Patents

Literature

45 results about "Cornering force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

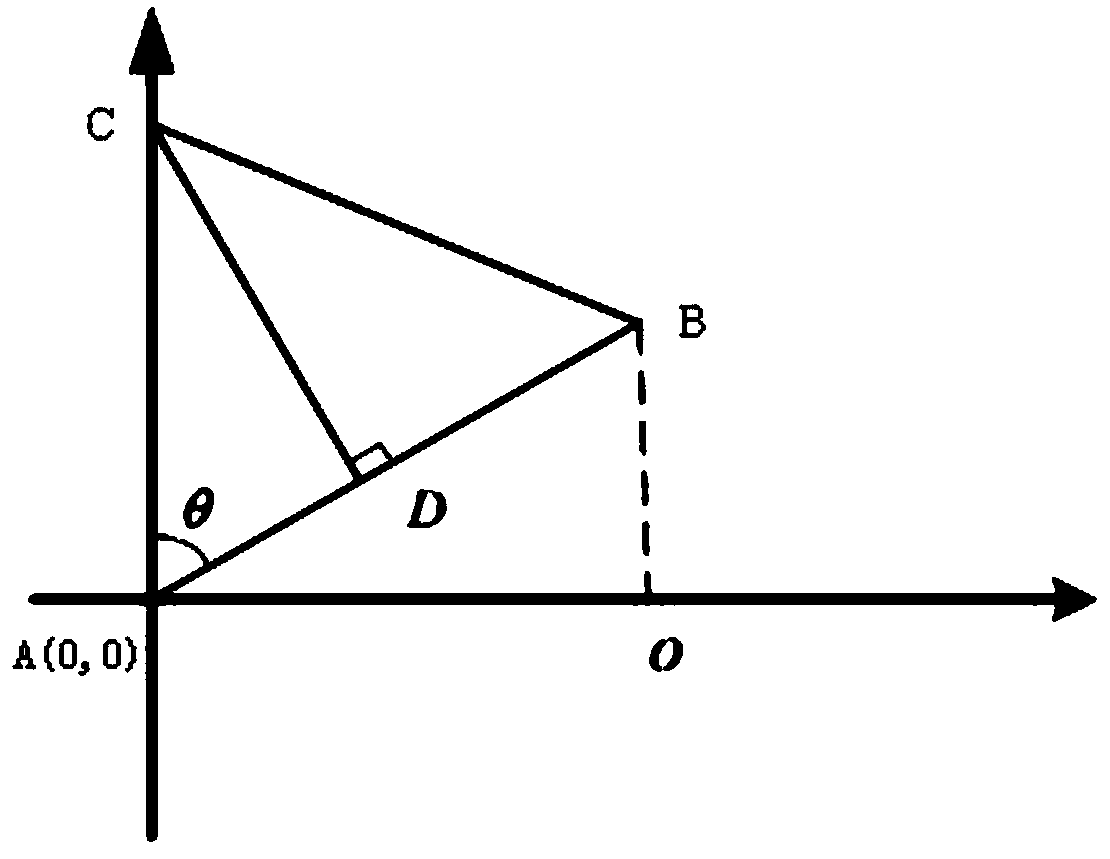

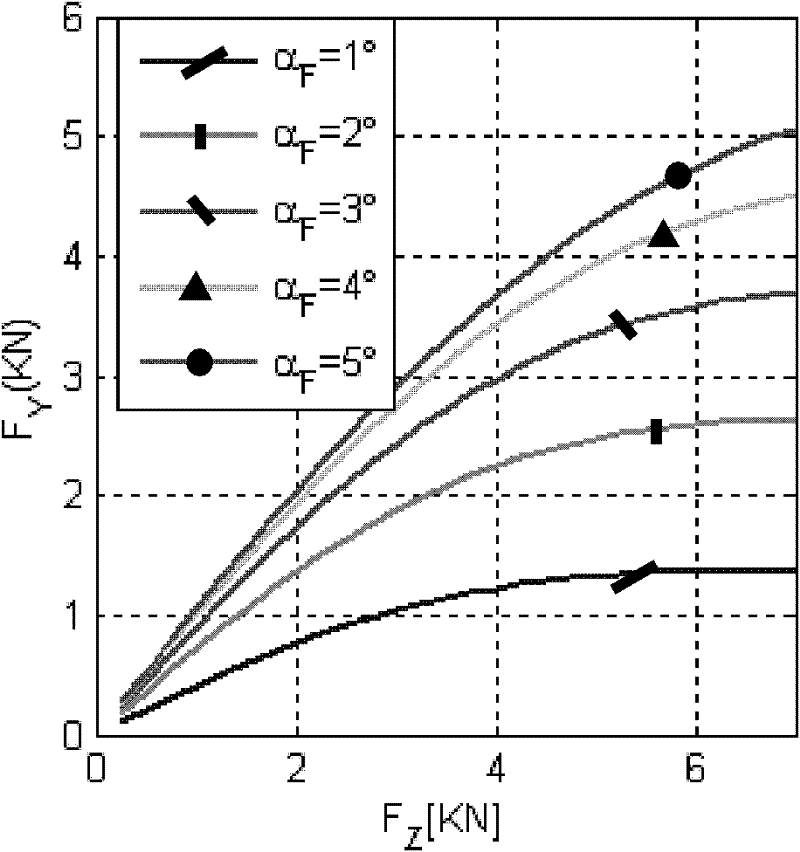

Cornering force or side force is the lateral (i.e., parallel to the road surface) force produced by a vehicle tire during cornering. Cornering force is generated by tire slip and is proportional to slip angle at low slip angles. The rate at which cornering force builds up is described by relaxation length. Slip angle describes the deformation of the tire contact patch, and this deflection of the contact patch deforms the tire in a fashion akin to a spring.

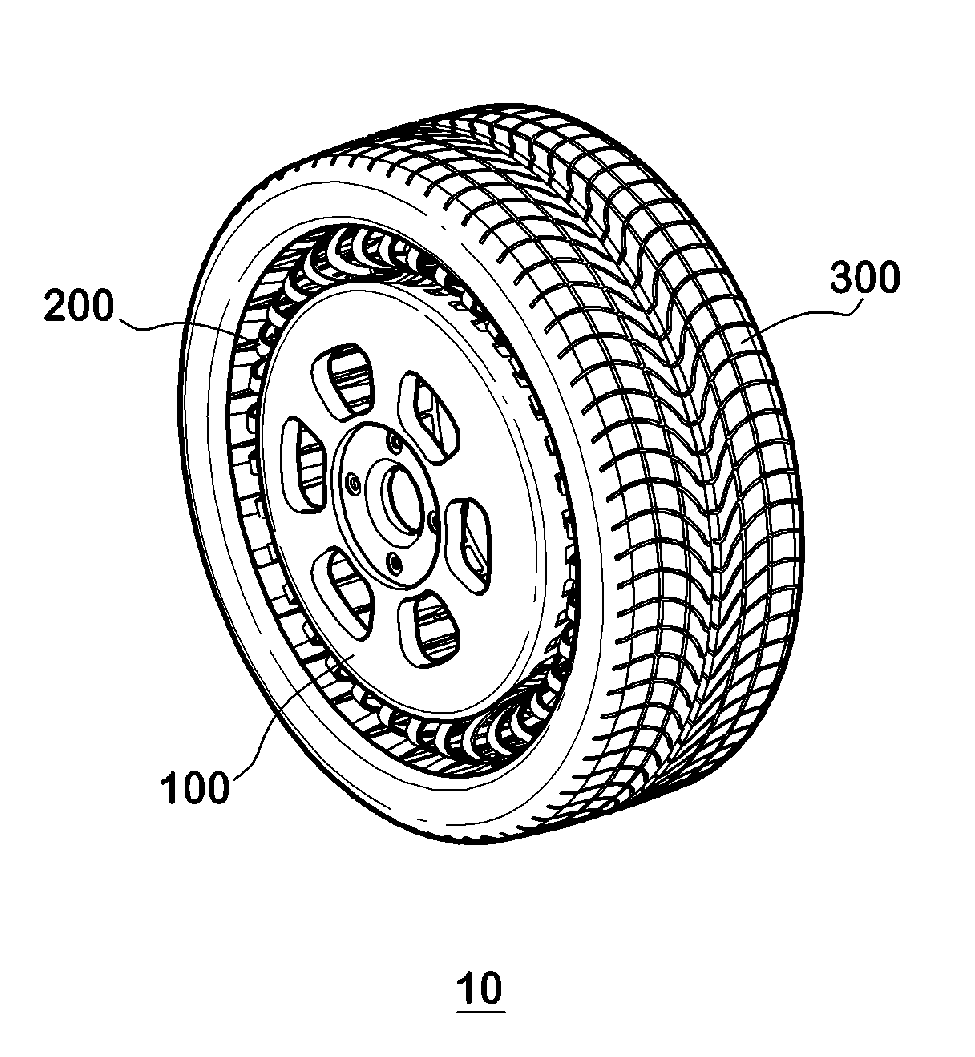

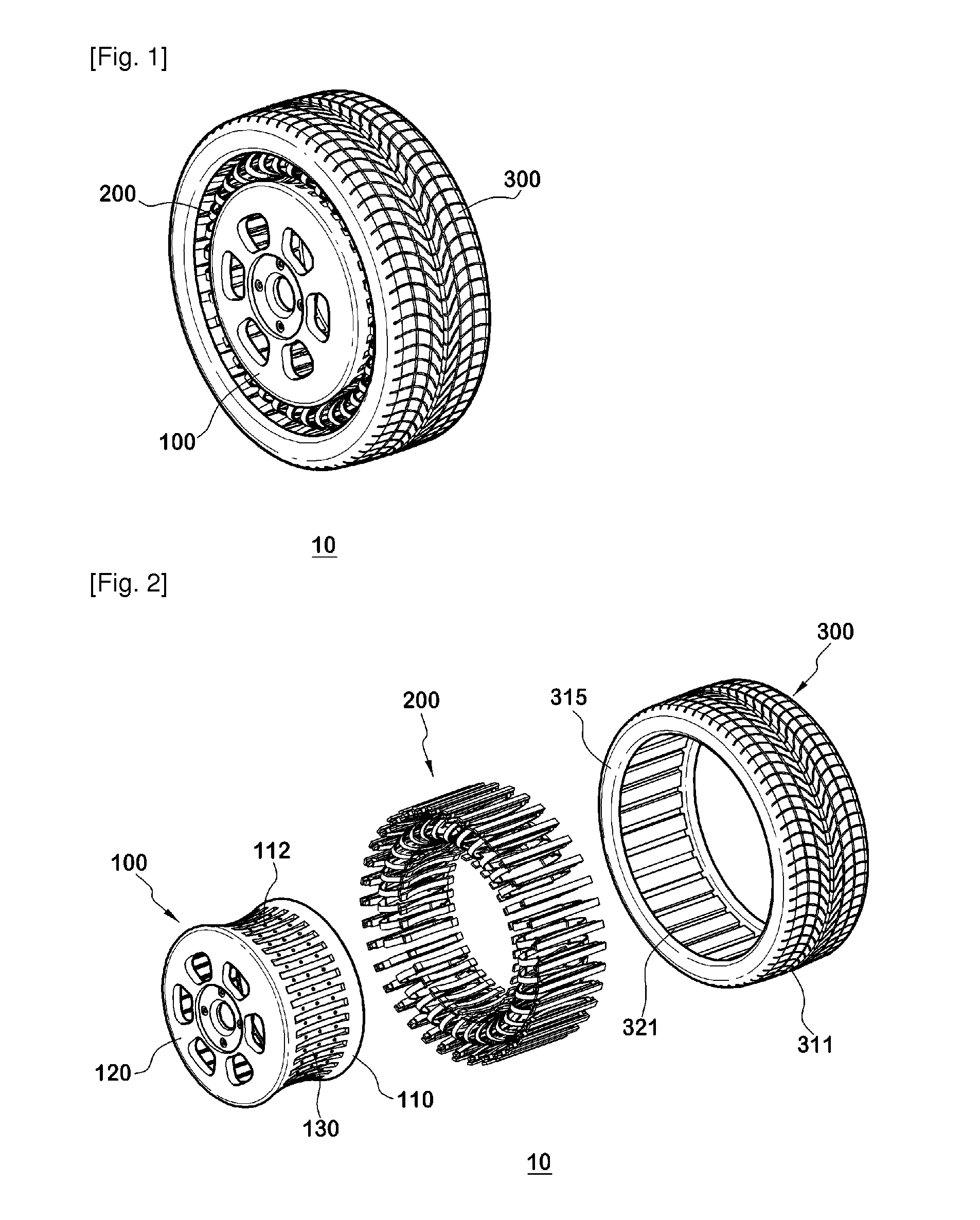

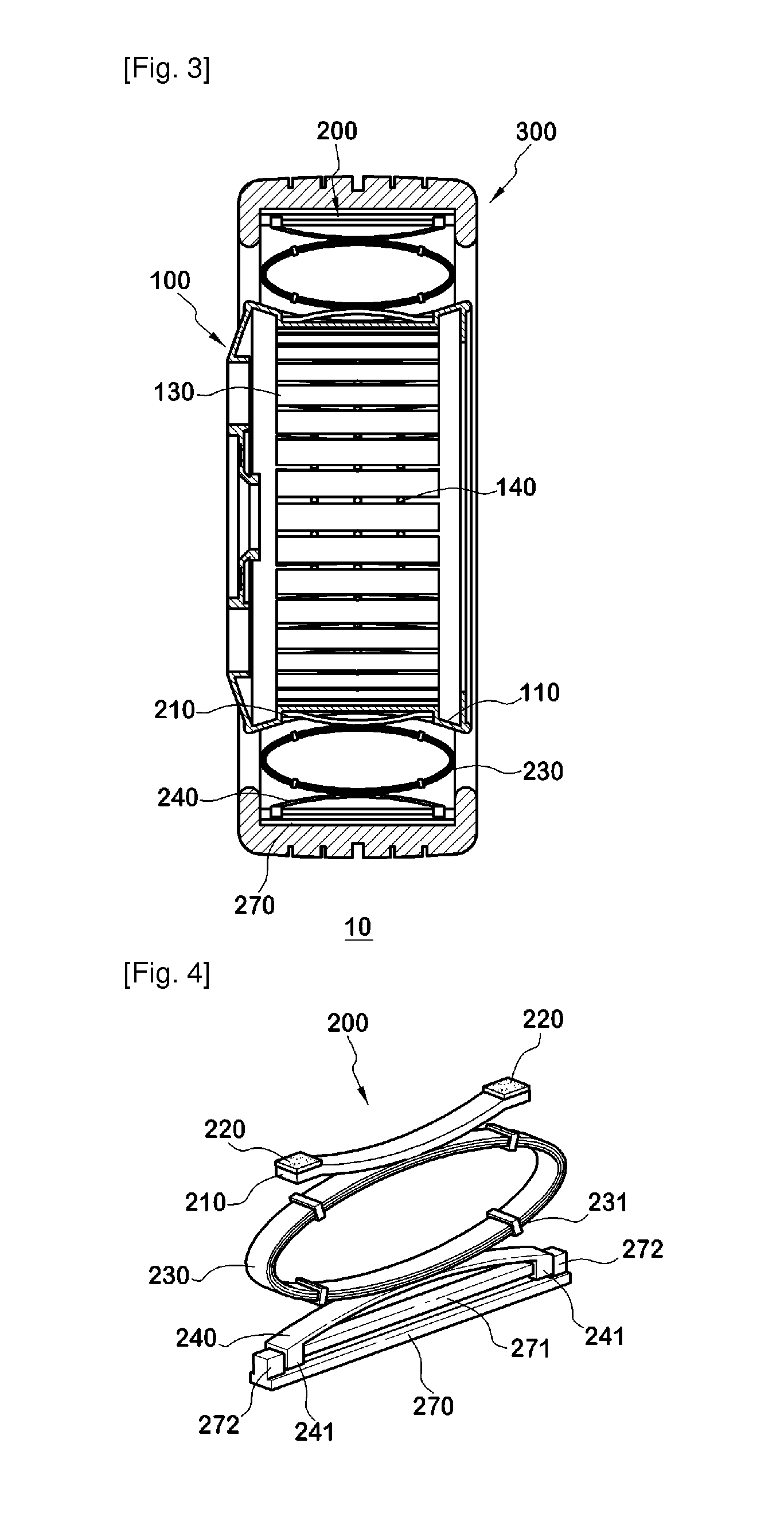

Non-pneumatic wheel and wheel, suspension and tire used therein

InactiveUS20110248554A1Prevent tire blowoutReduce vehicle accidentRimsLeaf springsCornering forceBrake fade

Provided is a non-pneumatic wheel (100) for a vehicle, and a wheel (100), suspension (200; 200-1), and tire (300) used therein that are capable of ensuring driving stability because there is no air chamber between a wheel (100) and a tire (300) to blowout. They are also capable of ensuring good road holding, preventing standing waves, reducing brake fade and cornering force, providing good handling and ride comfort, staying quiet when rolling, and are economical and environmentally friendly. The non-pneumatic wheel (100) includes a wheel (100), a shock absorbing member (220; 220-1) coupled to an outer periphery of the wheel (100) and absorbing or attenuating noise and vibration due to external shock, a plurality of resilient members (230; 230-1; 230-2) arranged around and coupled to an outer periphery of the shock absorbing member (220; 220-1) in a radial direction and having a plurality of resilient rings (230-1a) that are resiliently deformed in response to an external force, resilient links (240) respectively coupled to the resilient rings (230-1a) to evenly transmit external shock to the resilient rings (230-1a), rail plates (270) to which sliders (261) formed at both ends of the resilient links (240) are slidably coupled, and a tire (300) having a plurality of coupling grooves (321) formed along an inner periphery such that the rail plates (270) are inserted into the coupling grooves (321).

Owner:CHON YOUNG ILL +4

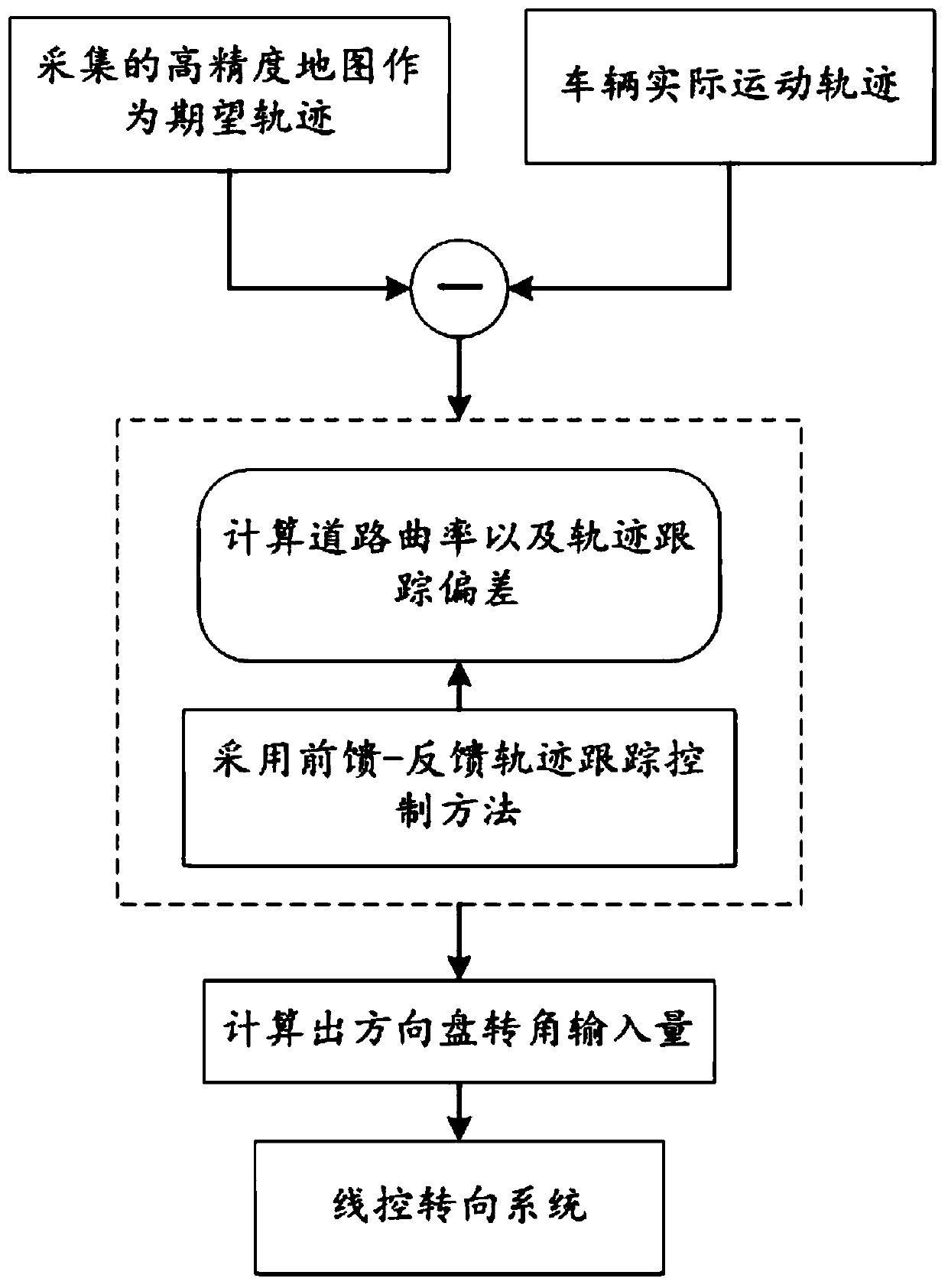

Trajectory tracking control method used for driverless vehicle

InactiveCN108622104AImprove rolling stabilityEliminate the effect of lateral deviation accelerationSteering partsExternal condition input parametersSteering wheelCornering force

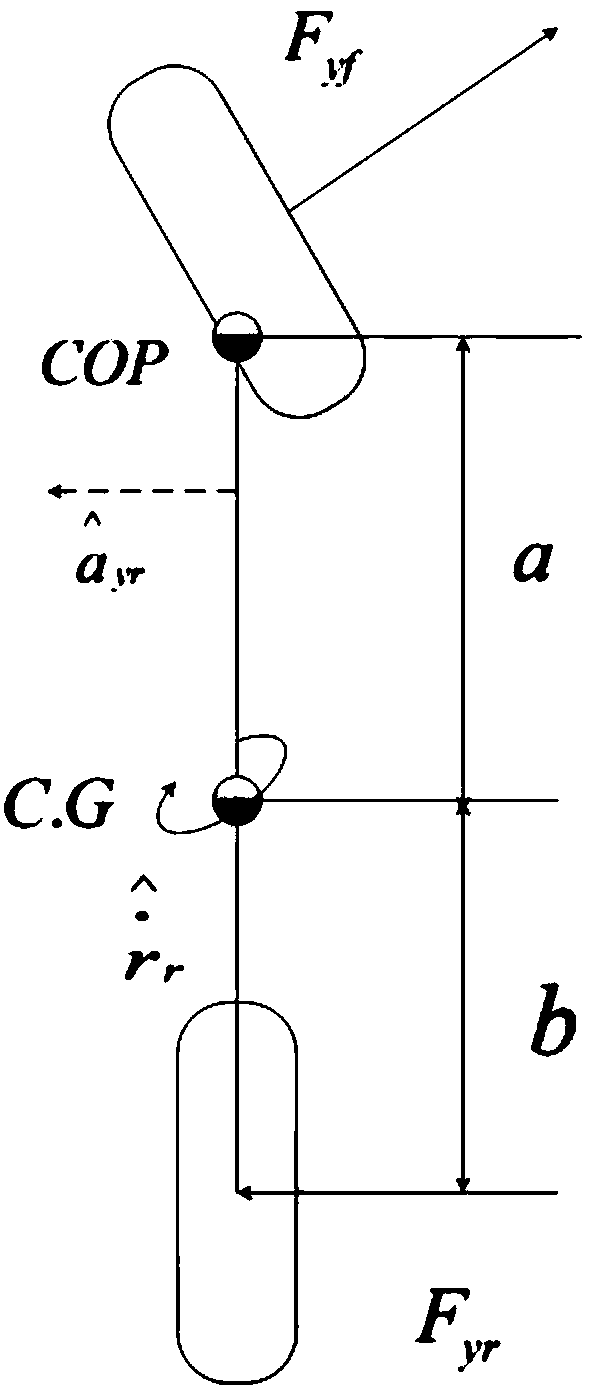

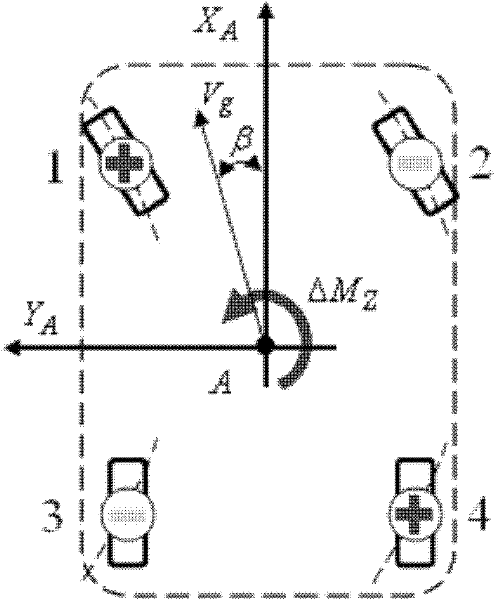

The invention discloses a trajectory tracking control method used for a driverless vehicle. The method includes the following steps that the current position point of a vehicle body is confirmed according to a reference trajectory; a matching point nearest to the current position point of the vehicle is found, and the road curvature of the nearest matching point is obtained according to a two-point curvature obtaining method; according to the current position point of the vehicle and the nearest matching point, a trajectory tracking error is obtained through calculation and comprises a transverse error and a head pointing error; a dynamic model feeding back cornering force on the basis of front wheels is established, and the optimal feedback control rate is obtained by the adoption of an LQR control algorithm; and the cornering force of the front wheels is determined, a front wheel slip angle is obtained on the basis of a reverse tire model, and then the steering wheel angle controlledquantity is obtained and issued to a steering-by-wire system to achieve trajectory tracking control. By the adoption of the method, the stability of trajectory tracking control of the driverless vehicle is improved, the trajectory tracking accuracy is improved, the tire slip angle is restrained, and the possibility that the tire force of the vehicle is saturated under an extreme working conditionand therefore the vehicle loses stability is avoided.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

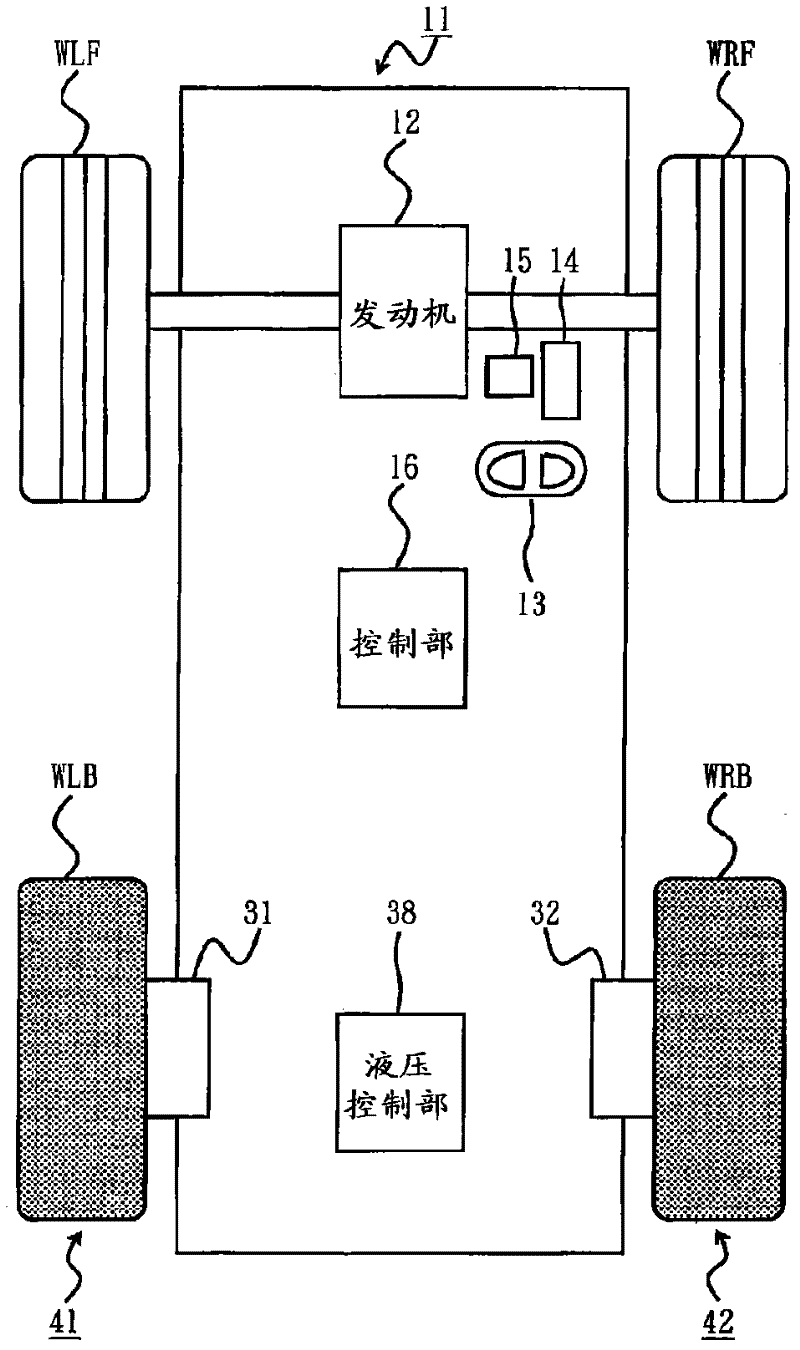

Method for controlling stability of vehicle based on vertical load distribution of tire

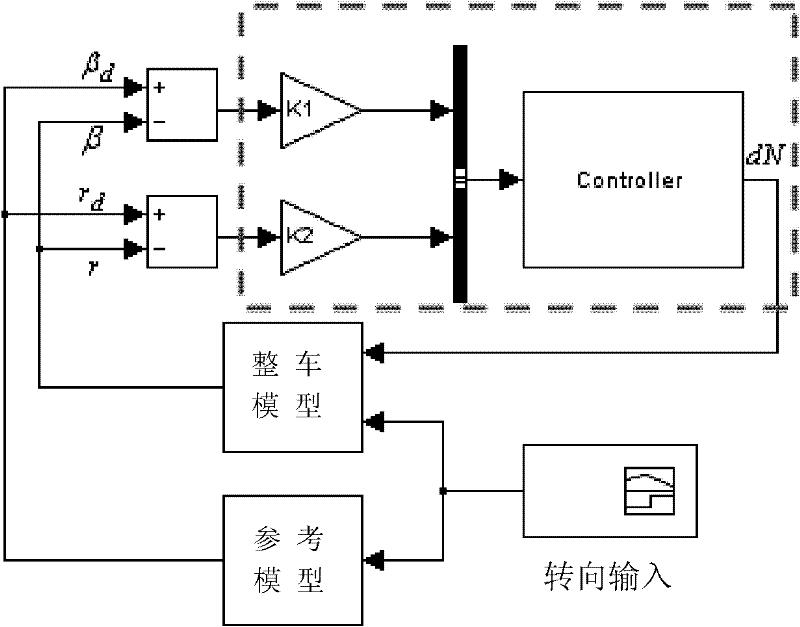

The invention discloses a method for controlling the stability of a vehicle based on vertical load distribution of a tire. The control method comprises the following steps of: 10, giving steering input out by a driver, estimating motion state information and ideal state information of the vehicle by using a finished vehicle model and a finished vehicle reference model, and judging whether the vehicle is positioned in a stable state or not by the comparison of vehicle information; 20, inputting tracking errors of the vehicle into a proportion integration differentiation (PID) controller, and acquiring an active force feedback of a suspension frame by a corresponding PID control algorithm; and 30, after feedback control is received by the vehicle, redistributing a vertical load of the tire of the vehicle to generate calibration yawing moment so as to restrain the sideslip of the vehicle and improve the stability of the vehicle. In the method, the vertical load of the tire is distributed by the active force of the suspension frame; the calibration yawing moment is generated due to a nonlinear coupling relationship between the vertical load of the tire and cornering force; therefore, yawing motion of the vehicle is controlled, the sideslip of the vehicle is restrained, and the lateral stability of the vehicle is improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Vehicle

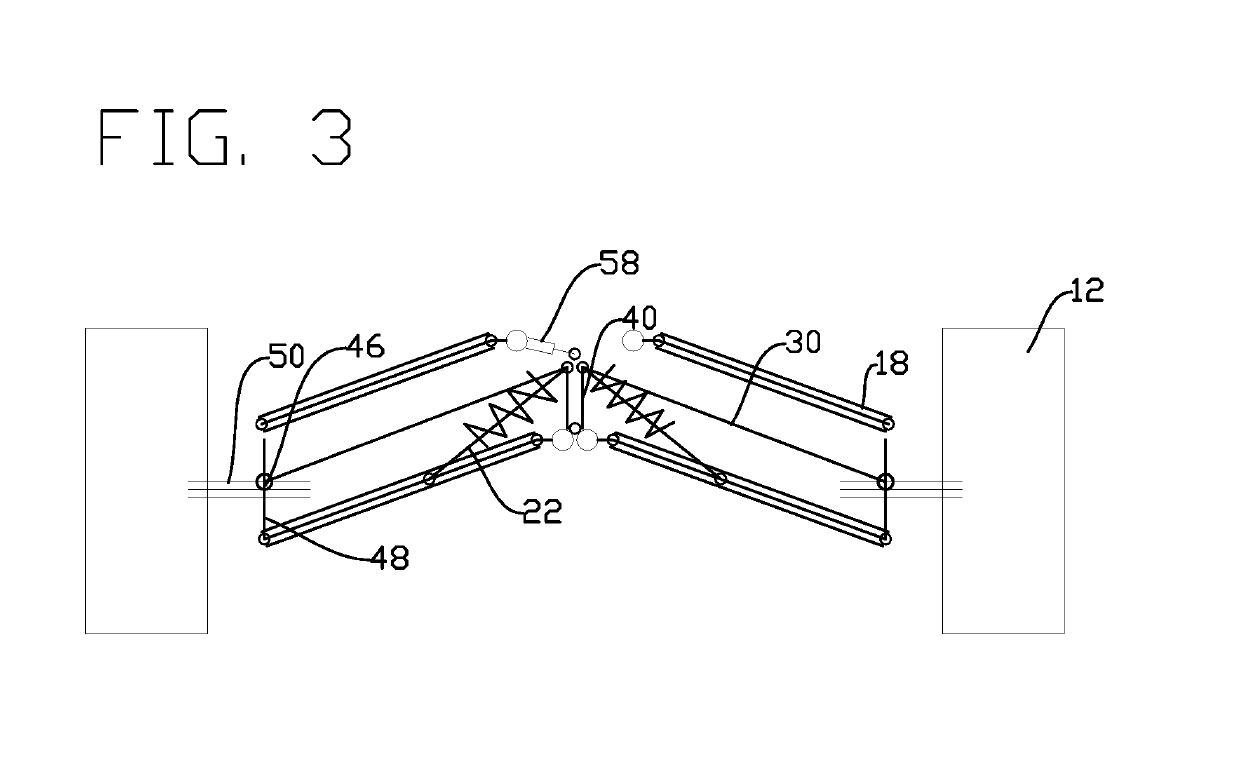

ActiveUS20090256331A1Increases cornering forceIncreased vertical loadVehicle body stabilisationVehicle cleaning apparatusCornering forceGravity center

By bending and stretching a link mechanism, both left and right wheels of a vehicle can be inclined toward inside of cornering to generate a camber thrust as a lateral force, i.e. an increase in cornering force. Further, by bending and stretching the link mechanism, the passenger compartment can be inclined in accordance with inclination of a connecting link, and thus the center of gravity of the vehicle can be moved toward its inner wheel during cornering. By preventing lifting of the inner wheel during cornering, cornering performance is improved. Because the passenger compartment is inclined toward the inner wheel during cornering, centrifugal force is less likely to be felt by the occupant.

