Patents

Literature

4084results about How to "Easy to demould" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing an adhesive closing element

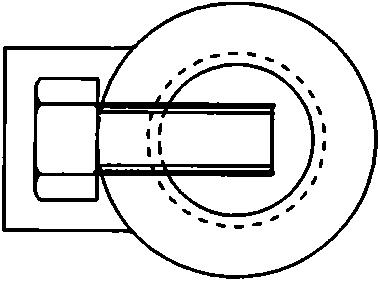

InactiveUS7198743B2Easy to demouldFavorable closing behaviorDischarging arrangementArtificial filament physical treatmentEngineeringHooking

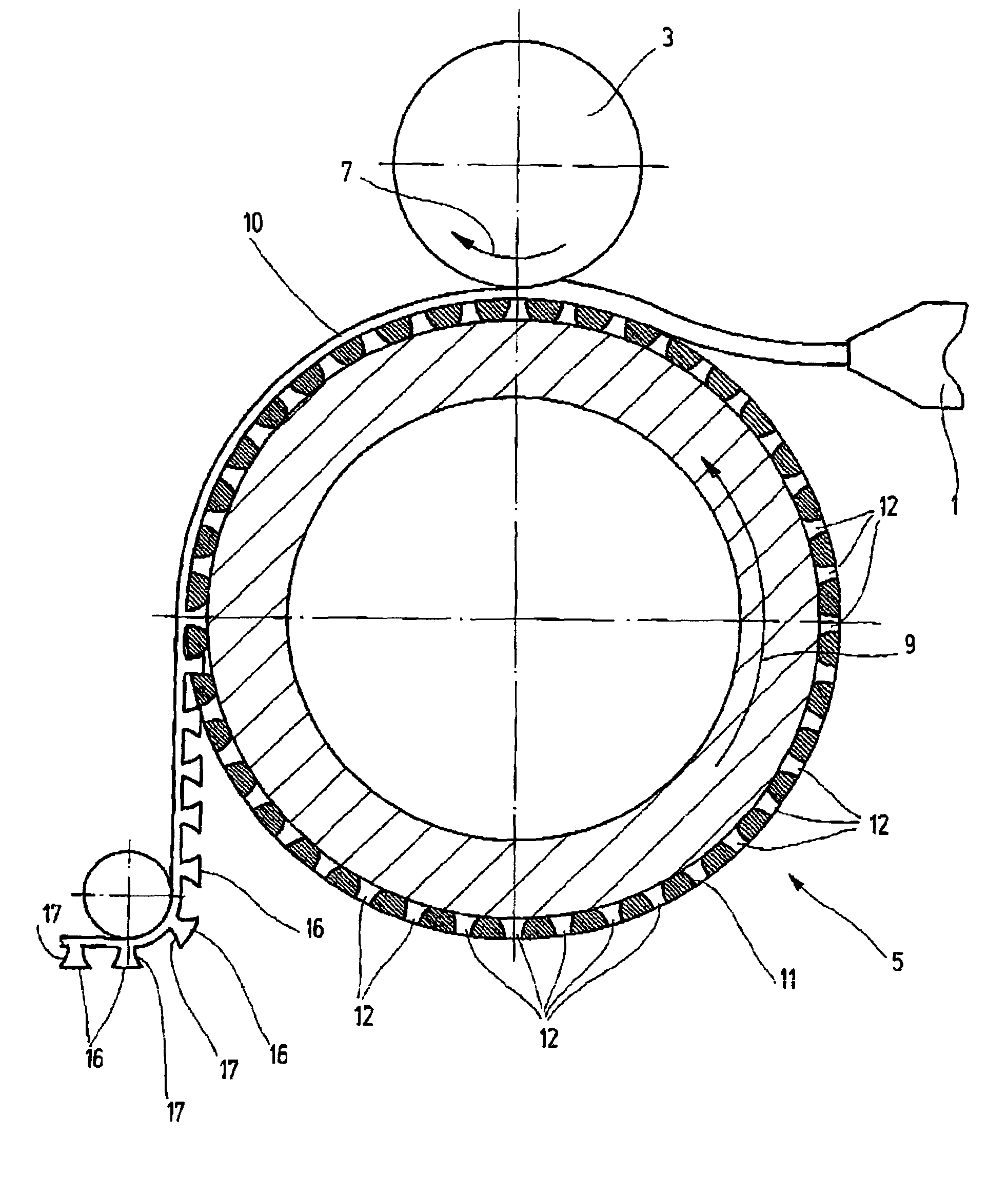

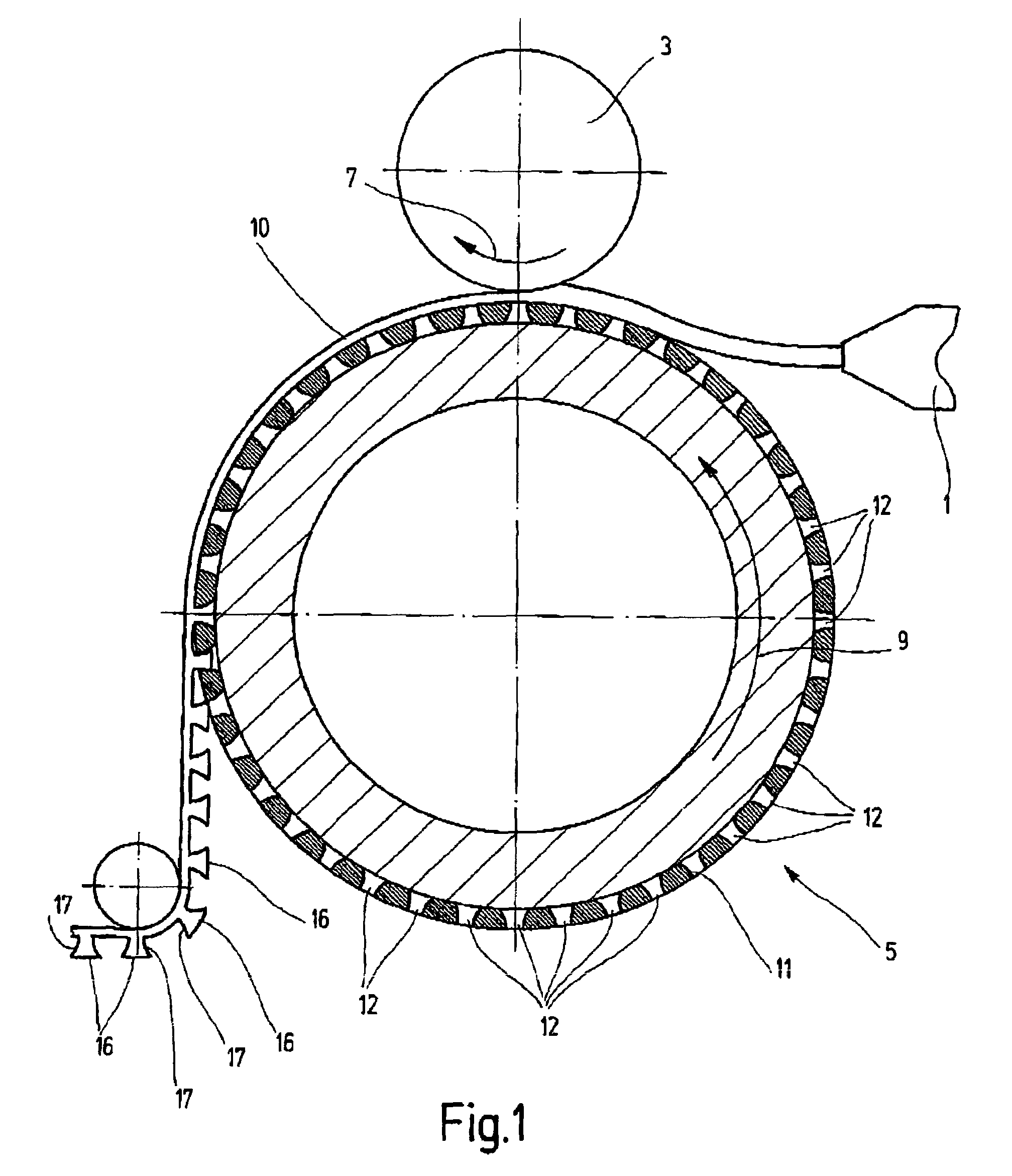

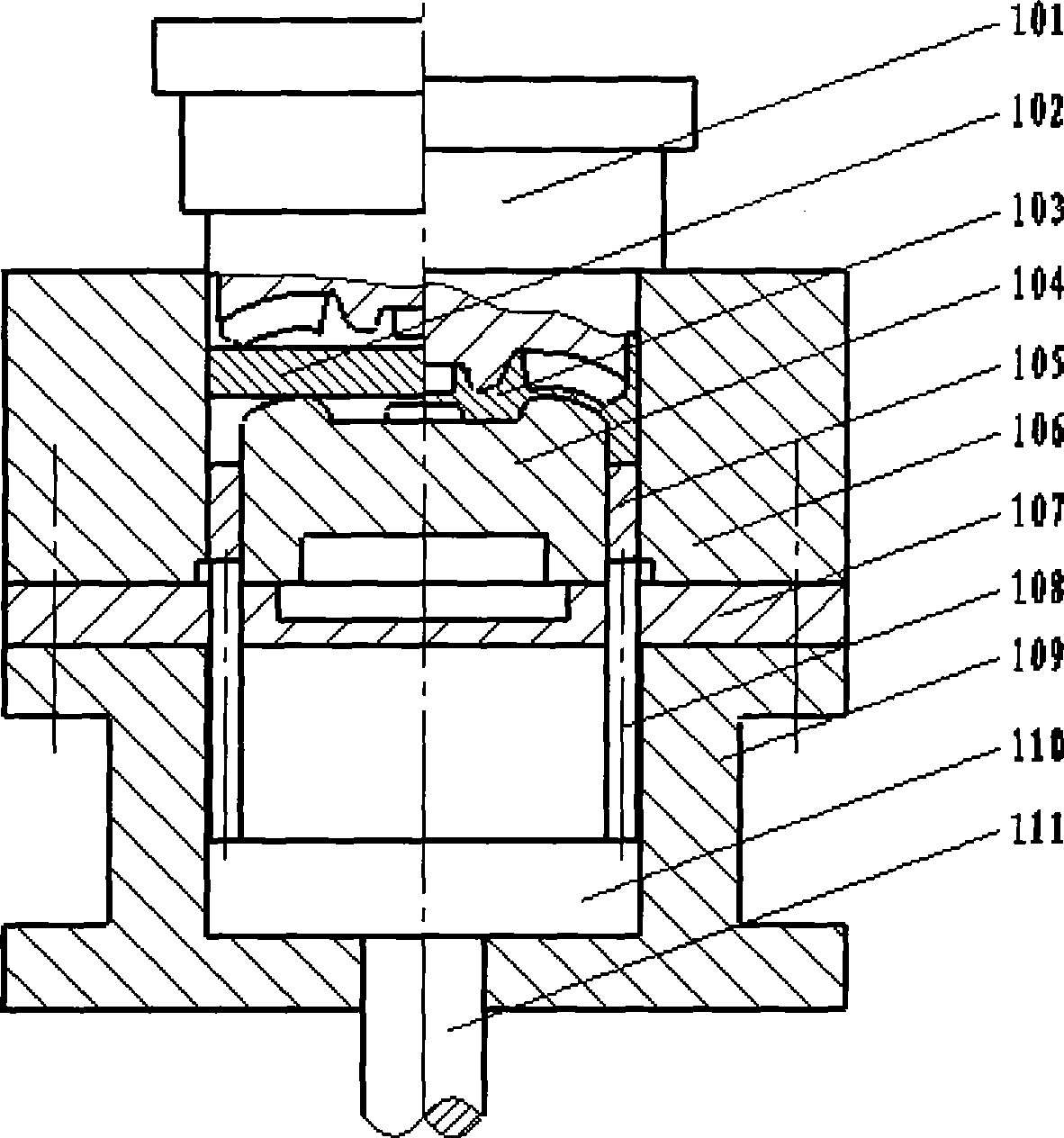

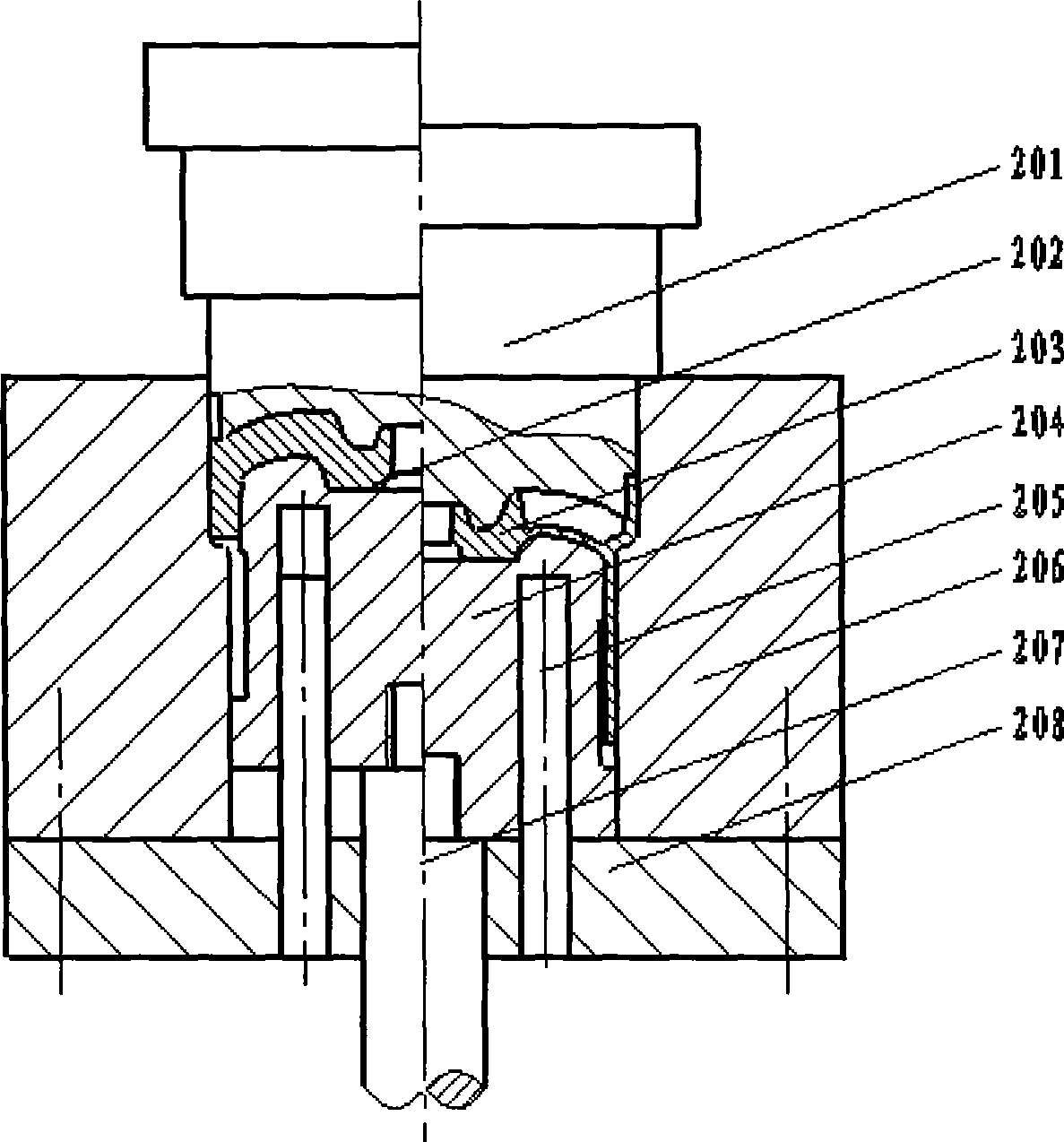

A process for produces an adhesive closing element including a plurality of hook elements connected to a backing (10) forming a single piece with the hook elements and being disposed symmetrically thereon. The hook elements are provided in the form of a stem component (17) having a head piece (16). A deformable material is introduced into a forming zone in between a production master (3) and a forming tool (5). The opposite-lying defining walls, at least when seen in a longitudinal section of the respective forming cavity (12), are provided with a continuous convex trajectory. A continuous transition between the cross-sectional forms of the stem component (17) and the head piece (16) is provided for a hooking of the backing (10) resulting in seamless removal.

