Device and method for processing polymer film surface microstructure based on roll-to-roll hot rolling

A polymer film and processing device technology, which is applied in the processing field of polymer film devices, can solve the problems of lack of quenching and shape-retaining modules, low forming precision, large microstructure springback, etc., and achieve low energy consumption and high forming precision , reduce the effect of rebound deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

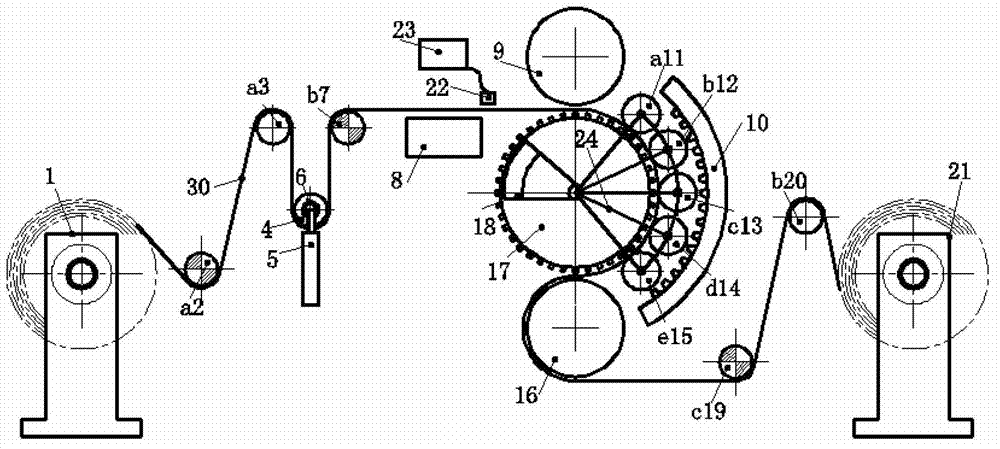

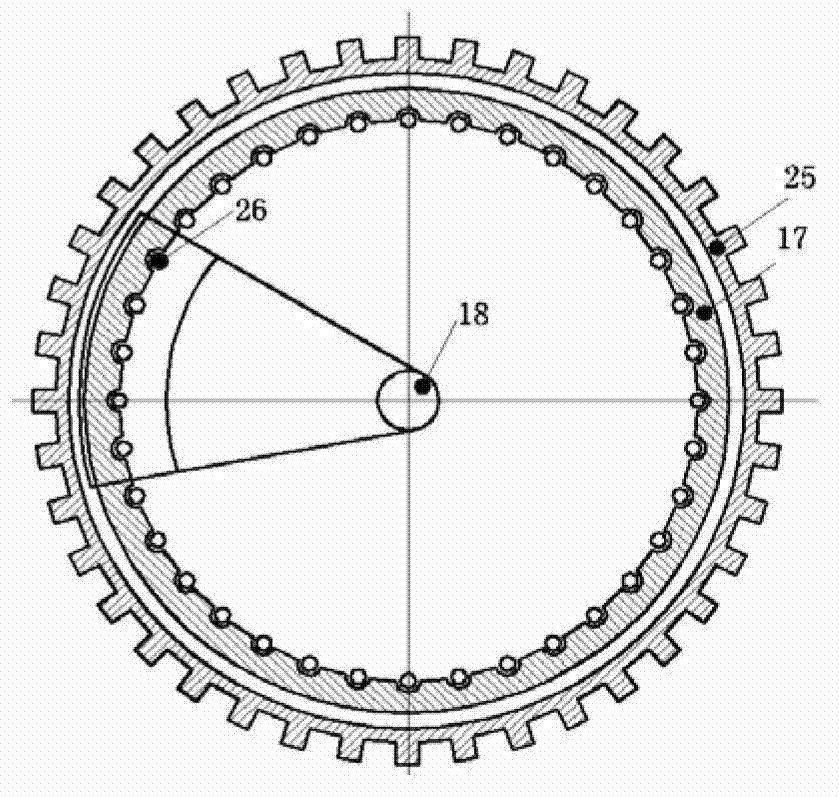

[0040] Such as figure 1 As shown, a surface microstructure processing device based on roll-to-roll hot rolling polymer film includes an unwinding device, a preheating device, a hot rolling device, a shape-keeping device, a cooling device, and a winding device arranged in sequence. The unwinding device includes an unwinding roller 1, a tension roller 4, a cylinder 5, a tension sensing device 6, a driving roller a2, a driving roller b7, a passive roller a3 and a control system; the cylinder 5 is connected to the tension roller 4, The tension roller 4 is provided with a tension sensing device 6, and the control system is connected to the tension sensing device 6 and the cylinder 5. When the tension sensing device 6 senses that the tension of