Patents

Literature

69results about How to "Reduce surface scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grinding fluid for processing LED (light-emitting diode) substrate and preparation method thereof

InactiveCN102337084AReduce surface roughnessReduce surface scratchesPolishing compositions with abrasivesSemiconductor devicesSolventSilicon dioxide

The invention relates to a grinding fluid for processing an LED (light-emitting diode) substrate. The grinding fluid comprises a solvent, an additive and a grinding agent, wherein the grinding agent consists of diamond micropowder and non-diamond nano polishing material; the purity of the diamond micropowder is more than 99%, and the particle size of the diamond micropowder is W0.5-W20; and the non-diamond nano polishing material is any one or a mixture of any of alumina, silicon dioxide, cerium oxide and chromic oxide, the particle size of the non-diamond nano polishing material is 10-100nm, and the purity of the non-diamond nano polishing material is more than 99%. According to the invention, micron diamond is used as a grinding material while the non-diamond nano polishing material is also compositely added, thereby ensuring the grinding rate and well guaranteeing the processing quality of the surface of a workpiece.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD +1

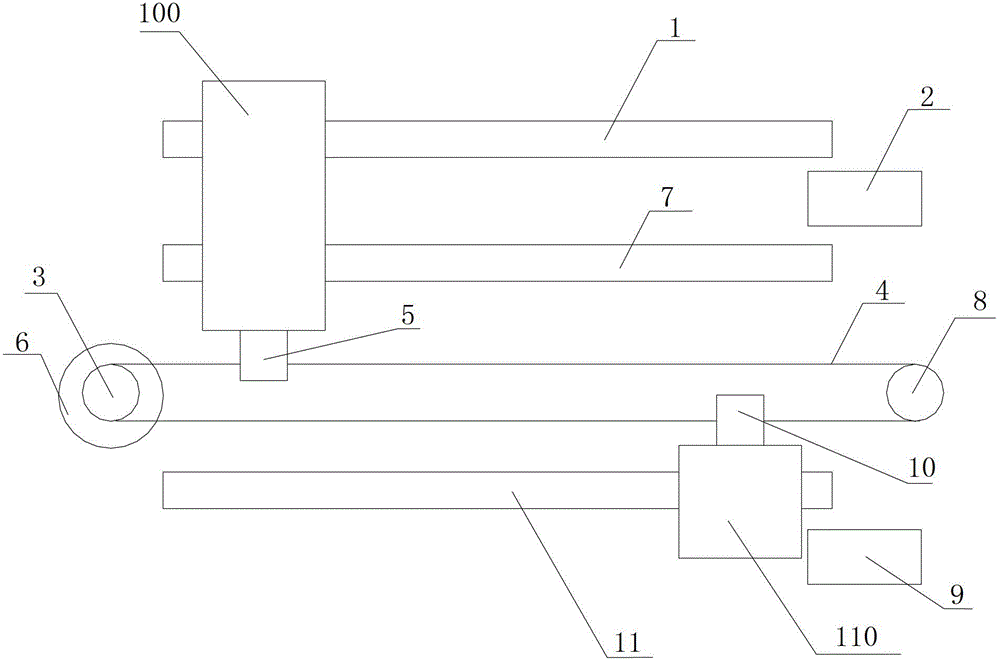

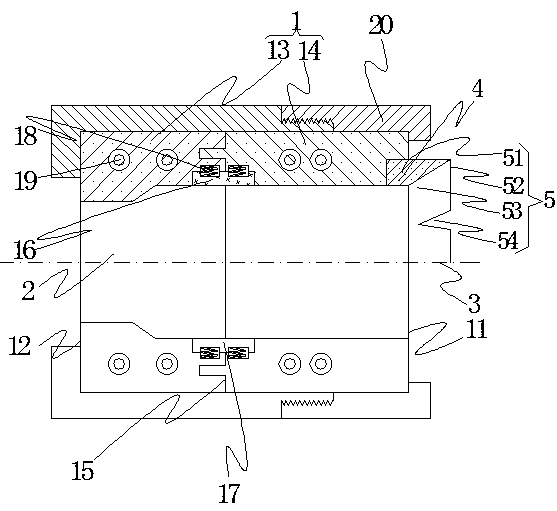

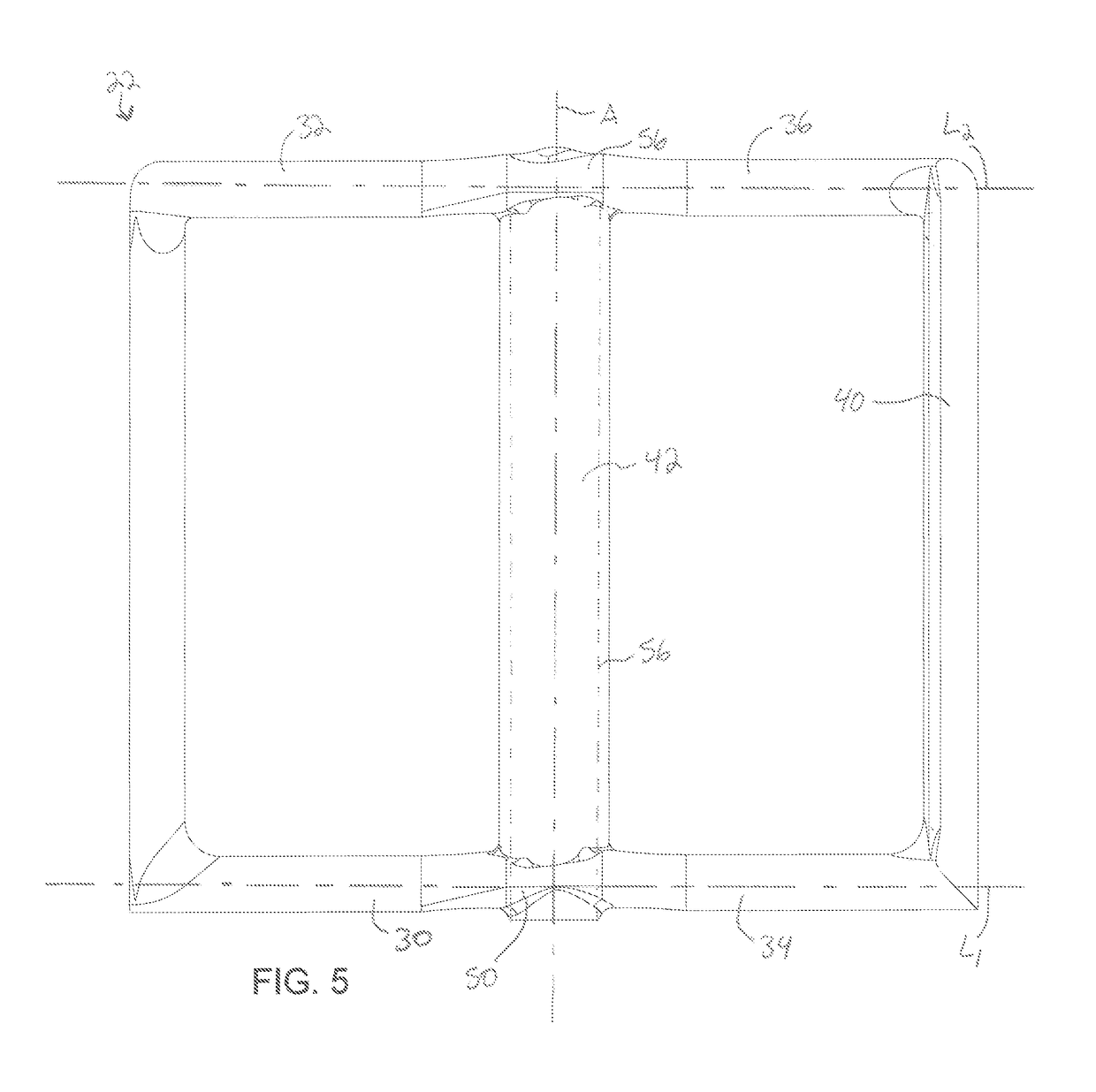

Alternated plate feeding device

InactiveCN102745459ARealize clamping and conveyingCompact structureConveyorsReciprocating motionEngineering

The invention discloses an alternated plate feeding device, which comprises a conveyor belt, at least two plate clamping mechanisms and a slide rail, wherein the conveyor belt comprises a plurality of working sections arranged in parallel, and at least two of all the working sections have opposite conveying directions; the plate clamping mechanisms are fixedly connected to different working sections; and the slide rail is used for bearing reciprocating motion of the plate clamping mechanisms. The alternated plate feeding device does not slip during clamping; and the feeding distance can be conveniently calculated through the conveying distance of the conveyor belt, so that the feeding precision is greatly promoted. In the optimal technical scheme, a first plate clamping mechanism and a second plate clamping mechanism are adopted, so that idle travel is avoided in the feeding process, uninterrupted feeding is realized, and the feeding efficiency is greatly improved; and only one clamping part is required in one feeding stroke, so that the surface of a material is scratched little. The device has the advantages of convenience in control, high feeding precision, little surface scratch, high feeding efficiency and the like.

Owner:ZHEJIANG UNIV

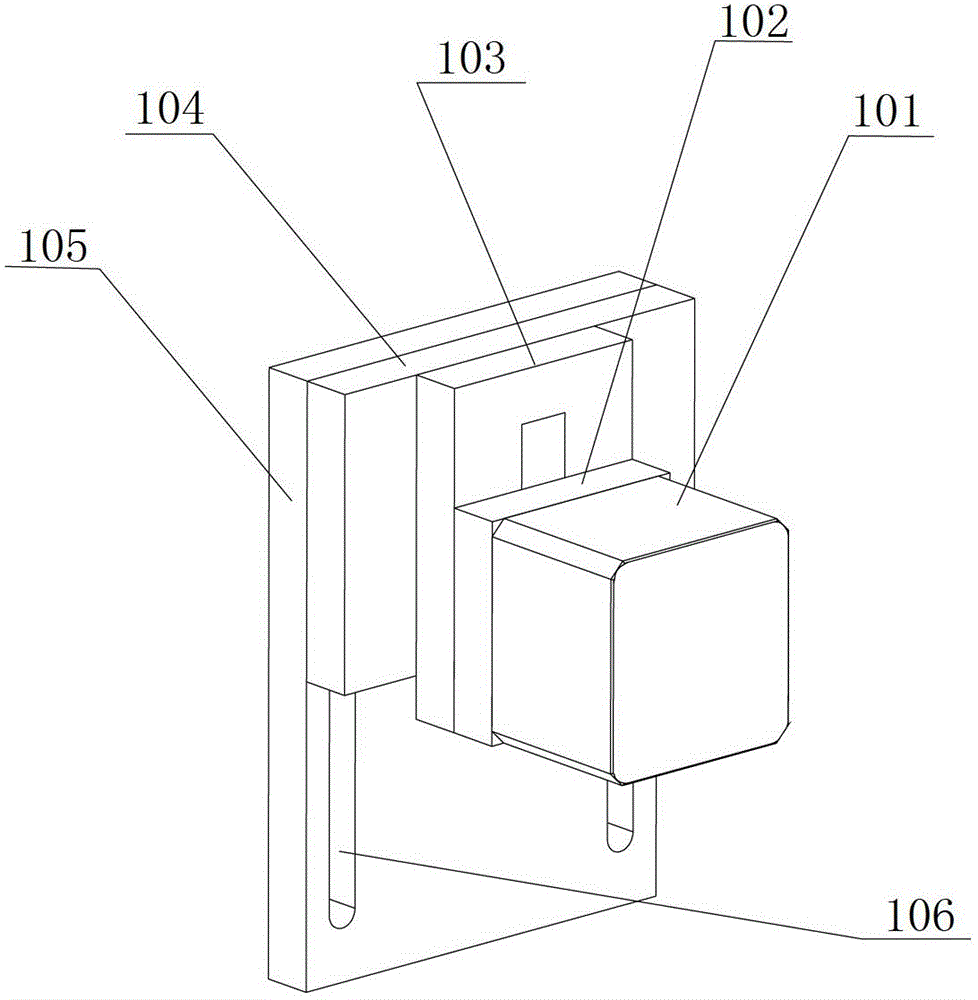

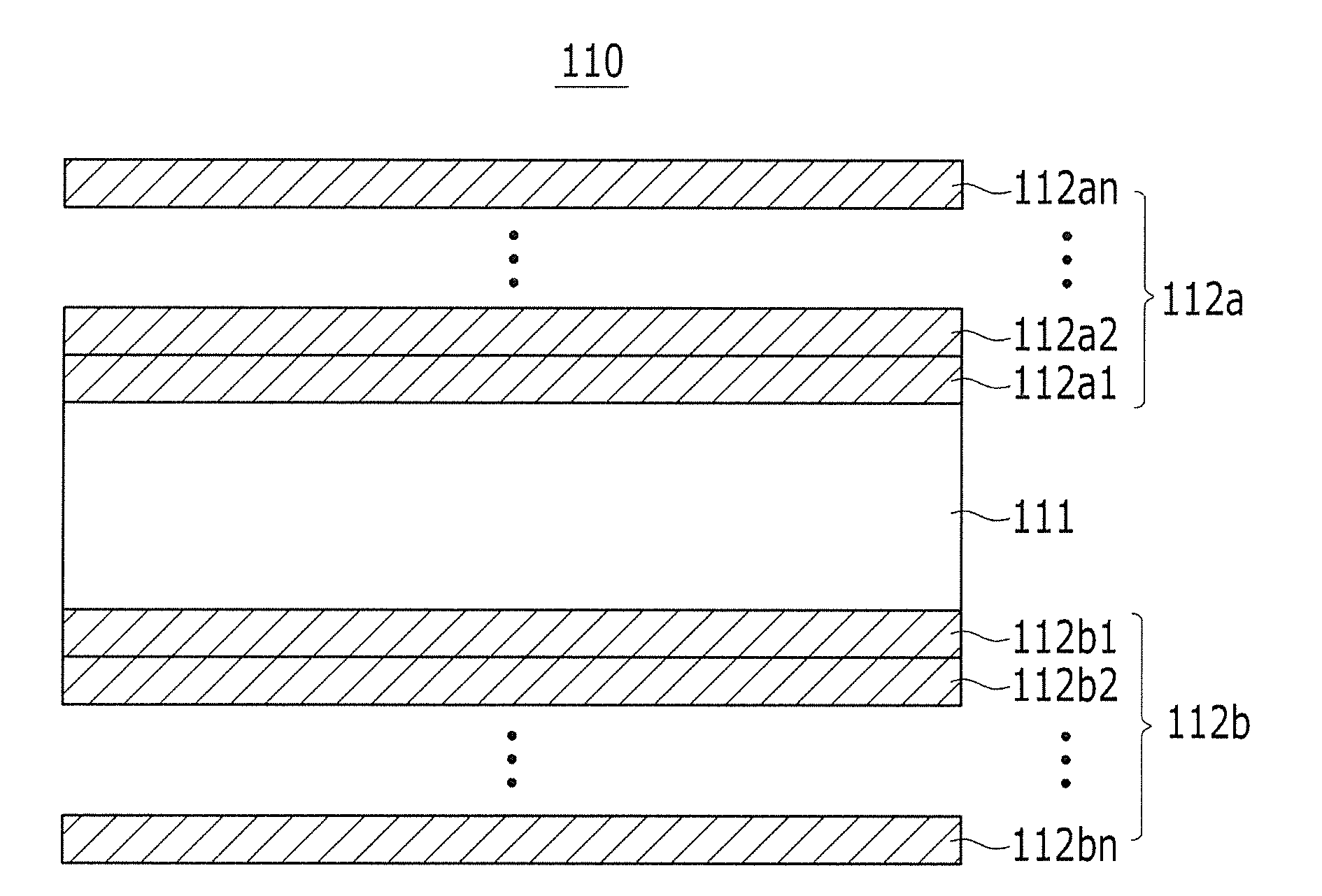

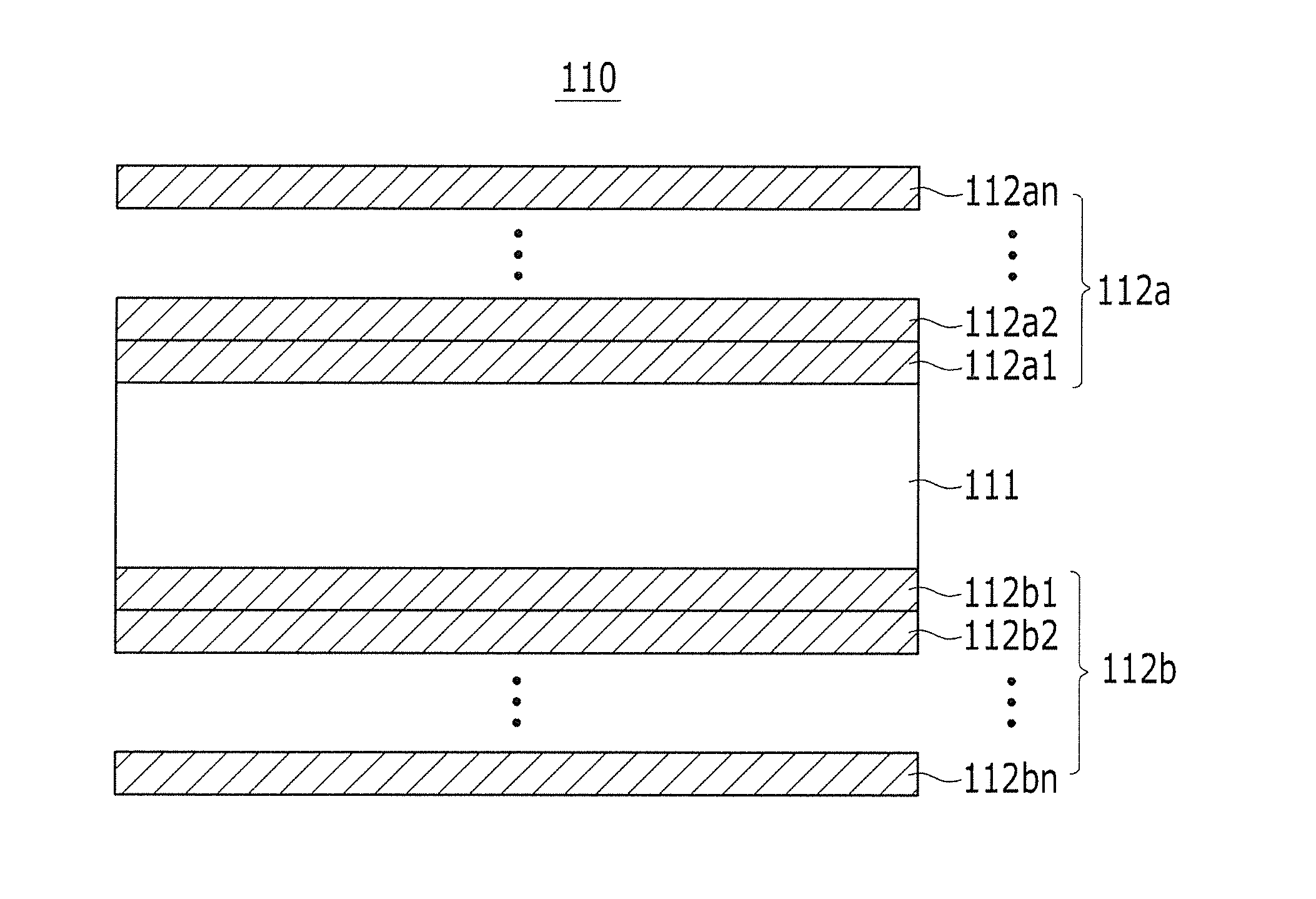

Window panel for display device and display device including the window panel

InactiveUS20130130002A1Reduce surface scratchesMaintain impact resistanceSynthetic resin layered productsRecord information storageDisplay deviceEngineering

A window panel for a display device including a plastic substrate, and a hard coating layer formed on at least one side of the plastic substrate and including at least two continuously deposited layers. Here, a display device includes the window panel.

