Patents

Literature

231results about "Bell type furnaces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

InactiveUS20060029897A1Ensuring spaceMaintainance of heating chambersCharge manipulationMetallurgyPorous ceramics

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

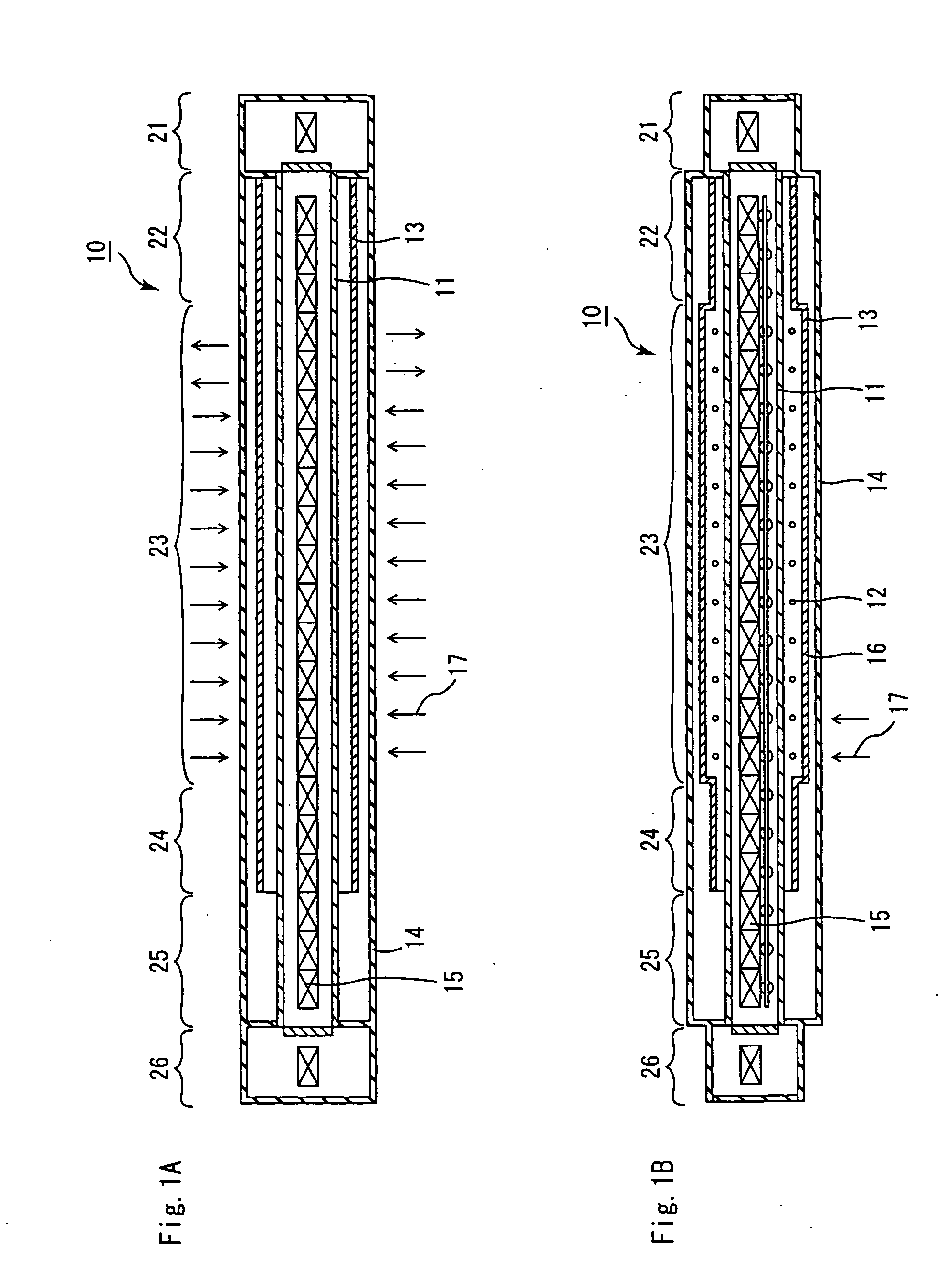

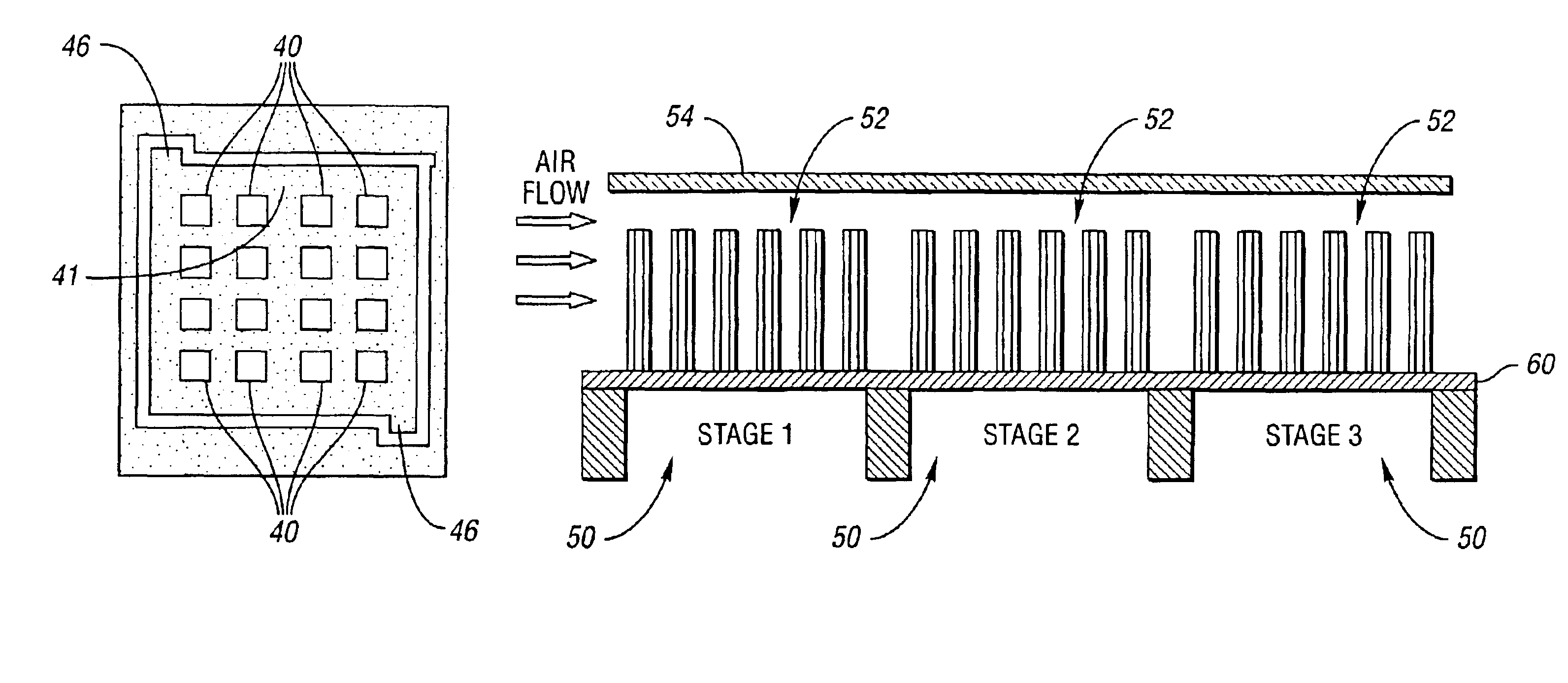

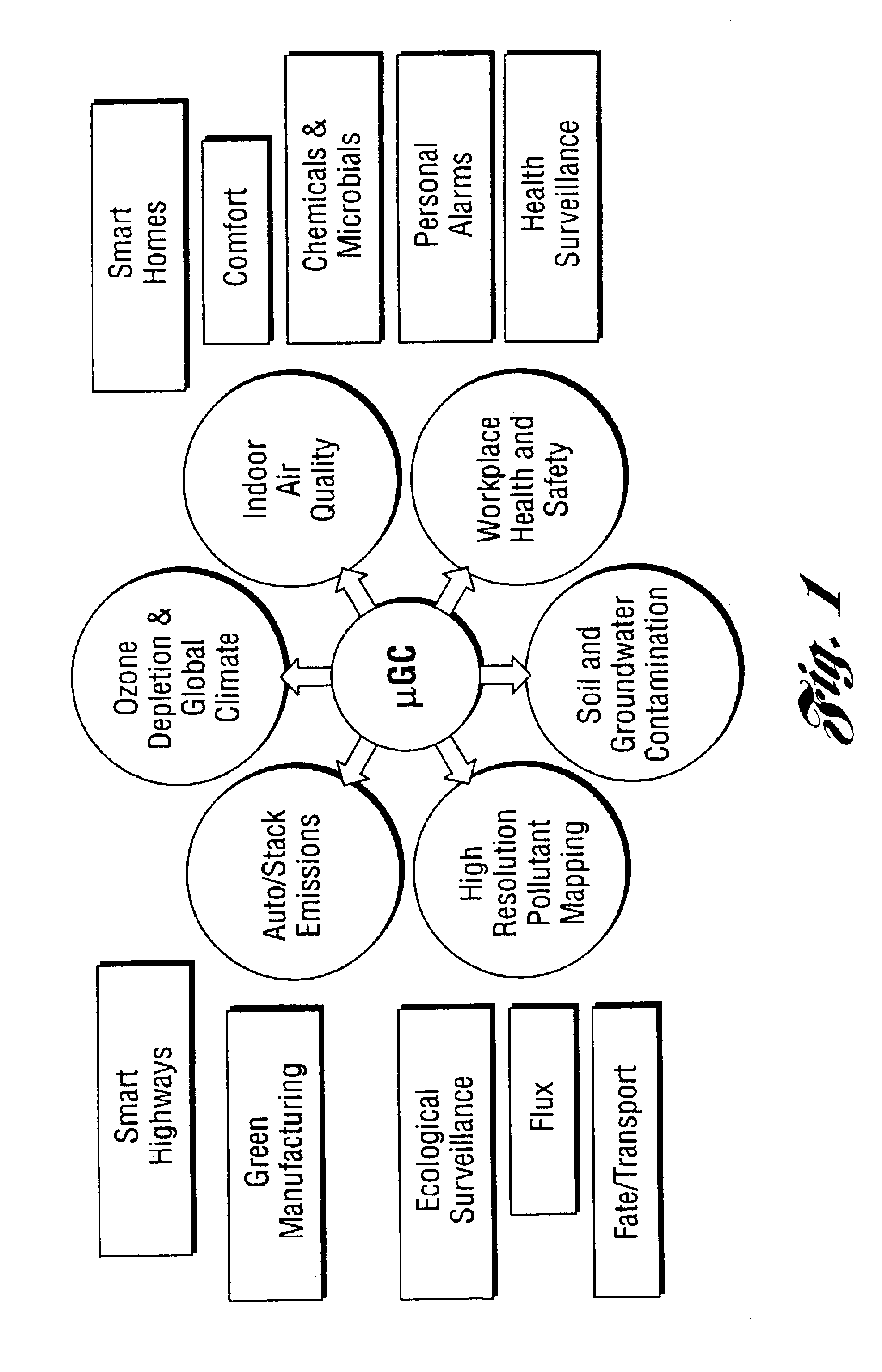

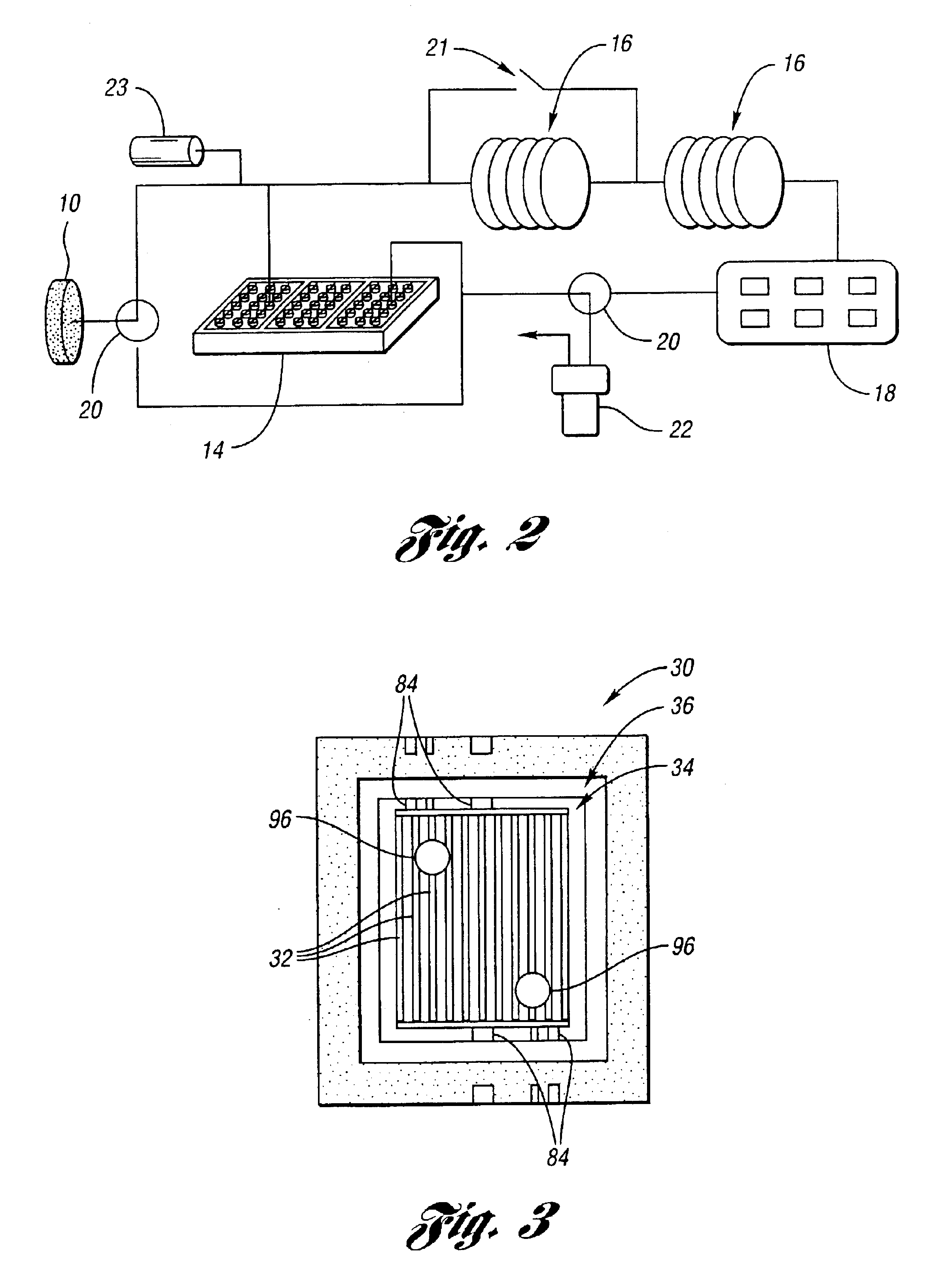

Microelectromechanical heating apparatus and fluid preconcentrator device utilizing same

InactiveUS6914220B2High porosityIncrease surface areaComponent separationBaking ovenThermal isolationEngineering

A microelectromechanical heating apparatus and fluid preconcentrator device utilizing same wherein heating elements of the apparatus are sized and spaced to substantially uniformly heat a heating chamber within a heater of the apparatus. Tall, thermally-isolated heating elements are fabricated in Si using high aspect ratio etching technology. These tall heating elements have large surface area to provide large adsorbent capacity needed for high efficiency preconcentrators in a micro gas chromatography system (μGC). The tall heating elements are surrounded by air gaps to provide good thermal isolation, which is important for a low power preconcentrator in the μGC system.

Owner:RGT UNIV OF MICHIGAN

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

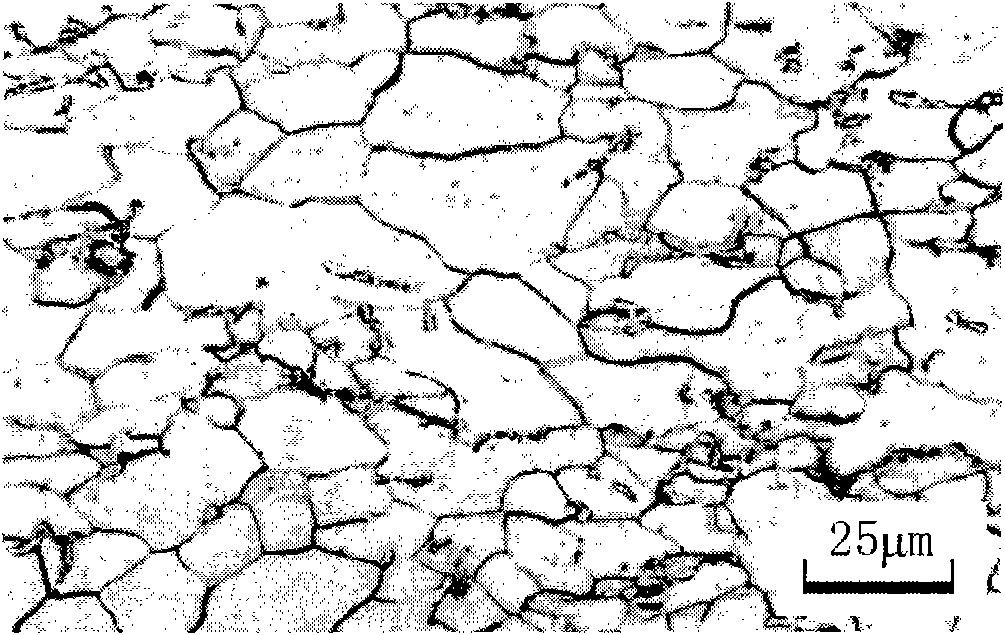

Production process of precise stainless steel band for vehicle sealing pad

InactiveCN101716594AImprove quality requirementsThickness tolerance fluctuations are smallBell type furnacesTension/compression control deviceSolution treatmentStress relieving

The invention relates to a production process of a precise stainless steel band for a vehicle sealing pad. The production process comprises the following working procedures of: first cold rolling, solid solution, second cold rolling, spraying and degreasing, hot water spraying, hot wind drying, pre-bending straightening, stress relieving annealing, final bending straightening, finished product cutting, and the like. The production process adopts a 20-roller sendzimir mill and a unique rolling process to carry out cold rolling. Through the processes of degreasing, solid solution treatment, bending straightening, stress relieving annealing, and the like, the thickness tolerance undulation of a product is small, mechanical properties are stable, the plate flatness is good, the product is not easy to generate cracks and secondary deformation during stamping, and the quality of the product is obviously improved, thus the production process is suitable for industrial production and can meet the requirement for high quality of the vehicle part industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

