Patents

Literature

619 results about "Retaining Pin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hairpin clip, also known as a retaining pin, is a type of formed wire used on a grooved shaft. It is designed to be easily installed and uninstalled, and is reusable. They are commonly made from 1050 carbon steel and 300 series stainless steel.

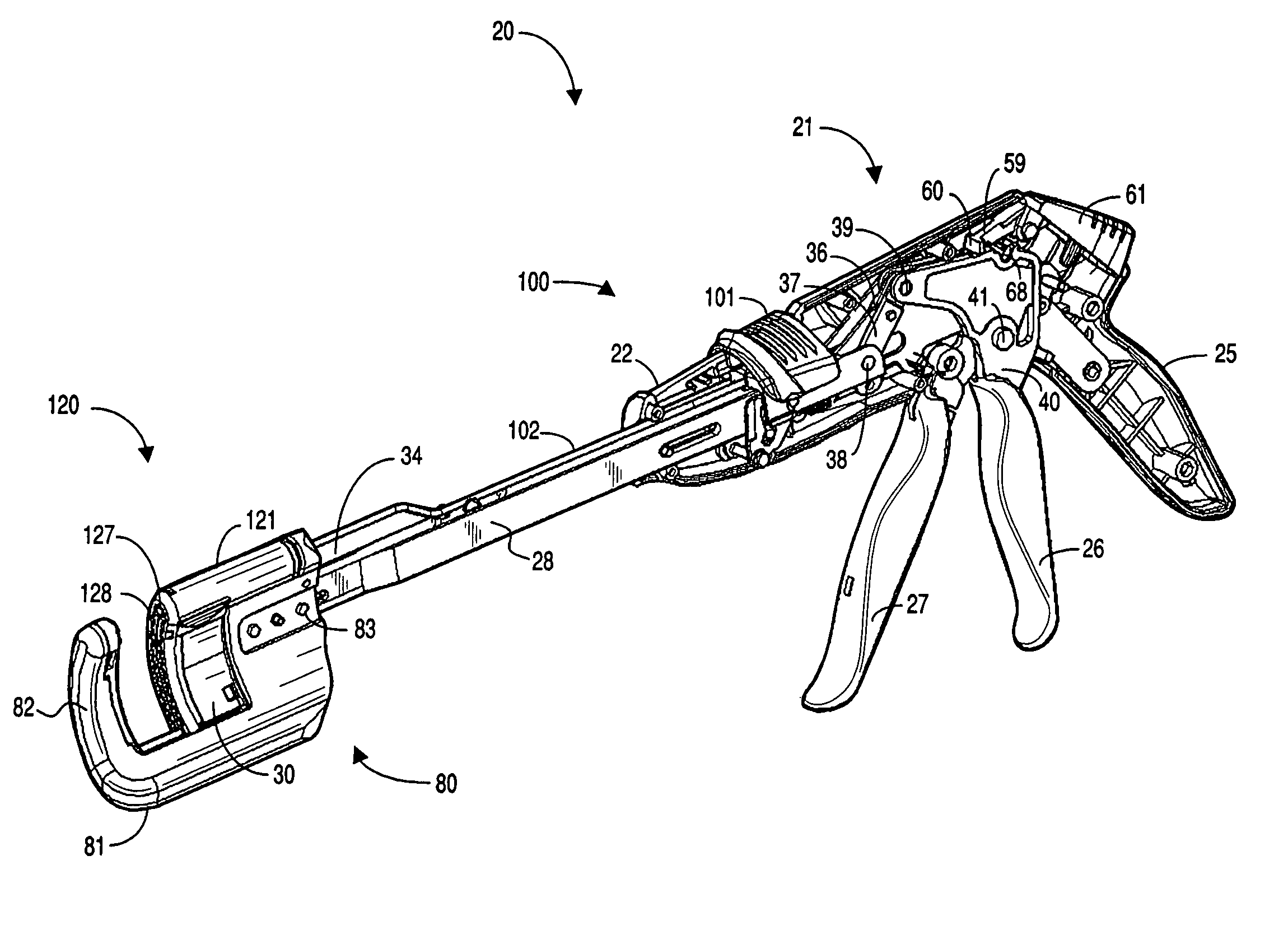

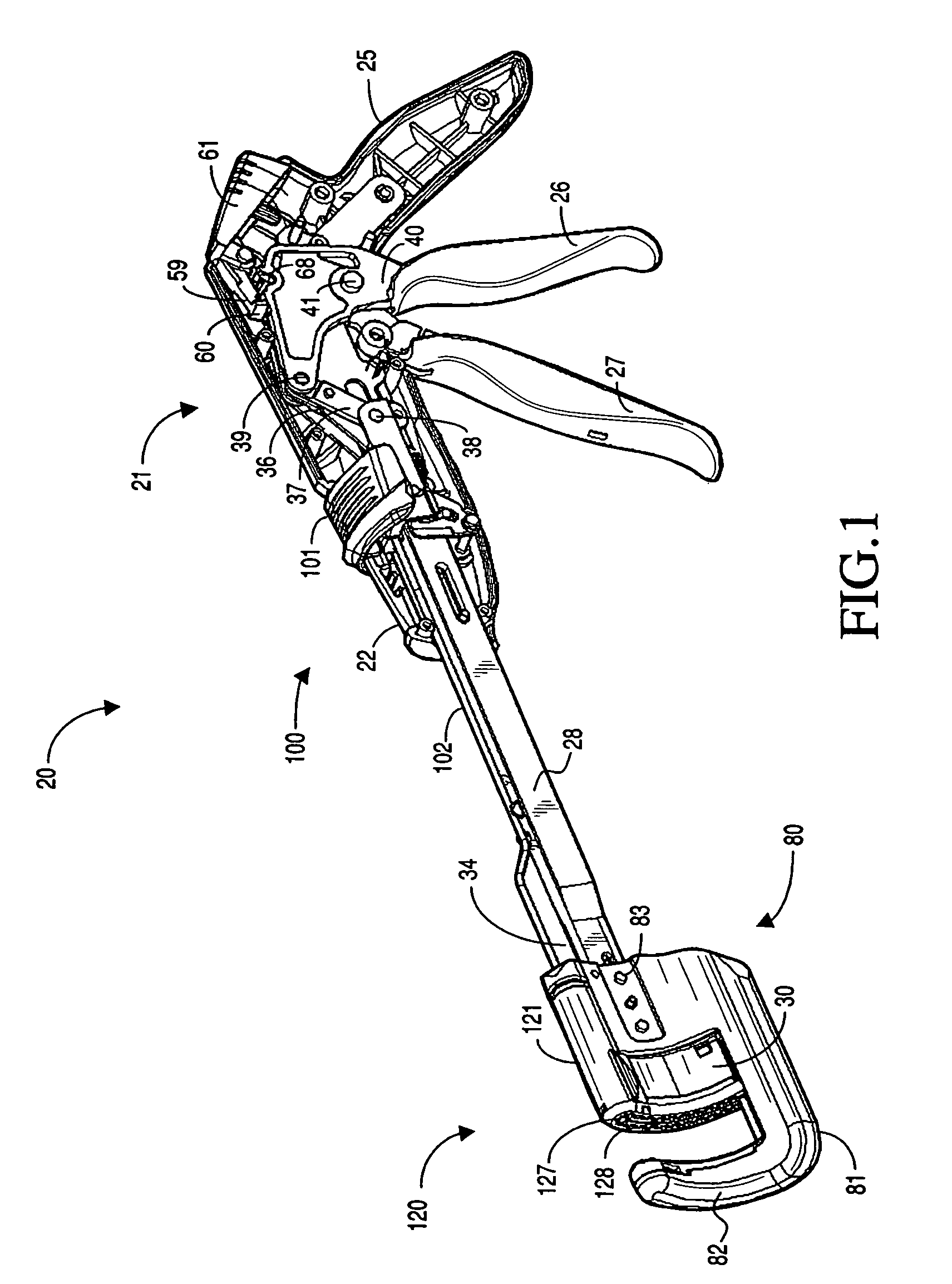

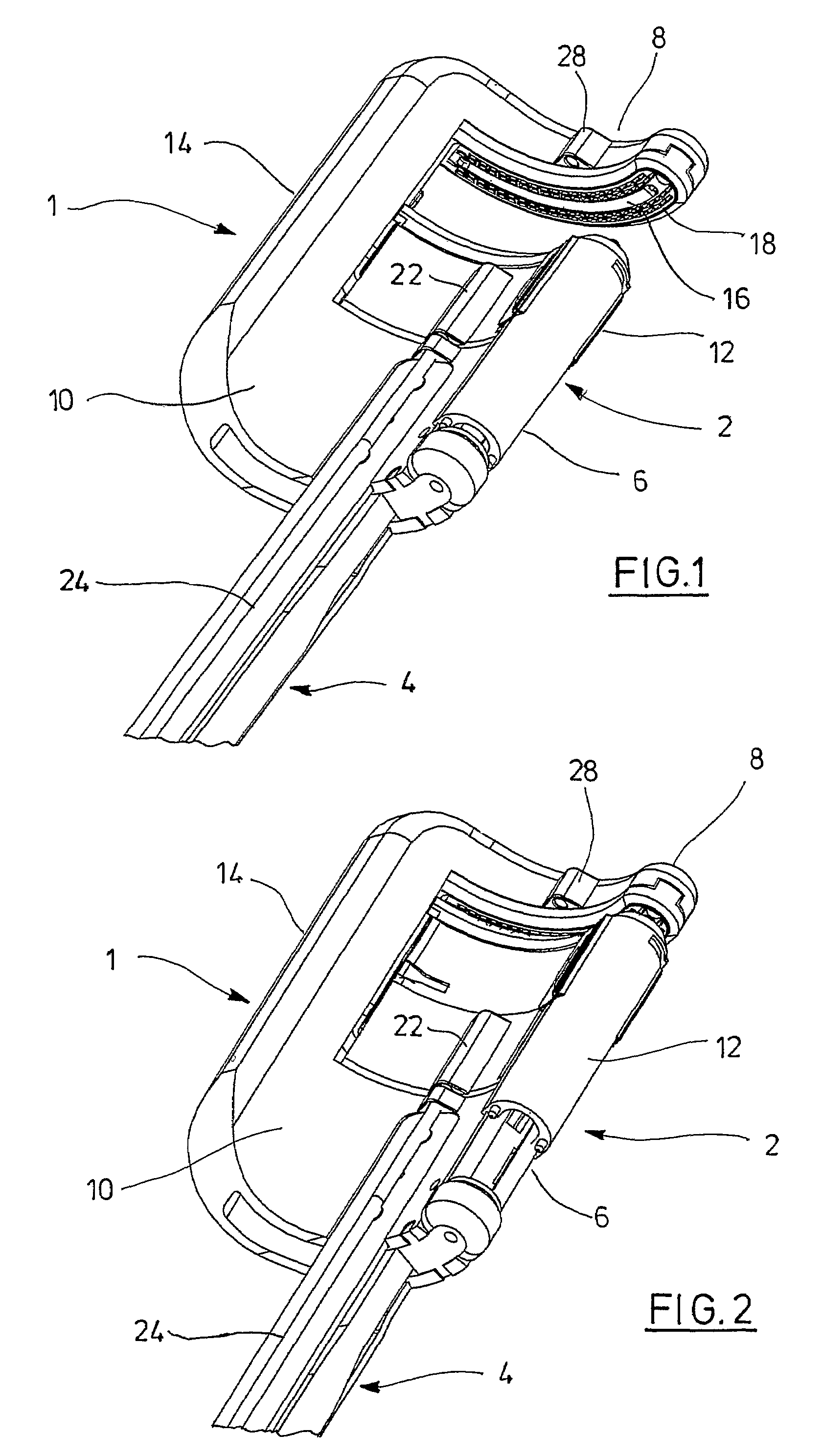

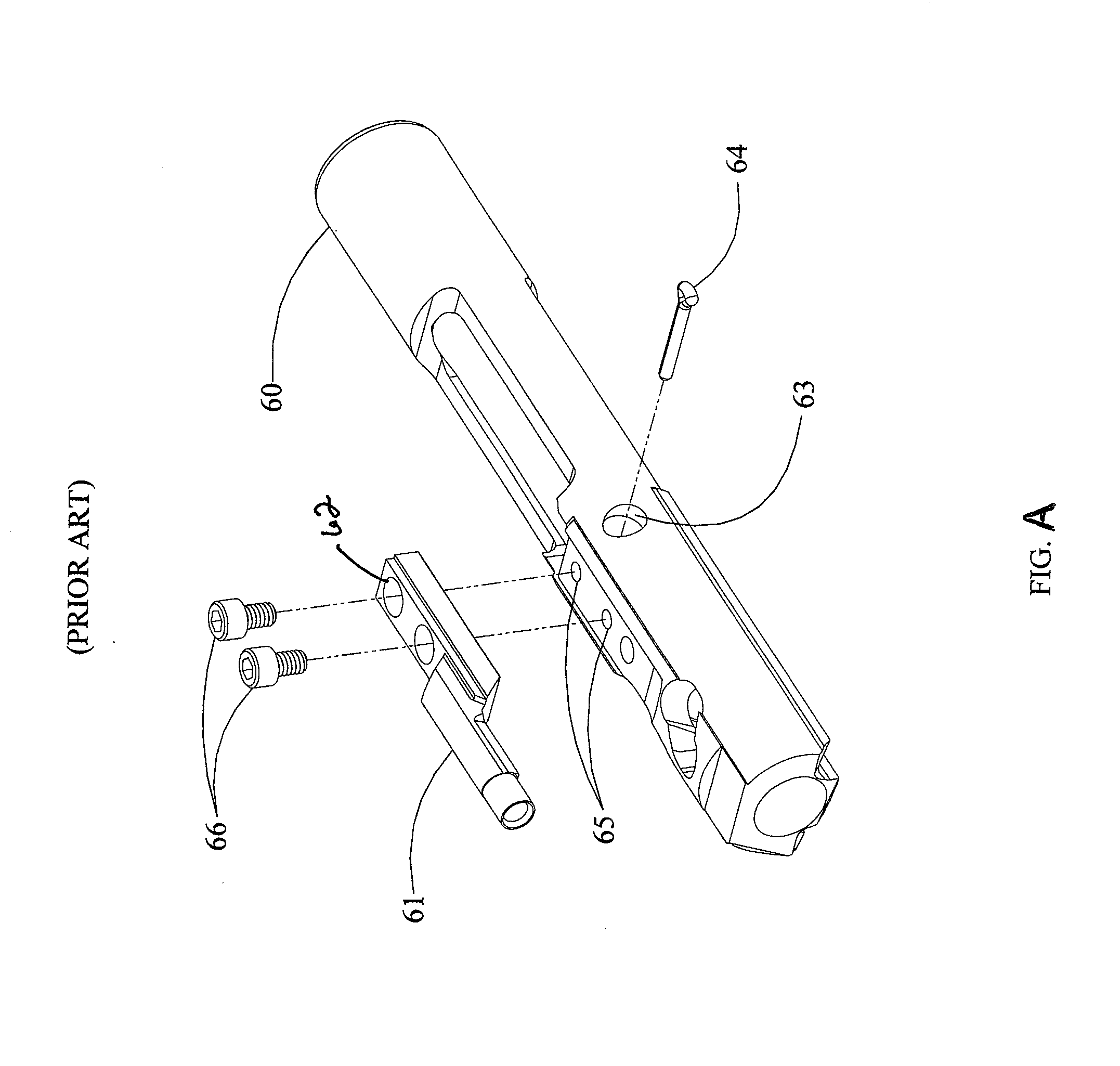

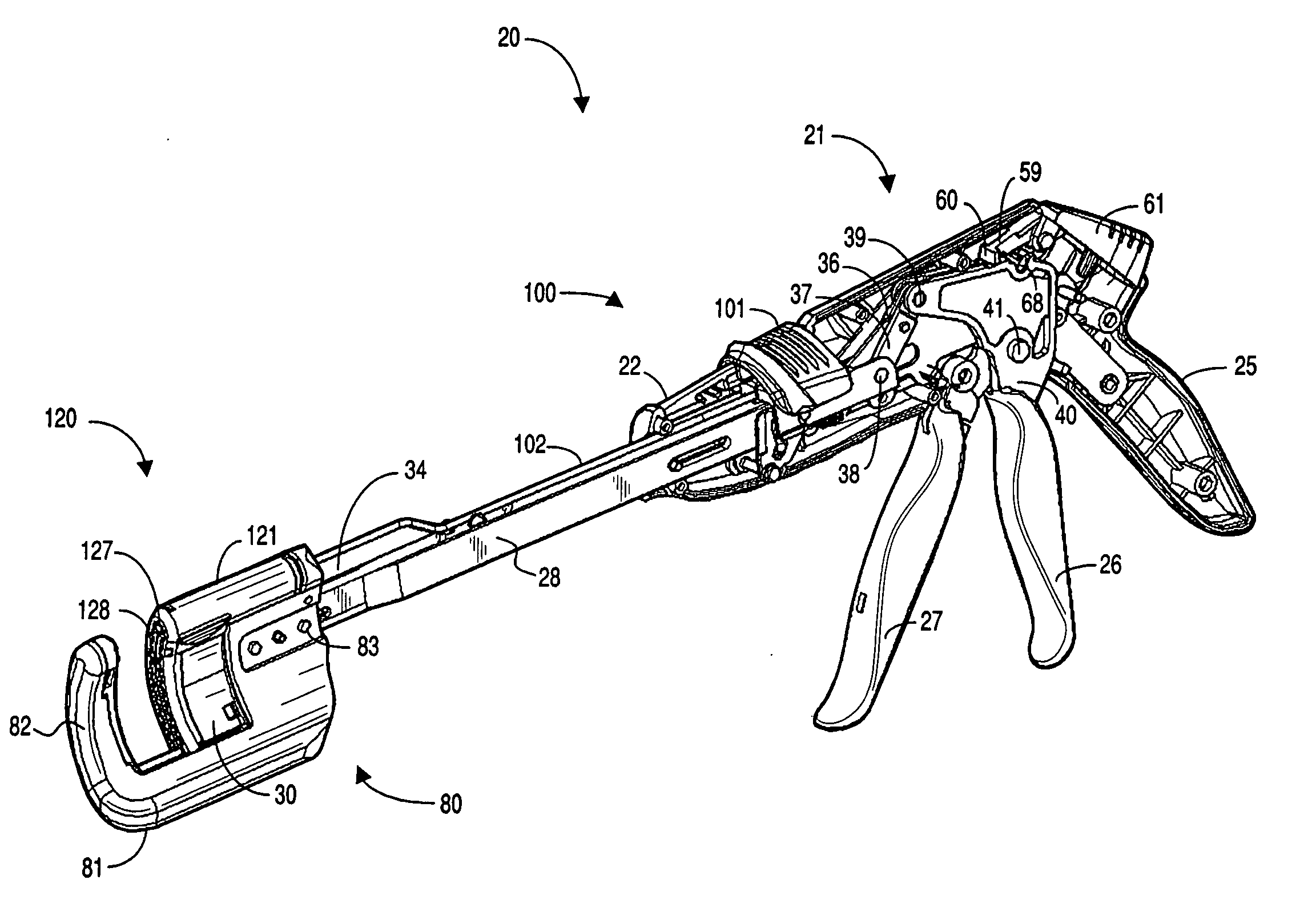

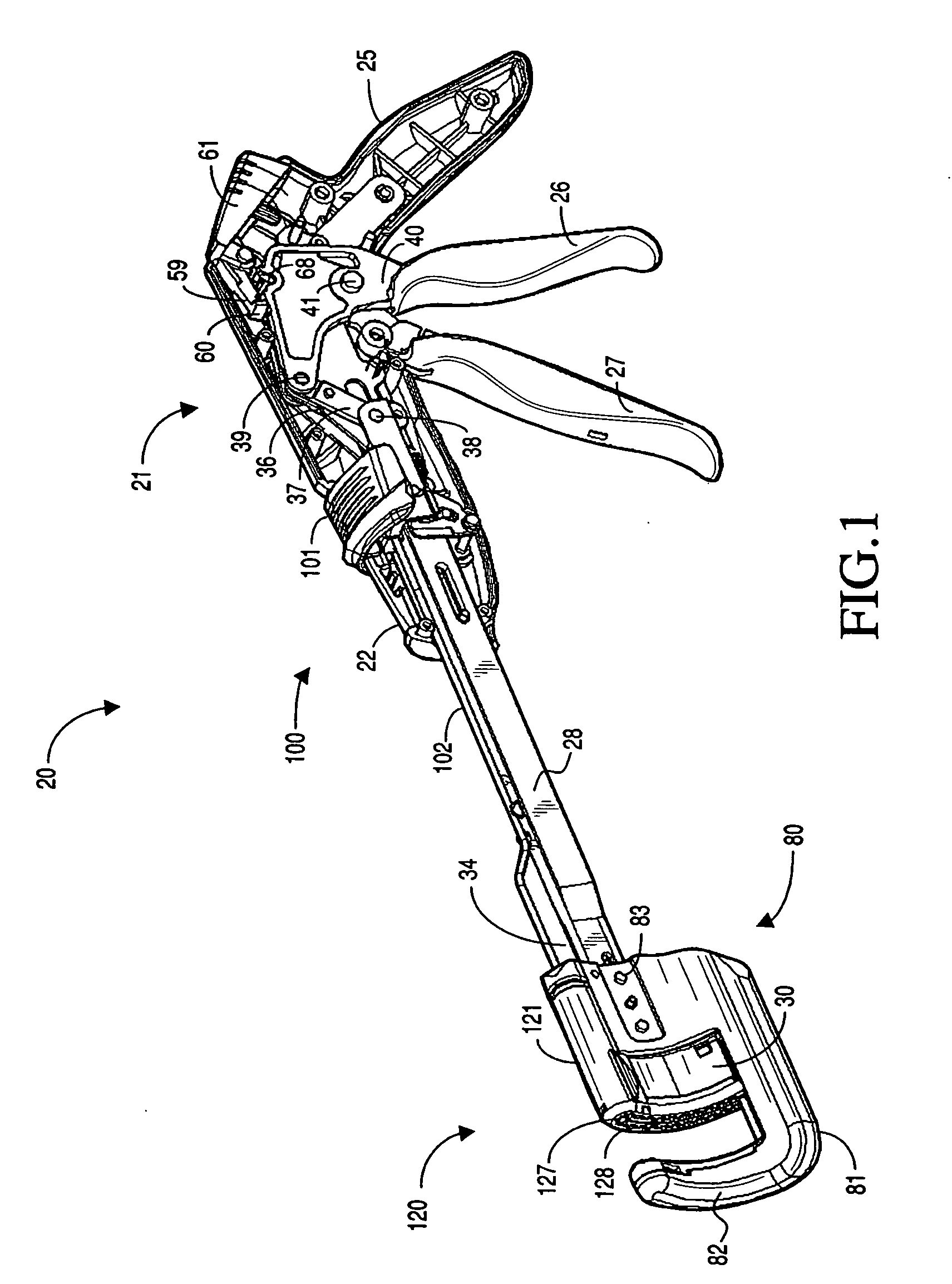

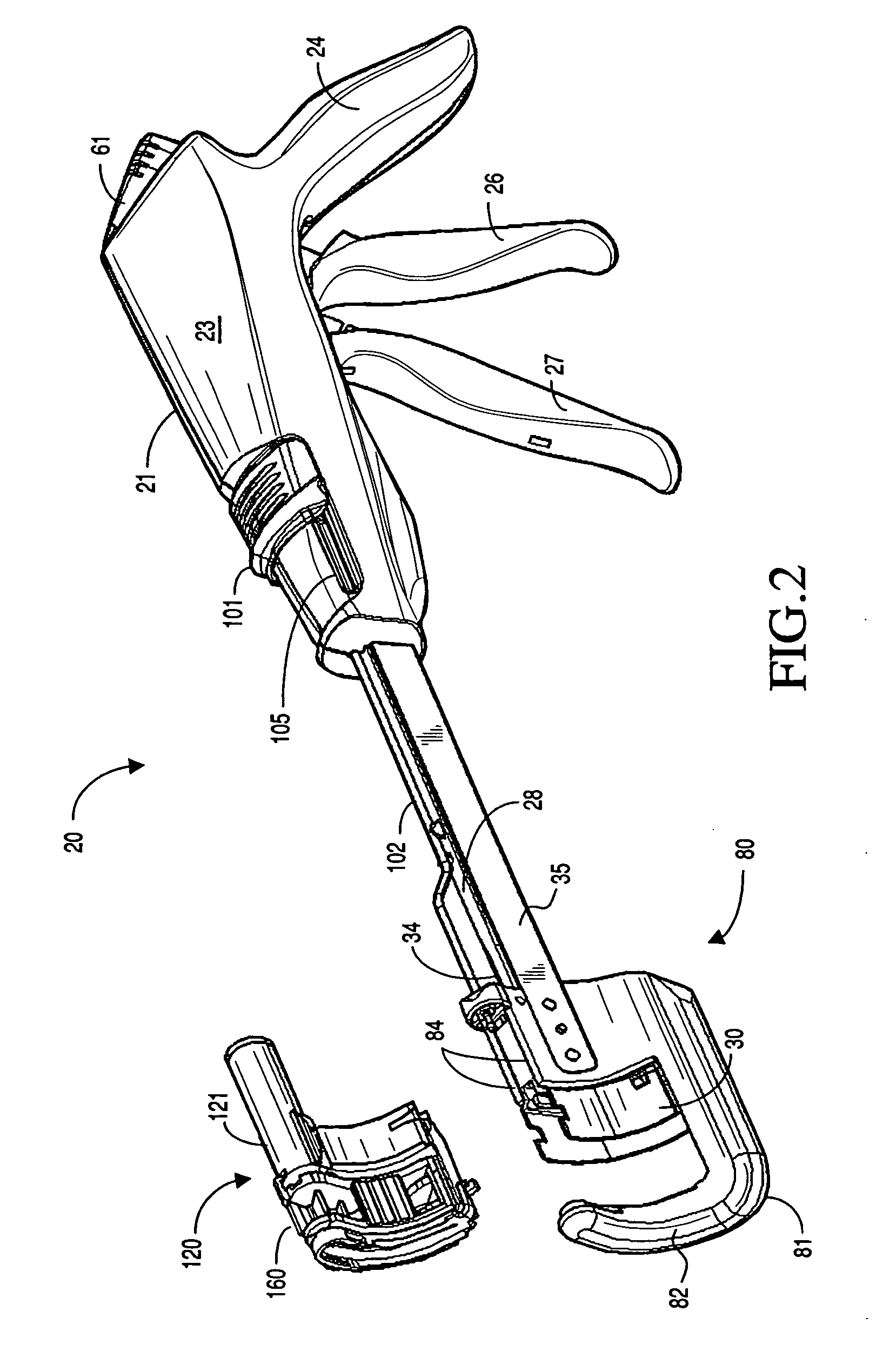

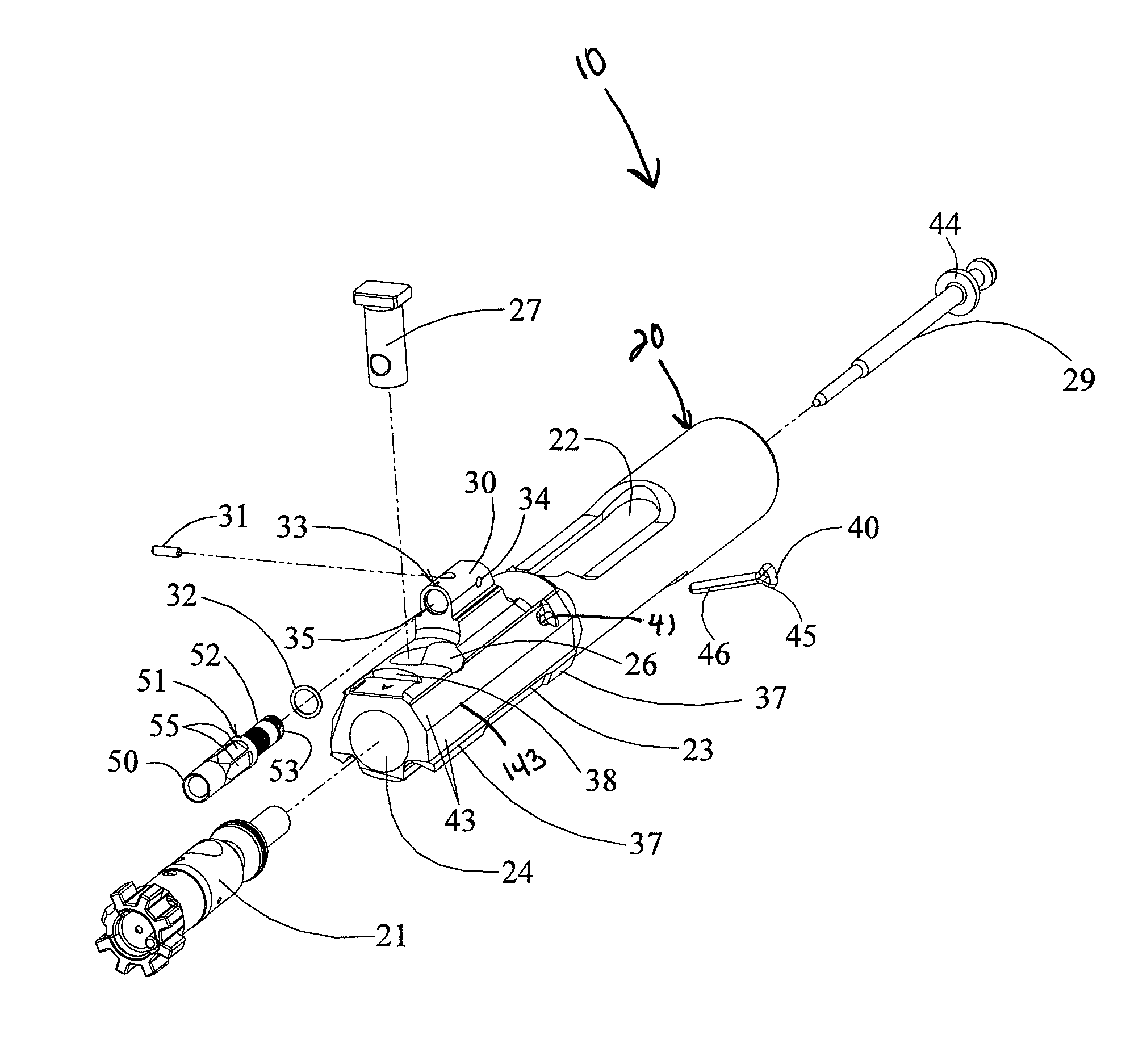

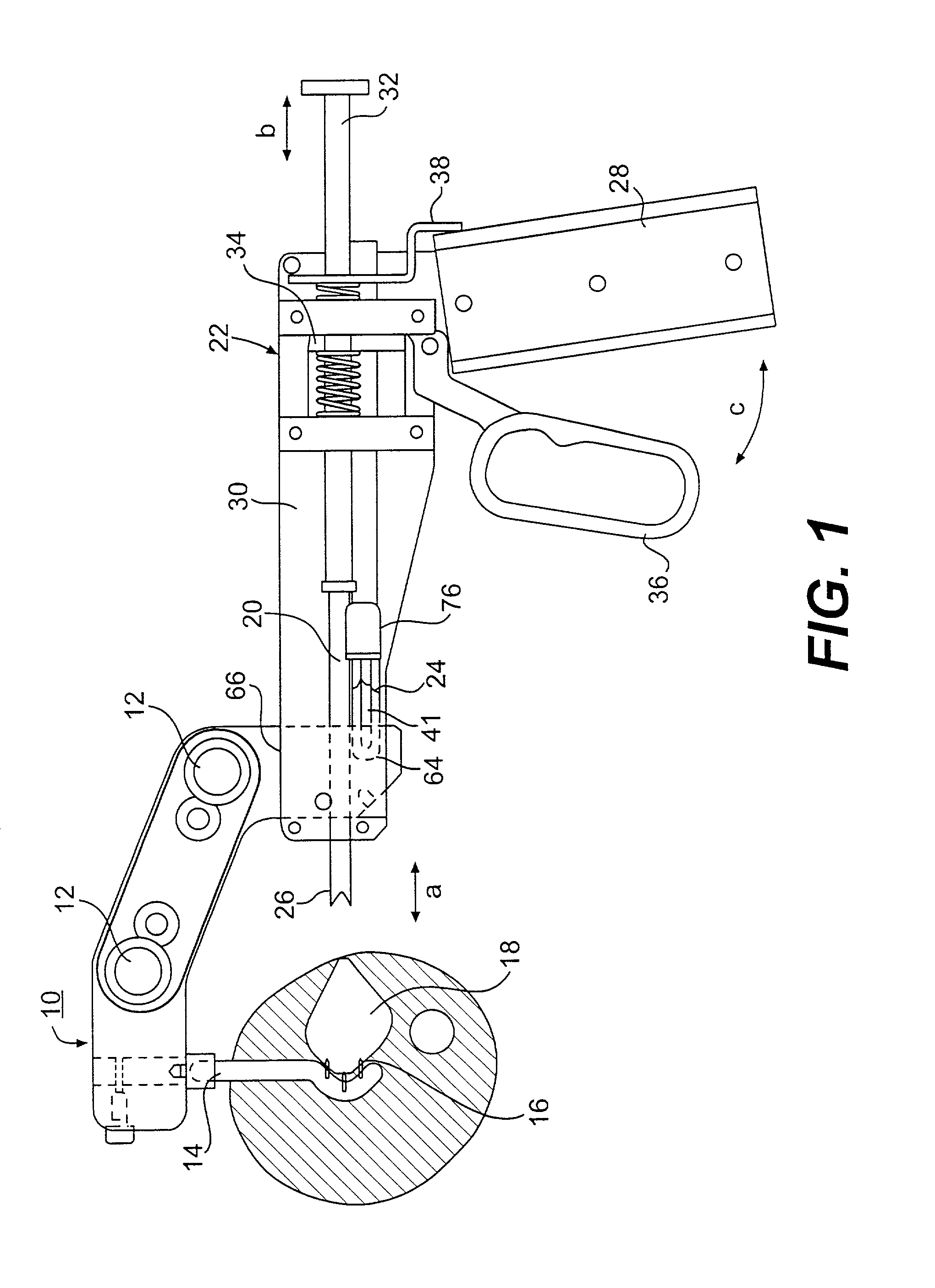

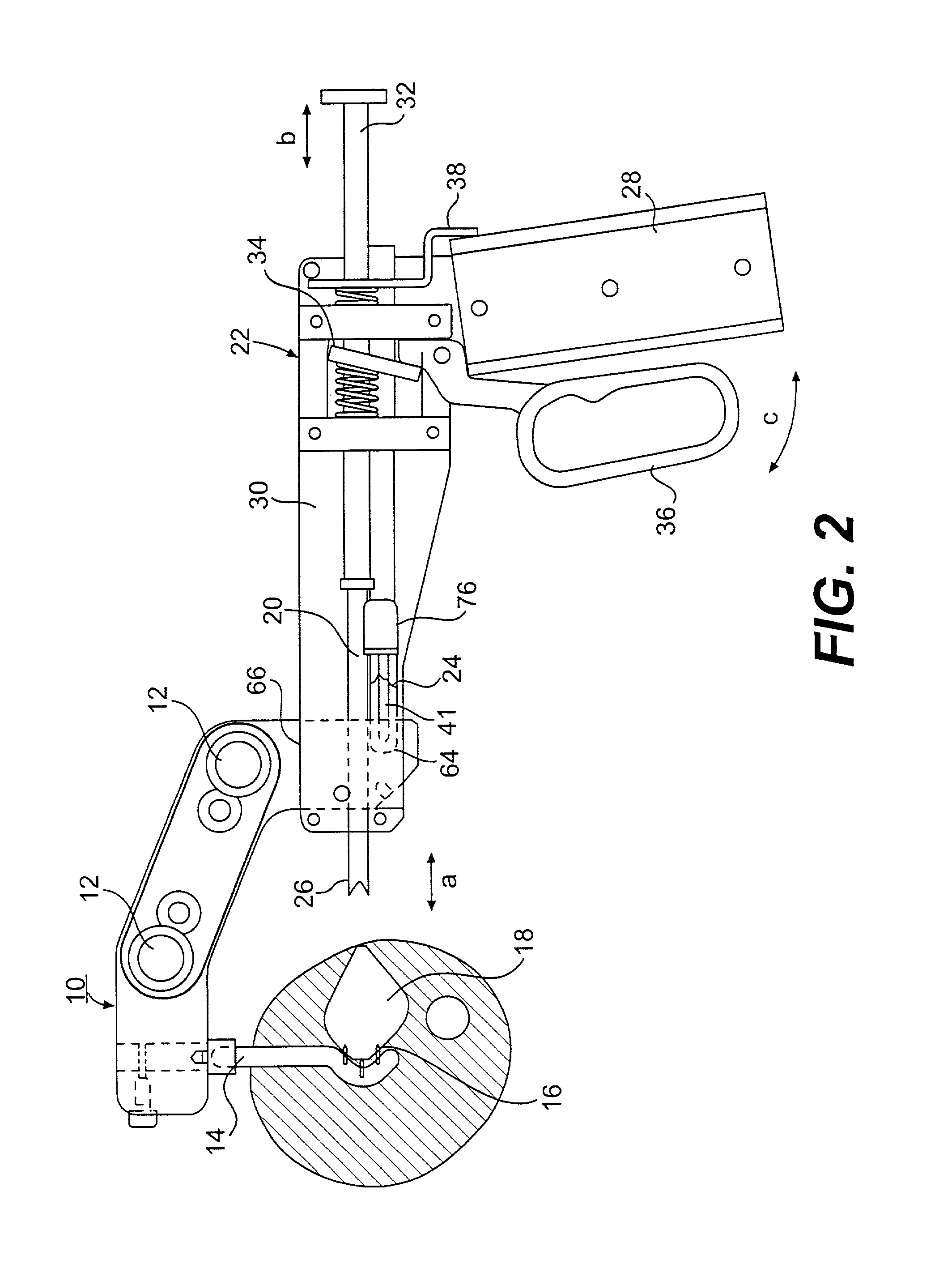

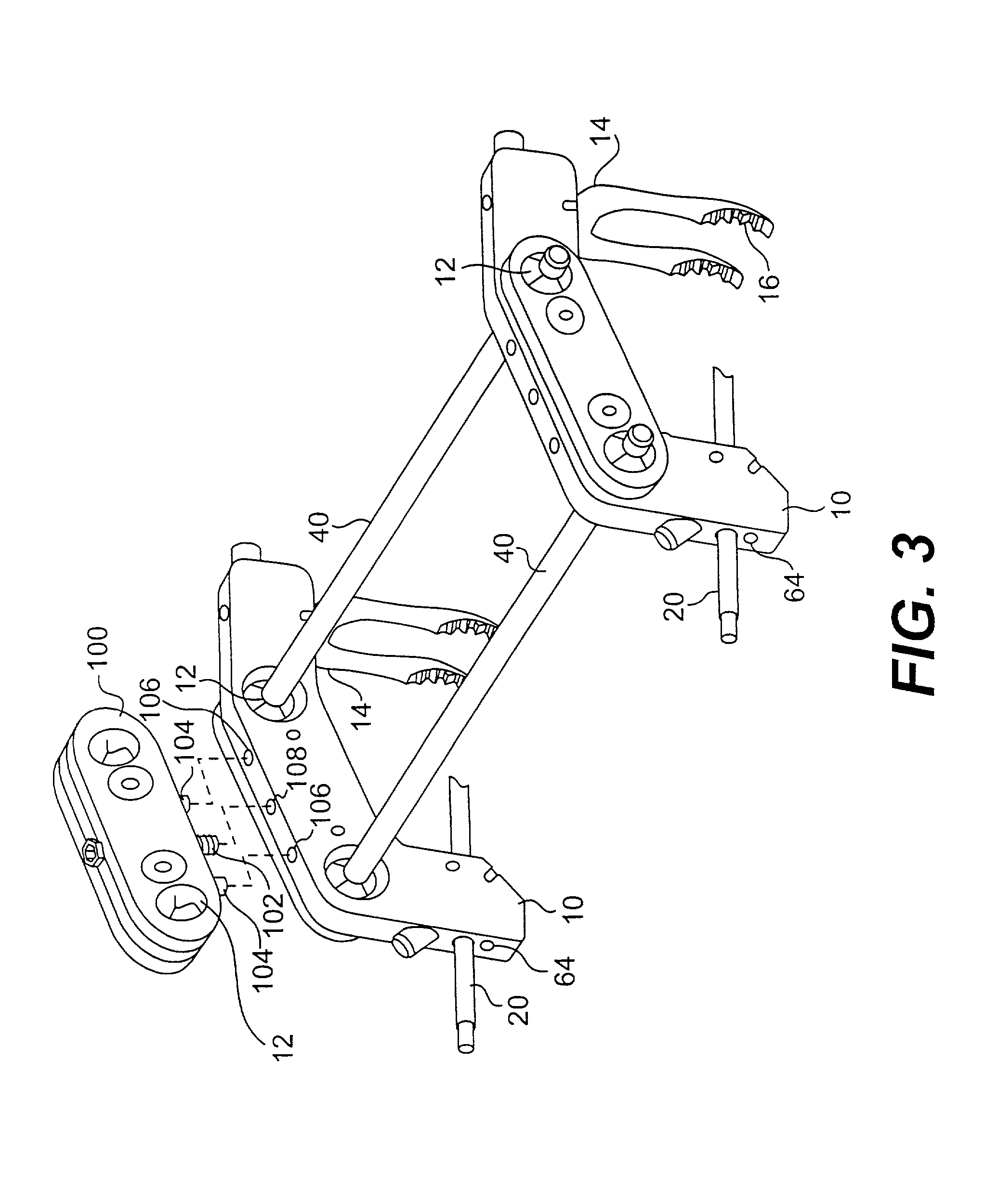

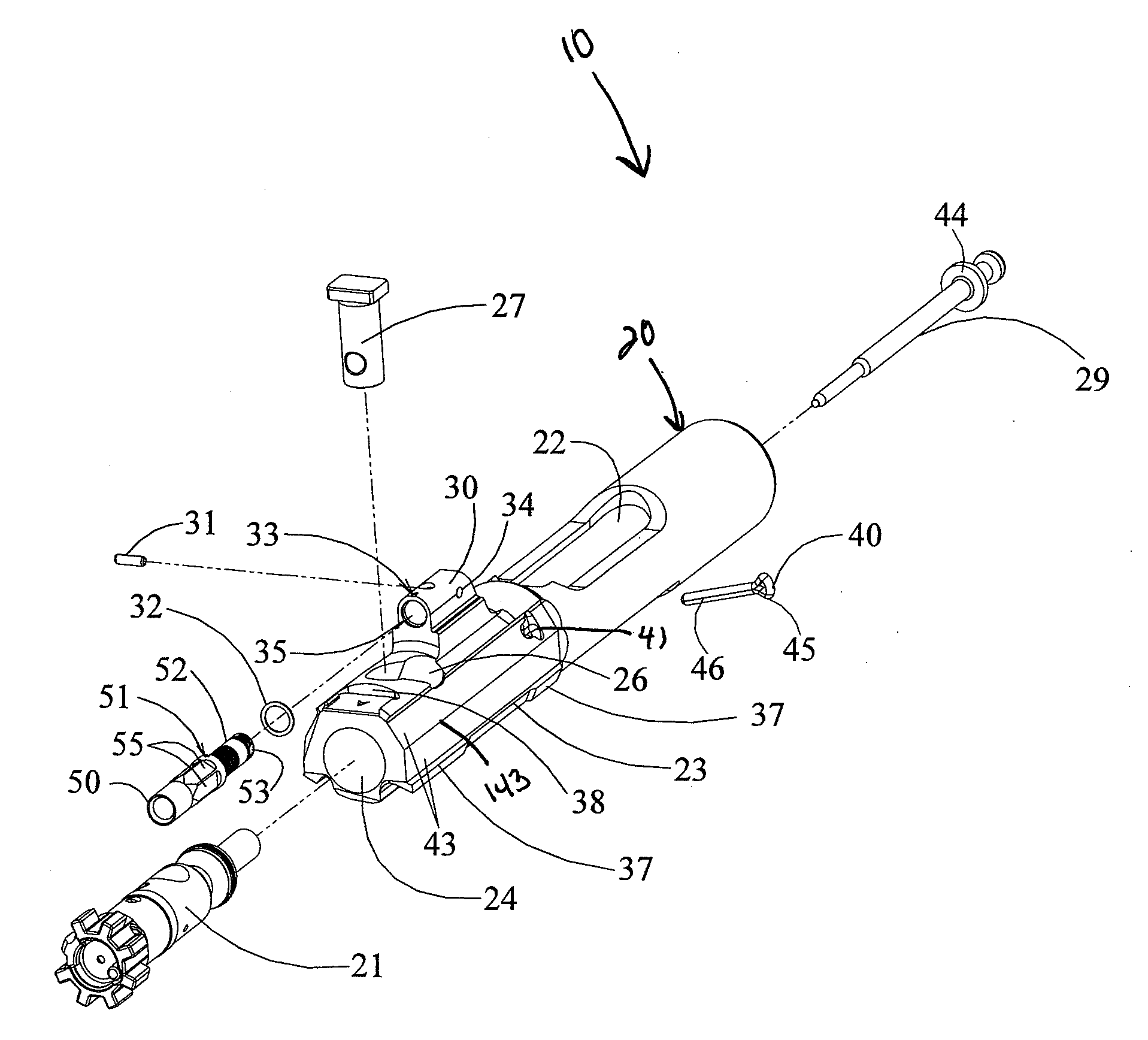

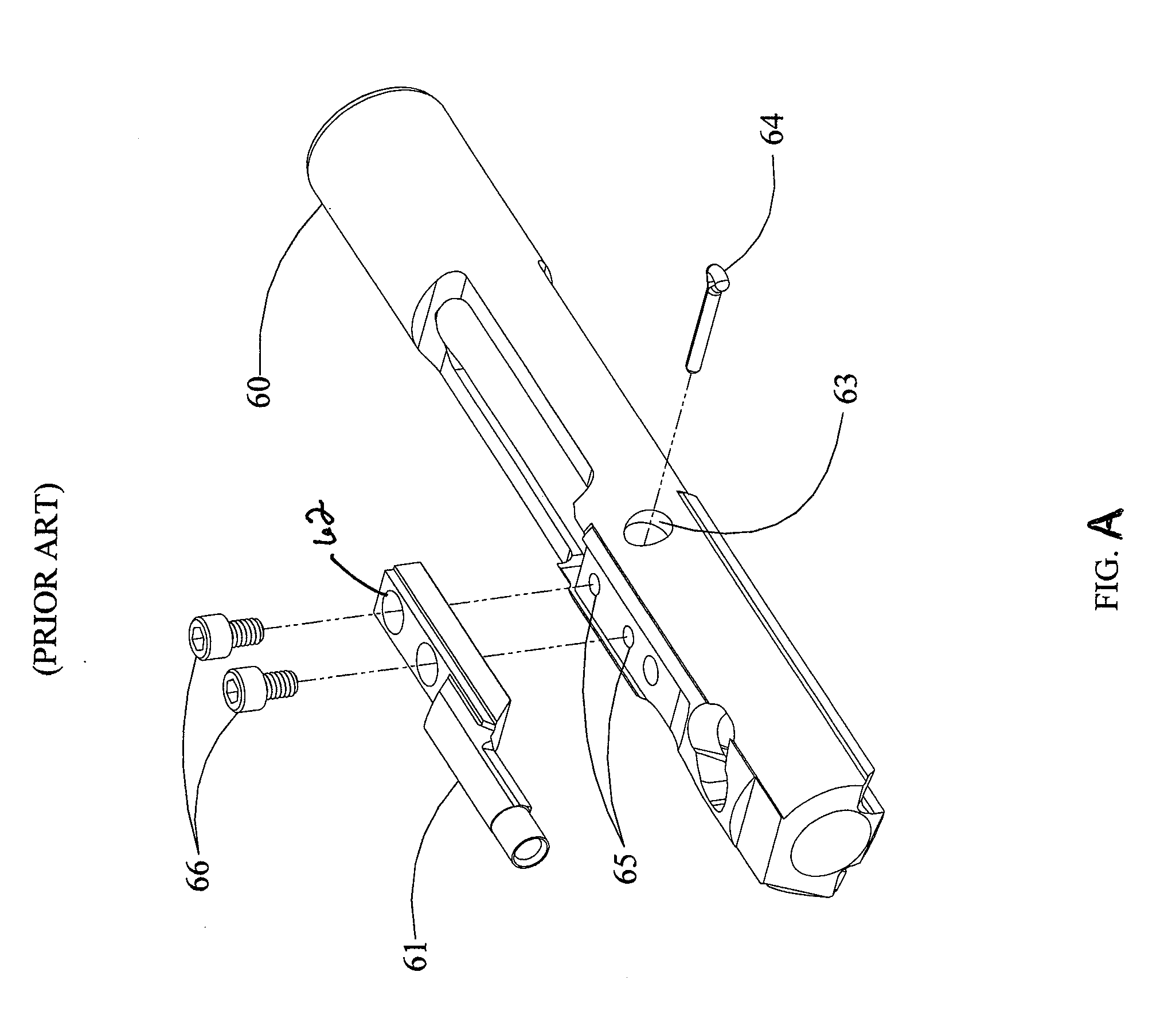

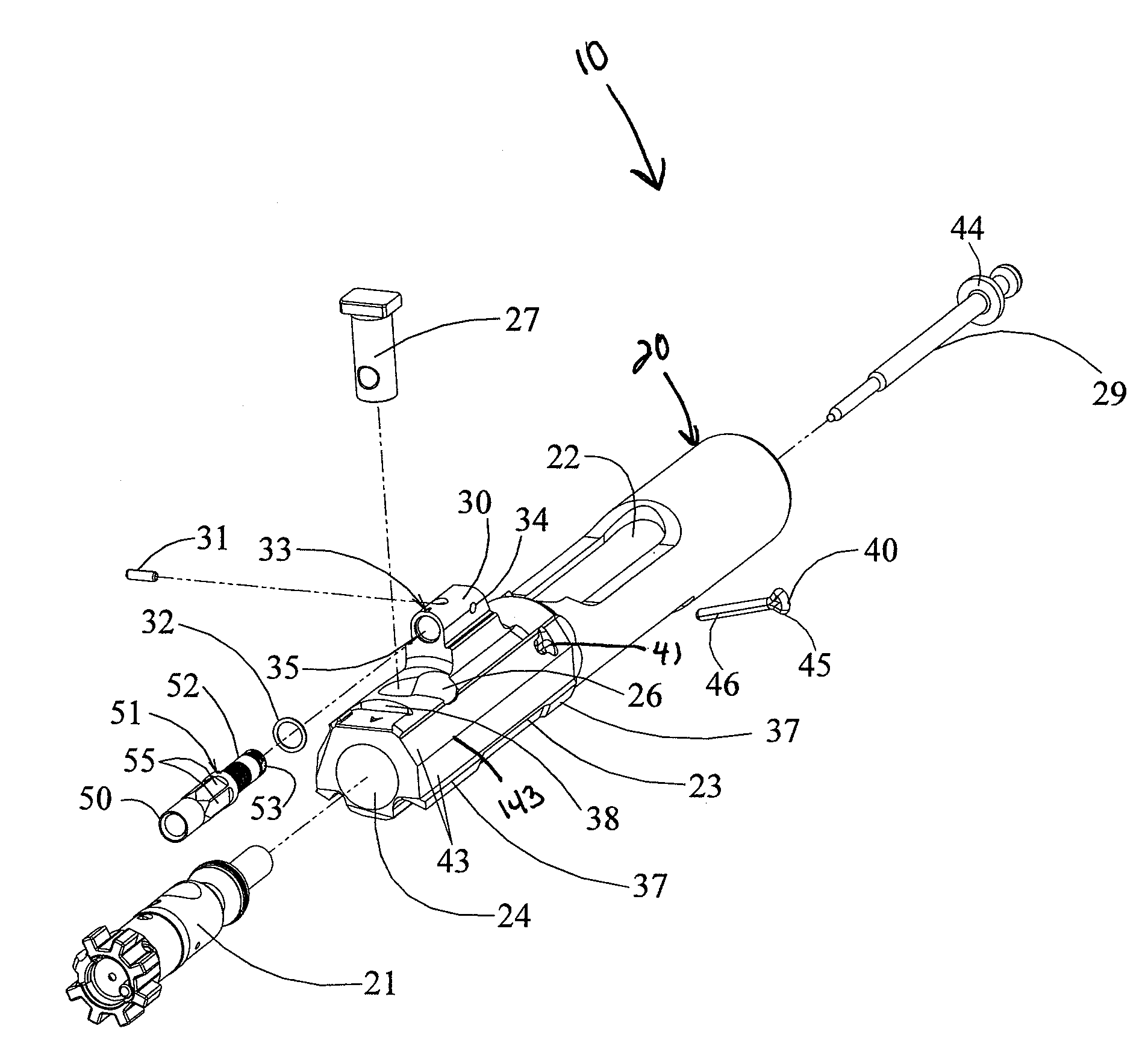

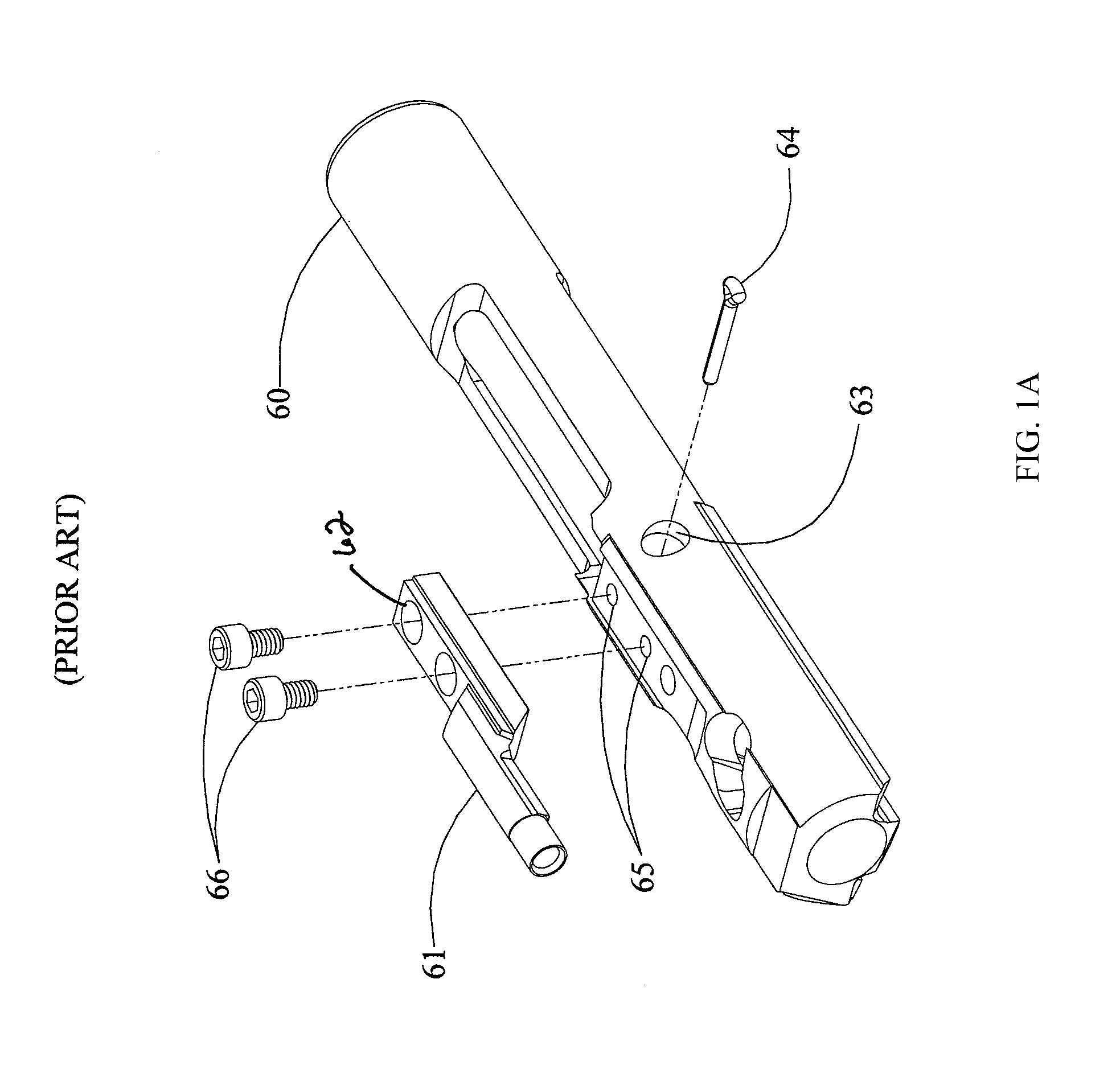

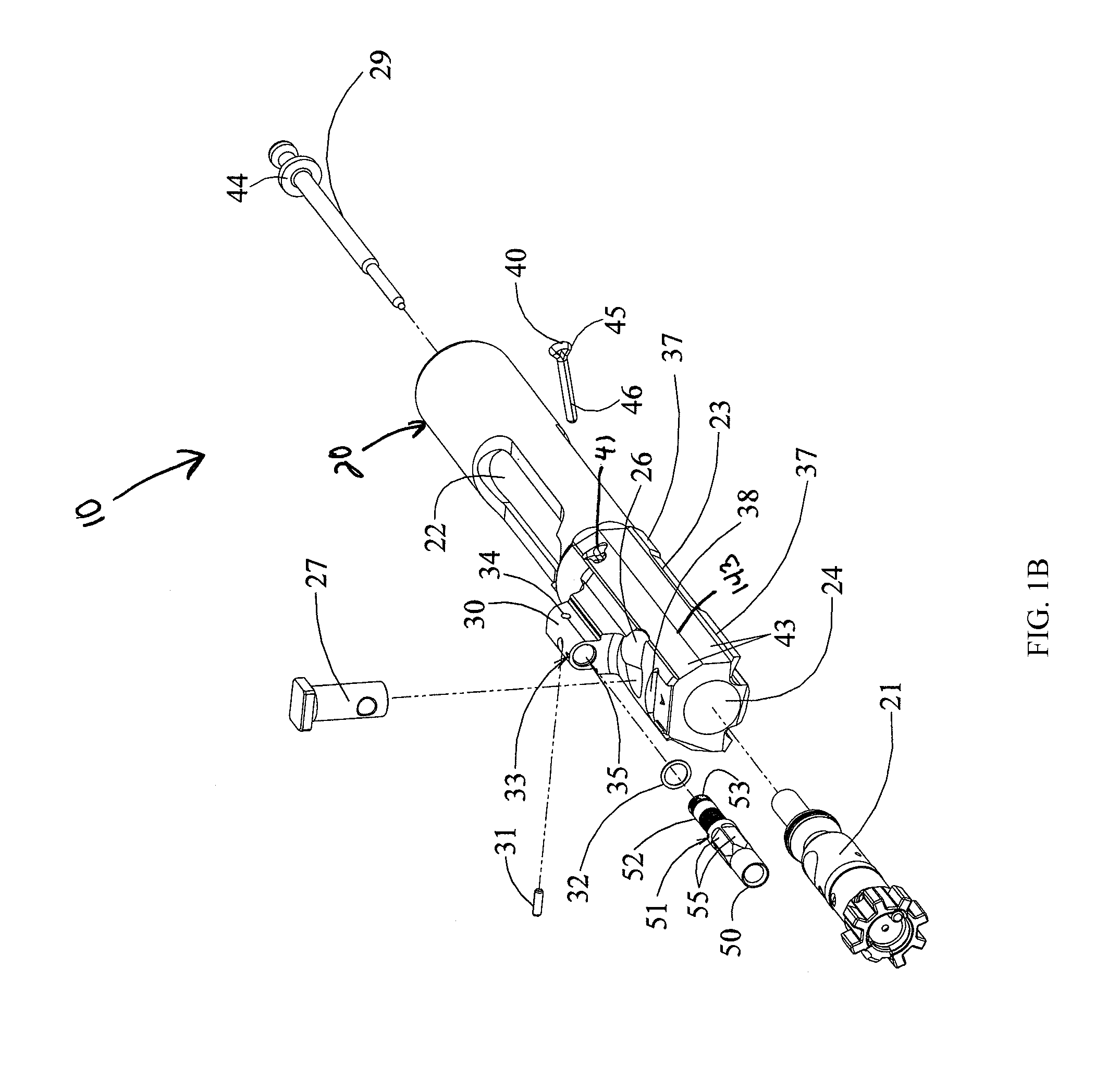

Retaining pin lever advancement mechanism for a curved cutter stapler

A surgical instrument is adapted for applying a plurality of surgical fasteners to body tissue. The surgical instrument includes a frame having a proximal end and a distal end, with a handle positioned at the proximal end and an end effector positioned at the distal end. The end effector is shaped and dimensioned for supporting a cartridge housing and an anvil, the cartridge housing and anvil being relatively movable by actuation of a closure mechanism. The surgical instrument further includes a firing mechanism associated with the end effector and the cartridge housing for selective actuation of the surgical fasteners features. The surgical instrument also includes a retaining pin for enclosing tissue between the anvil