Patents

Literature

1965results about "Leaf springs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

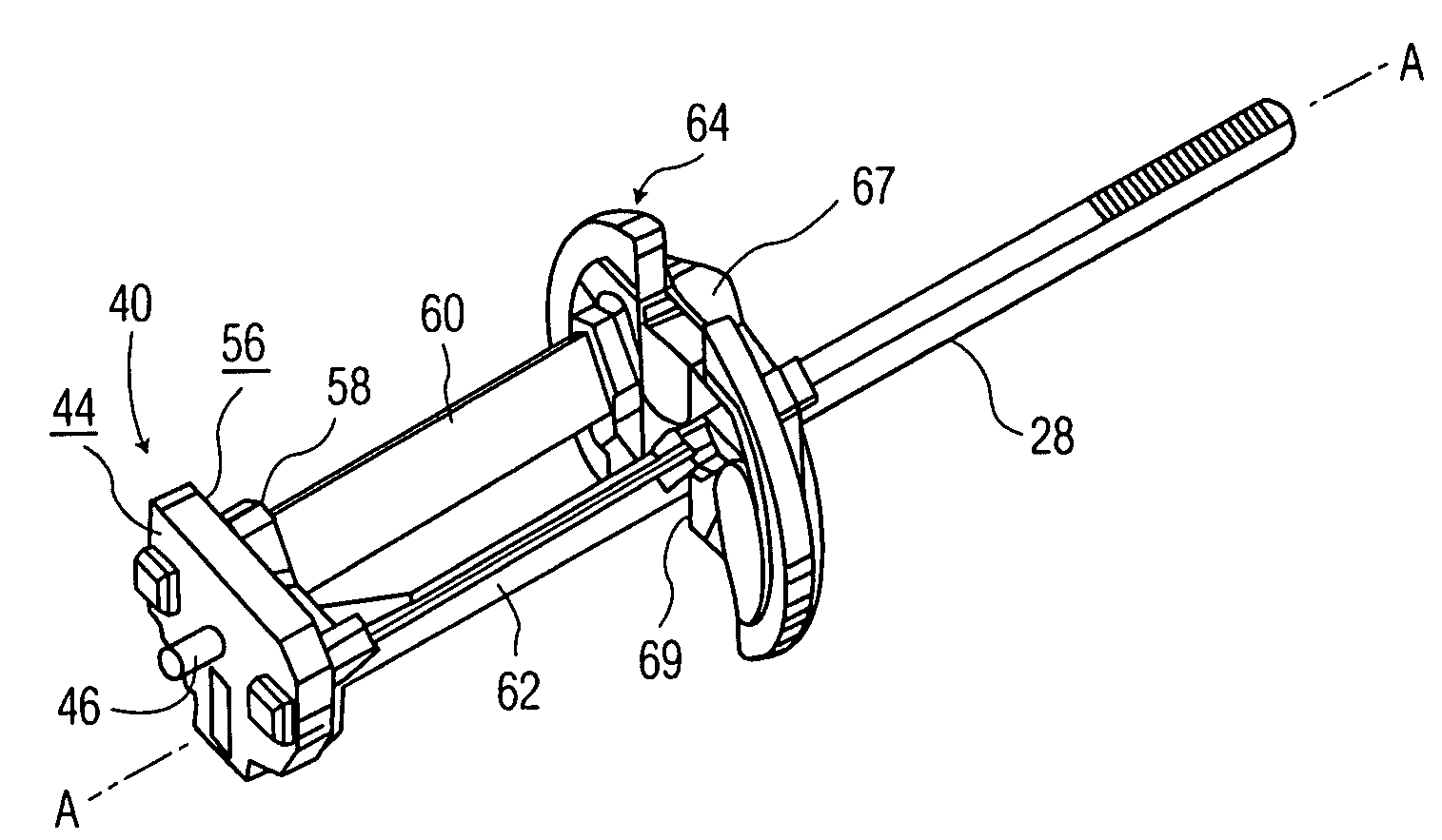

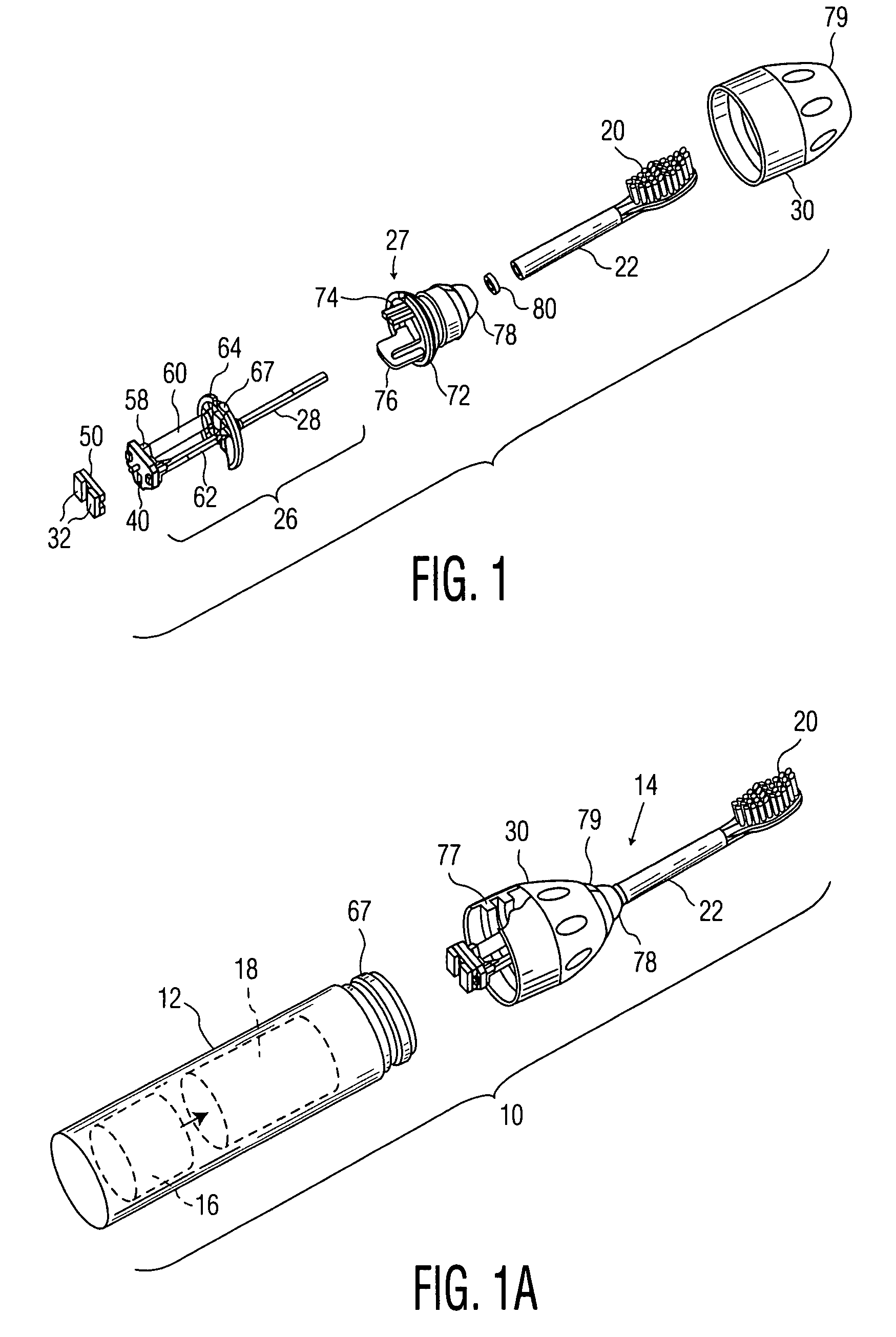

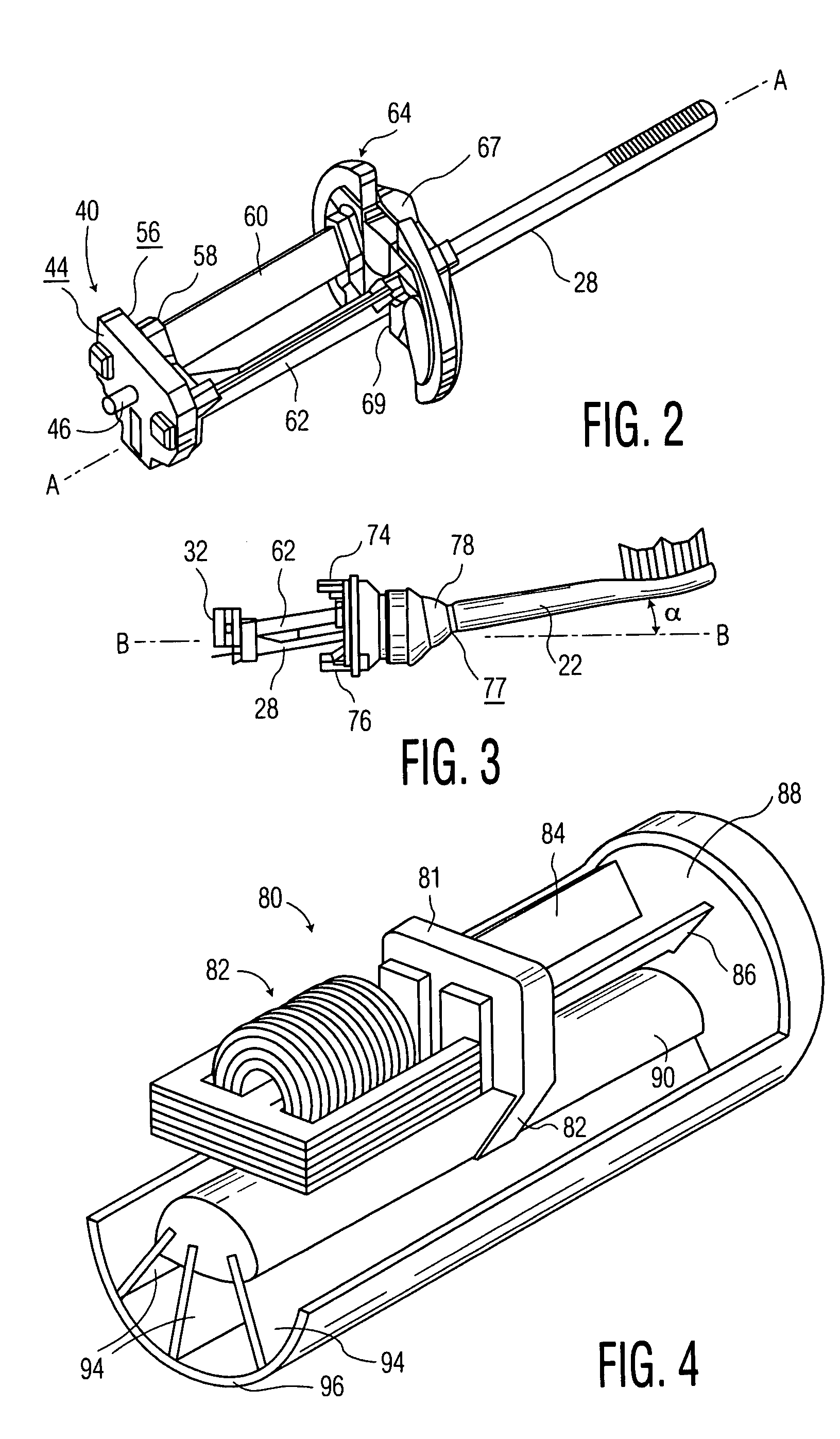

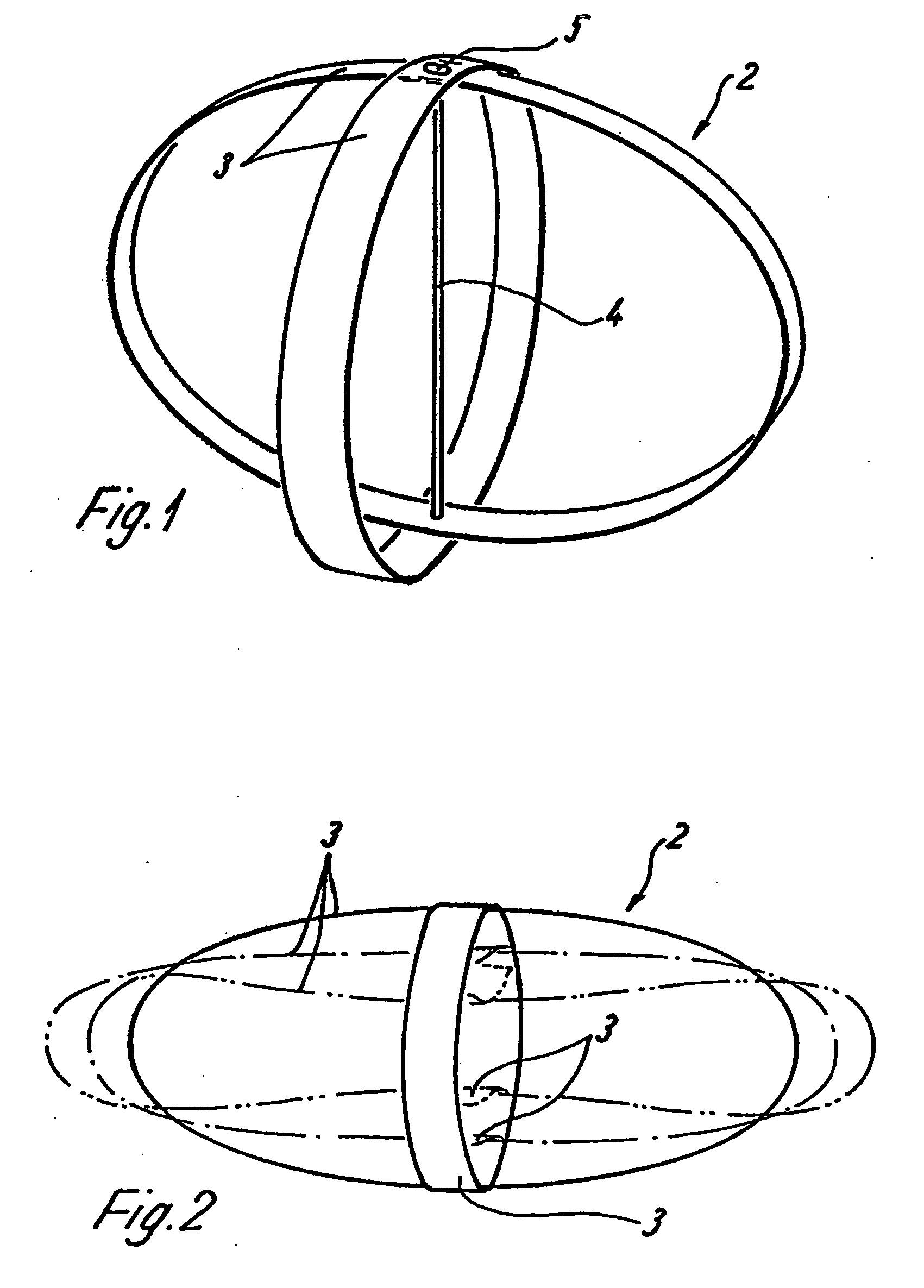

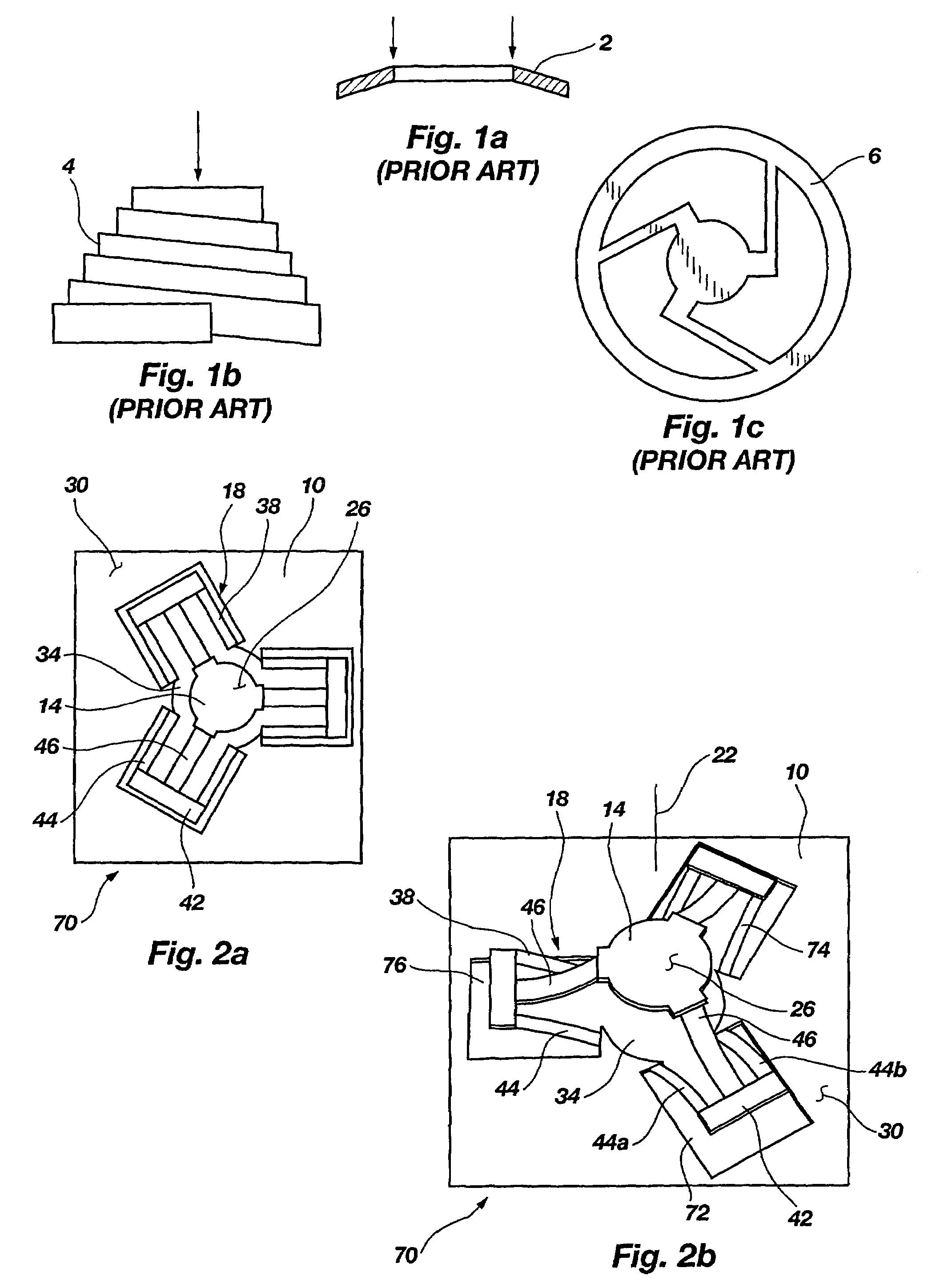

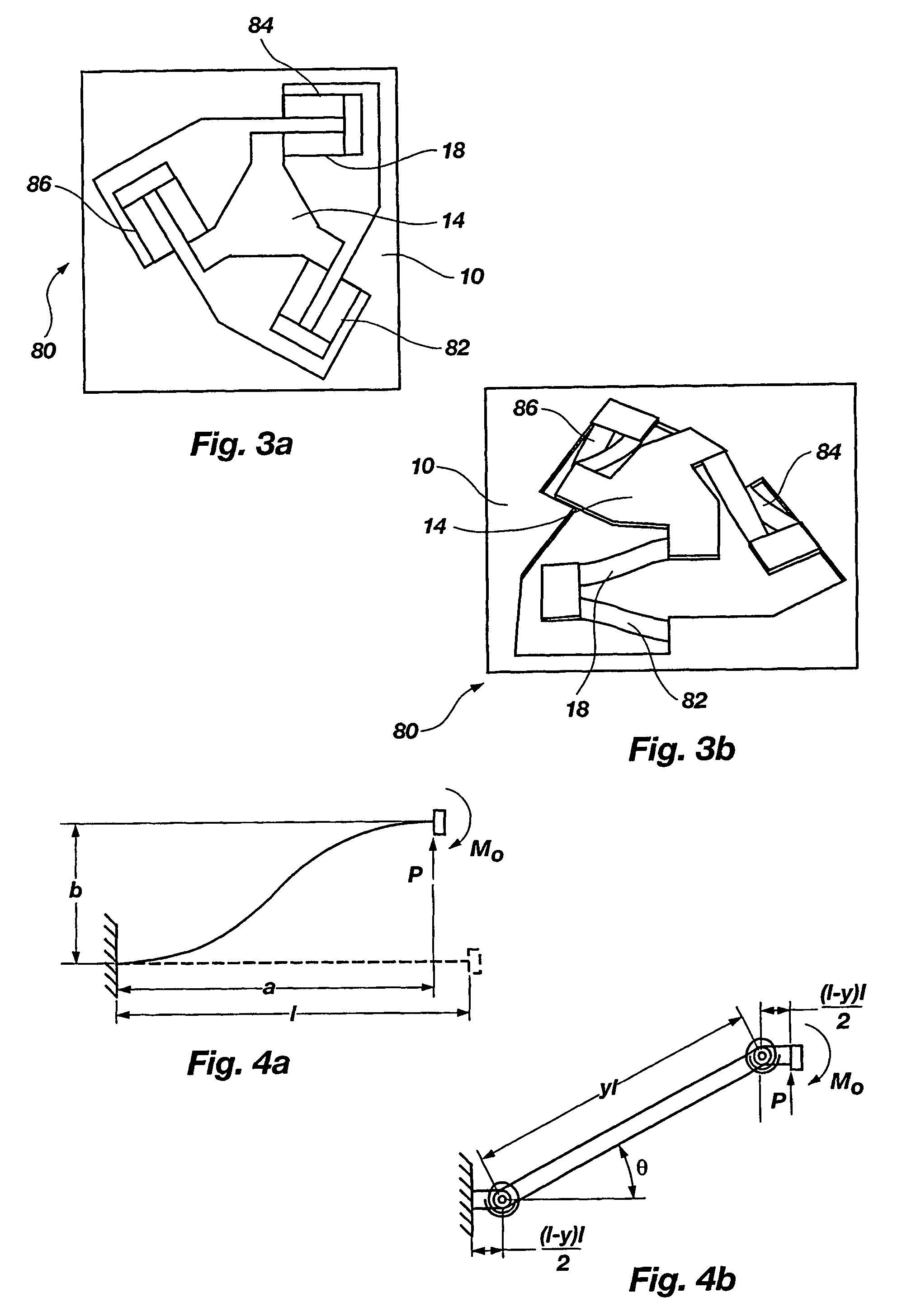

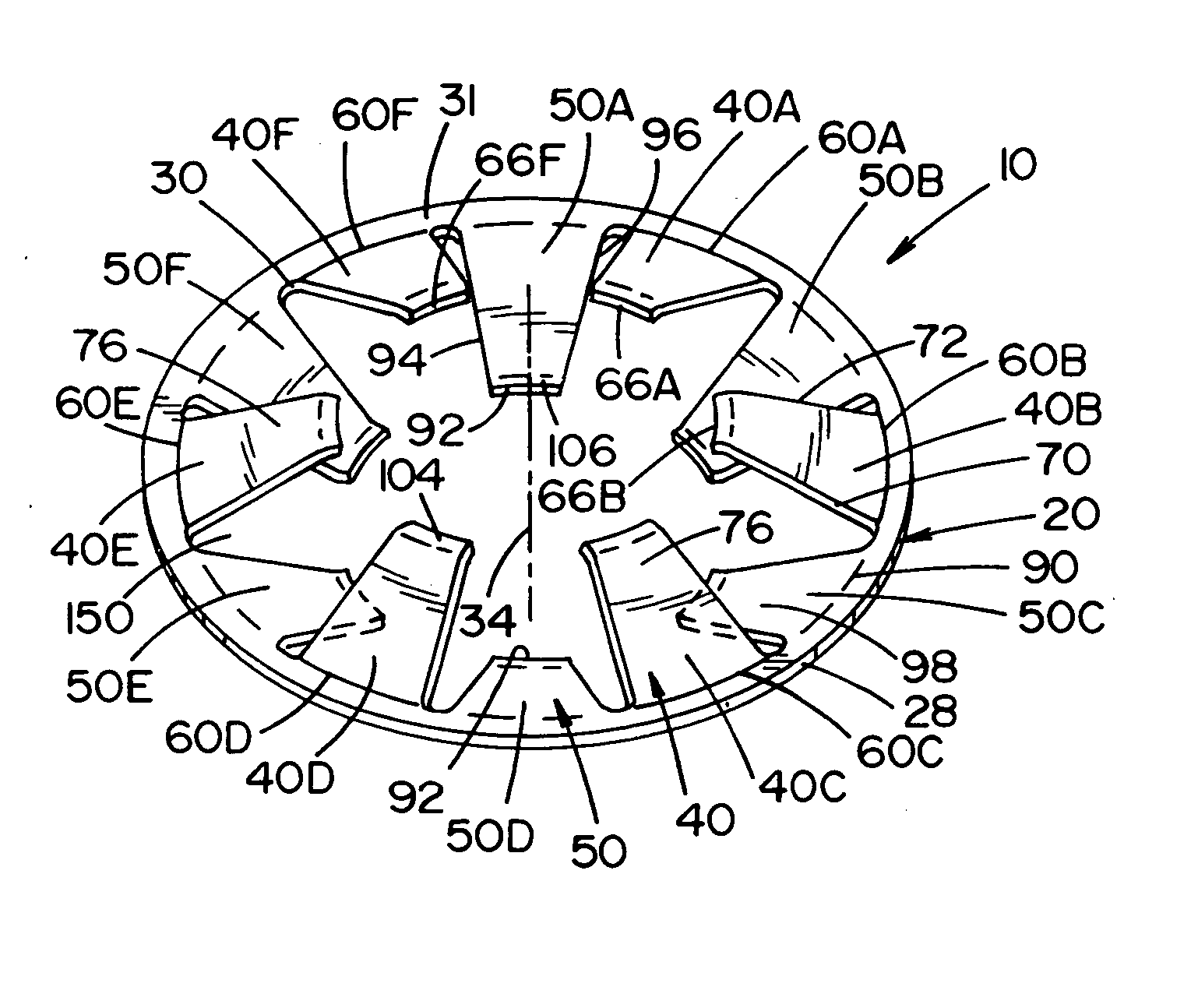

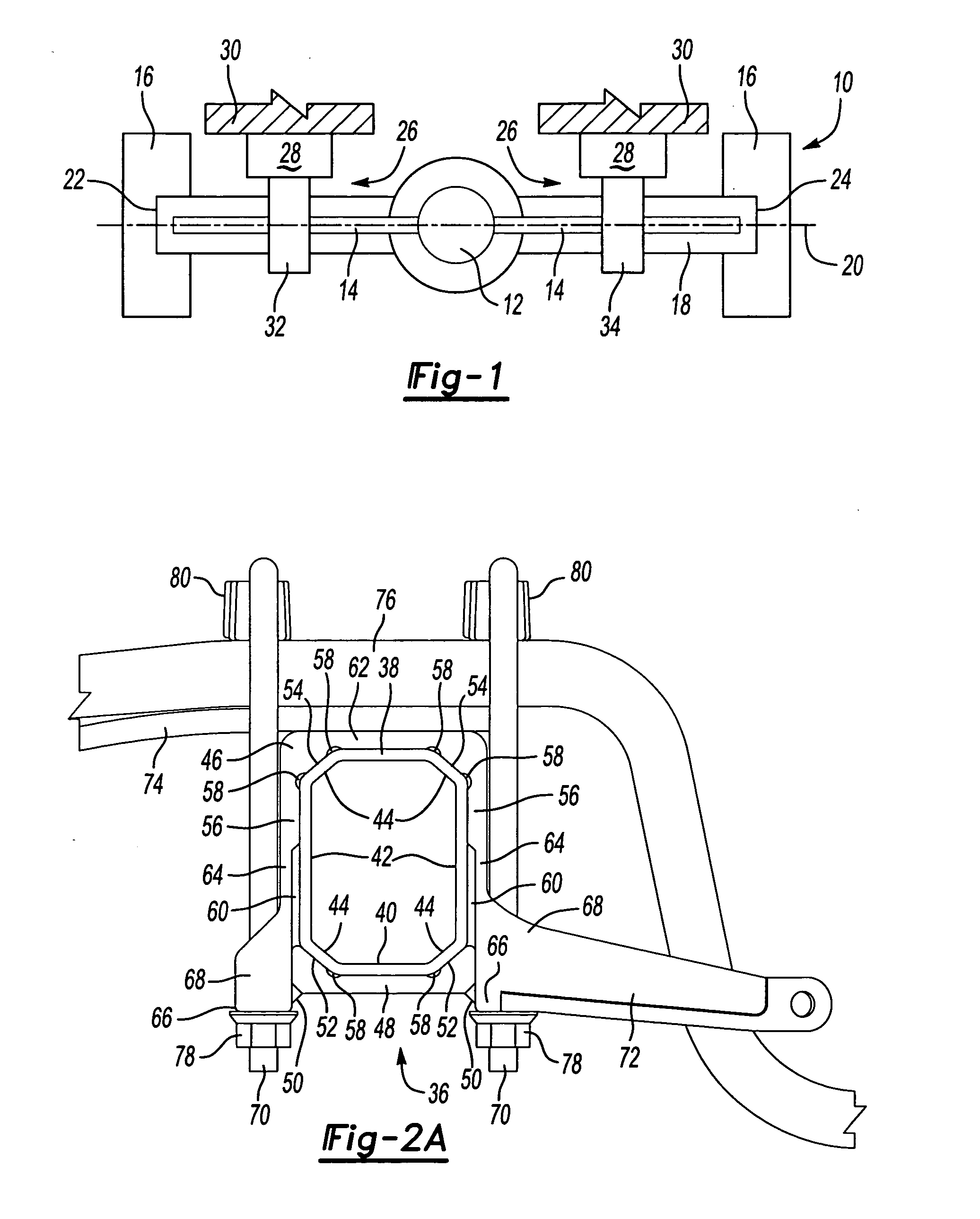

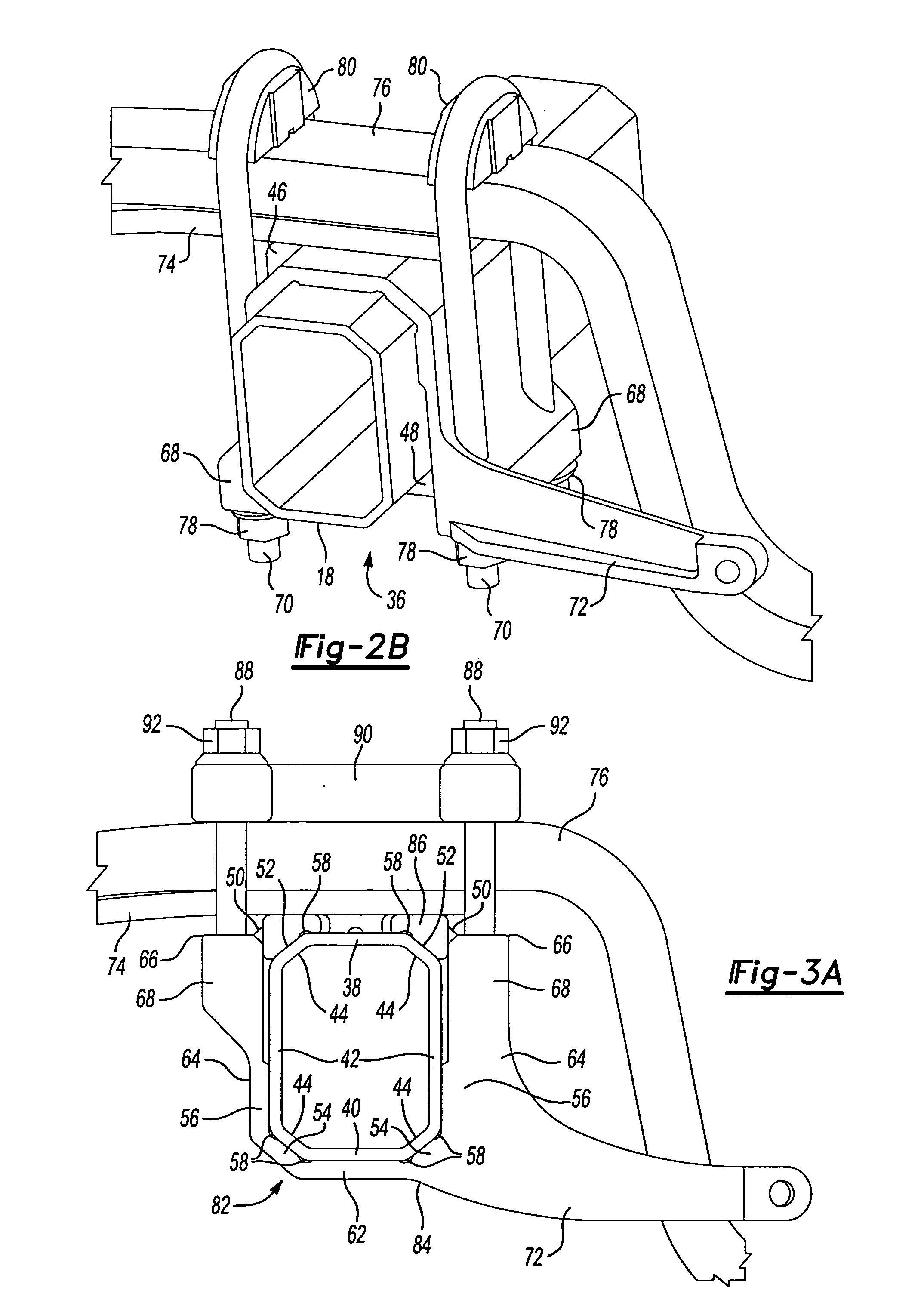

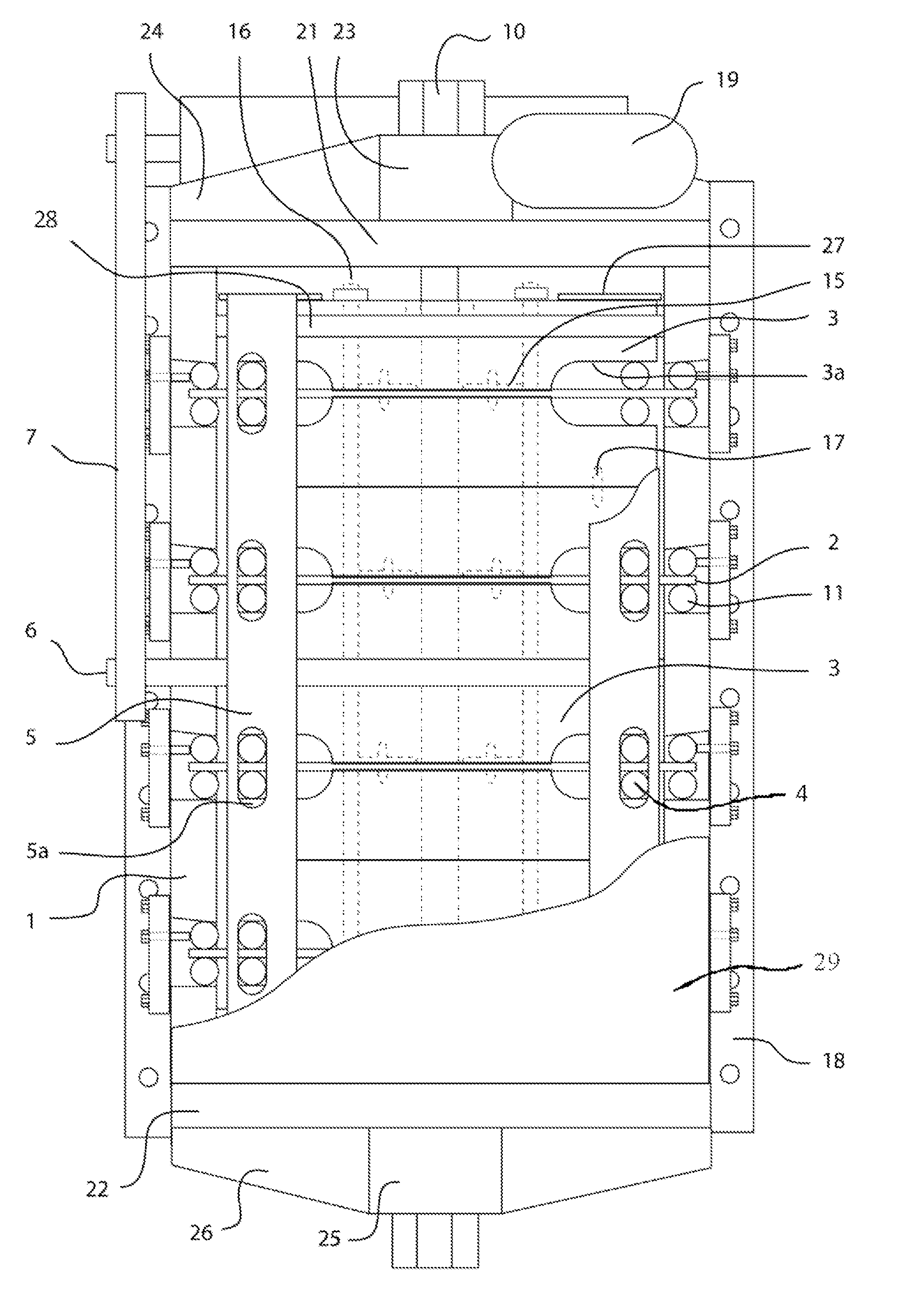

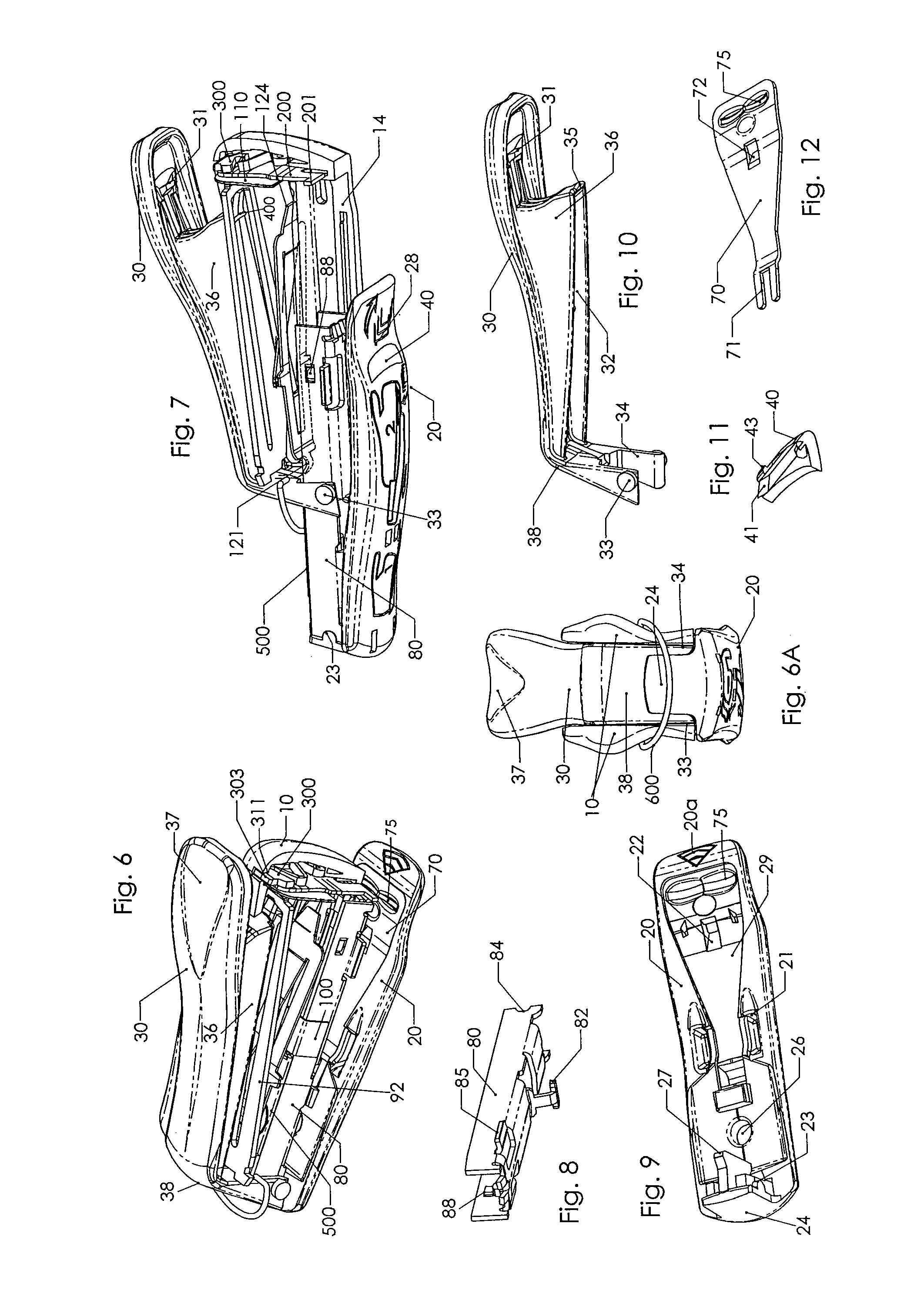

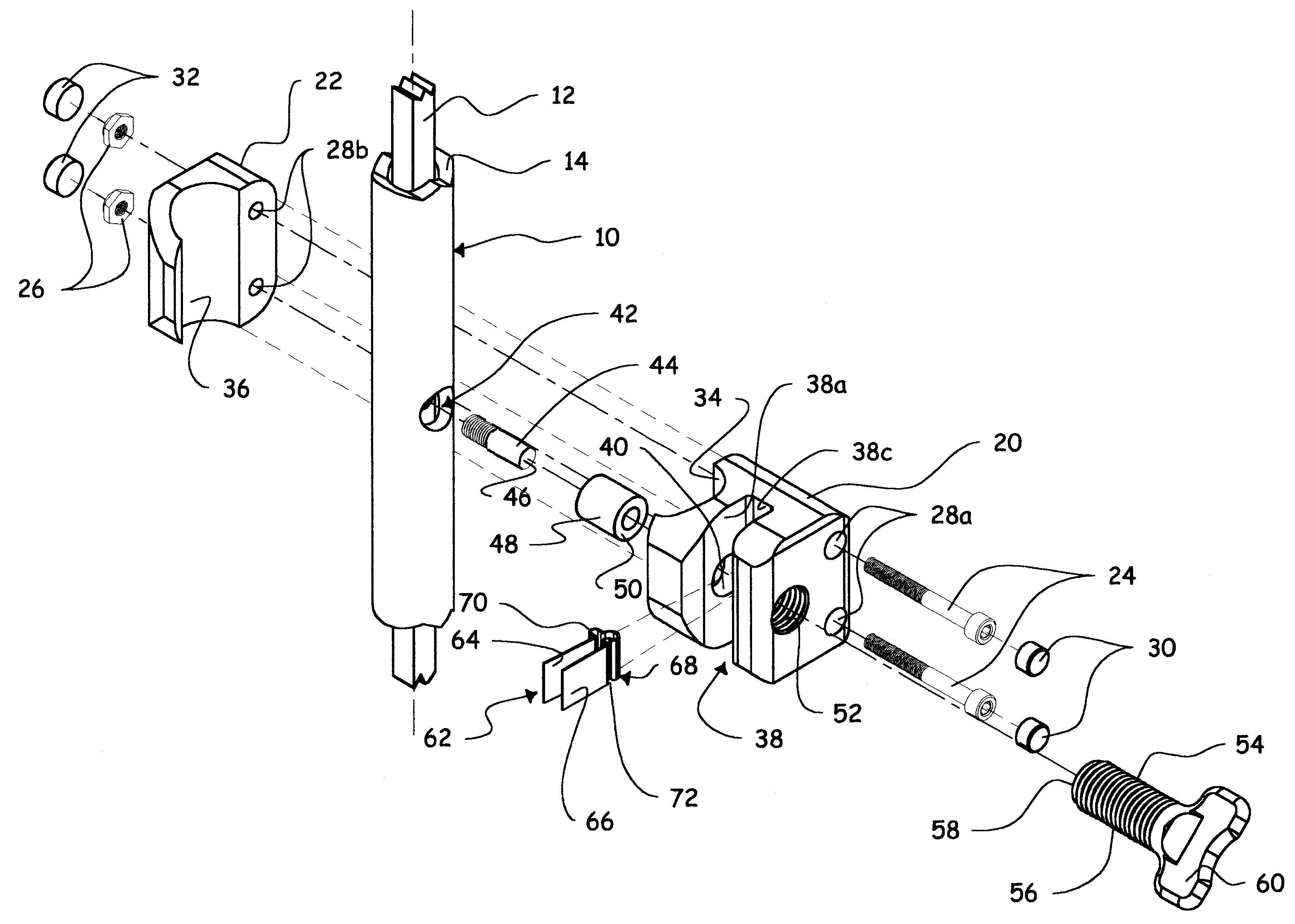

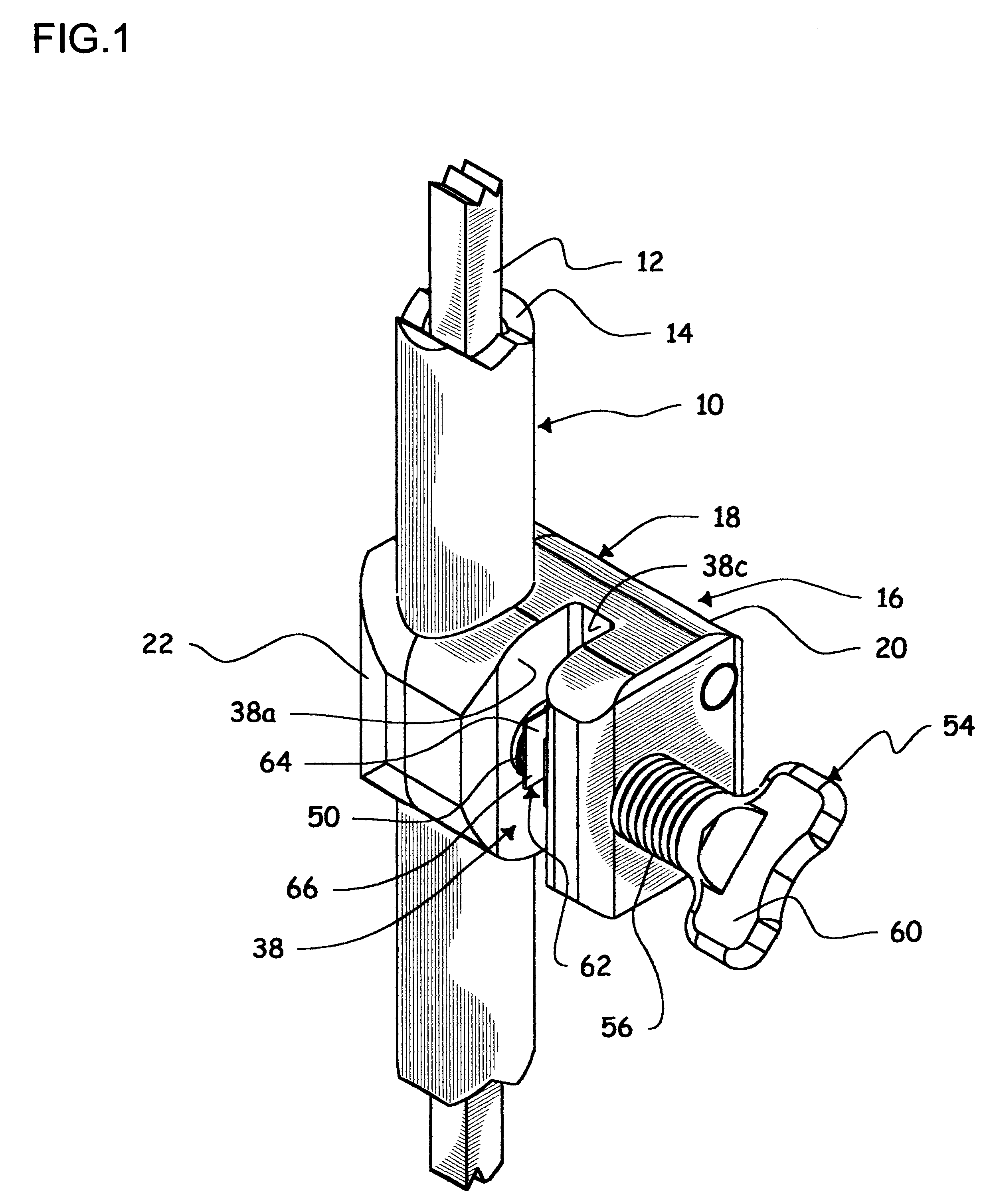

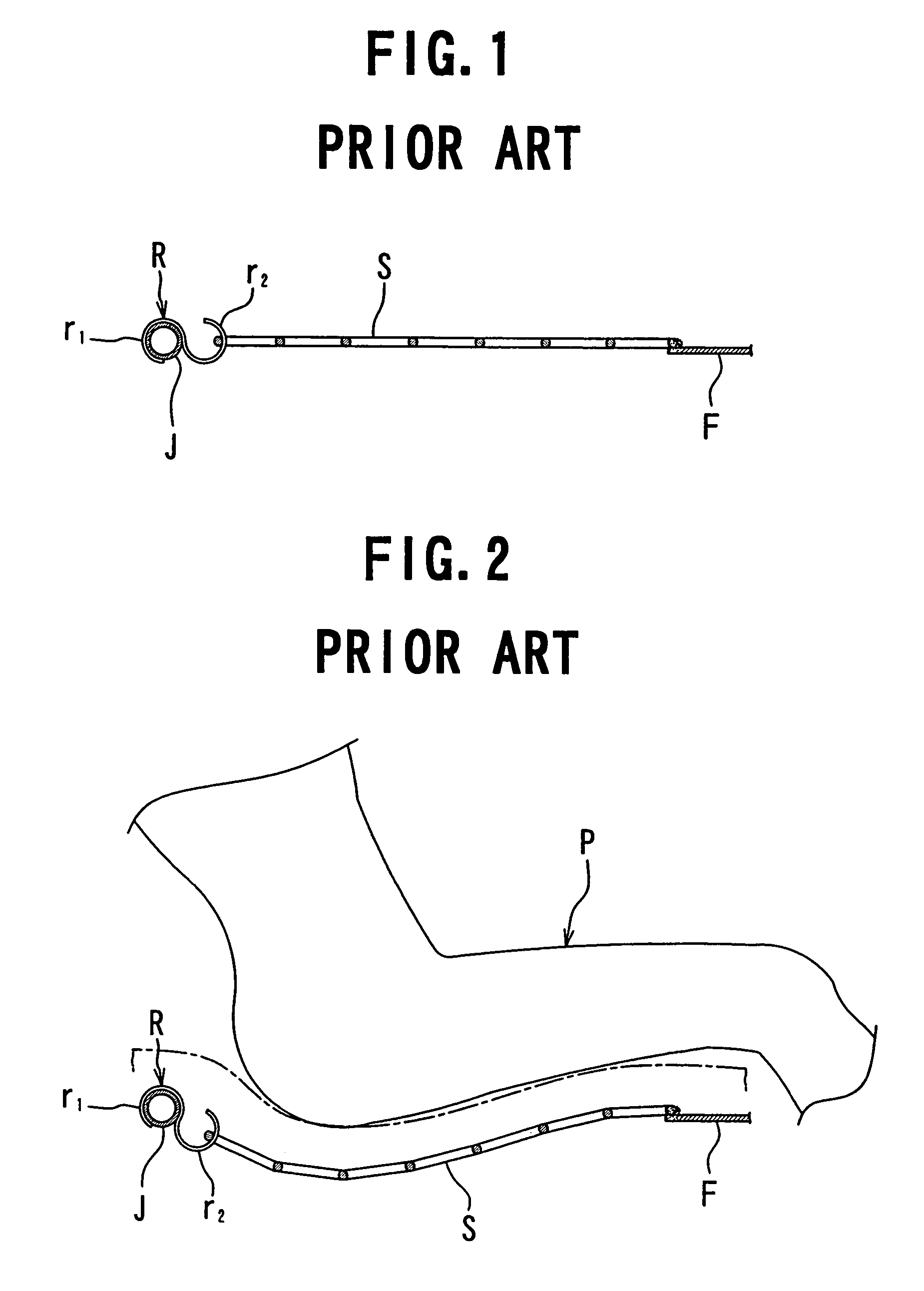

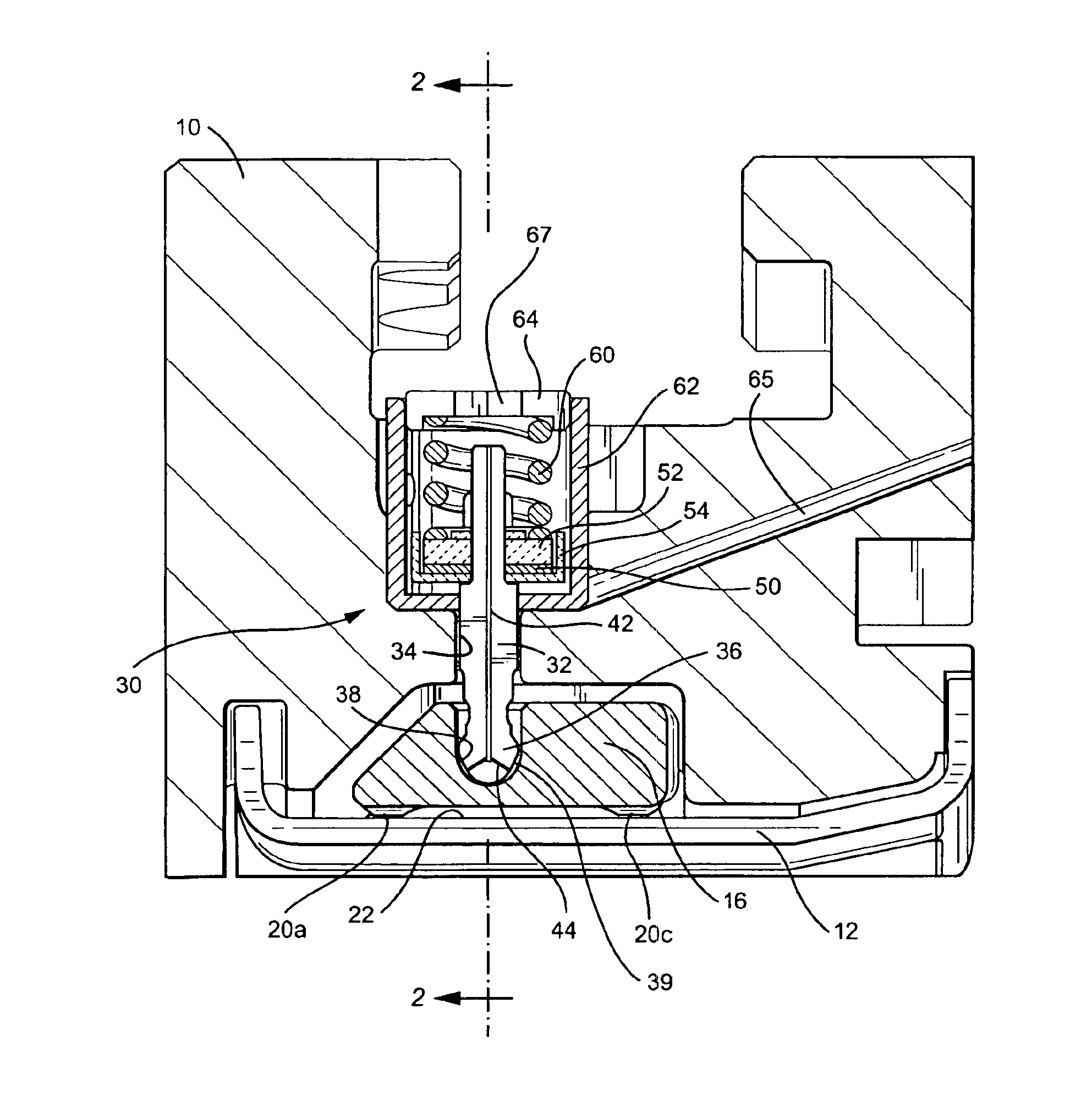

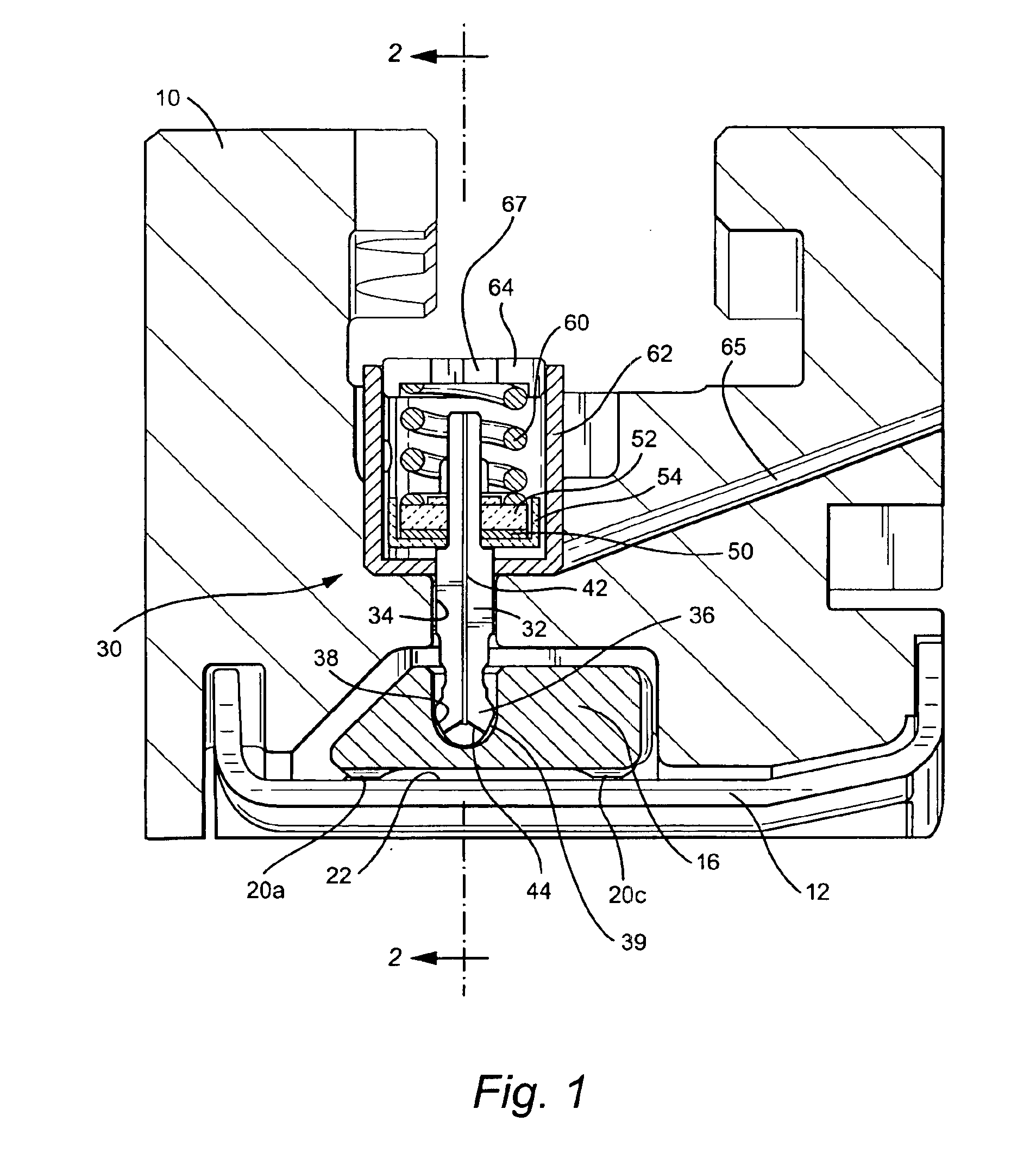

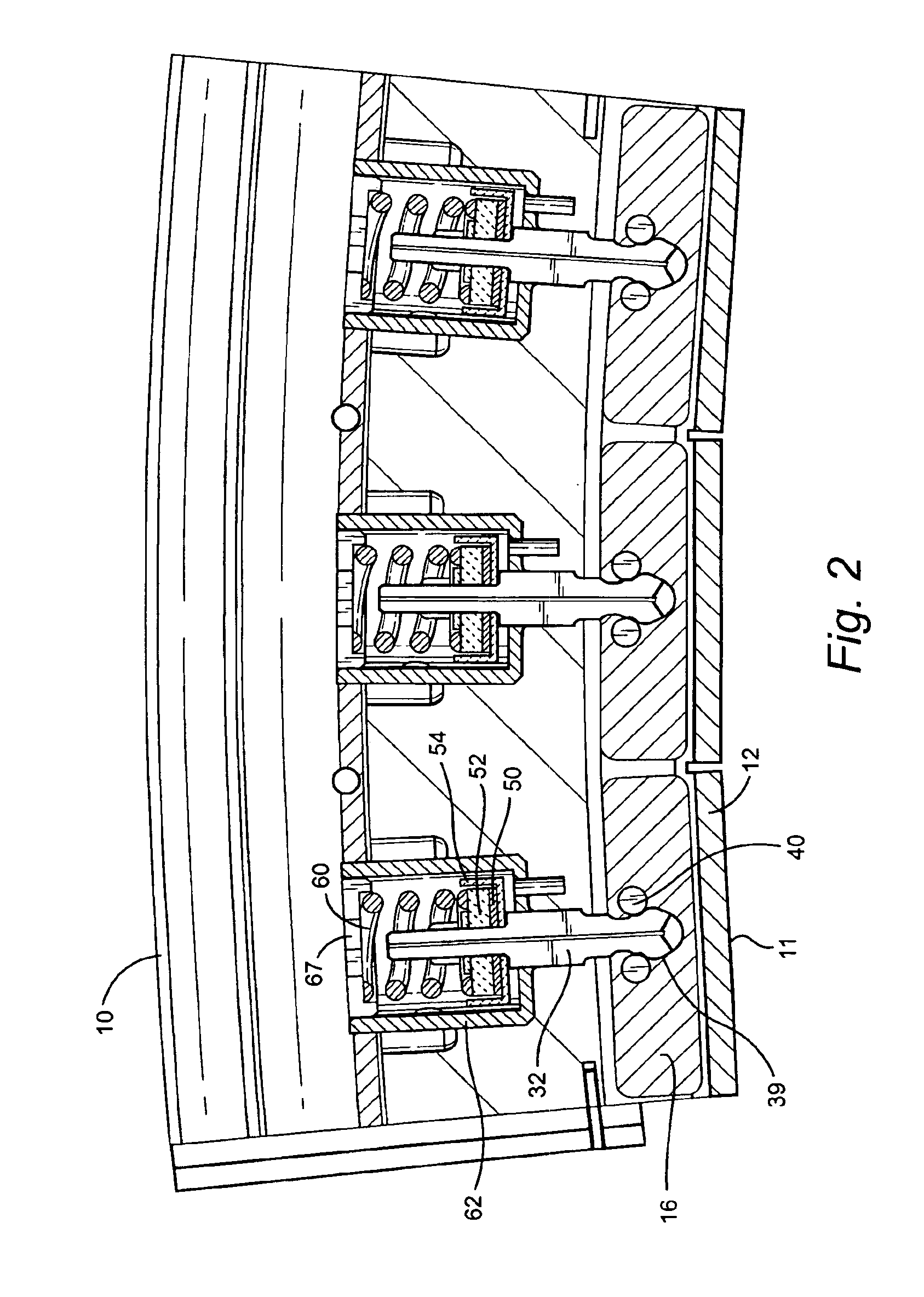

Apparatus for converting side-to-side driving motion to rotational motion with a spring assembly and system for tuning the spring assembly

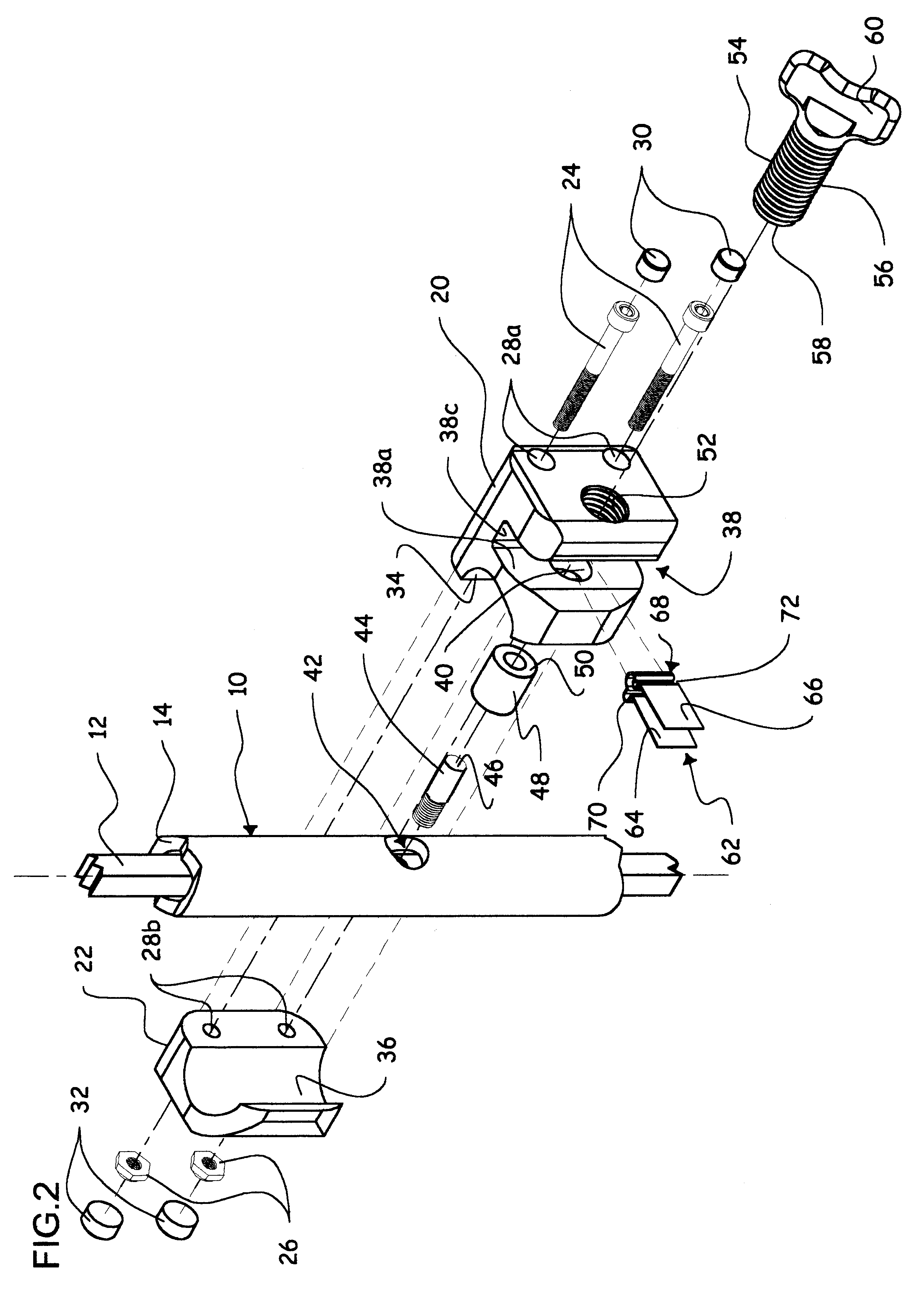

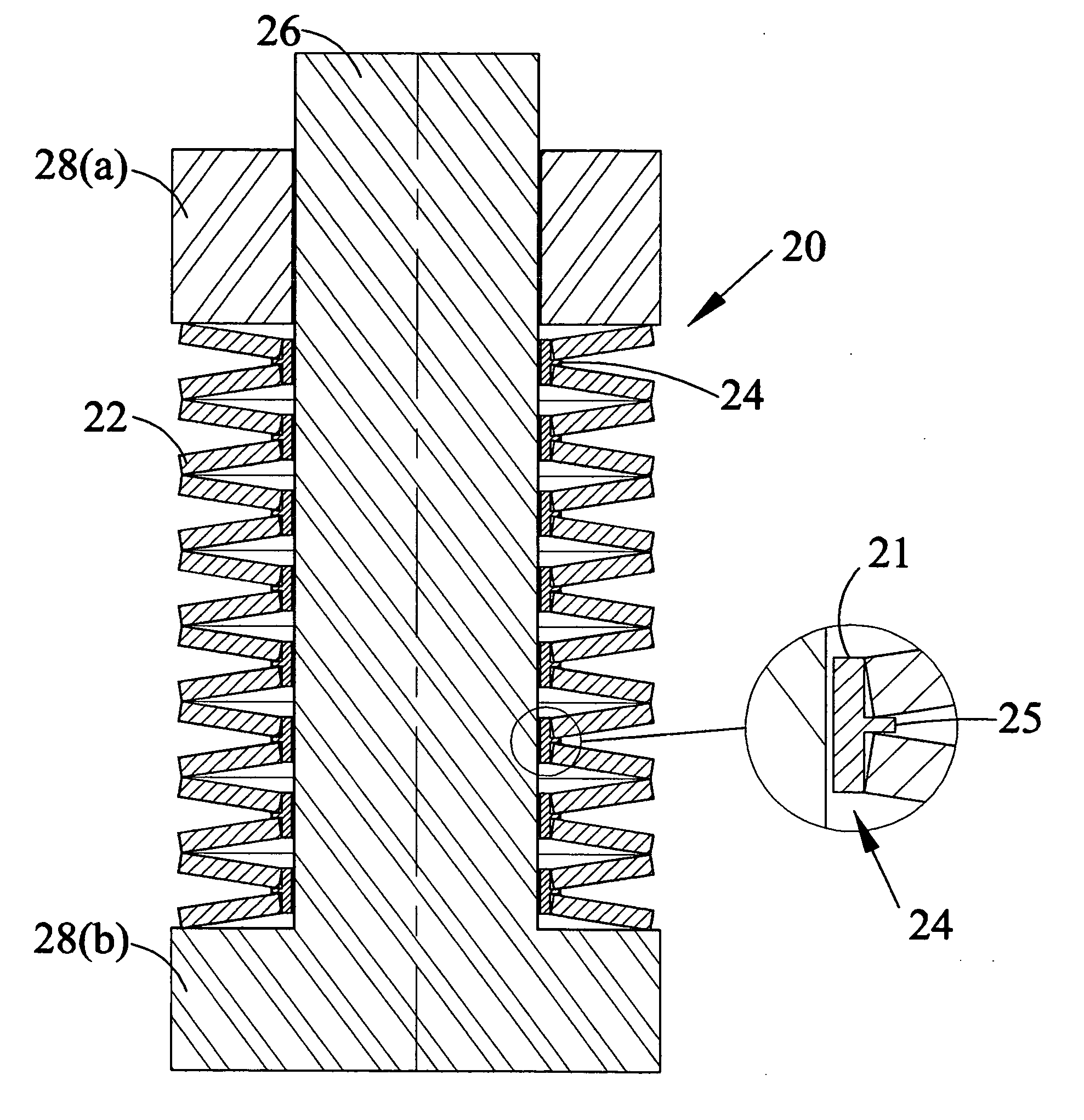

The apparatus for converting side-to-side to rotational motion for a workpiece includes a spring assembly with a movable base mounting element which is driven in a slightly arcuate reciprocal side-to-side motion and a fixed mounting element spaced apart from the base element and mounted in the appliance so that it does not rotate or move in operation of the apparatus. A spring member, such as two planar leaf springs positioned at an angle to each other, is mounted between the movable base element and the fixed mounting element. A drive shaft member extends from the movable base element through the fixed mounting element and beyond. A workpiece such as a brushhead is mounted on the distal end of the drive shaft. The spring member is configured so that it is substantially less resistant to twisting action than bending action, such that the side-to-side motion of the base element results in rotation of the