Patents

Literature

1840results about How to "Reduce sulfur content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

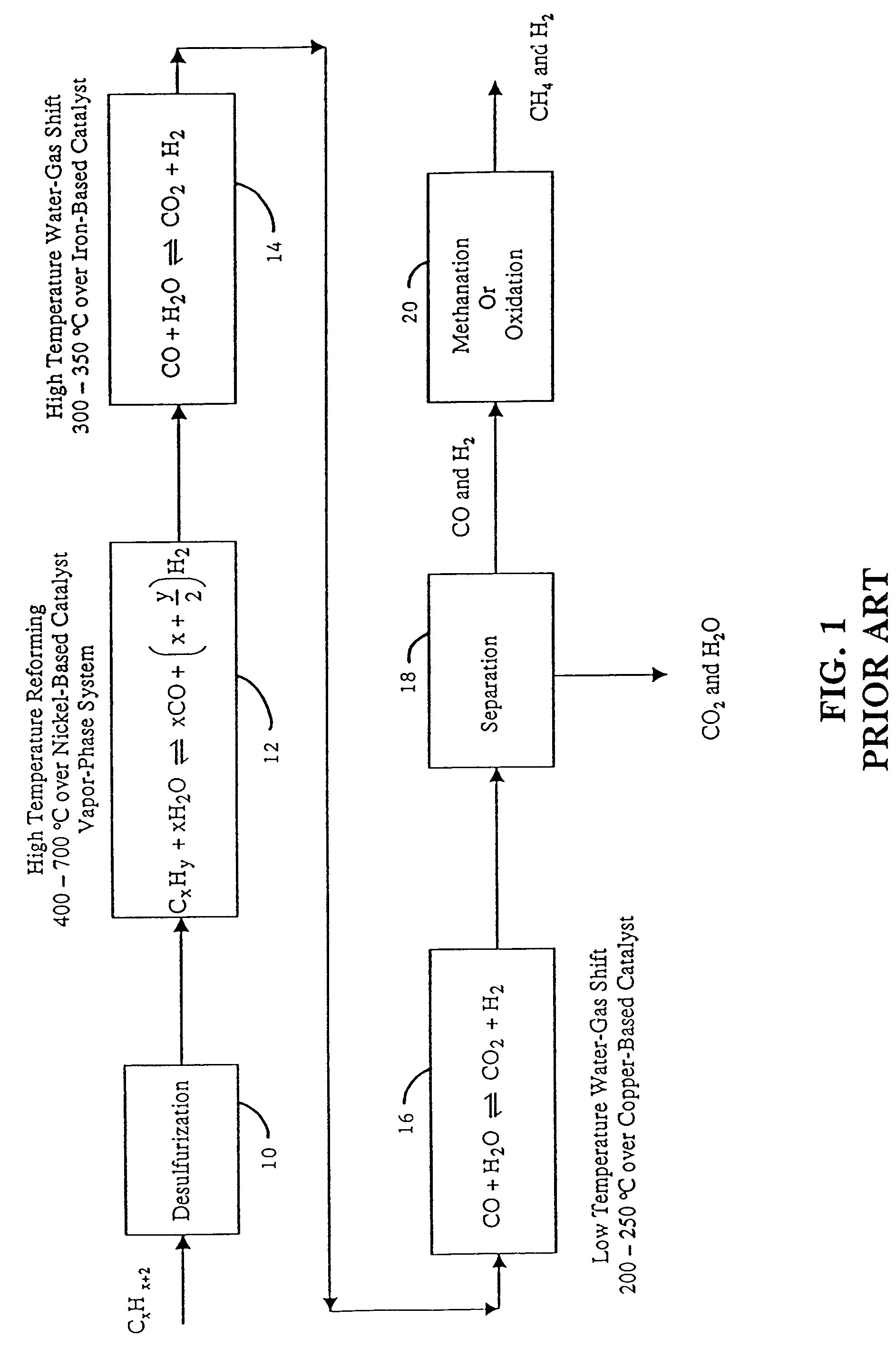

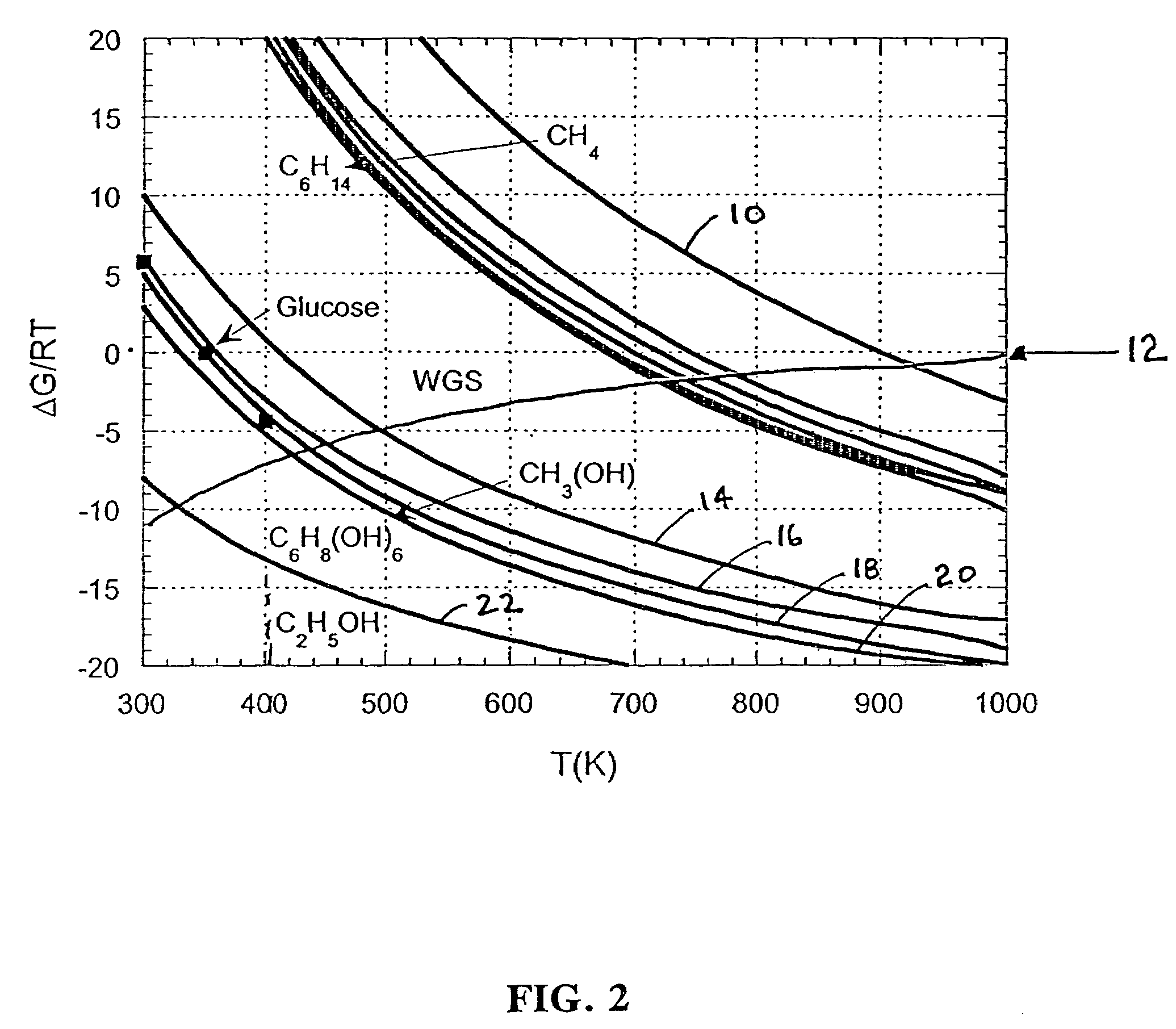

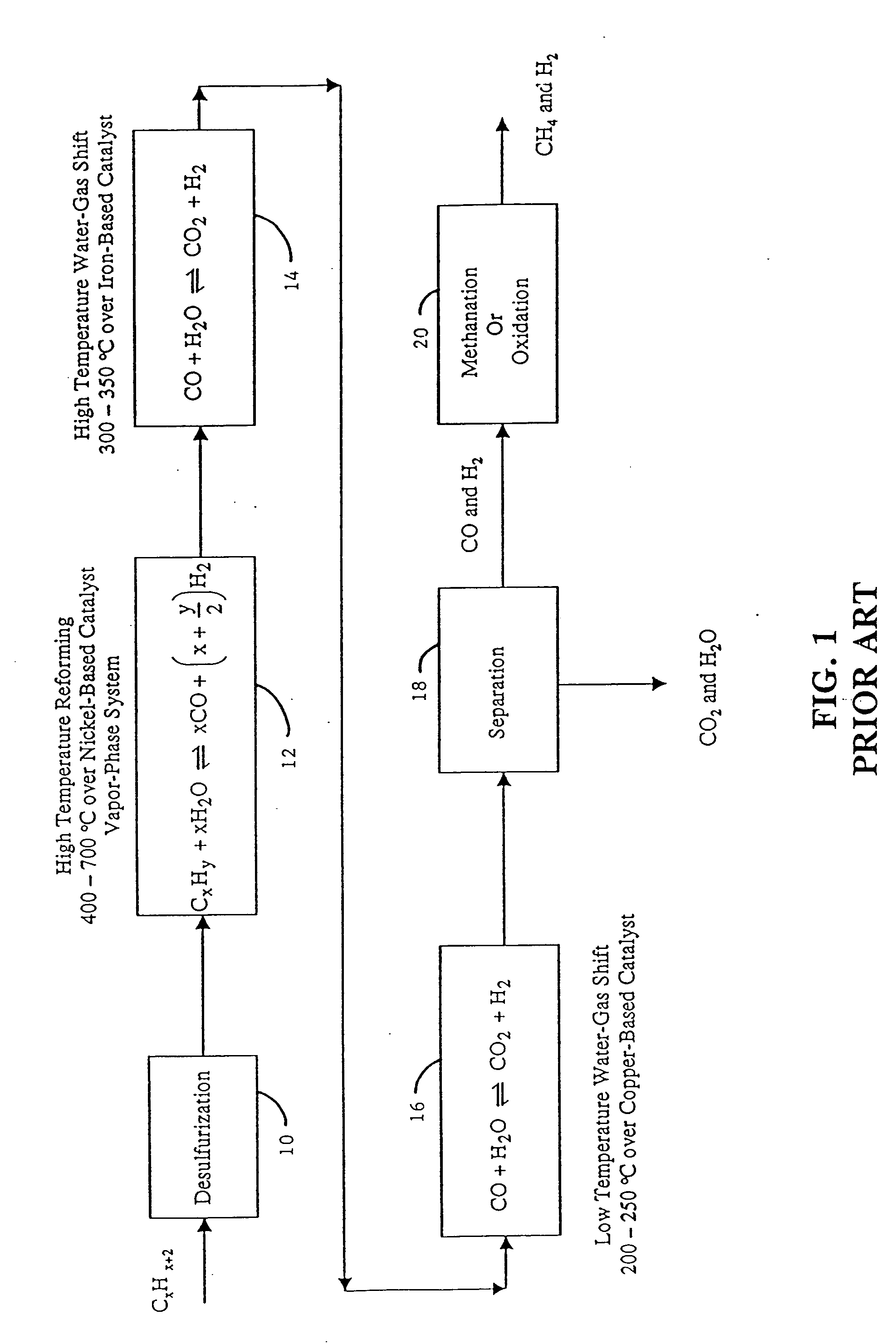

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS6964757B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