Owner:SAMSUNG DISPLAY CO LTD

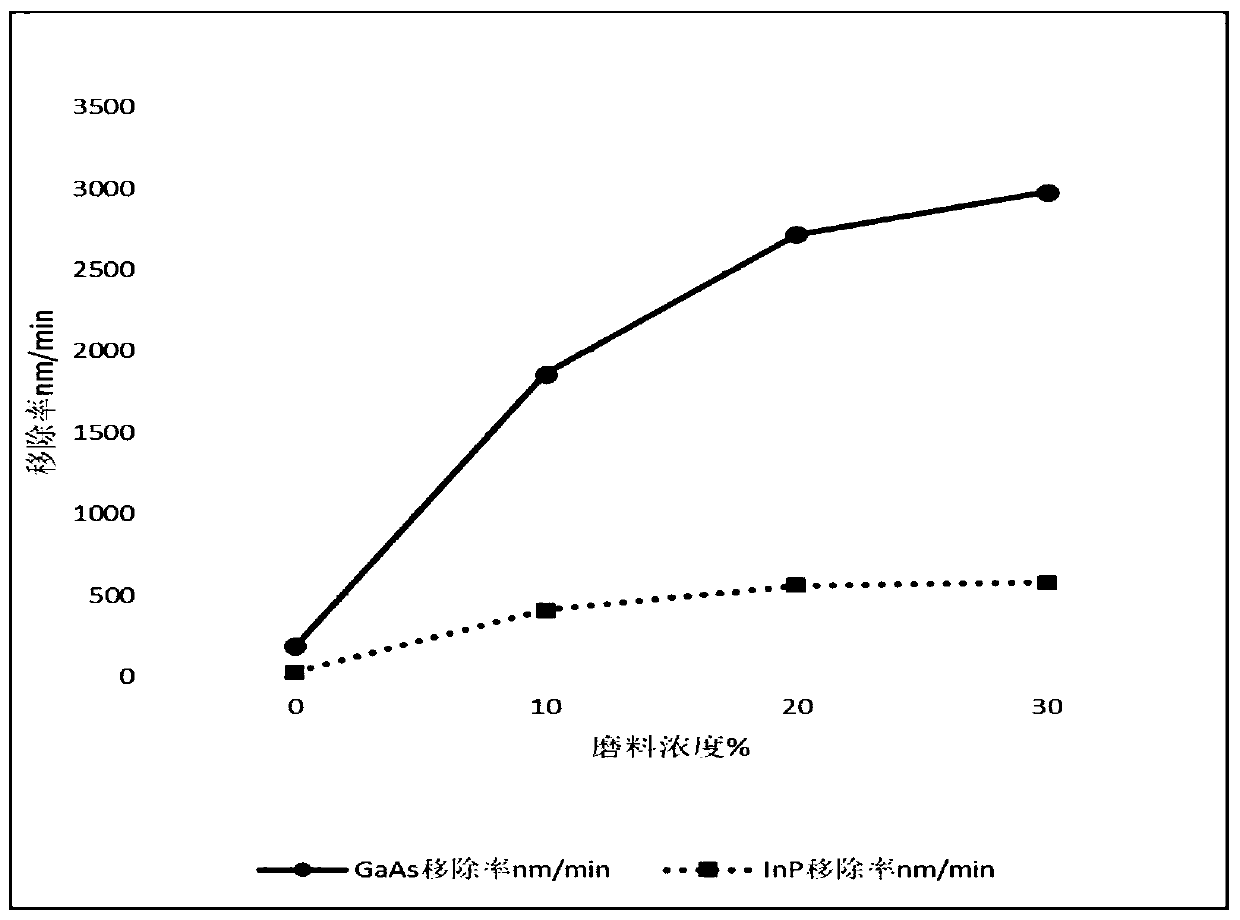

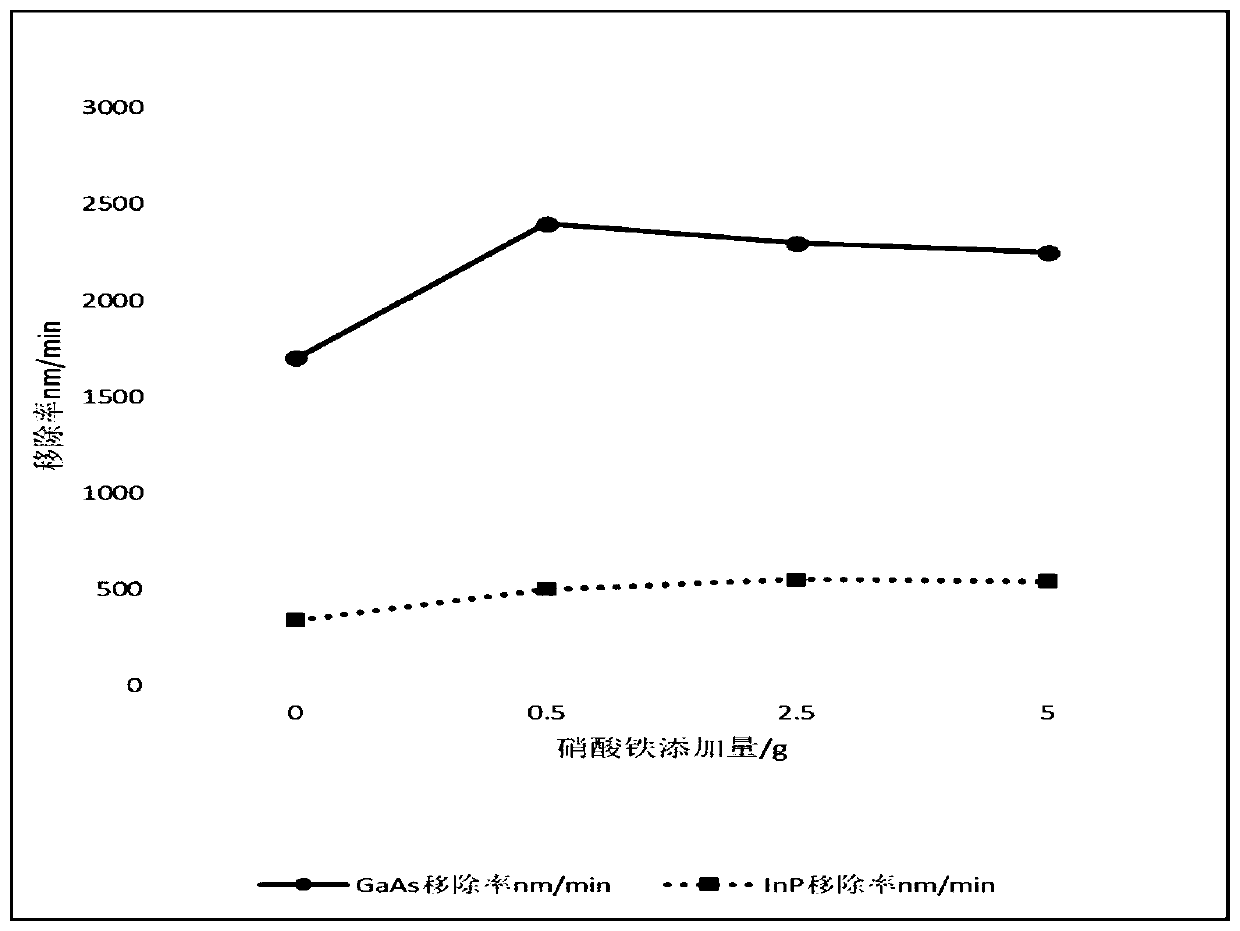

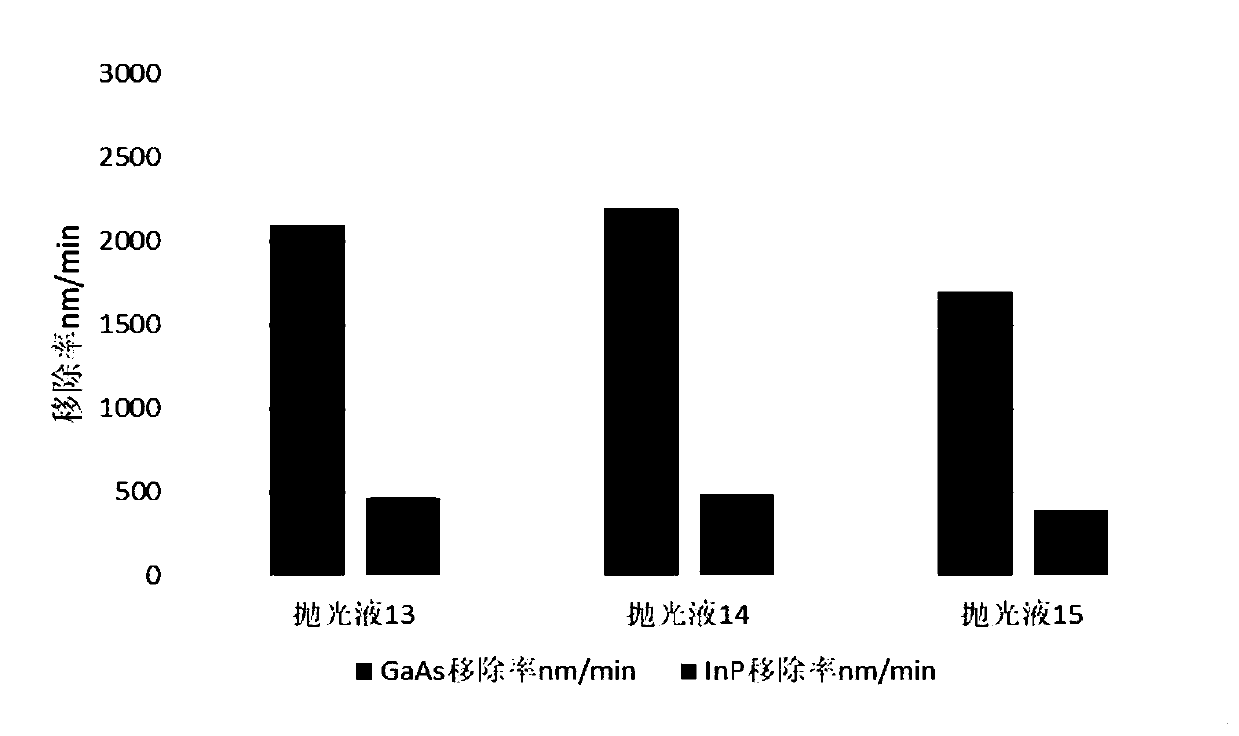

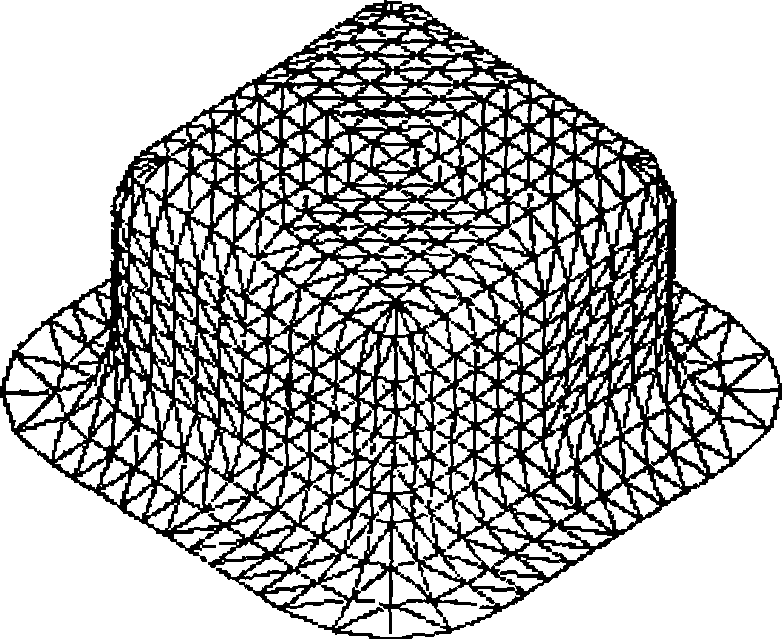

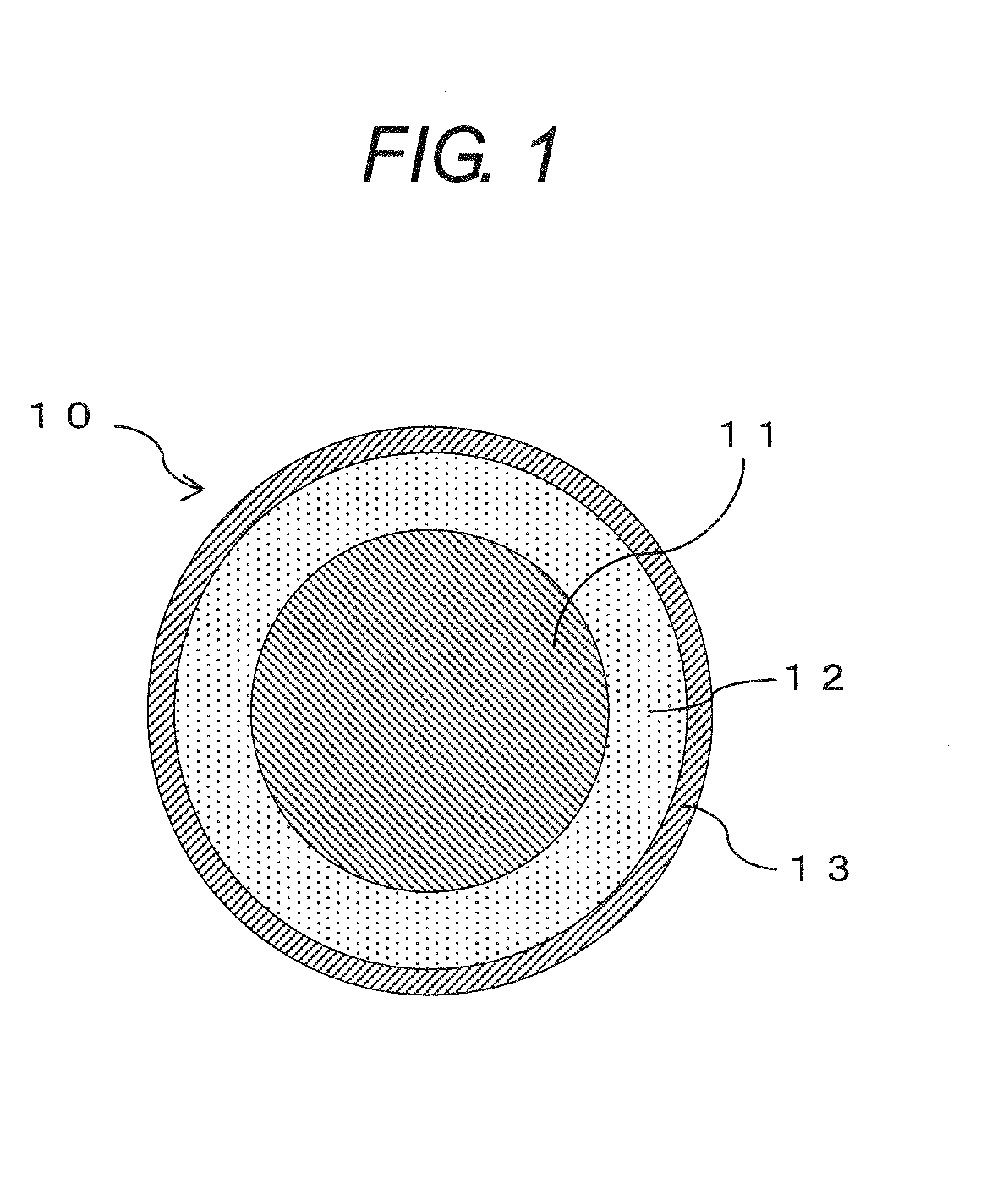

Grinding particle system and polishing liquid for CMP (Chemical Mechanical Polishing)

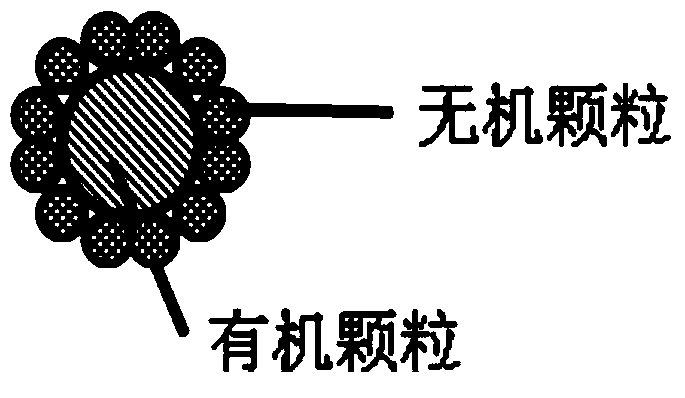

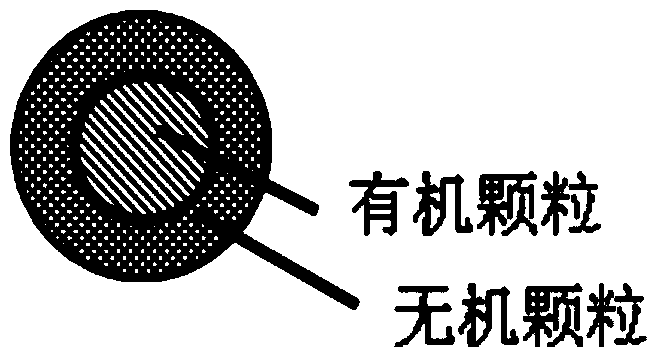

InactiveCN103725256AResidue reductionIncrease contact areaOther chemical processesPolishing compositions with abrasivesInorganic particleChemical solution

The invention discloses a grinding particle system and polishing liquid. The grinding particle system comprises organic particles, inorganic particles and a chemical solution, wherein the content of the organic particles is 3-10 times as much as that of the content of the inorganic particles. According to the grinding particle system, the control of a mixing ratio and the distribution of the particles is carried out so that the content of the inorganic particles in the grinding particle system is greatly reduced, and furthermore, the surface scratches and the particle residues caused by polishing are reduced; the shape of the organic particles is designed so as to enlarge the contact area of the particles in a polishing process and improve the polishing efficiency. The respective advantages of the inorganic particles and the organic particles are sufficiently expressed; the preparation process is simple and the manufacturing cost is low; the grinding particle system is particularly suitable for a surface polishing process of materials with ultra-low k values and metal materials with low rigidity, such as copper and aluminum.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