workpiece.A method for tuning resonant spring assembly systems used in appliances such as power toothbrushes, particularly leaf spring systems, includes the step of measuring the frequency-dependent amplitude of the appliance workpiece, and then removing a portion of the spring member so as to decrease its spring rate sufficiently that the resonant frequency of the spring member closely approximates the drive frequency of the appliance.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Spring core

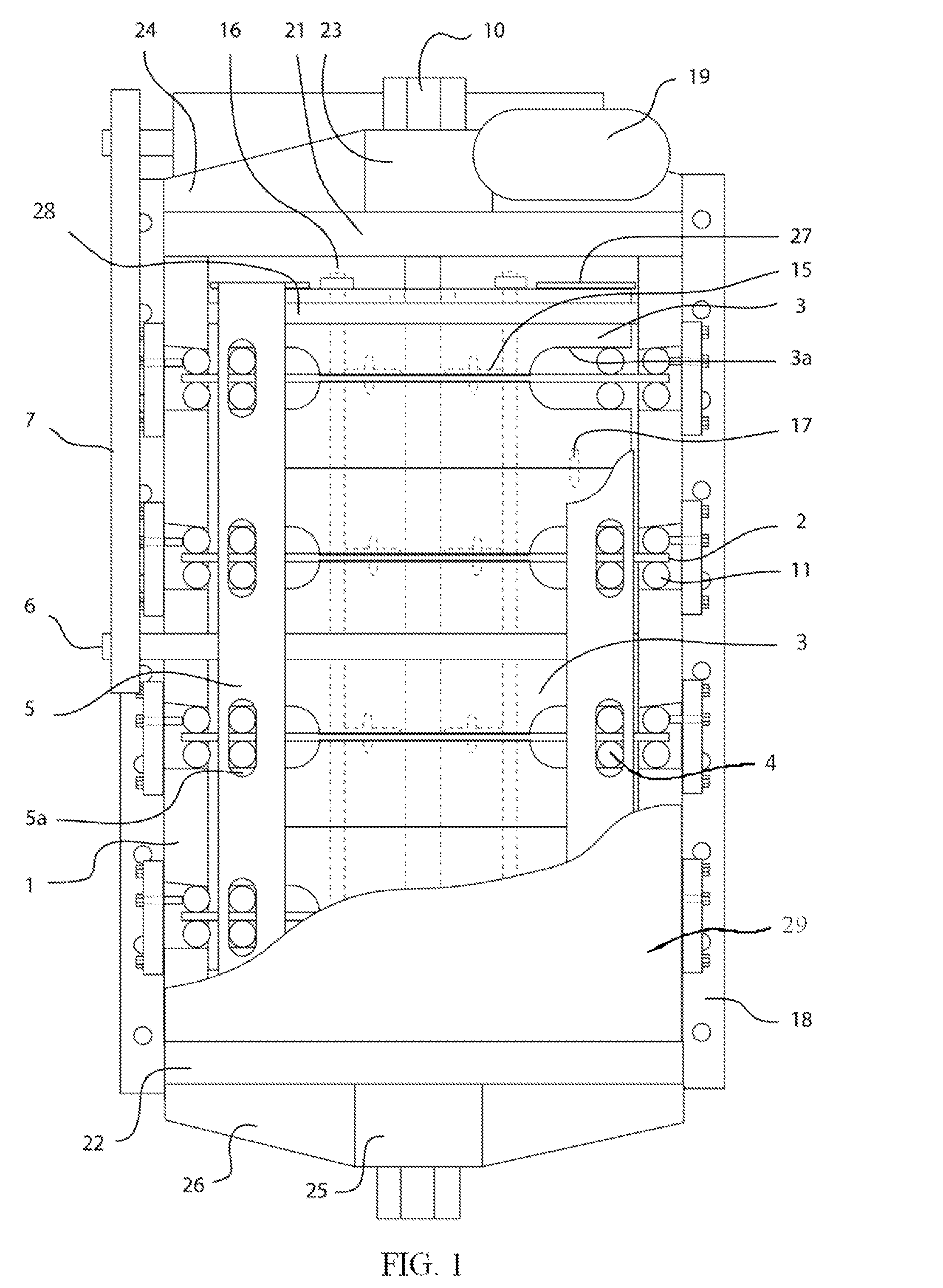

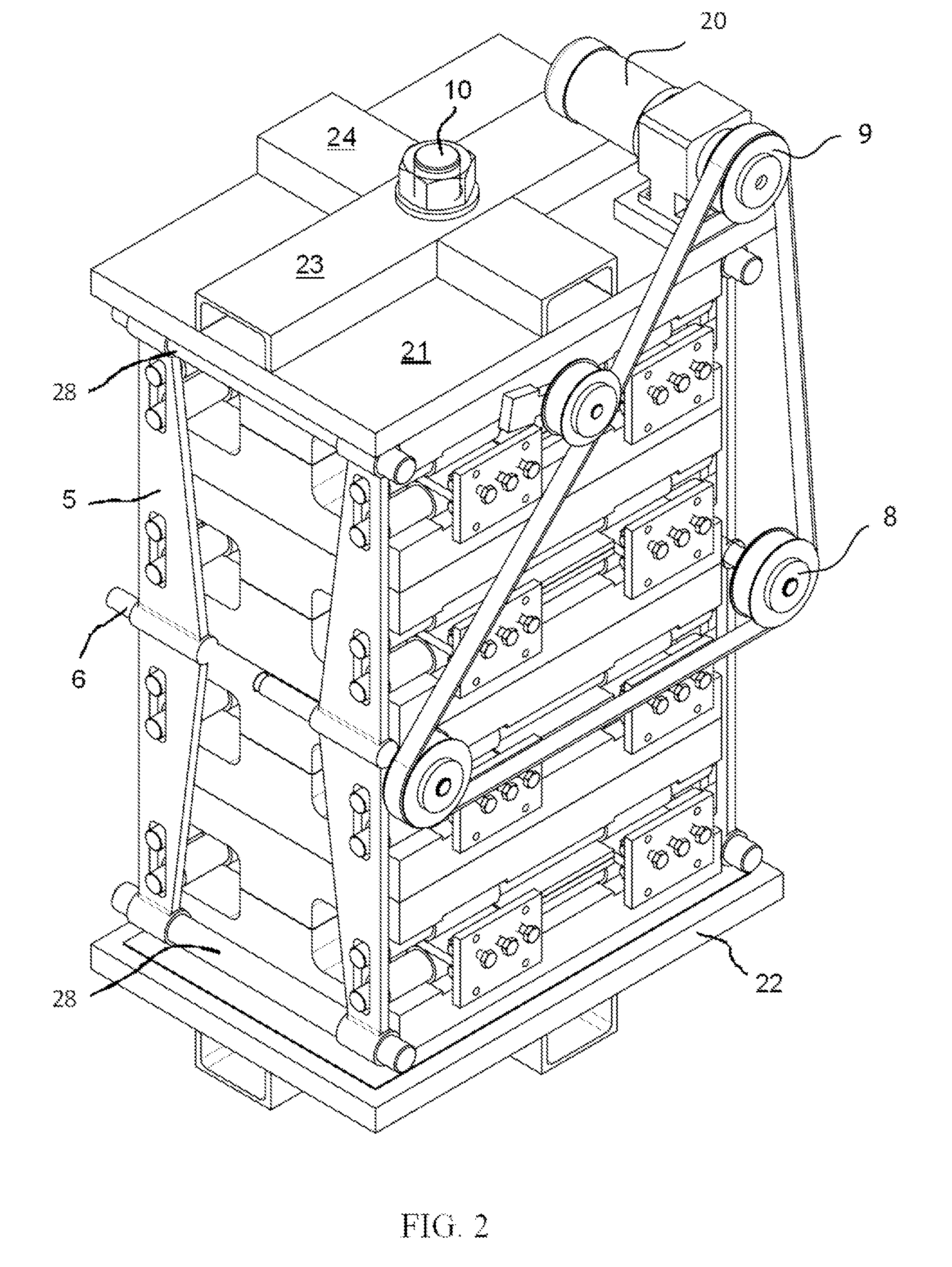

InactiveUS20070108679A1Formation of shortMore cost-effectiveStuffed mattressesLeaf springsEngineeringMechanical engineering

Owner:AGRO FEDERKERNPRODN

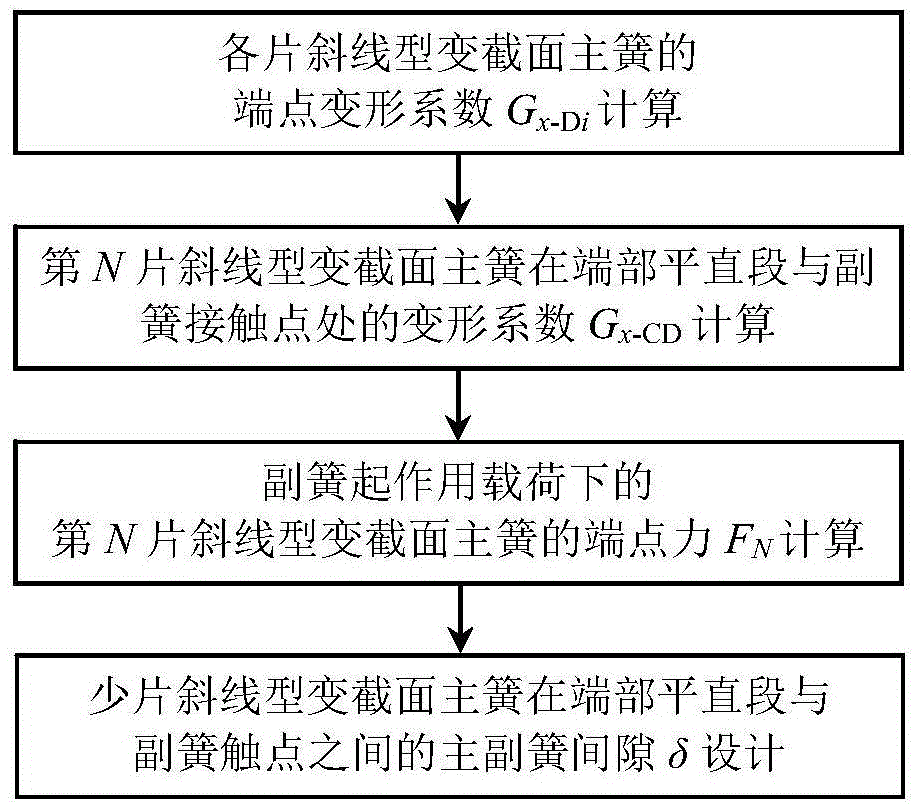

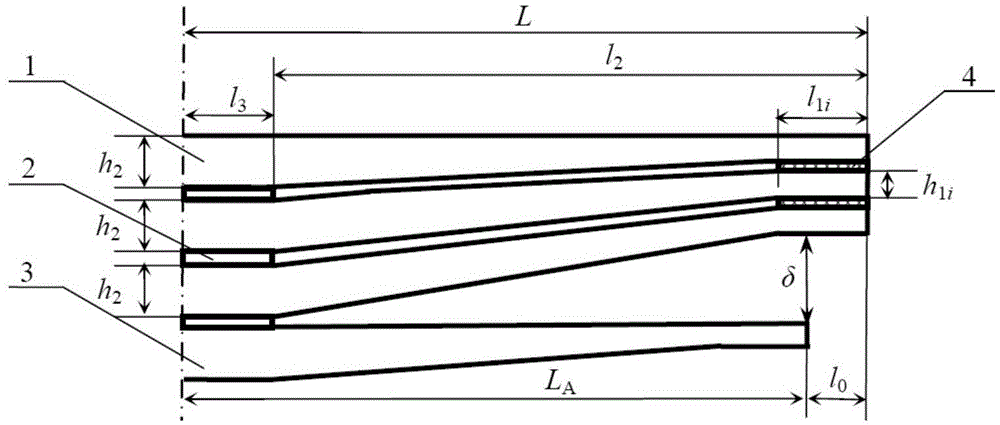

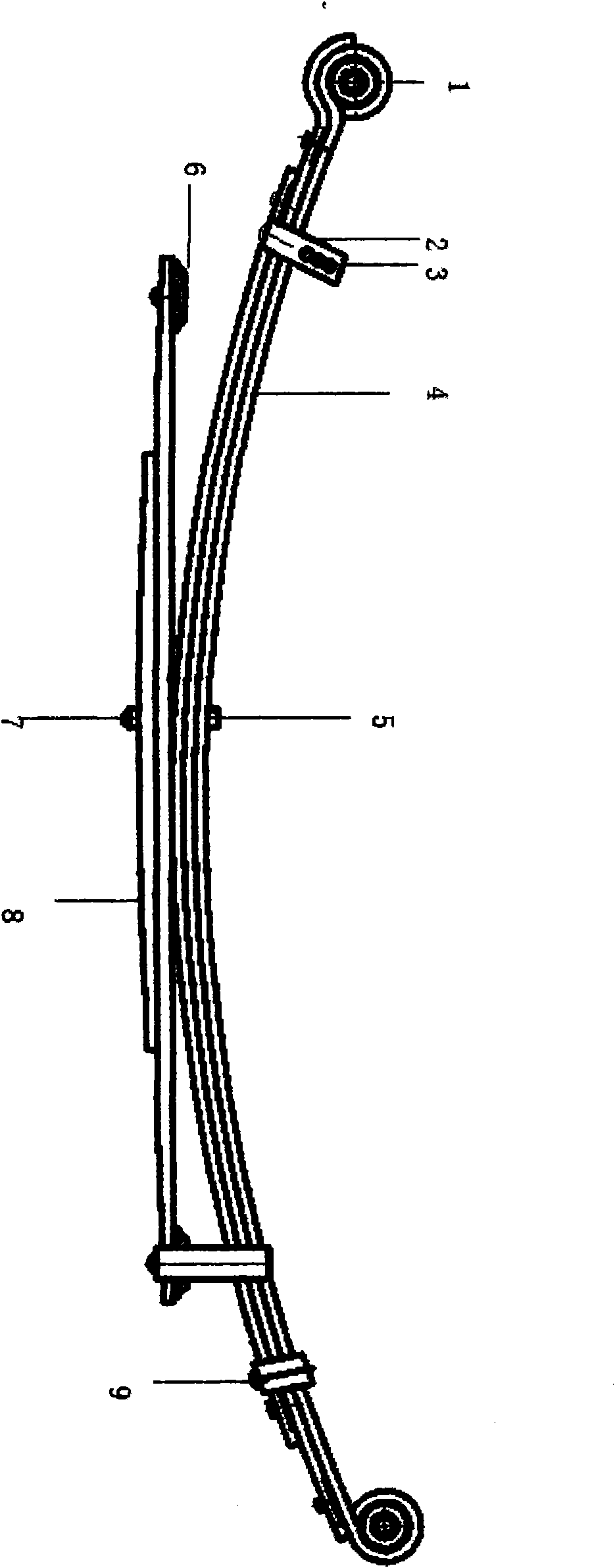

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

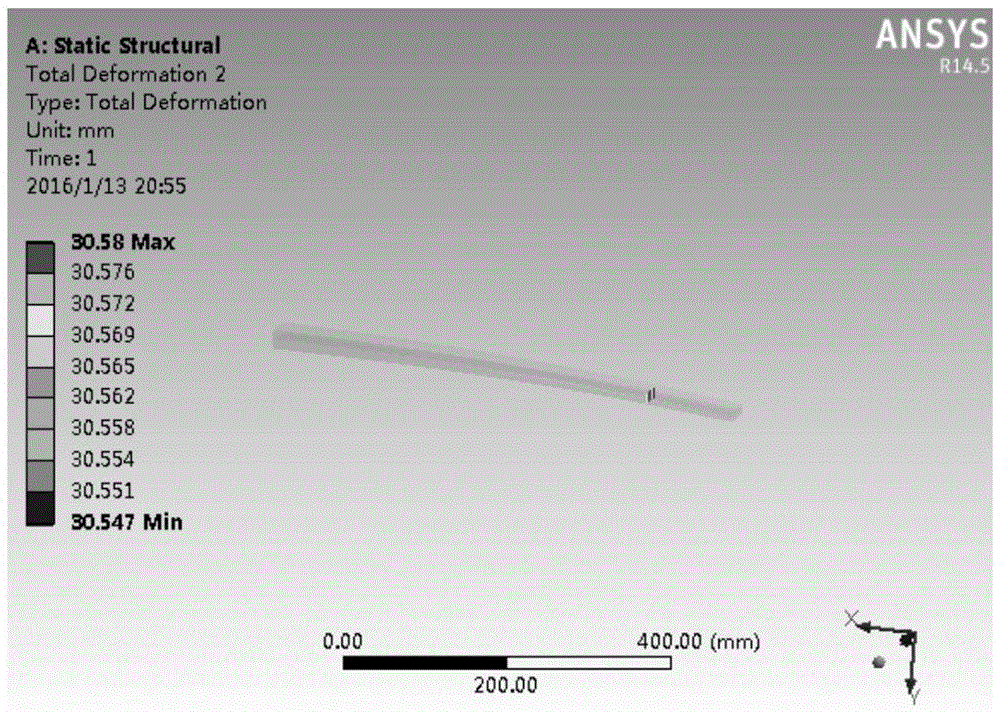

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

Yaw-rate sensor

ActiveUS20120060604A1Reduces space and power requirementEasy to make costAcceleration measurement using interia forcesLeaf springsEngineeringCoriolis force

A yaw-rate sensor having a substrate and a plurality of movable substructures that are mounted over a surface of the substrate, the movable substructures being coupled to a shared, in particular, central spring element, means being provided for exciting the movable substructures into a coupled oscillation in a plane that extends parallel to the surface of the substrate, the movable substructures having Coriolis elements, means being provided for detecting deflections of the Coriolis elements induced by a Coriolis force, a first Coriolis element being provided for detecting a yaw rate about a first axis, a second Coriolis element being provided for detecting a yaw rate about a second axis, the second axis being oriented perpendicularly to the first axis.

