Patents

Literature

221results about How to "Improve rolling stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

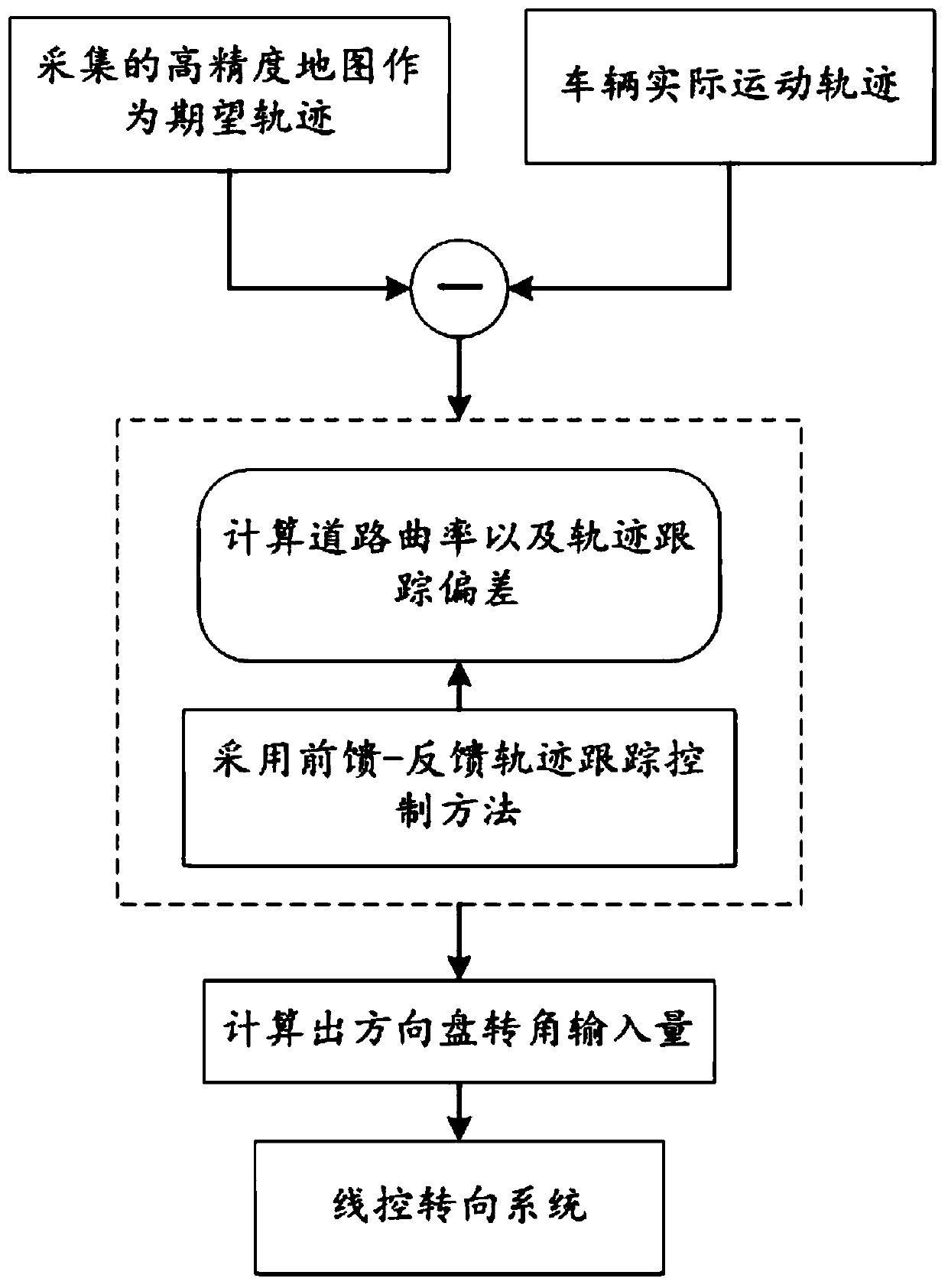

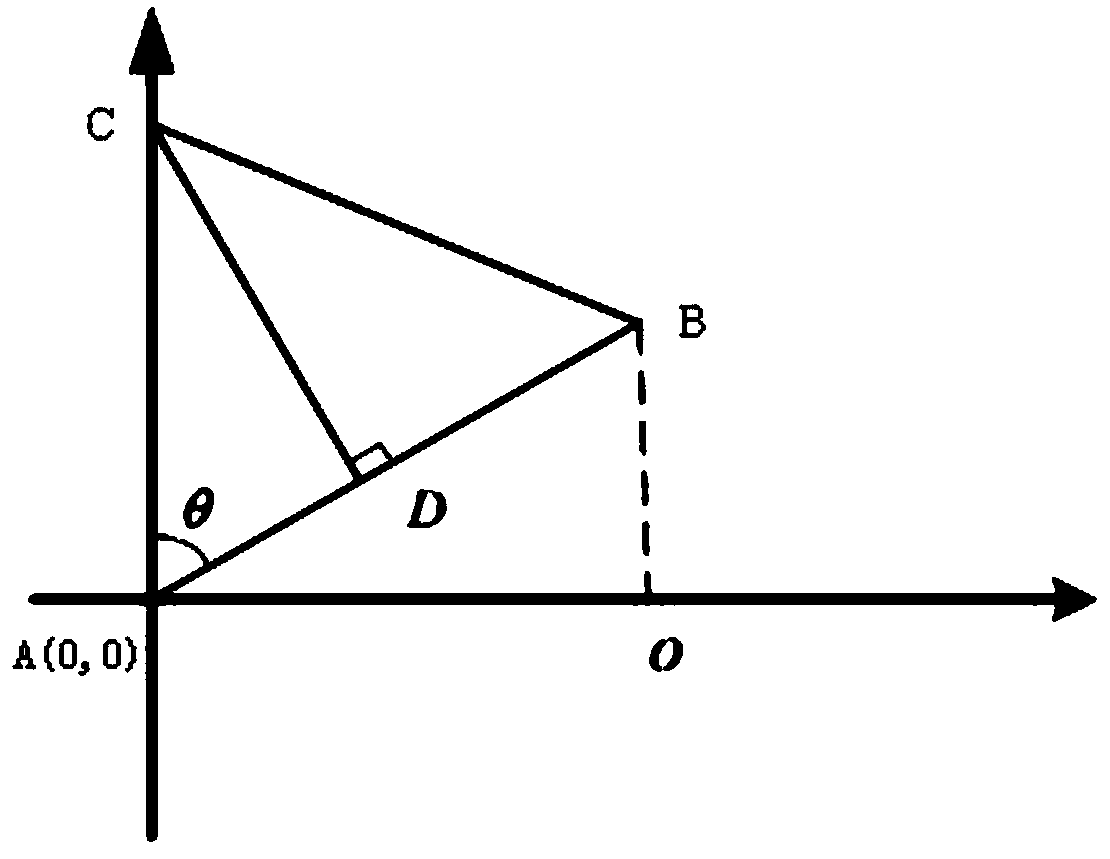

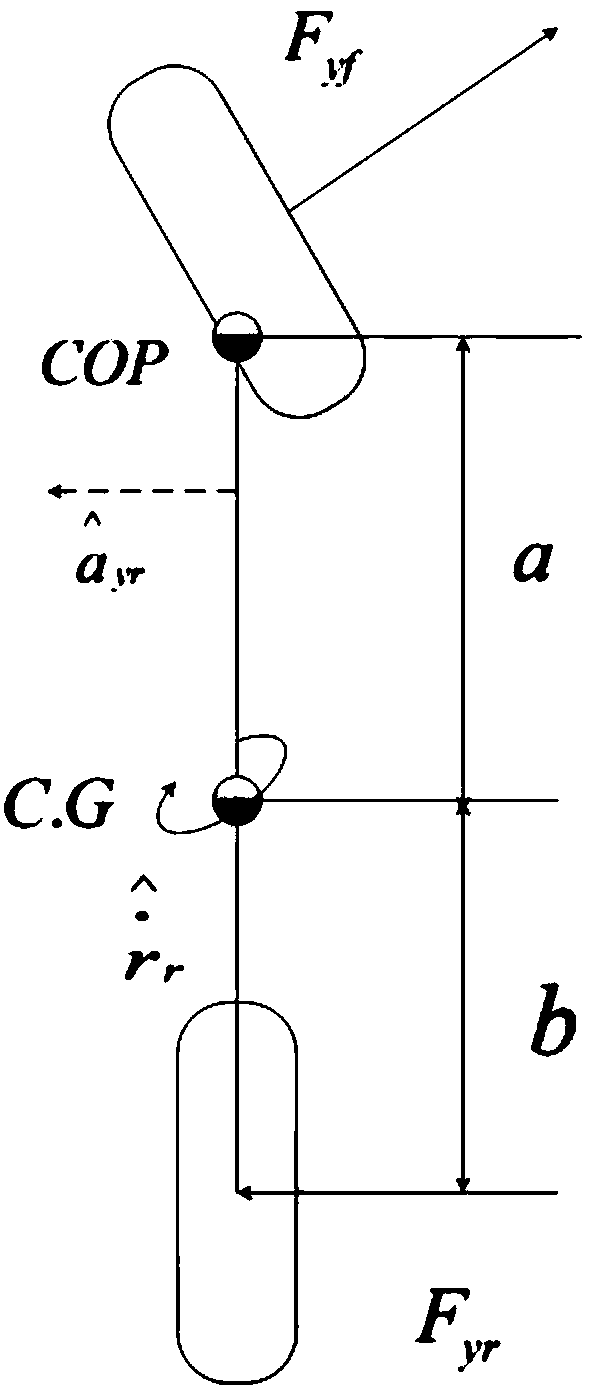

Trajectory tracking control method used for driverless vehicle

InactiveCN108622104AImprove rolling stabilityEliminate the effect of lateral deviation accelerationSteering partsExternal condition input parametersSteering wheelCornering force

The invention discloses a trajectory tracking control method used for a driverless vehicle. The method includes the following steps that the current position point of a vehicle body is confirmed according to a reference trajectory; a matching point nearest to the current position point of the vehicle is found, and the road curvature of the nearest matching point is obtained according to a two-point curvature obtaining method; according to the current position point of the vehicle and the nearest matching point, a trajectory tracking error is obtained through calculation and comprises a transverse error and a head pointing error; a dynamic model feeding back cornering force on the basis of front wheels is established, and the optimal feedback control rate is obtained by the adoption of an LQR control algorithm; and the cornering force of the front wheels is determined, a front wheel slip angle is obtained on the basis of a reverse tire model, and then the steering wheel angle controlledquantity is obtained and issued to a steering-by-wire system to achieve trajectory tracking control. By the adoption of the method, the stability of trajectory tracking control of the driverless vehicle is improved, the trajectory tracking accuracy is improved, the tire slip angle is restrained, and the possibility that the tire force of the vehicle is saturated under an extreme working conditionand therefore the vehicle loses stability is avoided.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

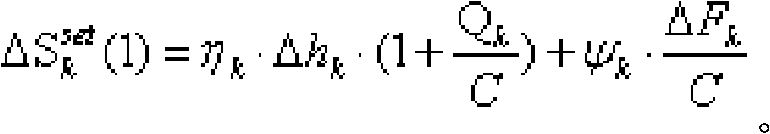

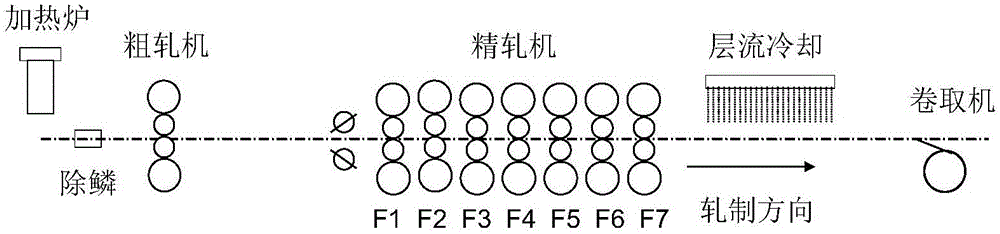

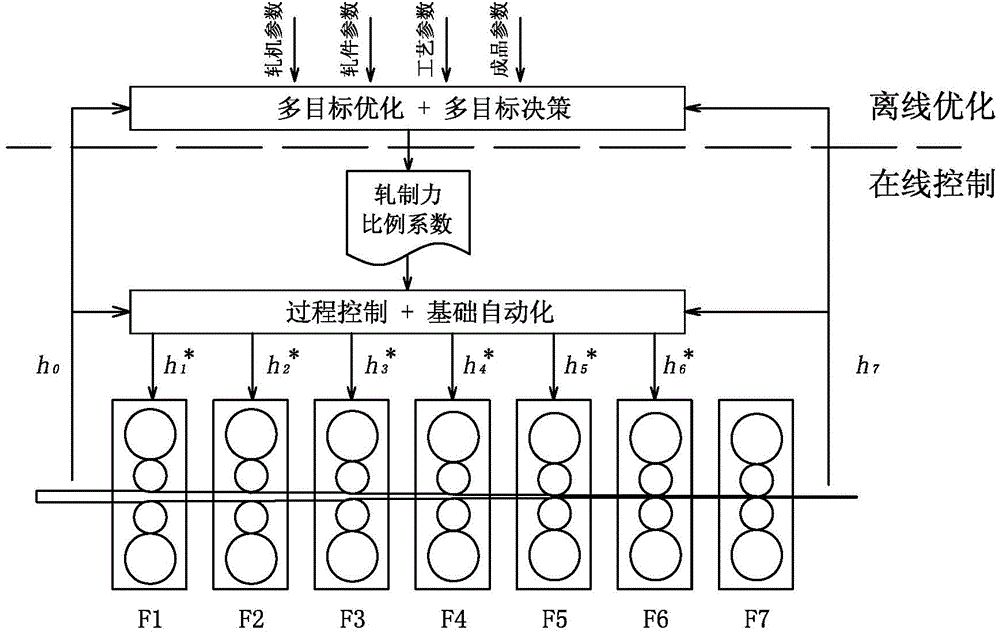

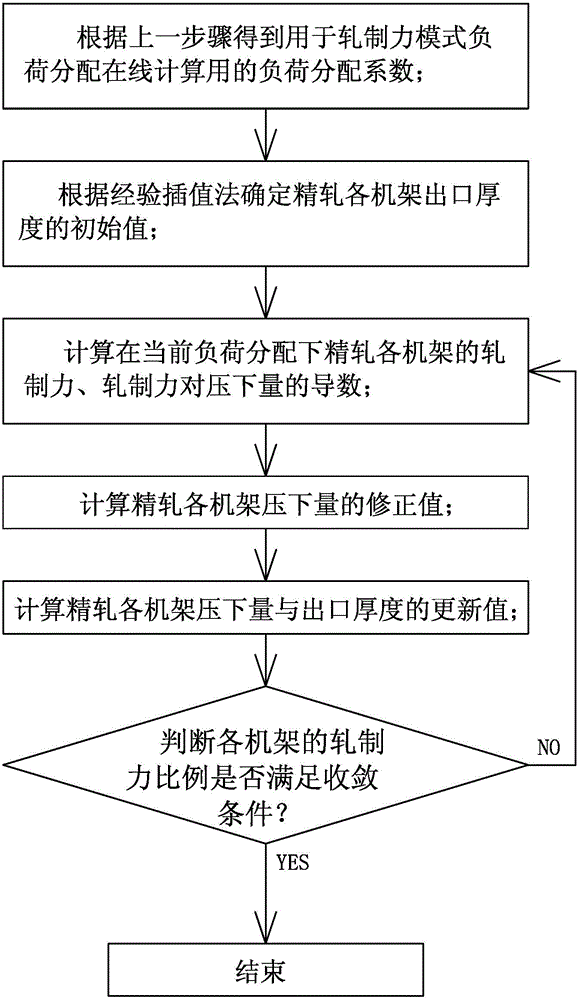

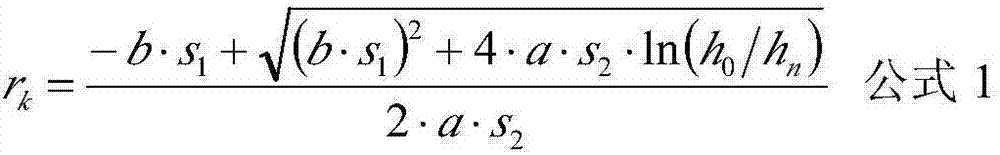

Method for setting load distribution of finish rolling band steel

ActiveCN102728624AHigh precisionImprove rolling stabilityRoll force/gap control deviceMetal rolling arrangementsLoad distributionMaterials science

The invention relates to a method for setting the load distribution of finish rolling band steel, belonging to the field of production control of finish rolling band steel, and solving the problems that the rolling force proportion of stands is large in fluctuation when the rolling condition is changed under the pressed-down distribution mode, and the thickness distribution of the stands is large in fluctuation when the rolling force model is large in deviation under the rolling force distribution mode. According to the invention, the pressed-down distribution mode and the rolling force distribution mode are combined; the rolling force distribution result is restricted by the distribution range determined by pressed-down distribution; the requirement that the rolling force of stands is decreased according to proportion is met while the thickness distribution fluctuation of the stands is reduced; the results of two distribution modes are gradually consistent, and the iterations are gradually reduced by learning a pressed-down rate learning table when the deviation of the rolling force model is small; and the fluctuation range of the pressed-down rate of the stands is effectively controlled through the pressed-down distribution amplitude limit when the deviation of the rolling force model is large. By adopting the method, the advantages of the two modes are combined and the shortages are overcome, so that the rolling schedule setting precision and the rolling stability of the finish rolling band steel are effectively improved.

Owner:BAOSHAN IRON & STEEL CO LTD

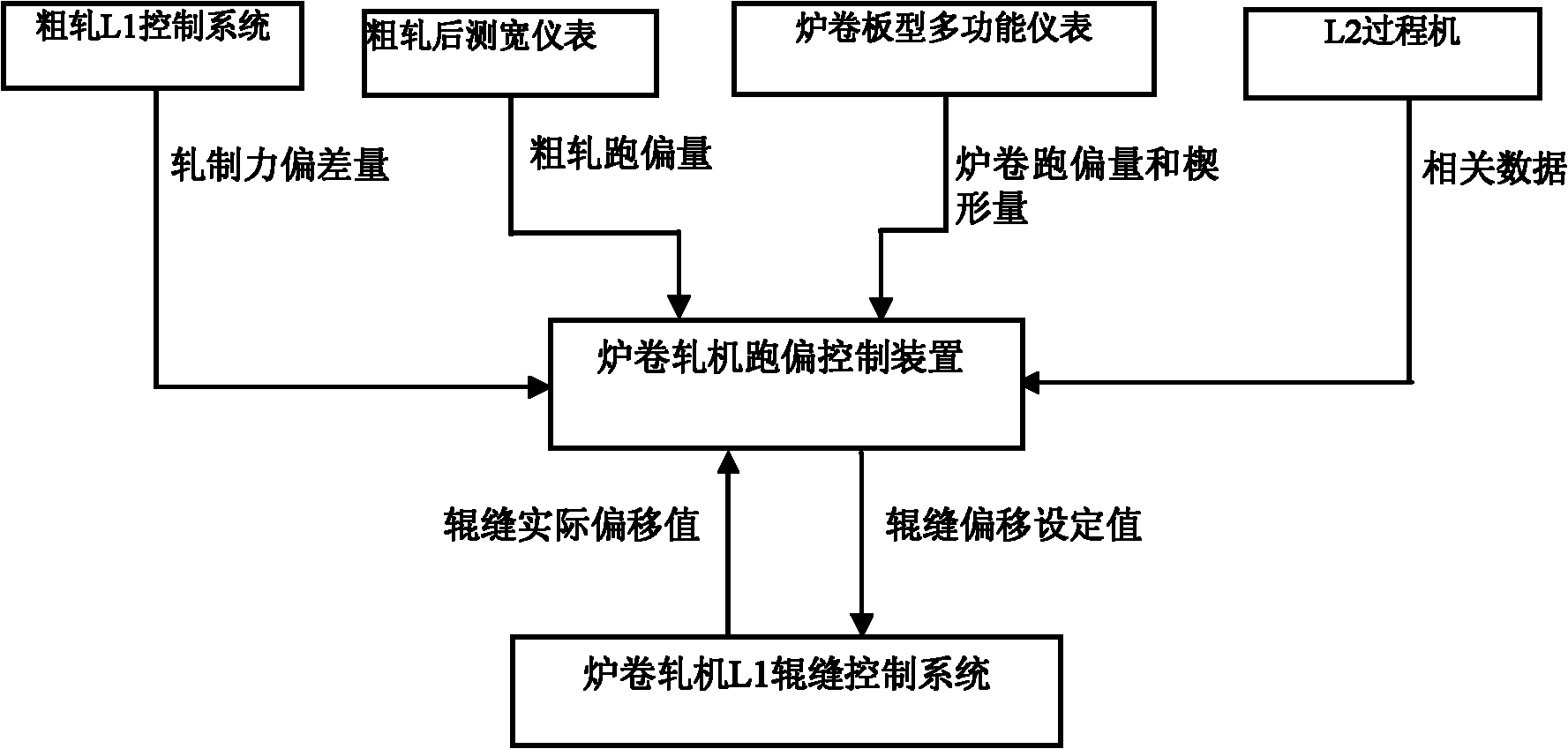

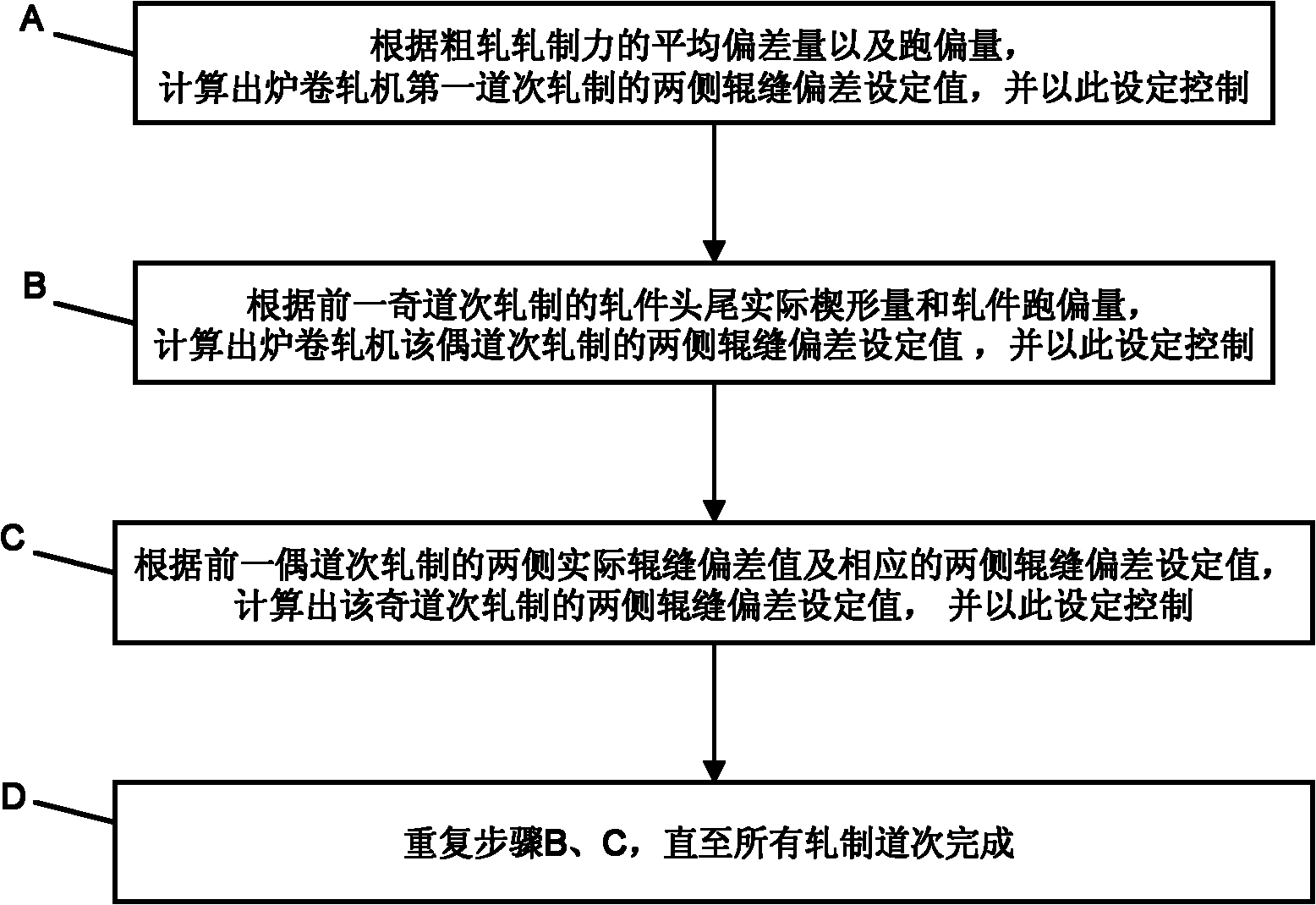

Steckel mill rolled piece head-and-tail deviation control method

InactiveCN102641903AImprove rolling stabilityPrevent set controlRare end control deviceRoll force/gap control deviceStrip millStrip steel

The invention discloses a steckel mill rolled piece head-and-tail deviation control method which comprises the following steps that: based on existing equipment configuration, different modes are distinguished by integrating the rolling information of a steckel mill according to the rolled piece deviation and rough rolling force in the final step of rough rolling, then the deviation controlled by roll gaps on both sides of the steckel mill is determined, and roll gap setting control for preventing deviation is carried out. Through the method, the hand-and-tail deviation of strip steel can be reduced, shut-down accidents caused by the deviation of strip steel can be prevented, and the rolling stability of the steckel mill can be improved.