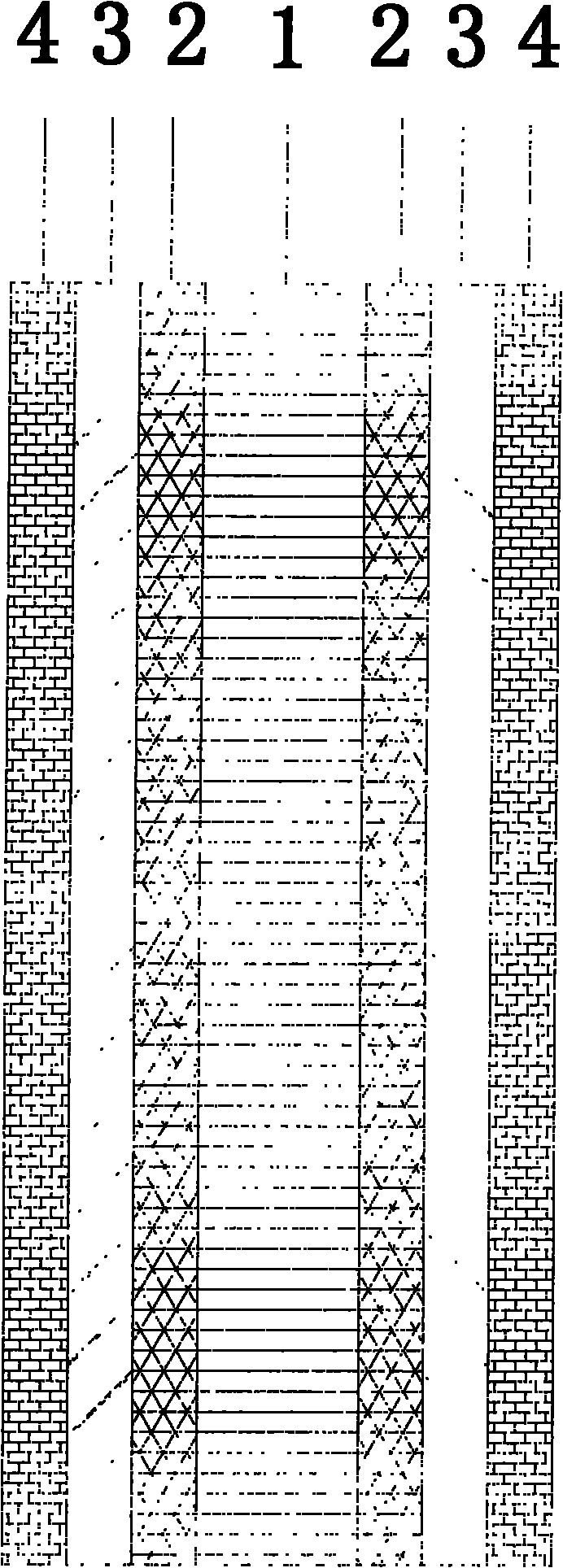

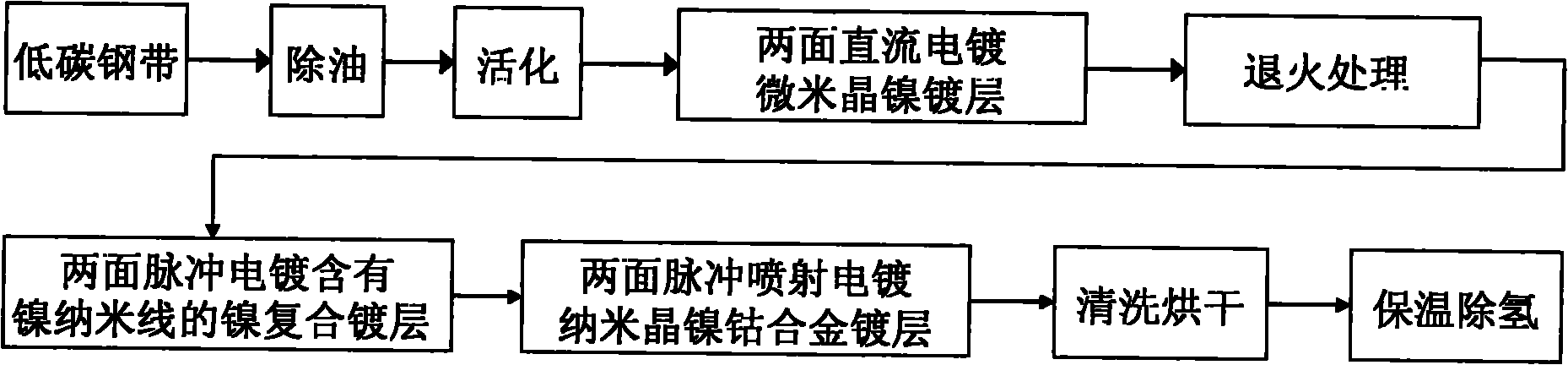

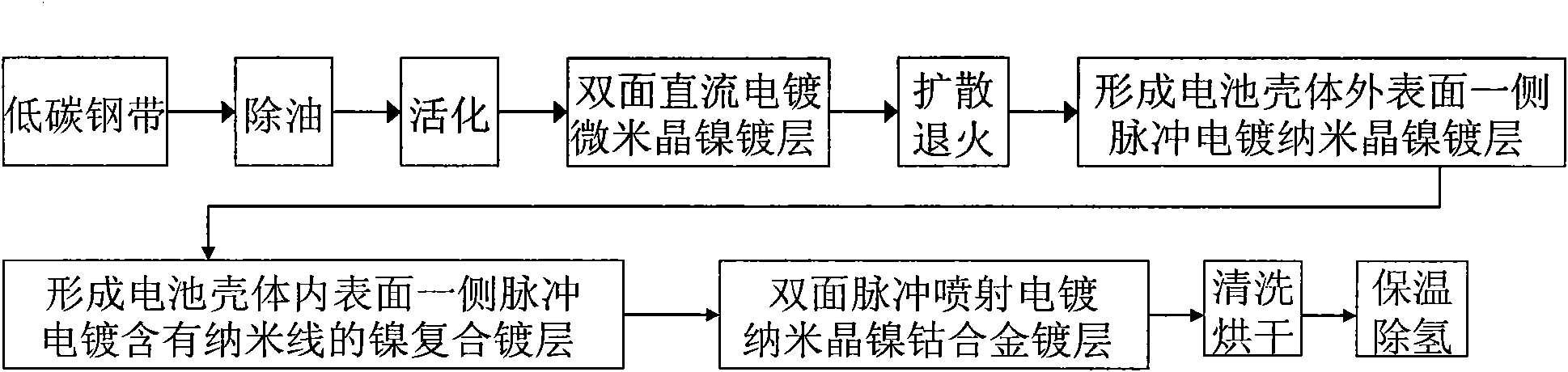

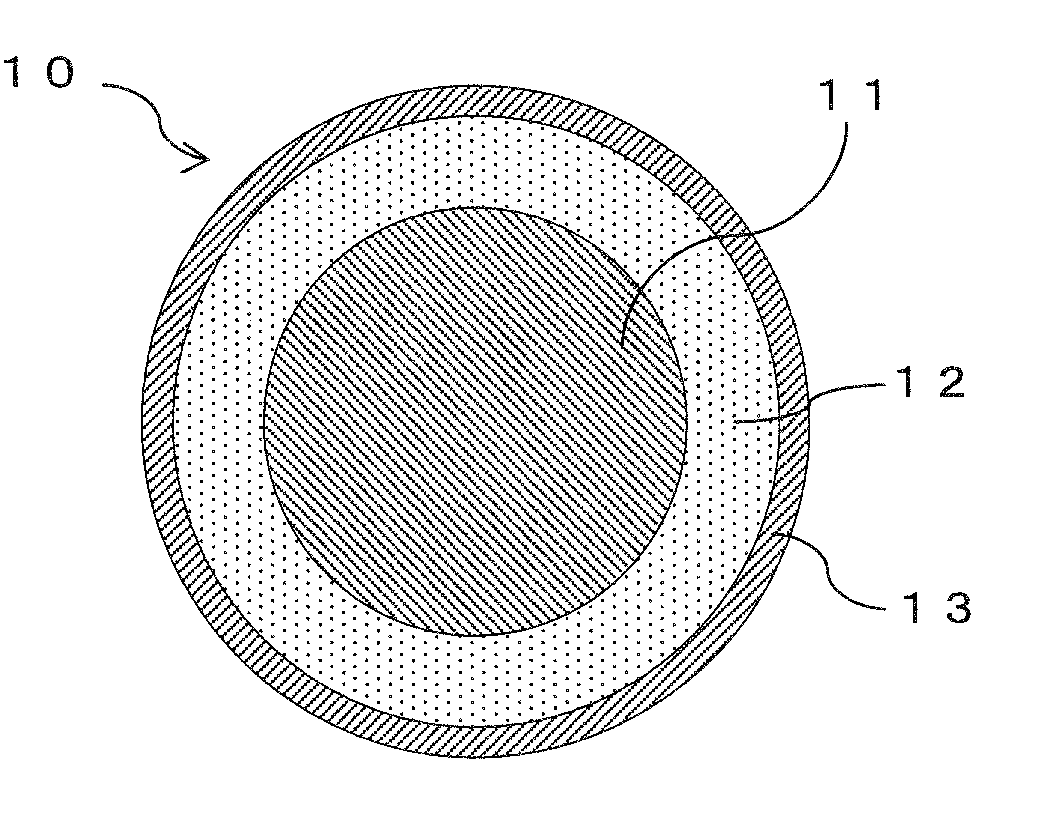

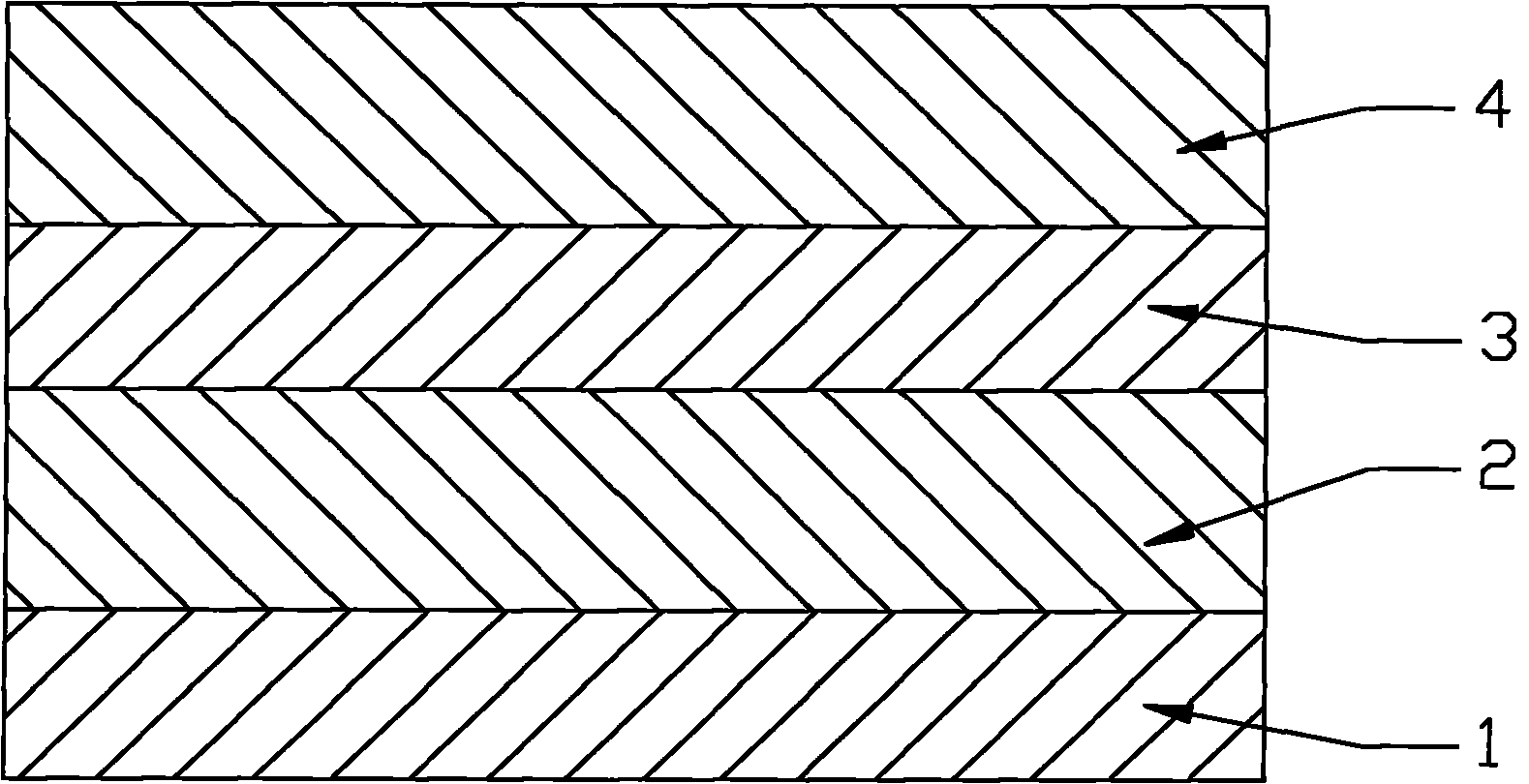

Nickeliferous nanowire laminated film plated steel belt and production method thereof

ActiveCN101954763AReduce corrosion rateHigh strengthElectrolytic coatingsCell component detailsNanowireMetallic Nickel

The invention discloses a nickeliferous nanowire laminated film plated steel belt and a production method thereof. A steel belt is used as a base, and both faces of the steel belt are respectively plated with a nickeliferous nanowire multilayer laminated film. The bottom layer of the nickeliferous nanowire multilayer laminated film is a micron-crystalline nickel plating layer, the middle layer isa nickeliferous nanowire nickel laminated plating layer, and the surface layer is a micron-crystalline nickel cobalt alloy plating layer. The invention also provides the production method of the steel belt, which comprises the following steps of: oiling and activating the base steel belt, and firstly preparing one micron-crystalline nickel plating layer on the base by using a DC electroplating mode; after annealing, preparing one nickeliferous nanowire nickel laminated plating layer on the nickel plating layer by using a pulse electroplating mode; then, preparing one micron-crystalline nickelcobalt alloy plating layer on the nickeliferous nanowire nickel laminated plating layer by using a pulse spraying mode, cleaning by using distilled water and drying; and finally, preserving temperature and removing hydrogen. The steel belt is formed by tightly combining the nickeliferous nanowire multilayer laminated film and a mild-carbon steel belt together, has good corrosion resistance, stamping performance and strong load resistance and can be applied to shell materials of lithium ion power batteries and high-performance alkaline manganese batteries.

Owner:XIANGTAN UNIV

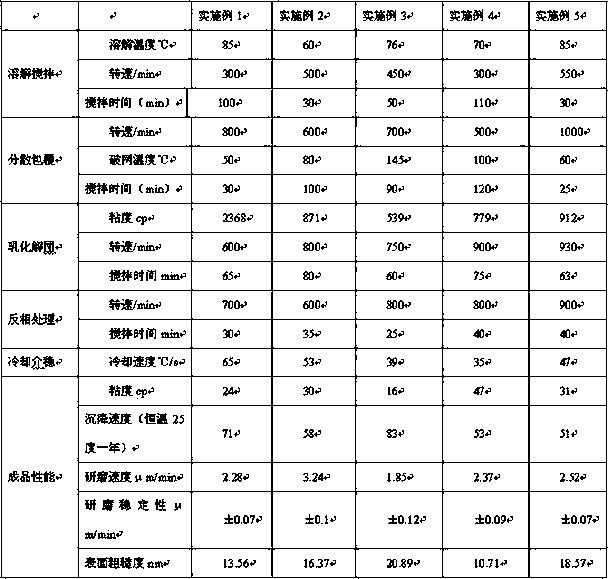

Environmental-friendly diamond grinding liquid and preparation process thereof

InactiveCN107603492AReduce sulfur contentImprove thermal stabilityPolishing compositions with abrasivesAlkaneParaffin wax

The invention relates to environmental-friendly diamond grinding liquid and a preparation process thereof. The environmental-friendly diamond grinding liquid is characterized by being prepared from the following components in percent by weight: 0.1-20wt% of grinding material, 60-99wt% of solvent, 1-20wt% of emulsifying agent, 1-20wt% of thickening agent and 1-20wt% of suspending agent, wherein thegrinding material contains at least one of polycrystalline diamond micropowder, polycrystalline-like diamond micropowder and monocrystalline diamond micropowder; the solvent contains at least one ofnaphtha, white oil, alkylbenzene and isoparaffin; the emulsifying agent contains at least one of an alkylphenol-series emulsifying agent, a benzenesulfonic-acid-series emulsifying agent, a polyoxyethylene-ether-series emulsifying agent and a sorbitol-series emulsifying agent; the thickening agent contains at least one of olefins polymer and silicon-alkane polymer; the suspending agent contains atleast one of paraffin series, epoxy resin, C9 petroleum resin and butadiene styrene rubber SBS. The environmental-friendly diamond grinding liquid is prepared by the steps of dissolving, stirring, dispersing, coating, emulsifying, disaggregating, reverse treatment, cooling and converting. The environmental-friendly diamond grinding liquid has the advantages of wide working-temperature range, longstability time and stable-controllable grinding speed and the like.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Polishing solution and preparation method thereof

InactiveCN111423819AReduce pollutionEnhanced chemical corrosionPolishing compositions with abrasivesMetallurgyOxidizing agent

The invention provides a polishing solution and a preparation method thereof. The polishing solution contains an abrasive, an oxidizing agent, a lubricating agent, a chelating agent and water. The polishing solution has the advantages of being high in polishing rate and high in universality.

Owner:深圳市朗纳研磨材料有限公司

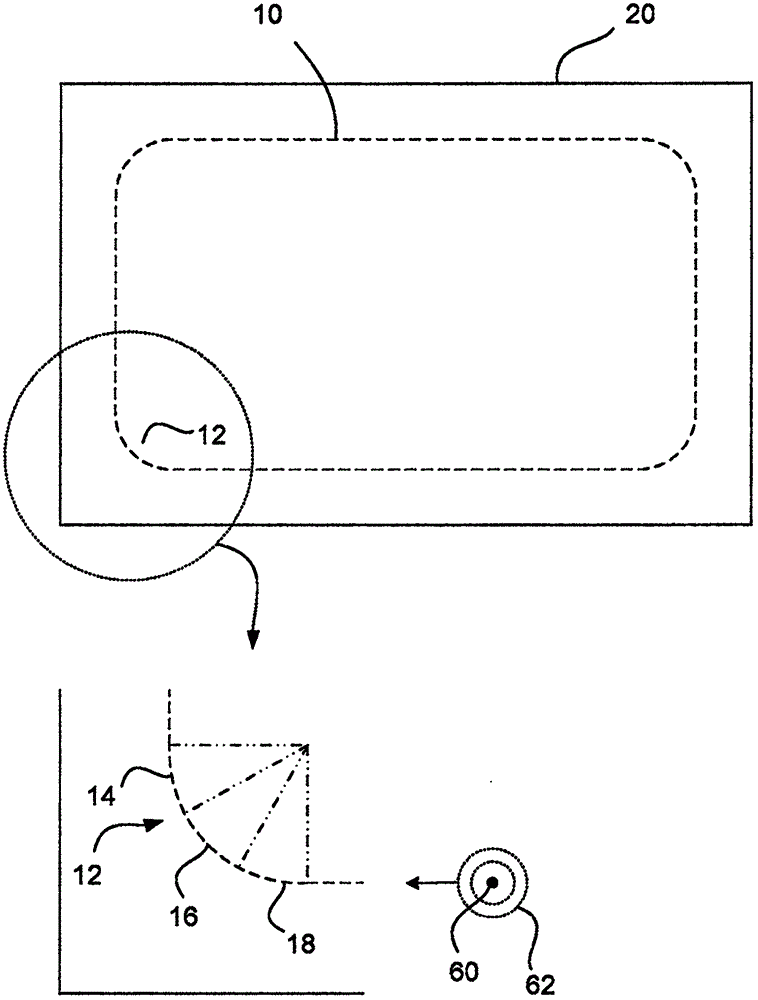

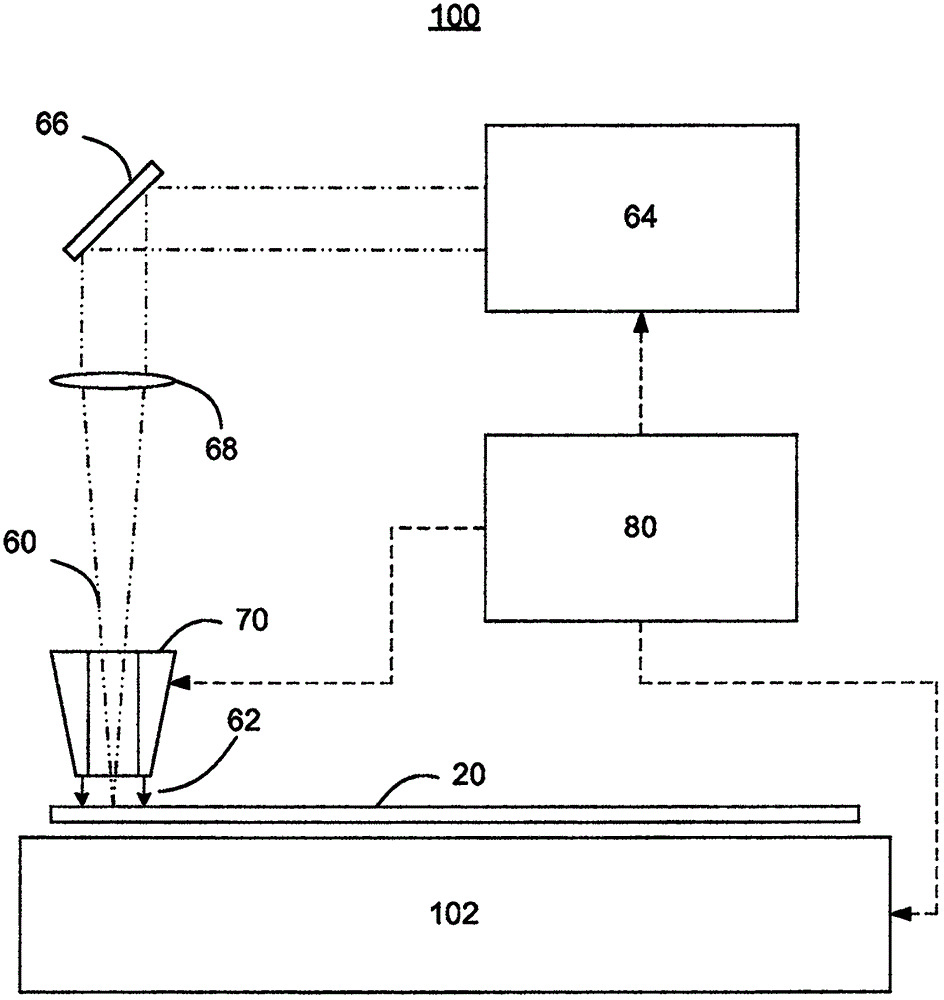

Methods and apparatus for cutting radii in flexible thin glass

ActiveCN106458693AReduce generationHigh strengthGlass severing apparatusWelding/soldering/cutting articlesLaser beamsCooling fluid

Methods and apparatus provide for: cutting a thin glass sheet along a curved cutting line, where the curve is divided into a plurality of line segments; applying a laser beam and continuously moving the laser beam along the cutting line; applying a cooling fluid simultaneously with the application of the laser beam in order to propagate a fracture in the glass sheet along the cutting line; and varying one or more cutting parameters as the laser beam moves from one of the plurality of line segments to a next one of the plurality of line segments, wherein the one or more cutting parameters include at least one of: (i) a power of the laser beam, (ii) a speed of the movement, (iii) a pressure of the cooling fluid, and (iv) a flow rate of the cooling fluid.

Owner:CORNING INC

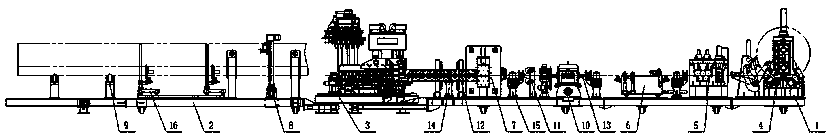

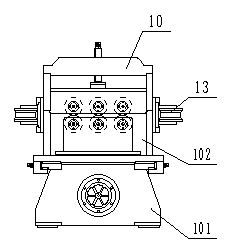

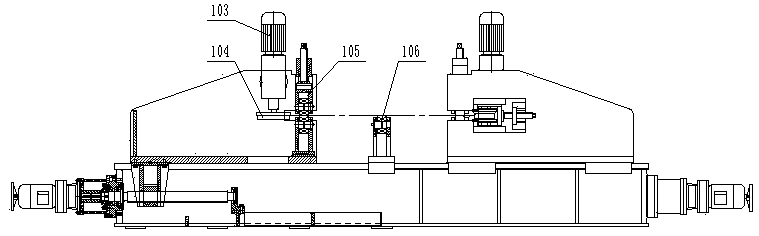

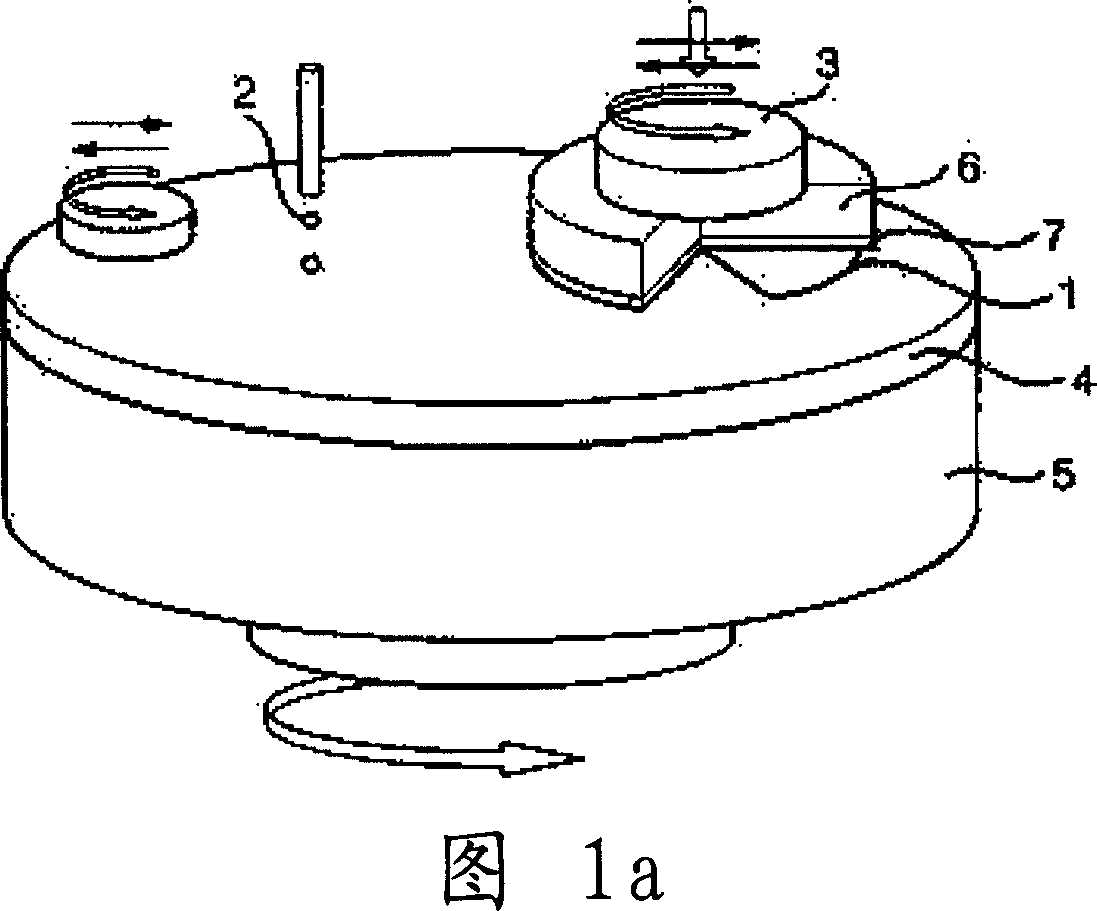

Magnesium aluminum alloy spiral welded pipe production unit

ActiveCN103722347AQuality assuranceAvoid damageOther manufacturing equipments/toolsLevel aluminumButt welding

The invention relates to a magnesium aluminum alloy spiral welded pipe production unit, and belongs to the technical field of magnesium aluminum alloy pipe producing devices. The magnesium aluminum alloy spiral welded pipe production unit is reasonable in structure, low in production cost and high in production efficiency; and the quality of machined magnesium aluminum alloy tubes is high. According to the technical scheme, one end of a front axle is hinged to the bottom of a forming machine; one end of a rear axle is fixed on the bottom of the forming machine; the front axle is coaxially provided with an uncoiler, a pinch leveller, a cutting butt welding machine and a delivery machine sequentially; the uncoiler is used for shoveling aluminum coils; the pinch leveller is used for leveling aluminum belts; the cutting butt welding machine is used for performing butt welding connection on the aluminum belts; the delivery machine serves as a power source of the unit; the rear axle is sequentially provided with an outer welding device and a plurality of supporting rollers; the supporting rollers are used for supporting a welded pipe; the aluminum belts welded by using the cutting butt welding machine enter the delivery machine after passing through an edge milling machine and a film sticking machine; and the delivery machine drives the aluminum belts to pass through a pre-bending machine and enter the forming machine, and the aluminum belts are then pressed into tubes. The magnesium aluminum alloy spiral welded pipe production unit is widely used for producing magnesium aluminum alloy tubes.

