Patents

Literature

40results about How to "Easy to implement modular design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

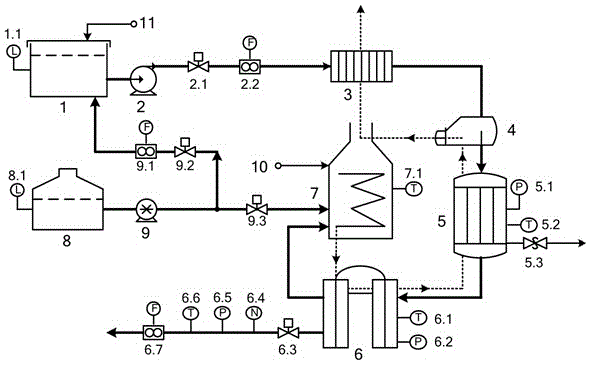

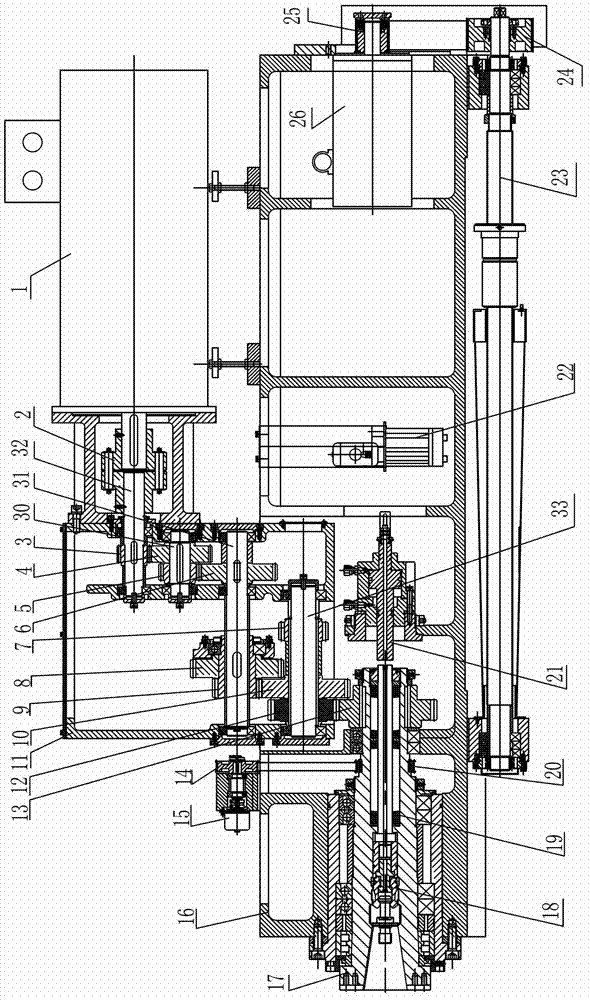

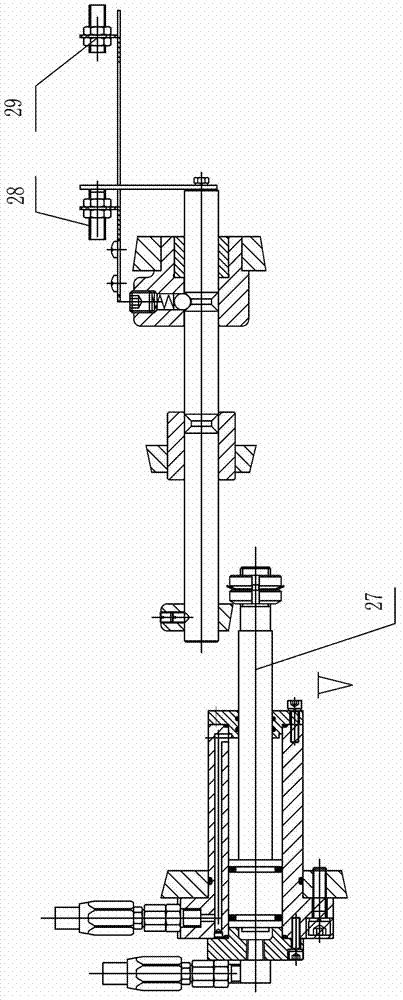

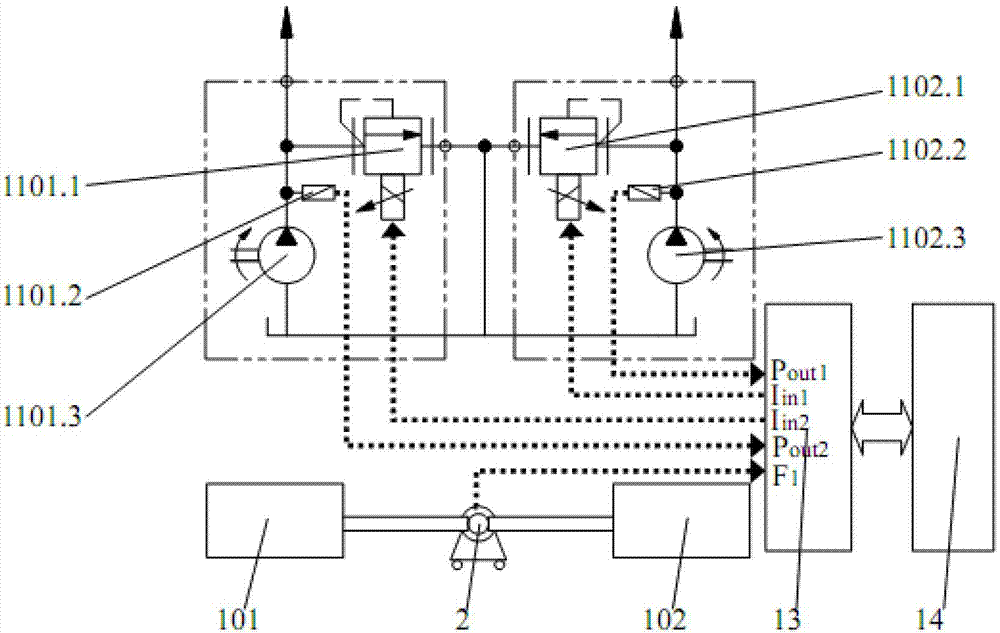

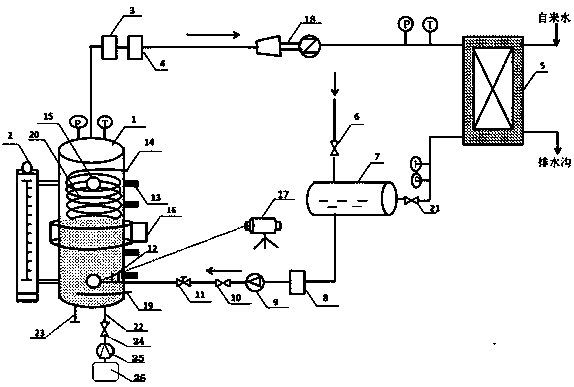

Online high-purity hydrogen preparation system for fuel cell and control method of online high-purity hydrogen preparation system

ActiveCN105152133AReduce energy consumptionLower requirementHydrogenSolid electrolyte fuel cellsHydrogen purityOxygen

The invention discloses an online high-purity hydrogen preparation system for a fuel cell. The online high-purity hydrogen preparation system comprises a methyl alcohol box as well as a raw material box and a catalytic burner which are connected with the methyl alcohol box through a methyl alcohol metering pump, wherein a fuel cell discharge water inlet is formed in the raw material box, an oxygen inlet is formed in the catalytic burner, an ethanol water metering pump and a heat exchanger are sequentially connected onto the raw material box, a vaporizer is connected onto the heat exchanger, a reforming reactor is connected onto the vaporizer, a palladium film purifier is connected onto the reforming reactor, and the palladium film purifier is connected with the catalytic burner; the invention further discloses a control method of the system. According to the system provided by the invention, online hydrogen supplying is performed through a manner of using a methanol water reforming reaction to produce hydrogen, the yield of pure hydrogen is controlled through adjusting the flow of an ethanol water mixture; the method has the characteristics of high hydrogen storage density, high hydrogen purity, low energy consumption, compact structure, simpleness and convenience in start-stop controlling, easiness in implementing modular design and the like.

Owner:武汉氢能与燃料电池产业技术研究院有限公司

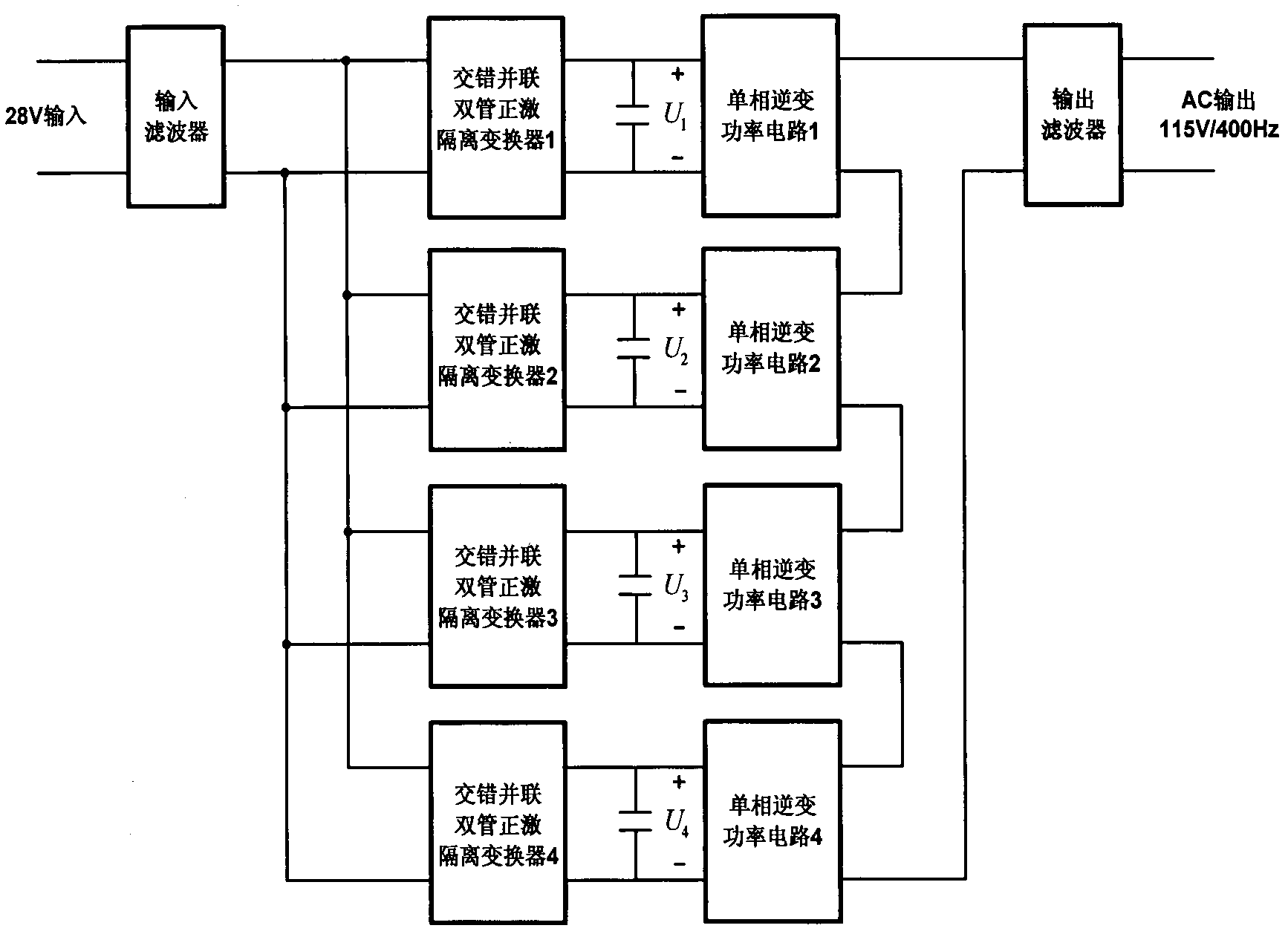

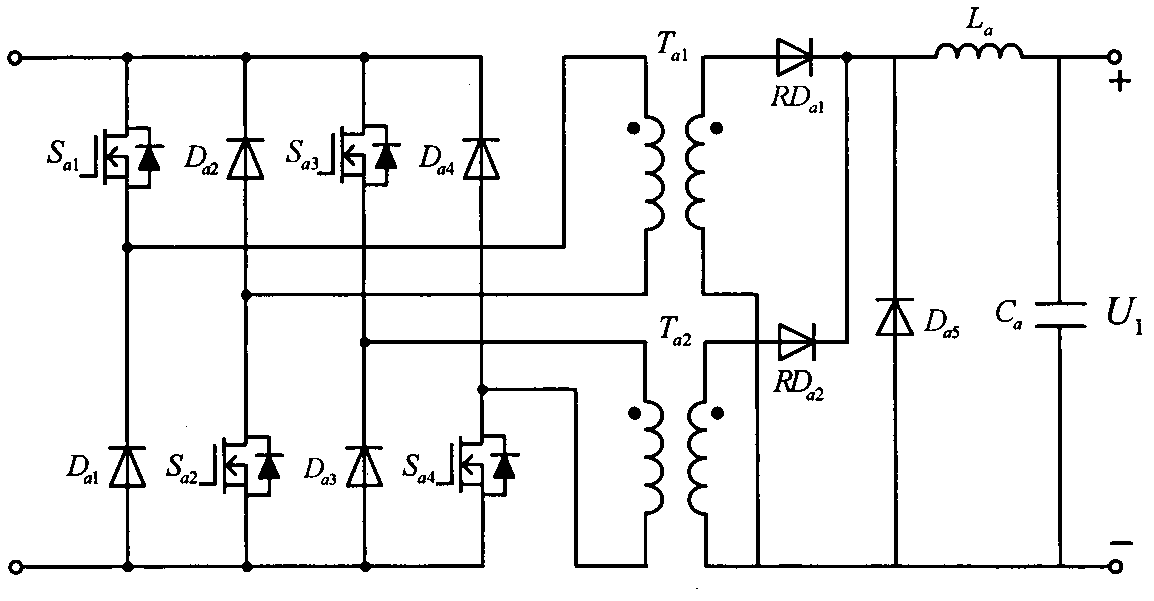

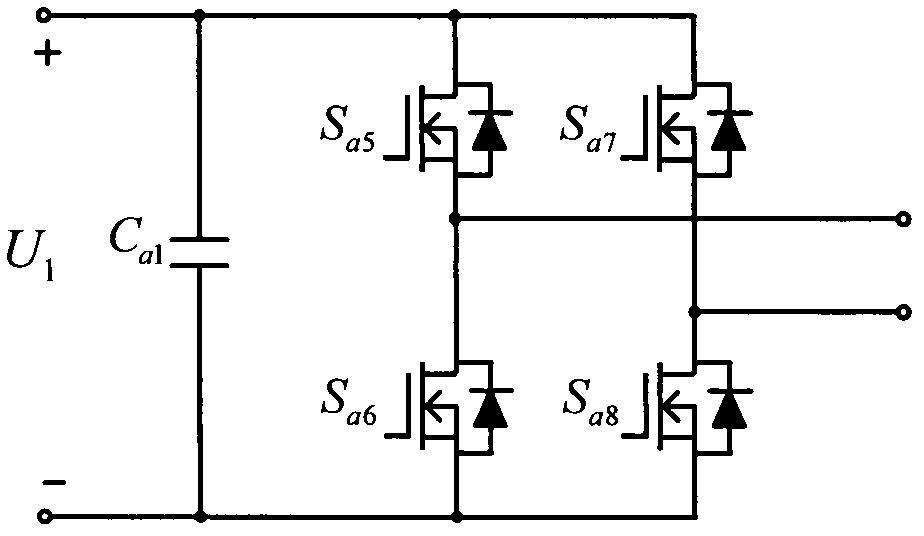

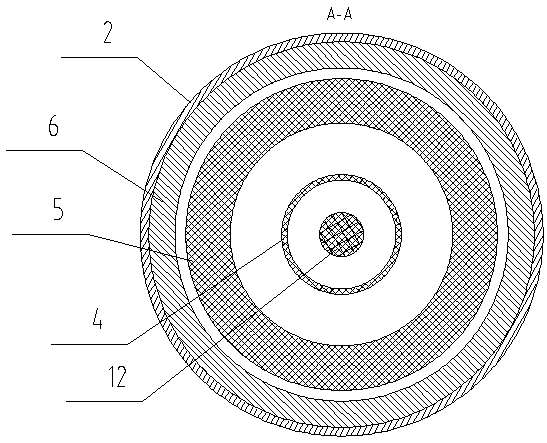

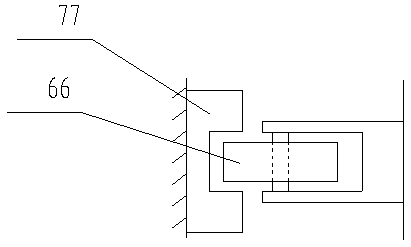

Cascade type time-interval variable-order multi-level static converter

InactiveCN102332839ASimple structureSimple modular structureDc-dc conversionElectric variable regulationDouble tubeTotal harmonic distortion

The invention provides a cascade type time-interval variable-order multi-level static converter, which can be modularized; a previous-stage four-way isolation DC-DC (Direct-Current-Direct-Current) converter (1) is connected to a subsequent-stage four-unit cascade inverter (2); a novel time-interval variable-order multi-level control circuit (3) is connected between the previous stage and the subsequent stage; the converter is characterized in that the previous stage is adopted with four ways of mutually independent, staggered and parallel double-tube forward direct-current converters; the subsequent stage is a cascade structure composed of four single-phase H bridges; a carrier phase-shifting frequency-doubling SPWM (Sinusoidal Pulse Width Modulation) technology is adopted; the time-interval variable-order multi-level control circuit is connected between the previous stage and the subsequent stage; the previous stage of the static converter is beneficial to reducing input current ripple and reducing the volume of a filter; the subsequent stage is low in voltage stress of a power switch device, high in circuit modularization degree and low in loss; and, by means of the time-interval variable-order multi-level control circuit, on the premise of not increasing the number of independent sources of the previous stage, the more level number of output can be realized, and the THD (Total Harmonic Distortion) of the harmonic wave is low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

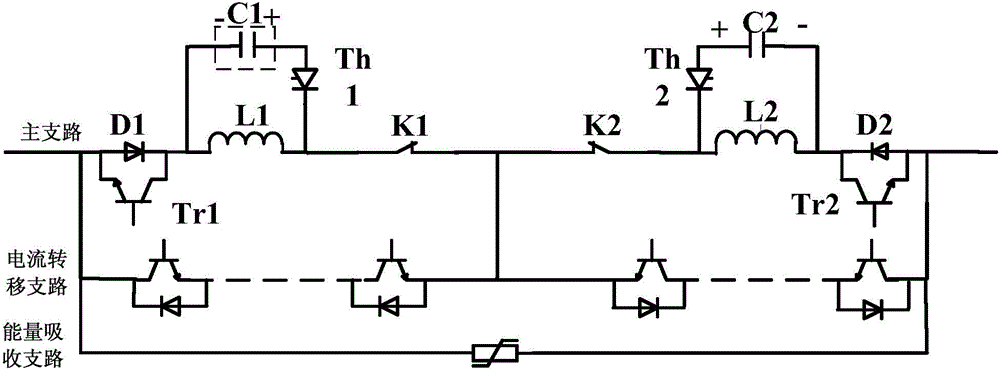

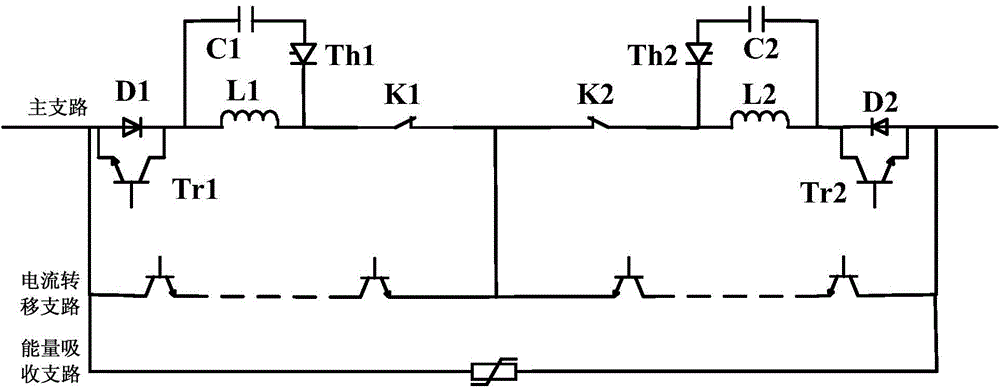

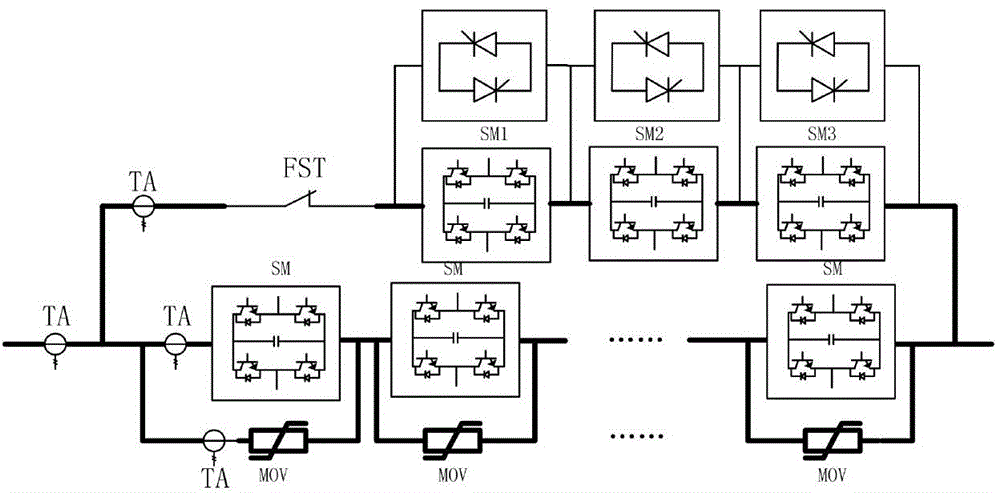

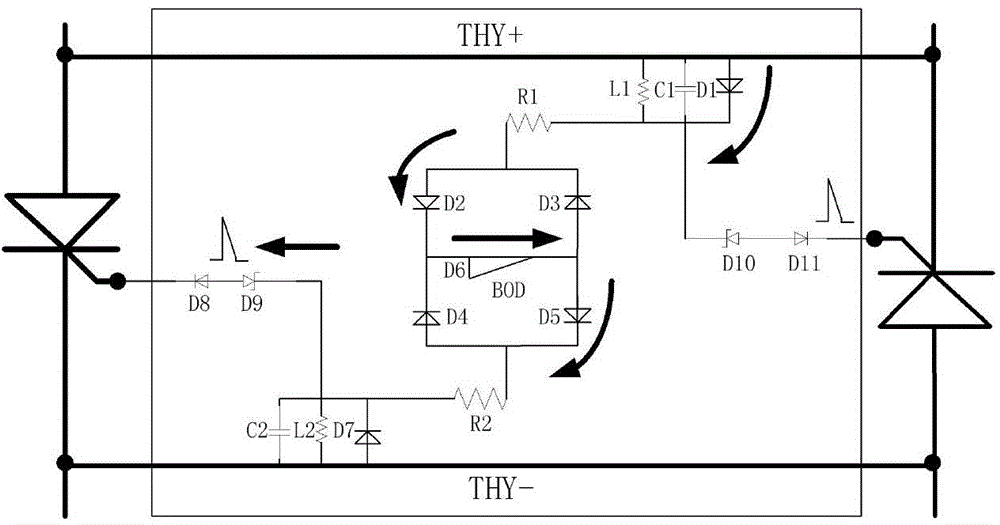

High voltage direct current circuit breaker topology circuit

ActiveCN104158171AReduce on-state lossImprove flow capacityDc network circuit arrangementsMain branchPower flow

The invention provides a high voltage direct current circuit breaker topology circuit which comprises a main branch, a current transfer branch and an energy absorption branch. The main branch, the current transfer branch and the energy absorption branch are connected in parallel. According to the high voltage direct current circuit breaker topology circuit provided by the invention, the structure of a circuit topology is simple; a stable current zero crossing point is in a breaking process; and the high voltage direct current circuit breaker topology circuit has the advantages of convenient control, flexible application, easy realization, high current breaking capacity, high withstand voltage level, high expansibility and low equipment cost.

