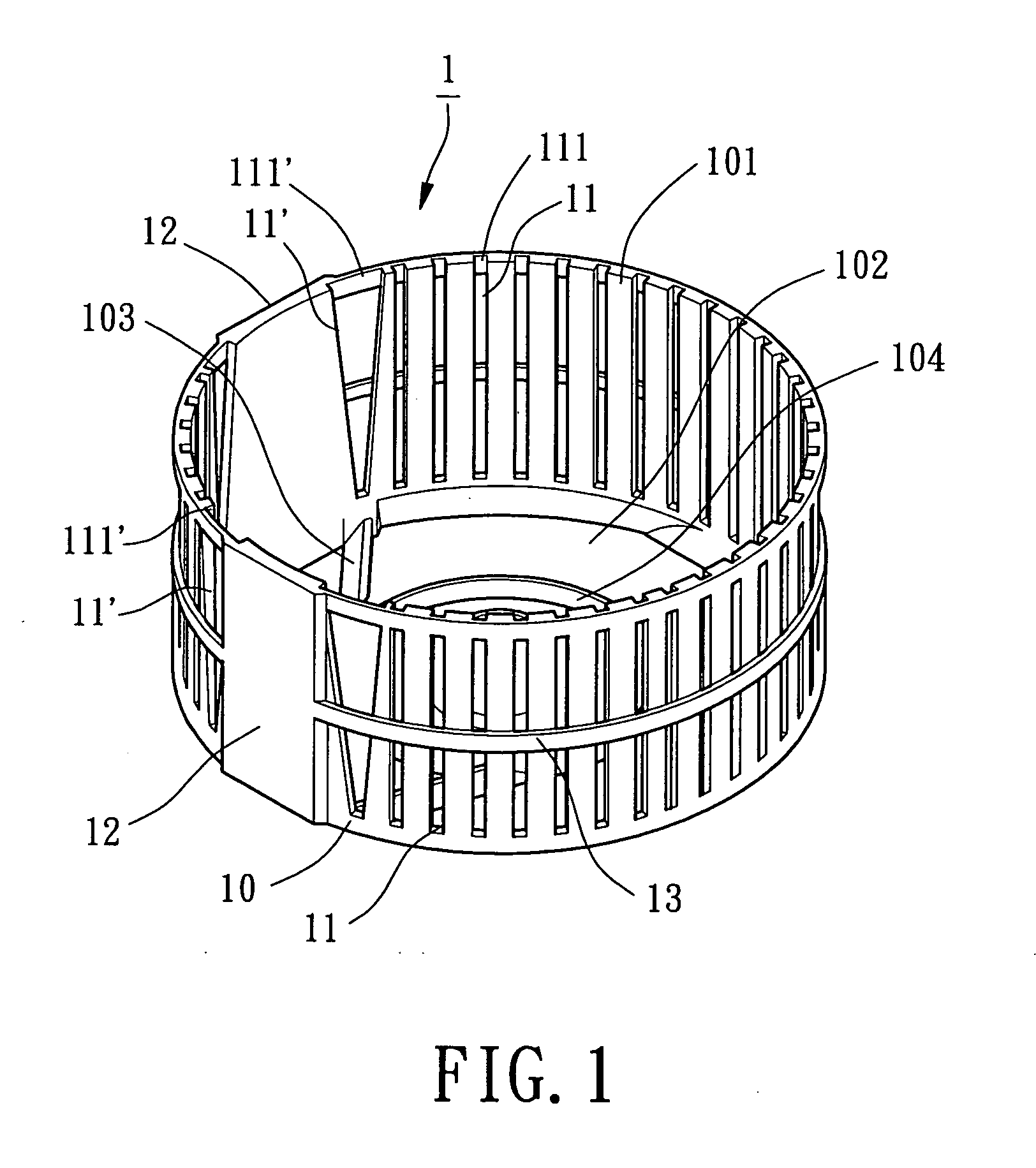

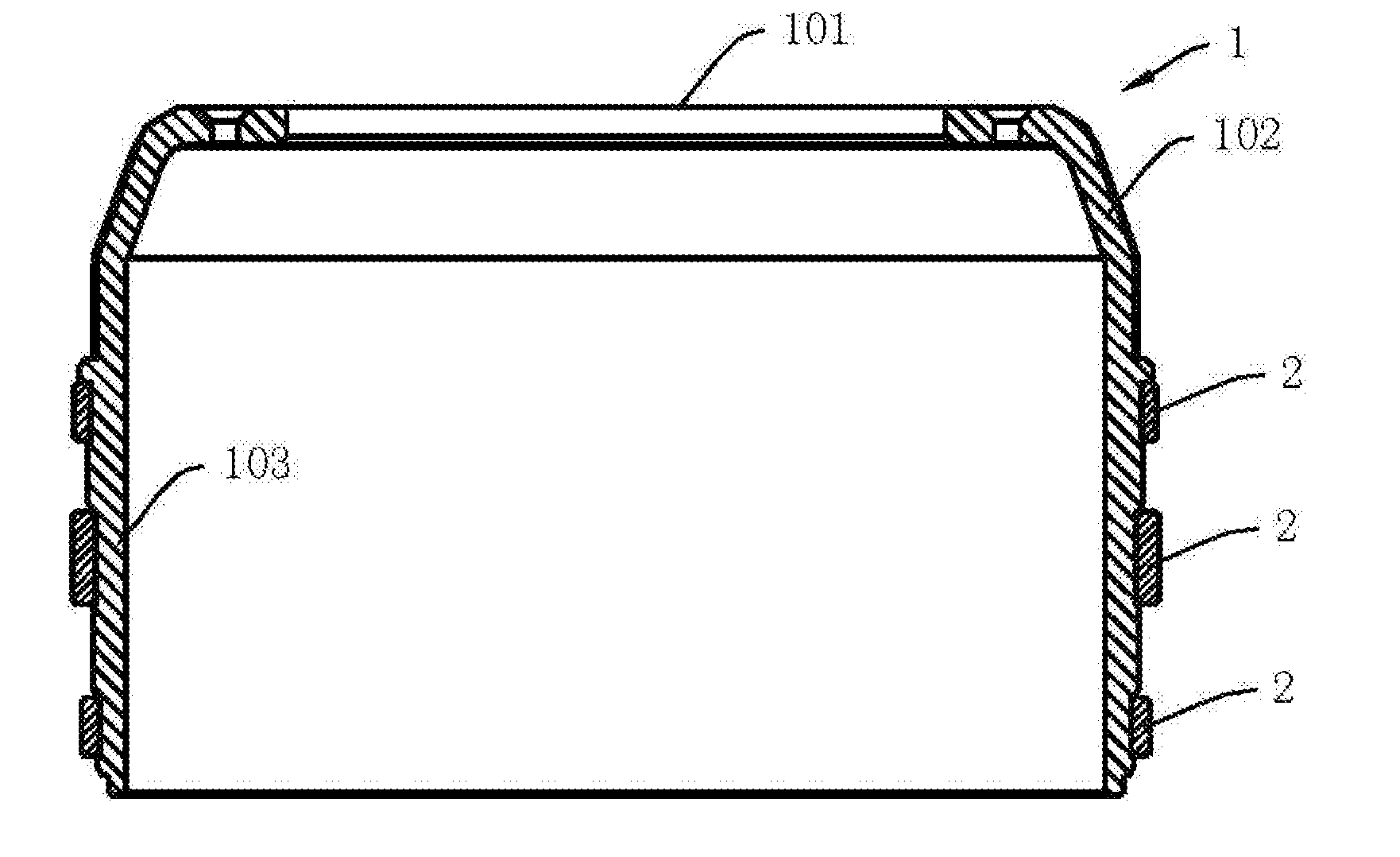

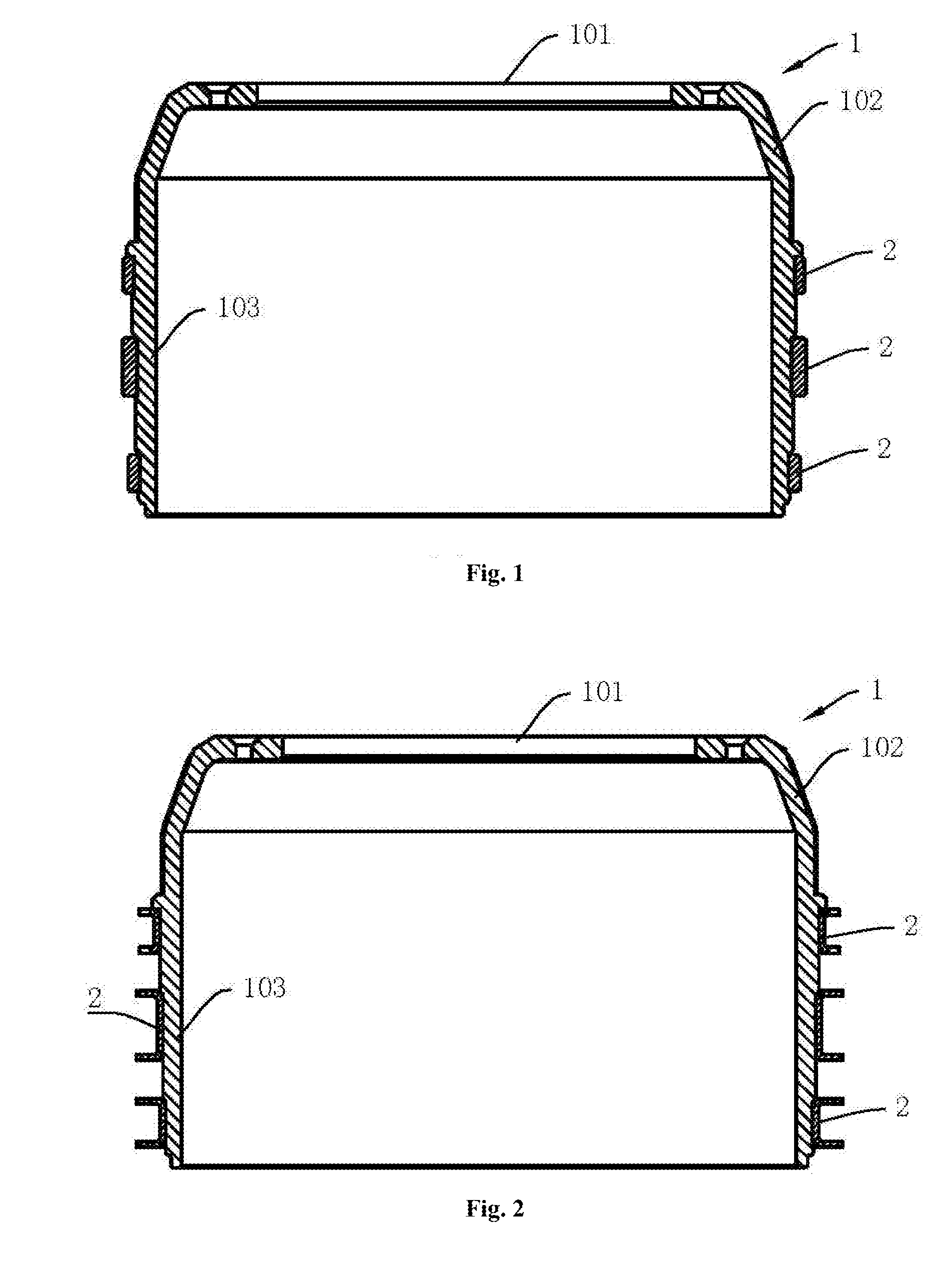

Housing for axial flow heat-dissipating fan

InactiveUS7080970B2Improve assembly stabilityIncrease assembly flexibilityPump componentsCombination enginesEngineeringComputer fan