Owner:BAOSHAN IRON & STEEL CO LTD

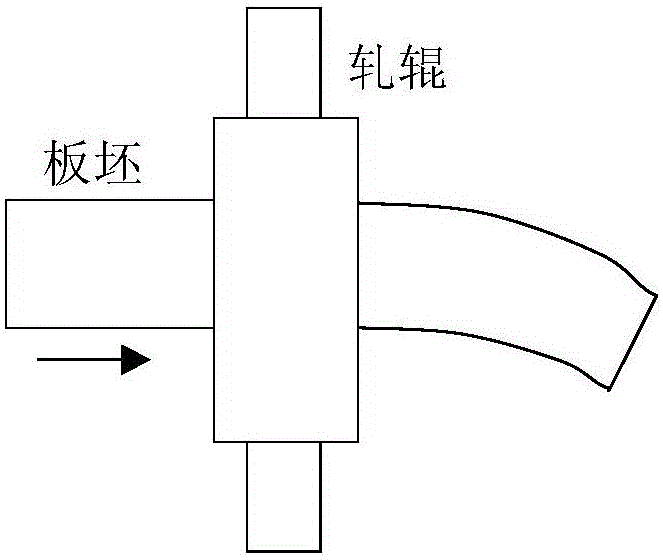

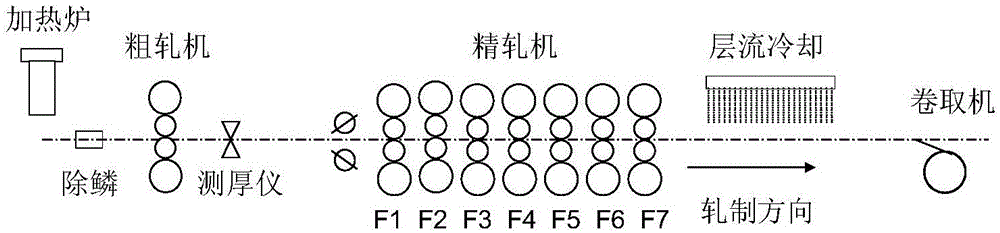

Control method of rolling deflection of hot-rolled strip steel

ActiveCN106475424AImprove rolling stabilityImprove shape qualityRoll force/gap control deviceStrip millEngineering

The invention relates to a control method of rolling deflection of hot-rolled strip steel. The control method comprises the following steps that horizontal thickness distribution of an intermediate billet is measured in a real-time manner at a rough rolling outlet; and the wedge compensation of a finishing roller gap is calculated according to the horizontal thickness measured data of the roughly rolled intermediate billet, and the rolling reductions of two sides of finishing mills are reasonably set. Steel scraps generated due to rolling deflection are decreased, and the hot rolling stability and the strip shape quality of a strip steel product are improved. The problem that since the roughly rolled intermediate billet is wedged, the finish rolling deflection of the strip steel is caused is solved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

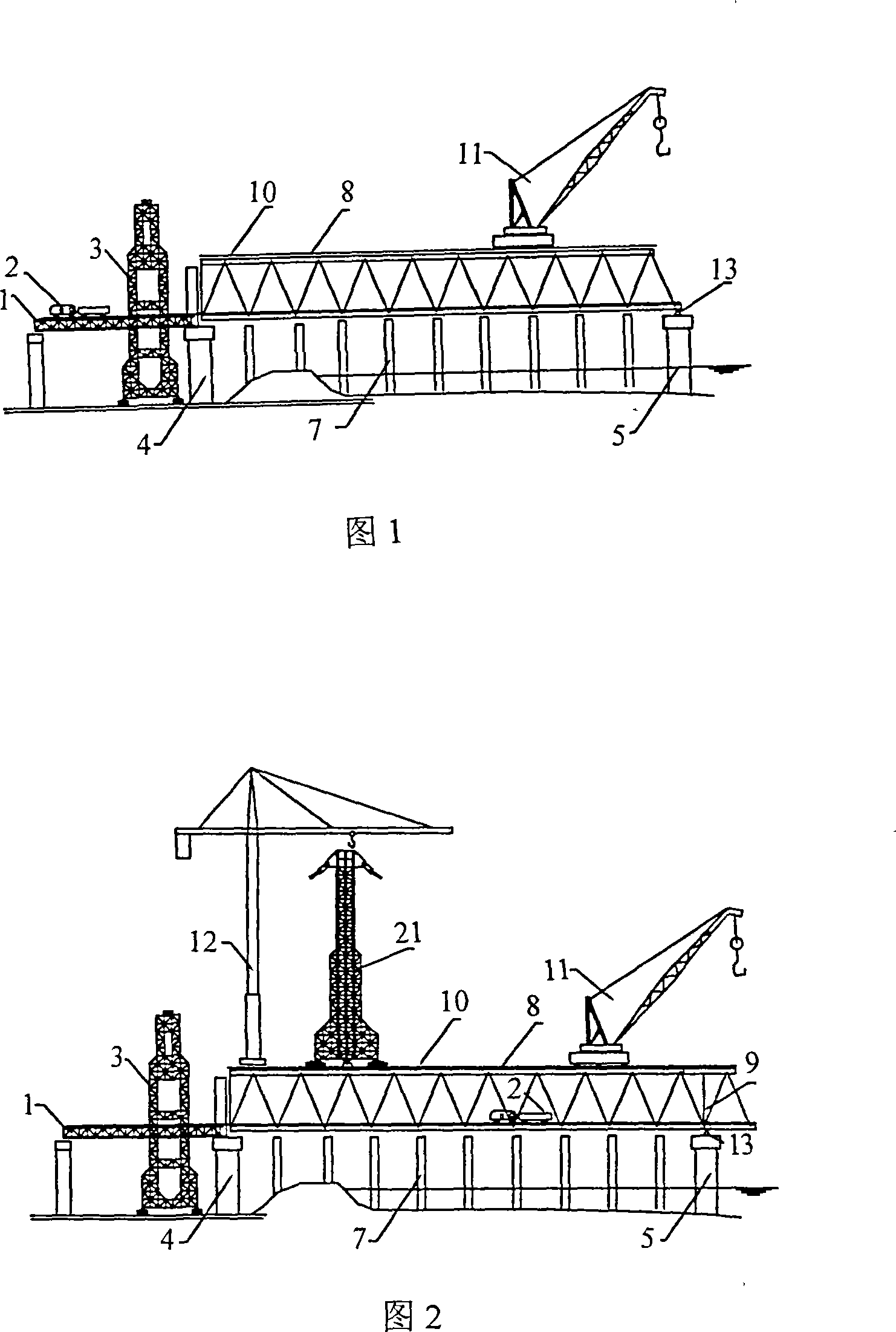

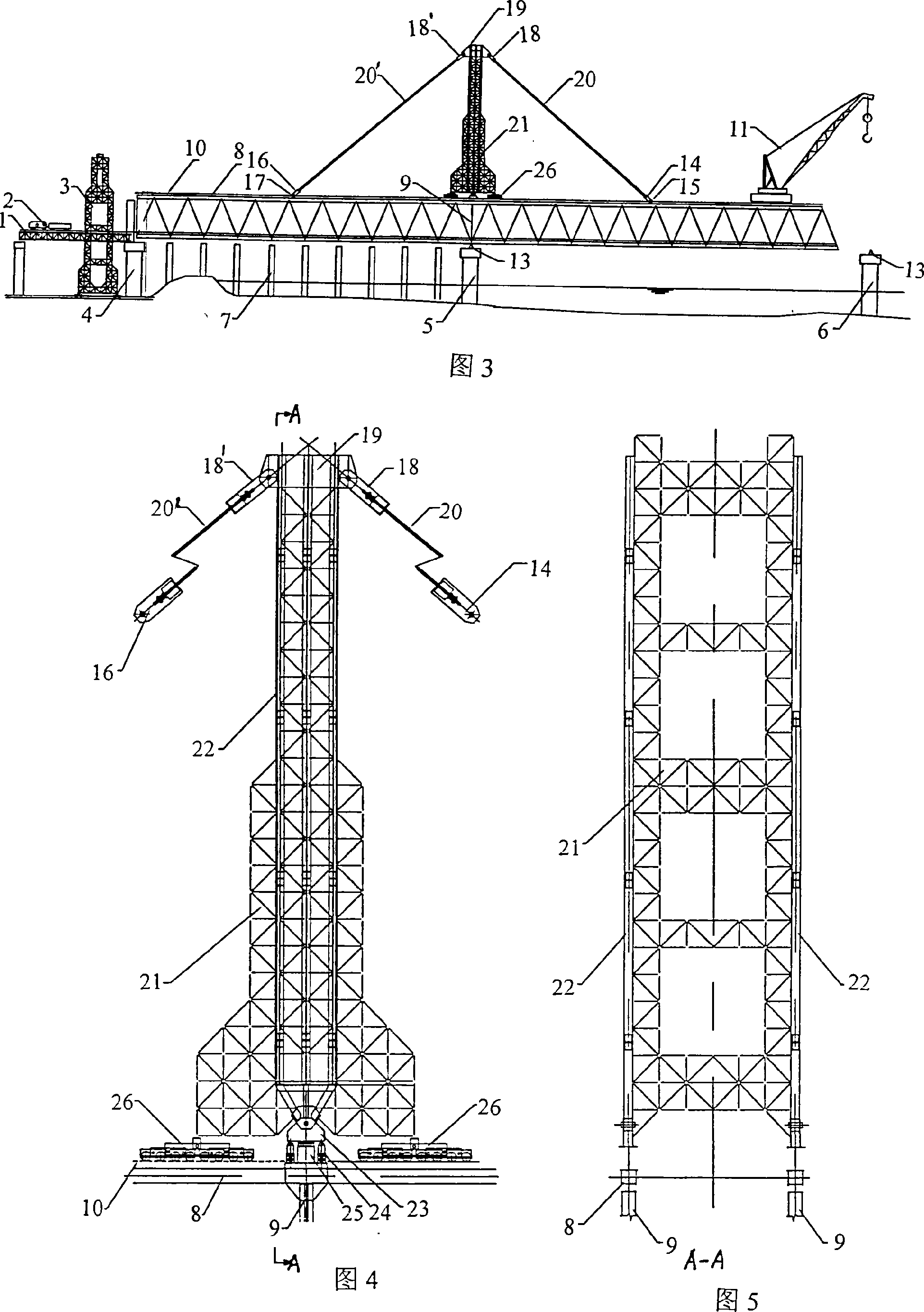

Method and system for erecting steel trusses by stay cable auxiliary complete cantilever

ActiveCN101139821AShort construction period for temporary structuresLess investmentTruss-type bridgeBridge erection/assemblyEngineeringPush ups

The invention is a method of erecting all-cantilever erected steel truss beams assisted by diagonal ropes, as well as a relevant system. The method utilizes a bearer cable tower combined with a steel structure center tower column with diagonal ropes; install a tower-type crane on the top face of the steel truss beam end at the first hole with an overhead bridge crane in a ground craning station; anchor cases below the front and rear diagonal ropes are connected with side plates at steel beam nodes, and after that, directly lift the tower to apply pre-tension on the diagonal ropes; perform all-cantilever erection for the front steel truss beam. After finishing erection of the orifice steel beam, complet load removal from the diagonal ropes with a method of pushing up the temporary seat for the front pier and lowering back a pushing and craning device between upper and lower seats of the bearer cable tower. The system comprises an auxiliary tower truss, a tower center vertical column, the upper and lower support seats, the front and rear diagonal ropes, the upper and lower anchor cases for diagonal ropes, a tower top anchor beam and a walking mechanism. The invention has the following advantages: For large-span continuous steel truss beams, utilize a special device additionally to erect multi-span steel truss beams, so as to reduce internal stress in installation of steel truss beam members, lower end deflection of the front extension arm, and increase the inclination stability of a steel truss beam on the extension arm. Meanwhile, the invention can low investment and short construction period and provide very convenient operation.

Owner:THE FOURTH ENG CO LTD OF CHINA ZHONGTIEMAJOR BRIDGE ENG GRP

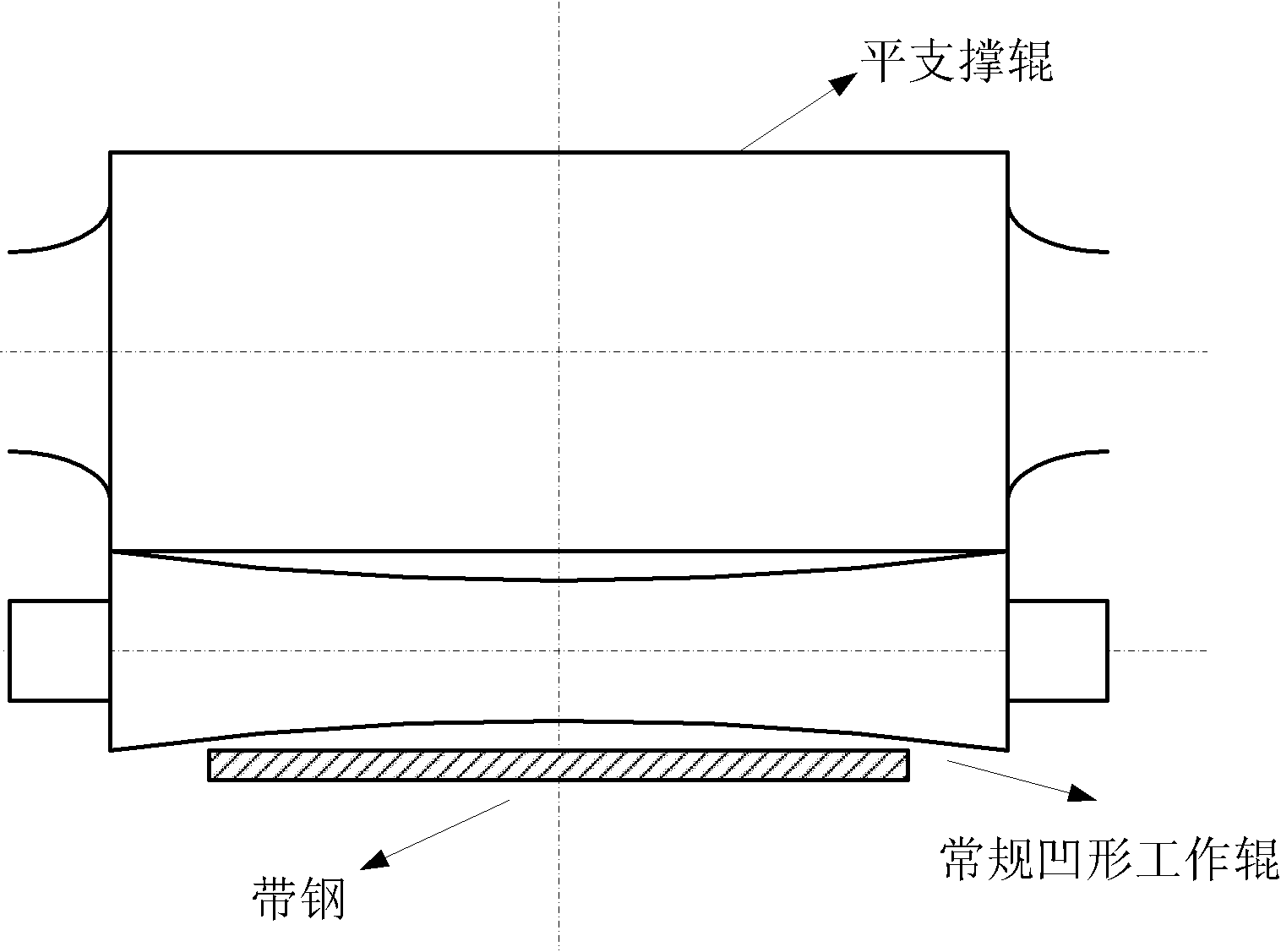

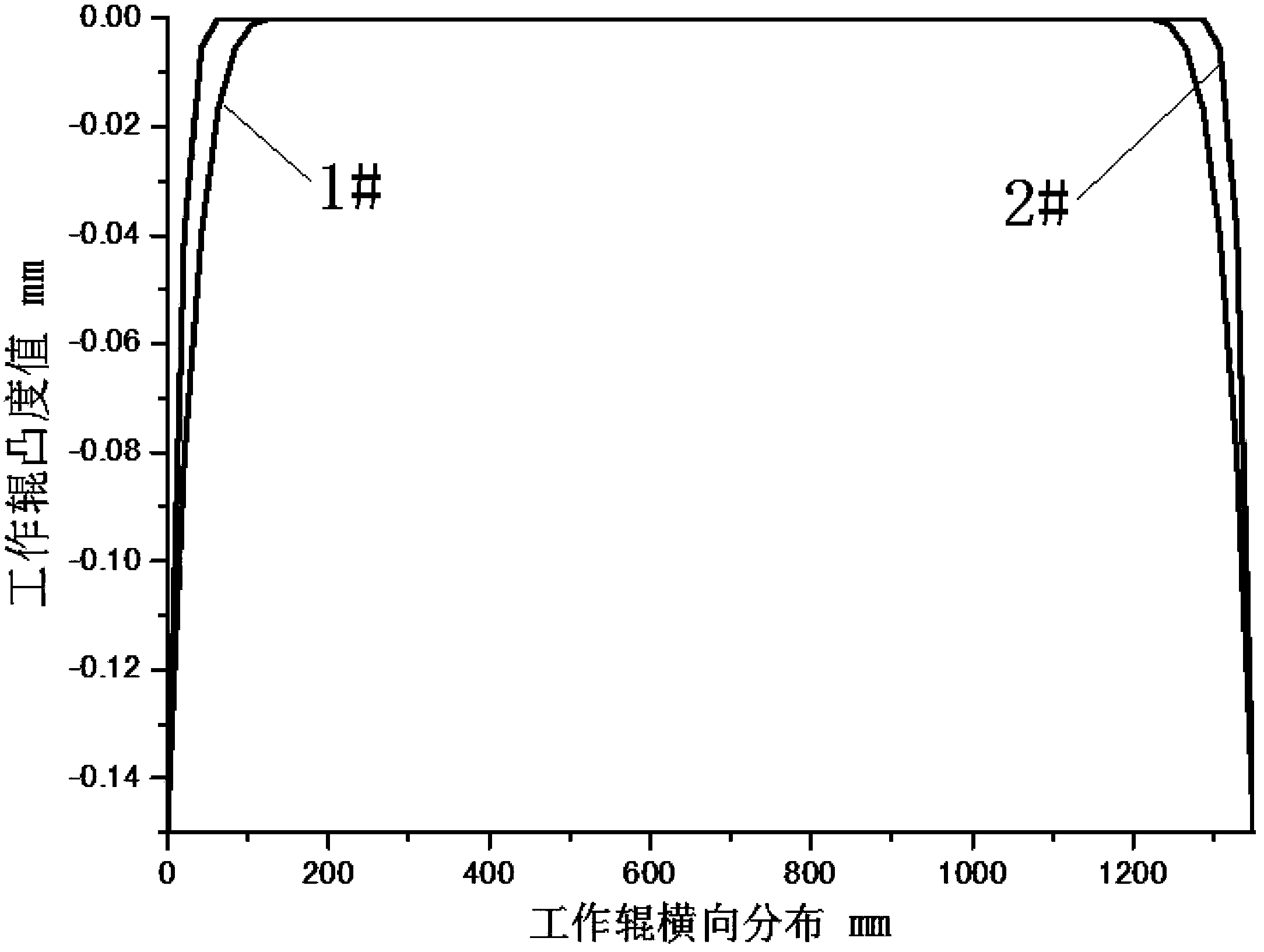

Configuration method of medium and heavy plate roll system with consideration of both rolling stability and cross-section shape

InactiveCN102009067ASuppression of rolling instabilityImprove controlCounter-pressure devicesRollsWork rollEngineering

The invention relates to a configuration method of a medium and heavy plate roll system with consideration of both rolling stability and cross-section shape, in particular to a fit way between a working roll and a supporting roll in different periods of service life of medium and heavy plate supporting roll. By comprehensively considering the impacts of a roll gap on the rolling stability and influencing factors of cross-section shape control, the invention provides the following scheme: the six-time polynomial curve supporting roll with big roll diameter at the middle and small roll diameter at two ends is adopted on a medium and heavy plate mill, and the six-time polynomial curve working roll with the small roll diameter at the middle and the big roll diameter at two ends is adopted for matching with the supporting roll; and the six-time polynomial curve working roll with the big roll diameter at the middle and the small roll diameter at two ends is adopted for matching with the supporting roll after abrasion during the later stage of the service life of the supporting roll. The configuration method of the roll system can solve the contradiction between the stability of medium and heavy plate rolling and the control of the cross-section shape, and the field application can obtain significant effects.