Owner:GOTTLIEB BINDER

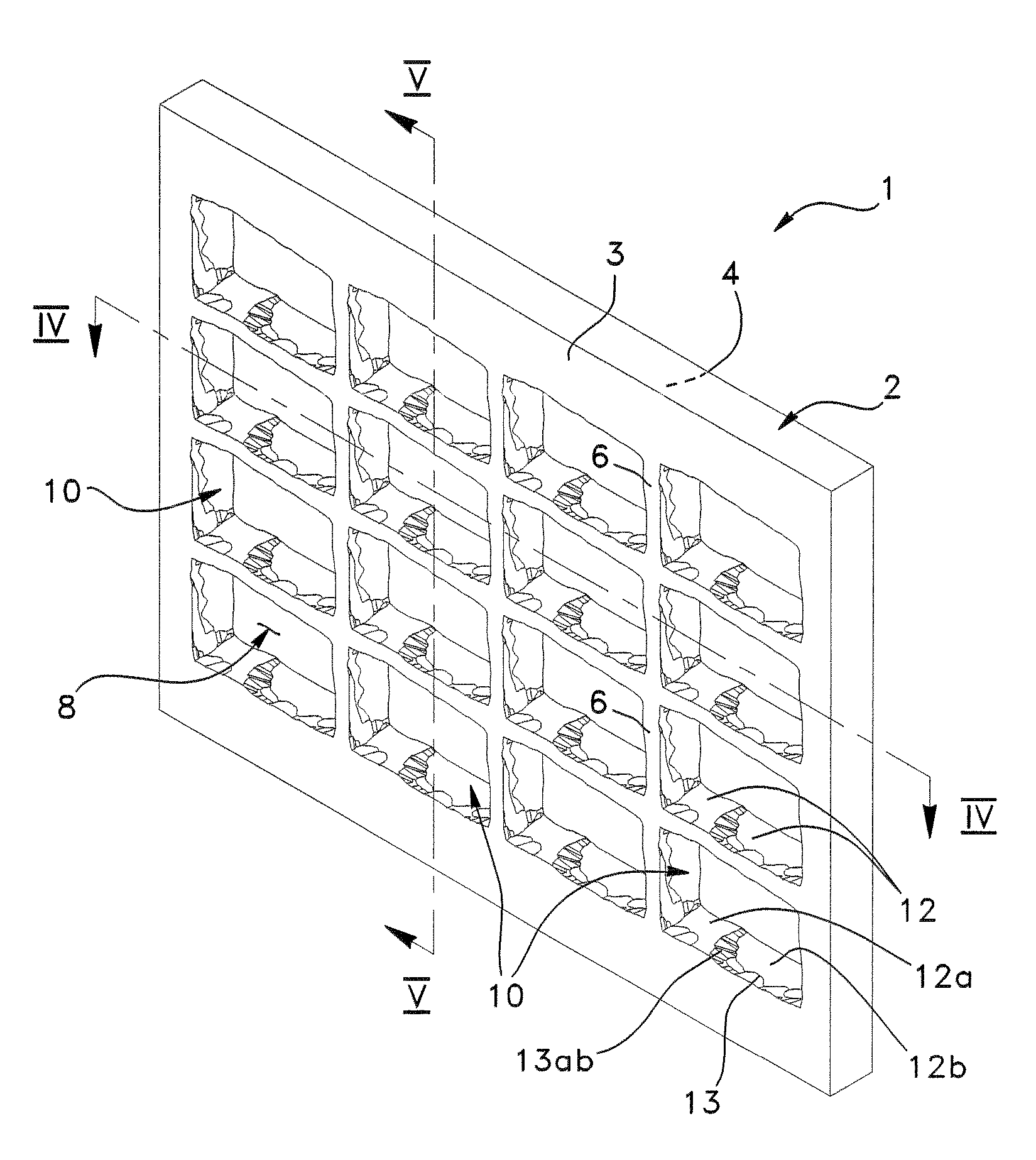

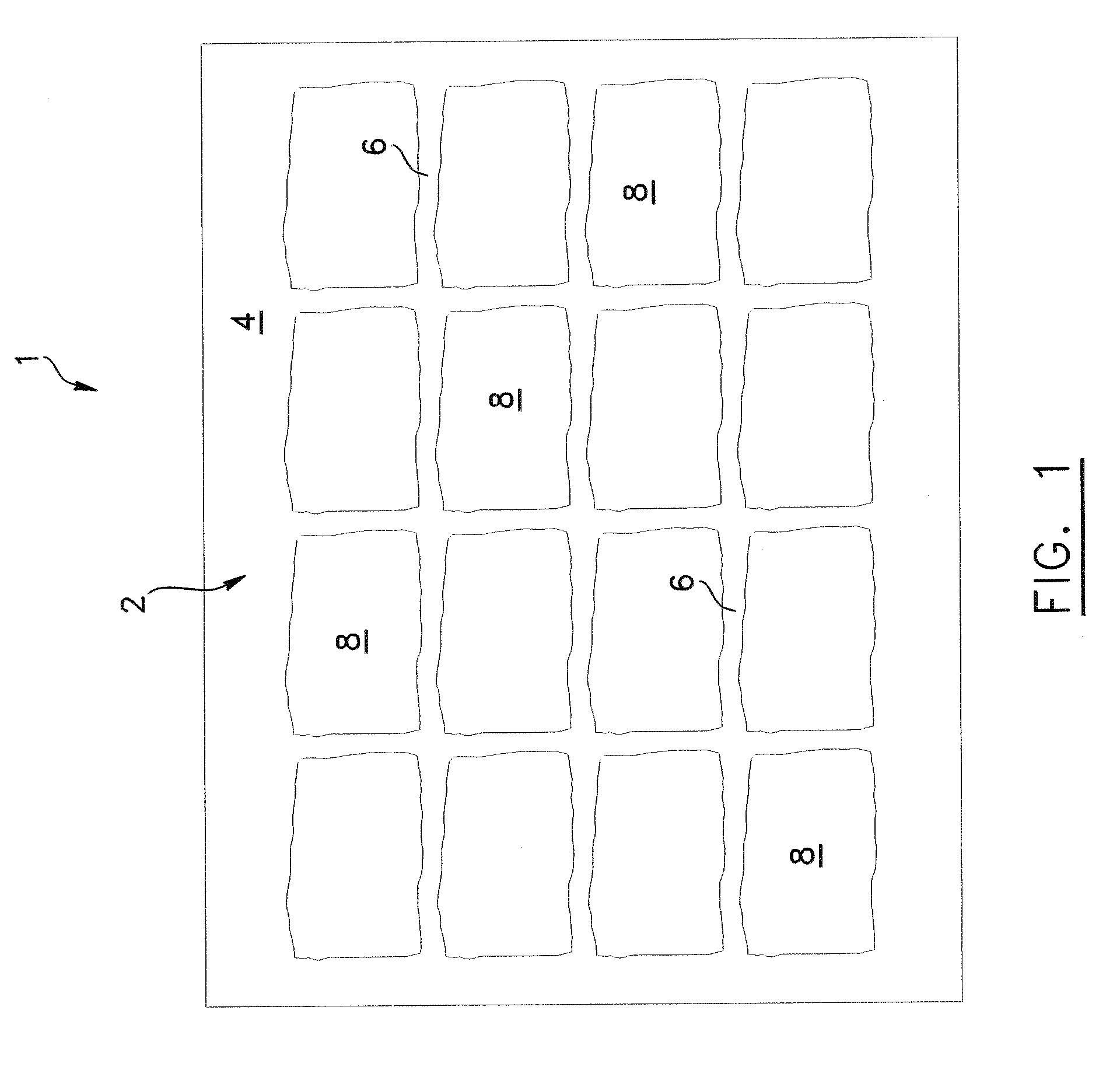

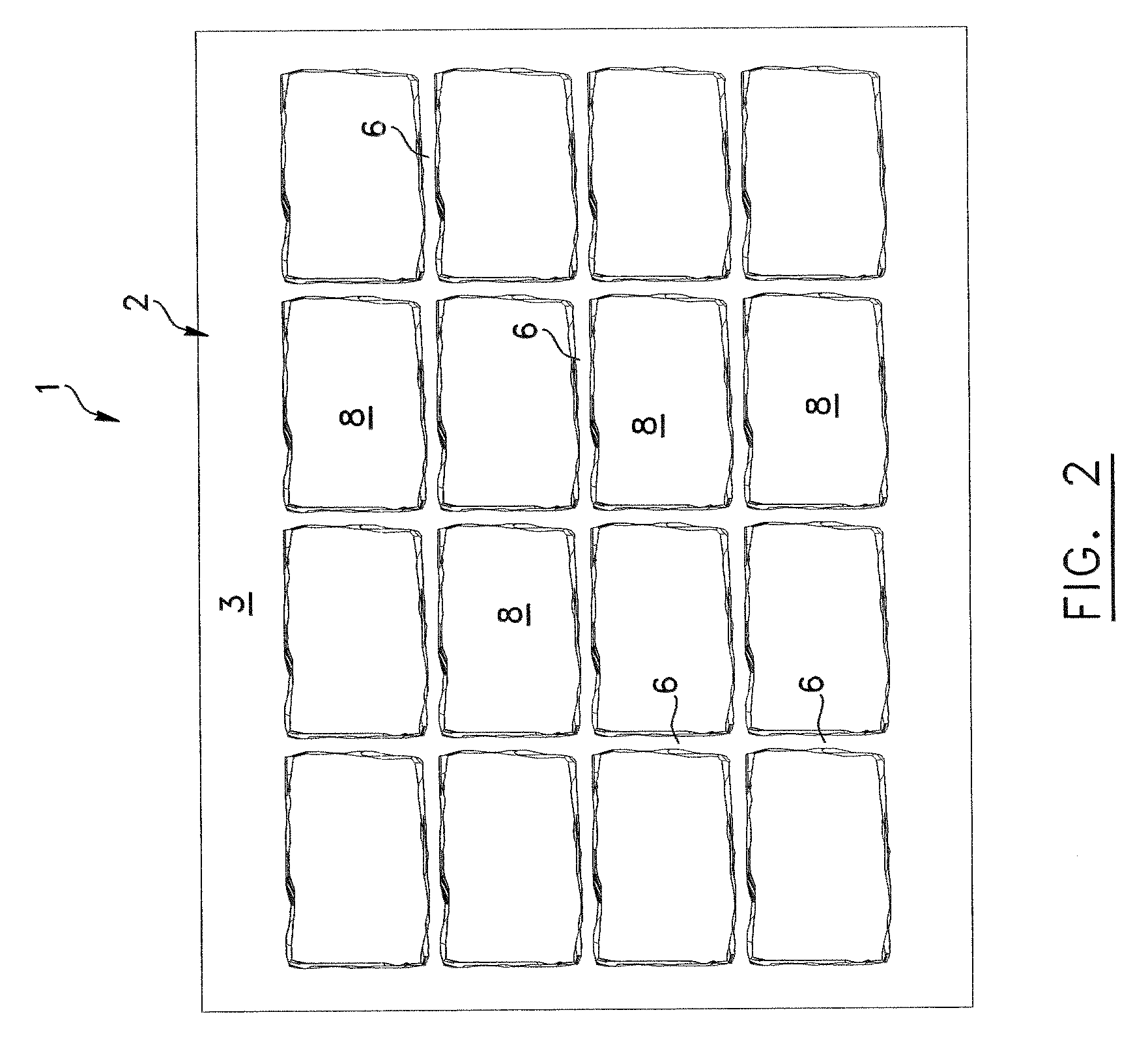

Molding apparatus for producing dry cast products having textured side surfaces

ActiveUS8101113B2Easy to demouldConstruction materialMould separation apparatusEngineeringMechanical engineering

Owner:OLDCASTLE BUILDING PROD CANADA INC

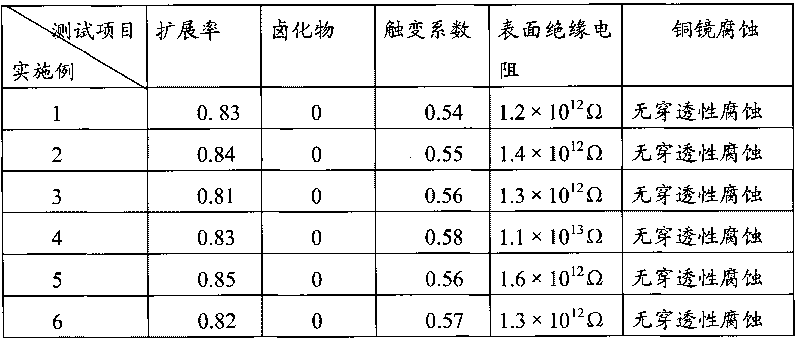

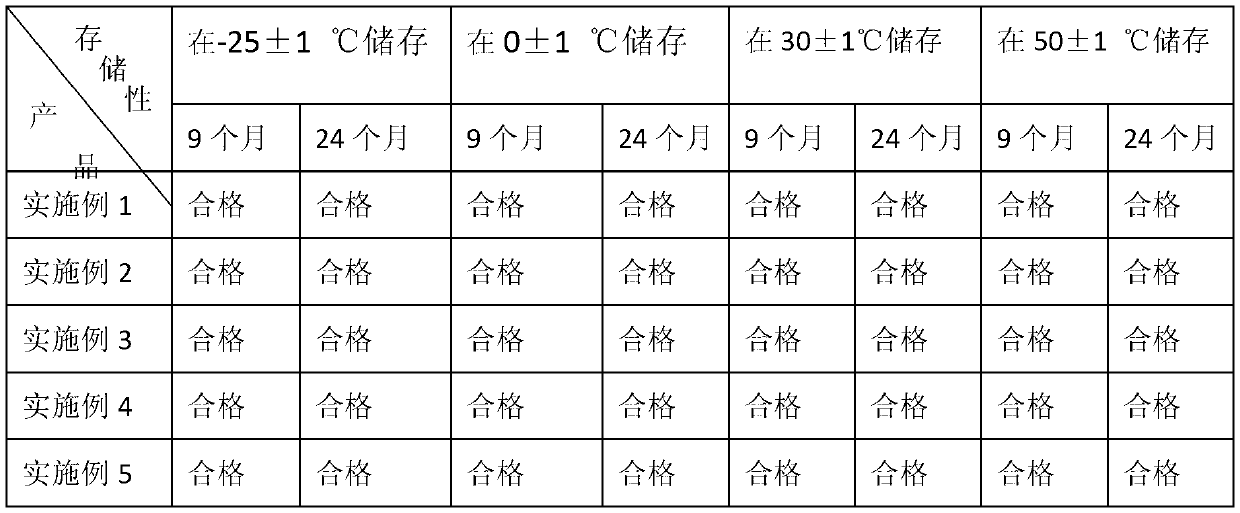

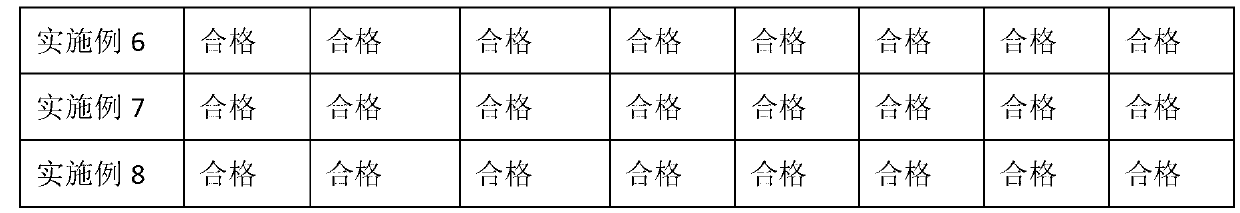

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

Special release agent for concrete and preparation method thereof

ActiveCN103103011AGood compatibilityGood antirust effectCeramic shaping apparatusAdditivesFatty acidSaponification

The invention relates to a special release agent for concrete, which comprises the following materials in parts by weight: 80-90 parts of mineral substance oil, 1-5 parts of an emulgator, 1-5 parts of a defoaming agent, 0.01-0.4 part of a corrosion inhibitor, and 1-10 parts of fatty acid. The invention also relates to a preparation method for the release agent. The special release agent for concrete adopts two substances, namely, a fatty acid active substance and the emulgator, the adhesive strength of the surface of the concrete is reduced when surface saponification is formed, so that demoulding is easier and the surface is smooth and has no defects. The product prepared by the method can be stored at temperature of wide range, is convenient to store and can be stored for a long time, has small relative density, can be diluted for use by adding 2-6 times of water, and lowers the transportation cost of the release agent.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Method for preparing sharp type epoxide resin binding agent diamond abrasive tool

ActiveCN103056788AImprove bindingInhibit sheddingAbrasion apparatusGrinding devicesFirming agentEpoxide

The invention discloses a method for preparing a sharp type epoxide resin binding agent diamond abrasive tool. A working layer is mainly made of diamond abrasive, an epoxide resin binding agent, a curing agent, an auxiliary abrasive, a filler and an auxiliary assistant. The method comprises steps of uniformly mixing 5-20 parts by mass of self-sharpening diamond, 5-28 parts by mass of auxiliary abrasive, 10-40 parts by mass of filler and 0.5-10 parts by mass of auxiliary assistant through a machine; uniformly mixing the mixture, 17-25 parts by mass of liquid epoxide resin and 5-25 parts of curing agent; injecting the fluid mixture to a plastic die through a pouring mode; and obtaining the sharp type epoxide resin binding agent diamond abrasive tool after curing. Compared with the method for preparing the abrasive tool through hot press molding, the method has the advantages that the process is simple, the energy is saved, the emission is reduced, the pollution of solid powder on the environment is reduced, the method is environment-friendly, the production speed is quick, the sharpening degree is high, the self-sharpening performance is good, the polishing effect is good and the service life is long.

Owner:惠安宇信金刚石工具有限公司

Lead-free halogen-free tinol and preparation process

ActiveCN1876311AImprove compatibilityImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaOrganic acidHalogen

The invention discloses a leadless and no-halogen tonal, comprising following components with percent by weight: alloy powder 80-98 and welding flux 2-20; said alloy powder is one of SnAgCu, SnAgNi, SnAgBiCu, SnAgBiSb, SnCu and SnAg; said welding flux concludes following components with percent by weight: modified resin antioxidant 30-60, organic acid activating agent 5-15, thixotropic agent 4-14, plasticizing agent 2-6, plasticizing agent 0.4-2, inhibitor 0.1-0.5 and organic solvent 20-40; said modified resin antioxidant comprises following components with percent by weight: modified rosin resin 80-90, anti-oxidant 2-8, and reducer 2-8. The tonal is characterized by good thixotropic behavior, no oxidation, no dry welding and no short circuit.

Owner:BEIJING XINLI MACHINERY

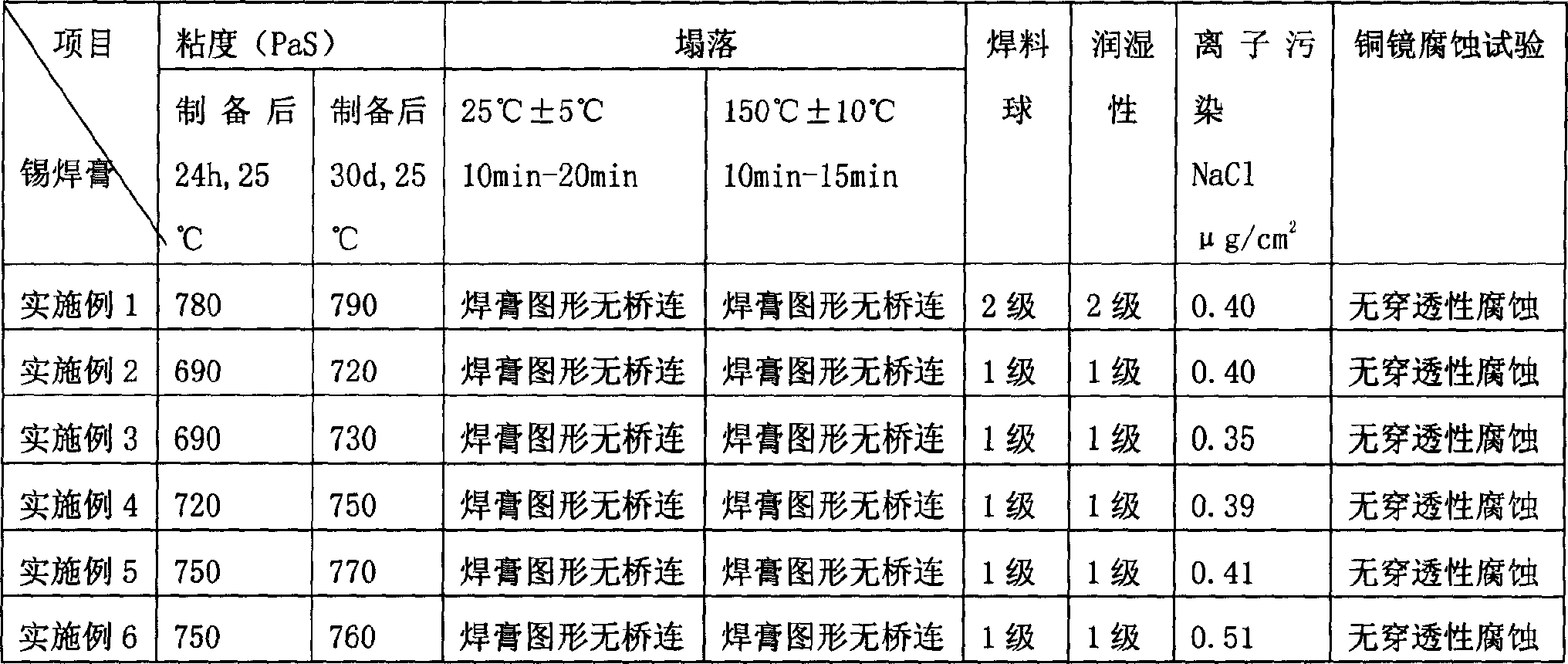

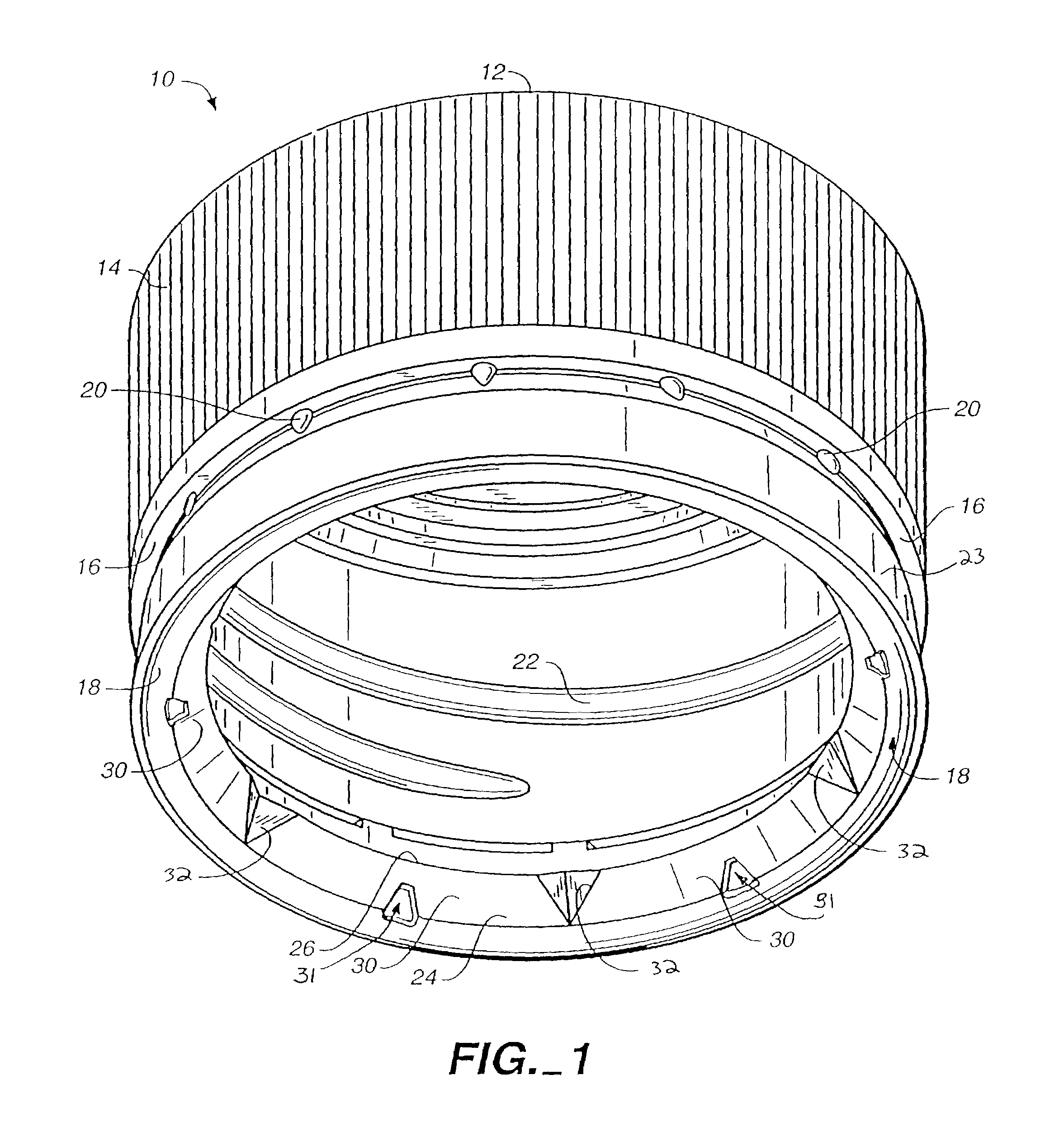

Tamper evident bottle cap

A closure for sealing the opening of a container. The closure may include an angled plug. The container includes an external thread configuration and the closure includes an internal thread configuration which are adapted to pass over each other with one of the external and internal thread configurations having at least one thread lead and the other having at least twice as many thread leads. The closure includes an inwardly turned retaining rim extends at least partially upwardly. The retaining rim has an attachment boss and an upwardly extending line of weakness adjacent the attachment boss such that when the closure is removed from the container, the line of weakness tears allowing the tamper-evidencing band to remain with the closure upon removal from the container. The closure may include a top having a periphery, an annular skirt depending downwardly from the periphery and including a lower edge and a line of weakness extending upwardly from the lower edge, a tear tab extending downwardly from the skirt below the lower edge, and a tamper-evidencing locking member including an inwardly extending locking ring that extends radially inwardly from the skirt intermediate the top and the bottom edge, the retaining rim including a free edge that is adapted to engage the radially extending locking bead of the container when the closure is removed from the container neck. A method of molding a closure including a tamper-evidencing band is also disclosed.