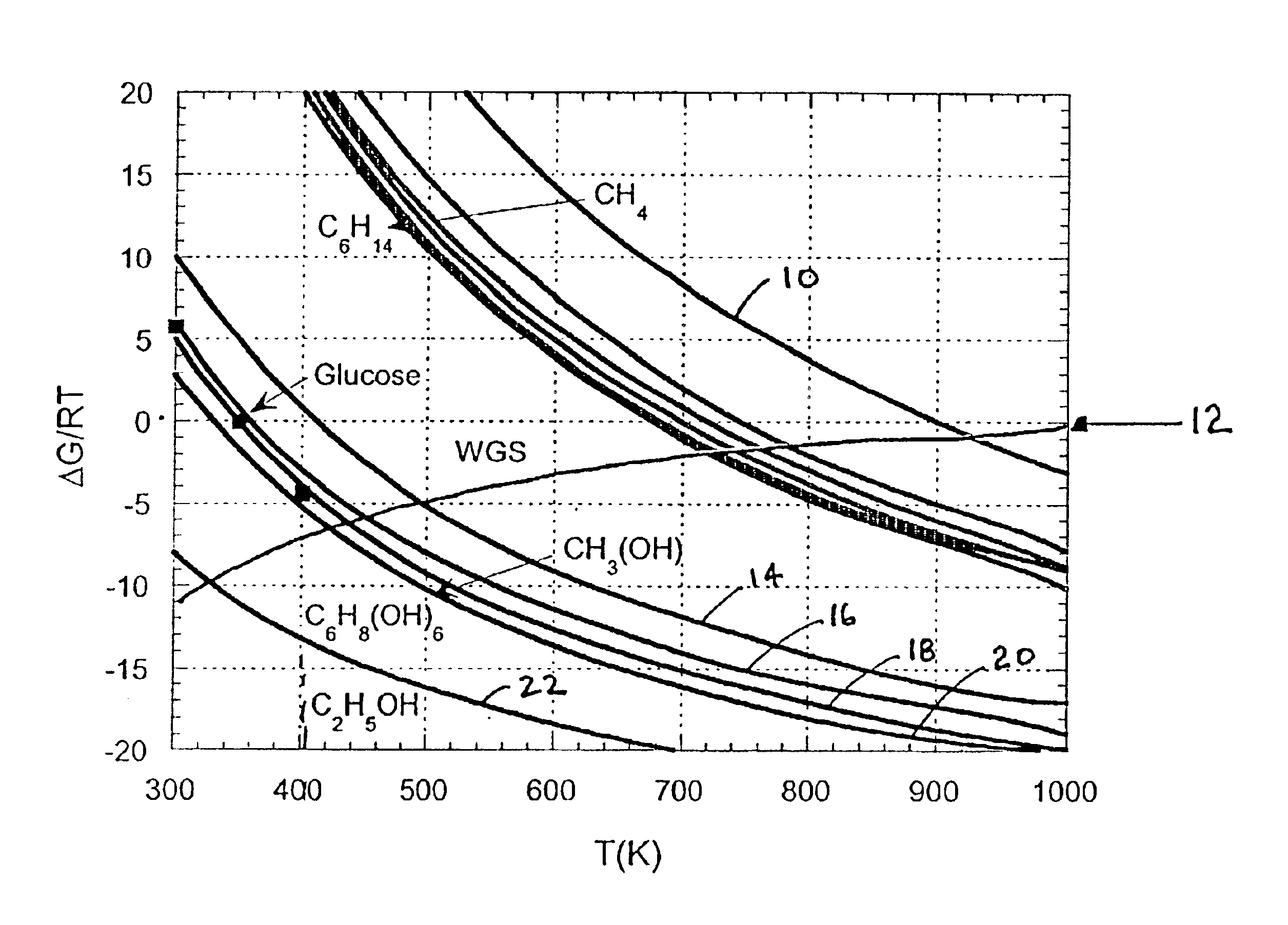

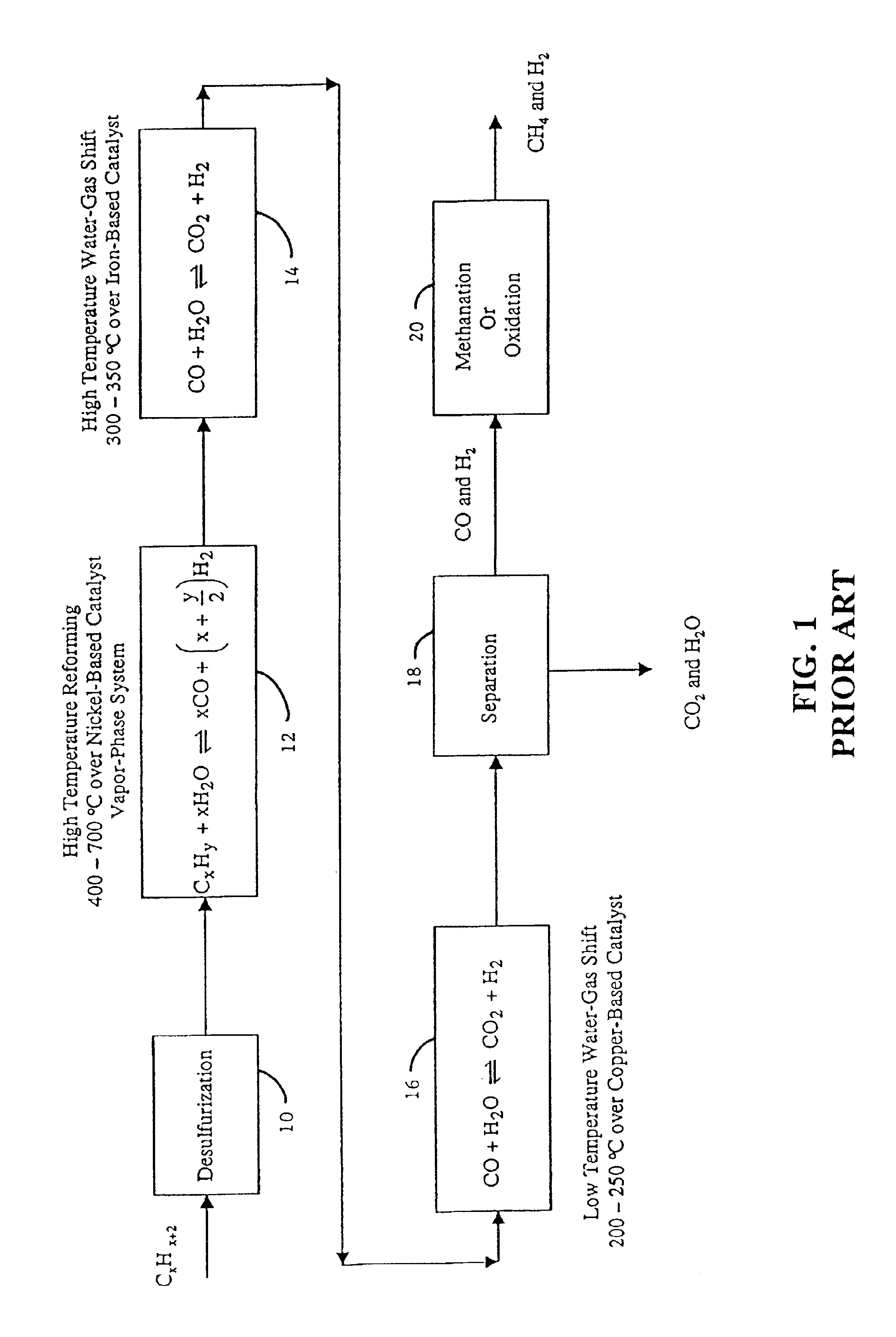

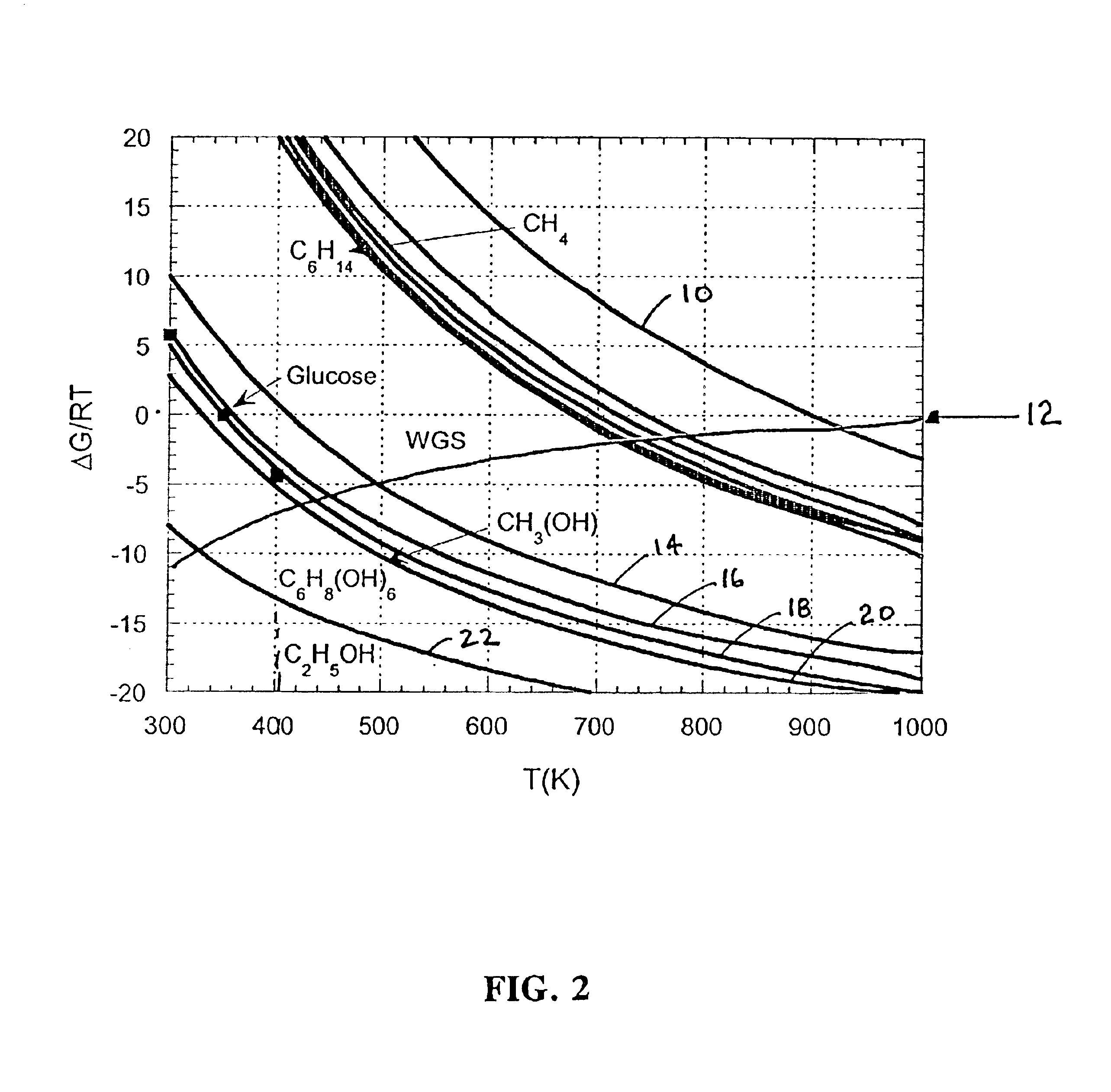

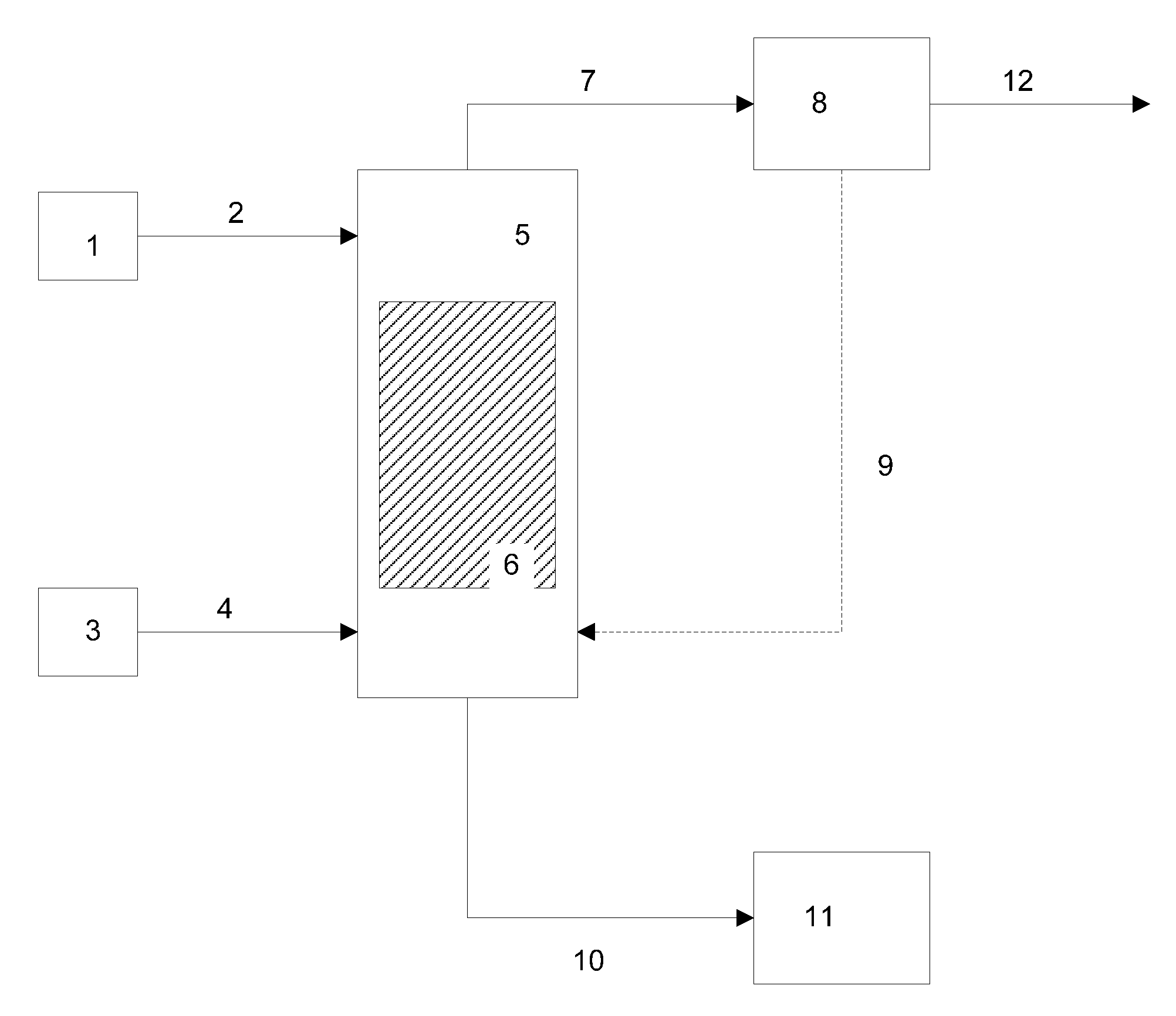

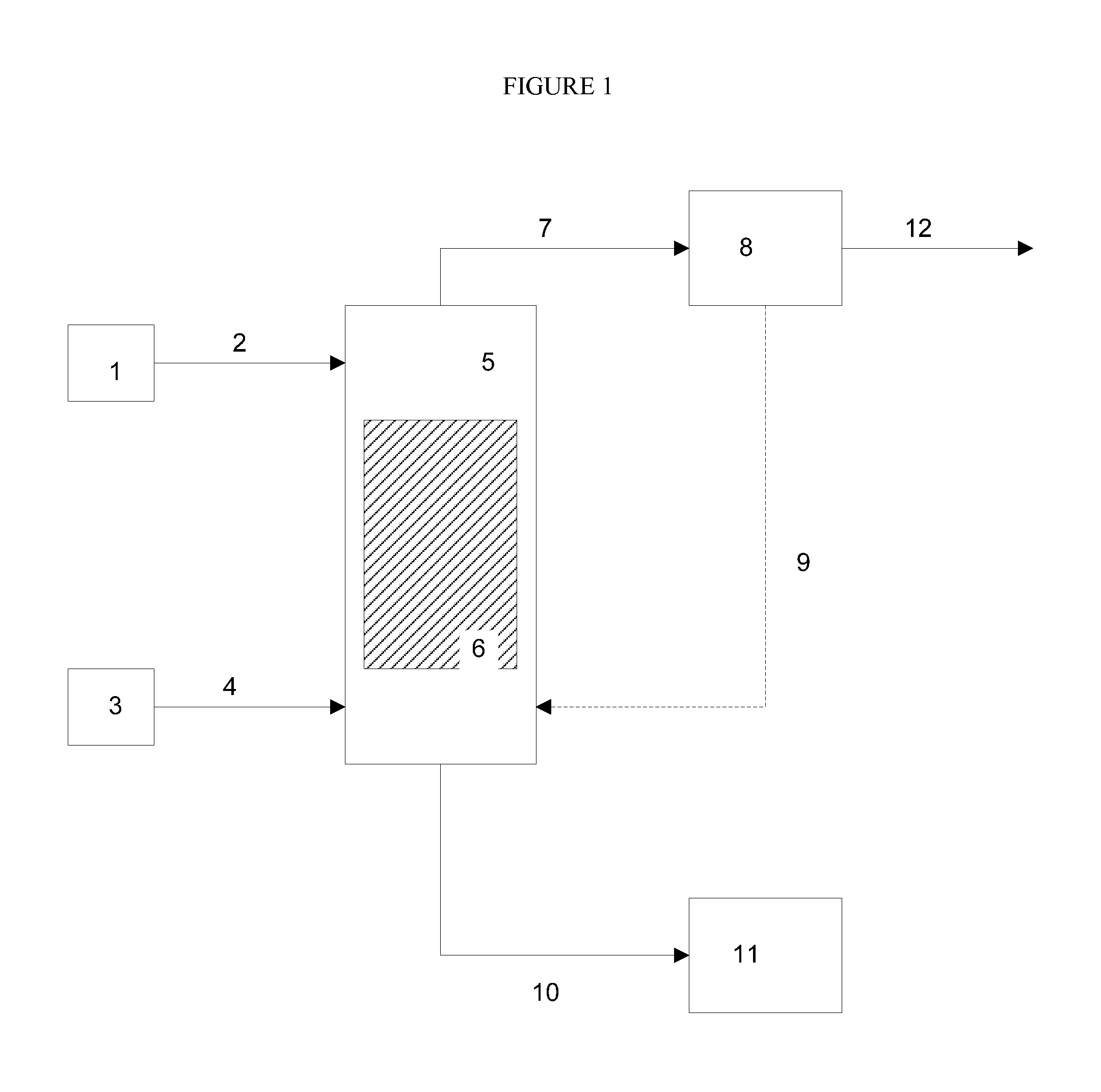

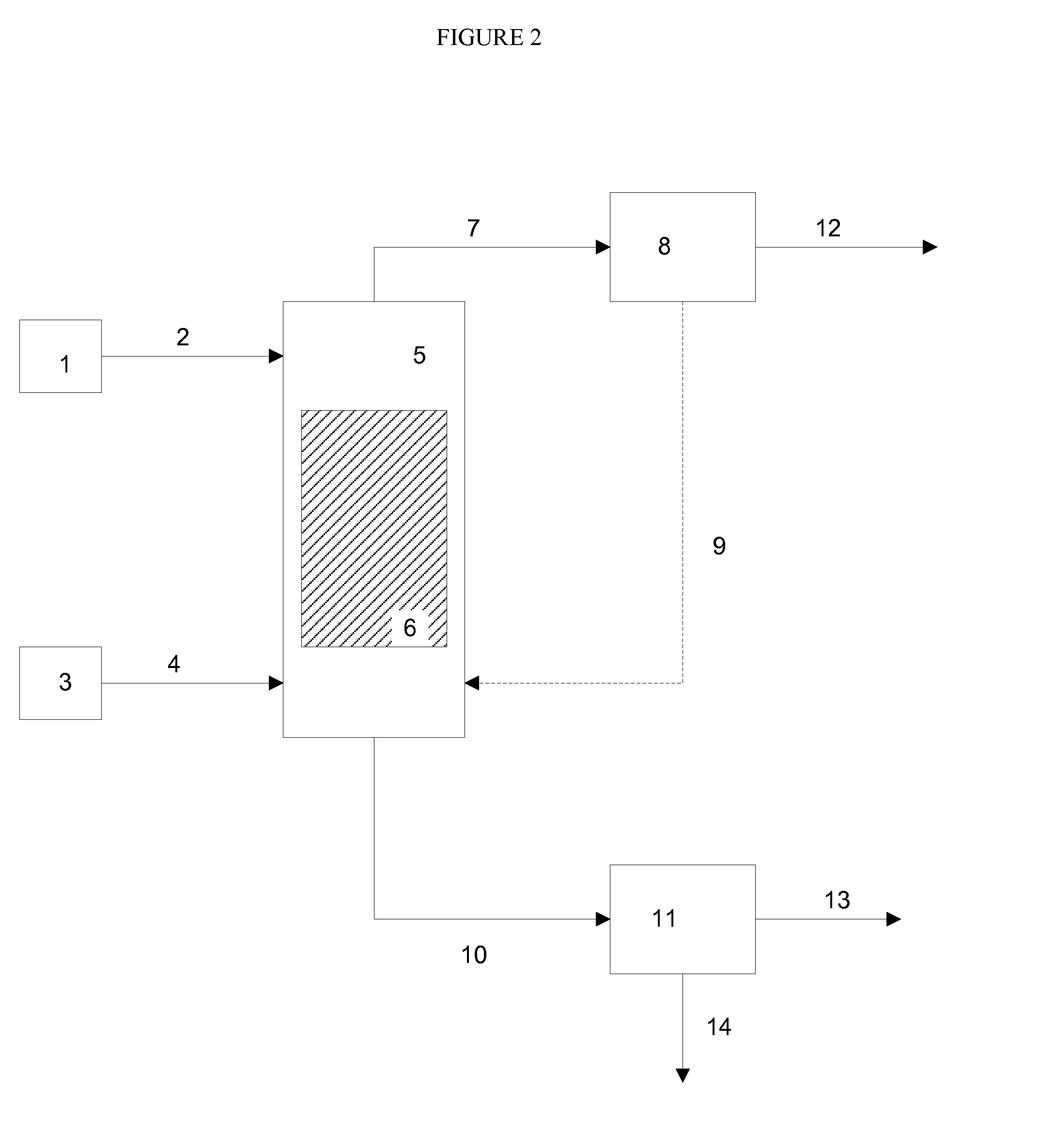

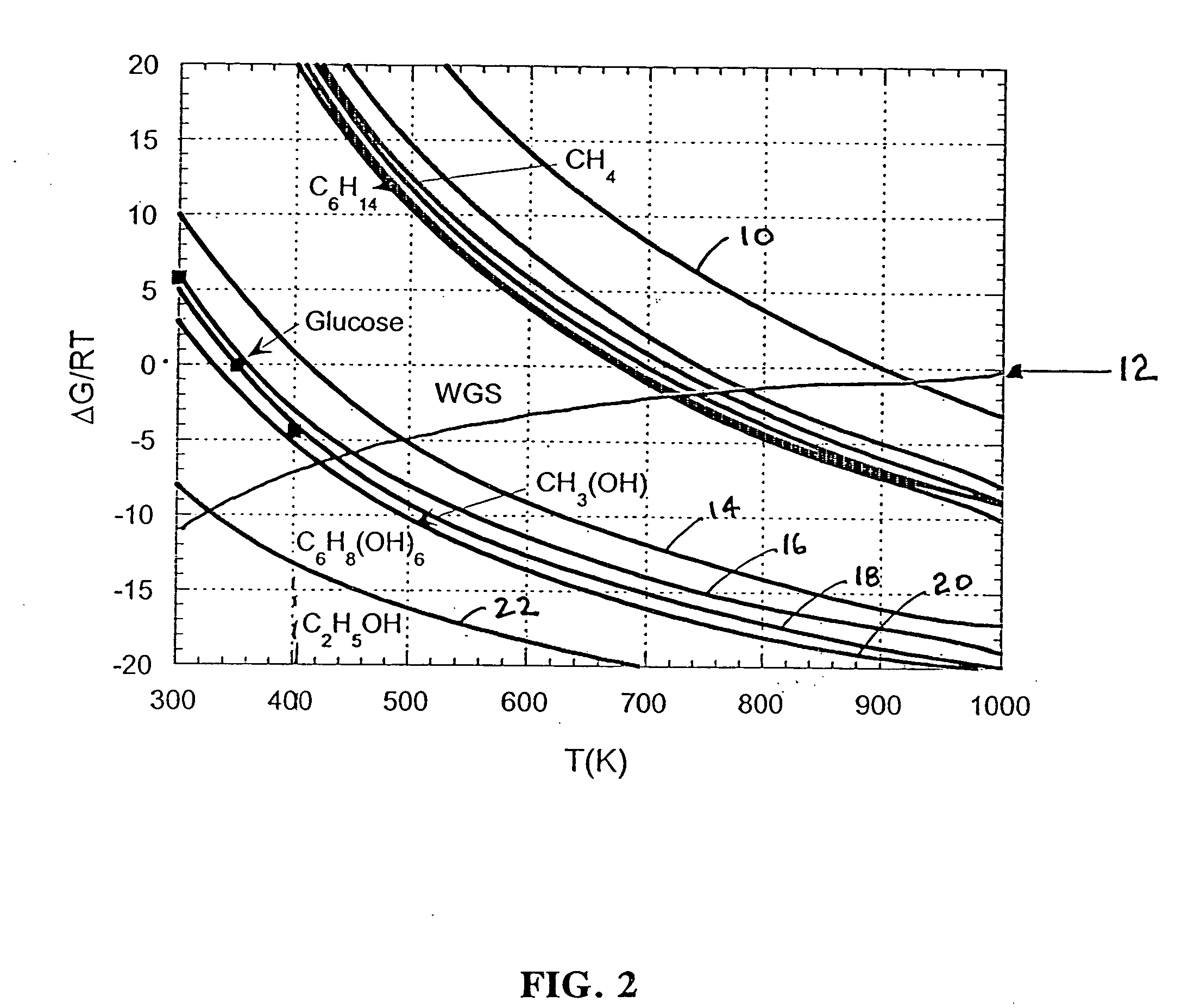

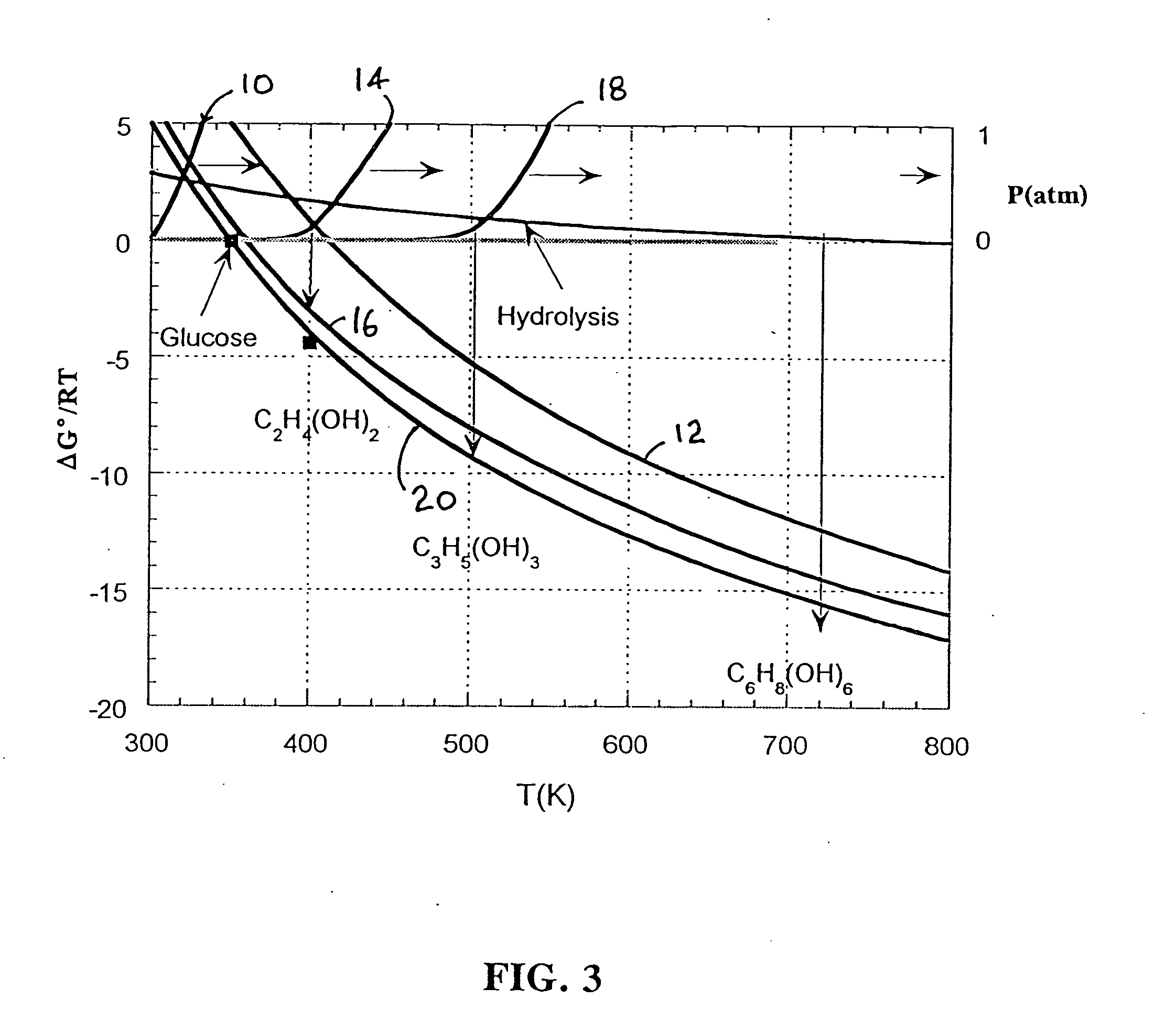

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

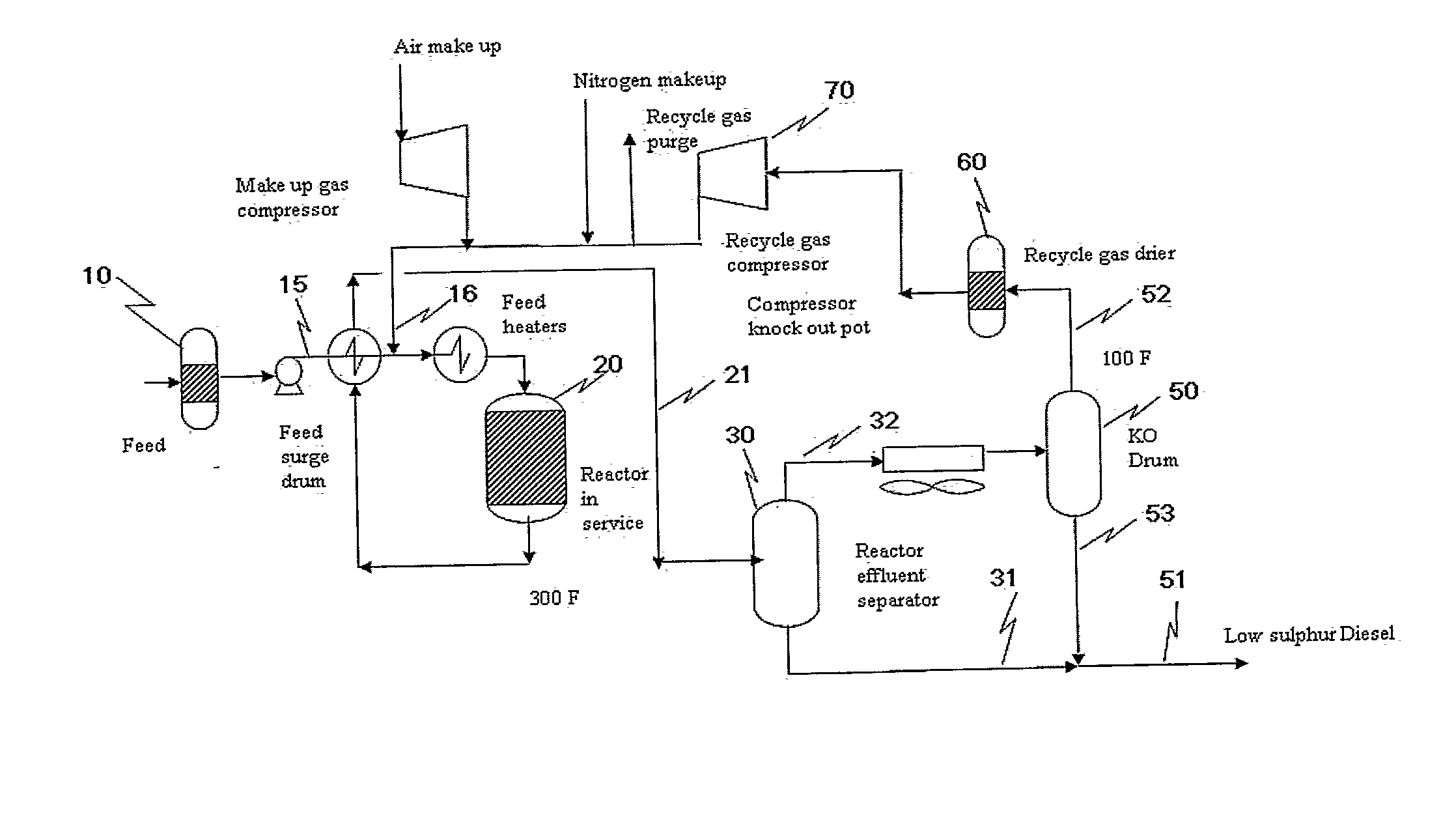

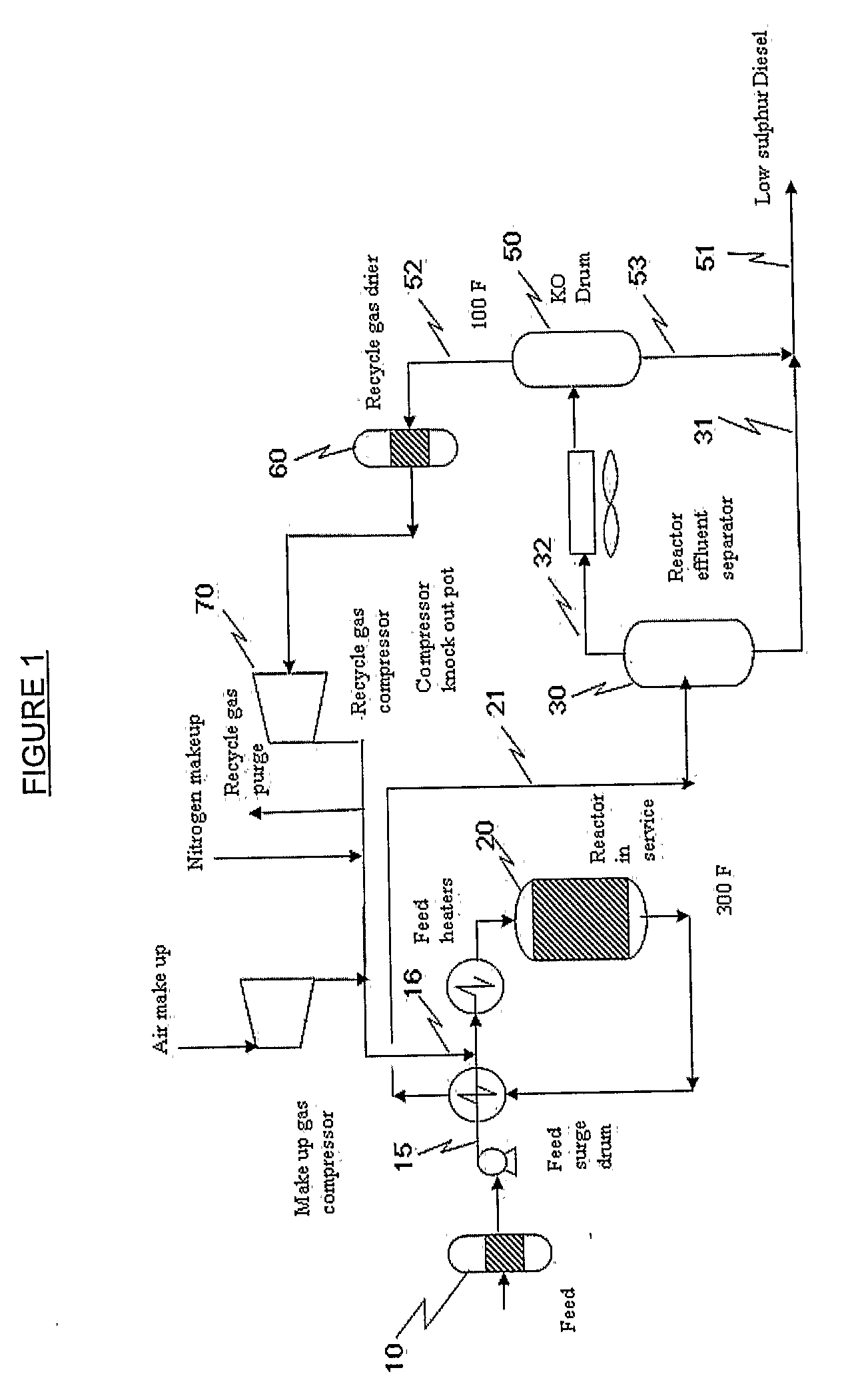

Heavy distillate oil hydrotreating method

ActiveCN101348732AQuality improvementQuality assuranceHydrocarbon oils refiningGasoline stabilisationWaxOil and grease

The invention relates to a method for hydrotreating heavy oil, in particular to the method for hydrotreating heavy oil, which improves the quality of diesel oil. Heavy distillate oil and animal and vegetable oil are used as raw material oil; under the hydrotreatment condition, the raw material oil and hydrogen gas are mixed and pass through a hydrotreatment reaction region; hydrogen-rich gas which is obtained by separating oil generated by hydrotreatment is circulated and utilized; and liquid obtained by separation is distillated to prepare a diesel oil product and hydrogenated wax oil. Compared with the prior art, the method can effectively improve the material source of a wax oil hydrotreatment device, ensure the quality of the hydrogenated wax oil, substantially increase the quality ofthe hydrotreated diesel oil and improve the storage stability of the animal and vegetable oil as fuel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for Obtaining Biodiesel, Alternative Fuels and Renewable Fuels Tax Credits and Treatment

InactiveUS20090076913A1Improve responseReduce sulfur contentFatty acid esterificationOrganic compound preparationAlternative fuelsTax credit

Owner:ENDICOTT BIOFUELS II

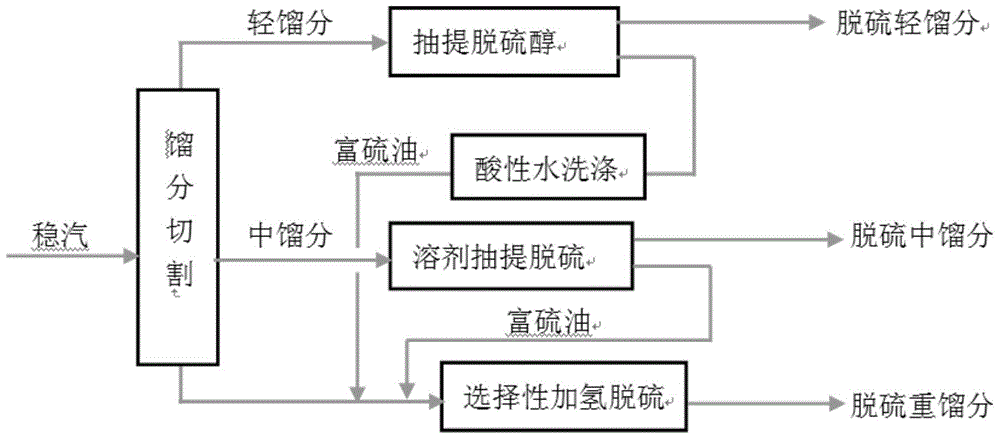

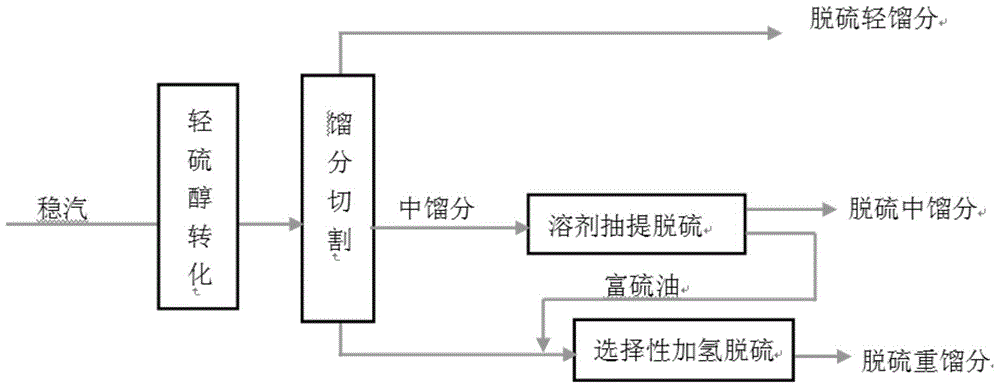

Method for producing low sulfur gasoline

InactiveCN1465668AReduce sulfur contentReduce saturationTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The method for producing low-sulfur gasoline includes the following steps: cutting gasoline raw material into light fraction and heavy fraction, making the light fraction undergo the processes of alkali refinement treatment and removing mercaptans, making the heavy fraction and hydrogen gas together by contacted with hydrogenation desulfurization catalyst to make selective hydrogenation desulfurization reaction, then hydrogenated gasoline fraction undergo the process of hydrogenation or non-hydrogenation to remove mercaptans, then mixing the above-mentioned desulfurized light and heavy fractions so as to obtain the invented gasoline product whose olefine saturation rate is less than 30%, and sulfur content is less than 200 ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

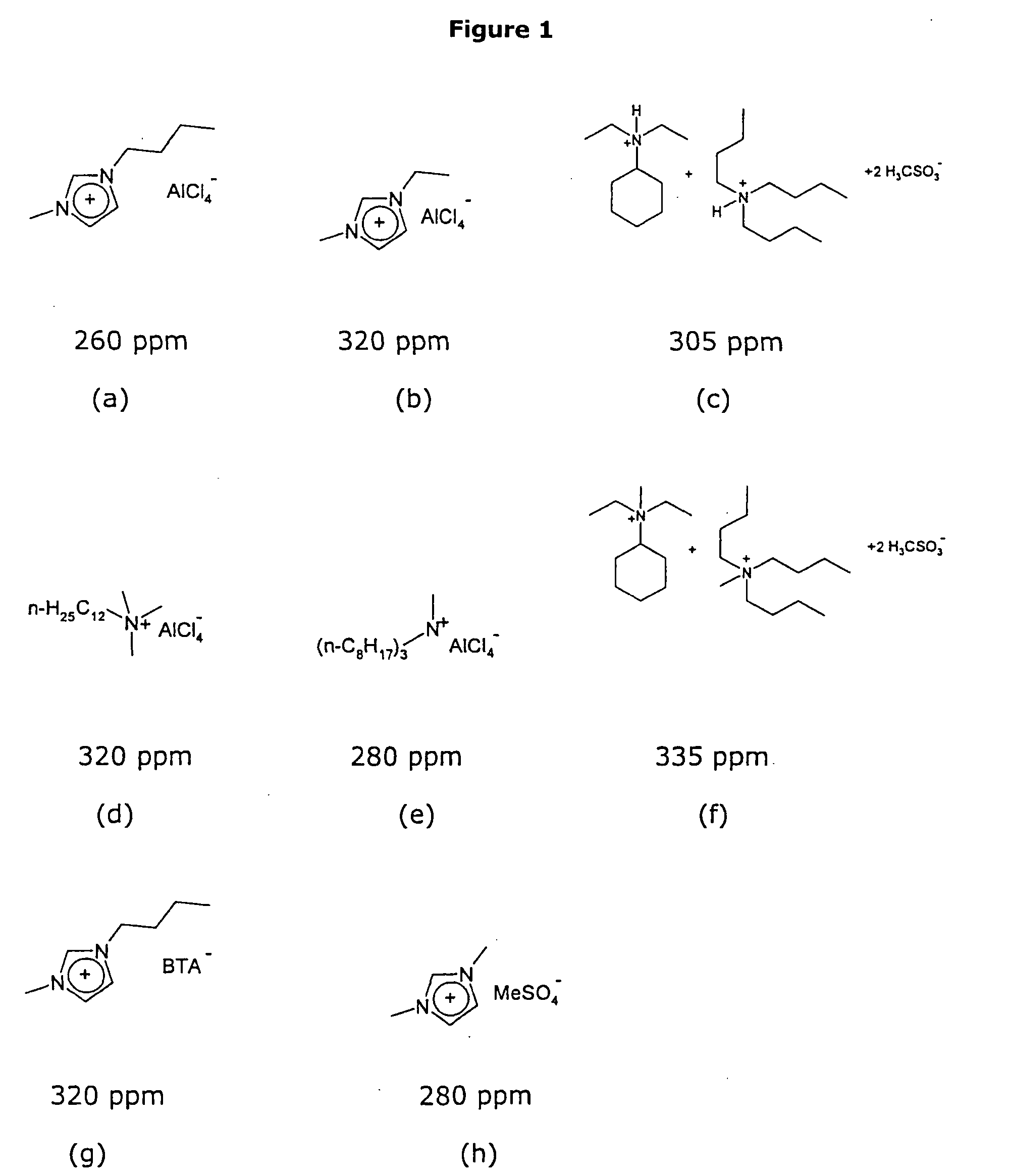

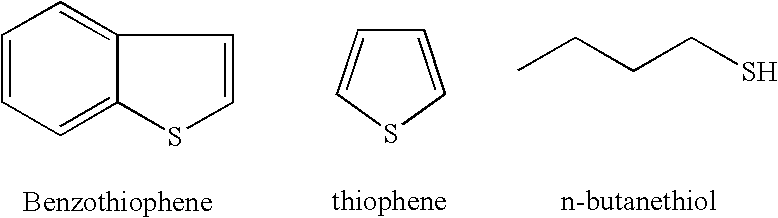

Method for extraction of organosulfur compounds from hydrocarbons using ionic liquids

InactiveUS7001504B2Reduce hydrocarbon contentReduce sulfur contentTreatment with plural serial refining stagesHydrocarbon oils refiningPartial oxidationOrganosulfur compounds

A process for the removal of organosulfur compounds from hydrocarbon materials is disclosed. The process includes contacting an ionic liquid with a hydrocarbon material to extract sulfur-containing compounds into the ionic liquid. The sulfur-containing compounds can be partially oxidized to sulfoxides and / or sulfones prior to or during the extraction step.

