Low temperature methanol washing integrated Claus sulfur recovery system and process

A low-temperature methanol washing and sulfur recovery technology, which is used in the fields of coal gas, treatment and recovery, natural gas and other carbonyl gas purification, and can solve the problems of increased methanol circulation, insufficient refrigeration supply, and venting tail gas that cannot meet national environmental protection standards. , to achieve the effect of large flexibility of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

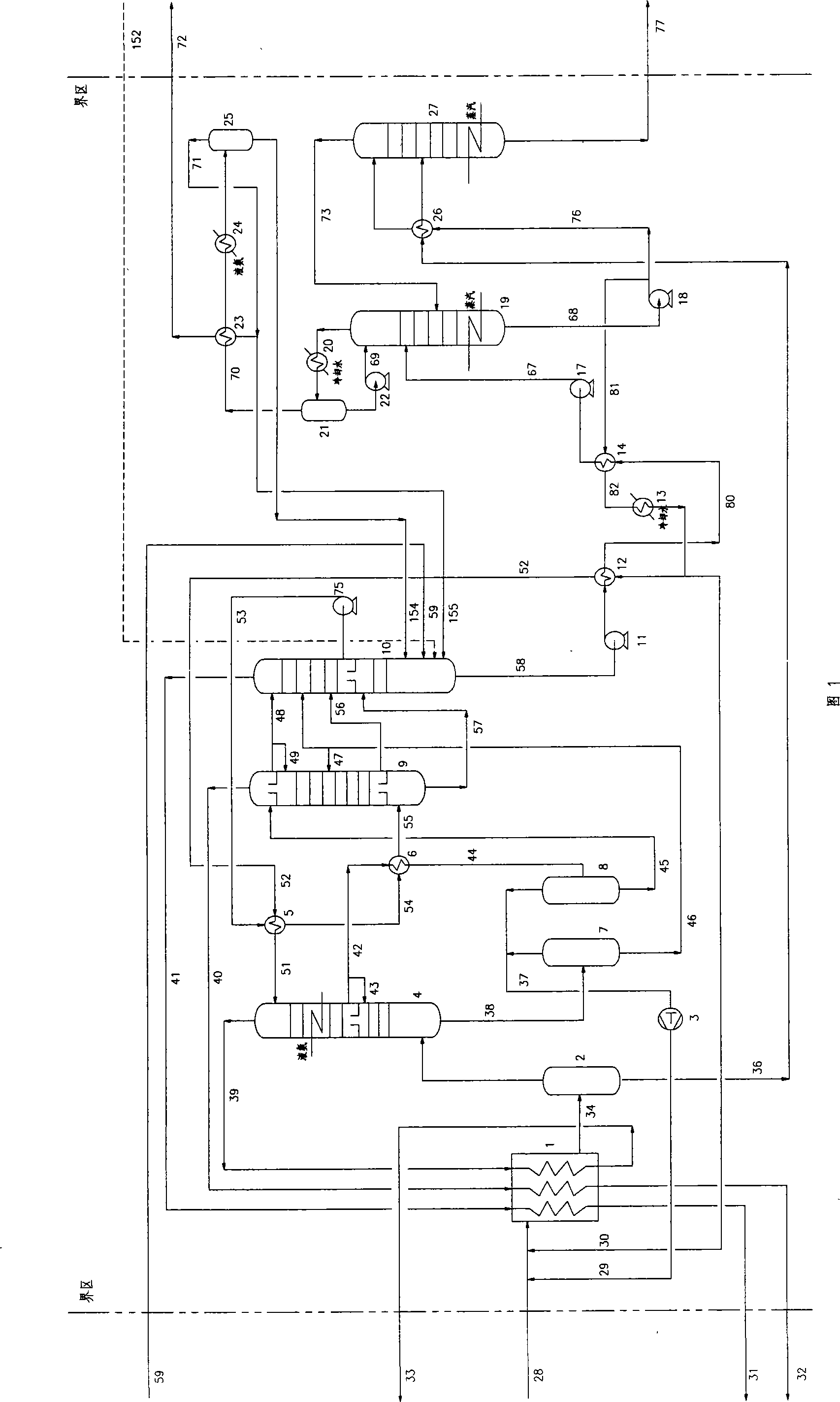