Owner:太原华欣诚机电设备有限公司

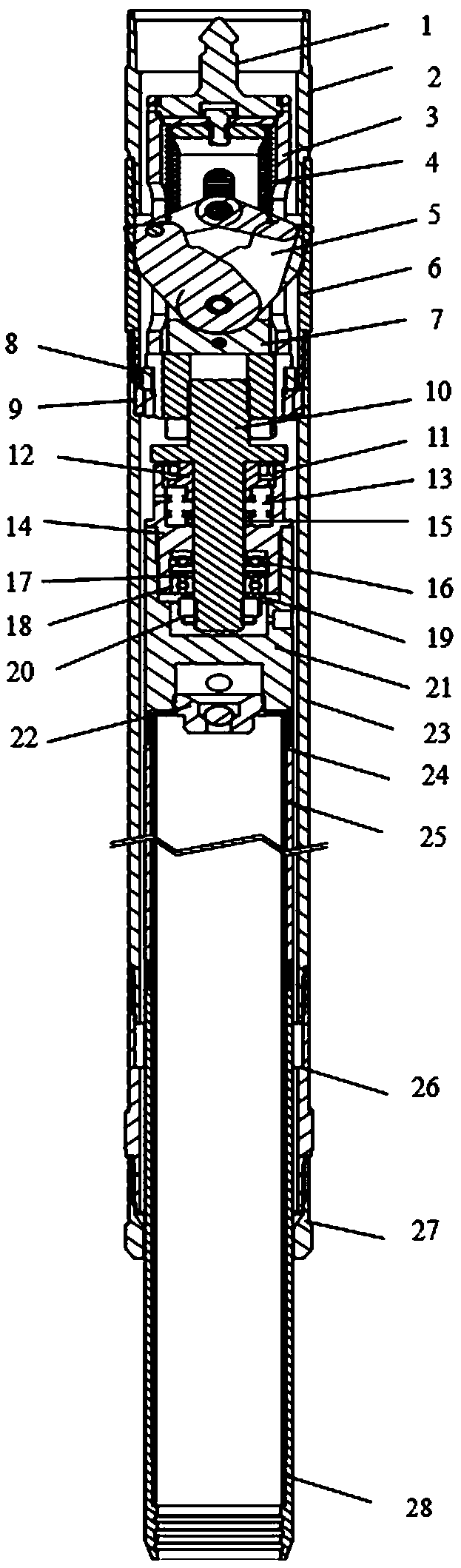

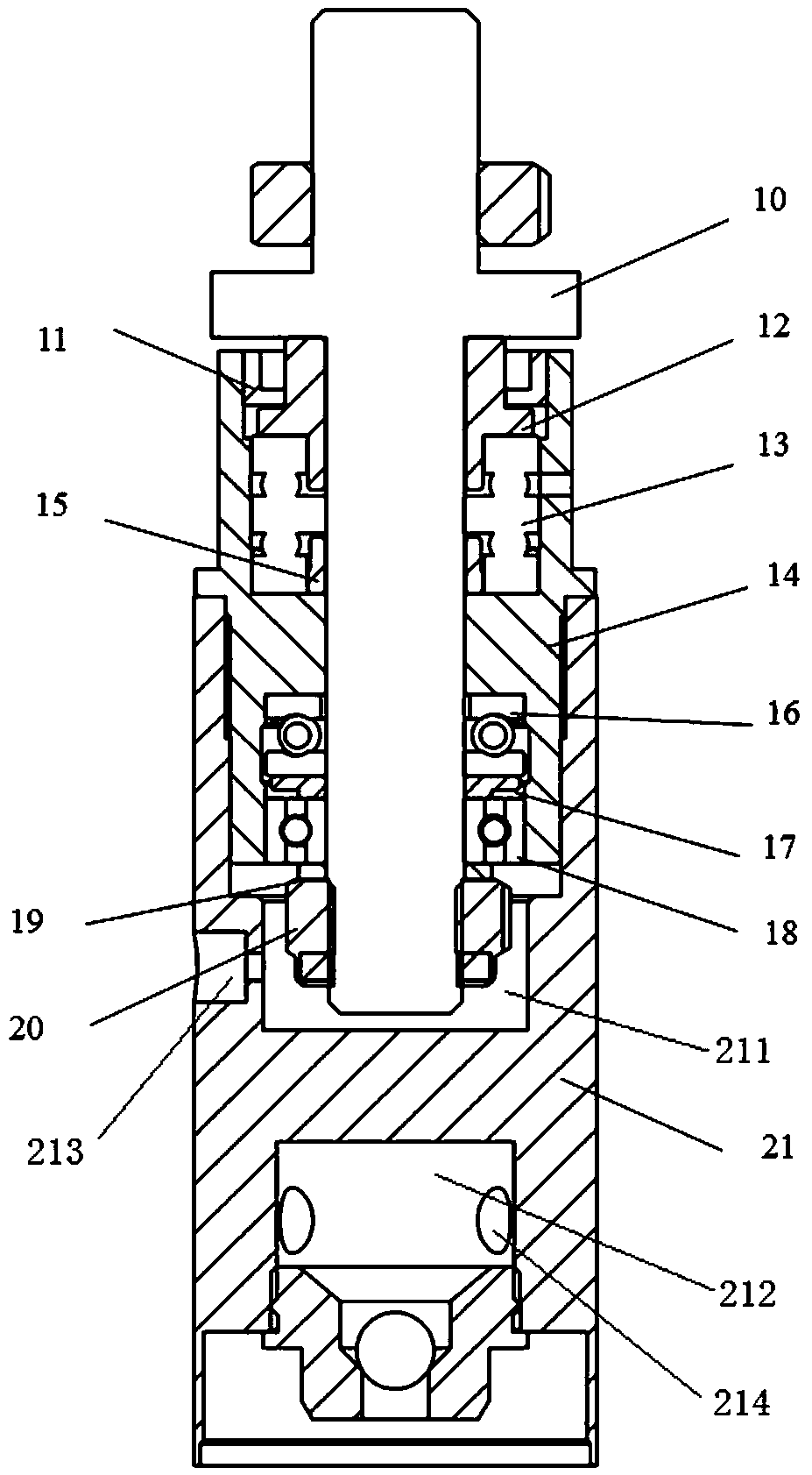

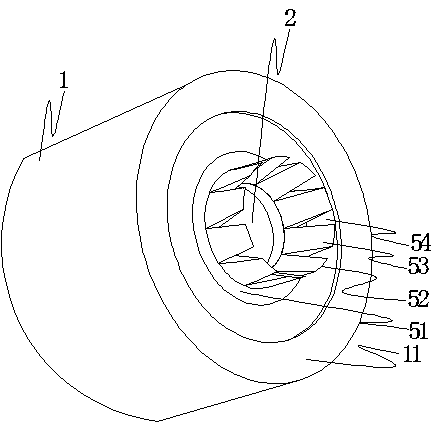

Engineering exploration wire line coring drilling tool suitable for seafloor drilling machines

The invention discloses an engineering exploration wire line coring drilling tool suitable for seafloor drilling machines. The engineering exploration wire line coring drilling tool includes an outertube assembly and an inner tube assembly; the outer tube assembly includes an elastic clamp blocking head, an elastic clamp chamber, an outer tube, a hole expanding machine and a drilling bit which are connected in sequence; the inner assembly includes a salvaging spearhead, an elastic clamp locating mechanism, an elastic clamp support, a single moving mechanism, an inner tube joint, a backwater ball valve, an inner tube and a core screened pipe; the salvaging spearhead is connected with the elastic clamp locating mechanism, and the elastic clamp locating mechanism is connected with the elastic clamp support; a dangling loop is arranged on the side wall of the elastic clamp support and is placed on a stay ring on the inner wall of the outer tube; the elastic clamp support is connected withthe single moving mechanism, and the single moving mechanism is connected with the inner tube joint; the lower end of the inner tube joint is connected with the upper end of the inner tube, and the core screened pipe is arranged in the inner tube; and the single moving mechanism includes a mandrel, a casing pipe end cover, an upper force transmission clamp sleeve and a lower force transmission clamp sleeve. According to the engineering exploration wire line coring drilling tool suitable for the seafloor drilling machines, the single moving performance is stable, the centering effect of a bearing is good, the disturbance degree for a soil sample is low, and the condition of sticking is prevented when the inner tube assembly is salved.

Owner:HUNAN UNIV OF SCI & TECH

Polishing slurry, method of producing same, and method of polishing substrate

ActiveCN1944496AImprove performanceAchieve elimination rateSemiconductor/solid-state device manufacturingLiquid spraying apparatusSlurrySemiconductor

The present invention relates to a polishing slurry, method of producing same, and method of polishing substrate. Disclosed herein is a polishing slurry for chemical mechanical polishing. The polishing slurry comprises polishing particles, which have a particle size distribution including separated fine and large polishing particle peaks. The polishing slurry also comprises polishing particles, which have a median size of 50-150 nm. The present invention provides the slurry having an optimum polishing particle size, in which the polishing particle size is controlled and which is useful to produce semiconductors having fine design rules by changing the production conditions of the slurry. The present invention also provides the polishing slurry and a method of producing the same, in which a desirable CMP removal rate is assured and scratches are suppressed by controlling a polishing particle size distribution, and a method of polishing a substrate.

Owner:K C TECH +1

Special cooling method for ferritic stainless steel

ActiveCN102581044AReduce the temperatureHigh surface hardnessWork treatment devicesMetal rolling arrangementsLaminar coolingStrip steel

A special cooling method for ferritic stainless steel includes cooling and coiling of the head of the ferritic stainless steel, and cooling and coiling of the tail of the ferritic stainless steel. The method is characterized in that a cooling device comprises 48 set of laminar cooling valves, namely from the 1# valve set to the 48# valve set, each set of valves includes an upper valve and a lower valve, the upper valve and the lower valve of 1-4# valve sets do not spray water, starting from the 5# valve set, water is sprayed from the front to the back, a type of the valves for dense water spraying type is chosen, opening and closing of the valves are automatically controlled by a computer, and the temperature of a coiled target is dynamically controlled by the aid of the automatic opening and closing of the valves. The cooling and coiling of the head includes the head cooling length and the head cooling temperature, and the cooling and coiling of the tail includes the tail cooling length and the tail cooling temperature, wherein the head cooling length is: Lh=10 / alpha_nn (meter) and the tail cooling length is: Lt=15 / alpha_nn (meter). The special cooling method for the ferritic stainless steel reduces the scratches on the surface of ferritic stainless strip steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

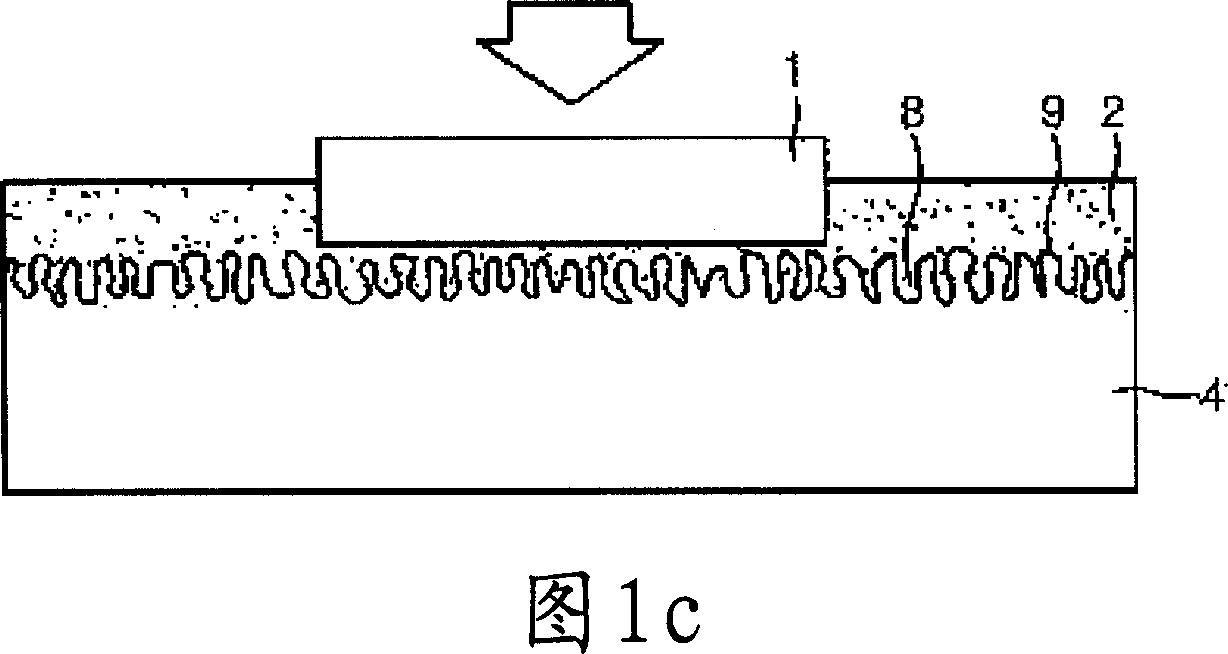

Paints protection method before drawing and forming sheet metal parts

InactiveCN101422772AAvoid damageReduce surface scratchesPretreated surfacesCoatingsPunchingOrganic solvent

The invention relates to a method for coating a lacquer for protection before sheet metal component stretching, which belongs to the material technical field. The method includes the following steps of: (1) degreasing a component to be protected by adopting an organic agent; (2) adding a thinner, X-1, into a PROPACO R lacquer and then uniformly stirring the mixture; and (3) uniformly coating the diluted lacquer on the surface of the component by adopting a spraying machine, wherein, the lacquer is coated in a manner that the thickness of the solidified lacquer ranges from 10 microns to 15 microns; and drying the coated lacquer. The component coated by adopting the method of the invention is treated with punching and stretching tests, surface scuffing is obviously reduced to a great extent after the formation of the component, and no deep scuffing happens; the actual operation time for stretching each component and for trimming and correcting the surface is obviously reduced; and the method not only improves the product quality, but also improves the machining speed, and simultaneously solves the problem of lacquer film agglutination and component scuffing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

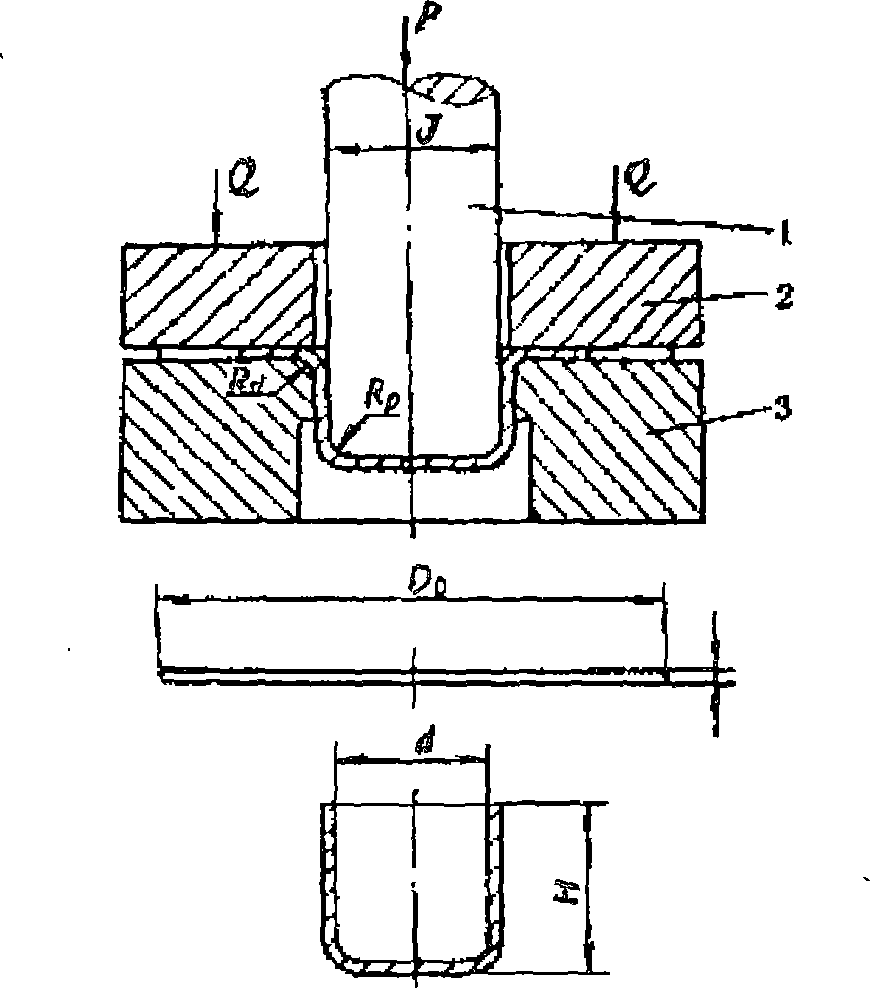

Alumina micropowder production process

ActiveCN103028482AReduce surface scratchesReasonable particle size distributionWet separationAluminium oxides/hydroxidesWork in processParticle-size distribution

The invention provides an alumina micropowder production process, which can ensure that the grain size distribution of alumina micropowder can be self-designed and that particles with various grain sizes can be optionally proportioned and can remarkably reduce the surface scratches of silicon wafers in the process of lapping. The alumina micropowder production process includes the following steps: (1) using the sedimentation method to extract certain central alumina micropowder particles; (2) then using the overflow method to extract alumina micropowder particles at a certain stage. The alumina micropowder production process is characterized in that: the semifinished particles extracted in the two steps are mixed, the uniformly mixed particle mixture then undergoes overflow again, and therefore the final finished product is obtained.

Owner:无锡成旸科技股份有限公司

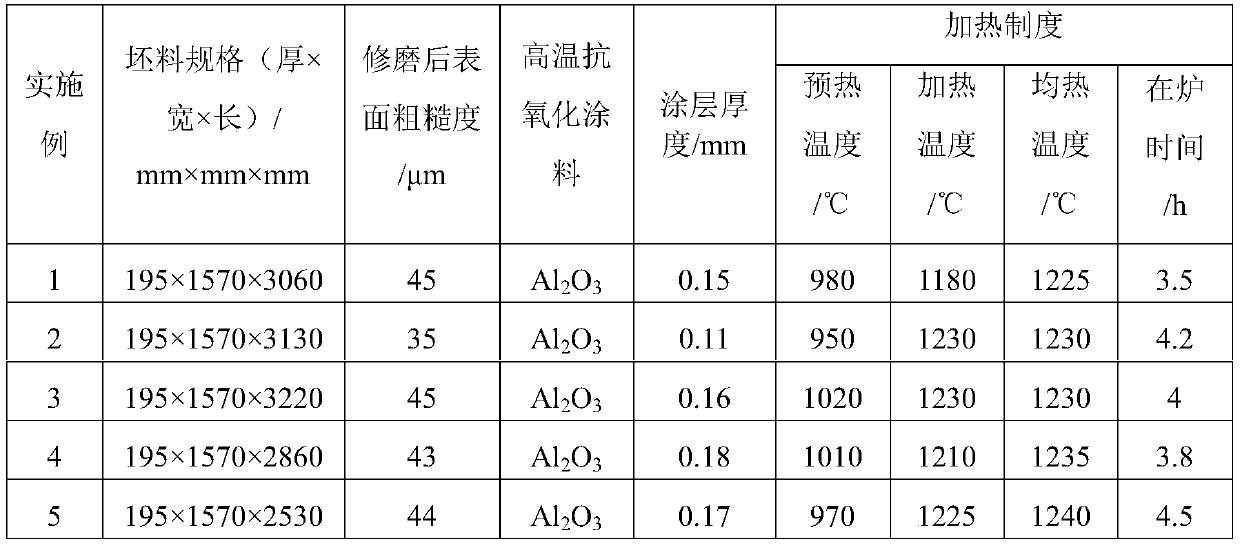

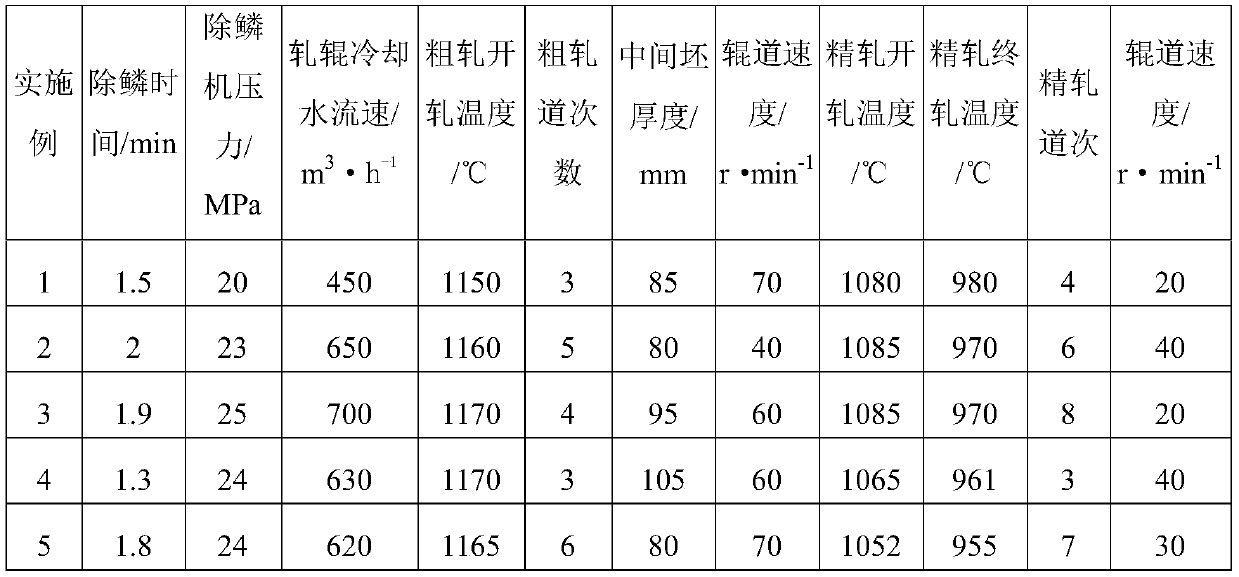

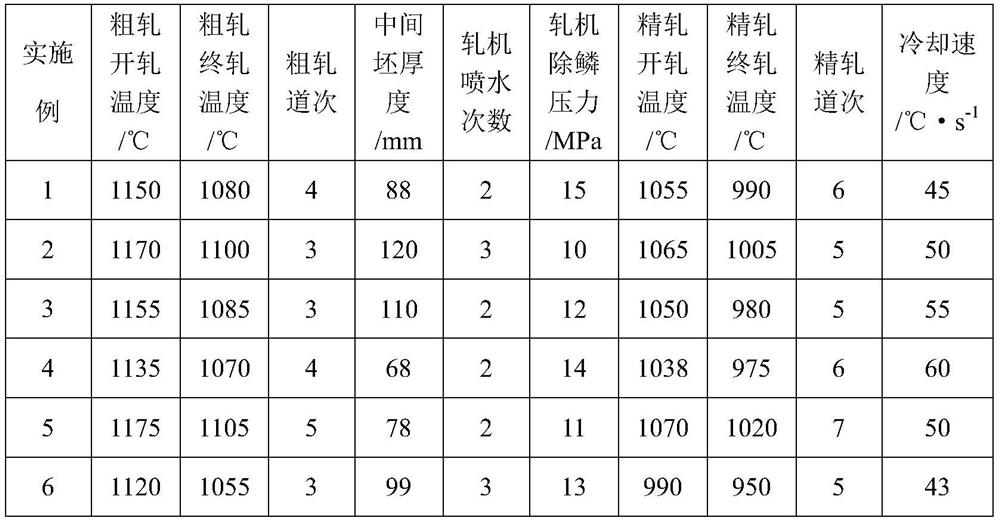

Ultra-wide economical duplex stainless steel medium plate and manufacturing method thereof

