Method for recovering waste heat of thermal power plant and heating and supplying heat to hot water in a stepping way

A technology of waste heat recovery and cascade heating, which is applied in the direction of steam engine device, combined combustion mitigation, steam application, etc., can solve the problems of non-compliance with the principle of energy cascade utilization and loss of effective energy, so as to improve the comprehensive energy utilization efficiency and reduce the loss of effective energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

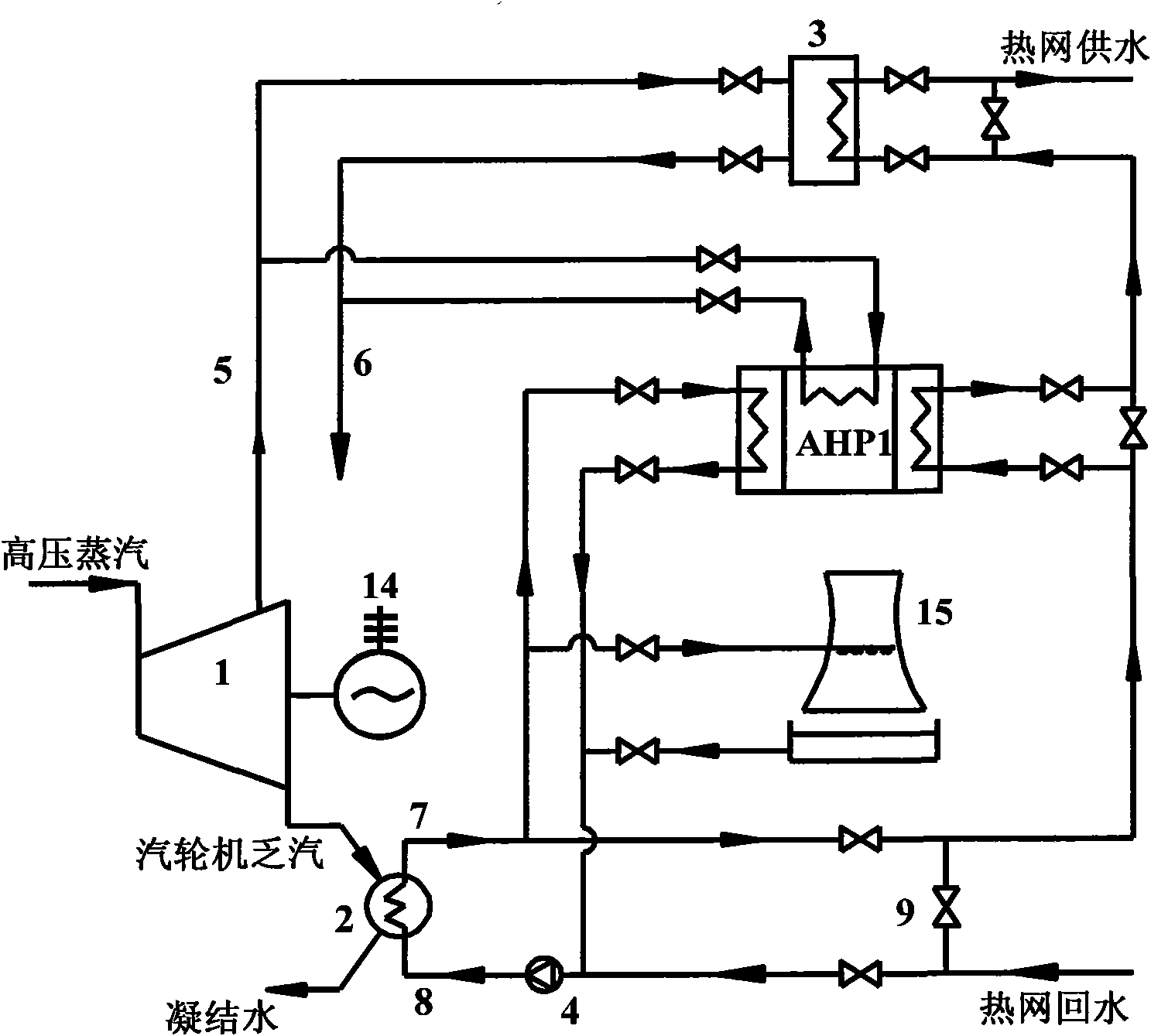

[0028] Example 1 Single-stage absorption heat pump heating method

[0029] Such as figure 1 As shown, the heating system consists of extraction condensing turbine 1, condenser 2, absorption heat pump AHP1, steam-water heat exchanger 3, circulating cooling water pump 4, steam pipeline 5, condensed water pipeline 6, circulating cooling water outlet pipe 7 , Circulating cooling water return pipe 8, bypass regulating pipeline 9, cooling tower 15 and various connecting pipelines.