Owner:EQUOS RES

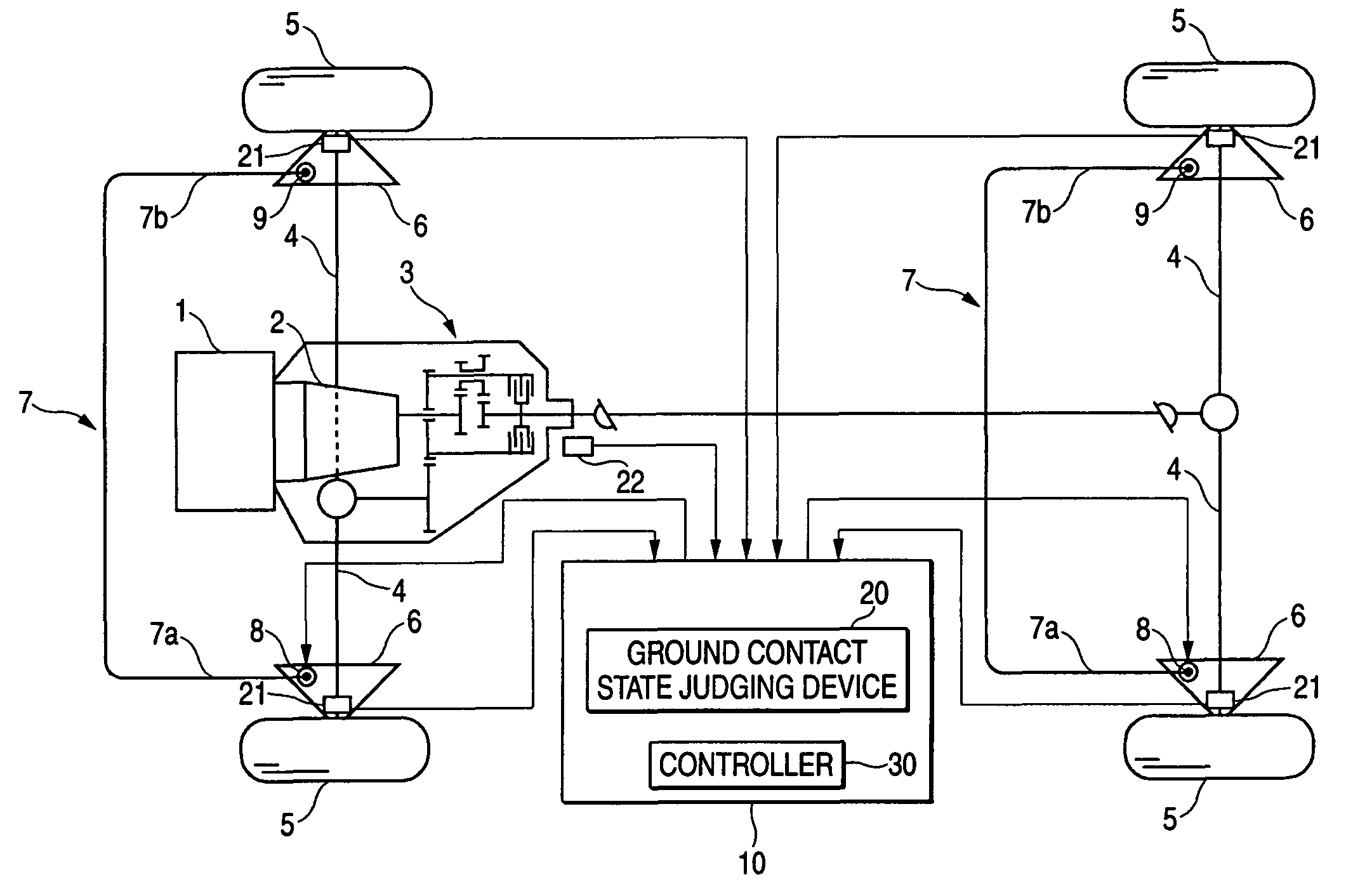

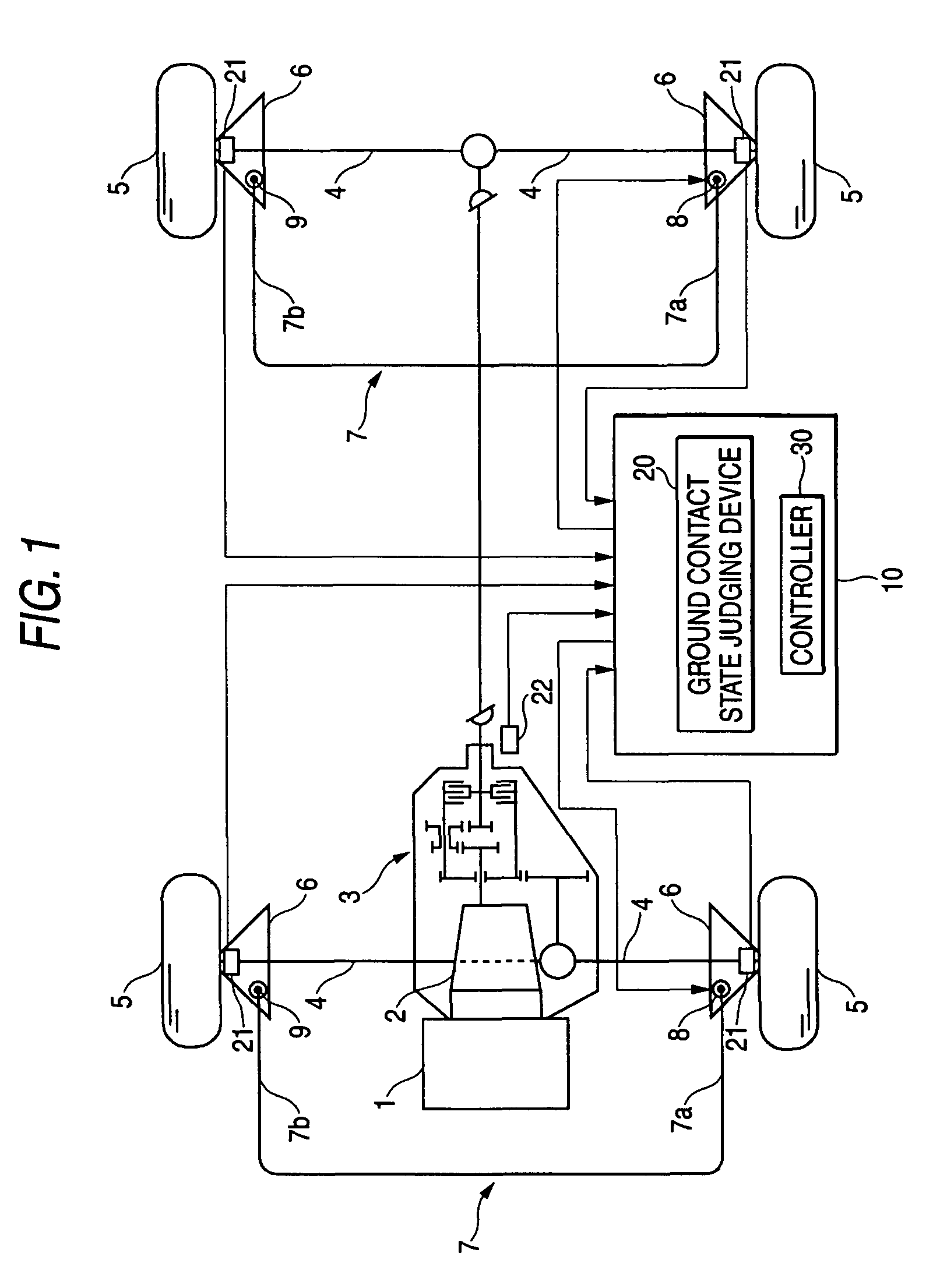

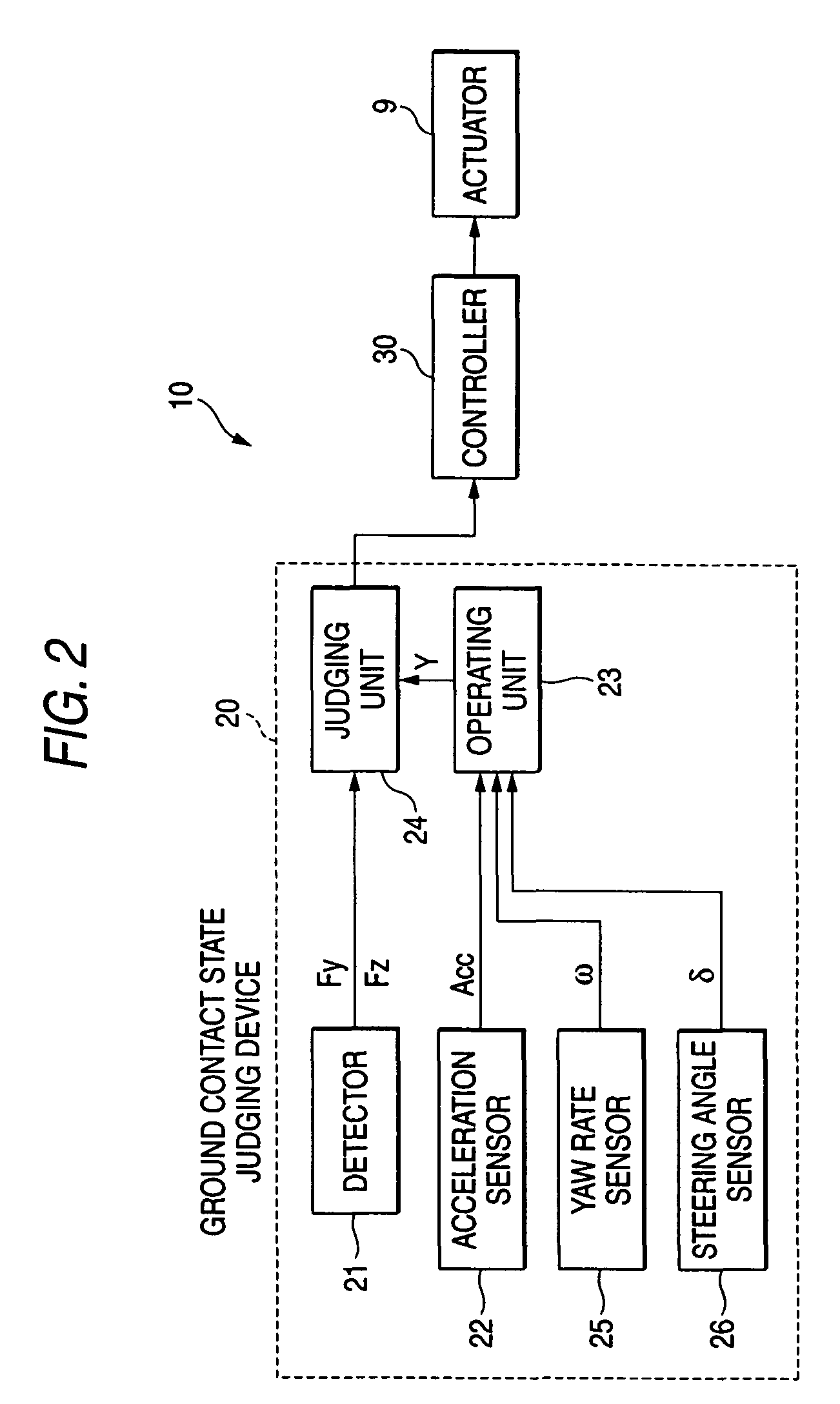

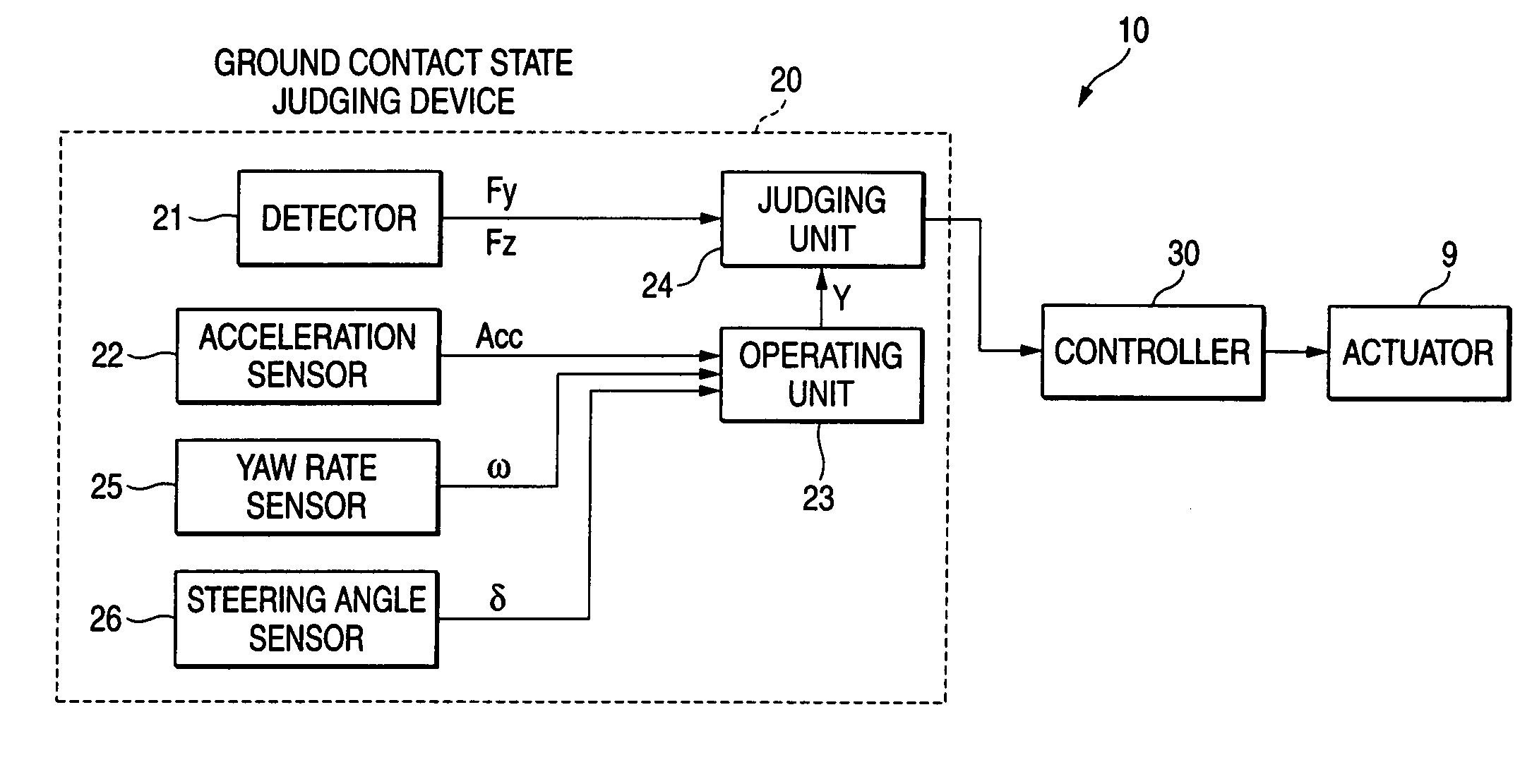

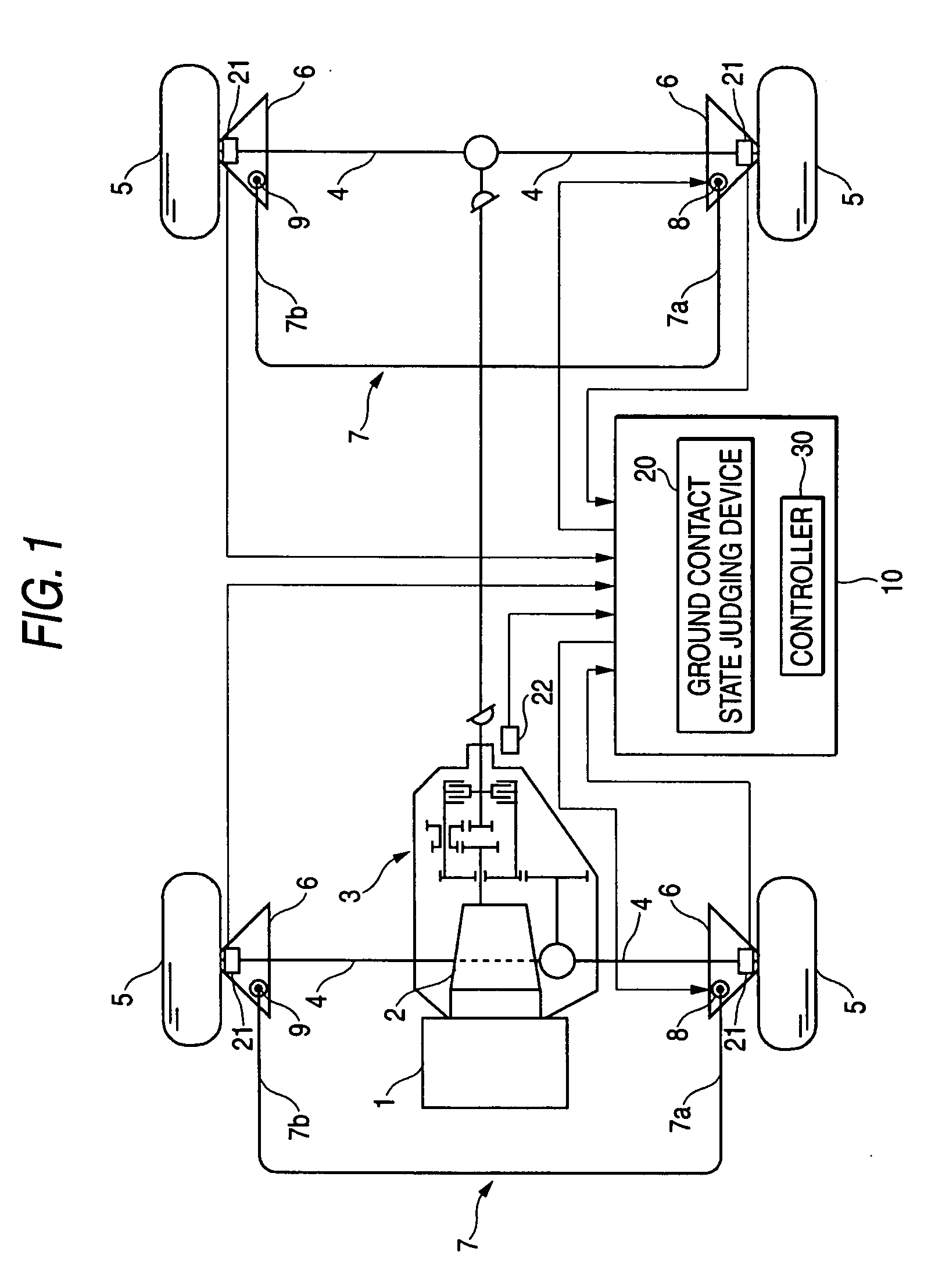

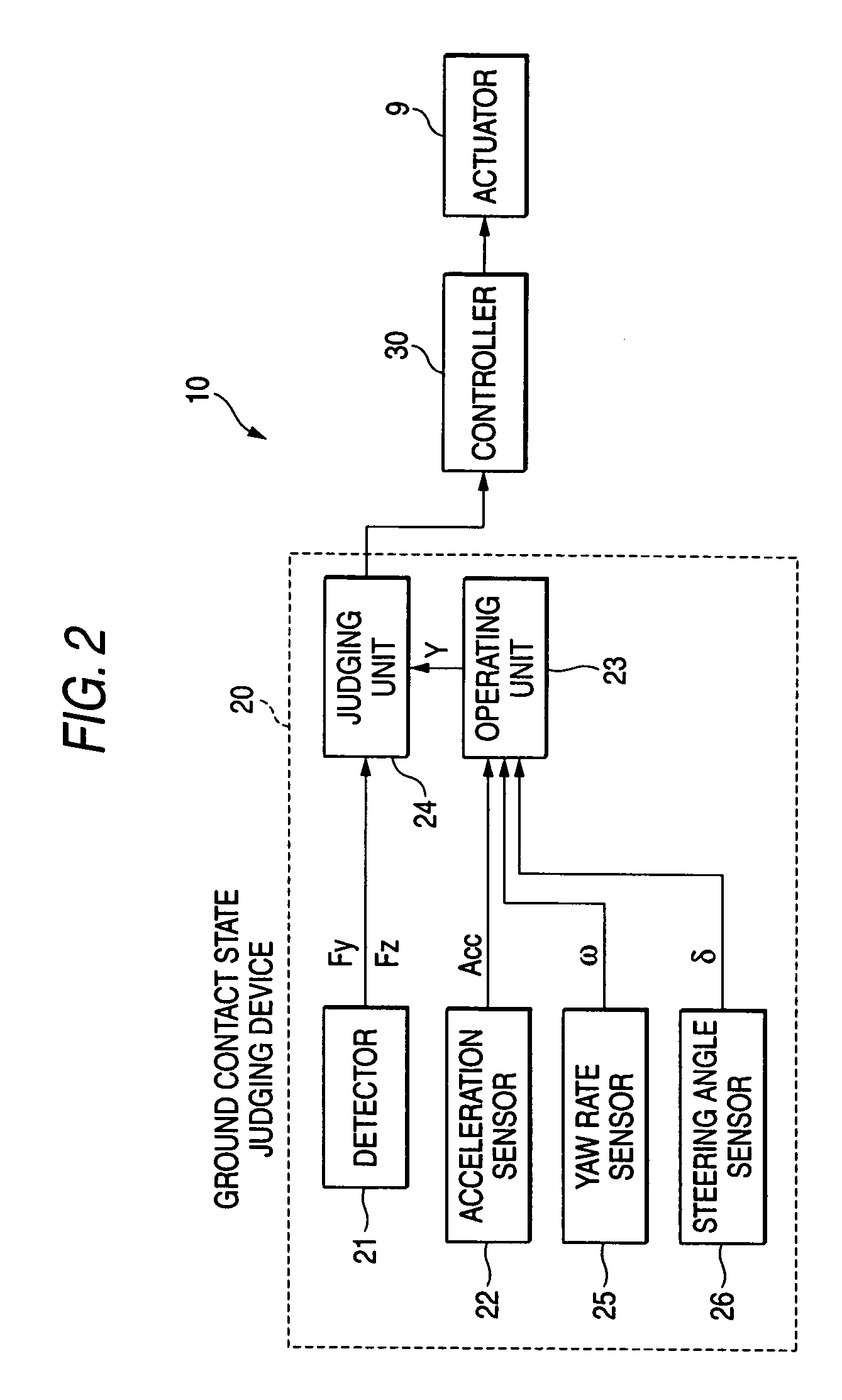

Wheel ground-contact state judging device and method

ActiveUS7797093B2Improve accuracyAnalogue computers for trafficAnimal undercarriagesGround contactCornering force

In wheel ground-contact state judging device and method, a detector directly detects a lateral force acting in a direction perpendicular to the wheel center plane of a wheel. An acceleration sensor detects an acceleration in the lateral direction of a vehicle. A calculator calculates a cornering force acting on each wheel on the basis of the acceleration in the lateral direction thus detected. A judging unit compares the detected lateral force with the calculated cornering force to judge whether the ground-contact state of the wheel is good or not.

Owner:SUBARU CORP

Wheel ground-contact state judging device and method and vehicle motion control device

ActiveUS20060006017A1Improve accuracyAnalogue computers for trafficAnimal undercarriagesGround contactCornering force

In wheel ground-contact state judging device and method, a detector directly detects a lateral force acting in a direction perpendicular to the wheel center plane of a wheel. An acceleration sensor detects an acceleration in the lateral direction of a vehicle. A calculator calculates a cornering force acting on each wheel on the basis of the acceleration in the lateral direction thus detected. A judging unit compares the detected lateral force with the calculated cornering force to judge whether the ground-contact state of the wheel is good or not.

Owner:SUBARU CORP

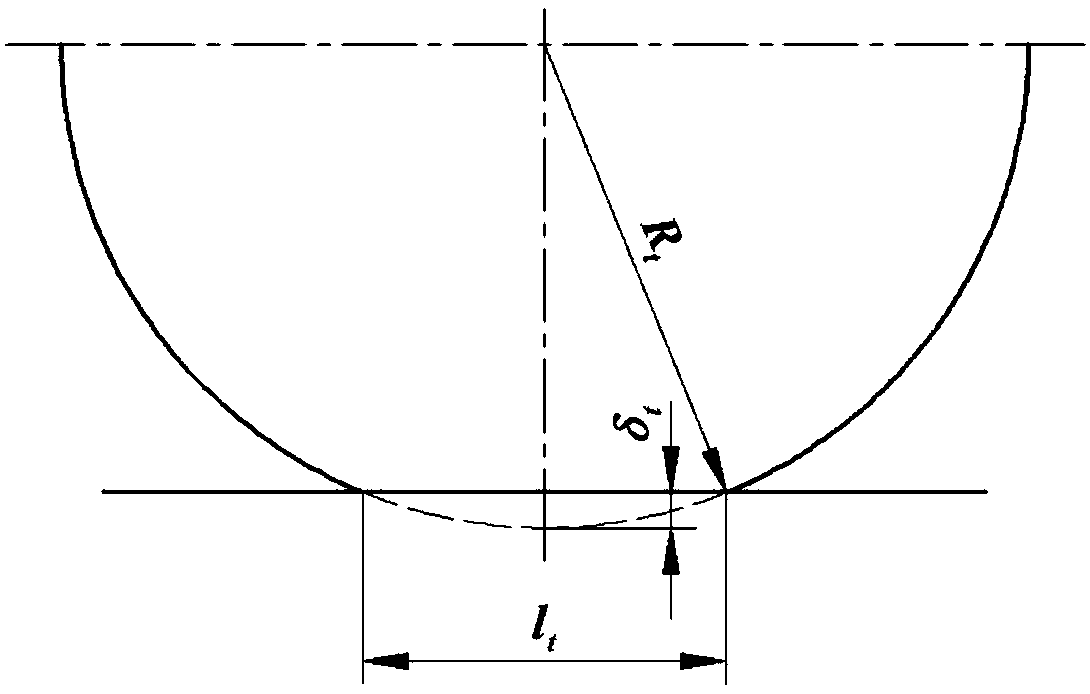

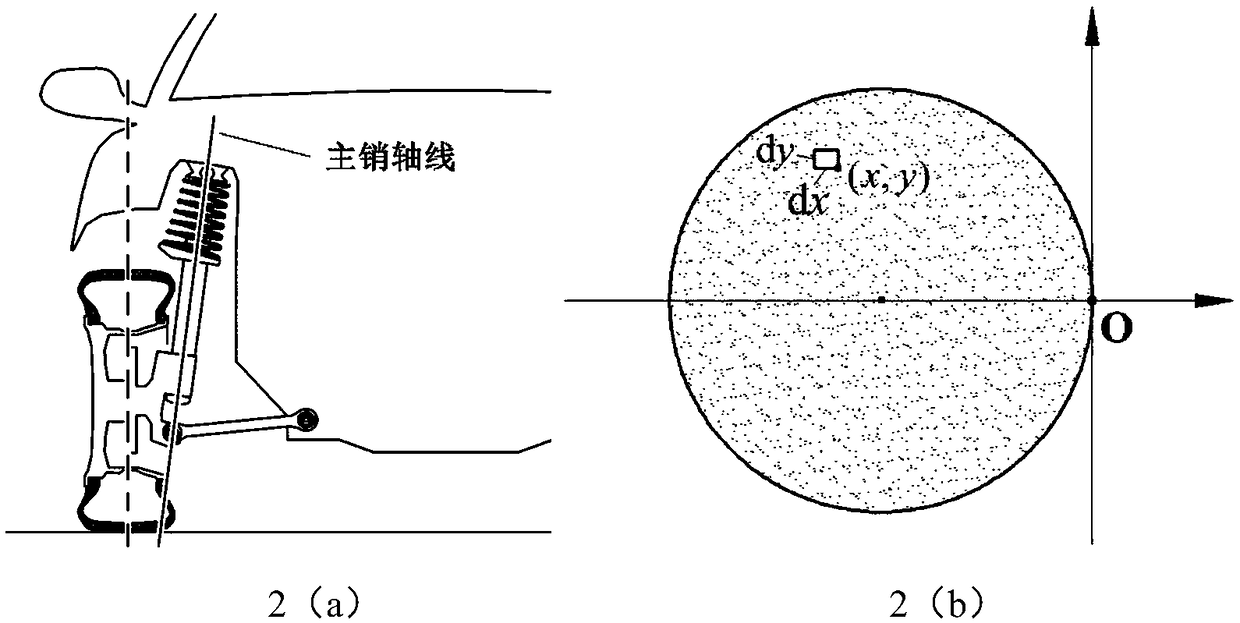

A method for calculating a vehicle steering resistance moment considering the friction between a tire and a road surface

ActiveCN109325268ADescribe wellImprove accuracyGeometric CADSustainable transportationLow speedSteering angle

The invention discloses a method for calculating a vehicle steering resistance moment considering the friction between a tire and a road surface. A vehicle steering resistance moment model is established and verified by calculating a tire / road in-place steering friction moment and a return moment generated by an inclination angle of a kingpin. By calculating the friction torque of tire / pavement low-speed steering and the rectifying torque of kingpin inclination angle, kingpin back inclination angle and tire towing distance, the model of vehicle low-speed steering resistance torque is established and verified. Based on this method, by taking into account the friction between the tire and the pavement, not only the relationship between the steering resistance torque described by the existingempirical formulas, the front axle load and the tire pressure is included, but also the influence of the inclination angle of the kingpin and the wheel steering angle on the steering resistance torque is considered, at the same time, the variation relationship of the low speed steering friction torque along with the vehicle speed and the correspondance relationship between the tire cornering force, the tire return torque and the vehicle speed and the wheel steering angle can be easily found out. The calculation method is more accurate.

