Patents

Literature

429results about How to "Will not oxidize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of graft copolymerization carboxylate high-performance dehydragent

InactiveCN101041570ANo pollution in the processLow conversion rate of esterificationNitrogen gasAqueous solution

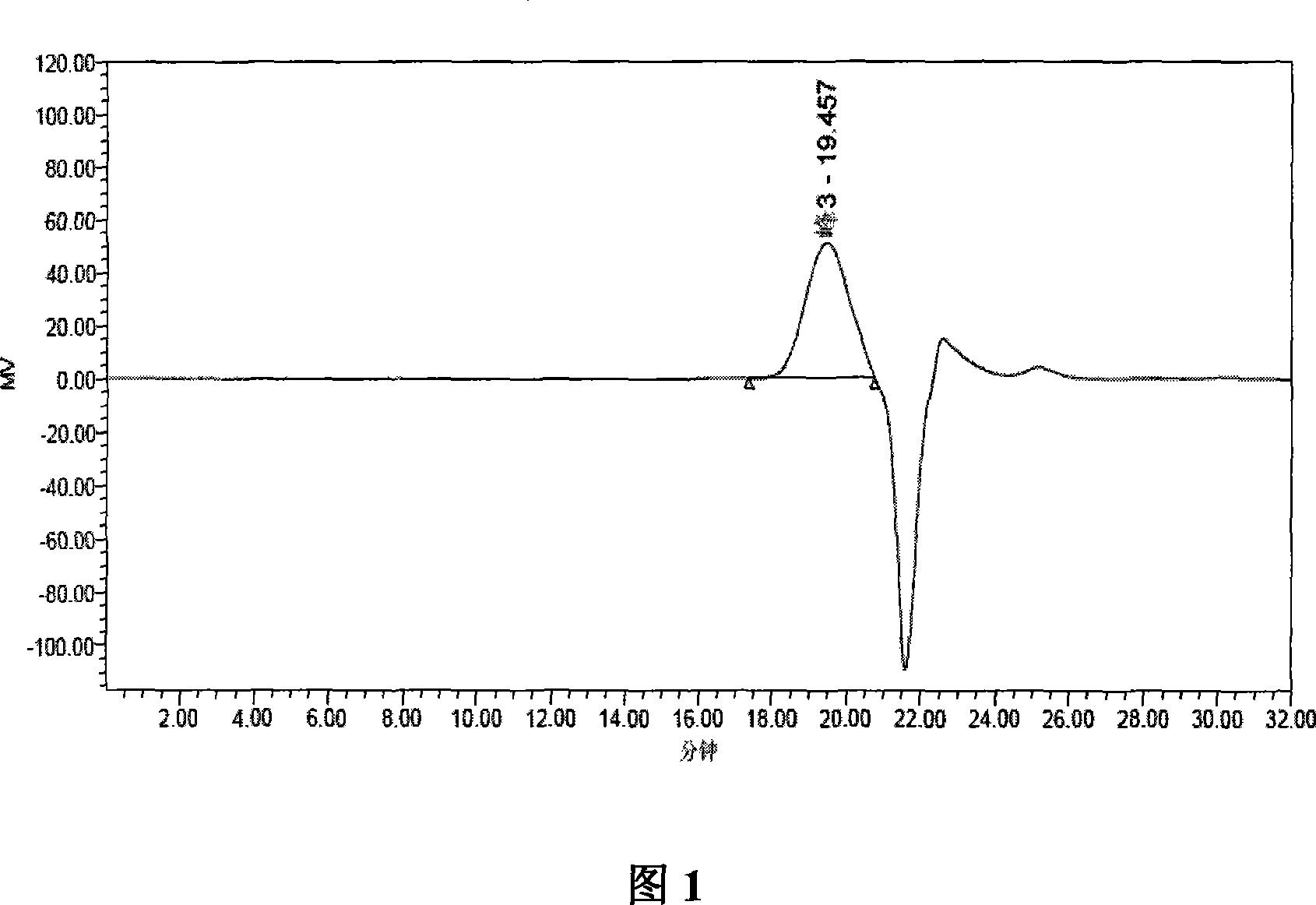

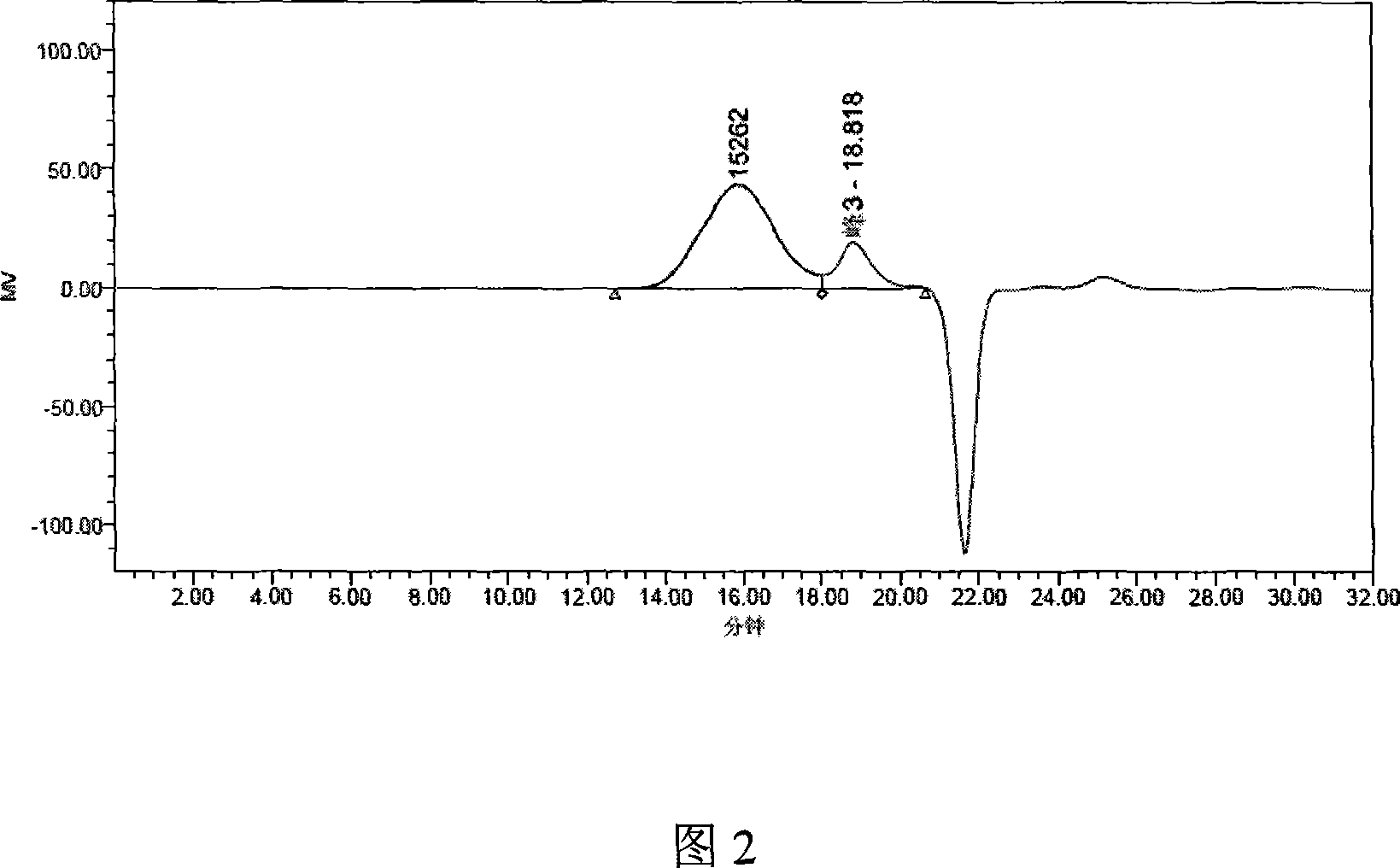

The invention discloses a preparing method of graft copolymerization carboxylate high-performance dehydragent belonging to dehydragent domain, which comprises the following steps: choosing methoxy carbowax with molecular weight distributing between 1000-2000 and acroleic acid or methacrylic acid as main raw material; adopting total acid method esterified priority method; preparing intermediate (big monomer) with polymerization activity; adding third monomer into polymerization reaction; adjusting polymerization activity of copolymerization system; proceeding technique route synthesis of main chain polymerization in the water solution. The getting big monomer possesses merits of high conversion rate, short reacting time, simple process flow and strong controlling property.

Owner:BEIJING UNIV OF TECH

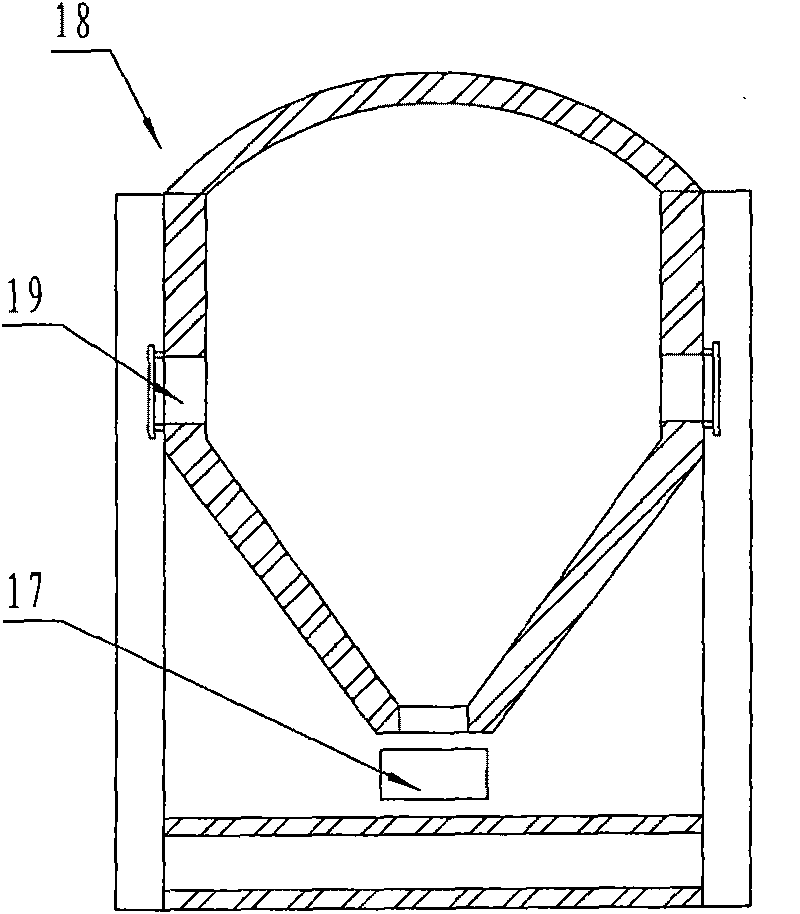

Process and device for processing liquid steel slag

ActiveCN101691620AImprove economic efficiencyReduce dust pollutionRecycling and recovery technologiesProcess efficiency improvementSlagLiquid steel

