Patents

Literature

579 results about "Transition point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the field of fluid dynamics the point at which the boundary layer changes from laminar to turbulent is called the transition point. Where the boundary layer becomes turbulent, drag due to skin friction is relatively high. As speed increases, the upper surface transition point tends to move forward. As the angle of attack increases, the upper surface transition point also tends to move forward.

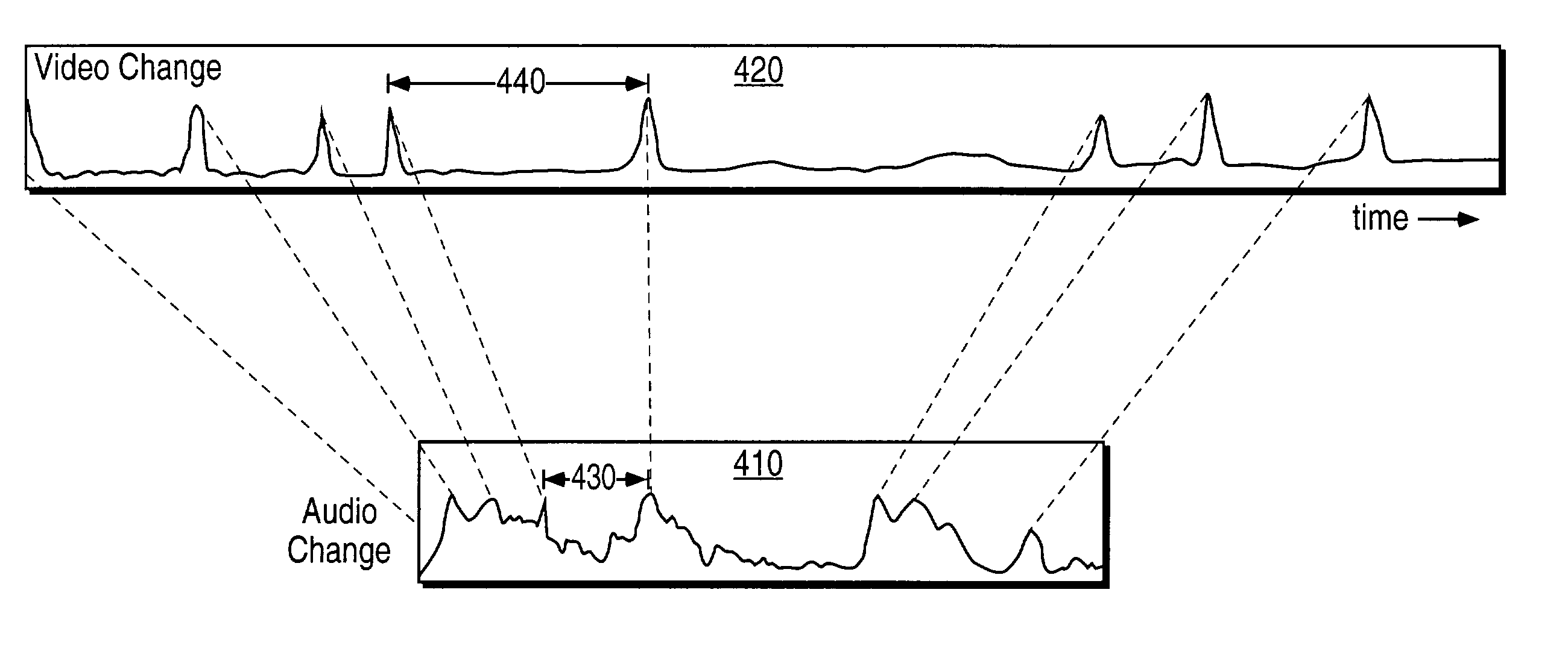

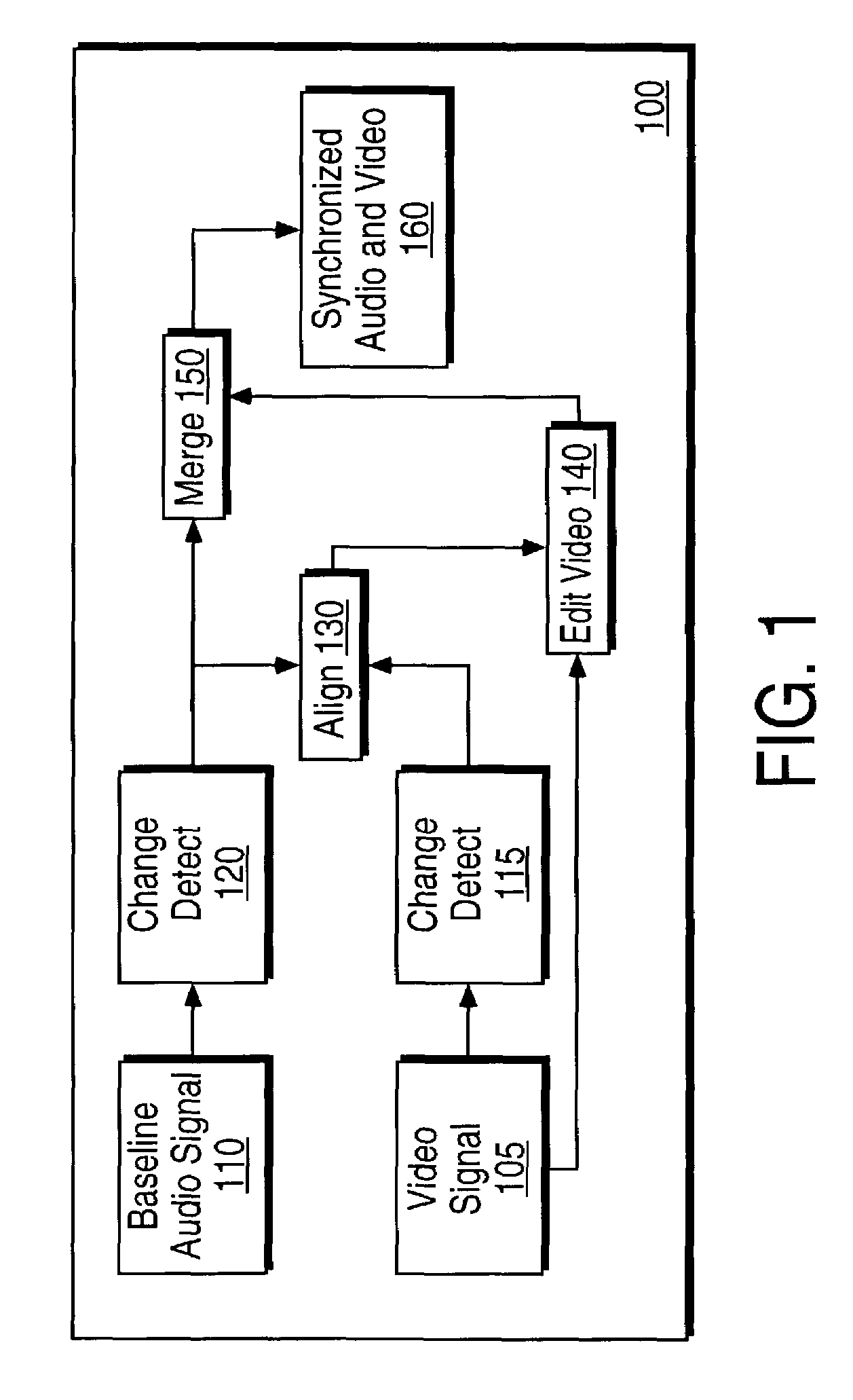

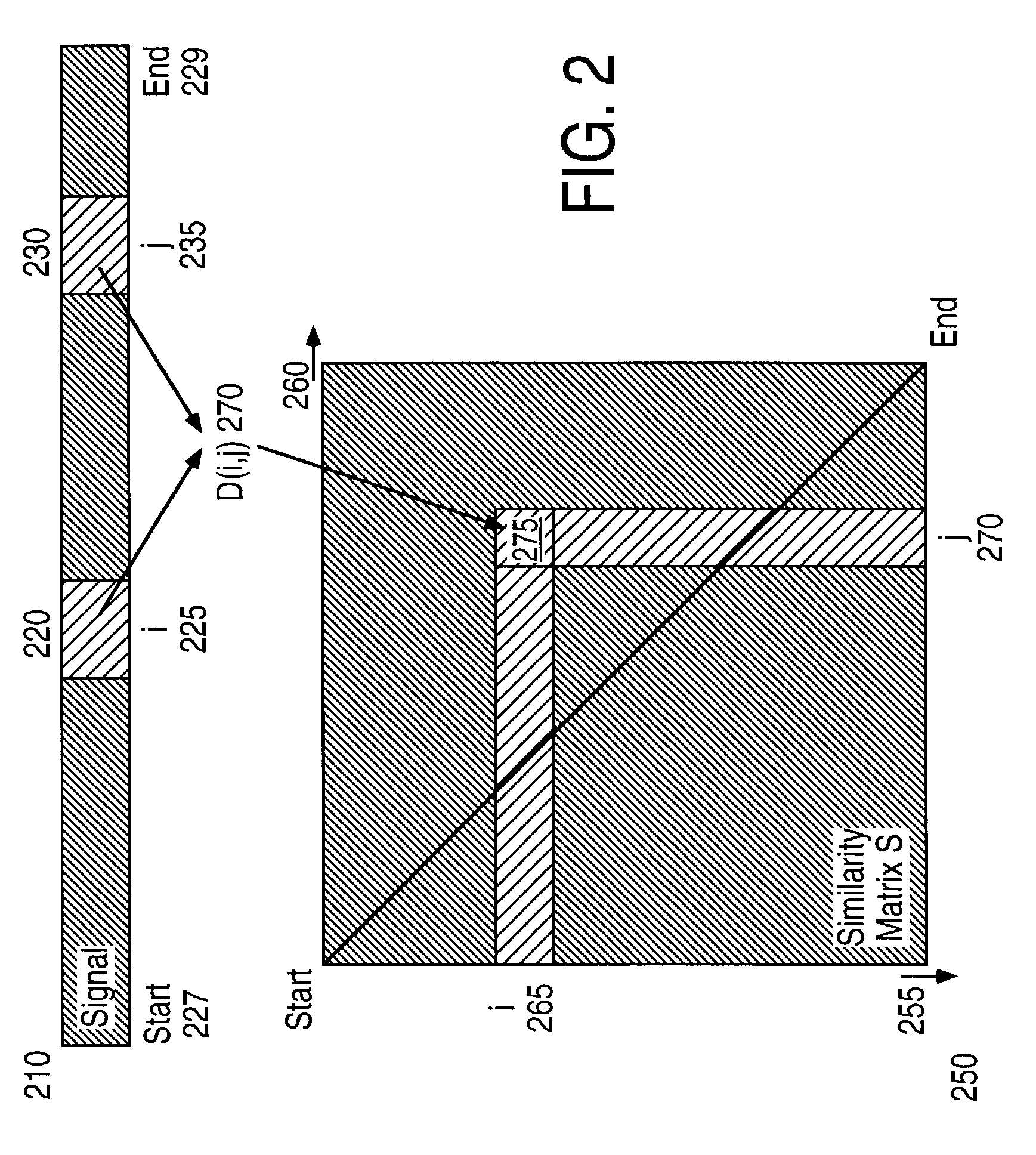

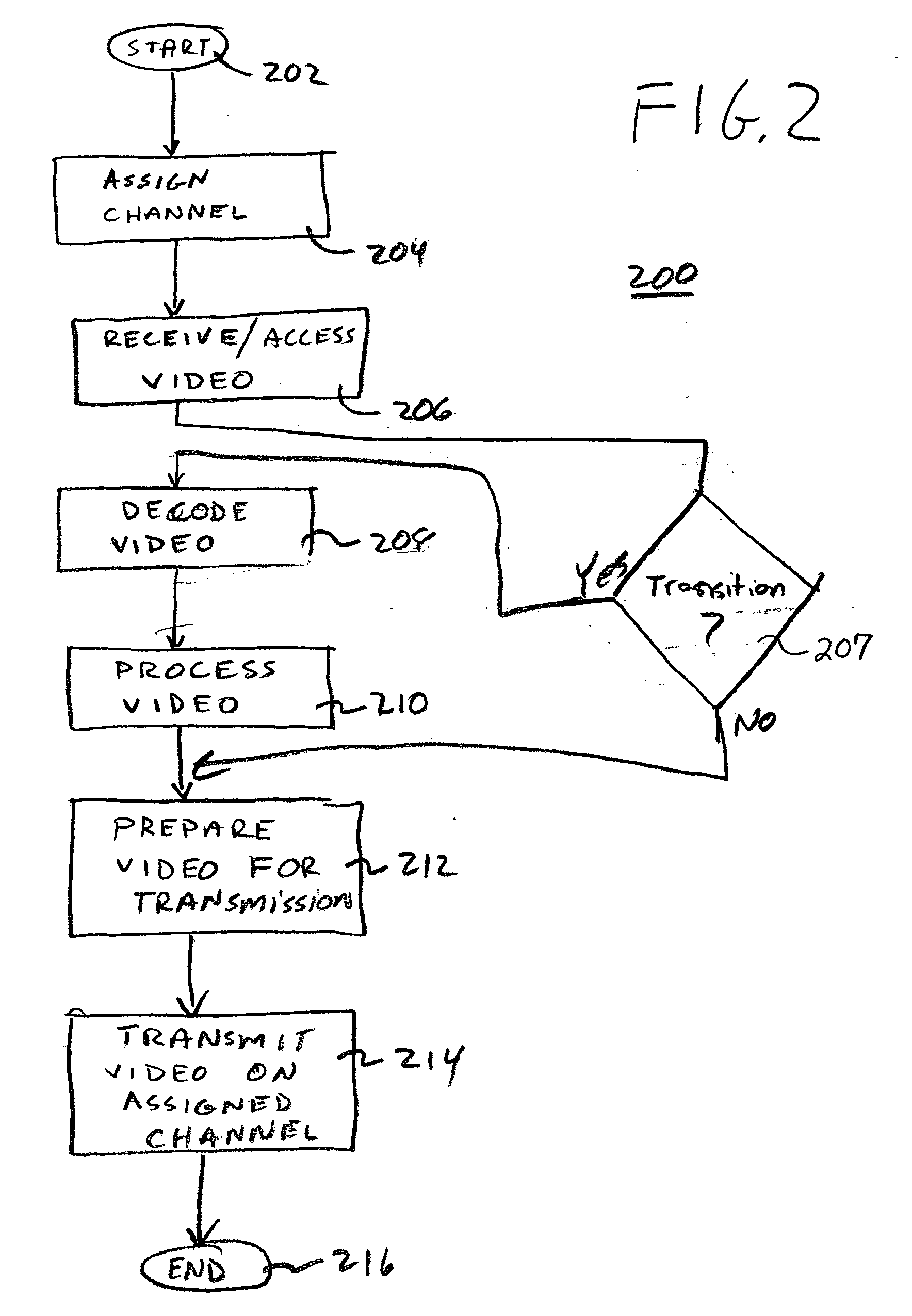

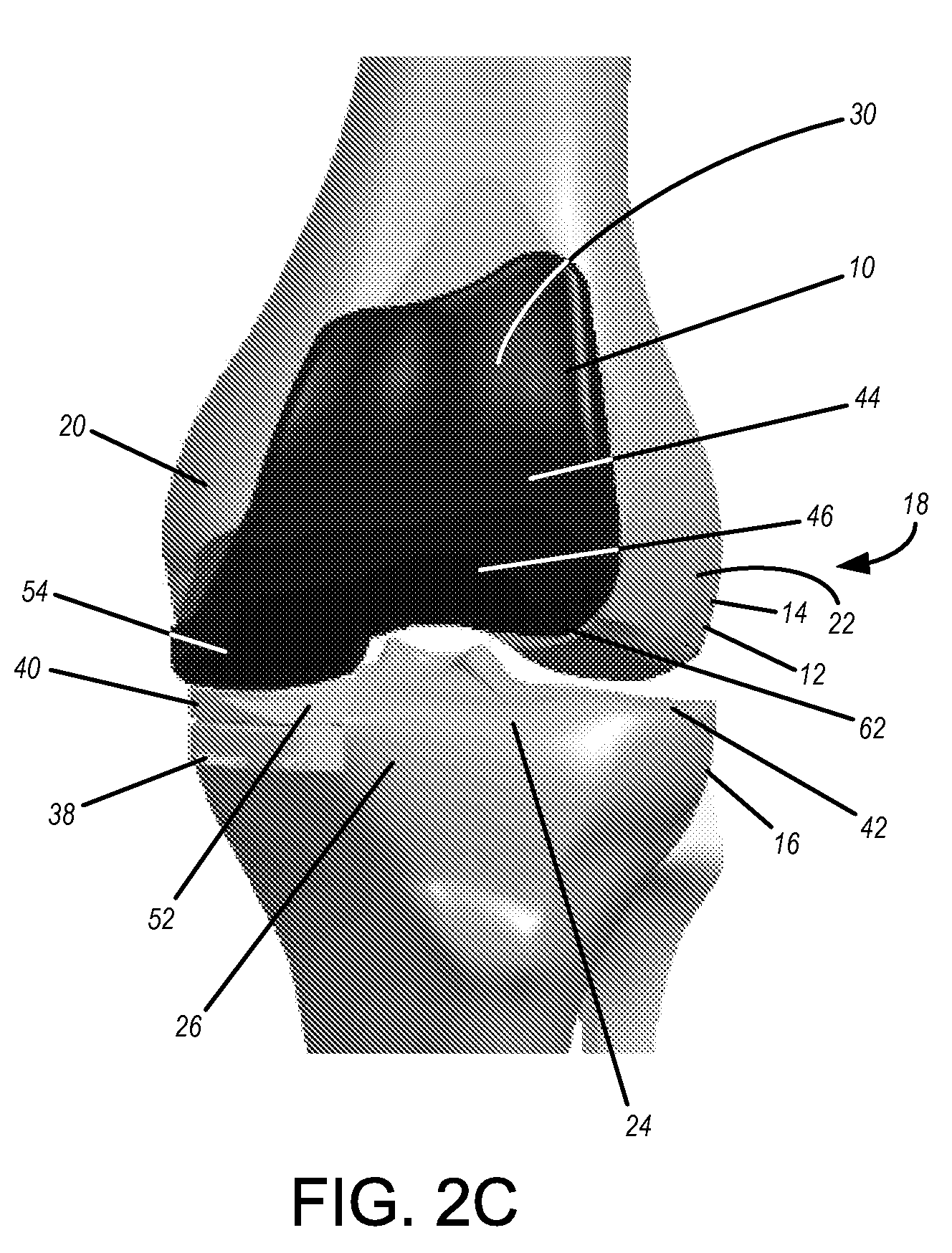

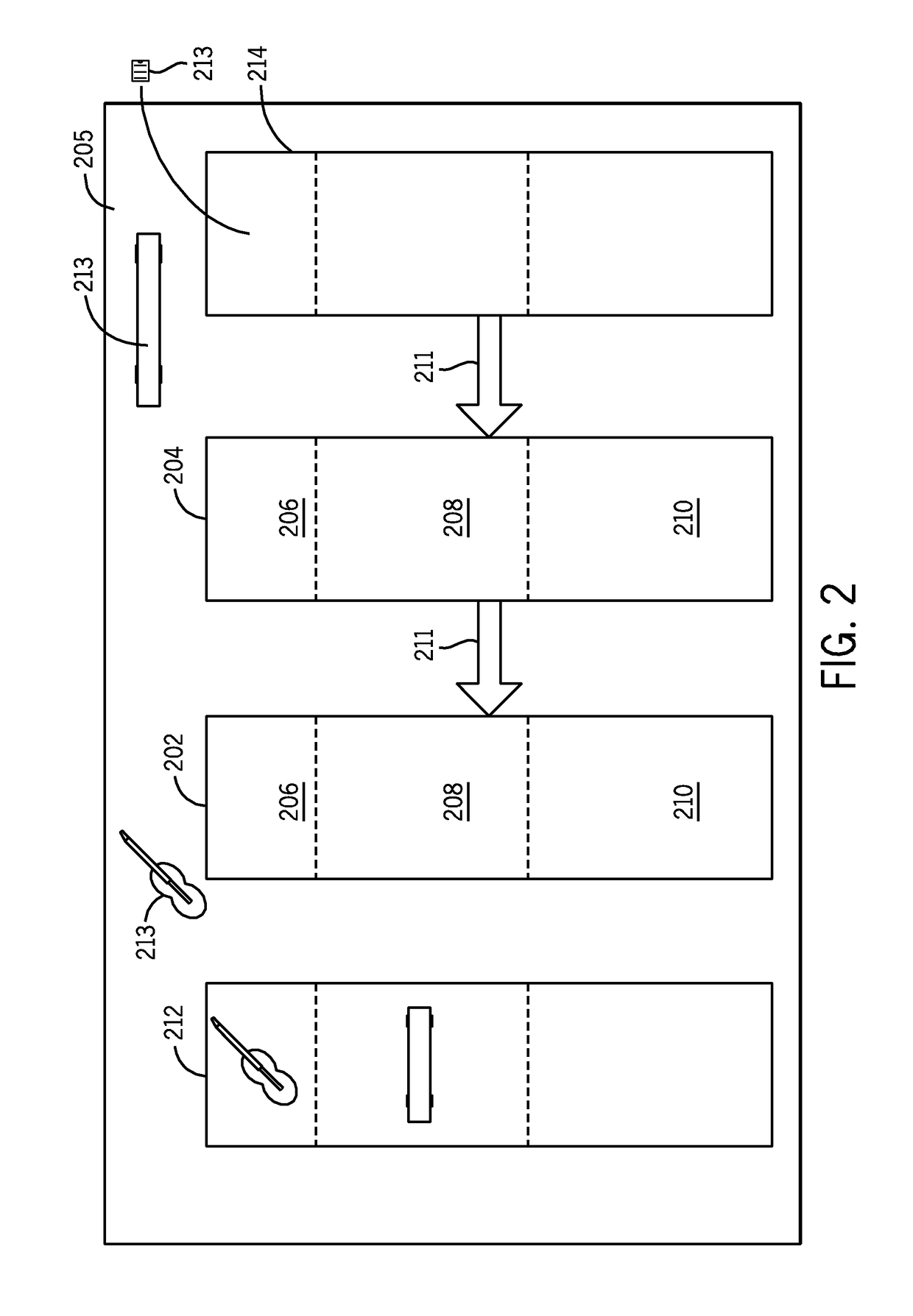

Method for automatically producing music videos

InactiveUS7027124B2Reduce adverse effectsImprove video qualityTelevision system detailsElectronic editing digitised analogue information signalsTransition pointAudio frequency

Music videos are automatically produced from source audio and video signals. The music video contains edited portions of the video signal synchronized with the audio signal. An embodiment detects transition points in the audio signal and the video signal. The transition points are used to align in time the video and audio signals. The video signal is edited according to its alignment with the audio signal. The resulting edited video signal is merged with the audio signal to form a music video.

Owner:FUJIFILM BUSINESS INNOVATION CORP

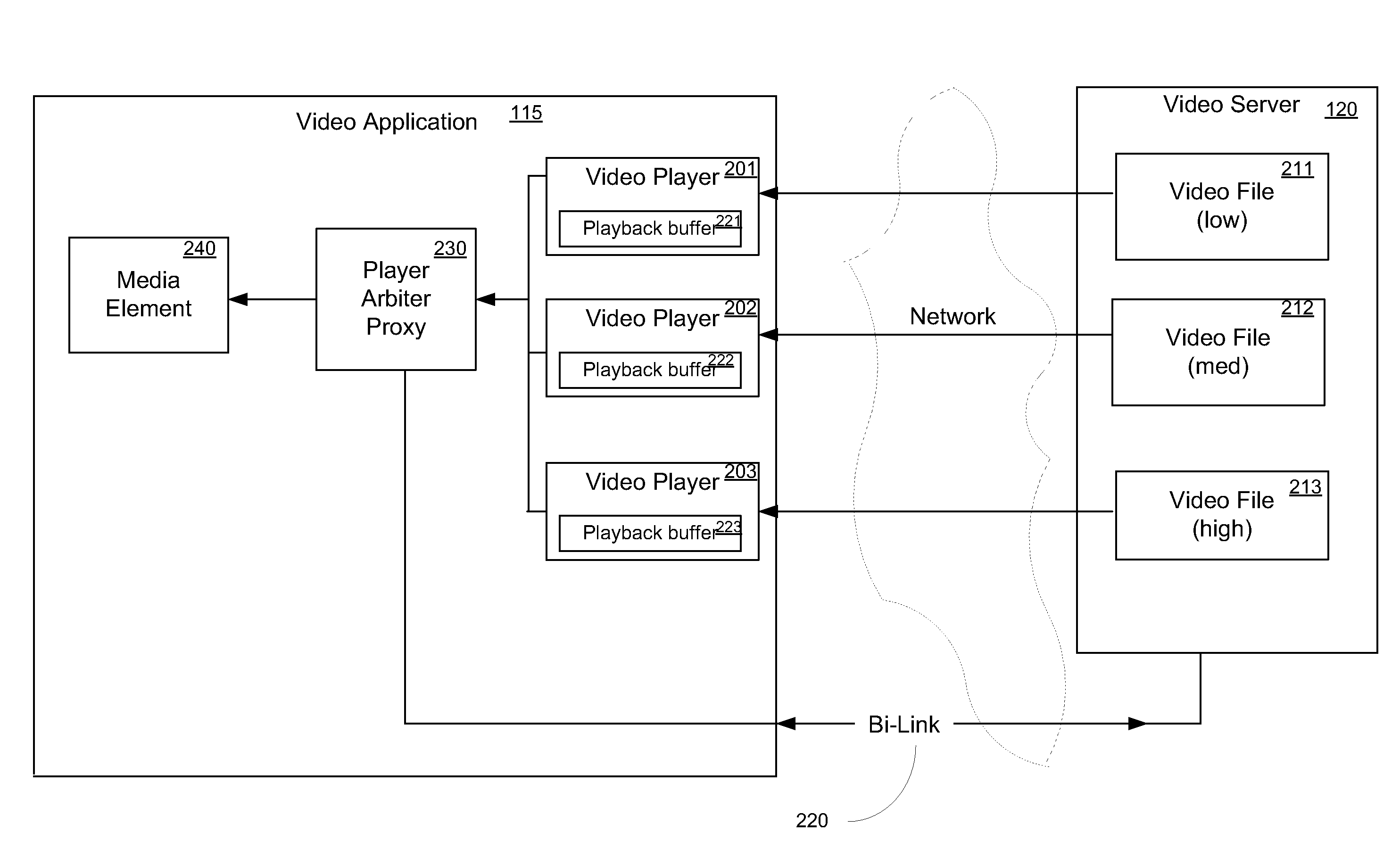

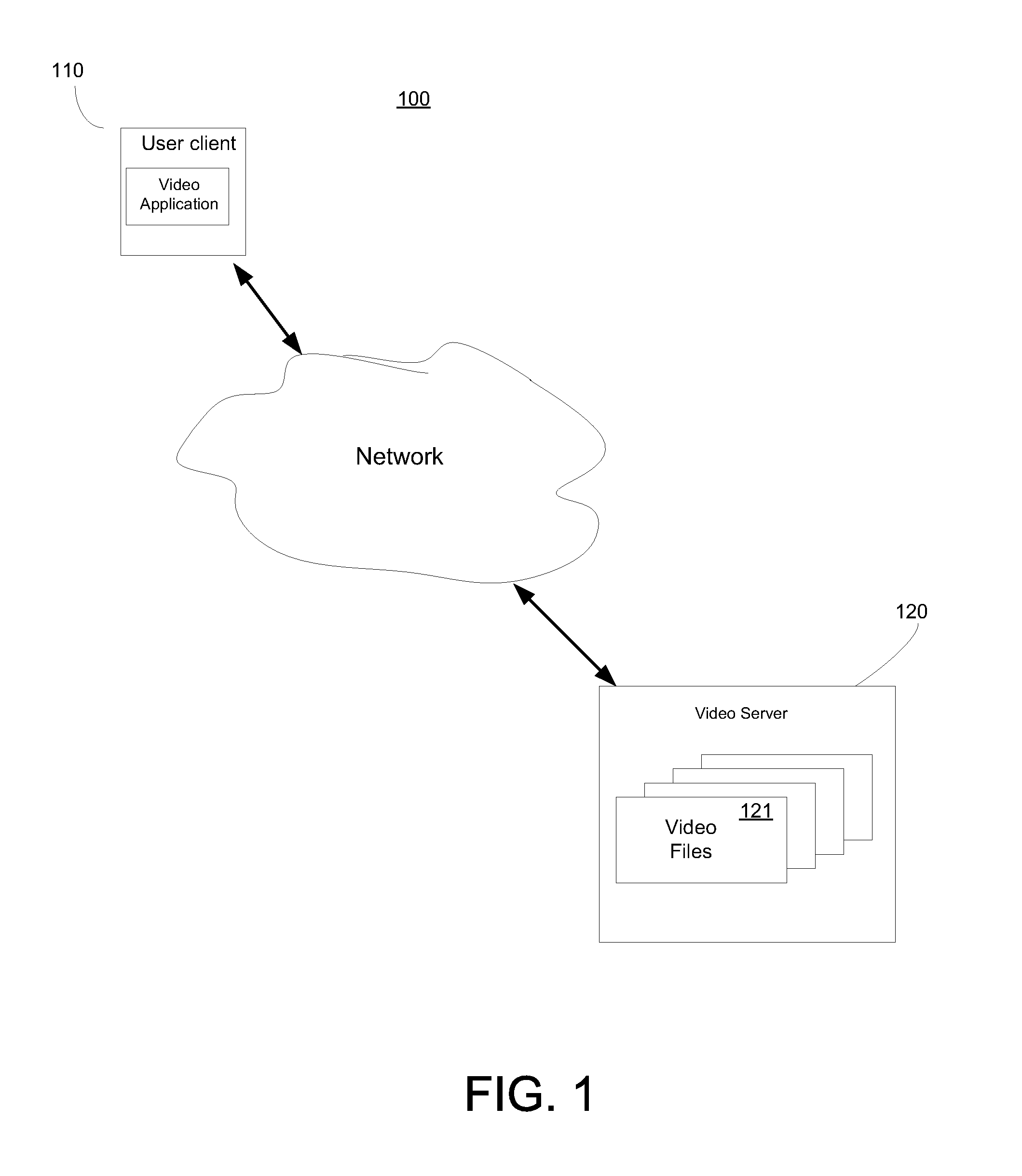

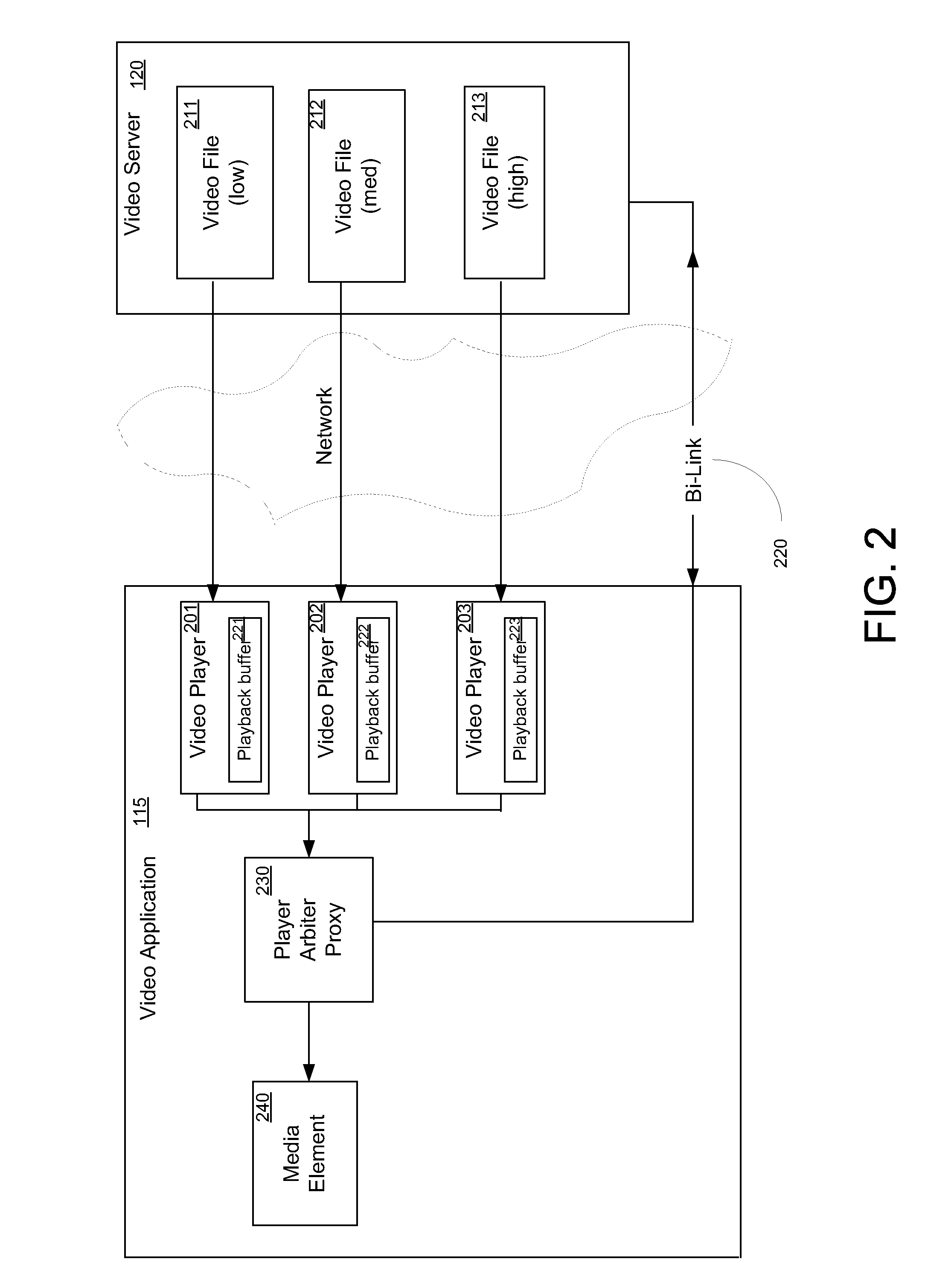

Adaptive video switching for variable network conditions

InactiveUS20090328124A1Color television with pulse code modulationColor television with bandwidth reductionComputer hardwareNetwork conditions

A method for video playback switching in response to changing network conditions. The method includes accessing a server to retrieve respective index files for a low bit rate version and a high bit rate version of the video file, and instantiating a low bit rate media player and a high bit rate media. Playback of the video file is begun by the high bit rate media player streaming the high bit rate version from the server. Upon an indication of impeded network conditions, a transition point is selected, wherein the transition point indicates where downloading of the high bit rate version stops and where downloading of the low bit rate version begins. The low bit rate media player is then positioned to begin playback at the transition point. Playback of the video file is then switched to the low bit rate player upon encountering the transition point.

Owner:MICROSOFT TECH LICENSING LLC

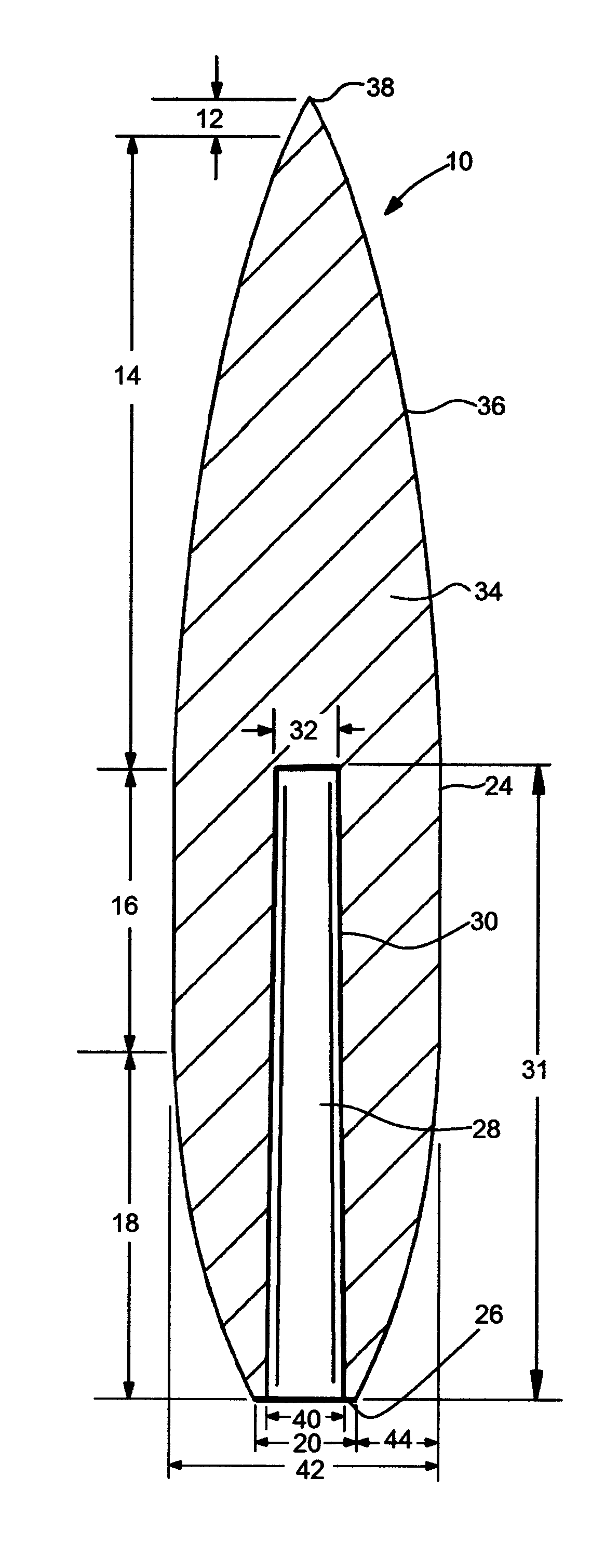

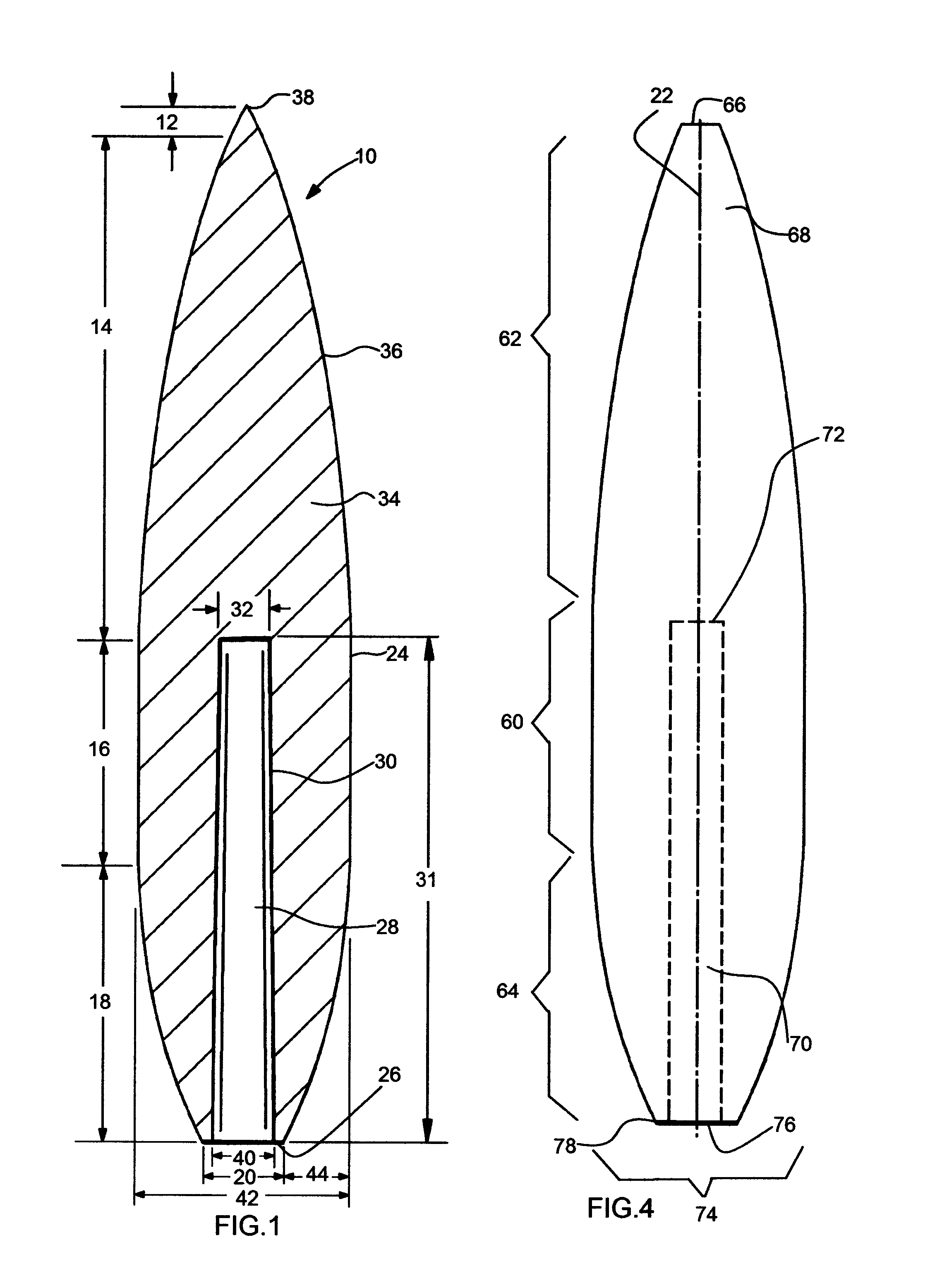

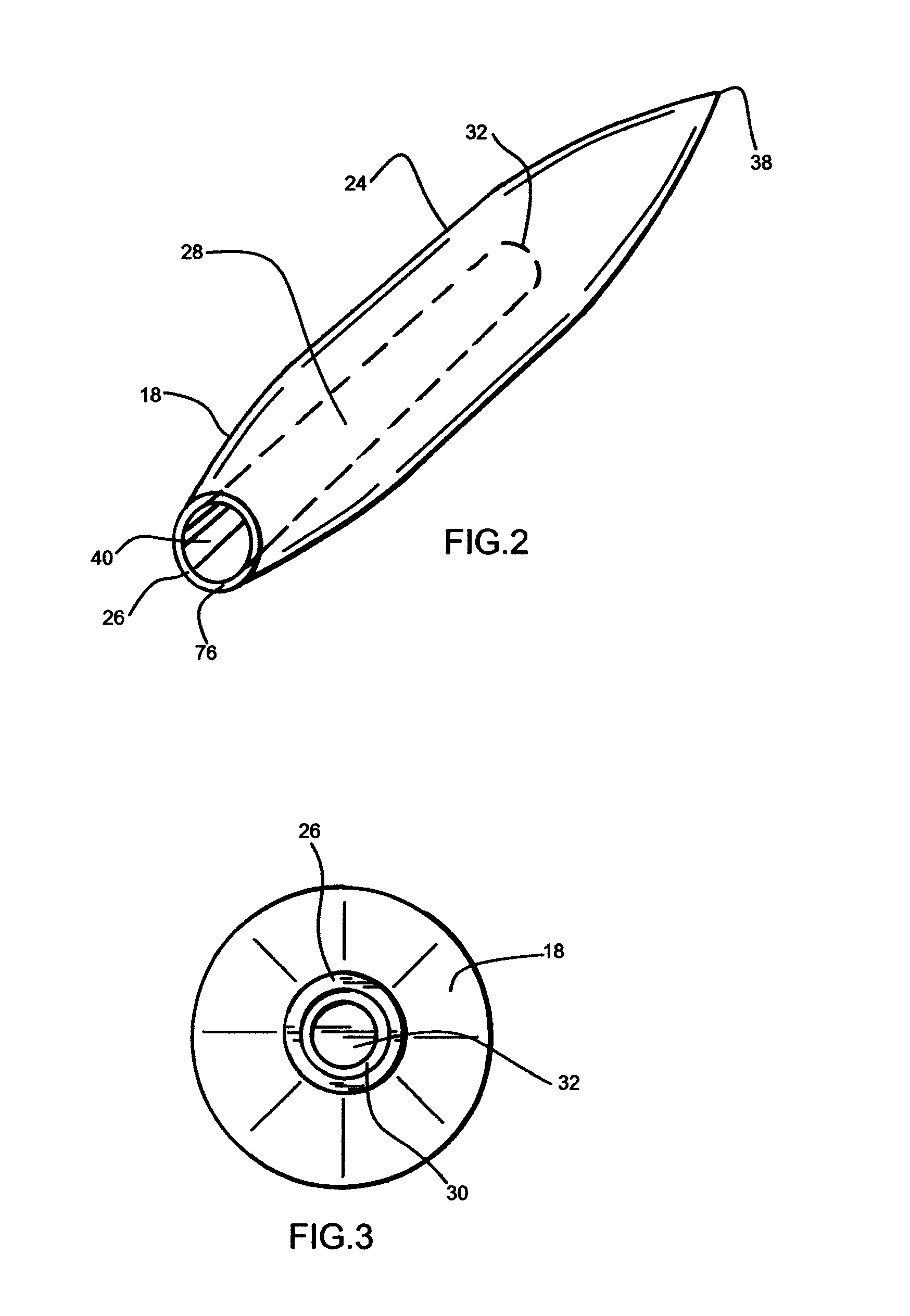

Projectile

ActiveUS8893621B1Superior flight stability characteristicHighly effectiveAmmunition projectilesTraining ammunitionEngineeringBearing surface

A projectile comprised of an ogive section, a bearing surface section and a boattail section. A cavity is formed inside the projectile from an aperture on the aft end of the boattail section and forward to about the transition point (shoulder) between the ogive section and bearing surface section. The cavity is centered about the centerline of the projectile and open on the aft end of the projectile.