Owner:JIANGSU UNIV

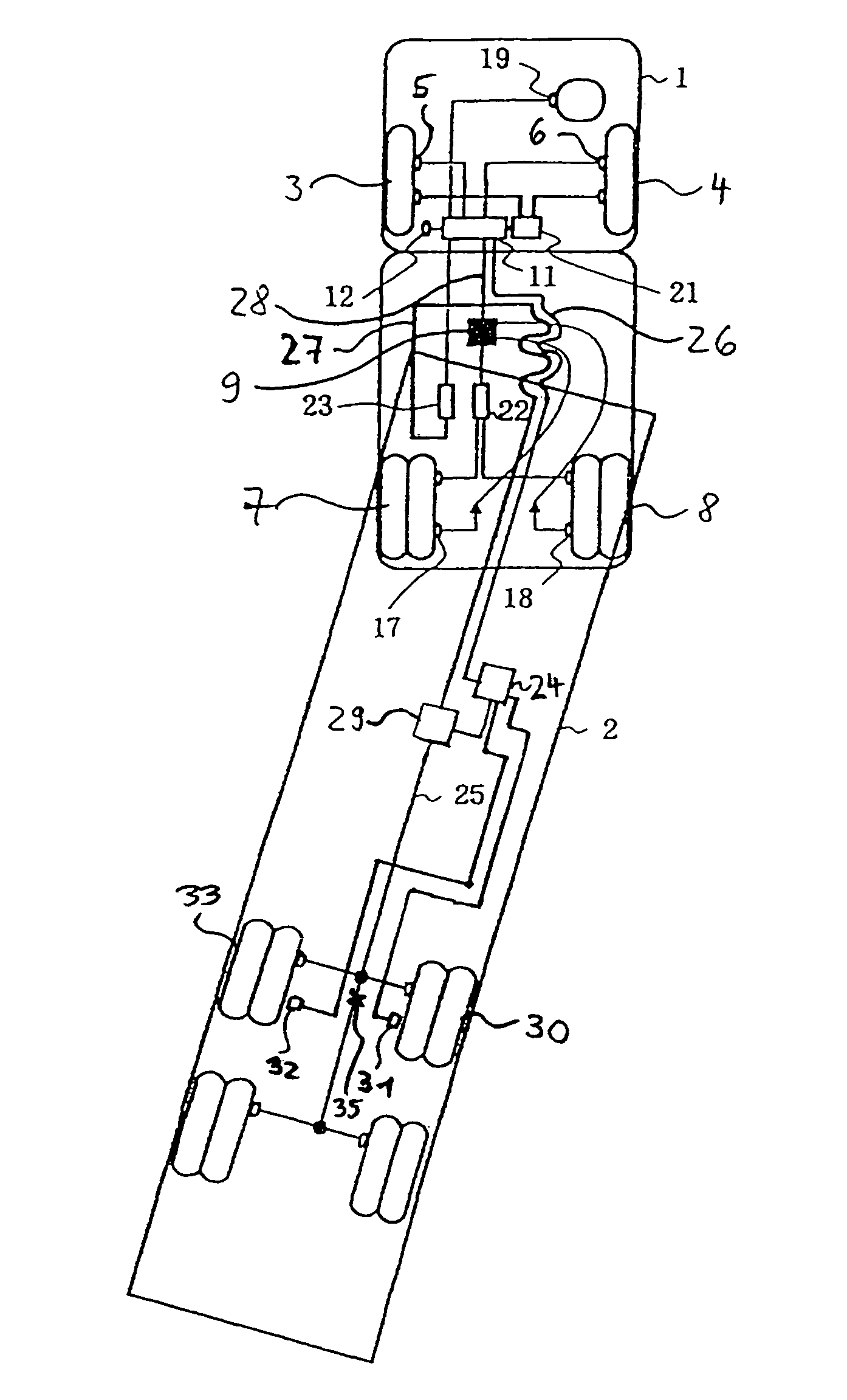

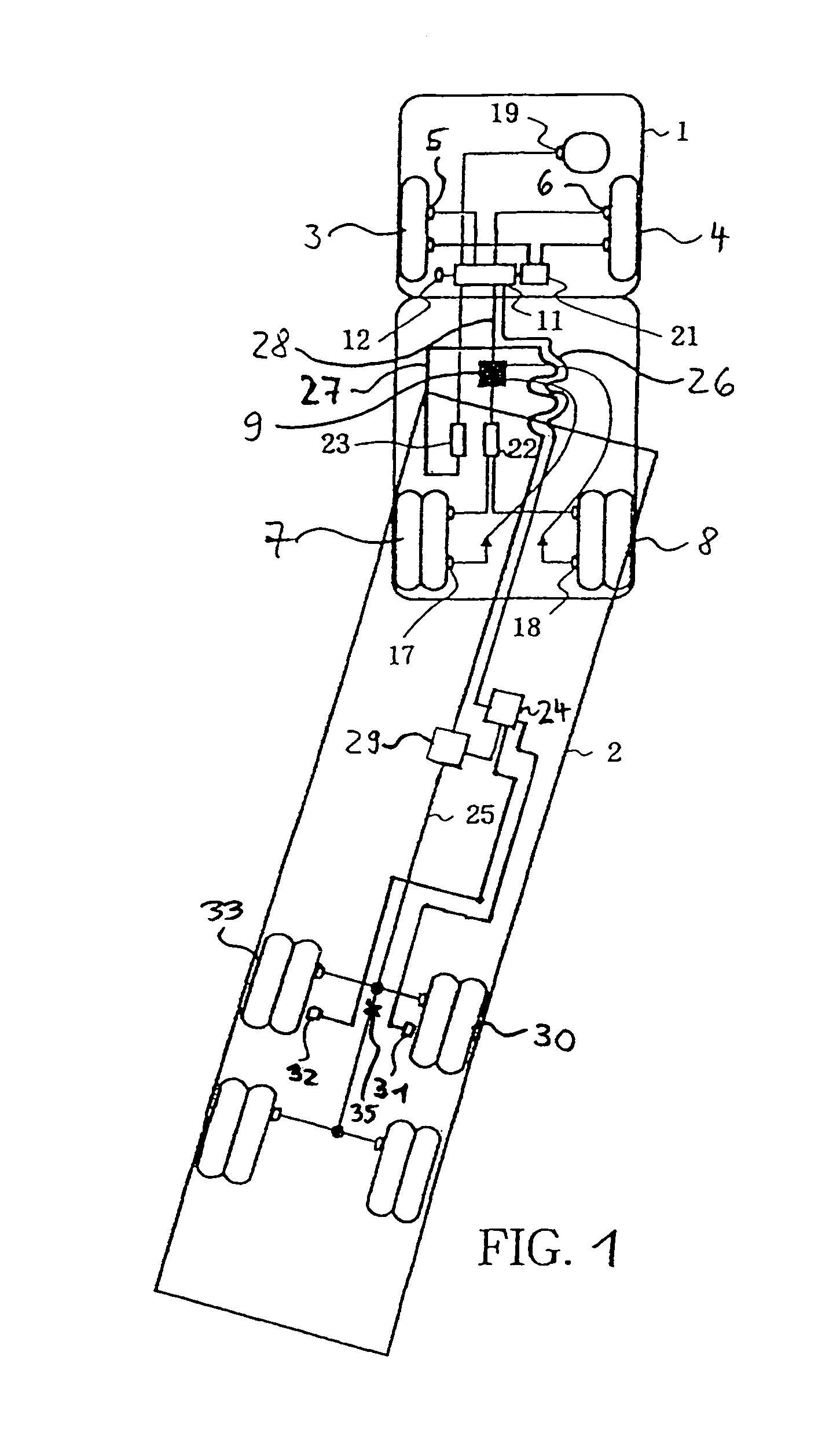

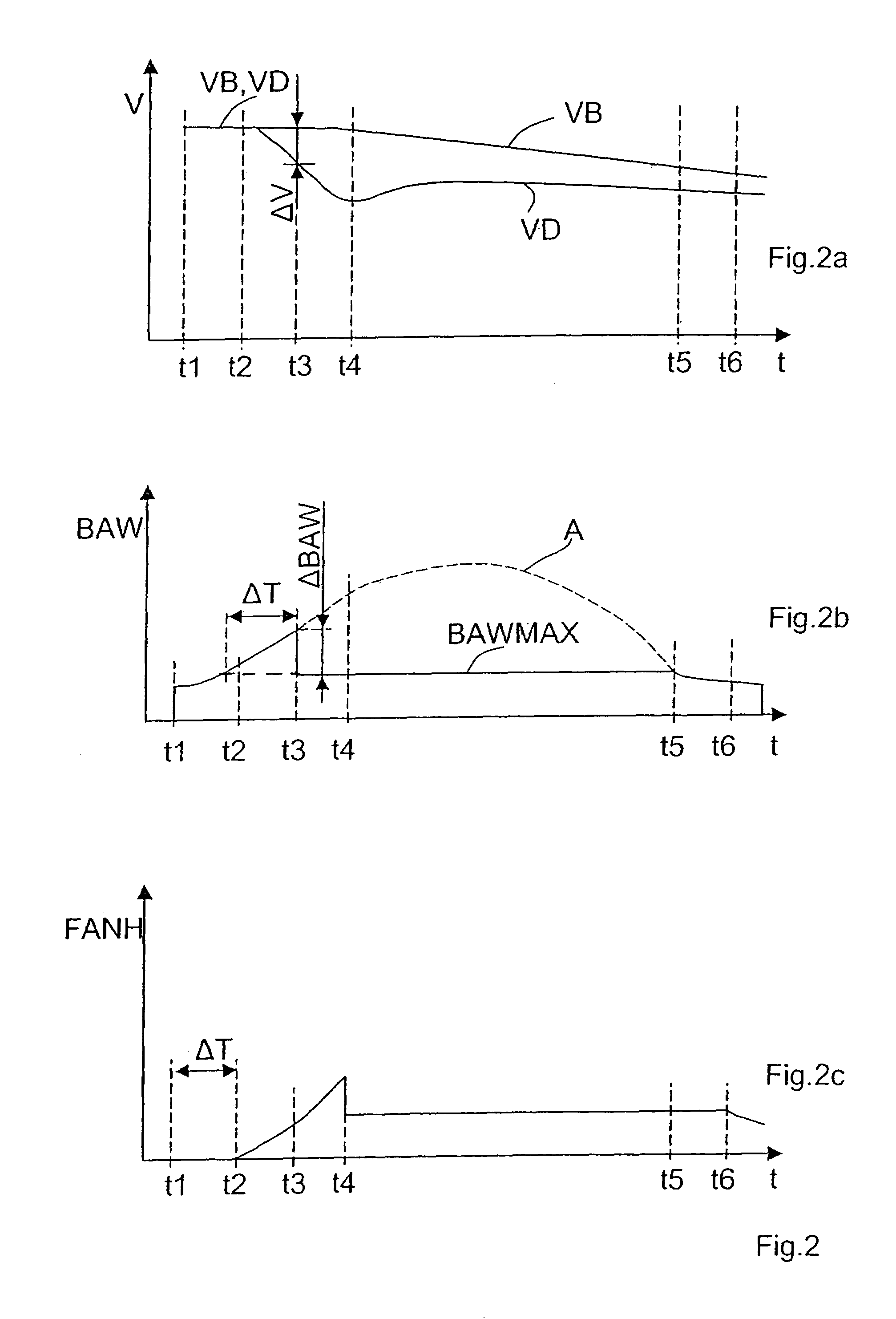

Vehicle-dynamics control method and system for a vehicle train

ActiveUS7216026B2Training safetyGood counteractingAnalogue computers for trafficPedestrian/occupant safety arrangementVehicle dynamicsControl system

A vehicle-dynamics control method and system for a vehicle train comprising a tractor vehicle and a trailer vehicle. The vehicle-dynamics control system provided in the tractor vehicle, on the basis of vehicle-dynamics signals measured in the tractor vehicle, delivers brake-demand values (BAW) to the trailer vehicle. The trailer vehicle is equipped with a brake system, in which the brakes of the trailer vehicle can be actuated on the basis of the BAW. The vehicle-dynamics control method and system use data signals received from the trailer vehicle and calculates the BAW and permits activation of the brake system of the trailer vehicle while at the same time avoiding an undesirably large reduction of the cornering forces on the wheels of the trailer vehicle.

Owner:WABCO GMBH

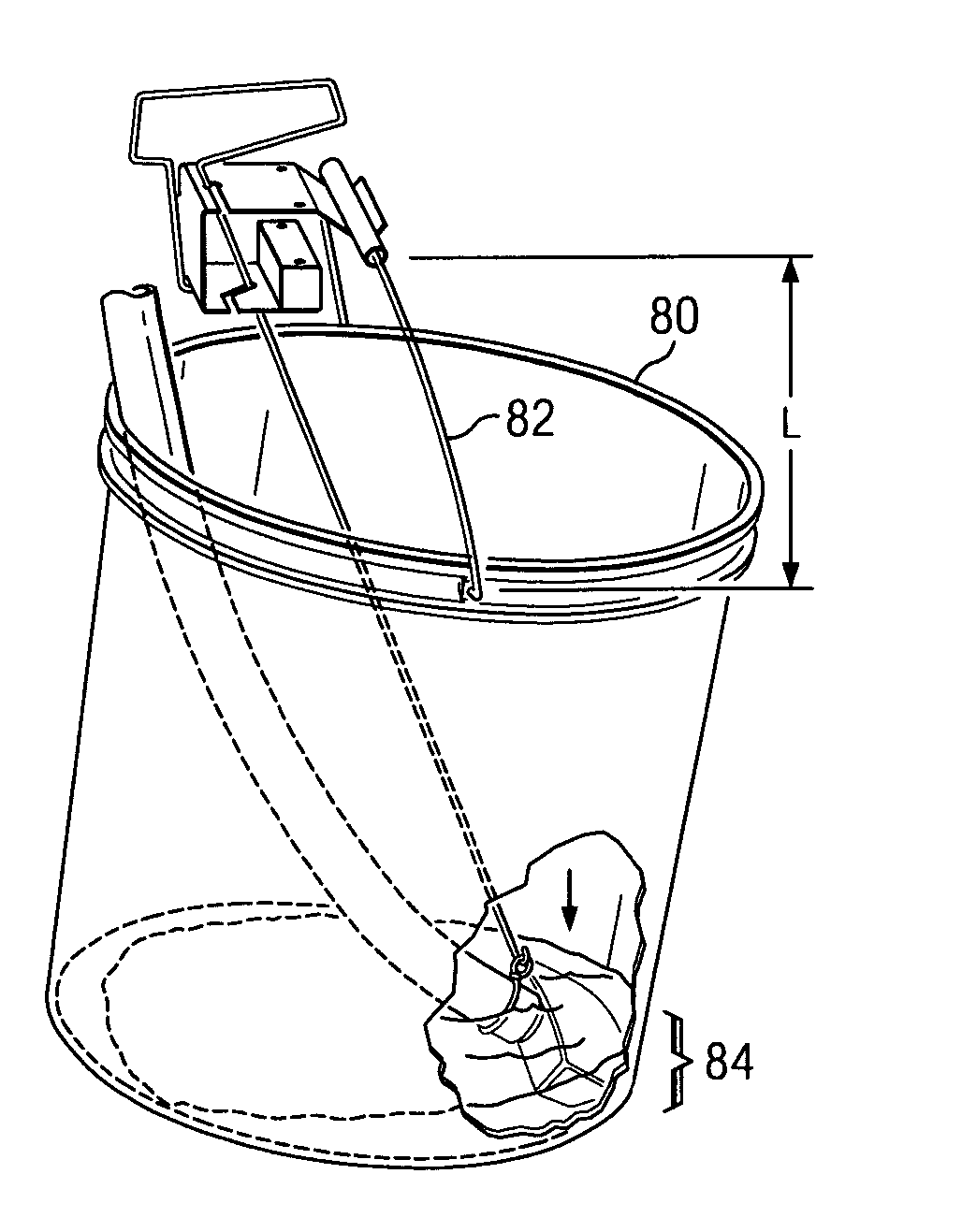

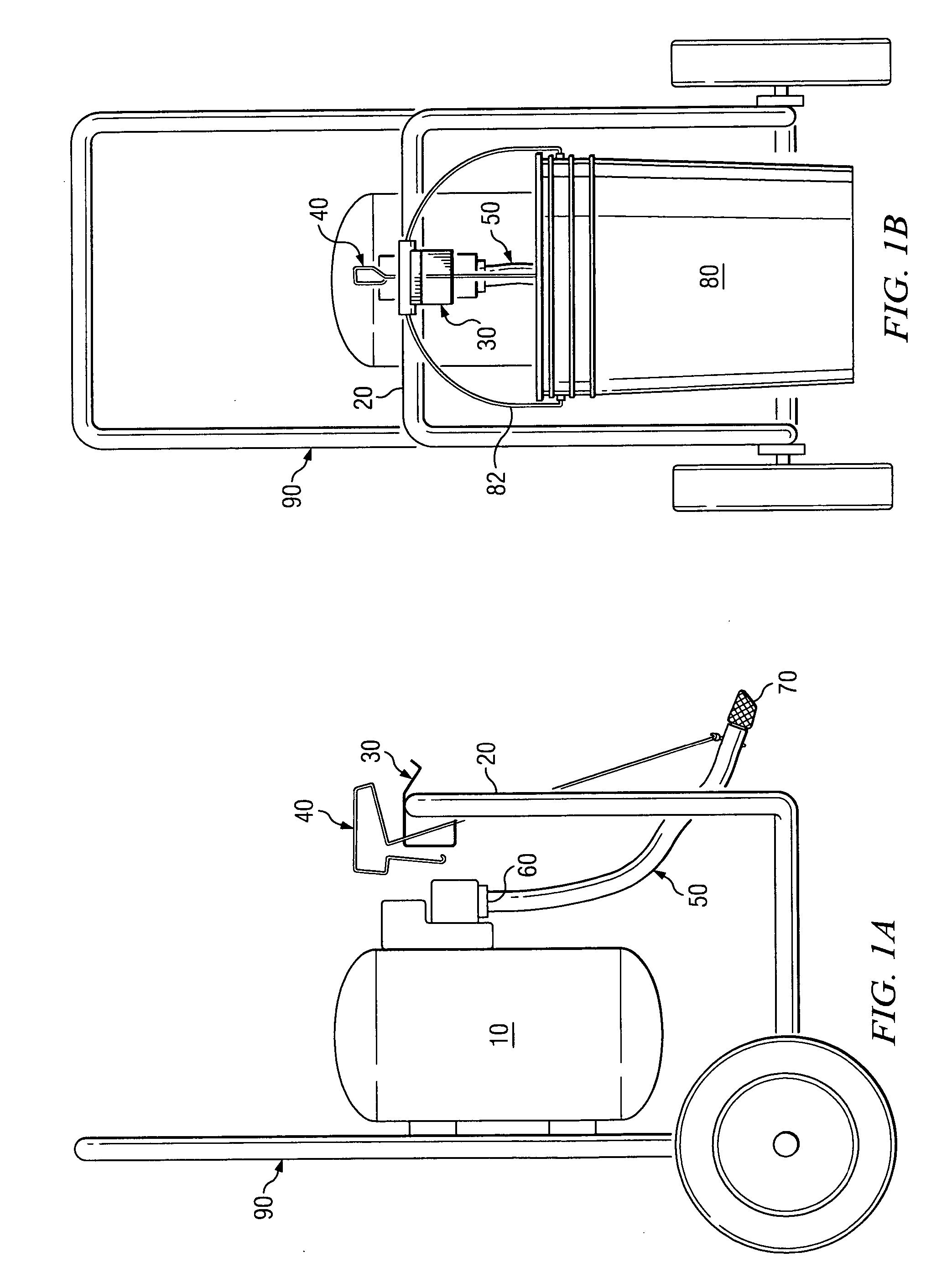

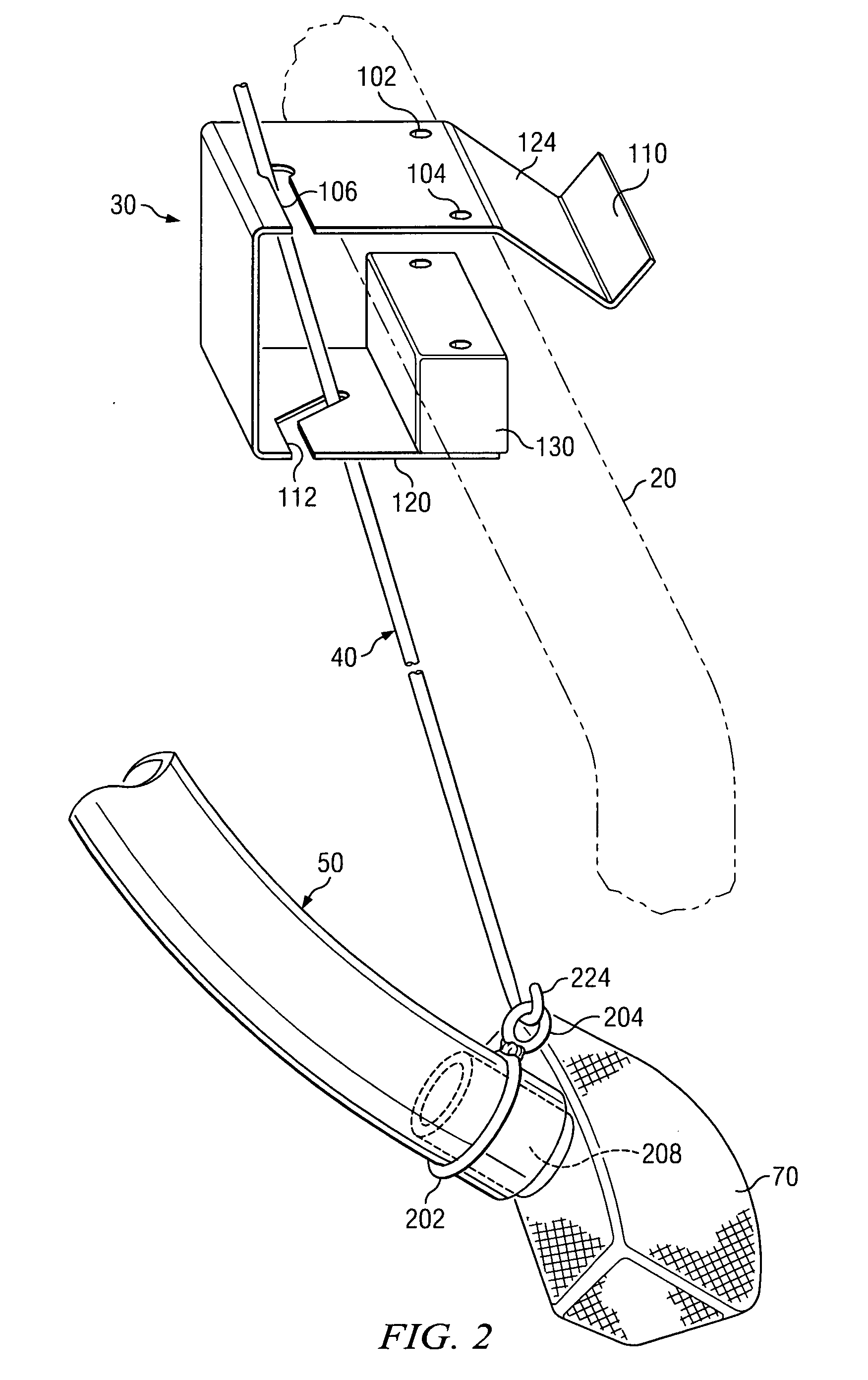

Apparatus and method for efficient dispensing of fluids from a container

InactiveUS20060131337A1Great suctionLiquid transferring devicesLiquid spraying apparatusMetal alloyCornering force

The invention provides an apparatus and method for tipping and efficiently drawing fluid from a bucket or container. In one exemplary embodiment, the apparatus includes a frame, a bracket attached to the frame, a pressure sprayer connected to a suction hose, and a guiding rod placed through the bracket and connected to the suction hose. In another exemplary embodiment, the device includes a bracket attached directly to the pressure sprayer. In one example, the bracket is made of a rigid metal alloy capable of supporting 5 gallons of paint. In use, the sprayer draws liquid from the container through the suction hose. As the container is emptied of fluid, the spring action provided by the handle raises the container. The guiding rod does not allow the bottom corner of the container to move; therefore, the container tilts toward the bottom corner forcing a pooling of liquid within reach of the suction hose. This invention also provides a rounded filter attached to the end of the suction hose which matches the bottom corner of the container and enhances the ability of the suction hose to gather fluid from low levels in the container.

