A direct contact compound heat exchange system

A heat exchange system and compound technology, which is applied in the field of direct contact compound heat exchange system, can solve problems such as the utilization gap of low-temperature waste heat resources, and achieve the effects of preventing high-temperature thermal decomposition, preventing safety accidents, and simplifying the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

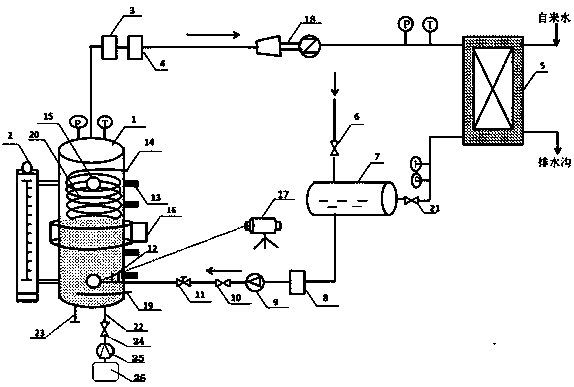

[0020] A direct contact compound heat exchange system, such as figure 1 Shown, including heat exchanger 1, liquid level meter 2, gas-liquid separator 3, gas mass flow meter 4, plate condenser 5, shut-off valve I 6, vacuum liquid storage tank 7, liquid mass flow meter 8, centrifugal pump 9 , Check valve 10, manual control valve 11, nozzle 12, 7 thermocouples 13, spiral channel inlet 14, 2 visible windows 15, 12-electrode electrical capacitance tomography system (ECT) 16, high-speed camera 17, turbine power generation Machine 18, spiral channel outlet 19, spiral channel 20, stop valve Ⅱ 21, heat transfer oil inlet 22, heat transfer oil outlet 23, valve 24, pump 25, heat transfer oil tank 26, multiple pressure gauges, multiple thermometers;

[0021] A spiral channel 20 is arranged inside the heat exchanger 1, the diameter of the spiral channel 20 is 0.8 of the inner diameter of the heat exchanger 1, the spiral channel inlet 14 is arranged on the upper part of the heat exchanger 1 an...

Embodiment 2

[0028] A direct contact compound heat exchange system, in which the spiral channels 20 of Example 1 are increased to two, the spiral channels 20 have the same inner diameter, which is 0.5 of the inner diameter of the heat exchanger 1, and the two spiral pipes are coaxial with the heat exchanger 1. The two spiral pipes are respectively provided with a spiral channel inlet 14 and a spiral channel outlet 19. The spiral channel 20 is a steel spiral channel. The heating medium connected to the spiral channel 20 is hot wastewater. The flow inlet of the hot wastewater is 3L / min. The inlet temperature of the hot waste water at the channel inlet 14 is 100°C, and the outlet temperature is 20°C. The other components and the connection relationship between the components are the same as in Embodiment 1.

[0029] Experiments were conducted with two different devices, the heat exchange system of this embodiment and the conventional direct contact heat exchanger. The experimental results show th...

Embodiment 3

[0031] A direct contact compound heat exchange system. The spiral channels 20 of Example 1 are increased to four. The four spiral channels 20 have the same inner diameter, which is 0.6 of the inner diameter of the heat exchanger 1. The four spiral pipes are all connected to the heat exchanger. 1 Coaxially arranged, each spiral pipe is provided with a spiral channel inlet 14 and a spiral channel outlet 19 respectively. The spiral channel 20 is a steel spiral channel. The heating medium connected by the two spiral channels 20 is hot wastewater. The inlet flow rate of the hot wastewater is 3L / min, the inlet temperature of the hot waste water at the inlet 14 of the spiral channel is 100°C, and the outlet temperature is both 20°C. The heating medium connected to the remaining two spiral channels 20 is hot flue gas, and the hot flue gas flow inlet is 5L / min. The inlet temperature of the hot flue gas at the inlet 14 is 100°C, and the outlet temperature is 20°C. The other components an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com