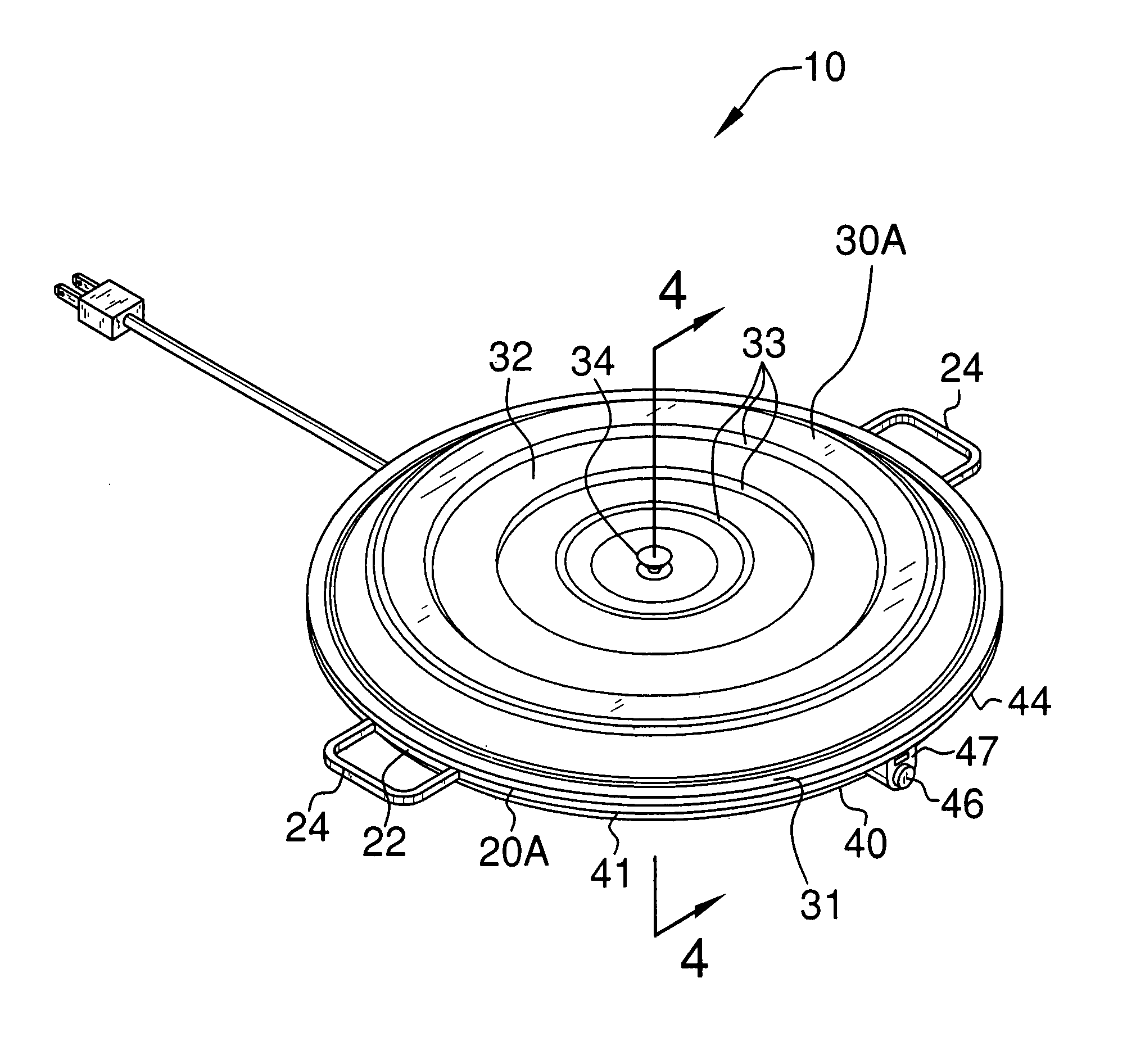

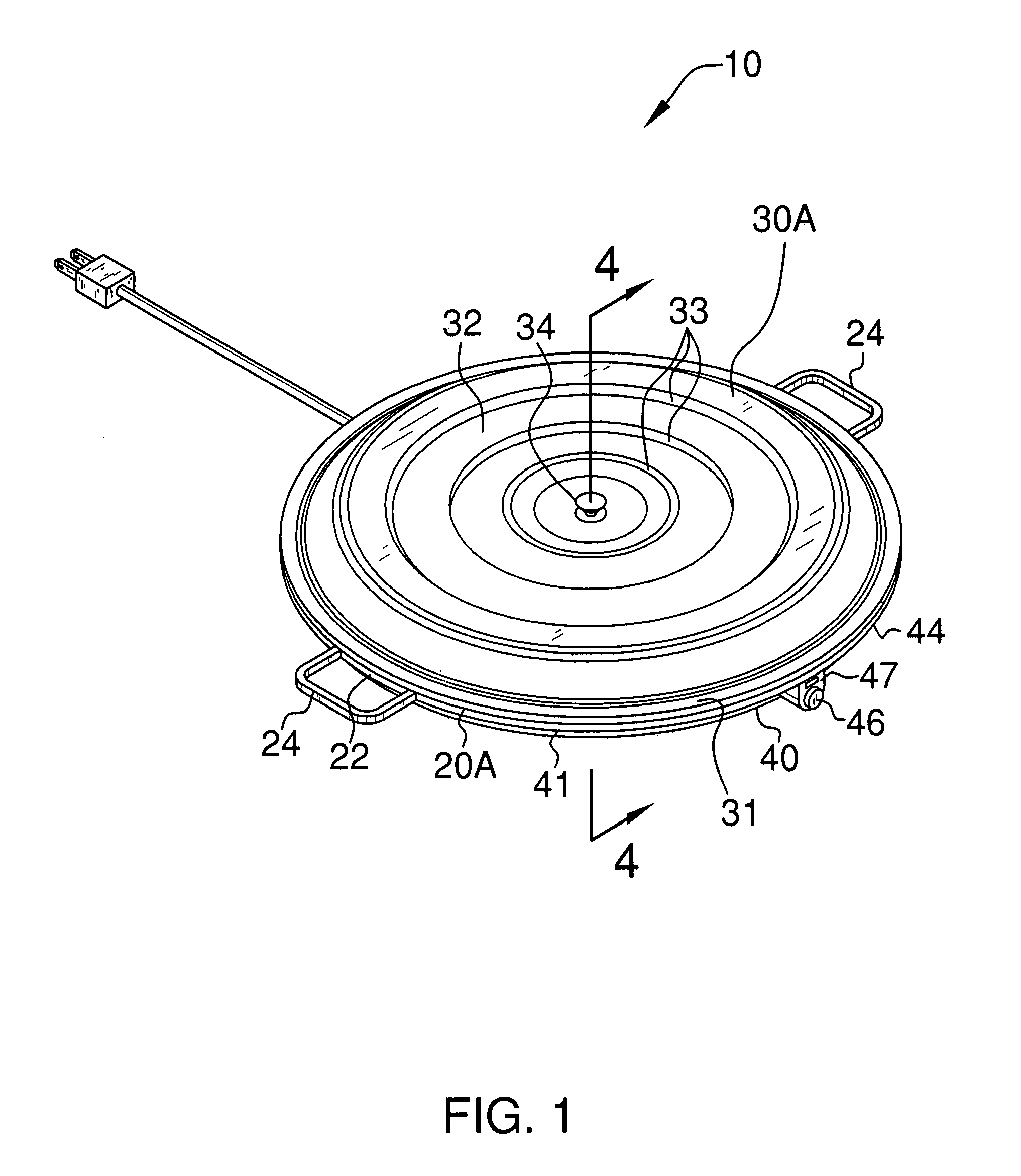

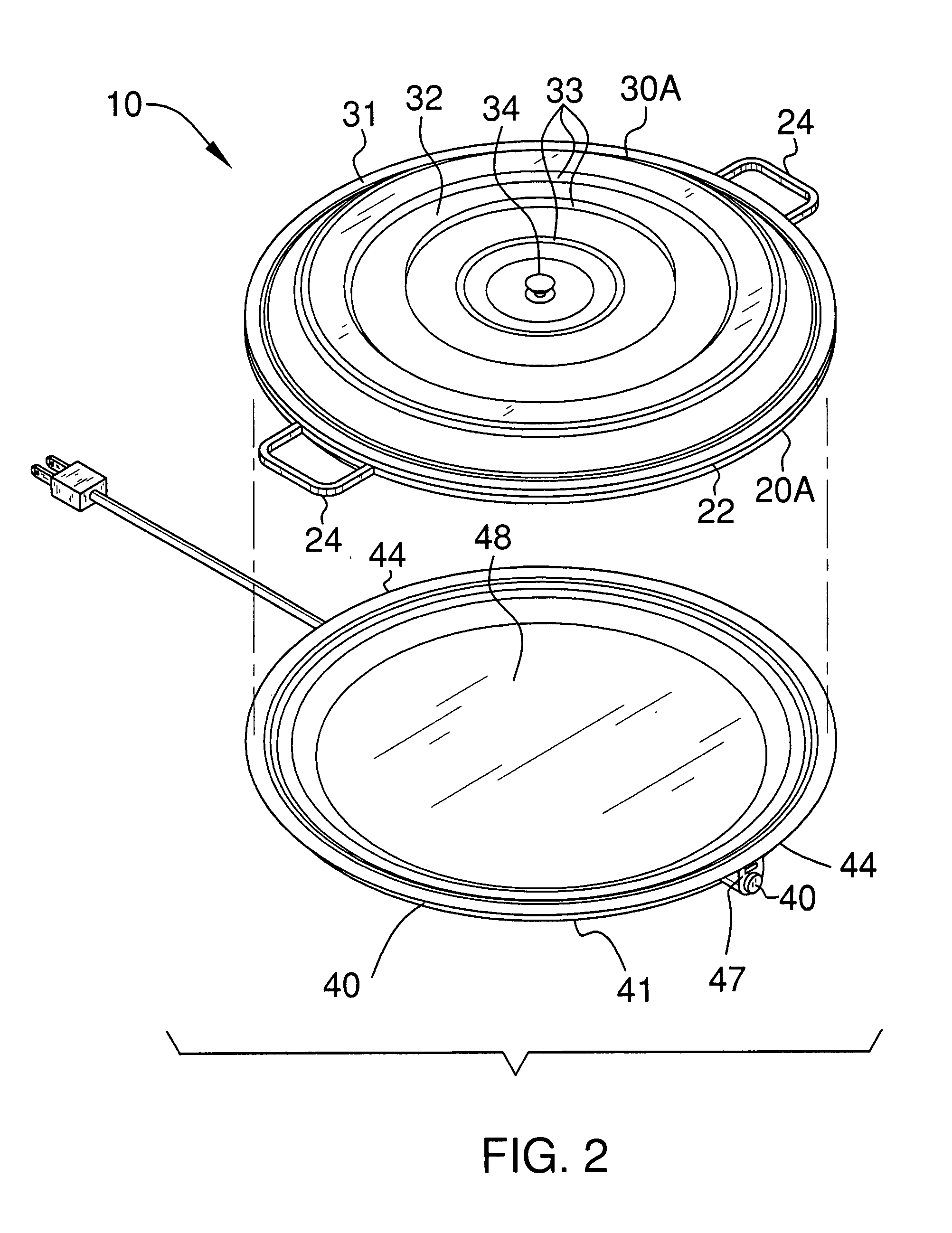

Combined food and food-plate warming device

InactiveUS7276676B1Power interruptionEffectively allowDomestic cooling apparatusBaking ovenEngineeringThreshold temperature

A food and food-plate warming device includes a base plate that has a planar top surface and has an outwardly beveled edge provided with laterally stepped ridges concentrically spaced from the top surface center. A cover plate is positioned on the base plate and has an outer lip that is nested on one of the stepped ridges. Handles are conjoined to the outer lip for receiving at least four contiguous metacarpals therethrough. A mechanism is included for heating the base plate top surface such that the food and food-plate interfitted between the base plate and the cover plate can be heated. The heating mechanism includes a heating element intercalated between the top and bottom surfaces of the first base plate. An automatic shut off switch is coupled to the heating element for interrupting power to the heating element when an interior temperature of the device reaches a maximum threshold temperature.

Owner:THOMPSON JENNIFER J

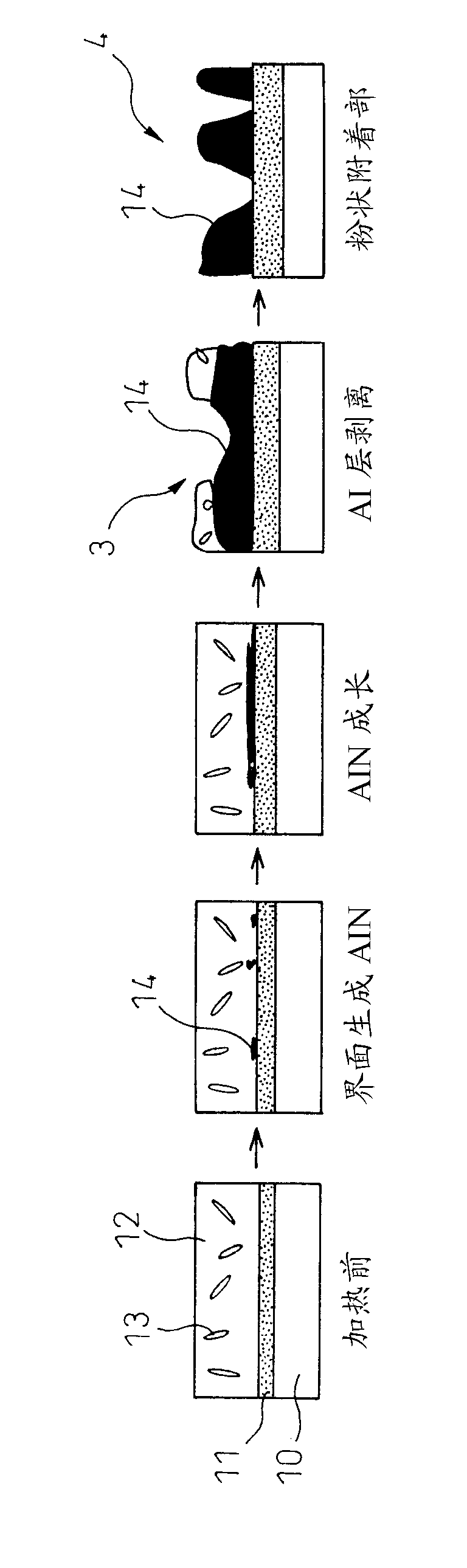

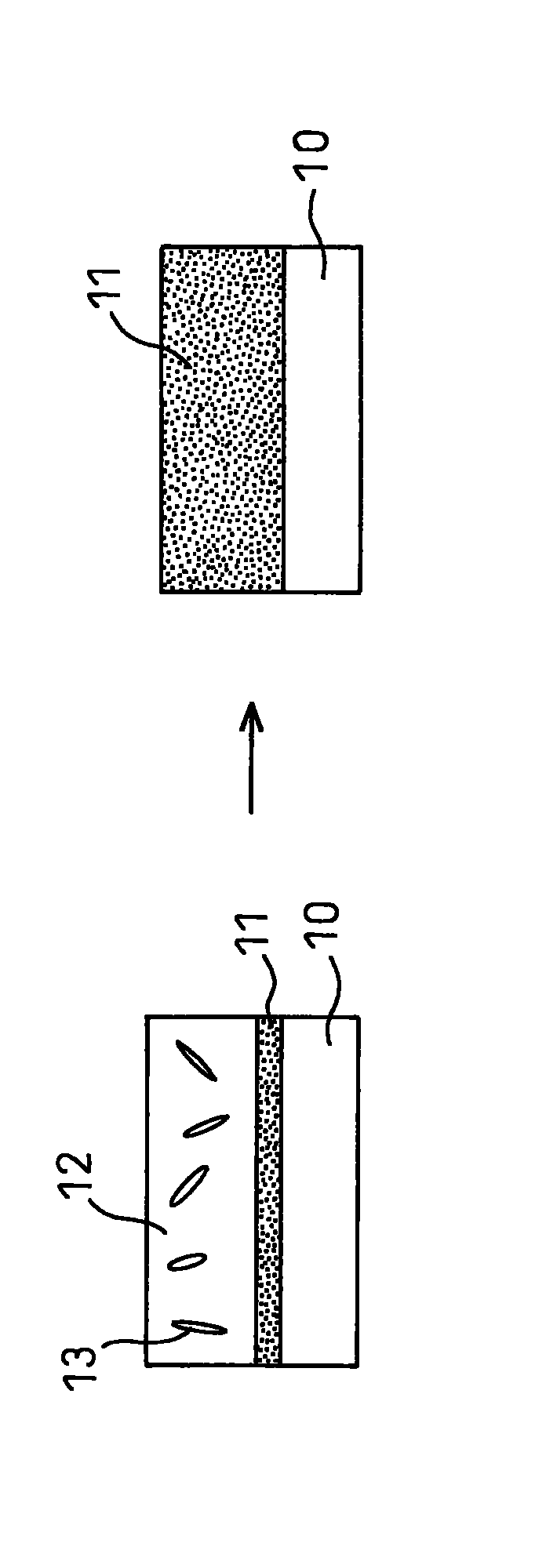

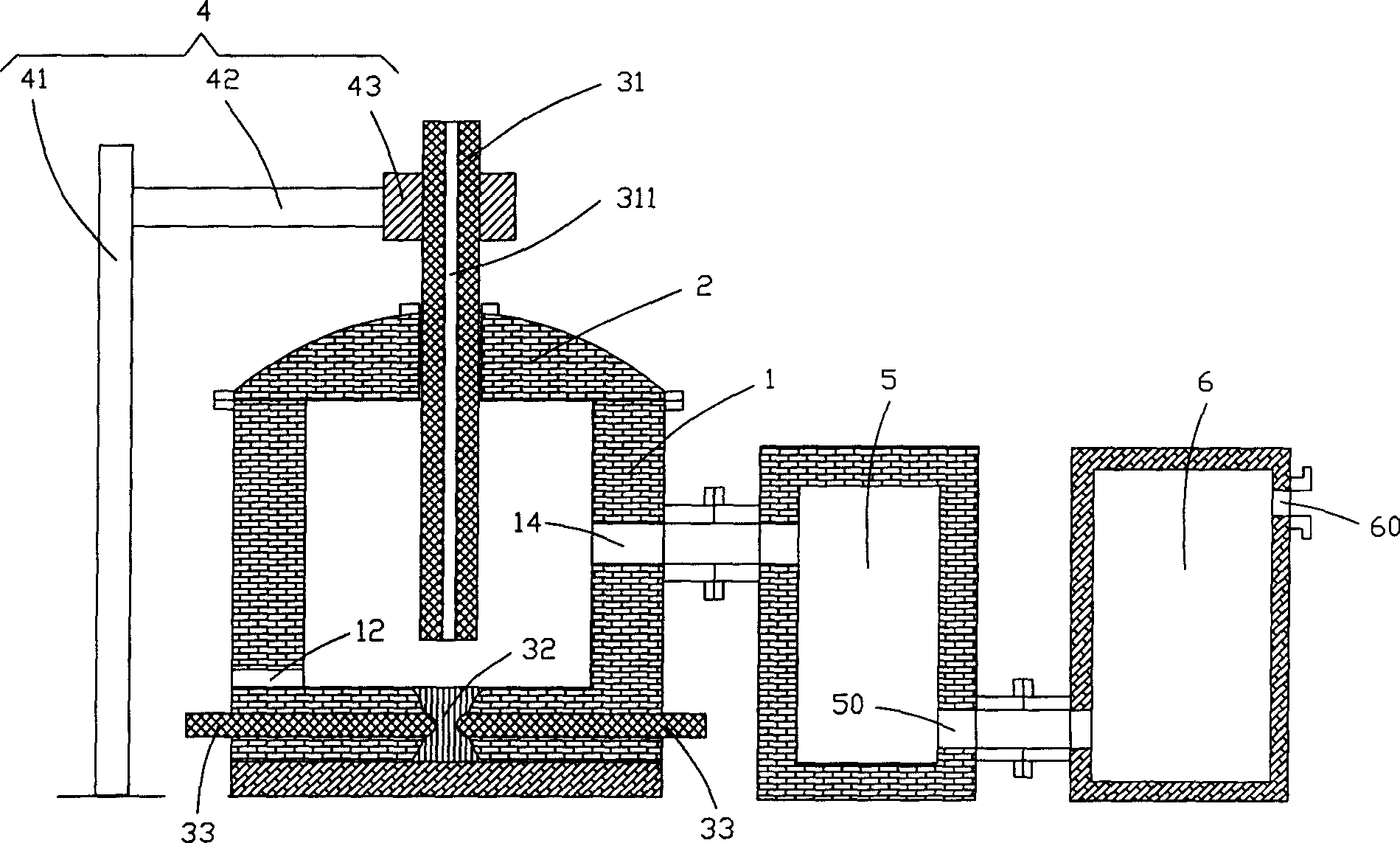

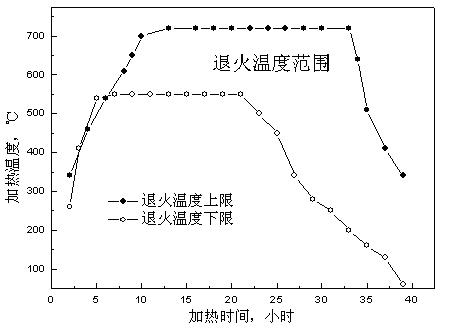

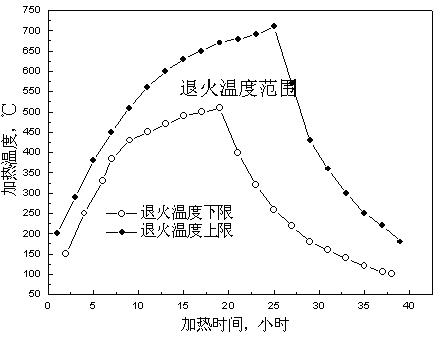

Aluminum-plated steel sheet for hot pressing with rapid heating, process for producing same, and method of hot-pressing same with rapid heating

ActiveCN102089451AIncrease production capacityPrevent saggingHot-dipping/immersion processesBell type furnacesHydrogenSheet steel

An aluminum-plated steel sheet for hot pressing is provided which is free from the conventional problem that an aluminum-plated steel sheet, when applied to hot pressing, suffers aluminum melting during preheating for the hot pressing. The steel sheet is further free from the problem concerning delayed fracture caused by residual hydrogen. Also provided are: a process for producing the aluminum-plated steel sheet; and a method of hot pressing with rapid heating in which the aluminum-plated steel sheet is used. The aluminum-plated steel sheet for hot pressing is produced by annealing an aluminum-plated steel sheet in a coiled state in an annealing box furnace under holding-time and temperature conditions which are within the range shown in Fig 5, whereby the aluminum deposit is alloyed with the steel sheet. The method of hot pressing with rapid heating is characterized in that a blank cut out of the aluminum-plated steel sheet for hot pressing is preheated at a heating rate of 40 DEG C / sec or higher on the average so that the time period over which the blank is exposed to an environment of 700 DEG C or higher is 20 seconds or shorter, and the preheated blank is hot-pressed.

Owner:NIPPON STEEL CORP

Plasma reaction furnace for processing waste

InactiveCN1825042AIncrease profitImprove processing efficiencyIncinerator apparatusBell type furnacesGraphite electrodeRefractory

The invention comprises a furnace body and a furnace lid. There is a refractory furnace liner and a thermal-protective insulating layer inside of the furnace body. A molten mass portal is disposed on the side of the hearth bottom. An air outlet is disposed on the furnace wall. A hollow graphite electrode disposed in the center of the furnace lid extends into the furnace. In the hollow graphite electrode there is a passageway. A second electrode against the hollow graphite electrode and a graphite lead-out electrode connected with the second electrode are disposed at the bottom of the furnace body. An arc zone is formed between the hollow graphite electrode and the second electrode to generate hot plasma.

Owner:黄建军

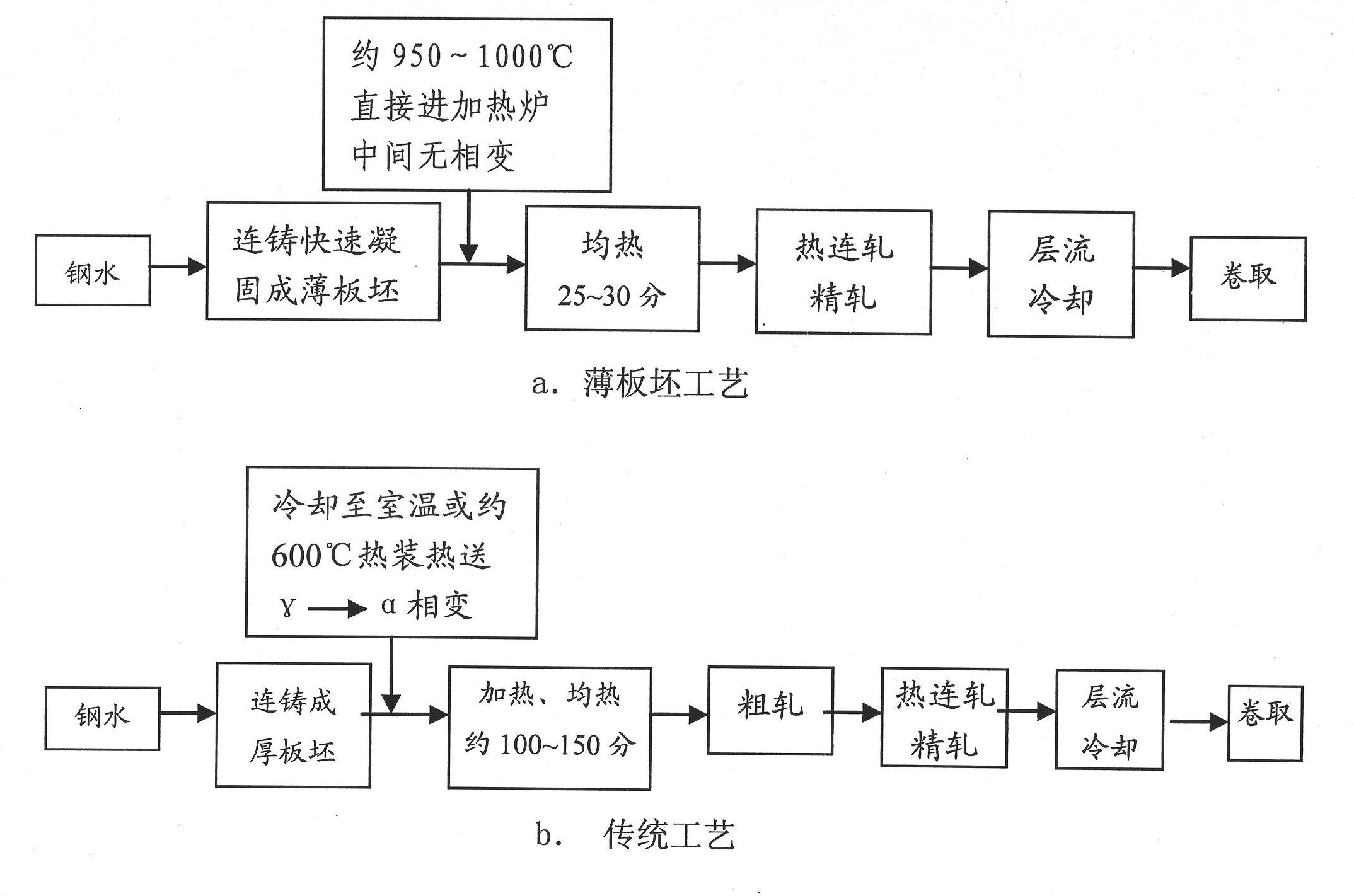

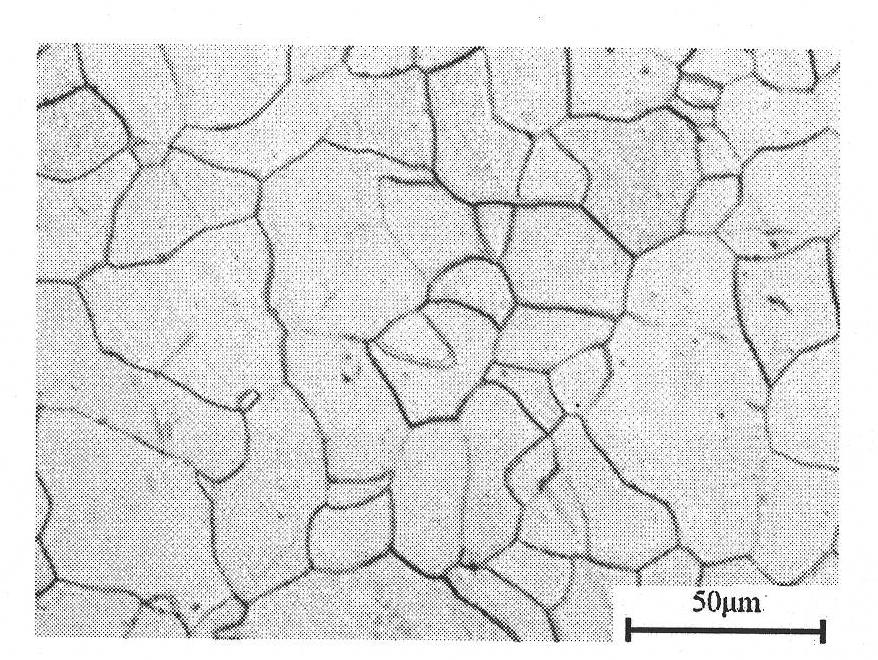

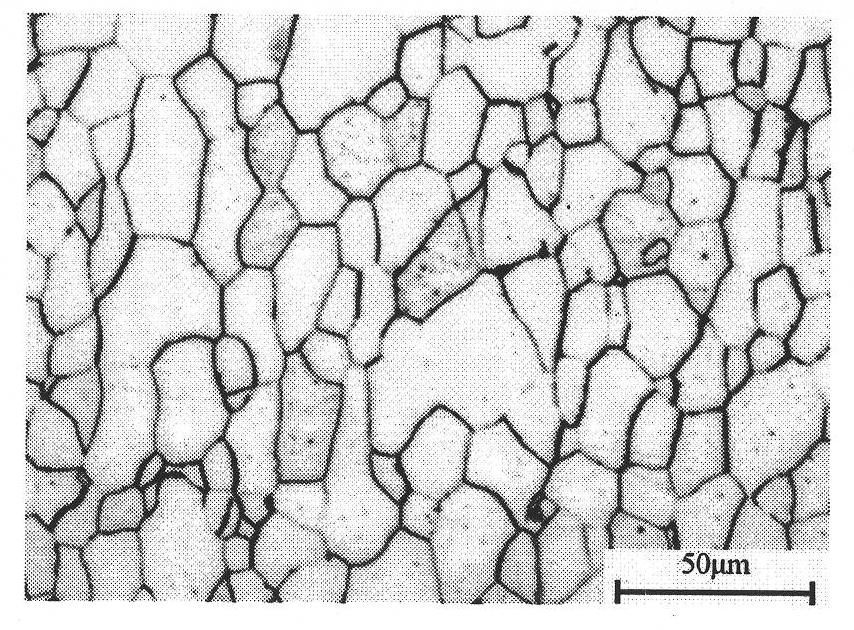

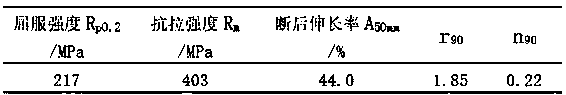

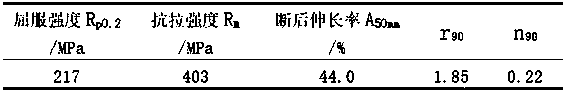

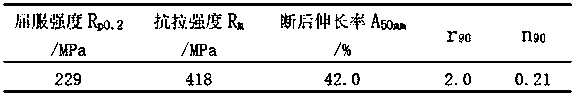

Method for producing extra-deep drawing cold-rolled steel plate based on ASP process

InactiveCN101941021AReduce manufacturing costMeet needsRoll mill control devicesWork treatment devicesProduction lineAcid washing

The invention discloses a method for producing an extra-deep drawing cold-rolled steel plate based on a sheet billet continuous casting and rolling process in ASP, and belongs to the technical field of rolled steel. After molten steel meeting the component requirement is obtained by adopting molten iron pretreatment, a converter, LF and RH, a hot-rolled substrate is produced by the sheet billet continuous casting and rolling process in the ASP, and the hot-rolled substrate is subjected to acid washing, cold rolling, cover annealing and leveling processes to obtain the extra-deep drawing cold-rolled steel plate. Compared with the prior art, the performance of the produced extra-deep drawing cold-rolled steel plate meets the European standard EN10130-2006, meanwhile, the production cost is reduced, energy is saved and consumption is reduced. The method broadens the variety range of products produced by a sheet billet continuous casting and rolling production line in the ASP, can meet the increasing requirements of the industries of automobiles, home appliances, buildings, transports, light industry and the like for plates, and improves the product competitiveness of enterprises.