and the cartridge housing. The retaining pin is moved by actuation of the closure mechanism from an open first position to a closed second position. A manual actuator is associated with the retaining pin for moving from the second position back to the first position and alternatively moving the retaining pin from the first position to the second position.

Owner:ETHICON ENDO SURGERY INC

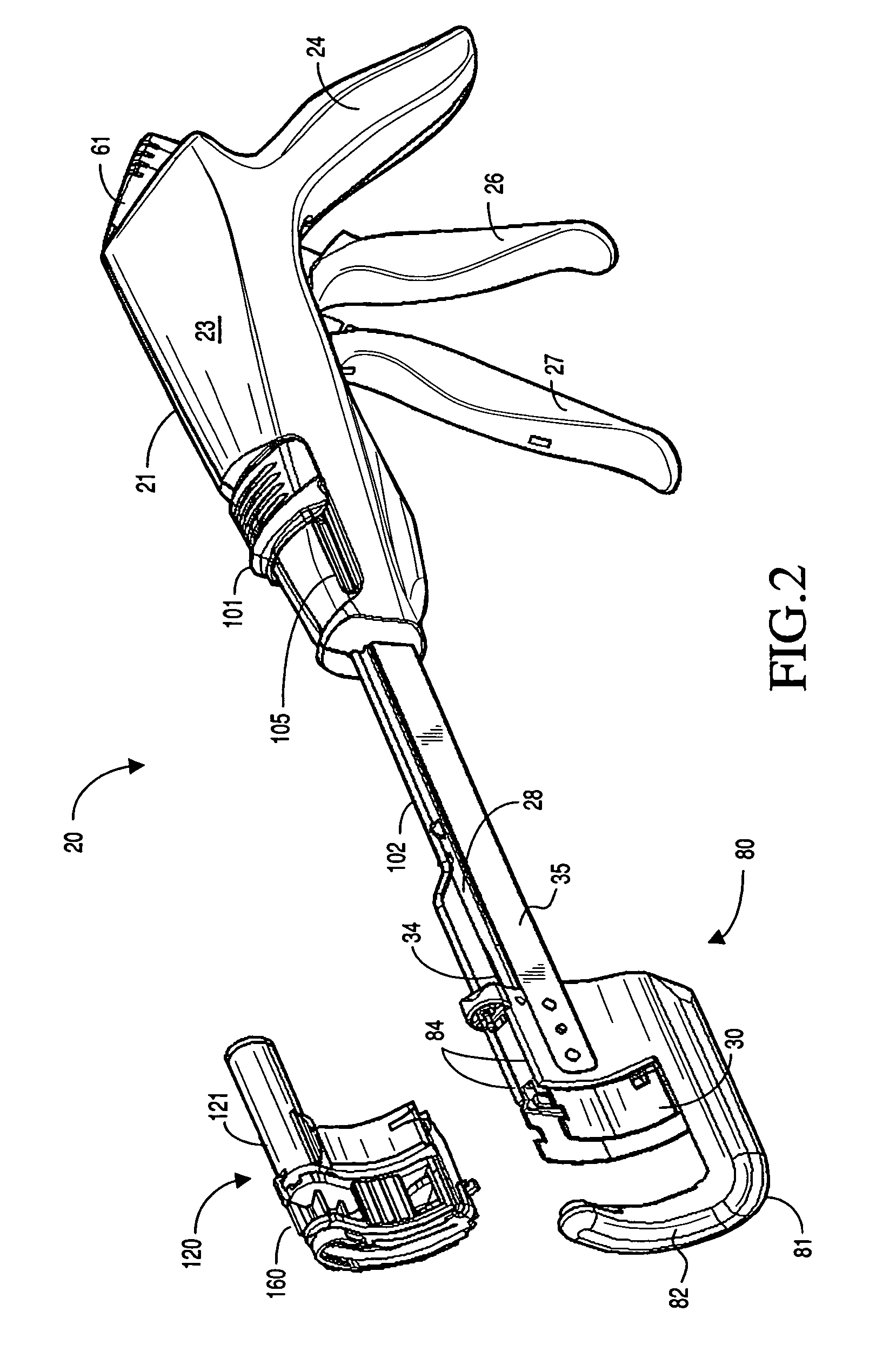

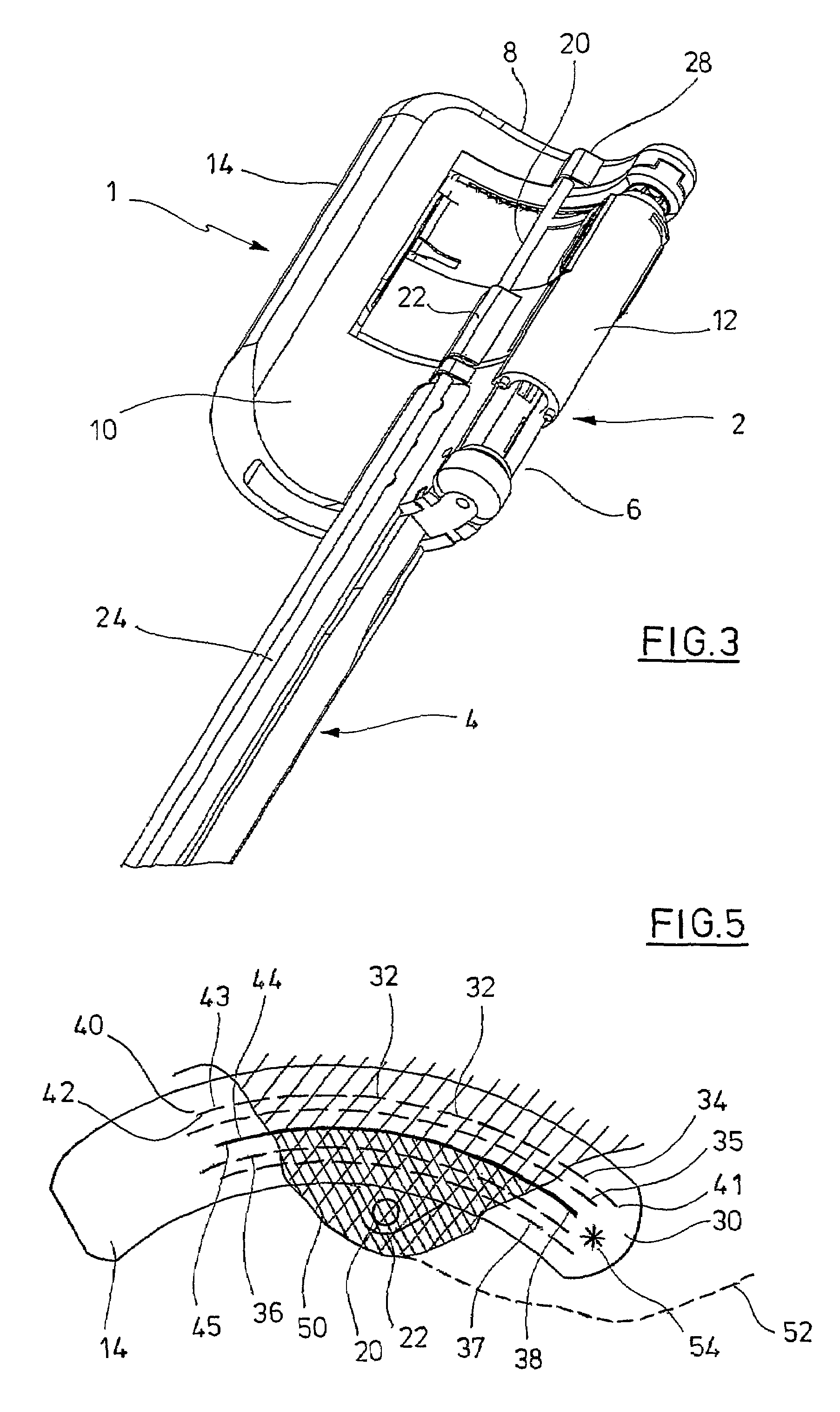

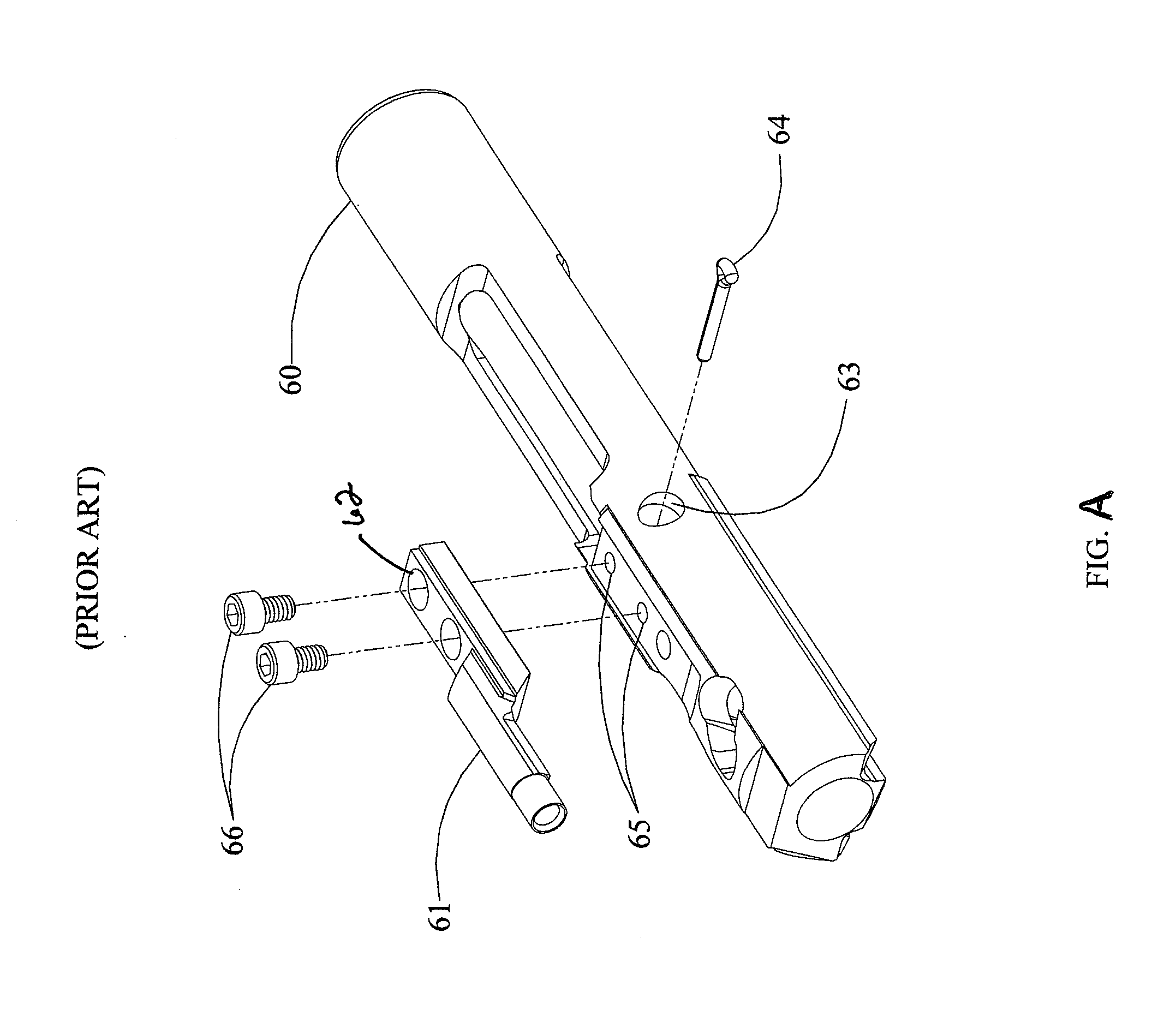

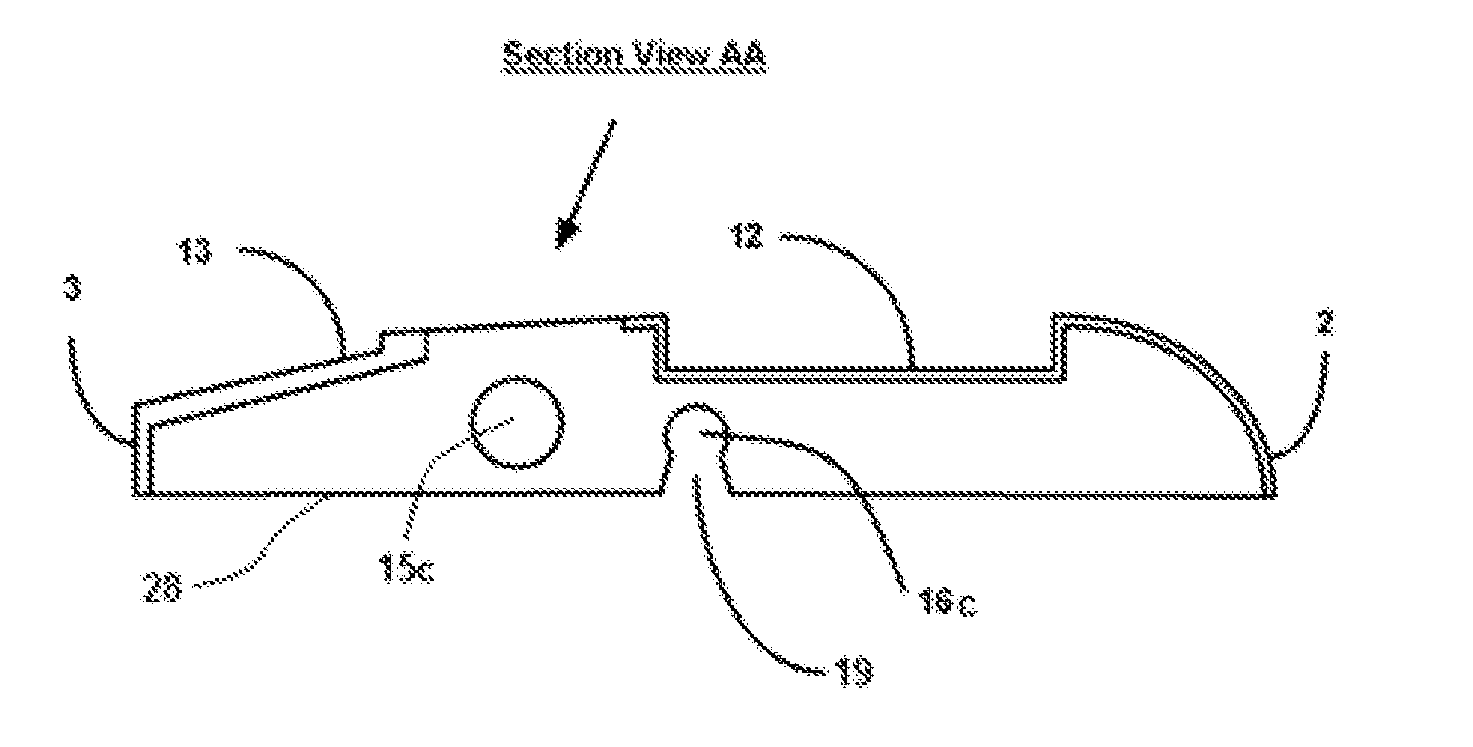

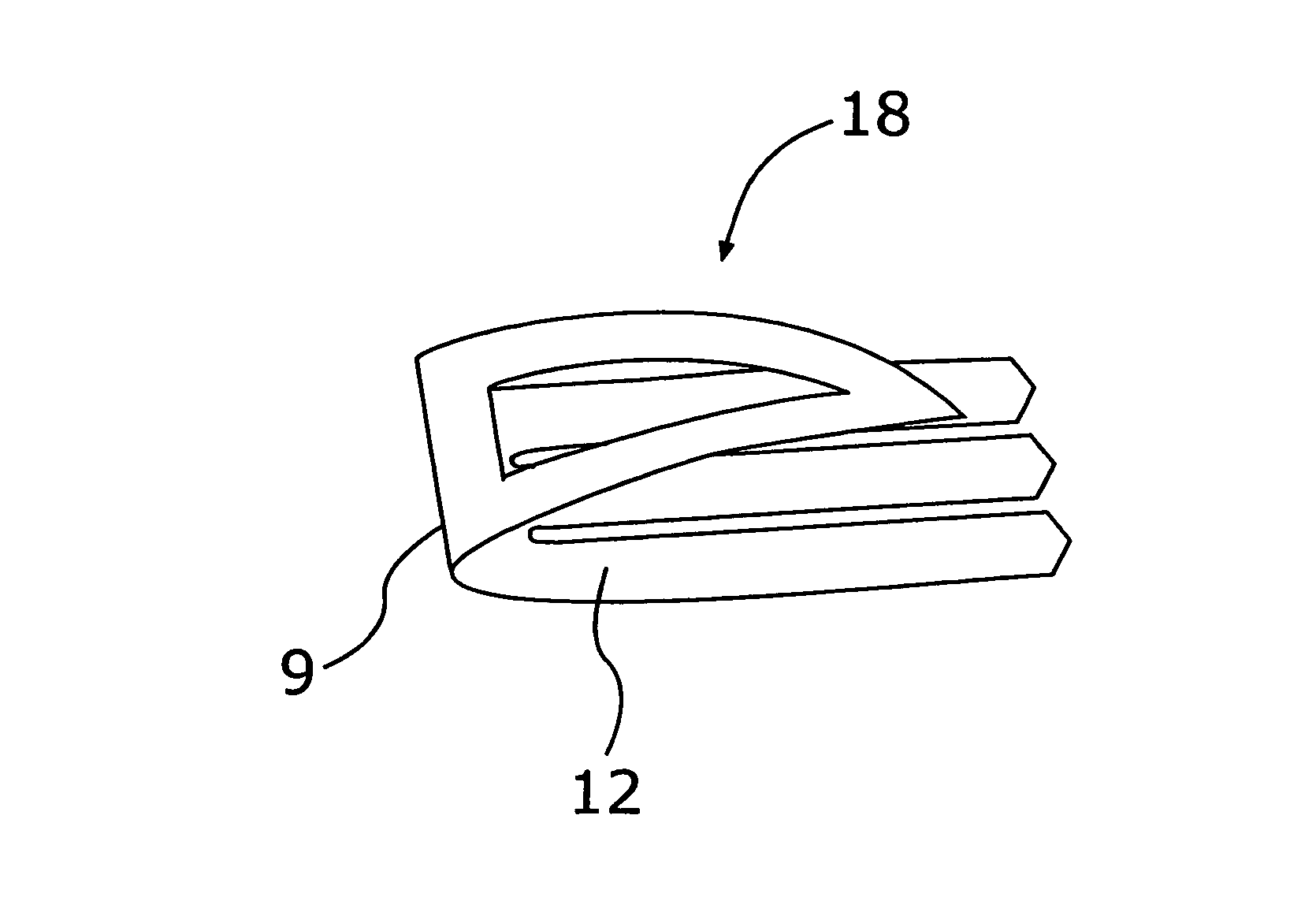

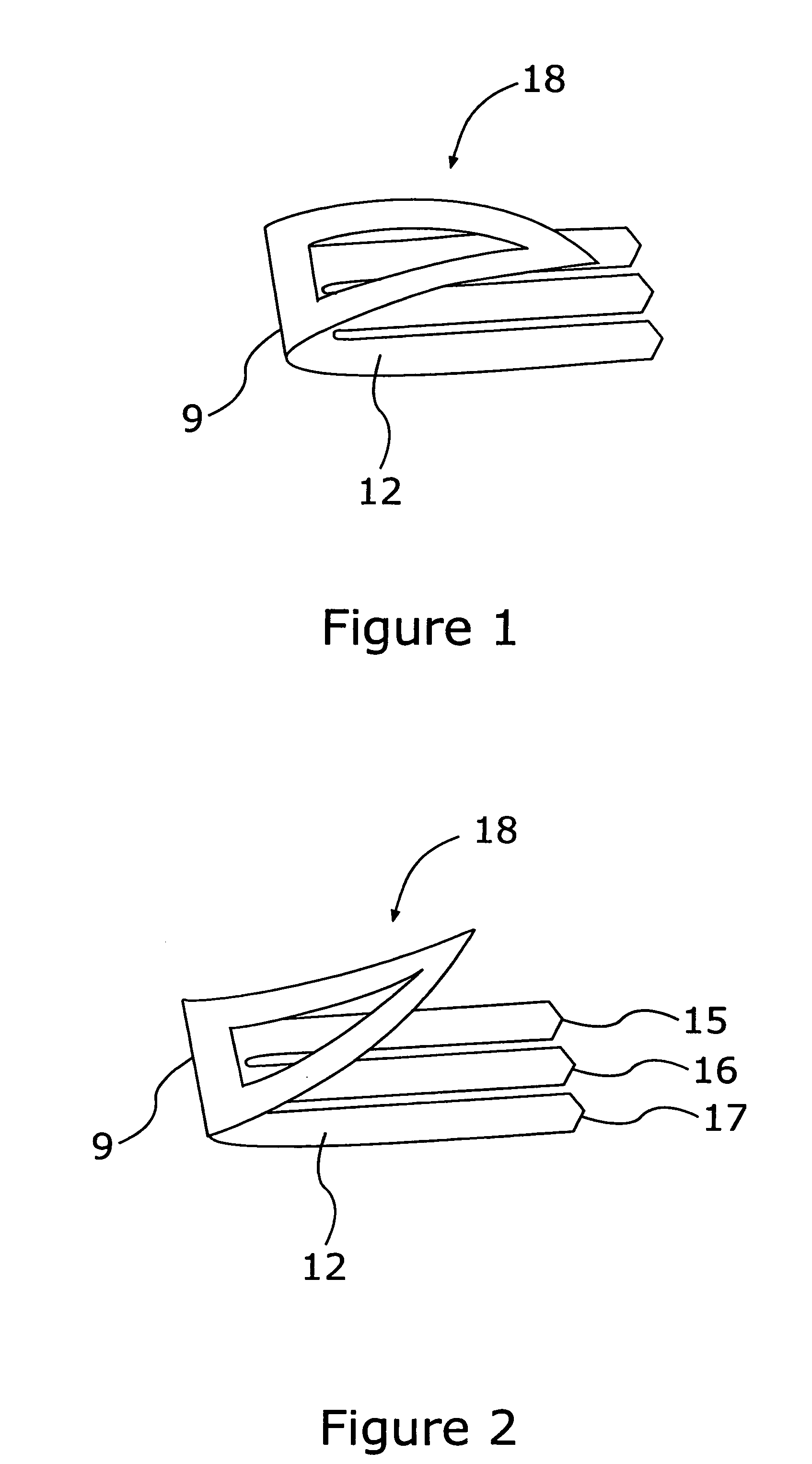

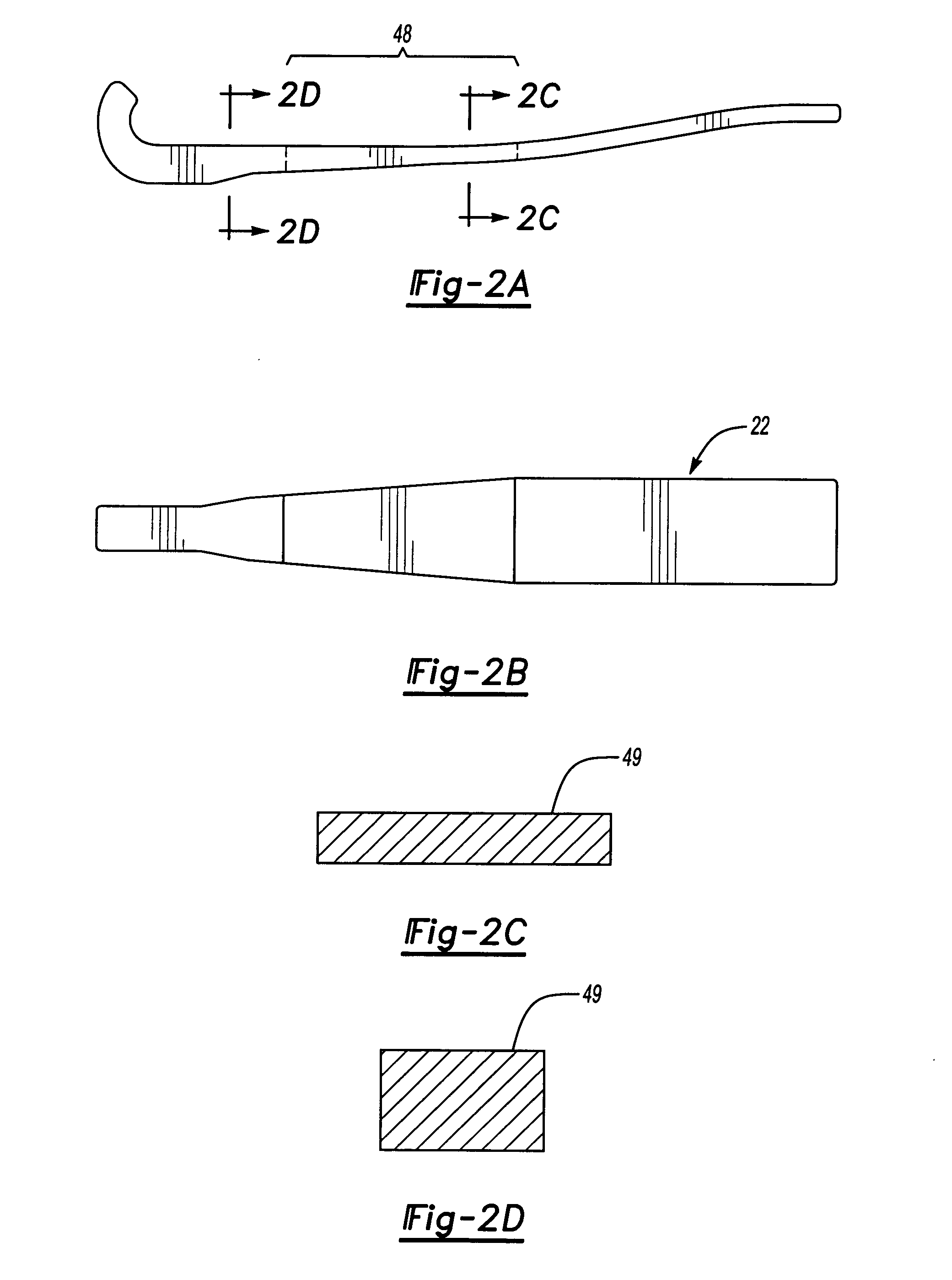

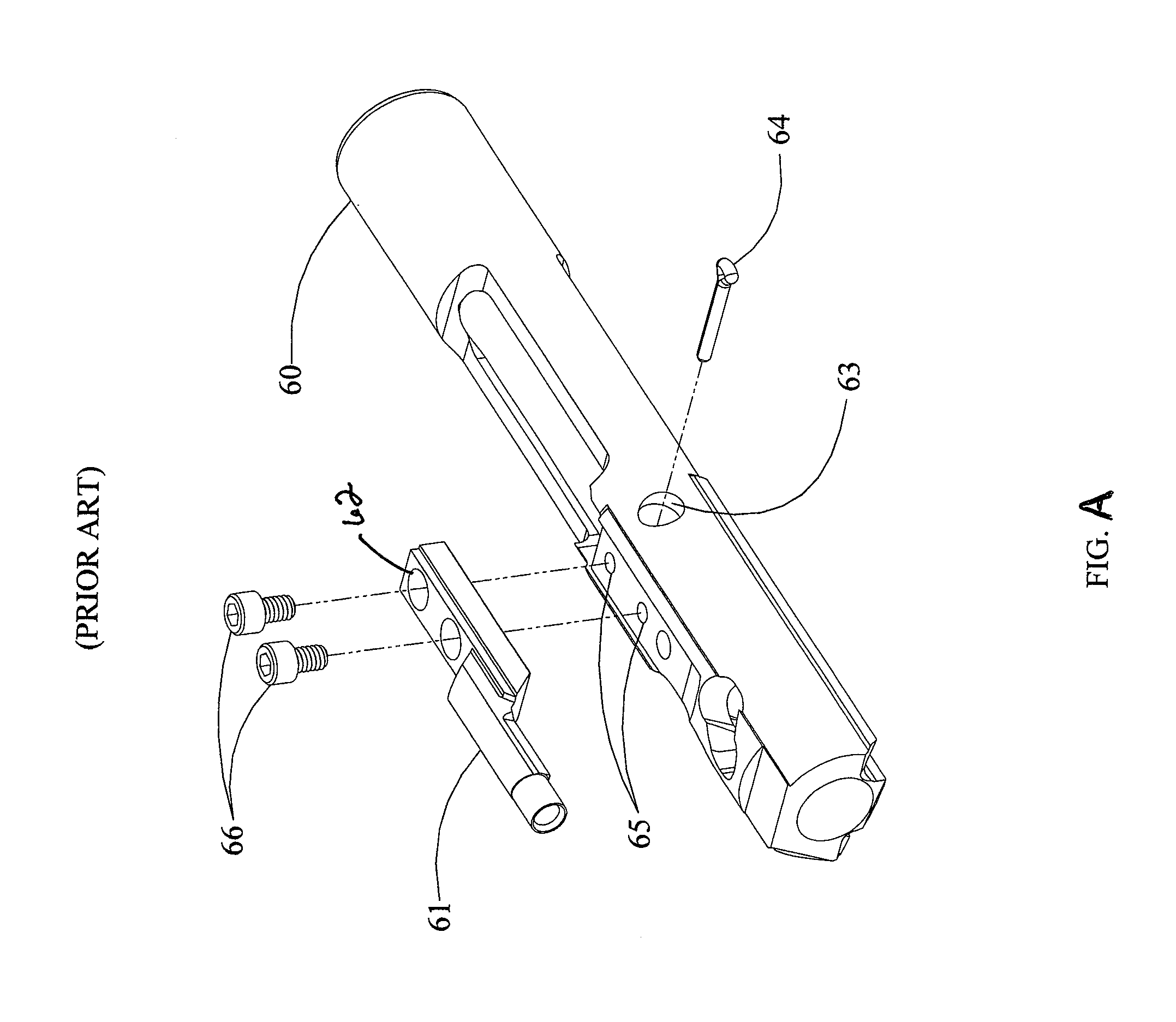

Surgical stapling instrument

A surgical stapling instrument having a staple fastening assembly including a curved cartridge device. The device has at least one curved open row of staples having a first and second ends and having a concave side and a convex side. Opposite to the cartridge device there is a curved anvil for forming the ends of the staples. The instrument also includes a moving device adapted to move the anvil with respect to the cartridge device in a parallel relationship. The instrument also includes a staple driving device adapted to drive the staples out of the cartridge device towards the anvil, and a knife. The knife has opposing first and second sides and is contained in the cartridge device. There is also a knife actuating device adapted to move the knife towards the anvil. The instrument includes staple fastening assembly having a retaining pin which moves between the cartridge device to align them. The retaining pin is located on the second side of the knife in an intermediate region between the first end and second ends of the curved row of staples.

