Patents

Literature

17073 results about "Exhaust heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

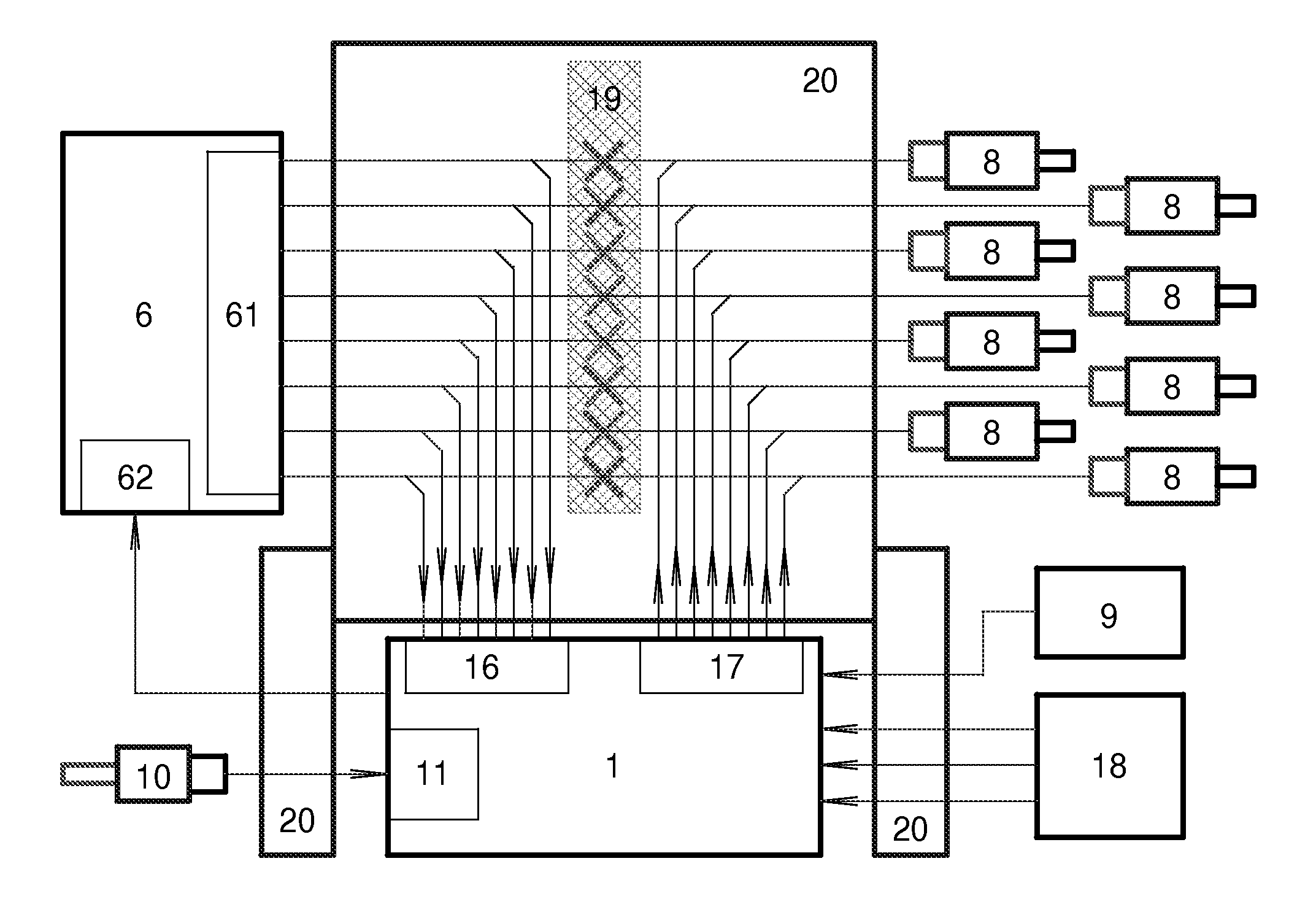

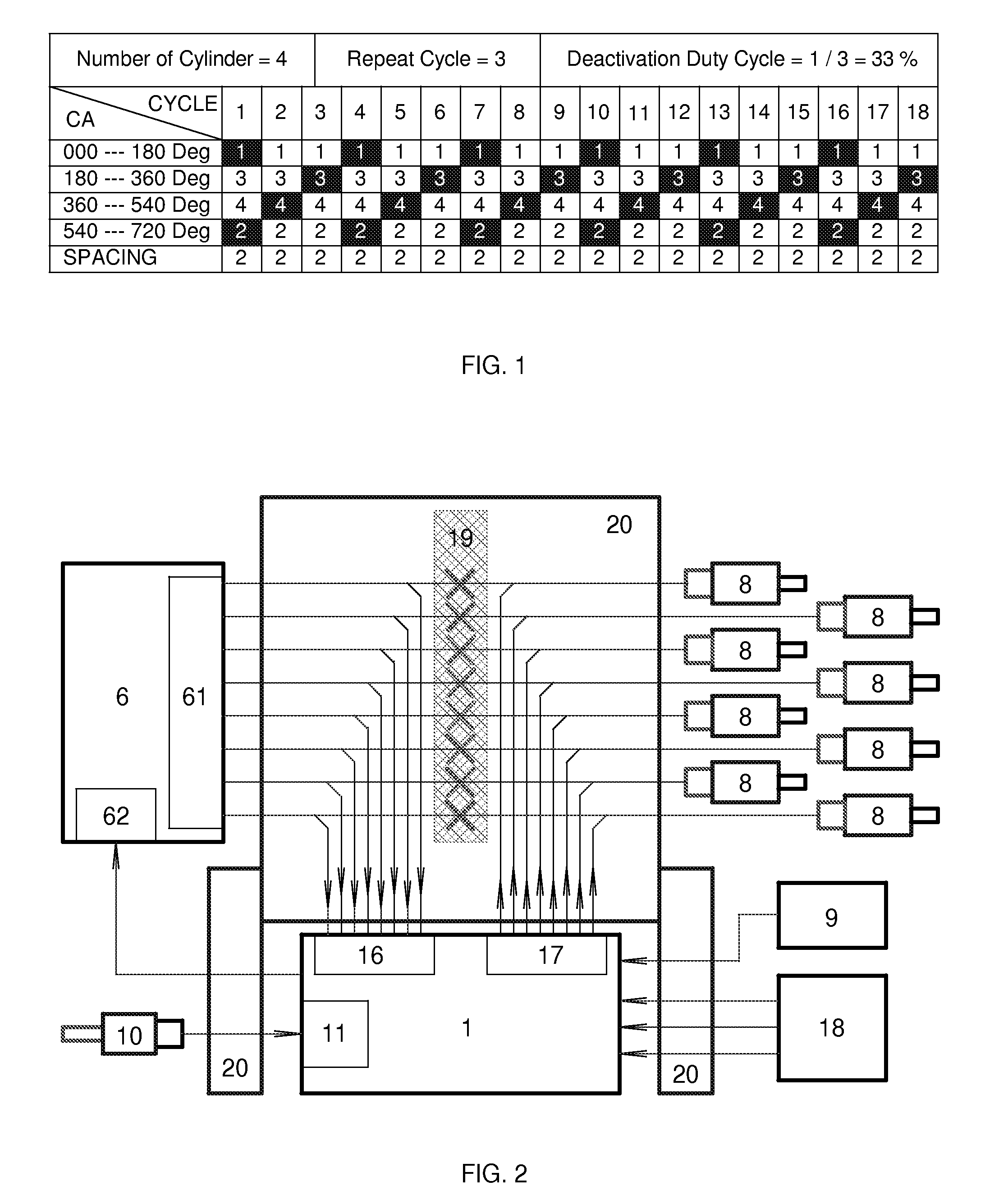

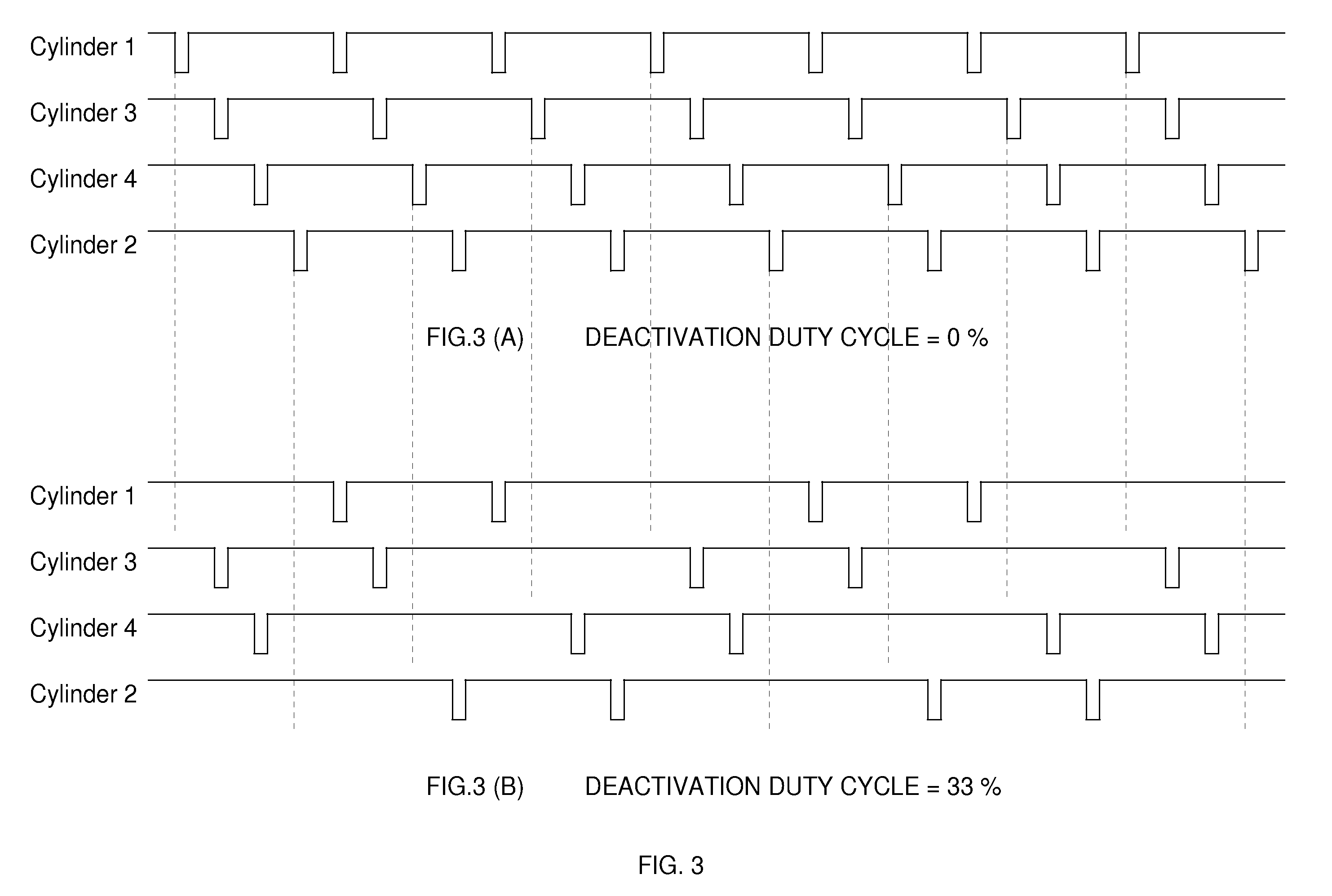

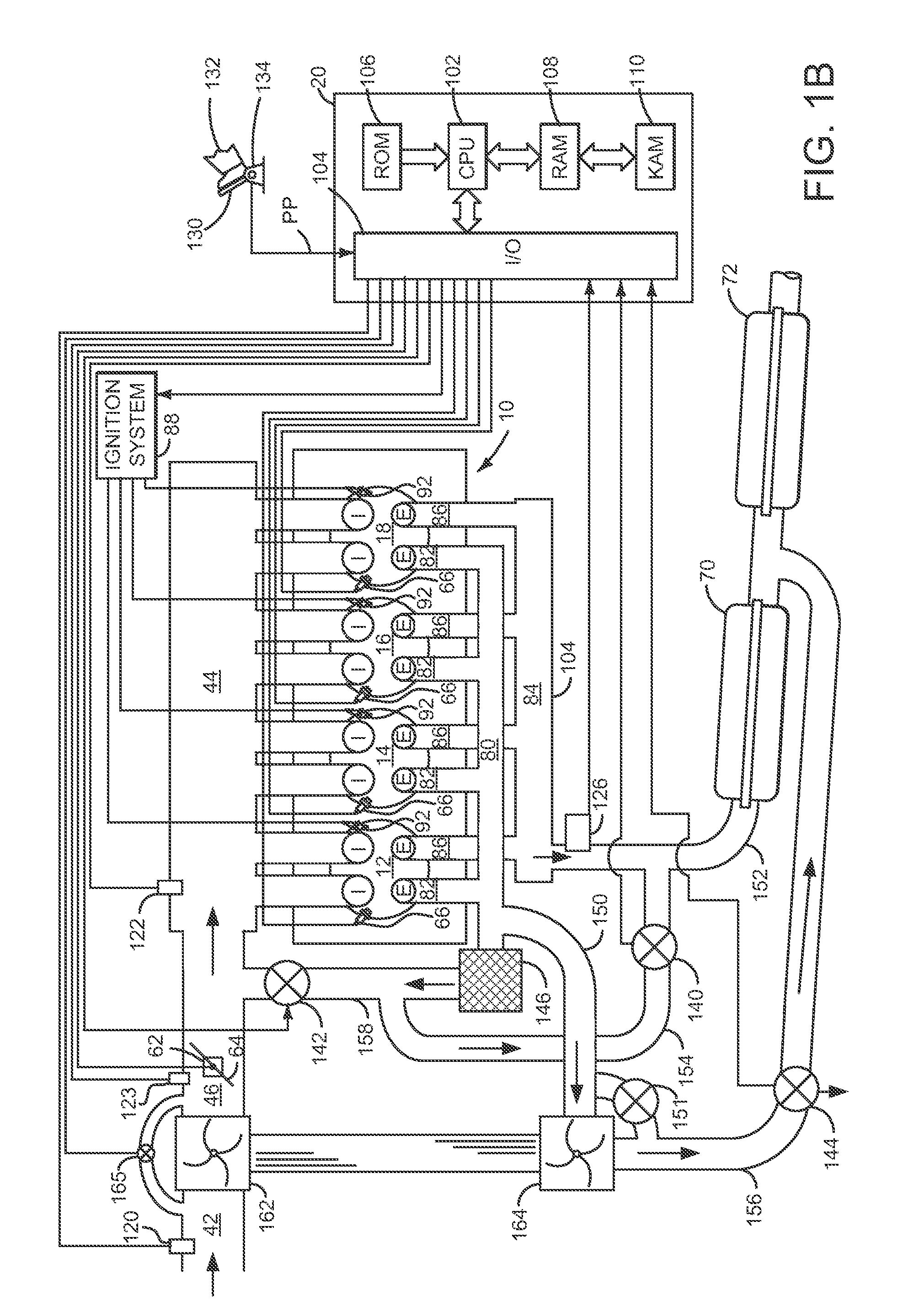

Dynamic Cylinder Deactivation with Residual Heat Recovery

InactiveUS20100050993A1Improve conversion efficiencyElectrical controlMachines/enginesEngine efficiencyFuel efficiency

Cylinder deactivation is a proven solution to improve engine fuel efficiency. The present invention is related to Dynamic Cylinder Deactivation (DCD) solution to conventional internal combustion engine. DCD is an energy saving method based on engine thermodynamics and residual heat recovery. It deactivates all the cylinders within the engine alternatively and dynamically, totally different from traditional sealed-valves cylinder deactivation solutions. DCD has many advantages over traditional sealed-valves cylinder deactivation. Thermodynamic efficiency gain, residual heat recovery, high Lambda and “Air-Hybrid” are the most attractive features of DCD. DCD also makes engine displacement variable.

Owner:ZHAO YUANPING +1

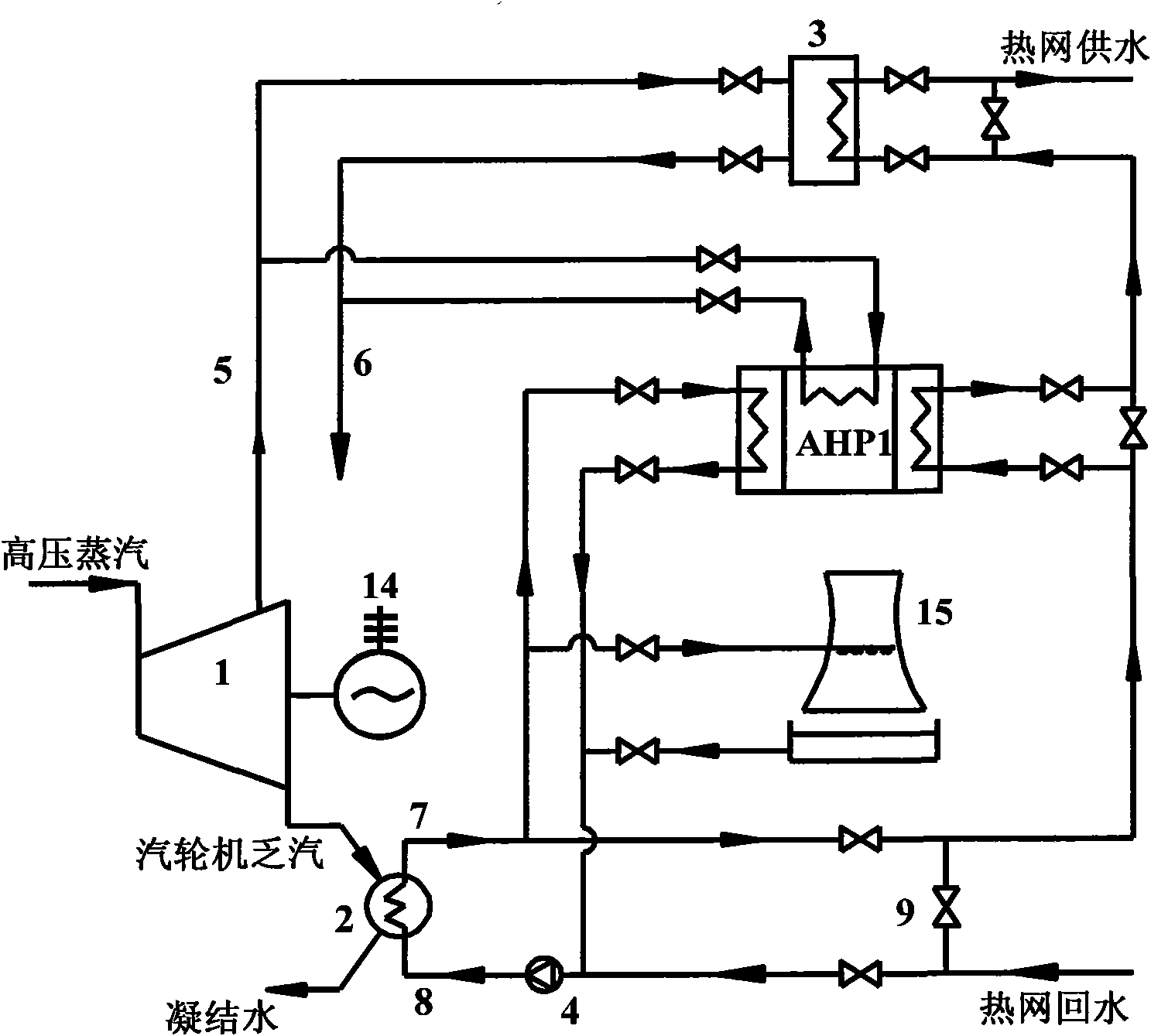

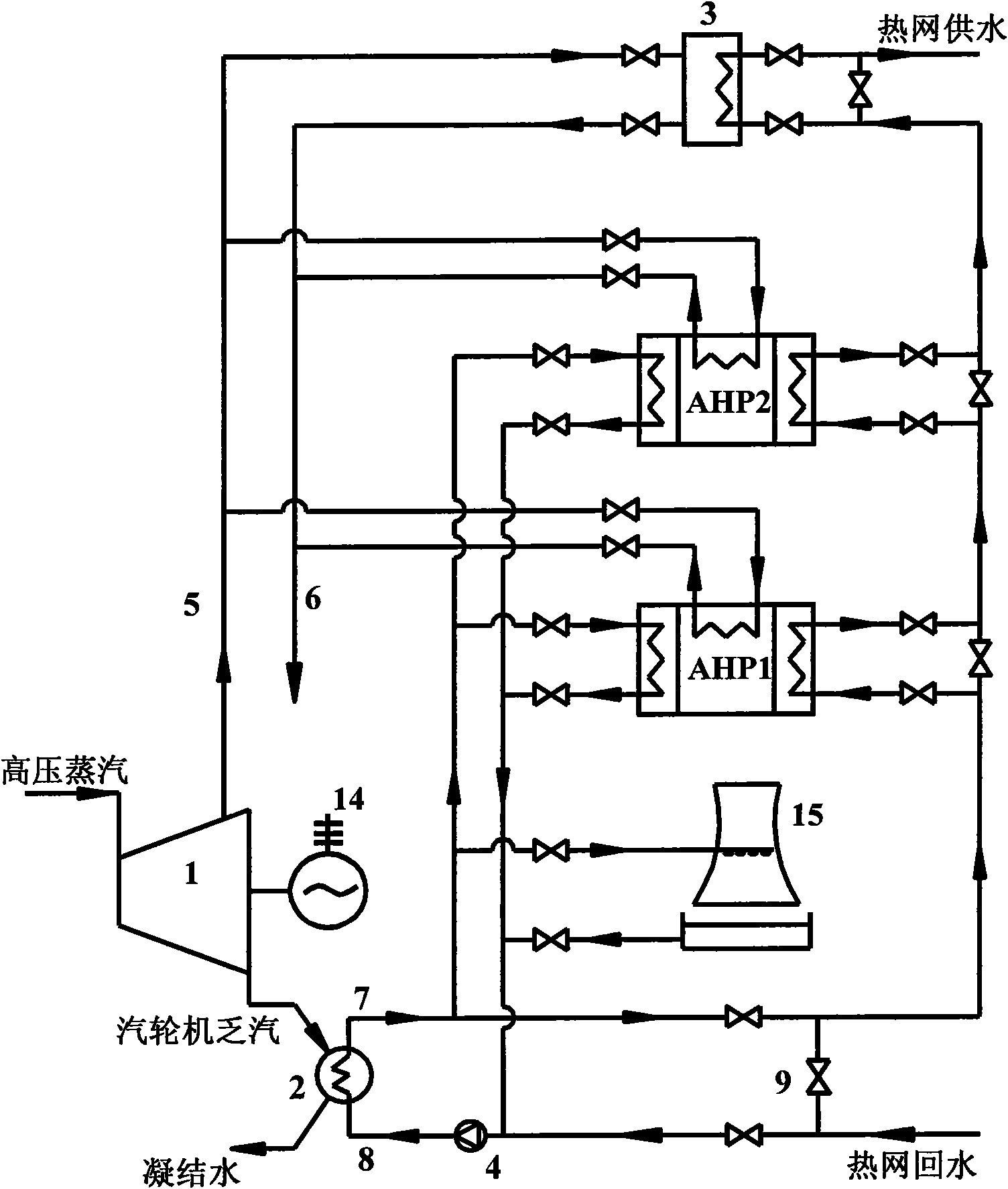

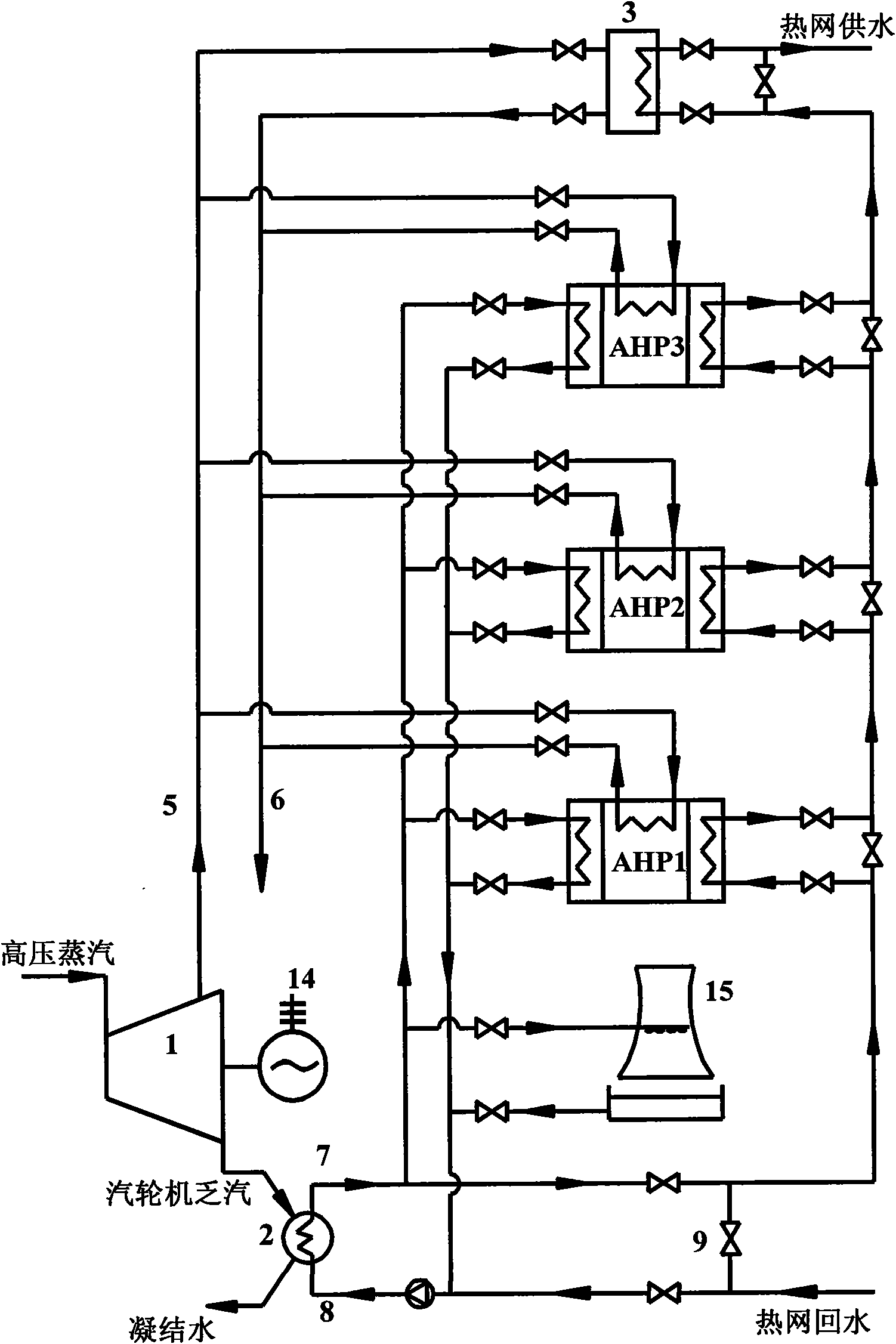

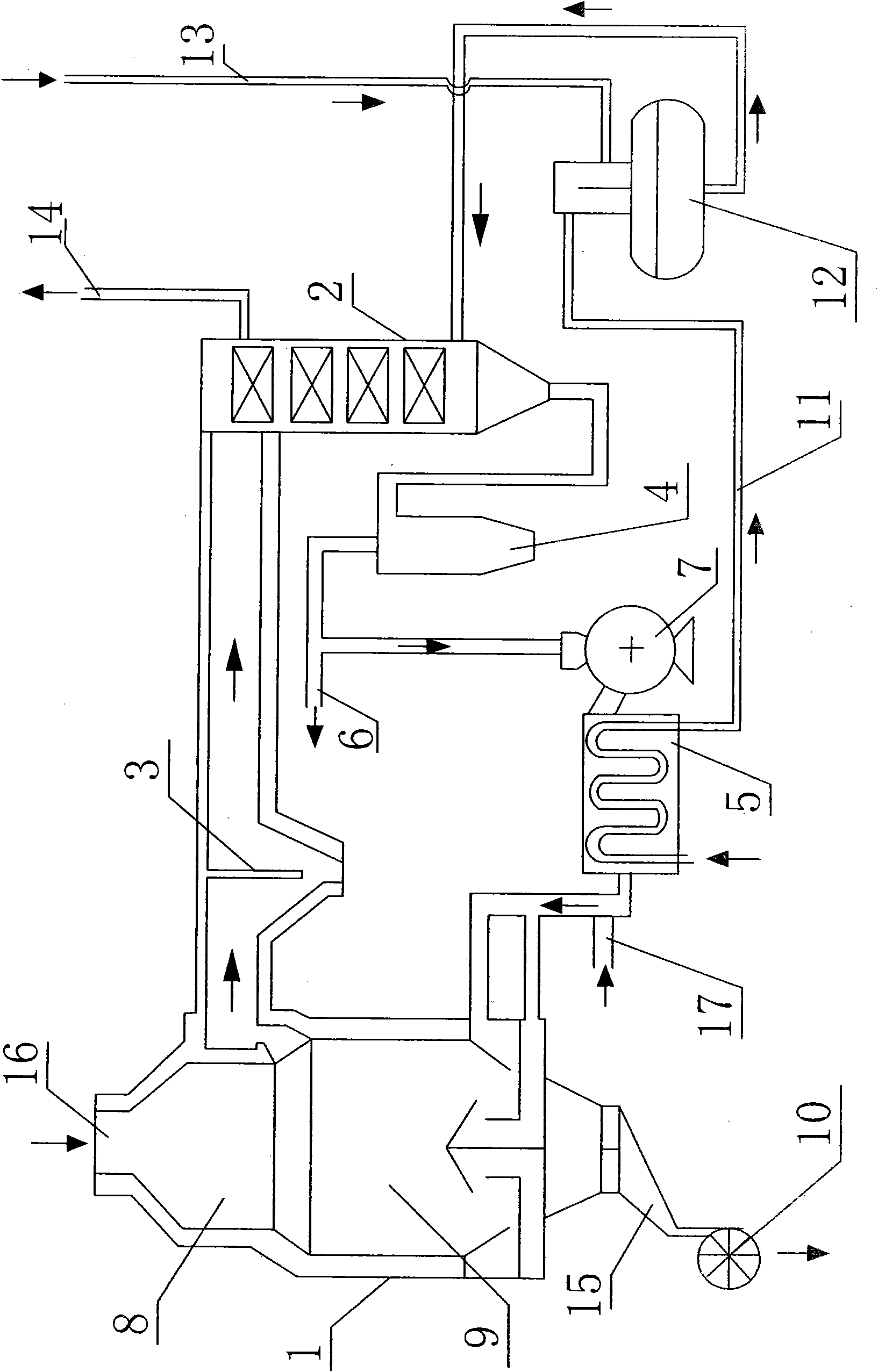

Method for recovering waste heat of thermal power plant and heating and supplying heat to hot water in a stepping way

ActiveCN101619662AImprove utilization efficiencyReduce exergy lossSteam useCombined combustion mitigationCooling towerSteam condensation

The invention discloses a method for recovering the waste heat of a thermal power plant and heating and supplying heat to hot water in a stepping way. In the method, low-temperature heat-net return water is firstly mixed with circulating cooling water positioned on an outlet of a cooling condenser or exchanges heat with the circulating cooling water positioned on the outlet of the cooling condenser to be increased in temperature and then sequentially delivered into an each-step vapour absorption type heat pump and a vapor-water heat exchanger in a series connection way to be gradually heated to be increased in temperature to heat supplying temperature and finally discharged through a water supplying pipeline; the circulating cooling water absorbs the waste steam condensation heat of a steam turbine in the cooling condenser, then one path of the circulating cooling water is directly mixed with the low-temperature heat-net return water or heats the low-temperature heat-net return water through the heat changer, the other path of the circulating cooling water is delivered into an each-step absorption type heat pump unit to be used as a low-order heat source of the absorption type heat pump unit, and the redundant heat of the circulating cooling water is discharged to the environment through a cooling tower. The invention uses the steam extraction of the steam turbine as a driving heat source of the absorption type heat pump so that the low-temperature heat-net return water is heated in a stepping way, thereby reducing the effective energy loss; the waste heat of the discharged steam of the steam turbine is sufficiently recovered in a direct heating way and an absorption type heat pump temperature increasing heating way, therefore, the comprehensive energy usage efficiency of the thermal power plant is enhanced.