Owner:SUNONWEALTH ELECTRIC MACHINE

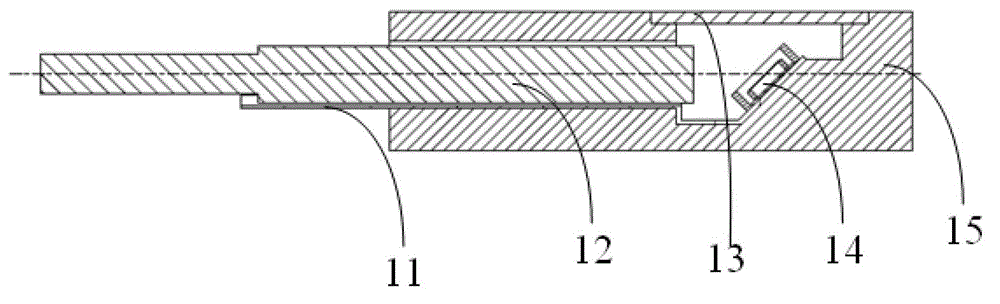

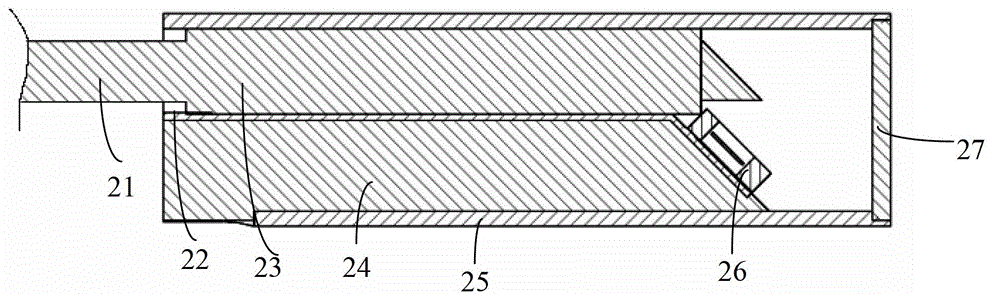

Double-working-mode micro electro mechanical system (MEMS) optical probe

ActiveCN103054544AFlexible useAdaptableEndoscopesOptically investigating flaws/contaminationElectricityWork pattern

The invention discloses a double-working-mode micro electro mechanical system (MEMS) optical probe which comprises a probe tube casing with a window base and a probe main body arranged in the probe tube casing, wherein the probe main body comprises a main body base, an MEMS micromirror with a base, a first lens assembly and a second lens assembly, wherein the first lens assembly and the second lens assembly are connected with optical fibers. The MEMS micromirror electrically connected with an external driving circuit is fixed at the front end of the main body base; the first lens assembly is fixed on one side of the main body base and achieves frontward scanning or lateral frontward scanning of frontward or lateral frontward scanning light beams through crosswise deflection of the MEMS micromirror; and the second lens assembly is fixed on the other side of the main body base and achieves lateral scanning of lateral scanning light beams through crosswise deflection of the MEMS micromirror. The double-working-mode MEMS optical probe performs probe assembling through the double lens assemblies, can achieve two working modes through one MEMS micromirror, can be used for scanning imaging of cavities of multiple organs in human bodies and performing diagnosis and can be used in the field of detection and measuring in industry and the like.

Owner:无锡微文半导体科技有限公司

Housing for axial flow heat-dissipating fan

InactiveUS20050281665A1Improve assembly stabilityIncrease assembly flexibilityPump componentsCombination enginesEngineeringMechanical engineering