Owner:PORTOLA PACKING INC

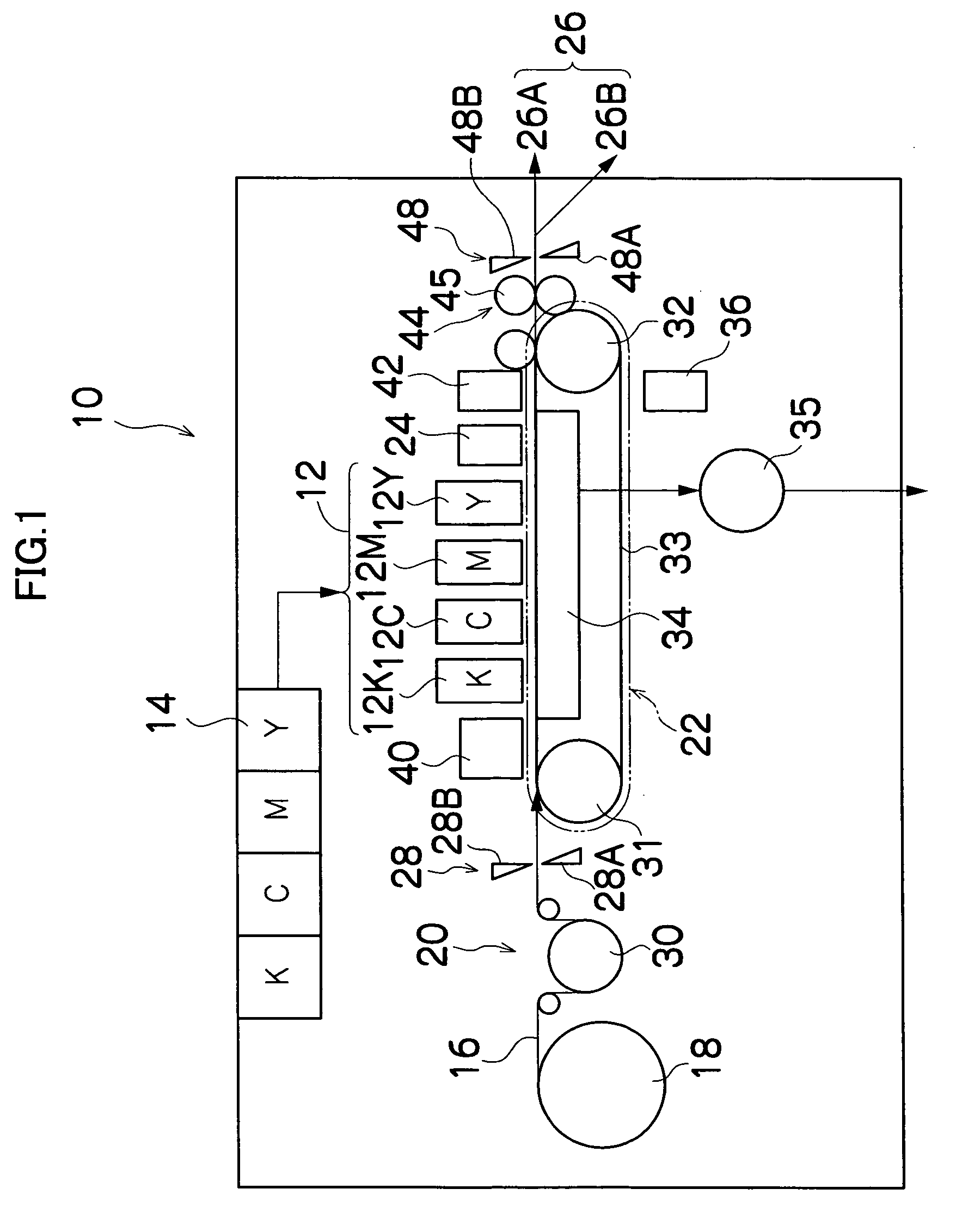

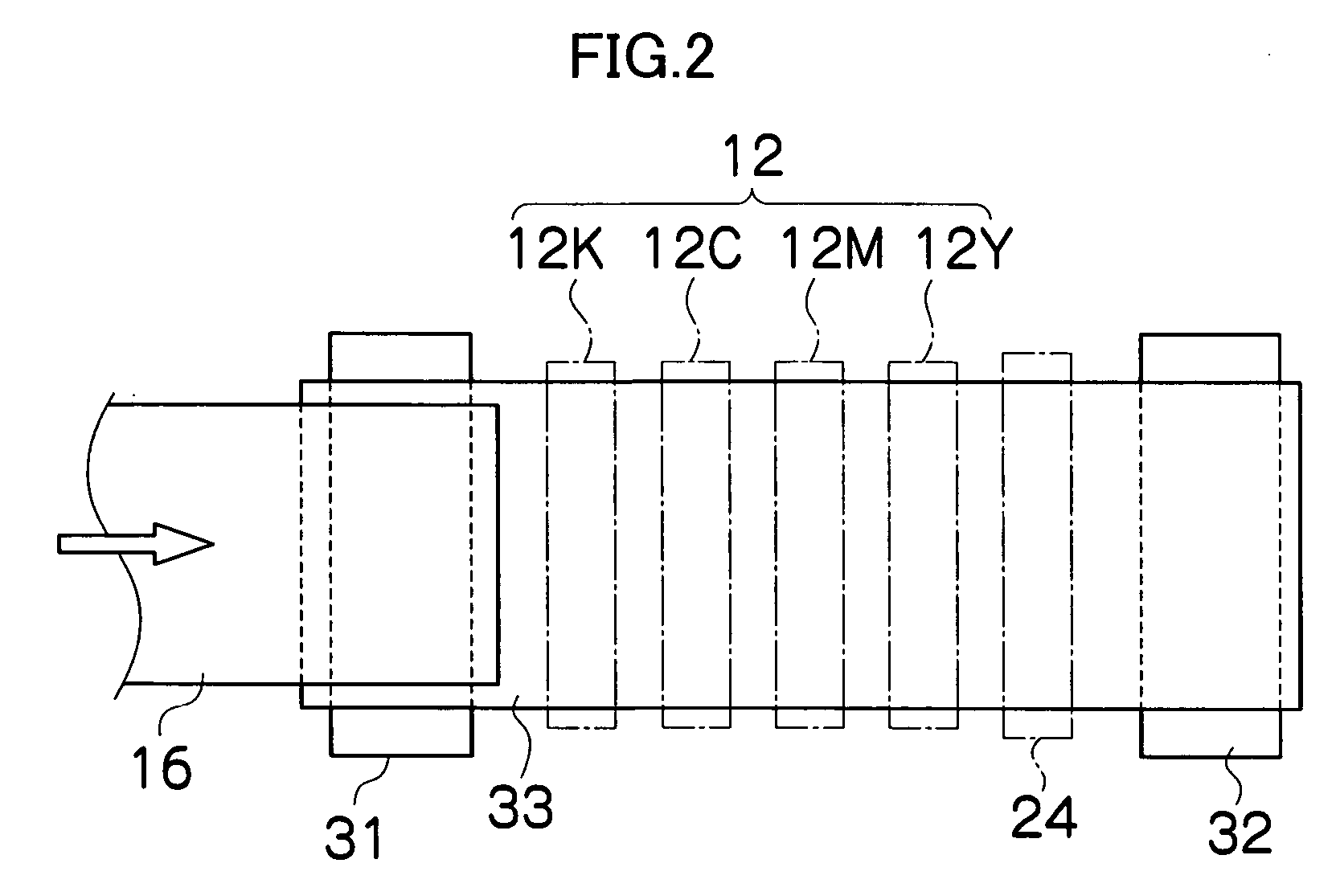

Transfer ink jet recording aqueous ink

ActiveUS20110269885A1Inhibit deteriorationExcellent ejection stabilityFilm/foil adhesivesInksIntermediate imageEther

An aqueous ink for a transfer ink jet recording method including applying to an intermediate transfer member a reaction liquid which forms an increased viscosity ink image by coming into contact with a coloring material in the ink, applying the ink to the intermediate transfer member by an ink jet device to form an intermediate image, and bringing a printing object into contact with the intermediate transfer member to transfer the image to the object. The aqueous ink contains a coloring material which is a polymer dispersion pigment dispersed in the aqueous medium with a polymer having a hydroxyl group in its structure as a dispersant, a nonionic surfactant which is an alcohol ether surfactant a 1% aqueous solution of which has a cloud point of 33° C. or less and which has a C4-C30 alkyl group and a propyleneoxy group in its structure, and an aqueous medium.

Owner:CANON KK

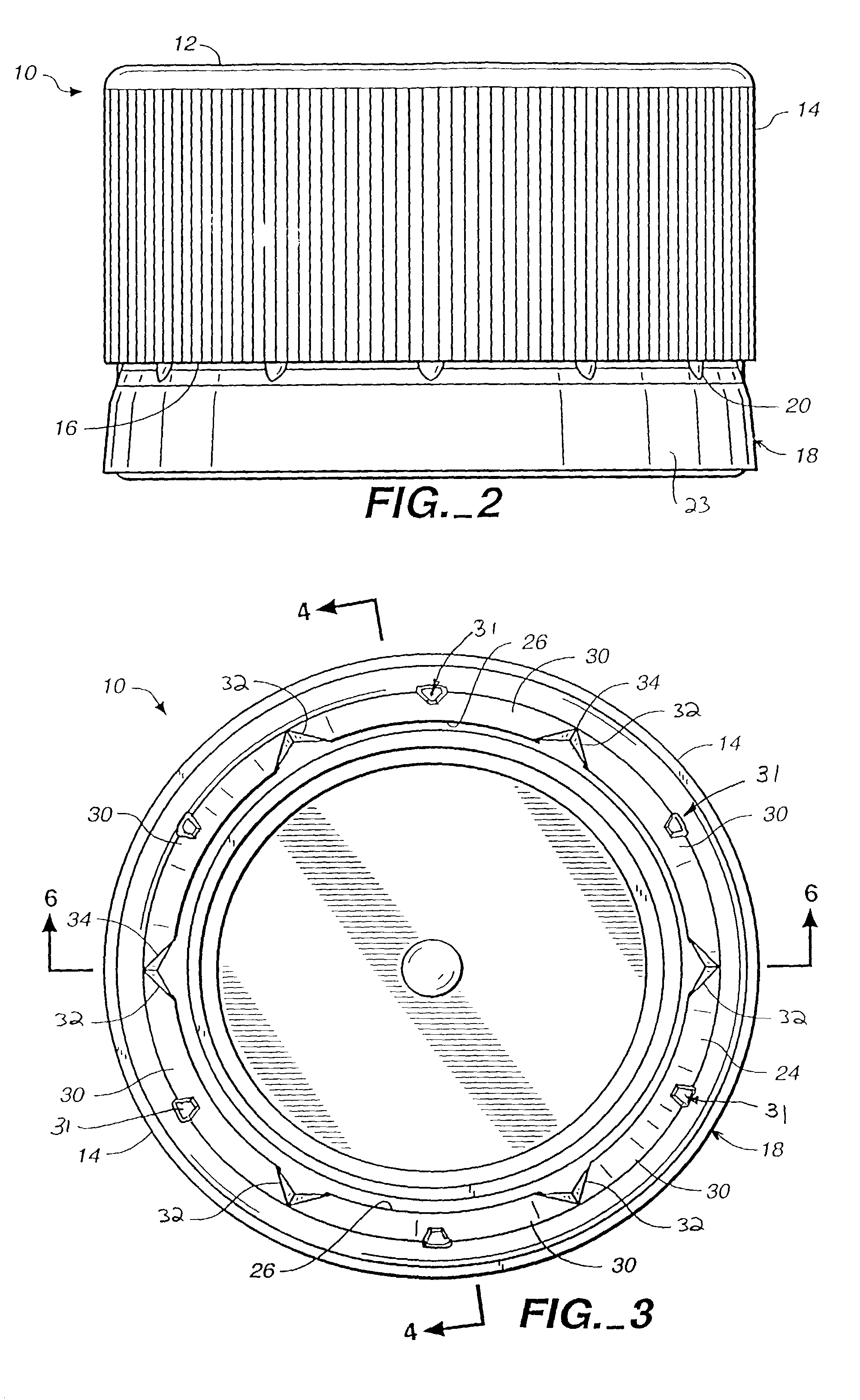

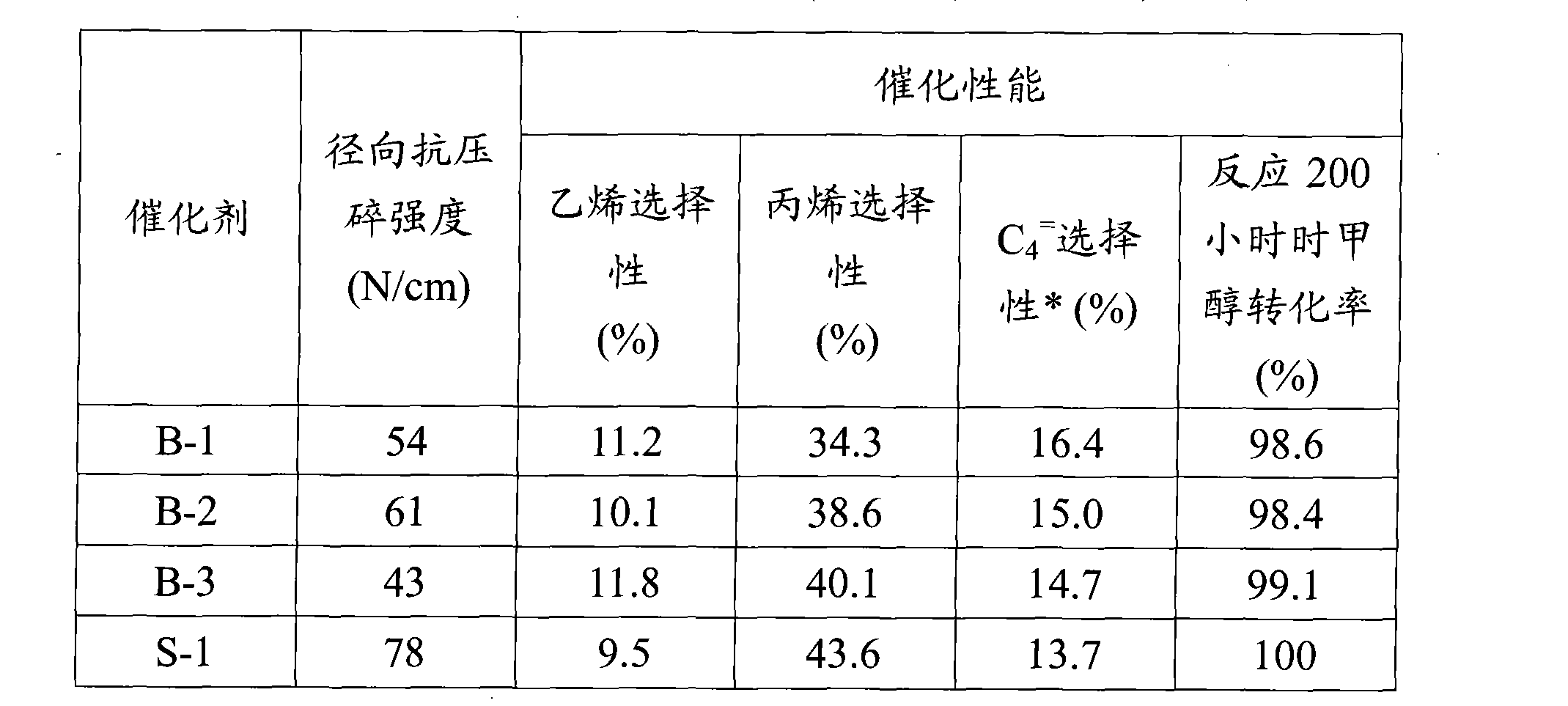

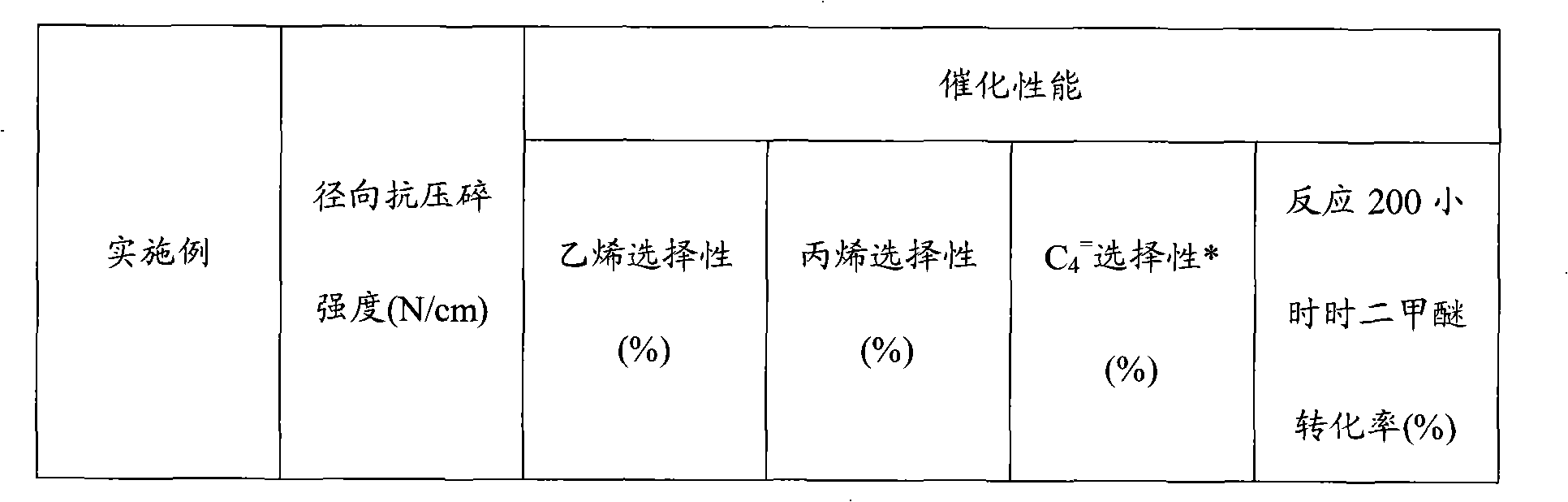

Molecular sieve catalyst for preparing low-carbon olefin and preparation method thereof

ActiveCN101628242ATotal pressure is smallSimplify production stepsMolecular sieve catalystsCatalyst activation/preparationMolecular sieveHigh activity

The invention provides a molecular sieve catalyst for preparing low-carbon olefin, and the catalyst comprises the following raw materials by parts by weight: 30-93.7 parts of Na-ZSM-5 zeolite, 5-40 parts of bonding agent, 0.1-10 parts of modifier of mixed elements, 1-15 parts of hole structure regulator and 0.1-5 parts of extrusion assistant, and the modifier of the mixed elements is a soluble substance containing one or a plurality of elements of B, P, La, Ca, Mg, Sr, Zn, Cu, Mn, Cd, Ga and In. The invention further provides a prepration method of the catalyst. The molecular sieve catalyst adopts the extrusion assistant and adds an appropriate amount of hole structure regulator, thereby improving product strength and hole structure, effectively improving diffusion performance of the catalyst and further improving selectivity of the low-carbon olefin. The catalyst has the advantages of appropriate strength, high hydrothermal stability, high activity and high selectivity of propylene.