Owner:STATE GRID CORP OF CHINA +2

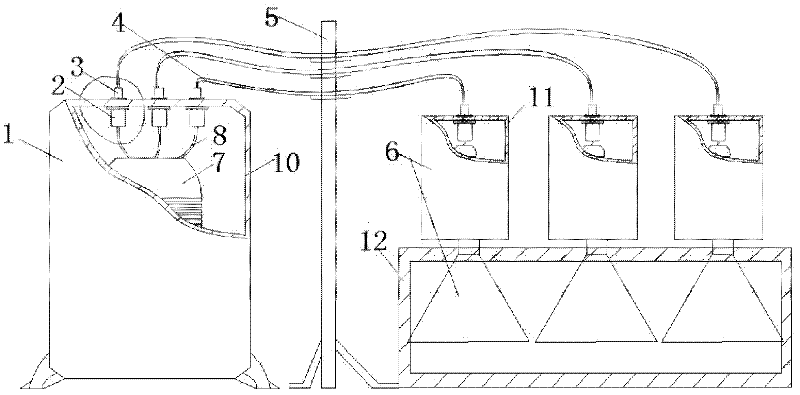

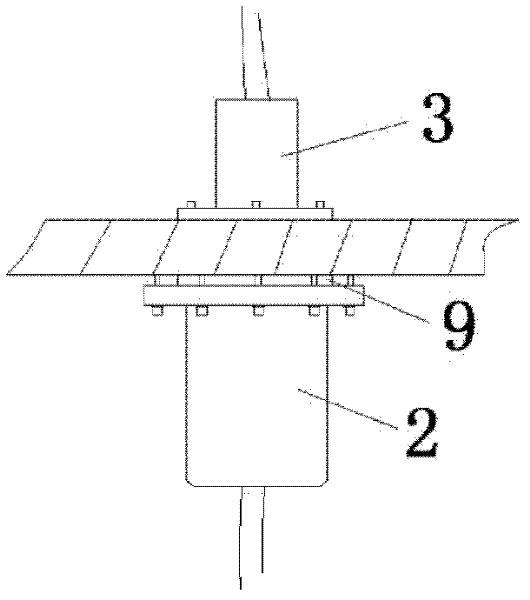

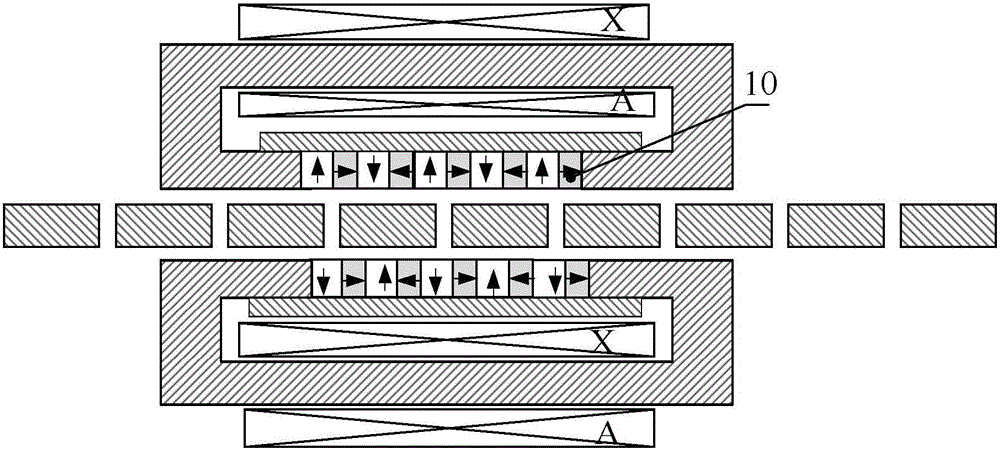

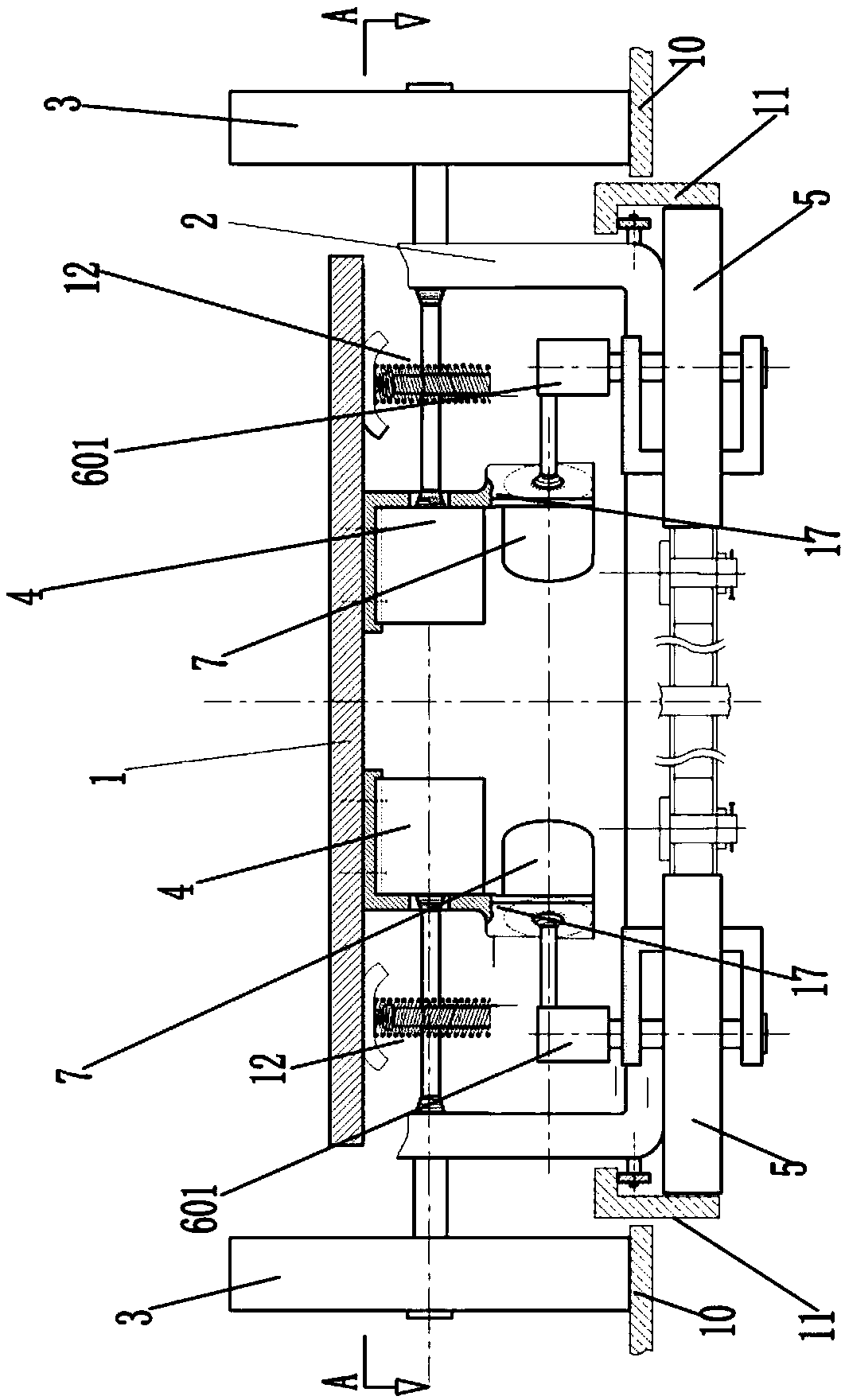

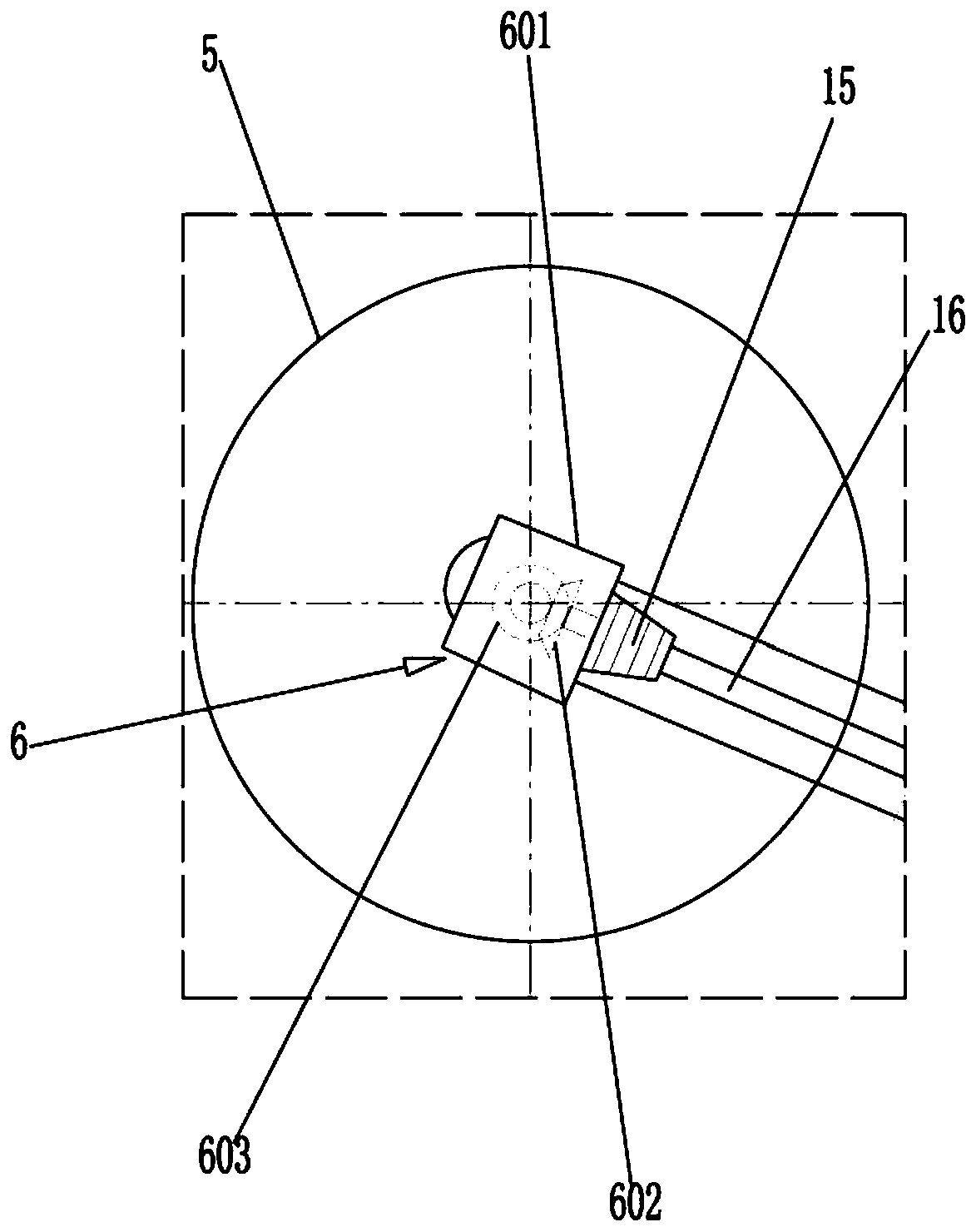

Electron accelerator

ActiveCN102340922AEasy to implement modular designEasy maintenanceDirect voltage acceleratorsModularityHigh pressure

Owner:江苏久瑞高能电子有限公司

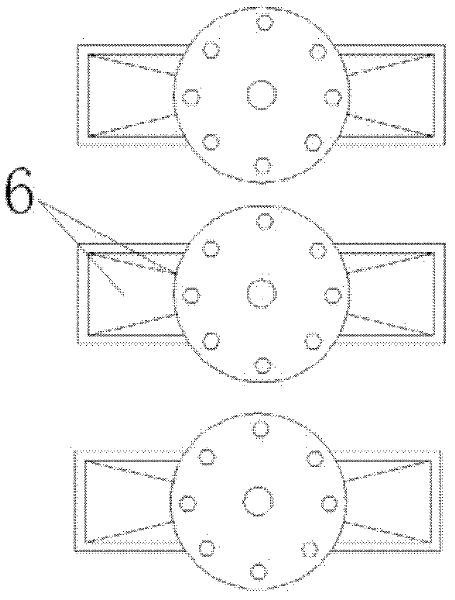

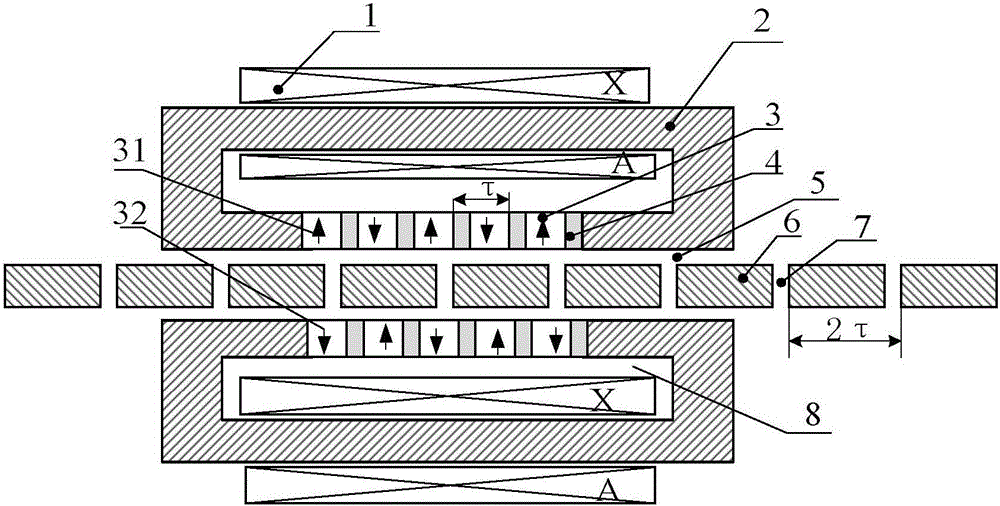

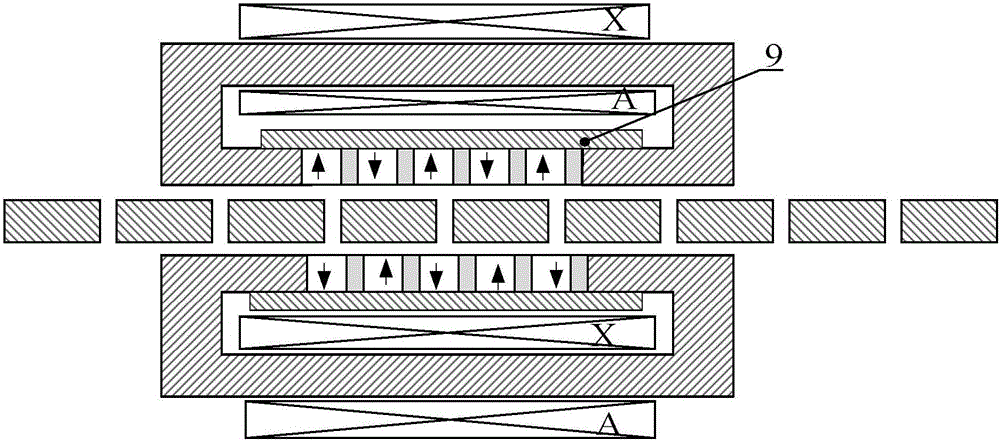

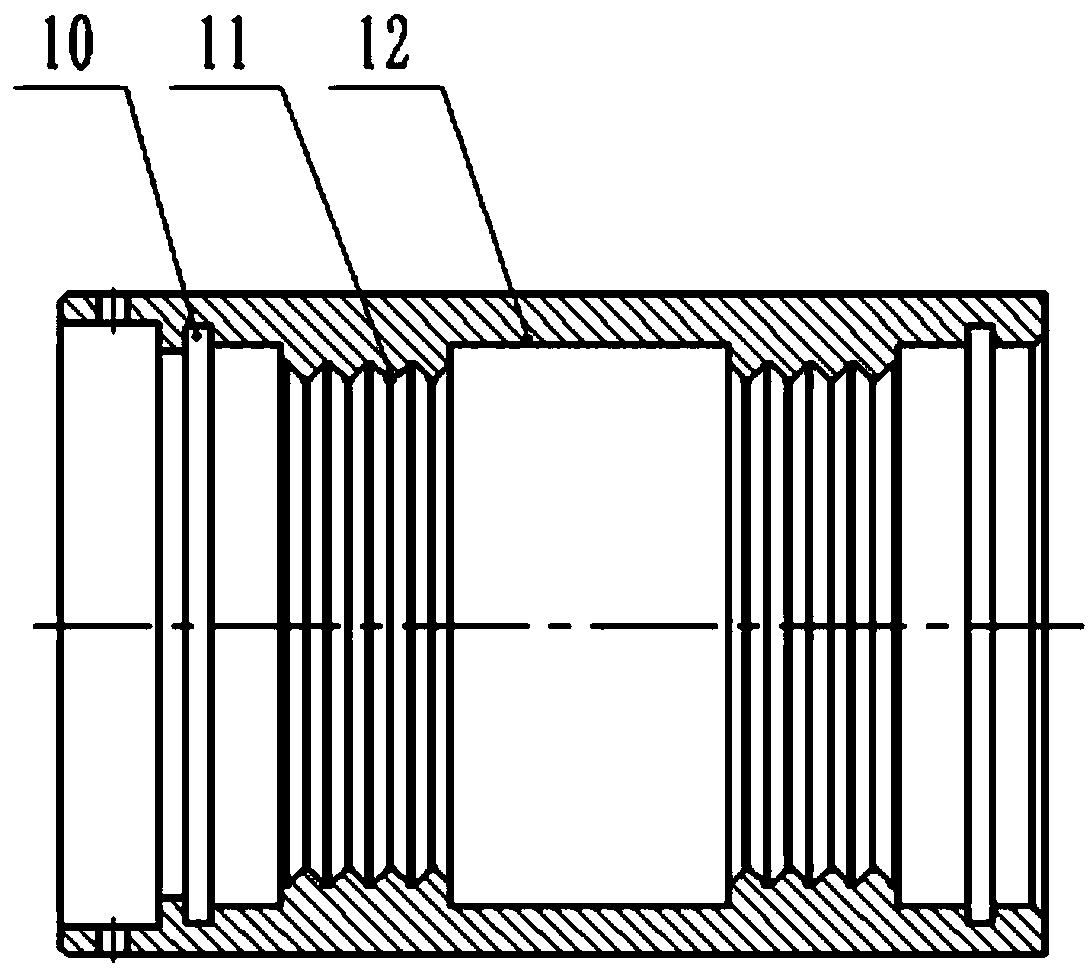

Independent-winding double-side plate permanent magnet linear motor

ActiveCN106100283ASimple winding processEasy to achieve coolingPropulsion systemsModular compositionElectricity

