Patents

Literature

48results about How to "Reduce exergy loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

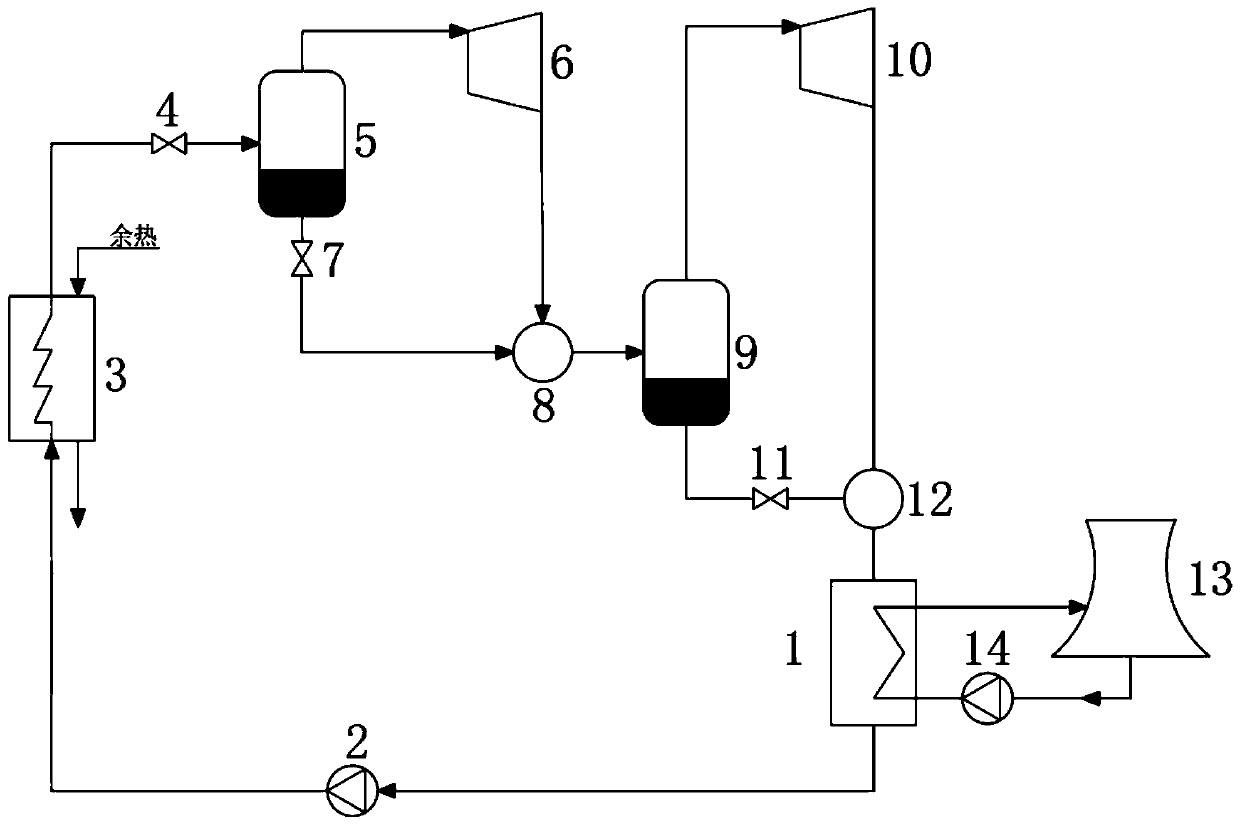

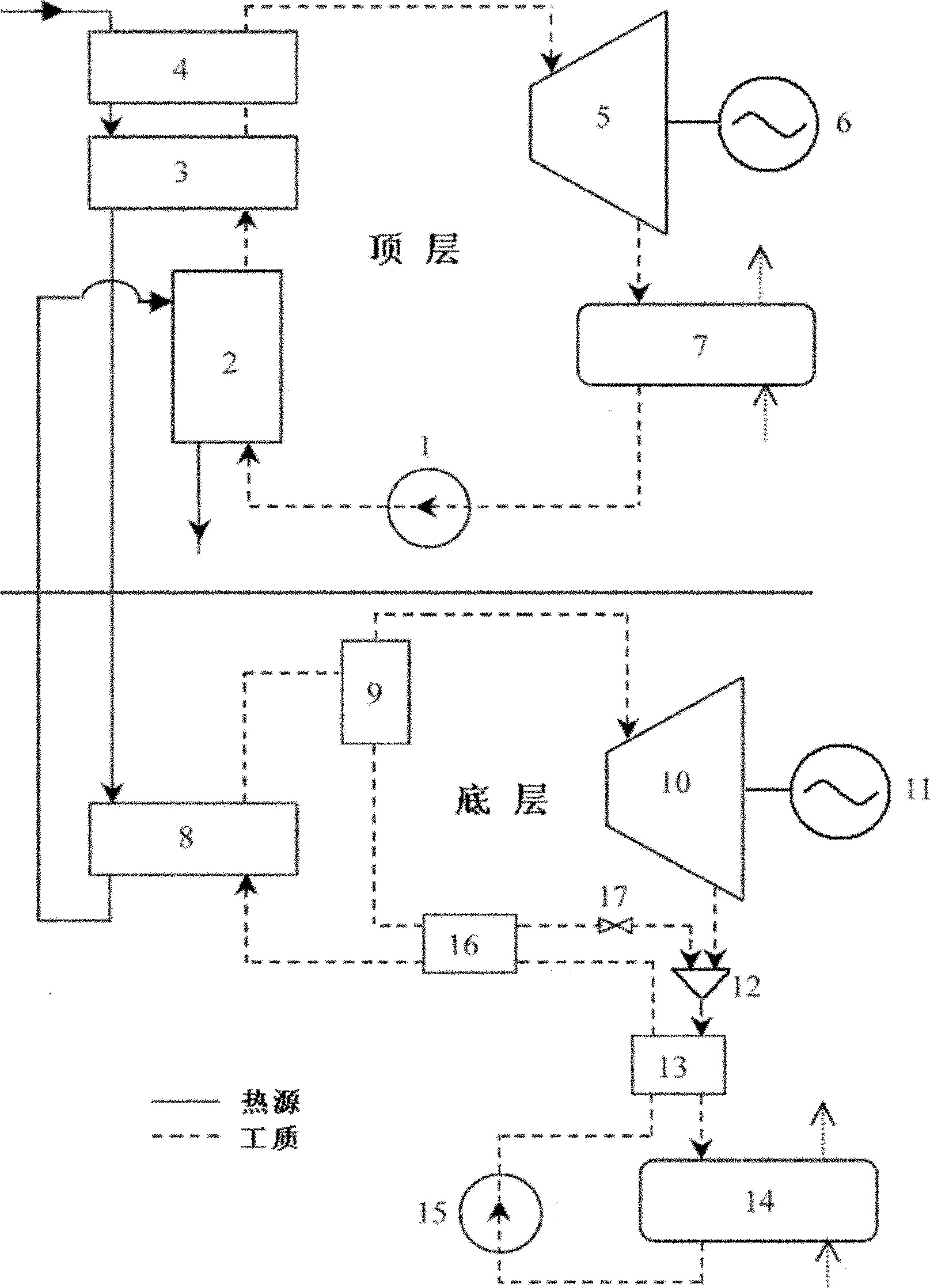

Medium-low temperature heat source generating set based on energy cascade utilization and thermal circulation method thereof

InactiveCN101929360AReduce exergy lossIncrease independenceSteam regenerationElectricityEnergy based

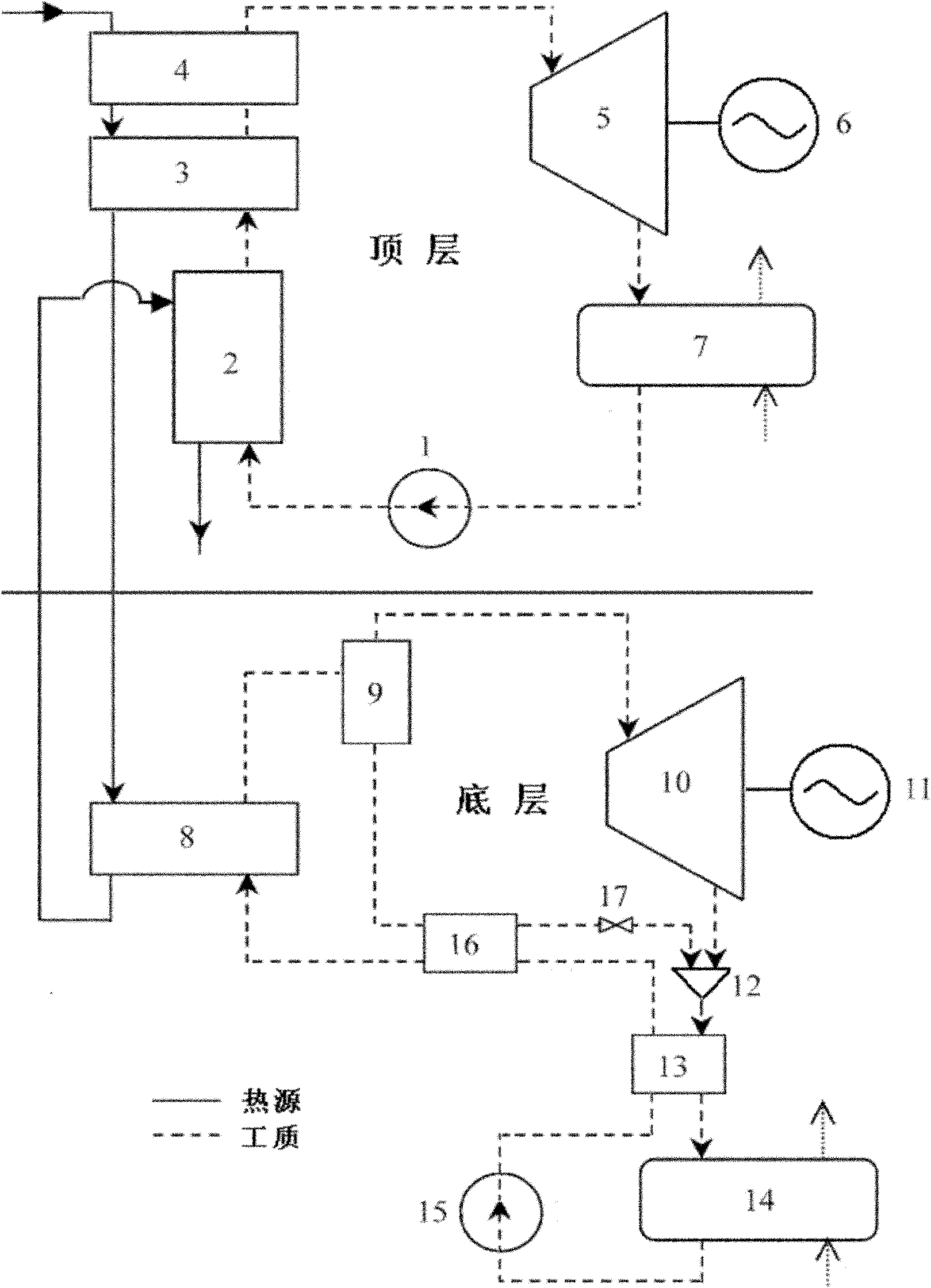

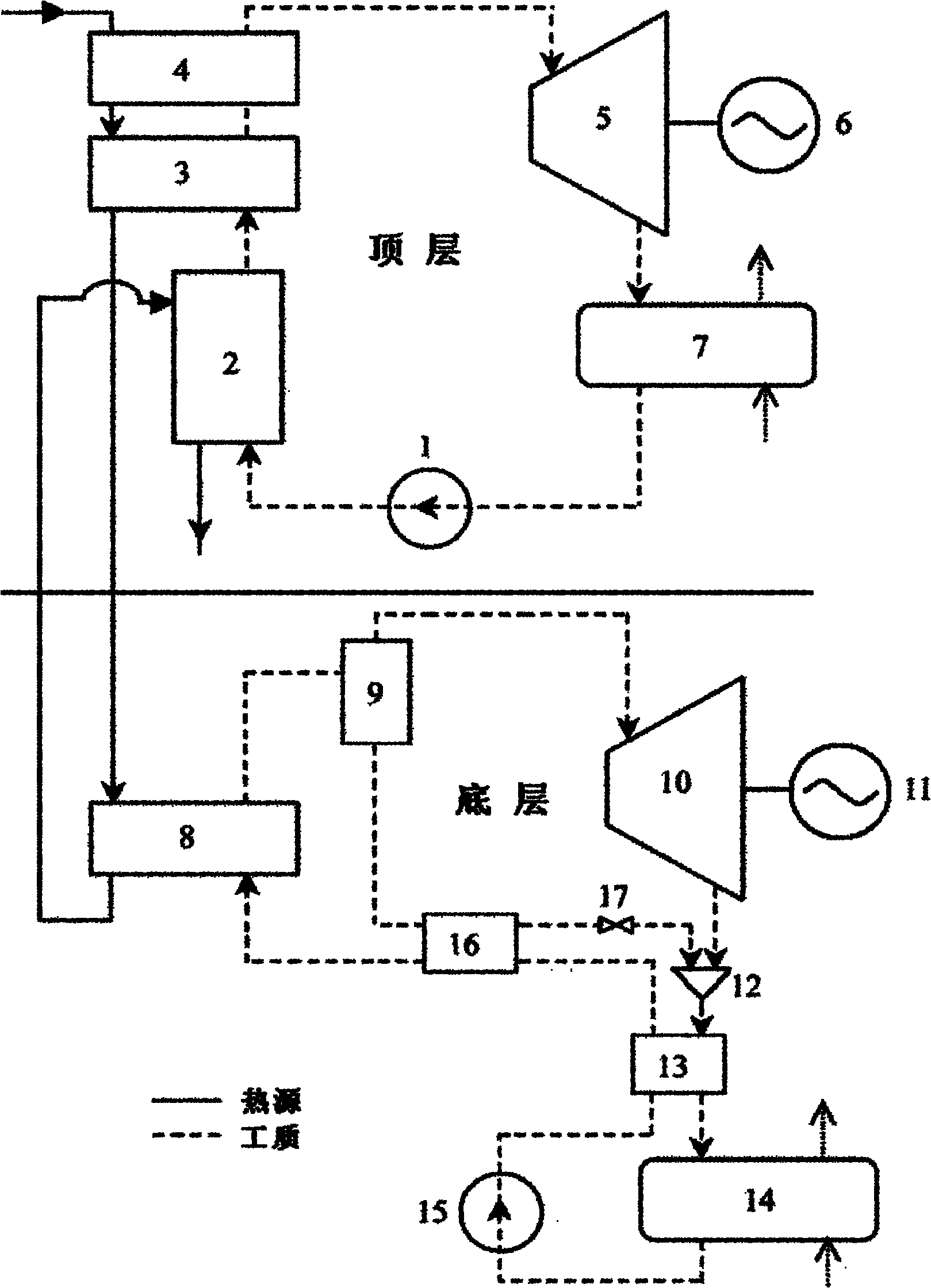

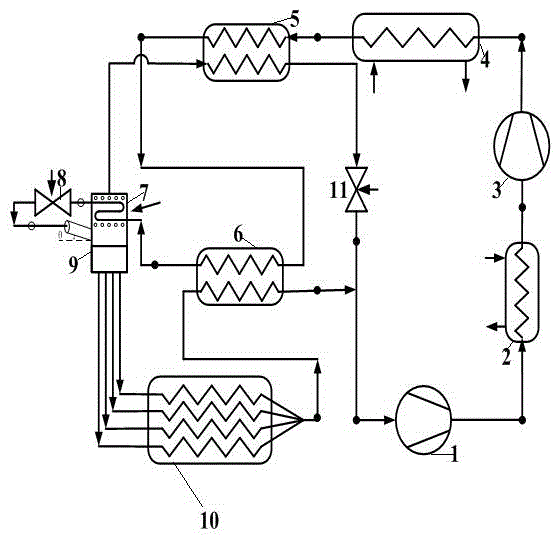

The invention relates to a medium-low temperature heat source generating set based on energy cascade utilization and a thermal circulation method thereof. The medium-low temperature heat source generating set comprises a top cycle system assembly and a bottom cycle system assembly connected with the top cycle system assembly. On the basis of the principle of energy cascade utilization, the generating set is formed by connecting two different medium-low temperature heat source generating cycles in parallel, wherein the top cycle is an organic matter Rankine cycle, and the bottom cycle is a Kalina cycle; and the thermal efficiency of the Kalina cycle at the bottom is higher than that of the organic matter Rankine cycle when electricity is generated by using the lower temperature heat sourcedischarged from the top cycle. The invention is more suitable for recycling low-grade heat sources, conforms to the principle of energy cascade utilization as compared with the original technique. Thus, the thermal efficiency of the generating set of the invention is further enhanced.