Owner:MERTINS LEE

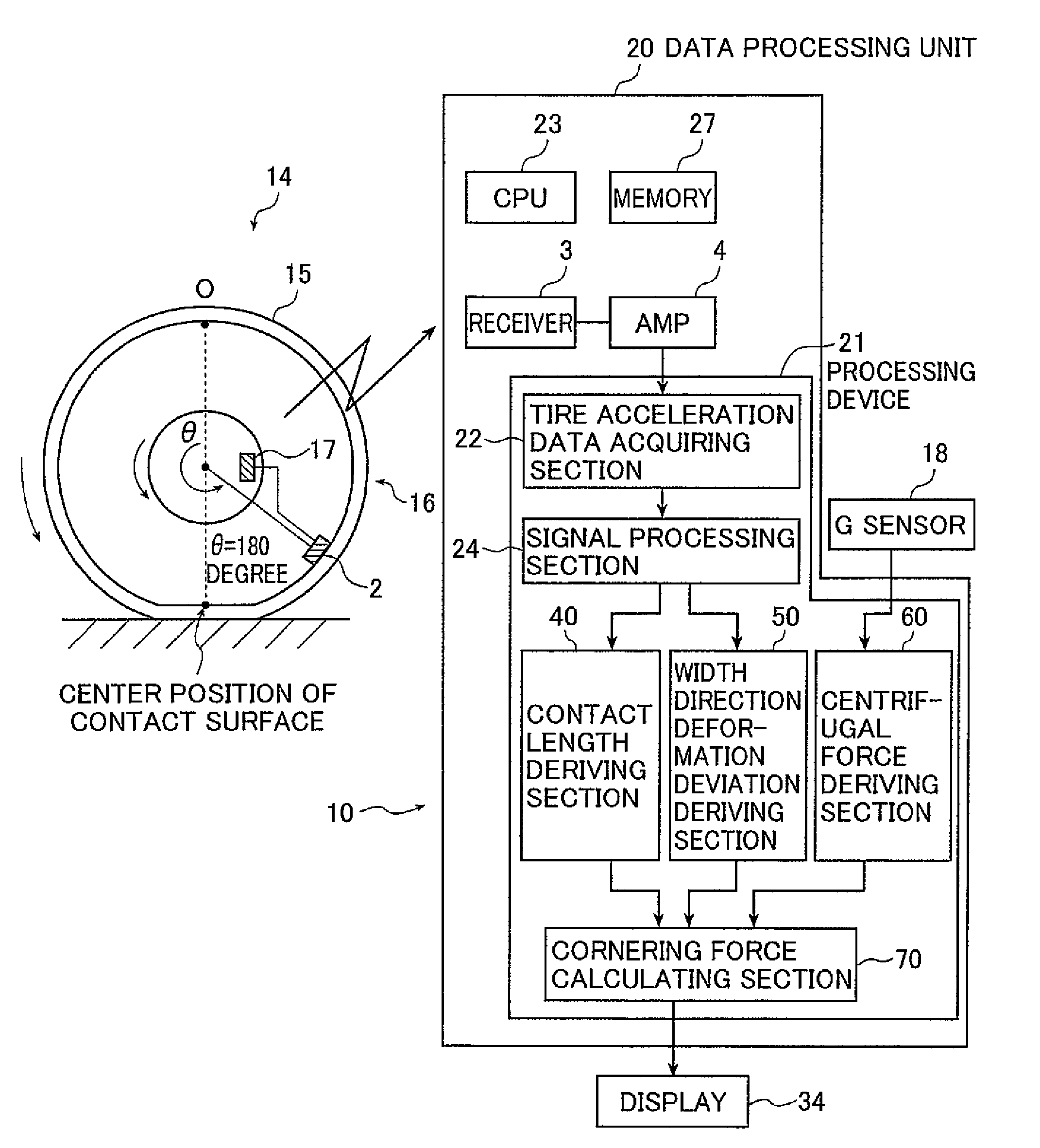

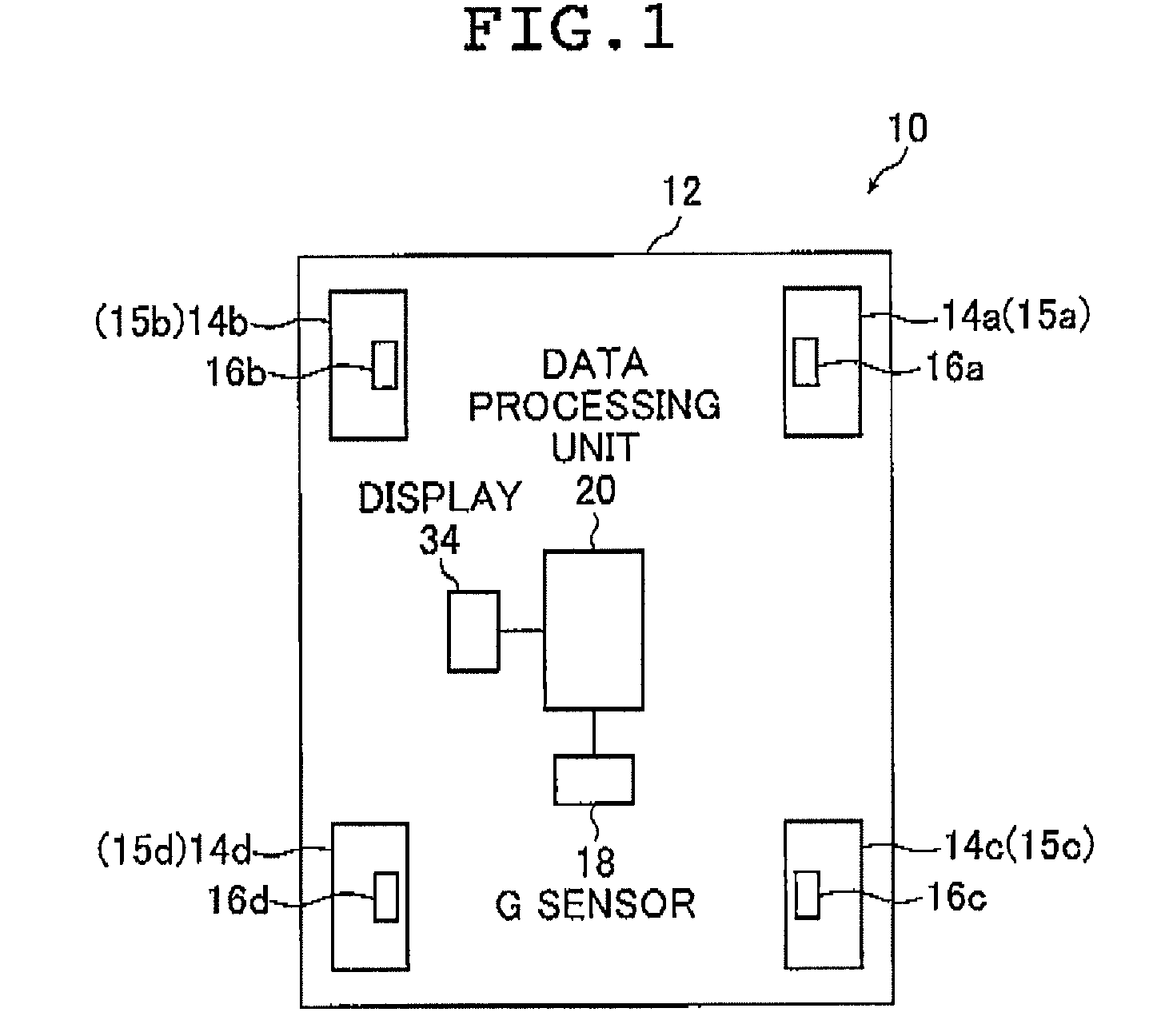

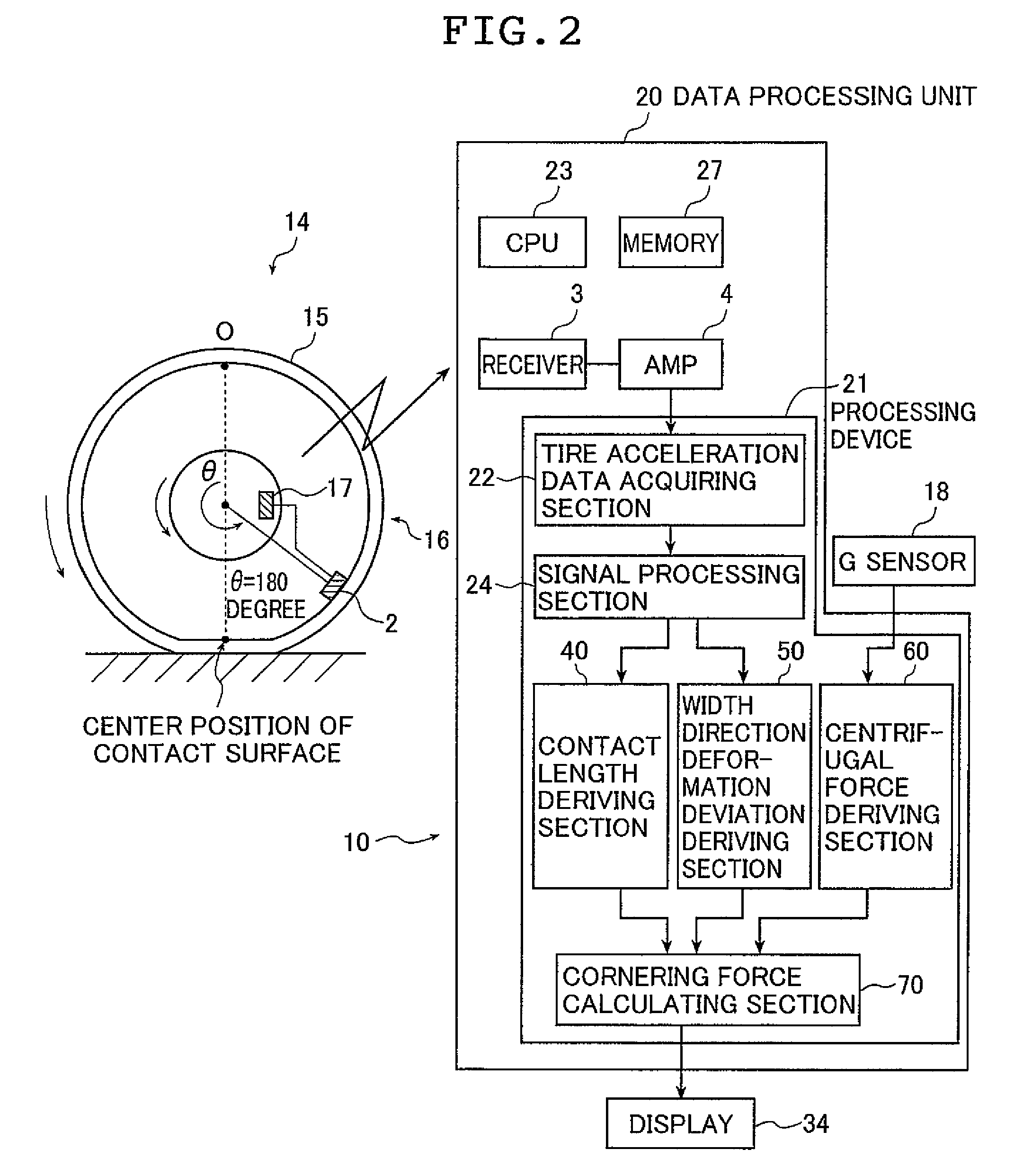

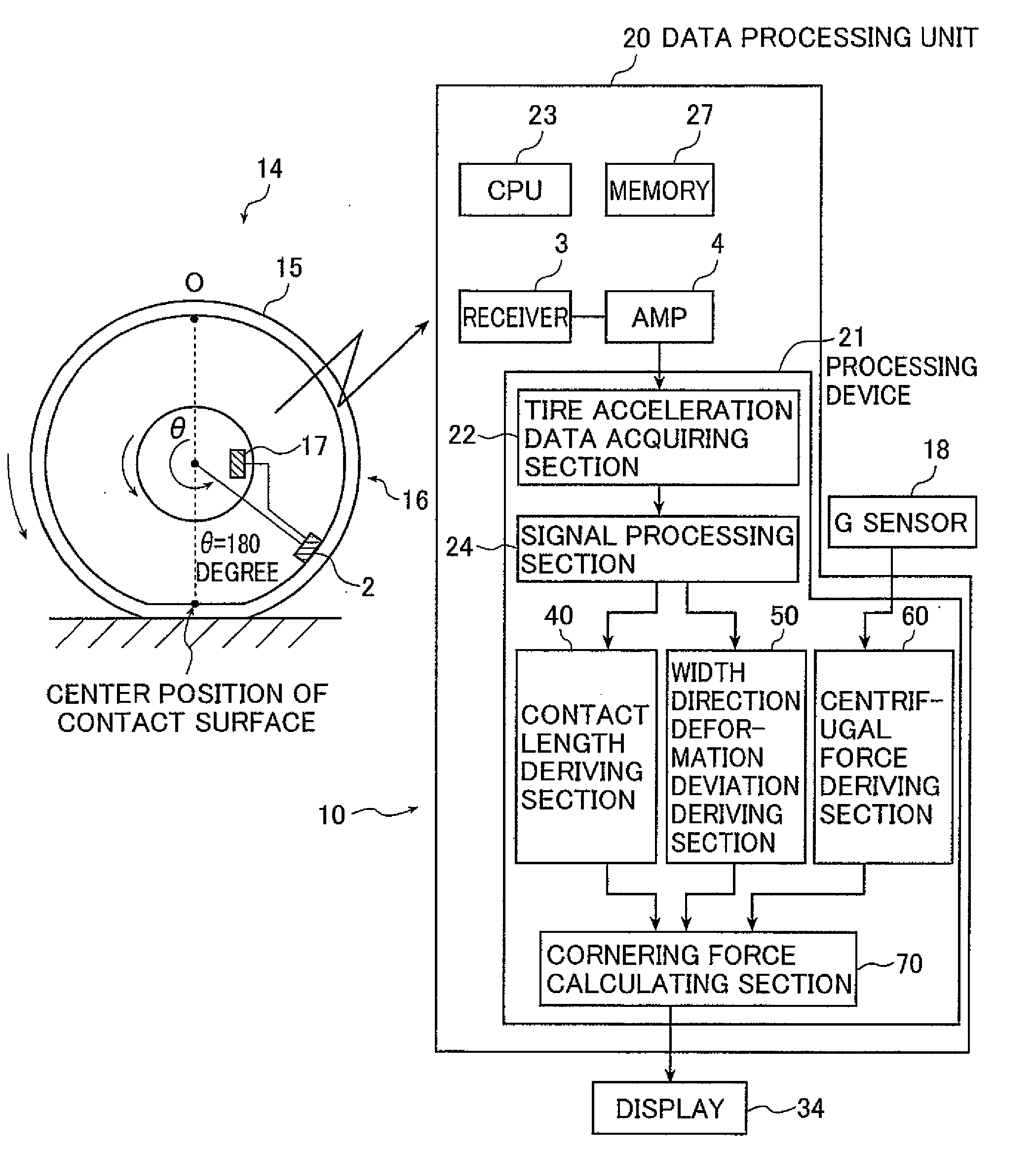

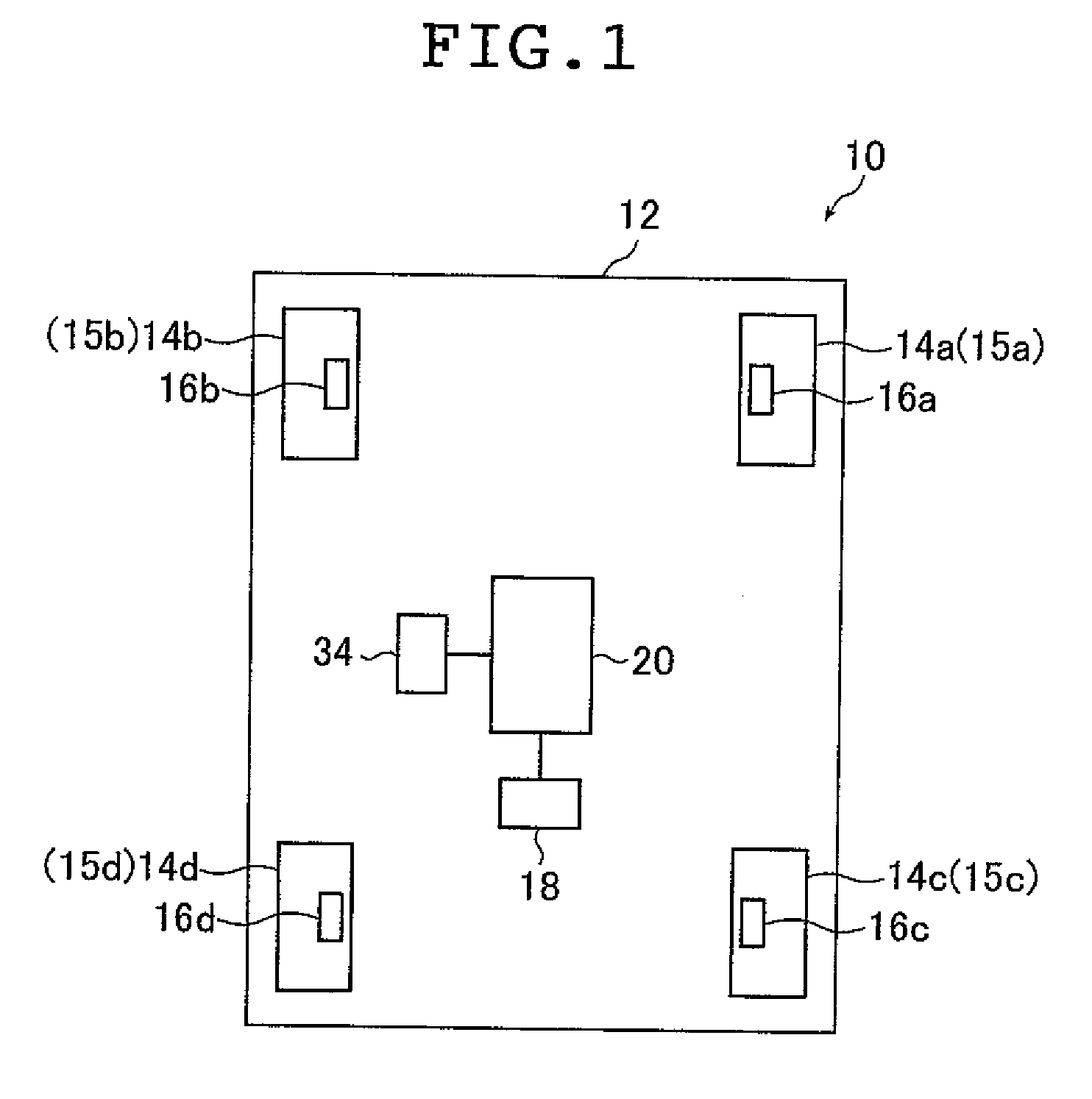

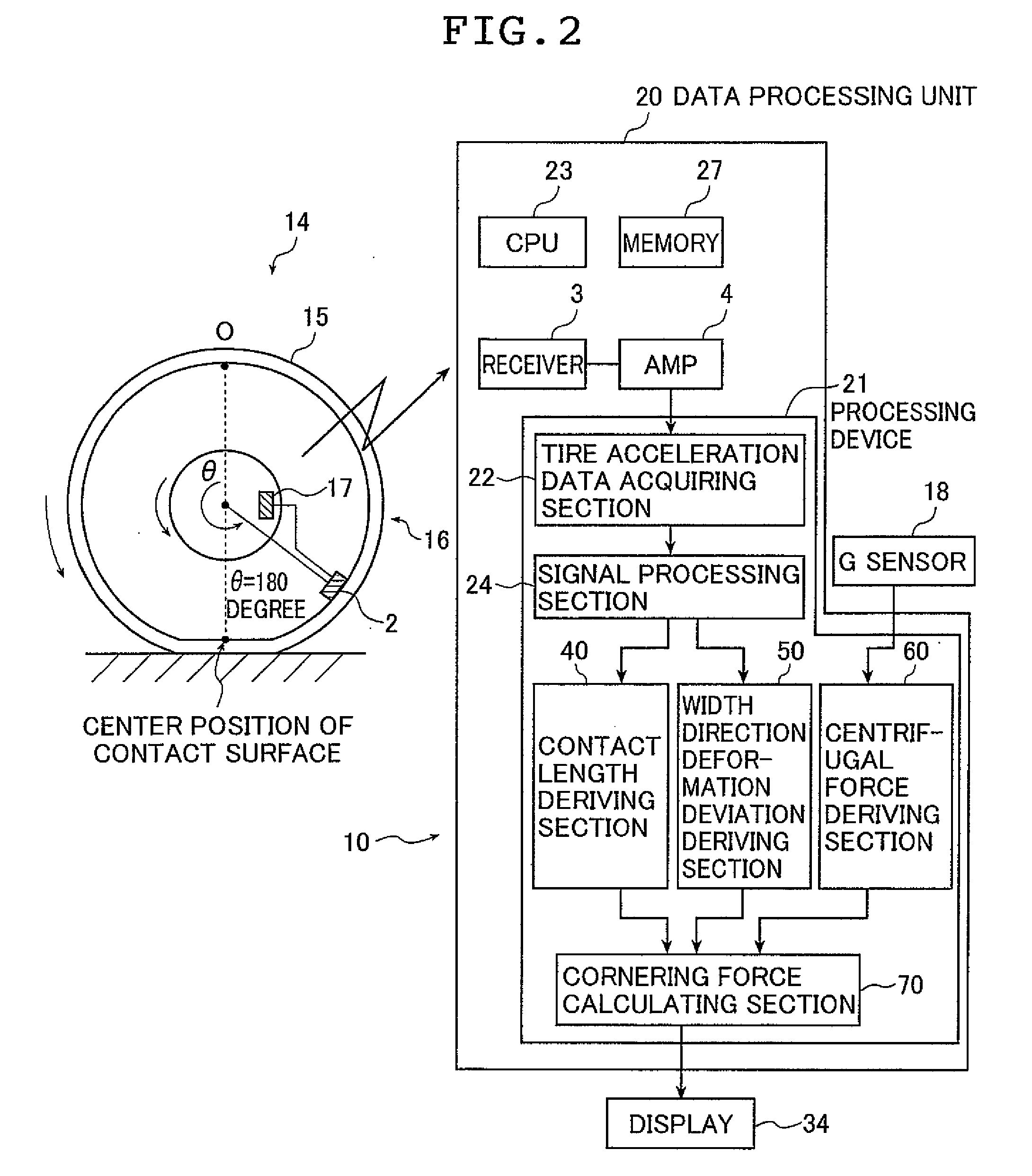

Method and device for calculating magnitude of wheel-generated cornering force

InactiveUS7822563B2Accurate calculationVehicle fittingsDigital data processing detailsCornering forceCentrifugal force

Owner:THE YOKOHAMA RUBBER CO LTD

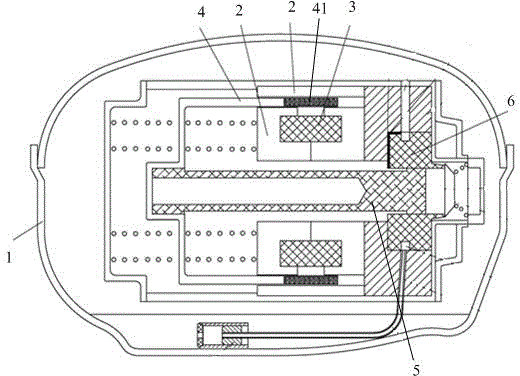

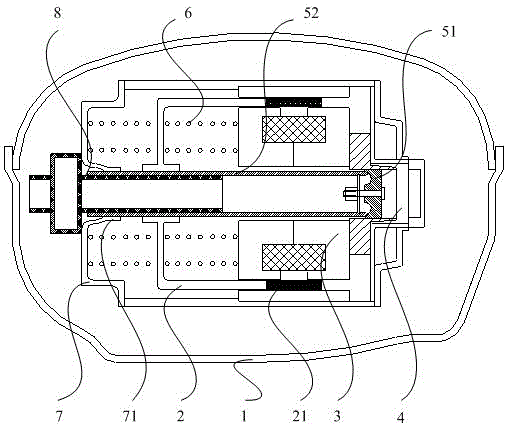

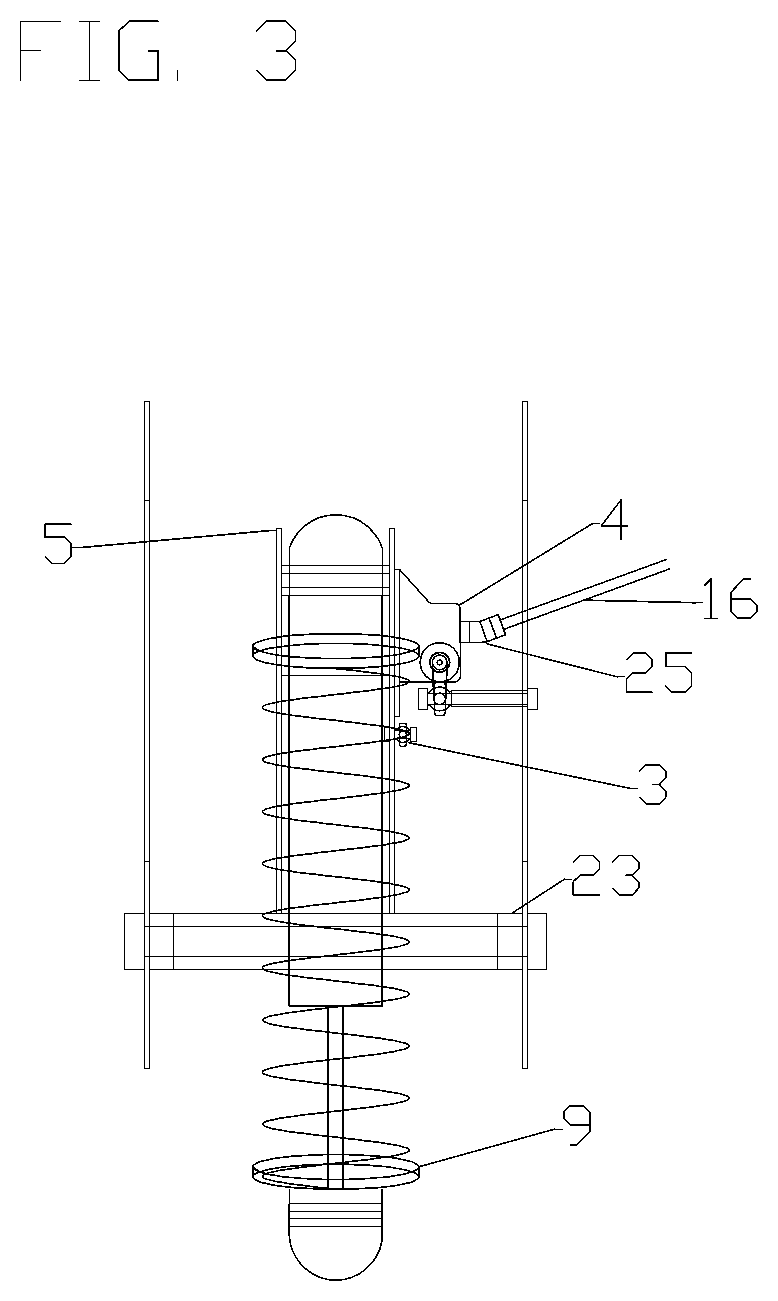

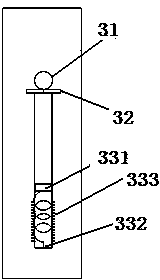

Linear compressor

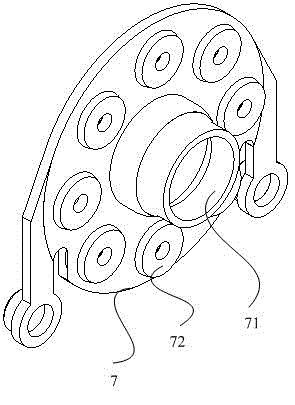

ActiveCN106150970AImprove reliabilityAvoid cornering forcePiston pumpsPositive-displacement liquid enginesLinear compressorCornering force

The invention provides a linear compressor. The linear compressor comprises a shell, a mover, a stator, an air cylinder, a piston, springs and a spring pressure plate, wherein the mover, the stator, the air cylinder, the piston, the springs and the spring pressure plate are arranged in the shell. The stator forms a magnetic field space. A magnetic body is arranged on the mover and inserted into the magnetic field space. The spring pressure plate and the air cylinder are correspondingly fixed to the two sides of the stator. The mover is located between the spring pressure plate and the stator. The springs are arranged between the mover and the spring pressure plate and arranged between the mover and the stator. The piston comprises a piston head and a piston rod which are connected together. The piston head is slidably arranged in the air cylinder. The piston rod is fixedly connected with the mover. A supporting sleeve is arranged on the spring pressure plate. The free end of the piston rod is slidably arranged in the supporting sleeve. The two sides of the piston are supported through the air cylinder and the supporting sleeve, the situation that the piston generates cornering force due to the weight of the mover is avoided, and the reliability of linear compressor is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

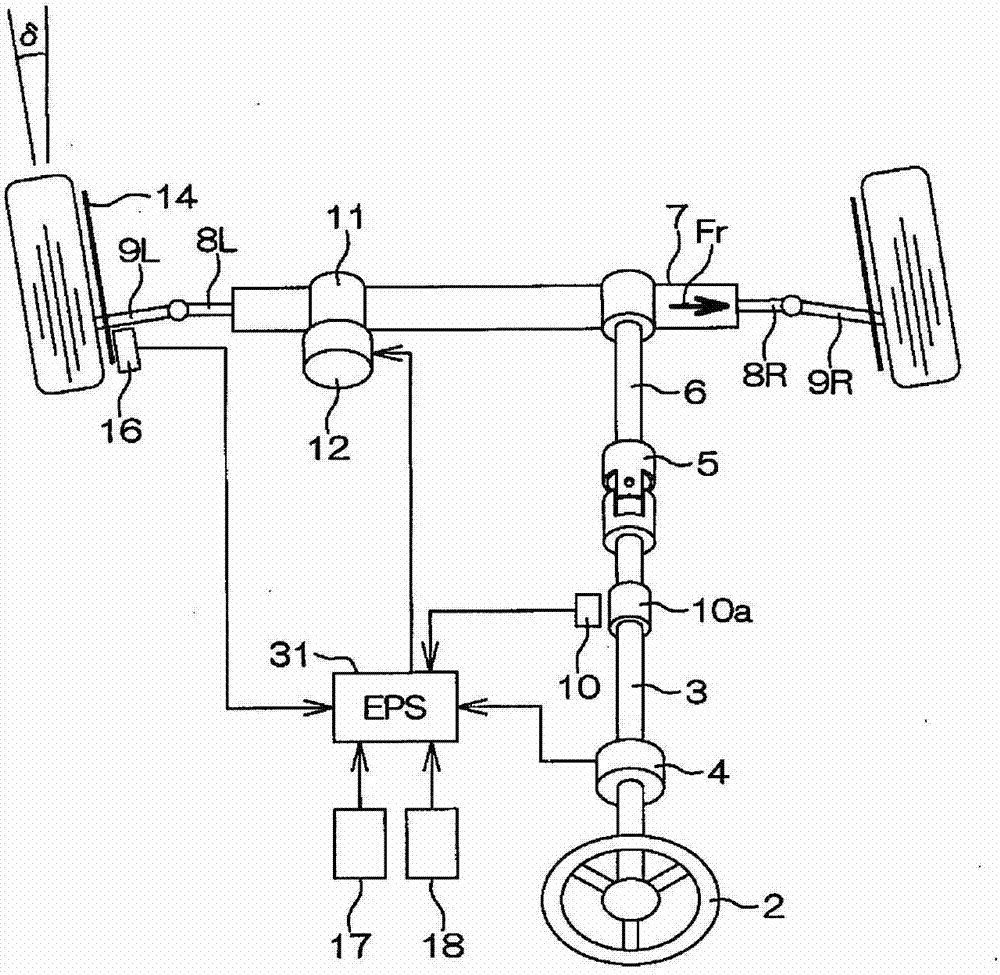

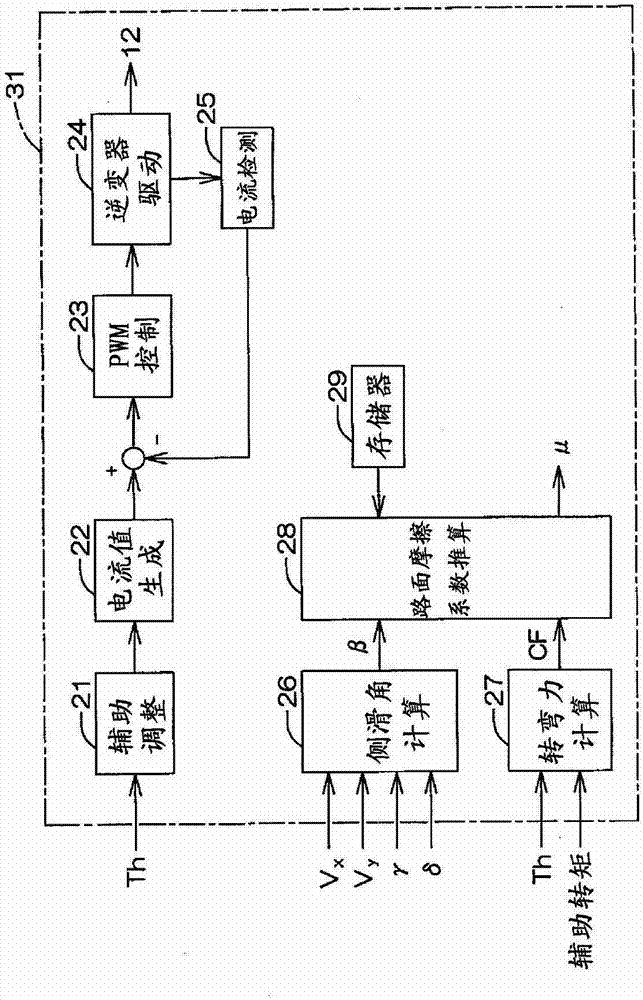

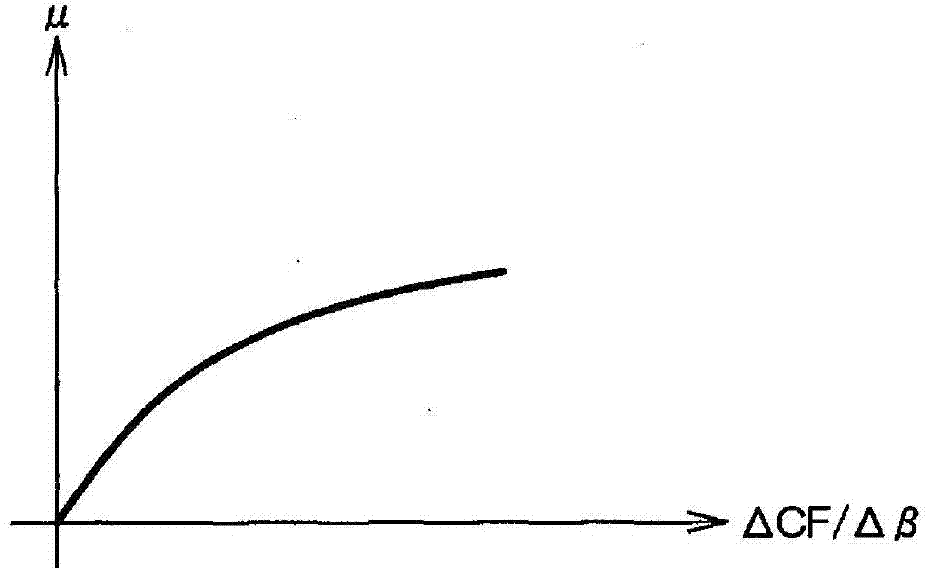

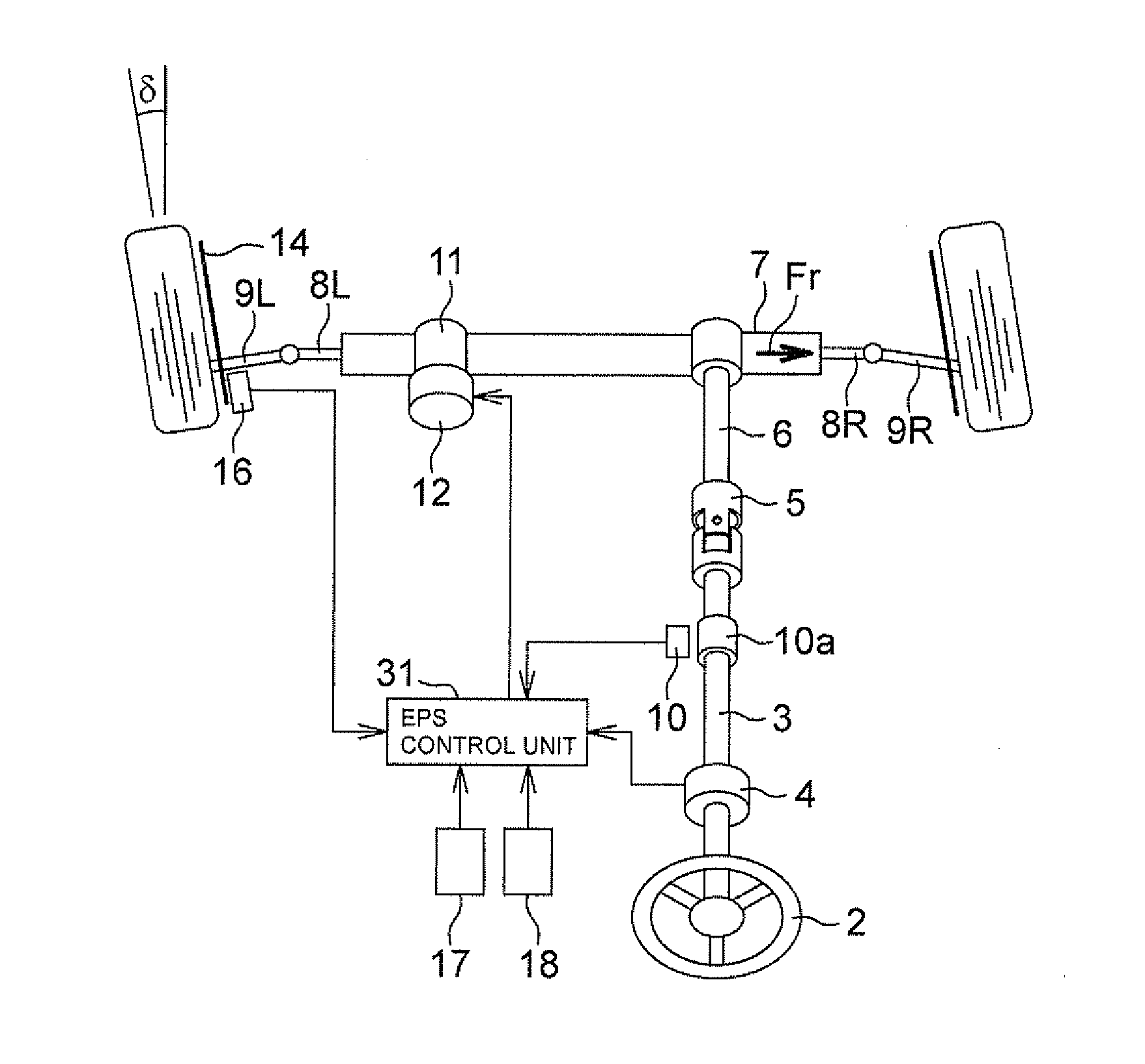

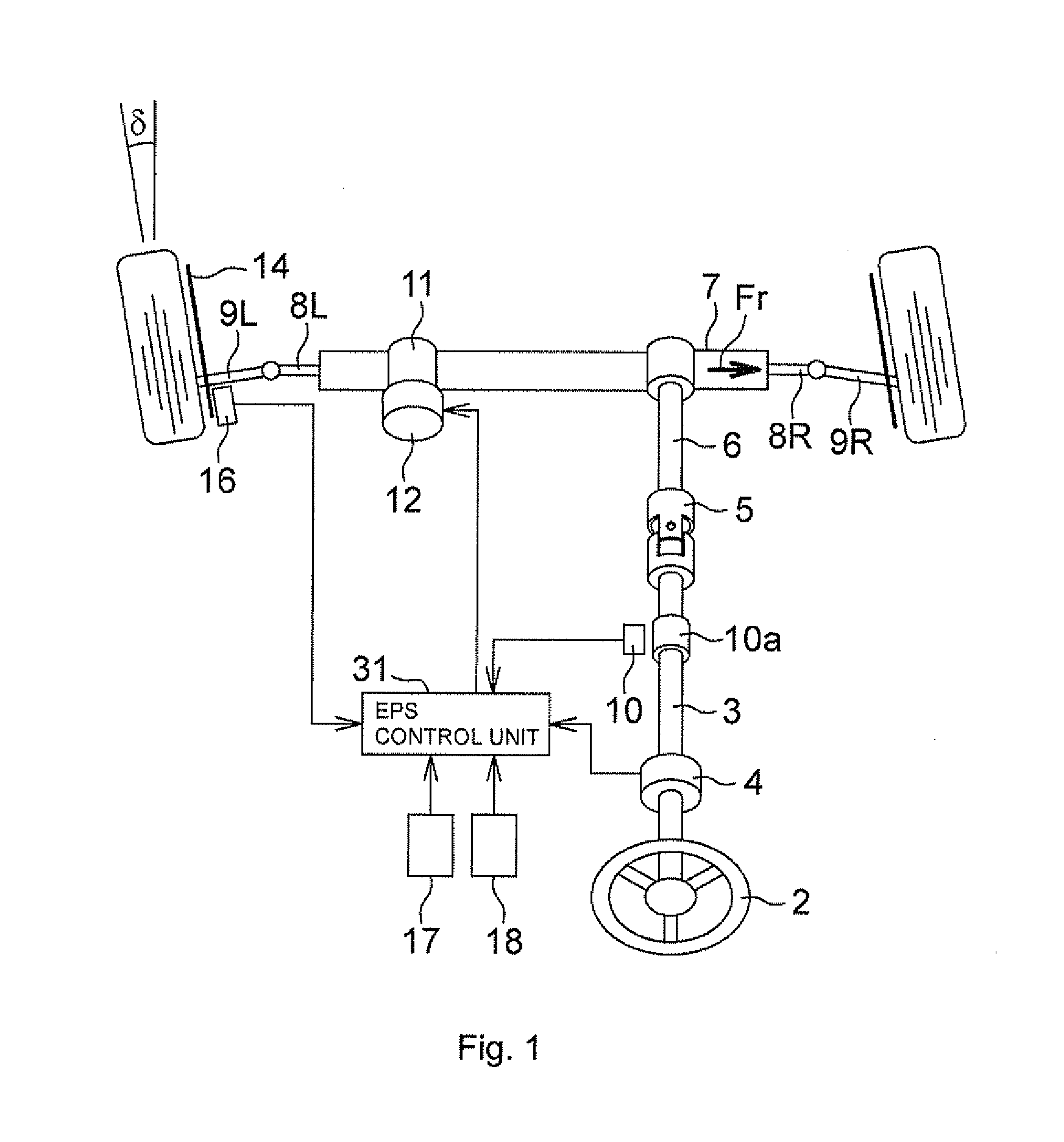

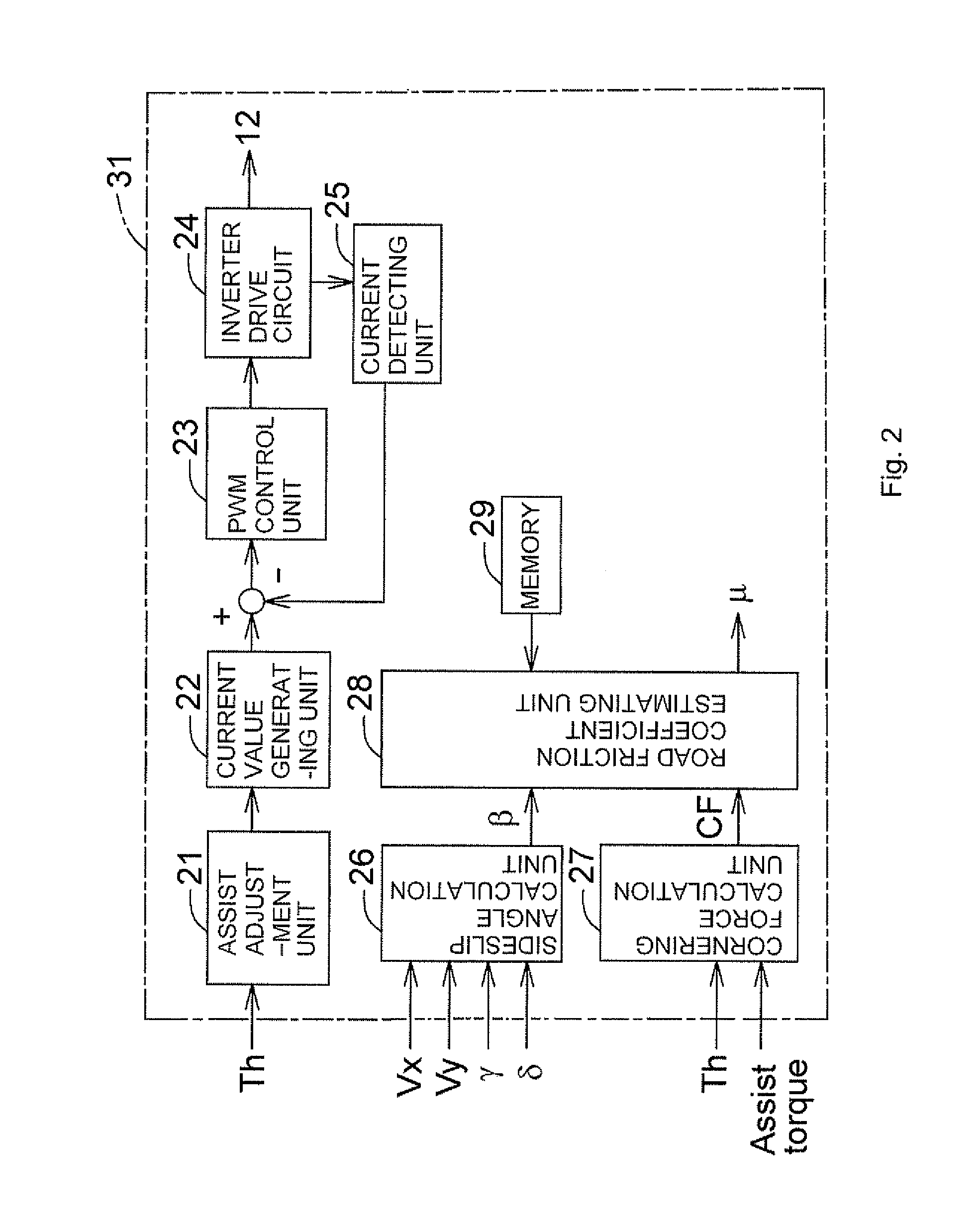

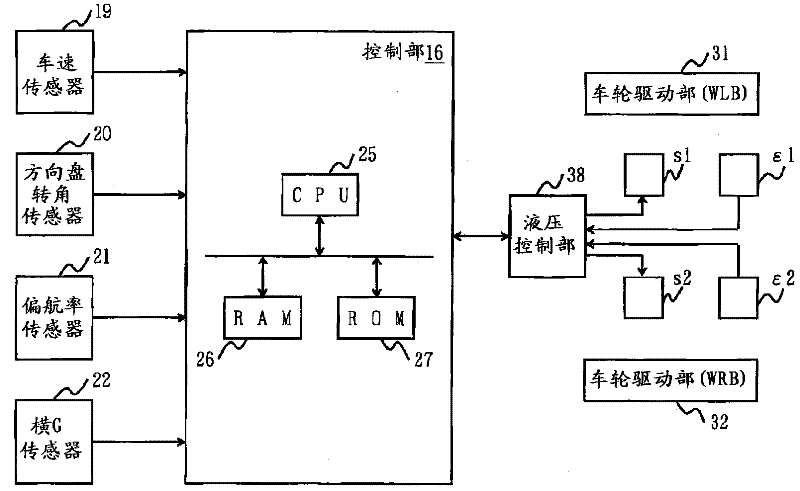

Road friction coefficient estimating unit and road friction coefficient estimating method

A road friction coefficient estimating unit (28) calculates a tire sideslip angle (²) and a cornering force (CF), and estimates a road friction coefficient on the basis of the ratio (”CF / A²) of the calculated cornering force (CF) to the calculated tire sideslip angle (²). A vehicle travels on multiple road surfaces that differ in road friction coefficient (µ), and tire sideslip angles (²) and cornering forces (CF) on the road surfaces are detected in advance. The road friction coefficient estimating unit (28) stores, in a memory (29), a correlation among the detected tire sideslip angles, the detected cornering forces, and the road friction coefficients in the form of numerical values or a mathematical expression, and estimates a road friction coefficient using the correlation stored in the memory (29).