The invention discloses an independent-winding double-side plate permanent magnet linear motor, which comprises primary sides, a secondary side and air gaps. Each primary side comprises an armature winding, a primary magnetic-conductive iron core and a permanent magnet array. The two primary side assemblies are arranged at the two sides of the secondary side respectively to form a double-side structure. The primary magnetic-conductive iron core forms a big open slot structure, and the permanent magnet array is arranged in the slot mouth. One side, opposite to the corresponding open slot, of each primary magnetic-conductive iron core is provided with the armature winding; and the armature windings of the two primary sides at the two sides of the secondary side are same-phase windings, but electrical angle difference is 180 degrees. The secondary side is formed by magnetic-conductive iron cores having a salient pole structure, and gaps. The two air gaps are formed between the two primary sides and the secondary side respectively. The motor is a single-phase motor or a multi-phase motor, wherein the multi-phase motor is modular combination of the single-phase motors. Permanent magnets and the armature windings of the permanent magnet linear motor are arranged at the primary sides; through the big open slot structure design, winding heat dissipation is realized helpfully, and through the design of a large electrical load, thrust is improved; and meanwhile, the secondary side is simple in structure and light in weight.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

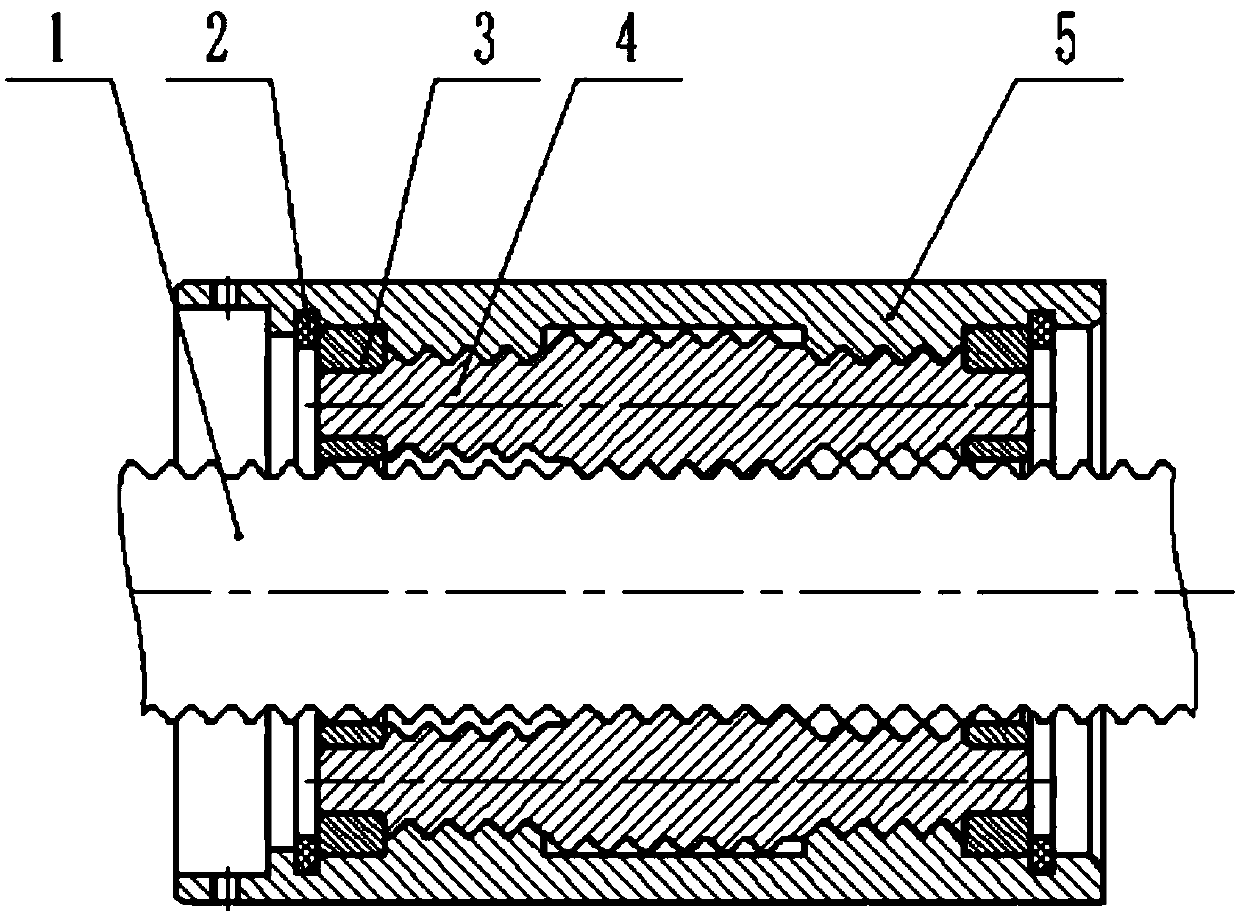

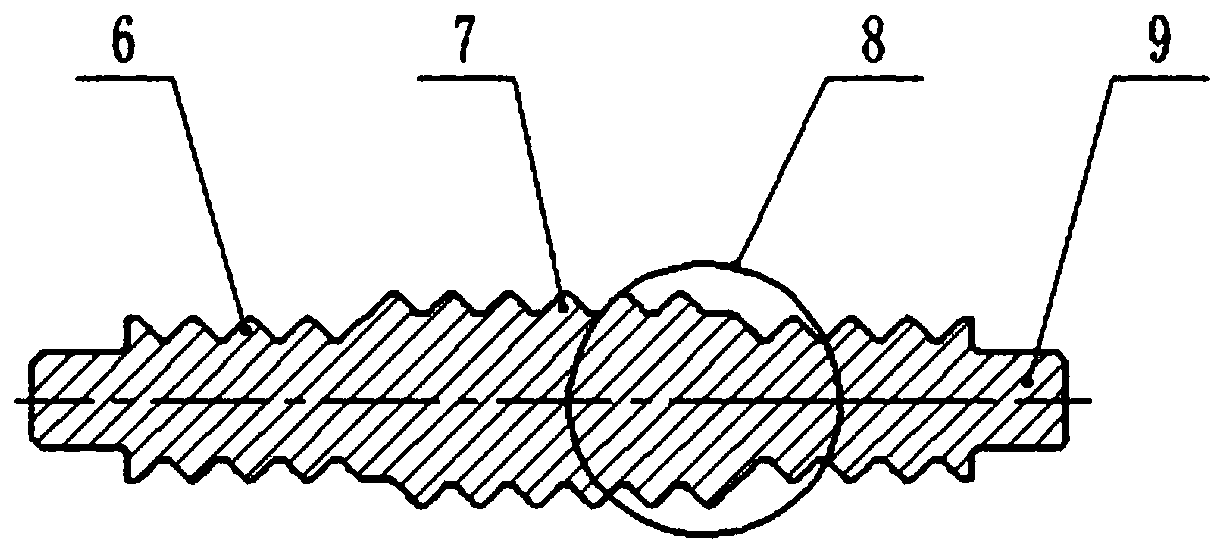

Planet roller screw electric cylinder

PendingCN109667901AGuaranteed transmission accuracyHigh precisionGearingRoller screwPulp and paper industry

The invention discloses a planet roller screw electric cylinder. The planet roller screw electric cylinder comprises a motor, a cylinder body, a power pipe and a planet roller screw pair transmissionmechanism. The motor outputs power to a lead screw. The power pipe is fixedly connected with a nut. The planet roller screw pair transmission mechanism is arranged inside the cylinder body. The powerpipe extends out of the cylinder body. The planet roller screw electric cylinder has the active and progressive effects that a novel planet roller screw pair structure is adopted, the planet roller screw electric cylinder does not slip under the heavy-load condition, the transmission precision is guarantee, and the engineering actual requirements of high precision, high-speed heavy-load and long service life can be met; the motor is can be arranged into a returning type and also can be arranged into a linear type; moving parts are arranged inside the cylinder body, seal parts are arranged inside a left end cover and a right end cover of the two ends of the cylinder body, the moving parts are isolated from the external environment, and the influence of the external environment on the key moving parts is completely eradicated; and the planet roller screw pair structure can be dismounted and replaced as needed, and modularized design can be achieved easily.

Owner:SEENPIN PROD ZHEJIANG

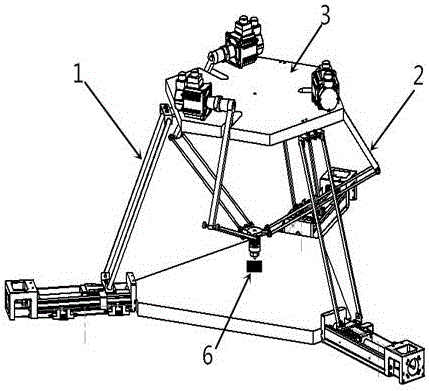

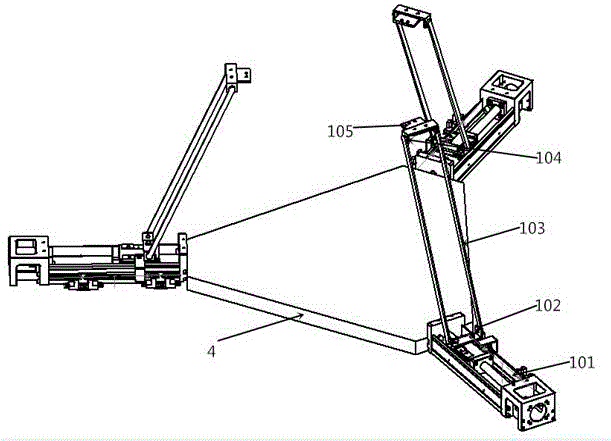

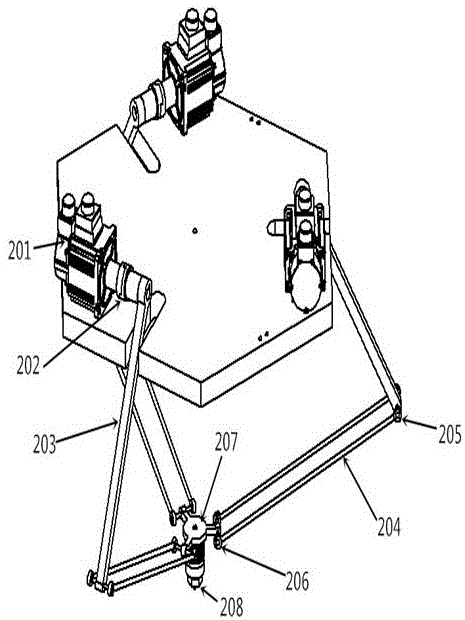

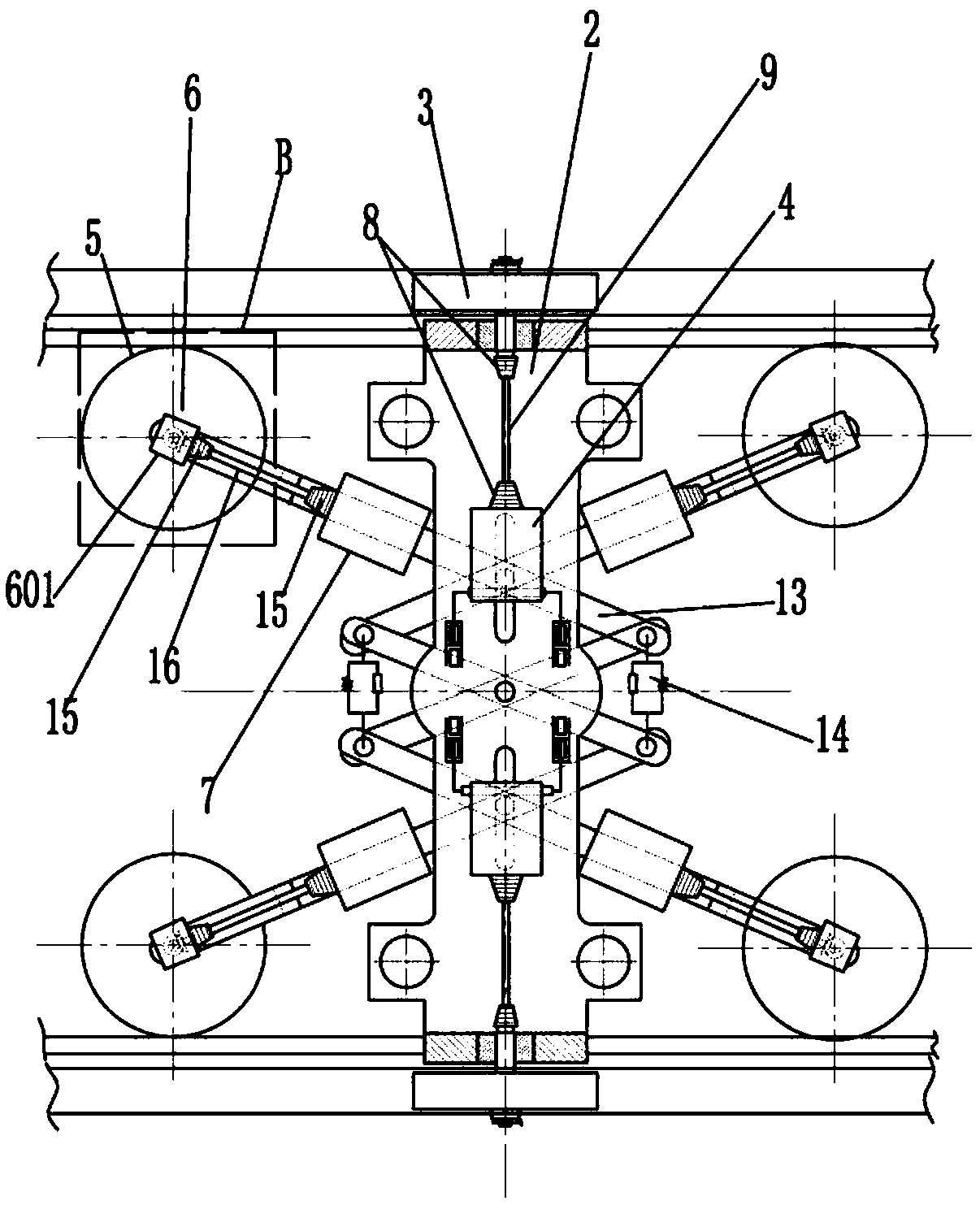

Parallel device based on Delta mechanism and 3D printer adopting same

InactiveCN106695767AImprove the shortcoming of narrow movement spaceLarge working spaceProgramme-controlled manipulatorComputer printingControl engineering

The invention provides a parallel device based on a Delta mechanism and a 3D printer adopting the same. The parallel device based on the Delta mechanism comprises a first-grade motion mechanism, a second-grade motion mechanism, a bearing main platform, a support platform and a terminal actuation platform. The 3D printer comprises a monitoring module, a control module and a feeding module. The feeding module is mounted in the middle position of the lower side of the bearing main platform; the monitoring module is connected with the control module; and the control module is respectively connected with the first-grade motion mechanism and the second-grade motion mechanism. The parallel device based on the Delta mechanism and the 3D printer adopting the same have the following beneficial effects: besides of overcoming the defects in the prior art, when the working space of the 3D printer is enlarged, the complex degree of the printer mechanical structure is reduced; and the 3D printer based on the Delta parallel mechanism is simple in structure, and is higher in precision and efficiency.

Owner:HEFEI UNIV OF TECH

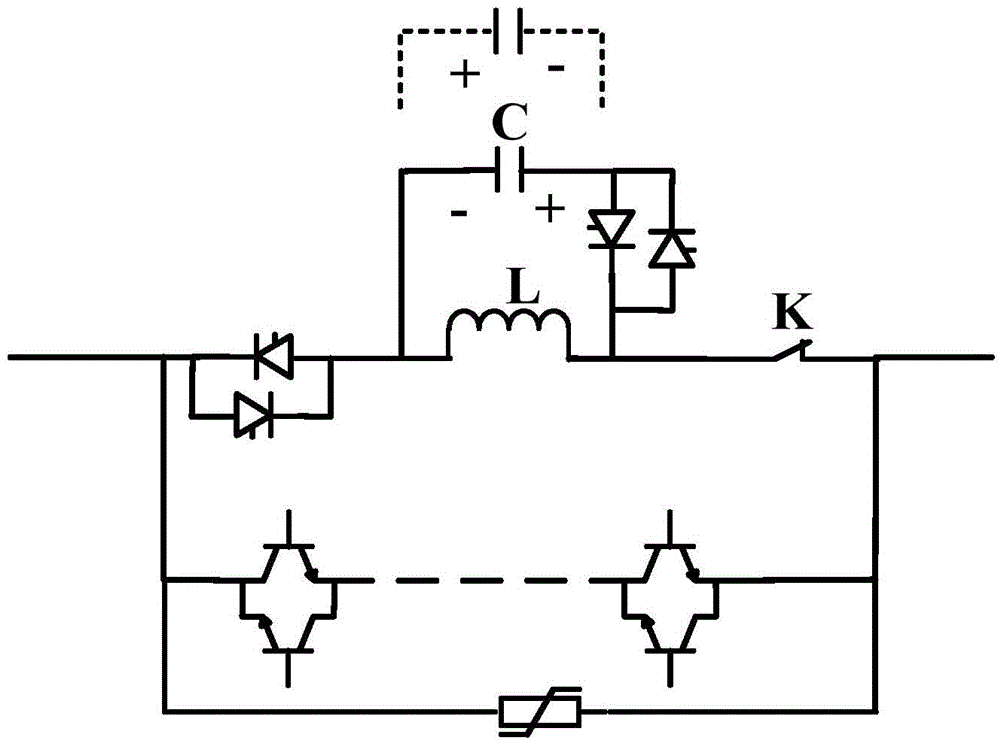

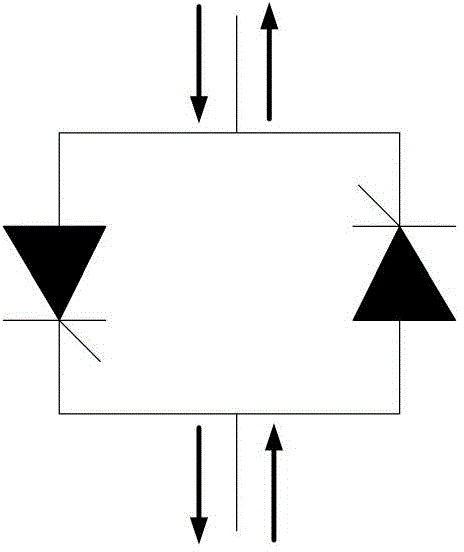

Bypass protection device for high-voltage DC circuit breaker and protection method thereof

ActiveCN105811369AGood effectTo achieve the purpose of two-way protectionEmergency protective circuit arrangementsMain branchDc circuit breaker

The invention relates to a bypass protection device for a high-voltage DC circuit breaker and a protection method thereof. The bypass protection device comprises a thyristor valve and a bridge type over-voltage protection circuit. The bridge type over-voltage protection circuit is connected between thyristors in anti-parallel connection with each other inside the thyristor valve. The two ends of each H-bridge sub-module of a main branch are connected in parallel with the thyristor valve. By means of the bypass protection device, during the abnormal shutting of the main branch of the circuit breaker, the circuit breaker is prevented from being damaged under the over-voltage effect of the sub-module. Namely, thyristors are connected in parallel with the sub-module of the main branch, wherein the thyristors are in compression joint in forward and reverse directions. During the normal operation, the current is switched on by a mechanical switch. During the occurrence of a fault, the current of the main branch is converted to the branch of a power electronic device in parallel connection with the main branch. After that, the current is switched off by the power electronic device. During the over-voltage period of the main branch, the thyristors are triggered, so that the current is enabled to pass through the thyristors to form a passageway. Therefore, the main branch is protected.

