Patents

Literature

1217 results about "Gas cooler" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drying machine

InactiveUS20050198852A1EfficientlyEfficient dryingDrying gas arrangementsDrying machines with non-progressive movementsAir cycleGas cooler

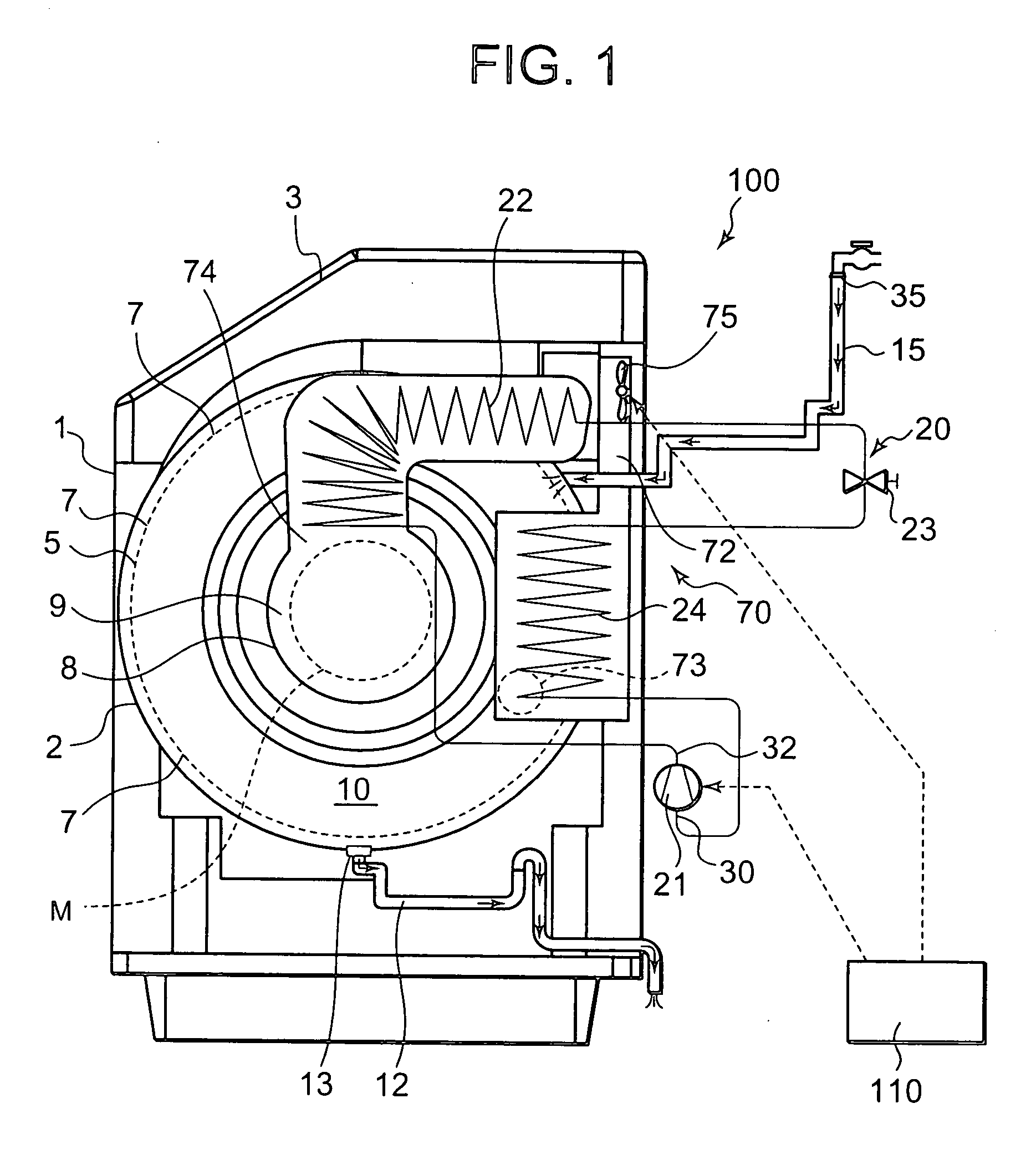

An object is to provide a drying machine capable of maintaining air discharged into a housing chamber while efficiently drying a matter to be dried in a short time. A drying machine provided with a housing chamber which houses the matter to be dried, and executing a drying operation of the matter to be dried in the housing chamber comprises: a gas cooler; an evaporator; a blower fan; an air circulation path for discharging air heated by the gas cooler into the housing chamber by the blower fan, sending the air passed through the housing chamber into the evaporator, and circulating the air in the gas cooler; and a closable outside air introduction port for mixing outside air with the air circulating in the air circulation path.

Owner:SANYO ELECTRIC CO LTD

Drying apparatus

ActiveUS20050044744A1Shorten the timeImprove energy efficiencyDrying solid materials with heatDrying gas arrangementsAir cycleProcess engineering

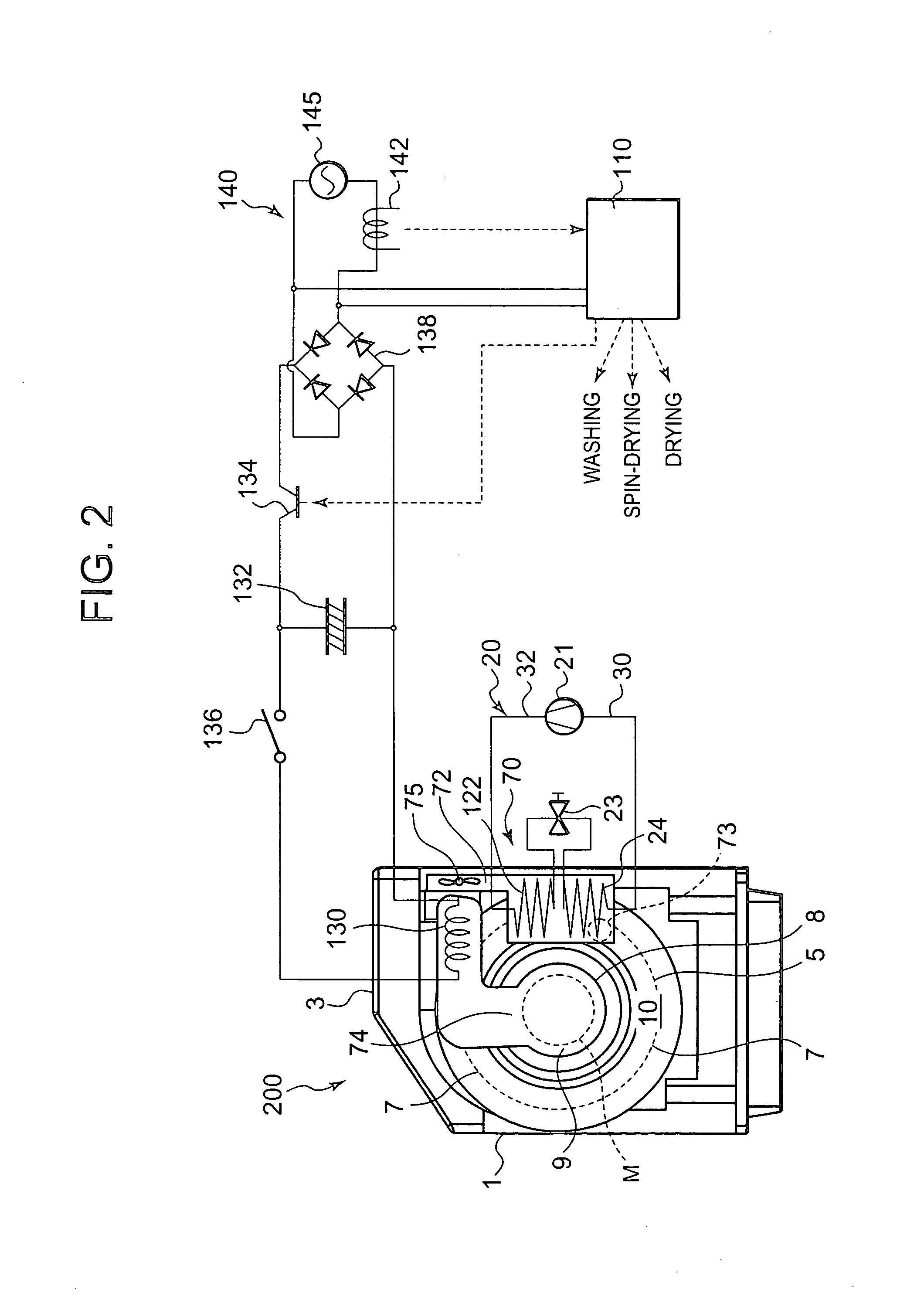

A drying apparatus having a purpose of shortening a drying time of laundry, comprising an accommodating chamber in which the laundry is accommodated, and executing a washing operation of the laundry and a drying operation after end of the washing operation in the accommodating chamber, the machine comprising: a refrigerant circuit in which a compressor, a gas cooler, an expansion valve, and an evaporator are successively connected to one another in an annular form via a piping; an air circulation path for discharging air which has exchanged heat with the gas cooler into the accommodating chamber by a blower to exchange the heat of the air passed through the accommodating chamber with the evaporator; and a control device for operating the compressor and the blower to perform the drying operation, wherein the control device starts the operation of the compressor before entering the drying operation.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Gas circulating apparatus

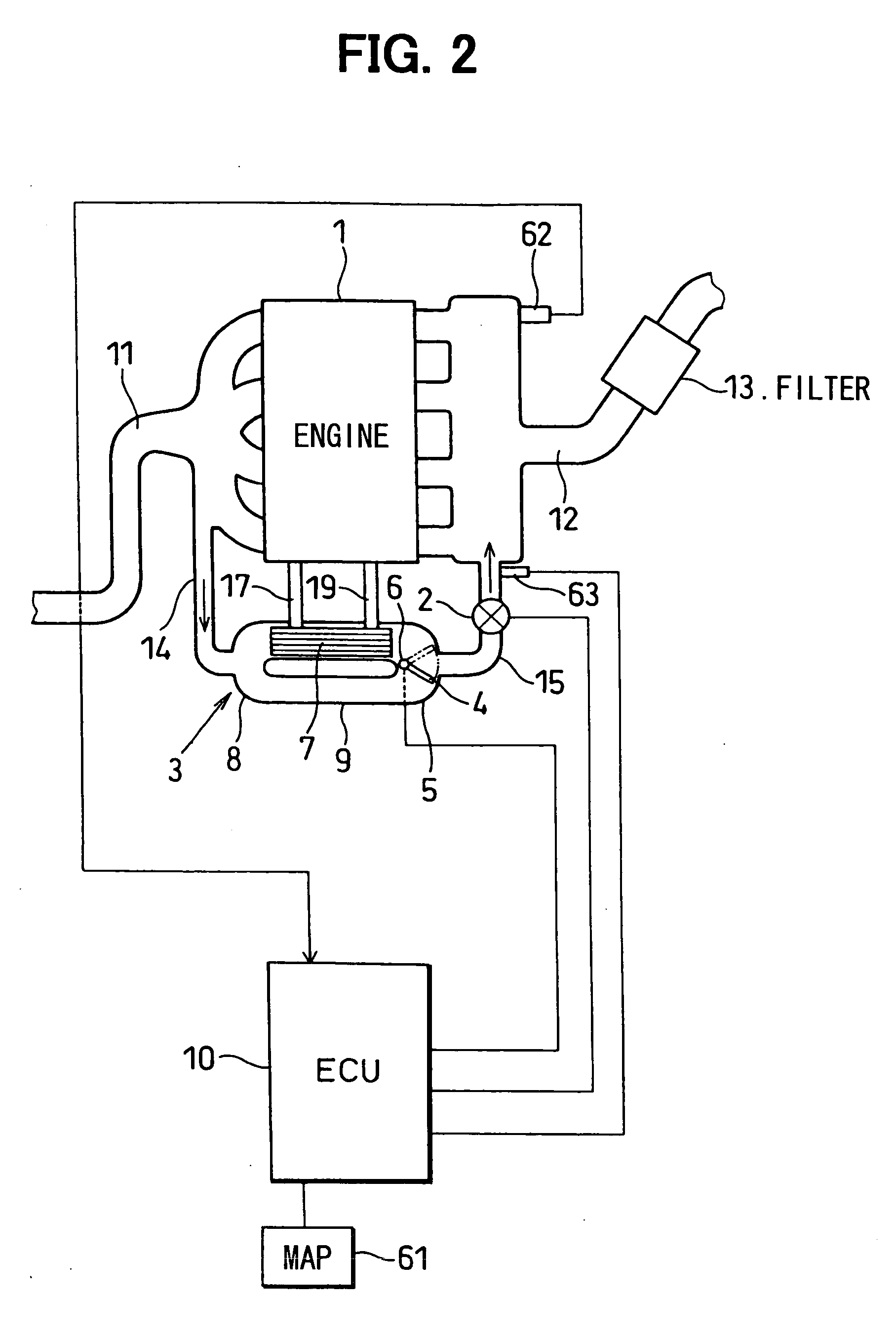

InactiveUS20070017489A1Reduce heat transferReducing ability of heatNon-fuel substance addition to fuelInternal combustion piston enginesHeat transmissionEngineering

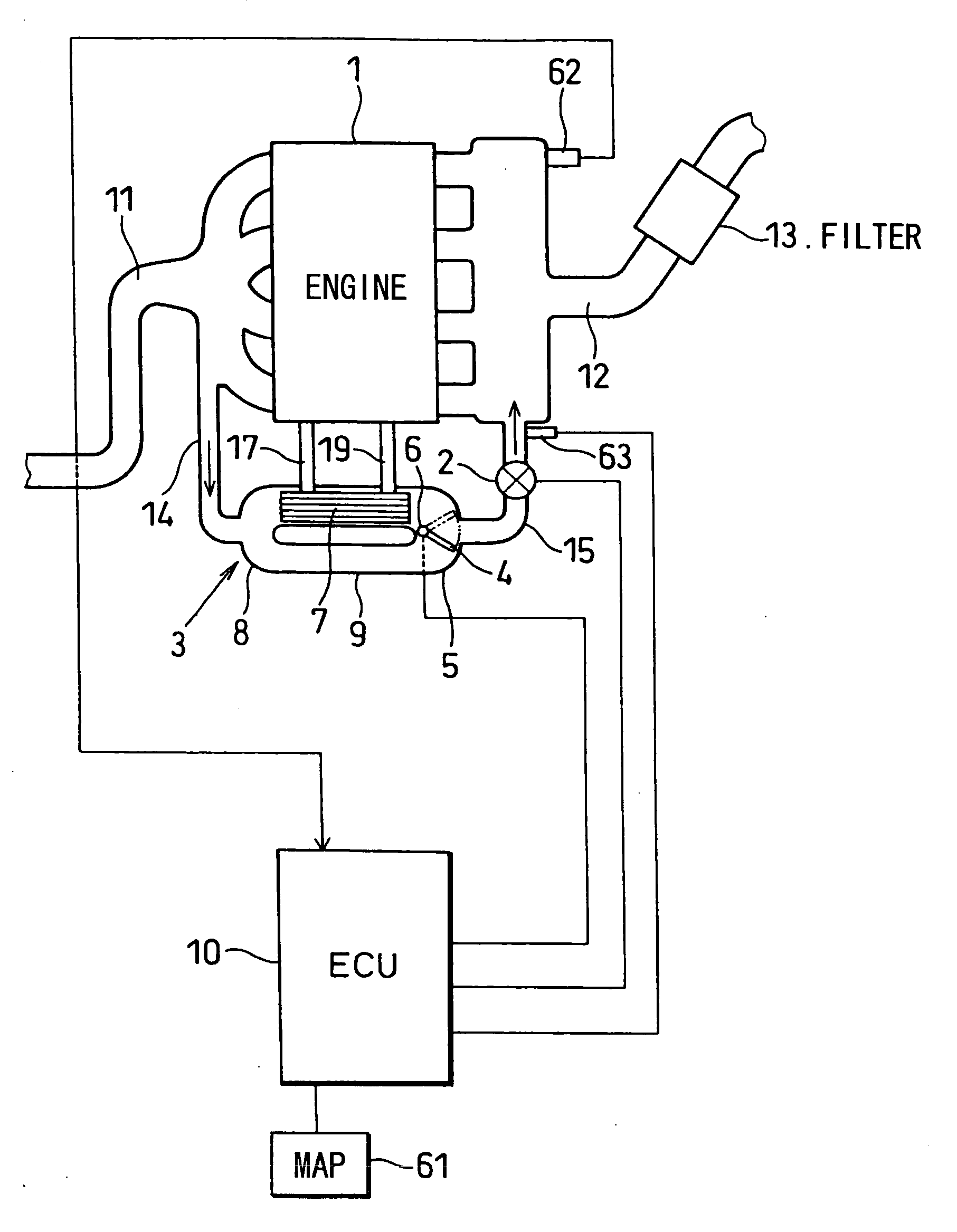

In a gas circulating apparatus, a bypass pipe extends in parallel with an EGR gas cooler. The aperture end of the bypass pipe is inserted to inside of a housing of a valve device and is positioned adjacent to a valve in the housing. Accordingly, the high-temperature EGR gas heat introduced to a second exhaust gas passage of the housing from the bypass pipe is difficult to be transmitted to a first exhaust gas passage of the housing. Thus, the heat transmission of the high-temperature EGR gas to the EGR gas cooler can be reduced.

Owner:DENSO CORP

Method for extracting carbon dioxide for use as a refrigerant in a vapor compression system

Owner:CARRIER CORP

Cooling and heating system

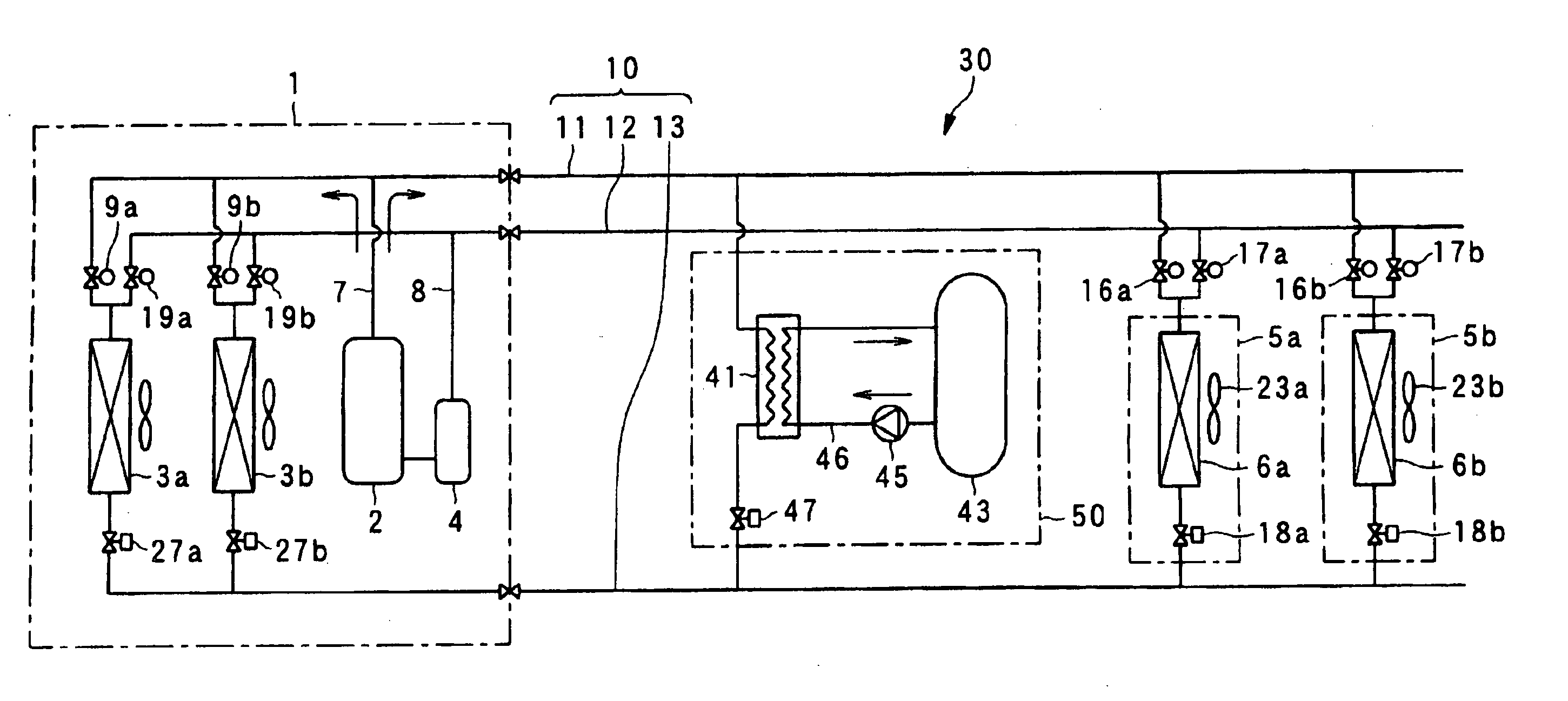

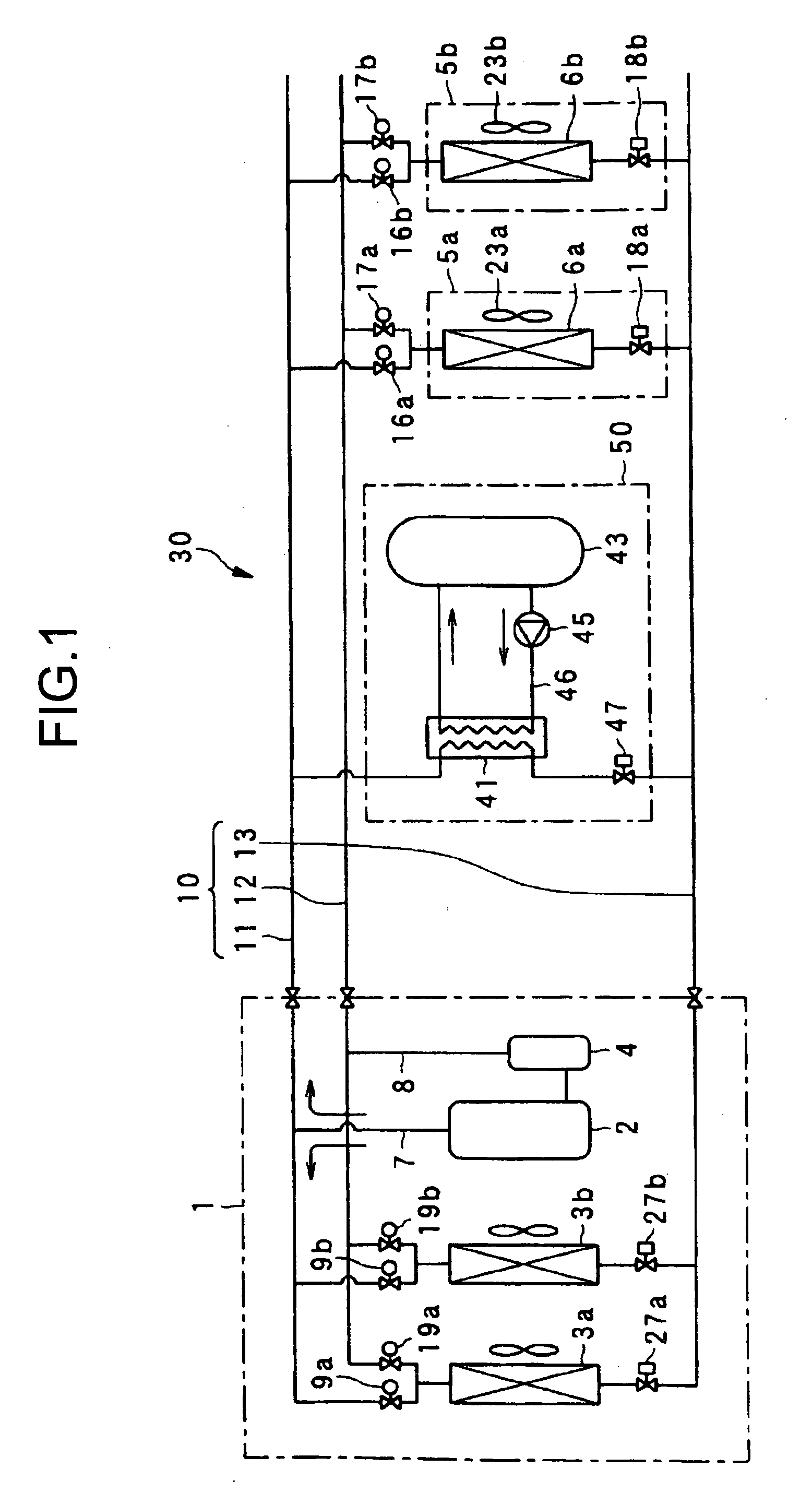

InactiveUS20060218948A1Maximizing coefficientReduce capacityEvaporators/condensersEfficient regulation technologiesEngineeringGas cooler

There is disclosed a cooling and heating system in which a refrigerant is used in a supercritical state and in which cooling and heating capacity can be controlled so as to maximize a coefficient of performance. A cooling and heating system 130 includes: an outdoor unit 101 indicating a compressor 102 and an outdoor heat exchanger 103a; a plurality of indoor units 105 including indoor heat exchangers 106; a high pressure tube 111; a low pressure tube 112; and an intermediate tube 113. The system includes: a refrigerant pressure detection unit PC01 for measuring a pressure of the refrigerant discharged from the compressor 102; a first refrigerant temperature detection unit TC03 which measures an outlet temperature of the refrigerant in a case where the outdoor heat exchanger 103 functions as a gas cooler and which measures an inlet temperature of the refrigerant in a case where the outdoor heat exchanger 103 functions as an evaporator; and a second refrigerant temperature detection unit TCO8 which measures an outlet temperature of the refrigerant in a case where the indoor heat exchanger 106 functions as a gas cooler and which measures an inlet temperature of the refrigerant in a case where the indoor heat exchanger 106 functions as an evaporator.

Owner:SANYO ELECTRIC CO LTD

Control of refrigeration system to optimize coefficient of performance

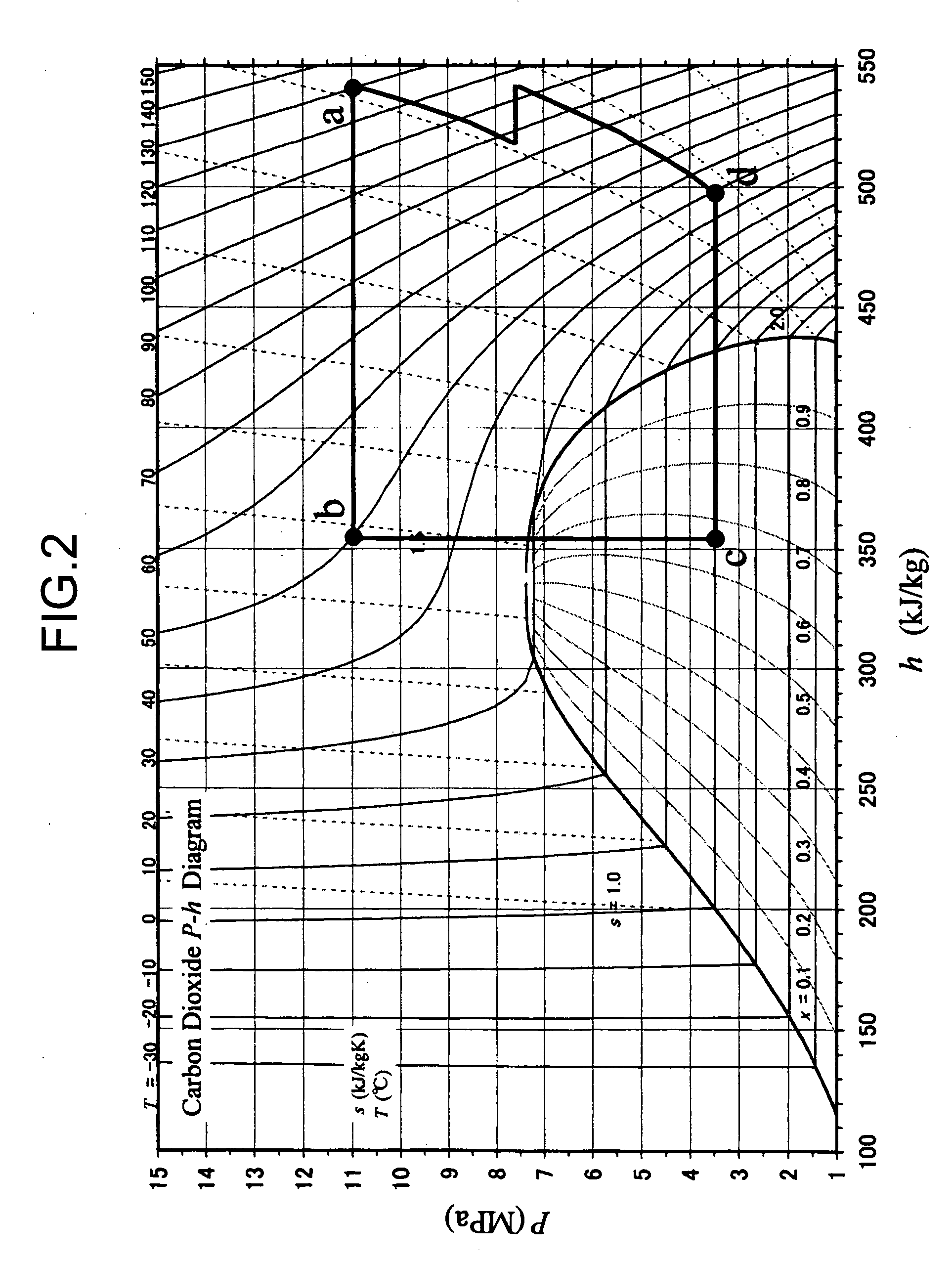

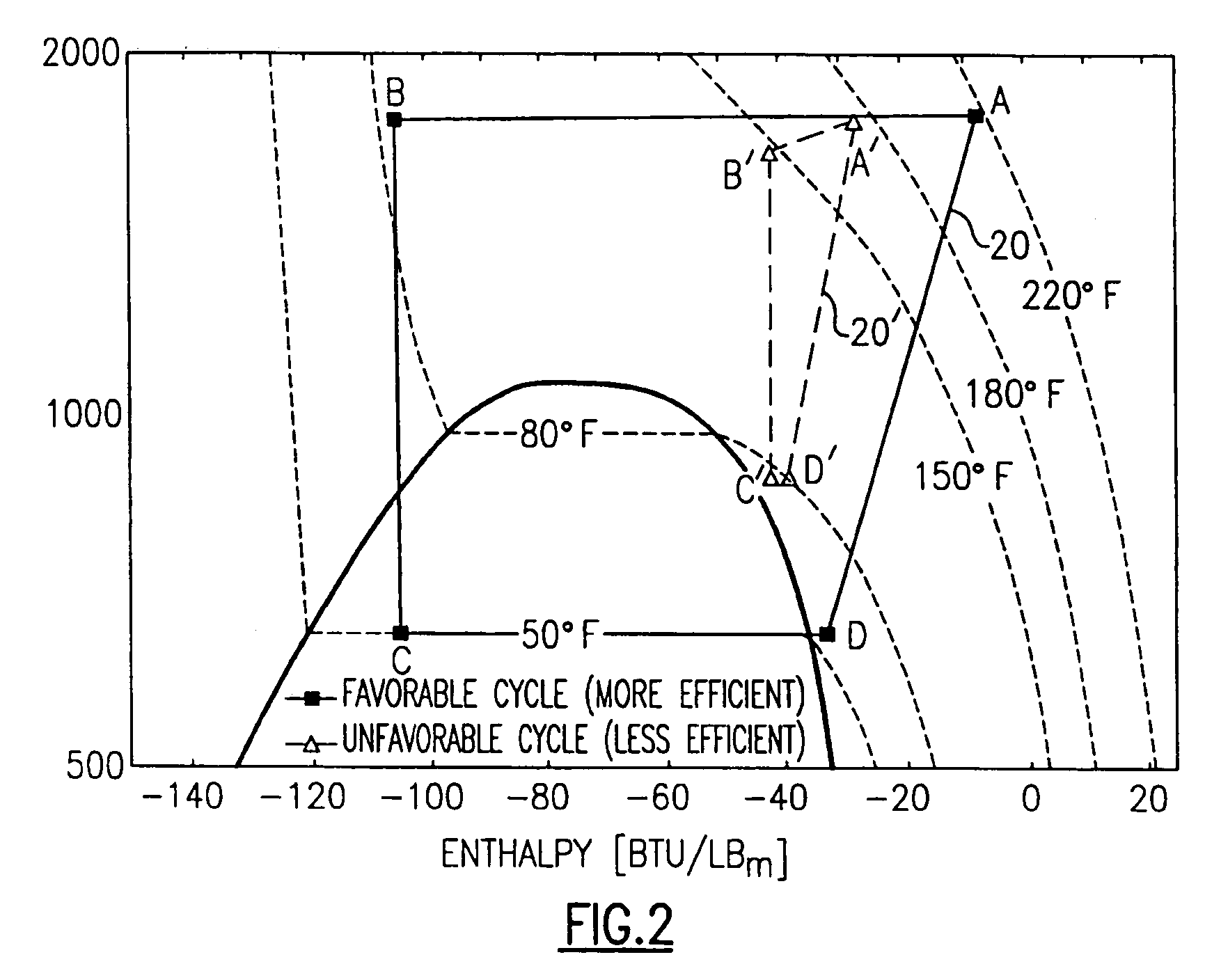

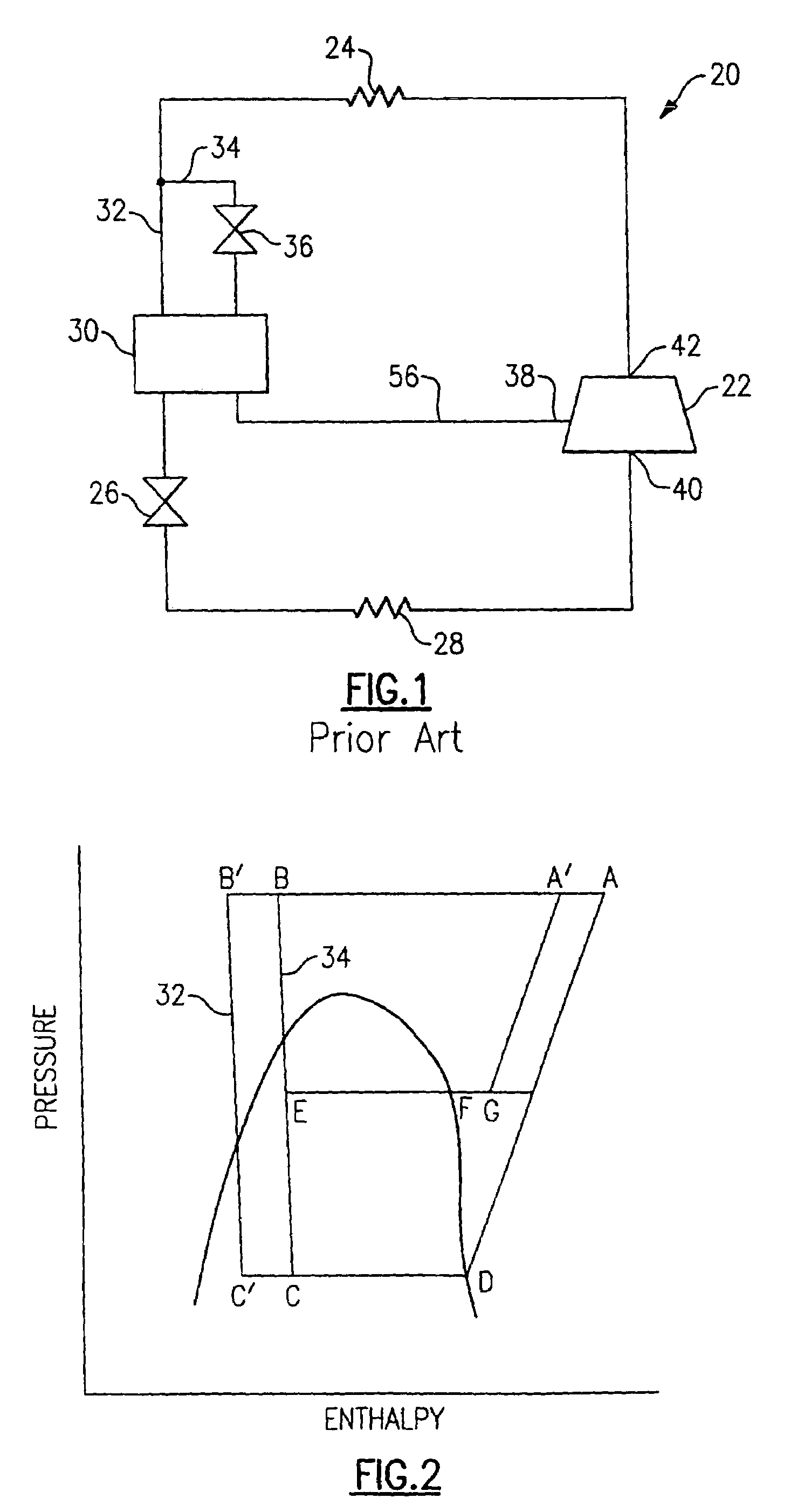

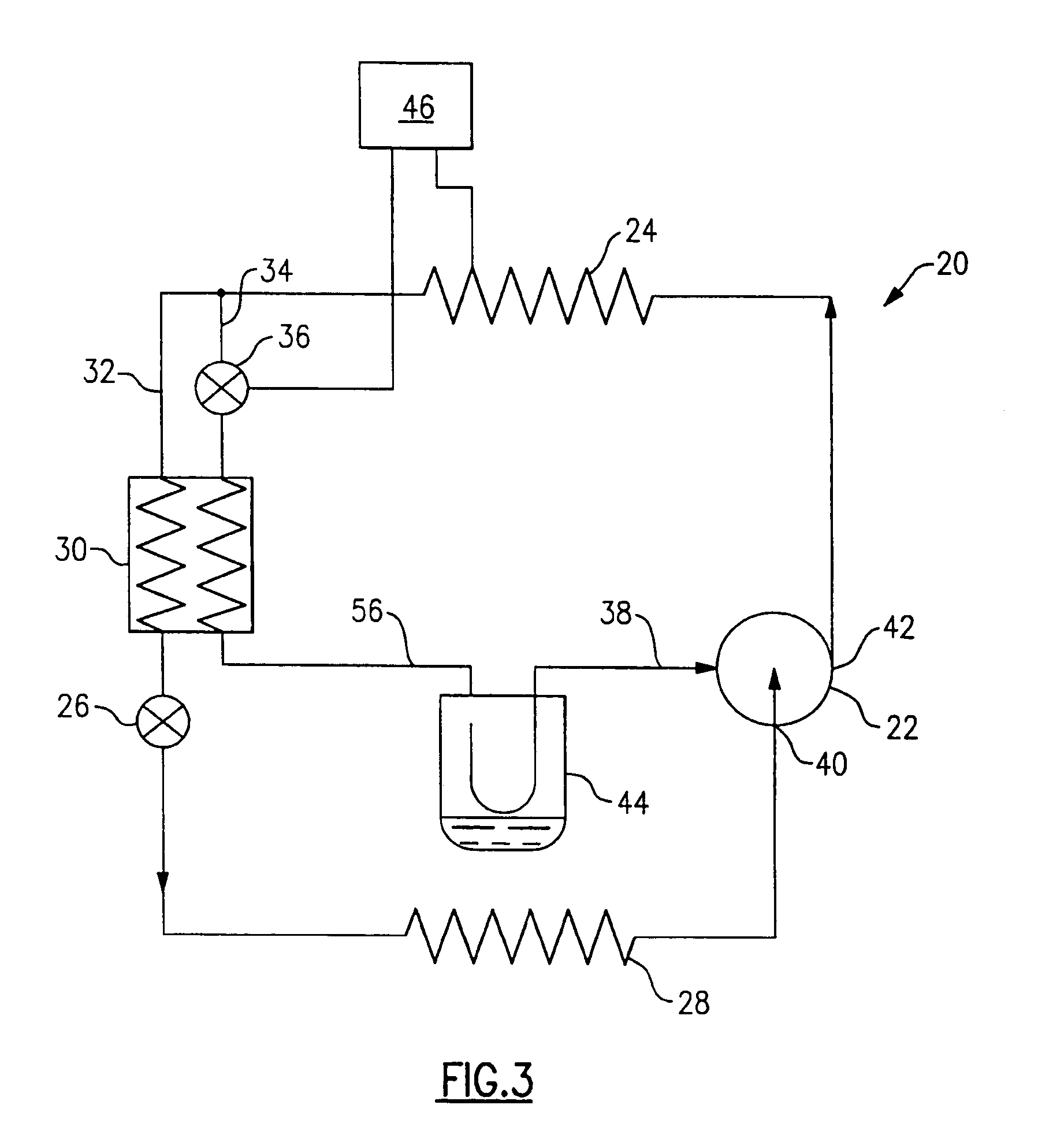

InactiveUS7000413B2Low pour pointCompression machines with non-reversible cycleEvaporators/condensersGas coolerEngineering

