System for recovering waste heat

a waste heat and waste heat technology, applied in the field of power generation, can solve the problems of large amounts of waste heat simply being dumped into the surroundings, reducing the efficiency of conventional heat recovery systems, and emitted oxides and particulates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

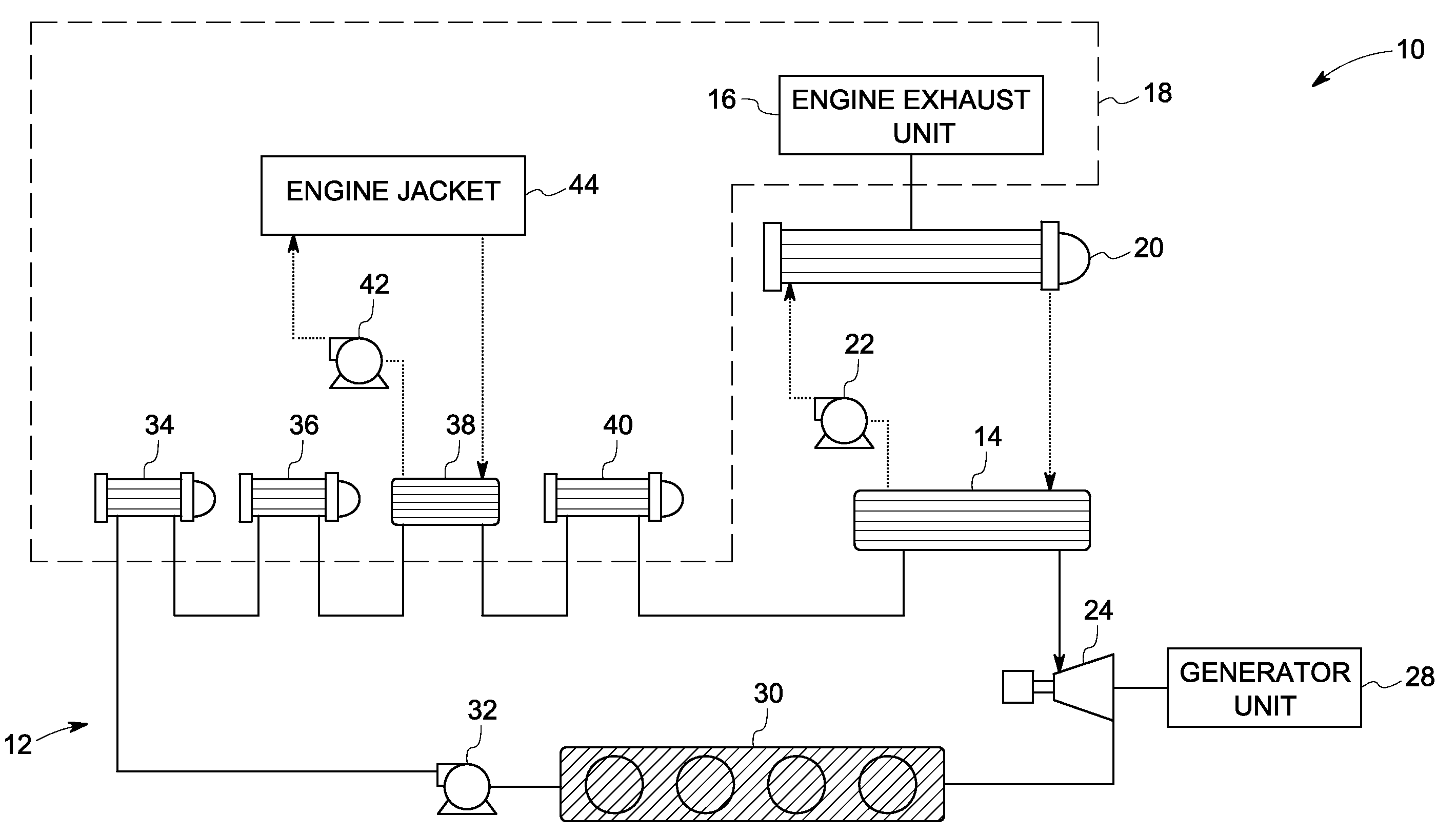

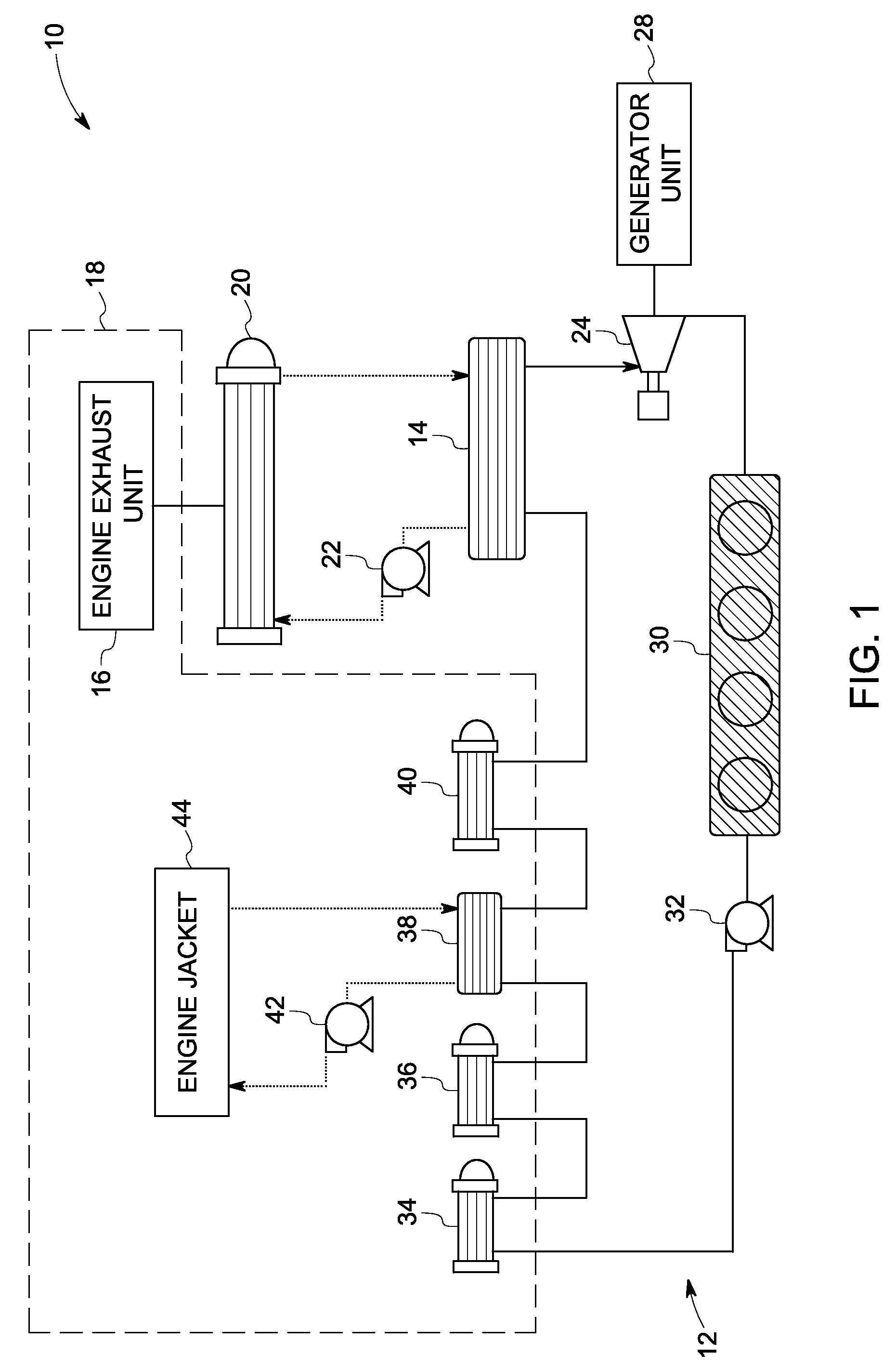

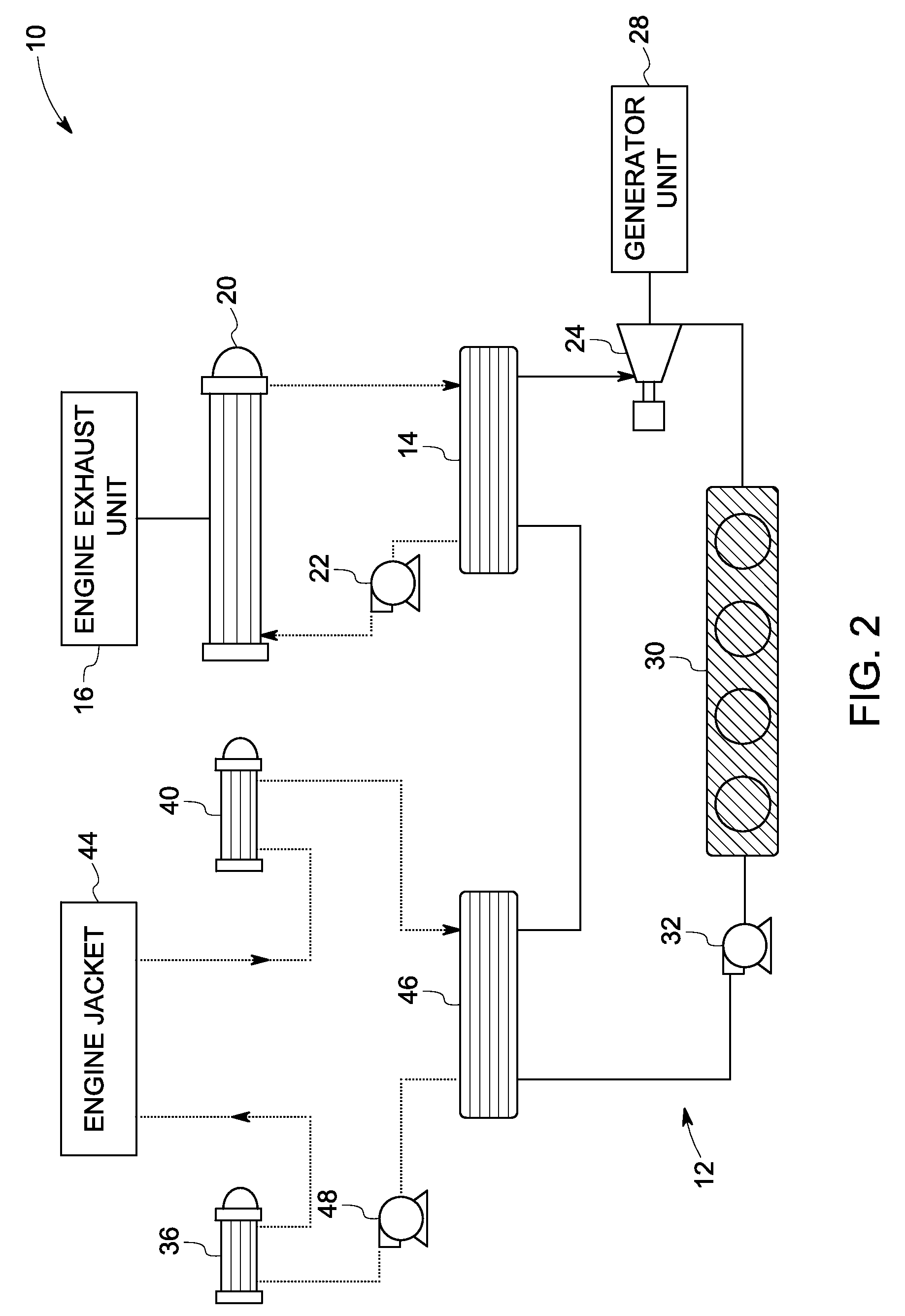

[0016]As discussed in detail below, embodiments of the present invention provide a waste heat recovery system having a heat generation system and one rankine cycle system. The heat generation system includes at least two separate heat sources having different temperatures. The rankine cycle system is coupled to at least two separate heat sources and configured to circulate a working fluid. The rankine cycle system is coupled to at least one heat source among the at least two separate heat sources and configured to remove heat from the at least one heat source to partially vaporize or preheat the working fluid before completely vaporizing or superheating the working fluid. The rankine cycle system is also coupled to another heat source among the at least two separate heat sources and configured to remove heat from the other heat source to completely vaporize or superheat the working fluid. In accordance with the exemplary embodiments of the present invention, the waste heat recovery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com