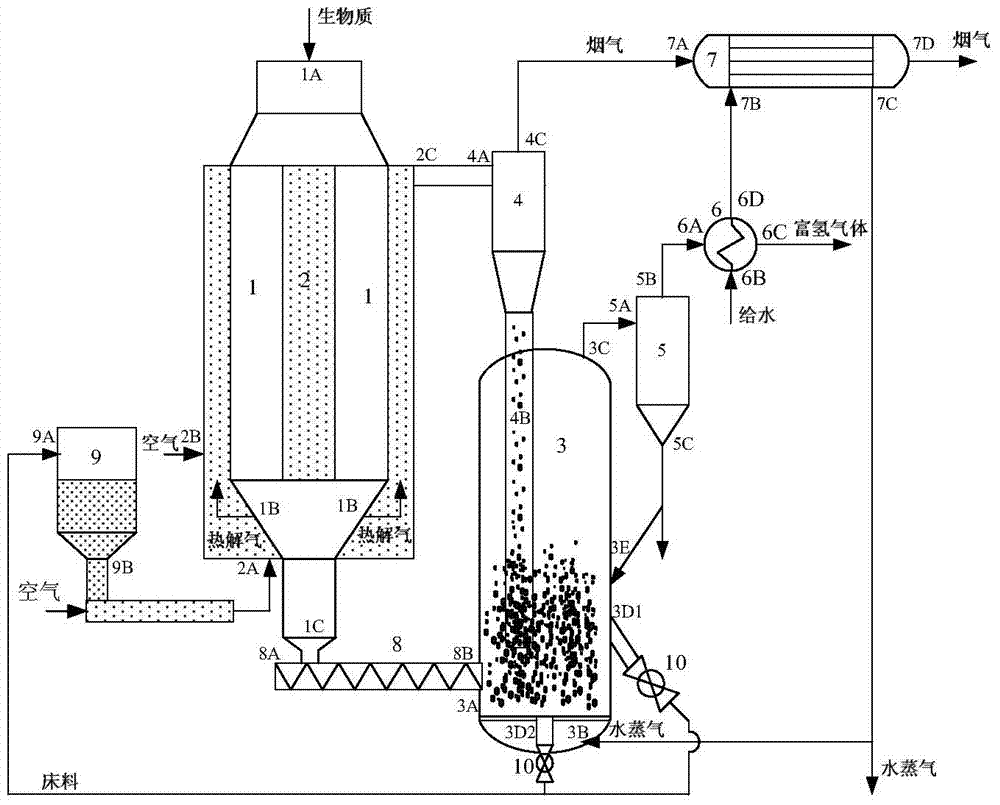

Device and method for preparing hydrogen-rich gas by gasifying biomass

A biomass and hydrogen-rich technology, applied in the manufacture of combustible gas, petroleum industry, energy input, etc., can solve the problems of difficult conversion and removal, high tar content, complicated purification, etc. The effect of self-heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Agricultural waste corn stalks are used as raw materials, and the gasification process is as described above: corn stalks are crushed to about 1mm, moisture content 2 o 3 and K 2 CO 3 , the ratio of the two is 4:1, the component H of the vaporized hydrogen-rich gas is condensed 2 : 63.9%, CO: 8.3%, CO 2 : 27.7%, CH 43 / kg cornstalk.

Embodiment 2

[0062] Agricultural waste straw is used as raw material, and the gasification process is as above: wheat straw is crushed to about 1mm, moisture content is 2 o 3 and K 2 CO 3 , the ratio of the two is 4:1, and the component H of the vaporized hydrogen-rich gas is condensed 2 : 63.1%, CO: 5.8%, CO 2 : 30.9%, CH 4 3 / kg.

Embodiment 3

[0064] Agricultural waste straw is used as raw material, and the gasification process is as above: wheat straw is crushed to about 1mm, moisture content is 2 o 3 、K 2 CO 3 and CaO mixture, the ratio of the three is 3:1:1, the composition of the vaporized hydrogen-rich gas after condensation is H2: 80.6%, CO: 3.8%, CO 2 : 15.5%, CH 4 3 / kg straw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com