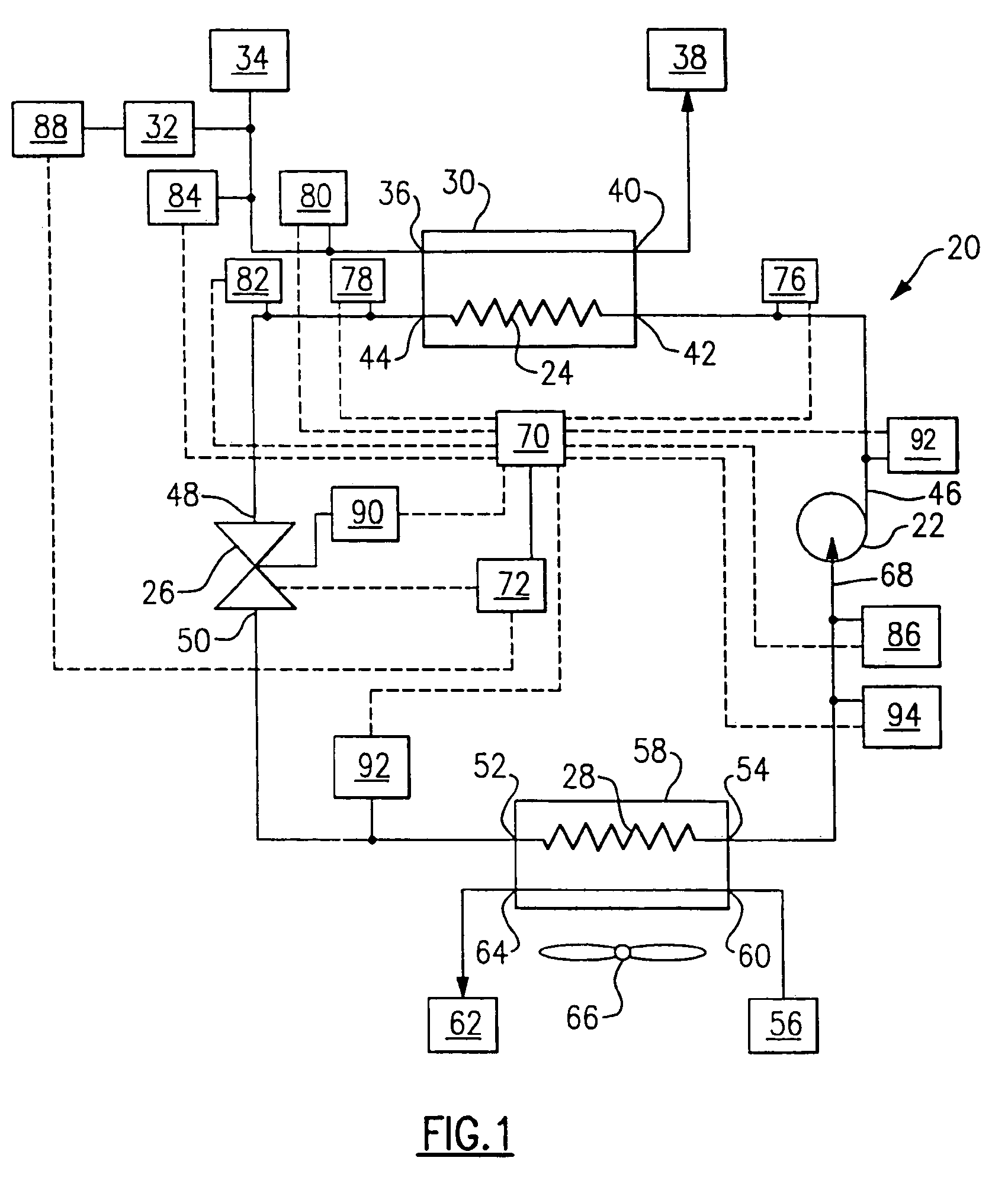

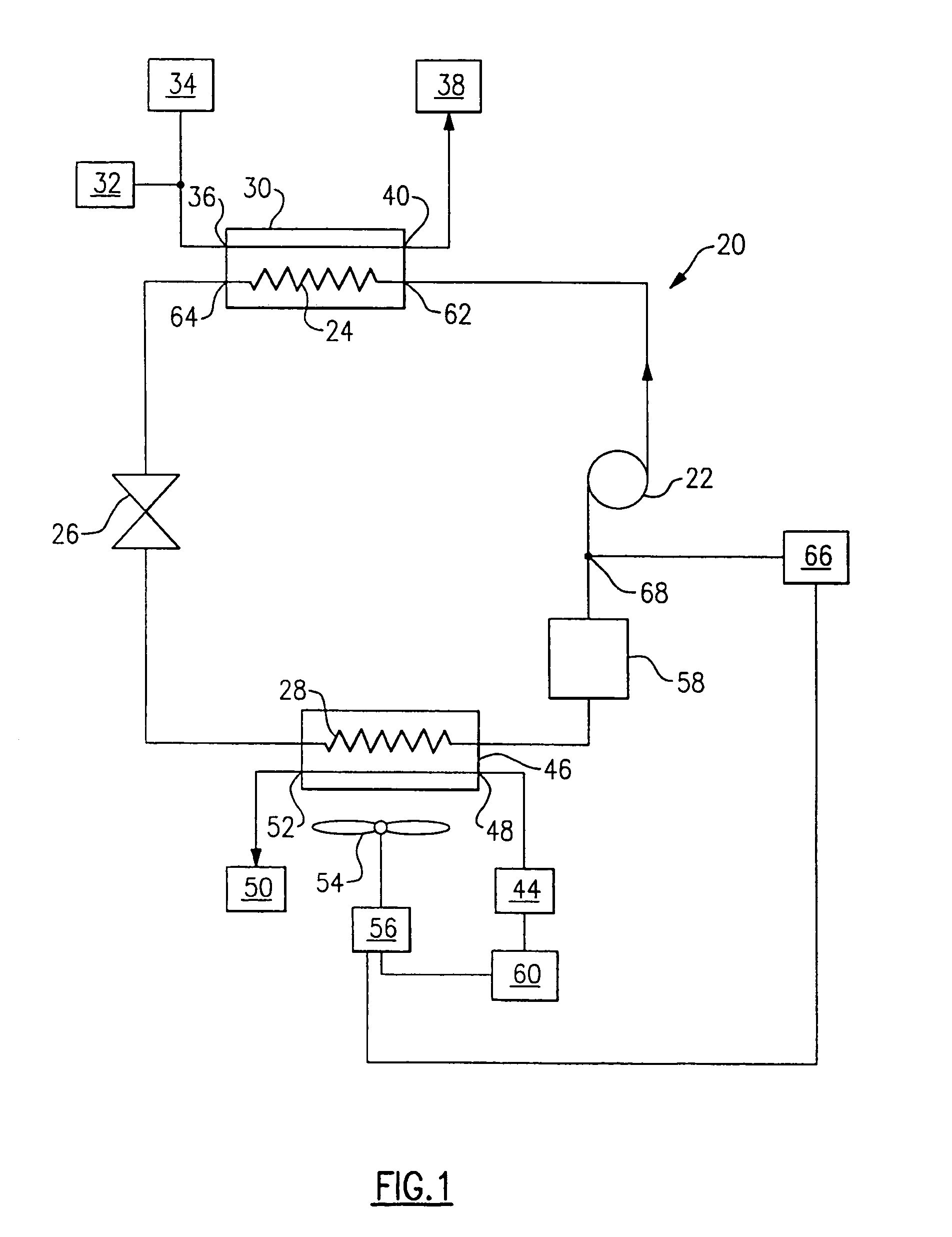

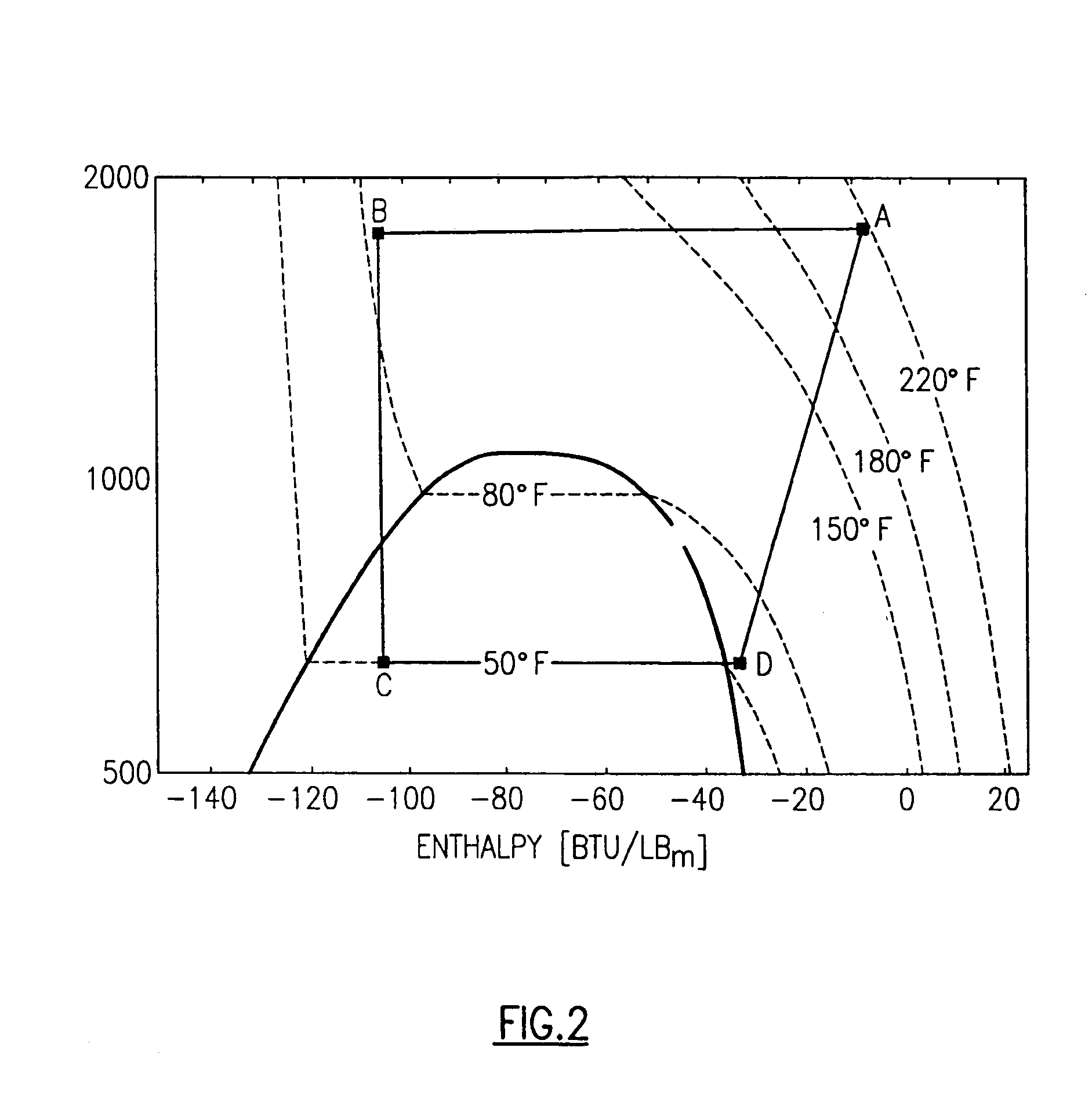

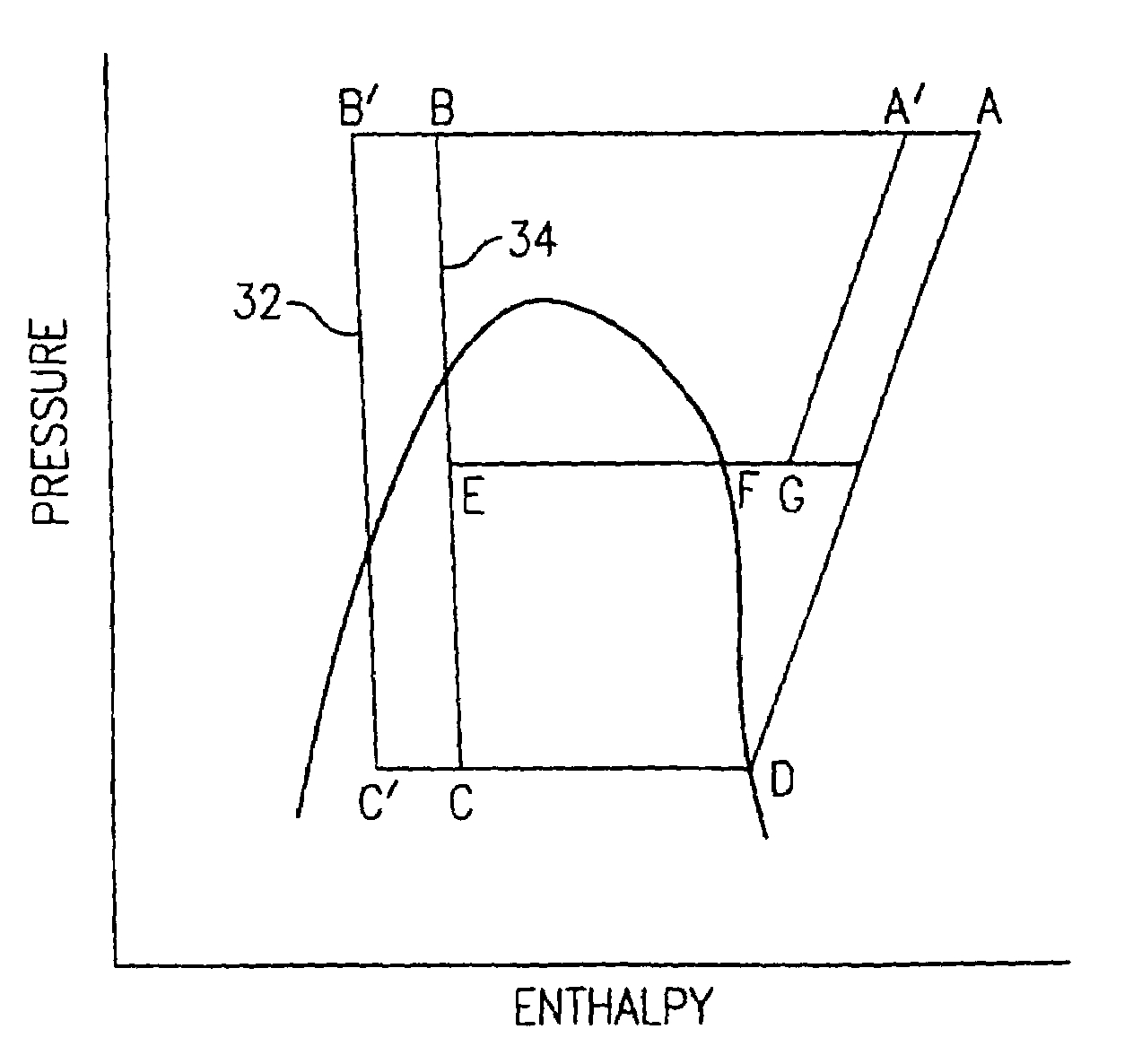

A refrigeration system includes a compressor, a gas cooler, an expansion device, and an evaporator. Refrigerant is circulated though the closed circuit system. Preferably, carbon dioxide is used as the refrigerant. As carbon dioxide has a low critical point, systems utilizing carbon dioxide as a refrigerant usually require the refrigeration system to run transcritical. When the system is operating inefficiently, the system is modified so the system operates efficiently. First, a parameter of the system is monitored by a sensor and the then compared to a stored value to determine if the system is operating inefficiently. If the system is operating inefficiently, the system is modified to an efficient system.

Owner:CARRIER CORP

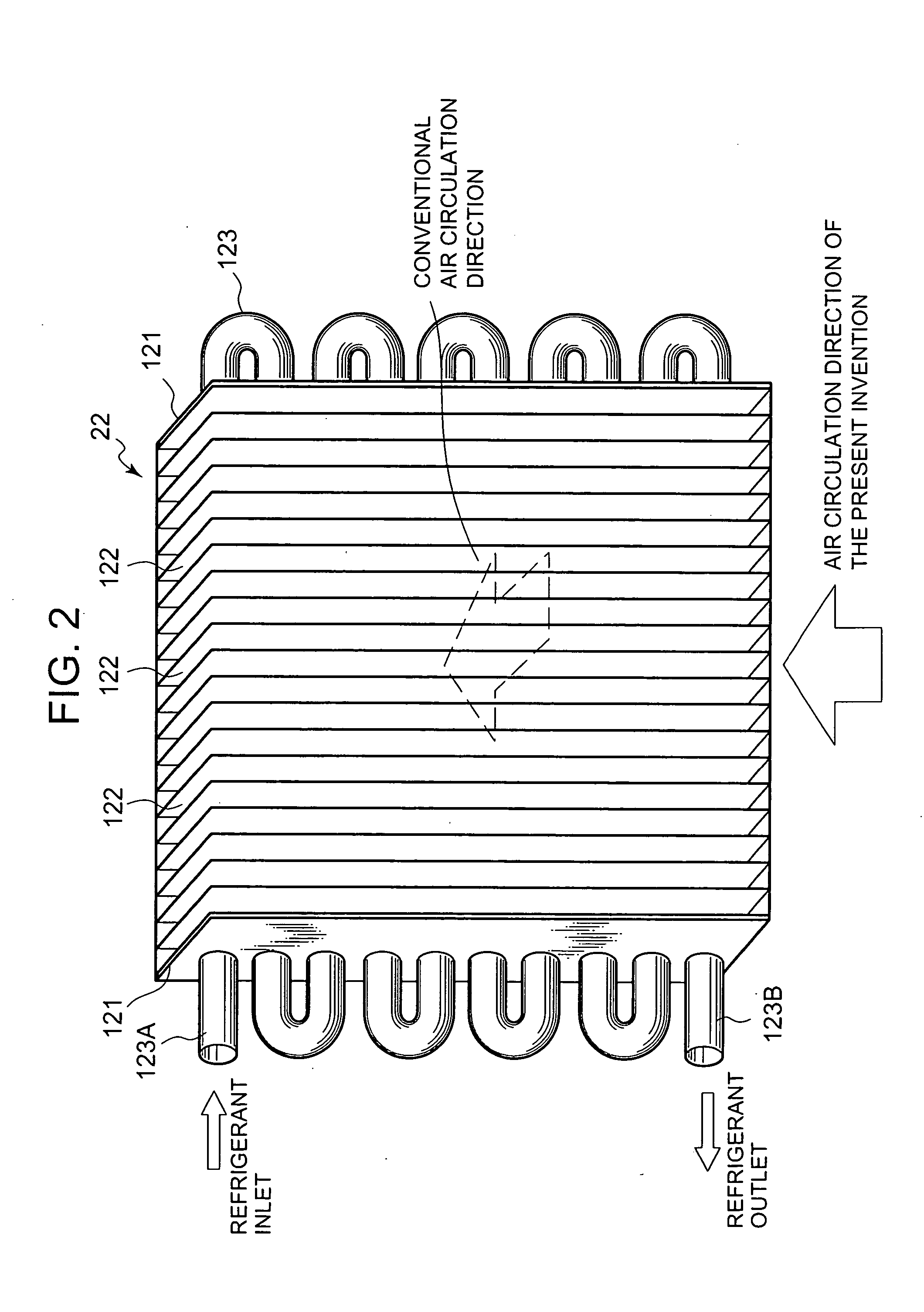

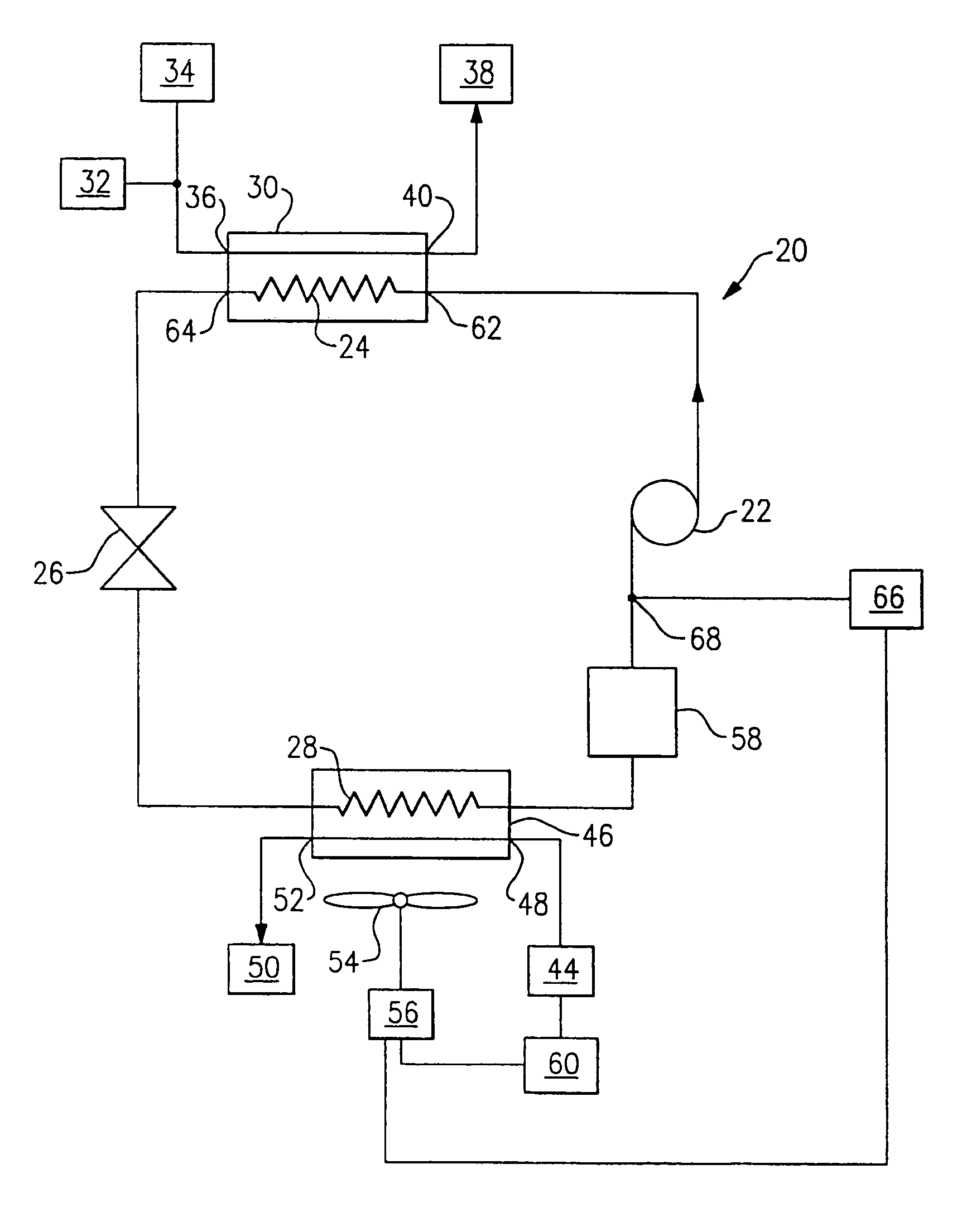

Integrated heat exchanger for use in a refrigeration system

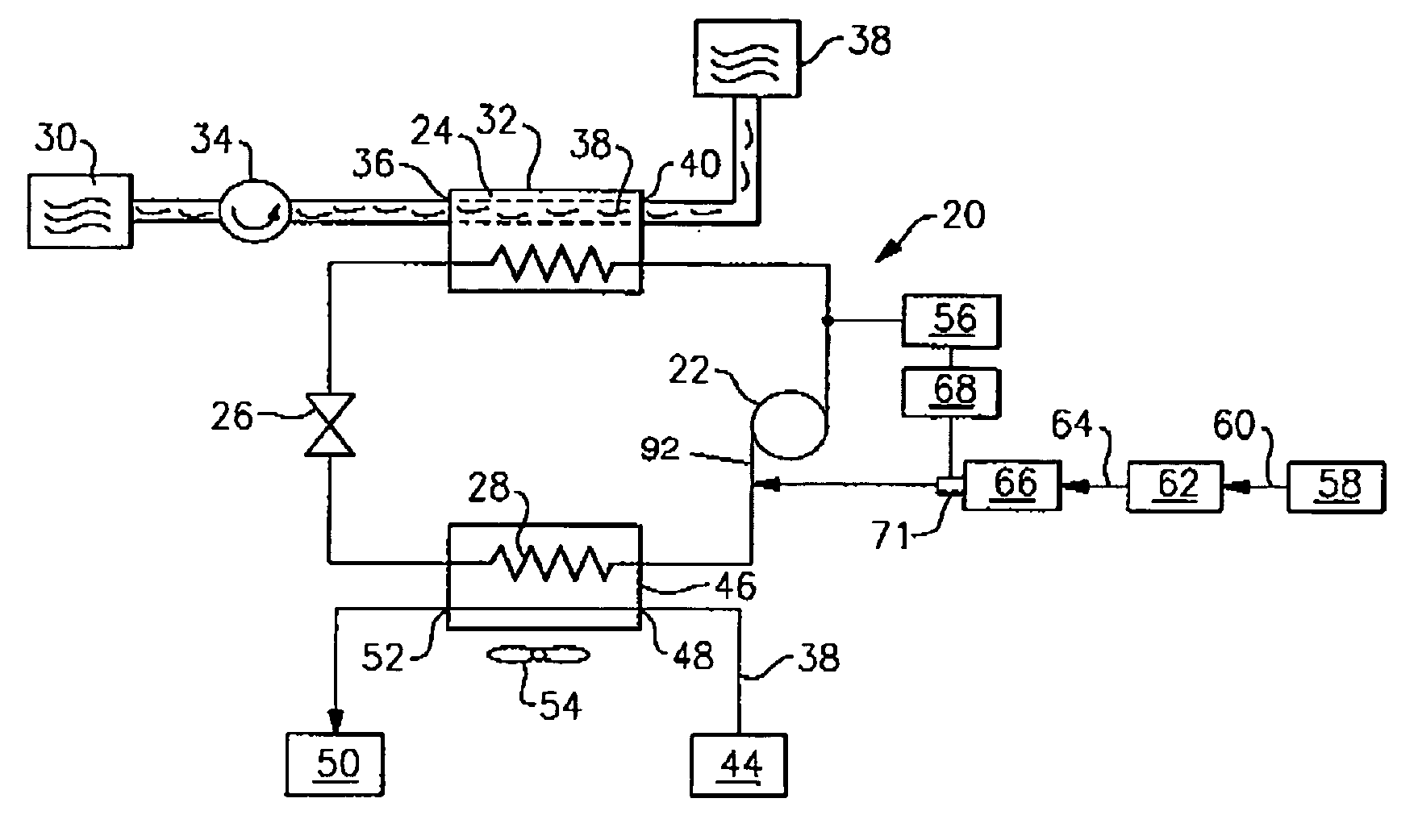

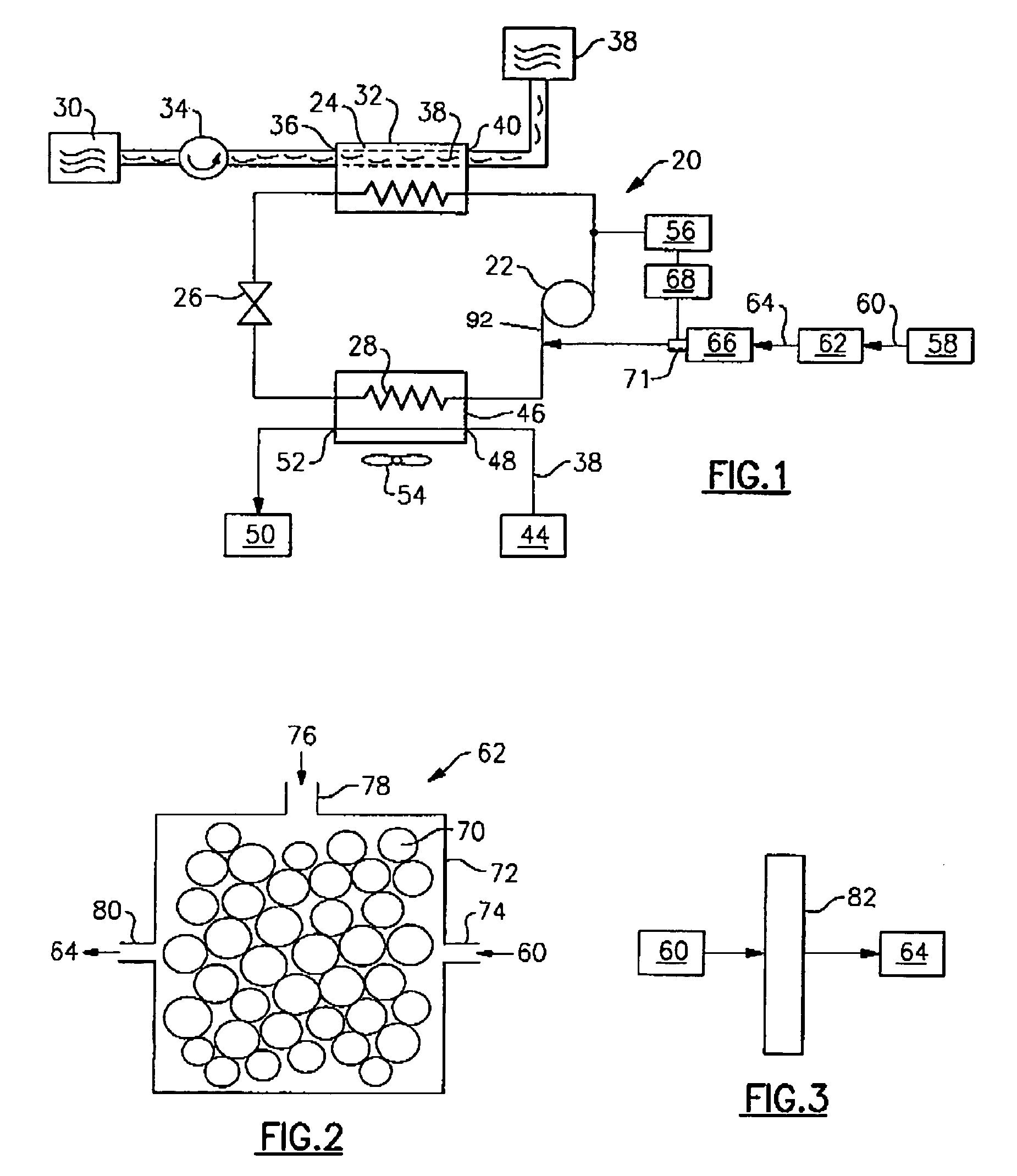

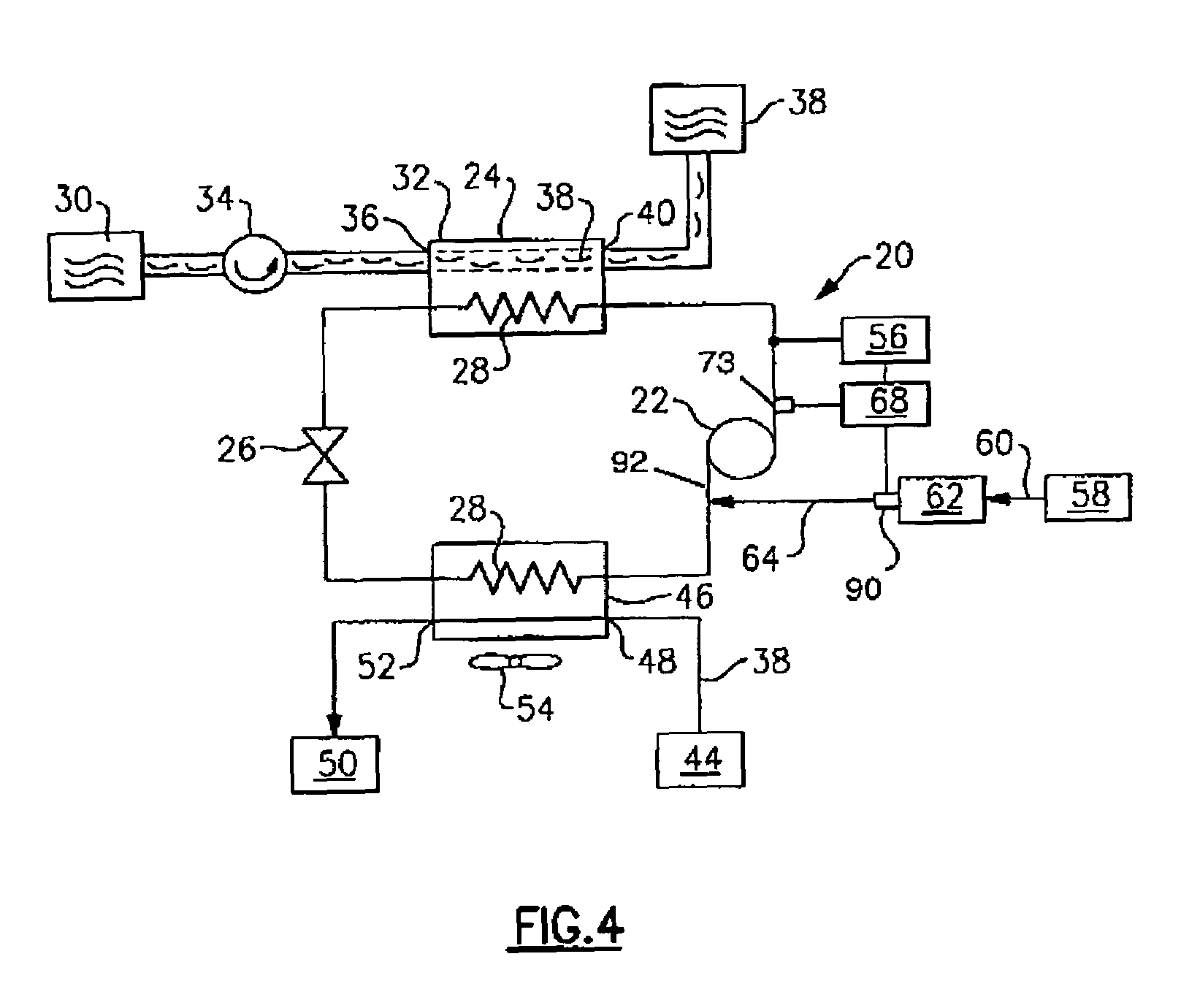

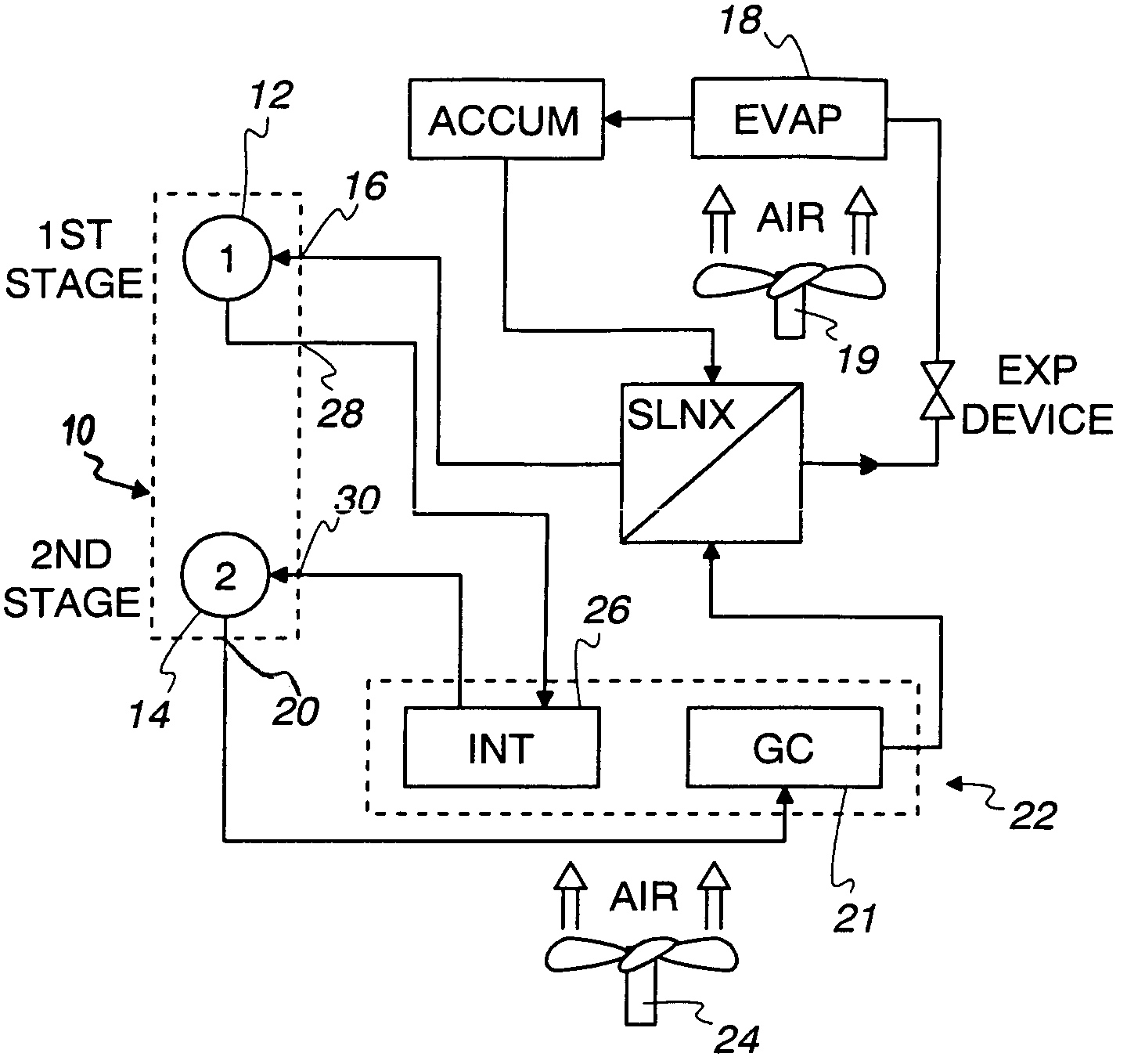

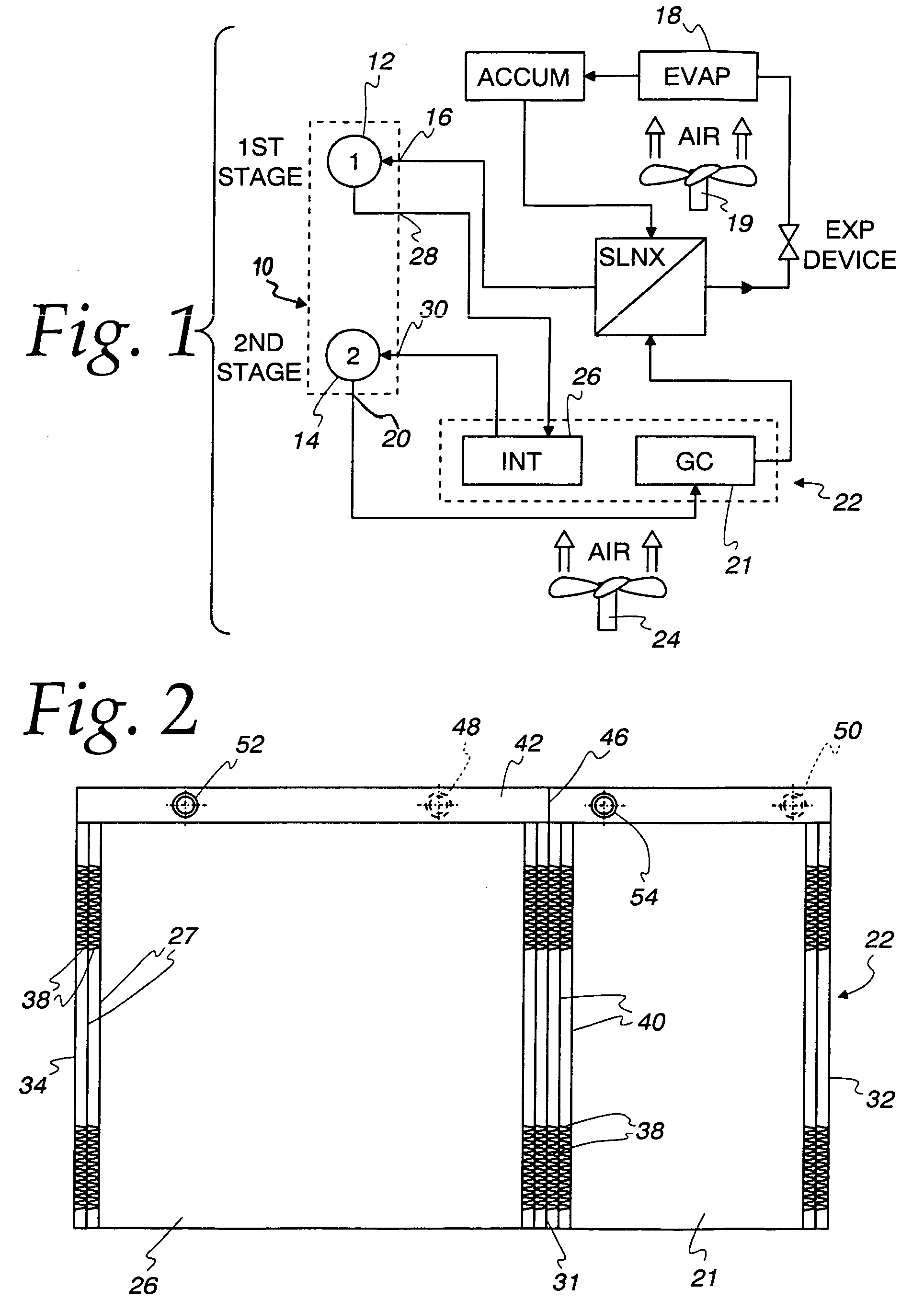

InactiveUS20050279127A1Compression machines with non-reversible cycleEvaporators/condensersGas coolerIntercooler