Owner:UNIV OF SCI & TECH BEIJING

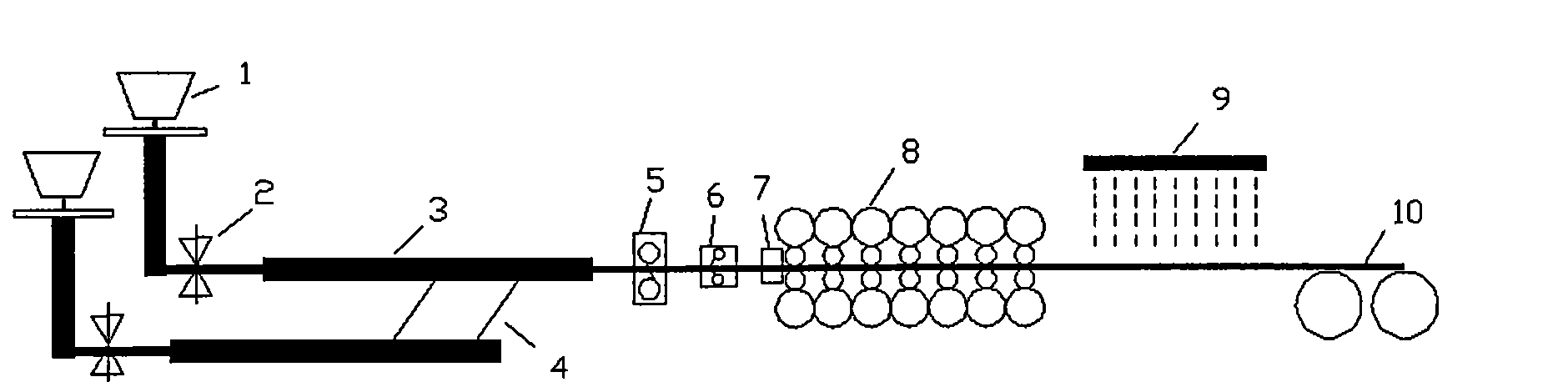

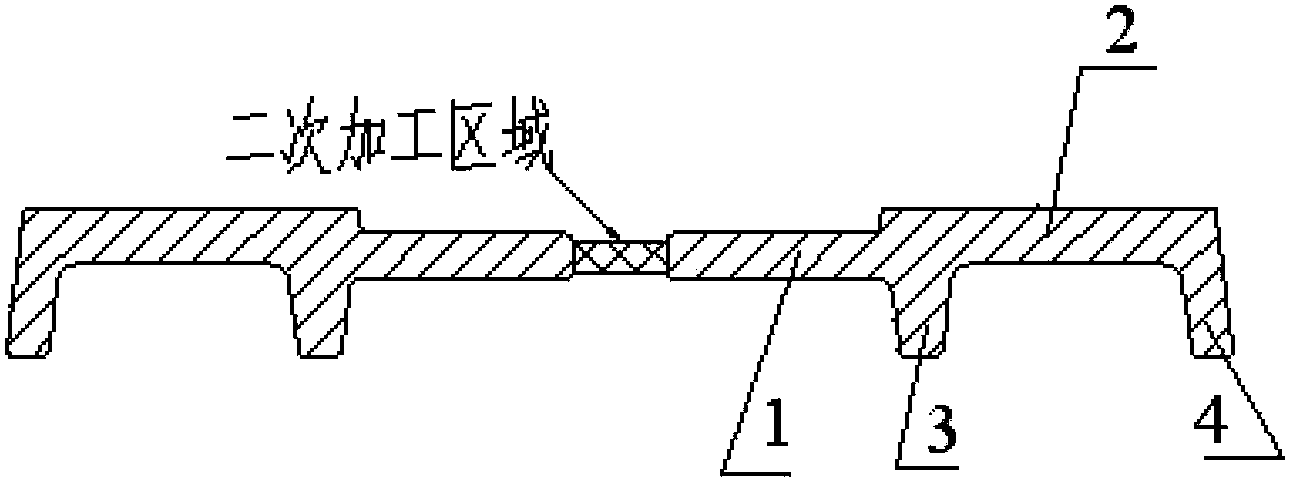

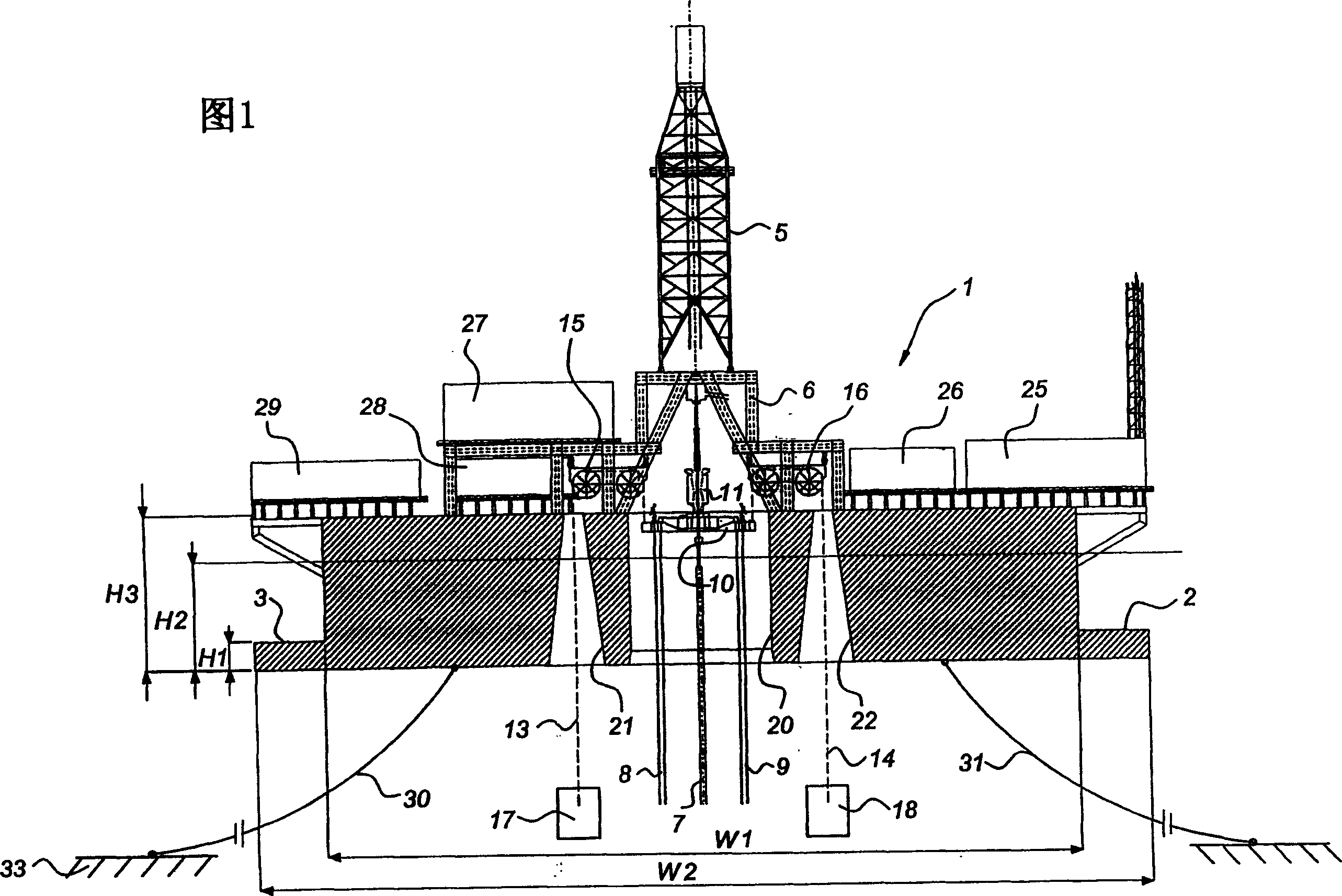

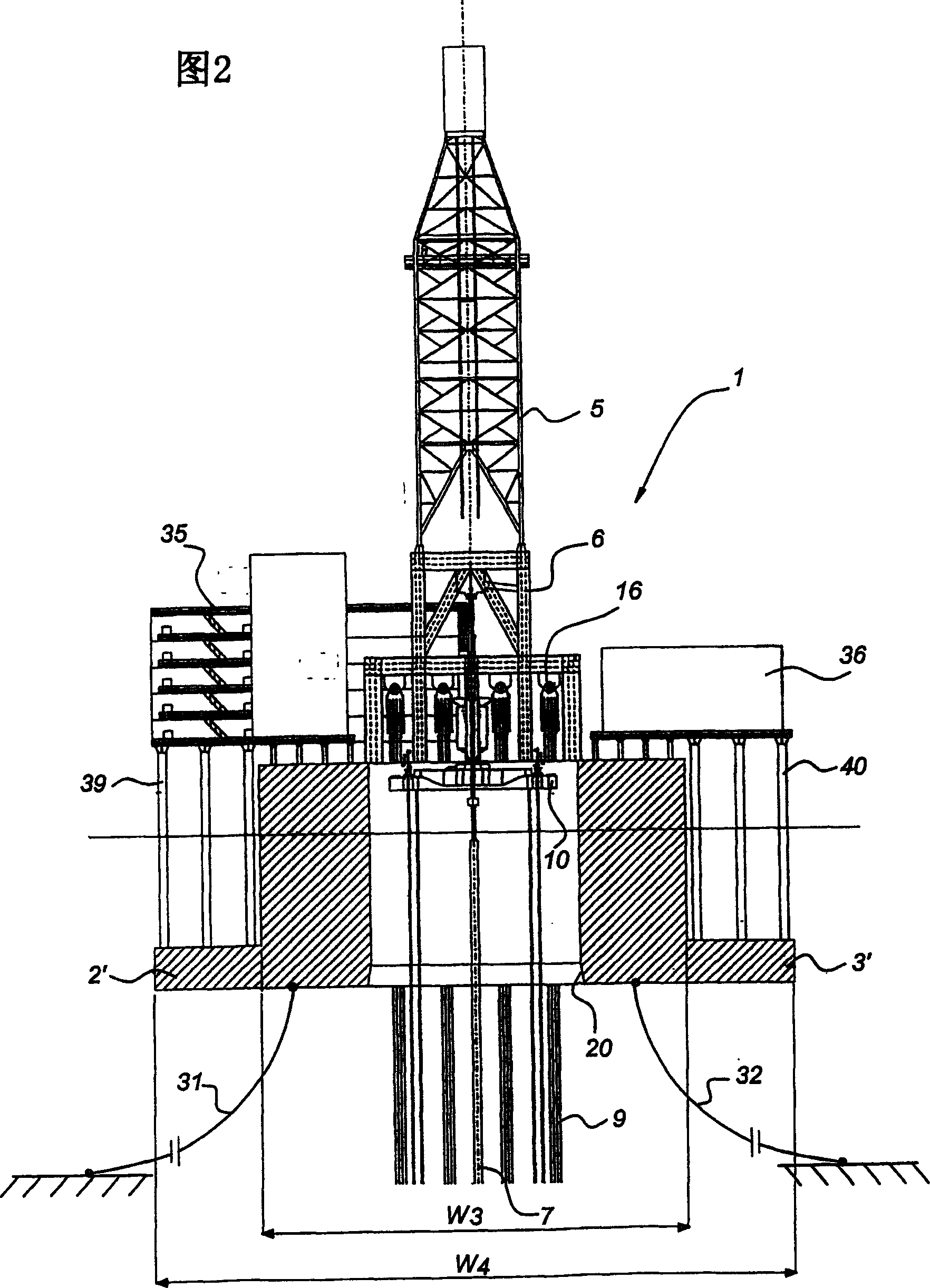

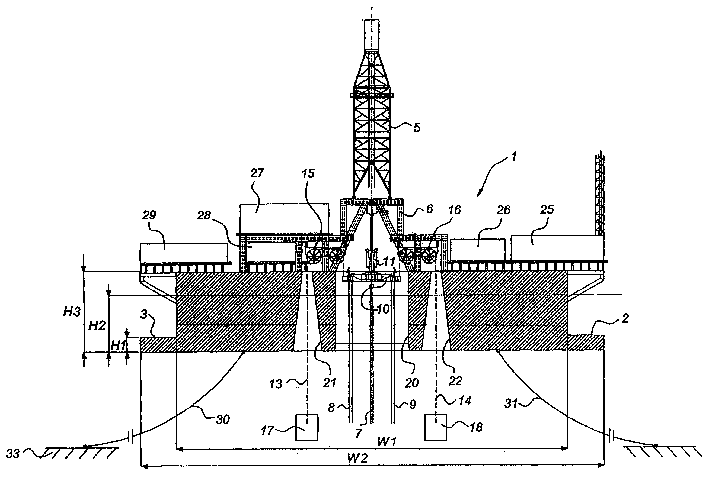

Sheet billet continuous casting and rolling production line

InactiveCN101658860AHigh speedReduce baking timeWork treatment devicesMetal rolling arrangementsProduction lineHearth

The invention relates to a sheet billet continuous casting and rolling production line and mainly solves the technical problems of high rigidity and low surface quality of produced sheet billets of the prior production line. The invention adopts a technical scheme that: the sheet billet continuous casting and rolling production line is sequentially provided with the following production line equipment: a continuous casting machine, swinging shears, a roller-hearth tunnel furnace, a descaling unit, a vertical roll, a rough mill, a coil box, a ultrafast water-cooling device, flying shears, a finishing mill, a laminar flow-cooling and ultrafast water-cooling device and a coiling machine, wherein a secondary descaling unit can be arranged between the flying shears and the finishing mill; and the continuous casting machine adopts two double flow roller-hearth tunnel heating furnaces, combines two flows of the two continuous casting machines into one flow through a transverse moving machineand is connected with a rolling line. The invention is mainly used for continuous casting and rolling of sheet billets.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

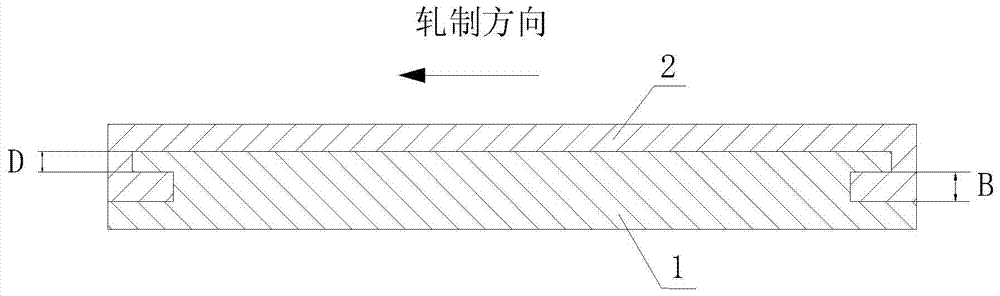

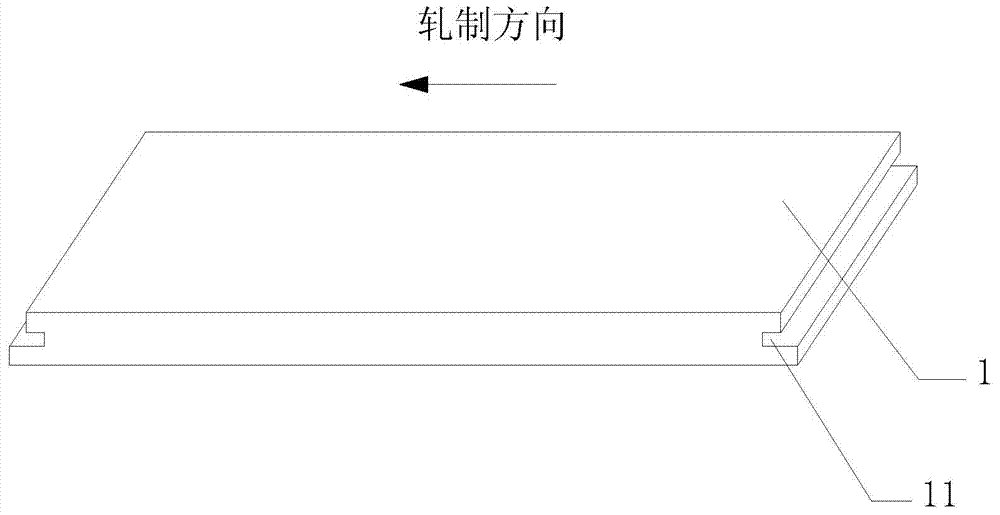

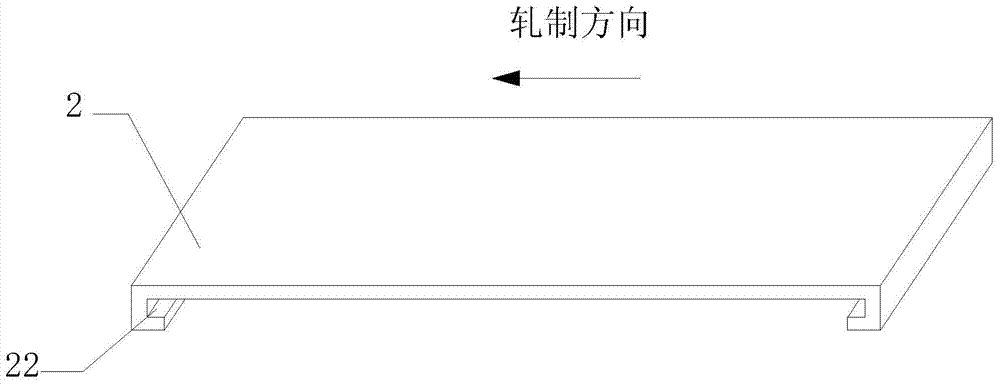

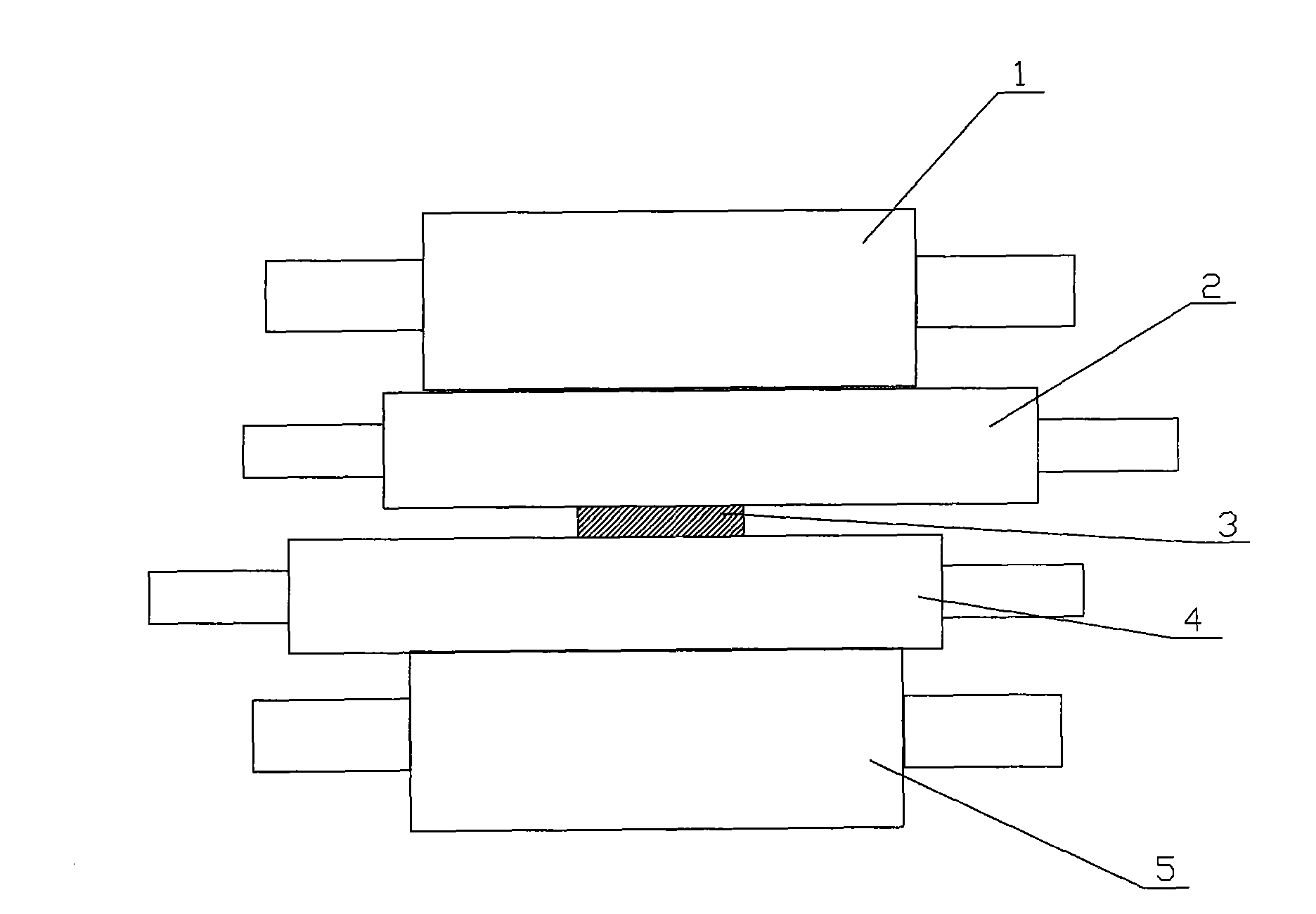

Method of lock catch type vacuum rolling metal composite plate

InactiveCN103495604AHigh composite strengthEasy to separateAuxillary arrangementsMetal rolling arrangementsComposite strengthVacuum pumping

A method of a lock catch type vacuum rolling metal composite plate comprises the following steps that penetrated grooves are machined in the end faces of the two ends, vertical to the rolling direction, of a base plate respectively, and correspondingly, L-shaped embedding strips are welded to corresponding positions at the two ends of a shroud plate respectively; greasy dirt on the surface to be compounded is cleaned; the L-shaped embedding strips at the two ends of the shroud plate slide into the grooves in the two ends of the base plate to enable a composite slab formed by the shroud plate and the base plate to be in an embedded state. Sealing plates are connected to the periphery of the composite slab in a welded mode to enable composite space to be sealed; holes are formed in the sealing plates, air between the shroud plate and the base plate is extracted through the holes, and the holes are blocked after vacuum pumping is carried out; the composite slab is heated to 950-1300 DEG C to be rolled until the composite slab reaches a needed thickness to form the metal composite plate; edge cutting is carried out on the rolled metal composite plate, the sealing plates are removed, and rolling of the composite plate is completed. According to the method, mutual movement of adjacent slabs in the rolling direction and the slab thickness direction can be effectively constrained, rolling stability is improved, and meanwhile composite strength of the metal composite plate is greatly increased.

Owner:武汉钢铁有限公司

Roller shifting method for controlling deviation of steel strip

InactiveCN102107216AIncrease productivityImprove rolling stabilityMetal rolling stand detailsMetal rolling arrangementsProduction lineStrip steel

The invention relates to the field of steel rolling, in particular a roller shifting method for controlling the deviation of a steel strip during a production process of a hot continuous rolling and finish rolling unit. By setting a roller shift frequency, a crossed roller shift mode and a roller shift step value of working rollers of two adjacent frames, the worn working rollers of two adjacent frames are crossed and shifted regularly. The method comprises the following steps: (1) the working rollers of the individual frames are set in initial center zero positions; (2) the working rollers of the individual frames are shifted at equal frequency in the range from 2 to 3; (3) the shift directions of two adjacent frames are opposite, and the roller shift step value is controlled within the range from 10 mm to 15 mm; and (4) the working rollers are shifted reversely when reaching the shift limit ranging from 100 mm to 150 mm. The invention has the benefits that: the roller shifting method is easy to implement and can achieve the purpose of shifting the rollers with box-shaped worn parts of two adjacent frames, so as to play the role of correcting the deviation and thus to increase the production efficiency of the hot rolling production line, stabilize the rolling condition and improve the product quality; and besides, the roller shifting method improves the transverse shift of the steel strip between the finish rolling units during the rolling process and enhances the rolling stability of the steel strip.

Owner:ANGANG STEEL CO LTD

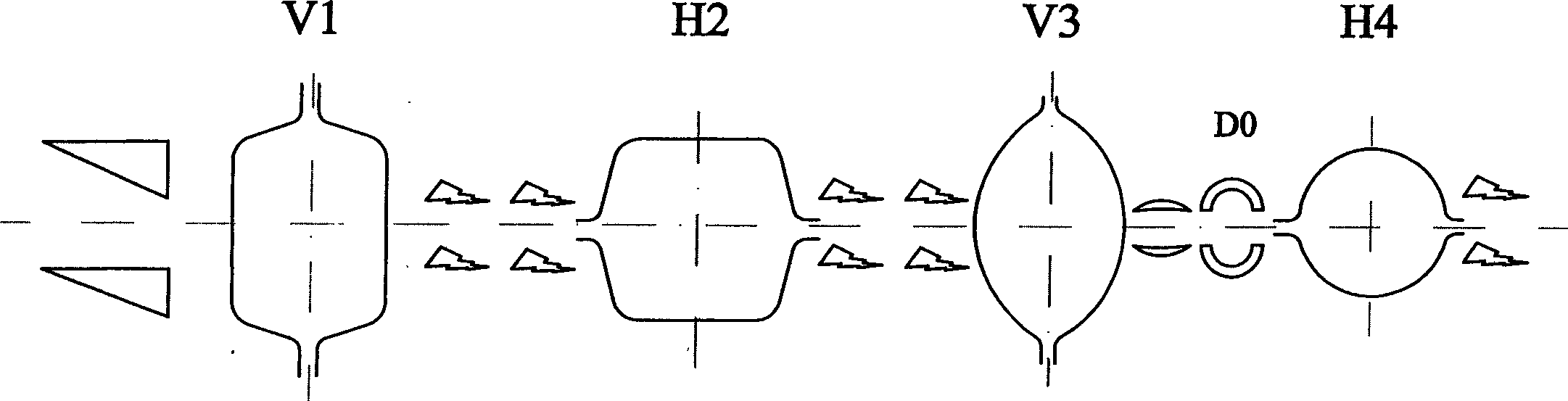

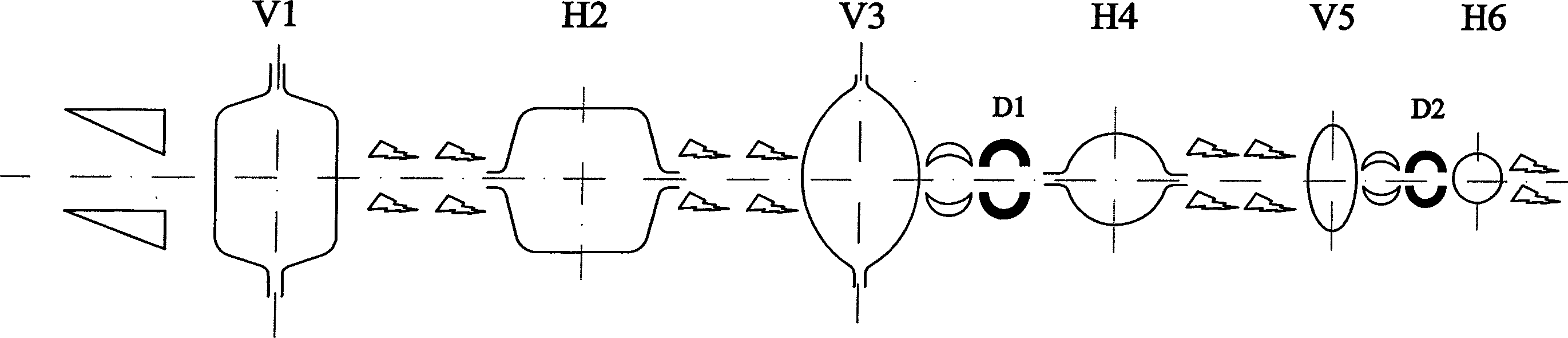

Small-norm steel rod continuous rolling method and its guide and guards

InactiveCN1640567AGood size controlEasy to makeGuiding/positioning/aligning arrangementsMetal rolling arrangementsEngineeringContinuous rolling

The present invention relates to a light-size round steel continuous-rolling method. It adopts a box-square-oval-round-oval-round system and makes the blank undergo the process of continuous rolling treatment by means of alternative six stands of vertical mills and horizontal mills so as to obtain the finished product, and before intermediate round pass stand and round former stand an inlet guide wheel is set.

