Refrigeration equipment capable of automatically balancing filling quantity of refrigerant

A technology of automatic balance and refrigeration equipment, which is applied in the direction of refrigerants, refrigerators, refrigeration components, etc., can solve the problem of small pressure difference of refrigeration equipment, and achieve the effect of simple control and easy modular design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

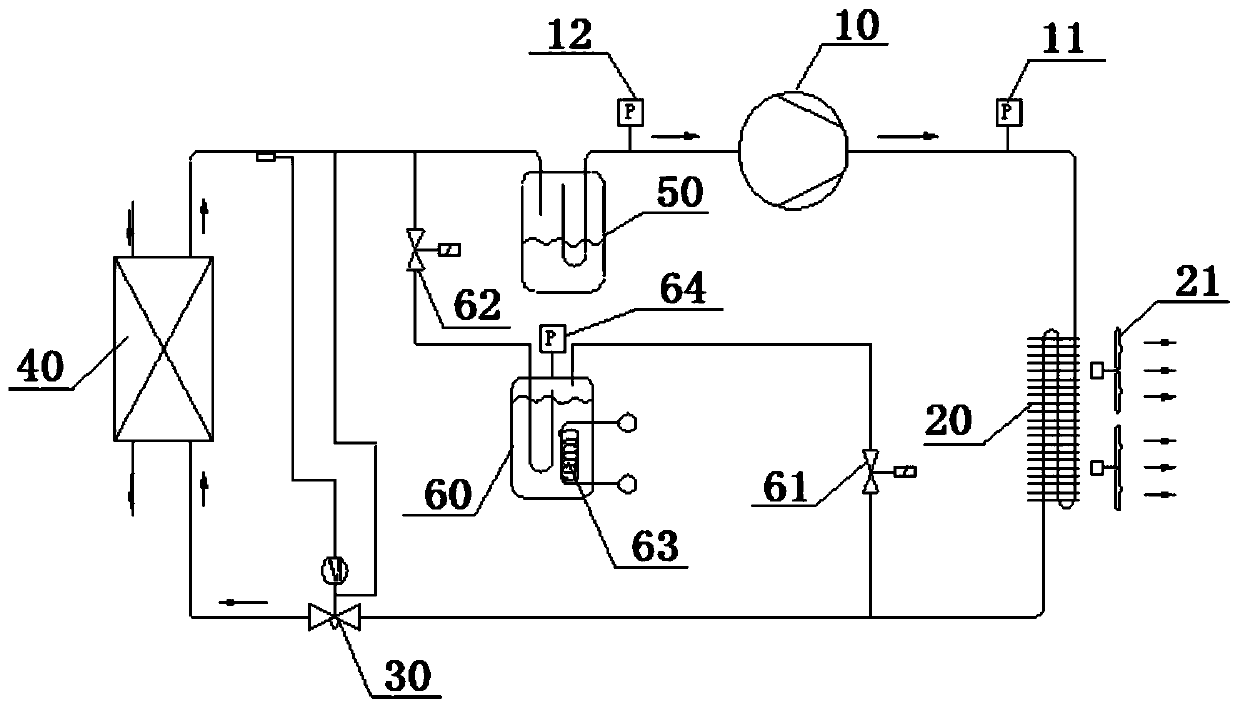

[0017] like figure 1 The shown water circulation cooling equipment includes a compressor 10, a condenser 20 equipped with a condensing fan 21, an expansion valve 30, a plate heat exchanger 40, a gas-liquid separator 50, high pressure and low pressure sensors 11 and 12, a make-up tank 60, The first solenoid valve 61 , the second solenoid valve 62 , the heating belt 63 and the pressure sensor 64 . The output end of the compressor 10 is connected to the input end of the condenser 20, and the connecting pipe between the compressor 10 and the condenser 20 is connected to install a high-pressure sensor 11, and the output end of the condenser 20 is provided with first and second branches, The first branch is connected to the input end of the expansion valve 30, the output end of the expansion valve 30 is connected to the input end of the plate heat exchanger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com