Owner:DATANG INT CHEM TECH RESINST

Composite fire resistant pouring material

The invention relates to an organic-inorganic composite combined advanced monolithic refractory which has the formula of 40 to 56 percent of 5-1mm corundum or bauxite, 12 to 30 percent of 1-0.0088mm corundum or bauxite, 16 to 25 percent of corundum or bauxite with d90 less than 0.088mm, 0 to 5 percent of alpha alumina micropowder, 1 to 8 percent of hydratable alumina, 1 to 6 percent of siliceous dust, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of external efficient water reducing agents (polycarboxylic acid plus sulfonation naphthaldehyde polymer plus sulfonation melamine polymer), 1 to 6 percent of latex of the system of external polyacrylic acid, 1 to 6 percent of external water and 0 to 3 percent of external heat-resistant steel fiber. Casting materials of the invention have excellent performances of condensation, hardening, demoulding, drying and heating and are suitable for high-temperature furnace projects with changeful field conditions.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

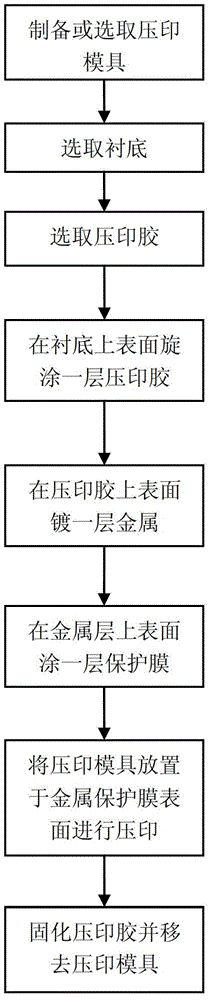

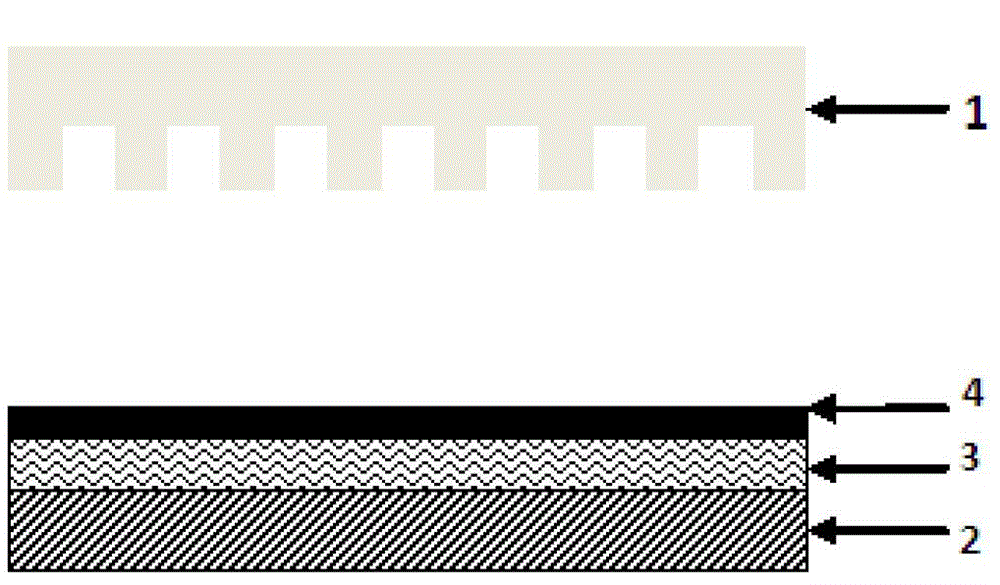

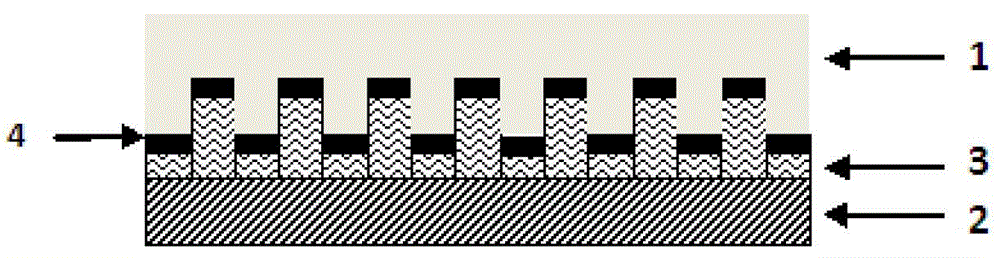

Preparation method of multilayer metal grating

InactiveCN103149615ANot easy to depositImprove fidelityPhotomechanical apparatusDiffraction gratingsTectorial membraneMetal

The invention relates to a preparation method of a multilayer metal grating. The preparation method comprises the following steps of: preparing or selecting an imprinting template; spin coating a layer of imprinting glue on an upper surface of a substrate; plating a metal layer on a surface of the imprinting glue; coating a layer of protection film on an upper surface of a metal layer; placing the imprinting template on an upper surface of the protection film, and carrying out nano-imprinting; and after curing the imprinting glue, removing the imprinting template to obtain a double-layer metal grating or the multilayer metal grating. According to the preparation method of the multilayer metal grating, a step of pattern transfer is omitted, the process is simpler, the cost is lower, a metal film obtained through the method cannot be coated on a side wall of a pattern to affect the transmission efficiency, the shape of a cross section of the metal film is strictly matched with the shape of a cross section of the imprinting template, and compared with adoption of a traditional method, the fidelity of the pattern and the TM transmission rate and the polarization rejection ratio of the grating are higher.

Owner:SHANGHAI JIAO TONG UNIV

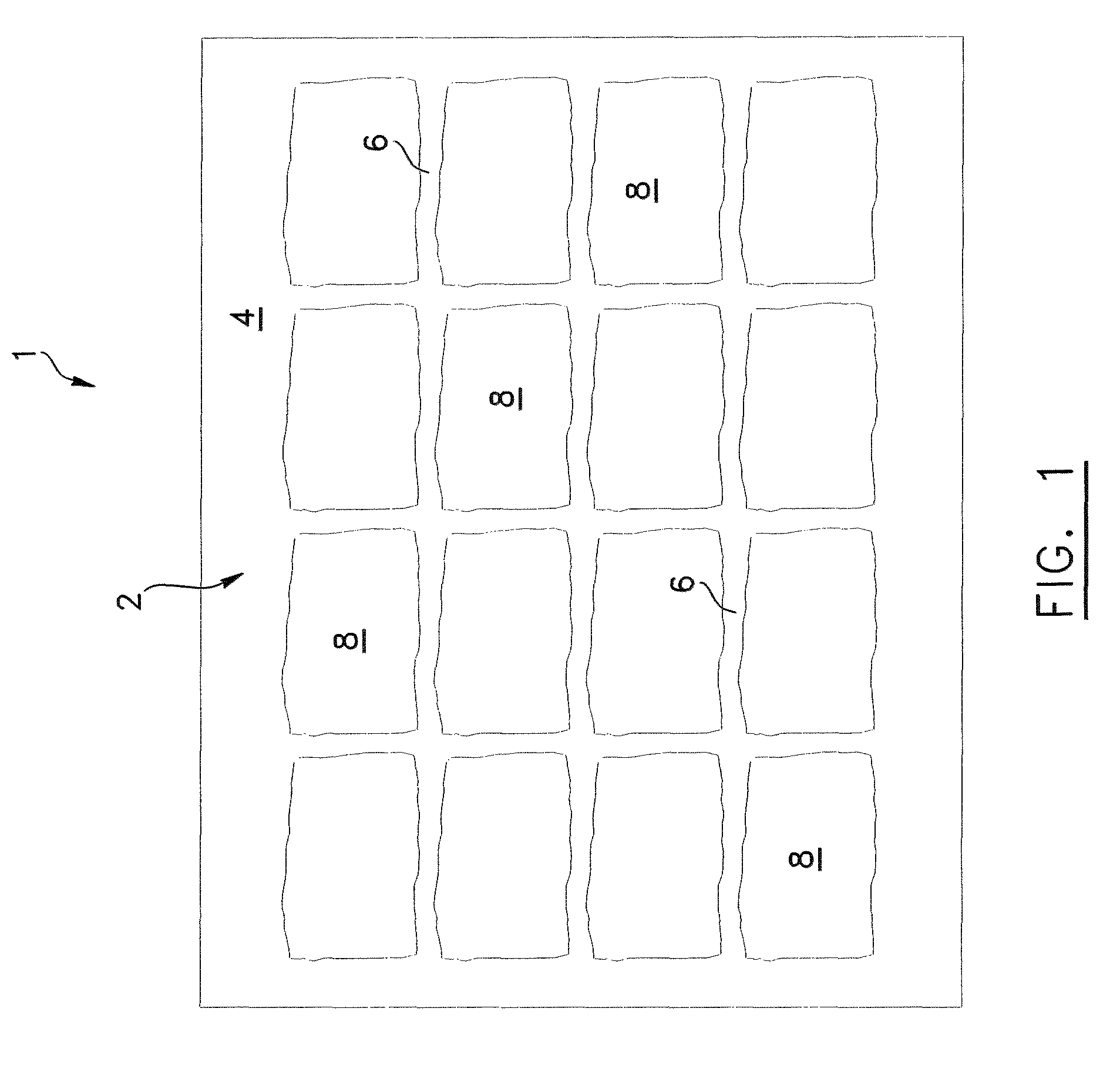

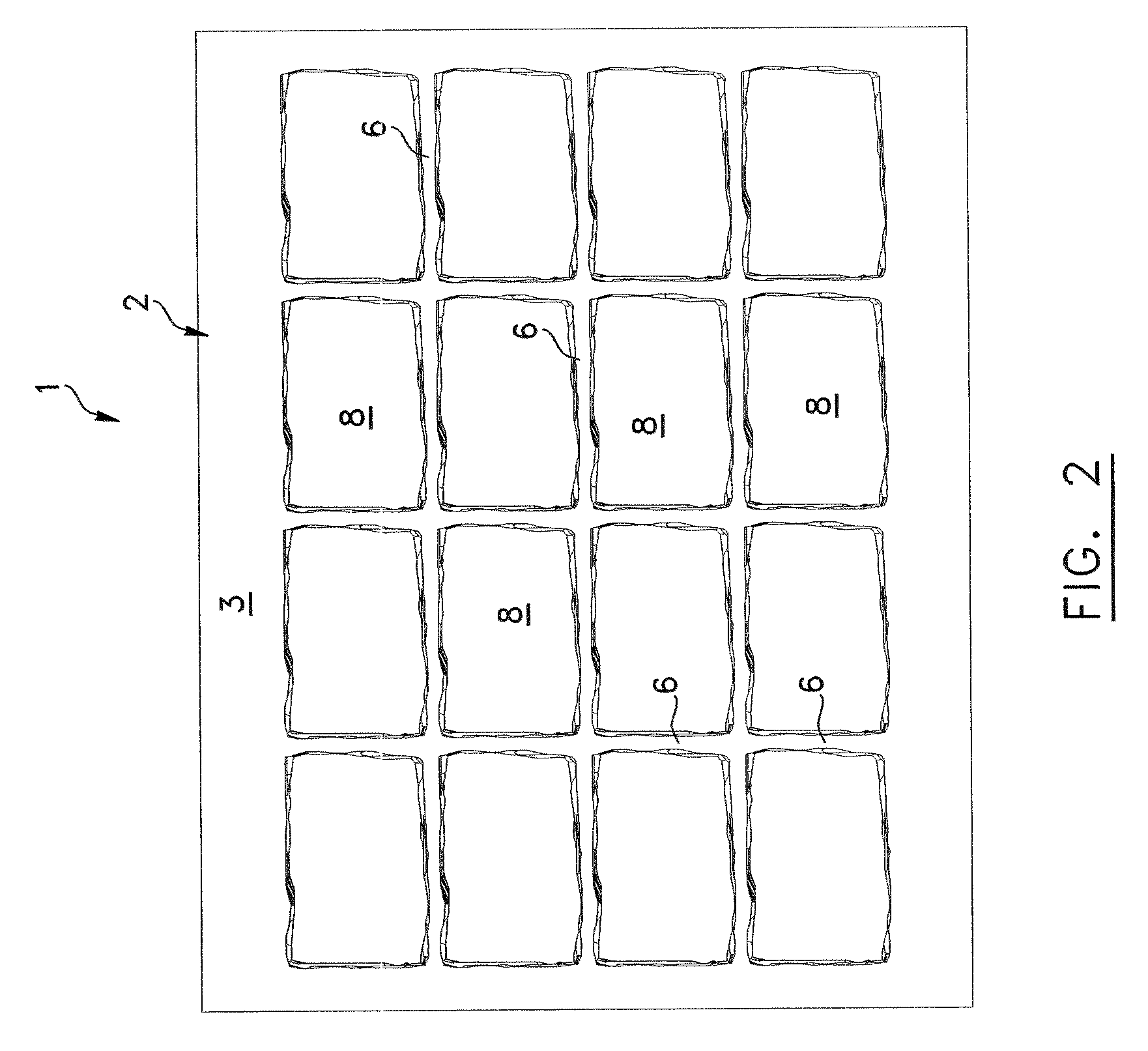

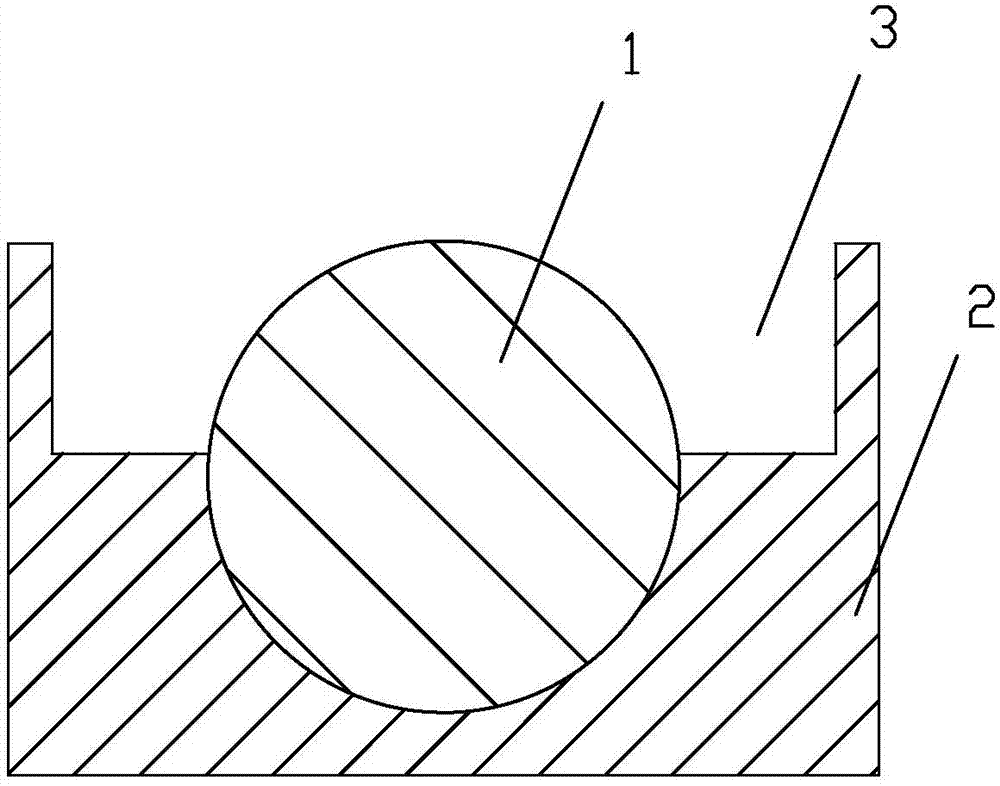

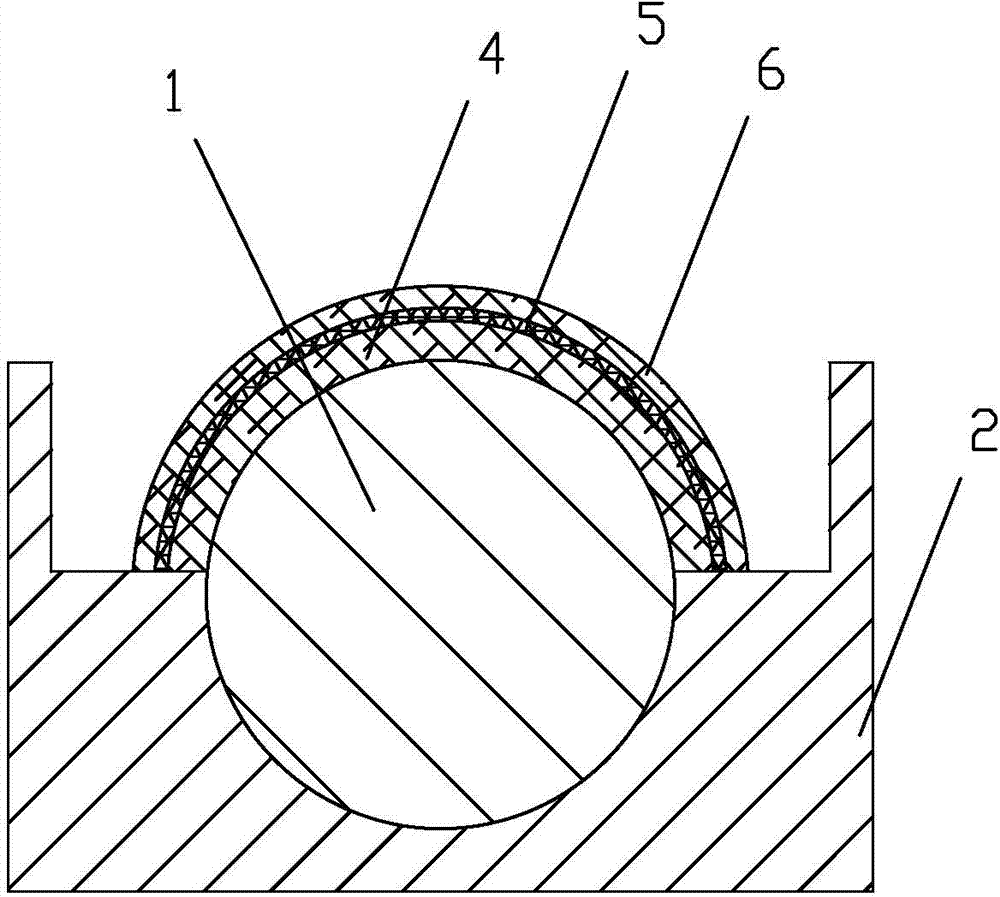

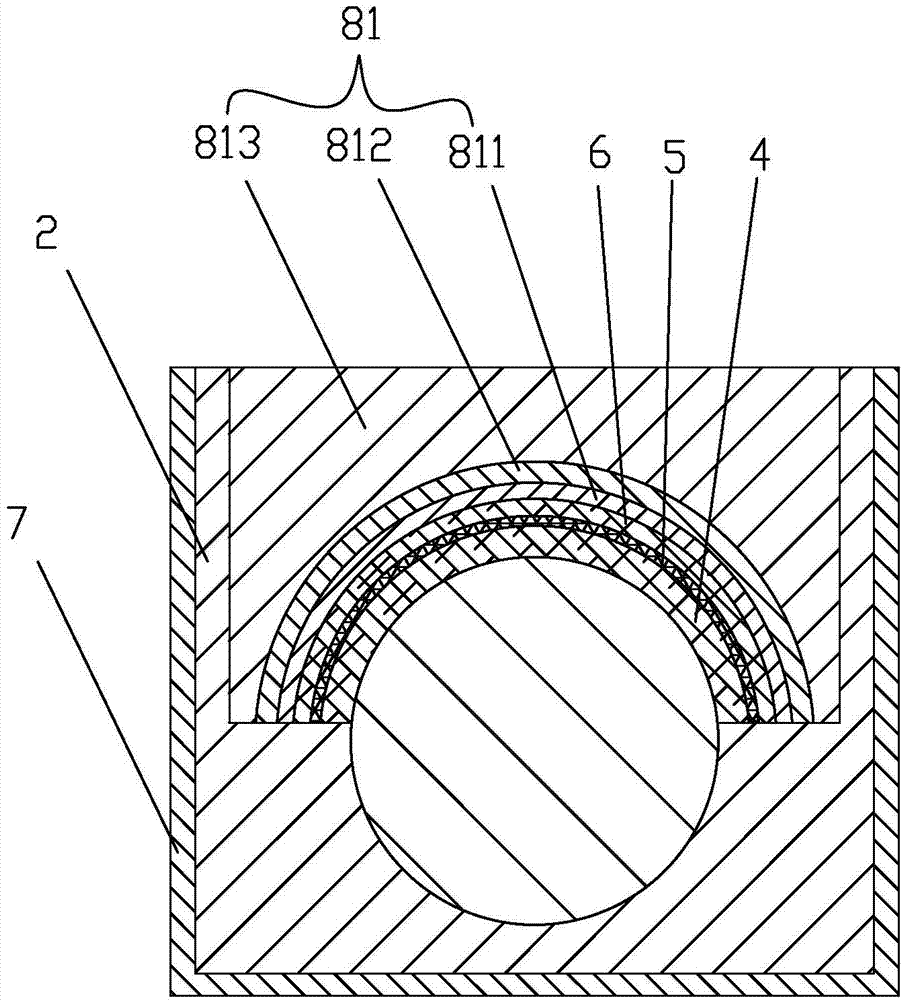

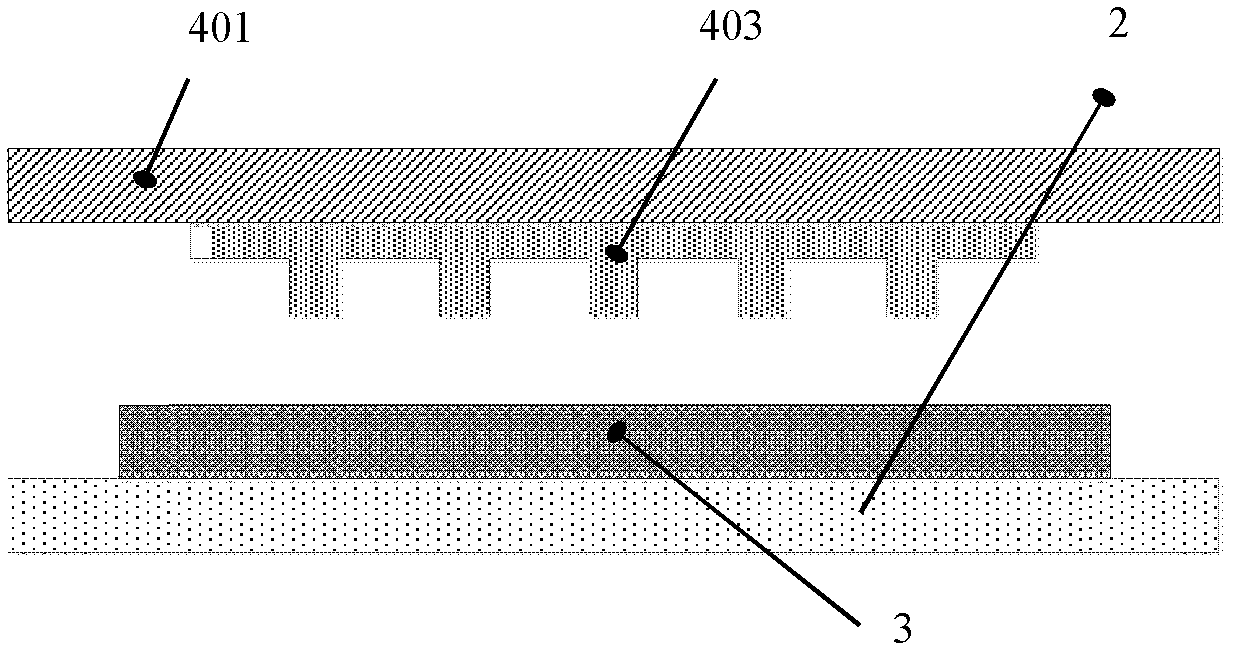

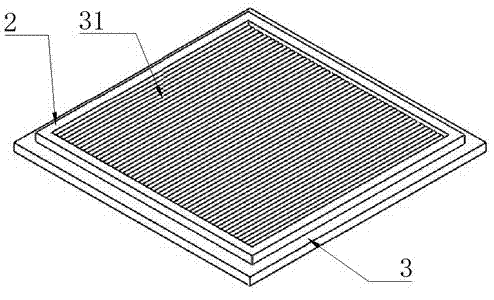

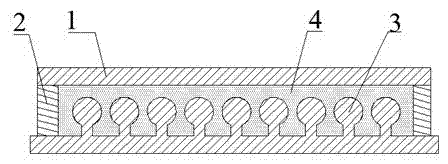

Multilayer composite plate for building templates and brick pallets and preparation process thereof