Owner:BAOSHAN IRON & STEEL CO LTD

Edge shape control method

ActiveCN102909223AImprove rolling stabilityImprove rolling qualityProfile control deviceWork rollStrip steel

The invention provides an edge shape control method. The edge shape control method includes that a shape detector is used for detecting shape values of a working side and a drive side edge of strip steel; the shape values are amended to obtain a comprehensive plate shape value of the working side and the drive side of the strip steel; a working roll channeling roll value is amended according to the comprehensive shape value of the working side and the drive side; and according to the amended channeling roll value, an upper single taper working roll channeling roll and a lower single taper working roll channeling roll of an end rack are individually controlled on line. By the aid of the edge shape control method, the problem that about 70 mm (millimeter) fragmentary edge wave of a strip width side can not be eliminated by a conventional automatic shape control model is solved, and stability of rolling and quality of a product are improved.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

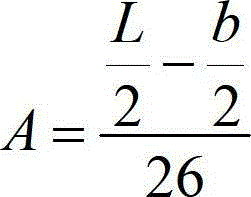

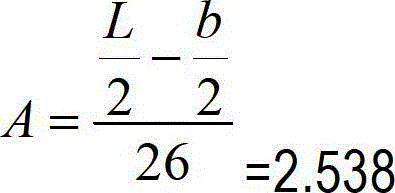

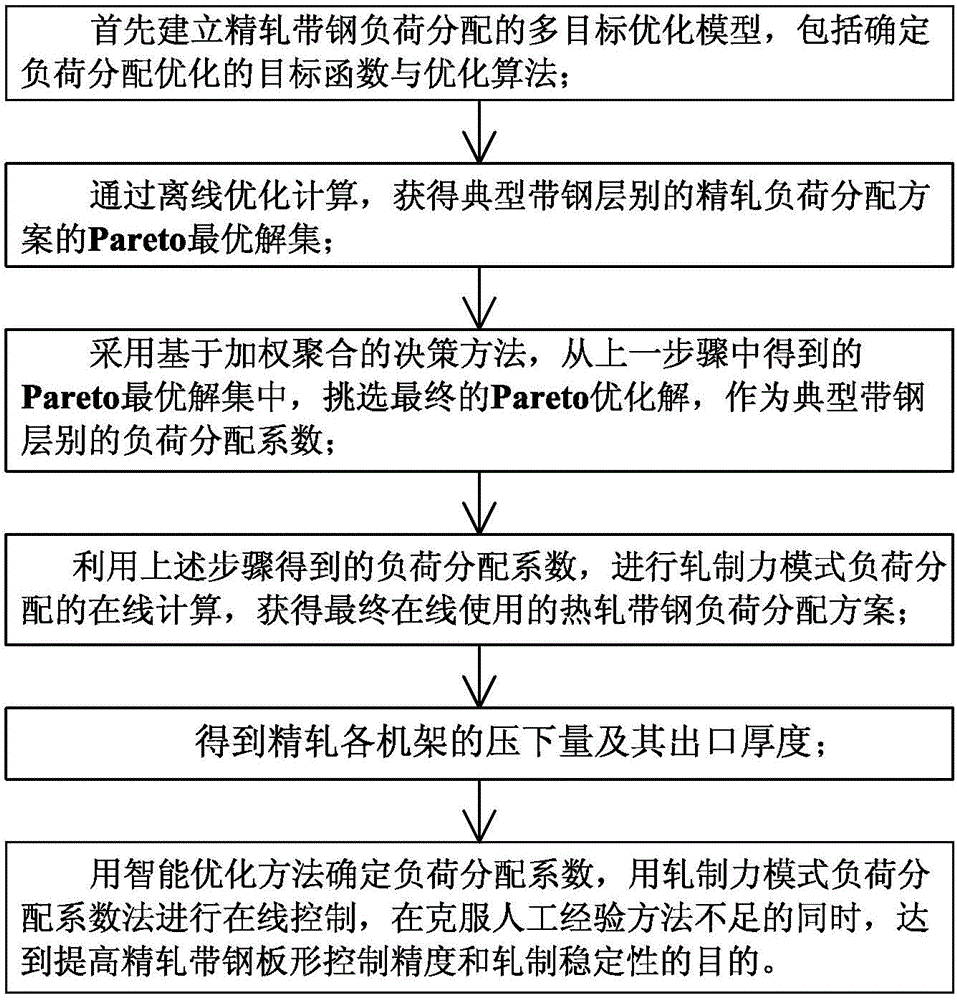

Hot rolled strip steel load distribution method giving consideration to rolling energy consumption and good strip shape

InactiveCN105013832AMeet time requirements for online calculation/controlHigh precisionRoll force/gap control deviceProfile control deviceQuality controlStrip steel

The invention discloses a hot rolled strip steel load distribution method giving consideration to rolling energy consumption and good strip shape, and belongs to the fieldof control. The hot rolled strip steel load distribution method comprises the following steps: step I, carrying out off-line optimization on finish rolling load distribution coefficients; step II, carrying out off-line decision making on finish rolling load distribution coefficients; and step III, carrying out distribution computation and online control on rolling thickness for finish rolling of each rack strip steel. According to the hot rolled strip steel load distribution method, off-line optimization and online control are combined; an intelligent optimization method is utilized to carry out off-line optimization to obtain load distribution coefficients of typical strip steel stratification; by utilizing a rolling force mode load distribution coefficient method, online computation is carried out and real-time online control is realized; when the intelligent optimization method is adopted to determine finish rolling load distribution coefficients off-line, the rolling energy consumption and the good strip shape for finish-rolling strip steel are taken into consideration; and whiledefects in a method based on artificial experience are overcome, the purpose of improving strip shape control precision and rolling stability of the finish-rolling strip steel is achieved. The hot rolled strip steel load distribution method can be widely applied to thefields ofproduction process control of strip steel of a hot continuous rolling mill, and the finish-rolling strip steel product quality control.

Owner:BAOSHAN IRON & STEEL CO LTD

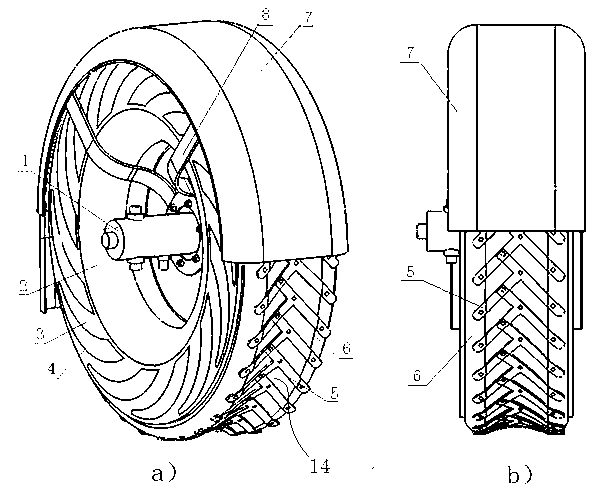

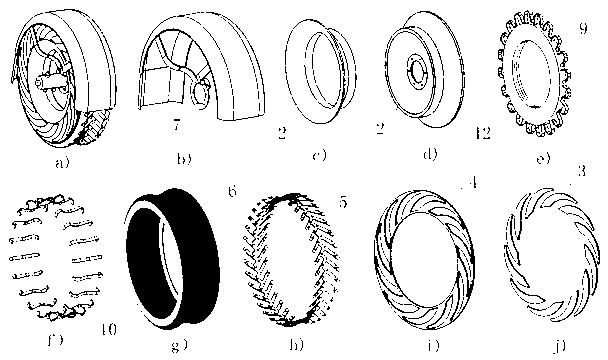

Concave elastic screen wheel

InactiveCN103342084AReduce subsidenceReduce squishingSpecial tyresWheel attachmentsConvex sideEngineering

The invention discloses a concave elastic screen wheel which comprises a hub and a supporting ring arranged on the hub. An annular metal wire mesh is arranged at the outer periphery of the supporting ring, an elastic element for supporting the metal wire mesh is positioned between the supporting ring and the metal wire mesh, an antiskid pawl is positioned at the outer periphery of the metal wire mesh, the metal wire mesh and the antiskid pawl are fixedly connected to form an arch concave elastic screen serving as a tire face, and the tire face is an arch concave face with the concave middle and the two convex sides. The concave elastic screen wheel can carry people to walk in soft, dusty, dry and low-gravity environments, can meet the requirements of high roll stability, high adhesion force and good shock absorption performance, can effectively prevent settlement and can effectively restrain raised dust.

Owner:HUNAN UNIV

Aluminum foil material for bottle cover and manufacturing method thereof

The invention relates to the manufacturing of aluminum alloy materials, in particular to an aluminum foil material for manufacturing an anti-fake bottle cover and a manufacturing method of the aluminum foil for the bottle cover. According to the invention, the aluminum foil material for the bottle cover comprises the following alloy components in percentage by weight: 0.55-0.65 % of Si (Silicon), 0.75-0.85 % of Fe (Ferrum), 0.03-0.15 % of Cu (Copper), 0.05 % of Mn (Manganese), 0.05 % of Mg (Magnesium), 0.05 % of Cr (Chromium), 0.05 % of Zn (Zinc), 0.05 % of Ti (Titanium) and the balance of Al (Aluminum). According to the invention, the material is optimized on the basis of the 8011 alloy, is integrated with the advantages of the 8011 alloy, has the advantages of high surface quality, high strength, good rupture strength and good rolling stability and can be used for effectively increasing the production efficiency and the yield. The aluminum foil material is completely comparable to hot rolled aluminum foil blanks in finished product quality and the rolling performance.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

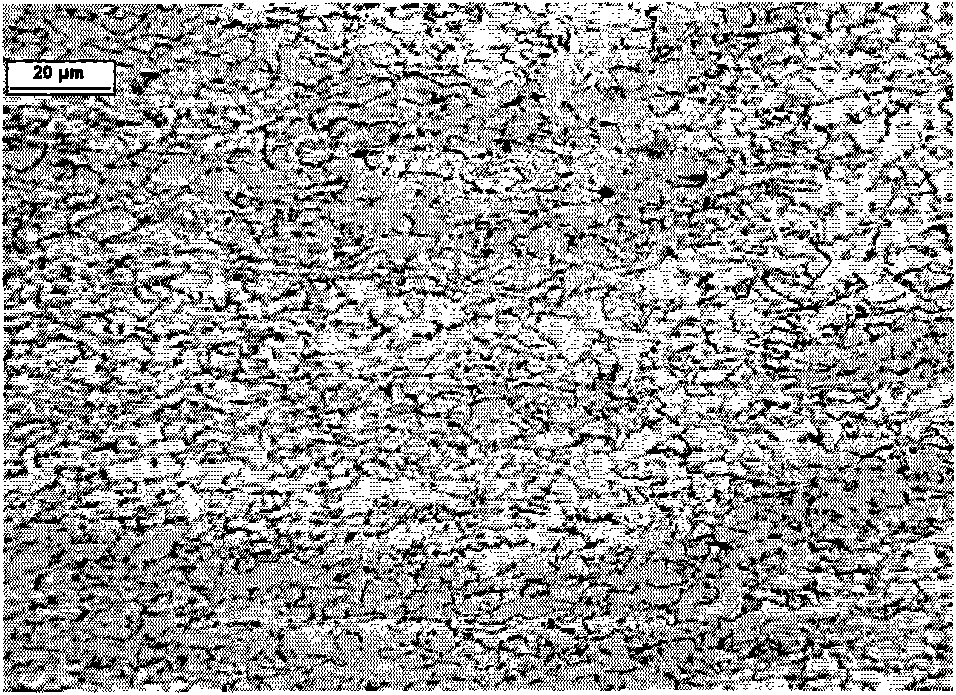

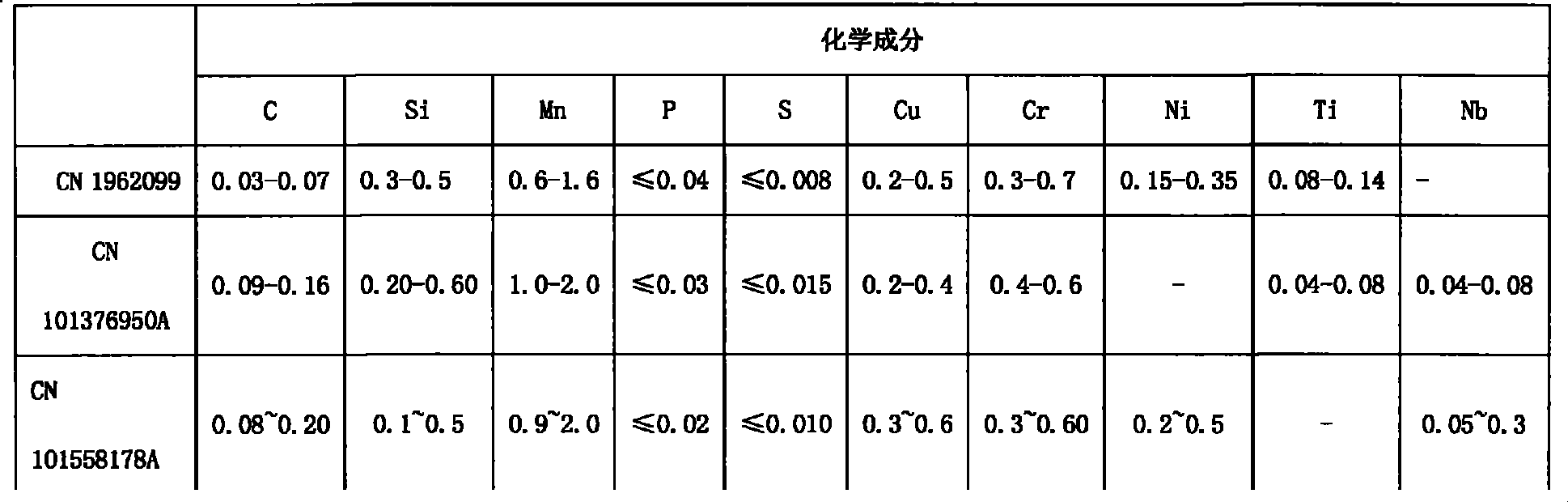

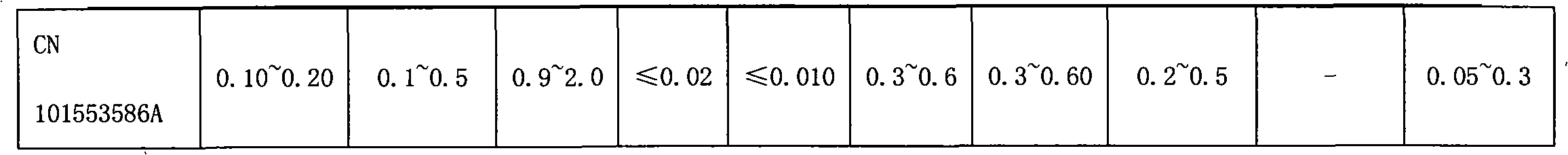

700MPa-grade cold rolled steel plate with high weather resistance and preparation method thereof

InactiveCN102011060AHigh standardAbundant resourcesTemperature control deviceBell type furnacesWeather resistanceChemical composition

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Rolling method for producing phase changes in finish rolling process of low-grade non-oriented silicon steel

ActiveCN102671940AStable deformation rateImprove rolling stabilityTemperature control deviceProfile control deviceHeating furnaceSilicon

The invention provides a rolling method for producing phase changes in the finish rolling process of low-grade non-oriented silicon steel, which belongs to the technical field of steel rolling and is characterized in that the target tapping temperature of a first heating zone of a heating furnace is minus 50 DEG C + / - 30 DEG C, the target tapping temperature of a second heating zone of the heating furnace is 20 DEG C + / - 30 DEG C, and the target tapping temperature of a soaking zone of the heating furnace is + / - 30 DEG C; the rolled thickness of a rough mill is adjusted to 40mm, the outlet temperature of the rough mill is adjusted to be in the range of 950 DEG C to 990 DEG C, and the fifth-pass speed of the rough mill is great than or equal to 4.7m / s; the percentages of reduction of first three racks of a finish milling group are all in the range of 59 percent to 37 percent, and the rolled thicknesses of the first three racks are all in the range of 20mm to 6.5mm; and the inlet temperatures of the first three racks are all in the range of 930 DEG C to 900 DEG C, and the rolling speeds of the first three racks are all in the range of 0.9m / s to 2.9m / s. By adopting the rolling method, the second flow among the racks of the finish mill is prevented from being influenced by changes of the deformation resistance, relative balance is maintained, the rolling stability is improved and safety production is guaranteed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

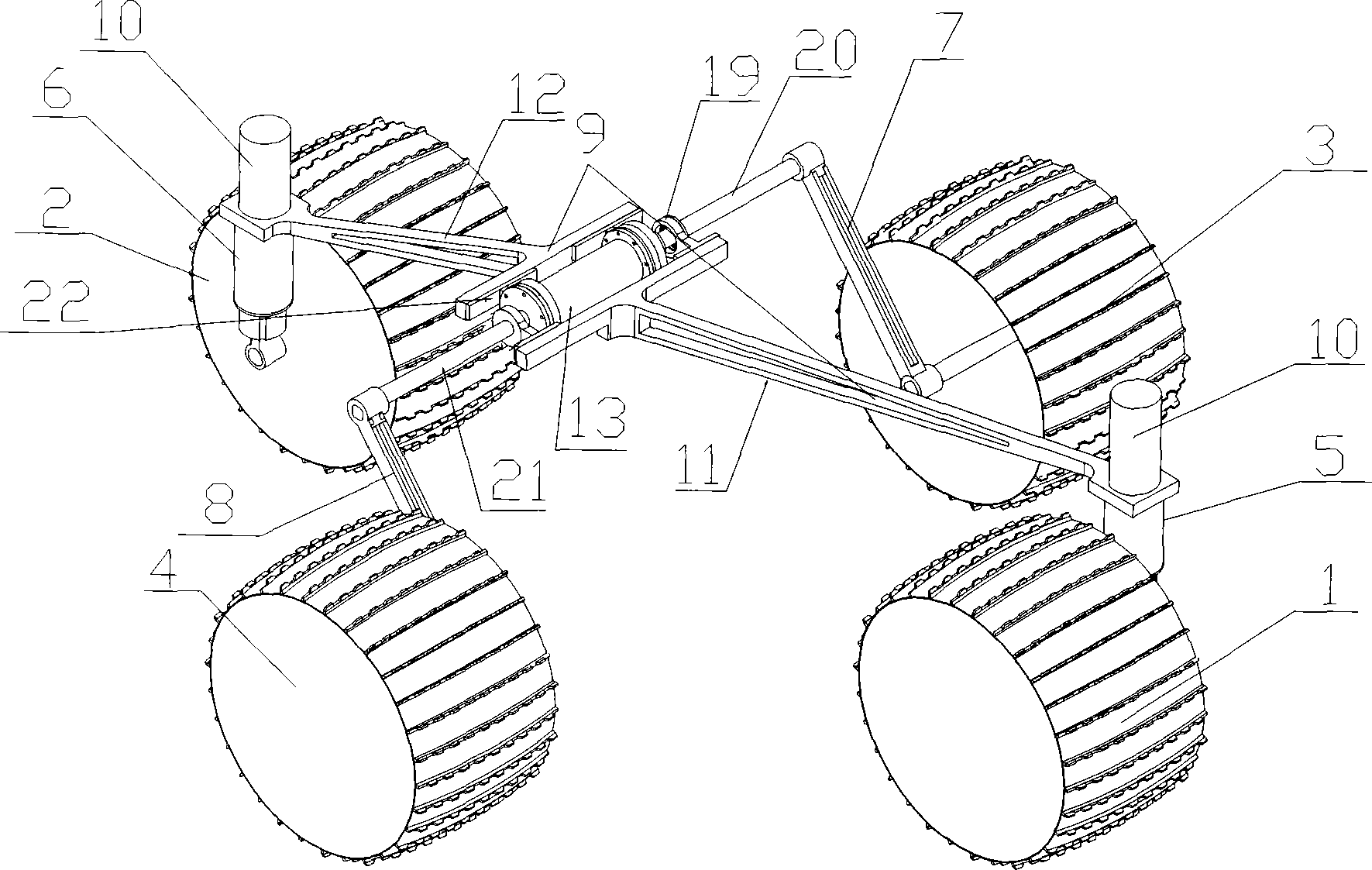

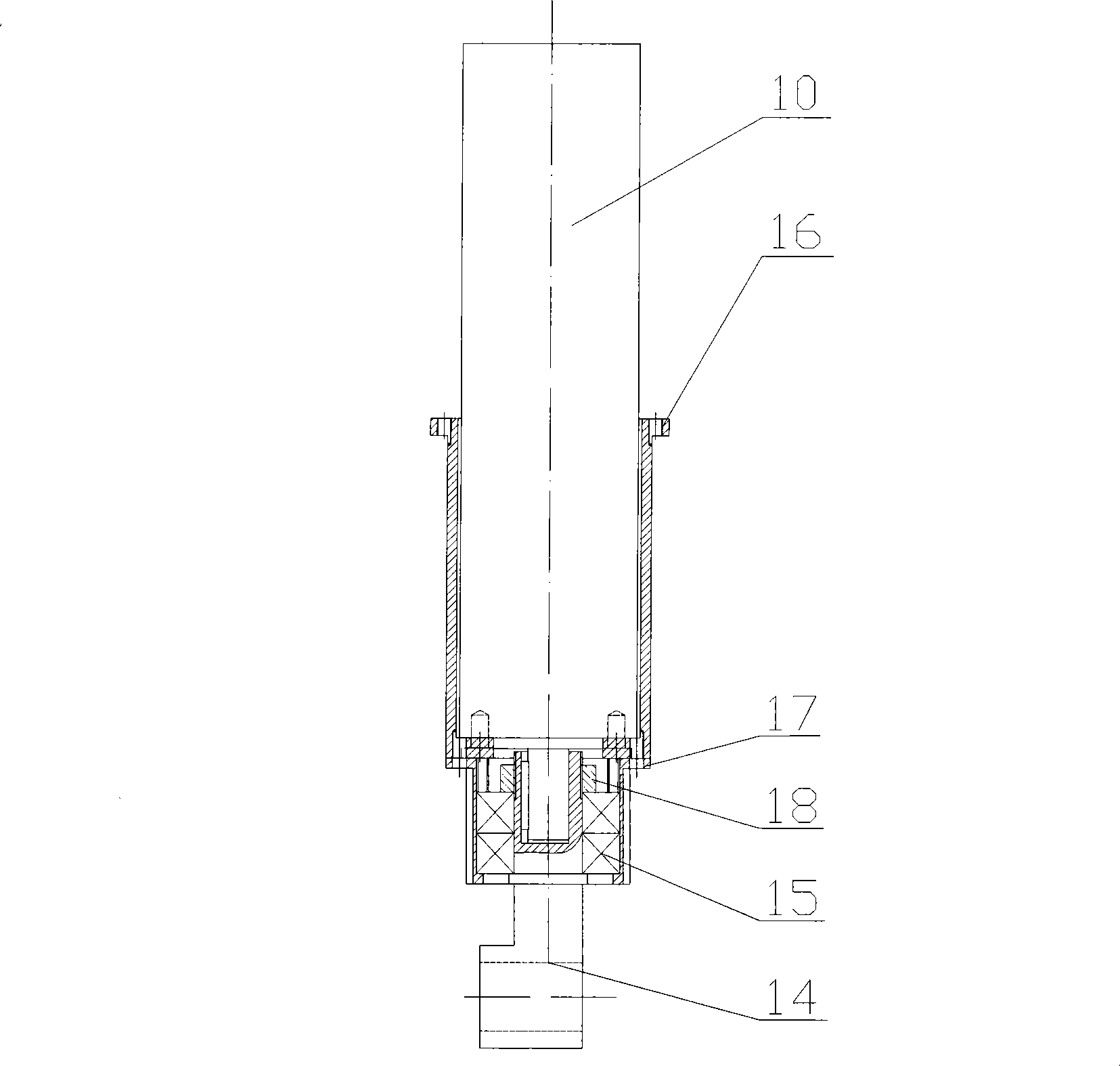

Pavement self-adaptive rhombic moonmobile moving system

InactiveCN101249854AImprove off-road performanceImprove mobile stabilityExtraterrestrial carsResilient suspensionsTerrainVehicle frame

Disclosed is a road surface self-adapting rhombus lunar rover moving system, which comprises a rotational lunar rover frame, a front wheel, a rear wheel, a left wheel and a right wheel, wherein the front wheel, the rear wheel, the left wheel and the right wheel are installed on the lunar rover frame and are in rhombus arrangement. The front wheel and the rear wheel are respectively fixed on the lunar rover frame via a front suspension system and a rear suspension system, the left wheel and the right wheel are respectively fixed on the lunar rover frame via a left suspension system and a right suspension system, the lunar rover frame comprises a front lunar rover frame and a rear lunar rover frame, the left suspension system is fixed on a left hinge joint shaft, the right suspension system is fixed on a right hinge joint shaft, the left hinge joint shaft is fixedly connected with the rear lunar rover frame via a connecting base, a motor is fixedly installed at the end of the left hinge joint shaft, the output shaft of the motor is fixedly connected with the right hinge joint shaft, a hinge joint bearing base is fixed on the front lunar rover frame, the left hinge joint shaft and the right hinge joint shaft are in hinge joint with the front lunar rover frame via the hinge joint bearing base with bearings. The lunar rover moving system utilizes a novel structure of a rhombus chassis with four wheels and three shafts, which is compact in structure, high in light weight degree, convenient in posture adjusting, fine in off-road performance, strong in terrain adaptive capacity and high in reliability.