Owner:TSINGHUA UNIV +1

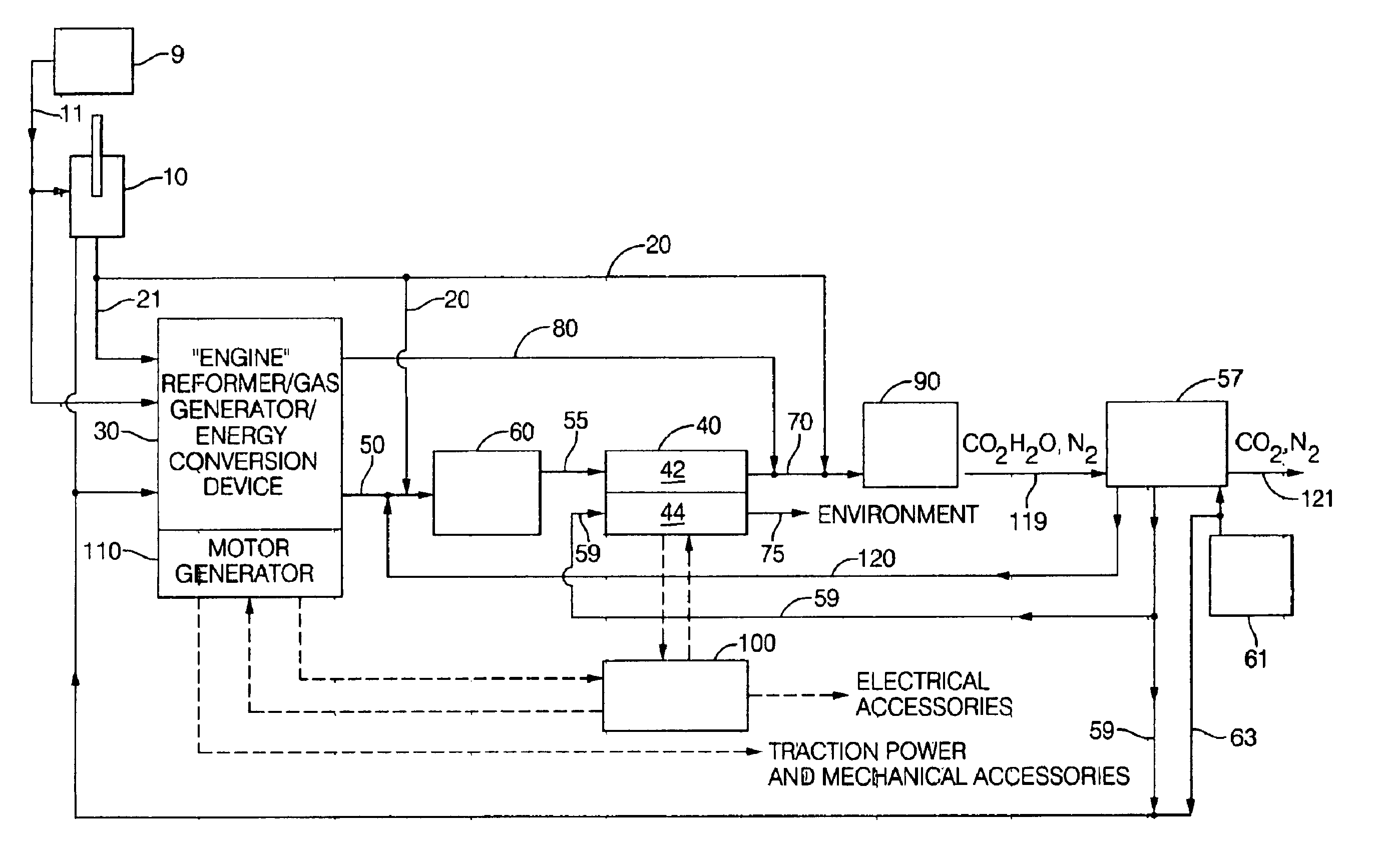

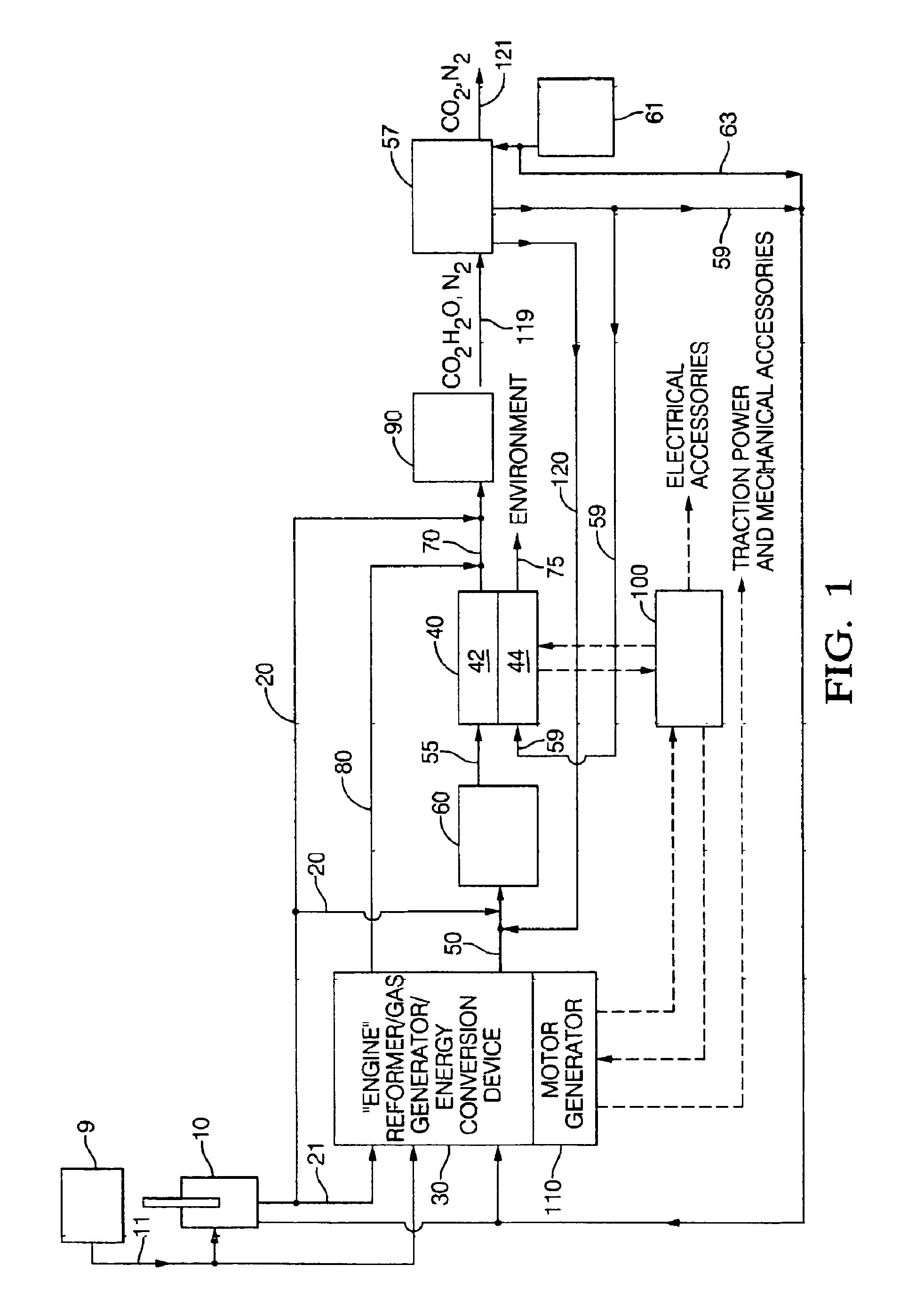

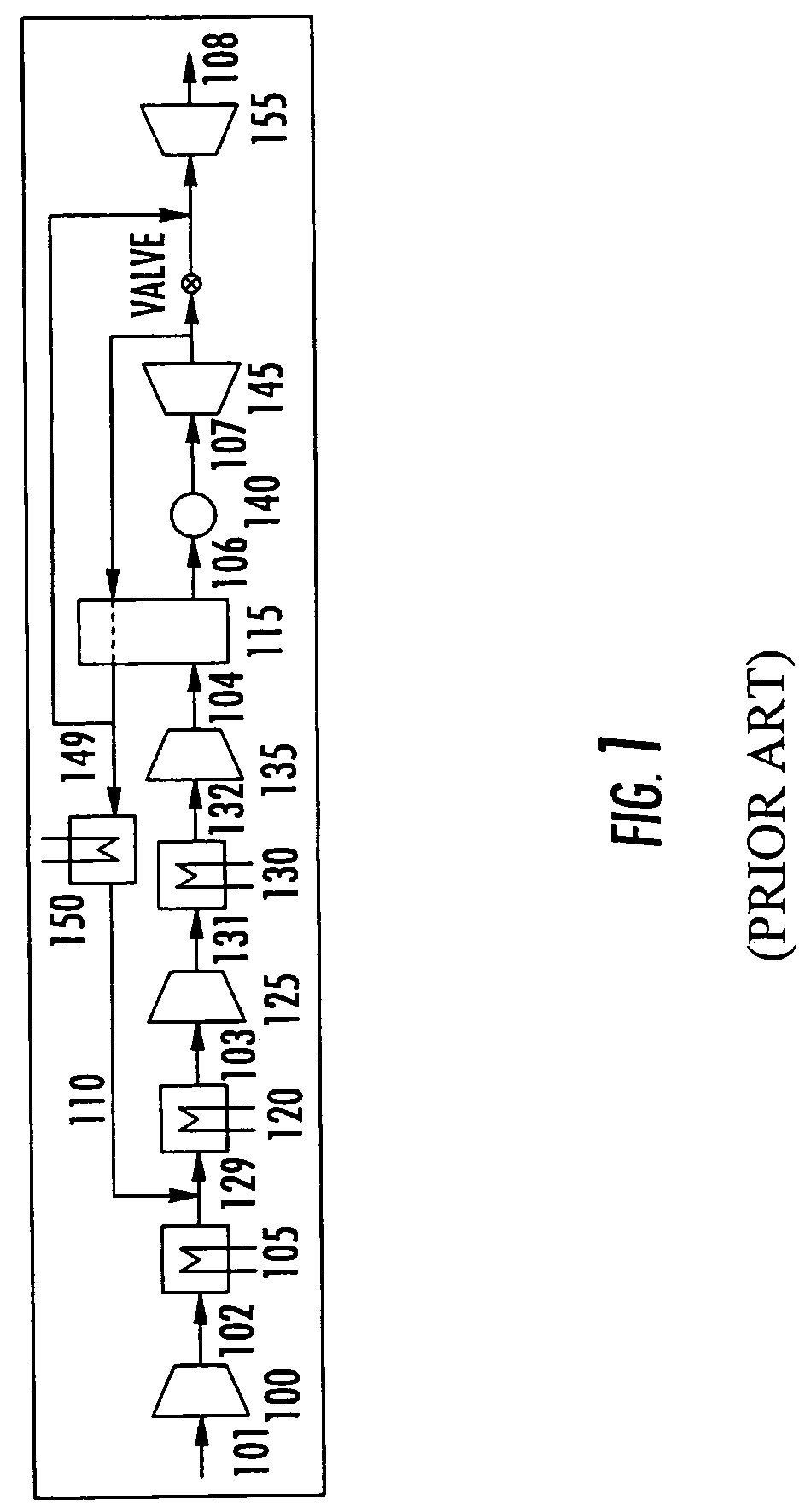

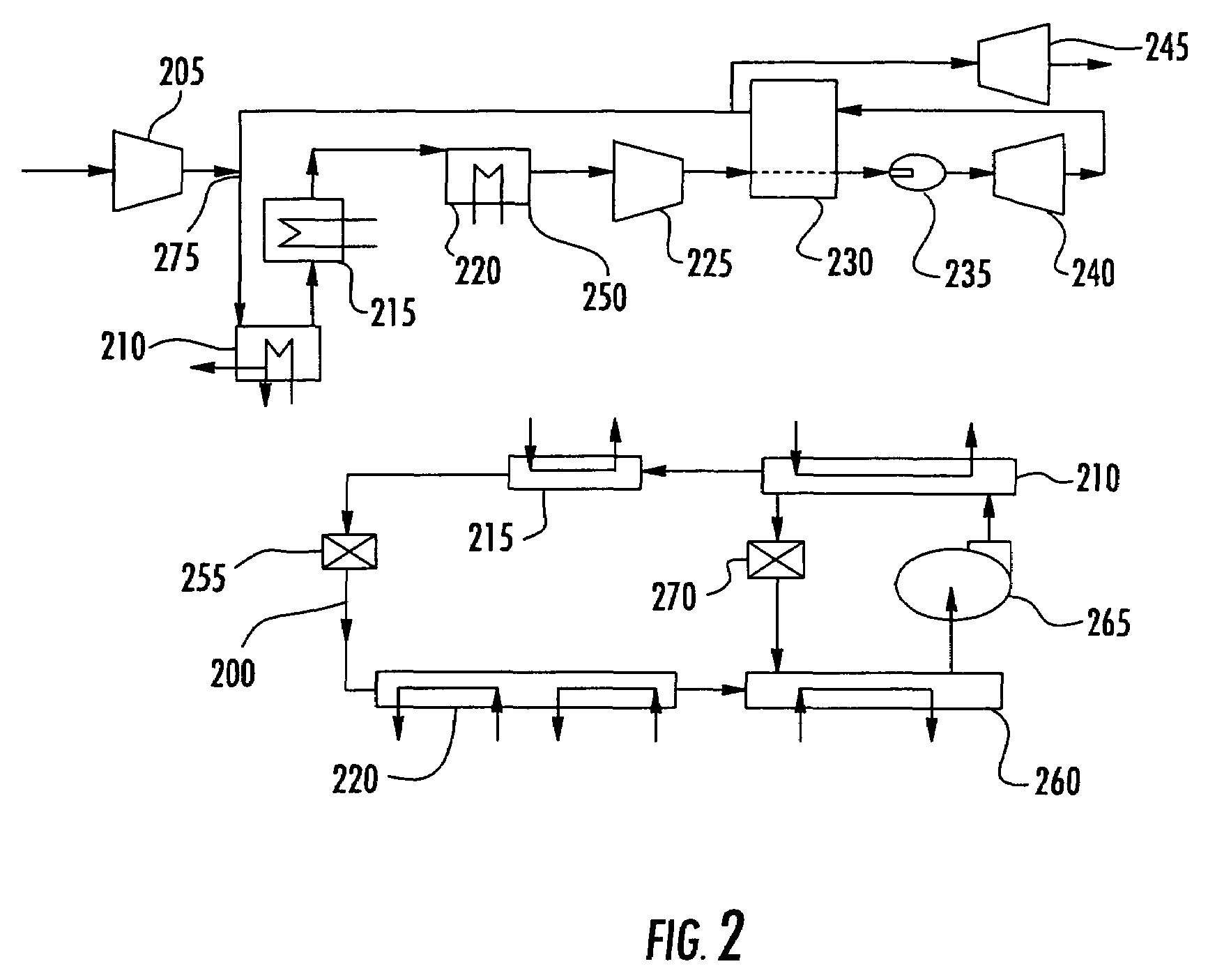

Power generation system and method

InactiveUS6915869B2Internal combustion piston enginesElectric propulsion mountingInternal combustion engineFuel supply

A power generation system and method providing an engine configured to produce hydrogen rich reformate to feed a solid oxide fuel cell includes an engine having an intake and an exhaust; an air supply in fluid communication with the engine intake; a fuel supply in fluid communication with the engine intake; at least one solid oxide fuel cell having an air intake in fluid communication with an air supply, a fuel intake in fluid communication with the engine exhaust, a solid oxide fuel cell effluent and an air effluent. Engines include a free piston gas generator with rich homogenous charge compression, a rich internal combustion engine cylinder system with an oxygen generator, and a rich inlet turbo-generator system with exhaust heat recovery. Oxygen enrichment devices to enhance production of hydrogen rich engine exhaust include pressure swing absorption with oxygen selective materials, and oxygen separators such as an solid oxide fuel cell oxygen separator and a ceramic membrane oxygen separator.

Owner:DELPHI TECH INC

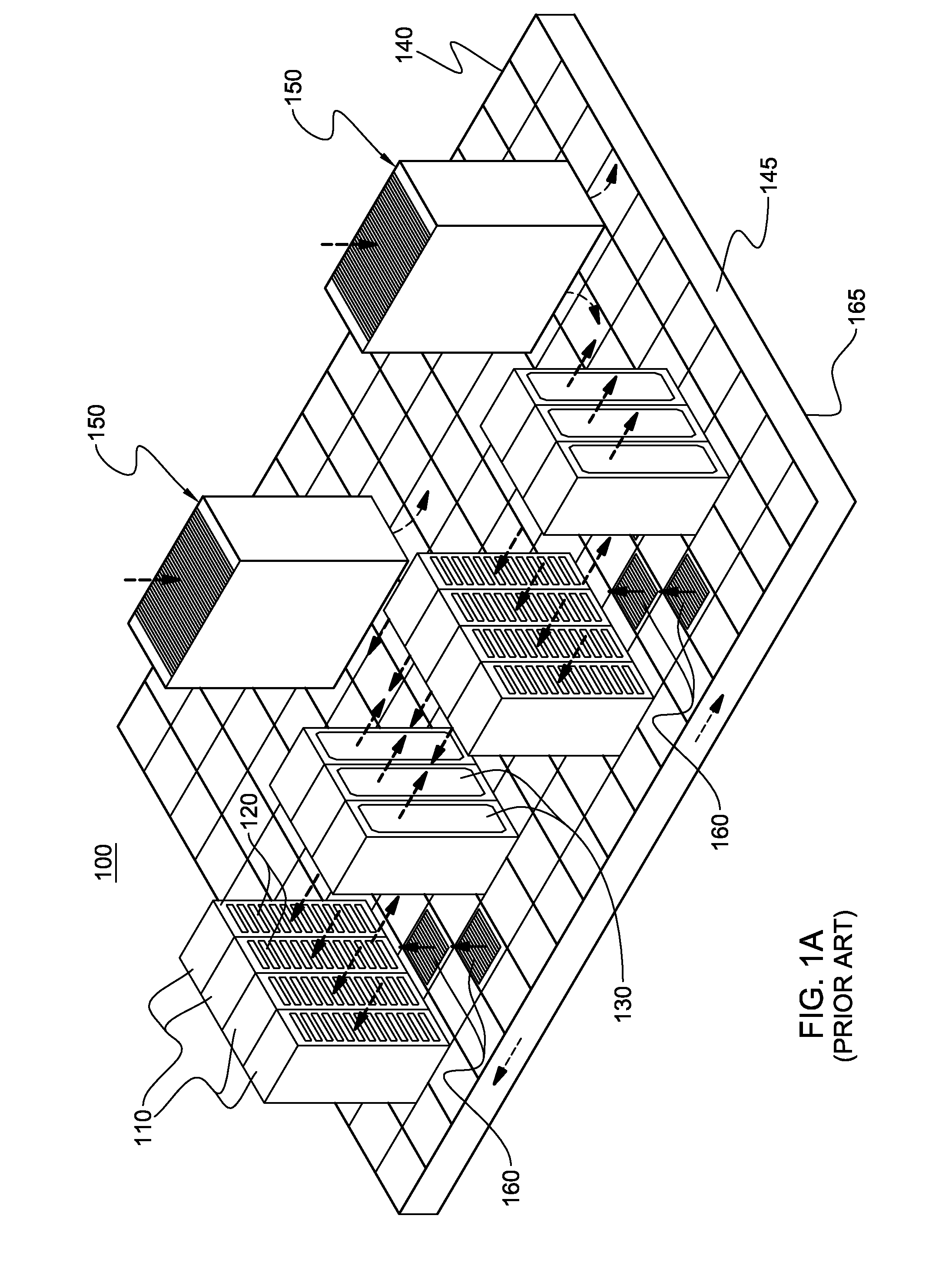

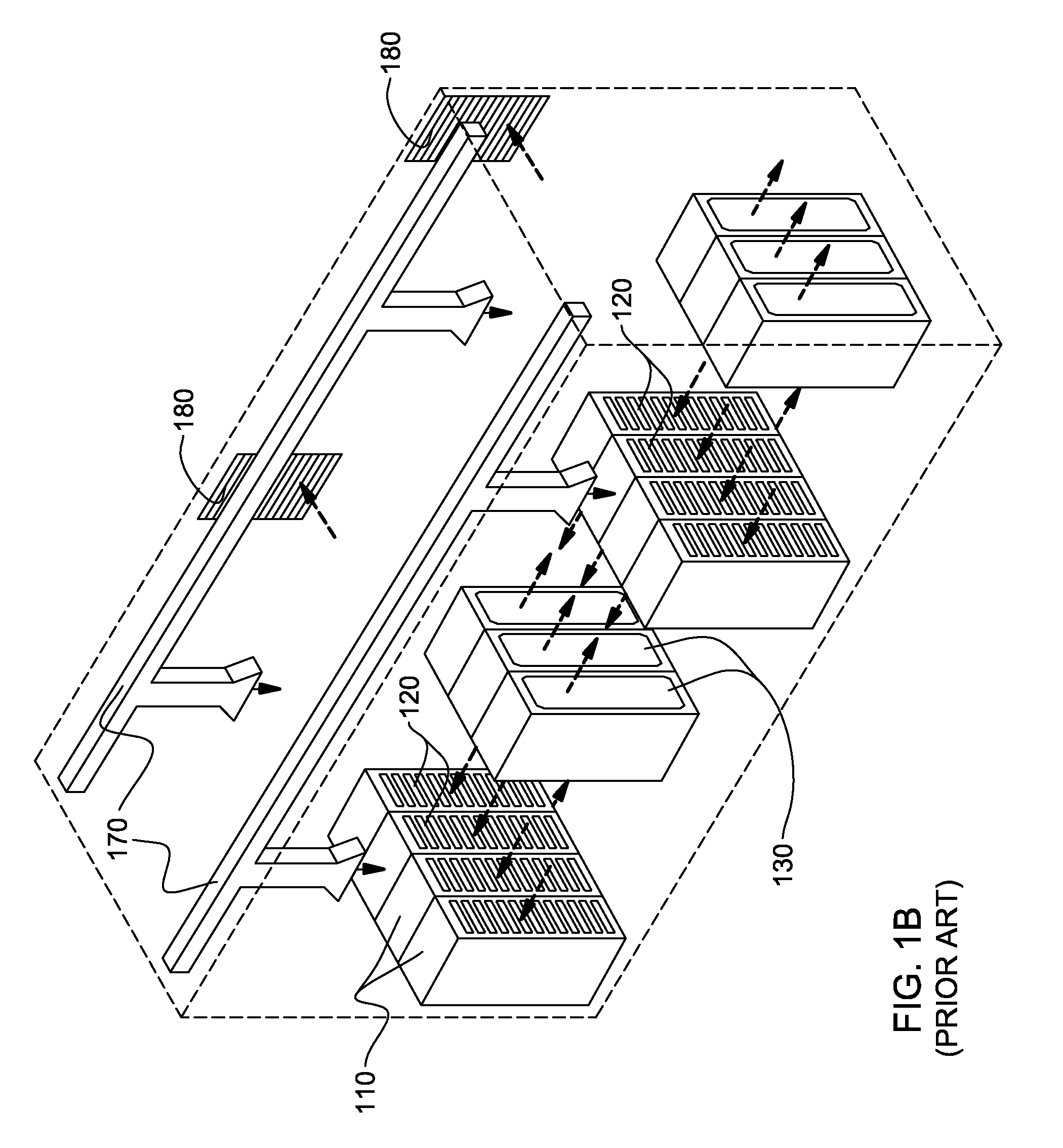

Vapor-compression heat exchange system with evaporator coil mounted to outlet door cover of an electronics rack

ActiveUS20090080173A1Substation/switching arrangement detailsIndirect heat exchangersCouplingEngineering

A vapor-compression heat exchange system for facilitating cooling of an electronics rack. The system includes employing an evaporator coil mounted to an outlet door cover, which is hingedly affixed to an air outlet side of the rack, as well as refrigerant inlet and outlet plenums and an expansion valve also mounted to the outlet door cover and in fluid communication with the evaporator coil. The evaporator coil includes at least one heat exchange tube section and a plurality of fins extending therefrom. Respective connect couplings connect the inlet and outlet plenums in fluid communication with a vapor-compression unit which includes a compressor and a condenser disposed separate from the outlet door cover. The vapor-compression unit exhausts heat from refrigerant circulating therethrough.

Owner:LENOVO GLOBAL TECH INT LTD

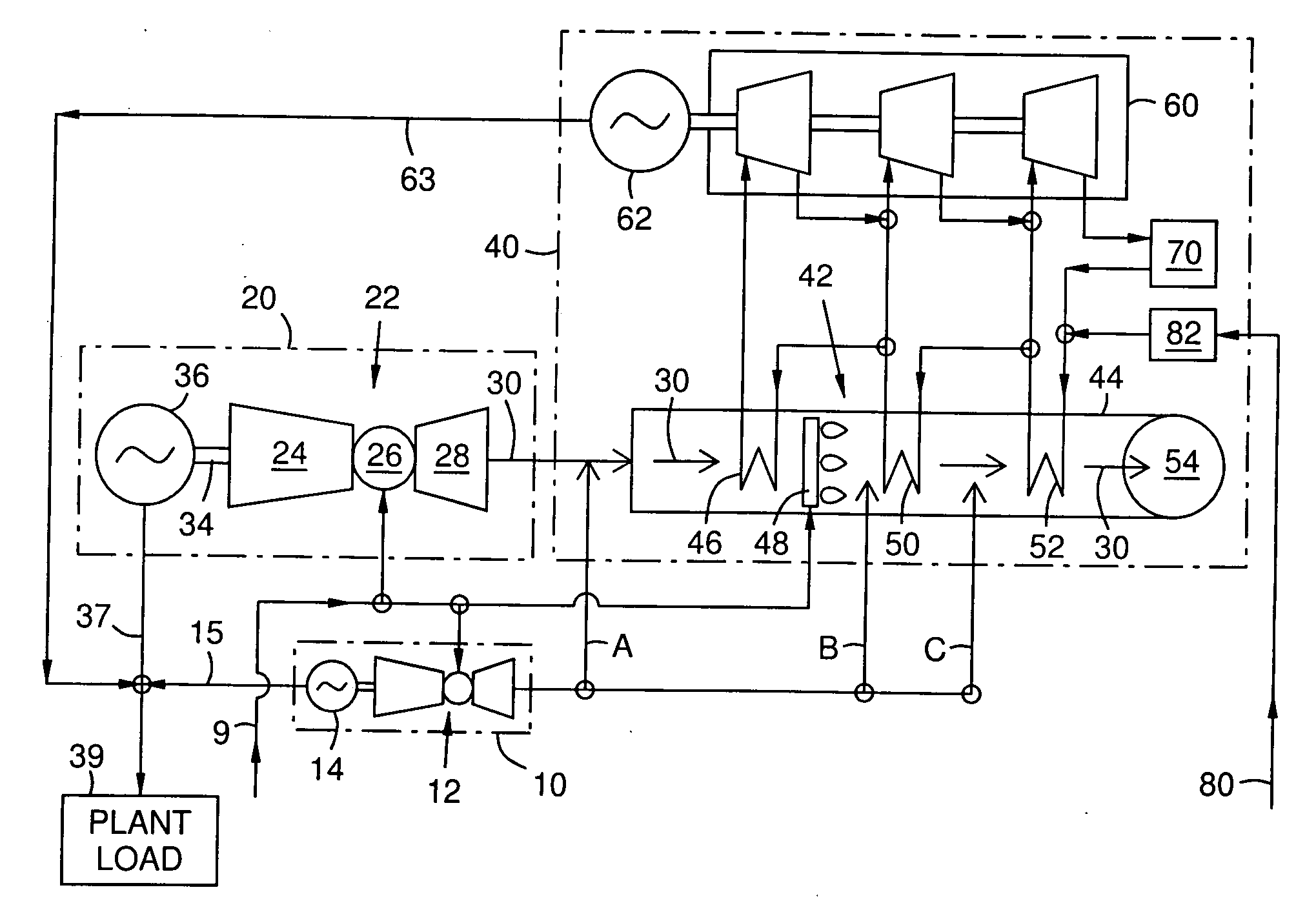

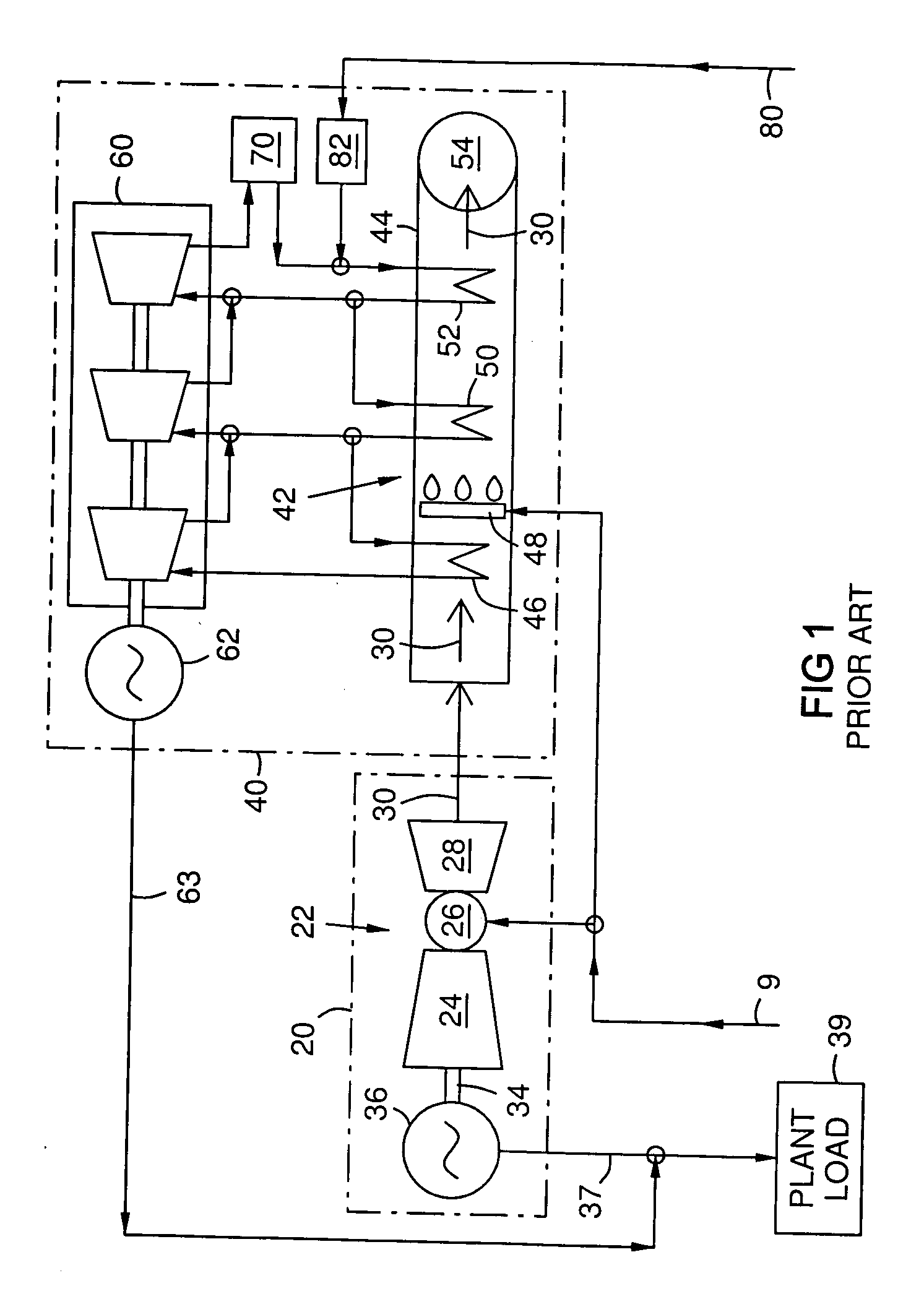

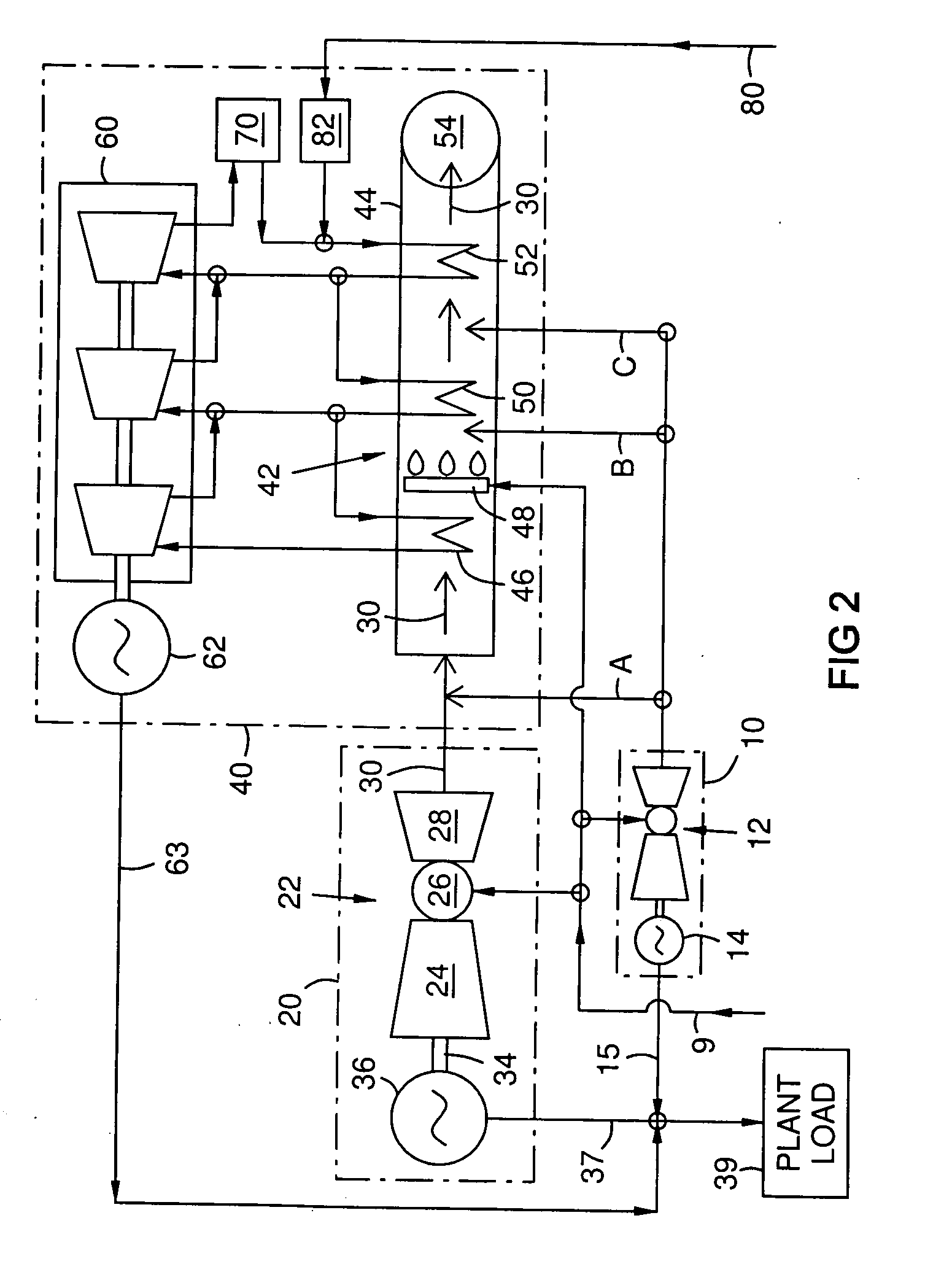

Exhaust heat augmentation in a combined cycle power plant

InactiveUS20070130952A1Gas turbine plantsCombined combustion mitigationPower stationElectric generator

A method and system for augmenting the output of a combined cycle power plant having a base gas turbine (22) driving a generator (36) and a heat recovery steam generator (42) that recovers exhaust heat (30) from the base gas turbine (22) to drive a steam turbine (60). A complementary gas turbine engine (12) is added to the power plant to drive a complementary generator (14). The exhaust (A, B, C) of the complementary gas turbine (12) is merged into the flow path of exhaust gas (30) from the base gas turbine (22) upstream of a selected one or more heat exchangers (46, 50, 52) in the heat recovery steam generator (42). Such a complementary system (10) may be used together with supplemental duct burners (48) in a hybrid augmentation embodiment.

Owner:SIEMENS ENERGY INC

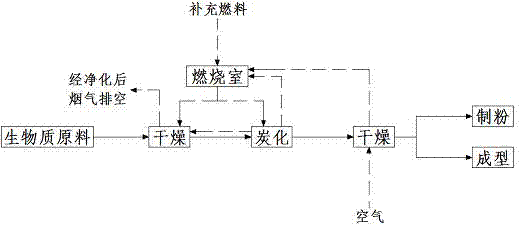

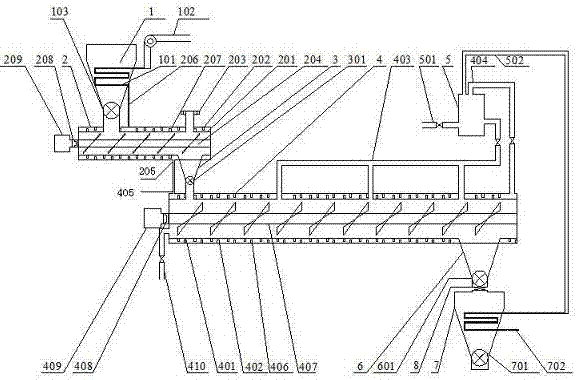

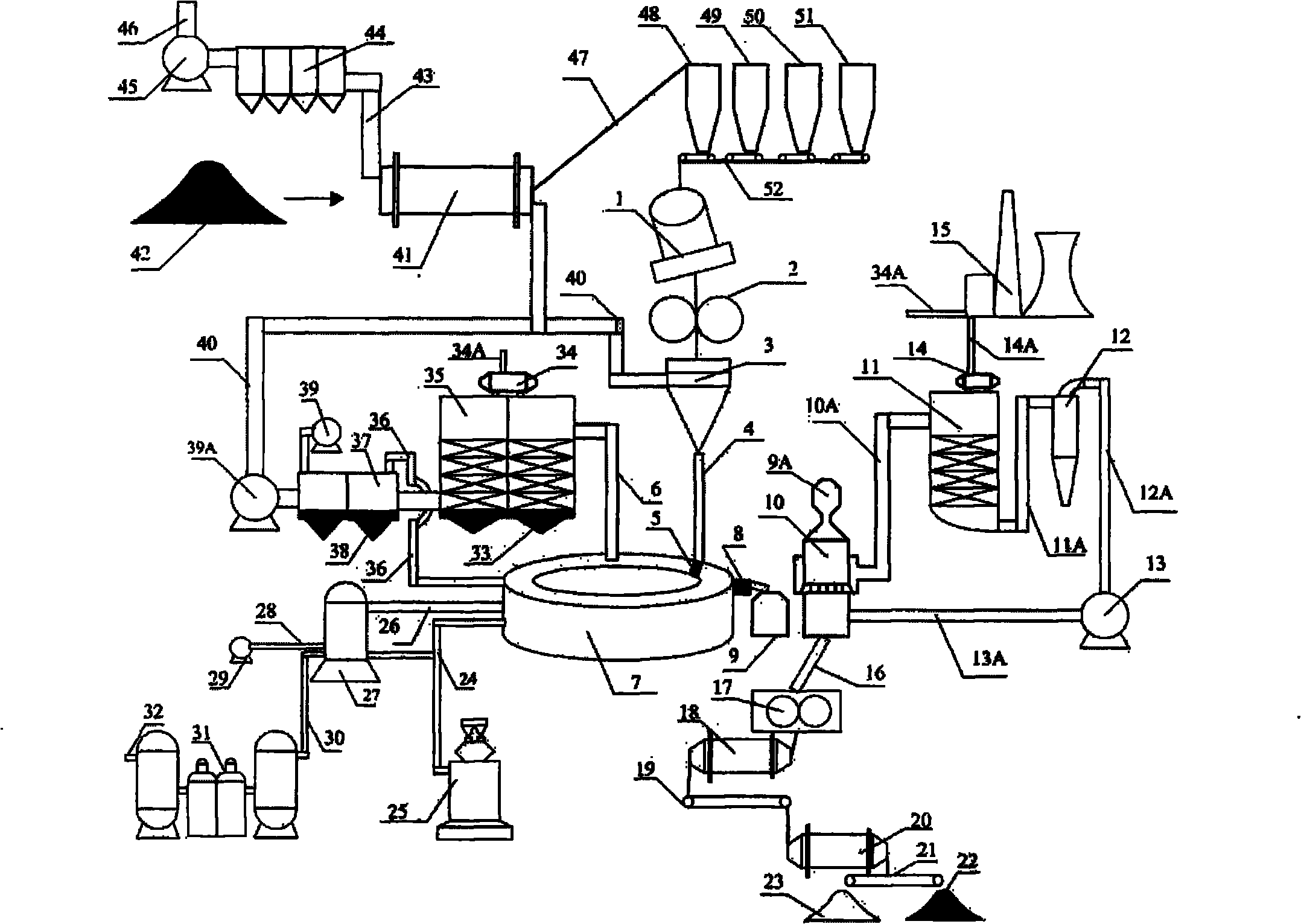

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

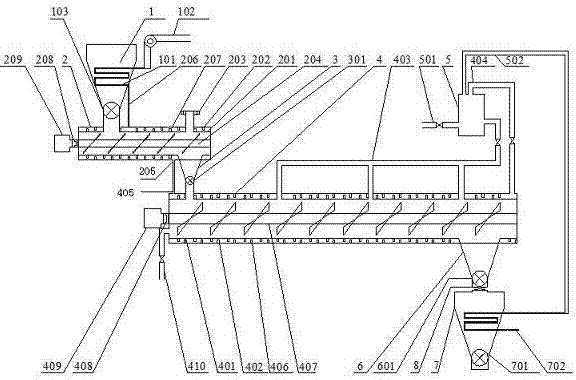

Combined cooling and power plant with water extraction

InactiveUS7472550B2Work lessImprove thermal efficiencyEngine fuctionsGas turbine plantsPower stationEngineering

A turbine engine system and a method for using the turbine engine system that includes at least one low-pressure compressor, at least one high-pressure compressor, at least one low-pressure turbine, and at least one high-pressure turbine. In addition, the turbine engine system includes an absorption refrigeration system that is used to pre-cool an air-gas mixture before it enters the high-pressure compressor. As such, the pre-cooled mixture is easier to compress, thereby increasing the thermal efficiency of the turbine engine. Additionally, the exhaust heat from the air-gas mixture that is pre-cooled may be used to drive the absorption refrigeration system. Lastly, water, may be extracted from the evaporator of the absorption refrigeration cycle.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