Owner:上海交通大学中原研究院

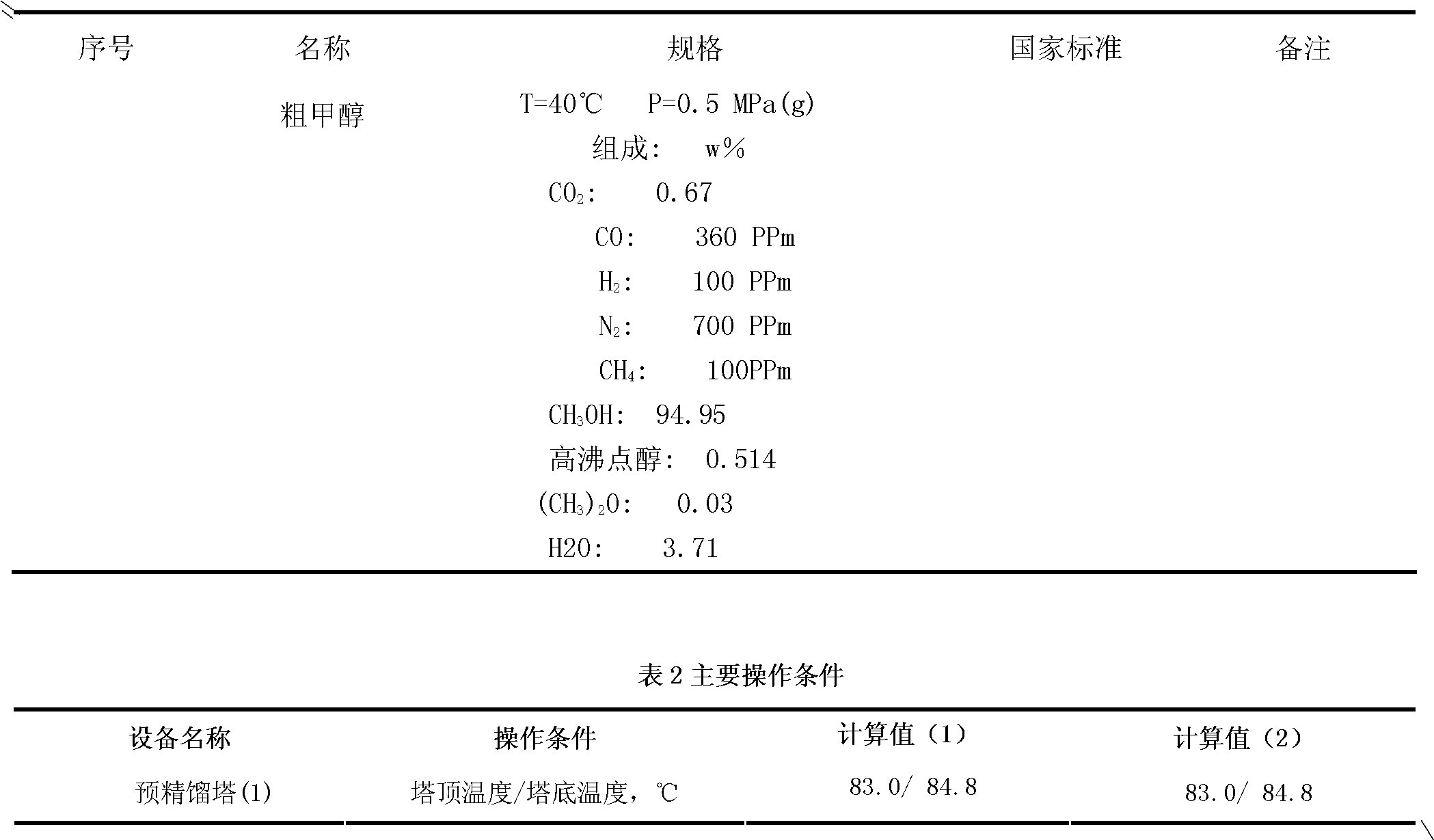

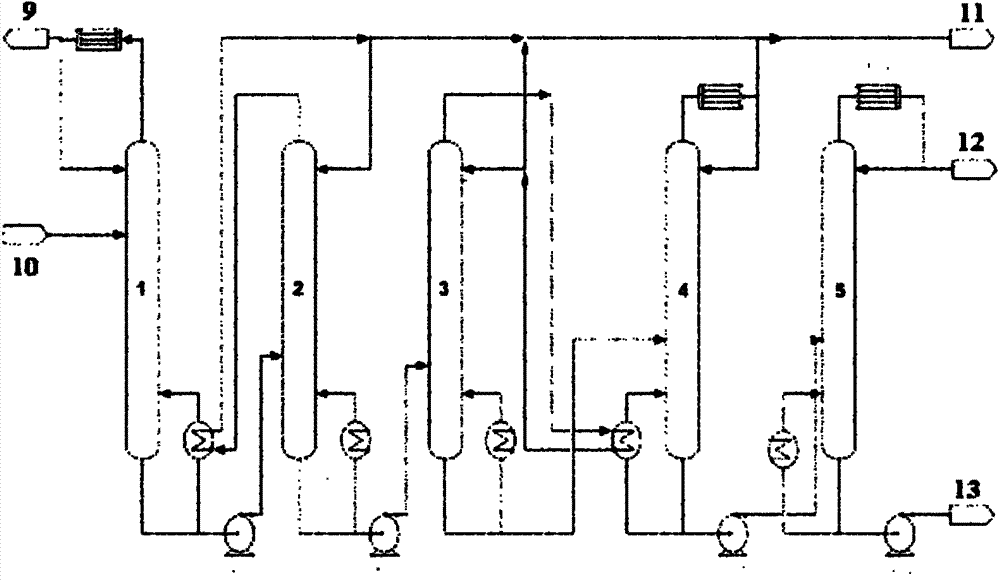

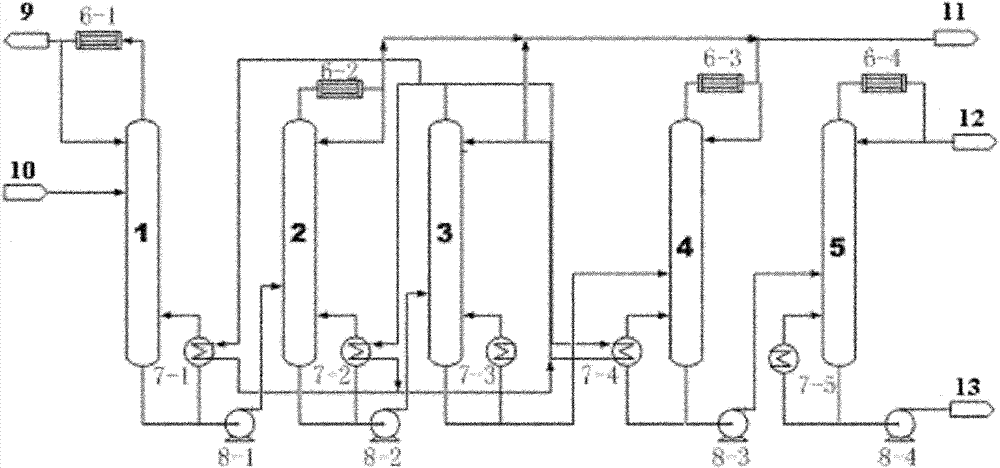

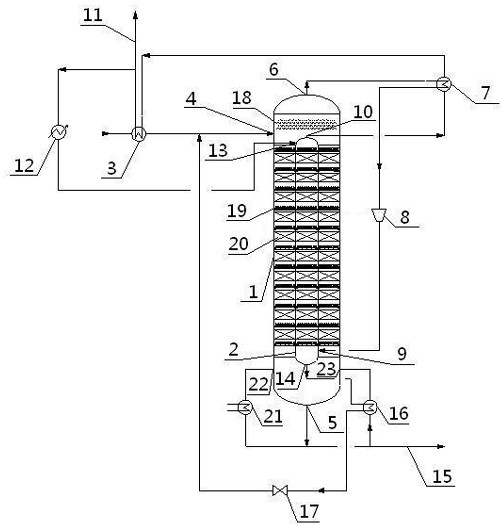

Large-scale methanol multi-effect energy-saving rectifying device and process

ActiveCN102039058AMake full use ofReduce exergy lossOrganic compound preparationChemical industryWastewaterProcess engineering

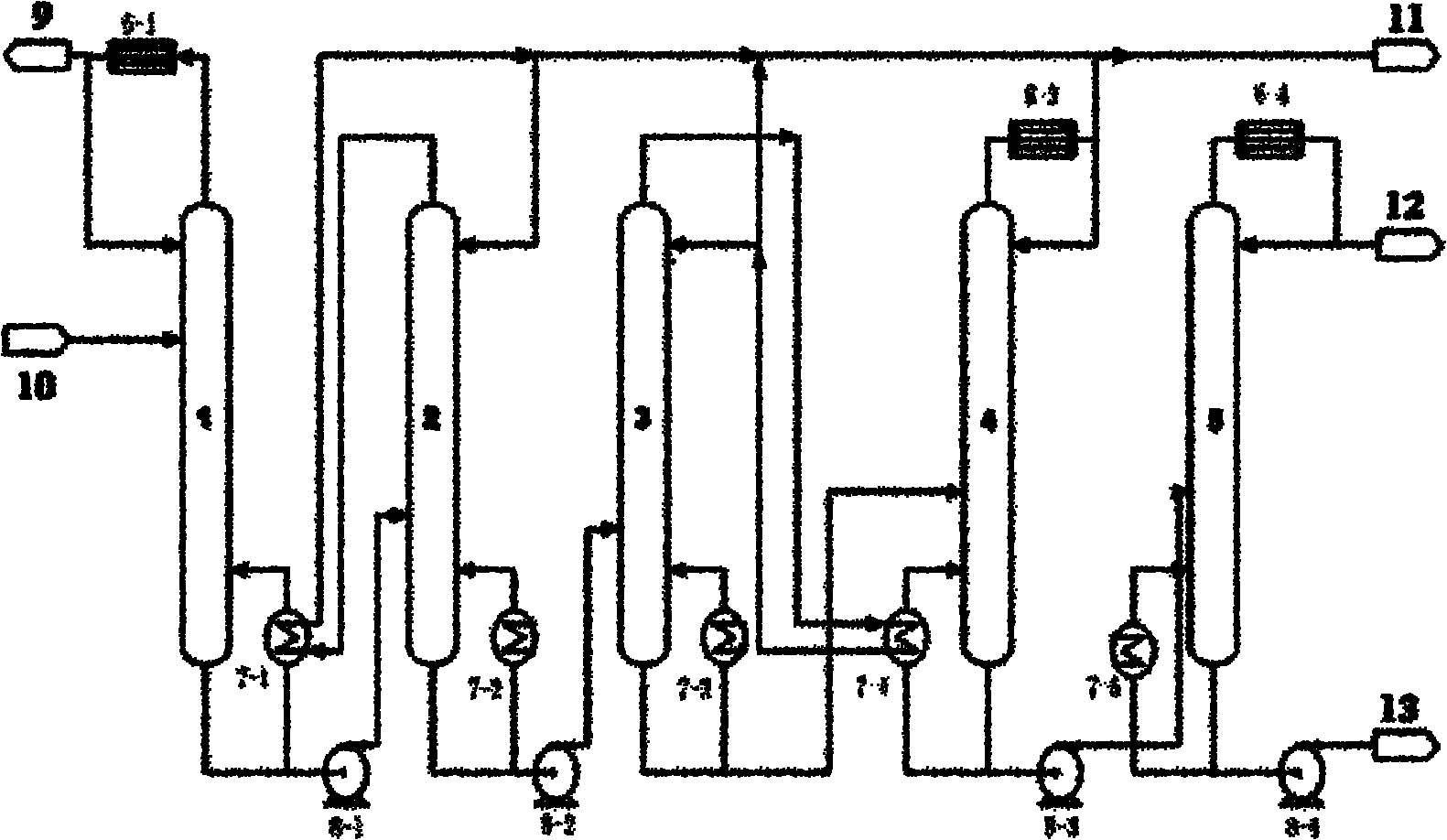

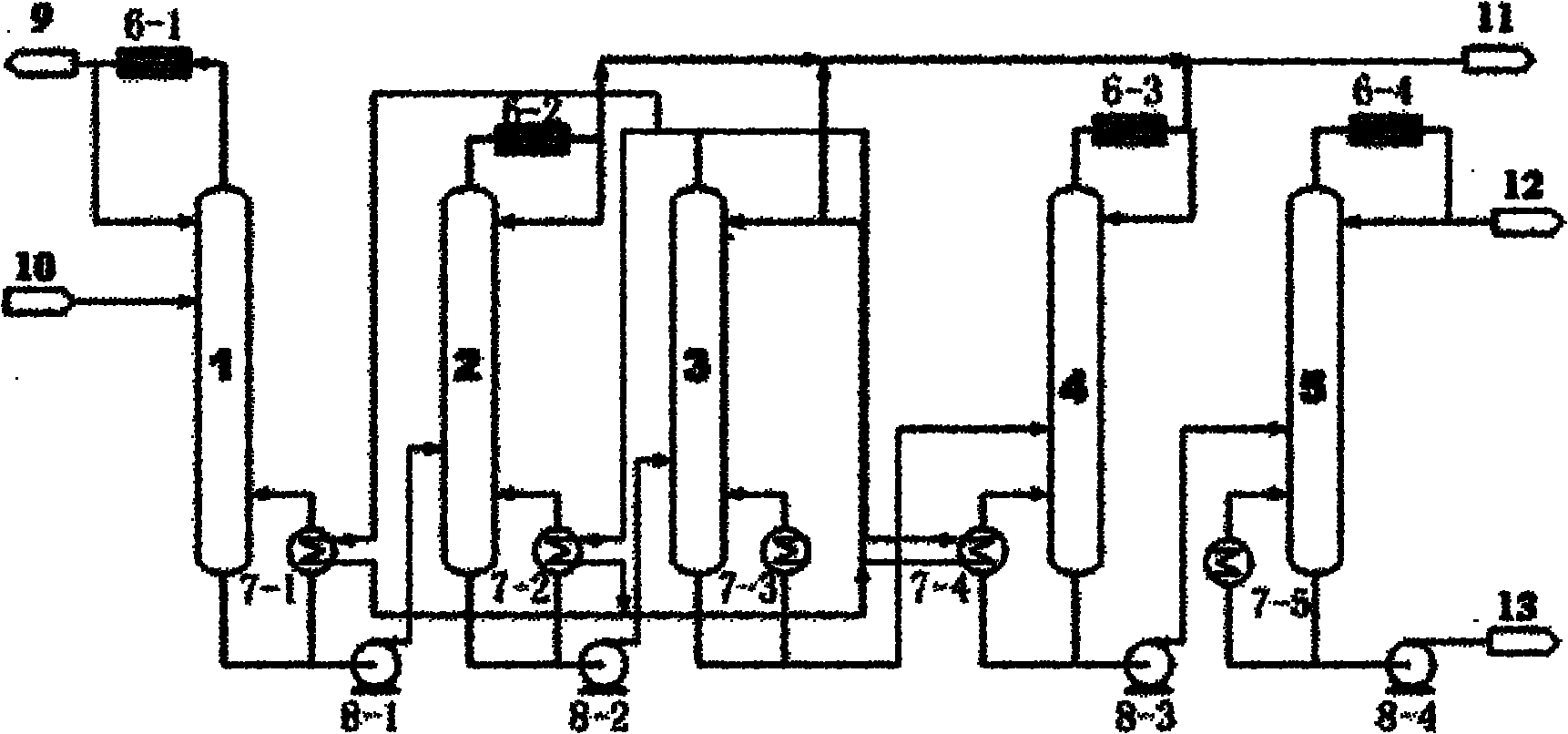

The invention relates to large-scale methanol multi-effect energy-saving rectifying device and process. Main equipment used in the process sequentially comprises a pre-rectifying tower, a second rectifying tower, a pressurizing tower, an atmospheric tower and a recovering tower, wherein the tops of the second rectifying tower, the pressurizing tower and the atmospheric tower are respectively usedfor discharging refined methanol, the top of the recovering tower is used for discharging fusel oil, and the bottom is used for discharging purified wastewater. Because one rectifying tower is additionally arranged, and the process parameter of each tower is adjusted, two methanol multi-effect energy-saving rectifying processes by five towers are obtained, the effective energy loss is reduced, thereby energy consumption is reduced. In addition, the diameter of each tower is reduced, the amplification effect of relevant equipment, caused by the oversize diameter of each tower, is greatly reduced. The process has the advantages of reasonable design, the energy is fully and reasonably utilized in the process, the energy consumption of the whole device used in the process is reduced by 20%-30% higher than that of the device used in the traditional double-effect process, and the purity of a product reaches the American AA-level standard.

Owner:TIANJIN UNIV

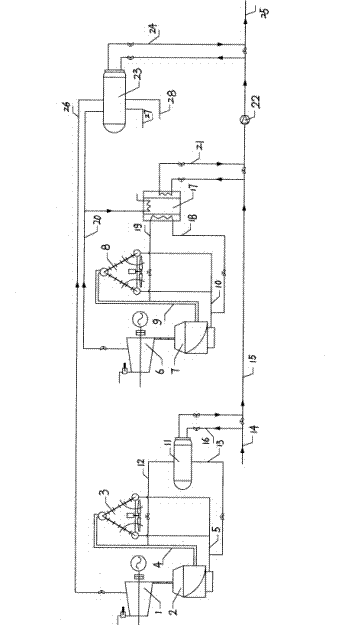

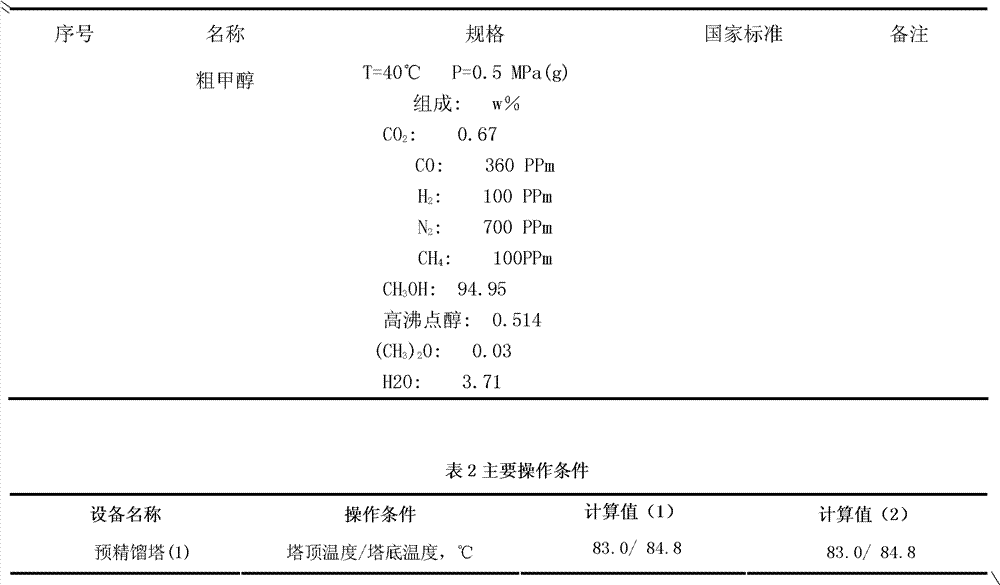

Separation and recovery device and method for argon and methane in synthetic ammonia relief gas

InactiveCN101968298AReduce exergy lossReduce device energy consumptionSolidificationLiquefactionChemistryMolecular sieve

The invention relates to a separation and recovery device and a method for argon and methane in synthetic ammonia relief gas, the separation and recovery device comprises a cold box, a raw material relief gas pipeline, a purification system which is communicated with the raw material relief gas pipeline and provided with a first molecular sieve adsorber MS1 and a second molecular sieve adsorber MS2, a refrigeration system for providing cold energy required for separating and liquefying, and a distillation system for separating raw material relief gas stage by stage, wherein the refrigeration system comprises a low-pressure circulation nitrogen compressor TC1, a medium-pressure circulation nitrogen compressor TC2, a low-temperature pressurized turbo-expander ET2, a high-temperature pressurized turbo-expander ET1, a main heat exchanger E1 and a liquefier E2, the distillation system comprises a flash evaporation tank S2, a dehydrogenation tower C1 equipped with a first condenser K4 and afirst evaporator K1, a dehydrogenation tower C2 equipped with a second condenser K5 and a second evaporator K2 and a product tower 3 equipped with a third condenser K6 and a third evaporator K3. The invention can obtain high product purify and high recovery rate.