Owner:CILAG GMBH INT

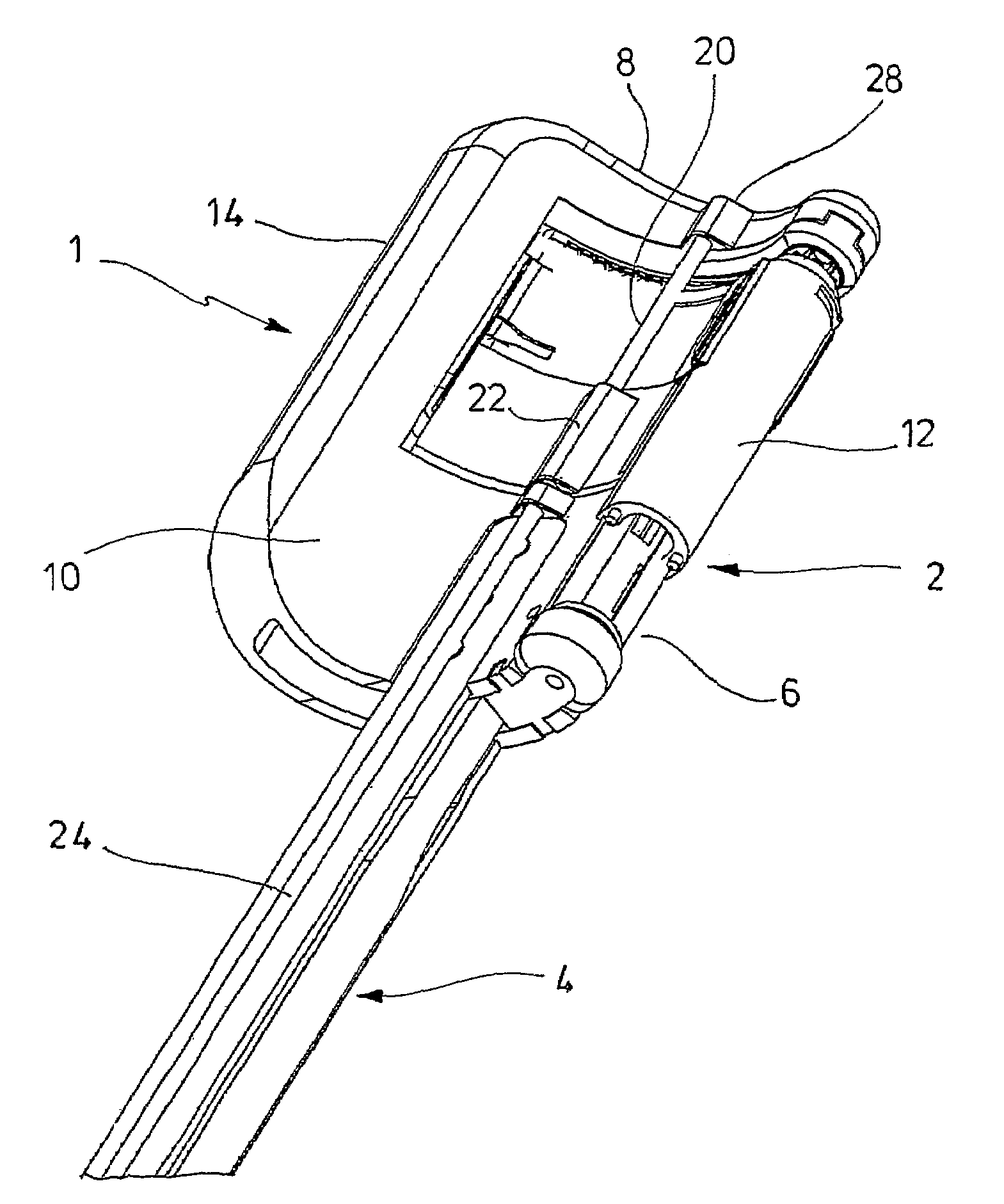

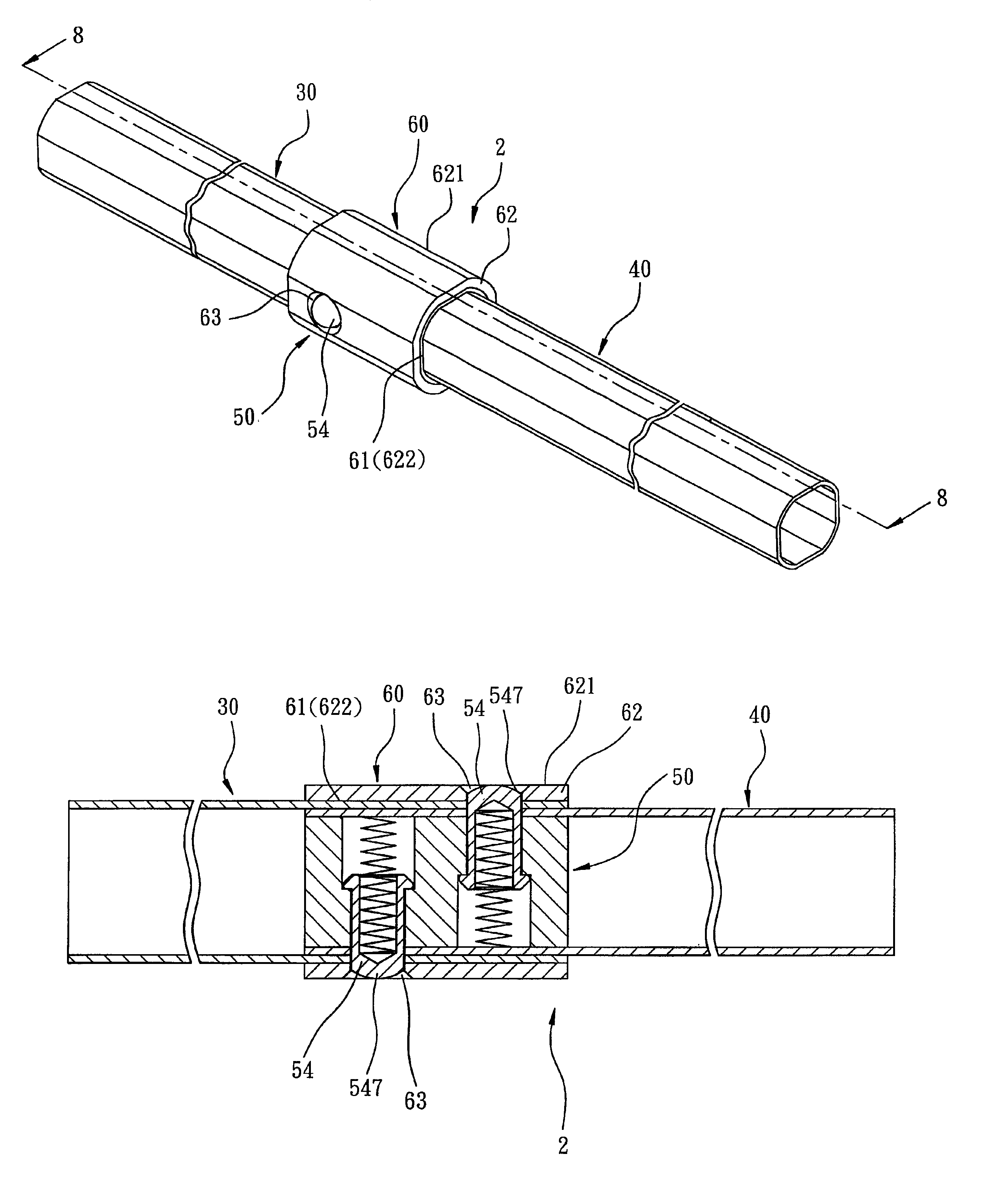

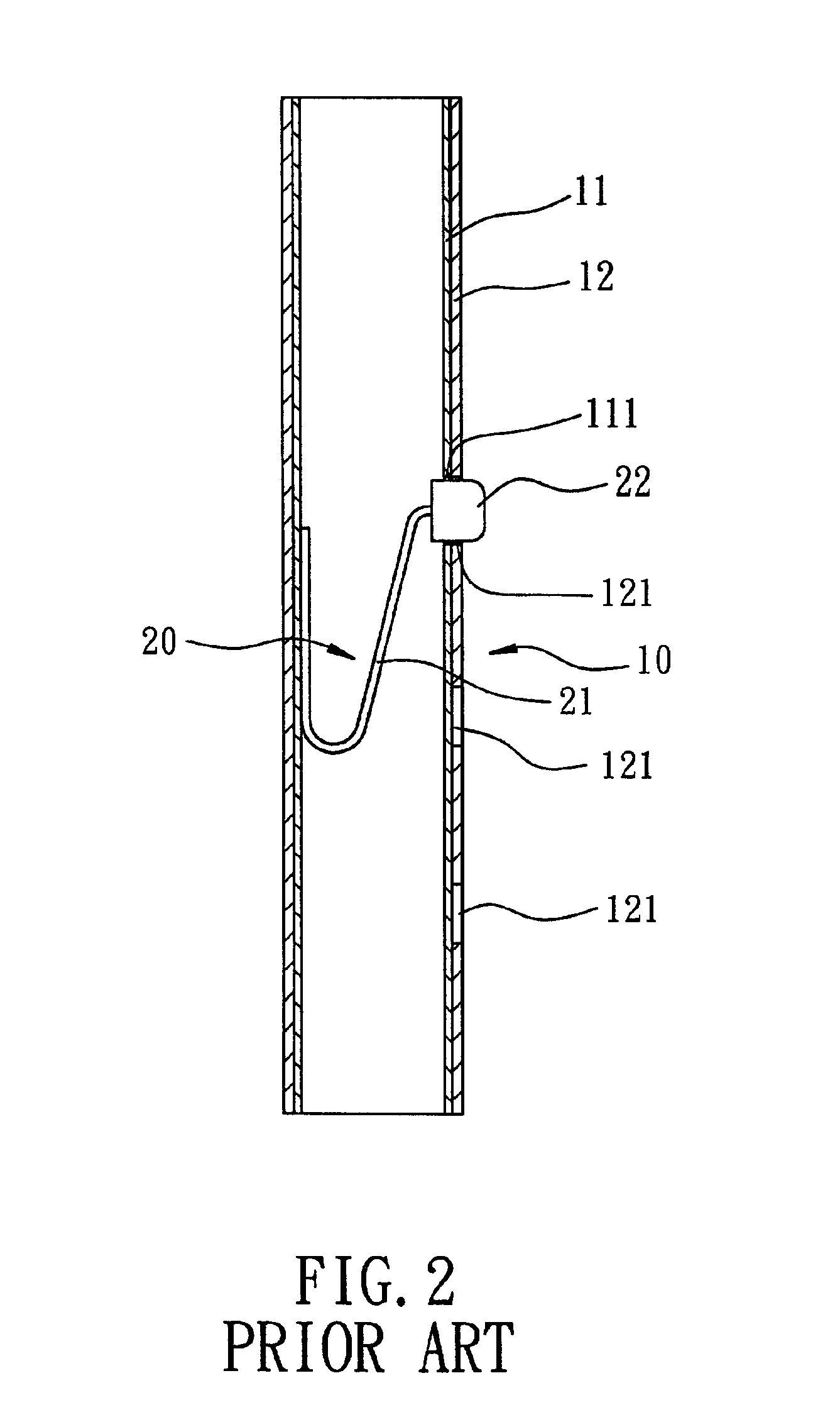

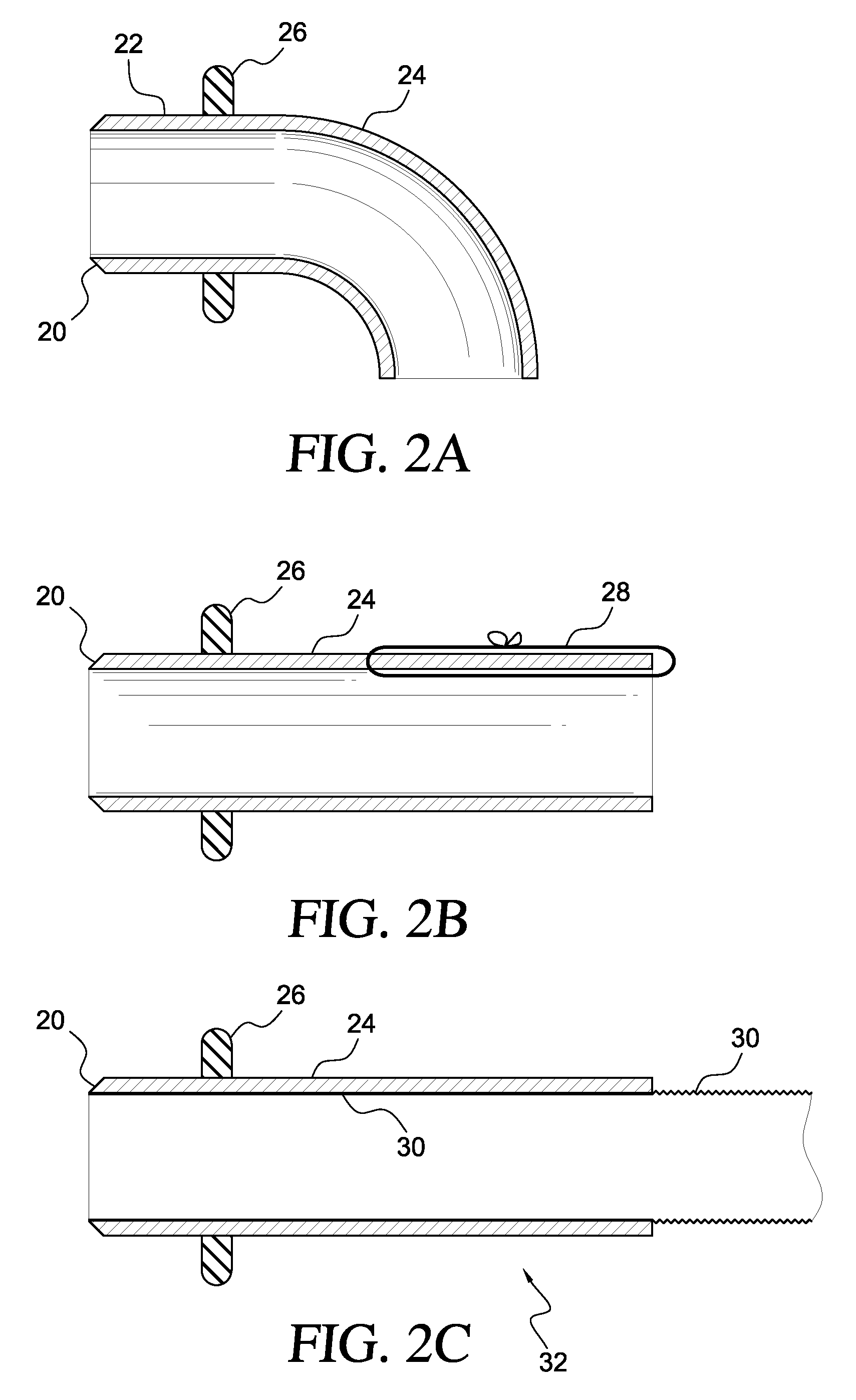

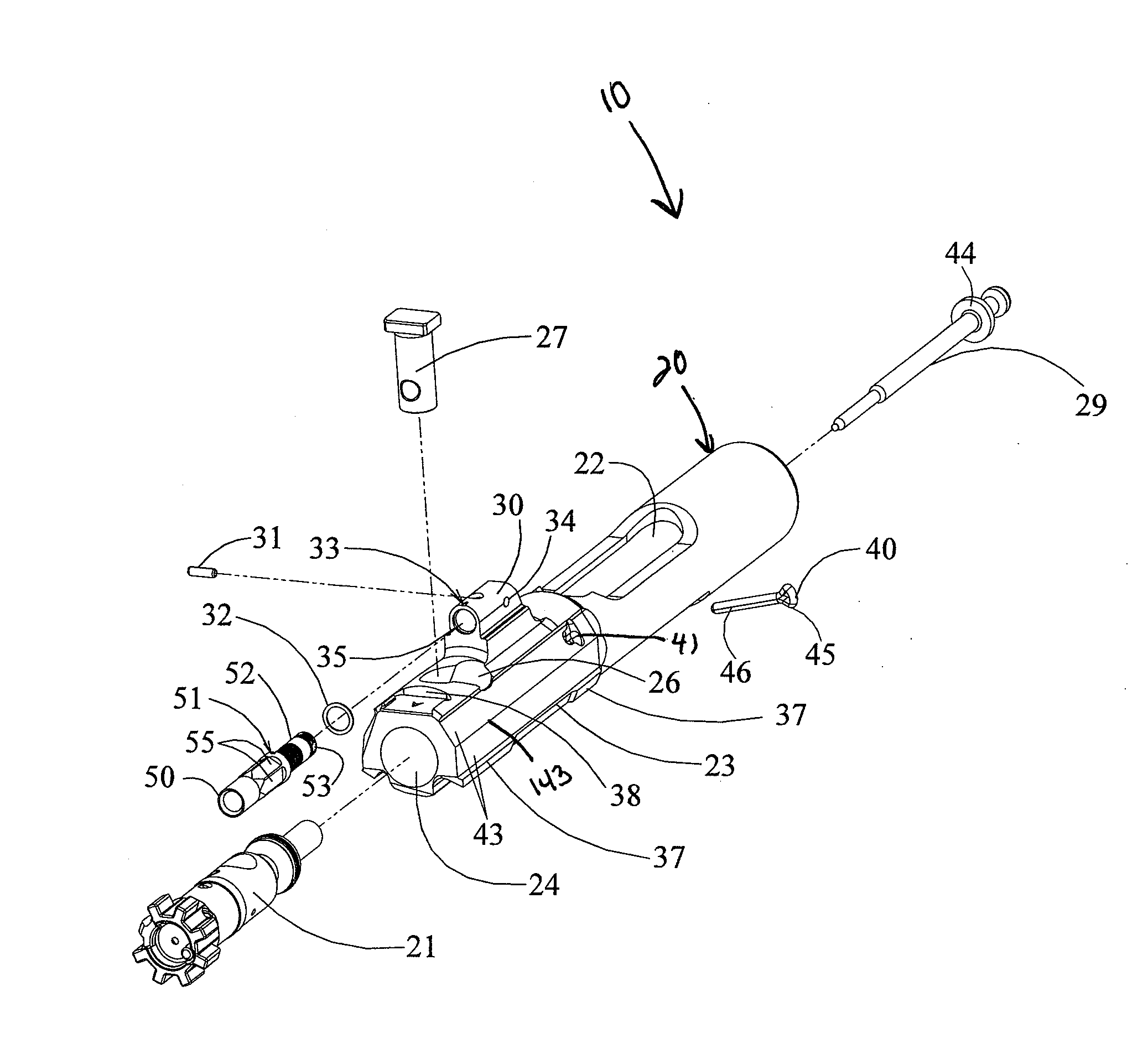

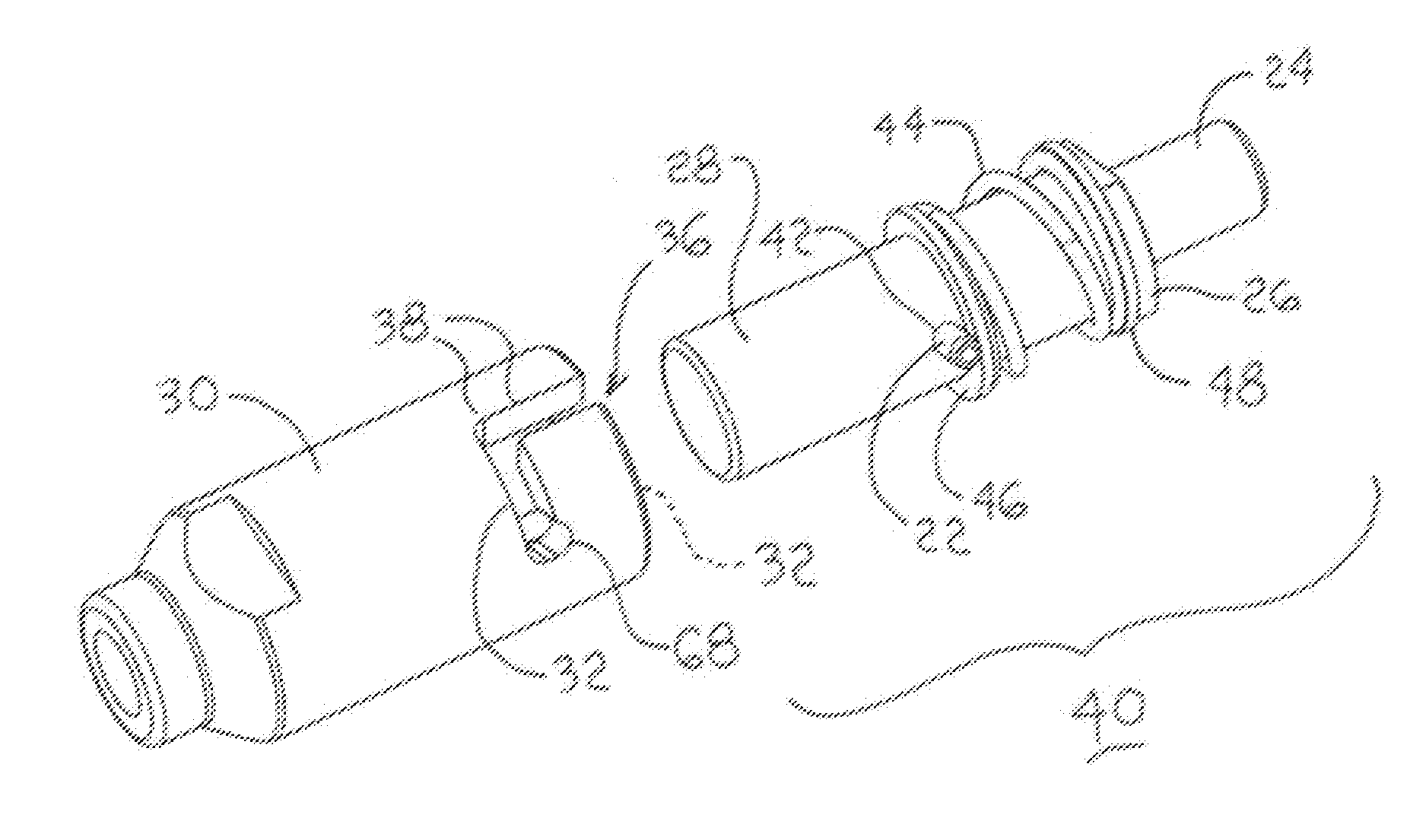

Retractable rod assembly

A retractable rod assembly includes outer and inner tubes, and a positioning device. An outer tube wall of the outer tube has two outer radial holes formed therein. An inner tube wall of the inner tube has two inner radial holes formed therein. The positioning device includes a mounting block and two spring-loaded retainers. The mounting block is disposed in the inner tube, and is formed with a pair of retainer passages respectively aligned with the inner radial holes. Each of the spring-loaded retainers, which are disposed respectively in the retainer passages, includes a retaining pin and a biasing member for biasing the retaining pin to extend out of aligned ones of the inner and outer radial holes to releasably secure the outer and inner tubes in an extended state.

Owner:HSIEH DAVID

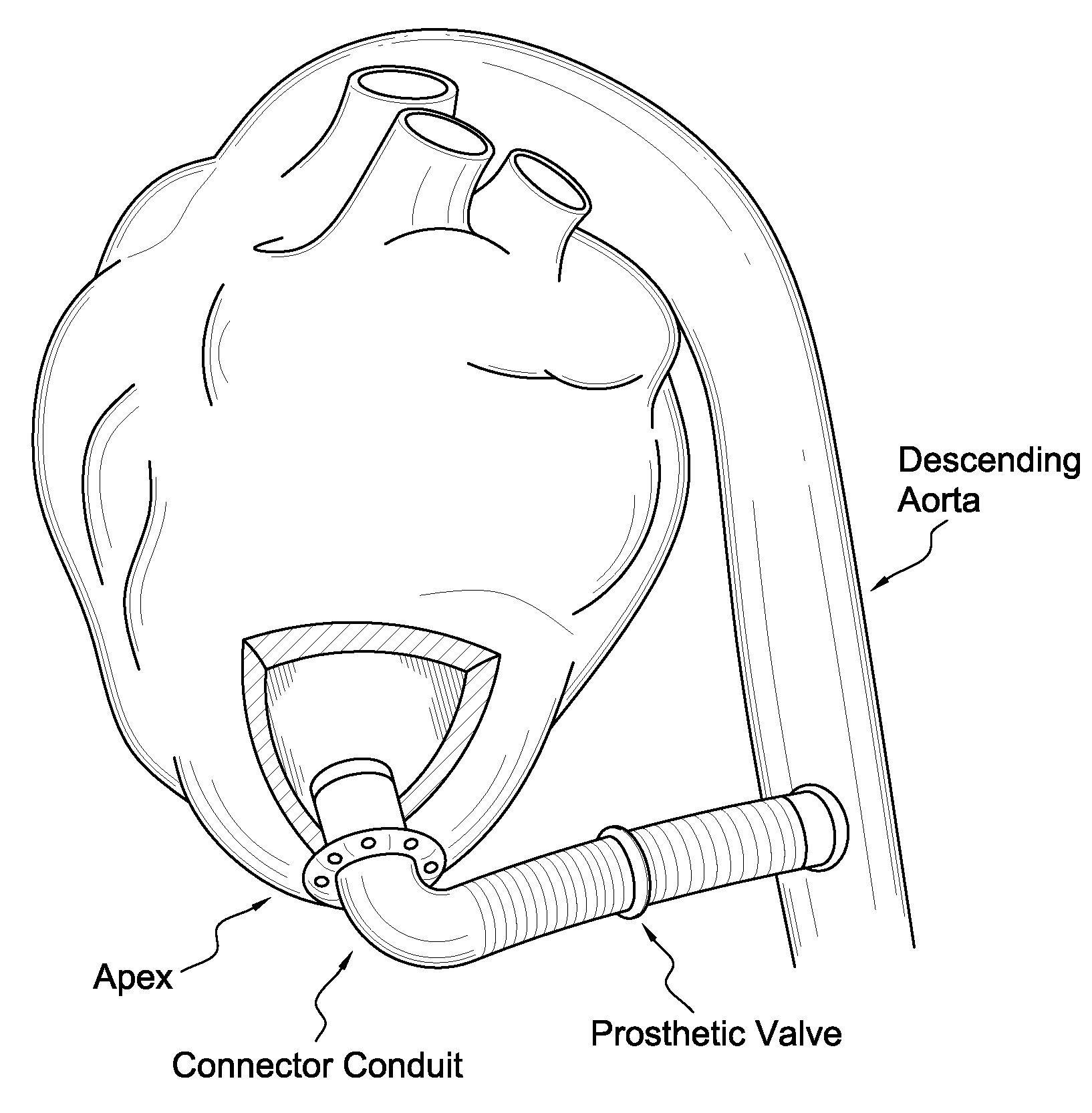

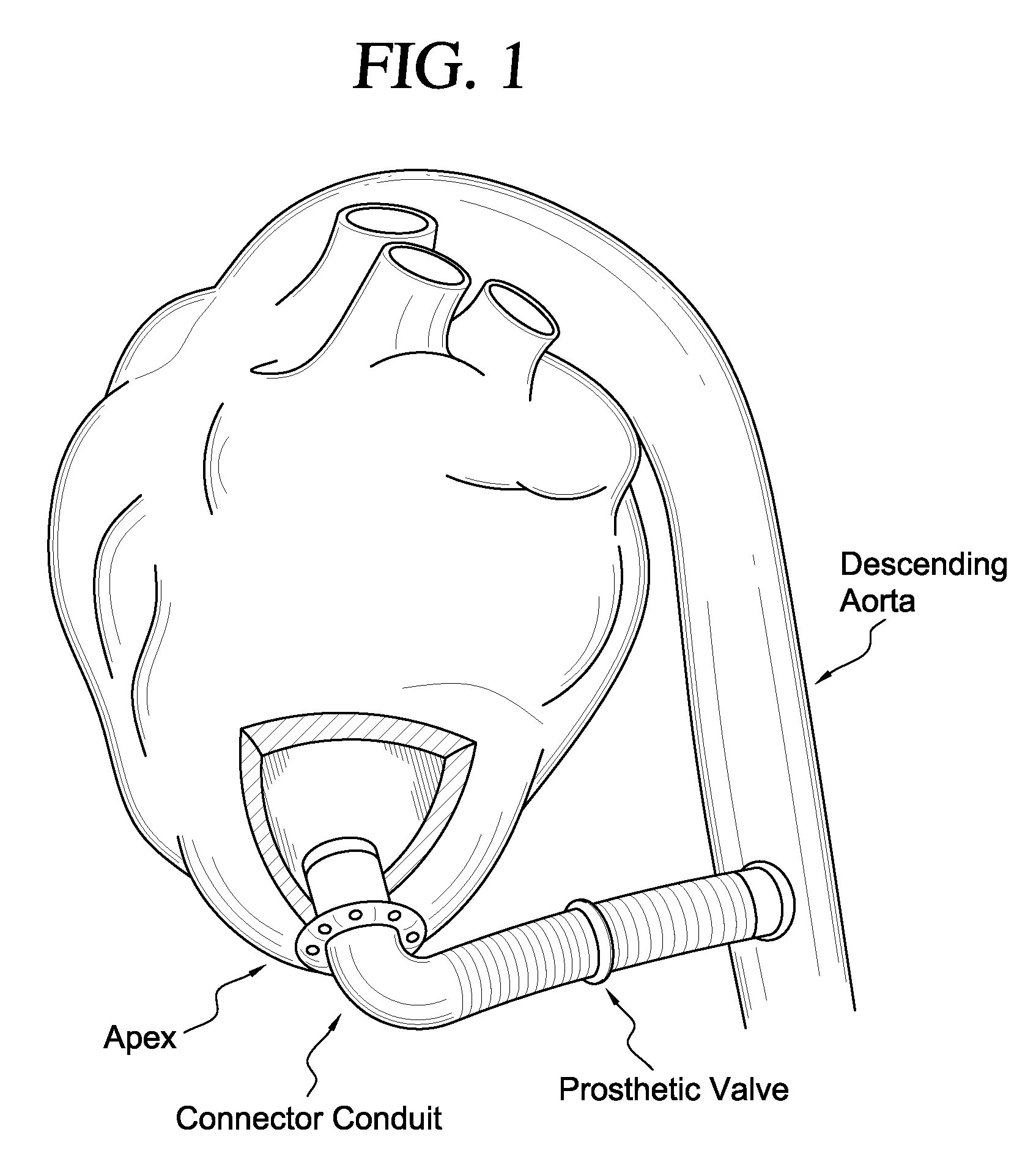

Apparatus and method for suturelessly connecting a conduit to a hollow organ

InactiveUS20070265643A1Avoid blood lossPrevent movementBlood vesselsWound clampsOrgan wallCoil spring

The present invention relates to an apparatus and method for securing a connector conduit to a hollow organ. The method comprises forming a hole in a wall of the organ; inserting a connector conduit through the hole in the wall of the organ until a flange element comes into contact with the wall of the organ, the flange element being positioned on the connector conduit; and engaging a retention means with the wall of the organ to prevent movement of the connector conduit relative to the wall of the organ, the retention means being positioned on the connector conduit. Exemplary retaining means include a plurality of retaining pins positioned circumferentially around the connector conduit, a plurality of prongs positioned circumferentially around the connector conduit, a balloon positioned on the connector conduit, a torsion spring positioned on the connector conduit, a spiral spring positioned on the connector conduit, or combinations thereof.

Owner:CORREX

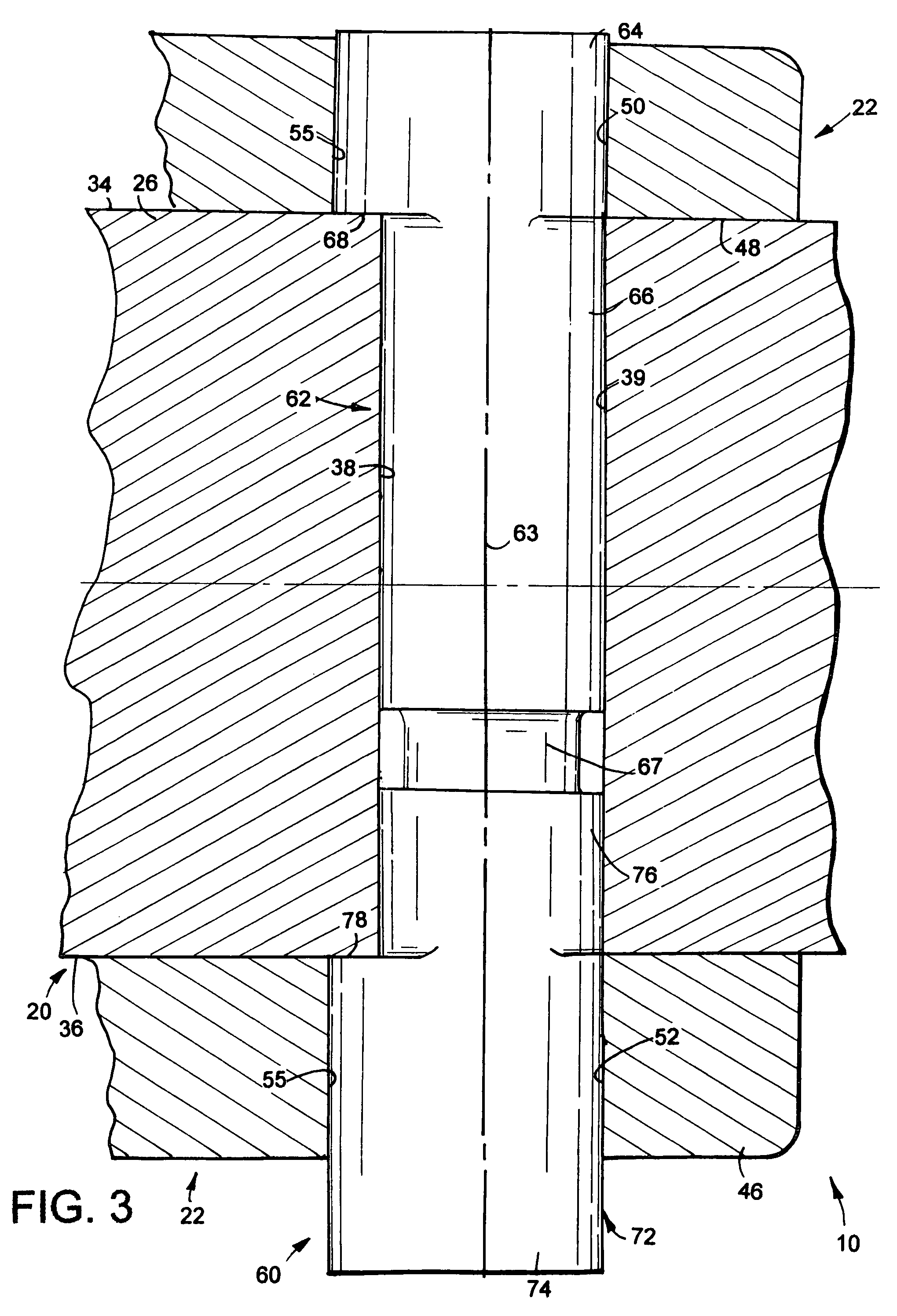

Bolt carrier and bolt for gas operated firearms

ActiveUS20140090283A1Prevent looseningMaximum service lifeCartridge extractorsBreech mechanismsSpray nozzleRetaining Pin

An improved bolt and bolt carrier with integral gas key having an extension nozzle threadedly secured and pinned to the gas key for use with a direct gas operated firearm is provided. The extension nozzle is designed to receive a portion of the host firearms gas operating system. The firing pin retaining pin is oriented so as to expose its widest profile to the firing pins annular flange, increasing its service life. The bolt has a plurality of lugs extending from its forward end and an extractor recess. The extractor recess is constructed to accommodate an enlarged extractor claw while not undercutting the bolt lugs adjacent thereto. The extractor engages approximately 57% more of a seated ammunition cartridges rim as compared to some prior art AR15 / M16 type extractors used with automatic firearms chambered in 6.8 SPC. The result is an improved bolt and bolt carrier which provides for increased operational reliability.

Owner:LWRC INTERNATIONAL

Bolt carrier and bolt for gas operated firearms

ActiveUS20140076144A1Improve safety and reliabilityReduce manufacturing costCartridge extractorsFiring/trigger mechanismsEngineeringRetaining Pin

An improved bolt and bolt carrier with integral gas key having an extension nozzle threadedly secured and pinned to the gas key for use with a direct gas operated firearm is provided. The extension nozzle is designed to receive a portion of the host firearm's gas operating system. The firing pin retaining pin is oriented so as to expose its widest profile to the firing pin's annular flange, increasing its service life. The bolt has a plurality of lugs extending from its forward end. The extractor recess is constructed so that the face of the bolt is round and the adjacent lugs fully supported. The extractor engages approximately 17% more of a seated ammunition cartridge's rim as compared to the prior art AR15 / M16 extractor. The result is an improved bolt and bolt carrier which provides for increased operational reliability.