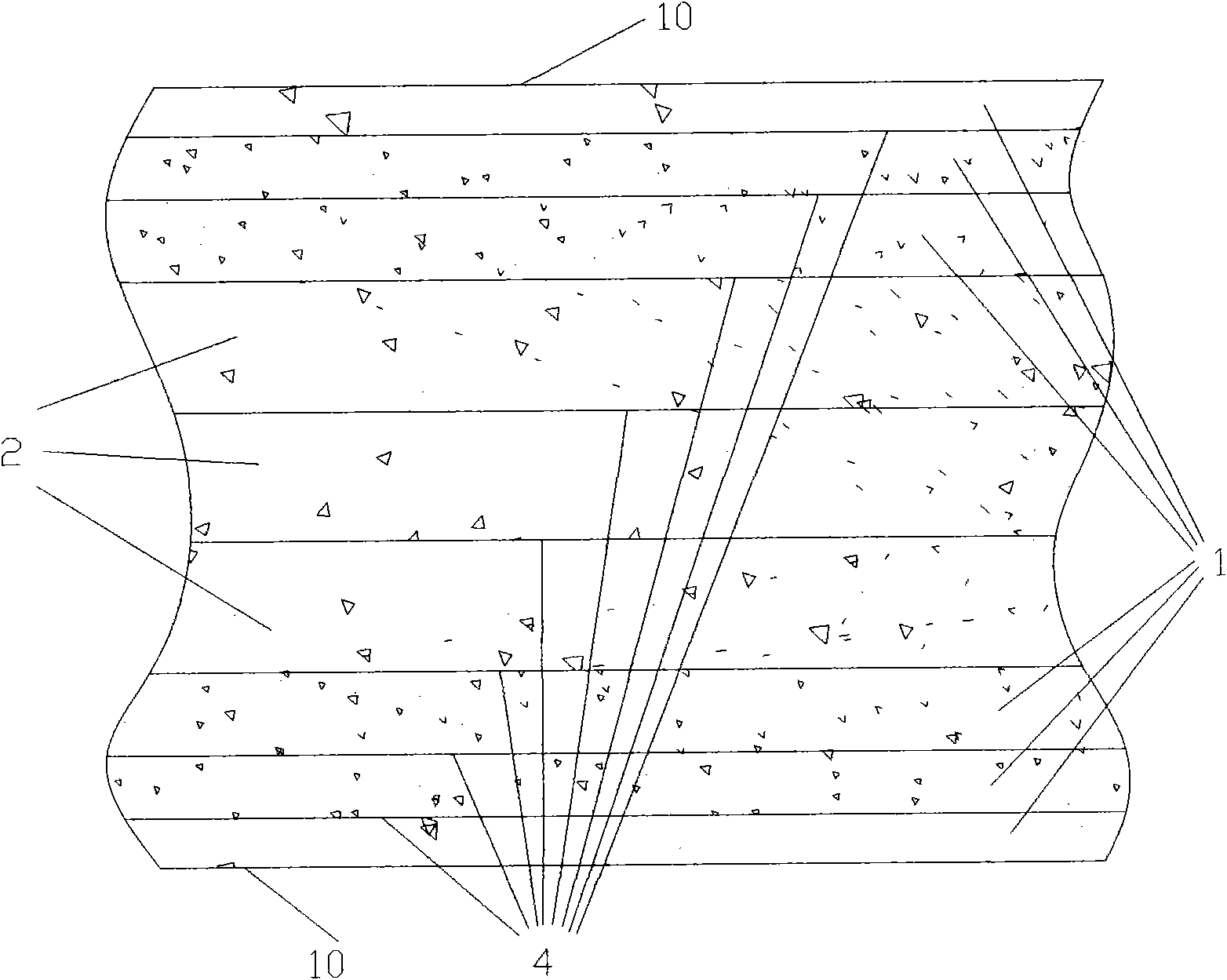

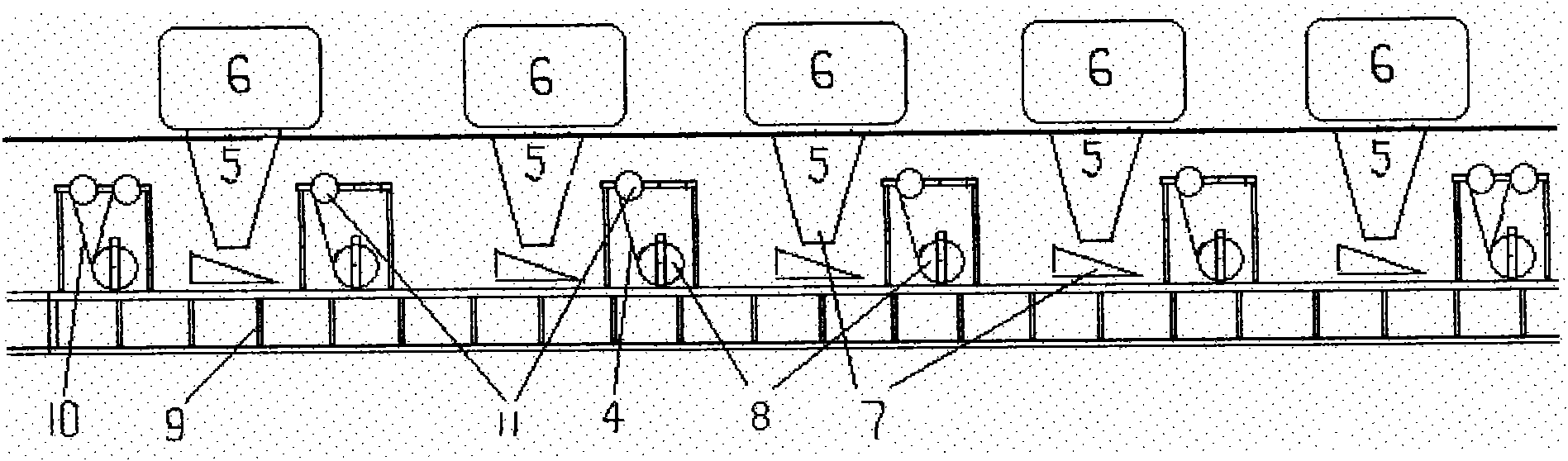

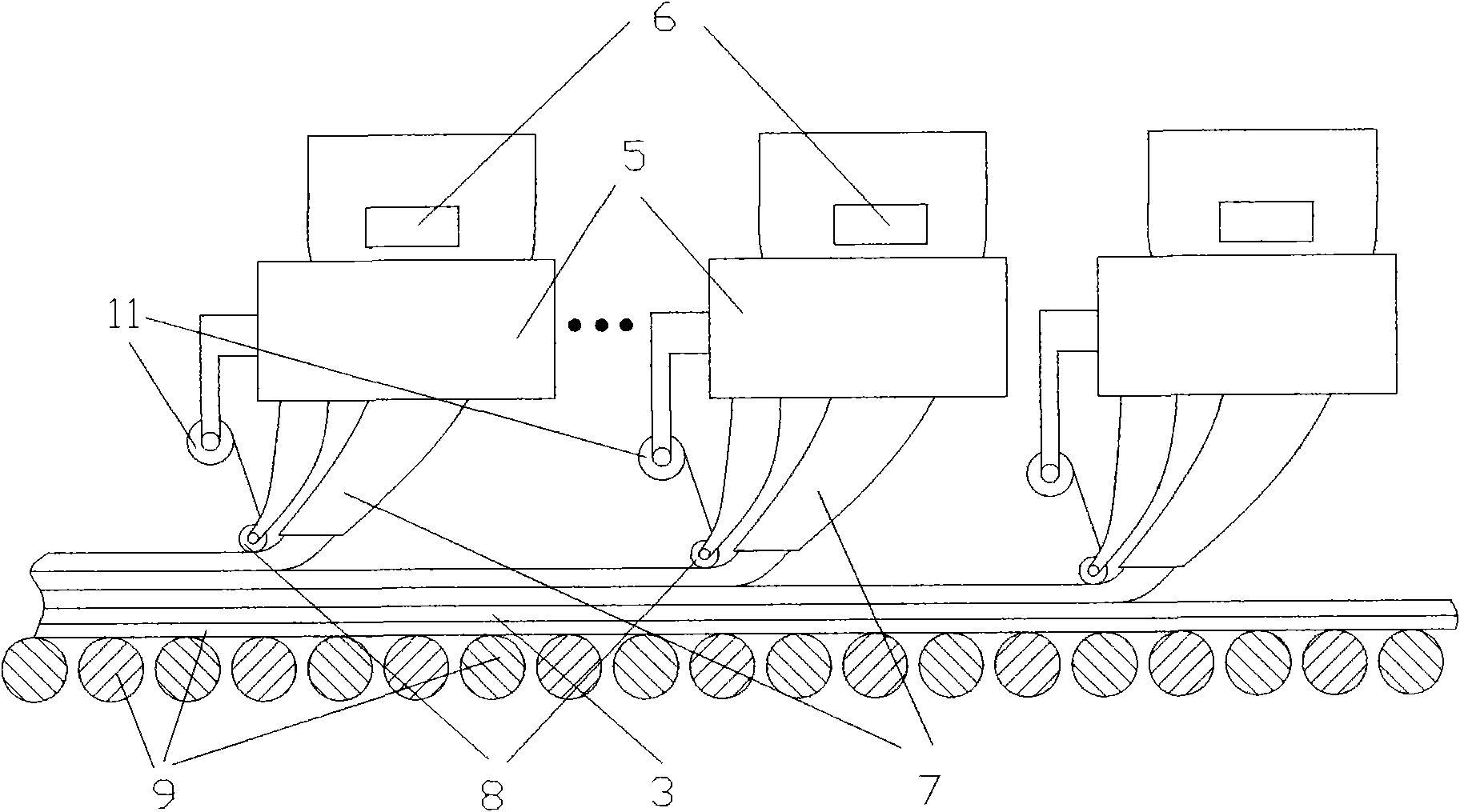

InactiveCN101633254AWith glazed effectEasy to demouldMouldsMixing operation control apparatusBrickSurface layer

The invention discloses a multilayer composite plate for building templates and brick pallets, which is prepared from magnesium cement gel added with a reinforcing material and a filler, and comprises surface layers (1) and sandwich layers (2); the surface layers (1) or / and the sandwich layers (2) comprise the filler or / and the reinforcing material with even content or gradient change; the number of the sandwich layers (2) is totally between 1 and 5; and the reinforcing material is arranged between adjacent sandwich layers (2). The invention also comprises a preparation process for the multilayer composite plate, which comprises that: production equipment with the capacity of stirring and preparing materials at multiple positions and rolling at multiple positions orderly rolls the surface layers (1) or / and the sandwich layers (2) on a subplate (3); and the reinforcing material is used as a reinforced structure between adjacent surface layers (1) or / and sandwich layers (2). The products corresponding to the invention have the characteristics of strong applicability, good technical effect and suitability for mechanical continuous production, and have predictable great economic and social values.

Owner:LIAONING FENGCHENG INDAL TECH

Liquid ejection head and liquid ejection apparatus

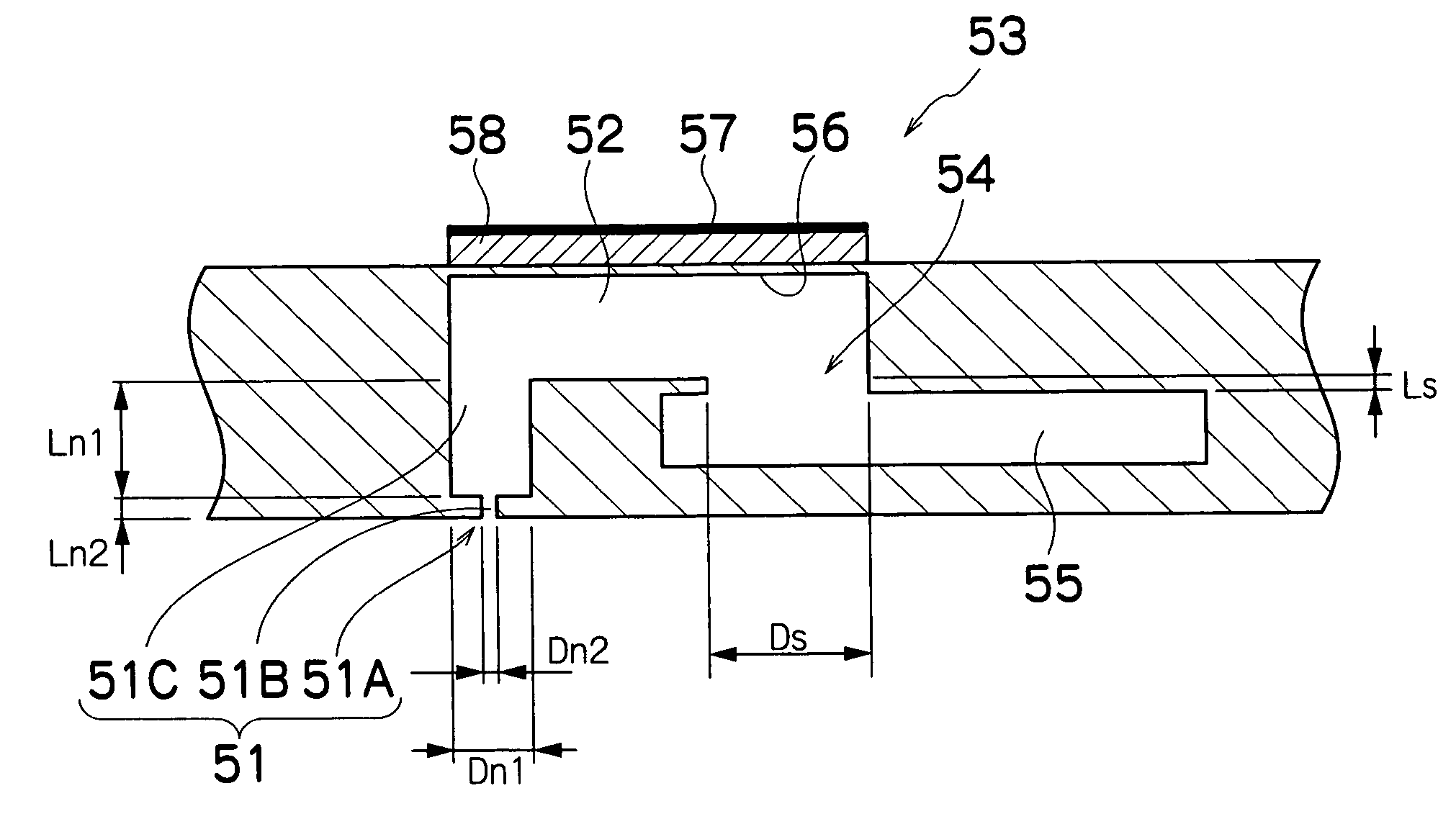

InactiveUS20060050111A1Supply side flow passageRaise the resonance frequencyInking apparatusInertanceHead parts

The liquid ejection head comprises: a nozzle through which liquid is ejected, the nozzle having an inertance Mn; a pressure chamber which accommodates the liquid to be ejected through the nozzle; a pressurizing device which applies pressure to the liquid accommodated in the pressure chamber by deforming the pressure chamber to eject the ink from the pressure chamber; and a supply side flow passage which communicates with the pressure chamber and supplies the liquid to the pressure chamber, the supply side flow passage having an inertance Ms smaller than the inertance Mn of the nozzle.

Owner:FUJIFILM CORP

Centrifugal casting roller coatings and preparation method thereof

ActiveCN101491823AImprove heat resistanceGood chemical stabilityFoundry mouldsFoundry coresFatty alcoholN-Butyl Alcohol

The invention relates to a centrifugal casting roller coating and a preparation method thereof. The centrifugal casting roller coating is characterized by comprising the following compositions in percentage by mass: 12 to 15 percent of zircon powder, 8 to 10 percent of quartz powder, 8 to 10 percent of bauxite, 0.3 to 0.6 percent of silica sol, 0.1 to 0.4 percent of sodium carboxymethyl cellulose, 0.15 to 0.35 percent of alkyl benzene sodium sulfonate, 0.15 to 0.35 percent of sodium sulfate, 0 to 0.02 percent of n-butyl alcohol, 0 to 0.02 percent of n-octyl alcohol, 0.10 to 0.18 percent of fatty alcohol polyethenoxy ether, and the balance being water, wherein the mass percentage of the zircon powder + the quartz powder + the bauxite is more than or equal to 30 percent and less than or equal to 35 percent, the mass percentage of the alkyl benzene sodium sulfonate + the sodium sulfate is more than or equal to 0.35 percent and less than or equal to 0.55 percent, and the mass percentage of the n-butyl alcohol + the n-octyl alcohol is more than or equal to 0.02 percent and less than or equal to 0.03 percent. The coating is used for centrifugal casting roller production after stirring, grinding and sieving, and has good use effect.

Owner:靖江市黎明铸造材料厂

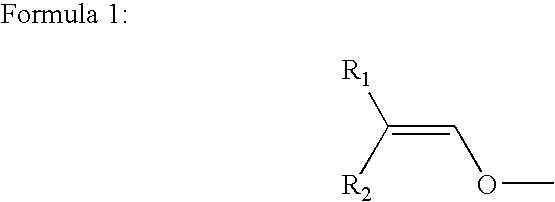

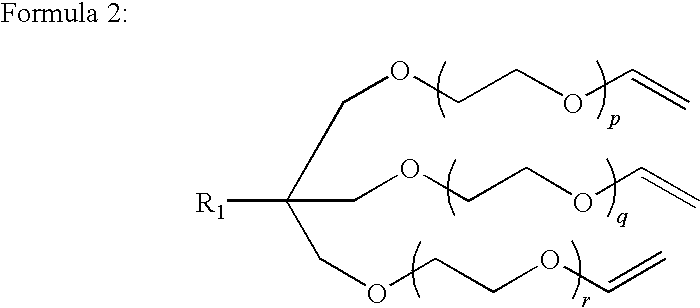

Actinic energy radiation curable ink-jet ink and ink-jet recording method

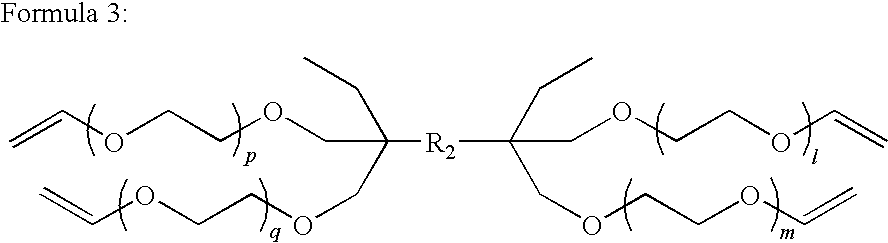

InactiveUS20100239777A1Low viscosityEjection is stableSurgical adhesivesMeasurement apparatus componentsVinyl etherEthylene

An actinic energy radiation curable ink-jet ink comprising an actinic energy radiation polymerizable compound, wherein the actinic energy radiation polymerizable compound comprises a vinyl ether compound, a total content of the vinyl ether compound is 30% or more by mass, the vinyl ether compound comprises a bis-vinyl ether compound and a multifunctional vinyl compound having three or more vinyl ether groups, 10 to 70% by mass of the ink is the bis-vinyl ether compound, and 5 to 70% by mass of the ink is the multifunctional vinyl compound having three or more vinyl ether groups.