Owner:KAIFENG AIR SEPARATION GROUP

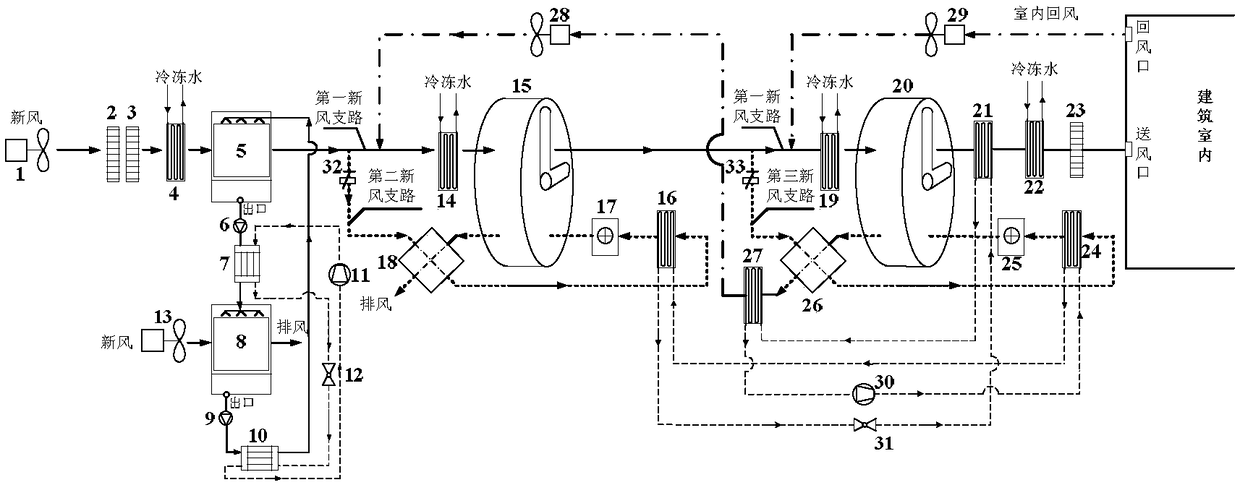

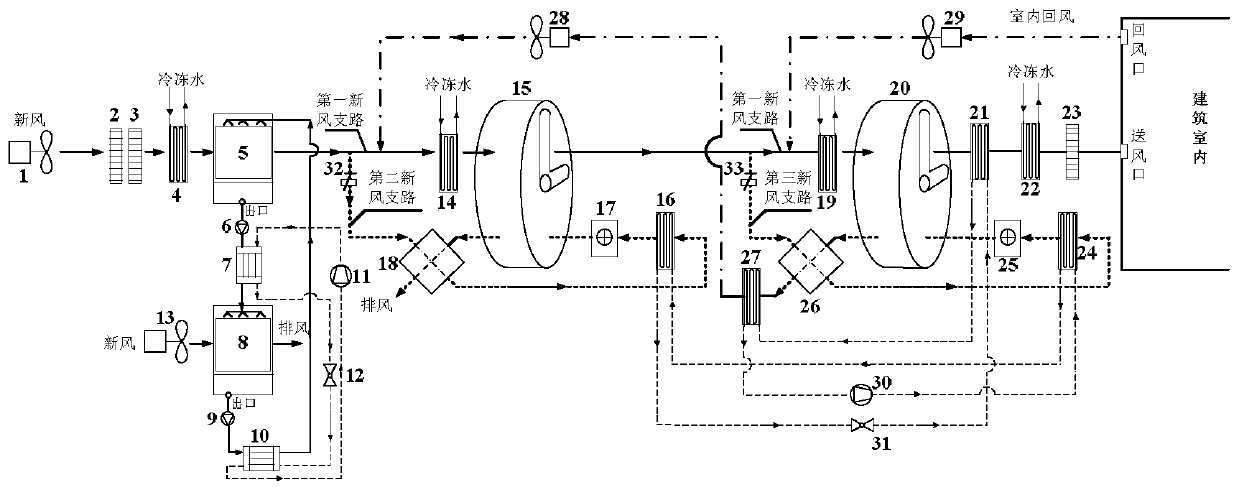

Multistage air deep dehumidification device for ultra-low dew point environments

ActiveCN108758807AReduce humidityLong-term stable operationAir treatment detailsLighting and heating apparatusElectricityFresh air

The invention discloses a multistage air deep dehumidification device for ultra-low dew point environments. The multistage air deep dehumidification device comprises a first fan, a primary efficiencyfilter, a medium efficiency filter and a first surface air cooler which are sequentially arranged in the outdoor fresh air direction and further comprises a solution dehumidification system, a first fresh air branch circuit, a second fresh air branch circuit, a third fresh air branch circuit, a first air returning branch circuit and a second air returning branch circuit which are arranged behind the first surface air cooler. A cold and heat source of a solution dehumidification cycle is provided by an independent vapor-compression-type refrigeration cycle, a regenerative heat source of two-stage rotary-wheel dehumidification uses condensation heat of another vapor-compression-type refrigeration cycle, and meanwhile shortage of the condensation heat is compensated in an electric heating mode. The evaporative cooling capacity of the vapor-compression-type refrigeration cycles is provided for an air-evaporator to cool air. After treating through the device, the humidity content of the fedair can be lowered to 0.01 g / kg.

Owner:SOUTHEAST UNIV

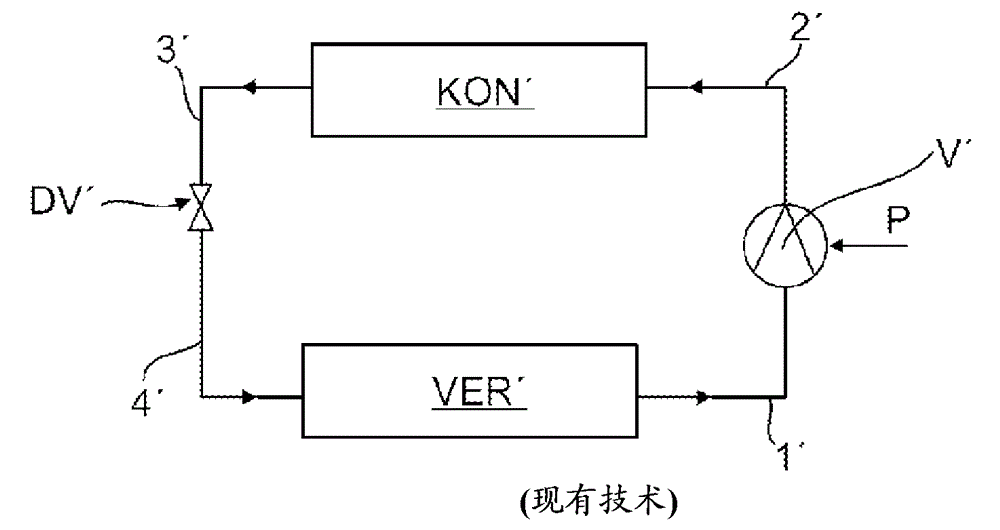

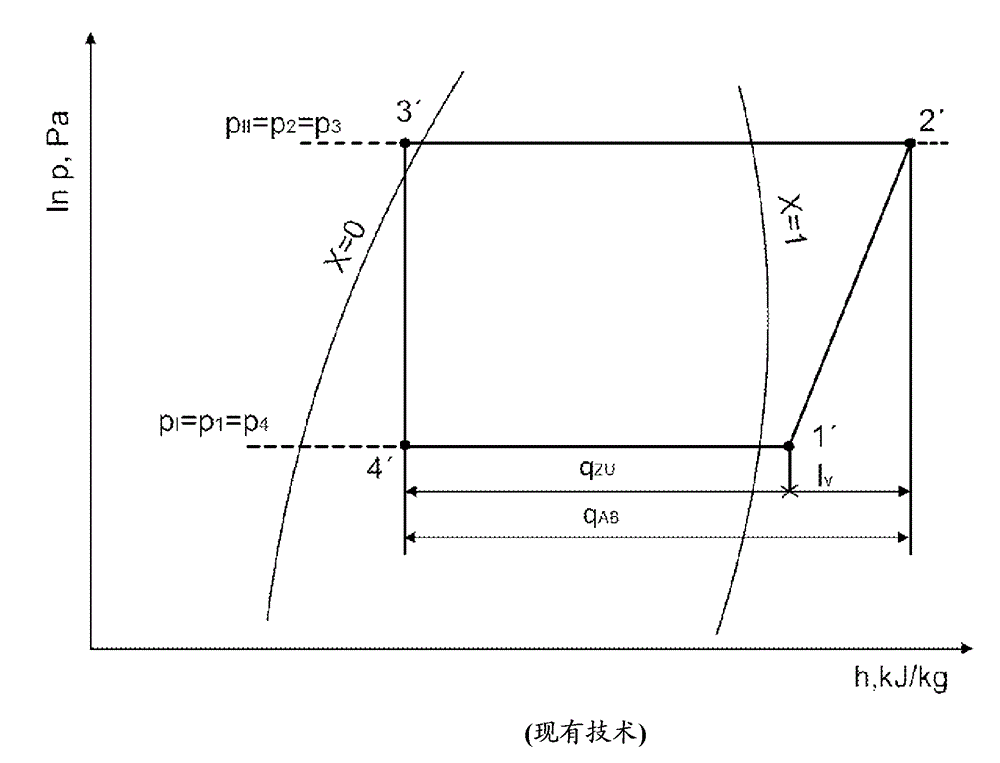

Heat pump, in particular for heating a vehicle interior, and method for operating a heat pump

InactiveCN104344602ALess compression workReduce consumptionHeat pumpsCompression machinesJet flowThrottle

A heat pump for heating a vehicle interior includes a compressor arranged in a heat-pump circuit of a working medium, a condenser, a throttle valve and an evaporator. Gaseous working medium is compressed in the compressor. The compressor outlet is connected to the inlet of the condenser in which the working medium condenses, at the same time discharging heat, the heat being delivered as useful heat directly or indirectly to a consumer. The condenser is followed by a jet pump, to which the liquid working medium coming from the condenser is delivered as driving medium and to which the gaseous working medium flowing out from the evaporator is delivered as suction medium, in such a way that the driving medium and suction medium are compressed in the jet pump as a two-phase mixture. The jet-pump outlet is connected to the inlet of a separator, to which the two-phase mixture is delivered and in which the gaseous working medium is separated from the liquid working medium. The gas outlet of the separator is connected to the compressor inlet and the liquid outlet of the separator is connected to the inlet of the throttle valve, the liquid working medium being throttled in the throttle valve, and the outlet of the throttle valve is connected to the inlet of the evaporator, in which, by the supply of heat, phase transformation takes place to the gaseous working medium.

Owner:MAN TRUCK & BUS AG

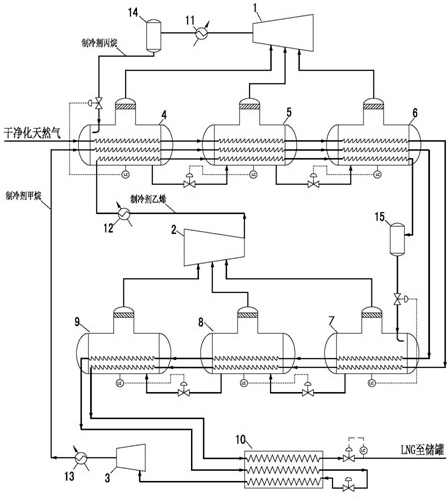

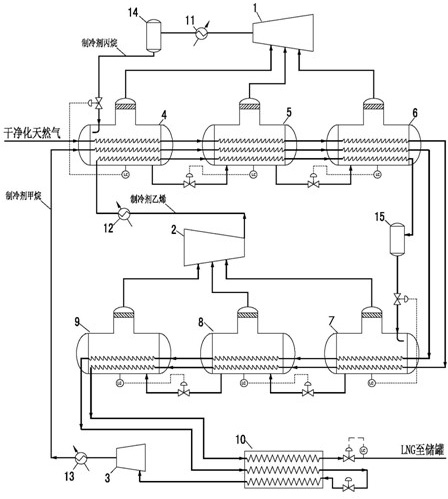

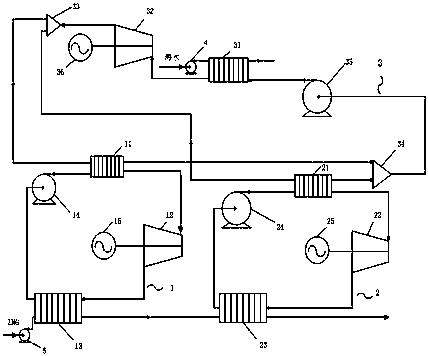

Multi-level single-component refrigeration natural gas liquefaction system and multi-level single-component refrigeration natural gas liquefaction method

ActiveCN102538391AEmbody adaptabilityRich adjustment meansSolidificationLiquefactionPlate fin heat exchangerMethane

The invention discloses a multi-level single-component refrigeration natural gas liquefaction system and a multi-level single-component refrigeration natural gas liquefaction method. Purified natural gas is cooled gradually in six heat exchangers (evaporators) and a plate fin type heat exchanger (natural gas subcooler) until being liquefied. Cold energy required by the liquefying process is provided by a propane system, an ethylene system and a methane system. The system is rich in adjusting means, the cold energy matched with the natural gas liquefying process can be provided for the naturalgas liquefying process, and thereby operational flexibility and adaptability to raw materials of the method are embodied. The system and the method have the advantages that the natural gas liquefyingprocess is low in energy consumption; refrigerant compressors are all single-component compressors, so that design is easier, purchase is more convenient, the compressors are more stable in operation, domestic equipment can be used, and construction investment of liquefaction factories can be effectively reduced; and the liquefying process is wide in heat exchanger selection range, and a cold boxstructure and a tube-shell structure can be used simultaneously or alternatively.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