Owner:ESCOBAR ROLANDO

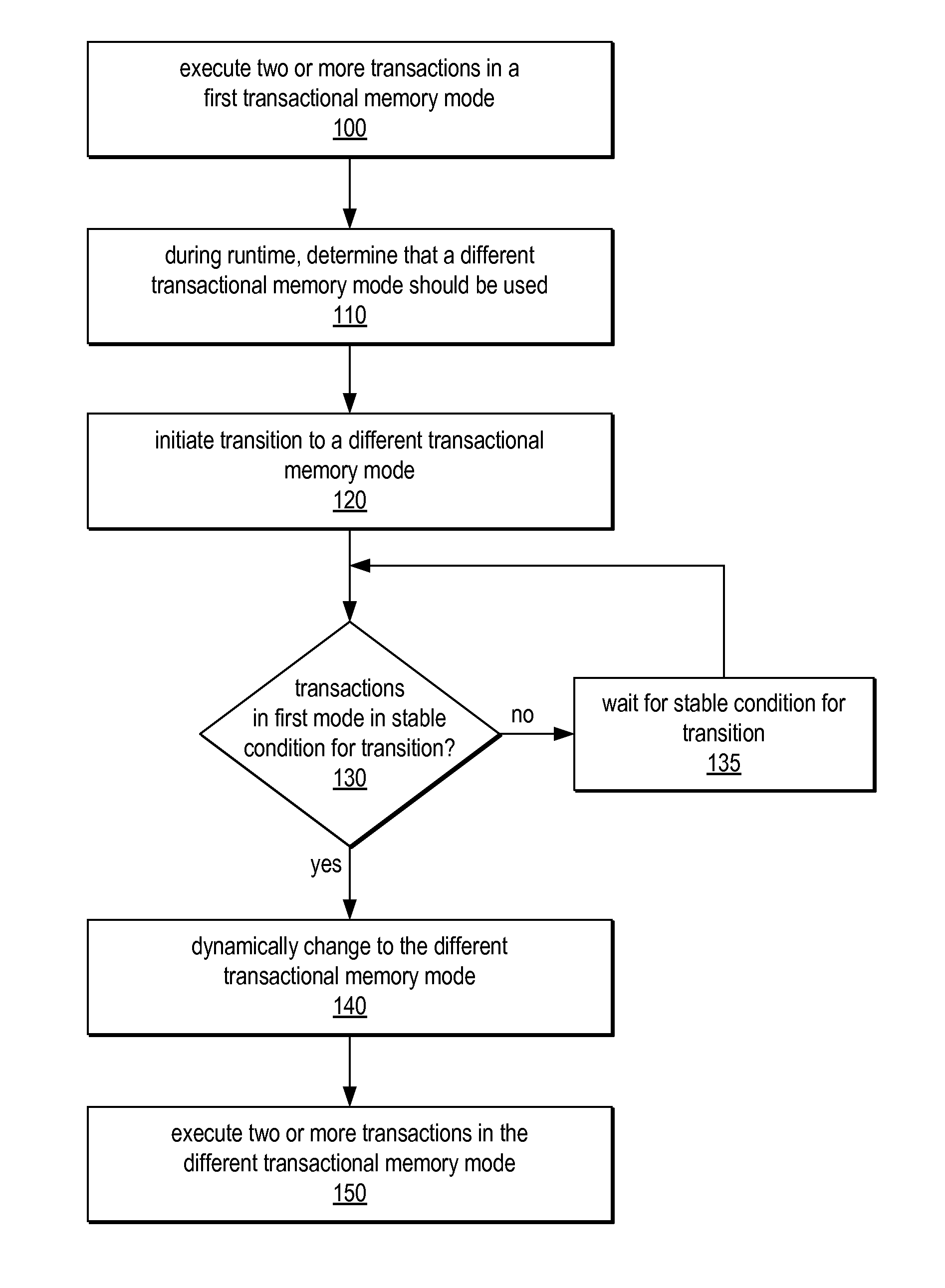

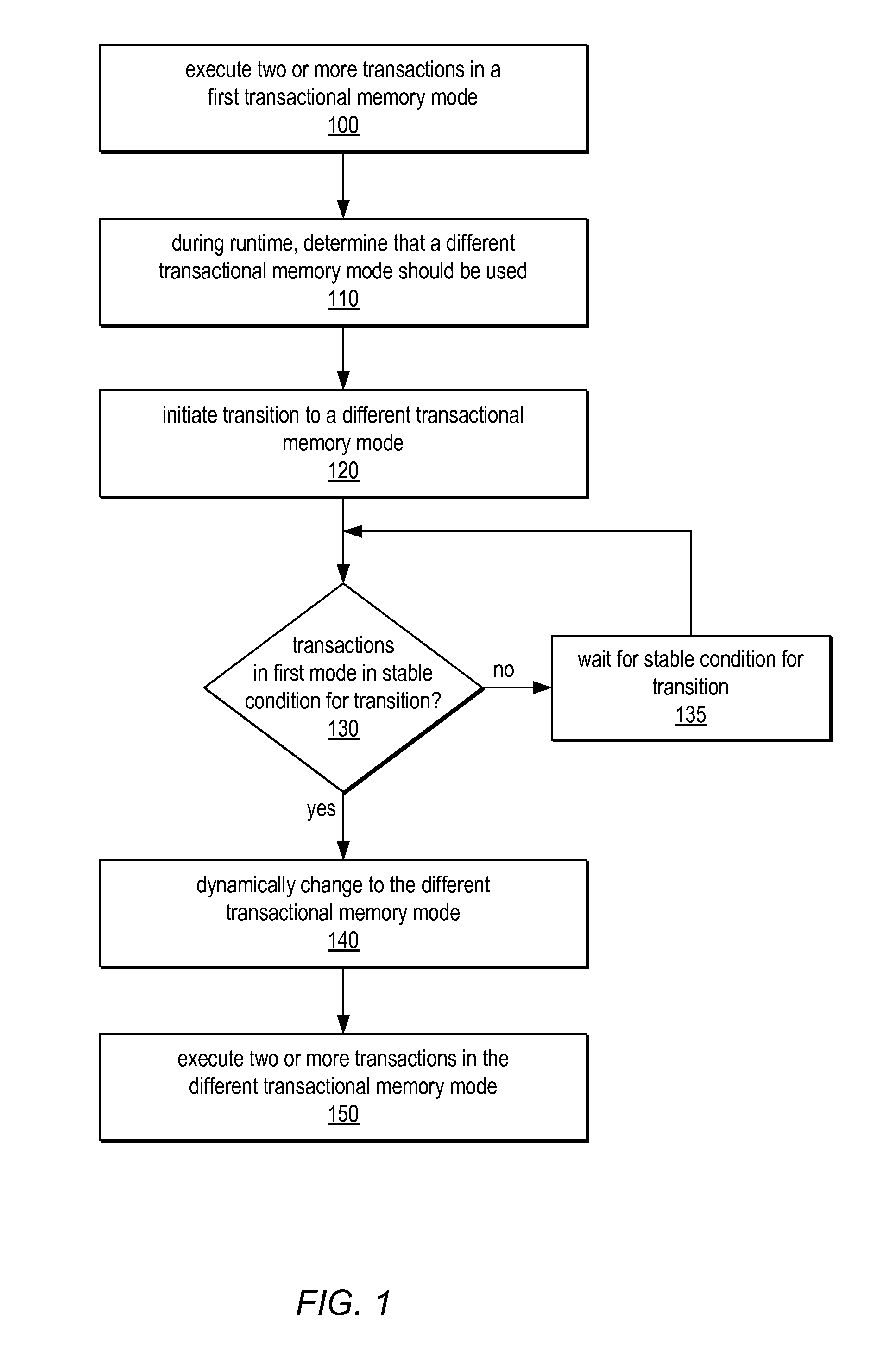

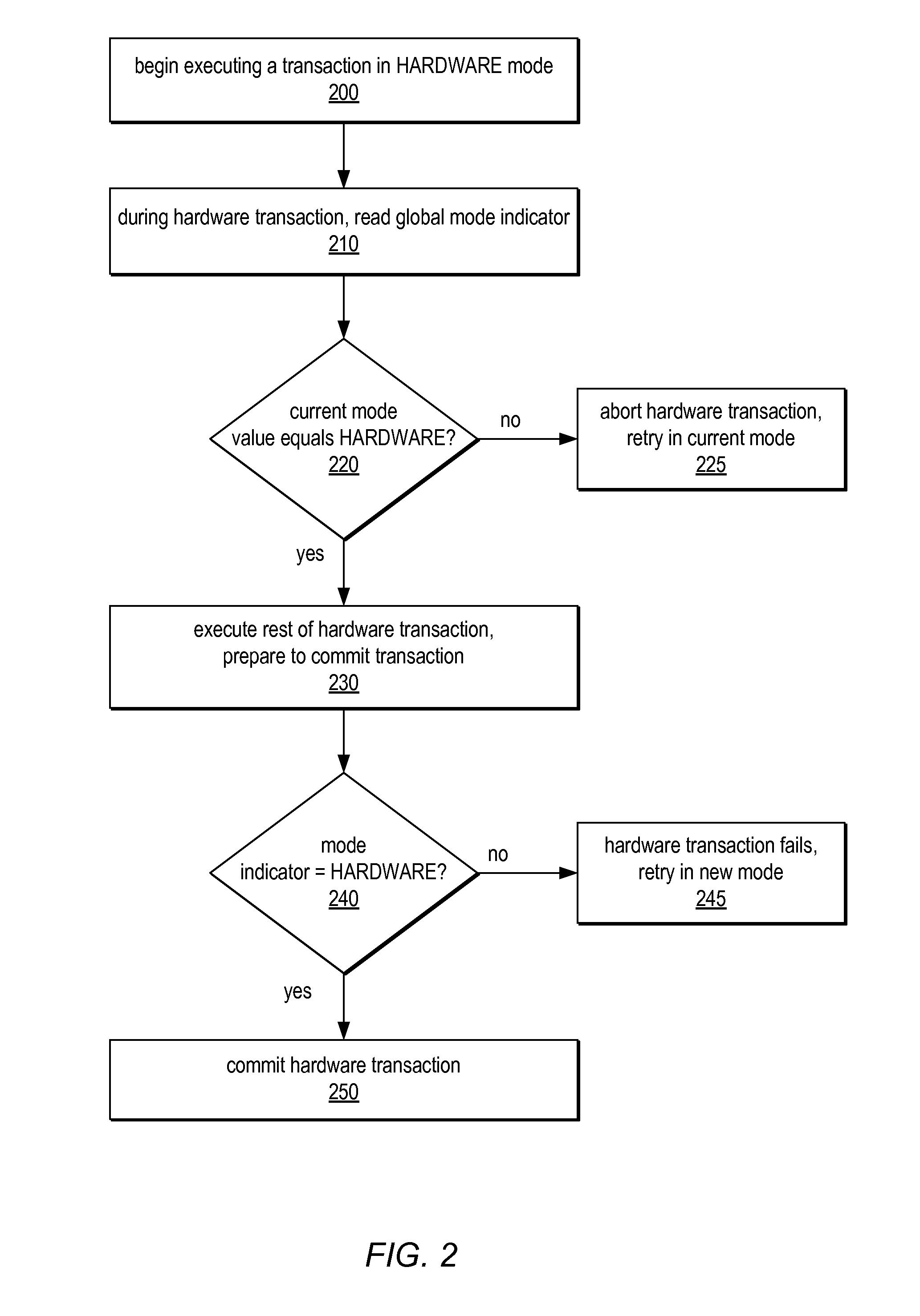

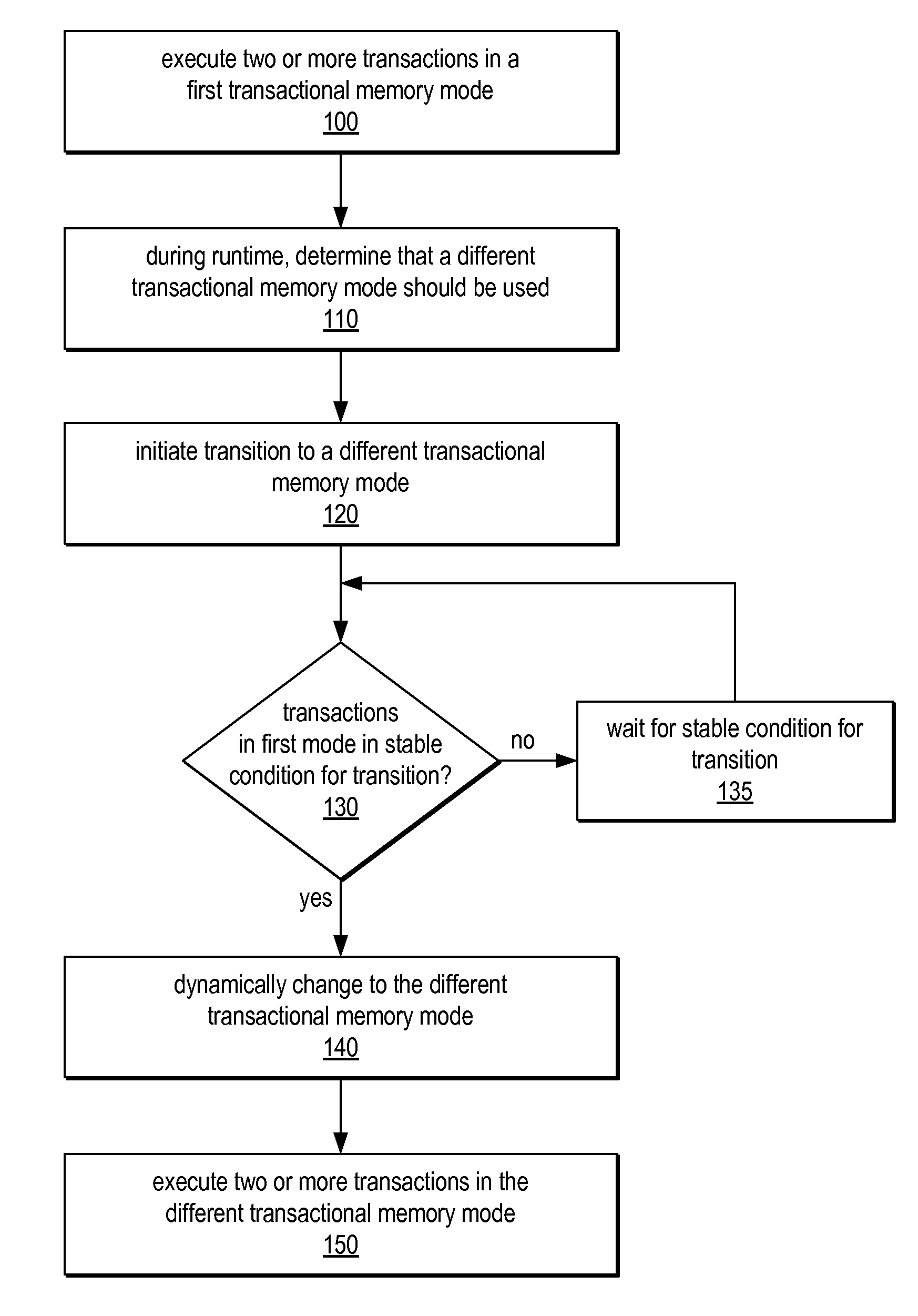

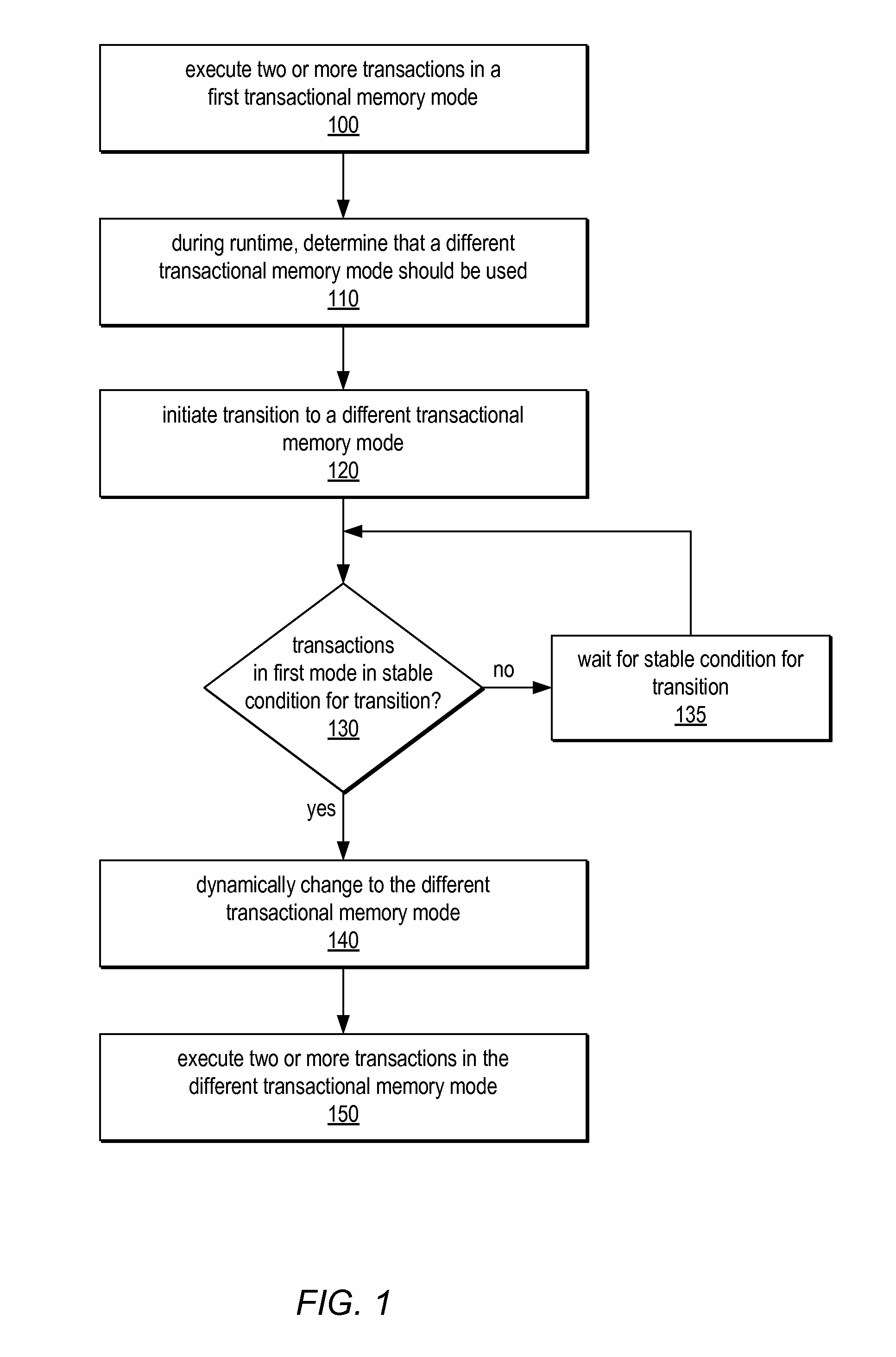

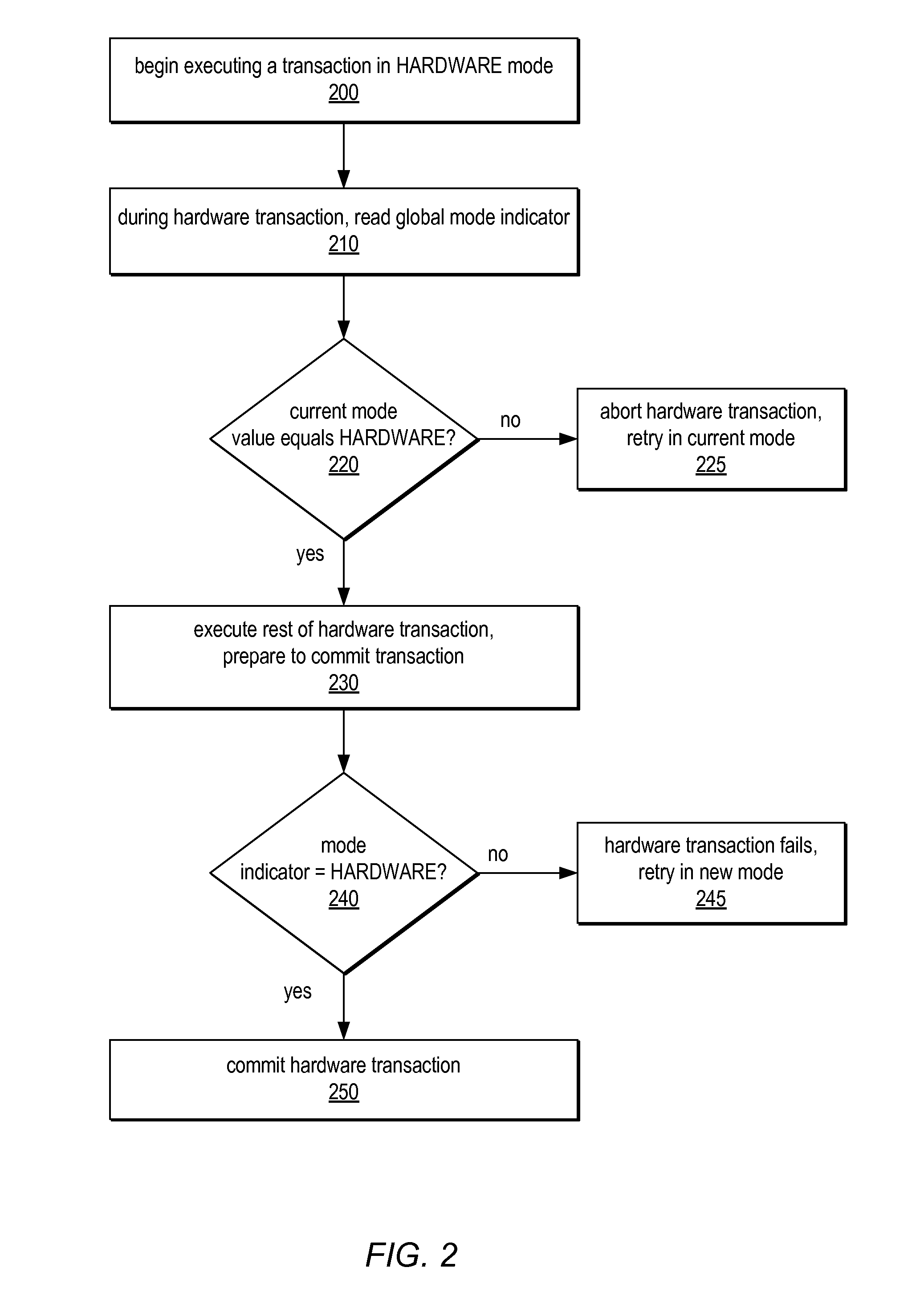

System and Method for Supporting Phased Transactional Memory Modes

ActiveUS20090172306A1Reduce difficultyMaximum flexibilityProgram control using stored programsDigital computer detailsParallel computingTransactional memory

A phased transactional memory (PhTM) may support a plurality of transactional memory implementations, including software, hardware, and hybrid implementations, and may provide mechanisms for dynamically transitioning between transactional memory modes in response to changing workload characteristics; upon discovering that the current mode does not perform well, is not suitable, or does not support functionality required for particular transactions; or according to scheduled phases. A system providing PhTM may be configured to transition from a first transactional memory mode to a second transactional memory mode while ensuring that transactions executing in the first transactional memory mode do not interfere with correct execution of transactions in the second transactional memory mode. The system may be configured to abort transactions in progress or to wait for transactions to complete, be aborted, or reach a safe transition point before transitioning to a new mode, and may use a global mode indicator in coordinating transitions.

