Environmental-friendly diamond grinding liquid and preparation process thereof

A preparation process and diamond technology, applied in polishing compositions containing abrasives, etc., can solve the problems of difficult to achieve technological breakthroughs, and achieve the effects of high control accuracy, high grinding efficiency and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

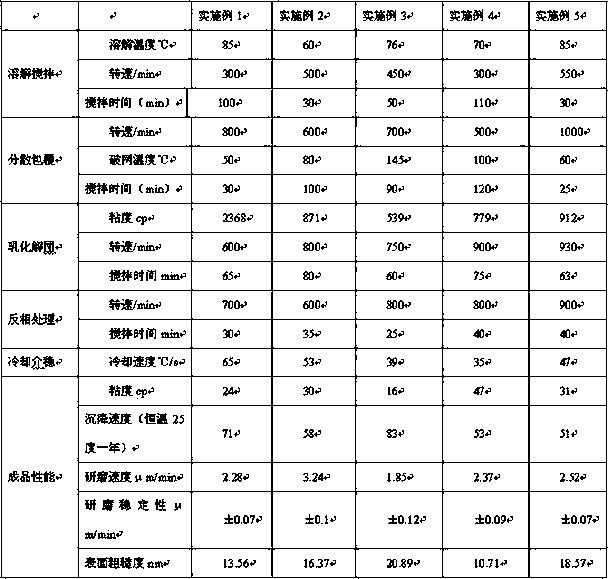

Examples

Embodiment 1

[0032] Example 1: The weight percentage of each component of the grinding fluid is abrasive: solvent: emulsifier: thickener: suspending agent=0.4wt%: 86.9wt%: 4.3wt%: 4wt%: 4.3wt%; among them, diamond The powder is 6-12μm polycrystalline diamond micropowder; the solvent is isododecane: alkylbenzene=95.4wt%: 4.6wt%; the emulsifier system is SPAN65: lauryl alcohol polyoxyethylene ether=53.5wt%: 46.5wt %; thickener is polyisobutylene 2400; suspending agent is paraffin 98-103#: epoxy resin E51=45.5wt%: 54.5wt%.

Embodiment 2

[0033] Example 2: The weight percentage of each component of the grinding fluid is abrasive: solvent: emulsifier: thickener: suspending agent=0.5wt%: 87.2wt%: 4wt%: 5wt%: 3wt%; among them, diamond powder is 6-12μm polycrystalline diamond powder; solvent is dodecane: alkylbenzene=90.9wt%: 9.1wt%; emulsifier is SPAN65: polyoxyethylene laureth=87.5wt%: 12.5wt%; increase Thickening agent is polyisobutylene 2400; suspending agent is epoxy resin E51.

Embodiment 3

[0034] Example 3: The weight percentage of each component of the grinding fluid is abrasive: solvent: emulsifier: thickener: suspending agent = 0.5wt%: 87.1wt%: 4.37wt%: 5wt%: 2.83wt%; among them, diamond The powder is 6-12μm polycrystalline diamond micropowder; the solvent is isododecane: heat transfer oil KD320=96.2wt%: 3.8wt%; the emulsifier is SPAN65: DPMA=57.2wt%: 42.8wt%; the thickener is Polyisobutylene 2400; suspending agent is C9 petroleum resin: styrene butadiene rubber SBS=85.8wt%: 14.2wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com