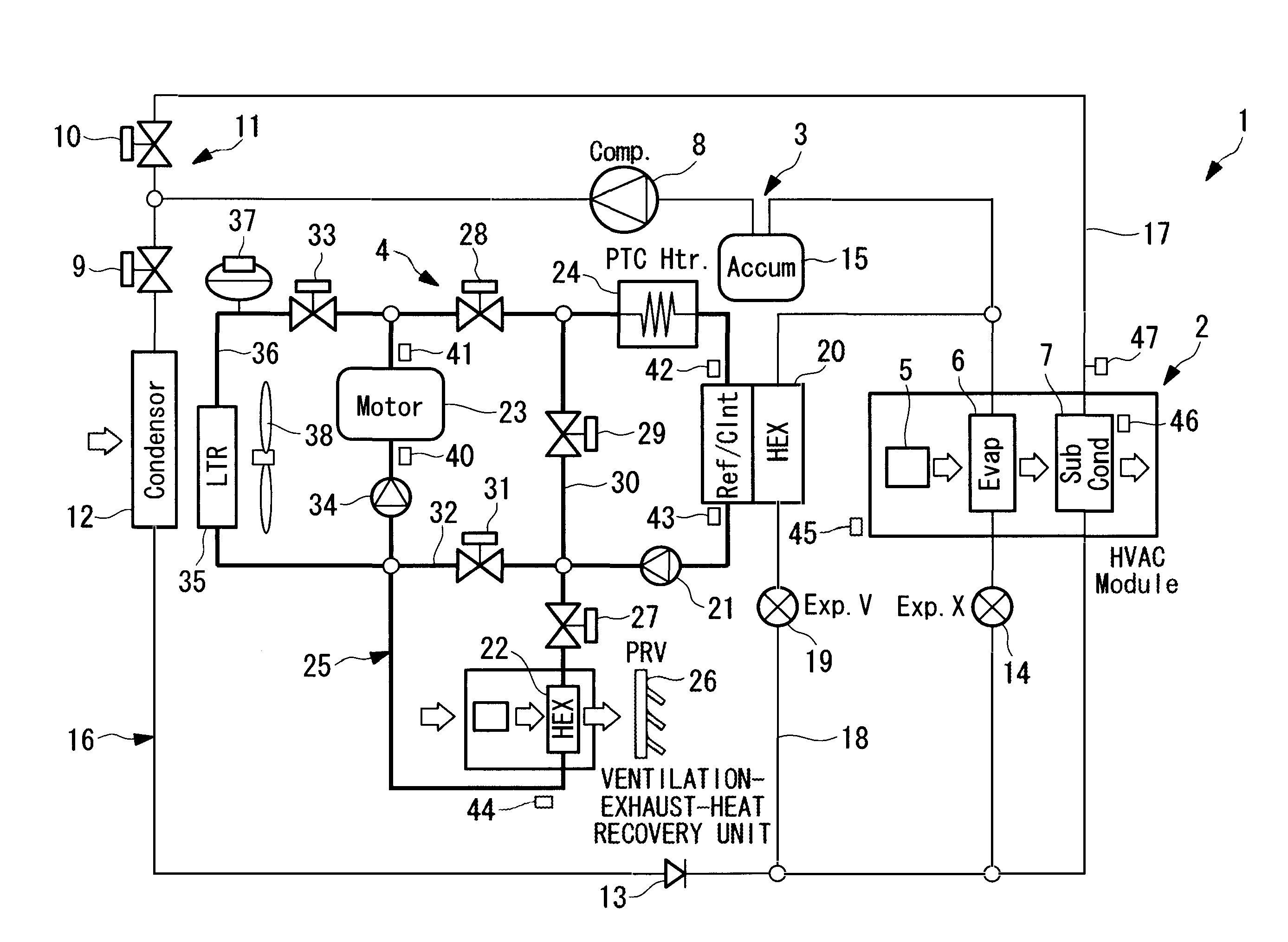

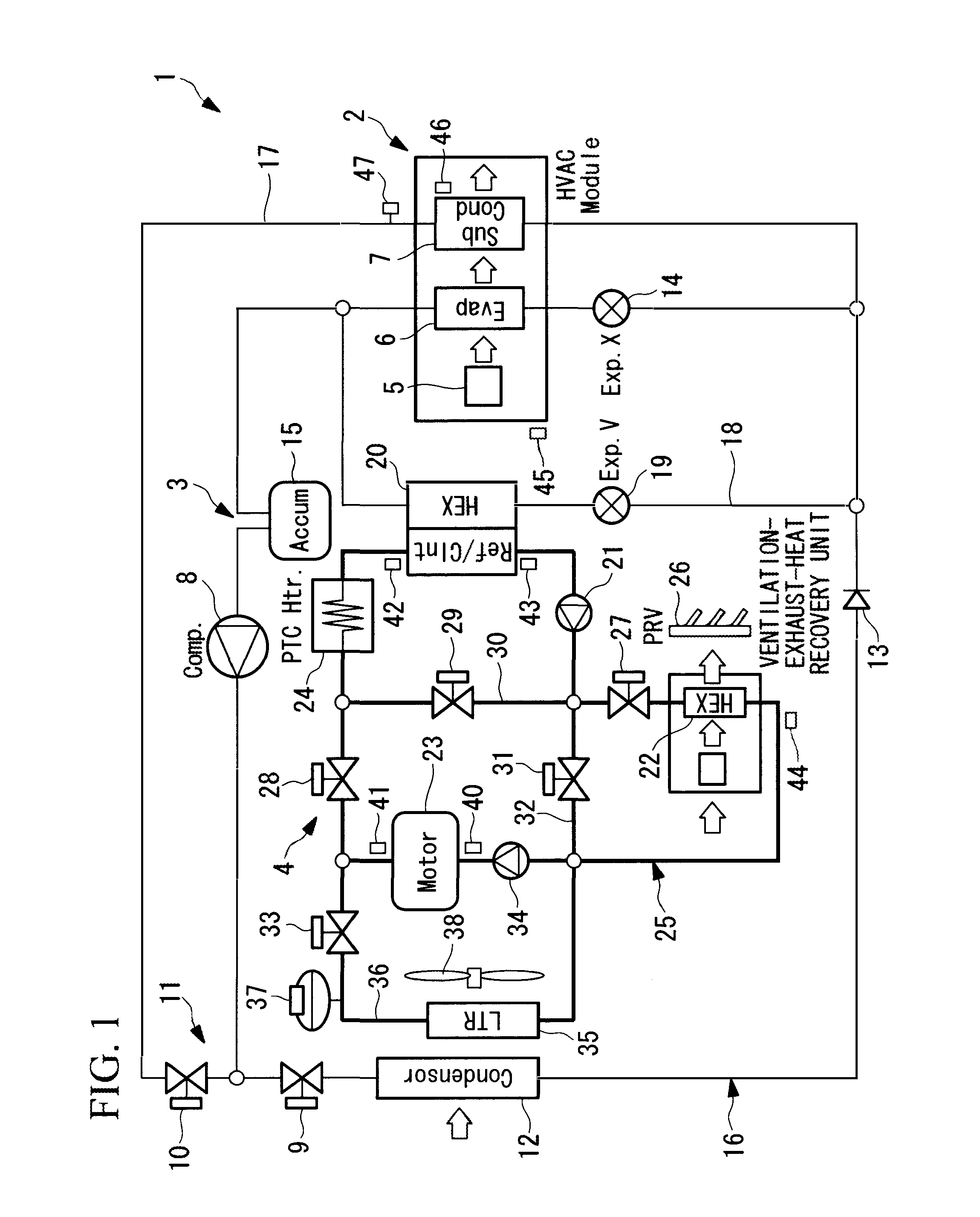

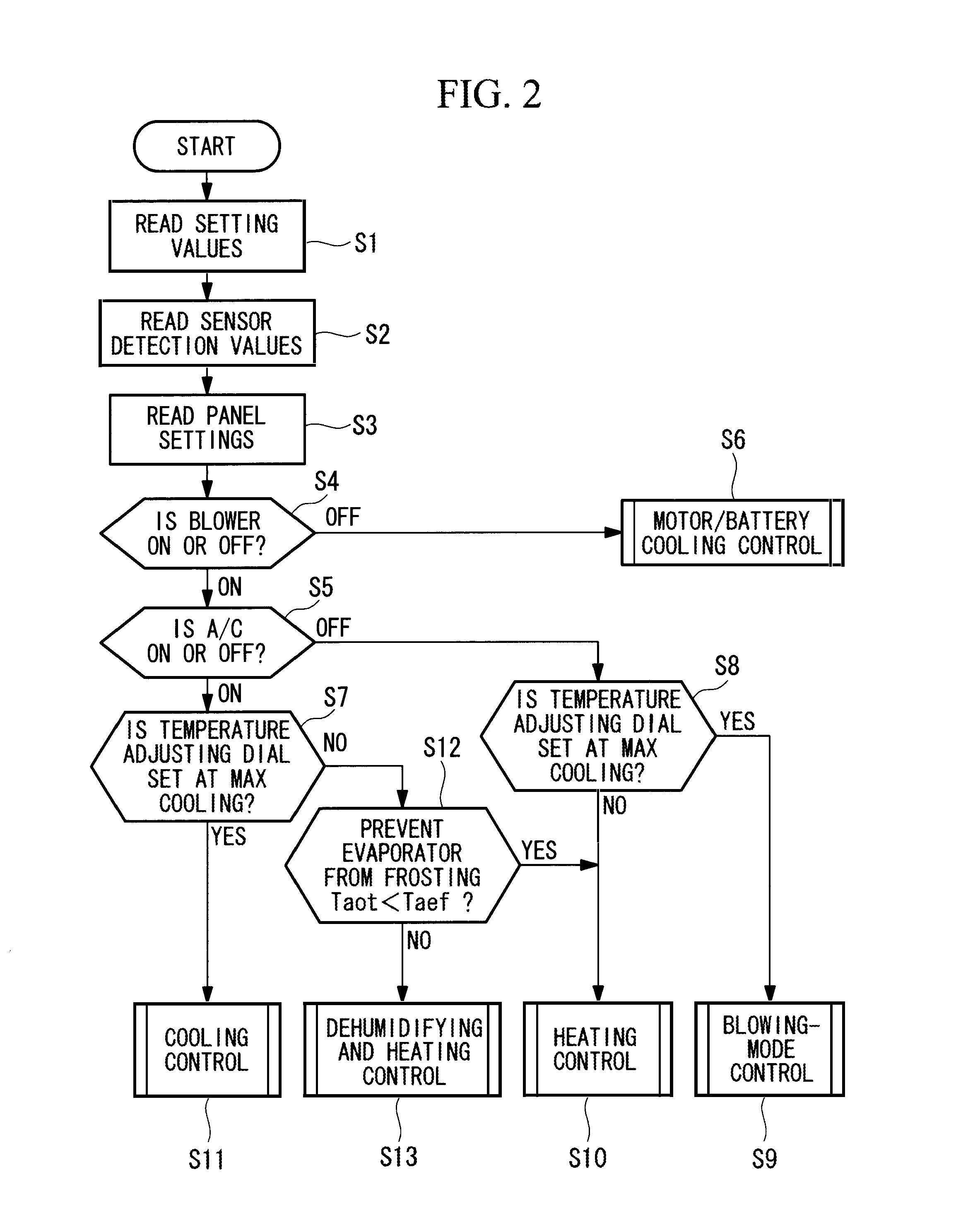

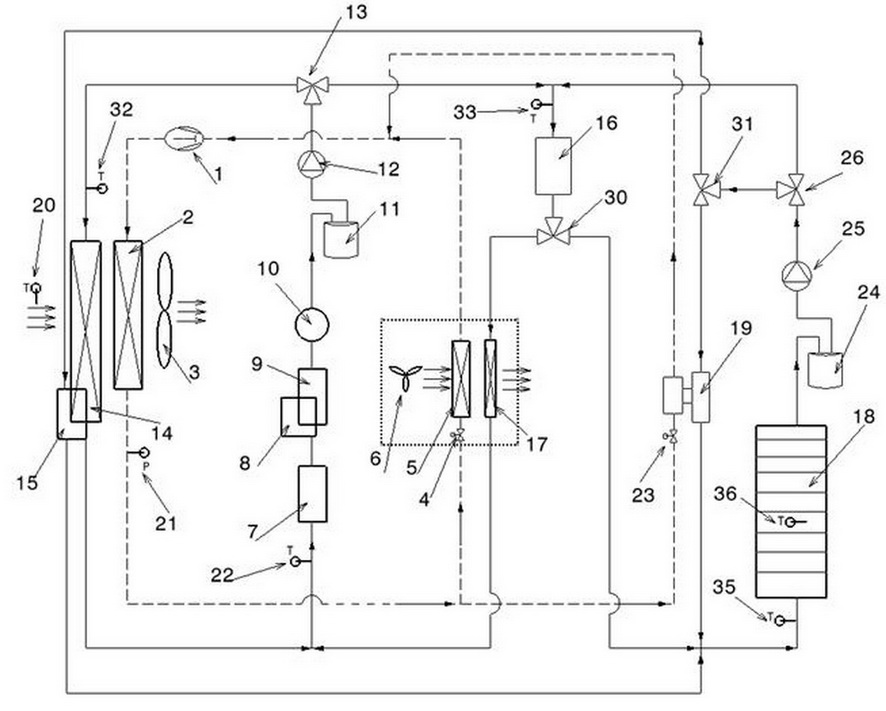

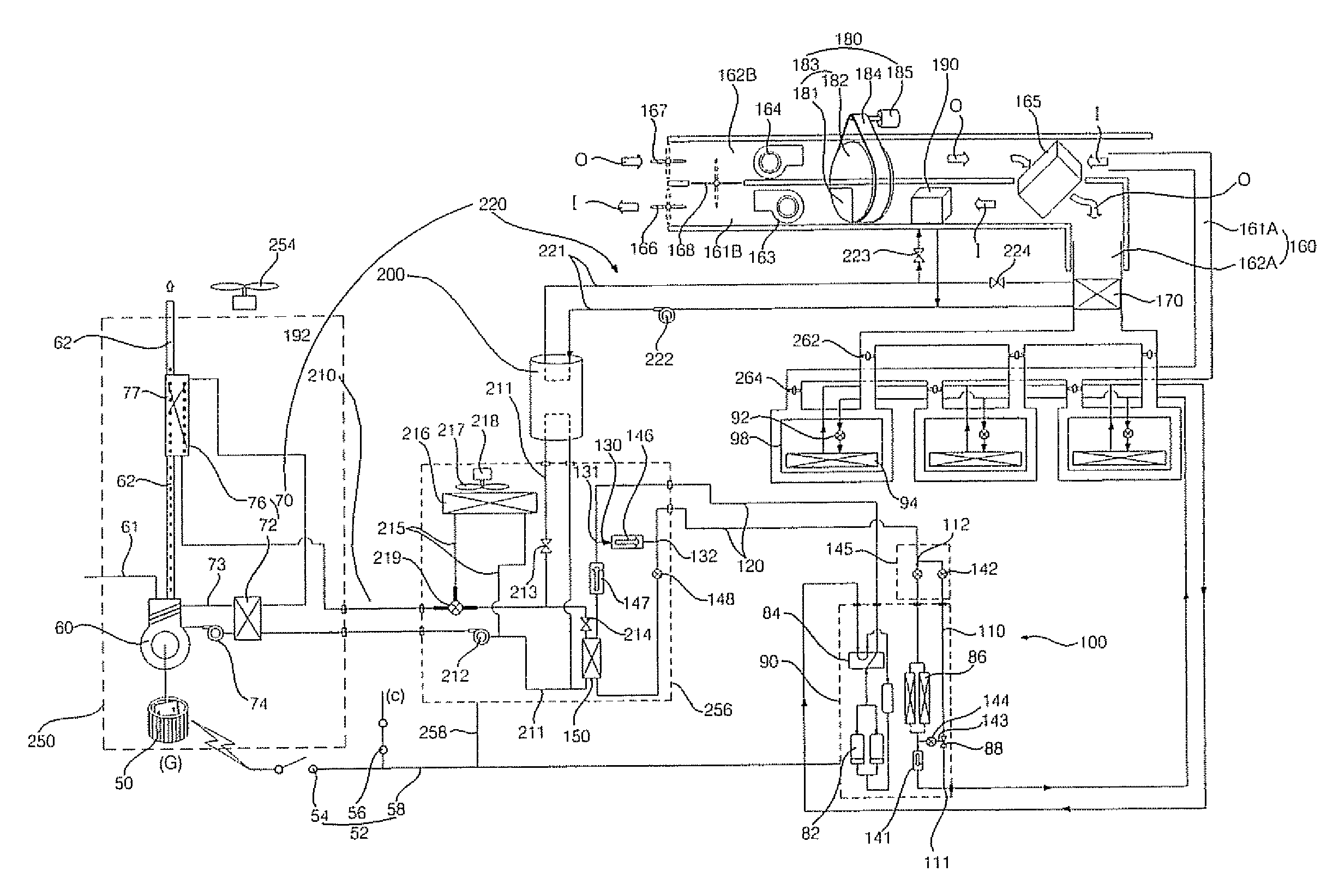

Vehicle air-conditioning system and operation control method therefor

ActiveUS20120205088A1Reduce usageHeat stableAir-treating devicesRailway heating/coolingEngineeringAir conditioning

A vehicle air-conditioning system includes: an HVAC unit that blows air whose temperature has been adjusted by a refrigerant evaporator and a second refrigerant condenser; a heat pump cycle in which a refrigerant compressor, a refrigerant circuit changeover section, a first refrigerant condenser, a first expansion valve, and the refrigerant evaporator are sequentially connected, in which a second expansion valve and a refrigerant / coolant heat exchanger are connected in parallel with the first expansion valve and the refrigerant evaporator, and in which the second refrigerant condenser is connected in parallel with the first refrigerant condenser; and a coolant cycle in which a coolant circulating pump, a ventilation-exhaust-heat recovery unit, a motor / battery, an electric heater, and the refrigerant / coolant heat exchanger are sequentially connected, and in which the ventilation-exhaust-heat recovery unit, the motor / battery, and the electric heater can be selectively used as a heat source.

Owner:MITSUBISHI HEAVY IND LTD

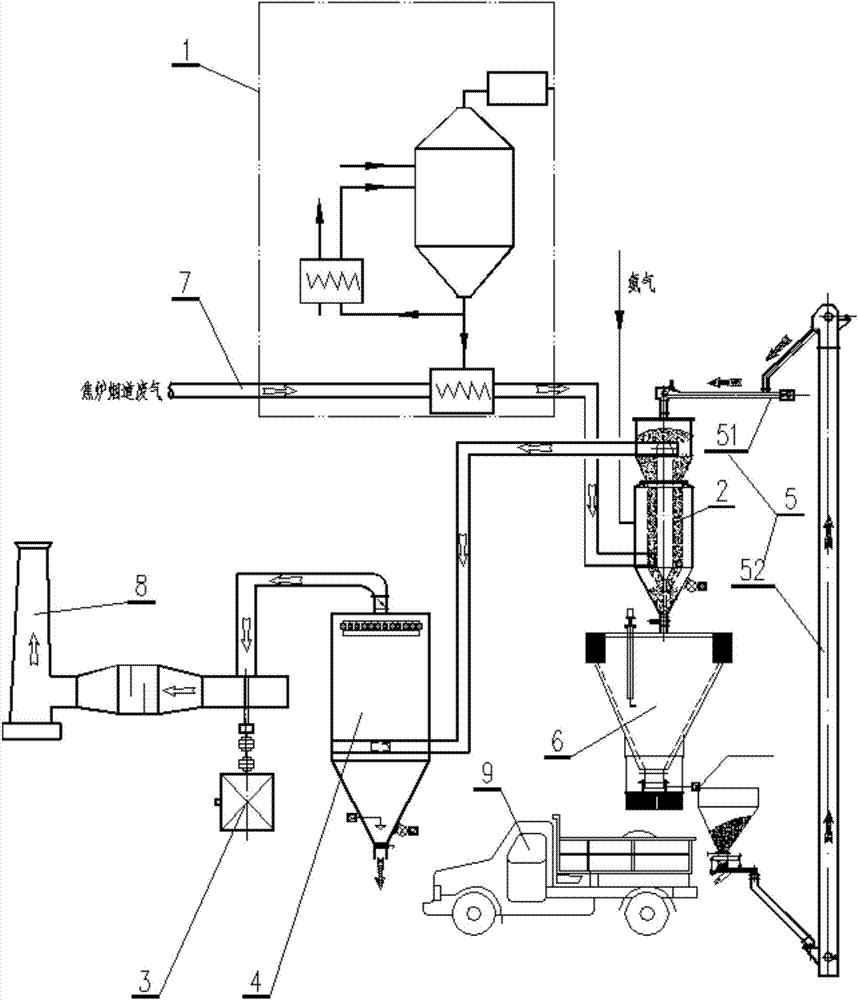

Coke oven flue gas waste heat utilization and purification method

ActiveCN103877856AReduce consumptionEfficient governanceDispersed particle separationPurification methodsCoking plant

The invention relates to the technical field of coke oven flue gas integrated utilization and pollution treatment and in particular relates to a coke oven flue gas waste heat utilization and purification method. The method is characterized in that flue gas waste heat is recovered by utilizing a flue gas waste heat recovery device, the temperature of the flue waste gas is reduced, and integrated desulfurization and denitration of the flue waste gas is realized by utilizing the activated adsorption capacity and low-temperature denitration catalytic capability of the coke. Compared with an existing process, the method has the beneficial effects that the flue waste gas desulfurization and denitration is performed under low-temperature working conditions, an additional heating system is not needed, and the energy consumption is reduced. In order to realize the desulfurization and denitration under low-temperature working conditions, the flue waste gas is cooled through the waste heat recovery device, so that the waste heat of the flue waste gas is fully utilized. The coke serves as a main catalyst for desulfurization and denitration and comes from a coking plant, the source is sufficient, and waste loss is avoided. The method disclosed by the invention can be widely applied to pollution treatment and integrated utilization of coke oven heated flue waste gas in coking production enterprises.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

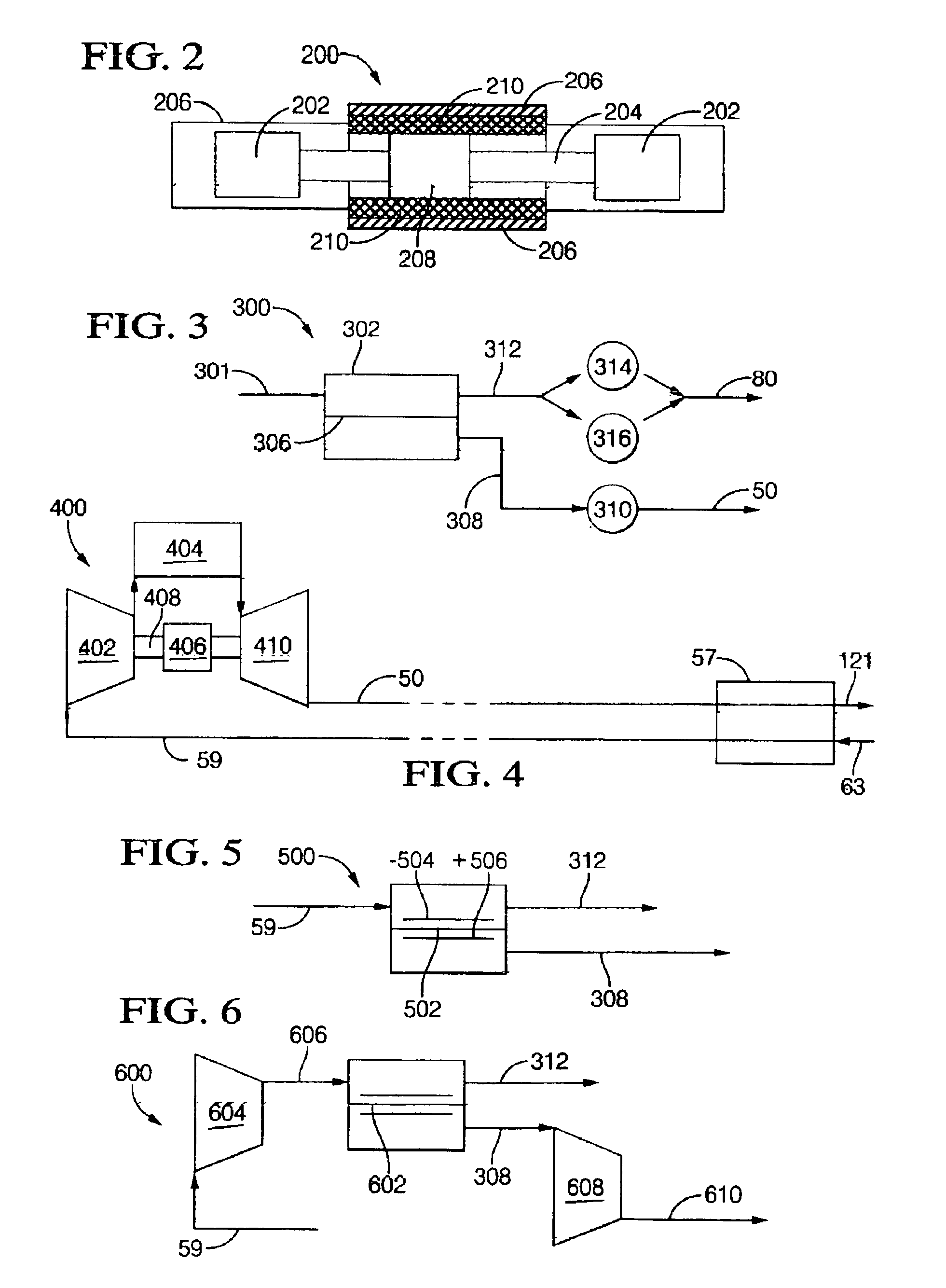

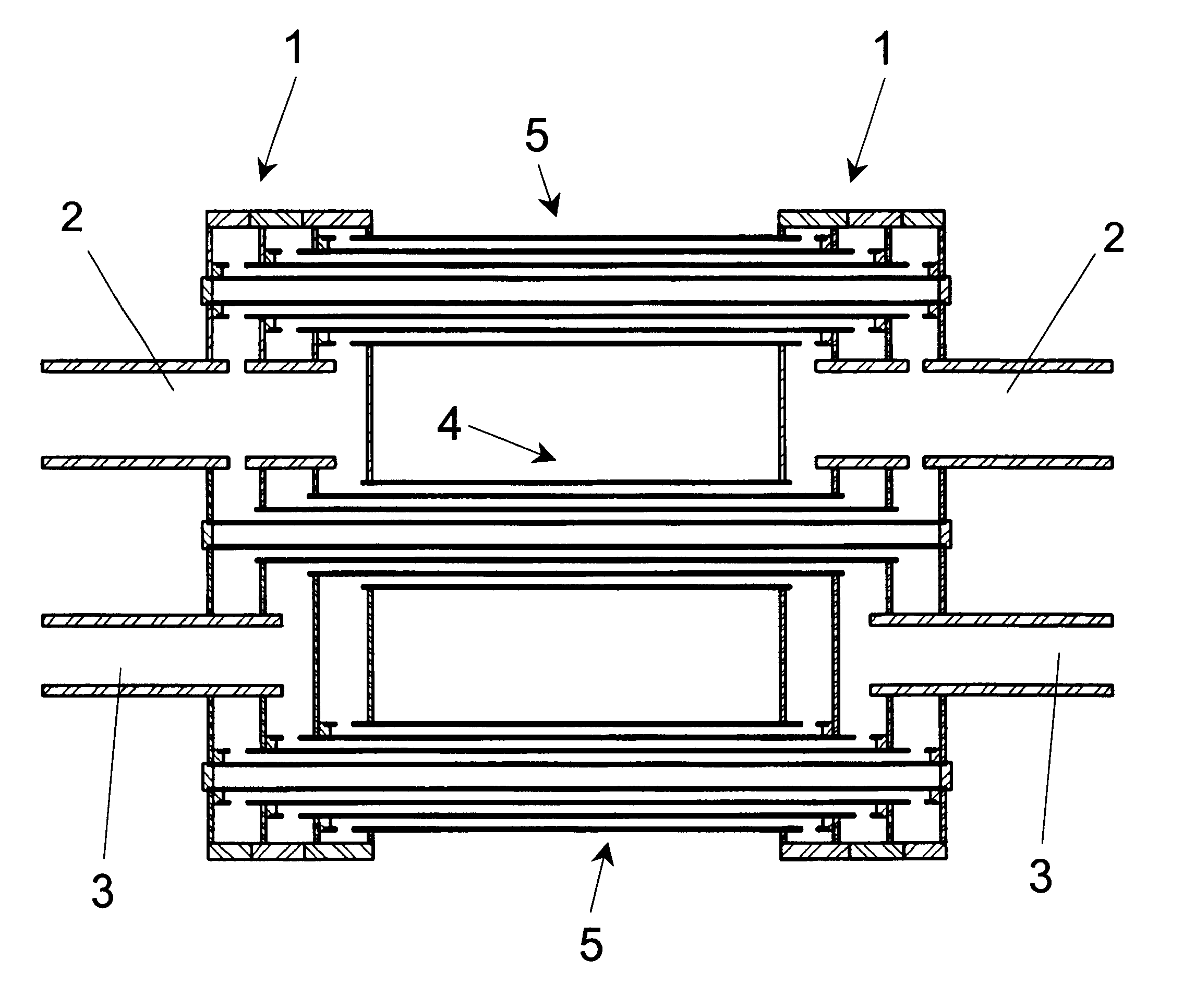

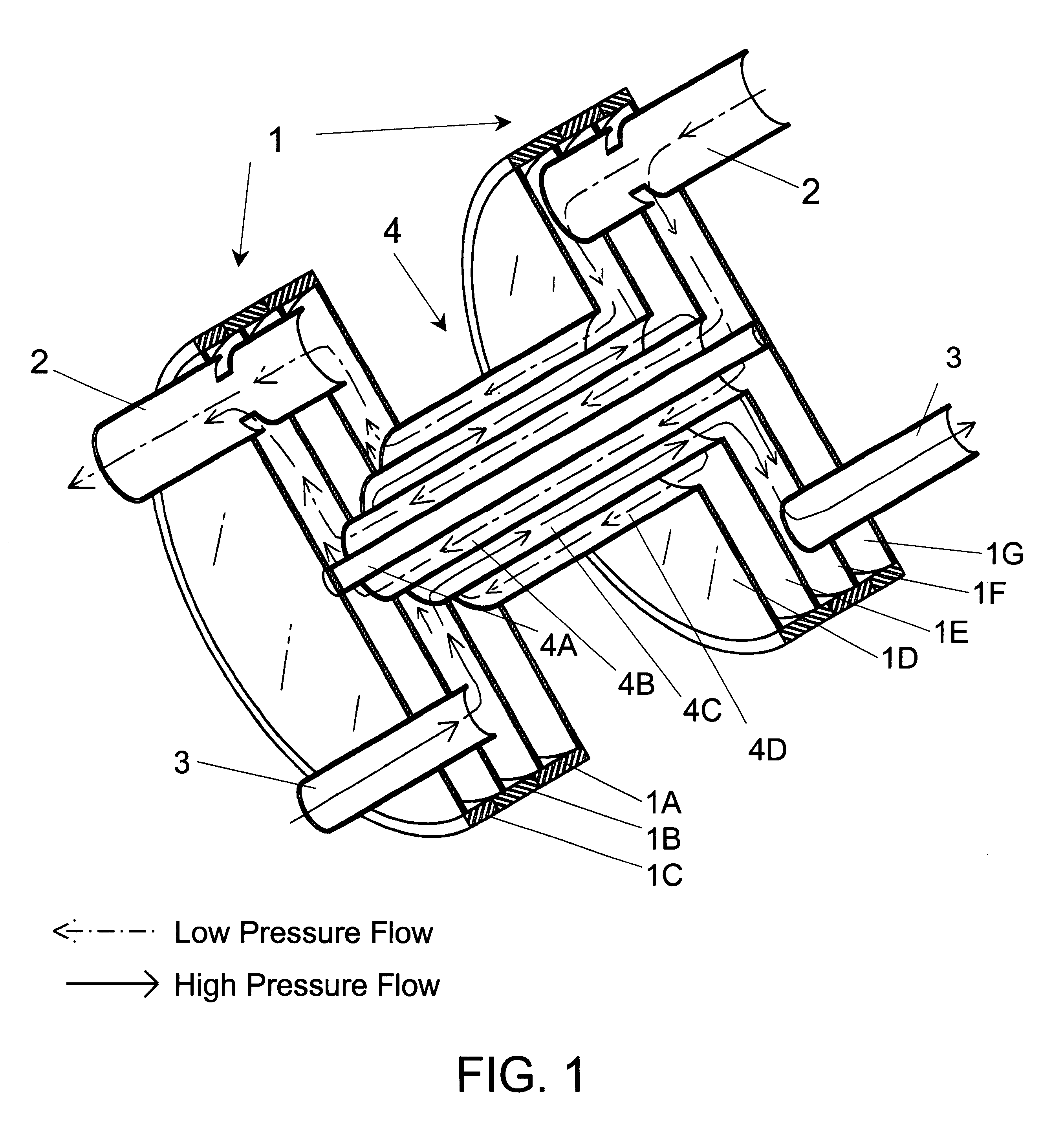

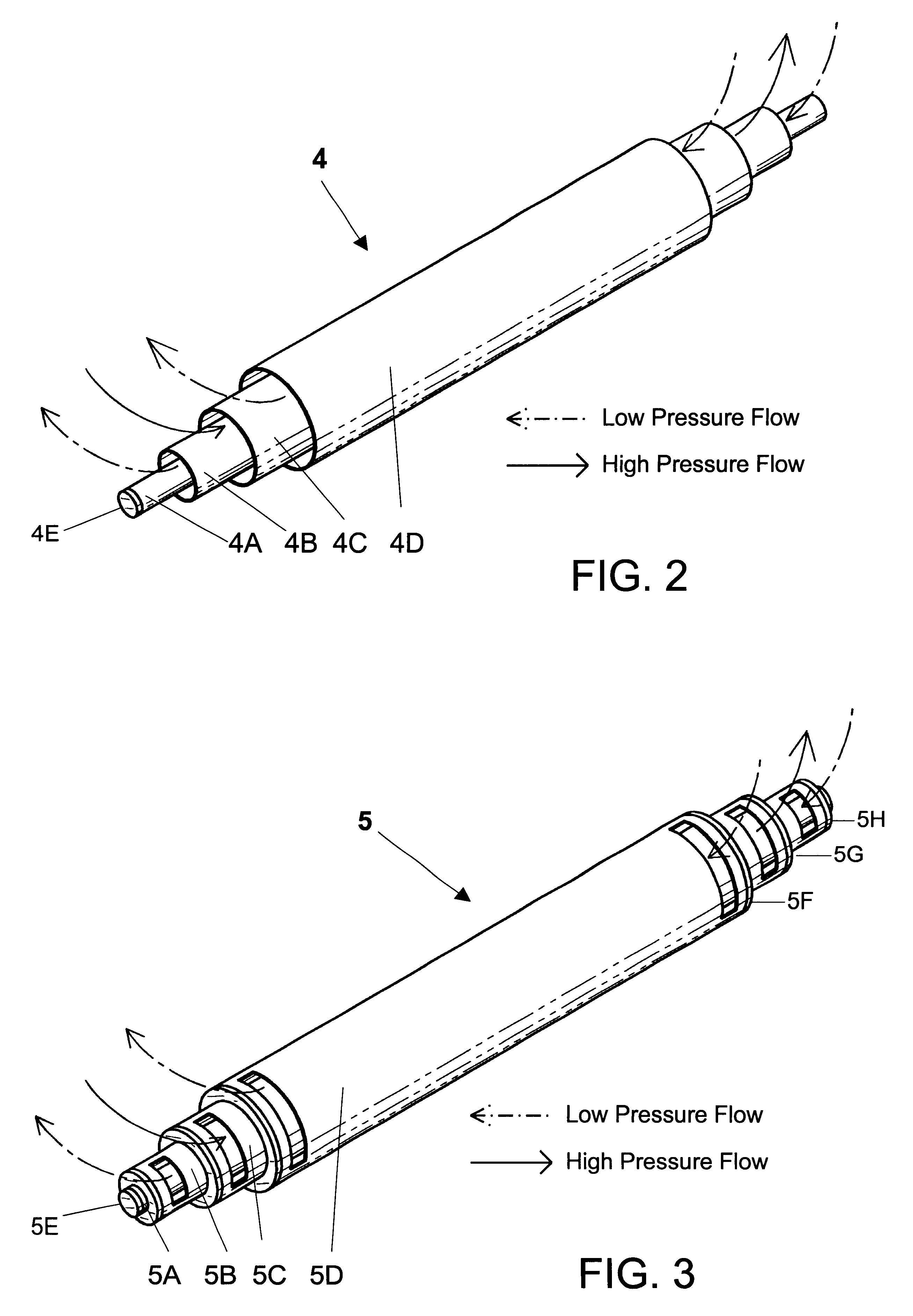

Annular flow concentric tube recuperator

InactiveUS6390185B1Minimal effectivenessNegligible reduction in effectivenessRecuperative heat exchangersStationary tubular conduit assembliesCounter flowVolumetric Mass Density

An annular flow concentric tube heat exchanger for heating two counter flowing fluid streams has been devised. Although capable of heating gases or liquids, the primary purpose of the invention is to function as an improved recuperator for recovering exhaust heat from a Brayton Cycle gas turbine engine, Ericsson Cycle engine or similar recuperated engine. The basic element of the recuperator is a concentric tube assembly that, in the preferred embodiment, is comprised of four concentric tubes that enclose three concentric annular flow passages. The low pressure exhaust flows through the inner and outer annular passages while the high pressure compressor exit air flows through the annular passage that is between the two low pressure passages. The high and low pressure flows are in opposite directions to achieve the high effectiveness that is only available with a counterflow heat exchanger. Heat is transferred from the exhaust gas to the compressor air though the tube walls on each side of the high pressure passage. Two low pressure passages are provided for each high pressure air passage to compensate for the lower pressure (and therefore lower density) of the exhaust gas. Multiple concentric tube assemblies are used to make a recuperator. The tube assemblies terminate in header assemblies located at each end of the concentric tube assemblies. The headers are made of simple plates and rings that serve the dual function of structurally locating the concentric tube assemblies and directing the flow to the proper passage in the concentric tube assemblies. High and low pressure flow tubes provide flow passages connecting the recuperator to the engine compressor air and exhaust tubing respectively. The annular flow concentric tube recuperator can be easily made from commercial tubing with minimal special tooling and is capable of very high effectiveness with very low pressure drop.