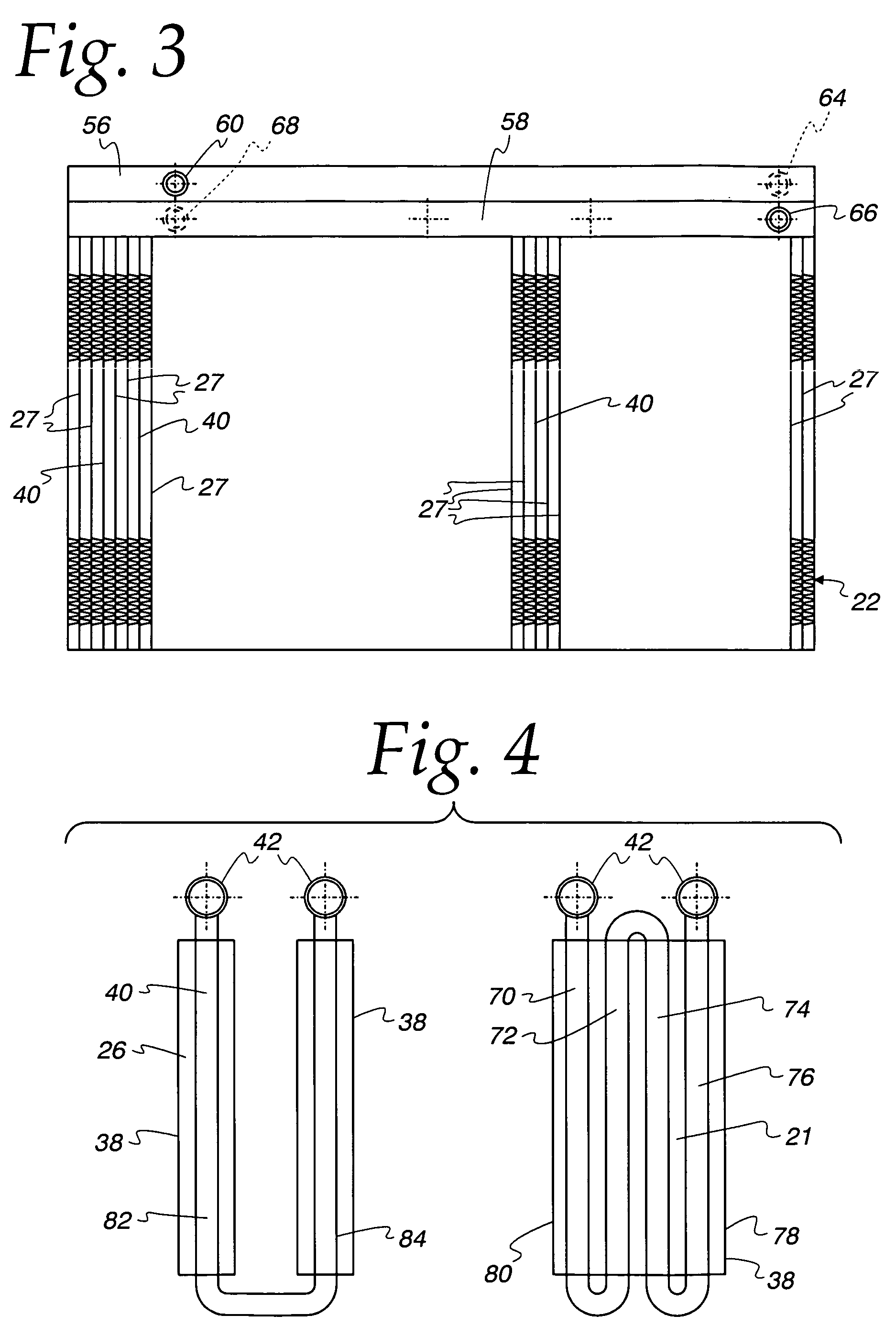

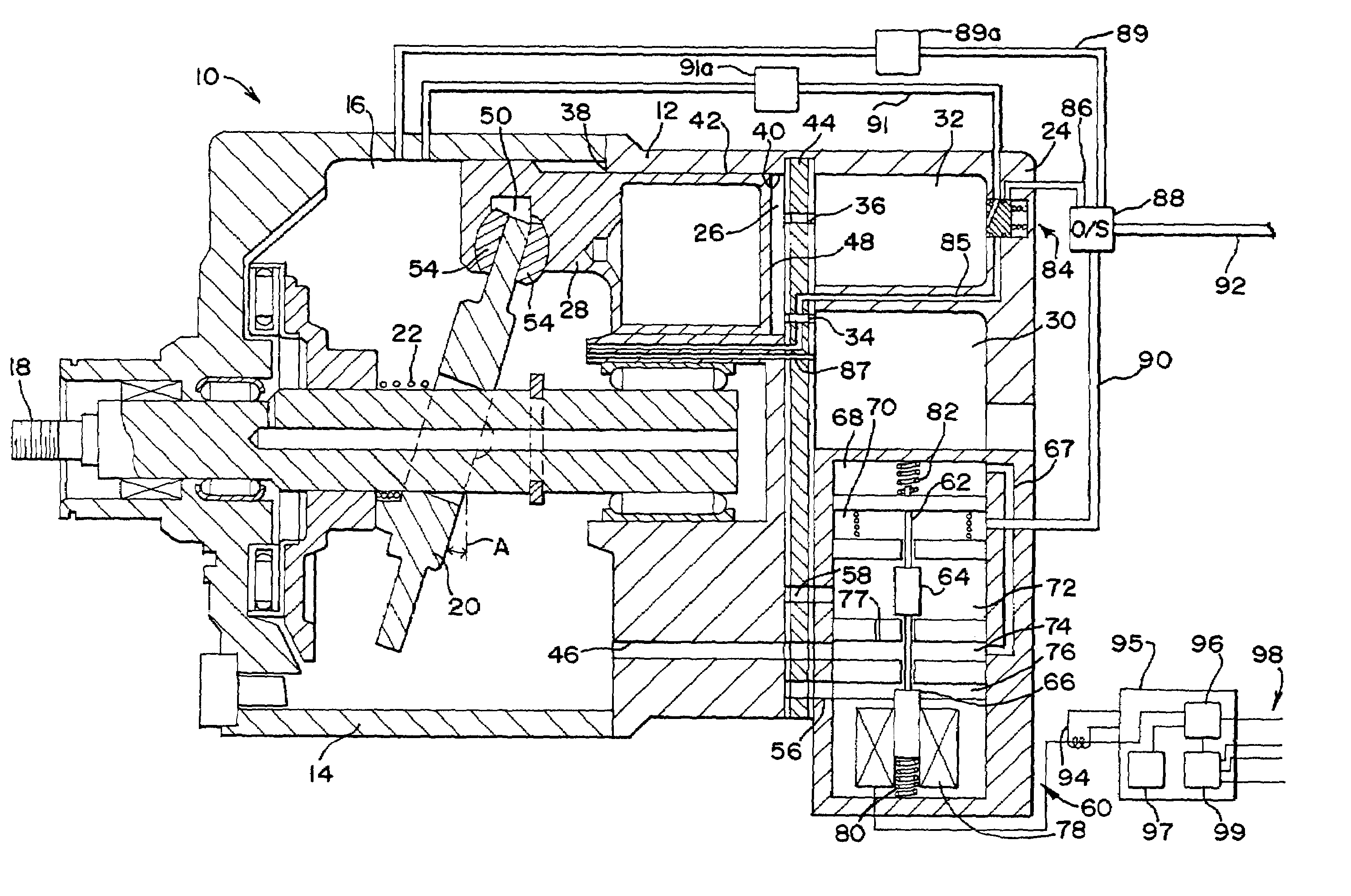

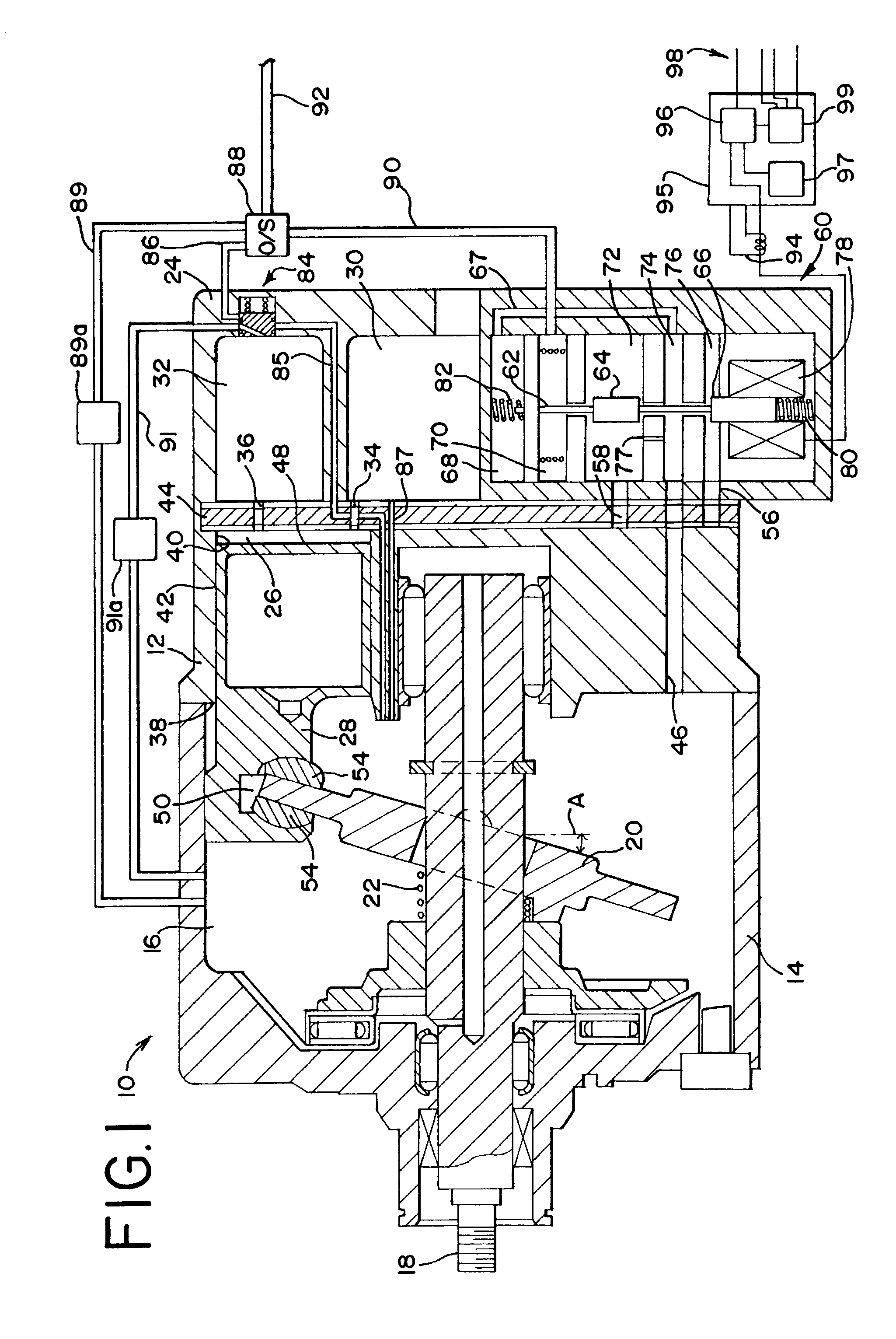

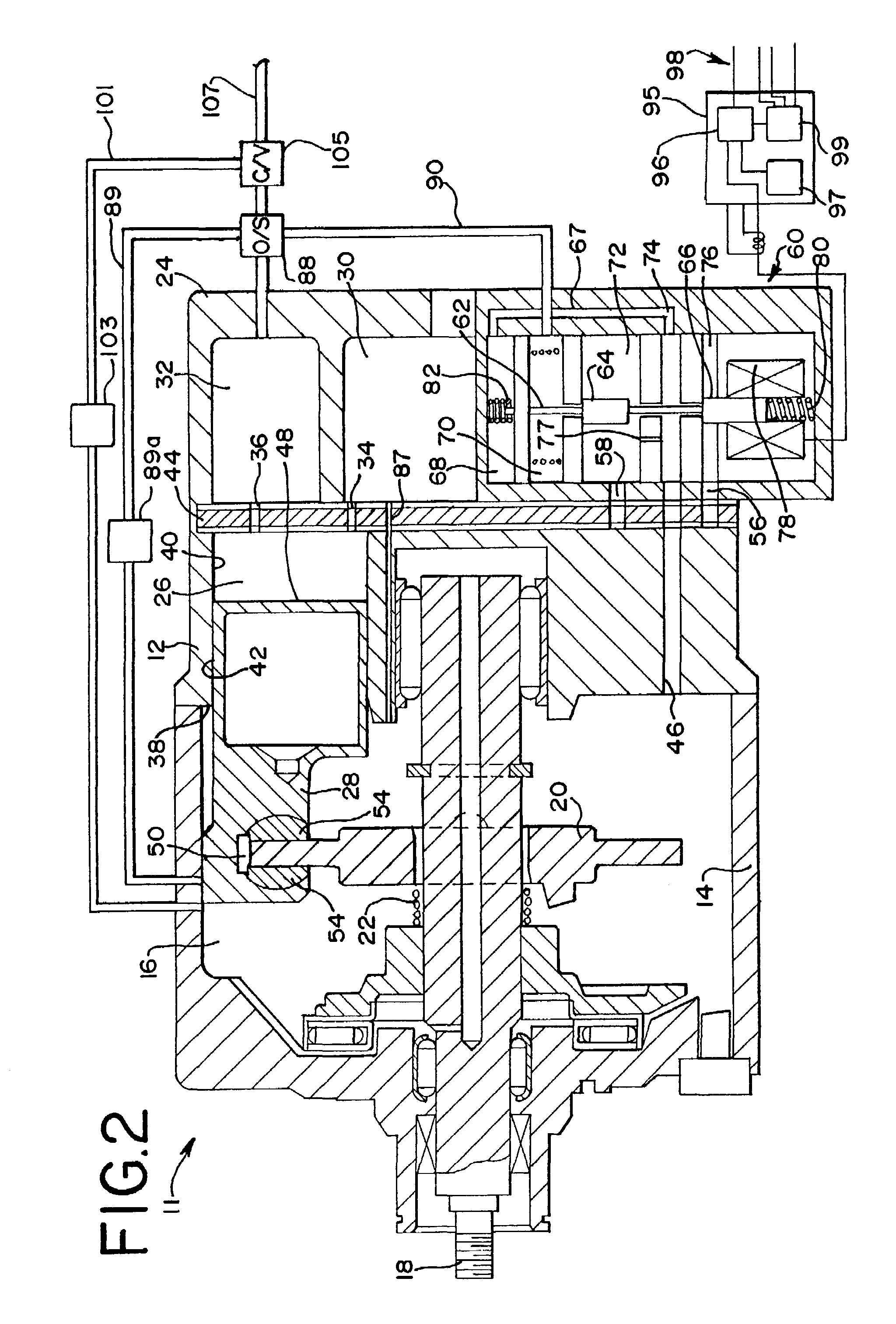

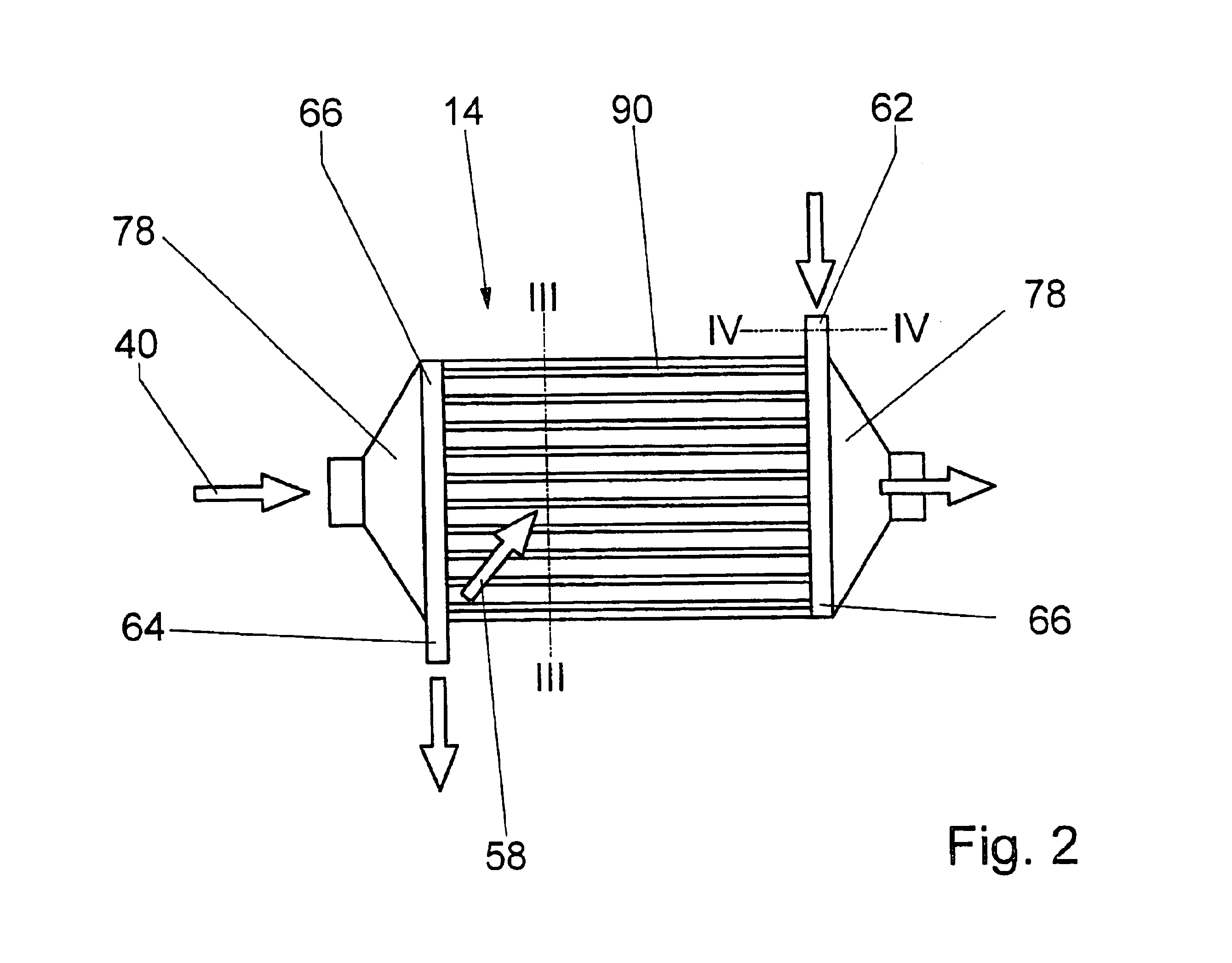

A refrigeration system includes a multiple stage compressor 10 having at least two stages 12,14 for sequentially compressing the refrigerant together with a gas cooler 21 connected to the compressor 10 for receiving compressed refrigerant from the last stage 14 of the compressor to cool the same. An evaporator 18 is connected to the gas cooler 21 via an expansion device to receive cool refrigerant therefrom and cool the fluid stream passing through the evaporator 18. A return passage connects the evaporator 18 to the first stage 12 of the compressor and an intercooler 26 is connected between the first stage 12 and the last stage 14 of the compressor to cool refrigerant compressed by the first stage 12 and direct the refrigerant cooled thereby to the last stage 14 for further compression. The intercooler 26 and the gas cooler 21 are integrated into a single unit 22 and receive a single cooling heat exchange fluid and the gas cooler 21 has a larger heat transfer surface area than the intercooler 26.

Owner:MODINE MFG CO

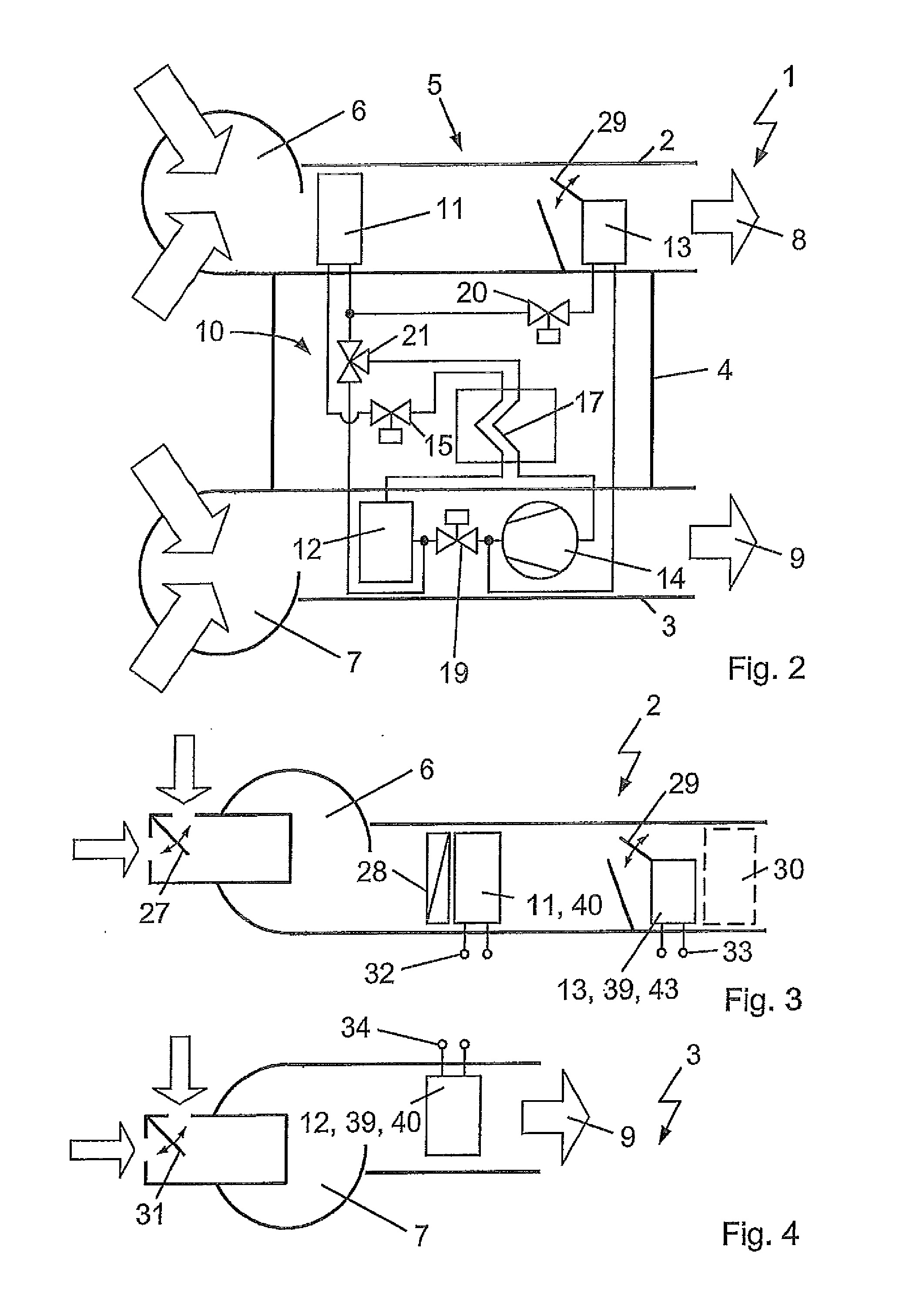

Modular refrigeration unit

InactiveUS20050172654A1Easy to removeEasily into and removedShow cabinetsCompression machinesModularityEngineering

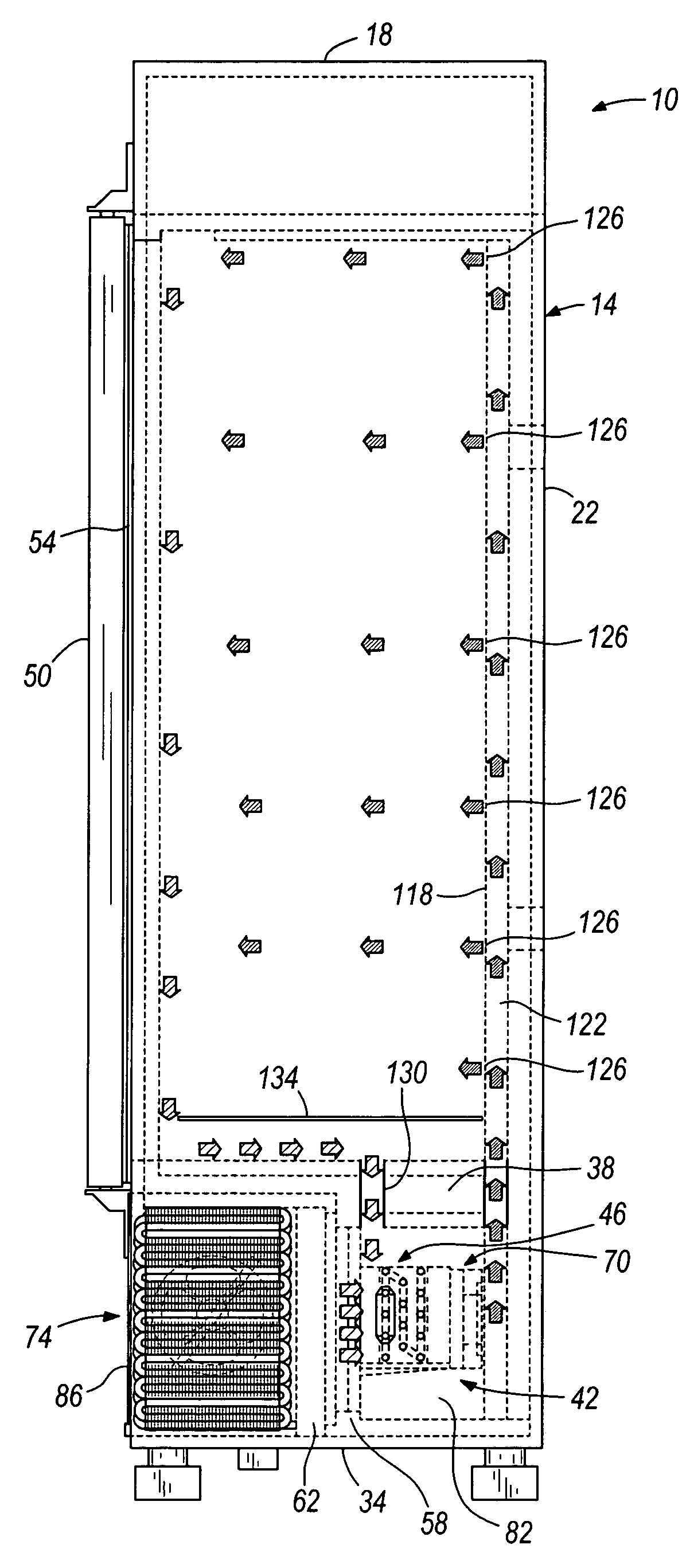

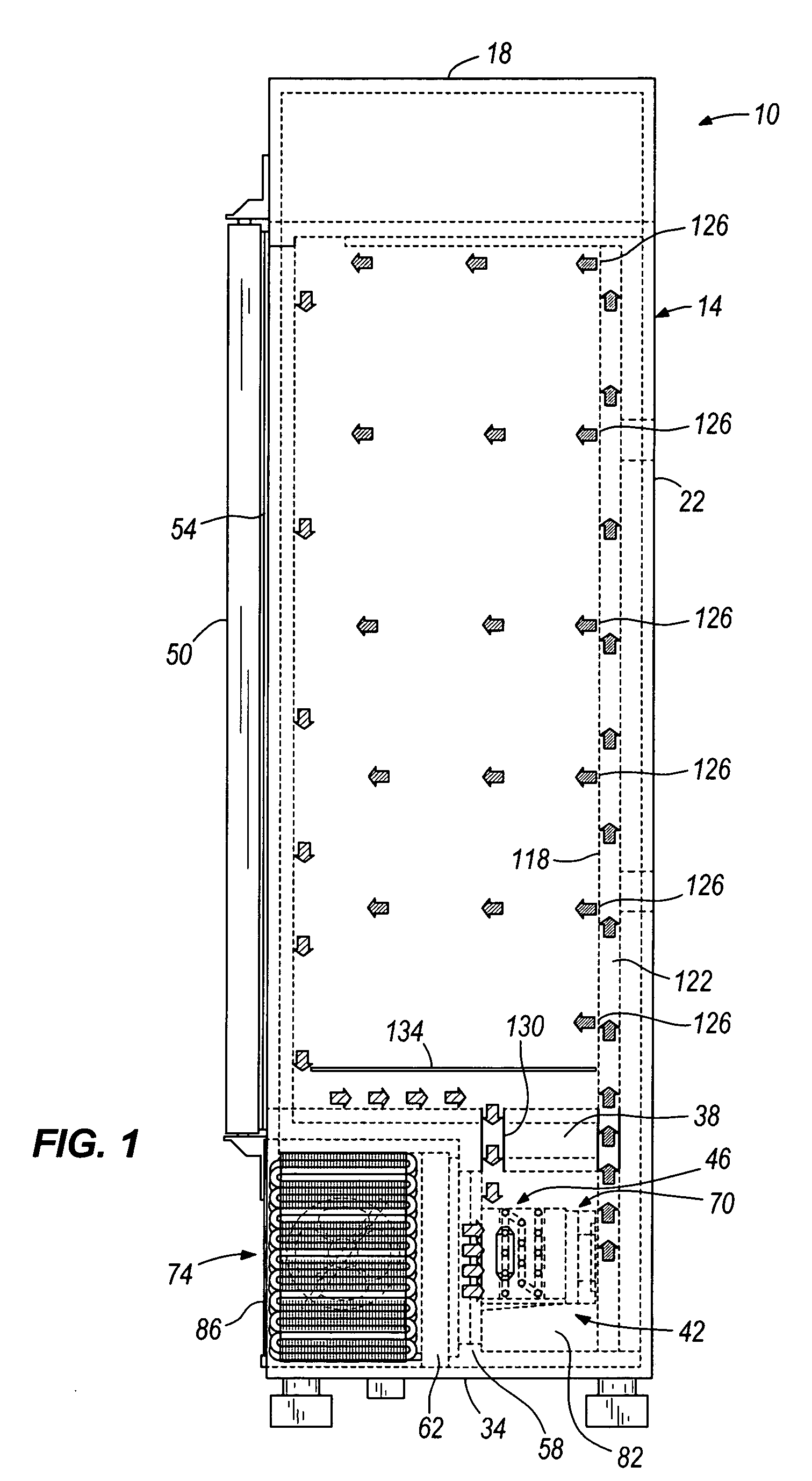

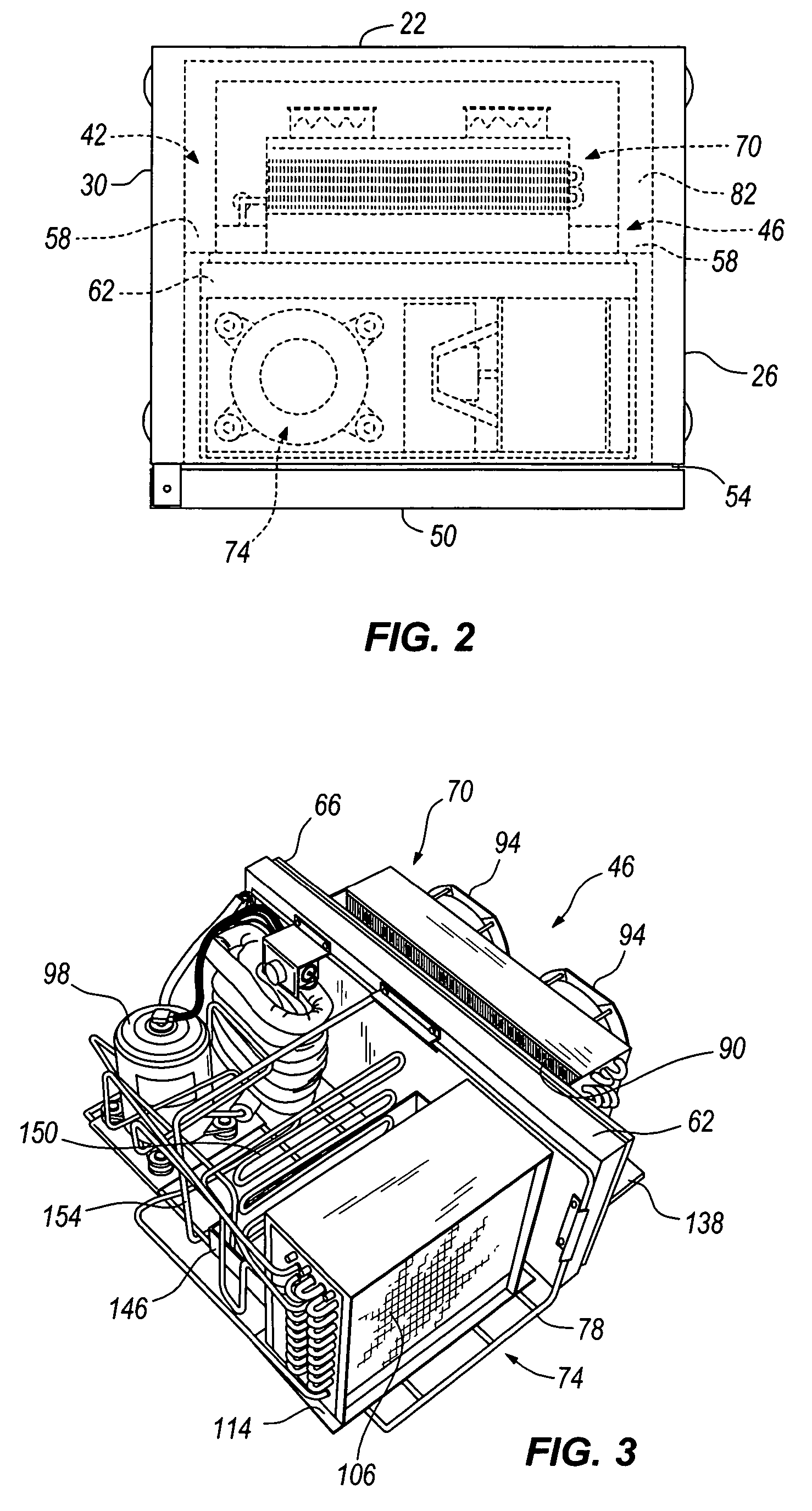

A modular refrigeration unit for use in an accessible compartment of a cooler, a cooler comprising a modular refrigeration unit, and a method for a modular refrigeration unit. The modular refrigeration unit can include a gas cooler assembly mounted to a support and positioned on one side of a dividing wall, and an evaporator assembly mounted to the dividing wall and positioned on the opposite side of the dividing wall from the gas cooler assembly. The modular refrigeration unit can include CO2 refrigerant adapted to be circulated between the evaporator assembly and the gas cooler assembly.