Owner:ORACLE INT CORP

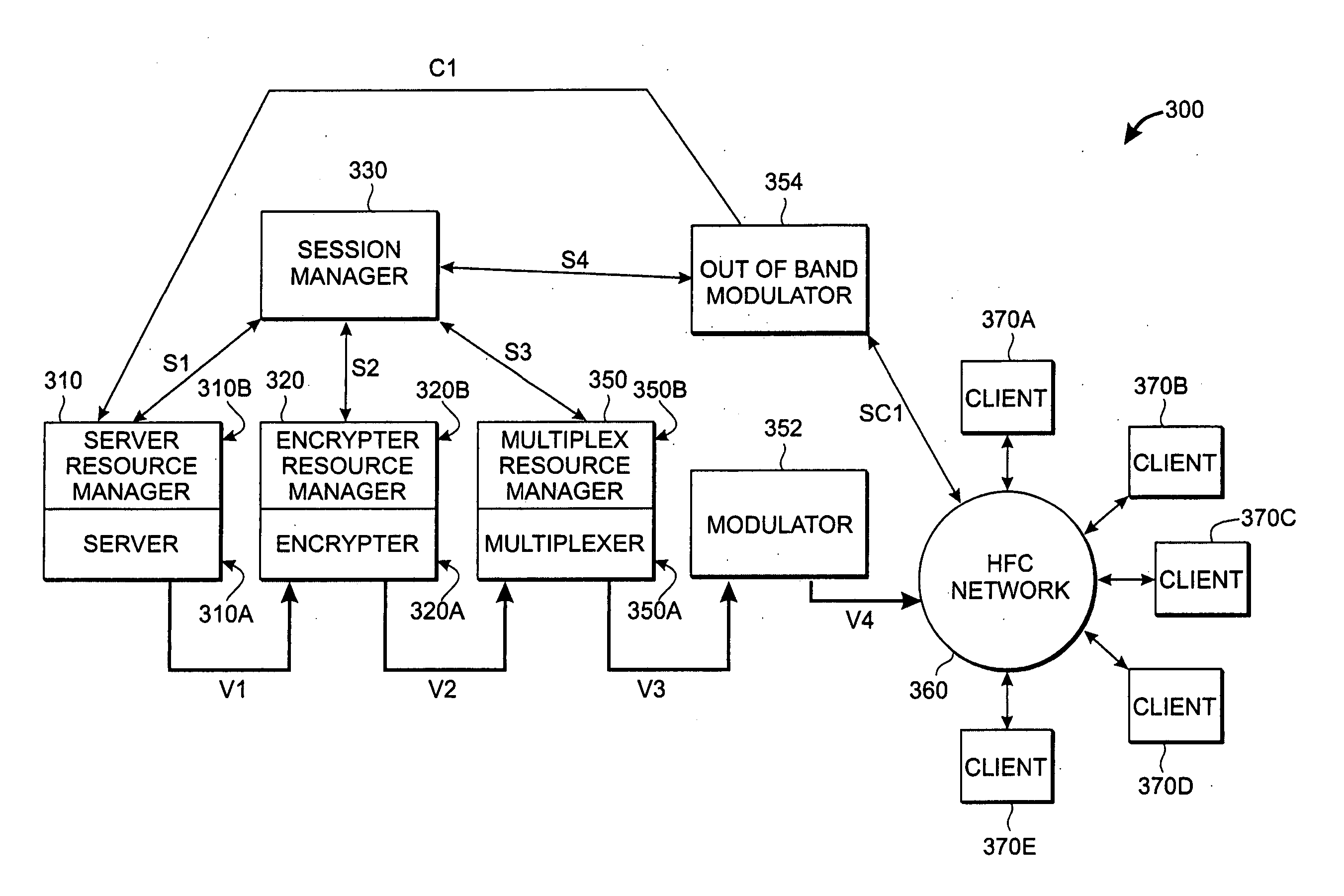

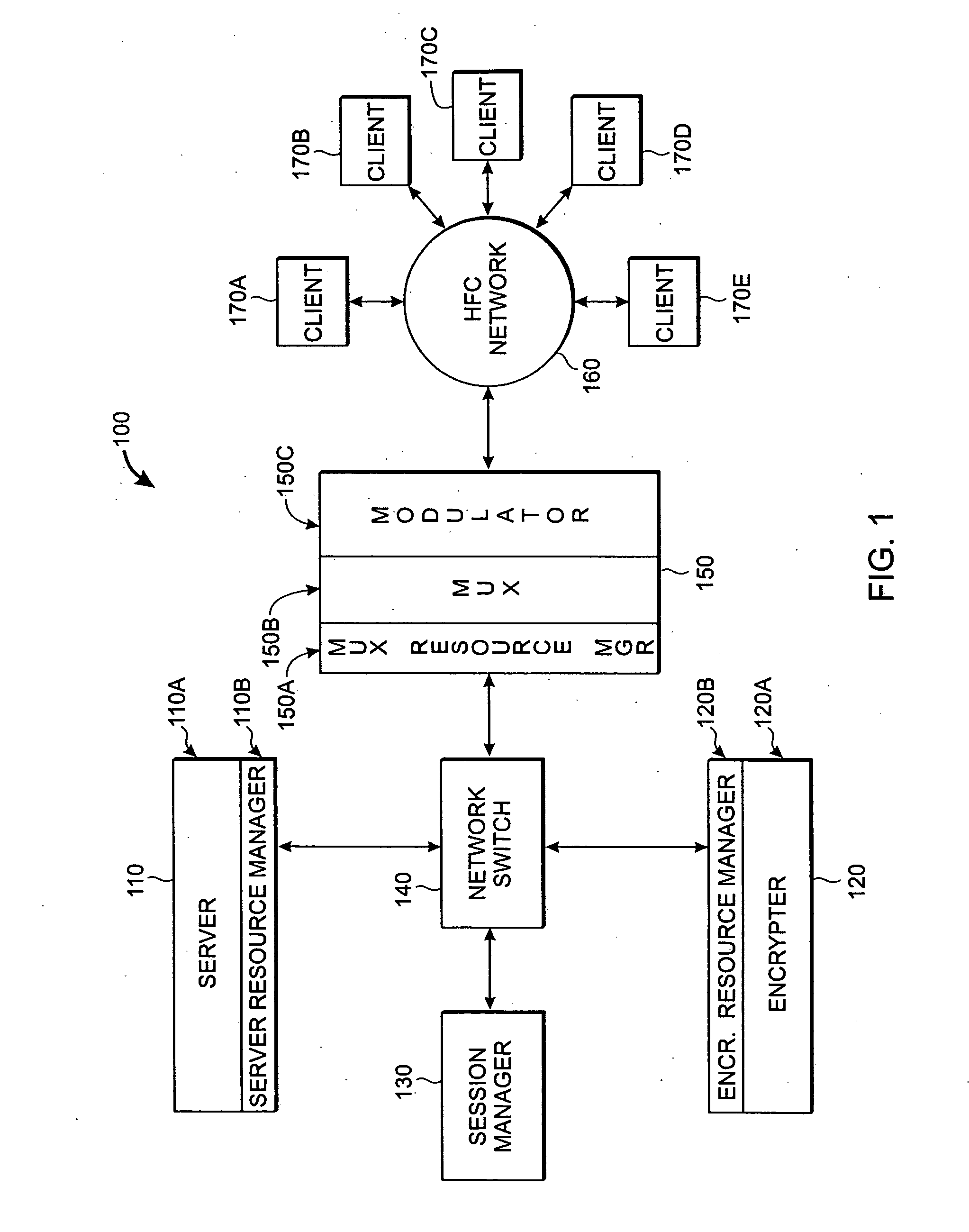

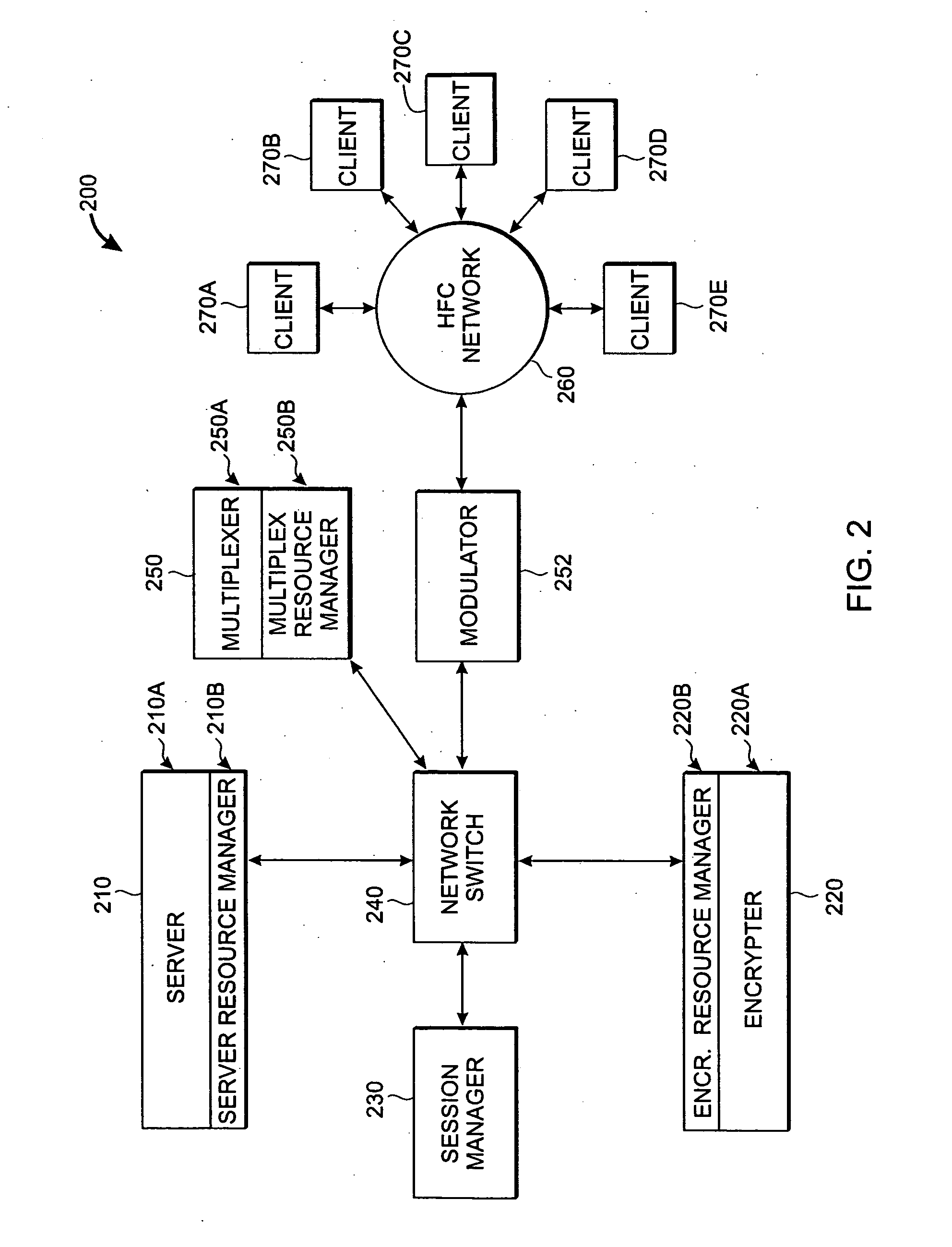

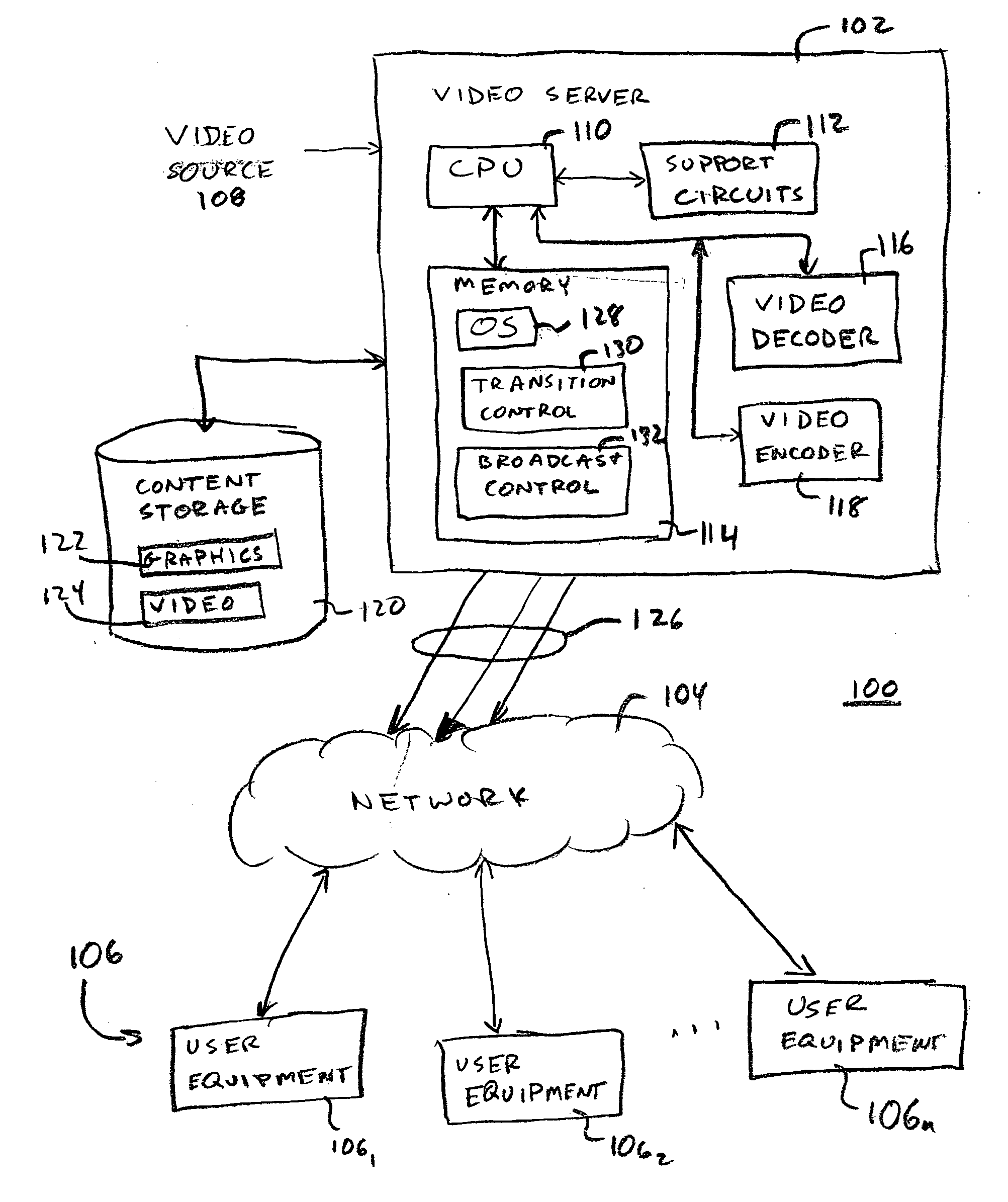

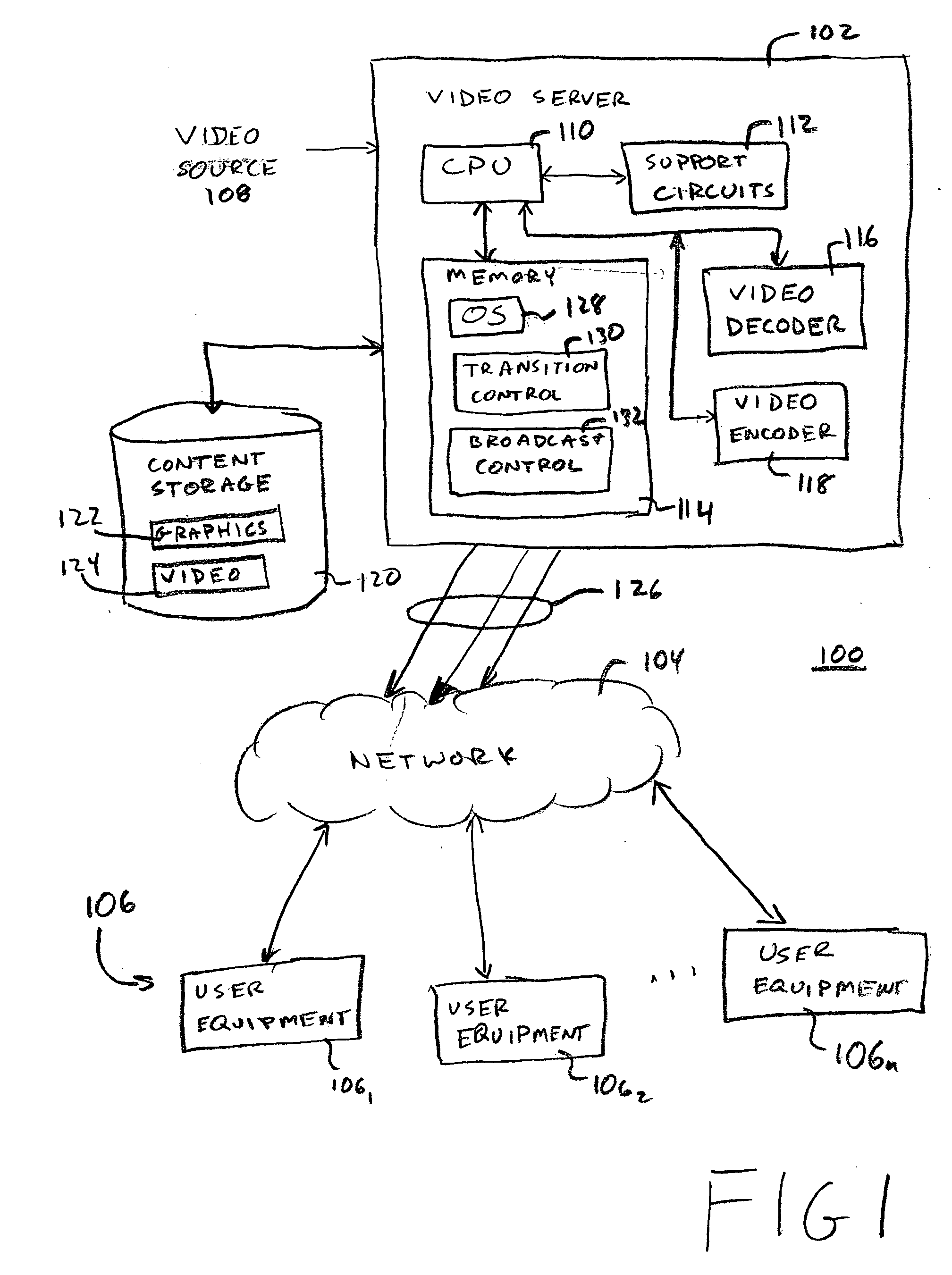

Video multiplexer system providing low-latency VCR-like effects and program changes

ActiveUS20050190794A1Minimal modificationMaximize compatibilitySpecial service provision for substationPulse modulation television signal transmissionQuality of serviceMultiplexer

An advanced multiplexer designed and optimized for next generation on-demand video distribution is described. Features and capabilities include low-latency client interactions, quality of service management, session based encryption management, support for multiple video formats, and support for multiple video decoding standards. Indicators are embedded in new video segments to identify start-of-segment transition points, enabling rapid transitions from one video segment to another. Low-latency operation is achieved by rapid switching, and by coordinating flushing of video buffers and buffer restoration.

Owner:IMAGINE COMM

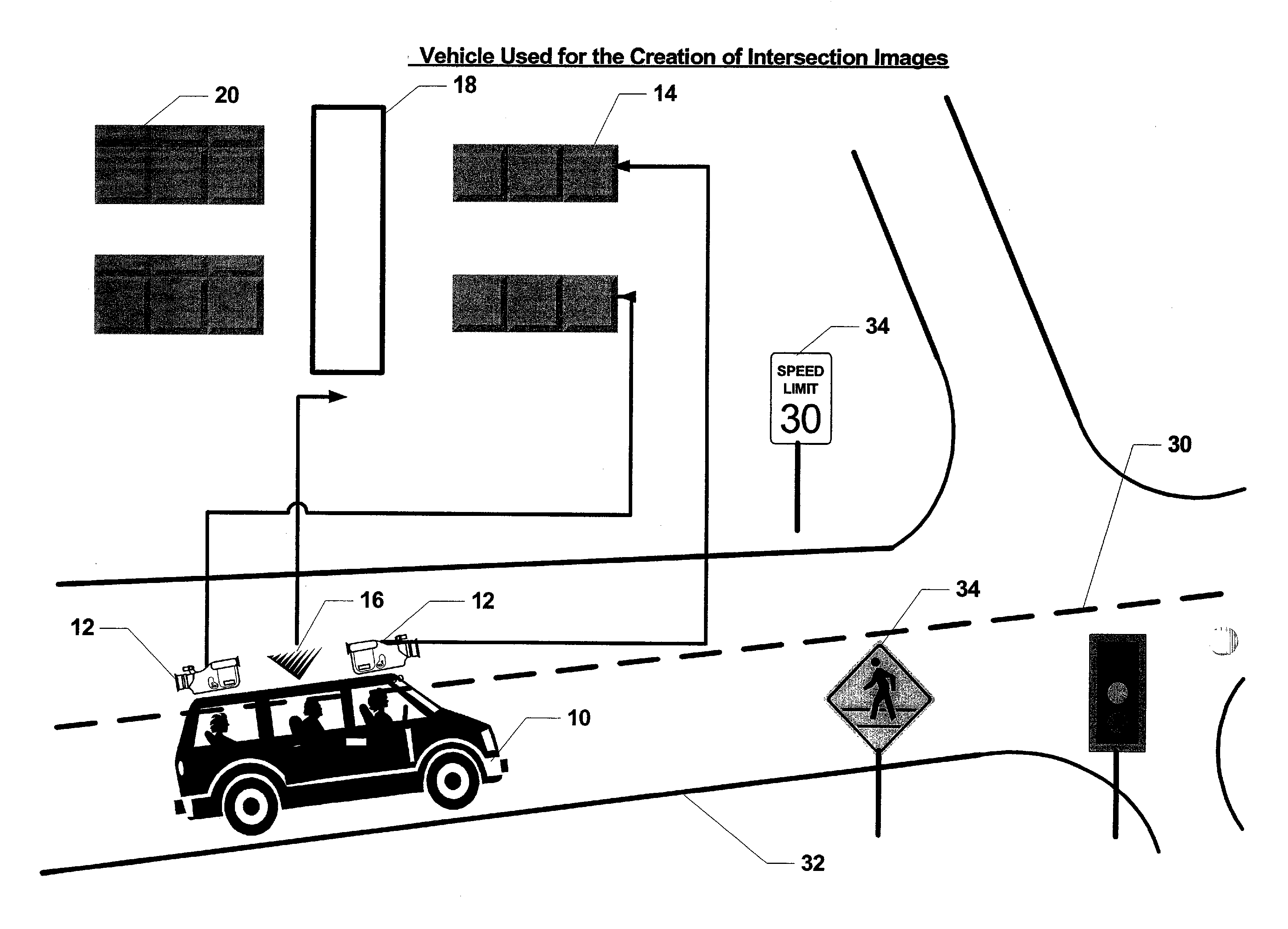

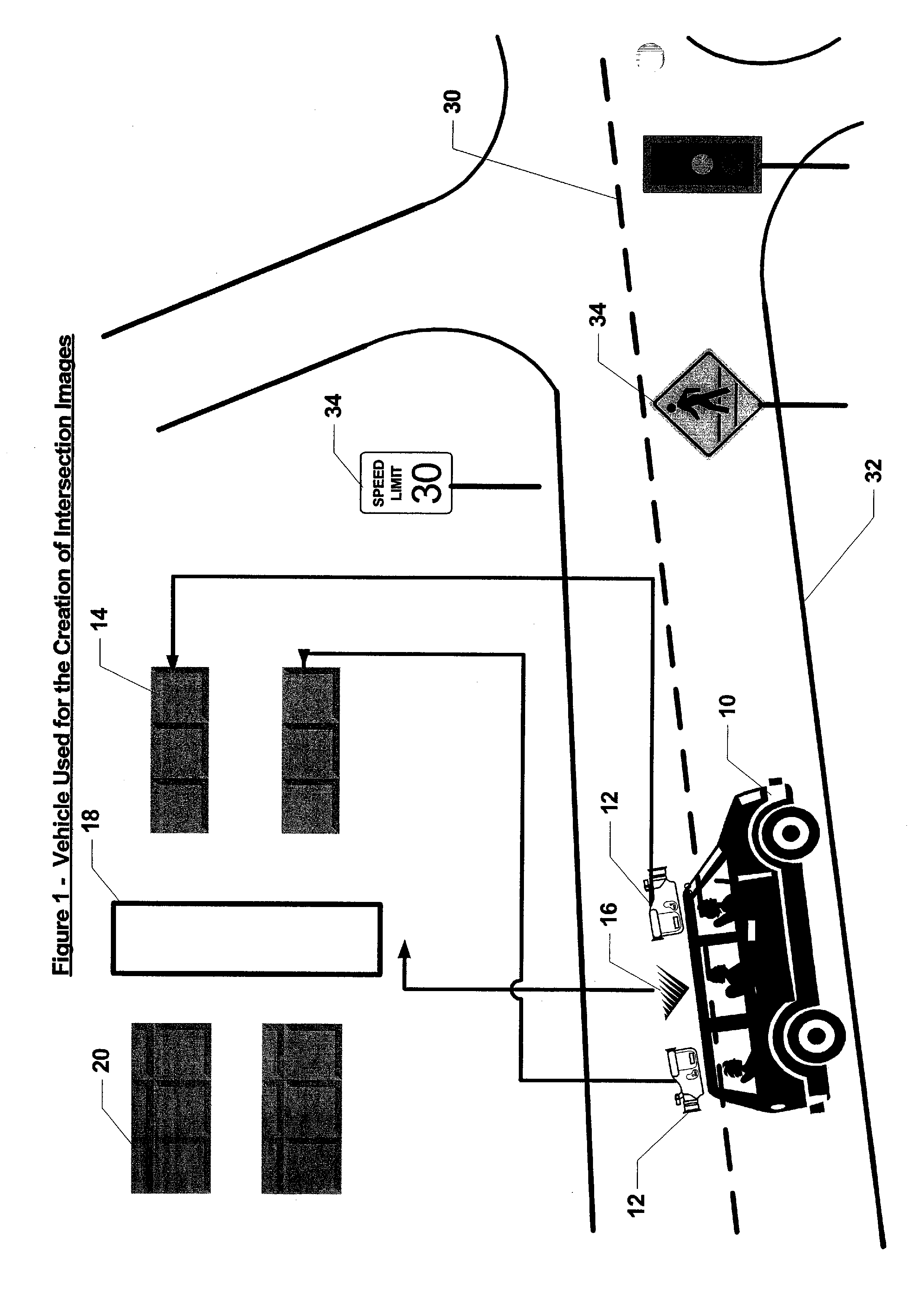

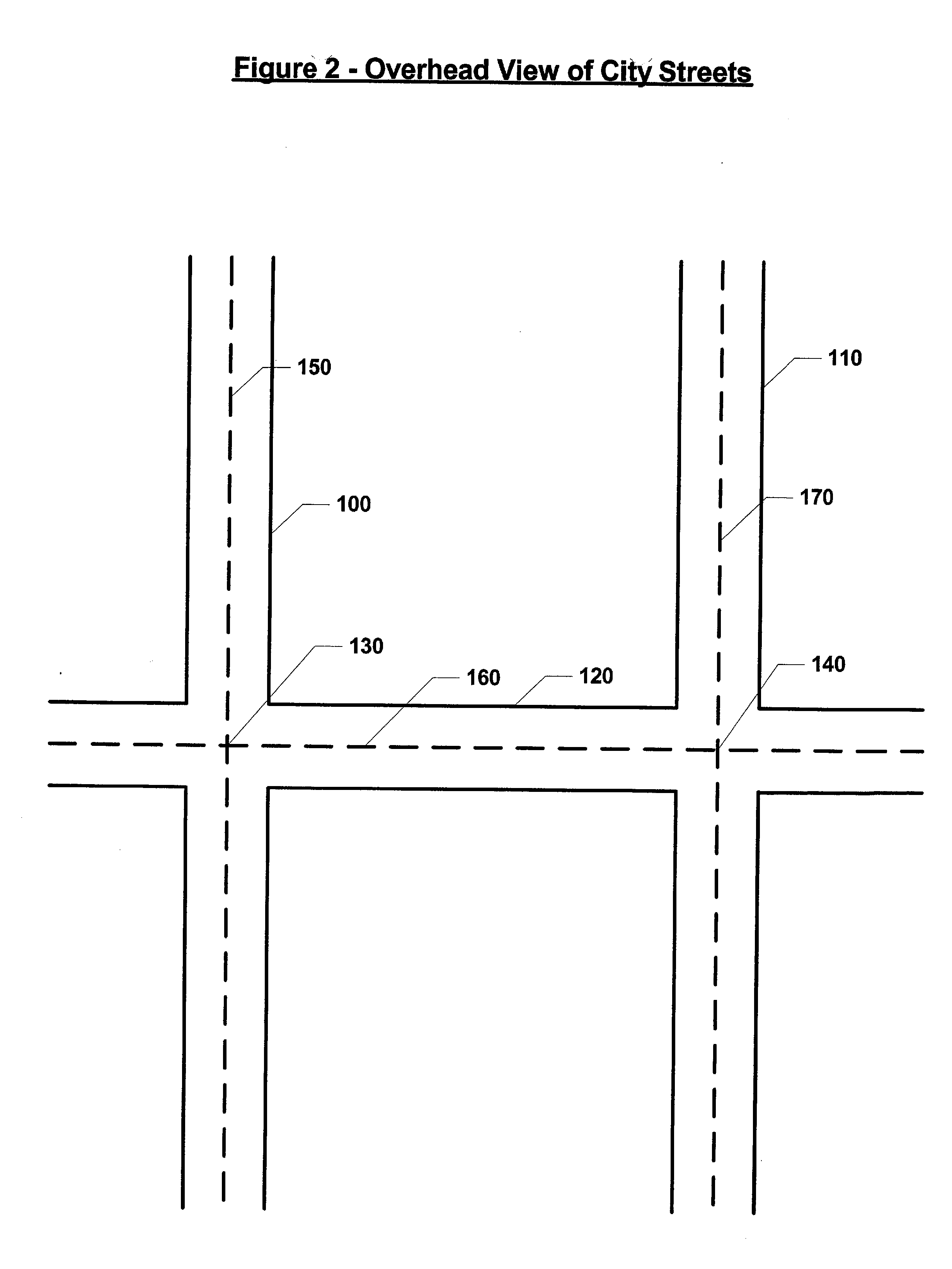

System for associating pre-recorded images with routing information in a navigation system

InactiveUS20070055441A1Good successSafer roadwayRoad vehicles traffic controlNavigation instrumentsNavigation systemTransition point

A vehicle navigation system uses prerecorded intersection images to more quickly and efficiently acquaint the driver with approaching intersections and other points of interest as part of a navigation system. The pre-recorded images are recorded, selected and processed with header information that associates the selected landmark images of approaching intersections and other points of interest to spatial nodes based on runs defined by routing information in the navigation system. The runs defined by the routing information correlate to a path or road segment to be traveled with the spatial nodes defining a transition point from one run to another, such as a roadway intersection where a turn is required to follow the routing information. Preferably, a multiplicity of recorded images are analyzed from a road segment to select a set of images that correspond to a plurality of distances from an approaching intersection, for example, where the selected images include a view of relevant visual information, such as road sign images, associated with the intersection.

Owner:FACET TECH LLC

System and method for supporting phased transactional memory modes

ActiveUS7966459B2Reduce difficultyMaximum flexibilityDigital computer detailsSpecific program execution arrangementsParallel computingTransactional memory

A phased transactional memory (PhTM) may support a plurality of transactional memory implementations, including software, hardware, and hybrid implementations, and may provide mechanisms for dynamically transitioning between transactional memory modes in response to changing workload characteristics; upon discovering that the current mode does not perform well, is not suitable, or does not support functionality required for particular transactions; or according to scheduled phases. A system providing PhTM may be configured to transition from a first transactional memory mode to a second transactional memory mode while ensuring that transactions executing in the first transactional memory mode do not interfere with correct execution of transactions in the second transactional memory mode. The system may be configured to abort transactions in progress or to wait for transactions to complete, be aborted, or reach a safe transition point before transitioning to a new mode, and may use a global mode indicator in coordinating transitions.

Owner:ORACLE INT CORP

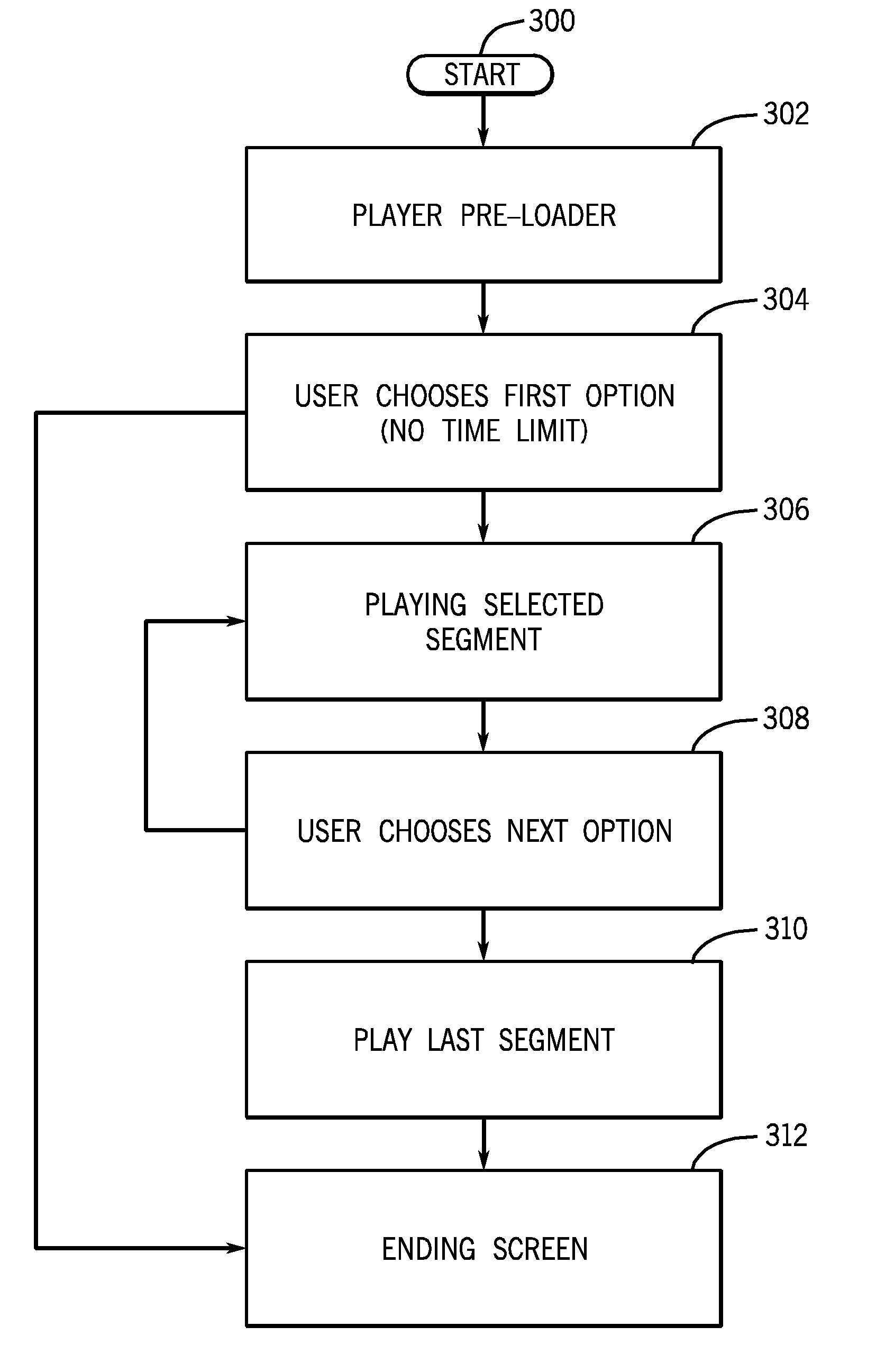

System and method for seamless multimedia assembly

ActiveUS20110200116A1Electrophonic musical instrumentsPicture reproducers using cathode ray tubesTransition pointAudio frequency

Systems and methods are provided for seamless assembly of video / audio segments. To achieve such seamless assembly during streaming / online progressive download of media, a second segment is downloaded to a client during the presentation of a first segment. The first segment is then attached to the beginning of the second segment, where no jitter or gap results with the transition point either in the video or audio portion of the segments. Hence, the merged segments are presented as a seamless assembly of video / audio segments, where the user is “unaware” that the merged segments are the result of two separate or different segments. To effectuate such gapless assembly of segments, a gapless media file is created for encoding the video and audio segments using a gapless audio encoding scheme, such as Ogg Vorbis, where synchronized, gapless audio tags are interleaved in the video segments.

Owner:JBF INTERLUDE 2009

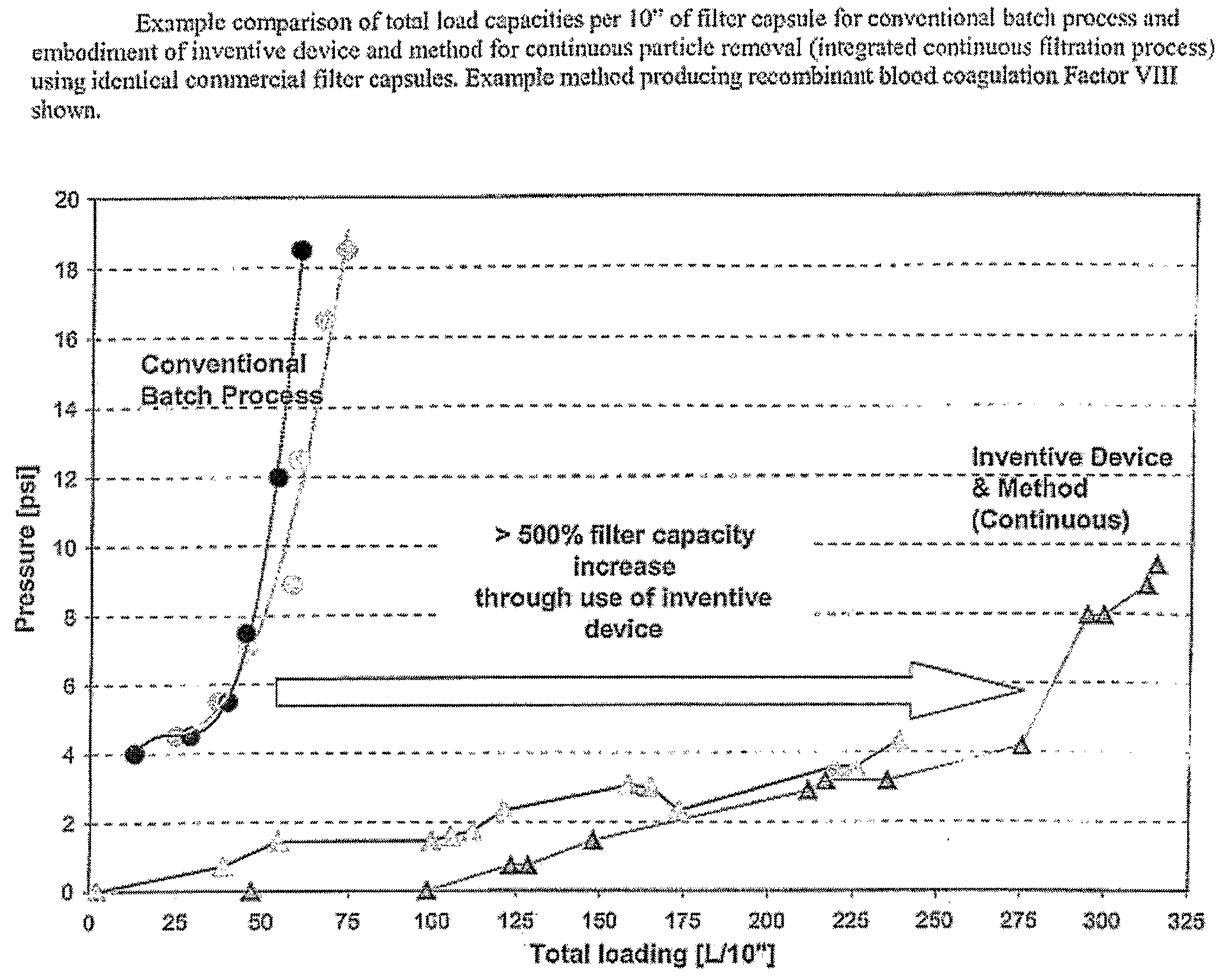

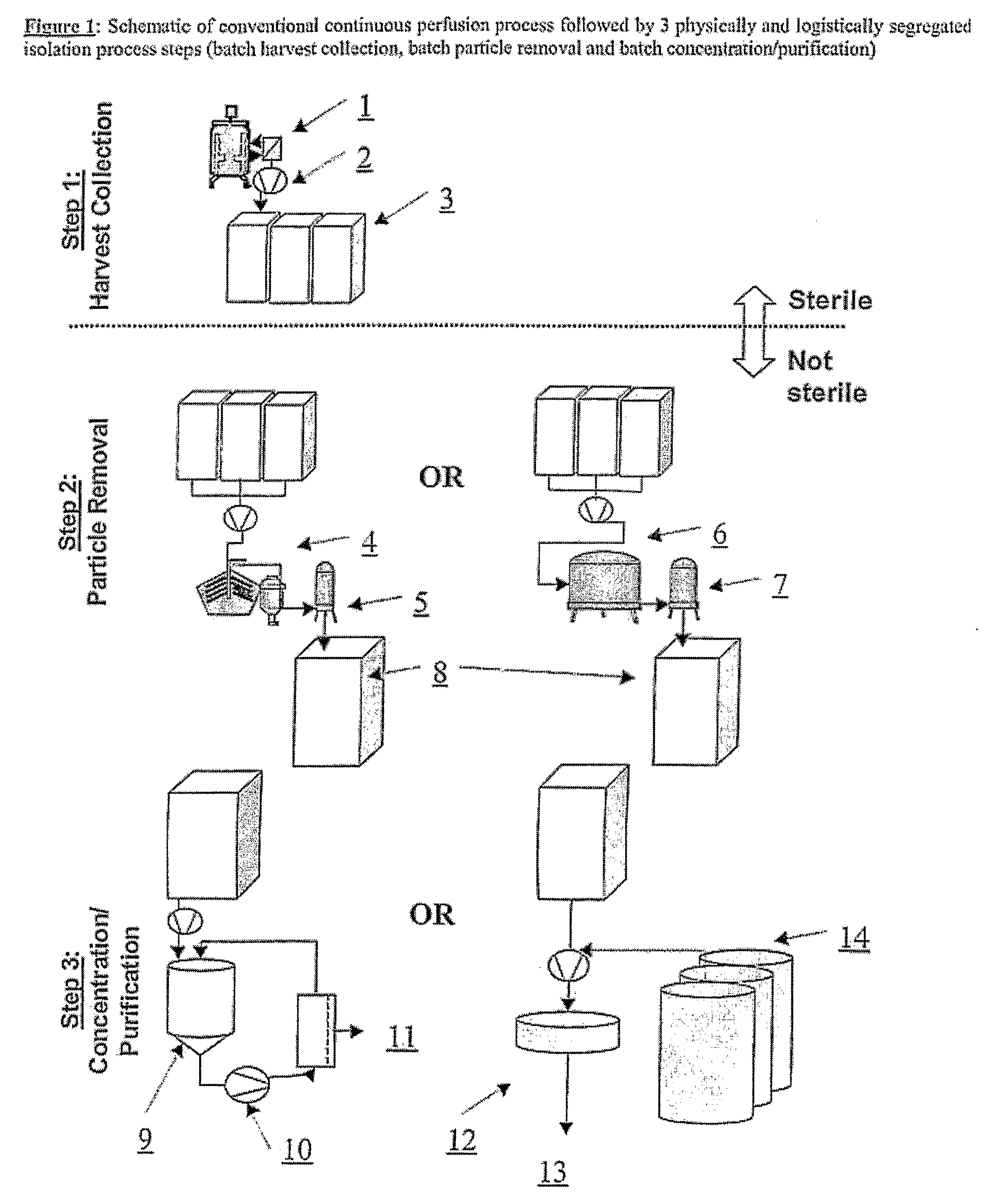

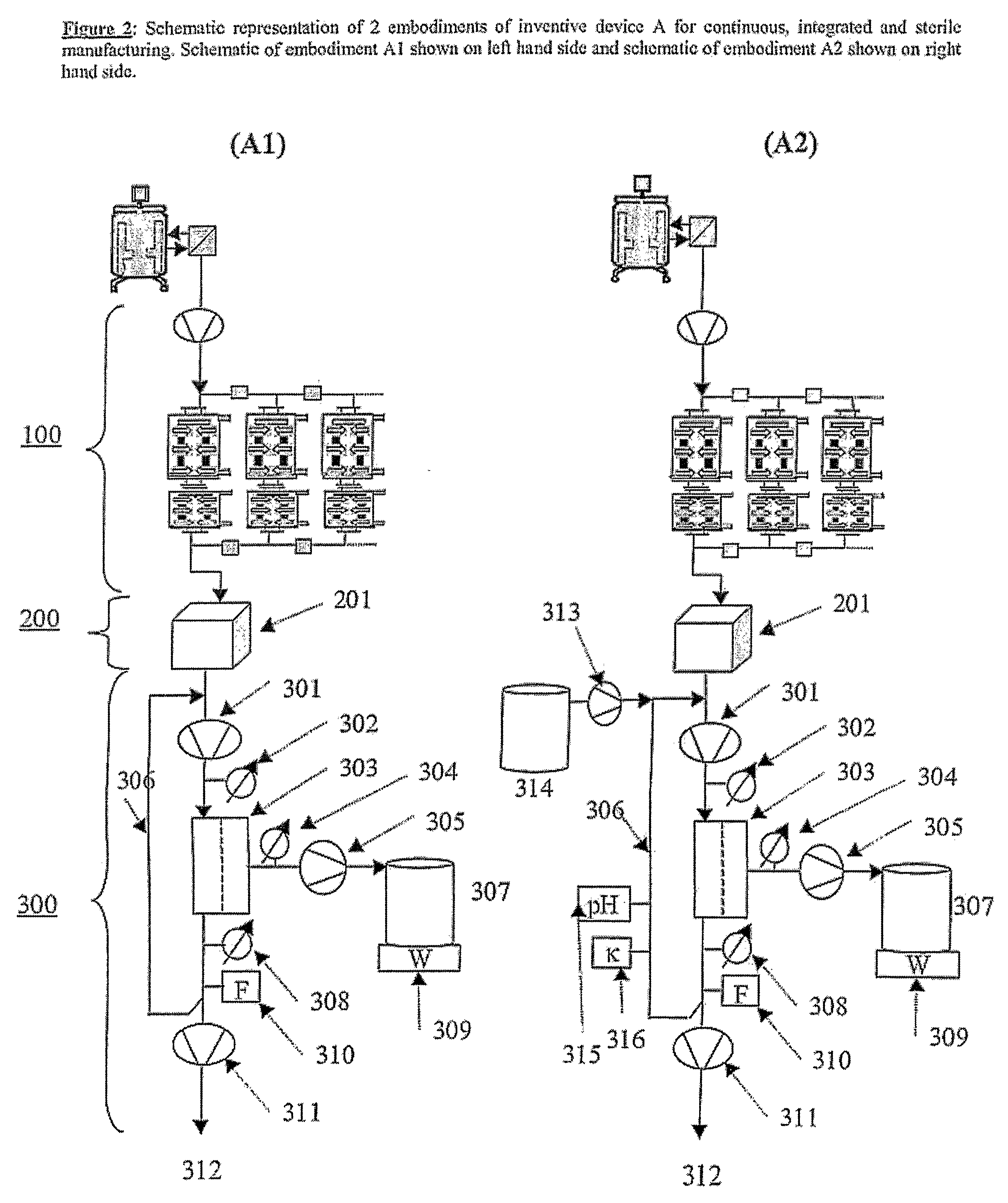

Devices and Methods for Integrated Continuous Manufacturing of Biological Molecules

ActiveUS20080269468A1Bioreactor/fermenter combinationsFactor VIIContinuous perfusionChemical physics

The present invention relates to a process and apparatus for purifying a molecule of interest from a heterogeneous clarified fluid mixture. The apparatus of the invention generally comprises a continuous perfusion fermentation system, a continuous particle removal system integrated with the perfusion fermentation system; and a continuous purification system integrated with the particle removal system, which is maintained under sterile conditions. The process comprises filtering a heterogeneous clarified fluid mixture by continuous ultrafiltration at a specific flow rate below the transition point of the molecule of interest in the pressure-dependent region of the flux versus TMP curve, wherein the specific flow rate is maintained substantially constant throughout the continuous ultrafiltration.