Owner:EXTRACTICA

Process to produce aromatics from crude oil

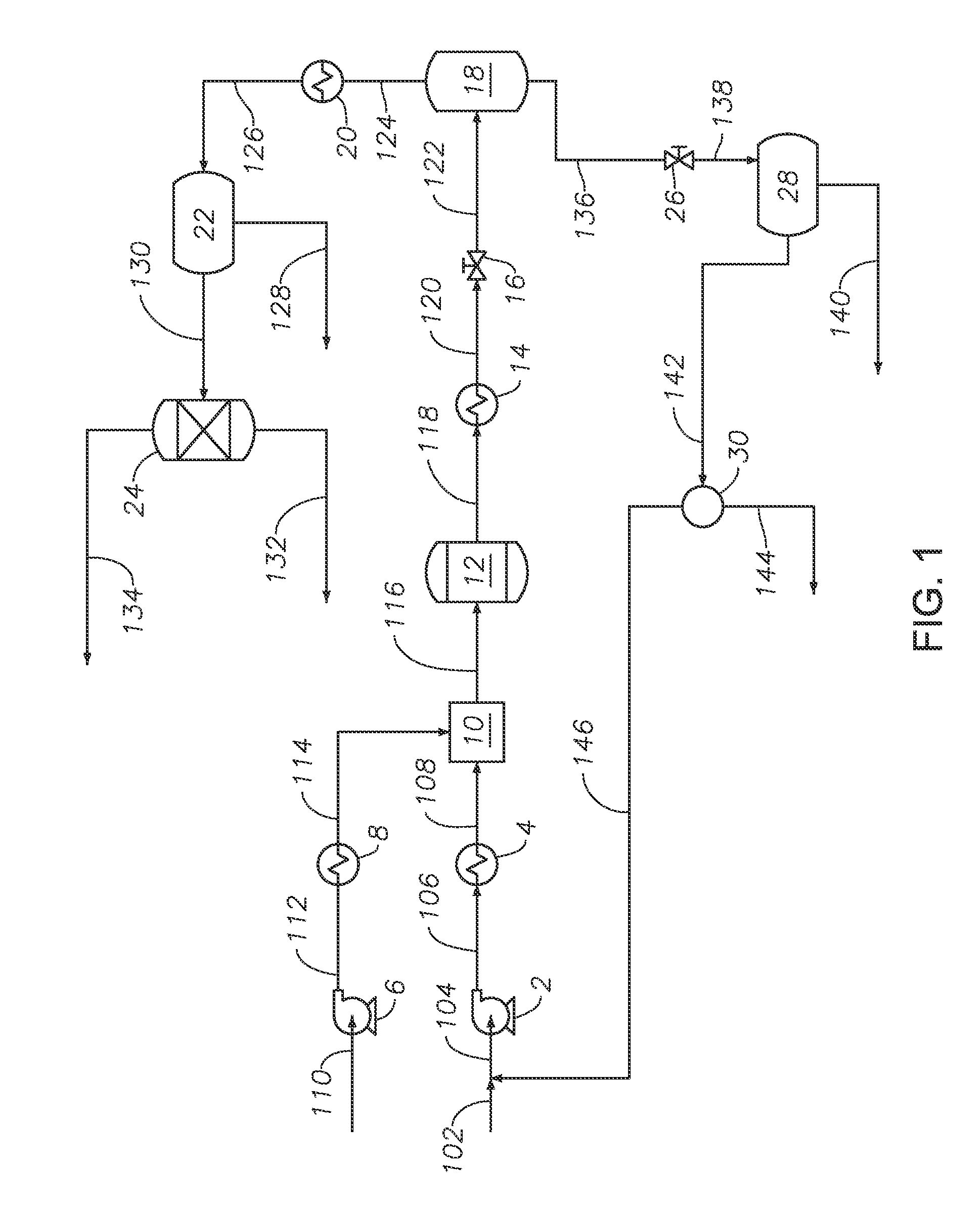

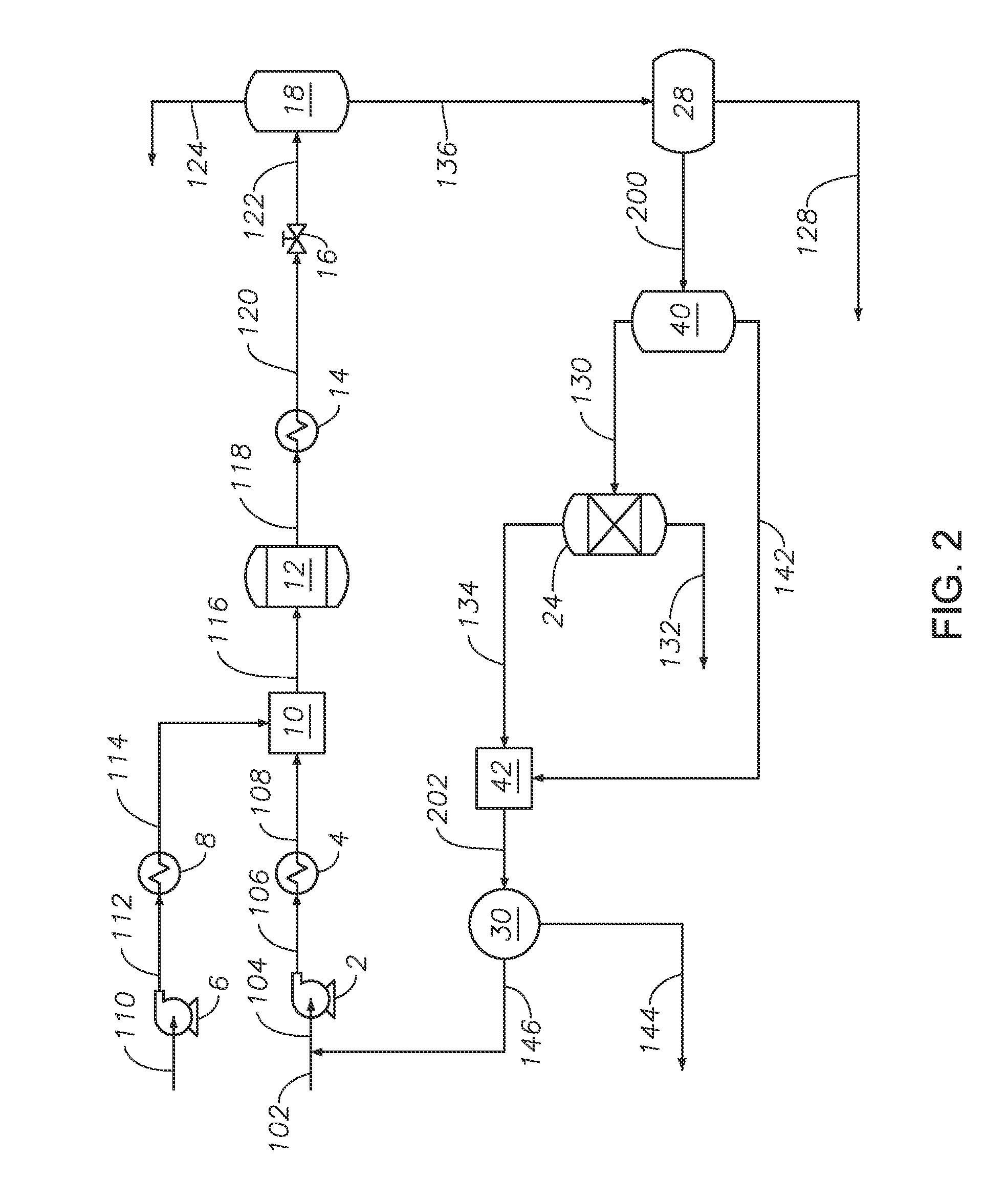

ActiveUS20150321975A1Low impurity contentHigh API gravityThermal non-catalytic crackingTreatment with plural serial stages onlyVapor–liquid separatorWater flow

A process for producing aromatics from a hydrocarbon source in the presence of supercritical water comprising the steps of mixing a pressurized, pre-heated water stream with a pressurized, pre-heated petroleum feedstock, the pressurized, pre-heated water stream at a pressure above the critical pressure of water and a temperature above the critical temperature of water, feeding the combined stream to a supercritical water reactor to create a modified stream, cooling and depressurizing the modified stream, separating the depressurized stream in a vapor-liquid separator, condensing the vapor stream, separating the condensed stream into a water recovery stream and a light product recovery stream, extracting the aromatics from the light product recovery stream, depressurizing the liquid stream, separating the depressurized liquid stream in a heavy separator into an upgraded product stream, and recycling part of the upgraded product stream to the pressurized, pre-heated petroleum feedstock as a product recycle.

Owner:SAUDI ARABIAN OIL CO

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS7618612B2Reduce riskWeaken energyHydrogen productionHydrogen/synthetic gas productionSteam reformingAlkane

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Process for removing polar impurities from hydrocarbons and mixtures of hydrocarbons

InactiveUS20050010076A1Avoid corrosion problemNovel and extremely efficientOrganic compounds purification/separation/stabilisationSolvent extractionEnvironmental chemistryHydrocarbon

This invention relates to a process for removing polarizable impurities from hydrocarbons and mixtures of hydrocarbons using ionic liquids as an extraction medium for reducing the degree of contamination of the hydrocarbon or mixture of hydrocarbons to a low or very low level.

Owner:MERCK PATENT GMBH

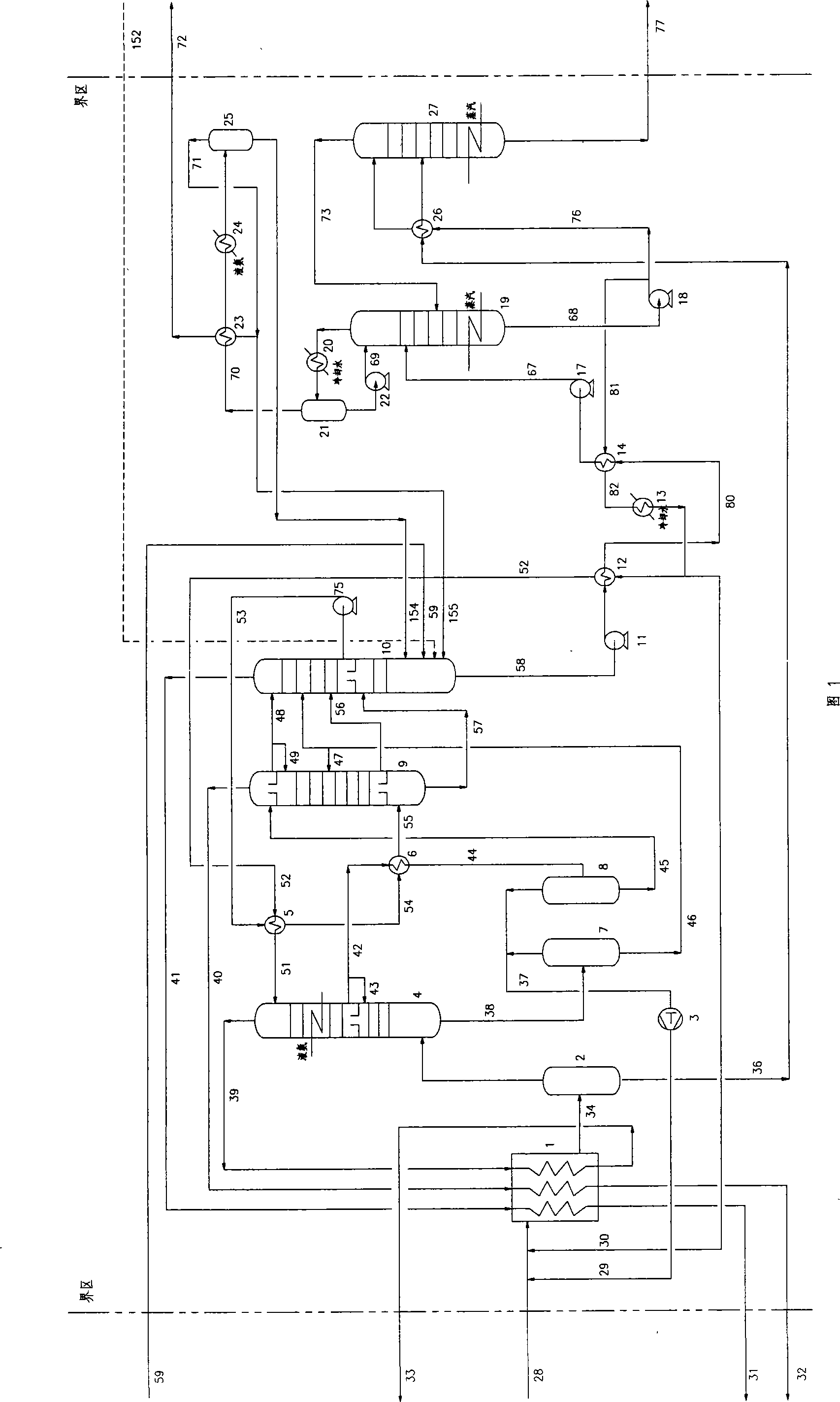

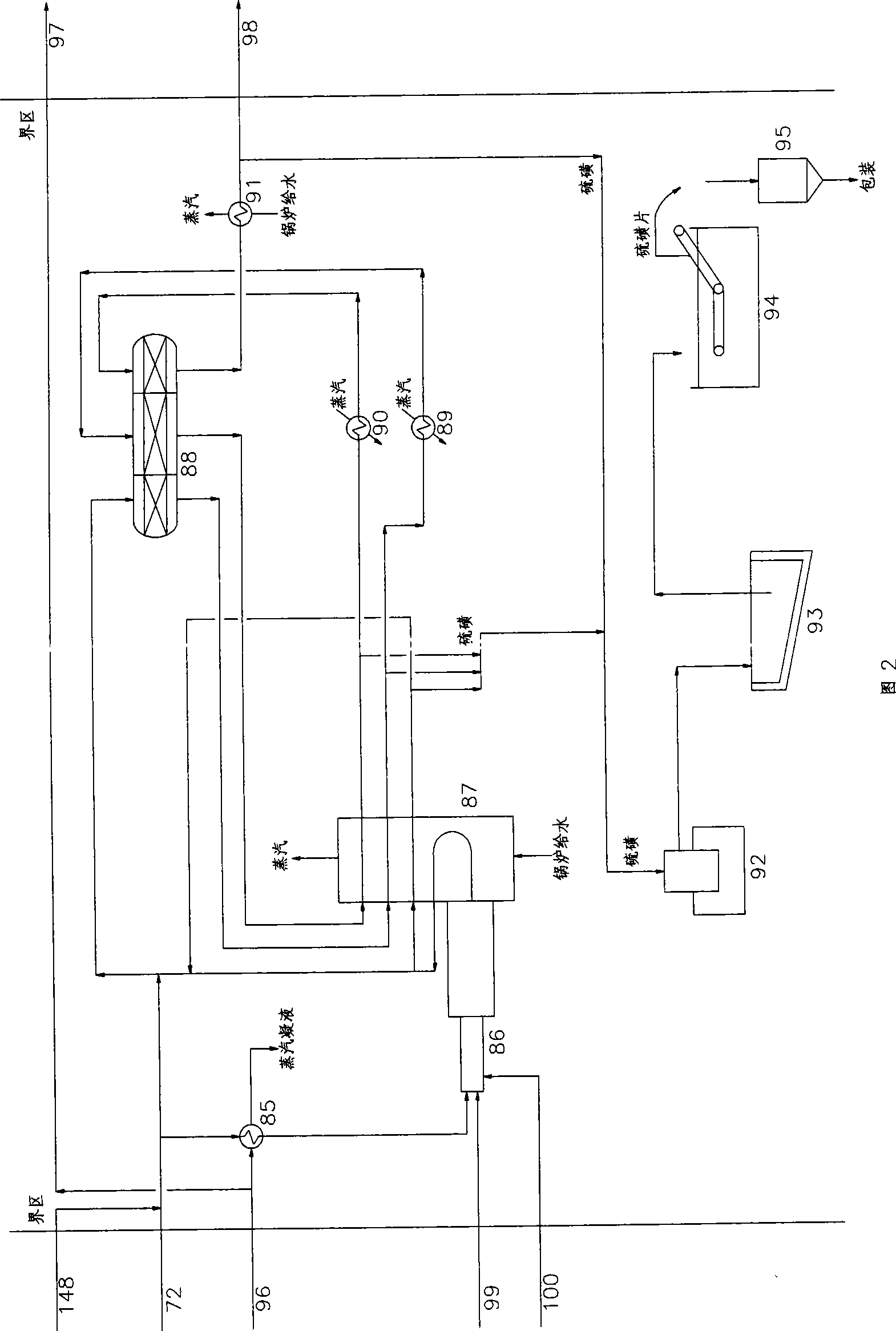

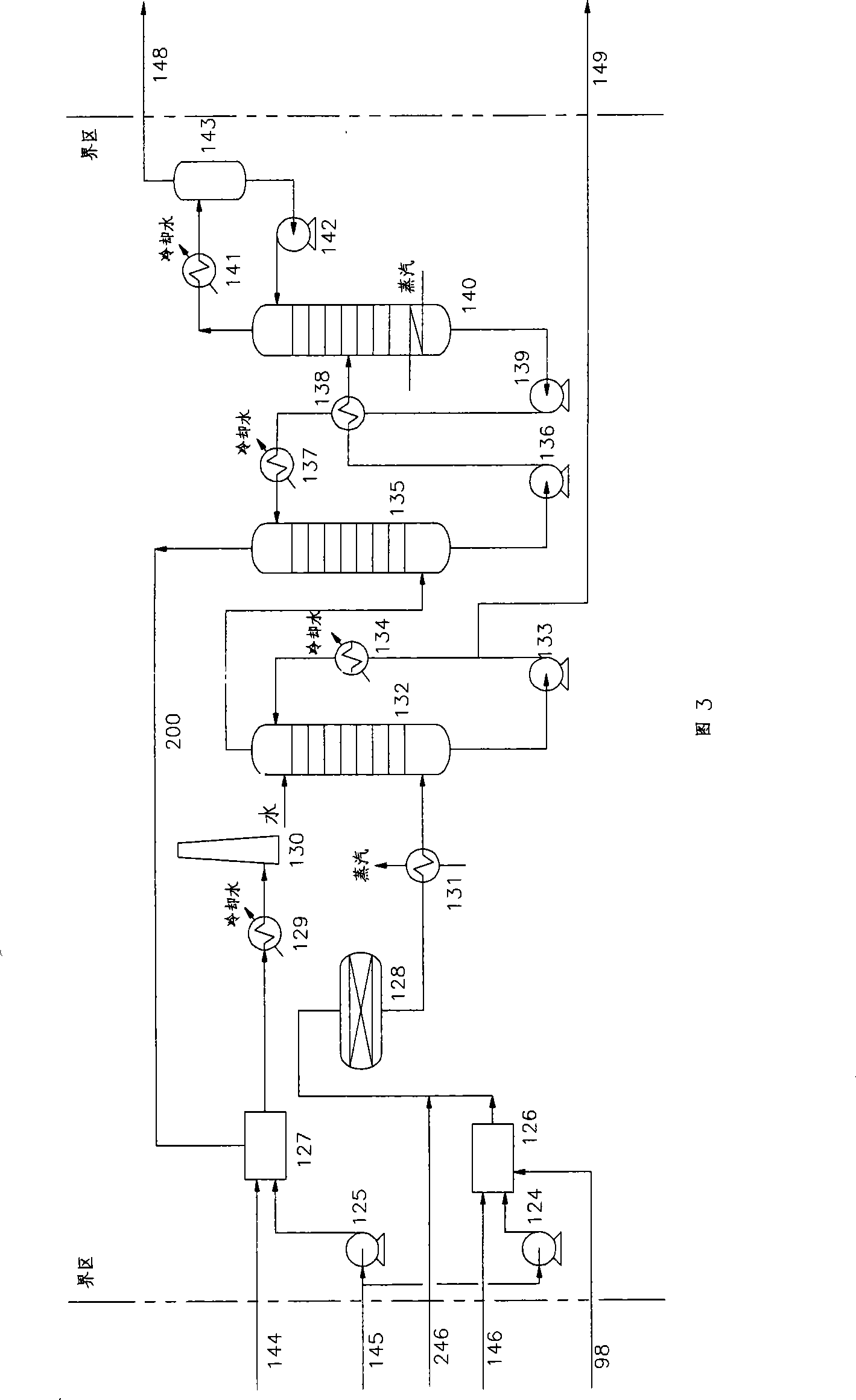

Low temperature methanol washing integrated Claus sulfur recovery system and process

ActiveCN101418246AFlexible processing capacityLow investment costProductsReagentsSulfurHydrogenation reaction

The invention relates to a reclaiming system and a process for low-temperature methanol washing integrated Claus sulfur of coal gas and natural gas. The system is additionally provided with a Claus tail gas washing tower and uses sulfur-free methanol saturated by CO2 from a CO2 product tower as a washing agent, and the washed liquid returns to an H2S concentrating tower; through combination of heating, gas stripping and pressure adjustment, concentration of H2S in acid gas washed by methanol is adjusted flexibly; at the same time, the system is additionally provided with a tail gas pre-heater before hydrogenation reaction to compensate heat loss of a hydrogenation reaction system. The process mainly comprises the following steps: removing H2S-CO2 gas, condensing H2S, reclaiming Claus sulfur, hydrogenising and reducing the gas, selectively absorbing and desulfurizing saturated cold methanol. The process has the advantages that the process can efficiently, flexibly, safely and energy-conservatively treat carbonyl gas with different pressures, temperatures, water content and sulfur concentration; and total sulfur reclamation ratio can reach more than 99.9 percent. The concentration of the H2S in emptied tail gas is below 25 mg / Nm3, so the H2S gas can meet the requirement of environmental protection, and can be exhausted directly without being burnt.