Owner:PROE POWER SYST

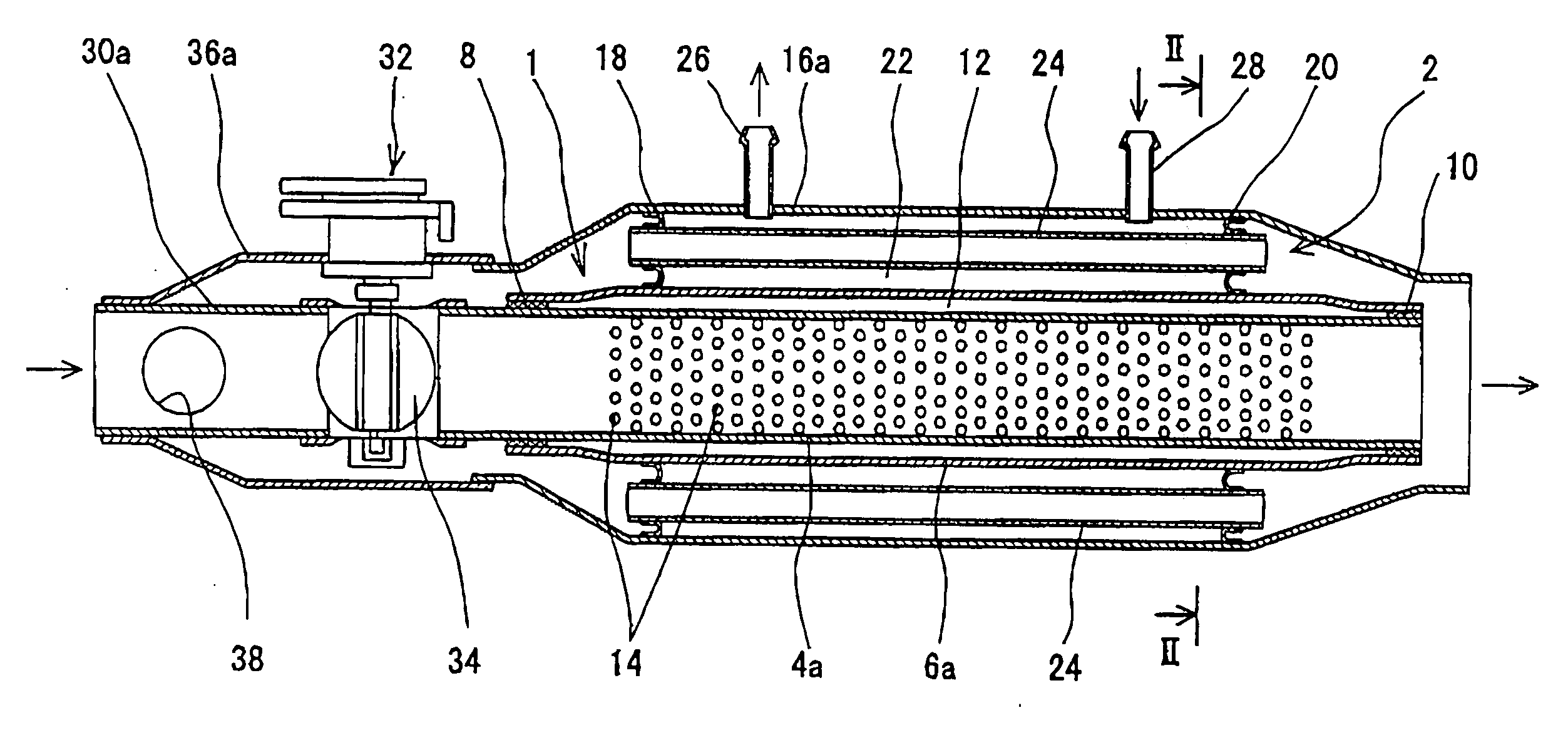

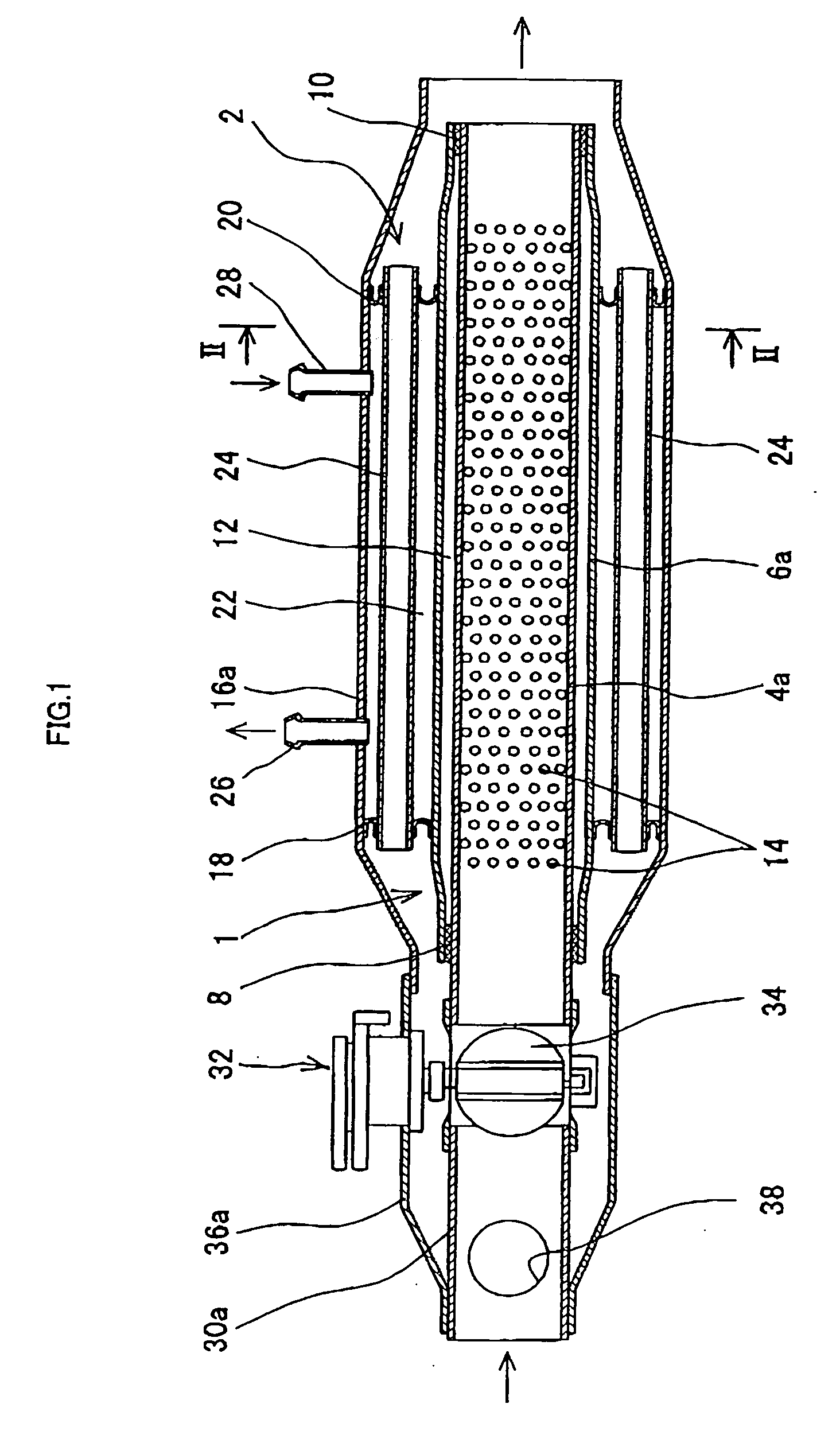

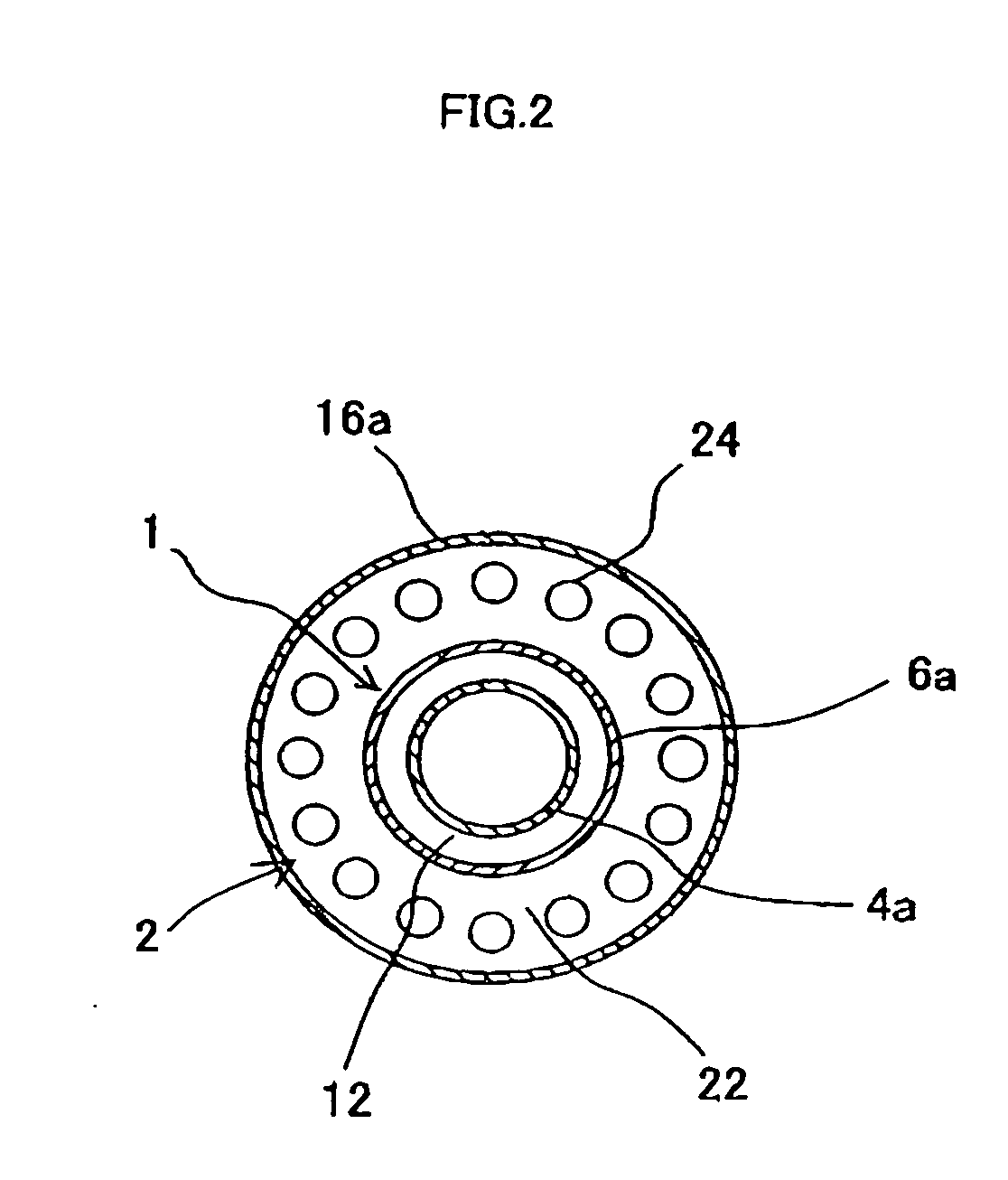

Exhaust heat recovery muffler

InactiveUS20060054381A1Easy to manufactureIncrease the cross-sectional areaInternal combustion piston enginesRecuperative heat exchangersWaste heat recovery unitEngineering

The exhaust heat recovery muffler includes a muffler unit having the outer surface thereof covered, an exhaust heat recovery unit disposed integrally with the muffler unit, and a switching valve that switches the flow of exhaust gas into the muffler unit and into the exhaust heat recovery unit. An outer pipe of the muffler unit and a cylindrical shell of the exhaust heat recovery unit, covering the outer circumference of the outer pipe, are coaxially disposed. The exhaust heat recovery unit includes a heat exchange chamber, formed by a pair of partitions provided between the inner circumference of the shell and the outer circumference of the outer pipe, and small-diameter pipes penetrating through the pair of partitions and extending through the heat exchange chamber. A heat exchange medium flows inside of the heat exchange chamber.

Owner:FUTABA IND CO LTD

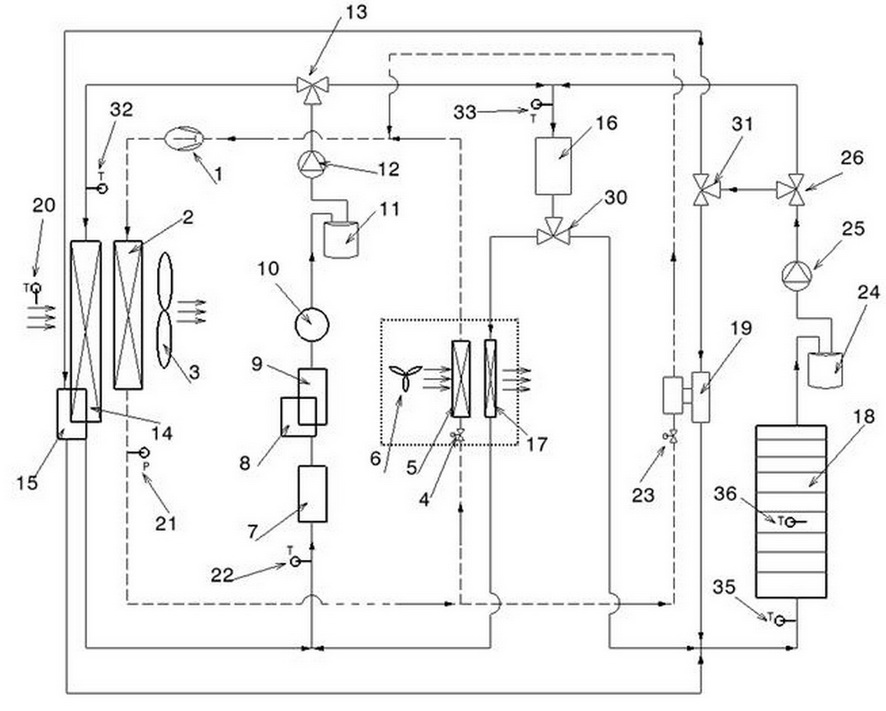

Control system for heat management of electric vehicle

InactiveCN102050007ASolve heating problemsEfficient thermal managementCompression machines with several evaporatorsComponent optimizationAutomotive batteryElectrical battery

The invention provides a control system for heat management of an electric vehicle. The control system is characterized in that the system comprises a refrigerant circulating system, a coolant circulating system and a battery pack temperature control system, wherein the refrigerant circulating system is communicated with the battery pack temperature control system via a water cooler, and the coolant circulating system is communicated with the battery pack temperature control system via a three-way water valve, so the three systems form an intercommunicating and circulating control system to control the temperature in the carriage and the working temperature of the electrical devices of the battery pack. The control system has the following positive effects: effective heat management can be carried out on each part of the electric vehicle; the problem of heating difficulty of the electric vehicle is solved by adopting the residual heat of the electrical devices in an economical and energy-saving manner; preheating and cooling of the power battery of the electric vehicle are well controlled; and the working temperature of the battery and electrical devices of the electric vehicle can be controlled, thus realizing complete heat system management of the electric vehicle.

Owner:VALEO AUTOMOTIVE AIR CONDITIONING HUBEI CO LTD

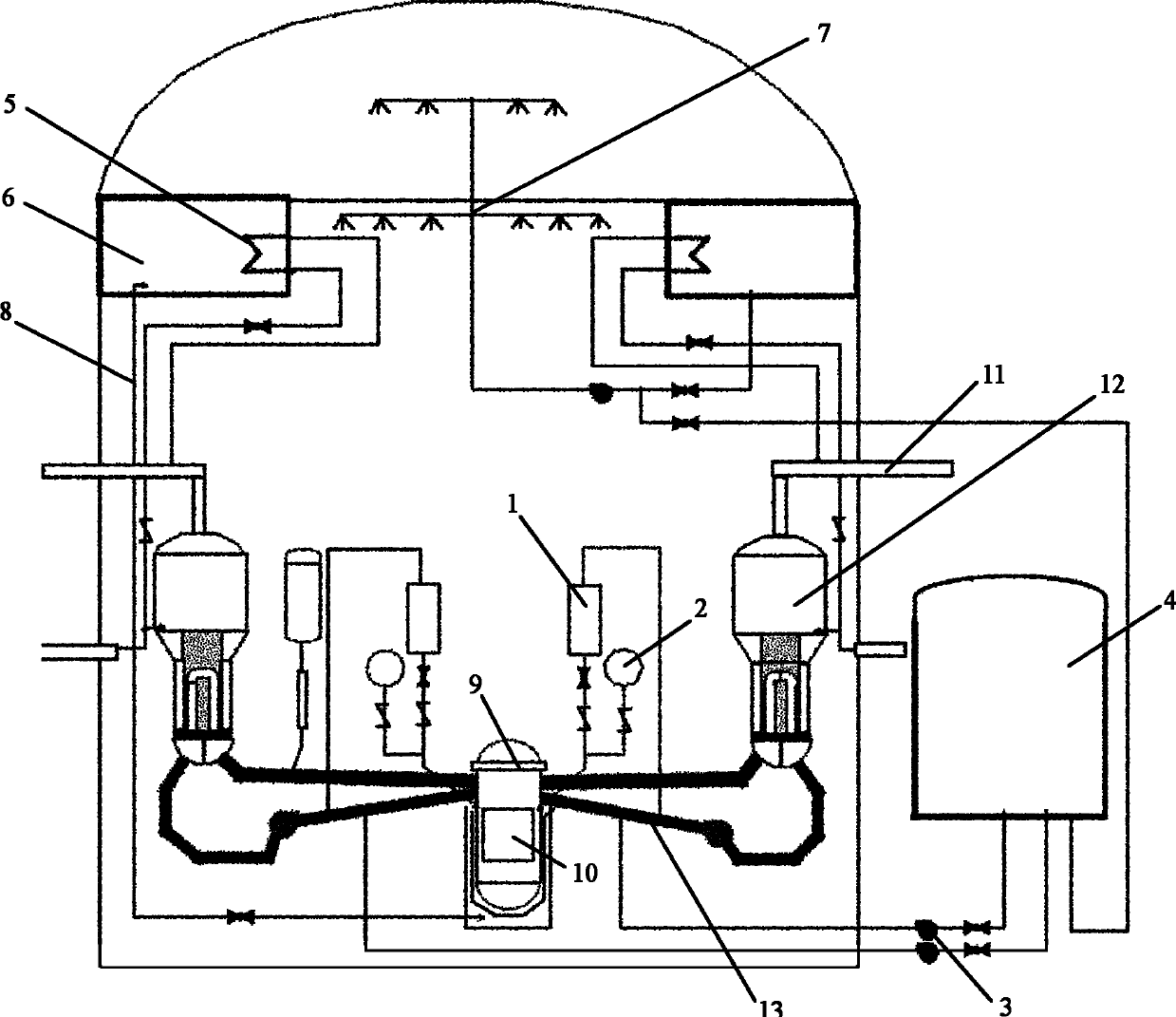

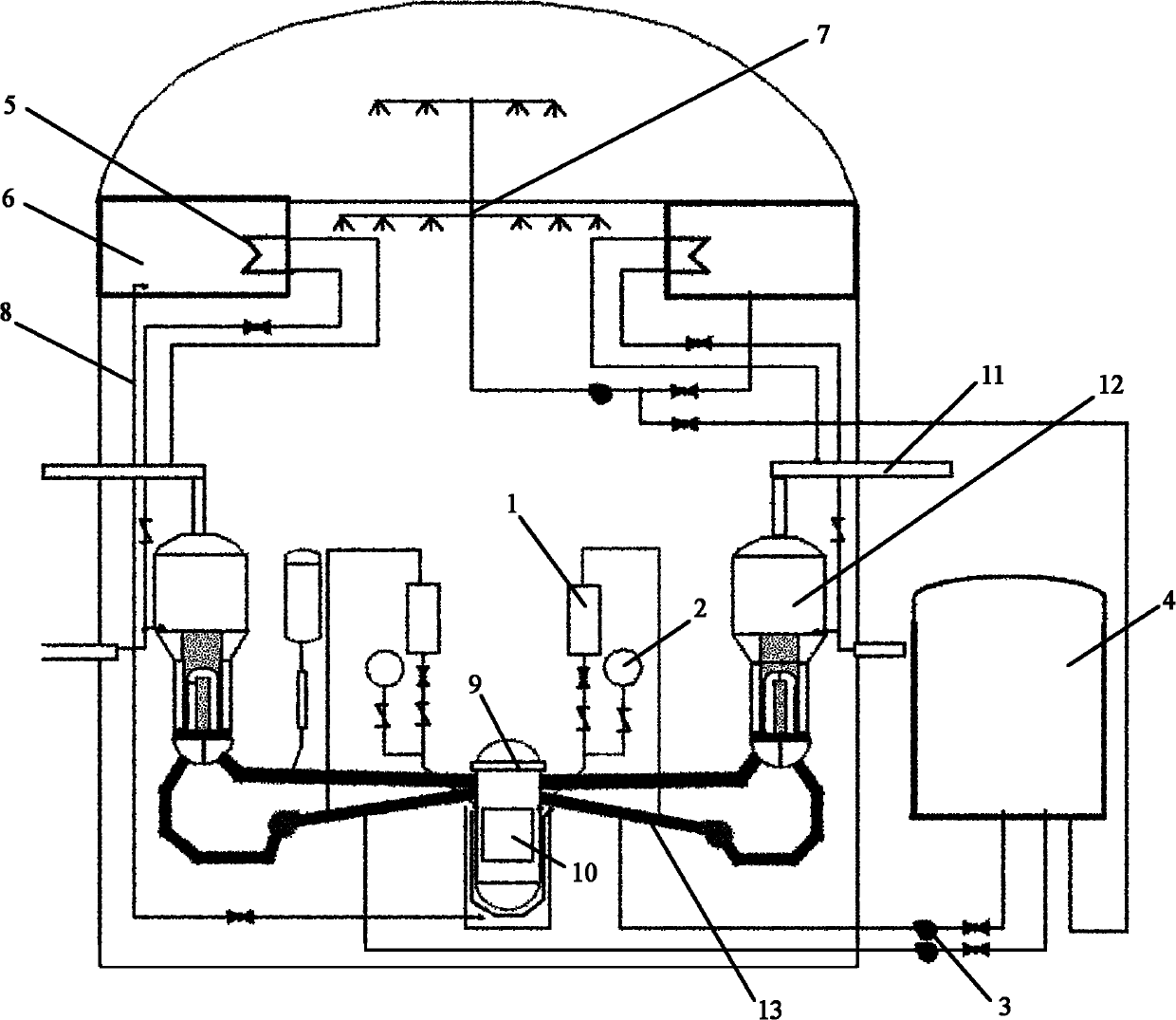

Passive and active combined special safety system for nuclear power plant

InactiveCN102169733AImprove securityReduced risk of serious accidentsNuclear energy generationCooling arrangementActive safetyNuclear power

The invention belongs to safety equipment for a nuclear power plant, in particular to a passive and active combined special safety system for the nuclear power plant. The system comprises a passive high-pressure core water supply tank, an accumulator, a low-pressure safety injection pump, a refueling water tank, a secondary-side passive residual heat removal heat exchanger, a vapor condensation water tank, a containment spray system, a passive reactor cavity water injection system, related valves and related pipes. When the nuclear power plant has a design basis accident or beyond design basis accident, through a series of passive and active safety facilities used in all steps, the circuit of a reactor and the core can be cooled effectively, so that the nuclear power plant can enter a safe cold shutdown condition smoothly; and thus, the serious accident consequence of the reactor is inhibited or relieved, damage caused by accidents is relieved, and the safety of the nuclear power plant is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

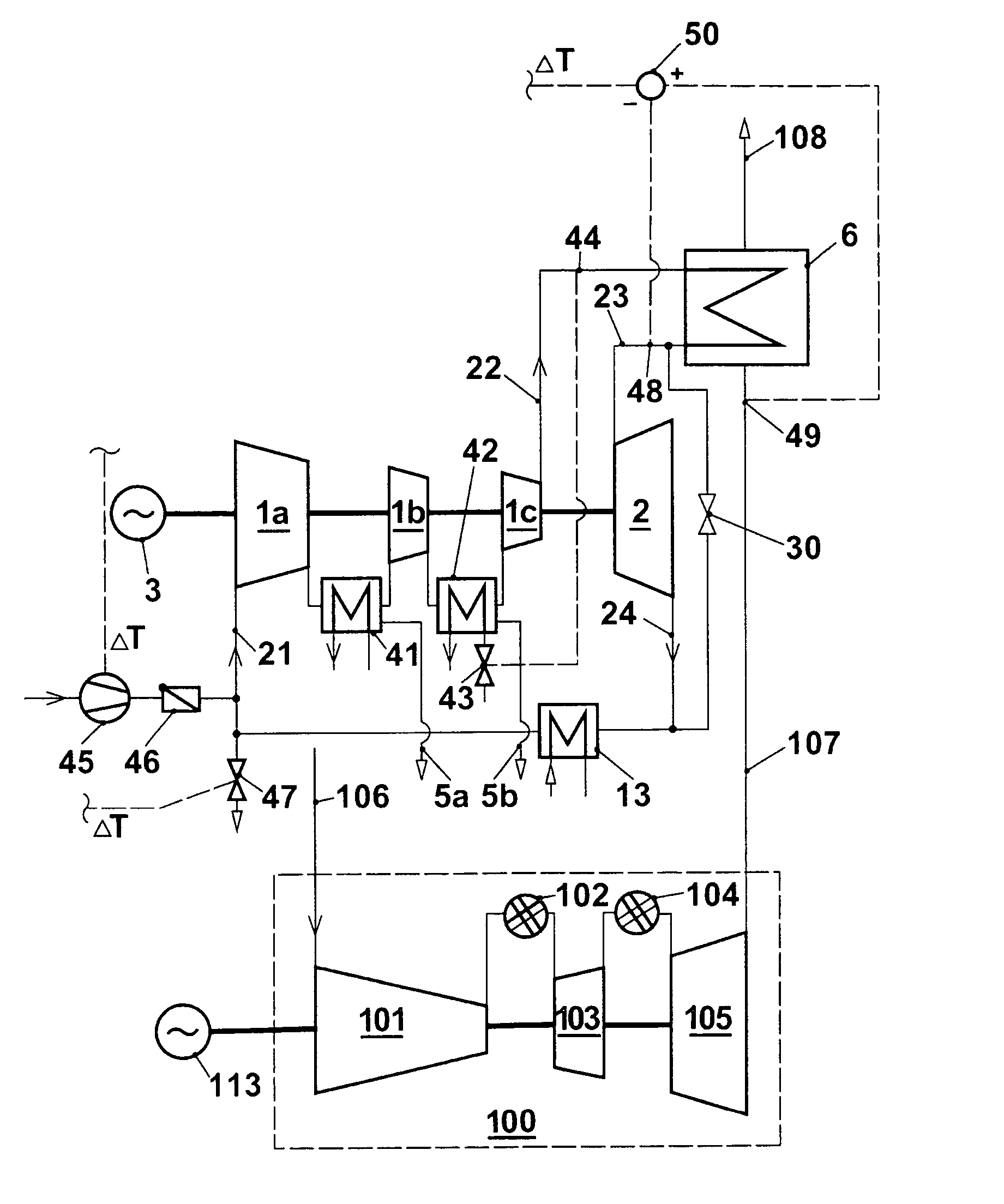

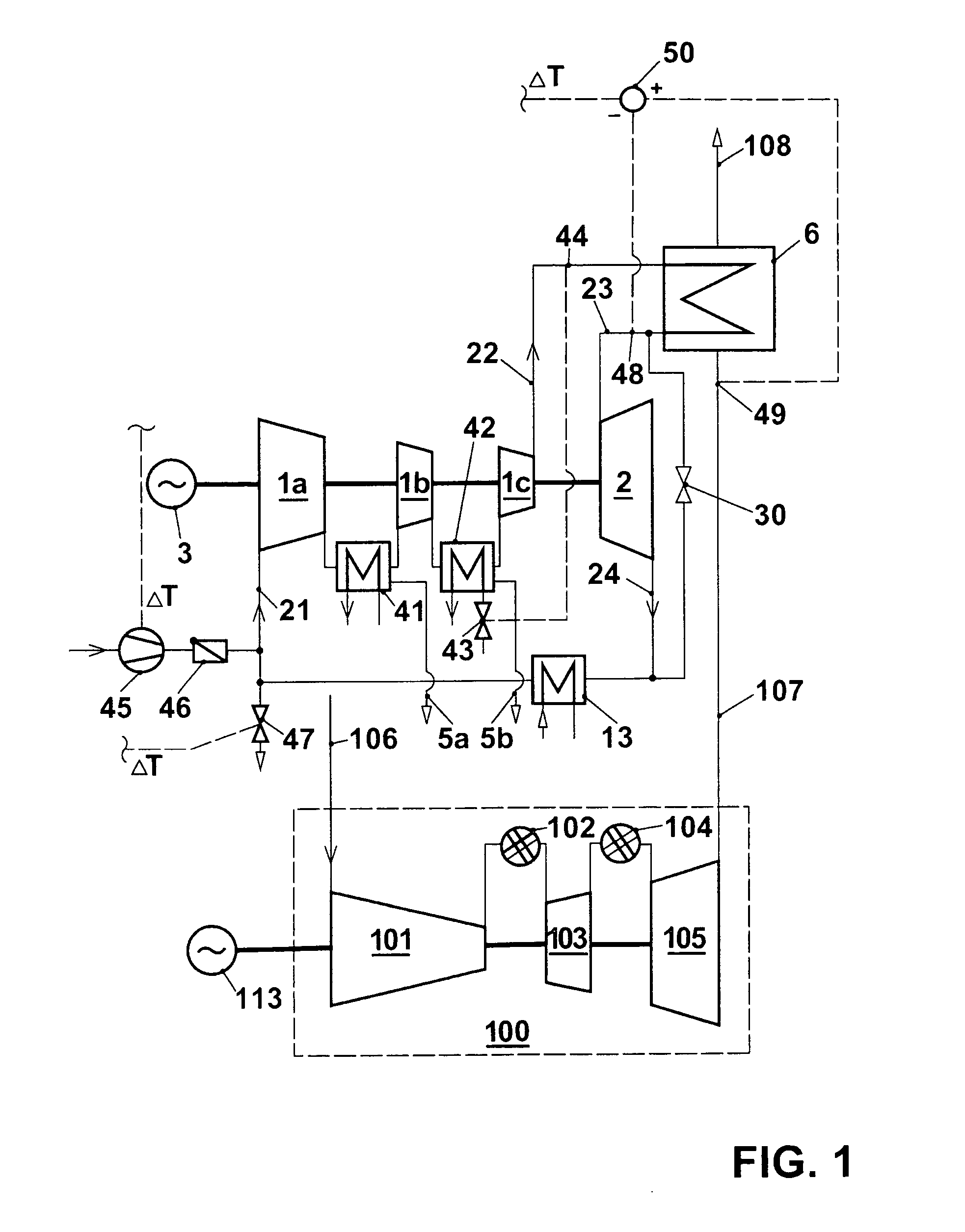

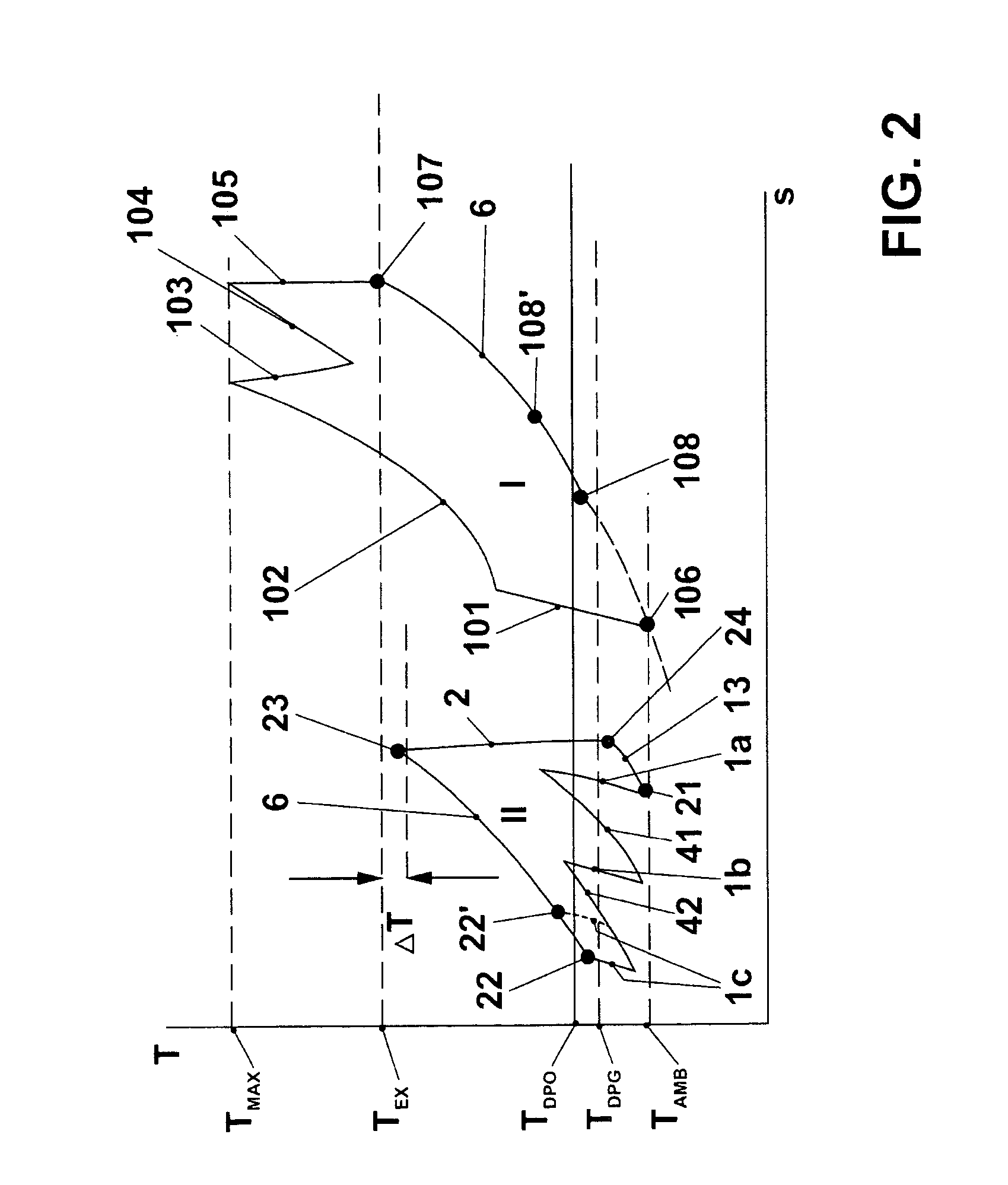

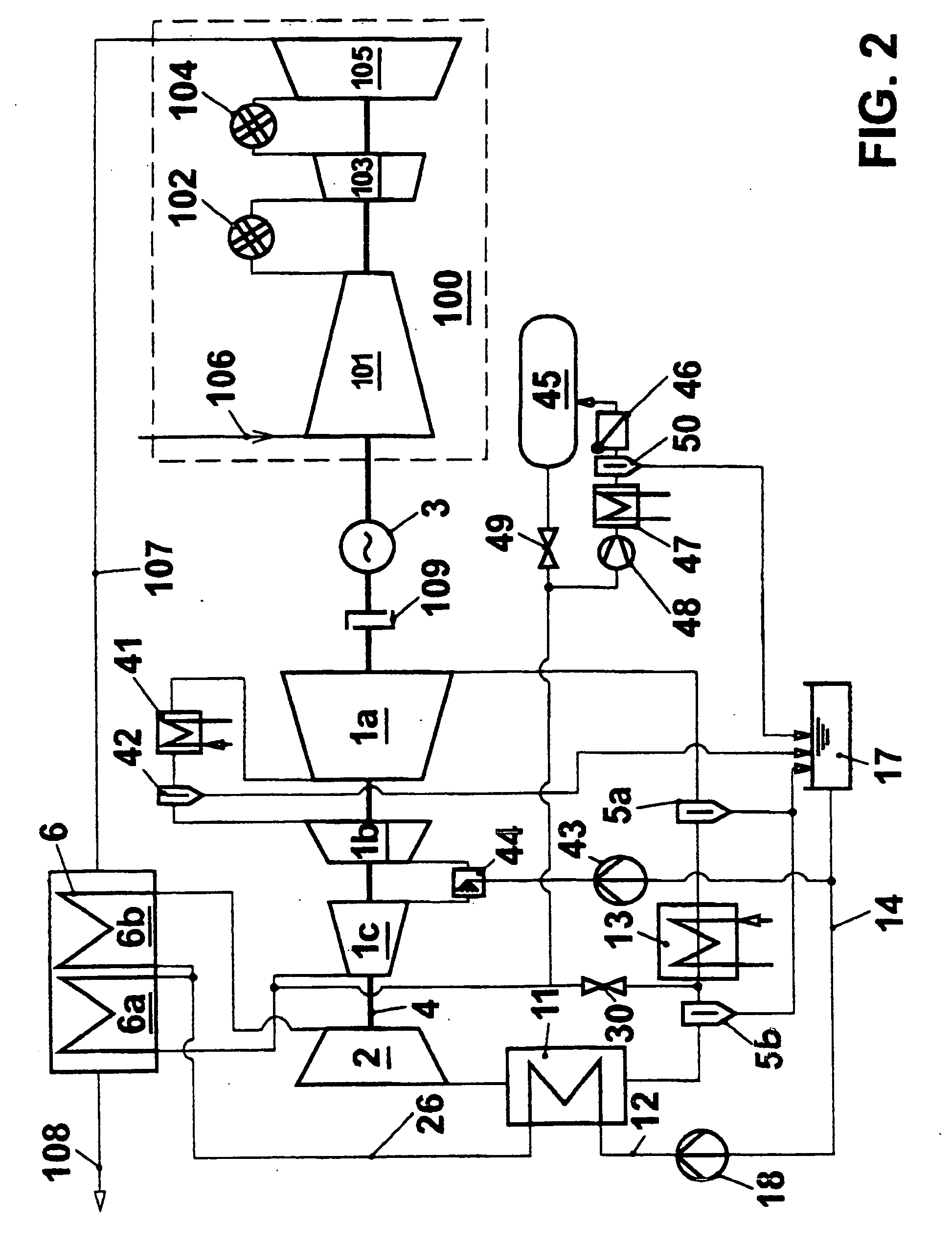

Power generation plant

InactiveUS20050056001A1Increase flexibilityAvoid disadvantagesEfficient propulsion technologiesGas turbine plantsElectricityPower station

In a power generation plant, for example a power station plant for the generation of electricity, a secondary machine (1a, 1b, 1c, 2) is connected downstream of an open-cycle gas turboset (100) for the utilization of the waste heat of the exhaust gases (107). The secondary machine is a machine working in a closed cycle with a gaseous process fluid, for example a closed-cycle gas turboset having a compressor (1a, 1b, 1c), a device for heating the compressed gas (6) which utilize the waste heat of the exhaust gas (107) of the primary gas turboset (100), a turbine (2) and at least one heat sink (13). In one embodiment, intercoolers (41, 42) are arranged during the compression process. A variable cycle charge of the secondary machine permits superior flexibility in the utilization of greatly varying supplies of waste heat available.