Owner:JTEKT CORP

Method and device for calculating magnitude of cornering force generated in wheel

InactiveUS20090043517A1Accurate calculationVehicle fittingsDigital data processing detailsCornering forceEngineering

A method of calculating a cornering force to be applied to each wheel provided to a vehicle which is cornering, comprising the steps of: obtaining a magnitude of a centrifugal force to the vehicle in a direction substantially orthogonal to a vehicle traveling direction, a contact length of each wheel during the cornering of the vehicle, and an amount of deformation in a wheel width direction at the contact portion of each wheel of the vehicle, calculating a difference between the obtained amount of the deformation and an amount of deformation in the wheel width direction under a straight forward travel condition of the vehicle for each wheel, and calculating a cornering force for each wheel based on the magnitude of the centrifugal force, the contact length, and the difference between amounts of deformation in the wheel width direction.

Owner:YOKOHAMA RUBBER CO LTD

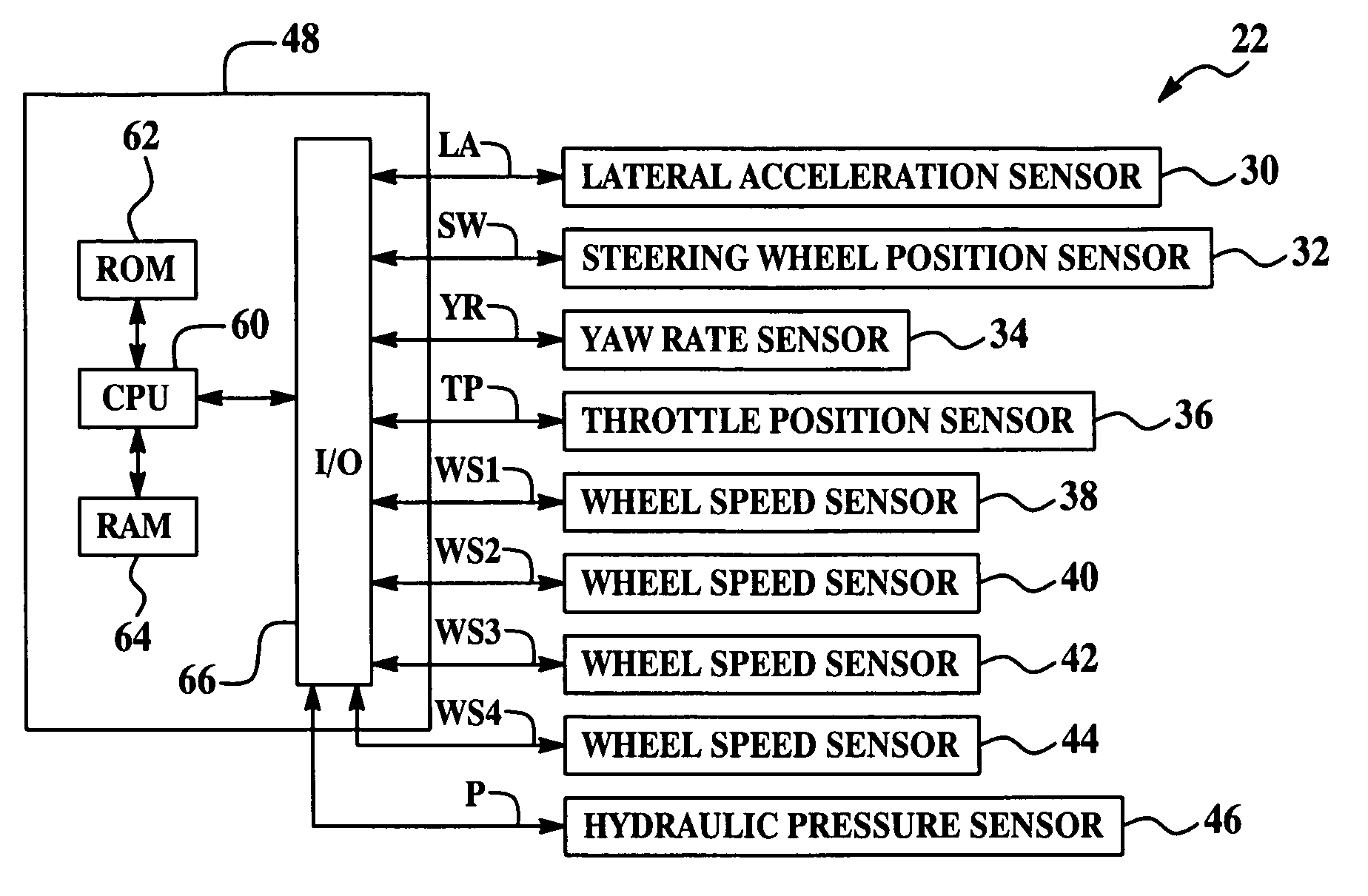

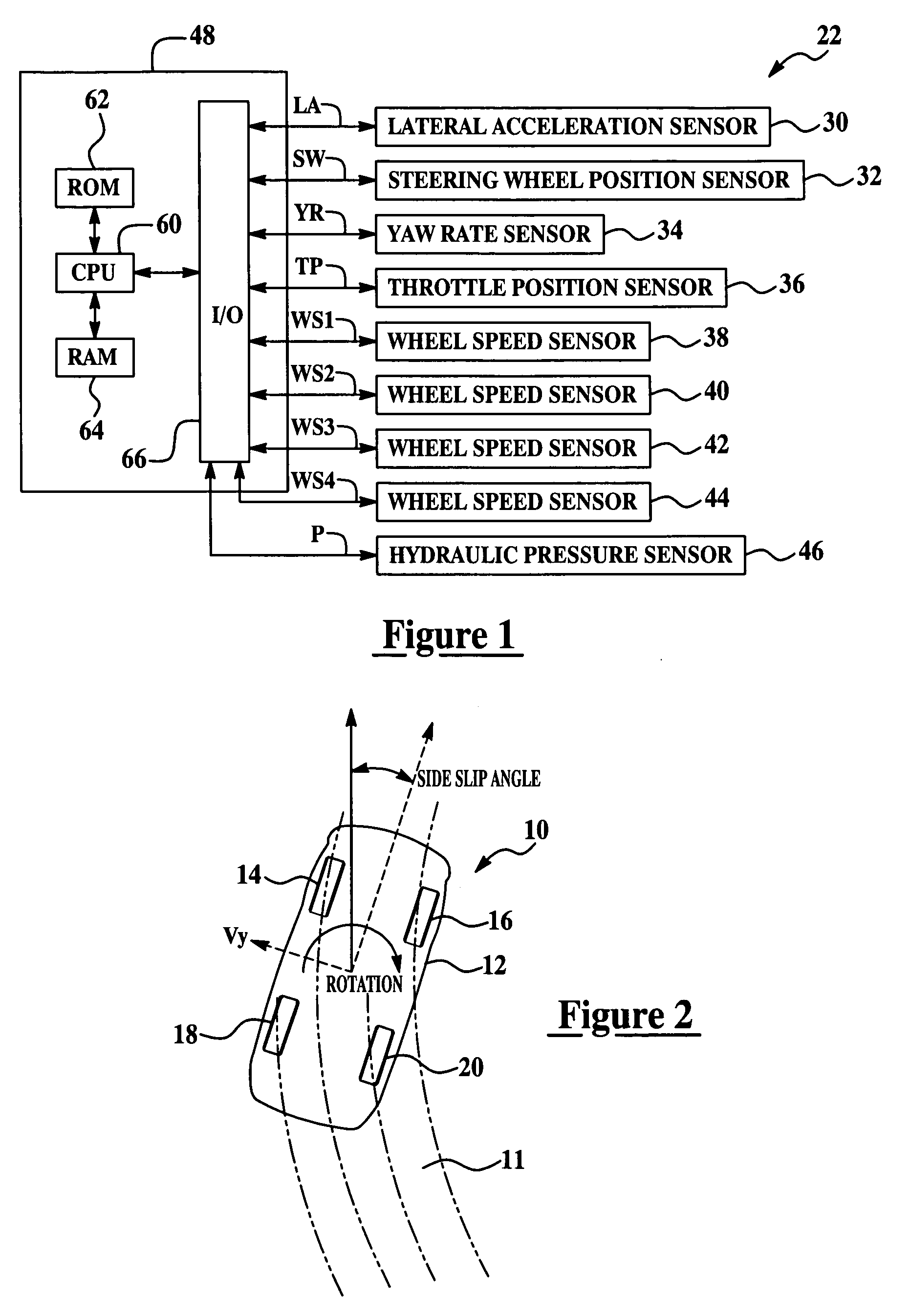

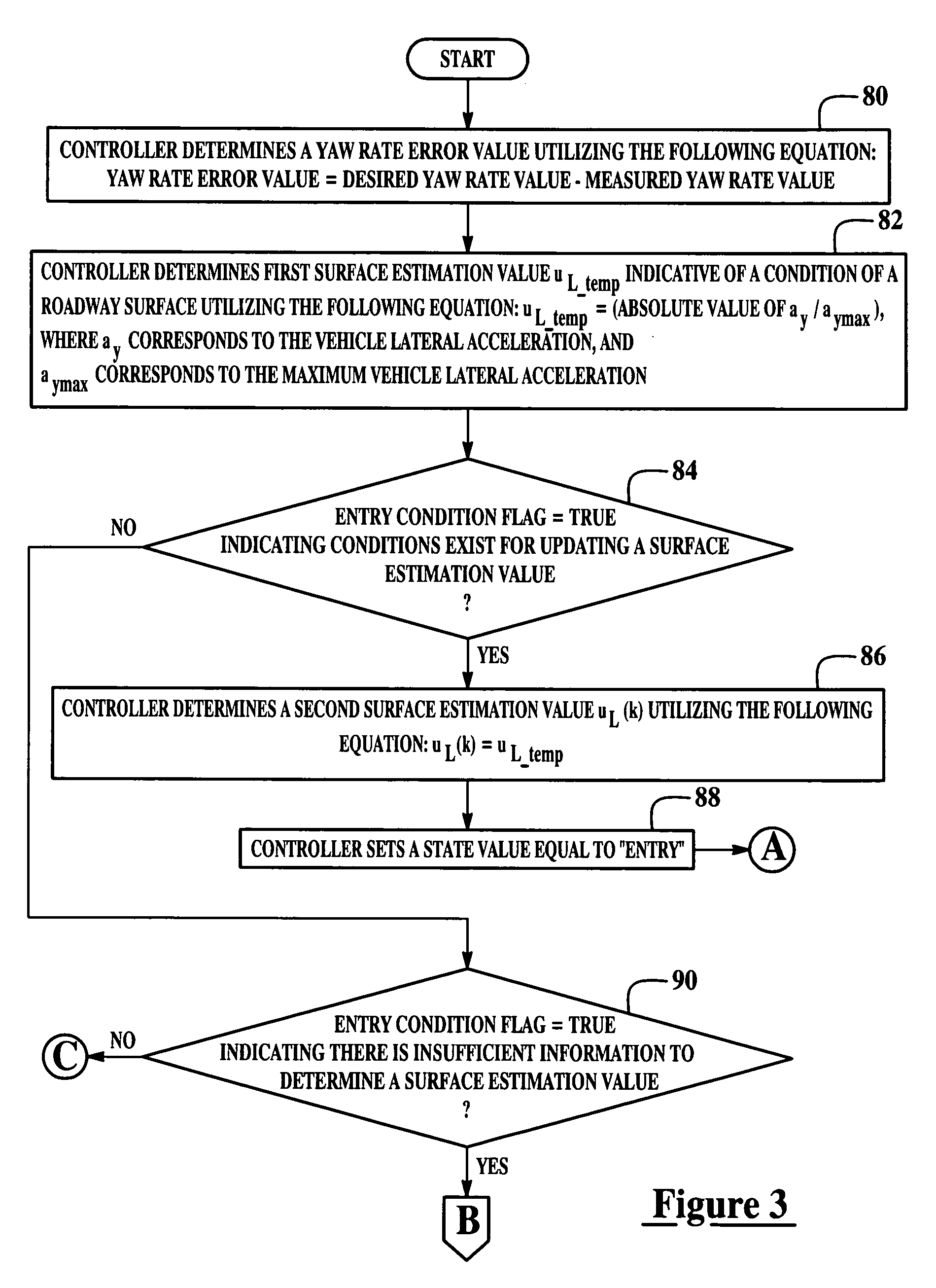

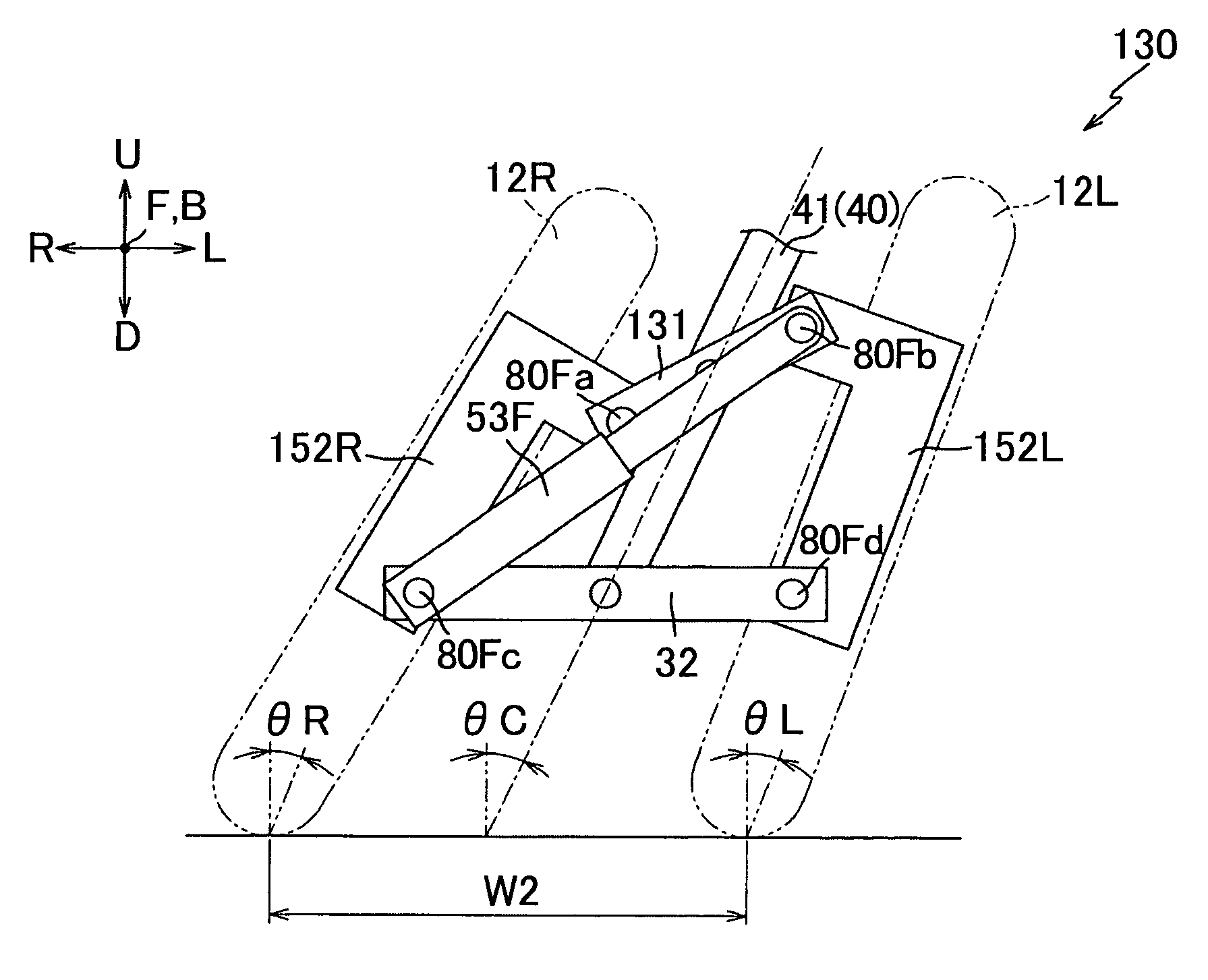

System and method for determining when to update a surface estimation value indicative of a condition of a roadway surface

ActiveUS20080021626A1Hand manipulated computer devicesDigital data processing detailsCornering forceReliability engineering

A system and a method for determining when to update a surface estimation value indicative of a condition of a roadway surface are provided. The method includes determining a front axle cornering force error value based on a predicted front axle cornering force value and a first front axle cornering force value. The method further includes determining a threshold yaw rate error value based on the front axle cornering force error value. The method further includes indicating that the surface estimation value is to be updated when a yaw rate error value is greater than the threshold yaw rate error value.

Owner:BWI

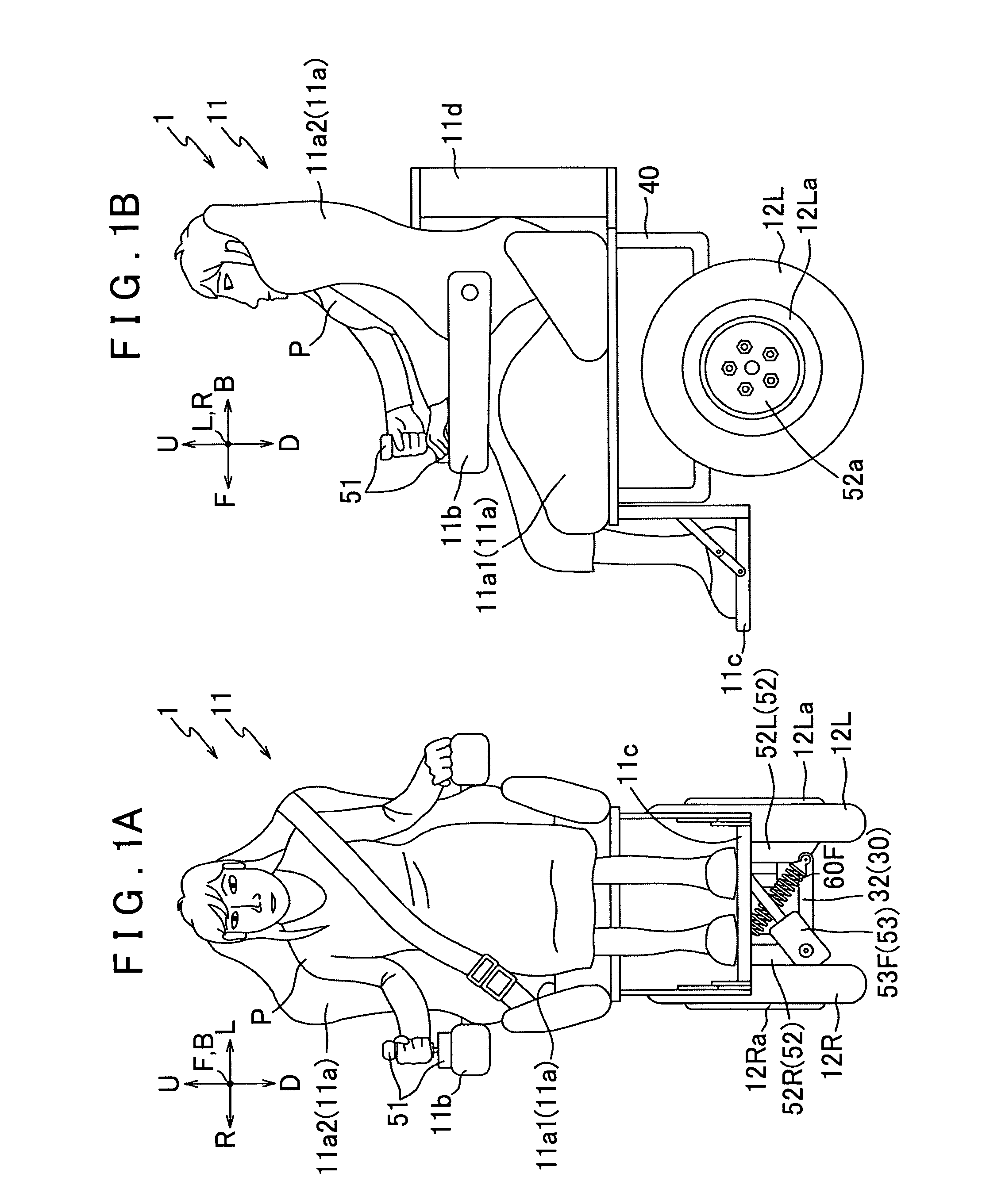

Vehicle

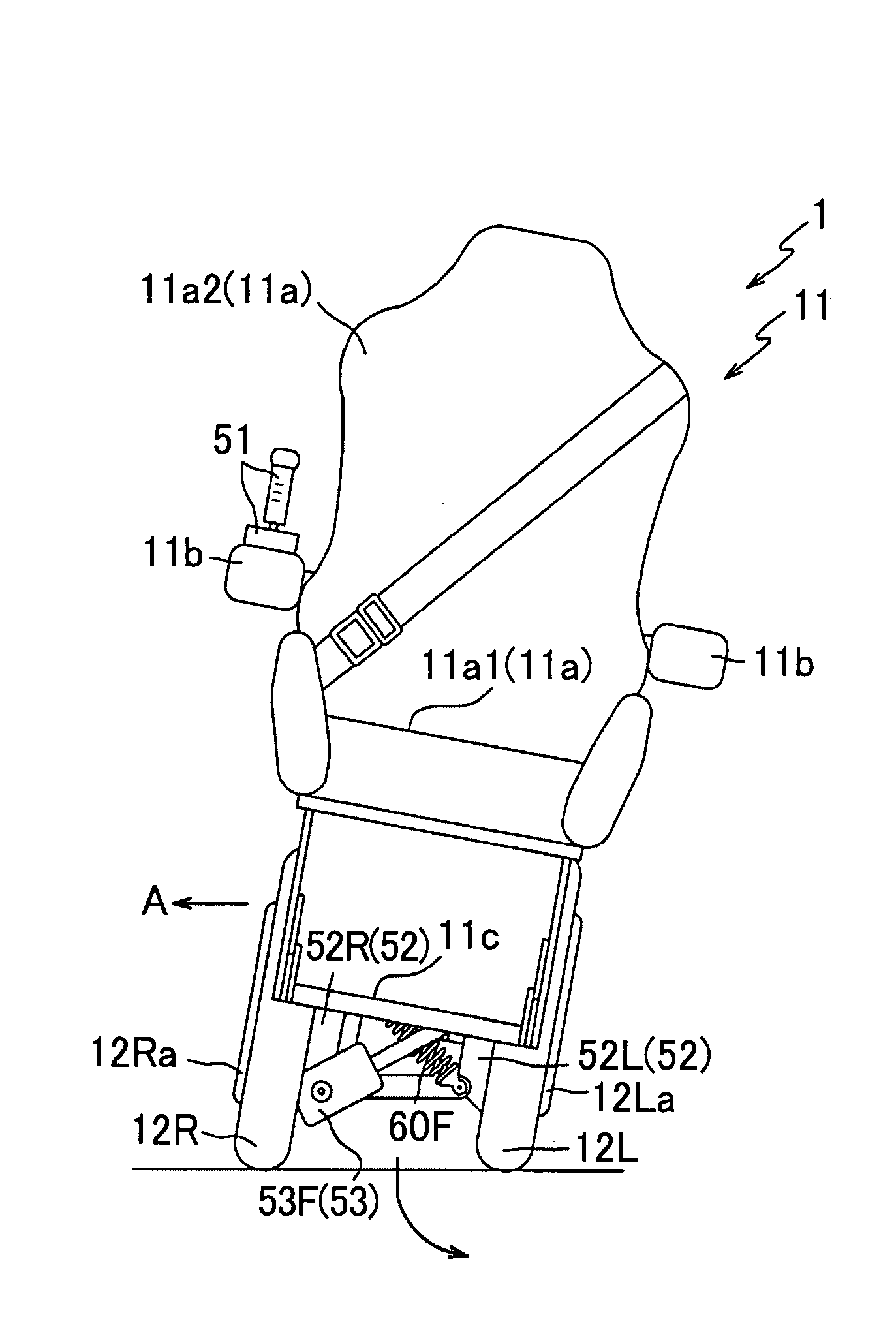

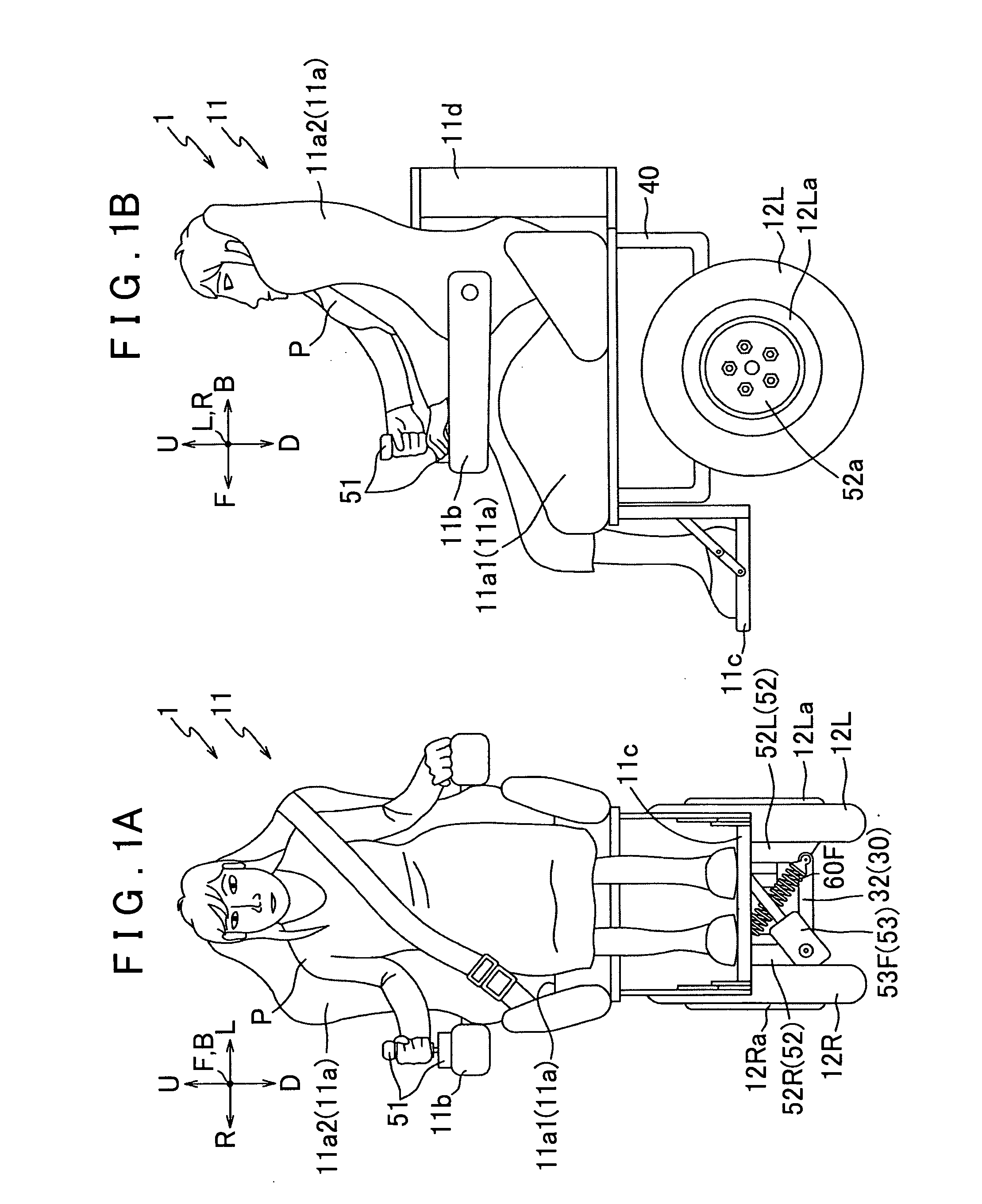

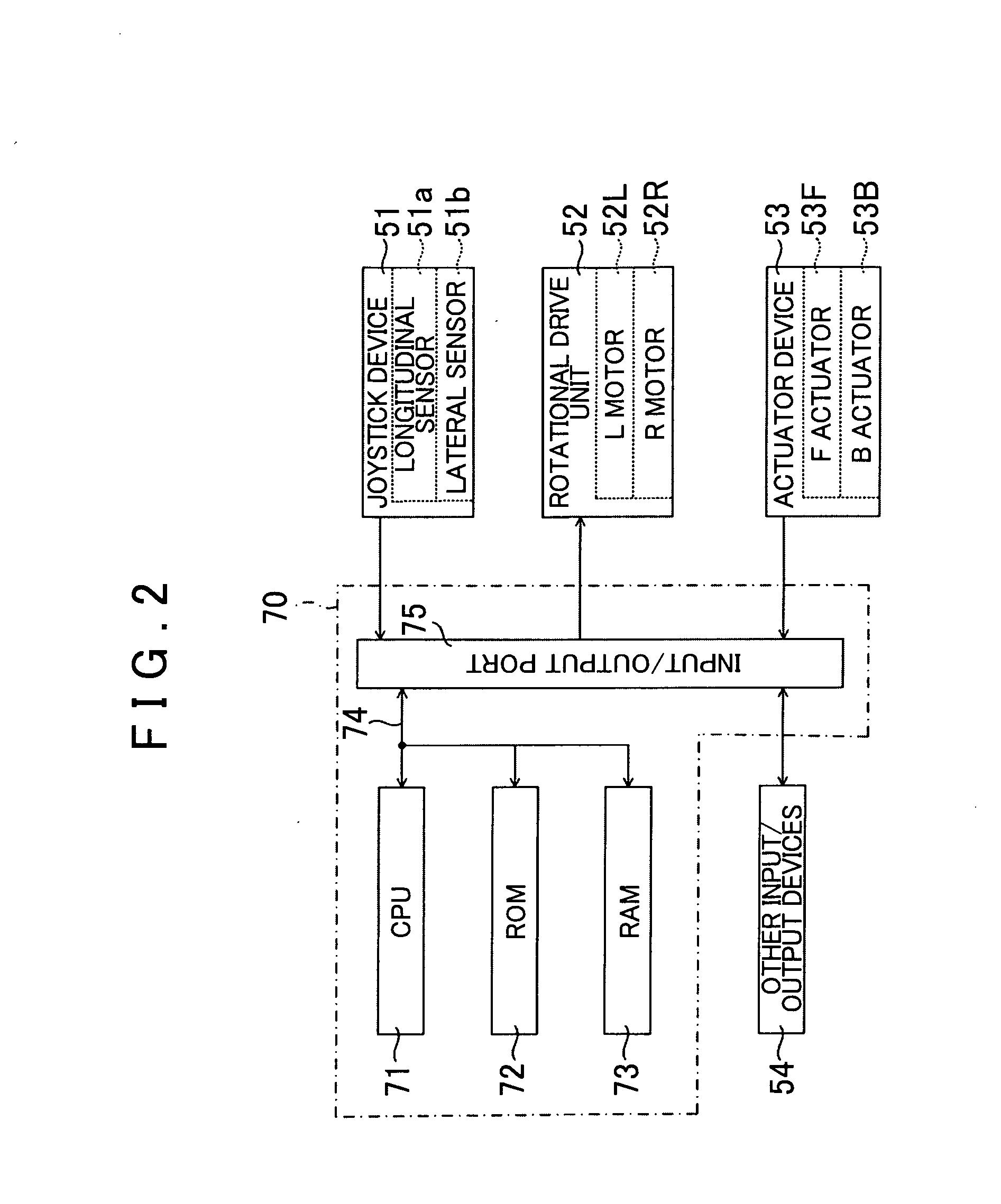

ActiveUS8162328B2Increase forceIncreased vertical loadVehicle body stabilisationWheelchairs/patient conveyanceCornering forceCentrifugal force

By bending and stretching a link mechanism, both left and right wheels of a vehicle can be inclined toward inside of cornering to generate a camber thrust as a lateral force, i.e. an increase in cornering force. Further, by bending and stretching the link mechanism, the passenger compartment can be inclined in accordance with inclination of a connecting link, and thus the center of gravity of the vehicle can be moved toward its inner wheel during cornering. By preventing lifting of the inner wheel during cornering, cornering performance is improved. Because the passenger compartment is inclined toward the inner wheel during cornering, centrifugal force is less likely to be felt by the occupant.