Owner:LWRC INTERNATIONAL

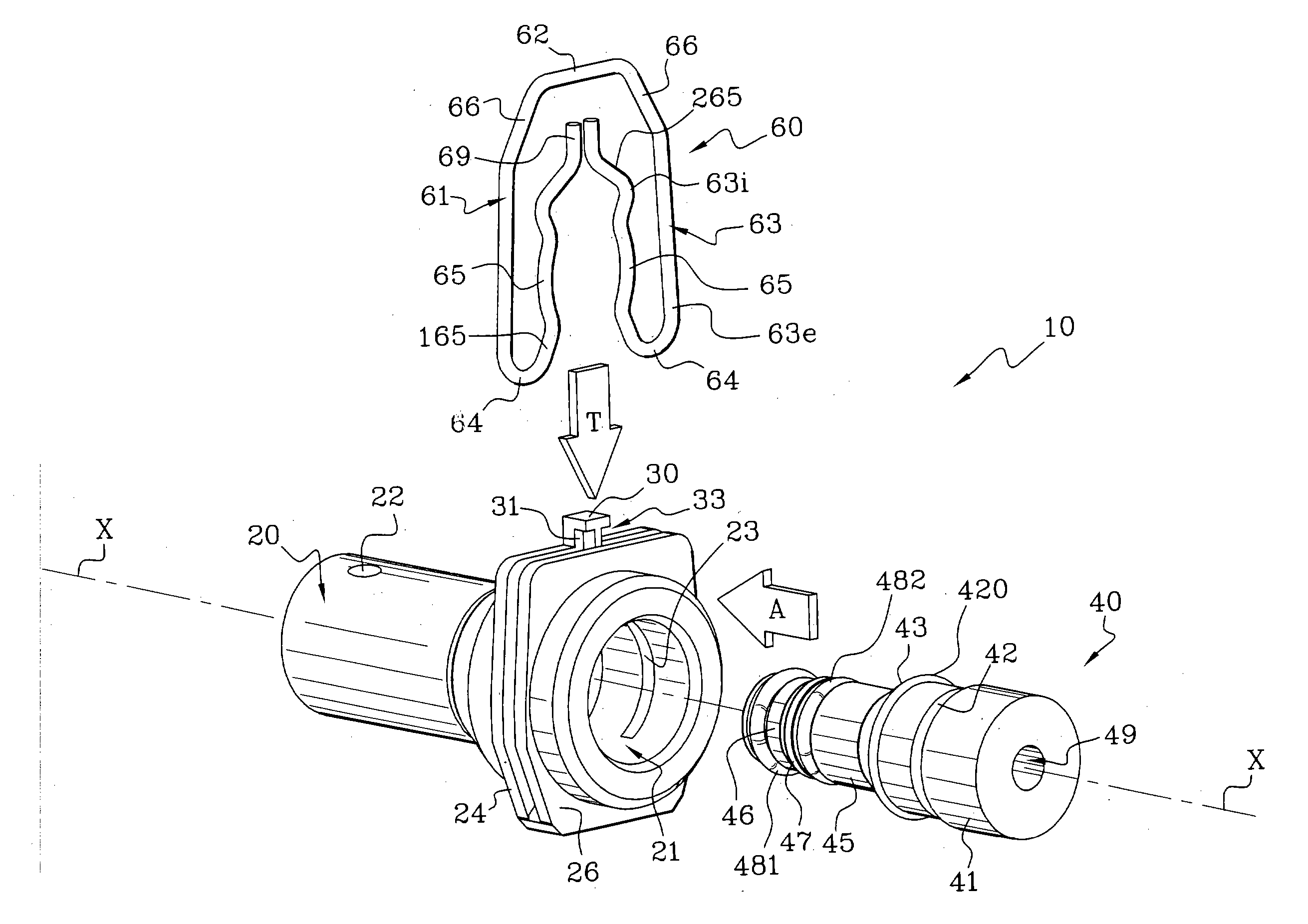

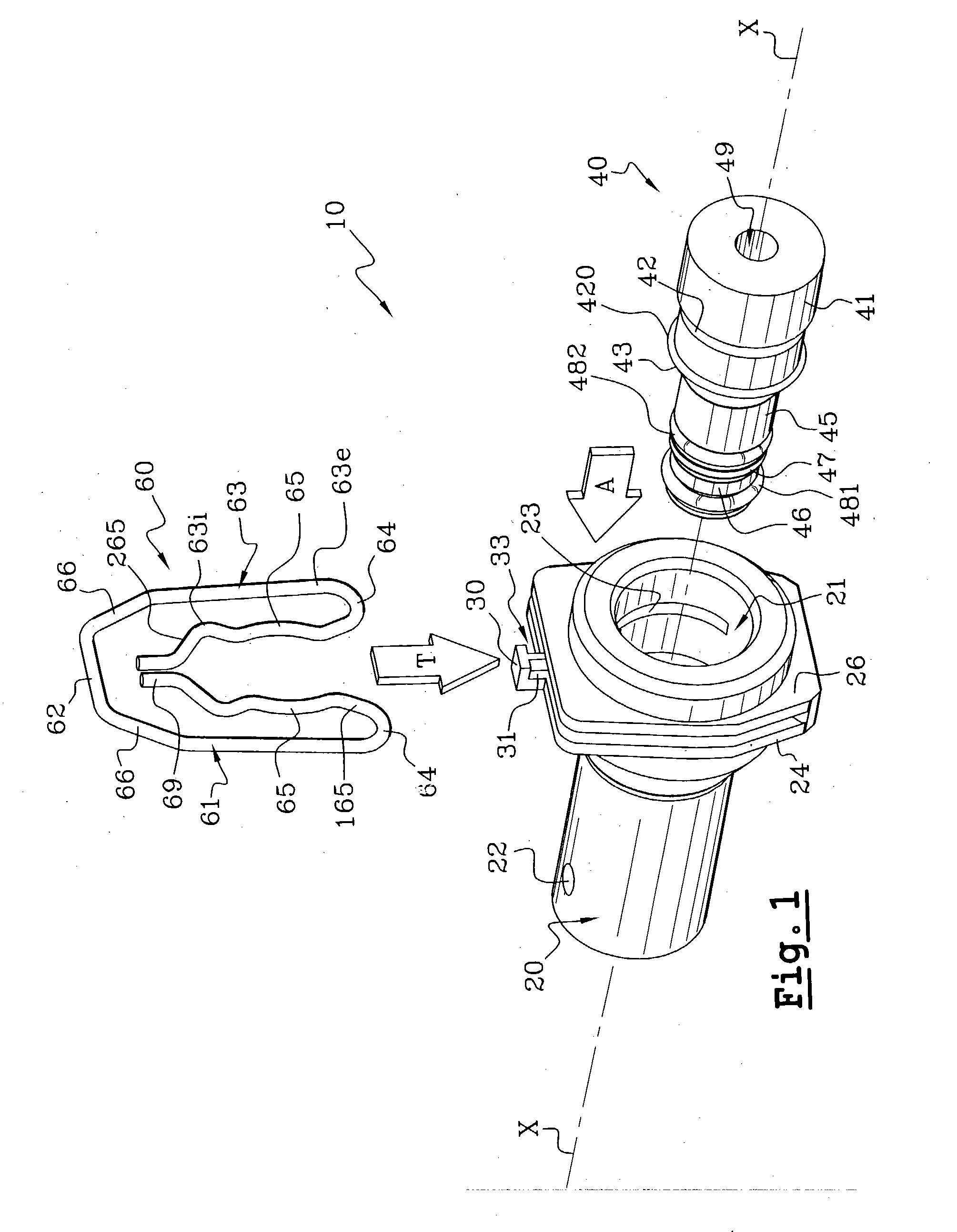

Feed pipe coupling for a pressurised fluid system

The invention proposes a feed pipe coupling for a pressurised fluid system, characterised in that the branch of the spring clip which includes the locking portion is configured generally as a hairpin having a radially internal, locking, first branch portion of which the locking portion is a part, together with a radially external, connecting, second branch portion which is connected at each of its ends, firstly to the operational locking branch portion through a bent connecting portion, and, secondly to the central connecting branch of the spring clip, in such a way as to give the locking branch a capacity for elastic deformation in the general transverse plane of the spring clip.

Owner:VALEO EMBRAYAGES SAS

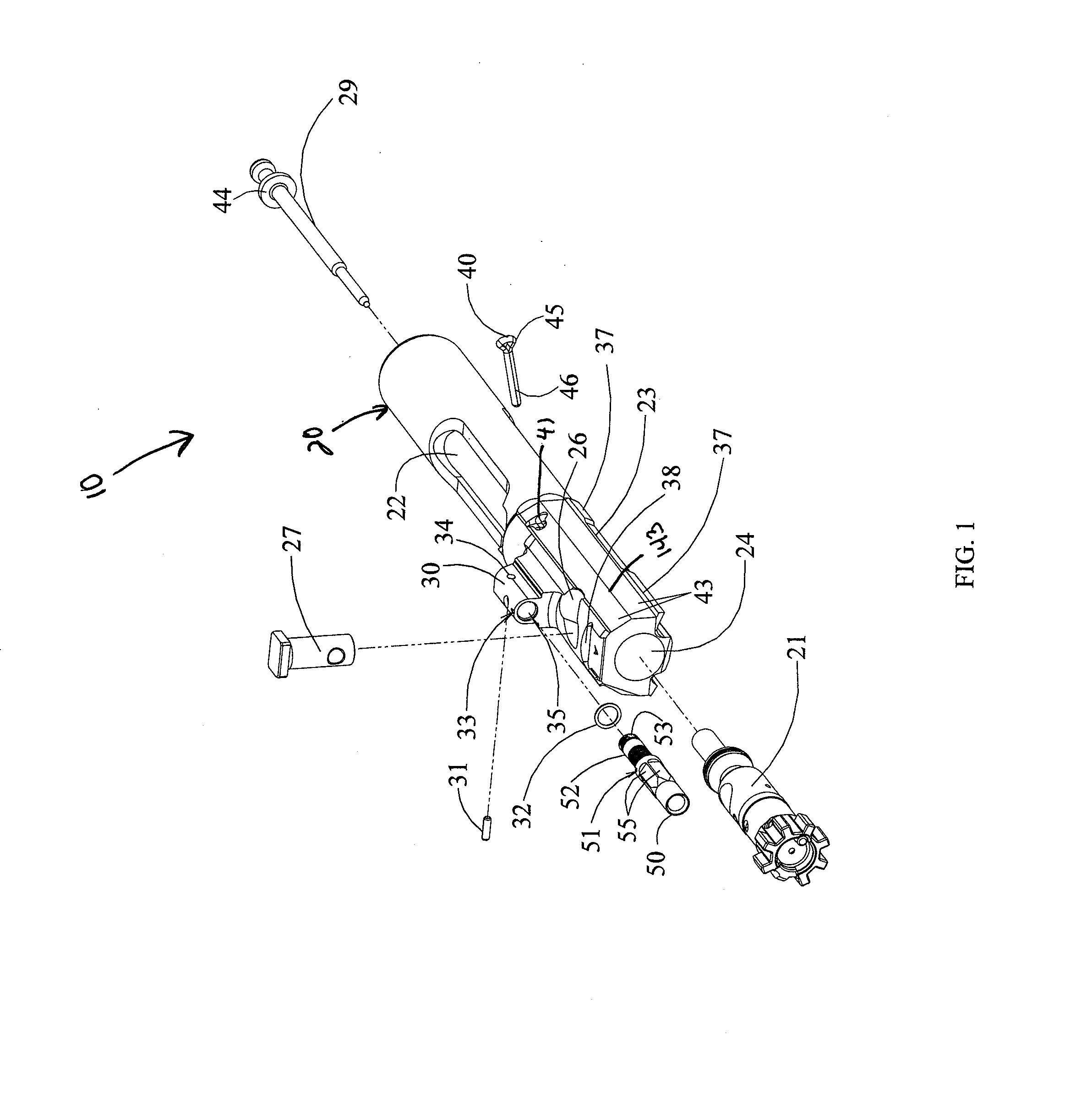

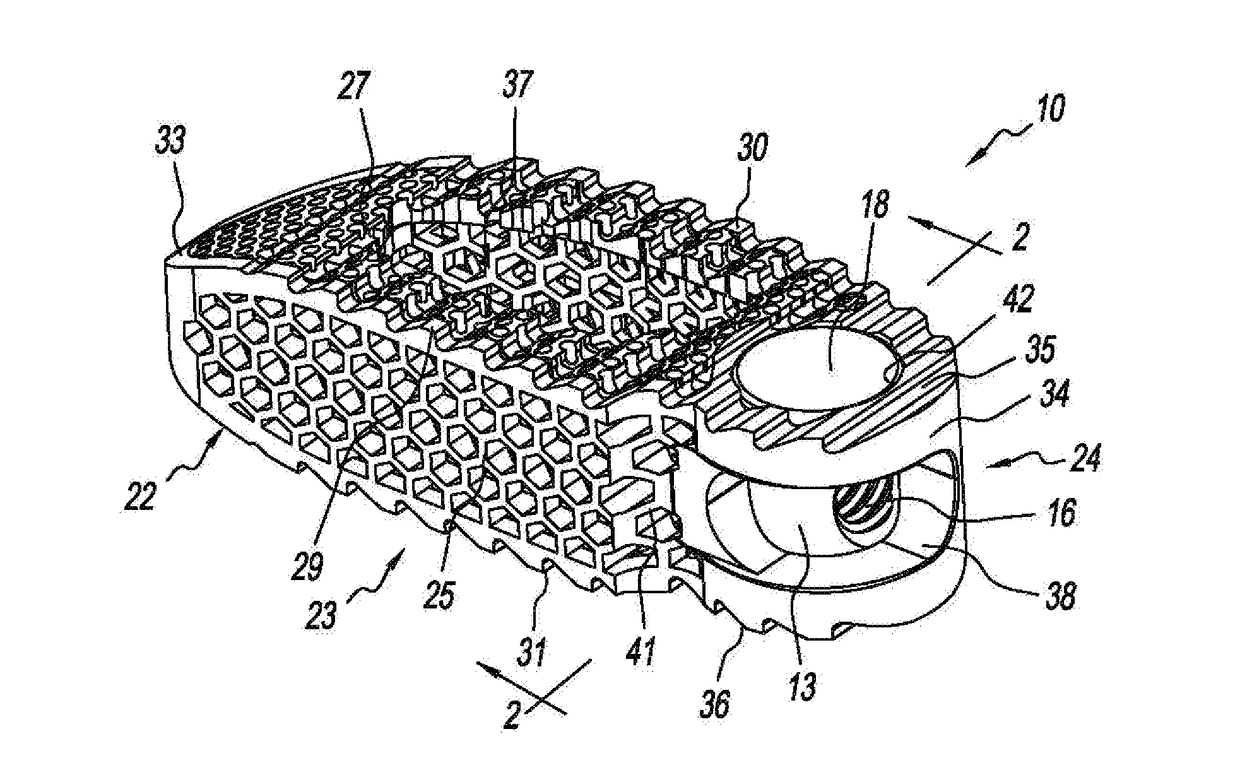

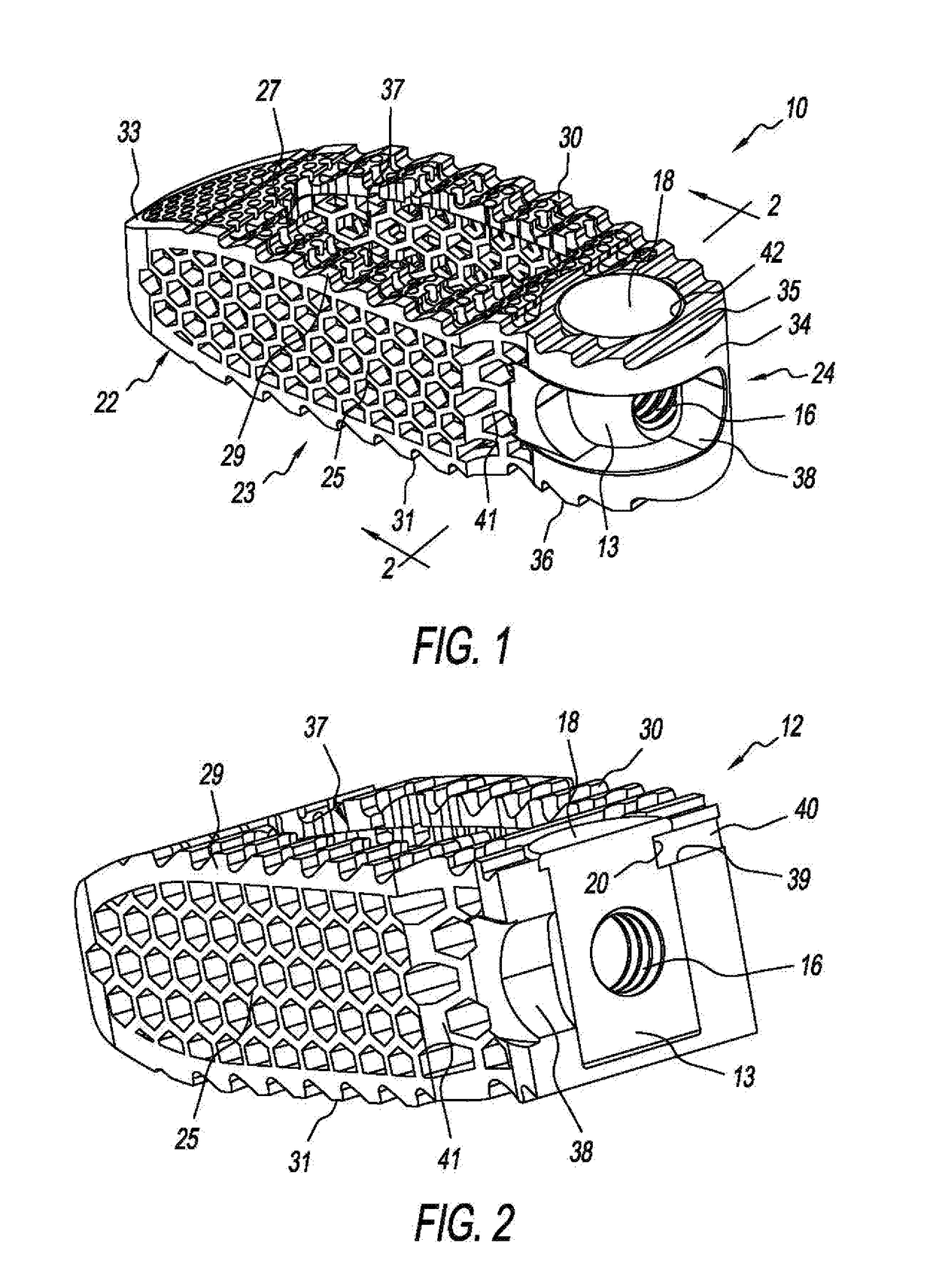

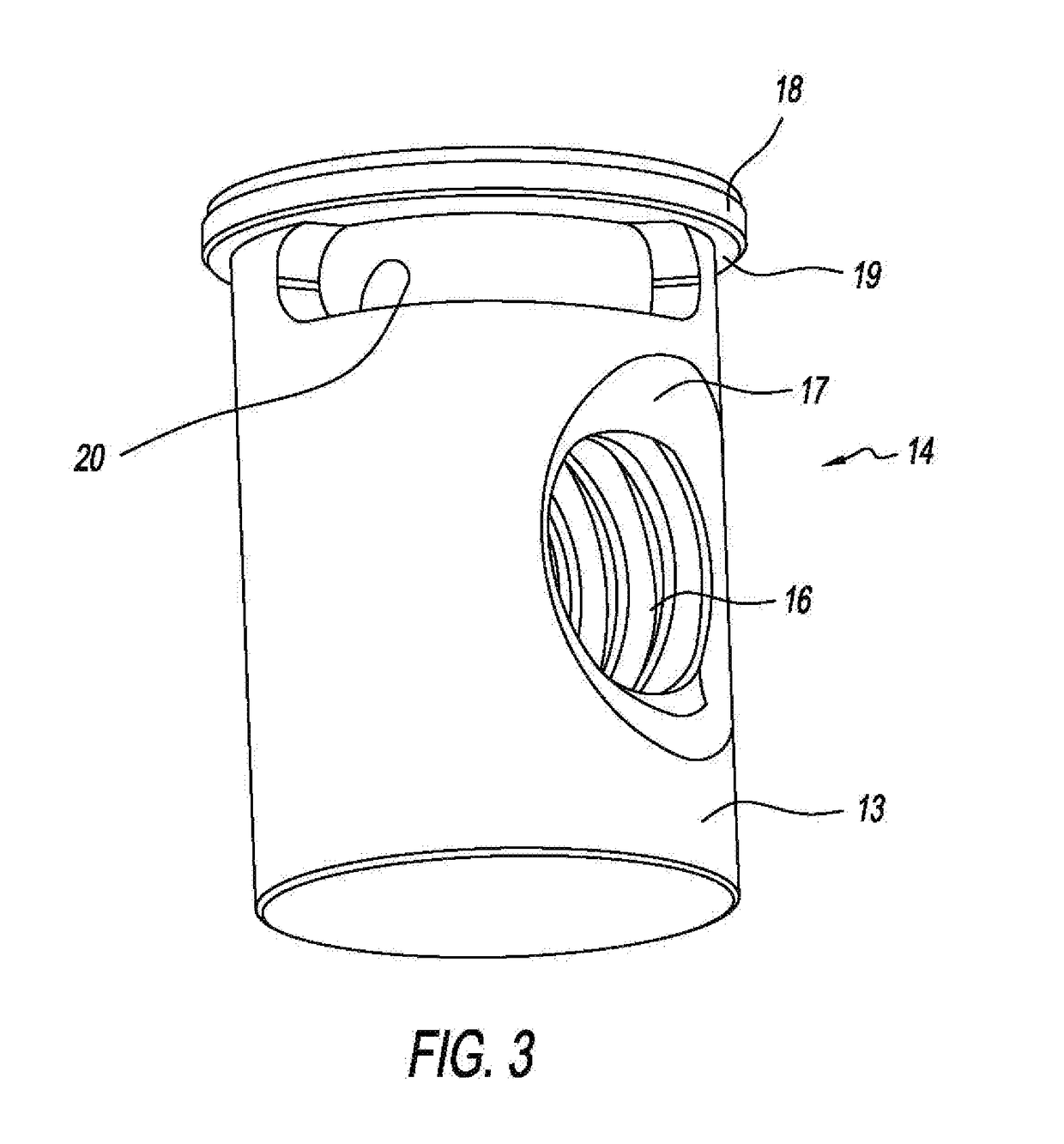

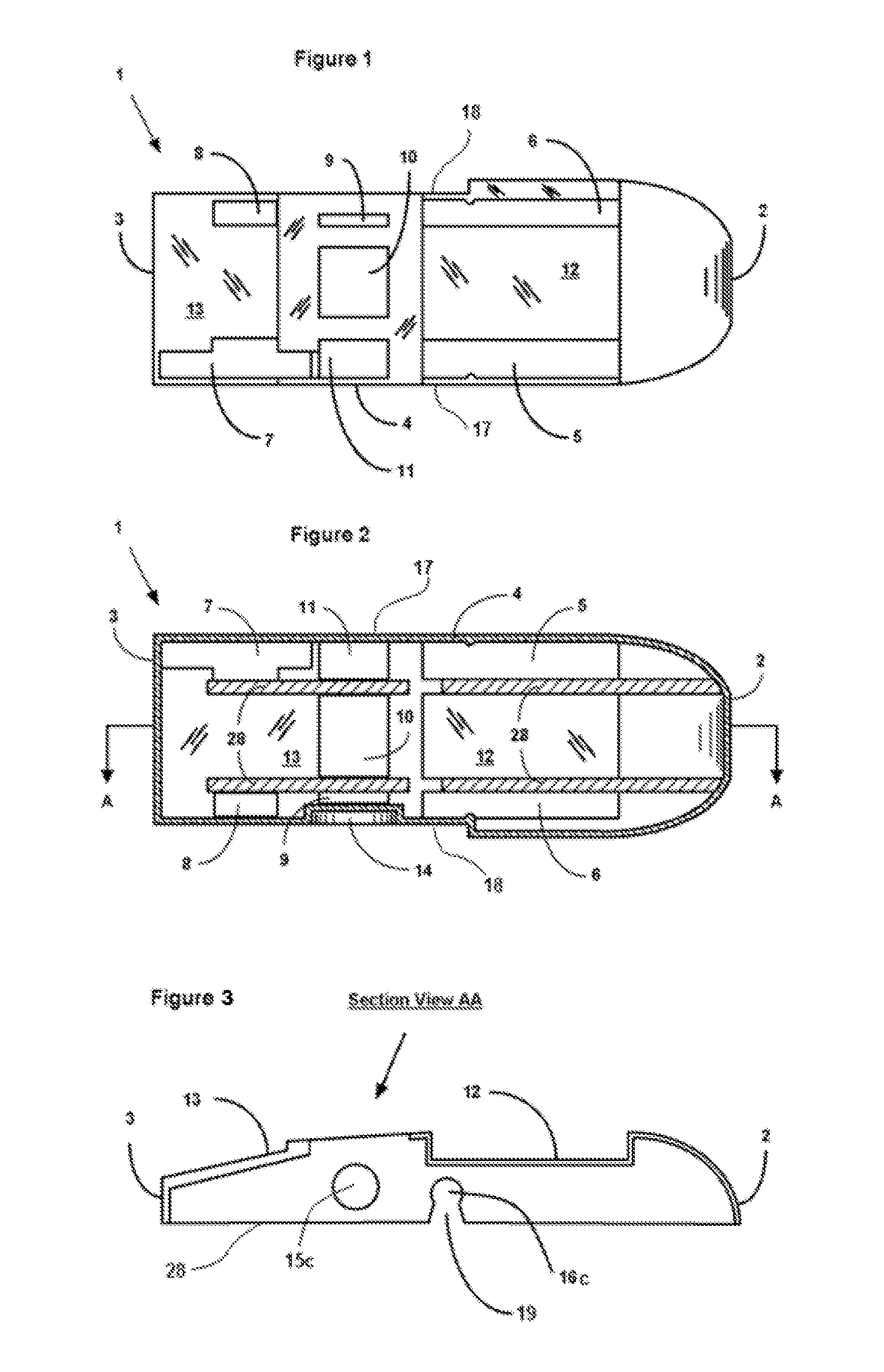

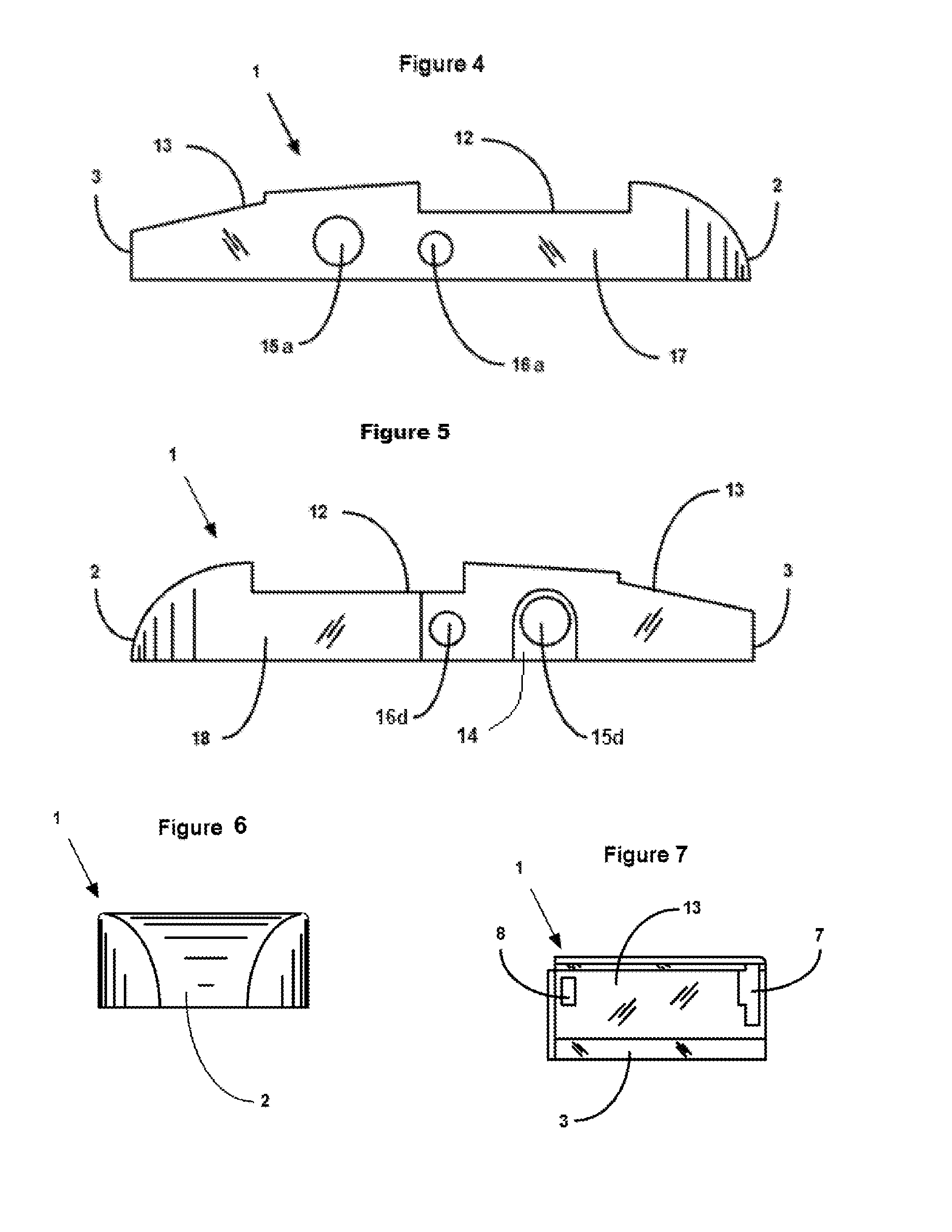

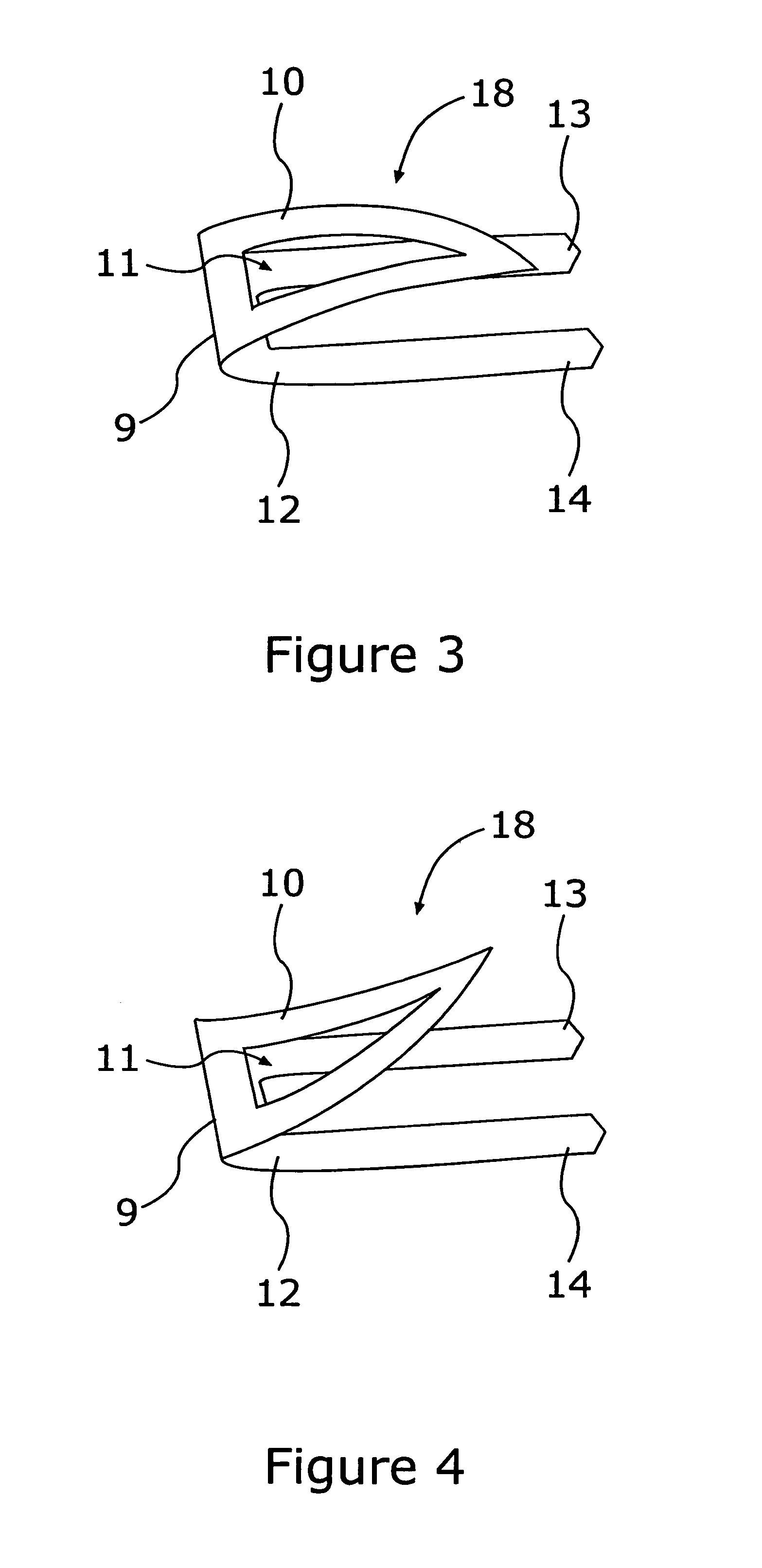

Steerable TLIF Spine Implants

A spine implant for a TLIF surgical procedure is configured to be steered into place during implantation in conjunction with a complementary insertion instrument. The cage of the implant is constrained to a limited range of rotation about a post carried by the cage. The insertion instrument is configured to hold the post while controllably rotating the cage relative to the post in order to angularly position the implant during implantation. Range of rotational motion is controlled by the configuration of a groove in the post. A retaining pin of the implant extends from the cage into the groove of the post to rotationally connect the cage to the post.