Owner:KONICA MINOLTA IJ TECHNOLOGIES INC

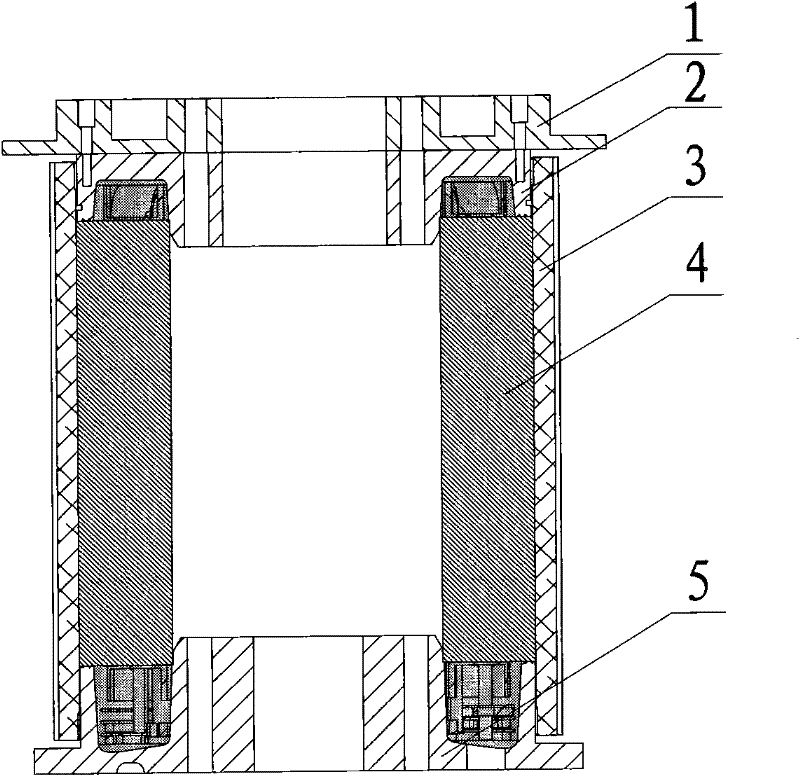

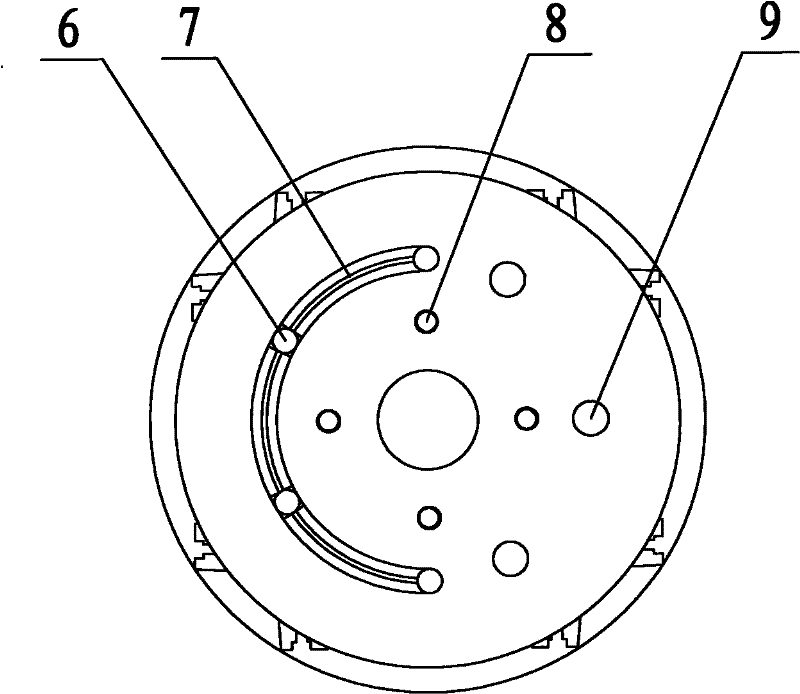

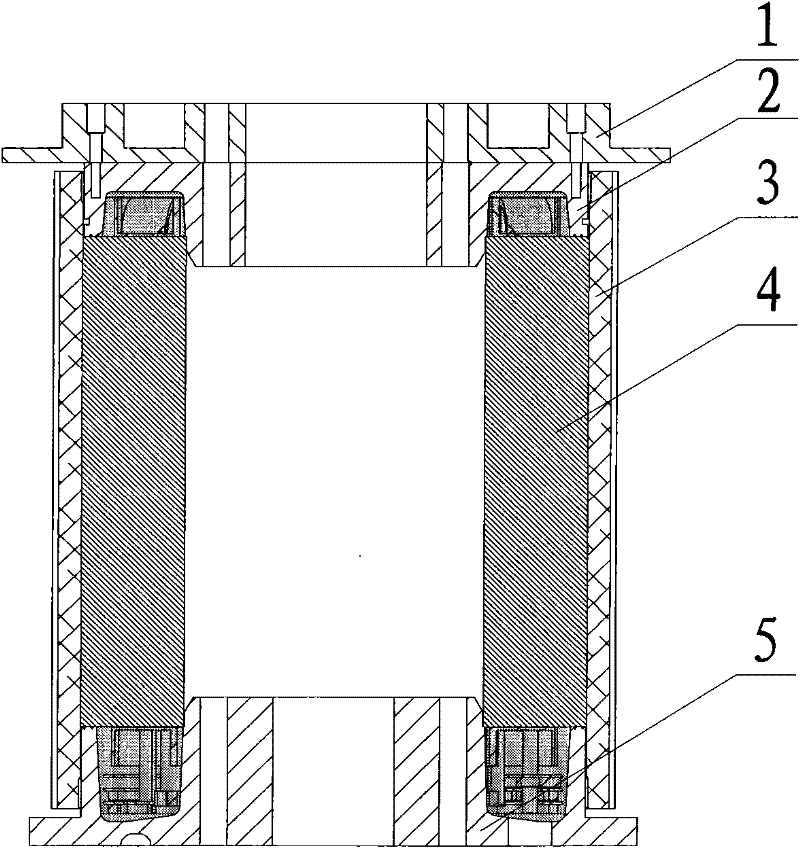

Motor stator core potting process

InactiveCN102280975AImprove potting efficiencyEasy to remove the moldManufacturing stator/rotor bodiesEpoxyEngineering

The invention provides a filling and sealing process of a motor stator core. The filling and sealing process comprises the following steps of: (1) preparing a filling and sealing material; (2) arranging an upper die filling and sealing die and a lower die filling and sealing die on a motor stator and positioning; (3) injecting the prepared filling and sealing material from an upper die plate; and (4) curing at 75-85 DEG C for 20-40 percent. The filling and sealing material is prepared from the following raw materials, such as epoxy resin, a diluting agent, a curing agent, a flexibilizer, silicon micropowder, and the like according to certain proportions. Compared with the prior art, the invention has the advantages that the filling and sealing time is greatly shortened, the operation is convenient, the filing and sealing efficiency of a motor is effectively improved, and energy consumption is saved; the stator has high surface finish quality and good insulation and waterproofing property; meanwhile, the mechanical property of the motor is improved, and the running stability of the motor is better ensured.

Owner:NANJING GAOQI ELECTRIC

Centrifugal casting radiant tube paint and preparation method thereof

ActiveCN101502868AWide variety of sourcesLow costFoundry mouldsFoundry coresCrack resistanceSodium Bentonite

The invention is a centrifugal casting radiant tube coating and a preparation method thereof, the coating comprises the ingredients (mass percent) of: 25-30% of diatomite of, 5-10% of zircon powder, 1.0-1.2% of titanium powder, 1.5-1.8% of iron powder, 4.5-5.0% of sodium bentonite, 2.0-2.5% of polyvinyl alcohol, 0.8-1.0% of sodium alginate, 3.5-4.0% of silica sol, 0.8-1.0% of sodium dodecylbenzene sulfonate, 0.05-0.08% of silane and 46.82-49.95% of water, wherein, the mass percent of the diatomite and the zircon powder is not less than 35% and not more than 37%, the mass percent of the titanium powder and the iron powder is not less than 2.7% and not more than 2.9%, and the mass percent of the sodium bentonite plus the polyvinyl alcohol plus the sodium alginate is not less than 8.0% and not more than 8.2%. The inventive coating is used for the centrifugal casting radiant tube after dry-blending, mixed grinding and sieving, uniformly distributed bulges (namely pitting surface) can be formed on the outer surface of the radiant tube to improve heat efficiency of the radiant tube. The inventive coating also has excellent adhesive force, high temperature strength and crack resistance, thus reducing defects on the surface of the radiant tube and improving quality of complex tube. Using the inventive coating to cast the radiant tube can result in remarkable economical benefit.

Owner:靖江市黎明铸造材料厂

Manufacturing method of simulation tree mould

The invention discloses a manufacturing method of a simulation tree mould. The method comprises the following steps: manufacturing a mould clamping fixture, and making a simulation tree by mixed resin; manufacturing an upper mould, namely, laying oil sludge on the ground, leveling the laid oil sludge, enabling half of the simulation tree to be embedded into the oil sludge, defining a frame made of the oil sludge around the simulation tree to form a pouring tank, coating the simulation tree with a layer of vaseline, coating the vaseline layer with a silica gel layer, covering the silica gel layer by an abrasive cloth layer, pouring silica gel into the pouring tank to form a second silica gel layer, manufacturing a box body, removing the oil sludge around the simulation tree, framing the simulation tree by the box body, injecting filler into the box body, forming a filling layer on the second silica gel layer, and standing still until the layer is cured; manufacturing a lower mould, wherein the method of manufacturing the lower mould is the same as that of manufacturing the upper mould. With the method, the manufacturing cost of the simulation tree mould is very low, and thus the method is suitable for popularization.

Owner:李东礼

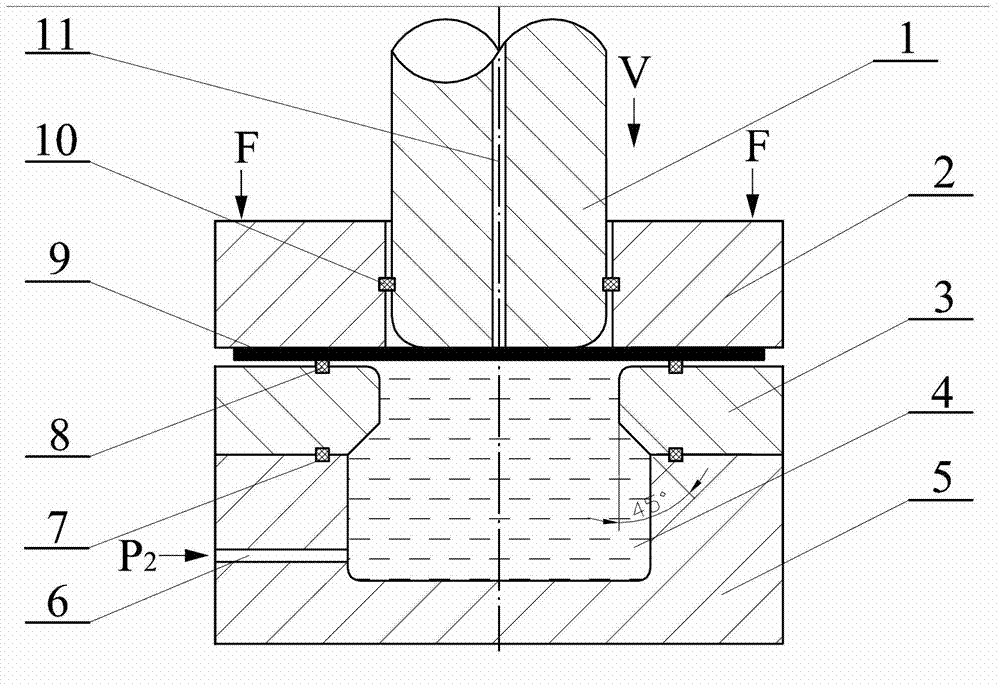

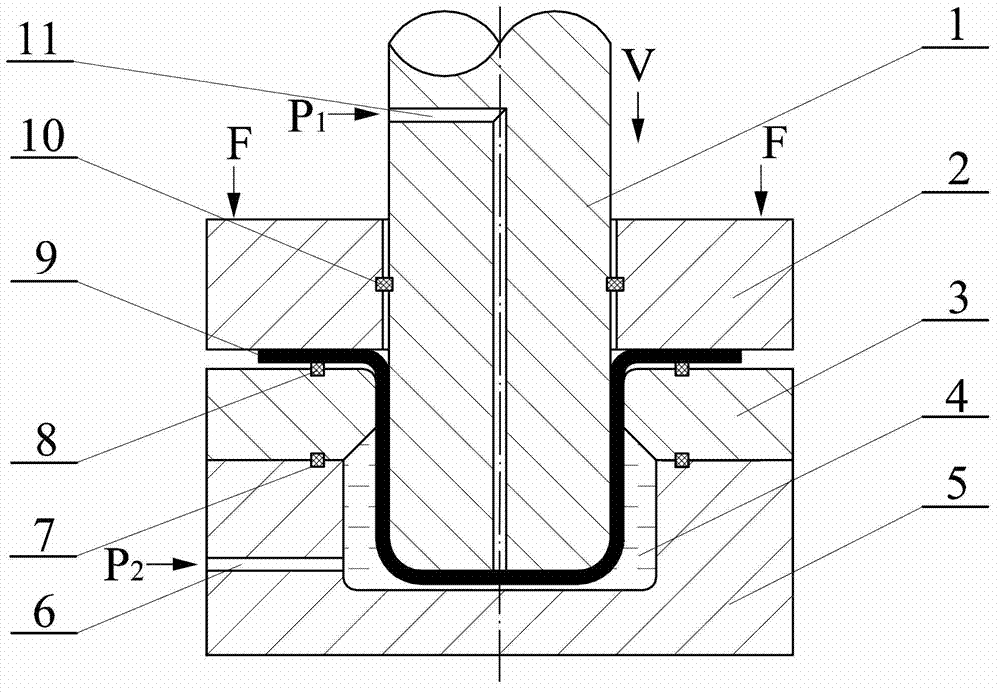

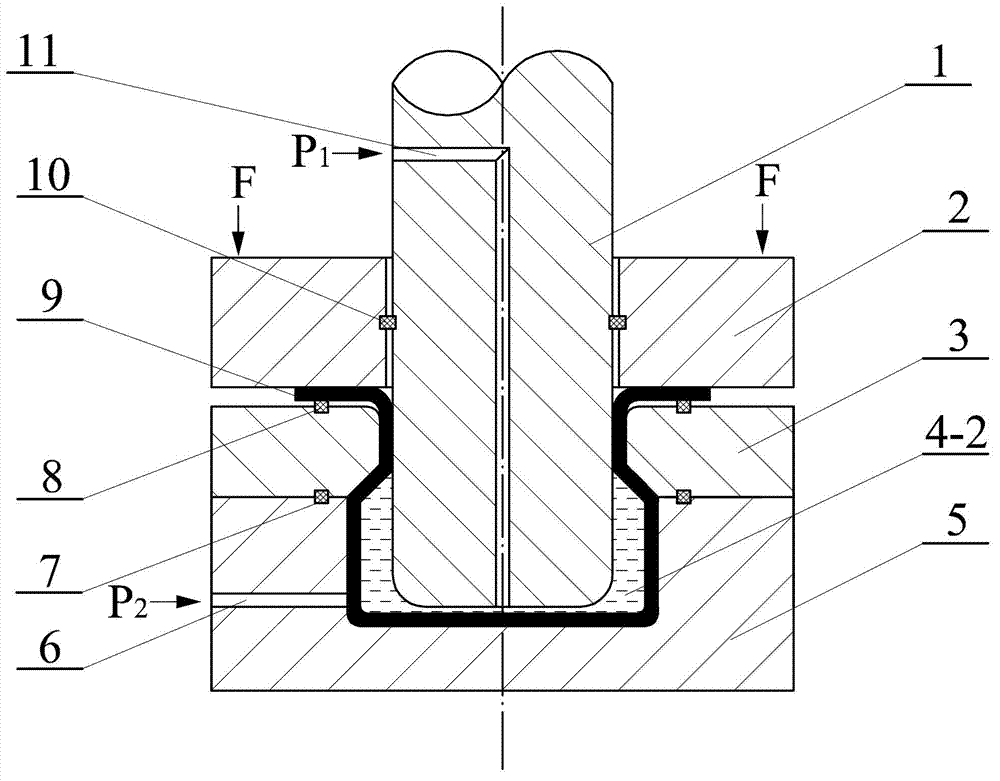

Hydraulic forming device and method of reducing cylindrical part

A hydraulic forming device and method of a reducing cylindrical part relate to a hydraulic forming device and method of a metal plate. Aiming at the bottleneck problems of high cost, long cycle and poor forming property in a roll welding process used due to the fact that the reducing cylindrical part, the section of an axis part of which is of a bottle shape with a small upper part and a big lower part, is difficult to machine by using the traditional plate hydraulic forming method, the device comprises a lower concave die and an upper concave die; a blank holder and a convex die are arranged above the upper concave die; the shape of a cavity in the concave die is in accordance with the shape of the outer outline of a finally-formed cylindrical part, namely the cavity is configured into a reducing cylinder with the aperture gradually reduced from the bottom to the top or reducing in a stepped form; and the lower concave die and the convex die are respectively provided with an injection hole. The forming method sequentially comprises the following steps of: injecting medium in the cavity, arranging blanks, pressing the blanks, applying backpressure, downwards moving the convex die, and pressing in the inner cavity of a pre-formed part in order to close to the die. The blanks are under the action of a pressure difference of inner and outer dynamic fluids in the forming process due to the injection holes arranged in the convex die, the die-close forming of the blanks is finished at one step, and the formed part can be smoothly taken out due to the design of the combined concave die.

Owner:HARBIN INST OF TECH

Device and method for large-area nano imprinting photoetching

ActiveCN102591143AHigh elastic modulusHigh complex precisionPhotomechanical apparatusNano structuringFluid control

The invention discloses a device and a method for large-area nano imprinting photoetching. A fluoropolymer-based thin film structure composite soft mould is introduced, and a gas assisting pressing mode and a mould micro-feed pressure pressing mode are adopted in the imprint process. The demoulding is carried out on the basis of low surface energy of a fluoropolymer base by a two-time solidifying and revealing type demoulding method, and thus the large area demoulding can be realized by small demoulding power. The device and the method for the large-area nano imprinting photoetching, disclosed by the invention, realize that a large-area nano-structure can be manufactured on various kinds of substrates, such as uneven (bent, cocked or stepped) substrates, curved substrates, or fragile substrates, and have the obvious advantages of high complex precision, large imprinting area, high efficiency, and low cost and a mould is long in service life. The device and the method for the large-area nano imprinting photoetching are suitable for LED (light emitting diode) nano-imaging technology and manufacturing of optical devices (such as optical lenses), butterfly solar condensers, micro-fluid control devices and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Novel fiber reinforced cellular board and preparation method thereof

InactiveCN101797822AImprove mechanical propertiesWon't hurtLaminationLamination apparatusEpoxyWhole body

The invention provides a novel fiber reinforced cellular board and a preparation method thereof. The novel fiber reinforced cellular board consists of panels on the two sides and a cellular core of a pyramid-shaped structure. The cellular core of the pyramid-shaped structure is prepared by the following steps: injecting high-strength dispersed short-cut fiber cotton / felt into an epoxy resin substrate; or presoaking the epoxy resin substrate by the high-strength dispersed short-cut fiber of 10 mm to 30 mm to form a pre-mixed molding material; and heating, pressurizing and molding the pre-mixed molding material. The prepared cellular core consists of a series of concave-convex staggered pyramid-shaped platform bodies which form a stable whole body together under the action of the two panels on the two sides, so the novel fiber reinforced cellular board has various high mechanical properties. The novel fiber reinforced cellular board has very simple molding process and low production cost, and can realize continuous high-efficiency production.

Owner:王韬

Cobalt less multi element high speed tool steel and its manufacturing method

InactiveCN1693527AReasonable range of performanceLow content of alloying elementsFurnace typesHeat treatment furnacesElectrical resistance and conductanceChemical composition

A non-Co multi-element high-speed tool steel contains proportionally C, Si, Mn, S, P, Cr, V, Mo, W, Ni, Nb, Ti, Mg, RE and Fe. Its preparing process includes such steps as smelting by MF furnace, modifying with Y-based RE alloy, centrifugal casting, and heat treating.