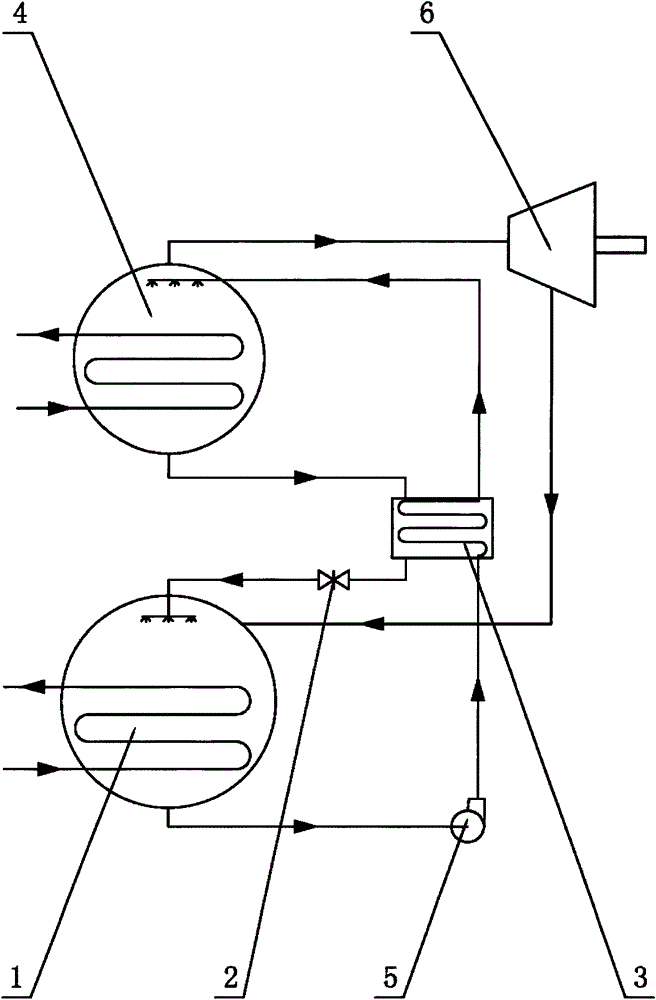

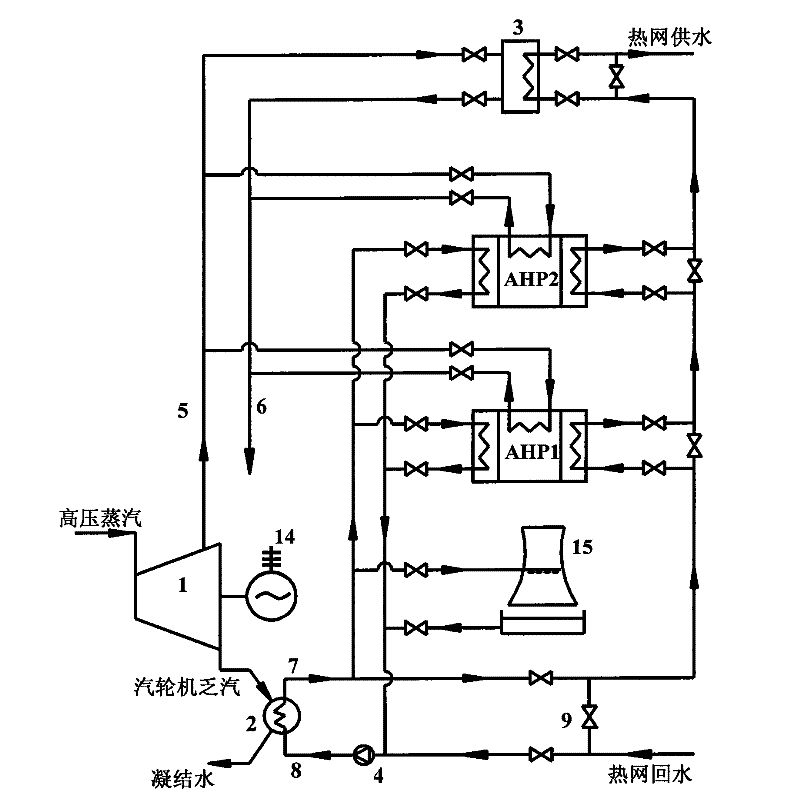

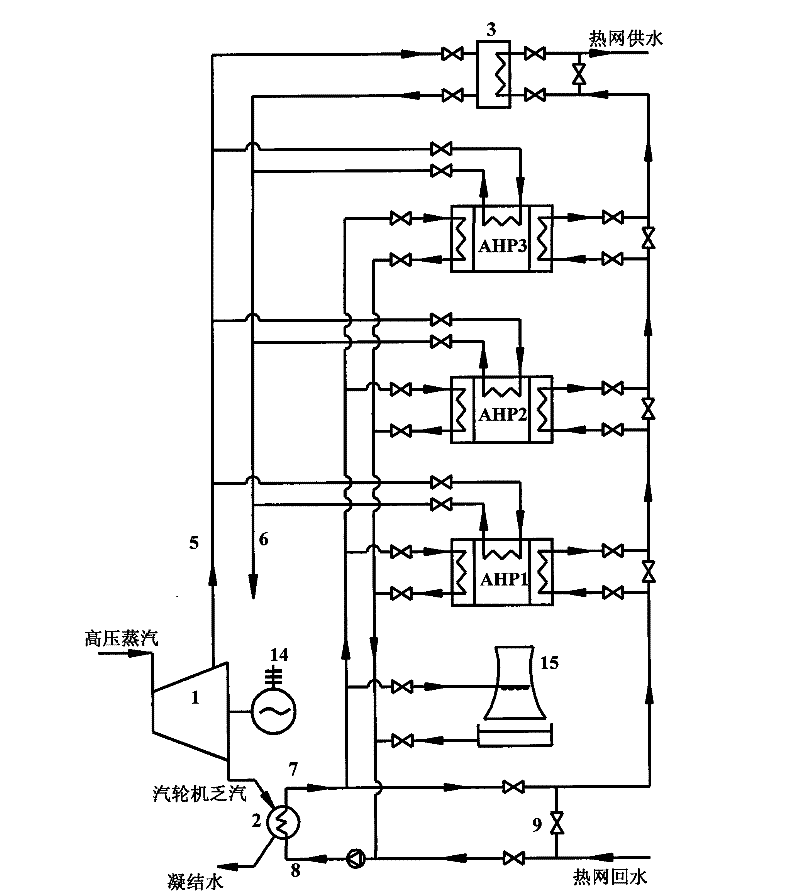

Stepped heating and supplying system sufficiently utilizing waste heat of power plant

InactiveCN104501275AReduce temperature gradient differenceReduce exergy lossLighting and heating apparatusHot-water central heatingThree stageEngineering

The invention discloses a stepped heating and supplying system sufficiently utilizing waste heat of a power plant and solves the problems that waste heat of the power plant is utilized at low rate and heat supply temperature is inflexible in adjustment in the prior art. The stepped heating and supplying system is a system combining a high-backpressure condenser of an air cooling unit with dead steam recovery heat supply manners of a heat pump turbine, and dead steam recovery heat supply by a heat pump, the high-backpressure condenser and pure steam extraction in the prior art are changed. The stepped heating and supplying system has the advantages that a water heating system of a heat supply net is provided with three-stage heating, temperature gradient difference of water of the hot net during heating is reduced, and energy loss is reduced. The system can be constructed by stages, initial investment is lower, and heat supply adjustment is flexible. The stepped heating and supplying system is applicable to direct air cooling units of power plants and particularly suitable for direct air cooling units costing 300,000 or lower than 300,000.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

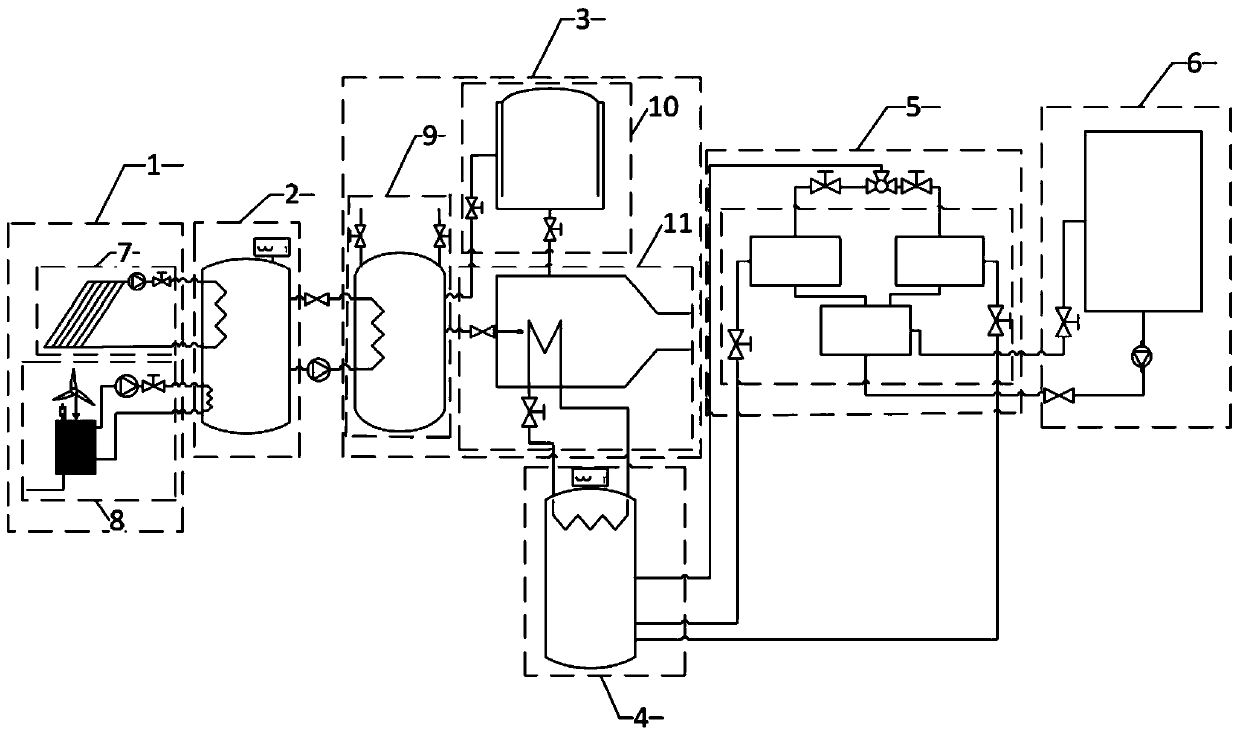

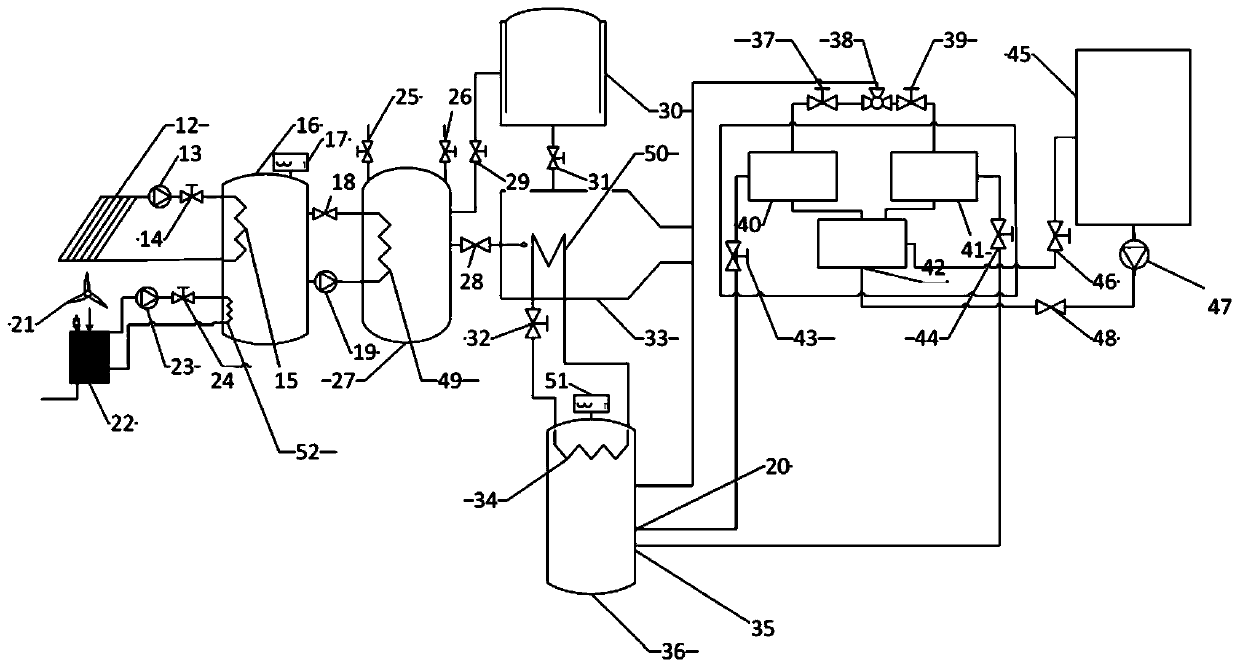

Integrated energy supply system for agricultural greenhouse and power supply method

InactiveCN110307612AMeet the needs of fermentation temperatureGuarantee continuous and stable operationSolar heating energySpace heating and ventilationAgricultural engineeringAbsorption heat pump

The invention discloses an integrated energy supply system for an agricultural greenhouse and a power supply method. The temperature of the greenhouse is automatically adjusted, heat required for maintaining the temperature of the greenhouse is provided, or the temperature of the greenhouse is reduced. According to the integrated energy supply system and the power supply method, a solar heat collection and wind power stirring heating combination effect is used for providing heat to a biogas generator, and the temperature of high-efficiency fermentation of a biogas raw material is maintained; and chemical energy released by biogas combustion is used for driving an absorption type heat pump to realize heating and cooling of the greenhouse, the utilization rate of renewable clean energy and the greenhouse heating efficiency are improved, a comprehensive energy supply operation strategy is proposed, the aim of adjusting the temperature of the greenhouse in different seasons and different weather conditions is achieved, and the needs for agricultural greenhouse energy supply are met.

Owner:XI AN JIAOTONG UNIV +1

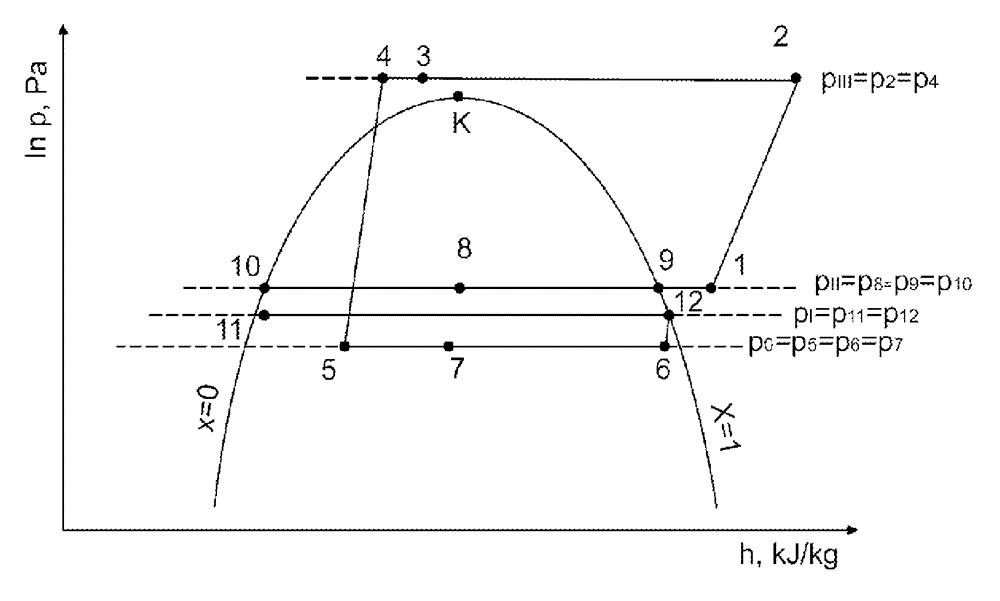

Dual-stage compression refrigeration circulating system for cooling flashing gas bypass in stepped mode

InactiveCN105650921AImprove efficiencySmall pressure lossMechanical apparatusCompression machines with non-reversible cycleDual stageGas passing

The invention discloses a dual-stage compression refrigeration circulating system for cooling a flashing gas bypass in a stepped mode. High-temperature gas refrigerant discharged by a high-pressure compressor enters a gas cooler to be primarily cooled, then gas refrigerant sequentially passes a flashing gas bypass external heat exchanger, an internal heat exchanger and a flashing gas bypass internal heat exchanger to be sufficiently cooled, and finally refrigerant gas passing through the flashing gas bypass external heat exchanger and refrigerant gas passing through the internal heat exchanger are input to a low-pressure compressor after being mixed. The key problems that CO2 refrigeration circulating throttling loss is large and circulating efficiency is low are solved, the efficiency of the CO2 trans-critical refrigeration circulating system is greatly improved, and the use range of the system is widened.