ActiveCN110453148AHigh strengthReduces surface scratches and cratersProcess efficiency improvementPapermakingReduction rate

The invention discloses an ultra-wide economical duplex stainless steel medium plate and a manufacturing method thereof. The medium axial crystal proportion of a continuous casting billet is not lowerthan 80%; the surface roughness Ra of the casting billet is smaller than or equal to 50 [mu]m, and high-temperature antioxidant coating is sprayed; the preheating section temperature of the casting billet is 960-1100 DEG C, the heating section temperature is 1150-1230 DEG C, and the soaking section temperature is 1220-1250 DEG C; the rough rolling starting temperature is larger than or equal to 1150 DEG C, the first pass reduction amount is larger than or equal to 25%, the subsequent pass reduction amount is smaller than or equal to 20%, the roller speed is 40-70 r / min, and the thickness of an intermediate blank is 60-120 mm; the finish rolling start temperature is larger than or equal to 1050 DEG C, the finish rolling temperature is larger than or equal to 950 DEG C, the rolling reduction rate is smaller than or equal to 20%, product specifications are 2800-4000 mm wide and 20-60 mm thick, and the surface crack rejection rate is decreased from above 10% to below 1.5%. The product iswidely applied to the engineering fields of nuclear power, oil and gas, shipbuilding, papermaking, seawater desalination and the like.

Owner:ANGANG STEEL CO LTD

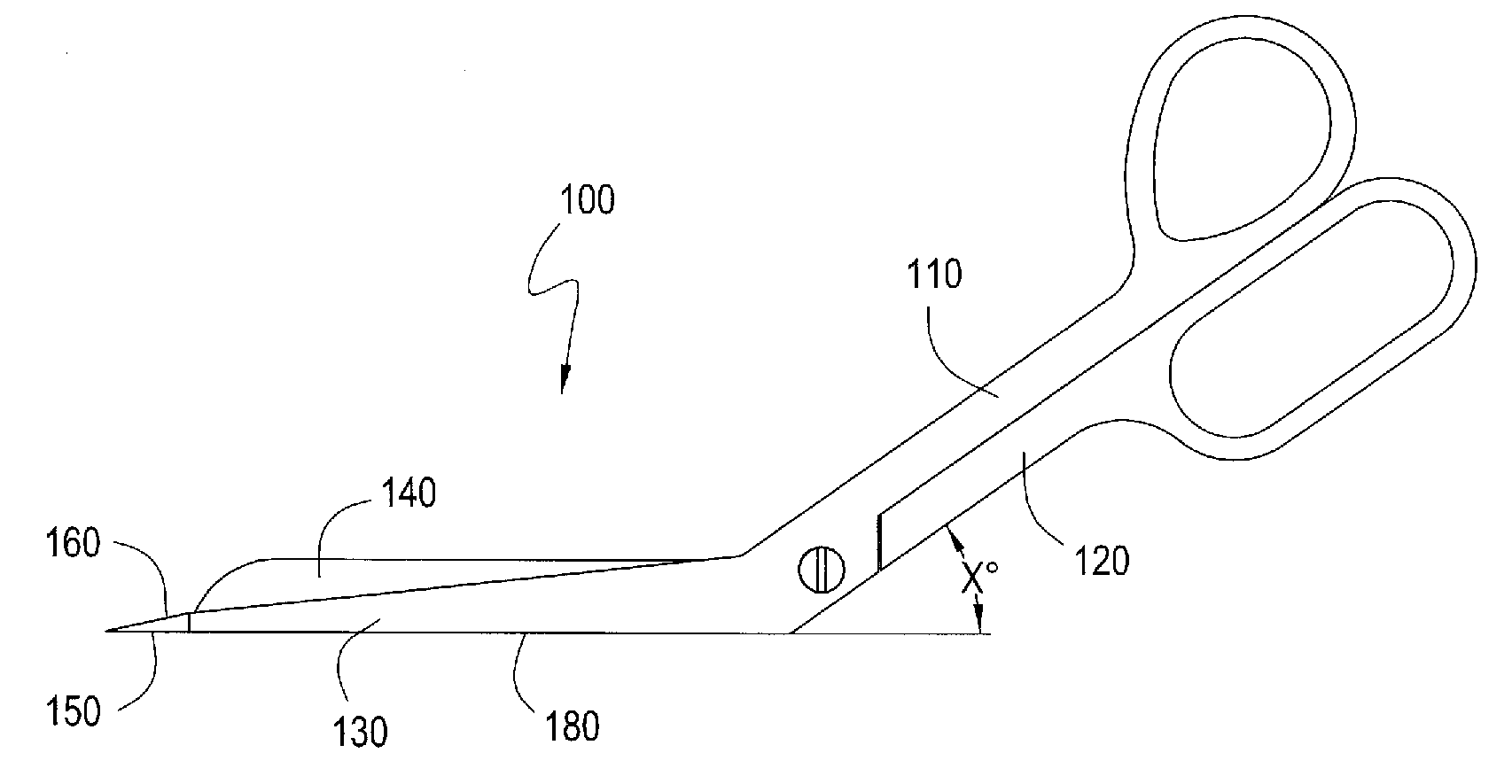

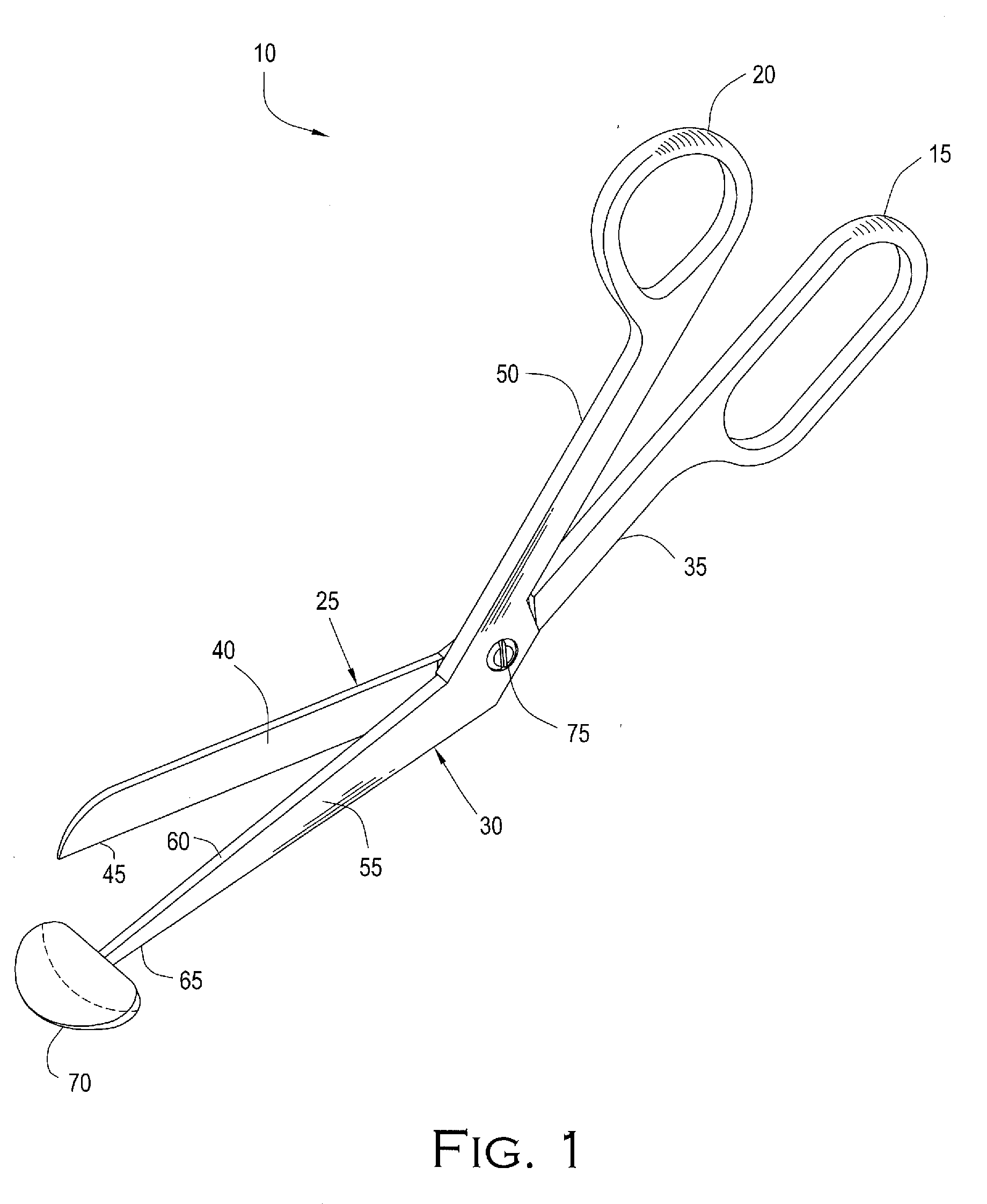

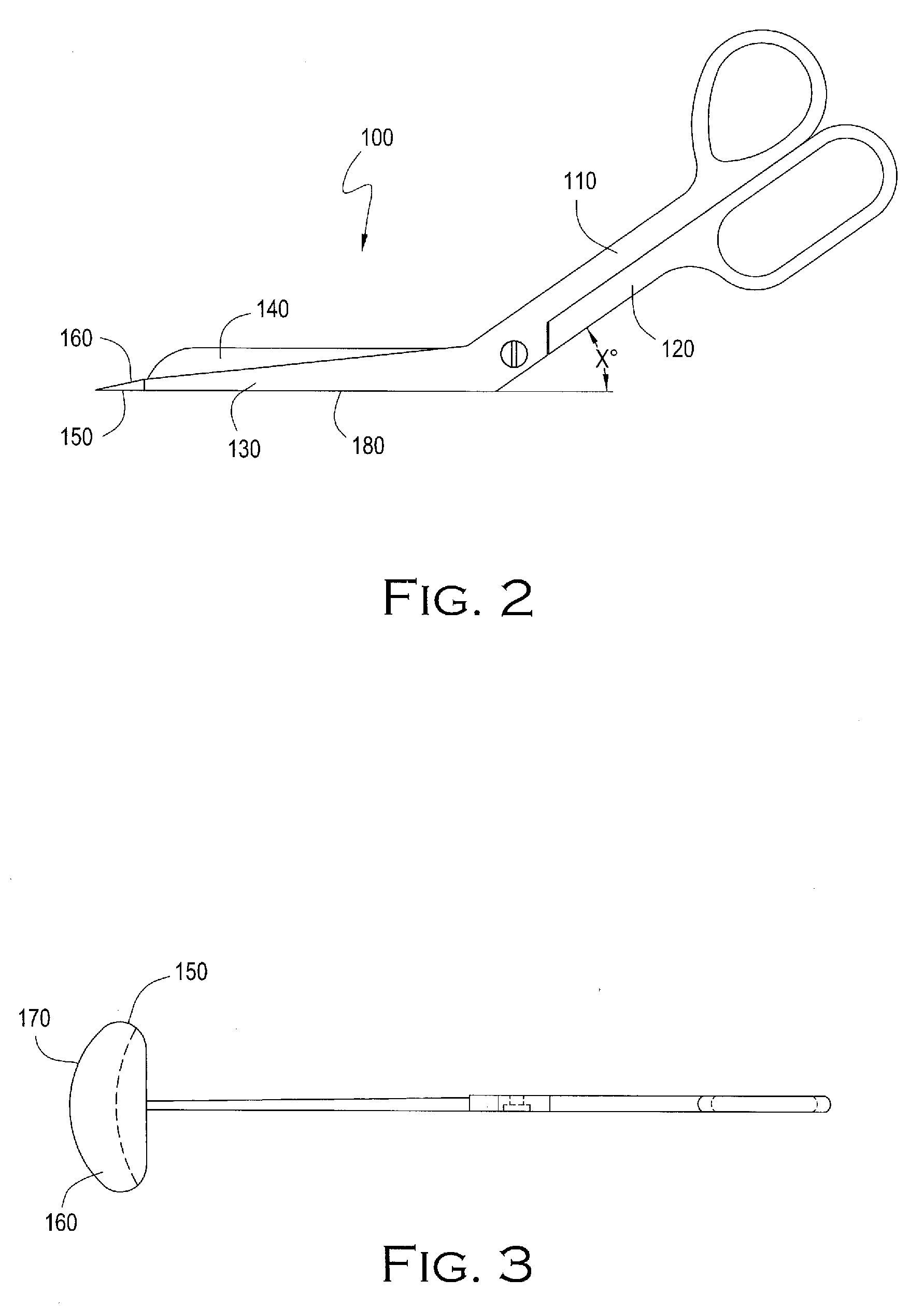

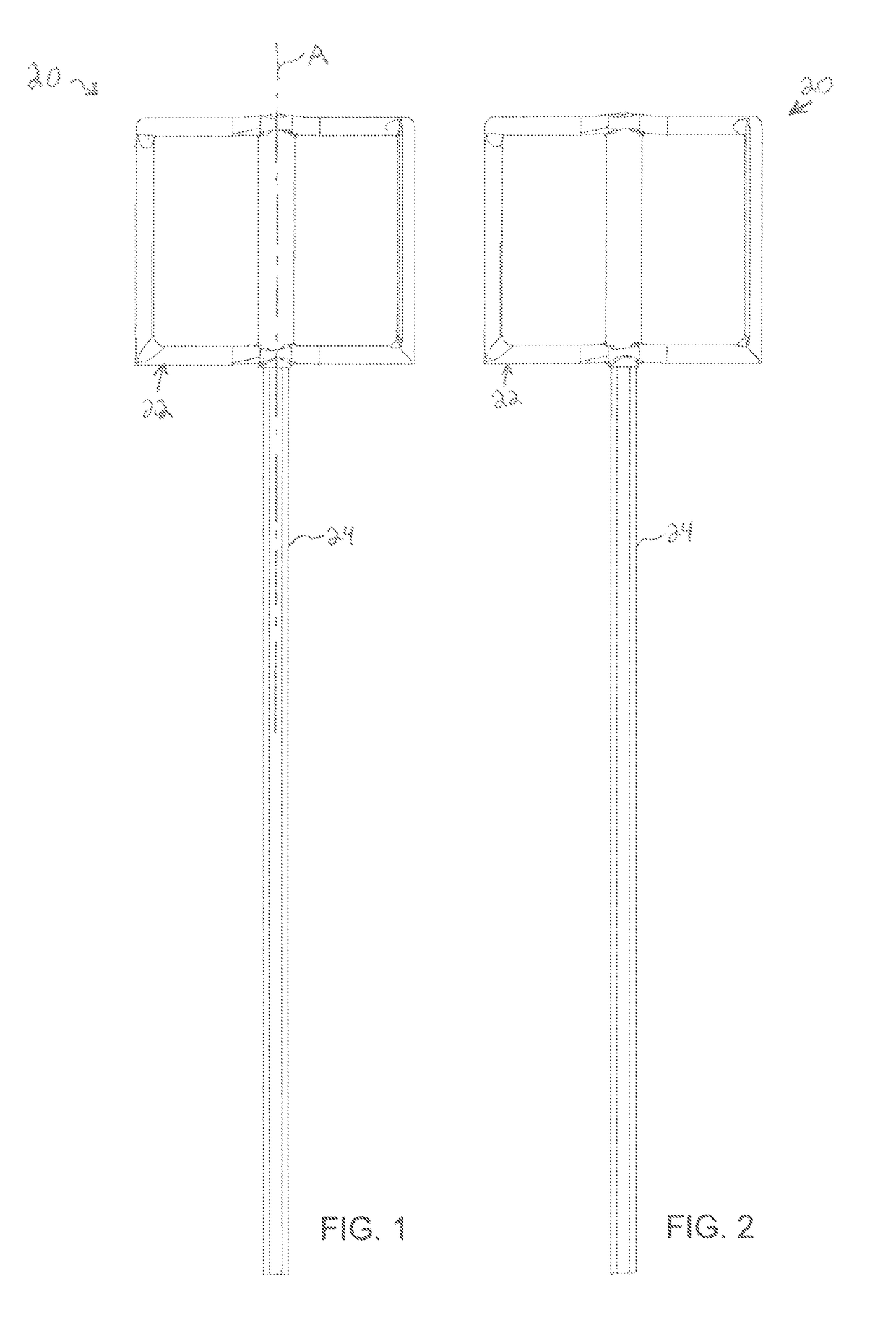

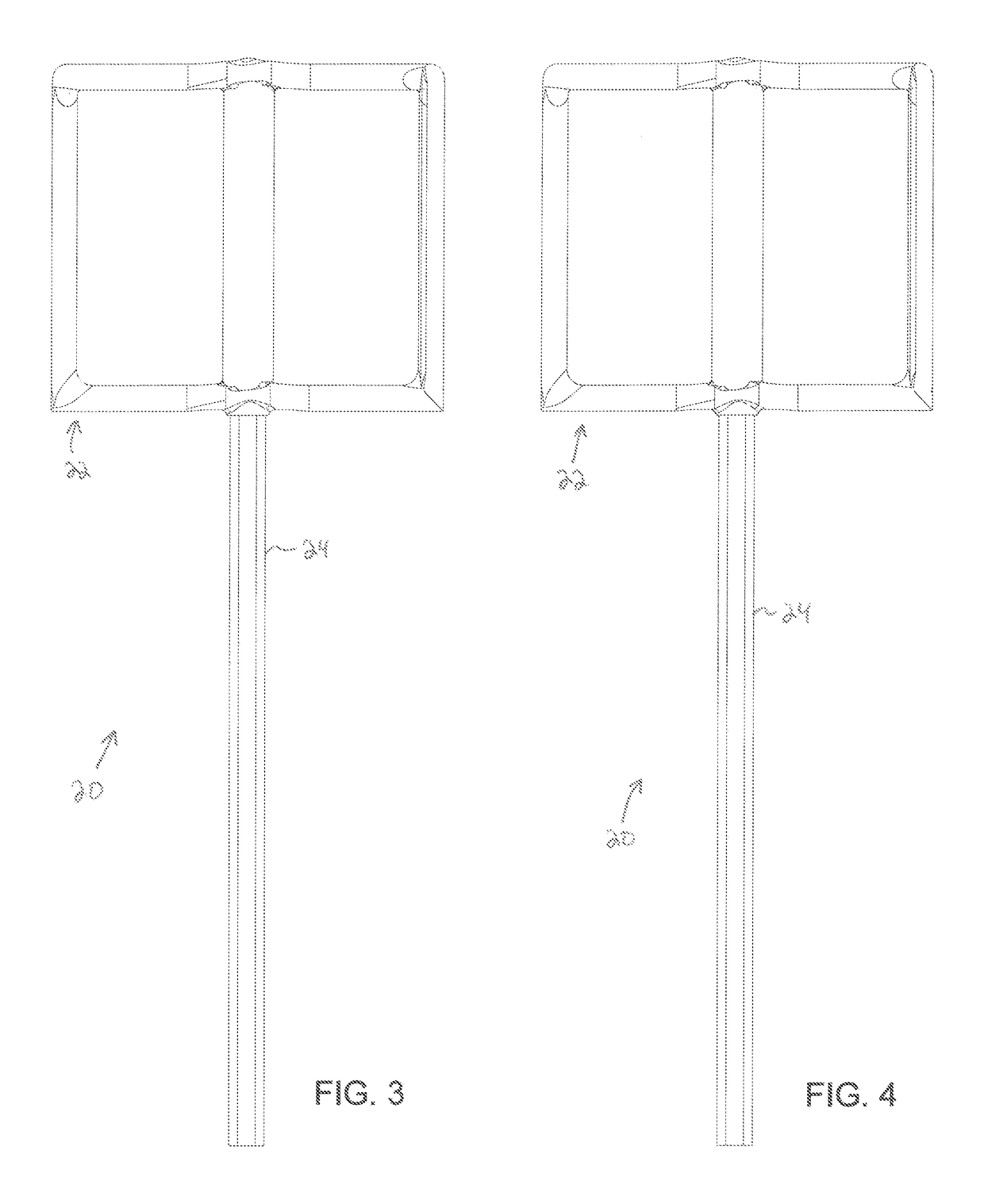

Cutting Device and Associated Methods

A cutting device or food scissor apparatus includes a first cutting element which has a shank section, a first handle, and a blade section with a cutting edge and a second cutting element having a shank section, a second handle, and a blade section with a cutting edge and an endpoint. The first and second cutting elements of the apparatus are connected about a rotational pin. The apparatus includes an orthogonal tip connected to the endpoint of the second cutting element. Various tip designs may be removably attached to the apparatus. The perpendicular tip promotes cutting stability and reduces damages to a surface from which material is being cut.