Owner:BAYER HEALTHCARE LLC

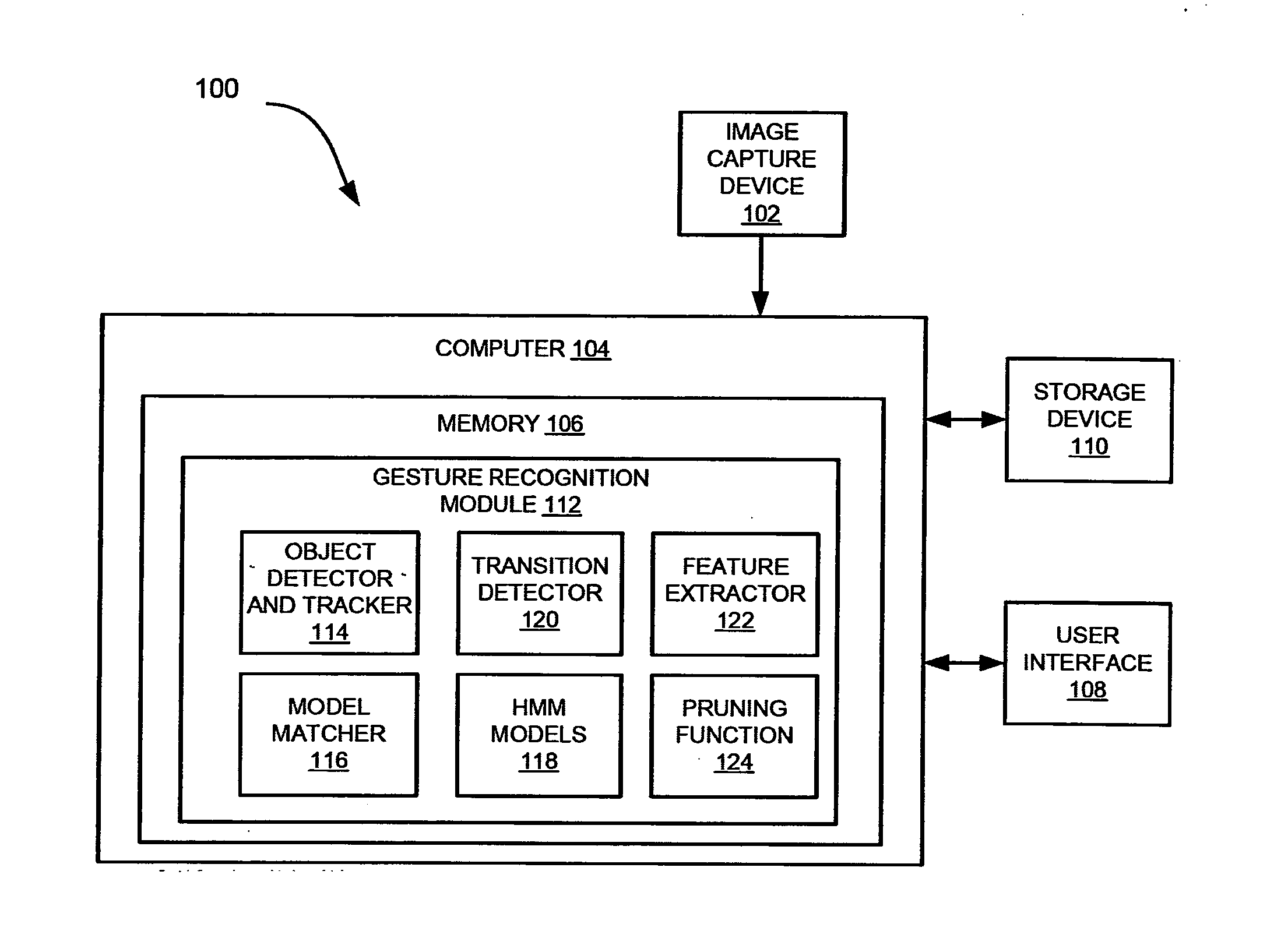

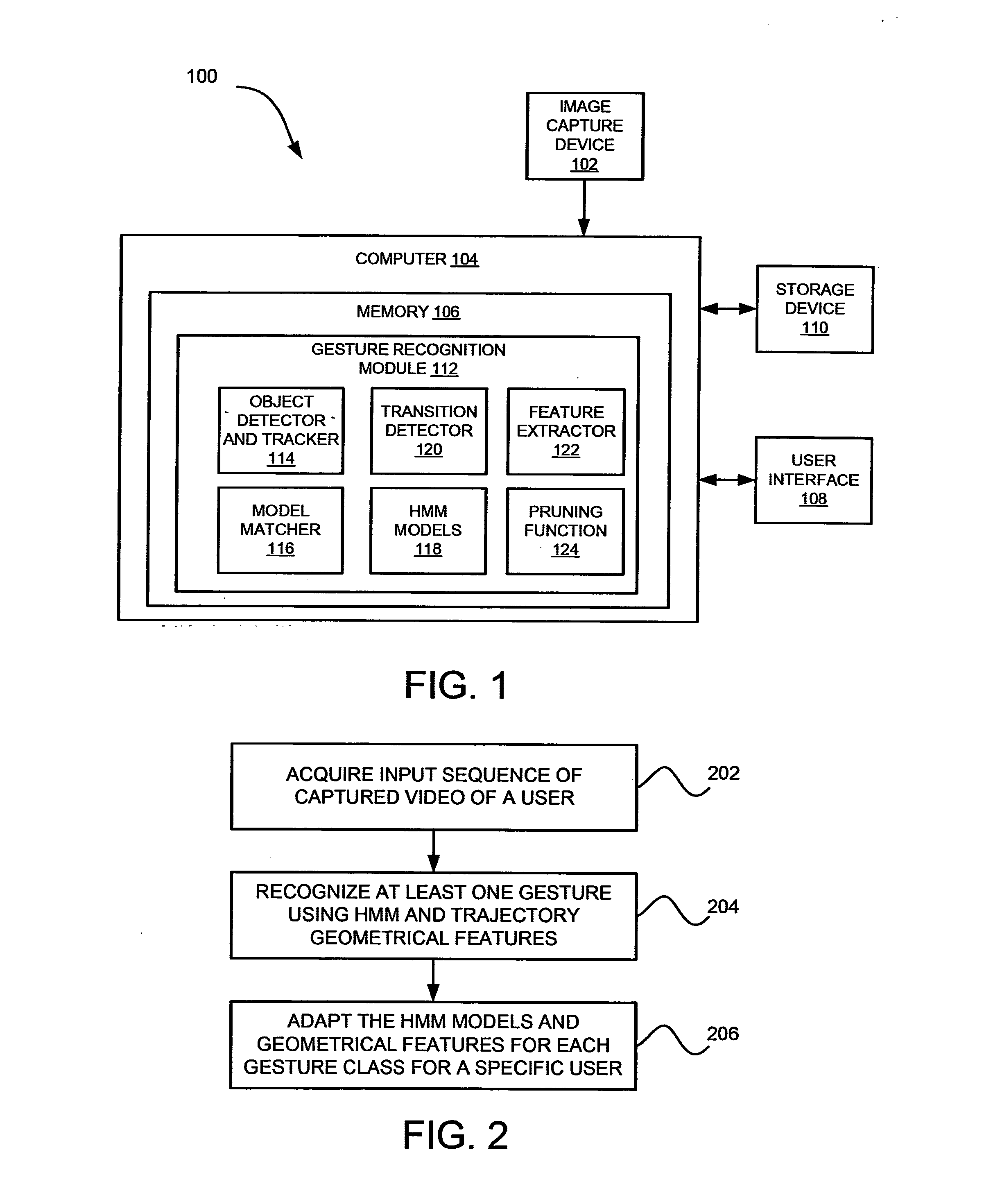

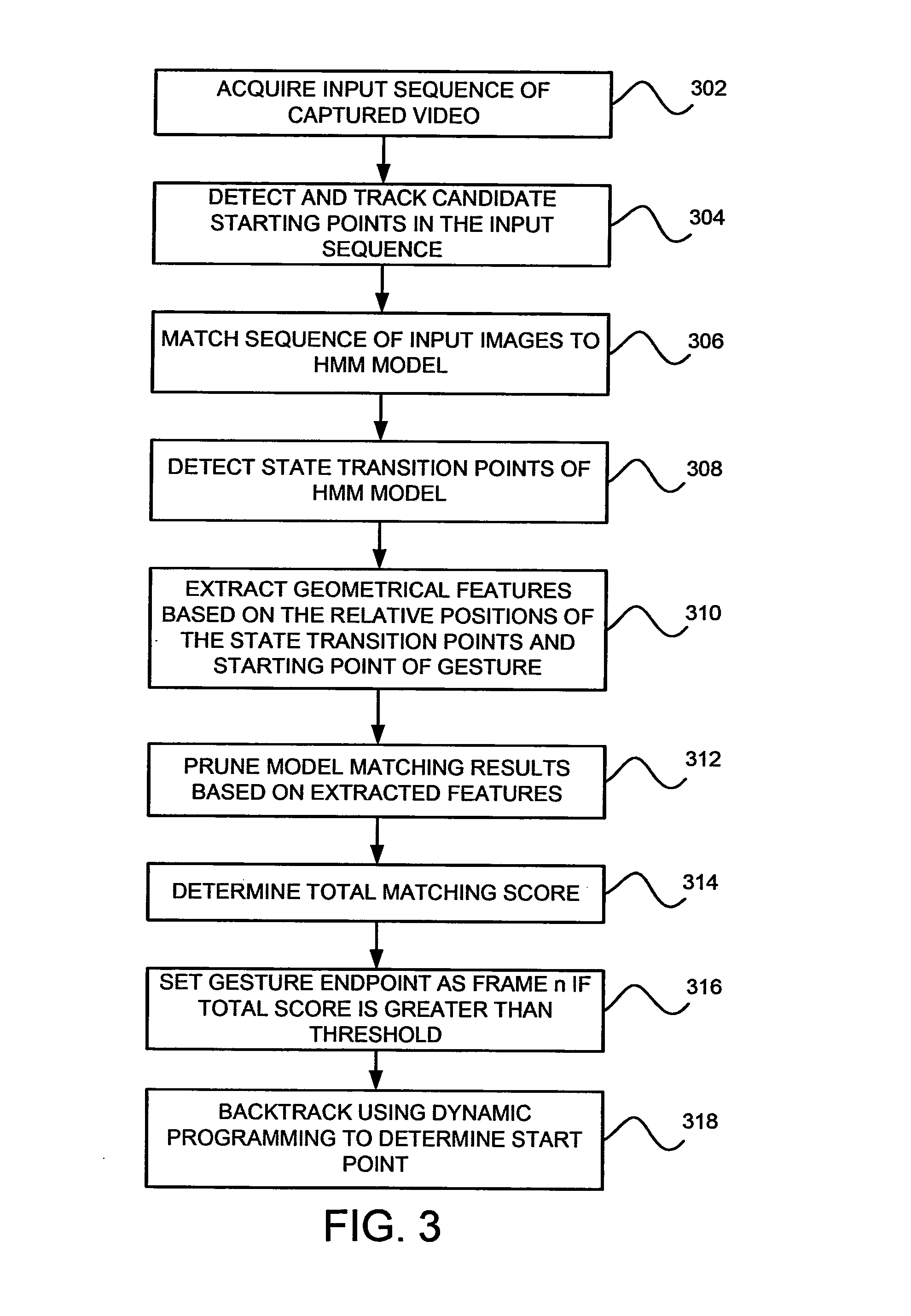

System and method for gesture recognition

ActiveUS20130294651A1More accurate and robust gesture spotting and recognitionInput/output for user-computer interactionImage analysisHide markov modelTransition point

A system and method for gesture spotting and recognition are provided. Systems and methods are also provided employing Hidden Markov Models (HMM) and geometrical feature distributions of a hand trajectory of a user to achieve adaptive gesture recognition. The system and method provide for acquiring a sequence of input images of a specific user and recognizing a gesture of the specific user from the sequence of input images based on a gesture model and geometrical features extracted from a hand trajectory of the user. State transition points of the gesture model are detected and the geometrical features of the hand trajectory of the user are extracted based on the relative positions of the detected state transition points and a starting point of the gesture. The system and method further provide for adapting the gesture model and geometrical feature distribution for the specific user based on adaptation data.

Owner:THOMSON LICENSING SA

Method and apparatus for providing a transition between multimedia content

InactiveUS20070033633A1Television system detailsColor signal processing circuitsComputer hardwareTransition point

A method and apparatus for providing a transition between multimedia content, e.g., video clips. The method and apparatus detects a transition trigger that identifies that a transition is necessary at a specific point within a currently playing video clip. The method and apparatus select a driver level API for producing a desired transition effect, then executes the selected API to produce the transition effect. The transition API controls a video decoder such that a currently playing video can be altered at the transition point to have a specific transition effect. Controlling the luminance and audio signal levels of the decoder creates the desired transition effect.

Owner:TELVUE CORP

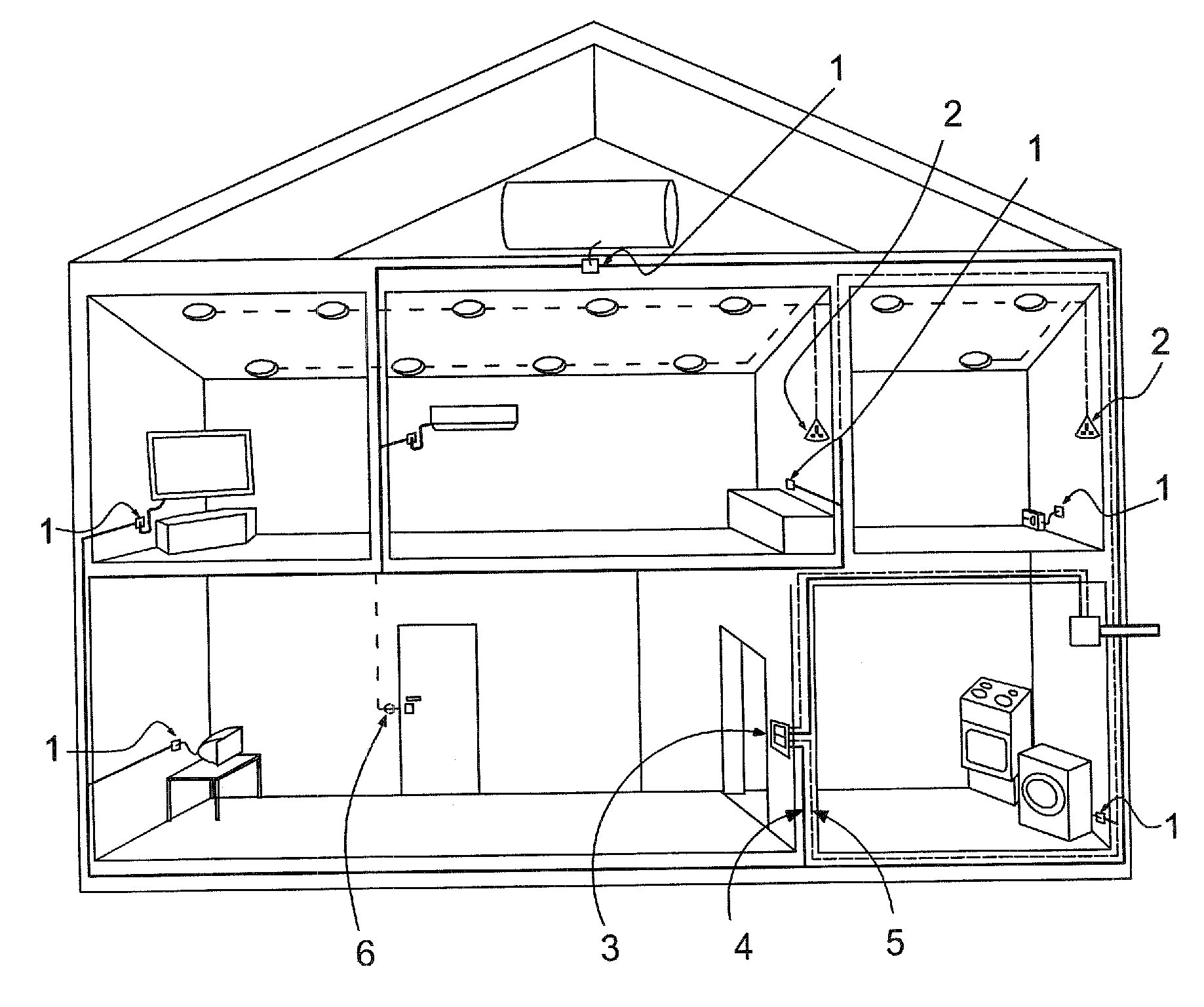

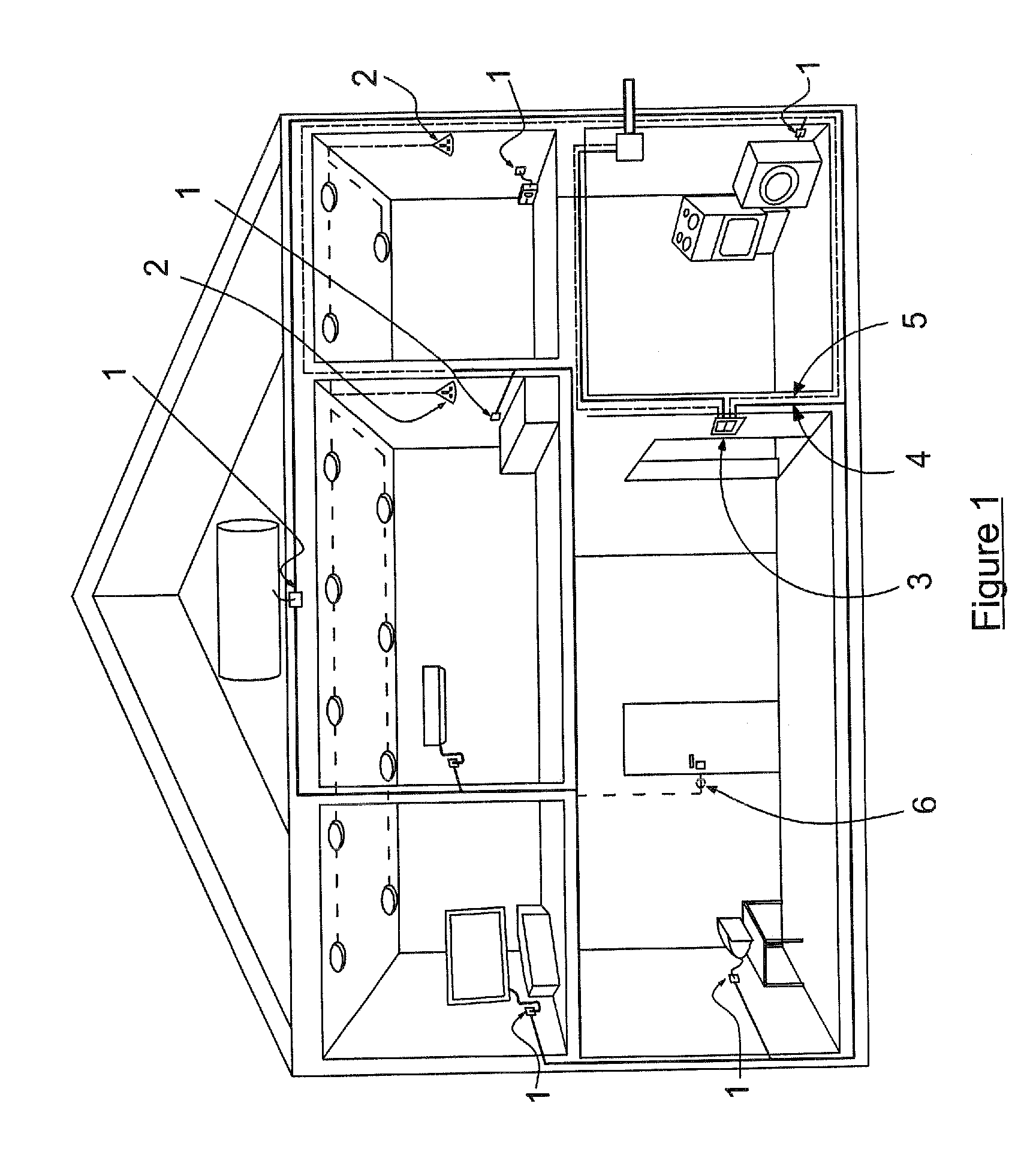

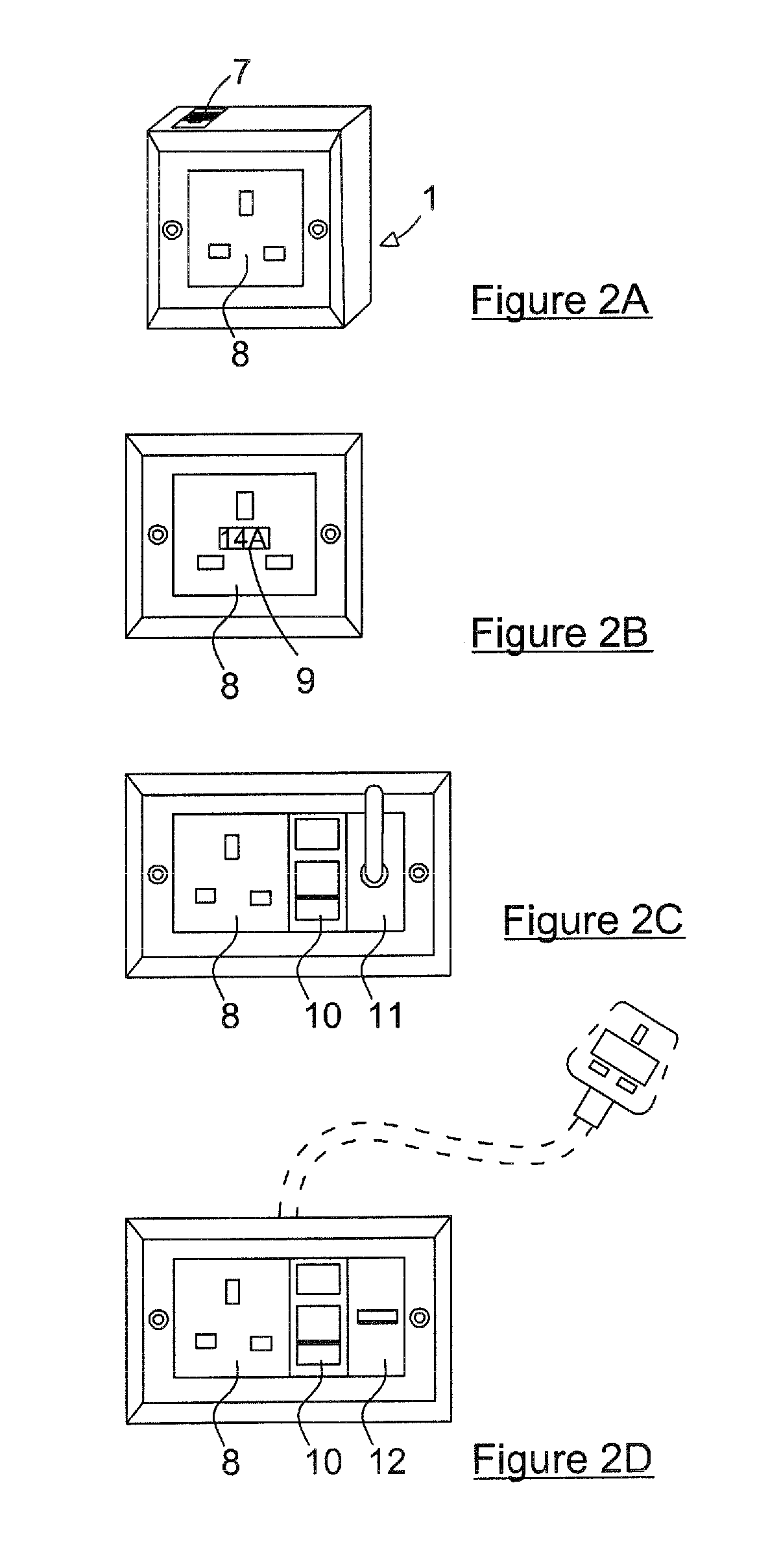

Ethernet over power

InactiveUS20120275526A1Save energyDesigning can be facilitatedPower distribution line transmissionLock network applicationsMicrocontrollerTransceiver

The present disclosure relates to Ethernet-over-Power and provides communication to and from the powerline hardware, e.g. power sockets or light fittings, and through the powerline itself. In one aspect a Power and Data transmission terminal that is a MAC addressable power outlet, switch or transition point is provided, the Power and Data transmission terminal having a PLC Transceiver, a microcontroller, a power consumption meter and a transmission router between the microcontroller and the PLC Transceiver, the system thereby being able to both monitor energy usage and allow data communication over the powerline with a single microcontroller at the or each Power and Data transmission terminal. The system provides I. P addresses to the electrical outlets from which a wide range of devices run and in so doing it can communicate with the electrical outlets themselves.

Owner:HUGHES GLYN

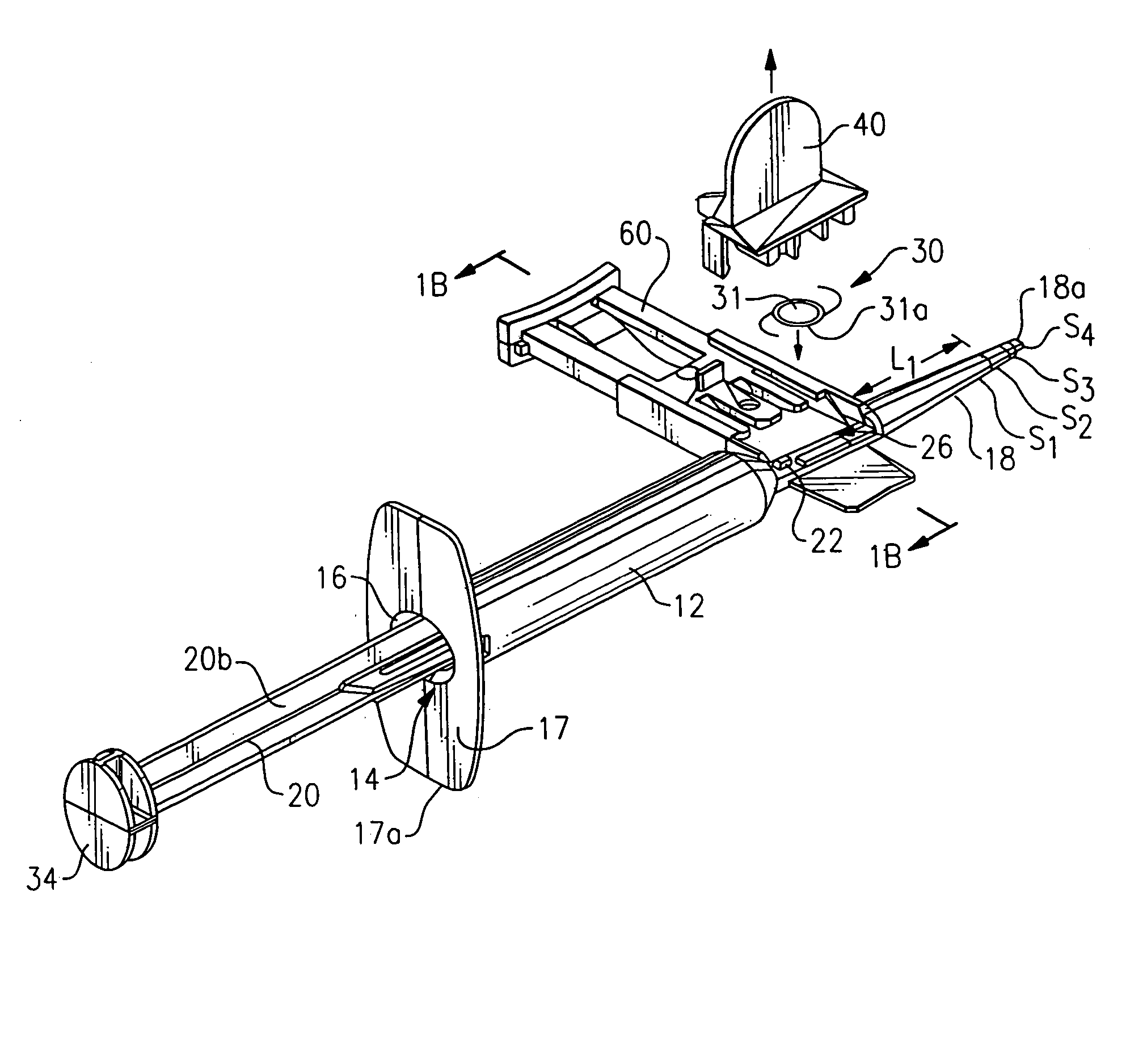

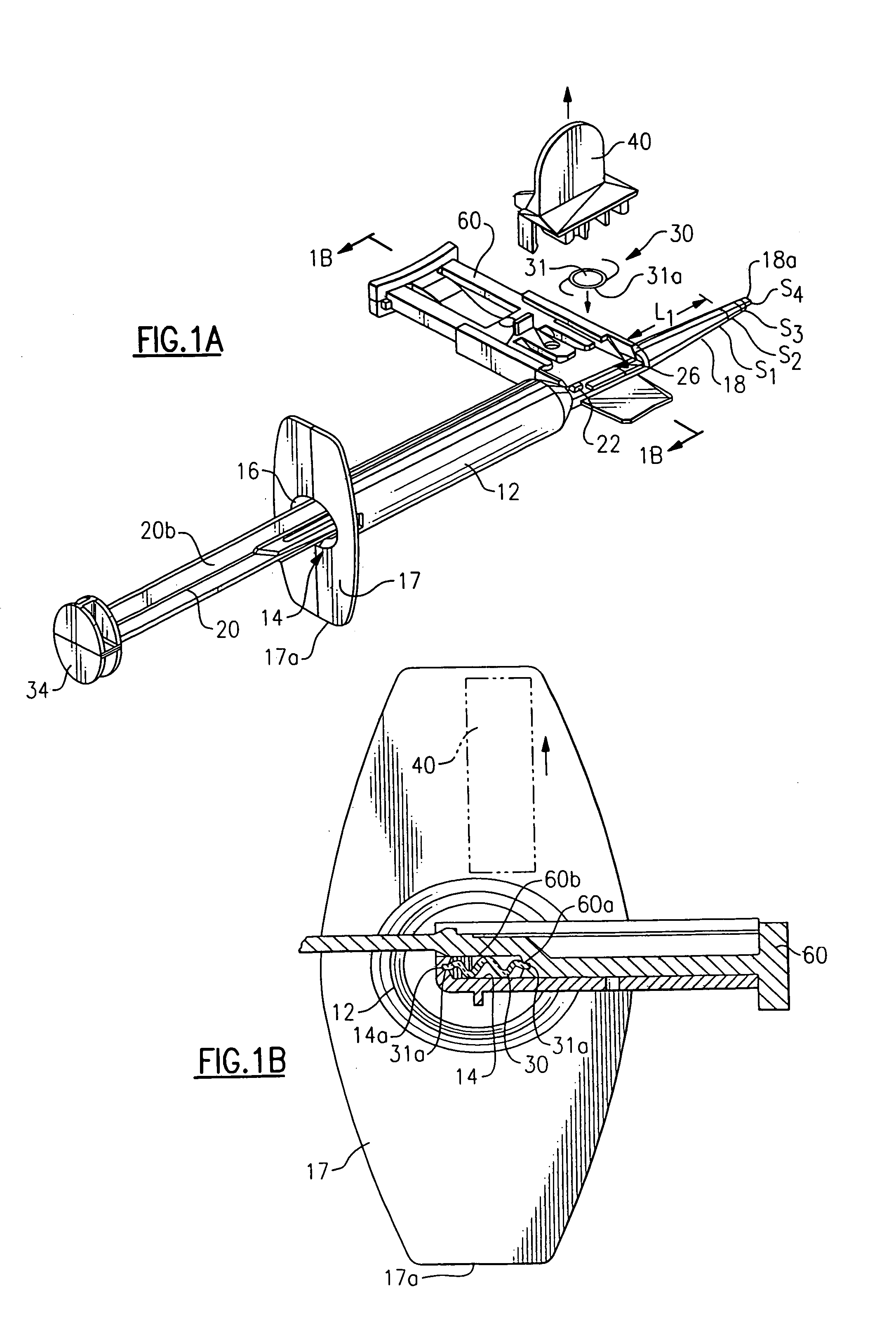

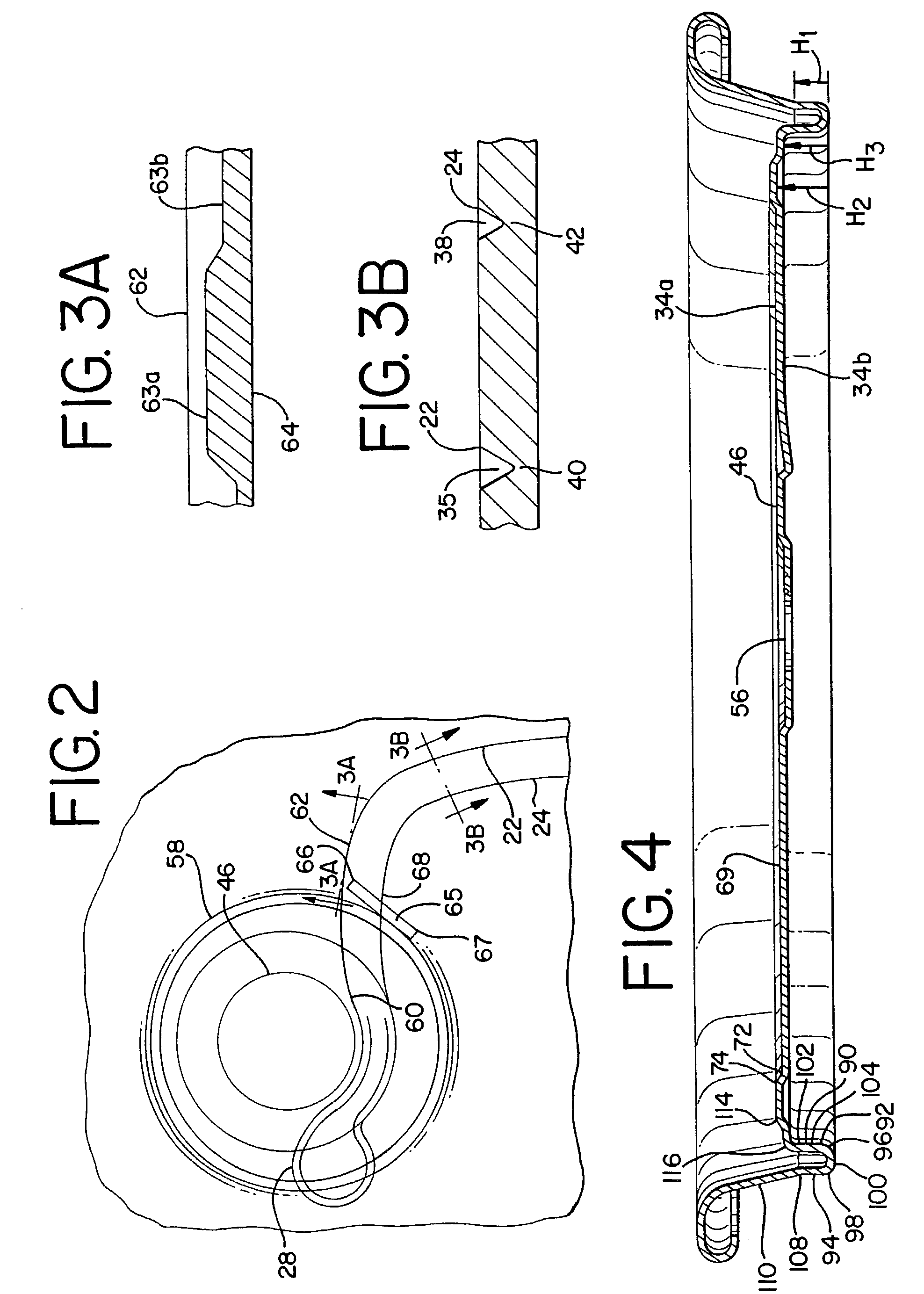

IOL injector

ActiveUS20050222577A1Reduce hoop (radial) strengthPreventing losing controlEye treatmentIntraocular lensInsertion depthEngineering

A device for injecting an intraocular lens (IOL) into an eye, the device having an injector body including a lumen and an open tip wherethrough the IOL is expressed from the device. An IOL loading bay is located in the passageway wherein the IOL is positioned and compressed. The injector tip is dimensioned to allow the surgeon to choose an insertion depth between first, second and third transition points defined on the tip, the first and second transition points having a larger diameter than the third transition point which is located closer to the open tend of the tip. If the surgeon wishes to insert through a very small incision size (e.g., about 2.4 mm), the surgeon will insert the tip only up to the third transition point. The injector is stable during delivery of the IOL therethrough due to a spreading of the tip within the eye which effectively anchors the tip during IOL delivery.

Owner:BAUSCH & LOMB INC

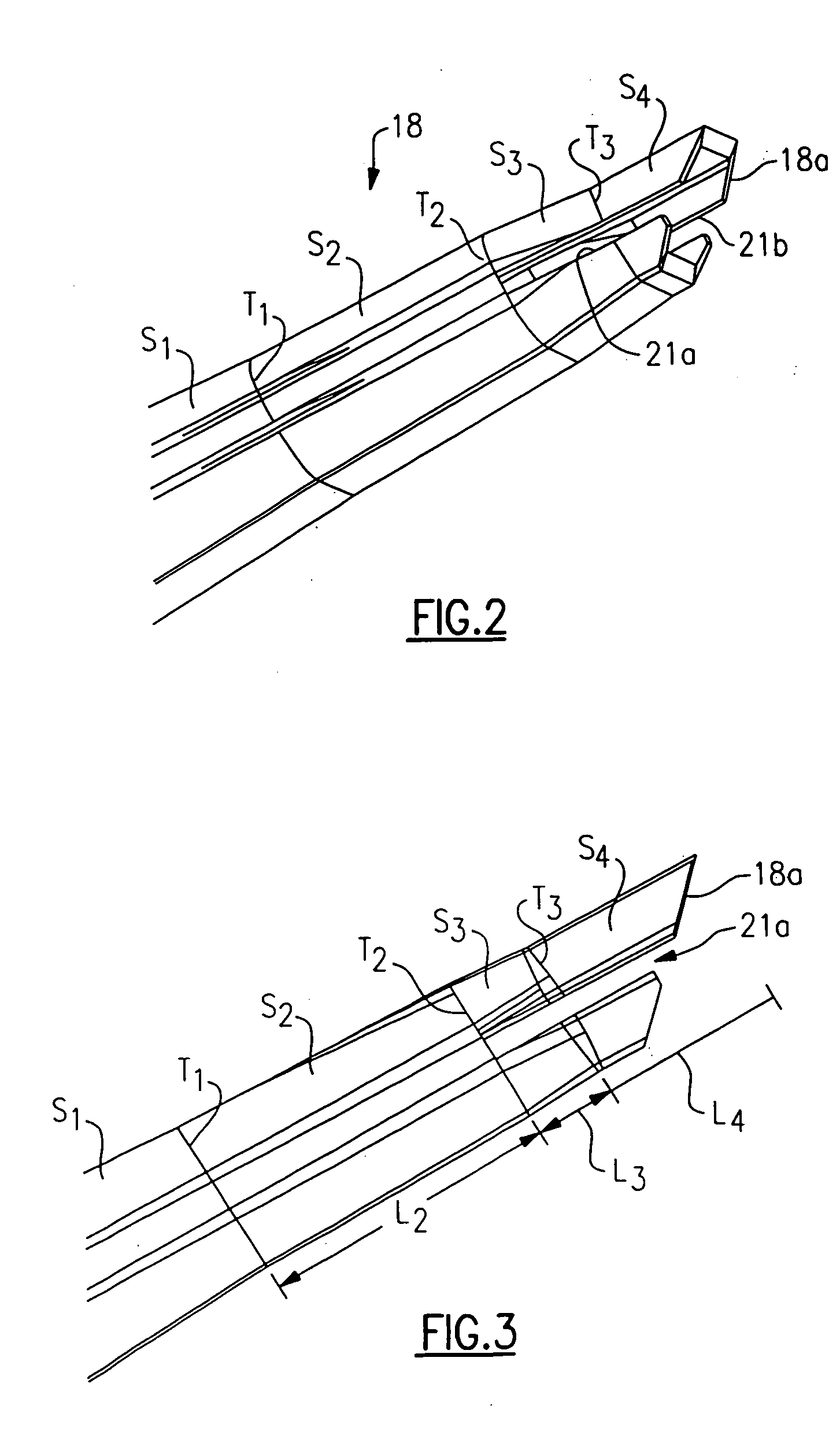

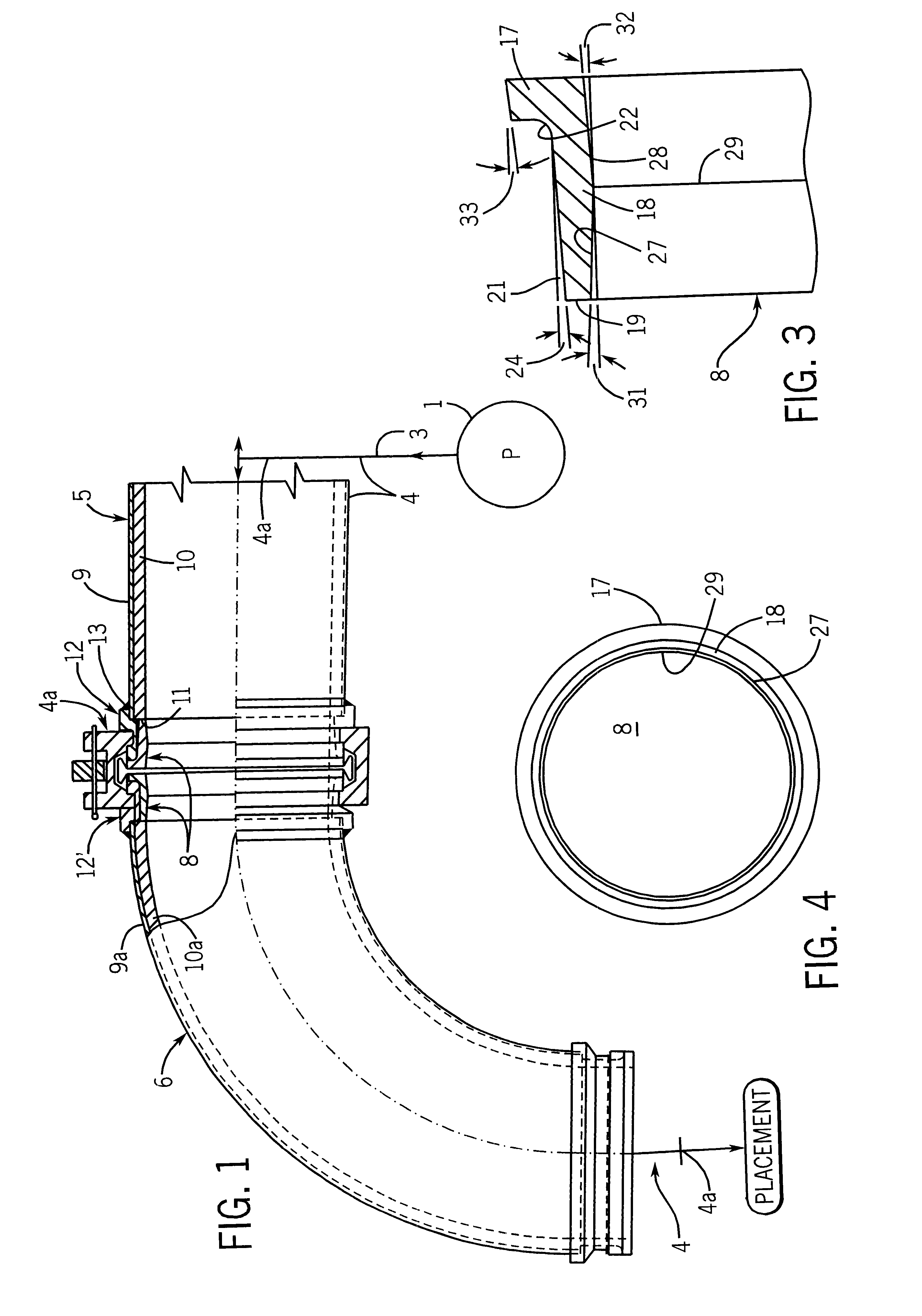

Pipe having replaceable wear resistant lined coupler

InactiveUS6467812B1Rapid and cost-effective formationQuick inexpensive replacementFlanged jointsThermal insulationWear resistantEngineering

A pipe section for concrete includes an end coupler interconnecting to another pipe section in a flow line. The coupler has an outer clamp secured extended from the pipe end with a coupling groove. An encircling clamp has sides located in the grooves of adjacent pipe sections to lock the pipe section together. The body and pipe end form an inner recess extending from the pipe end. An insert liner has a tubular portion matching the recess, with the outer surface of the tubular portion tapered to form a gap within the recess. The insert liner has an outer flange matching the outer diameter of the body and abuts the body. The inner wall of the liner has a central transition point from which the wall tapers inwardly in opposite directions to the outer end. The body member is formed of a high strength ductile steel. The insert liner is formed of a wear resistant material having a Rockwell hardness of 80 to 90. A carbide alloy consisting essentially of carbides, martensite, bainite and austenite, and 12-15% chromium, 2-3% carbon and traces nickel, molybdenum and austenite. A toughened ceramic is disclosed. The liner is adhesively bonded to the body using an epoxy adhesive which is responsive to heat for release of the liner. The liner is inserted by applying adhesive on the tubular portion and then pushing the liner into the recess.