Owner:TIANJIN UNIV OF COMMERCE

Sludge drying device and method

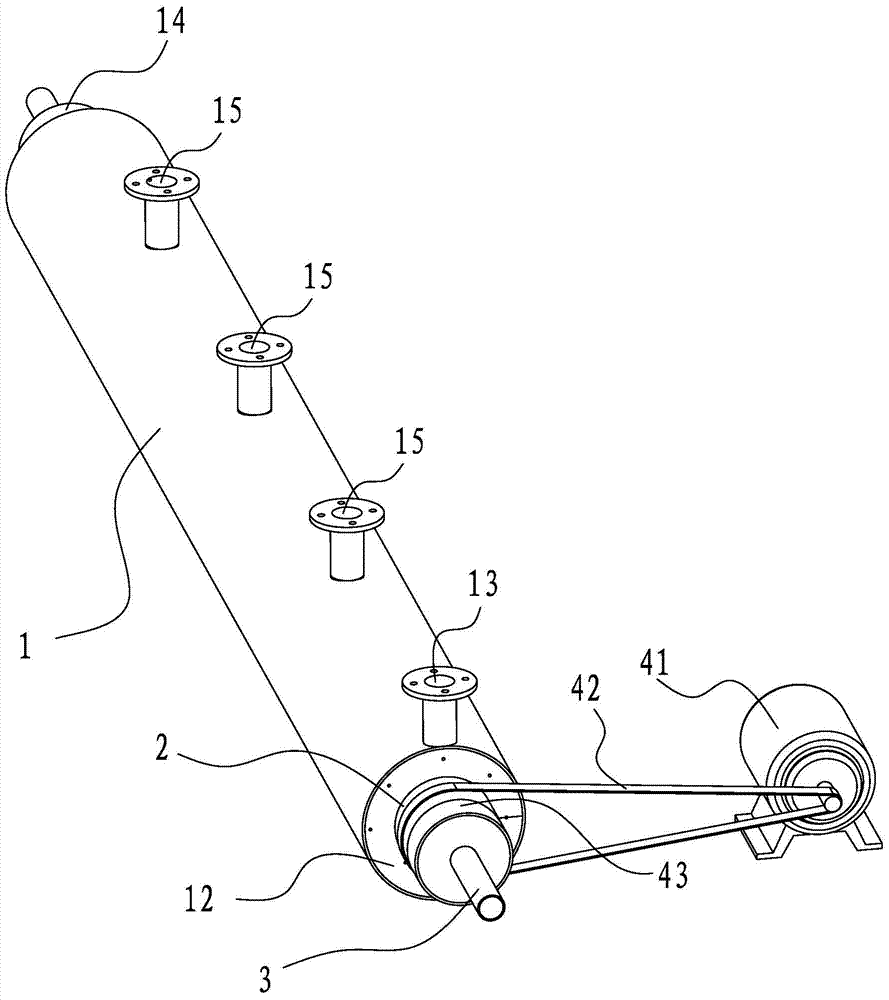

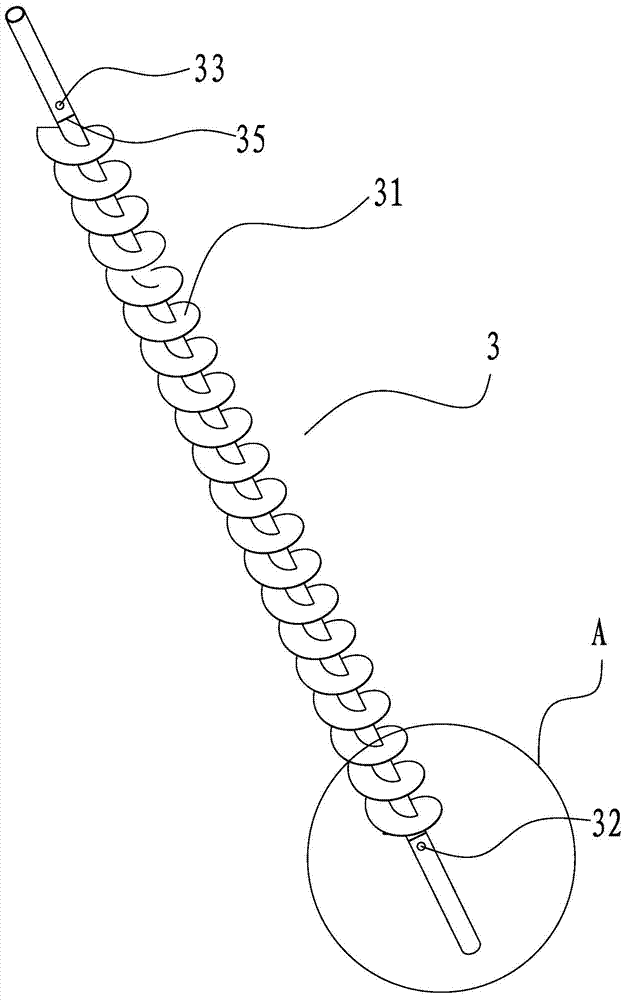

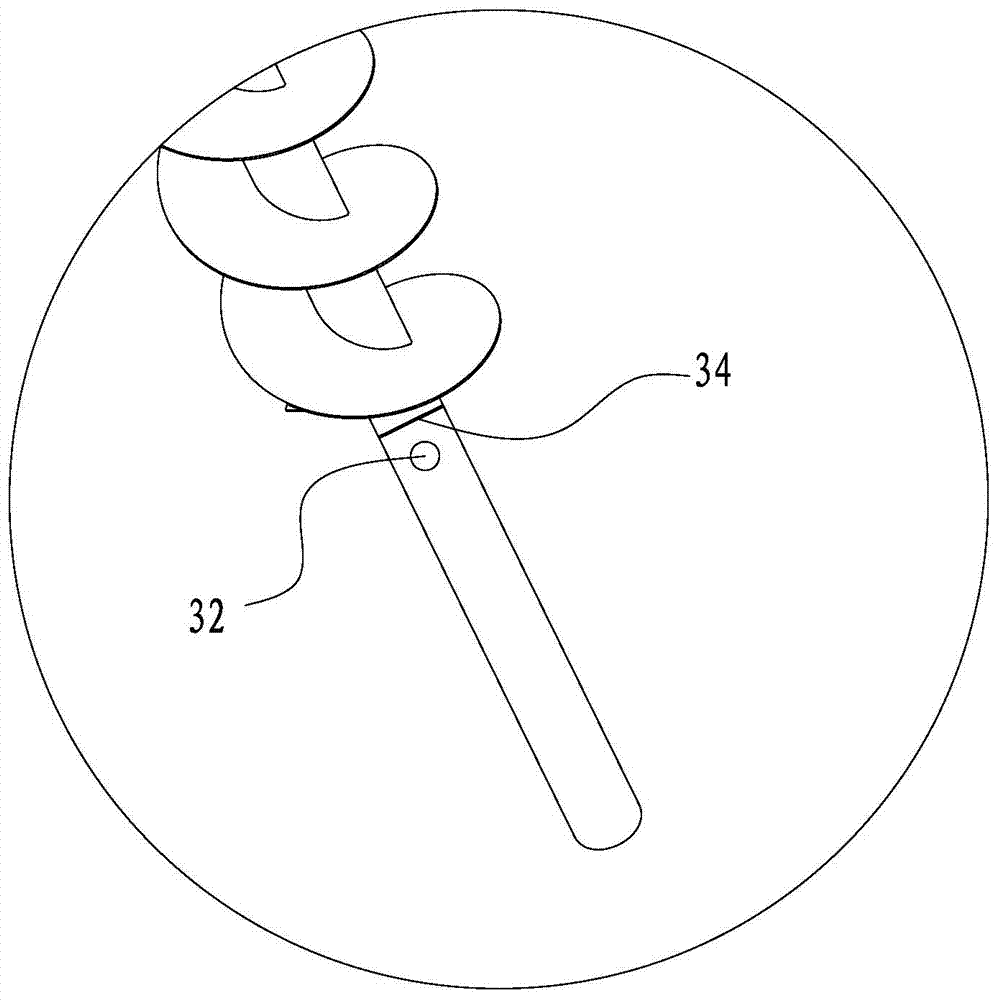

ActiveCN103693838AExtended stayIncrease the range of motionSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringSludge

The invention discloses a sludge drying device and method belonging to the technical field of sludge treatment. The device comprises a shell, a middle sleeve, a central shaft and a driving mechanism, wherein the central shaft is sleeved in the middle sleeve; a first chamber is formed by the outer wall of the central shaft and the inner wall of the middle sleeve; both ends of the first chamber are respectively provided with a first inlet and a first outlet; the middle sleeve is sleeved in the shell; a second chamber is formed by the outer wall of the middle sleeve and the inner wall of the shell; both ends of the shell are respectively provided with a second inlet and a second outlet; the outer wall of the central shaft is provided with a helical first partition board along the axial direction of the central shaft; the outer wall of the middle sleeve is provided with a helical second partition board along the axial direction of the middle sleeve; and the driving mechanism drives the middle sleeve to rotate along the axial direction thereof. According to the device and method disclosed by the invention, the heat exchange energy efficiency is increased, and the sludge treatment operating cost is reduced. The invention is low in initial cost and operating cost, can be widely applicable to industrial and municipal sludge treatment and has wide application prospects.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

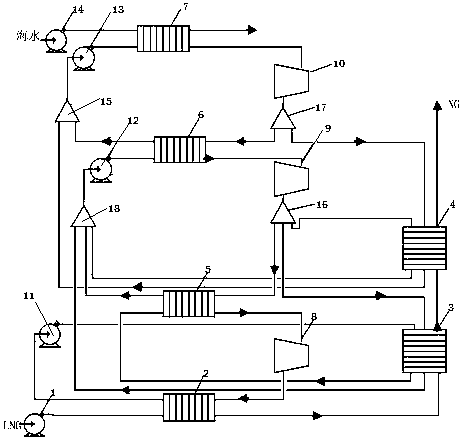

Supercritical secondary divided flow type longitudinal three-level Rankine cycle power generation system

InactiveCN107725130AReduce exergy lossReduce heat transfer temperature differenceSteam engine plantsThree levelClosed loop

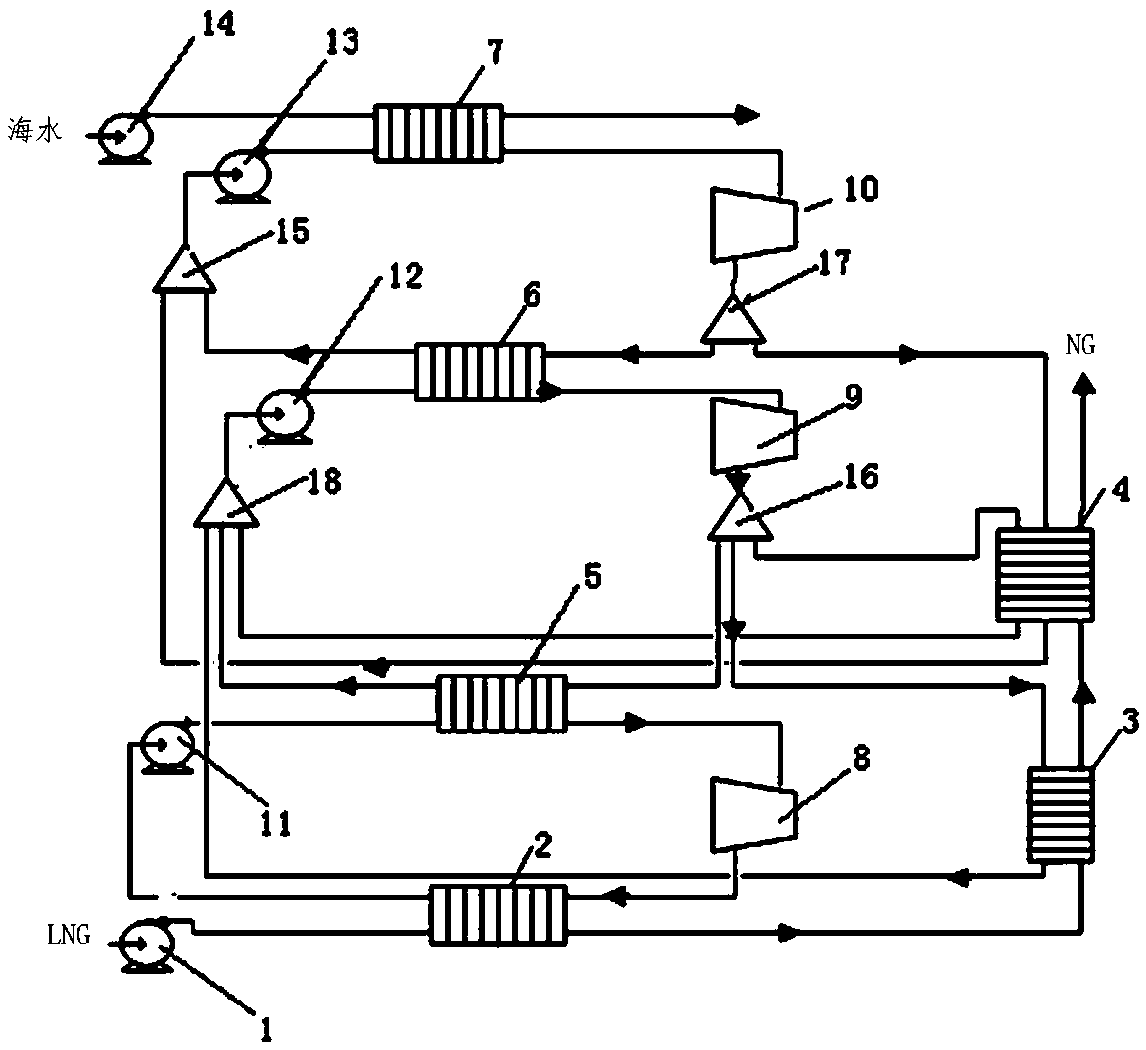

The invention relates to a supercritical secondary divided flow type longitudinal three-level Rankine cycle power generation system. The system comprises an LNG circulating pump and a sea water pump.The system also comprises a first-level power generation unit, a second-level power generation unit and a third-level power generation unit which are distributed successively in a longitudinal array;the first-level power generation unit comprises a first-level evaporator, a first-level turbine, a first-level condenser and a first-level working medium pump which are successively connected; the second-level power generation unit comprises a second-level evaporator, a second-level turbine, a second-level flow divider, a second-level condenser, a second-level mixer and a second-level working medium pump which are successively connected to form a closed loop; and the third-level power generation unit comprises a third-level evaporator, a third-level turbine, a third-level flow divider, a third-level condenser, a third-level mixer and a third-level working medium pump which are successively connected to form a closed loop. The supercritical secondary divided flow type longitudinal three-level Rankine cycle power generation system provided by the invention has the advantages of being simple in structure and convenient to use, and can be widely applied to the field of LNG cold energy power generation.

Owner:JIANGSU UNIV OF SCI & TECH +1

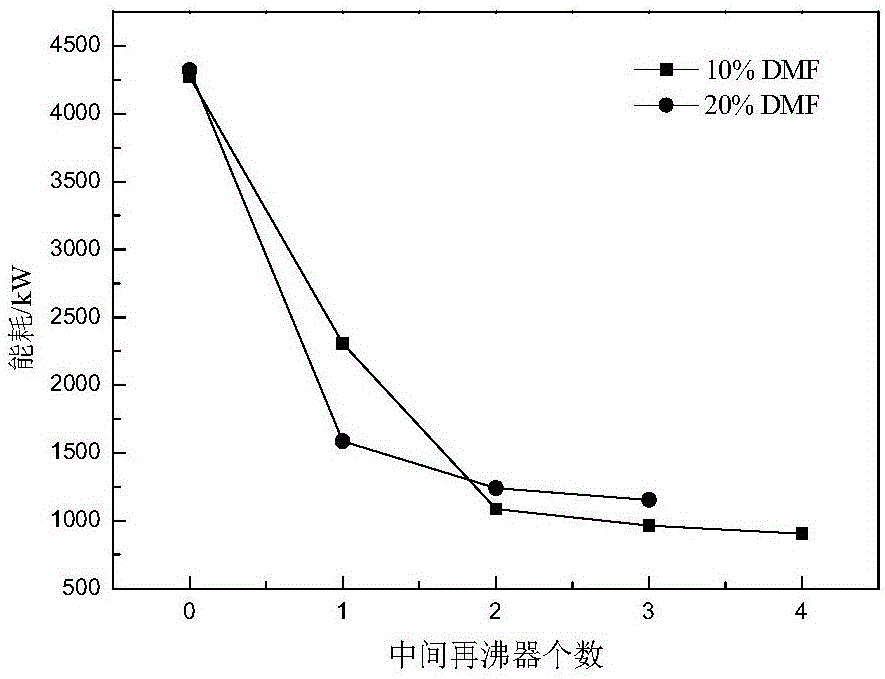

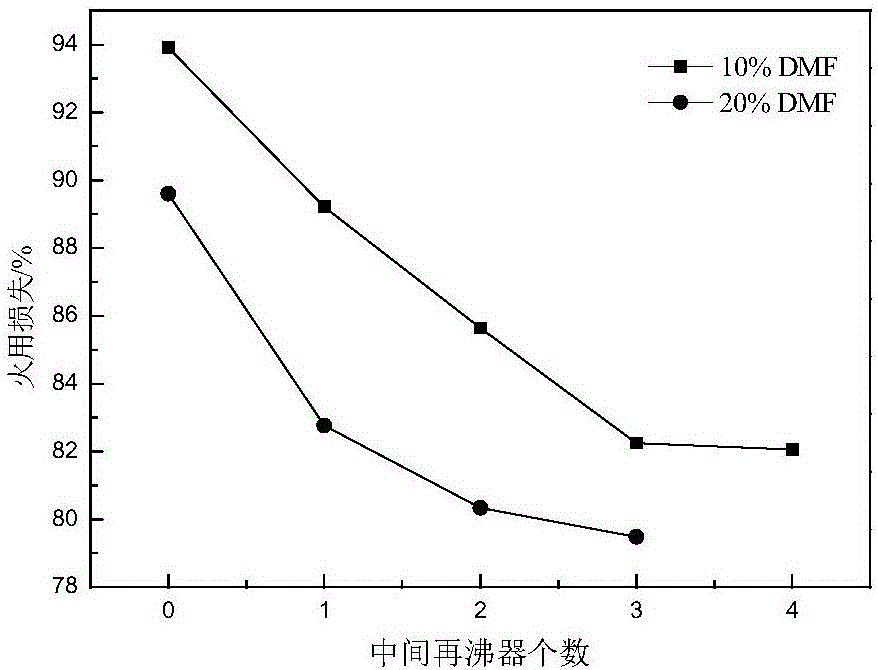

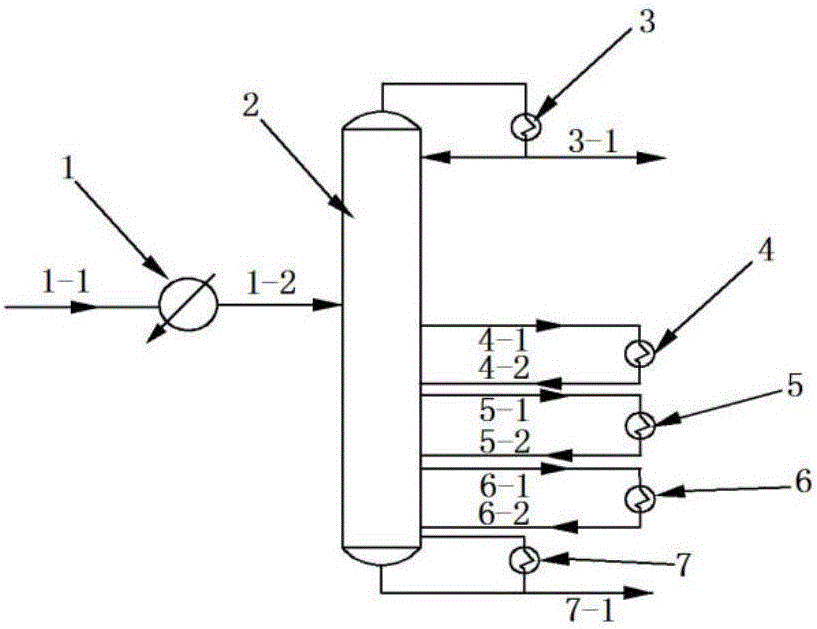

Low-concentration DMF wastewater treatment system by distillation method with multiple intermediate heat exchangers

InactiveCN106745421AReduce consumptionFlat heat transfer areaWater contaminantsCarboxylic acid amide separation/purificationIntermediate heat exchangerReboiler

The invention relates to a low-concentration DMF wastewater treatment system by a distillation method with multiple intermediate heat exchangers. The system comprises a raw material preheater, a normal-pressure rectification tower, a plurality of intermediate reboilers, an overhead condenser and a tower kettle reboiler, wherein DMF wastewater is preheated to a bubble point in the preheater and is separated in the rectification tower. According to the system, consumption of high-grade steam can be reduced by adopting the plurality of intermediate reboilers, and the material extracted from the side line of an intermediate plate is heated by steam having a relatively low energy grade, so that the consumption of steam at the tower bottom can be saved, and the thermodynamic efficiency of a separation system can be improved. Compared with a traditional rectification method, the system has the advantage that the thermodynamic efficiency can be increased by over 39 percent.

Owner:CHANGZHOU UNIV

Supercritical one-time diverting type longitudinal three-stage Rankine cycle power generation system

InactiveCN107780985AReduce exergy lossReduce heat transfer temperature differenceSteam engine plantsThree stageClosed loop

The invention relates to a supercritical one-time diverting type longitudinal three-stage Rankine cycle power generation system. The system comprises an LNG (liquefied natural gas) circulating pump and a sea water pump and also comprises a primary power generation unit, a secondary power generation unit and a tertiary power generation unit which are sequentially distributed in longitudinal arrays,wherein the primary power generation unit comprises a primary evaporator, a primary steam turbine, a primary condenser and a primary working medium pump which are connected sequentially to form a closed loop; the secondary power generation unit comprises a secondary evaporator, a secondary steam turbine, a secondary diverter, a secondary condenser, a secondary mixer and a secondary working mediumpump which are connected sequentially to form a closed loop; the tertiary power generation unit comprises a tertiary evaporator, a tertiary steam turbine, a tertiary diverter, a tertiary condenser, atertiary mixer and a tertiary working medium pump which are connected sequentially to form a closed loop. The supercritical one-time diverting type longitudinal three-stage Rankine cycle power generation system has the advantages as follows: the system is simple in structure, convenient to use and capable of being widely used in LNG cold energy power generation field.