Owner:ROBERT BOSCH GMBH

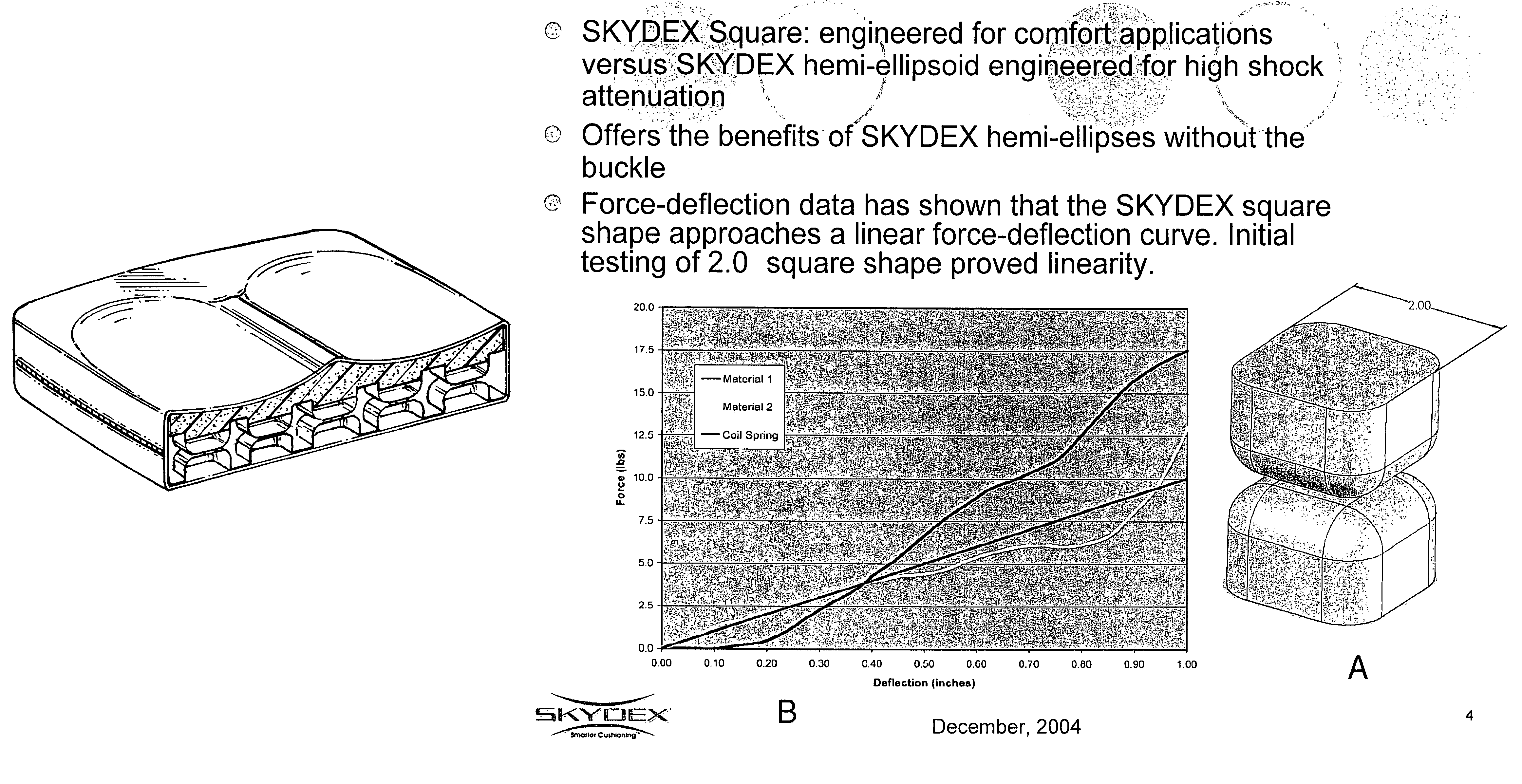

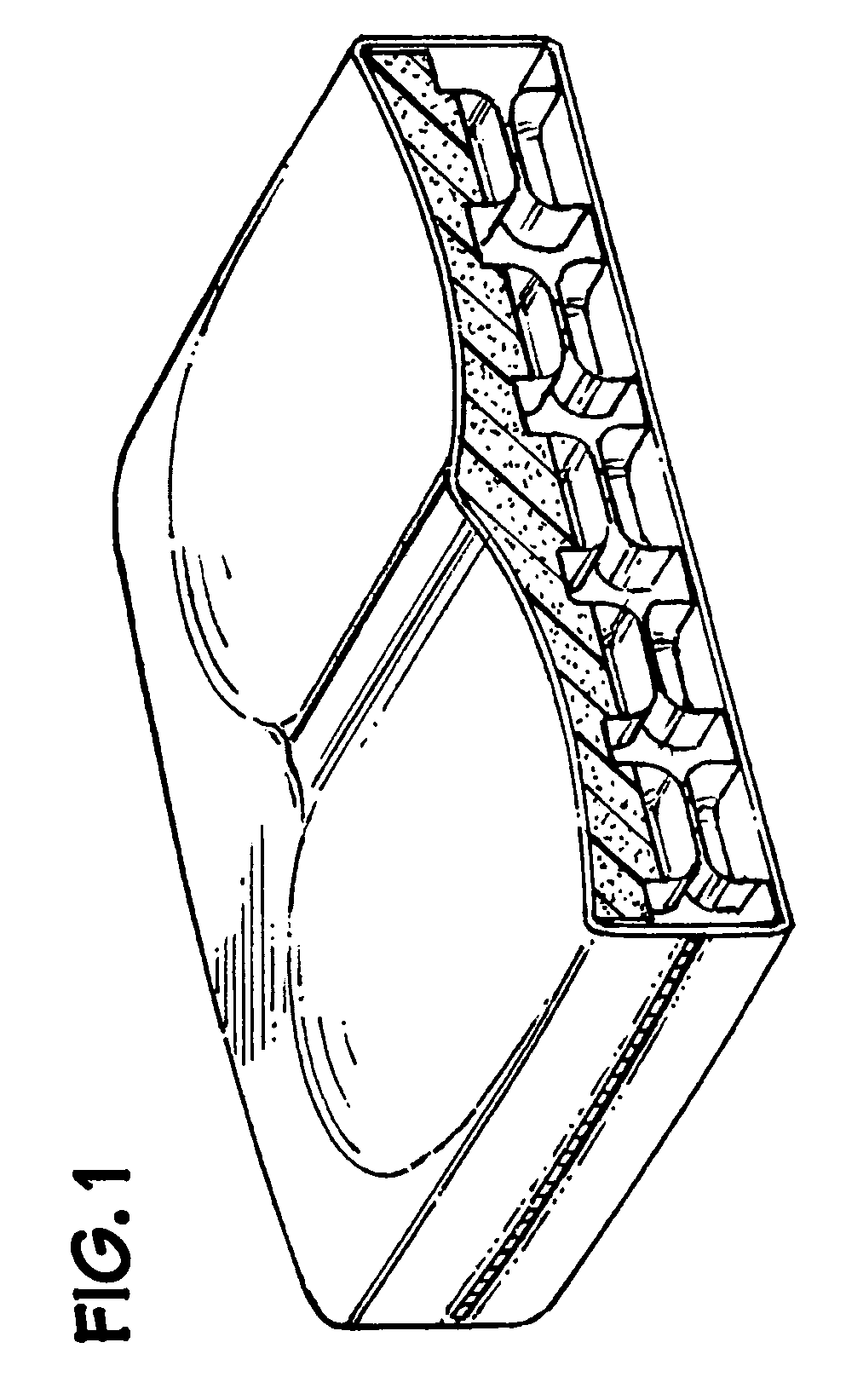

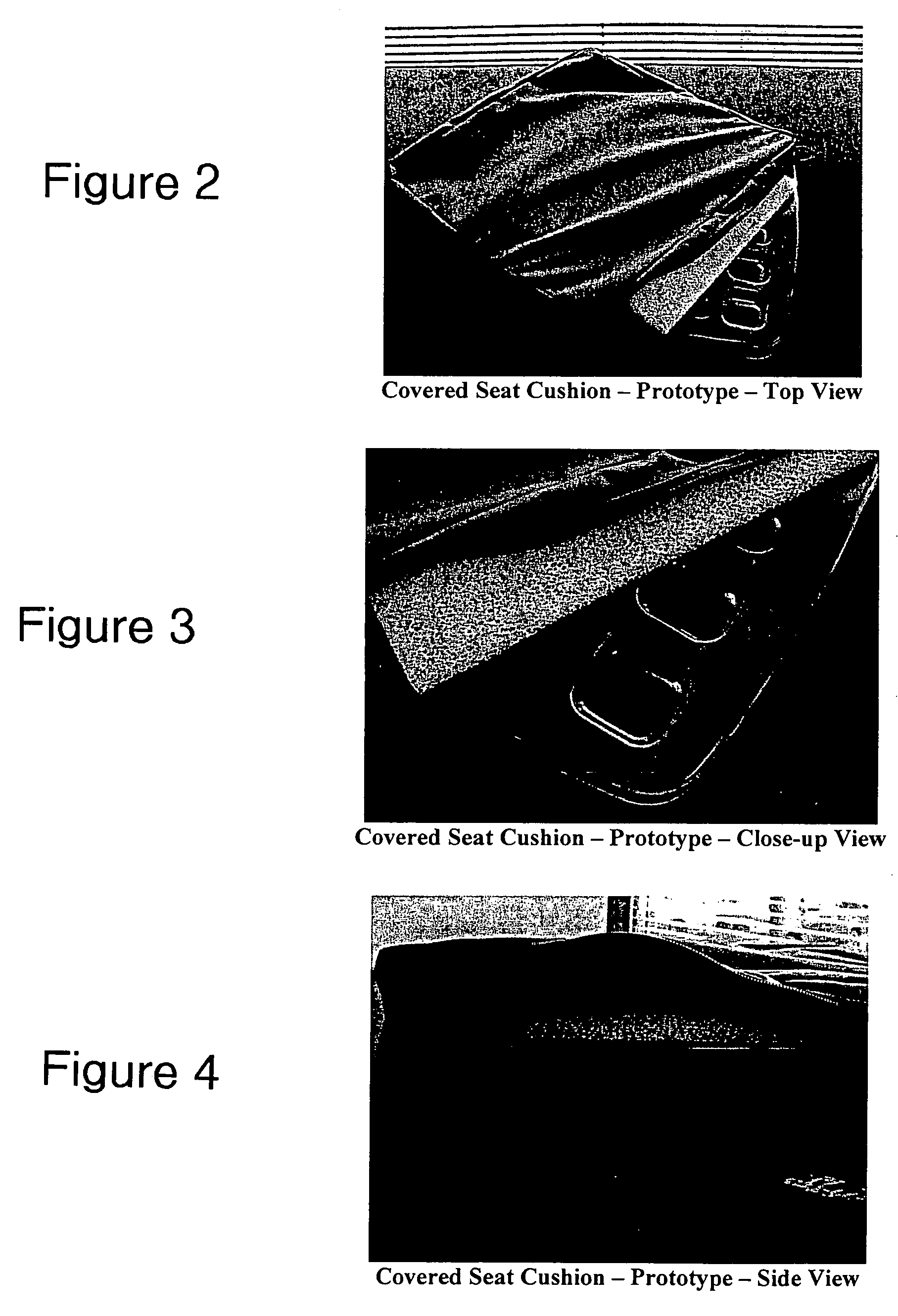

Cushioning system with parallel sheets having opposing indentions for linear deflection under load

ActiveUS7574760B2Resistant to tear and punctureEasy to cleanStuffed mattressesLeaf springsEngineeringBiomedical engineering

A cushion comprises a first surface made of flexible high polymer resin; a second surface made of flexible high polymer resin, in at least partially coextensive relation to the first surface to define a cavity therebetween, the coextensive relation defining opposing corresponding portions of the first and second surfaces; a plurality of support members comprising inwardly directed indentations in both of the first and second surfaces extending into the cavity, a plurality of the indentations in each of the first and second surfaces having a square shape and an outwardly facing recess, a plurality of the indentations in the first surface abutting the indentations in the second surface; a layer of viscoelastic foam substantially overlying the first surface; and, a fabric enclosure surrounding the first surface, the second surface and the foam layer.

Owner:SKYDEX TECH INC

Shackle assembly

InactiveUS7229088B2Increase travelImprove performanceLeaf springsRigid suspensionsElastomerLateral stiffness

Owner:HENDRICKSON USA L L C

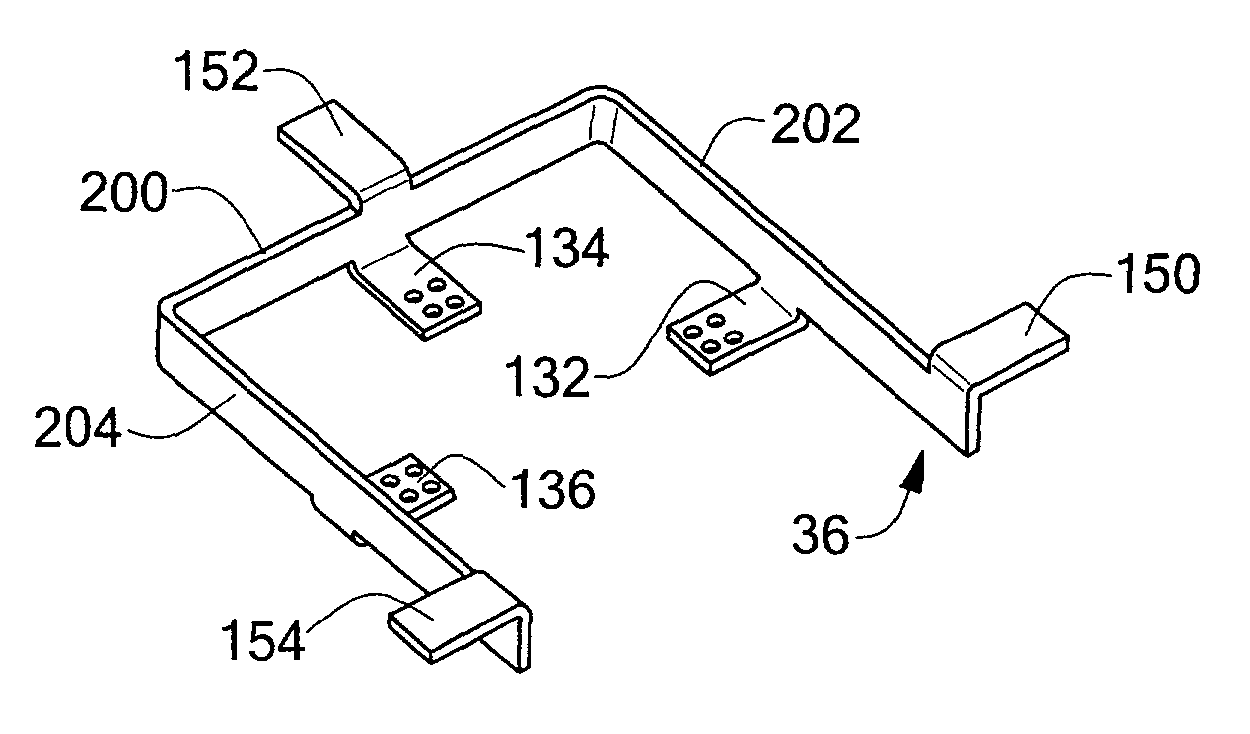

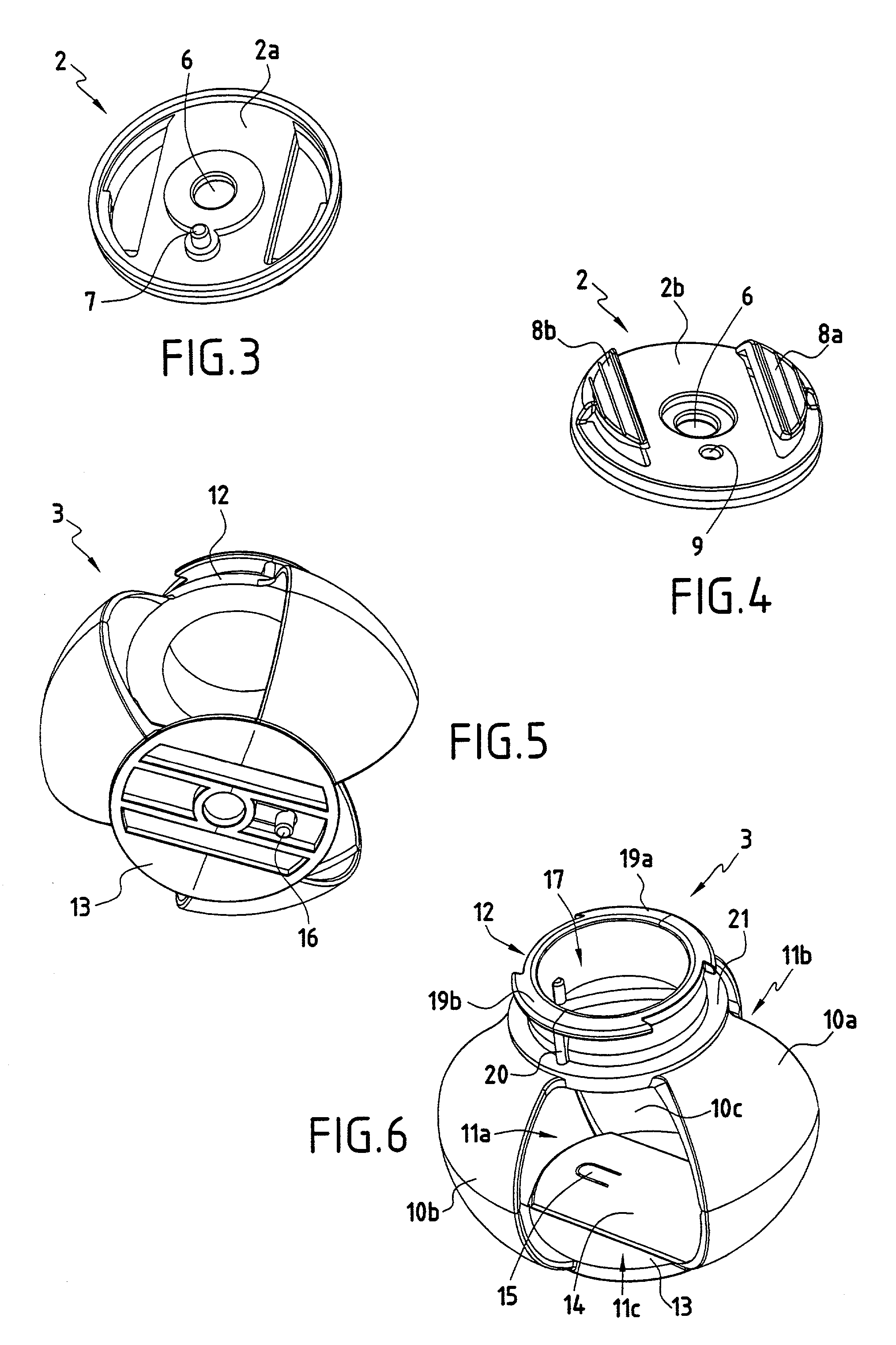

Compliant, ortho-planar, linear motion spring

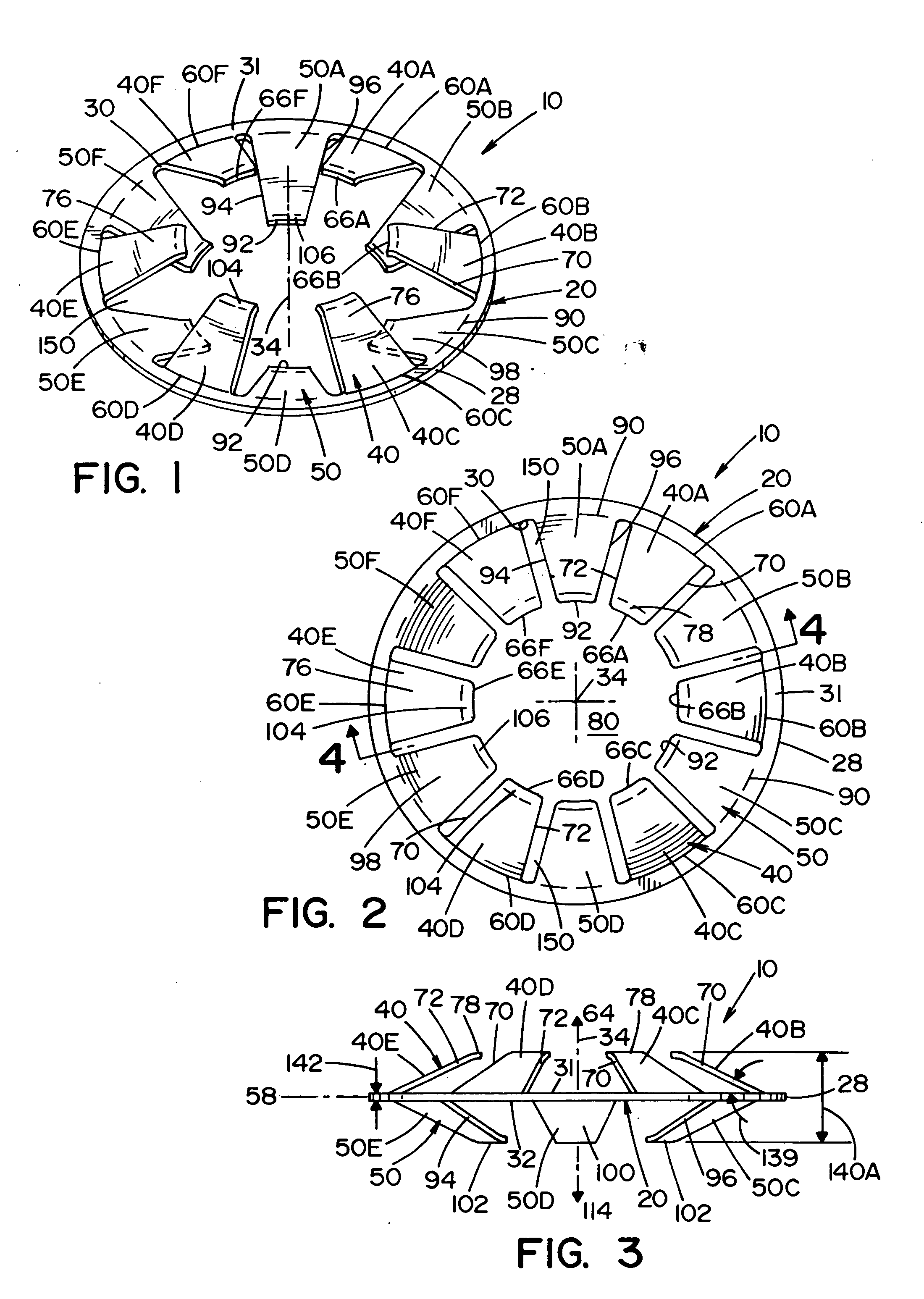

An ortho-planar spring has a platform movably coupled to a base and being movable linearly with respect to the base along at least a portion of an axial direction perpendicular to both a base surface and a platform surface. A resilient and flexible connecting structure is connected to and between the base and platform. The connecting structure is bendable to develop (i) an axial force along the axial direction to bias the platform in a stable position with respect to the base, and (ii) non-axial forces which substantially sum to zero to preserve the orientation of the platform with respect to the base. Thus, the spring is very compact and does not have rotation between the deflecting ends. The spring may be associated with a valve opening, and a button for restricting flow through the valve opening, to bias the button at a position with respect to the valve opening.

Owner:BRIGHAM YOUNG UNIV

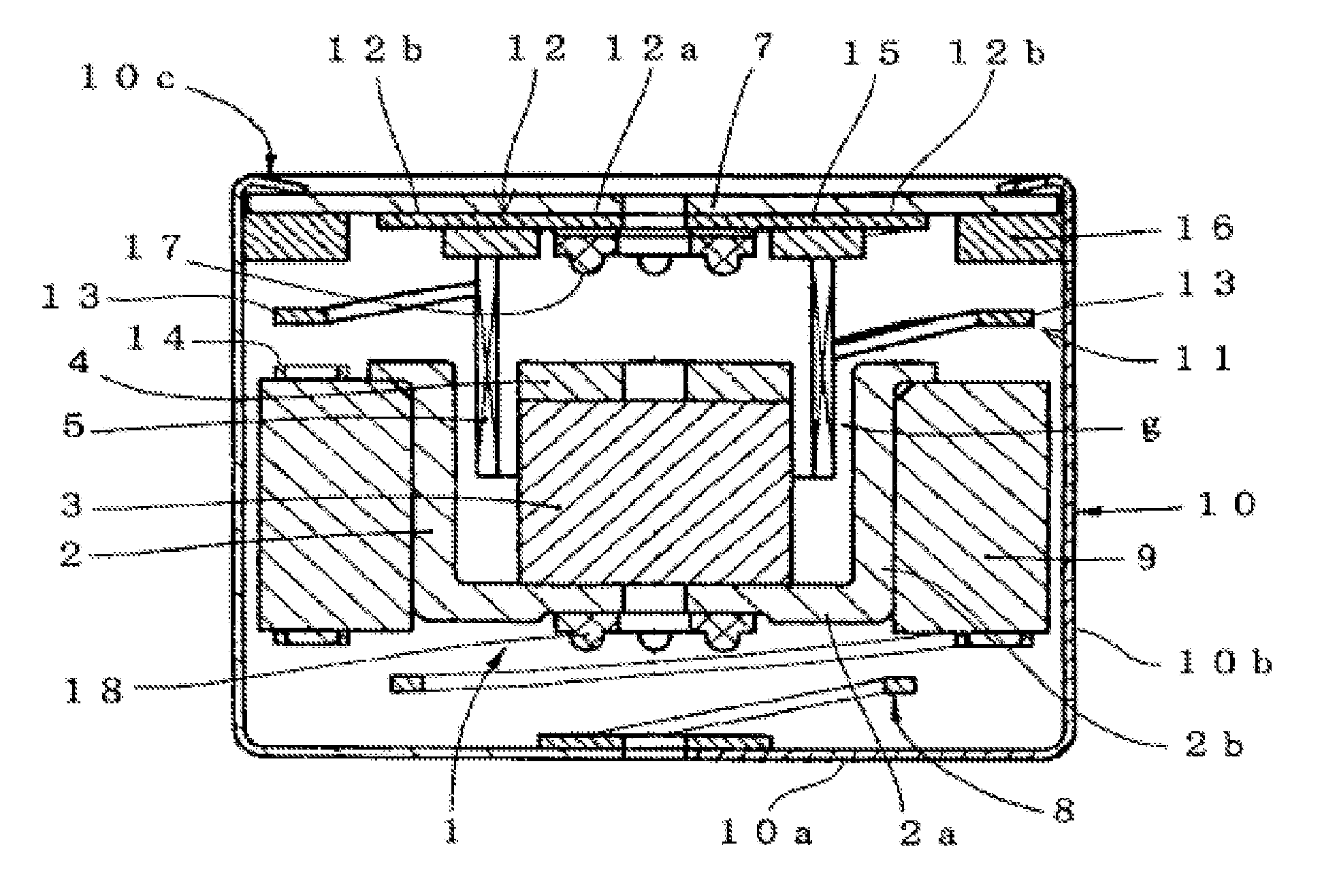

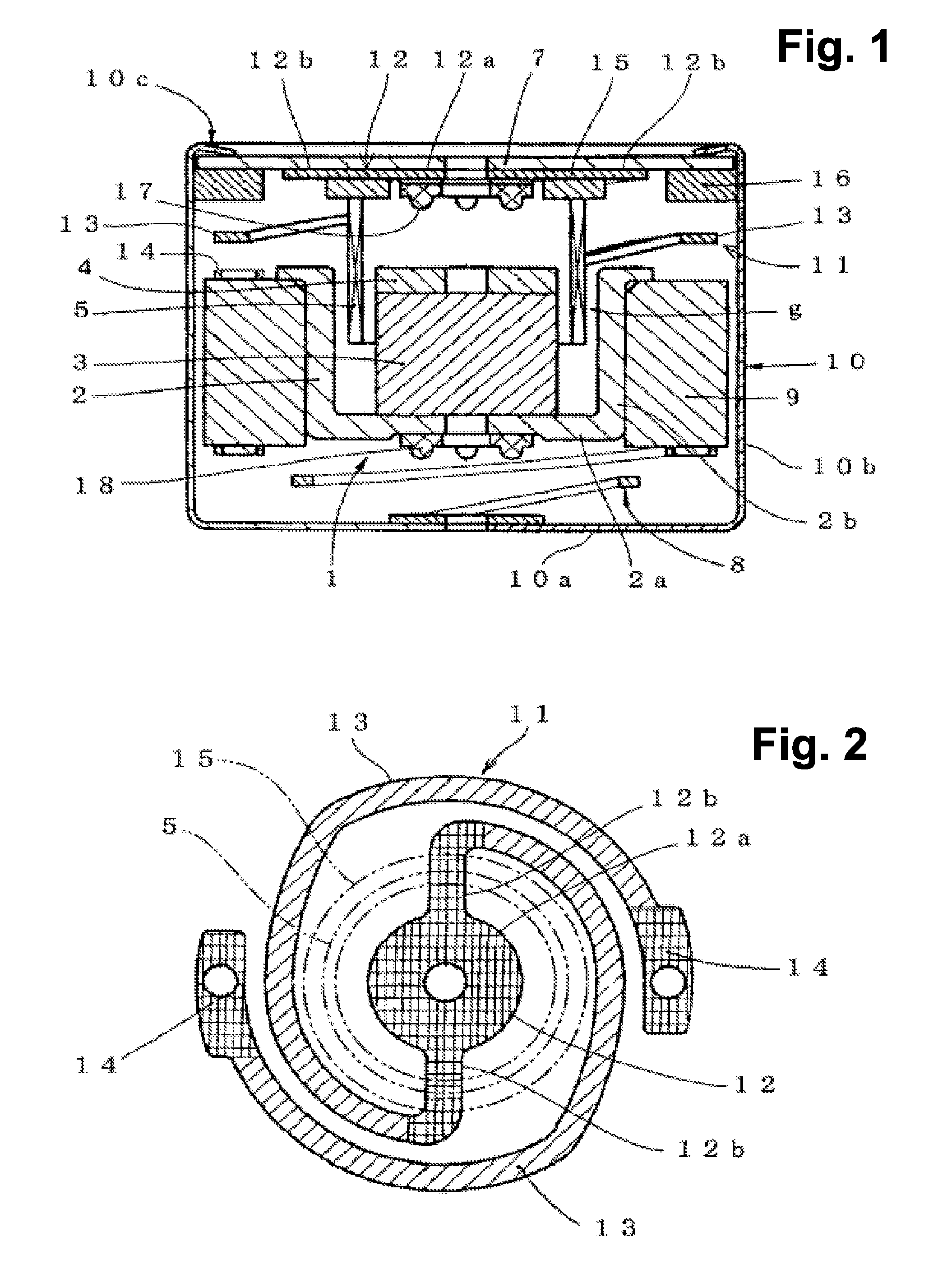

Vibrator

InactiveUS7619498B2Increase amplitudeLeaf springsMechanical vibrations separationVoice coilElectrical and Electronics engineering

Owner:CITIZEN ELECTRONICS CO LTD

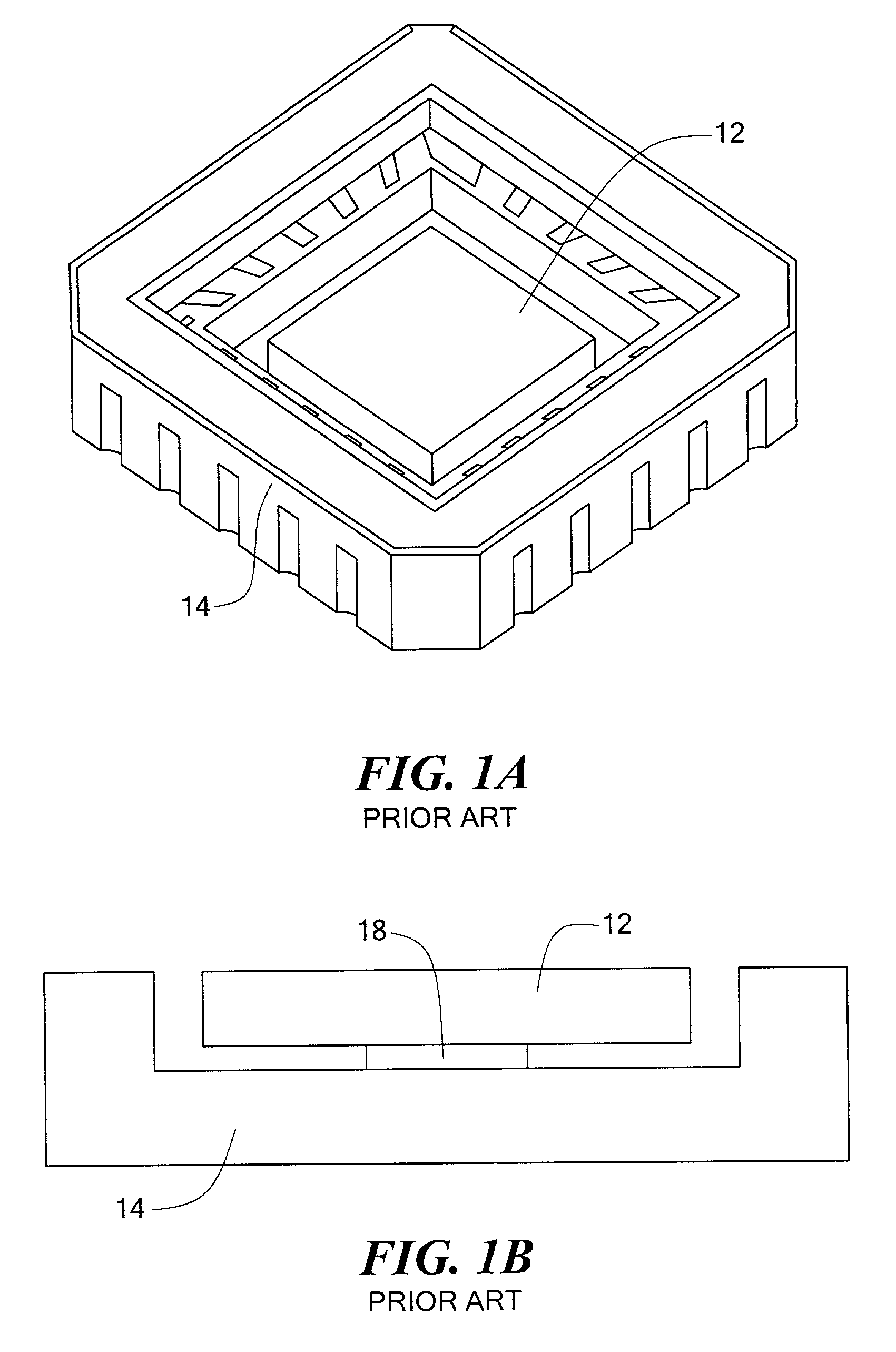

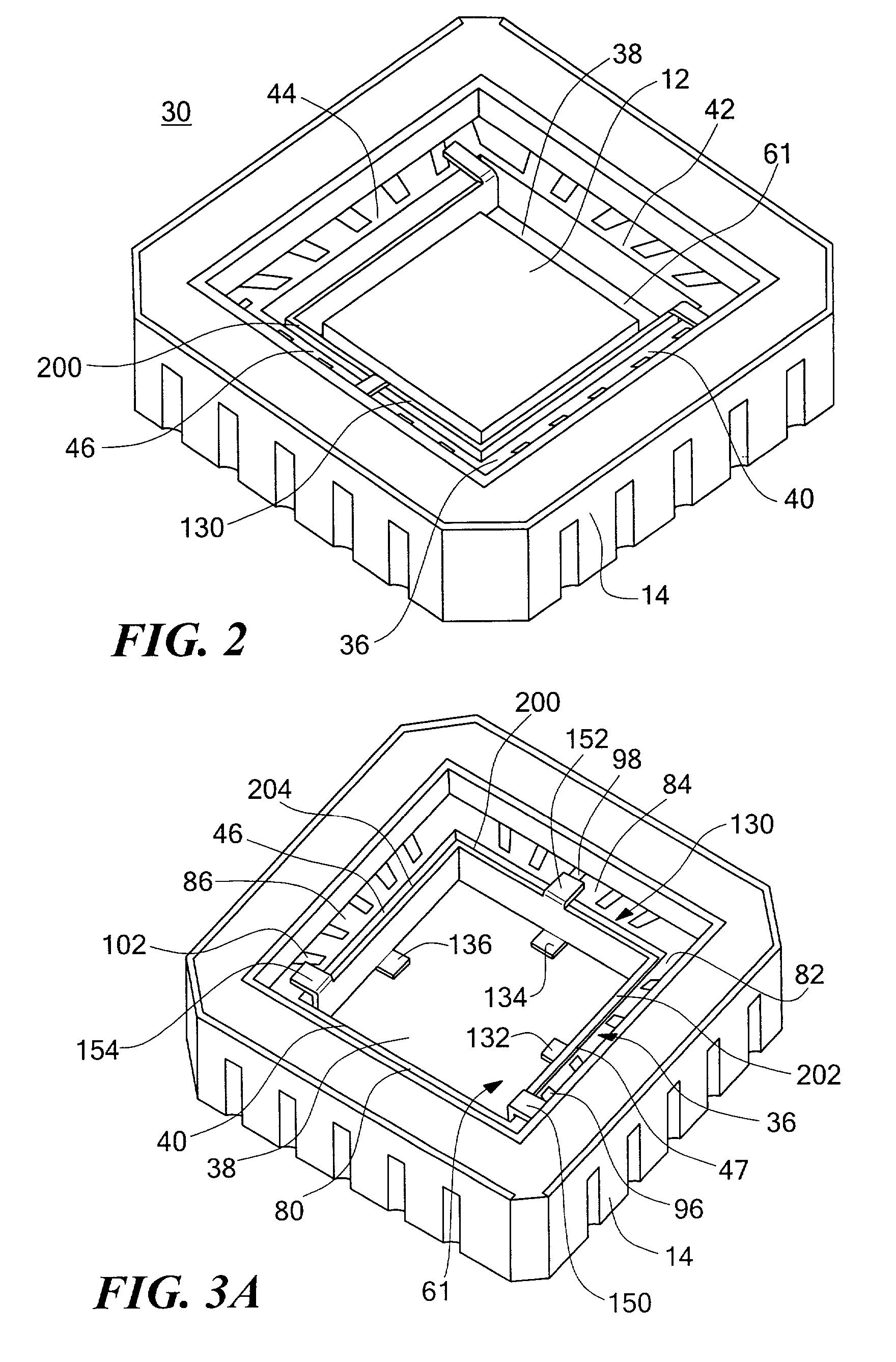

Sensor isolation system

InactiveUS20030038415A1Eliminate the problemReduce warpagePortable framesMeasurement apparatus componentsInterposerEngineering

A sensor isolation system including a sensor, a package for the sensor, and a compliant interposer disposed between the sensor and the package and interconnecting the sensor to the package to isolate the sensor from thermal and mechanical stresses and yet at the same time providing a physical interconnect between the sensor and the package.