Owner:HUSNN

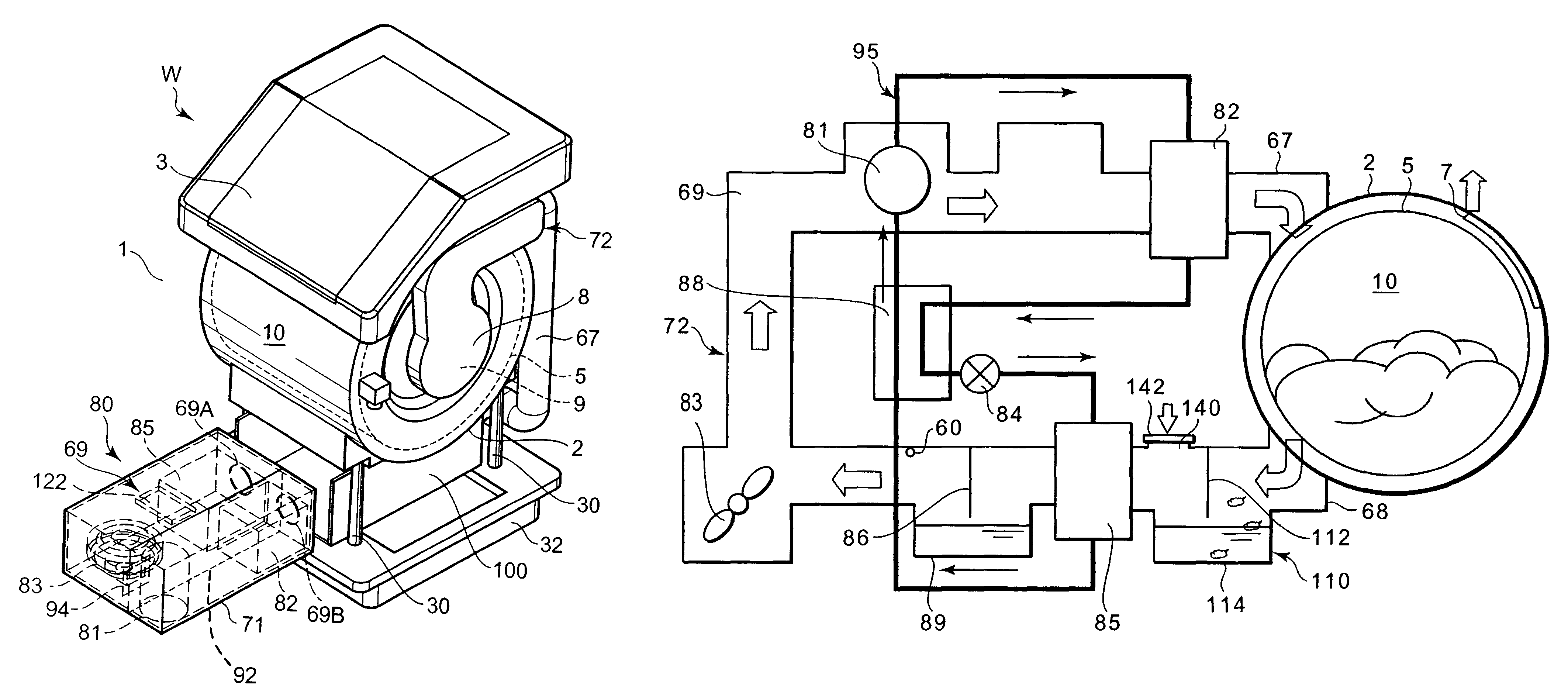

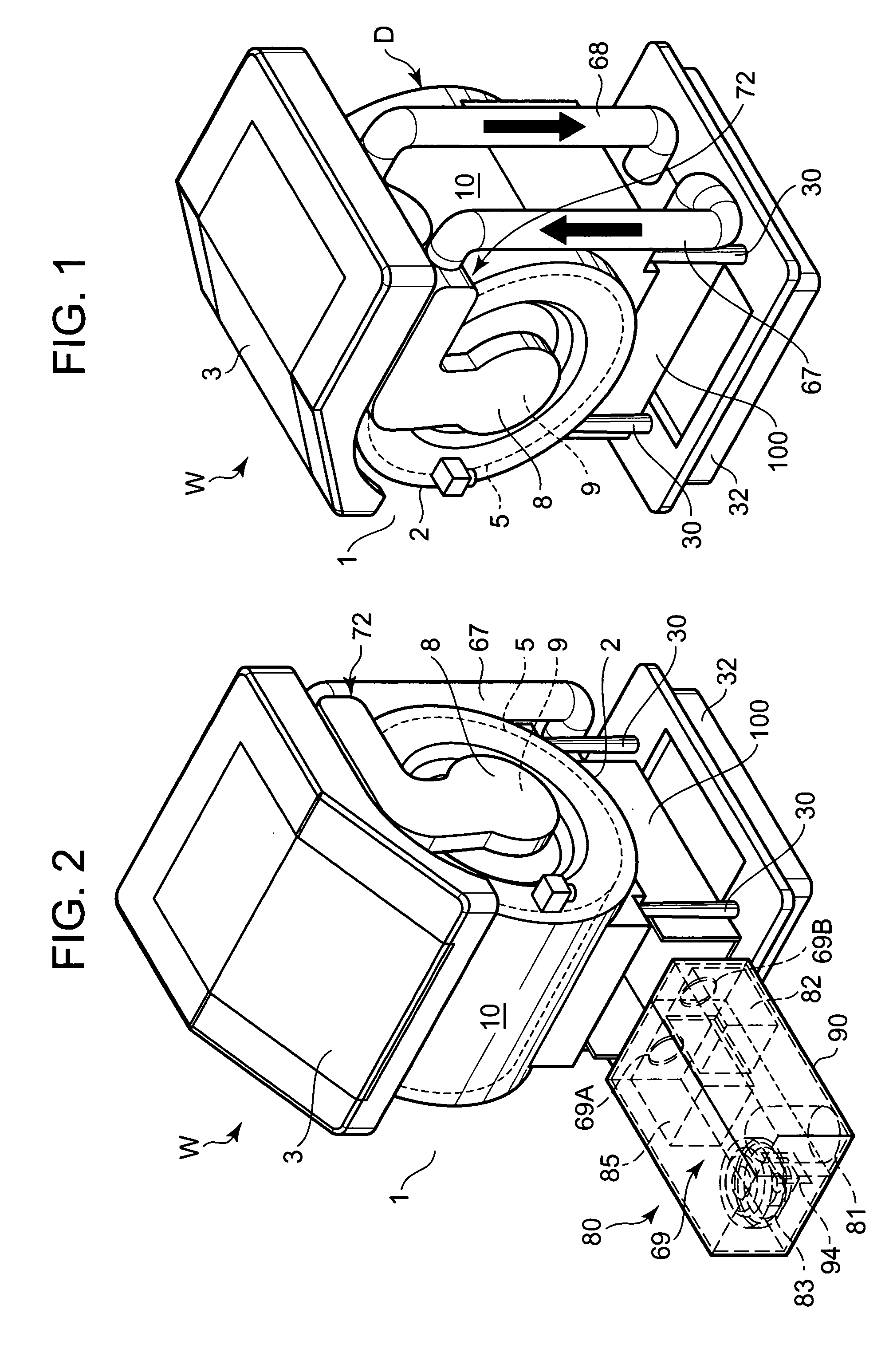

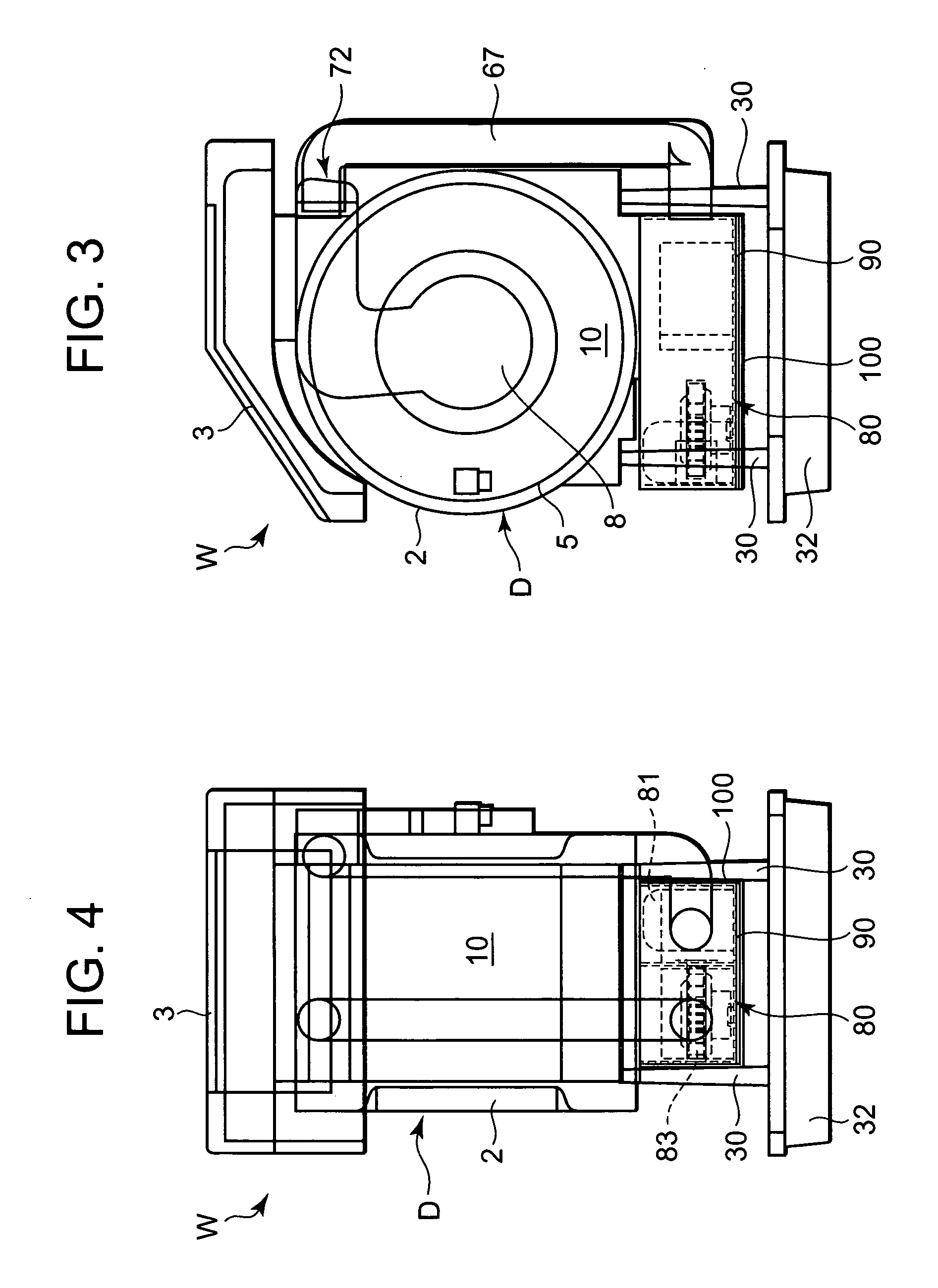

Drying apparatus

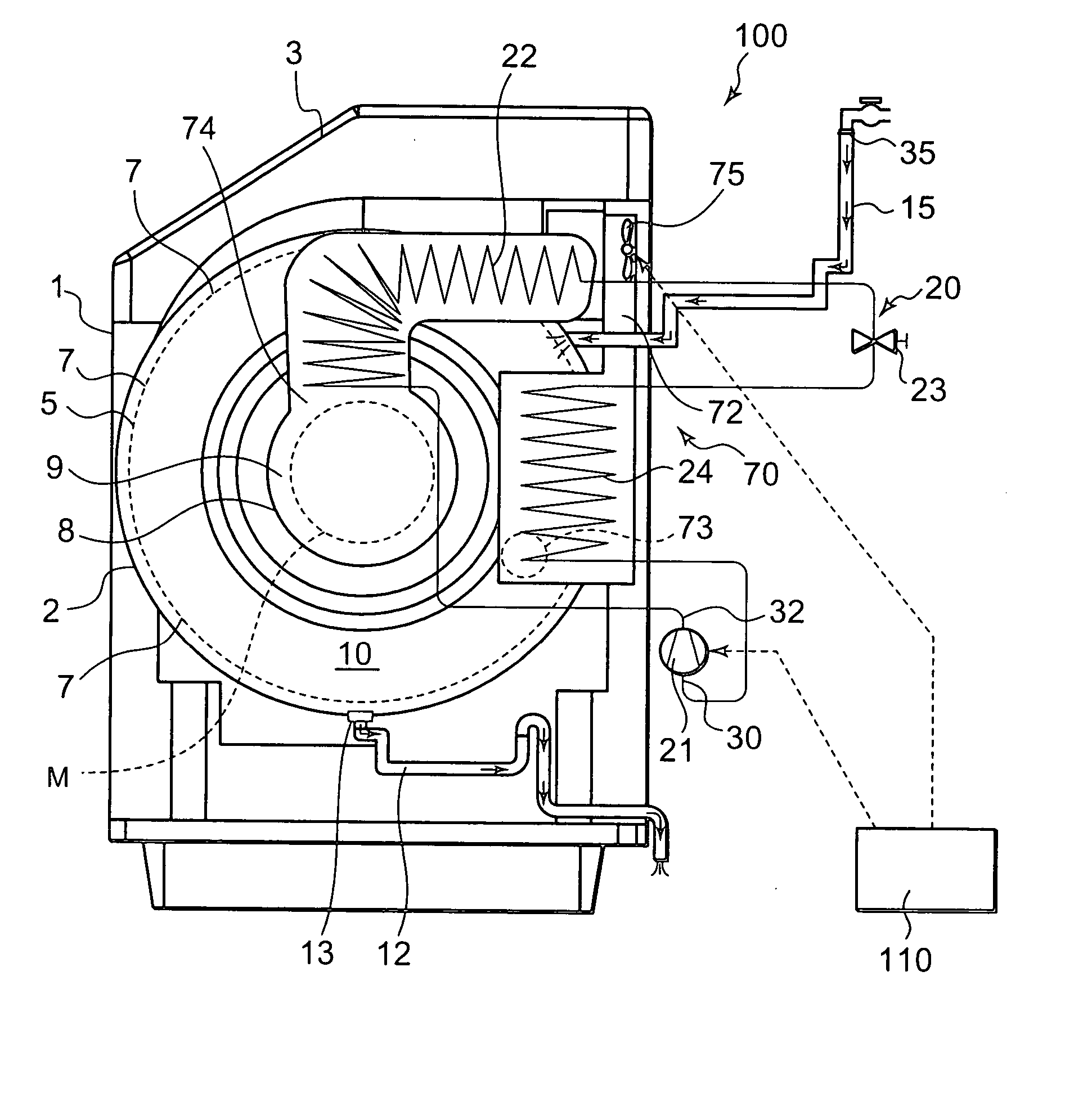

ActiveUS7024795B2Evenly heatedEven dehumidificationDrying solid materials with heatDrying gas arrangementsAir cycleProcess engineering

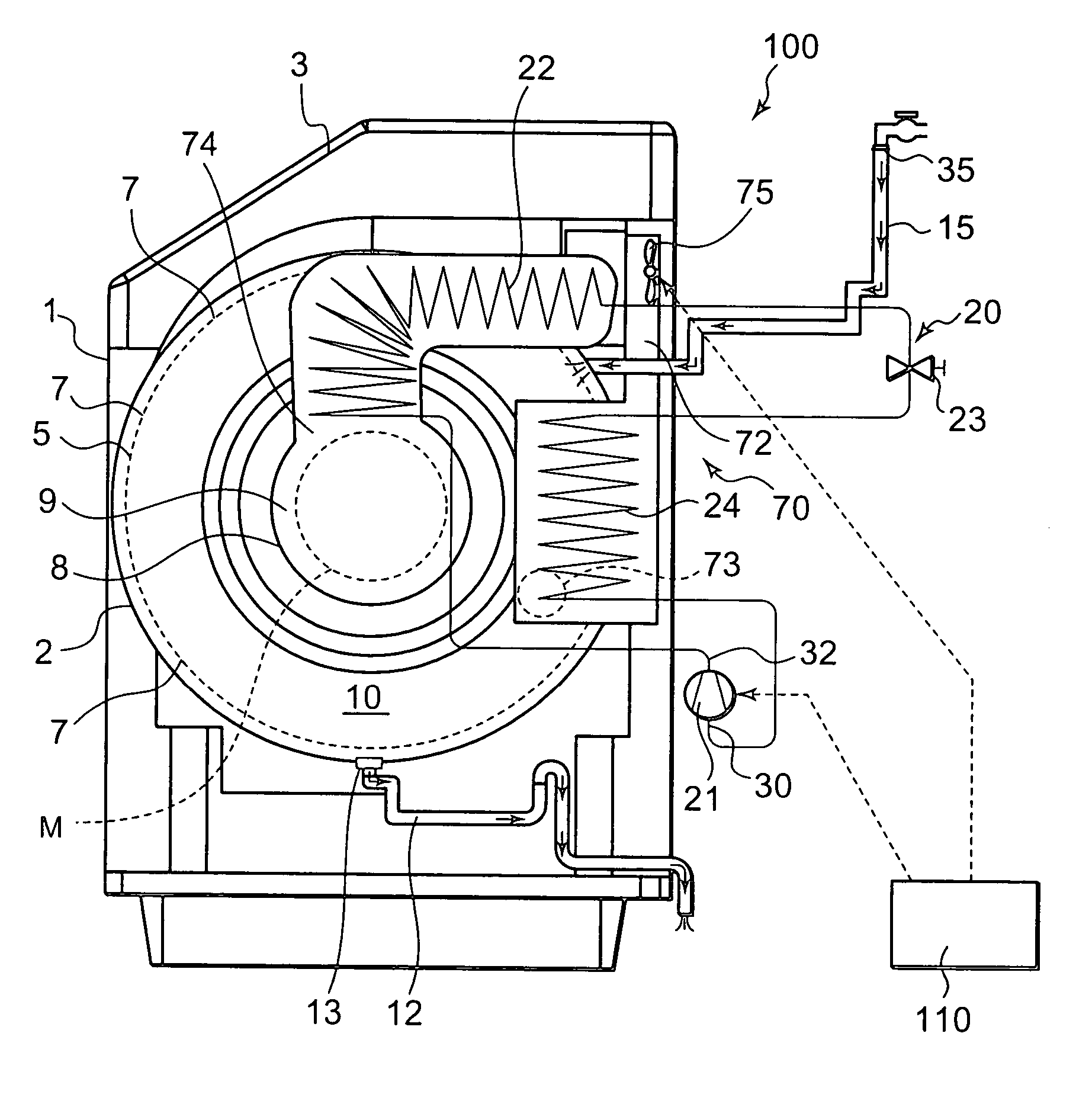

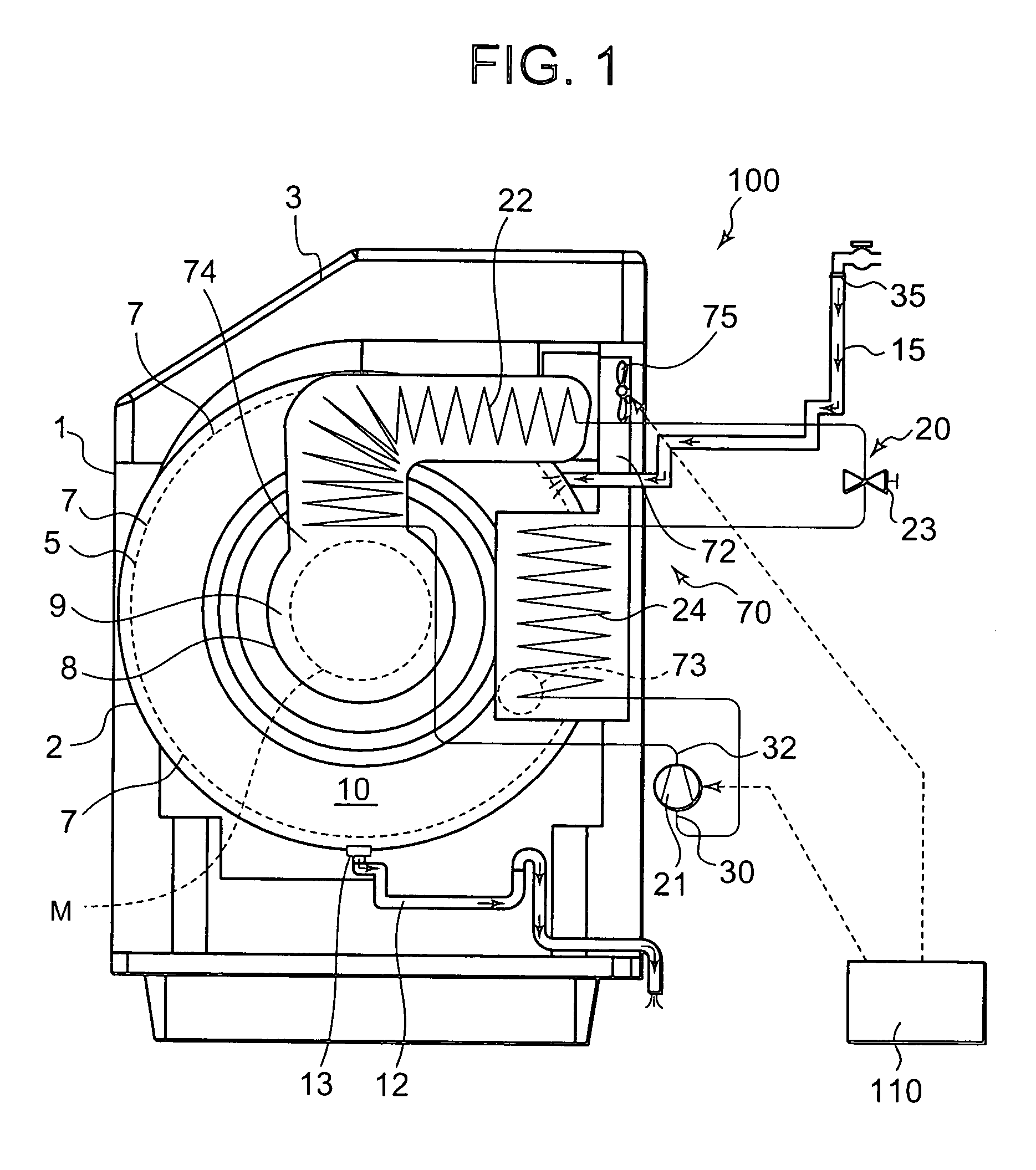

A drying apparatus having a purpose of shortening a drying time of laundry, comprising an accommodating chamber in which the laundry is accommodated, and executing a washing operation of the laundry and a drying operation after end of the washing operation in the accommodating chamber, the machine comprising: a refrigerant circuit in which a compressor, a gas cooler, an expansion valve, and an evaporator are successively connected to one another in an annular form via a piping; an air circulation path for discharging air which has exchanged heat with the gas cooler into the accommodating chamber by a blower to exchange the heat of the air passed through the accommodating chamber with the evaporator; and a control device for operating the compressor and the blower to perform the drying operation, wherein the control device starts the operation of the compressor before entering the drying operation.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

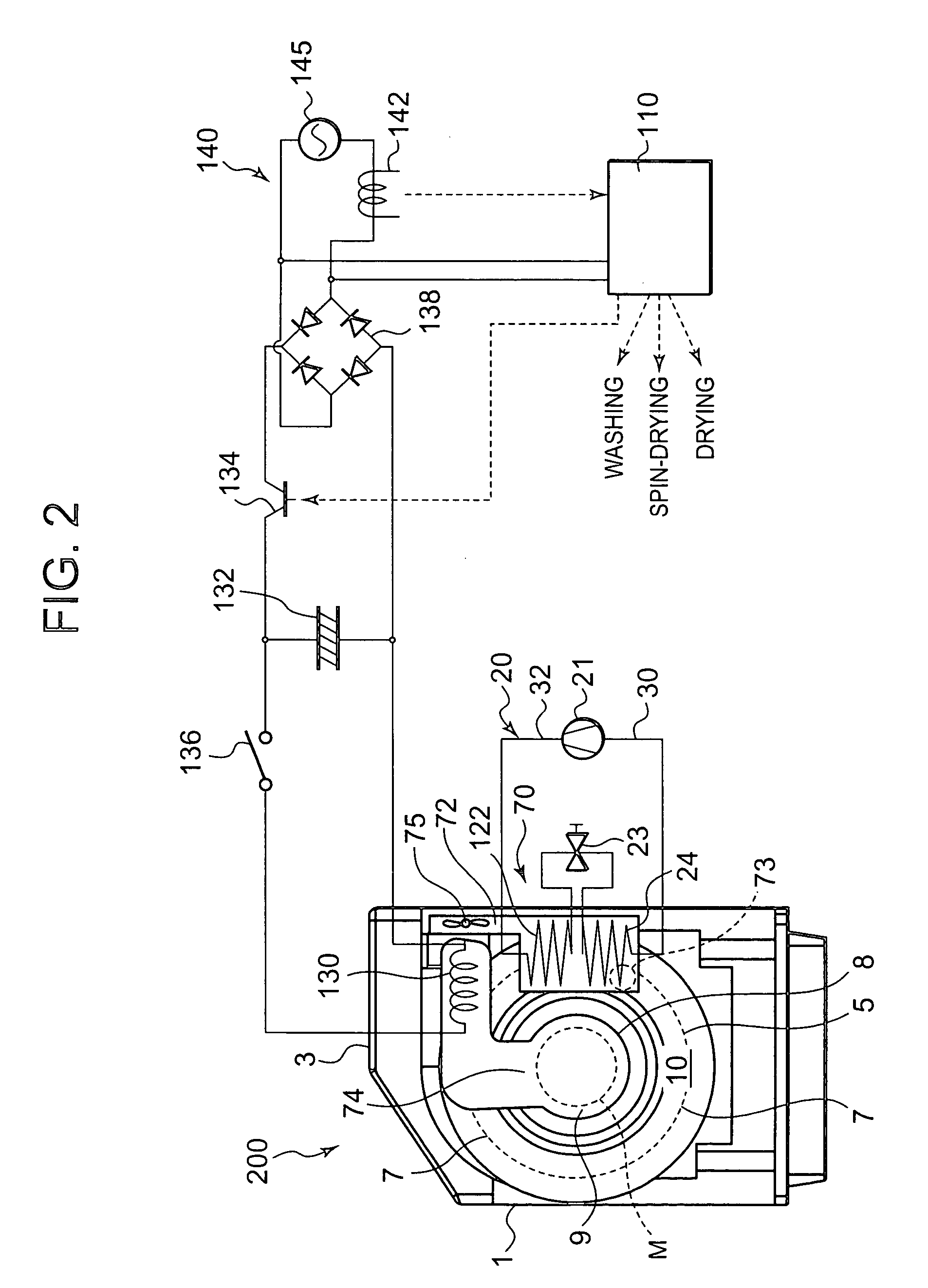

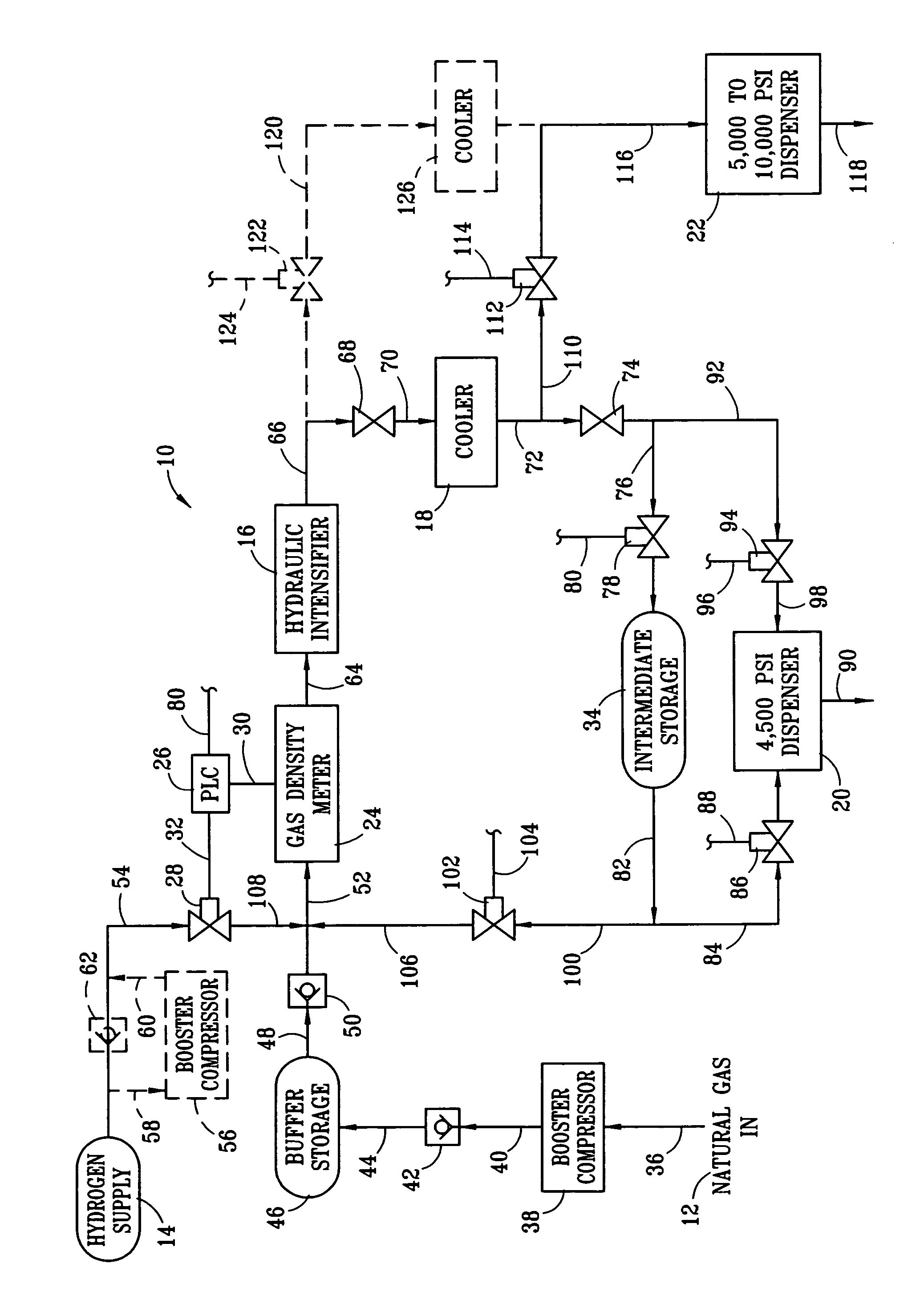

Dual-service system and method for compressing and dispensing natural gas and hydrogen

InactiveUS7168464B2Easy to switchFacilitate pressureLiquid fillingFrozen sweetsVolumetric Mass DensityGas cooler

A dual service system and method for selectively compressing and dispensing methane, hydrogen, and variable mixtures of methane and hydrogen for use as a gaseous fuel. The use of an in-line gas density meter, hydraulic intensifier, pressurized gas cooler, optional intermediate storage and multiple dispensers are disclosed. An inline gas density meter is used in combination with a programmable logic controller and a control valve on the hydrogen supply line to create a closed feedback loop for selectively controlling the hydrogen content of the resultant pressurized fuel gas.

Owner:INTEGRYS TRANSPORTATION FUELS

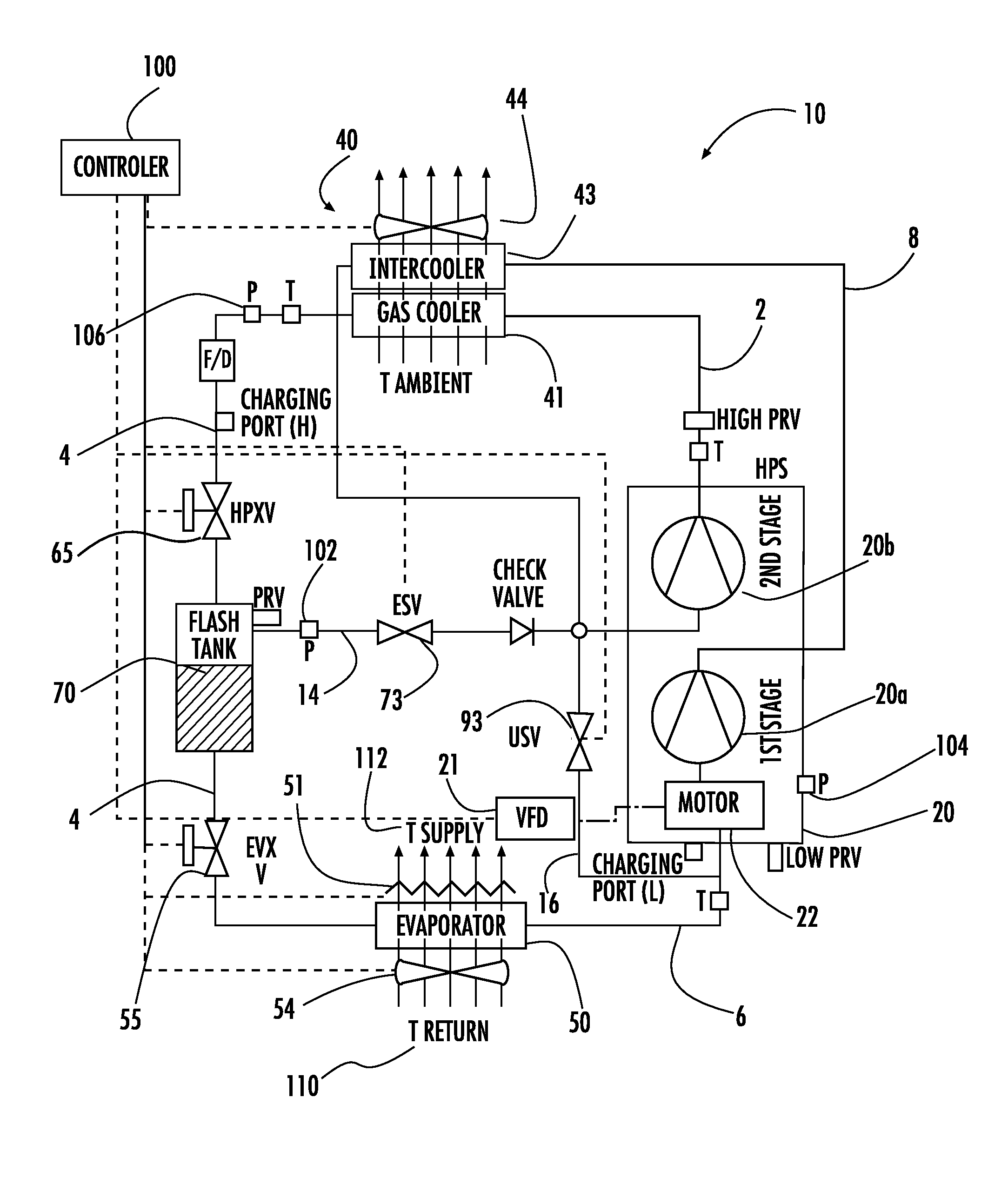

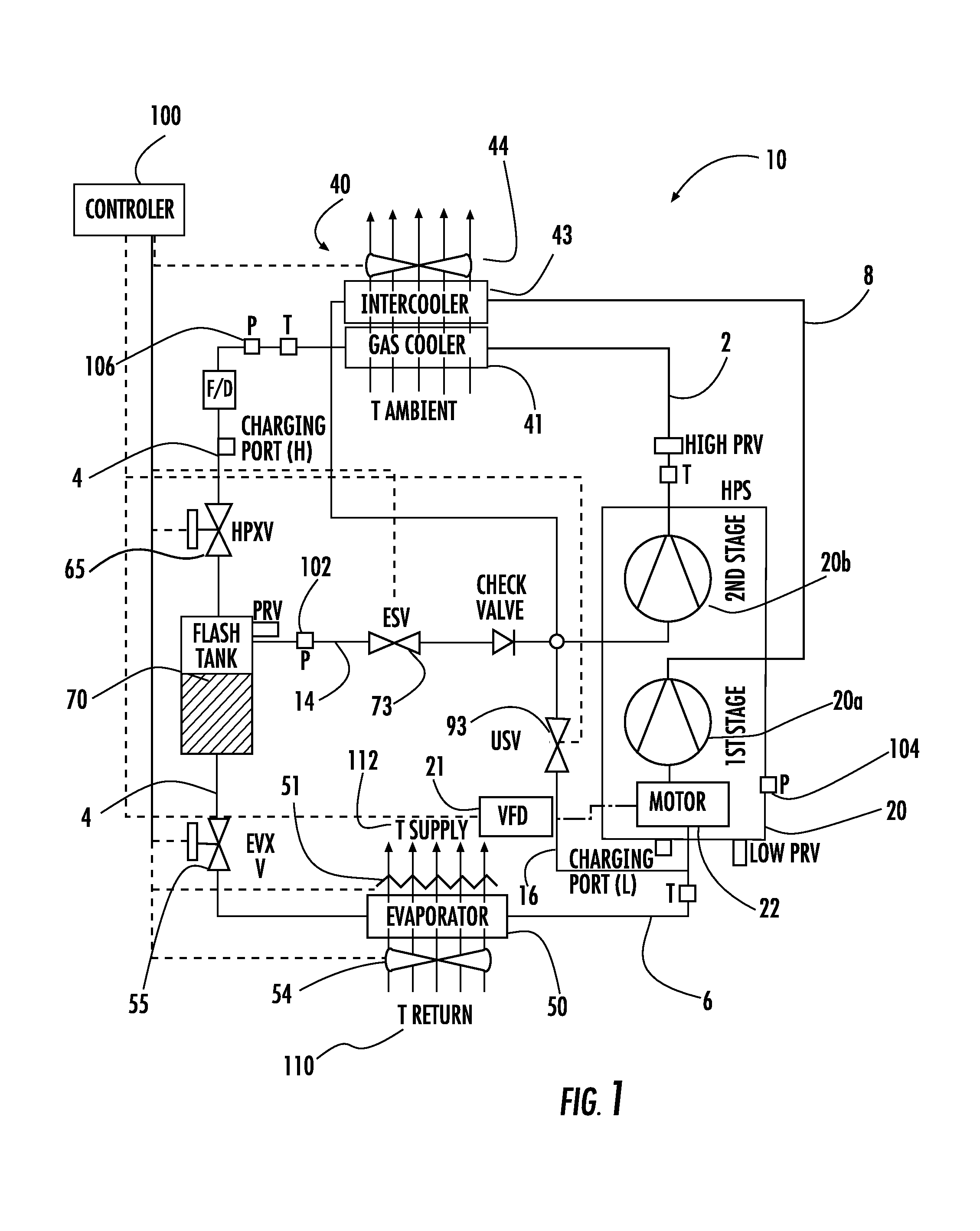

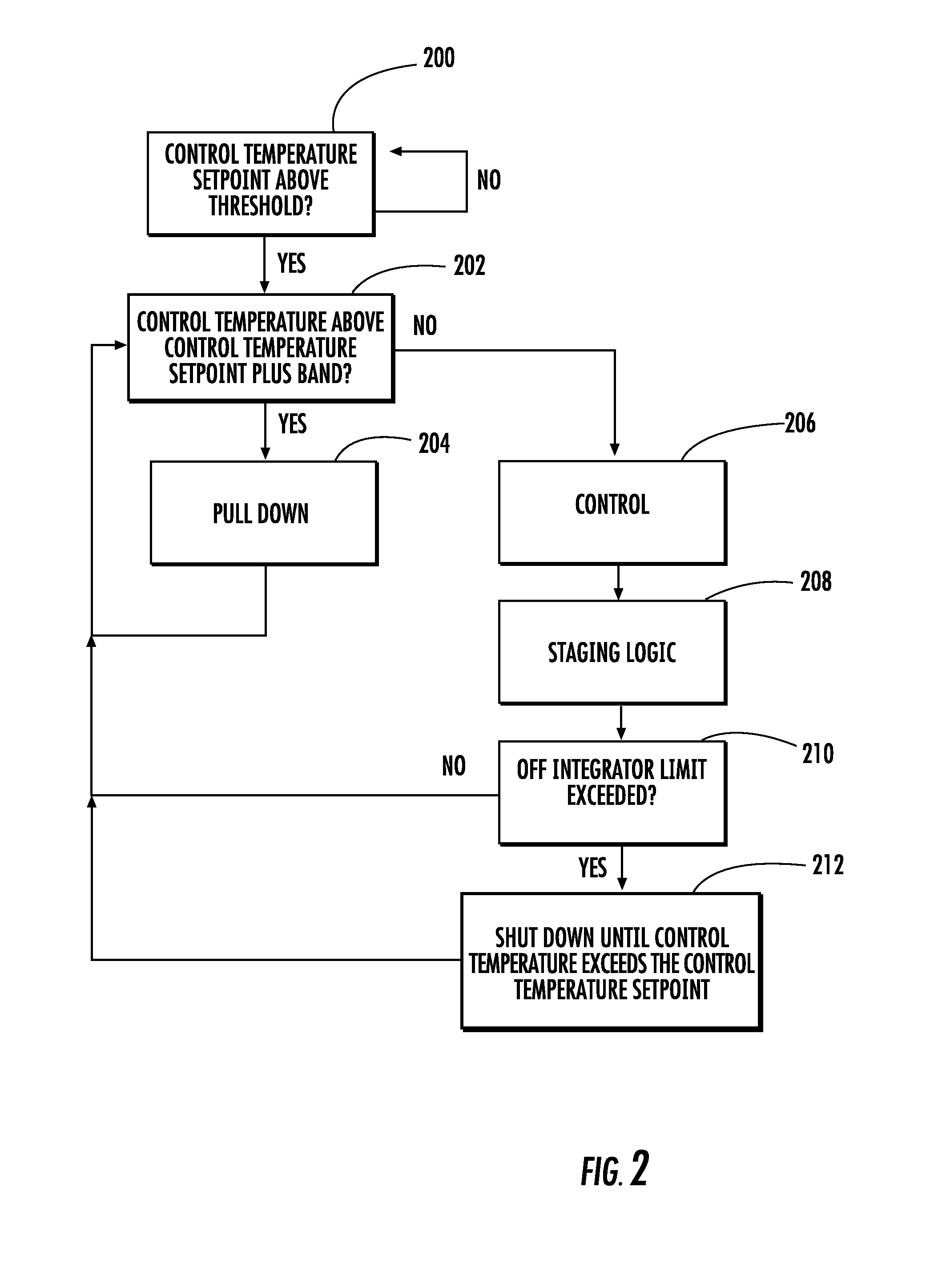

Termperature Control Logic For Refrigeration System

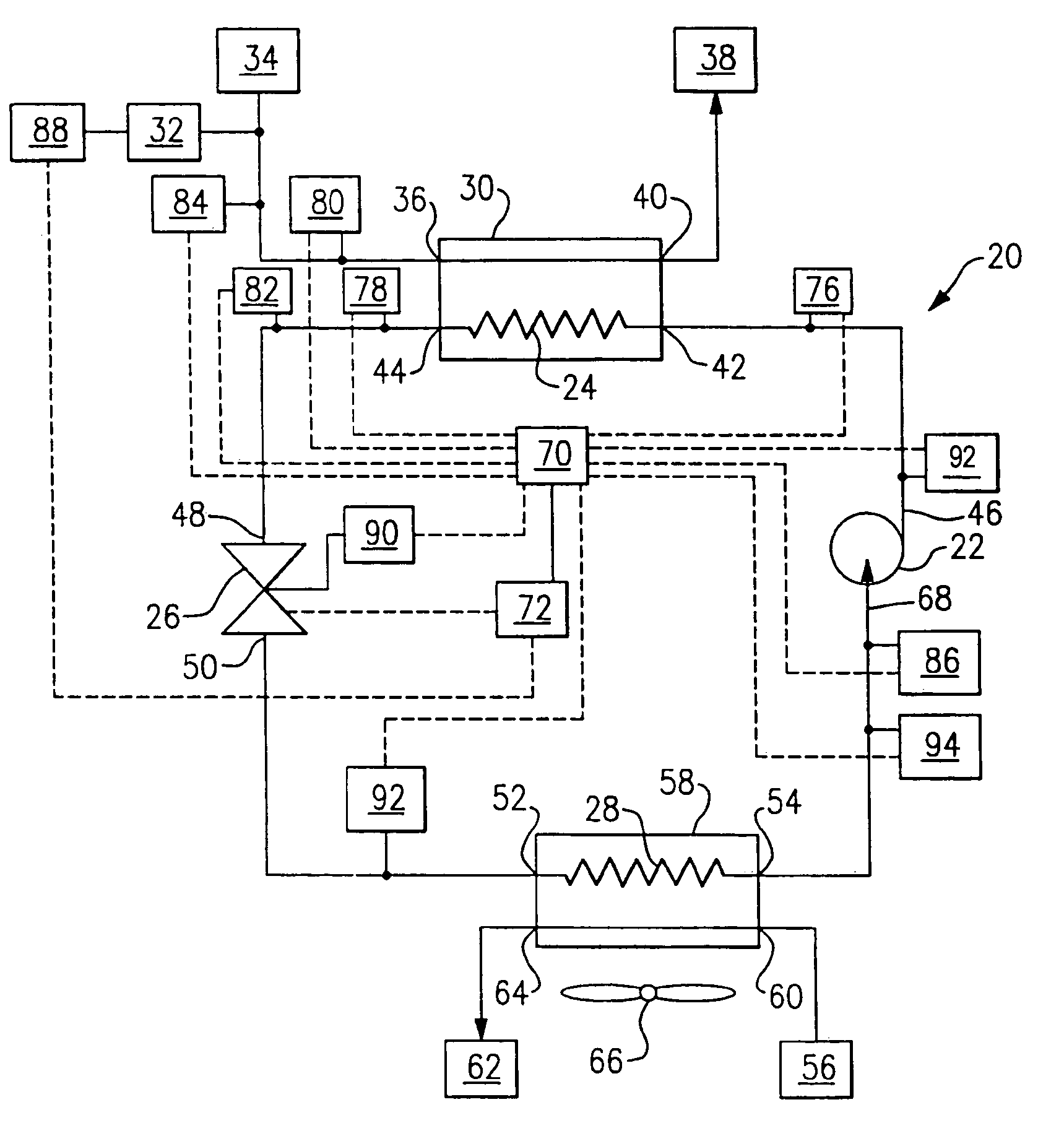

InactiveUS20140151015A1Mechanical apparatusCompression machines with non-reversible cycleTemperature controlProcess engineering