Owner:POTTER JACK G

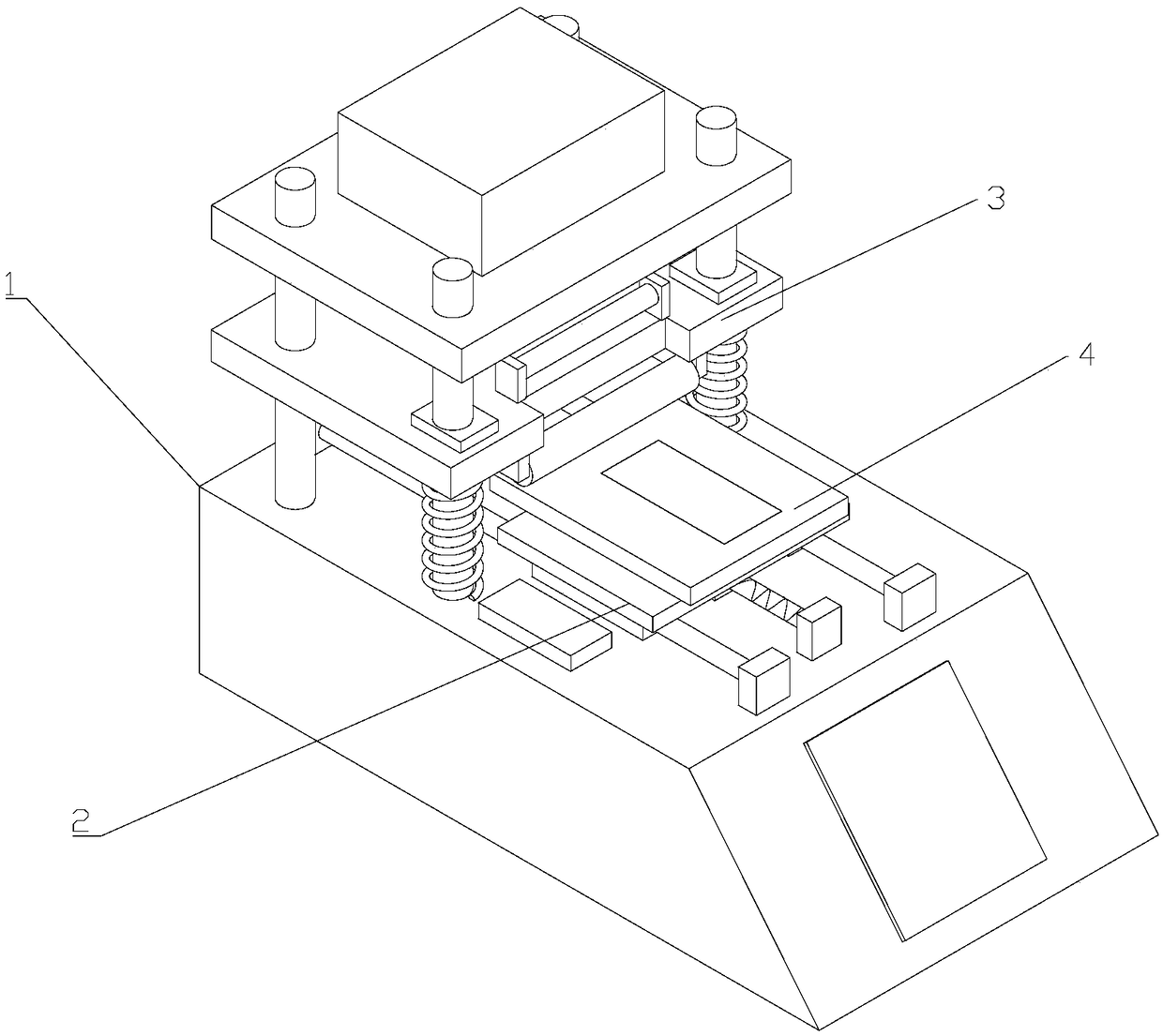

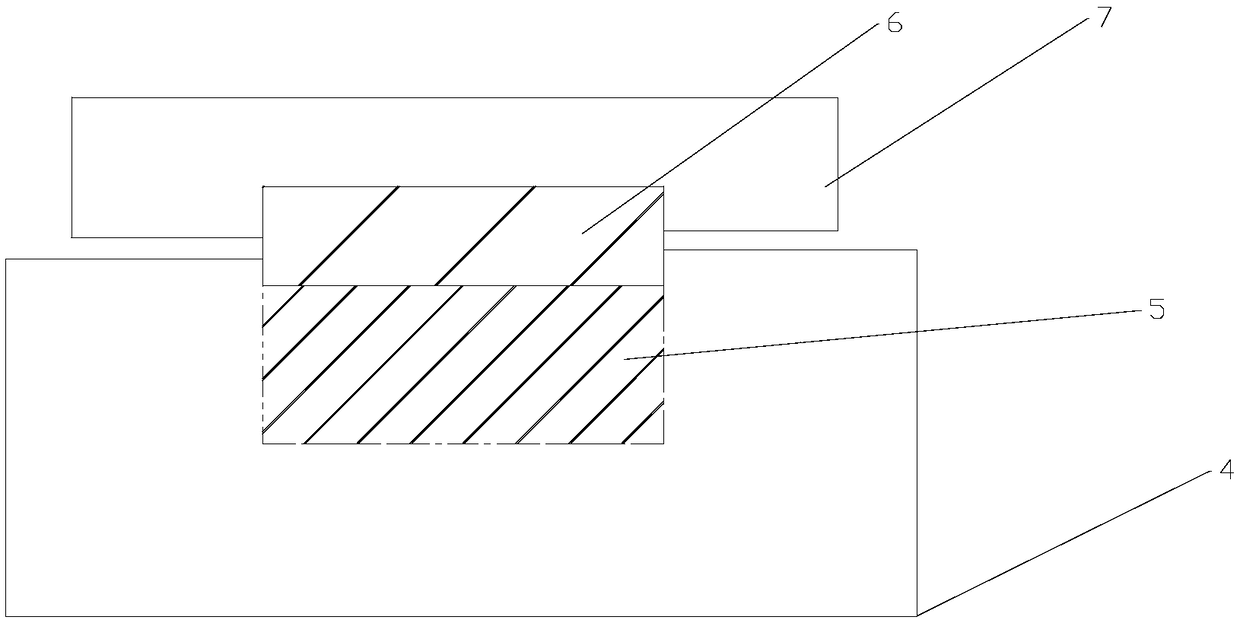

Glue clearing equipment for display screen

PendingCN108816962ARealize automatic glue removalReduce surface scratchesCleaning processes and apparatusAdhesive glueEngineering

The invention relates to the technical field of automation equipment, in particular to glue clearing equipment for a display screen. The glue clearing equipment comprises a rack and further comprisesa fixing assembly and a glue clearing assembly which are arranged on the rack. The glue clearing assembly is located above the fixing assembly. The fixing assembly comprises a fixing plate. A groove matched with the display screen is formed in the upper surface of the fixing plate. The surface of the display screen is provided with a to-be-cleared adhesive glue layer. The glue clearing assembly comprises a rolling wheel. The rolling wheel moves in a reciprocating mode along the upper surface of the fixing plate, and the moving trajectory of a central shaft of the rolling wheel is parallel to the upper surface of the fixing plate. The display screen is fixed through the fixing plate, the rolling wheel moves in the reciprocating mode along the upper surface of the fixing plate, and the moving trajectory of the central shaft of the rolling wheel is parallel to the upper surface of the fixing plate, so that automatic glue clearing of the display screen is achieved to replace manual glue clearing, the glue clearing efficiency is improved, the surface scratching ratio or deformation reject ratio of the display screen is decreased, and the labor cost is reduced.

Owner:XIAMEN CHANGJIANG SERVICE NET CO LTD

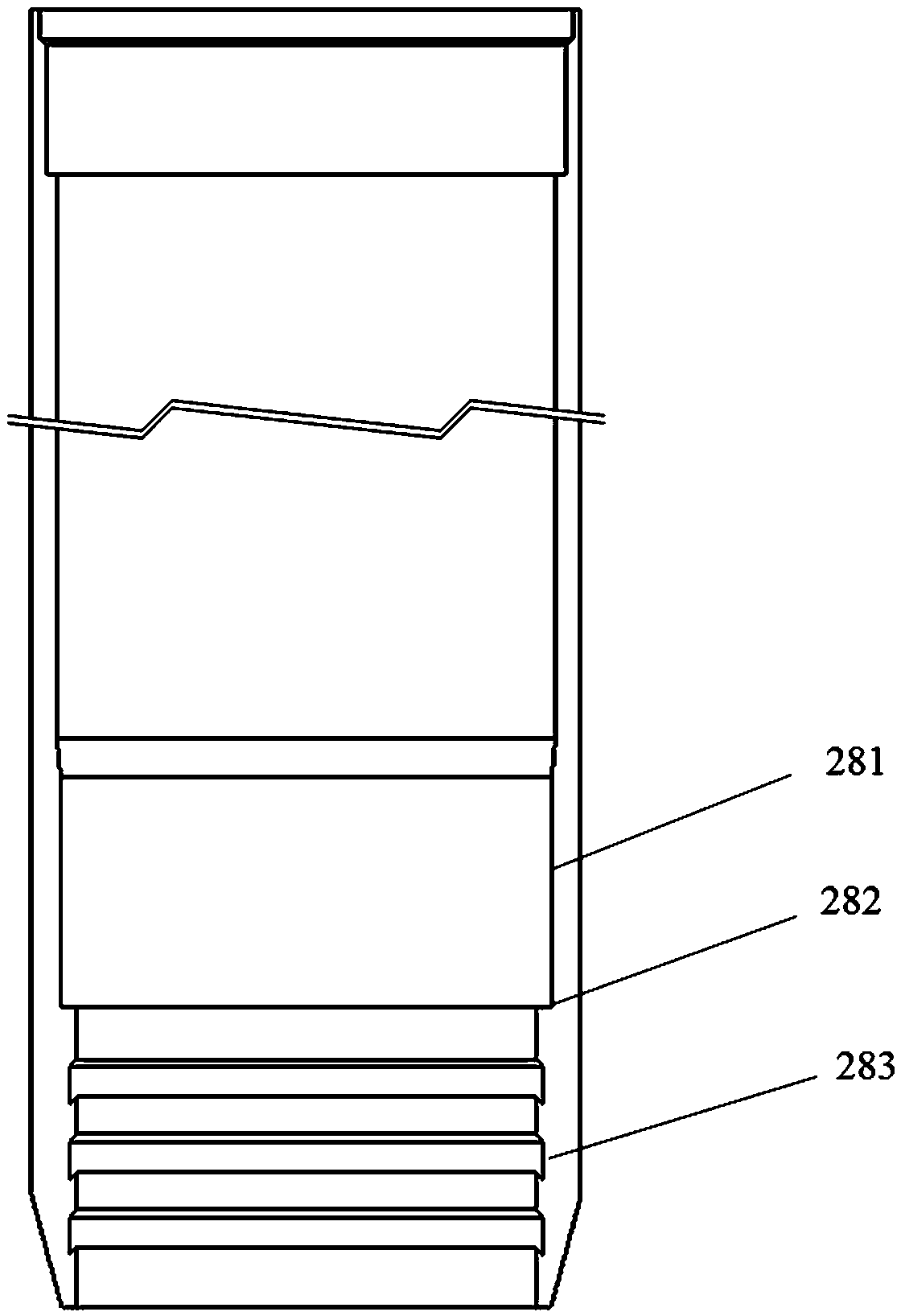

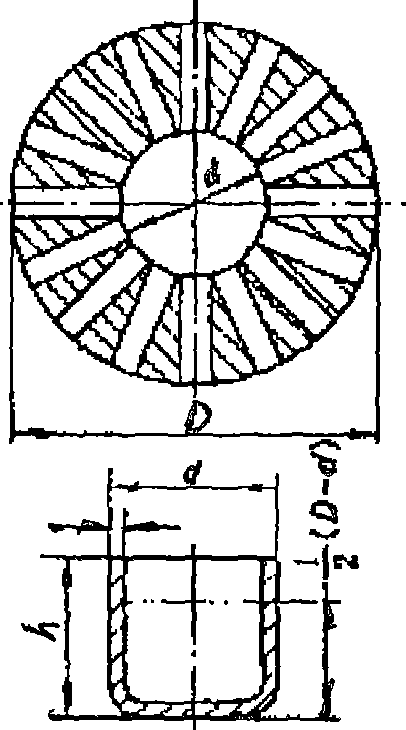

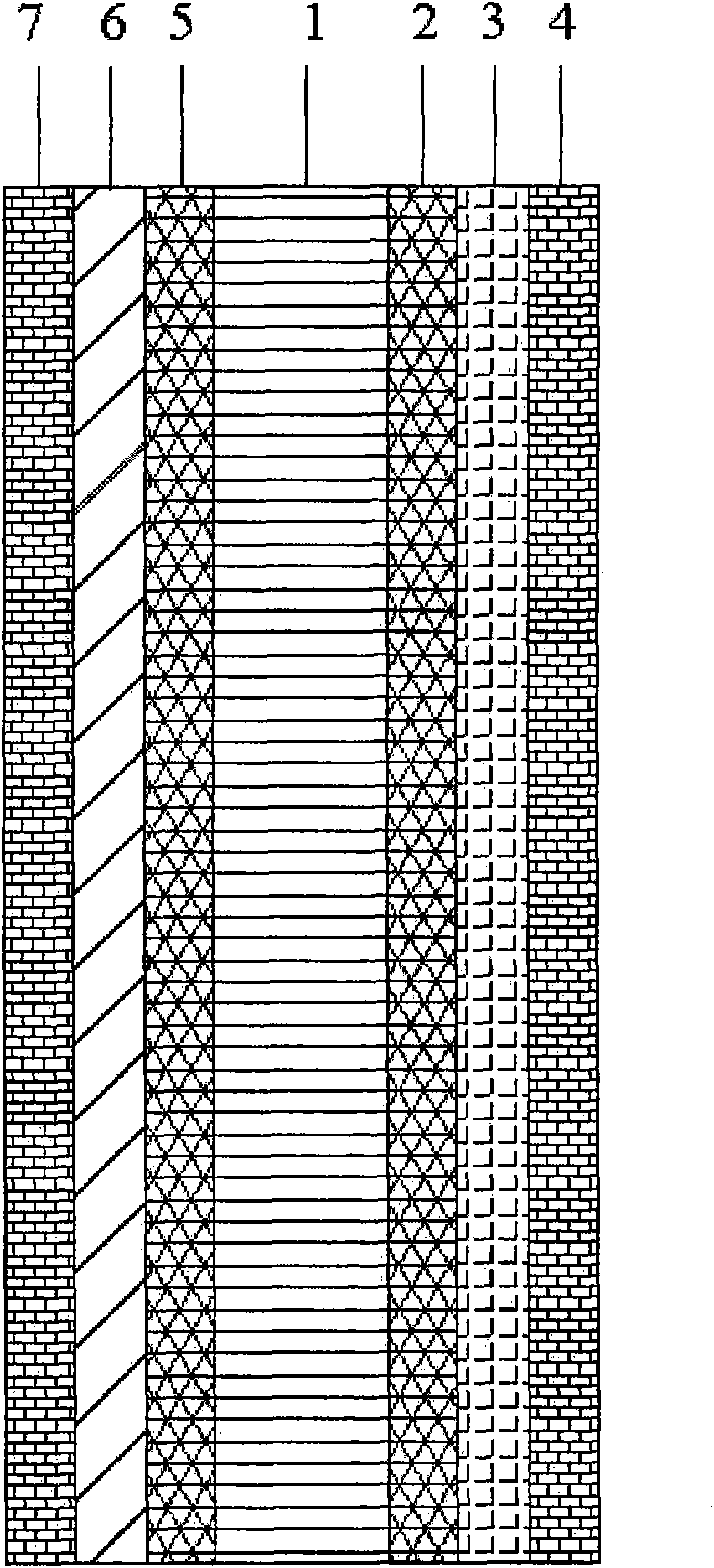

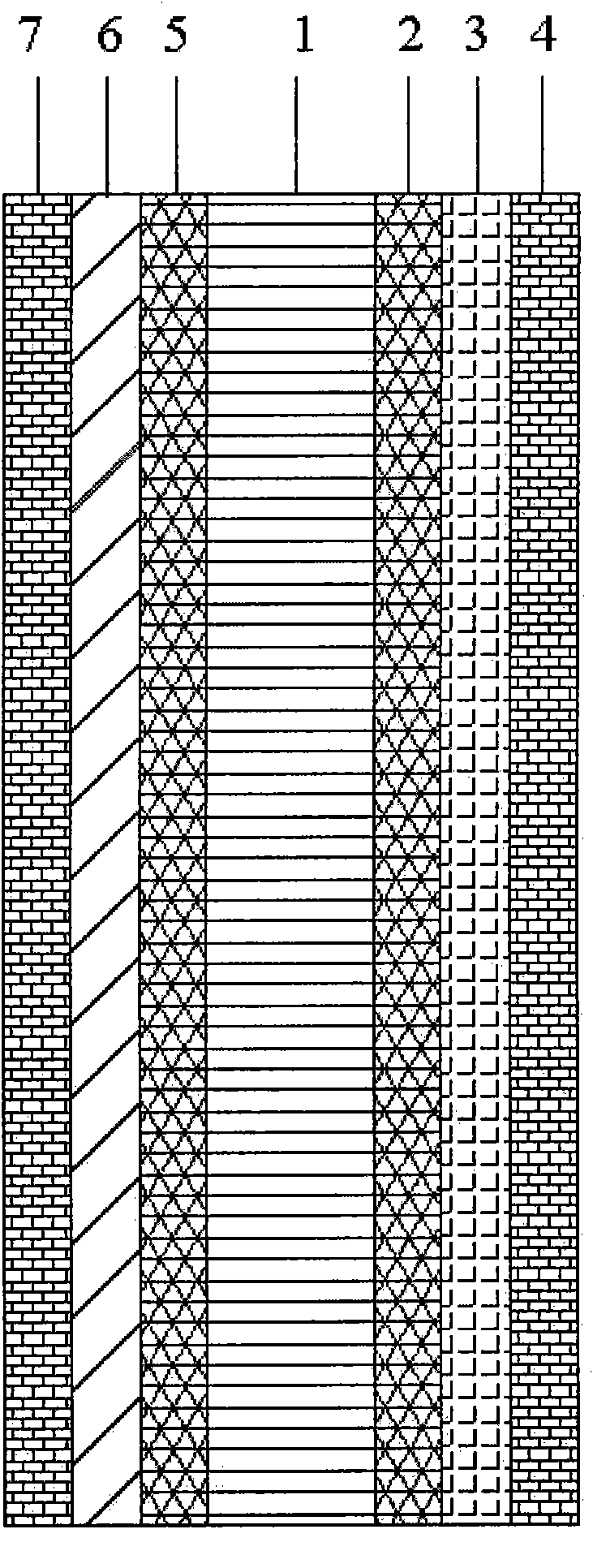

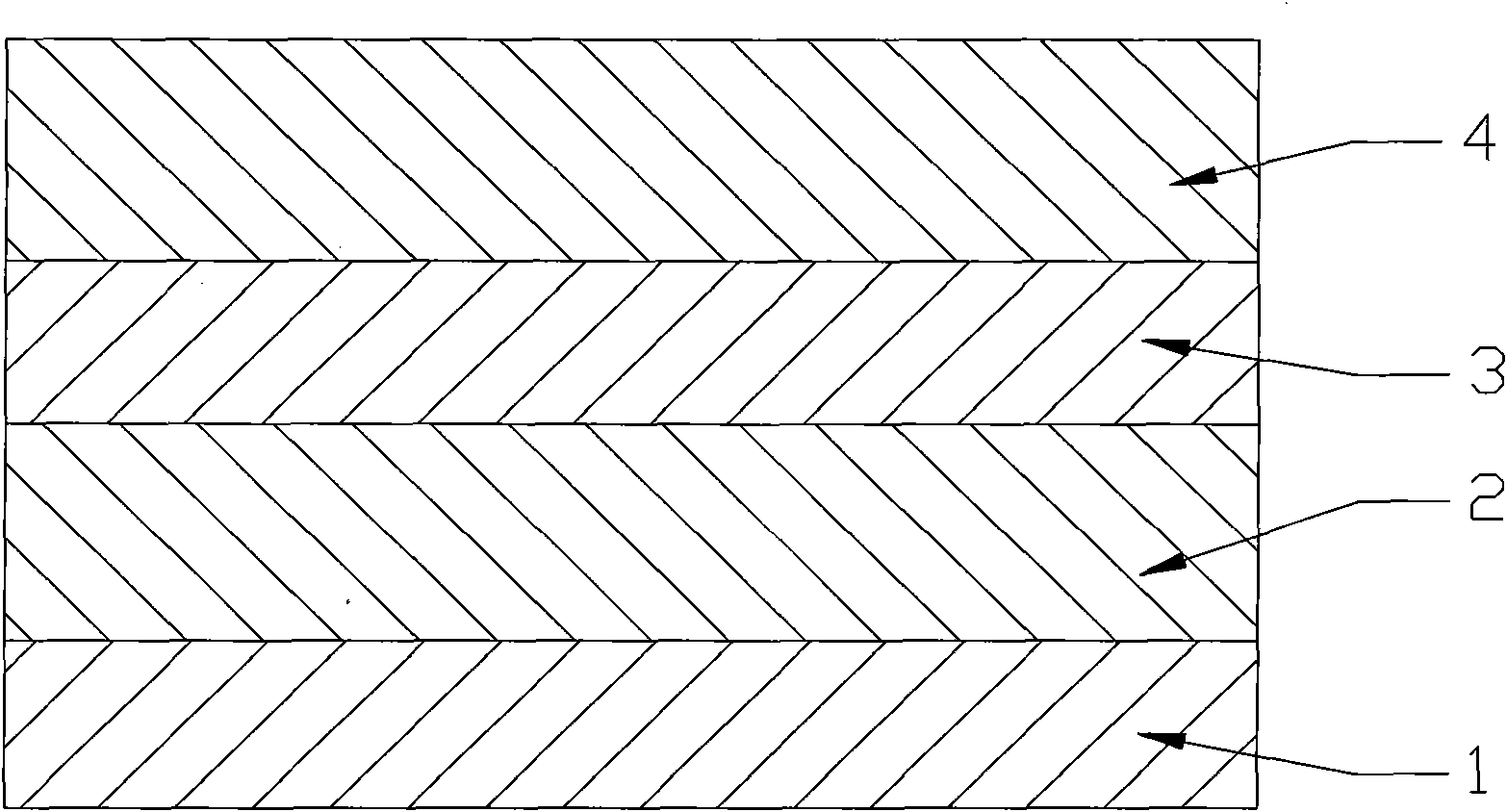

Nanowire-containing multilayer composite thin film plated steel belt and preparation method thereof

ActiveCN101958404AHigh hardnessImprove corrosion resistanceCell component detailsChemical industryNanowire

The invention discloses a nanowire-containing multilayer composite thin film plated steel belt and a preparation method thereof. The steel belt is specifically applied to a battery outer shell material of a mercury-free alkaline battery, a lithium ion battery, a nickel-metal hydride battery and the like and also applied to the field of chemical industry, electrons, packaging, magnetic materials and the like. The preparation method comprises the following steps of: on one face of a steel belt serving as a substrate, plating a layer of micron-crystalline nickel as an outer bottom layer in a DC plating way, wherein the face corresponds tothe outer surface of a battery shell, plating a layer of micron-crystalline nickel serving as an outer middle layer in a pulse plating way, and plating a layer of nano-crystalline nickel-cobalt alloy layer serving as an outer surface layer in a pulse injection plating way; and on one face of the steel belt corresponding to the inner surface of the battery shell, plating a layer of micron-crystalline nickel coated layer as an inner bottom layer in the DC plating way; plating a layer of nanowire-containing nickle composite thin film as an inner middle layer in the pulse plating way, and plating a layer of nano-crystalline nickel-cobalt alloy layer as an inner surface layer in the pulse injection plating way. The steel belt prepared by the invention has the advantages of good corrosion resistance and pressing resistance.