Owner:ALSTOM TECH LTD

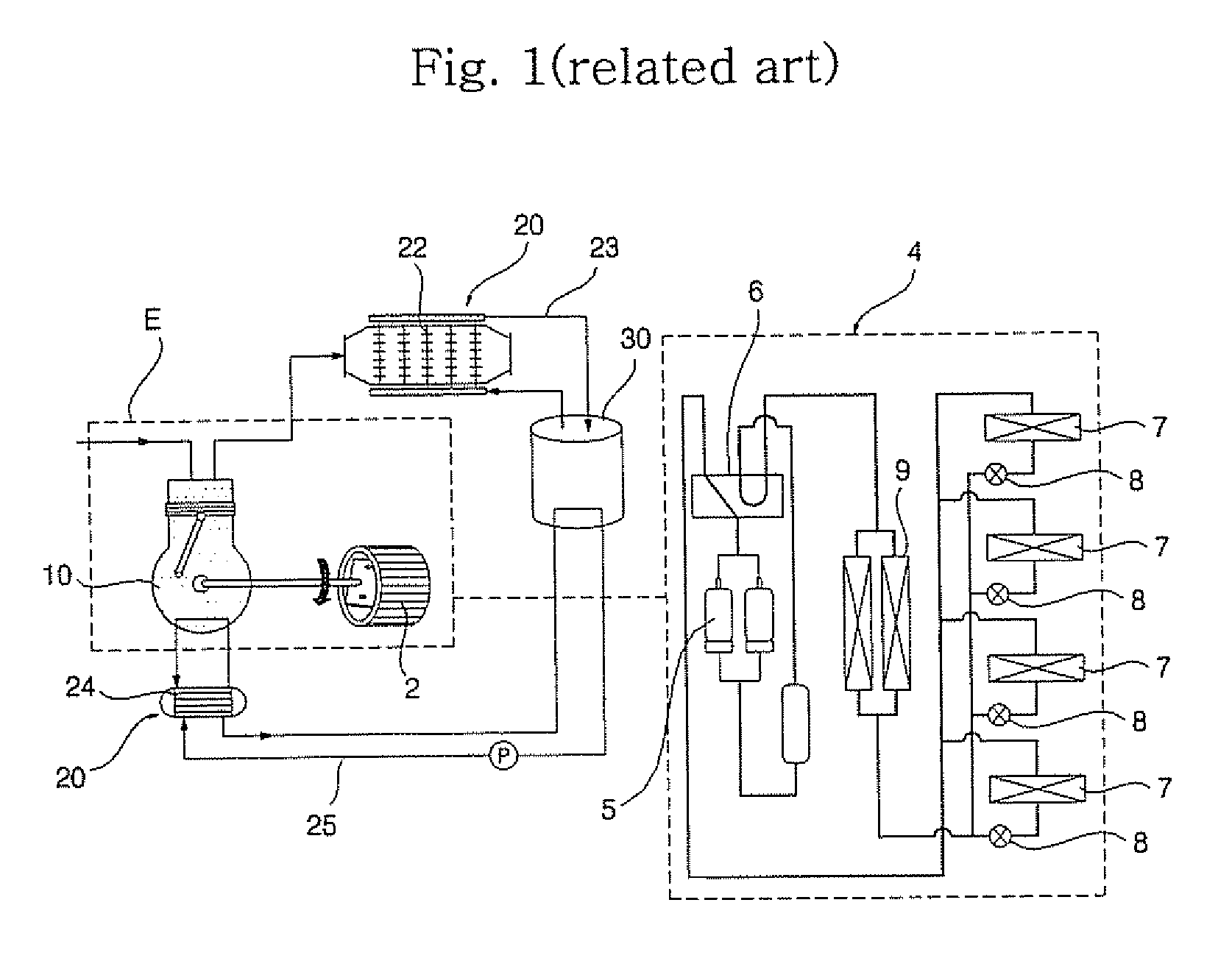

Cogeneration system

InactiveUS20060283967A1Maximum energy efficiencyImprove the heating effectMechanical apparatusHeat pumpsCogenerationProcess engineering

A cogeneration system is disclosed which includes a generator, a drive source for driving the generator, a waste heat supplying heat exchanger for enhancing the heating performance of a heat pump type air conditioner, an auxiliary heating heat exchanger using the waste heat of the drive source as a heat source for heating indoor air, and a regeneration heat supplying heat exchanger using the waste heat of the drive source as a heat source for regenerating a dehumidifier. The cogeneration system can use the waste heat of the drive source for diverse purposes in accordance with the indoor environment, and can have a maximal efficiency.

Owner:LG ELECTRONICS INC

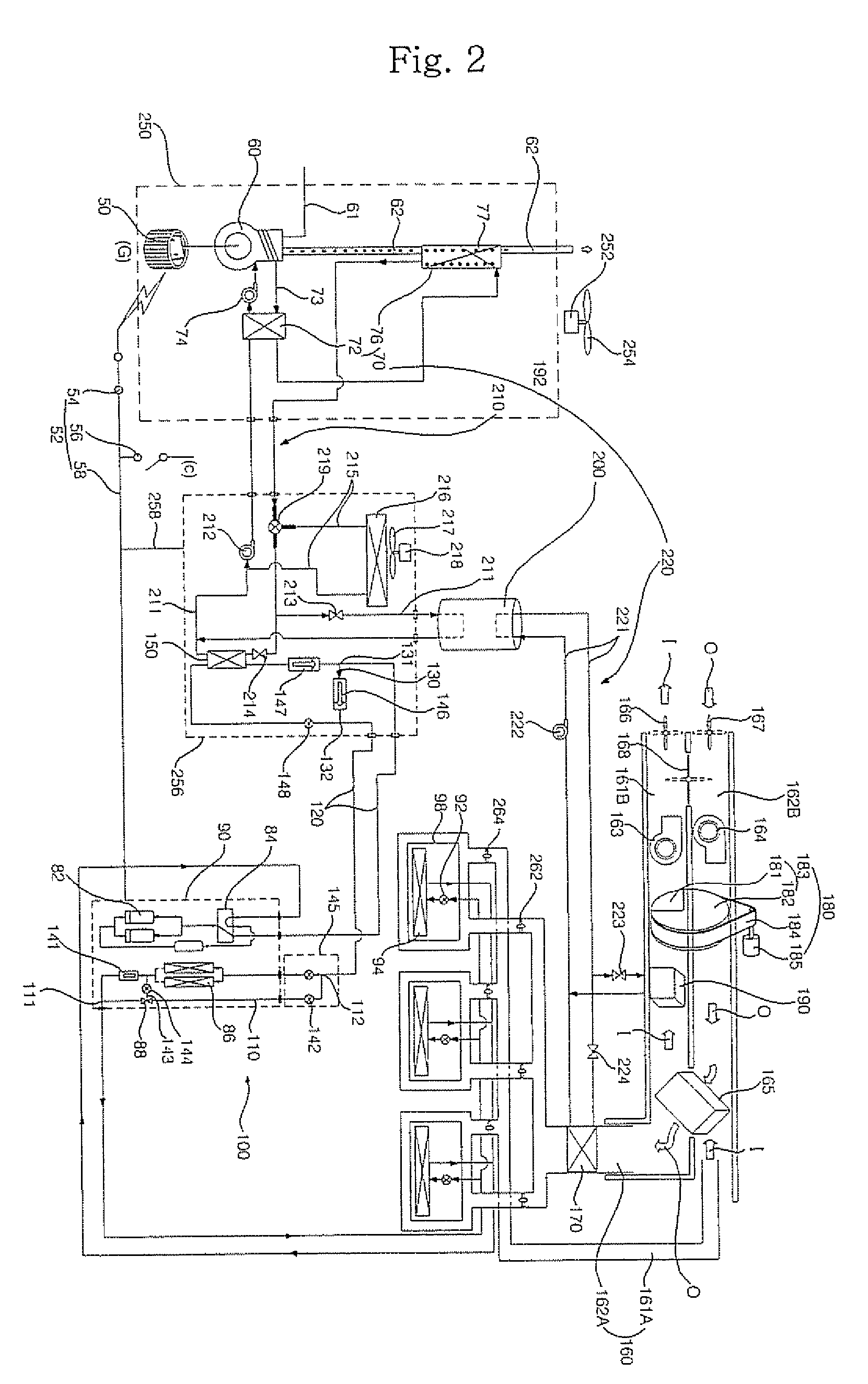

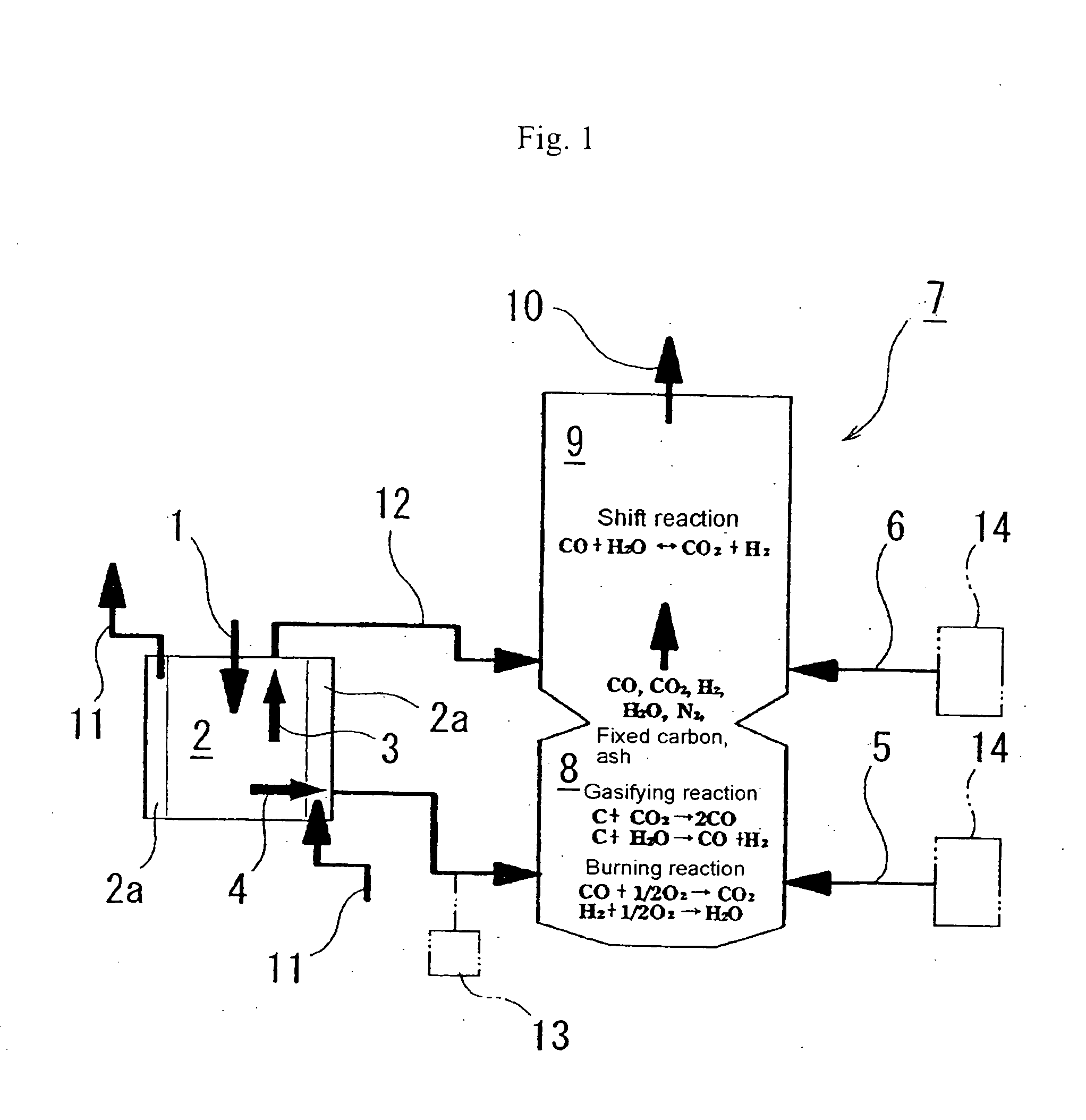

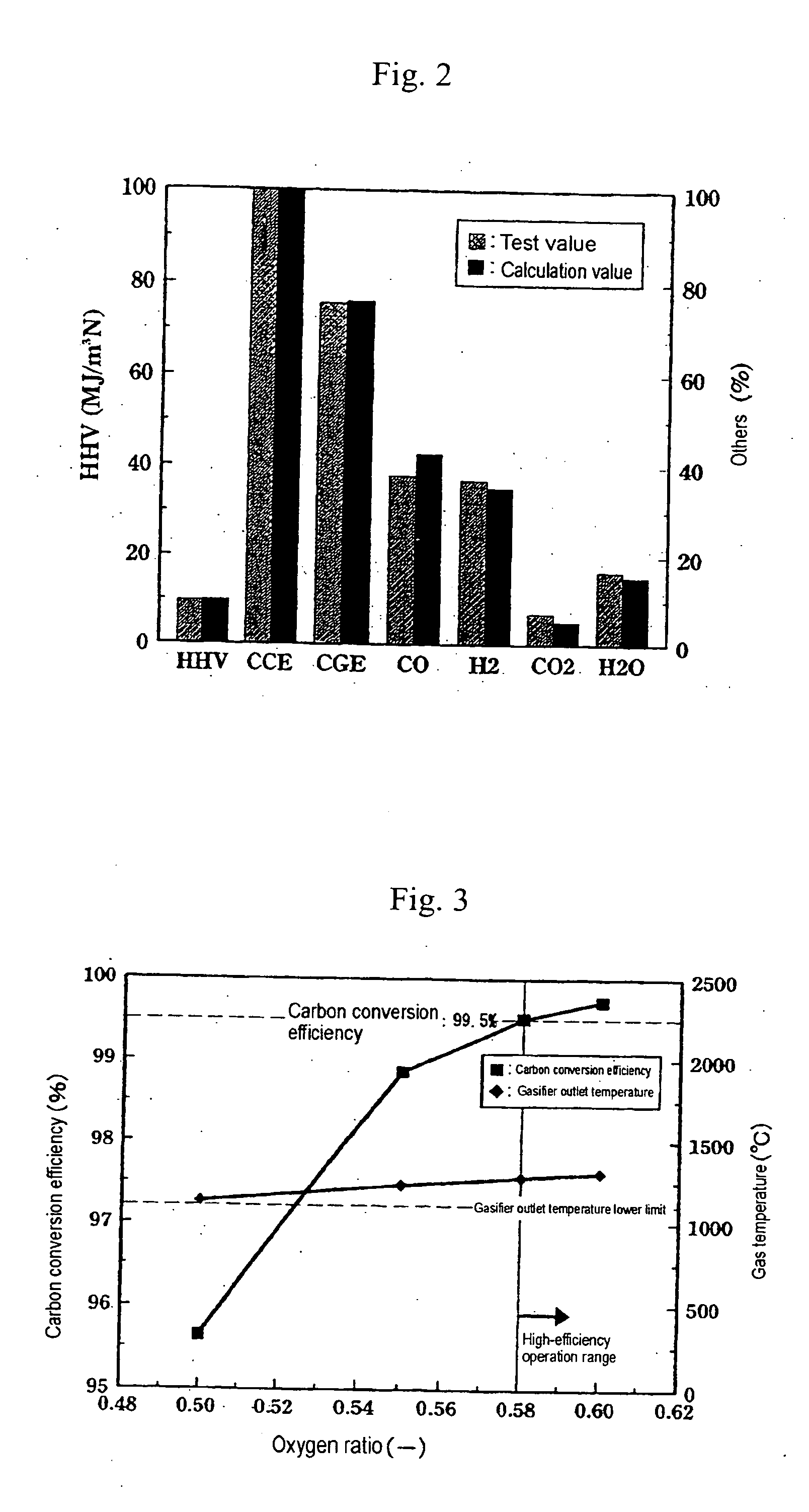

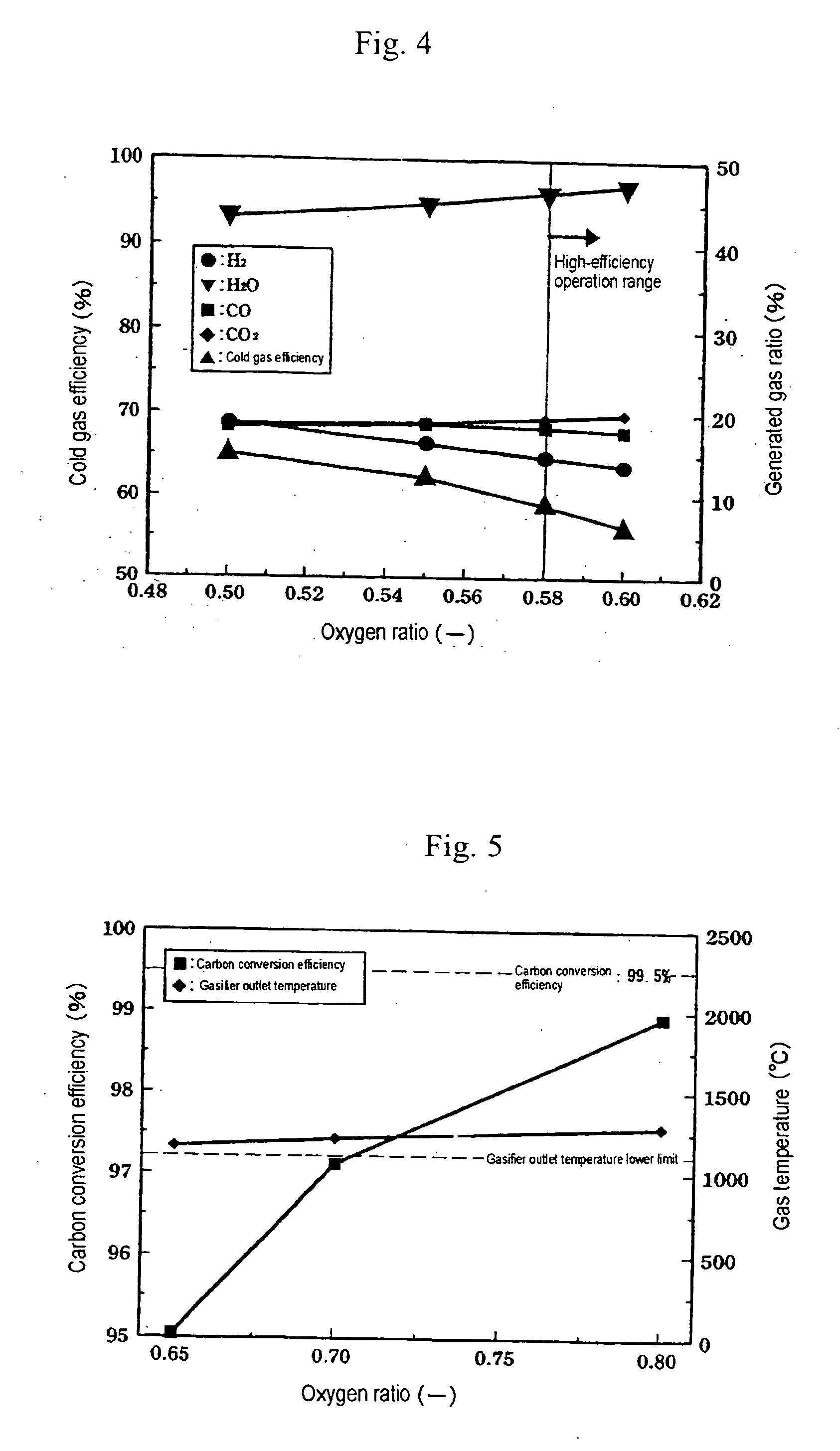

Carbonization and gasification of biomass and power generation system

InactiveUS20050247553A1Increase temperatureHigh thermal efficiencyBeehive ovensCombustible gas catalytic treatmentCarbonizationTar

Biomass, including waste biomass, is gasified by a process in which the biomass is first carbonized, and the char and pyrolysis gas from the carbonizer are respectively fed to a high temperature gasifying part and a gas reformer part of a two-stage gasifier. A gasifying agent is continuously fed to the gasifying part, and intermittently fed to the gas reformer, to maintain the temperature required to avoid tar formation in the gas reformer stage. Multiple carbonization chambers are operated in rotation. When the carbonization / gasification apparatus is used to provide fuel to an electric power generator set, exhaust heat from the generator power plant is fed back to the carbonizer, and can be supplemented by exchange of heat from the gas delivered to generator power plant from the outlet of the gasifier.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

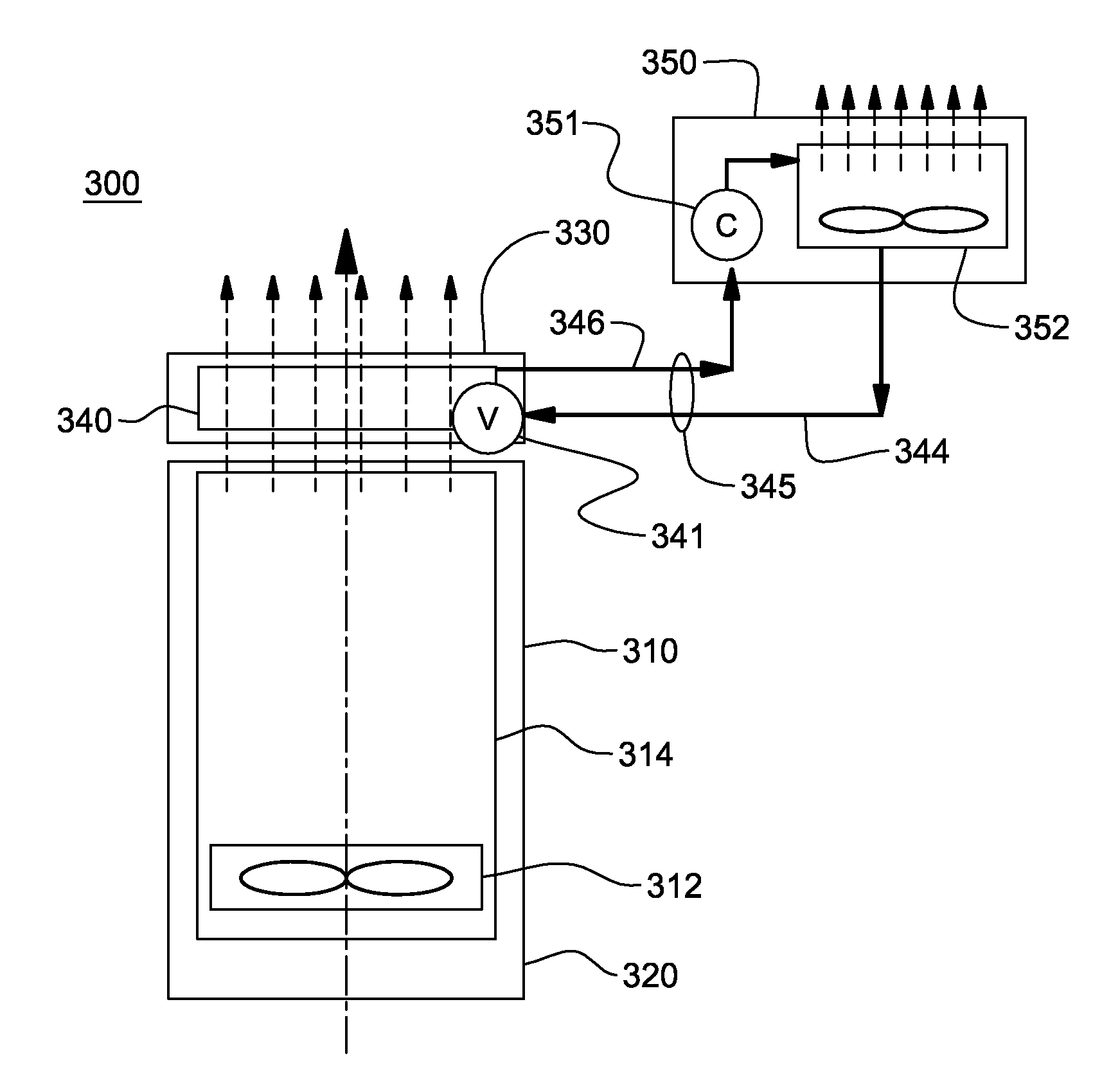

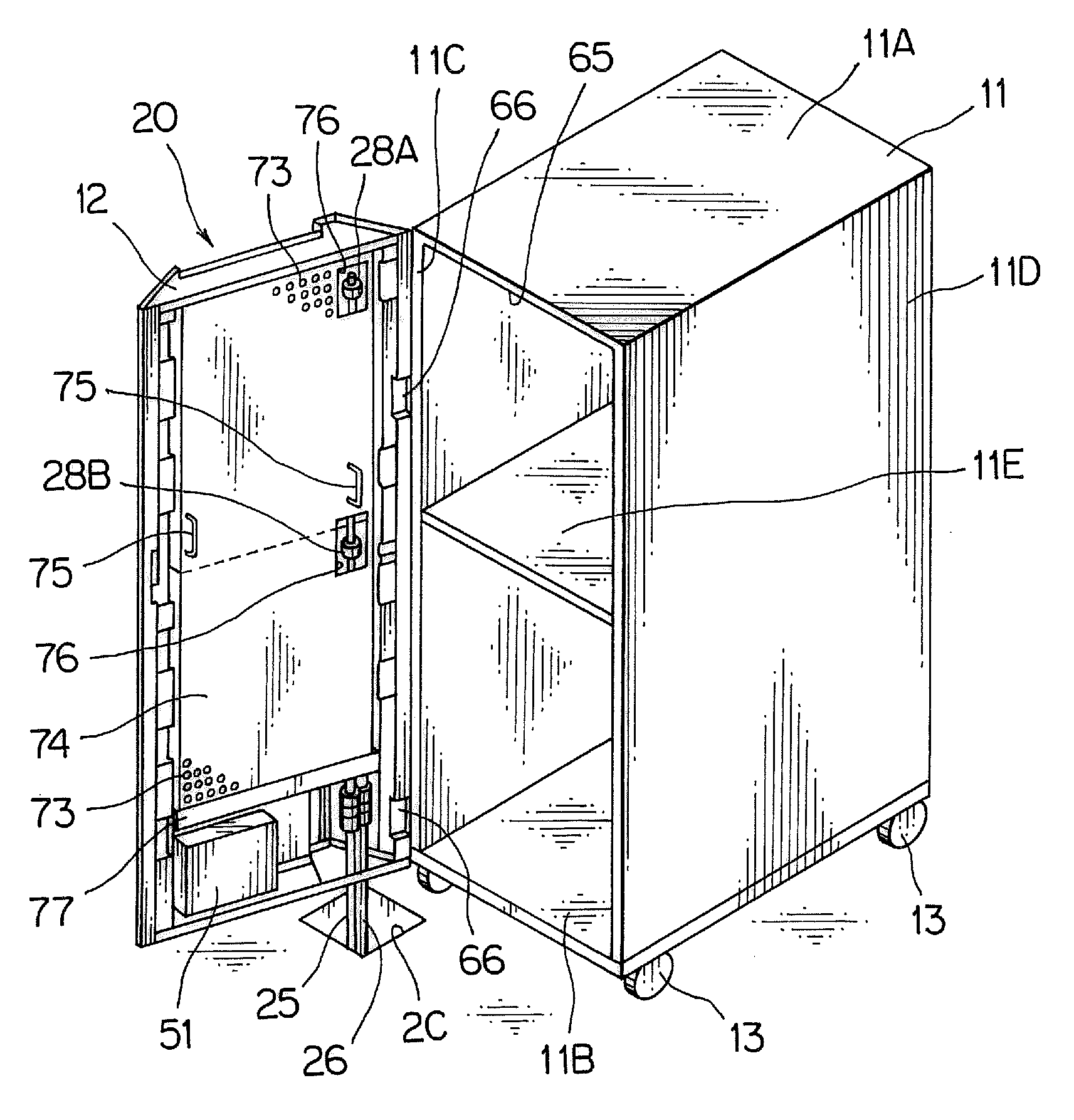

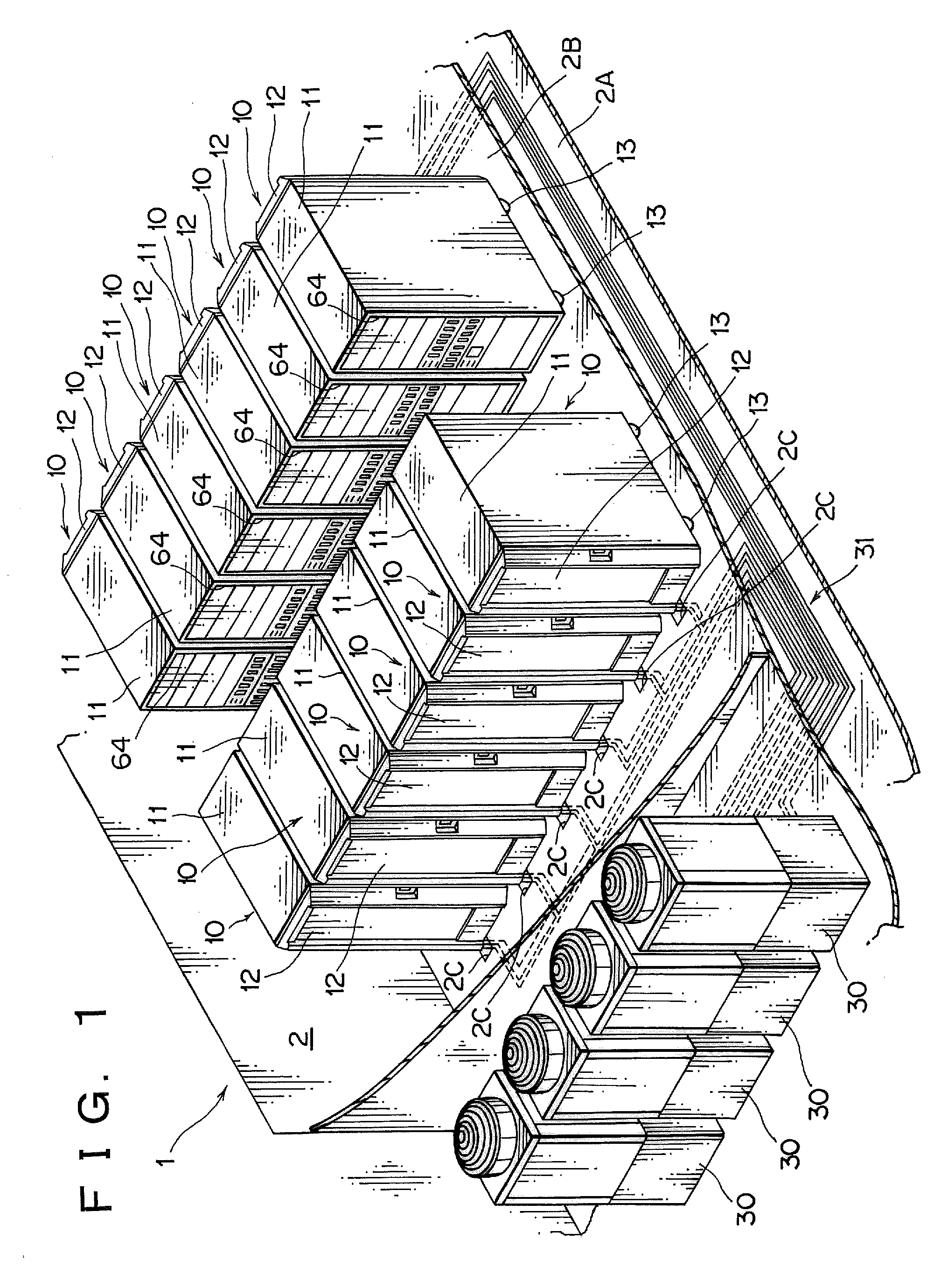

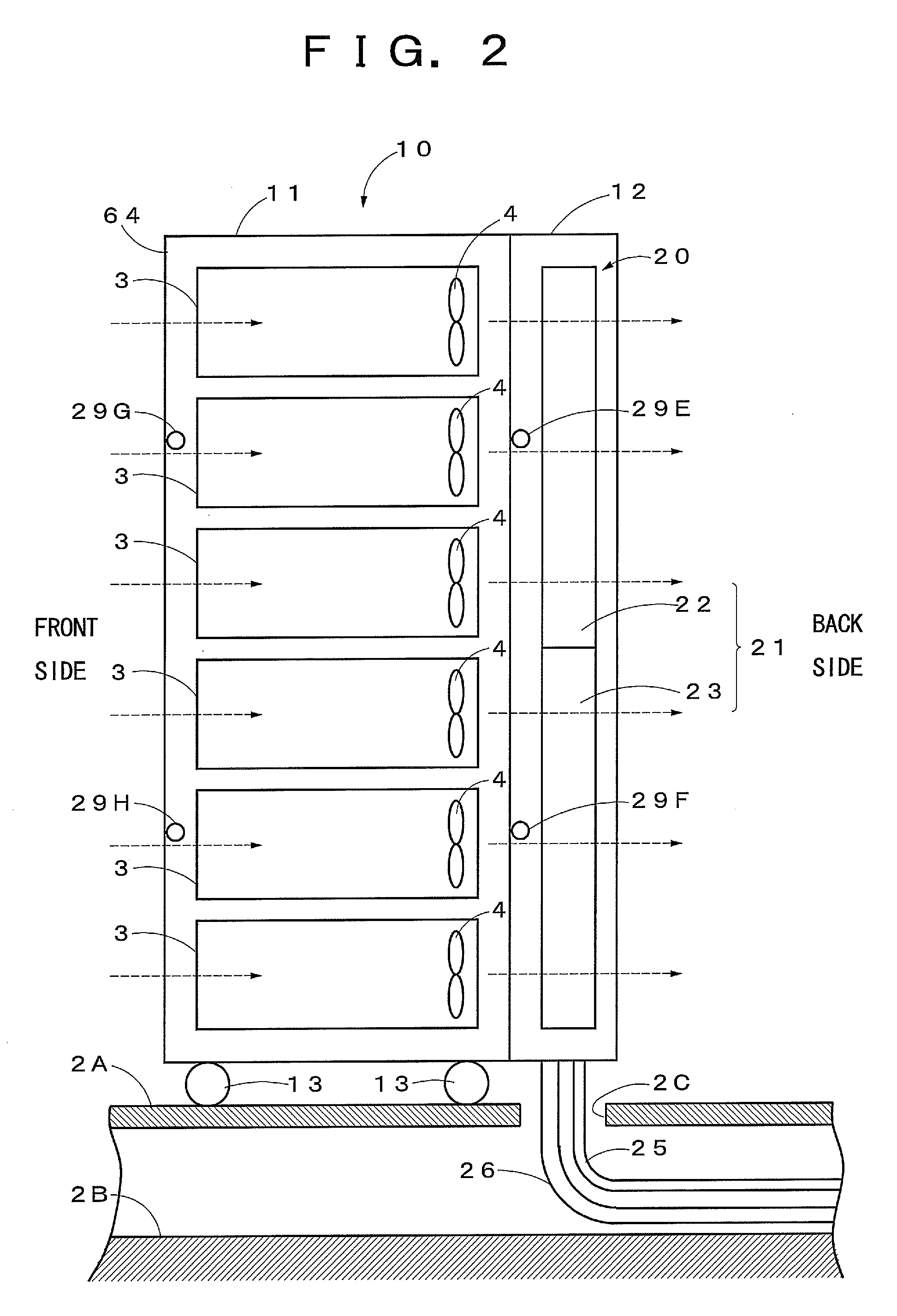

Electronic device cooling system and electronic device cooling apparatus

InactiveUS20090100848A1Avoid condensationEasy constructionCompression machines with non-reversible cycleEvaporators/condensersElectronics coolingRefrigerant

An electronic cooling apparatus has a cabinet which is open at the front and rear sides thereof and accommodates plural electronic devices each having a fan, and a rear door which is provided with an evaporator. Air blown by the fan is cooled by the evaporator and then returned to a room. An expansion valve and control. A drain pan with an extension portion having hole portions through which refrigerant pipes extend is provided. A drain hose discharges drain water from the drain pan. An exhaust heat temperature detecting unit and a control for controlling the refrigerant supply to the evaporator are provided. When the exhaust heat temperature is equal to or less than a set exhaust temperature, the controller stops the refrigerant supply to the evaporator. When the exhaust heat temperature exceeds the set temperature, the controller starts the refrigerant supply.