Owner:LIFE SPINE INC

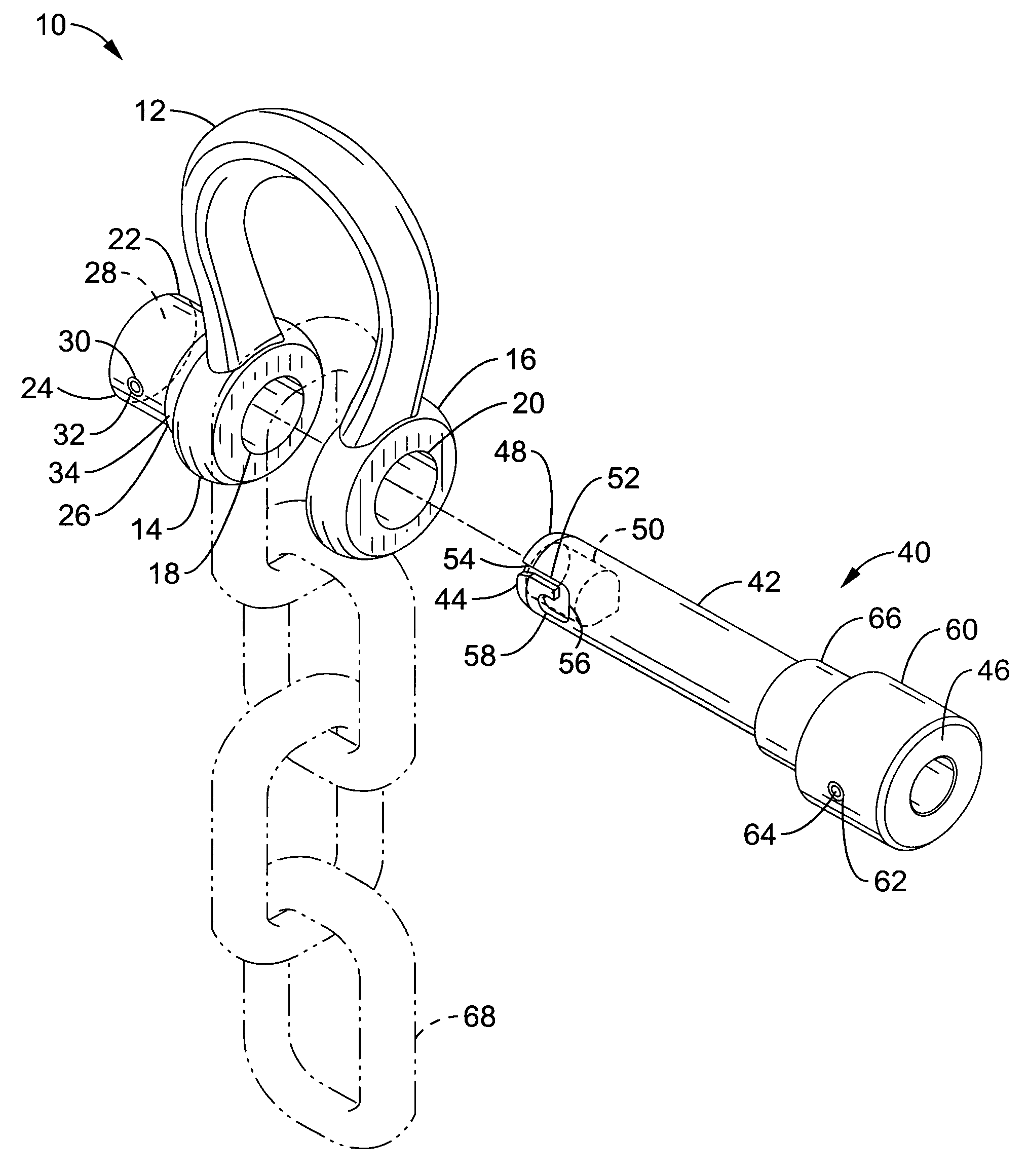

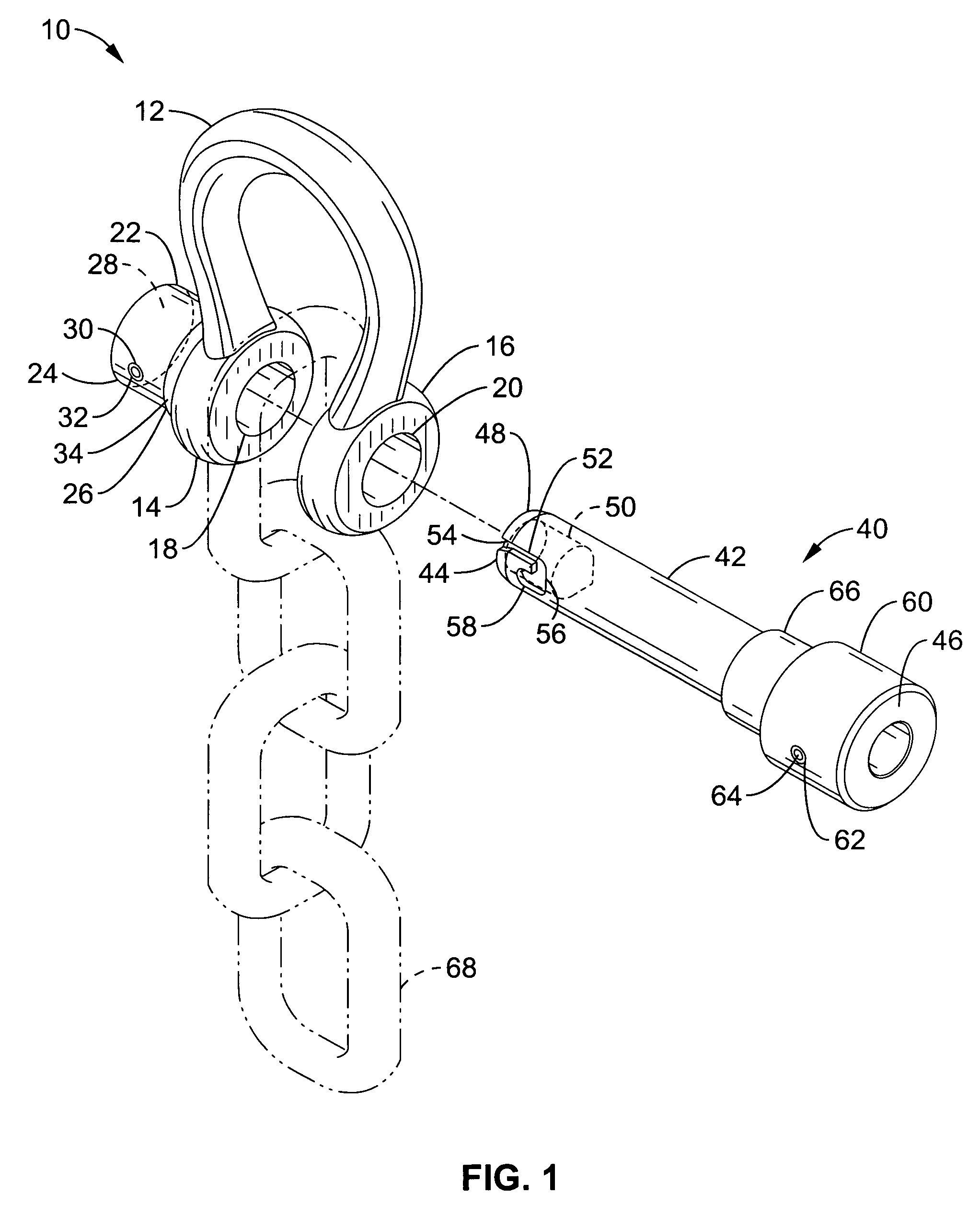

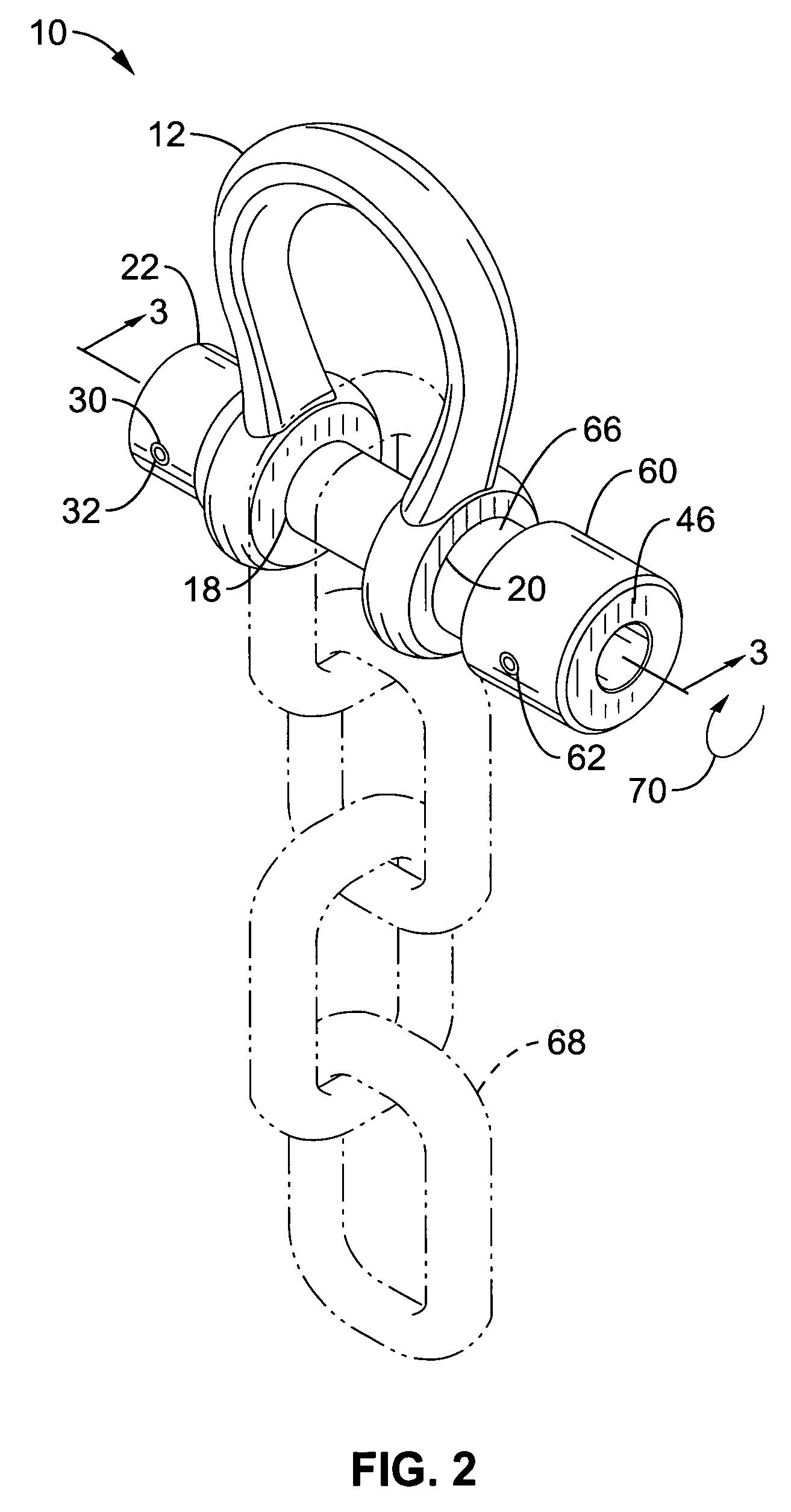

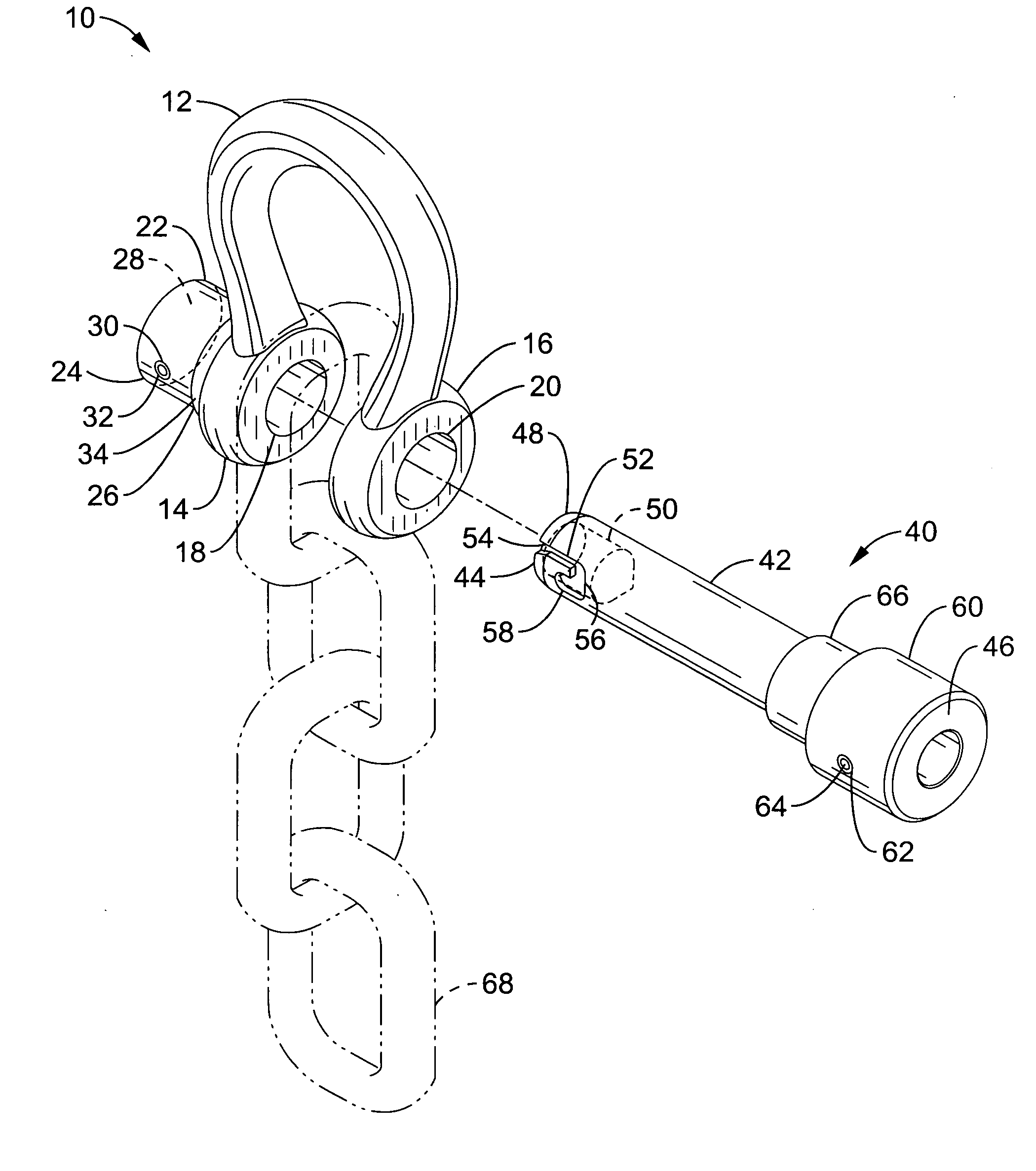

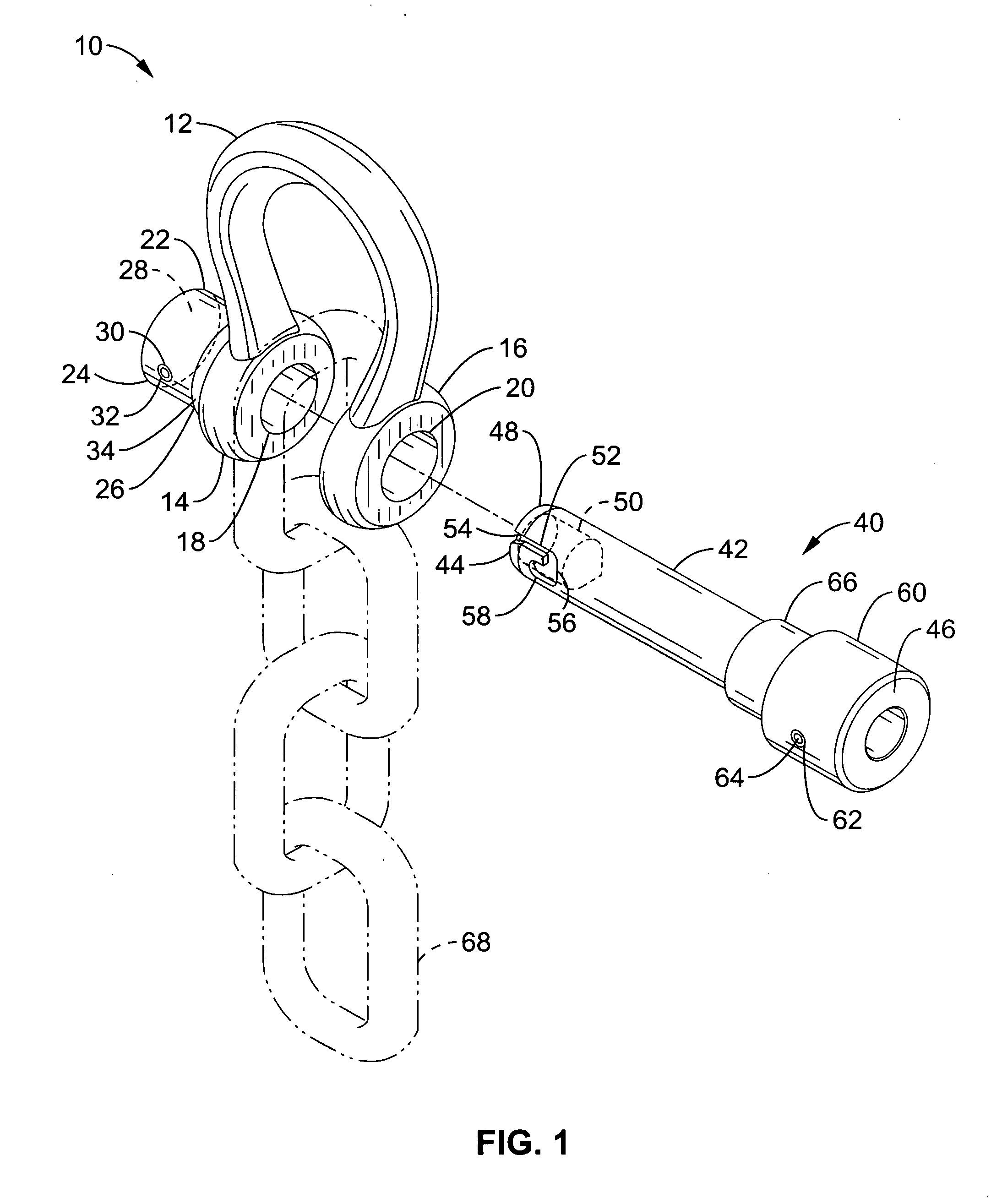

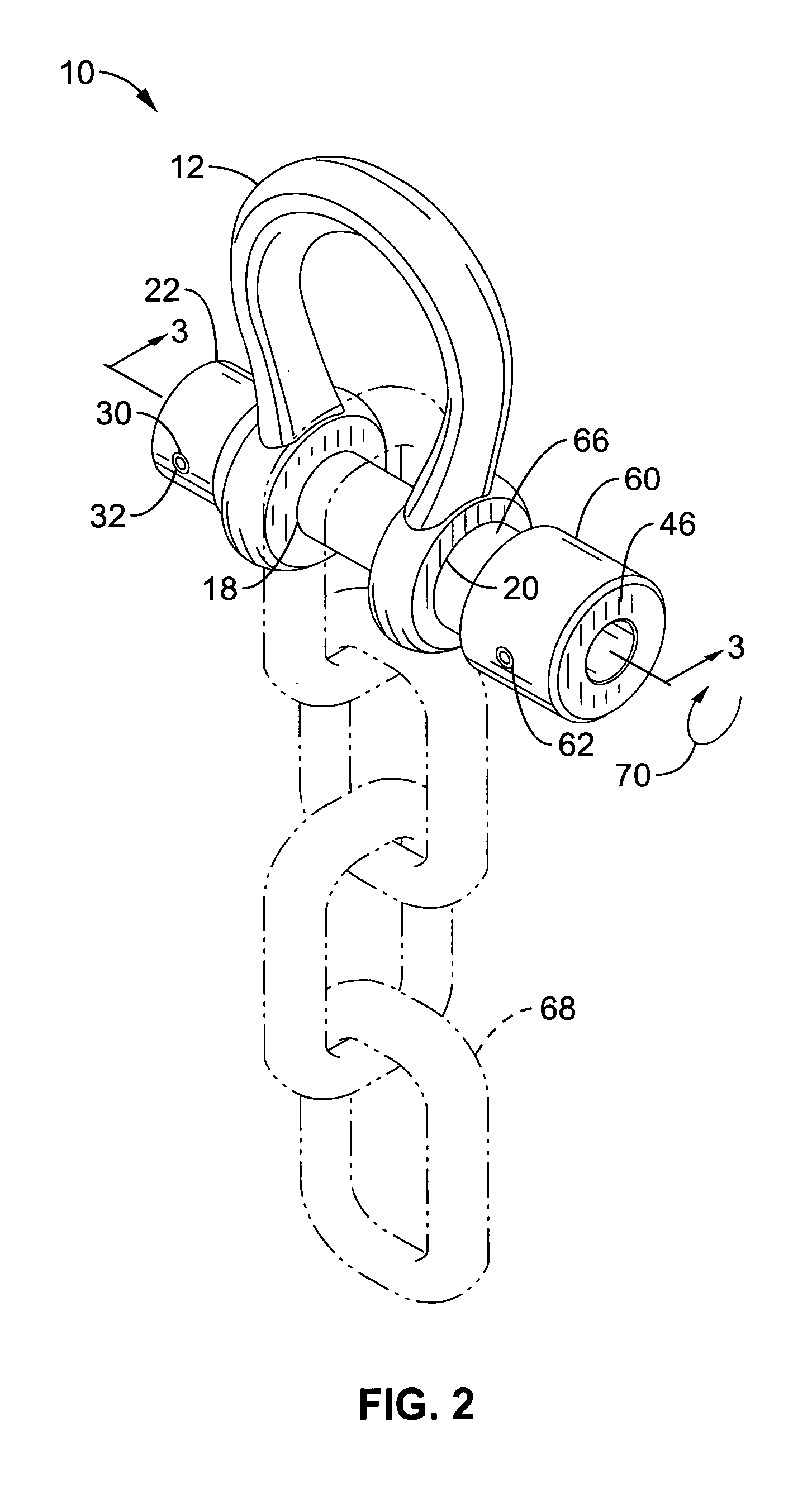

Quick release shackle pin system

A spring loaded quick release pin and tubular receiver with a retainer pin configured to secure the quick release pin in a shackle, clevis, yoke or forked rod end. The receiver is welded to a shackle or cast with the shackle as a single body. One end of the quick release pin has aligned J slots that engage the retainer pin positioned in the receiver with a clockwise twist. The other end of the quick release pin has a cap and a spring loaded sleeve that biases the cross pin against outside of the second leg of the shackle. The spring bias keeps the short leg of the J slot engaged with the retaining pin. The quick release pin is removed with a push and counter clockwise twist. The invention includes a kit with a receiver, a bushing and a quick release pin for installing or retrofitting existing shackles.

Owner:SILVA FRED

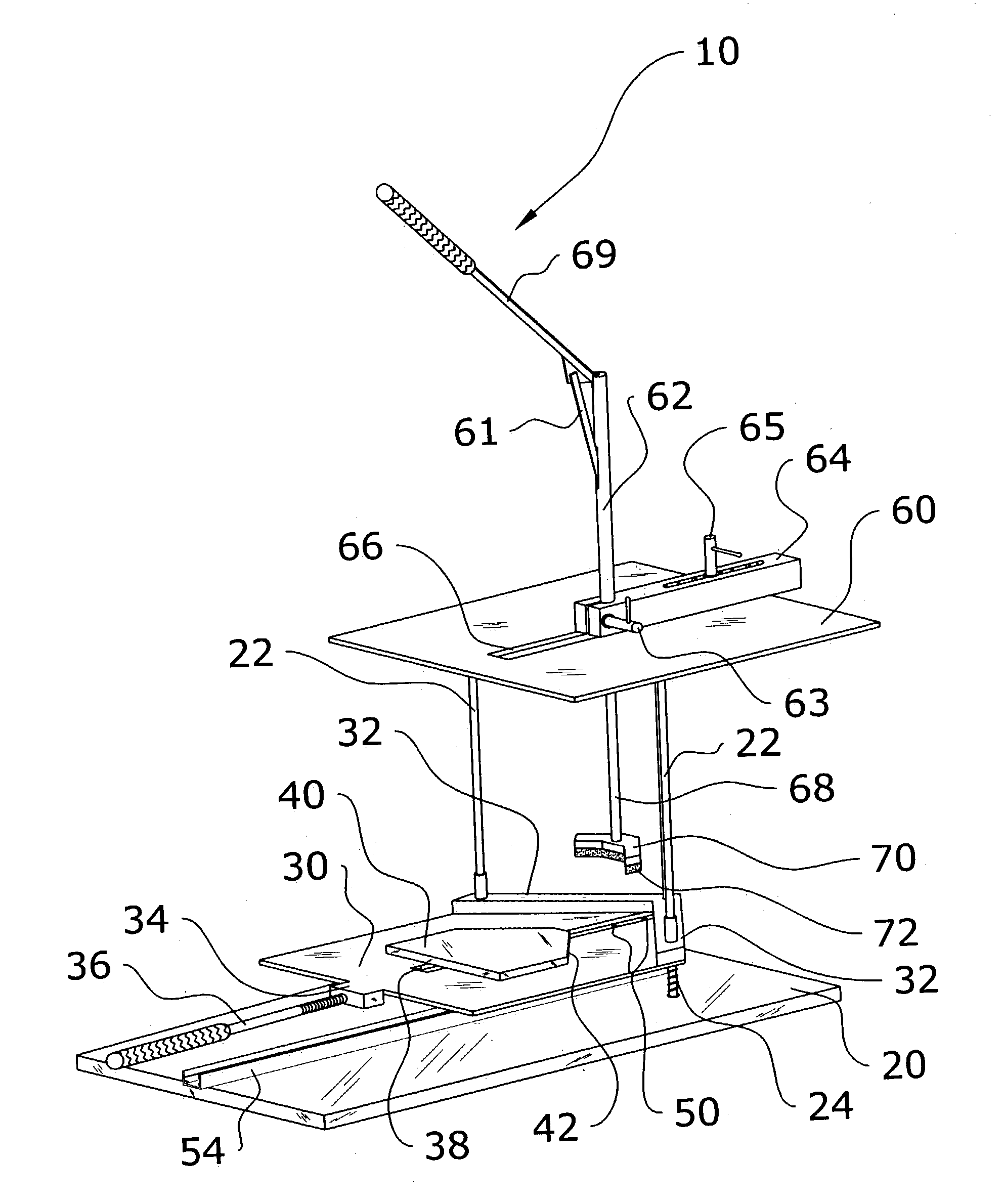

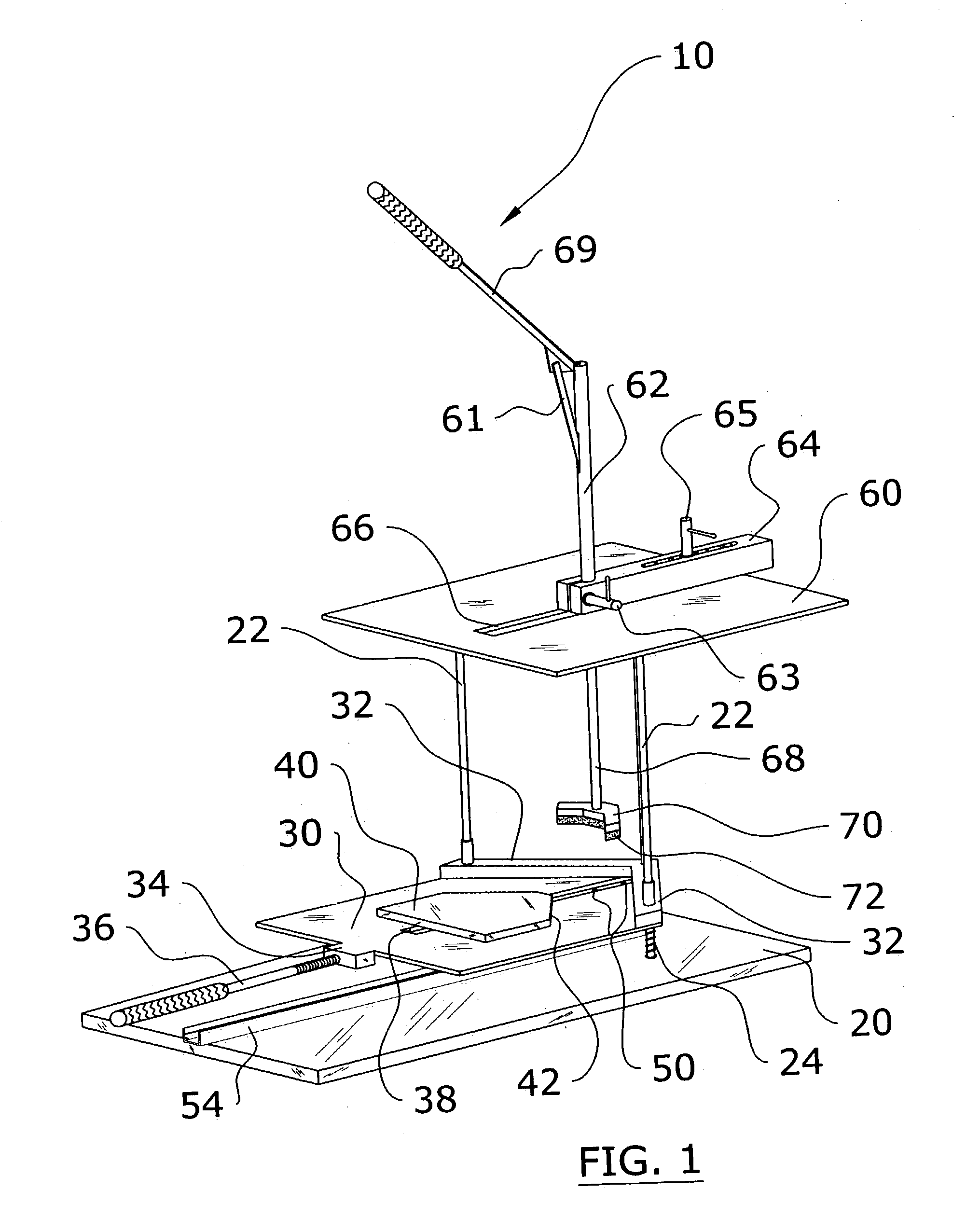

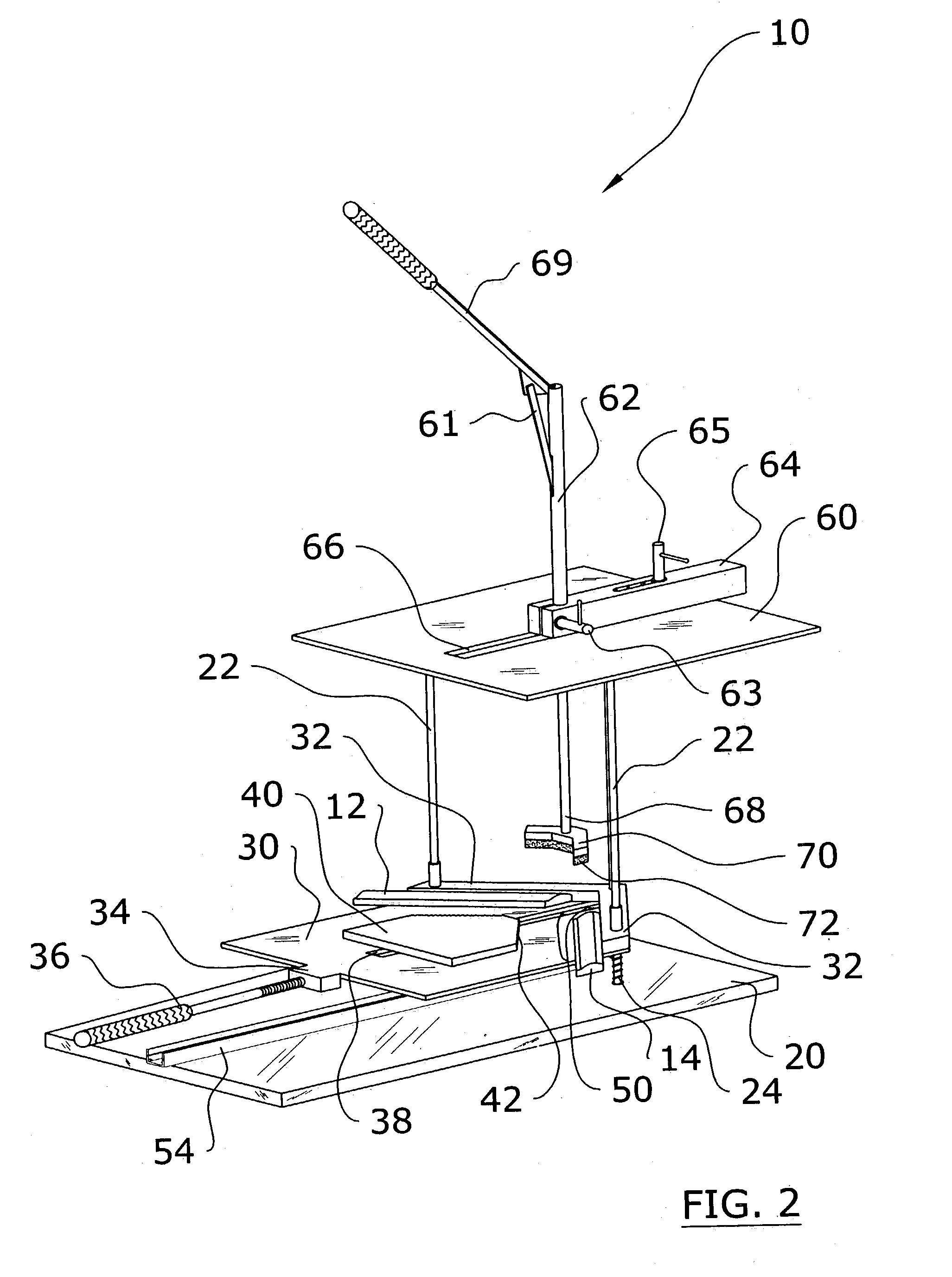

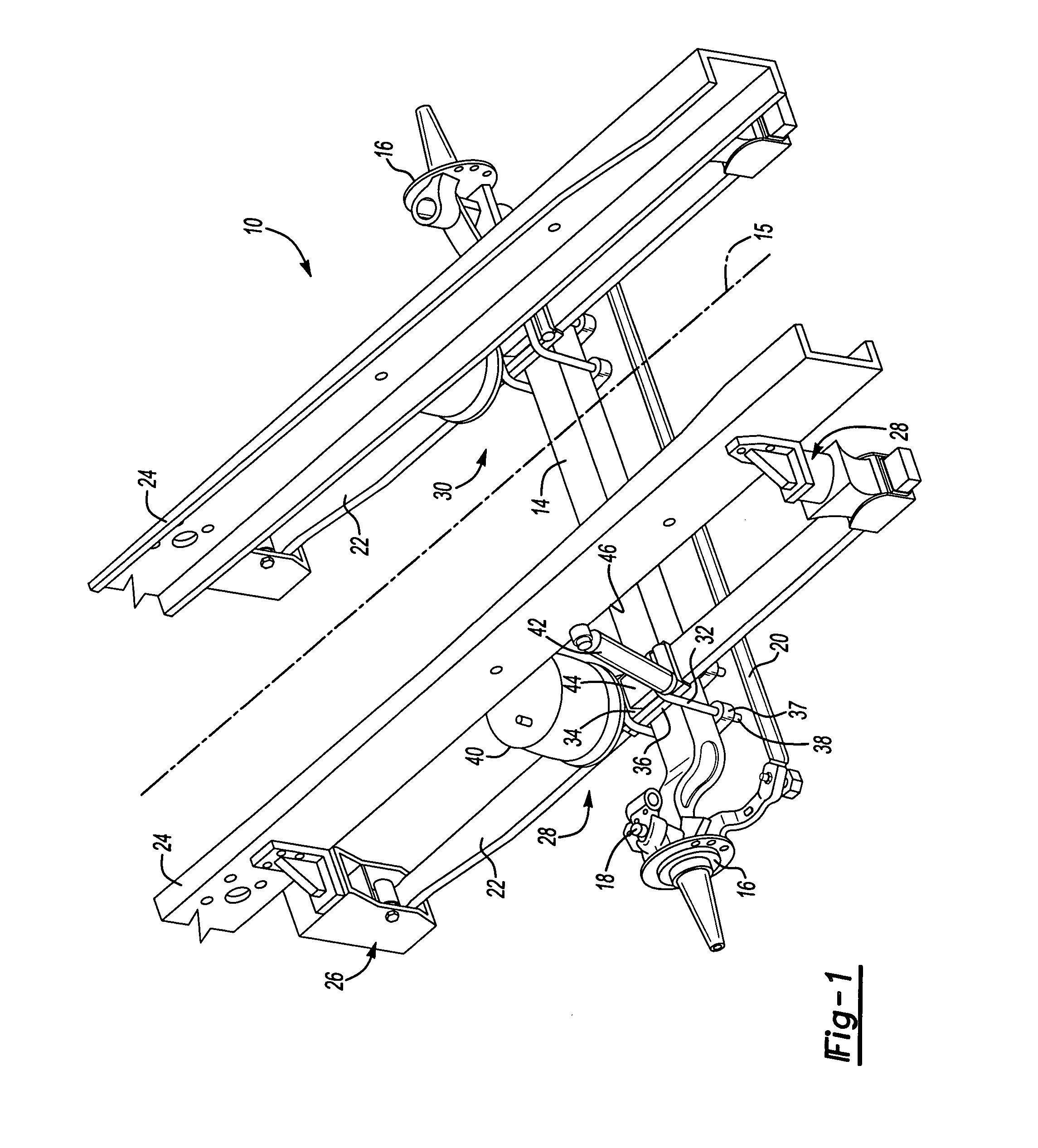

Frame joiner press system

InactiveUS6954979B2Efficient driveReduce the amount requiredStapling toolsPicture framesEngineeringRetaining Pin

A frame joiner press system for efficiently driving a V-nail into two adjacent members of a picture frame. The frame joiner press system includes a base, a plurality of support shafts extending upwardly from the base, a support platform slidably positioned upon the support shafts, a plurality of retaining pins movably positioned within a support housing attached to the base, and a leverage structure for applying a downward force upon a pair of frame members. The retaining pins receive one or more V-nails and are springably positioned within the support housing. When the frame members are pressed upon the V-nails, the retaining pins are depressed into the support housing.

Owner:LOGAN CURT

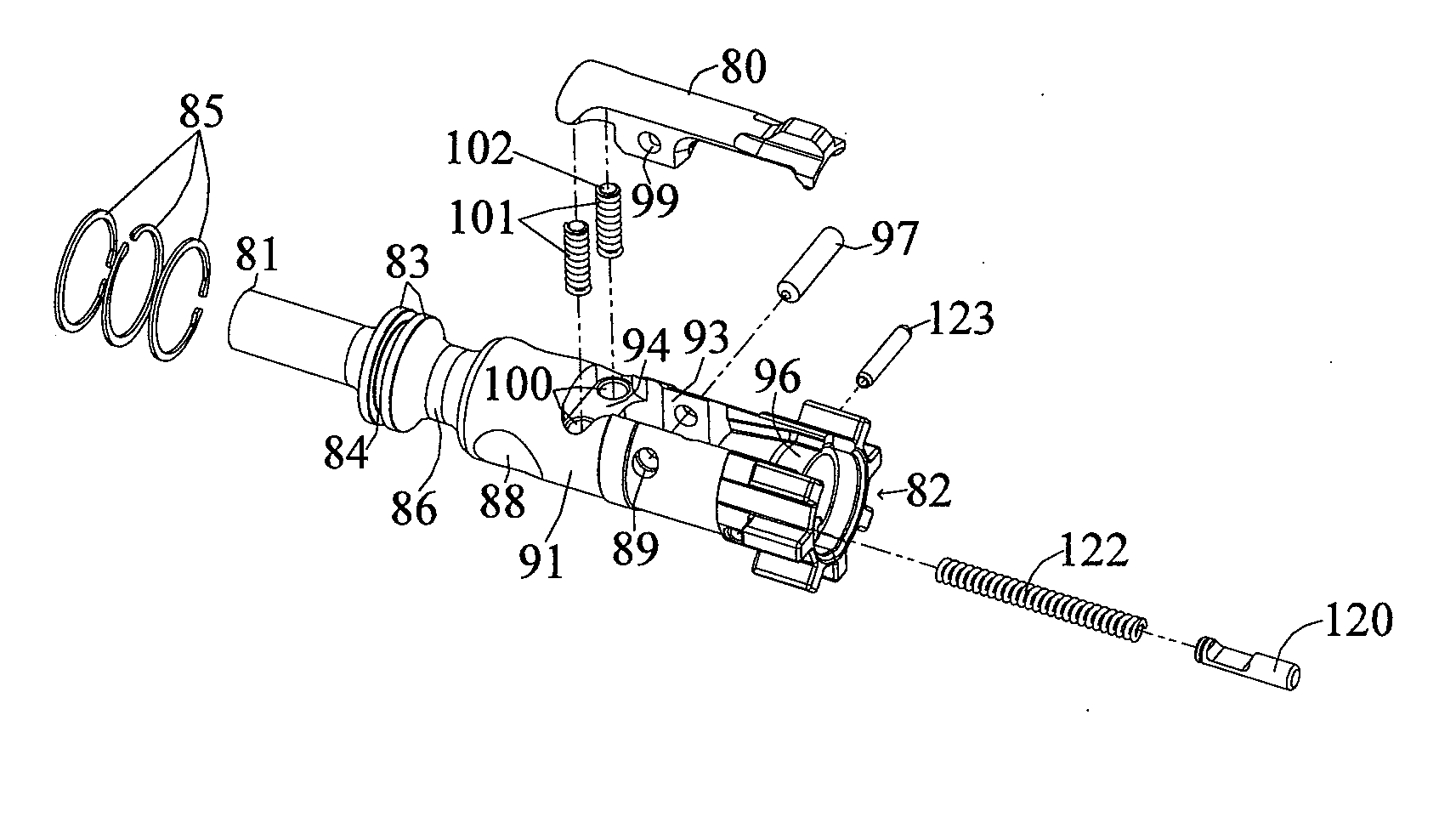

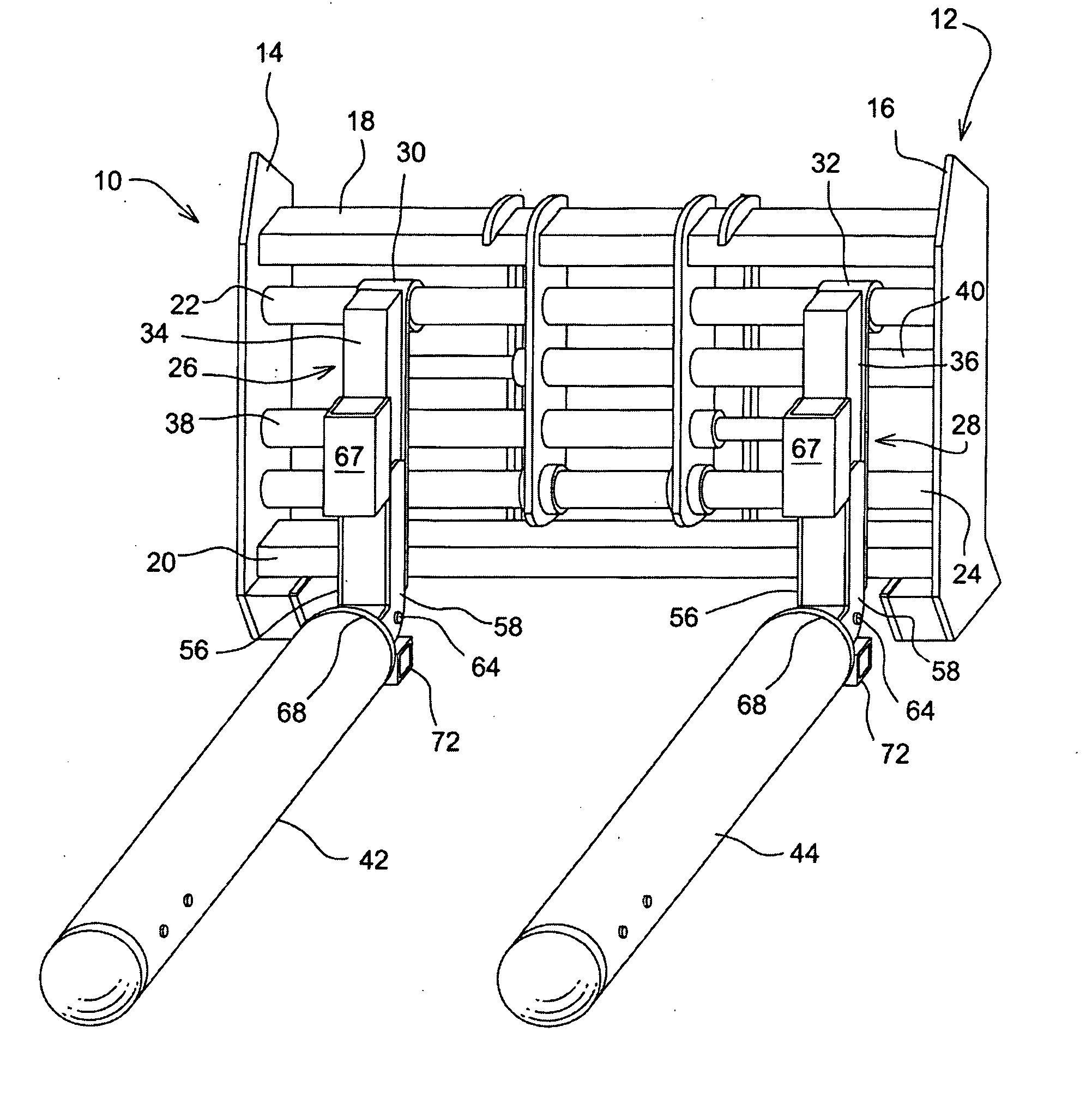

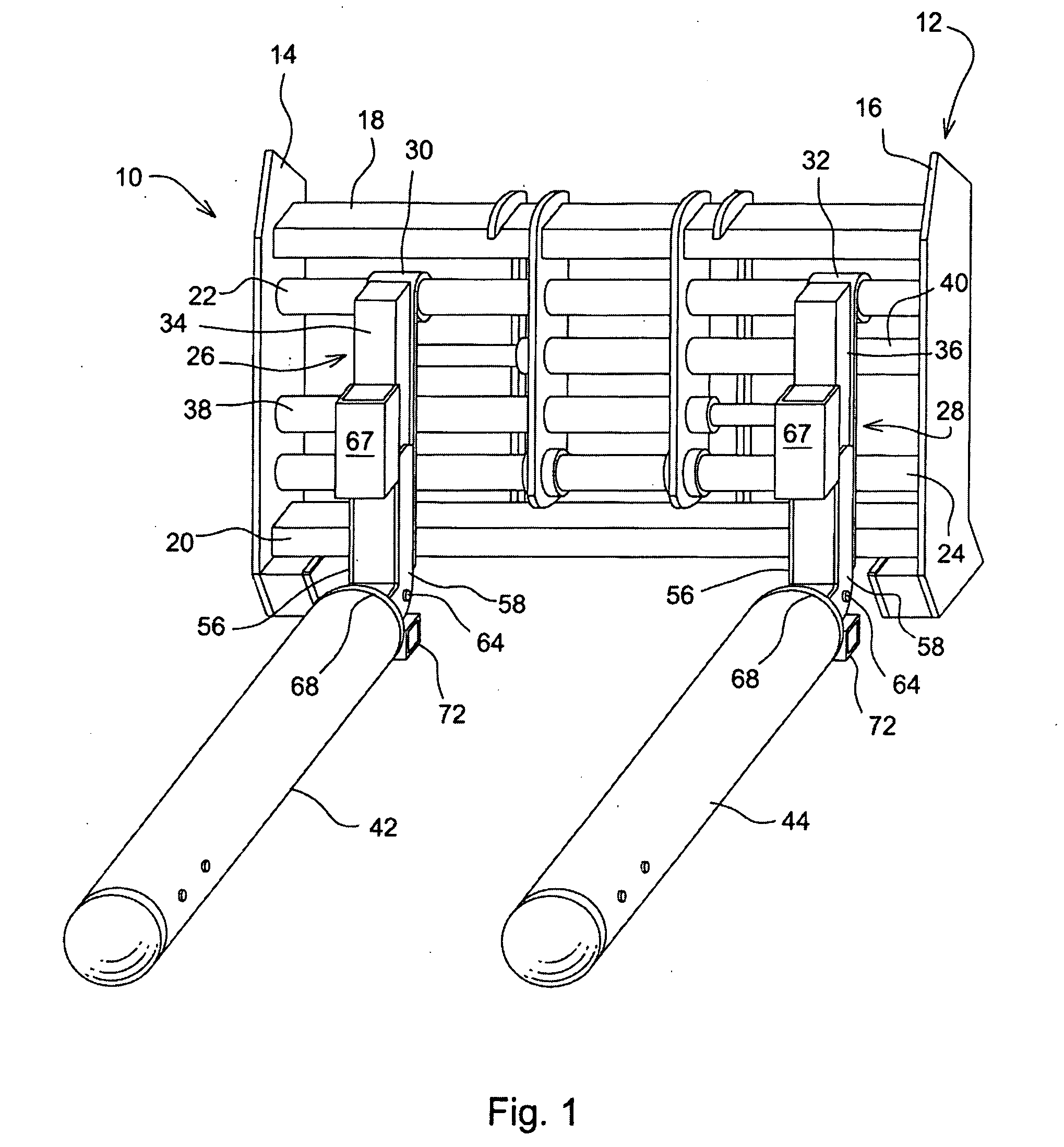

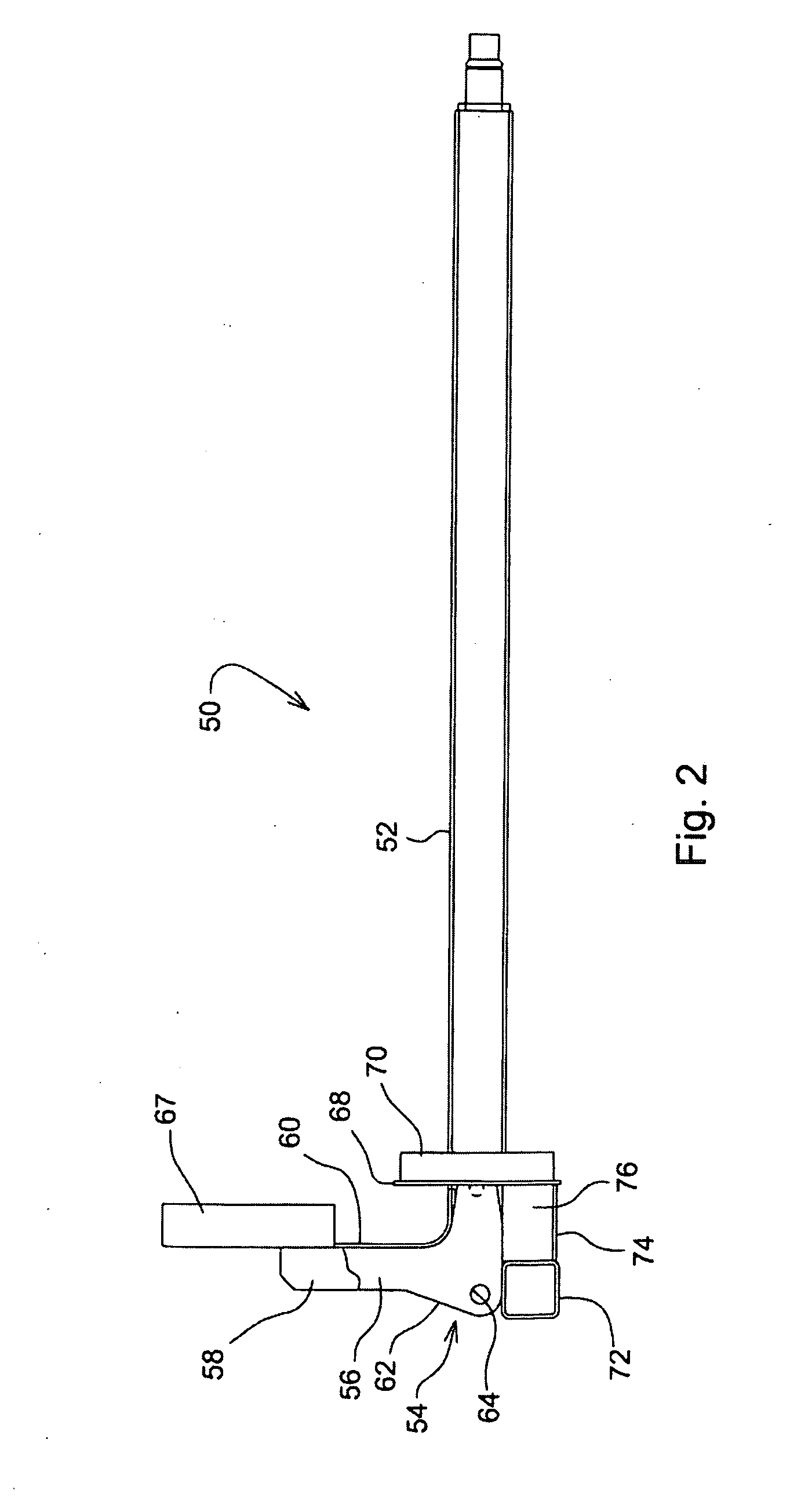

Retaining pin leaver advancement mechanism for a curved cutter stapler

A surgical instrument is adapted for applying a plurality of surgical fasteners to body tissue. The surgical instrument includes a frame having a proximal end and a distal end, with a handle positioned at the proximal end and an end effector positioned at the distal end. The end effector is shaped and dimensioned for supporting a cartridge housing and an anvil, the cartridge housing and anvil being relatively movable by actuation of a closure mechanism. The surgical instrument further includes a firing mechanism associated with the end effector and the cartridge housing for selective actuation of the surgical fasteners features. The surgical instrument also includes a retaining pin for enclosing tissue between the anvil and the cartridge housing. The retaining pin is moved by actuation of the closure mechanism from an open first position to a closed second position. A manual actuator is associated with the retaining pin for moving from the second position back to the first position and alternatively moving the retaining pin from the first position to the second position.

Owner:ETHICON ENDO SURGERY INC

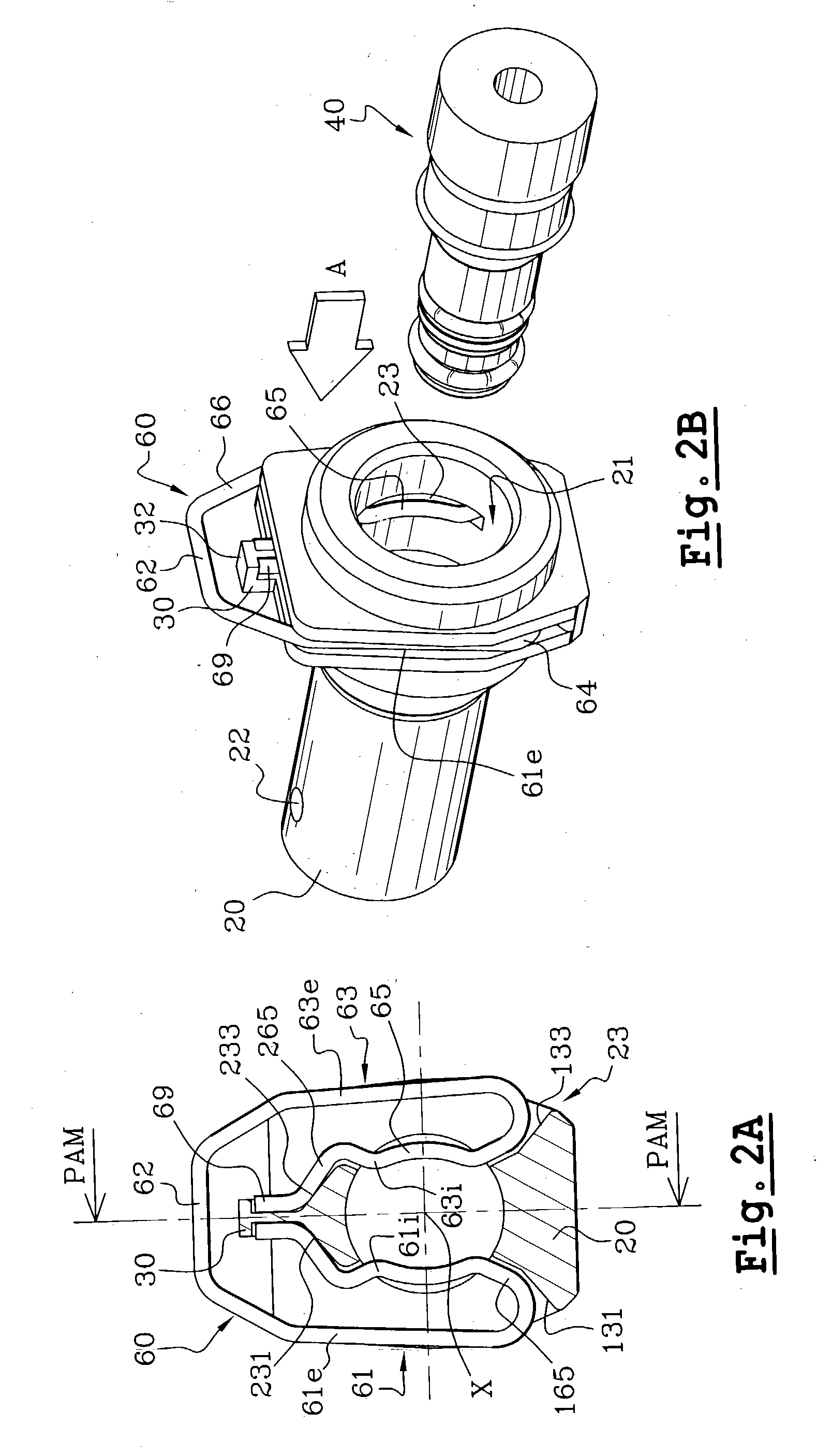

Windshield wiper connector

A connector for a windshield wiper, and a wiper blade assembly including same, that accommodates multiple pin-type windshield wiper arms having varying pin lengths and locking mechanisms. The connector for connecting a windshield wiper assembly to a wiper arm may have a peripheral wall having at least two opposing peripheral side walls and a top surface extending from one of the two opposing peripheral side walls to the other. The opposing peripheral side walls may each have a retaining pin aperture aligned with one another and sized to be capable of slidably accepting a retaining pin of at least one pin-type windshield wiper arm.