Owner:CONSTR FORMS

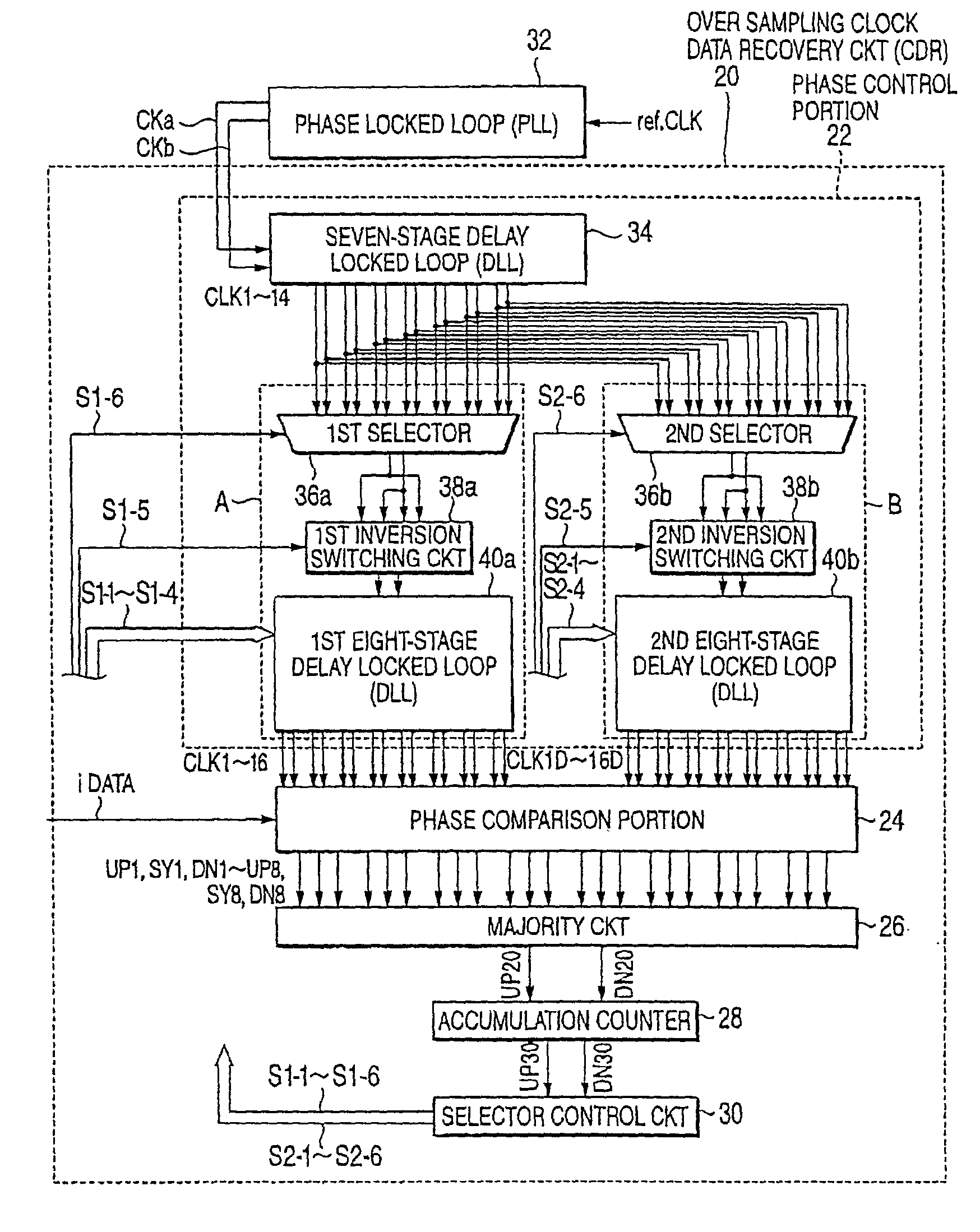

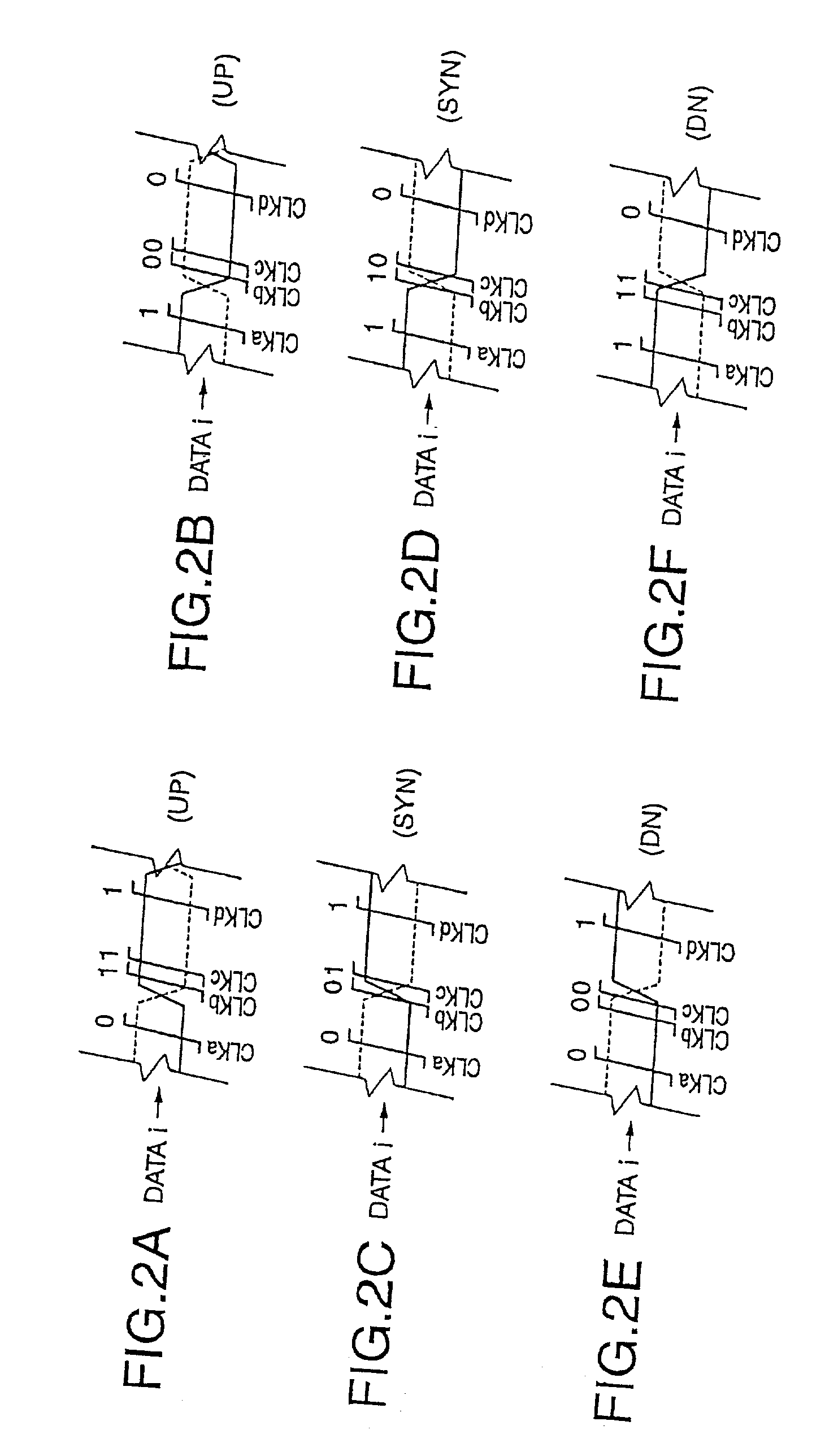

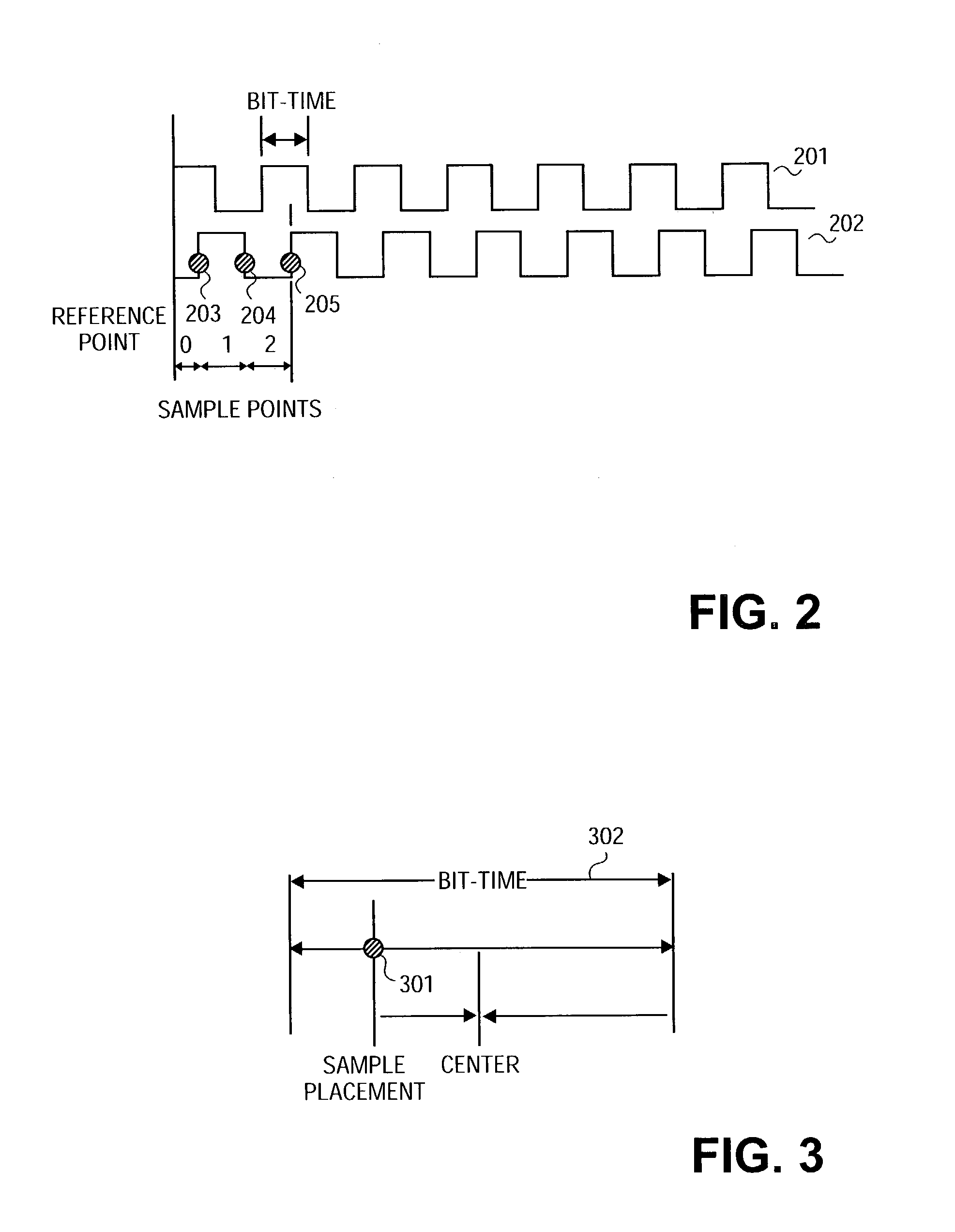

Oversampling clock recovery having a high follow-up character using a few clock signals

InactiveUS7010074B2High follow-up characterReduce the numberPulse automatic controlTime-division multiplexDelay-locked loopClock recovery

An oversampling clock recovery method according to this invention generates non-uniform three-phase clock signals CLKa, CLKb, and CLKc having non-uniform intervals for one bit of an input data i and controls phases of the clock signals so that either phase of two edges of two-phase clock signals CLKb and CLKc having a relatively narrower interval of 57 ps synchronizes with a phase of a transition point of the input data i. By changing clock signals to be phase-locked in three delay locked loops (DLLs), a phase interval of 57 ps is formed.

Owner:RENESAS ELECTRONICS CORP

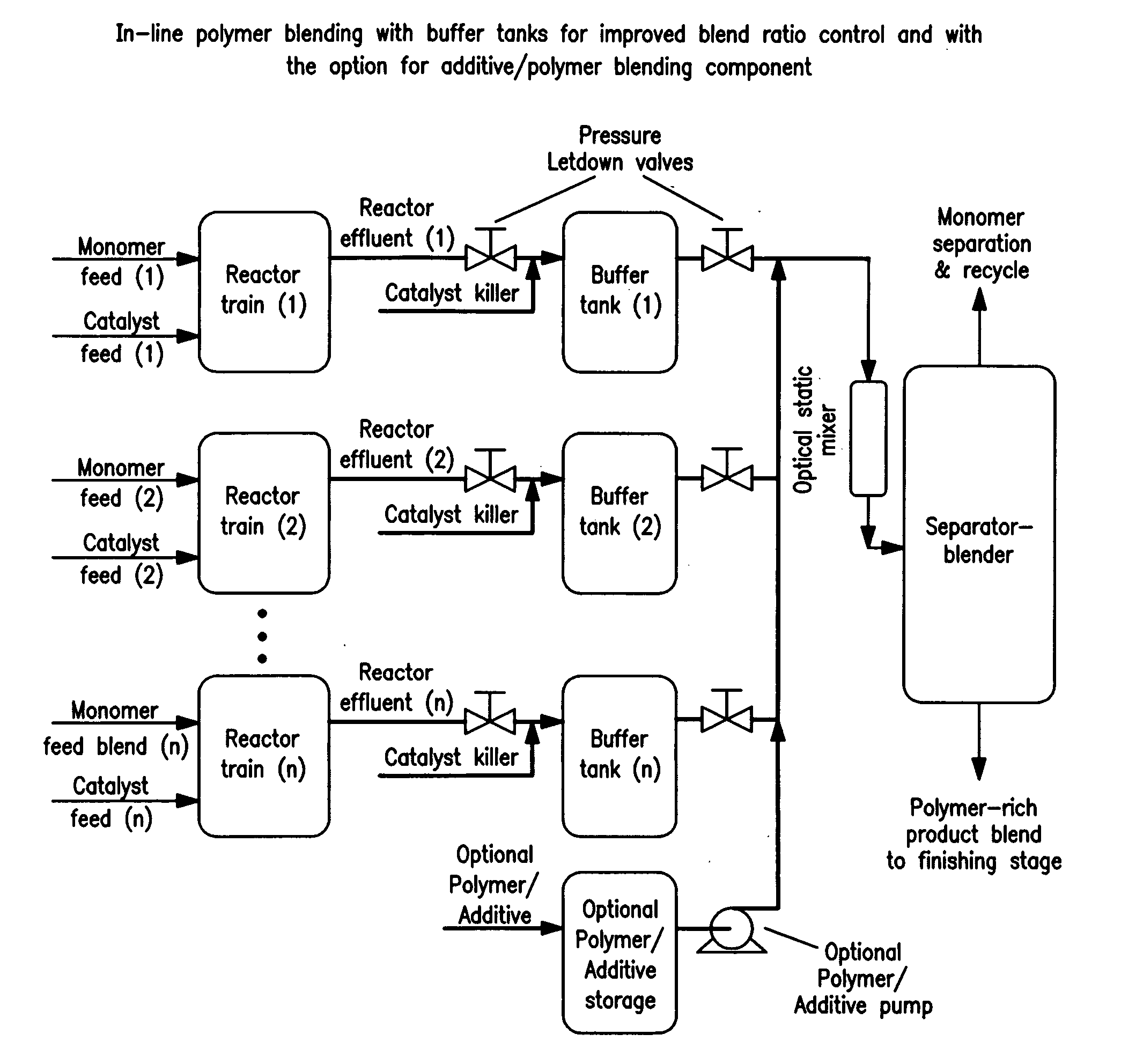

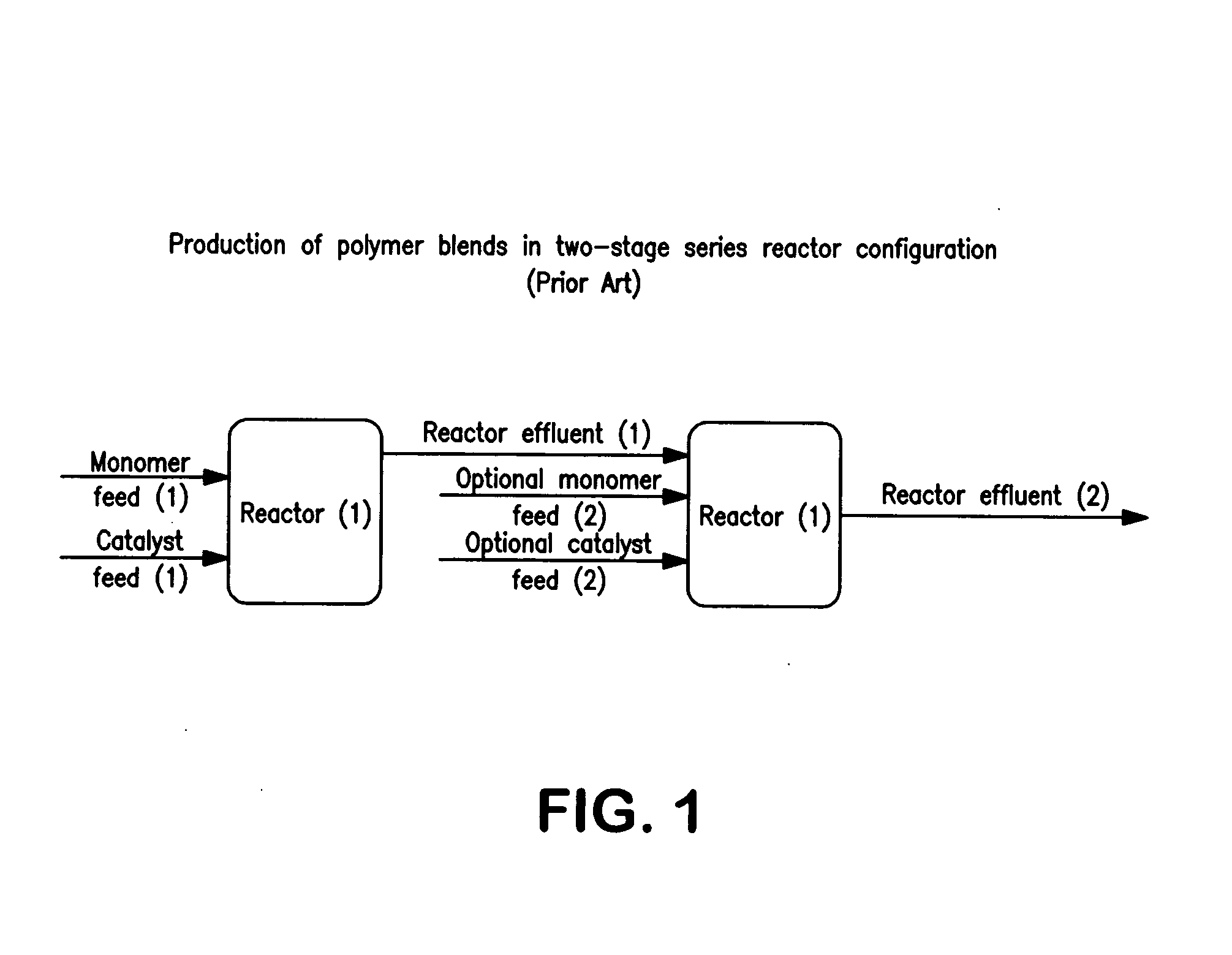

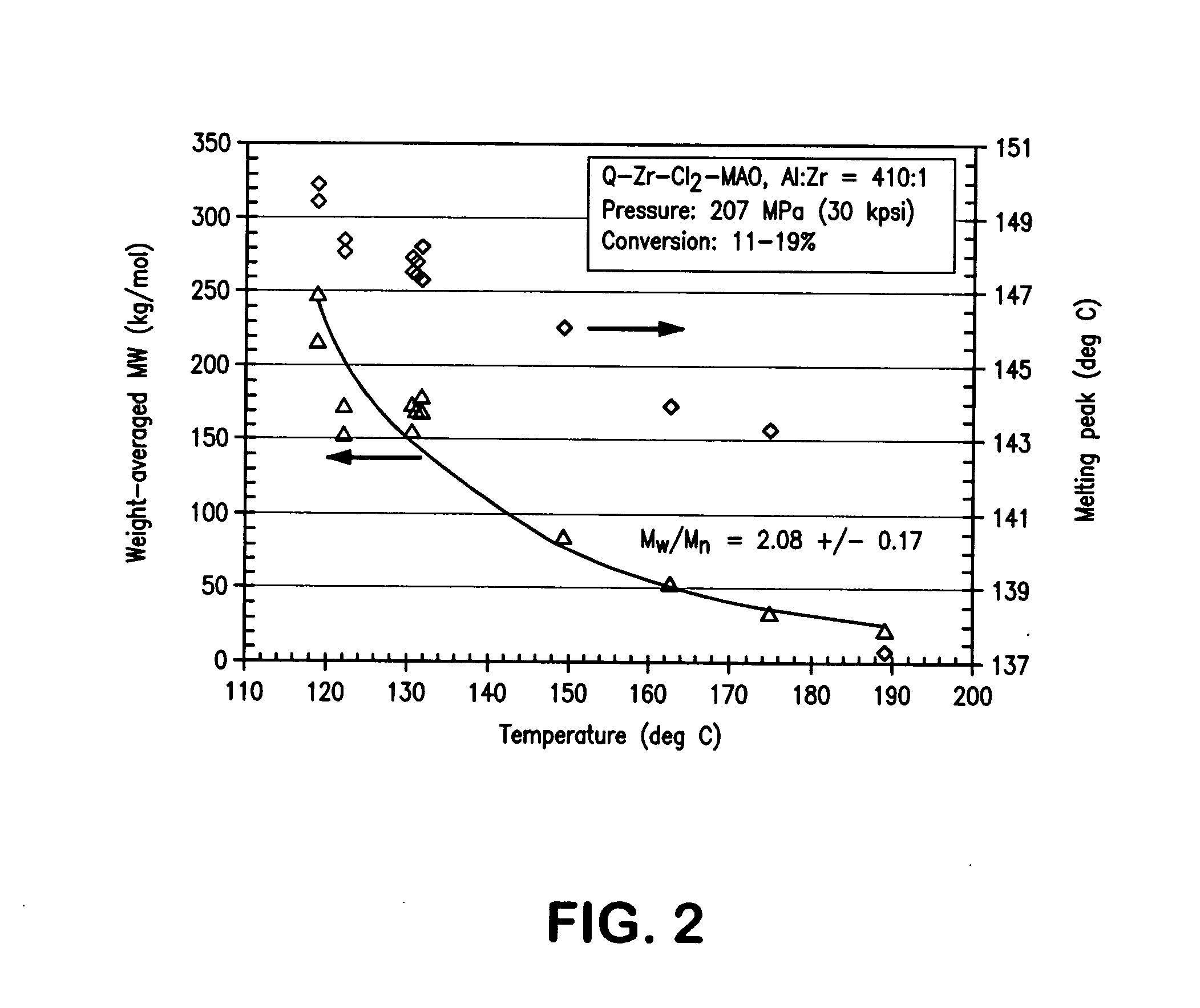

Process for fluid phase in-line blending of polymers

ActiveUS20080234443A1Maintain temperatureSpecial tyresChemical/physical/physico-chemical stationary reactorsScavengerSolvent

A process for fluid phase in-line blending of polymers. The process includes providing two or more reactor trains configured in parallel and a separator for product blending and product-feed separation; contacting in at least one of the parallel reactor trains olefin monomers having three or more carbon atoms, catalyst systems, optional comonomers, optional scavengers, and optional inert diluents or inert solvents, at a temperature above the solid-fluid phase transition temperature of the polymerization system and a pressure no lower than 10 MPa below the cloud point pressure of the polymerization system and less than 1500 MPa; forming a reactor effluent including a homogeneous fluid phase polymer-monomer mixture in each parallel reactor train; combining the reactor effluent from each parallel reactor; passing the combined reactor effluent through the separator; maintaining the temperature and pressure within the separator above the solid-fluid phase transition point but below the cloud point pressure and temperature to form a fluid-fluid two-phase system including a polymer-rich blend phase and a monomer-rich phase; and separating the monomer-rich phase from the polymer-rich blend phase. The separated monomer-rich phase is recycled to the polymerization reactor bank. The polymer-rich blend phase is conveyed to a downstream finishing stage for further monomer stripping, drying and / or pelletizing to form a polymer product blend.

Owner:EXXONMOBIL CHEM PAT INC

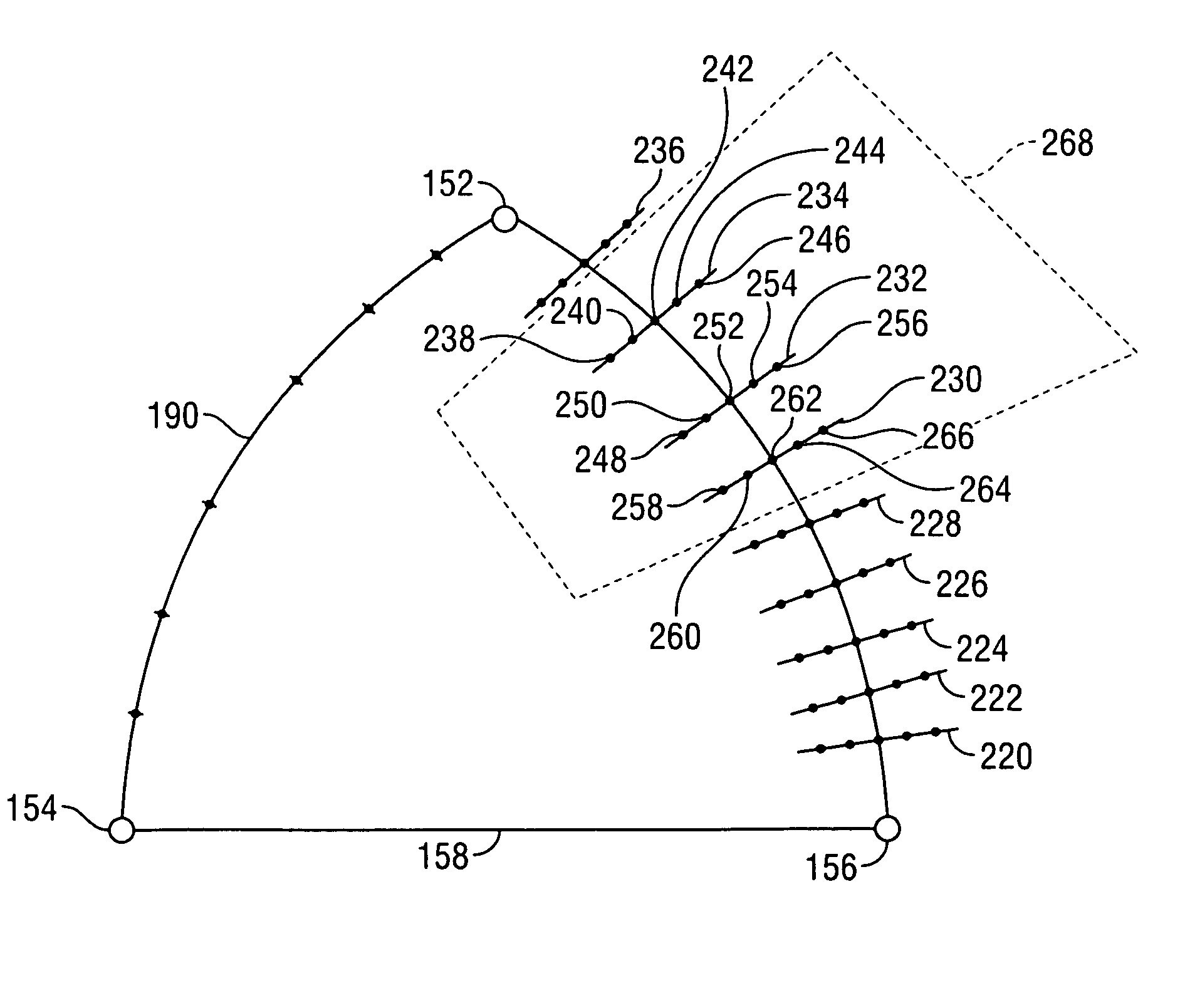

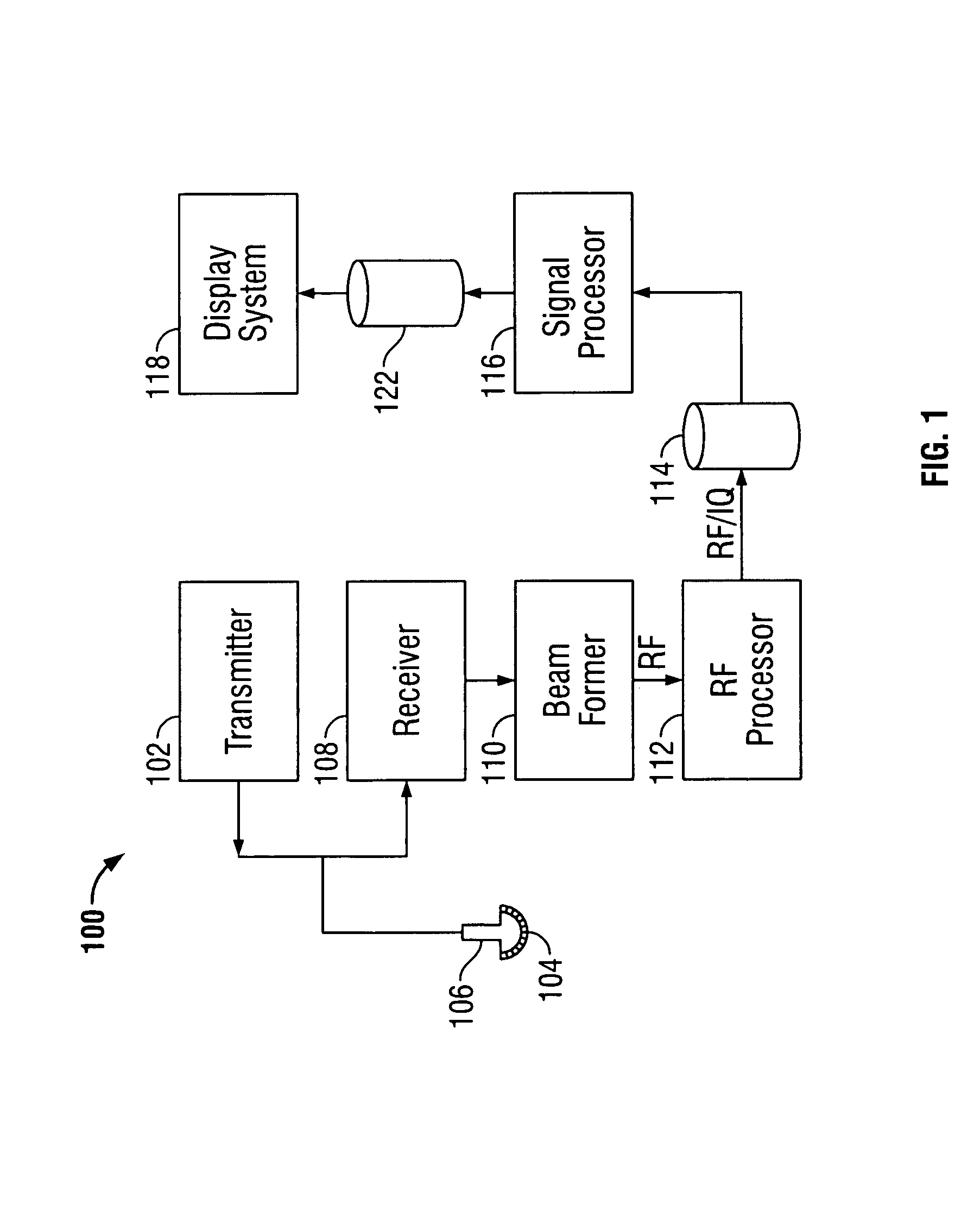

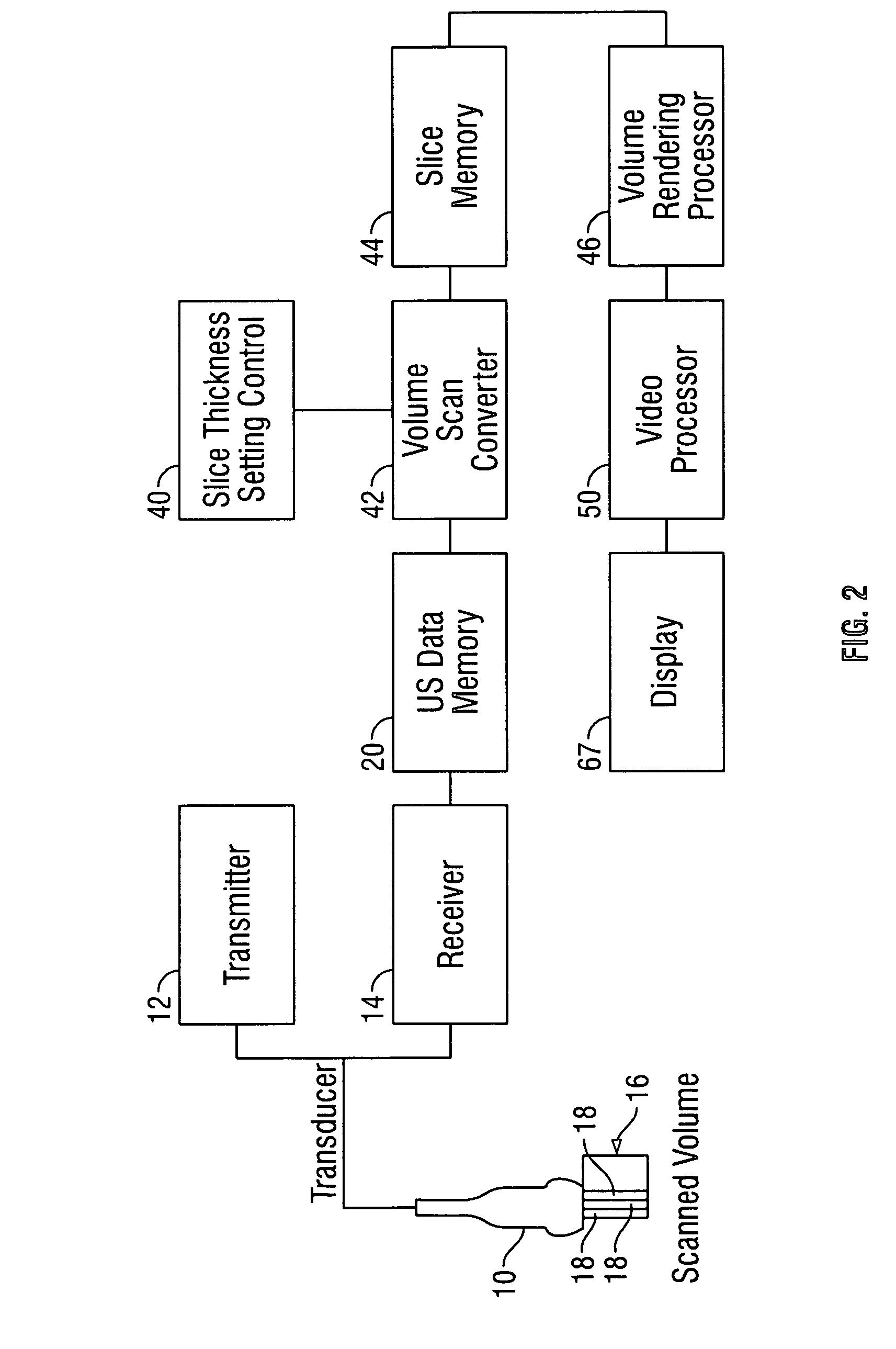

Method and apparatus for detecting anatomic structures

An anatomic structure is detected based on a medical diagnostic imaging data set. The anatomic structure comprises at least two different types of tissue. At least one anatomic landmark is identified within the data set, the data set is overlaid with a contour template, and a search region of the data set surrounding the contour template is scanned to identify transition points associated with a predefined characteristic of the anatomic structure.

Owner:GENERAL ELECTRIC CO

Can end for a container

InactiveUS7000797B2Vent safelySlowing the fracture of the scoreRefuse receptaclesRigid containersEngineeringTransition point

An end member for a container having a circumferential sidewall, the end member having a peripheral seaming edge adapted to be integrally connected to the sidewall, and having a central panel wall with a means for opening a frangible panel segment of the panel wall is claimed. The end member comprises a deboss panel recessed in the central panel. The deboss panel has first and second spaced apart end portions joined by first and second sidewalls. The first spaced apart end portion has an apex and first and second arcuate portions. A distance between the first and second arcuate portions is defined by a plurality of progressively increasing secant lengths located in spaced relation from the apex. A score groove is located within the deboss panel defining an outer perimeter of the frangible panel segment. The score groove has a first end and a second end joined to the first end by a curvilinear segment. The first end and the second end are separated by a generally linear hinge segment of the central panel wall. The curvilinear segment includes first and second curved segments joined by a transition point located adjacent the apex of the deboss panel. The generally arcuate transition region is defined by a plurality of progressively increasing chordal lengths located in spaced relation from the apex of the deboss panel. A ratio of the plurality of progressively increasing secant lengths to the progressively increasing chordal lengths increases along respective lengths of the first and second arcuate portions of the deboss panel.