Owner:HUNAN UNIV

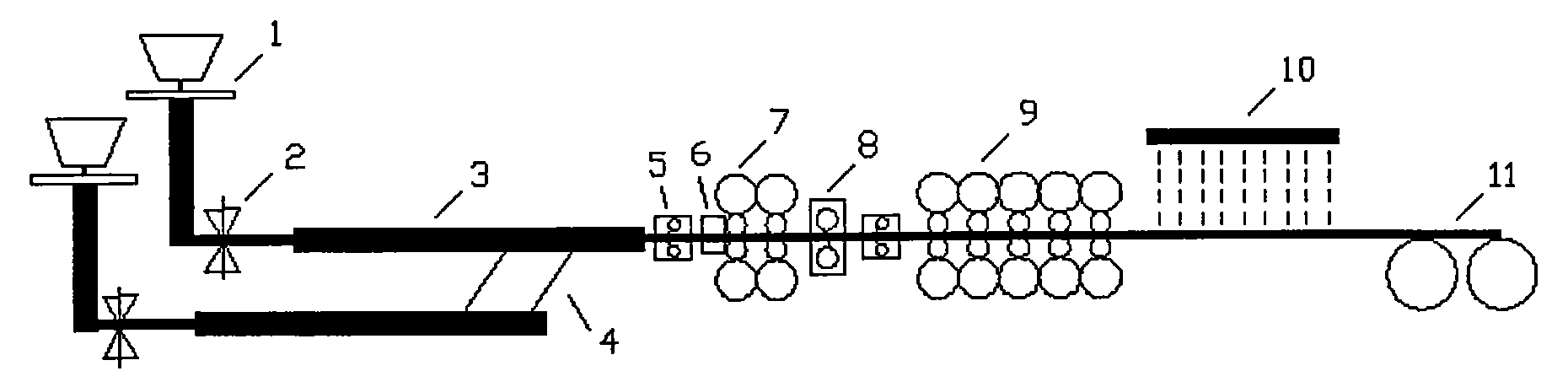

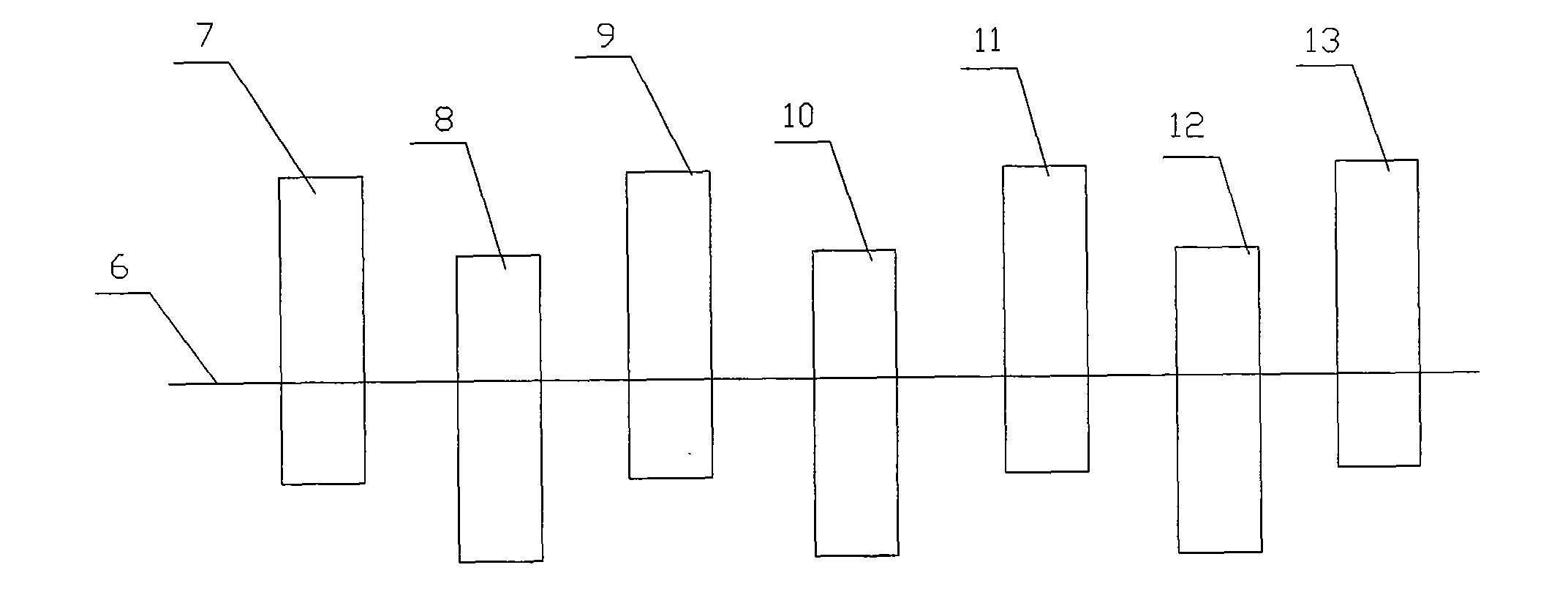

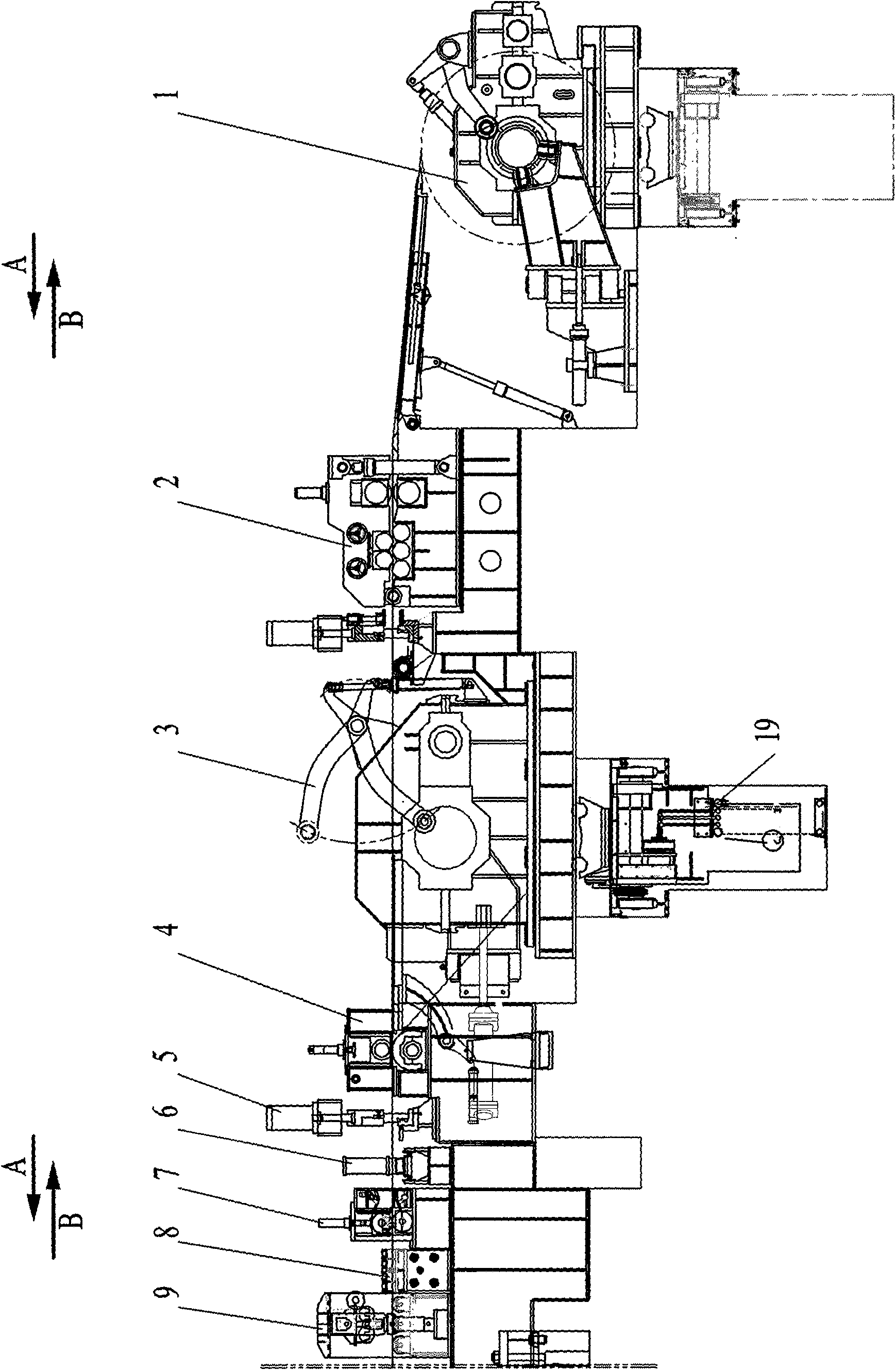

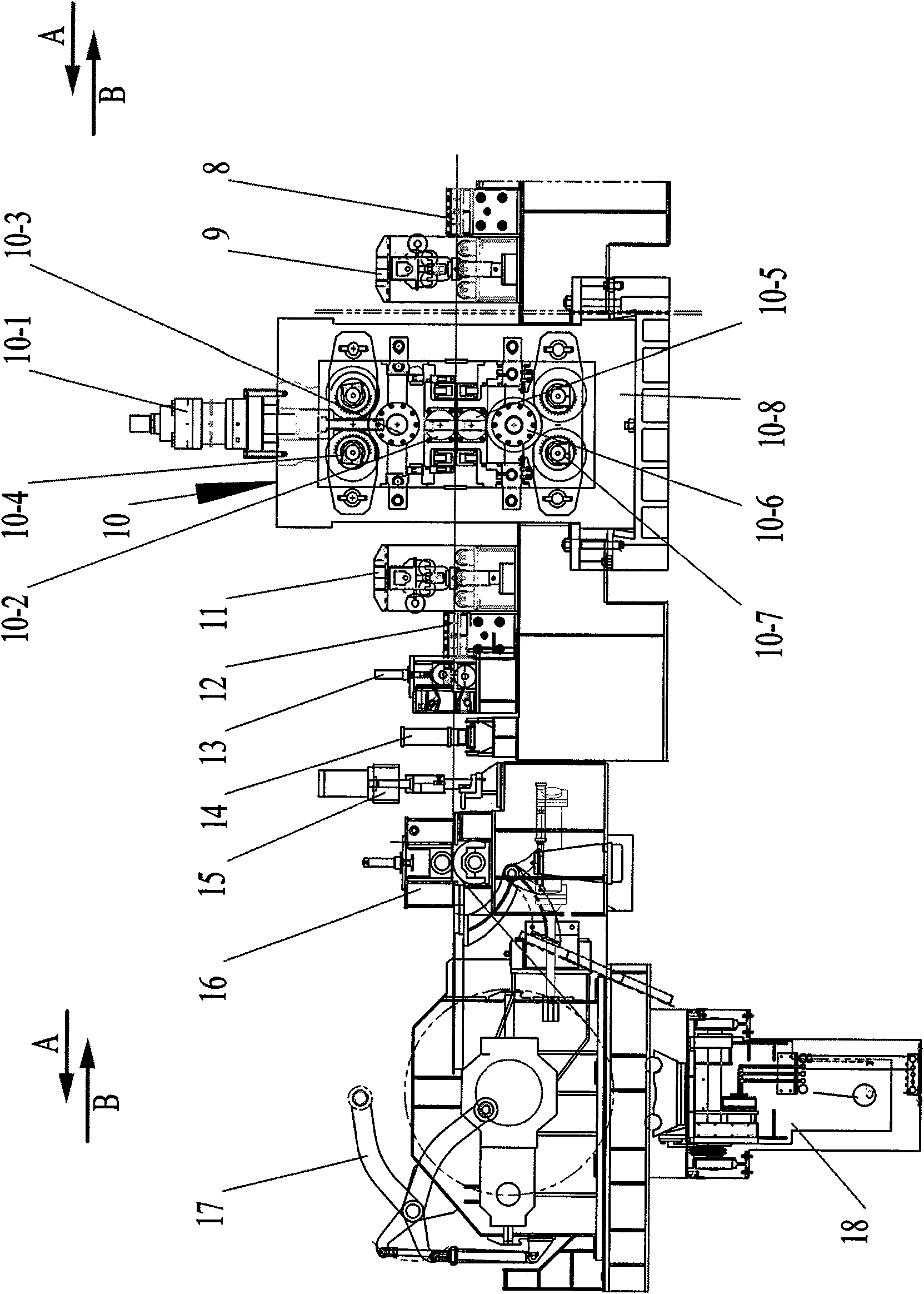

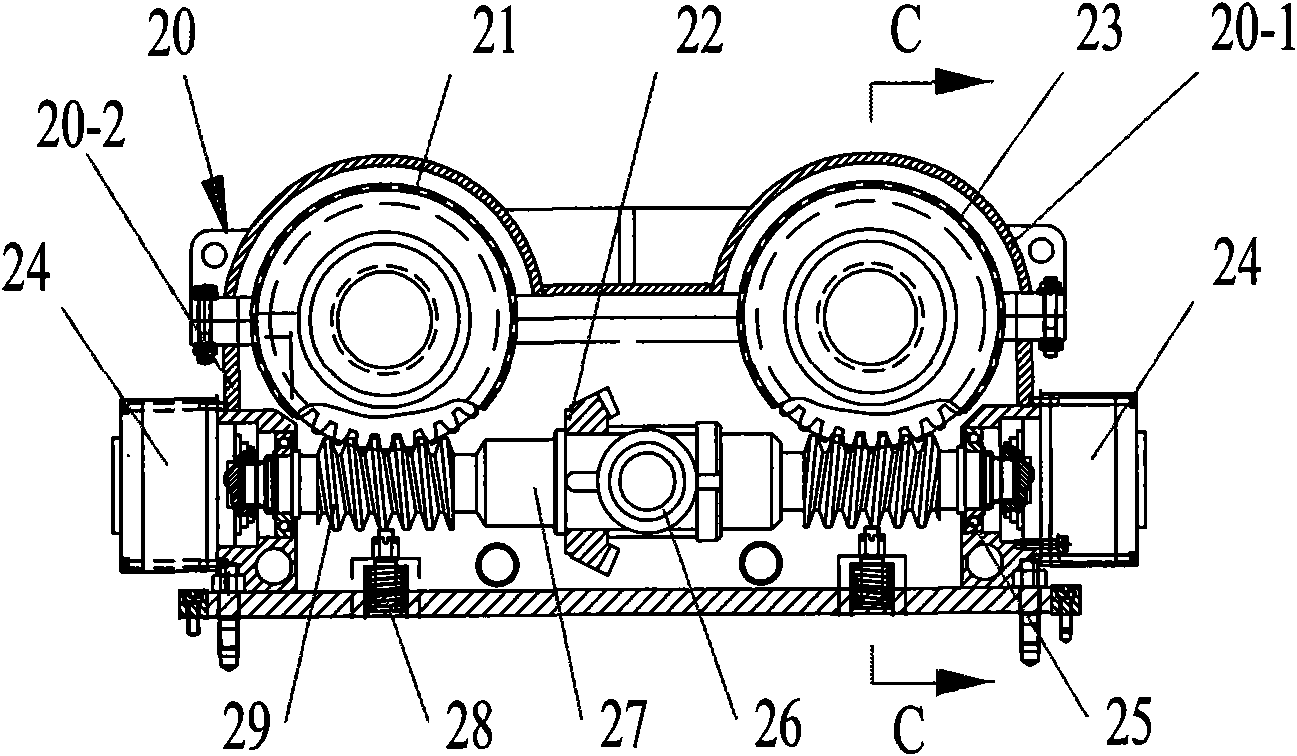

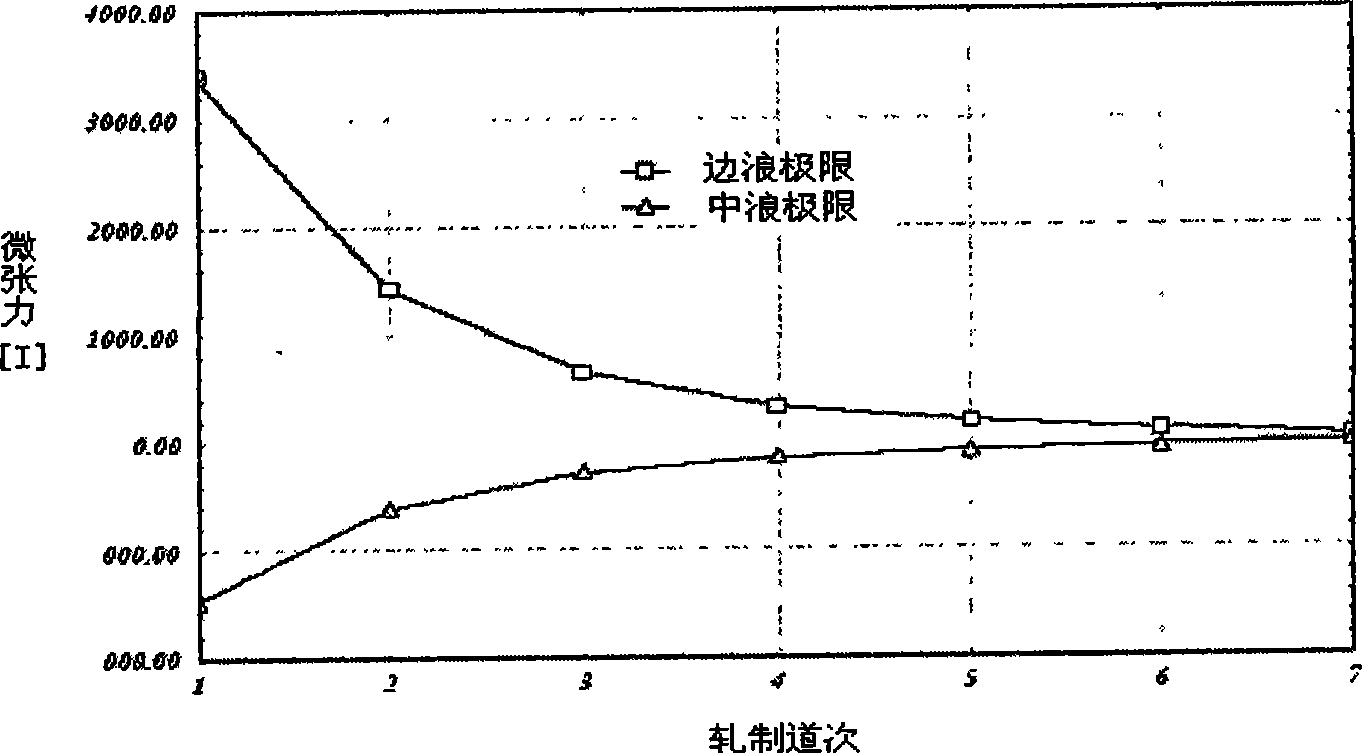

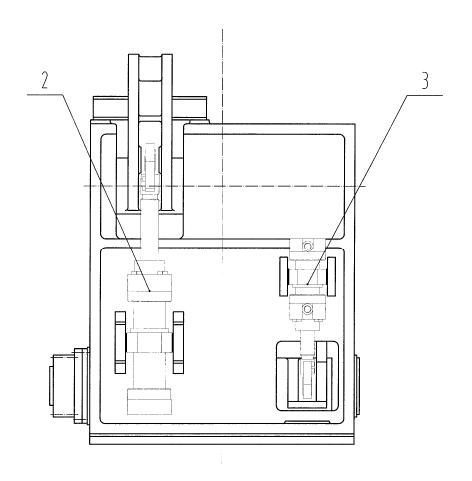

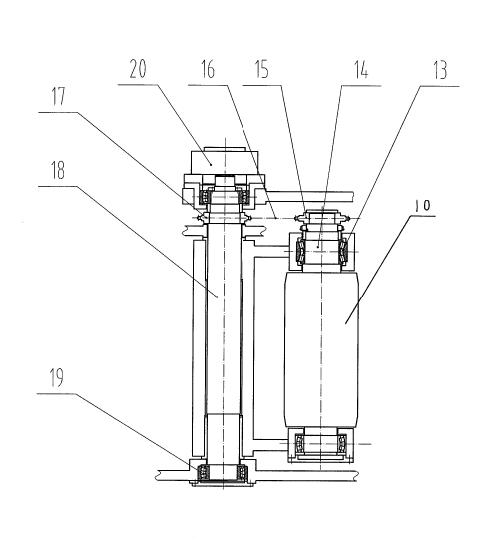

Reversible cold-rolling equipment and production method thereof

InactiveCN101817016ASatisfy the bite conditionNo possibility of skewMetal rolling stand detailsRolling mill drivesLow speedWork roll

The invention discloses reversible cold-rolling equipment, which comprises a main rolling mill, and a front tension device (9), a front alignment device (8), a rear tension device (11) and a rear alignment device (12) positioned on front and rear sides of the main rolling mill. The middle roll of the eight-roll rolling mill is a transmission roll, the transmission side of two lower supporting rolls (10-7) is provided with a lower rolling wire adjusting device connected with an eccentric shaft thereof, and the lower rolling wire adjusting device comprises a box body (20), a driving mechanism and two sets of worm gear transmission mechanisms placed in the box body. The invention also discloses a production method for the reversible cold-rolling equipment, which comprises working roll opening adjustment before rolling, low-speed direct bite of a to-be-rolled strip steel head, high-speed rolling operation and tensioned low-speed rolling operation of a to-be-rolled strip steel tail. The method can meet the bite condition of the rolling mill, realizes a reversible cold-rolling process without leading strip, has high rolling stability and high production efficiency, and is particularly suitable for reversibly cold-rolling thin specification strip steels.