Owner:PYLON MFG

Quick release shackle pin system

A spring loaded quick release pin and tubular receiver with a retainer pin configured to secure the quick release pin in a shackle, clevis, yoke or forked rod end. The receiver is welded to a shackle or cast with the shackle as a single body. One end of the quick release pin has aligned J slots that engage the retainer pin positioned in the receiver with a clockwise twist. The other end of the quick release pin has a cap and a spring loaded sleeve that biases the cross pin against outside of the second leg of the shackle. The spring bias keeps the short leg of the J slot engaged with the retaining pin. The quick release pin is removed with a push and counter clockwise twist. The invention includes a kit with a receiver, a bushing and a quick release pin for installing or retrofitting existing shackles.

Owner:SILVA FRED

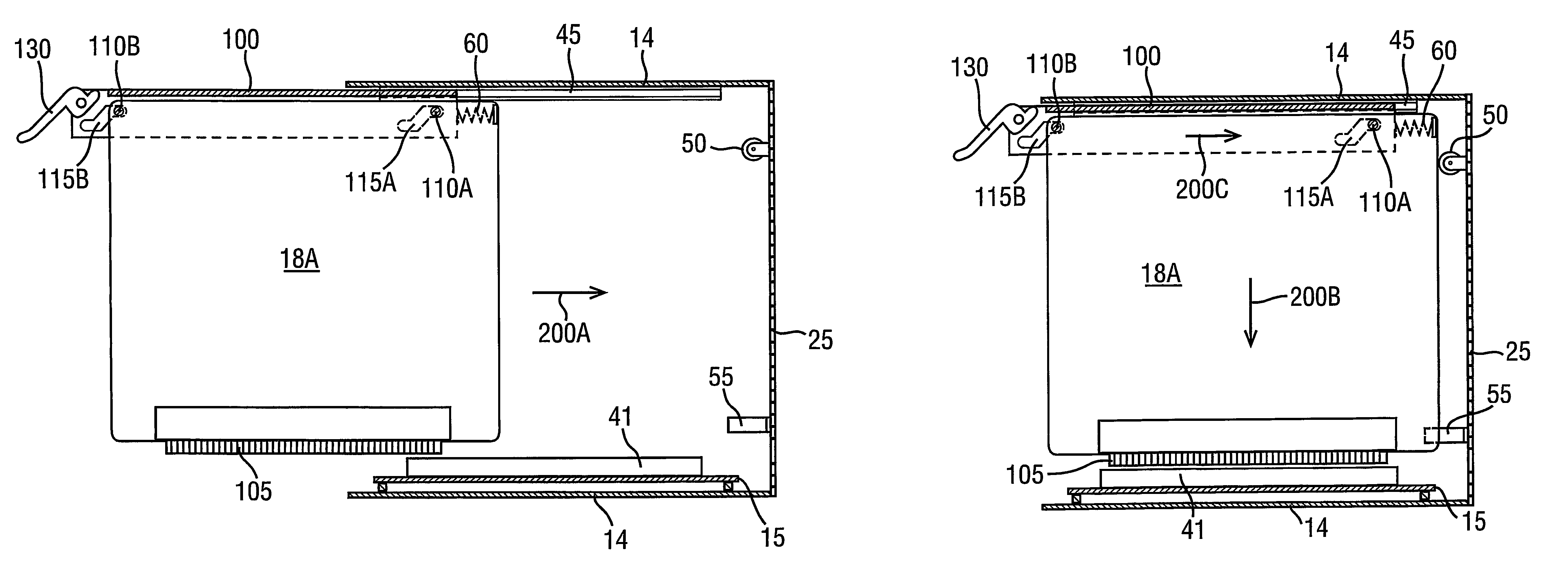

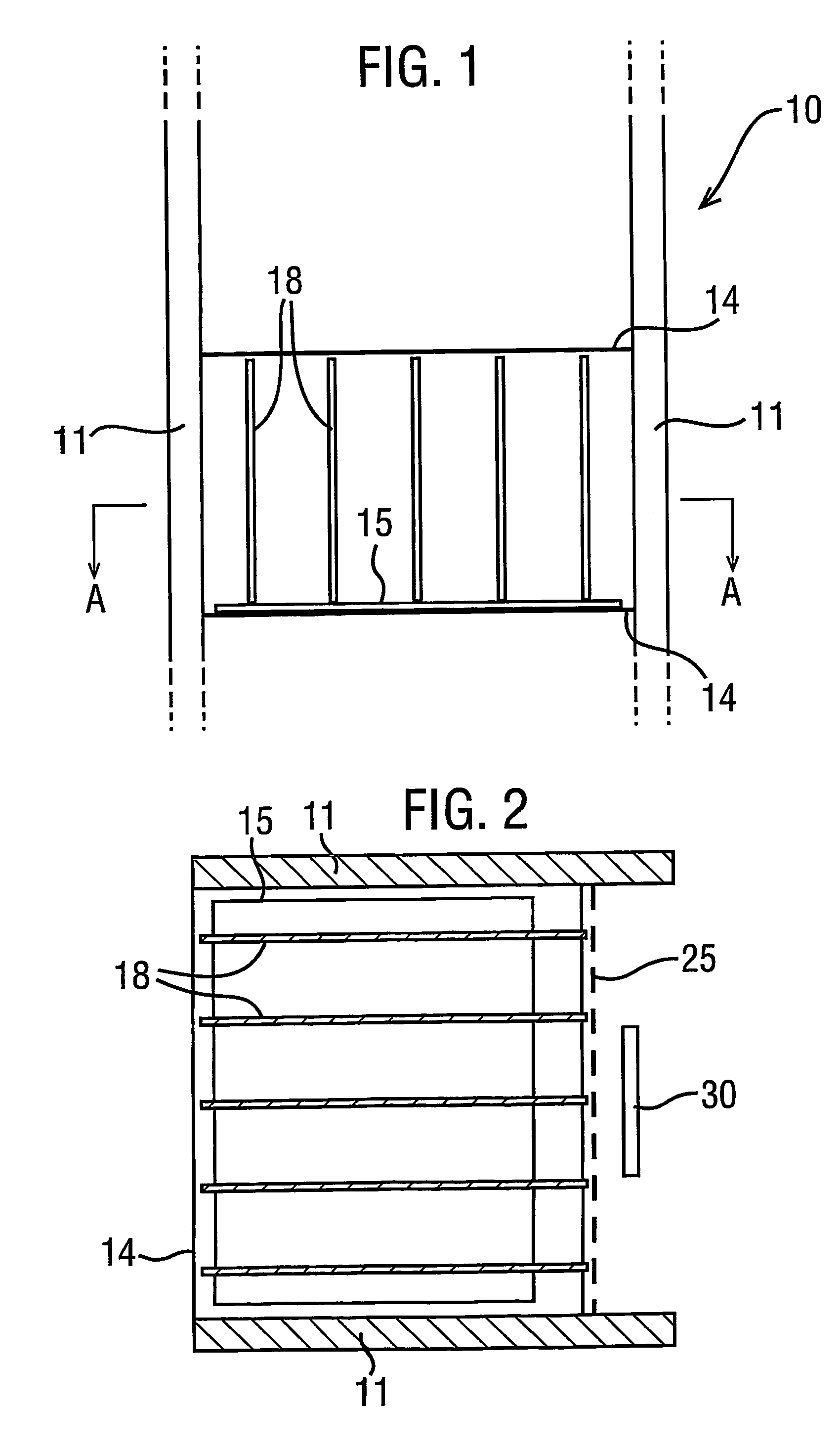

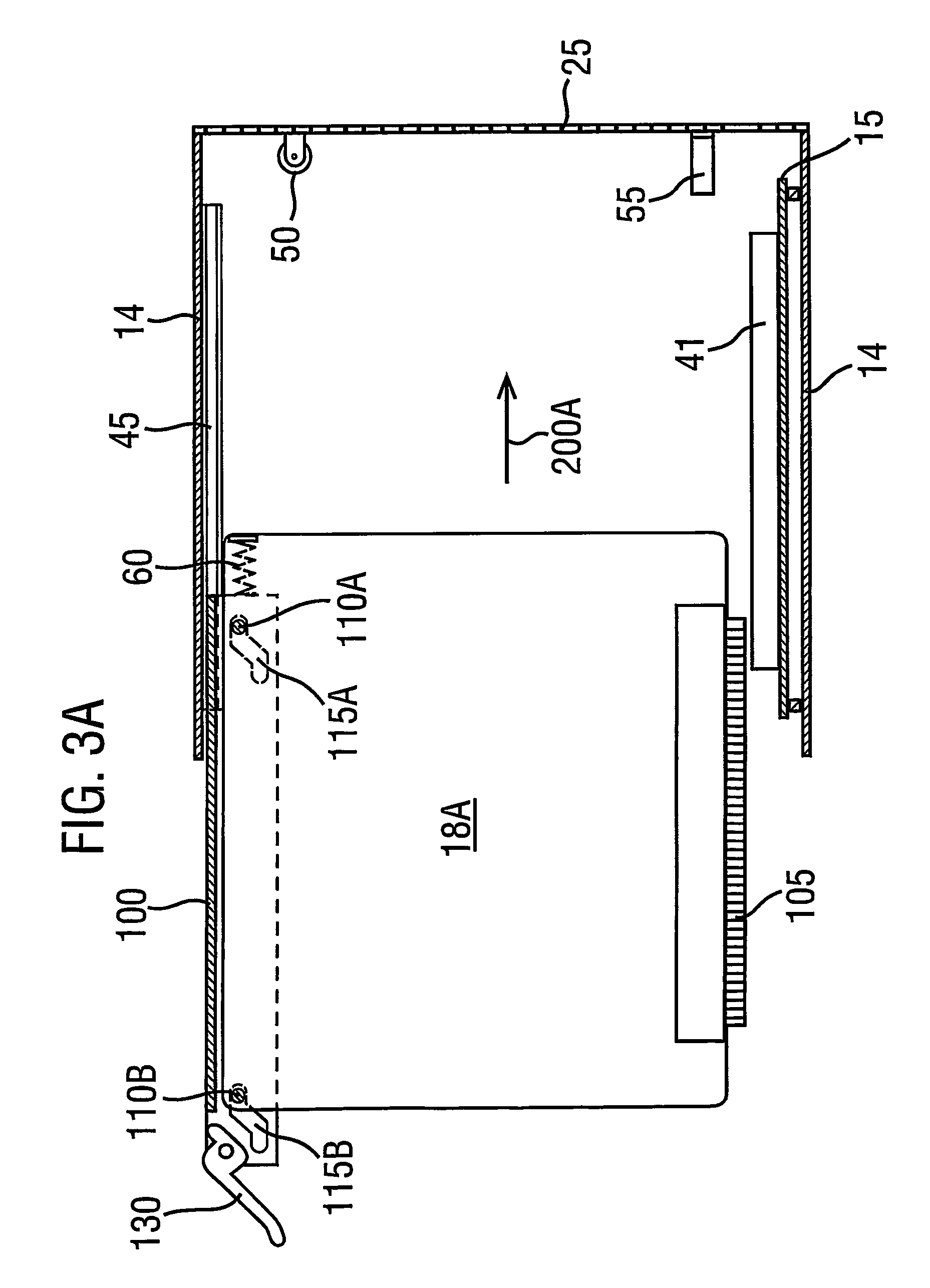

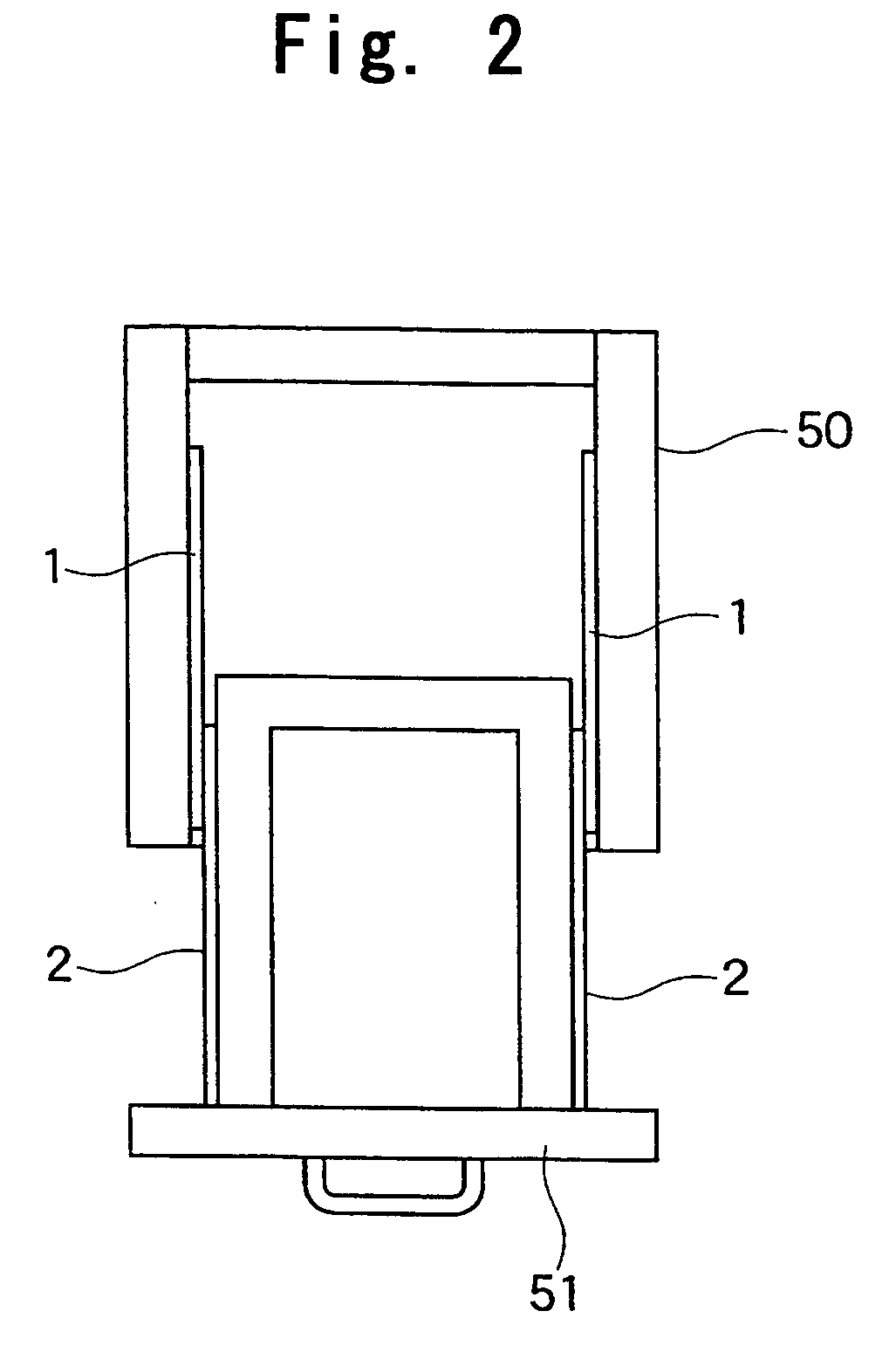

Rack-mountable systems

InactiveUS7215556B2Avoid relative motionPrecise alignmentIncorrect coupling preventionClamping/extracting meansDiagonalRetaining Pin

A rack-mounted assembly (10) comprises one or more racks, each capable of containing one or more printed circuit boards (PCB) (18), interconnected by a backplane (15) which is located along the bottom of a shelf (14). This position of the backplane (15) allows the rear wall of the rack-mounted assembly to be perforated, thereby permitting a cooling airflow for the PCBs to pass in through the front of the assembly and then out through the back. An insertion mechanism is provided to allow a PCB to be inserted into a rack. To achieve this, the PCB must first travel backwards into the rack-mounted assembly, and then downwards into engagement with the backplane (15). In one embodiment, this is accomplished by supporting the PCB from a hanger (100) which moves in and out of the rack-mounted assembly along a guide rail (45). The hanger includes slots (115) that retain pins (110) from the PCB. The slots are orientated diagonally upwards and backwards. A compression spring (60) is also provided to urge the pins (and hence PCB) forwards. Upon insertion, the hanger moves along guide rail (45) until the PCB abuts a stop (50). At this point further insertion of the hanger forces the pins (110) to move along slots (115) in opposition to spring (60), thereby driving the PCB down into engagement with the backplane (15).

Owner:ORACLE INT CORP

Flexible hair clip and comb combination

Owner:HELEN OF TROY LIMITED

Composite leaf spring having an arcuate attachment arrangement for vehicle mounting

InactiveUS20050051933A1Light weightAvoids dissimilar material wear pointsLeaf springsResilient suspensionsEngineeringRetaining Pin

A suspension system includes a composite leaf spring having an arcuate segment that is located between a retaining pin and a bumper. The retaining pin includes a shank surrounded by a resilient tube. The bumper is located adjacent a rear wall of the bracket opposite the retaining pin. The bumper includes an arcuate face to engage the outer arc of the arcuate segment while the pin is at least partially surrounded by the arcuate segment. The end of the composite leaf spring is thereby securely yet resiliently retained within the front leaf spring attachment system without penetrating fasteners.

Owner:ARVINMERITOR TECH

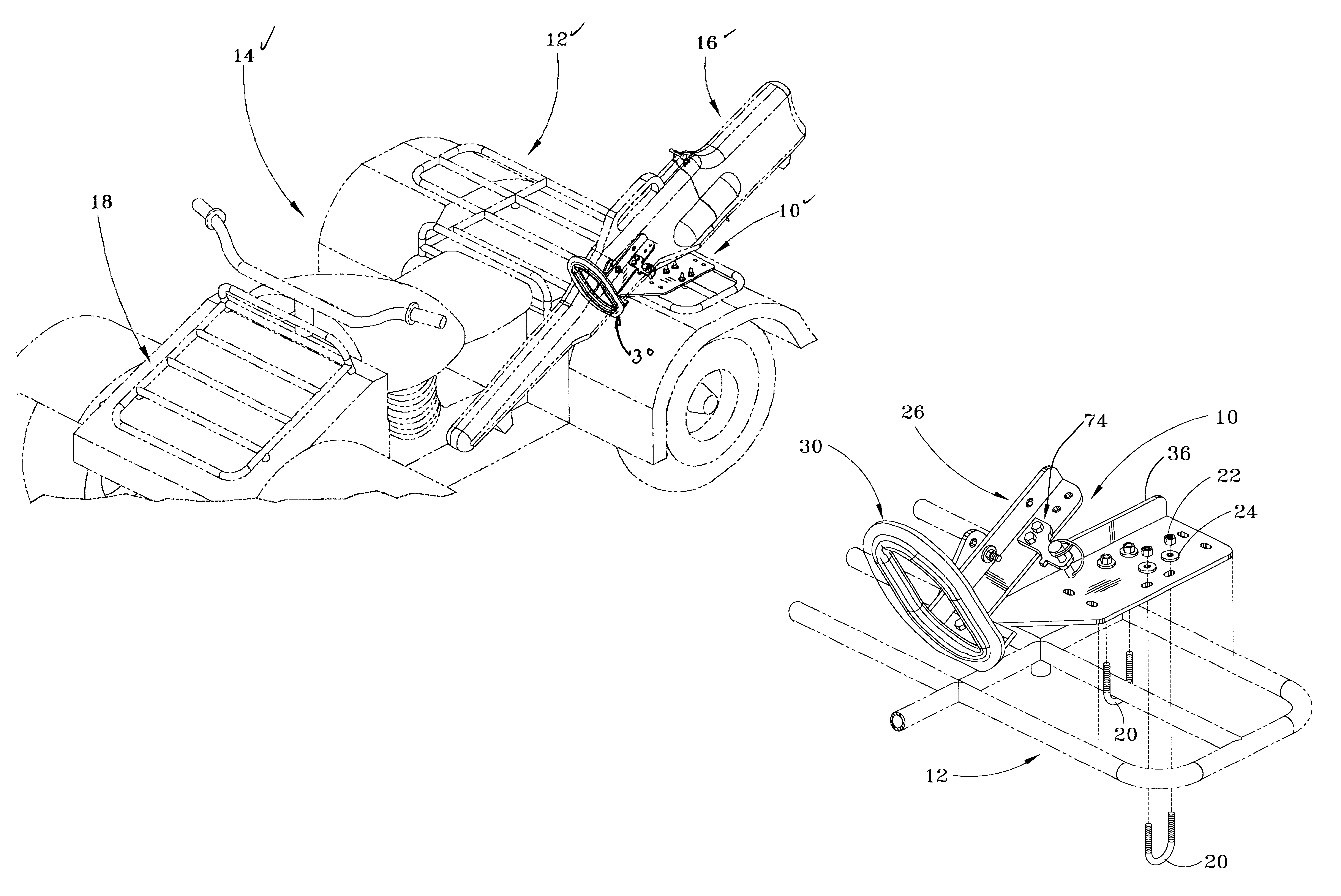

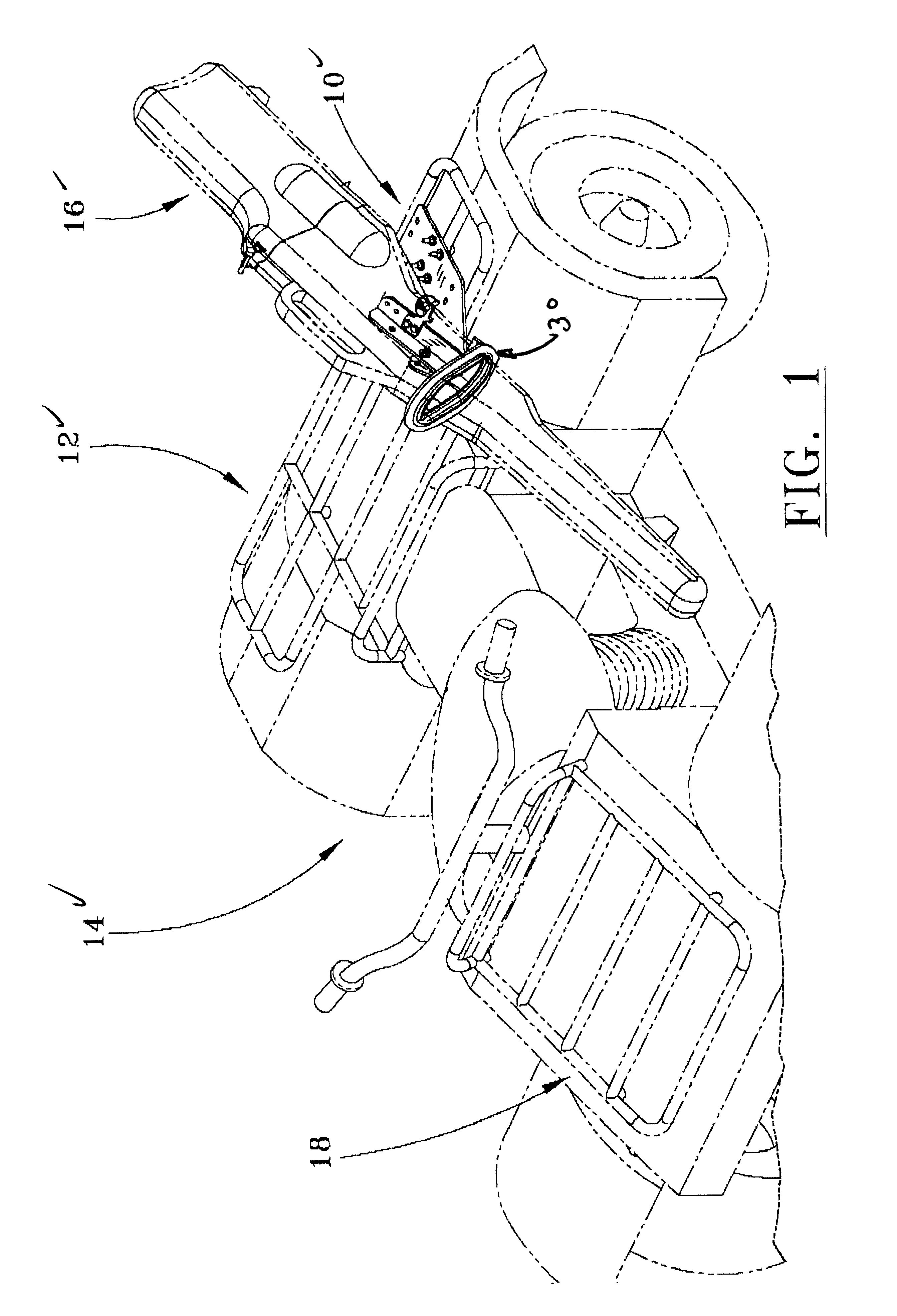

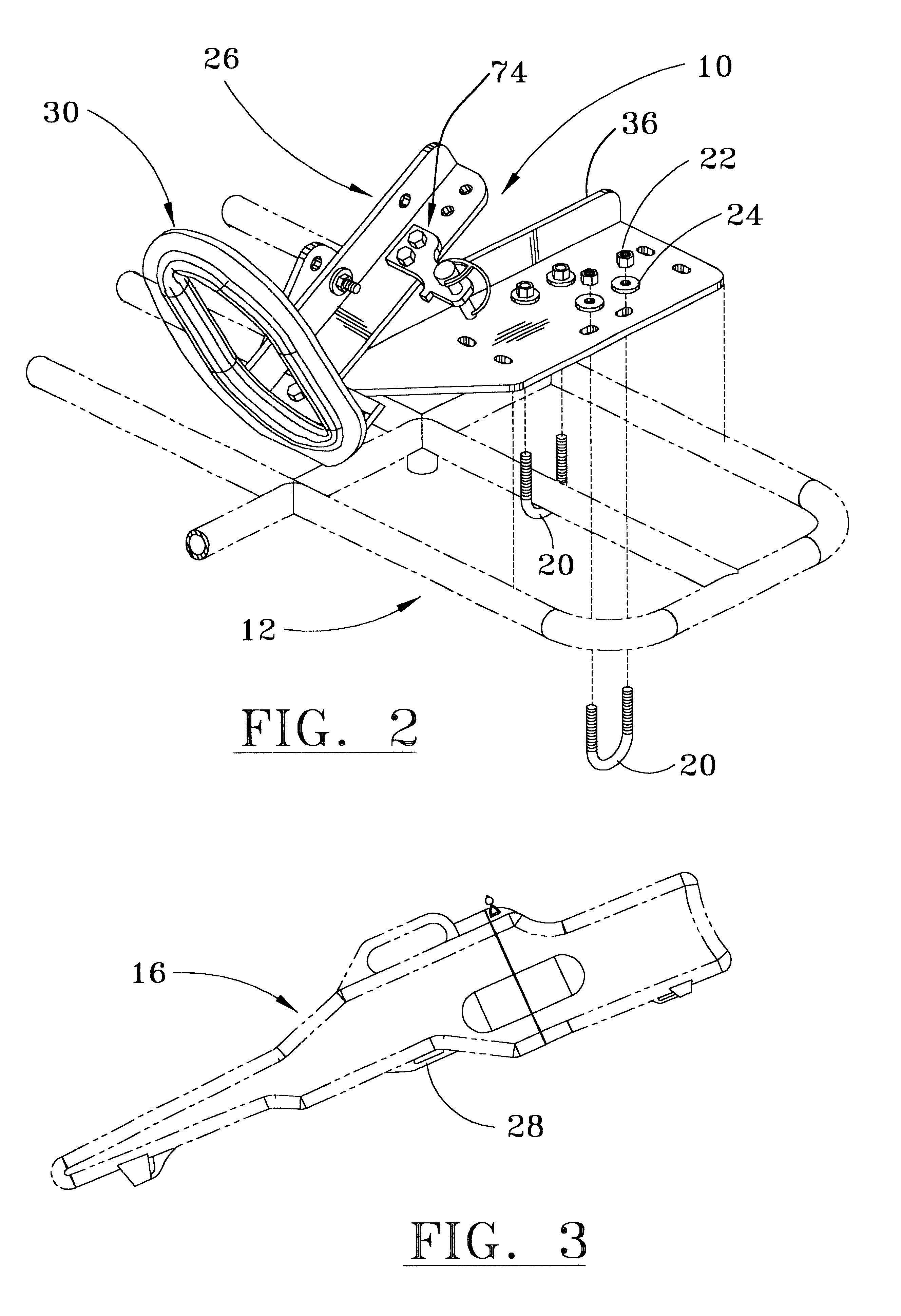

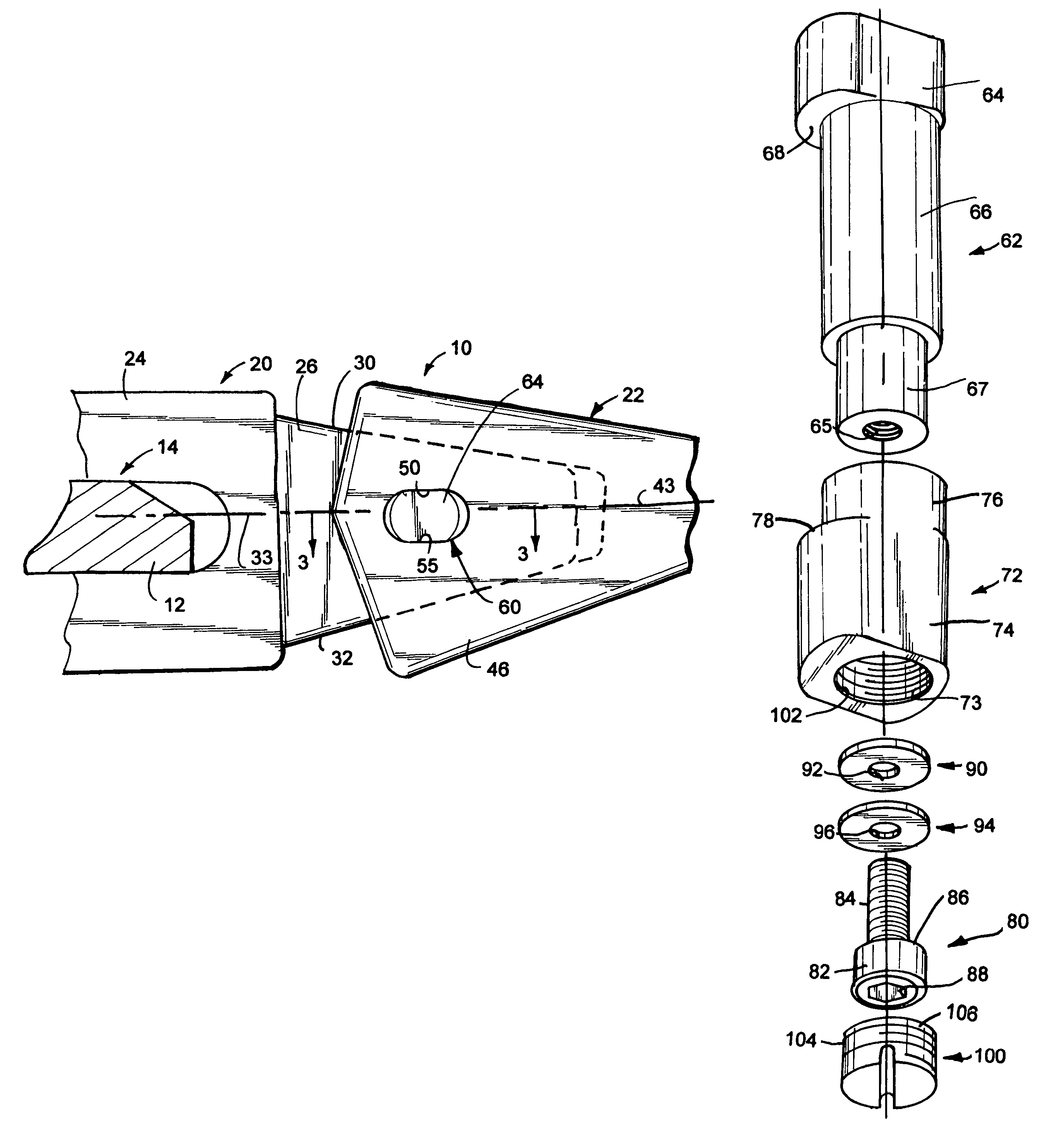

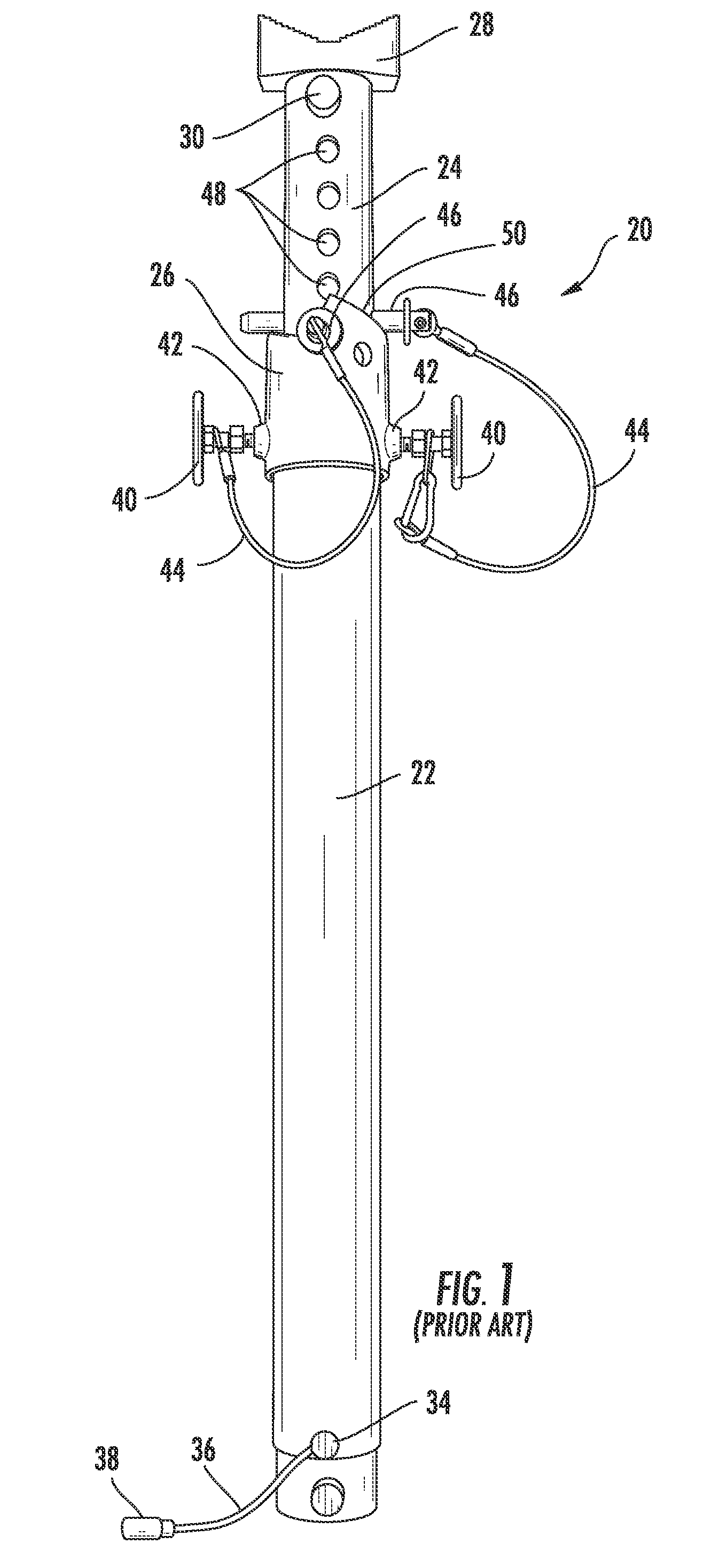

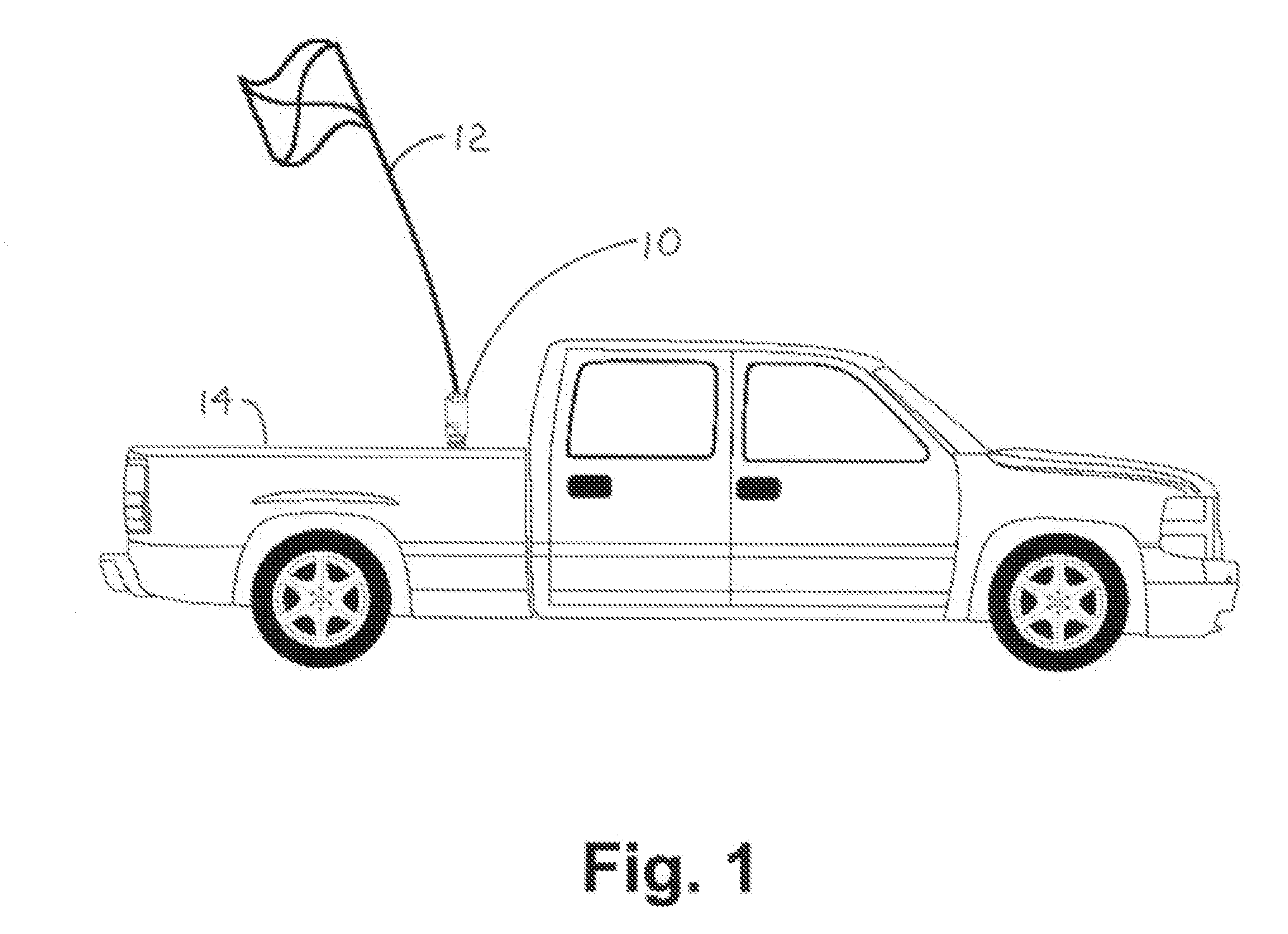

Gun boot mount for ATV

A gun-mounting bracket for ATV's adaptive to a variety of cargo racks generally employed by ATV's and further providing adaptability to a wide range of gun scabbards or boots designed for a variety of different type guns. The bracket includes a base plate member having a plurality of holes and slots which may be used in combination with U-bolts and clamps for attachment, an interchangeable pivotal plate member which provides a method for rotating the boot to angular positions relative to the base plate, and an interchangeable bracket member attached perpendicular thereto adapted to receive the barrel portion of the gun boot. The bracket member, having an elongated opening for receiving the barrel portion of the gun boot, is provided with a polymeric edge molding and allows the barrel portion of the gun boot to extend therethrough to a point which generally positions the boot relative to the bracket and its bar latch member. The bar latch and its retaining pin arrangement, secured to the pivotal plate, is positional and cooperative with a retaining loop generally found approximately midway along the base of most rigid gun boots.

Owner:SAVANT KEVIN D

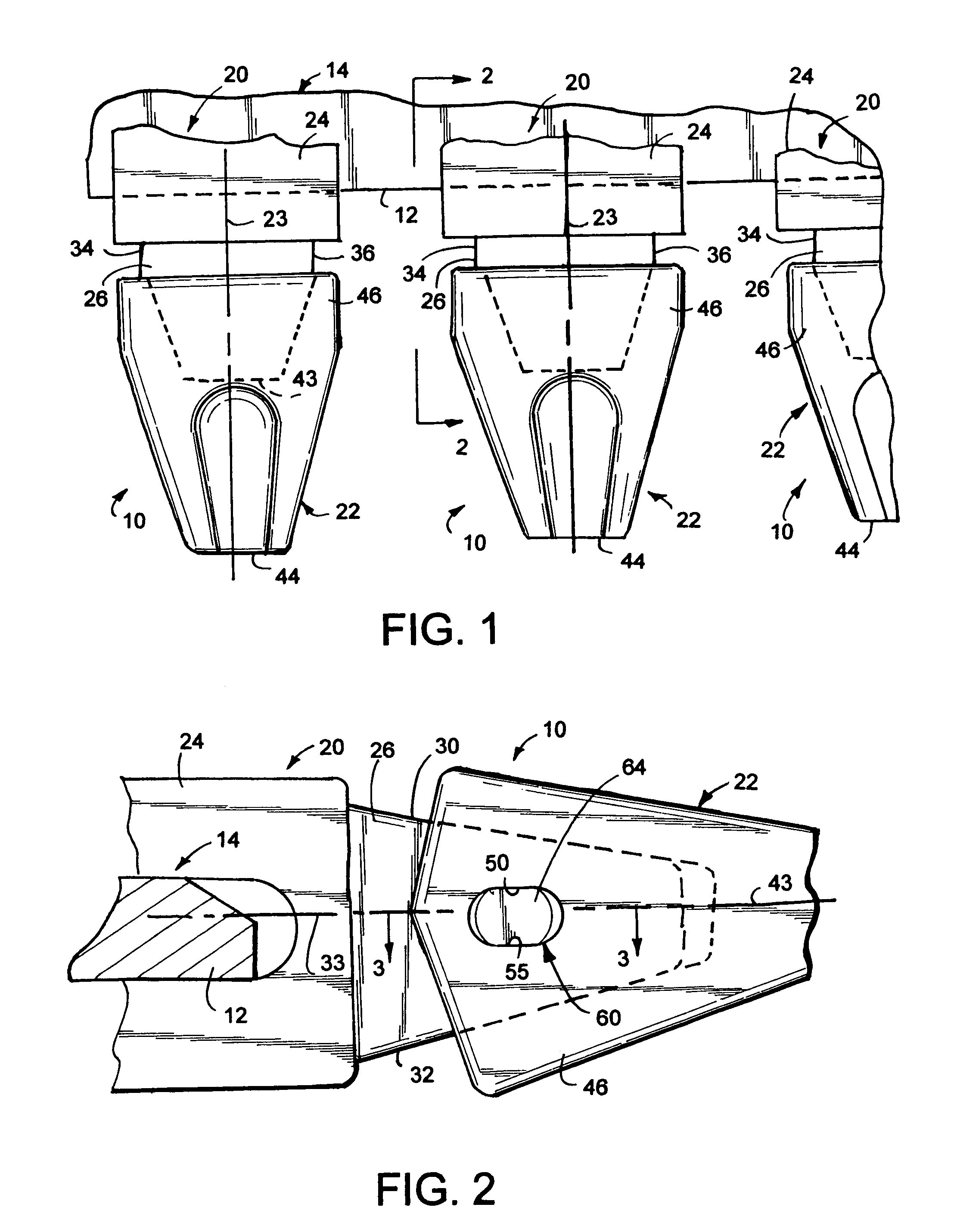

Pin assembly for a two-part ground engaging tooth system and method for connecting components of a two-part ground engaging tooth system to each other

InactiveUS7313877B2Flexural rigiditySoil-shifting machines/dredgersCouplings for rigid shaftsEngineeringBiomedical engineering

A pin assembly for releasably maintaining an adapter and replaceable part or tool of a two-part digging system in operable combination relative to each other. The pin assembly includes a pair of axially aligned retaining pins whose opposed ends are arranged in operable combination relative to each other. Each retaining pin has an enlarged head portion configured to fit within one of the openings defined by the tool, and a shank portion. An axially arranged and rotatable fastener maintains the opposed distal ends of the pins in releasably secured relation relative to each other. A method for releasably maintaining the digging tooth / tool and adapter is operable combination is also disclosed.