Owner:SANYO ELECTRIC CO LTD

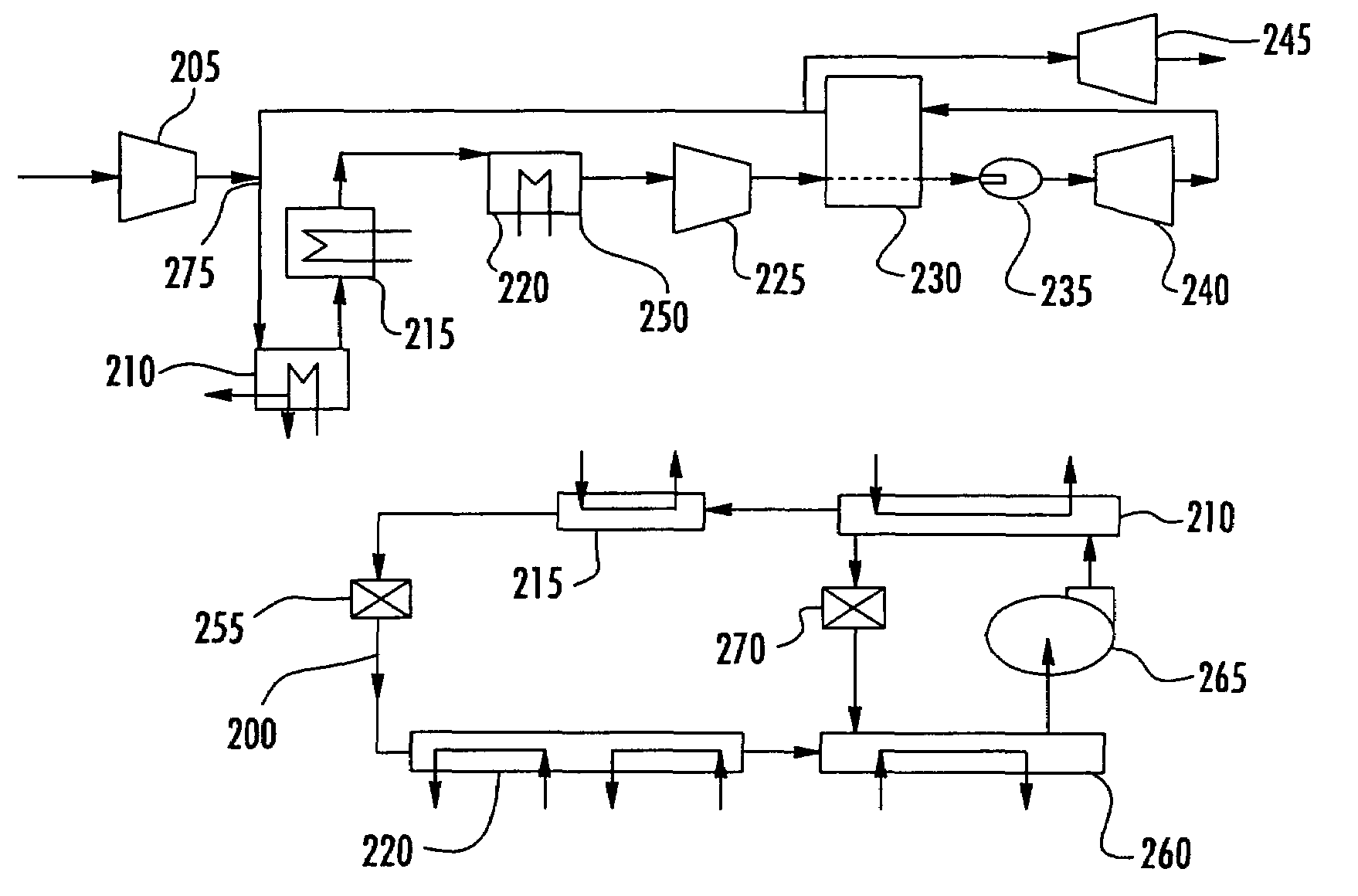

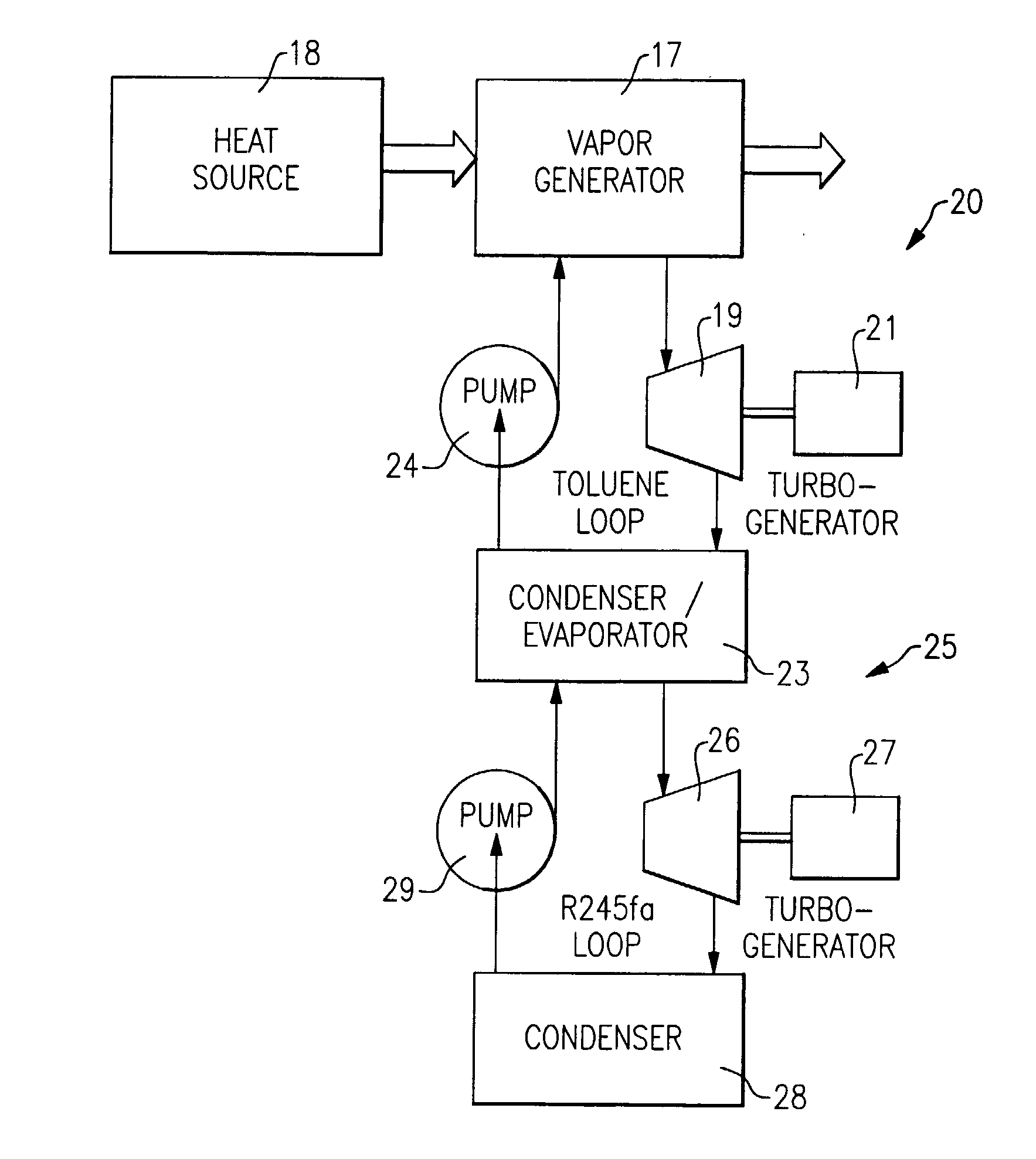

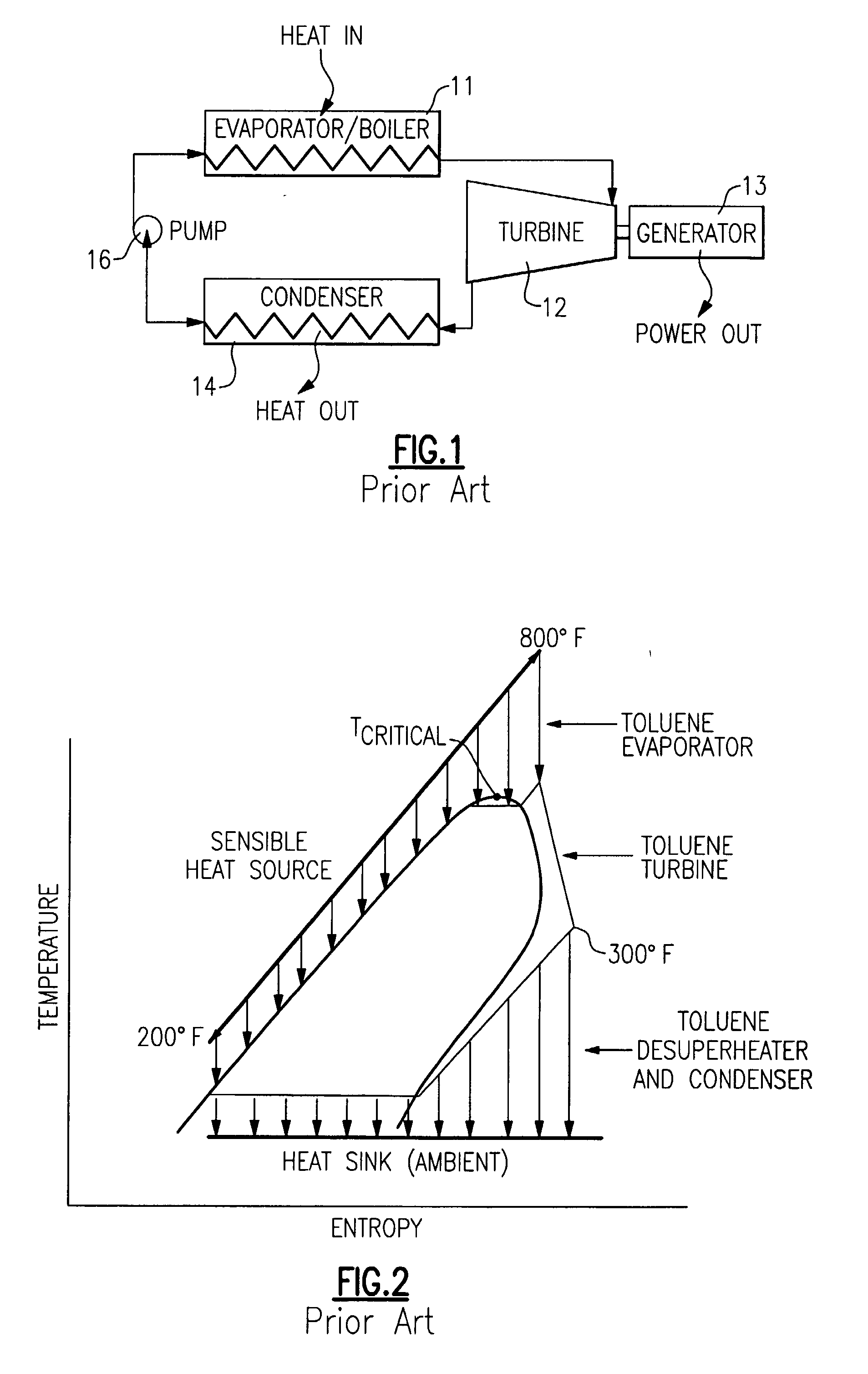

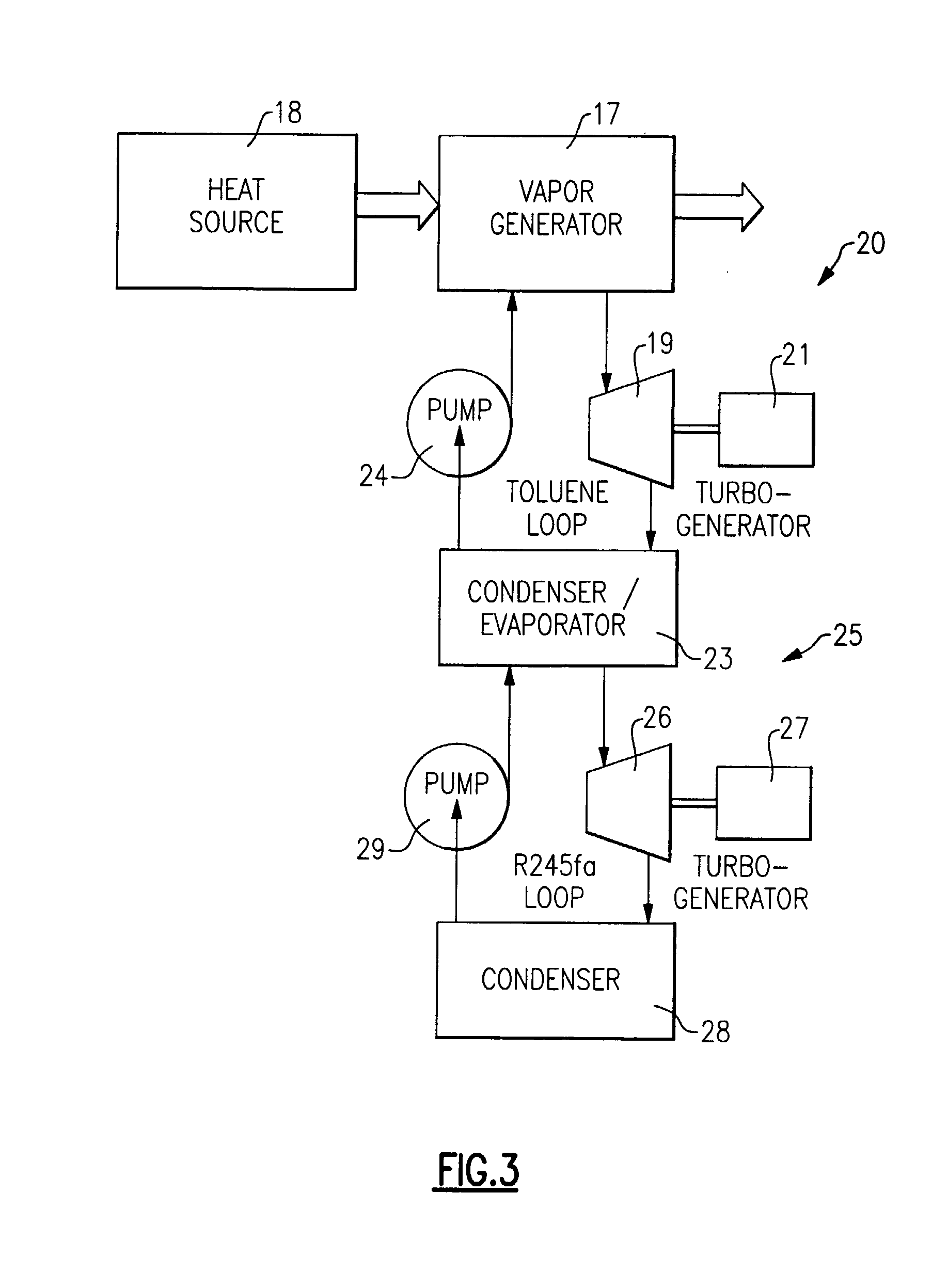

Cascaded Organic Rankine Cycles for Waste Heat Utilization

InactiveUS20080168772A1Improve efficiencyReduce waste heatSteam engine plantsWorking fluidOrganic Rankine cycle

A pair of organic Rankine cycle systems (20, 25) are combined and their respective organic working fluids are chosen such that the organic working fluid of the first organic Rankine cycle is condensed at a condensation temperature that is well above the boiling point of the organic working fluid of the second organic Rankine style system, and a single common heat exchanger (23) is used for both the condenser of the first organic Rankine cycle system and the evaporator of the second organic Rankine cycle system. A preferred organic working fluid of the first system is toluene and that of the second organic working fluid is R245fa.

Owner:INT FUEL CELLS

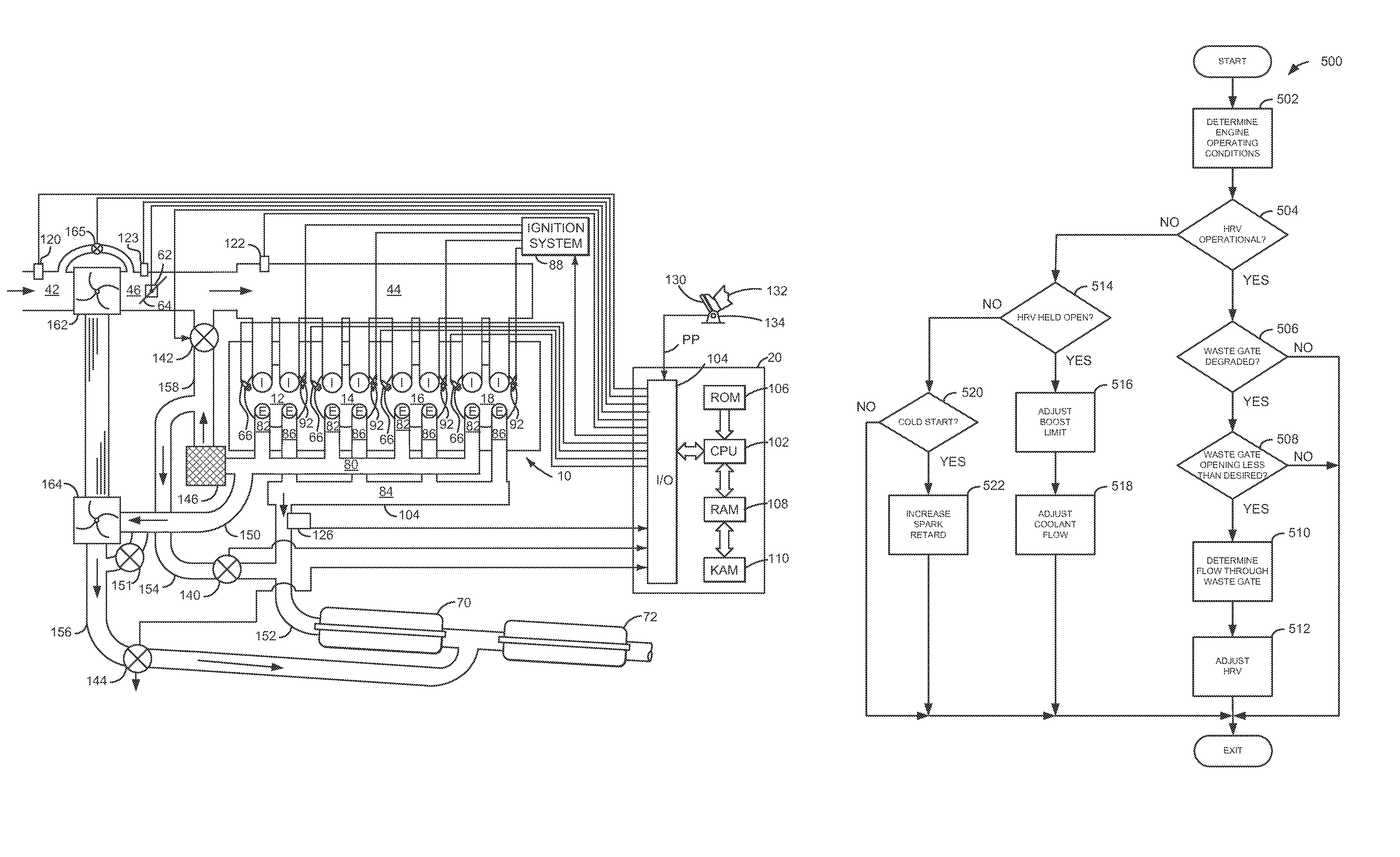

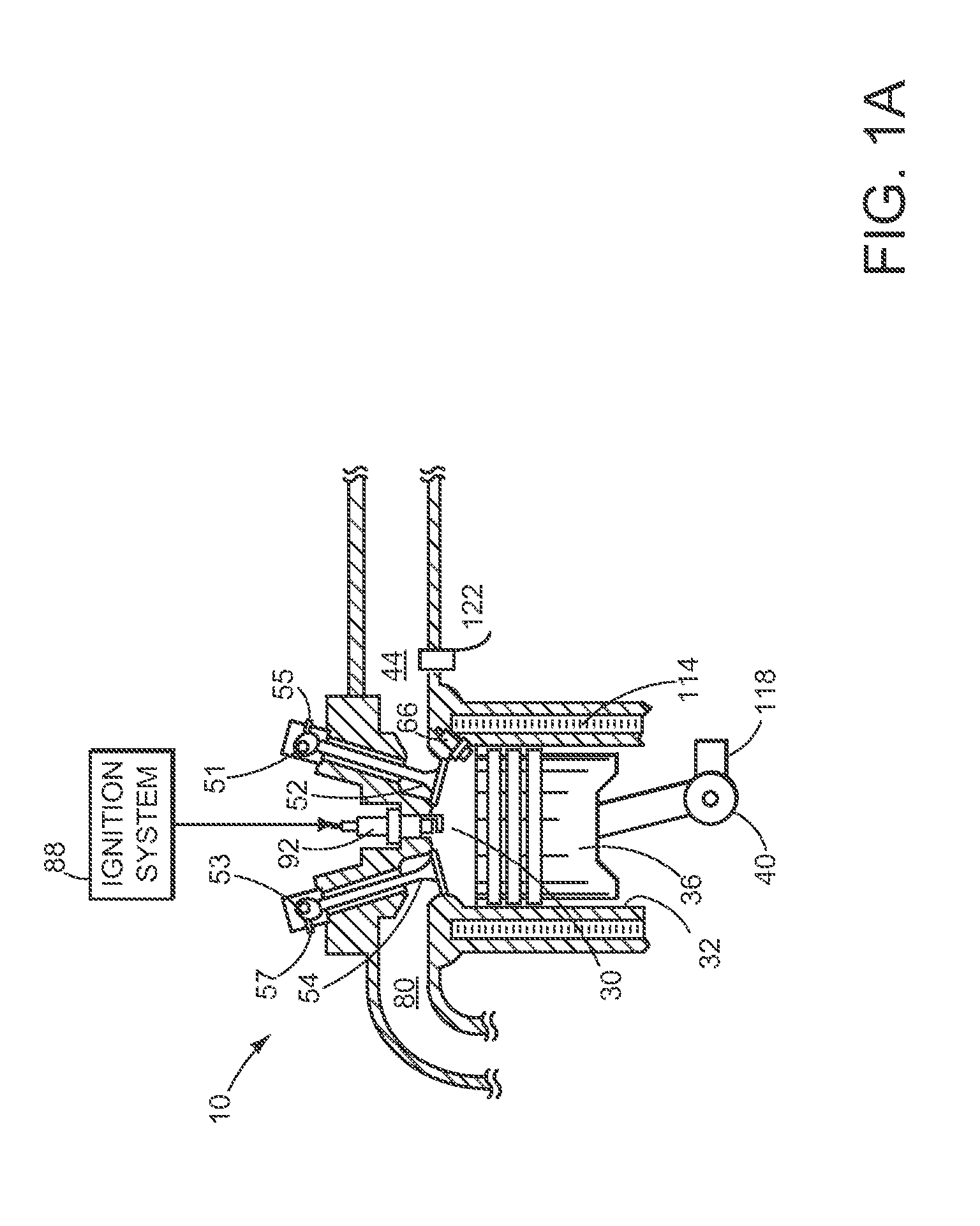

Method and system adjusting an exhaust heat recovery valve

ActiveUS8601811B2Improve engine efficiencyReduce displacementElectrical controlInternal combustion piston enginesTurbochargerProcess engineering

A method for adjusting an exhaust heat recovery valve is presented. In one embodiment, the method may control an amount of boost provided by a turbocharger to an engine.

Owner:FORD GLOBAL TECH LLC

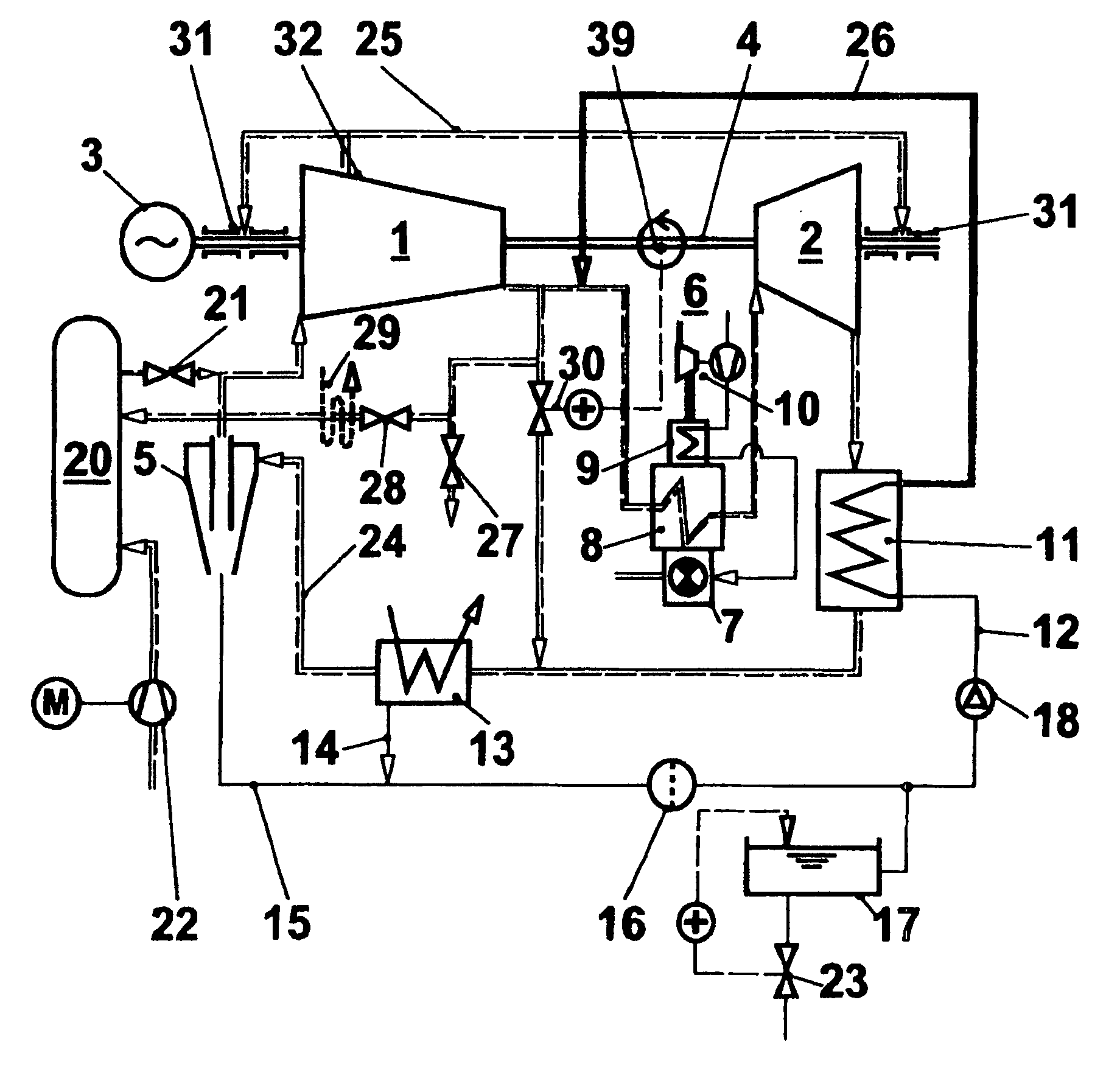

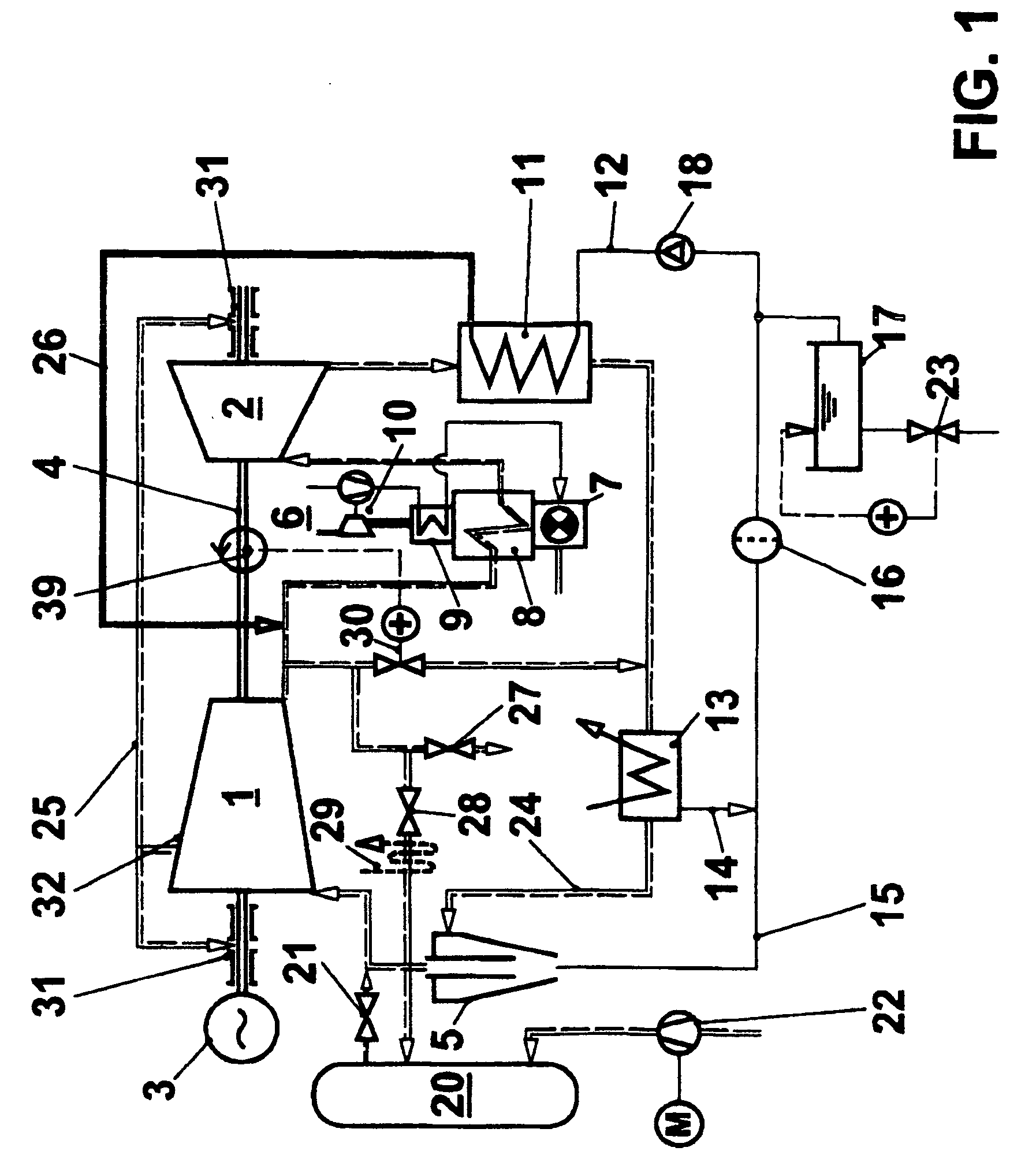

Thermal power process

InactiveUS20050072154A1Increased processing pressureStrong dimensionSteam accumulatorsGas turbine plantsCompression deviceEngineering

In a power generation unit, especially in a gasturbo group, a gaseous process fluid is guided in a closed cycle. The gaseous process fluid flows through a compression device (1), a heater (6) and an expansion device (2), especially a turbine. Downstream from the expansion device at least one heat sink (11, 13) is arranged in which the gaseous process fluid is cooled before it is returned to the compressor device (1). At least one heat sink includes a waste heat steam generator in which an overheated amount of steam (26) is generated that is added to the compressed gaseous process fluid. Together with the gaseous process fluid the steam flows through the heater (6) if necessary and is expanded together with it. The expanded steam condenses in the waste heat steam generator (11) and another heat sink (13); the condensate is processed in a filter (16) and is returned to the waste heat steam generator (11) under pressure via a feed pump (18). Due to the closed process any kind of process fluid and process filling for controlling performance can be used.