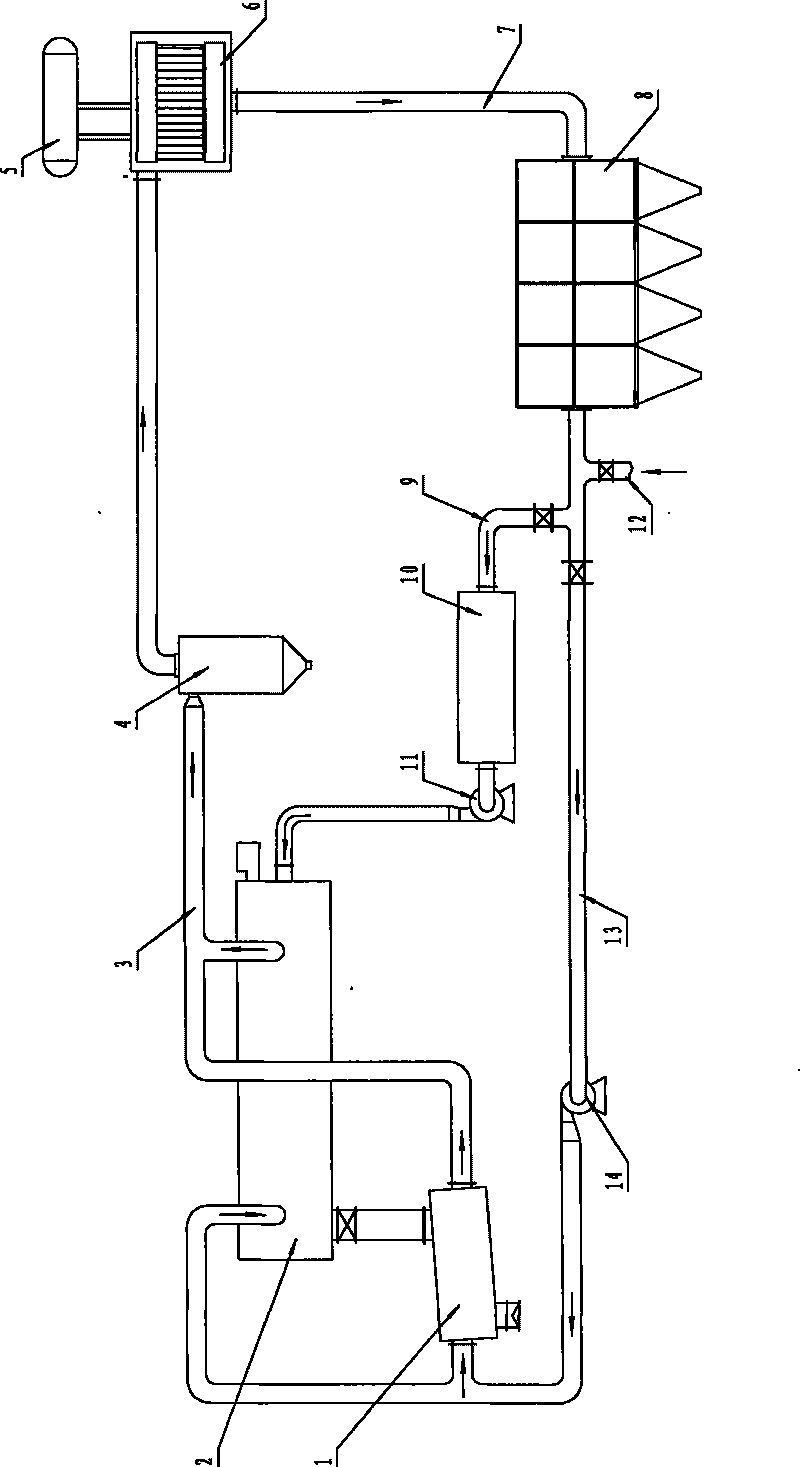

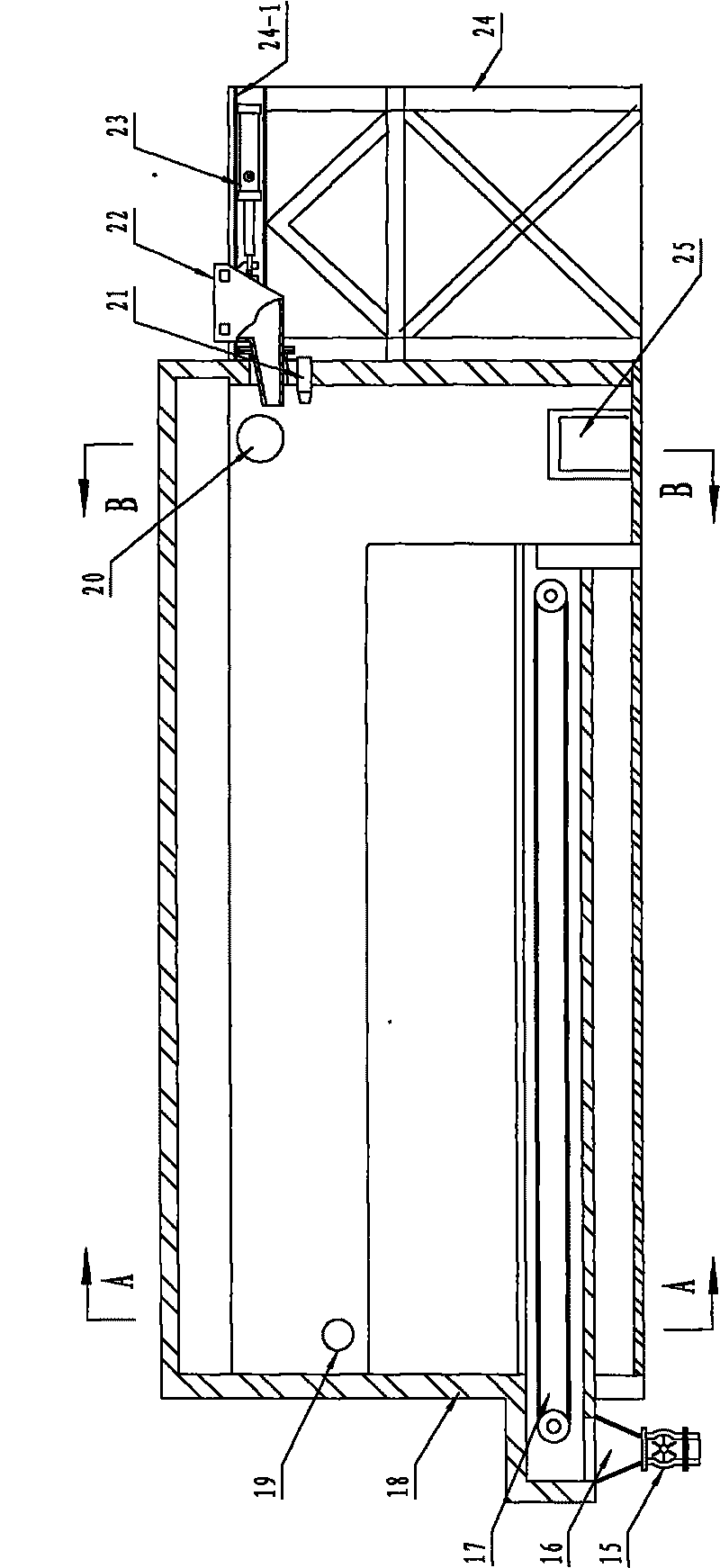

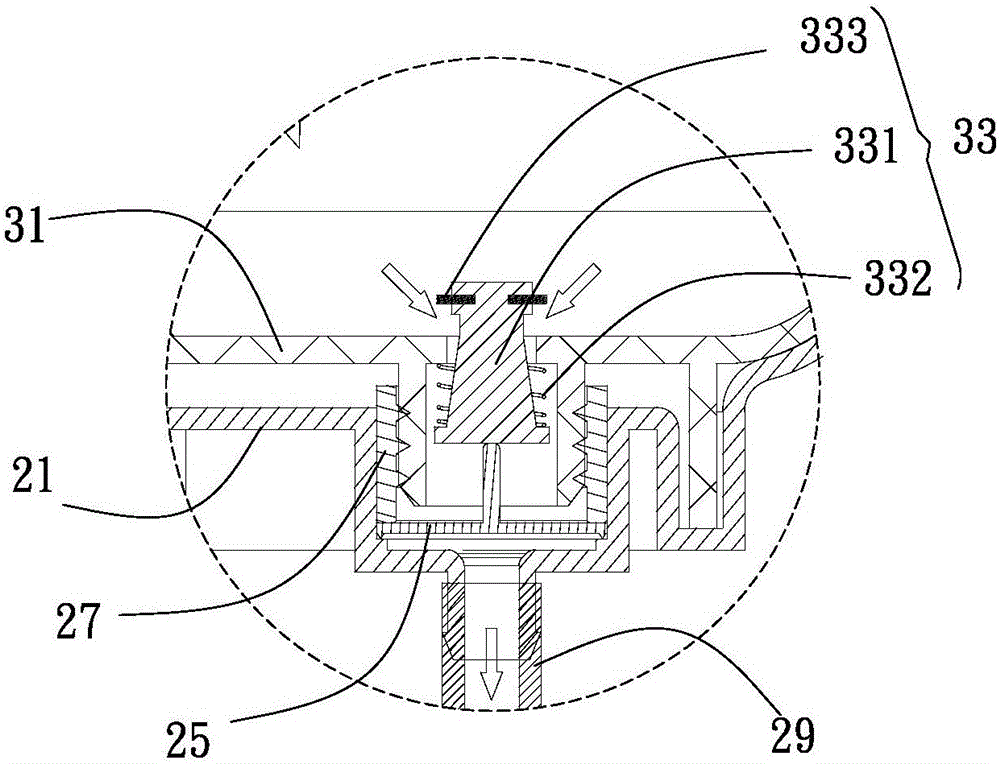

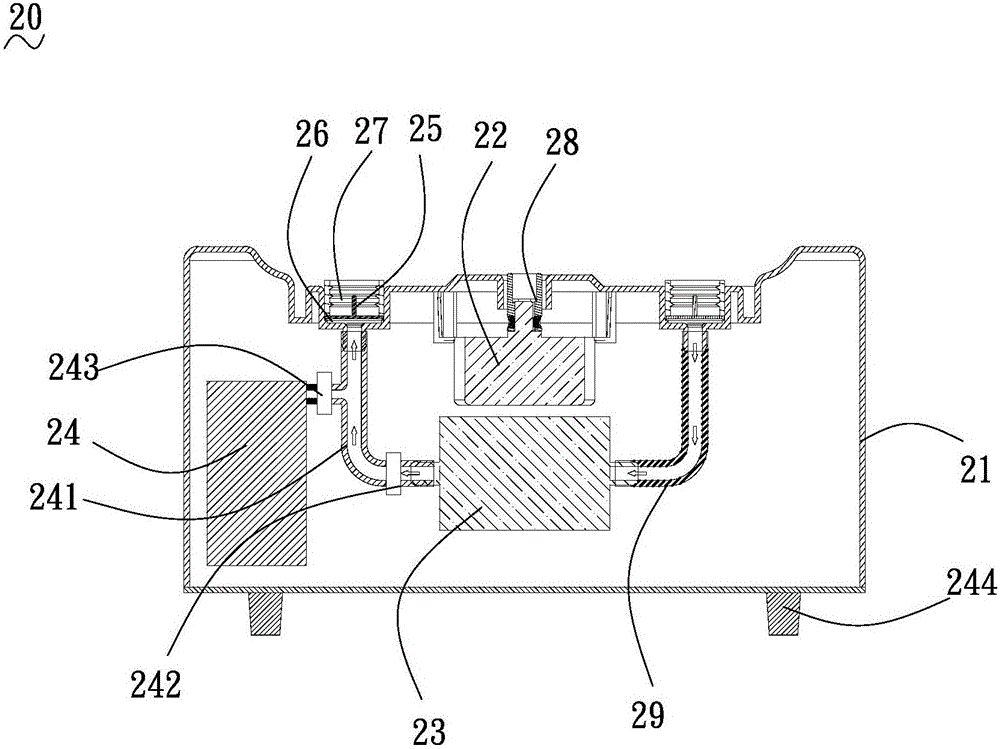

The invention provides a process and device for processing liquid steel slag, belonging to the technical field of the metallurgical equipment and aiming at solving the problems of liquid steel slag granulation and liquid steel slag sensible heat recovery. The process for processing the liquid steel slag comprises the following steps: a, granulating the liquid steel slag by quenching gas; b, cooling the high-temperature liquid solid steel slag; c, recovering liquid steel slag sensible heat; and d, reusing cooling gas. The invention also provides a device for processing liquid steel slag. The invention is mainly characterized in that firstly, the liquid steel slag is granulated in a sealed granulating tank, the liquid steel slag is small and uniform, the pure Fe in the liquid steel slag can not be oxidized and the economic benefit of the liquid steel slag processing process is improved; secondly, the liquid solid steel slag is cooled in a sealed cooling tank, less cooling gas leaks, the dust pollution is reduced, and less cooling gas is supplemented; and thirdly, the inert gas is used as the cooling gas in the granulating tank and the cooling tank, and the cooling gas inversely exchanges heat with the liquid steel slag, thus the efficiency of exchanging heat between the liquid steel slag and the cooling gas is improved, the temperature of the cooling gas at the outlet is increased, and the liquid steel slag sensible heat is recovered.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Preparation method of titanium-steel single-sided composite board

ActiveCN102773254AReasonable process designLow requirements for welding conditionsMetal rolling arrangementsLayer removalTechnical design

The invention discloses a preparation method of a titanium-steel single-sided composite board, comprising the following processing steps of: (1) respectively selecting two titanium plates with same size and two steel plates with same size and carrying out rust and oxide layer removal treatment on the surfaces of the plates; (2) assembling to form multiple layers of symmetrical combined blank sequentially including a steel plate, a transition layer, a titanium plate, a parting agent, a titanium plate, a transition layer and a steel plate, wherein a gap exists between the periphery of the titanium plate and a barrier strip in the combined blank; (3) compressing the combined blank and respectively welding the barrier strip with a first steel plate and a second steel plate to form a closed cavity among the first steel plate, the second steel plate and the barrier strip, drilling holes in the barrier strip and welding a steel tube in the holes, and communicating the steel tube and the closed cavity; (4) conveying the combined blank into a heating furnace to heat and vacuumizing; (5) sealing the outer end of the steel tube and then conveying the combined blank into a rolling mill; and (6) cutting the combined blank after rolling to obtain the titanium-steel single-sided composite board. The preparation method disclosed by the invention is rational in technical design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

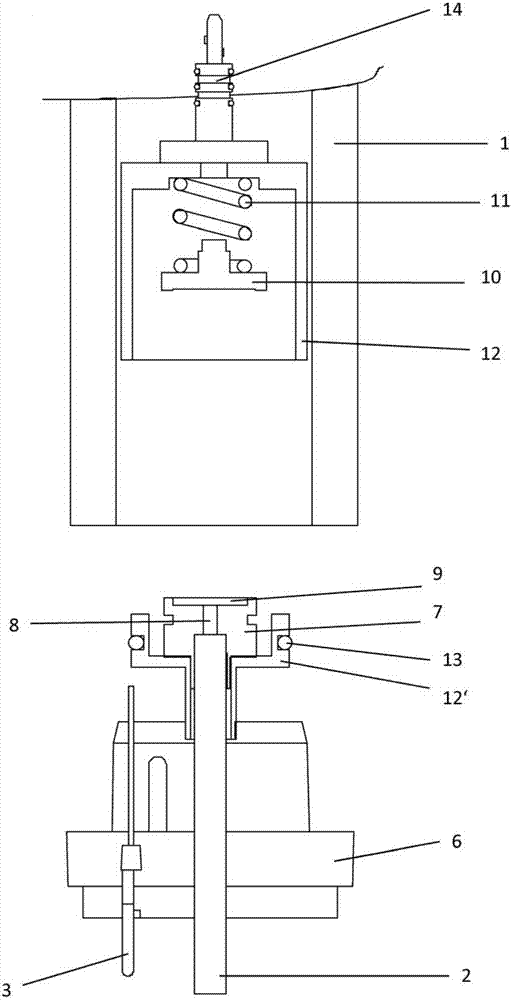

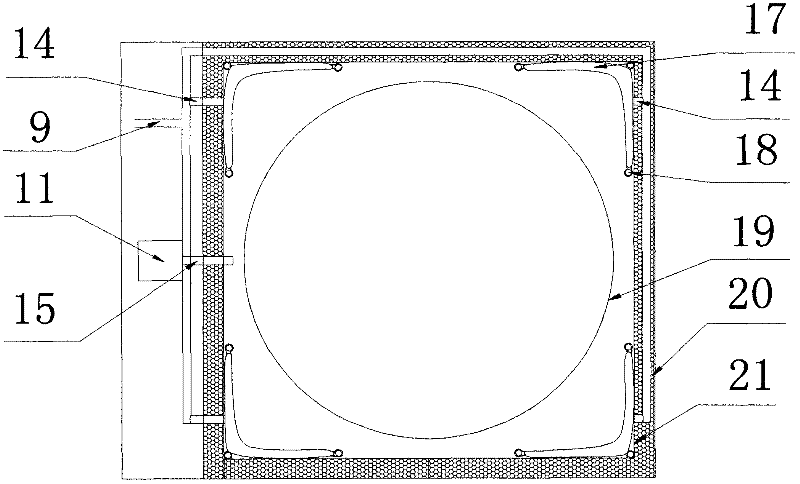

Plasma reaction furnace for processing waste

InactiveCN1825042AIncrease profitImprove processing efficiencyIncinerator apparatusBell type furnacesGraphite electrodeRefractory

The invention comprises a furnace body and a furnace lid. There is a refractory furnace liner and a thermal-protective insulating layer inside of the furnace body. A molten mass portal is disposed on the side of the hearth bottom. An air outlet is disposed on the furnace wall. A hollow graphite electrode disposed in the center of the furnace lid extends into the furnace. In the hollow graphite electrode there is a passageway. A second electrode against the hollow graphite electrode and a graphite lead-out electrode connected with the second electrode are disposed at the bottom of the furnace body. An arc zone is formed between the hollow graphite electrode and the second electrode to generate hot plasma.

Owner:黄建军

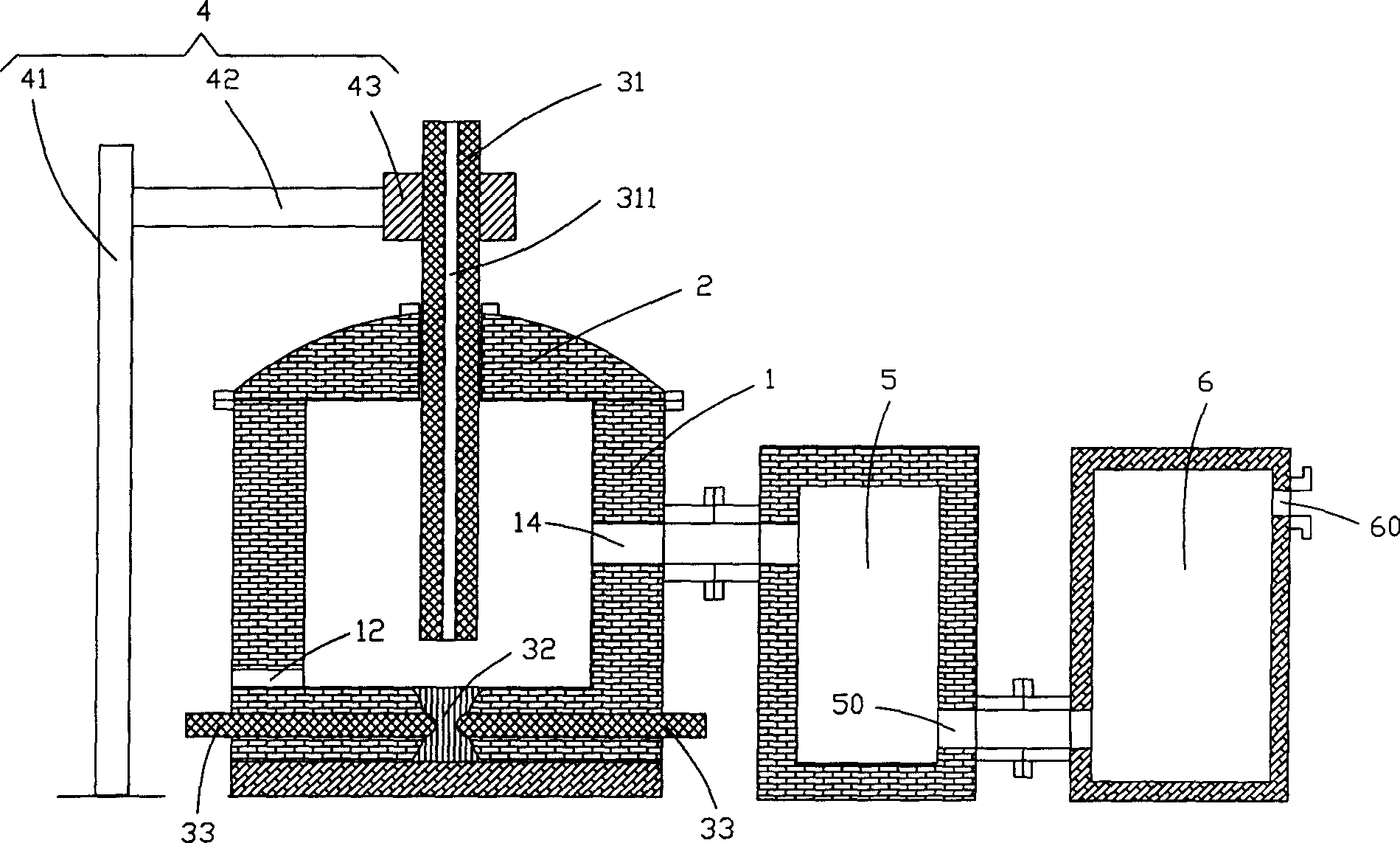

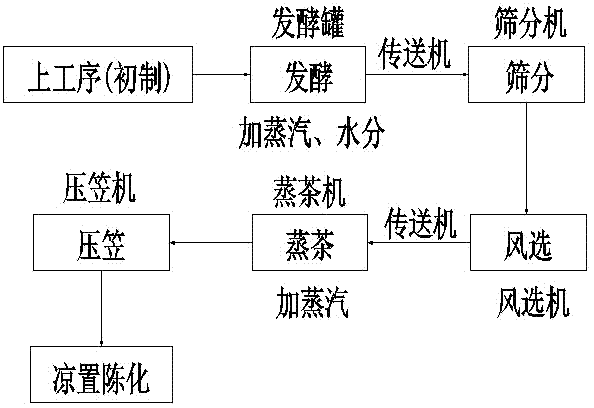

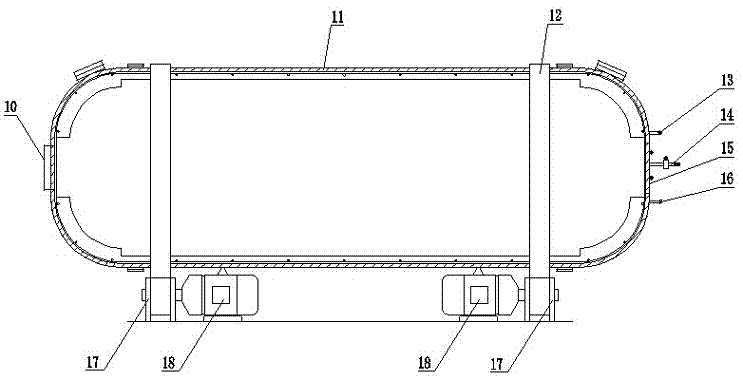

Technology and device for making Liupu tea

ActiveCN103202356AReduce labor intensityHigh degree of automationPre-extraction tea treatmentPulp and paper industryFermentation

The invention discloses a technology and a device for making Liupu tea; the invention is characterized by adopting the mechanical making technology, and the technology comprises the steps of fermenting, screening, winnowing, streaming tea, pressing a bamboo hat, cooling, ageing and the like; the device comprises a fermentation tank, a screening machine, a winnowing machine, a tea steaming machine, a bamboo hat press machine and a conveying machine, wherein the fermentation tank, the screening machine, the winnowing machine, the tea steaming machine and the bamboo hat press machine are sequentially connected by the conveying machine; the fermentation tank is connected with the screening machine by a conveying frame; the screening machine is connected with the winnowing machine by a material pipe; and the front end of the bamboo hat press machine is connected with an automatic electronic weighing machine. The technology and the device for making Liupu tea have the characteristics of being high in degree of automation, safe, sanitary, good in tea quality and the like.

Owner:广西梧州业胜茶叶有限公司

Manufacturing method of titanium-steel-titanium two-sided composite plate

ActiveCN102773670AReasonable process designLow requirements for welding conditionsSheet steelTitanium

The invention discloses a manufacturing method of a titanium-steel-titanium two-sided composite plate. The manufacturing method comprises the following processing steps: (1) four titanium plates with the same dimension and three steel plates with the same dimension are selected respectively, and rust and oxide layer removal processing is performed on the surfaces of the titanium plates and the steel plates; (2) a multilayer combination blank with three layers of steel plates, four layers of titanium plates and four layers of transition layers is formed through assembly, and gaps are arranged between the peripheries of the titanium plates and barrier strips in the combination blank; (3) the combination blank is pressed tightly and enables the barrier strips to be welded to a first steel plate and a third steel plate so as to enable the first steel plate, the second steel plate and the inner portions of the barrier strips to form a closed cavity, holes are drilled on the barrier strips, steel tubes are welded in the holes, and the steel tubes are communicated with the closed cavity; (4) the combination blank is sent to a heating furnace to be heated and vacuumized; (5) the combination blank is sent to a rolling mill to be rolled after the outer ends of the steel tubes are sealed; and (6) one titanium-steel-titanium two-sided composite plate and two titanium-steel single-sided composite plates are obtained by slitting the combination blank after the combination blank is rolled. The manufacturing method of the titanium-steel-titanium two-sided composite plate is reasonable in design and low in production cost.

Owner:河南盛荣金属复合新材料有限公司

Plane button type packing technology of integrated circuit or discrete component and its packing structure

ActiveCN1725460ASmooth productionImprove yieldSolid-state devicesSemiconductor/solid-state device manufacturingIntegrated circuitEngineering

This invention relates to a plane salient point encapsulation technology and its structure of IC or discrete components, among which, the technology includes: taking a base plate, dry-film layers are pasted to the front and back side of the base plate, removing part of the upper layer for the preparation of forming a basic island and pins, plating metal layers on the front, removing the rest dry film on the upper layer of the base plate, semi-etching it, removing the dry film on the back, implanting the chip, wiring, packaging with plastic capsule, pasting a dry film on the back of the base plate again, etching the dry film at the back and the rest of the metal of the semi-etched zone again so as to enable the back of the basic island and the pin projecting over the plastic capsule, removing the rest dry film, plating metal layers on the surface, pasting film on the front of the plastic capsule then cutting.