Owner:H & L TOOTH

Bolt carrier and bolt for gas operated firearms

ActiveUS8844424B2Improve safety and reliabilityReduce manufacturing costSafety arrangementCartridge extractorsSpray nozzleEngineering

An improved bolt and bolt carrier with integral gas key having an extension nozzle threadedly secured and pinned to the gas key for use with a direct gas operated firearm is provided. The extension nozzle is designed to receive a portion of the host firearms gas operating system. The firing pin retaining pin is oriented so as to expose its widest profile to the firing pins annular flange, increasing its service life. The bolt has a plurality of lugs extending from its forward end and an extractor recess. The extractor recess is constructed to accommodate an enlarged extractor claw while not undercutting the bolt lugs adjacent thereto. The extractor engages approximately 57% more of a seated ammunition cartridges rim as compared to some prior art AR15 / M16 type extractors used with automatic firearms chambered in 6.8 SPC. The result is an improved bolt and bolt carrier which provides for increased operational reliability.

Owner:LWRC INTERNATIONAL

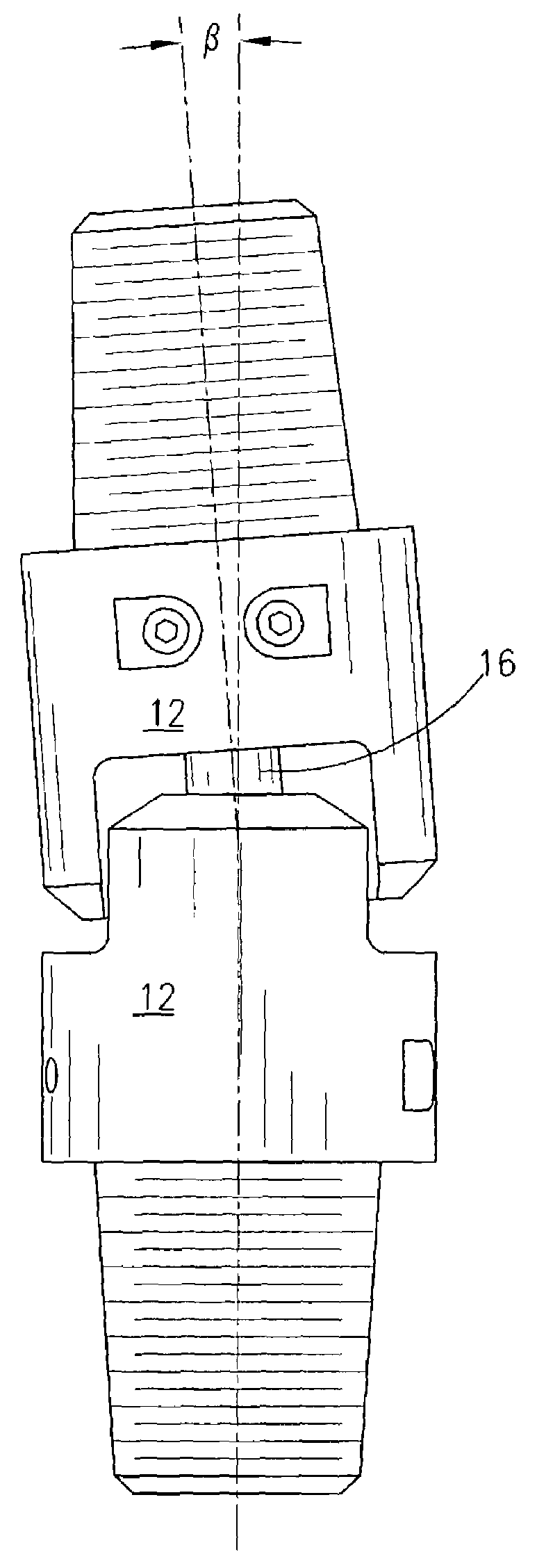

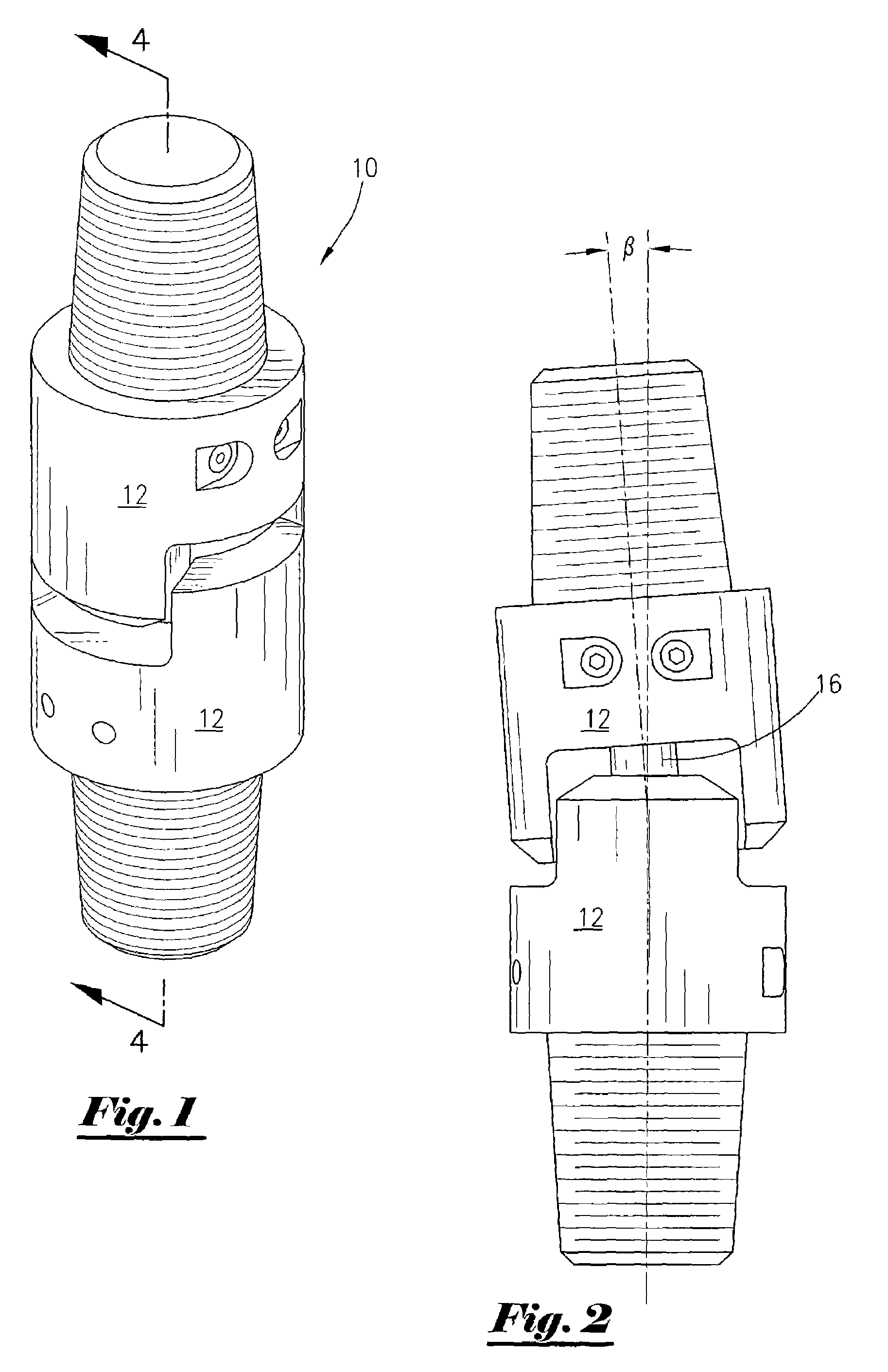

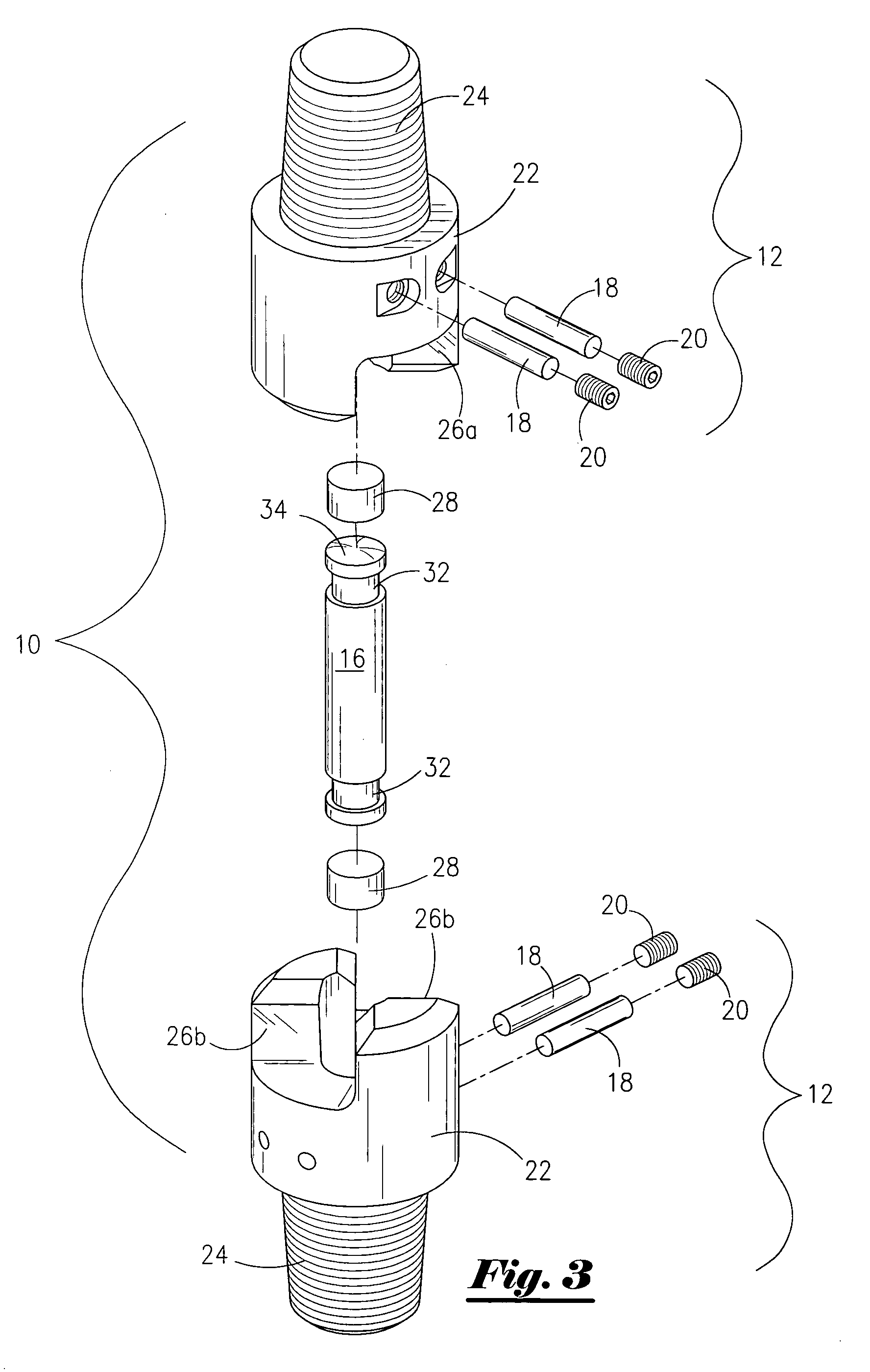

Flexible universal joint sub connection for down hole mud motor method and apparatus

ActiveUS7004843B1For quick replacementNominal costYielding couplingDrilling rodsUniversal jointMud motor

A mud motor universal joint assembly that includes a pair of adjacent cylindrical joints having threaded connection means at one end and interlocking jaws at the other, each cylindrical joint having an internal blind tapered bore within the interlocking jaw portion containing a hard cylindrical load bearing member. The two joints are connected by a hardened cylindrical rod member inserted into the internal blind tapered bore of each joint and retained therein by perpendicular retaining pins. The joints, connecting rod, and bearing members are surface hardened to improve wear. No balls or seals are required and the internal hardened connecting rod and bearing members are easily replaced if necessary at a nominal cost.

Owner:NAT OILWELL VARCO LP

Fixation device

InactiveUS20010051806A1Applied rapidly and simplyAvoid pollutionFractureInvalid friendly devicesBiomedical engineeringRetaining Pin

Owner:BALLIER ROLAND

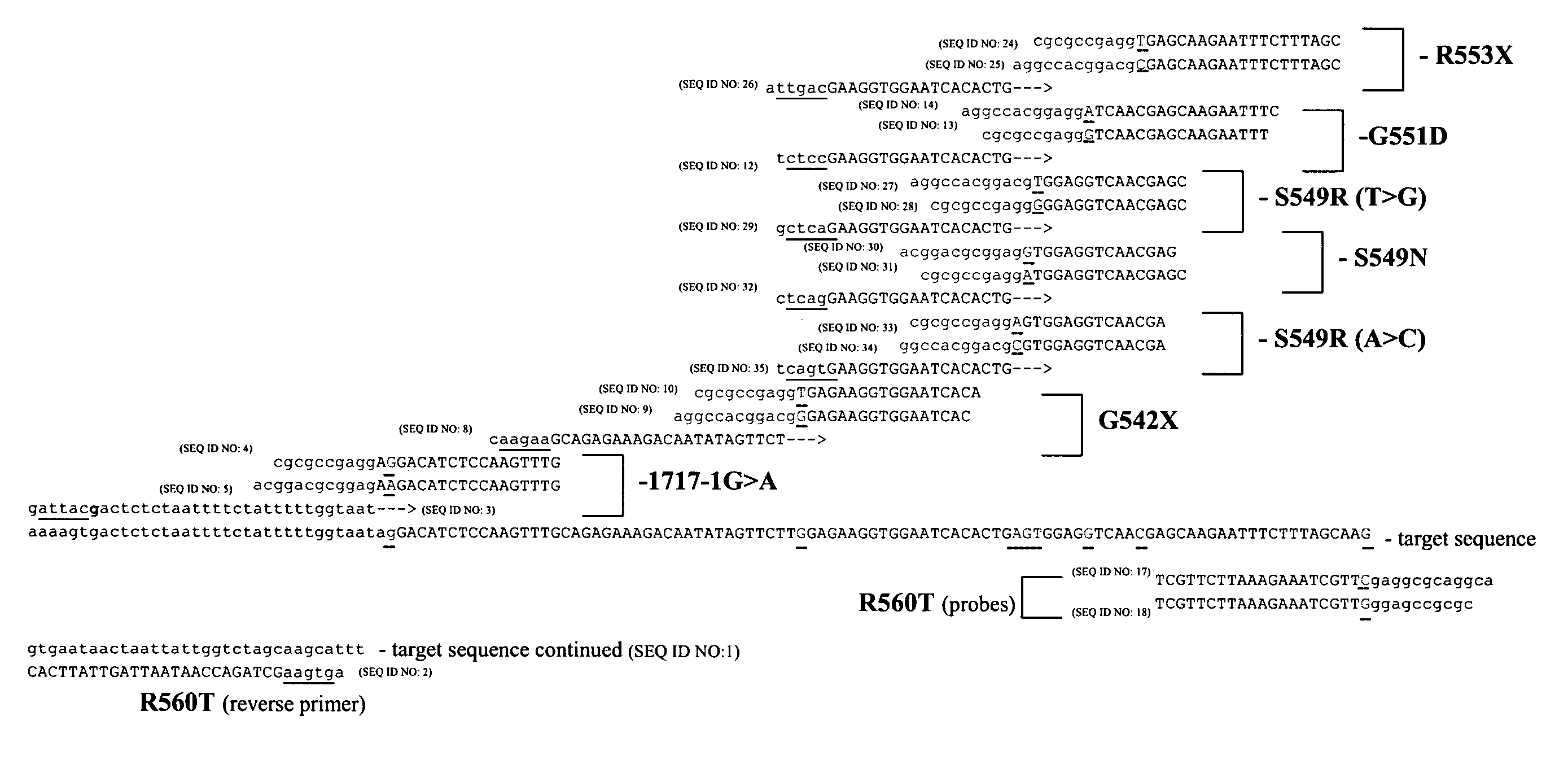

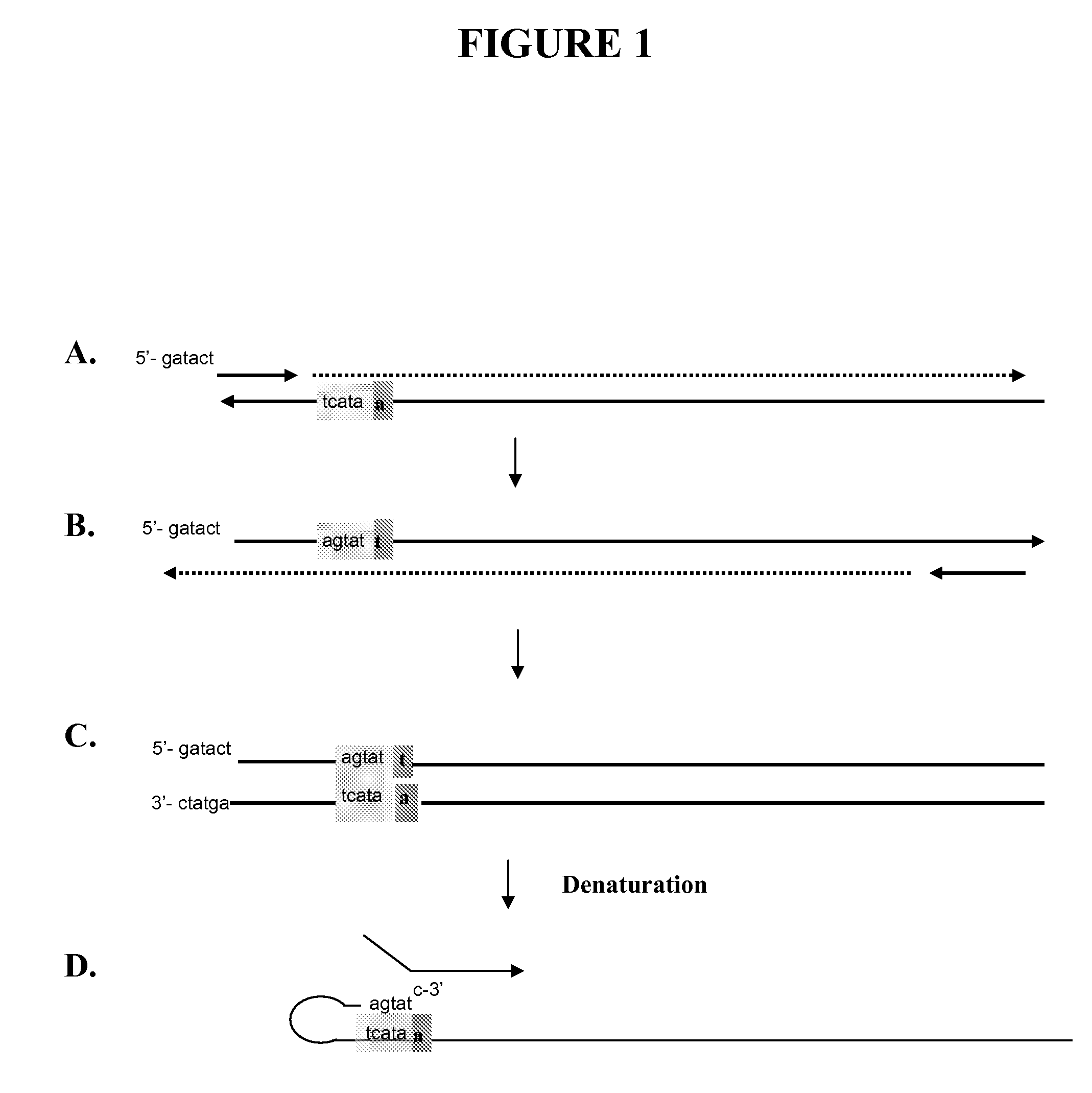

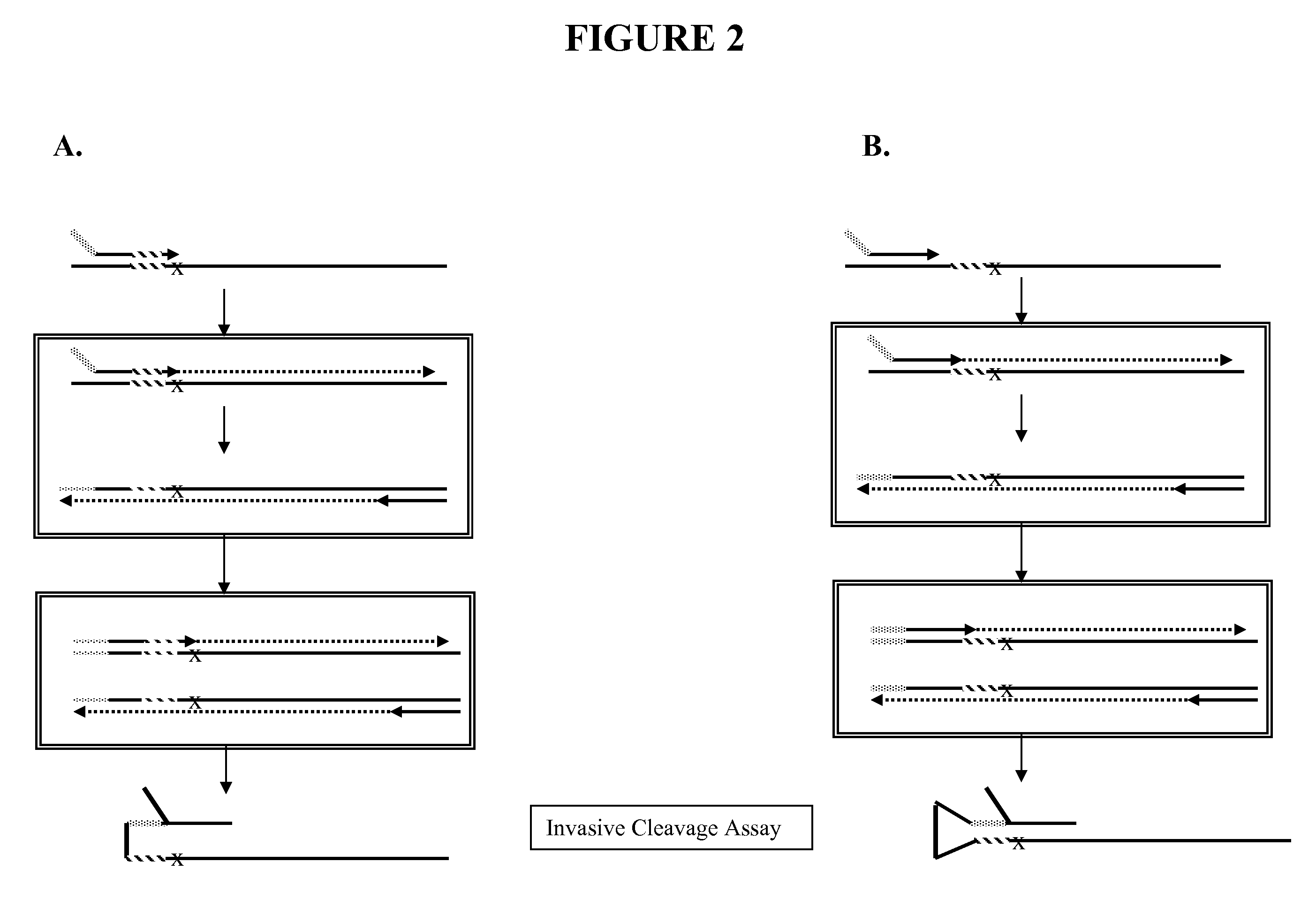

Snap-Back Primers And Detectable Hairpin Structures

The present invention provides methods, compositions, and kits comprising snap-back primers used for forming 3′ hairpin structures, 5′ hairpin structures, and double hairpin structures. The hairpin structures may be used for detecting target sequences (e.g., such as small RNA target sequence), for detecting polymorphisms in target sequences (e.g., such as polymorphisms located near the 5′ or 3′ ends of the target sequence), or other nucleic acid characterization methods. In certain embodiments, the hairpin structures form invasive cleavage structures (e.g., in combination with a probe or upstream oligonucleotide) which may be cleaved by structure-specific enzymes in order to detect the presence or absence of a particular nucleotide or nucleotide sequence.

Owner:GEN PROBE INC

Bolt carrier and bolt for gas operated firearms

ActiveUS20160116240A1Improve safety and reliabilityReduce manufacturing costCartridge extractorsBreech mechanismsSpray nozzleRetaining Pin

An improved bolt and bolt carrier with integral gas key having an extension nozzle threadedly secured and pinned to the gas key for use with a direct gas operated firearm is provided. The extension nozzle is designed to receive a portion of the host firearms gas operating system. The firing pin retaining pin is oriented so as to expose its widest profile to the firing pins annular flange, increasing its service life. The bolt has a plurality of lugs extending from its forward end and an extractor recess. The extractor recess is constructed to accommodate an enlarged extractor claw while not undercutting the bolt lugs adjacent thereto. The extractor engages approximately 57% more of a seated ammunition cartridges rim as compared to some prior art AR15 / M16 type extractors used with automatic firearms chambered in 6.8SPC. The result is an improved bolt and bolt carrier which provides for increased operational reliability.

Owner:LWRC INTERNATIONAL

Bolt carrier and bolt for gas operated firearms

ActiveUS8950312B2Improve safety and reliabilityReduce manufacturing costCartridge extractorsFiring/trigger mechanismsEngineeringScrew thread

An improved bolt and bolt carrier with integral gas key having an extension nozzle threadedly secured and pinned to the gas key for use with a direct gas operated firearm is provided. The extension nozzle is designed to receive a portion of the host firearm's gas operating system. The firing pin retaining pin is oriented so as to expose its widest profile to the firing pin's annular flange, increasing its service life. The bolt has a plurality of lugs extending from its forward end. The extractor recess is constructed so that the face of the bolt is round and the adjacent lugs fully supported. The extractor engages approximately 17% more of a seated ammunition cartridge's rim as compared to the prior art AR15 / M16 extractor. The result is an improved bolt and bolt carrier which provides for increased operational reliability.

Owner:LWRC INTERNATIONAL

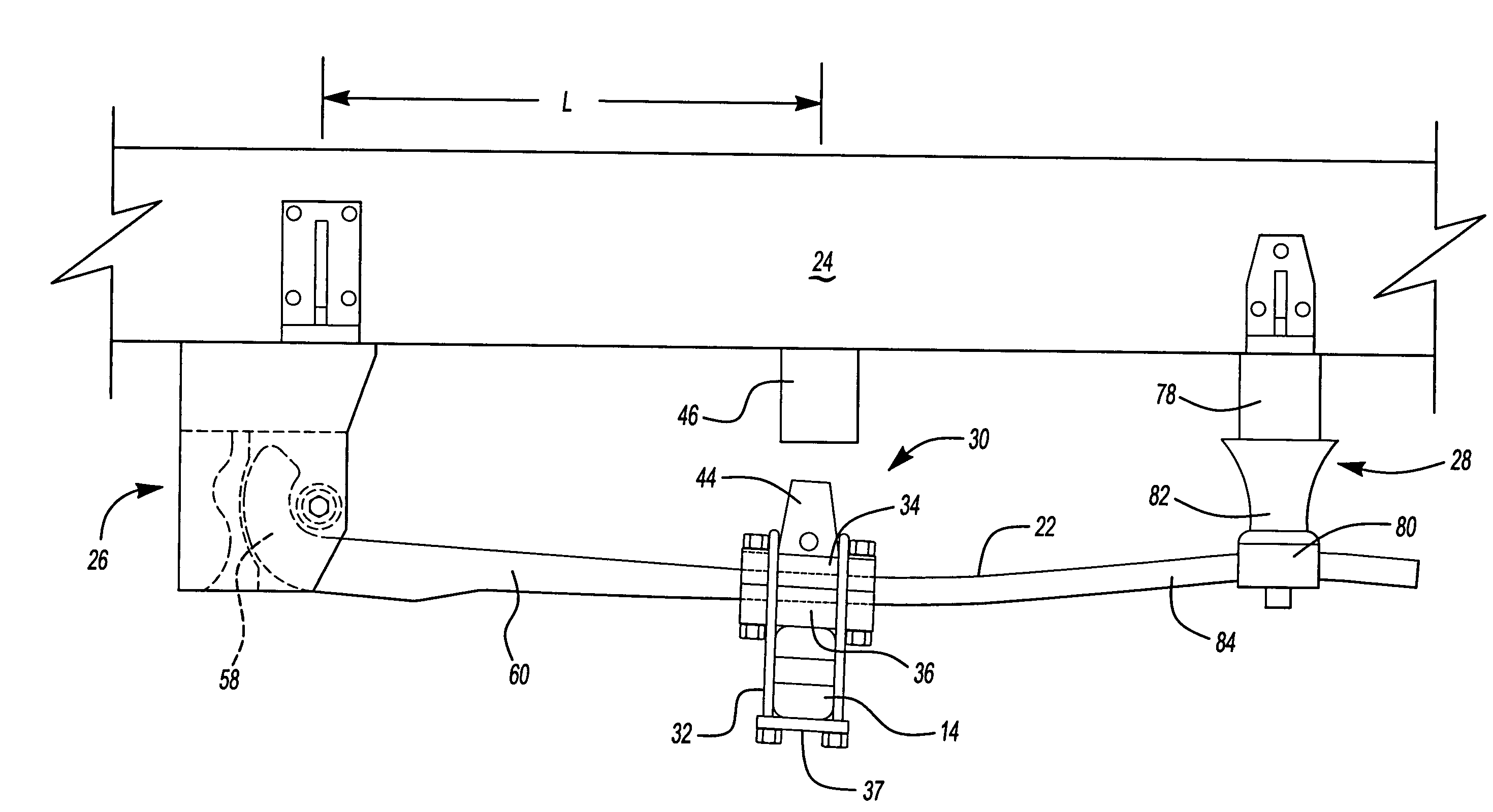

Module Handler Cylindrical Tines Equipped With Retractable Spikes, And Mounting And Drive Arrangements For The Tines

A cylindrical cotton module handling device includes an attachment having a pair of selectively spreadable, powered cylindrical tines adapted for supporting and rotating a module. Each powered tine is constructed from a cylindrical tube supported from a conventional L-shaped fork by a tubular sleeve received on, and dimensioned for fitting closely to, the horizontal leg of the conventional fork. The tubular sleeve is held in place by an L-shaped bracket forming a rearward extension of the sleeve and formed for embracing a region of the convention fork at the junction of its vertical and horizontal legs, with a retaining pin extending through vertical side plates of the bracket at a location just to the rear of the junction. An endless roller chain bearing arrangement is secured in encircling relationship to the tubular sleeve and supports the associated cylindrical tine for rotation. A hydraulic motor drive arrangement is mounted to the sleeve and has a shaft borne chain sprocket meshed with a drive chain carried by a rotating drive plates that are keyed to the cylindrical tube. A hydraulically retractable spike assembly is located inside a forward end section of the cylindrical tube and includes a plurality of spikes mounted for being selectively extended outwardly through holes in the tube for engaging a module wrapping during removal of the wrapping from the module.

Owner:DEERE & CO

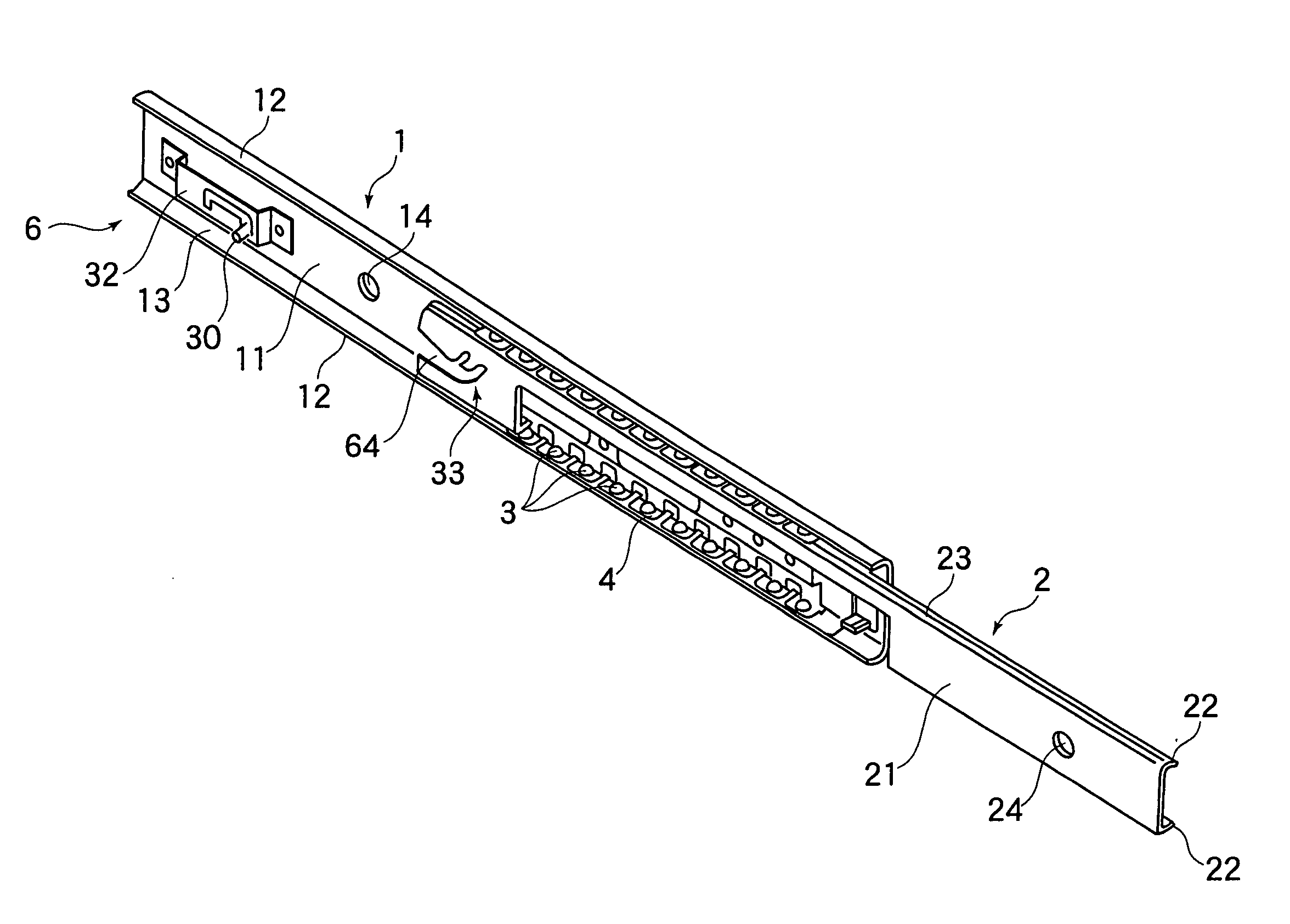

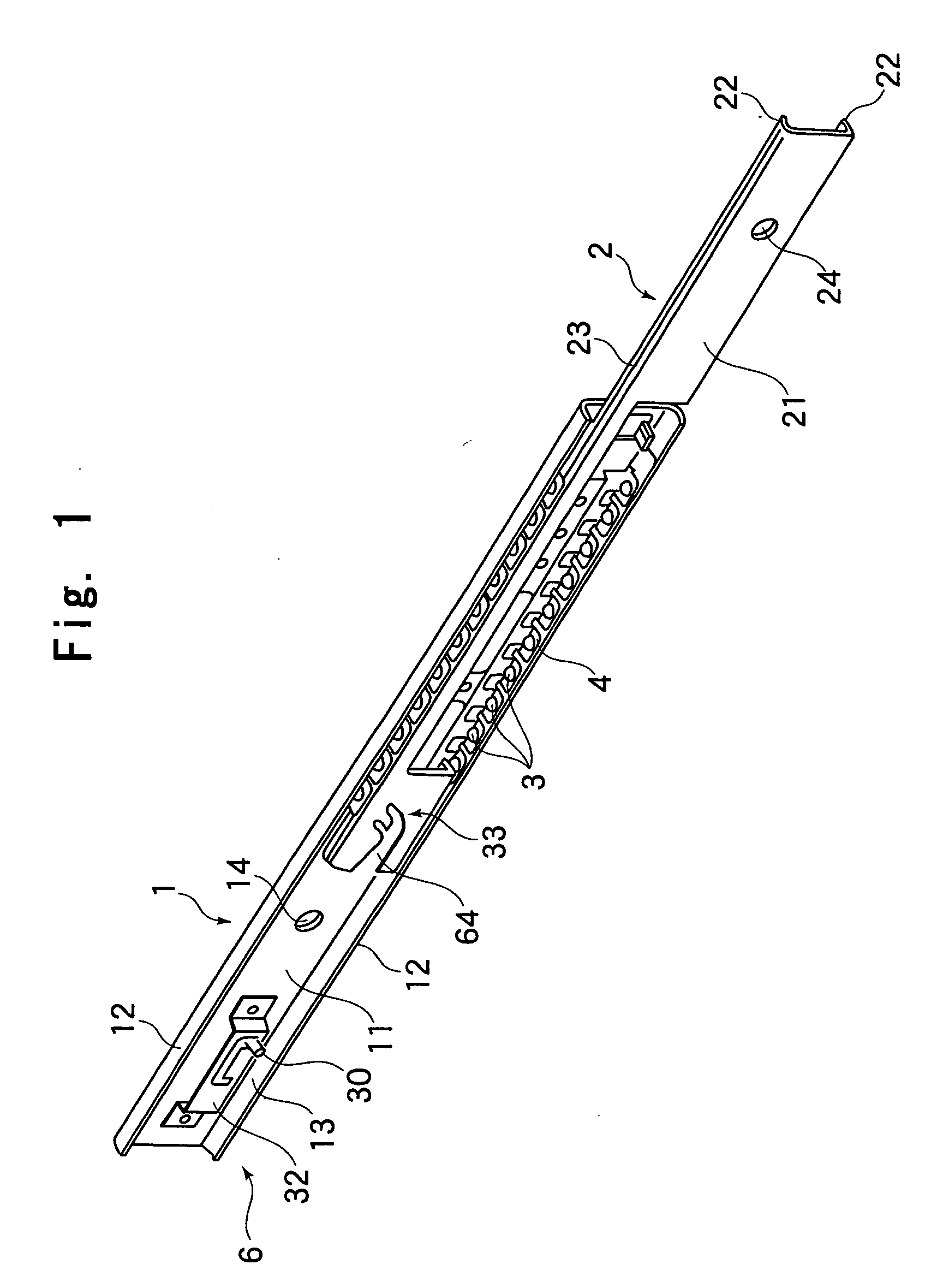

Slide Rail Unit With Retaining Function

Provided is a slide rail unit which, when accommodating a second rail (2) in a first rail (1), can automatically draw in the second rail to an end position and retain it at that position and which can be produced easily with a small number of parts and at low cost, the slide rail unit being equipped with a retaining pin (30) provided upright so as to be movable with respect to the first rail (1) in the longitudinal direction and the width direction thereof, an elastic member (31) for urging the retaining pin (30) toward the stroke end of the second rail (2), a pin guide member (32) provided on the first rail (1) and adapted to lock the retaining pin (30) at a standby position spaced apart from the stroke end against an urging force of the elastic member (31) and to guide the retaining pin (30) detached from the standby position toward the stroke end with the urging force, and a cam member (33) provided on the second rail (2) and adapted to detach the retaining pin (30) from the standby position of the pin guide member (32) and lock the retaining pin as it overlaps the pin guide member (32).