Owner:REXAM BEVERAGE CAN

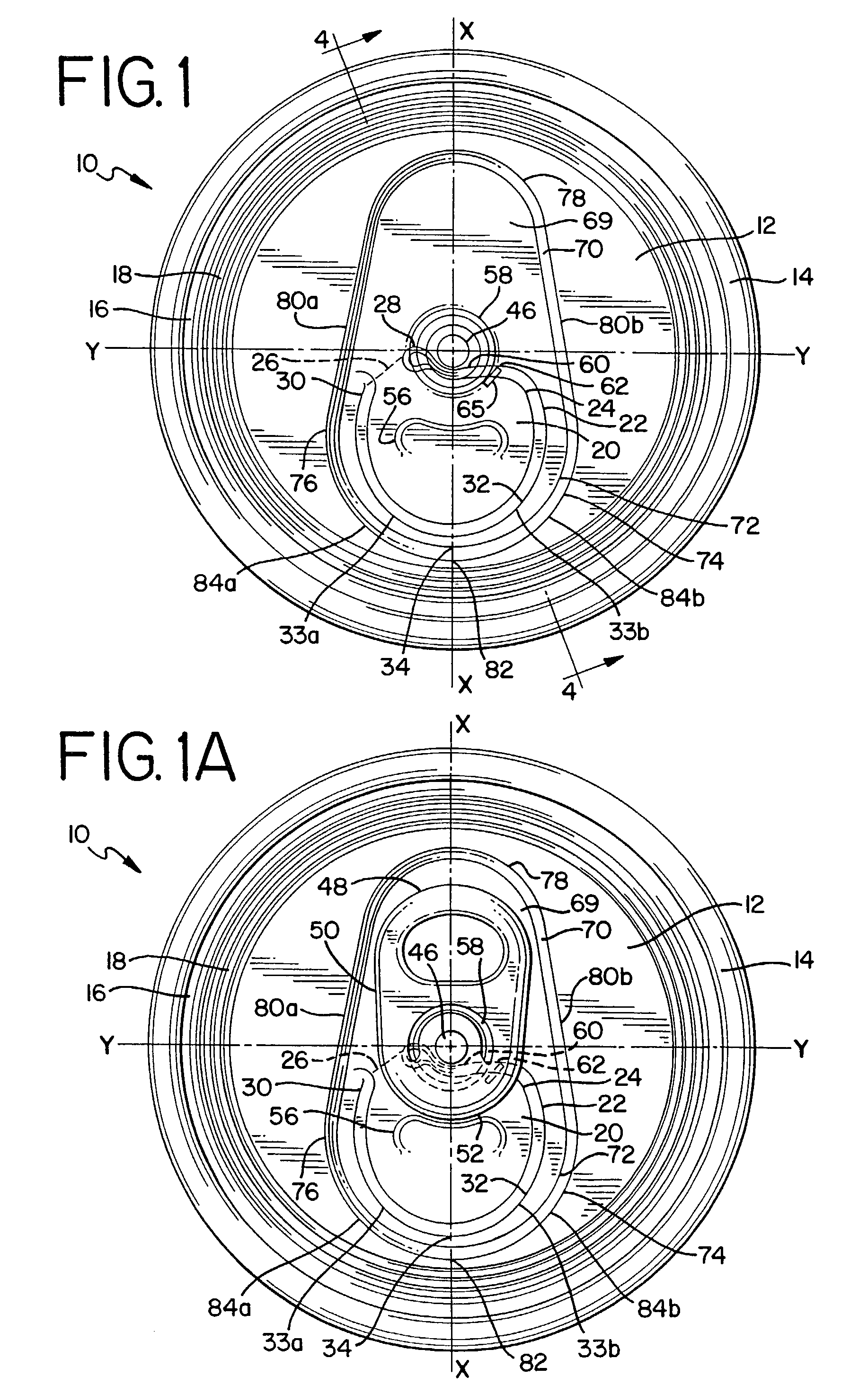

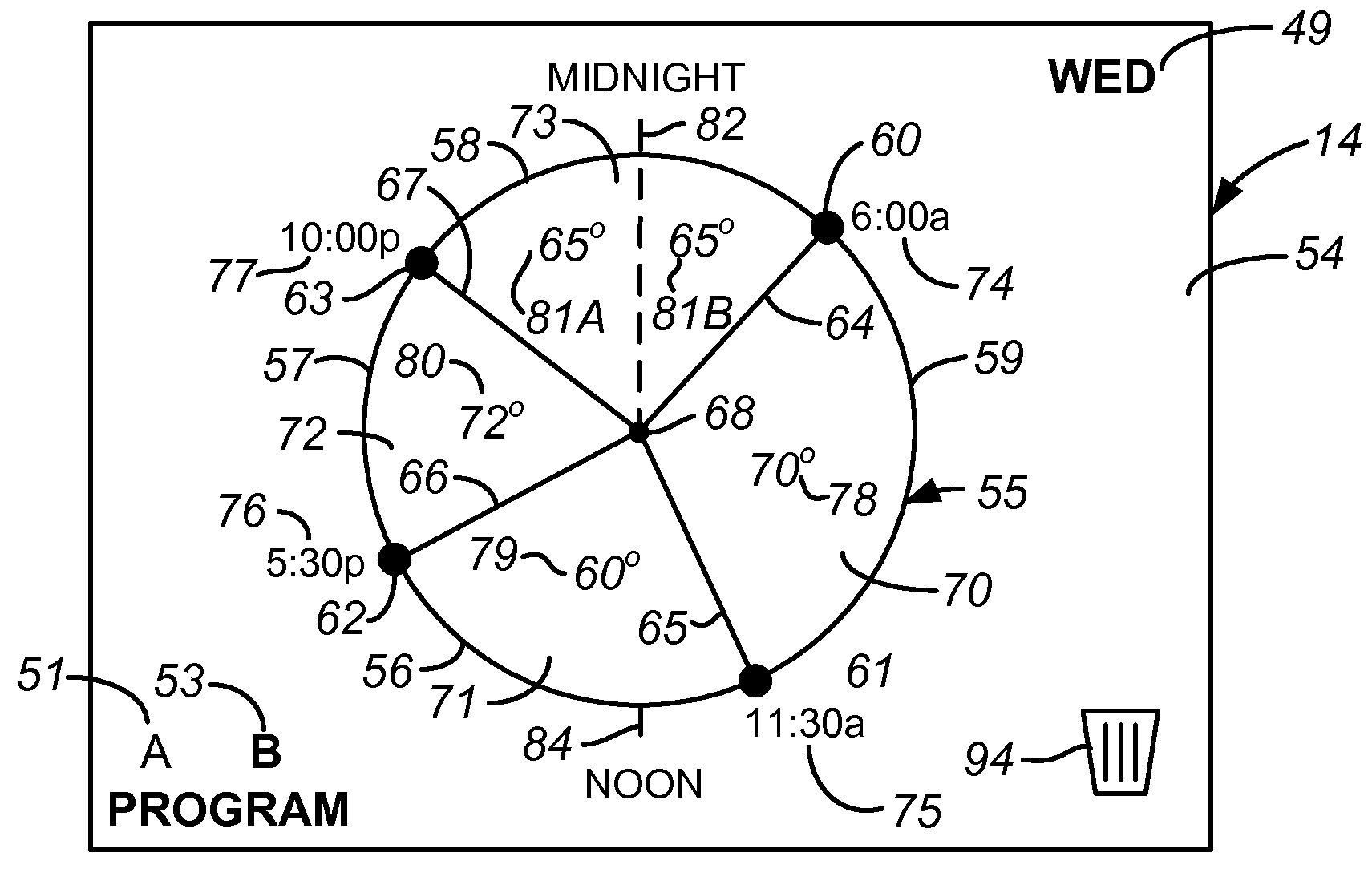

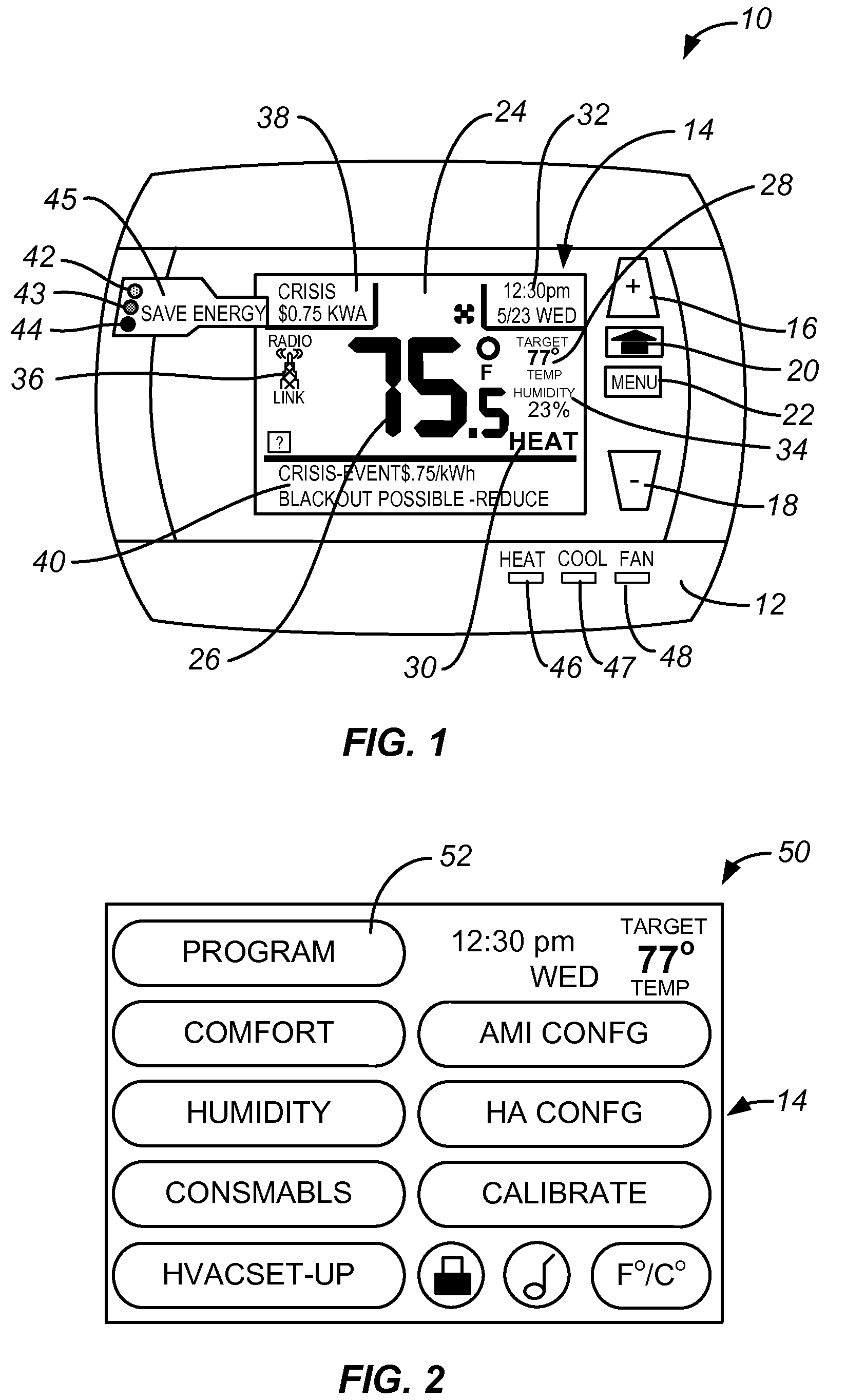

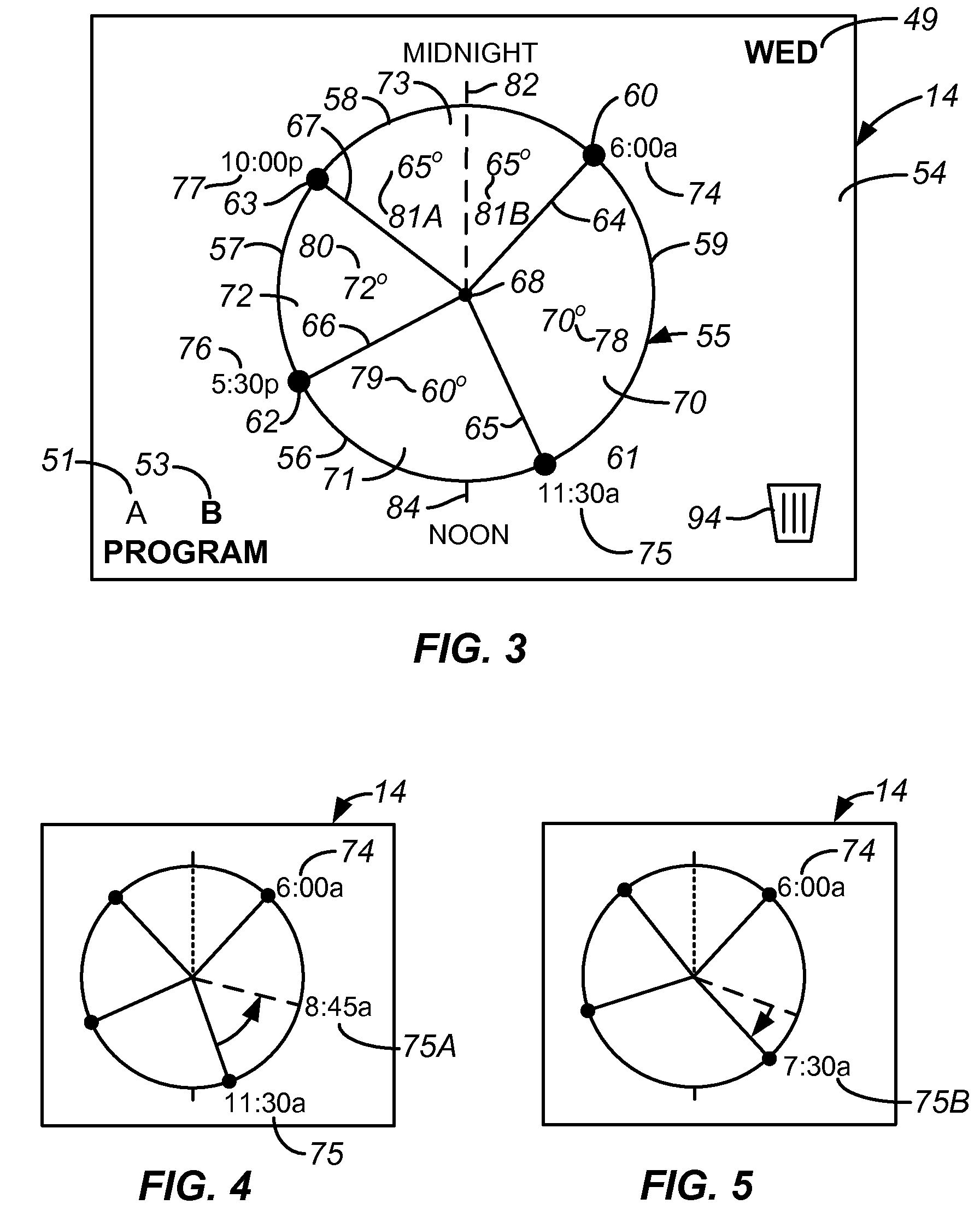

Programmable thermostat time/temperature display and method

A programmable thermostat time / temperature display has a continuous loop timeline with a plurality of temperature transition points along the timeline to define a plurality of timeline segments. Temperature and time IDs are displayable on the display and are associated with at least some of the timeline segments and temperature transition points. A thermostat can be programmed by touching a position on a touchscreen associated with a temperature transition point on a continuous loop timeline on the touchscreen. The touching step may be carried out by moving the first temperature transition point from a first position along the timeline to a second position along the timeline so to change the first timeline segment. An updated time ID may be selected for the first temperature transition point.

Owner:TIM SIMON

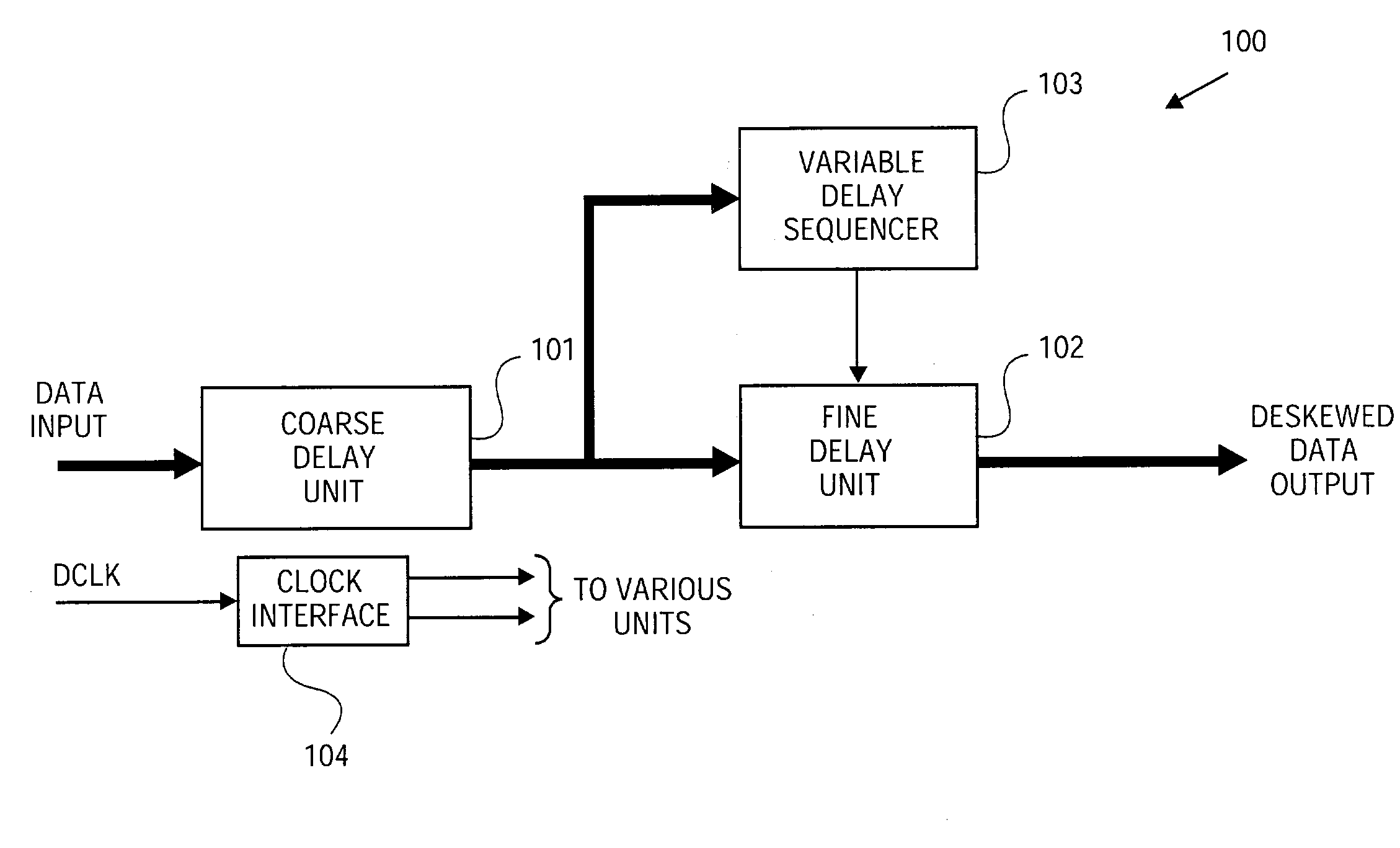

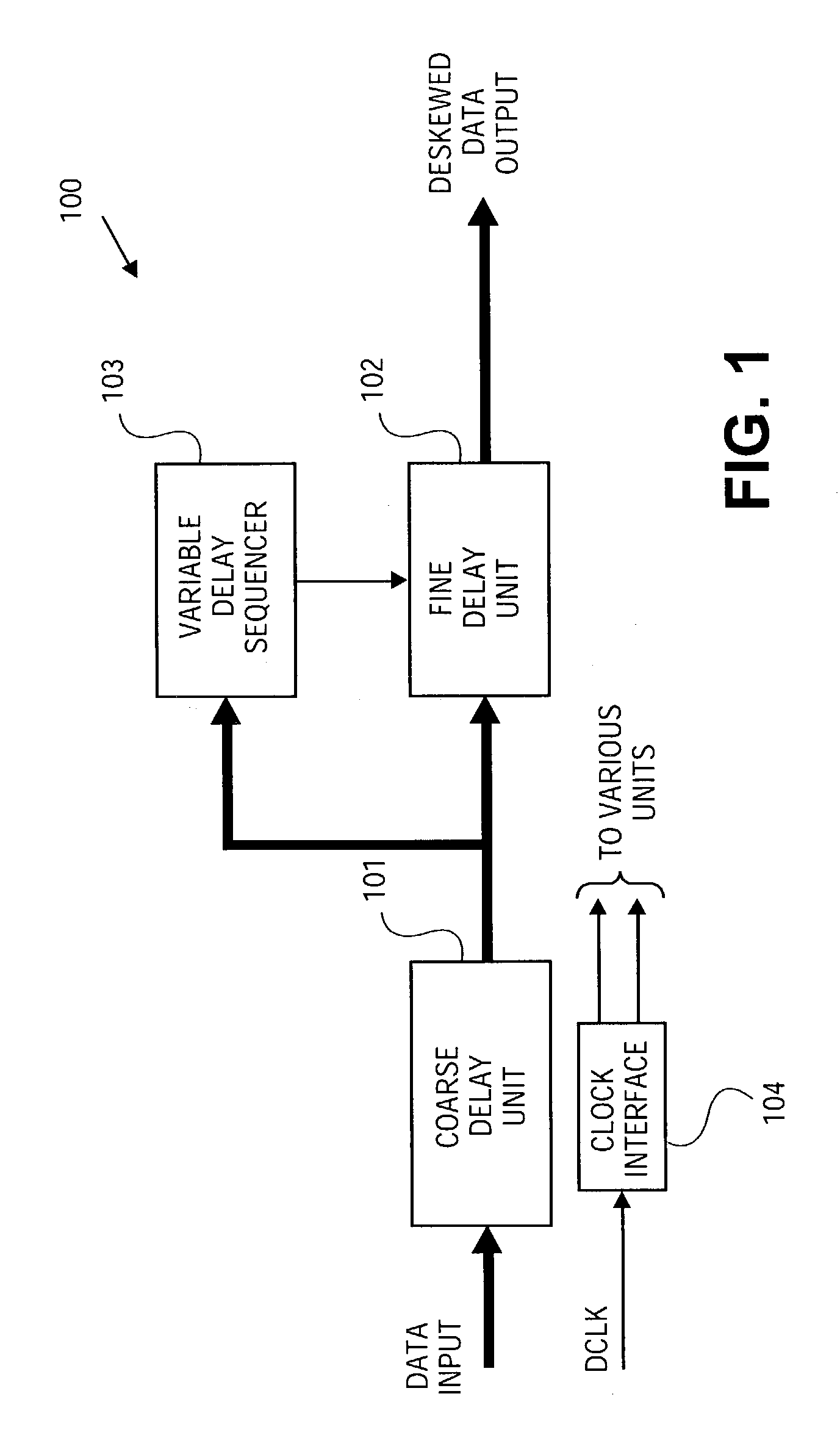

Apparatus and method for data deskew

ActiveUS7209531B1Time-division multiplexSynchronisation signal speed/phase controlTransition pointComputer science

A deskew circuit utilizing a coarse delay adjustment and fine delay adjustment centers the received data in a proper data window and aligns the data for proper sampling. In one scheme, bit state transitions of a training sequence for SPI-4 protocol is used to adjust delays to align the transition points.

Owner:MARVELL ASIA PTE LTD

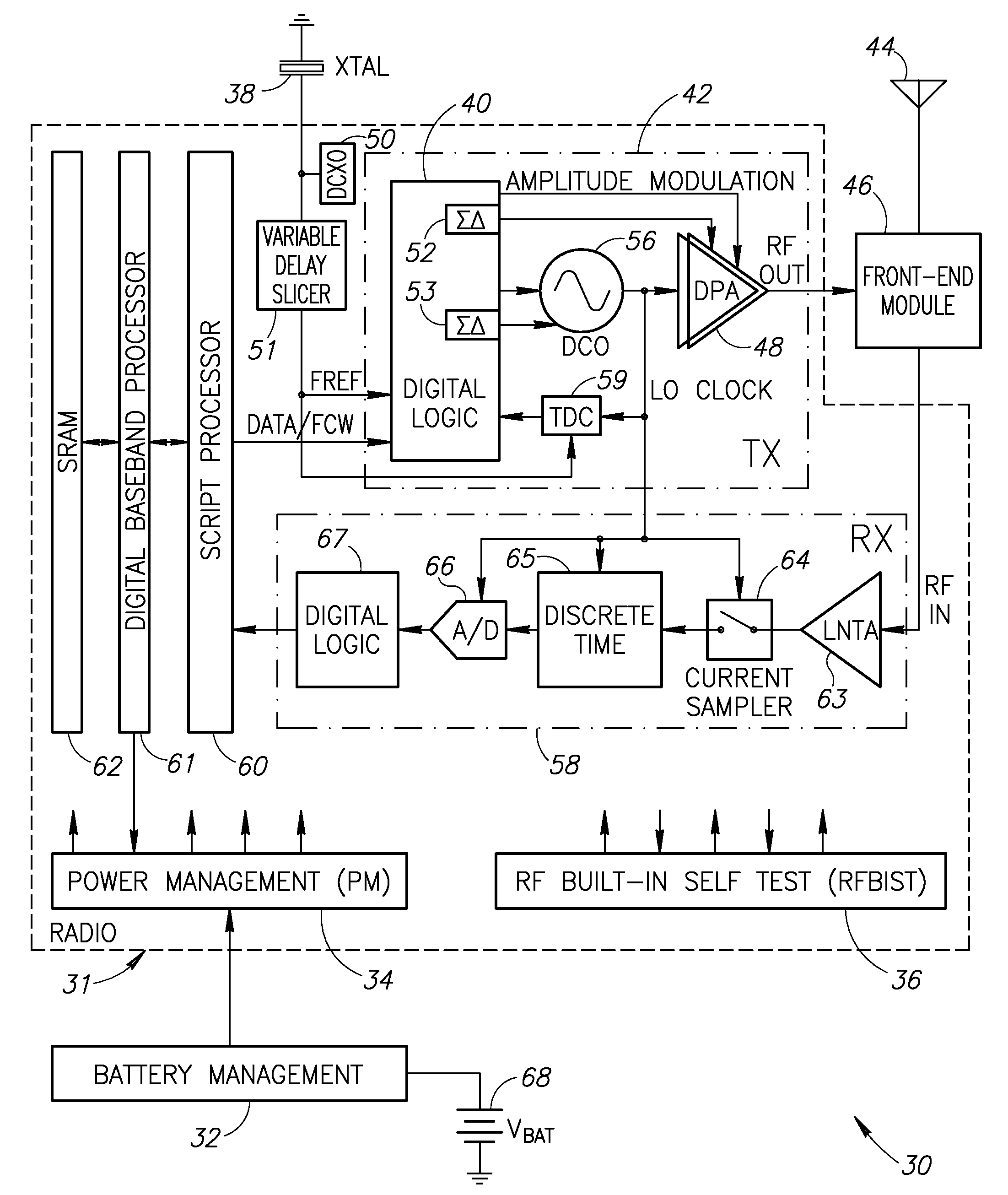

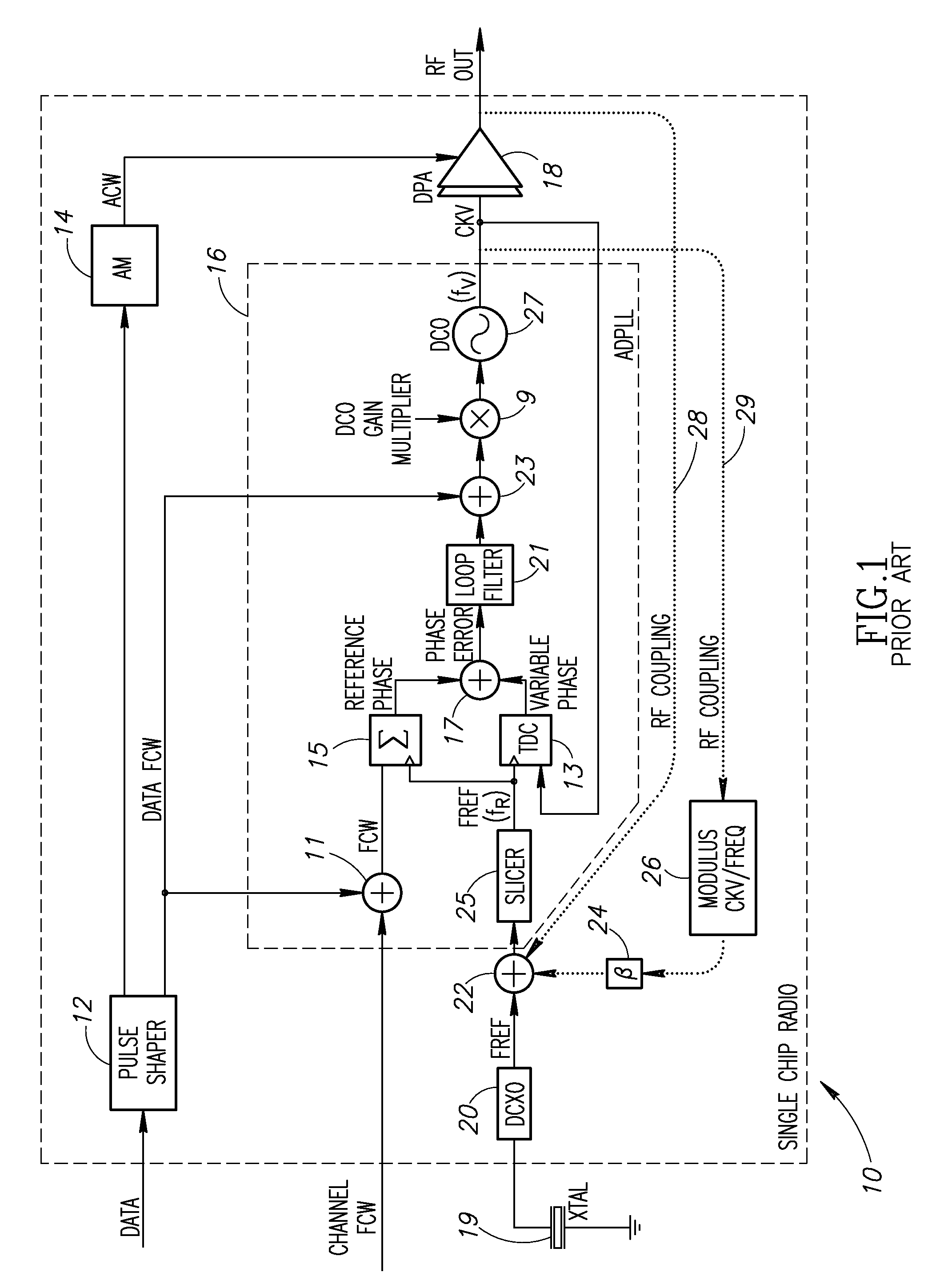

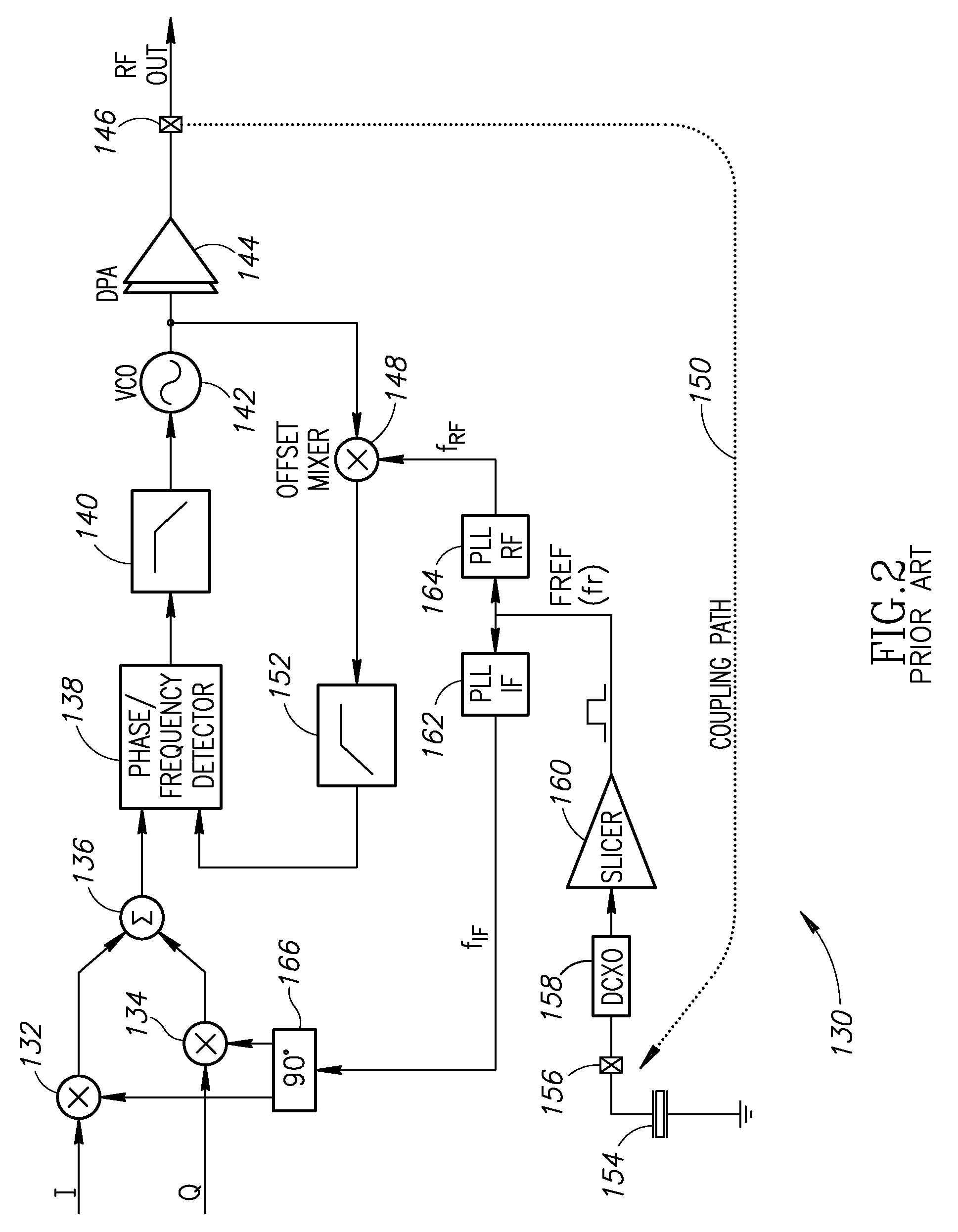

Variable delay oscillator buffer

ActiveUS20080192876A1Alleviate subharmonic mixing based deteriorationReduce mixPulse automatic controlAngle demodulation by phase difference detectionLoop filterHarmonic

A novel and useful variable delay digitally controlled crystal oscillator (DCXO) buffer (i.e. slicer). A conventional slicer following the DCXO is modified to introduce a controlled random variable delay into the buffered DCXO clock. The resultant output clock signal is then used as input to the TDC of an ADPLL circuit to alleviate the subharmonic mixing based deterioration caused by LO / TX coupling through the crystal pins, and to alleviate the dead-beat effects caused by the finite resolution of the TDC. Two mechanisms for introducing variable delay into the buffered DCXO output clock signal are presented: a first mechanism that creates variable delay in fine steps and a second mechanism that creates variable delay in coarse steps. In both mechanisms, switches are incorporated into the slicer circuitry and controlled using digital bit sequences which may comprise dithering signals. The switches are turned on and off via the digital bit sequences which varies the delay of the slicer clock output which serves to shift the rising and falling transition points of the resultant output clock signal. The jitter is shifted to higher frequencies where it is filtered out by the PLL loop filter.

Owner:TEXAS INSTR INC

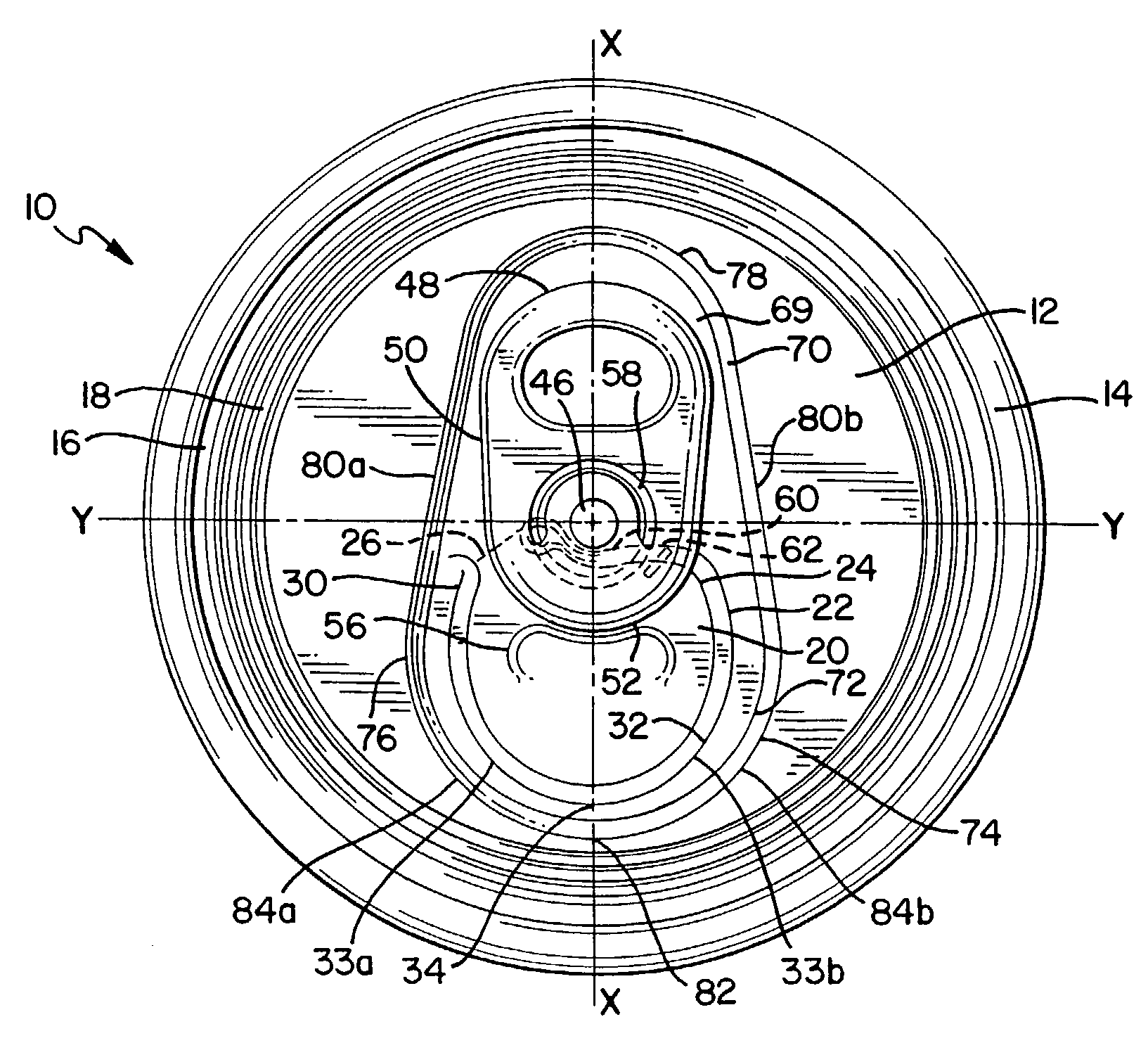

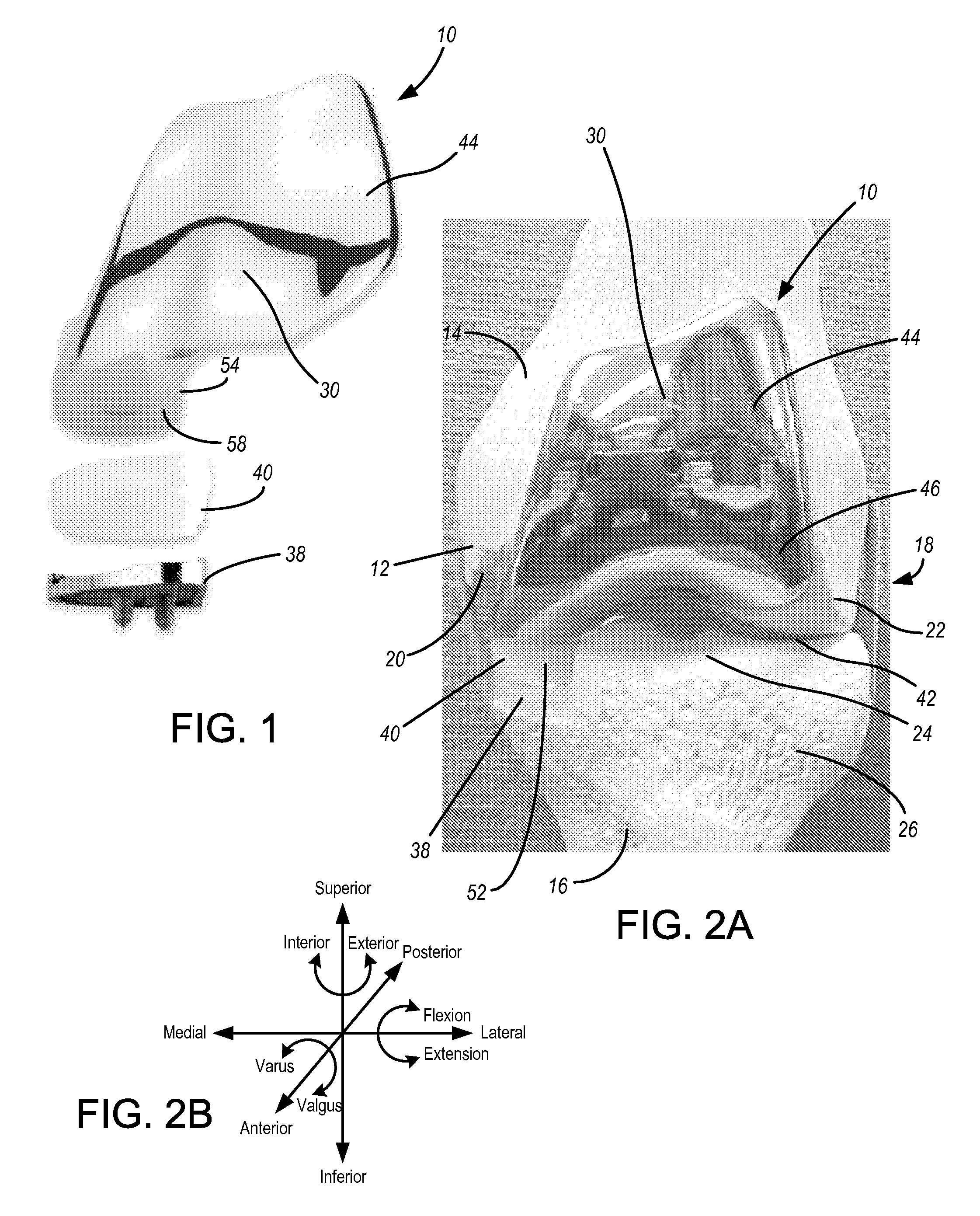

Implants with Transition Surfaces and Related Processes

InactiveUS20080058949A1Reduce discontinuitySmooth transitionJoint implantsKnee jointsLess invasive surgeryTibia

Implants, and processes for installing them, which replace the medial condyle and portions of the patellofemoral channel but preferably not portions of the lateral condyle that articulate relative to the tibia. Processes are provided which allow proper location and orientation of an anterior resection and a distal resection on the femur, which make use of a transition point which can be designated on the bone, for navigating proper positioning of such implants. Proper positioning of the implant relative to the femur for insuring a smooth transition between lateral portions of the implant and the lateral condyle is thus reduced to determining proper medial / lateral location of the implant on the anterior and distal resections. Such implants and processes can allow, among other things, for controlled location and orientation of an implant on the bone which saves lateral compartment bone, which eliminates the need to sacrifice the anterior and posterior cruciate ligaments, and which is adapted for minimally invasive surgery with its attendant benefits.