Owner:CHARLES STARK DRAPER LABORATORY

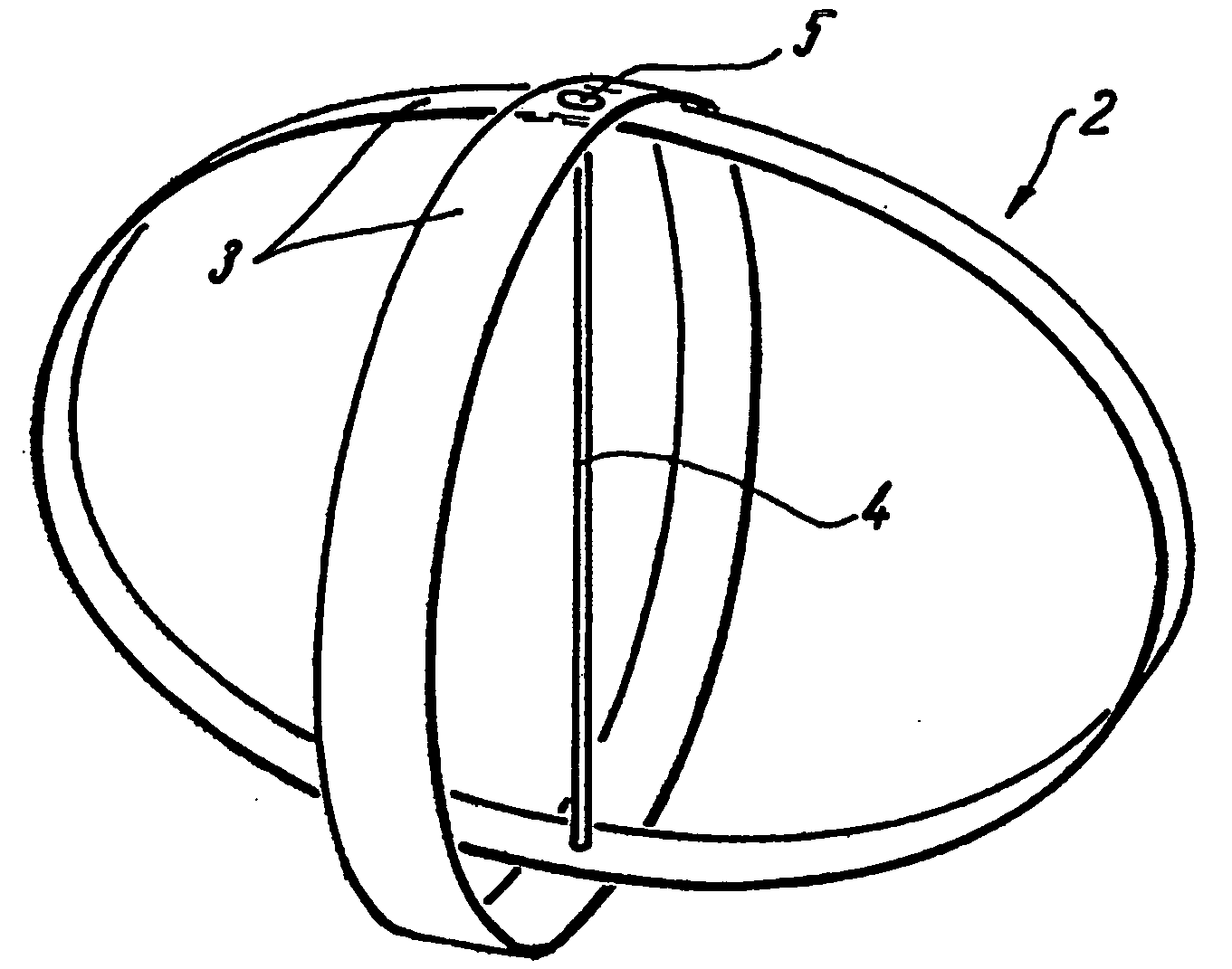

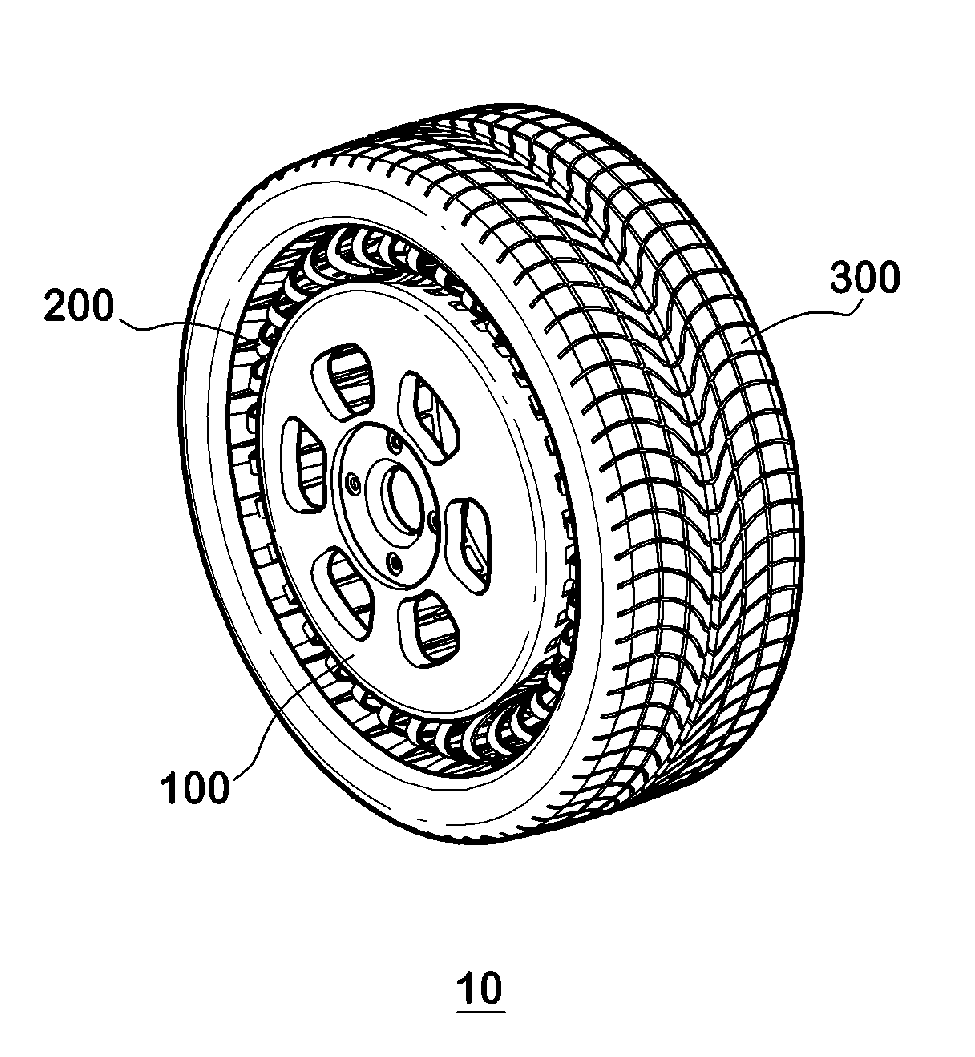

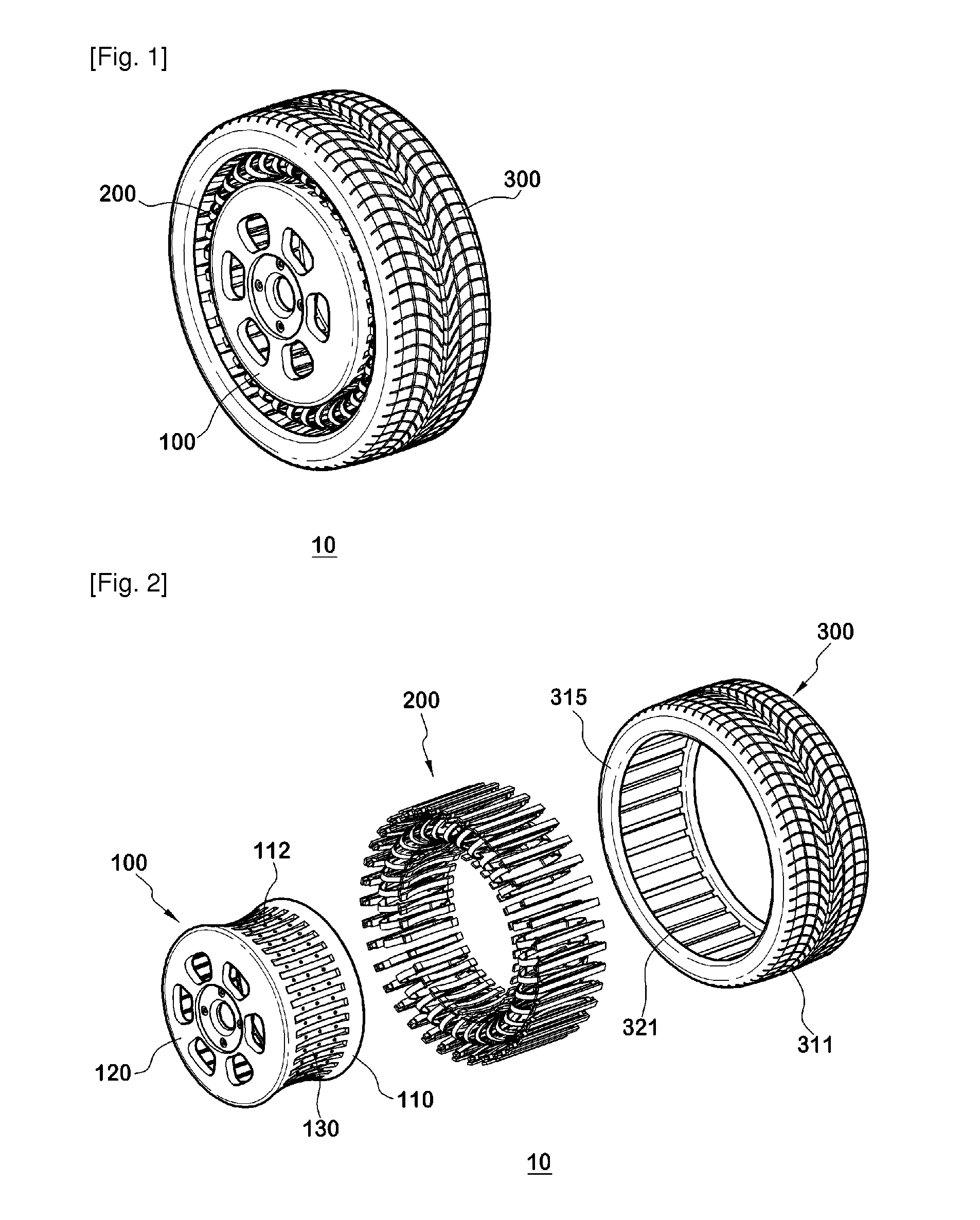

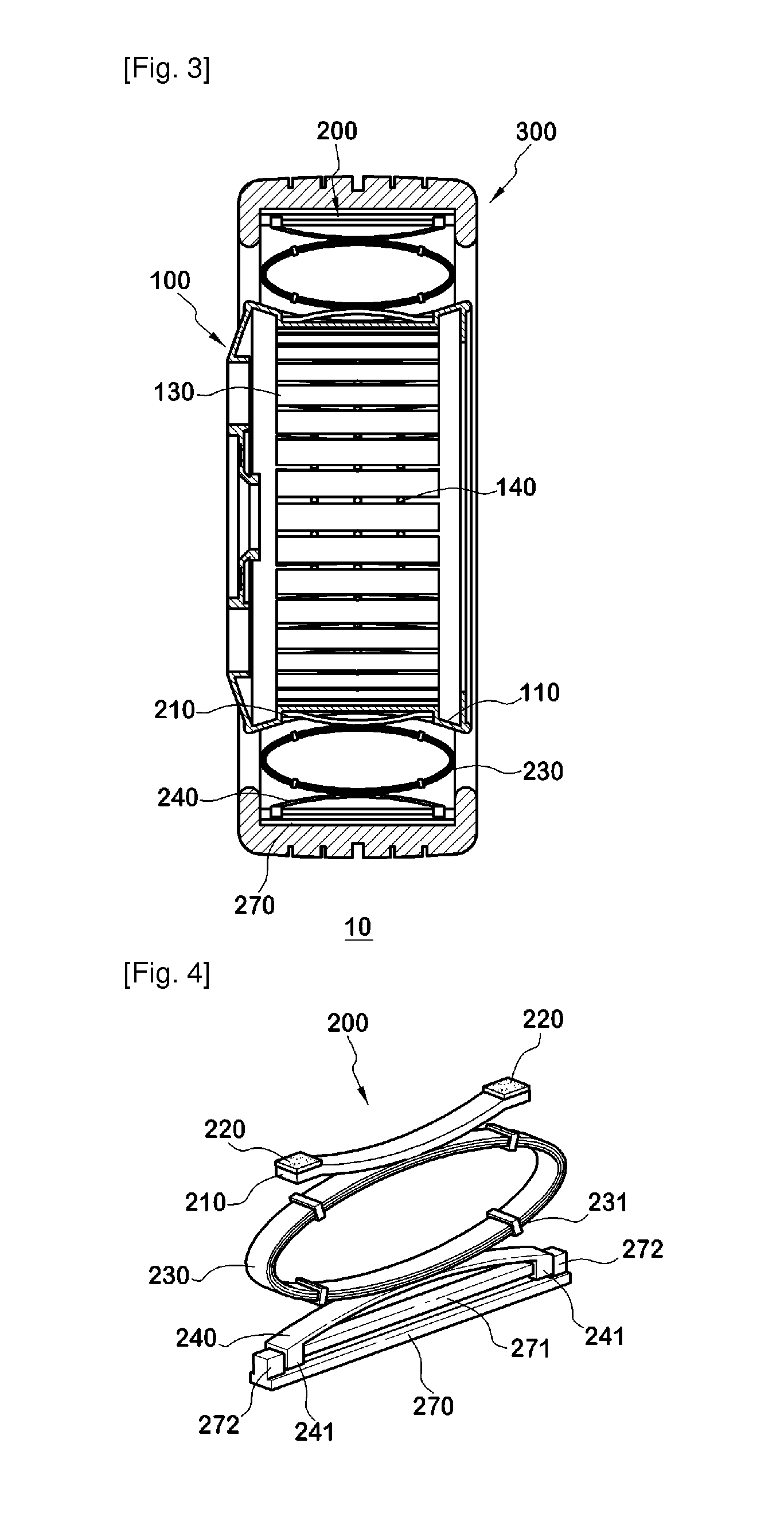

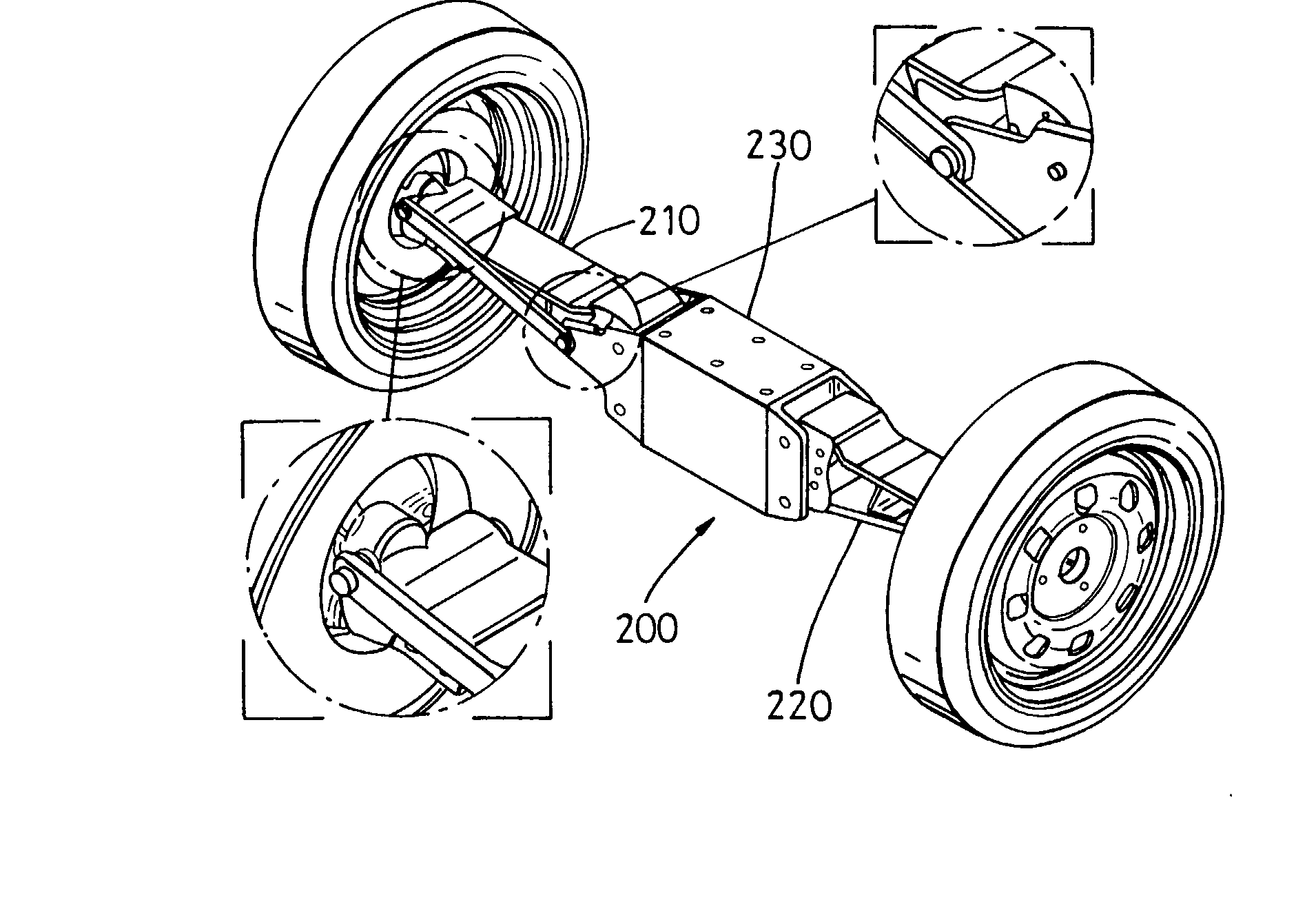

Non-pneumatic wheel and wheel, suspension and tire used therein

InactiveUS20110248554A1Prevent tire blowoutReduce vehicle accidentRimsLeaf springsCornering forceBrake fade

Provided is a non-pneumatic wheel (100) for a vehicle, and a wheel (100), suspension (200; 200-1), and tire (300) used therein that are capable of ensuring driving stability because there is no air chamber between a wheel (100) and a tire (300) to blowout. They are also capable of ensuring good road holding, preventing standing waves, reducing brake fade and cornering force, providing good handling and ride comfort, staying quiet when rolling, and are economical and environmentally friendly. The non-pneumatic wheel (100) includes a wheel (100), a shock absorbing member (220; 220-1) coupled to an outer periphery of the wheel (100) and absorbing or attenuating noise and vibration due to external shock, a plurality of resilient members (230; 230-1; 230-2) arranged around and coupled to an outer periphery of the shock absorbing member (220; 220-1) in a radial direction and having a plurality of resilient rings (230-1a) that are resiliently deformed in response to an external force, resilient links (240) respectively coupled to the resilient rings (230-1a) to evenly transmit external shock to the resilient rings (230-1a), rail plates (270) to which sliders (261) formed at both ends of the resilient links (240) are slidably coupled, and a tire (300) having a plurality of coupling grooves (321) formed along an inner periphery such that the rail plates (270) are inserted into the coupling grooves (321).

Owner:CHON YOUNG ILL +4

Check valve

Check valve includes a housing, a bore, and a movable valve body, which is spring-loaded and rests with a sealing action on a valve seat, where the bore is designed as a stepped bore, where the bore with the smaller diameter has the valve seat, and where the bore with the larger diameter holds the movable valve element. The valve body is designed as a ball, which is guided in the bore by at least two guide ribs, and a retaining element in the terminal area of the bore captures the ball and simultaneously spring-loads it.