Owner:STATE GRID CORP OF CHINA +2

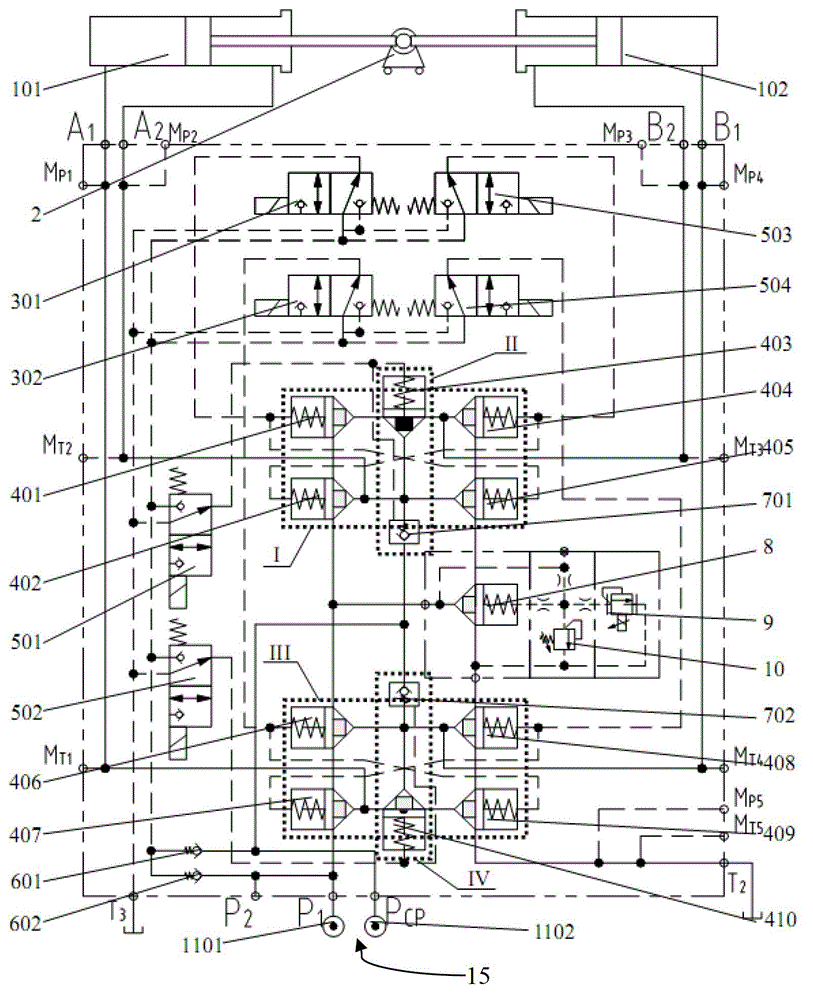

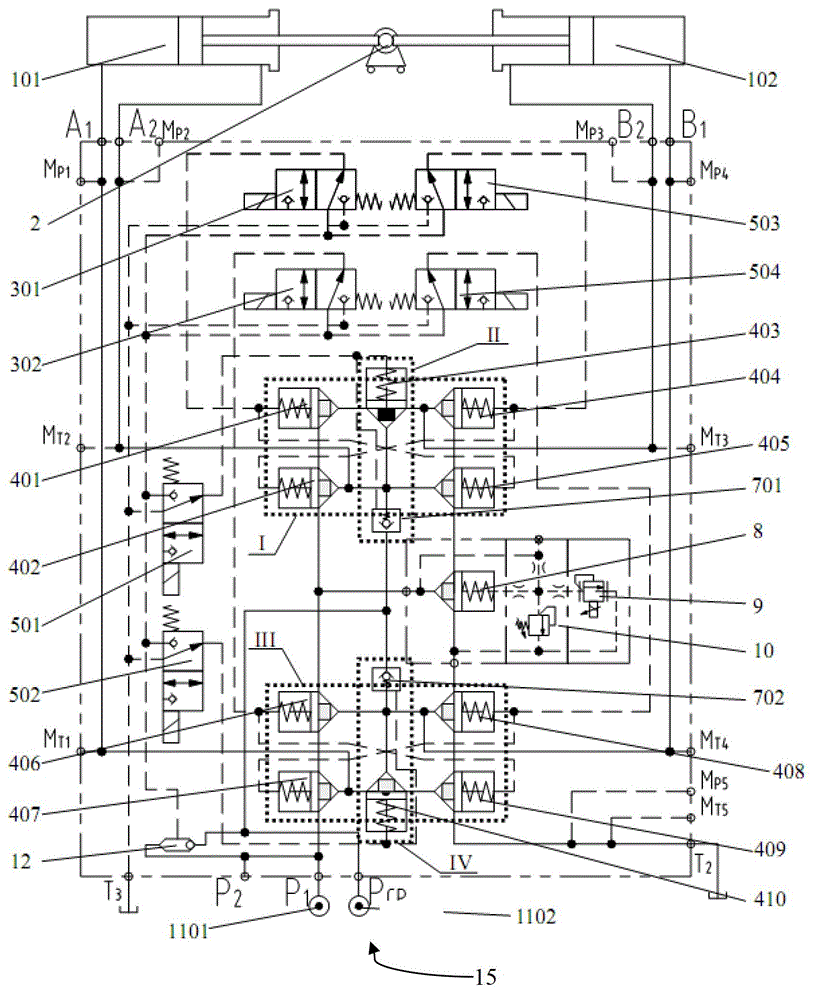

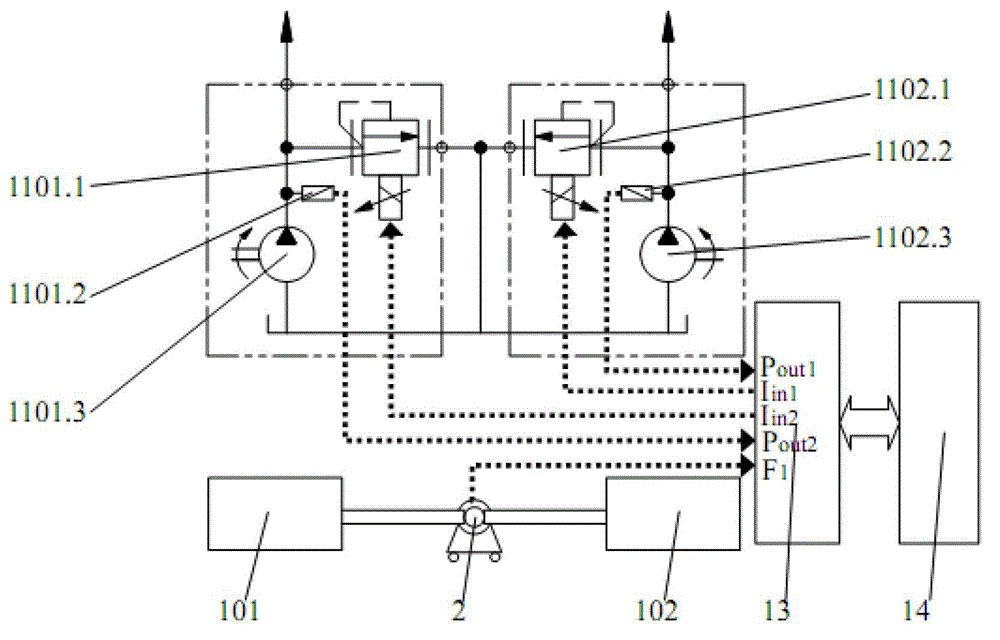

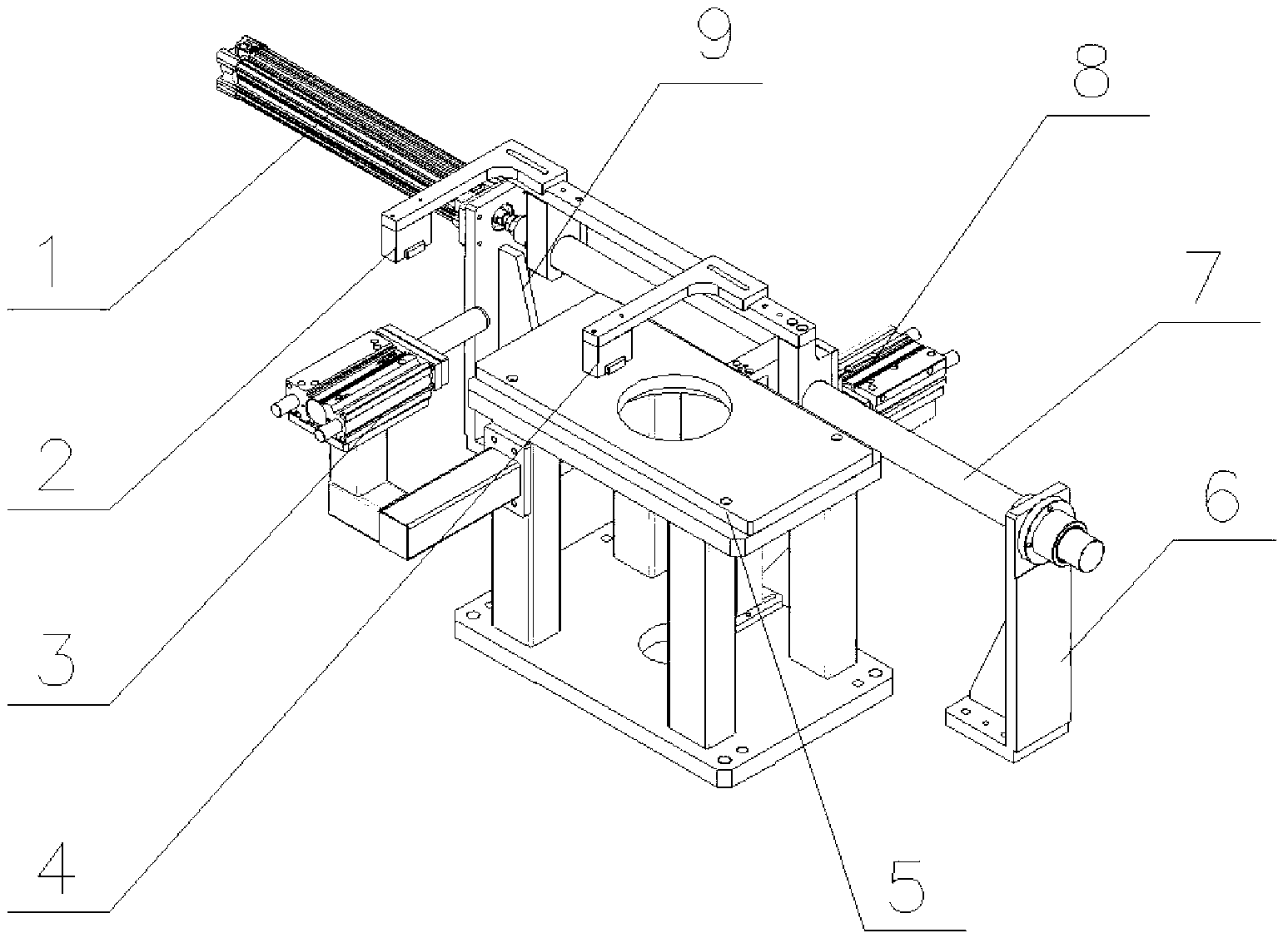

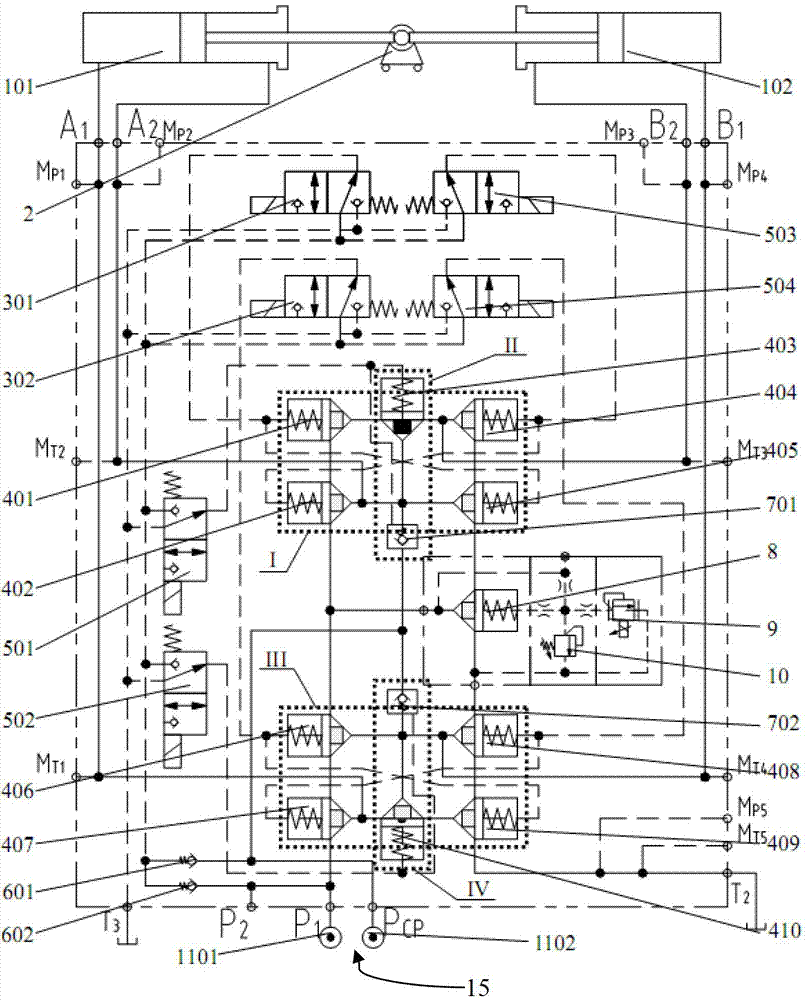

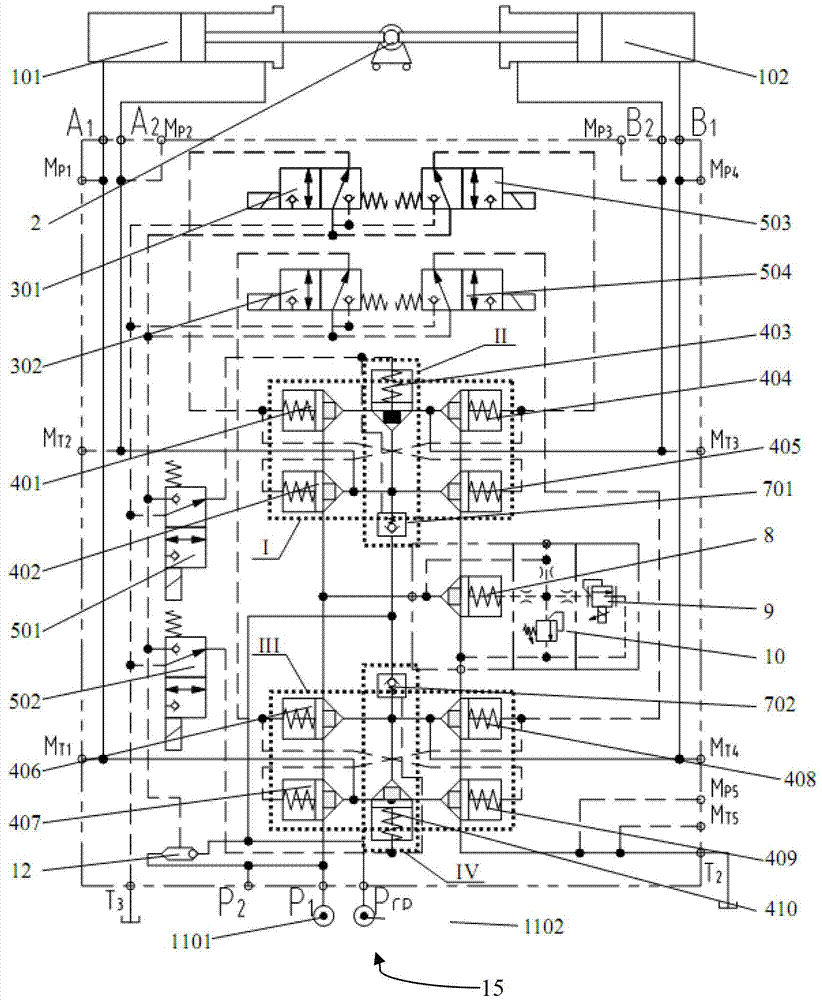

Control valve block system and method for testing hydraulic cylinders

ActiveCN103148042AReduce system oil leakageSystem pressure loss is smallFluid-pressure actuator testingServomotor componentsEngineeringHydraulic control

The invention provides a control valve block system for testing hydraulic cylinders, and belongs to the field of mechanical hydraulics. The system comprises a first main oil port and a second main oil port that are used for receiving hydraulic oil from oil sources, hydraulic cylinder connectors connected with rod cavities and rodless cavities of the hydraulic cylinders, at least two groups of function reversal valves, at least two groups of selection reversal valves and selection units, wherein pressure ports of two-position three-way reversal valves are communicated with each other, and connected with outlets of the selection units; the first main oil port is communicated with a working cavity of a cartridge valve in each cartridge valve unit; the second main oil port is communicated with inlets of hydraulic control one-way valves in the selection reversal valves; and the first main oil port and the second main oil port are communicated with the two-position three-way reversal valves communicated with each other through the selection units. The invention further provides a method. According to the system and the method, mounting is required only once; the two hydraulic cylinders are measured simultaneously; an independent overflow loading device is avoided; the efficiency is improved; and the cost is lowered.

Owner:CHINA RAILWAY CONSTR HEAVY IND

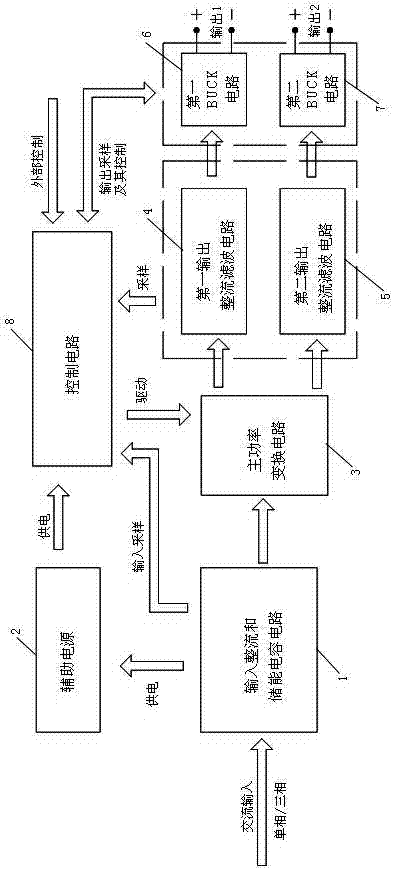

High-power switching power supply circuit with multiple outputs

InactiveCN102761266ASimple structureCompact structureDc-dc conversionElectric variable regulationCapacitancePower switching

The invention relates to a high-power switching power supply circuit with multiple outputs. The high-power switching power supply circuit comprises an input rectifying and energy storage capacitive circuit, wherein an input end of the input rectifying and energy storage capacitive circuit is connected to alternating current, and an output end of the input rectifying and energy storage capacitive circuit is respectively connected with the input ends of an auxiliary power supply, a main power converting circuit and a control circuit; the auxiliary power supply provides electricity for the control circuit; an output end of the main power converting circuit is connected with the input ends of at least two output rectifying and filtering circuits; the output ends of the output rectifying and filtering circuits are connected with an input end of a BUCK circuit; an output end of the BUCK circuit is sampled and serves as an input of the control circuit; and a driving end of the control circuit is respectively connected with the main power converting circuit and the BUCK circuit. The BUCK circuit is relatively simple in structure, a control protection circuit of the BUCK circuit is easy to implement, the modularization design of the BUCK circuit is easy to implement, the structure is compact and the efficiency is high.

Owner:ECU ELECTRONICS INDAL

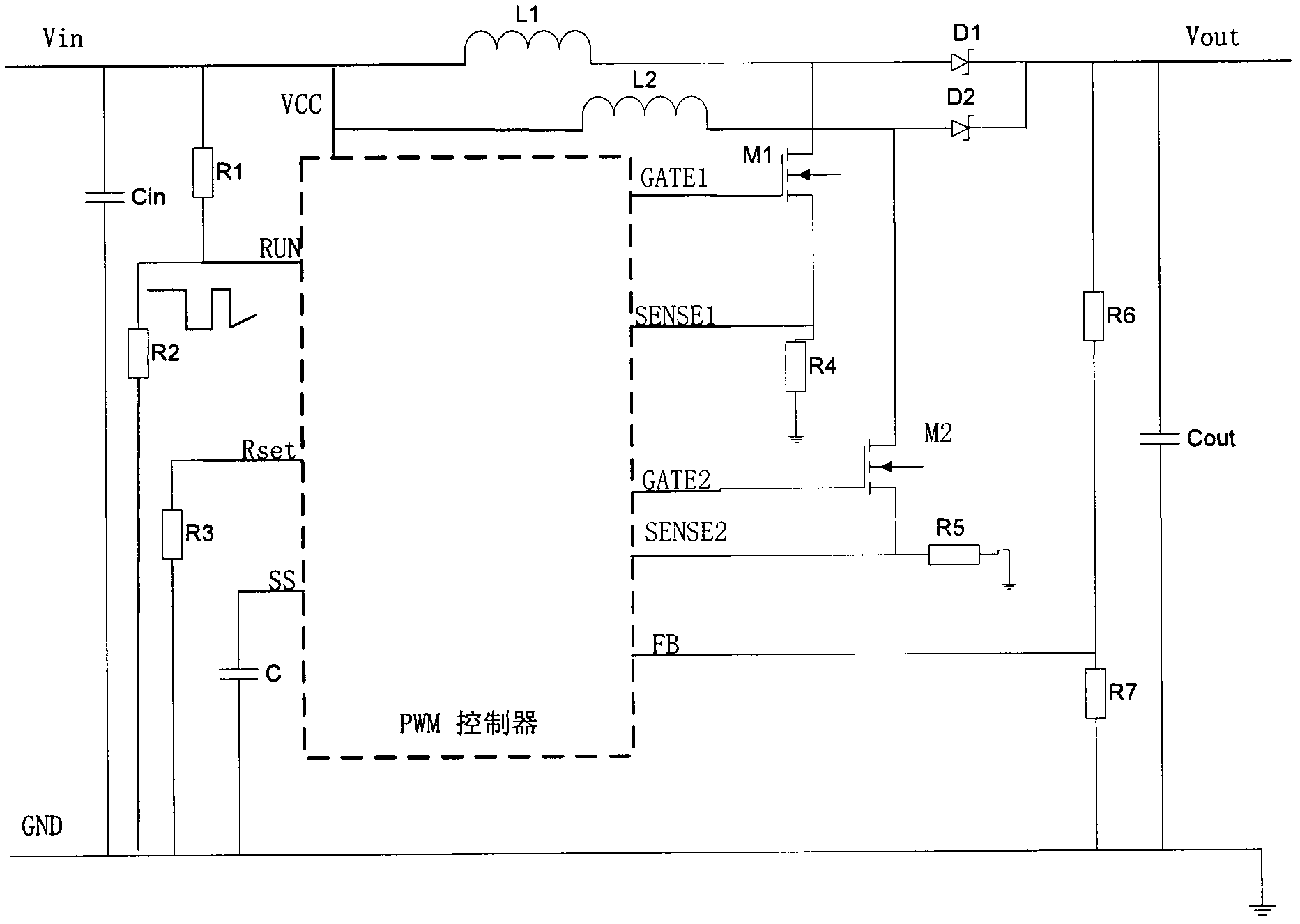

High-power supply based on multi-phase PWM controller

InactiveCN102545609AImprove work efficiencyEasy to achieve high powerDc-dc conversionElectric variable regulationMOSFETCapacitance

A high-power supply based on a multi-phase PWM (Pulse Width Modulation) controller comprises the multi-phase PWM controller, an input capacitor Cin, a soft-start capacitor C, an output capacitor Cout, resistors R1 to R7, a power tube M1, a power tube M2, an inductor L1, an inductor L2, a diode D1 and a diode D2. The supply provided by the invention is designed on the basis of the multi-phase PWM controller and facilitates implementing a high-power low-voltage DC power supply; the adopted devices are common RC (Resistance-Capacitance) inductive and MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) devices; compared with a power supply module with the same power, the adopted RC inductive devices have small sizes, the demands on both peripheral output capacitors and output inductors are lowered, the power density is increased, heat dissipation is more convenient in comparison with a well packaged power supply module, and the conversion efficiency is high; and power supplies conforming to various different application environments can be constructed through selection of suitable devices, and the comprehensive performance of the power supplies are optimized simultaneously.