Owner:长电科技管理有限公司

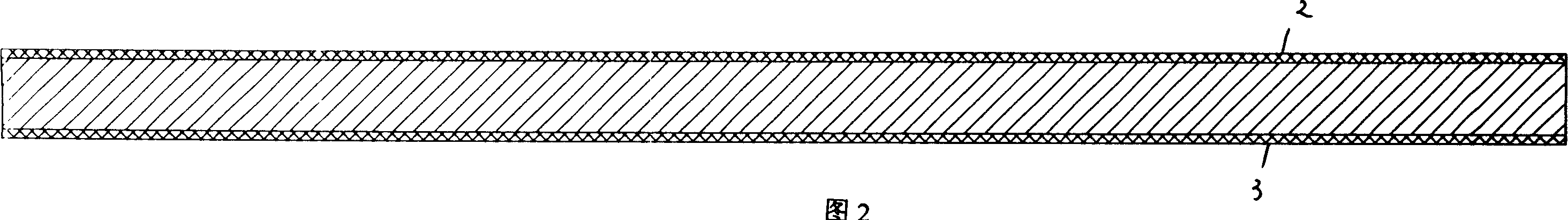

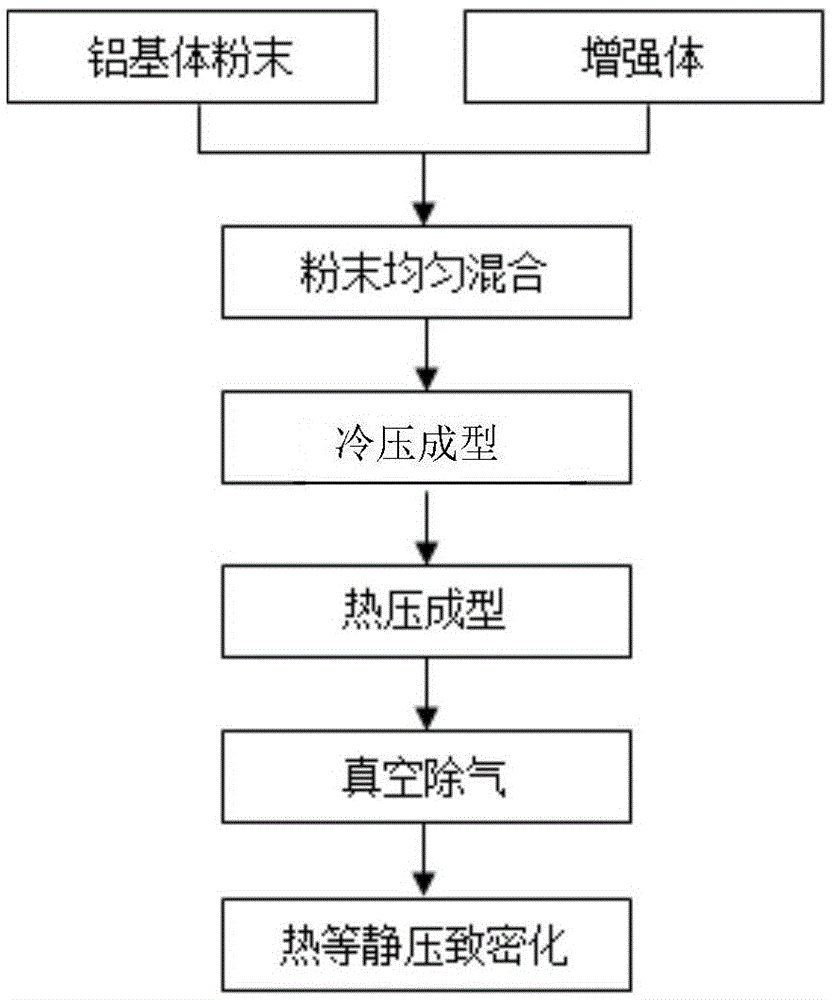

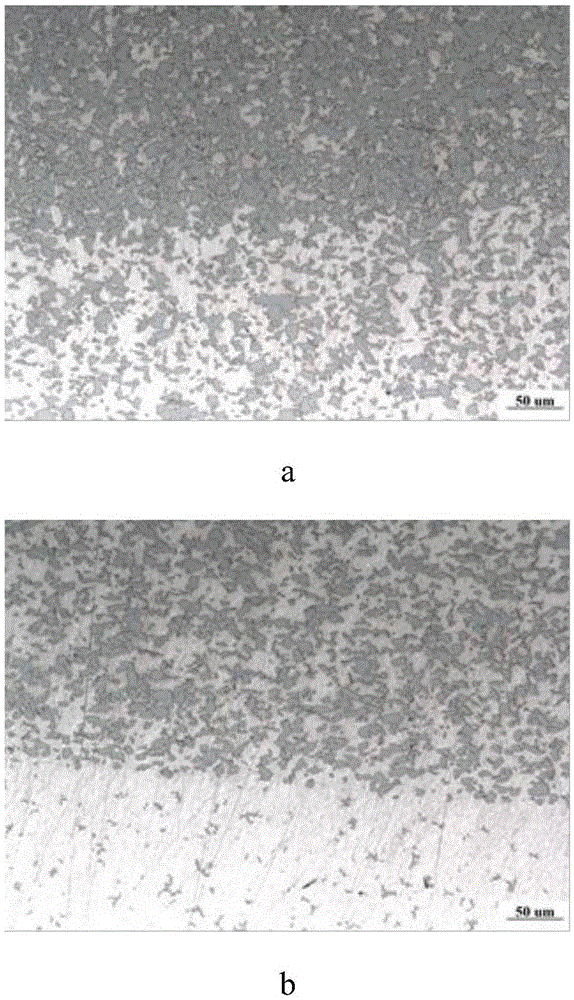

Manufacturing method of laminated aluminum matrix composite for electronic packaging

ActiveCN105483454AWill not oxidizePrecise content controlElectronic packagingCeramic matrix composite

The invention relates to a manufacturing method of a laminated aluminum matrix composite for electronic packaging. The method includes the steps that reinforcement powder and aluminum matrix powder are evenly mixed according to different proportions, obtained composite powder with different reinforcement contents is sequentially packaged to cylindrical steel dies to be subjected to cold press molding, and cold press billets are subjected to hot press molding in the inert gas atmosphere, so that the density of the billets is increased, the hot press billets are degassed in a high-temperature vacuum manner and then subjected to hot isostatic pressing densification, and the completely-dense billets are manufactured. The manufacturing method is simple and low in cost, the quality is stable, and the composite has the characteristics of being high in strength and tenacity and good in welding performance and can be applied to the electronic packaging field.

Owner:有研金属复材技术有限公司

Rapid salting method of low-salt salted pork

ActiveCN103750389AModerate contentLittle damage to human healthClimate change adaptationFood mechanical treatmentFleshChemistry

The invention relates to a rapid salting method of low-salt salted pork. The method comprises the following steps of 1. cutting selected streaky pork with equivalent fat-muscle into strips; 2. measuring table salt and pork according to the salt-to-pork ratio being 3 to 4 percent, dissolving 2 percent of table salt into little water, and uniformly injecting the salty water into the pork by utilizing a salty water syringe; 3. respectively measuring 2 to 2.5 percent of white spirit, 0.2 to 0.6 percent of paprika powder and 0.2 to 0.4 percent of fennel powder, mixing the white spirit, the paprika powder and the fennel powder with the residual table salt, and kneading the pork with the mixture; 4. arranging the pork into a rolling kneading machine, and vacuum intermittently rolling kneading the pork at the low temperature at the condition of controlling the temperature at 0 to 4 DEG C, the vacuum degree to be 0.08MPa and the rotating speed to be 10r / min,; 5. hanging the pork under the condition that the temperature is 8 to 12 DEG C and the relative humidity is 60 to 70 percent, and standing and drying the pork for 2days; 6. Carrying out fire curing; 7. naturally carrying out air drying and cooling for 24h, and carrying out vacuum packaging on the pork to obtain a finished product. The low-salt salted pork is bright in color, delicious in taste, tender in tissue and obvious in scent and can be reserved for one year under the vacuum packaging cold storage condition without going bad.

Owner:西林县招商中心

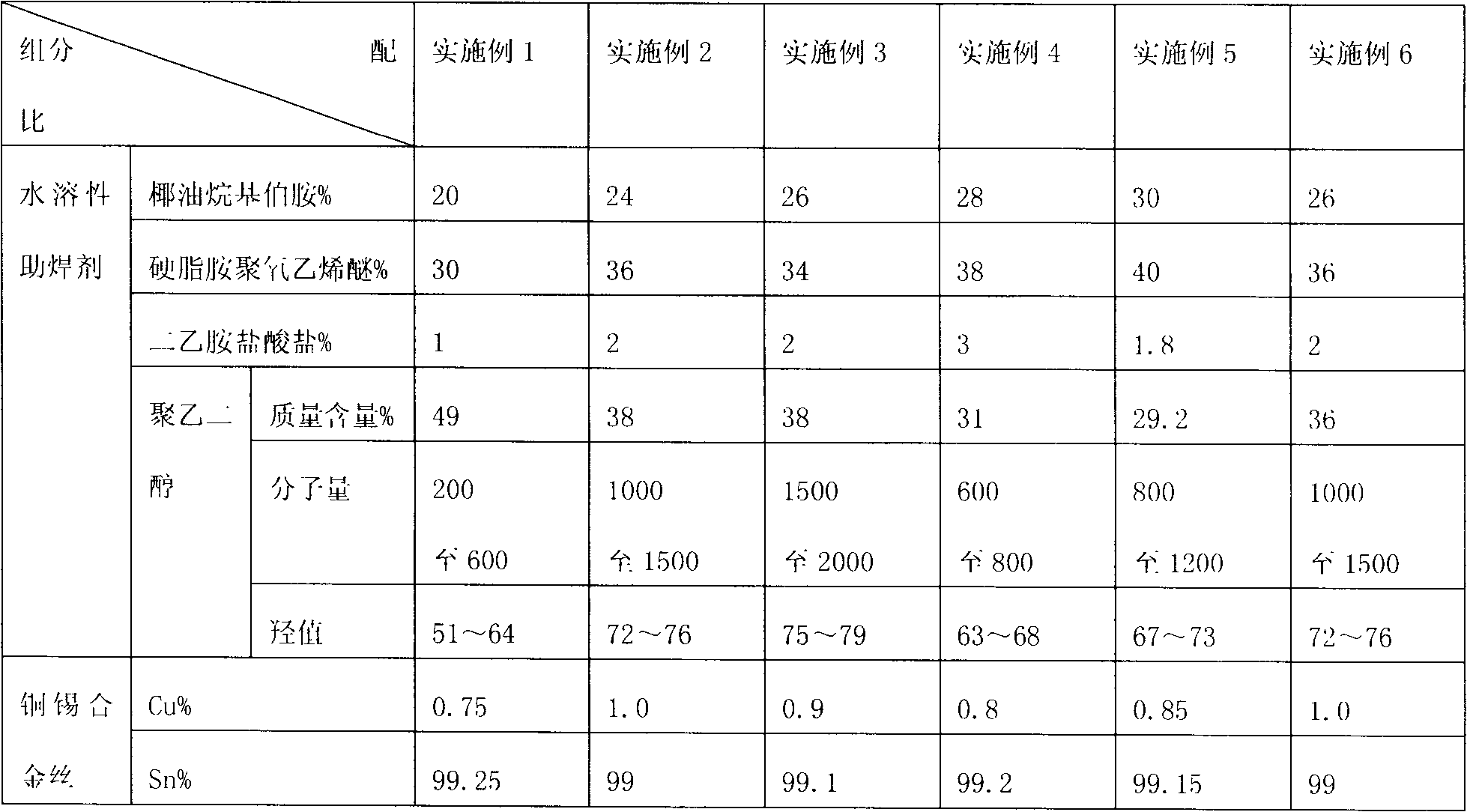

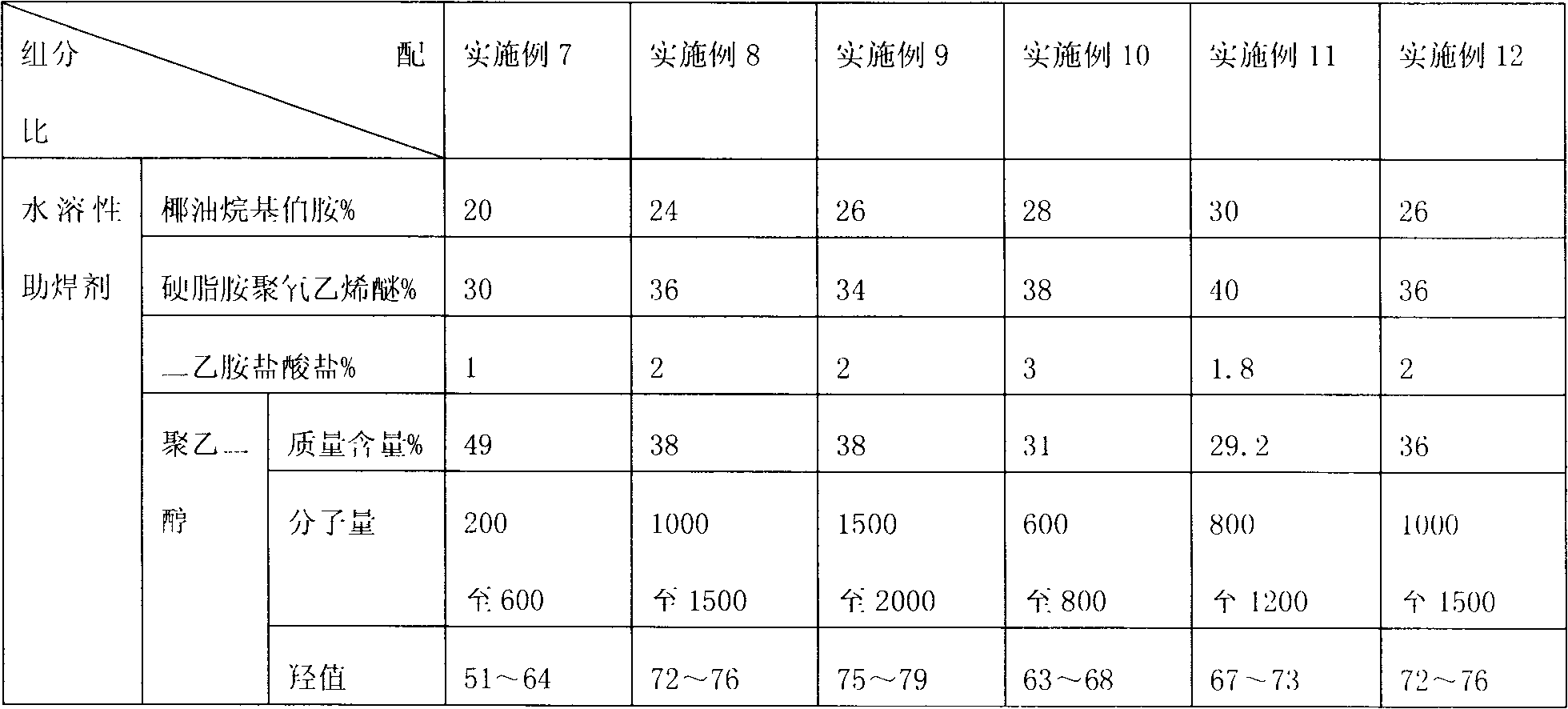

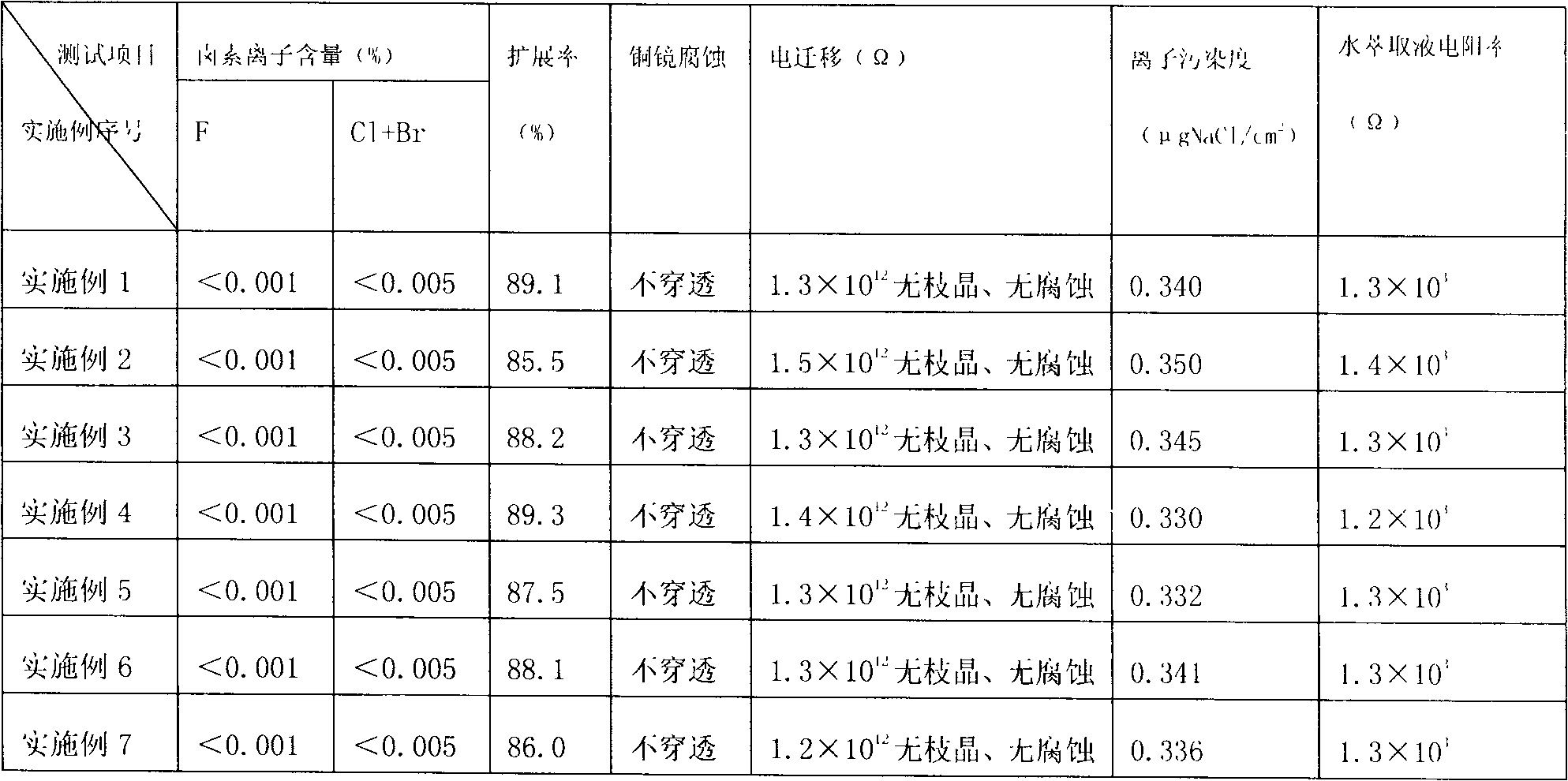

Lead-free welding tin wire and water-soluble welding flux used by same

ActiveCN102161135AReduce pollutionReduce interfacial tensionWelding/cutting media/materialsSoldering mediaPolyethylene glycolAlloy

The invention discloses a lead-free welding tin wire and a water-soluble welding flux used by the same. The lead-free welding tin wire comprises a copper-tin alloy wire provided with a hole cavity and the water-soluble welding flux arranged in the hole cavity; the proportion of the copper-tin alloy wire and the water-soluble welding flux is as follows: 2.0-2.2wt% of the water-soluble welding fluxand the balance of the copper-tin alloy wire, wherein the copper-tin alloy wire comprises the following components: 0.75-1.0wt% of Cu and the balance of Sn; the water-soluble welding flux comprises the following components: 20-30wt% of coconut oil alkyl carbinamine, 30-40wt% of octadecyl amine polyoxyethylene ether, 1-3wt% of diethylammonium chloride and the balance of water-soluble macromoleclarpolymer; the ammonium salt halogenide is diethylammonium chloride; and the water-soluble macromoleclar polymer is polyethylene glycol with the molecular weight of 200-2000. The lead-free welding tin wire provided by the invention has better welding performance and the water-soluble welding flux provided by the invention has better wettability.