Owner:HUALU ENG & TECH

Catalytic conversion method and apparatus for upgrading poor gasoline

InactiveCN1401740AReduce olefin contentReduce sulfur contentTreatment with plural serial stages onlyCatalytic transformationFuel oil

A catalytic converting process for upgrading poor-quality gasoline with high olefine content incldues a conventional catalytic cracking step for heavy oil and a catalytic converting step for upgrading said gasoline. It is characterized by in that two steps a common catalyst regenerator and a same catalyst are used. It can decrease olefine content by 15-50 vol% and S content by 5-30% and increase RON by 0.2-2 units.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP

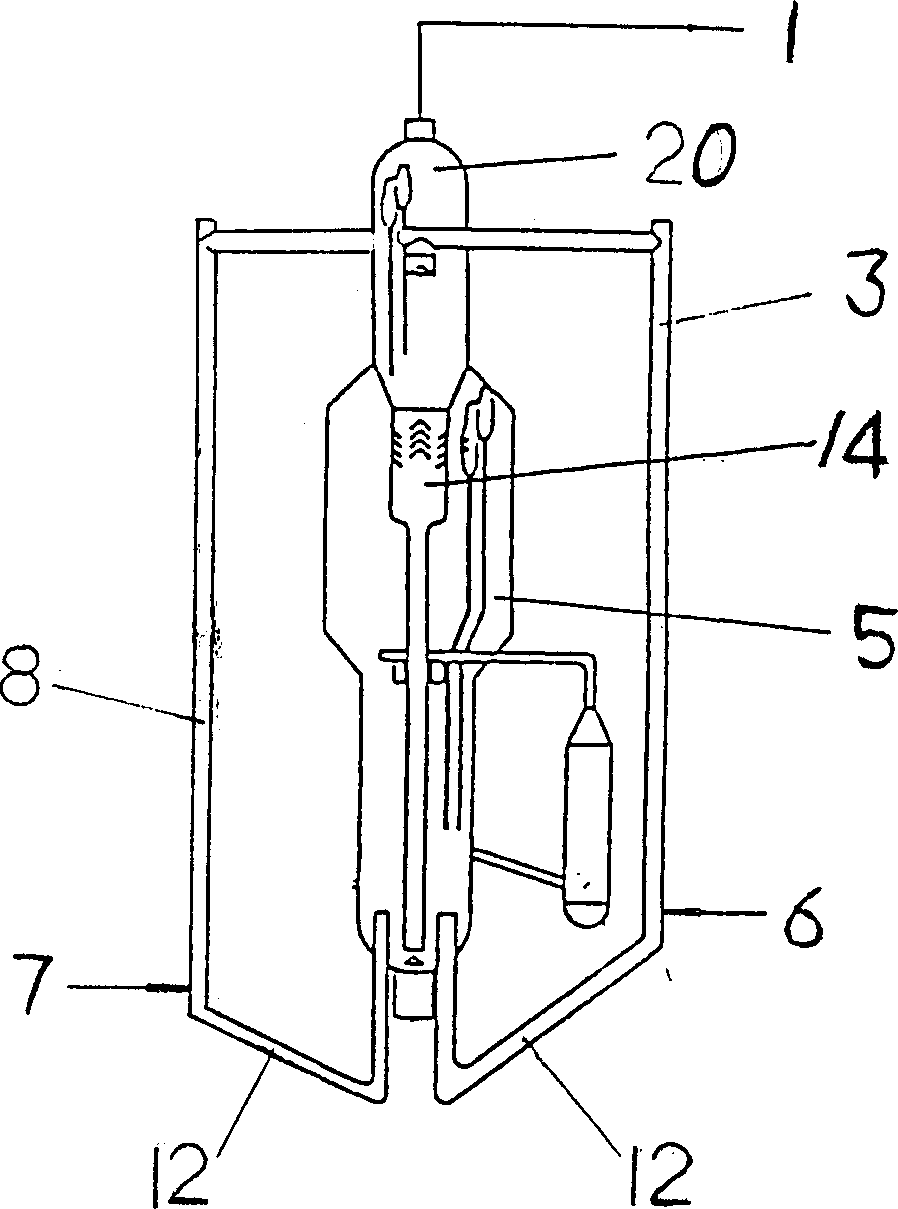

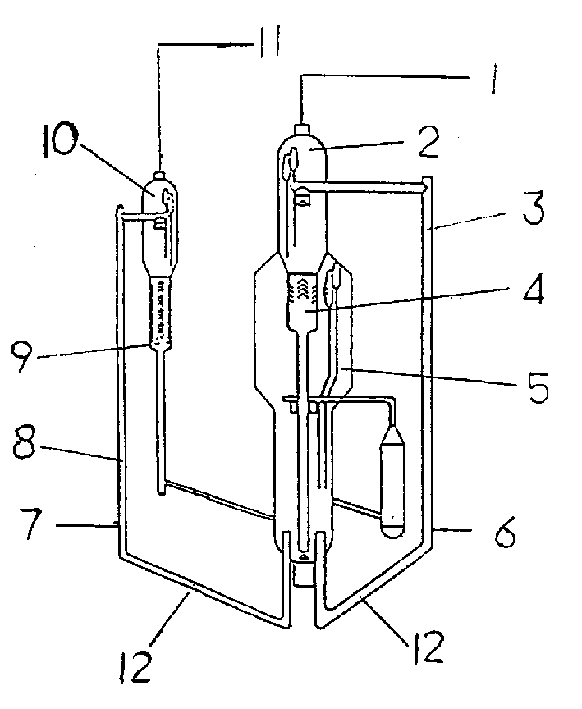

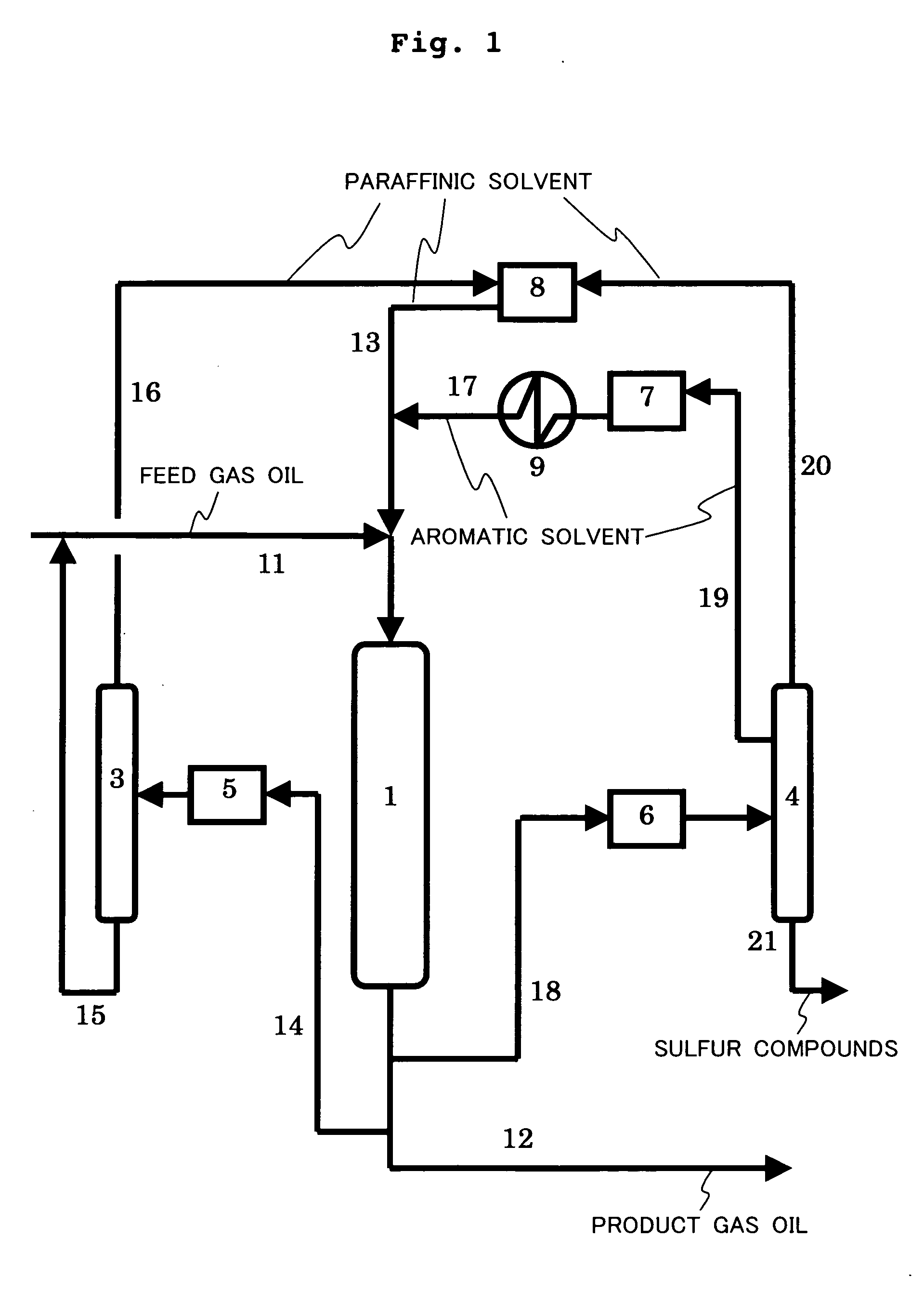

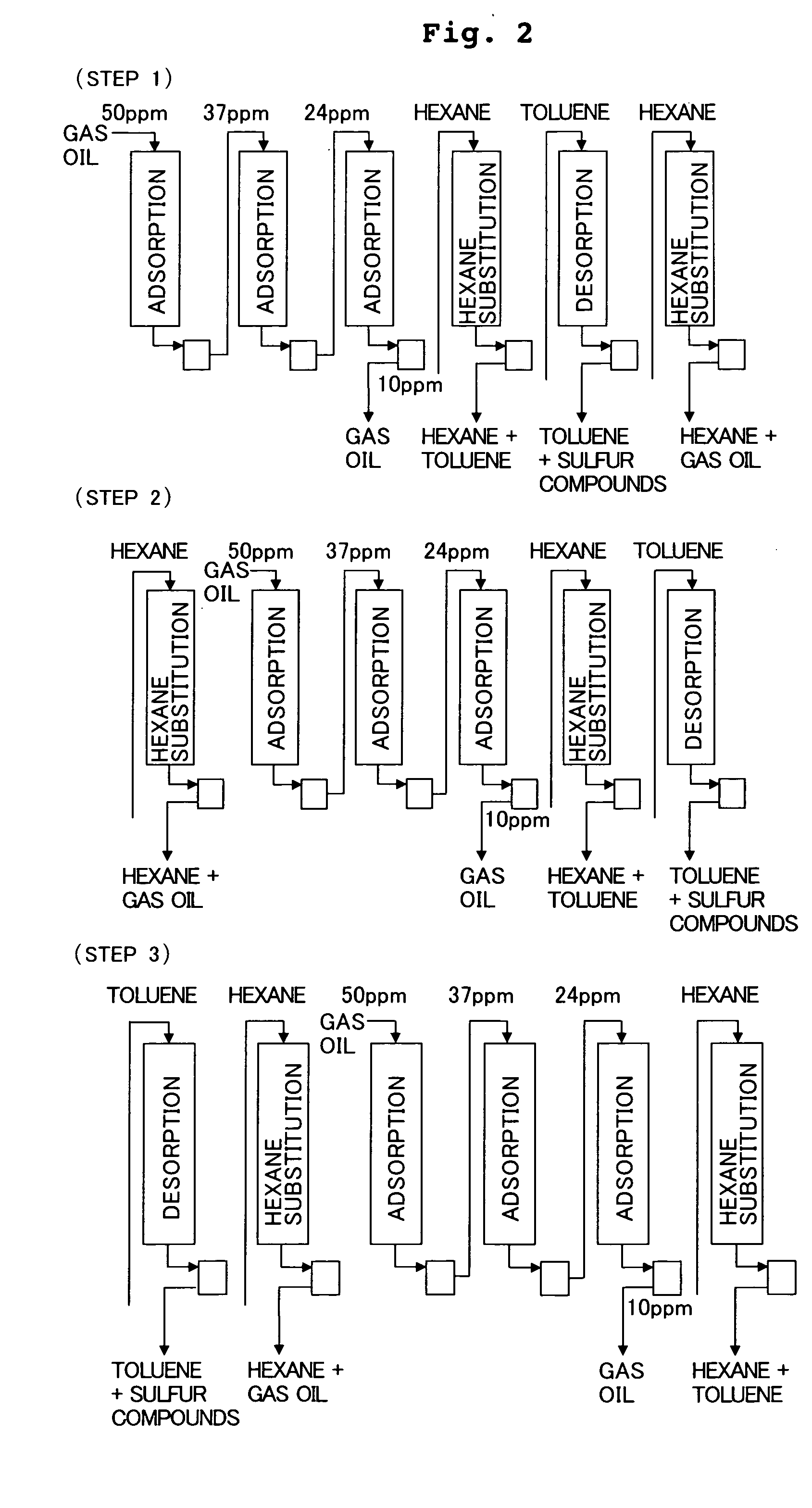

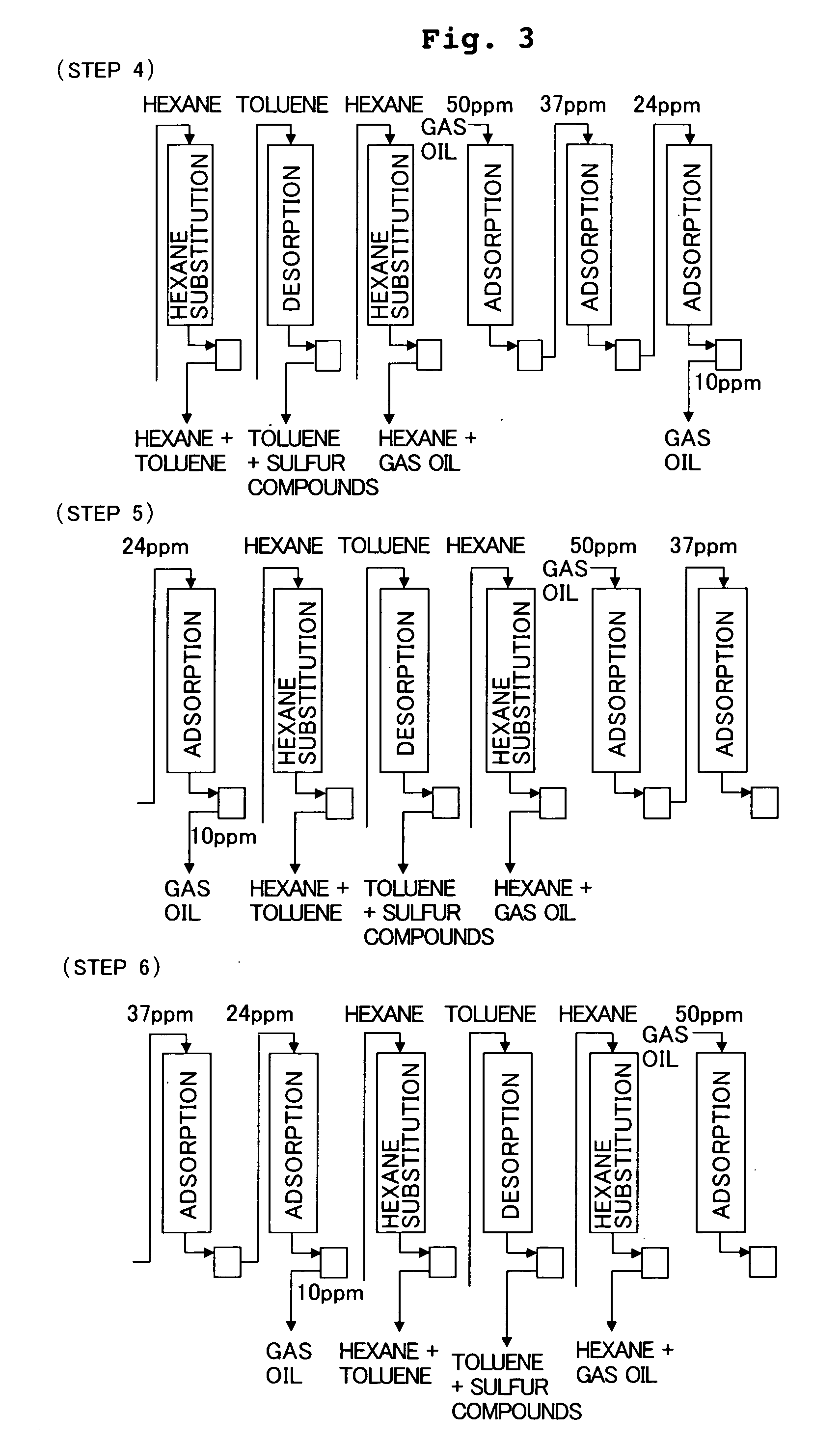

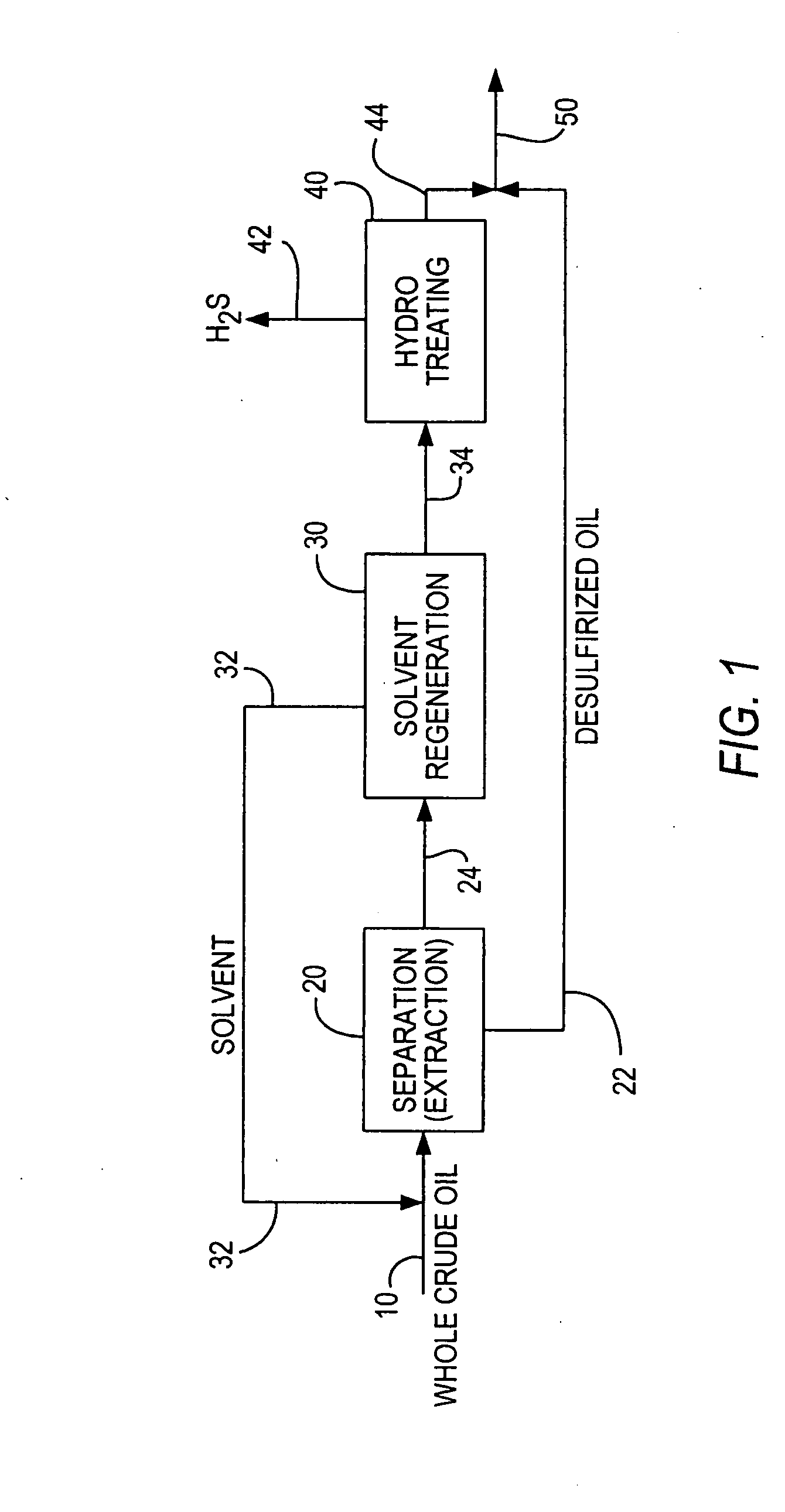

Adsorption desulfurization agent for desulfurizing petroleum fraction and desulfurization method using the same

InactiveUS20050173297A1Reduce equipment costsLow running costOther chemical processesLiquid organic insulatorsDesorptionTower

A desulfurization method for a gas oil which includes a step of removing sulfur compounds contained in a gas oil distillate product by the adsorption with an adsorptive desulfurization agent formed of a fibrous active carbon and provided in an adsorption tower (1), and a desorption regeneration step of washing the used adsorptive desulfurization agent with an aromatic solvent to regenerate the desulfurization agent. The method allows the production of gas oil being satisfactorily freed of sulfur content at relatively low equipment and operation costs over a long period of time, and in the method, difficult-to-remove sulfur compounds, such as 4,6-DMDBT, and polycyclic aromatic compounds having two or more rings are selectively removed.

Owner:JAPAN ENERGY CORP

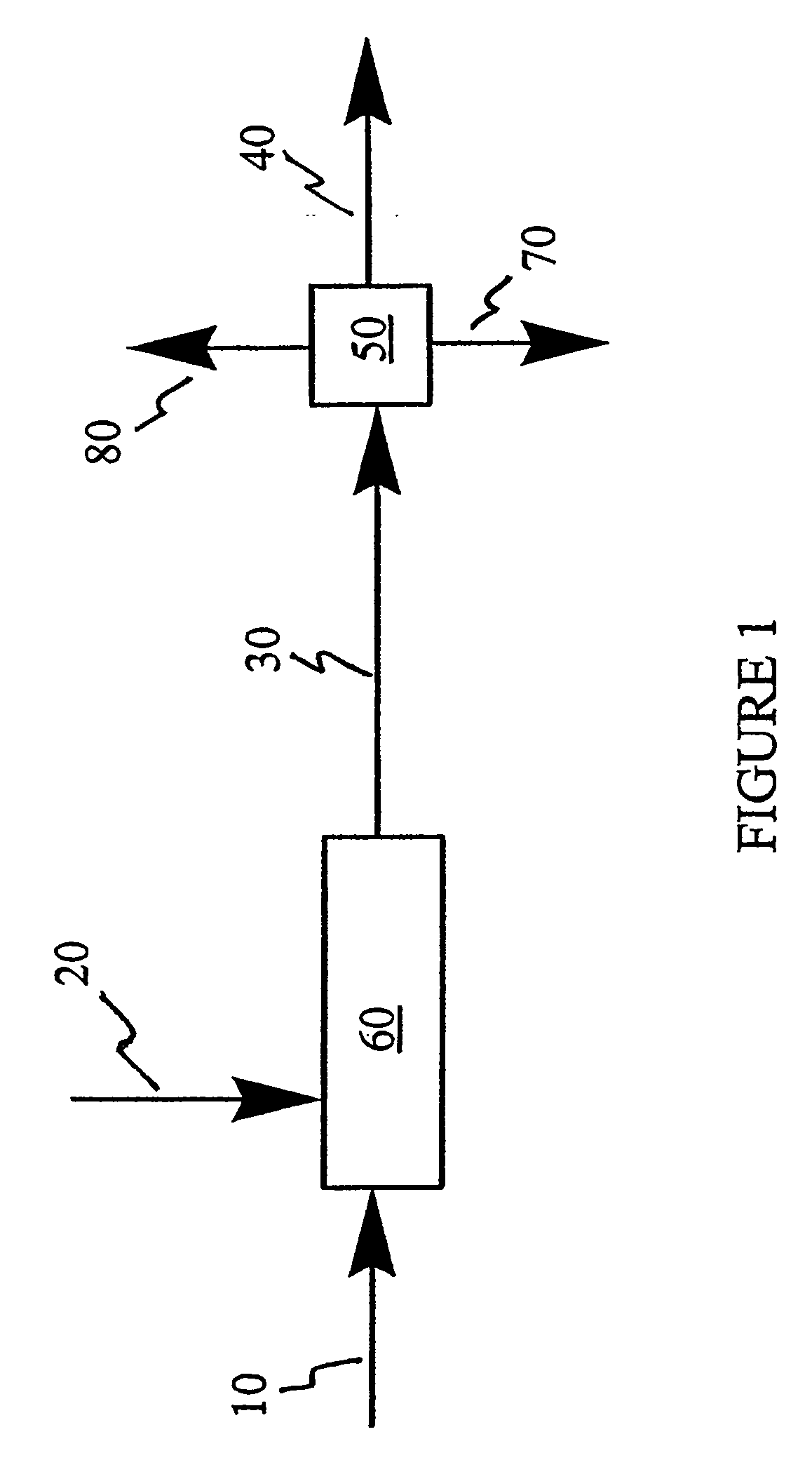

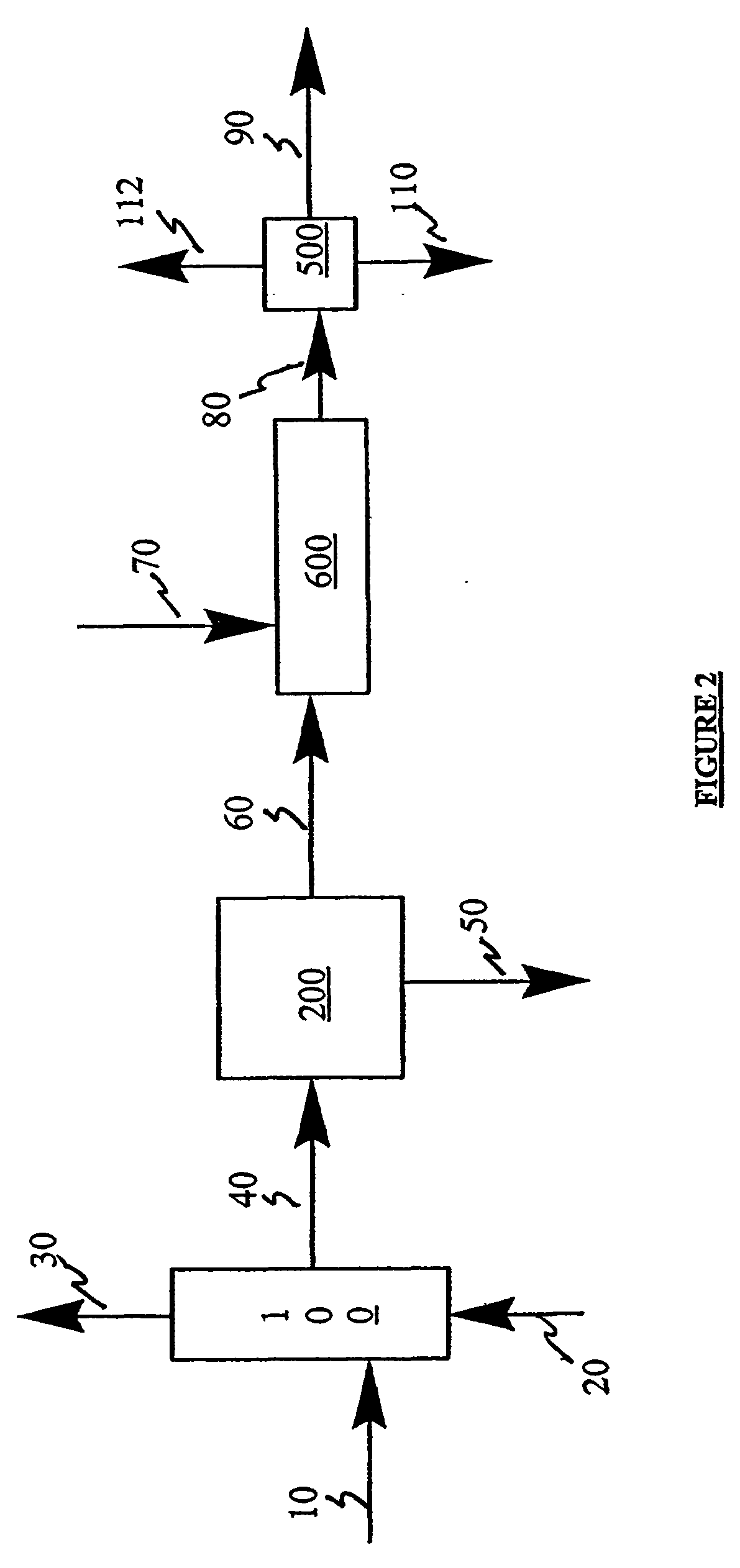

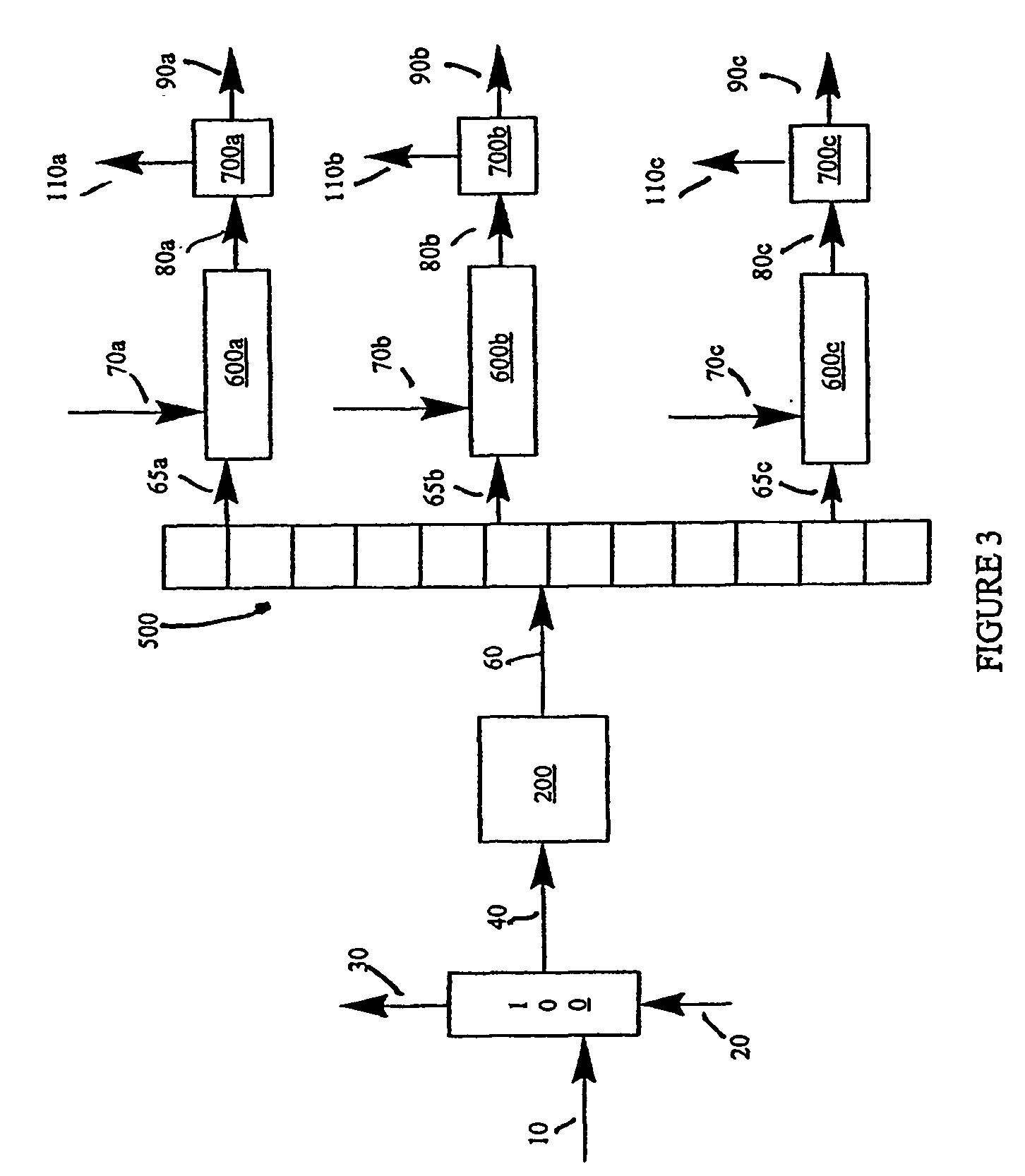

Oxidative desulfurization of sulfur-containing hydrocarbons

InactiveUS20050150819A1Reduce sulfur contentLow sulfurRefining with oxygen compoundsRefining with metal oxidesGas phaseOxygen

A method for desulfurizing a hydrocarbon stream (10) containing heterocyclic sulfur compounds, which process comprises contacting the heterocyclic sulfur compounds in the gas phase (60) in the presence of oxygen (70) with a supported metal oxide catalyst, or with a bulk metal oxide catalyst (600) to convert at least a portion of the heterocyclic sulfur compounds to oxygenated products as well as sulfur-deficient hydrocarbons and separately recovering the oxygenated products separately from a hydrocarbon stream with substantially reduced sulfur.