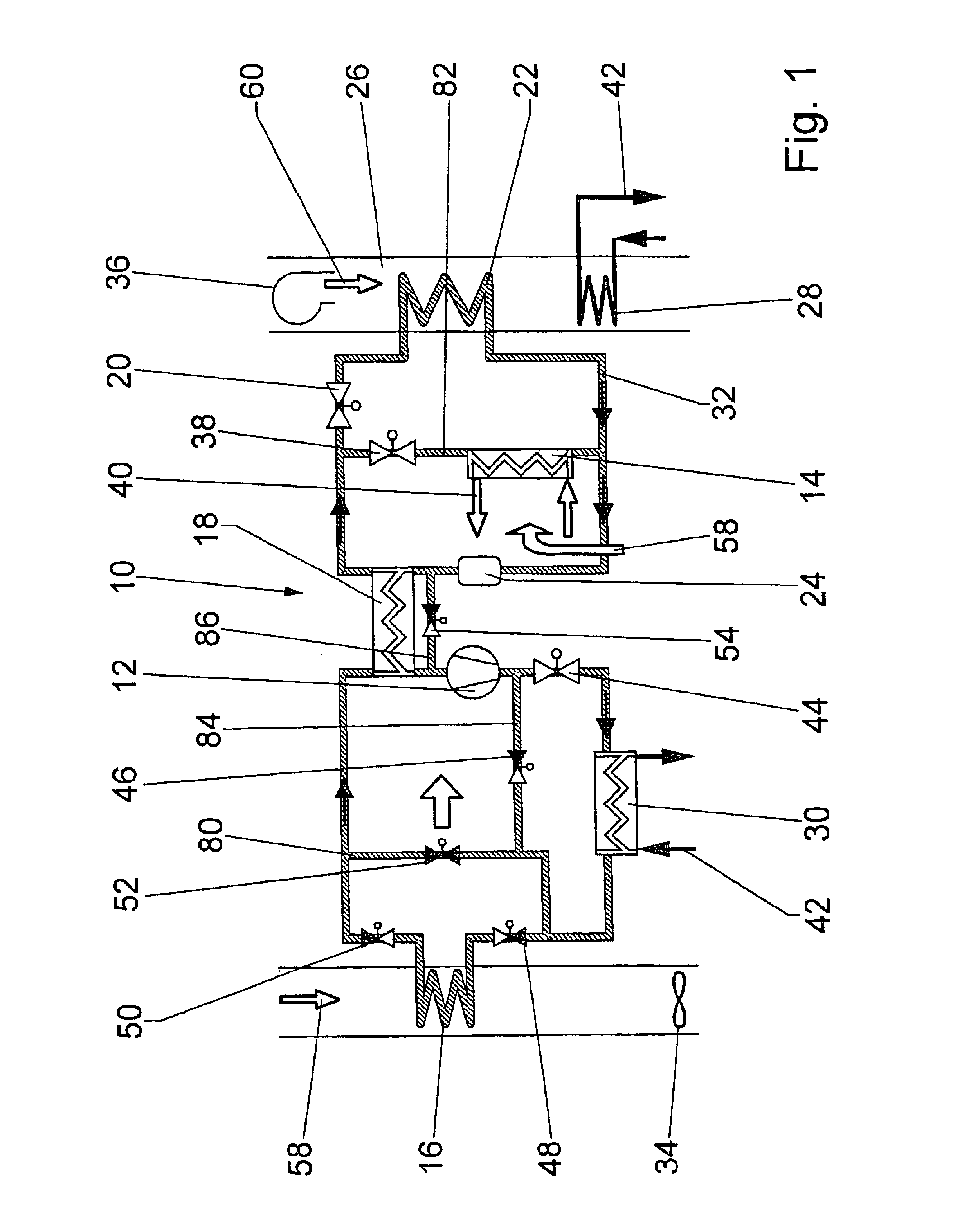

A refrigeration system includes a compressor having a first stage (20a) and a second stage (20b); a motor (22) driving the compressor; a heat rejecting heat exchanger having a fan (44) drawing ambient fluid over the heat rejecting heat exchanger, the heat rejecting heat exchanger including an intercooler (43) and a gas cooler, the inter-cooler coupled to an outlet of the first stage and the gas cooler (41) coupled to an outlet of the second stage; a flash tank (70) coupled to an outlet of the gas cooler; a primary expansion device (55) coupled to an outlet of the flash tank; a heat absorbing heat exchanger (50) coupled to an outlet of the primary expansion device, an outlet of the heat absorbing heat exchanger coupled to the suction port of the first stage; and a controller (100) for implementing a pulldown mode, a control mode and a staging logic mode.

Owner:CARRIER CORP

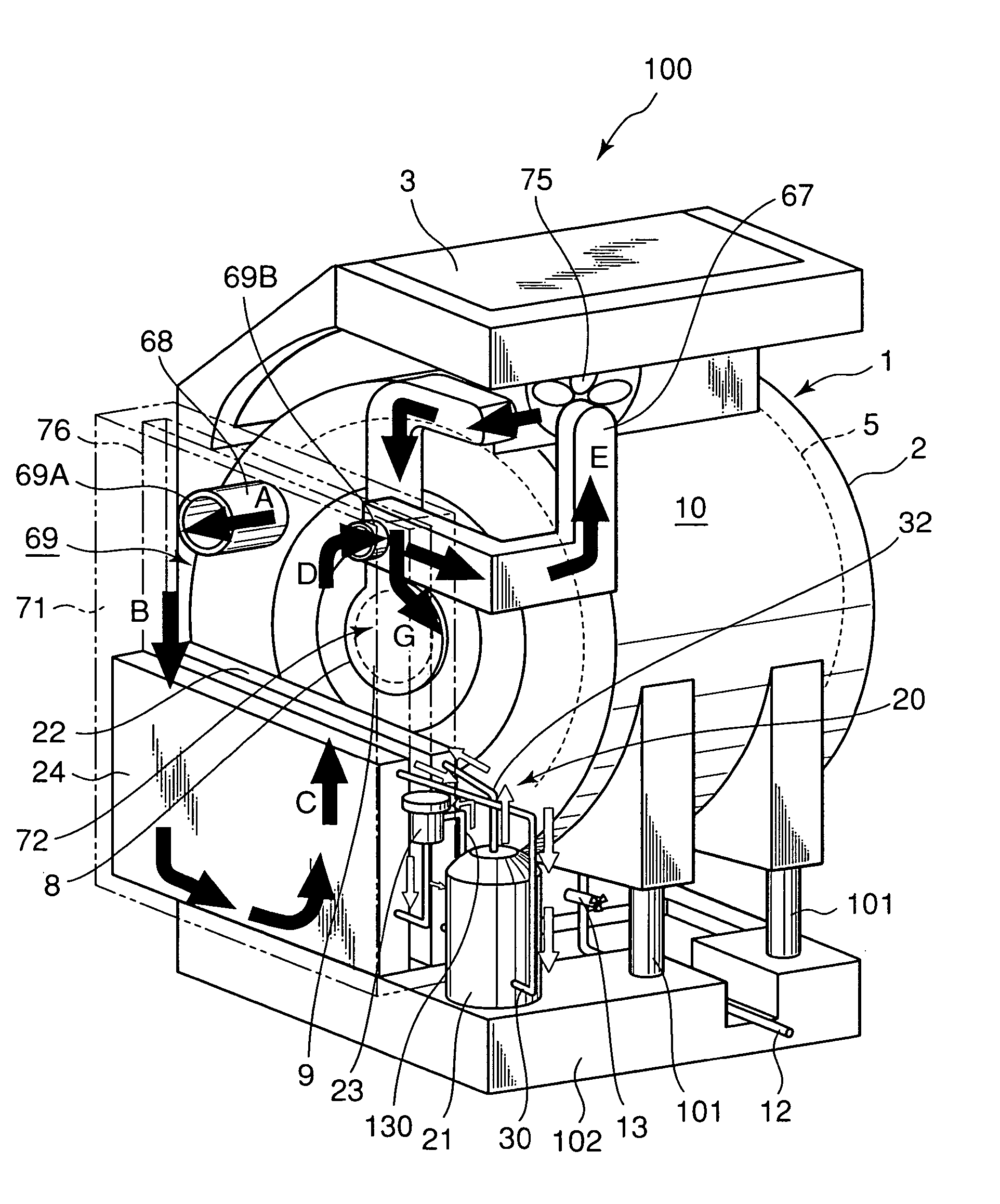

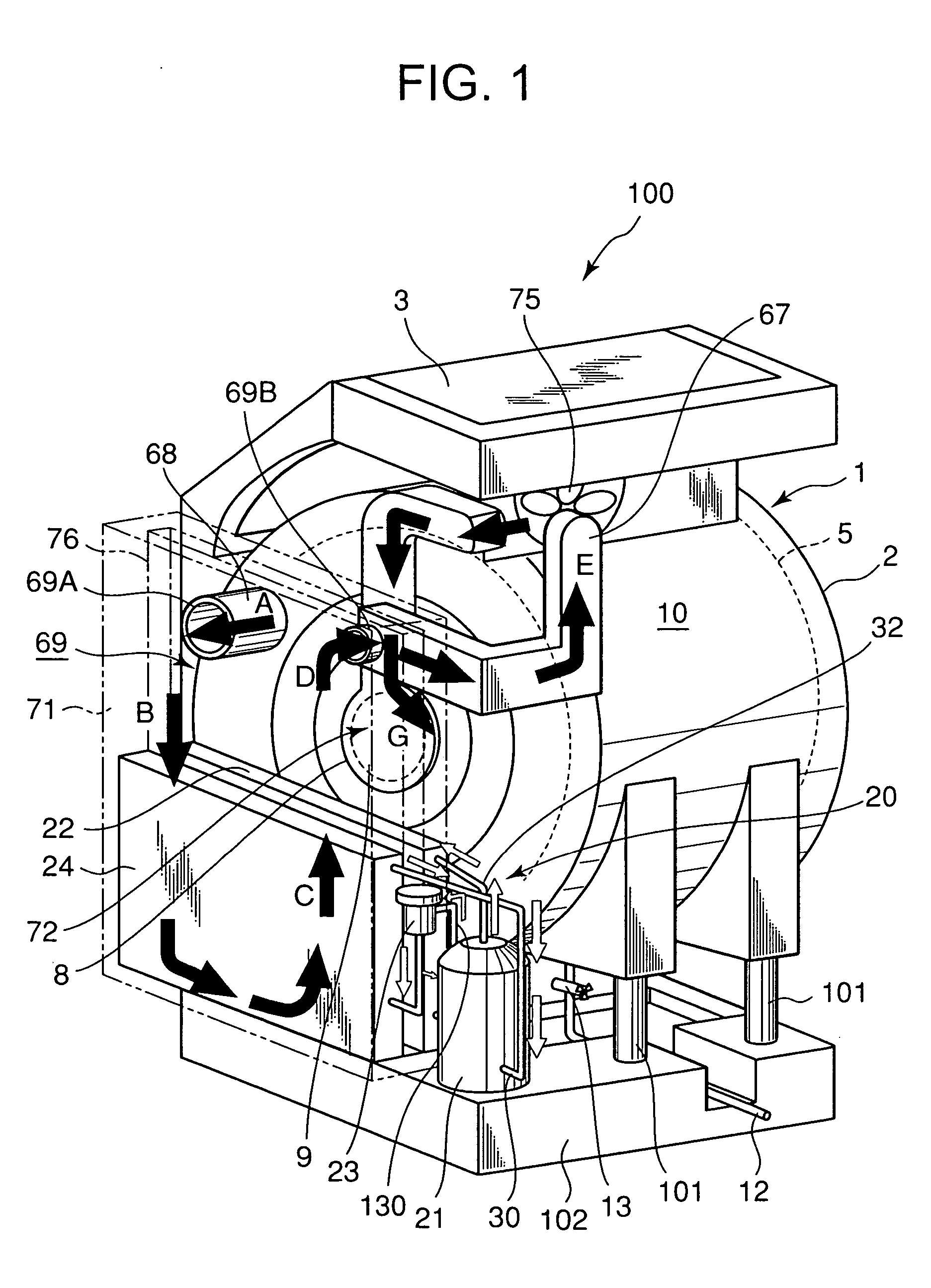

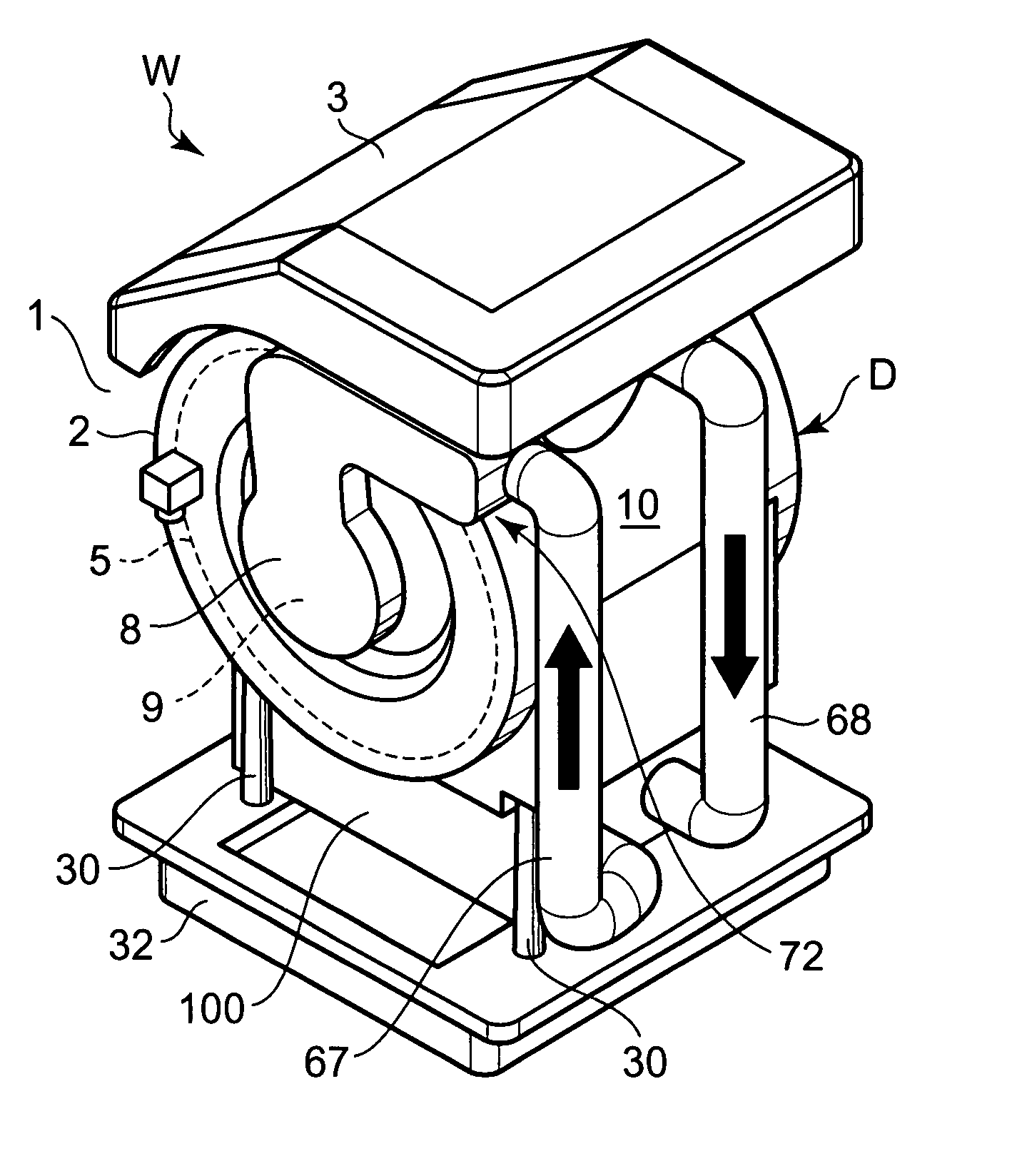

Drying machine

ActiveUS20050086827A1Efficient dryingGuaranteed heat exchange effectCompression machines with non-reversible cycleEvaporators/condensersCounter flowEngineering

A washing / drying machine has objects to shorten a time required for a washing operation, to improve a heat exchange capability in a radiator and an evaporator, and to shorten a drying time for things to be dried, and comprises: an accommodating chamber in which things to be washed (things to be dried) are accommodated and in which a drying operation of the things to be washed is performed; a refrigerant circuit in which a compressor, a gas cooler, a decompression device, an evaporator and the like are successively connected to one another in an annular form via a piping and in which carbon dioxide is used as a refrigerant and which has a supercritical pressure on a high pressure side thereof; and blower means for blowing air which has exchanged heat with the radiator into the accommodating chamber to allow the air passed through the accommodating chamber to exchange the heat with the evaporator, wherein the blower means constitutes a circulation direction of the air passed through the gas cooler, and that of the refrigerant flowing in the gas cooler in such a manner as to form a counter-flow, and constitutes a circulation direction of the air passed through the evaporator, and that of the refrigerant flowing in the evaporator in such a manner as to form a counter-flow.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

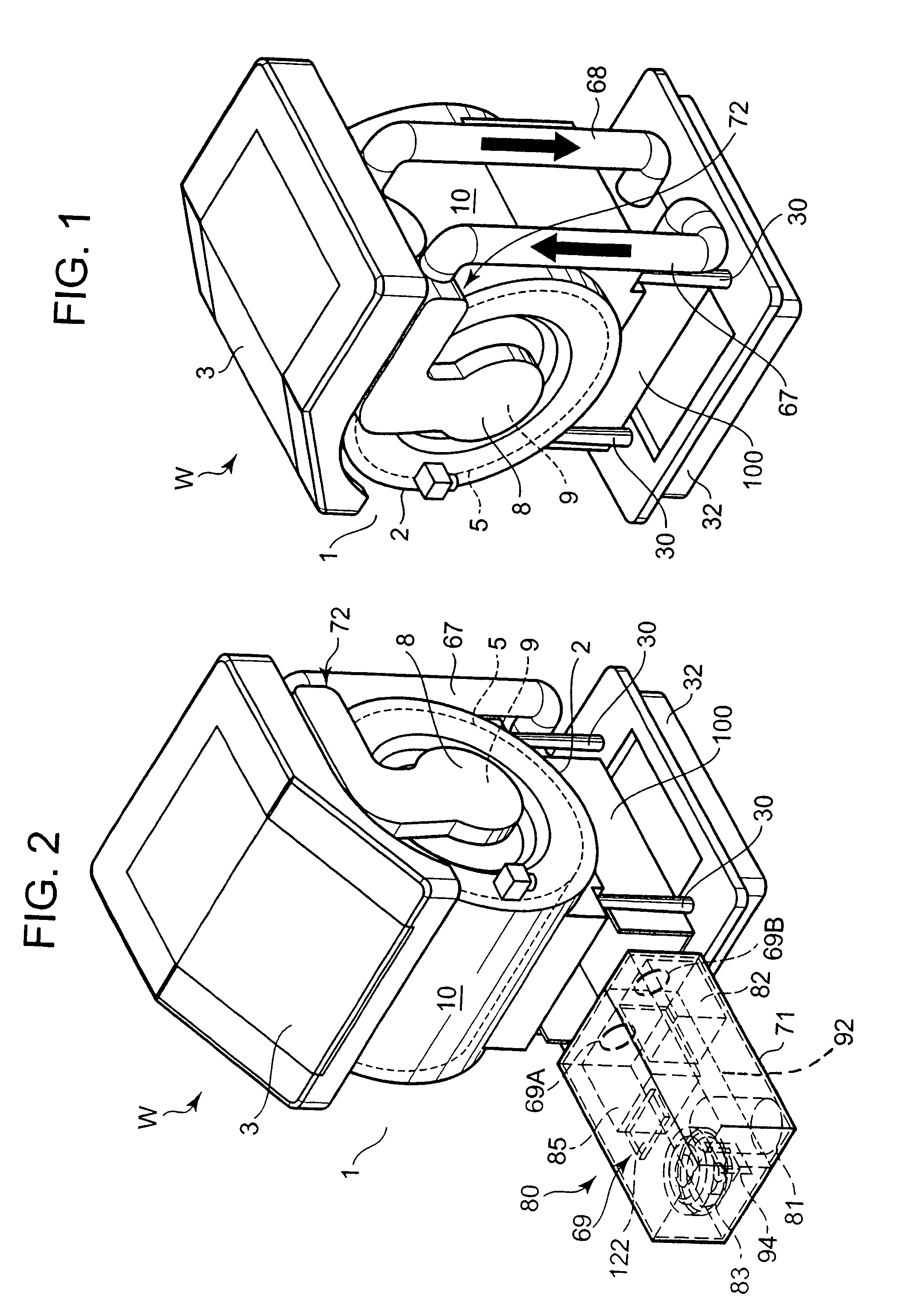

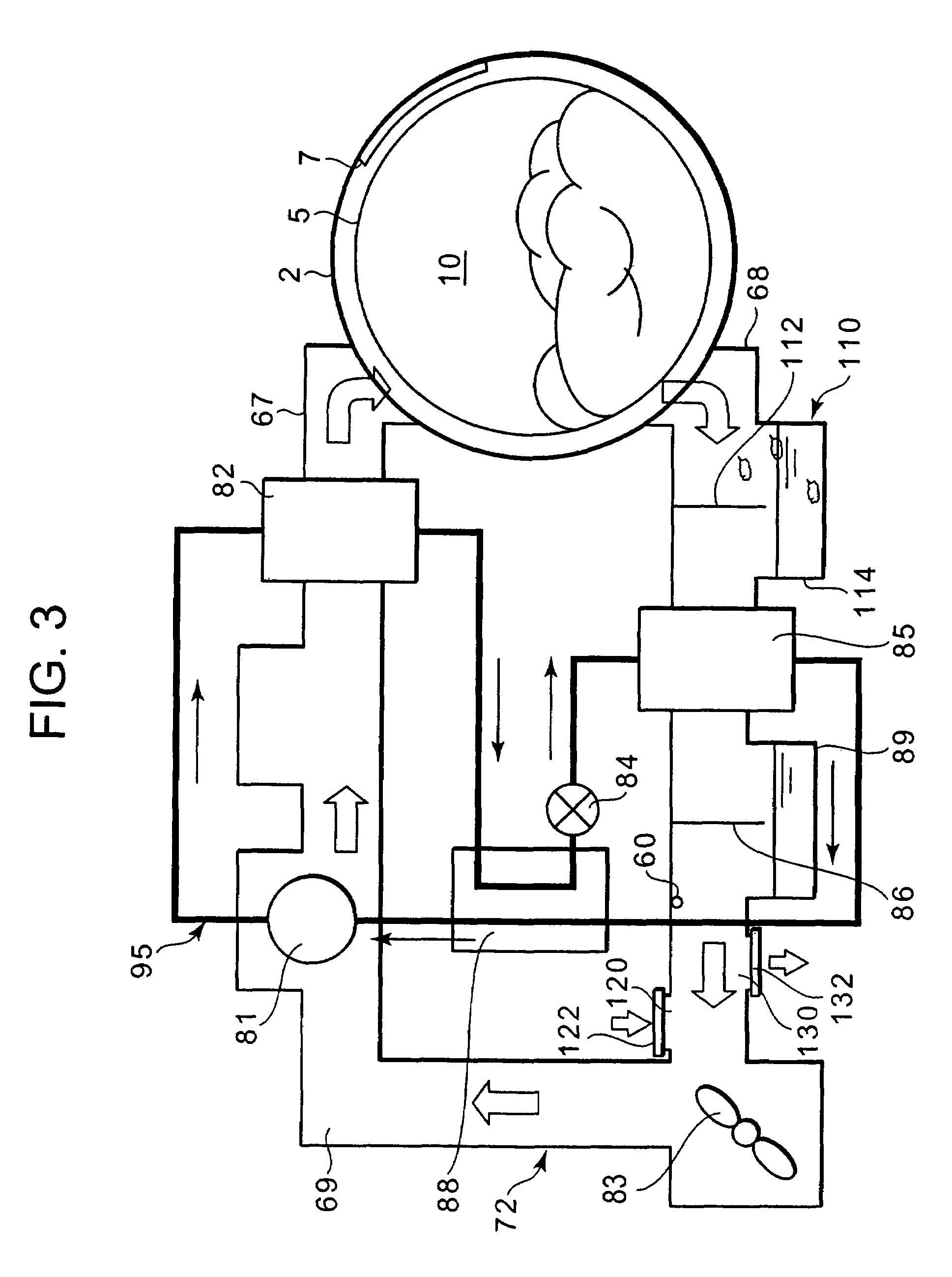

Drying machine with inner and outer drums and outside air introduction

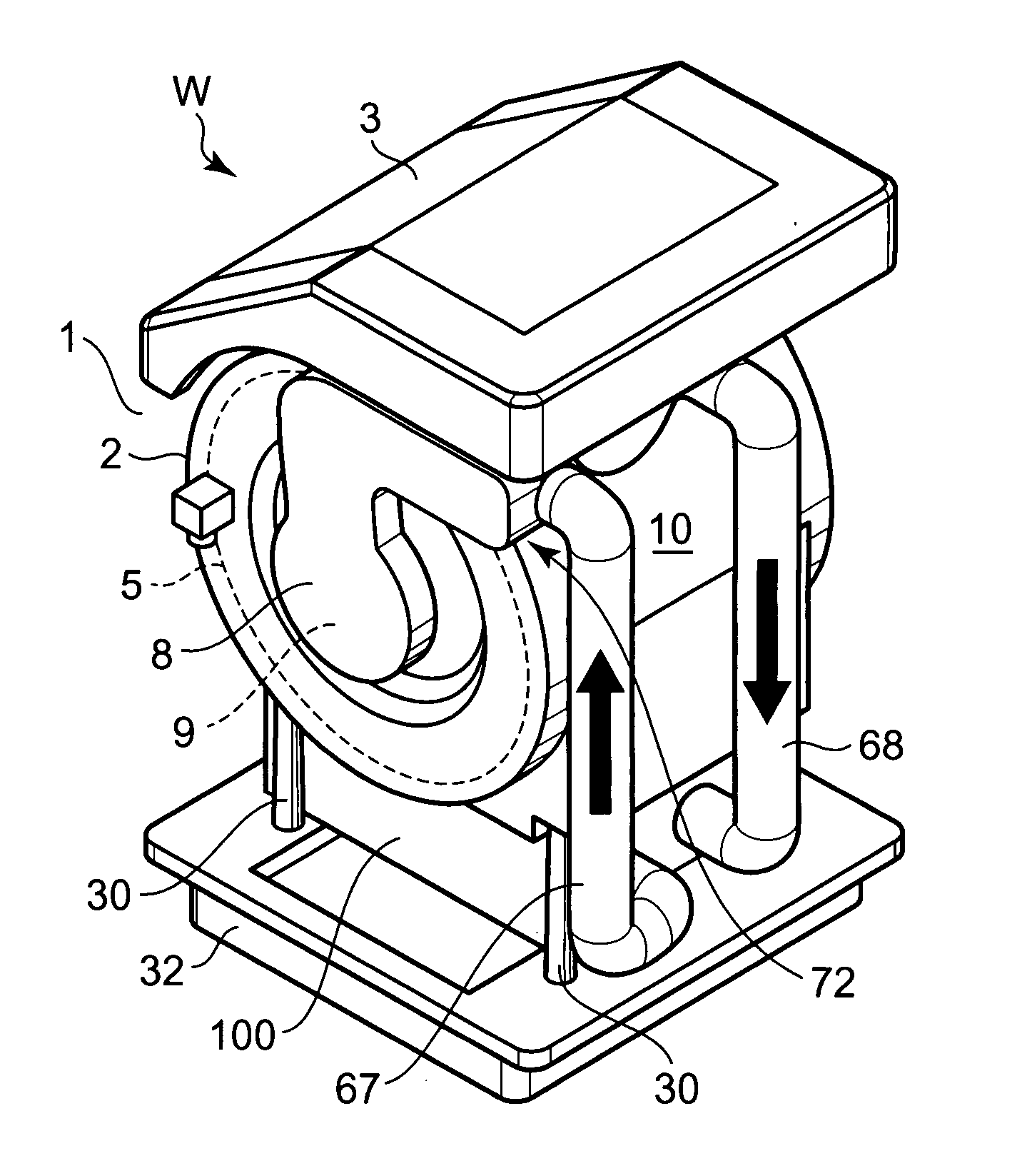

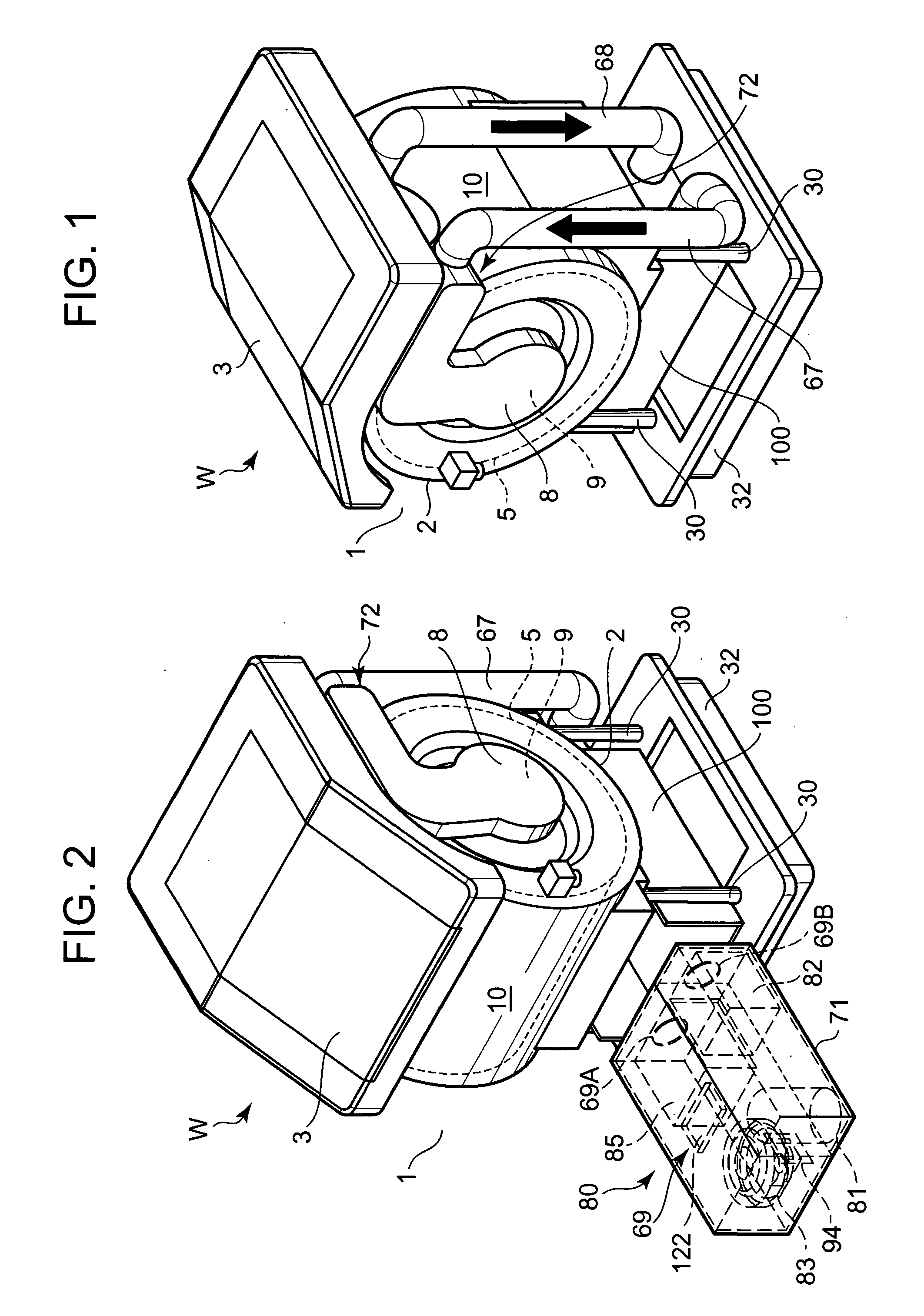

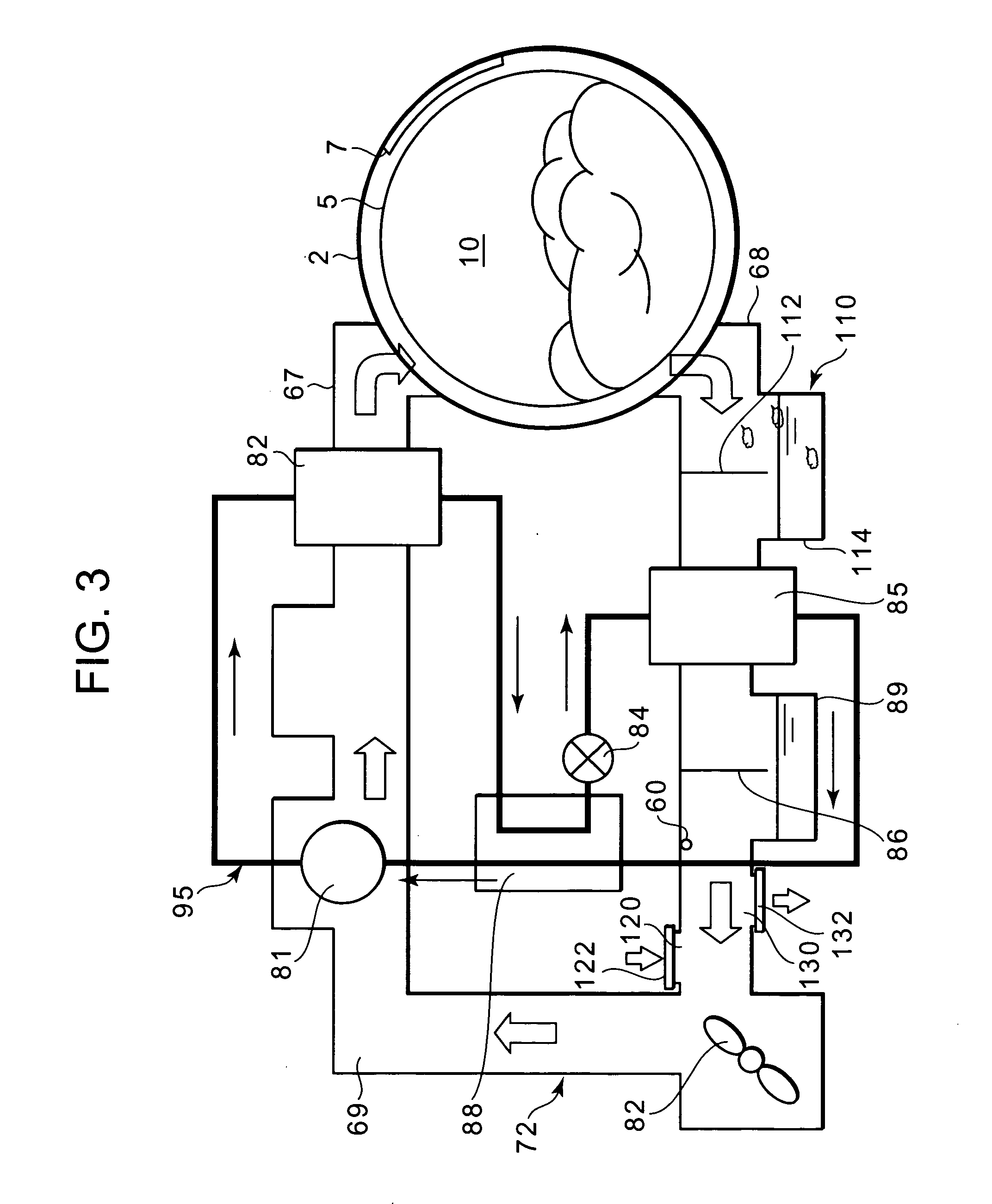

InactiveUS7409776B2Efficient dryingShort timeDrying gas arrangementsDrying machines with non-progressive movementsAir cycleGas cooler

An object is to provide a drying machine capable of maintaining air discharged into a housing chamber while efficiently drying a matter to be dried in a short time. A drying machine provided with a housing chamber which houses the matter to be dried, and executing a drying operation of the matter to be dried in the housing chamber comprises: a gas cooler; an evaporator; a blower fan; an air circulation path for discharging air heated by the gas cooler into the housing chamber by the blower fan, sending the air passed through the housing chamber into the evaporator, and circulating the air in the gas cooler; and a closeable outside air introduction port for mixing outside air with the air circulating in the air circulation path.