Owner:SMITH & NEPHEW INC

System and method for seamless multimedia assembly

ActiveUS9607655B2Electrophonic musical instrumentsPicture reproducers using cathode ray tubesTransition pointLine segment

Systems and methods are provided for seamless assembly of video / audio segments. To achieve such seamless assembly during streaming / online progressive download of media, a second segment is downloaded to a client during the presentation of a first segment. The first segment is then attached to the beginning of the second segment, where no jitter or gap results with the transition point either in the video or audio portion of the segments. Hence, the merged segments are presented as a seamless assembly of video / audio segments, where the user is “unaware” that the merged segments are the result of two separate or different segments. To effectuate such gapless assembly of segments, a gapless media file is created for encoding the video and audio segments using a gapless audio encoding scheme, such as Ogg Vorbis, where synchronized, gapless audio tags are interleaved in the video segments.

Owner:JBF INTERLUDE 2009

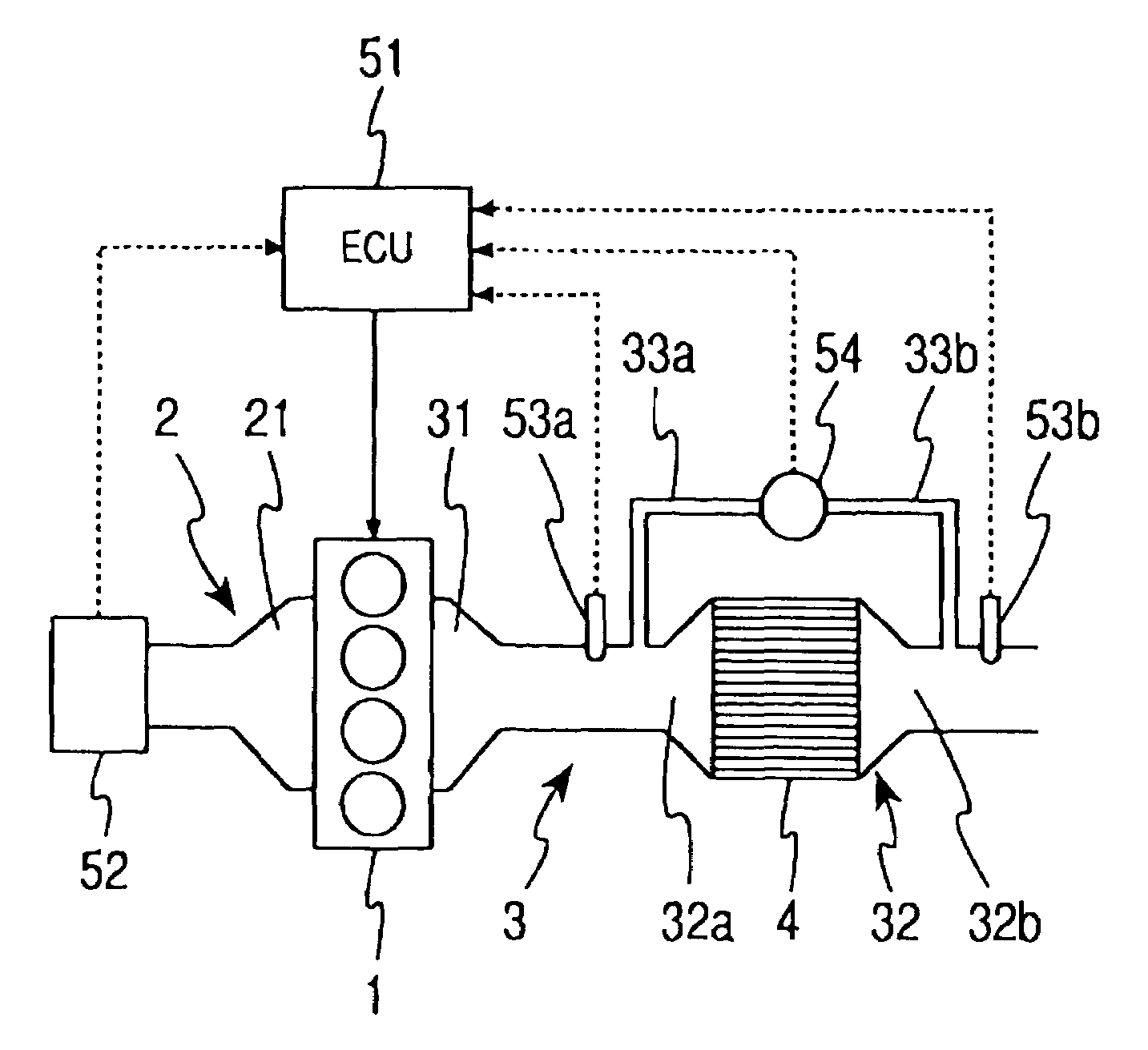

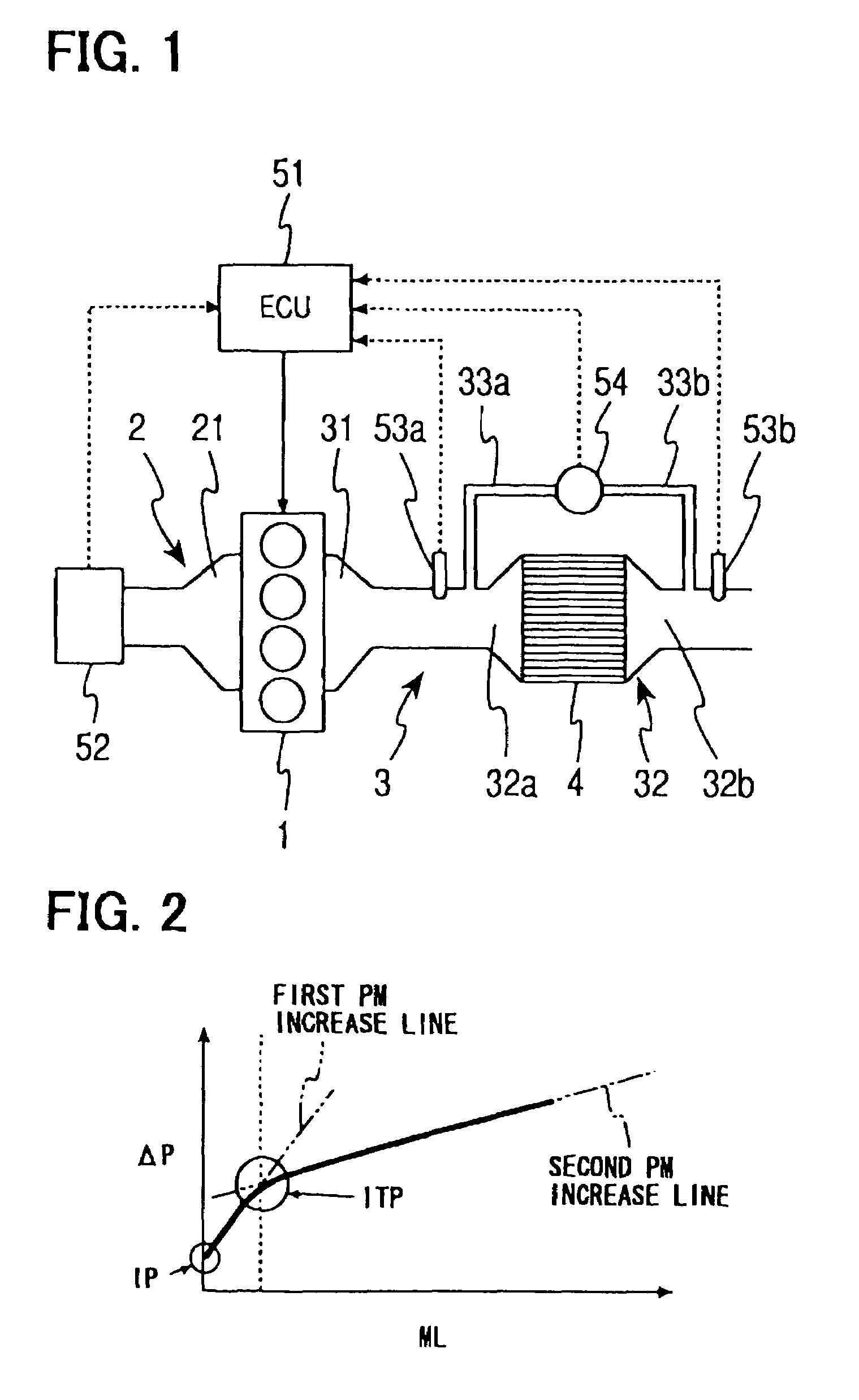

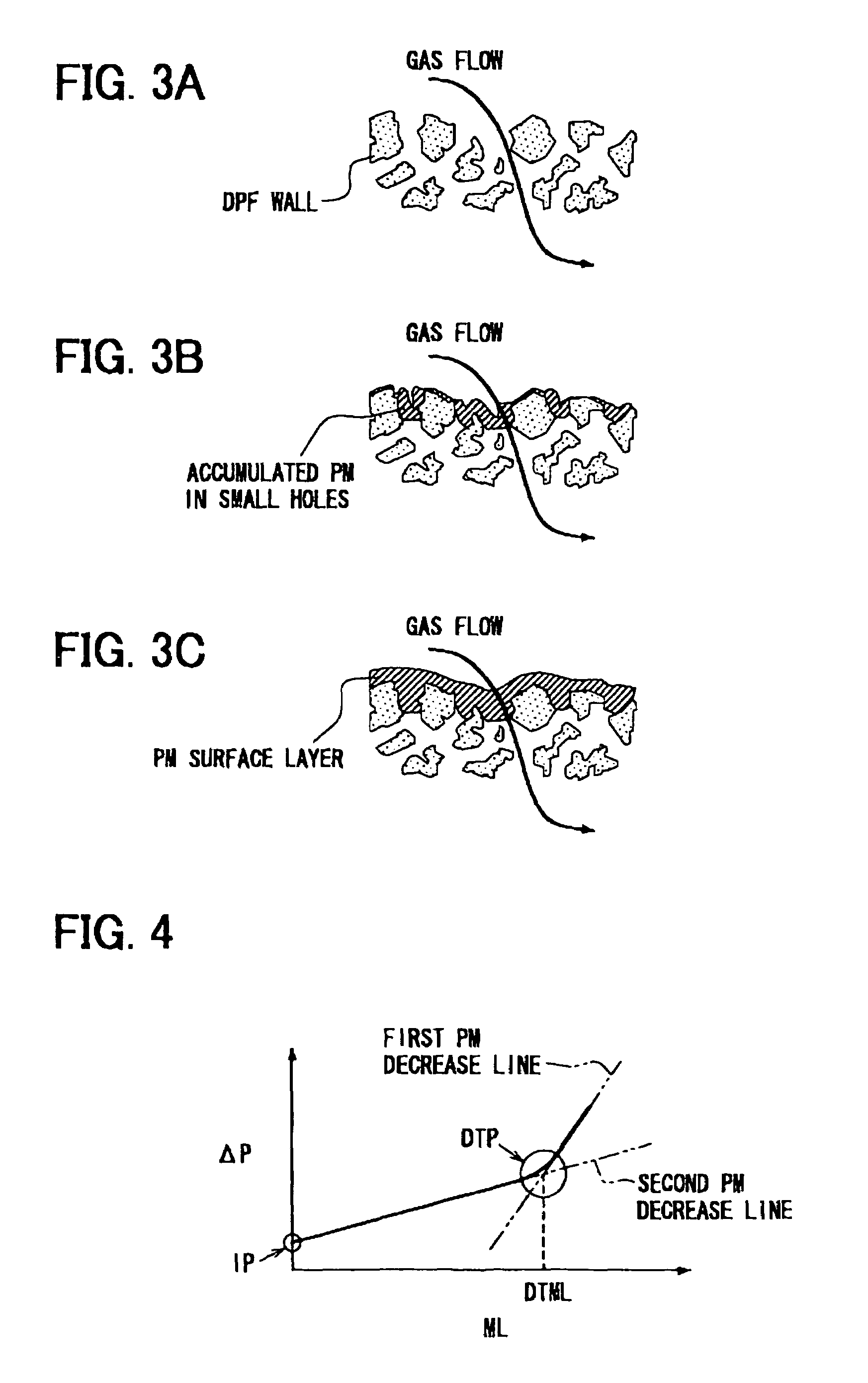

Internal combustion engine exhaust gas purification system

An amount ML of particles accumulated in small holes of a particulate filter is calculated in accordance with a pressure drop ΔP detected by a pressure sensor and a characteristic line. The characteristic line is defined by a first characteristic line and a second characteristic line, which is defined after exceeding a transition point TP. When the particles accumulated in the small holes are burned while remaining accumulated particles on the surface, the second characteristic line is shifted in a parallel fashion and compensated. Thus, the characteristic line is corrected so that the accumulation amount ML can be precisely calculated, even if particles accumulated in small holes are burned and the characteristic is changed.

Owner:DENSO CORP

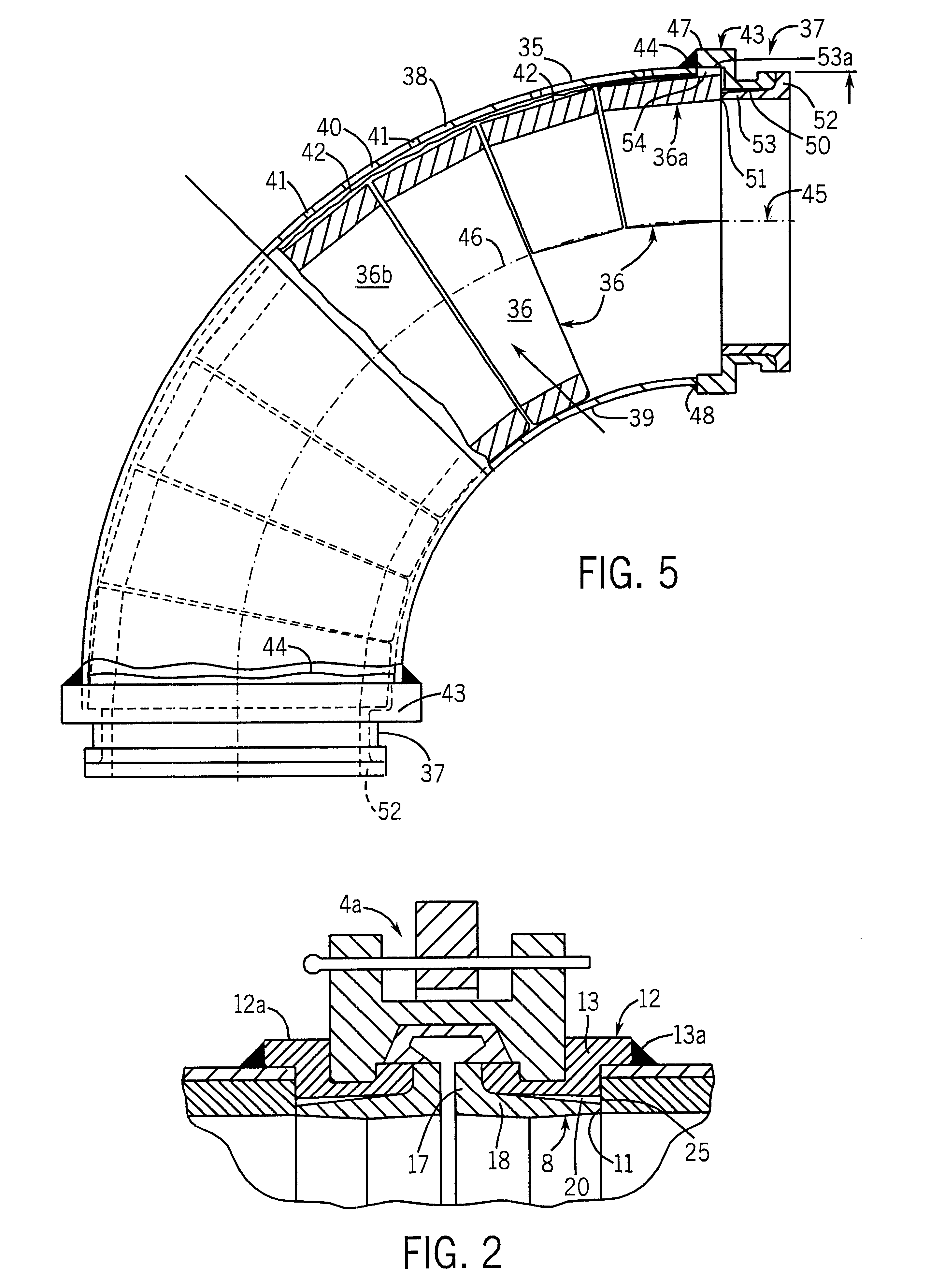

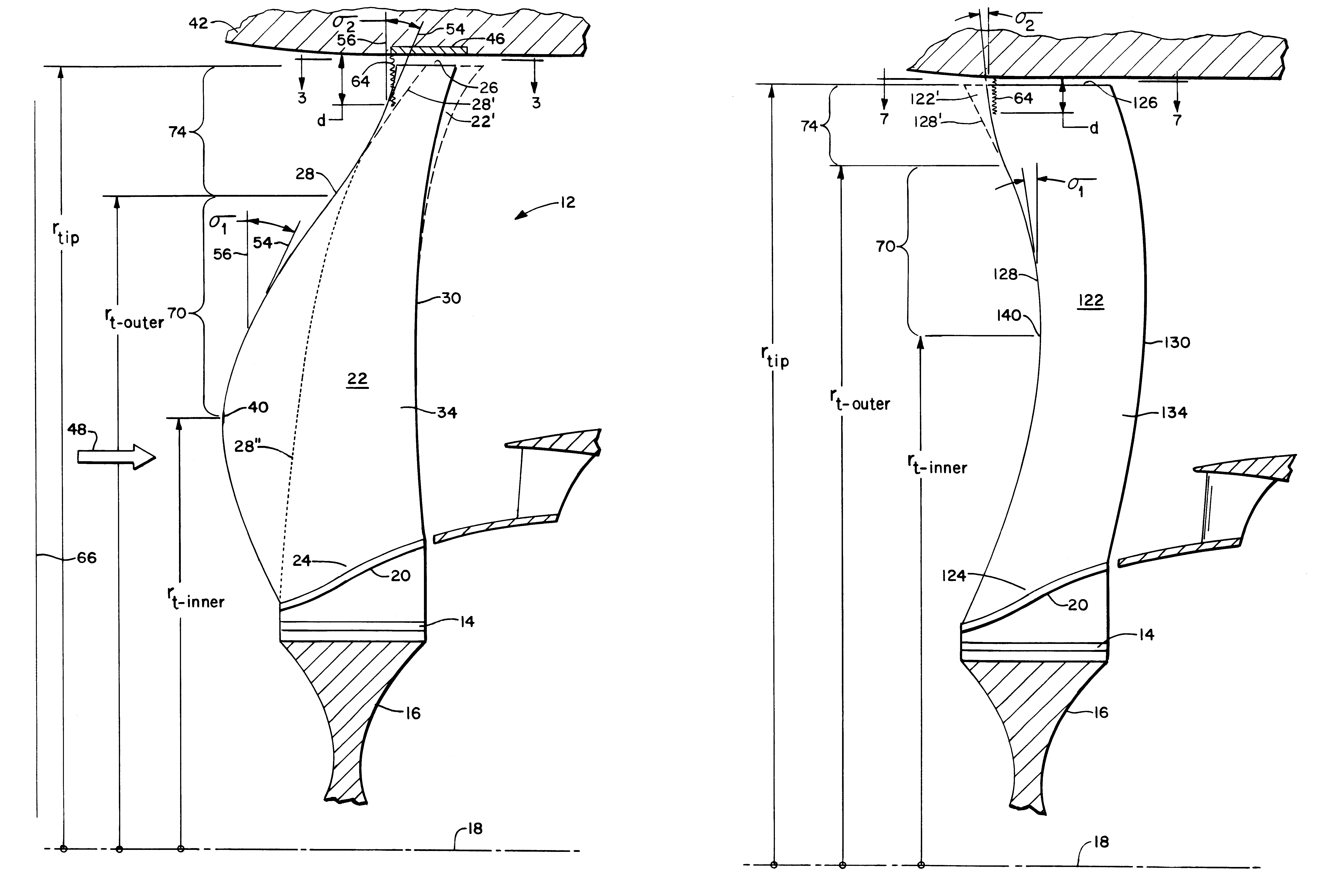

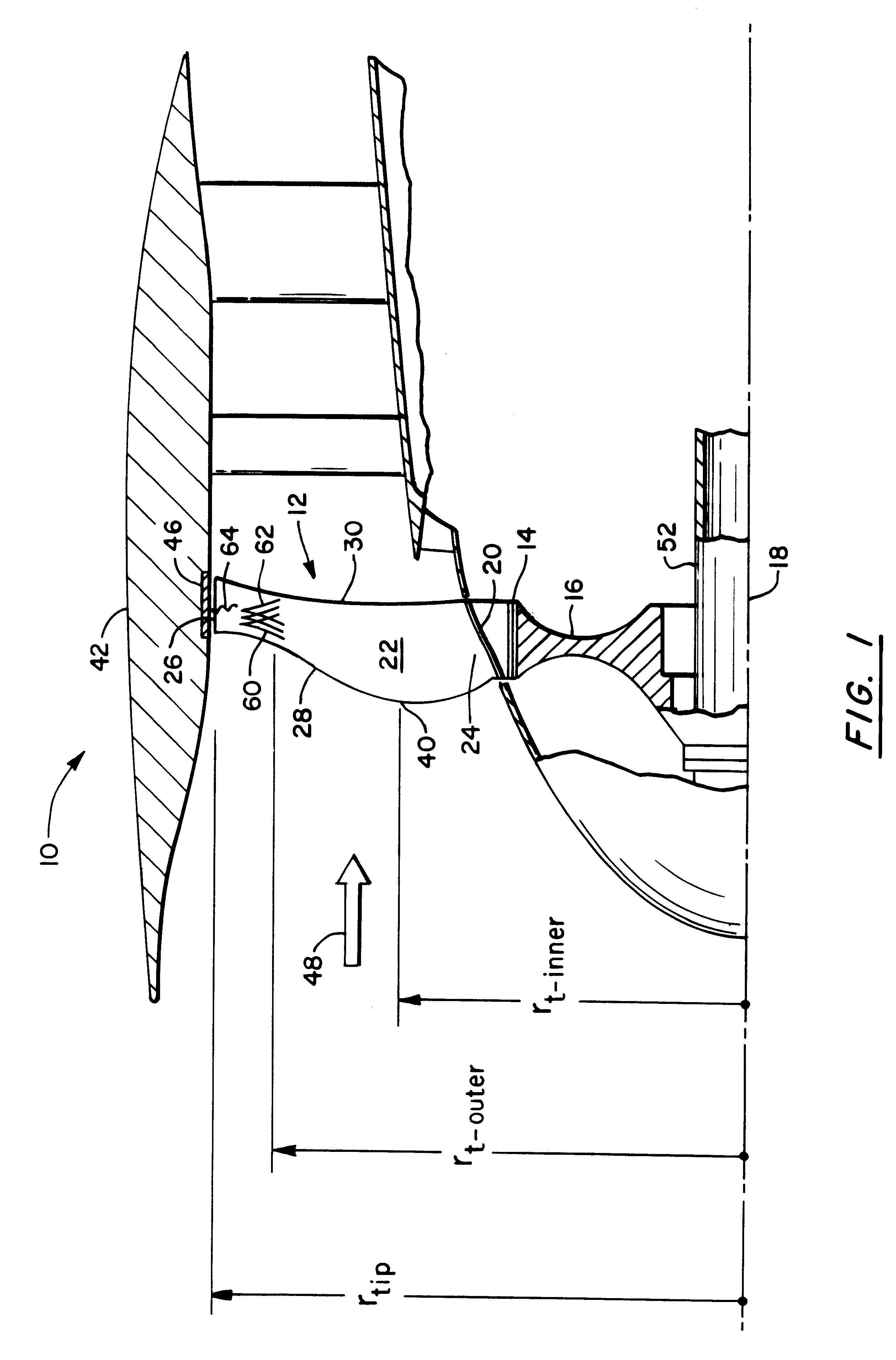

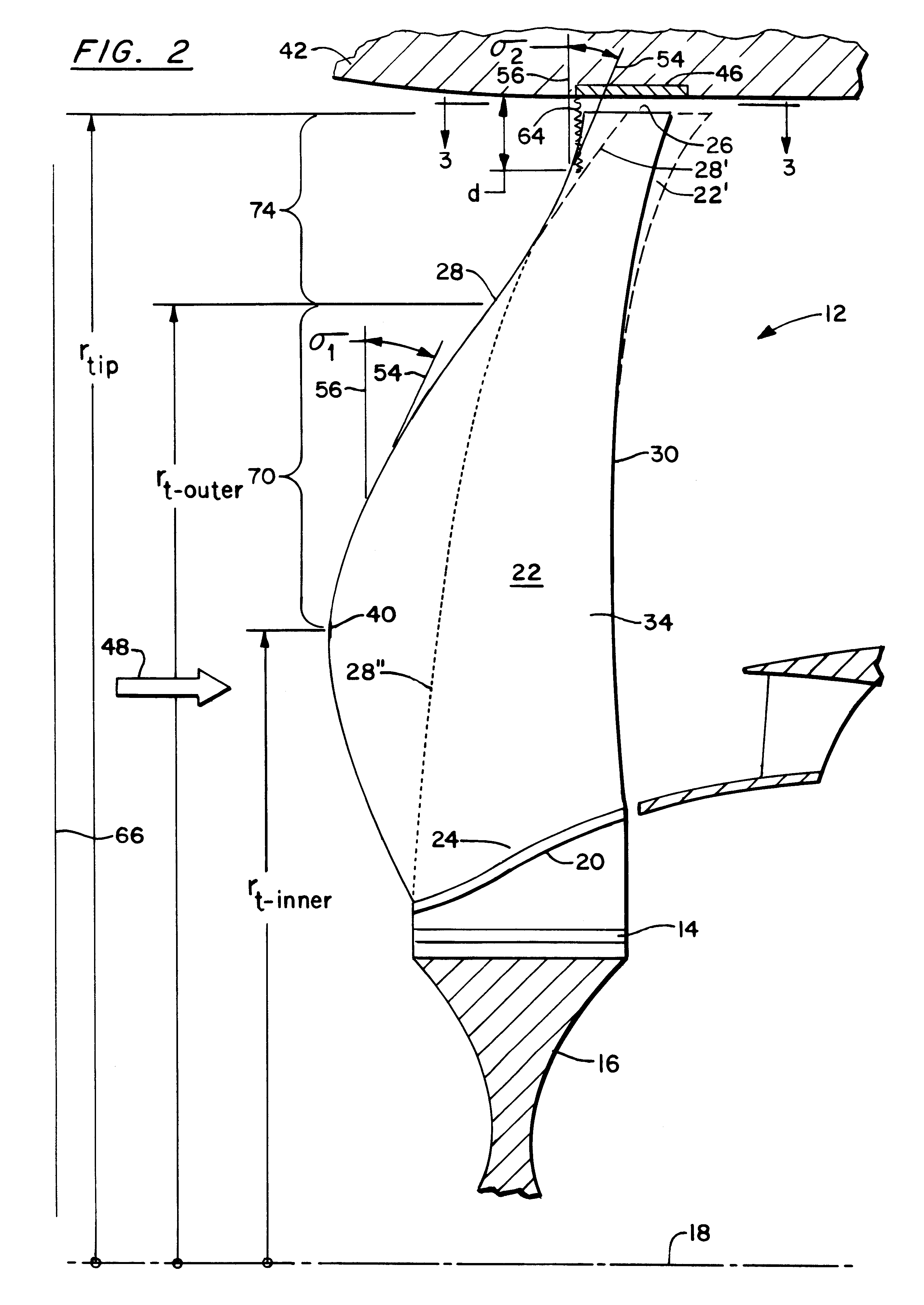

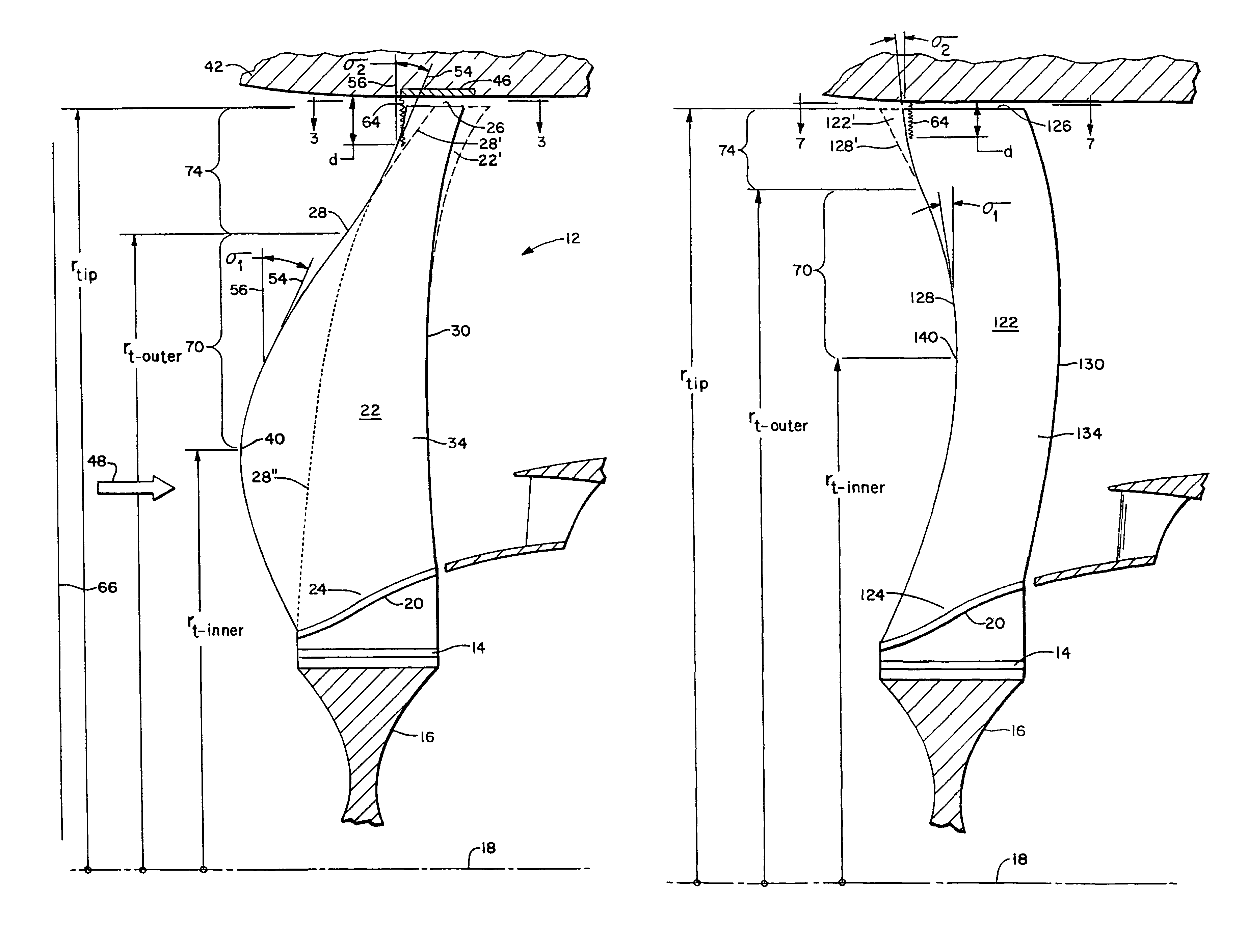

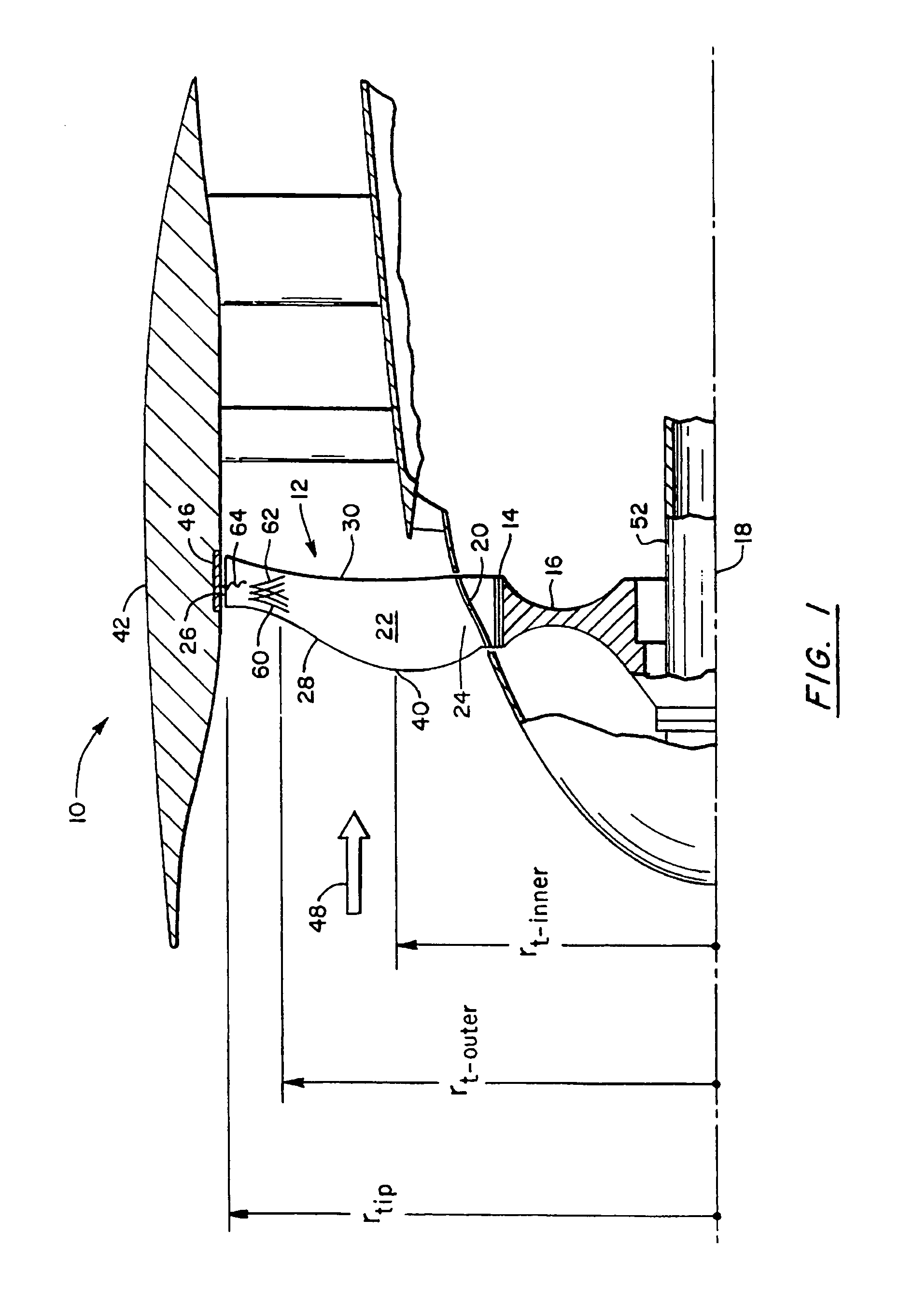

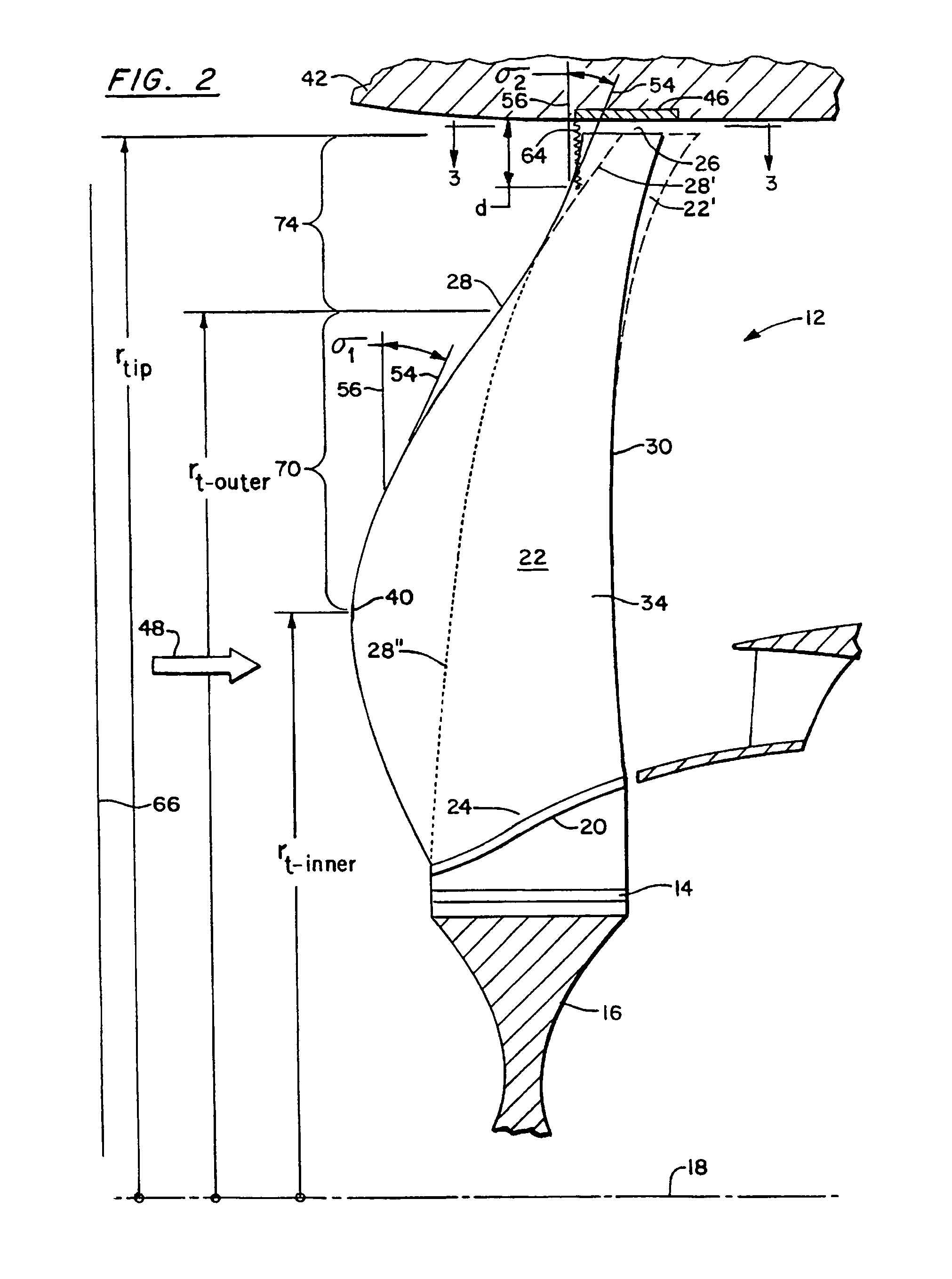

Swept turbomachinery blade

InactiveUSRE38040E1Maximize engine efficiencyReduce in quantityPropellersSupersonic fluid pumpsEngineeringTransition point

A swept turbomachinery blade for use in a cascade of such blades is disclosed. The blade (12) has an airfoil (22) uniquely swept so that an endwall shock (64) of limited radial extent and a passage shock (66) are coincident and a working medium (48) flowing through interblade passages (50) is subjected to a single coincident shock rather than the individual shocks. In one embodiment of the invention the forwardmost extremity of the airfoil defines an inner transition point (40) located at an inner transition radius rt-inner. The sweep angle of the airfoil is nondecreasing with increasing radius from the inner transition radius to an outer transition radius rt-outer, radially inward of the airfoil tip (26), and is nonincreasing with increasing radius between the outer transition radius and the airfoil tip.