Owner:XIANGTAN UNIV

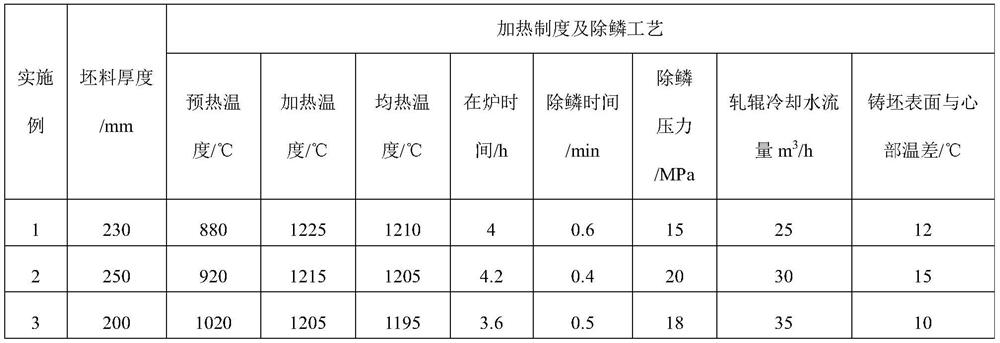

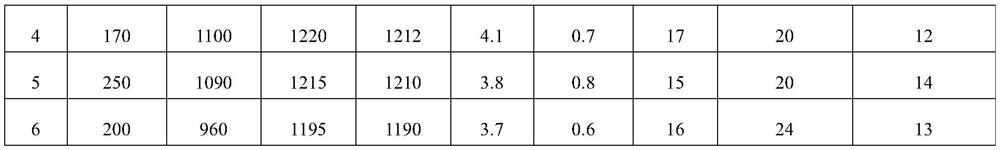

Method for controlling grain size of low-carbon austenitic stainless steel extra-thick plate

ActiveCN113560343AHigh strengthReduce surface scratchesTemperature control deviceWork cooling devicesThick plateSS - Stainless steel

The invention relates to a method for controlling the grain size of a low-carbon austenitic stainless steel extra-thick plate. The method comprises the following steps of that 1) a casting blank is heated, specifically, the casting blank with the thickness of 250 mm or below is fed into a stepping heating furnace for heating, after the casting blank is sequentially treated through a preheating zone, a heating zone and a soaking zone, and the casting blank is discharged out of the furnace; after high-pressure water descaling, the temperature difference between the surface of the casting blank and the center of the casting blank is controlled to be 10-15 DEG C; (3) the initial rolling temperature of rough rolling is greater than or equal to 1110 DEG C, and the surface is not descaled in the rough rolling stage; the finish rolling temperature in the rough rolling stage is greater than or equal to 1050 DEG C; after rough rolling is finished, the steel plate passes through 2-3 passes in an idle mode, and descaling water of a rolling mill is sprayed in each pass; the initial rolling temperature of finish rolling is greater than or equal to 980 DEG C, and the finish rolling temperature in the finish rolling stage is greater than or equal to 950 DEG and controlled cooling is carried out, specifically, the hot-rolled steel plate quickly passes through an ultra-fast cooling system after finish rolling. The method has the advantages that the problem that the surface grain size and the center grain size of the steel plate are inconsistent can be solved, and the grain size of the steel plate reaches level 3 or above.

Owner:ANGANG STEEL CO LTD

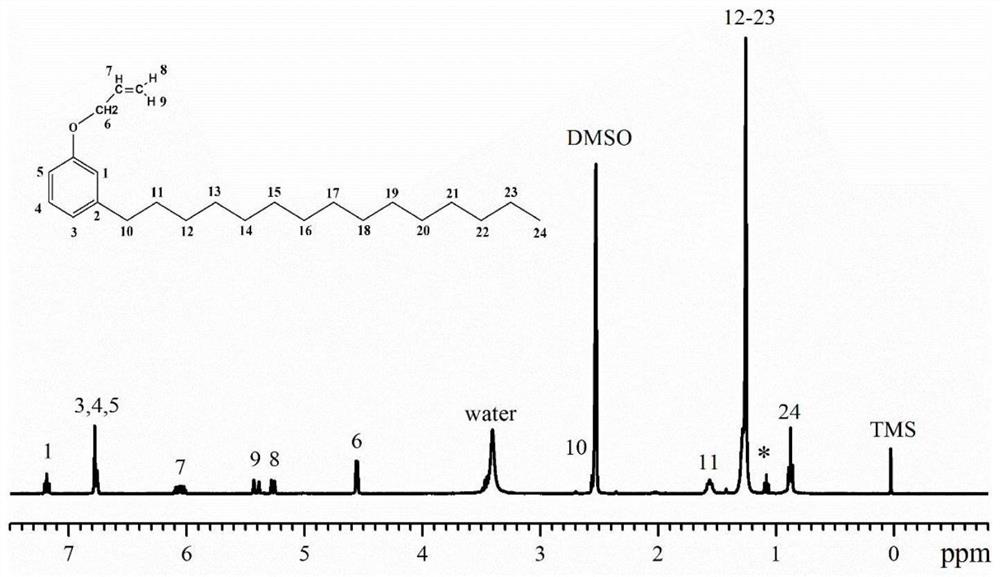

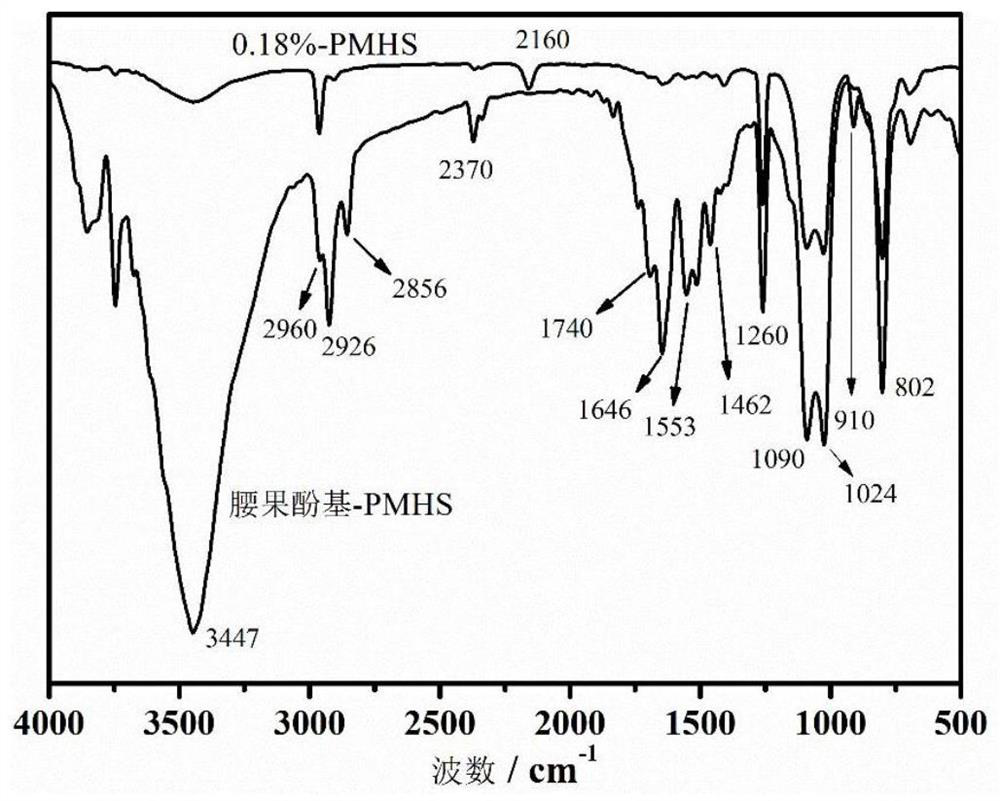

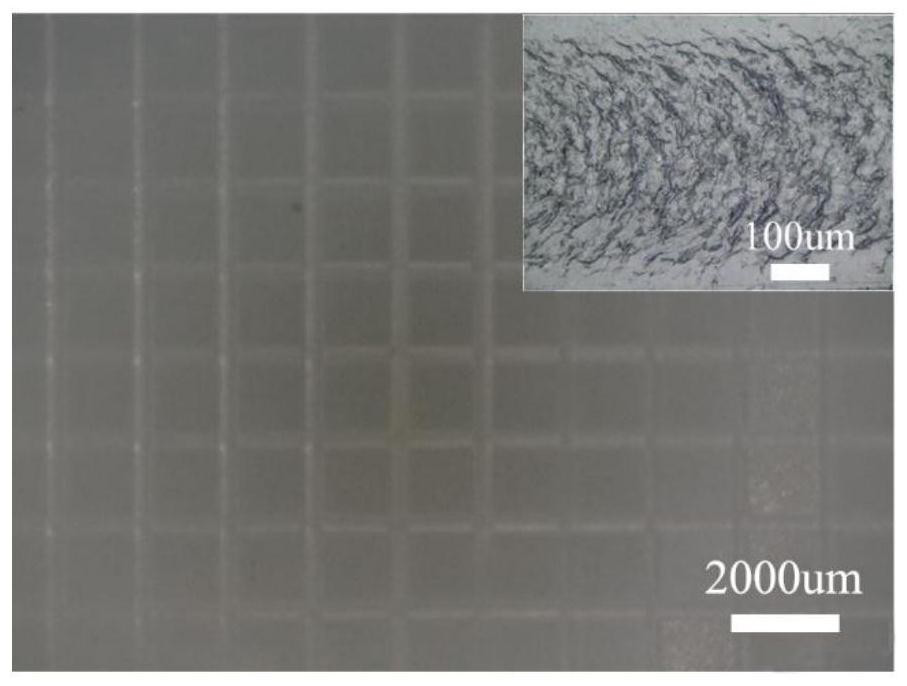

Bio-based polysiloxane scratch-resistant auxiliary agent and preparation method thereof, and scratch-resistant composite material

The invention relates to the technical field of scratch resistance, and provides a bio-based polysiloxane scratch-resistant auxiliary agent and a preparation method thereof, and a scratch-resistant composite material. A green and renewable bio-based material derivative is utilized to carry out modification grafting on low-hydrogen-content polysiloxane, and the bio-based polysiloxane scratch-resistant auxiliary agent is designed and synthesized. When the bio-based polysiloxane scratch-resistant auxiliary agent is used for a scratch-resistant composite material, a main chain of the bio-based polysiloxane scratch-resistant auxiliary agent can migrate to the surface of the composite material to form a layer of lubricating film in a polymer base material forming process, so that the scratch resistance of the composite material is improved; and the side chain of the rigid benzene ring structure can endow the polymer base material with certain hardness and higher thermal performance, so that the scratch resistance and the separation-out viscosity resistance of the composite material are further improved. Experimental results show that the bio-based polysiloxane scratch-resistant auxiliary agent provided by the invention can obviously improve the scratch resistance of a polymer base material; meanwhile, a step curve test further proves that the scratch resistance of the polymer base material is obviously improved.

Owner:HUNAN UNIV OF TECH

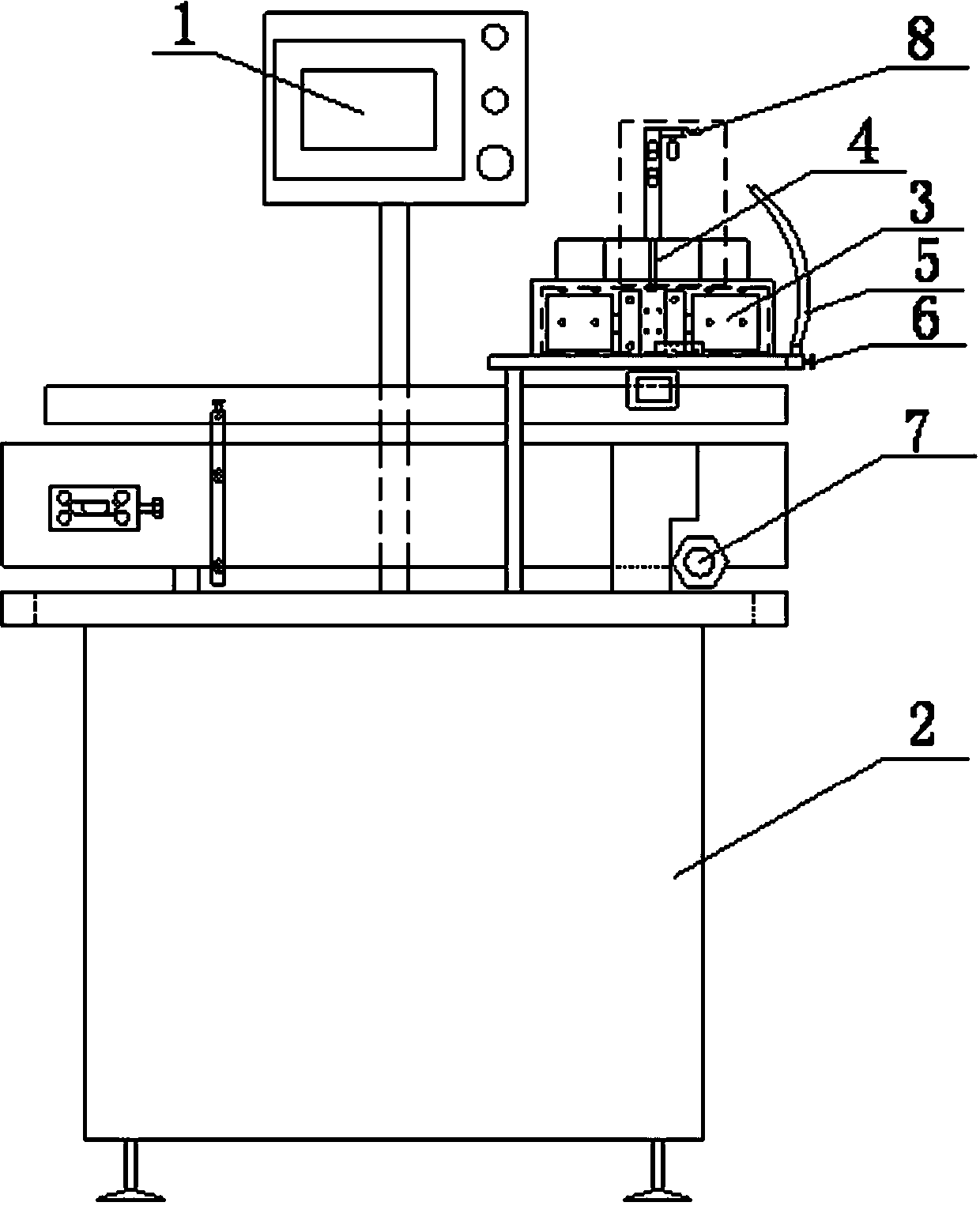

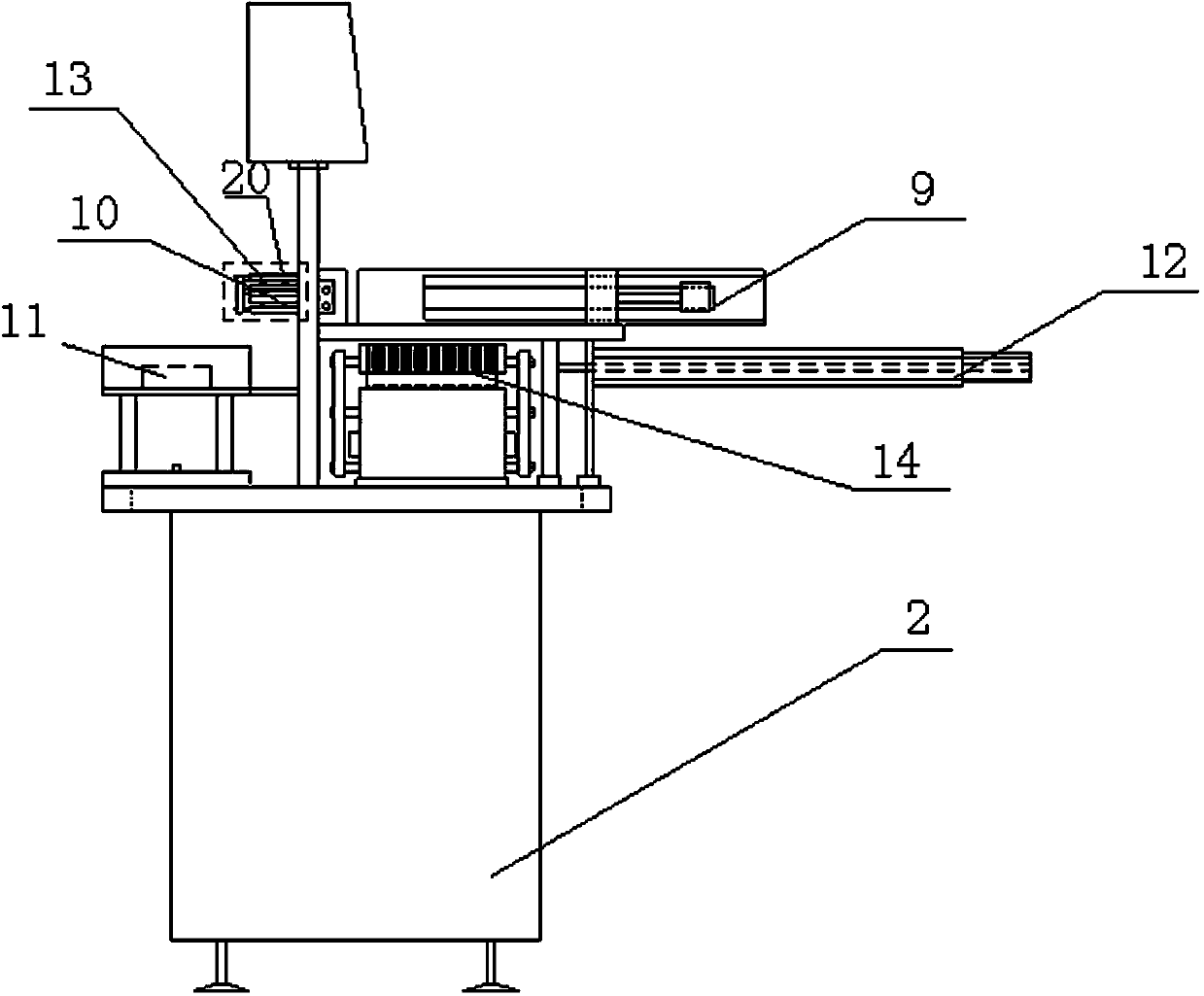

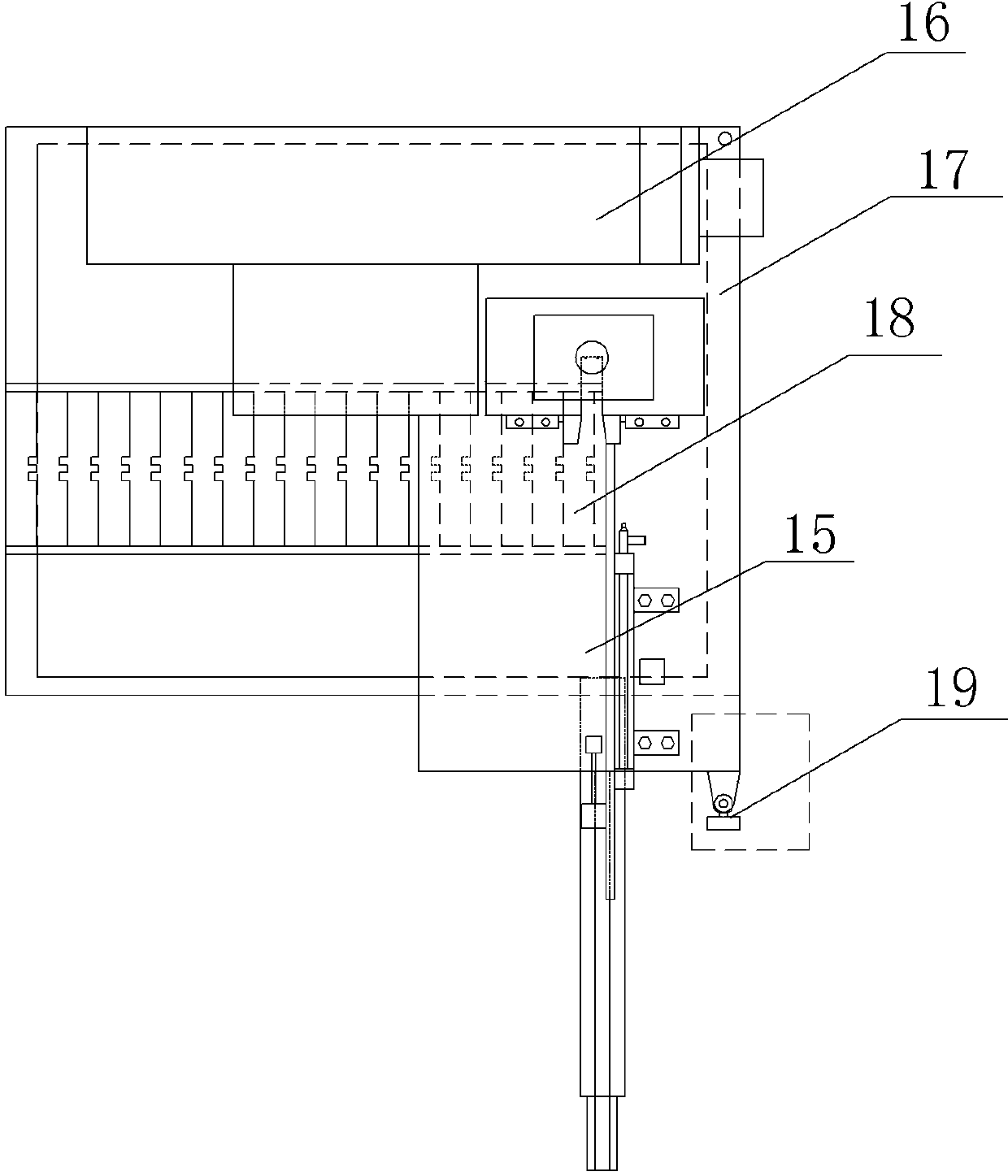

Glass slide inserting machine

ActiveCN104085678AAvoid damageAvoid edge burstCharge manipulationConveyor partsMetallic materialsEngineering

The invention discloses a glass slide inserting machine which comprises a display screen, a worktable surface and an electrical cabinet, wherein the electrical cabinet is fixedly mounted at the lower end of the worktable surface, and the display screen is fixedly mounted at the upper end of the worktable surface. The glass slide inserting machine has the benefits that a glass slide is kept wet due to a spraying device, so that surface scratches caused by dryness of the glass slide in a slide inserting process can be reduced; a plastic film is arranged on a copper rod, so that the edge cracking caused by contact between the bottom of the glass slide and a metal material can be prevented; a rubber contactor is arranged on a pneumatic push cylinder II, so that the damage caused by contact between the contactor and glass can be reduced; a mechanized slide inserting technology is adopted, so that more glass slides can be inserted within the same time, the slide inserting efficiency is improved, the manpower is lowered, and the waste is reduced.