Owner:JIUQUAN IRON & STEEL GRP

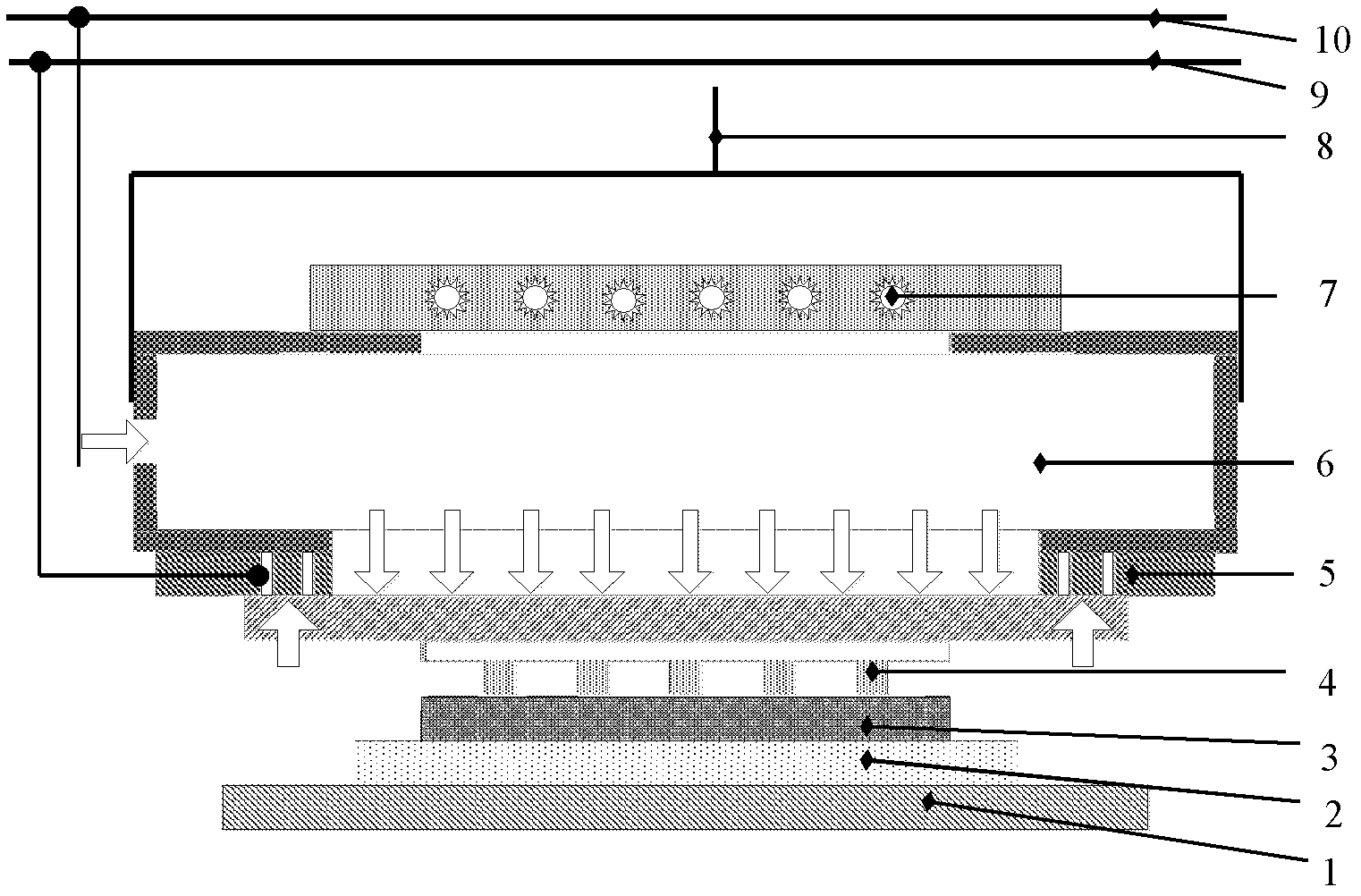

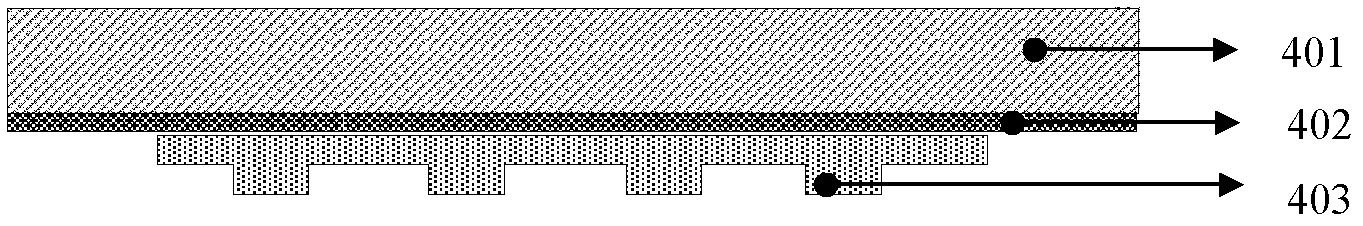

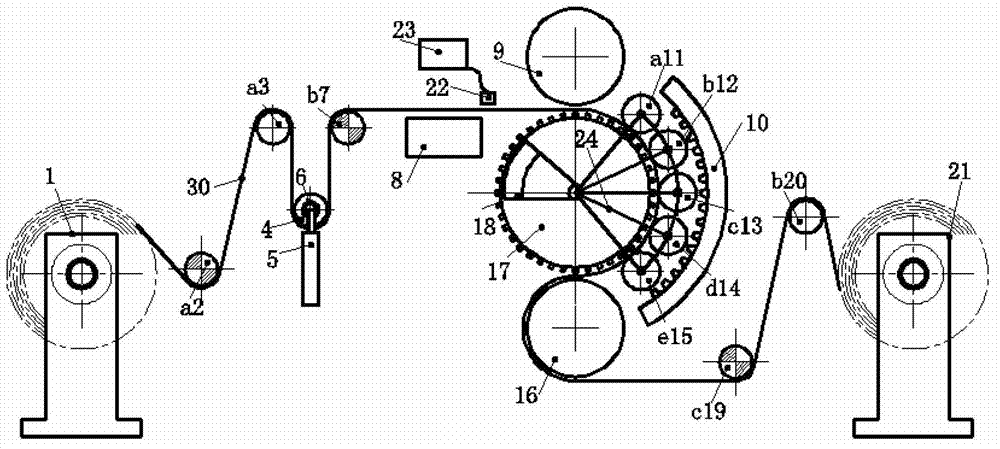

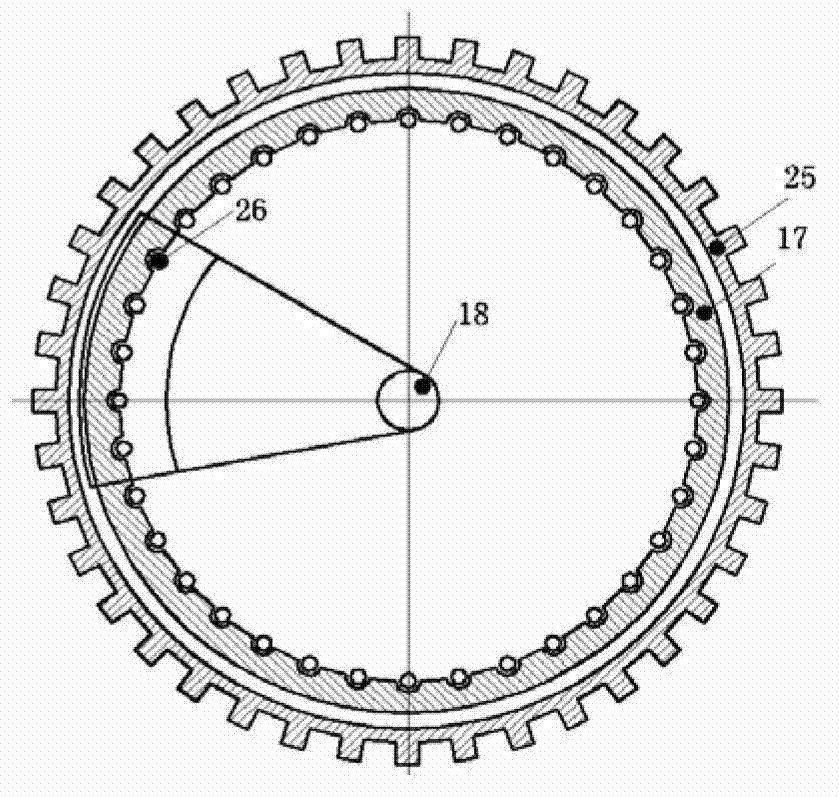

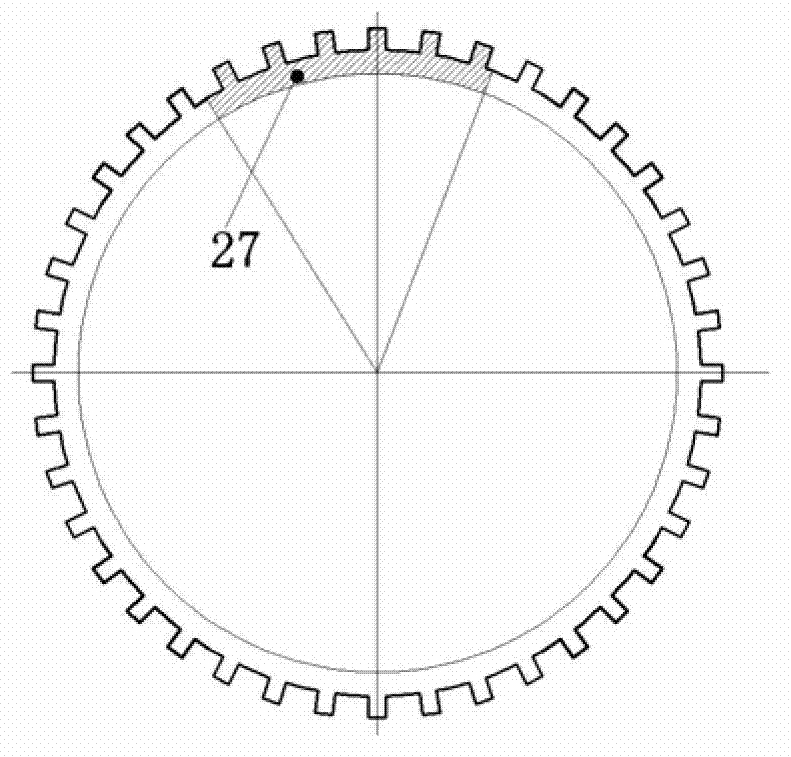

Device and method for processing polymer film surface microstructure based on roll-to-roll hot rolling

The invention relates to device and method for processing a polymer film surface microstructure based on roll-to-roll hot rolling. The method comprises the following six steps: unrolling, pre-heating, hot-rolling, conforming, cooling and rolling. The unrolling step includes continuously drawing a polymer film from a rolled material and removing static electricity on the surface of the film. After the pre-heating step, the polymer film is heated to a temperature below the glass transition temperature thereof to get ready for the hot-rolling step. The local heating treatment is conducted on a plate roller to allow only the temperature of the stamping surface to rise above the glass transition temperature, so as to roll-form the preheated film. The conforming step enables the rolled film in close contact with the surface of the plate roller, so that the film is completely deformed. The formed film is subjected to both cooling and conforming to cause rapid curing of the surface microstructure and reduce rebound. Compared with the prior art, the device and method have the advantages of reducing the risk of rebound and deformation, improving the forming precision of the microstructure, making demoulding easier and increasing the processing efficiency.

Owner:SHANGHAI JIAO TONG UNIV

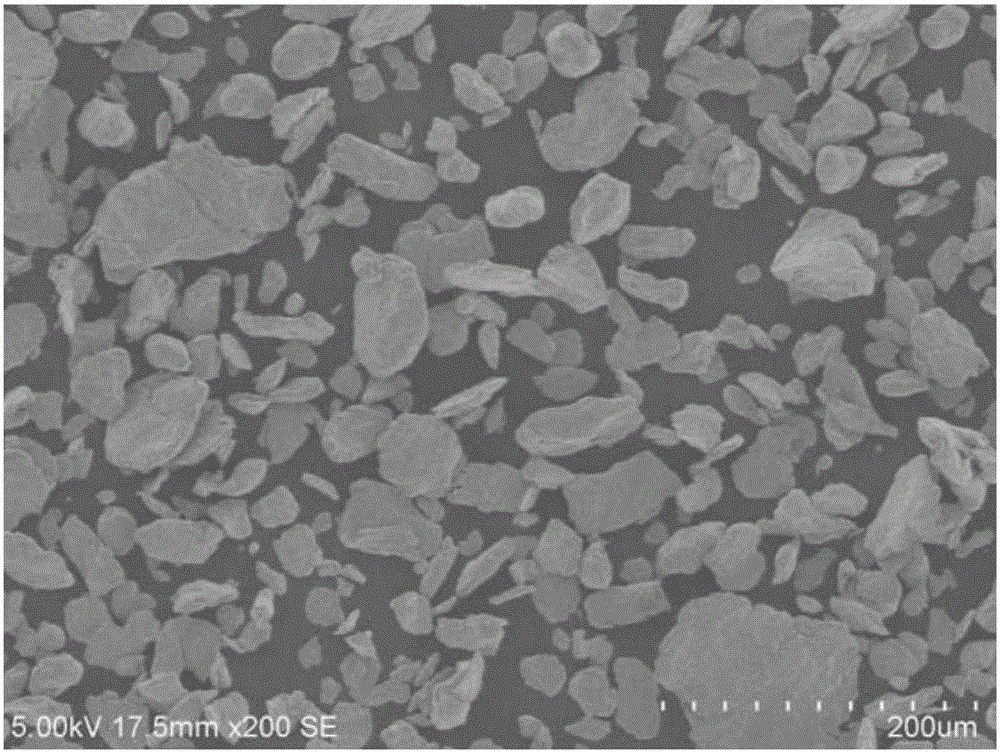

Preparation method of Fe-based metal soft magnetic powder core

ActiveCN105185560APowder moldingEasy to shapeInorganic material magnetismInductances/transformers/magnets manufactureEpoxyMaterials preparation

The invention relates to a preparation method of a Fe-based metal soft magnetic powder core, and belongs to the technical field of magnetic material preparation. The method comprises the following steps: with Fe-based flake-like metal soft magnetic powder as raw material powder, carrying out annealing treatment; carrying out passivation and insulated coating treatment on the annealed powder; carrying out drying treatment on the passivated and insulated powder; pressing the dried metal powder into a magnetic powder core blank, and adopting zinc stearate powder as a releasing agent; and carrying out annealing treatment on the molded magnetic powder core blank and spraying a layer of epoxy resin insulating paint on the surface of the magnetic powder core blank, so as to obtain the metal soft magnetic powder core. The density of the magnetic powder core prepared by the method is greatly improved; the density distribution is even; the magnetic powder core has relatively high compactness and good mechanical strength; and meanwhile, the magnetic powder core has relatively high magnetic conductivity and relatively low magnetic loss. In addition, the prepared magnetic powder core also has the characteristics of high magnetic conductivity, high quality factor and low loss.

Owner:有研增材技术有限公司

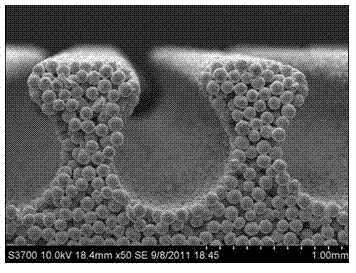

Inner groove porous strengthened boiling micro-channel structure, manufacture method and application

InactiveCN102878845AHigh transmission frequencyHigh porosityIndirect heat exchangersHeat flowEnhanced heat transfer

The invention discloses an inner groove porous strengthened boiling micro-channel structure, which includes a metal sintered felt formed by sintering metal powder and provided with uniformly-distributed particles, wherein a plurality of inner grooves are uniformly distributed in the metal sintered felt. The porous surface of the inner groove porous strengthened boiling micro-channel structure has excellent capillary characteristics, can keep the wall surface to be sufficiently damp, avoids the local scabbing and polymer deposit caused by hot spot and local drying, improves the heat transfer coefficient and critical heat flux density by adopting the porous structure for strengthened boiling heat transfer, and has excellent strengthened heat transfer effect.