Owner:SANYO ELECTRIC CO LTD

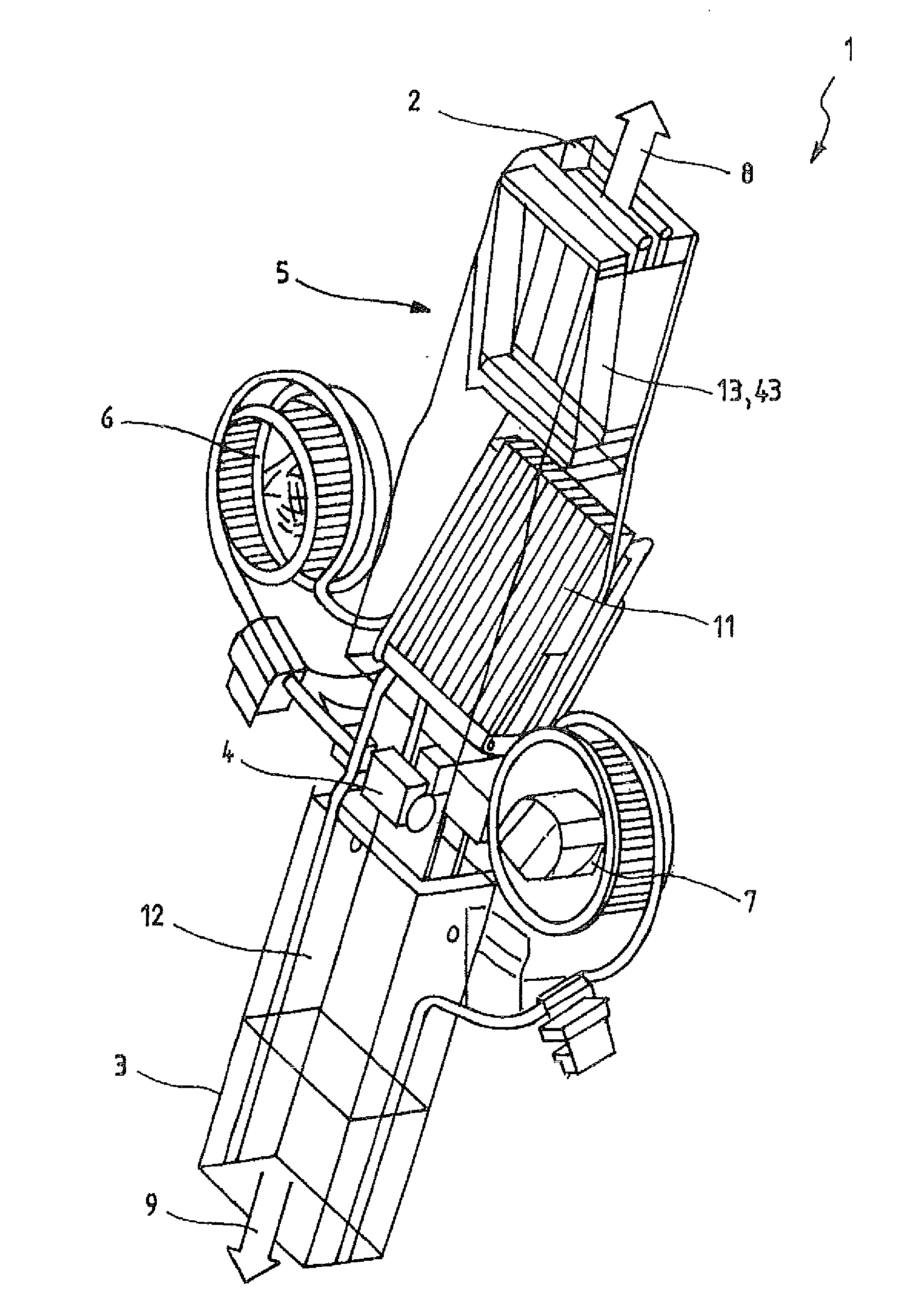

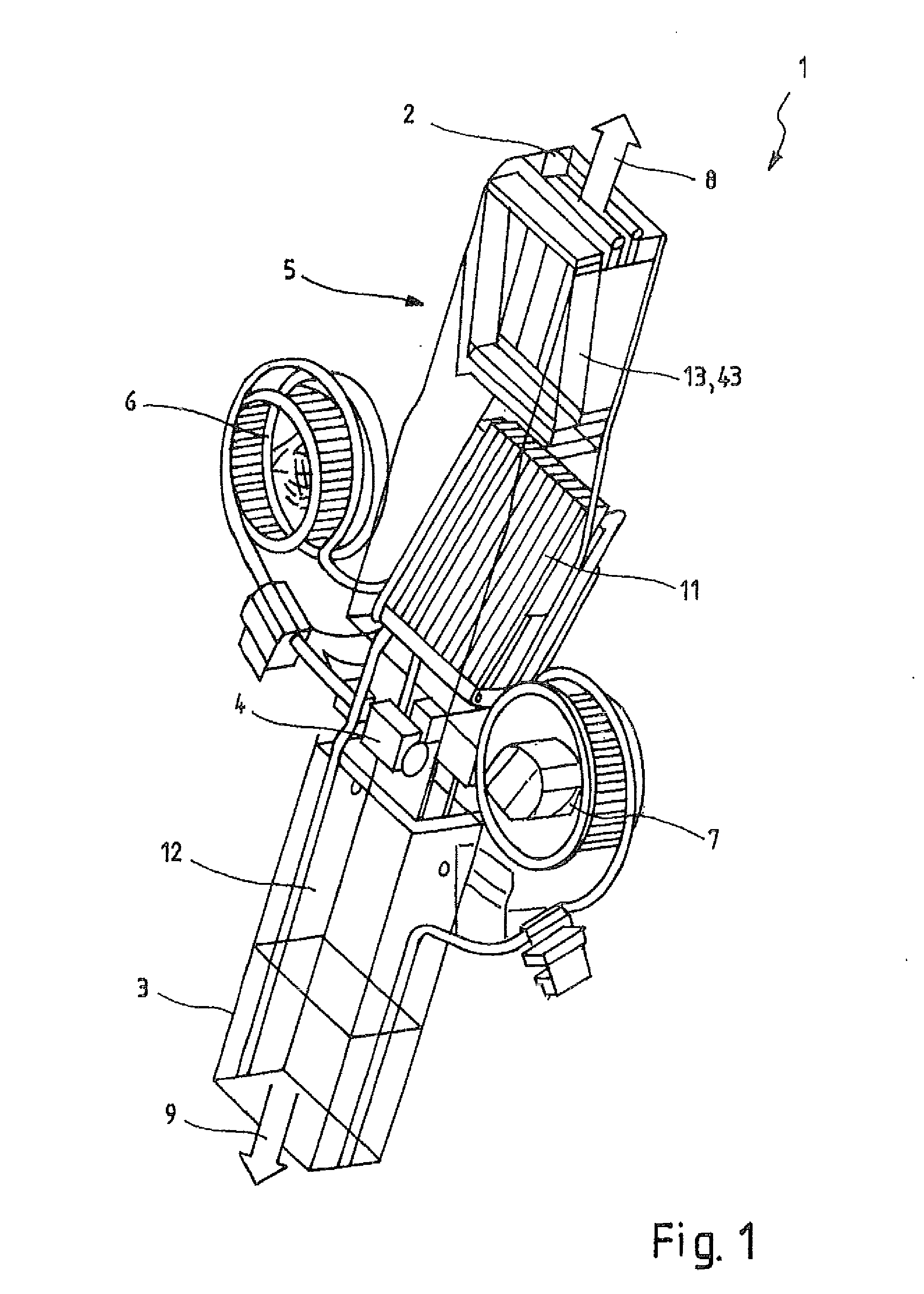

Compact HVAC system for a motor vehicle

InactiveUS20110036117A1Improve controllabilityReduce capacityEvaporators/condensersVehicle heating/cooling devicesGas coolerEngineering

The invention relates to a compact vehicle HVAC system including an evaporator unit, a condenser unit, and a component unit, as well as a refrigerant circuit. The evaporator unit and the condenser unit each are provided with air-passed heat exchangers and a fan in a casing. Further circuit components are displaced within the component unit. The casings of the evaporator unit, the condenser unit, and the component unit advantageously establish a connected compact casing arrangement. The heat exchangers are displaced within the compact casing arrangement. The refrigerant circuit is established for a combined refrigeration plant and heat pump operation as well as an afterheating operation, whereby in the afterheating operational mode the heating power of the afterheater established as condenser / gas cooler and the cooling power of the evaporator are controllable independently of each other.

Owner:HANON SYST

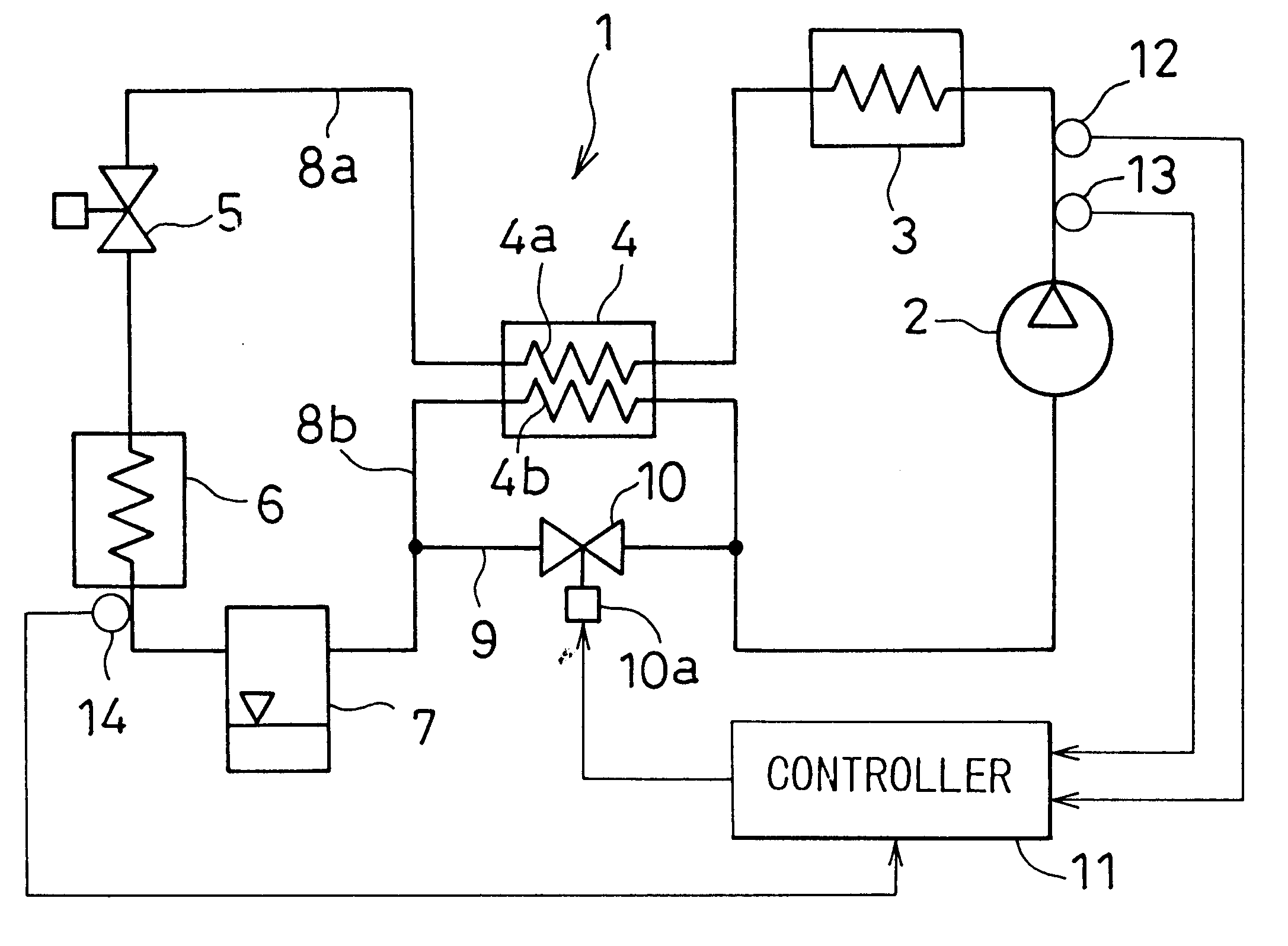

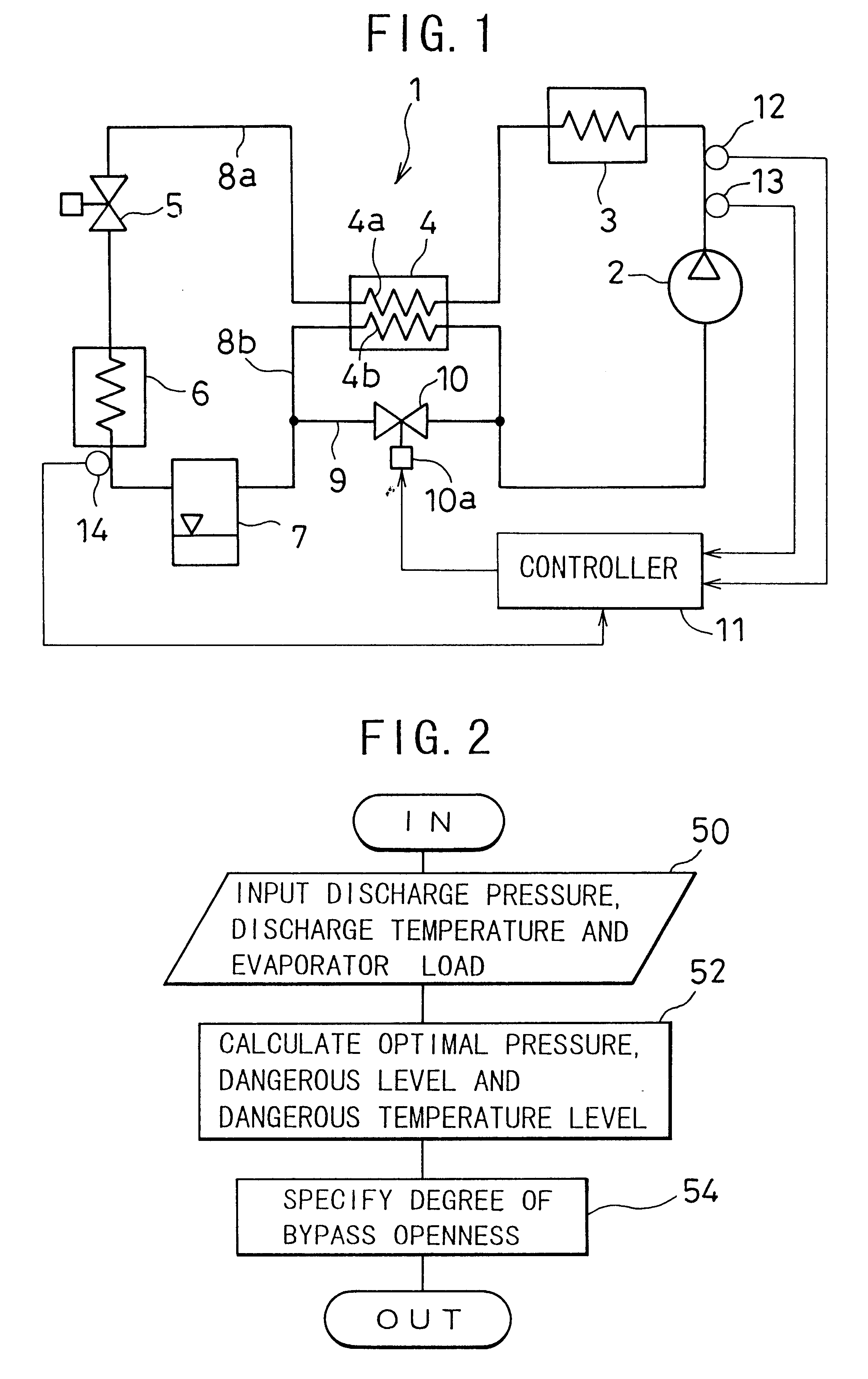

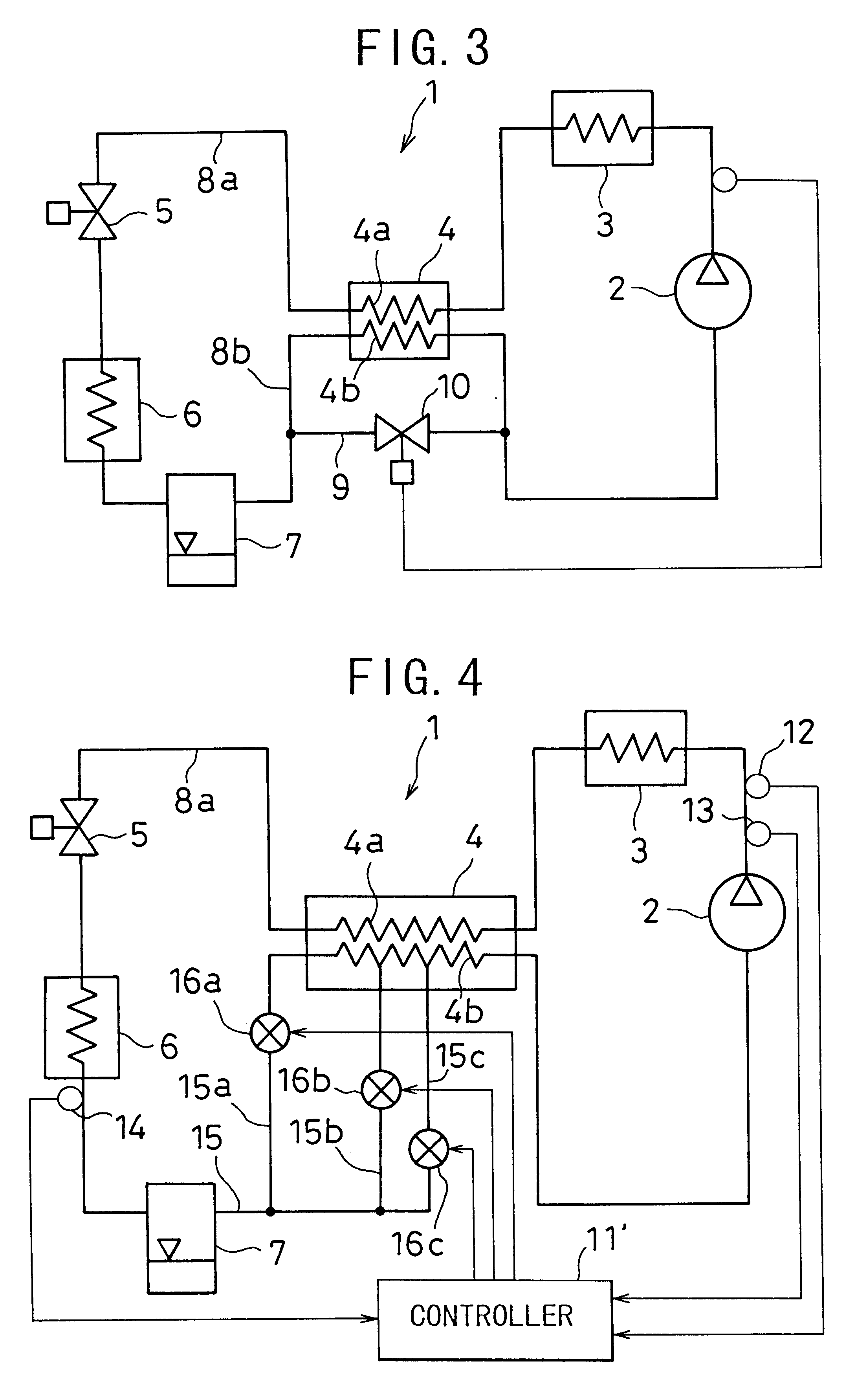

Refrigerating cycle

InactiveUS6260367B1Mechanical apparatusCompression machines with non-reversible cycleSolenoid valveCoolant flow

In a freezing cycle that utilizes a supercritical fluid as its coolant and employs an internal heat exchanger that performs heat exchange on the coolant on the outlet side of a gas cooler and on the intake side of a compressor, a means for adjustment that adjusts the quantity of heat exchange performed by the internal heat exchanger (4) is provided. The means for adjustment is constituted of a bypass passage (9) that bypasses the internal heat exchanger (4) and a flow-regulating valve (10) that adjusts the coolant flow rate in the bypass passage (9). The flow-regulating valve (10) is constituted of an electromagnetic valve, the degree of openness of which is determined based upon information with respect to the cycle state, or a bellows regulating valve that operates in correspondence to the pressure on the high-pressure side. Alternatively, the means for adjustment may perform adjustment by varying the passage length over which heat exchange is performed by the internal heat exchanger (4). Good cycle efficiency is achieved by maintaining the optimal high-pressure through cycle balance control. The freezing cycle can be temporarily protected against excessively high-pressure or excessively high discharge temperature at the compressor.

Owner:ZEXEL VALEO CLIMATE CONTROL CORP SAITAMA

Refrigeration system

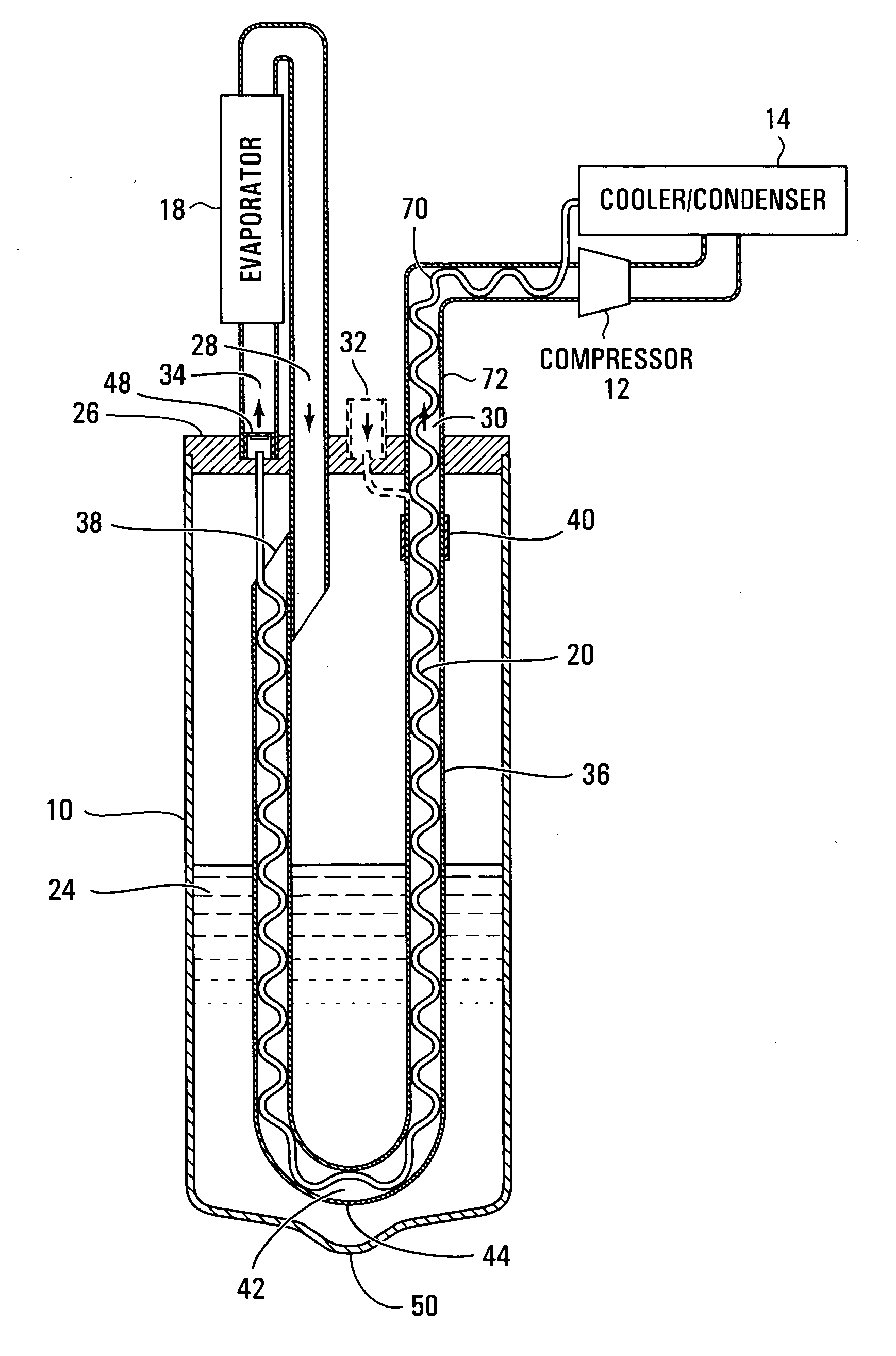

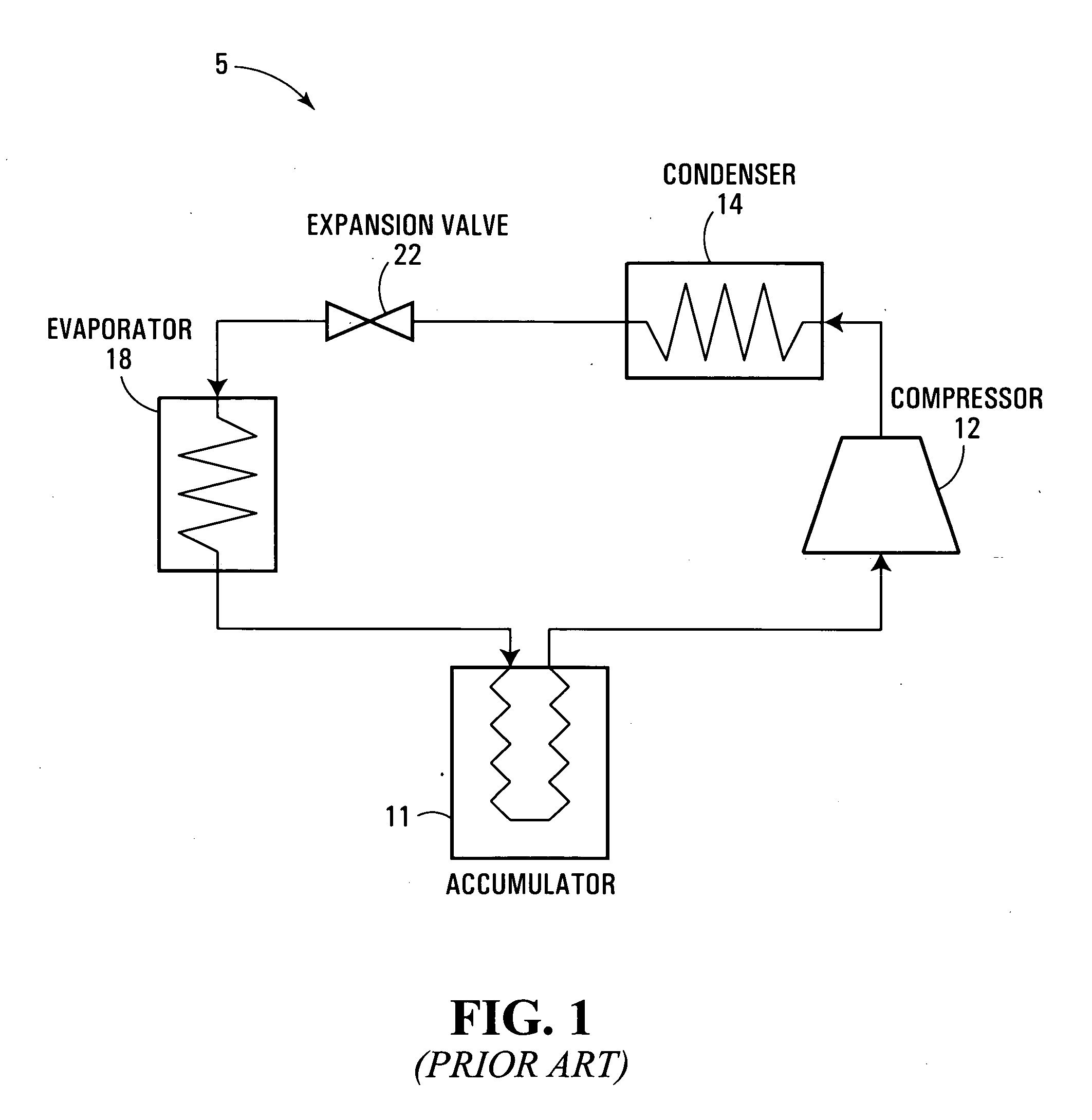

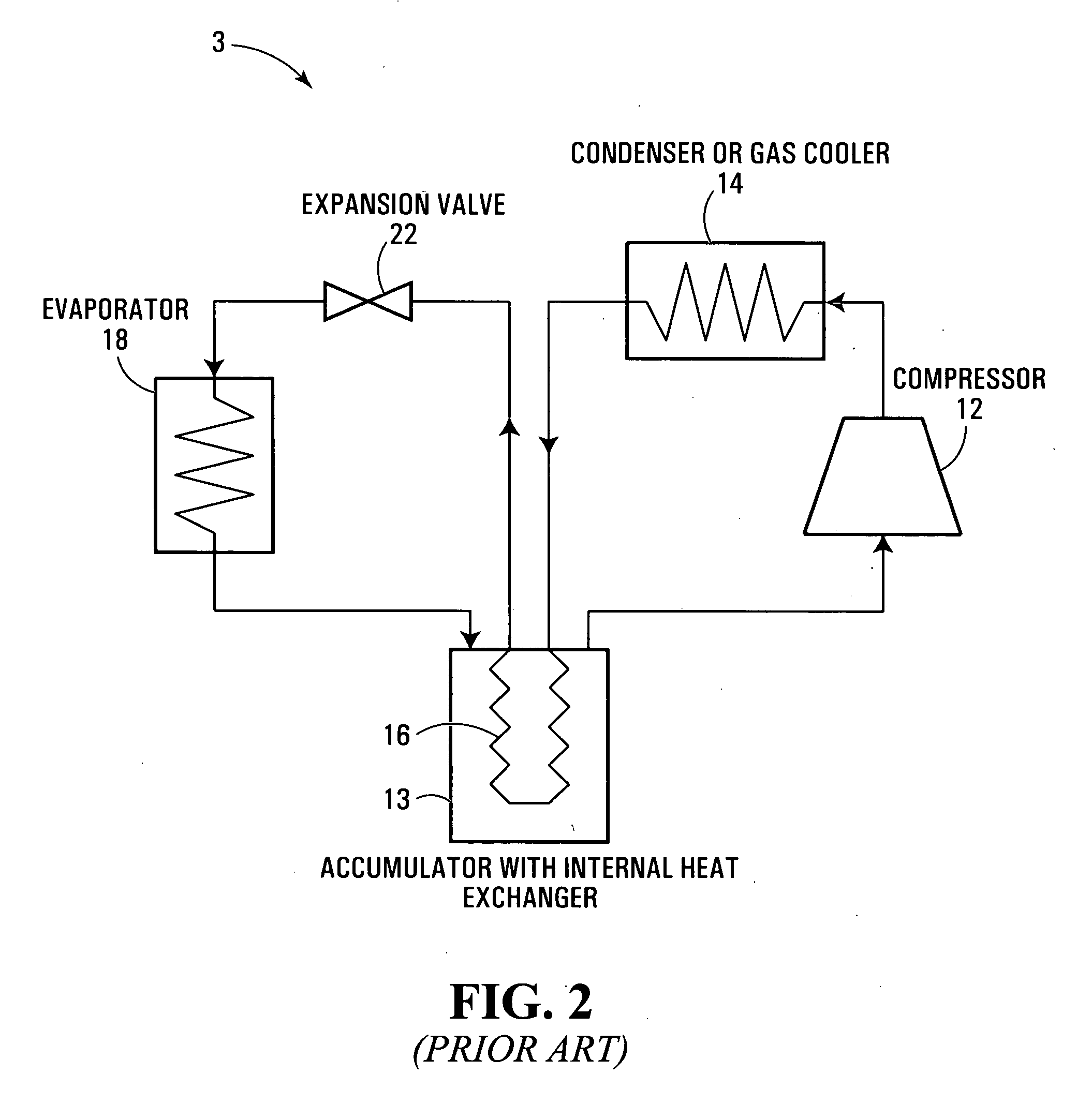

ActiveUS20060010905A1Increasing efficiency and cooling capacityEliminate needMechanical apparatusCompression machinesCapillary TubingEngineering

A refrigeration system with integrated accumulator-expander-heat exchanger is disclosed. Refrigerant from a condenser / gas cooler is throttled through a capillary tube while at the same time undergoing a heat exchanging process with refrigerant from an evaporator. This method can elevate the compressor efficiency, increase the specific cooling capacity, and enhance the system performance. The capillary tube, which has dual functions of expansion device and heat exchanger, is placed inside a canister which also functions as an accumulator. The new device combining three separate parts into one can simplify the manufacturing process, lower the system size and weight, and thus decrease cost of the whole system.

Owner:ANHUI WATERPOWER ENERGY SAVING TECH

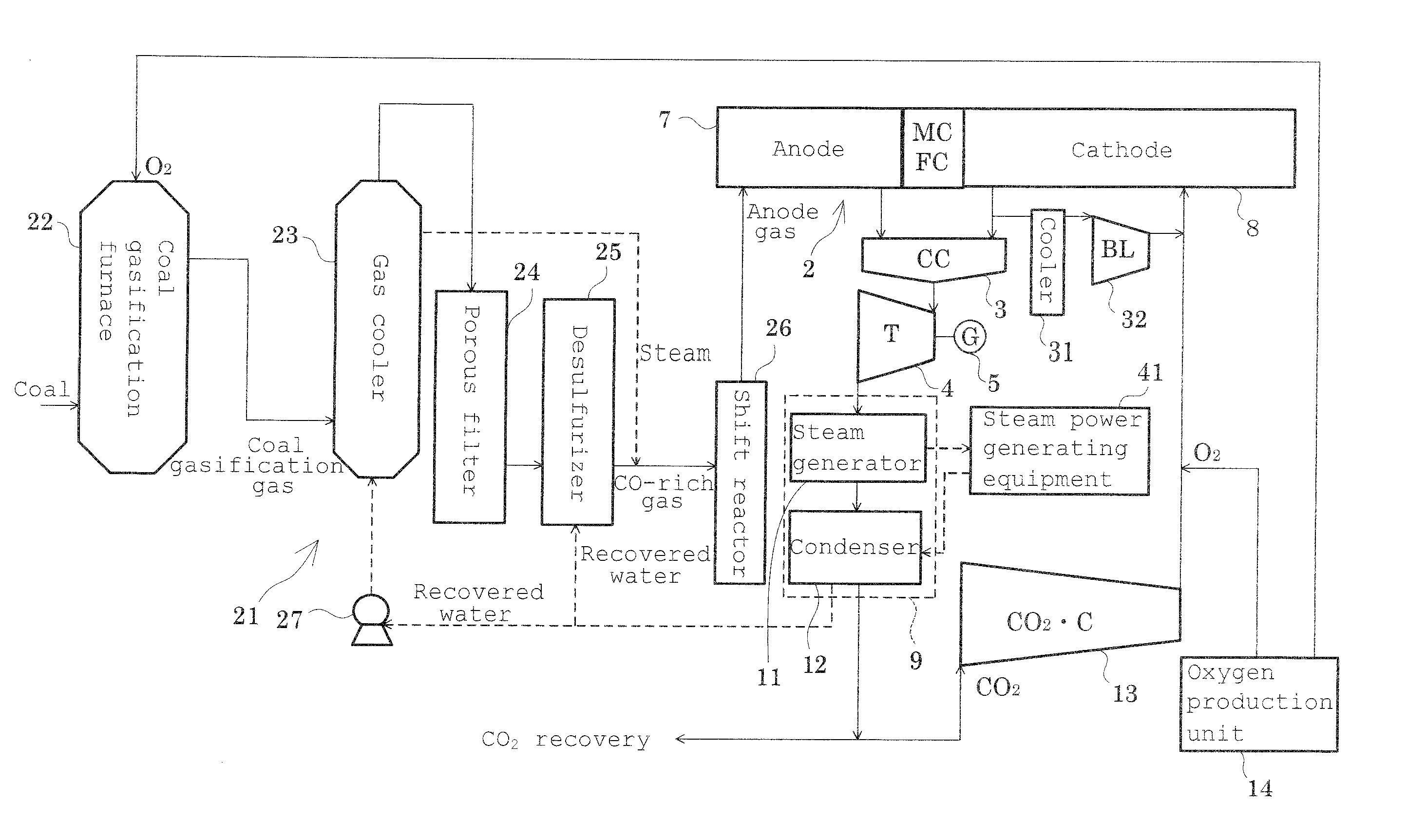

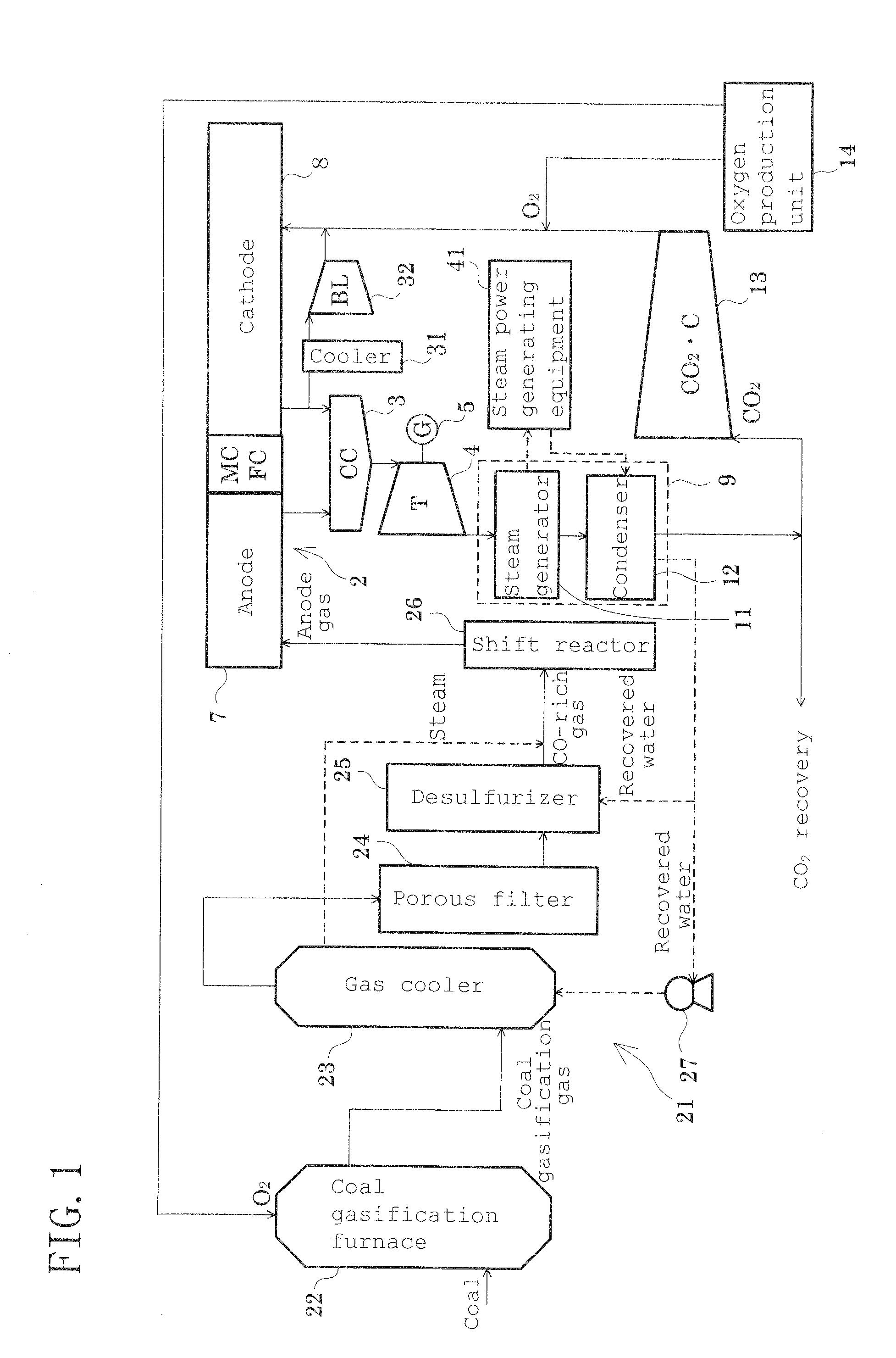

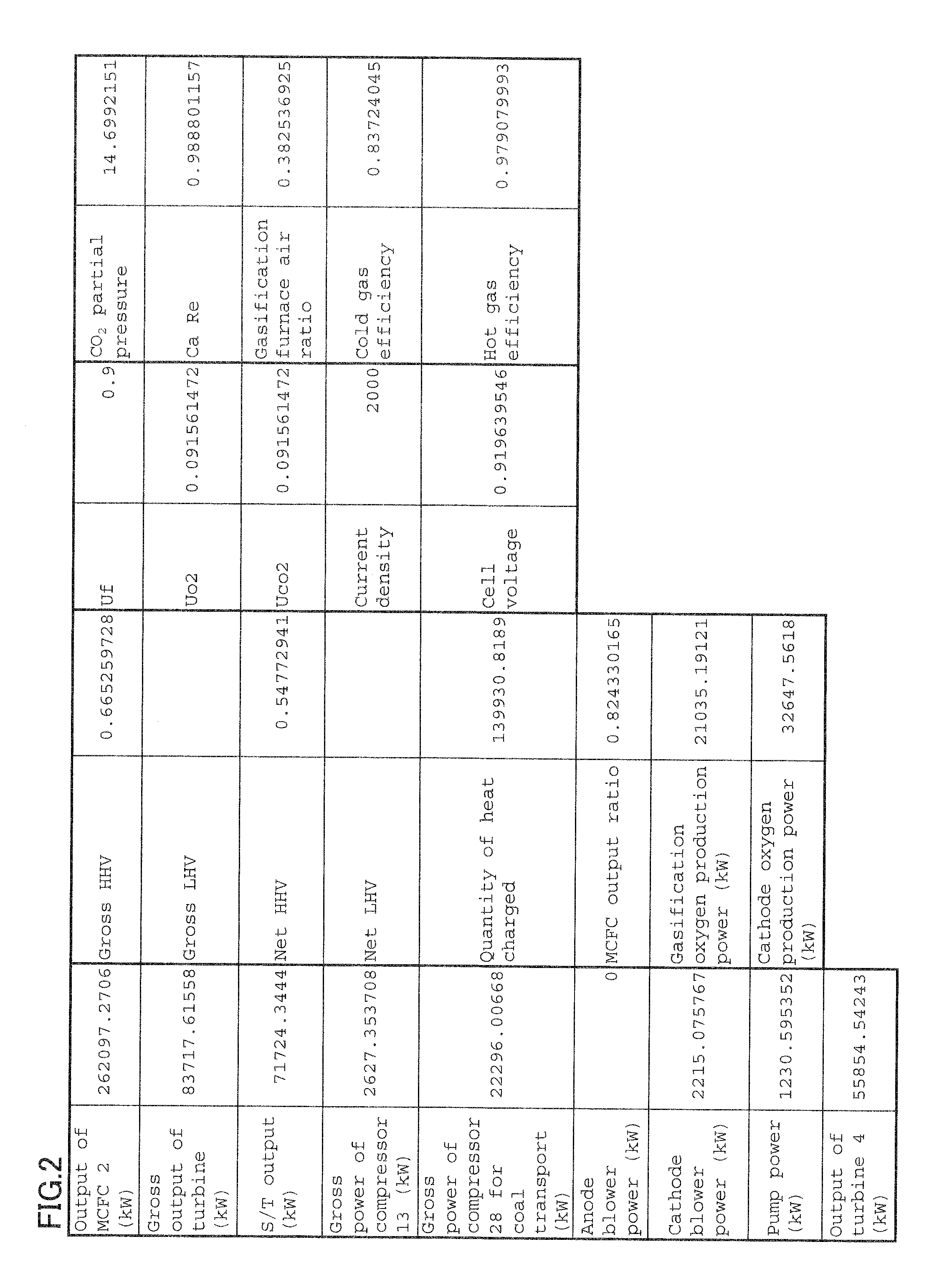

Power generating plant

InactiveUS20100015486A1Maintain performanceElectricity cogenerationFuel cell heat exchangePower stationGas cooler