Owner:JIANGSU UNIV OF SCI & TECH +1

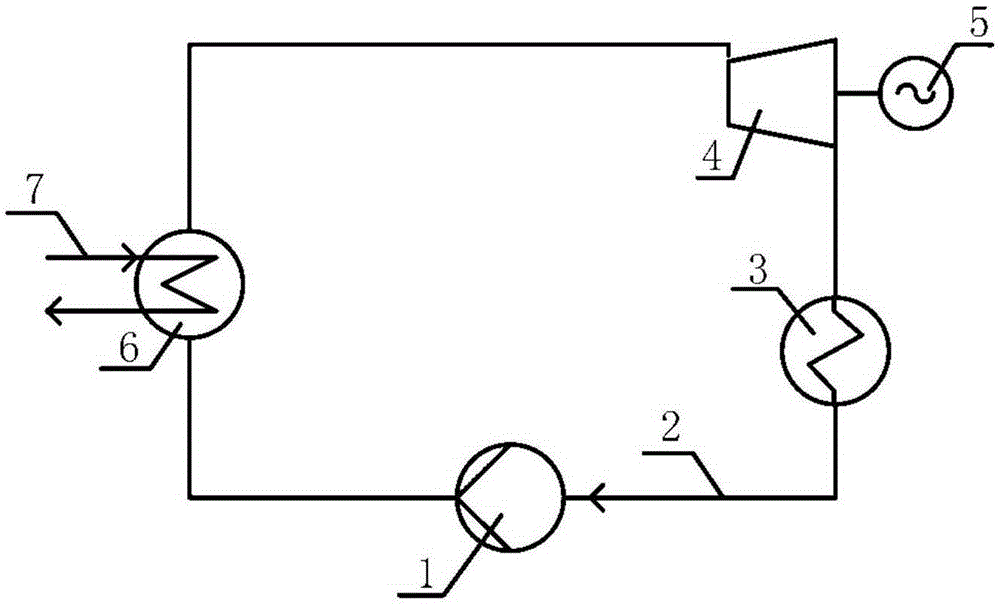

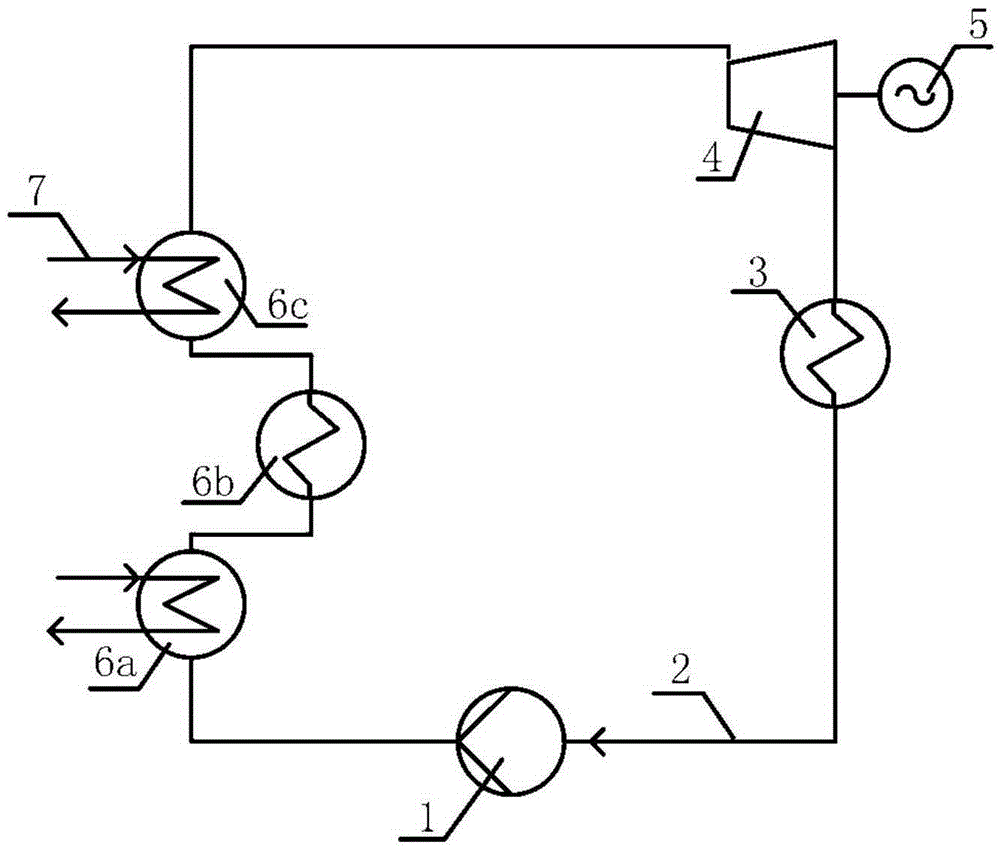

Rankine cycle system with phase change energy storage heat exchanger

ActiveCN106703908ASmall heat transfer temperature differenceReduce exergy lossFrom solar energySteam engine plantsElectric generatorEngineering

The invention provides a Rankine cycle system with a phase change energy storage heat exchanger. The Rankine cycle system comprises an overheating heat exchanger, heat-into-power conversion equipment, a condensation heat exchanger and a pump which are sequentially connected in series. The heat-into-power conversion equipment is connected with an electric generator. The Rankine cycle system further comprises the phase change energy storage heat exchanger and a preheating heat exchanger. One end of the phase change energy storage heat exchanger is connected with one end of the preheating heat exchanger, and the other end of the phase change energy storage heat exchanger is connected with the overheating heat exchanger. The other end of the preheating heat exchanger is connected with the pump. According to the Rankine cycle system provided by the invention, the phase change energy storage heat exchanger is combined with an existing Rankine cycle technology, the small heat transfer temperature difference between a working medium at the evaporation stage and a heat-transfer medium in cycle is guaranteed, the heat transfer temperature difference is kept unchanged, and the exergy loss of the system is reduced.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

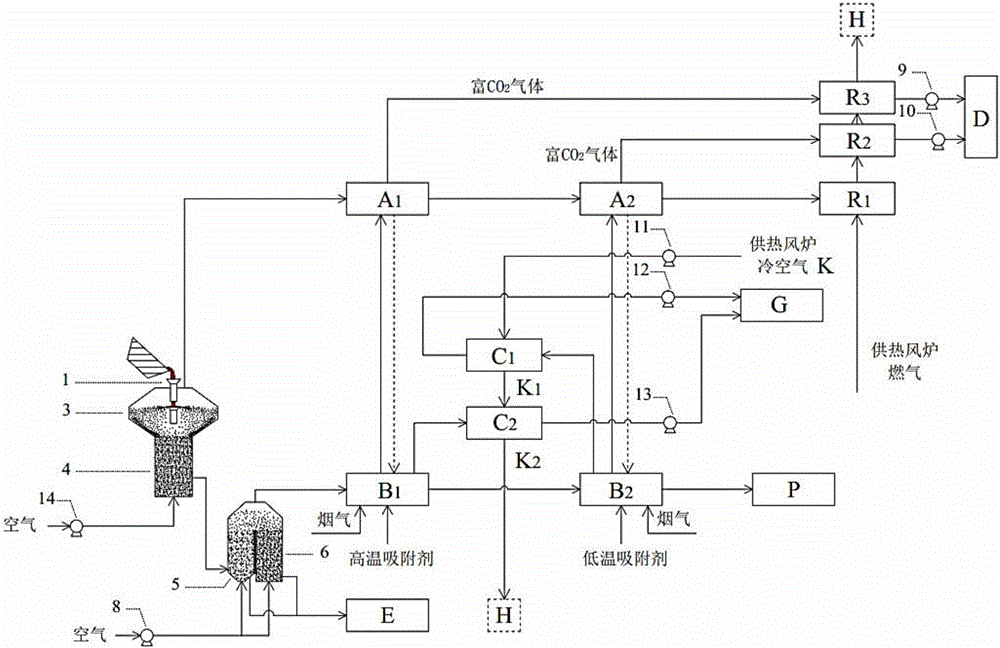

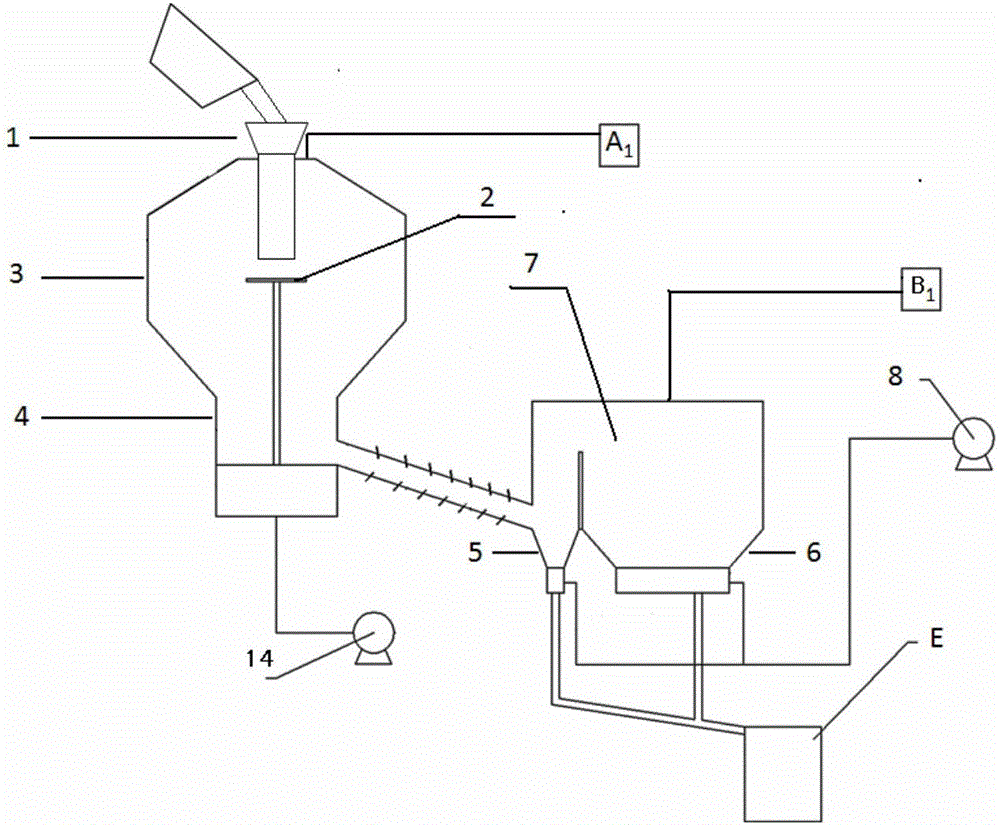

Blast furnace slag waste heat recycling and flue gas CO2 adsorption/desorption coupling system, and method

ActiveCN106521054AEmission reductionReduce exergy lossIncreasing energy efficiencyRecycling and recovery technologiesSlagSorbent

The invention discloses a blast furnace slag waste heat recycling and flue gas CO2 adsorption / desorption coupling system, and a method. The blast furnace slag waste heat recycling and flue gas CO2 adsorption / desorption coupling method comprises following steps: blast furnace slag is subjected to crushing and pelletizing so as to obtain blast furnace slag particles; heat exchange between the blast furnace slag particles and fluidizing air is carried out so as to obtain a first high temperature gas; after heat exchange, the blast furnace slag particles are delivered into a next grade furnace slag cooling device, secondary cooling of the blast furnace slag particles is carried out with fluidizing air so as to obtain a second high temperature gas; a high temperature adsorbent is delivered into a high temperature adsorption plant, flue gas to be treated is delivered into the high temperature adsorption plant, and the second high temperature gas is used for supplying the high temperature adsorption plant with heat energy, the high temperature adsorbent is used for adsorbing CO2 in the flue gas to be treated, and obtained purified flue gas is discharged. The blast furnace slag waste heat recycling and flue gas CO2 adsorption / desorption coupling method is capable of realizing graded high efficiency utilization of recycled blast furnace slag waste heat, and reducing available energy loss in waste heat recycling process; and a novel method is provided for energy conservation and emission reduction in the field of steel-smelting.

Owner:CHONGQING UNIV

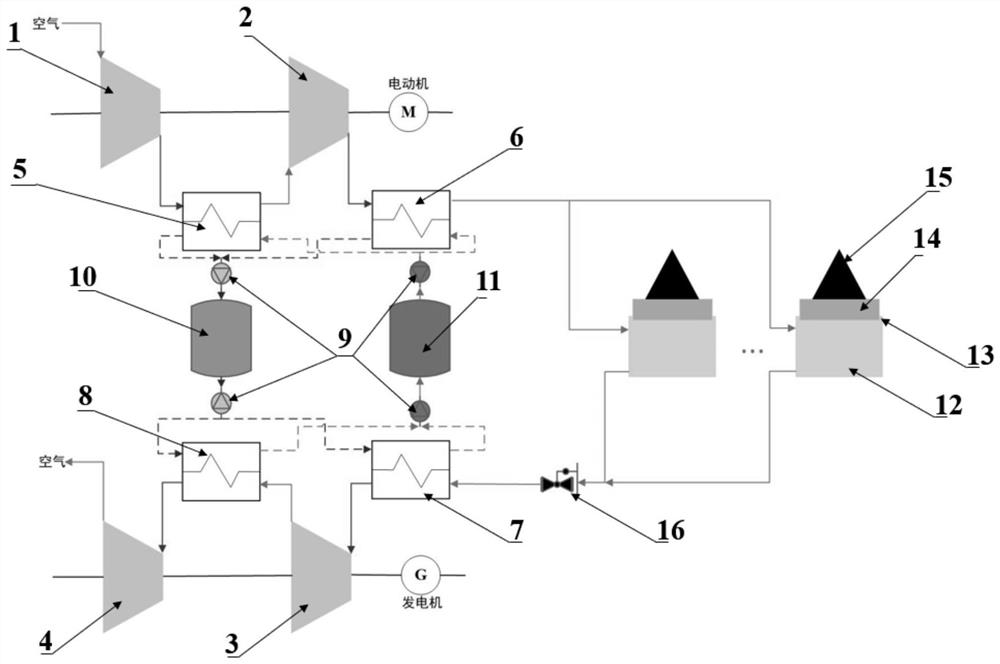

Gravity compressed air energy storage system and method based on coal yard of thermal power plant

PendingCN114087046AImprove efficiencyImprove energy storage capacitySteam useEnergy storageElectric generatorStorage tank

The invention discloses a gravity compressed air energy storage system and method based on a coal yard of a thermal power plant. In the system, a coal yard bearing plate is hermetically connected with the upper end of an air storage chamber; the input ends of the first-stage compressor and the second-stage compressor are connected with a motor, an outlet of the first-stage compressor is connected with a heat inlet of the first-stage interstage heat exchanger, and a heat outlet of the first-stage interstage heat exchanger is connected with an inlet of the second-stage compressor; an outlet of the second-stage compressor is connected with a heat inlet of the first-stage rear heat exchanger, and a heat outlet of the first-stage rear heat exchanger is communicated with the air storage chamber; the output ends of the first-stage expansion machine and the second-stage expansion machine are connected with a generator; an outlet of the air storage chamber is connected with a cold inlet of the second-stage front heat exchanger; an inlet of the first-stage expansion machine is connected with a cold outlet of the second-stage front heat exchanger, an outlet of the first-stage expansion machine is connected with a cold inlet of the second-stage inter-stage heat exchanger, and an inlet of the second-stage expansion machine is connected with a cold outlet of the inter-stage heat exchanger; and inlets and outlets of the heat storage tank and the cold storage tank are connected with the heat exchangers. The gravity energy storage technology and the compressed air energy storage technology are coupled.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

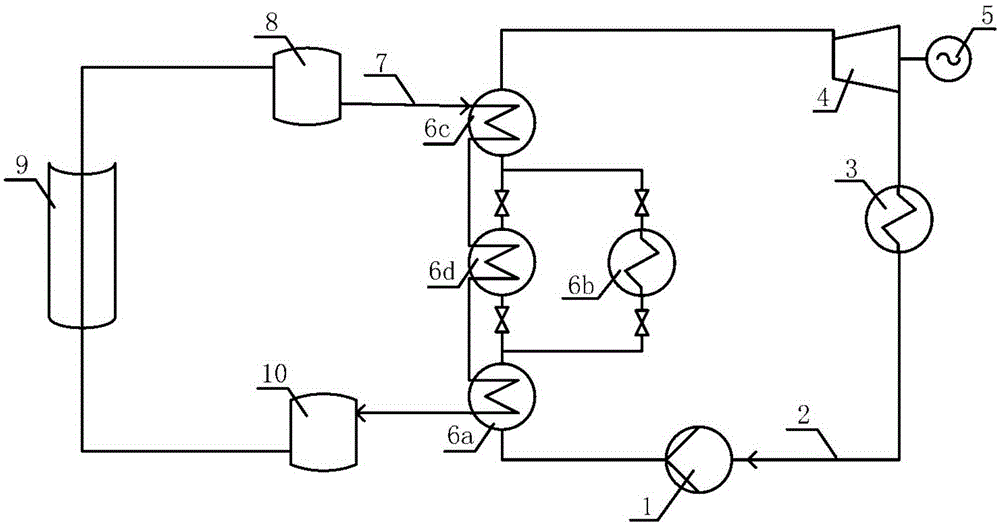

Non-azeotropic working medium dual-stage organic flash evaporation circulation system and heat energy recovery method thereof

InactiveCN110685764AExpand the scope of selectionRealize complementary advantagesSteam regenerationVapor–liquid separatorEngineering

The invention discloses a non-azeotropic working medium dual-stage organic flash evaporation circulation system and a heat energy recovery method thereof, and belongs to the field of energy recovery.A working medium exchanges heat with a waste heat medium in a heat exchanger after being pressurized by a working medium pump, and enters a high-pressure-stage gas-liquid separator after being throttled by a first throttle valve; a saturated steam after high-pressure-stage flash evaporation enters a high-pressure-stage turbine to do work through expansion, and saturated liquid is throttled again through a second throttle valve to change into a gas-liquid mixture; the gas-liquid mixture and exhaust gas are mixed in a high-pressure-stage mixer, and then enter a low-pressure-stage gas-liquid separator together; saturated steam after the low-pressure-stage flash evaporation enters a low-pressure-stage turbine to do work through expansion, saturated liquid is throttled through a third throttledvalve to change to a gas-liquid mixture, and the gas-liquid mixture and the exhaust gas are mixed in a low-pressure-stage mixer; and the gas-liquid mixture and the exhaust gas are jointly cooled in acondenser. The temperature matching between the circulation and a cold source is improved, the exergy loss caused by single-stage OFC direct throttling is reduced, the system efficiency is improved,and the stepwise efficient use of medium and low temperature thermal energy is realized.