Owner:LEHIGH UNIVERSITY

Deep desulfurization method for liquefied petroleum gas

The liquefied petroleum gas deep desulfurizing process includes the following steps: mixing alcohol amine treated liquefied petroleum gas with desulfurizer aqua, feeding the mixture into a reactor with carbonyl sulfide hydrolyzing catalyst for hydrolyzing carbonyl sulfide into hydrogen sulfide and CO2 and eliminating hydrogen sulfide, regenerating the used desulfurizer, water washing the liquefied petroleum gas to eliminate residual desulfurizer with water containing dissolved oxygen or hydrogen peroxide in a water washing tower with hydrogen peroxide decomposing catalyst in the stuffing layer, eliminating mercaptan from the liquefied petroleum gas through oxidizing mercaptan into disulfide in a mercaptan eliminating reactor with catalyst, and final rectifying in a rectifying tower to eliminate disulfide. The process is simple and practical, and can lower the total sulfide content in liquefied petroleum gas to below 5 ppm.

Owner:北京石大世通科技发展有限公司

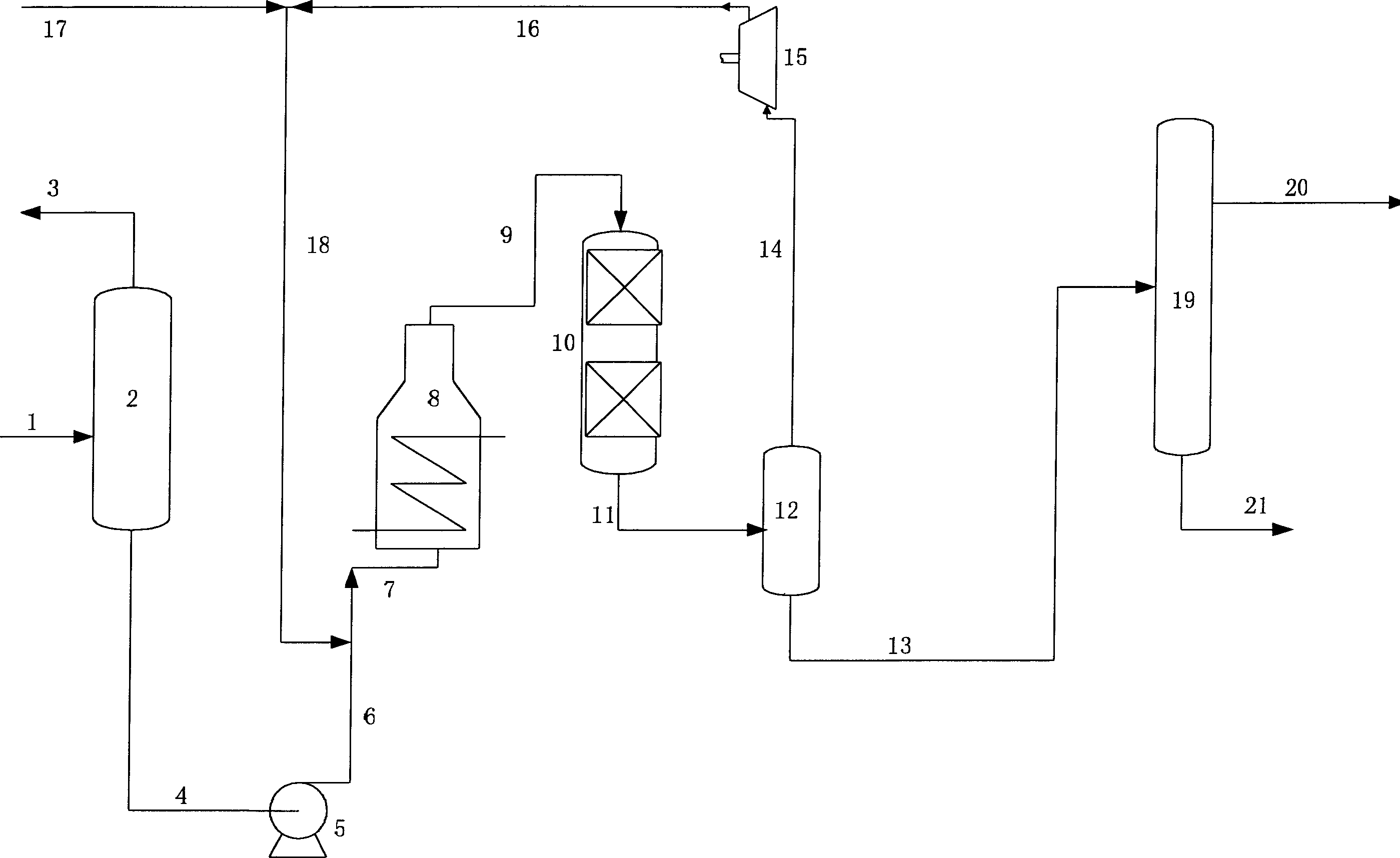

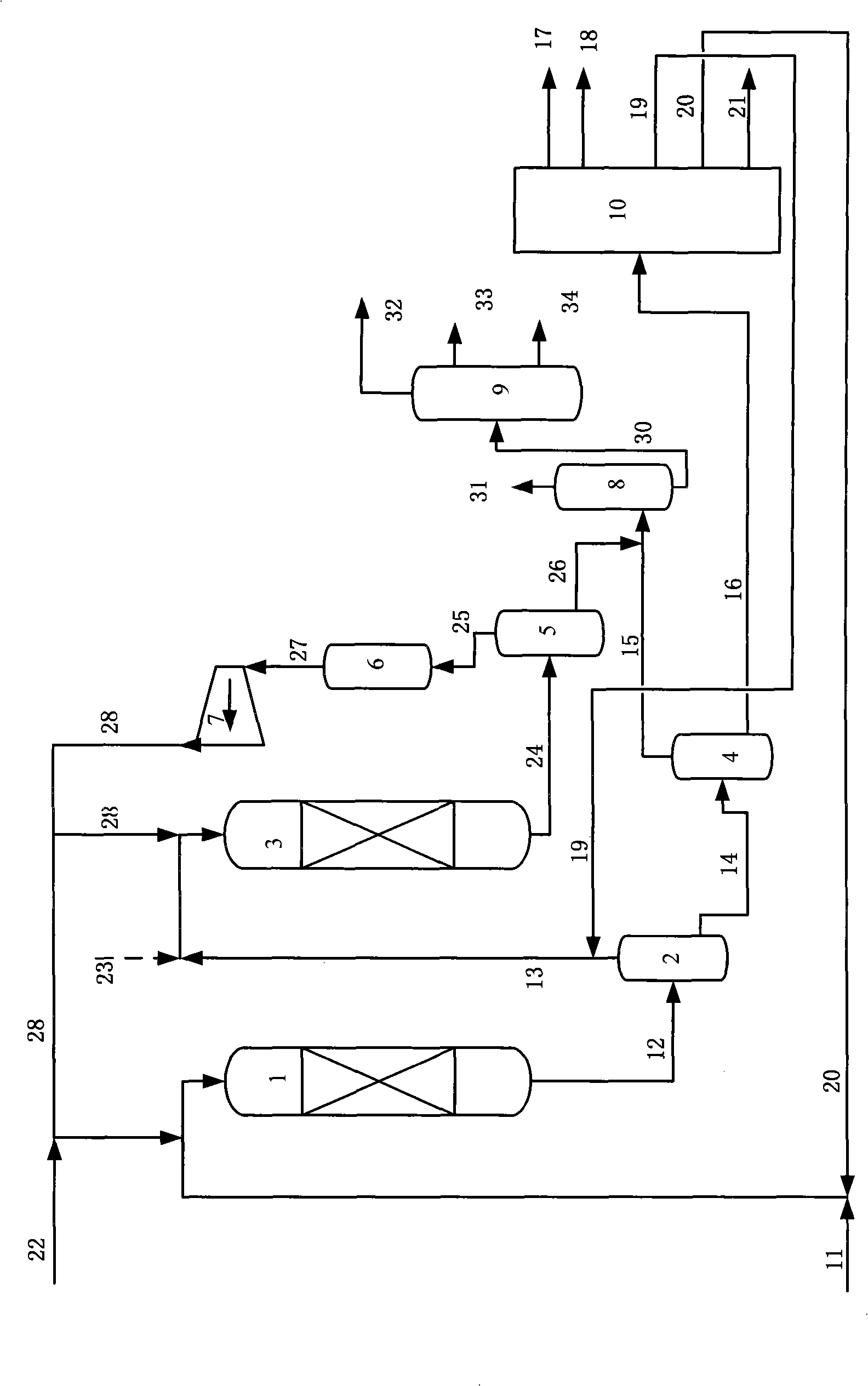

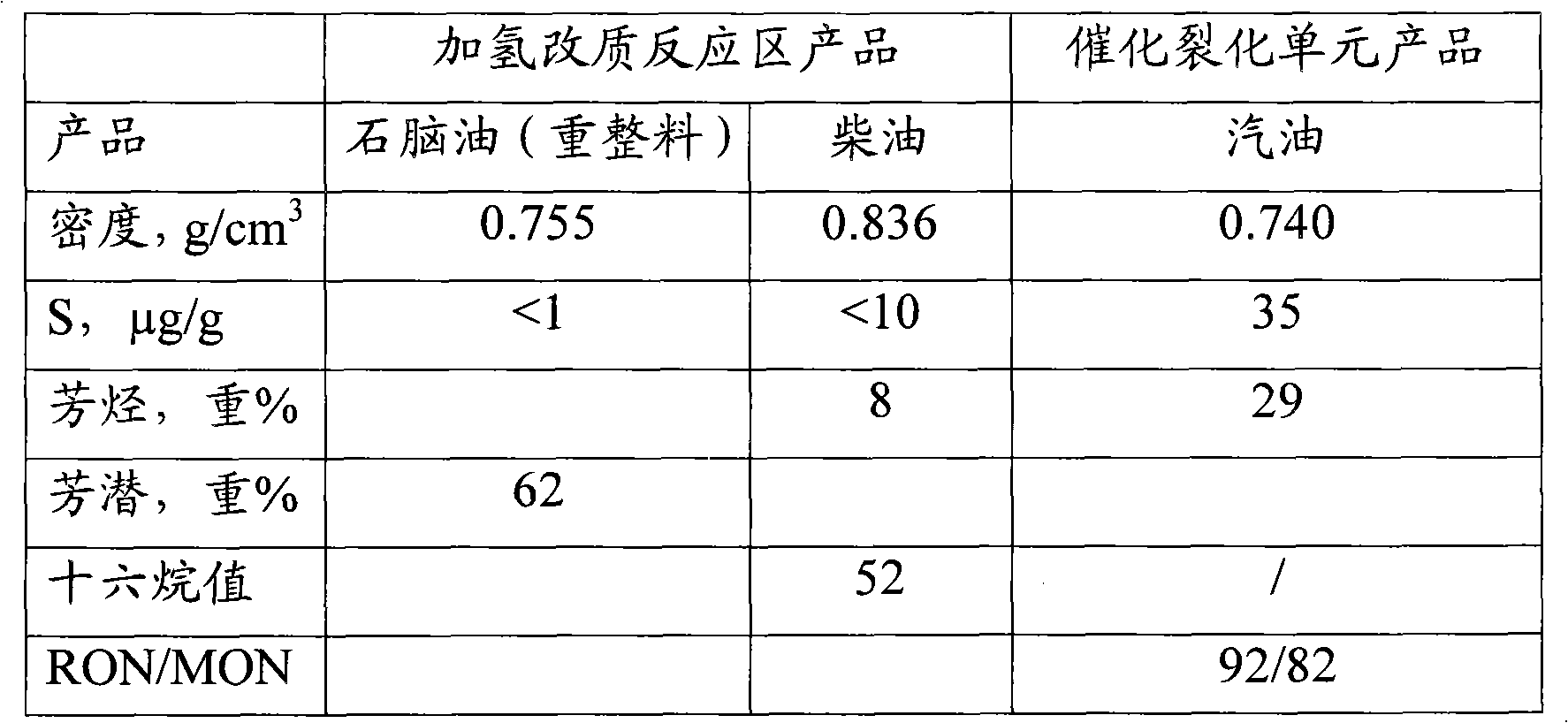

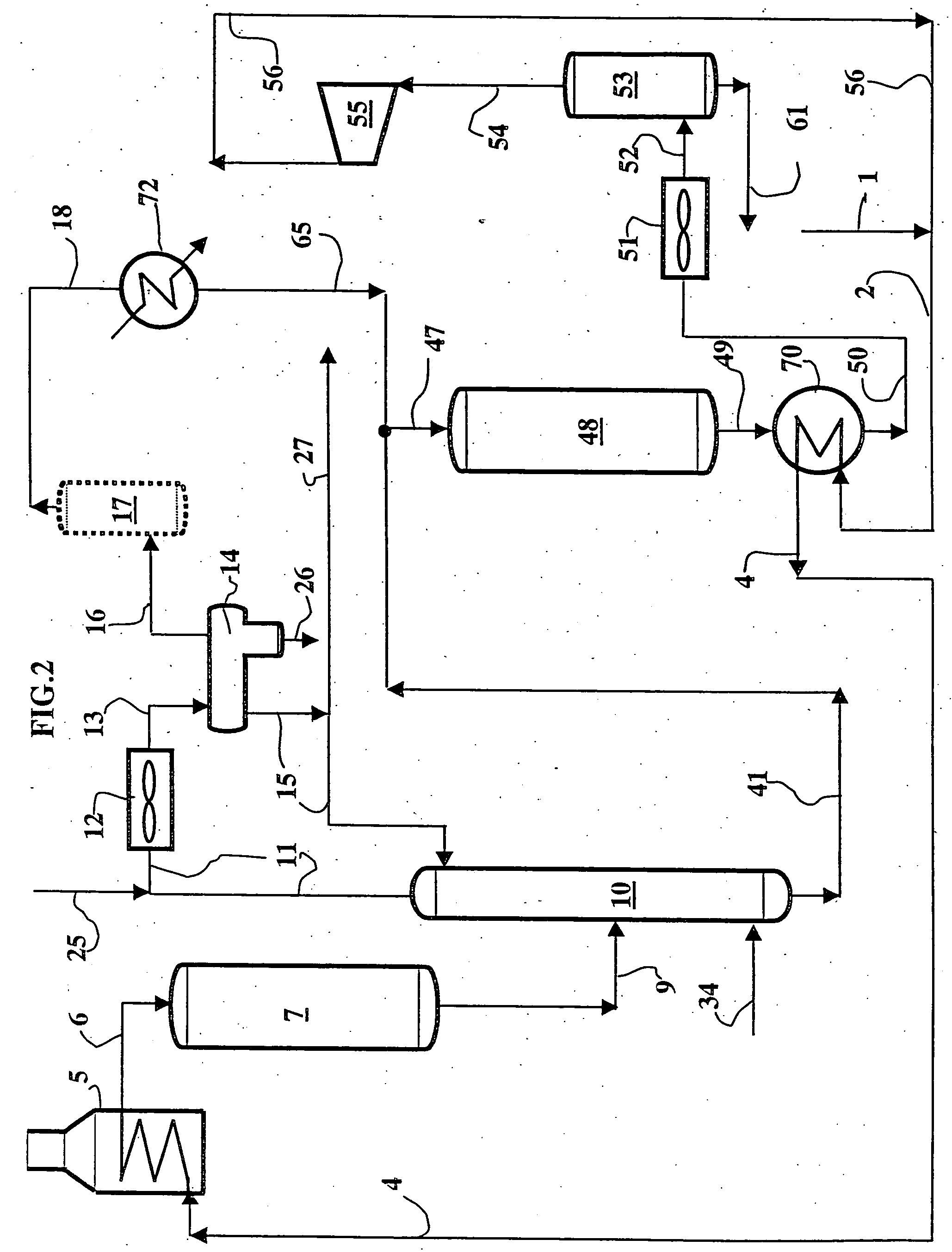

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

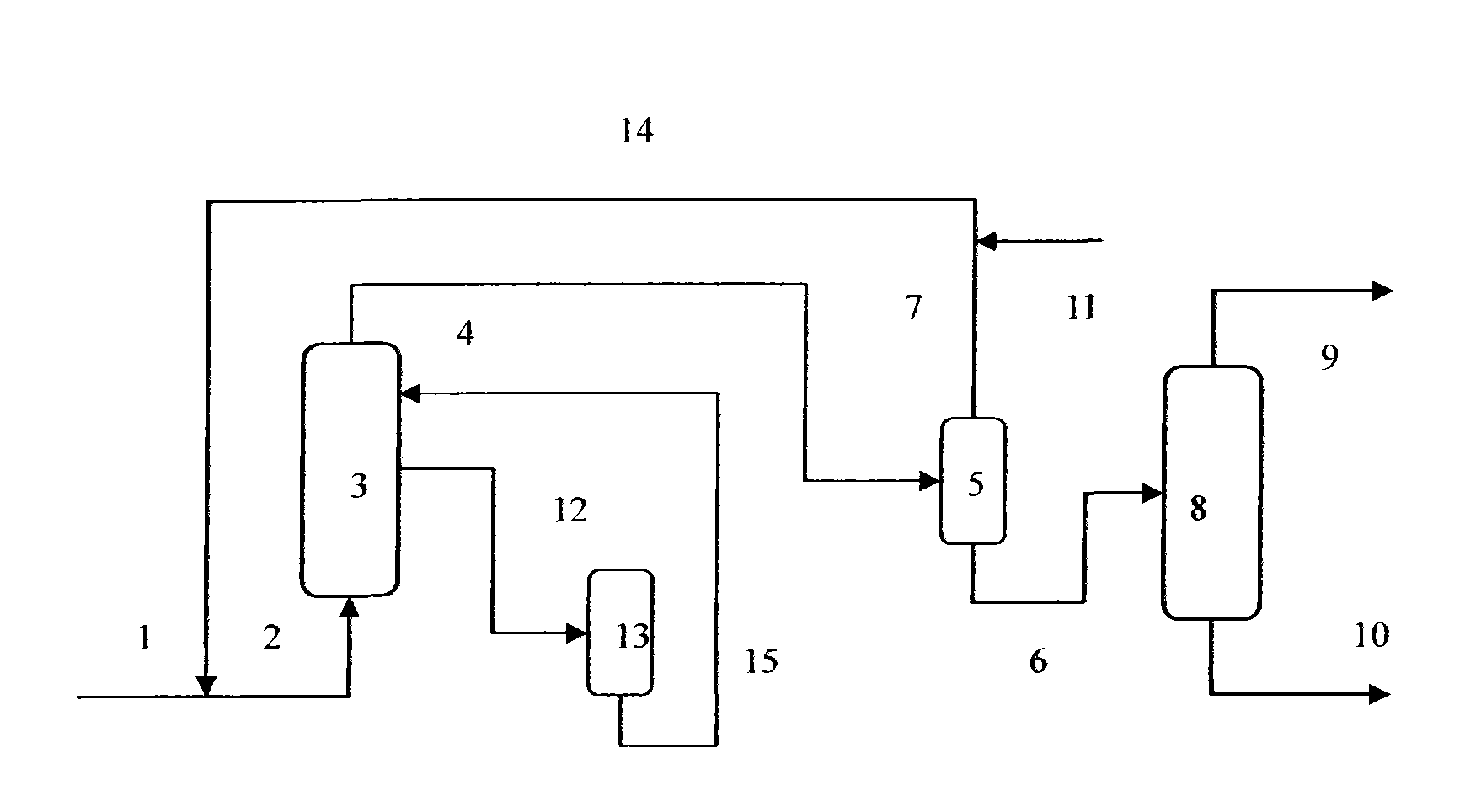

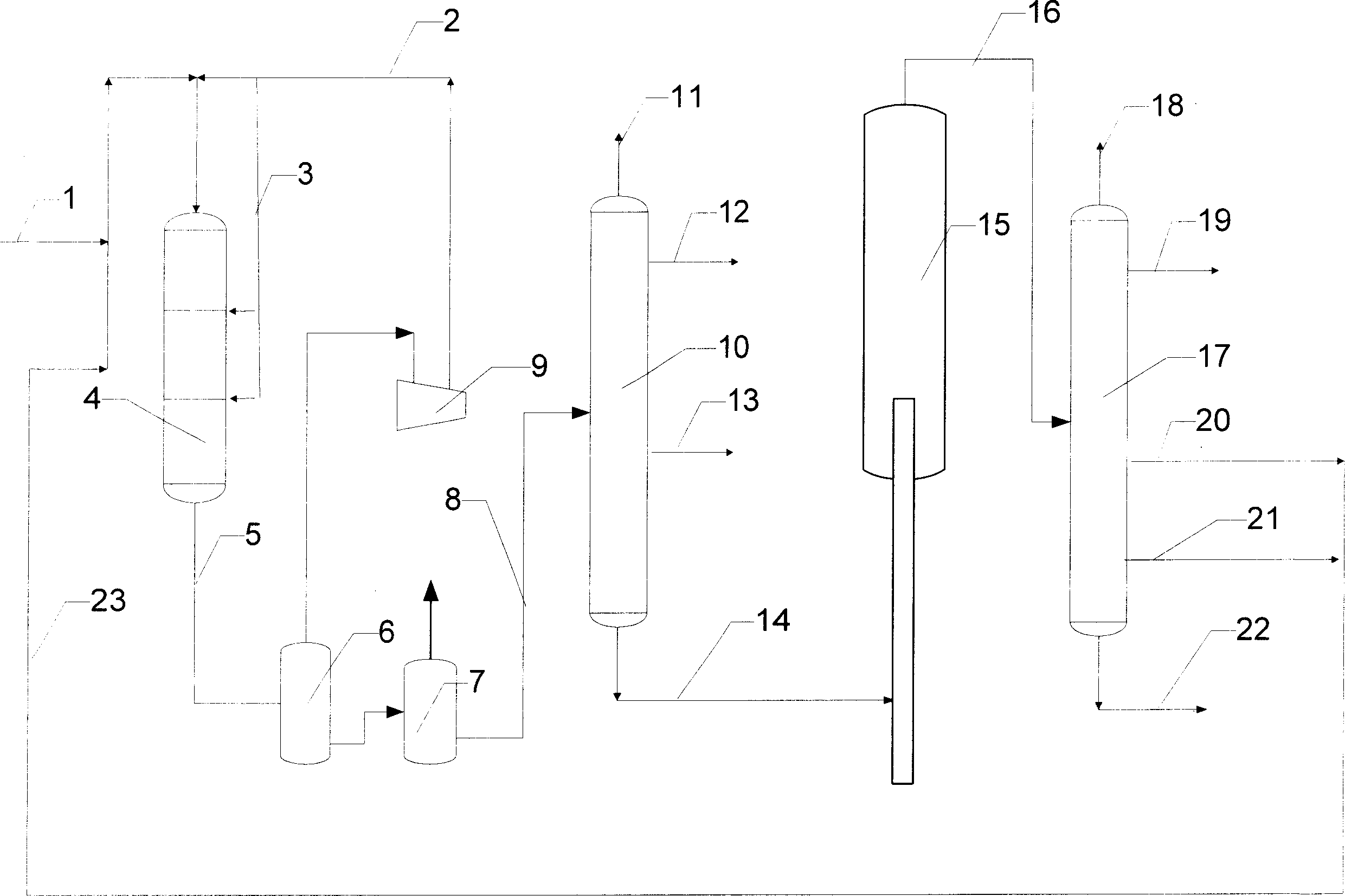

Two-step method for hydrotreating of a hydrocarbon feedstock comprising intermediate fractionation by rectification stripping

InactiveUS20060118466A1Reduce sulfur contentReduce nitrogen contentHydrocarbon distillation control/regulationTreatment with hydrotreatment processesPtru catalystPhysical chemistry

A process for hydrotreatment of a hydrocarbon feed comprises at least two reaction steps with intermediate fractionation of the effluent from the first step to eliminate unwanted impurities for the catalyst of the second step and to produce a desulphurized light liquid fraction. The intermediate fractionation comprises stripping the liquid effluent from the first step using low pressure hydrogen with rectification of the stripping vapours using a substantially desulphurized liquid reflux. The conditions for said fractionation and for the first hydrotreatment step can produce a substantially desulphurized light liquid fraction which is not supplied to the second step.

Owner:INST FR DU PETROLE

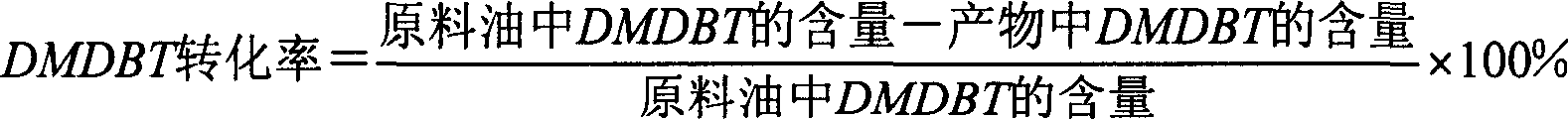

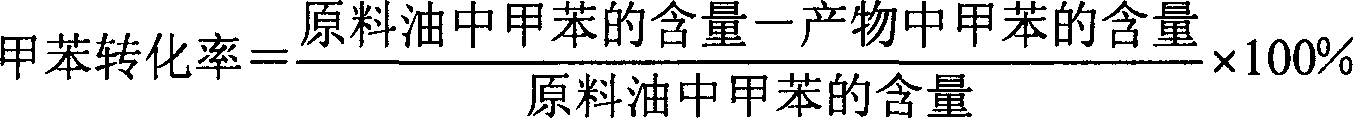

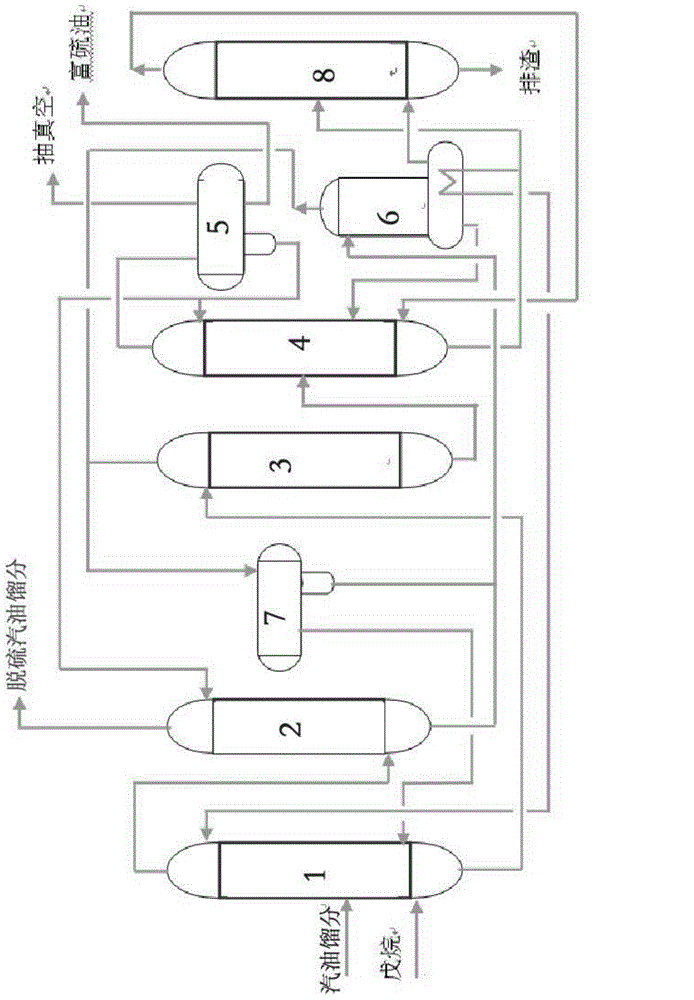

Method for deep desulfurization olefin hydrocarbon reduction of inferior gasoline

ActiveCN101492608AStructuring reaction does not affectReduce olefin contentRefining to eliminate hetero atomsCatalytic pyrolysisHydrogen

The invention discloses a gasoline deep desulphurization and olefin reduction method, comprising that the gasoline raw material and hydrogen are contacted with hydrogenation absorption desulphurization and olefin aromatization difunctional catalyst to remove sulfur in the gasoline and reduce the olefin content in the gasoline product. The method of the invention can produce gasoline product with the sulfur content lower than 50 micrograms per gram, and can further produce gasoline product with the sulfur content lower than 10 micrograms per gram while the olefin content is lower than 20v%, and meanwhile the antiknock quality index loss is low. The method of the invention can be applied to deep desulphurization and olefin reduction process of FCC gasoline, catalytic pyrolysis gasoline, coker gasoline, pyrolysis gasoline and pressure gasoline or the mixed gasoline raw material thereof.

