L-shaped aluminum profile arc bending die

An aluminum profile and arc bending technology, which is applied in the field of L-shaped aluminum profile arc bending molds, can solve problems such as scratches on the surface of aluminum profiles, low production efficiency, and poor arc bending effects, so as to reduce local deformation, improve molding quality, The effect of reducing springback problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

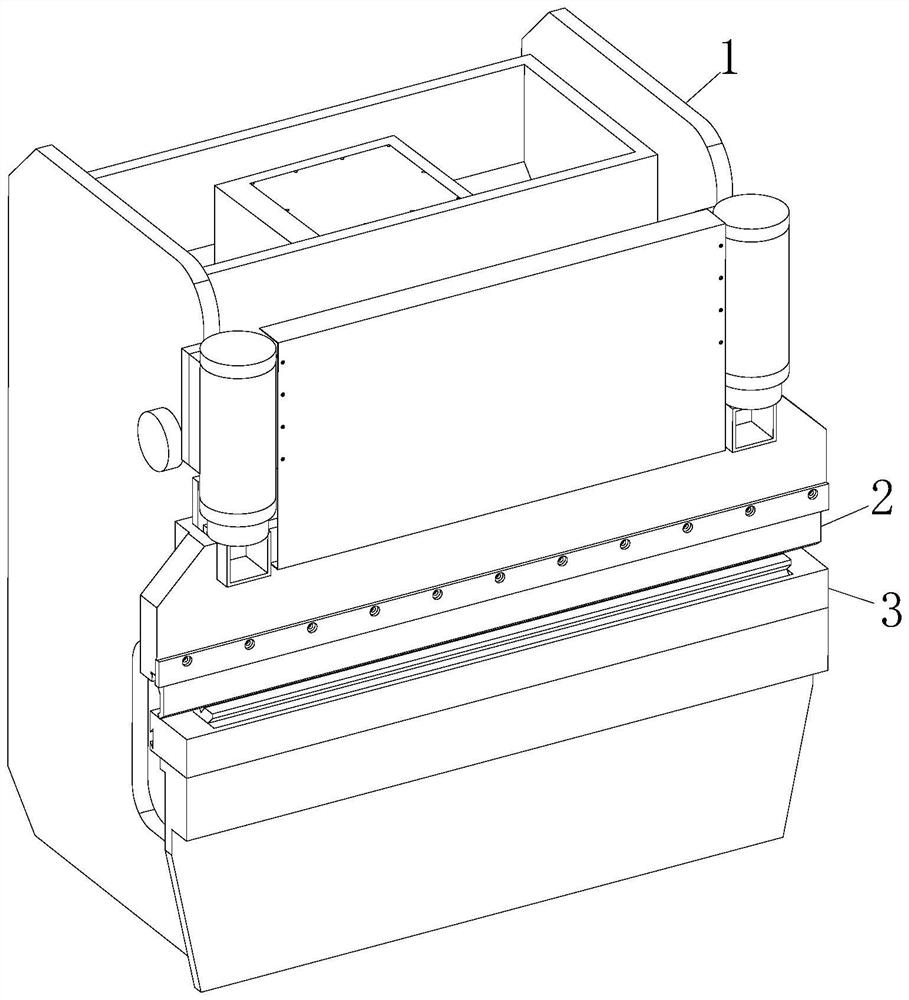

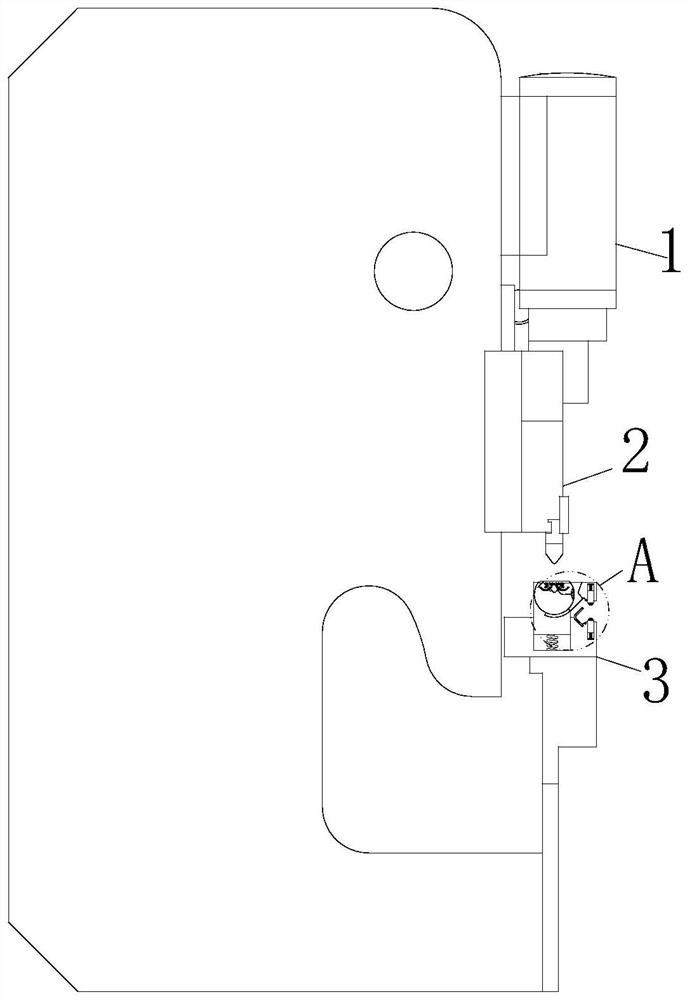

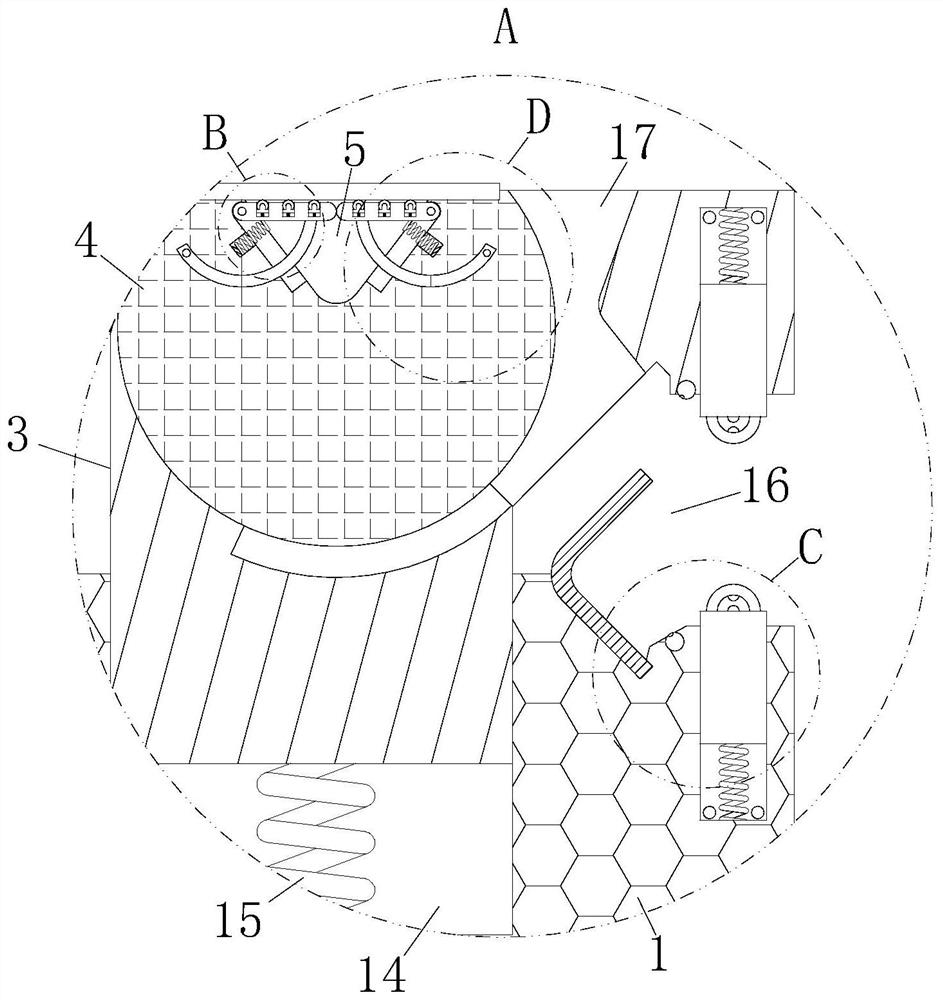

[0030] like Figure 1-Figure 3 As shown, an L-shaped aluminum profile arc bending mold according to the embodiment of the present invention includes a body 1, an upper template 2 and a lower template 3; the surface of the body 1 is slidably connected with an upper template 2; The bottom position of the surface and the upper template 2 is provided with a lower template 3; the top surface of the lower template 3 is provided with a shaped block 4; the top surface of the shaped block 4 is provided with a shaped groove 5; the inner surface of the shaped groove 5 is provided with A rotating groove 6; a rotating plate 7 is rotatably connected inside the rotating groove 6; a mounting groove is formed at the bottom of the rotating groove 6; a first spring 8 is fixedly connected to the inside of the mounting groove, and the first spring 8 It is fixedly connected with the turning plate 7; when working, when bending the aluminum profile, it is necessary to extrude the aluminum profile thr...

Embodiment 2

[0039] like Image 6 As shown, Comparative Example 1, in which another embodiment of the present invention is: the bottom surface of the rotating plate 7 near the guide hole 17 is fixed with a connecting rope 24; the surface of the shape block 4 is connected to the guide hole 17. There is a fixing slot at the position; the slot of the fixing slot is fixed with the elastic plate 25, and the connecting rope 24 passes through the shape block 4 and is fixedly connected with the elastic plate 25; the elastic plate 25 is connected to the bottom of the fixing slot. There is a spring piece 26 fixed between them; during operation, when the turning plate 7 rotates, the turning plate 7 will pull the connecting rope 24, and the connecting rope 24 will drive the elastic plate 25 to deform, so that the elastic plate 25 squeezes the spring piece 26. At this time, the guide hole 17 In the normal open state, when the rotating plate 7 is rotated to the inside of the rotating groove 6, under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com