Owner:SUNONWEALTH ELECTRIC MACHINE

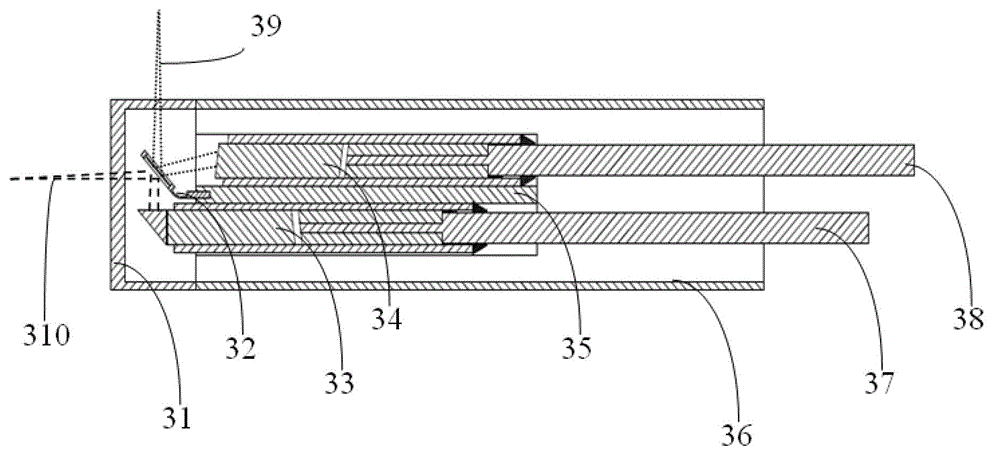

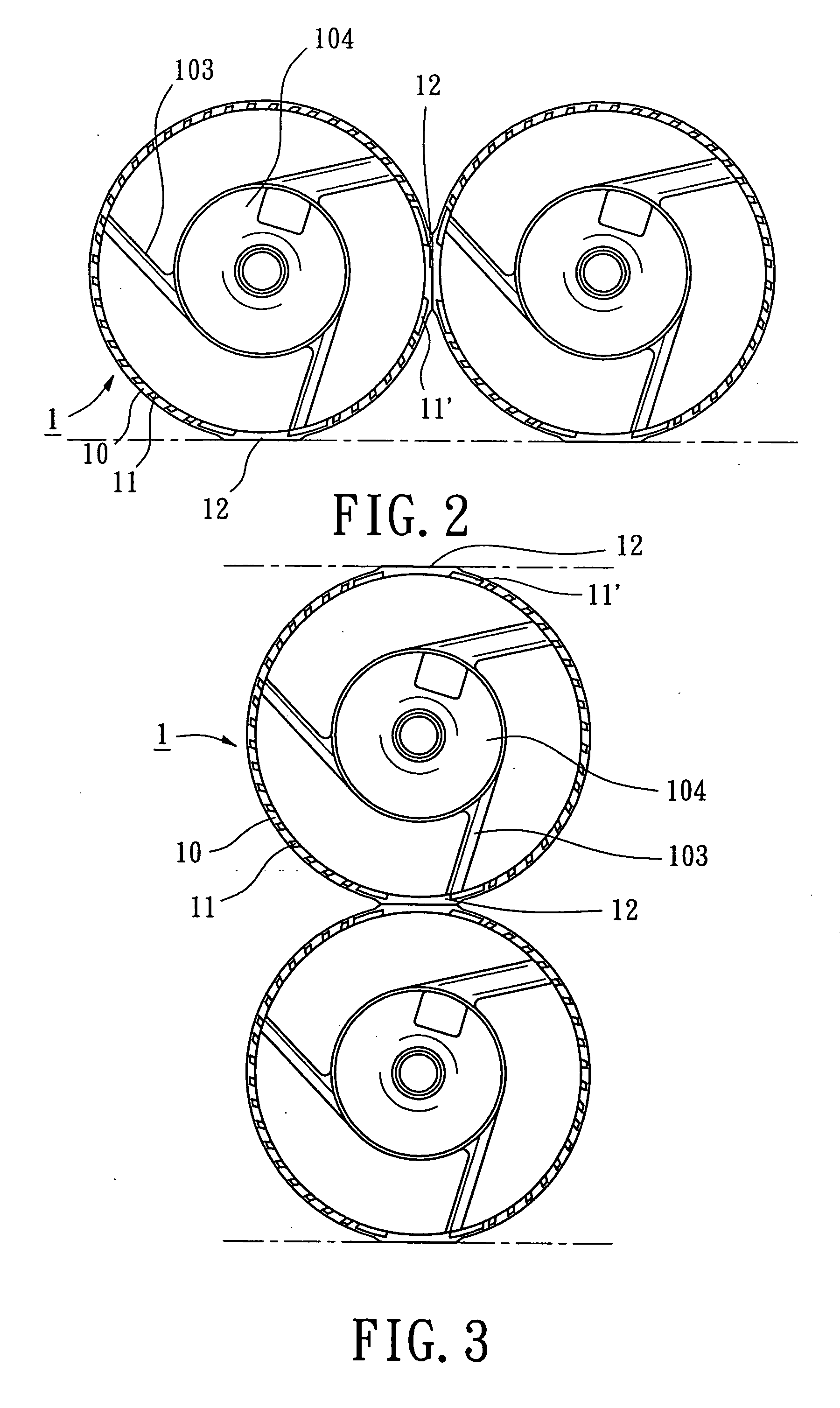

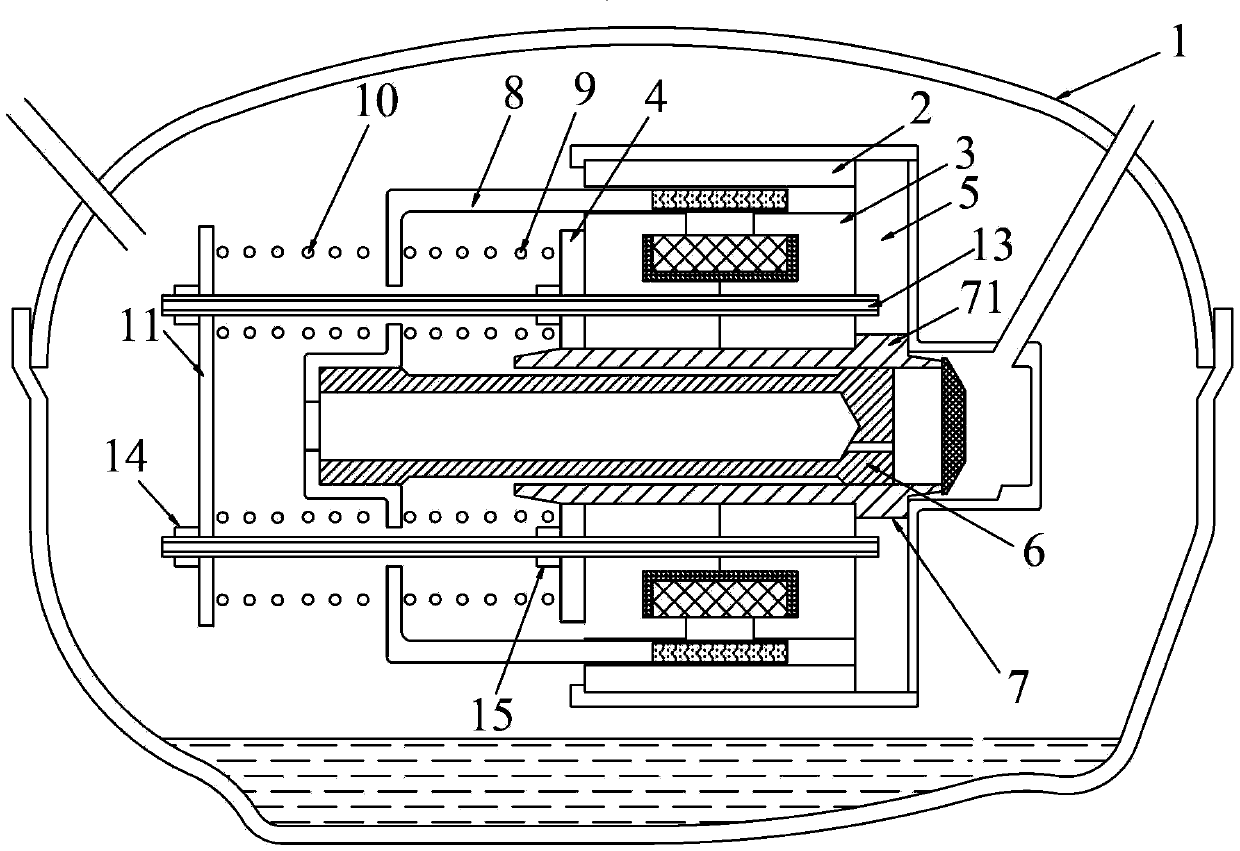

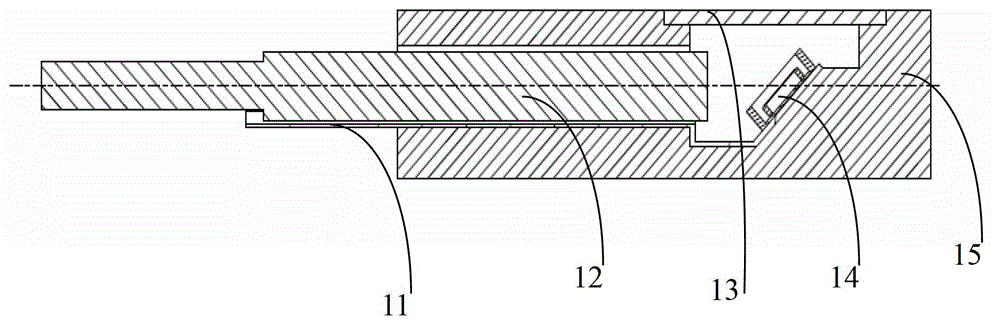

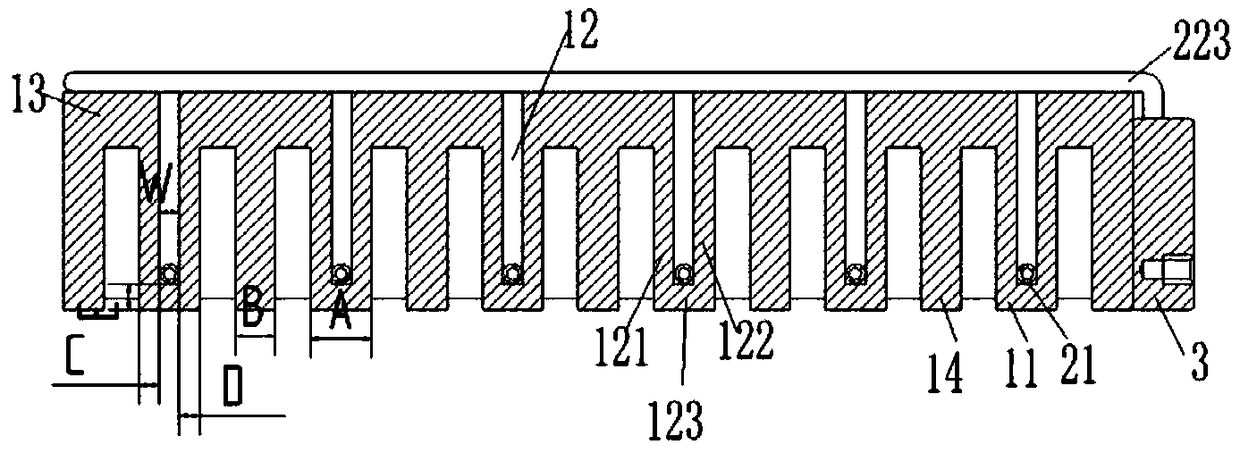

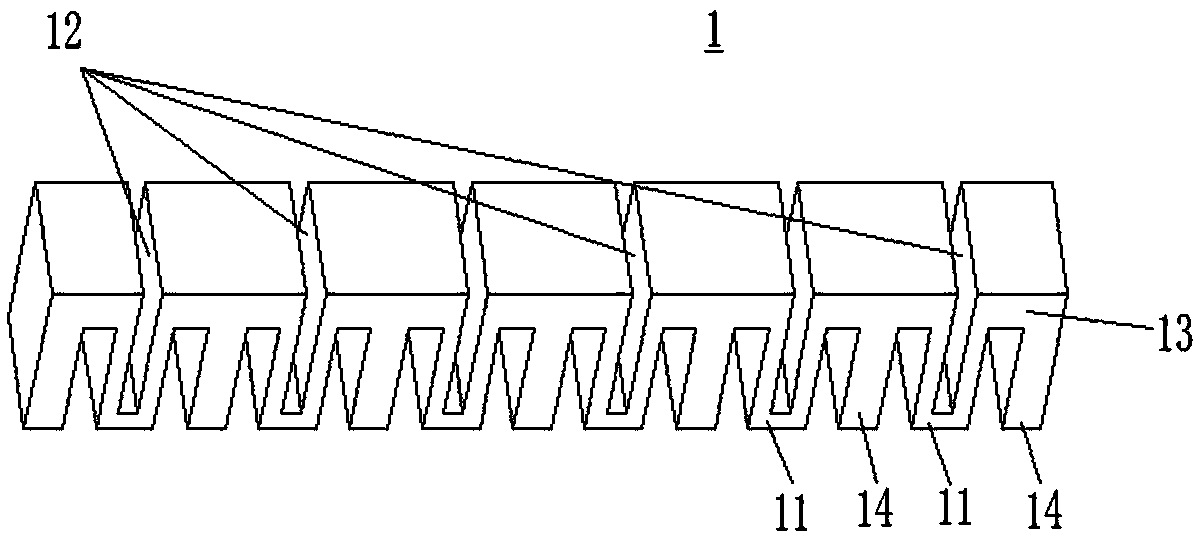

Linear compressor

InactiveCN103967748AIncrease assembly flexibilityGuaranteed coaxialityPiston pumpsPositive-displacement liquid enginesLinear compressorStator

The invention provides a linear compressor comprising an inner stator and an outer stator which are cylindrical. The outer stator is disposed on the outer side of the inner stator, a flange is arranged at one end of the inner stator, an air cylinder is fixed on the flange, a cylinder body of the air cylinder extends into the inner stator, a piston is arranged in the air cylinder, a stator pressing plate is arranged at the other end of the inner stator, a spring retaining plate is arranged oppositely to the stator pressing plate, a rotor frame connected with the piston is arranged between the inner stator and the outer stator and positioned between the spring retaining plate and the stator pressing plate, the linear compressor further comprises a fixing mechanism, and the fixing mechanism penetrates the rotor frame and the inner stator respectively to fix the spring retaining plate, the stator pressing plate and the flange together. Consequently, needs of the whole linear compressor can be guaranteed, and firmness in fixing of parts which are coaxial can can be guaranteed, so that coaxiality of the linear compressor is guaranteed, and improving of reliability of the linear compressor is facilitated.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD

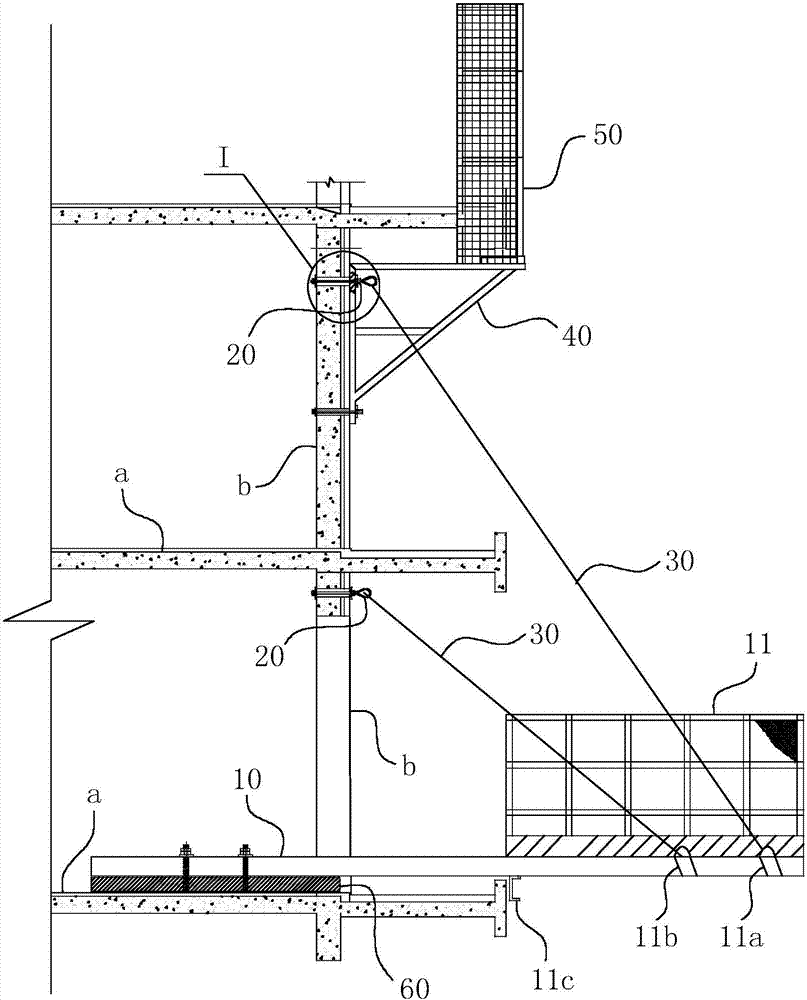

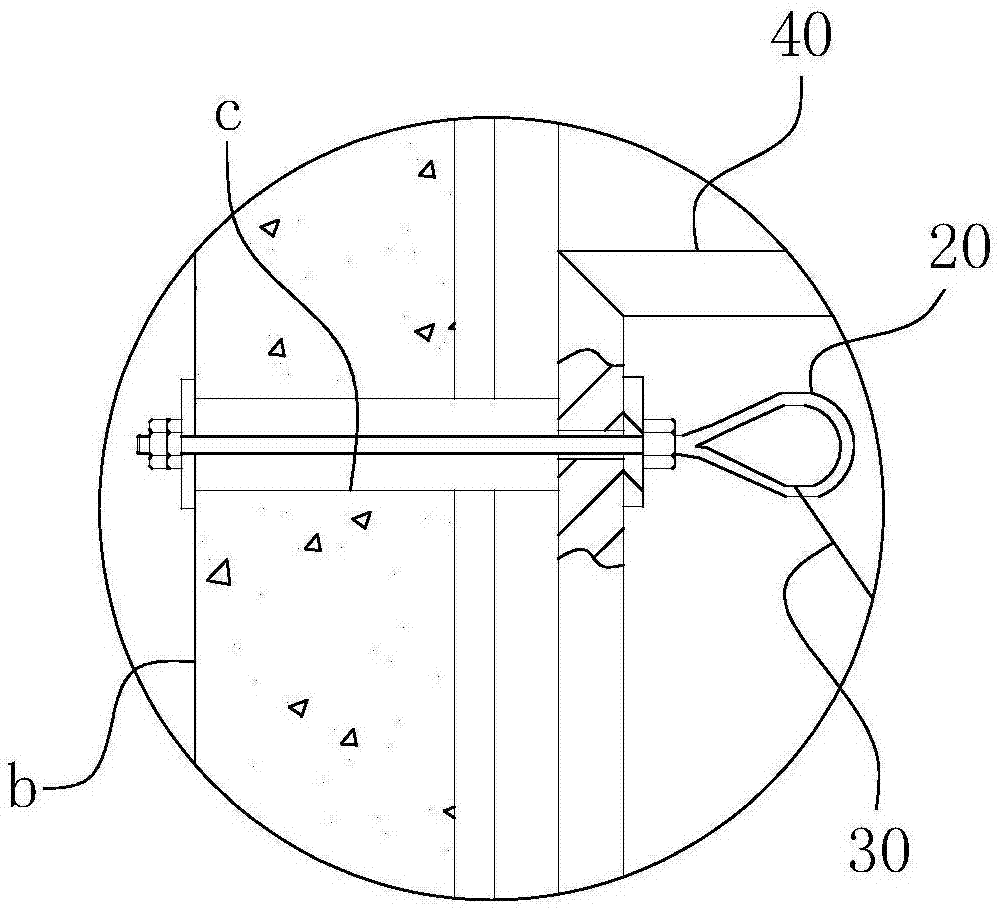

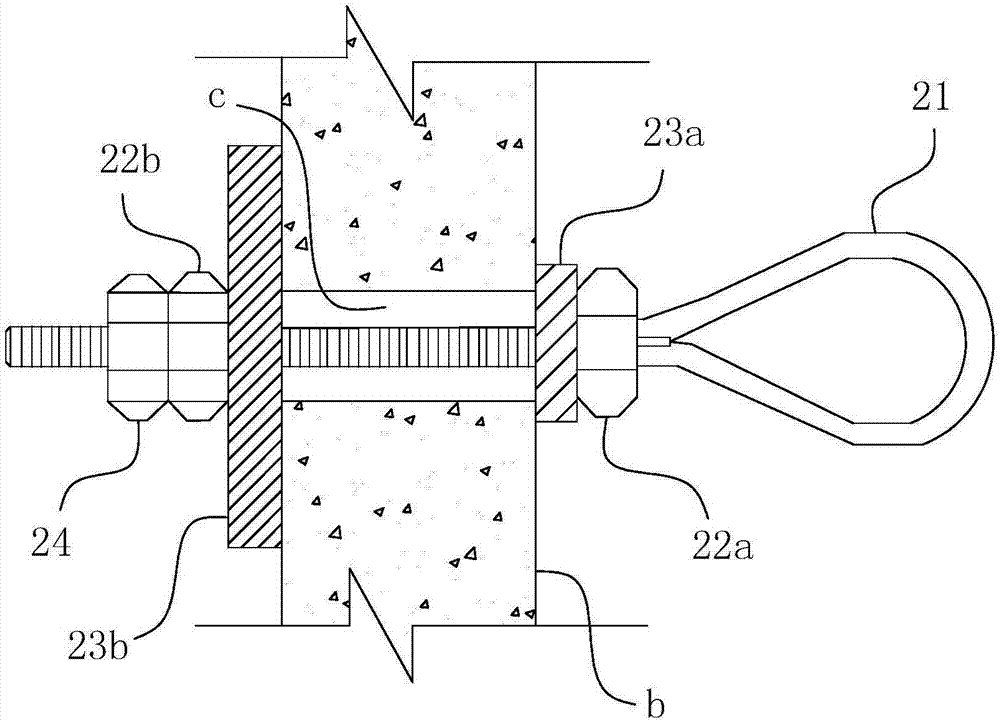

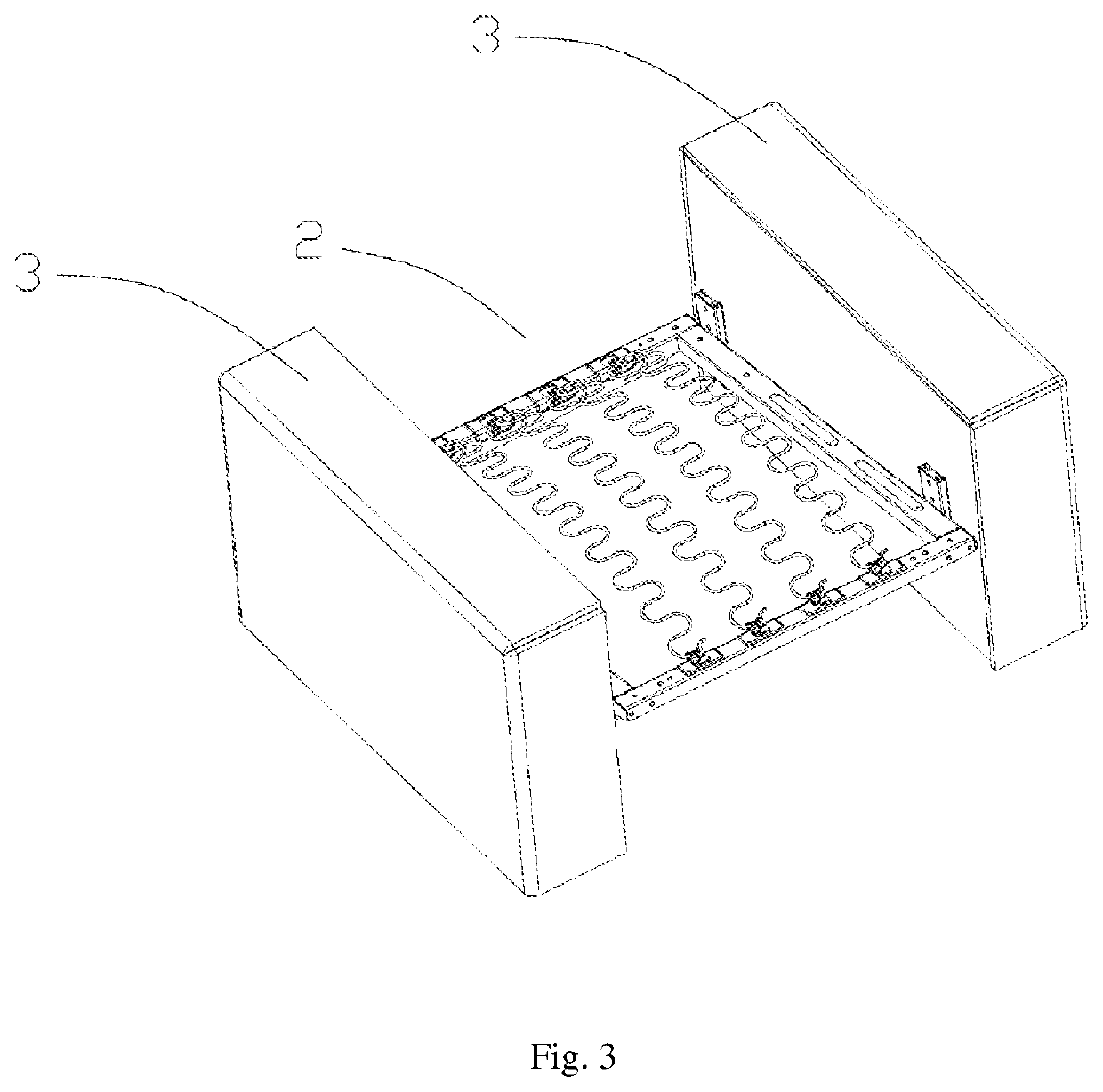

Modularized rapid-installation-type unloading and external protecting integrated system for fabricated building

InactiveCN107338965ARealize the purpose of stable installationLow costBuilding material handlingClosed loopModularity

The invention belongs to the technical field of building construction, and in particular relates to a modular quick-loading unloading and external protection integrated system for prefabricated buildings. The system includes a steel platform; the outer walls of the structural floors of each floor are provided with reserved holes through the outer walls; Screw rods are threaded with compression nuts; hanging lugs are arranged on both sides of the cantilever section, and a traction rope connecting the two is set between the lifting lugs and the closed-loop end of the pulling screw; the system also includes a support frame, A mounting hole is arranged on the support frame, and the pull screw rod penetrates into the mounting hole and the support frame is compressed and fixed at the reserved hole by the compression nut; the top of the support frame is fixed with a mesh screen plate-like external rack. The system has a high degree of modularization, good safety in use, simple and quick operation, and low production cost. The whole system can rise and fall simultaneously with the building structure operation, which can significantly improve the actual construction progress.

Owner:ANHUI BAOYE CONSTR ENG GRP CO LTD

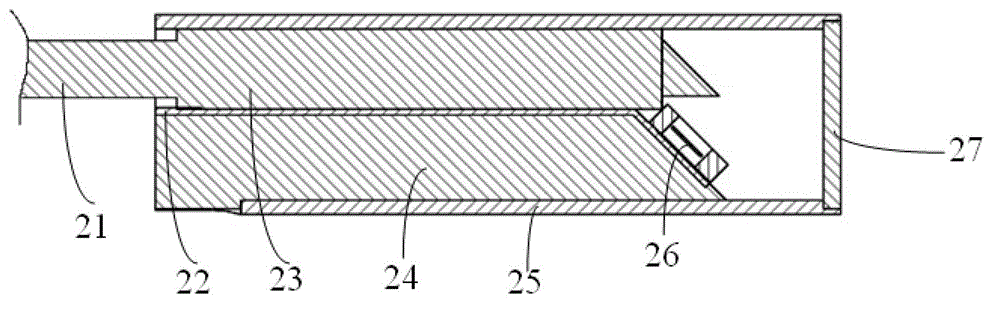

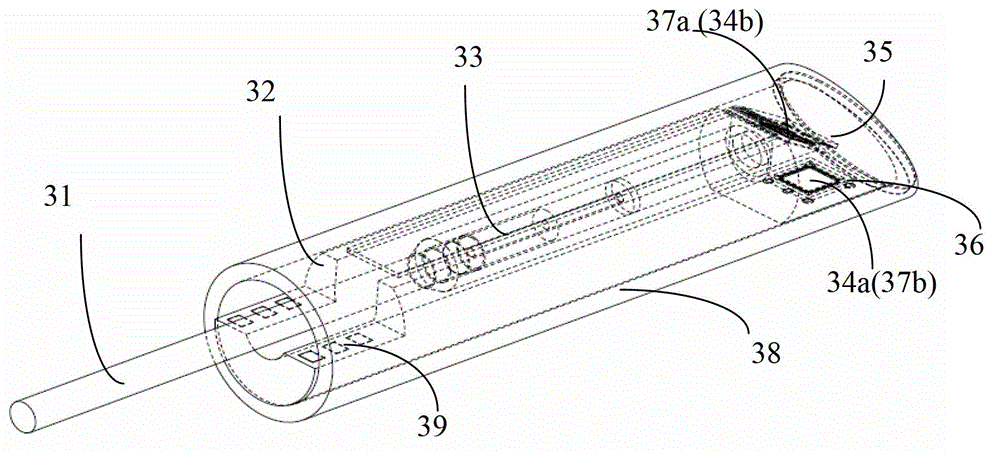

MEMS (micro electronic mechanical system) optical scanning probe

ActiveCN103142201AWith distortion correction functionSmall sizeSurgeryTelescopesTissue sampleOptical scanning

The invention discloses a lateral and forward scanning optical probe based on an MEMS (micro electronic mechanical system) and a realization method of the lateral and forward scanning optical probe. A base, an optical fiber and a lens are arranged in an outer tube, the optical fiber and the lens are arranged on the base, an MEMS micromirror A or a reflector A is arranged in front of the base, a reflector B or an MEMS micromirror B is arranged in front of the lens, in addition, an obtuse angle is formed between a lens axis and a mirror surface of the MEMS micromirror B or the reflector B, the foremost end of the outer tube is provided with a window, and the window is in a preset angle with the axial direction of the outer tube. The MEMS optical scanning probe has the advantages that the lateral scanning imaging can be realized on the side walls of tissue samples, the scanning imaging on sequestered tissues or internal organs of human bodies can also be realized, meanwhile, the functions of the lateral scanning probe and the forward scanning probe are considered, and the lateral and forward scanning can be realized.