Owner:THK CO LTD

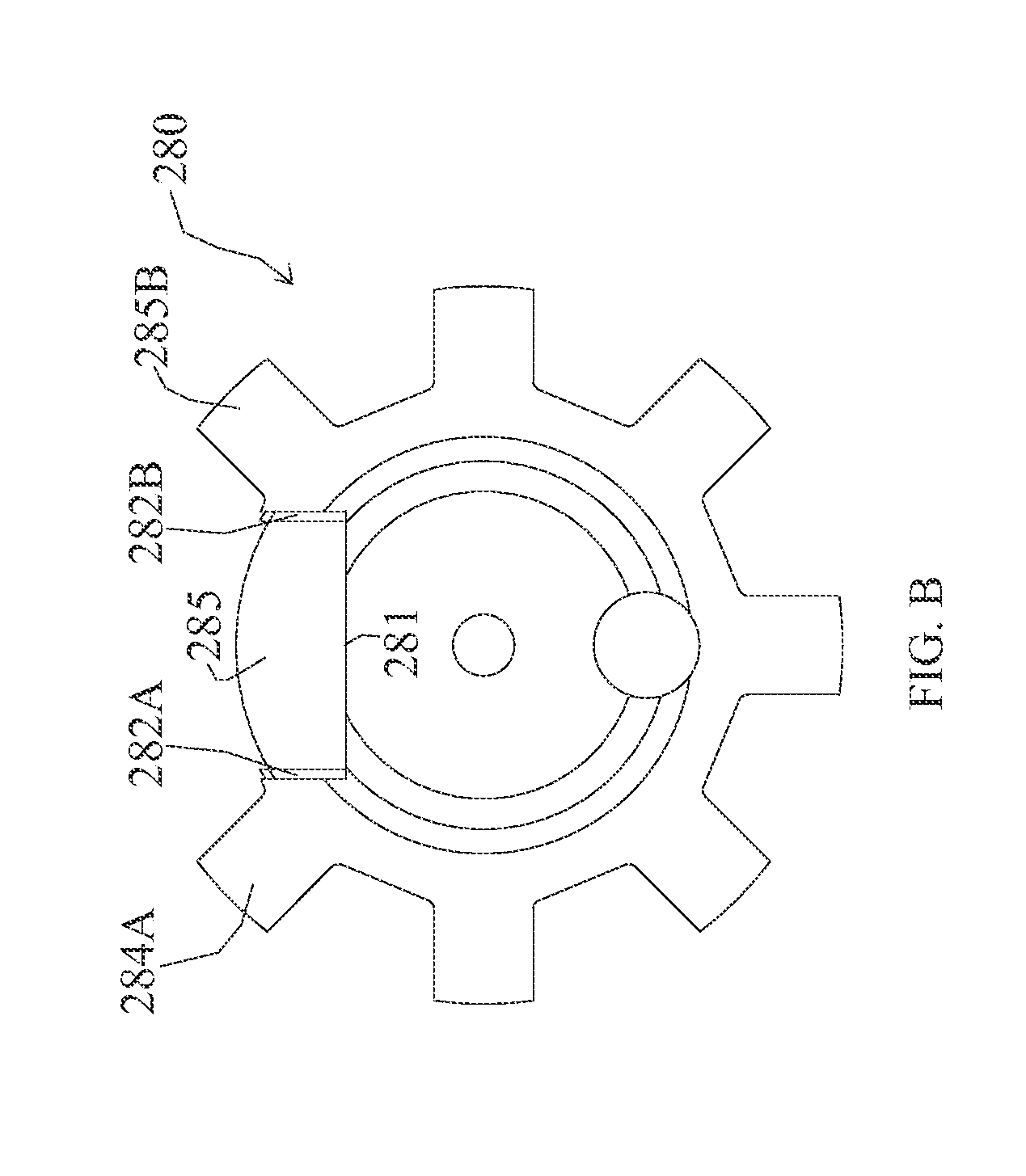

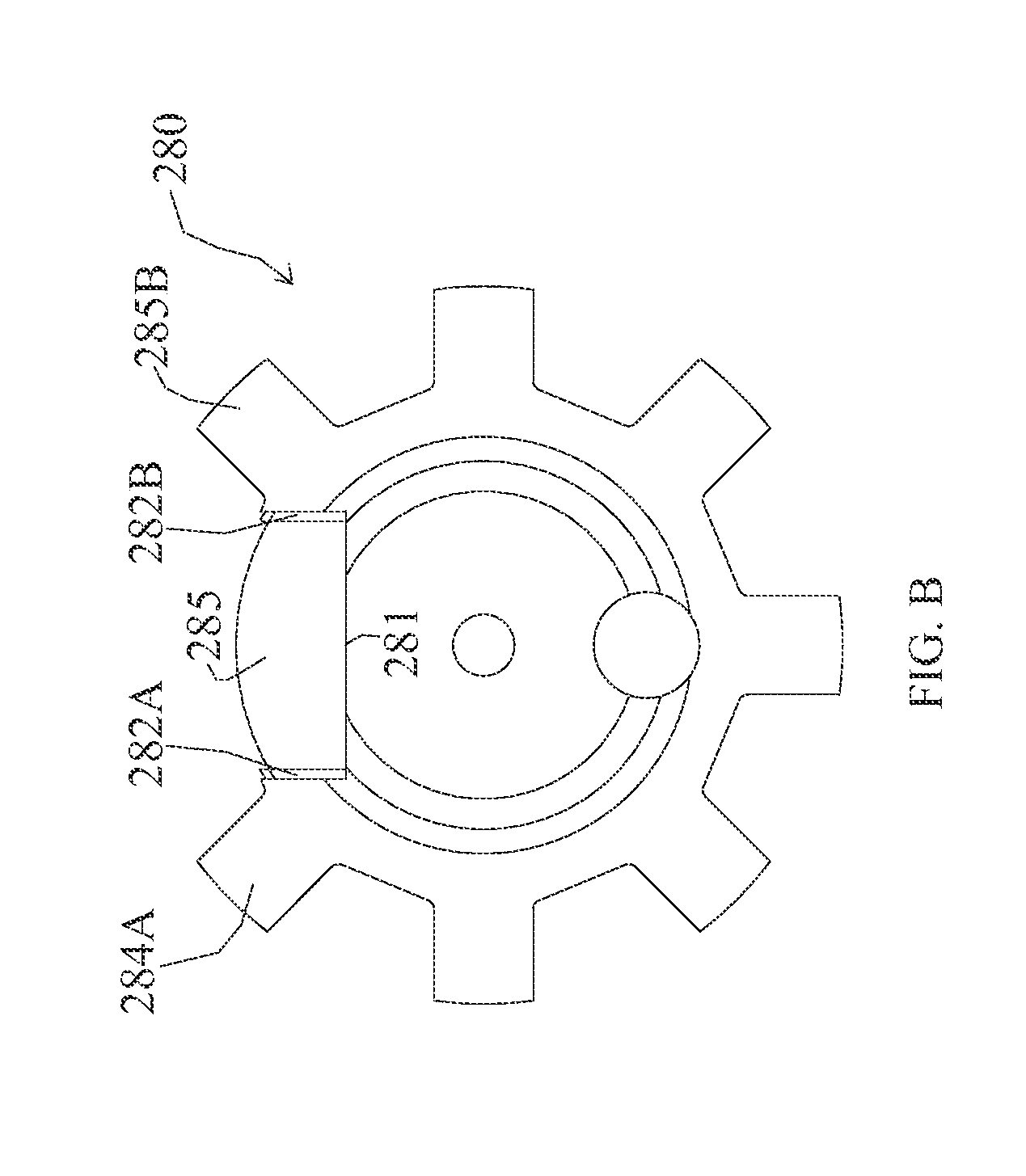

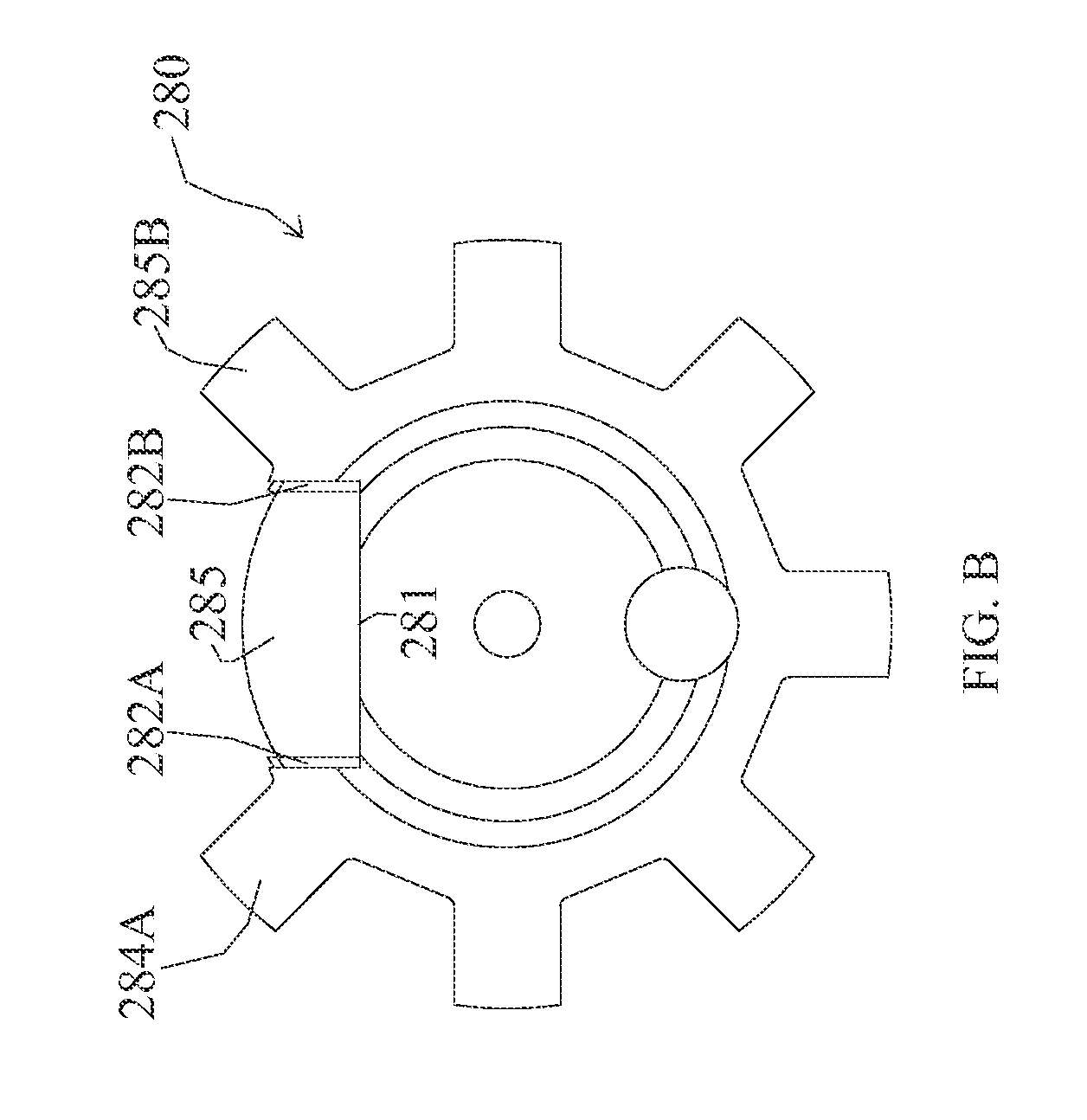

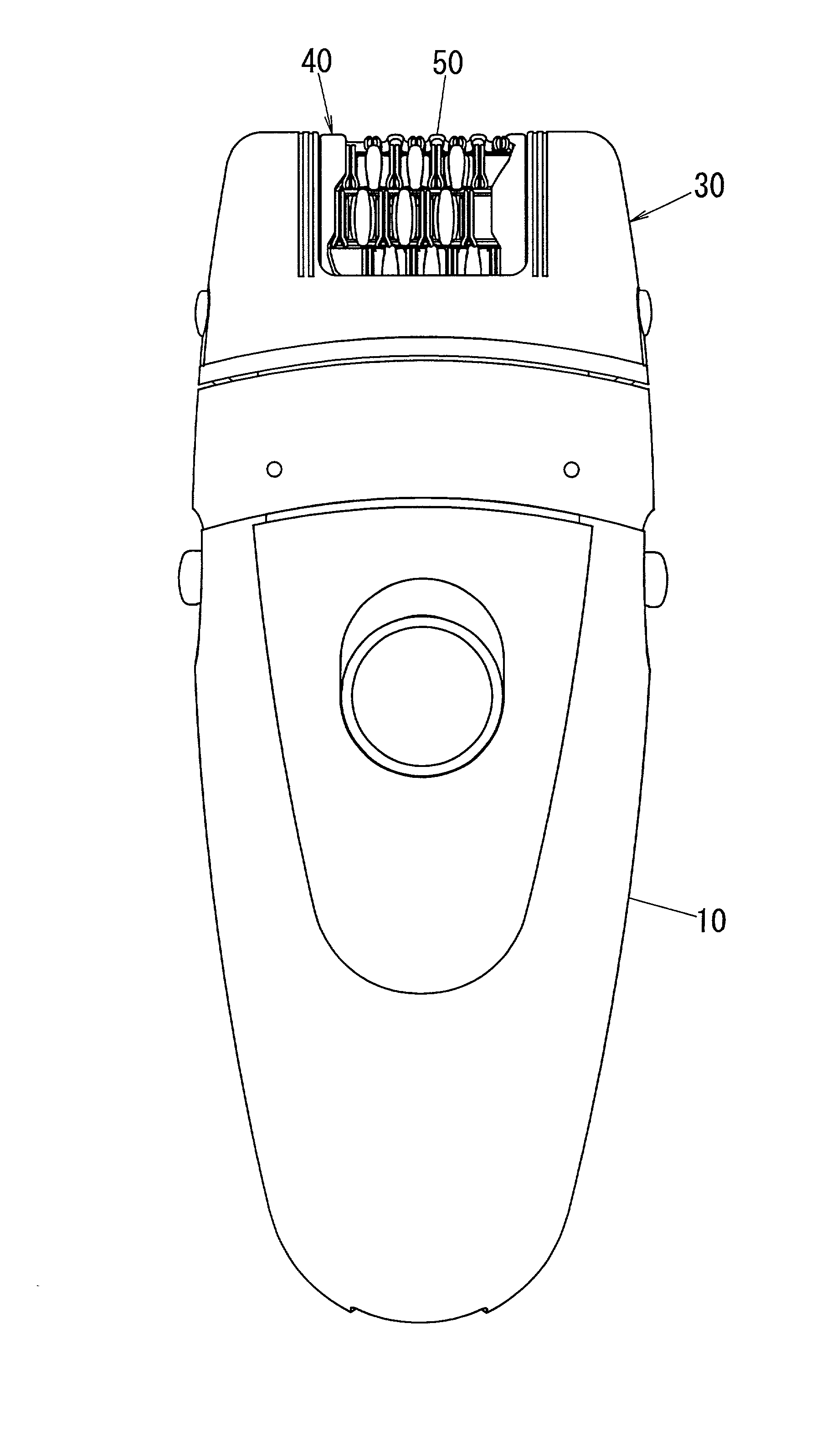

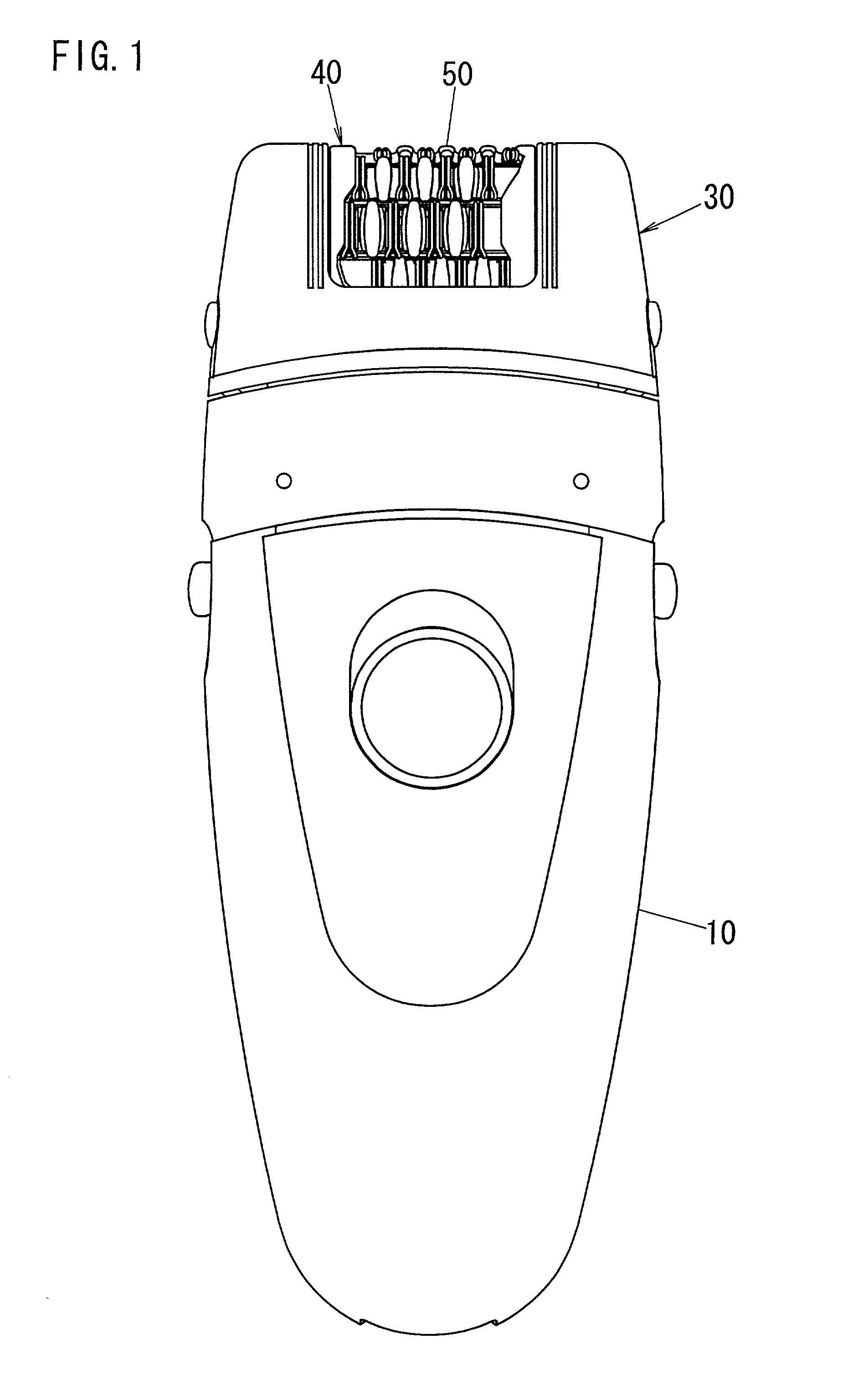

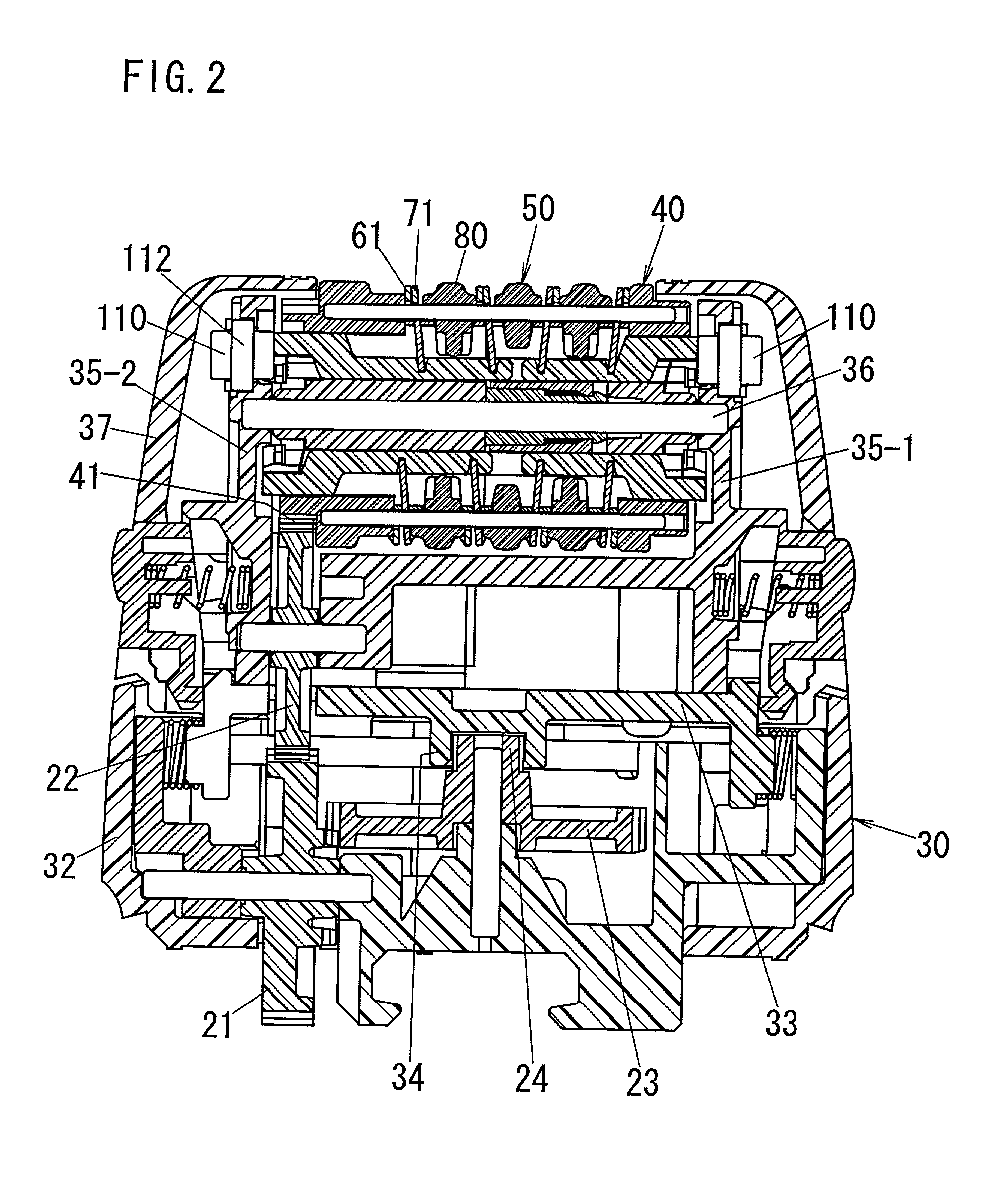

Hand-held epilating device

InactiveUS20020052611A1Efficient hair pluckingImprove trapping efficiencyHair-singeingSurgeryHand heldActuator

An epilating device has a rotary cylinder carrying a plurality of pinching row units arranged around the cylinder. An actuator bar is connected to movable blades in each row unit and is caused by a driven mechanism to move the movable blades towards the adjacent blades for pinching body hairs therebetween and plucking the hairs as the cylinder rotates. After the actuator bar is released from the driven mechanism, the bar is urged by a return spring to move the blades away from the adjacent blade to be ready for subsequent hair pinching. All the actuator bars spaced circumferentially around the cylinder and provided respectively for the row units are coupled commonly to the one return spring so that the epilating device can have an increased number of the row units around the cylinder only at a minimum number of the springs.

Owner:MATSUSHITA ELECTRIC WORKS LTD

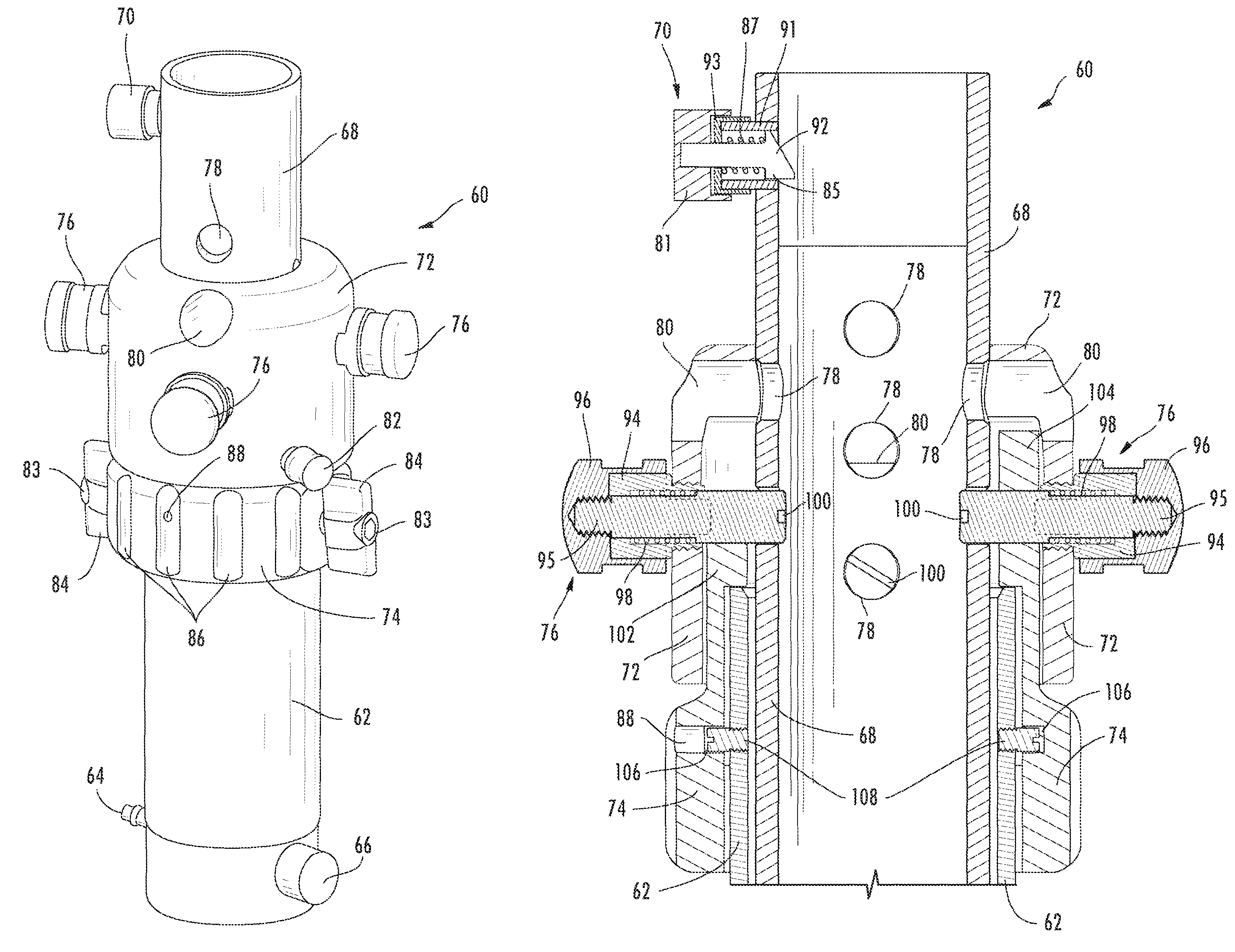

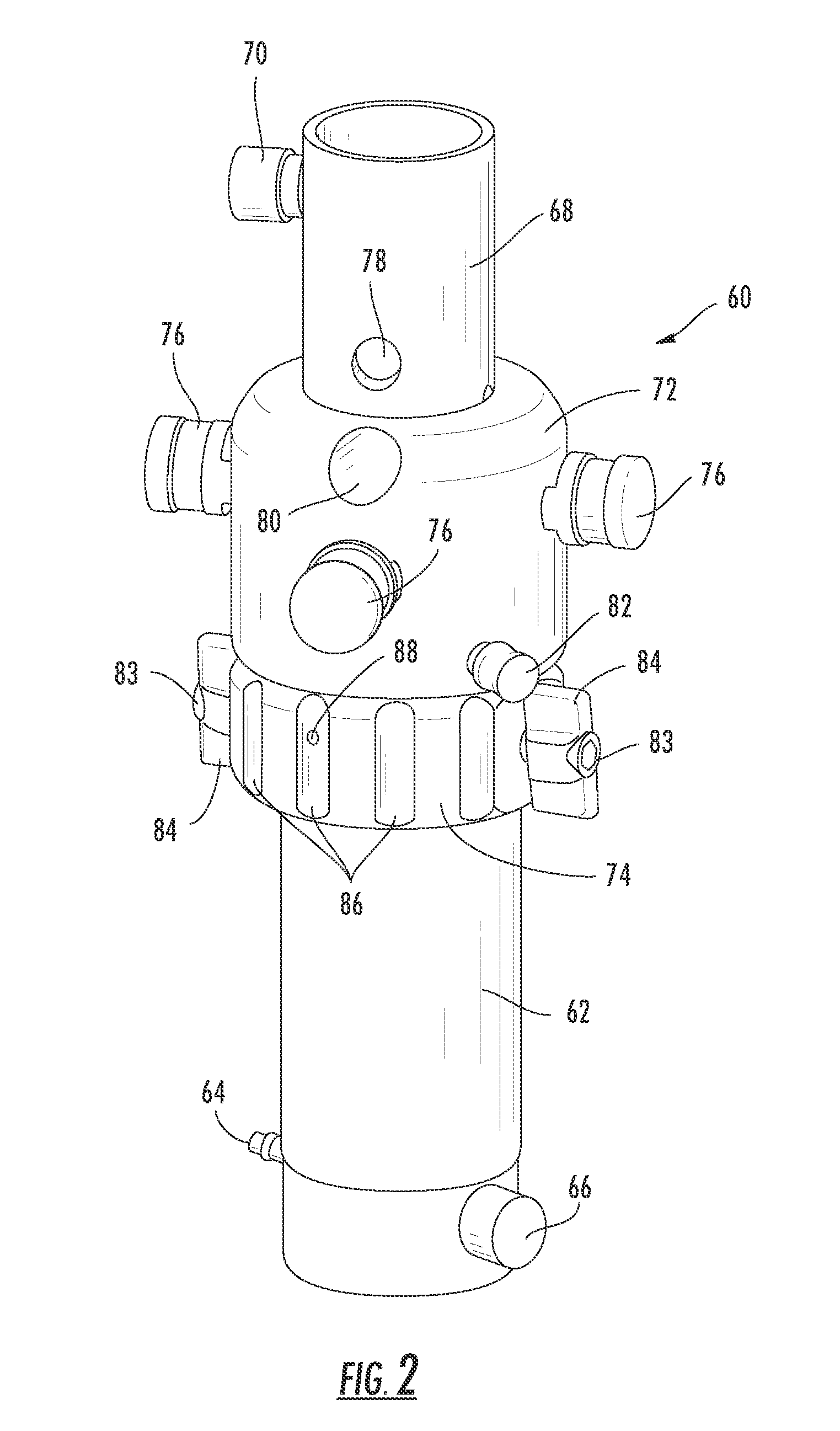

Stabilization and support strut with secure deployment features

A stabilization and support strut for use in rescue operations in buildings, trenches, vehicle accidents, and the like has secure deployment features including first and second inter-fitting collar assemblies, the first collar assembly including a first collar, circumferentially based spring-biased piston-retaining pins mounted in the collar for fitting into orifices in a piston body, and a locking pin for precluding rotation and axial movement of the first collar on the strut; and the second collar assembly including a second collar rotatingly secured on the barrel with a portion of the second collar underlying the first and having a circumferentially inclined ratchet surface for snugly engaging the piston-retaining pins upon rotation of the second collar, the second collar further including rotatable studs for engaging the barrel and precluding rotation of the second collar about the barrel when snug against the piston-retaining pins.

Owner:HALE PRODUCTS INC

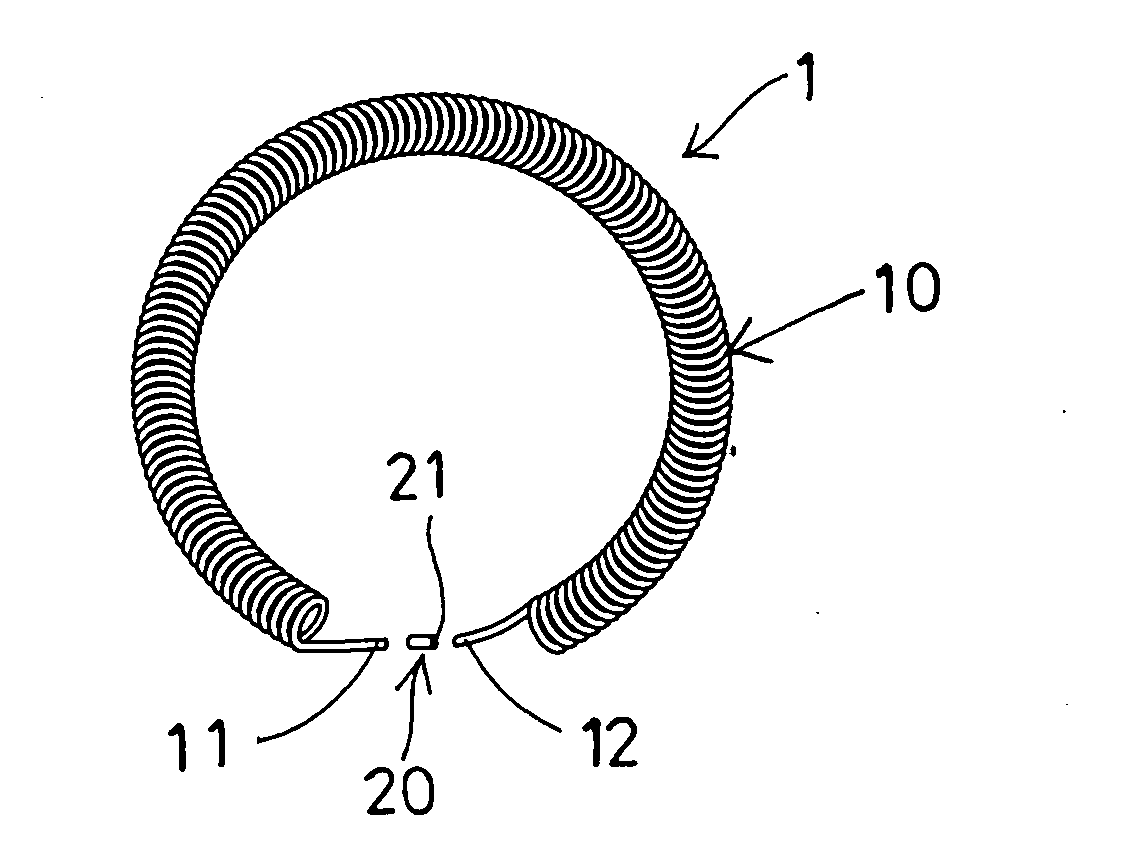

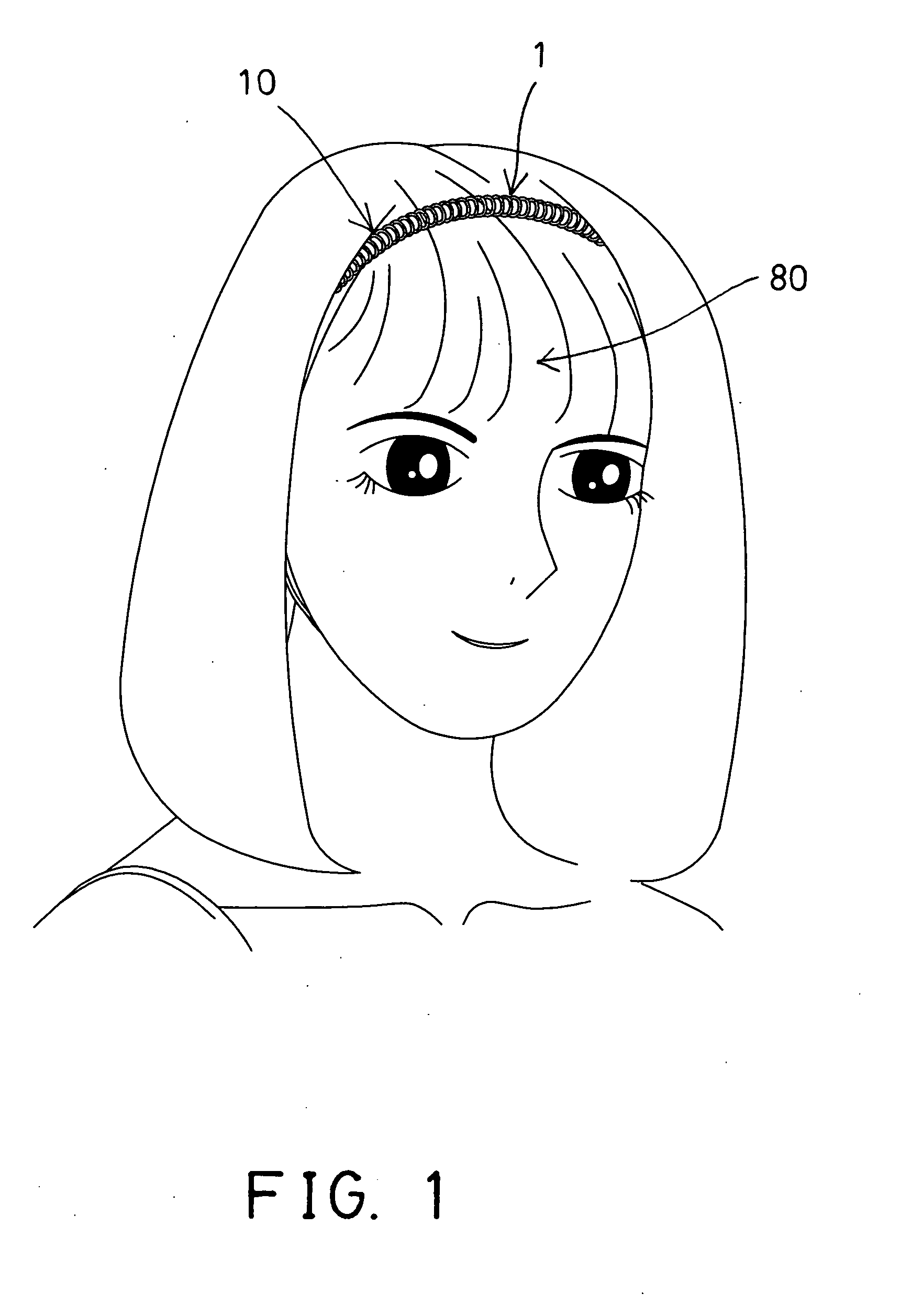

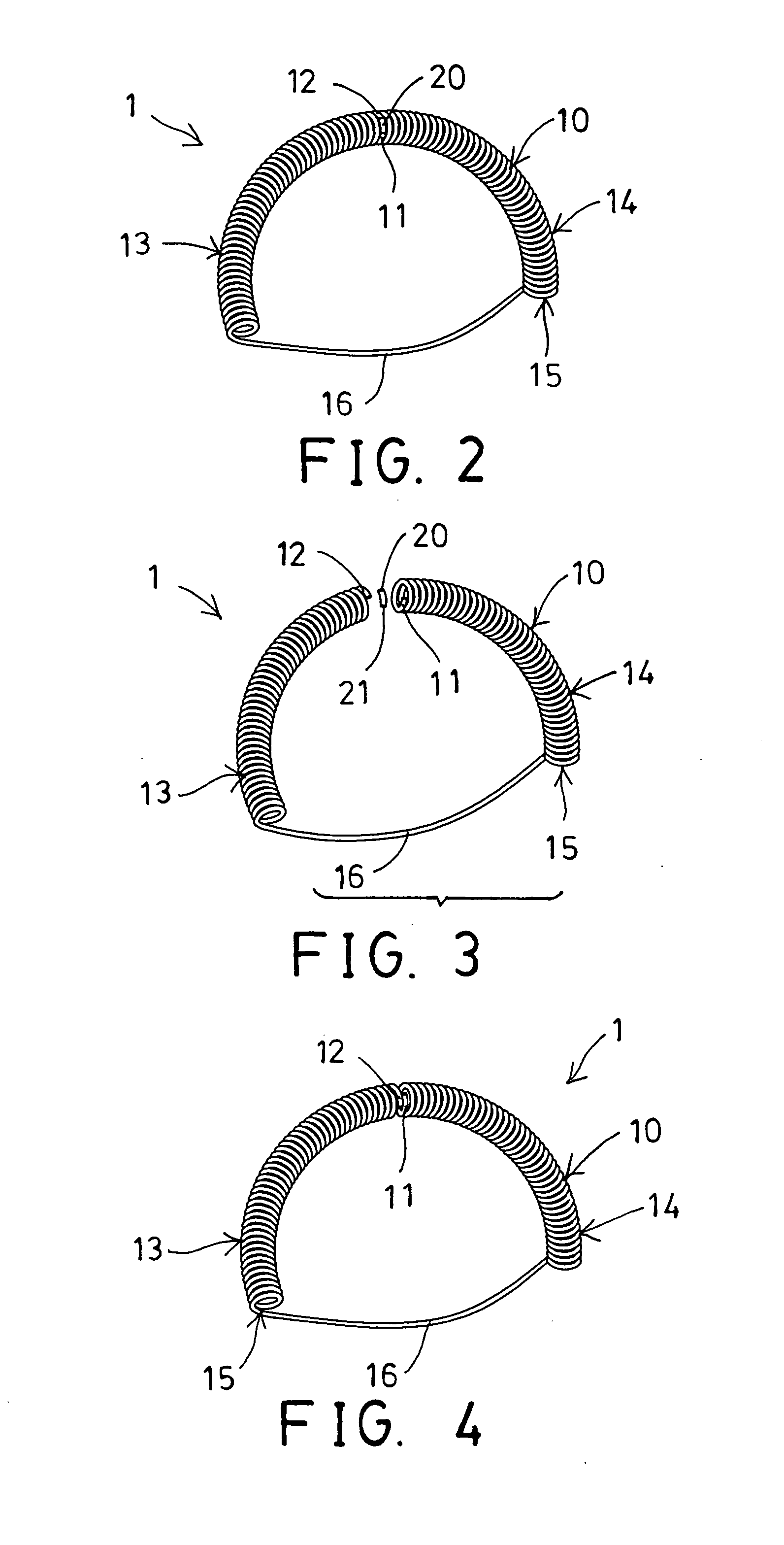

Hair barrette having helical structure

InactiveUS20090301510A1Easy and fast assemblyQuick and easy to manufactureCurling devicesClosed loopEngineering

A hair barrette includes an elongated coil member having two ends, and a tubular connecting member for securing the ends of the elongated coil member together and for forming a closed loop structure and for allowing the hair barrette to be easily and quickly attached or engaged onto the head of the user. The tubular connecting member includes a bore for receiving the ends of the elongated coil member and for securing the ends together with an adhesive material. The elongated coil member includes two or more coil segments connected together with elongated wire members for forming the closed loop structure, and may be easily and quickly manufactured and assembled.

Owner:HSU WEI CHENG

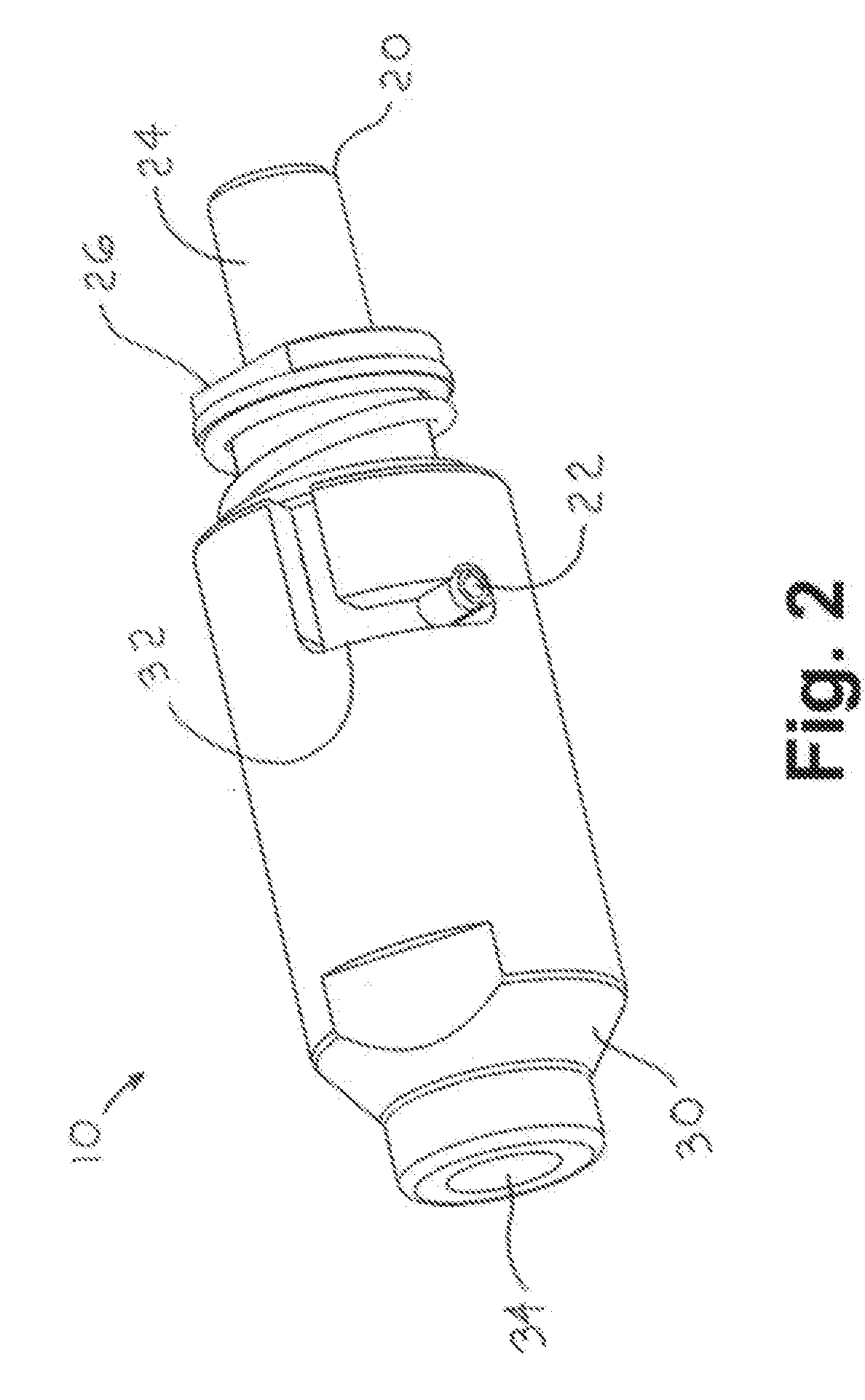

Coupler device

A coupler assembly is disclosed comprising: a mounting sleeve including at least one L-shaped slot; a mounting support including an insertion stud, the insertion stud configured to fit into the mounting sleeve; the insertion stud further including a radial through-hole: a compression spring disposed over the insertion stud, the compression spring functioning to exert a separation force between the mounting sleeve and the mounting support; and a retaining pin disposed in the radial through-hole wherein the insertion stud is inserted into the mounting sleeve by sliding an end of the retaining pin inside the at least one L-shaped slot.

Owner:KALAVITZ MICHAEL V

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com