Owner:YUNNAN UNIV

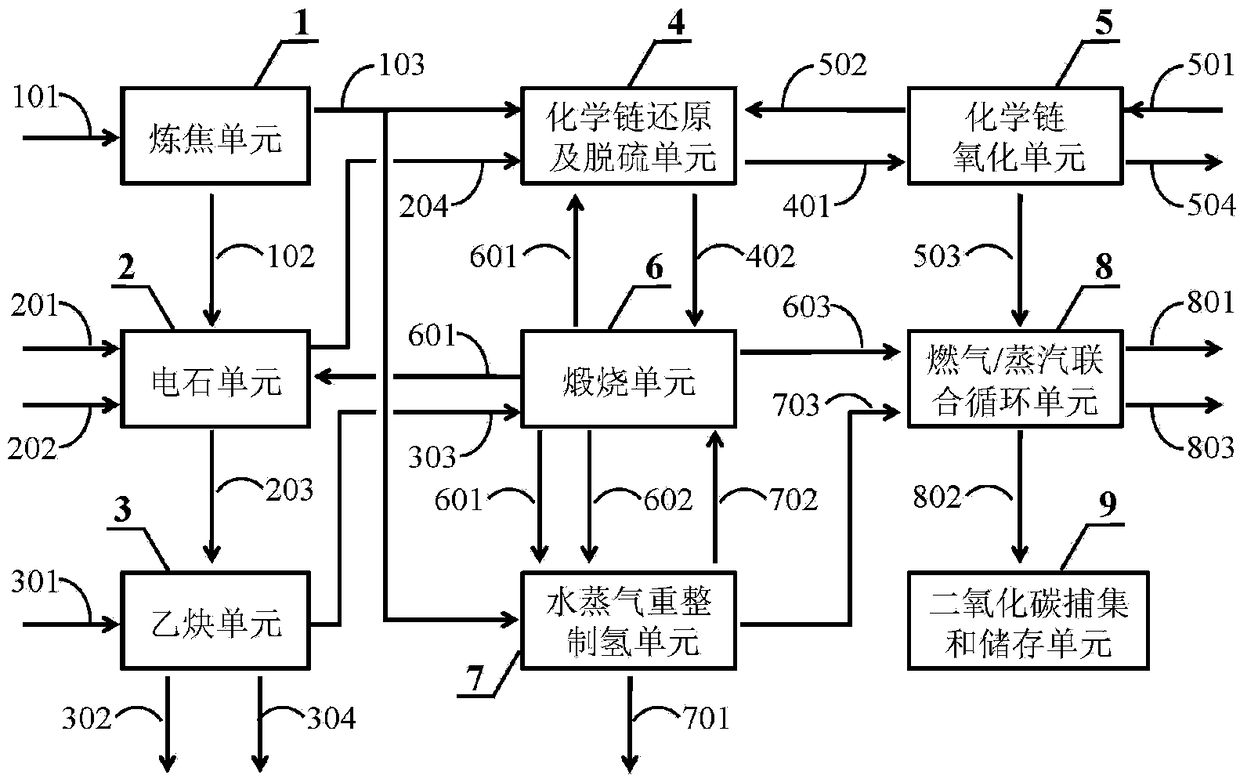

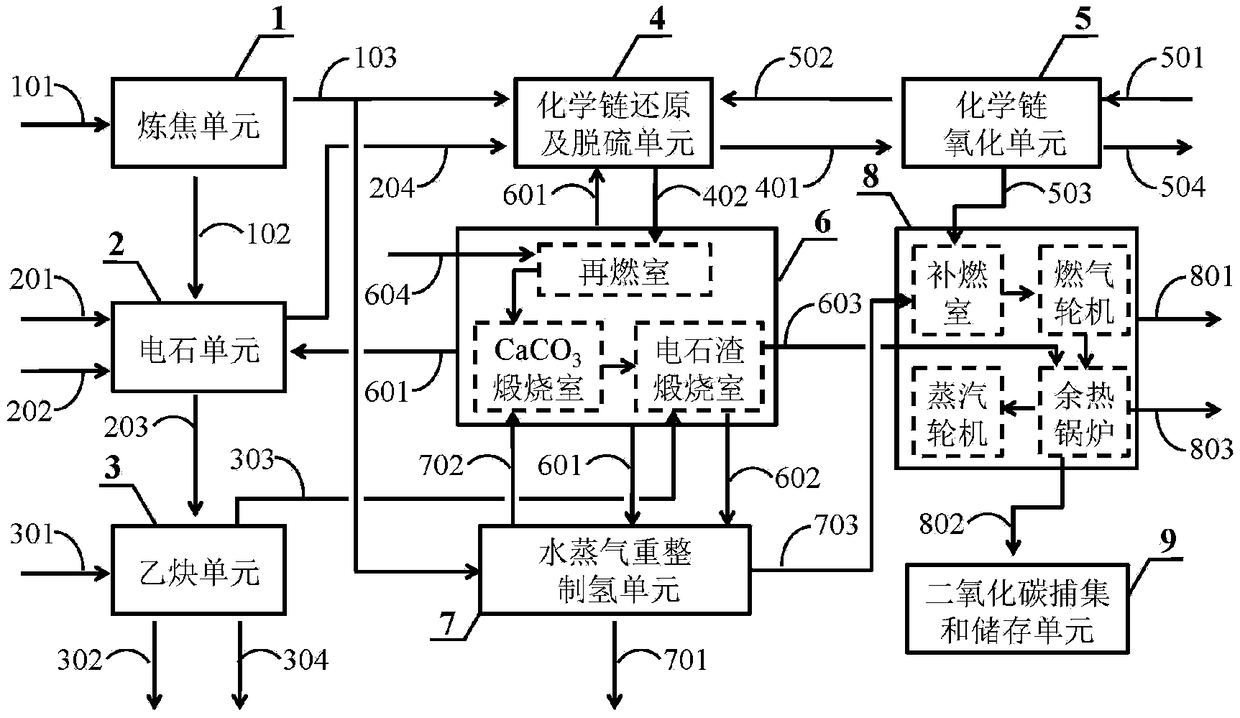

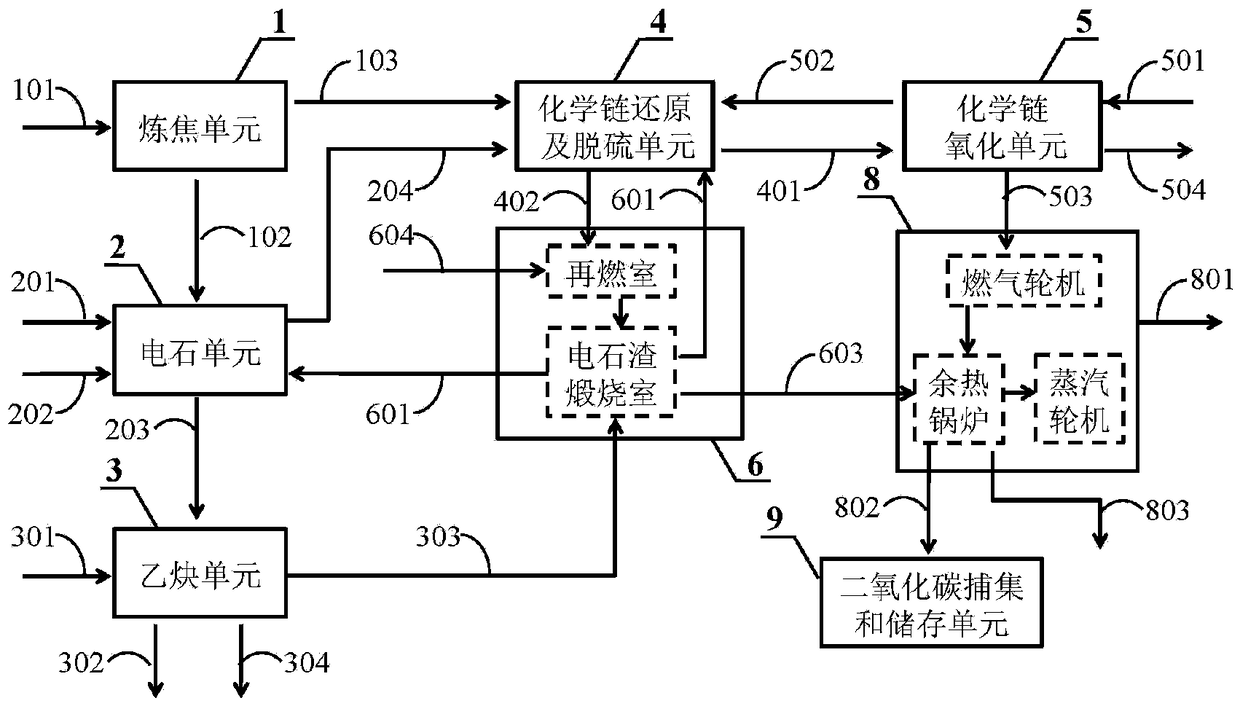

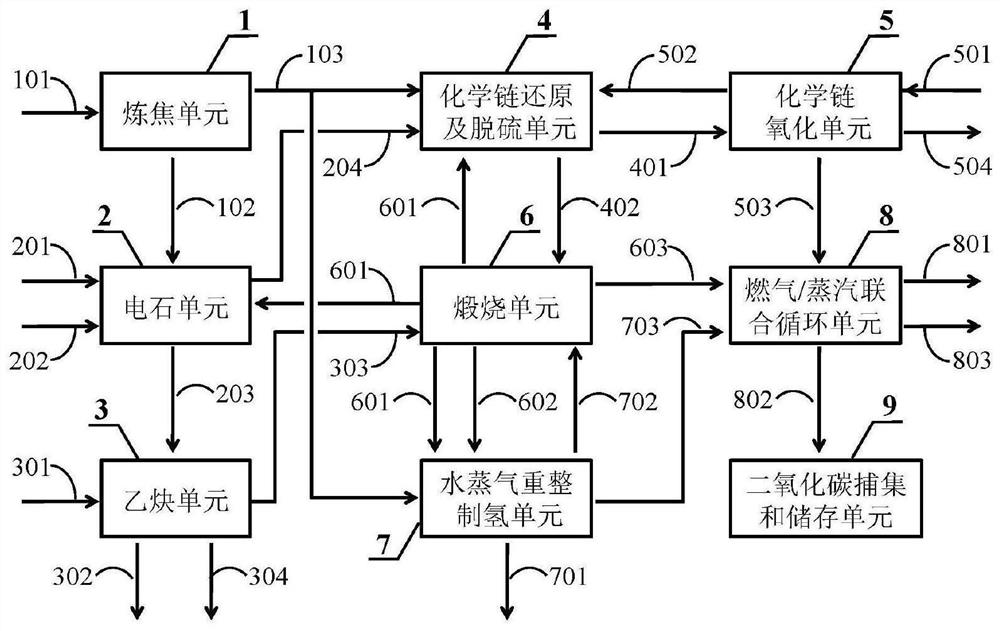

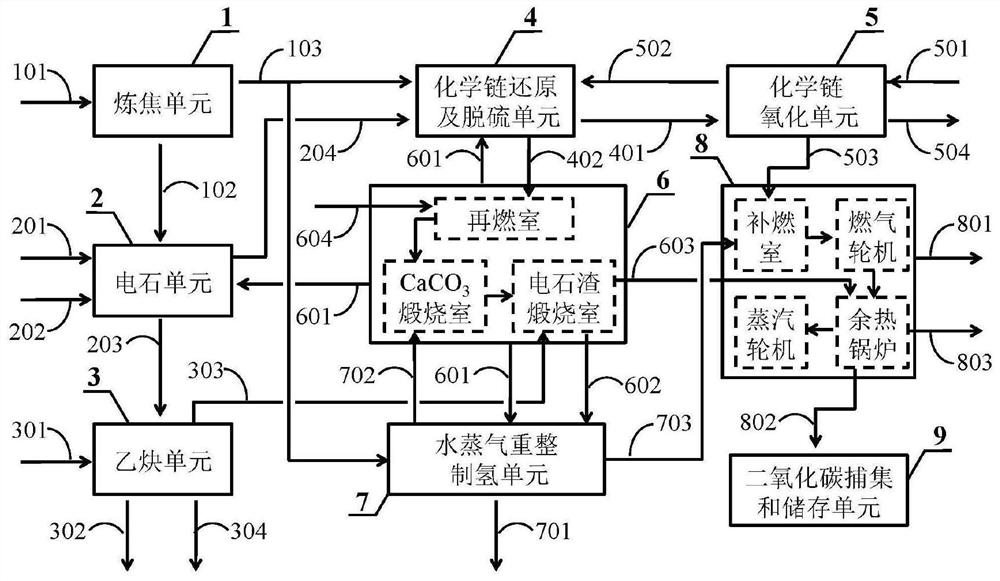

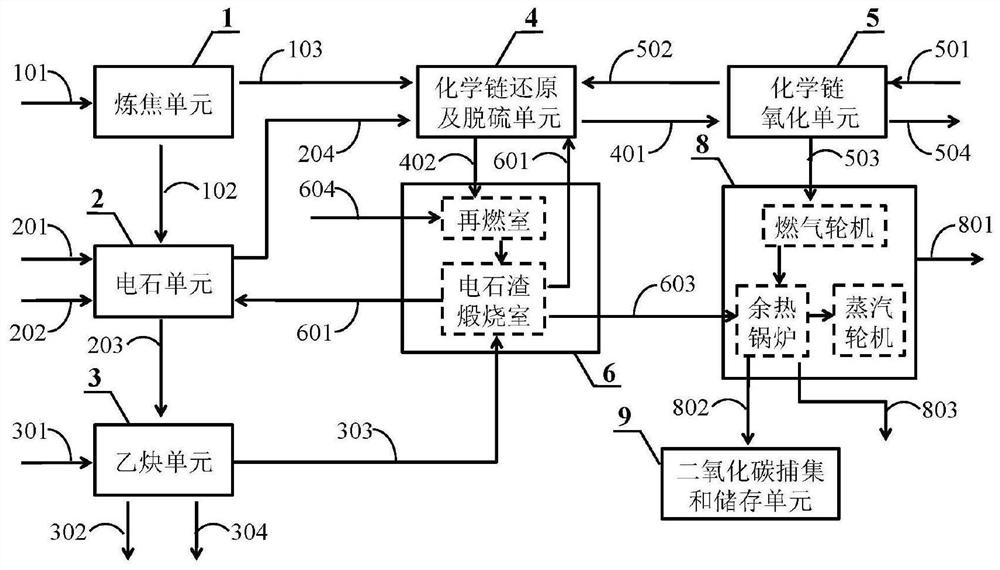

Power multi-generation system based on calcium-based compound and used in coal chemical industry

ActiveCN109266373AReduce processing costsReduce exergy lossChemical industrySpecial form destructive distillationSteam reformingChemical industry

The invention discloses a power multi-generation system based on a calcium-based compound and used in coal chemical industry. The system comprises a coking unit 1, a calcium carbide unit 2, an acetylene unit 3, a chemical chain reduction and desulfuration unit 4, a chemical chain oxidization unit 5, a roasting unit 6, a water steam reforming hydrogen production unit 7, a gas / steam united circulation unit 8 and a CO2 capture and storage unit 9. According to circular conversion of the system based on the calcium-based compound, efficient energy utilization and substance conversion are achieved.Compared with an existing process, the system directly uses calcium carbide furnace tail gas and coke oven gas as fuel, energy loss is reduced, and the treatment cost is saved; by adopting a chemicalchain combustion adopting mode, the fuel fire loss is reduced, meanwhile CO2 is captured, and greenhouse gas discharge is reduced; carbide slag is used as a desulfurizing agent, a chemical chain combustion oxygen carrier and a reforming hydrogen production absorbent, waste utilization is achieved; fuel gas produced after chemical chain combustion is used for combined cycled power generation, and the power generation efficiency of the system is improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Large-scale methanol multi-effect energy-saving rectifying device and process

ActiveCN102039058BMake full use ofReduce exergy lossOrganic compound preparationChemical industryWastewaterProcess engineering

The invention relates to large-scale methanol multi-effect energy-saving rectifying device and process. Main equipment used in the process sequentially comprises a pre-rectifying tower, a second rectifying tower, a pressurizing tower, an atmospheric tower and a recovering tower, wherein the tops of the second rectifying tower, the pressurizing tower and the atmospheric tower are respectively used for discharging refined methanol, the top of the recovering tower is used for discharging fusel oil, and the bottom is used for discharging purified wastewater. Because one rectifying tower is additionally arranged, and the process parameter of each tower is adjusted, two methanol multi-effect energy-saving rectifying processes by five towers are obtained, the effective energy loss is reduced, thereby energy consumption is reduced. In addition, the diameter of each tower is reduced, the amplification effect of relevant equipment, caused by the oversize diameter of each tower, is greatly reduced. The process has the advantages of reasonable design, the energy is fully and reasonably utilized in the process, the energy consumption of the whole device used in the process is reduced by 20%-30% higher than that of the device used in the traditional double-effect process, and the purity of a product reaches the American AA-level standard.