Owner:UNITED TECH CORP

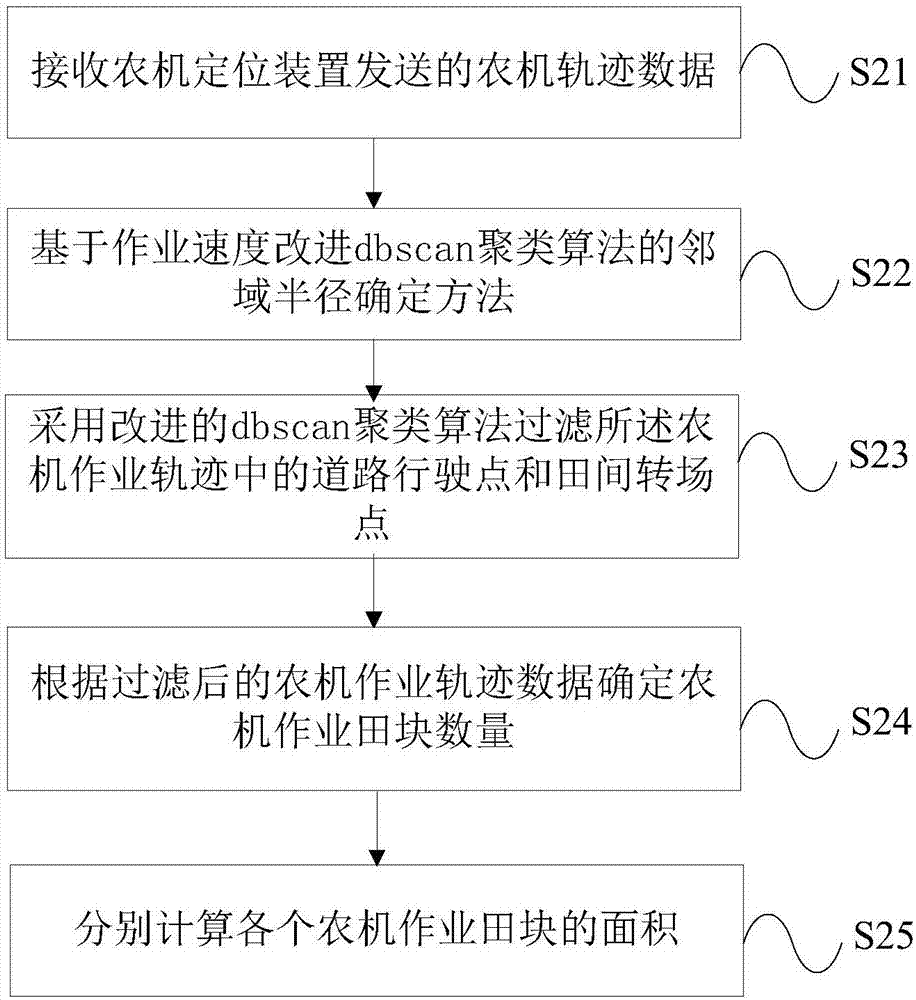

Acquisition method and apparatus of operation area of farm machinery

ActiveCN107036572AHigh precisionHigh degree of automationMeasurement devicesCluster algorithmFarm machine

The invention provides an acquisition method and apparatus of the operation area of farm machinery. The acquisition method of the operation area of farm machinery includes the steps: receiving the farm machinery operation track data sent from a farm machinery positioning device; based on the operation speed, improving the neighborhood radius determination method of the dbscan clustering algorithm; utilizing the improved dbscan clustering algorithm to filter the road driving point and the field transition point in the farm machinery operation track data; according to the filtered farm machinery operation track data, determining the number of fields operated by the farm machinery; and utilizing the distance method to calculate the area of each field operated by the farm machinery. The acquisition method and apparatus of the operation area of farm machinery can adaptively determine the neighborhood radius according to the operation speed of farm machinery, can effectively segment the adjacent fields operated by the farm machinery, and can improve the accuracy and automation degree for acquisition of the operation area of the farm machinery.

Owner:CHINA AGRI UNIV

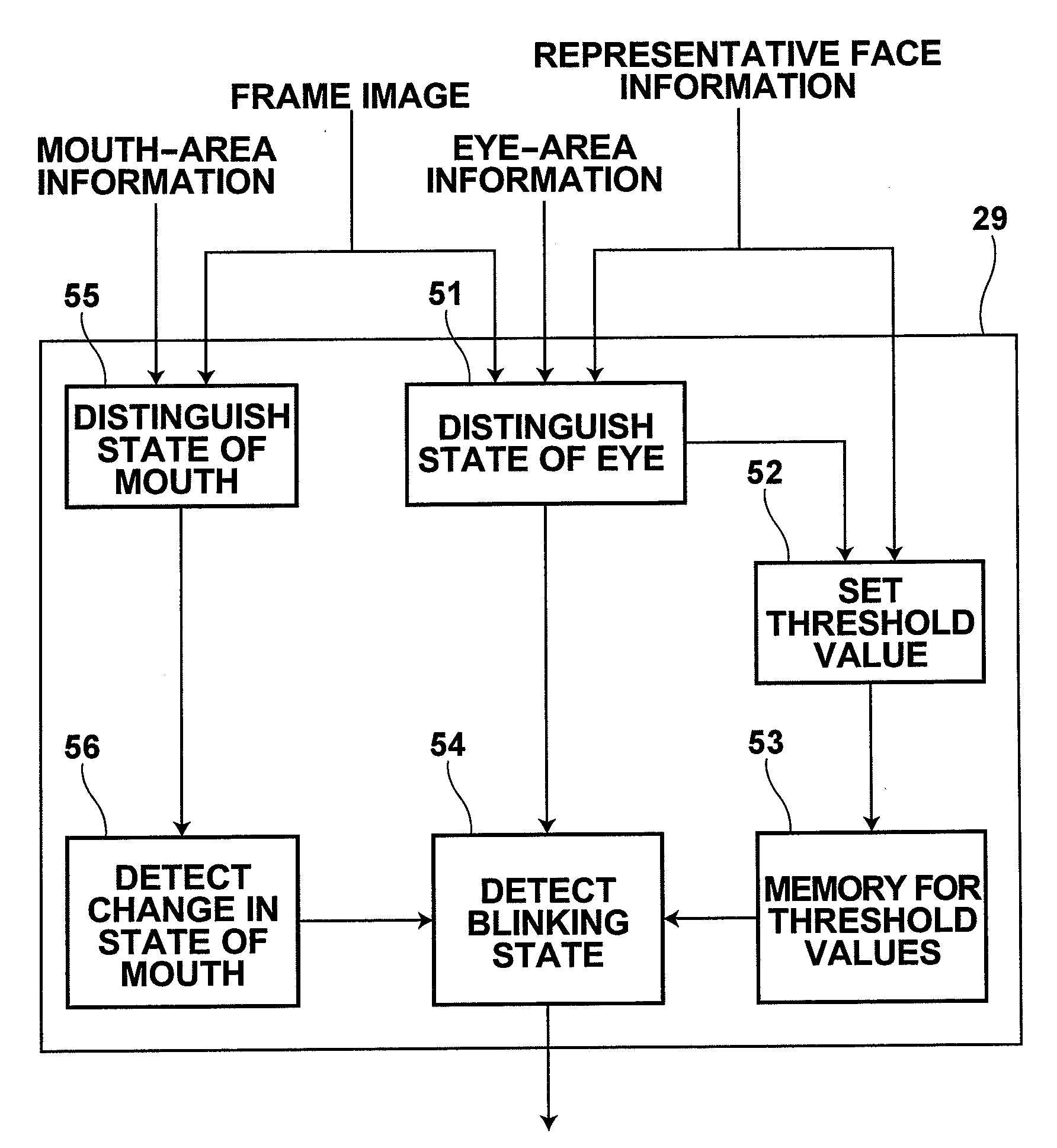

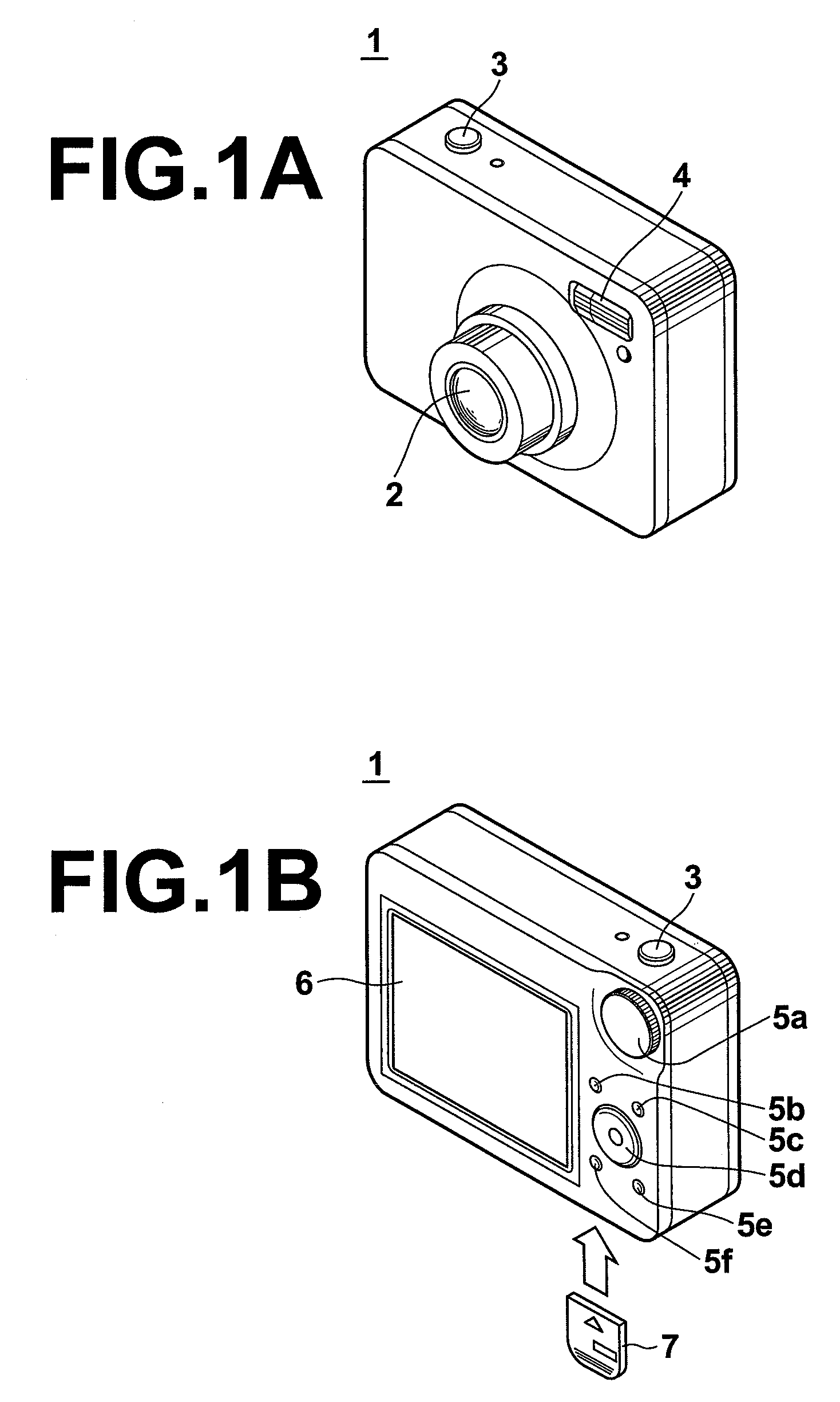

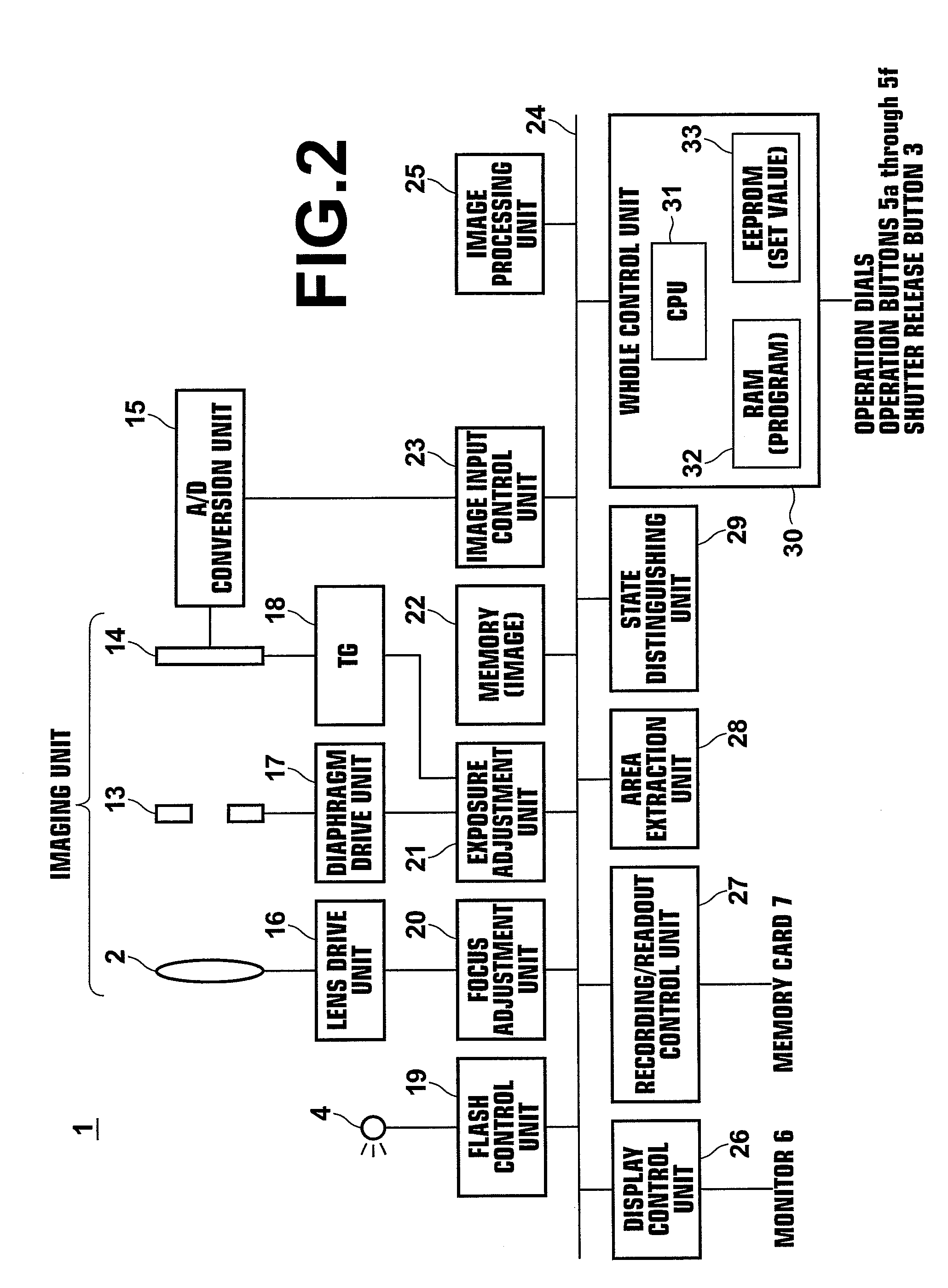

Apparatus for detecting blinking state of eye

ActiveUS20080252745A1Eliminate differencesConstantly detectTelevision system detailsCharacter and pattern recognitionOphthalmologyComputer vision

A state-of-eye distinguishing means calculates a feature value that represents a state of an eye, for an eye-area based on pixel data of pixels that constitute the eye-area. A threshold value setting means calculates a first threshold value representing a feature value at a first transition point from an open state to a closed state and a second threshold value representing a feature value at a second transition point from the closed state to the open state, based on a feature value calculated for a targeted eye when the targeted eye is open. A blinking state detection means detects the blinking state of the eye corresponding to the eye-area, by sequentially comparing feature values which are sequentially calculated for a series of frame images by the state-of-eye distinguishing means with one of the first threshold value and the second threshold value.

Owner:FUJIFILM CORP

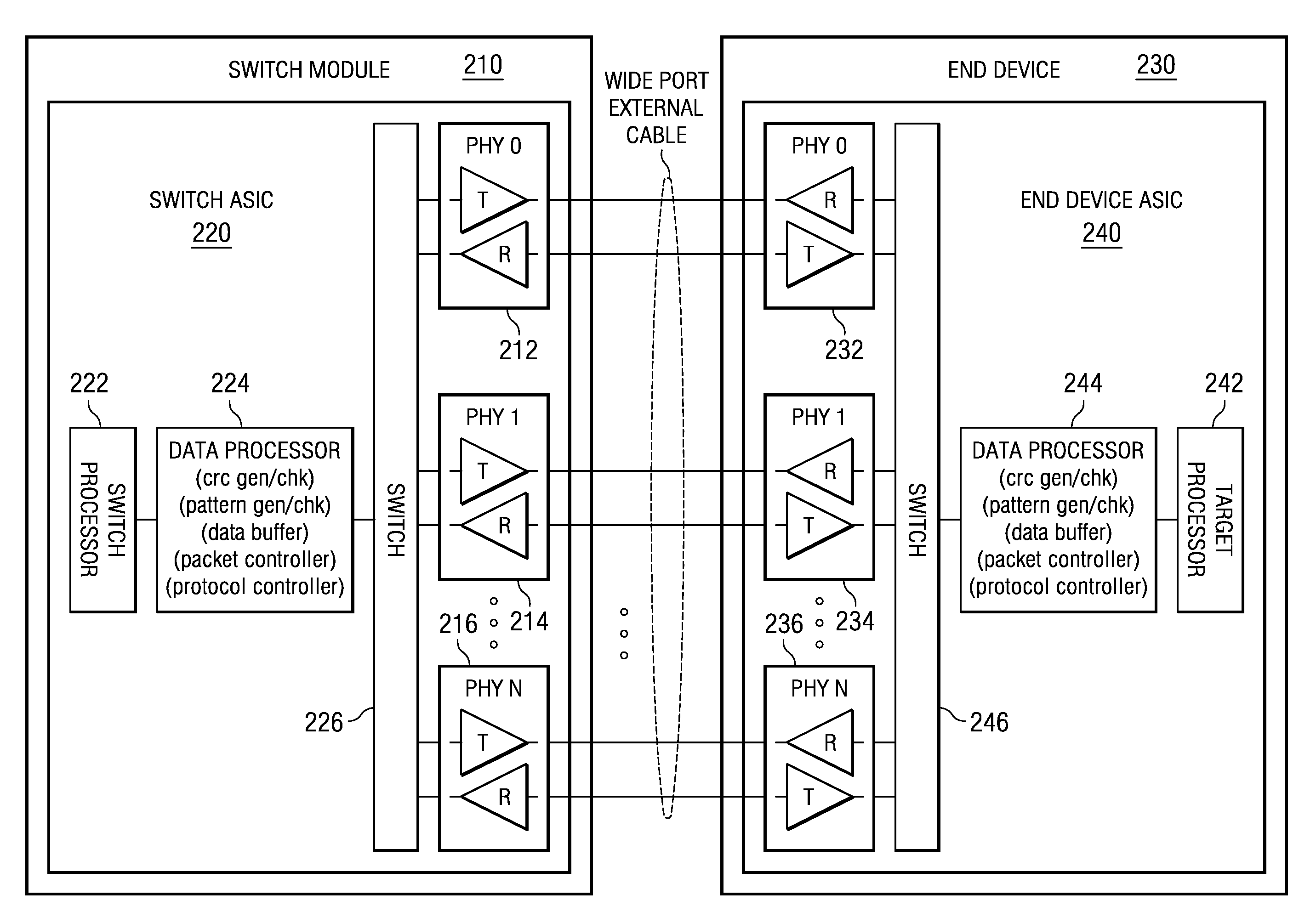

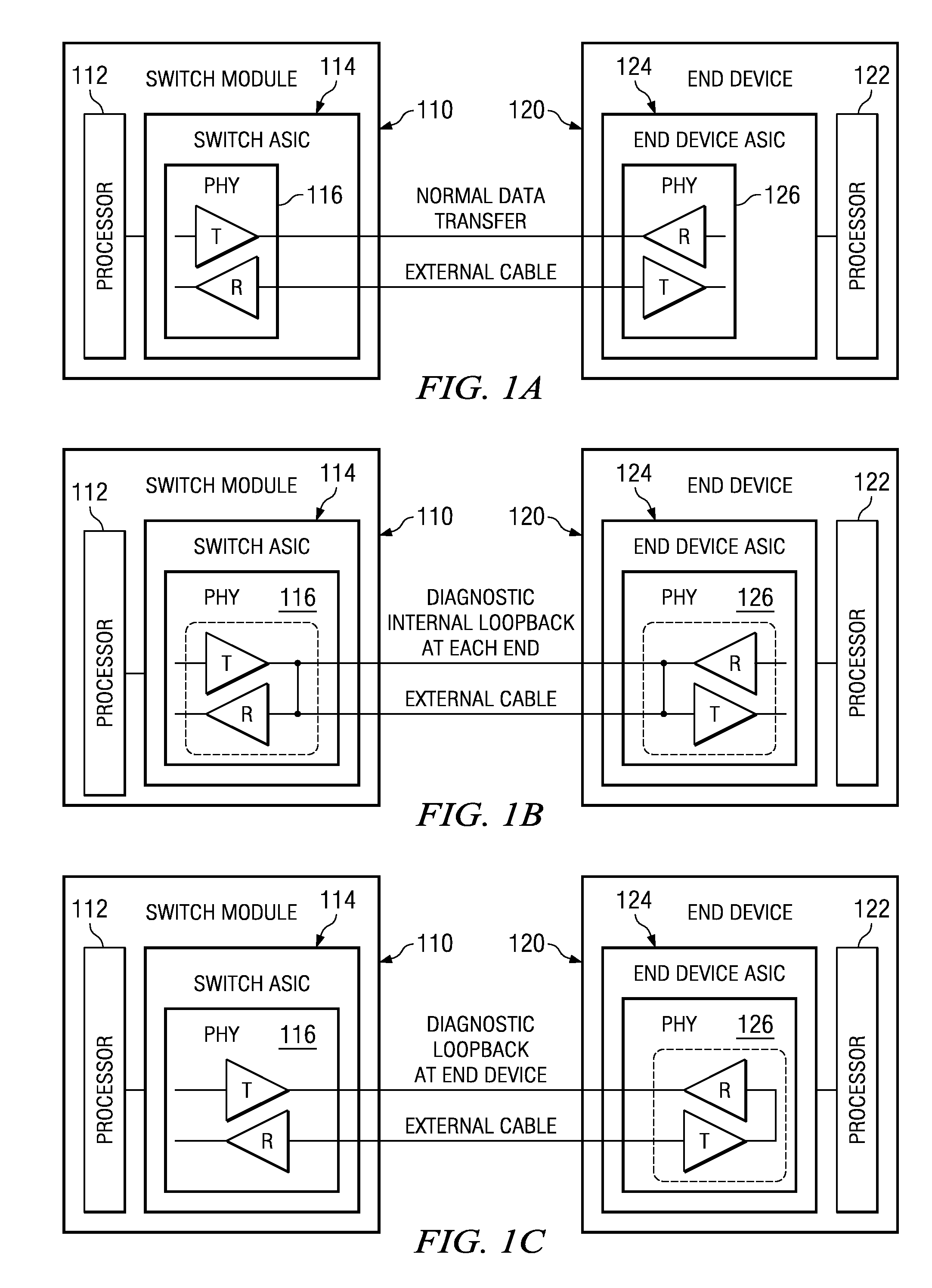

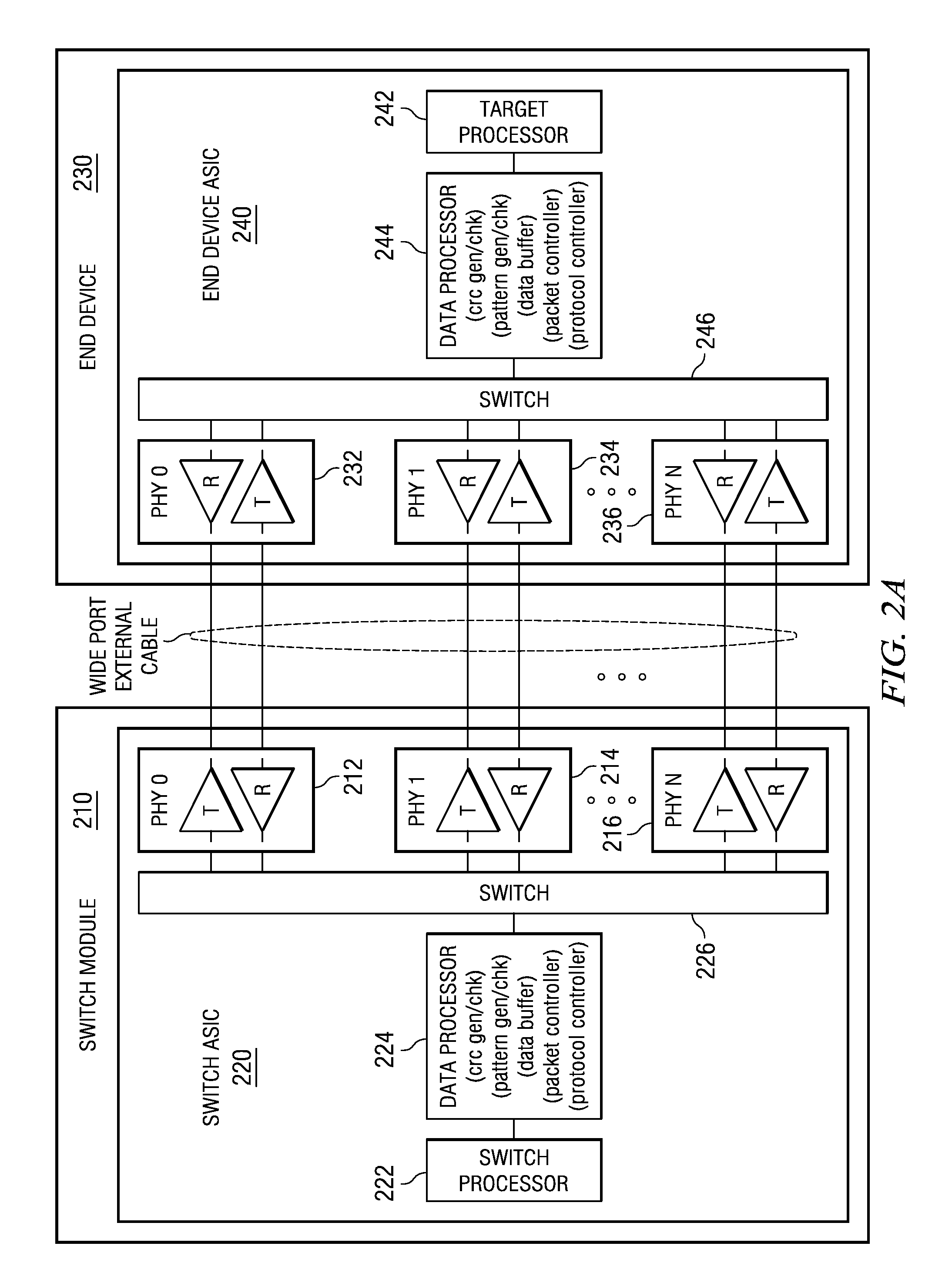

Method and Procedure for Detecting Cable Length in a Storage Subsystem with Wide Ports

InactiveUS20090028229A1Improve transmission performanceReduce needElectronic circuit testingTransmission monitoringEngineeringCorrection technique

A mechanism detects cable length in a storage subsystem with wide ports. The mechanism uses in-situ bidirectional cable wrapping for determining different cable lengths. The mechanism under-margins transmitter output to failure for each external port and even for each PHY within a wide port. Based on the transition point from “good” wrap to “bad” wrap, the cable length may be determined. The transition point identifies if the cable is long or short, at which point the optimum tuning parameters can accordingly be set. A calibration mechanism calibrates the high speed transmitter / receiver pair characteristics, and, thus, optimizes the transmission performance between subsystems. The calibration mechanism mitigates the need for frequent error correction and does not incur the performance degradation associated with error correction techniques.

Owner:IBM CORP

Swept turbomachinery blade

InactiveUSRE43710E1Minimize the aerodynamic losses and efficiency degradationMaximize efficiencyPropellersSupersonic fluid pumpsEngineeringTransition point

A swept turbomachinery blade for use in a cascade of such blades is disclosed. The blade (12) has an airfoil (22) uniquely swept so that an endwall shock (64) of limited radial extent and a passage shock (66) are coincident and a working medium (48) flowing through interblade passages (50) is subjected to a single coincident shock rather than the individual shocks. In one embodiment of the invention the forwardmost extremity of the airfoil defines an inner transition point (40) located at an inner transition radius rt-inner. The sweep angle of the airfoil is nondecreasing with increasing radius from the inner transition radius to an outer transition radius rt-outer, radially inward of the airfoil tip (26), and is nonincreasing with increasing radius between the outer transition radius and the airfoil tip.

Owner:UNITED TECH CORP

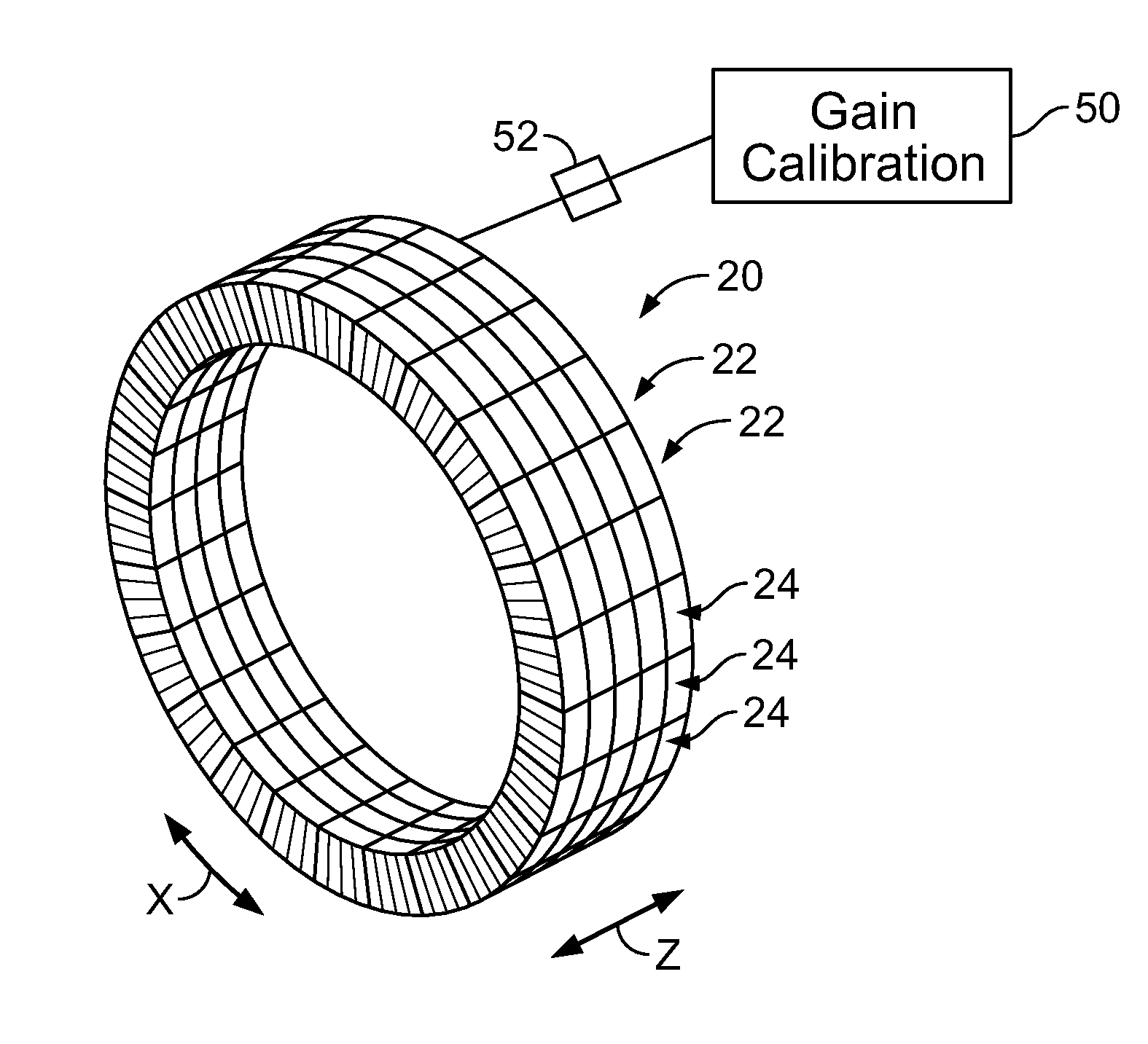

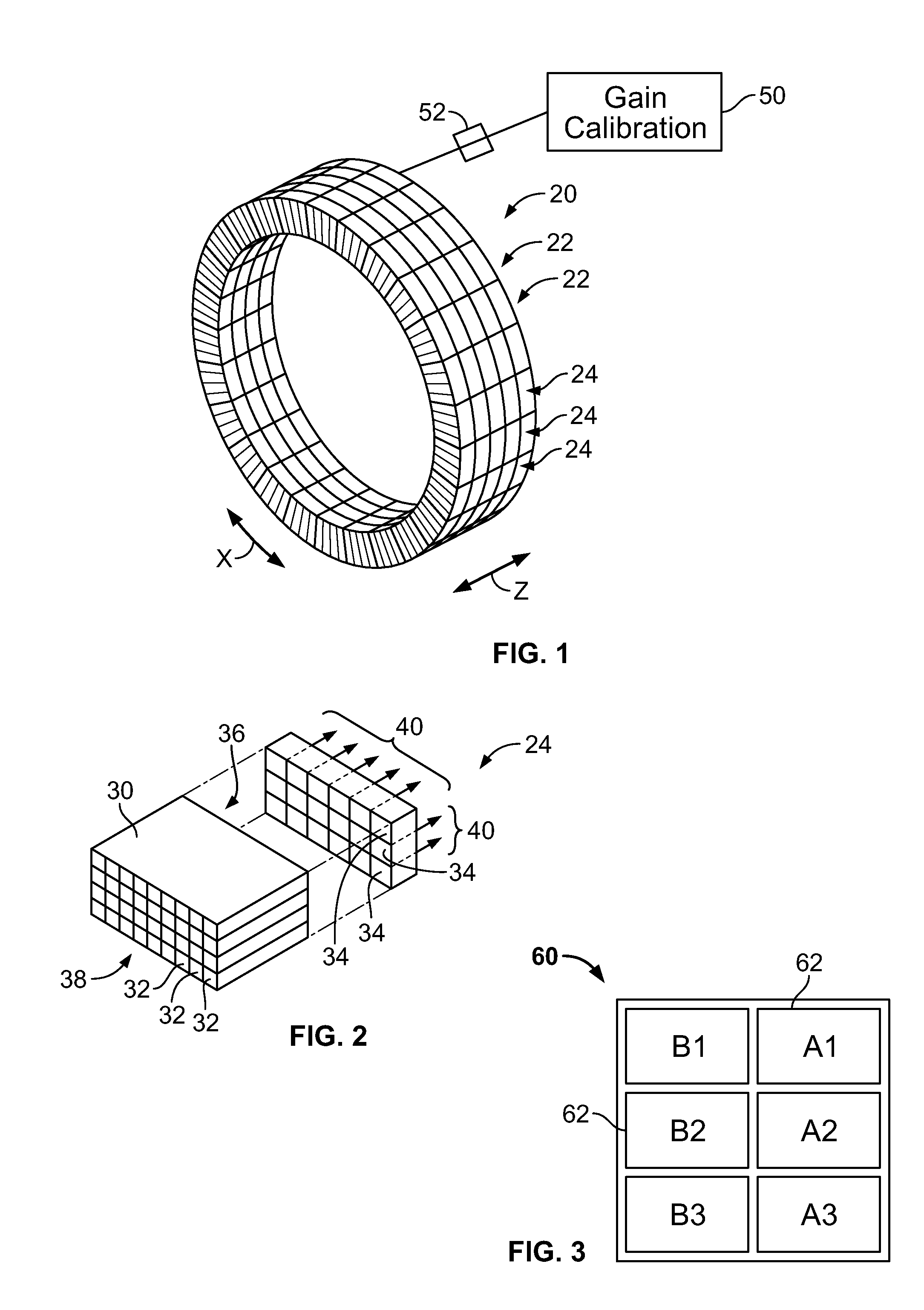

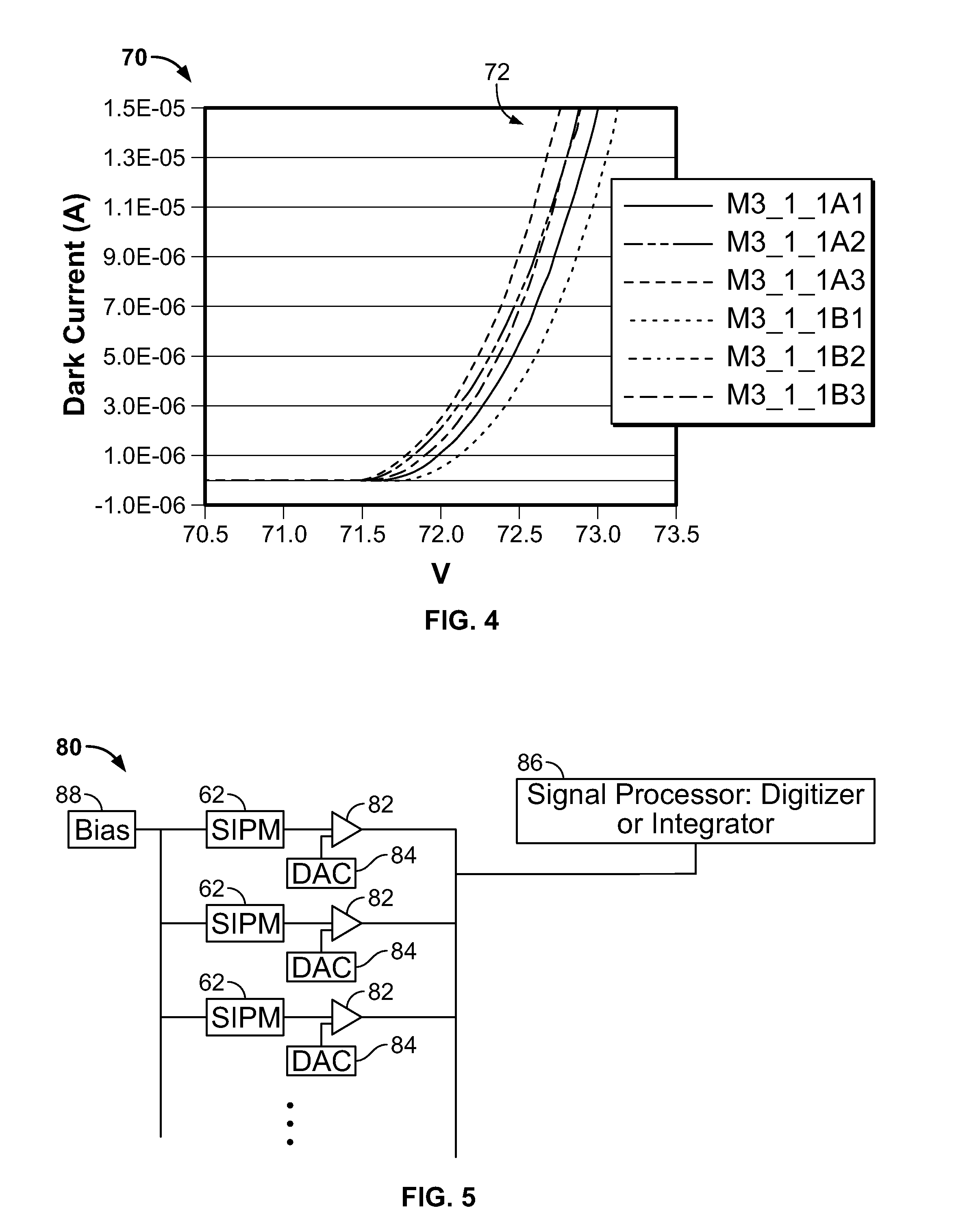

Methods and systems for gain calibration of gamma ray detectors

ActiveUS20130327932A1Material analysis by optical meansCalibration apparatusTransition pointCondensed matter physics

Methods and systems for gain calibration of a gamma ray detector are provided. One method includes measuring signals generated by one or more light sensors of a gamma ray detector, generating one or more derived curves using the measured signals as a function of bias voltage and identifying a transition point in the one or more derived curves. The method also includes determining a breakdown voltage of the one or more light sensors using the identified transition point and setting a bias of the one or more light sensors based on the determined breakdown voltage.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com