Owner:ALSTOM TECH LTD

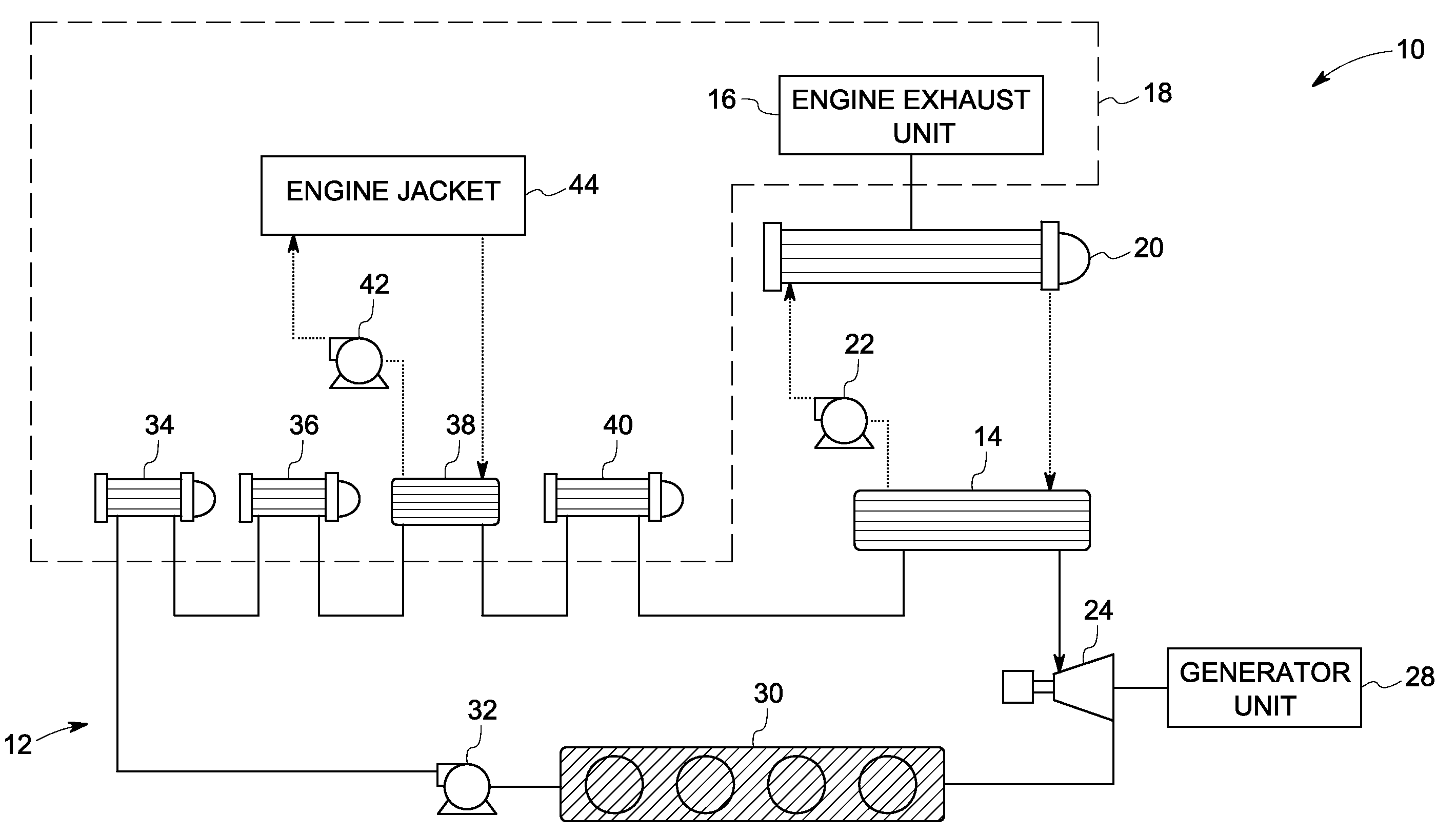

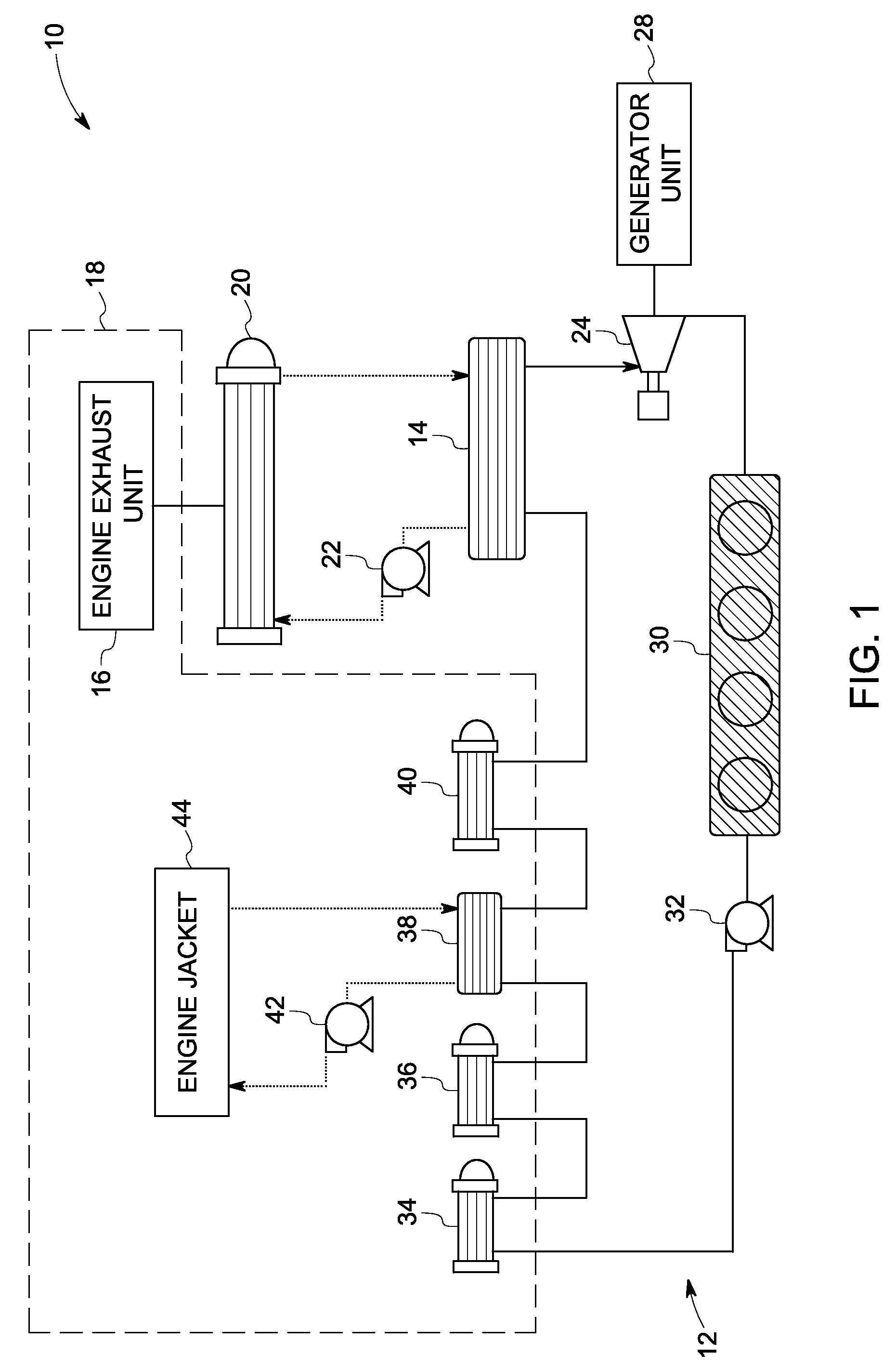

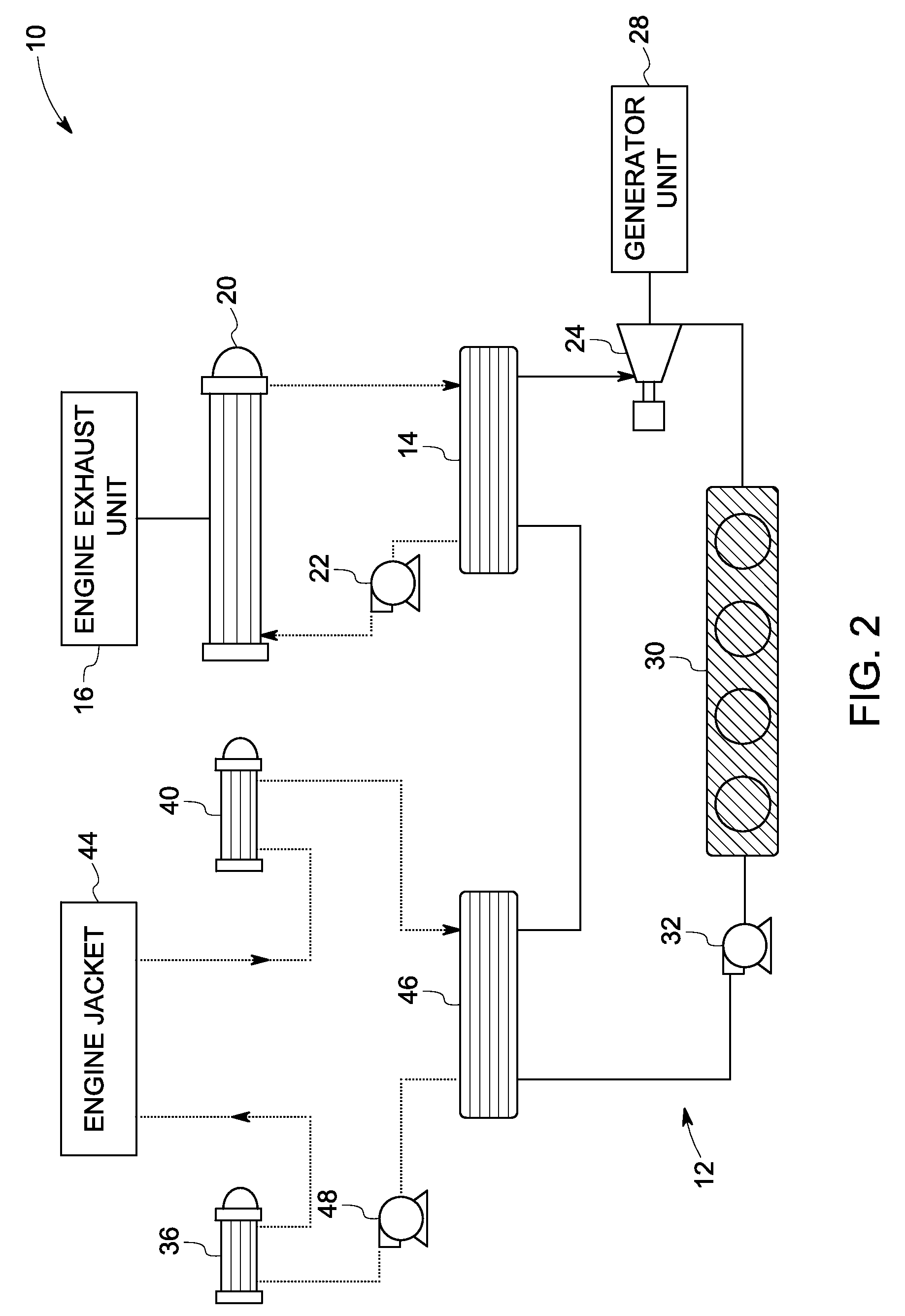

System for recovering waste heat

A waste heat recovery system includes a heat generation system including at least two separate heat sources having different temperatures. A rankine cycle system is coupled to the at least two separate heat sources and configured to circulate a working fluid. The rankine cycle system is coupled to at least one heat source and another heat source among the at least two separate heat sources. The rankine cycle system is configured to remove heat from the at least one heat source to partially vaporize or preheat the working fluid; and remove heat from the other heat source to vaporize or superheat the working fluid.

Owner:GENERAL ELECTRIC CO

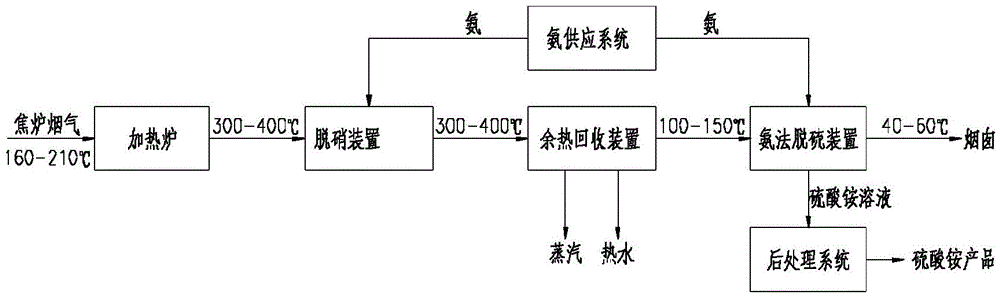

Coke oven flue gas desulfurization, denitration and waste heat recovery integrated method

InactiveCN104923046ASimple processWork lessDispersed particle separationEnergy inputFlue gasReaction temperature

The invention relates to a coke oven flue gas desulfurization, denitration and waste heat recovery integrated method. Flue gas from a coke oven firstly enters a heating furnace to be heated to 300 to 400 DEG C, and then the flue gas enters a denitration device for removing nitrogen oxide in the flue gas through a denitration reducer and a denitration catalyst, wherein the denitration reducer is ammonia; and the flue gas discharged from the denitration device is subjected to heat recovery through a waste heat recovery device and cooled to 100 to 150 DEG C, and then the flue gas enters an ammonia desulfurization device for removing sulfur dioxide in the flue gas. Both a desulfurization absorbent and the denitration reducer in the method are ammonia, and public ammonia is supplied to a system, so that operation and maintenance work is reduced. The heating furnace for heating and the waste heat recovery device are arranged, so that the flue gas temperature reaches the optimal denitration and desulfurization reaction temperatures respectively, relatively high denitration and desulfurization efficiency can be achieved, and flue gas waste heat can be recycled for greatly reducing the operation cost of coke oven flue gas treatment.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

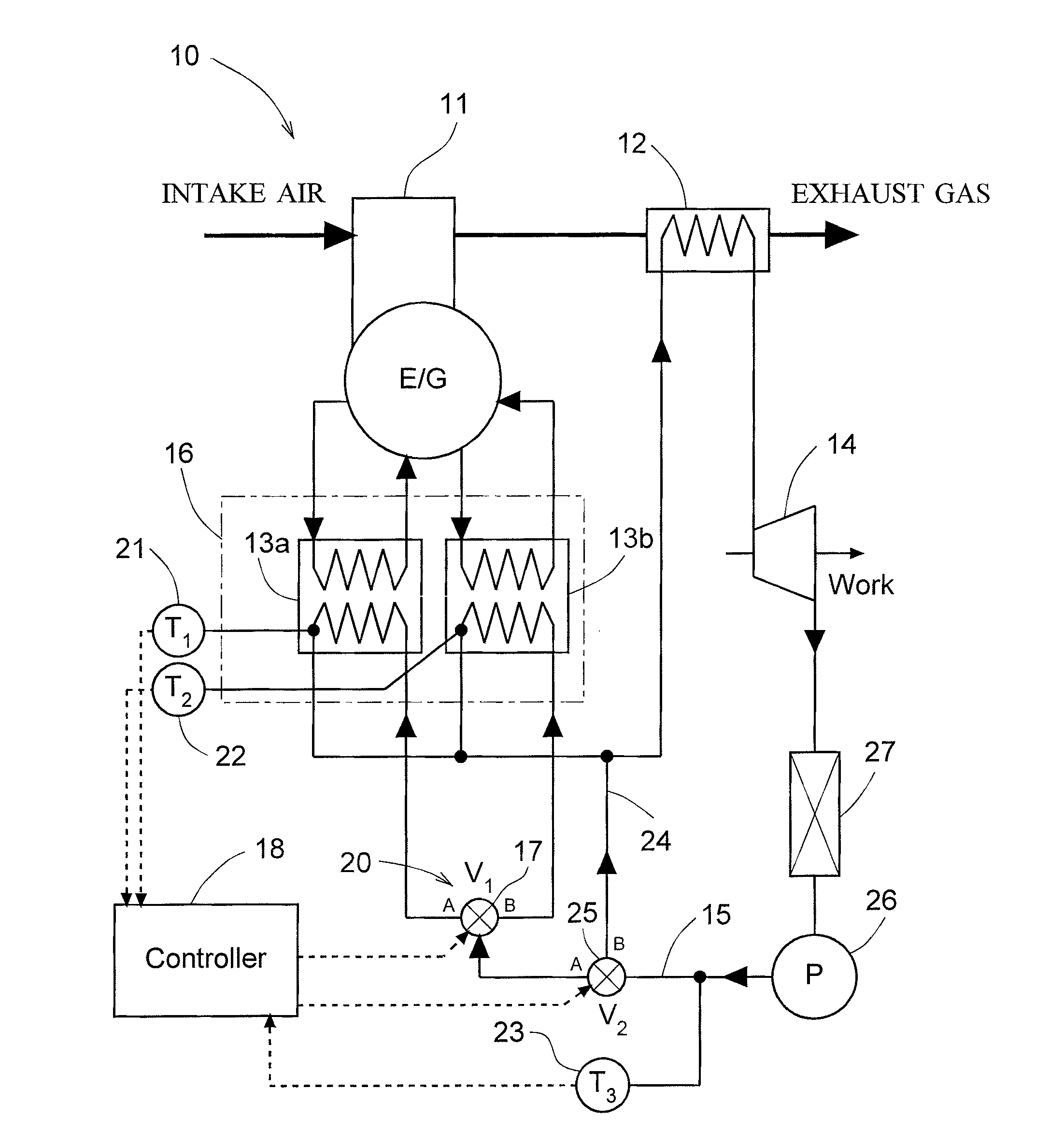

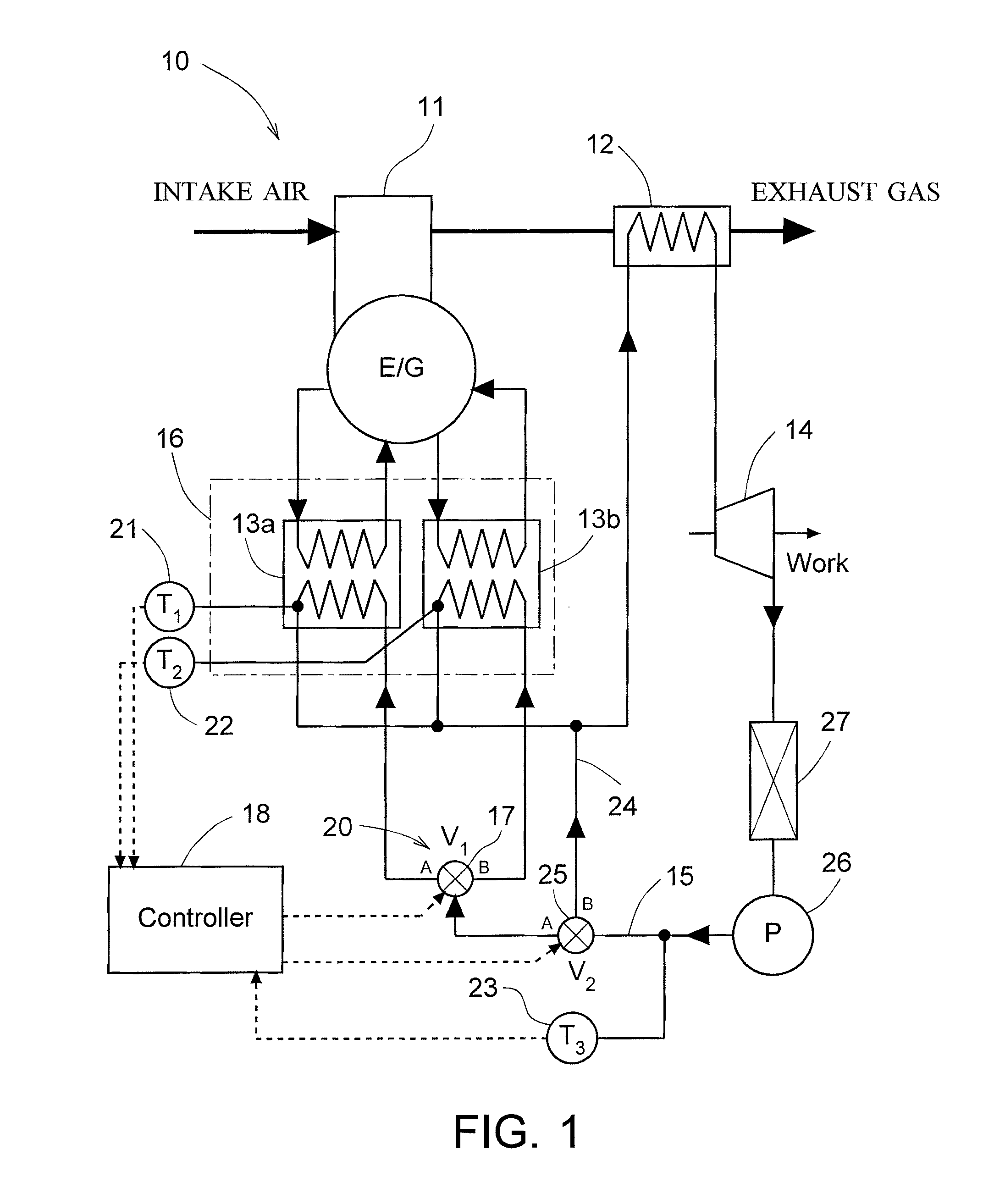

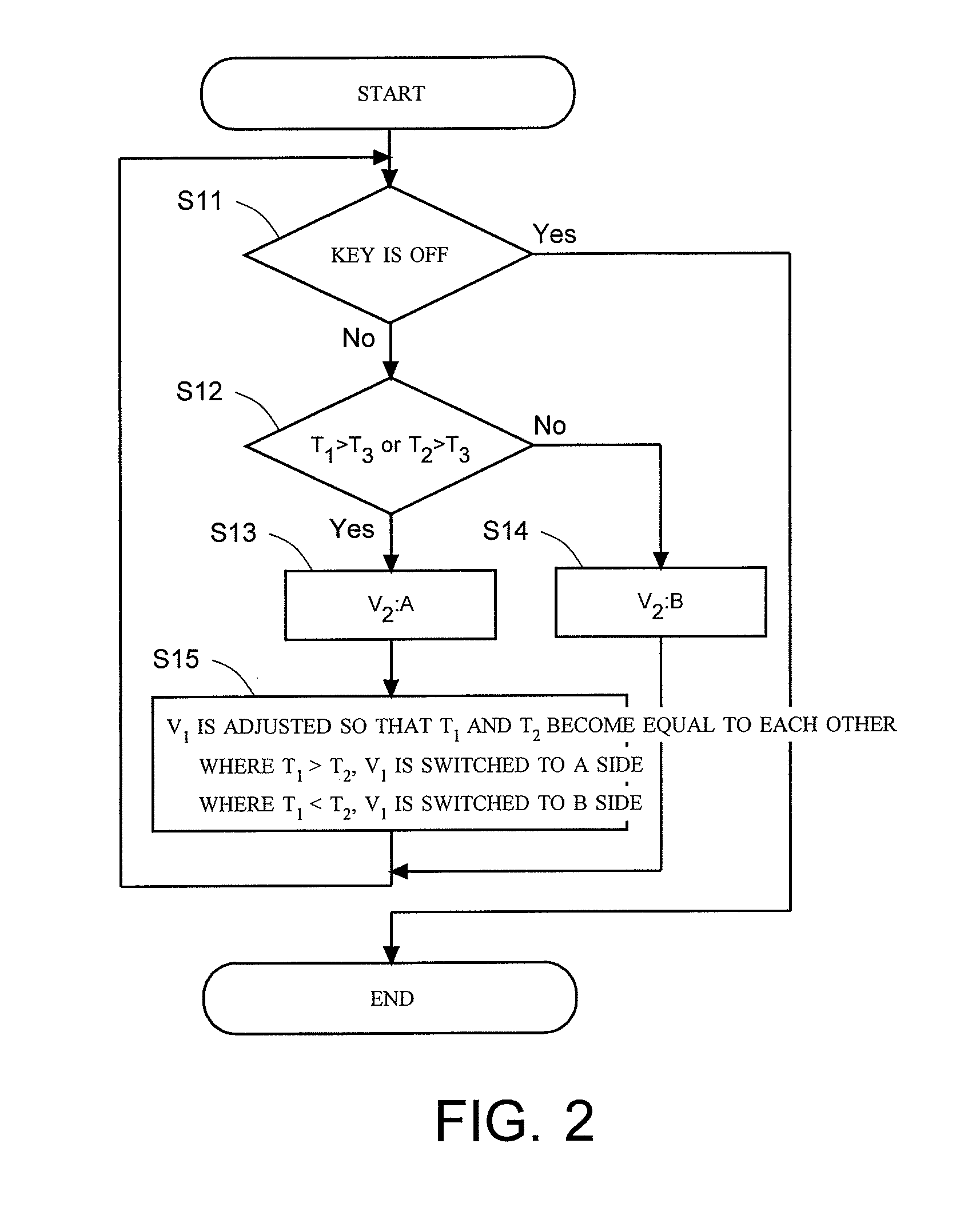

Waste heat recovering device

InactiveUS20110005477A1Efficient waste heat recoveryGood effectLiquid coolingInternal combustion piston enginesWorking fluidEngineering

The present invention provides a waste heat recovering device capable of recovering waste heat with good efficiency from various heat sources in an internal combustion engine. The waste heat recovering device for driving an expander 14 by evaporating a working fluid by waste heat of an internal combustion engine 11 includes: a working fluid circulation flow path 15 in which the working fluid of the expander 14 is caused to circulate; a high-temperature heat exchanger 12 for heating the working fluid flowing in the working fluid circulation flow path 15 by a high-temperature fluid such as exhaust gas of the internal combustion engine 11; a low-temperature heat exchanger group 16 having, for each of low-temperature fluids such as cooling water and oil of the internal combustion engine 11, a low-temperature heat exchanger 13a, 13b for heating the working fluid flowing in the working fluid circulation flow path 15 by any one of the low-temperature fluids, the low-temperature heat exchangers 13a, 13b being disposed in parallel with each other; a flow rate control valve 17 that controls a flow rate of the working fluid flowing into each low-temperature heat exchanger 13a, 13b of the low-temperature heat exchanger group 16; and control means 18 for controlling the flow rate control valve 17.

Owner:ISUZU MOTORS LTD

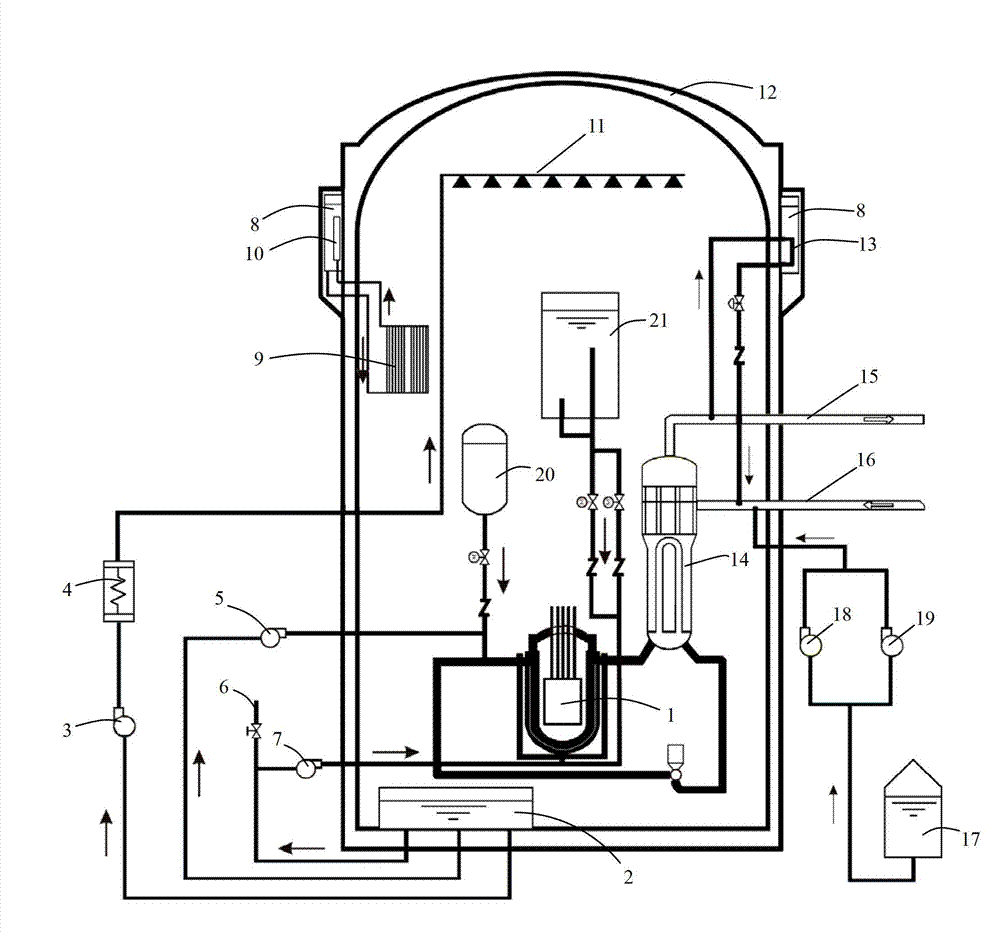

Active-passive combined reactor core residual heat removal system for nuclear power station

ActiveCN102903404AReduced risk of serious accidentsGuaranteed completeness of security functionsNuclear energy generationCooling arrangementNuclear powerNuclear engineering

The invention relates to an active-passive combined reactor core residual heat removal system for a nuclear power station. The active-passive combined reactor core residual heat removal system comprises a safety injection system, a containment spraying system, an auxiliary water supply system, a reactor cavity water injection system, a secondary side passive residual heat removal system, a passive containment heat leading-out system and related valves and pipelines. The active-passive combined reactor core residual heat removal system provided by the invention realizes three safety functions of controlling reactivity, discharging reactor core heat and containing radioactive substance when an accident occurs in an active-passive combined multi-redundancy diversity manner. The active-passive combined reactor core residual heat removal system provided by the invention can completely realize the safety functions of safety injection and safety spraying under the condition that the accident occurs in a nuclear power plant, reactor cavity water injection under the serious accident working condition and the like, effectively improve reliability of a safety system, enhance coping capability of the safety system under the working condition that the accident occurs in the nuclear power station, can effectively prevent and relieve the serious accident, reduce the reactor core melting probability and risk probability of large-scale radioactivity release and greatly improve safety performance of the nuclear power station.

Owner:CHINA NUCLEAR POWER ENG CO LTD

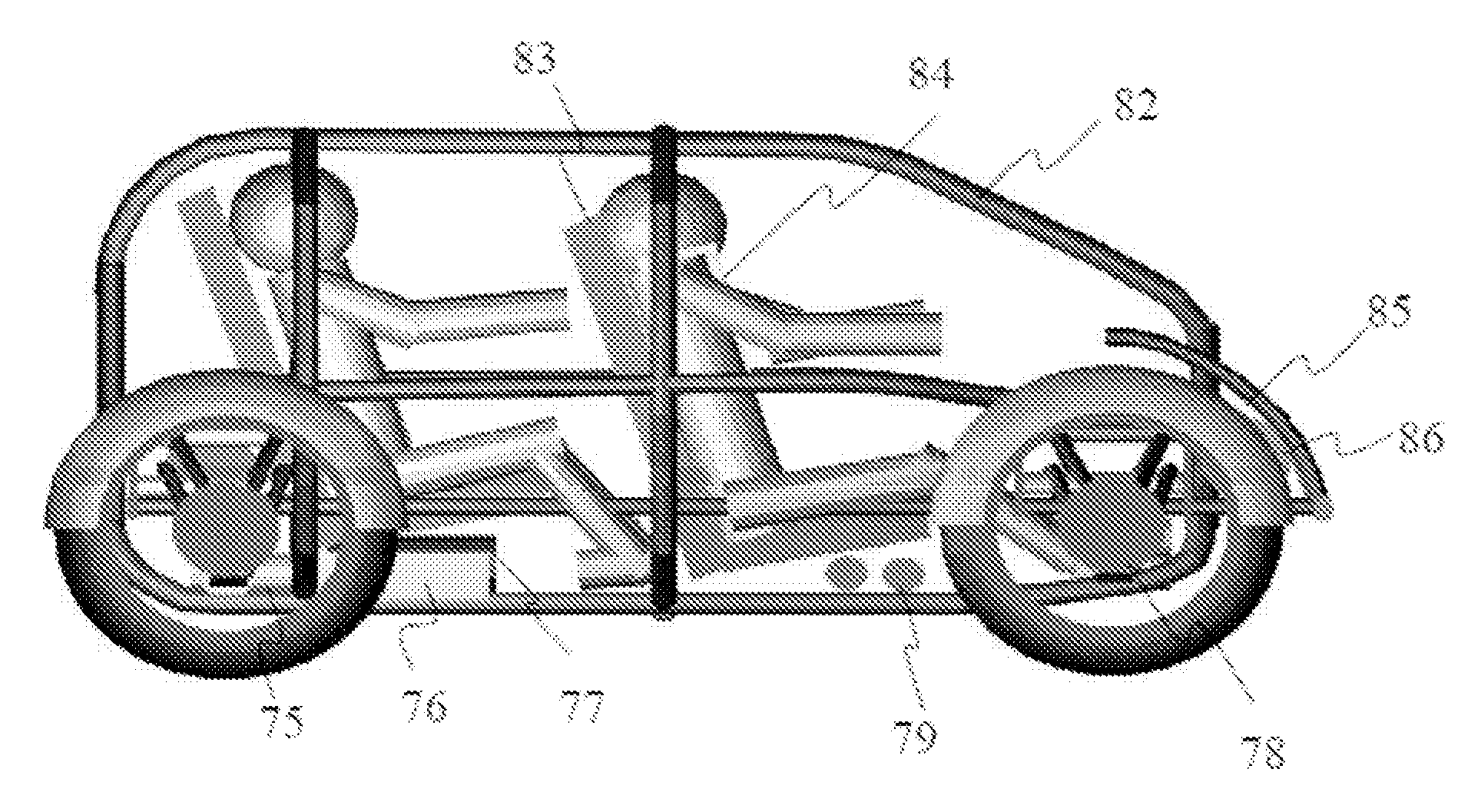

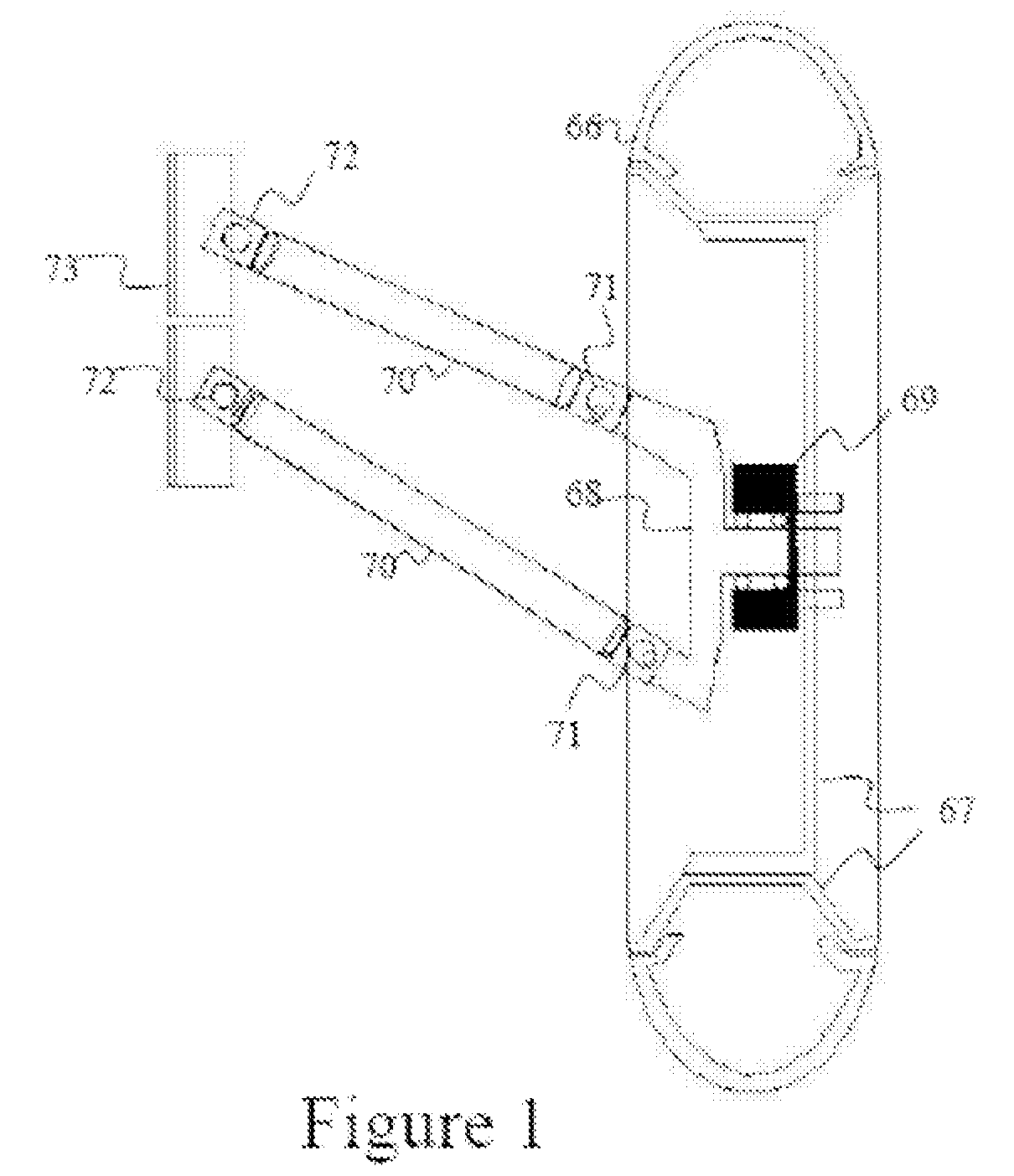

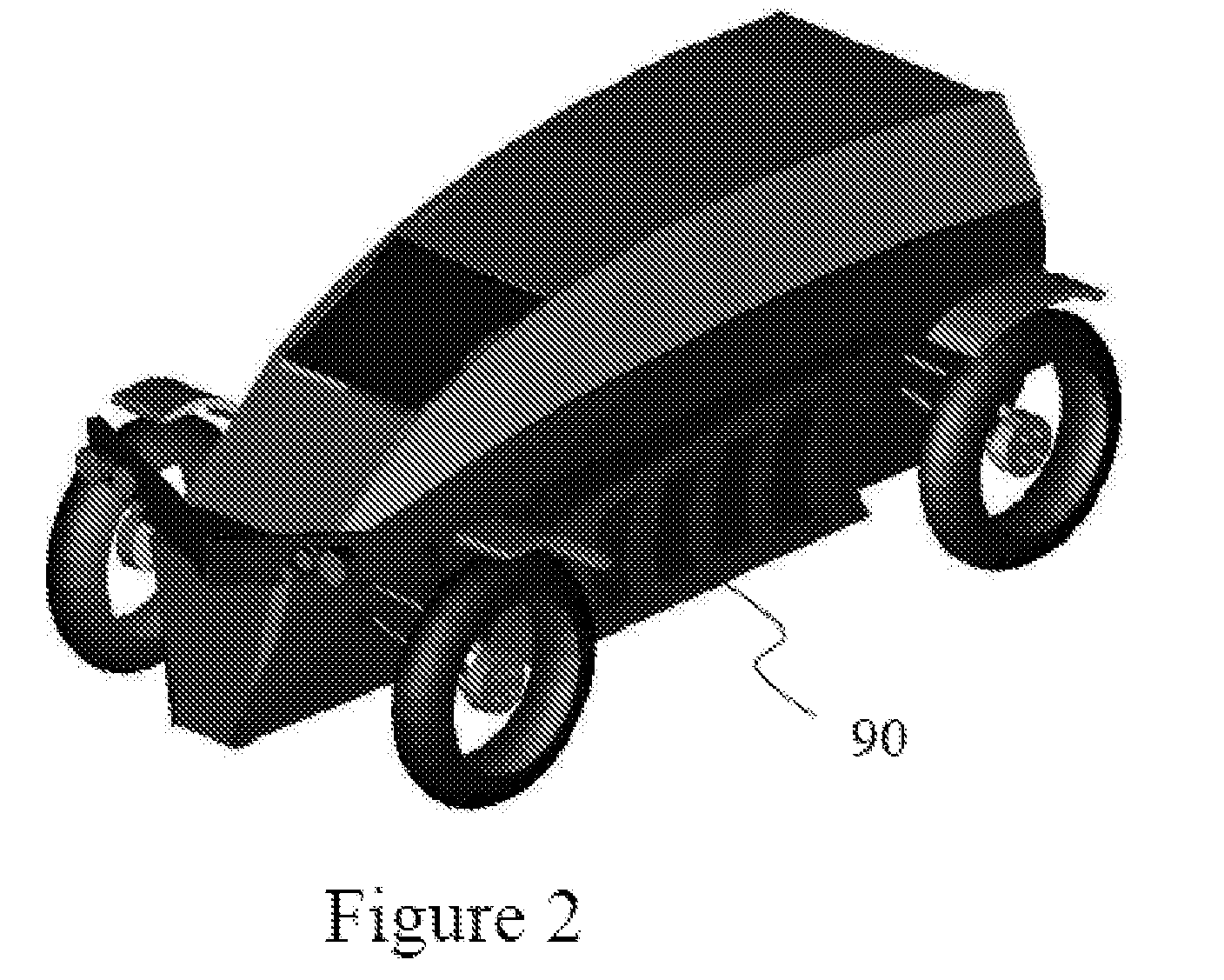

Safe, Super-efficient, Four-wheeled Vehicle Employing Large Diameter Wheels with Continuous-Radius Tires, with Leaning Option

InactiveUS20080223637A1Advanced cornering capabilityAdded driving excitementMechanical machines/dredgersUnderstructuresThermal energyDrivetrain

A “super fuel efficient”, safe, low-cost and yet high performance 4-wheeled vehicle is configured with motorcycle wheels and tires having continuous radius tires and of outside diameter (20-26 inches). A special configuration of the invention permits a 4-wheeled vehicle to naturally camber while engaging a corner, or while maneuvering on a slope. Integration of a “short-cycling”, low storage mass hybrid drivetrain into the vehicle, and further, an exhaust heat energy recovery system, secures the efficiency opportunity.

