Brush-seal and matrix for regenerative heat exchanger, and method of adjusting same

a heat exchanger and matrix technology, applied in the field of heat exchangers, can solve the problems of increasing seal wear, clogging of porous matrix, reducing the efficiency of the regenerator, etc., and achieve the effect of preventing fluid flow mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]The detailed description explains embodiments of the invention, together with advantages and features, by way of example with reference to the drawings.

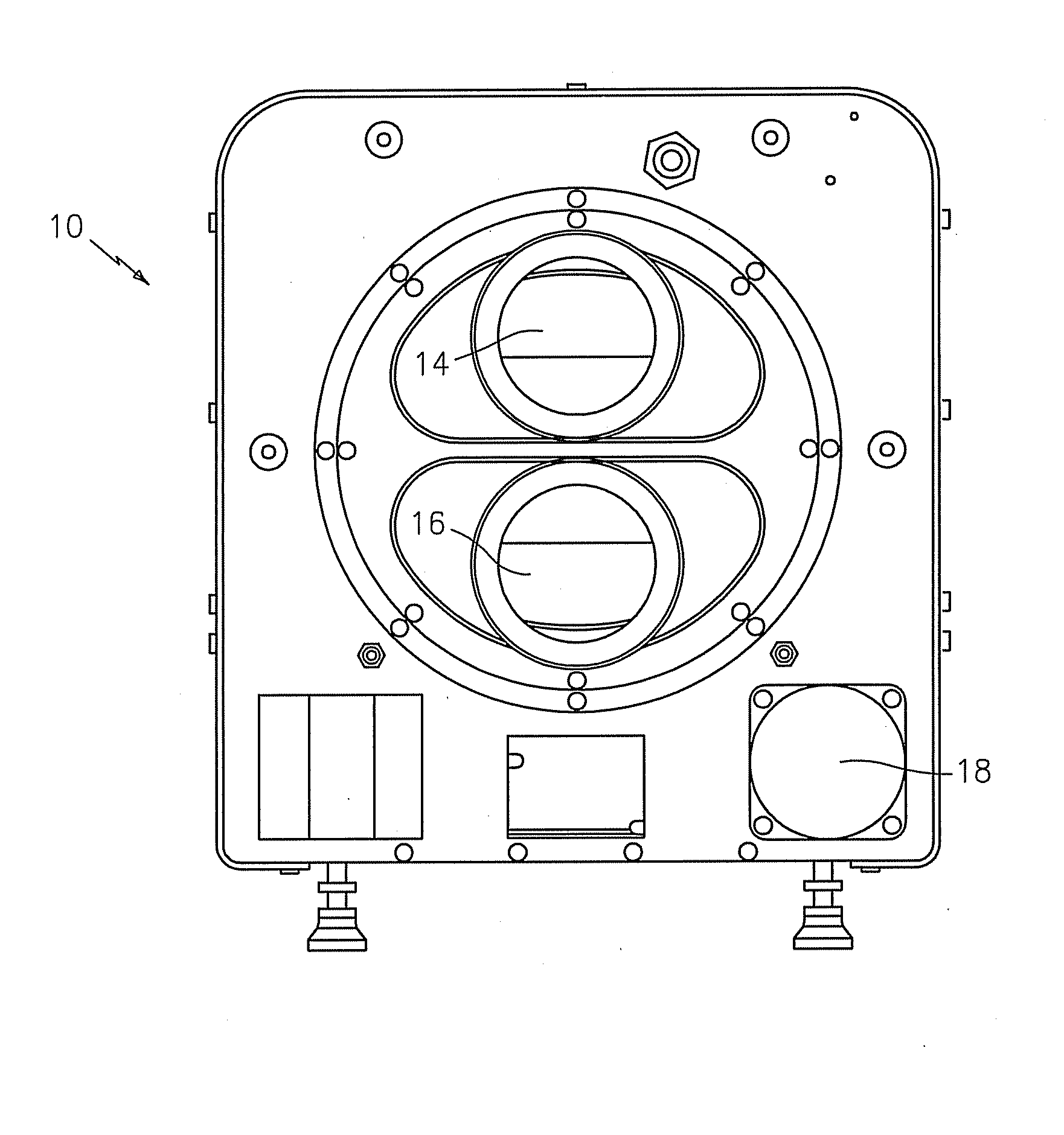

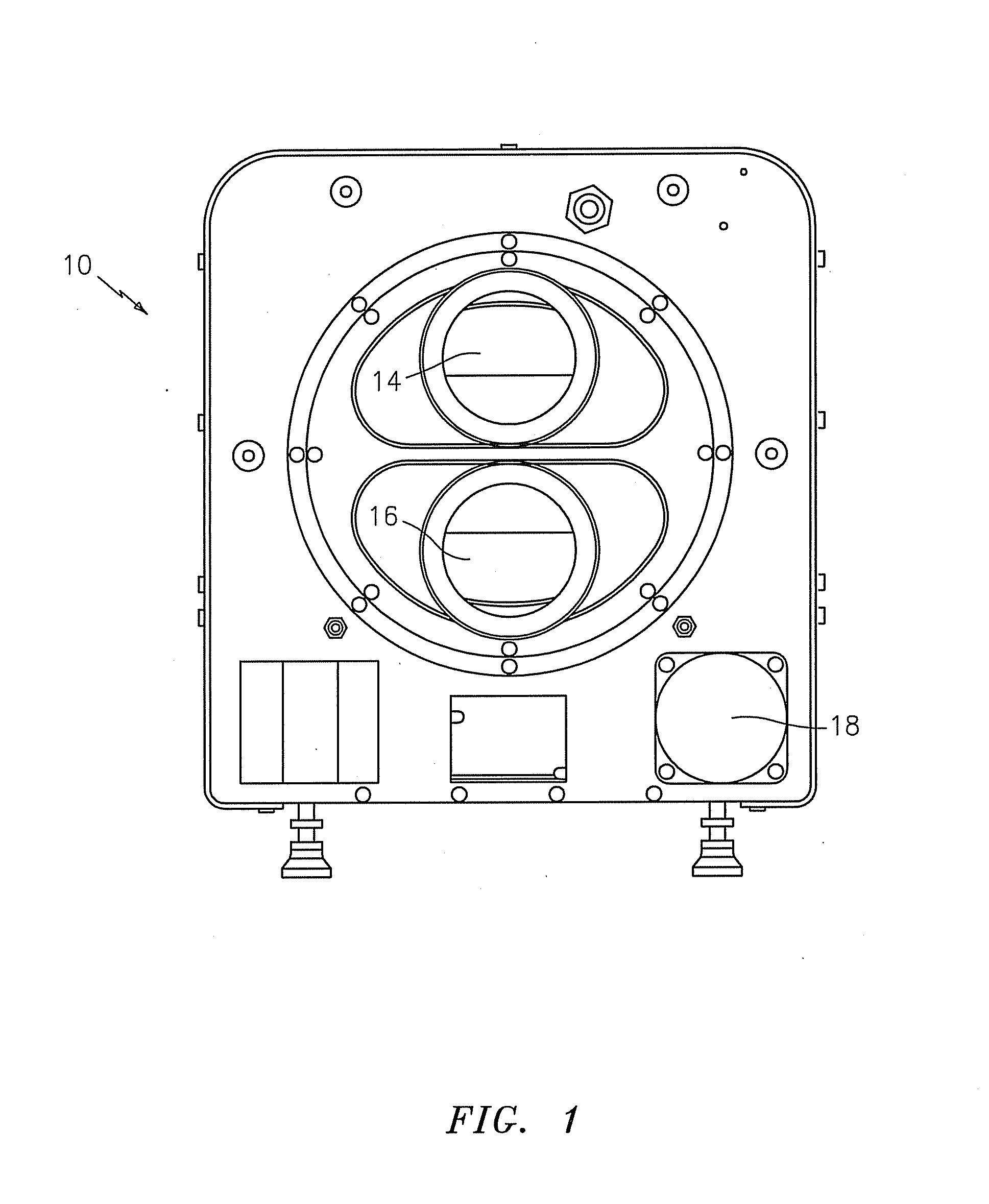

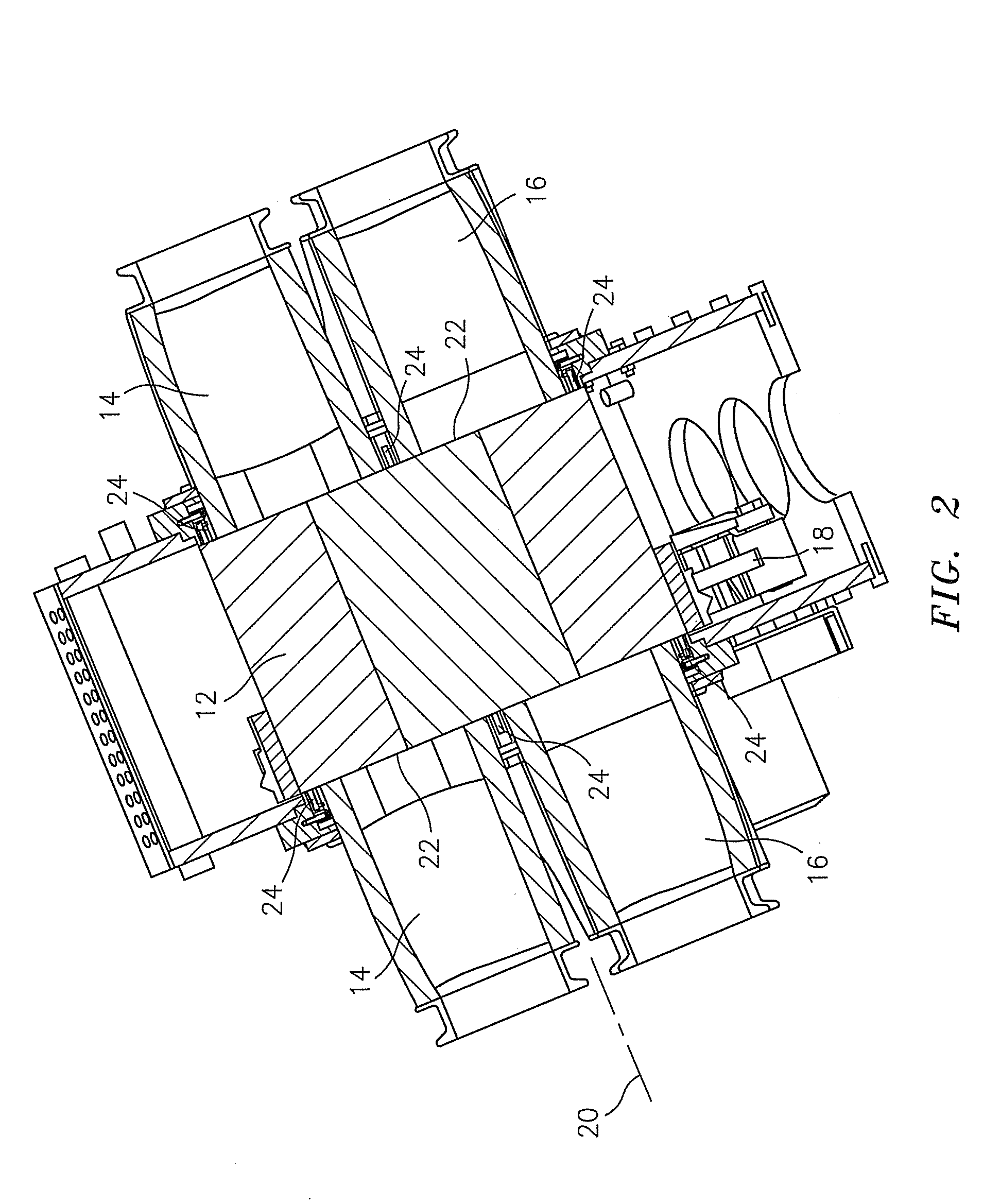

[0011]Shown in FIG. 1 is an embodiment of a regenerative heat exchanger (regenerator) 10. Referring now to FIG. 2, the regenerator 10 includes a regenerator matrix 12. The matrix 12 generally comprises a body having a plurality of internal passageways (not shown) oriented in all axial direction, and may be formed of a low-thermal-conductivity and high-heat-capacity material, for example, a ceramic material. In some embodiments, the matrix 12 may include an abradable coating layer (not shown) to protect the matrix 12 material from wear. The matrix 12 in some embodiments is cylindrical in shape, but other shapes are contemplated within the scope of this invention. The matrix 12 is disposed across two or more fluid streams. Each fluid stream is carried in a conduit. In this embodiment, a cold fluid stream is carried in a first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com