Owner:BEIJING RES INST OF TELEMETRY

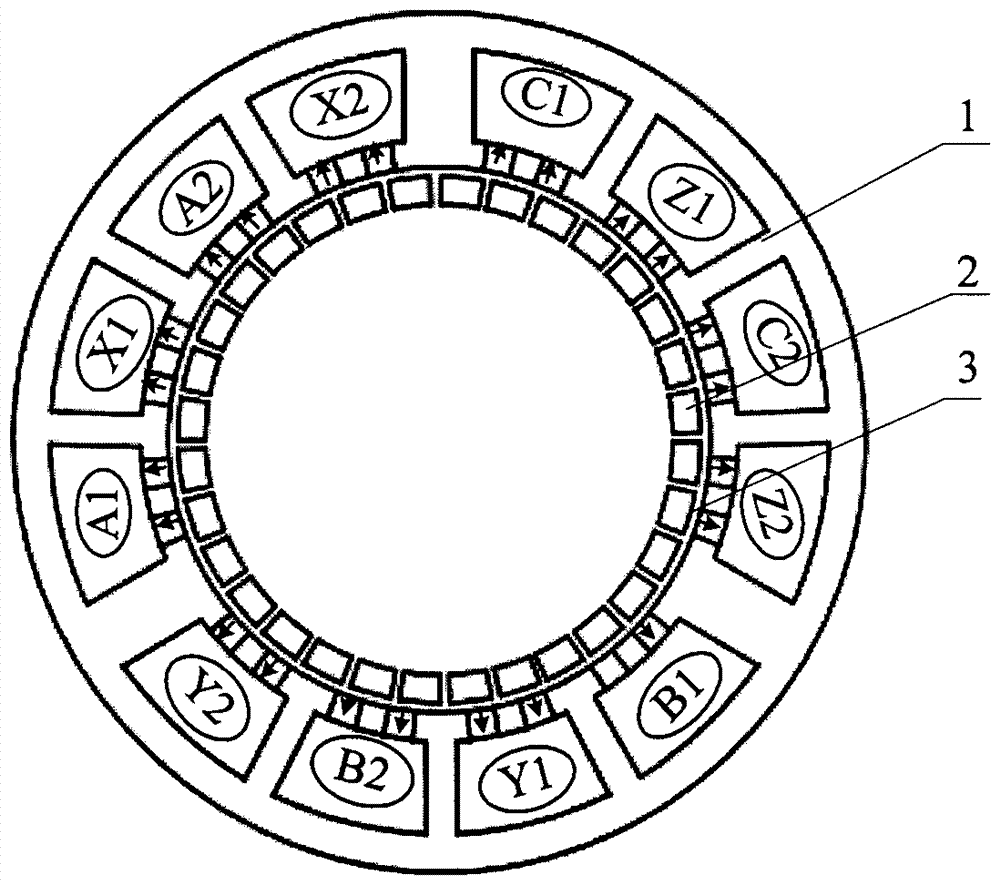

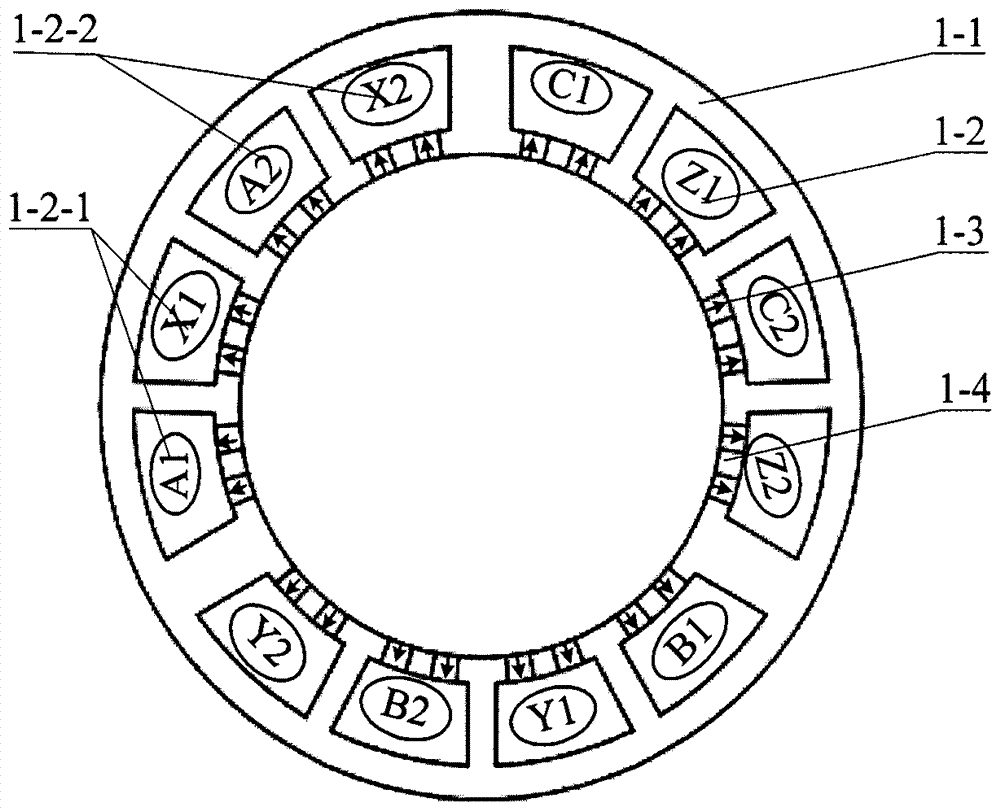

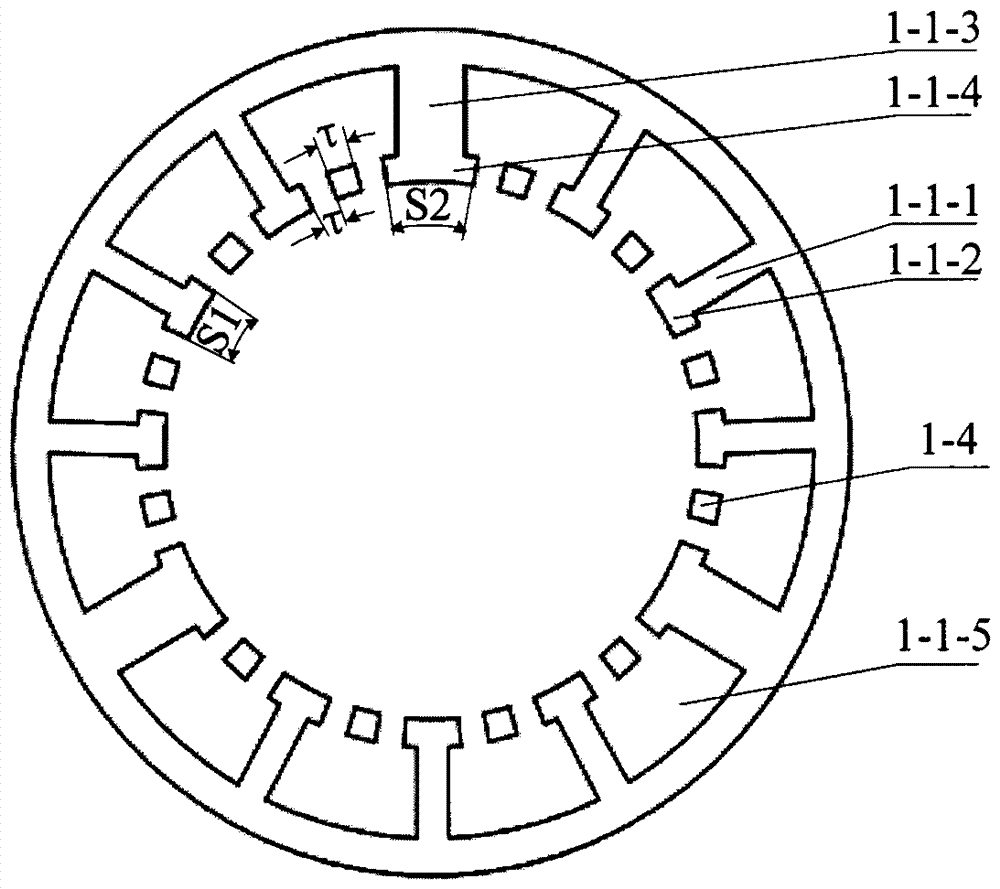

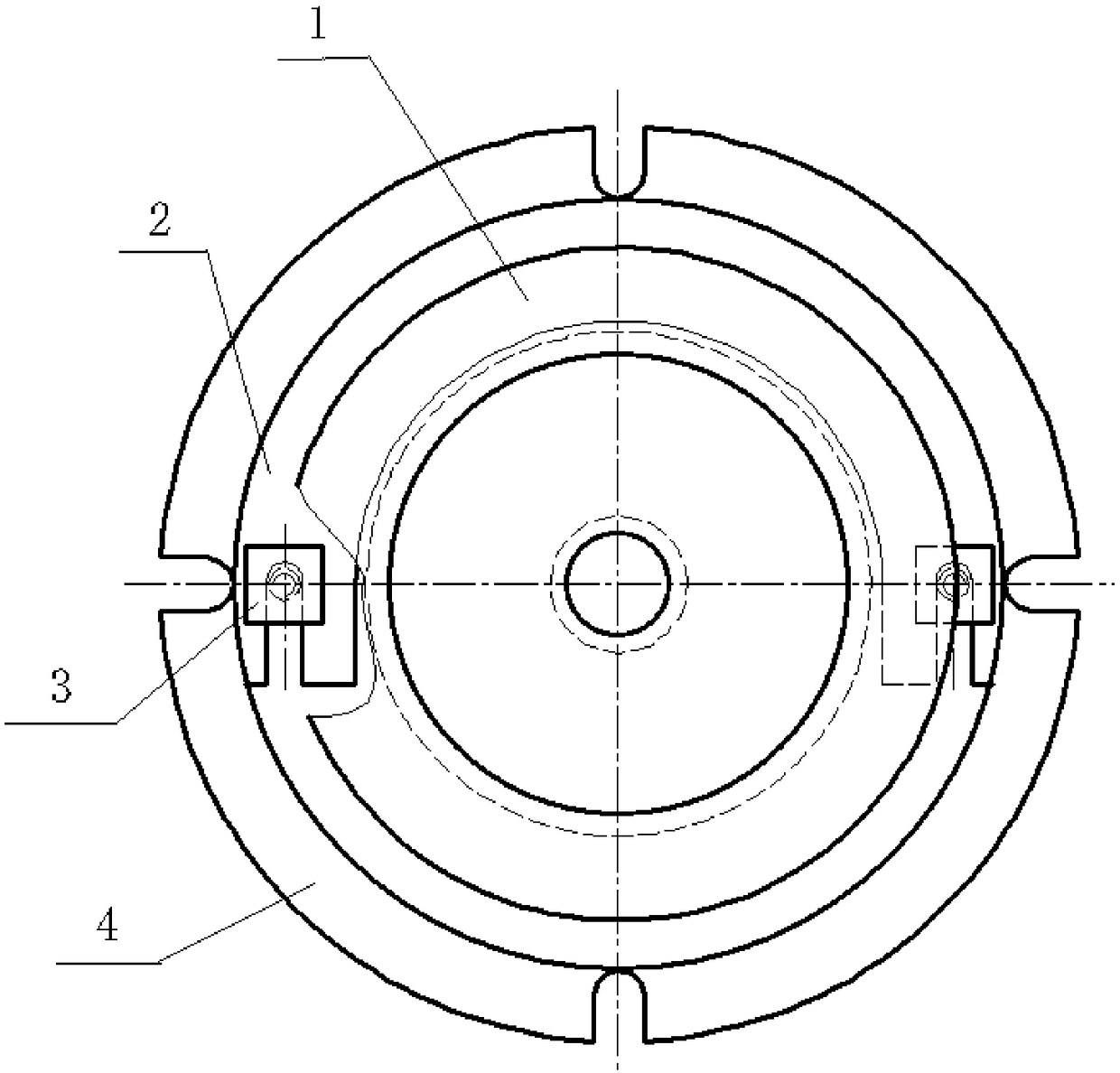

Winding modular permanent-magnet motor

ActiveCN107359712AIncrease profitShorten the lengthMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetizationTorque density

The invention provides a winding modular permanent-magnet motor. The winding modular permanent-magnet motor comprises a stator, a rotor and air gaps, wherein the stator comprises a stator core, armature windings, permanent magnets and magnetic conduction small teeth, large grooves are formed in the stator core, the permanent magnets and the magnetic conduction small teeth are arranged at groove openings facing the air gaps, the arc lengths of the permanent magnets and the magnetic conduction small teeth both are Pi, the magnetization direction of the permanent magnets are same, a positive winding and a negative winding of a single effective coil of each phase are arranged in two adjacent large grooves, N coils in the same phase are sequentially wound around adjacent 2N large grooves according to a single coil winding method, teeth among the grooves where the same phase winding is located are first teeth, teeth among different phase windings are second teeth, the rotor comprises rotor cores and gaps, the arc length distance between adjacent rotor cores is 2Pi, and an air gap is formed between the stator and the rotor. The motor employs a same-phase winding modular structure design, the winding structure is simplified, the length of an end part of the winding is shortened, the winding utilization ratio is improved, and the torque density is improved.

Owner:北京华晖恒泰能源科技有限公司

Ram type main transmission mechanism for milling machine

InactiveCN102922355ASimple structureSmall sizeFeeding apparatusDriving apparatusGear driveDrive shaft

The invention provides a ram type main transmission mechanism for a milling machine. The ram type main transmission mechanism comprises a spindle driving servo motor, a transmission gear box and a machine tool spindle, wherein the machine tool spindle is arranged in the front of a ram; the transmission gear box is arranged at a position, which corresponds to the machine tool spindle, of the ram; the lower part of the transmission gear box is positioned in the ram; the spindle driving servo motor is arranged on the ram; an input shaft of the transmission gear box is connected with the spindle driving servo motor through a coupling; an output shaft of the transmission gear box is connected with the machine tool spindle through an output gear and a machine tool spindle gear; and the input shaft and the output shaft of the transmission gear box can be connected with each other through multilevel gear transmission pairs which are arranged on different transmission shafts and can realize high-gear and low-gear rotational speed output. The transmission gear box and the ram are separated from each other, transmission of the transmission gear box is realized by gears, transmission rigidity is high, the size of the ram is small, the ram is simple in structure, the transmission gear box is convenient to mount and maintain, and the ram type main transmission mechanism is modularly designed and manufactured easily.

Owner:GUILIN MACHINE TOOL

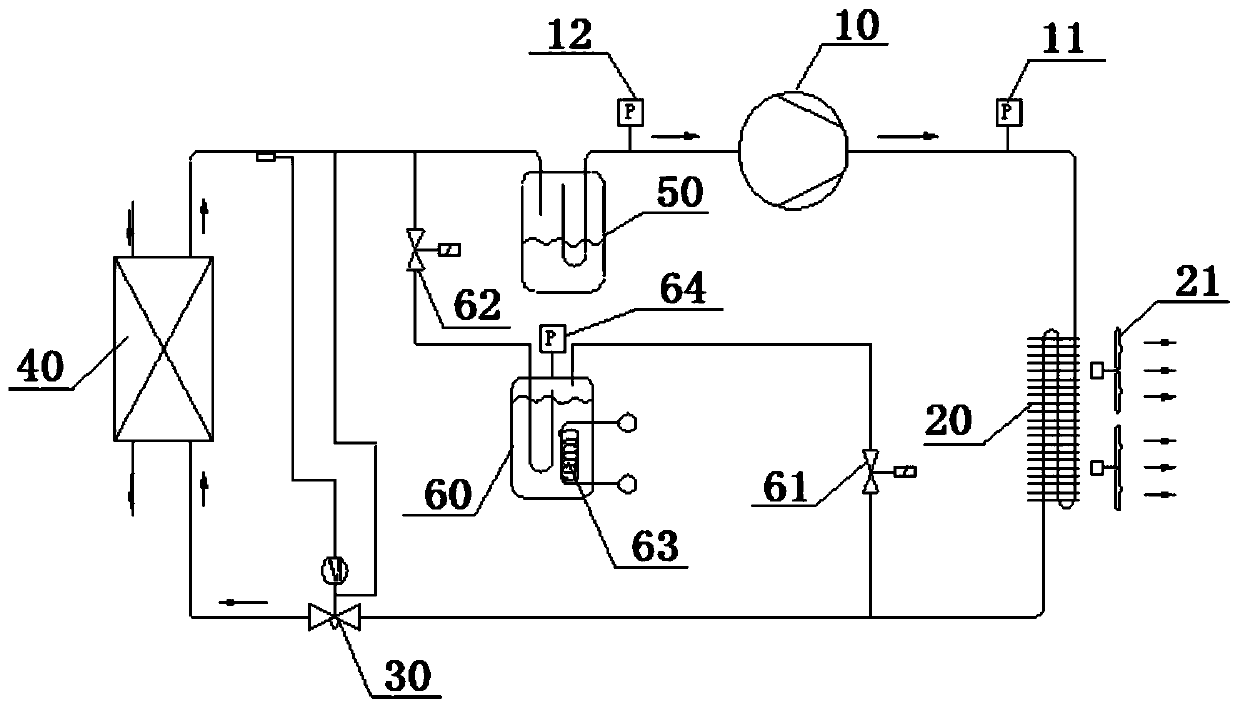

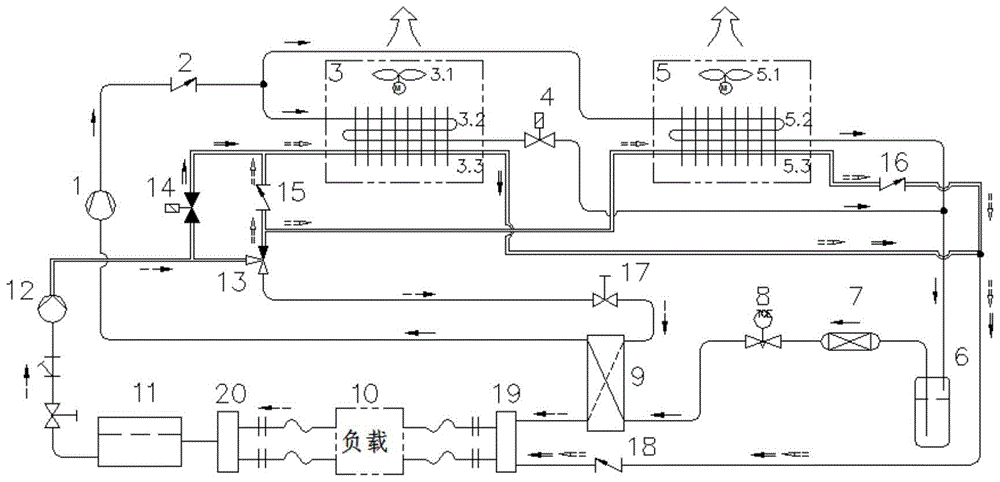

Refrigeration equipment capable of automatically balancing filling quantity of refrigerant

PendingCN111271888AAdapt to the working environmentSimple and fast operationMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorSolenoid valve

The invention discloses refrigeration equipment capable of automatically balancing the filling quantity of a refrigerant. The refrigeration equipment comprises a compressor, a condenser, a condensatefan, an expansion valve, a plate type heat exchanger, a gas-liquid separator, high-pressure and low-pressure sensors, a filling tank, two solenoid valves, a heating belt and a pressure sensor; and theoutput end of the compressor is connected with the input end of the condenser, the high-pressure sensor is connected to a connecting pipe, the output end of the condenser is provided with a first branch circuit and a second branch circuit, the first branch circuit is connected with the input end of the expansion valve, then sequentially connected with the plate type heat exchanger and the gas-liquid separator, and finally connected into the input end of the compressor, the low-pressure sensor is connected to a connecting pipe between the gas-liquid separator and the input end of the compressor, the second branch circuit of the output end of the condenser is connected with the input end of the filling tank, the first solenoid valve 61 is arranged on a connecting pipe, the output end of thefilling tank is connected with the input end of the gas-liquid separator, the second solenoid valve is arranged on a connecting pipe, and the electric heating belt is wound around the surface of a tank body of the filling tank, and the tank body is connected with the pressure sensor. The pressure of the filling tank can be controlled by controlling on-off of the electric heating belt.

Owner:合肥天鹅制冷科技有限公司

Design method applied to car frame assembly structure of two-step urban passenger car

InactiveCN101987634AReduce manufacturing costReduce weightUnderstructuresVehicle frameDesign methods

The invention relates to a design method applied to a car frame assembly structure of a two-step urban passenger car. The car frame assembly structure comprises a front-section car frame module, a front-shaft car frame module, a middle-section car frame module, a rear-axle car frame module and a back-section car frame module and is characterized in that vertical beams arranged at both sides of the front-section car frame module, the middle-section car frame module and the rear-section car frame module are in a transverse n-shaped structure, planes of vertical beams at the front side and the back side of the front-shaft car frame module are respectively connected with planes for connecting the vertical beams at both sides of the front-section car frame module and the middle-section car frame module into the transverse n-shaped structures through screw bolt and screw nut structures, and the planes of the vertical beams at the front side and the back side of the rear-axle car frame module are respectively connected with planes for connecting the vertical beams at both sides of the middle-section car frame module and the rear-section car frame module into the transverse n-shaped structure through the screw bolt and screw nut structures. The invention can solve the problem of small utilization rate of a low-floor passenger region, meanwhile, the modularized design and the remote transportation and assembly of car frame parts can be realized.