Owner:EQUOS RES

Road friction coefficient estimating unit and road friction coefficient estimating method

ActiveUS20130074576A1Using mechanical meansInvestigating abrasion/wear resistanceCornering forceRoad surface

A road friction coefficient estimating unit calculates a tire sideslip angle and a cornering force, and estimates a road friction coefficient on the basis of the ratio of the calculated cornering force to the calculated tire sideslip angle. A vehicle travels on multiple road surfaces that differ in road friction coefficient, and tire sideslip angles and cornering forces on the road surfaces are detected in advance. The road friction coefficient estimating unit stores, in a memory, a correlation among the detected tire sideslip angles, the detected cornering forces, and the road friction coefficients in the form of numerical values or a mathematical expression, and estimates a road friction coefficient using the correlation stored in the memory.

Owner:JTEKT CORP

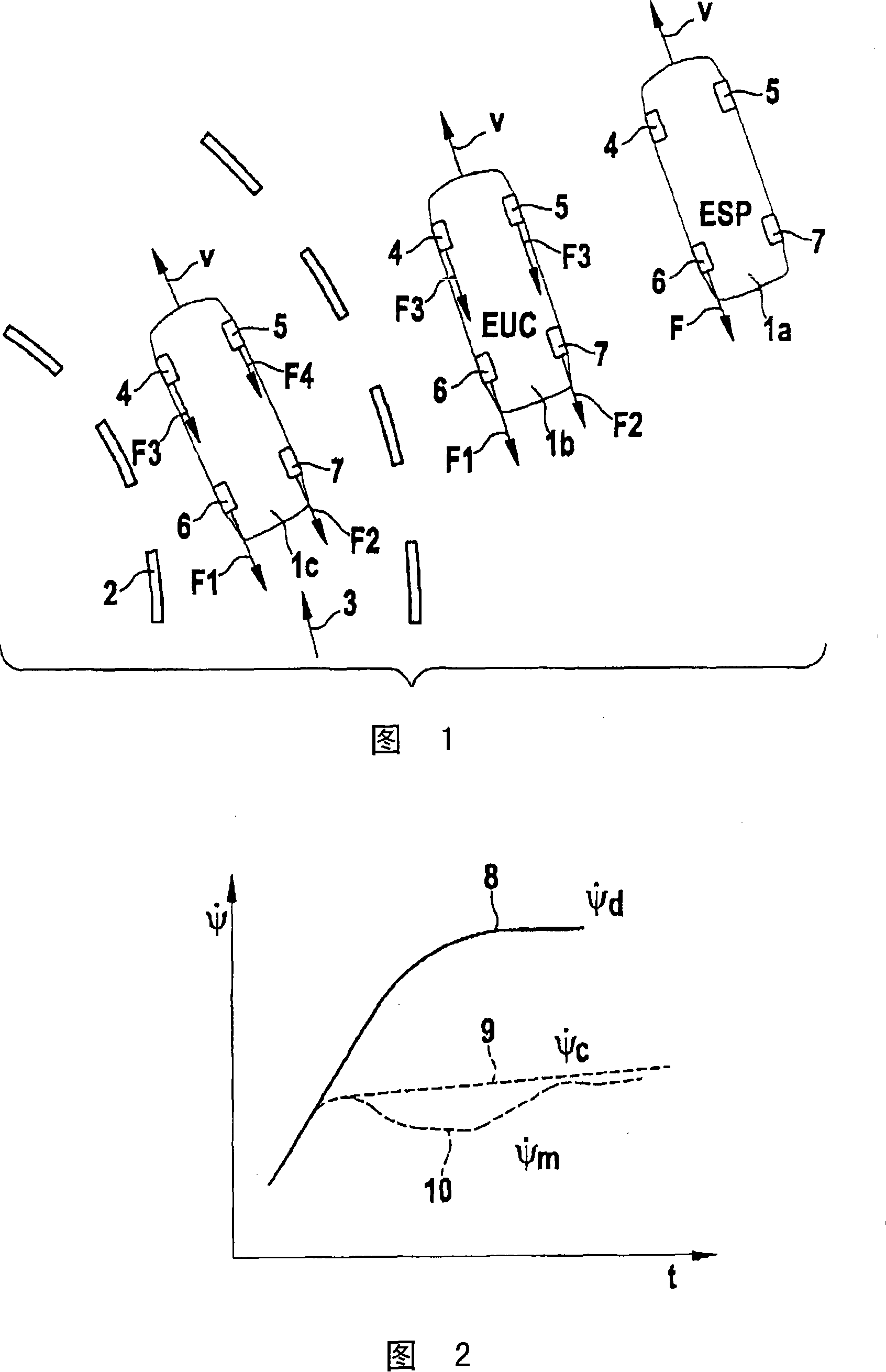

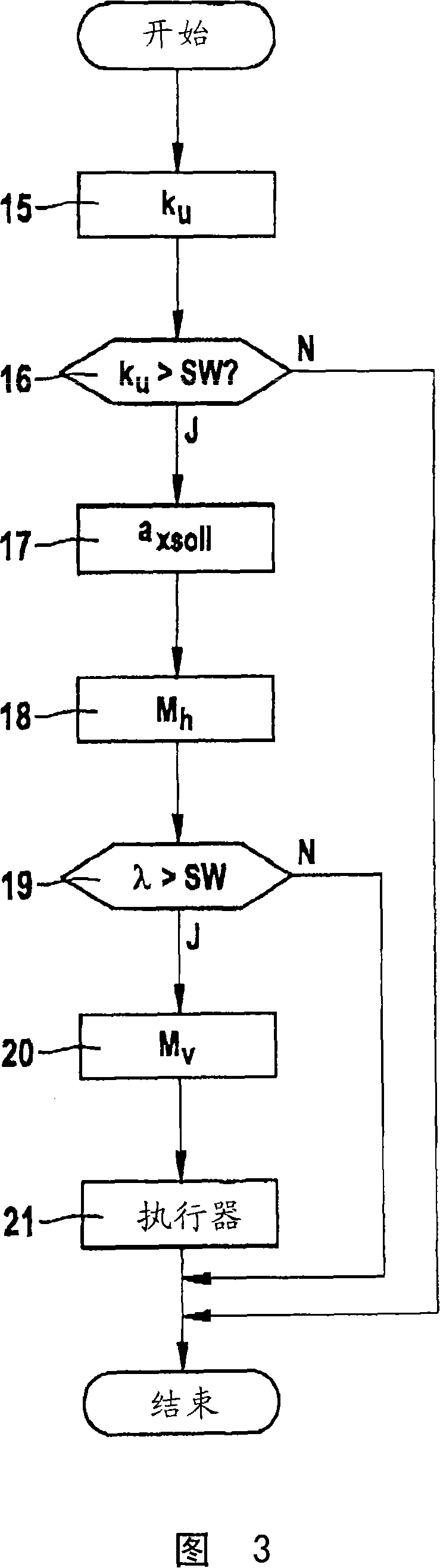

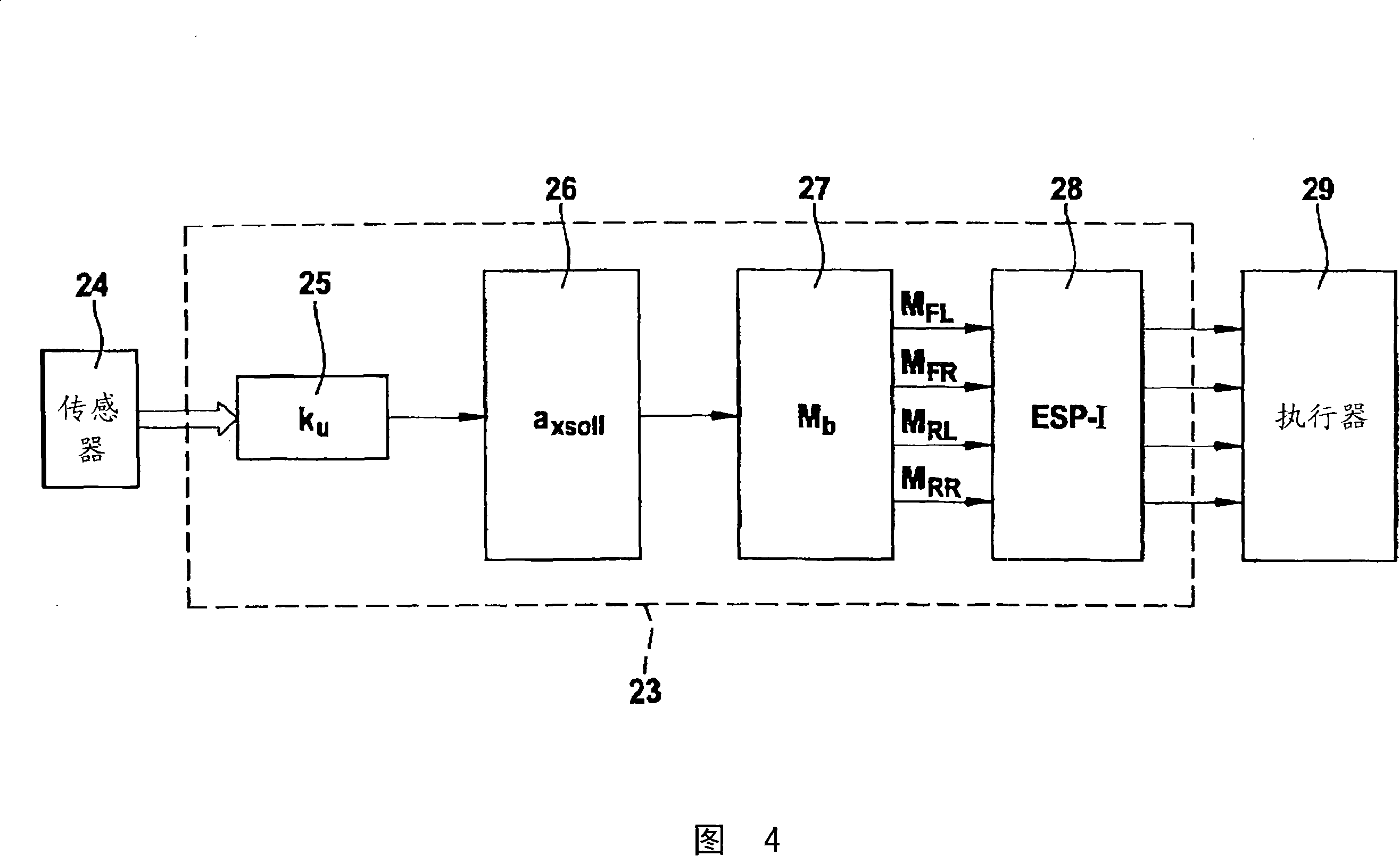

Driving dynamics control system having an expanded braking function

In a method for stabilizing a vehicle in extreme driving situations, in particular when understeering while cornering, multiple wheels are decelerated in order to reduce the driving speed. A maximum cornering force of the wheels and thus a minimal curve radius may be achieved if in particular the rear wheels are decelerated and a higher braking torque is applied on the rear wheels than on the front wheels and in the process in particular the outside front wheel remains highly underdecelerated.

Owner:ROBERT BOSCH GMBH

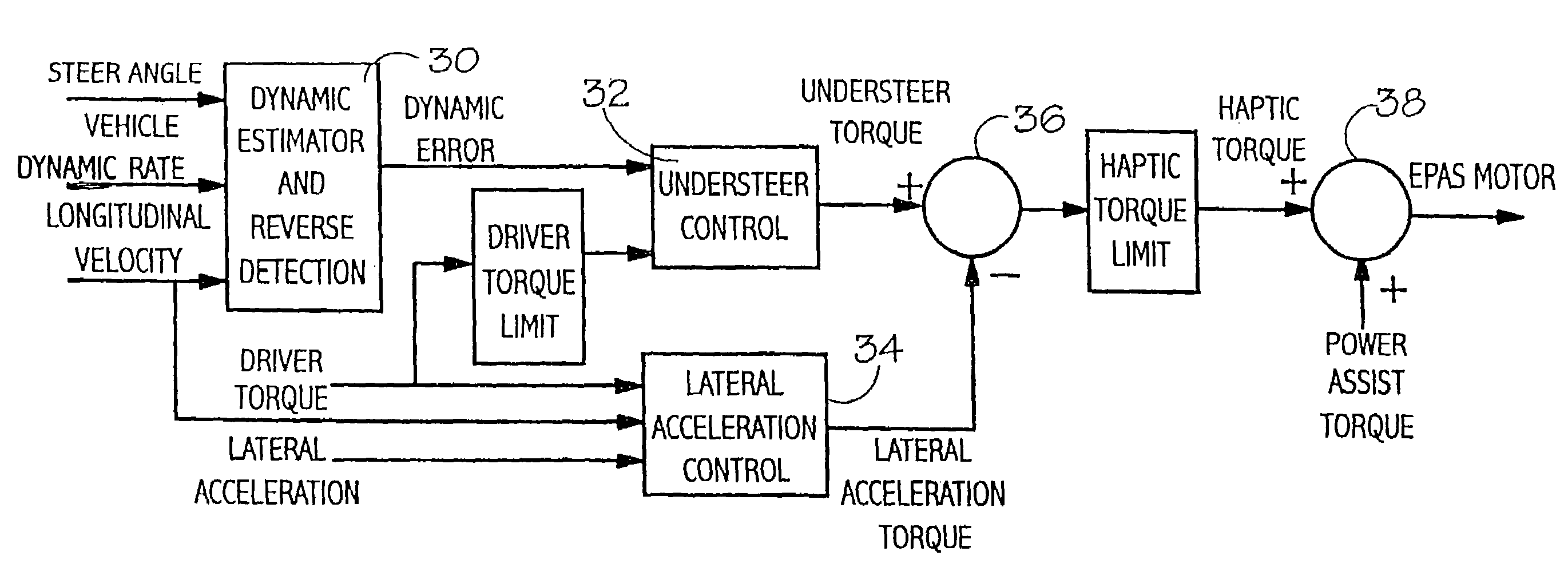

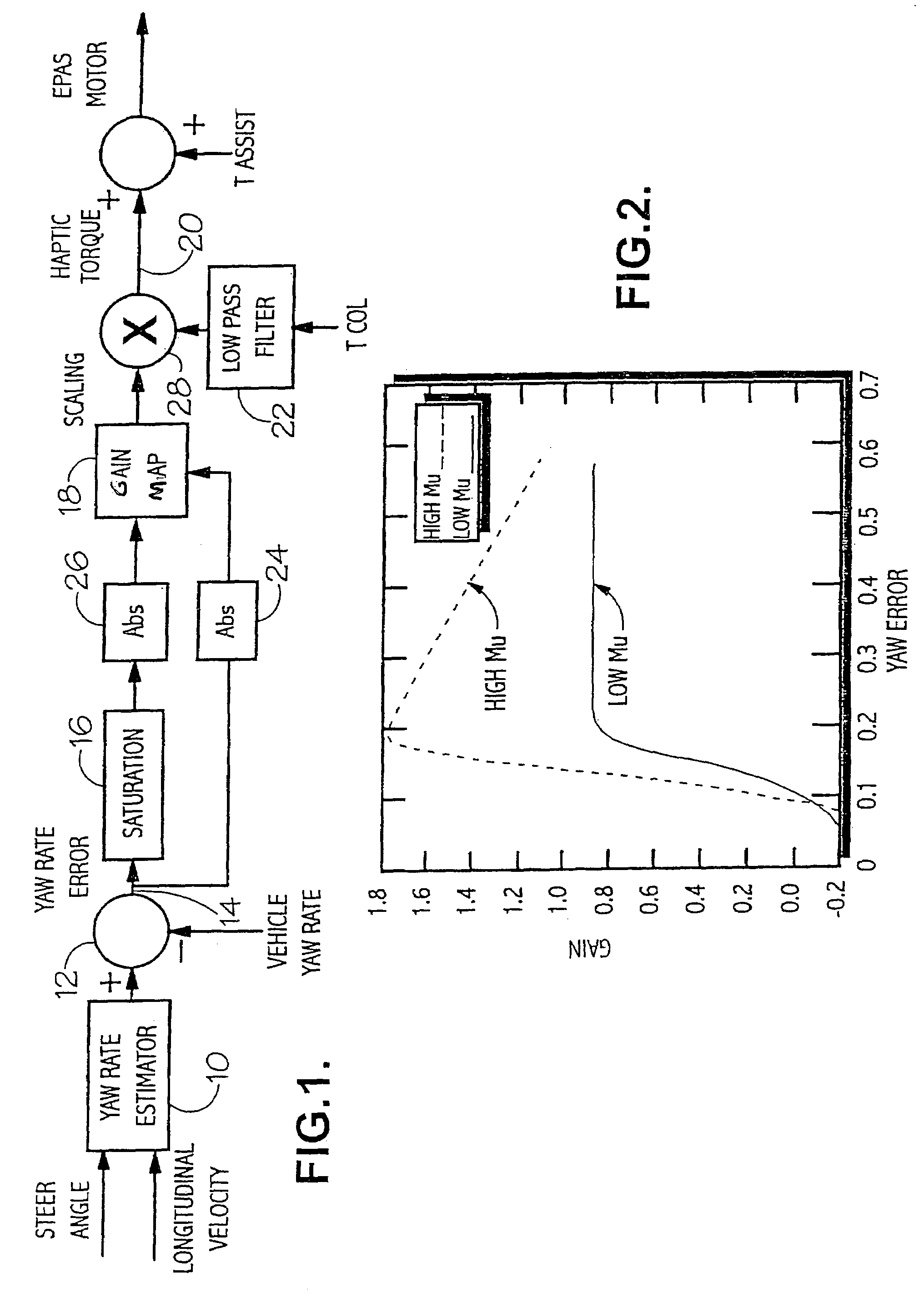

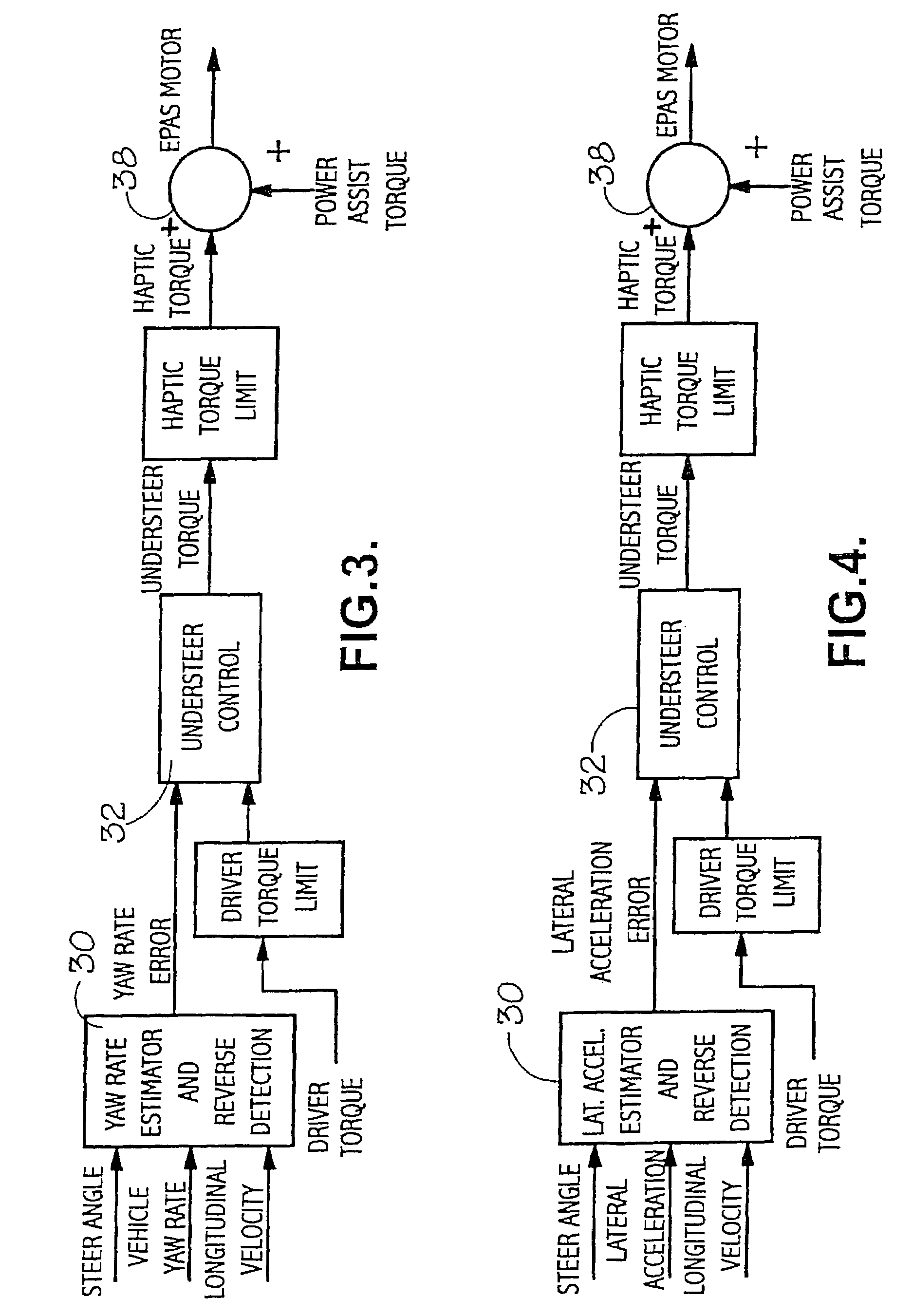

Haptic controller for road vehicles

InactiveUS7185731B2Improve haptic informationSteering initiationsDigital data processing detailsDriver/operatorMotor drive

Owner:TRW LIMITED

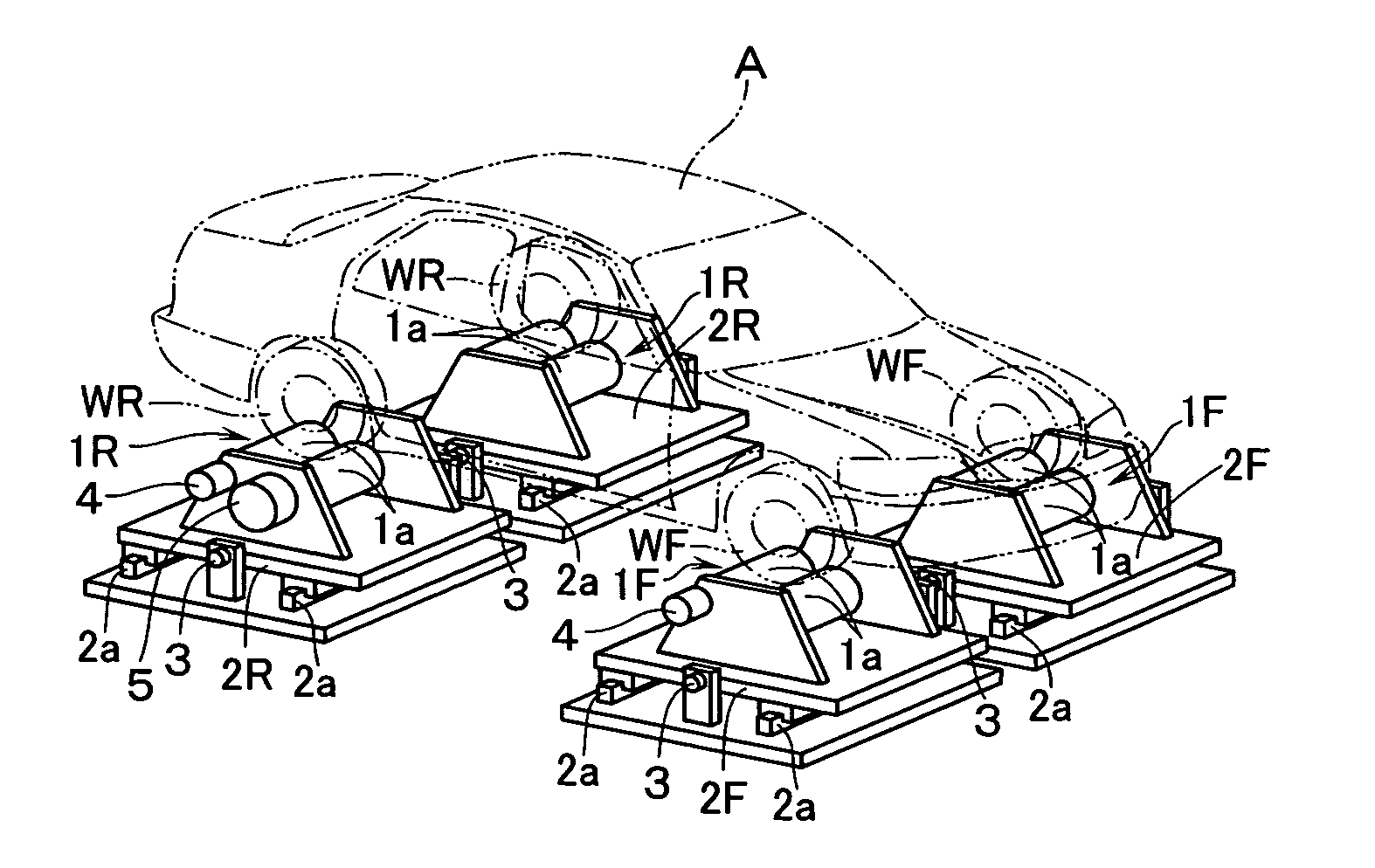

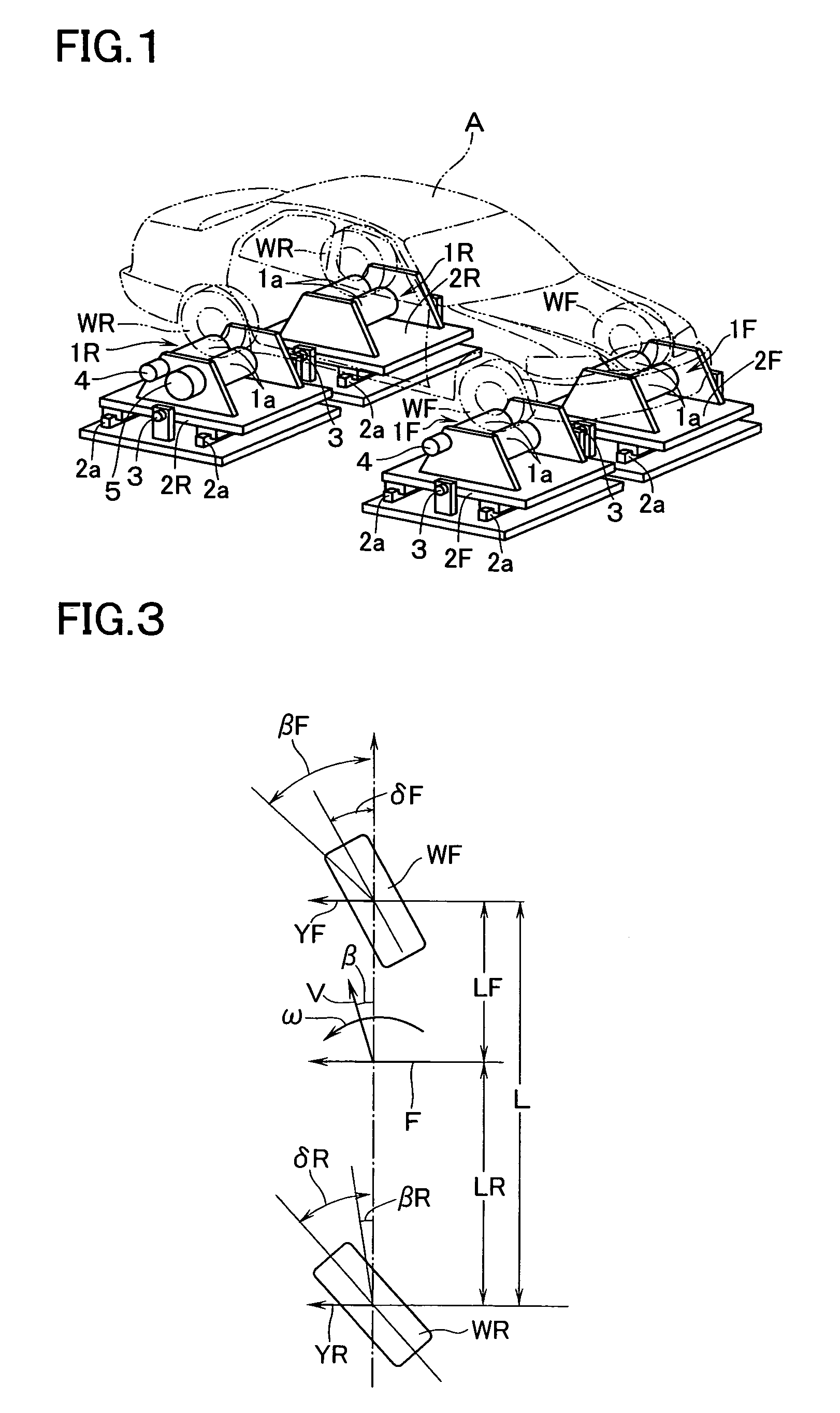

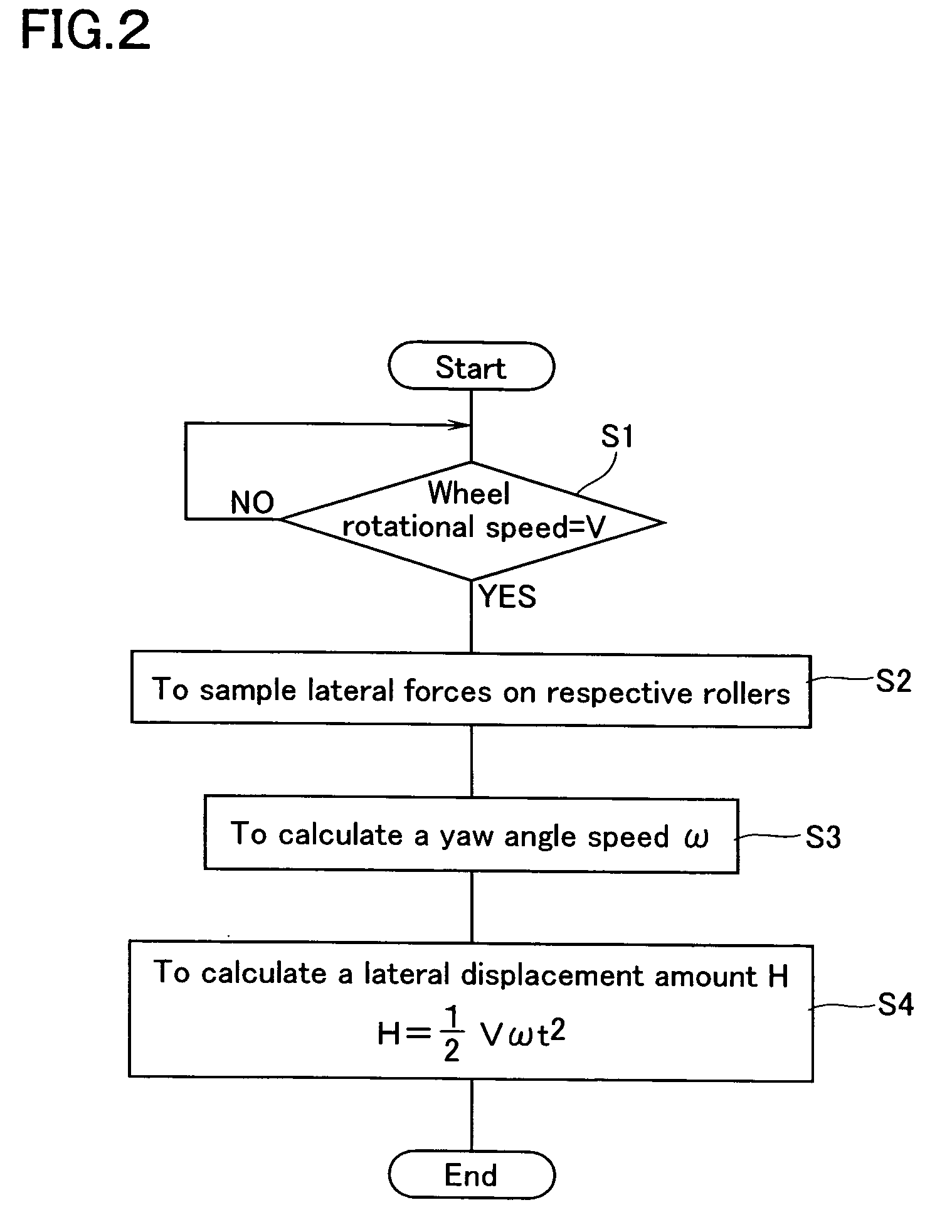

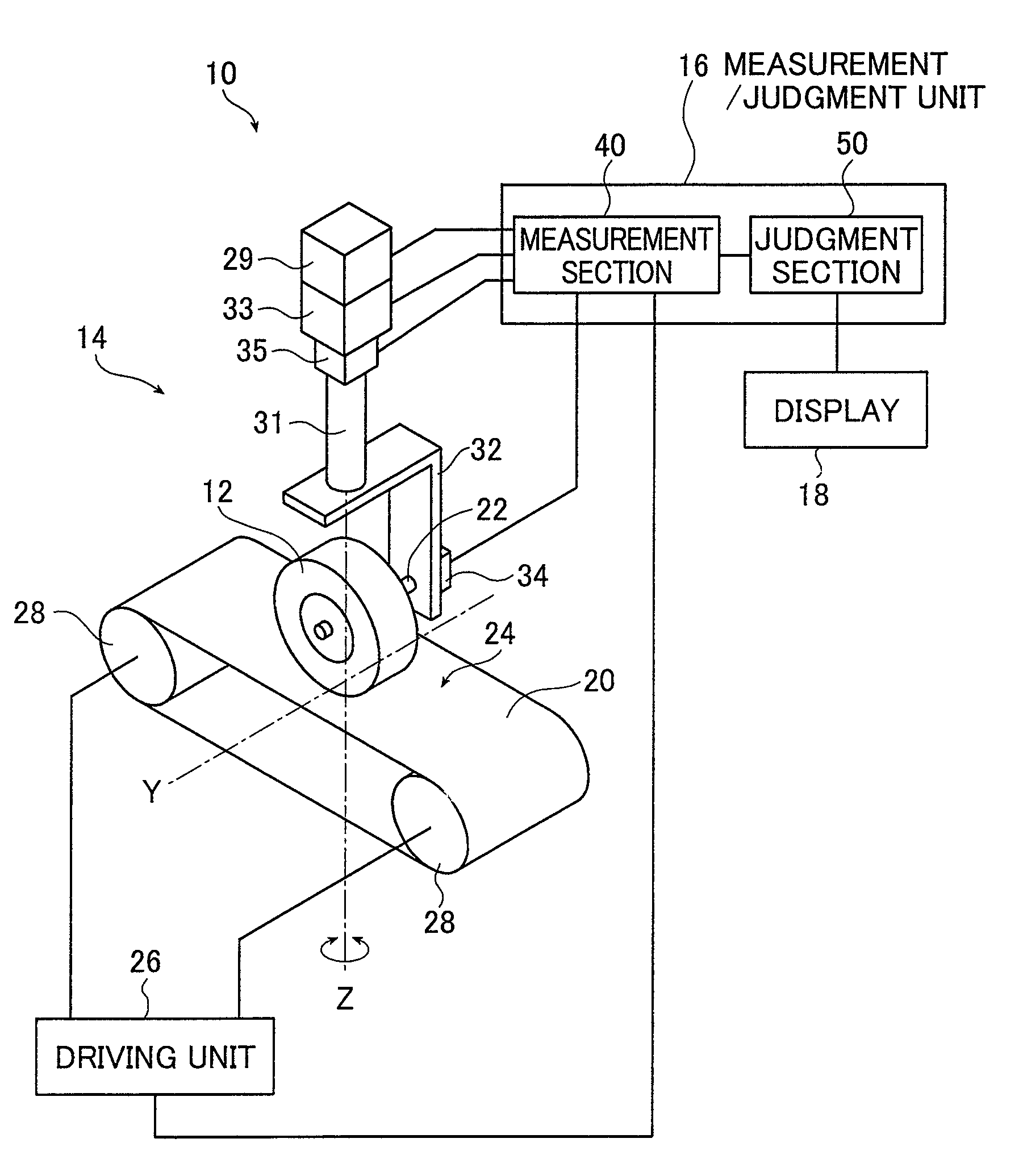

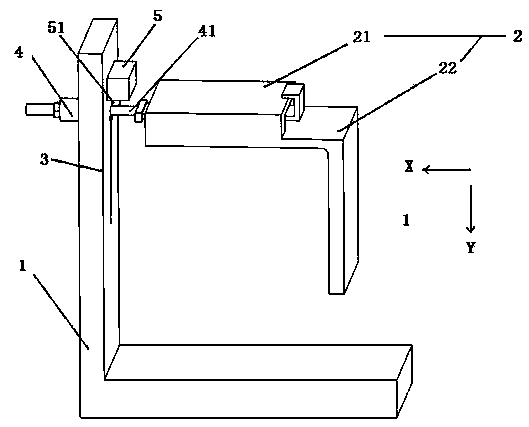

Method of measuring unilateral flow rate of vehicles

InactiveUS7100290B2Reduced measurement timeAvoid damageAngles/taper measurementsEngine testingCornering forceEngineering

The invention makes it possible to measure a lateral displacement amount of a vehicle accurately in a short time on a bench testing machine without damaging a vehicle body and tires.Respective rollers 1F, 1R on which respective wheels WF, WR of the vehicle A are placed respectively are made movable in a lateral direction. In a state in which the respective wheels WF, WR are rotating at a predetermined speed, lateral forces (cornering forces) acting on the respective rollers 1F, 1R are detected by respective detectors 3. Then, a yaw angle speed when the vehicle A is brought into a state of steady circular turning is calculated based on the lateral forces acting on the respective rollers 1F, 1R and the lateral displacement amount is calculated from the yaw angle speed.