Owner:CHINA PETROLEUM & CHEM CORP +1

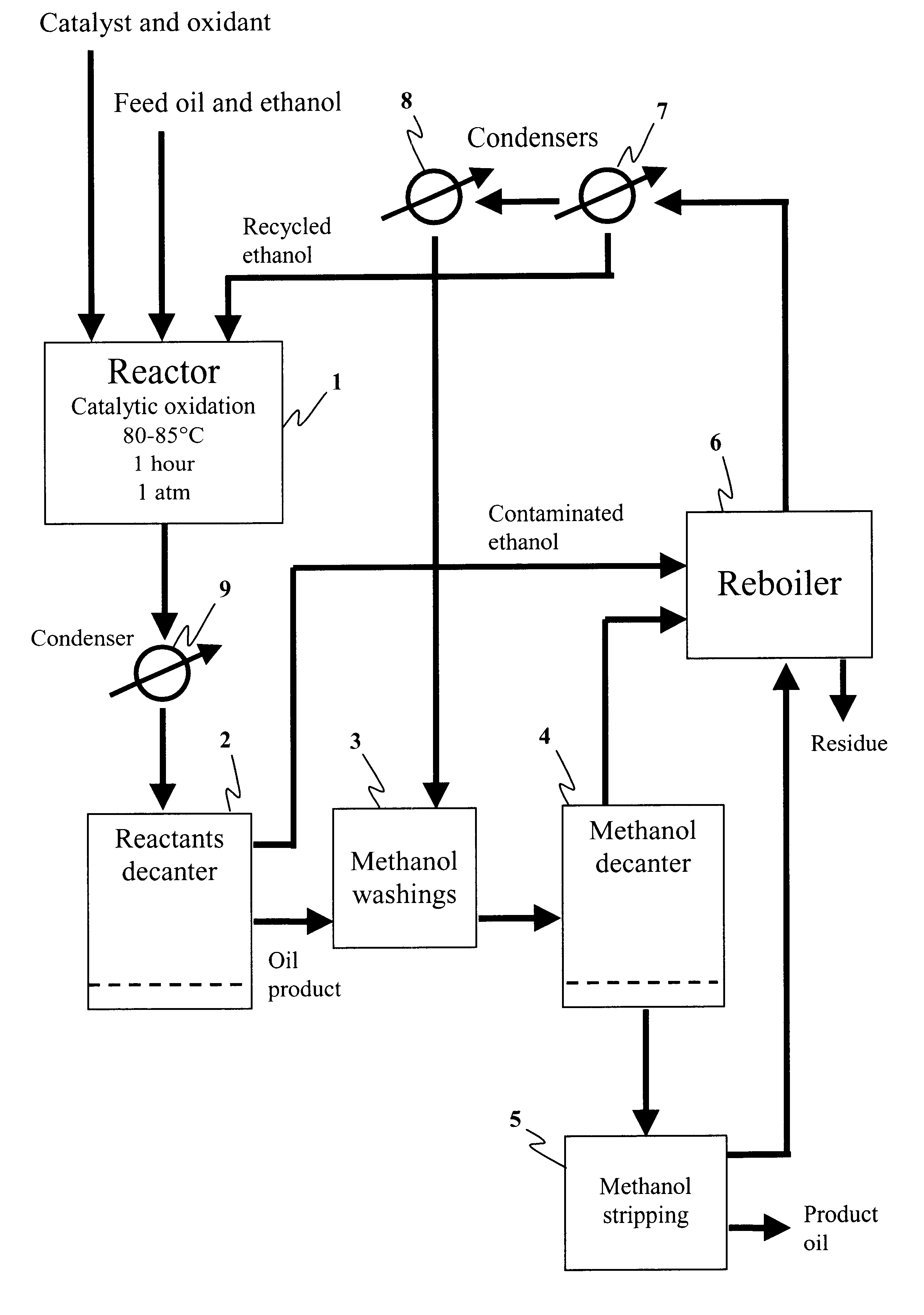

Method for the production of hydrocarbon fuels with ultra-low sulfur content

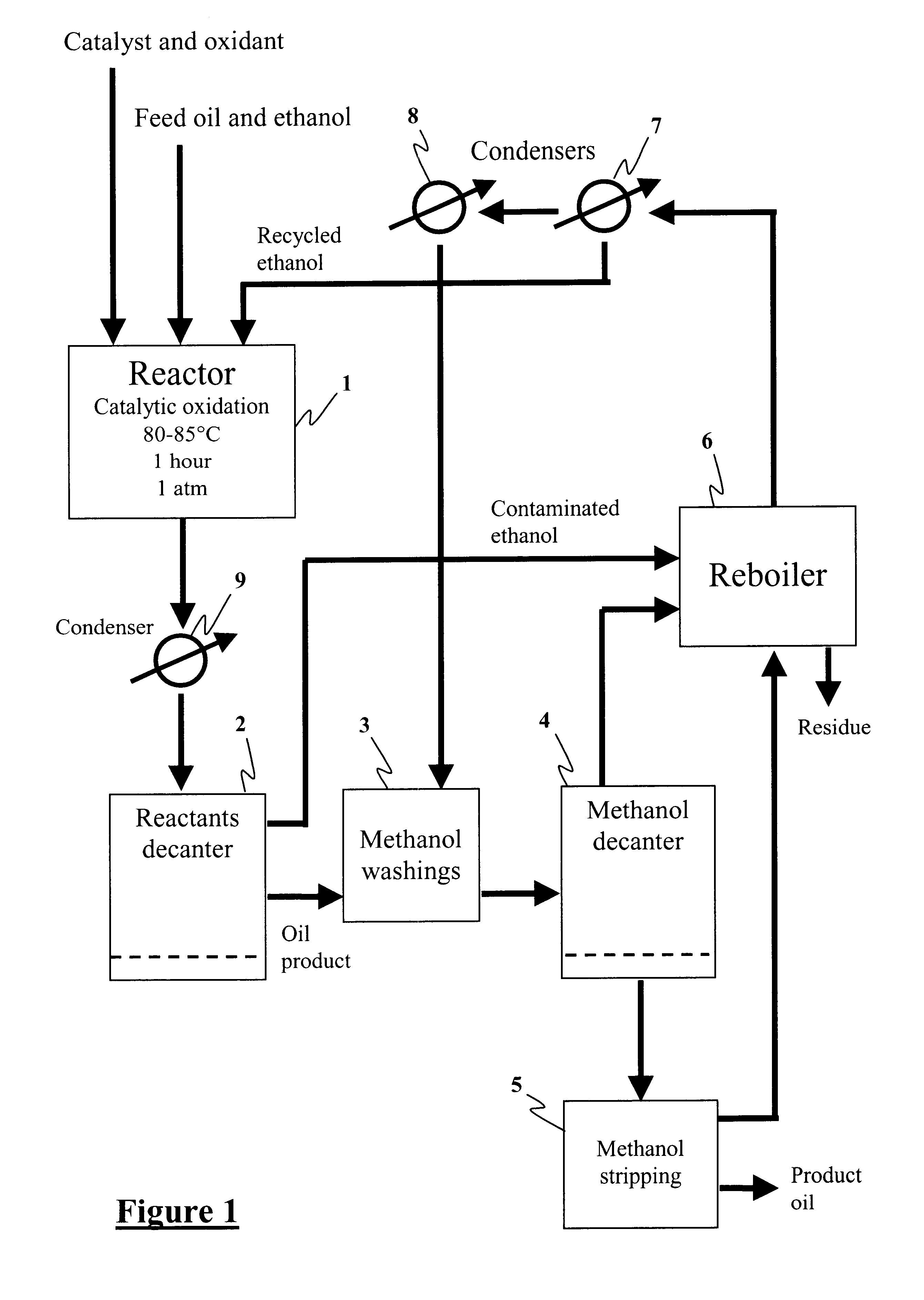

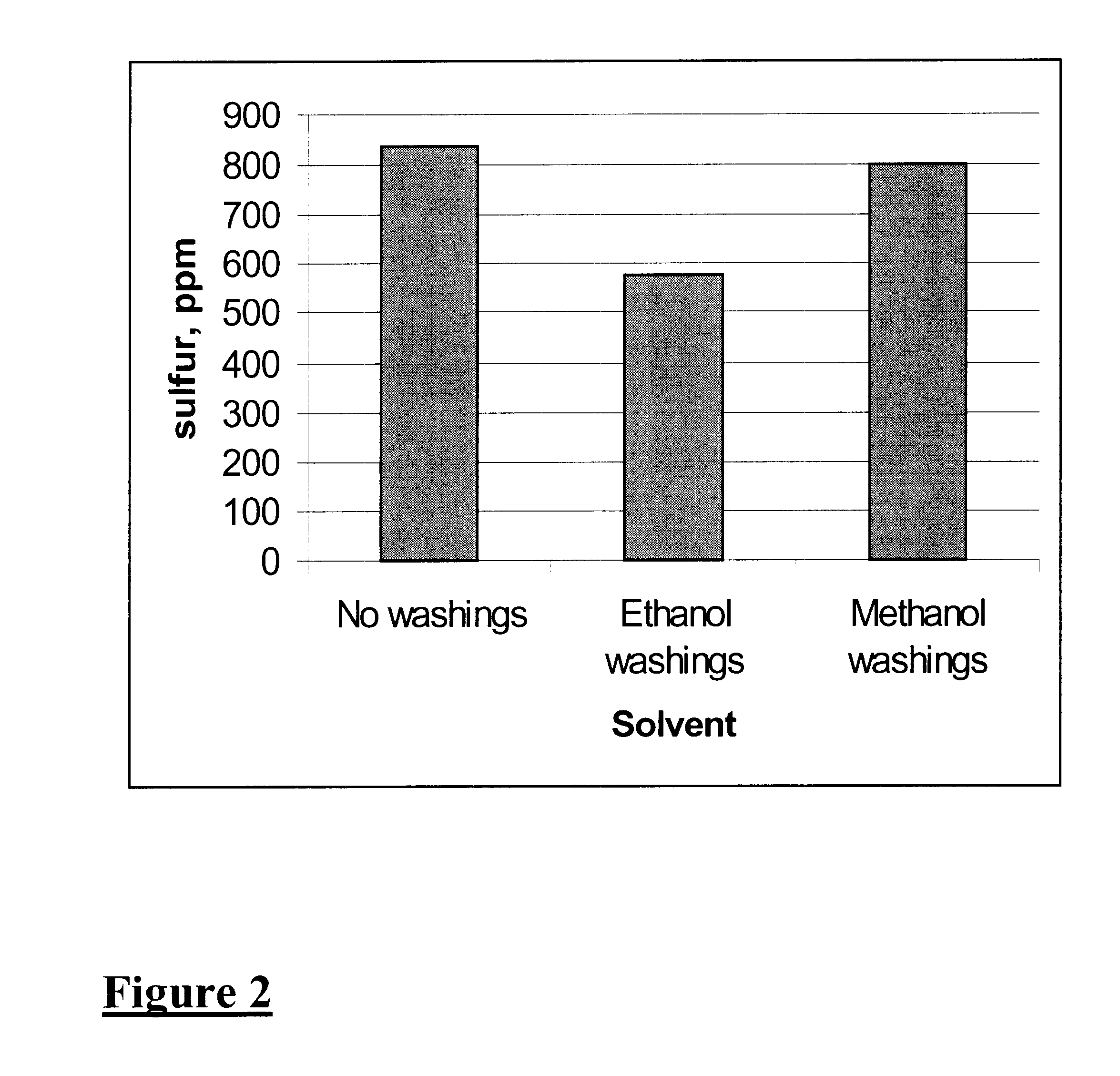

InactiveUS6673236B2Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

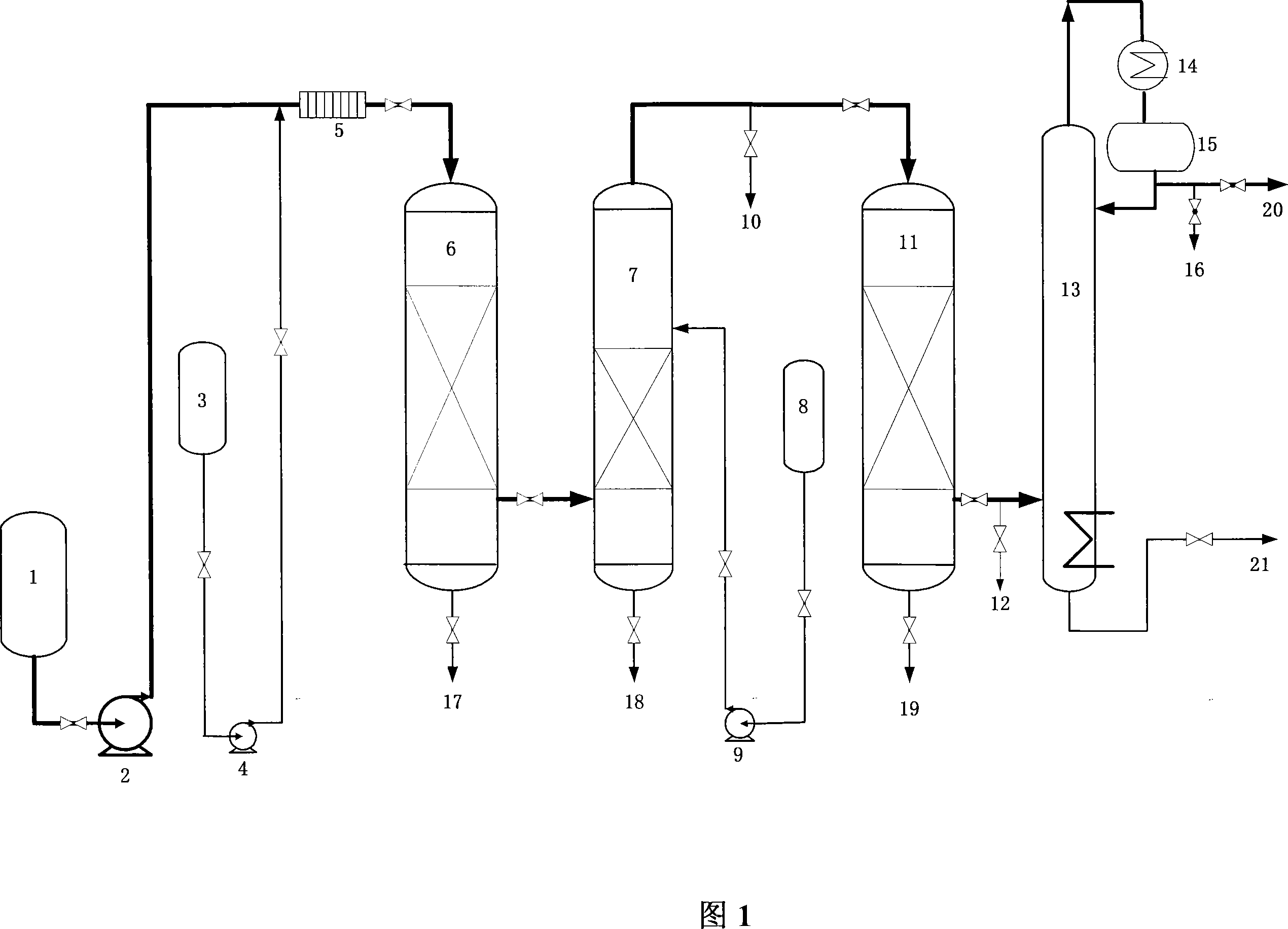

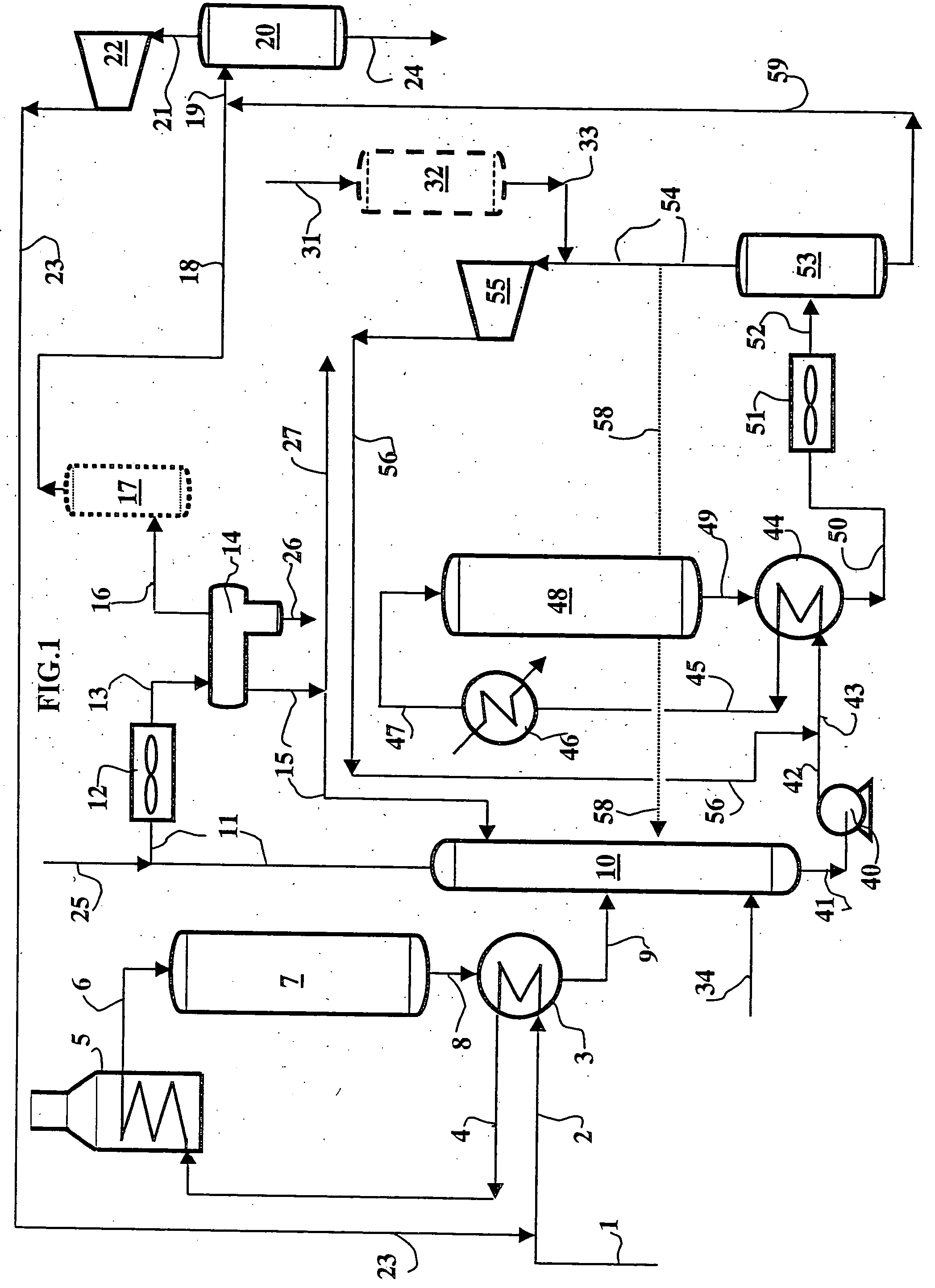

Two-way combined process of wax-oil hydrogenation treatment and catalytic cracking

A two-way combined process of wax oil hydro-process and catalytic crack is carried out by entering wax oil, catalytic cracking re-circulating oil and catalytic cracking diesel oil into hydro-processor, hydrogenation reacting under existence of hydrogen and hydrogenation catalyst, separating for reactant to obtain gas, hydrogenation naphtha oil, hydrogenation diesel oil and hydrogenation tail oil, entering hydrogenation tail oil into catalytic cracker, crack reacting under existence of catalytic cracking agent, separating to obtain dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil and catalytic cracking re-circulating oil and oil slurry, and circulating for catalytic cracking diesel oil and catalytic cracking re-circulating oil to hydro-processor. It has higher recovery rate and cetyl value, less sulfur content, arene content and coke output.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst of catalyzing, cracking for reducing sulfur content in gasoline and preparation process thereof

InactiveCN1597850AGood dispersionGood hydrothermal stabilityCatalytic crackingMolecular sieveIn situ crystallization

The invention is a catalytic cracking catalyst to reduce sulfur content of gasoline and its preparing method, synthesis gama-type molecular sieve by kaoline in-situ crystallization and making exchange sodium reduction or / and rare-earth ion exchange processing to prepare it, and its characteristic: the weight percent of sodium oxide contained in it is less than 0.75%, the ratio of zeolite to silica-alumina is above 4.5, and it adds one or several of the sourish metal elements: Cu, Zn, Fe, Al, Ni, Zr, Sn, Ga, Ti and V in weight percent of 0.1-10%. It has good zeolite dispersivity and excellent hydrothermal stability, good catalytic cracking property, and excellent function of reducing sulfur content of gasoline. It can be used by mixing with routine FCC catalyst and also be singly applied in the catalytic cracking process course.

Owner:PETROCHINA CO LTD

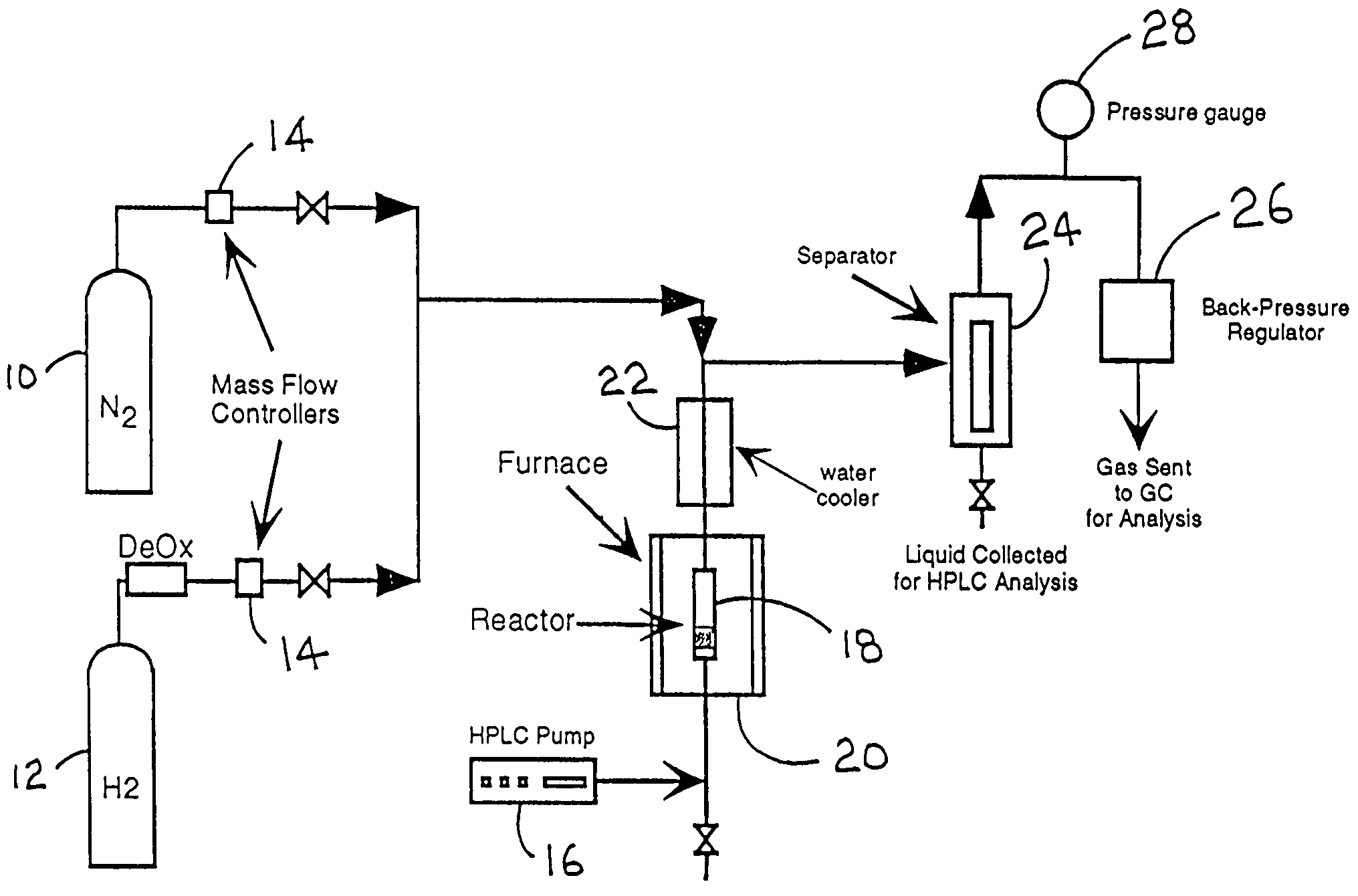

Low-temperature hydrogen production from oxygenated hydrocarbons

InactiveUS20050207971A1Reduce riskHigh energy costHydrogen productionHydrogen/synthetic gas productionAlkaneSteam reforming

Disclosed is a method of producing hydrogen from oxygenated hydrocarbon reactants, such as methanol, glycerol, sugars (e.g. glucose and xylose), or sugar alcohols (e.g. sorbitol). The method takes place in the condensed liquid phase. The method includes the steps of reacting water and a water-soluble oxygenated hydrocarbon in the presence of a metal-containing catalyst. The catalyst contains a metal selected from the group consisting of Group VIIIB transitional metals, alloys thereof, and mixtures thereof. The disclosed method can be run at lower temperatures than those used in the conventional steam reforming of alkanes.

Owner:WISCONSIN ALUMNI RES FOUND

Oxidative Desulfurization Process

InactiveUS20080308463A1Reduce sulfur contentRefining with metalsMolecular sieve catalystsSulfurNitrogen

Disclosed is a process which reduces the sulfur and / or nitrogen content of a distillate feedstock to produce a refinery transportation fuel or blending components for refinery transportation fuel, by contacting the feedstock with an oxygen-containing gas in an 5 oxidation / adsorption zone at oxidation conditions in the presence of an oxidation catalyst comprising a titanium-containing composition whereby the sulfur species are converted to sulfones and / or sulfoxides which are adsorbed onto the titanium-containing composition.