Owner:SHAANXI EUROSTAR AUTOMOBILE

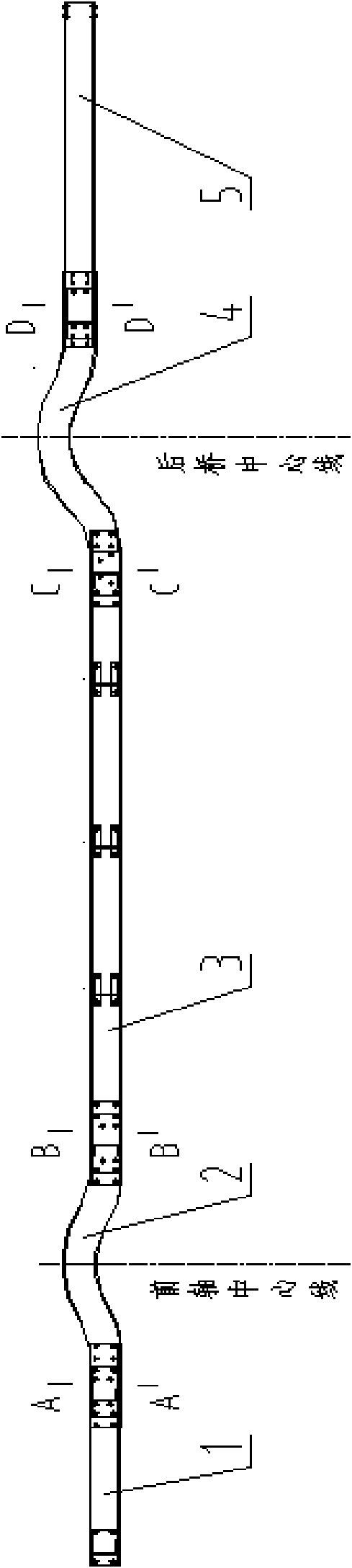

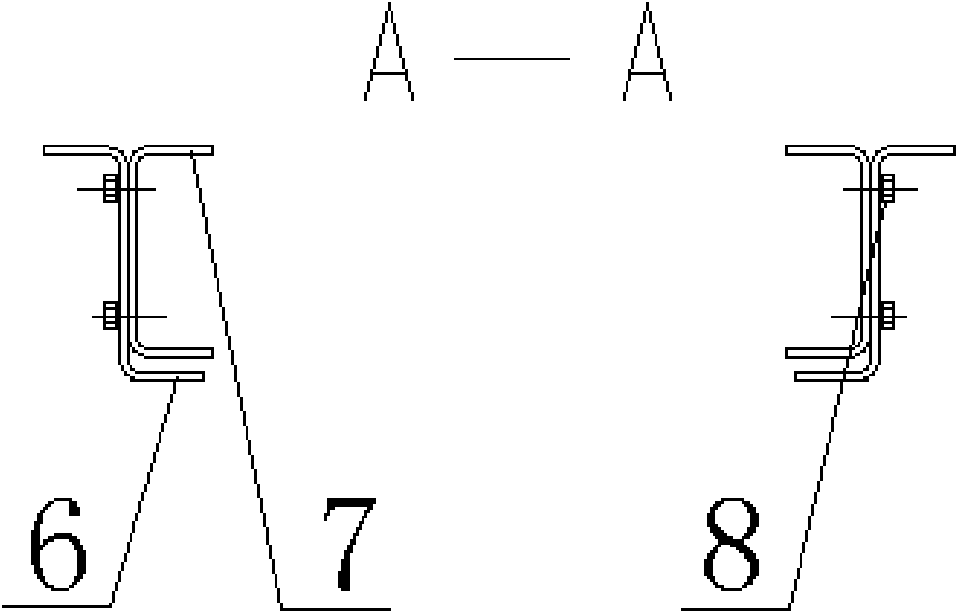

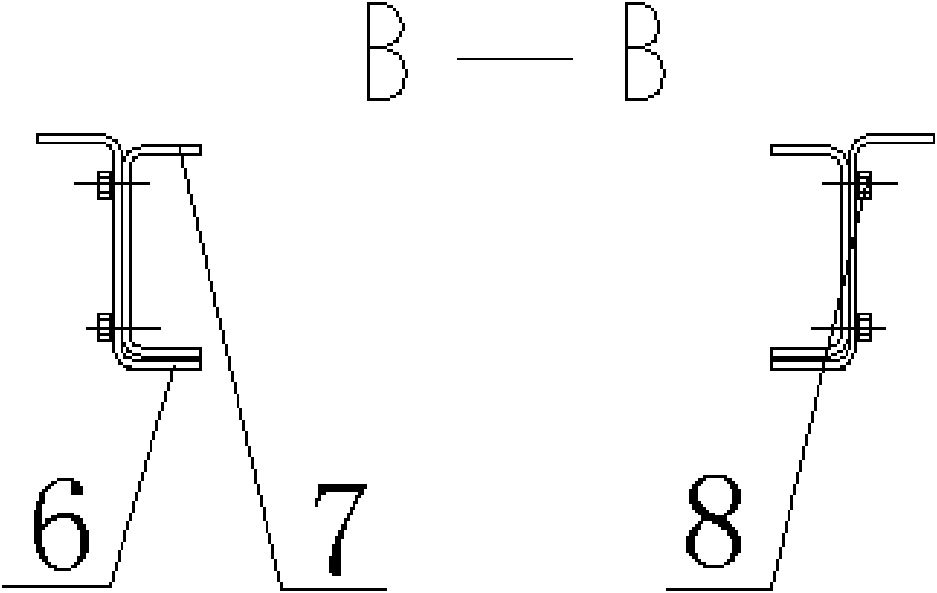

Distributed driving new wheel-rail high-speed train system

The invention relates to a distributed driving new wheel-rail high-speed train system in the technical field of rail transit, comprising a plurality of bogie bodies and a pair of rail assemblies, wherein each rail assembly comprises a load bearing rail and a guide rail; each bogie body comprises a compartment connecting frame, a load bearing frame, load bearing wheels, guide wheels, a transverse telescopic linkage mechanism, a spring damping assembly, a shock absorbing assembly, and a motor mounting frame; the load-bearing wheels of each bogie body are two and roll on two load bearing rails respectively; the guide wheels of each bogie body are provided with two groups and roll on two guide rails respectively; each load-bearing wheel is provided with a power unit including a load-bearing wheel drive motor mounted on a motor mounting bracket; and the output spindle of the load-bearing wheel drive motor is drivingly connected to the wheel axle of the load-bearing wheel. Therefore, the distributed driving new wheel-rail high-speed train system enables each load-bearing wheel to be equipped with an independent power source.

Owner:TONGJI UNIV +1

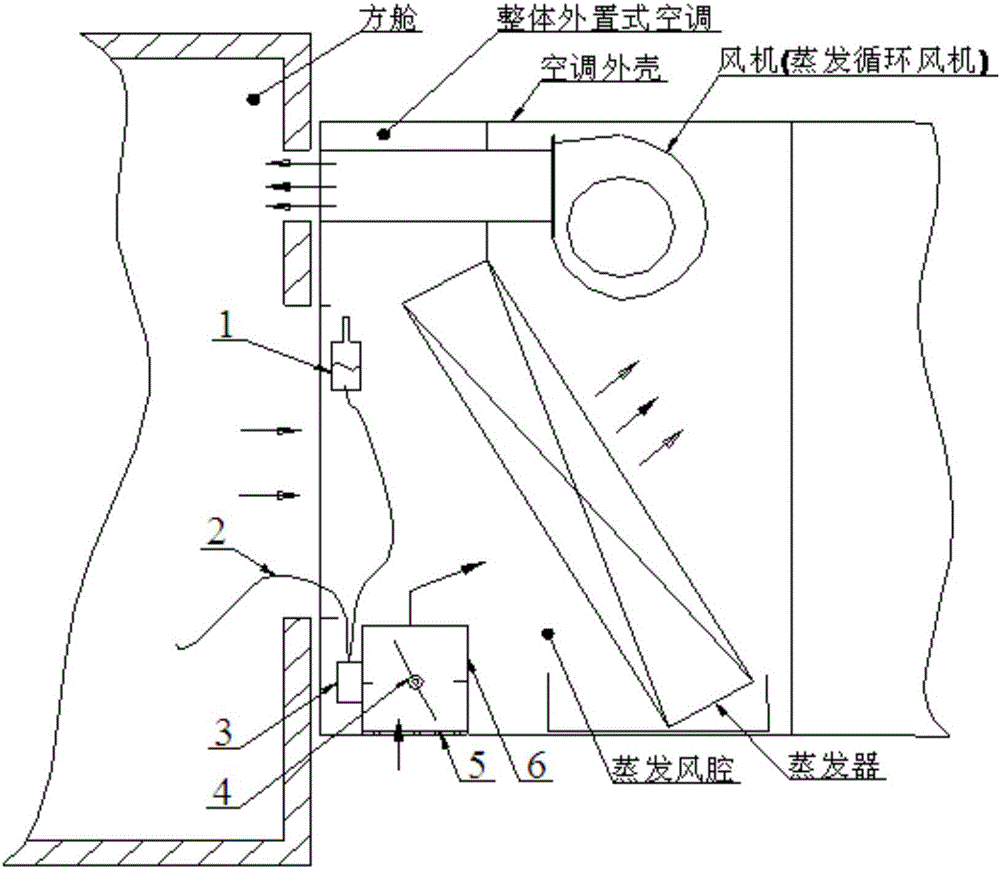

Device for automatically realizing fresh air replacement for integral external air conditioner

InactiveCN105890096ADangers of lack of fresh air to breatheEasy to controlSpace heating and ventilation safety systemsLighting and heating apparatusElectricityHigh concentration

The invention discloses a device for automatically realizing fresh air replacement for an integral external air conditioner. The device comprises a square cabin and the integral external air conditioner, wherein a carbon dioxide sensor is arranged at an air return opening of the integral external air conditioner; a ventilation air valve assembly is arranged in an evaporation air cavity of the integral external air conditioner; an air inlet of the ventilation air valve assembly is led to an external environment, and the ventilation air valve assembly comprises an air valve mechanism and a driving mechanism for driving the air valve mechanism to work; the carbon dioxide sensor and the driving mechanism are electrically connected with a control panel of the integral external air conditioner respectively through signal cables. By detection of the concentration of carbon dioxide in the square cabin or a room, fresh air replacement is automatically and intelligently realized, so that fresh air can be automatically supplemented into the square cabin; therefore, potential safety hazards caused by extremely high concentration of the carbon dioxide in the closed square cabin where a worker stays for a long time are avoided.

Owner:合肥天鹅制冷科技有限公司

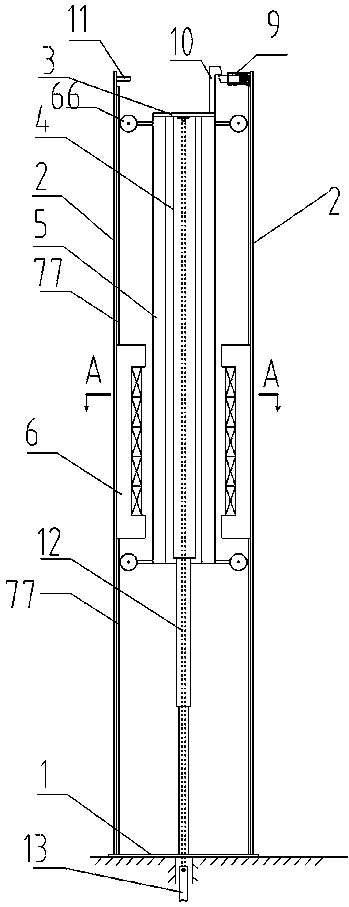

Modular height adjusting device, support and intelligent adjusting system

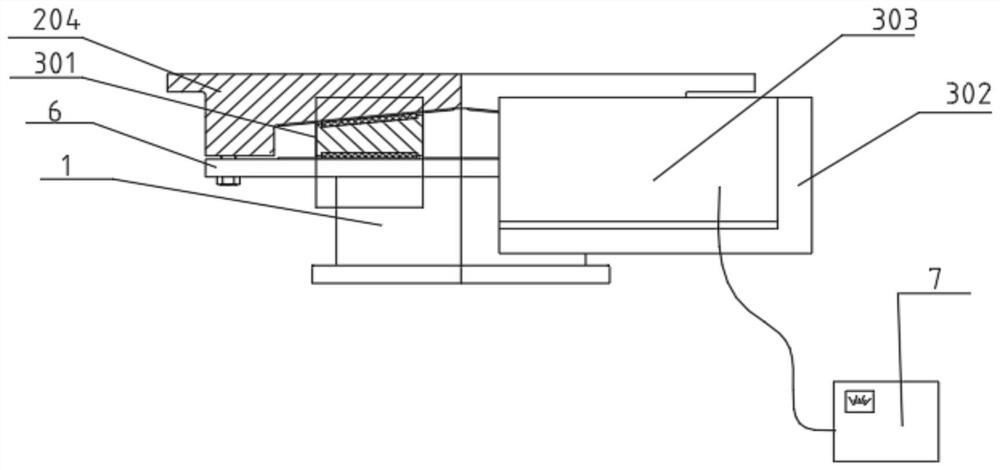

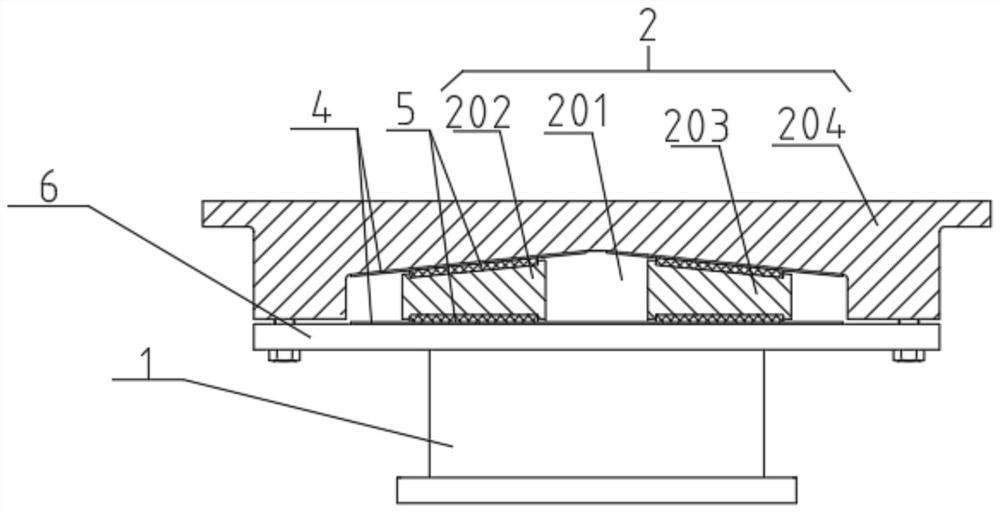

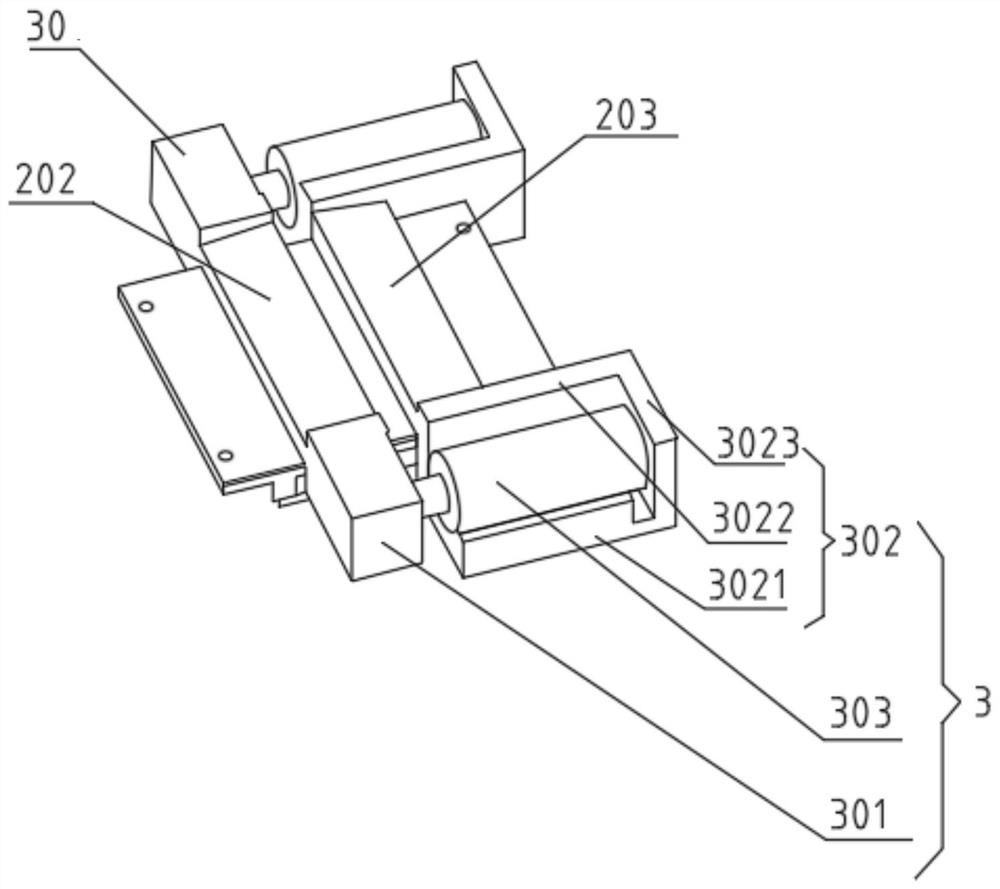

PendingCN111877150AImprove height adjustment efficiencyEasy to implement modular designBridge structural detailsControl engineeringModular design

The modular height adjusting device and support comprises a support body, a height adjusting mechanism is arranged above or below the support body, a connecting part used for being connected with a module power device is arranged on the height adjusting mechanism, and the module power device provides adjusting power for the height adjusting mechanism. The driving device is connected with a controller for controlling the action of the driving device. According to the scheme, modular design of heightening power is achieved, mounting and dismounting are convenient, and meanwhile intelligent and accurate heightening is achieved.

Owner:DATONG INC

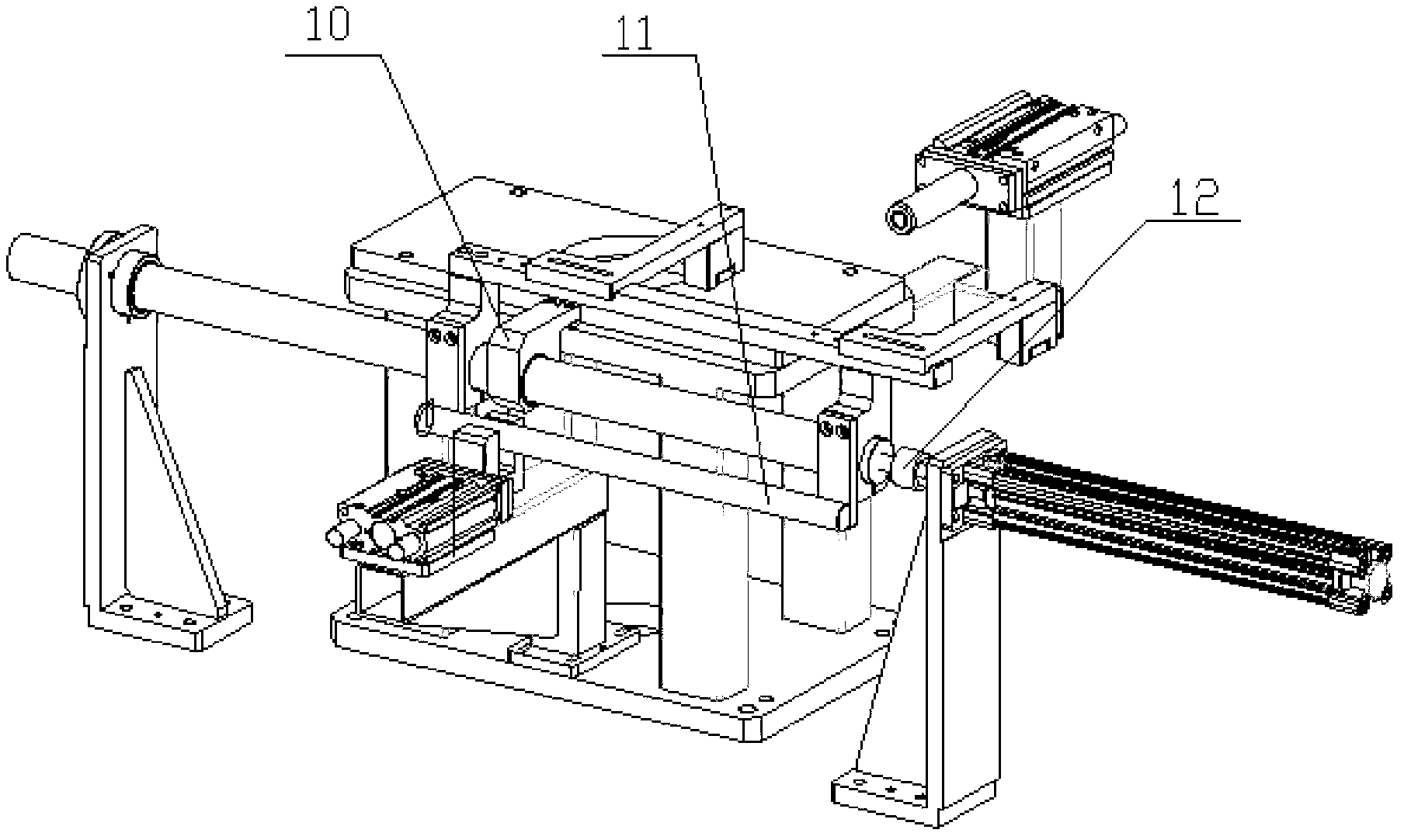

Automatic loading and unloading device of numerical control honing machine

InactiveCN103231307ASimple structureCompact structureGrinding machine componentsNumerical controlOptical axis

The invention relates to an automatic loading and unloading device of a numerical control honing machine. The automatic loading and unloading device is suitable for automatic loading and unloading parts to be processed during processing of the honing machine in the cylinder linear processing industry. The automatic loading and unloading device is characterized by comprising an optical axis (7), two ends of the optical axis (7) are respectively installed on a middle auxiliary supporting base (10) and a right auxiliary supporting base (6), the optical axis (7) is in gap matching with the middle auxiliary supporting base (10) and the right auxiliary supporting base (6), and the middle auxiliary supporting base (10) is fixed on a working table (5). A loading shifting block (2) and an unloading shifting block (4) are respectively and fixedly installed on the optical axis (7), and the loading shifting block (2) is in rigid connection with the unloading shifting block (4) through a connection shaft (11). The automatic loading and unloading device of the numerical control honing machine can totally replace manual loading and unloading and greatly improves the production efficiency of manufacturing industry.