Owner:浙江强力控股有限公司

Microporous ceramic thick film heating element for electronic cigarette tar atomization core and manufacturing method of element

PendingCN110074463AImprove liquidityHigh bonding strengthTobacco devicesHeating element shapesElectrical resistance and conductanceTar

The invention relates to the technical field of electronic cigarettes, and particularly discloses a microporous ceramic thick film heating element for an electronic cigarette tar atomization core anda manufacturing method of the element. The microporous ceramic thick film heating element comprises a microporous ceramic base plate, a heating resistance film layer and an electrode layer, wherein the heating resistance film layer comprises a middle part and two connecting parts; the electrode layer comprises two electrode films arranged at intervals; the two connecting parts are respectively connected with the upper ends of the two electrode films; the middle part is connected with the upper surface of the microporous ceramic base plate; the heating resistance film layer is used for heatingthe microporous ceramic base plate so that the cigarette tar of an electronic cigarette is atomized and escapes through micropores of the microporous ceramic base plate. The microporous ceramic thickfilm heating element disclosed by the invention has the advantages that the use is safe and reliable; the service life is long; the cigarette tar reducing degree is high; the user experience and the mouthfeel are good, and the like; the manufacturing method of the element is simple and efficient; the operation and control are convenient; the product quality is stable; industrialized production isfacilitated.

Owner:东莞市东思电子技术有限公司

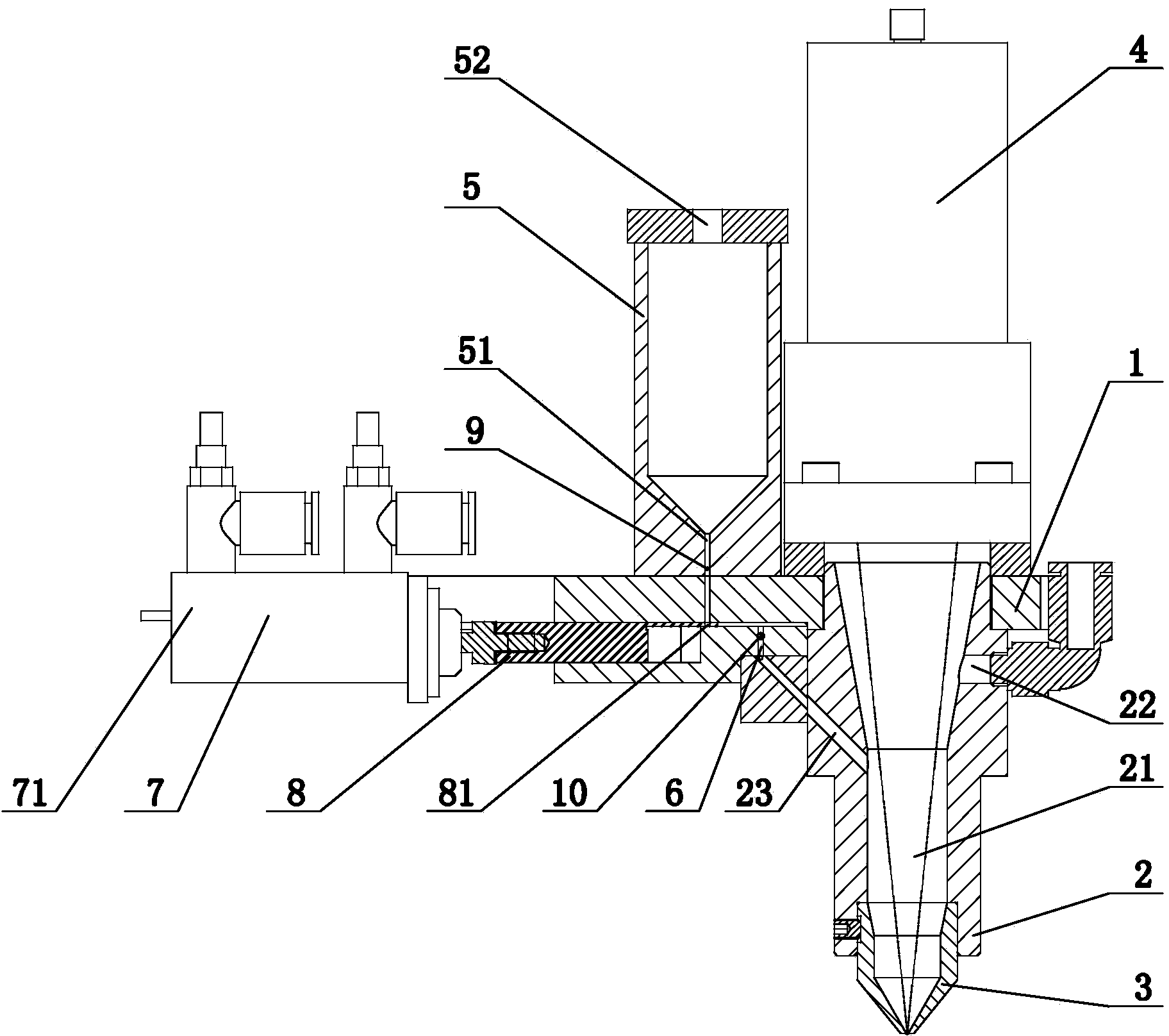

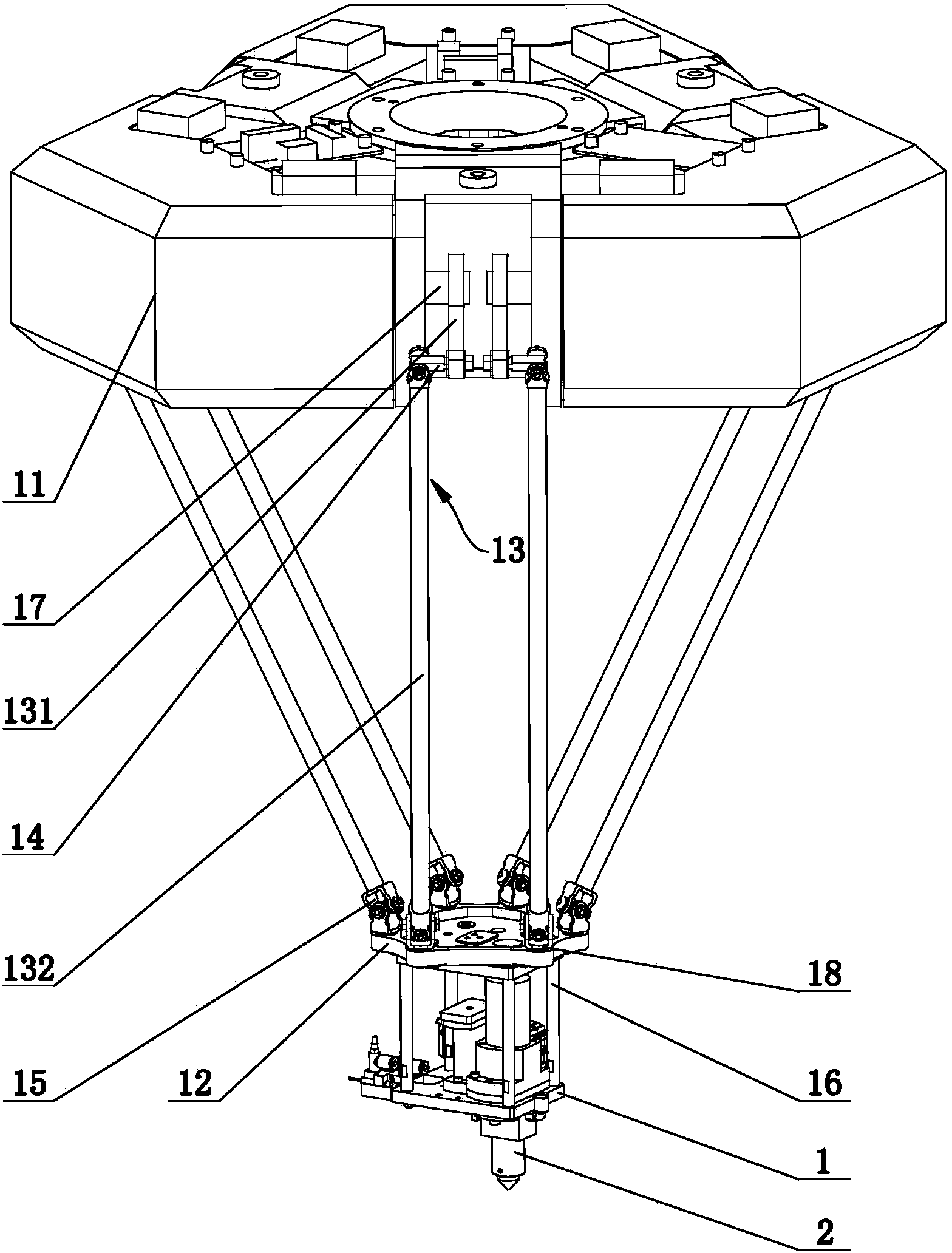

Laser welding head and laser welding machine

ActiveCN103962721AWill not oxidizeImprove cleanlinessLaser beam welding apparatusSolder feeding devicesEngineeringNitrogen gas

The invention discloses a laser welding head, and belongs to the technical field of laser remelting equipment. The laser welding head comprises a base plate, wherein a fixing block and a storage bin are installed on the base plate, the lateral wall of the fixing block is respectively provided with an air inlet and a feeding passage, a tin outlet nozzle is installed at the bottom of the fixing block, a laser device optical fiber head is installed at the top of the fixing block, a discharging through hole is formed in the bottom of the storage bin, the base plate is provided with a falling passage communicated with the feeding passage, a material dividing sliding block driven by a linear driving device is installed on the base plate in a sliding mode, and a positioning hole is formed in the material dividing sliding block. The invention further discloses a laser welding machine with the laser welding head. The laser welding head and the laser welding machine are simple and reliable in structure, small and exquisite in size, light in weight and low in cost. Nitrogen is blown in for protection at the same time of laser remelting welding, and welding point formation and appearance are good.

Owner:WEIFANG LOKOMO PRECISION IND

Production technology for polycrystalline silicon

The invention discloses a production technology for polycrystalline silicon. The production technology includes the following steps: 1, a first coating, a second coating and a third coating are sequentially arranged on the surface of a crucible from inside to outside, and a crystalline silicone leftover material layer is laid; 2, a small quantity of raw polycrystalline silicon materials in the melted state is contained in the crucible, and the temperature of the crucible is controlled to be lower than the melting point of the crystalline silicone leftover material layer to enable the small quantity of melted raw polycrystalline silicon materials to form a crystallization protection layer; 3, in the vacuum environment, to-be-processed raw polycrystalline silicon materials are contained in the crucible, placed in a melting furnace with an electron beam generating device and processed through laser irradiation; 4, high-frequency induction heating is carried out in the vacuum environment, a slag forming constituent is added, plasma heating is carried out, steam-and-hydrogen-mixed argon is introduced, and directional solidification is carried out to obtain the polycrystalline silicon serving as the target product. By means of the production technology, the boron content, the phosphorous content and the metal impurity content can be effectively reduced, the complete polycrystalline silicon is prepared, long crystal dislocation is less, grain boundaries are proper, and the conversion rate of a polycrystalline silicon battery is increased.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