Coal is reacted in a furnace 22 to obtain a coal gasification gas. The coal gasification gas is cooled by a gas cooler 23, passed through a porous filter 24, and desulfurized by a desulfurizer 25 to produce a CO-containing gas as an anode. The CO gas-containing gas is subjected to an exothermic reaction in a shift reactor 26 to form H2 and CO2, and the anode gas containing H2 is supplied to an anode 7 of MCFC 2. Thus, in the absence of an extra heat source and a heat exchange source, a desired anode gas is obtained from the coal gasification gas, and with heat buildup of the MCFC 2 being inhibited and its performance being maintained, reduction of CO2 is taken into consideration. A power generating plant equipped with the MCFC 2 capable of using a coal gasification fuel substantially containing a CO gas is thus achieved.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

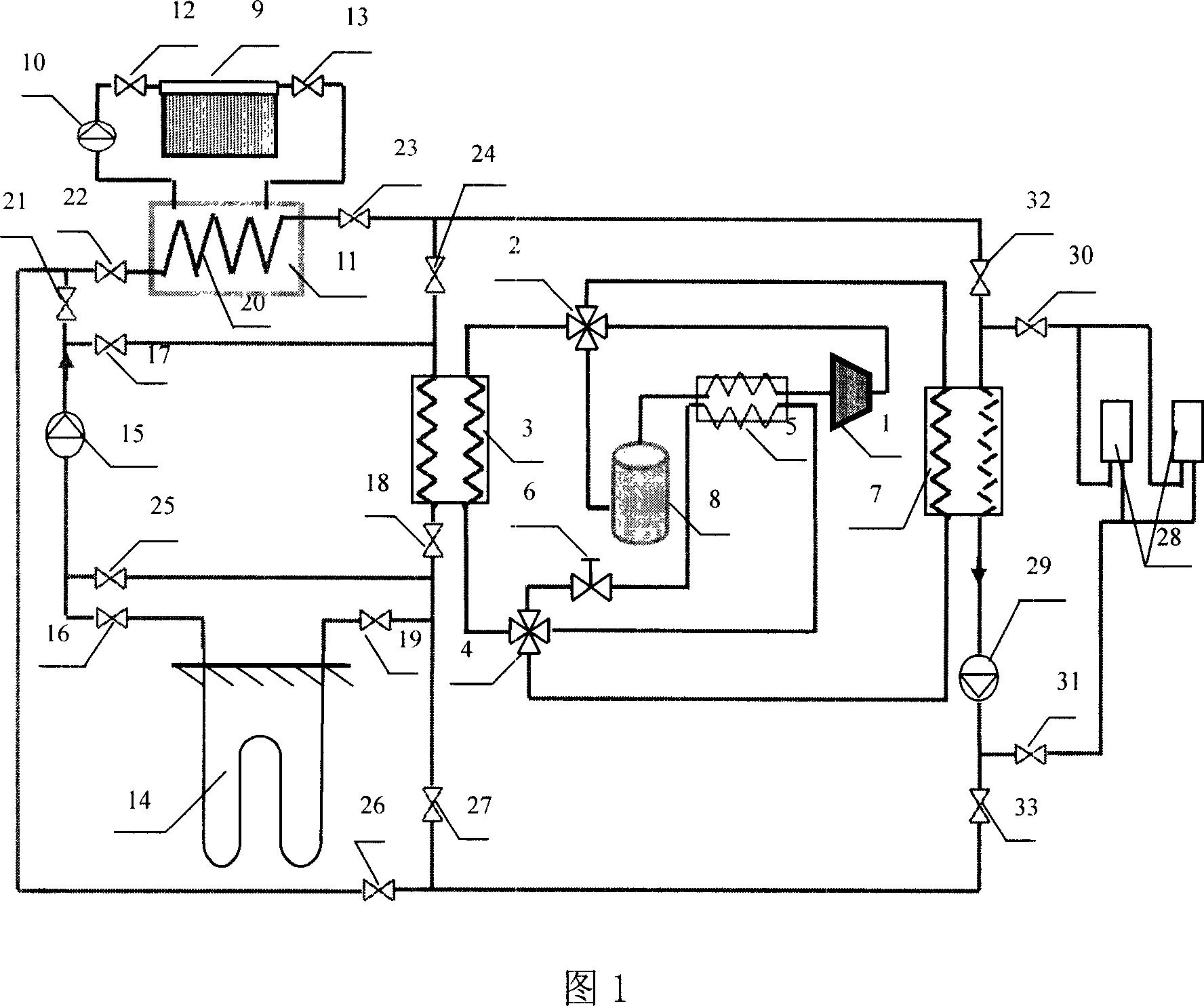

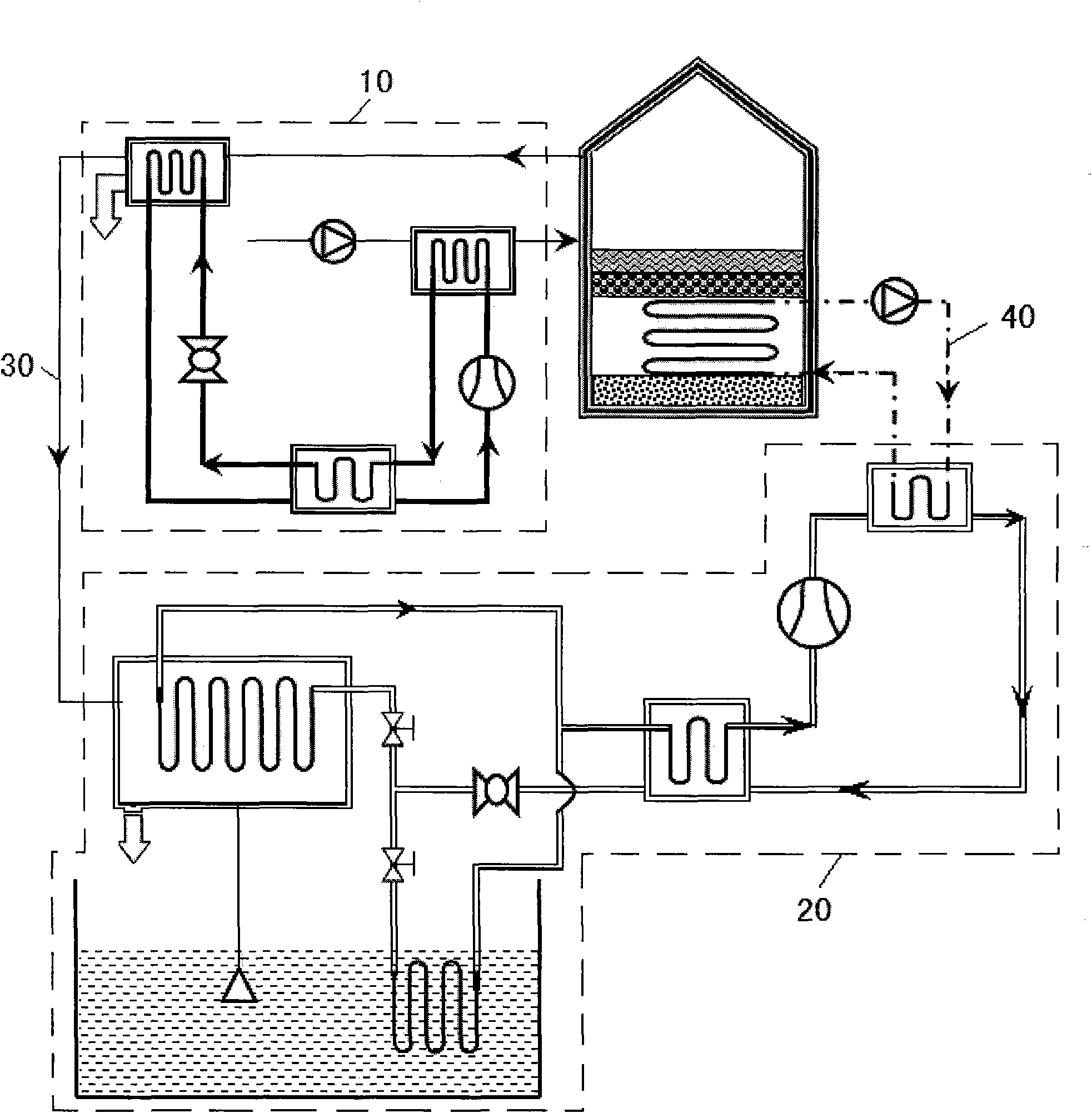

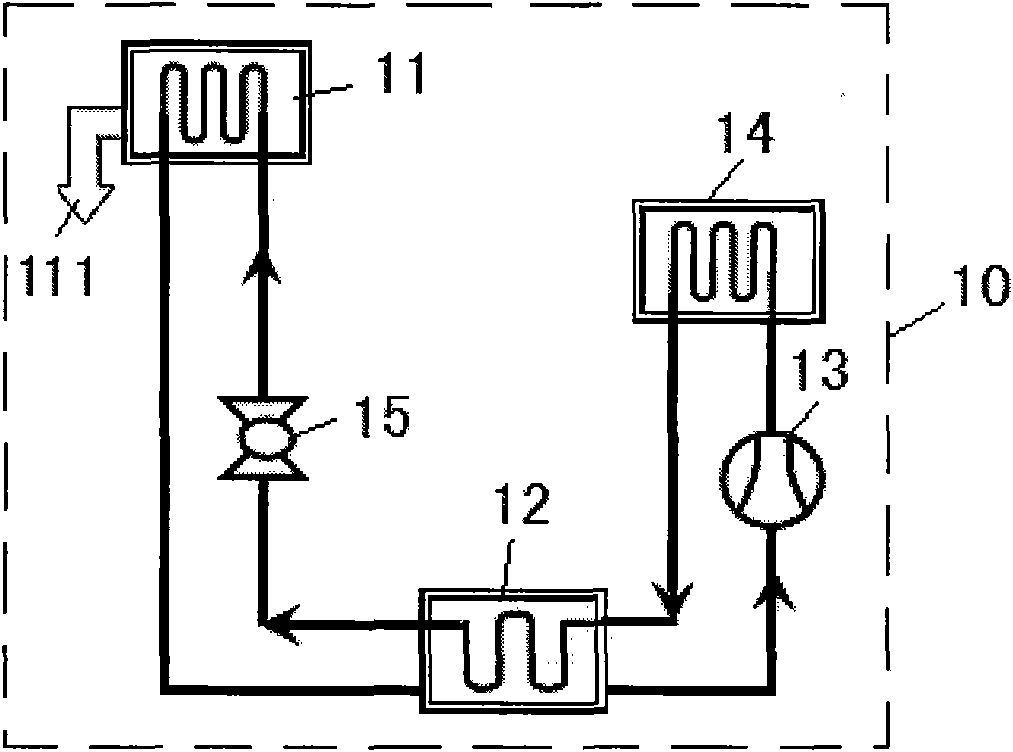

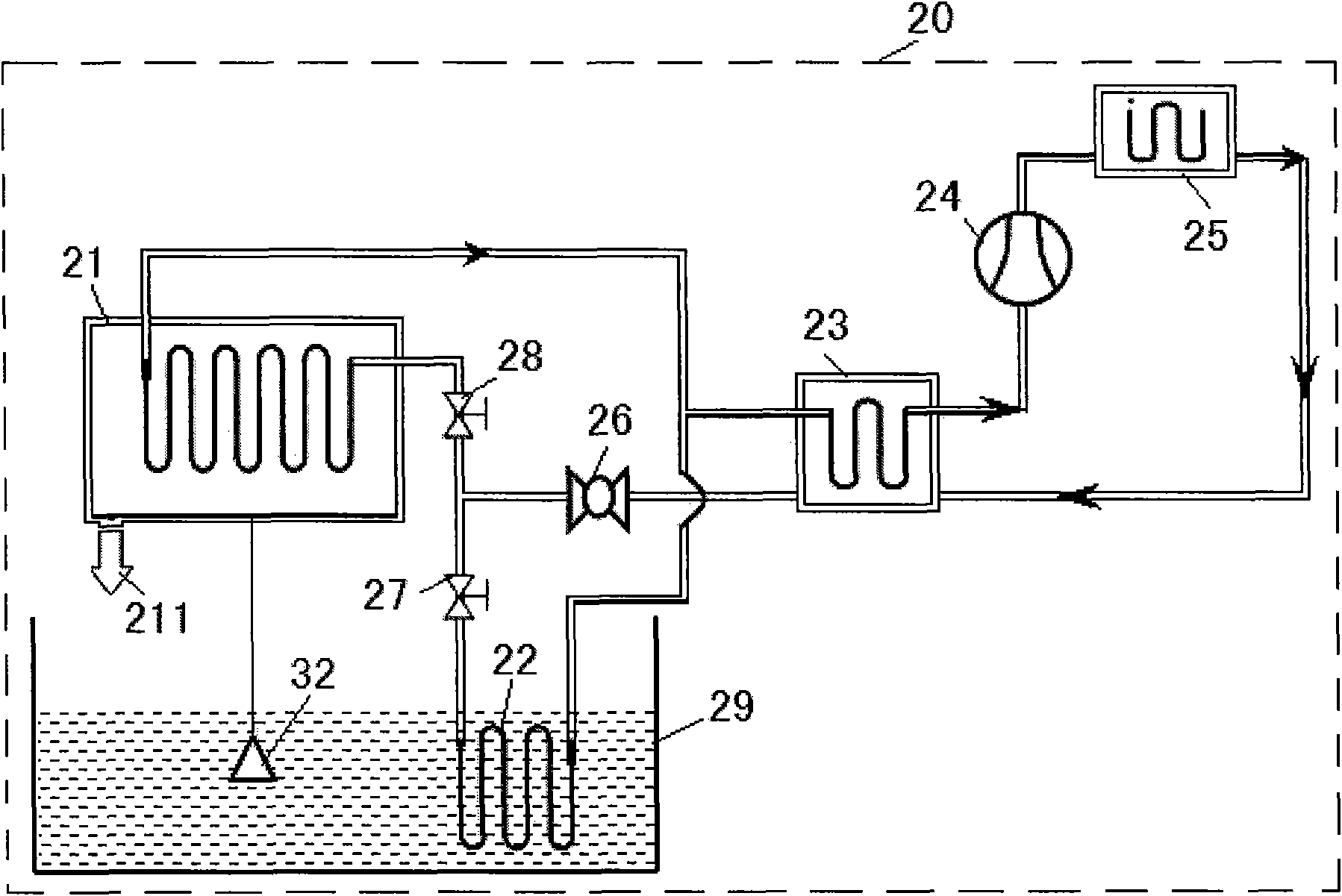

Integrated air-conditioning system of solar-assisted soil source CO2 trans-critical heat pump

ActiveCN101008537AVersatileReduce energy consumptionHeat pumpsCompression machinesFour-way valveGas cooler

The invention discloses a solar-energy soil ultra-critical carbon dioxide heat pump air-conditioning system. The invention comprises an ultra-critical carbon dioxide heat pump medium circulator, a solar-energy collector, an underground tube heat exchanger, and an indoor air-conditioning tube. The invention arranges heat exchange coil tube, evaporator / gas cooler in the heat accumulating box, via four-way valve and valves to connect them into one air-conditioning system. The invention can work in five modes as heating, refrigerating, heating water, heating-heating water, and refrigerating-heating water, to heat water, refrigerate and supply heat.

Owner:TSINGHUA UNIV

Refrigeration system having variable speed fan

InactiveUS6968708B2Improve the coefficient of performanceIncreasing refrigerant mass flow rateCompression machines with non-reversible cycleEvaporators/condensersUnit massGas cooler

A transcritical refrigeration system includes a compressor, a gas cooler, an expansion device, and an evaporator. Refrigerant is circulated though the closed circuit system. Preferably, carbon dioxide is used as the refrigerant. A fan moves outdoor air that exchanges heat with the refrigerant across the evaporator. The speed of the fan is regulated to regulate the evaporator pressure and to adapt the evaporator to different environmental conditions to achieve the optimal coefficient of performance. During high ambient conditions, the fan speed is decreased, decreasing the refrigerant mass flowrate in the system. The energy exchange per unit mass of the refrigerant in the gas cooler increases and the work of the fan decreases, increasing the coefficient of performance of the system. During low ambient conditions, the mass flowrate of the system is low and there is more heat transfer thermal resistance on the refrigerant side at the evaporator. The speed of the fan is lowered to decrease the work of the fan. Therefore, the coefficient of performance increases.

Owner:CARRIER CORP

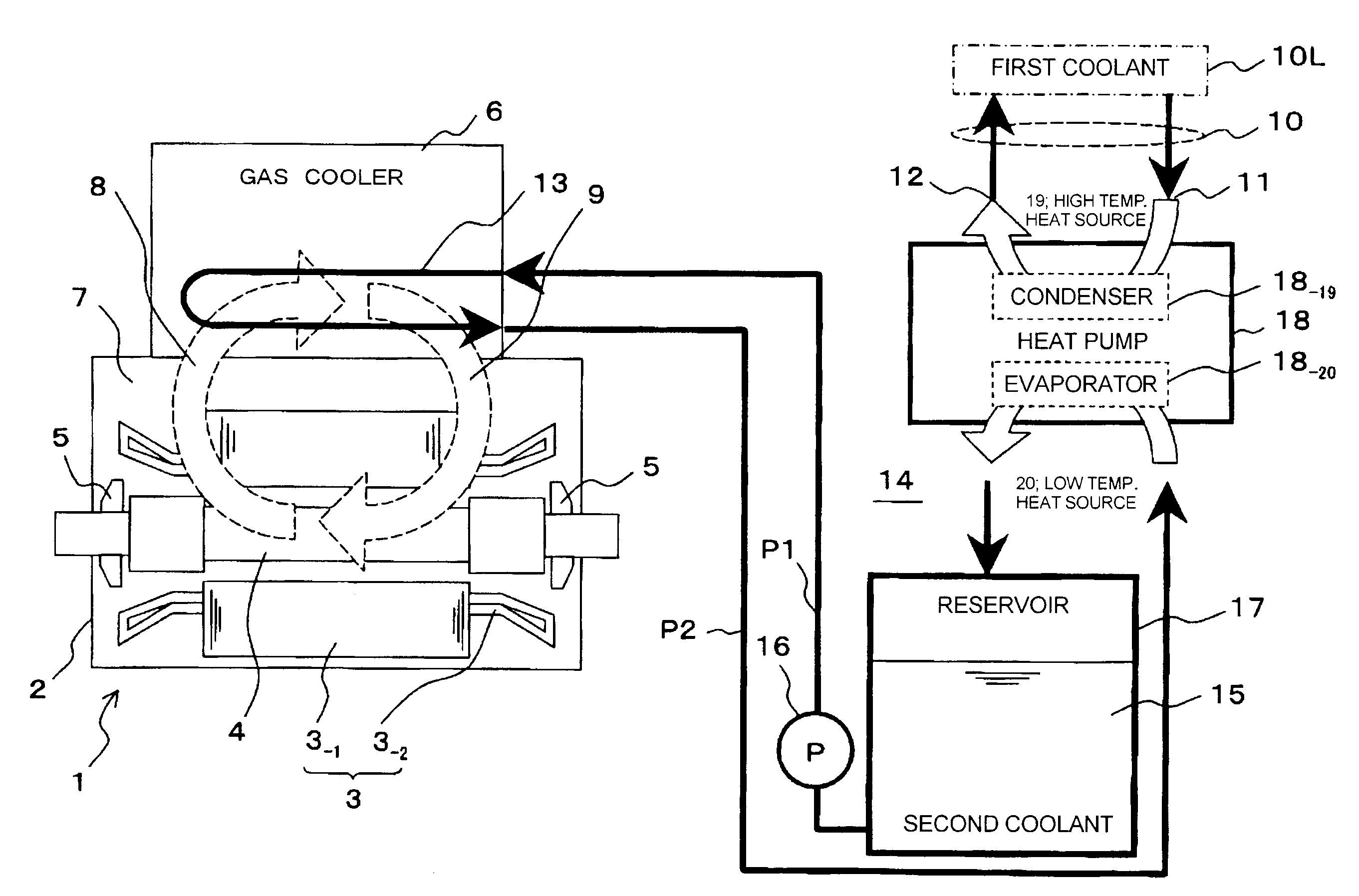

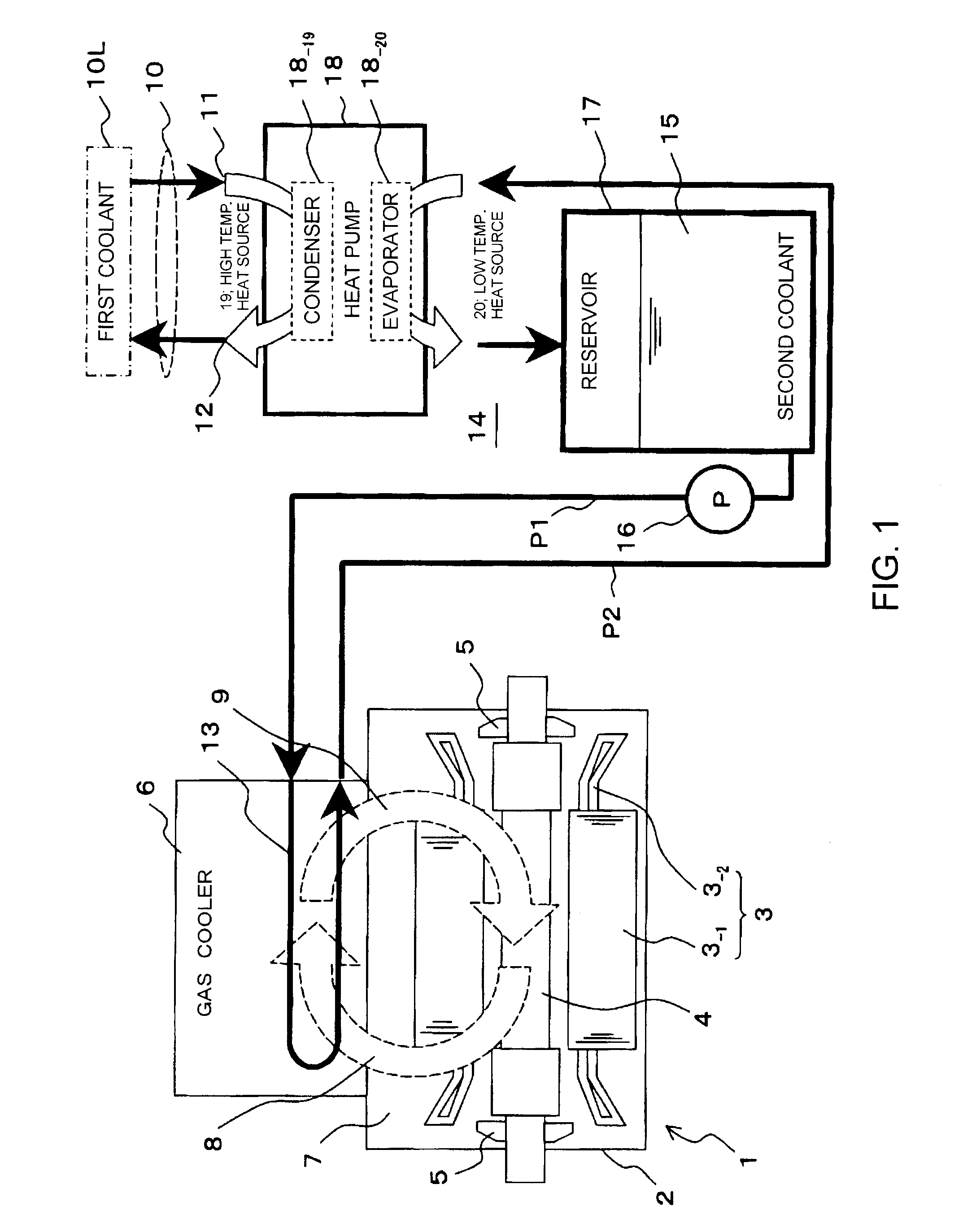

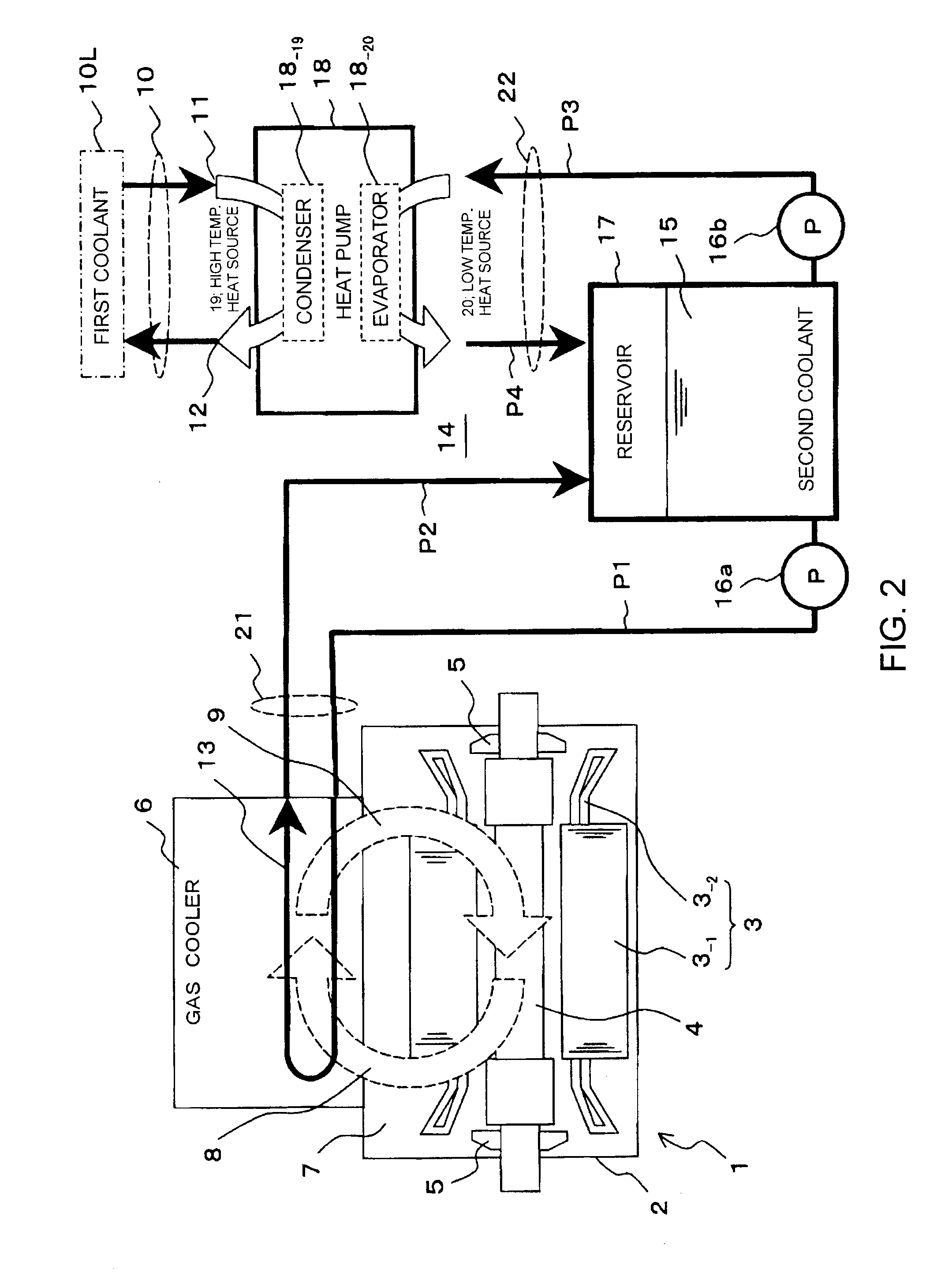

Rotary electric machine

InactiveUS20080012437A1Cooling/ventillation arrangementWindings conductor shape/form/constructionElectric machineEngineering

A rotary electric machine includes: a stator, a rotor and rotor fans contained in a closed type frame. The cooling gas is circulated in the frame by the rotor fans and warmed as a result of heat exchange with the stator and the rotor is cooled by a gas cooler. A heat pump is adapted to use cooling water or ambient air as high temperature heat source and liquid coolant as low temperature heat source. A liquid coolant circulation system for supplying liquid coolant to the heat exchange section of the gas cooler is provided. The liquid coolant is cooled by the heat pump and is supplied to the heat exchange section of the gas cooler by means of the coolant circulation system.

Owner:KK TOSHIBA

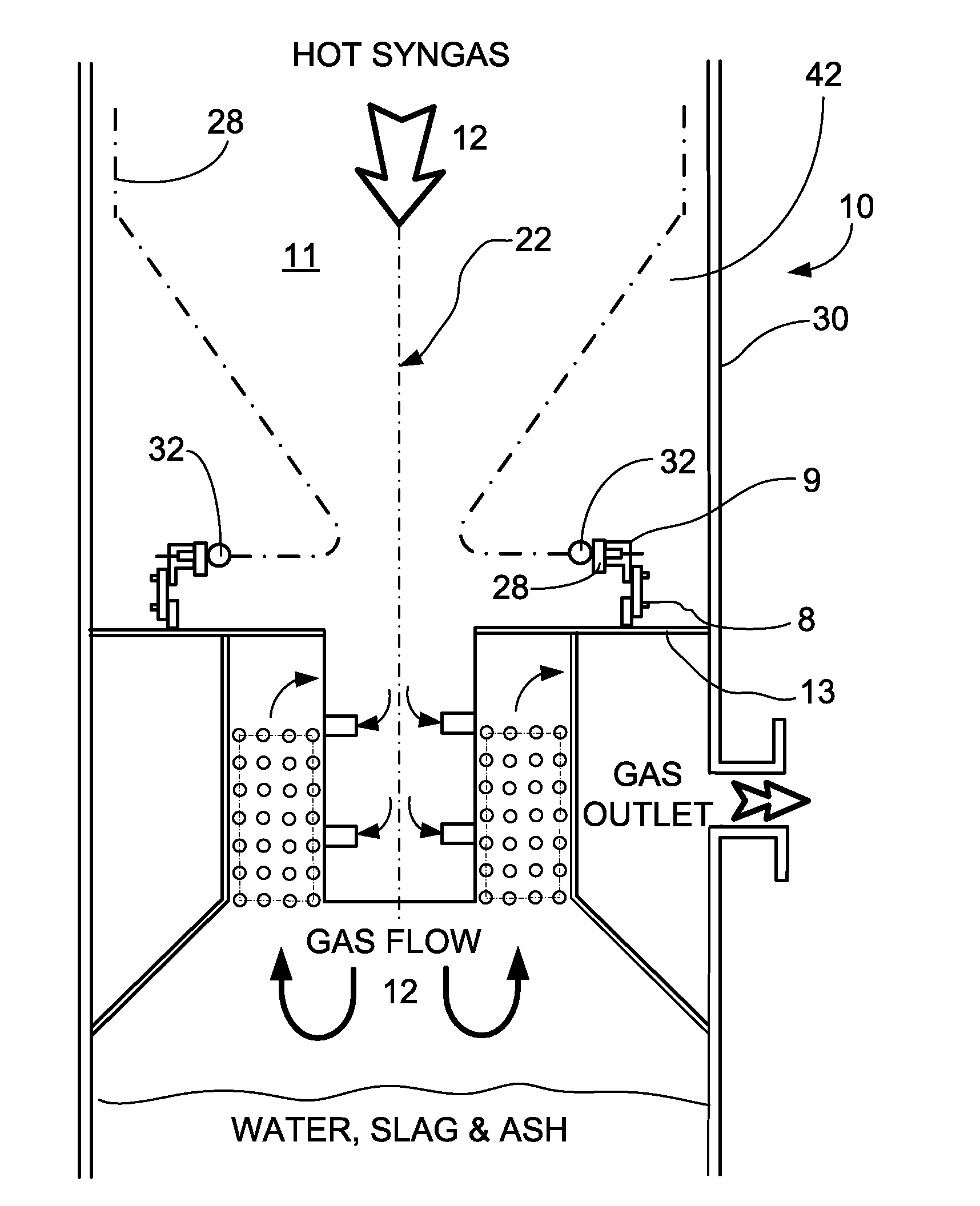

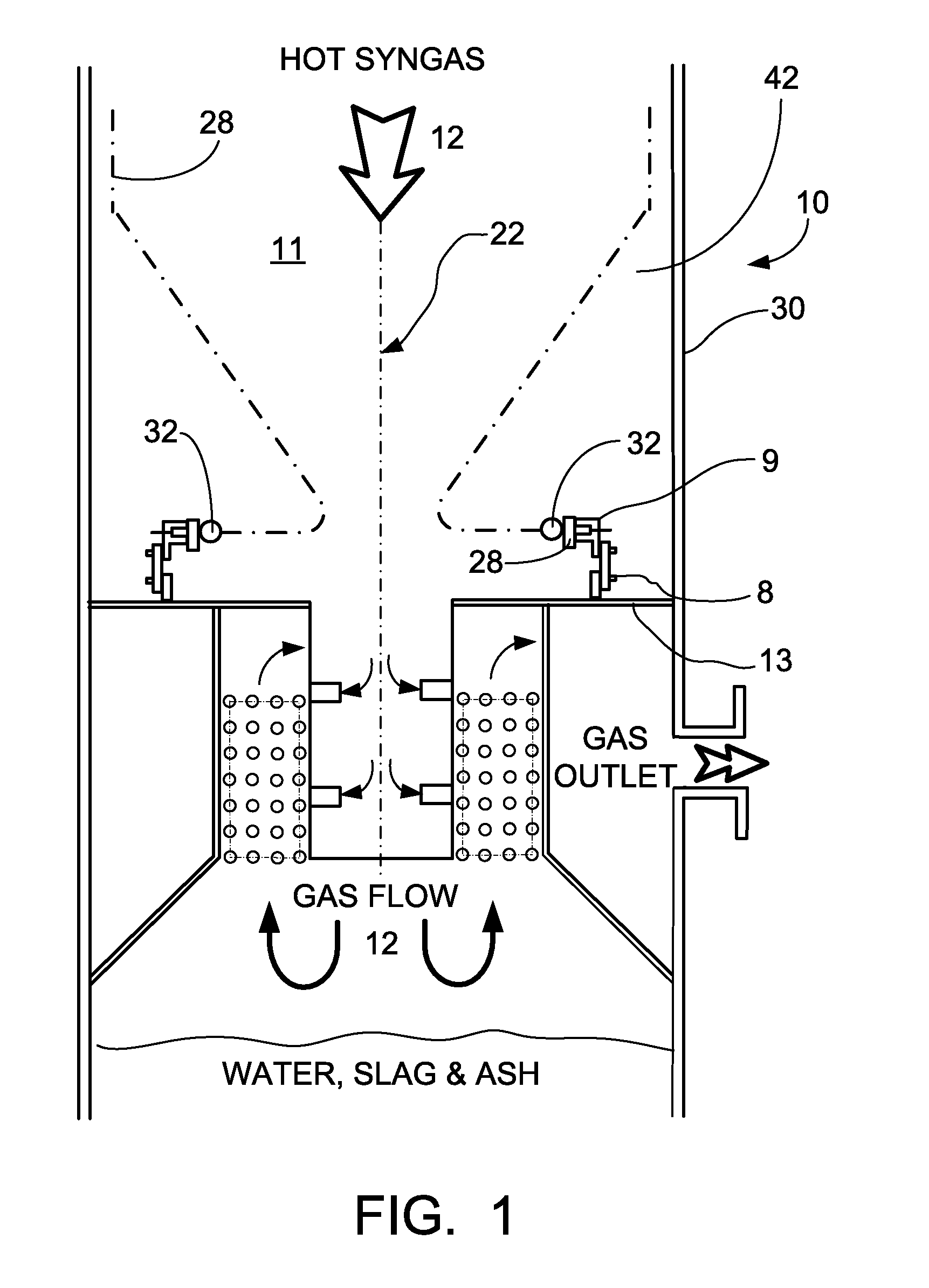

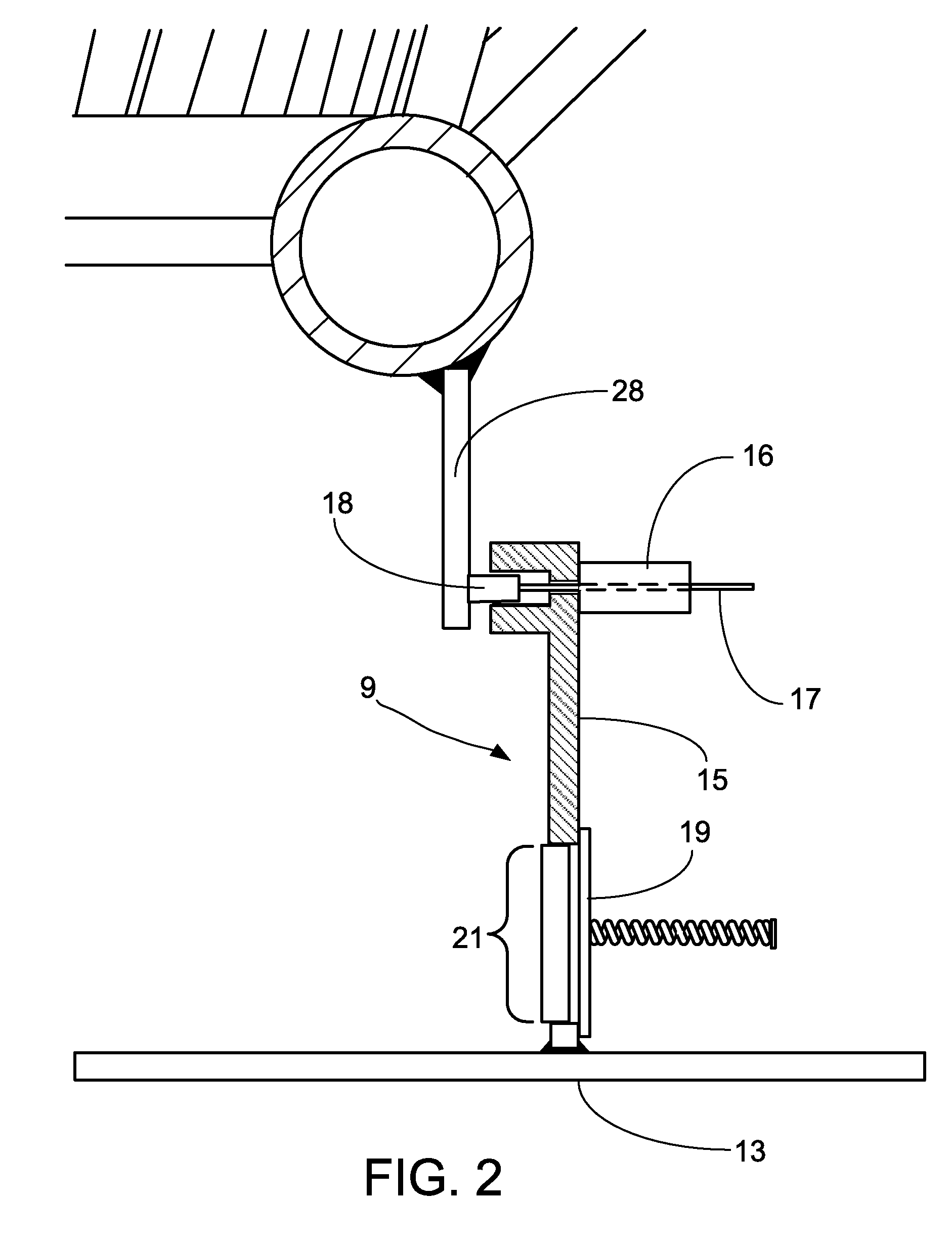

Sealing arrangement with a segmented seal and pressure relief

ActiveUS20080042373A1Reduce differential pressureAvoid exposureGasifier mechanical detailsCheck valvesEngineeringGas cooler

A sealing apparatus adapted for use in a pressure vessel such as a synthesis gas cooler. The sealing apparatus is of a segmented plate construction formed around an outer wall section of a conduit means of the pressure vessel that defines at least part of a passage for receiving effluent from a gasification process. Pressure responsive mechanisms are provided on the plate segments to maintain the pressure difference across the sealing apparatus within the acceptable operating limits as well as to permit instantaneous pressure release to prevent damage to the pressure part assembly or cage. The seal is also maintained continuously through the differential growth movement between the conduit means and the pressure vessel during heat up and cool down cycles.