Owner:HONDA MOTOR CO LTD

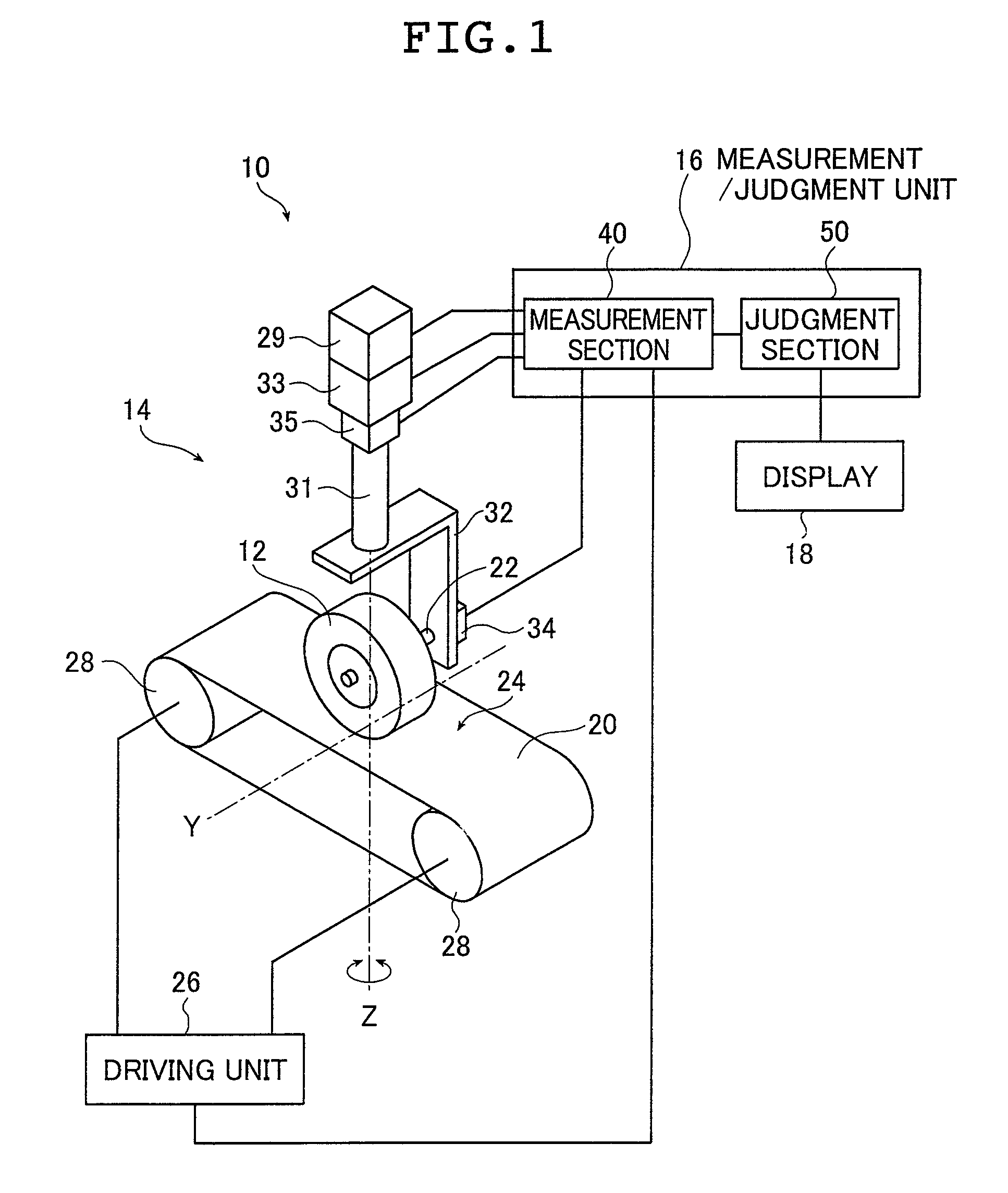

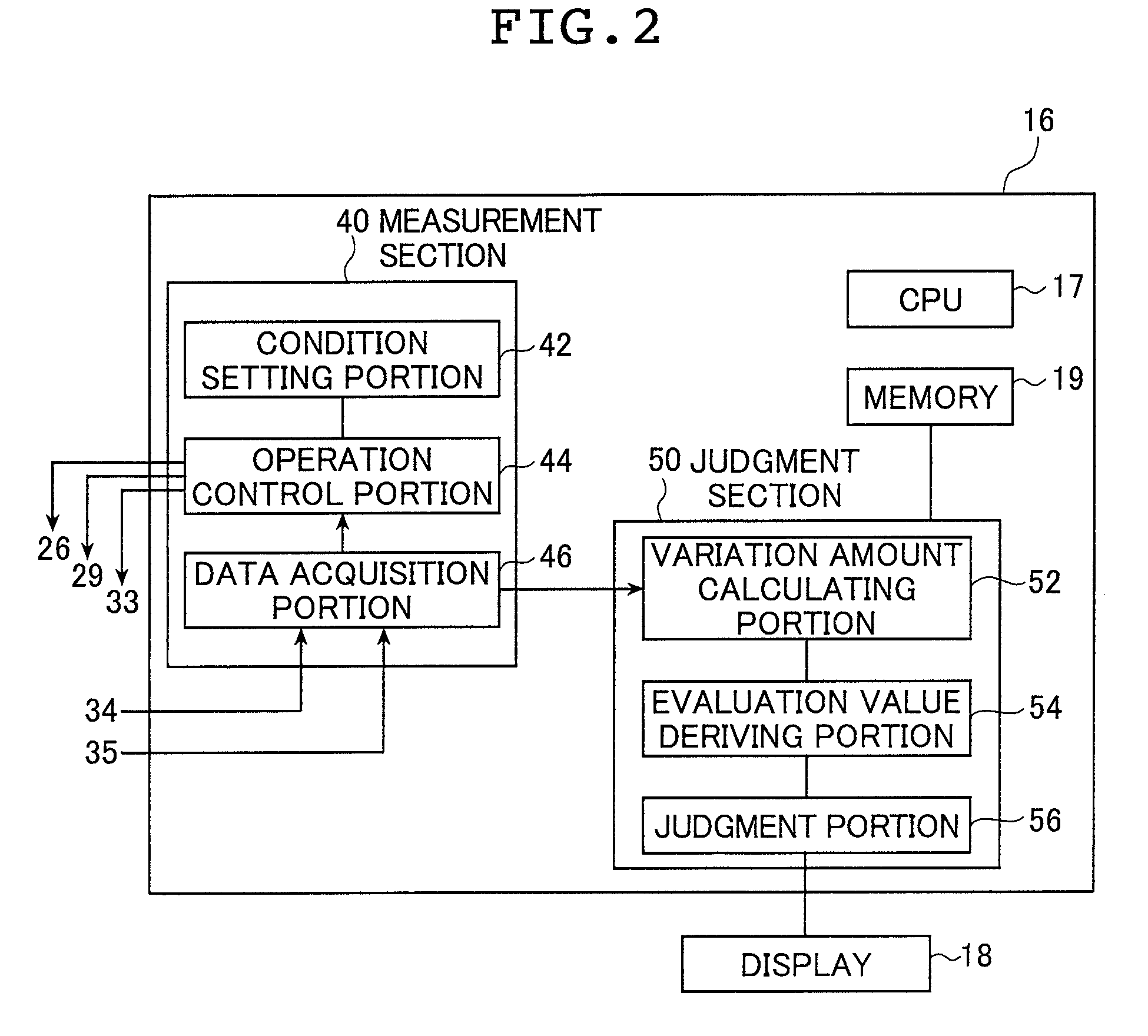

Tire characteristic judging method and tire characteristic judging device

A tire characteristic judging device judges a tire characteristic in the following way. At first, a load applied to a tire and a cornering force generated in the tire in time series while the tire is rolling are acquired. Then, an applied load variation amount is calculated from the acquired time-series applied load information and a cornering force variation amount calculated from the acquired time-series cornering force information. Next, an evaluation value is calculated based on the applied load variation amount and the cornering force variation amount. The calculated evaluation value and a preset reference value are compared with each other and whether or not the tire satisfies a desired characteristic is judged according to a result of comparison.

Owner:THE YOKOHAMA RUBBER CO LTD

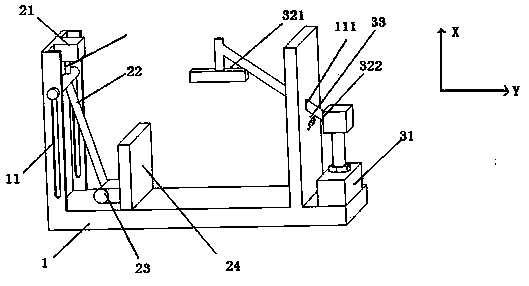

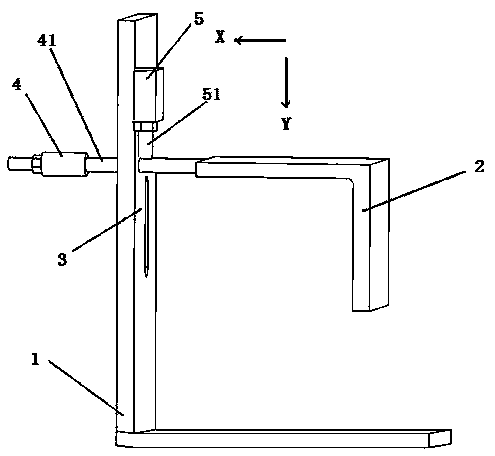

Tenoning assist mechanism

InactiveCN104290154ALower center of gravityCompact structureWood mortising machinesWood slotting machinesCornering forceEngineering

The invention belongs to the technical field of wood processing and relates to a tenoning assist mechanism comprising a U-shaped bench rack, a first mechanism and a second mechanism. The U-shaped bench rack providing a workpiece with side clamping force is used for supporting the workpiece. The first mechanism is used for providing side clamping power. The second mechanism is used for providing top clamping power. The first mechanism and the second mechanism are arranged on two vertical sides of the U-shaped bench rack. The first mechanism and the second mechanism providing the side clamping force and top clamping force respectively are applied to replace existing simple clamping structures, the whole structure is compact, the center of gravity of the tenoning assist mechanism is lowered, the first mechanism, the second mechanism and the U-shaped mechanism co-act to provide the top compressing force, side compressing force and corner force to clamp the workpiece, and tenoning precision is improved.

Owner:杨绍波

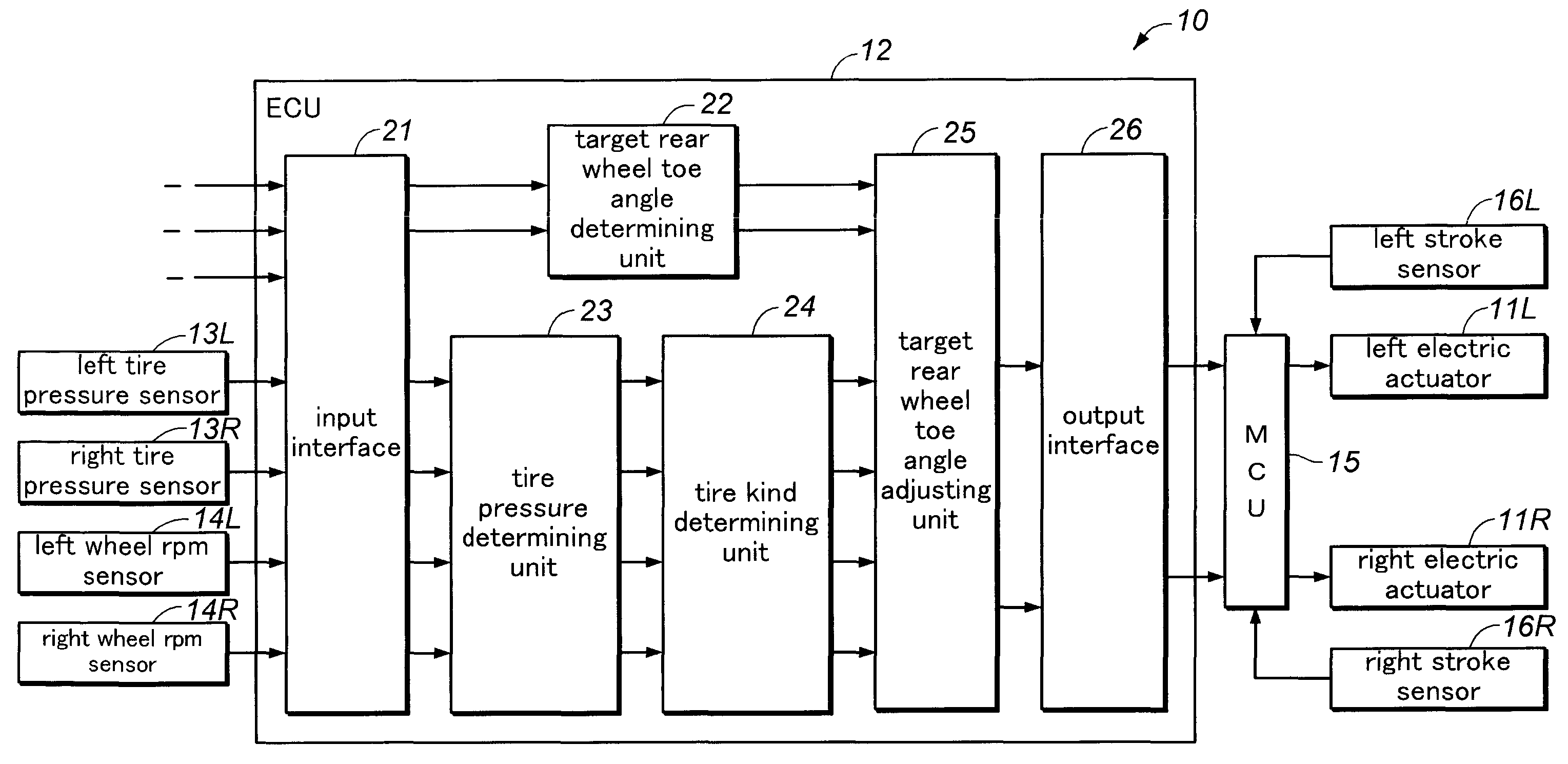

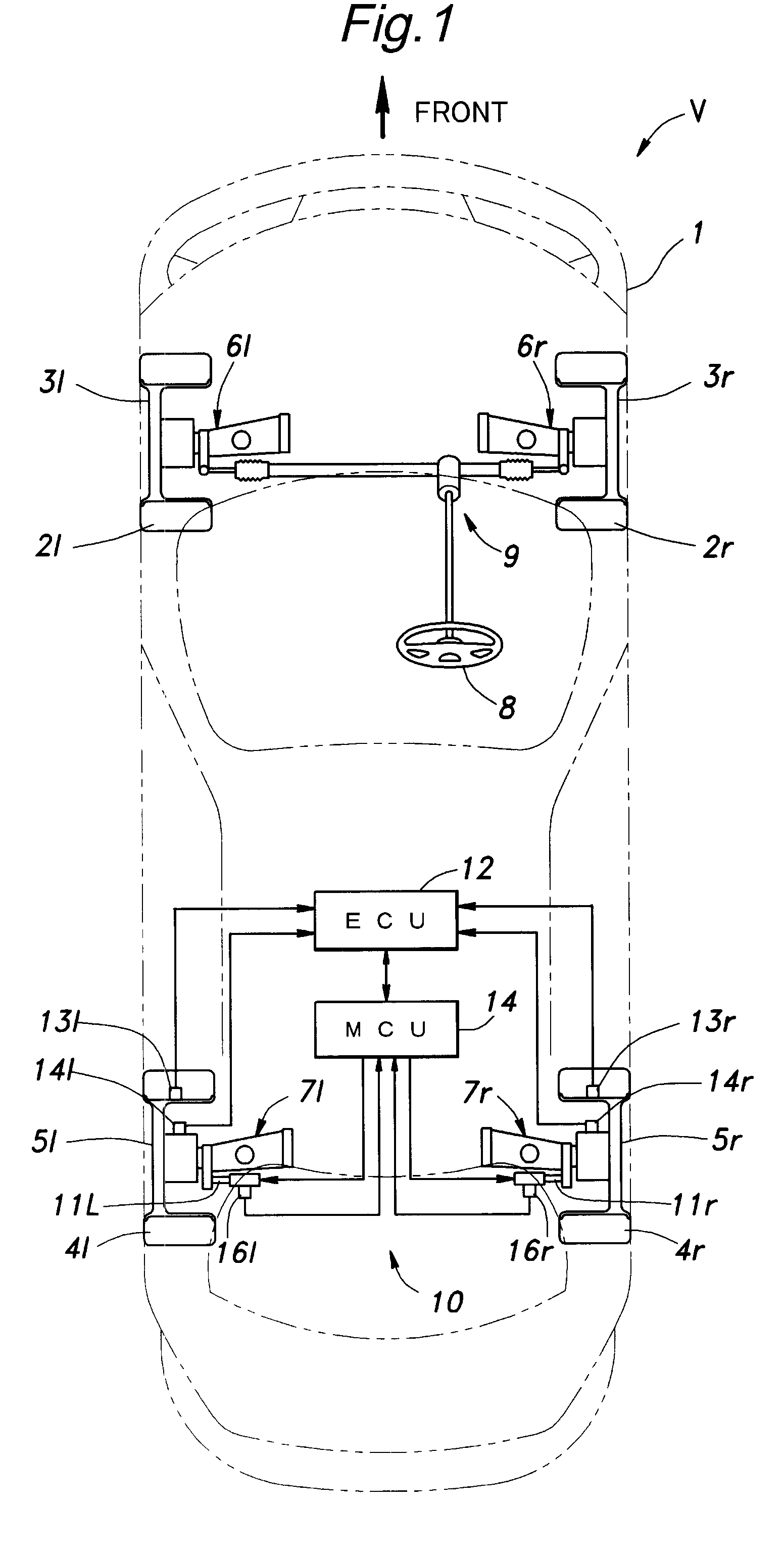

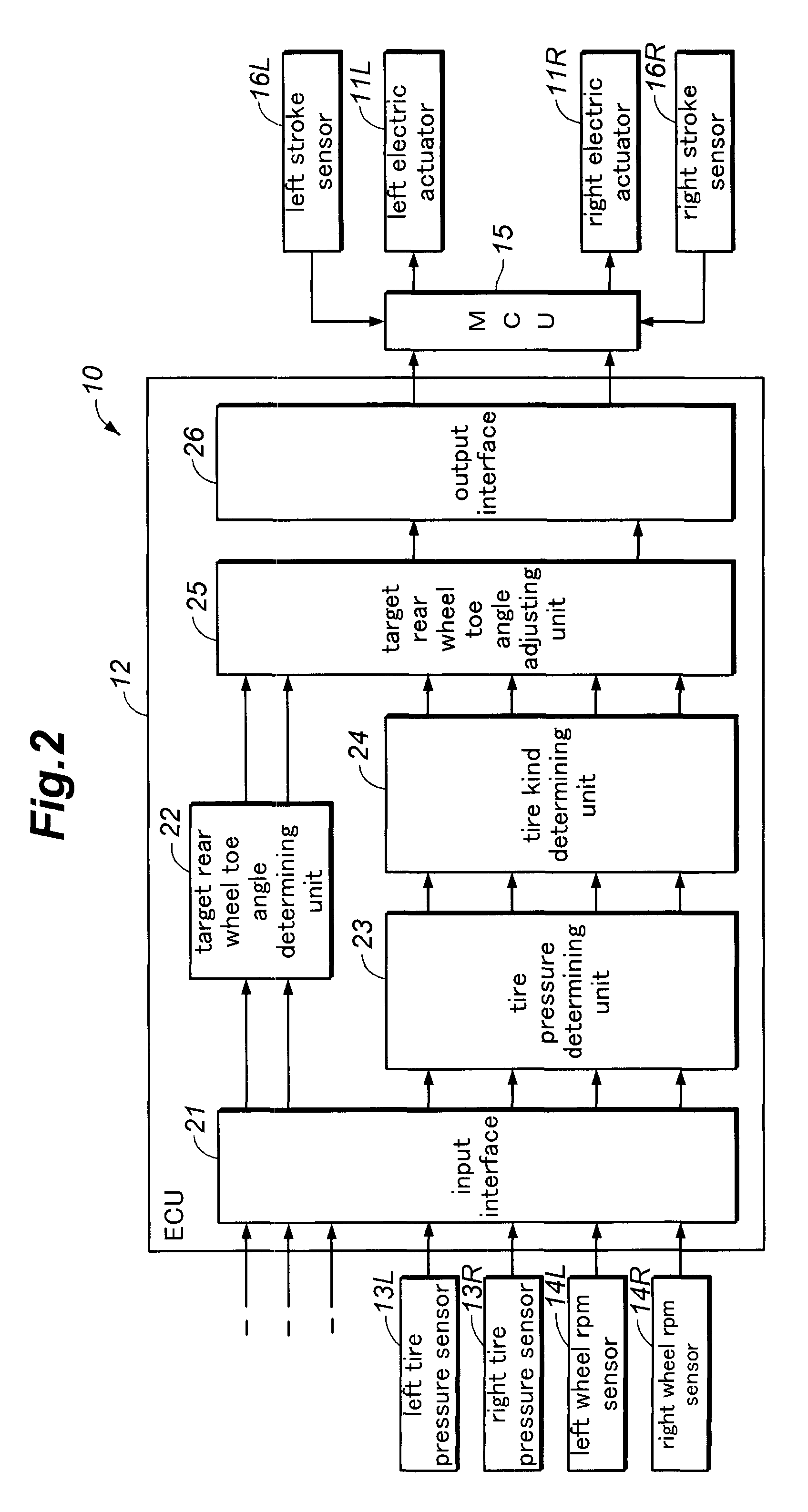

Rear wheel toe angle control device

InactiveUS7871085B2Improve performanceGuaranteed uptimeHand manipulated computer devicesDigital data processing detailsCornering forceNormal level

Owner:HONDA MOTOR CO LTD

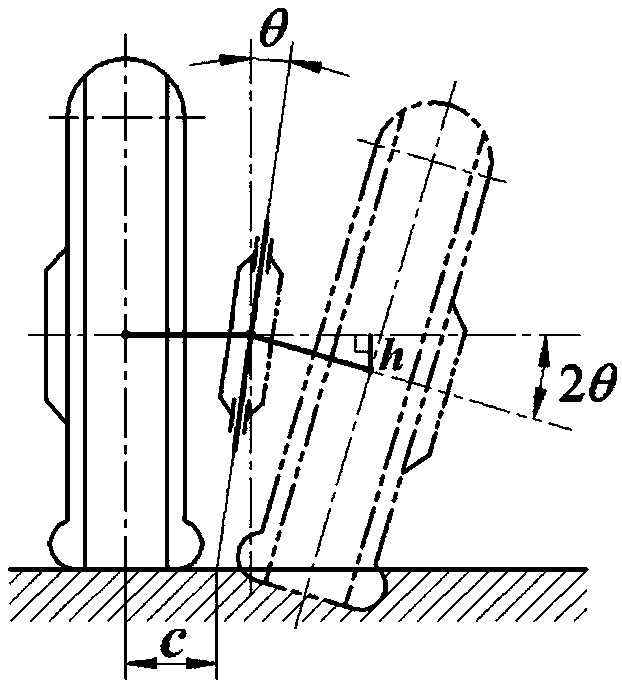

Method for measuring large components, especially the body of rail cars

InactiveUS20050030552A1Low costShorten the timeActive open surveying meansUsing optical meansMeasurement deviceCornering force

The invention relates to a method for measuring large components, especially the body of rail cars, which is characterized by the following features: a) producing a stressfree position of the large component in which it is not buckled, by means of a mechanical corner force measuring device, b) producing a reference position of the large component, likewise using a corner force measuring device, c) measuring the z dimensions of the large component using an electronic, self-leveling all-round laser and laser receivers, said laser describing a horizontal plane and the receivers which are disposed on the large component or on the measuring adapters automatically searching the laser plane, and d) measuring the x dimensions and the y dimensions of the large component using a tachymeter.

Owner:SIEMENS AG

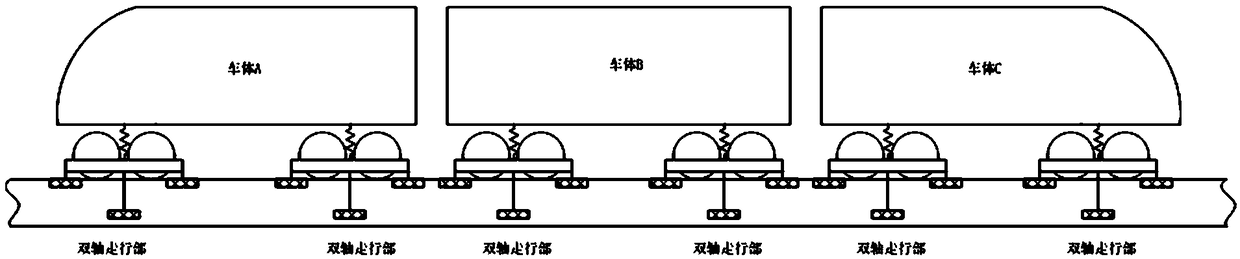

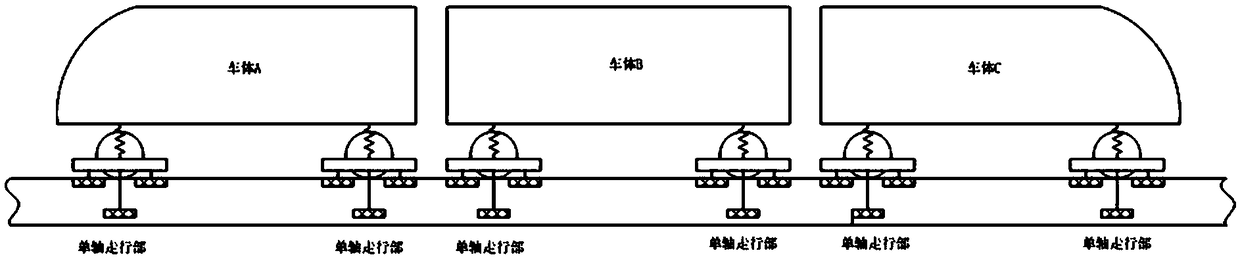

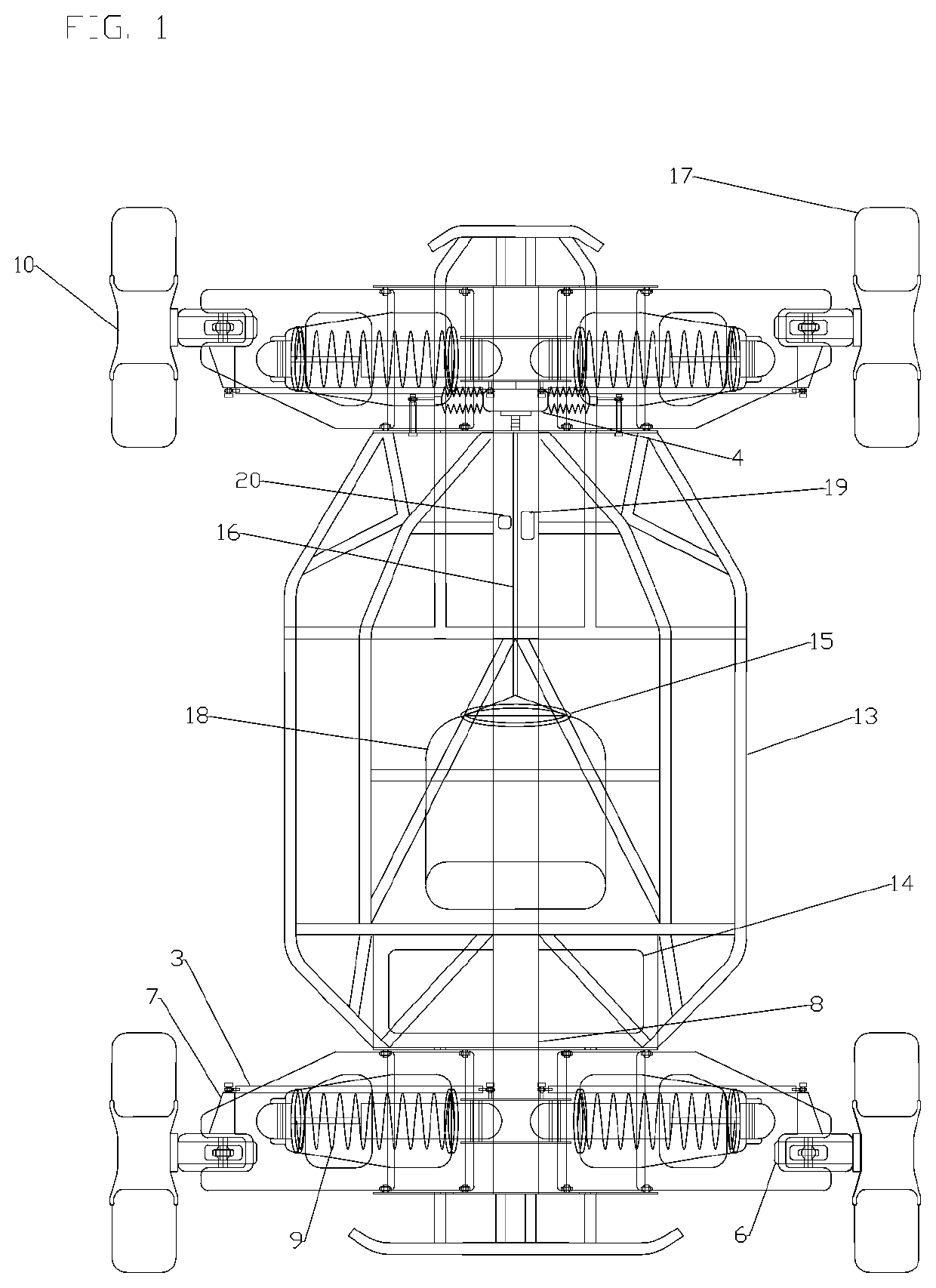

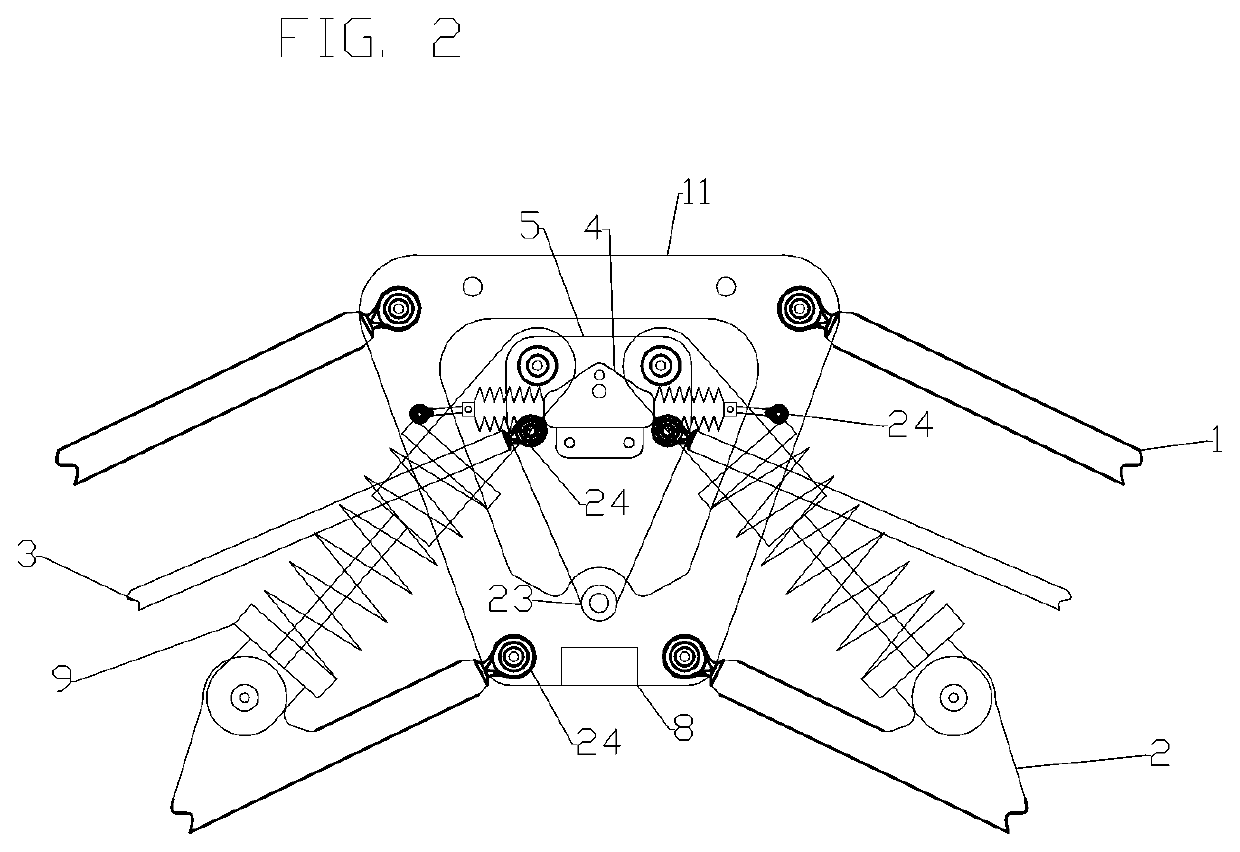

Coupling bogie system of straddling type monorail train double-connecting-rod coupling

The invention relates to an elastic coupling bogie of a double-connecting-rod coupling straddling type monorail vehicle. Each single-axle bogie comprises a framework, walking wheels, guide wheels andstabilization wheels, the walking wheels, the guide wheels and the stabilization wheels are installed on the corresponding frameworks, each framework comprises a side beam, a crossbeam and a verticalcantilever beam, two elastic connecting rods are further arranged, and the two single-axle bogies are connected with each other through the two elastic connecting rods arranged in parallel. Compared with the prior art, the elastic coupling bogie can make the two single-axle bogies located in the radial positions of a circular curve, the radial force of guide tires is reduced, the vehicle curve passing safety is improved, the cornering force of walking tires is reduced, and the eccentric wear of the walking tires is reduced.