[0030] The high-pressure steam from the boiler expands in the extraction condensing turbine 1 to provide power to the generator 14. Then, the steam is divided into two parts, and a part of the steam is extracted and sent to the absorption heat pump AHP1 and the steam-water heat exchanger through the steam pipeline 5 3. As the heat source of the absorption heat pump and the steam-water heat exchanger 3, the steam condenses into condensed water and then flows out through the condensed water pipeline 6. Th...

Embodiment 2

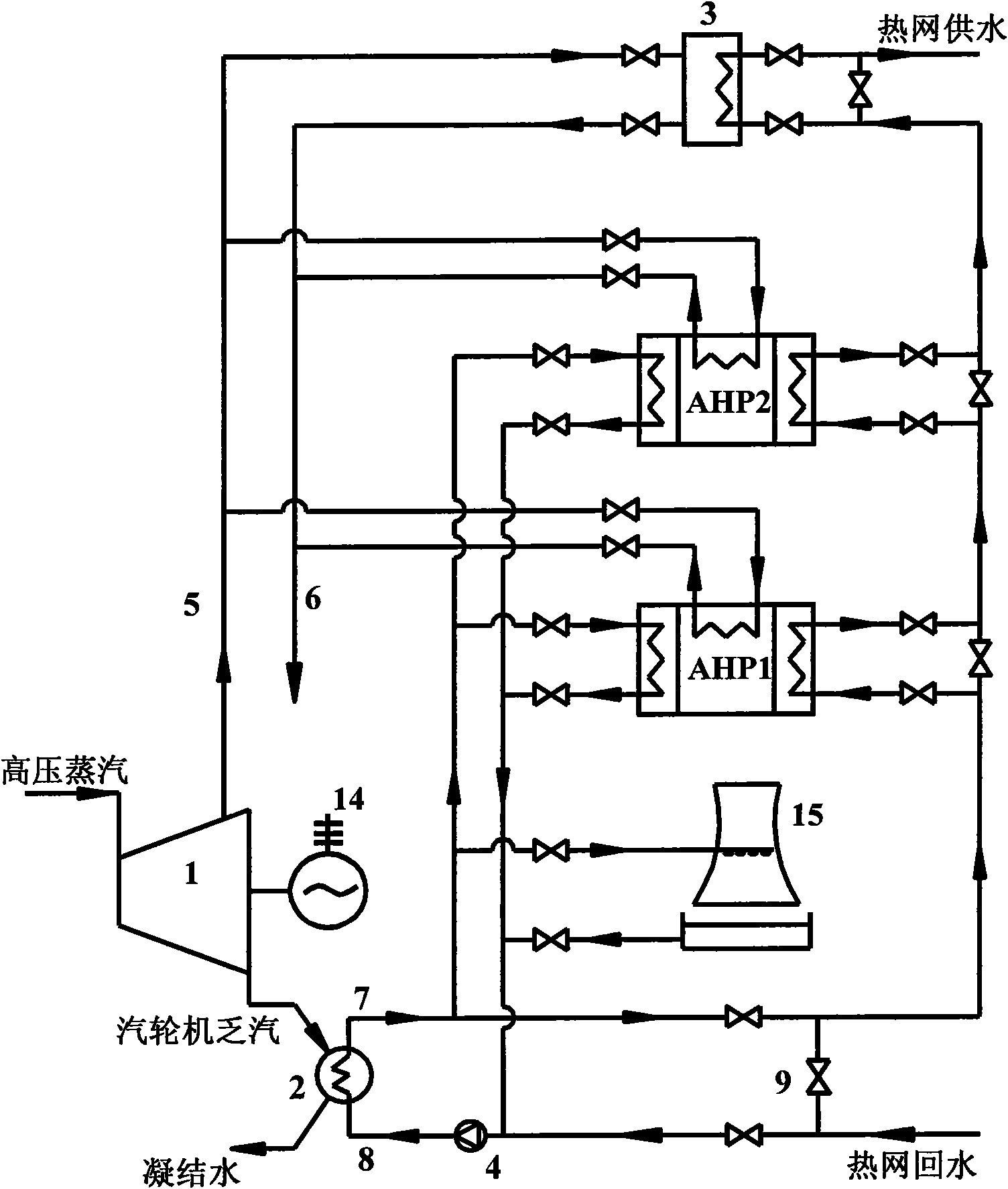

[0034] Example 2 Two-stage series absorption heat pump heating method

[0035] Such as figure 2 As shown, the heating system consists of extraction condensing turbine 1, condenser 2, first-stage absorption heat pump AHP1, second-stage absorption heat pump AHP2, steam-water heat exchanger 3, circulating cooling water pump 4, steam pipeline 5, Condensate water pipeline 6, circulating cooling water outlet pipe 7, circulating cooling water return pipe 8, bypass regulating pipeline 9, cooling tower 15 and various connecting pipelines.

[0036]The high-pressure steam from the boiler expands in the extraction condensing turbine 1 to provide power to the generator 14. Then, the steam is divided into two parts, and a part of the steam is extracted and sent to the first-stage absorption heat pump AHP1 through the steam pipeline 5. The two-stage absorption heat pump AHP2 and the steam-water heat exchanger 3 are used as heat sources for the first-stage absorption heat pump AHP1, the sec...