Owner:无锡微文半导体科技有限公司

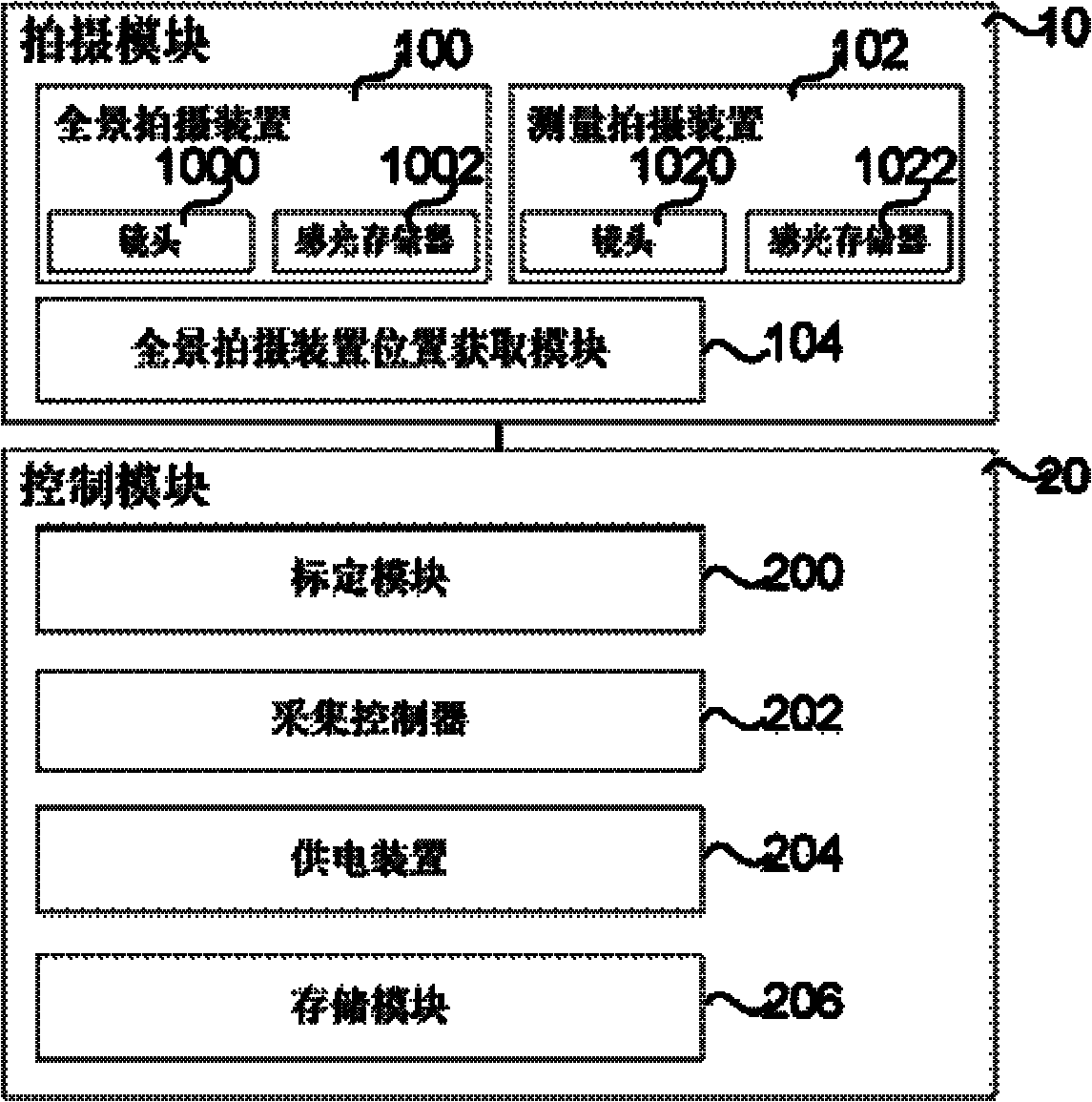

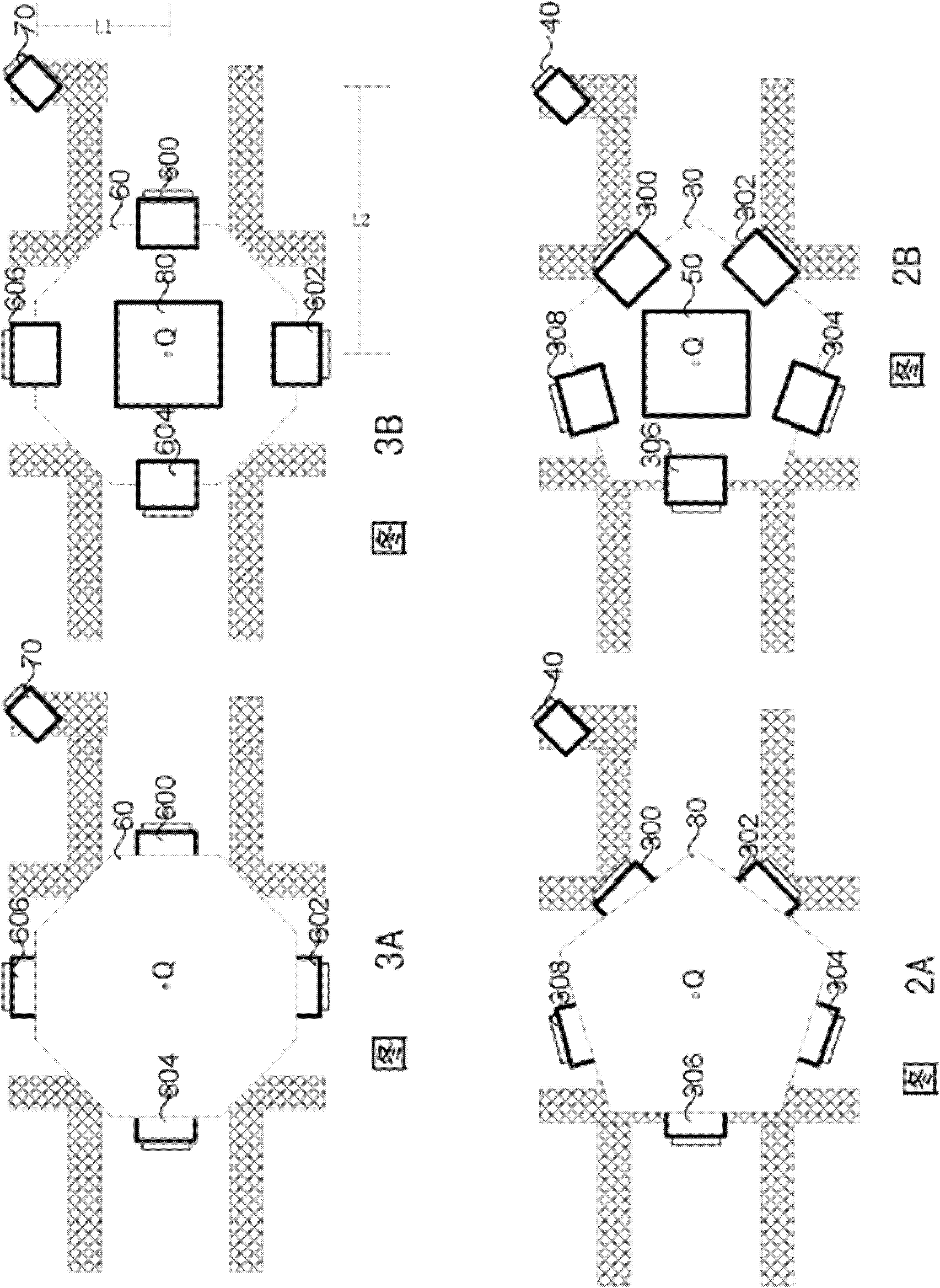

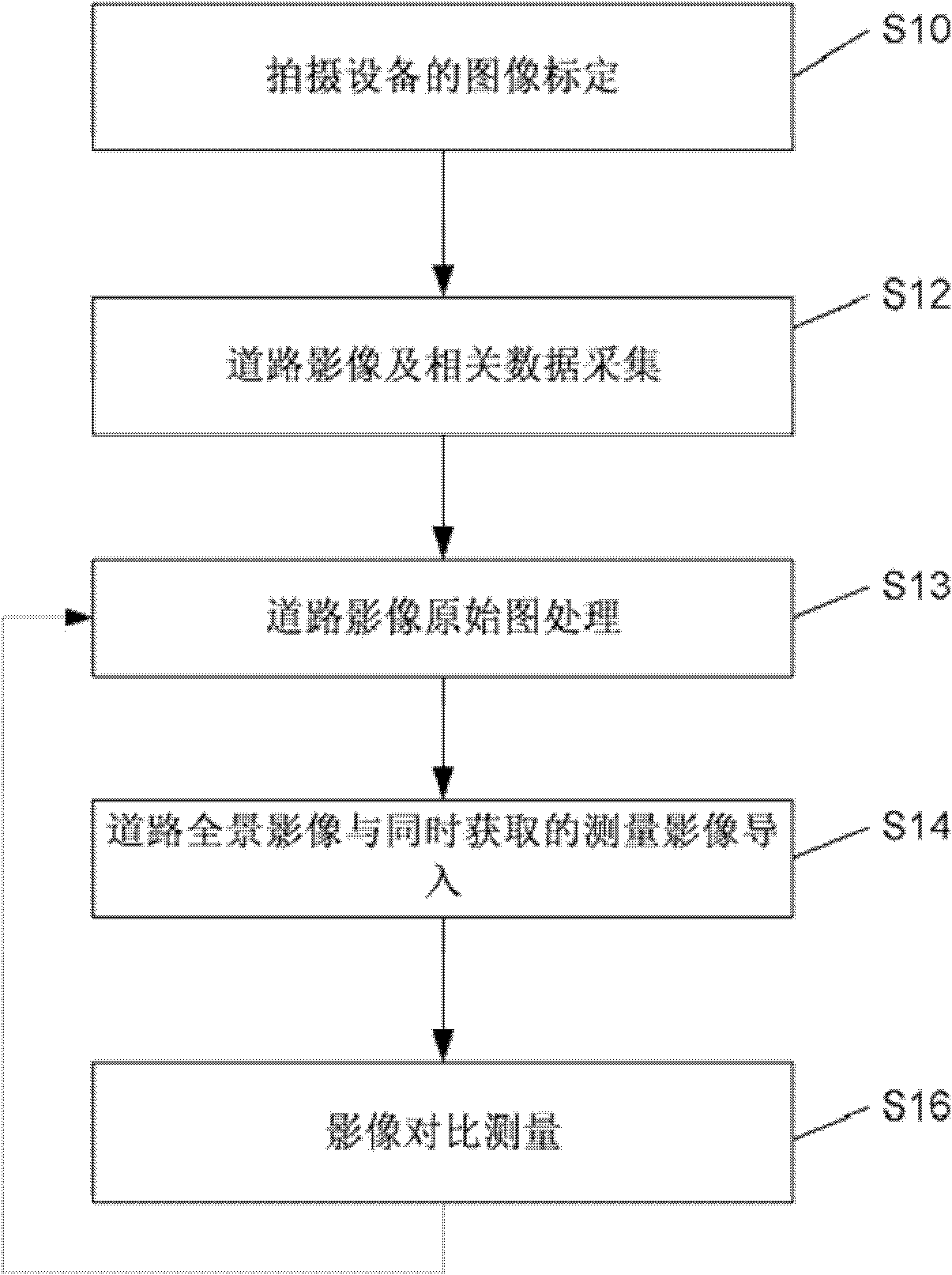

Panoramic image acquisition and measurement system and panoramic image spatial measurement method

ActiveCN102519435AAchieve leapfrog developmentIncrease assembly flexibilityPhotogrammetry/videogrammetryComputer graphics (images)Visual perception

The invention discloses a panoramic image acquisition and measurement system and a panoramic image spatial measurement method. Panorama can be acquired individually, or a part of space or a whole 360 DEG space can be measured according to demand, so as to realize leap-forward development from a panoramic image acquisition system to a panoramic image acquisition and measurement system. A technical scheme is as below: panoramic image acquisition is isolated into an acquisition module; and based on the acquisition module and combined with binocular measurement principle, other non-laser principle optical acquisition equipment is further added, such as fish eye or wide-angle lens and matched apparatus for assisting measurement, so as to substantially widen a measure visual angle to be larger than a traditional binocular visual angle. Meanwhile, as combination of the panoramic acquisition equipment and large visual angle measurement equipment, complexity of 360 DEG measurement is reduced by a large margin.