Owner:THE BABCOCK & WILCOX CO

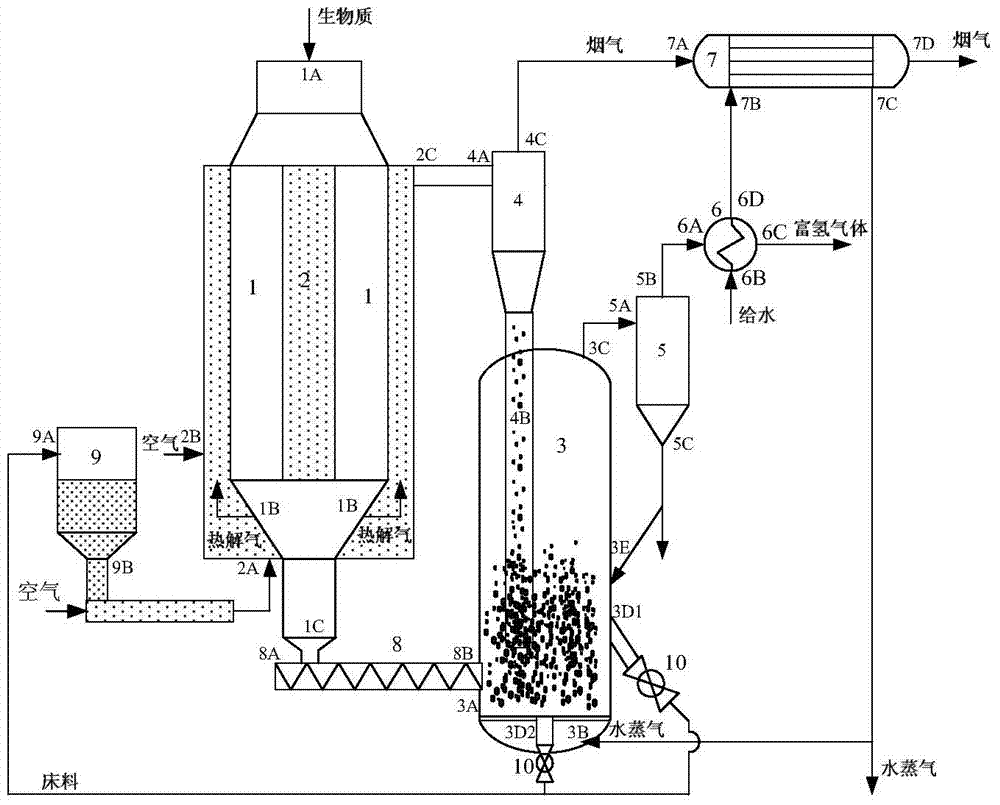

Device and method for preparing hydrogen-rich gas by gasifying biomass

ActiveCN103923705AAvoid mixingEfficient use ofEnergy inputGasification with fuel pre-distillationWater vaporGas cooler

The invention discloses device and method for preparing hydrogen-rich gas by gasifying biomass. The device mainly comprises a pyrolysis reactor, a combustion reactor, a gasification reactor, a gas-solid separator, a gas cooler and an exhaust heat boiler, wherein the pyrolysis reactor is arranged in the combustion reactor. In a process course, the biomass is firstly pyrolyzed in the pyrolysis reactor to generate pyrolysis gas and coke, the pyrolysis gas is directly combusted to provide heat for biomass pyrolysis and gasification, and the coke is subjected to gasification reaction with water vapor to obtain the hydrogen-rich gas. The device and method disclosed by the invention realize the separation of the pyrolysis process and coke gasification process of the biomass and can be used for displacing the hydrogen contained in the water vapor by sufficiently utilizing fixed carbon contained in the biomass. According to the device and method, the obtained hydrogen-rich gas mainly contains H2, CO2 and a small amount of CO, so that the conventionally gasified hydrogen-rich gas product is prevented from being mixed with low-carbon hydrocarbon gas and tar, and the subsequent decontamination and purification utilization are simple, convenient and economic.

Owner:SOUTHEAST UNIV

Drying machine

InactiveUS20050198851A1Reduce vibrationDrying solid materials with heatDrying gas arrangementsEngineeringGas cooler

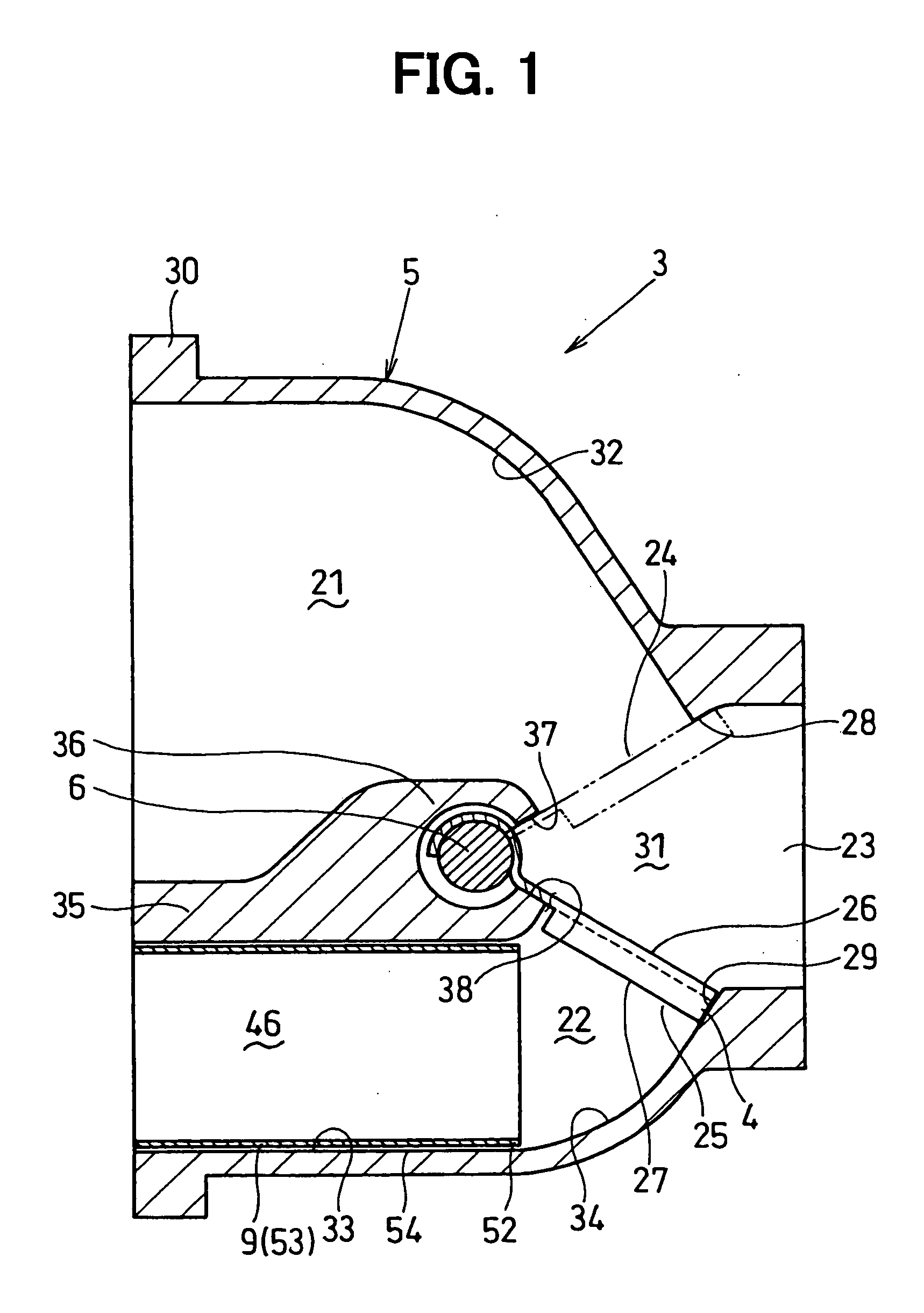

An object is to provide a drying machine capable of reducing vibration generated by rotation of a rotary drum. There is provided a drying machine which executes a drying operation of a matter to be dried in a housing chamber constituted in an inner drum of a drum main body constituted of an outer drum and the inner drum disposed inside the outer drum, the drying machine comprising: a refrigerant circuit constituted by successively piping / connecting a compressor, a gas cooler, an expansion valve, and an evaporator in an annular shape; and an air circulation path for discharging air whose heat has been exchanged with the gas cooler into the housing chamber by a blower fan, and allowing the air which has passed through the housing chamber to exchange the heat with the evaporator, wherein a drum main body is attached to a base via a suspension, and the compressor is attached to a lower part of the drum main body.

Owner:SANYO ELECTRIC CO LTD

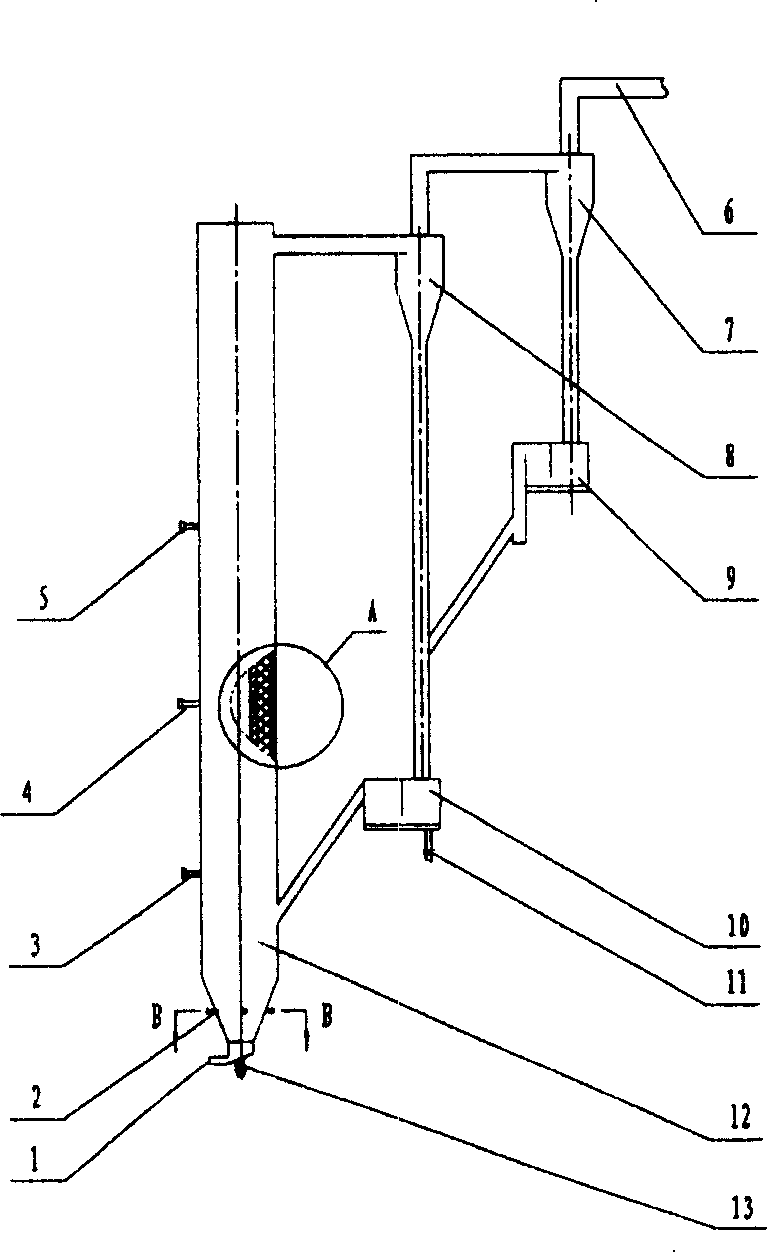

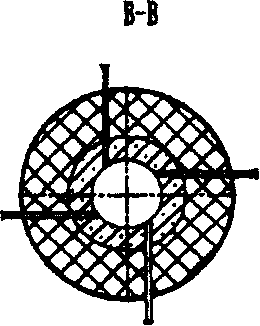

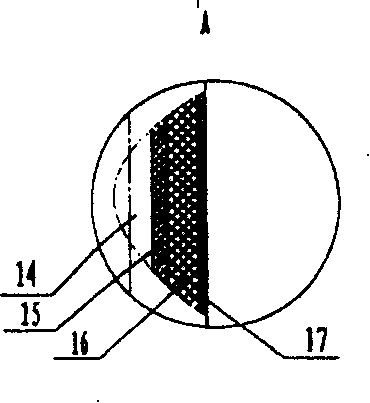

Fine coal pressurization dense phase transporting bed gasification method and device

ActiveCN101240196AIncrease speedGuaranteed to loop multiple timesCombined combustion mitigationGranular/pulverulent flues gasificationHigh rateHigh flux

A pulverized coal pressure dense transport bed gasification method and installation of the invention relates to gasification technology and employs in-furnace desulfurization craft. Pulverized coal and desulfurizer are sent into gasification furnace through the middle and lower part of gasification furnace by a feeder, and then react with a gasifying agent. Reaction mass flow upward from the bottom of the gasification furnace, and enter into a multistage gas-solid separator from an export on the top of the gasification furnace. Most solids are separated in the gas-solid separator and enter into the low part of the gasification furnace by a high flux return feeder to continue to participate in reaction. Gas products with a small amount of solid enter into a gas cooler which can recover gas manifested heat to generate steam. The enter modes of the gasifying agent are bottom once wind and cyclone twice wind, otherwise, the reactor can also be use to burn. Because of the high-rate cycle, high solid content and high gas-solid mixing in the gasification furnace of the invention, the gasification strength and gasification rate of the gasification furnace can be improved and higher gasification efficiency and carbon conversion rate can be obtained.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

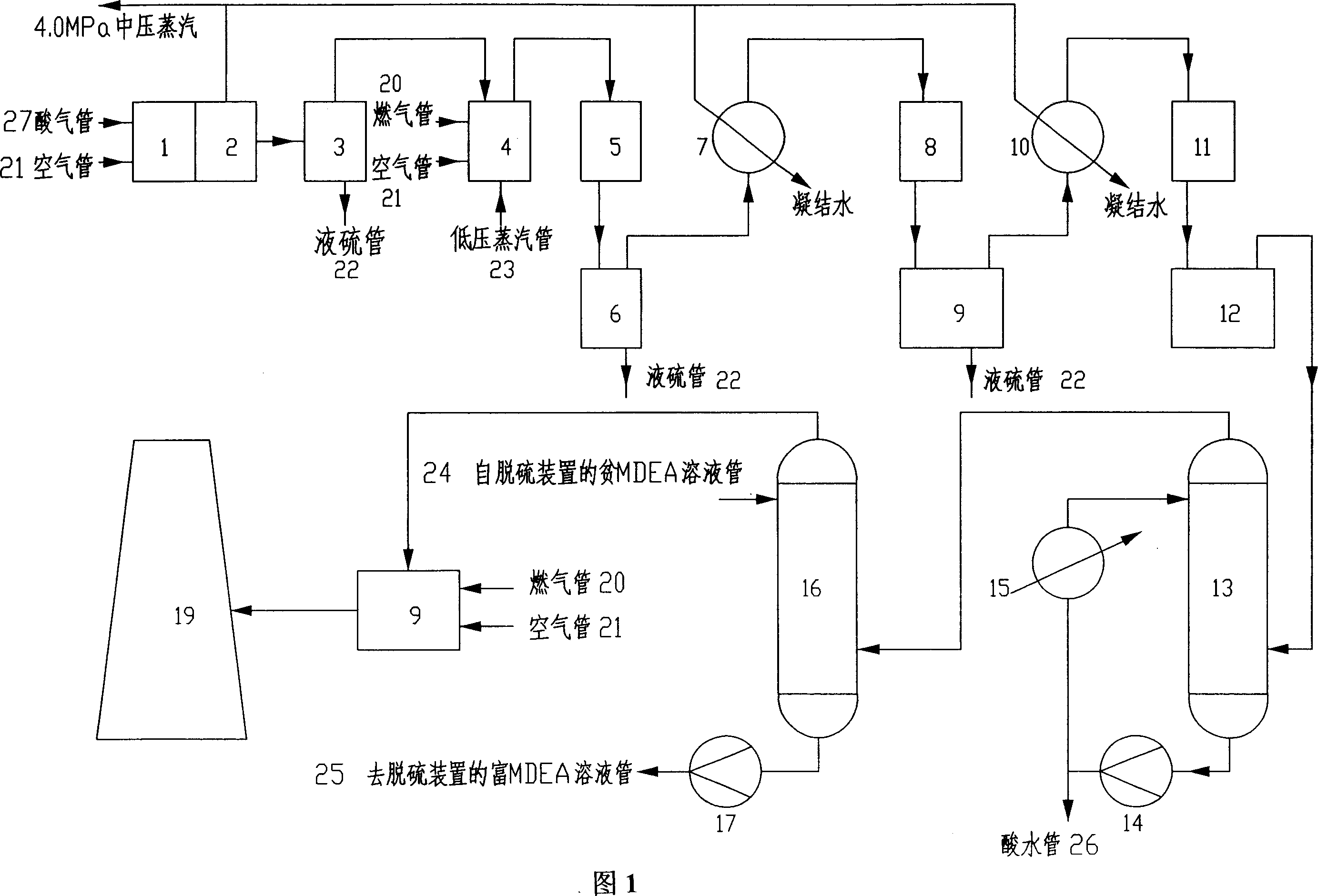

Device and method of reclaim and processing tail gas of sulfur

InactiveCN101054165AWide applicabilityReduce the amount of hydrogenDispersed particle separationEnergy inputHydrogenation reactionGas cooler

A sulfur recovery and offgas processing device and a method therefor is characterized in that the device comprises a thermal reaction section, a catalytic reaction section and a reducing absorption section. In the thermal reaction section, hydrogen sulfide acid gas is partly burnt in a main burner (1) to convert into sulfur dioxide, hydrogen sulfide and sulfur dioxide proceed claus reaction to generate process gas such as elemental sulphur, the process gas is cooled by a waste-heat boiler (2) and a primary condensate cooler (3) to obtain liquid sulfur; in the catalytic reaction section, the process gas is reacted through a primary reheat hydrogen furnace (4), a secondary steam reheater (7), two stage reactor (5, 8), then separating liquid sulfur is cooled by two stage condensate cooler (6, 9) then enters into the reducing absorption section; in the reducing absorption section, the process gas is heated by a steam heater (10) then hydrogenizated in a hydrogenation reactor (11), cooled in a process gas cooler (12) and enters into a quench tower (13) which top connecting with bottom of a absorber (16), top of the absorber connects with a incinerator (18), the incinerator connects with a chimney (19).

Owner:东营科瑞泛能油气技术服务有限公司

Controls for variable displacement compressor

A control system for a variable displacement compressor uses a mechanical valve to minimize energy consumption in an air conditioning system. The control system can also provide instantaneous indications to the vehicle controller of air conditioning power consumption to avoid engine loading. Controls are also used to contain oil within the compressor and to minimize its presence downstream of the compressor into the gas cooler and evaporator parts of the system.

Owner:HANON SYST

Supercritical pressure regulation of economized refrigeration system by use of an interstage accumulator

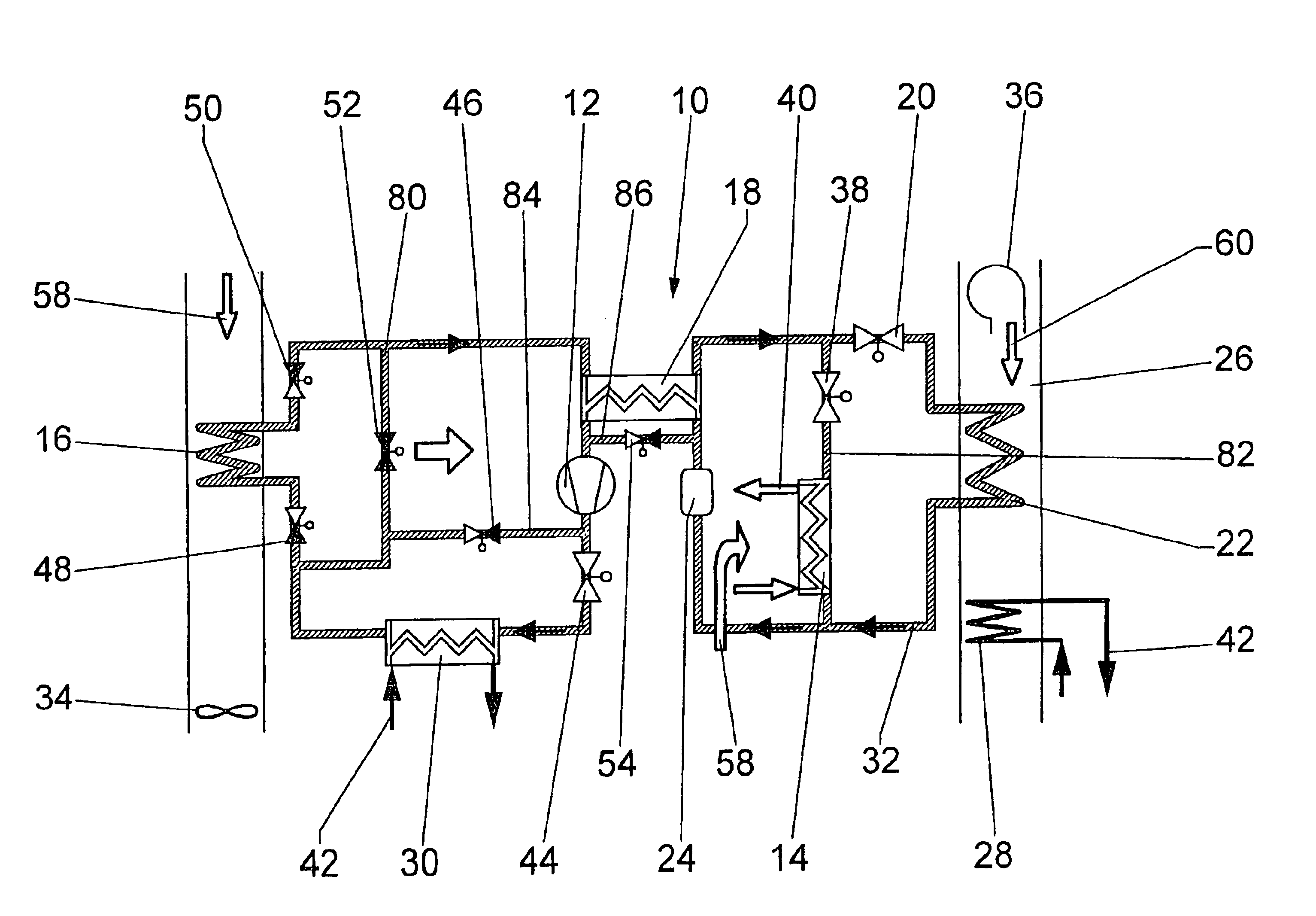

InactiveUS7424807B2Reduce the amount of solutionImprove pressure resistanceCompression machines with non-reversible cycleCompression machines with several evaporatorsGas coolerEngineering

Refrigerant is circulated through an economized refrigeration system including a compressor, a gas cooler, a main expansion device, an economizer heat exchanger and an evaporator. After cooling, the refrigerant splits into an economizer flow path and a main flow path. Refrigerant in the economizer flow path is expanded to a low pressure and exchanges heat with the refrigerant in the main flow path in the economizer heat exchanger. The refrigerant in the main flow path is then expanded and heated in the evaporator and enters the compressor, completing the cycle. An accumulator positioned between the economizer heat exchanger and the compressor stores excess refrigerant in the system, regulating the amount of refrigerant in the system and the high pressure in the system. The amount of refrigerant in the accumulator is controlled by regulating the economizer expansion device. By adjusting the amount of refrigerant in the accumulator, the amount of refrigerant in the system, and therefore the high pressure of the system, can be regulated.

Owner:CARRIER CORP

Air-conditioning unit with additional heat transfer unit in the refrigerant circuit

InactiveUS6910345B2Burn quicklyIncrease heatAir-treating devicesCompression machines with non-reversible cycleGas coolerEngineering

The invention relates to an air-conditioning unit (10) for a motor vehicle with a heating heat transfer unit (28) connected to a coolant circuit (42) in an internal combustion engine and comprising an evaporator (22) installed upstream in the direction of flow of a fan (36). A compressor (12) in a refrigerant circuit (32) pumps a refrigerant through a gas cooler (16) and an expansion valve (20) during a cooling operation, and pumps said refrigerant to the evaporator (22) via the expansion valve (20) by by-passing the gas cooler (16) during a heating operation. A coupled heat exchanger (30) is provided between the coolant circuit (42) and the refrigerant circuit (32). The invention provides that the coupled heat exchanger (30) is located in the refrigerant circuit (32) on the pressure side of the compressor (12) upstream of the gas cooler (16), a first by-pass line (80) is provided parallel to the gas cooler (16) and the flow through the gas cooler (16) and the first by-pass line (80) is controlled by a switching valve (52) in the first by-pass line (80) and a switching valve (48, 50) located at each of the inlet and outlet of the gas cooler (16), depending on operating parameters, and a heat transfer unit (14) for a medium in a unit in the refrigerant circuit (32) is connected behind an expansion valve (20 or 38) and serves as heat source in heating operation.

Owner:ROBERT BOSCH GMBH

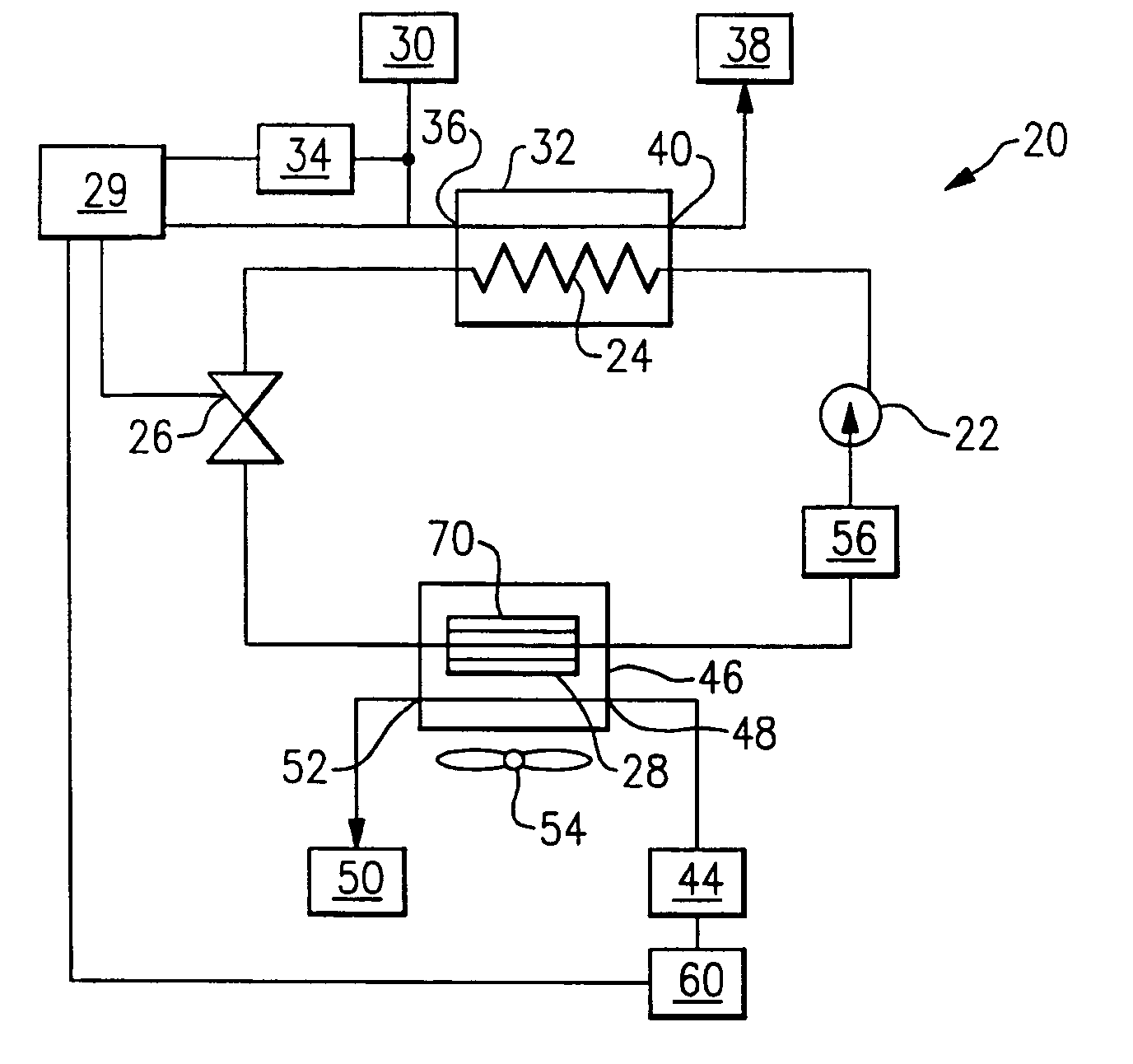

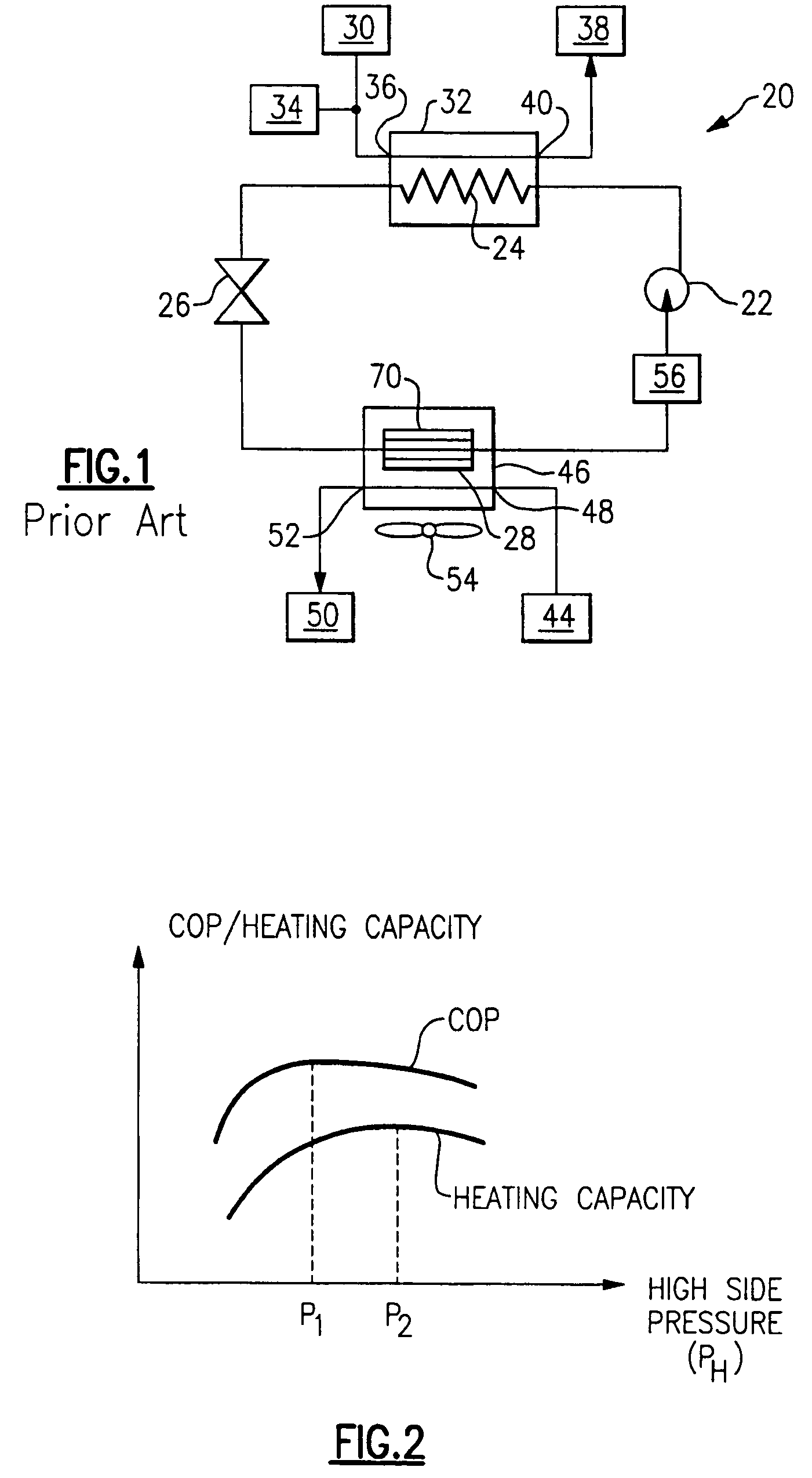

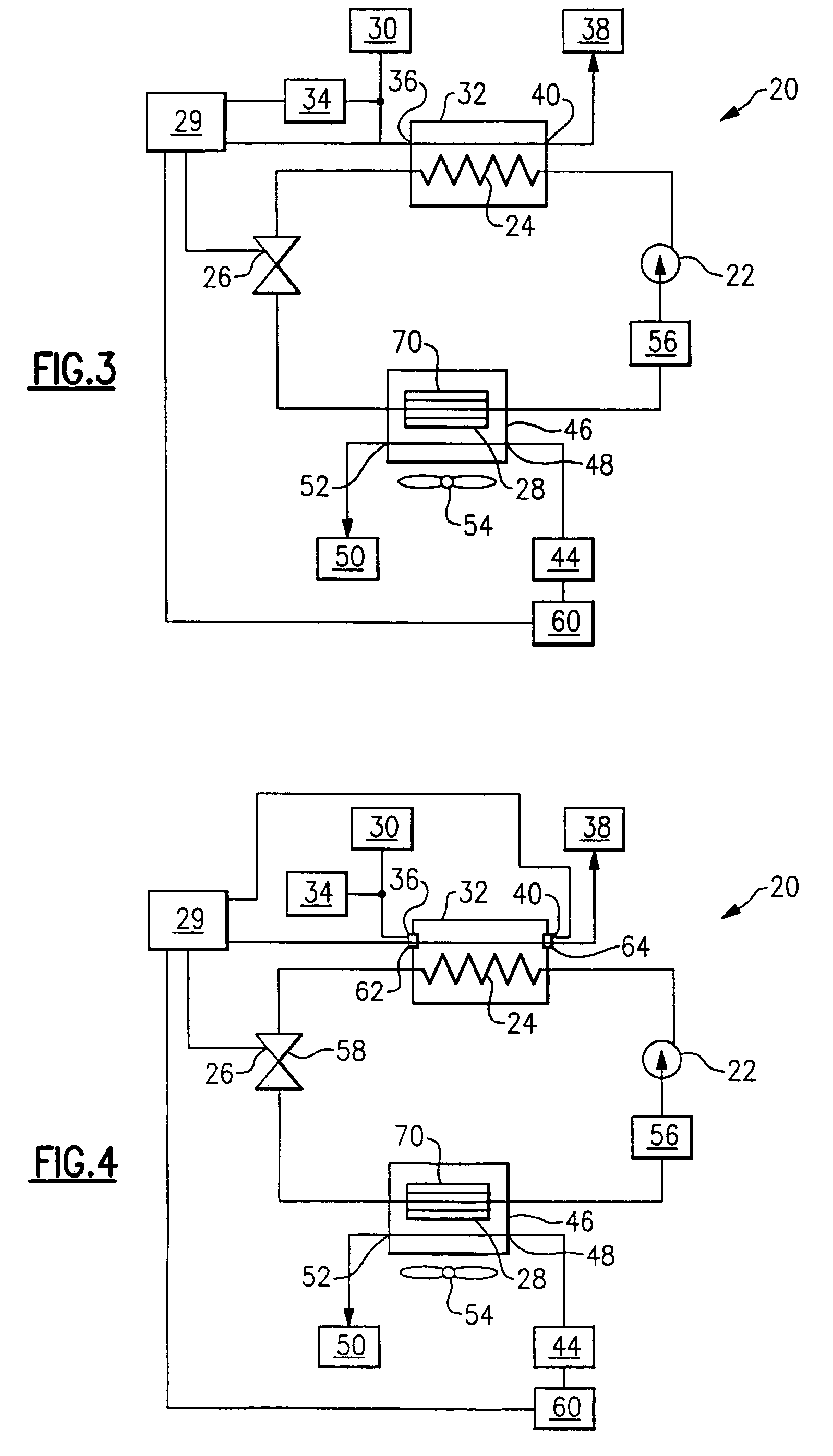

Transcritical vapor compression optimization through maximization of heating capacity

A vapor compression system includes a compressor, a gas cooler, an expansion device, and an evaporator. Refrigerant is circulated through the system. The high side pressure of the vapor compression system is selected to optimize the heating capacity. In one example, the optimal high side pressure is obtained by determining the high side pressure that correlates to the maximum current required to operate to the water pump. In another example, the actual temperature of the water entering the gas cooler, the water exiting the gas cooler, and the ambient air temperature are measured and compared to a predetermined value to determine the optimal high side pressure.

Owner:CARRIER CORP

Mud drying system and use method thereof

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com