700MPa-grade cold rolled steel plate with high weather resistance and preparation method thereof

A technology of cold-rolled steel plate and weather resistance, which is applied in the field of cold-rolled steel plate and its preparation, can solve the problems of increasing the rolling reduction force in the cold-rolling process, large investment in continuous annealing furnace, and high alloy cost, so as to solve the problems of large performance fluctuation, Excellent processability and low product cost

Inactive Publication Date: 2011-04-13

GUANGZHOU PEARL RIVER STEEL & IRON

View PDF7 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

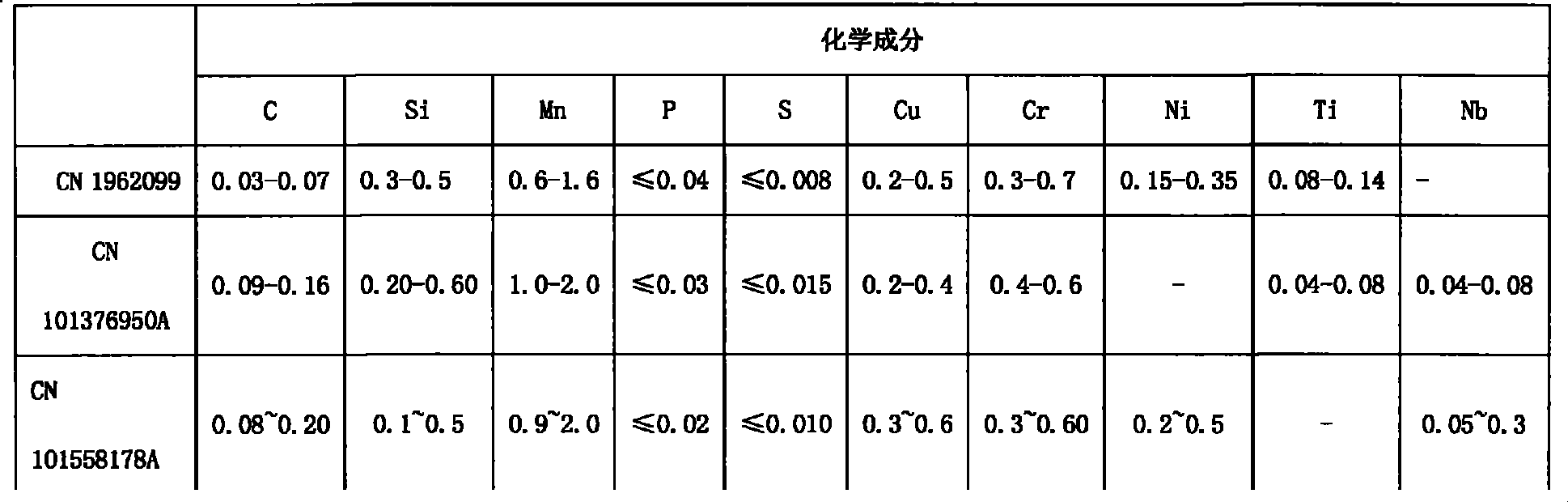

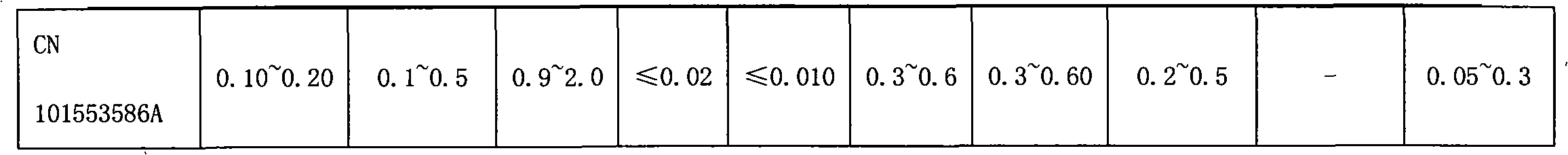

Similarly, this technology uses hot-rolled plates produced in the traditional process and then undergoes cold rolling and continuous annealing processes. The process is complicated and the energy consumption is high; at the same time, a large amount of precious metals such as Nb, Ti, and Mo are added to the patent as reinforcing components. , the cost of the alloy is high, and the process control is complicated; a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses 700MPa-grade cold rolled steel plate with high weather resistance and a preparation method thereof. In the invention, a thin plate black continuous casting and continuous rolling flow is adopted. The refined molten steel mainly comprises the following chemical components: 0.03 to 0.07 weight percent of C, less than or equal to 0.35 weight percent of Si, 0.4 to 1.8 weight percent of Mn, less than or equal to 0.020 weight percent of P, less than or equal to 0.010 weight percent of S, 0.25 to 0.50 weight percent of Cu, 0.25 to 0.80 