Embodiment 3

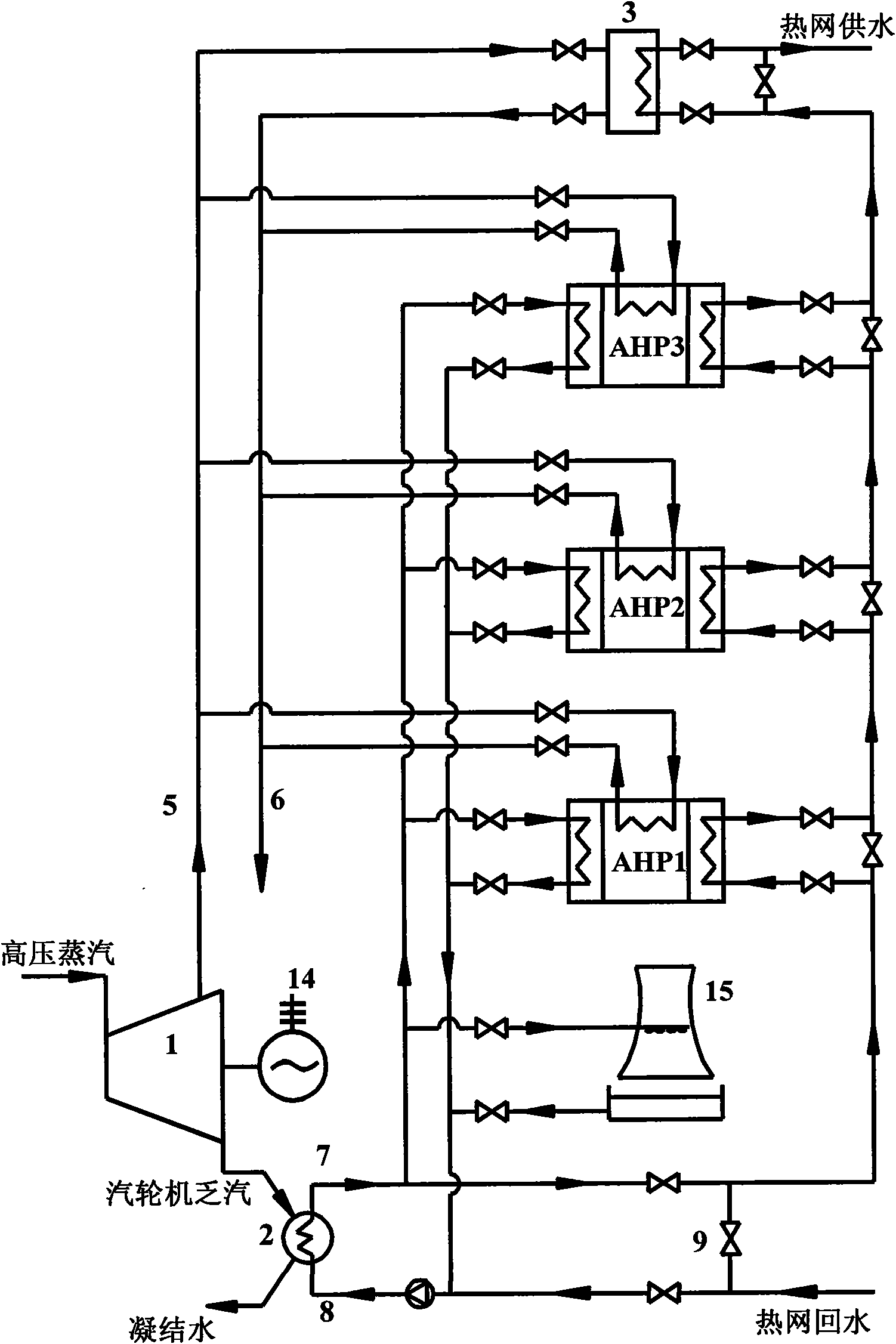

[0040] Example 3 A heat supply system with condenser, three-stage absorption heat pump and steam-water heat exchanger

[0041] Such as image 3 As shown, the heating system consists of extraction condensing turbine 1, condenser 2, first-stage absorption heat pump AHP1, second-stage absorption heat pump AHP2, third-stage absorption heat pump AHP3, steam-water heat exchanger 3, circulating cooling Water pump 4, steam pipeline 5, condensate water pipeline 6, circulating cooling water outlet pipe 7, circulating cooling water return pipe 8, bypass regulating pipeline 9, cooling tower 15 and various connecting pipelines.

[0042] The high-pressure steam from the boiler expands in the extraction condensing turbine 1 to provide power to the generator 14. Then, the steam is divided into two parts, and a part of the steam is extracted and sent to the first-stage absorption heat pump AHP1 through the steam pipeline 5. Second-stage absorption heat pump AHP2, third-stage absorption heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com