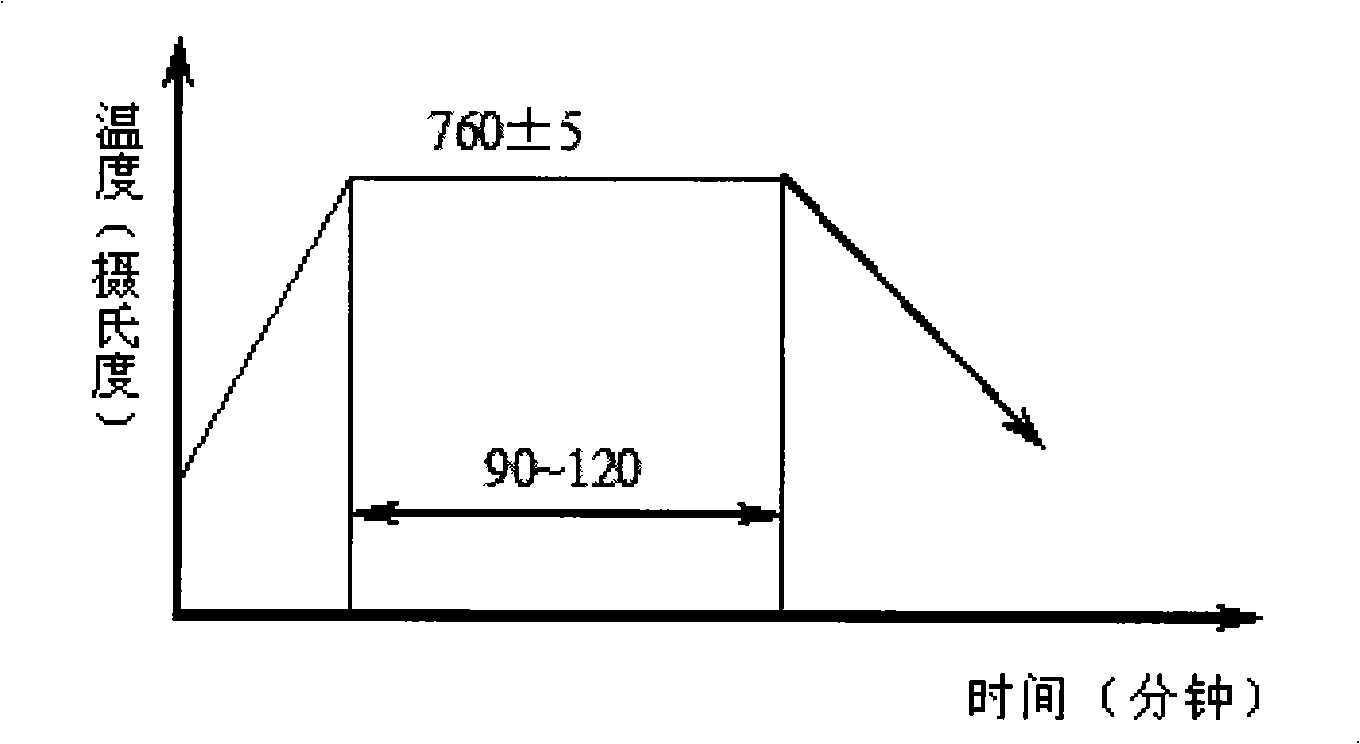

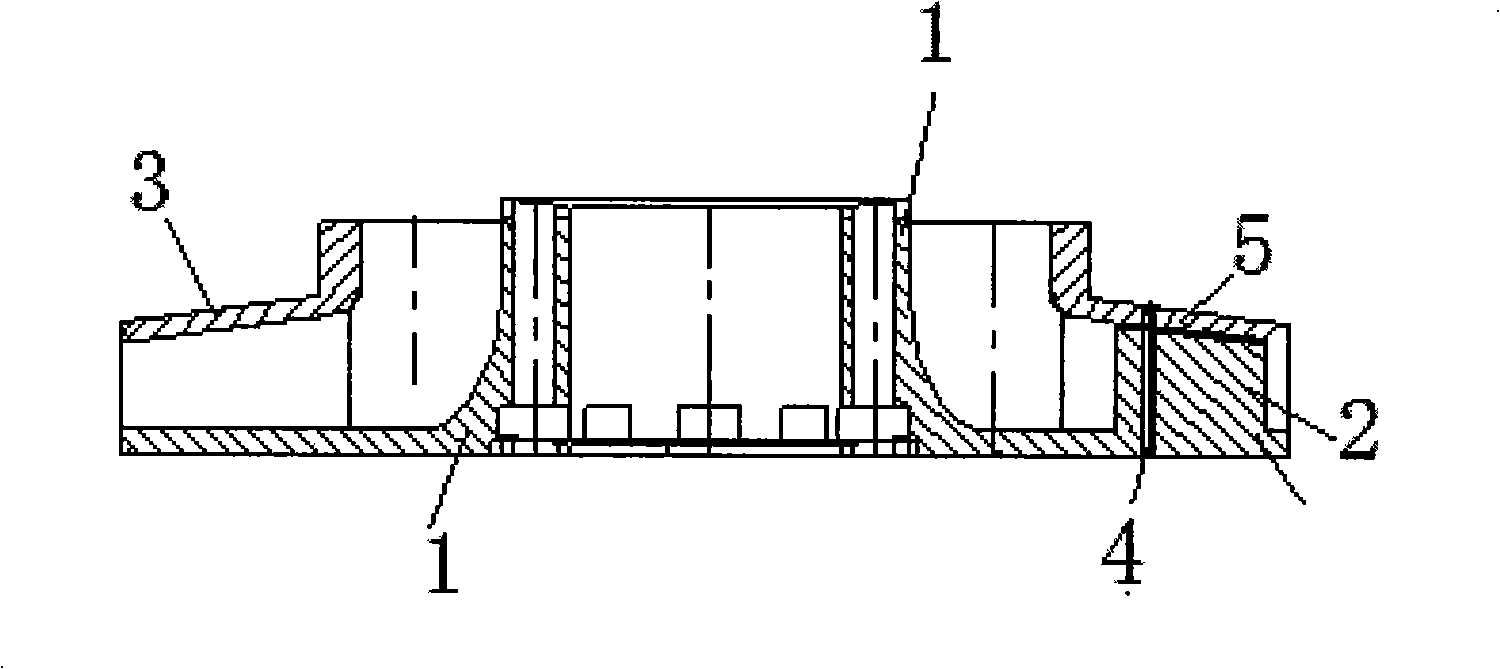

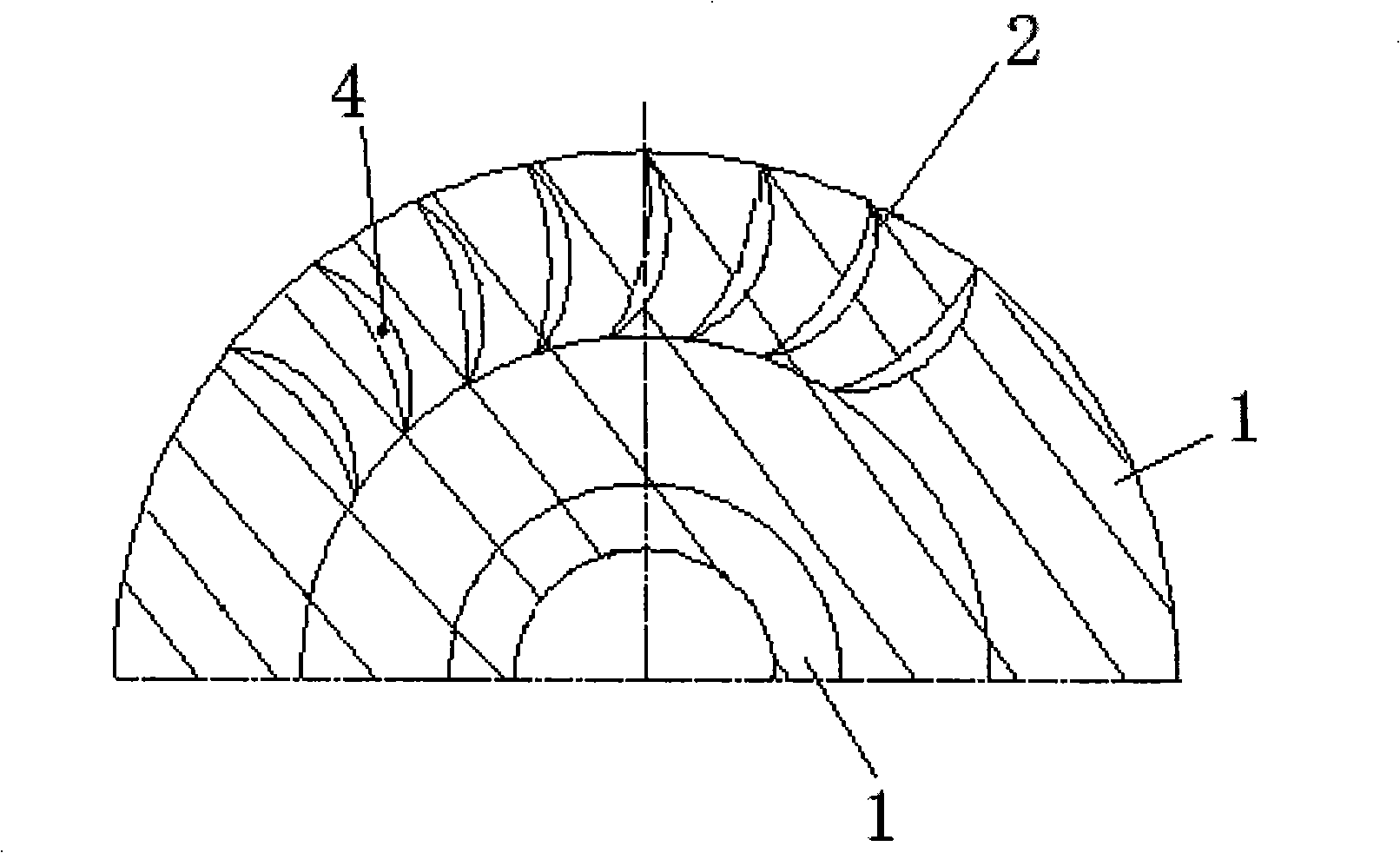

Vacuum brazing method for pump impeller

The invention relates to a vacuum brazing method for a pump impeller, which comprises the following steps: 1) cutting soldering terminals into shapes corresponding to those of the cross sections of blades on an impeller, and punching positioning holes on the 2 to 3 soldering terminals; 2) cleaning a pump impeller to be welded and the soldering terminals, and checking the smoothness of welding surfaces of the blades; 3) preheating the pump impeller to be welded; 4) coating the welding surfaces of the blades to be welded with welding flux, placing the soldering terminals on the welding surfaces of the blades, and then coating the welding flux on the upper surfaces of the soldering terminals; 5) using a pump cover to cover the upper surfaces of the soldering terminals, and using positioning pins to fix the pump cover on the soldering terminals; 6) assembling an upper pressed tyre and a lower pressed tyre together by the pump impeller to be welded; 7) sending an assembly into a heating chamber in a vacuum furnace for heating; and 8) taking out a workpiece after the temperature reduction. The pump impeller brazed by the method has uniform and full welding seams, apparent circular arcs at interfaces, compactly combined welding surfaces, no air holes, high welding strength, and longer service life.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

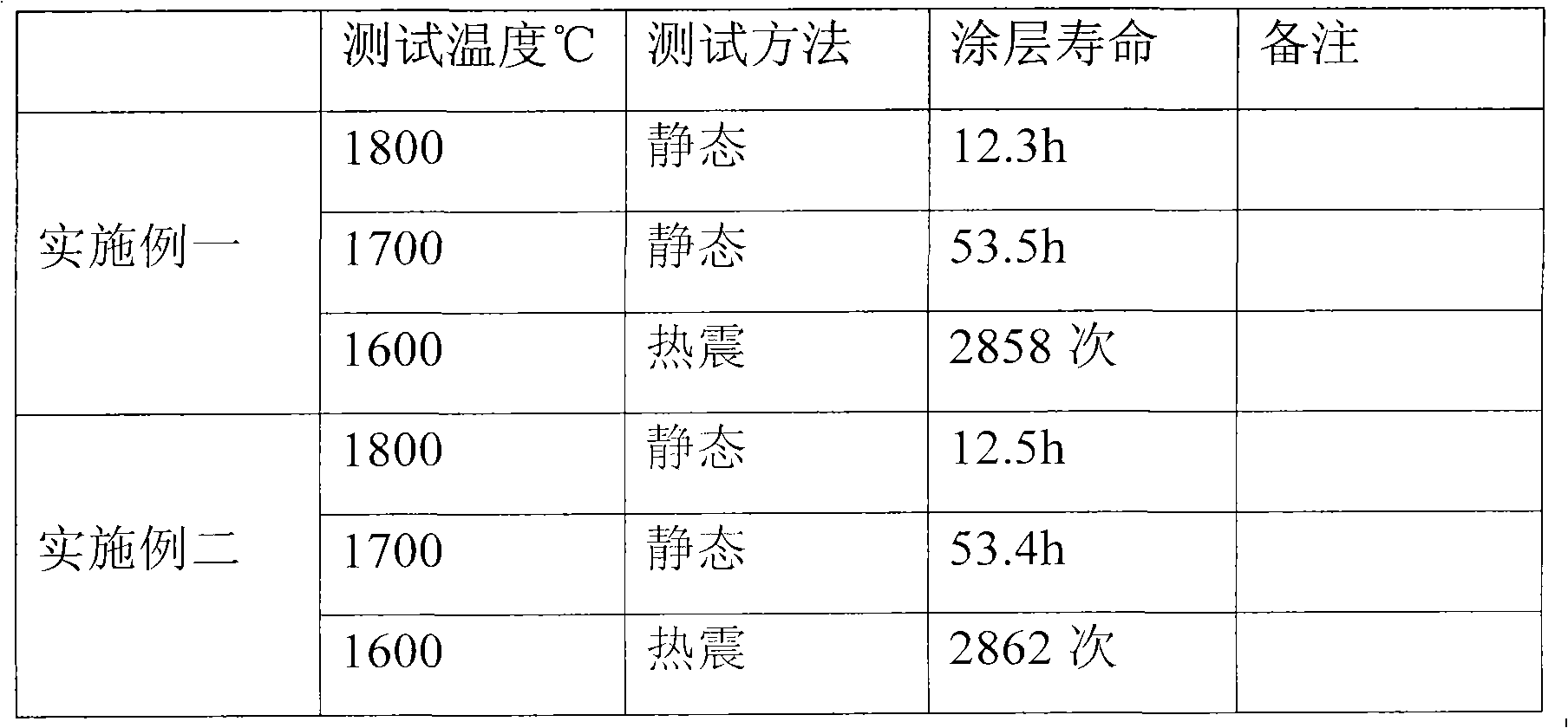

Method for preparing high-temperature oxidation-resistant coating on niobium tungsten alloy

ActiveCN102071419ACompact structureImprove densification performanceMetallic material coating processesLaser beam welding apparatusNiobiumNanocomposite coating

The invention relates to a method for preparing a high-temperature oxidation-resistant nanocomposite coating on the surface of niobium tungsten alloy (Nb521) by cold spraying and laser cladding technology, in particular to a method for preparing a high-temperature oxidation-resistant coating on niobium tungsten alloy. The method is characterized by comprising the following steps of: a, processing molybdenum (Mo) and silicon (Si) components in a high-temperature oxidation-resistant material respectively to be nanopowder for later use, mixing the rest components, and processing the mixture to be nanopowder for later use; b, cold-spraying the Si nanopowder on a niobium tungsten alloy base material; c, cold-spraying the nanopowder of the mixed rest components in the step a on the niobium tungsten alloy base material; d, cold-spraying the Mo nanopowder on the niobium tungsten alloy base material, wherein the total thickness of all the coatings is controlled to be 50 to 140 mu m; and e, irradiating, scanning and melting the coatings of the sprayed niobium tungsten alloy base material by using laser beams. By the method, the tissues among the coating powder are compact; and compactness of the coatings is greatly improved.