Owner:BP CORP NORTH AMERICA INC

Hydrotreatment catalyst and its preparing method

ActiveCN1803283AImprove performanceReduce sulfur contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHydrogenDistillation

The invention discloses a making method of hydrogen-adding disposal catalyst, which comprises the following steps: 1) preparing slurry with hydrated aluminum oxide; 2) mixing the carbonate solution and VIII valence metal salt solution and 1) slurry; stewing at 20-150 deg C for 0.5-10 h; 3) mixing the VIB valence metal salt solution and 2) slurry; stewing at 40-150 deg C for 1-6 h; 4) modeling the 3) product; drying at 100-200 deg C for 1-6 h; sintering at 350-600 deg C for 1-6 h. The catalyst possesses higher hydrogenation active property, which can be applied in hydrogenation refining or hydrogenation disposal reaction for kinds of distillation oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

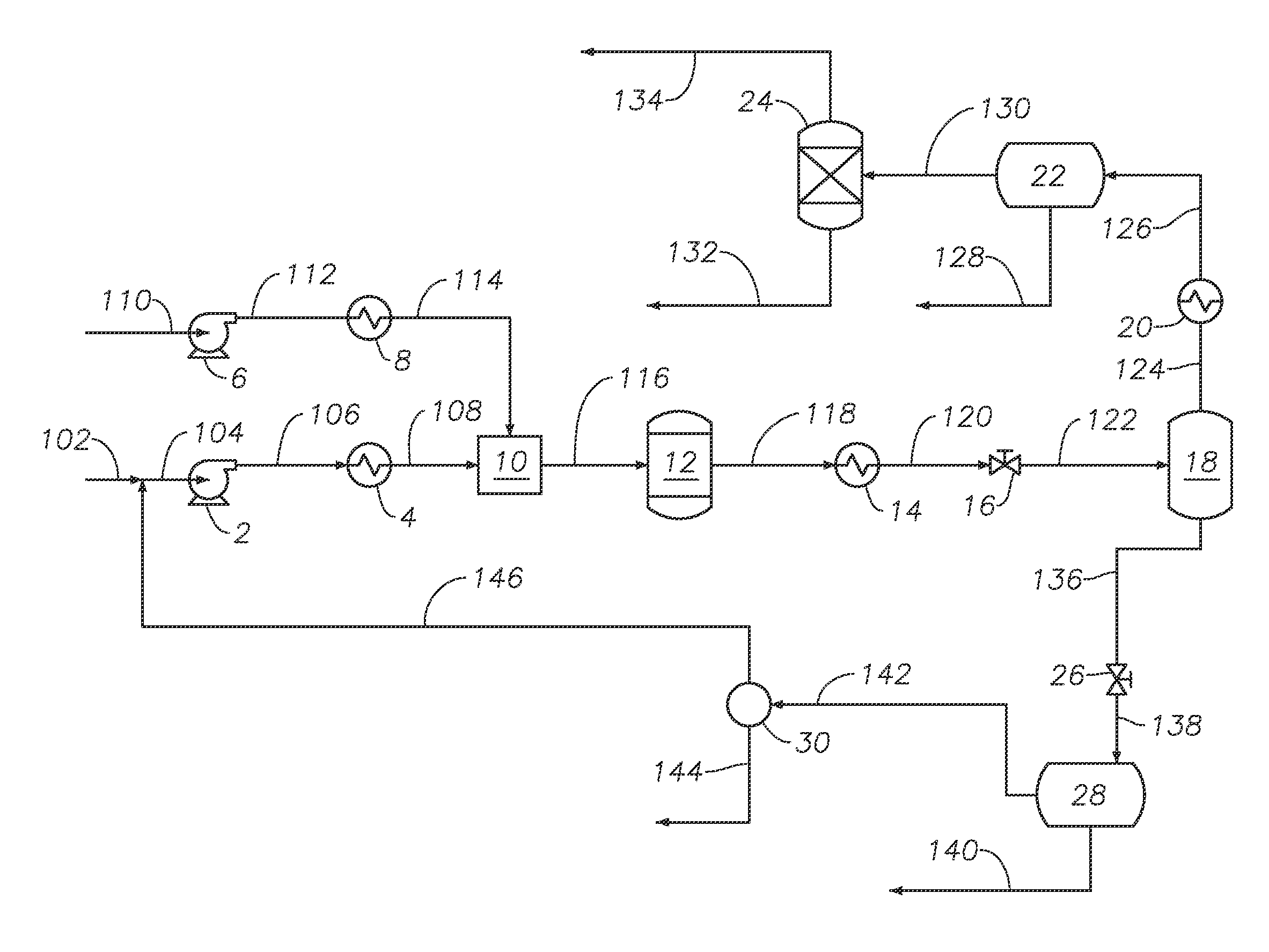

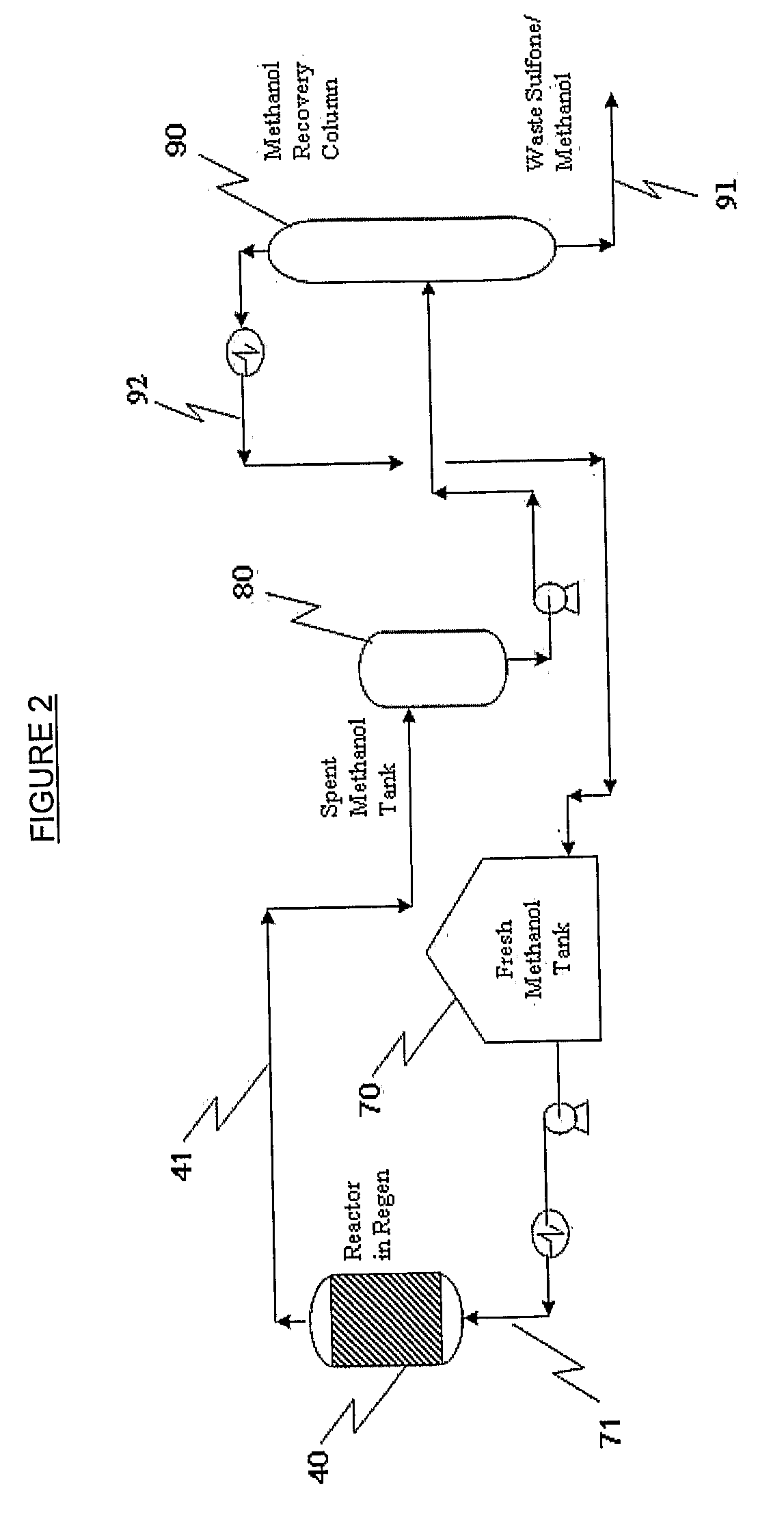

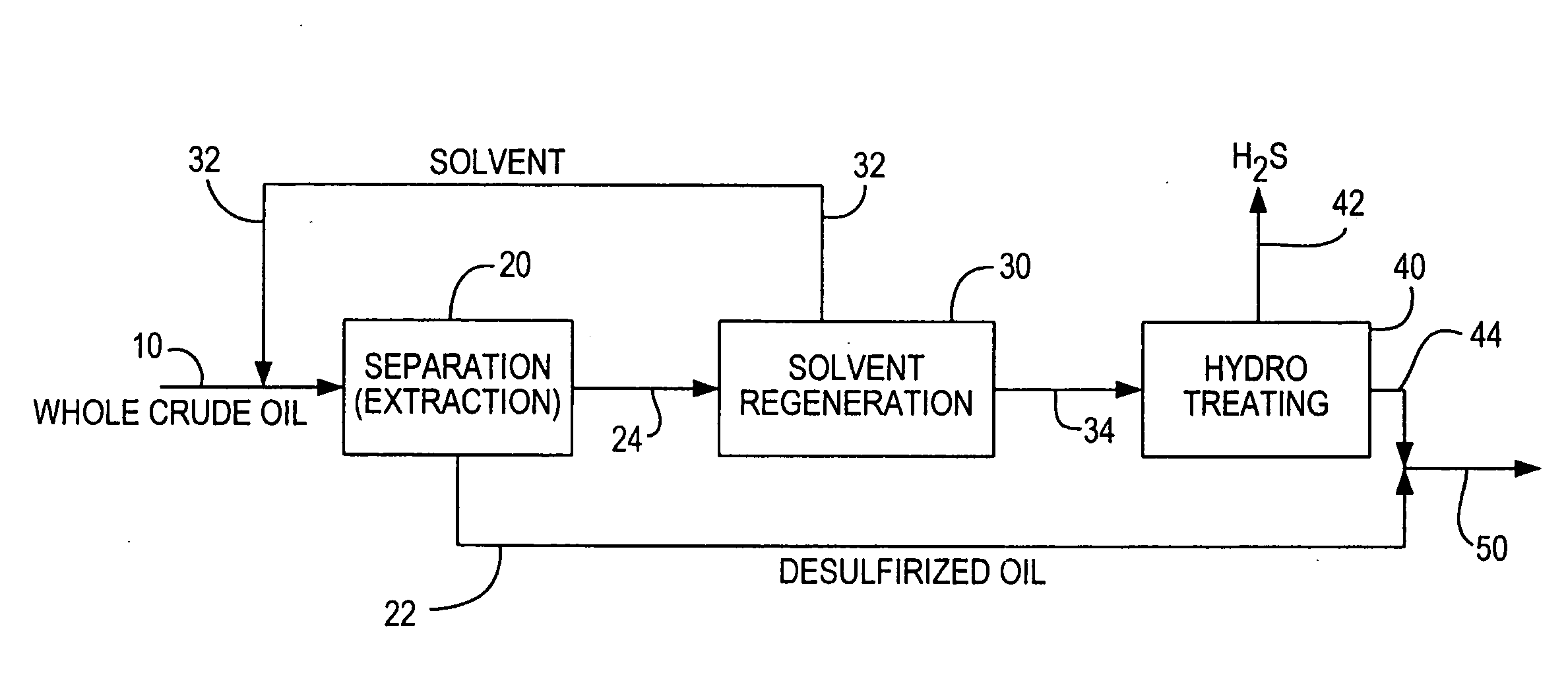

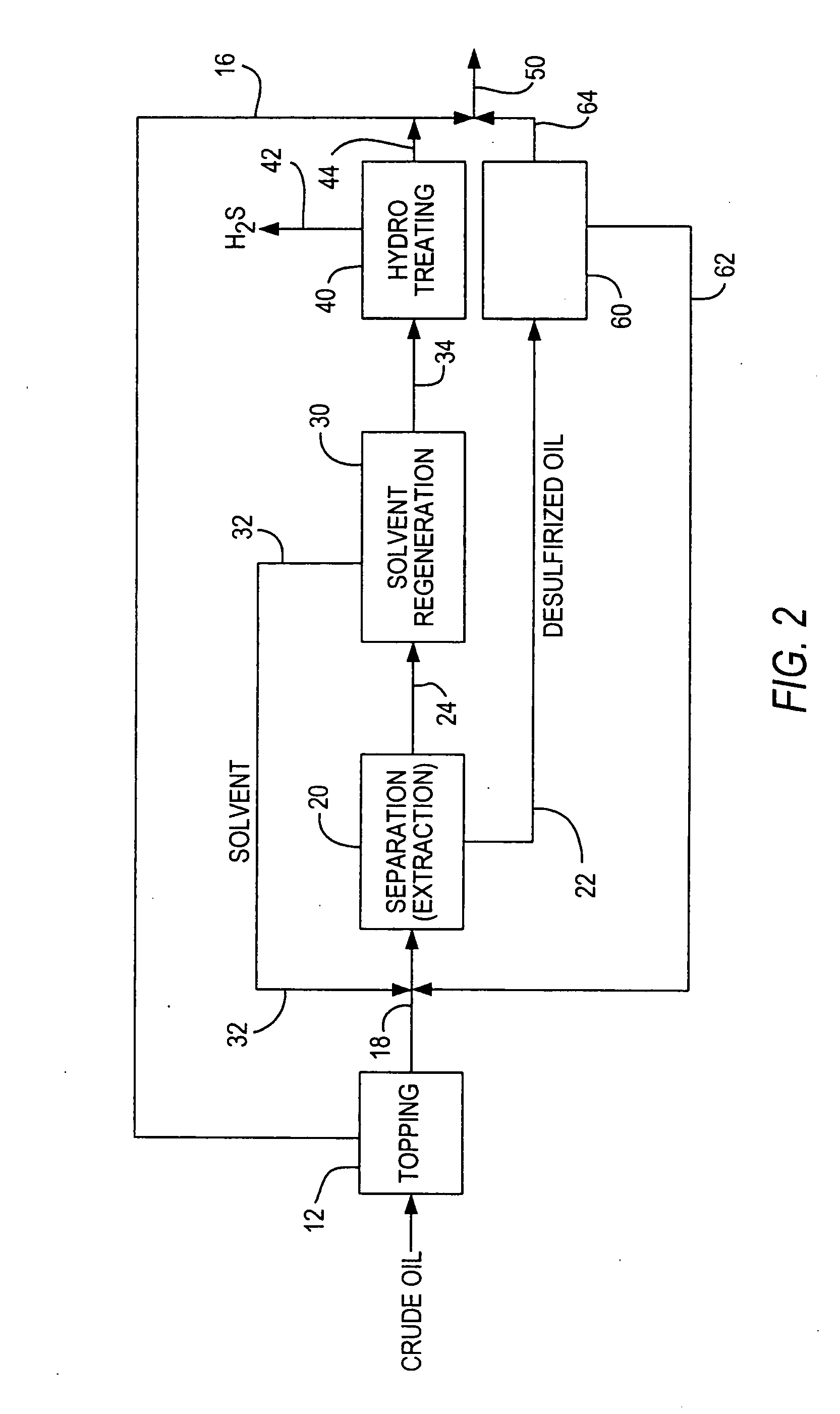

Desulfurization of whole crude oil by solvent extraction and hydrotreating

ActiveUS20090107890A1Eliminate and linimize needReduce and break emulsionTreatment with hydrotreatment processesHydrocarbon oils refiningSolventSulfur containing

A high sulfur content crude oil feedstream is treated by mixing one or more selected solvents with a sulfur-containing crude oil feedstream for a predetermined period of time, allowing the mixture to separate and form a sulfur-rich solvent-containing liquid phase and a crude oil phase of substantially lowered sulfur content, withdrawing the sulfur-rich stream and regenerating the solvent, hydrotreating the remaining sulfur-rich stream to remove or substantially reduce the sulfur-containing compounds to provide a hydrotreated low sulfur content stream, and mixing the hydrotreated stream with the separated crude oil phase to thereby provide a treated crude oil product stream of substantially reduced sulfur content and without significant volume loss.

Owner:SAUDI ARABIAN OIL CO

Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

ActiveCN1840618AHigh activityImprove hydrogenation activityRefining to eliminate hetero atomsSilicon oxideHydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

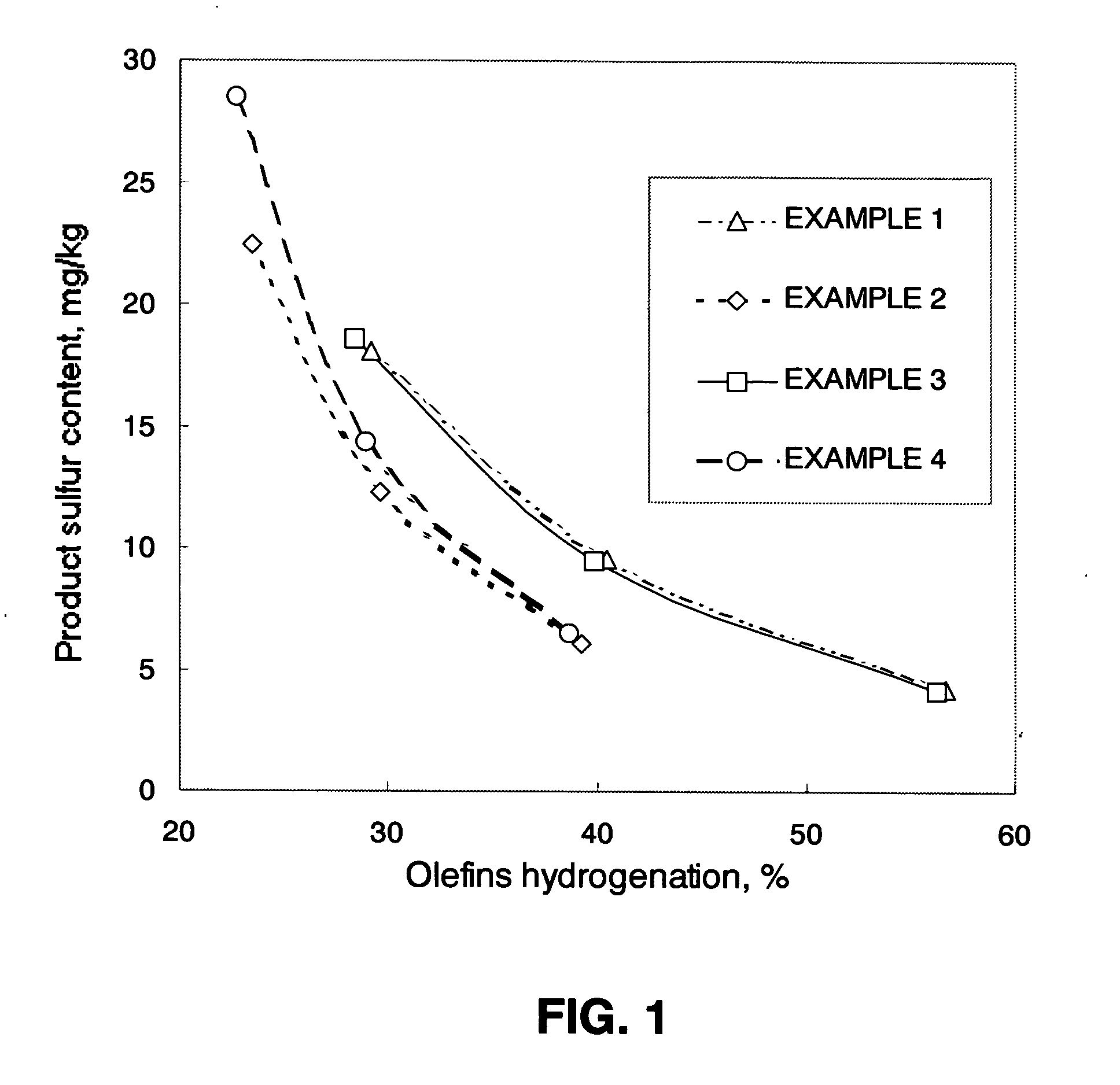

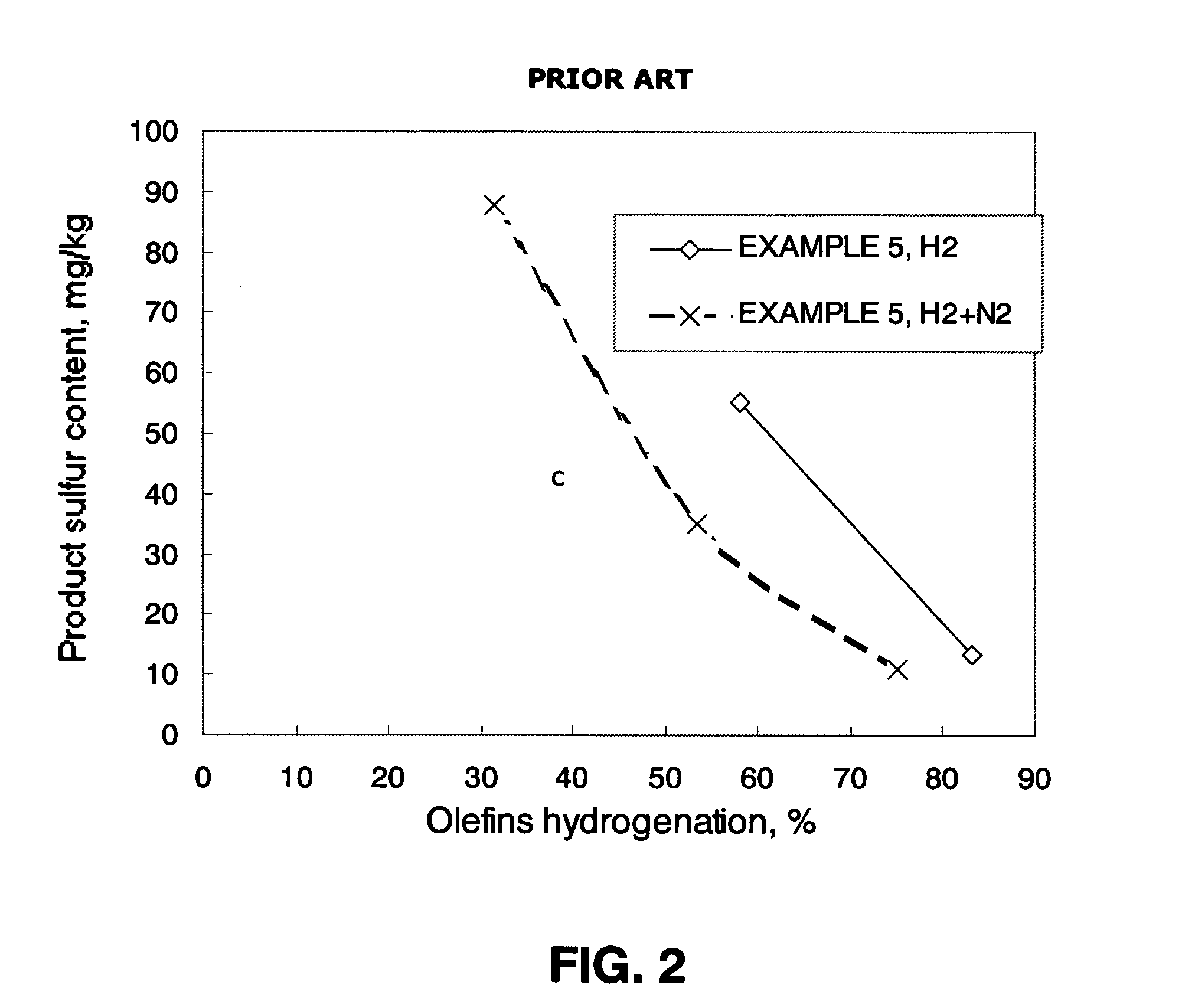

Process for selective hydrodesulfurization of naphtha

ActiveUS20060096893A1Reduce sulfur contentMinimize hydrogenationRefining with acid-containing liquidsTreatment with hydrotreatment processesChemistrySulfur content

A process for the selective hydrodesulfurization of a naphtha containing olefins and organosulfur compounds is disclosed, which minimizes the hydrogenation of the olefins and results in a product with a low sulfur content. The process involves a two-stage hydrodesulfurization with H2S removed from the first stage effluent. A flow of hydrogen and at least one added non-reactive compound is fed into the first stage, wherein the H2 molar fraction ranges from 0.2 to 1.0, and with H2S at the reactor intake limited to a maximum of 0.1% by volume. The second stage involves a feedstream of hydrogen and at least one added non-reactive compound, wherein the H2 molar fraction ranges from 0.2 to 0.7 and with H2S at the reactor intake limited to a maximum of 0.05% by volume.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

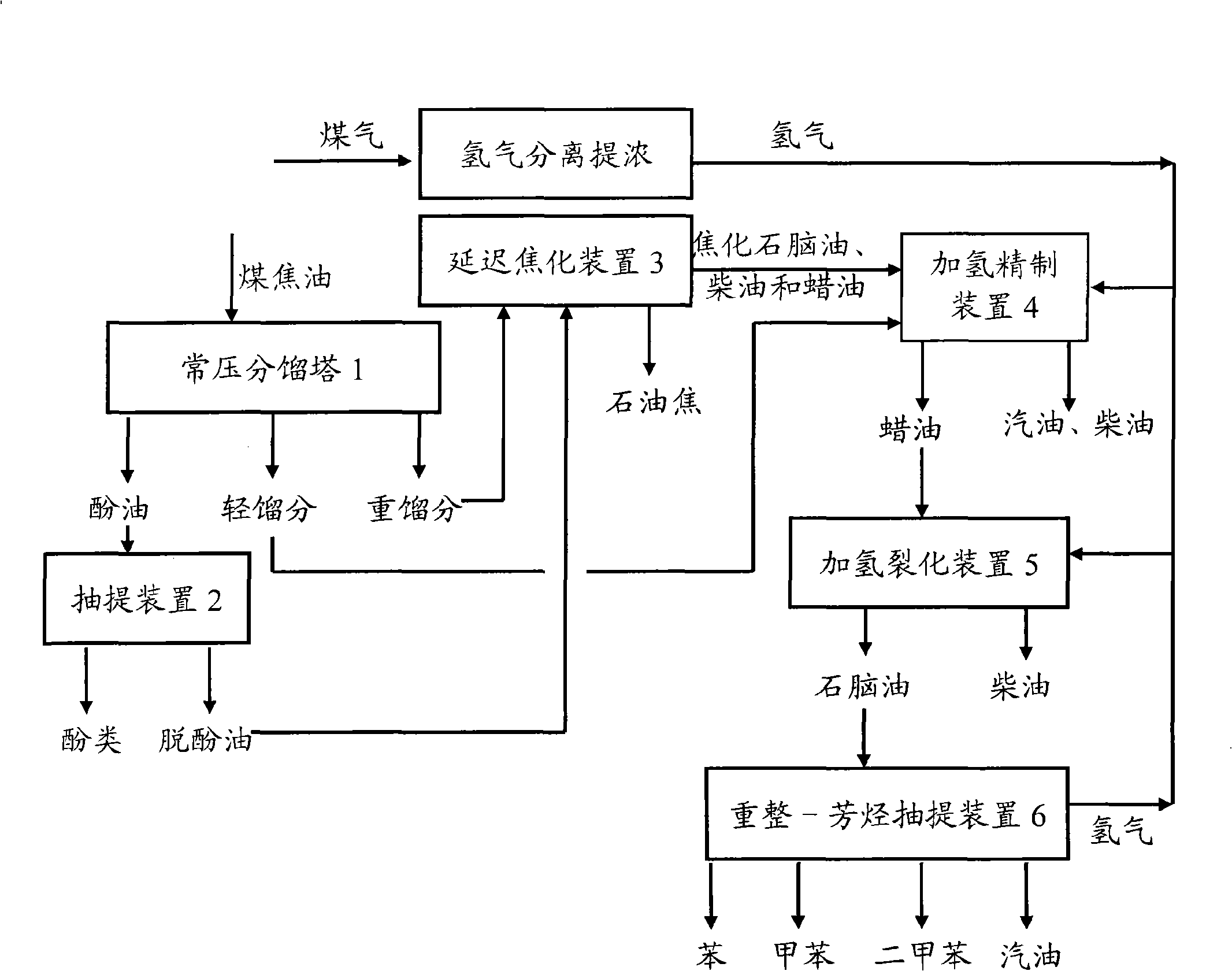

Medium and low temperature coal tar deep processing method

InactiveCN101538482AImprove performanceEfficient use ofThermal non-catalytic crackingCatalytic naphtha reformingCatalytic reformingFractionation

The invention discloses a medium and low temperature coal tar deep processing method. Medium and low temperature coke material is pretreated and fractionated to obtain light fraction, carbolic oil and heavy fraction, dephenolization treatment is carried out on the carbolic oil to obtain phenols product and dephenolized oil, the dephenolized oil and the above heavy fraction carry out pyrogenetic reaction jointly to obtain various carbonized products, wherein carbonized naphtha, at least one of carbonized diesel oil and carbonized wax oil is mixed with the light fraction obtained by material fractionation to carry out hydrofining and hydrocracking reaction, hydrogenated naphtha obtained by hydrocracking carries out catalytic reforming-aromatics extraction to obtain benzene, toluol, xylene, solvent oil and other products. Compared with the prior art, gasoline fraction and diesel oil fraction obtained by the inventive method are clean and stable in properties. In addition, the invention can produce a plurality of chemical products with high added value, truly realizes the effective utilization of medium and low temperature coal tar, and greatly improves the service life of devices.