Owner:SHANDONG IRON & STEEL CO LTD +1

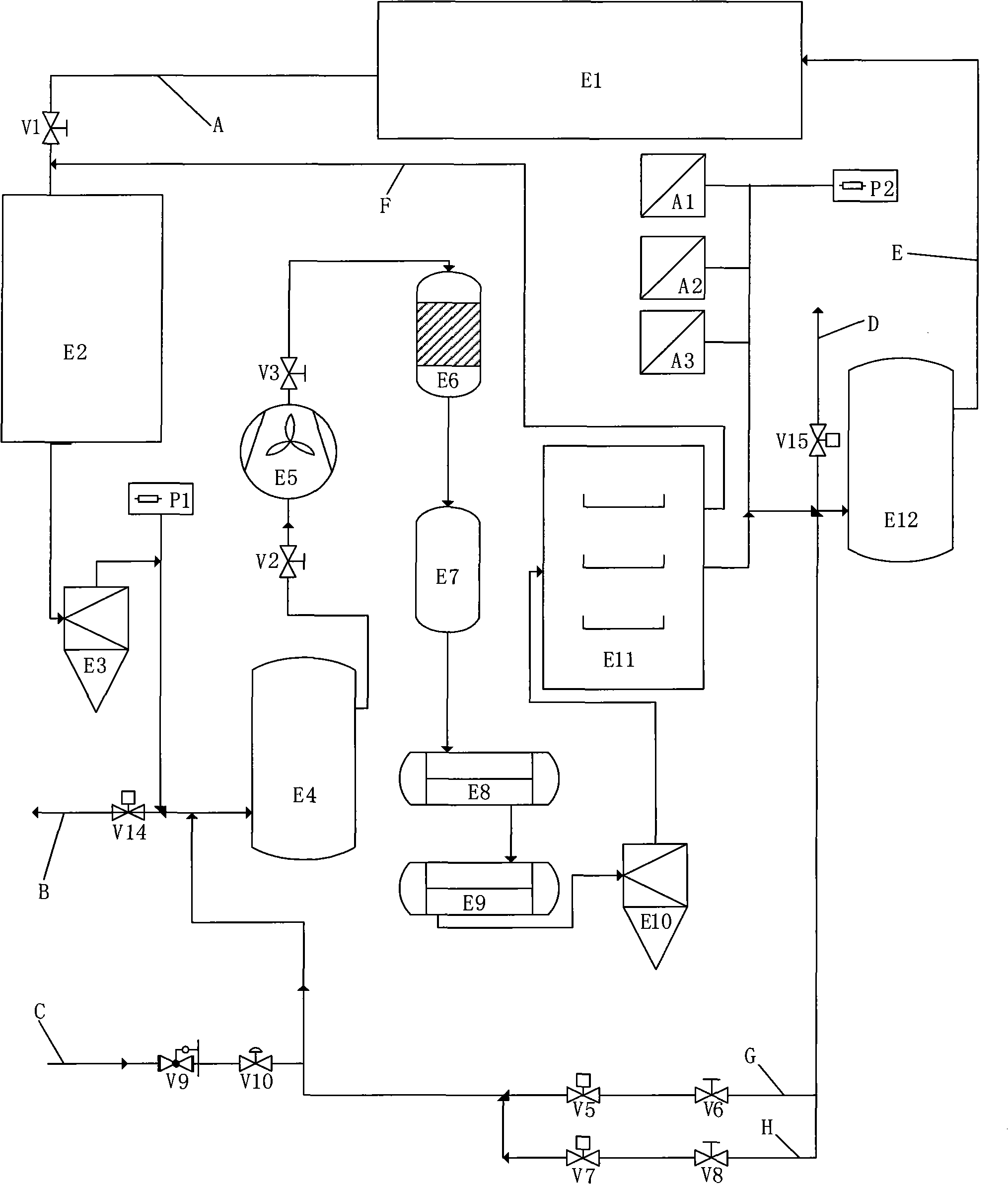

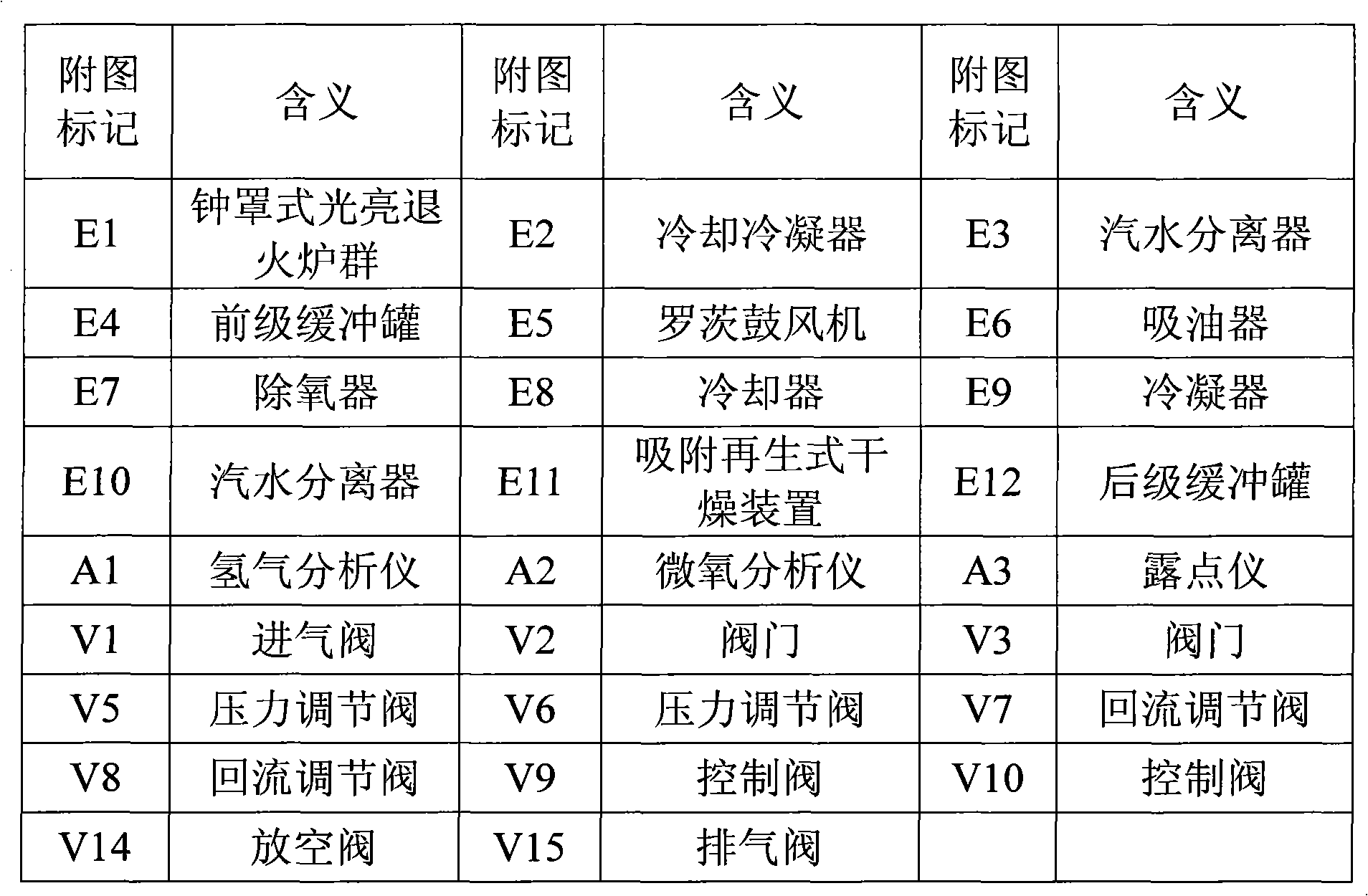

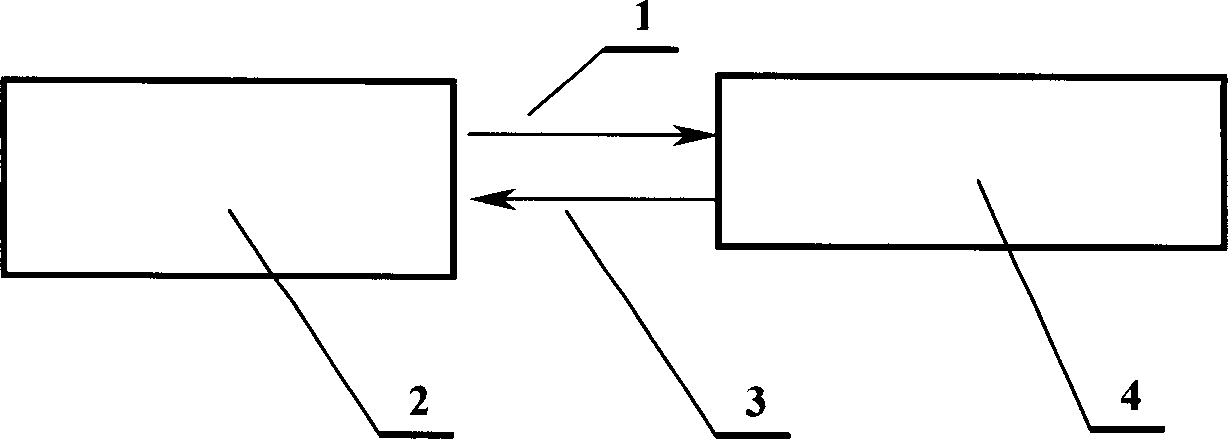

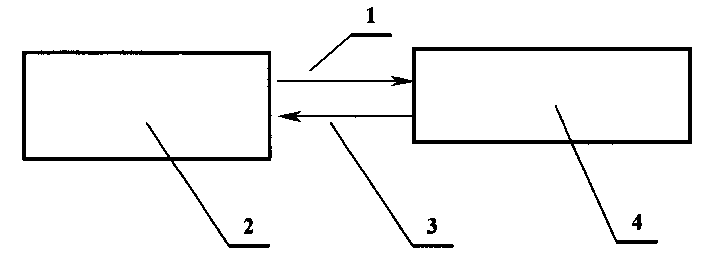

Process and device for recovering and recycling protective gas of bell-type bright annealing furnace

ActiveCN101956061AAvoid direct burningAvoid emptyingMaintainance of heating chambersBell type furnacesBuffer tankDeaerator

The invention relates to a process and a device for recovering and recycling protective gas of a bell-type bright annealing furnace. The process comprises the following steps of: performing cooling and condensation of oil and gas in refluxing protective gas of a bell-type bright annealing furnace group; allowing the cooled and condensed protective gas to enter a water separator to remove most of water and oil; allowing the cooled protective gas from which the oil and the gas are removed to enter a preceding stage buffer tank; after the protective gas is buffered by the preceding stage buffer tank, pressurizing by using a roots blower; allowing the pressurized protective gas to enter an oil absorption device to remove oil and enter a deaerator to remove oxygen; reacting in the deaerator to generate water and discharge heat; cooling the protective gas by using a cooler and removing water from the protective gas by using a condenser; allowing the cooled and dehydrated protective gas to enter the water separator to separate water; allowing the protective gas to enter an absorption regeneration drying device for removing water and impurities deeply; and performing decompression and voltage stabilization on the purified gas by using a post-stage buffering tank and then supplying the purified gas to the bell-type bright annealing furnace group. Through the process and the device, the refluxing protective gas of the bell-type bright annealing furnace group is recovered and purified and enters the annealing furnace to be recycled as the protective gas again.

Owner:苏州品源气体设备有限公司

Control method of protective atmosphere of stainless steel cover type annealing furnace

ActiveCN101760606ASolve the problem of not being able to put in normallyReduce consumptionBell type furnacesMetallurgyNitrogen

The invention relates to a control method of a protective atmosphere of a stainless steel cover type annealing furnace, which is characterized by sequentially comprising the following steps of: a. blowing air inside an inner cover of a furnace platform; b. replacing nitrogen inside the inner cover with hydrogen: setting the maximum discharge flow rate of an electromagnetic valve into 30 m3 / h according to process requirements; introducing the hydrogen into the inner cover to replace the nitrogen inside the inner cover according to the set flow rate for normally operation; discharging a mixed gas of the hydrogen and the nitrogen through a waste gas regulating valve and a discharge pipe, wherein when the total amount of the hydrogen reaches 22 m3 during the operation, the electromagnetic valve of hydrogen flow rate is automatically closed; c. stabilizing voltage: ensuring pressure inside the annealing furnace to be kept between 2 kPa and 6 kPa; and d. blowing the hydrogen inside the inner cover of the furnace platform after annealing is finished. The invention solves the problem that the hydrogen can not be normally introduced at a debugging stage and reduces the hydrogen consumption of a whole annealing period, one annealing cycle period of an original process needs to consume the hydrogen about 240 m3, and one annealing cycle period of the control method needs to consume the hydrogen about 30 m3-35 m3, thus production cost is greatly saved.

Owner:NINGBO BAOXIN STAINLESS STEEL

1800MPa-level plating-free thermoforming steel with low high-temperature friction coefficient and preparation method of 1800MPa-level plating-free thermoforming steel

InactiveCN111041382AIncrease productivityLow costBell type furnacesHeat treatment furnacesMetallurgyRaw material

The invention discloses 1800MPa-level plating-free thermoforming steel with a low high-temperature friction coefficient and a preparation method of the 1800MPa-level plating-free thermoforming steel.Main chemical components of the 1800MPa-level plating-free thermoforming steel comprise, by mass percent, 0.25%-0.35% of C, not larger than 0.5% of Si, 0.5%-1.5% of Mn, not larger than 0.020% of P, not larger than 0.010% of S, not larger than 0.50% of Cr, 0.01%-0.06% of Al, not larger than 0.04% of Ti, not larger than 0.5% of Nb+V+Mo, not larger than 0.003% of B and the balance Fe and inevitable impurities. Through optimization to components and processes, the surface state of the plating-free thermoforming steel raw material is improved, and a good thermoforming steel raw material is providedfor subsequent preparation of thermoforming parts.

Owner:MAANSHAN IRON & STEEL CO LTD

390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip and LF-RH duplex production process thereof

InactiveCN108842024AChemically stableStable mechanical propertiesManufacturing convertersBell type furnacesMechanical propertyContinuous rolling

The invention discloses a 390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip and an LF-RH duplex production process thereof, and belongs to the technical field of production of interstitial-free steel. The steel strip comprises, by weight, less than or equal to 0.0050% of C, 0.030-0.055% of Si, 0.55-0.60% of Mn, 0.055-0.070% of P, less than or equal to 0.008% of S, 0.020-0.040% of Als, 0.035-0.050% of Nb, 0.015-0.035% of Ti, 0.0005-0.0010% of B and the balance Fe, Ca, Cr and inevitable trace elements. The production process flow comprises the steps of blast furnace hotmetal smelting, converter molten steel smelting, LF molten steel refining, RH molten steel refining, CSP sheet billet continuous casting and rolling, pickling cold continuous rolling, cover furnace annealing, leveling and inspection, packaging and storage. The composition design thoughts of micro-carbon smelting, [Nb, Ti] microalloying and solid solution strengthening of P and Mn are adopted, the390MPa grade cold-rolled phosphorus-containing IF high-strength steel strip with stable chemical compositions and stable mechanical properties is obtained through an LF-RH duplex refining process, hot rolling, cold rolling and an annealing process, the production cycle is short, the production cost is low, the steel strip is stable in quality, and the requirements of the automobile industry on the high-strength steel strip can be met.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

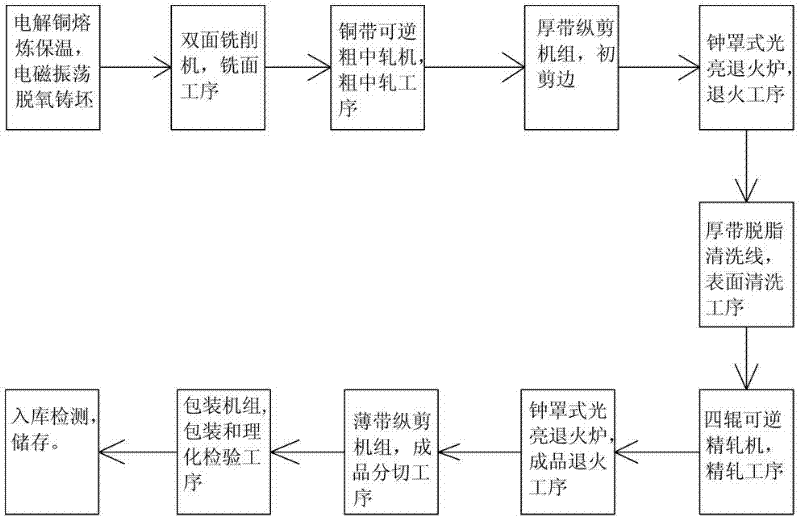

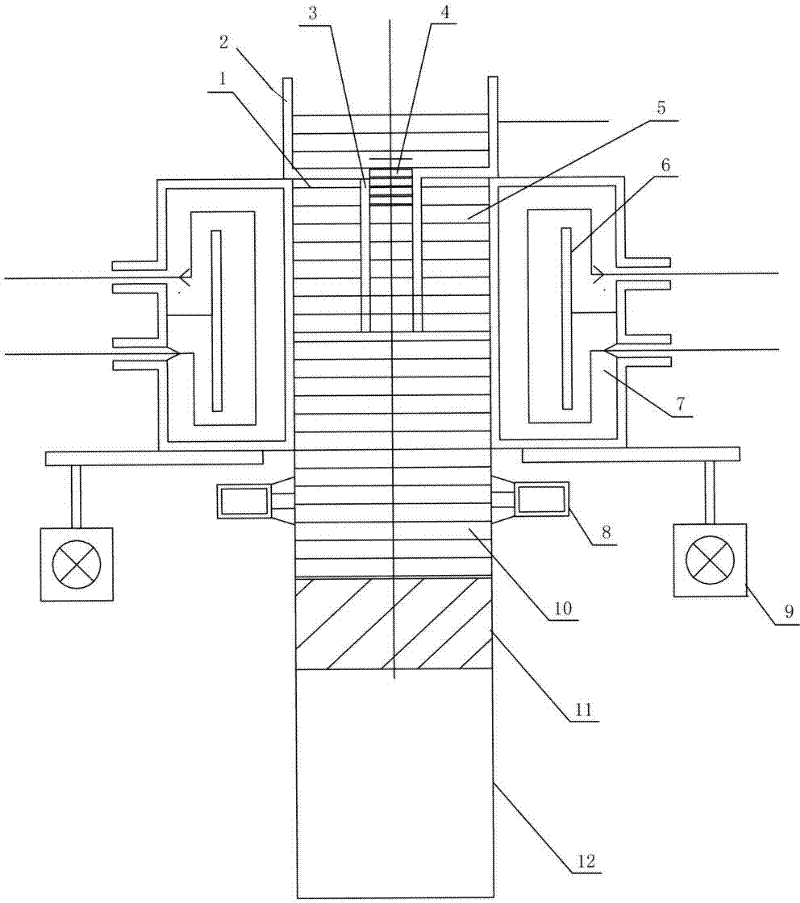

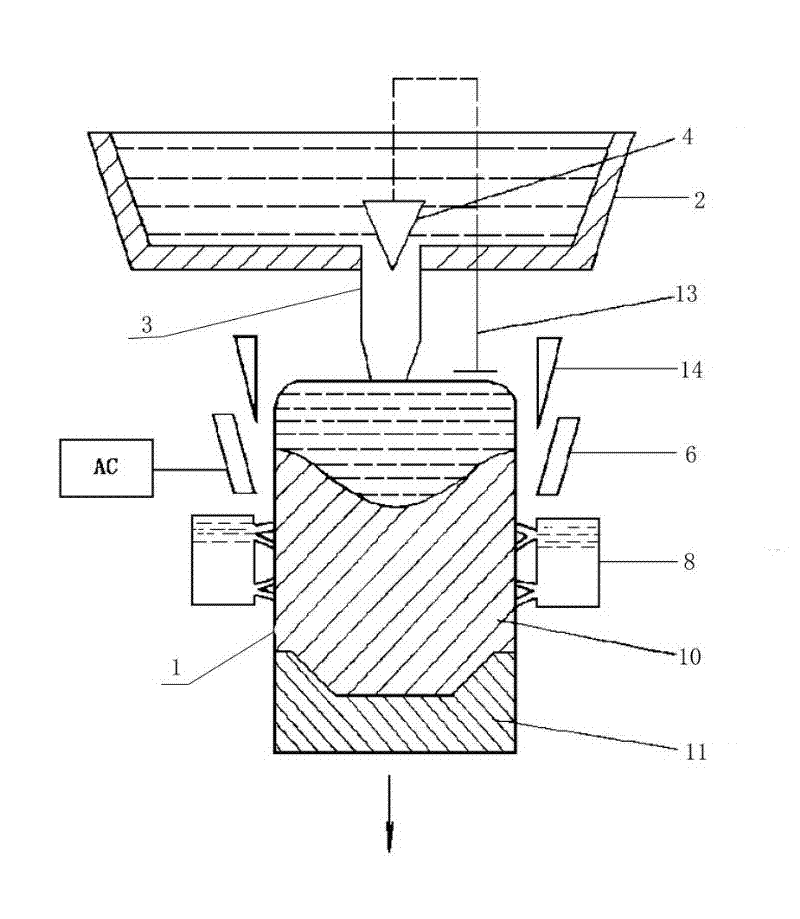

Production method of high-precision ultralong oxygen-free copper strip

ActiveCN102199711ACompact structureGuaranteed oxygen contentRoll mill control devicesBell type furnacesElectrolysisIngot

The invention relates to a production method of a high-precision ultralong oxygen-free copper strip and belongs to the technical field of oxygen-free copper strip production, processing and manufacturing. The production method of the high-precision ultralong oxygen-free copper strip comprises: (1) selecting electrolytic copper as a raw material, adding the electrolytic copper into a melting furnace, smelting the melting furnace, allowing molten copper to flow into a crystallizer added with an electromagnetic oscillation coil, performing electromagnetic deoxidization of the molten copper and horizontally casting a blank by electromagnetic continuous casting in the electromagnetic continuous casting crystallizer added with the electromagnetic oscillation coil, cooling in the electromagnetic continuous casting crystallizer, crystallizing to form strip copper blanks, and stretching by an ingot leading machine; (2) milling a strip blank by a double-sided miller; (3) performing reversible coarse medium rolling of the copper strip; (4) performing primary trimming by a thick strip longitudinal shearing machine; (5) annealing in a bell type bright annealing furnace; (6) cleaning surface on a thick strip degreasing cleaning line; (7) finely rolling in a four-roller reversible fine rolling machine; (8) annealing a finished product in the bell type bright annealing furnace; (9) cutting the finished product by a thin-strip longitudinal shearing machine; (10) packing in a packaging machine and performing physical and chemical examination; and (11) performing incoming inspection and storing.