weight percent of Cr, 0.05 to 0.30 weight percent of Ni, 0.06 to 0.20 weight percent of Ti, and the balance of Fe and inevitable impurities. In an annealing process, steel is annealed in a cover annealing furnace at the temperature of 500 DEG C to an A1 transition point. The yield strength of the cold rolled steel plate with high weather resistance exceeds 700MPa, and the elongation rate is over 5 percent, and the cold rolled steel plate has high machinability and high weather resistance.

Description

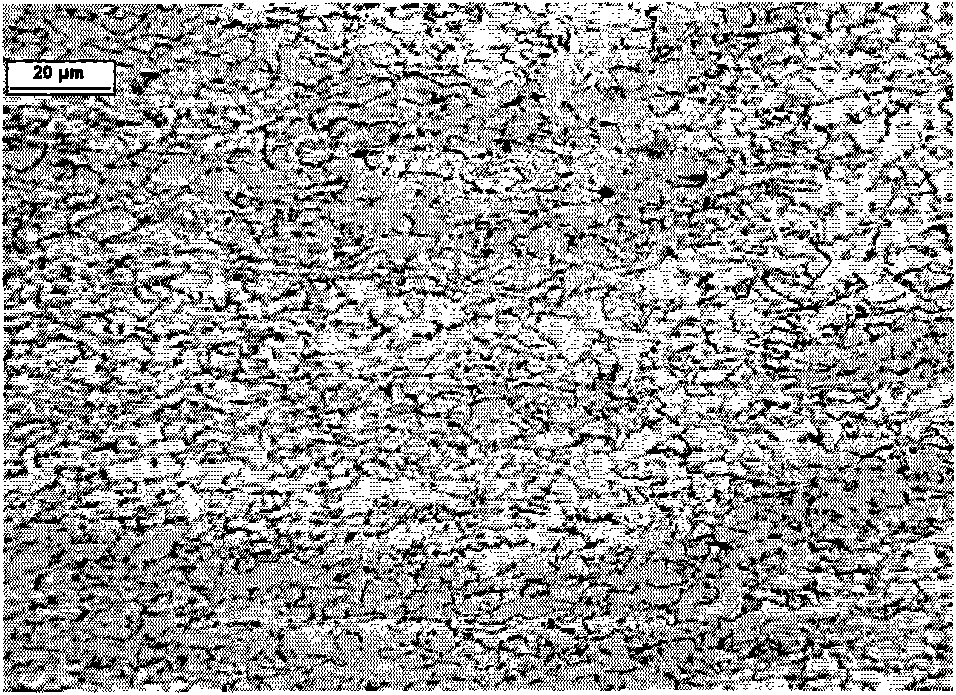

technical field [0001] The invention relates to a 700MPa grade cold-rolled steel plate with excellent weather resistance and a preparation method thereof. Background technique [0002] In recent years, in order to reduce costs and solve environmental problems, the peripheral structural components of containers or vehicles need to use thinner, higher-strength steel plates, and such ultra-thin, high-strength steel is difficult to achieve at the current level of hot-rolling technology and equipment , Therefore, it can only be prepared and produced by cold rolling, annealing and other reprocessing processes. High-strength cold-rolled steel plate with excellent weather resistance can significantly reduce the thickness of the steel plate while ensuring sufficient structural stability. At the same time, because the container should be subjected to various climatic conditions on land or sea, according to the transportation conditions, the container mainly Manufactured using steel w...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/50C22C38/58B21B37/74B21B1/46C21D9/663

Inventor 毛新平朱达炎陈麒琳林良怀

Owner GUANGZHOU PEARL RIVER STEEL & IRON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com