Owner:NINGXIA ORIENT TANTALUM IND

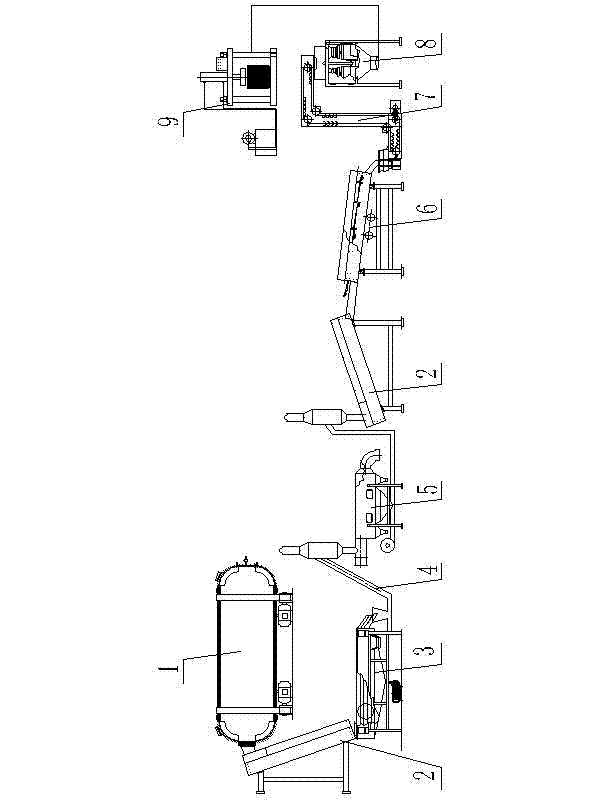

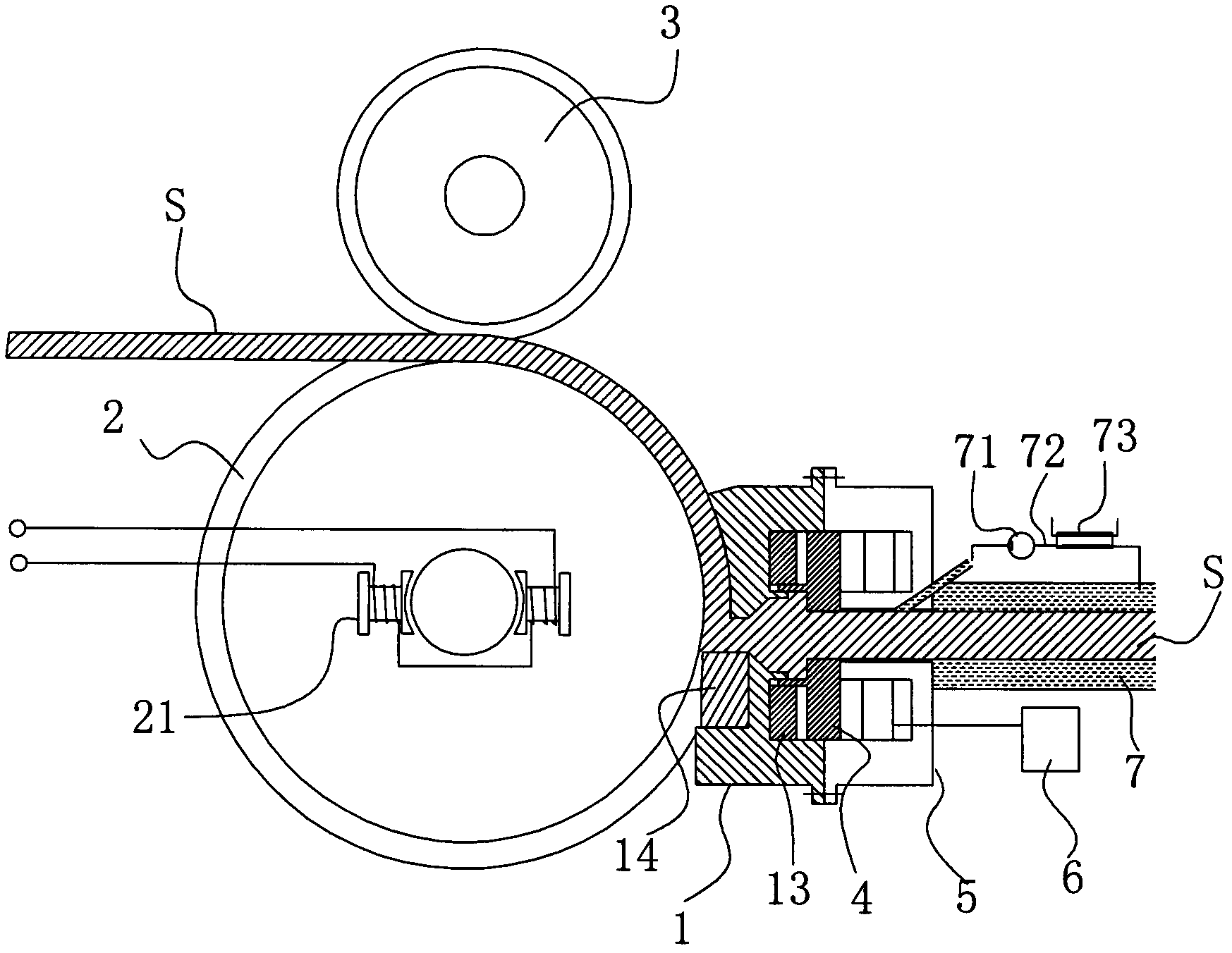

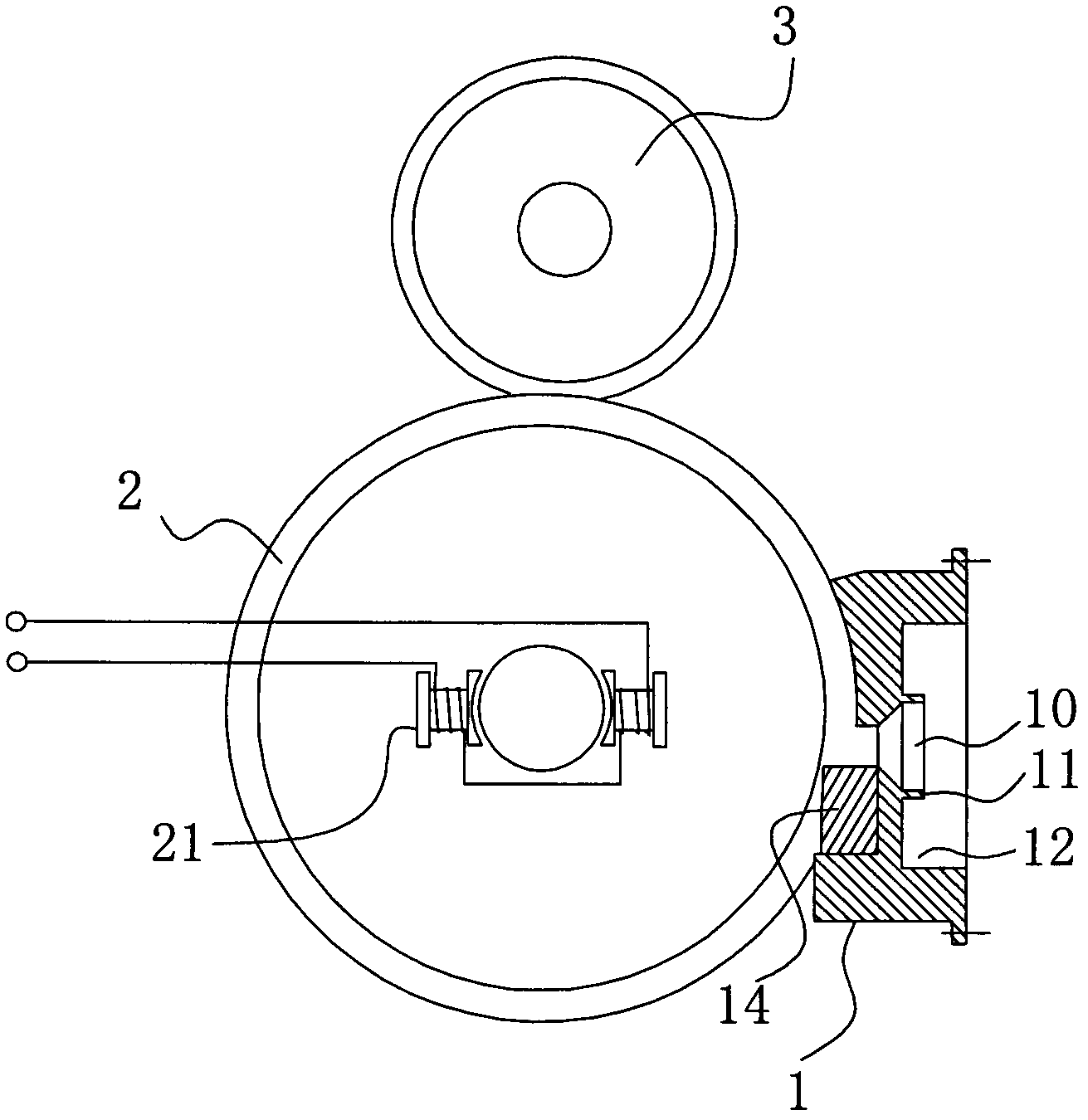

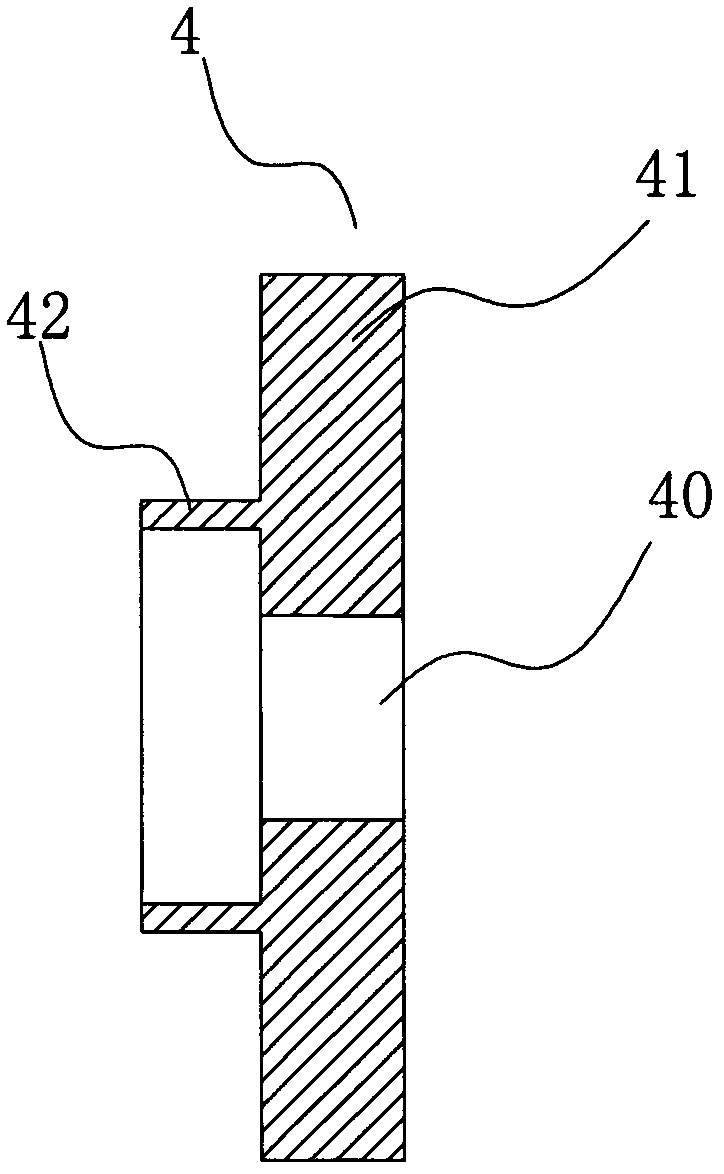

Microcrystal extrusion equipment and production method thereof

ActiveCN102294377ASmall particlesUniform particlesExtrusion diesExtrusion control devicesEngineeringMethods of production

The invention discloses microcrystalline extrusion equipment and a microcrystalline extrusion production method. The microcrystalline extrusion equipment comprises a machine base, an extrusion wheel and a compaction wheel which are arranged on the machine base, and a power source, wherein an extrusion mould cavity is formed in the machine base; a movable mould which is butted with the extrusion mould cavity and a power mechanism for driving the movable mould are arranged on the machine base; the power mechanism is arranged at the extrusion end of the movable mould, and is provided with a fixed end which is coupled with the machine base and a movable end which is pressed against the outer side of the movable mould; and the power source is coupled with the power mechanism. By the microcrystalline extrusion equipment and the microcrystalline extrusion production method, process parameters in the extruding process can be detected in real time and adjusted in time, so that a metal material is under ideal extrusion pressure and at an ideal extrusion temperature all the time in the extruding process, and the high uniformity of the material performance of the extruded metal material can be ensured. The microcrystalline extrusion equipment has a rational and simple structure and is convenient to operate and maintain, the influence of man-made factors on product quality can be reduced, and the product quality can be improved.

Owner:佛山市承安集团股份有限公司

Continuous deformation magnesium alloy extruding method

InactiveCN1974045AReduce the temperatureWill not oxidizeExtrusion control devicesRams/plungersAviationNonferrous metal

The present invention is continuous deformation magnesium alloy extruding method, and belongs to the field of non-ferrous metal plastic forming technology. The technological scheme includes extruding deformation magnesium alloy wire blank in a continuous rotary extruder and regulating the contact surface length and running interval between the extruding wheel and the block so as to produce extrusion force between the deformation magnesium alloy blank and the rotary extruding wheel and friction heat for extruding the blank in the mold into product in continuous great shearing deformation mode. The product of the present invention may be used widely in aerospace, aviation, communication, computer, traffic and other fields.

Owner:HUNAN HUAKANG NEW MATERIAL

Processing method of dry bamboo shoot slices

ActiveCN104095032ADry evenlyShorten the production cycleFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by dehydrationBamboo shootsChemistry

The invention discloses a processing method of dry bamboo shoot slices. The processing method comprises the following steps: cleaning, slicing, color protecting, drying, packaging and sterilizing, and is characterized in that: fresh bamboo shoots are selected and then shells of the bamboo shoots are peeled off, the peeled-off bamboo shoots are cleaned and then cut into bamboo shoot slices, the bamboo shoot slices are immediately put into a color protection solution and then subjected to three-time heated air circulation drying and airing, and the dry bamboo shoot slices are obtained, vacuumized and then sterilized. The processing method has features of simple process, unchanged color of the dried bamboo shoot slices, and long preservation time and high quality of the bamboo shoot slices.

Owner:尹大建

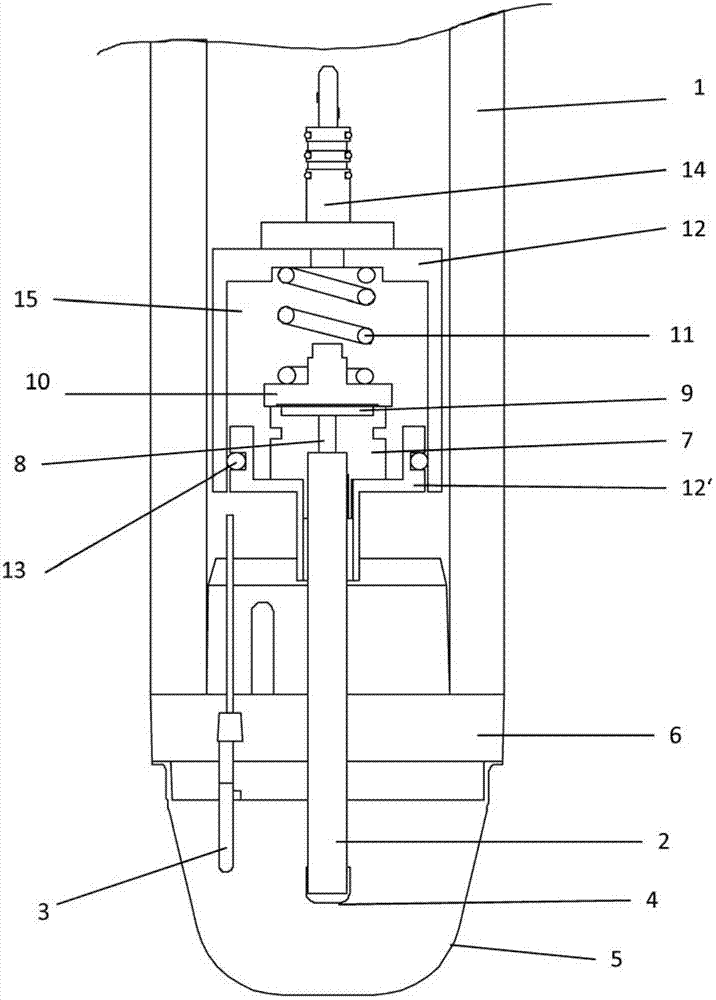

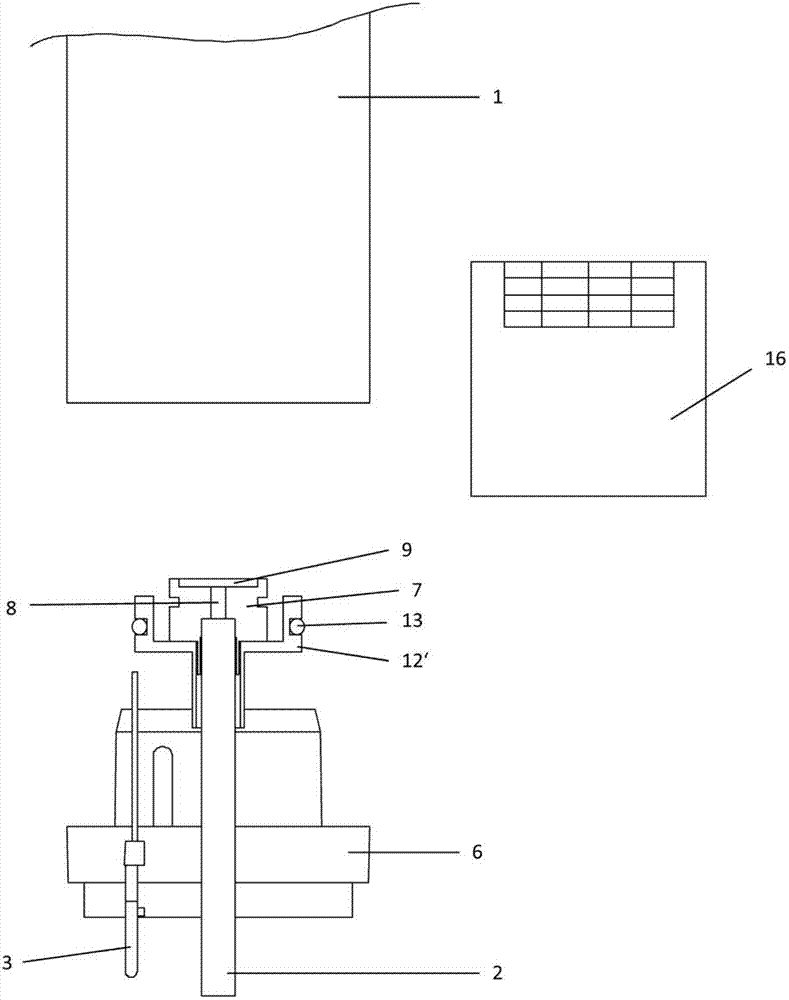

Sampler for taking samples from melts having a melting point higher than 600c, and method for taking samples

ActiveCN102788715AWill not oxidizeAvoid enteringWithdrawing sample devicesTesting metalsBiomedical engineeringSample chamber

A sampler is provided for taking samples from melts having a melting point higher than 600 DEG C., in particular for metal or cryolite melts. The sampler includes a carrier tube having an immersion end and having a sample chamber assembly arranged on the immersion end of the carrier tube. The assembly has an inlet opening and a sample cavity for the melt and is arranged at least partly inside the carrier tube. The sample chamber assembly has on a part of its outer surface a coupling device, arranged inside the carrier tube, for coupling a carrier lance. A method is also provided for taking samples using such a sampler.

Owner:HERALUS ELECTRO NITE INT NV

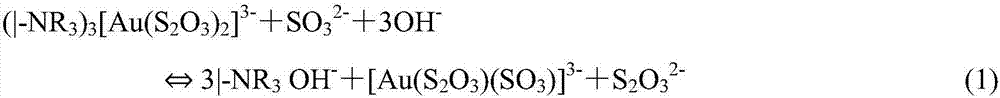

Method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin

ActiveCN107488789AStable in natureReduce desorption costProcess efficiency improvementNitrateDesorption

The invention discloses a method for synergistically desorbing gold thiosulphate coordination ions from strongly-alkaline anion exchange resin. A mixed solution of Na2SO3 and NaOH serves as a desorption agent, and dynamic desorption is conducted on the strongly-alkaline anion exchange resin loaded with the gold thiosulphate coordination ions. According to the method, the synergistic effect of two components, namely SO3<2> and OH, is utilized, and desorption is conducted on the [Au(S2O3)2]<3> coordination ions adsorbed on the strongly-alkaline anion exchange resin; and the desorption rate of gold can reach 97% or above. Compared with traditional methods that a thiocyanate solution or a polythionate solution or a nitrate solution or another type of solution composed of a single component is adopted for desorption, the desorption method has the remarkable beneficial effects that reagents are free of toxicity; performance is stable; desorption cost is low; resin desorption and regeneration are completed by the same step; and the gold in the desorption solution can be further recycled conveniently. And good industrial application prospect is achieved.

Owner:CENT SOUTH UNIV

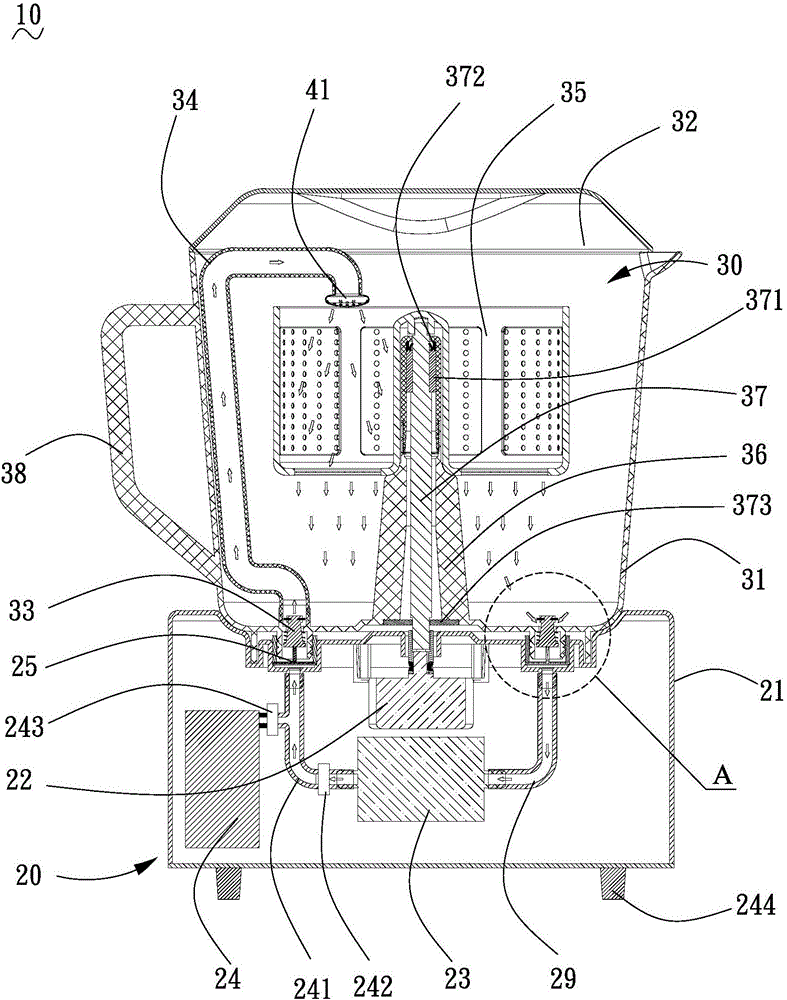

Vacuumized iced coffee machine

ActiveCN106798496AGood fresh-keeping effectImprove the preparation effectBeverage vesselsMotor driveEngineering

The invention relates to a vacuumized iced coffee machine which comprises a main engine assembly, and a coffee cup assembly mounted on the main engine assembly, wherein the main engine assembly comprises a main engine seat, a motor mounted on the main engine seat, a water pump, a vacuum pump and a touch filter disc; a control valve connected with the main engine seat and the water pump is arranged on the vacuum pump; the coffee cup assembly comprises a cup body, a cup cover, a movable valve, a drainage pipe and a net bag; the cup body is mounted on the main engine seat; the cup cover and the movable valve are mounted on the cup body; the drainage pipe and the net bag are arranged in the cup body; the movable valve is positioned at the bottom of the cup body and is opposite to the touch filter disc; the drainage pipe extends to the upper side of the net bag from the movable valve; the net bag is connected with the motor; the motor drives the net bag to rotate during driving. According to the vacuumized iced coffee machine, due to the vacuum pump, the movable valve, the water pump, the motor, the net bag and the like, coffee can be prevented from being oxidized, the preservation effect is good, the coffee in the net bag is repeatedly flushed, the blending ratio accuracy is guaranteed, coffee grounds are avoided, and the vacuumized iced coffee machine is excellent in making effect and simple and efficient in operation.

Owner:SHINY ELEC CO LTD

Preparation method of silver product with colored surface

ActiveCN104372330AStable in natureWill not oxidizeMetallic material coating processesChemistryAmmonium chloride mixture

The invention provides a preparation method of a silver product with a colored surface. The preparation method comprises the following steps: removing grease from the surface of a silver product, and then making a coloring agent carry out reactions with the surface of the silver product to obtain a silver product with a colored surface. The preparation method comprises the following specific steps: mixing potassium sulfide and ammonium chloride to prepare a mixed solution taken as the coloring agent; immersing a silver product into the coloring agent, soaking, and making the coloring agent carry out reactions with the silver of the silver product surface, wherein during the process the potassium sulfide reacts with the silver to generate silver sulfide, at the same time the ammonium chloride can assist the complexing action of silver sulfide, and finally a silver product with a jazz silver surface is obtained. The obtained jazz silver color silver product has a stable property in the air and will not be oxidized or faded.