Owner:ZHONGTIAN ALLOY TECH

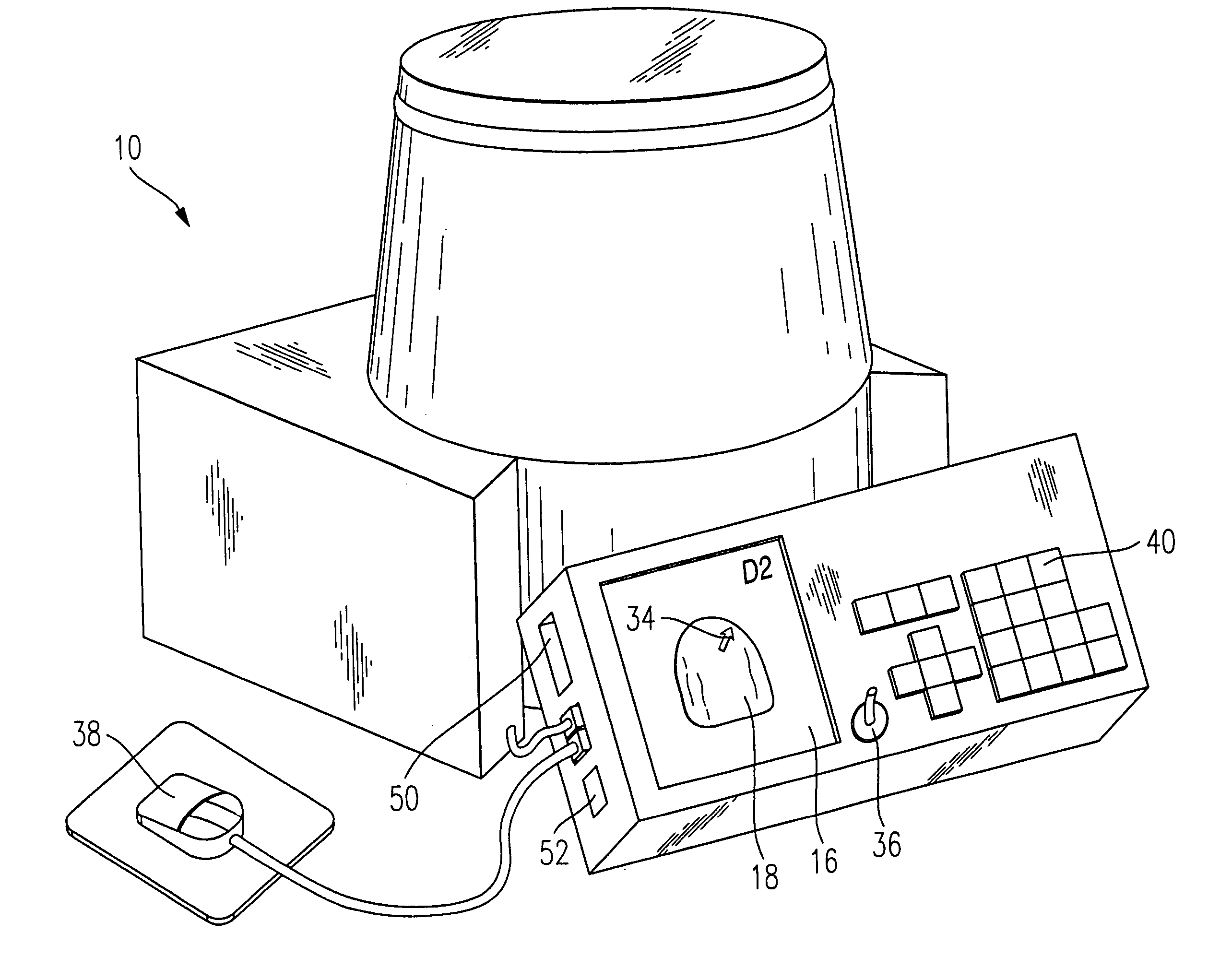

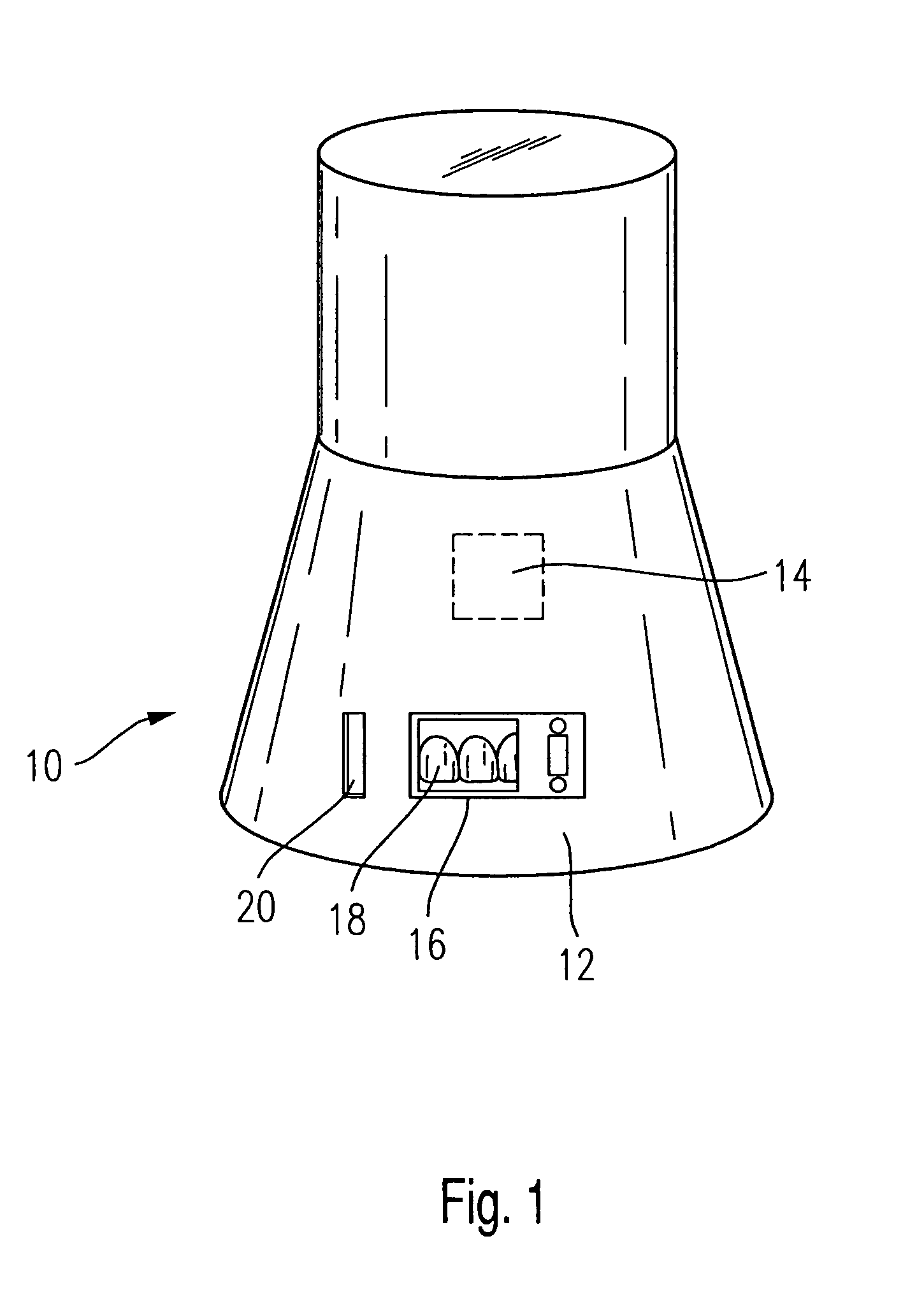

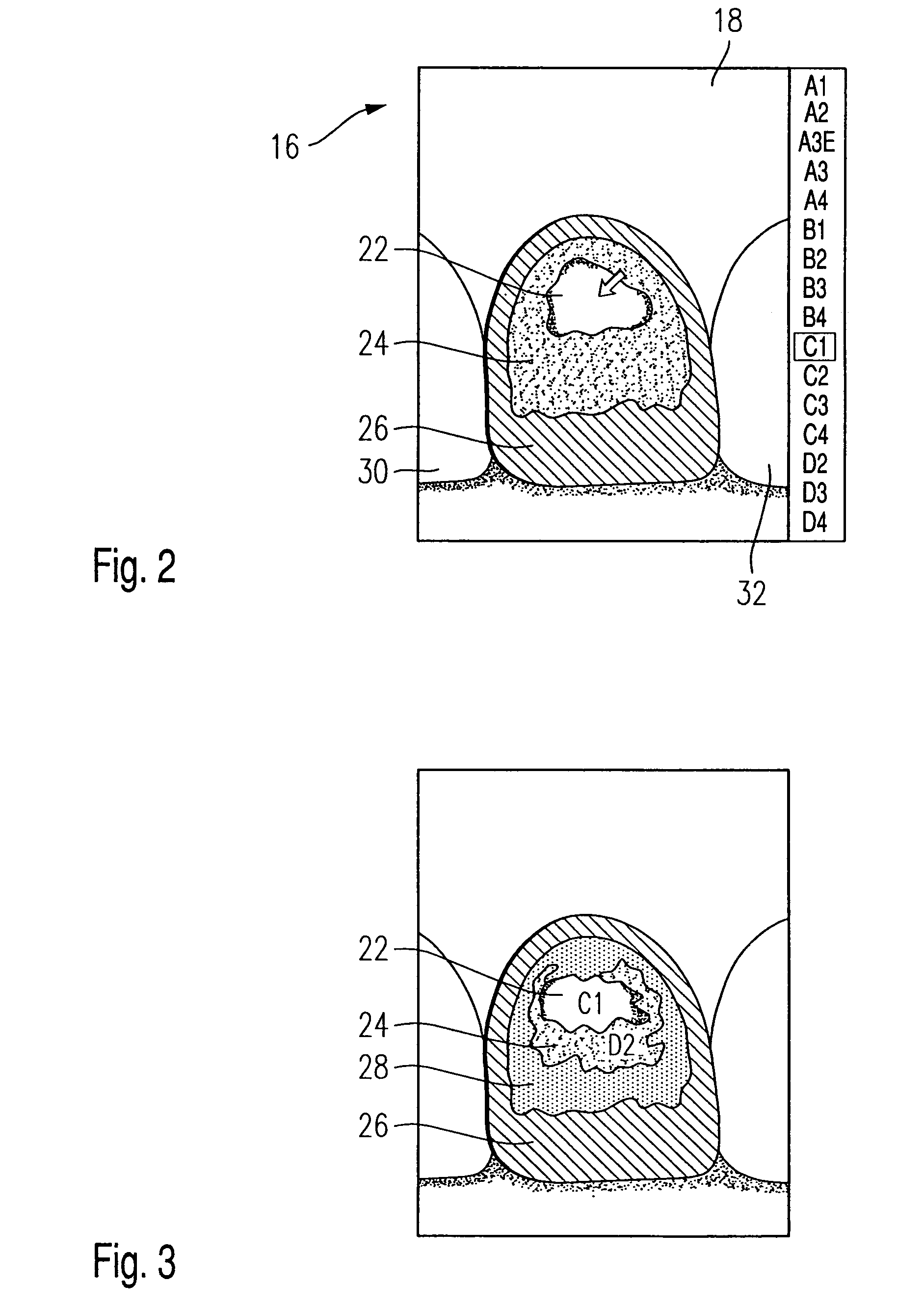

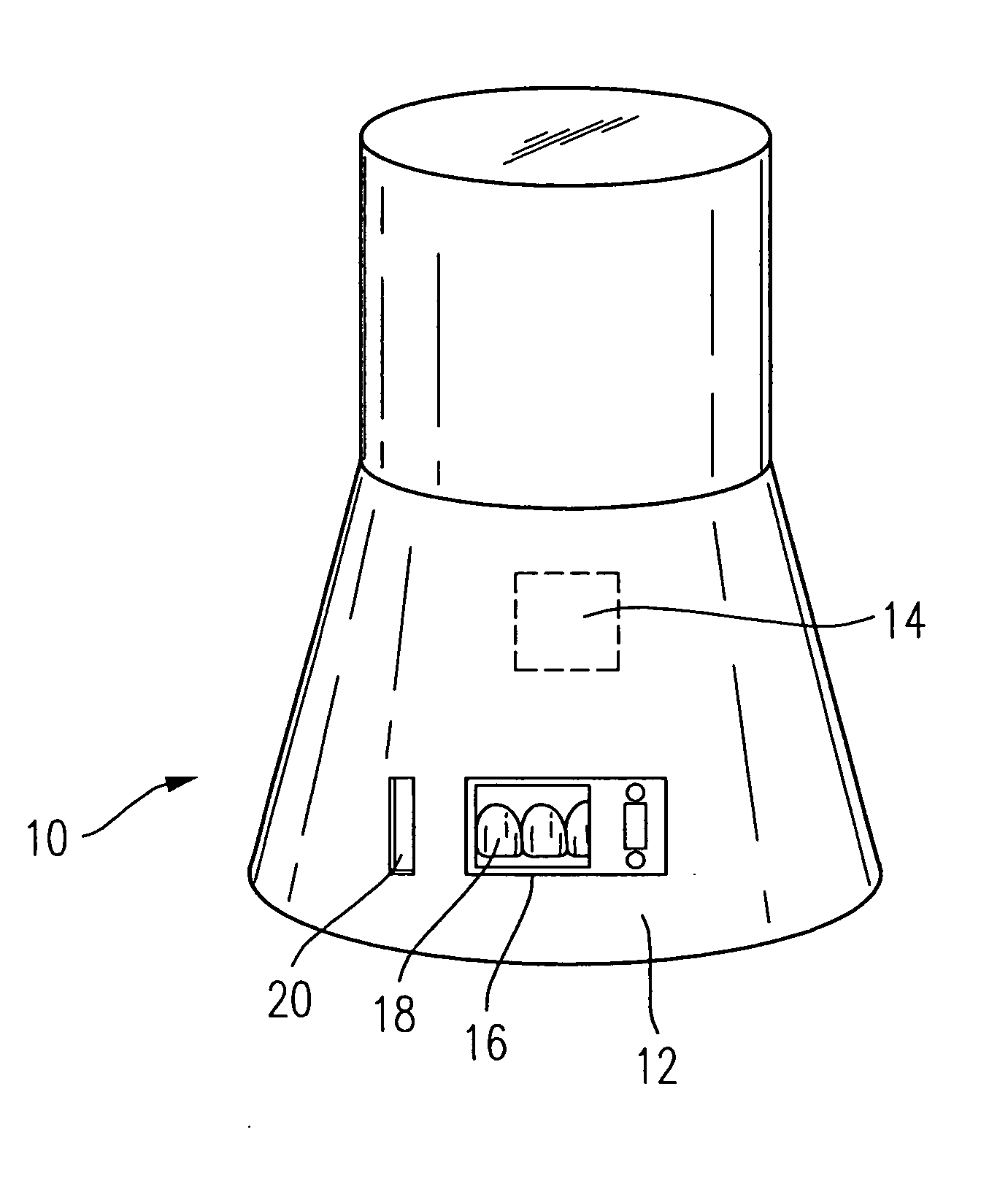

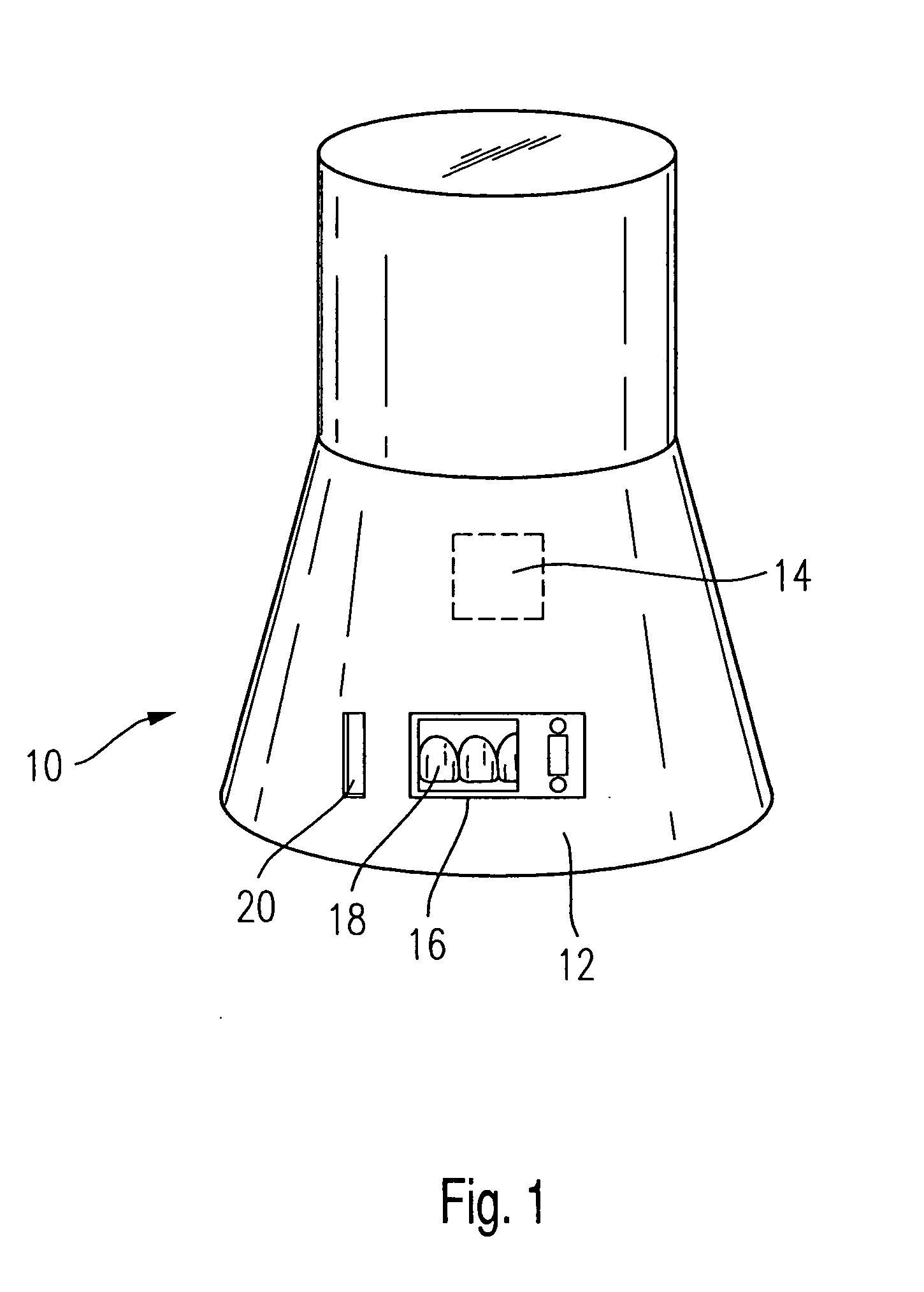

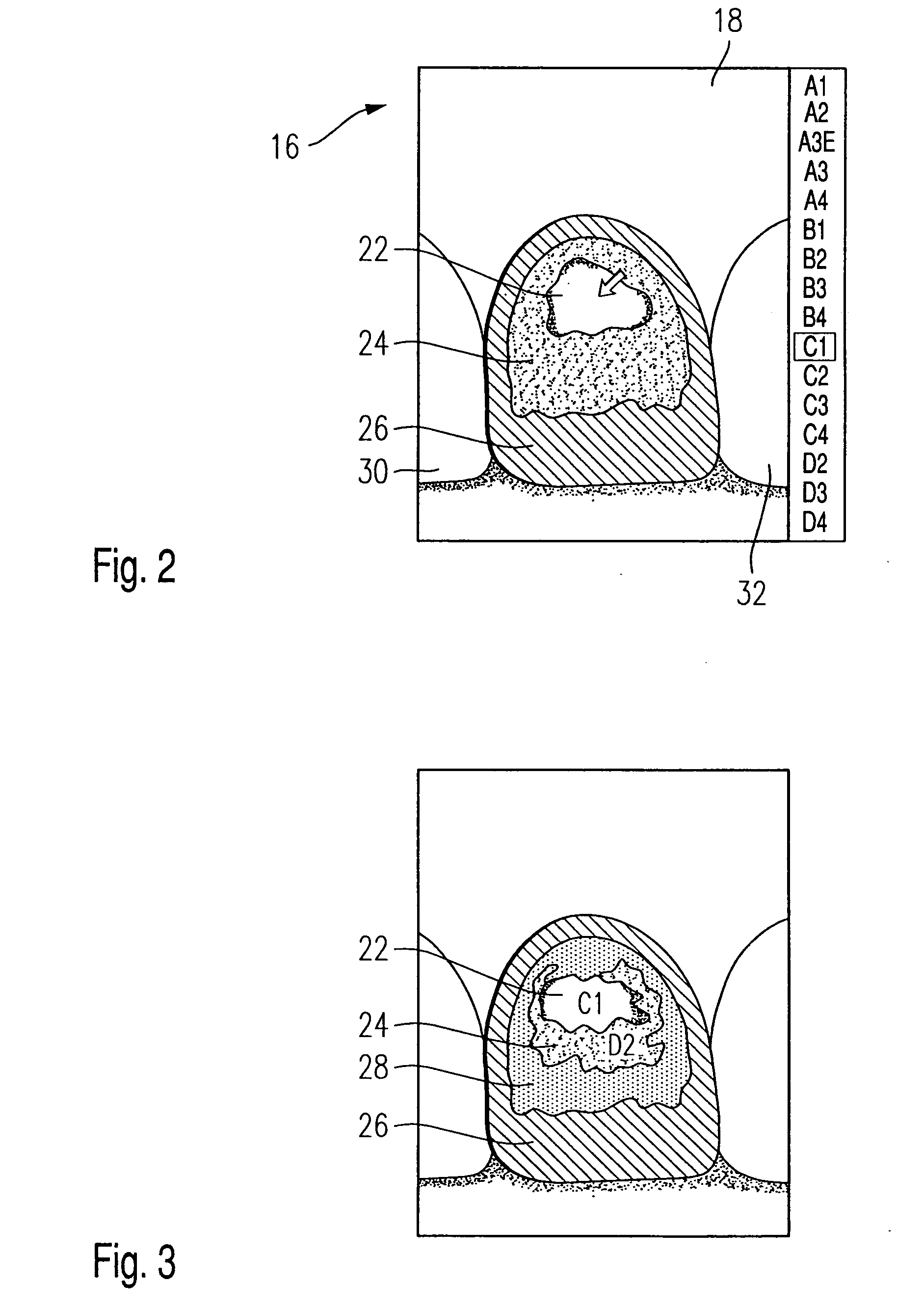

Method and apparatus for using a display associated with a dental kiln

ActiveUS7001178B2Reduce probabilityCorrectness of possible handwritten notesTeeth fillingArtificial teethDisplay deviceComputer science

An kiln for dental restoration components is provided, and comprises an indicator having an image screen for displaying information. The image screen is provided with at least two, and in particular at least three, surface areas with which optically distinguishable features, including colors, types and structures, can be represented. The surface areas together essentially form a front and / or side view of at least one tooth.