Owner:ZF FRIEDRICHSHAFEN AG

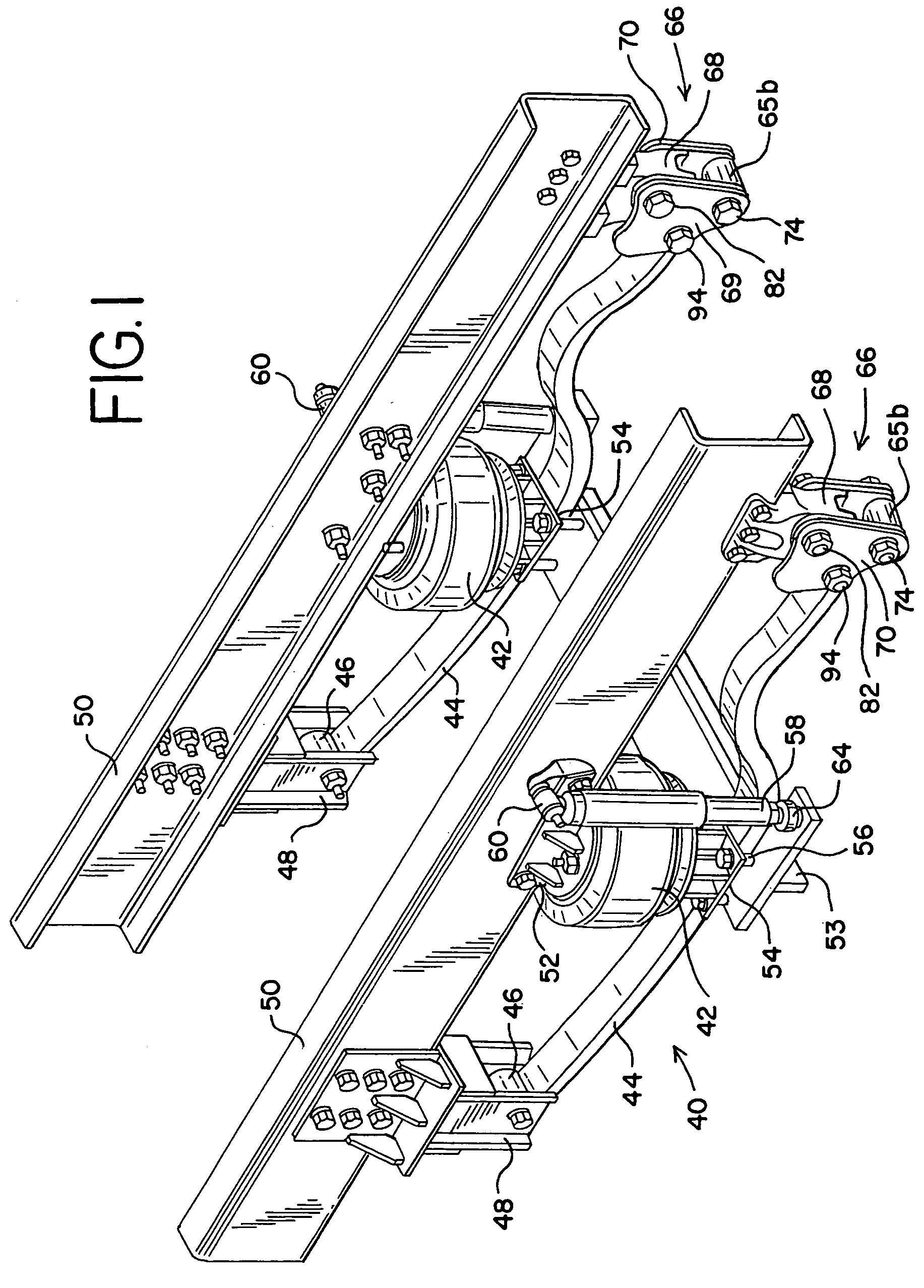

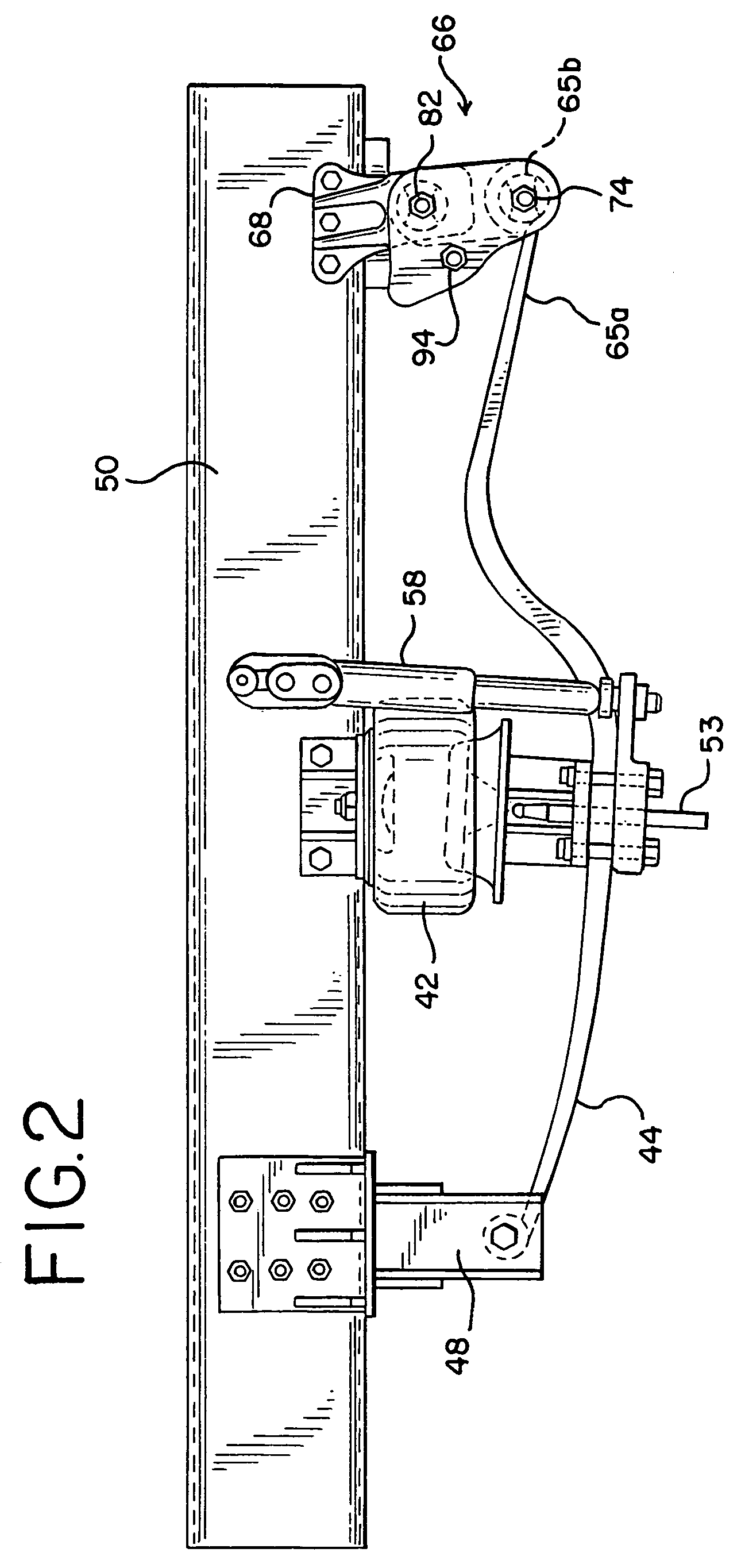

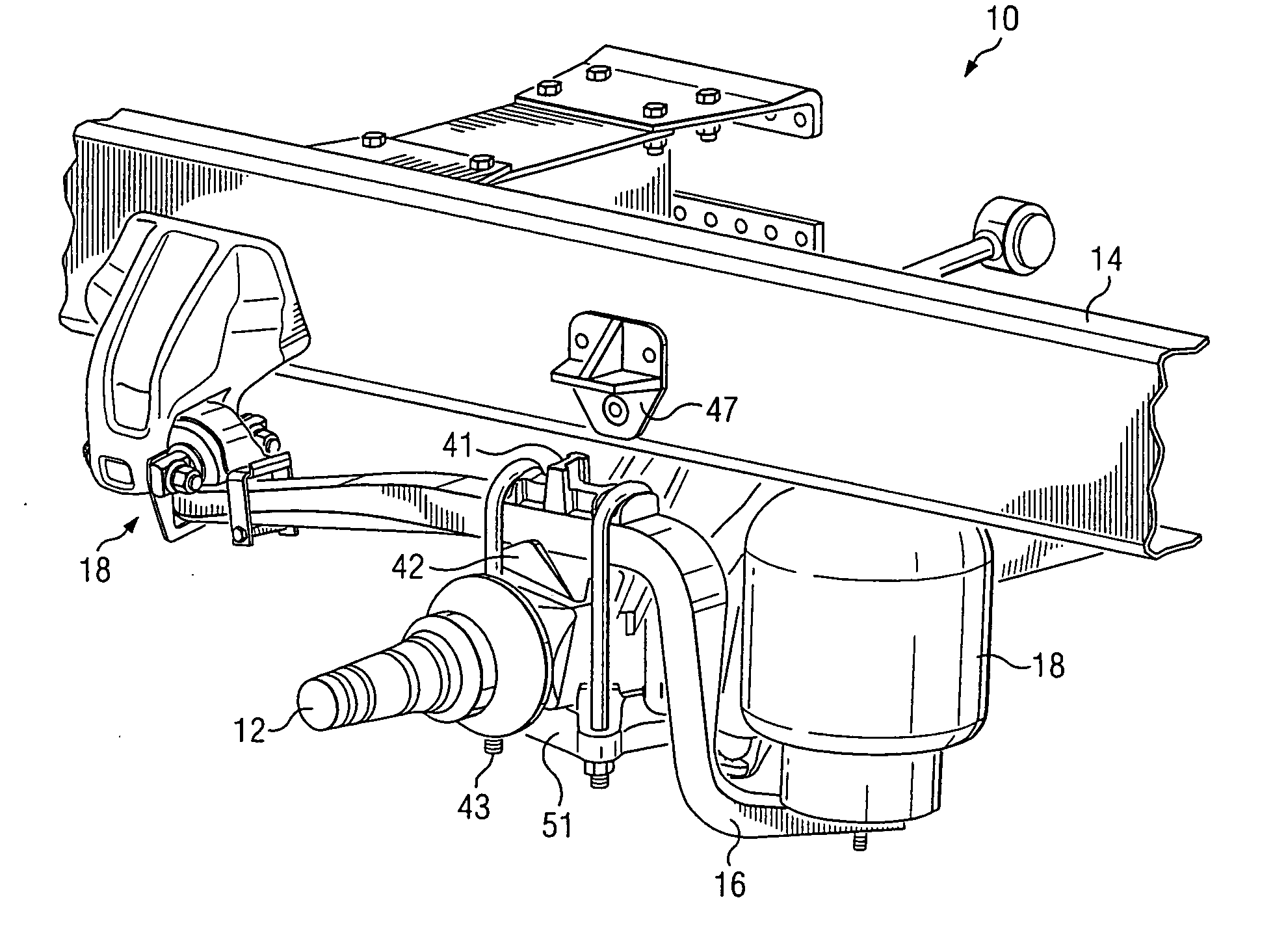

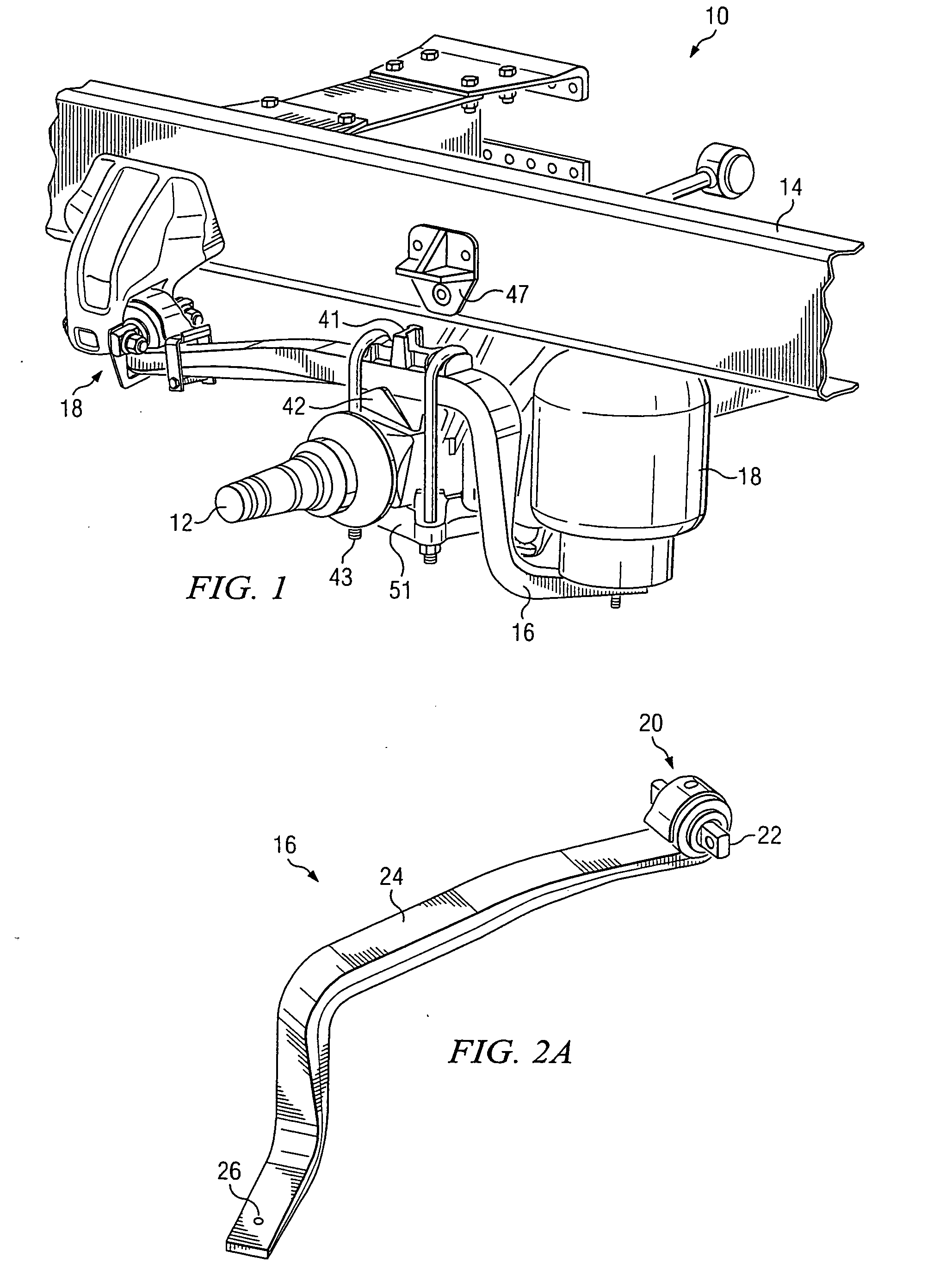

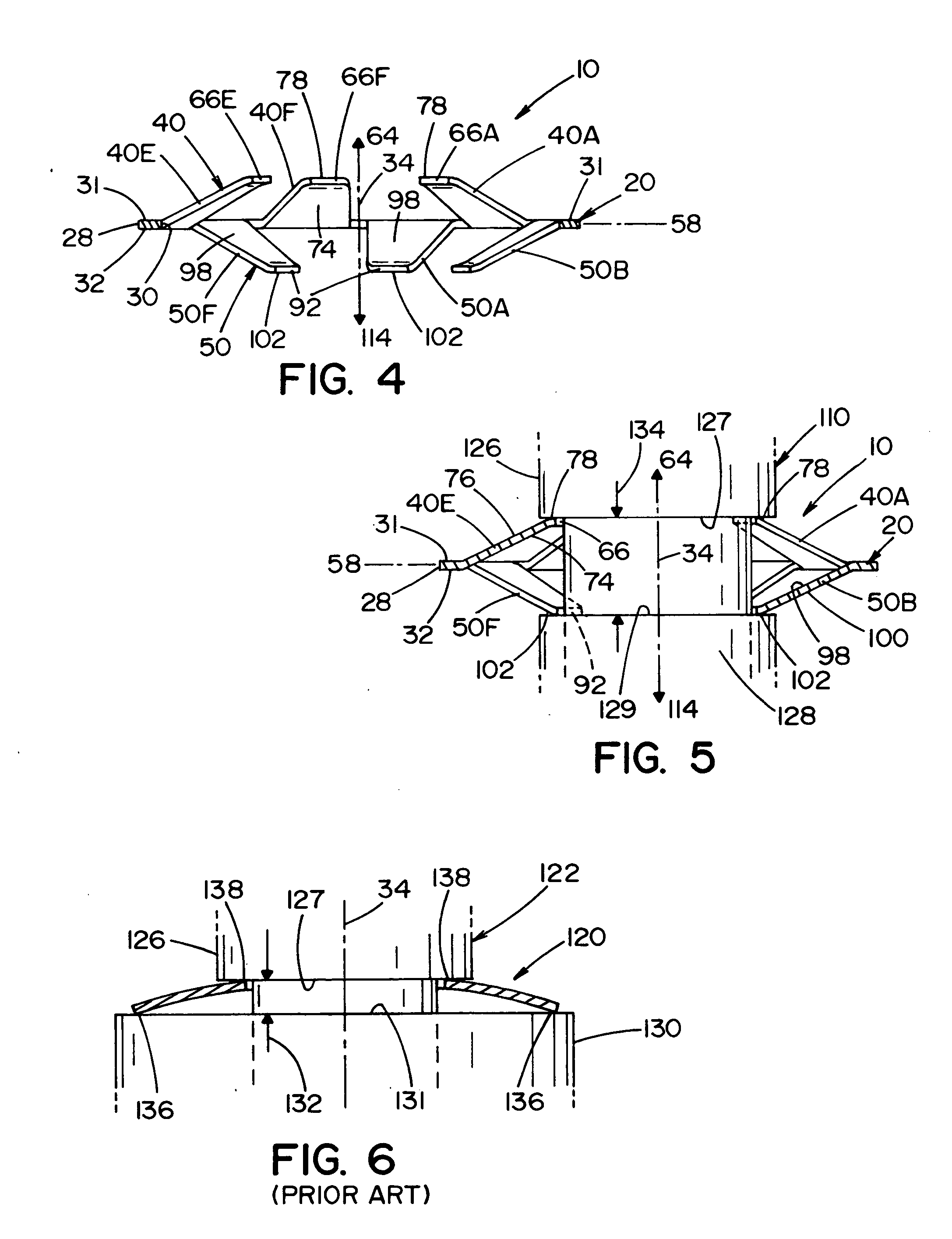

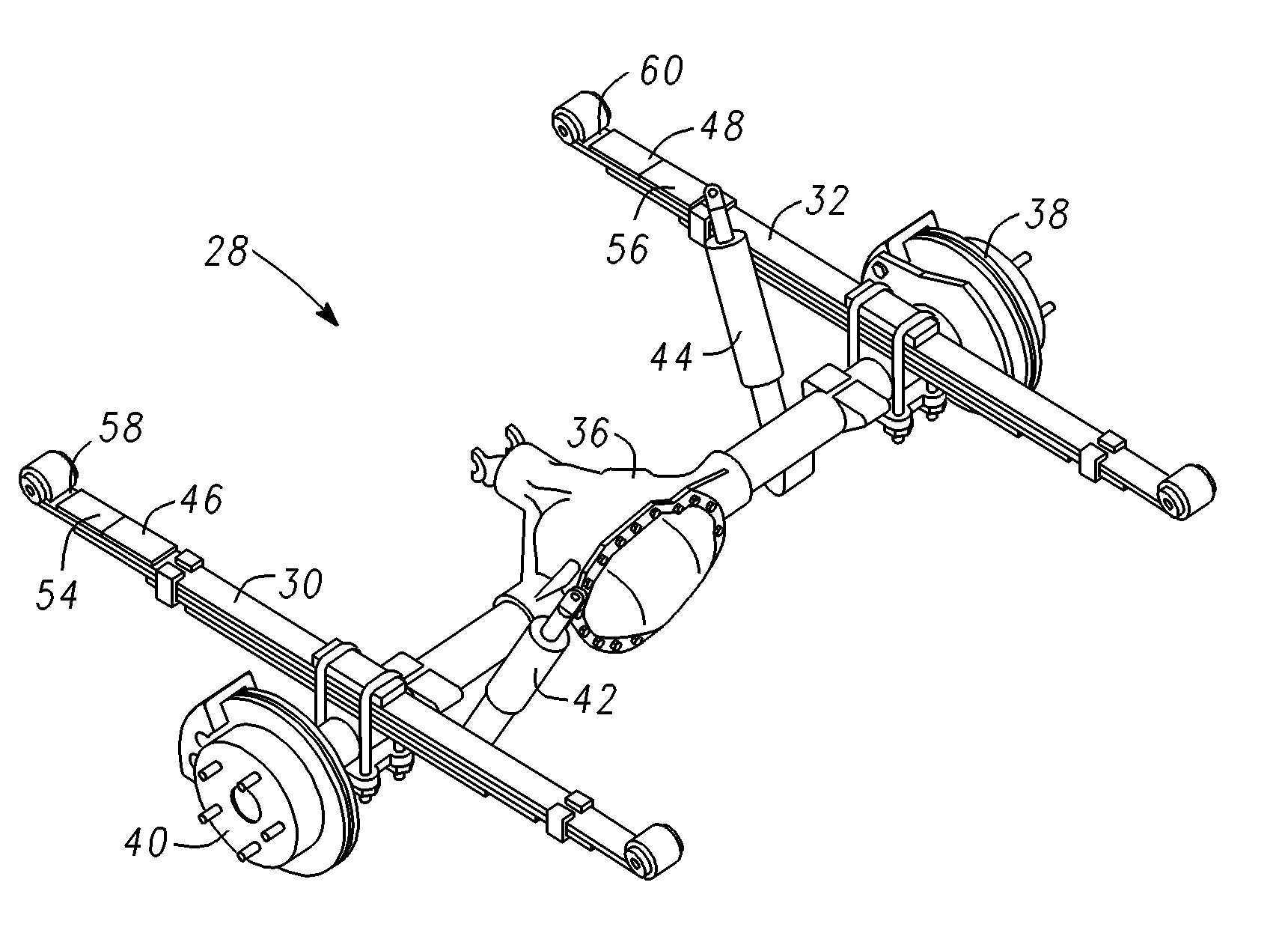

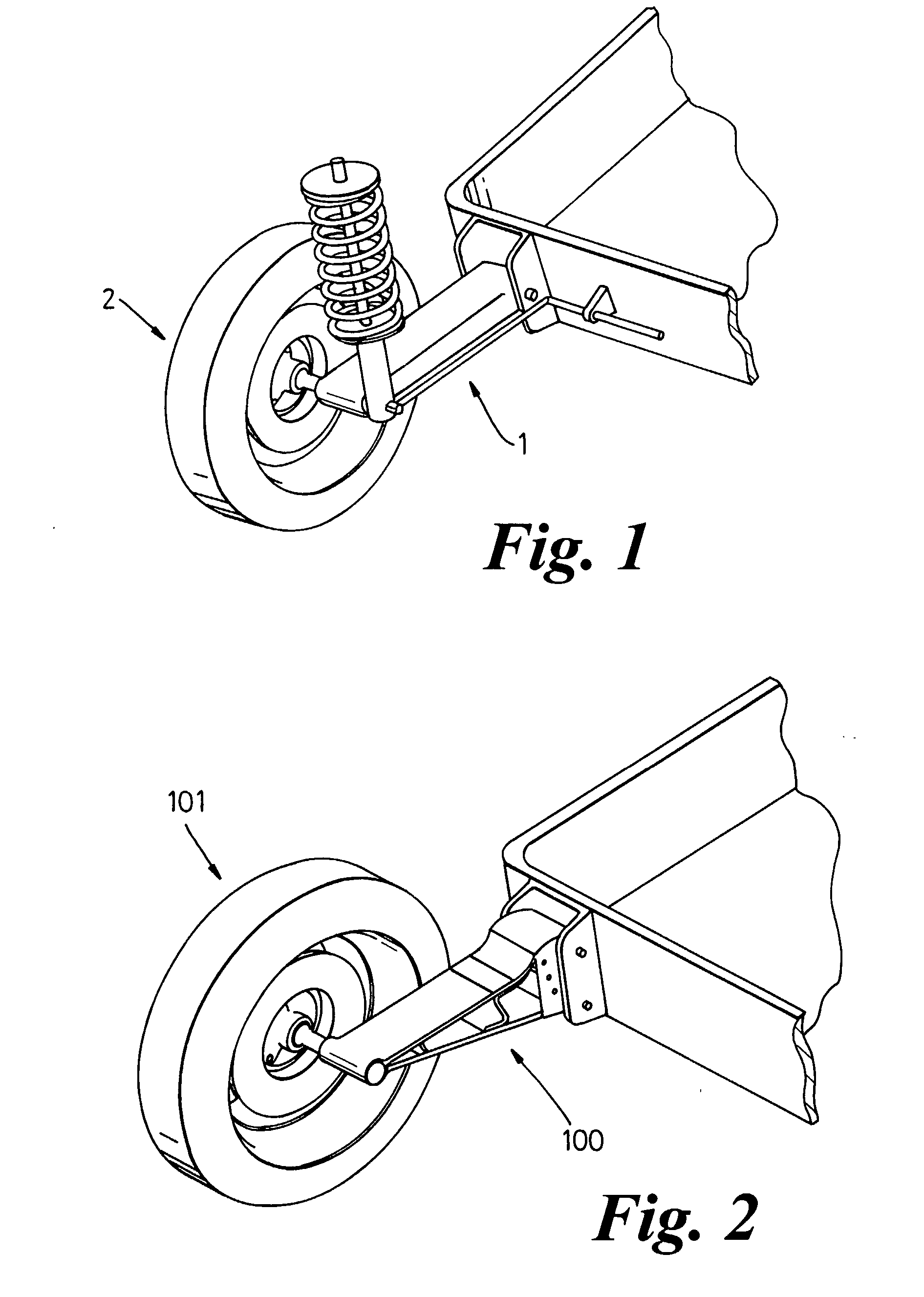

Lightweight, low part-count, suspension system for wheeled vehicles

InactiveUS20060103103A1Few partsReduce weightLeaf springsResilient suspensionsVehicle frameAir spring

A low part count, light weight, low-rise air leaf suspension system is provided. One end of the leaf spring has a formed eye pivotally mounted by a pin to a lightweight bracket mounted to the vehicle frame. The leaf spring is tapered toward the ends to reduce weight. Light weight clamping blocks attach an axle to a central portion of the leaf spring. The other end of the leaf spring is curved down and laterally inward so that the end of the leaf spring is positioned directly underneath the vehicle frame and the air spring may be connected directly between the leaf spring and frame.

Owner:PACCAR INC

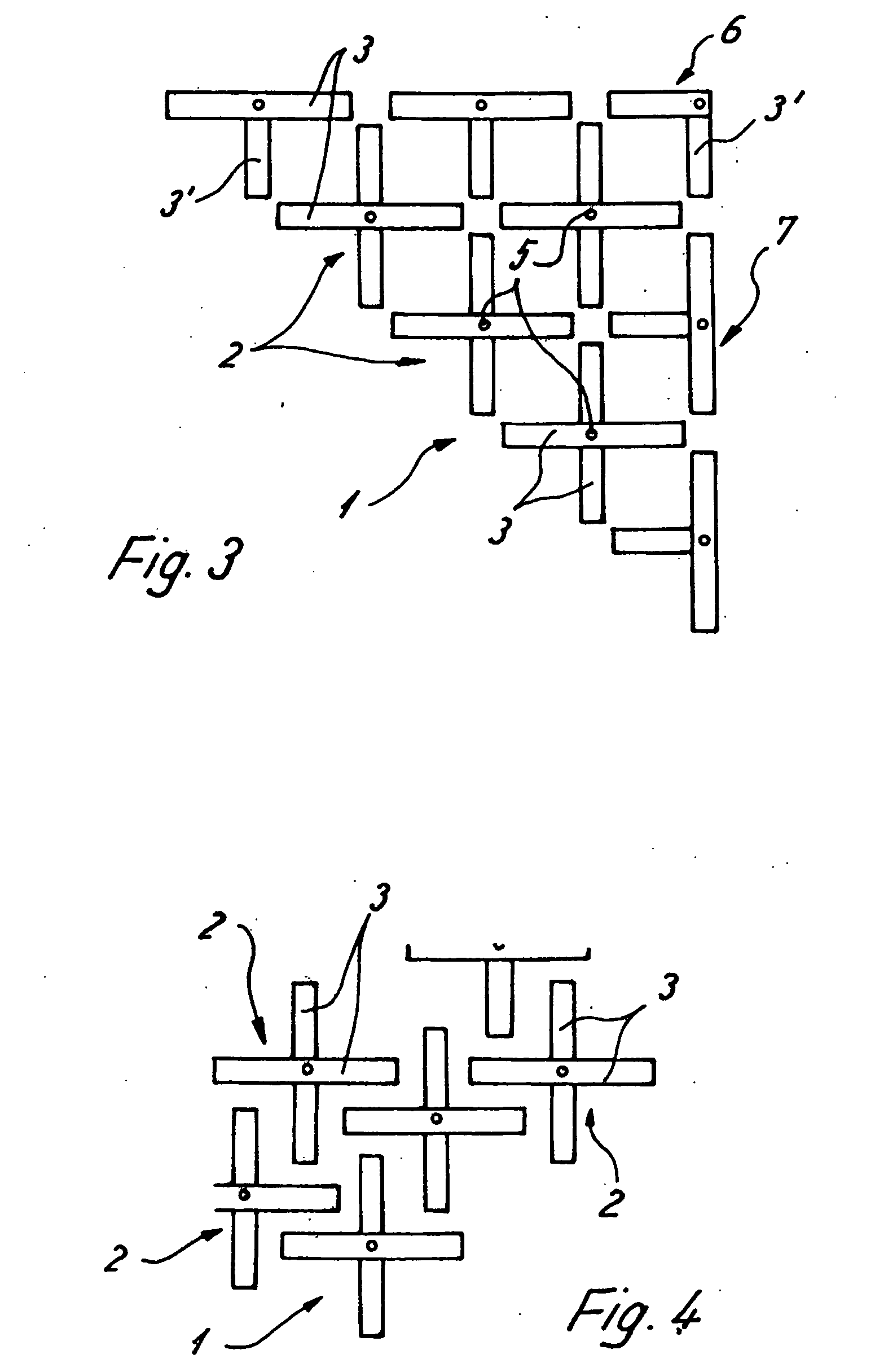

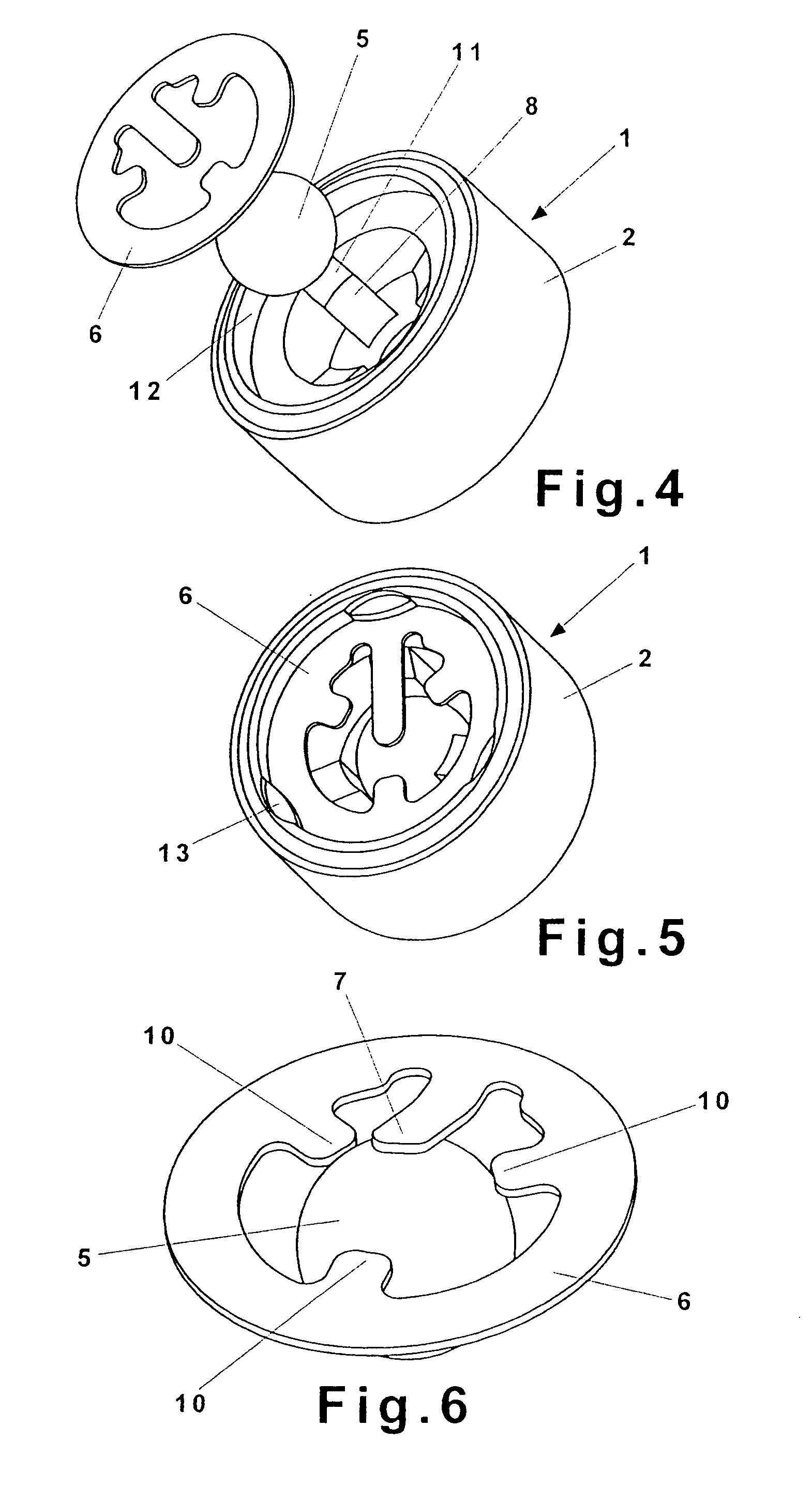

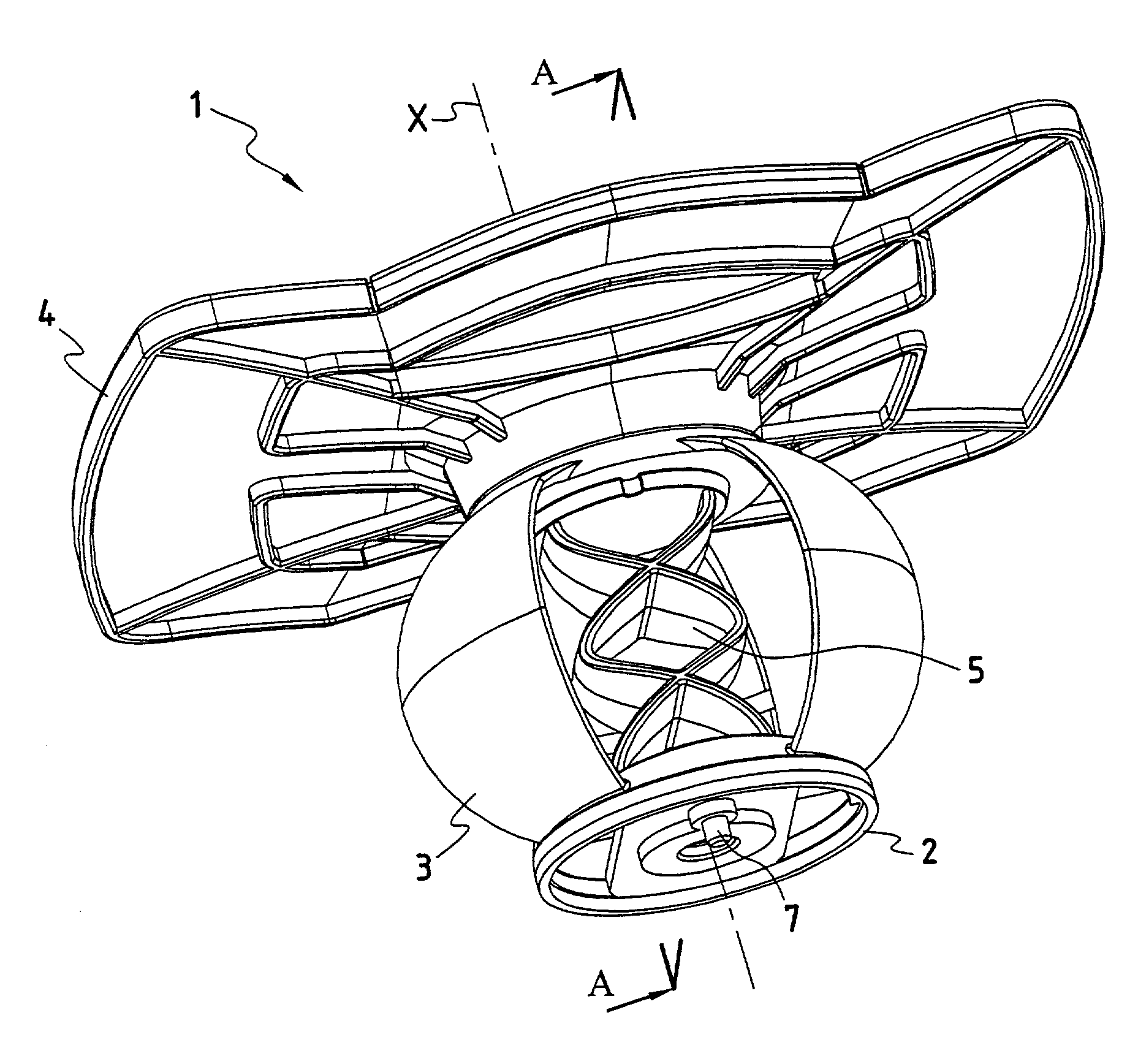

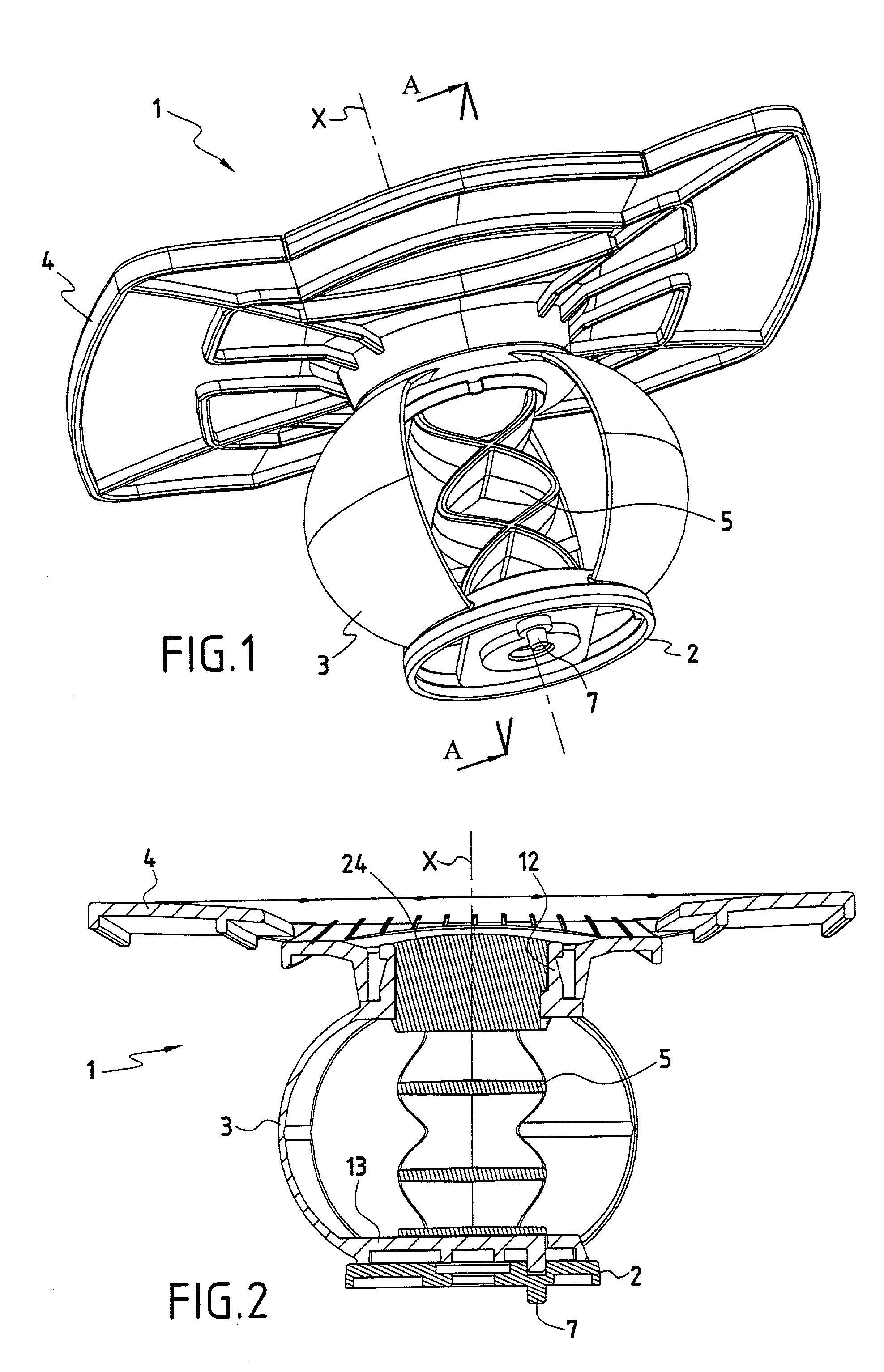

Suspension device for a bed or seat base of the multielement type

InactiveUS20020163114A1Precise positioningStuffed mattressesLeaf springsSynthetic materialsEngineering

The invention provides an individual suspension device for a bed or seat base of the multi-element type, the device being for interposing between a platform determining a support surface and a padding element such as a mattress, and comprising a foot for fixing to an element of the platform, a suspension structure fixed to the foot, and a top plate carried by the suspension structure and serving as a support for the padding element, said suspension structure being circularly symmetrical about a vertical axis, wherein the suspension structure is a single hollow piece and is made of a flexible synthetic material or a vulcanized rubber having hardness lying in the range 40 on the Shore A scale to 70 on the Shore D scale.

Spring washer

InactiveUS20050151310A1Reduce manufacturing costEasy to useBelleville-type springsRing springsEngineeringMechanical engineering

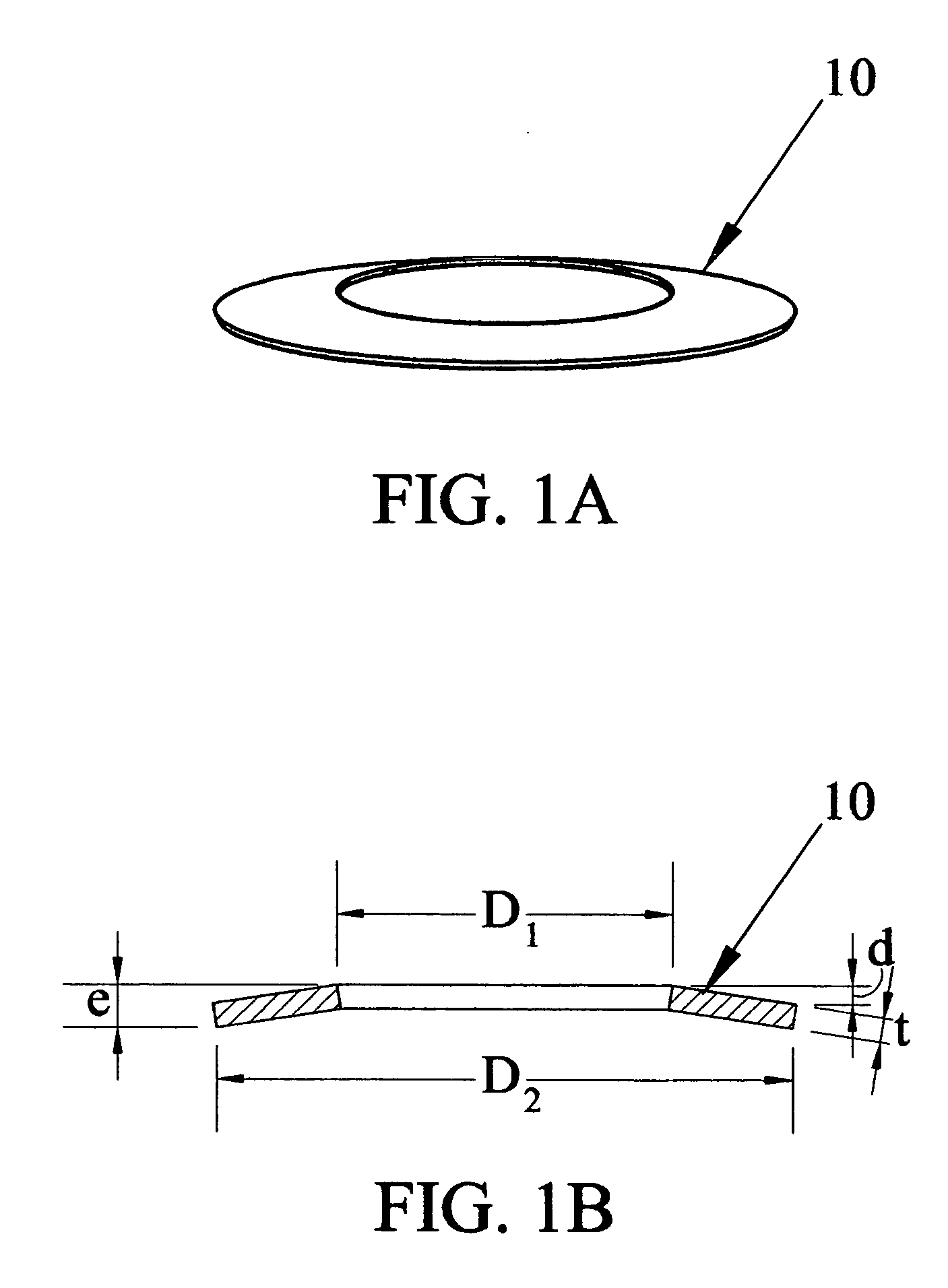

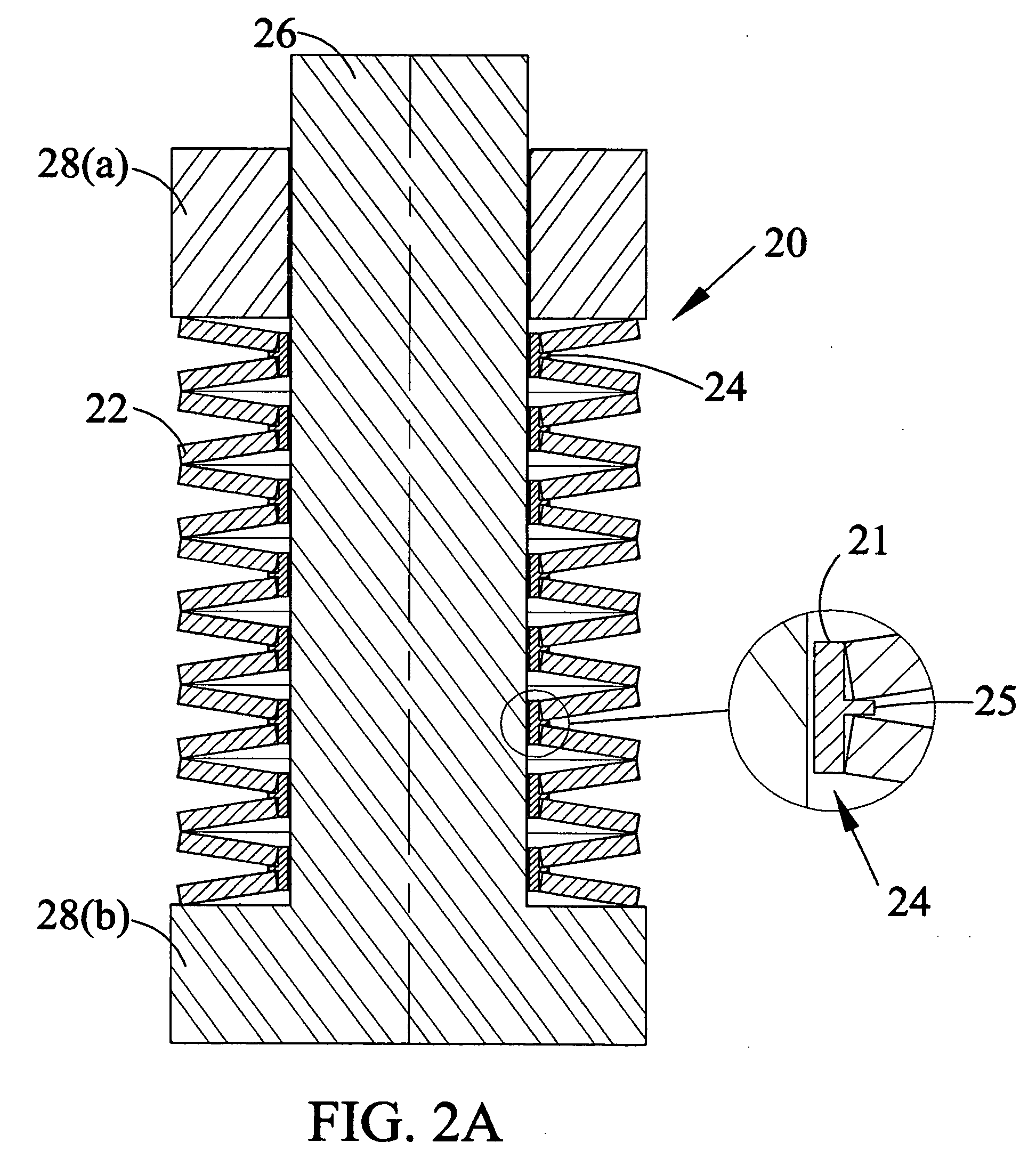

A spring washer for producing a load in an axial direction which includes an outer spring body extending about a central washer axis parallel to the axial direction. The washer further includes a central opening coaxial to the washer axis for accepting at least a portion of an elongated object extending in the axial direction. The washer has a plurality of circumferentially spaced spring fingers each extending inwardly towards the central washer opening. Each finger including a finger base attached to the outer body and a finger end adjacent to the central opening. The finger end of every other one of the plurality of spring fingers being axially spaced on either side of said outer spring body.