Owner:SHANGHAI JEITU SOFTWARE

Outer sidewall retention scheme for a singlet first stage nozzle

InactiveUS7850425B2Improve stabilityImprove insulation performancePump componentsGas turbine plantsEngineeringGas turbines

An outer sidewall retention scheme for a singlet first stage nozzle of a gas turbine. The retention scheme includes a circumferential retaining ring with a main body and a pair of circumferential retaining lands projecting inward radially. A circumferential annular retaining groove is formed between the pair of circumferential retaining lands. A first lug and a second lug mounted on an outer face of the outer sidewall of each nozzle are adapted to fit within the circumferential annular retaining groove of the retaining ring and are supported radially and circumferentially by a first retaining pin and a second retaining pin, each pin passing though the circumferential retaining lands. Each nozzle further includes a chordal hinge rail and seal on the outer sidewall and a chordal hinge rail and seal on the inner sidewall providing axial support for the nozzle.

Owner:GENERAL ELECTRIC CO

Composite Brake Drum with Bands

InactiveUS20160195149A1Improve securityExtended service lifeBraking drumsBraking discsTemperature differenceEngineering

The present invention discloses a brake drum comprising: a brake drum body, which comprises a mounting portion for connecting a wheel, a braking portion for engagement with a brake shoe, and a transitional connecting portion disposed between the mounting portion and the braking portion; a hoop device is tightly mounted to the outer peripheral surface of the brake portion. The hoop device adopts a plurality of split-type hoop ferrules, or one unibody hollowed-out hoop case. The hoop device tightly mounted to the outer peripheral surface of the brake portion can not only effectively restrain the radial expansion deformation, thereby improving the fatigue resistance of the brake drum body, but also applies a clasp force to the brake drum body, thereby avoiding the danger of burst and flying out of the brake drum body, which greatly improves service life and safety. Moreover, the thickness of the brake portion wall corresponding to the hoop device can be effectively reduced, which not only effectively decreases the temperature difference between the interior and exterior of the brake drum body, but also increases heat conductivity, thereby laying foundation for both heat dissipation and prevention of the happening of the multiple cracks in the inner wall of the brake drum body.