Owner:SOUTH CHINA UNIV OF TECH

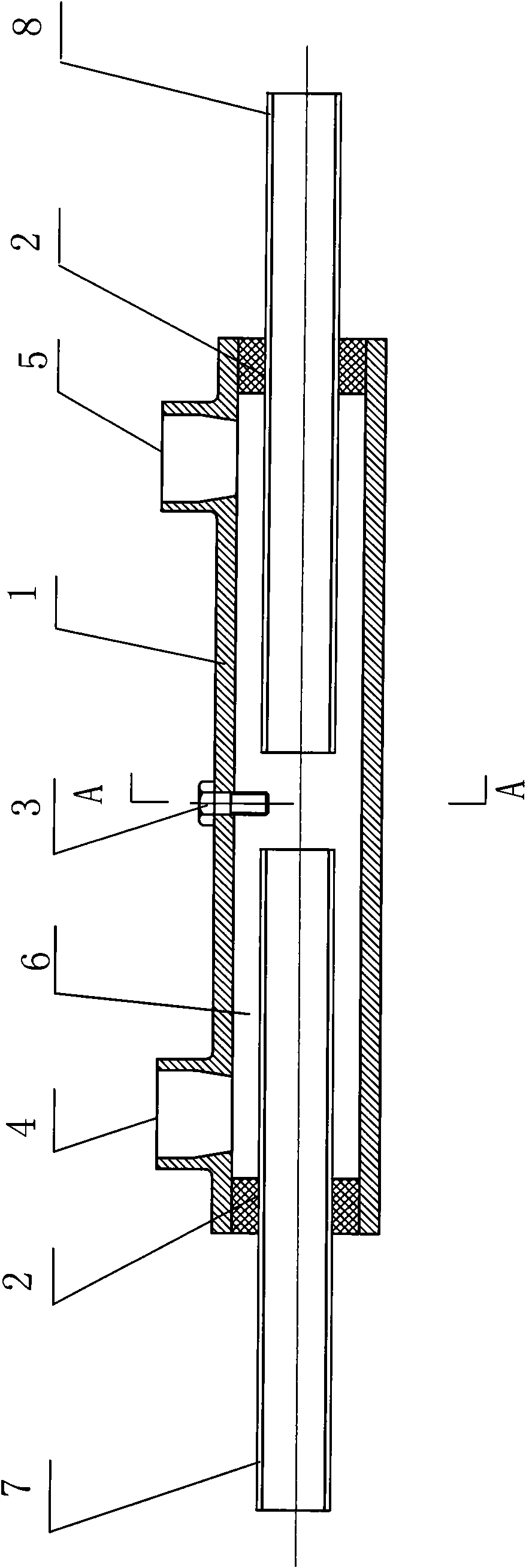

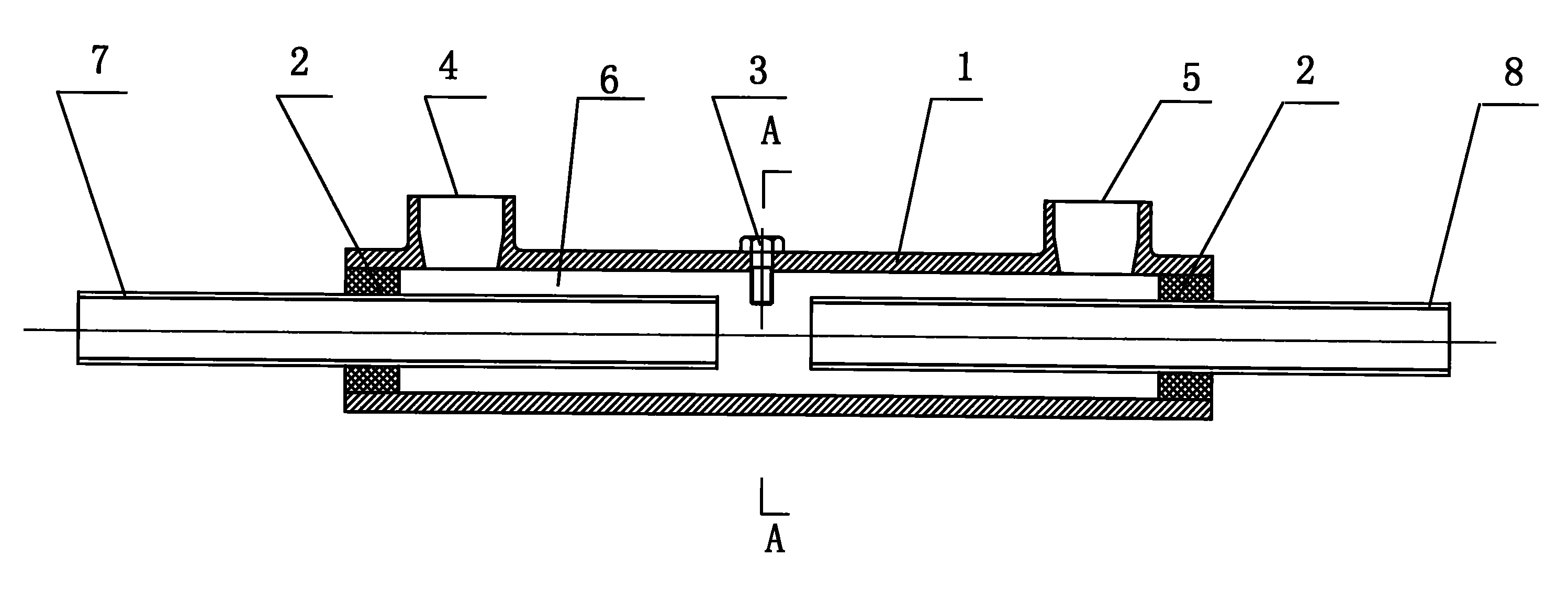

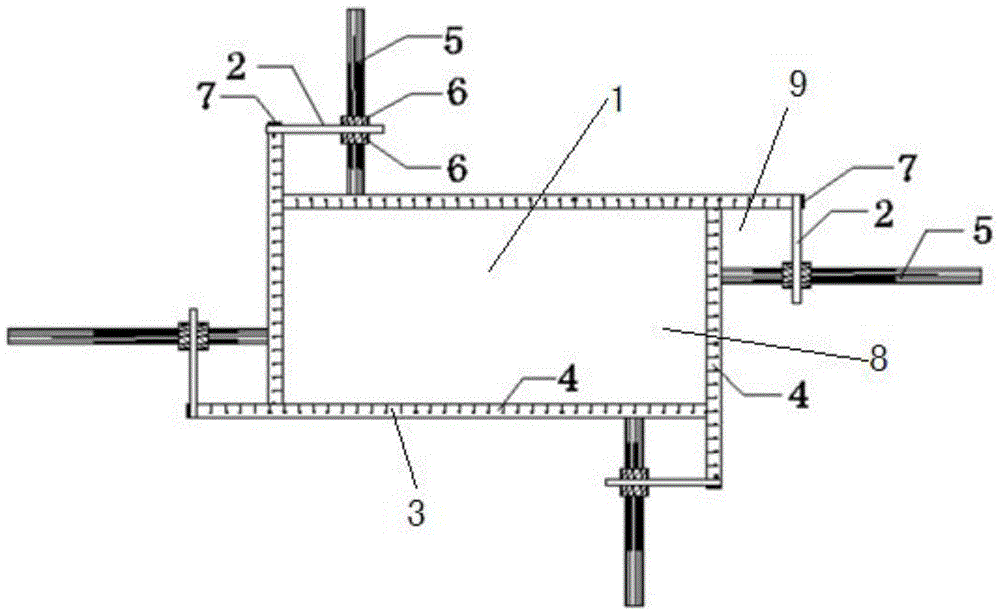

Precast grouted steel bar connecting sleeve and construction method thereof

The invention discloses a precast grouted steel bar connecting sleeve and a construction method thereof. In the traditional cast-in-place concrete structure, steel bars are mainly connected by adopting a mechanical connecting method such as lapping, welding or sleeve extrusion or the like, the construction for connecting the steel bars is complex, and the connection of the steel bars must be completed before the concrete is poured, so the connecting method is not suitable for an assembled construction method for a precast concrete structure. The precast grouted steel bar connecting sleeve comprises a sleeve body (1), two ends of the sleeve body (1) are provided with elastic rubber sealing rings (2), a limiting bolt (3) is arranged in the middle of the interior of the sleeve body (1), two ends of the sleeve body are provided with a grouting hole (4) and an exhaust hole (5) communicated with the interior, and the inner wall of the sleeve body is provided with a conical thread (6). The precast grouted steel bar connecting sleeve is suitable for assembled connection construction of the steel bars.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

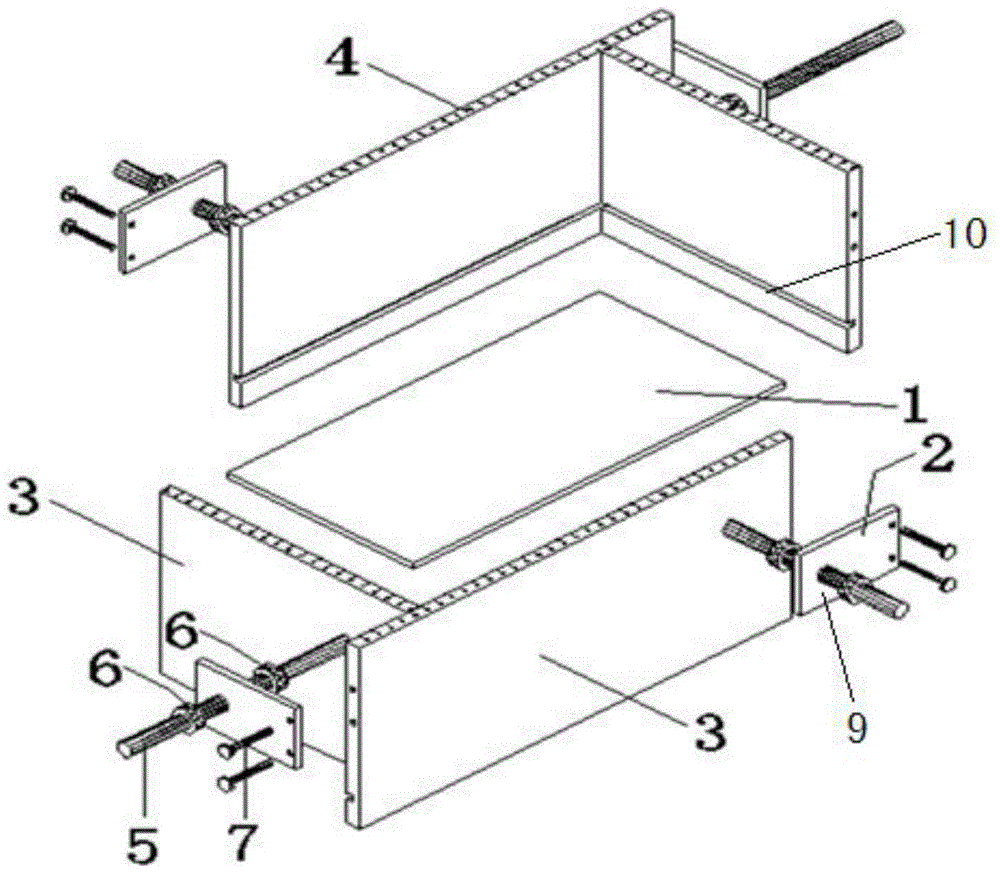

Size-adjustable mold adaptive to concrete samples in various sizes

InactiveCN105699161ASolve the defect that only fixed size test pieces can be madeEasy to makePreparing sample for investigationStructural engineeringEngineering

The invention discloses a size-adjustable mold adaptive to concrete samples in various sizes.The size-adjustable mold is characterized by comprising a size-adjustable frame (8) formed by four side formworks (3) staggered in pairs, a guide device (9) is movably connected with every two adjacent side formworks (3), a scaleplate (4) is arranged on the upper surface of each side formwork (3), and grooves (10) used for installing a bottom plate (1) are formed in the corresponding positions of the four side formworks (3) respectively.The size-adjustable mold adaptive to concrete samples in various sizes is easy to manufacture, facilitates manual demolding and is suitable for processing concrete members and concrete samples in various sizes.The defect that only samples in a fixed size can be manufactured through a concrete mold in the past is overcome, and the concrete samples in various sizes can be manufactured.

Owner:HOHAI UNIV

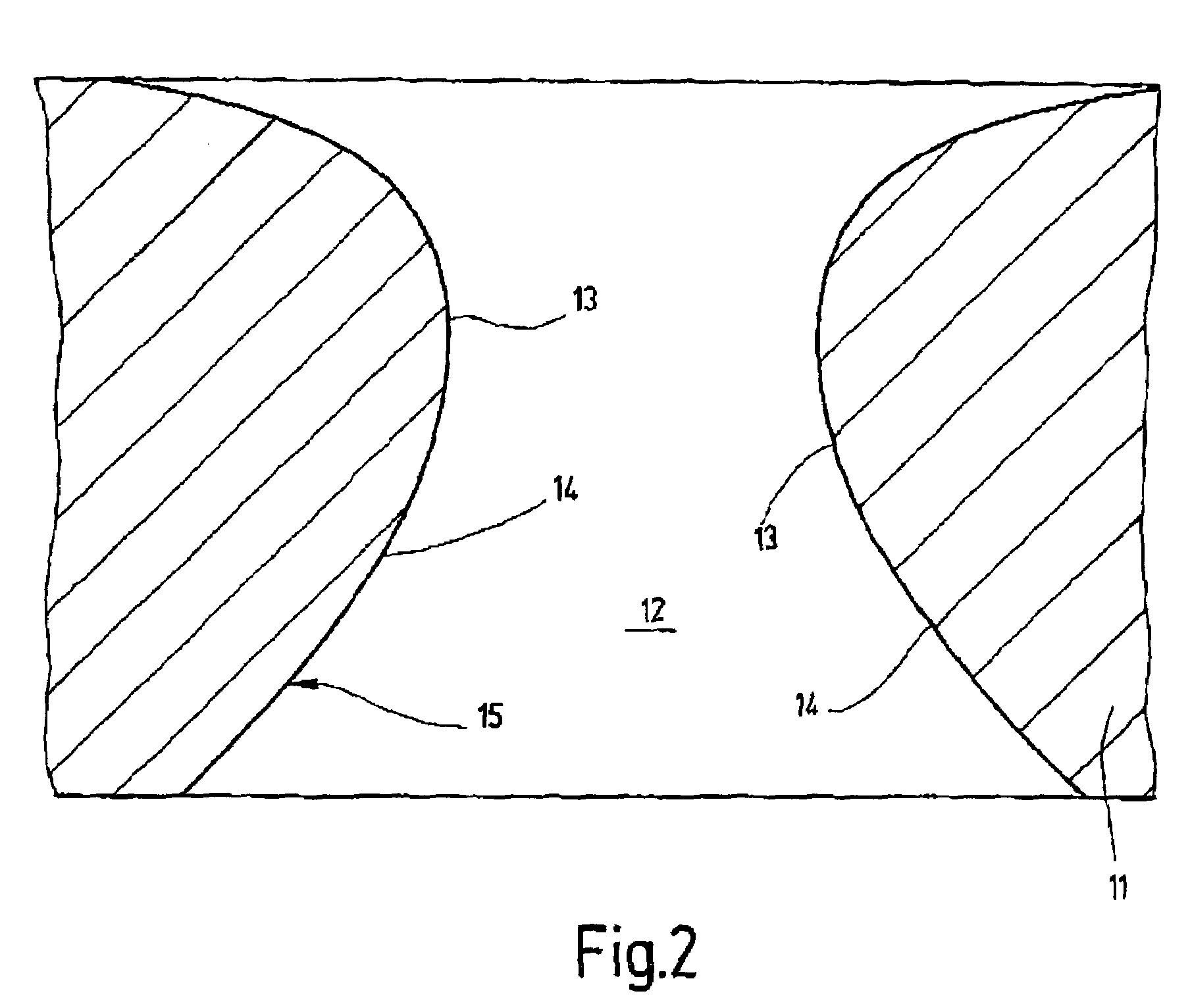

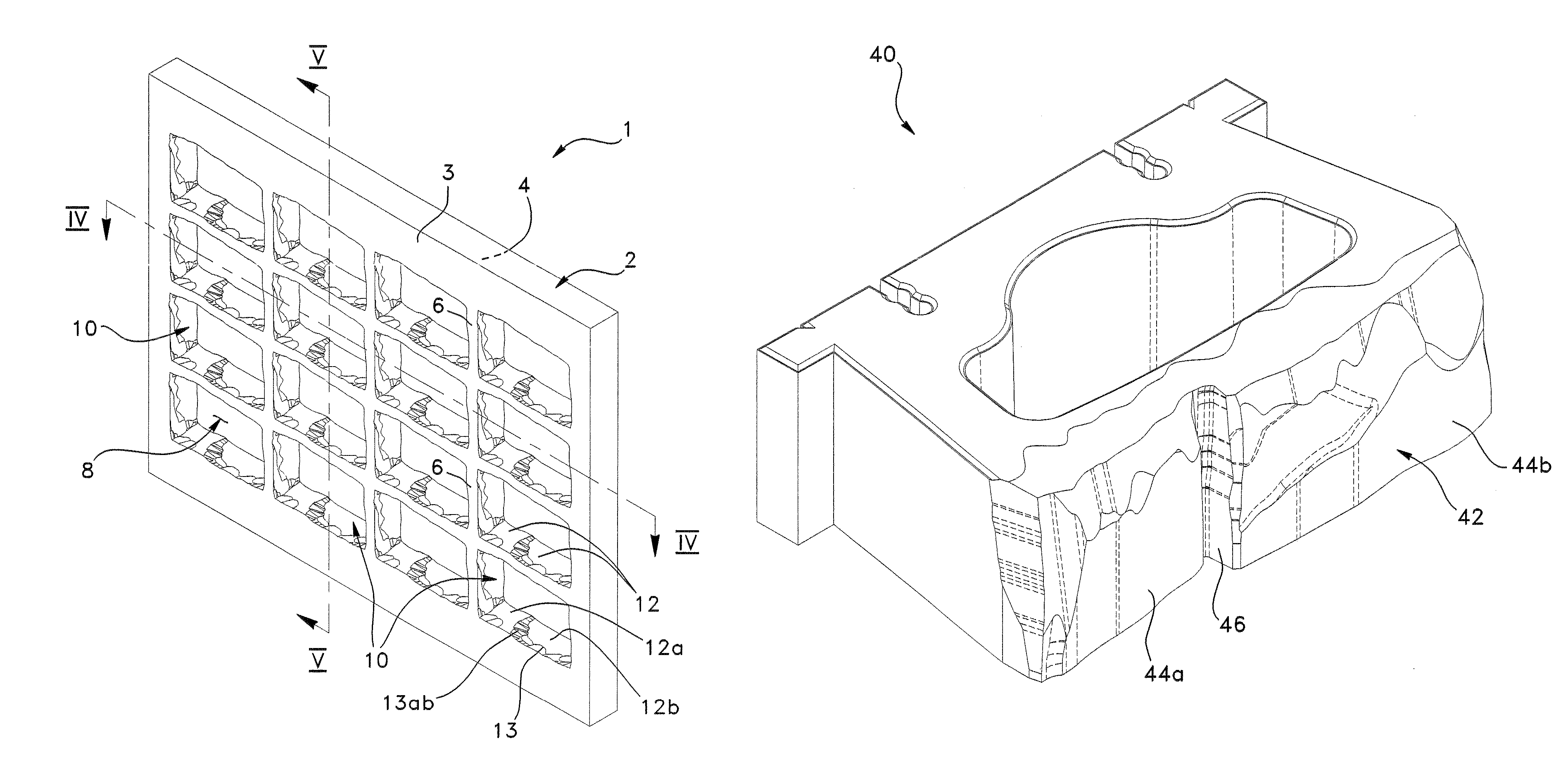

Molding Apparatus for Producing Dry Cast Products Having Textured Side Surfaces

ActiveUS20060249881A1Easy to demouldConstruction materialMould separation apparatusEngineeringMechanical engineering

Owner:OLDCASTLE BUILDING PROD CANADA INC

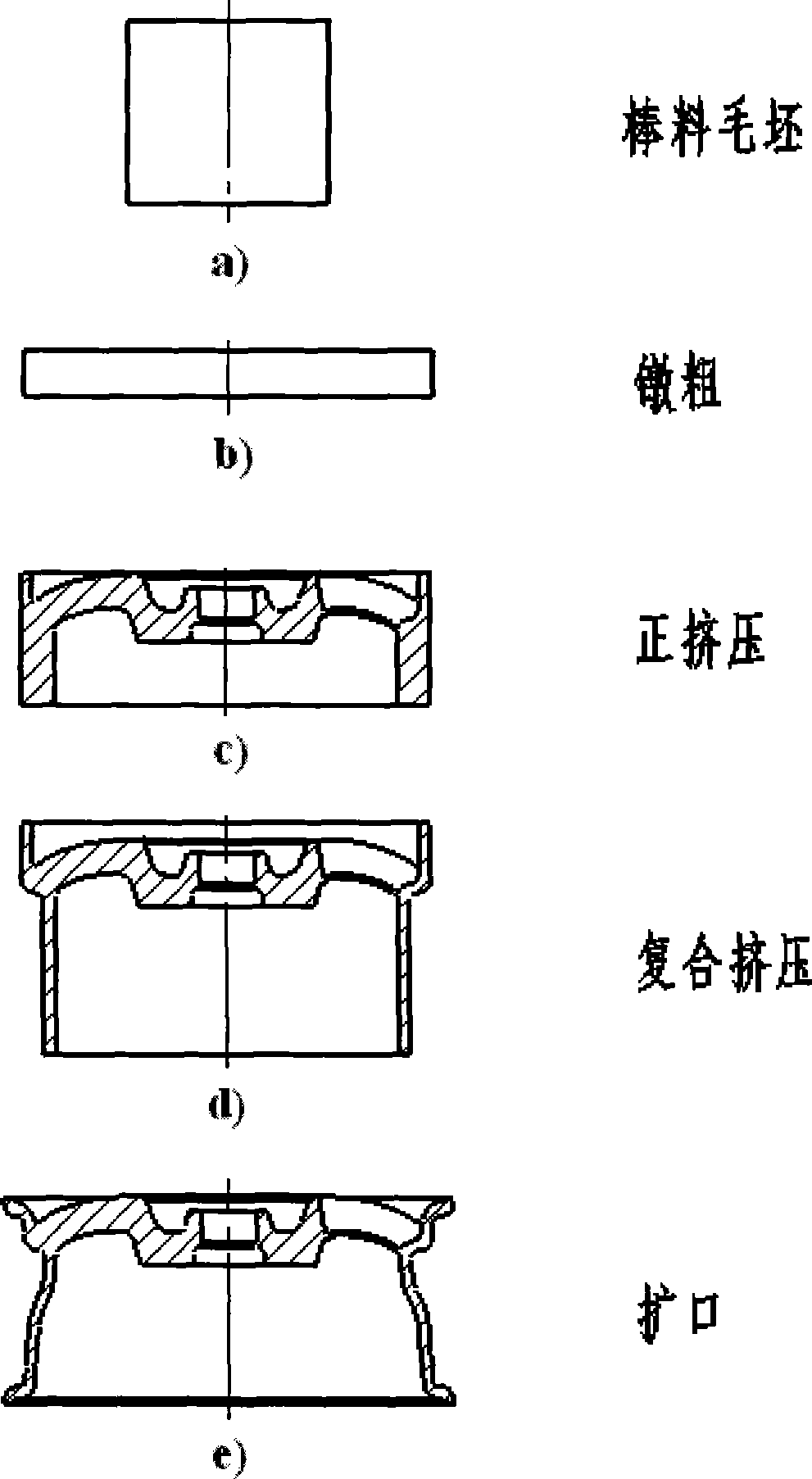

Press forming method of automobile hub and matched forming mold thereof

The invention relates to an extrusion forming method for a wheel hub of an automobile, and an extrusion piece for the wheel hub is formed by adopting work division procedures isothermally. The method comprises the following steps: a biscuit which has the same outside dimension as the outside dimension of the wheel hub to be formed is taken, and is subjected to processing and forming through forward extrusion, combined extrusion and a flaring procedure in sequence, wherein the forward extrusion forms a wheel arm and enables the rest metal to be gathered evenly in the peripheral positions of the wheel arm preliminarily; the combined extrusion pre-forms a barrel-shaped wheel rim and the upper and the lower wheel flanges of the wheel rim; and the flaring process enables the wheel rim to be formed. The invention further relates to three sets of moulds, which include a forward extrusion and forming mould, a combined extrusion and forming mould and a wheel rim flaring mould. The technical proposal of the invention can reduce the forming force, save the investment of the equipment and the mould, lower the production cost, and improve the quality of forming products.

Owner:HENAN UNIV OF SCI & TECH

Composite board produced with waste and old plastic and coal ash, and producing method thereof

The invention discloses a composite board made from waste plastics and fly ashes and a method for producing the same. The composite board is prepared from the waste plastics and the fly ashes according to certain weight ratio. The main raw materials for producing the composite board comprise the waste plastics and the fly ashes, wherein the waste plastics are discarded in industrial production and in human life and comprise waste polypropylene plastic, waste polyethylene plastic, waste polystyrene plastic and waste polyvinyl chloride plastic and the like, and the fly ashes are discharged by coal-fired power plants and the chemical industry; the main raw materials are manufactured into the composite board through crushing and hot pressing; the manufactured composite board meets the national standards for construction templates, not only reduces the environmental pollution caused by industrial fly ashes and plastic wastes, but also can be applied to replacing wooden construction templates or steel construction templates widely used in the prior building operations, and not only has the advantages of low production cost, light weight, high strength, impact resistance, and easy demoulding, but also 'turns harmful into beneficial and changes waste into valuable', and significantly speeds up the process of recycling wastes in China.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com