Owner:北京维时正喜科技有限公司

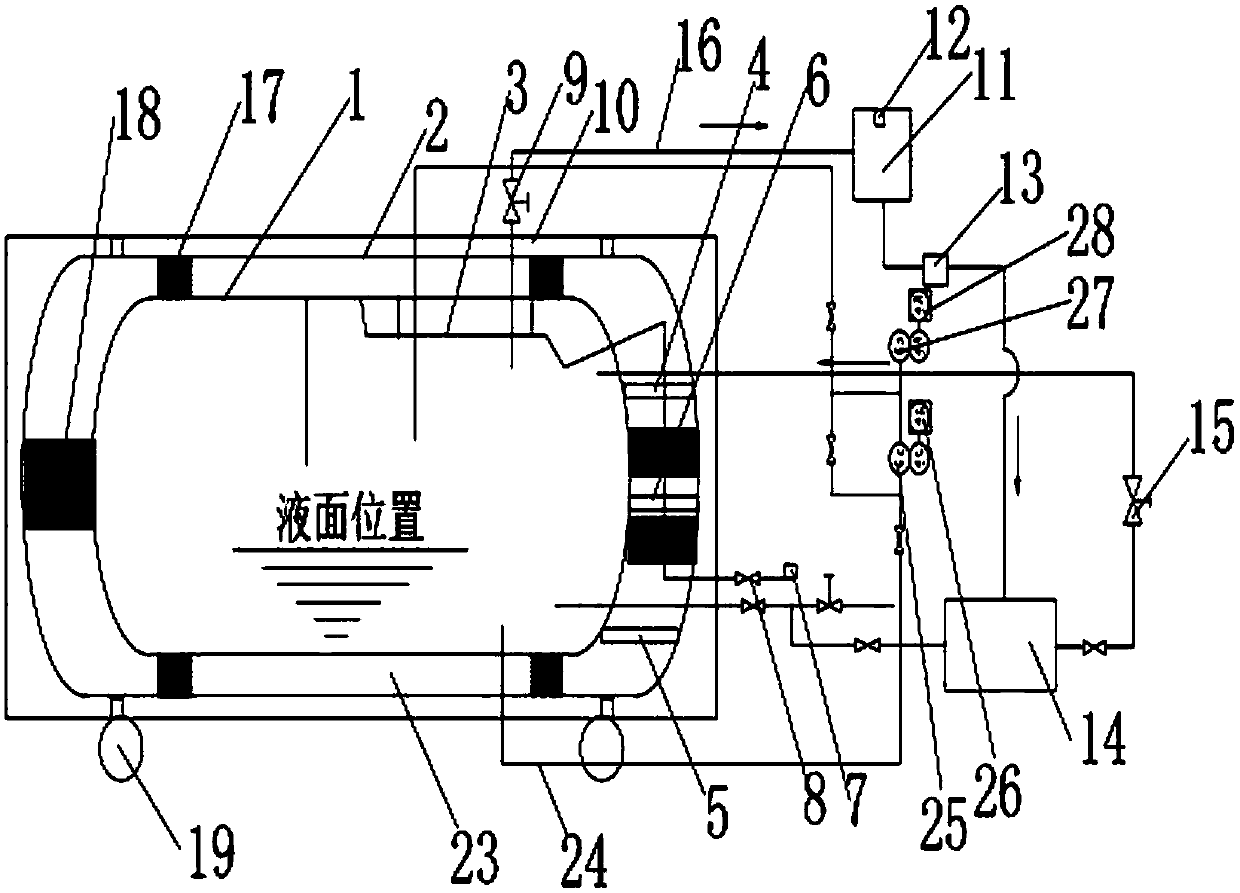

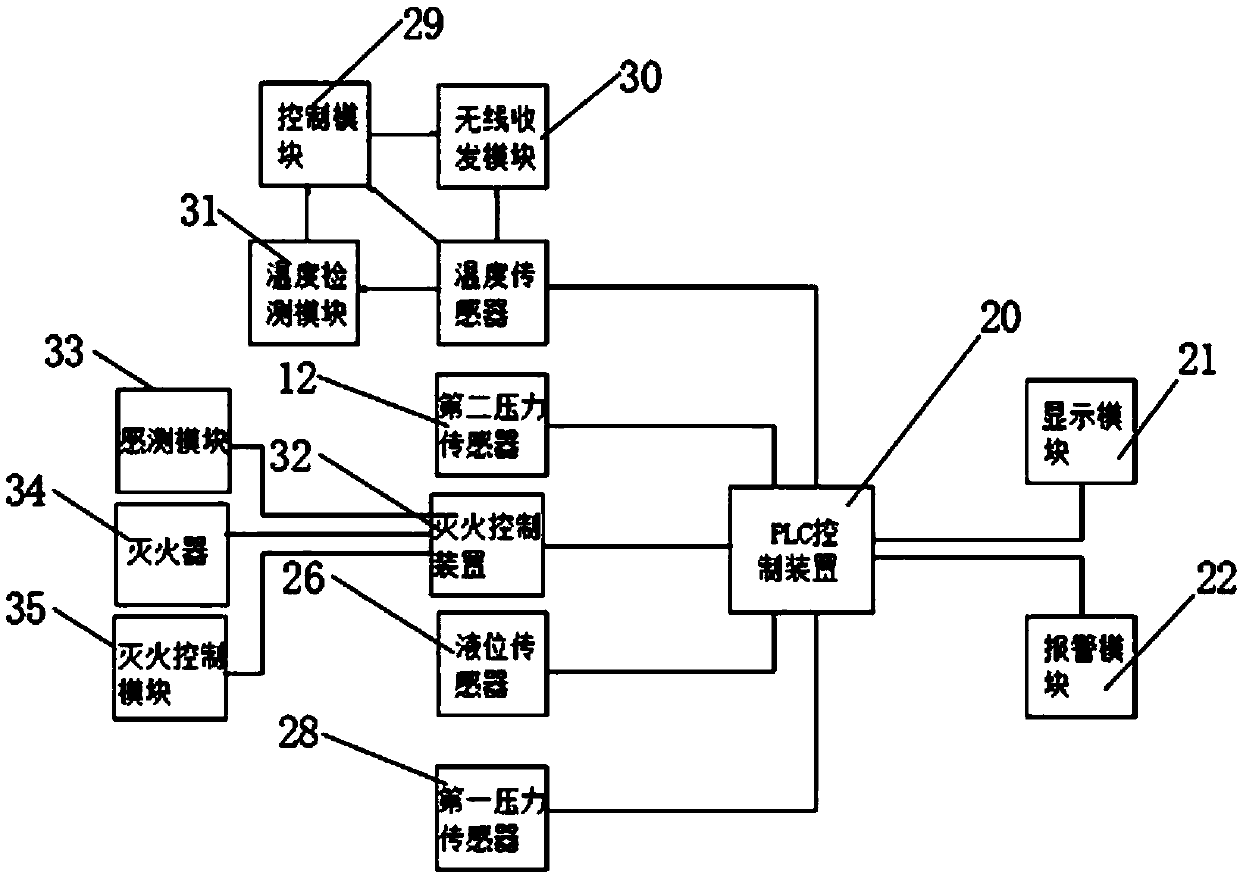

High-protecting-performance LNG low temperature storage tank convenient to move

InactiveCN107934260AImprove securityImprove monitoring accuracyLarge containersCornering forceTemperature difference

The invention belongs to the technical field of LNG low temperature storage tanks and particularly relates to a high-protecting-performance LNG low temperature storage tank convenient to move. A tankbody, a corner force bearing framework playing a protecting and hoisting role around the tank body, a liquid level monitoring device, a self-supercharging device, a leakage monitoring device, a PLC control device and a cold insulation device are included; universal wheels are arranged at the bottom end of the corner force bearing framework; the corner force bearing framework is arranged around thetank body, and plays the tank body protecting and hoisting role; the corner force bearing framework is provided with the universal wheels, movement is convenient, filling is easy and convenient, andthe safety risk is greatly reduced; the leakage monitoring device judges whether leakage happens or not by detecting the tank body temperature and outside environment temperature difference, the structure is simple, the monitoring precision is high, and the leaking risk is reduced; the liquid level monitoring device is used for monitoring the liquid level in the tank body, measuring is accurate, and the safety performance of the tank body is improved; the arrangement of the cold insulation structure facilitates keeping the low temperature environment in the tank body; and the overall structureis simple, design is reasonable, and the safety performance is high.

Owner:JIANGSU HANTONG SHIP HEAVY IND

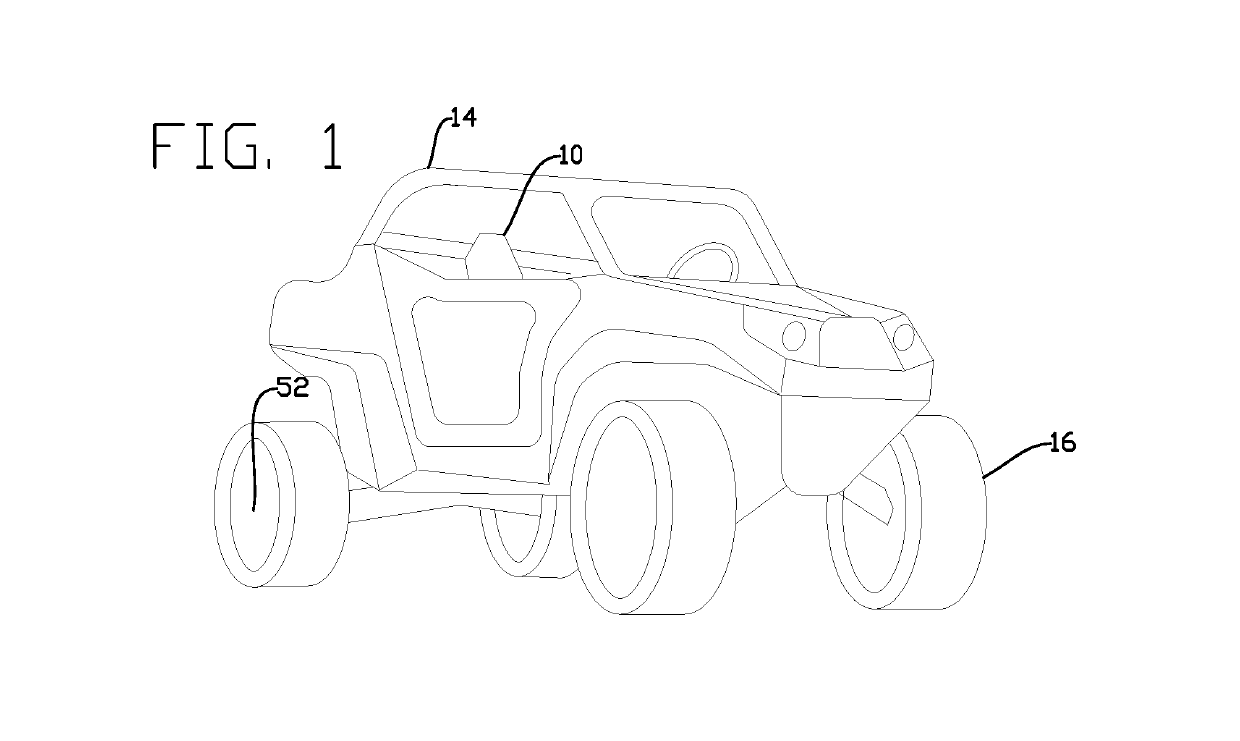

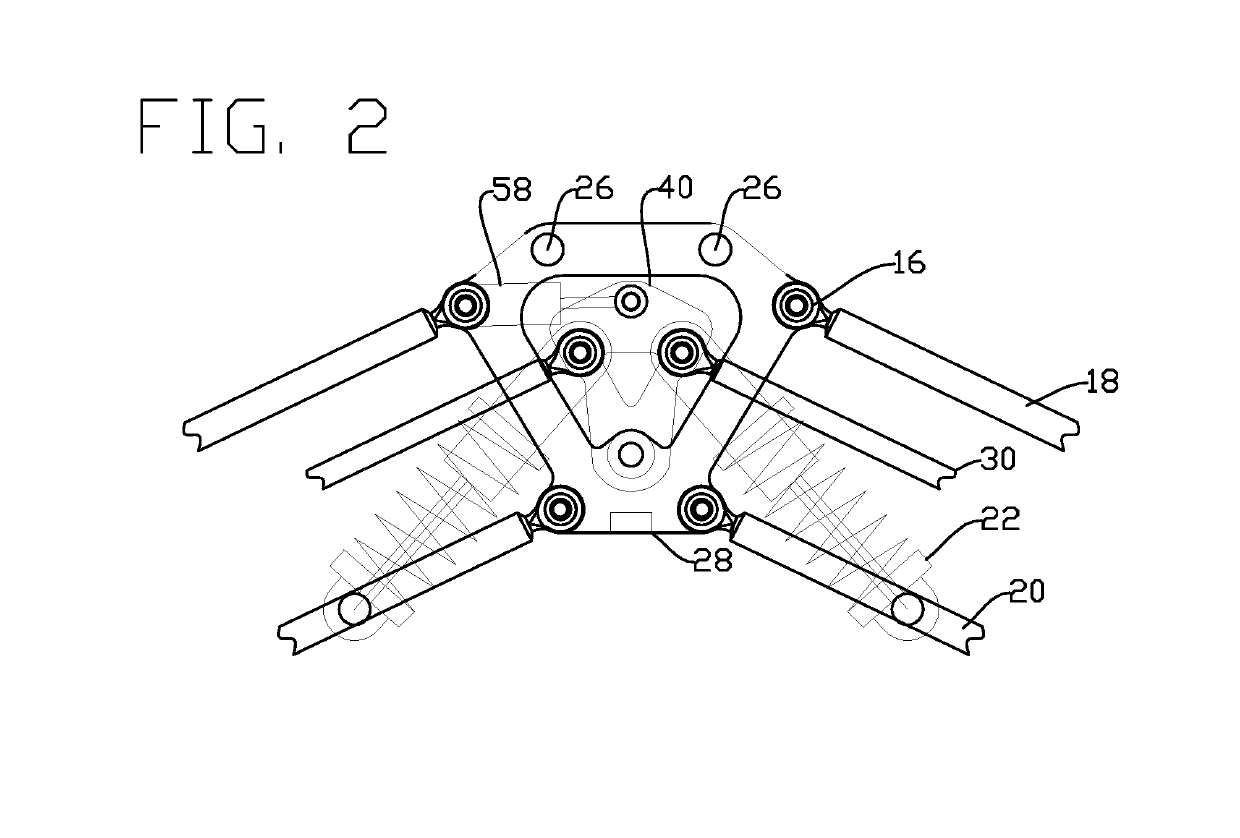

Roll induced four wheel steering vehicle

ActiveUS11358634B2Reduce centrifugal forceDeflectable wheel steeringResilient suspensionsDriver/operatorSteering wheel

Owner:MAINVILLE MICHAEL J

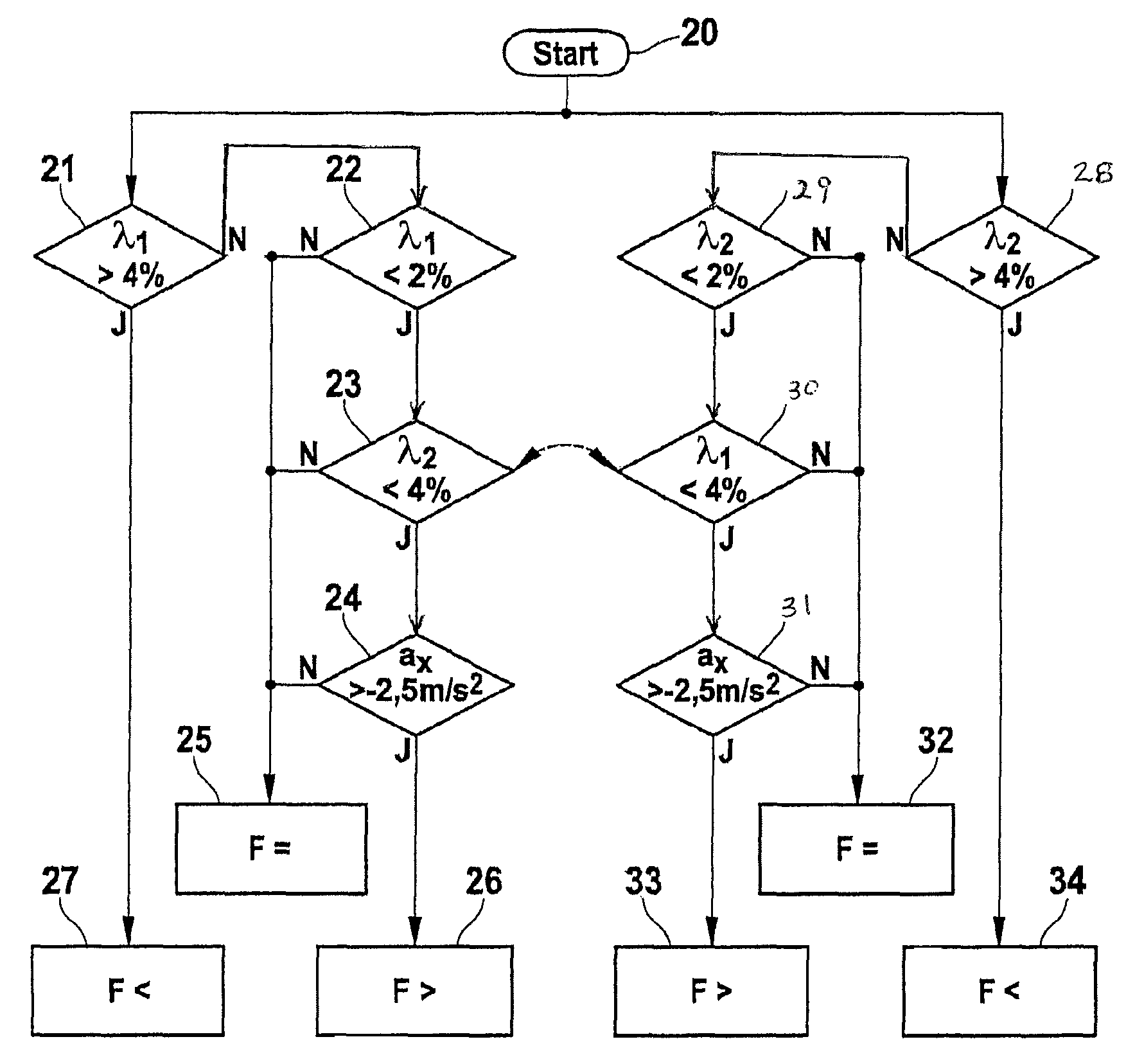

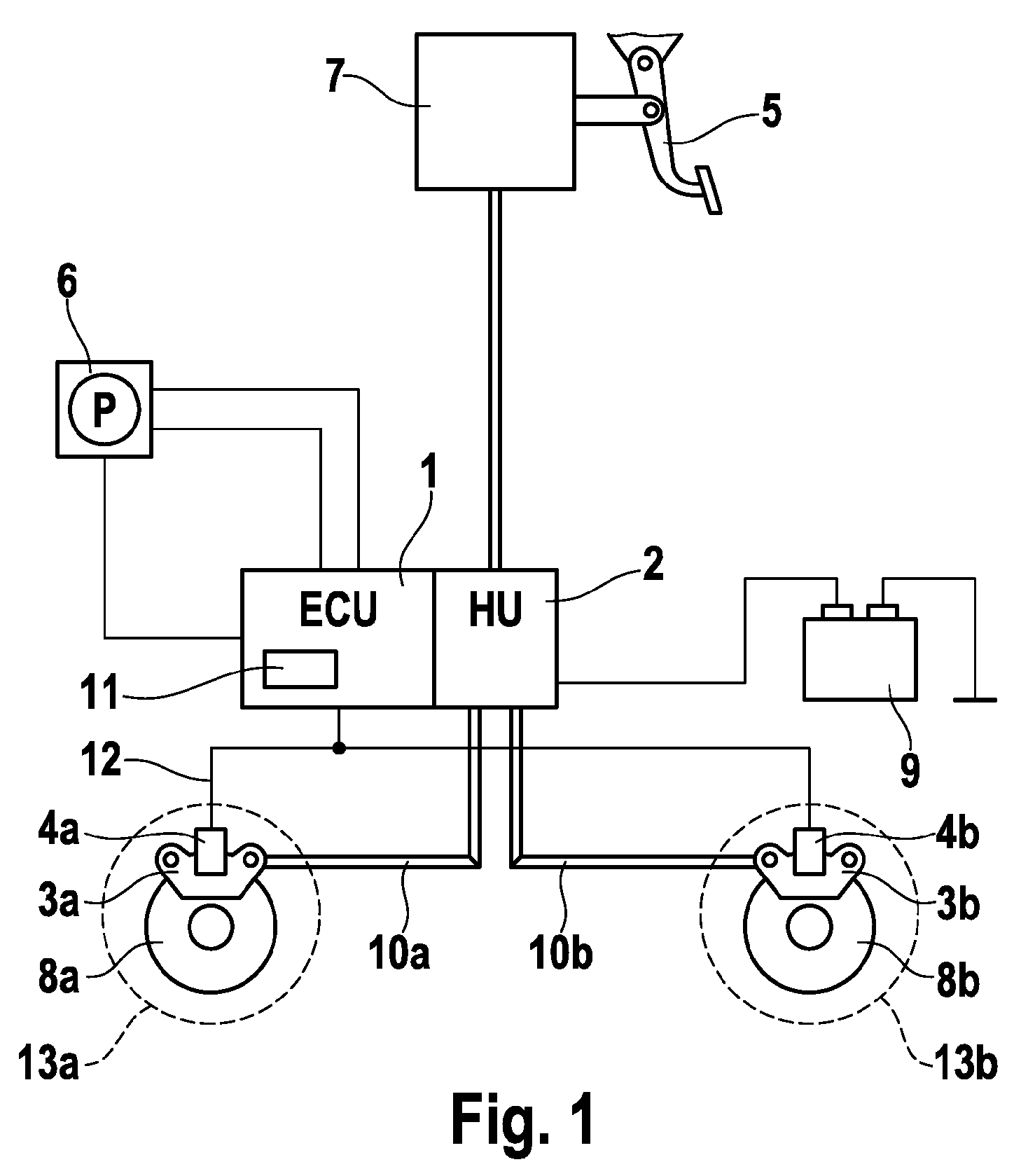

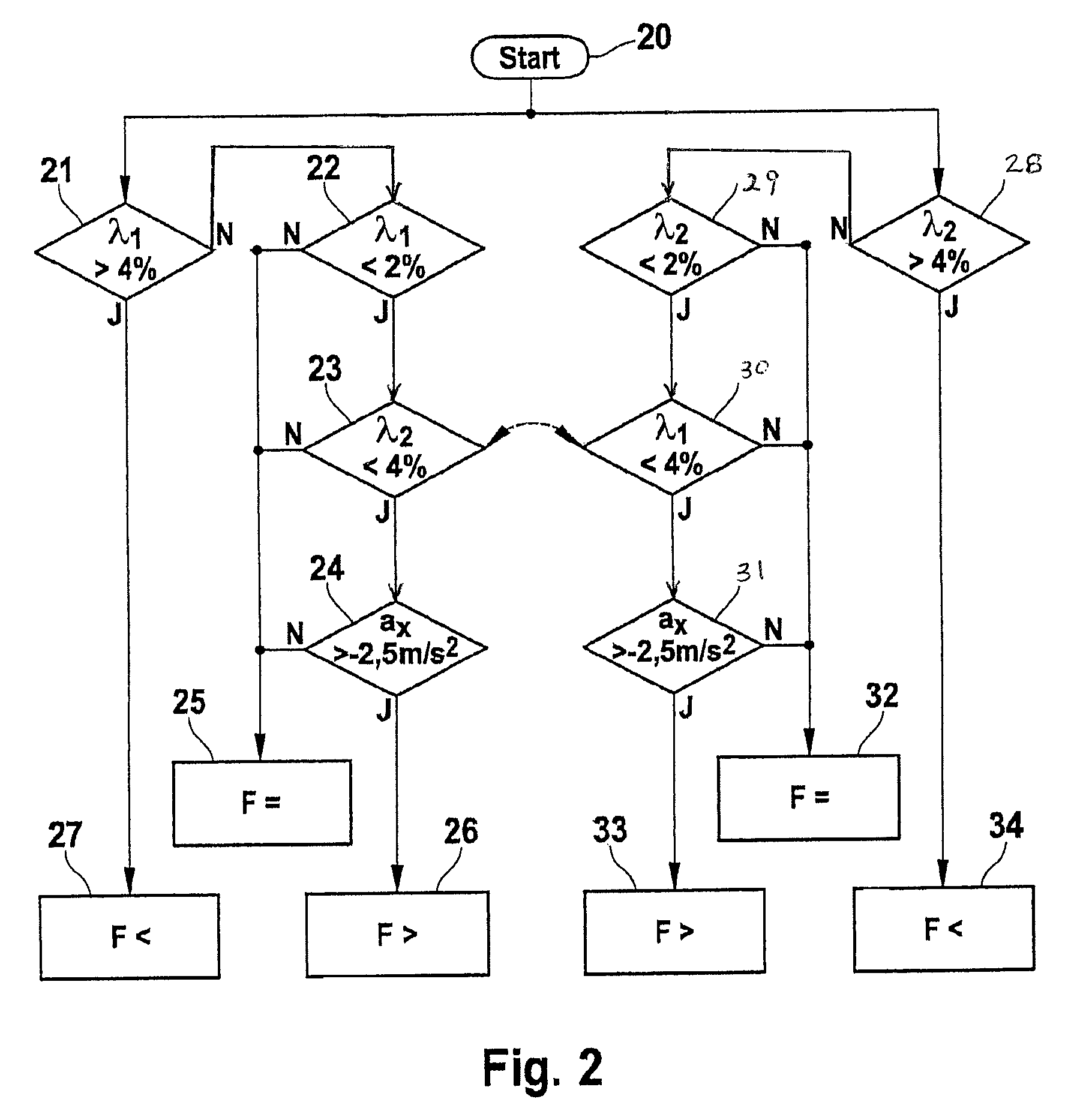

Automatic parking brake having a slip controller

ActiveUS8991943B2Increase braking powerPrevent lockMechanically actuated brakesDigital data processing detailsMobile vehicleCornering force

A system, method and device are provided which relate to an automatic parking brake for motor vehicles having multiple brake actuators and an operating element for operating the parking brake. In embodiment, the brake actuators are connected to a controller, which is able to perform a wheel-specific slip control when a critical driving situation occurs. For example, a simultaneous locking and the loss of the cornering force can be prevented by a controller. The controller is designed in such a way so that when controlling the slip on a first wheel, the slip (λ2) of a second wheel is taken into account.

Owner:ROBERT BOSCH GMBH

Tenoning clamping mechanism

InactiveCN104385395ASimple structureReduce in quantityWood mortising machinesWood slotting machinesCornering forceMechanical engineering

The invention relates to a tenoning clamping mechanism, and belongs to the technical field of wood industry processing. The tenoning clamping mechanism comprises a worktable frame, a pressing plate, a first air cylinder and a second air cylinder, wherein the worktable frame is used for supporting a tenoning workpiece, the pressing plate is integrally formed, and is used for providing upward pressing force and lateral pressing force for the tenoning workpiece, the first air cylinder and the second air cylinder are used for providing pressing power, the worktable frame is in an L shape, the longitudinal edge of the worktable frame is provided with a movable area, an air cylinder shaft of the first air cylinder transversely penetrates through the movable area and is connected with the pressing plate, the second air cylinder is arranged at the longitudinal edge of the worktable frame, an air cylinder shaft of the second air cylinder longitudinally acts on the shaft of the first air cylinder, and the first air cylinder and the pressing plate are moved along the longitudinal axis direction of the movable area. The tenoning clamping mechanism has the advantages that the structure is simple; by arranging the integral forming pressing plate, the number of pressing plates is reduced, the operation of operators is convenient, the upward pressing force, lateral pressing force and edge and corner force are simultaneously provided, the tenoning workpiece is clamped, and the tenoning accuracy is provided.

Owner:安吉胜达竹木制品有限公司

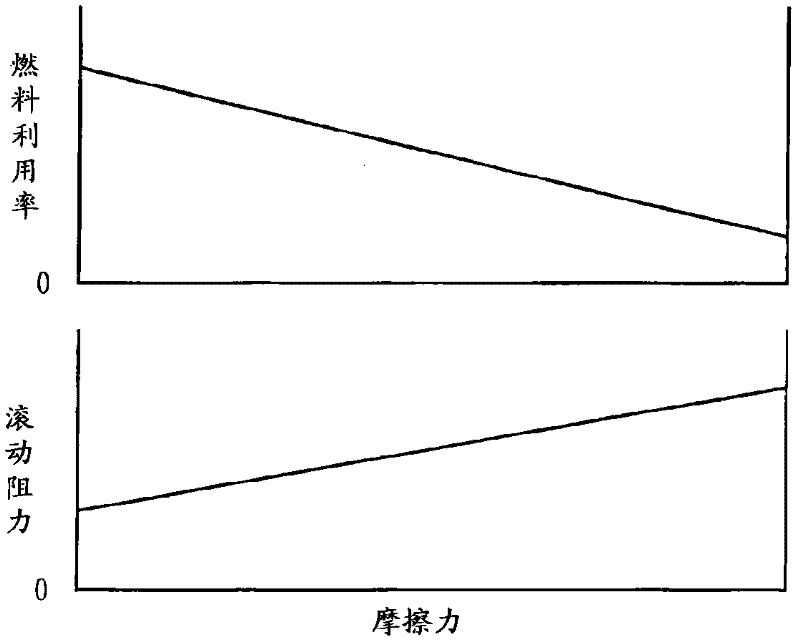

low fuel consumption vehicle

InactiveCN102300728AImprove cornering performanceSuppresses the decrease in driving feelingInflatable tyresTyre tread bands/patternsCamber angleCornering force

The fuel efficiency can be improved, and the braking performance and cornering performance can be improved. A vehicle body (11), front wheels and rear wheels rotatably arranged with respect to the body (11), and a wheel drive unit (31) arranged between the rear wheels and the body (11) and imparting a camber angle to the rear wheels , 32). The coefficient of friction between the tires of the rear wheels and the road surface is smaller than the coefficient of friction between the tires of the front wheels and the road surface. Since the coefficient of friction between the respective tires of the rear wheels and the road surface is smaller than that between the respective tires of the front wheels and the road surface, fuel efficiency can be improved. In addition, since the coefficient of friction between each tire of the front wheels and the road surface is large, acceleration and braking performance can be sufficiently improved. In addition, since the rear wheel is provided with a camber angle, a lateral force can be generated, a lateral resistance force can be generated, and turning performance can be improved.

Owner:EQUOS RES

Roll induced four wheel steering vehicle

The roll induces four wheel steering vehicle employs a frame system to protect the driver and serves as an attachment point for, independent suspension links pivotally connect to the wheel assemblies enabling four wheel independent suspensions. A mechanically manipulated centrally mounted steering and suspension pivot, provides both steering control and suspension attachment for the shock and spring. The device is controlled by the driver using typical steering wheel and pedal movement. Steering movement by the driver produces proportionally appropriate camber, steering angle, and roll simultaneously. The invention provides a feeling of integration with the vehicle as the driver rolls into turns with the vehicle, while minimizing fatigue caused by the continuous resistance to centrifugal cornering forces.

Owner:MAINVILLE MICHAEL JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com