Owner:唐山一重机械制造有限公司 +2

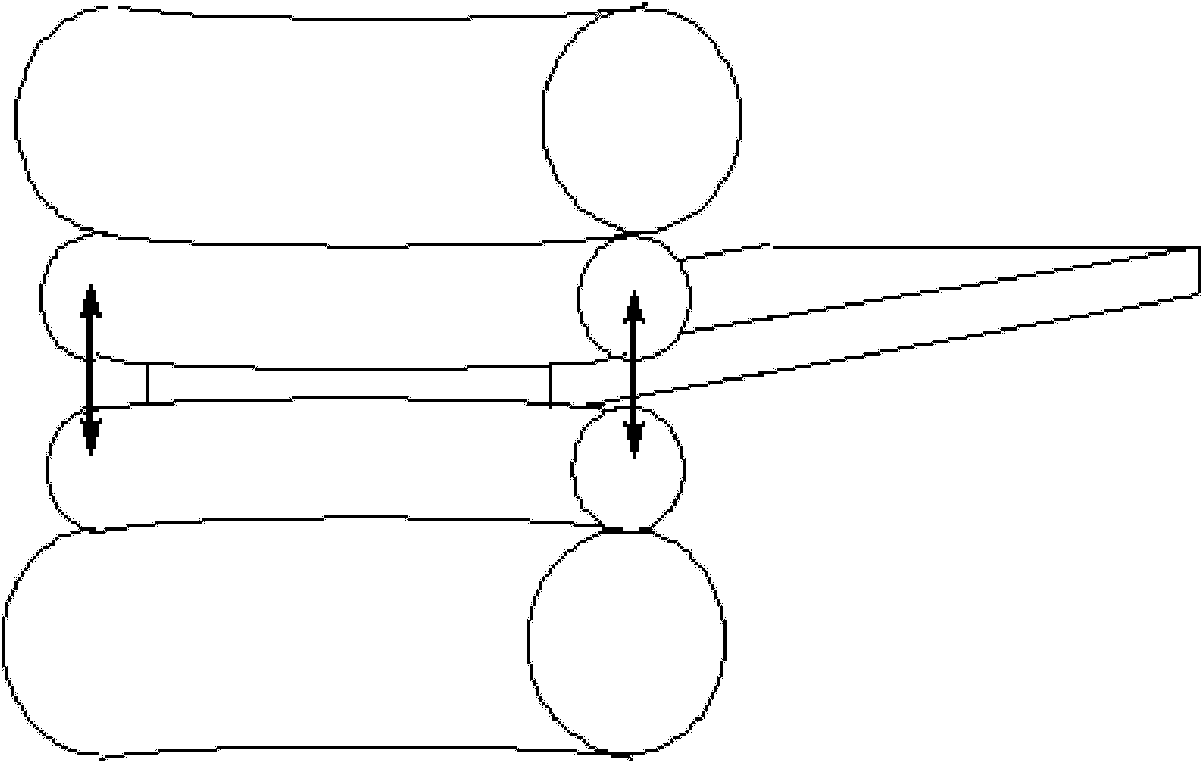

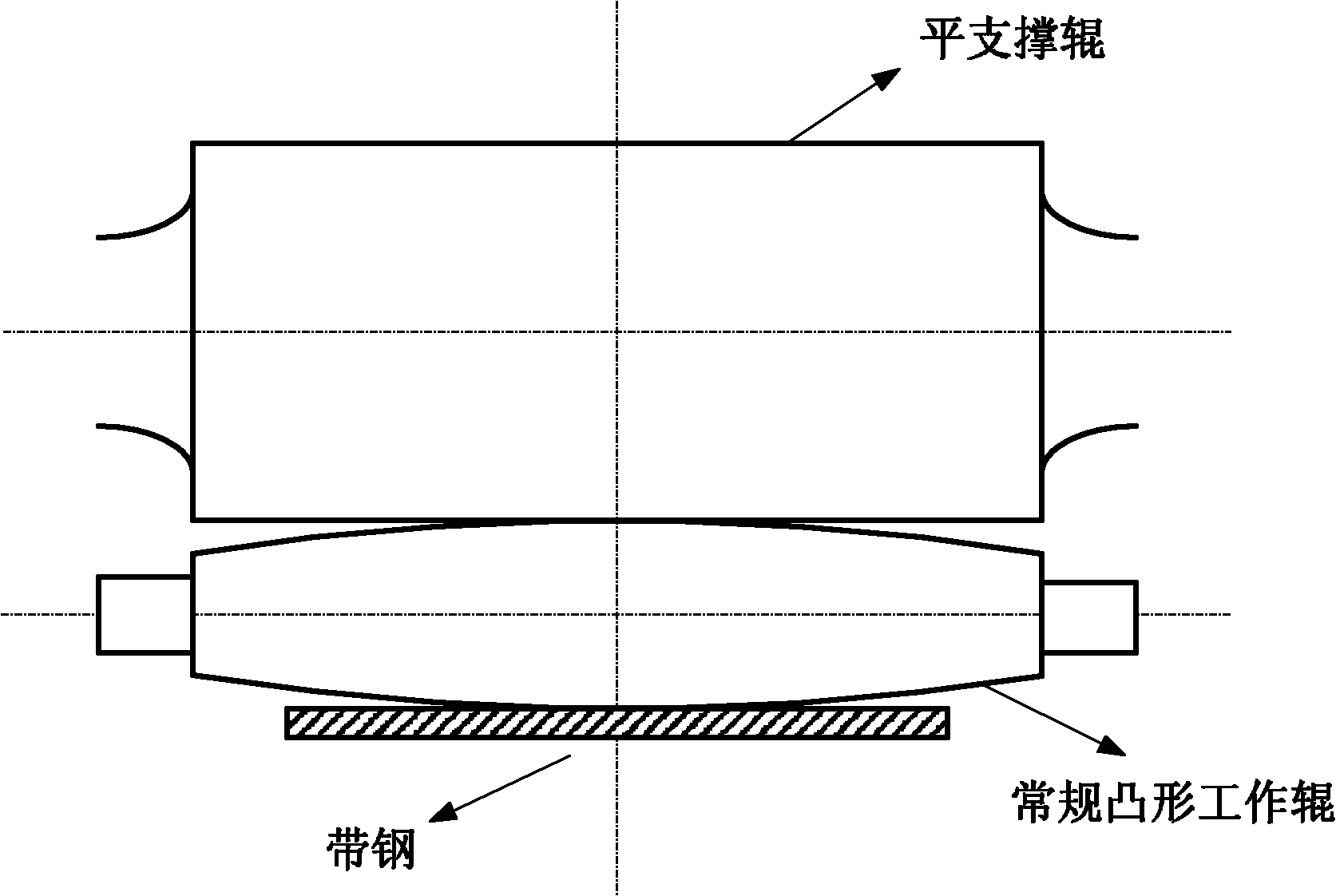

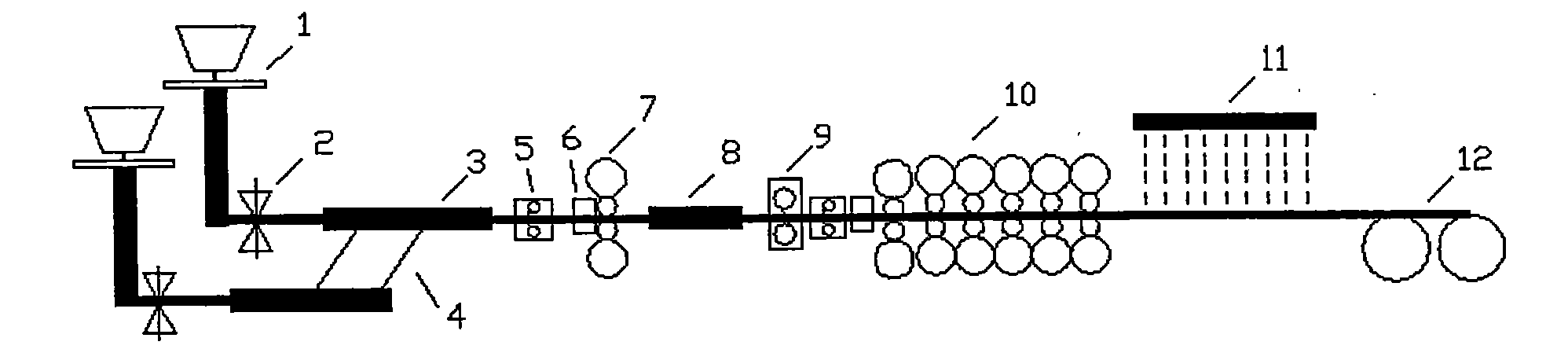

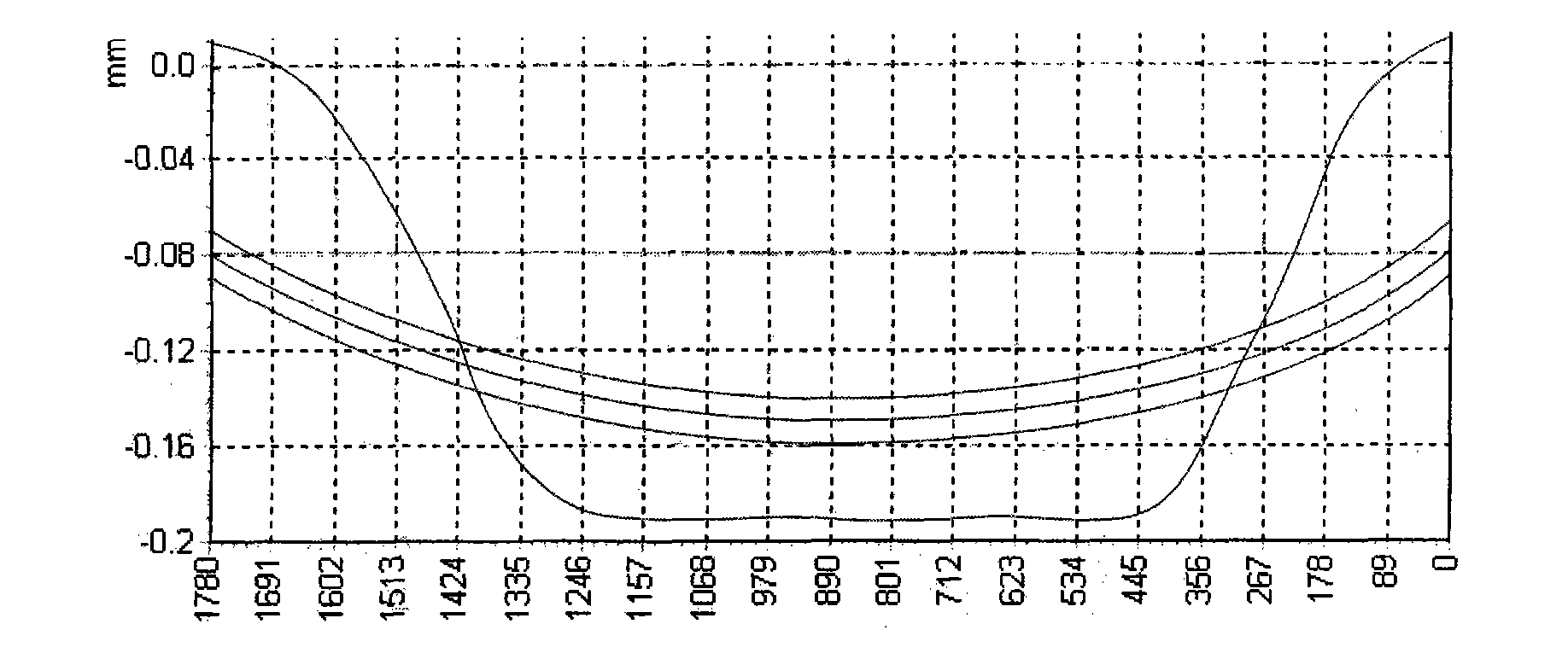

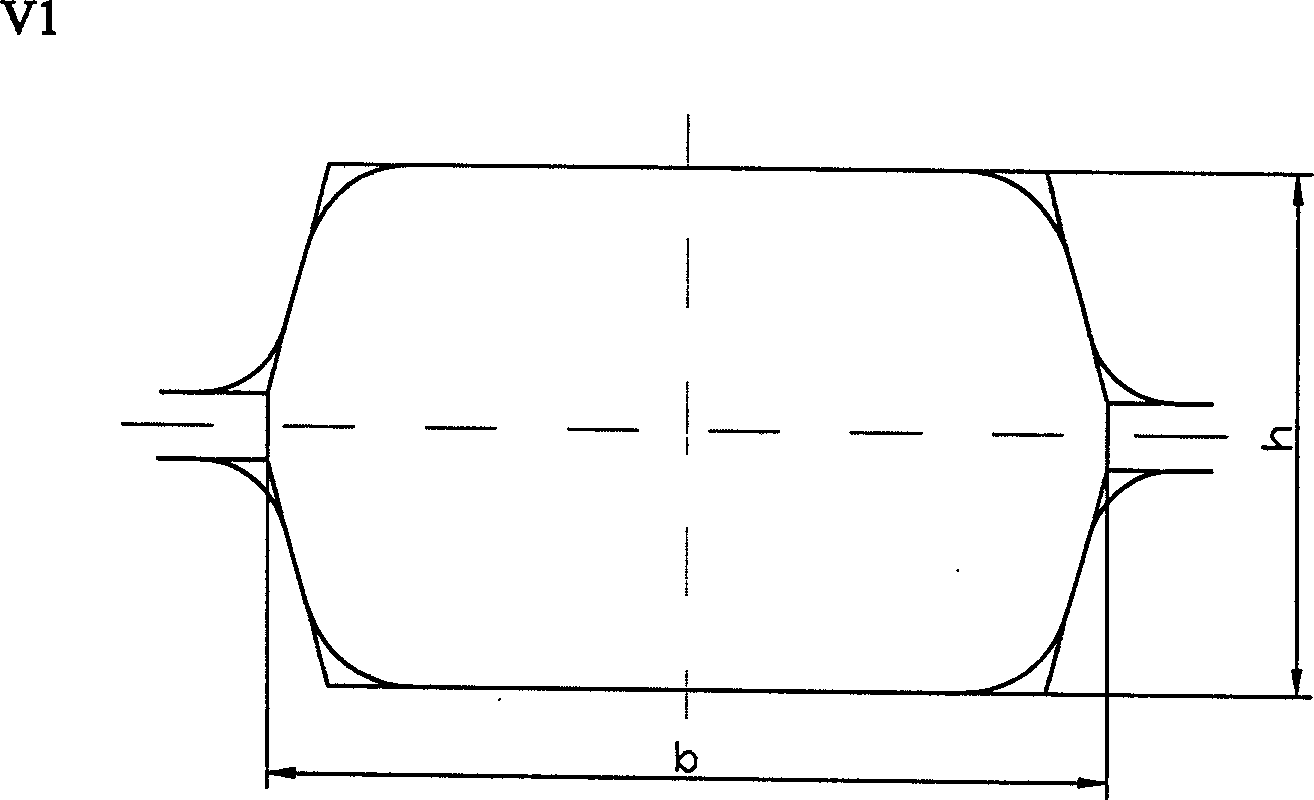

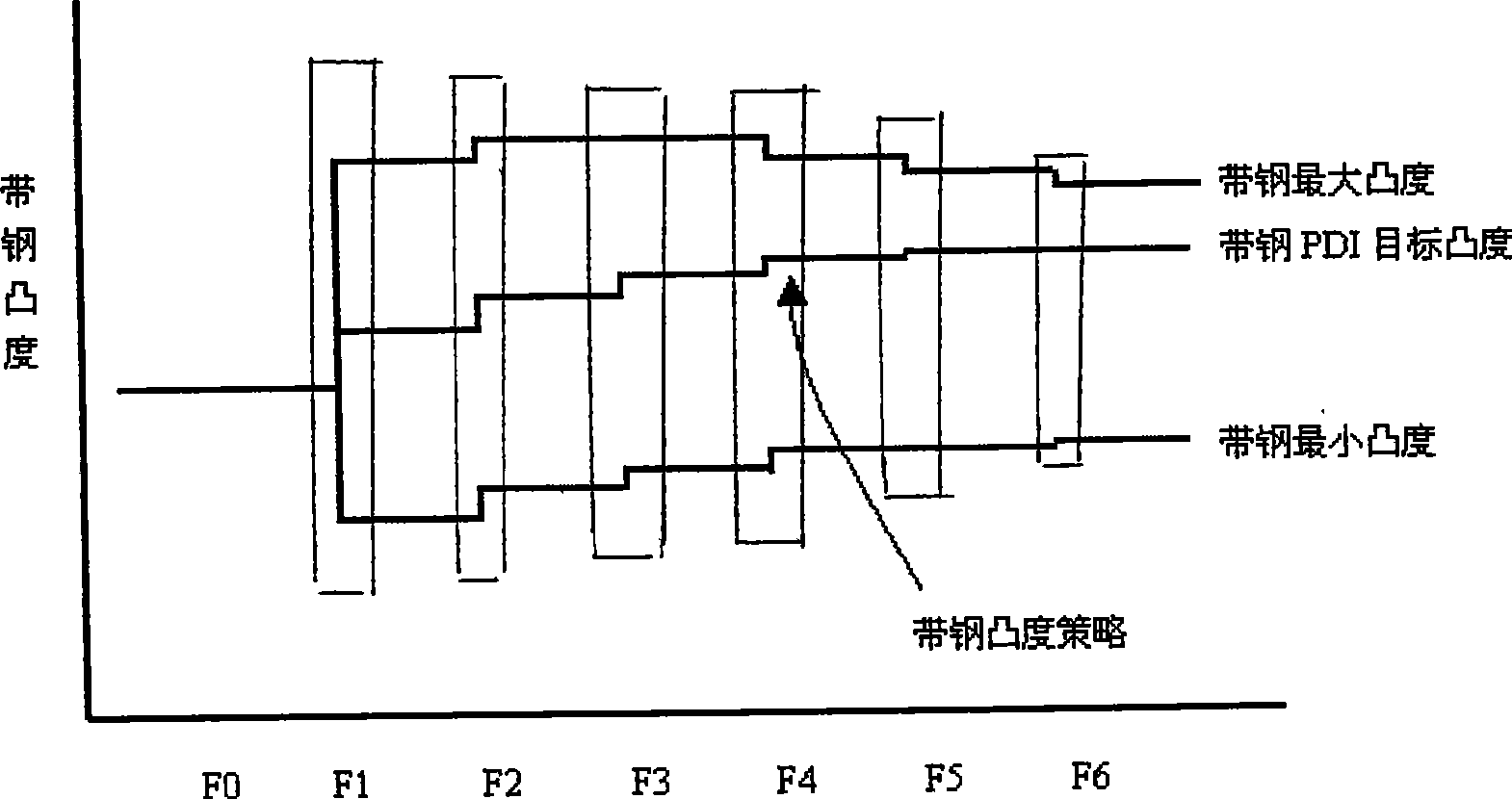

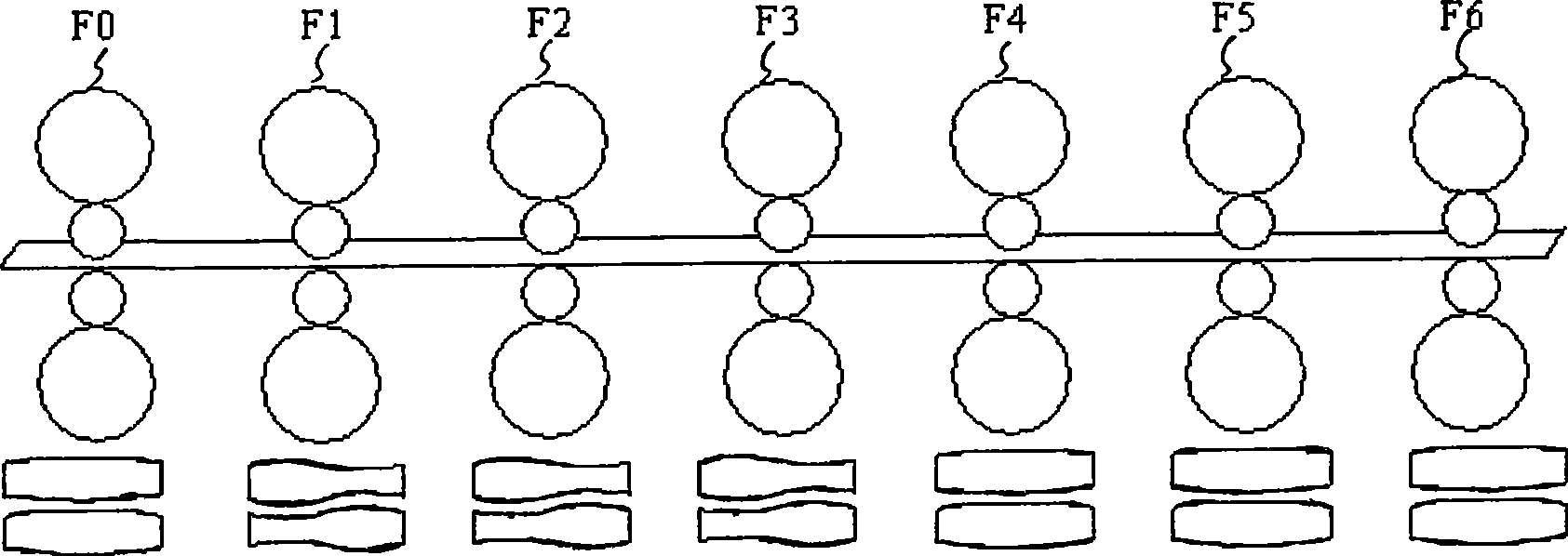

Roll shape configuration method for whole-set precision rolling working roll

InactiveCN101486042AImprove straightnessImprove rolling stabilityRollsMetal rolling arrangementsCurve shapeEngineering

The invention relates to roller arrangement for production of band steel for hot rolled plates, in particular to a method for arranging a complete finish-rolling working roll profile, and mainly solves the technical problem that the prior roll arrangement method cannot meet the requirement of large convexity degree at the tail of a cold supply rolling material. The invention adopts the technical proposal that the method for arranging the complete finish-rolling working roll profile comprises the steps of arranging 7 finish-rolling working rolls and finish-rolling a first F0 flat roll; F1 to F3 adopt CVC rolls, and F4 and F5 adopt parabolic concave rolls; and the method is characterized in that F6 adopts a CVC roll, the roll shape of the F6 is of a curve shape, and the cubic curve equation of the curve is Ru0(x)=A0+A1x+A2x+A3x. By arranging the prior finish-rolling working roll profile, the method plays a key role in plate shape control.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