Owner:SHANDONG HAOXIN MACHINERY

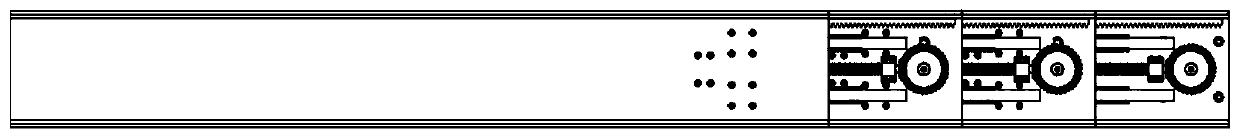

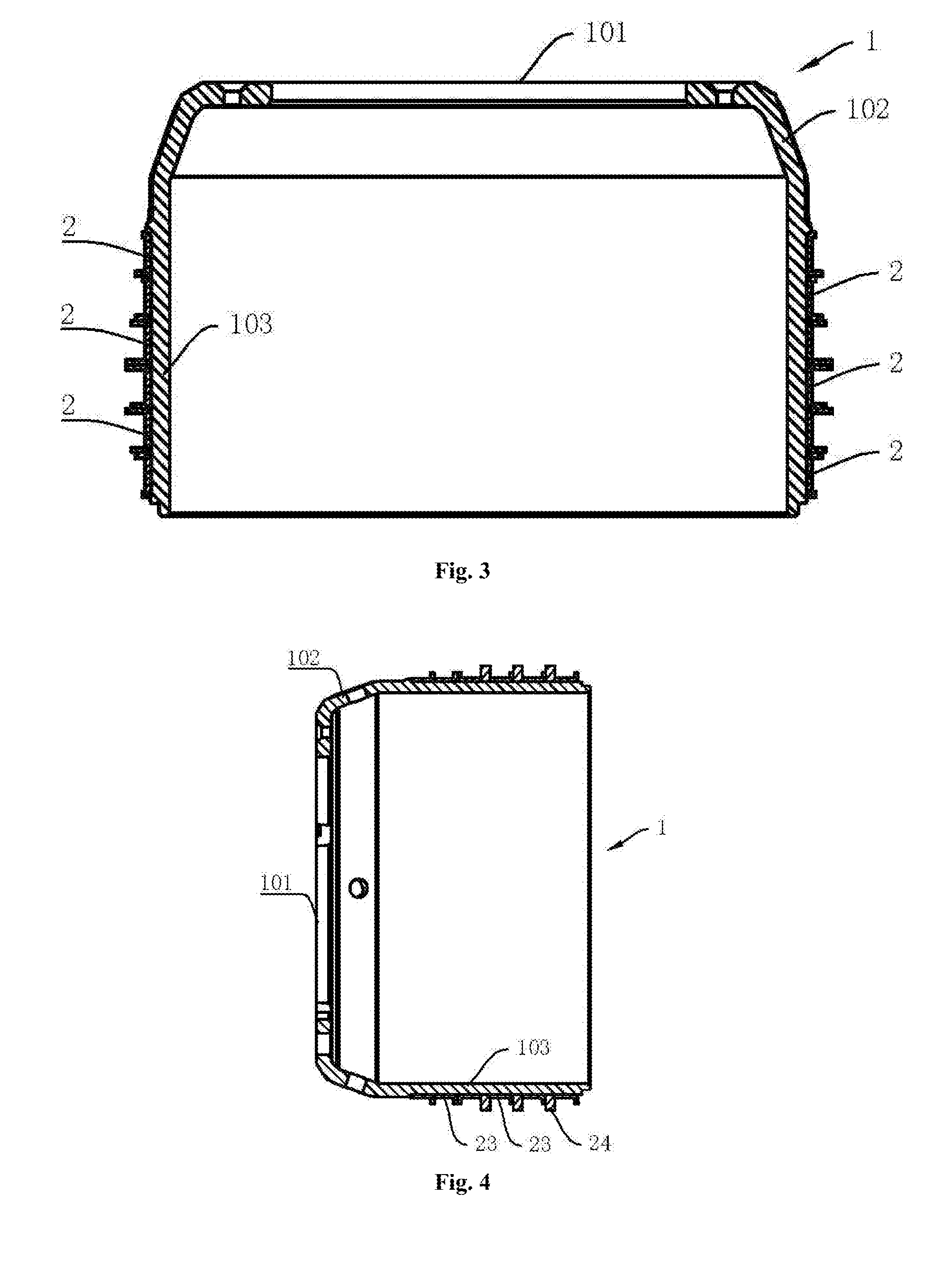

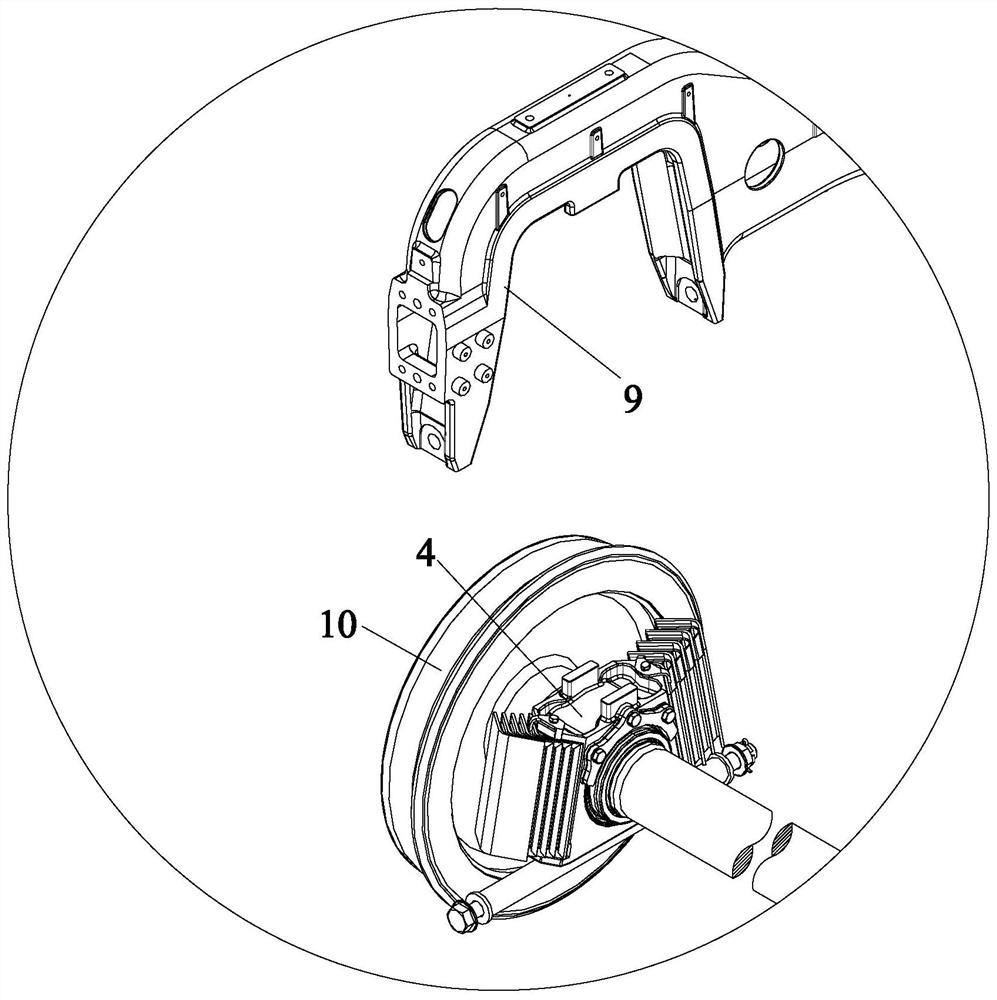

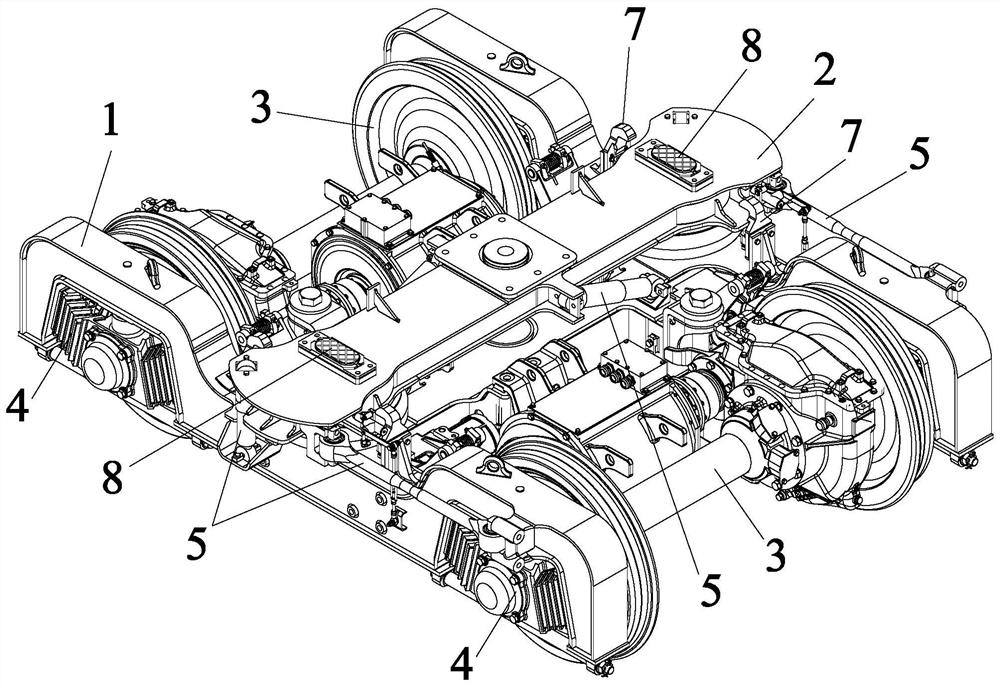

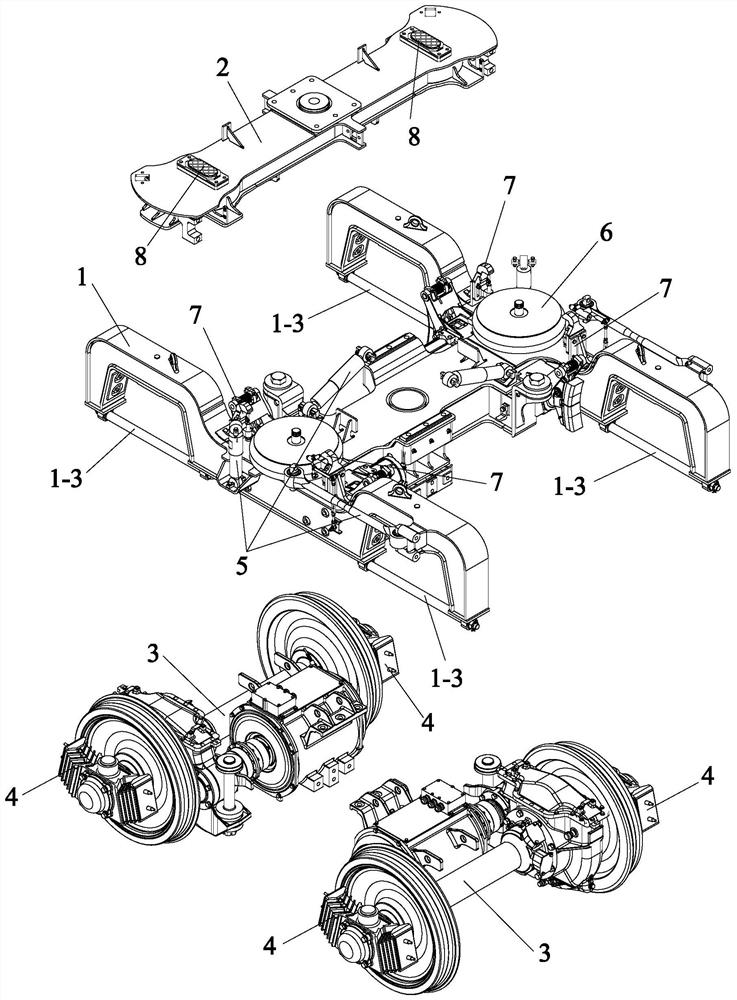

Axle box external subway bogie with integrated swing bolster and hoisting support device

PendingCN112693491AImproved mechanical properties of structural stiffnessReduce the number of weldsAxle-boxesBogiesBogieElectric machinery

An axle box external subway bogie with an integrated swing bolster and a hoisting support device belongs to the field of railway vehicle bogie devices and comprises a framework, the swing bolster, a wheel set device, a trapezoidal axle box device and a secondary suspension system. A cross beam and a side beam of the framework are of a box-shaped structure. The cross beam upper cover plate also serves as a side beam middle upper cover plate, a motor lifting seat upper cover plate and a gear box lifting seat upper cover plate, and the cross beam lower bottom plate also serves as a side beam middle lower bottom plate, a motor lifting seat lower bottom plate and a gear box lifting seat lower bottom plate; and trapezoidal axle box devices are arranged on the outer sides of wheels of the wheel set devices, upper cover plates in the middles of side beams are fixedly connected with hoisting supporting devices, and side bearings with grooves are fixedly connected to the tops of swing bolsters. The number of welding seams is effectively reduced, stress concentration is reduced, the efficiency of car falling and overhauling procedures is improved, and the overhauling and debugging process of height matching and leveling of the swing bolster and the car body floor end face and the platform after wheel turning is remarkably improved; and the wheel can be effectively protected, and the service life of the side bearing is long.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

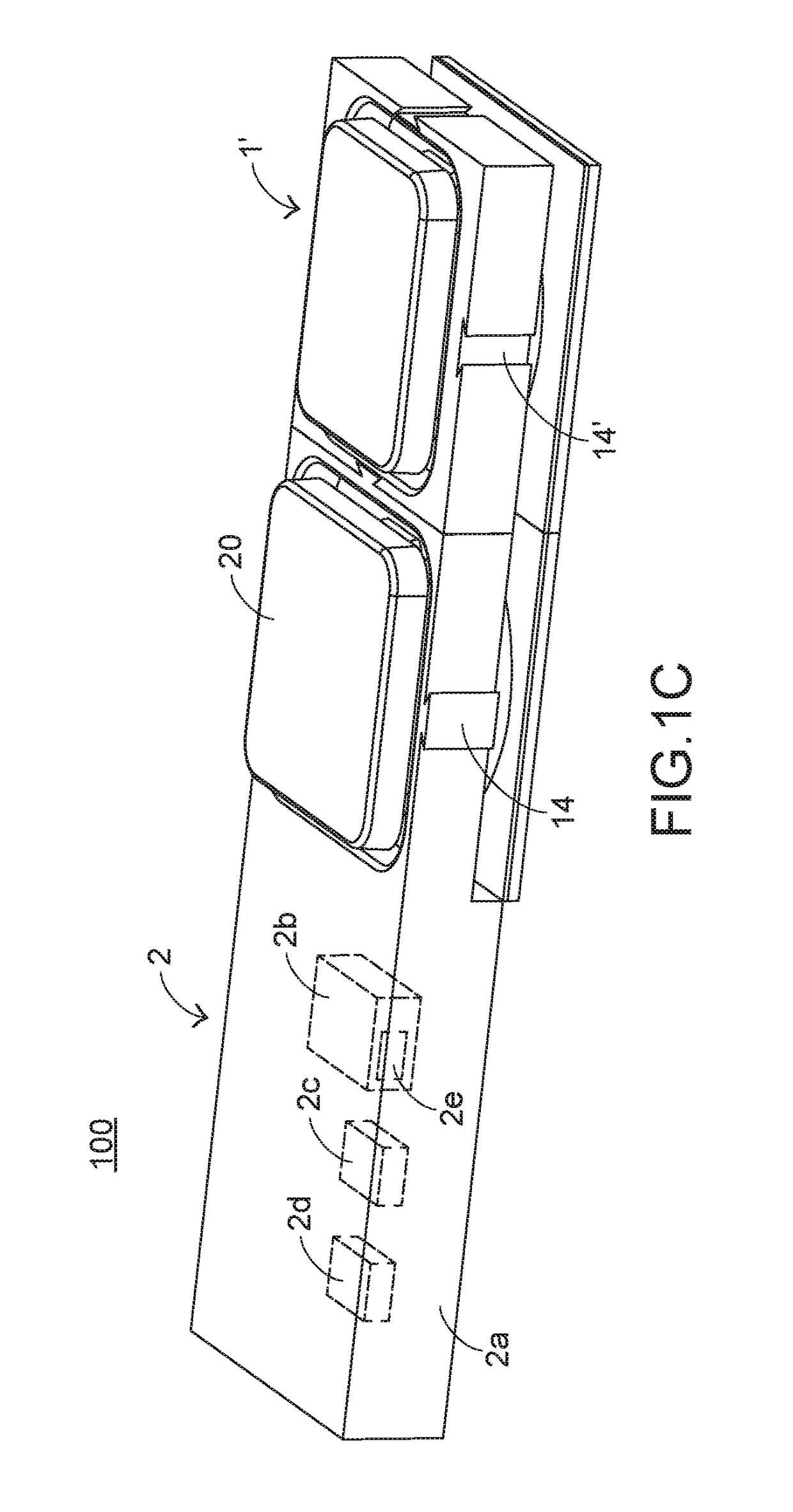

Assemblable keyboard and assemblable key

ActiveUS20170308178A1Save layout spaceEasy to assembleInput/output for user-computer interactionEmergency casingsElectricityCoupling

An assemblable keyboard includes plural assemblable keys and a main control key. Each assemblable key can be triggered to generate a key signal. The assemblable key includes a pedestal, a key structure and a conductive structure. The main control key includes a key processor and a transmission interface. The assemblable key includes plural coupling structures with the conductive structure. Every two adjacent assemblable keys are combined together and electrically connected with each other through the corresponding coupling structures. After the key signal generated by each assemblable key is transmitted to the main control key, the key signal is further outputted to a computer host. The layout space of the assemblable keyboard is reduced. Moreover, the assembling flexibility of the keyboard is enhanced.

Owner:PRIMAX ELECTRONICS LTD

Wall construction method using injected urethane foam between the wall and autoclaved concrete (AAC) blocks

InactiveUS9745739B2Reducing need for painting and maintenanceImprove heat resistanceWallsHeat proofingFastenerStucco

The present invention provides novel wall construction systems and materials for residential and commercial construction that incorporate grooved lightweight building material units (e.g., blocks, panels, and the like), a plurality of connection devices, a track system, and (injected) polyurethane structural foam. The wall construction system comprises building material units married to a building frame with a plurality of connection devices (e.g., clip fasteners) slidingly retained in a track system that is attached to the building's structural (e.g., load-bearing) framing. The building material units are joined to each other with a suitable binding agent. The cavity between the frame and the building material units is injected with an insulating structural polyurethane foam. The exterior of the wall is finished with a waterproof applied finish such as cementitious stucco. The interior of the wall is amenable to standard finish options.