Owner:TIANJIN UNIV

Terrestrial heat generating system

InactiveCN104420900AReduce exergy lossImprove the efficiency of cycle power generationSteam engine plantsCondensation processPlate heat exchanger

The invention discloses a terrestrial heat generating system, and belongs to the technical field of generating systems. The terrestrial heat generating system comprises a generator, a heat exchanger, an absorbing device and a steam turbine; a water inlet of a heat exchange pipe of the heat exchanger communicates with a shell pass of the absorbing device through a solution pump, and a water outlet of the heat exchange pipe of the heat exchanger communicates with the shell pass of the generator; a steam outlet which communicates with an inlet of the steam turbine is arranged in the top part of the generator; an outlet of the steam turbine communicates with a housing of the absorbing device; a shell pass water inlet of the heat exchanger is connected with a shell pass water outlet of the generator; the shell pass water outlet of the heat exchanger is connected with the shell pass water inlet of the absorbing device through a throttle valve; a hot water circulating pipe is arranged in the generator; a cold water circulating pipe is arranged in the absorbing device; ammonia and water mixture is used as the circulating medium. The terrestrial heat generating system has the advantages that the ammonia and water mixture is used as the circulating medium, thus the useful energy loss caused by evaporating and condensing can be reduced, and the circulating generating efficiency can be raised.

Owner:郭庆梅

Method for recovering waste heat of thermal power plant and heating and supplying heat to hot water in a stepping way

ActiveCN101619662BImprove utilization efficiencyReduce exergy lossSteam useCombined combustion mitigationCooling towerSteam condensation

The invention discloses a method for recovering the waste heat of a thermal power plant and heating and supplying heat to hot water in a stepping way. In the method, low-temperature heat-net return water is firstly mixed with circulating cooling water positioned on an outlet of a cooling condenser or exchanges heat with the circulating cooling water positioned on the outlet of the cooling condenser to be increased in temperature and then sequentially delivered into an each-step vapour absorption type heat pump and a vapor-water heat exchanger in a series connection way to be gradually heated to be increased in temperature to heat supplying temperature and finally discharged through a water supplying pipeline; the circulating cooling water absorbs the waste steam condensation heat of a steam turbine in the cooling condenser, then one path of the circulating cooling water is directly mixed with the low-temperature heat-net return water or heats the low-temperature heat-net return water through the heat changer, the other path of the circulating cooling water is delivered into an each-step absorption type heat pump unit to be used as a low-order heat source of the absorption type heat pump unit, and the redundant heat of the circulating cooling water is discharged to the environment through a cooling tower. The invention uses the steam extraction of the steam turbine as a drivingheat source of the absorption type heat pump so that the low-temperature heat-net return water is heated in a stepping way, thereby reducing the effective energy loss; the waste heat of the discharged steam of the steam turbine is sufficiently recovered in a direct heating way and an absorption type heat pump temperature increasing heating way, therefore, the comprehensive energy usage efficiencyof the thermal power plant is enhanced.

Owner:TSINGHUA UNIV +1

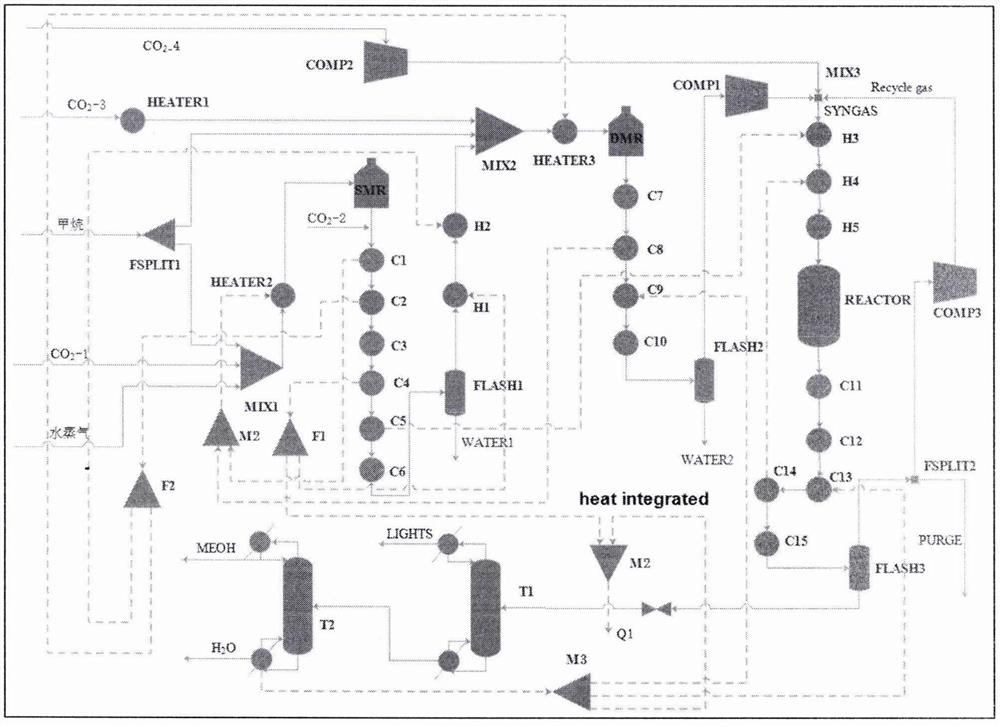

Heat-integrated process design for four carbon dioxide supplementing positions in methanol synthesis

PendingCN111943807AEmission reductionRealize the concept of sustainable green developmentHydrogenOrganic compound preparationPhysical chemistryProcess engineering

The invention discloses a heat-integrated process design for four carbon dioxide supplementing positions in methanol synthesis. First-stage steam methane reforming (SMR) and carbon dioxide methane reforming (DMR) are combined, carbon dioxide is supplemented in front of and behind an SMR reforming furnace, in front of the DMR reforming furnace and at circulating gas, and the whole process is subjected to heat integration. The process sequentially comprises the following steps: first-stage steam methane reforming, carbon dioxide methane reforming, compression, methanol synthesis and rectification to finally obtain refined methanol with the purity of 1 (mass fraction). The process design effectively solves the problems of high energy consumption, large CO2 emission and the like in the traditional methanol process.

Owner:CHONGQING UNIV

Hybrid electricity generation system

ActiveCN105509022AImprove power generation efficiencyReduce exergy lossSteam generation plantsMachines/enginesPower capabilityEngineering

The invention provides a hybrid electricity generation system. The hybrid electricity generation system comprises a steam turbine, an electricity generator, a condenser, a waste heat boiler and a biomass boiler, wherein the electricity generator is connected to the steam turbine and is used for converting the mechanical work into the electric energy, the condenser is connected to the steam turbine and is used for condensing waste steam exhausted by the steam turbine for forming condensation water, and the waste heat boiler and the biomass boiler are connected to the condenser; the waste heat boiler heats and evaporates the condensation water flowing into the waste heat boiler for obtaining a first branch of saturated steam; the biomass boiler heats and evaporates the condensation water flowing into the biomass boiler for obtaining a second branch of saturated steam; the waste heat boiler conveys the first branch of saturated steam to the biomass boiler, and the biomass boiler carries out superheating treatment on the first branch of saturated steam and the second branch of saturated steam through high-temperature biomass smoke for obtaining superheated steam and conveying the superheated steam to the steam turbine. According to the invention, the power capability of industrial waste heat is improved, the exergy loss of the biomass energy is reduced, and the electricity generation efficiency of the whole electricity generation system is improved.

Owner:TOP RESOURCE CONSERVATION & ENVIRONMENT CORP

Medium-low temperature heat source generating set based on energy cascade utilization and thermal circulation method thereof

The invention relates to a medium-low temperature heat source generating set based on energy cascade utilization and a thermal circulation method thereof. The medium-low temperature heat source generating set comprises a top cycle system assembly and a bottom cycle system assembly connected with the top cycle system assembly. On the basis of the principle of energy cascade utilization, the generating set is formed by connecting two different medium-low temperature heat source generating cycles in parallel, wherein the top cycle is an organic matter Rankine cycle, and the bottom cycle is a Kalina cycle; and the thermal efficiency of the Kalina cycle at the bottom is higher than that of the organic matter Rankine cycle when electricity is generated by using the lower temperature heat sourcedischarged from the top cycle. The invention is more suitable for recycling low-grade heat sources, conforms to the principle of energy cascade utilization as compared with the original technique. Thus, the thermal efficiency of the generating set of the invention is further enhanced.

Owner:上海交通大学中原研究院

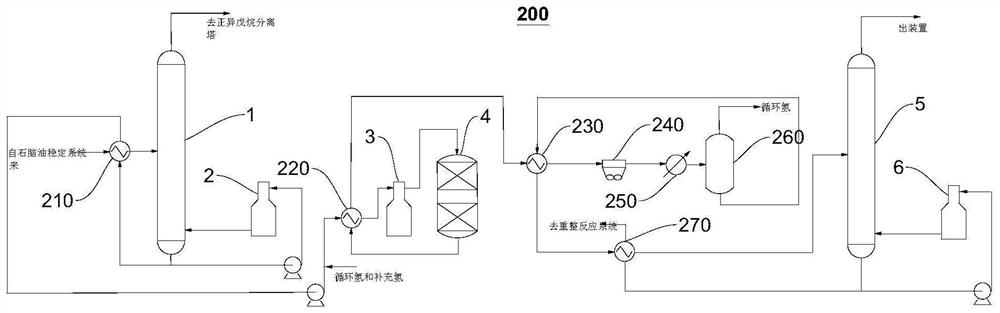

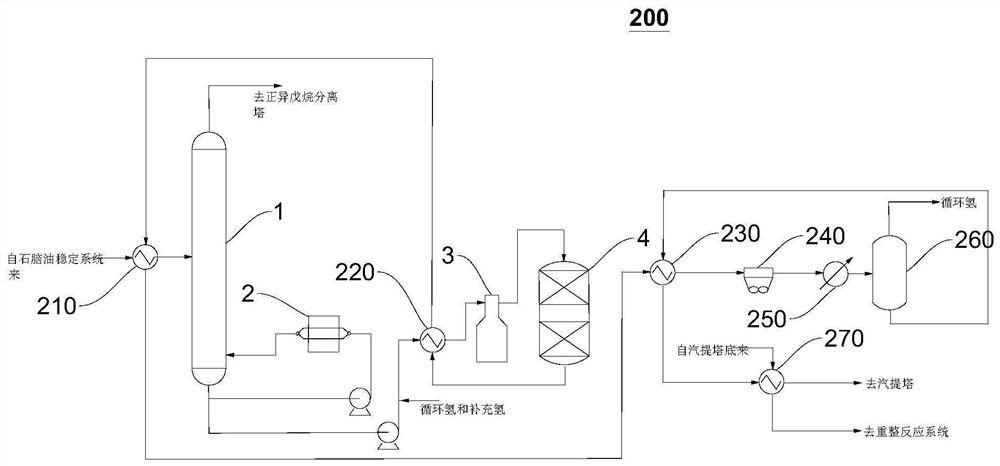

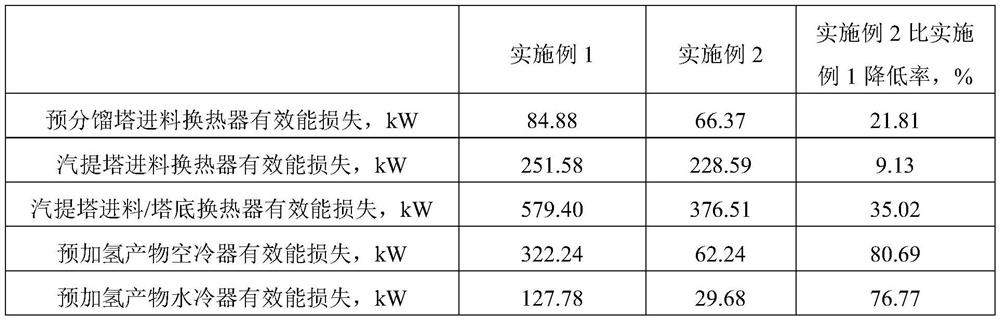

A reforming pretreatment system, reforming pretreatment method and application

ActiveCN111534327BImprove energy savingIncrease temperatureTreatment with hydrotreatment processesCatalytic reformingPretreatment method

The invention discloses a reforming pretreatment system, a reforming pretreatment method and an application thereof, and relates to the technical field of catalytic reforming. On the basis of studying the characteristics of the process flow of the reforming pretreatment system and combining the first and second laws of thermodynamics, the optimal design of the effective energy recovery and utilization of the pretreatment system is carried out. By fully recovering the heat of the pre-hydrogenation reaction product, the naphtha feed of the pre-fractionation tower is added to exchange heat with the pre-hydrogenation reaction product, the temperature of the depentanized oil at the bottom of the pre-fractionation tower is increased, and the bottom oil of the pre-fractionation tower is separated from the pre-fractionation tower bottom oil. The hydrogenation feed heat exchanger directly performs heat exchange and temperature rise, which saves the energy consumption of the heating furnace and reduces the loss of effective energy. Compared with the prior art, the energy saving effect of the reforming pretreatment system provided by the present invention is obvious.

Owner:CHINA PETROLEUM & CHEM CORP +1

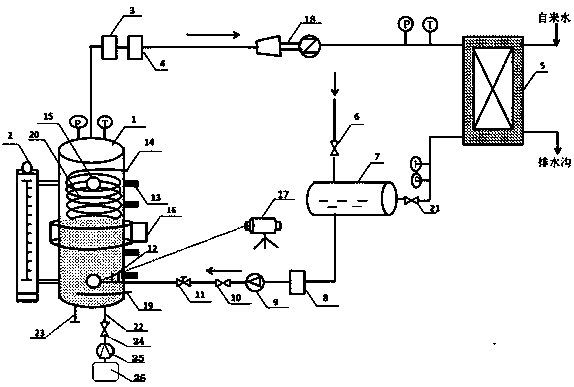

A direct contact compound heat exchange system

ActiveCN109945681BIncrease profitSimple structureSteam separation arrangementsDirect contact heat exchangersLiquid storage tankInternal heat transfer

The invention discloses a direct contact composite type heat exchange system. The system comprises a heat exchanger, a liquid level apparatus, a gas and liquid separator, a gas mass flowmeter, a platetype condenser, a stop valve I, a vacuum liquid storage tank, a liquid mass flowmeter, a centrifugal pump, a check valve, a manual adjusting valve, a nozzle, a turbine generator, a spiral channel, astop valve II, a heat conduction oil inlet, a heat conduction oil outlet, a valve, a pump, a heat conduction oil storage tank, multiple pressure meters, and multiple thermometers. Heat media enter thespiral channel, the reverse flow manner from top to bottom is adopted for transferring heat to matter in the heat exchanger, the stirring in the heat exchanger is increased, the two-phase flow innerheat transfer is greatly reinforced, and when the system is applied to the power generation field, the power generation efficiency is higher; and compared with an outer heating device of a common direct contact heat exchanger, the inner spiral channel makes direct contact with the heat exchanger, the heat exchange process can be reduced, the fire losses are reduced, and the energy use rate is improved.

Owner:KUNMING UNIV OF SCI & TECH

A coal chemical power polygeneration system based on calcium-based compounds

ActiveCN109266373BReduce processing costsReduce exergy lossChemical industrySpecial form destructive distillationSteam reformingChemistry

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Internal energy integrated rectification device and rectification method using same

PendingCN112742057AReduce exergy lossReduce separation energy consumptionFractional distillationReboilerSuperheater

An internal energy integrated rectification device comprises a rectification tower with an inner layer tower body and an outer layer tower body, the outer layer tower body is a stripping section, the inner layer tower body is a rectification section, a feed inlet I formed in the upper portion of the outer layer tower body is externally connected with a feed preheater, a liquid outlet I is formed in the bottom of the outer layer tower body, and the liquid outlet I is connected with a tower bottom discharge pipe and connected with a feed inlet V after passing through a reboiler; a gas outlet I is formed in the top of the outer layer tower body, is externally connected with a compressor inlet superheater and a compressor in sequence, and is connected with a feeding hole II in the bottom of the inner layer tower body; a gas outlet II is formed in the top of the inner layer tower body, is externally connected with a compressor inlet superheater and a feeding preheater in sequence and then is connected with a tower top discharging pipe and a feeding hole III in the top of the inner layer tower body; a liquid outlet II is formed in the bottom of the inner layer tower body and is connected with a feeding hole I after passing through a reboiler and a throttling valve in sequence; a silk screen condensation plate is arranged below the top gas outlet I in the outer layer tower body; and liquid distribution devices and packing layers which are distributed at intervals are arranged in the outer layer tower body and the inner layer tower body. When the device is used for rectification, the effective energy loss in the rectification process is reduced, and the separation energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Multistage deep air dehumidification device for ultra-low dew point environment

ActiveCN108758807BAchieve a reasonable matchReduce exergy lossAir treatment detailsLighting and heating apparatusFresh airEngineering

Owner:SOUTHEAST UNIV

Supercritical rankine cycle power generation system with two transverse stages and one longitudinal stage

The invention relates to a supercritical rankine cycle power generation system with two transverse stages and one longitudinal stage. The supercritical rankine cycle power generation system with two transverse stages and one longitudinal stage comprises an LNG circulation pump, a seawater pump, a first-stage power generation unit, a second-stage power generation unit and a third-stage power generation unit; the first-stage power generation unit and the second-stage power generation unit are transversely distributed in parallel; the first-stage power generation unit comprises a first-stage evaporator, a first-stage steam turbine, a first-stage condenser and a first-stage working medium pump which are sequentially connected with one another through a pipeline to form a closed loop; the second-stage power generation unit comprises a second-stage evaporator, a second-stage steam turbine, a second-stage condenser and a second-stage working medium pump which are sequentially connected with one another through a pipeline to form a closed loop; and the third-stage power generation unit is longitudinally distributed above the first-stage power generation unit and the second-stage power generation unit and comprises a third-stage evaporator, a third-stage steam turbine, a third-stage shunt, a third-stage mixer and a third-stage working medium pump. The supercritical rankine cycle power generation system has the advantages that by adopting an LNG cold energy to perform power generation, an LNG high-grade cold energy is effectively utilized, and energy consumption and water source consumption of an enterprise in the LNG gasification process are reduced.

Owner:JIANGSU UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com