Owner:BARNES GROUP

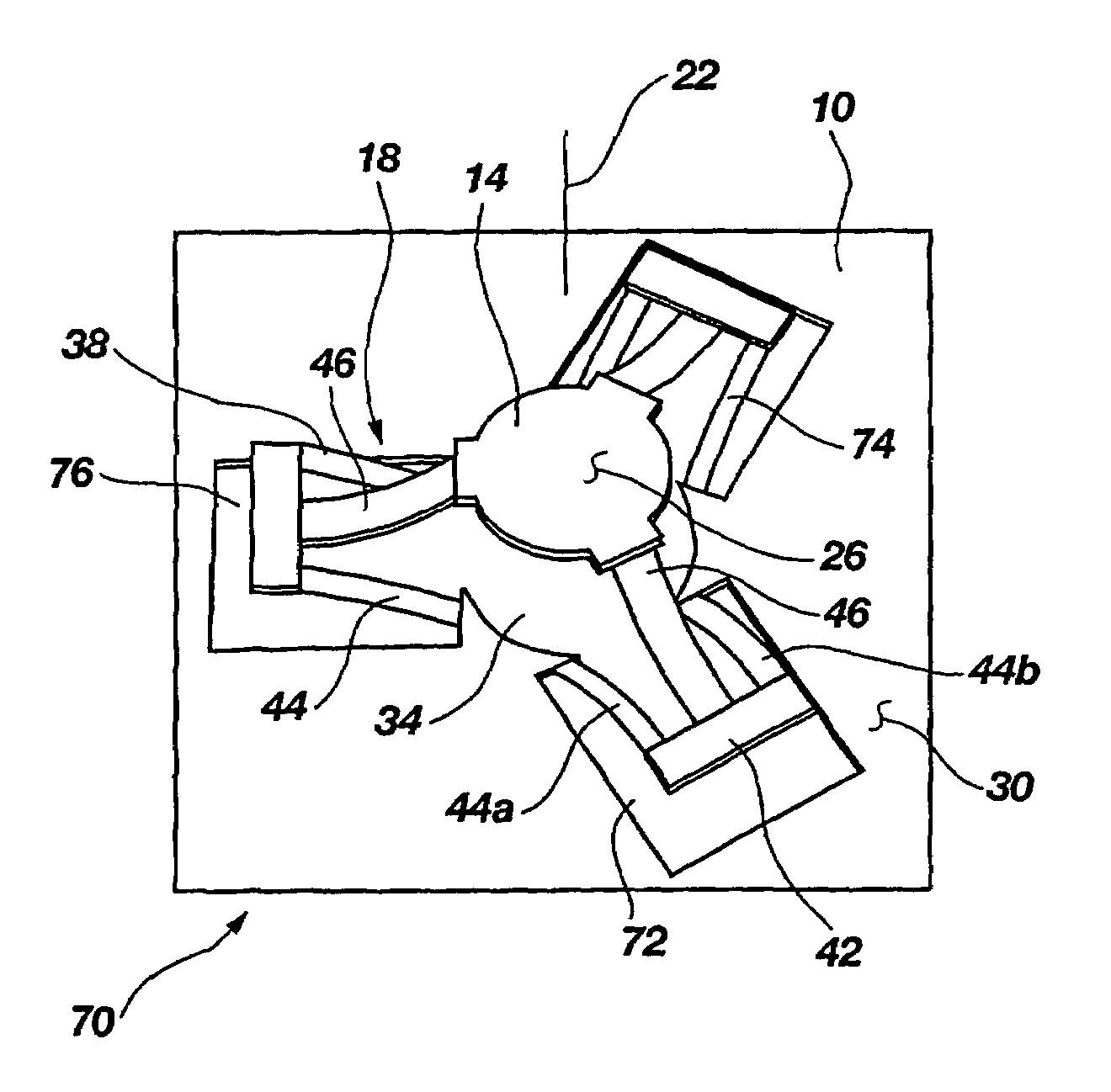

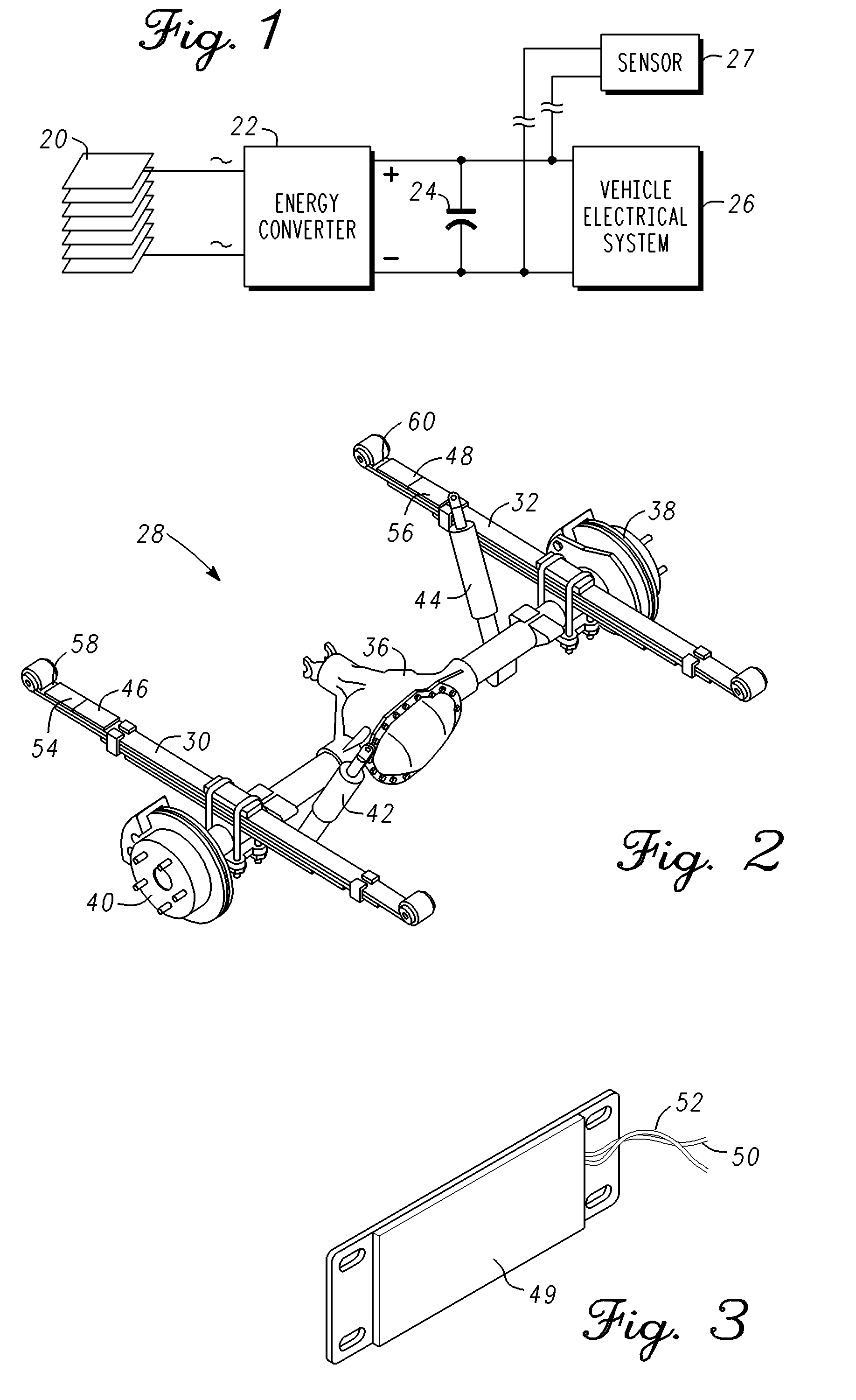

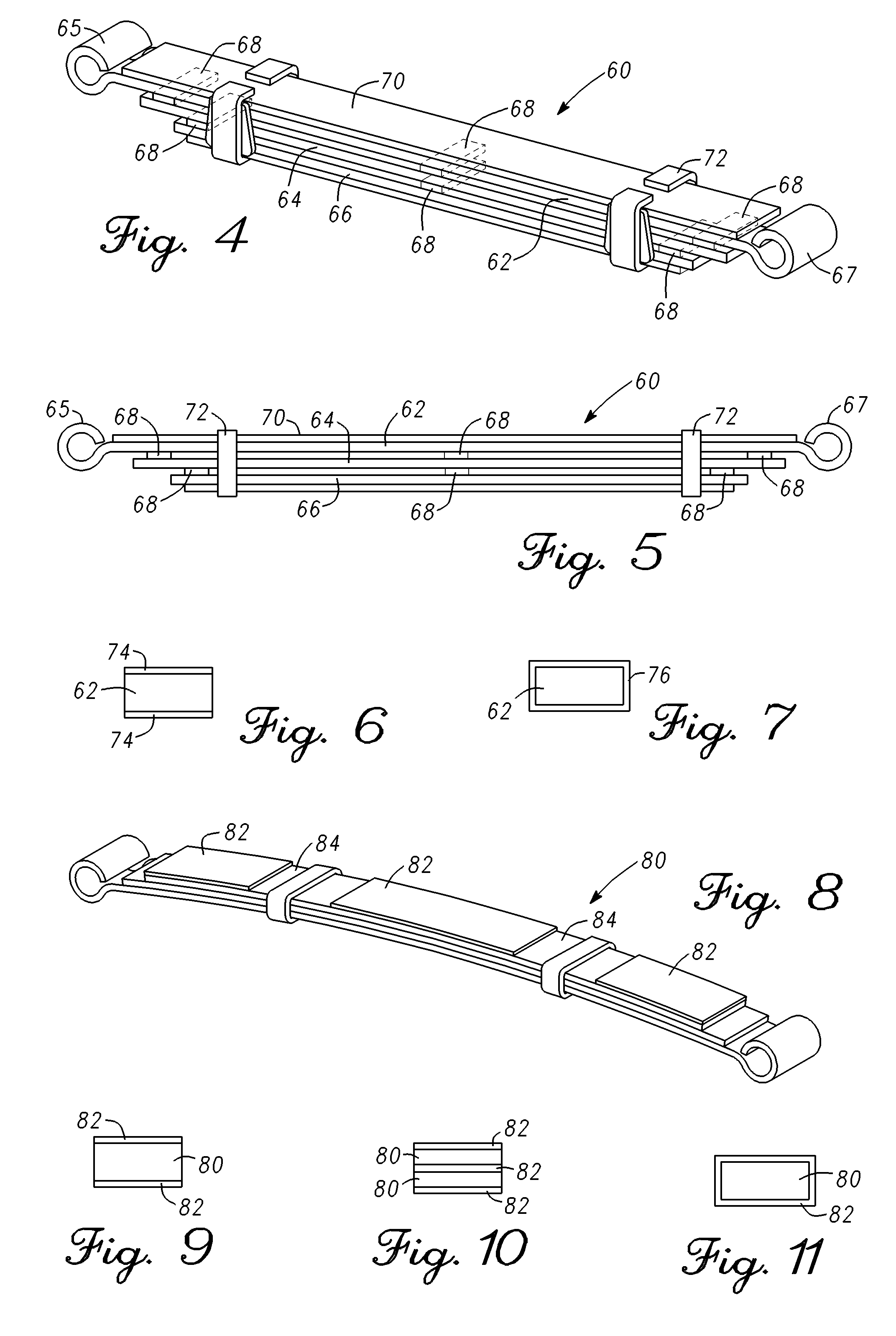

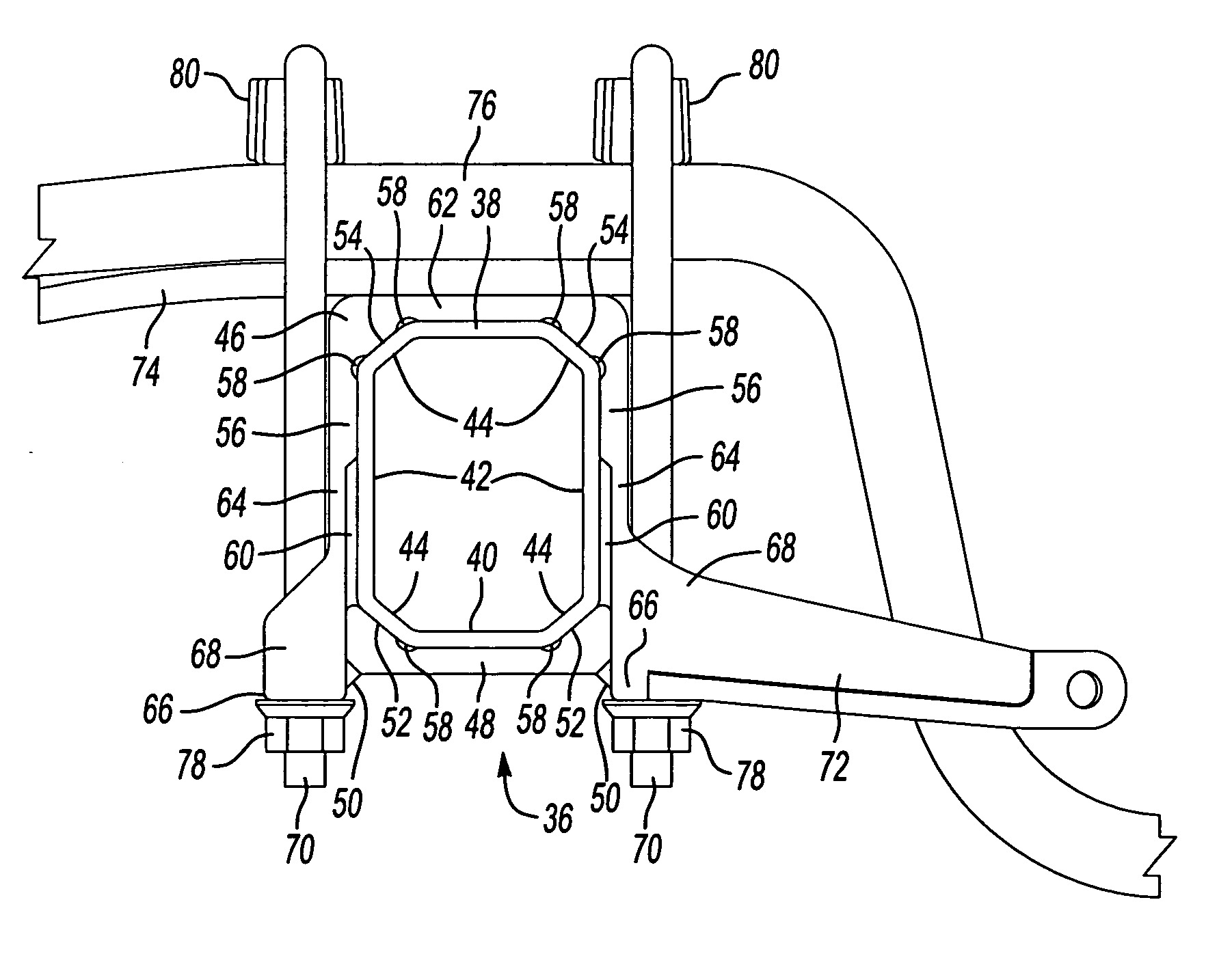

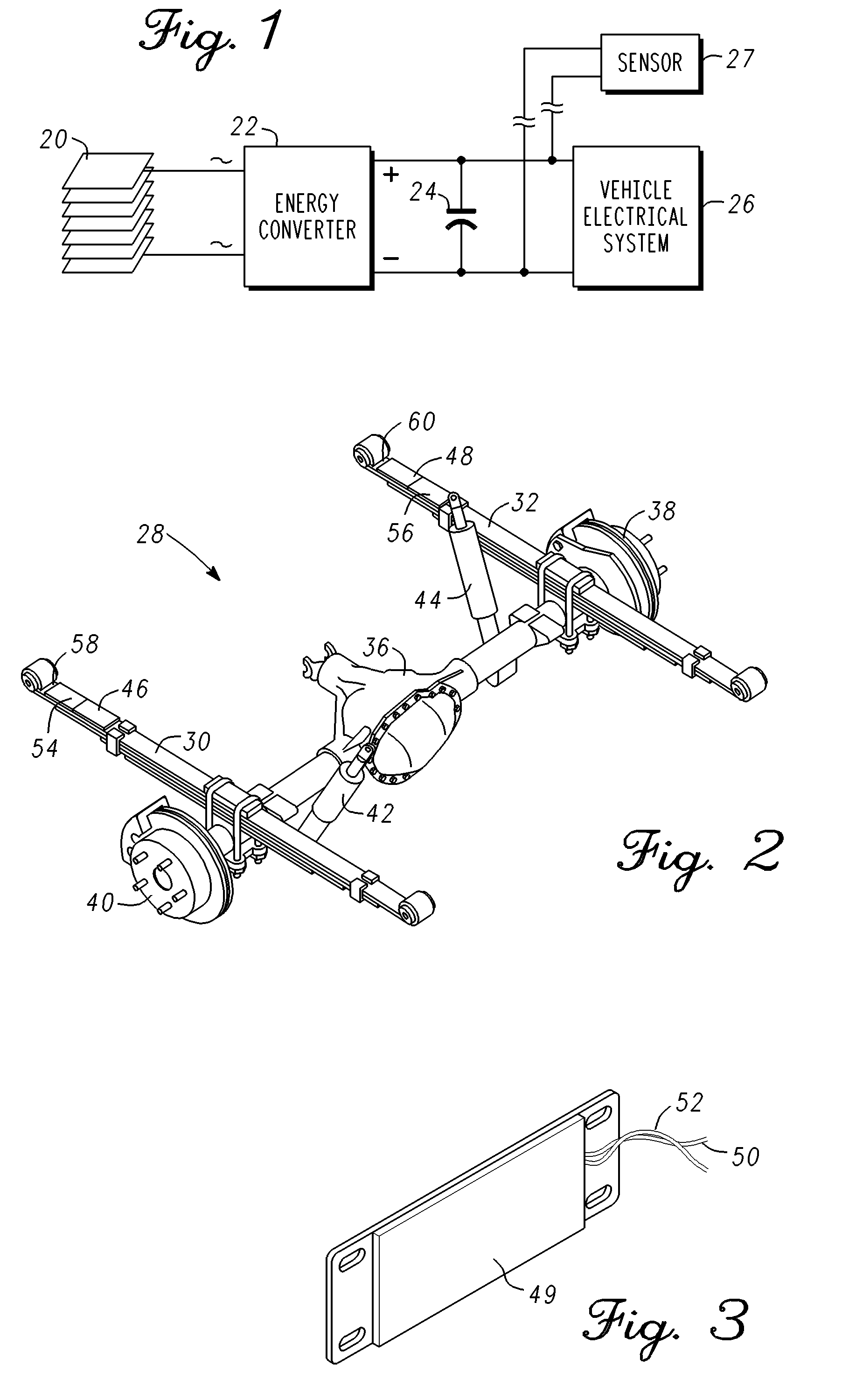

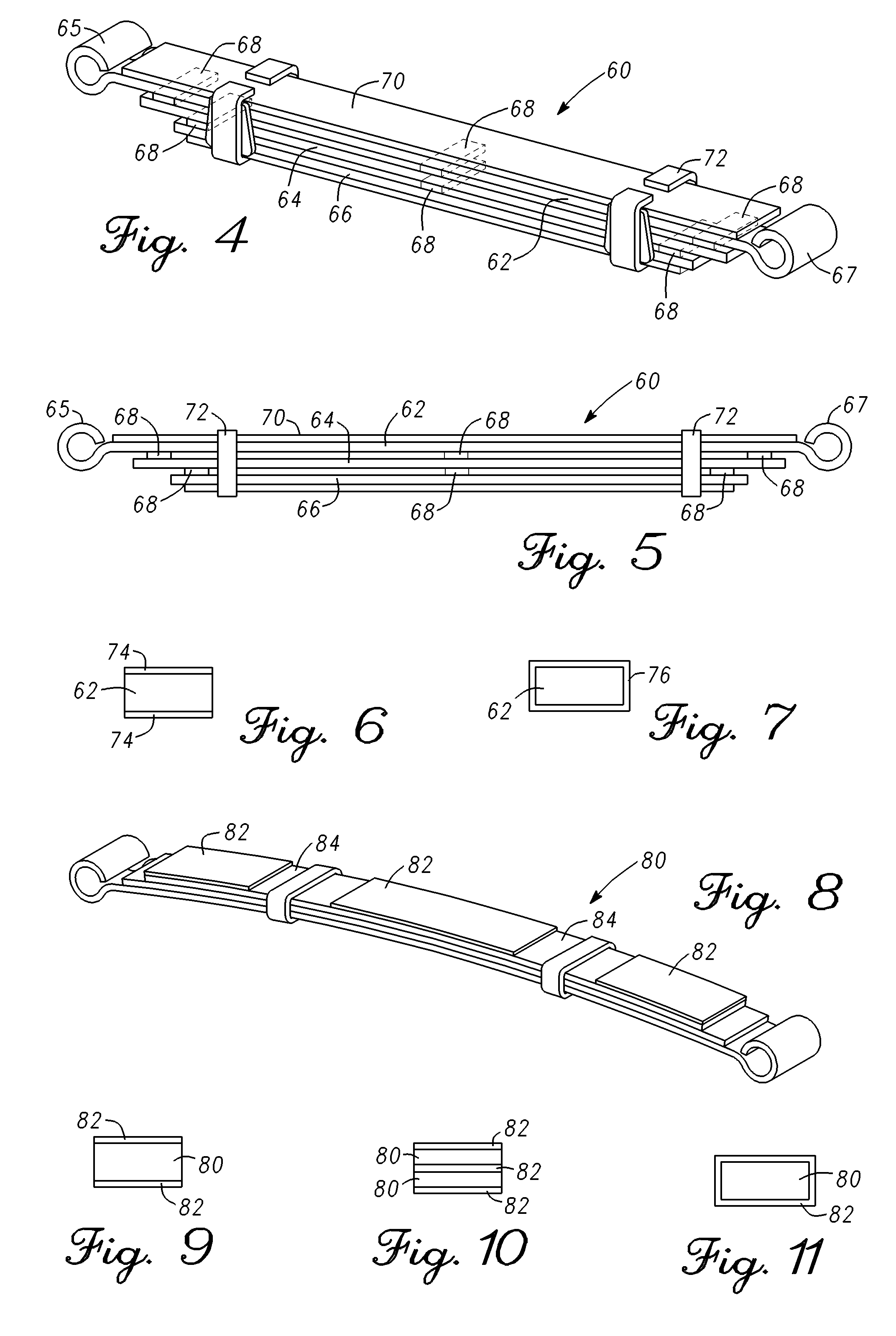

Harvesting energy from vehicular vibrations using piezoelectric devices

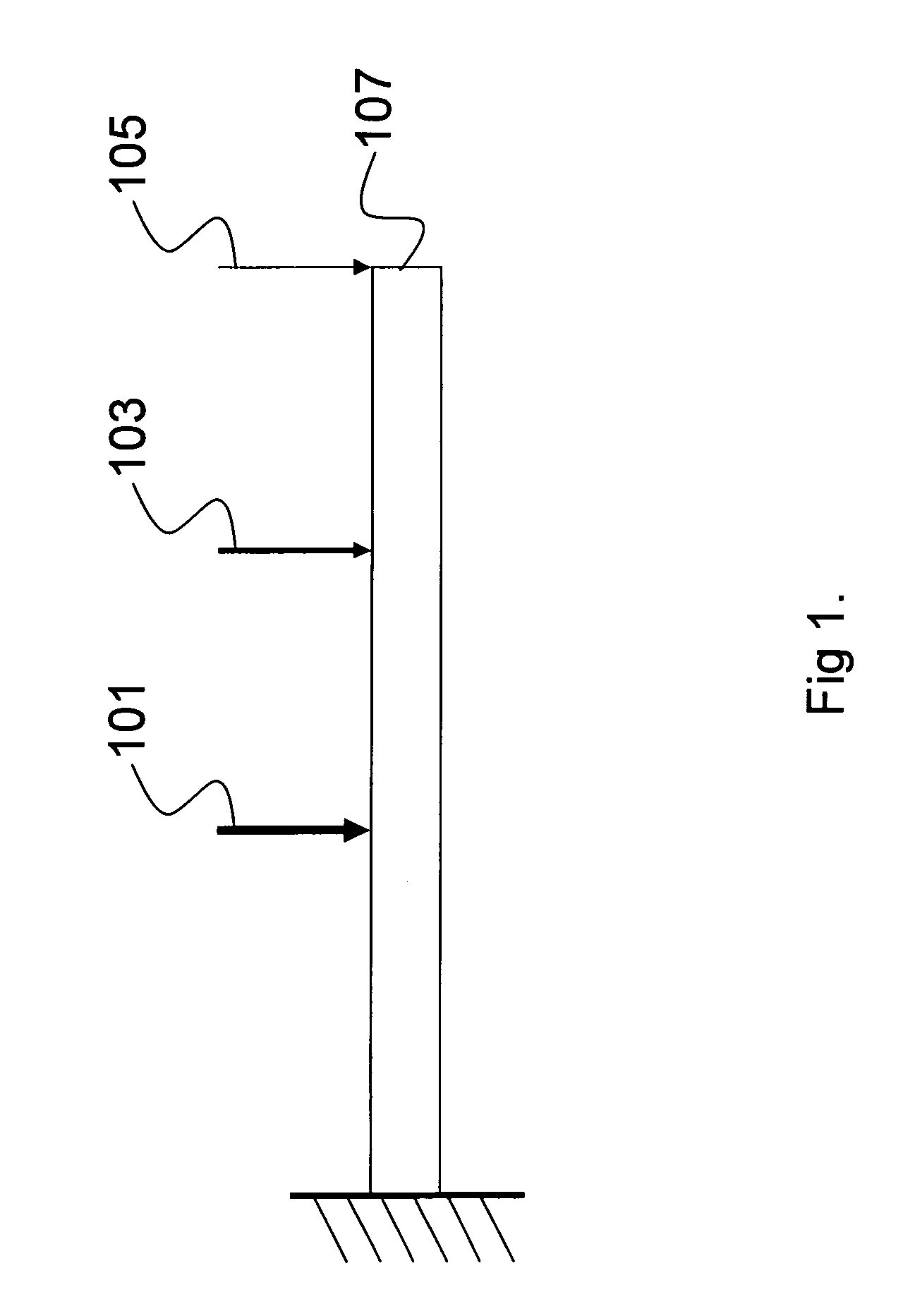

ActiveUS20100219720A1Piezoelectric/electrostriction/magnetostriction machinesLeaf springsRectifierElectric energy

An energy harvesting apparatus for deployment on a vehicle having a frame includes a spring assembly coupled to the frame and configured for compressions and extensions during vehicle travel. A piezoelectric device is mounted on the spring assembly for generating electrical energy in response to the strain imposed thereon. A rectifier is coupled to the piezoelectric device for converting AC electrical energy to DC.

Owner:GM GLOBAL TECH OPERATIONS LLC

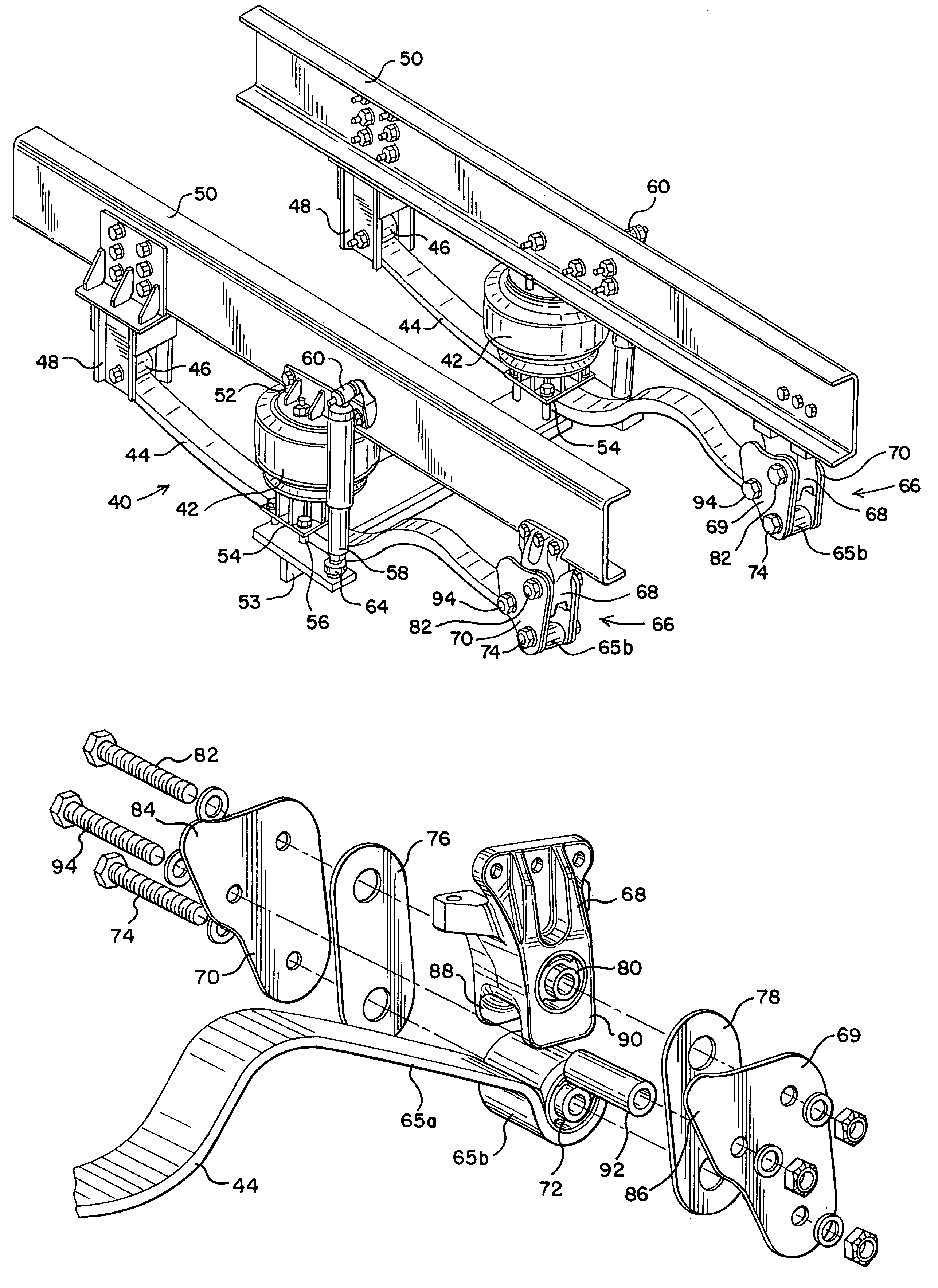

Preloaded suspension bracket assembly for axle housing

InactiveUS20050253351A1Easy to mergeSimple interfaceLeaf springsResilient suspensionsEngineeringMechanical engineering

An axle housing includes a suspension mount interface for mounting a vehicle suspension to the axle housing. The axle housing includes a first leg portion extending to a first wheel assembly and a second leg portion extending to a second wheel assembly. The first and second leg portions each include a suspension mount interface. Each suspension mount interface includes first and second bracket portions. The first and second bracket portions are clamped together prior to attachment to the axle housing to form a suspension bracket assembly. One clamped suspension bracket assembly is then slid over each axle housing leg portion. The first and second bracket portions are subjected to a preload force as they are welded or fastened to each other, providing a preload effect to define a suspension load path that has positive contact only at desired locations on the axle housing.

Owner:ARVINMERITOR TECH

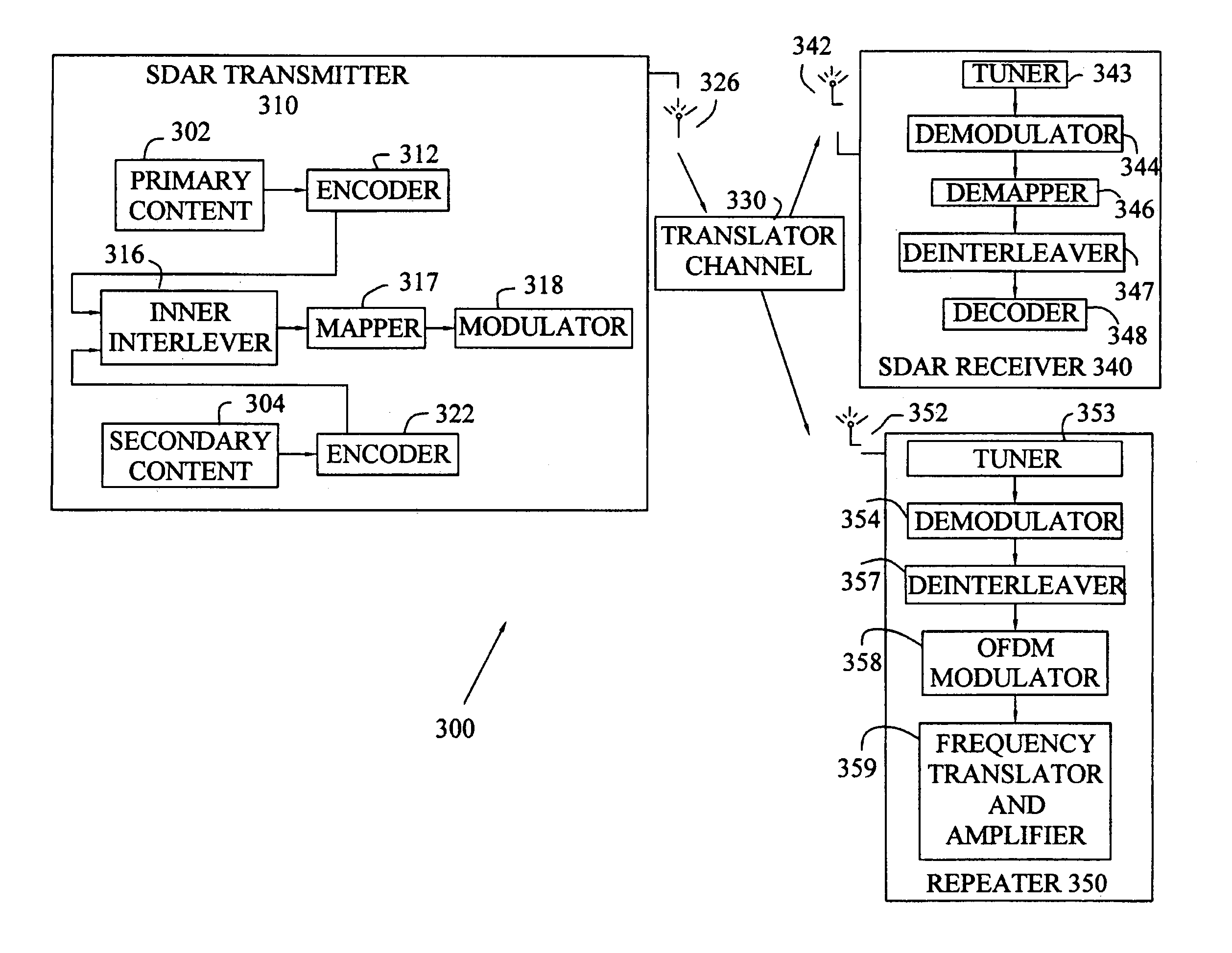

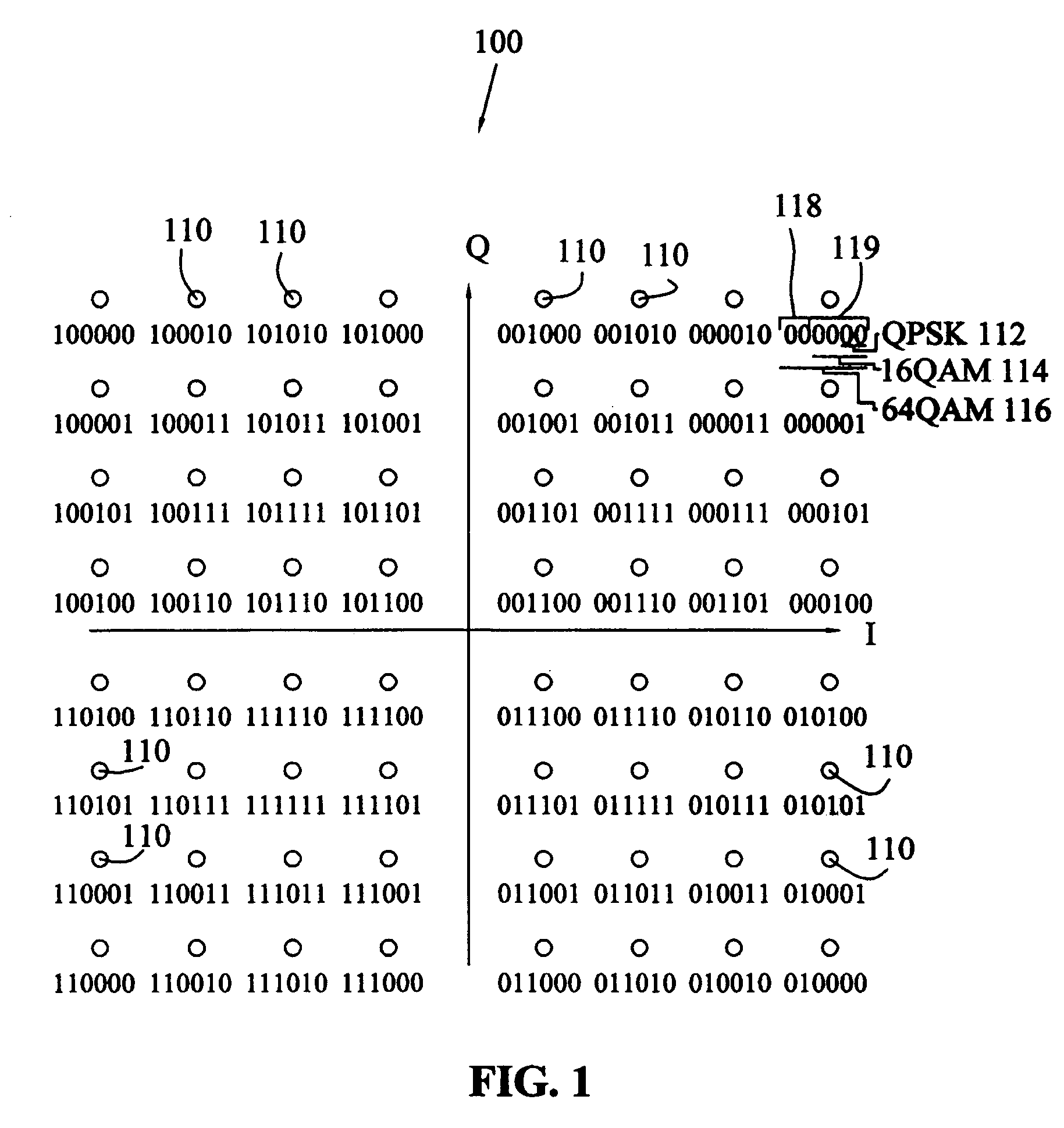

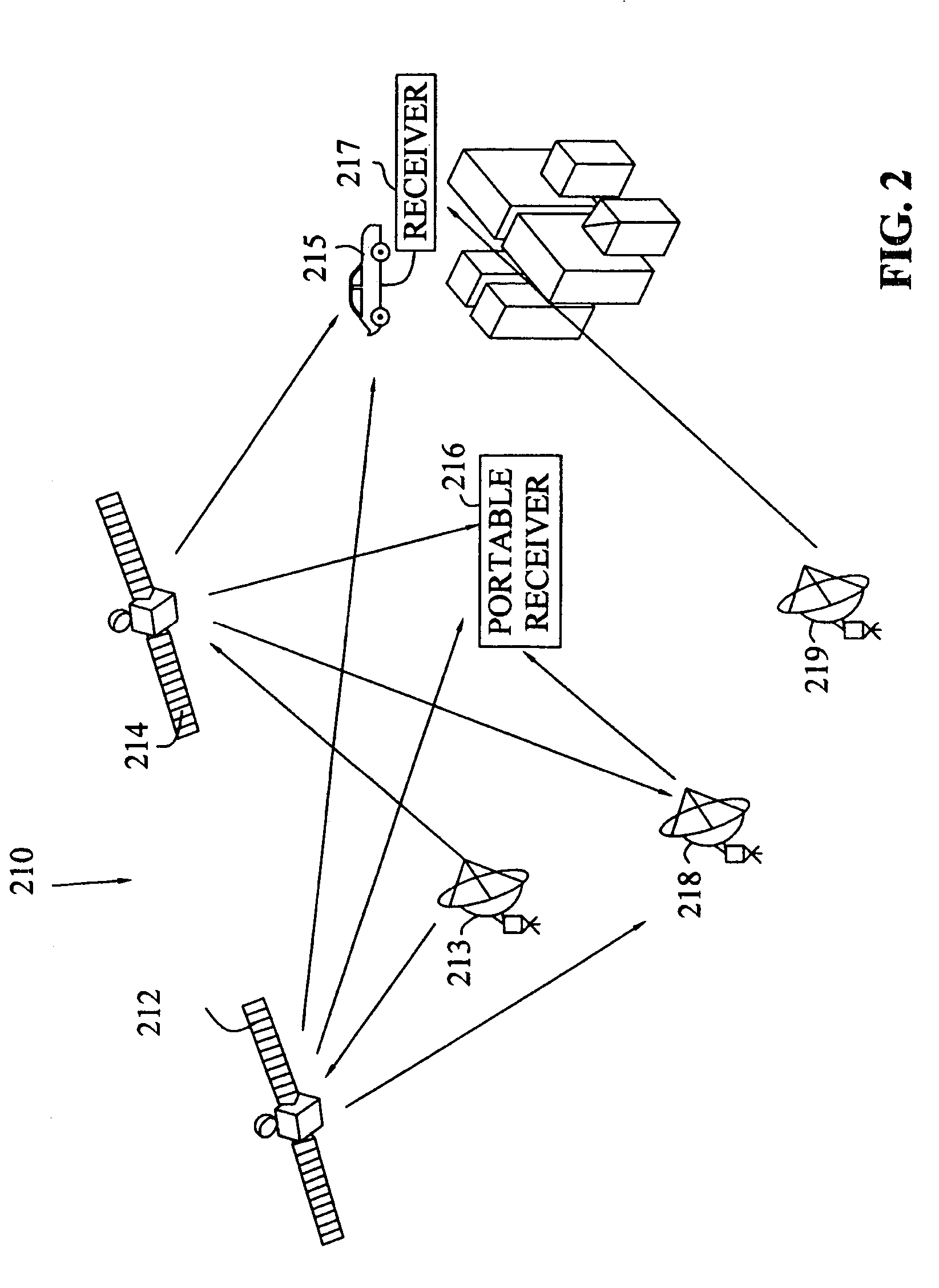

Method to minimize compatibility error in hierarchical modulation

ActiveUS7215713B2Increase volumeIncrease the amount of dataLeaf springsMultiplex communicationData signalData rate

The present invention involves a method and system for transmitting two levels of data in a hierarchical transmission schema. A first modulated signal is generated based on first input. A second modulation signal is generated based on a second input that has a data rate that is a fraction of the data rate of the first modulated signal. The second modulation signal has known instances where the second modulation signal has no energy. In a system where the first modulation is quadrature phase shift keying (QPSK), the second modulation signal can be a secondary phase offset. A receiver in the system that has a priori knowledge about the timing relationship between the first data signal and the instances when the second data signal is present will be able to detect both data signals optimally.

Owner:APTIV TECH LTD

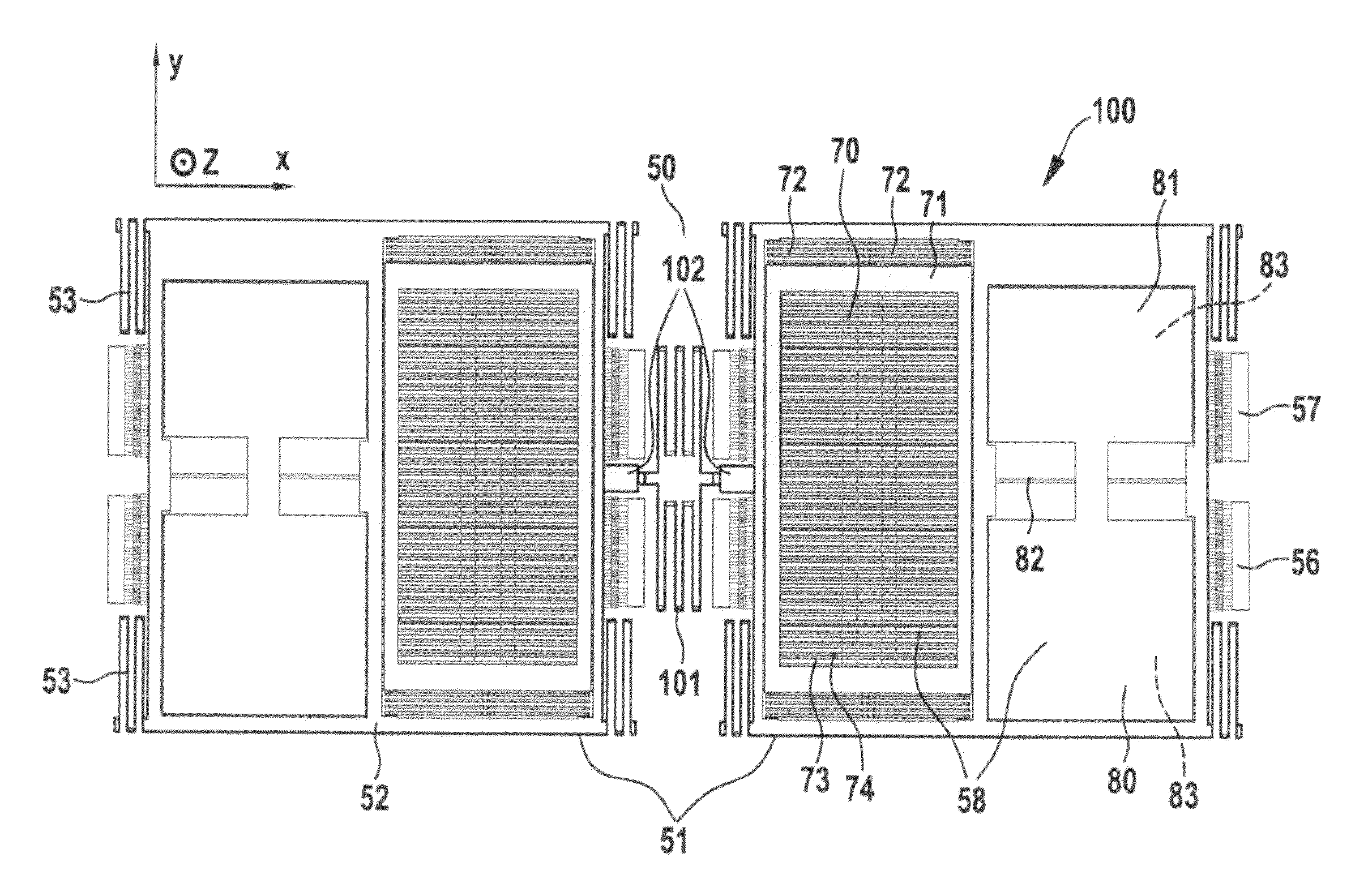

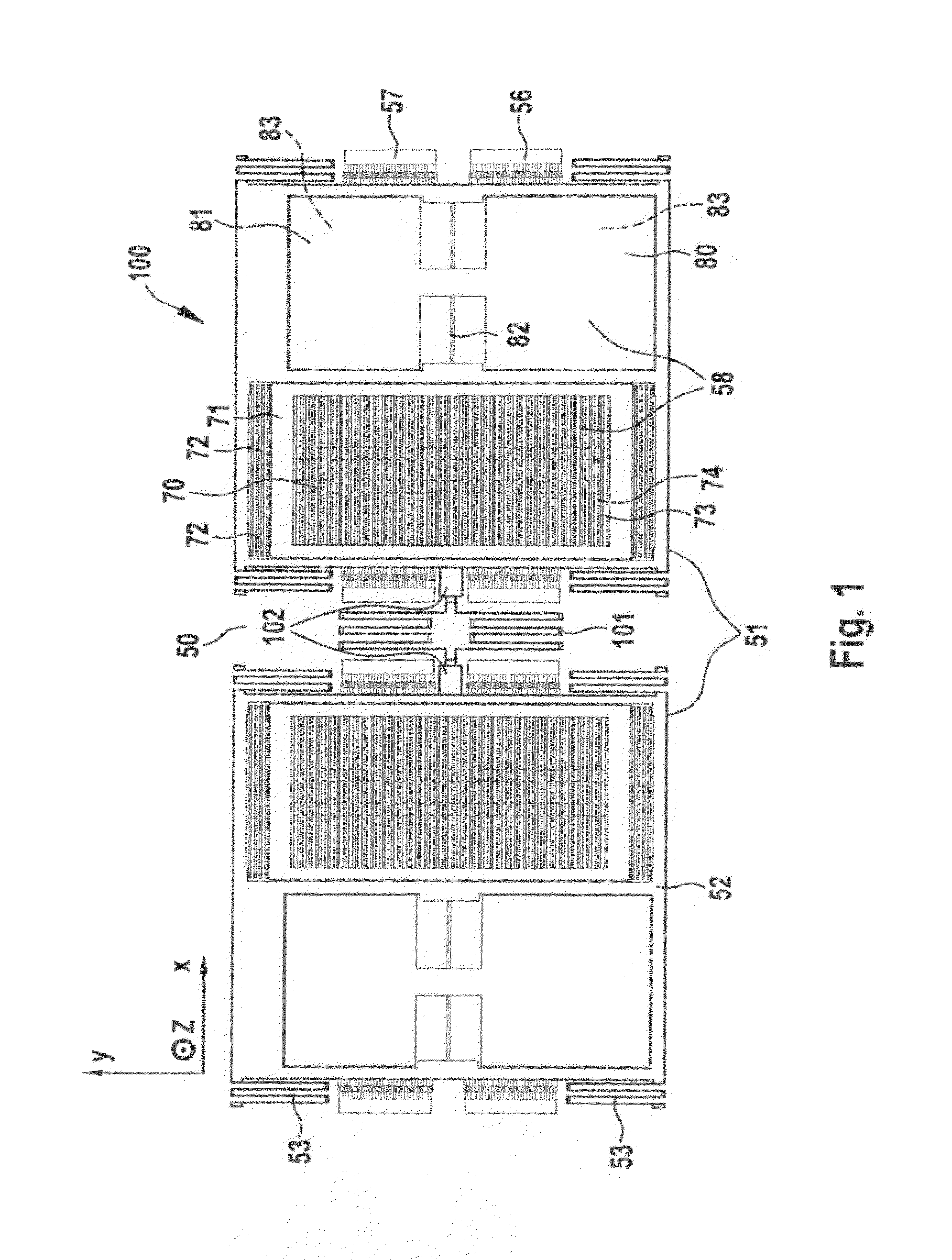

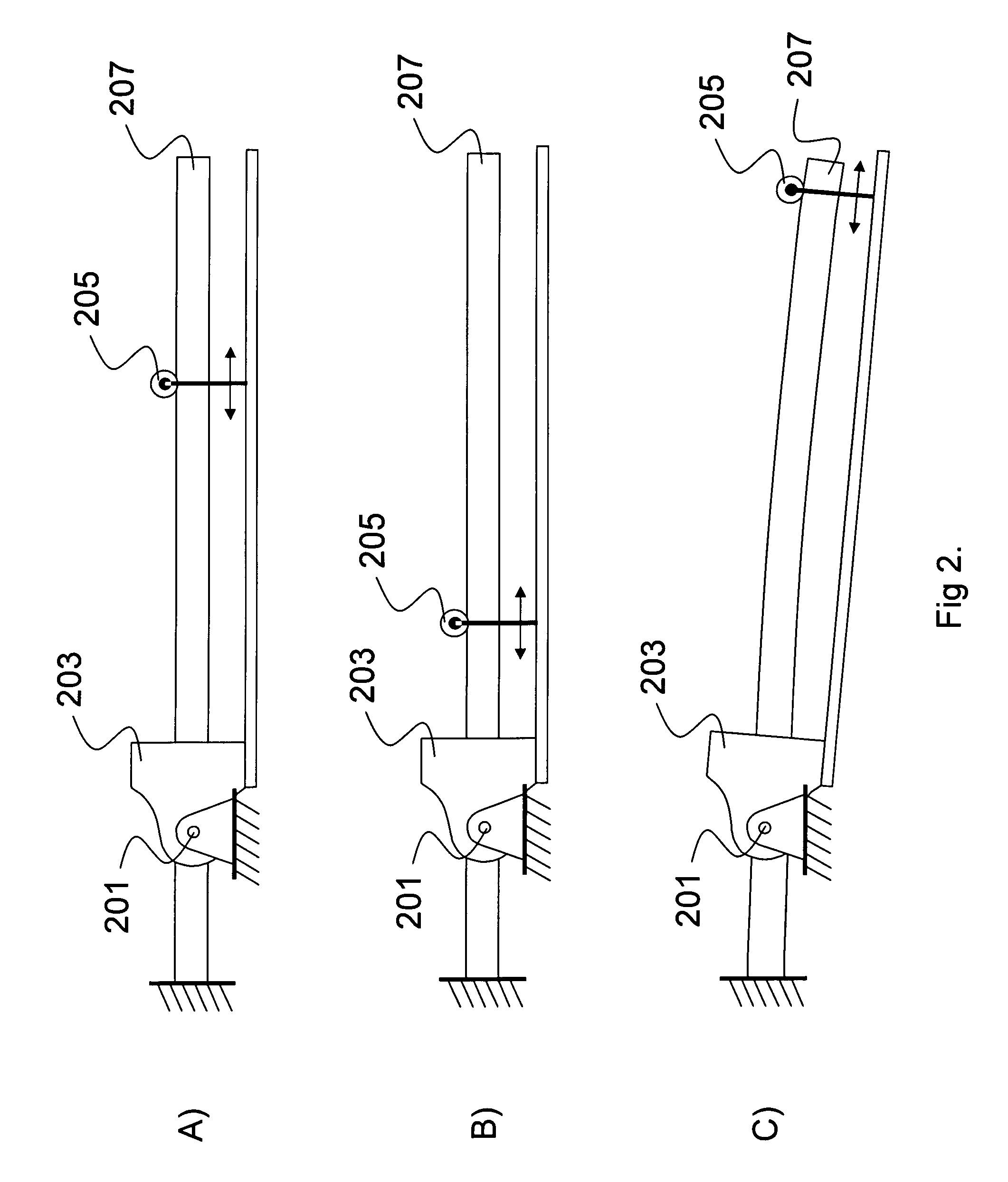

Mass damper

ActiveUS20140008163A1Reduce tensionSmall sizeRotating vibration suppressionNon-rotating vibration suppressionEngineeringTuned mass damper

A tuned mass damper comprising a frame, at least one bendable spring element being connected from its ends to the frame, and at least one mass element being connected to the spring element at a distance from the ends of the spring element, at least one movable spring support element for adjusting the tuning frequency of the damper, and means for moving the spring support element.