Owner:GUOJIN GOLD CO LTD

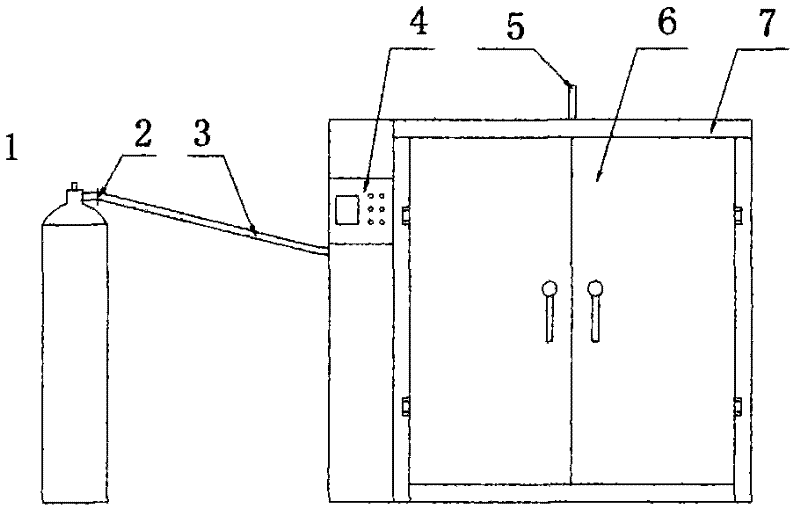

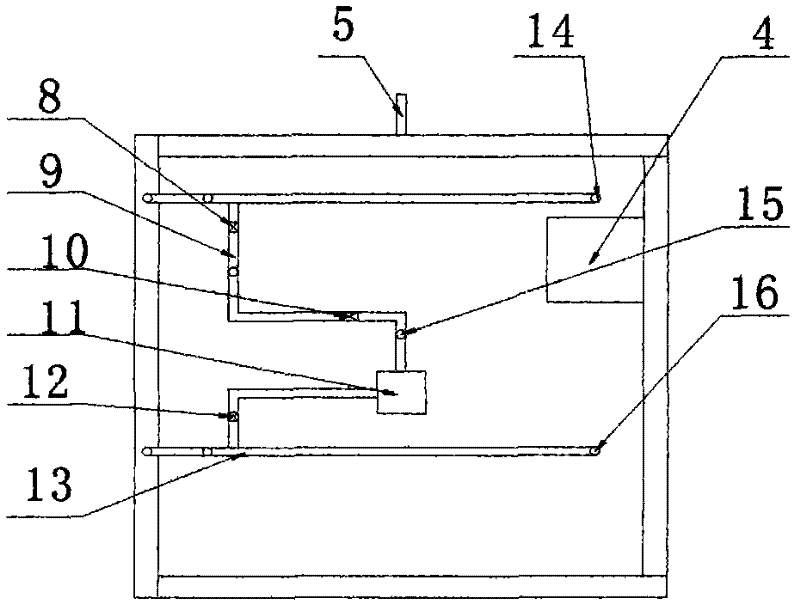

Device for gas displacement of working chambers of oven and sintering furnace

InactiveCN102393134AReduced sealing requirementsWill not oxidizeDrying gas arrangementsMaintainance of heating chambersVacuum pumpingFree cooling

The invention discloses a device for gas displacement of working chambers of an oven and a sintering furnace. The device comprises a gas bag, a suction pump and the like and is characterized in that a cylindrical gas bag with an elliptic cross section is arranged in the working chamber. When inert gases such as nitrogen gas and the like are filled in the gas bag, the gas in the working chamber is extruded and discharged by the gas bag; and when the gas in the gas bag is pumped and transferred to the working chamber, the gas in the working chamber is replaced by the nitrogen gas. The invention has the beneficial effects that: the working chamber has no need of vacuum pumping, the requirements for the strength of steel products and the sealing performance of an oven door are relatively low, the manufacturing cost is lowered, and the using process is safer; when articles are baked, dried, heated and treated by other heating modes in the oven, the articles can not be oxidized; and the natural cooling mode of the oven can be changed, the baking time can be shortened, and the efficiency can be improved.

Owner:HEFEI HUAYU RUBBER EQUIP

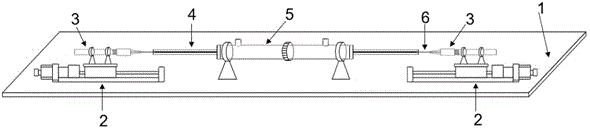

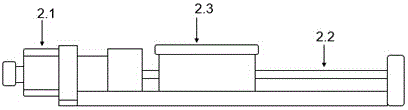

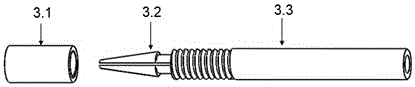

Atmosphere protection type chalcogenide glass optical fiber tapering device and use method

ActiveCN105731785APrevent surface oxidationGood temperature control effectGlass fibre drawing apparatusElectrical resistance and conductanceTemperature control

The invention discloses an atmosphere protection type chalcogenide glass optical fiber tapering device and a use method.The device comprises an optical platform, two electric displacement platforms, two optical fiber clamps, a seamed quartz tube and an atmosphere protection tube type resistance furnace.Firstly, the seamed quartz tube filled with a chalcogenide glass optical fiber penetrates through the atmosphere protection tube type resistance furnace and is clamped and fixed through a diaphragm; then the two ends of the optical fiber are fixed to the electric displacement platforms through the optical fiber clamps, inert gas is introduced into the furnace, the optical fiber is softened after being heated, and the electric displacement platforms are started for two-way traction tapering; finally ultraviolet curing glue is injected into the two ends of the seamed quartz tube for fixing the tapered optical fiber in situ.The device can taper the optical fiber under inert atmosphere protection, and oxidation of the surface of the optical fiber is effectively avoided; the temperature control effect on the periphery of the optical fiber is good, and the tapering success rate is high; in-situ fixing or packaging of the tapered optical fiber can be achieved; operation is simple, cost is low, and efficiency is high.

Owner:XUZHOU NORMAL UNIVERSITY

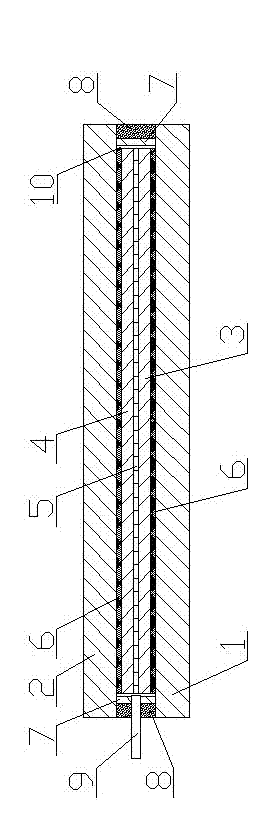

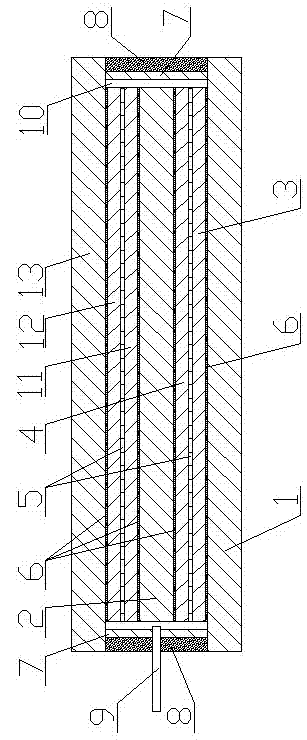

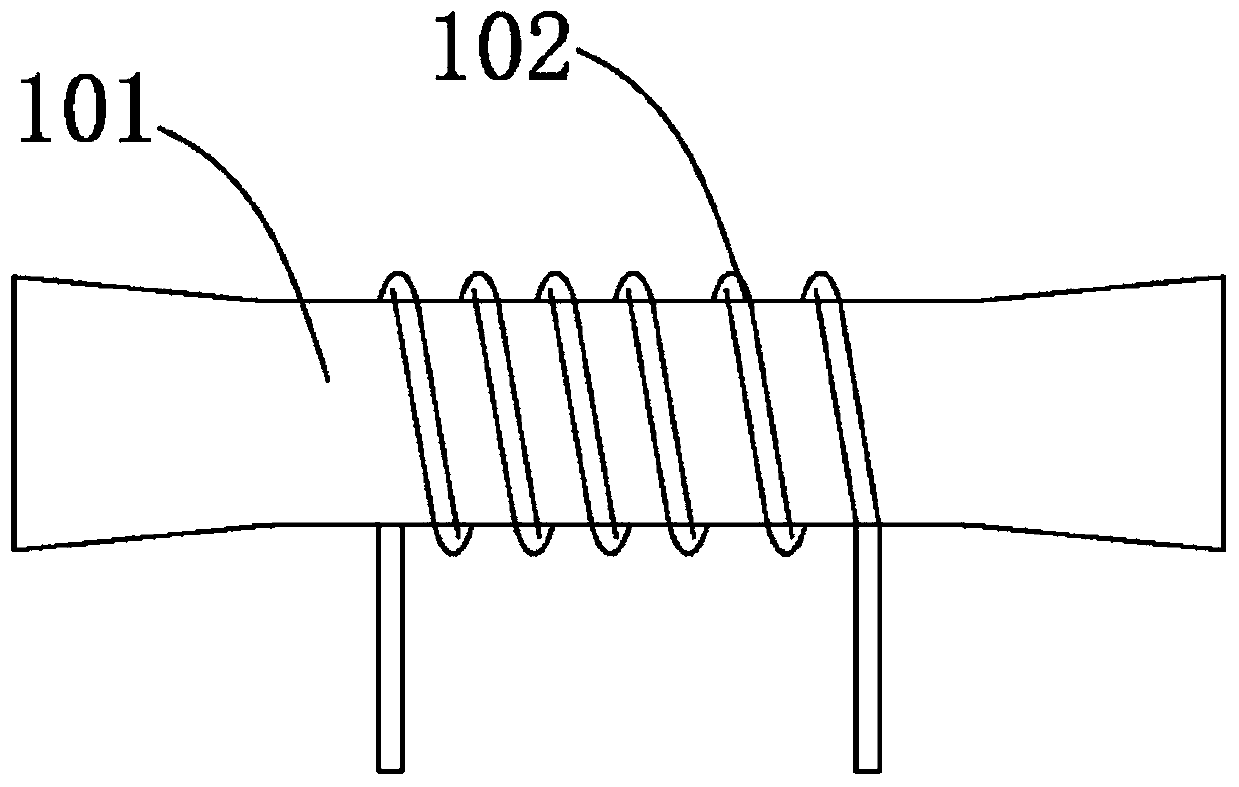

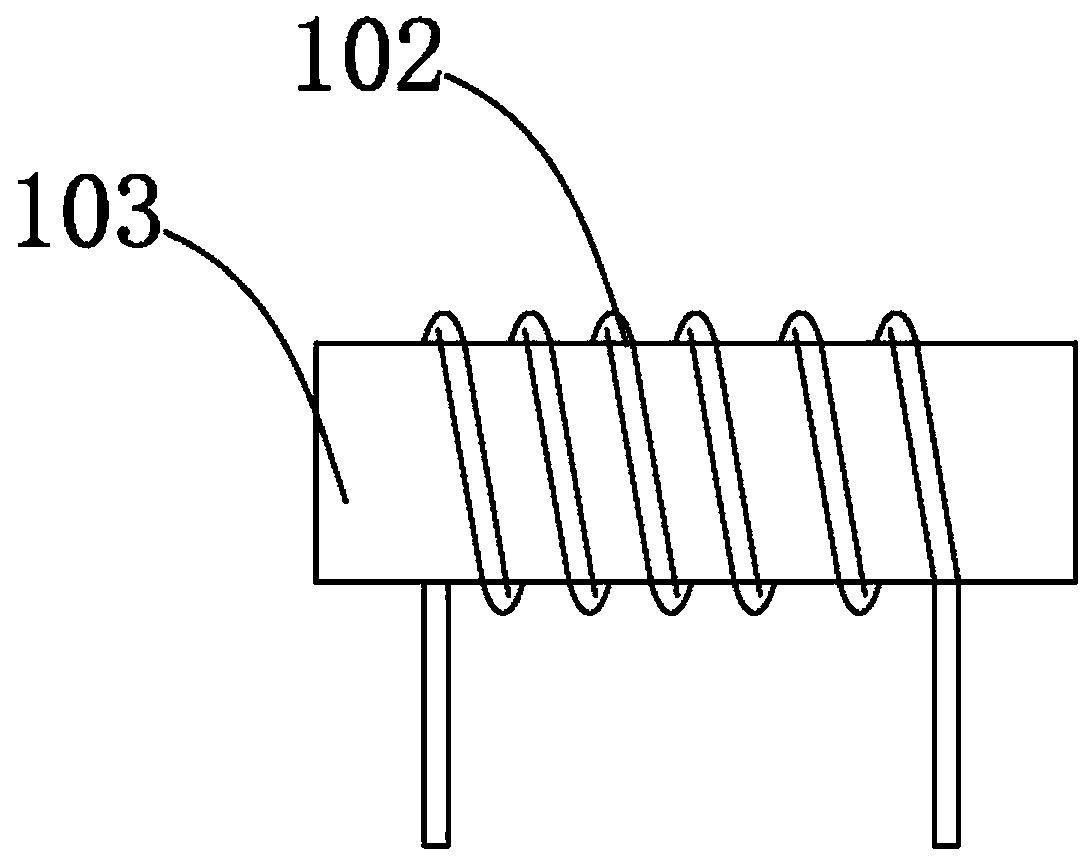

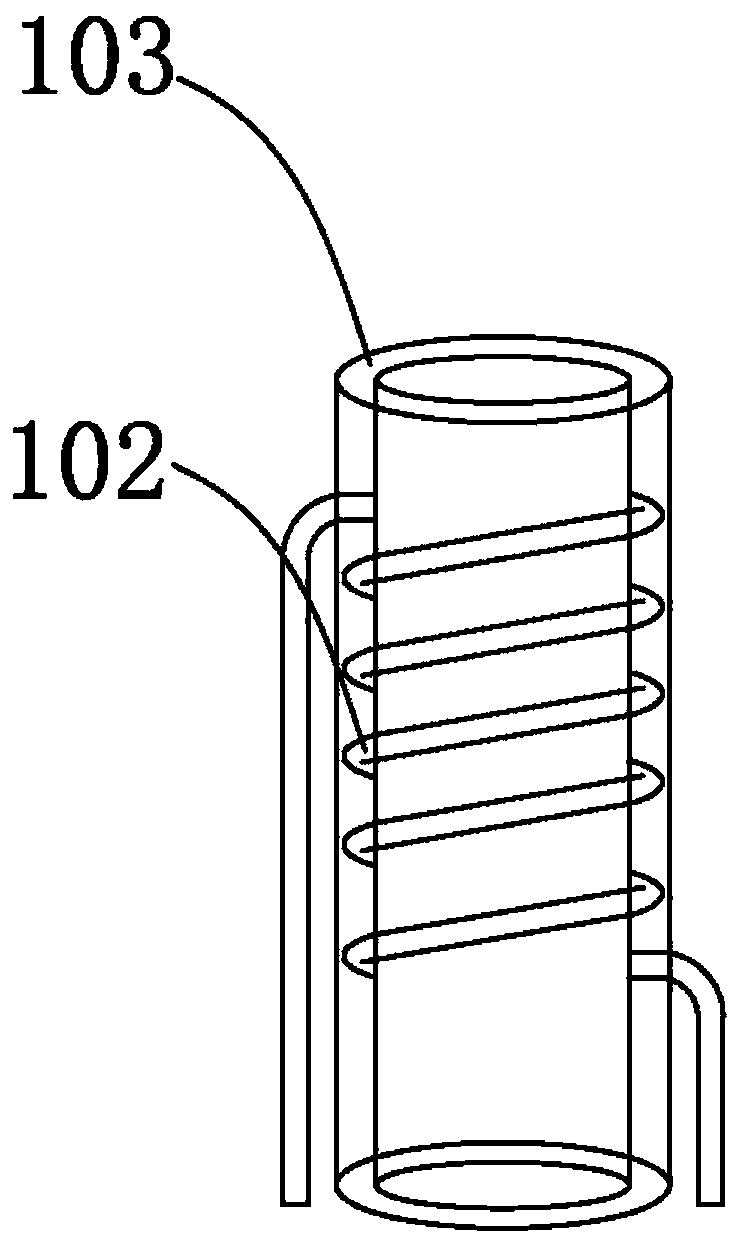

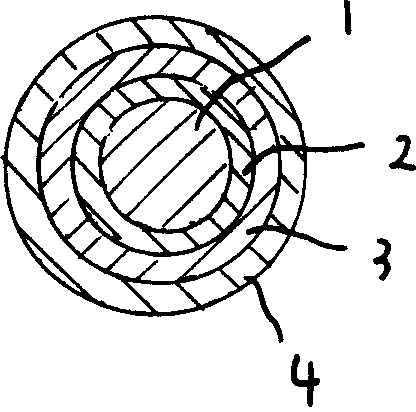

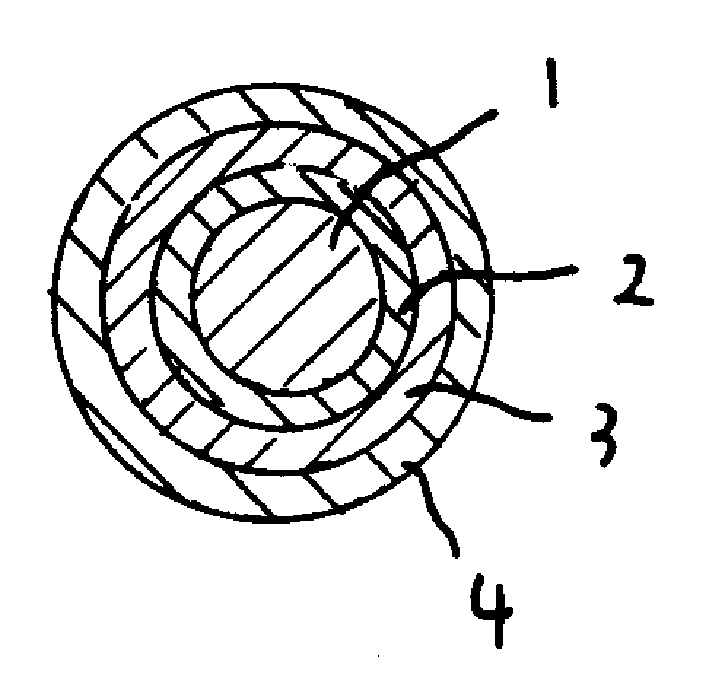

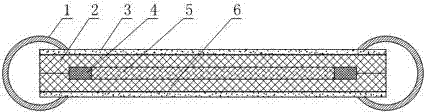

Silicon rubber heat resistant wire for heating coil

InactiveCN1490824AHigh strengthGood environmental protectionTransformers/inductances coils/windings/connectionsInsulated cablesLeading lineWear resistance

The present invention relates to a heat-resistant wire coated with silicone rubber which is used for the heating coil, the wire being mainly suitable to the coil winding and the leading line of microwave oven. It includes from the inner to outer portion a core 1 made of nickel plated copper wires, an insulating layer 2 made of silicone rubber, a weaving layer 3 made of Dacron and an outer heat-resistant coating 4. The weaving layer of the invention has high strength, good wear-resistance, long operating life and good firmness of color attachment.