the film to be embossed is greater than the set value, the control system drives the cylinder 5 to drive The tension roller 4 moves to relax the tension of the film to be embossed, otherwise, the control system drives the cylinder 5 to drive ...

Embodiment 2

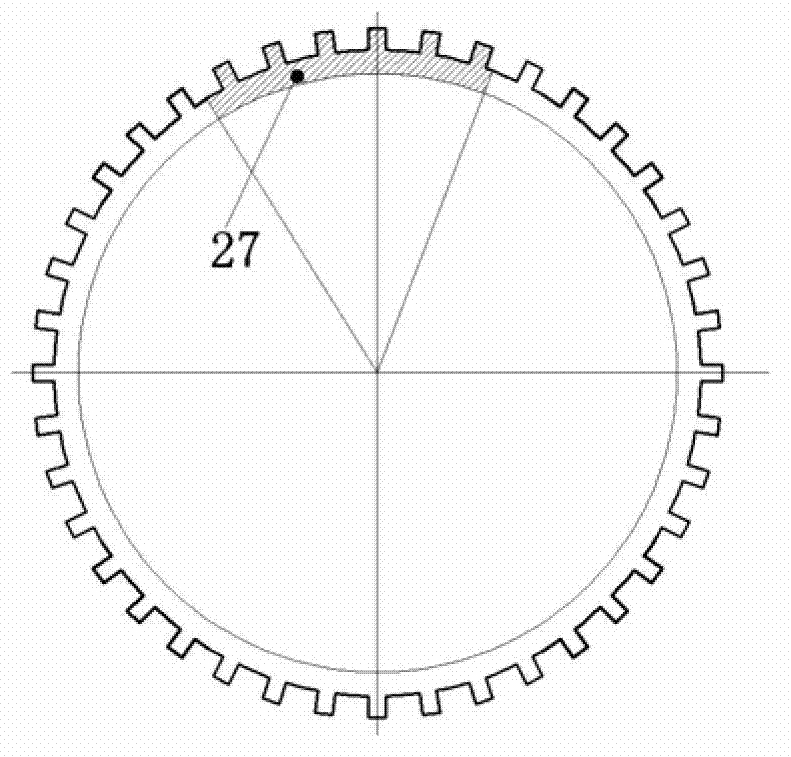

[0057] Such as Figure 4 As shown, on the basis of Example 1, the plate roll 17 is changed to a solid roll, the pair of brushes and the resistance wire are eliminated, and an infrared radiation heating device 18' is placed on the outside of the plate roll 7 close to the embossing surface, and the cooling roll 16 adopts Oil cooling method for cooling. In addition, positioning systems such as Figure 5 As shown, the positioning system is provided with an automatic deviation correction device 28 and an infrared sensor 29, and the automatic deviation correction device 28 is connected to the roller shaft of the transmission device (taking the driving shaft 2 as an example), when the infrared sensor 29 detects the film 30, if an offset occurs during the transmission process, the automatic deviation correction device 28 will control the axial displacement and horizontal angular displacement of the roller shaft.

[0058] The size of the surface fine structure pattern is 500 μm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com