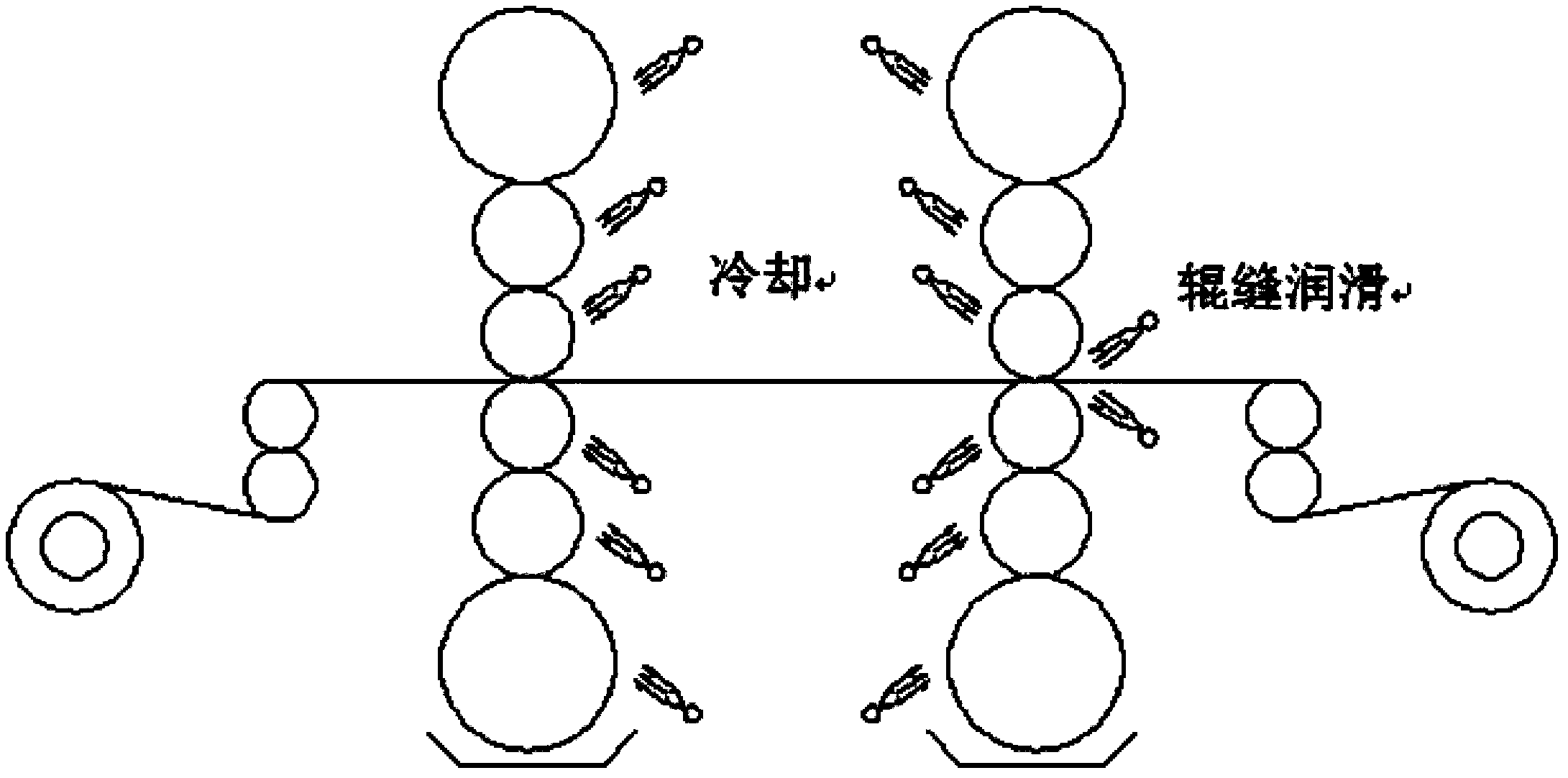

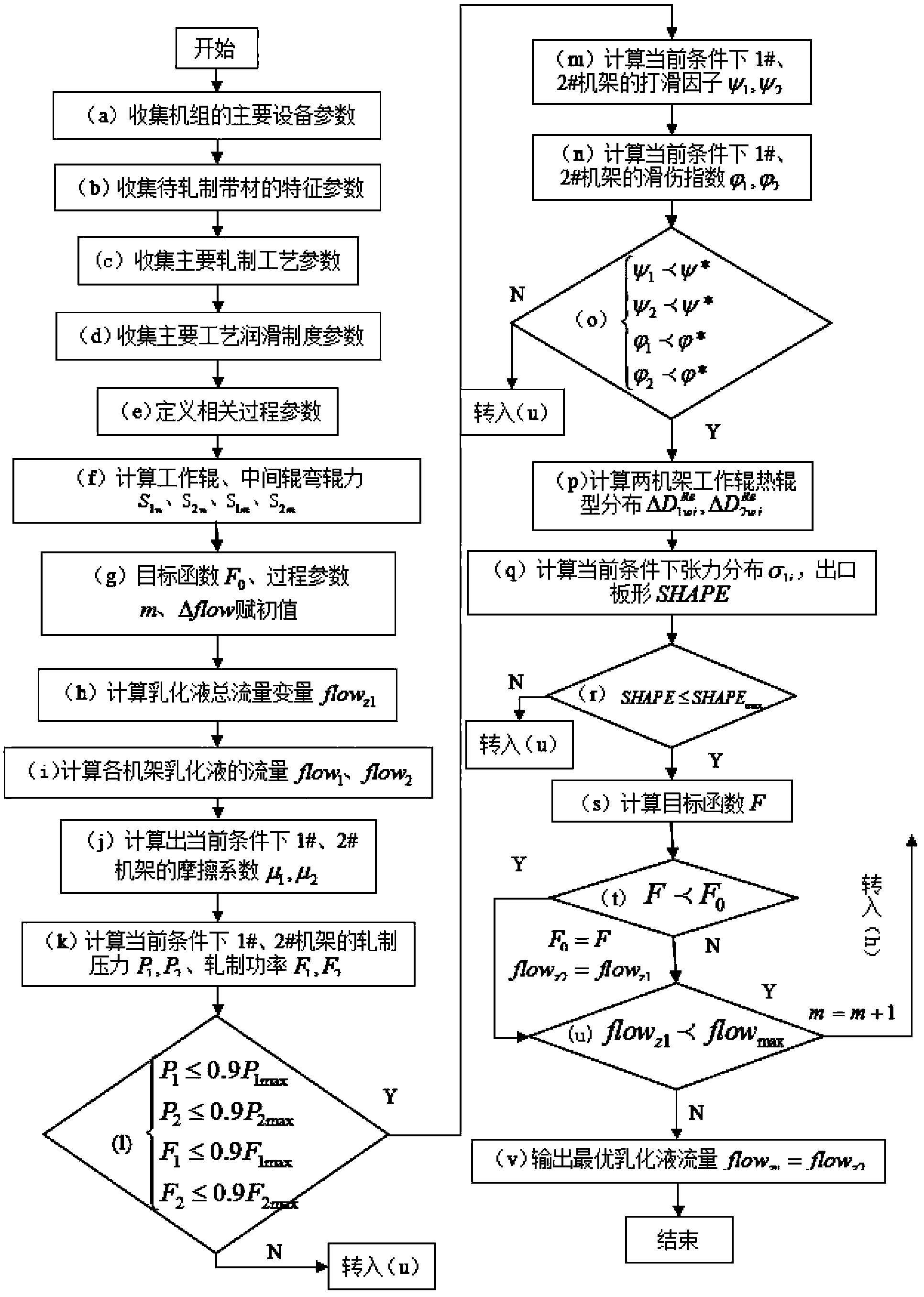

Emulsified liquid total flow setting method during cold rolling of double-rack six-roller mill

ActiveCN104289525AImprove shape qualityReduce thermal slipProfile control deviceField testsProcess engineering

The invention discloses an emulsified liquid total flow setting method during cold rolling of a double-rack six-roller mill. On the basis of a large number of field tests and theoretical researches, giving consideration to equipment characteristics of the double-rack six-roller mill and process characteristics of high-stage automobile sheet rolling, an emulsified liquid total flow optimization setting technology suitable for the high-stage automobile sheet cold rolling process of the double-rack six-roller mill is provided on the basis that sheet shape, surface quality and rolling stability comprehensive control indicators are introduced; three functions of improving the sheet shape quality of finished strip steel to the maximum degree, reducing the occurrence probability of hot slip damage to improve the product surface quality and avoiding slip to the maximum degree so as to improve the rolling stability can be achieved through the technology.

Owner:上海宝钢钢材贸易有限公司

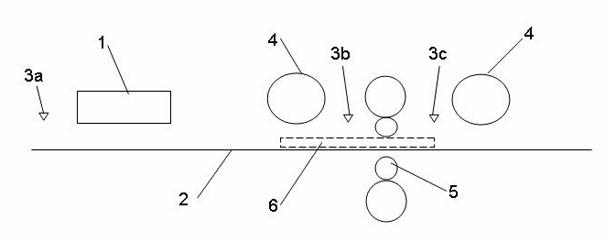

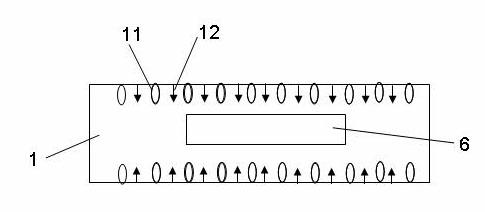

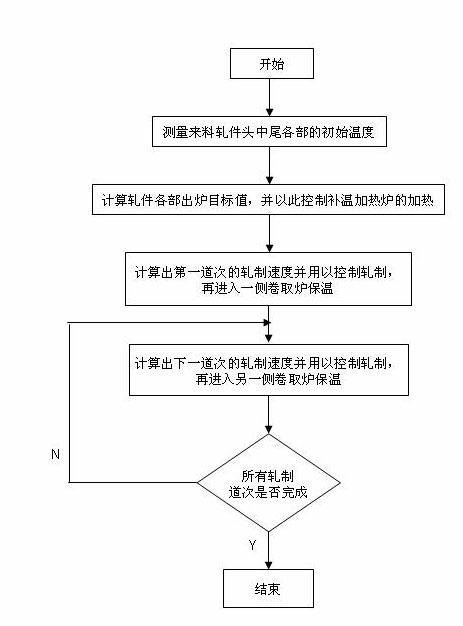

Temperature difference control method for rolling pieces for steckel mill

InactiveCN102601128AReduce temperature differenceImprove calculation accuracyTemperature control deviceProduction lineStrip mill

The invention discloses a temperature difference control method for rolling pieces for a steckel mill. The method includes steps of measuring initial temperature of the rolling pieces; calculating discharging target temperature value of a temperature complement furnace and heating the rolling pieces according to the target temperature value; calculating a set value of rolling speed of each rolling step and performing controlled rolling at each step according to the set value to reduce temperature difference; and measuring actual temperature of an exit and an entrance of a rolling mill and comparing the actual temperature with corresponding values to realize self-learning of the model and enhance calculating precision of the model. By the method, the temperature differences among the head, the middle and the tail of each rolling piece are reduced greatly, and rolling stability and quality of finished products and production ability of a production line are enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

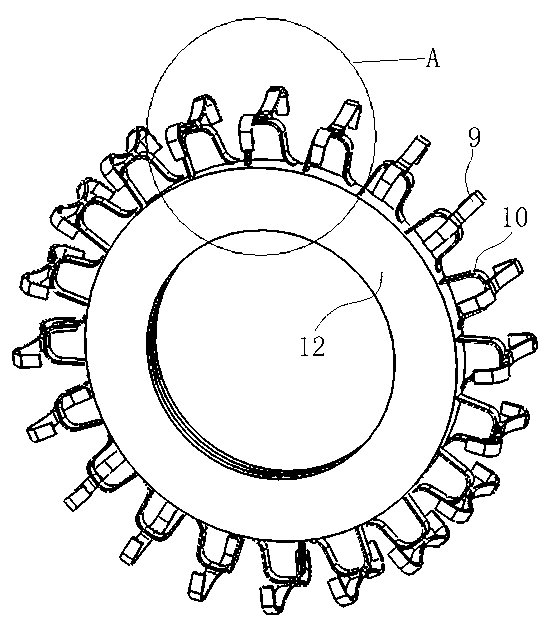

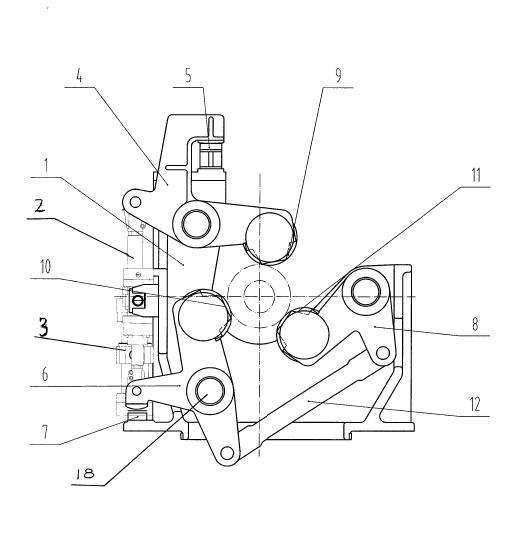

Three-roller centering device for rolling mill

InactiveCN102327904AEasy to navigateImprove rolling stabilityGuiding/positioning/aligning arrangementsDrive motorSprocket

The invention discloses a three-roller centering device for a rolling mill, which solves the problem that the guide device can not adapt steel pipes with different specifications. The three-roller centering device for the rolling mill comprises an upper guide roller driving cylinder (2) and a lower guide roller driving cylinder (3) which are arranged on a rack (1). An L-shaped swing arm (4), a T-shaped swing arm (6) and a reversed V-shaped swing arm (8) are hinged on the rack (1), a first adjusting pad (5) which can adjust the amplitude of swing of the L-shaped swing arm (4) is arranged between the L-shaped swing arm (4) and the rack (1), and a second adjusting pad (7) which can adjust the amplitude of swing of the T-shaped swing arm (6) is arranged between the T-shaped swing arm (6) and the rack (1). A hinged shaft (18) connected with a driving motor (20) is provided with a driving sprocket (17), and a driven sprocket (15) is arranged on a shaft (14) of one end of a lower left guide roller (10). A chain (16) is arranged between the driven sprocket (15) and the driving sprocket (17). The three-roller centering device for the rolling mill adapts the steel pipes with different specifications and reduces the operation cost of equipment.

Owner:TAIYUAN TONGZE HEAVY IND

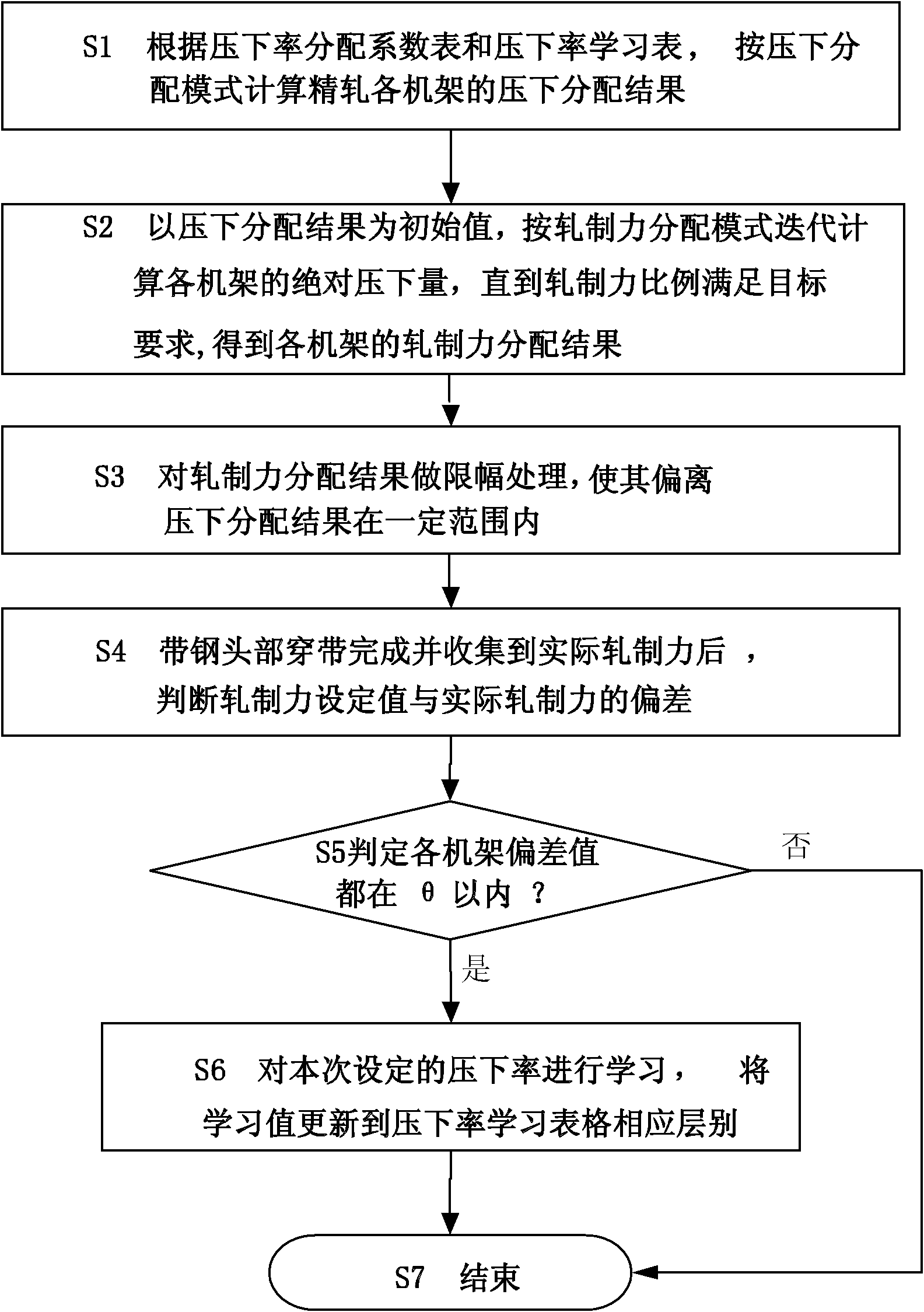

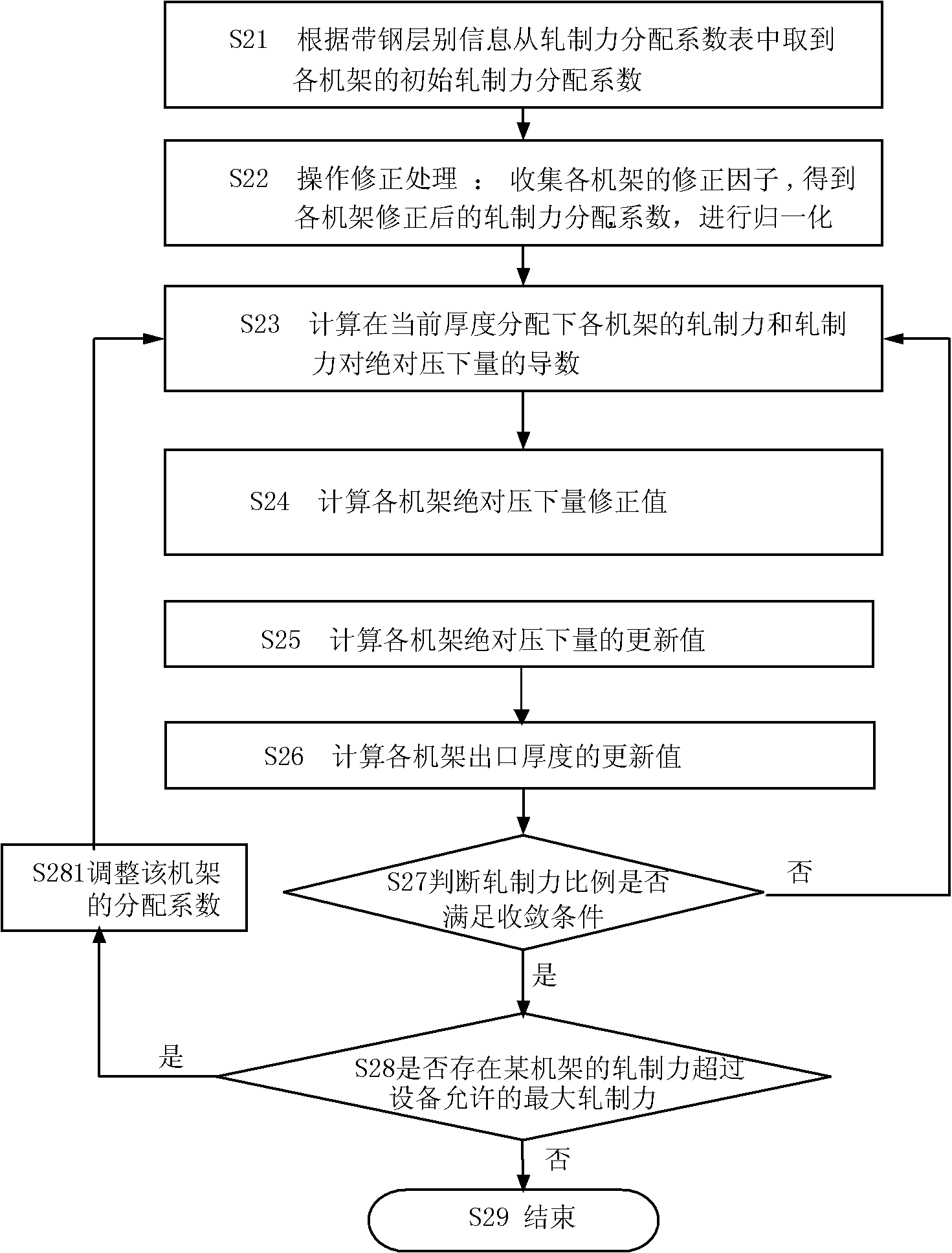

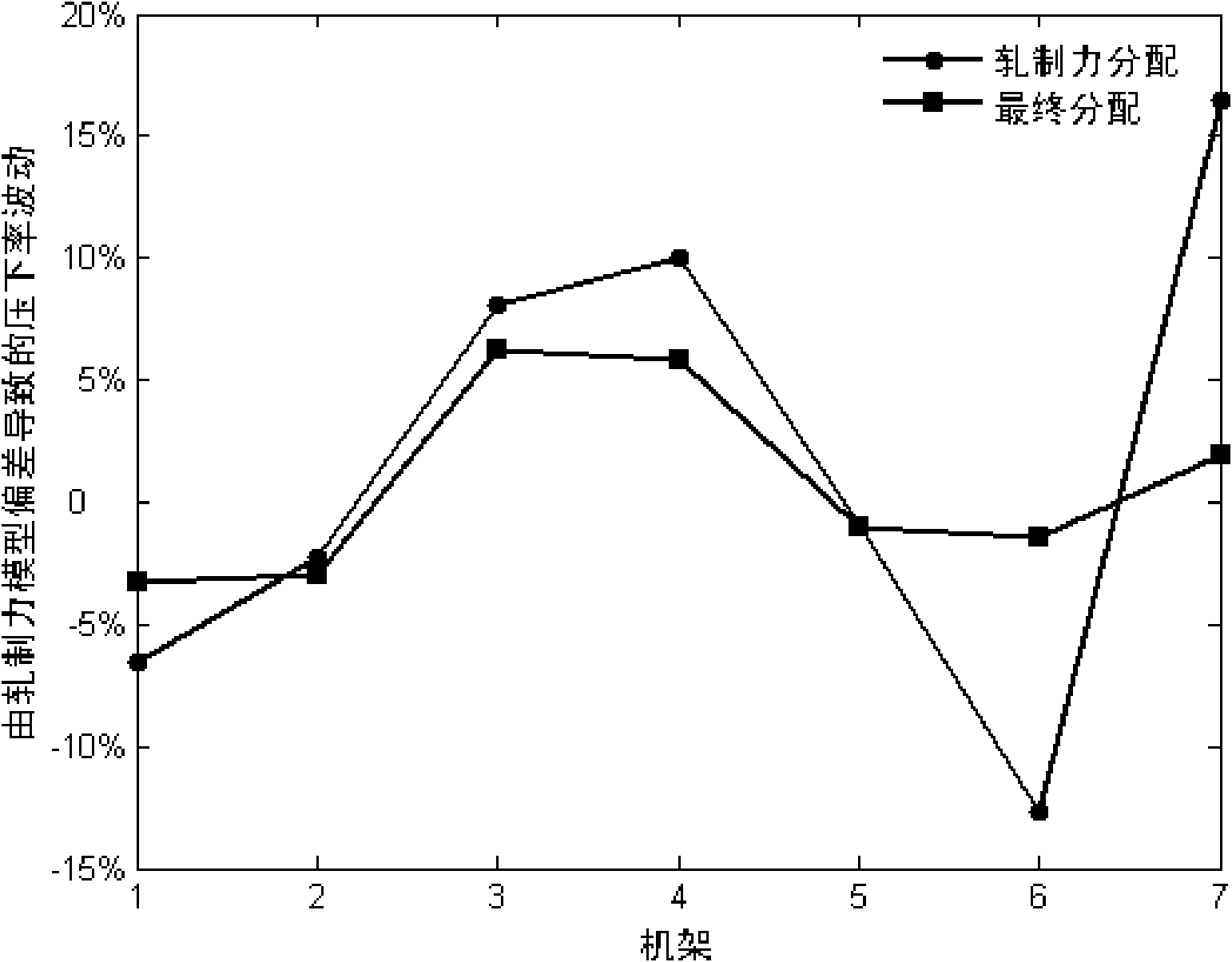

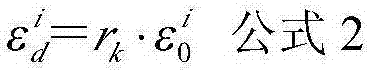

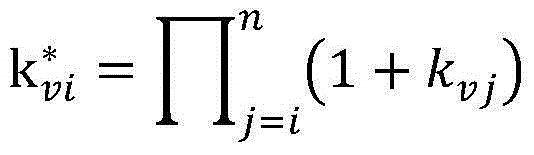

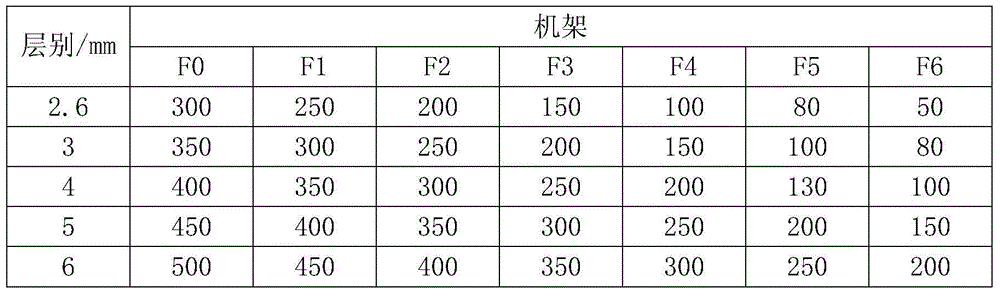

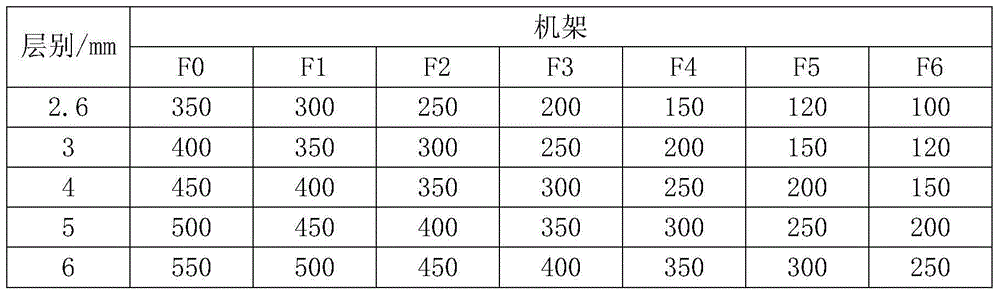

Finish rolling strip steel load distribution setting method

InactiveCN107442577AConstrained rolling force distribution resultsConstraint assignment resultsRoll force/gap control deviceMetal rolling arrangementsReduction rateStrip steel