Owner:BRETON SYST LLC

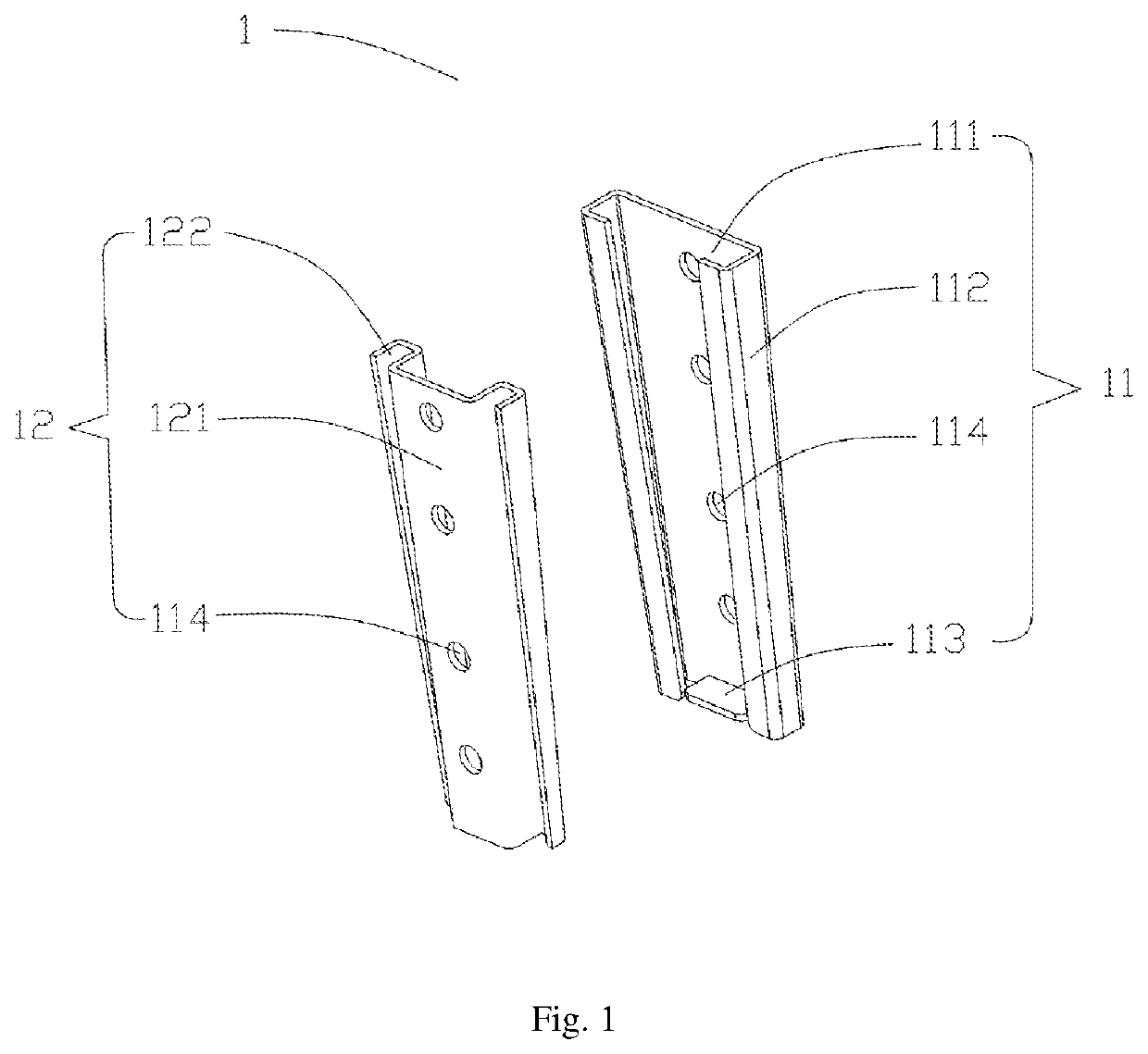

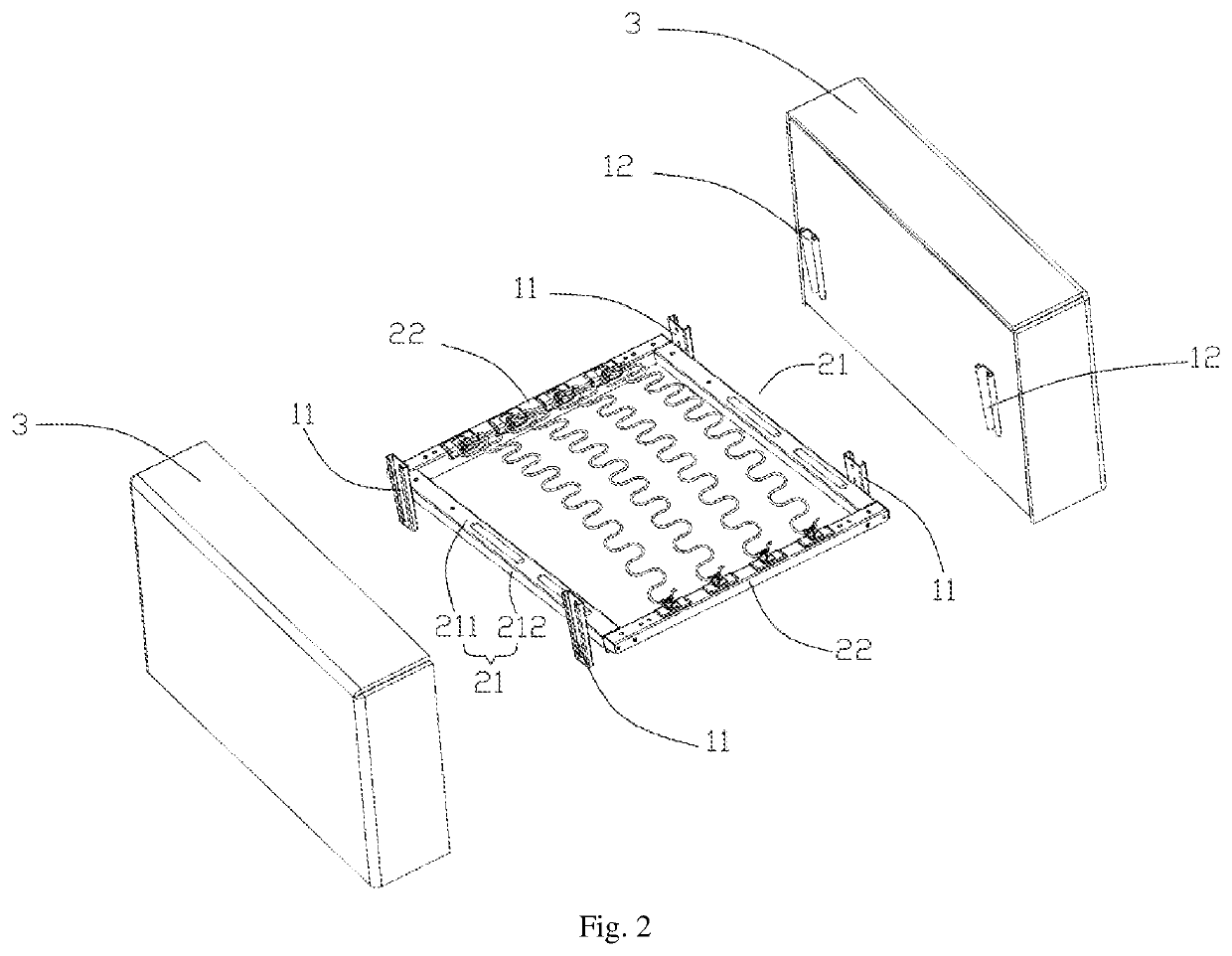

Sofa armrest connection structure and sofa assembly

ActiveUS11484122B2Easy to assembleIncrease assembly flexibilityBenchesDismountable chairsStructural engineeringMechanical engineering

The disclosure discloses a sofa armrest connection structure and a sofa assembly. The connection structure includes a first member and a second member, wherein the first member includes a first base plate, two guide rails symmetrically arranged on the first base plate, and a limiting part which is arranged on the first base plate and located under the two guide rails; the second member includes a second base plate and two guide bars symmetrically arranged on the second base plate; the two guide bars are in sliding insertion-fit with the two guide rails correspondingly; the first base plate and the second base plate are each provided with a plurality of bolt holes; the first base plate is used for being connected with a sofa seat frame, and the second base plate is used for being connected with a sofa armrest.

Owner:REMACRO TECH CO LTD

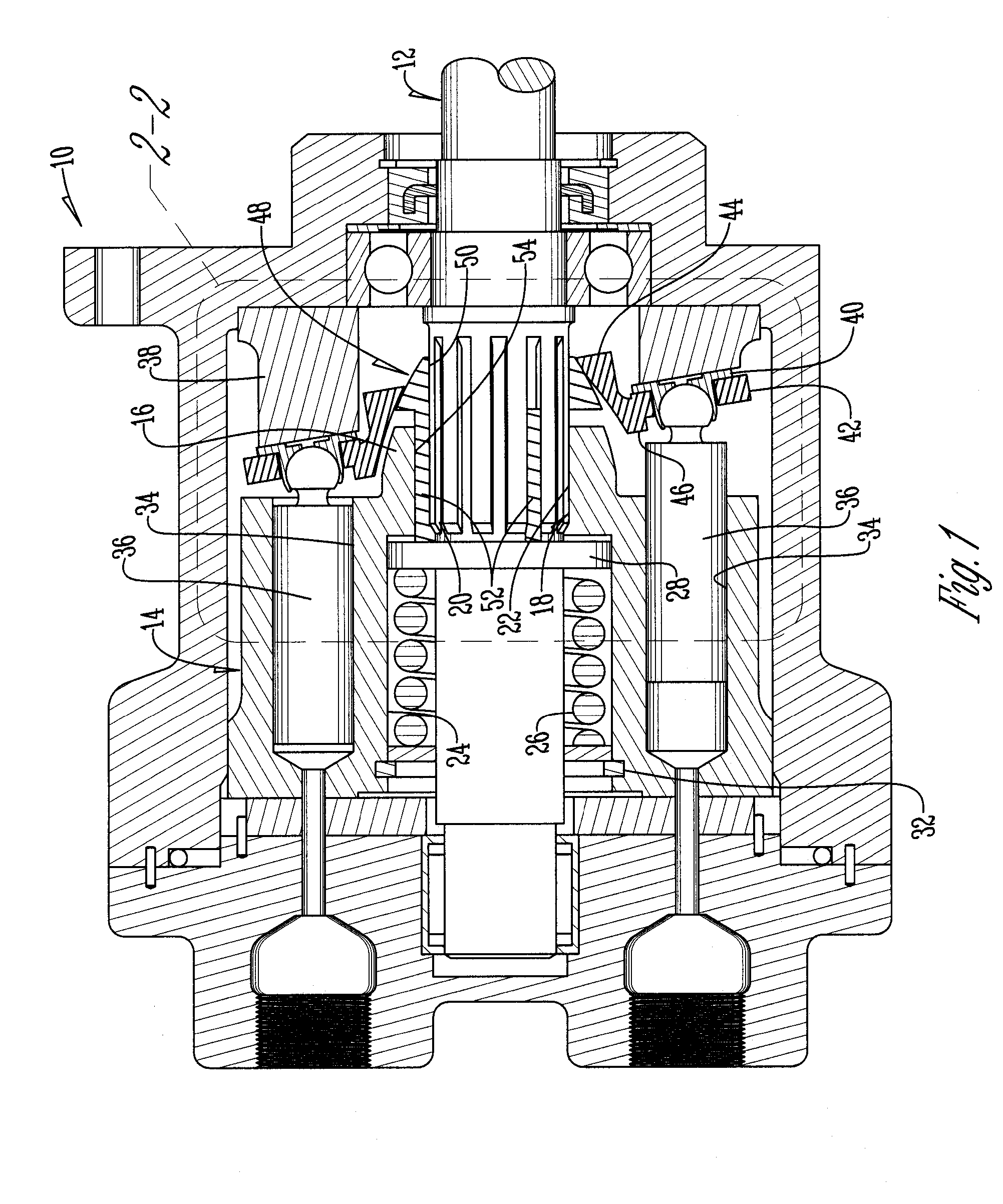

One piece slipper holddown device

InactiveUS7546797B2Increase assembly flexibilityEasy to assemblePositive-displacement liquid enginesEngines with rotating cylindersHydraulic cylinderEngineering

A holddown pin mechanism for hydraulic power units is a ball guide with a cylindrical flat base having a central opening, a plurality of spaced elongated holddown pins have one end rigidly secured to one side of said ball guide. The pins extend outwardly at right angles from the side of said washer to which they are secured. The holddown pin mechanism is placed in a hydraulic cylinder block having a center bore, with the pins extending into holes in the block. A flat washer on a shaft extending through the block engages the free ends of the pins.

Owner:SAUER DANFOSS NORDBERG

Assemblable keyboard and assemblable key

ActiveUS9898094B2Save layout spaceEasy to assembleInput/output for user-computer interactionEmergency casingsElectricityCoupling

An assemblable keyboard includes plural assemblable keys and a main control key. Each assemblable key can be triggered to generate a key signal. The assemblable key includes a pedestal, a key structure and a conductive structure. The main control key includes a key processor and a transmission interface. The assemblable key includes plural coupling structures with the conductive structure. Every two adjacent assemblable keys are combined together and electrically connected with each other through the corresponding coupling structures. After the key signal generated by each assemblable key is transmitted to the main control key, the key signal is further outputted to a computer host. The layout space of the assemblable keyboard is reduced. Moreover, the assembling flexibility of the keyboard is enhanced.

Owner:PRIMAX ELECTRONICS LTD

Mover module and linear motor

PendingCN108964405AImprove compactnessReduce the difficulty of assembly and manufacturingMagnetic circuit rotating partsPropulsion systemsLinear motorConductor Coil

The present invention provides a mover module and a linear motor. The mover module comprises a mover iron core, the mover iron core comprises a first tooth portion, a holding cavity is constructed atthe inner side of the first tooth portion, the mover module further comprises a cooling pipeline, and the cooling pipeline comprises a tooth portion pipe section which is arranged in the holding pipe.The mover module and the linear motor can greatly improve the structure compaction of the mover module, can reduce the assembling and manufacturing difficulty of the mover module, can effectively control the temperature rise of the mover module and even the linear motor through targeted cooling of the mover iron core tooth portion and the coil winding and can facilitate ensuring of the performance reliability and the operation stability of the motor.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com