Owner:IVOCLAR VIVADENT AG

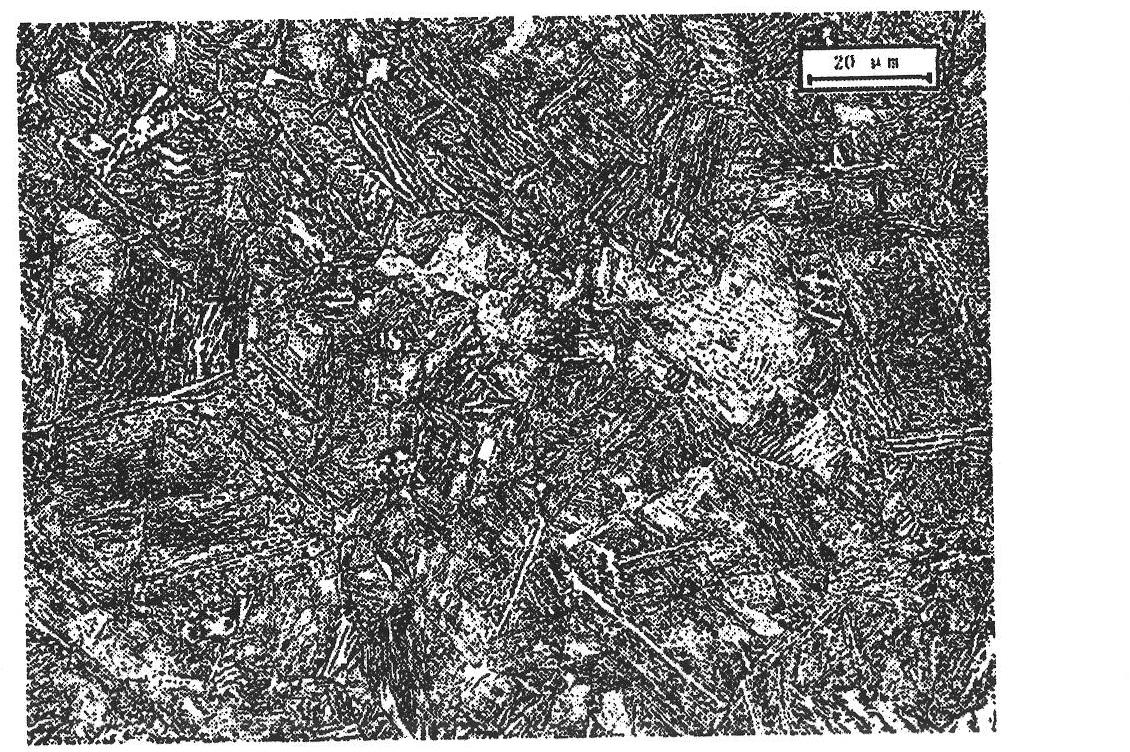

TRIP (Transformation-Induced Plasticity) steel and production method thereof

Owner:SHOUGANG CORPORATION

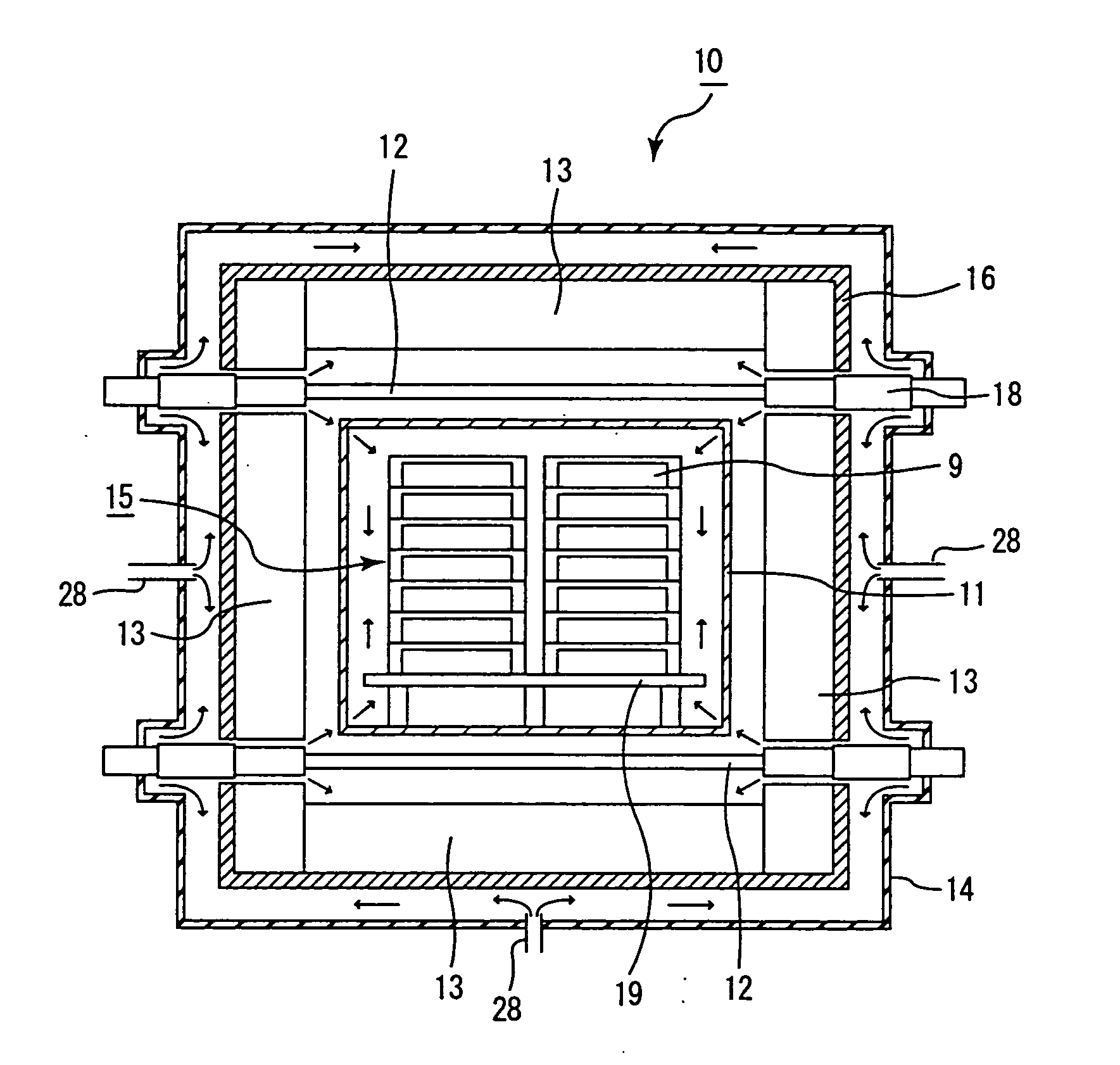

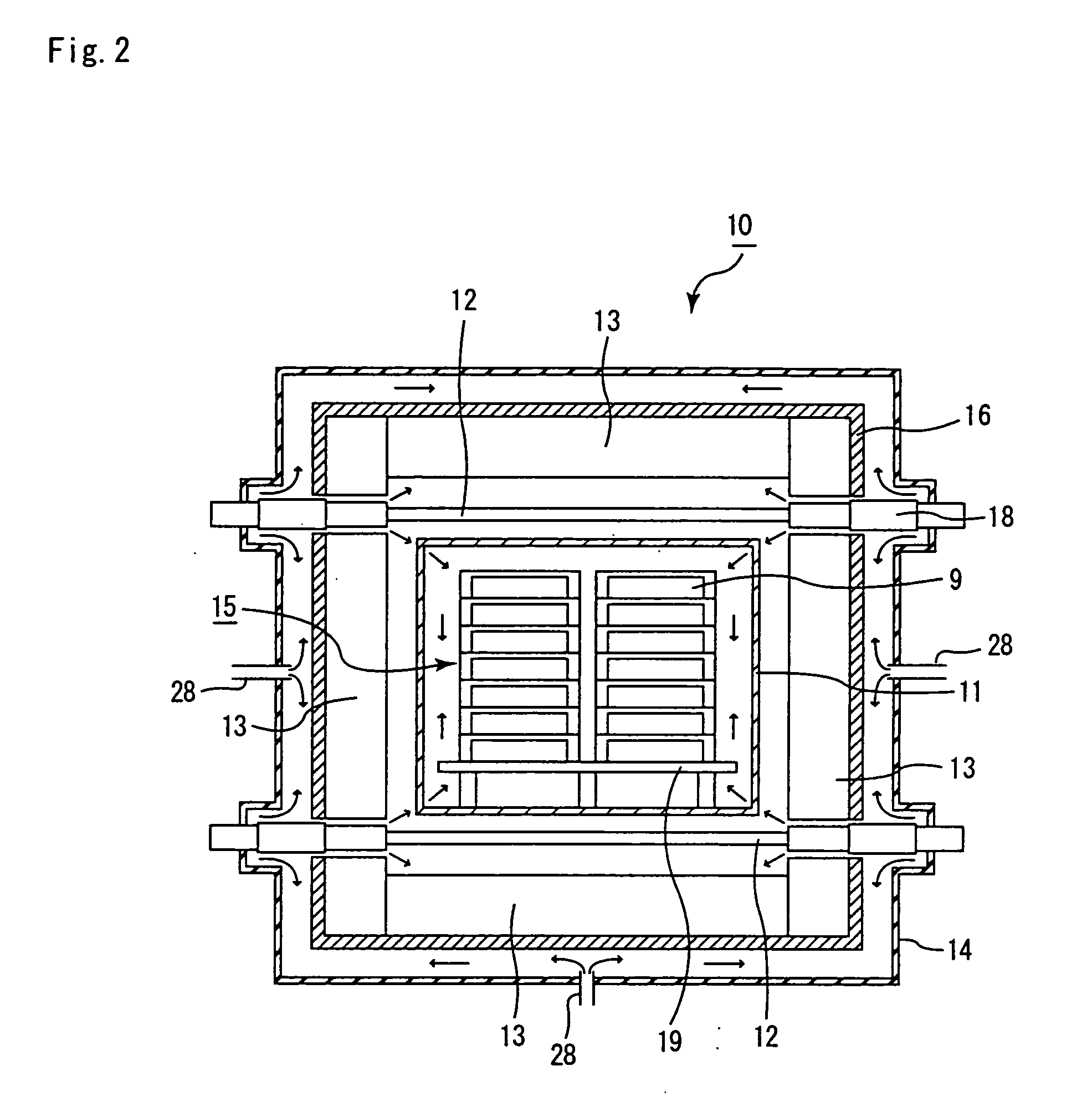

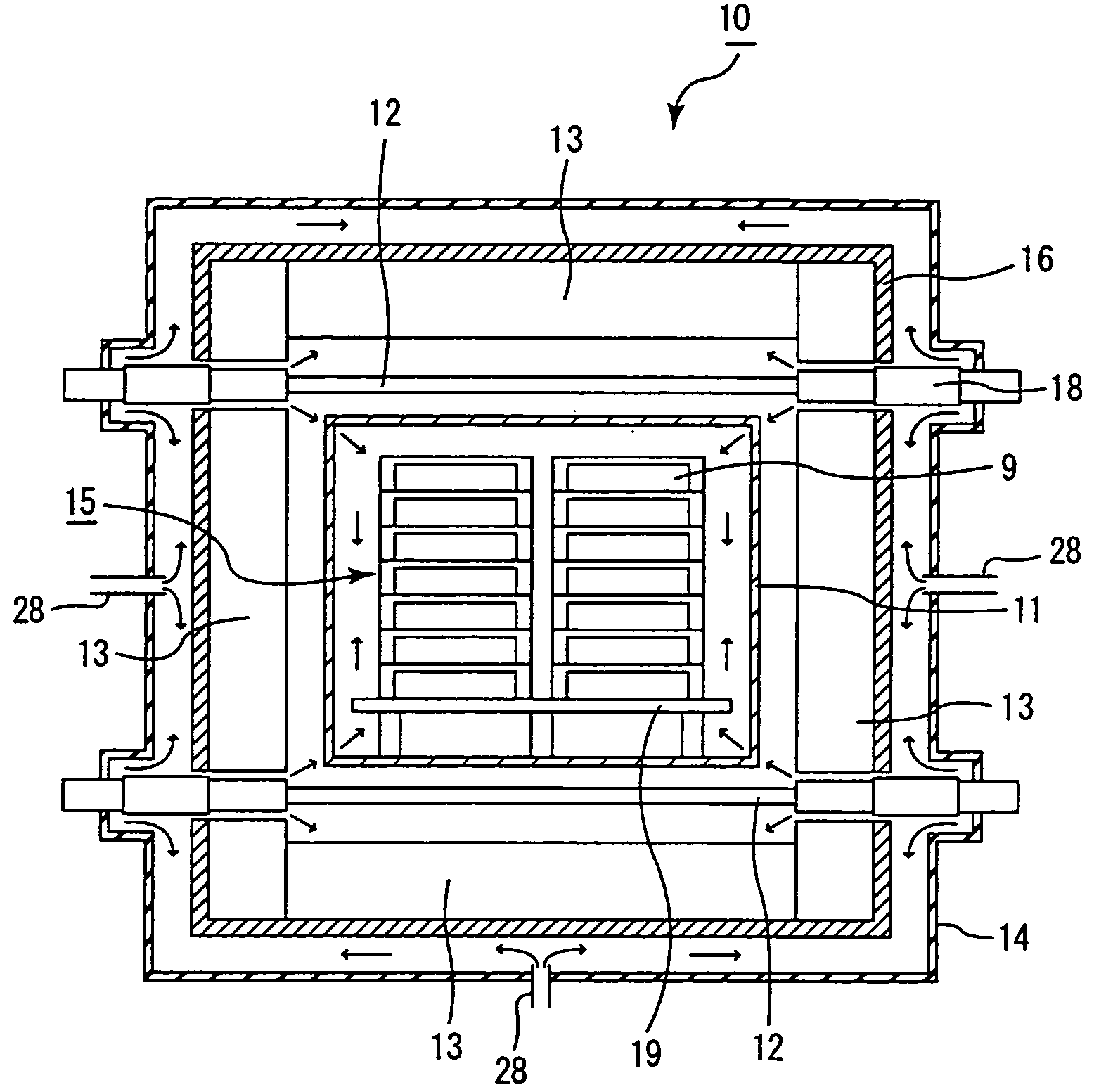

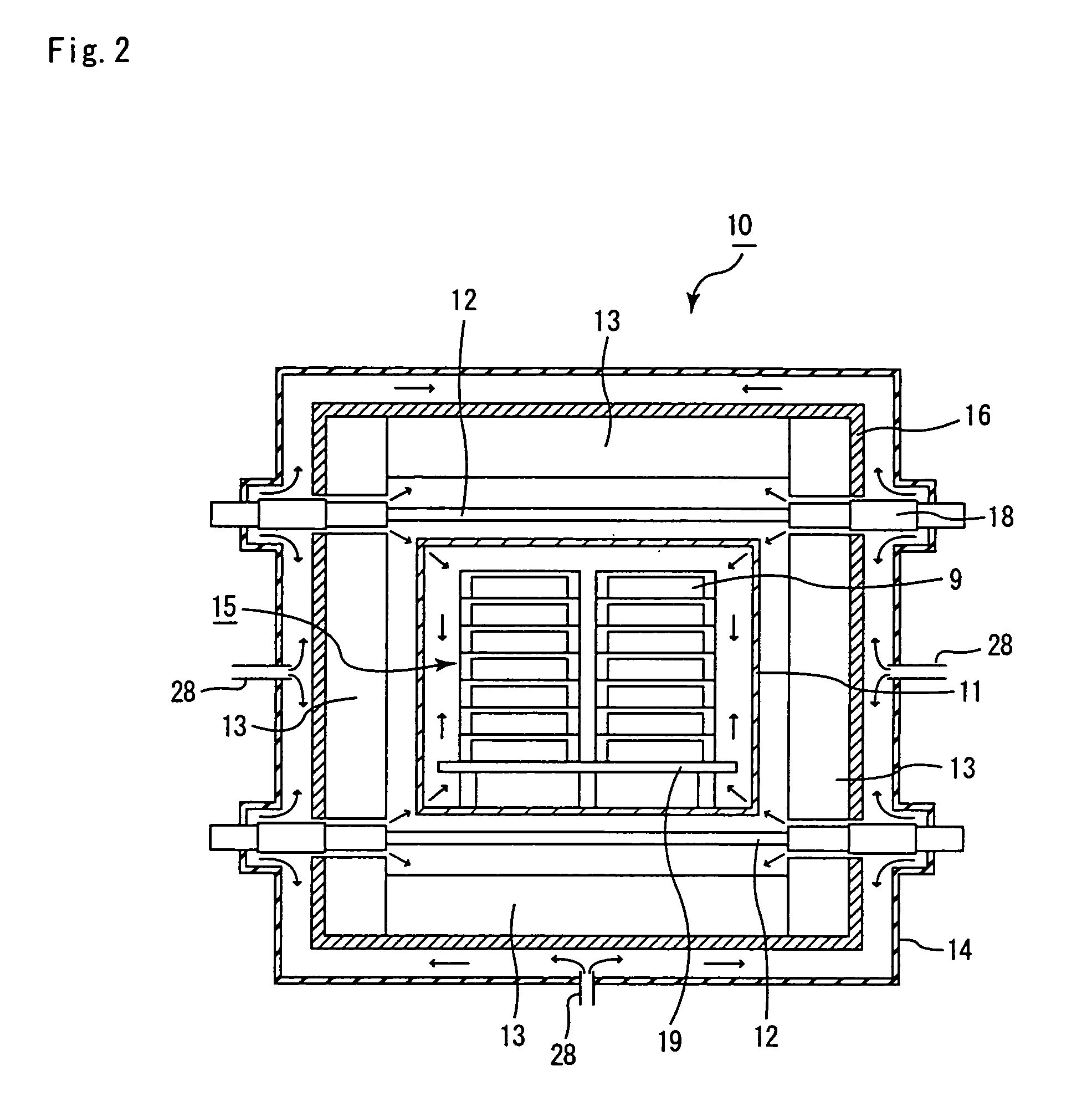

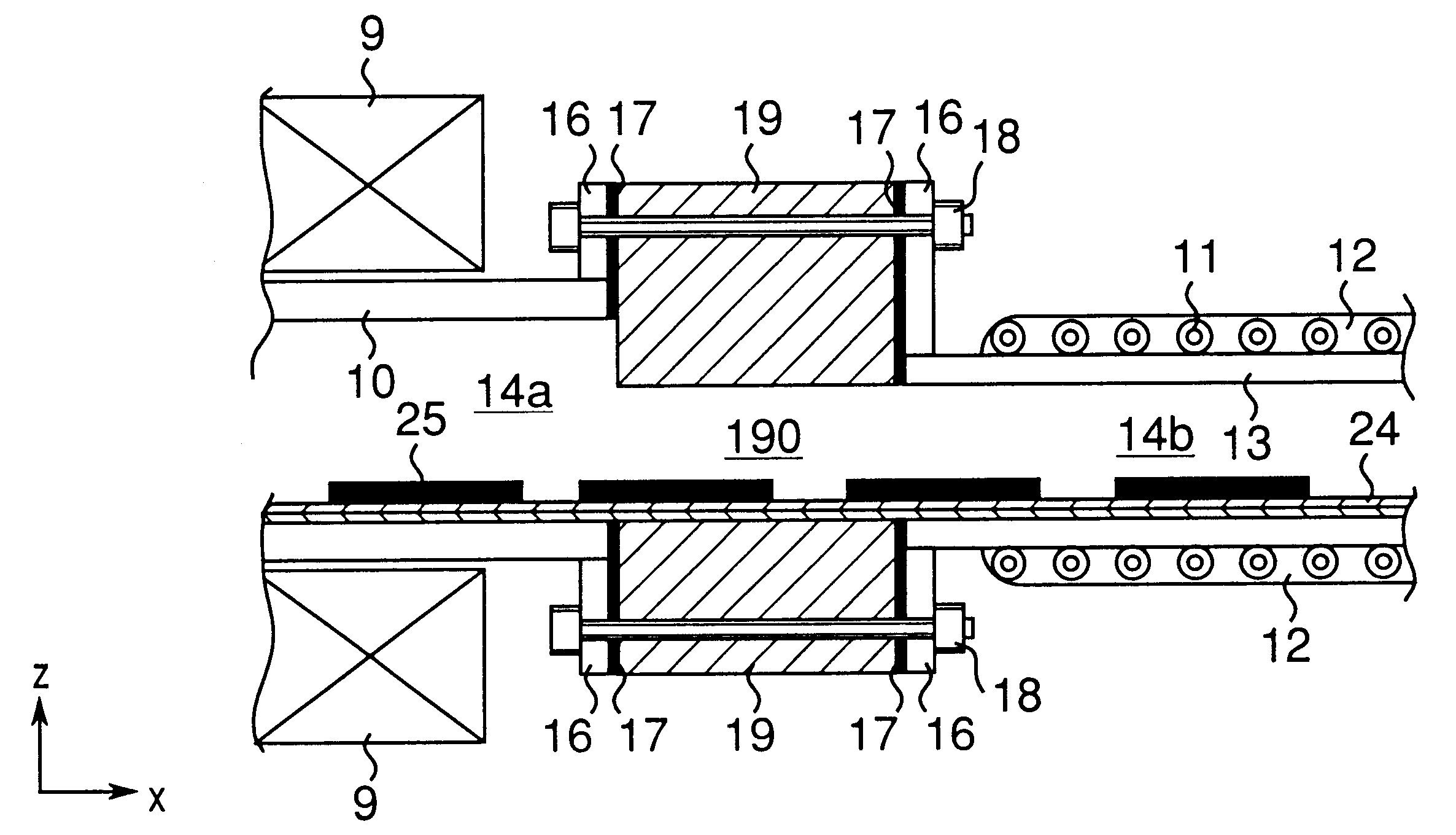

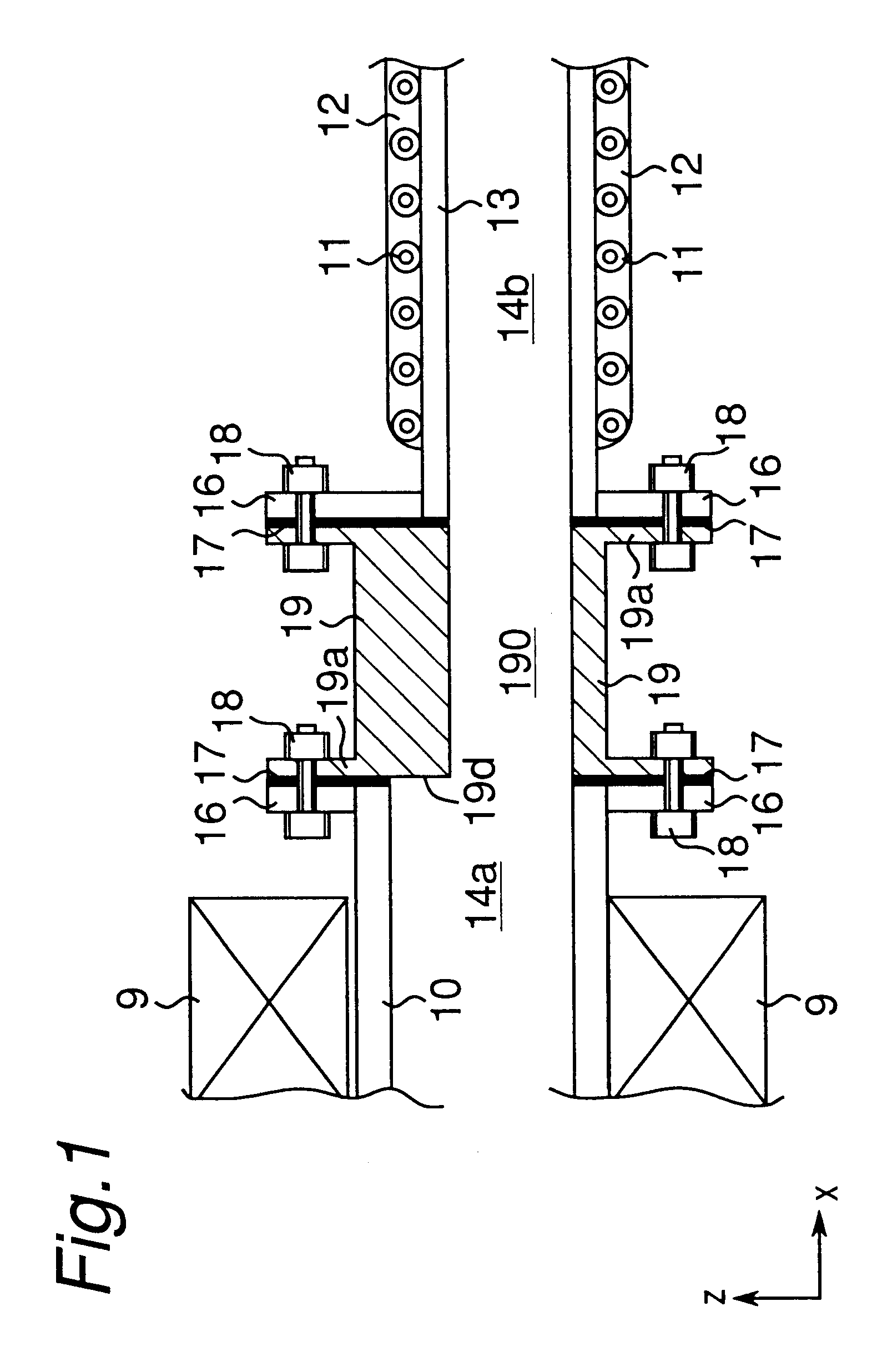

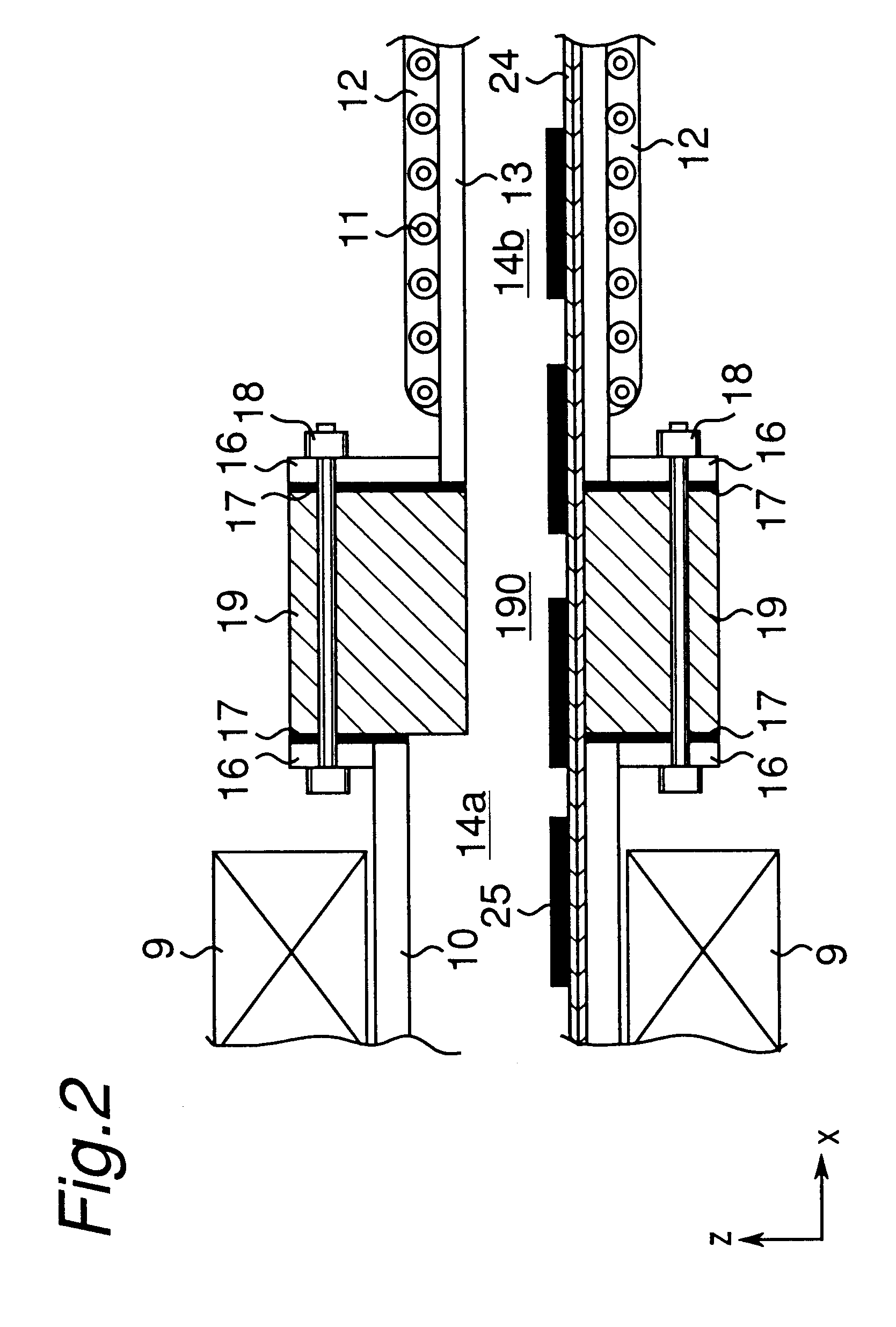

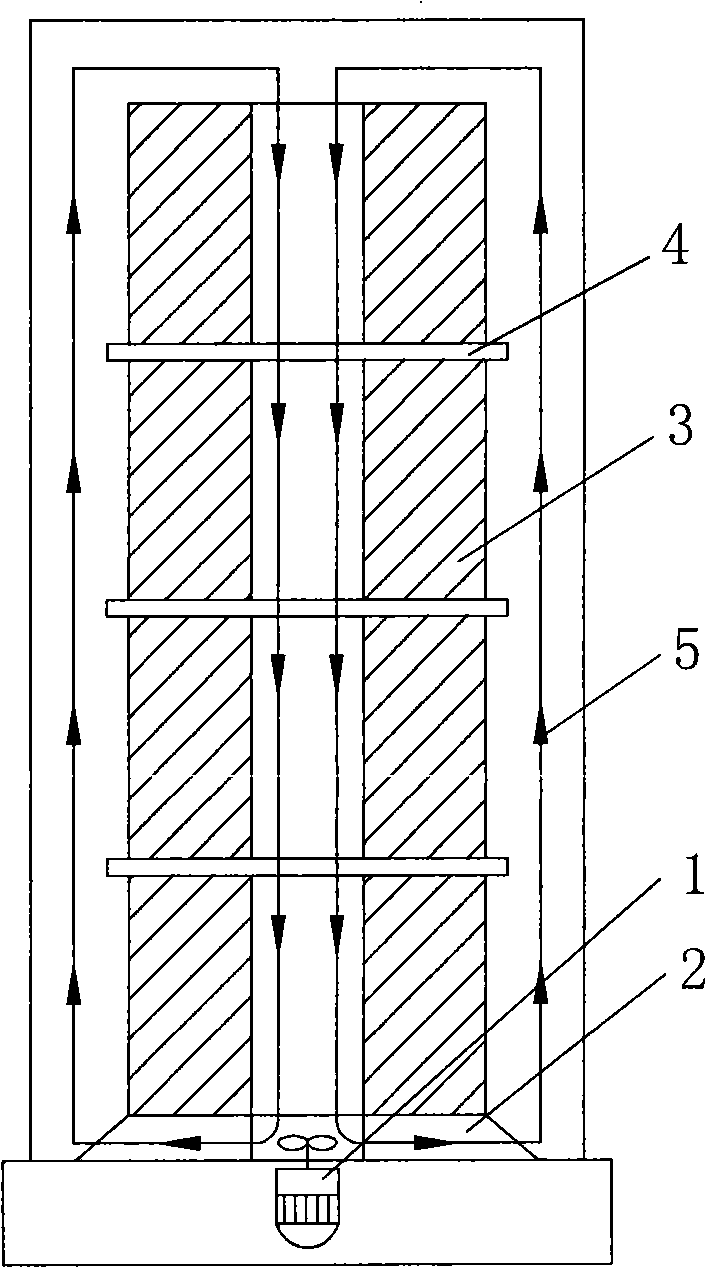

Thermal treatment apparatus

InactiveUS6623269B2Small heat lossAvoid heat conductionLining supportsGlass transportation apparatusThermal energyHeat losses

A thermal treatment apparatus has a plurality of thermal treatment chambers in which an object to be treated is thermally treated while being transported, and at least one pair of two adjacent thermal treatment chambers of which inside temperatures are different from each other. The thermal treatment chambers are connected through a thermal insulating structural member, whereby thermal conduction between the chambers, such as muffles, is prevented to reduce a heat loss caused in the thermal treatment apparatus. Therefore, input thermal energy which is necessary to carry out a predetermined thermal treatment is significantly reduced without affecting quality and yield of the object.

Owner:PANASONIC CORP

Method and apparatus for using a display associated with a dental kiln

ActiveUS20050175949A1Reduce probabilityCorrectness of possible handwritten notesTeeth fillingArtificial teethDisplay deviceComputer science

An kiln for dental restoration components is provided, and comprises an indicator having an image screen for displaying information. The image screen is provided with at least two, and in particular at least three, surface areas with which optically distinguishable features, including colors, types and structures, can be represented. The surface areas together essentially form a front and / or side view of at least one tooth.

Owner:IVOCLAR VIVADENT AG

Method for making orientation-free cold-rolled electric steel-board

InactiveCN101069943AAvoiding Electromagnetic Performance DeteriorationReduce adverse effectsOther manufacturing equipments/toolsHeat treatment process controlElectrical steelSheet steel