Owner:宁夏巨能机器人股份有限公司

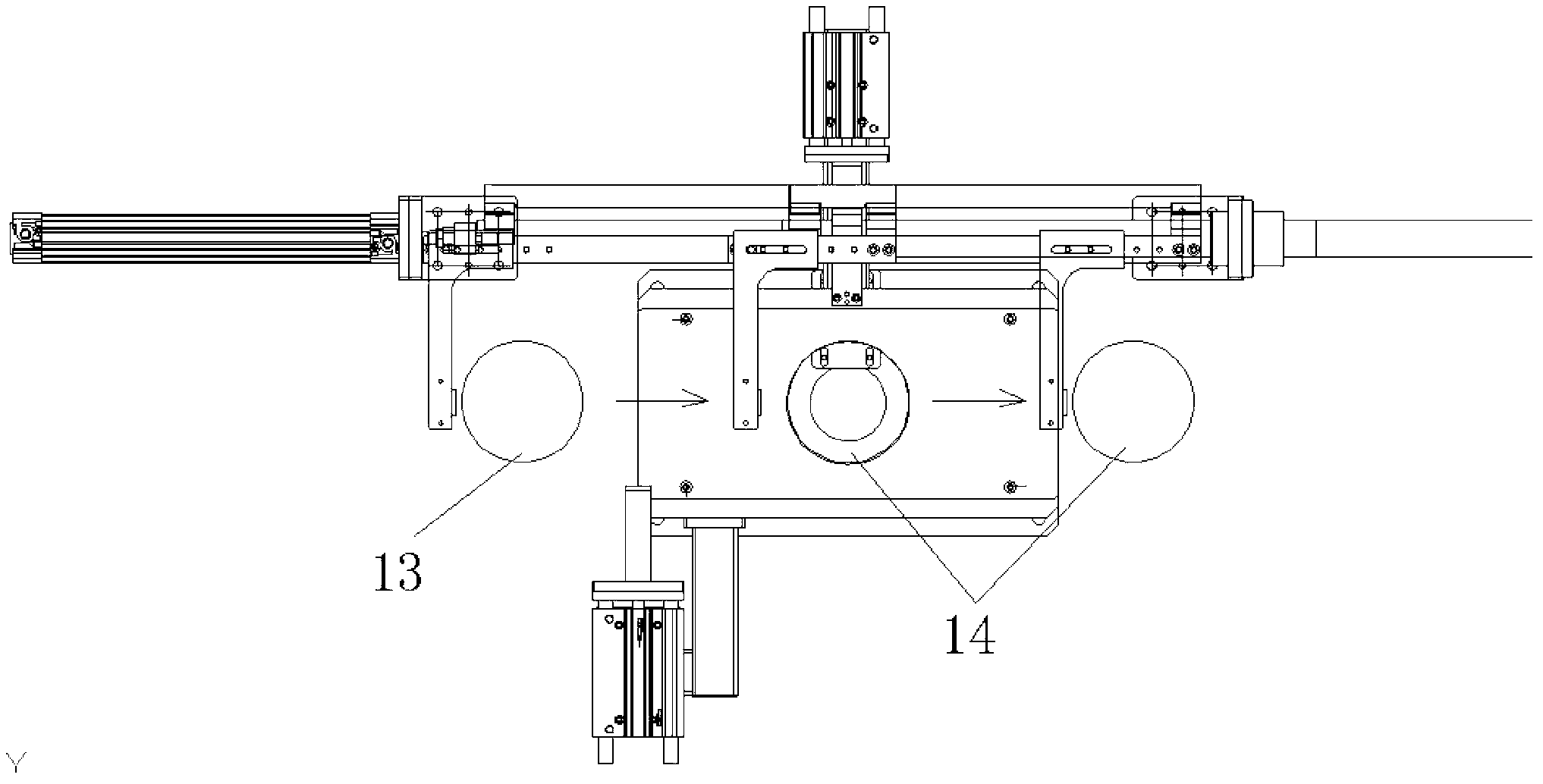

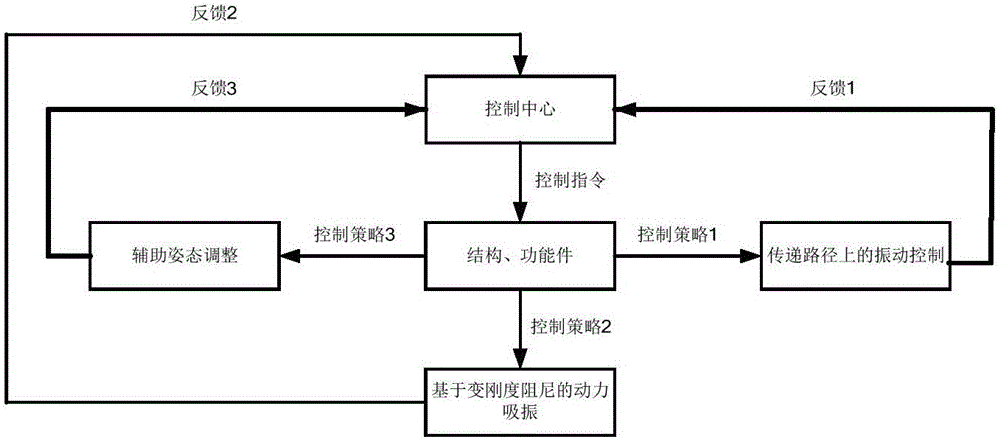

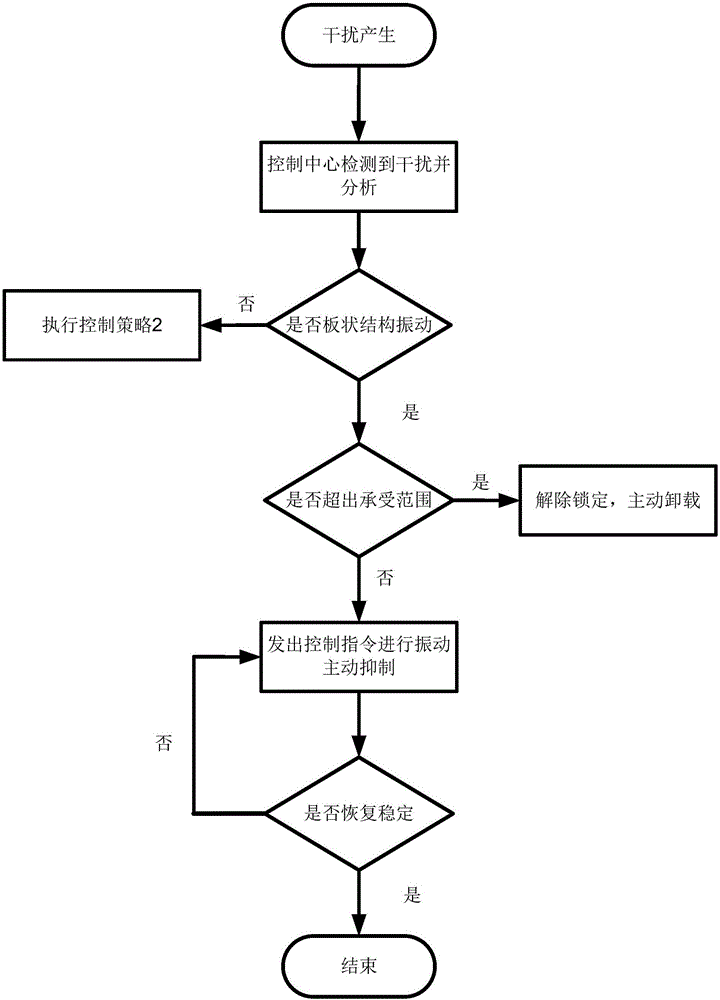

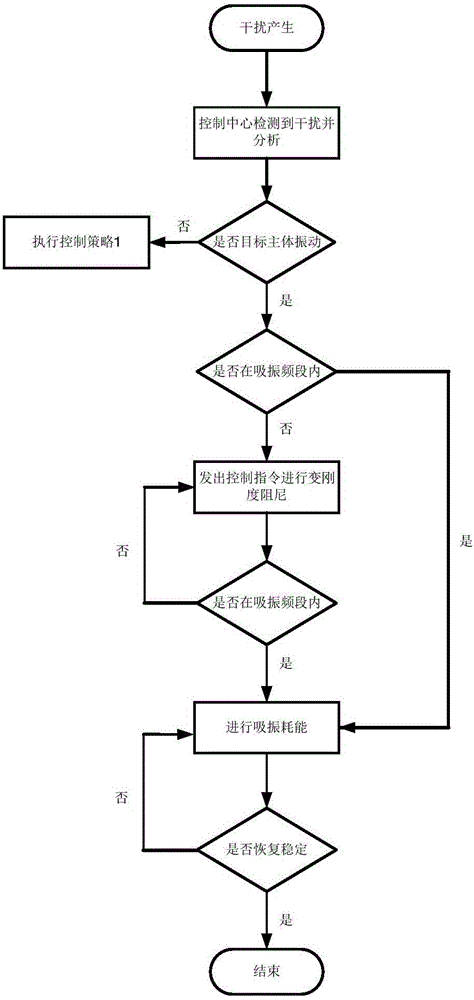

Object under force balance state and vibration control and posture adjustment method for object

ActiveCN106246799AAvoid destructionSimple control algorithmVibration suppression adjustmentsSimultaneous control of multiple variablesStructure functionEngineering

The invention provides an object under a force balance state. The object comprises a subject main body, a structural body array and a connector; and a plurality of structural bodies are sequentially connected through a variable-rigidity active execution part. The invention further provides a corresponding vibration control and posture adjustment method which comprises a vibration control step on a transmission path, a dynamic vibration absorption step based on variable-rigidity damping characteristics and an auxiliary posture adjustment step. The object is the variable-rigidity execution part based on structure-function integration, damages on a plate-shaped structure main body, and even the subject main body are avoided, and a control algorithm is simpler and more effective; active vibration suppression can be separately carried out on disturbance from a plate-shaped structure, and active dynamic vibration absorption is carried out on vibration from the subject main body; and the method can be carried out at multiple frequency bands and in multiple freedom directions; and posture of the subject can be adjusted in an auxiliary manner.

Owner:SHANGHAI JIAO TONG UNIV

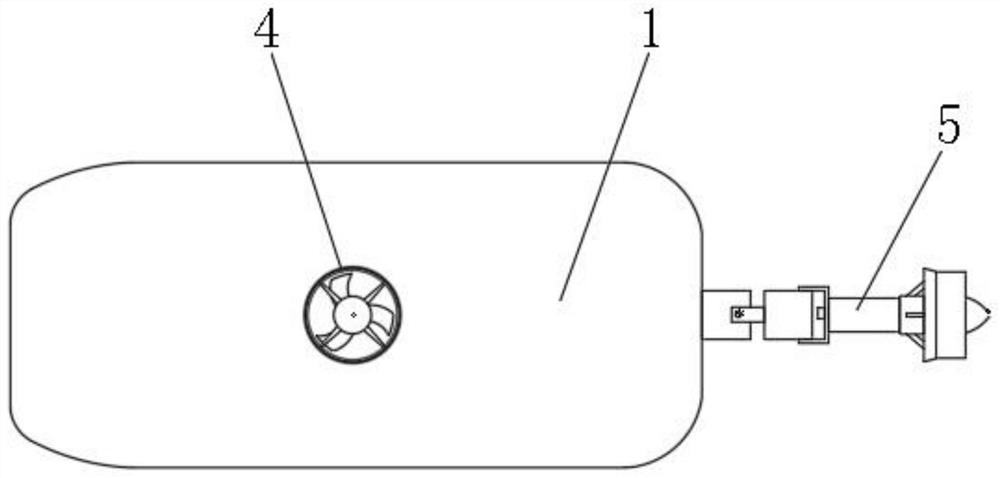

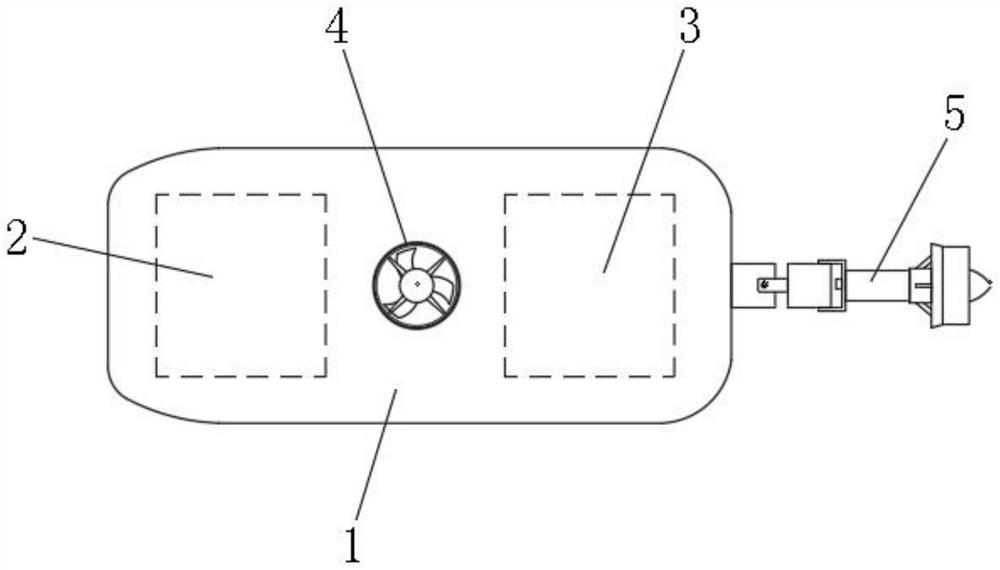

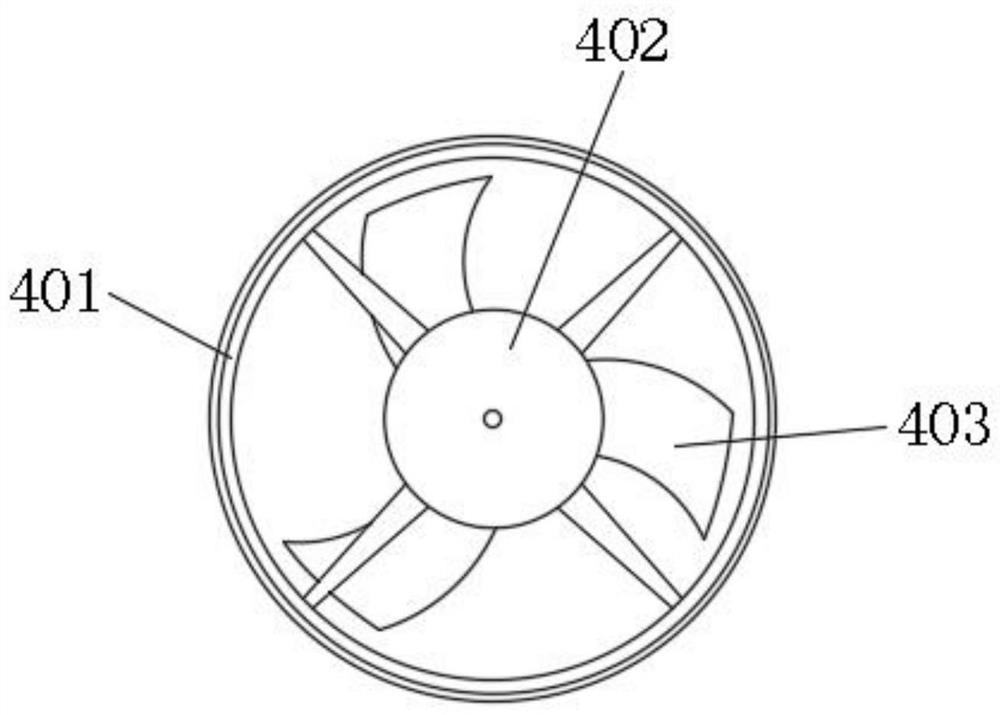

Novel two-propeller intelligent underwater robot

PendingCN113371161AHigh control precisionReduce development costsUnderwater vesselsUnderwater equipmentControl systemControl engineering

The invention provides a novel two-propeller intelligent underwater robot, and relates to the technical field of intelligent underwater robots. The novel two-propeller intelligent underwater robot comprises a robot framework, a front sealed cabin and a rear sealed cabin are arranged on the two sides of the center of the robot framework respectively, and a directional propeller is installed in the center of the robot framework; the directional propeller comprises a duct, a waterproof motor and blades, the duct is installed in the center of the robot framework, the waterproof motor is installed in the center of the duct, the vector thruster is installed in the center of the tail end of the robot framework, and the vector propeller comprises a first underwater steering engine, a second underwater steering engine, a connecting shaft, a connecting frame and a main propeller. The intelligent underwater robot not only is simple in structure, high in reliability and low in cost, but also has the advantages that the control logic is simple, the control system is easy to realize, the response is quick, the control precision is high and the like, and the development and manufacturing cost of the underwater robot is reduced on the premise of meeting the technical requirements.

Owner:蓓伟机器人科技(上海)有限公司 +1

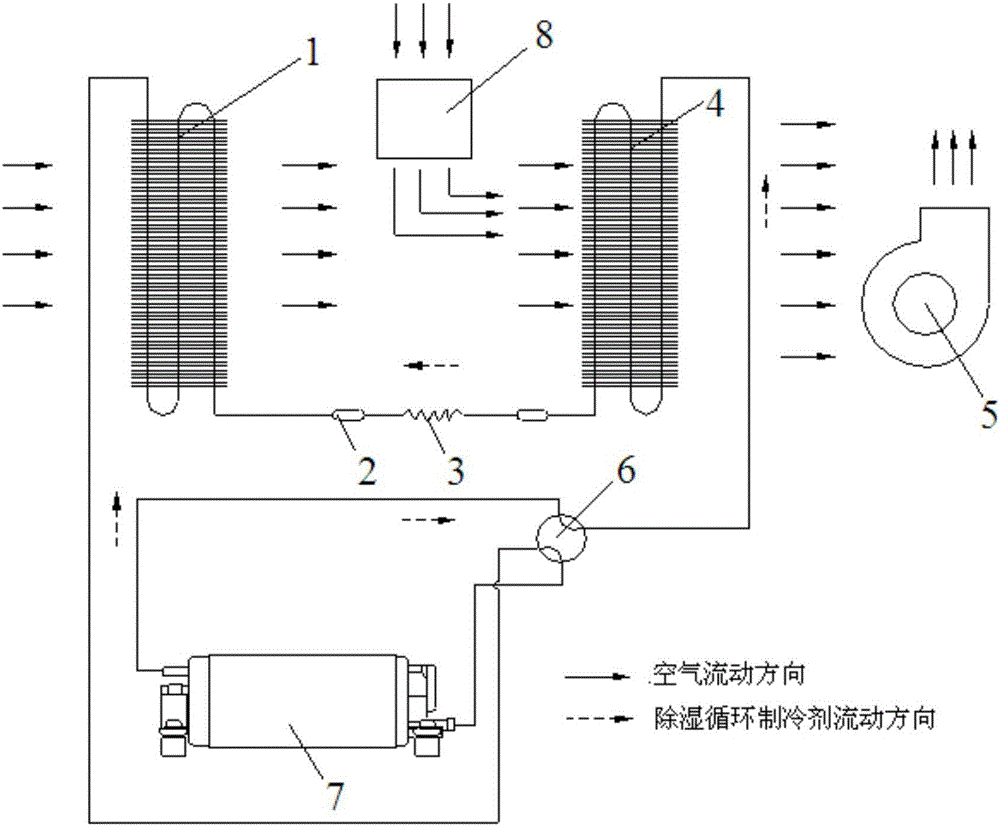

Device for increasing air volume of dehumidifier condenser

InactiveCN106594913AImprove dehumidification effectHigh precisionMechanical apparatusSpace heating and ventilation safety systemsElectricityAir volume

The invention discloses a device for increasing air volume of a dehumidifier condenser. The device comprises a dehumidifier composed of an evaporator, a filter, a capillary tube, the condenser, a centrifugal fan, a reversing valve and a compressor. An air door is arranged between the air output end of the evaporator and the air input end of the condenser. A temperature sensor is arranged at the air output end of the condenser. On one hand, the temperature sensor is electrically connected with a drive mechanism of the air door through a controller; on the other hand, the temperature sensor is connected with an alarm circuit through the controller. The device additionally provided with the air door is used, during high temperature, the air volume of the condenser is increased, while the air volume of the evaporator is kept unchanged, or the air volume is reduced appropriately, thus, the evaporating point of the evaporator is controlled, the dehumidifying ability and precision of the dehumidifier are improved, and the device can work stably and reliably in a high-temperature environment.