Owner:WARTSILA FINLAND OY

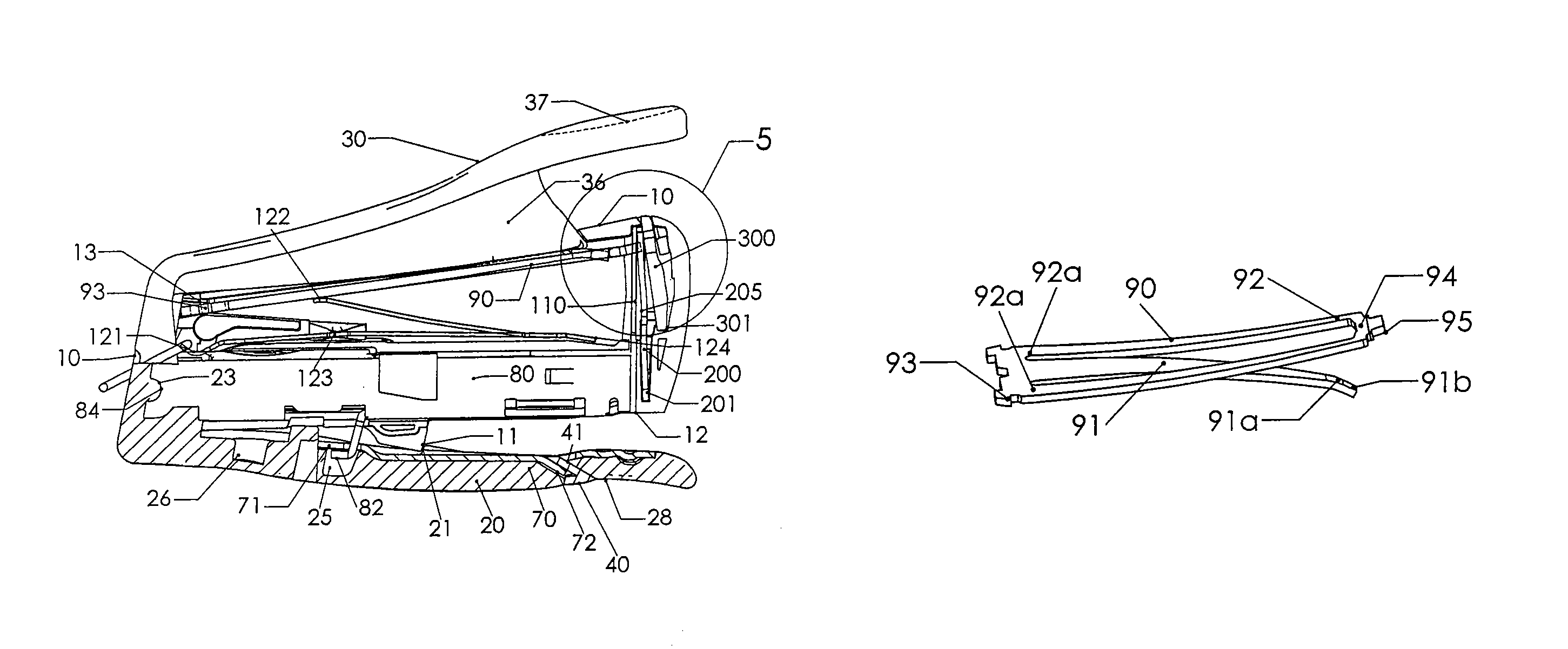

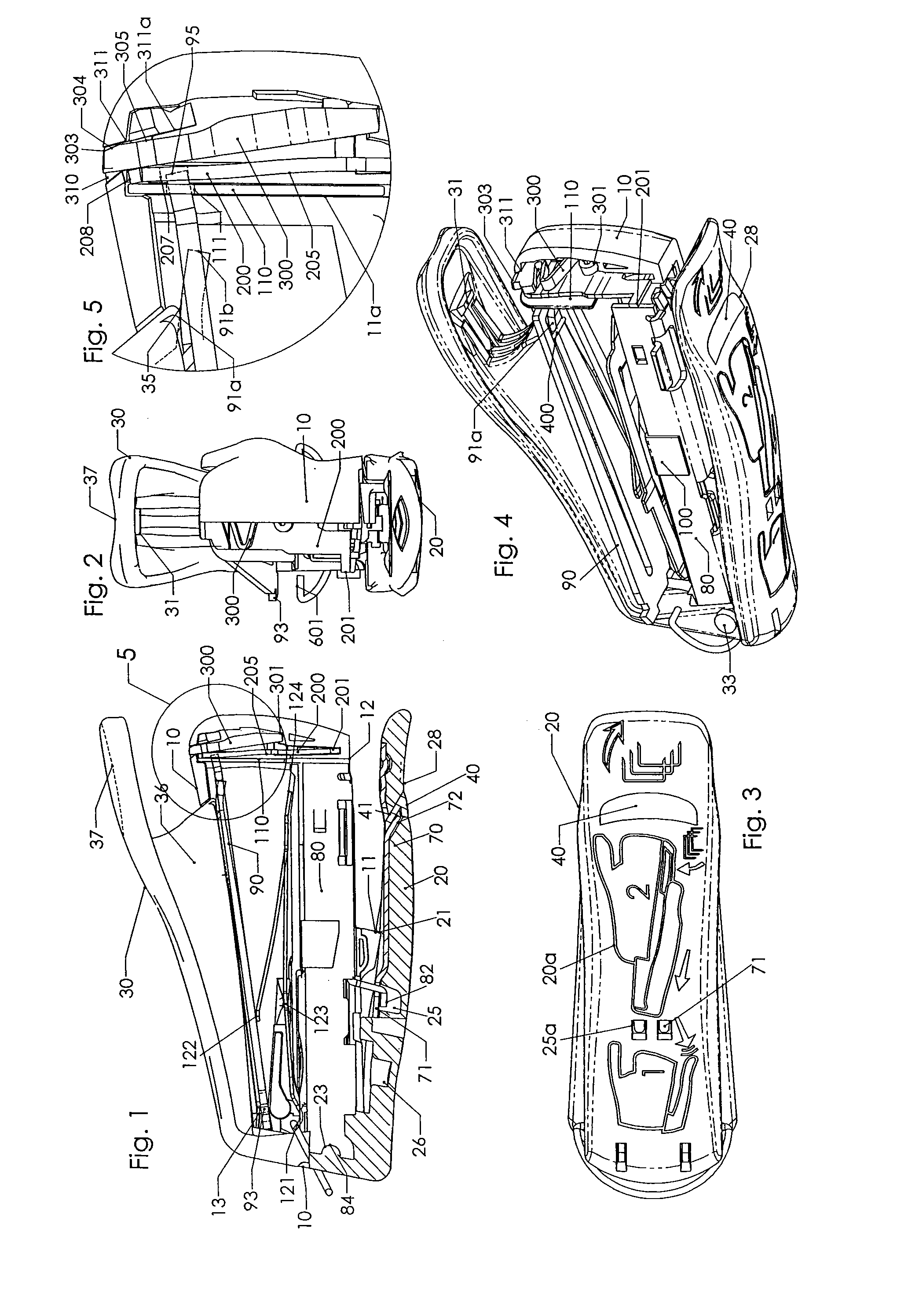

Mini desktop stapler

ActiveUS7299960B1Easy to installMinimally tallStapling toolsLeaf springsEngineeringMechanical engineering

A miniature spring-actuated stapler includes a tapered, flat power spring to store energy and eject staples. The power spring pivots at a rear of the stapler housing and includes three co-extensive arms terminating near the striker. As the L-shaped handle of the stapler is pressed, it acts on the center arm of the power spring to deflect it downward while the outer arms deflect upward. The arms are integral at a rear end and the outer arms are linked to the striker at the front. A tapered, flat reset spring disposed generally parallel to the power spring is used to reset the internal action. The housing includes open top and rear areas with the handle providing the enclosure thereof. A base assembly is slidably attached at a bottom of the stapler with an open position exposing a staple-loading chamber.

Owner:WORKTOOLS

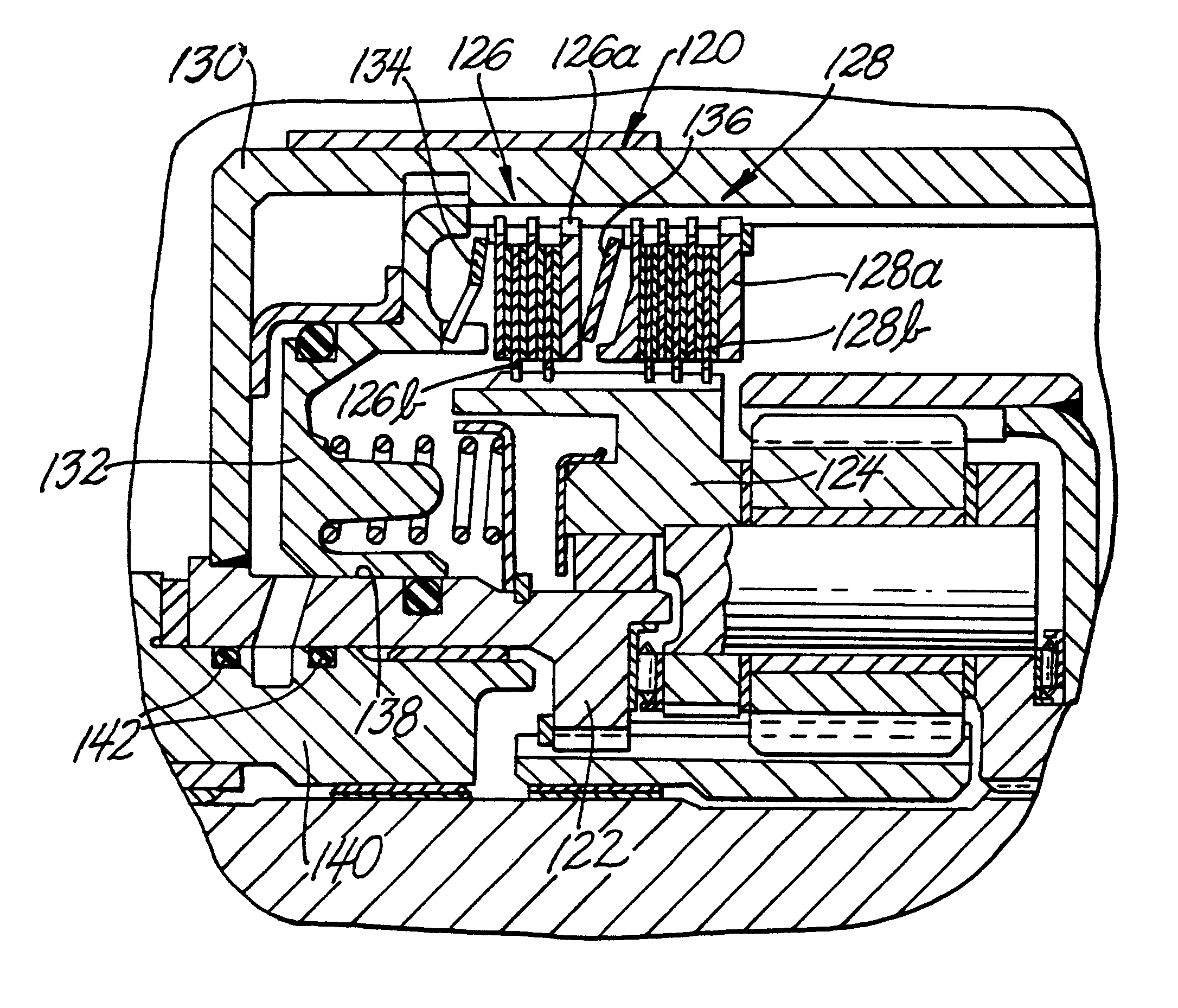

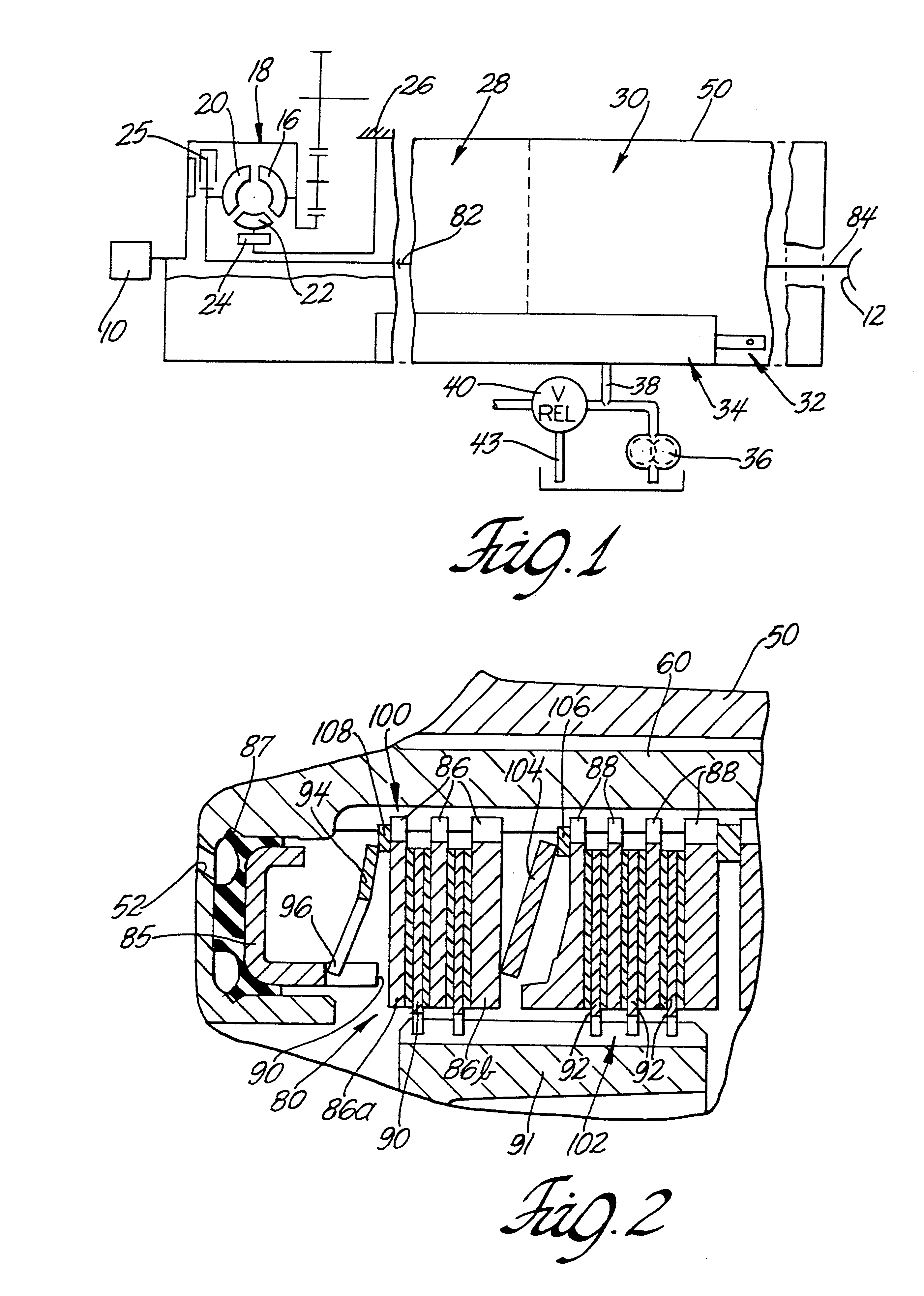

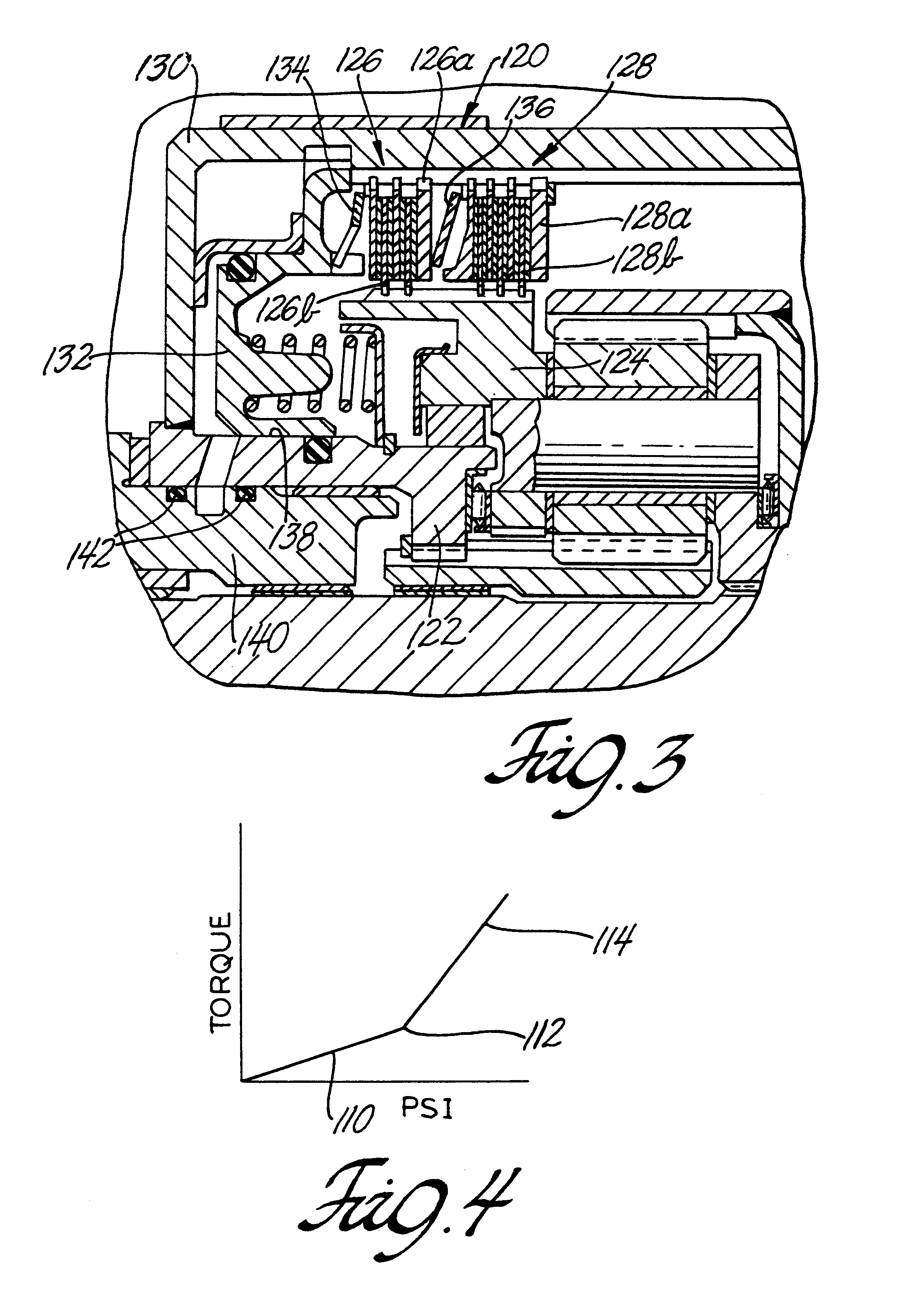

Automatic transmission with dual gain multi-disk friction device

InactiveUS6227340B1Suitable for useReduce widthFluid actuated brakesFluid couplingsAutomatic transmissionCoupling

A fluid pressure operated friction coupling comprising a multiple friction disc assembly having a single piston actuator and having first and second springs operatively configured and arranged in response to pressurization of the piston actuator to selectively engage first and second sets plates and friction components for varying the gain of the coupling.

Owner:BORGWARNER INC

Suspension Apparatus

InactiveUS20080007022A1Easy loadingEasy to controlLeaf springsHigh internal friction springsUnit structureMechanical engineering

Owner:TRW LIMITED

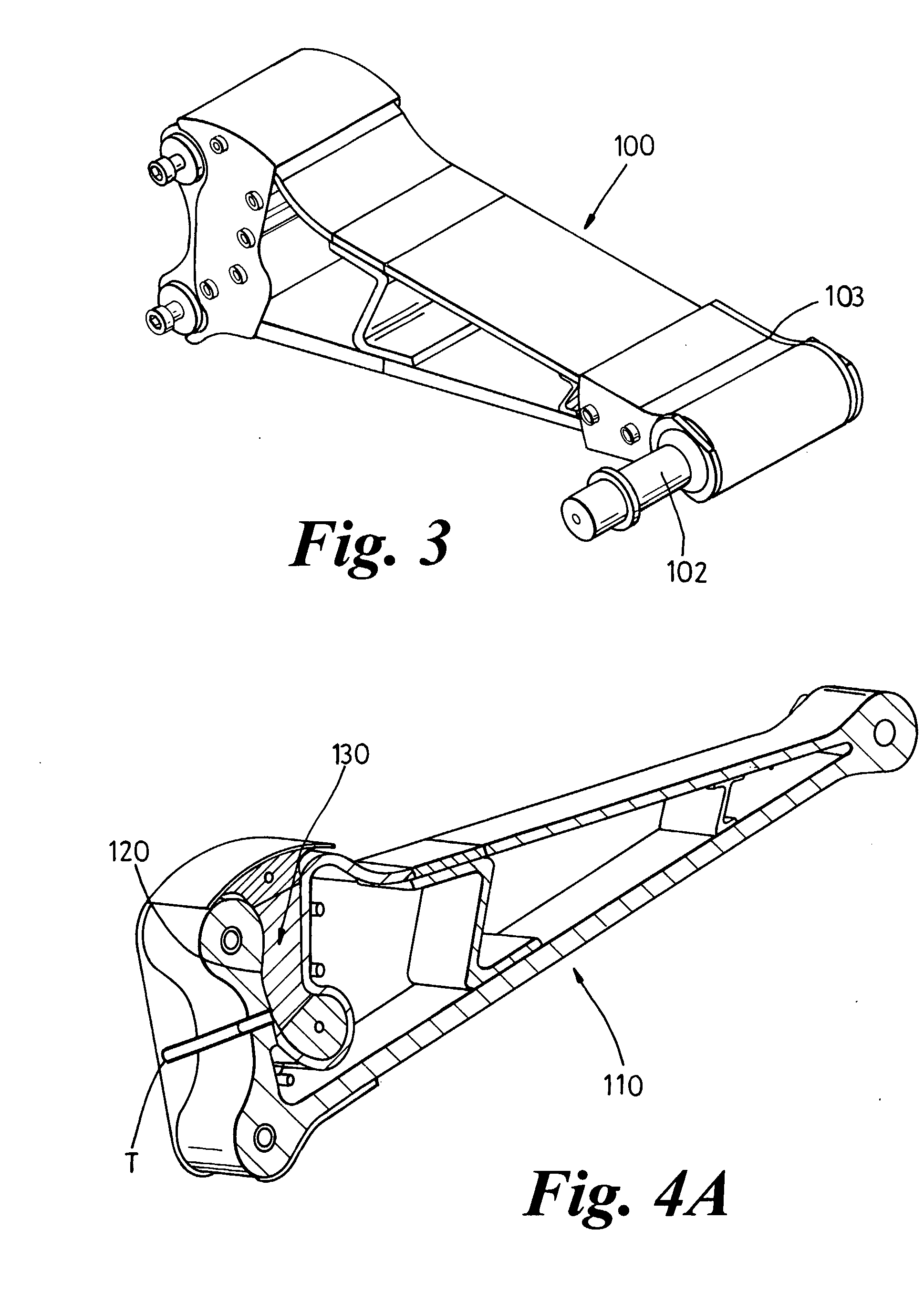

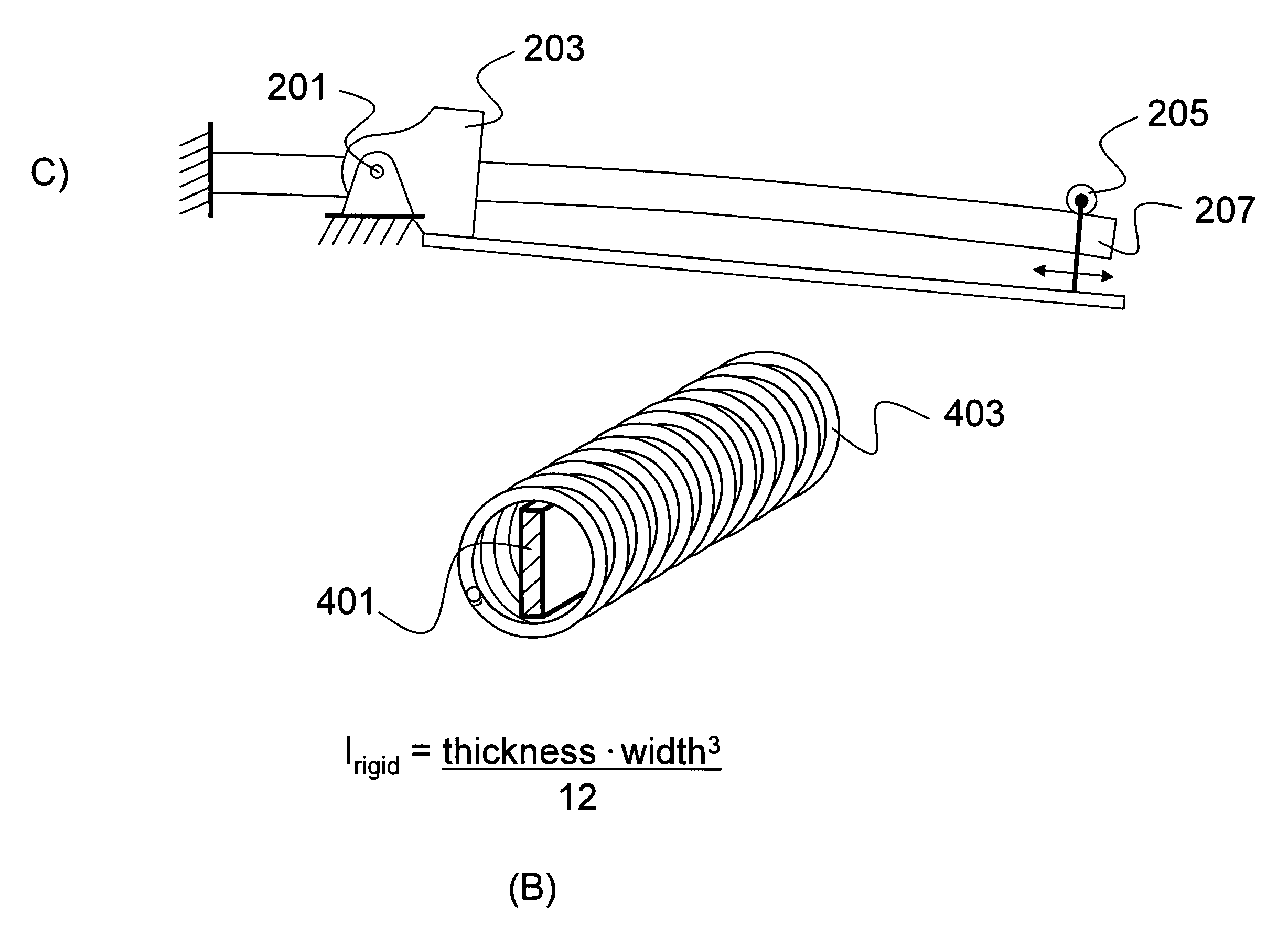

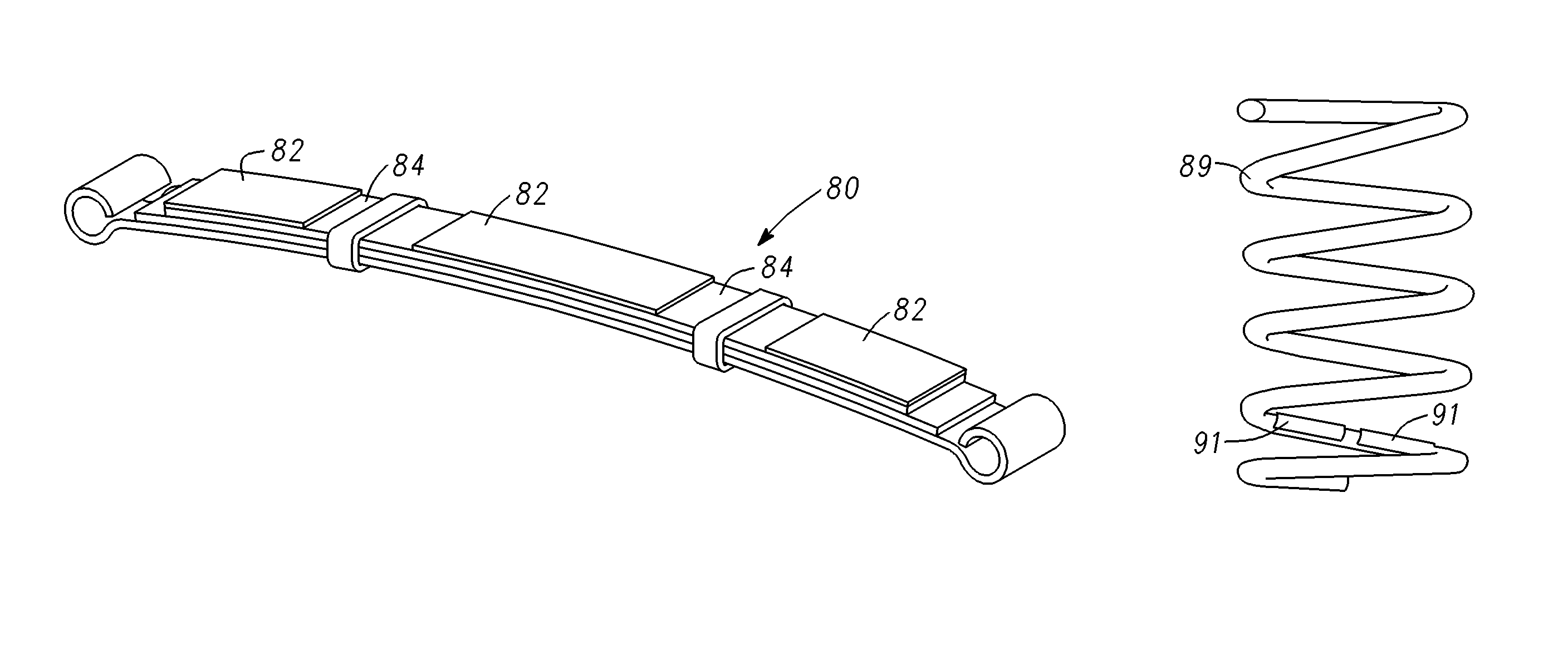

Adjustable stiffness leaf spring actuators

The present invention is a spring based actuator with a leaf spring having a length, width and thickness and a coil spring positioned over the leaf spring. The coil spring further comprises: a first end; a second end; and at least one force generator acting on either the first end of the coil spring and the second end of the coil spring to deflect the coil spring and the leaf spring.

Owner:HOLLANDER KEVIN +1

Clamp for electroplating articles

InactiveUS6342138B1Relieve pressurePrevent accidental releaseCandle holdersLighting support devicesEngineeringElectroplating

An electroplating rack includes a cathode flight bar from which depends an insulated rack bar over an acid bath. A clamp is fixed to the rack bar, and has a bridge electrically connected to the flight bar through a conducting core inside the insulated rack bar. The clamp has a main body made of plastic, which includes a slot in which protrudes the bridge. An electrically conducting spring clip is installed in the slot, and is formed of two arms continuously biased into a spreaded, opened condition in the slot. A screw carried by the main body, when rotated in a first direction, can force the spring clip into a closed condition, in which it can hold an article to be electroplated between its two arms, and in which one of the spring clip arms is forced against the bridge member. Thus, electrical current can pass through the rack flight bar and conducting core, then through the bridge member, the spring clip and finally into the article to be electroplated. Once the rack is lowered to submerge the article into the acid bath, the latter will be electroplated with this current passing through the article.

Owner:M & B PLATING RACKS

Belleville spring guide system

ActiveUS20070138720A1Reduce frictionReduce lateral forceBelleville-type springsRing springsFriction effectEngineering

Owner:HALLIBURTON ENERGY SERVICES INC

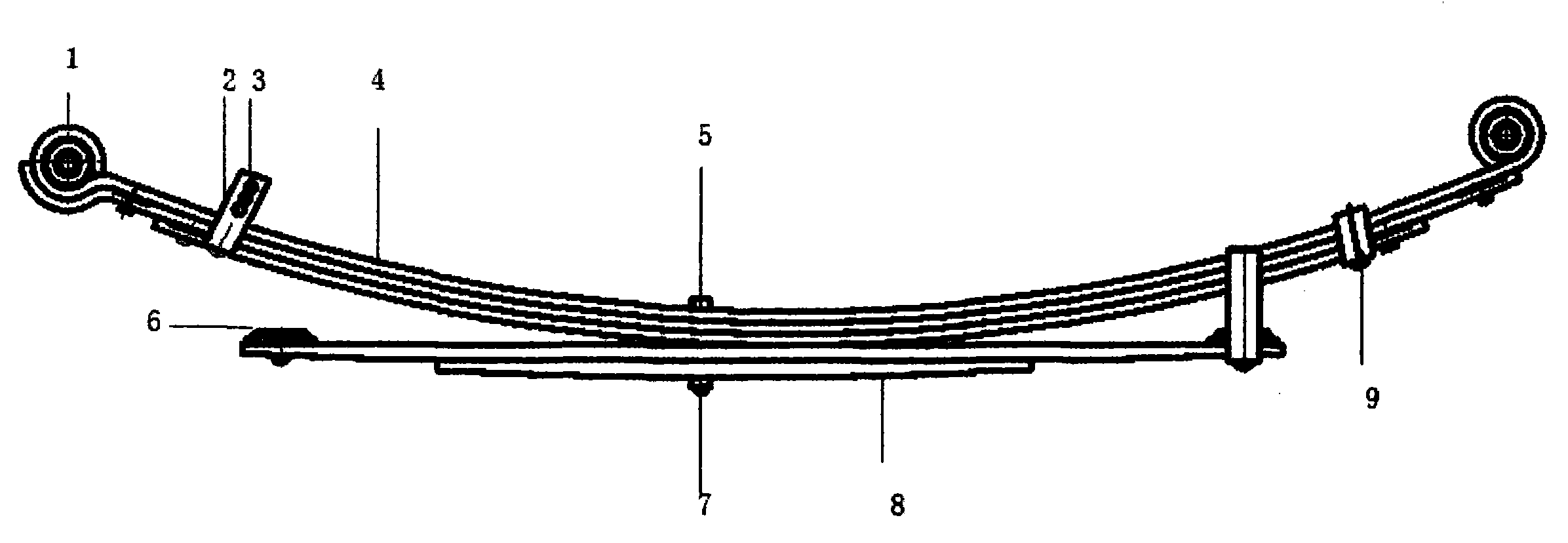

Leaf spring with gradually-varied rigidity

The invention relates to a leaf spring with gradually-varied rigidity, which comprises at least one primary spring sheet and at least one secondary spring sheet, wherein the primary spring sheet and the secondary spring sheet are fixed by a central bolt; the central bolt is positioned in the centers of the primary spring sheet and the secondary spring sheet; a central nut is sleeved on the central bolts; clamp hoops are arranged on both sides of the central bolt on the primary spring sheet; clamp hoop bolts are arranged on the clamp bolts; a clamp sleeve is also sleeved on the primary spring sheet; and different rigidities and axis moments of the primary spring sheet and the secondary spring sheet can be selected. The leaf spring has a simple structure, high elasticity, long service life and good smoothness, and has the equifrequent property.