The invention relates to a preparation method of the non-oriented cold rolling electrotechnical steel plates. It provides convenience for small and medium-sized enterprises to produce the non-oriented cold rolling electrotechnical steel plates by using materials from normal smelting method without costly continuous annealing line. The preparation steps are as follows: it selects hot rolling silicon steel coils (whit C<800ppm) produced by normal smelting method for pickling and cold rolling. To complete final annealing in the bell furnace, heat the temperature to 700-880 C degree quickly and keep for 8-16h, cooling slowly and naturally below 80 C degree to convert. The invention adopts annealing technology of the bell furnace instead of vacuum smelting greatly reducing the C content to dissolves C into the steel during heating. There is no dissolved carbon in unstable state in the final steel plates, which avoid magnet aging or electromagnetic properties deterioration. The products have good performance and can save producing cost.

Owner:湖北方盛合力金属材料有限公司 +1

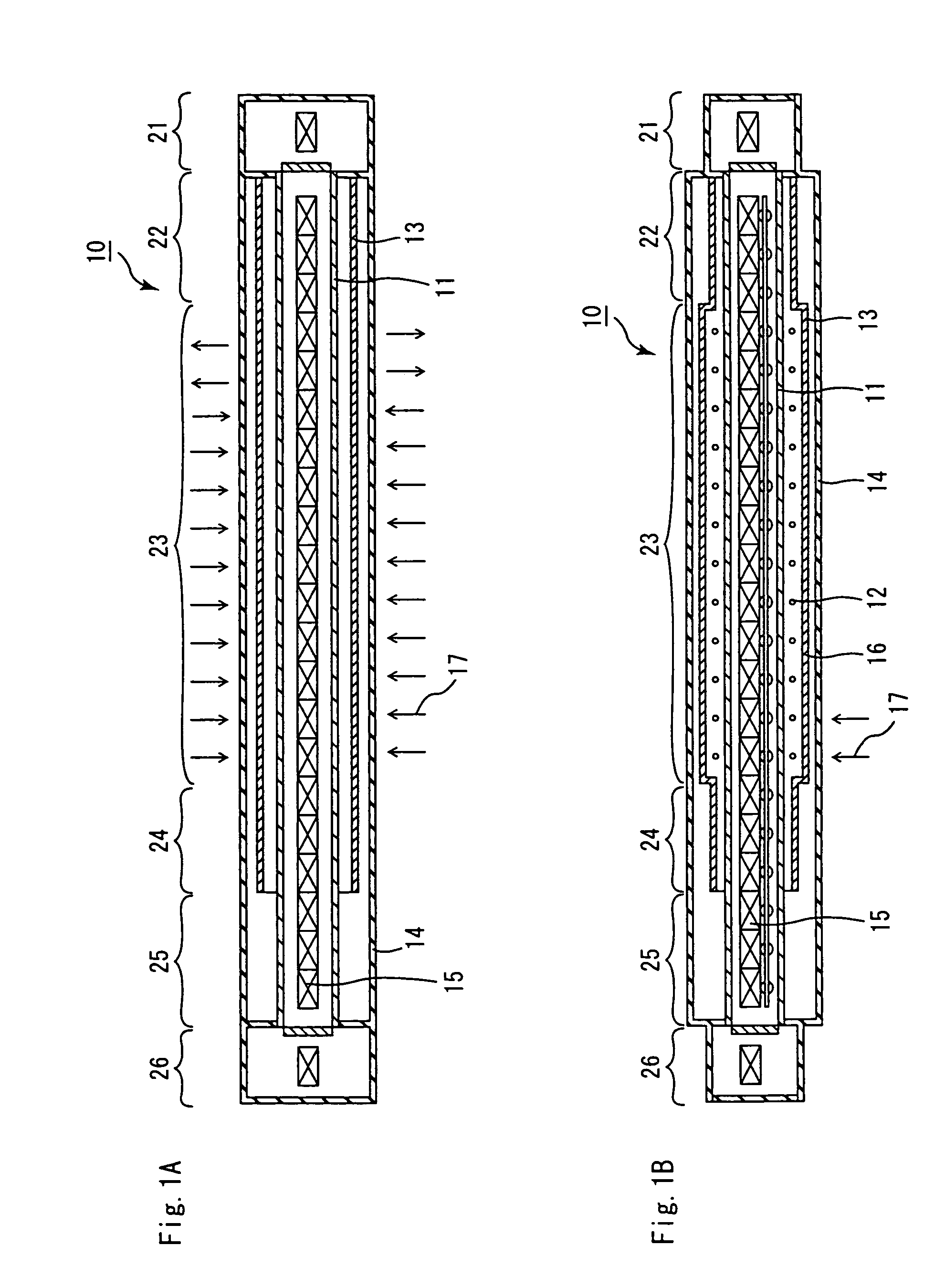

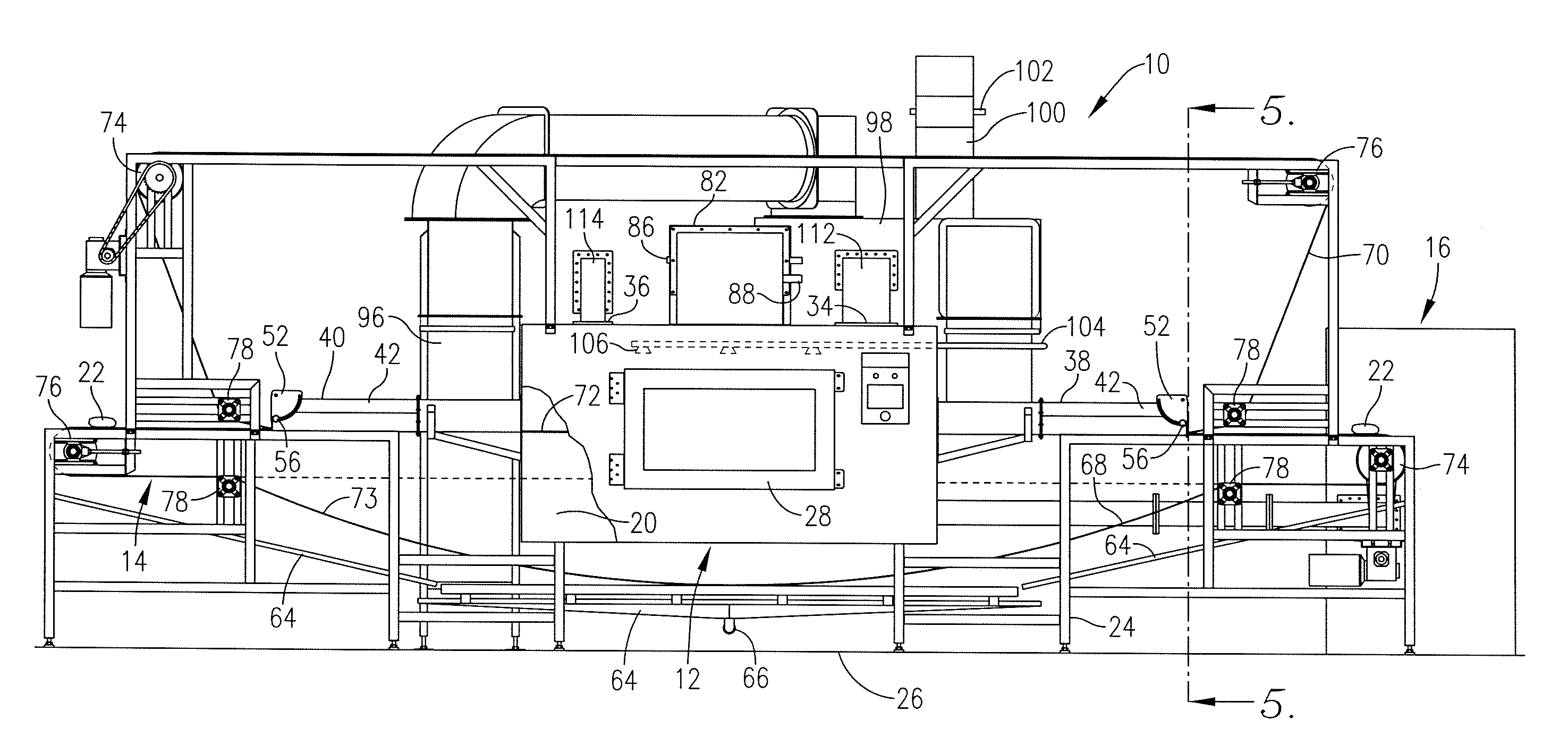

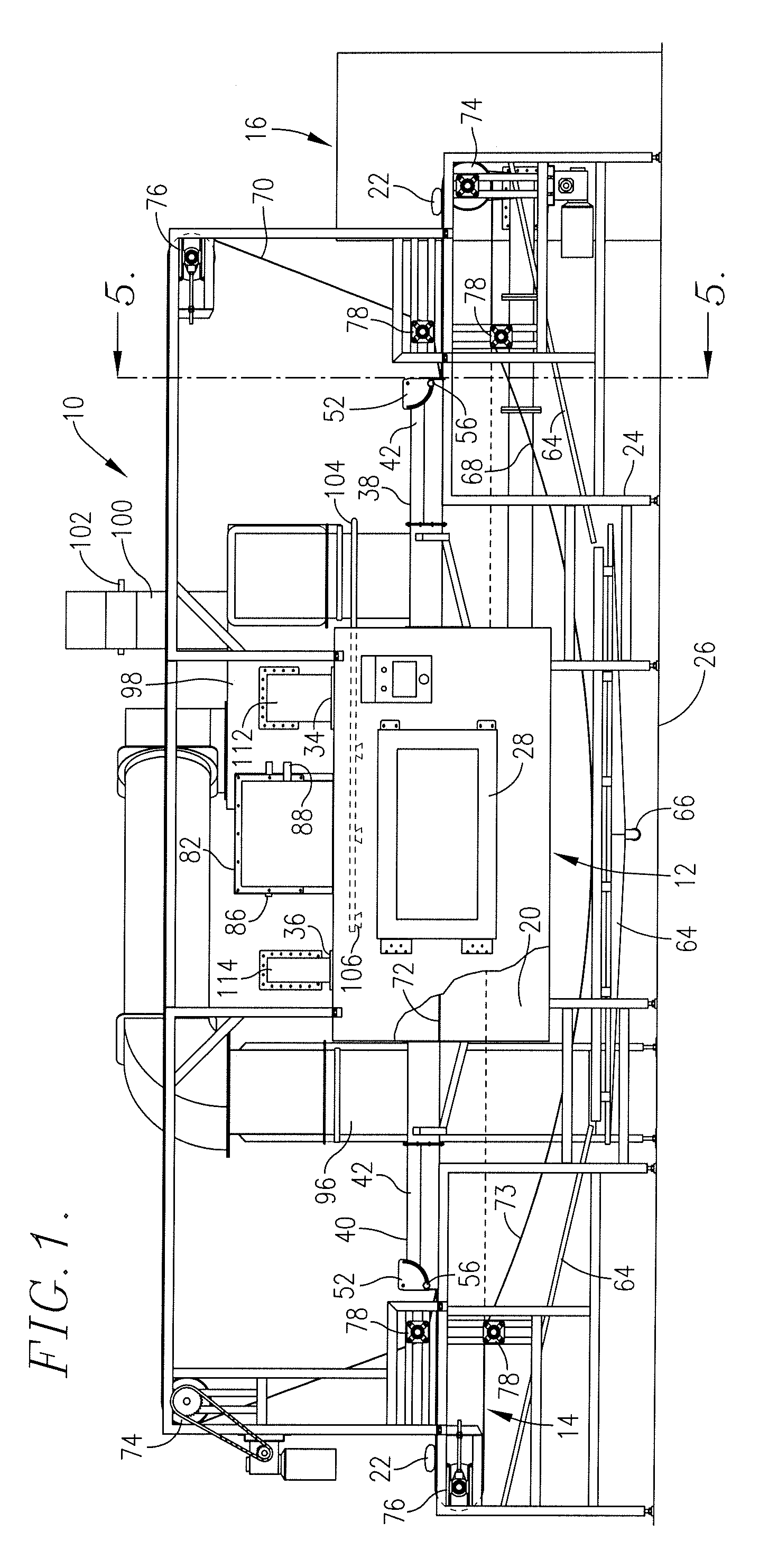

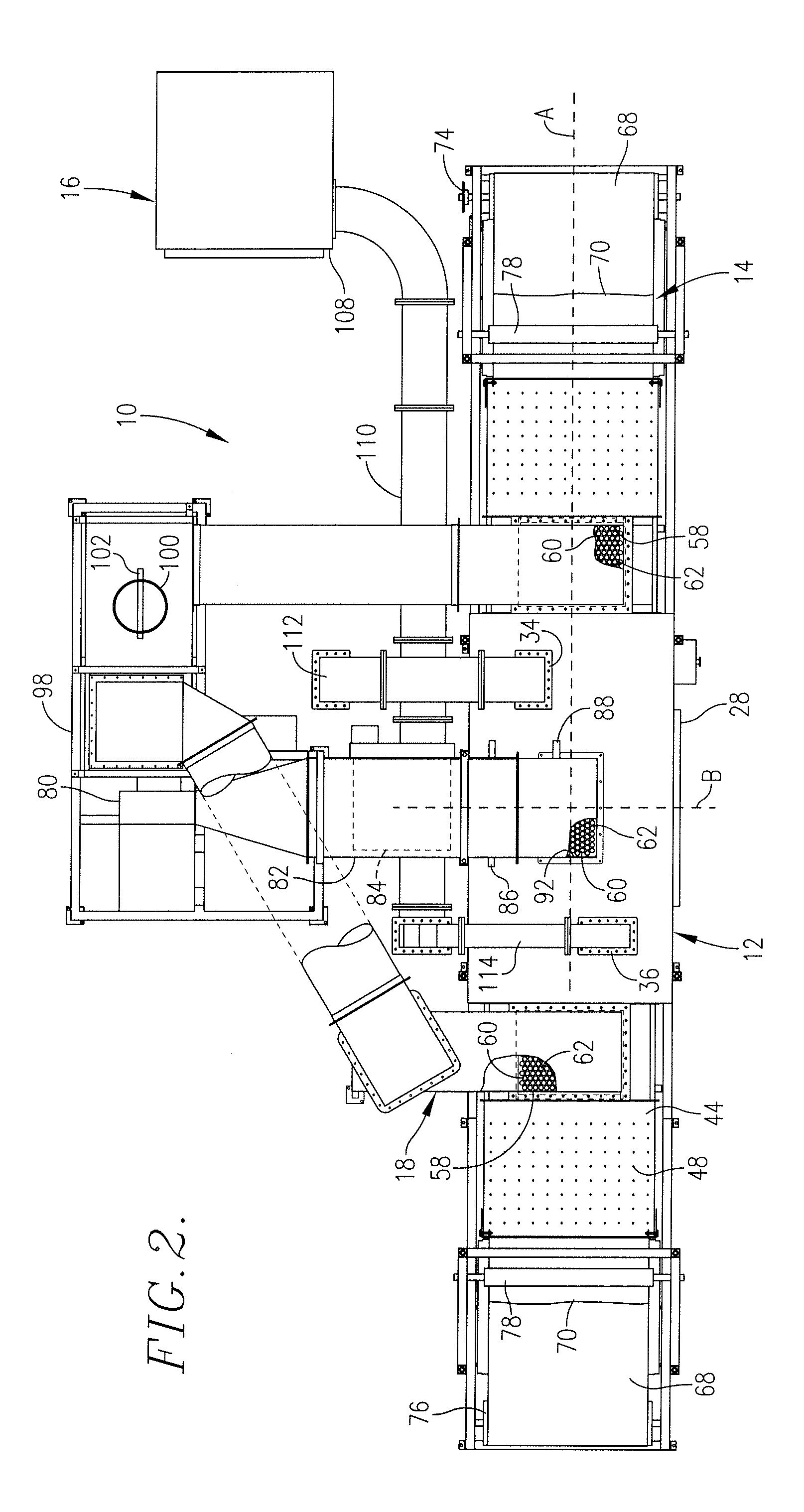

Continuous feed volumetric heating and convection oven

InactiveUS7432483B2Rapid and thorough heatingAdd control functionDrying solid materials with heatHigh-frequency/infra-red heating bakingMicrowaveProcess engineering

A continuous feed volumetric heating and convection oven for heating articles includes an oven body, a conveyor for moving the articles therethrough, a volumetric heating source for delivering microwave or other volumetric heating energy to the oven body, and a ventilation system for delivering a flow of heated air to the oven body. The ventilation system includes a heater and at least one damper associated with an exhaust whereby air may be partially recirculated and partially exhausted from the oven body. Microwave chokes and microwave suppression tunnels are provided for limiting the escape of volumetric heating energy such as microwave energy into the surrounding area and into the ventilation system.