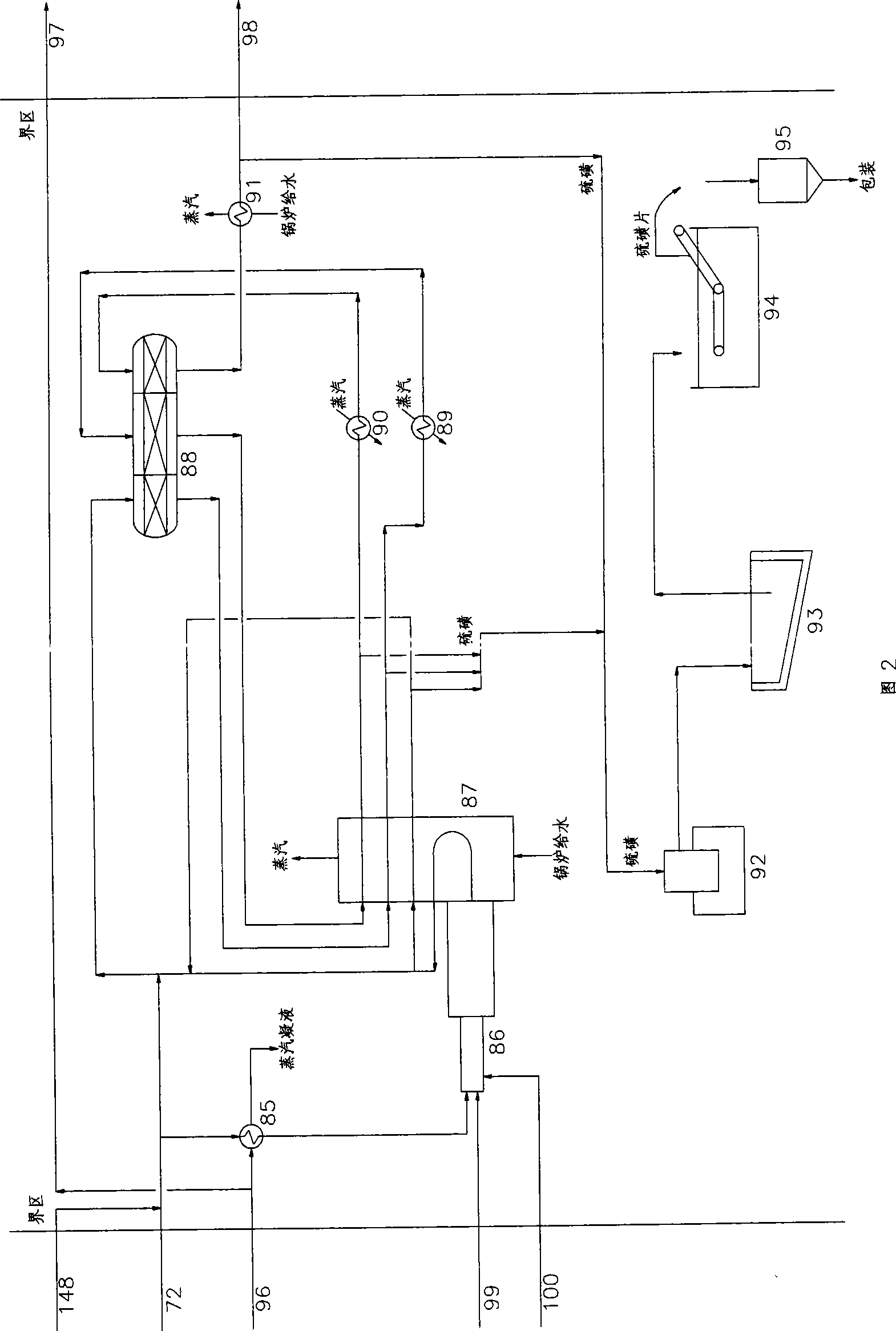

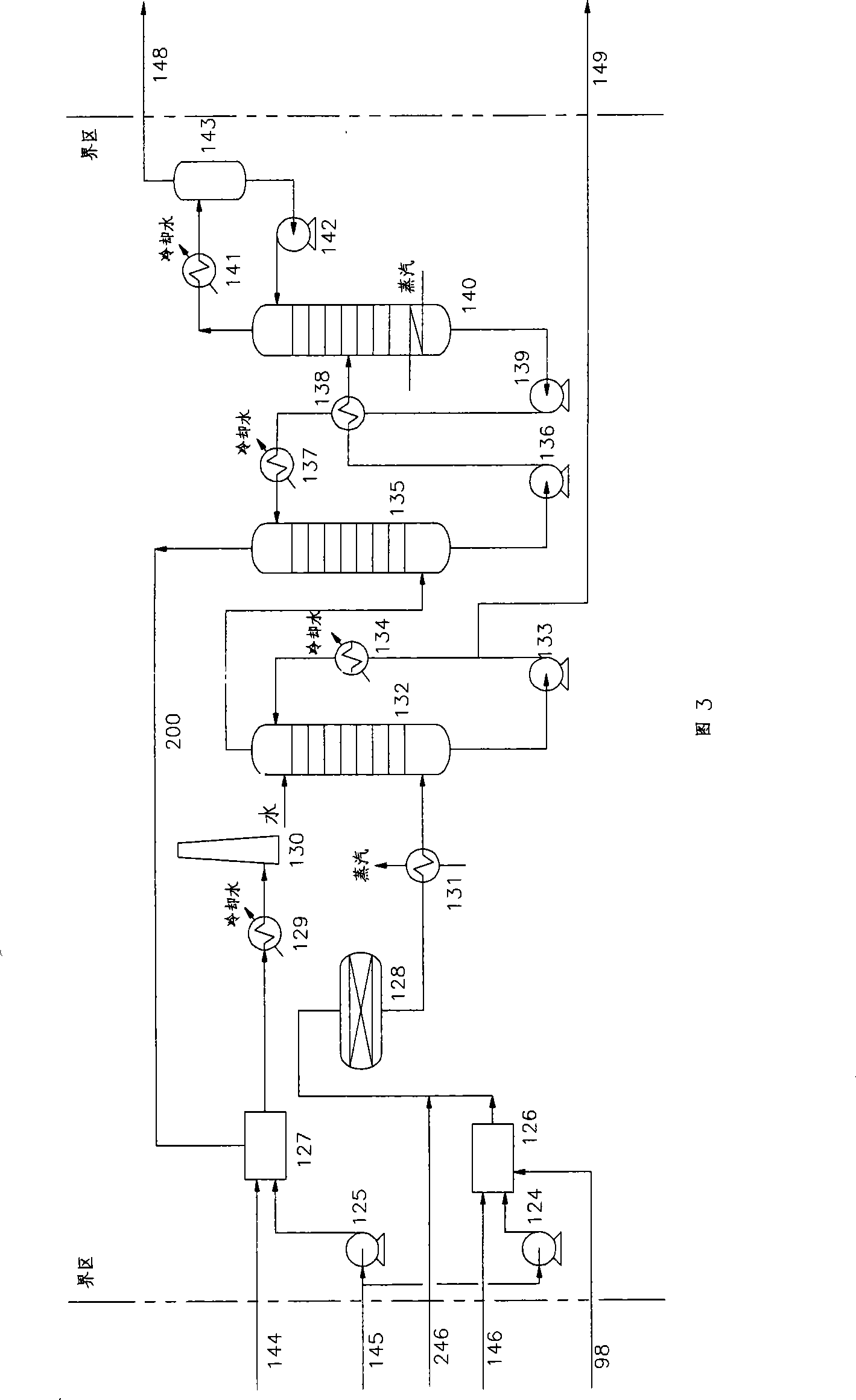

[0053] Below in conjunction with accompanying drawing 5,6,7 the present invention is further described:

[0054] The temperature of raw material gas (28) is 40°C, the pressure is 5.3MPa, and the flow rate is 254125.5Nm 3 / hr, after merging with spray methanol (30) and cycle gas (29), it is cooled to about -12.0°C through the feed gas cooler (1), and enters the gas-liquid separator (2). After separation and dehydration, the liquid enters the methanol / water separation tower (27), the gas enters the methanol scrubber (4), and uses the cold methanol (51) that flows down from the top of the tower to complete decarburization in the upper section of the tower, and partially absorbs the CO 2 The rich methanol (43) completes the desulfurization in the lower section of the tower, and the purified gas (39) exits the bounding area after recovering the cooling capacity, and the two streams of rich methanol (42) and (38) coming out of the tower are flashed in the second and first cycle ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com