The invention relates to a finish rolling strip steel load distribution setting method and mainly aims to solve the technical problem that in the existing depressing distribution mode, the rolling force proportions of all racks greatly fluctuate when the rolling condition changes, and in the rolling force distribution mode, the thickness distribution of all racks greatly fluctuates when the deviation of a rolling force model is large. The finish rolling strip steel load distribution setting method comprises the following steps: S1, calculating the thickness distribution of carrying out finish rolling on all racks according to the depressing distribution mode, taking out the reduction rate distribution coefficient of each rack from a depressing distribution coefficient graph, and obtaining the reduction rate and outlet thickness of depressing distribution according to the reduction rate distribution coefficient of each rack; S2, taking the depressing distribution result as an initial value, and carrying out iterative computation on rolling reduction of each rack according to the distribution mode of rolling force until the proportion of the rolling force meets the target requirement; and S3, carrying out amplitude limiting treatment and relativization calculation on the distribution result of the rolling force mode. With adoption of the finish rolling strip steel load distribution setting method, the setting precision and rolling stability of the rolling schedule of finish rolling strip steel are improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

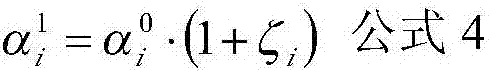

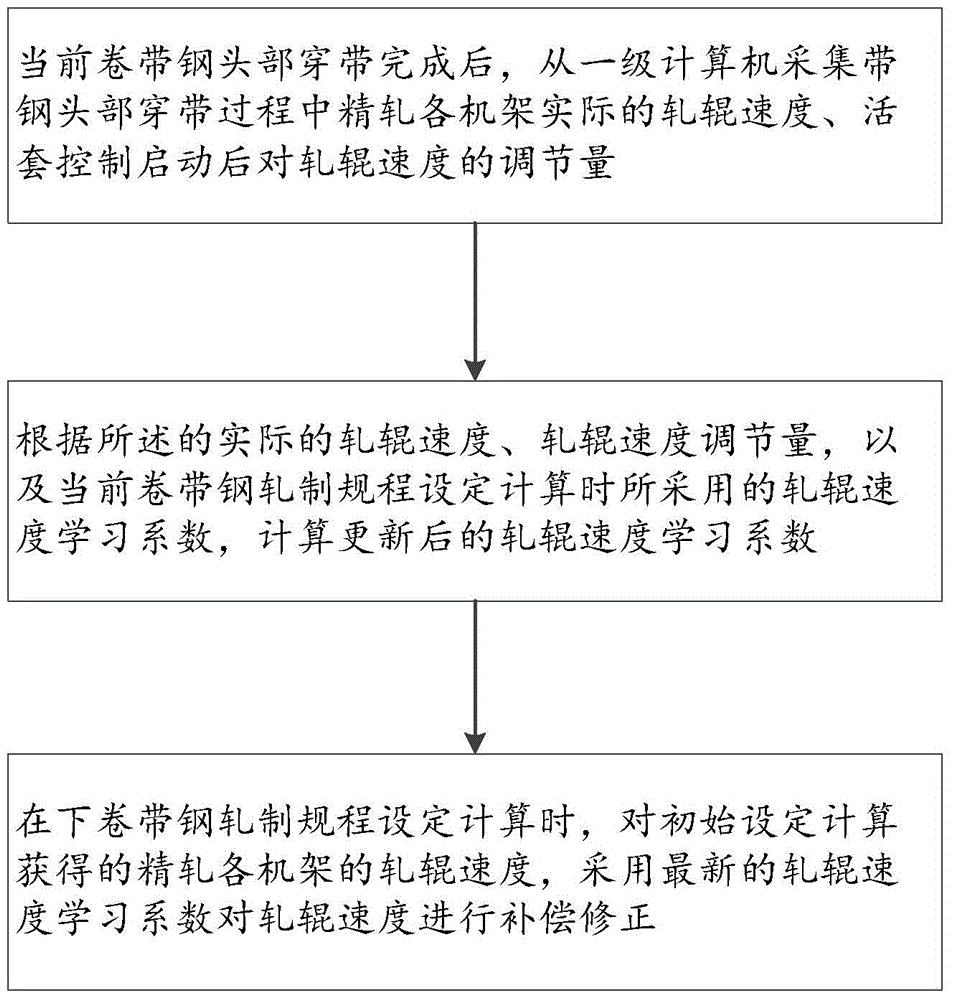

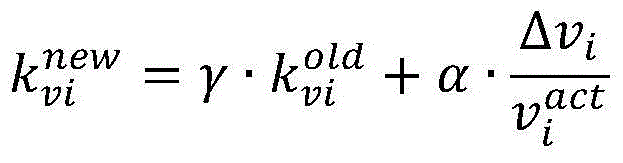

Method for realizing flow per second balance among hot rolling continuous mill stands through rolling mill speed compensation

ActiveCN104874613AReduce the sizeCan't afford to reduceMass flow control deviceMetal rolling arrangementsAdaptive learningLoop control

The invention discloses a method for realizing flow per second balance among hot rolling continuous mill stands through rolling mill speed compensation, relates to the field of hot-rolling production process control, and aims to solve the problem of flow per second imbalance in the head wearing process of a hot rolling strip steel. The practical roll speed for finish rolling of each frame and the roll speed regulating quantity required by loop control is acquired from a level 1 computer according to the regulating process of the roll speed for finish rolling of each frame required by loop control in a threading process, specification-classifying self-adaptive learning is performed on the change rate of the roll speed required by the loop control according to steel type*thickness*frame, and the roll speed is corrected by adopting a latest learning coefficient during setting calculation of a next roll of strip steel in order that the flow per second among the finish-rolled frames tends to be balanced. By adopting the method, the phenomena of large loop rise or no loop rise, finish rolling steel scrap, width reduction and the like can be reduced, and the rolling stability of a finish rolling process is improved remarkably.

Owner:科大集智数据科技(武汉)有限公司

Control method of thin plate hot rolling wire finishing mill AGC system

InactiveCN104907341AHigh control precisionImprove pass rateRoll mill control devicesMetal rolling arrangementsEconomic benefitsStrip steel

The invention discloses a control method of a thin plate hot rolling wire finishing mill AGC system. According to the control method, the adjusting amplitude is subdivided according to the different thickness of the finished strip steel and different racks, and the adjusting amplitude is increased when the thickness of the finished strip steel is increased, and is decreased when the sequence number of the rack is increased. Therefore, the control concept that the adjusting amplitude of all finished strip steels at each rack of the finishing mill is a certain value is changed. The linear setting is conducted based on different thickness at each rack outlet of the racks F0, F1...Fn, the control precision of the AGC system is raised; the qualified rates of the strip steels in both thick and thin specification are increased and the production stability is improved. Therefore, the strip steels in smalllot, multi steel types and multi specification can be produced at the same time based on the order, and substantial economic benefit is realized.

Owner:SHANDONG IRON & STEEL CO LTD

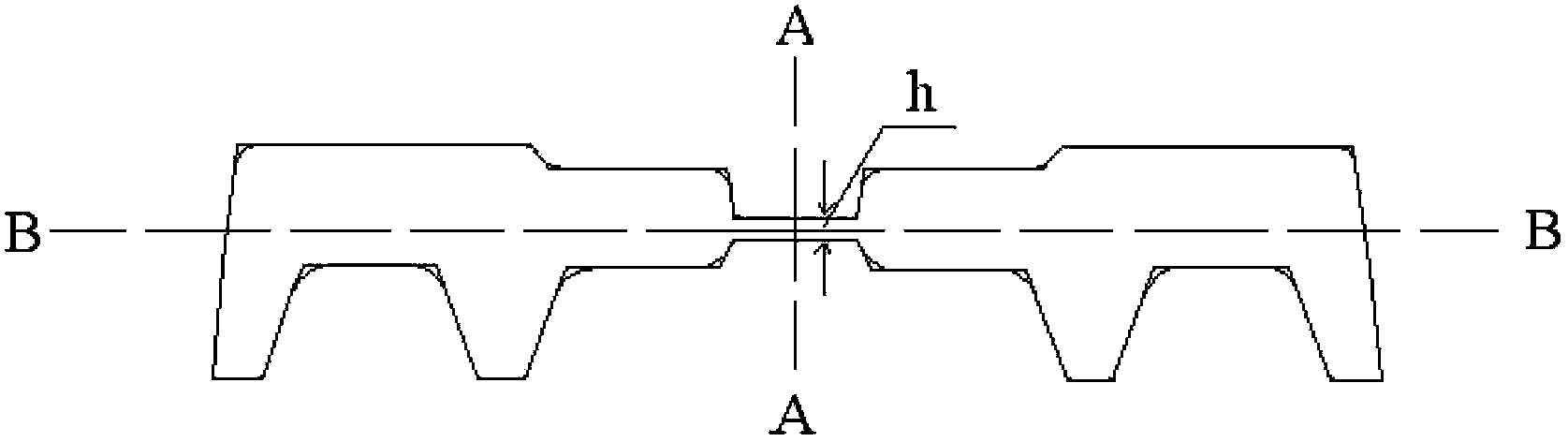

F-shaped steel mill roll double-hole type and rolling method

ActiveCN103357663AIncrease rolling speedImprove rolling stabilityRollsMetal rolling arrangementsProduction lineEngineering

The invention discloses an F-shaped steel mill roll double-hole type and a rolling method. The double-hole type is formed by splicing an upper roll and a lower roll of a rolling mill and is a pair of F-shaped steel hole types which is symmetric along an axial line AA and are communicated through a connecting area. The axial line AA is perpendicular to the horizontal central ling BB of the double-hole type; and the connecting area is used for connecting one side, corresponding to the free end of a wing plate of the rolled F-shaped steel, of each F-shaped steel hole type. According to the rolling method, rolling is performed through a production line consisting of a reversible roughing mill and a universal rolling mill group; and each universal rolling mill of the universal rolling mill group is provided with the mill roll of the F-shaped steel mill roll double-hole type. The F-shaped steel mill roll double-hole type is used for rolling, so the rolling speed, namely the yield of steel per hour can be increased, the production cost can be reduced, the rolling stability can be improved, and the yield of finished products can be increased.

Owner:LAIWU IRON & STEEL GRP

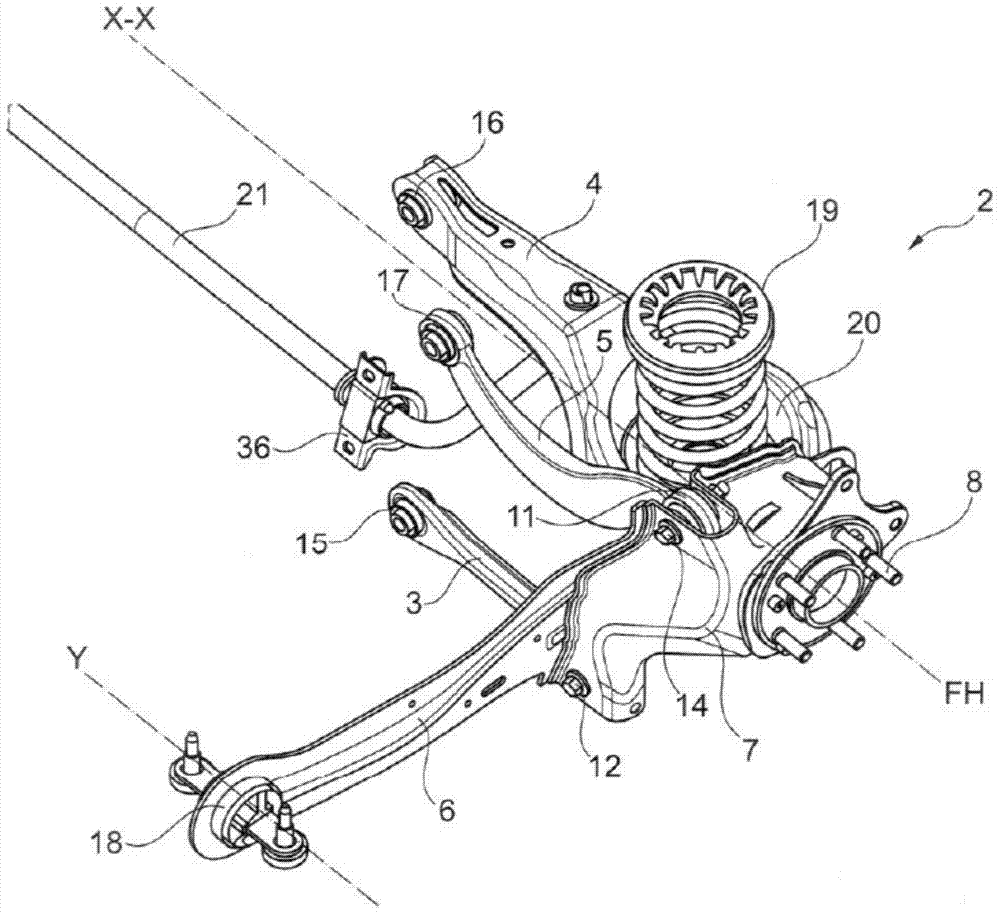

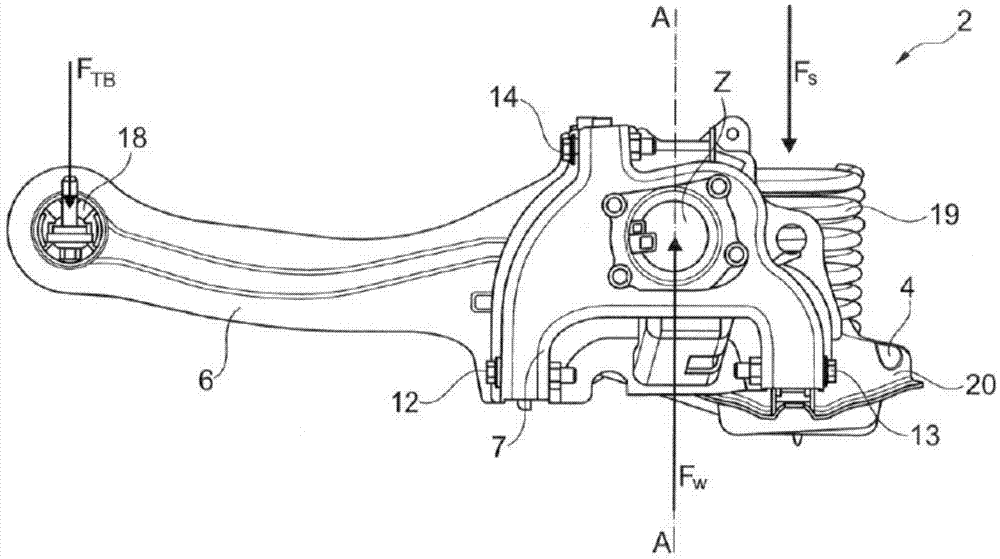

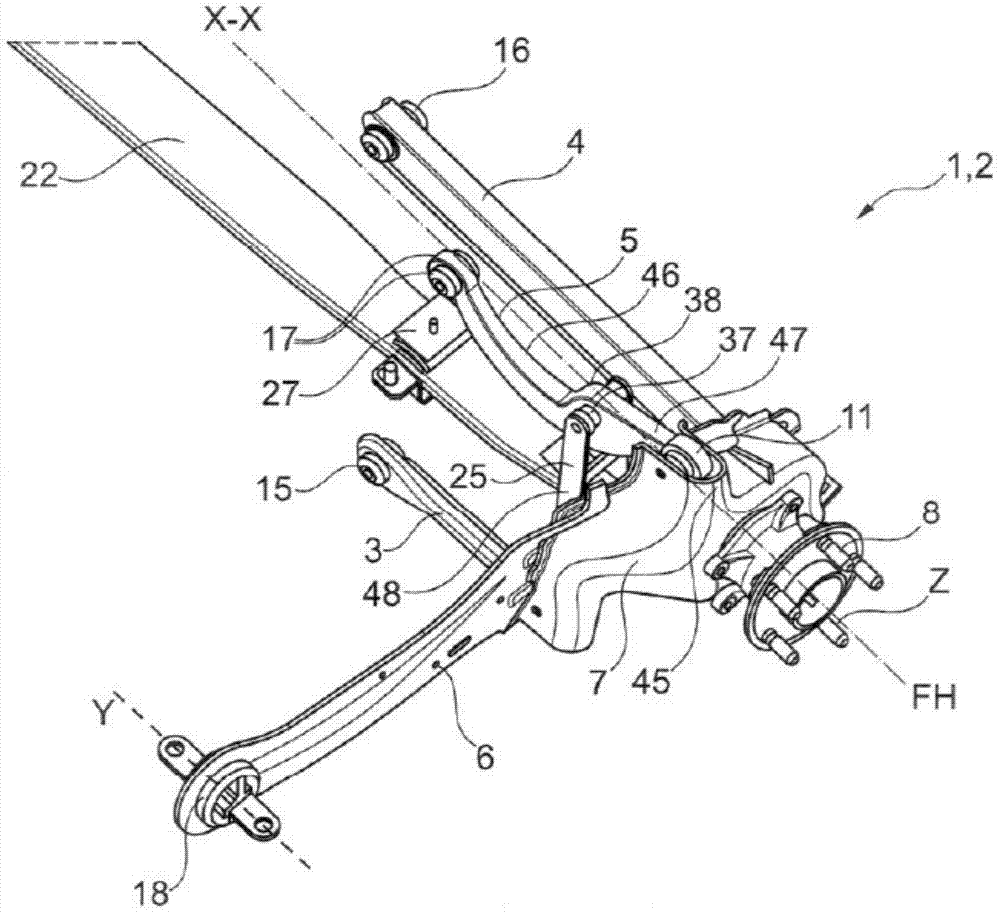

Multilink rear axle for a motor vehicle

ActiveCN104210321AReduce weightImprove rolling stabilityInterconnection systemsResilient suspensionsMobile vehicleControl arm

A multilink rear axle comprises a wheel carrier, a leaf spring, a first lower control arm, an upper control arm, and at least one member. The wheel carrier can rotatably support a wheel of the vehicle. The leaf spring can extend in a width direction of the vehicle that is transverse to a longitudinal direction of the vehicle. The first lower control arm can extend in the width direction and is pivotably coupled to the wheel carrier at a rear half thereof. The upper control arm can extend in the width direction and can be pivotably coupled to the wheel carrier at an attachment point that is offset from the rotation axis of the supported wheel in the longitudinal direction by less than or equal to 100 mm. The at least one member can pivotably couple the leaf spring to the upper control arm.

Owner:FORD GLOBAL TECH LLC

Household aluminum foil material and preparation method of household aluminum foil

ActiveCN102409199AReduce intensityHigh elongationMetal rolling arrangementsHigh surfaceUltimate tensile strength

The invention relates to the preparation of an aluminum alloy material, in particular to a household aluminum foil material and a preparation method of the household aluminum foil. The aluminum alloy material comprises the following alloy components by weight percent: 0.2-0.25% of Si, 0.77-0.83% of Fe, 0.05% of Cu, 0.1% of Zn, 0.05% of Ti and the balance Al. The material combines the advantages of the series 1 alloy and the 8011 alloy, has low strength, high elongation rate, high surface quality and good rolling stability; and by adopting the material, the production efficiency and yield can be effectively increased and the production cost can be reduced. The hole number of the household aluminum foil prepared by the method is below 200 per square meter, the tensile strength is 80-100Mpa and the elongation rate is no less than 1%.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

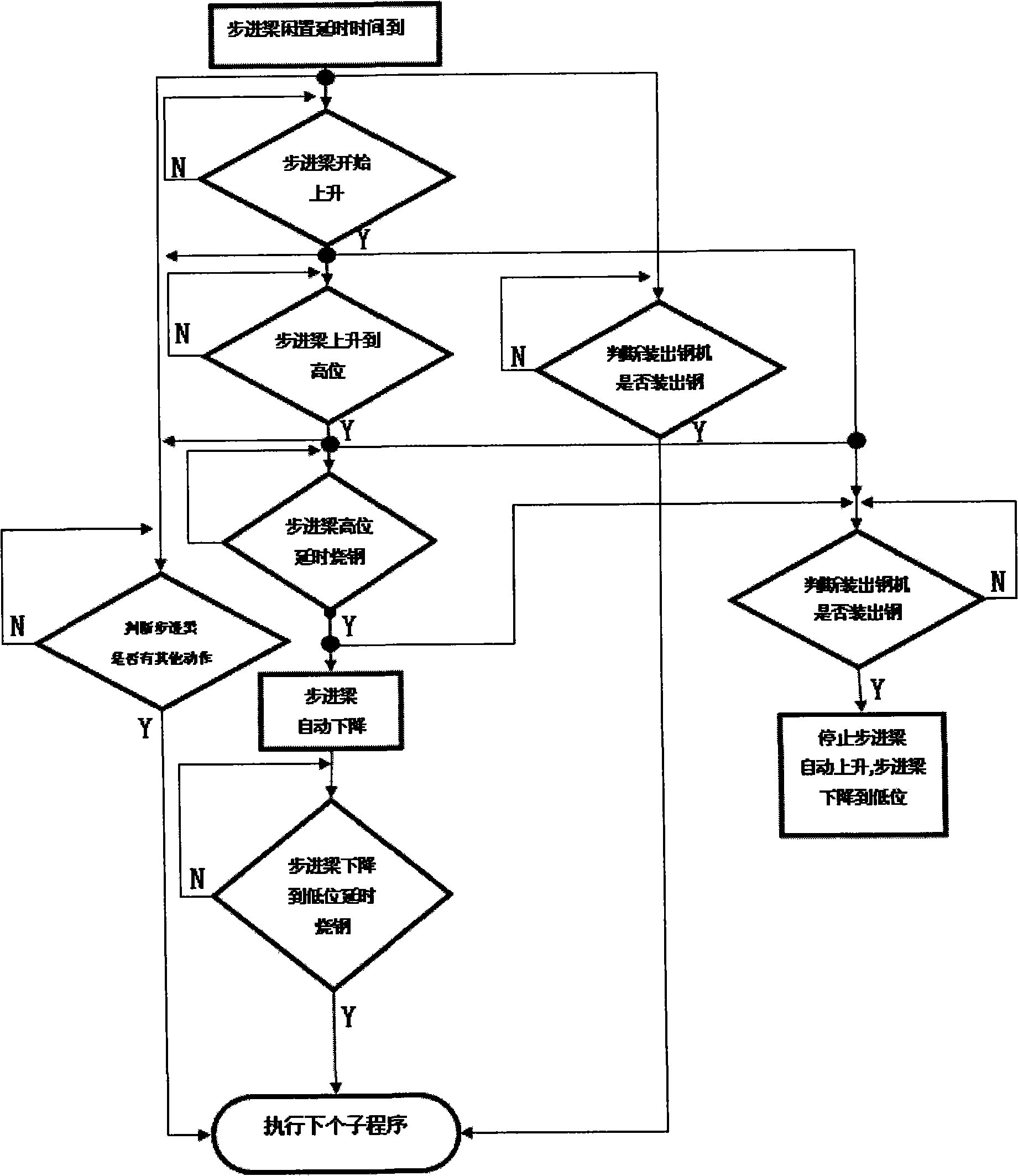

Method for automatic jump steel reheating of walking beam of stepping type heating furnace

ActiveCN101619384AEliminate watermark temperature differenceImprove rolling stabilityFurnace typesHeat treatment furnacesTemperature differenceHeating furnace

The invention discloses a steel reheating method for a stepping type heating furnace. In the steel heating process, a walking beam is mainly in an operating state or idling state; when the walking beam is in the idling state, the walking beam starts automatic high-low lifting motion; and when the walking beam is in the operating state, the walking beam stops the automatic high-low lifting motion. By the high-low automatic jump steel heating of the walking beam at the quench time before steel tapping and the reasonable setting of the staying time of the walking beam on high and low positions, the serious water mark temperature difference caused by overlong time of a plate blank stayed on a fixed beam can be effectively eliminated, and the performance requirements on special products such as greatly improving the dimensional accuracy of products, enhancing the rolling stability of a finishing mill, greatly improving silicon steel and the like can be met.

Owner:ANGANG STEEL CO LTD

Vessel comprising transverse skirts

The invention relates to a vessel having an elongated shape, and being moored to the sea bed in a substantially fixed orientation. The vessel comprises at least along its longitudinal sides, near keel level, two transverse skirts having such a width that the natural roll period of the vessel is above a predetermined period, the natural roll period of the vessel without the skirts being below said predetermined period.

Owner:SINGLE BUOY MOORINGS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com