Owner:FLINT HILLS FOODS

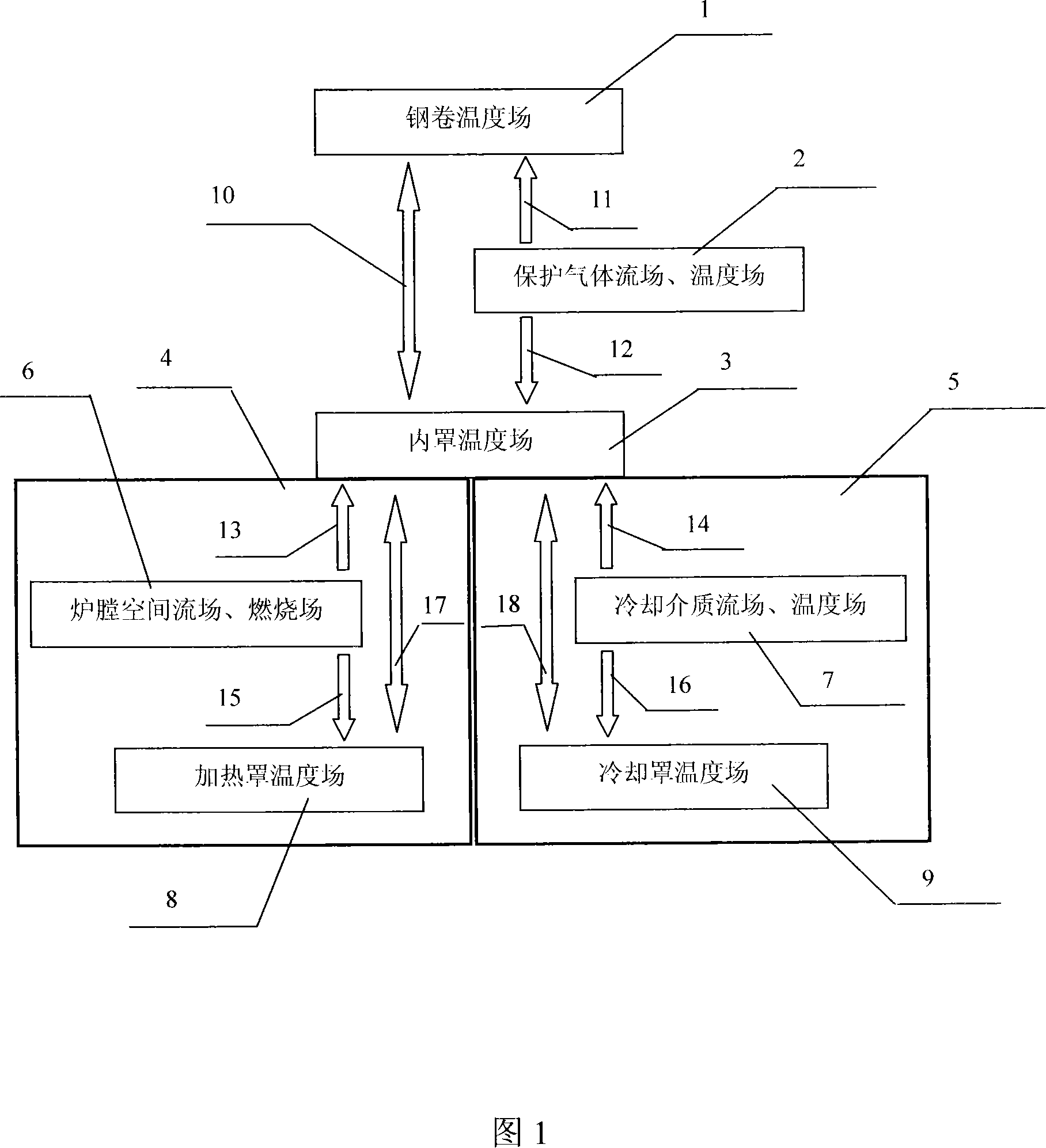

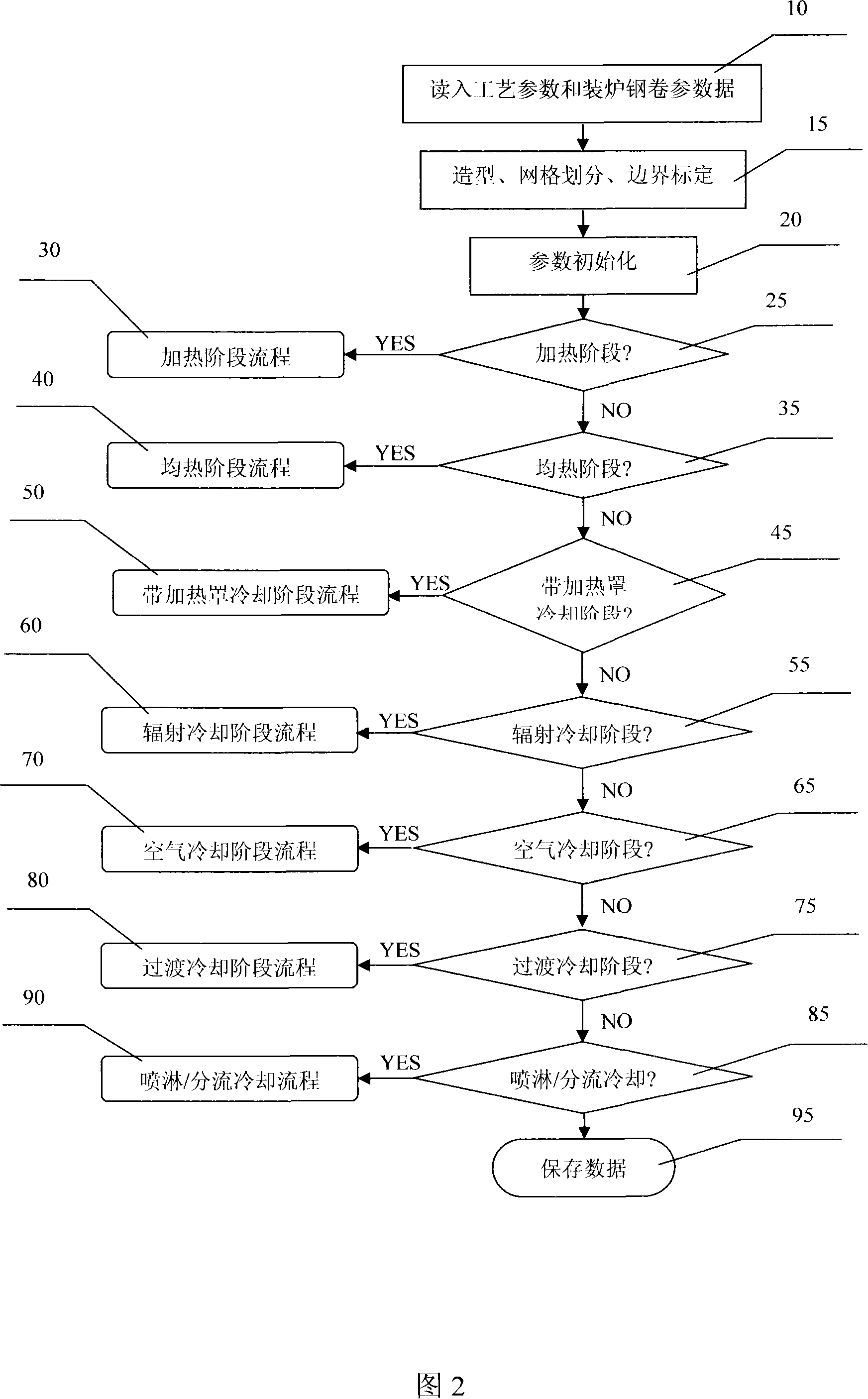

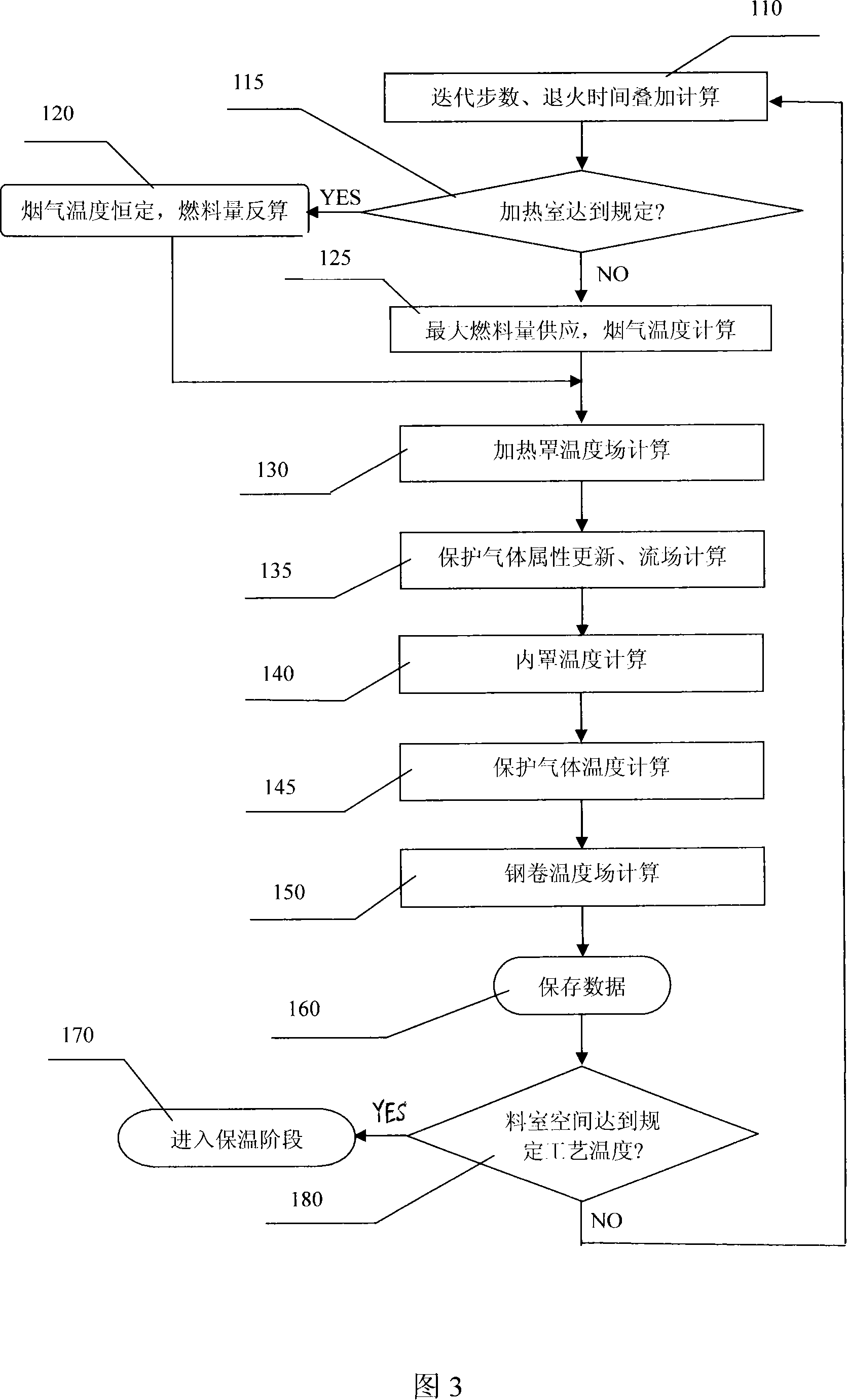

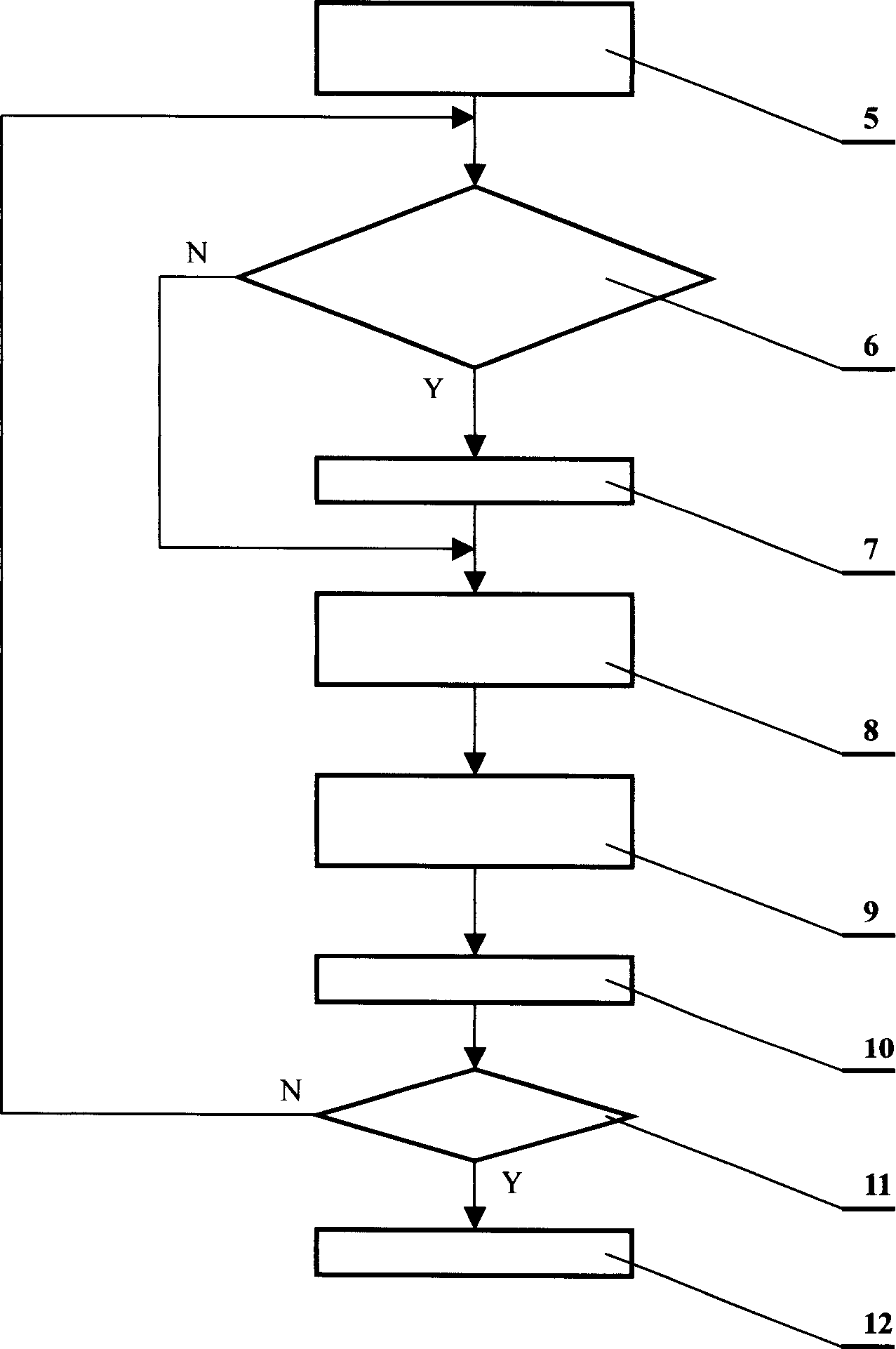

Off-line prediction method for bell-type furnace steel roll annealing process

InactiveCN101139652AImprove the stability of annealing performanceImproving Offline Prediction AccuracyBell type furnacesHeat treatment furnacesShielding gasMaterials science

The invention provides an off-line predicting method for annealing process of a hood type steel coil, which comprises predication at heating phase, soaking phase and cooling phase. The predication at heating phase comprises calculation of smoke temperature, calculation of heating hood temperature, calculation of the updating for protective gas property and flow field, calculation of inner hood temperature, calculation of protective gas temperature, and calculation of steel coil temperature field; the predication at soaking phase comprises calculation of smoke temperature, reverse calculation of fuel volume, calculation of heating hood temperature field, calculation of the updating for protective gas property and flow field, calculation of inner hood temperature, and calculation of steel coil temperature field; the predication at cooling phase comprises calculation of cooling media temperature, calculation of cooling hood temperature, calculation of protective gas physical property and flow field, calculation of inner hood temperature, calculation of protective gas temperature and calculation of steel coil temperature field. The off-line predicting method can give max. role of the producing capability of a coil base.

Owner:武钢集团有限公司

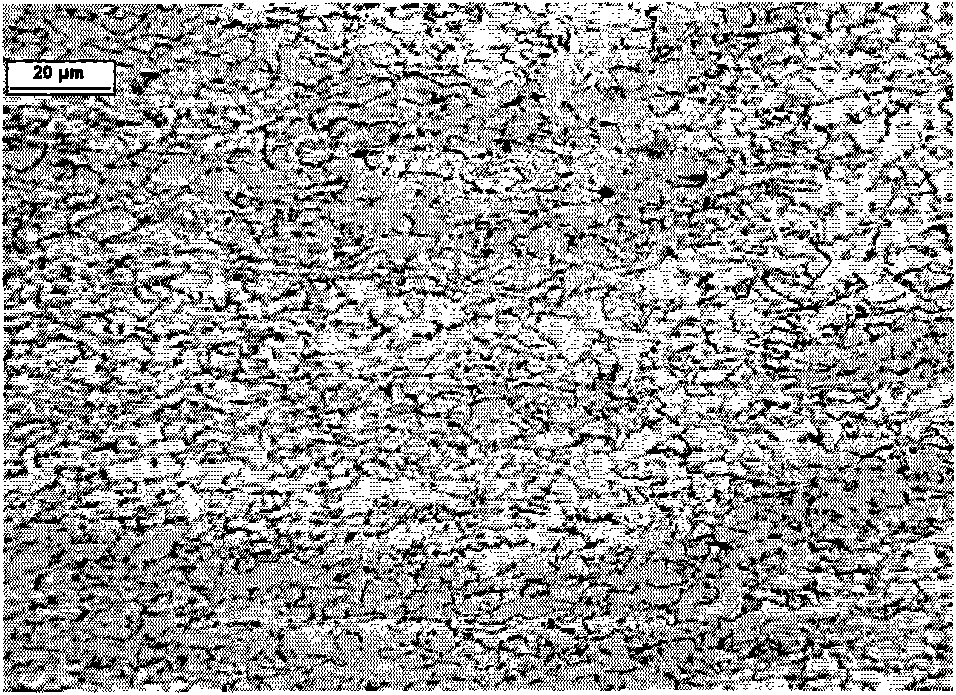

700MPa-grade cold rolled steel plate with high weather resistance and preparation method thereof

InactiveCN102011060AHigh standardAbundant resourcesTemperature control deviceBell type furnacesWeather resistanceChemical composition

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

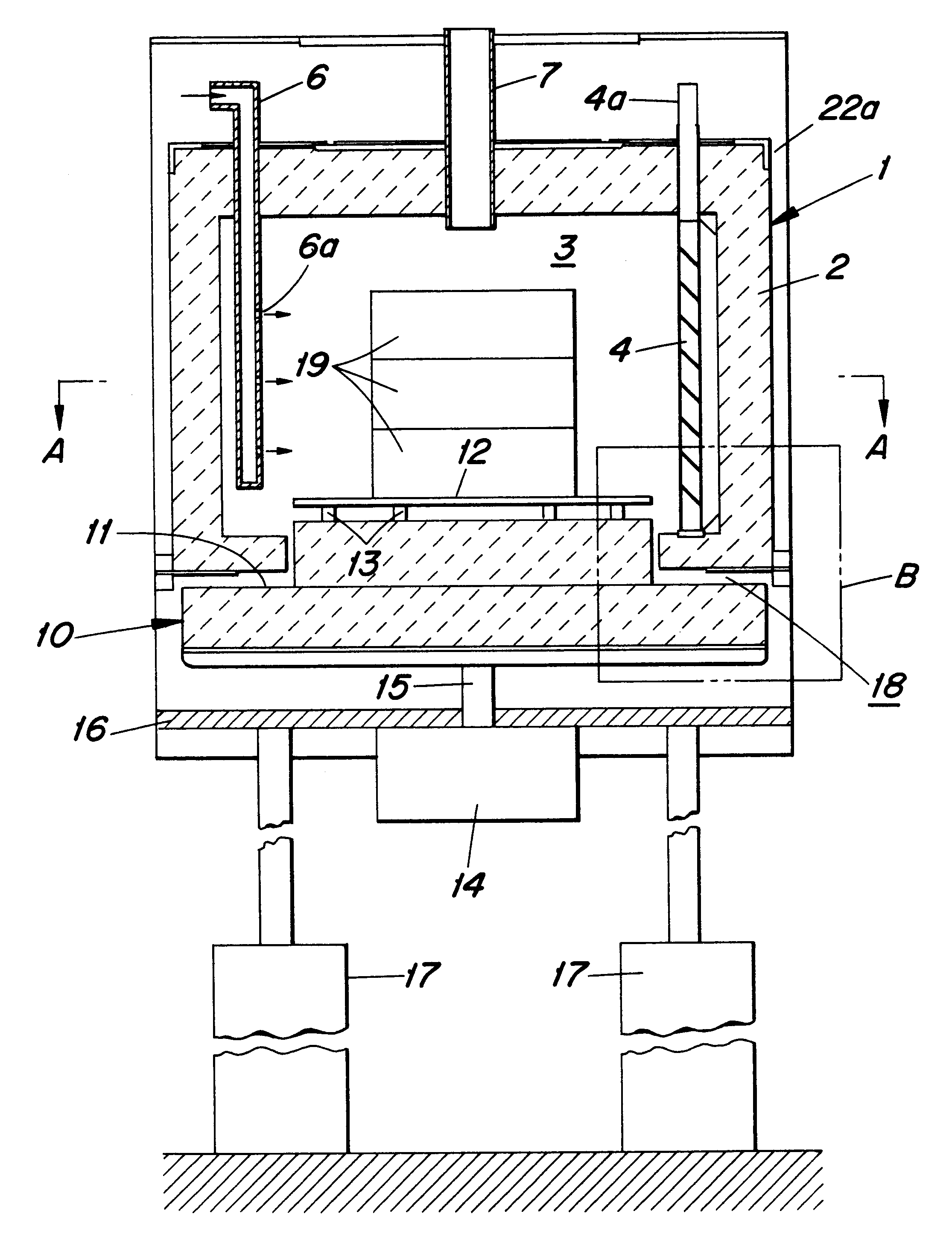

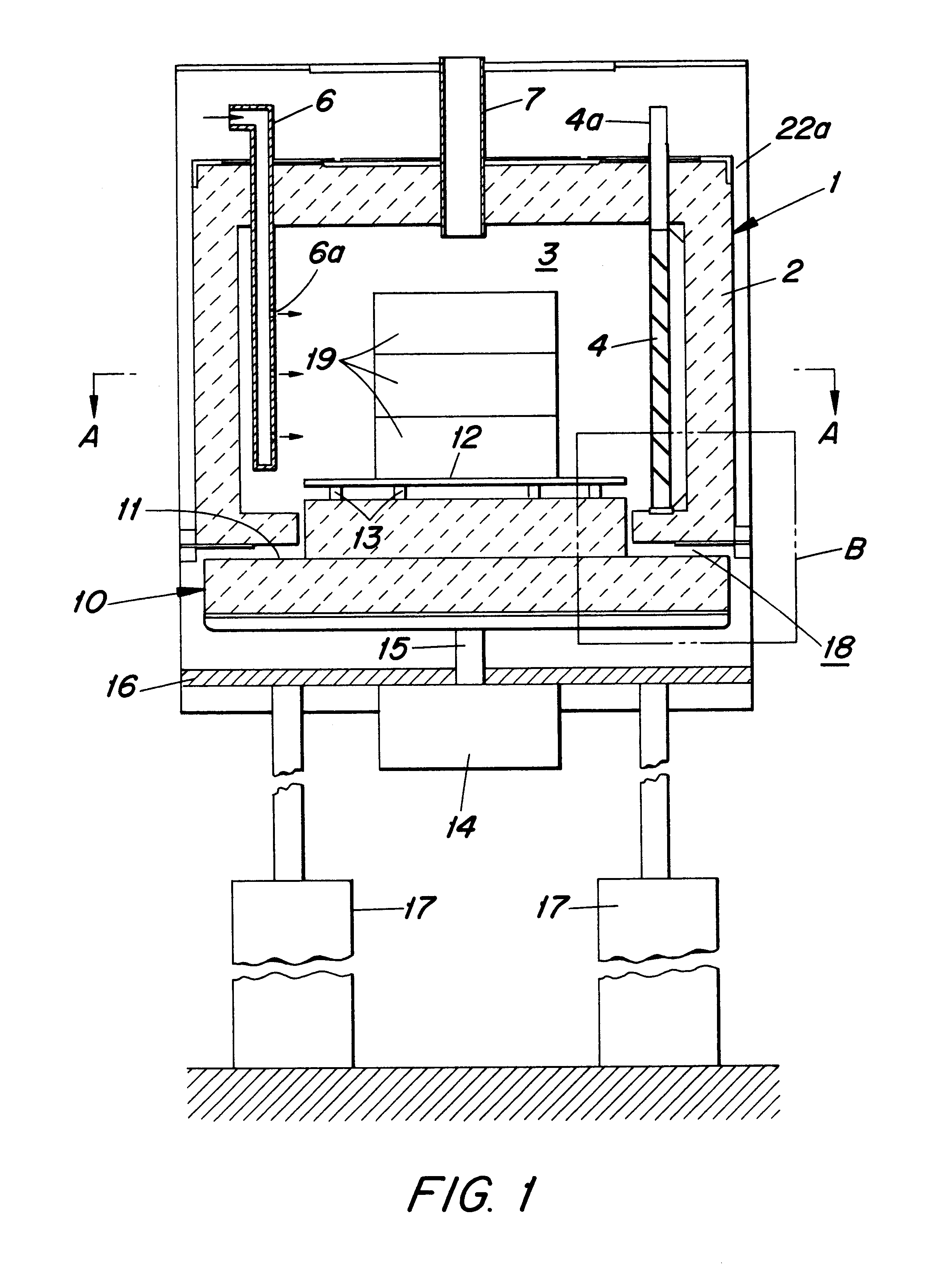

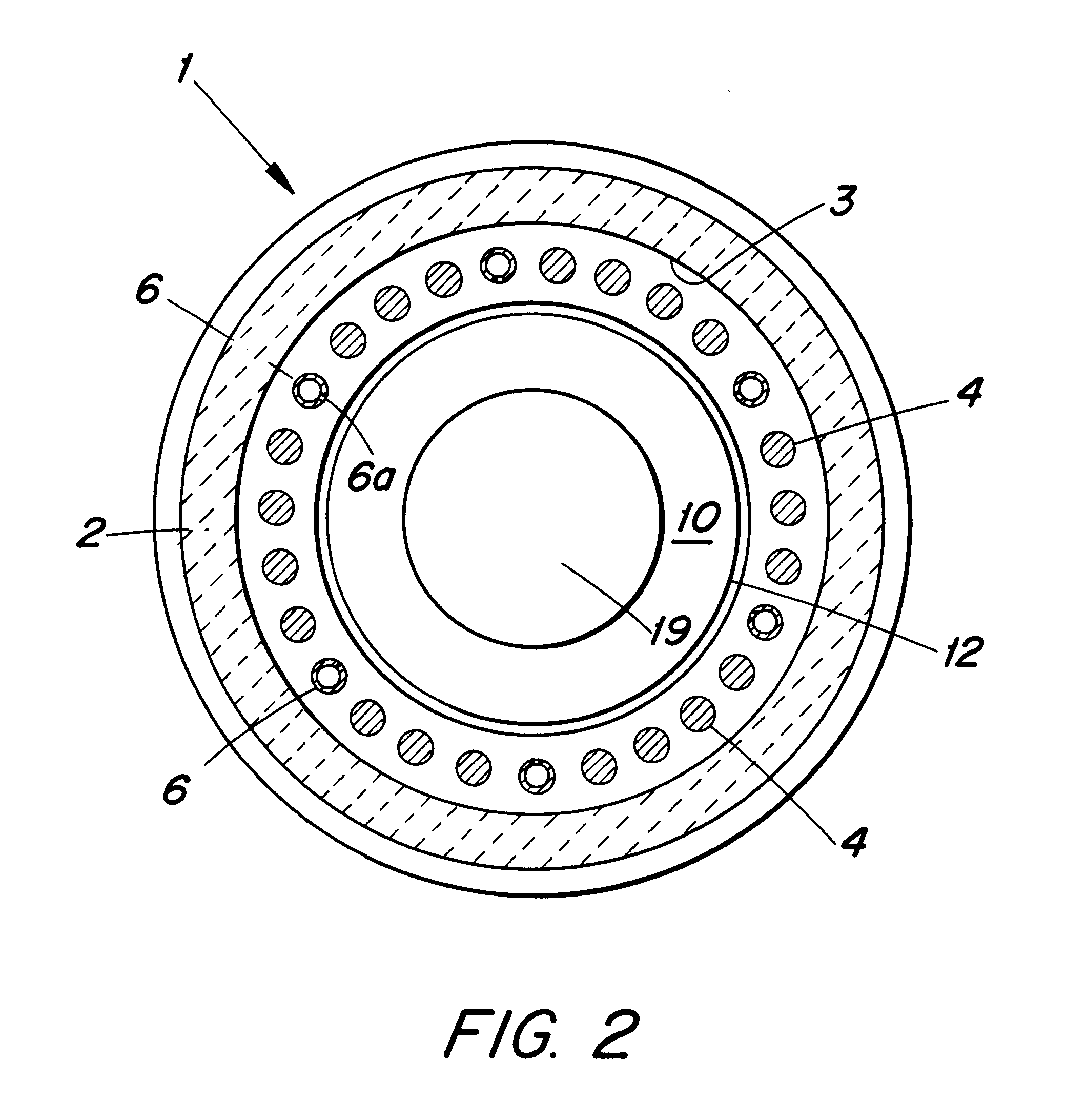

Batch-type kiln

A novel batch-type kiln and a method of use thereof are provided. The kiln comprises a kiln body and a heating chamber disposed within the kiln body, which has a heater disposed therein. A table is disposed at the bottom of the heating chamber, the table having a peripheral portion and an upper surface for supporting an object to be treated. The peripheral portion of the table and a portion of the kiln body define a gap therebetween. This gap forms a gas-introducing path for introducing a gas into the heating chamber. The batch-type kiln is capable of preventing accumulation of a binder component in the gap between the table and the kiln wall.

