Plasma reaction furnace for processing waste

A plasma and waste disposal technology, applied in furnaces, incinerators, furnace types, etc., can solve problems such as unseen waste, achieve the effect of simple and convenient treatment process, reduced cost investment, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

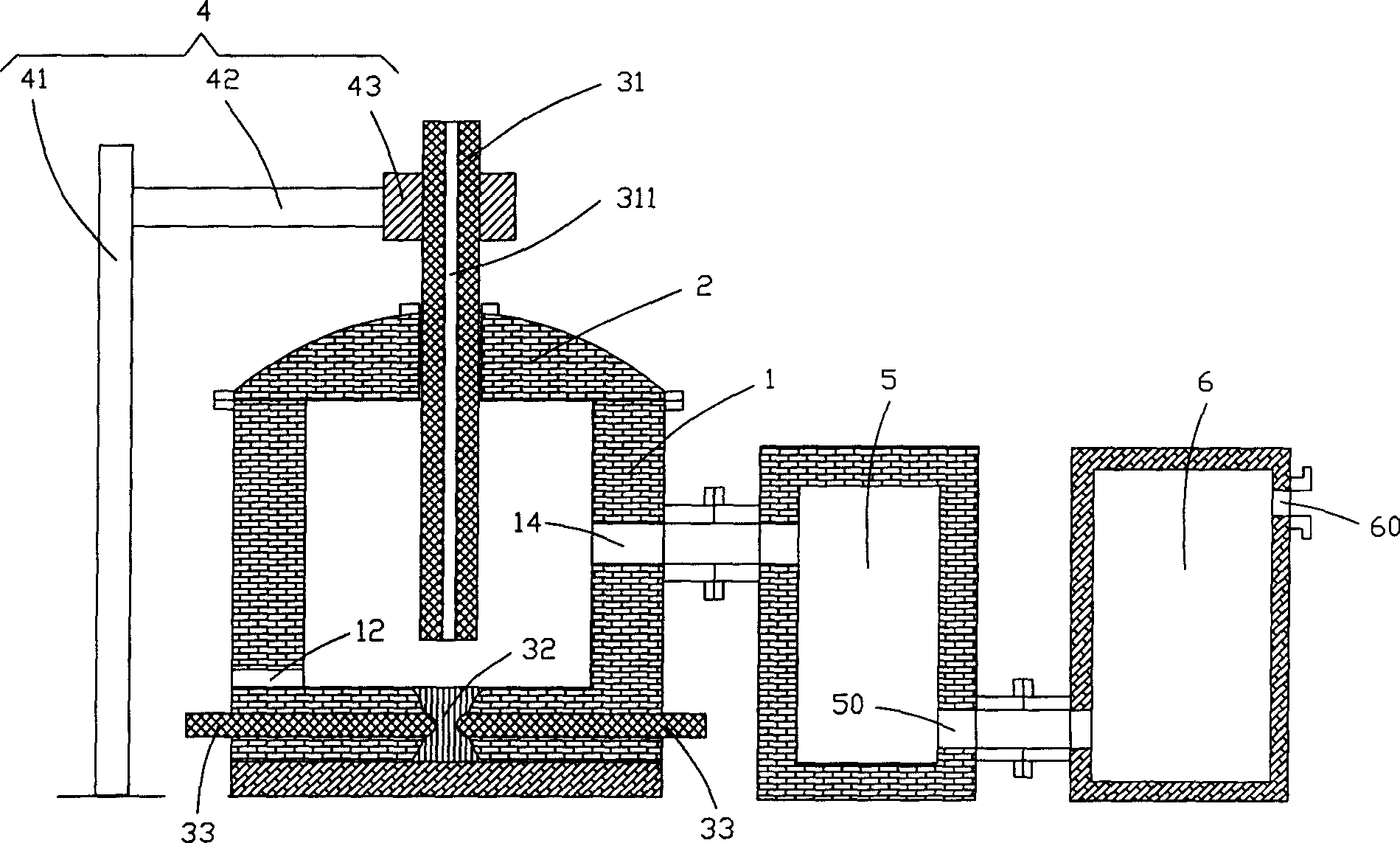

[0026] Such as figure 1 As shown, the present invention provides a plasma reaction furnace for waste disposal, which includes a furnace body 1 , a furnace cover 2 , electrodes, a bracket 4 , a continuous reaction chamber 5 and a quenching device 6 .

[0027] Wherein, the inner side of the furnace body 1 is provided with a refractory material lining and a thermal insulation layer, a melt discharge port 12 is provided on the side of the furnace bottom of the furnace body 1, and a furnace wall for high temperature pyrolysis is provided on the furnace wall of the furnace body 1. Gas outlet 14 for gas discharge.

[0028] The center of the furnace cover 2 is provided with a hollow graphite electrode 31 extending into the interior of the furnace body 1. The interior of the hollow graphite electrode 31 has a passage 311 that runs through the entire hollow graphite electrode 31 for the waste to be treated to be transported into the interior of the furnace body 1; 1 is also provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com