Owner:HUNAN YITONG AUTOMOBILE PARTS SCI & TECH DEV

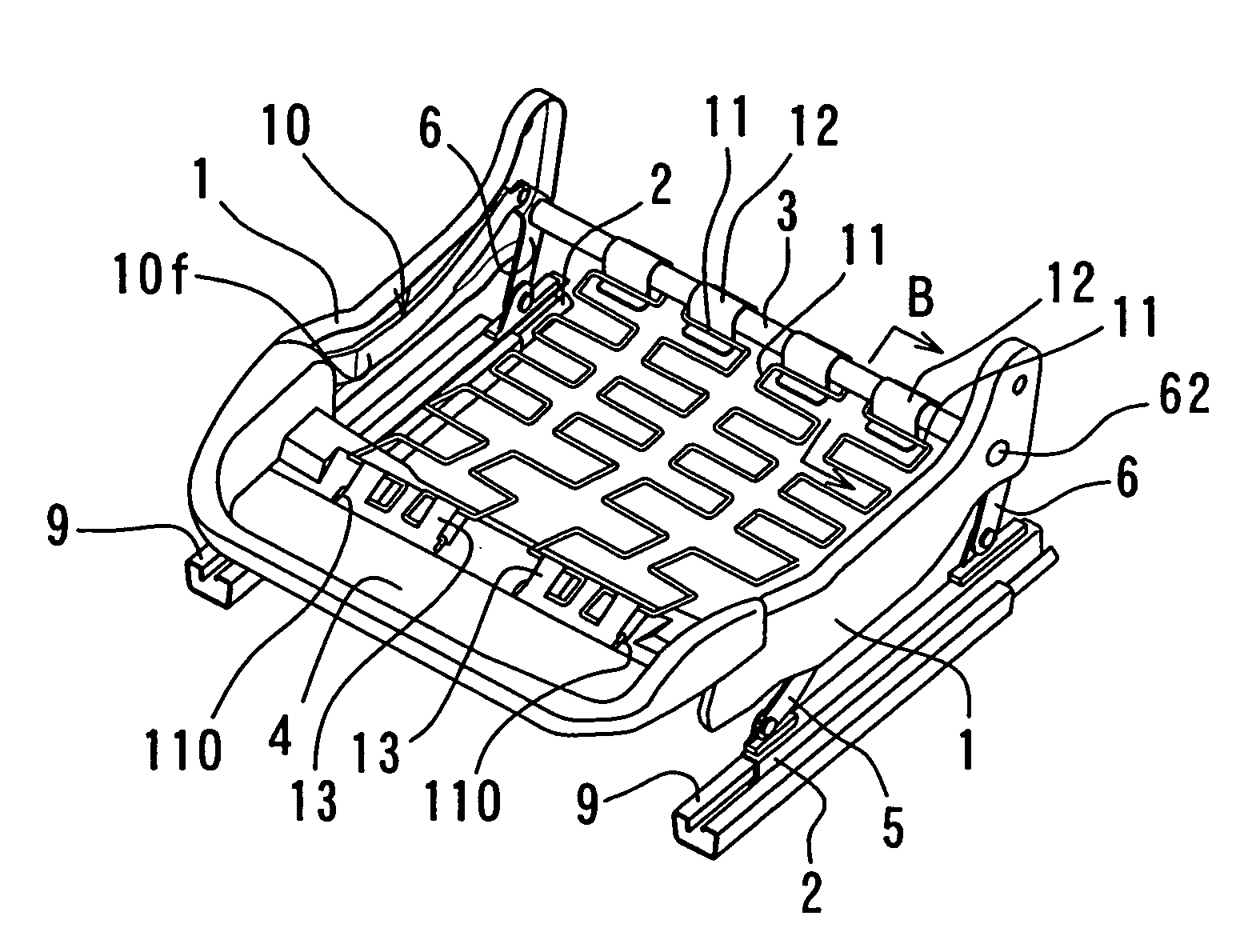

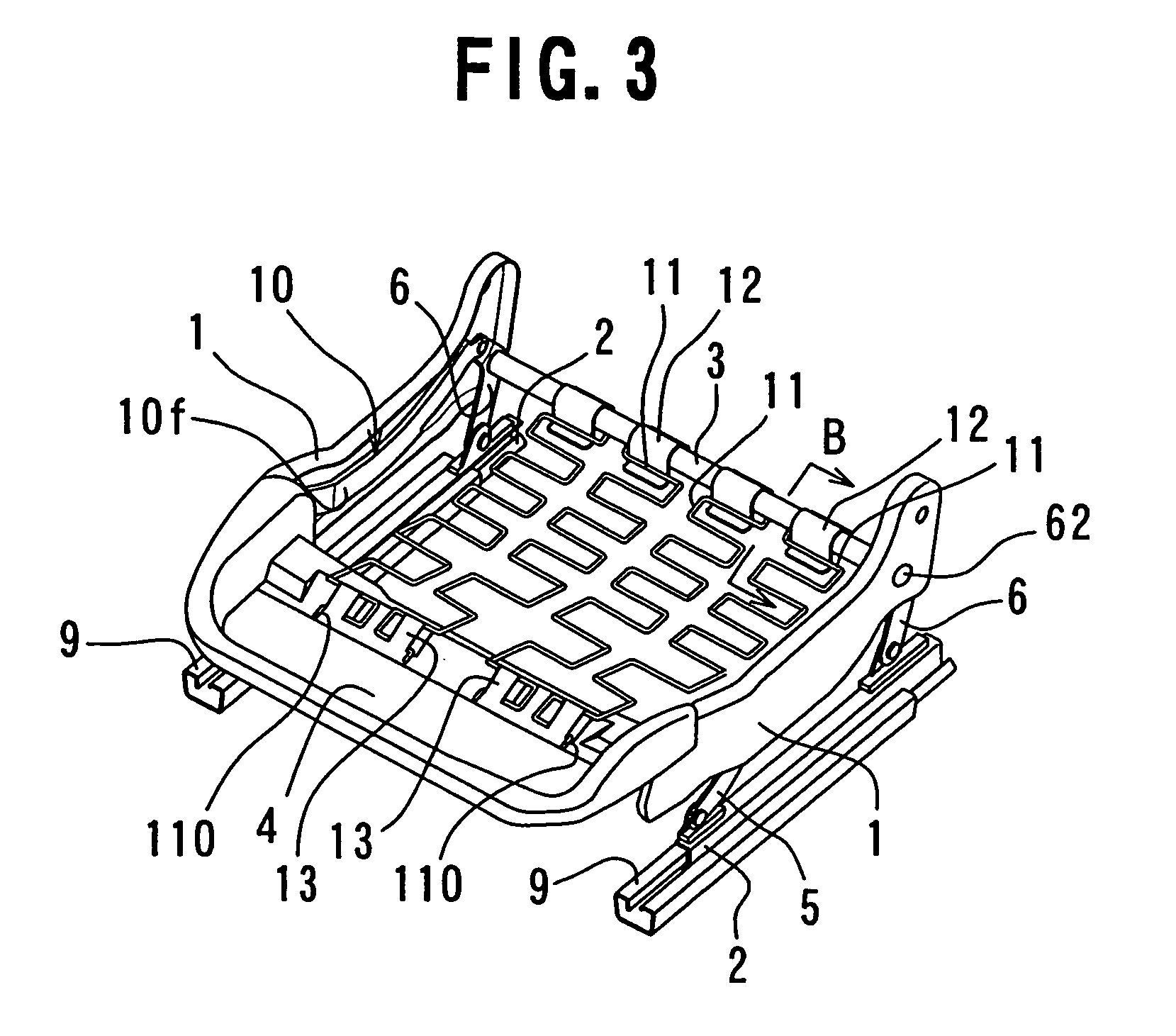

Vehicle seat

A vehicle seat includes a seat cushion which has a frame structure and a cushion member combined with the frame structure, the frame structure including a pair of spaced apart side frame members, a front frame member fixed to forward end portions of the side frame members, a connecting shaft extending between rearward end portions of the side frame members and interconnecting the rearward end portions of the side frame members, a plurality of zigzag springs stretched between the front frame member and the connecting shaft, the cushion member being laid on the zigzag springs, and retainers mounted on the connecting shaft, the zigzag springs being engaged at one terminals thereof with the retainer.

Owner:TS TECH CO LTD

Spring mass damper system for turbine shrouds

InactiveUS6942203B2Avoid heat loadEnhance long-term wear capabilityPump componentsGas turbine plantsCeramic compositeEngineering

The damper system includes a ceramic composite shroud in part defining the hot gas path of a turbine and a spring-biased piston and damper block which bears against the backside surface of the shroud to tune the vibratory response of the shroud relative to pressure pulses of the hot gas path in a manner to avoid near or resonant frequency response. The damper block has projections specifically located to bear against the shroud to dampen the frequency response of the shroud and provide a thermal insulating layer between the shroud and the damper block.

Owner:GENERAL ELECTRIC CO

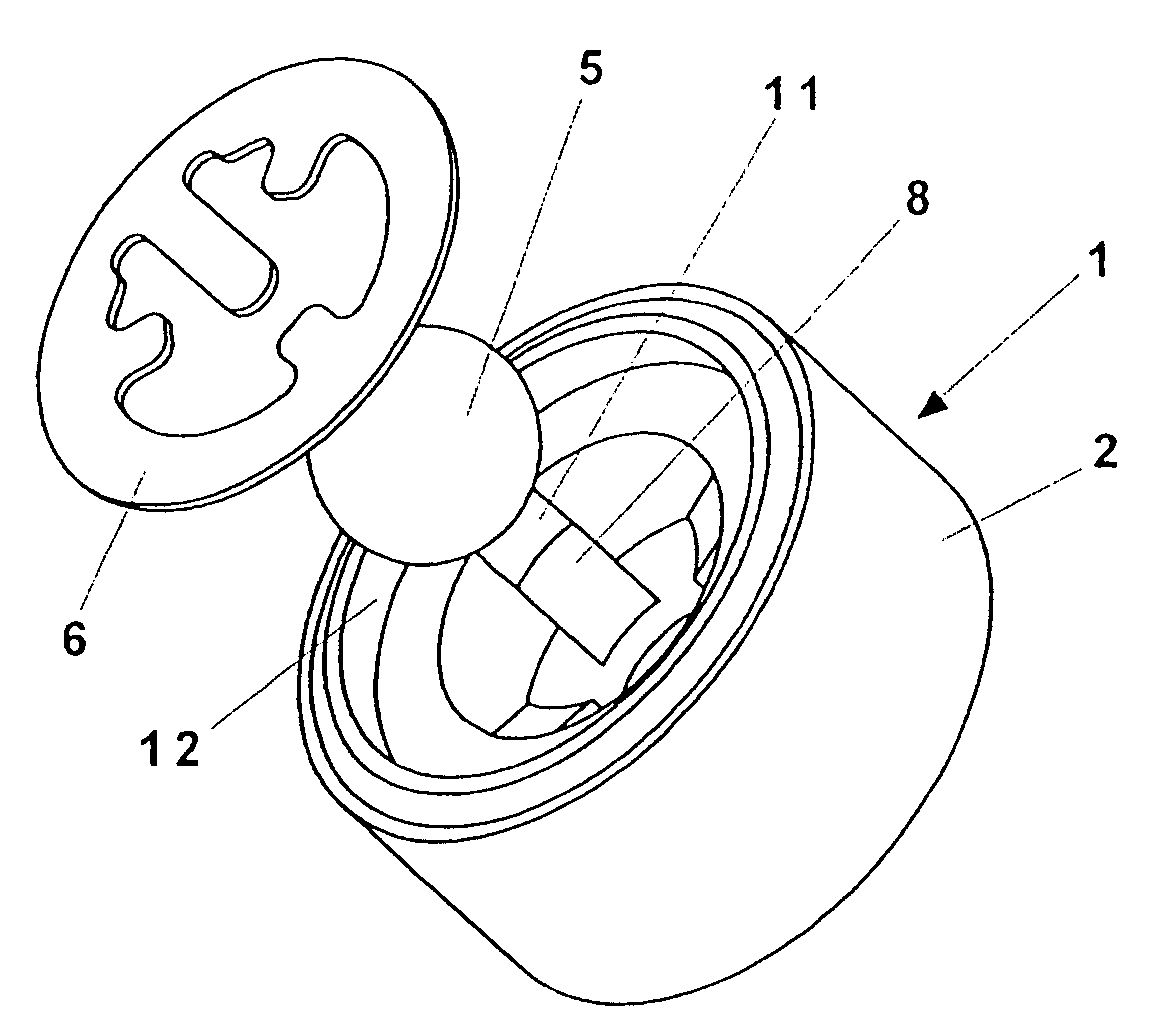

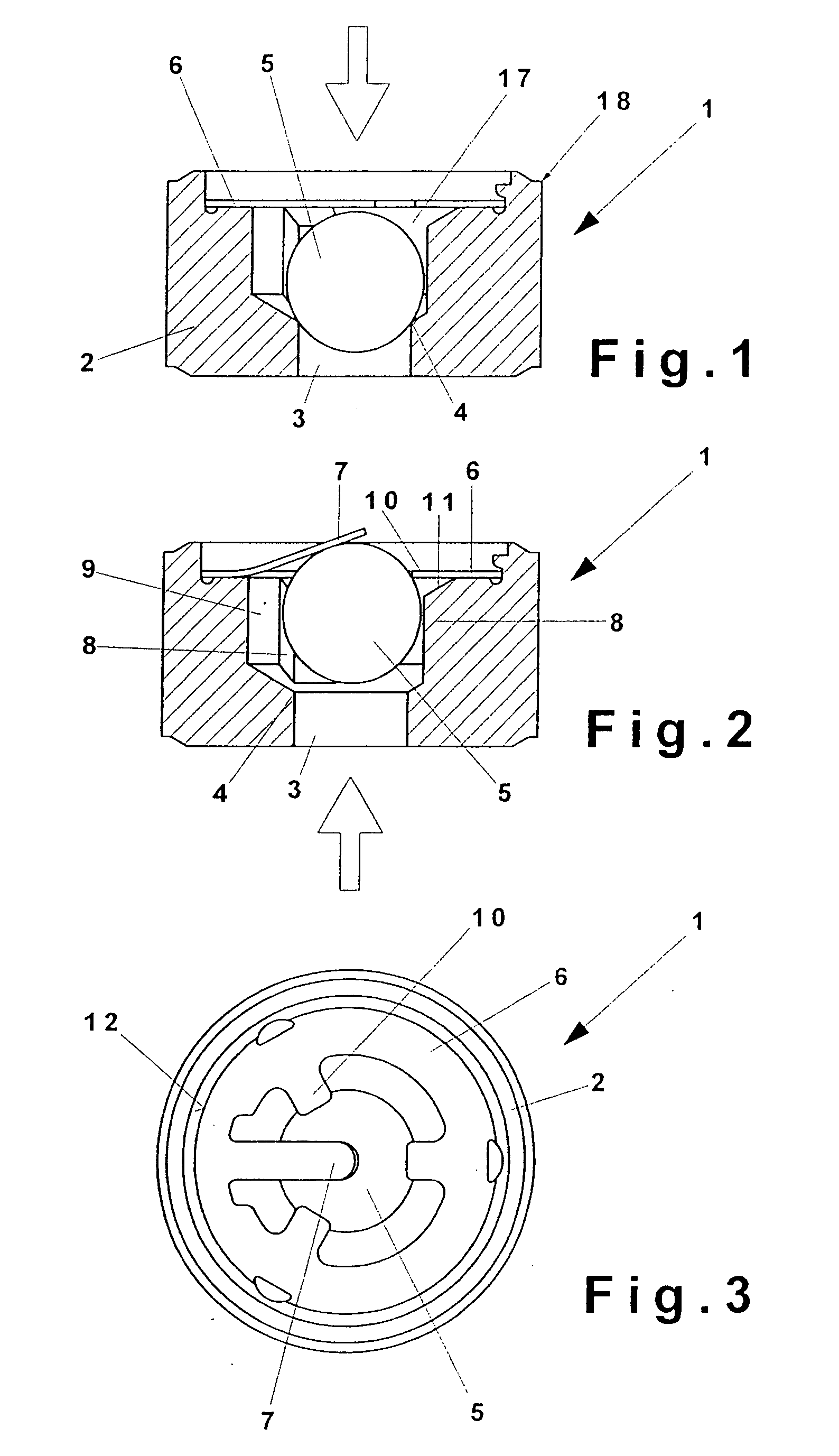

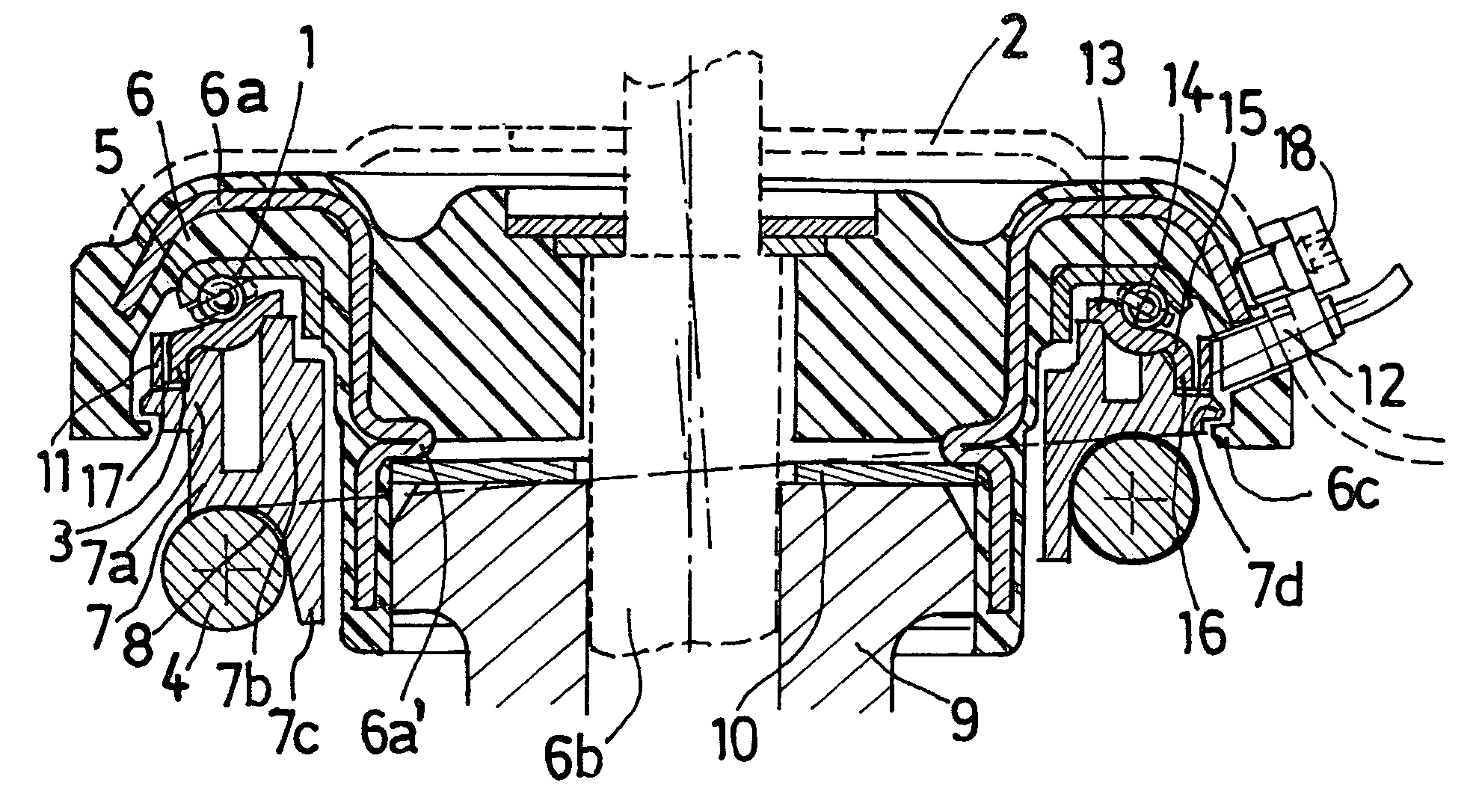

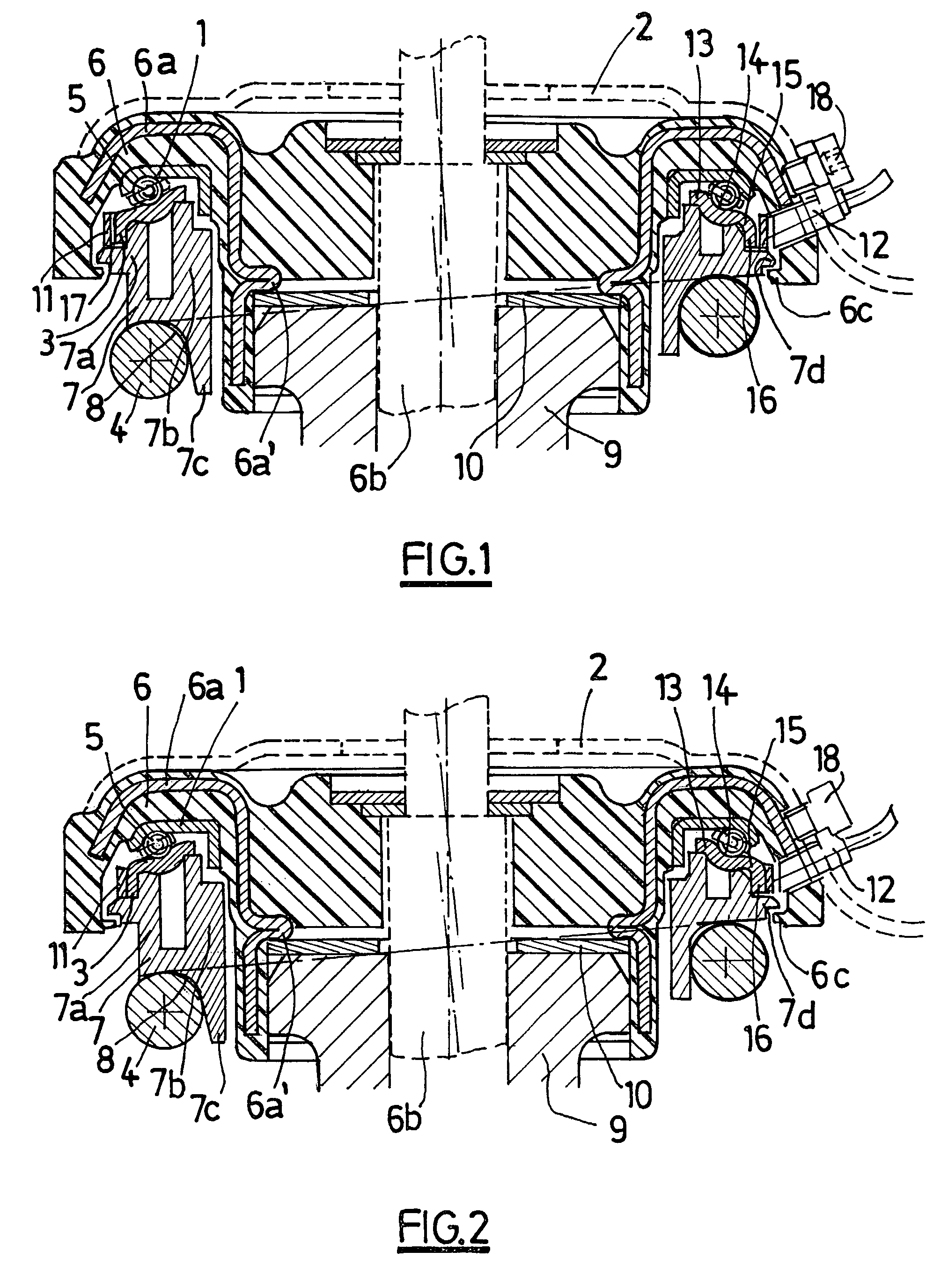

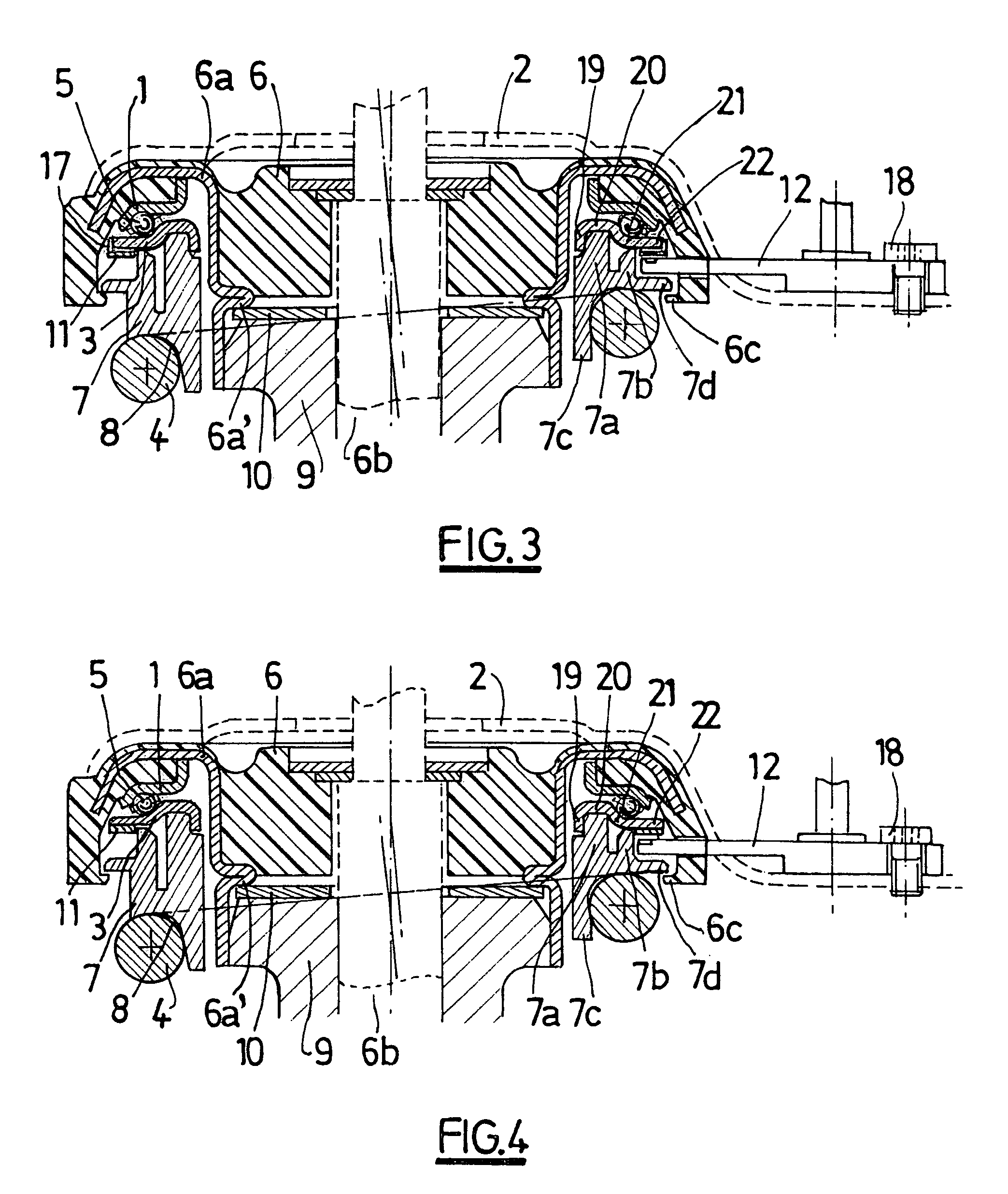

Rotating instrumented suspension stop for measuring vertical forces

A suspension stop for a motor vehicle wheel assembly comprising a fixed member adapted to be fixed to the chassis (2) of the vehicle and a rotating member adapted to be fixed to the suspension spring (4) so as to be rotationally moved under the effect of the forces exerted by the spring. The stop includes a device for measuring the vertical forces applied to the vehicle wheel. The device includes a pulse-generating coder (11) fixed to one of the members, a sensor (12) fixed to the other member which is able to detect these pulses so as to determine the angular position of the rotating member with respect to the fixed member, and a calculation device able, from this position, to calculate the corresponding vertical force applied.A method of measuring the vertical forces applied to a wheel associated with the chassis (2) of a vehicle by such a stop is also provided.

Owner:SNR ROULEMENTS SA

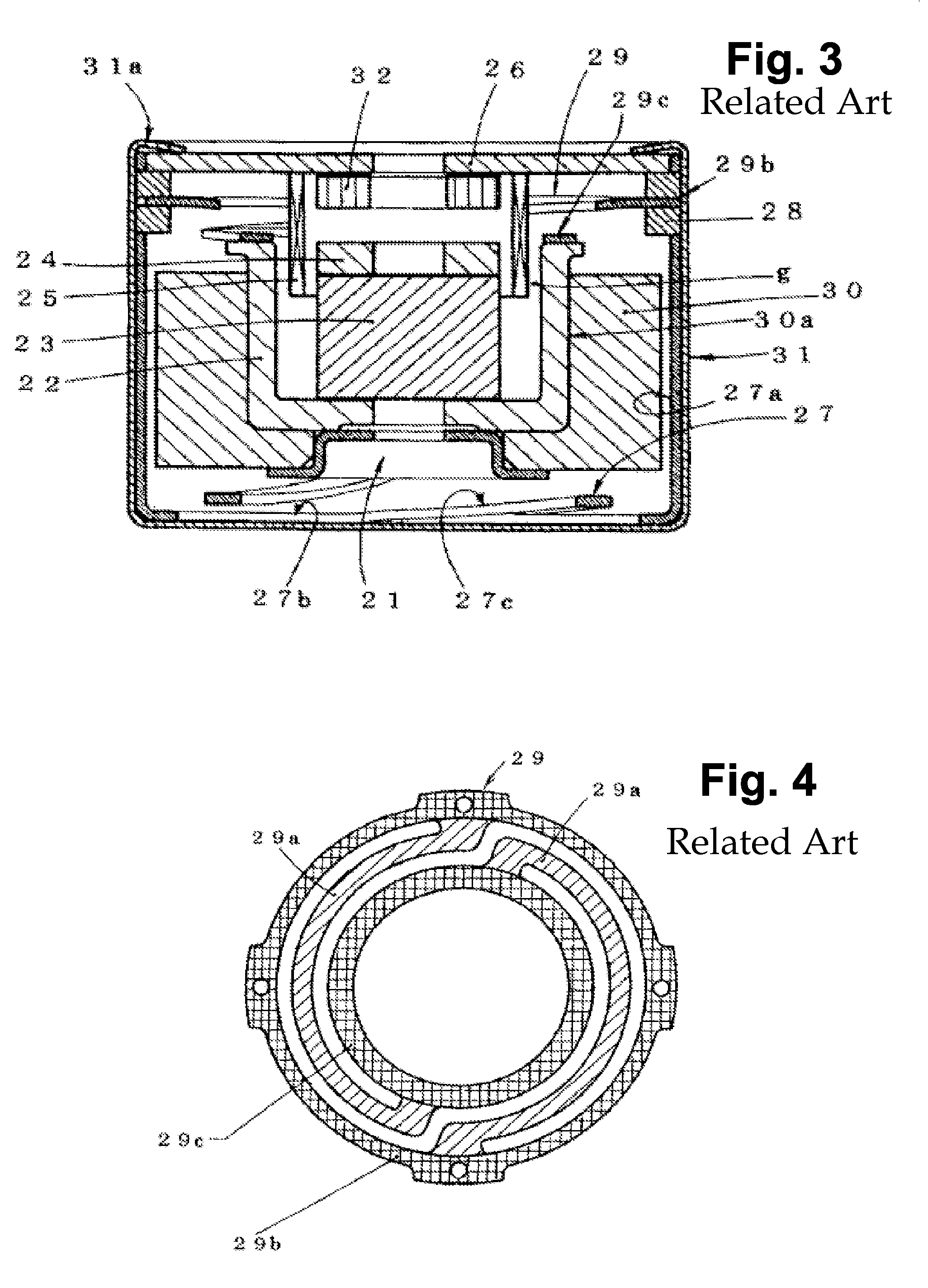

Leaf spring with high vickers hardness

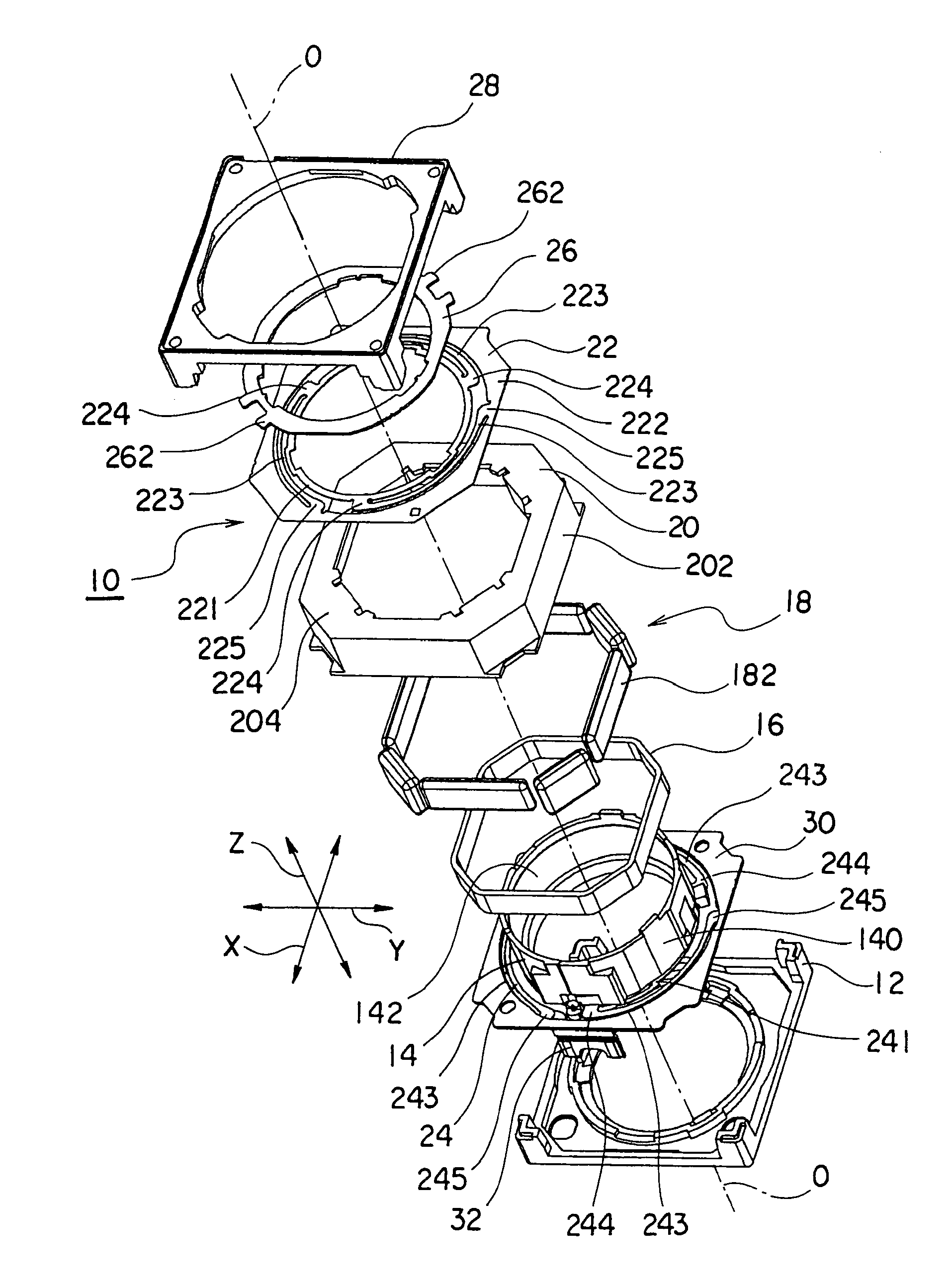

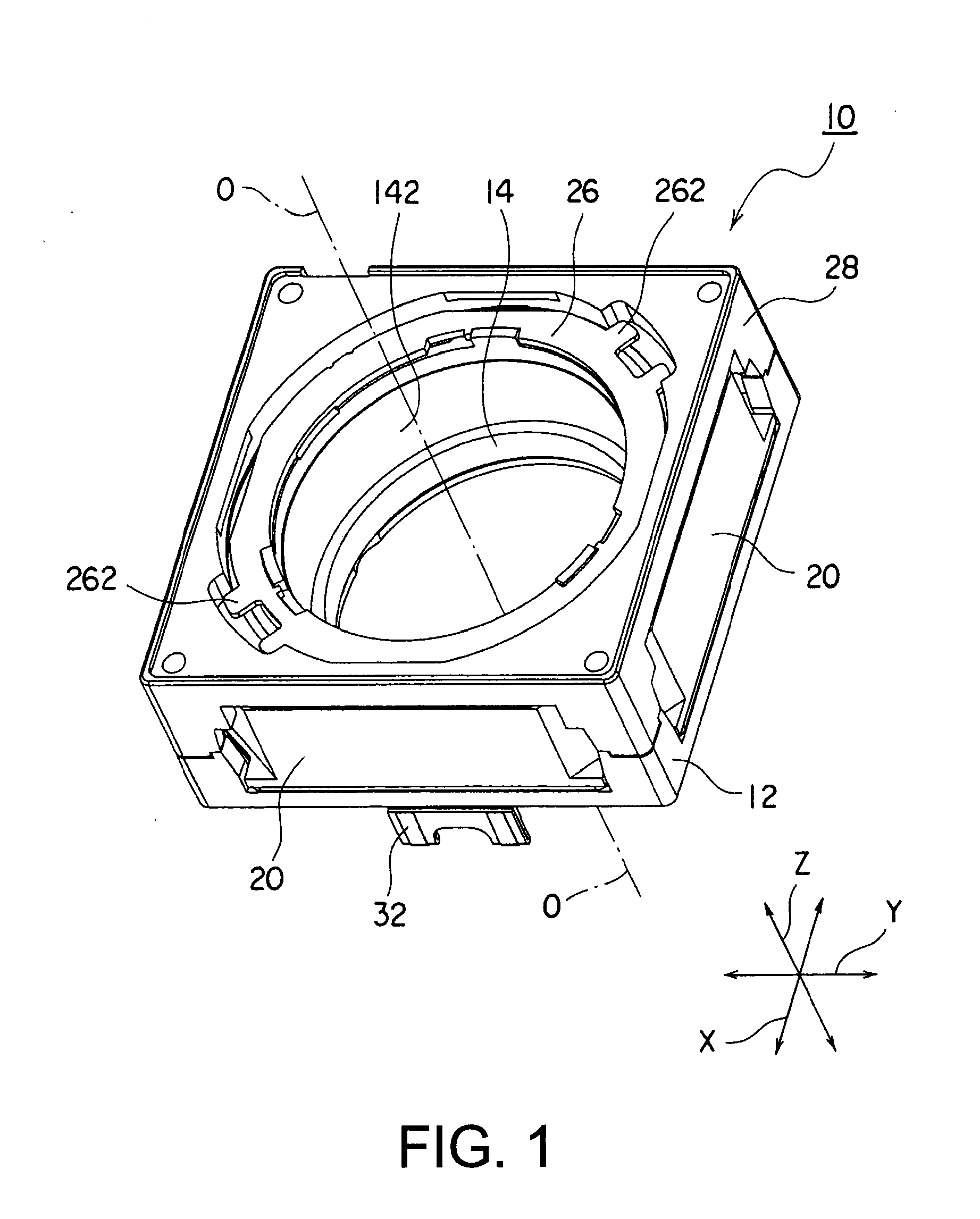

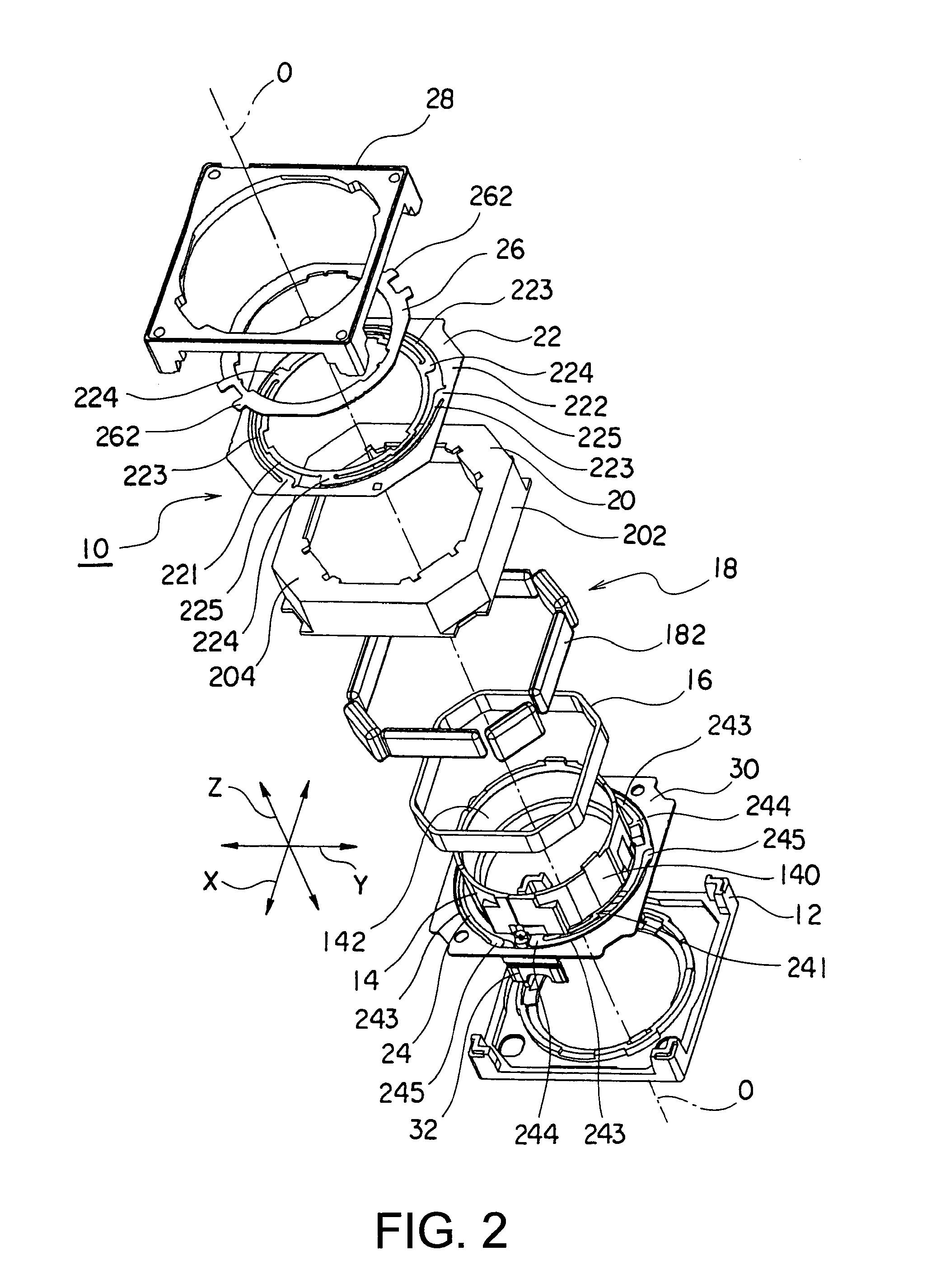

ActiveUS20110205646A1Increase inclinationImprove performanceLeaf springsMountingsHardnessLeaf spring

A leaf spring supports a pillar shaped movable portion disposed in a center portion with respect to a cylindrical fixed portion disposed around the movable portion in the direction of a center axis shiftably so as to position the movable portion in a radial direction. The leaf spring is made of a material having Vickers hardness which is not less than 500 (HV).

Owner:MITSUMI ELECTRIC CO LTD

Harvesting energy from vehicular vibrations using piezoelectric devices

ActiveUS8143766B2Piezoelectric/electrostriction/magnetostriction machinesLeaf springsElectricityPiezoelectric coefficient

An energy harvesting apparatus for deployment on a vehicle having a frame includes a spring assembly coupled to the frame and configured for compressions and extensions during vehicle travel. A piezoelectric device is mounted on the spring assembly for generating electrical energy in response to the strain imposed thereon. A rectifier is coupled to the piezoelectric device for converting AC electrical energy to DC.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com