Owner:胜帮科技股份有限公司

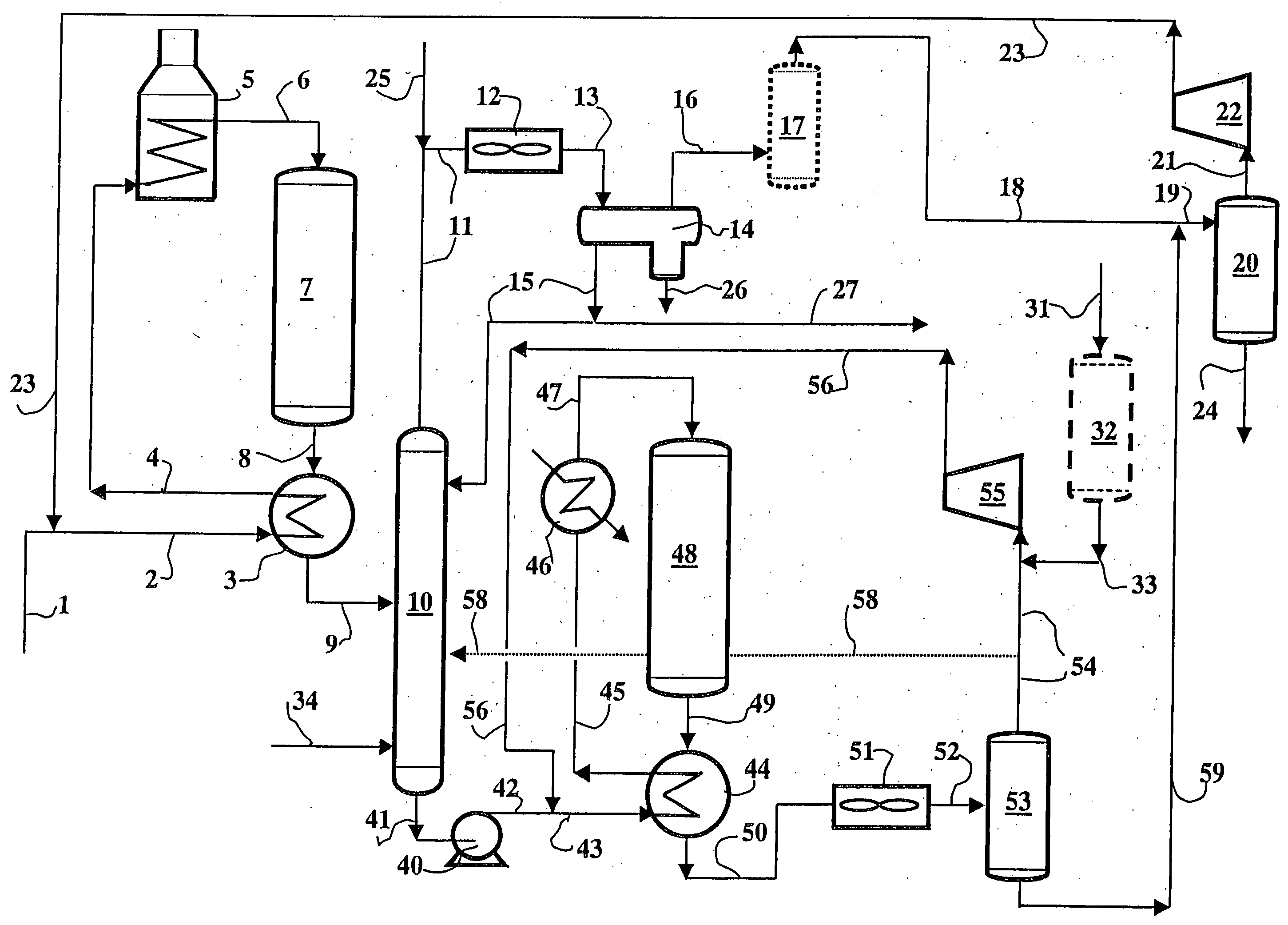

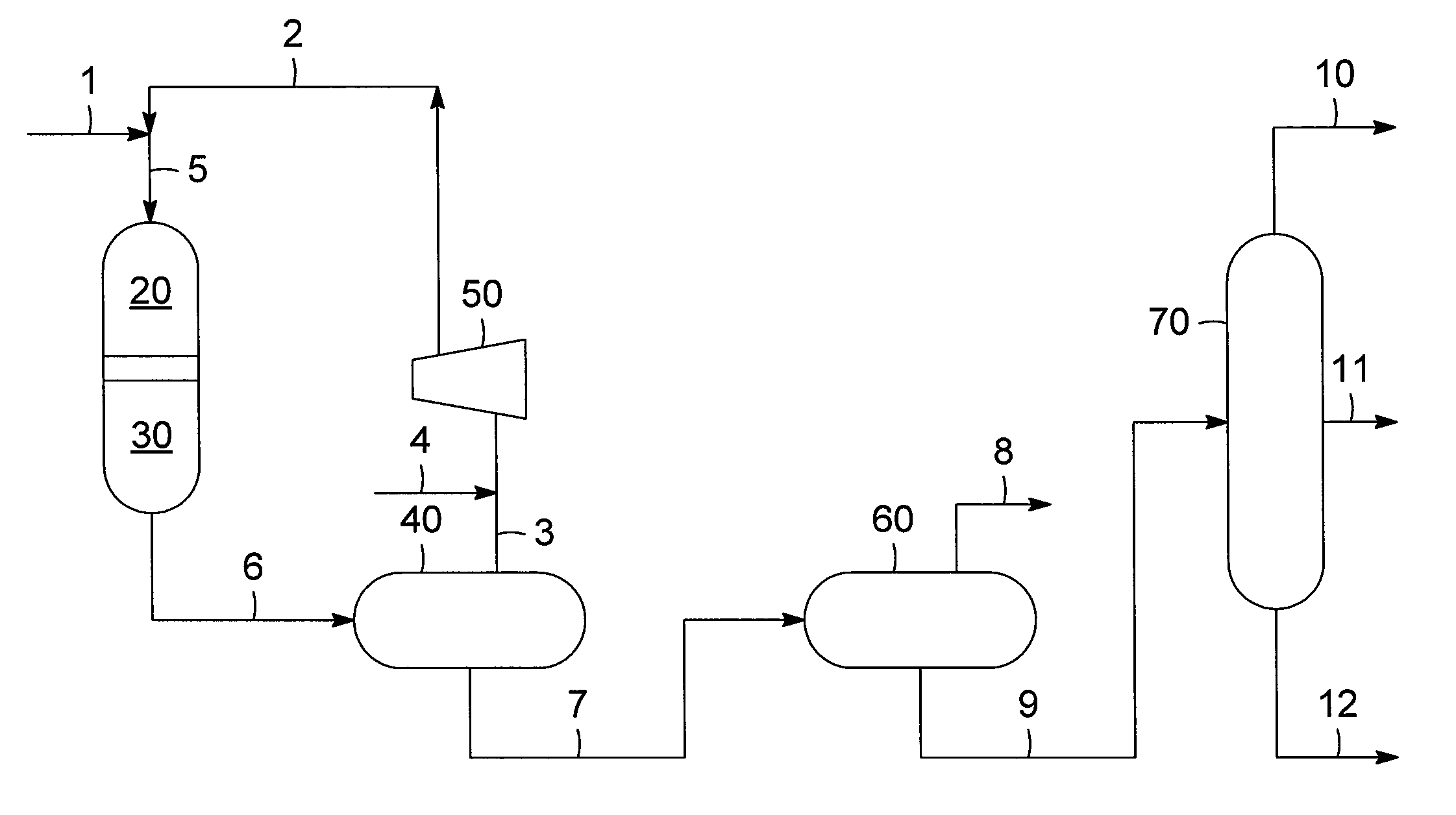

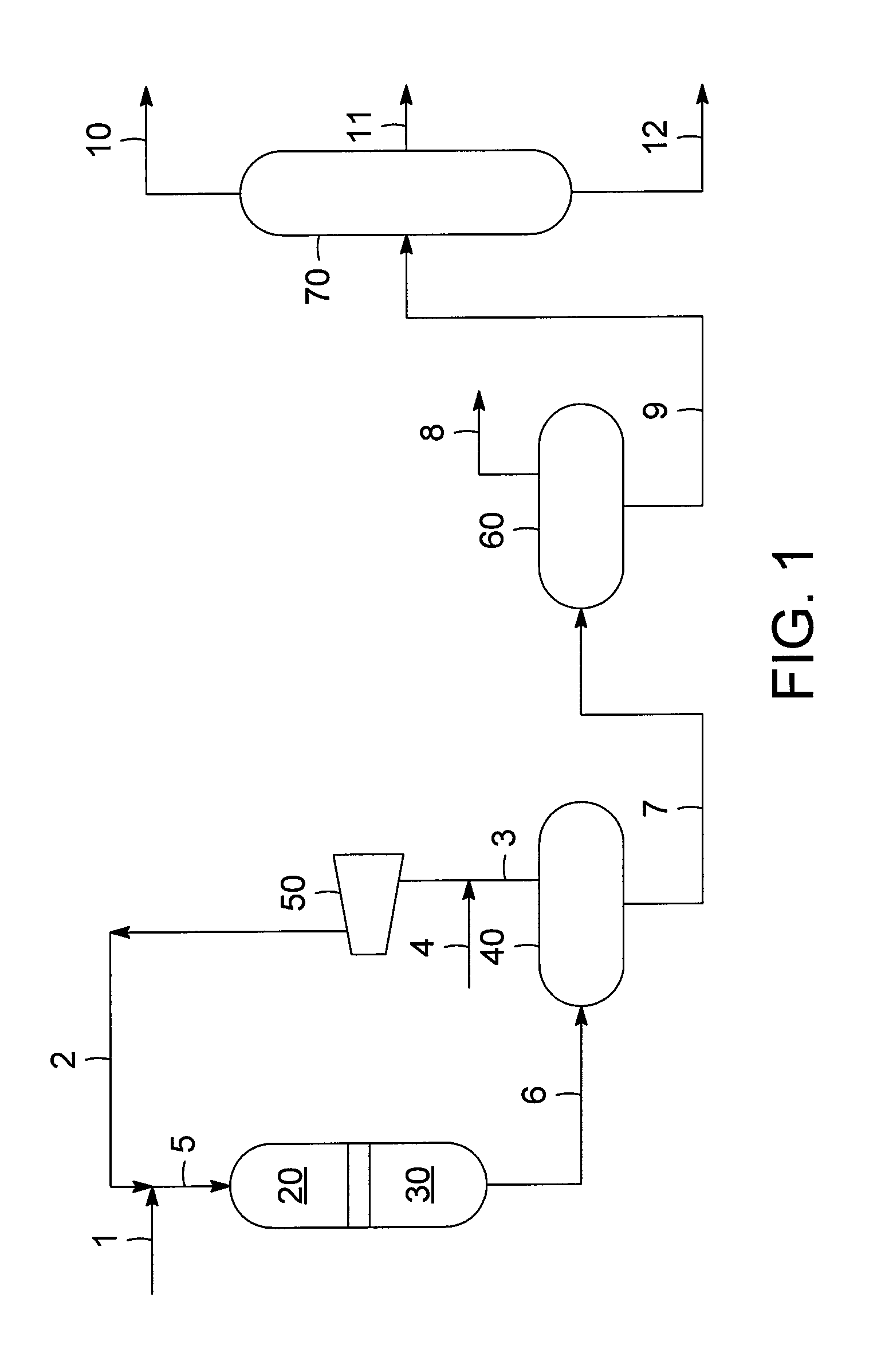

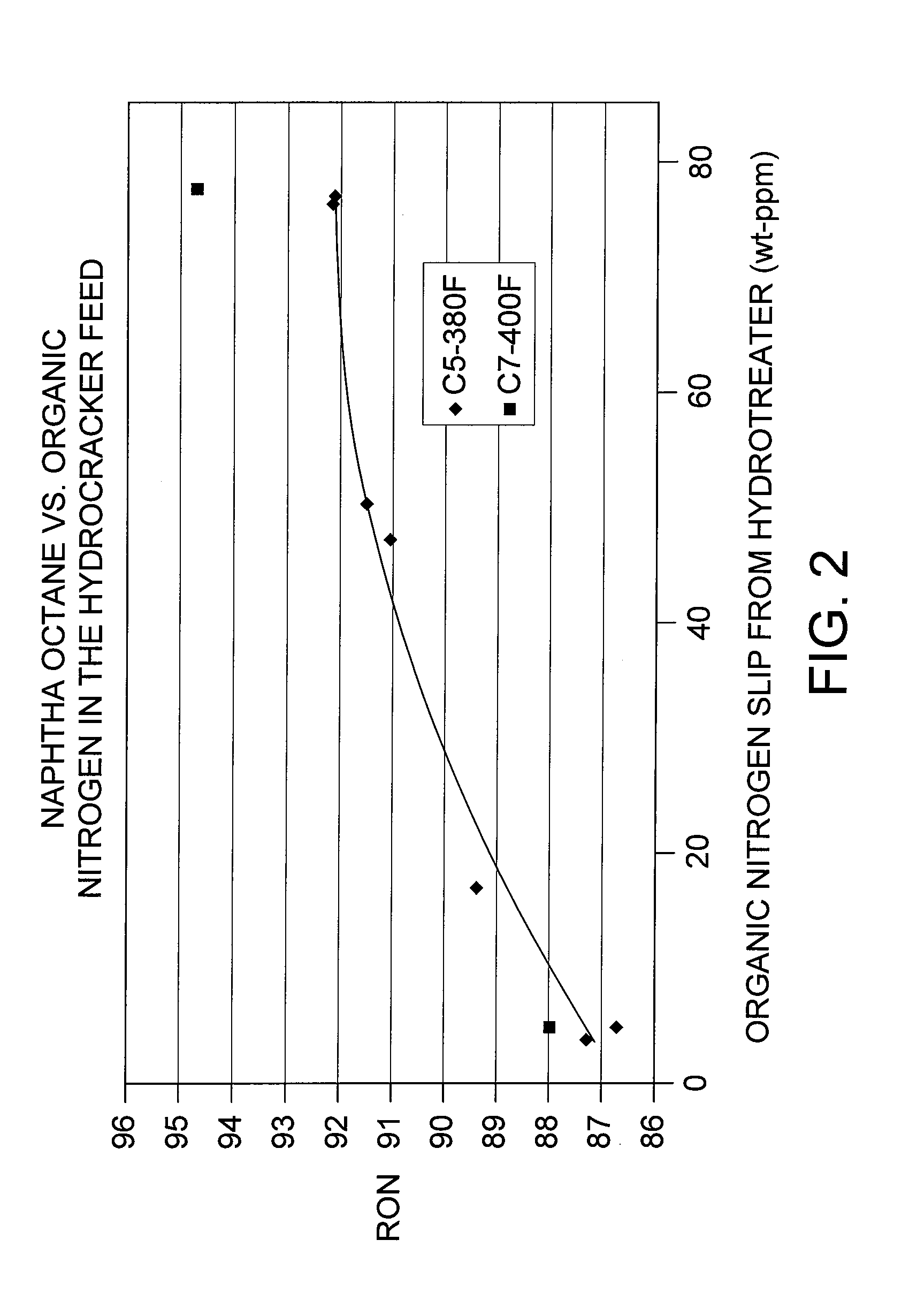

Combination of mild hydrotreating and hydrocracking for making low sulfur diesel and high octane naphtha

ActiveUS20100116712A1Suppresses hydrogenation functionIncreasing aromatic retentionTreatment with hydrotreatment processesHydrocarbon oils refiningNaphthaPtru catalyst

Methods are disclosed for the hydrotreating and hydrocracking of highly aromatic distillate feeds such as light cycle oil (LCO) to produce ultra low sulfur gasoline and diesel fuel. Optimization of hydrotreater severity improves the octane quality of the gasoline or naphtha fraction. In particular, the operation of the hydrotreater at reduced severity to allow at least about 20 ppm by weight of organic nitrogen into the hydrocracker feed is shown to lead to these important benefits. Post-treating of the hydrocracker effluent over an additional hydrotreating catalyst bed may be desired to meet specifications for ultra low sulfur fuel components.

Owner:UOP LLC

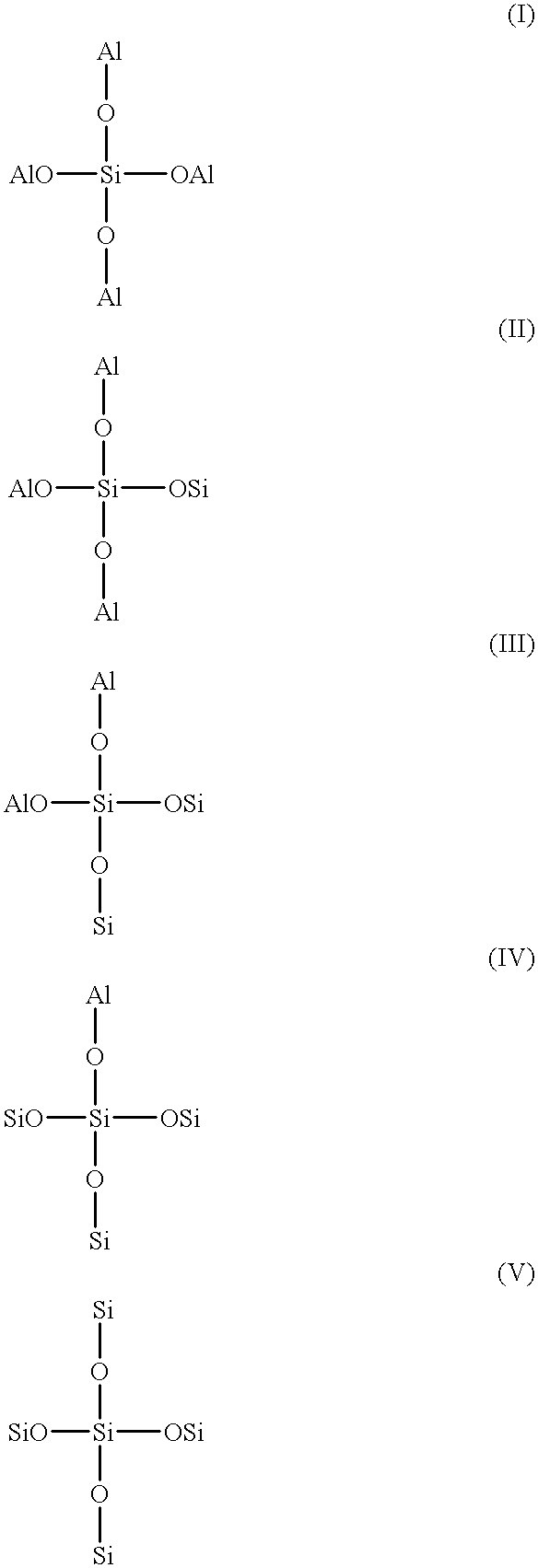

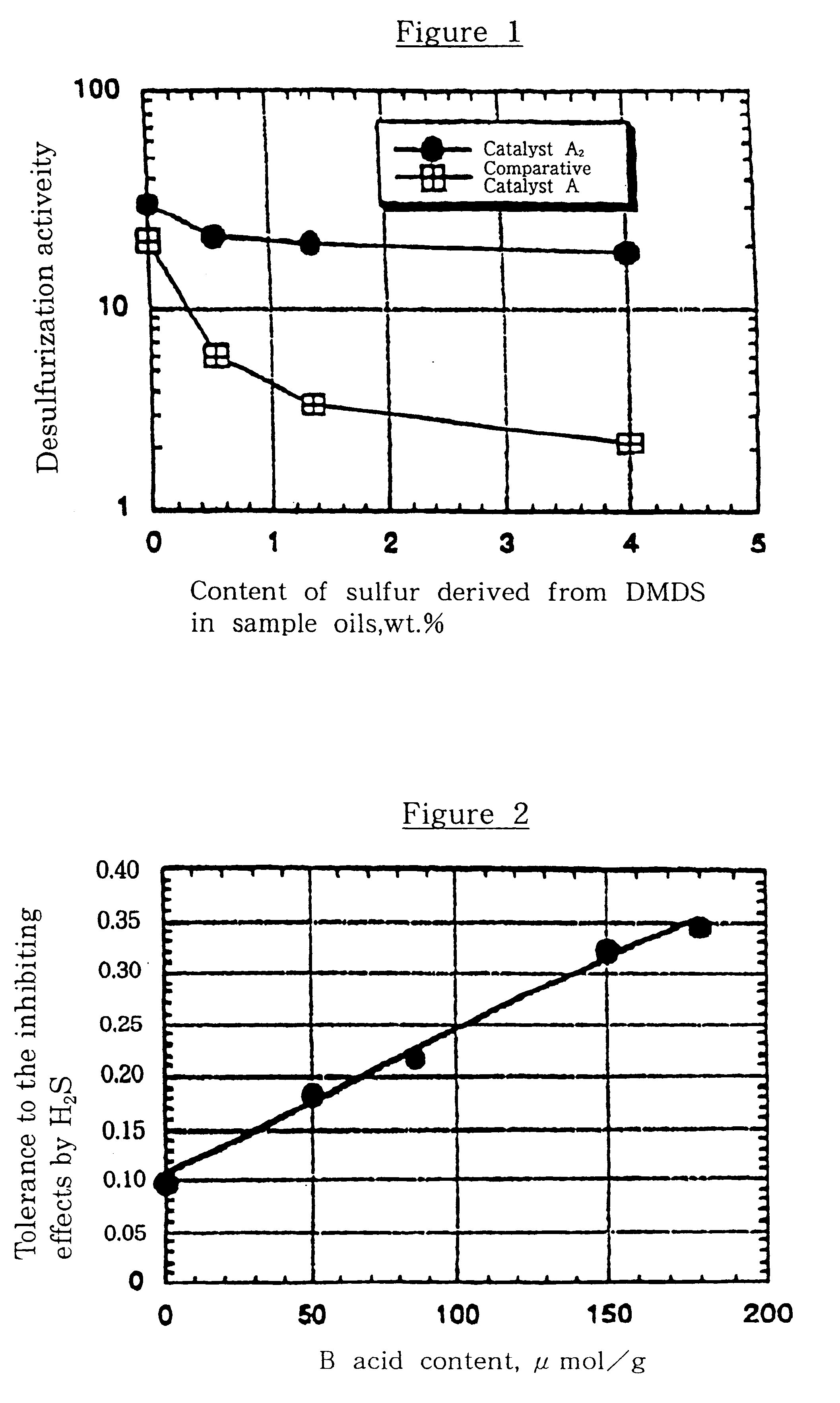

Hydrotreating catalyst and processes for hydrotreating hydrocarbon oil with the same

InactiveUS6267874B1Improve toleranceEfficient removalHydrocarbon oil crackingTreatment with hydrotreatment processesActive componentSilicon dioxide

The present invention relates to a hydrotreating catalyst composed of a carrier having a Brønsted acid content of at least 50 mumol / g such as a silica-alumina carrier or a silica-alumina-third component carrier, in which the silica is dispersed to high degree and a Brønsted acid content is at least 50 mumol / g, and at least one active component (A) selected from the elements of Group 8 of the Periodic Table and at least one active component (B) selected from the elements of Group 6 of the Periodic Table, supported on said carrier. The present invention also relates to a method for hydrotreating hydrocarbon oils using the same. The hydrotreating catalyst of the present invention provides excellent tolerance to the inhibiting effect of hydrogen sulfide, high desulfurization activity, and exhibits notable effects for deep desulfurization of hydrocarbon oils containing high contents of sulfur, in particular gas oil fractions containing difficult-to-remove sulfur compounds. The hydrotreating catalyst of the present invention is also very effective for hydrodenitrogenation, hydrocracking, hydrodearomatization, hydroisomerization, hydrofining and the like of hydrocarbon oils.

Owner:TONENGENERAL SEKIYU

Deep desulfurization method for catalytically cracked gasoline

ActiveCN103555359AWide applicabilityReduce sulfur contentTreatment with plural parallel refining stagesTreatment with hydrotreatment processesSulfurGasoline

The invention provides a gasoline fraction solvent extraction desulfurization method comprising the steps of enabling a gasoline fraction to enter from the lower middle part of an extraction tower, enabling a solvent to enter from the top of the extraction tower, filling saturated C5 into a reflux device at the bottom of the extraction tower, controlling the temperature of the top of the extraction tower at 55-100 DEG C, the temperature of the bottom of the extraction tower at 40-80 DEG C, the pressure of the top of the extraction tower at 0.2-0.7MPa, the solvent to gasoline fraction ratio at 1.0-5.0 and the saturated C5 to gasoline fraction feeding ratio at 0.1-0.5, ejecting the extracted and desulfurized gasoline fraction out of the extraction tower, and washing to obtain a desulfurized gasoline fraction; discharging the solvent from the bottom of the extraction tower, separating a C5-contained light component, a sulfur-rich component, water and the solvent, returning the light component to the reflux device of the extraction tower, returning the water to the washing step, and returning the solvent to the top of the extraction tower, wherein sulfides, aromatic hydrocarbons and the C5 are extracted by the solvent. The invention also provides a deep desulfurization method for catalytically cracked gasoline. The solvent extraction desulfurization method is flexibly combined with the traditional desulfurization technology used by an enterprise, so that the deep desulfurization is realized, and meanwhile, the octane value loss of the gasoline fraction is remarkably reduced.

Owner:HEBEI REFINING TECH CO LTD

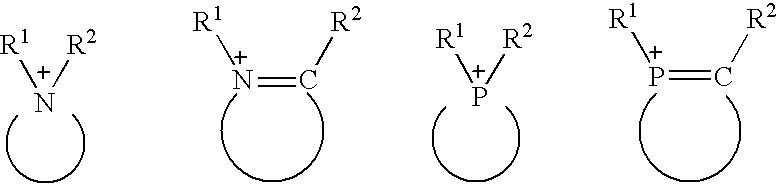

Processing for eliminating sulfur-containing compounds and nitrogen-containing compounds from hydrocarbon

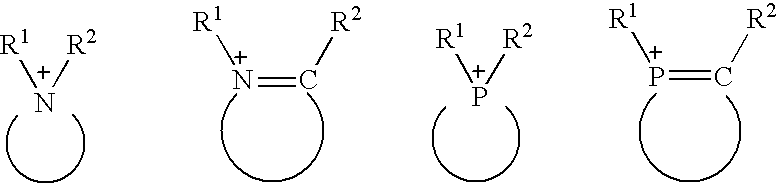

InactiveUS7198712B2Increase contentReduce sulfur contentPhysical/chemical process catalystsElectrolysis componentsSolubilityPhosphonium

For desulfurization and, if necessary, for denitrification of hydrocarbon fractions the hydrocarbon mixture is brought into contact with a non-aqueous ionic liquid of general formula Q+A−, wherein Q+ is a ammonium, phosphonium or sulfonium cation, that contains at least one alkylating agent of the formula RX−, making it possible to form ionic sulfur-containing derivatives (and, if necessary, nitrogen-containing derivatives) that have a preferred solubility in the ionic liquid; and the ionic liquid is separated from the hydrocarbon mixture that is low in sulfur and nitrogen by decanting.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com