Implants with Transition Surfaces and Related Processes

a transition surface and implant technology, applied in the field of joint replacement surgery, can solve the problems of other types of problems, bone-on-bone contact can be very painful and damaging, and the bone beneath the cartilage is left exposed, so as to reduce pain, reduce blood loss, and accelerate recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

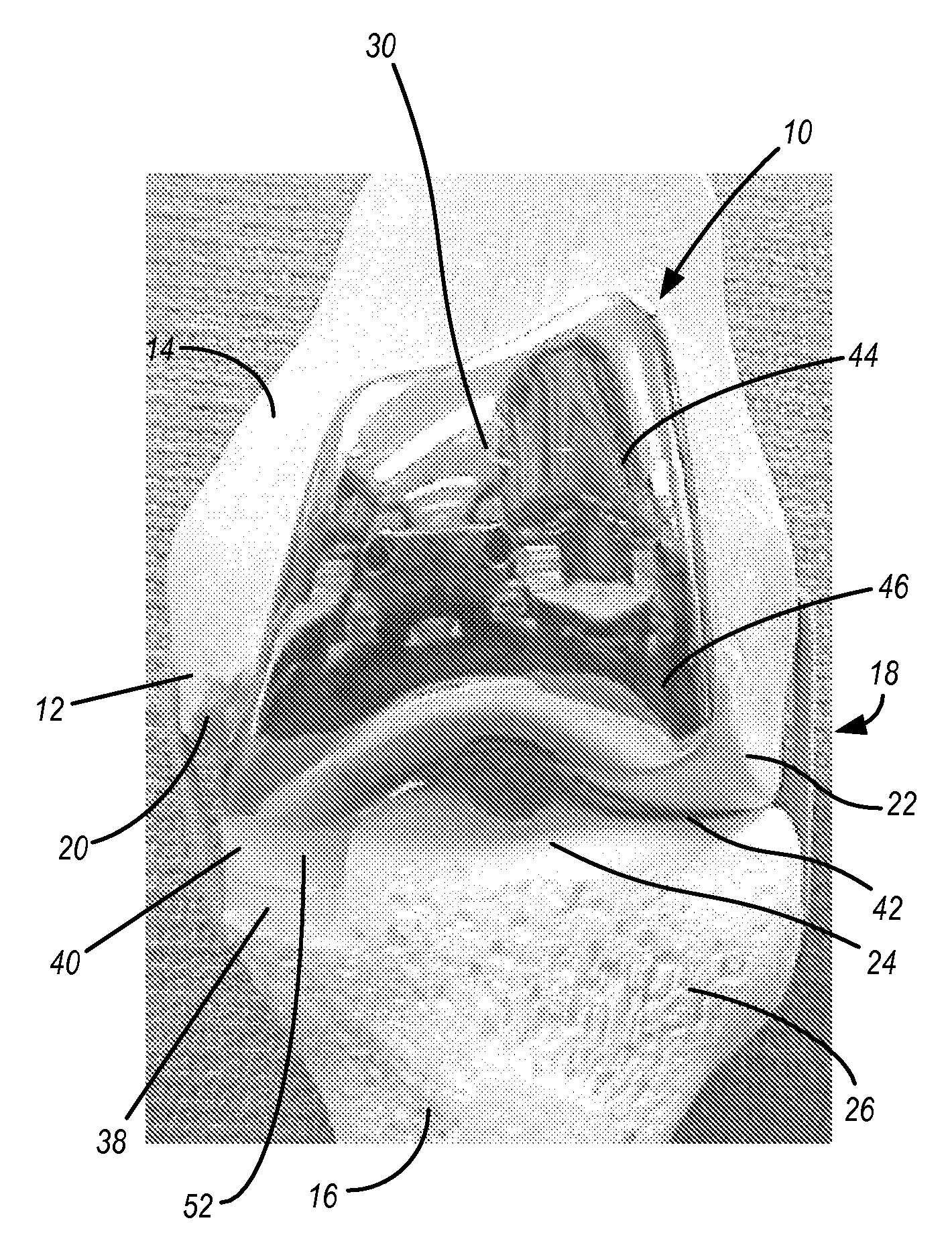

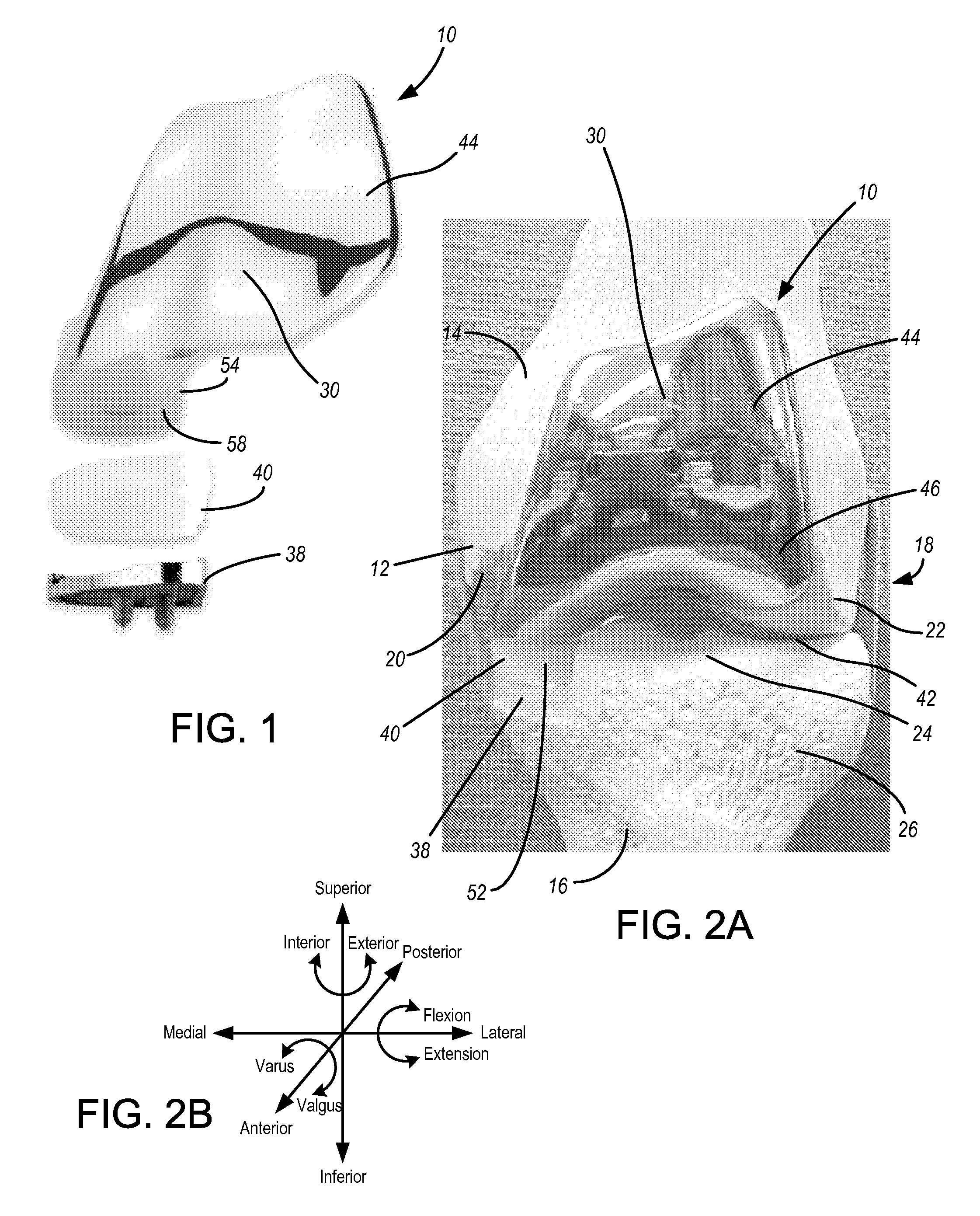

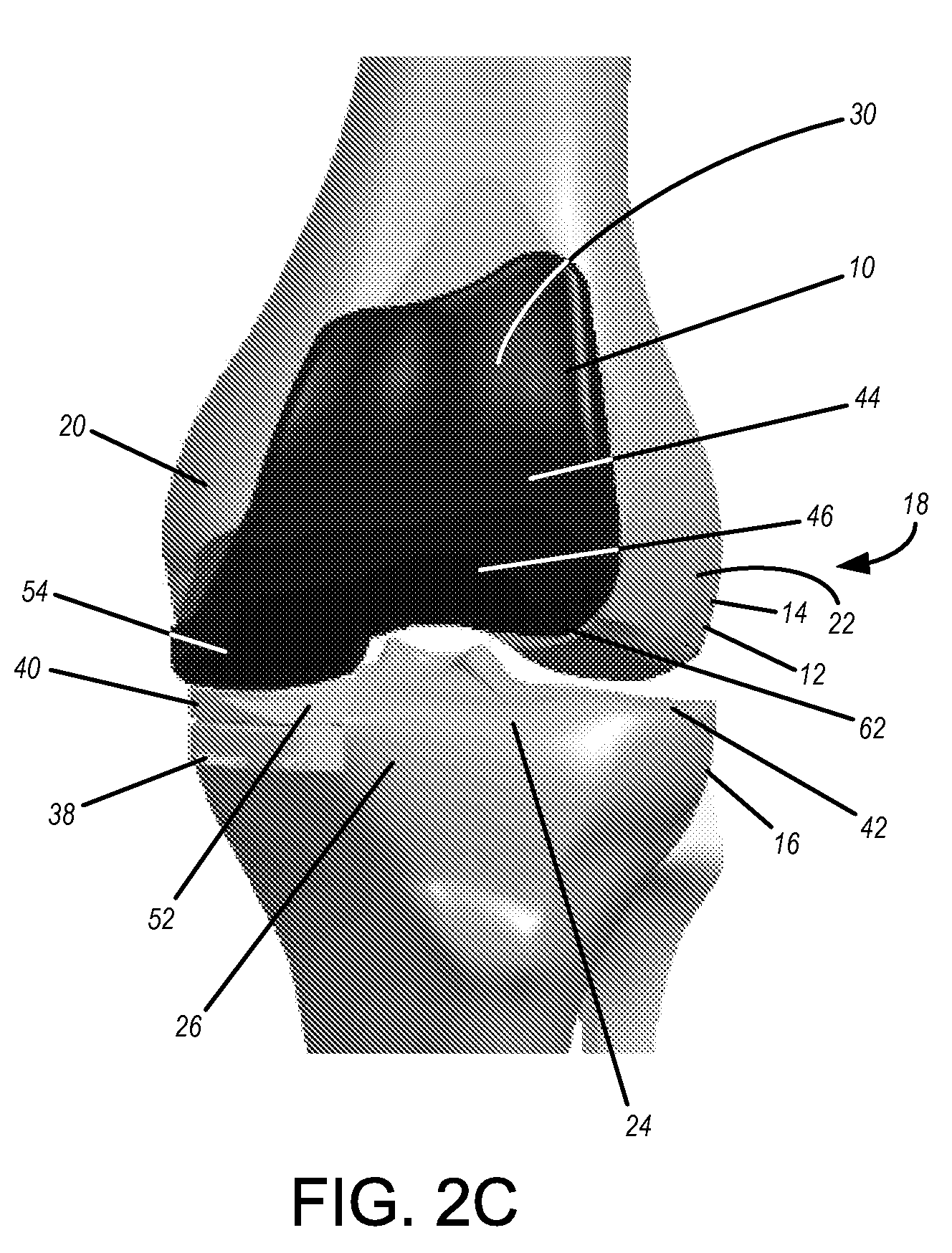

[0066]FIGS. 1 and 2A are front views of an implant 10 according to an embodiment of the invention. Implant 10 is adapted to be installed on the distal portion 12 of a human femur 14. The femur can be that of a human or other being with appropriate hinge joints. FIG. 2A shows an implant 10 placed on a sawbones model of a human femur 14. Anatomically, the femur 14 cooperates with the tibia 16 to form the knee joint 18. The distal portion 12 of the femur 14 includes two condyles, a medial condyle 20 and a lateral condyle 22. These condyles articulate (move in gross motion, whether rotational or translational or both) relative to the tibial plateau 24 which is a surface on the proximal portion 26 of tibia 16. Not shown is a patella which is connected to a patella tendon, also not shown, which in turn inserts on the tibia and attaches to the head of quadricep muscles to apply traction for extension of the knee joint. The patella tracks, as by sliding, in the patellofemoral channel 30. Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com