Owner:马仕兴

Instant solid mango juice drink and processing method thereof

The invention discloses an instant solid mango juice drink and a processing method thereof, belonging to the instant drink field. The drink comprises the following components in parts by weight: 20-70 parts of lyophilized mango powder, 10-50 parts of lyophilized honey powder, 20-60 parts of corn non-dairy creamers and 3-20 parts of lyophilized plant spice powder. Each component of the drink is produced by freezing at the temperature below minus 25-35 DEG C in the absence of oxygen in vacuum, the intrinsic shapes are not likely to shrink, the thermosensitive substances are free from damage, the aromatic substances are not likely to be lost and the readily oxidizable substances are not likely to be oxidized; therefore, the shapes, colors, tastes and nutrients of the substances after processing and the fresh products are basically the same, and the drink is good rehydration property and is liable to mass production. Besides, the drink contains the essential vitamins and mineral elements for human bodies, can enhance the human immunity and is a new generation nutritious and healthy drink featuring quick use and convenient carrying.

Owner:艾志毅 +2

High performance hot work mould steel

This high performance hot-work die steel accounting for weight has following chemical composition: C: 0.70-1.98,Si:0.30-1.50,Mn:0.20-0.70,Cr:0.80-2.00,W:0.80- 1.40,Mo:1.00-1.80,Ni:1.00-3.00,V:0.30-1.20,Bi:0.01-0.02,rare earth Si and Mg:0.05-0.08,P<0.03,S<0.03, the rest is Fe and inevitable impurity. The HRC hardness of it can be adjust by need from 20-60 degree, through the way of heat treatment such as annealing and quenching. The invention has enough mechanical strength and toughness, super ordinary thermal oxidation resistance and cold-heat impact resistance, heat resistance, wear resistance, and aluminium liquid resistance. After process into die, not need surface treatment of 'nitriding', just need quenching and tempering for needed hardness.

Owner:易正伦

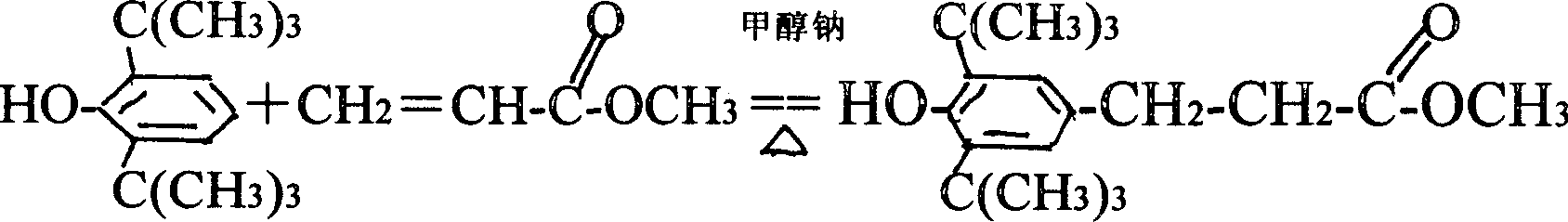

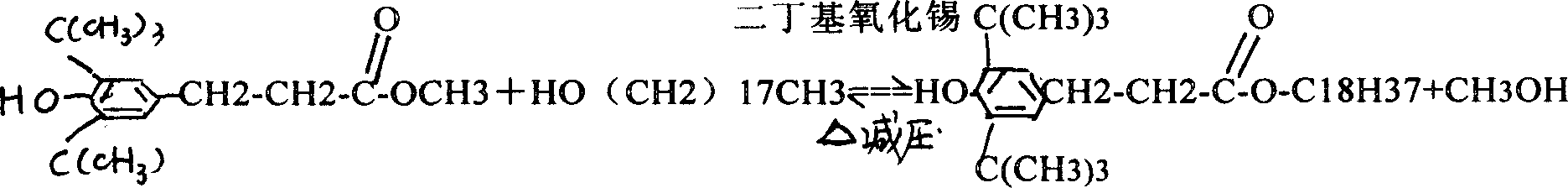

Two-step industrial synthesis method of beta-(3,5-di tertiary butyl-4-hydroxyl phenyl )octadecyl propionate

InactiveCN1733692AWill not oxidizeWhite colorPreparation by transesterificationSodium methoxideReaction temperature

The invention provides a process for two-step industrial synthesis of octadecyl-Beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate, wherein the first step comprises hot melting 2,6-ditertiary butyl phenol at 46-56 deg C, purging nitrogen and charging sodium methoxide as catalyst, between a reaction temperature of 90-105 deg. C, dripping methylacrylate, maintaining 4-4.5 hours at 110-124 deg. C, charging acetic acid and water solution of methanol at 8-80 deg C, carrying out crystallization separation, and the second step comprises reacting octadecyl alcohol, 3,5 methyl ester and dibutyl stannic oxide catalyst, after the reaction finishes, charging acetic acid and water solution of methanol for crystallization.

Owner:TIANJIN CHENGUANG CHEM

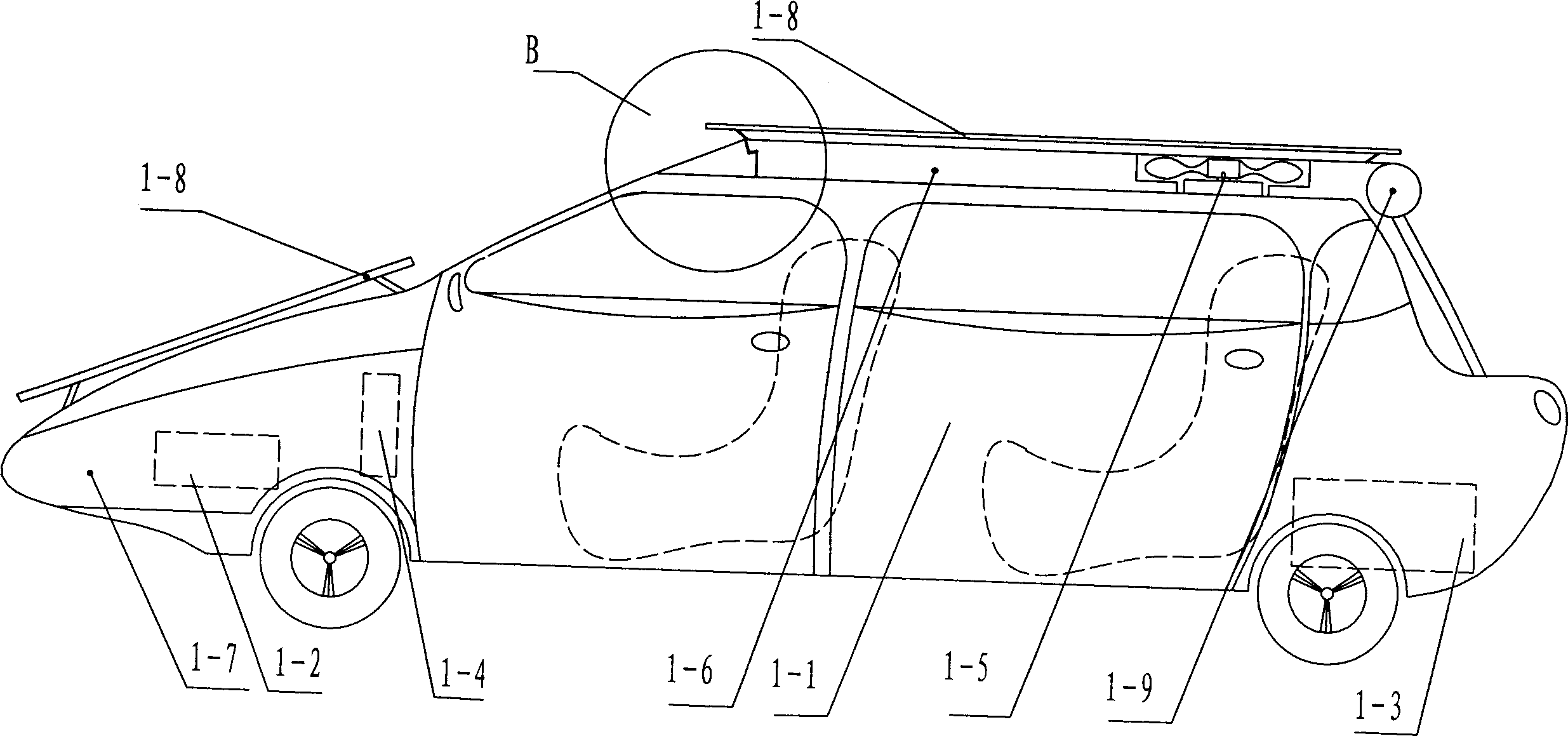

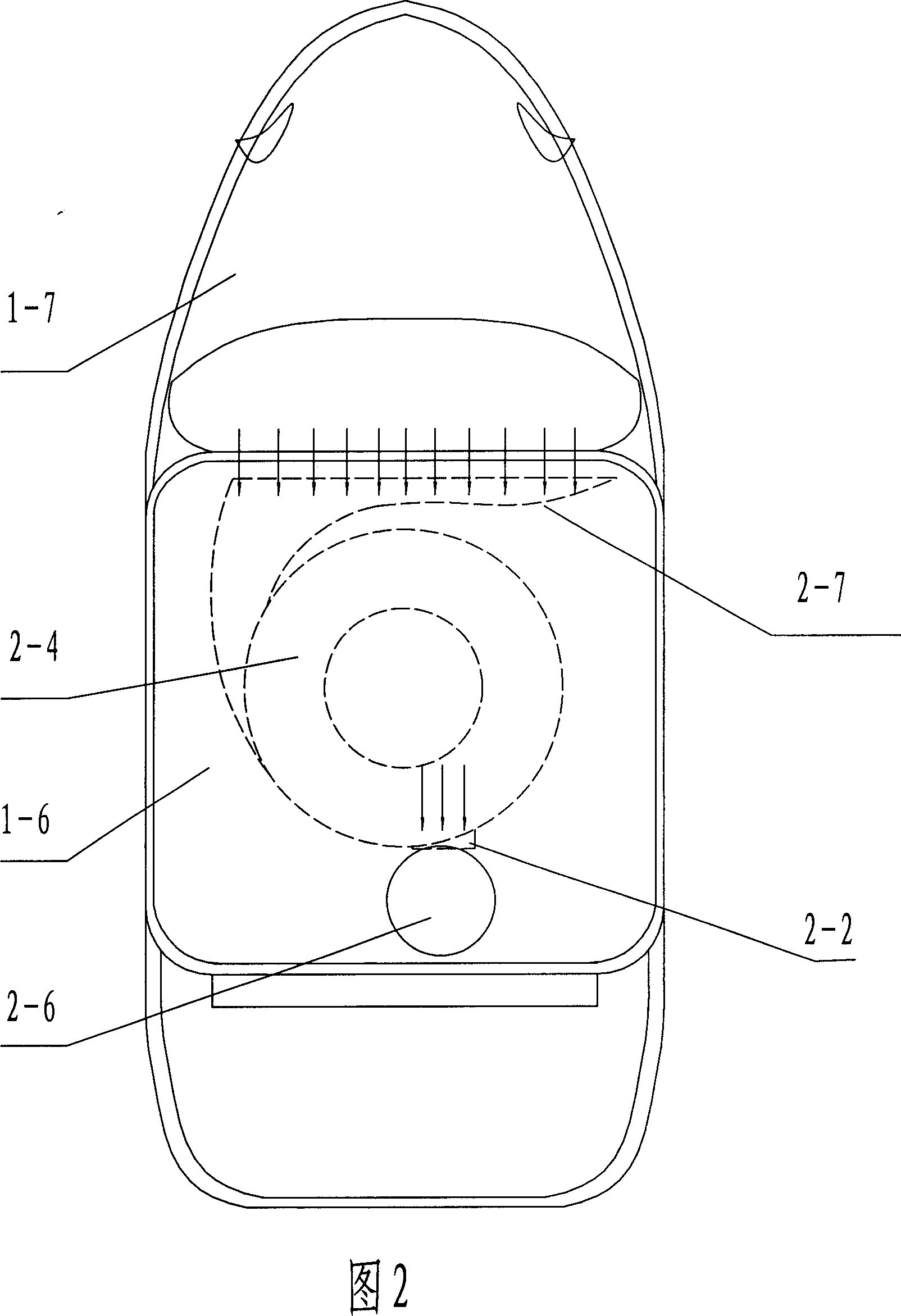

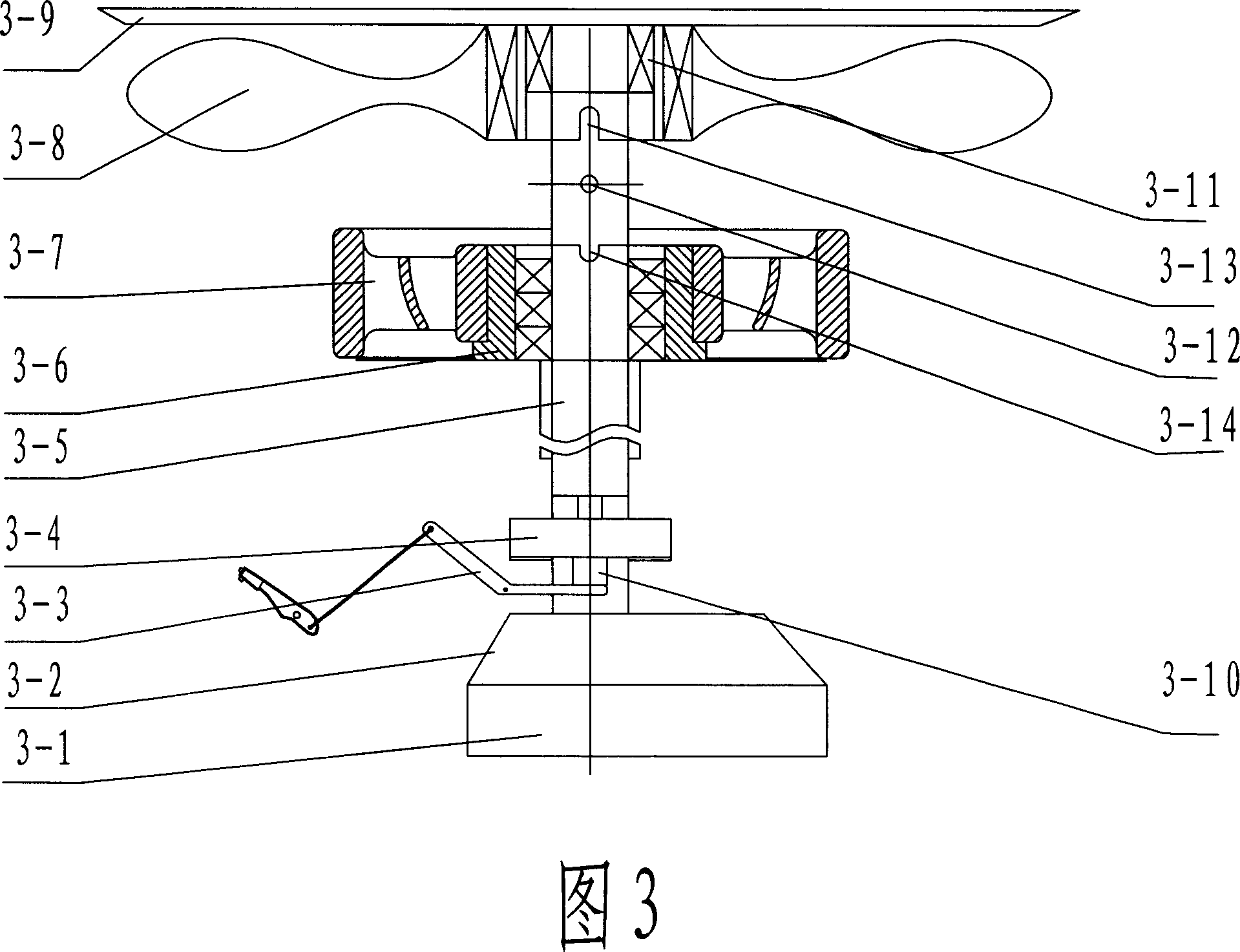

Electric automobile

InactiveCN1958328ATake advantage ofReduce consumptionVehicular energy storageElectric propulsionWind drivenElectricity

An electric car is composed of car body, electric driver unit, and electric accumulator unit and control system. It features that said car body has a wind driven electric generator and several solar cell boards connected electrically with said electric accumulator unit.

Owner:HUNAN FENGRIFUYUE NEW ENERGY ELECTRIC VEHICLES CO LTD

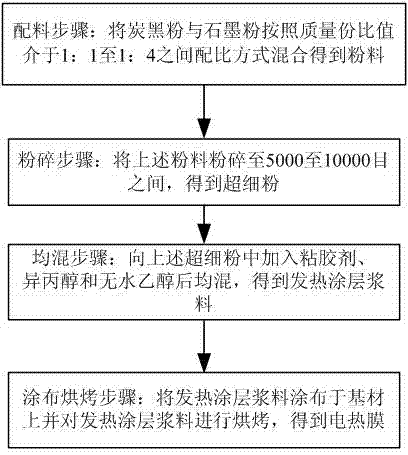

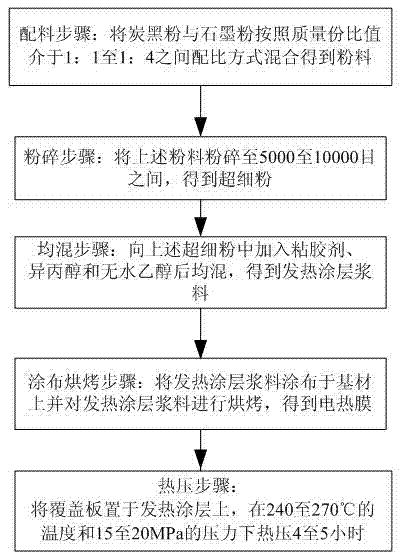

Electric heating film, electric heating plate and corresponding manufacturing methods

ActiveCN104780630AEvenly heatedNo electromagnetic radiationOhmic-resistance heatingElectricityAdhesive

The invention discloses an electric heating film, an electric heating plate and corresponding manufacturing methods. The electric heating film comprises a substrate and a heating coating, wherein the heating coating comprises an adhesive and a carbon heating material; the carbon heating material is the mixture of carbon black power and graphite powder. Moreover, the invention discloses an electric heating plate using the electric heating film, and manufacturing methods for the electric heating film and the electric heating plate. The electric heating film and the electric heating plate, obtained by the manufacturing methods, are very uniform in heating, free from electromagnetic radiation and harmless to humans, emits no visible light at a temperature of below 500 DEG C and is very high in electricity-heat conversion efficiency; because the heating body is made of a carbon powder material and cannot be oxidized by the oxygen in the air, the service life is long; according to the electric heating film obtained according to the formula and the electric heating plate containing the electric heating film, under the condition of meeting the using power, heat is emitted from a surface and the electric heating film and the electric heating plate are very thin and very small in mass, and the instantaneous heating capacity is very small, so that heating is fast, and the purpose of plugging and heating is achieved.

Owner:CHENGDU YANGZHONG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com