Owner:BARTILSON BRADLEY WAYNE

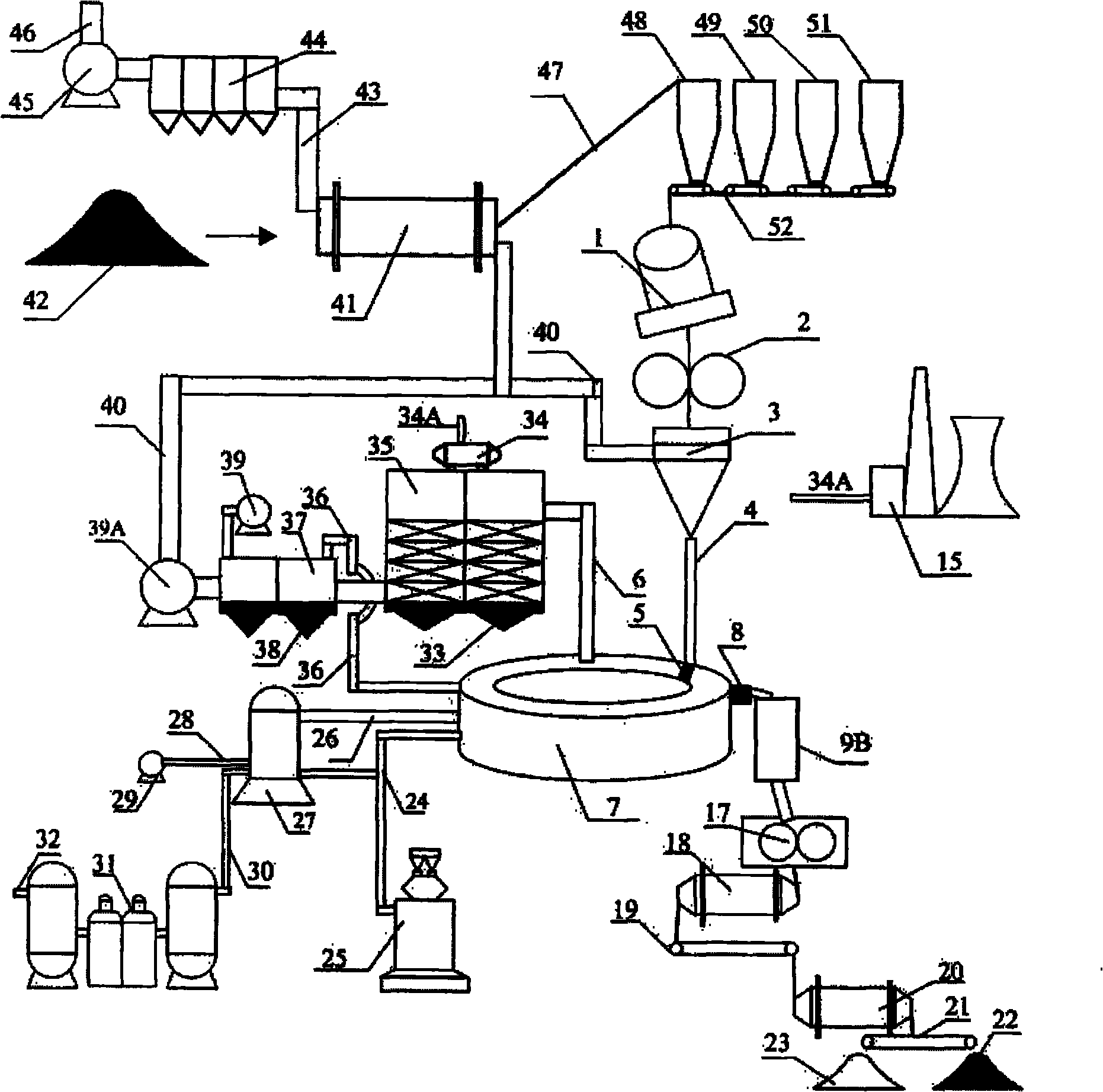

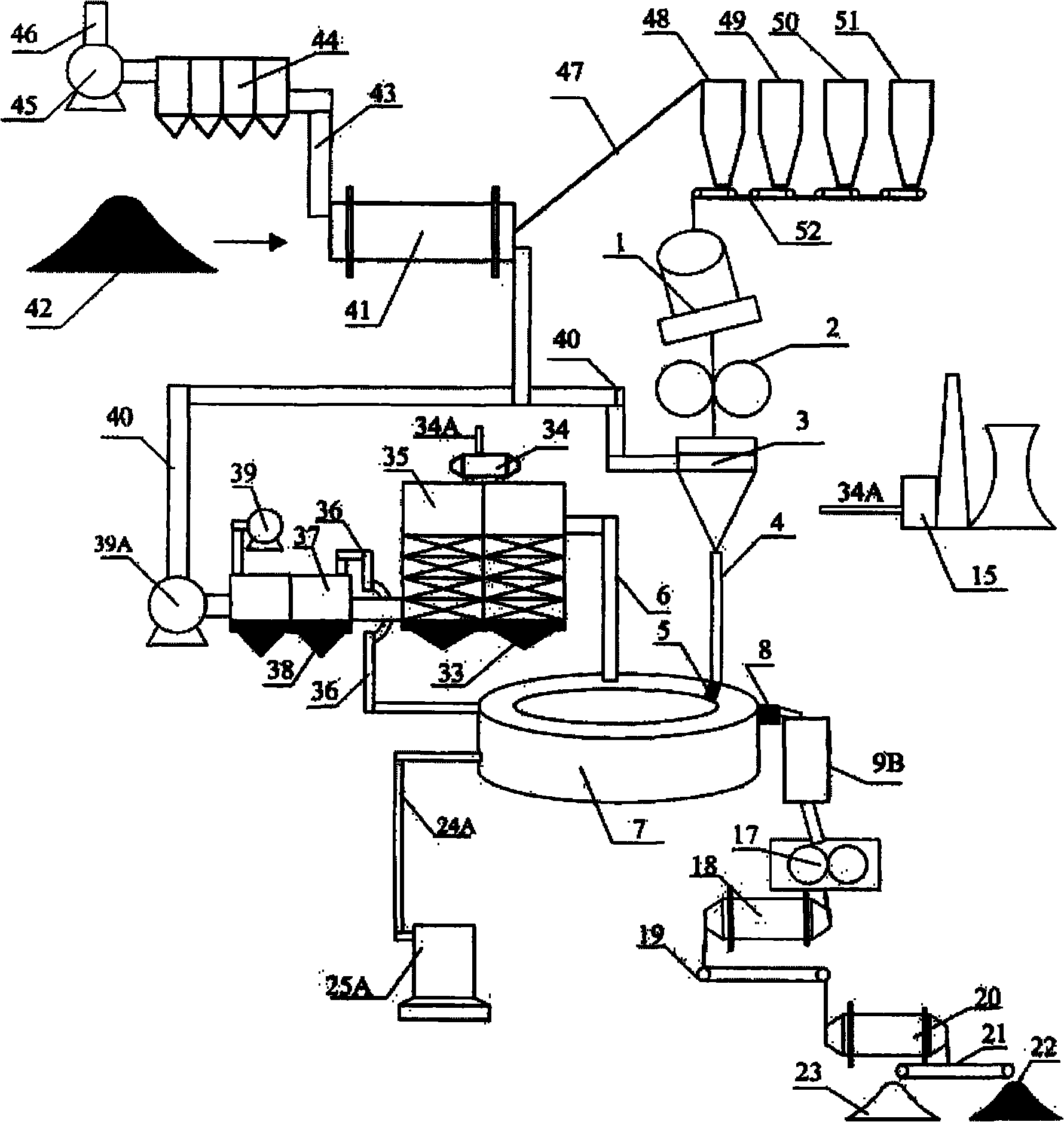

Grading recycling and cascade utilization method of residual heat resources in sintering process and device thereof

ActiveCN101655320AOvercome congenital deficienciesSolve the problem of air leakageLiquid degasificationIncreasing energy efficiencyThermodynamicsEngineering

The invention relates to a method for effectively recycling and utilizing residual heat resources in a sintering process and a device thereof. The invention has the main contents that a fiery sinter ore is filled in a vertical and sealed tank body, air is led from the tank body so as to cool the sinter ore, sensible heat of the sinter ore is almost totally carried by the air and is exhausted fromthe top of the tank body at the same time; and hot air is led into a residual heat boiler to generate steam to synchronously generate power. Compared with the prior sintering residual heat recycling and utilization technology, the invention has higher residual heat recycling utilization ratio, effectively reduces the energy consumption of the sintering procedure with reasonable and effective method, simple apparatus and easy operation, and is relatively favorable for popularization and application in the technical field of residual heat resource recycling and utilization in a metallurgy process.

Owner:NORTHEASTERN UNIV

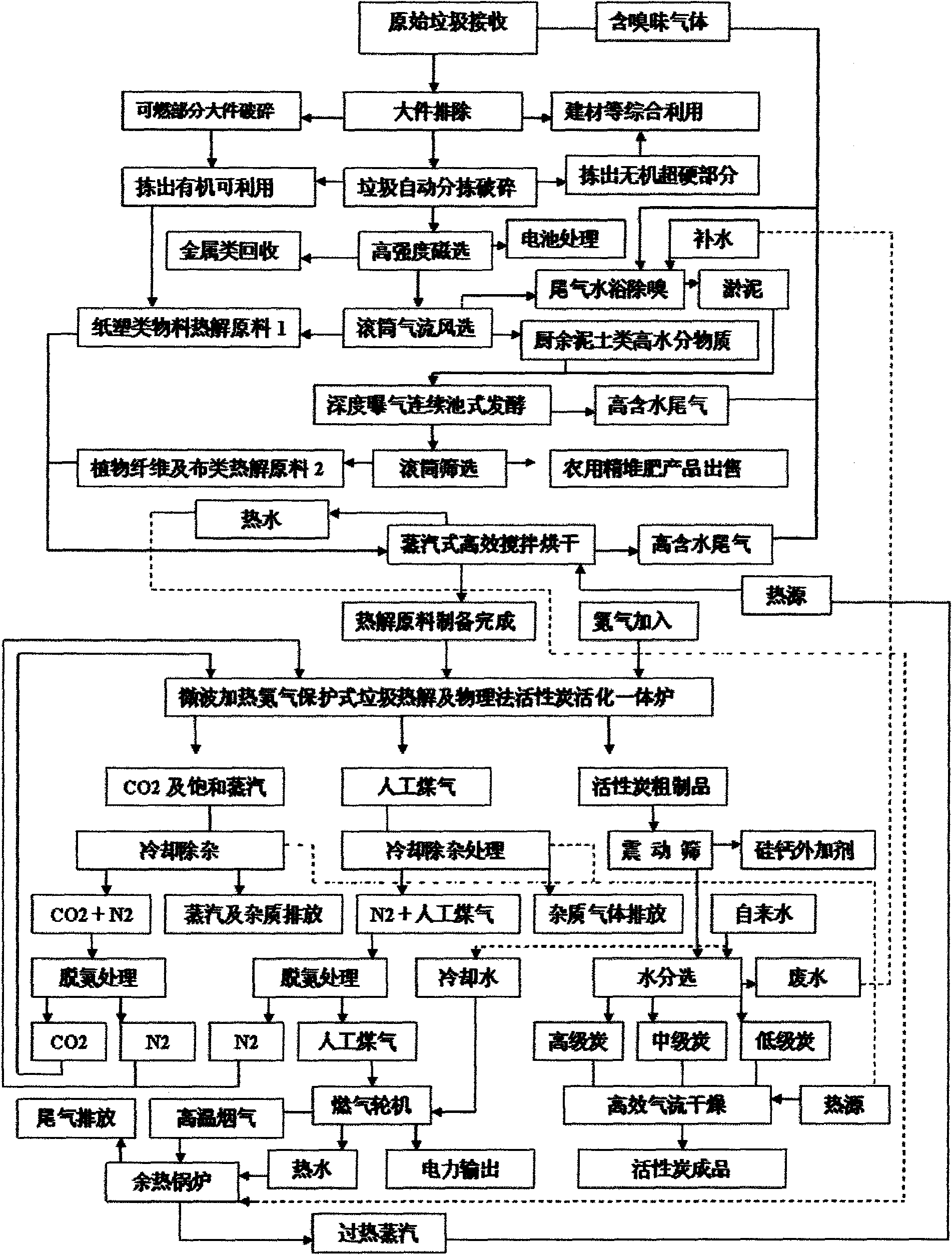

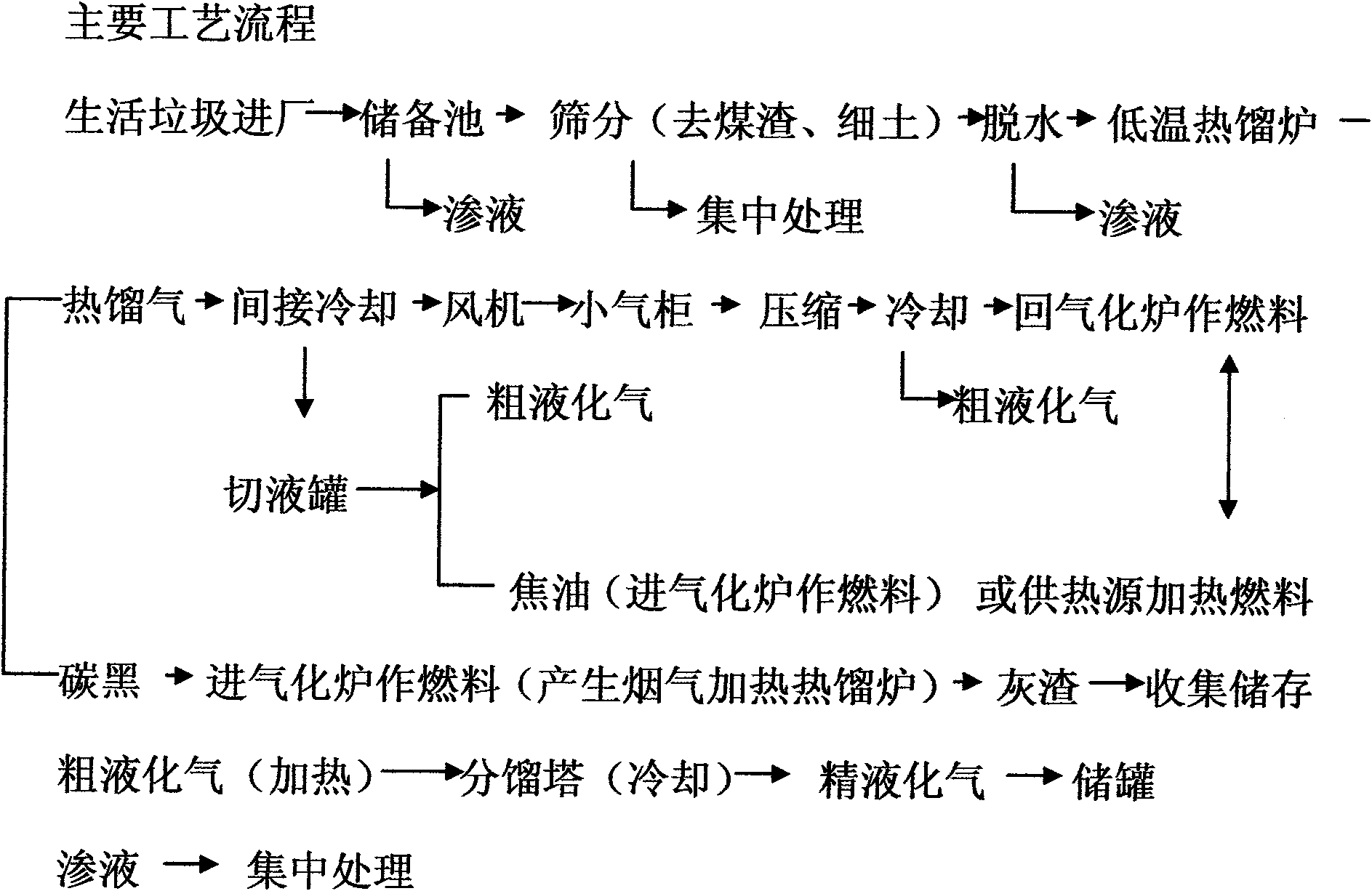

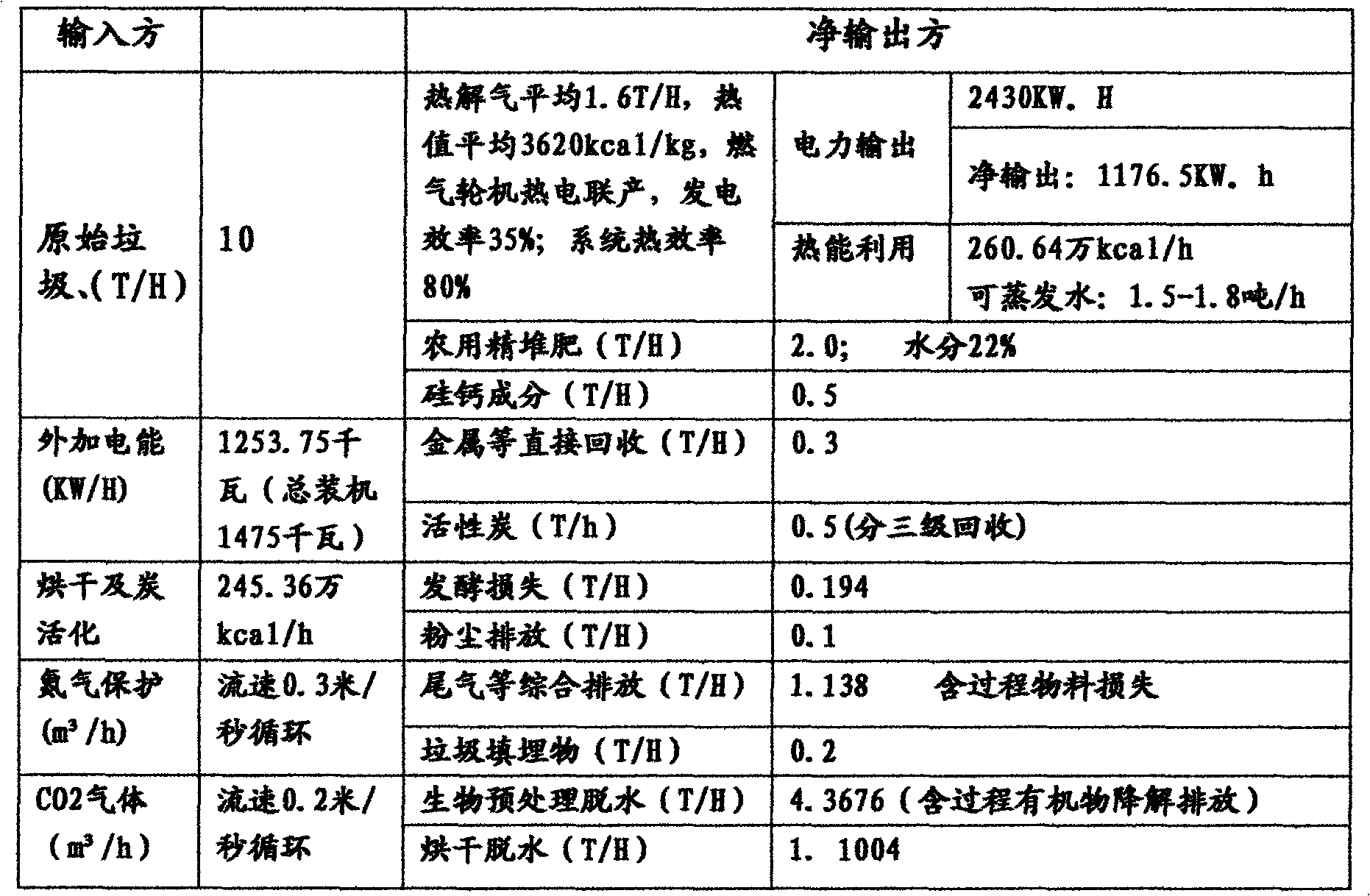

Technological method of comprehensive utilization of separation and pyrolysis treatment of garbage

InactiveCN101618392AAchieve harmless disposal rateReduce energy consumptionDrying solid materials with heatCarbon compoundsEvaporationOxygen

The invention relates to a technological method of comprehensive utilization of separation and pyrolysis treatment of garbage, which solves the problem of comprehensive utilization of separation pretreatment and pyrolysis gas in the process of separation treatment of garbage. The method comprises the following steps: separating and crushing the garbage for secondary classification; classifying the available components in the garbage into three classes, wherein the first class comprises paper, plastic and the like which are used as pyrolysis raw materials 1, the second class comprises the mixture of soil, kitchen wastes and the like, and the third class comprises the mixture of rag, fresh branches, vines and the like; chopping the mixture of the third class, and mixing the chopped mixture of the third class with the mixture of the second class; treating the mixture of the second class and the mixture of the third class by aerobic fermentation, and using penetrant for direct back-spraying and evaporation in high-temperature regions; treating the obtained product by secondary sieving to obtain pyrolysis raw materials 2; mixing and drying the pyrolysis raw materials 1 and the pyrolysis raw materials 2; condensing the generated steam to obtain hot water which back flows into a waste heat boiler of a power generating system to be used as supplemental water; commercializing and recovering the pyrolysis raw materials; and burning the obtained combustible gas for power generation. The invention has the advantages of high recovery rate, low energy consumption and no pollution caused by discharge.

Owner:SHEN ZHEN A MART IND

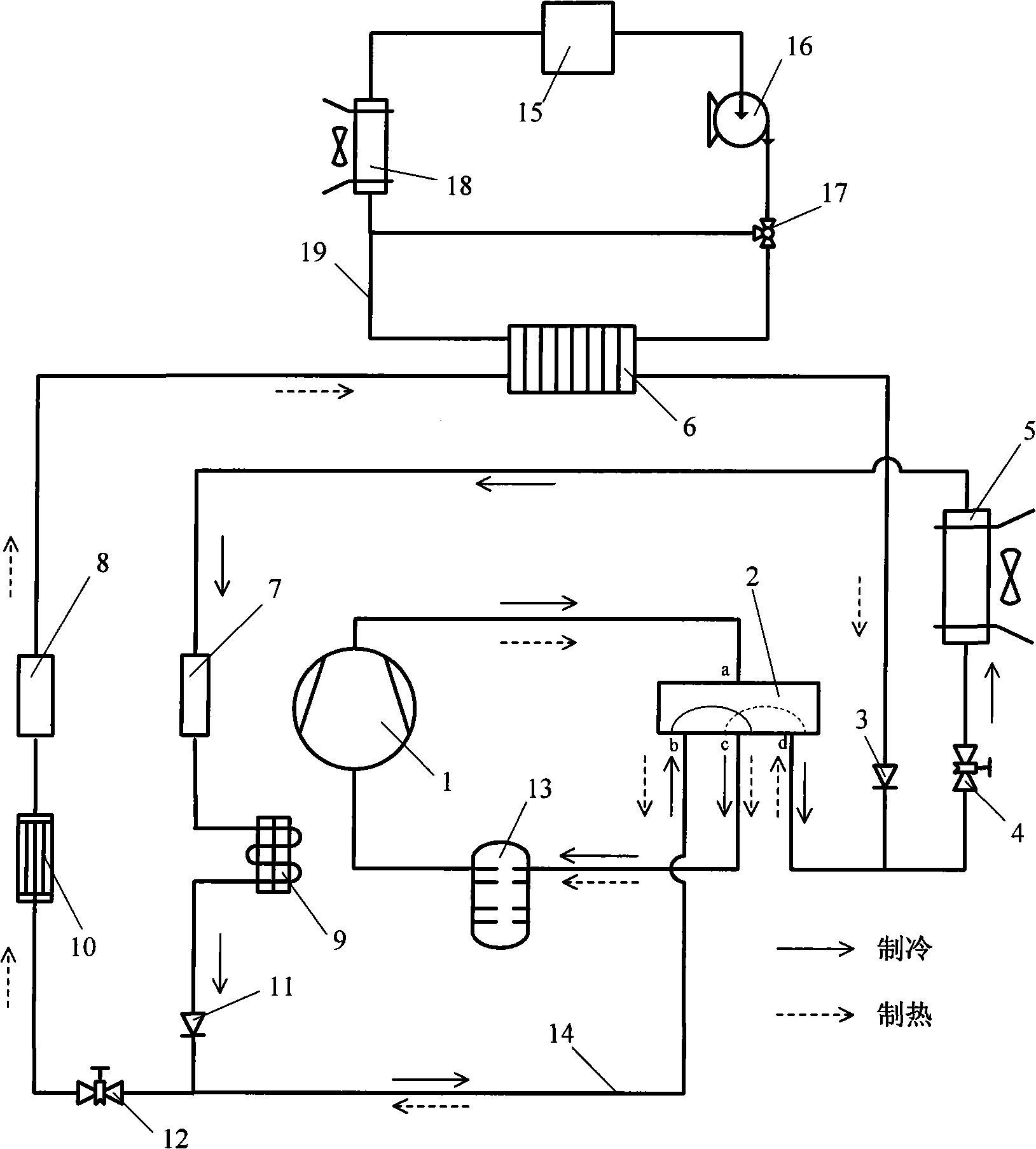

Residual heat pump air conditioner system for fuel-cell vehicle

InactiveCN101279580AAchieve the desired purposeAir-treating devicesHeat recovery systemsFuel cellsVapor–liquid separator

The invention relates to a residual heat pump air conditioning system for fuel cell vehicle, which belongs to the technical field of the air conditioner for fuel cell vehicle. The invention is characterized in that the residual heat pump air conditioning system comprises a refrigerating circuit and a heating circuit, the refrigerating circuit and the heating circuit are connected with a compressor via a four-way valve, an inlet of the four-way valve is connected with an outlet of the compressor, a first outlet and a second outlet of the four-way valve are connected with the refrigerating circuit and the heating circuit, and a third outlet of the four-way valve is connected with the inlet of the compressor via a gas-liquid separator; the heating circuit comprises an external evaporator, the heat side of the external evaporator is connected in a cooling circuit of the fuel cell and the cool side is connected in the heating circuit; the cooling circuit of the fuel cell also comprises an electric control three-way valve, one end of which is connected with the fuel cell via a water pump and a second end and a third end respectively are connected with the inlet and the outlet at the heat side of the external evaporator. The air conditioning system can use the residual heat of the fuel cell for heat supply and has the advantages of energy saving, simple structure and wide adaptability to use area, etc.

Owner:TSINGHUA UNIV

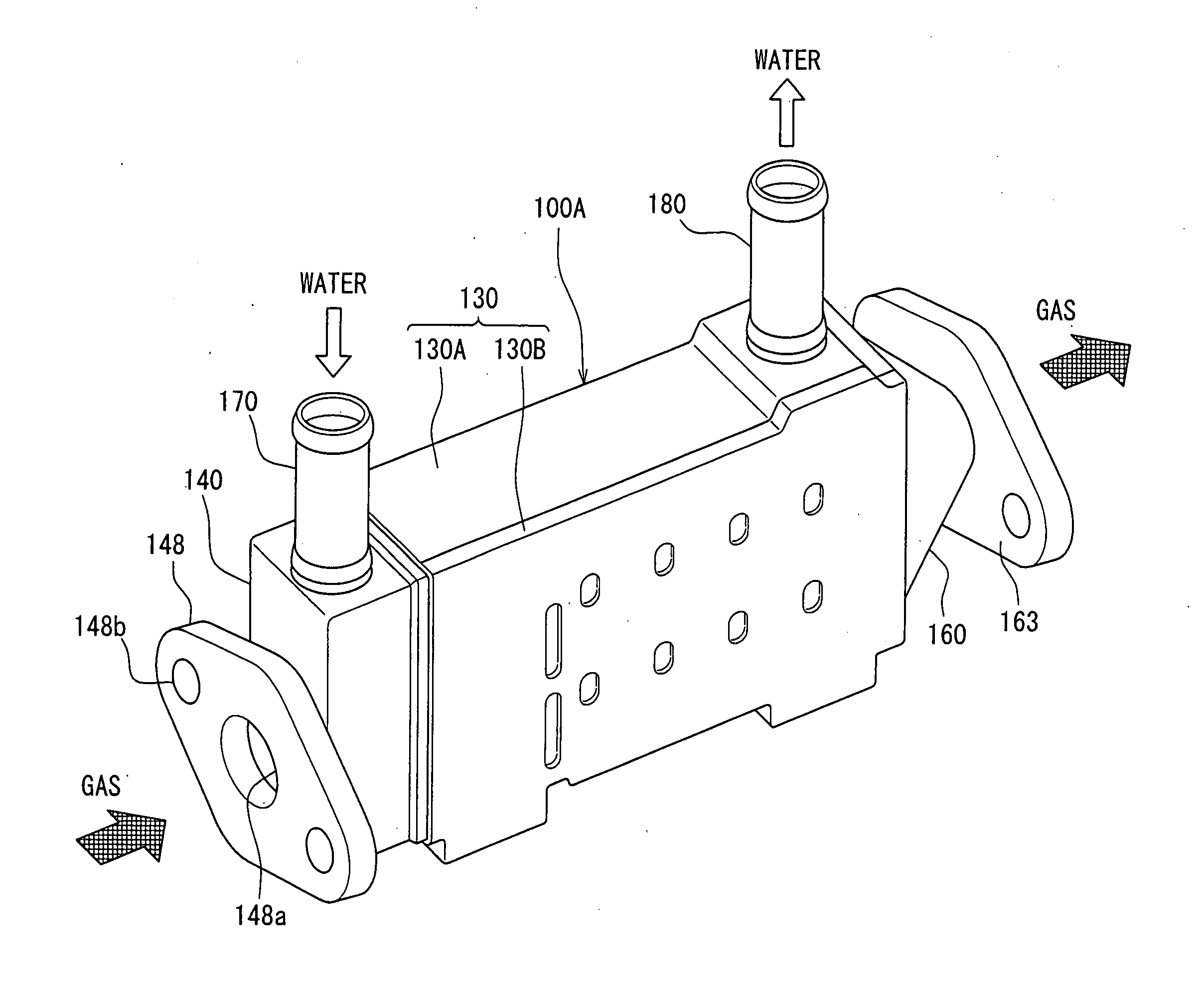

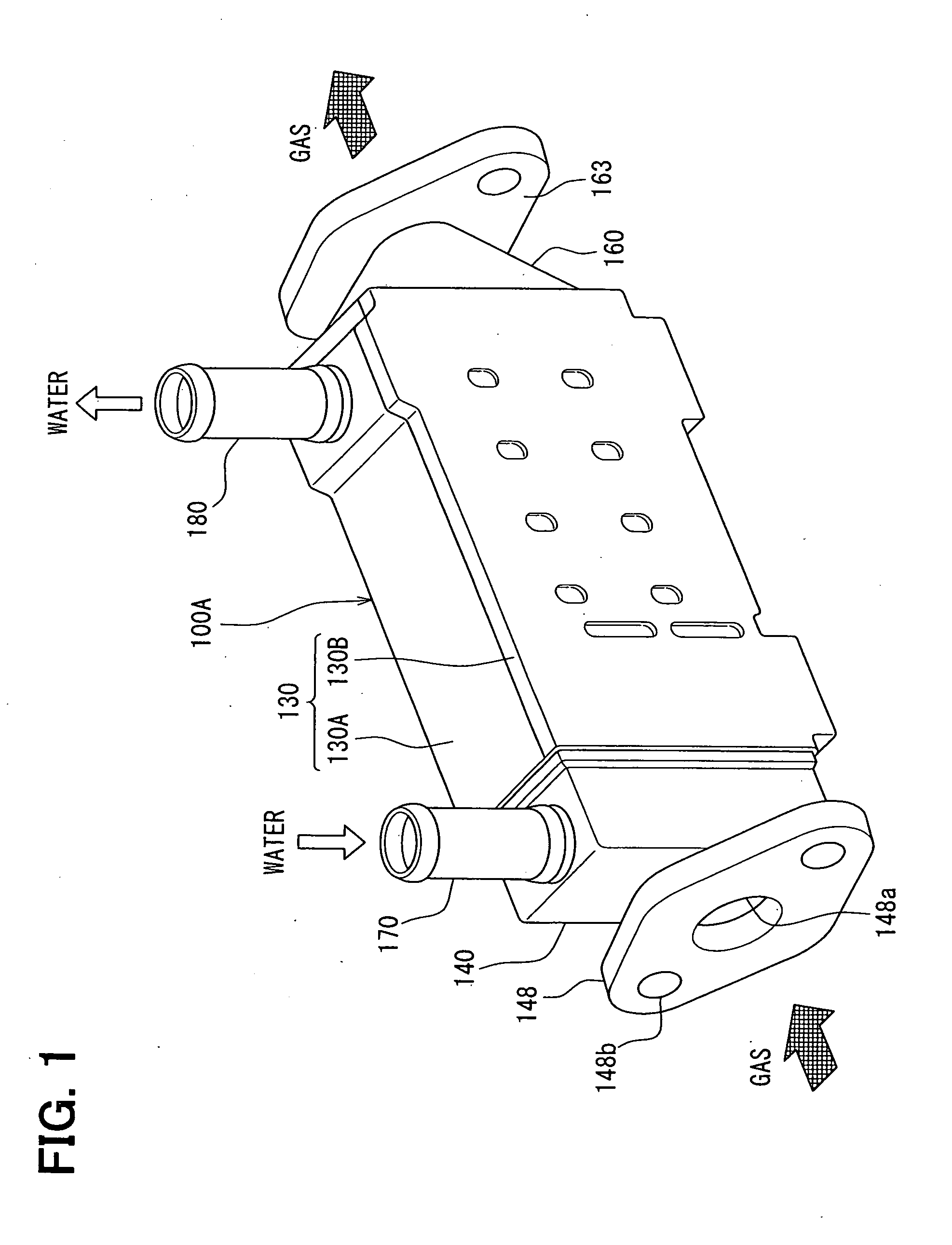

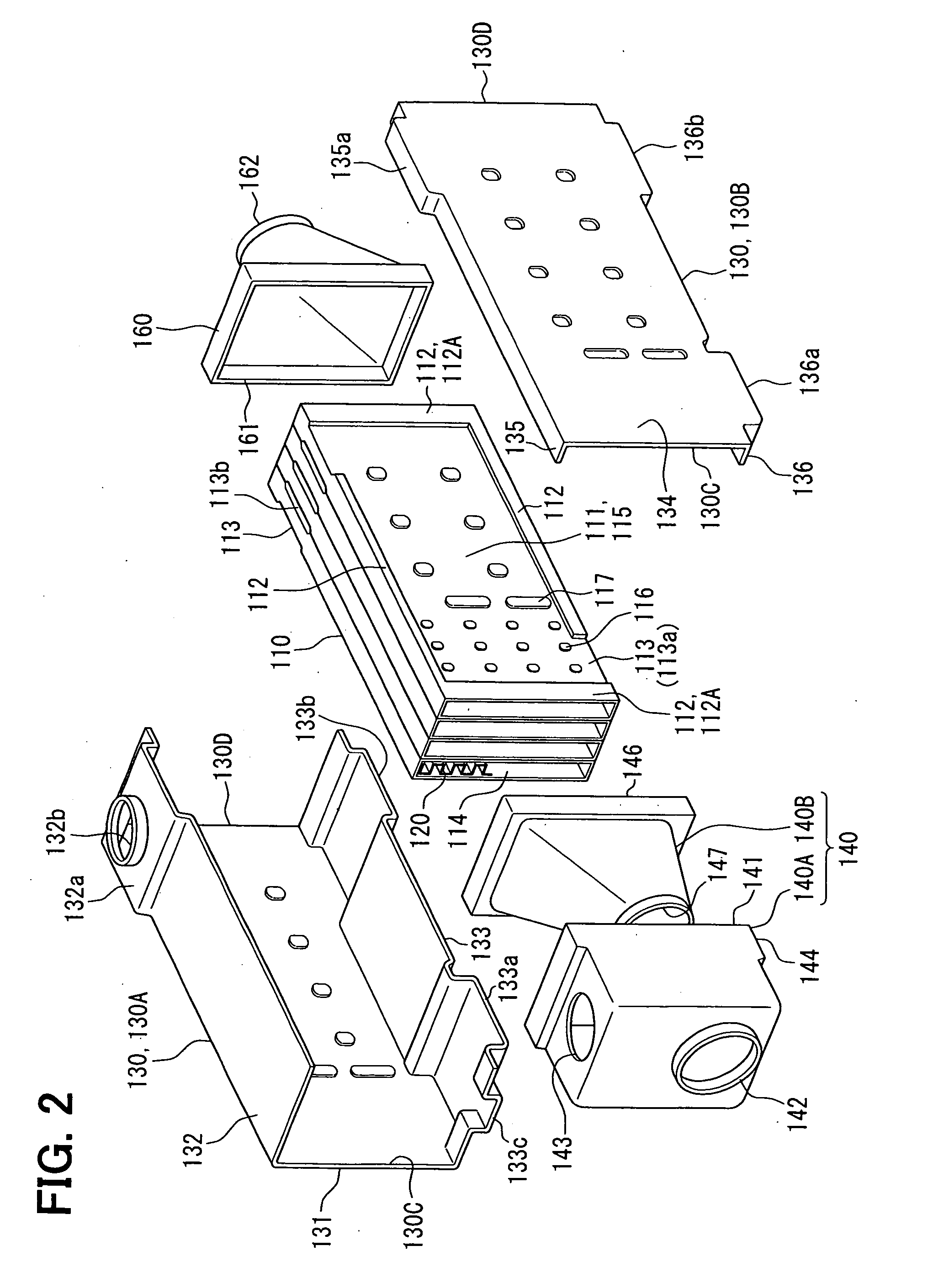

Exhaust heat exchanger

InactiveUS20110247318A1Non-fuel substance addition to fuelInternal combustion piston enginesNuclear engineeringWater tanks

An exhaust heat exchanger includes a water tank accommodating tubes and having an outside space defined outside of the tubes, a gas tank having an exhaust passage and an outside space defined outside of the exhaust passage, a dividing portion to separate the outside space of the water tank from the exhaust passage of the gas tank, and a communication portion. The outside space of the gas tank and the outside space of the water tank communicate with each other through the communication portion.

Owner:DENSO CORP

Short-process comprehensive red mud utilization method and equipment

The invention relates to a short-process environmentally-friendly comprehensive red mud utilization method and equipment for comprehensively utilizing energy, which can be used for refining iron in high-pollution red mud difficult to treat, with high efficiency, high quality and high benefits, and applying the iron to electric furnace steel making or steel casting and the like, without using coke, so as to realize the large-scale comprehensive utilization of the red mud. High-temperature smoke of a revolving bed is used for waste heat generation, secondary-combustion hot wind preheating, pellets preheating and red mud drying, a dry quenching pellet technology is used for applying the heat of high-temperature pellets to waste heat generation so that waste heat is fully utilized, a low-cost pressure swing adsorption oxygen generation technology is utilized, and therefore, the comprehensive energy consumption and the production cost are low. Aluminum silica residues are used for producing high-grade cement or used as the raw material for refractory materials; and Na2O and K2O and other alkaline metallic oxide powder are used for refining metal Na and K, or used for producing the raw materials of fertilizers, or used as chemical raw materials. Accordingly, the problems on environmental pollution, land occupation for stacking and safety due to the red mud are thoroughly solved, and the economic and social benefits are obvious.

Owner:董亚飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com