Owner:JIANGSU CITOTEST LABWARE MFG

Insulating coating composition and an insulated wire, and a coil formed using the same

ActiveUS20100231345A1Good insertion effectIncrease surface lubricityPlastic/resin/waxes insulatorsSynthetic resin layered productsCarbon numberPolyamide-imide

An insulating coating composition that improves lubricity without reduction of the varnish adhesion strength and an insulated wire using the insulating coating composition, and a coil using the insulated wire are provided. An insulating coating composition comprises a polyamide-imide resin, which is obtained through a synthetic reaction of isocyanate component with acid component, and a lubricant component, wherein the terminal isocyanate group of the polyamide-imide resin is capped with a blocking agent of higher alcohol having a carbon number of eight or more.

Owner:HITACHI MAGNET WIRE CORP

Split type profile material forming die

The invention relates to the technical field of dies and discloses a split type profile material forming die comprising a die body. The die body is provided with a forming inner cavity. The forming inner cavity is a cavity penetrating through from the rear side to the front side. The die body also has a center connection line connecting the rear side center with the front side center. The die bodyis composed of two dies. The two die single bodies are the front single body at the front and a rear single body in the rear position correspondingly. The connection positions of the front single body and the rear single body are joints. The joints are matched and connected, and the die body is formed. The joints longitudinally cut the forming inner cavity, the joint on the side face of the forming inner cavity is provided with a groove for holding a graphite block, the graphite block is put in the groove, and the surface of the graphite block and the side face of the forming inner cavity form a smooth transition structure after the graphite block is put into the groove. The split type profile material forming die has the advantages that few scratches are generated on the surface of a produced product, flatness is high, and production efficiency is high.

Owner:张变妮

Tinsel wallpaper

The purpose of the invention is to provide tinsel wallpaper which has a simple structure, a simplified process, an unhardened substrate, and high flatness and smoothness. The tinsel wallpaper comprises, from bottom to top, a substrate, a glue-coating layer, and a tinsel layer; the substrate is a nonwoven paper substrate.

Owner:LIYANG CITY ZHENGXIANG PRECISION MACHINERY

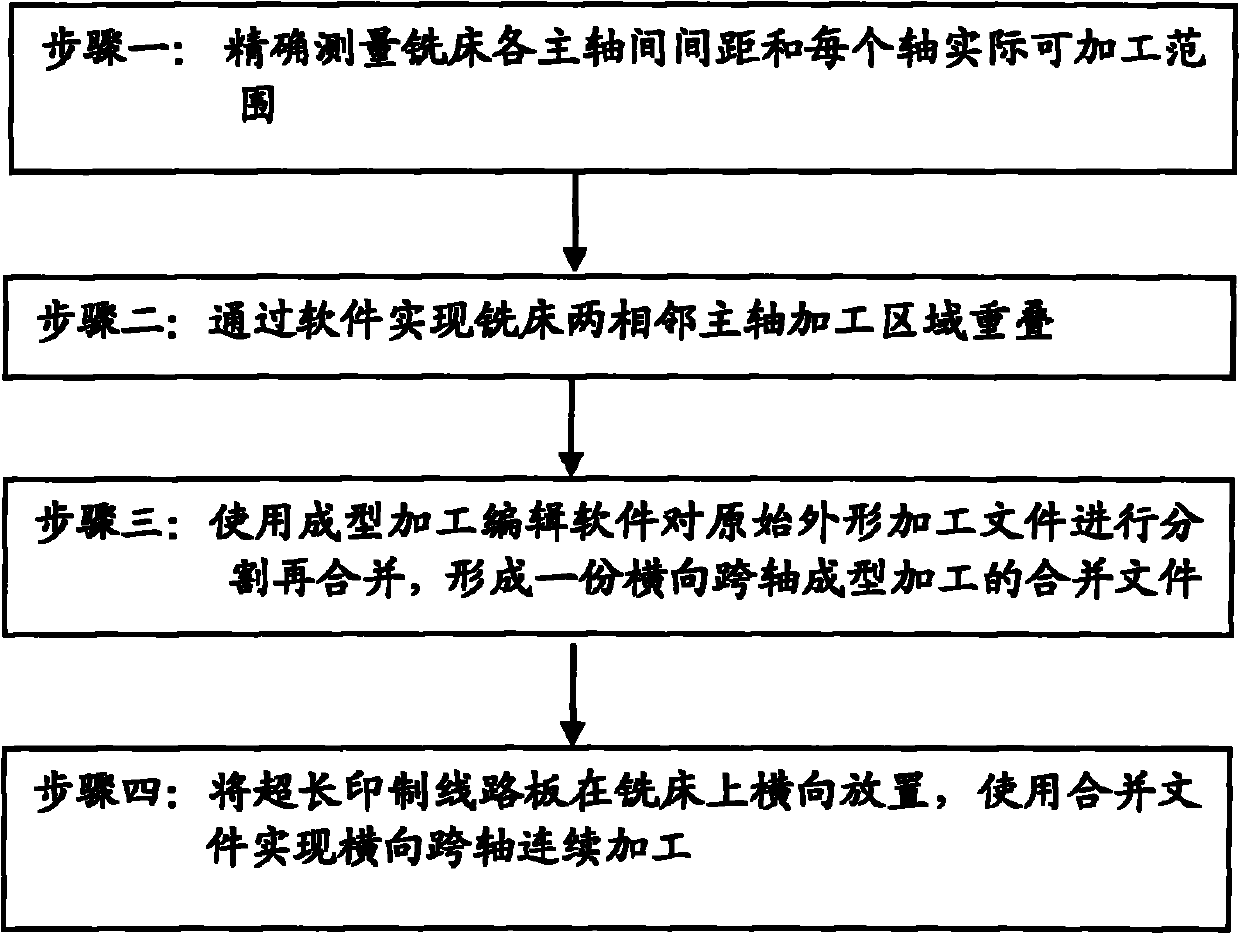

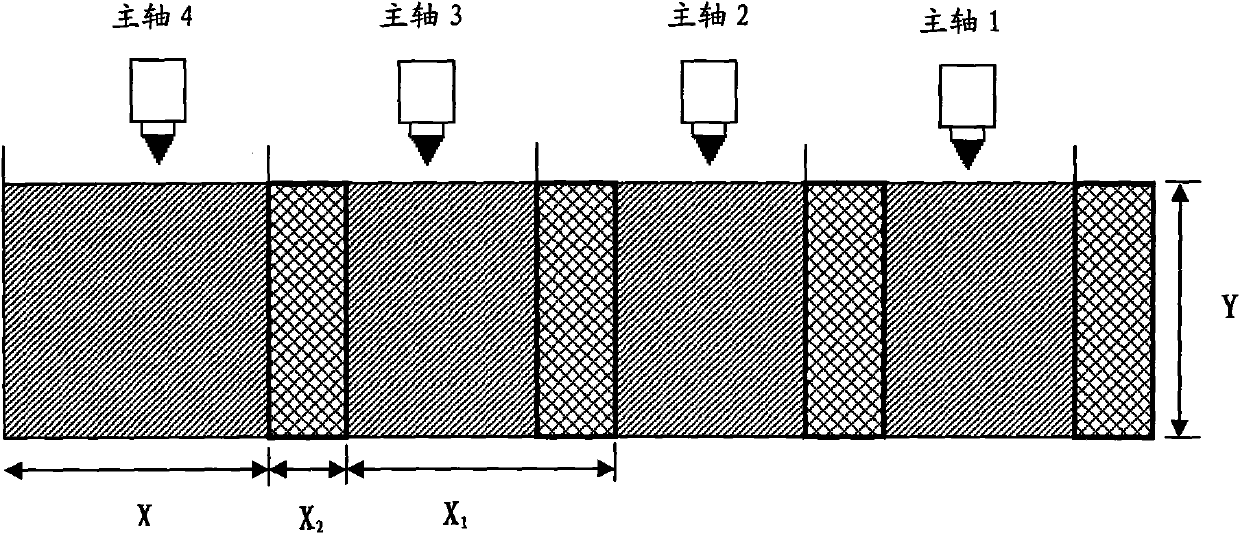

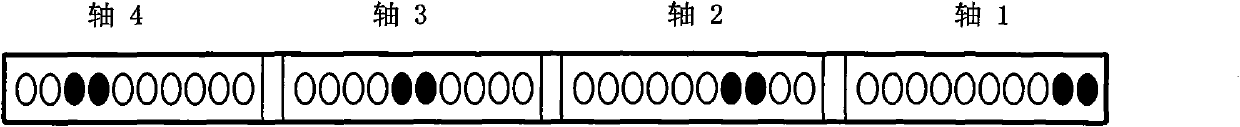

Method for molding transverse span shaft of milling machine

InactiveCN101954505AReduce scratchesReduce surface scratchesMilling equipment detailsComputer sciencePrinted circuit board

The invention discloses a method for molding a transverse span shaft of a milling machine, which comprises the following steps: (1) measuring the spacing interval between each two main shafts of the milling machine and the actual processable range of each main shaft; (2) realizing the overlapping of processing regions of the adjacent two main shafts of the milling machine through software; (3) using molding editing software to carry out segmentation and re-merging on an original shape processing file and forming a merged file of molding of the transverse span shaft; and (4) transversely placing an ultra-long printed circuit board on the milling machine, and calling the merged file for realizing the continuous processing of the transverse span shaft of the ultra-long printed circuit board. The adoption of the method can lead the ultra-long printed circuit board to continuously complete the molding once on the ordinary multi-shaft milling machine, avoid multi-positioning and plate loading and unloading operation, reduce lines and surface scratches of the circuit, ensure the molding precision and simultaneously improve the production efficiency and the product qualification rate to the maximum extent.

Owner:GCI SCI & TECH

Preparation method of novel superlarge-particle-size high-concentration silicon sol

InactiveCN102417185AIncrease concentrationImprove stabilitySilicaOther chemical processesHigh concentrationPtru catalyst

The invention provides a preparation method of novel superlarge-particle-size high-concentration silicon sol. The preparation method comprises the following steps: based on silicon powder, sodium hydroxide, ammonium ceric nitrate and pure water as raw materials, preparing the silicon powder into activated silicon powder, preparing sodium hydroxide into a sodium hydroxide catalyst, and preparing ammonium ceric nitrate into an ammonium ceric nitrate aqueous solution, wherein the weight ratio of silicon powder to sodium hydroxide to ammonium ceric nitrate is 200:3:1.5. The preparation method provided by the invention has the following technical effects: 1) by adopting a simple substance silicon hydrolysis method, the novel superlarge-particle-size silicon sol, which can be used for an abrasive material of a CMP (chemical-mechanical polishing) liquid, is prepared, wherein the particle size of the silicon sol is more than 150nm, and the concentration of the silicon sol is more than 45%, thus the concentration of the silicon sol is improved, and the stability of the silicon sol is good; 2) reaction time is short and is only 30 hours, thereby saving the reaction time; and 3) Ce doping is carried out in the preparation process, and the polishing rate is improved by about 15%, thereby effectively saving the polishing rate of the CMP liquid and reducing surface scratch and surface roughness after polishing.

Owner:JIANGSU TIANHENG NANO SCI & TECH

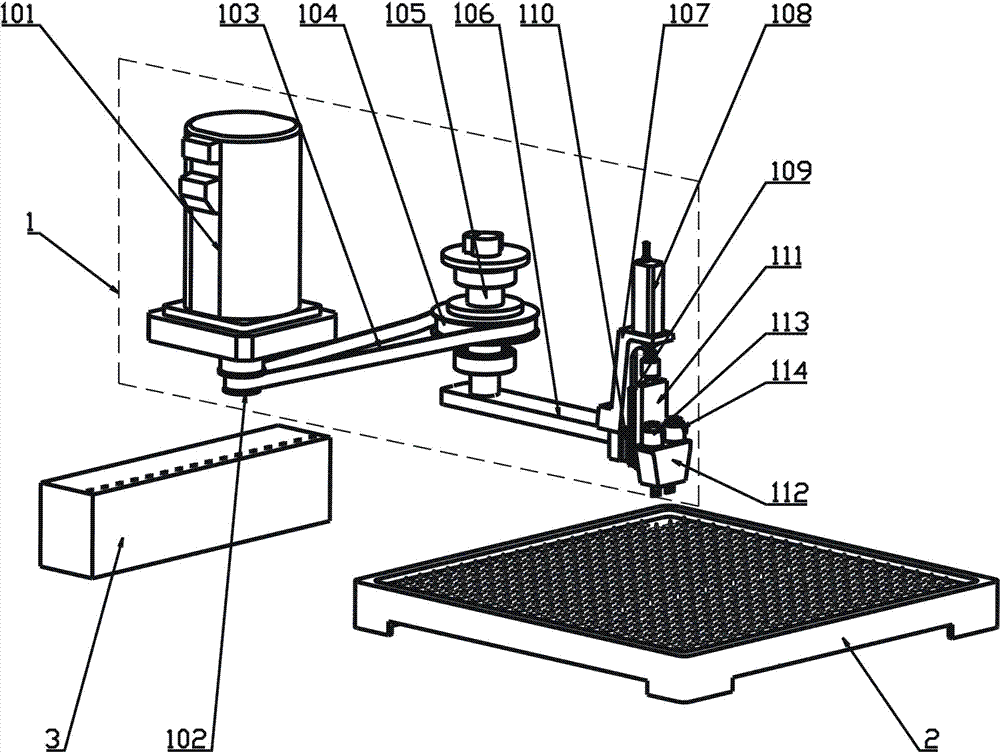

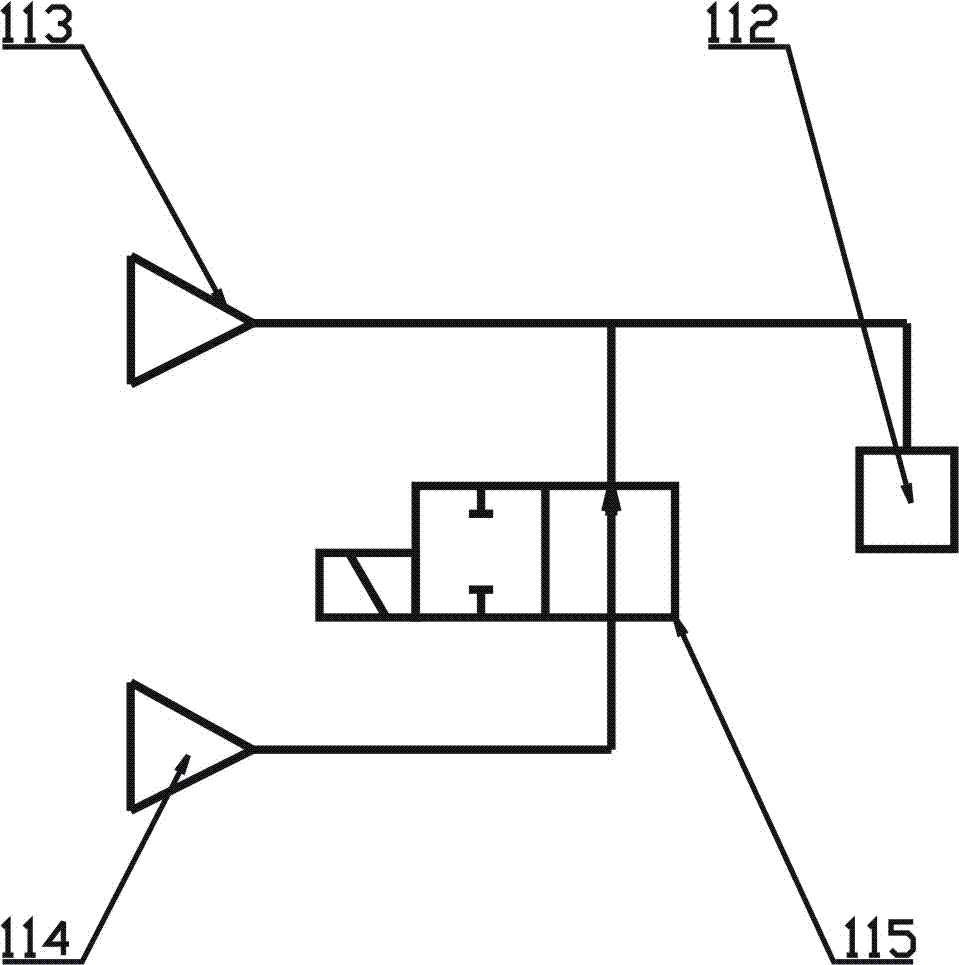

Feeding device for taking and placing materials through air pressure change

PendingCN108002032AShorten the stroke of the downward movementReduce surface scratchesConveyor partsPositive pressureAtmospheric pressure

The invention relates to a feeding device for taking and placing materials through the air pressure change. The feeding device aims to solve the problems that inserting head and inserting piece clamping locating precision and efficiency are low, and the surface is scratched easily. The feeding device is composed of a feeding mechanical hand, a loading tray and a locating jig. The loading tray andthe locating jig are located on the two sides of the feeding mechanical hand correspondingly. The feeding mechanical hand comprises a drive carrying portion and a vertical taking and placing portion.The vertical taking and placing portion can move between the loading tray and the locating jig under driving of the drive carrying portion. The vertical taking and placing portion is composed of an installing support, an air cylinder, a guide rail, a sliding block, a sliding bottom plate and a vacuum sucking disc. The installing support is fixed to the drive carrying portion. The air cylinder is supported on the installing support. The sliding bottom plate is installed on the installing support in a sliding manner through the guide rail and the sliding block and moves up and down under controlling of the air cylinder. The vacuum sucking disc is fixed to the sliding bottom plate. The vacuum sucking disc is provided with a vacuum air way and a positive pressure air way. The vacuum air way isconnected continuously. The positive pressure air way is controlled by an electromagnetic valve to be connected or disconnected.

Owner:BEIJING JINGDIAO GRP CO LTD

Silicon through hole barrier layer alkaline polishing solution

ActiveCN113913115AHighlight substantive featuresReduce corrosionSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesGlycineArginine

The invention relates to a silicon through hole barrier layer alkaline polishing solution, which comprises glycine, arginine and an azole compound, wherein the addition mass of the arginine is at least one time of the addition mass of the glycine, the arginine contains guanidyl, and when the guanidyl in the arginine is combined with the azole compound for use, the removal rate ratio of tantalum to copper is adjusted. According to the invention, the molecular structure of arginine contains amino and hydroxyl to provide chelation, the arginine contains guanidyl and is alkaline amino acid, the arginine is used as a rate improver of tantalum to accelerate removal of tantalum, the removal rate selection ratio of metal tantalum and copper is adjusted by adjusting the content of the guanidyl in the arginine, and the azole compound acts with the amino and the hydroxyl and also acts with the guanidyl, so that the azole compound not only can play a role in corrosion inhibition of metal copper, but also can play a good role in correcting the dish-shaped pit.

Owner:博力思(天津)电子科技有限公司

Mixing device for joint compound

ActiveUS10220358B2Well mixedIncreased durabilityTransportation and packagingRotary stirring mixersPlastic materialsJoint compound

Owner:BUDDY TOOLS

Polishing accelerating agent for glass and silicon-containing compound and production method and application thereof

InactiveCN102627917AImprove suspension abilityNot suitable for depositionPolishing compositions with abrasivesDispersion stabilityRare earth

A polishing accelerating agent for glass and silicon-containing compound and a production method thereof. The agent is characterized by containing 0.001-50 wt% of silicate polymer with a molecular weight between 100 and 20000, and 0.001-20wt % of polymer containing more than one polar functional groups or copolymer containing different polar functional group monomers, with a molecular weight between 500 and 20000. The production method is as below: adding the above components sequentially into water to form a suspension, and adjusting a pH to 5-12; and heating the suspension to 20-90 DEG C, insulating for 0.1-6 h and cooling to 10-25 DEG C. The production method of the accelerating agent is simple; the product has good dispersion stability, high polishing efficiency and reduces dosage of rare rare-earth polishing powder; meanwhile, environmental pollution is reduced.

Owner:JIANGSU SINO KRYSTALS OPTROINCS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com