Owner:MURATA MFG CO LTD

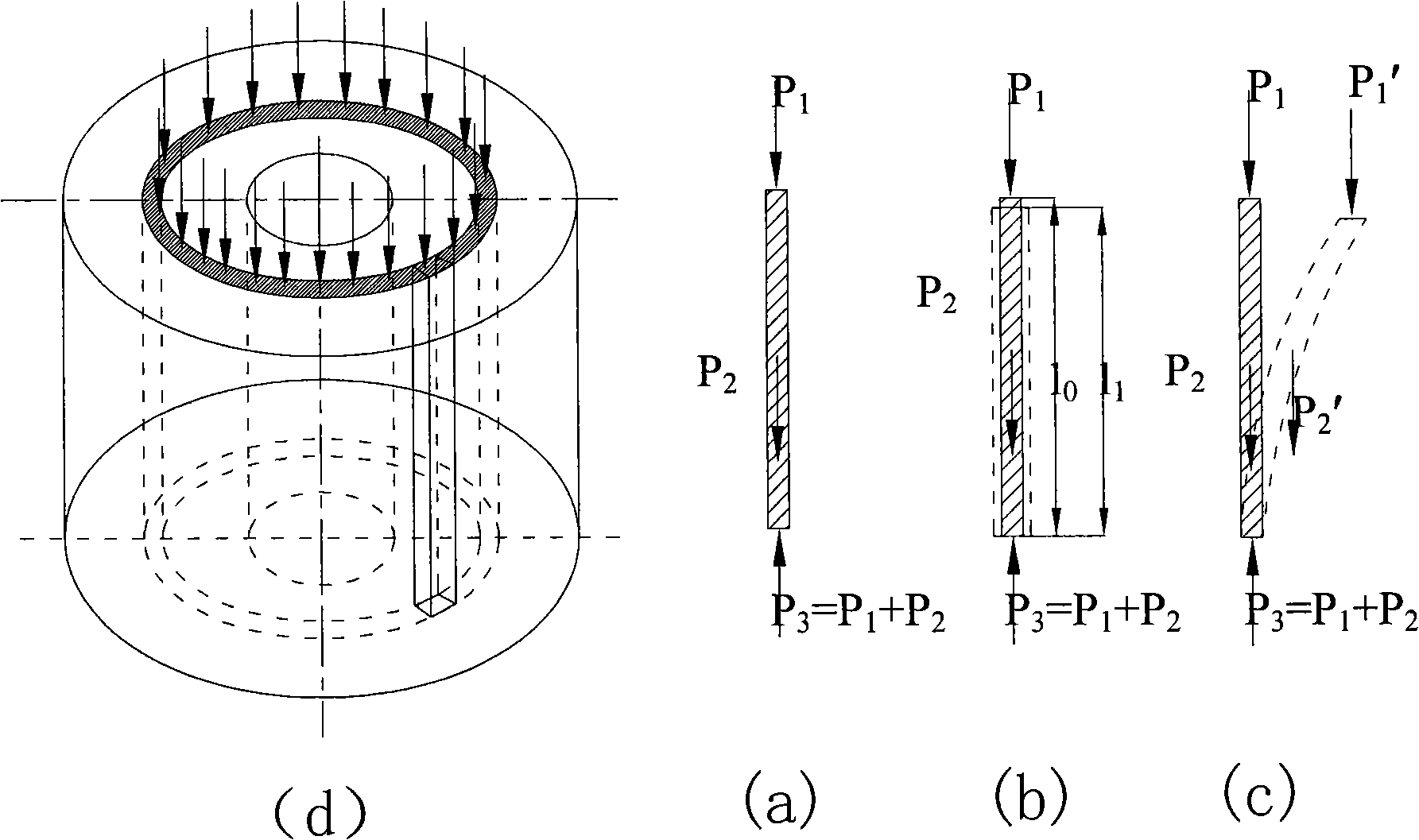

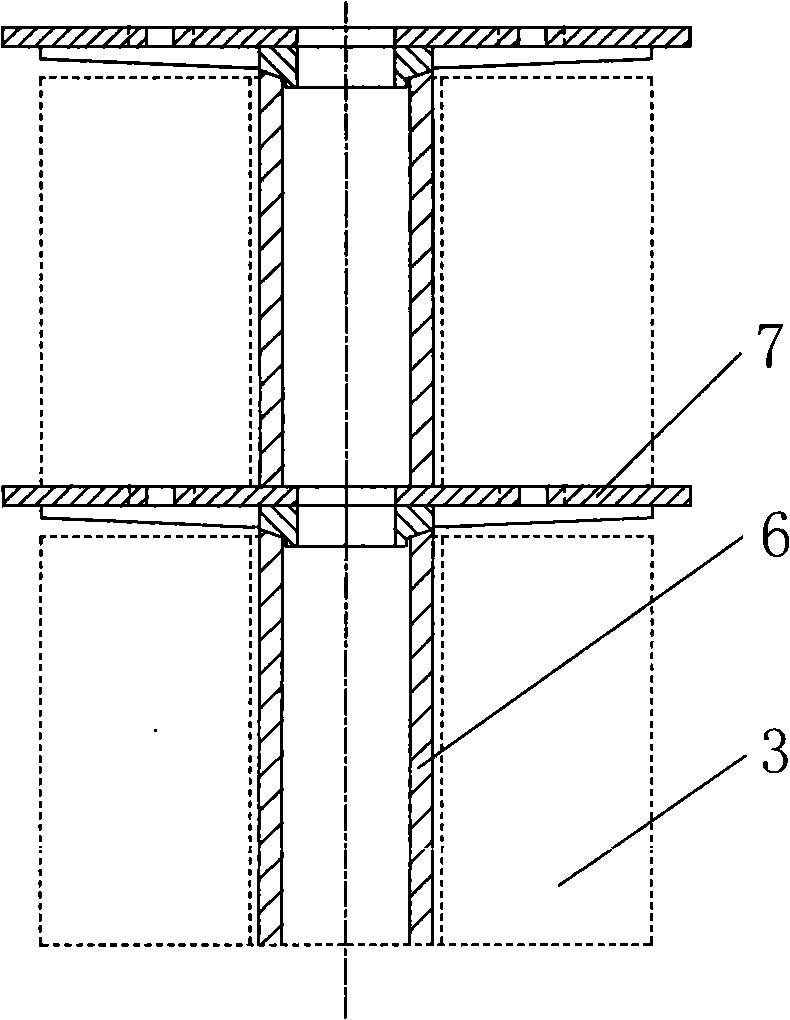

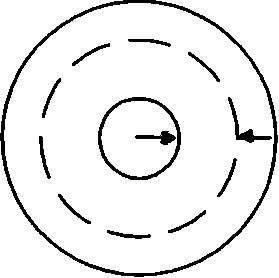

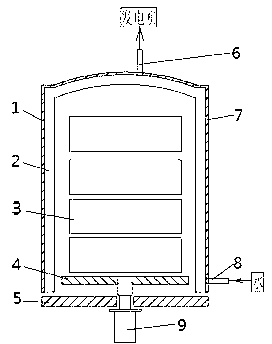

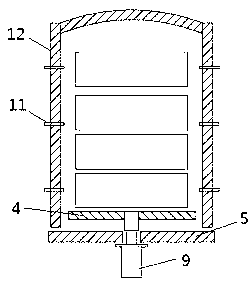

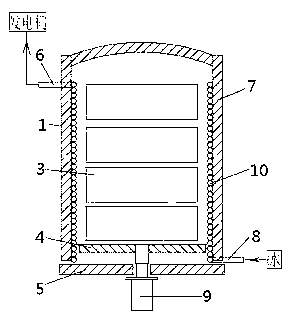

Suspending type convection current clamp method for bell type annealing furnace

InactiveCN101294241AReduce the chance of vertical foldingSolve the problem of vertical compressionBell type furnacesMetallurgyCurrent clamp

The invention relates to a convective stacking method of a hood-type annealing furnace, in particular to a suspended-type convective stacking method used on the hood-type annealing furnace. The method is characterized in that: first, the inner rings of steel strip rolls are attached with sleeves; second, one steel strip roll is stacked on a charging floor of the annealing furnace, a convective plate is arranged above the steel strip roll in an overlapping manner, the bottom of the convective plate is matched with the sleeve in the steel strip roll, the sleeve supports the convective plate, and the upper surface of the steel strip roll is not contacted with the convective plate; third, the steel strip roll is put on the convective plate in an overlapping manner, the lower surface of the steel strip roll is contacted with the convective plate, and the sleeve in the steel strip roll is positioned on the upper part of the convective plate, so that all the steel strip rolls are installed layer upon layer in an overlapping manner. The convective stacking method can lead only the lower surfaces of the relative steel strip rolls to be contacted with the convective plate, and lead the upper surfaces thereof to be not contacted with the convective plate, thereby solving the problem that the lower layer steel strip rolls are pressed lengthways in traditional equipment; therefore, the bonding incidence rate of the lower layer steel strip rolls is greatly reduced, in addition, the lengthways folding occurrence probability of the steel strip rolls is also reduced correspondingly.

Owner:BAOSHAN IRON & STEEL CO LTD

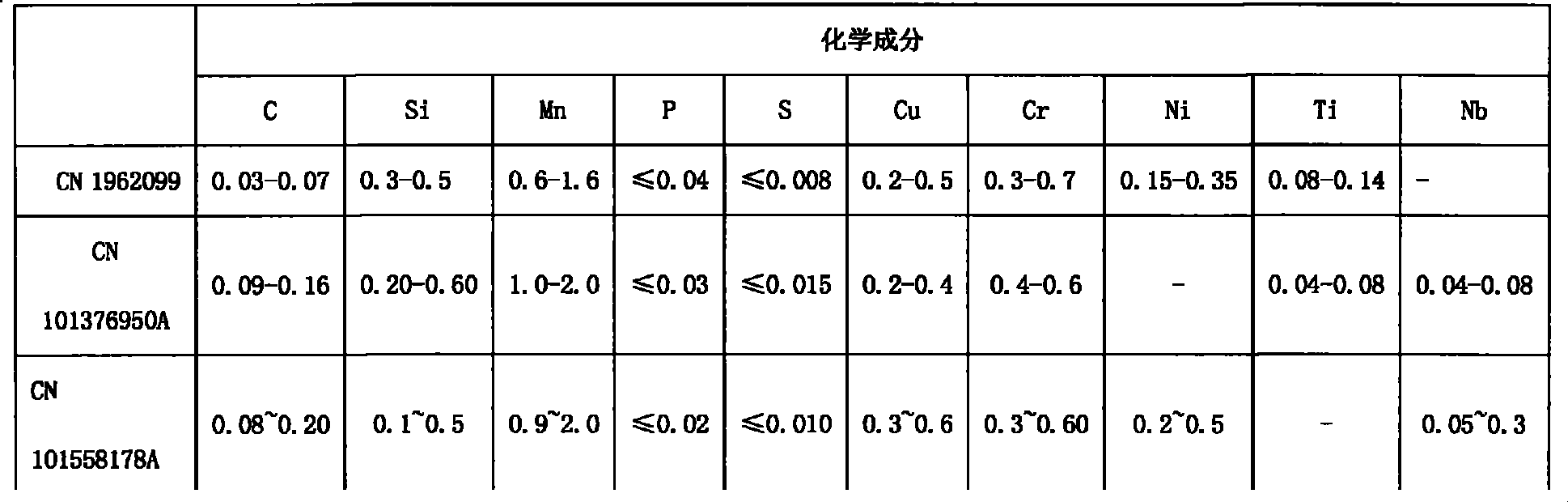

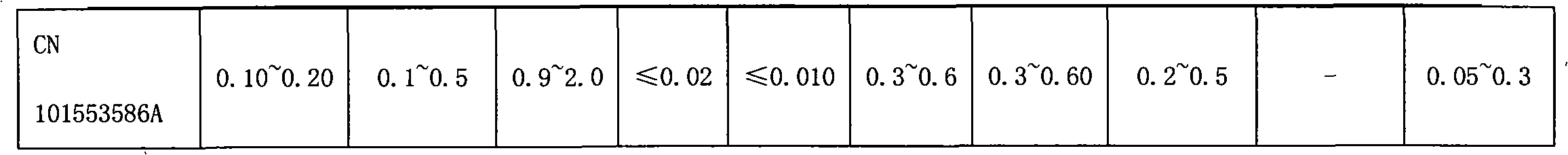

Boron containing steel plate for heat treatment and manufacturing method thereof

ActiveCN102199732AHigh strengthReduce manufacturing costTemperature control deviceBell type furnacesIn vehicleBoron containing

A boron containing steel plate for heat treatment and a manufacturing method thereof. The steel plate comprises 0.15-0.4wt% of C, 0.20-0.60 wt% of Si, 1.00-2.00wt% of Mn, P no more than 0.030wt%, S no more than 0.015wt%, N no more than 0.008wt%, 0.0005-0.005wt% of B, 0.02-0.06wt% of Al, 0.1-0.5wt% of Cr, and 0.01-0.08wt% of Ti, wherein an atomic ratio of Ti to N is 1-50, and others are Fe and inevitable impurities. According to the invention, a contradiction between that steel plate is not easy to be shaped complexly and that a final component intensity is required to be higher than 1000Mpa can be solved. A routine manufacturing process is employed in the invention to produce the steel plate, so that a set does not need to be reconstructed or upgraded, and production costs are low. The steel plate of the invention can be used for manufacturing automobile safety components such as reinforcement rod in vehicle door, back and forth bumpers, and A / B column reinforcements.

Owner:BAOSHAN IRON & STEEL CO LTD

Optimized arrangement method of annealing production for bell-type furnace

InactiveCN1422964AReduce labor intensityImprove accuracyHeat treatment process controlBell type furnacesProduction modelTube furnace

There is a cover annealing production and optimized excluding method in a computer. The method belongs to information technology field, refers to the application of genetic arithmetic and computer simulation in mantle quenched production. The character lies in that the method is made up of genetic arithmetic model and computer simulation quenched production model. The simulation model is used in simulating the whole quenche production process, the genetic arithmetic model optimizes the work scheme, the best scheme can be achieved through the interaction of the two models.

Owner:DALIAN UNIV OF TECH +1

Low-silicon cold rolled precision strip steel for copper-lead bearing steel back and production method thereof

InactiveCN101787484AImprove stamping effectHigh strengthTemperature control deviceManufacturing convertersHigh surfaceMechanical property

The invention discloses low-silicon cold rolled precision strip steel for copper-lead bearing steel back and a production method thereof. The strip steel comprises the following chemical components in percentage by weight: 0.09 to 0.15 percent of C, less than or equal to 0.01 percent of Si, 0.25 to 0.55 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.015 of S, 0.02 to 0.06 percent of Al, and the balance of Fe and inevitable impurities. The production method comprises the steps of molten iron desulfuration, refining in a converter, argon blowing, continuous casting, slab heating, hot continuous rolling, laminar cooling, coiling, acid cleaning, cold rolling, whole hydrogen cover annealing, levelling, finishing and the like. By detecting the comprehensive mechanical property of the strip steel, the strip steel has the advantages of high strength, high hardness, excellent cohesiveness and high surface accuracy; and the method has the advantages of simple production process and low production cost.

Owner:武汉钢铁有限公司

Method for avoiding cold rolled strip bonding and bonding-free hood-type annealing furnace

InactiveCN101250620ASolve the worldwide problem of "bonding"Solve bonding problemsBell type furnacesHeat treatment furnacesTube furnaceTreatment field

Owner:WUHAN IRON & STEEL (GROUP) CORP

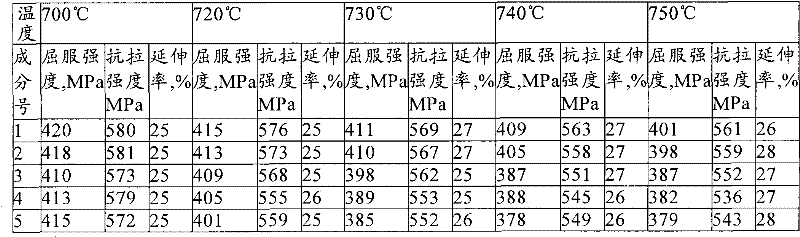

High performance b4003m stainless steel manufacturing method for trucks

ActiveCN102260833AUniform performanceHigh yield strengthRoll mill control devicesBell type furnacesStrip steelTruck

The invention relates to stainless steel for a high-performance B4003M truck. The stainless steel comprises the following components in percentage by mass: 0.010 to 0.015 percent of C, 0.20 to 0.60 percent of Si, 0.80 to 2.5 percent of Mn, 11.0 to 13.0 percent of Cr, less than or equal to 0.040 percent of P, less than or equal to 0.010 percent of S, 0.60 to 1.5 percent of Ni, less than or equal to 0.020 percent of N, less than or equal to 0.20 percent of Cu, less than or equal to 0.0050 percent of O, 0.10 to 0.30 percent of Ti, less than or equal to 0.030 percent of C and N, and the balance of Fe and inevitable impurities. The yield strength of the stainless steel reaches over 350MPa, and the elongation reaches over 25 percent. In the length of the whole strip steel, the performance of the strip steel is very uniform; and the yield of the finished strip steel is improved.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

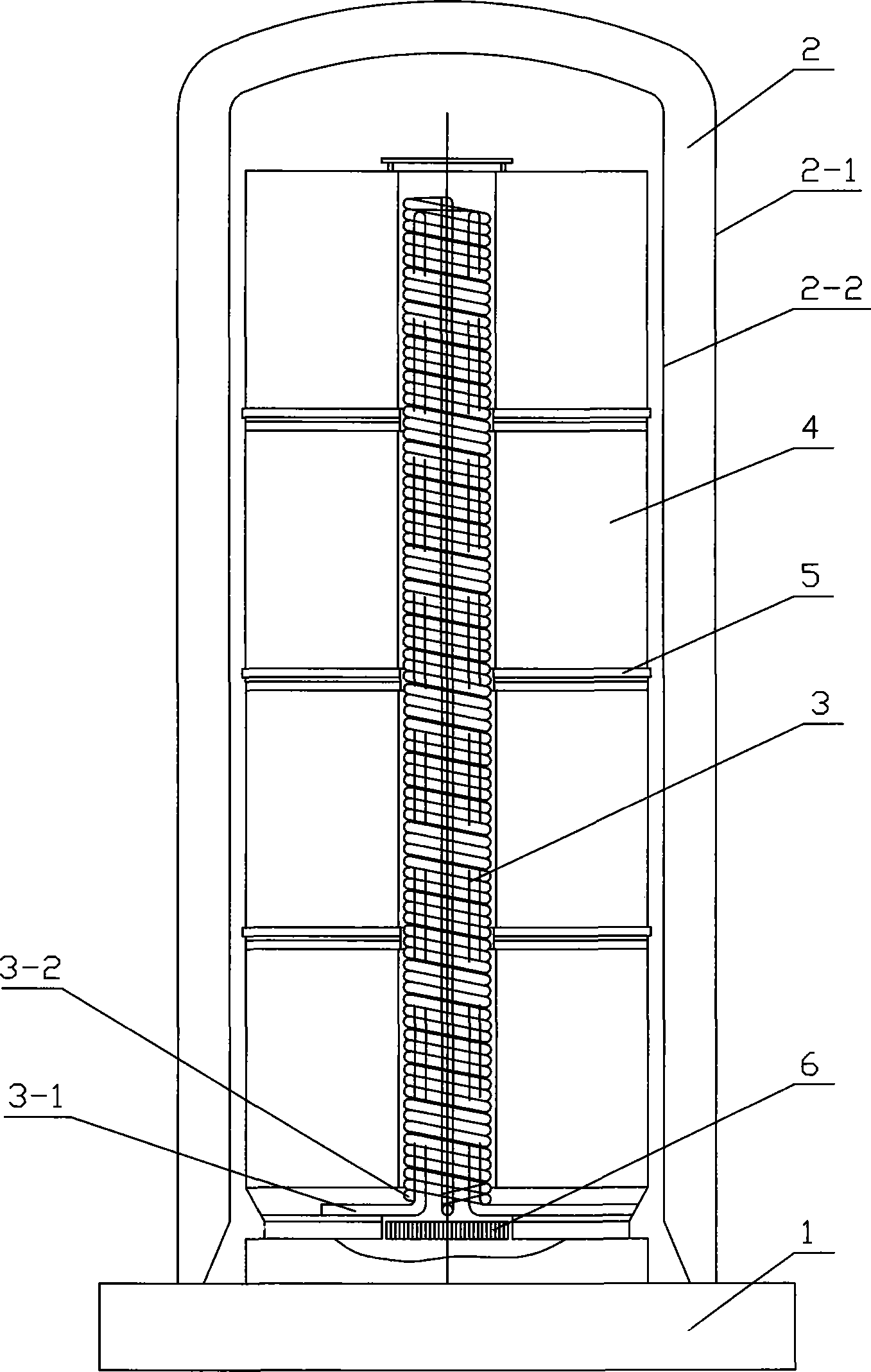

Cover-type furnace generating steam by using waste heat

InactiveCN103233100AImprove protectionSave energyIncreasing energy efficiencyBell type furnacesEngineeringThermal treatment

The invention relates to a cover-type furnace generating steam by using waste heat. The bell-type furnace generating steam by using waste heat comprises a furnace platform, a stock supporting plate, a heating cover and a cooling cover, wherein the stock supporting plate is located above the furnace platform; a circulating fan device is arranged at the lower part of the furnace platform; the heating cover is provided with a heating nozzle; the heating nozzle is connected with gas and air pipelines; the cooling cover is provided with a steam generator; the steam generator consists of a heating jacket and a steam coil pipe; the steam generator is provided with a water inlet and a steam outlet; the water inlet is located at the lower part of the steam generator; the steam outlet is located at the upper part of the steam generator; the water inlet is connected with a water pipeline; and the steam outlet is connected with a steam pipe net. By additionally mounting the steam generator on the inner wall and the top of the cooling cover, the steam is generated by using the heat radiated in the cooling process after thermally treating steel billets, incorporated into the steam pipe network and used for generating via a generator or other purposes, so that the cover-type furnace generating steam by using waste heat has the advantages of making full use of the waste heat in the thermal treatment on the steels, saving energy, reducing thermal treatment production cost and being good for environment protection.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Cold-rolling production process of high-carbon steel

ActiveCN111054746AExtended service lifeSpheroidizing annealing reducesRoll mill control devicesBell type furnacesCarbon steelPickling

The invention discloses a cold-rolling production process of high-carbon steel. The cold-rolling production process comprises the following steps of pickling, first annealing, first calendering, second annealing, second calendering, third annealing, finishing and warehousing of finished products. According to the cold-rolling production process, the first annealing temperature after pickling is reduced, so that production is carried out in a conventional annealing furnace, the production cost is lower, the service life of the production equipment is prolonged, and the produced products have excellent performance.

Owner:佛山市高明基业冷轧钢板有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com