Owner:合肥天鹅制冷科技有限公司

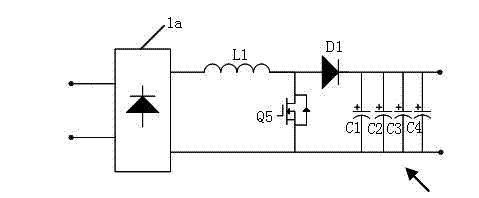

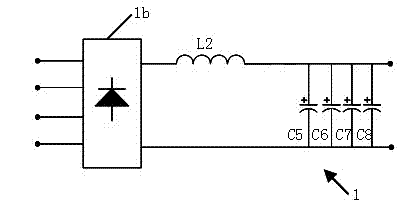

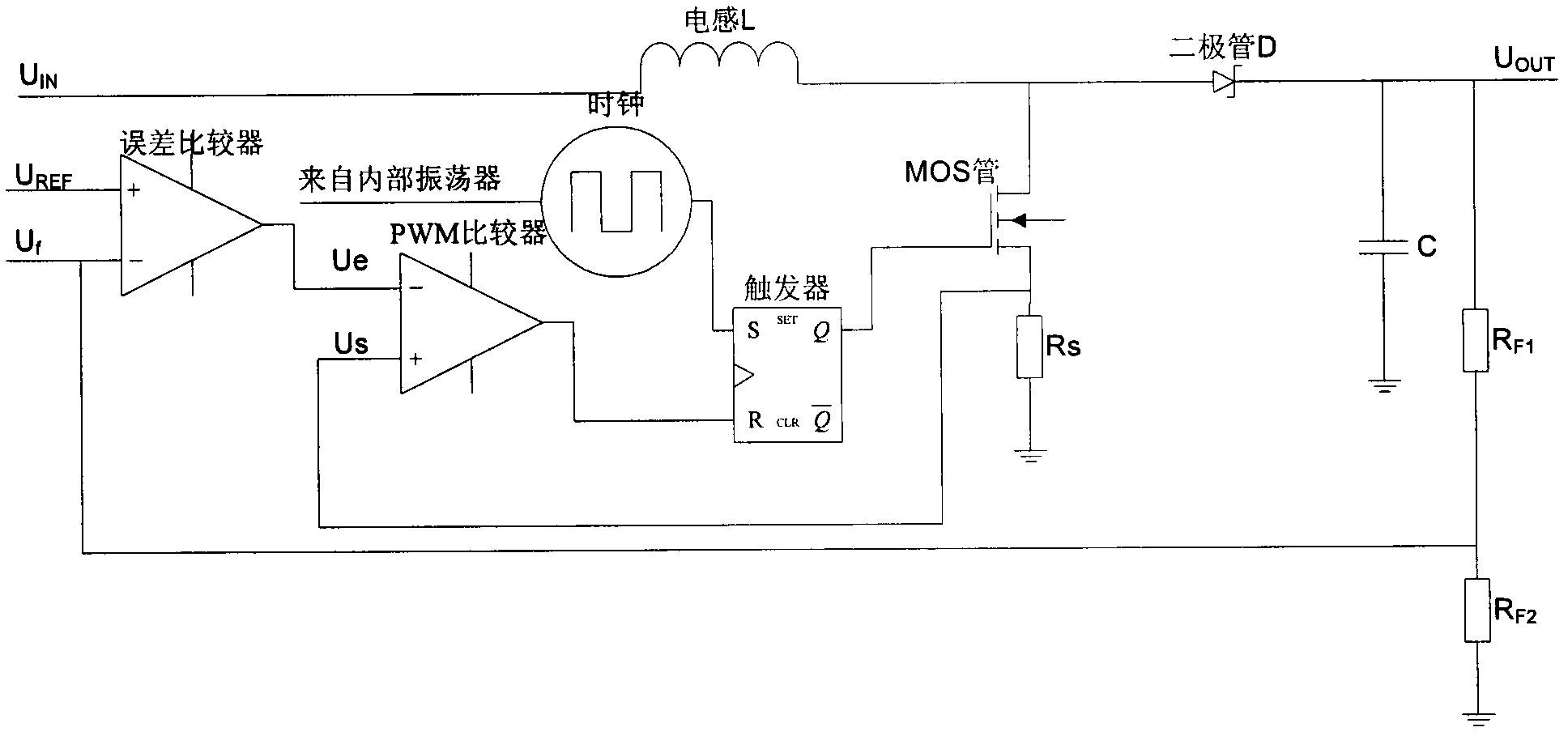

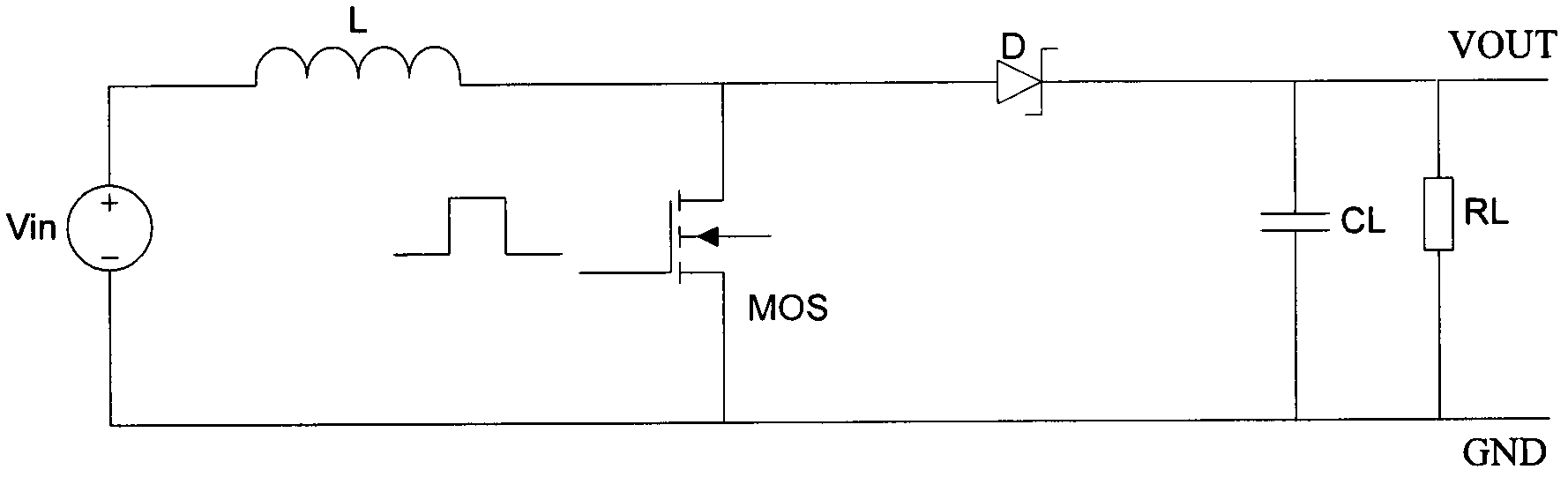

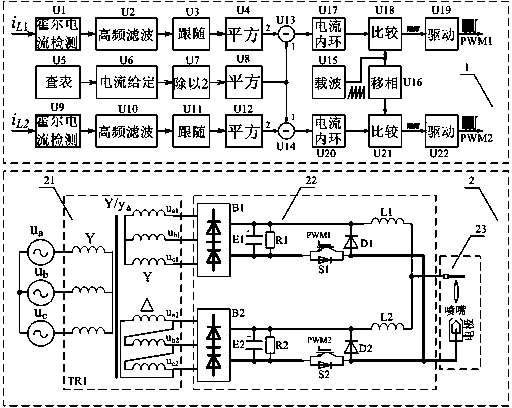

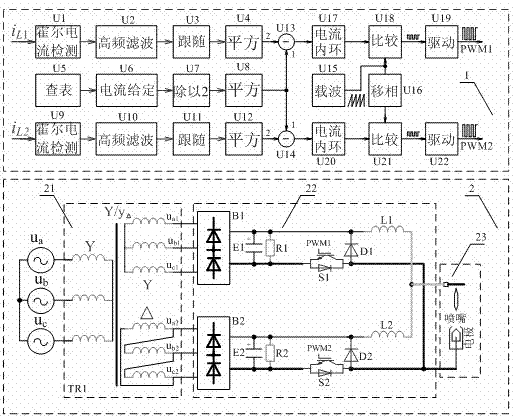

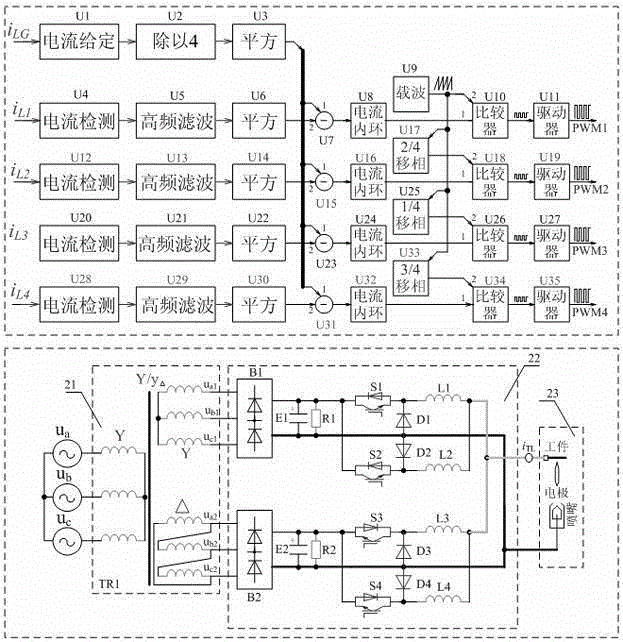

Direct stored energy control system of plasma-cutting power source and control method thereof

ActiveCN103722283ASmall rippleImprove power factorAc-ac conversionPlasma welding apparatusEnergy controlPower factor

The invention relates to a direct stored energy control system of a plasma-cutting power source and a control method of the direct stored energy control system. The system comprises a power circuit and a control circuit, wherein the power circuit comprises a voltage reduction circuit and a chopper circuit. The voltage reduction circuit is an industrial frequency transformer which comprises a primary coil and two secondary coils, the chopper circuit comprises two BUCK circuits in parallel, and the two BUCK circuits are connected with the two secondary coils respectively. According to the direct stored energy control system of the plasma-cutting power source and the control method of the direct stored energy control system, the output direct current can be supported to reach 260A, the circuits are simple, controlling is convenient, and meanwhile the direct stored energy control system and the control method have the advantages of being high in input power factor (larger than 0.96), low in ripple of the output direct current and the like.

Owner:江苏博大数控成套设备有限公司

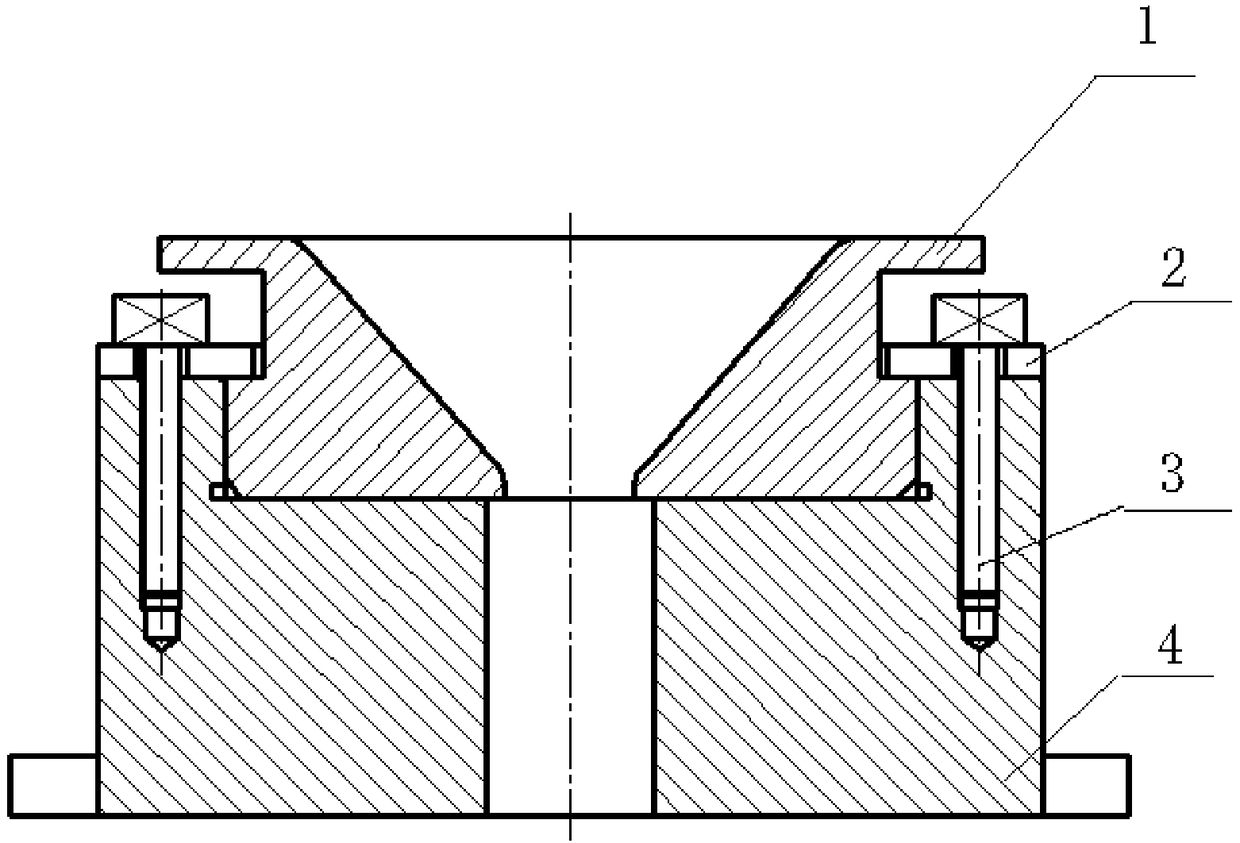

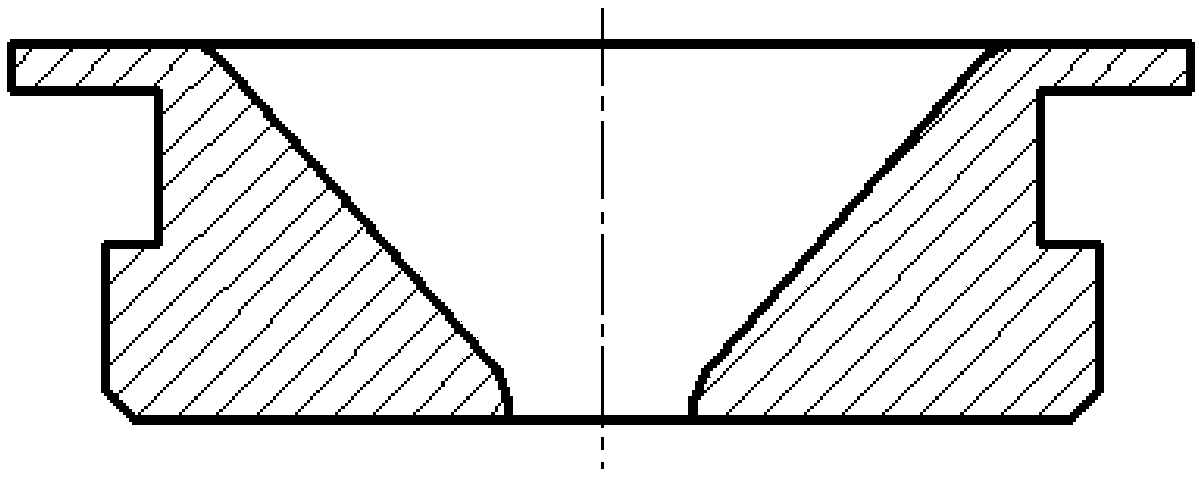

A quick-change valve hot forging die and its installation method and disassembly method

InactiveCN106180521BReduce die change timeSave operating timeForging/hammering/pressing machinesConvex structureChange Type

The invention relates to a quick-change type valve hot forging die. The quick-change type valve hot forging die comprises a quick-change forging die body, a U-shaped gasket, a die holder and screws. The U-shaped gasket is fixed to the die holder through the screws. The quick-change forging die body is clamped on the die holder through the U-shaped gasket. The side wall of the quick-change forging die body is composed of an upper convex structure, a middle concave structure and a lower convex structure. The upper surface of the middle concave structure is the lower surface of the upper convex structure. The lower surface of the middle concave structure is the upper surface of the lower convex structure. During die installation, the U-shaped gasket is fixed to the die holder through screwed screws, and the U-shaped gasket ejects the upper surface of the lower convex structure. During die detachment, the unscrewed screws eject the lower surface of the upper convex structure. The invention further relates to an installation method of the quick-change type valve hot forging die, and a detachment method of the quick-change type valve hot forging die. By means of the quick-change type valve hot forging die, the installation method and the detachment method, the operation time is greatly saved, materials are effectively saved, and operation is easy and convenient. The invention belongs to the technical field of hot forging dies.

Owner:SOUTH CHINA UNIV OF TECH

Control valve block system and method for testing hydraulic cylinders

ActiveCN103148042BImprove test efficiencyChange installationFluid-pressure actuator testingServomotor componentsHydraulic cylinderEngineering

Owner:CHINA RAILWAY CONSTR HEAVY IND

Plasma cutting power supply direct energy storage control system and its control method

ActiveCN103722283BSmall rippleImprove power factorAc-dc conversion without reversalPlasma welding apparatusStored energyDc current

The invention relates to a direct stored energy control system of a plasma-cutting power source and a control method of the direct stored energy control system. The system comprises a power circuit and a control circuit, wherein the power circuit comprises a voltage reduction circuit and a chopper circuit. The voltage reduction circuit is an industrial frequency transformer which comprises a primary coil and two secondary coils, the chopper circuit comprises two BUCK circuits in parallel, and the two BUCK circuits are connected with the two secondary coils respectively. According to the direct stored energy control system of the plasma-cutting power source and the control method of the direct stored energy control system, the output direct current can be supported to reach 260A, the circuits are simple, controlling is convenient, and meanwhile the direct stored energy control system and the control method have the advantages of being high in input power factor (larger than 0.96), low in ripple of the output direct current and the like.

Owner:江苏博大数控成套设备有限公司

Cooling machine with double condensation and double cooling

ActiveCN104315739BGive full play to the effect of forced air coolingGood energy saving effectMechanical apparatusCompression machines with several condensersTemperature controlDual mode

Owner:合肥天鹅制冷科技有限公司

A direct contact compound heat exchange system

ActiveCN109945681BIncrease profitSimple structureSteam separation arrangementsDirect contact heat exchangersLiquid storage tankInternal heat transfer

The invention discloses a direct contact composite type heat exchange system. The system comprises a heat exchanger, a liquid level apparatus, a gas and liquid separator, a gas mass flowmeter, a platetype condenser, a stop valve I, a vacuum liquid storage tank, a liquid mass flowmeter, a centrifugal pump, a check valve, a manual adjusting valve, a nozzle, a turbine generator, a spiral channel, astop valve II, a heat conduction oil inlet, a heat conduction oil outlet, a valve, a pump, a heat conduction oil storage tank, multiple pressure meters, and multiple thermometers. Heat media enter thespiral channel, the reverse flow manner from top to bottom is adopted for transferring heat to matter in the heat exchanger, the stirring in the heat exchanger is increased, the two-phase flow innerheat transfer is greatly reinforced, and when the system is applied to the power generation field, the power generation efficiency is higher; and compared with an outer heating device of a common direct contact heat exchanger, the inner spiral channel makes direct contact with the heat exchanger, the heat exchange process can be reduced, the fire losses are reduced, and the energy use rate is improved.

Owner:KUNMING UNIV OF SCI & TECH

A pumping unit driven by a cylindrical linear motor

ActiveCN104806206BHigh energy storageImprove suspension accuracyFluid removalMechanical energy handlingSingle stageGas spring

The invention provides an oil pumping unit of which a sucker rod is directly driven by a linear motor. The oil pumping unit comprises a rack, a linear motor driving device, a single-stage or multi-stage telescopic machine or a gas spring energy storage device, a linear motor rotor, a sucker rod connector and the like, wherein the linear motor driving device, the single-stage or multi-stage telescopic machine or the gas spring energy storage device, the linear motor rotor, the sucker rod connector and the like are arranged on the rack. The oil pumping unit cancels the connection of elastic pieces or radial components such as hair braids, steel wire ropes and belts for an original oil pumping unit, adopts a direct balance mode, and thus cancels the reversing device (head sheave) of an existing non-beam oil pumping unit, so that the efficiency of the oil pumping unit is further improved, the height and weight of the oil pumping unit are reduced, and the service life, reliability and safety of the oil pumping unit are improved.

Owner:华鹰云智(深圳)技术有限公司

Interleaved parallel buck chopper DC current source energy storage control system and its control method

The invention relates to an interleaving buck chopper direct-current source energy storage control system and method. The system comprises a power circuit and a control circuit, and the power circuit comprises a buck circuit and a chopper circuit; the buck circuit is an industrial frequency transformer, the industrial frequency transformer comprises a primary coil and two secondary coils, the chopper circuit comprises two groups of BUCK circuits which are connected in parallel, and the two groups of BUCK circuits are connected with the two secondary coils respectively. The interleaving buck chopper direct-current source energy storage control system and method can support 260A output direct currents, are simple in circuit and convenient to control, and meanwhile have the advantages of being high in input power factor (above 0.96), low in output direct current ripple and the like.

Owner:江阴市六和智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com