Modular height adjusting device, support and intelligent adjusting system

A height-adjusting device and modular technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of long height adjustment period, complex lifting process, low accuracy, etc., to achieve intelligent adjustment and simplify the height adjustment process. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

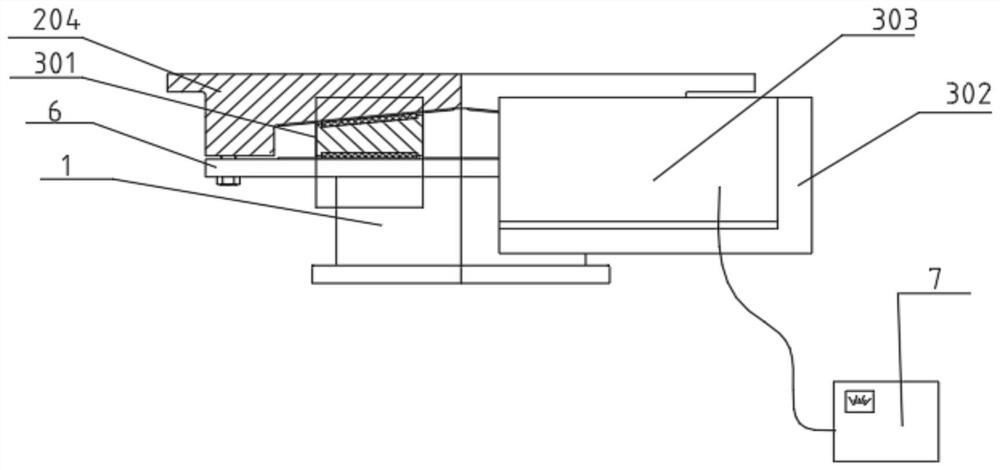

[0025] Such as Figure 1-3 As shown, a modular height-adjusting device and a support include a support body 1, and a height-adjusting mechanism 2 is provided above or below the support body 1, and the height-adjusting mechanism 2 is used for height adjustment of the support. The high mechanism 2 is provided with a connection part for connecting the module power device 3, the module power device 3 is a modular design, and the module power device 3 is provided with a connection structure matching the connection part, which can be adjusted when the height of the support needs to be adjusted. It can be fixed on the height adjustment mechanism 2 through the connecting part, or it can be fixed on the height adjustment mechanism 2 in advance, and the module power device 3 can provide adjustment power for the height adjustment mechanism 2, and drive the height adjustment mechanism 2 to adjust the height of the support, so that the The scheme realizes the modular design of the height a...

Embodiment 2

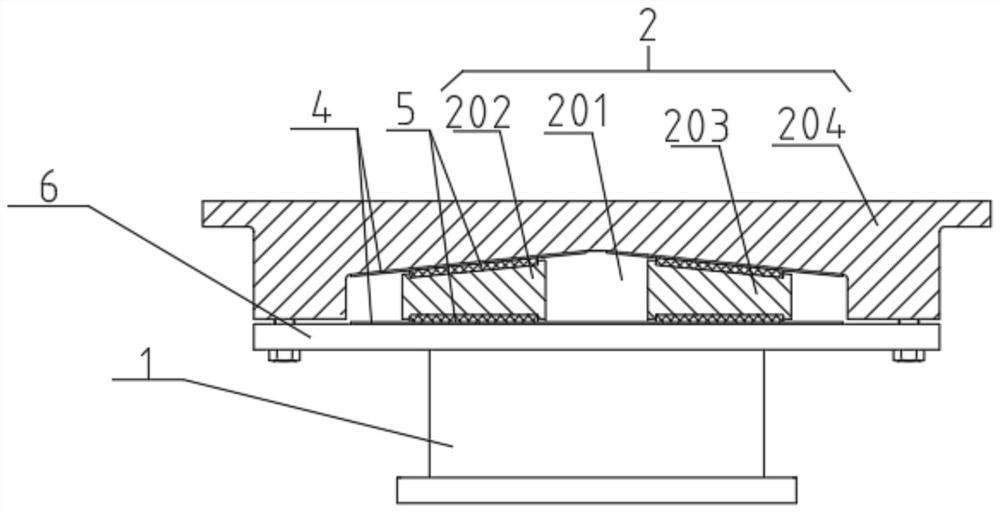

[0027] Such as Figure 1-3 As shown, the height adjustment mechanism 2 includes a height adjustment plate 204, a first adjustment block 202 and a second adjustment block 203. The bottom surface of the height adjustment plate 204 is provided with an adjustment cavity 201 with an opening facing downwards, and the top surface of the adjustment cavity 201 is two Symmetrical inclined surface, the top surface of the two adjustment blocks is an inclined surface, and the bottom surface is a plane. A stainless steel plate 4 is provided on the top surface of the adjustment chamber 201 to enhance the wear resistance of the top surface of the adjustment chamber 201. The first adjustment block 202 and the second adjustment block The top surface and the bottom surface of the block 203 are all embedded with a wear-resistant plate 5 of tetrafluoropolyethylene, and the cooperation of the wear-resistant plate 5 and the stainless steel plate 4 makes the sliding of the adjustment block more smooth...

Embodiment 3

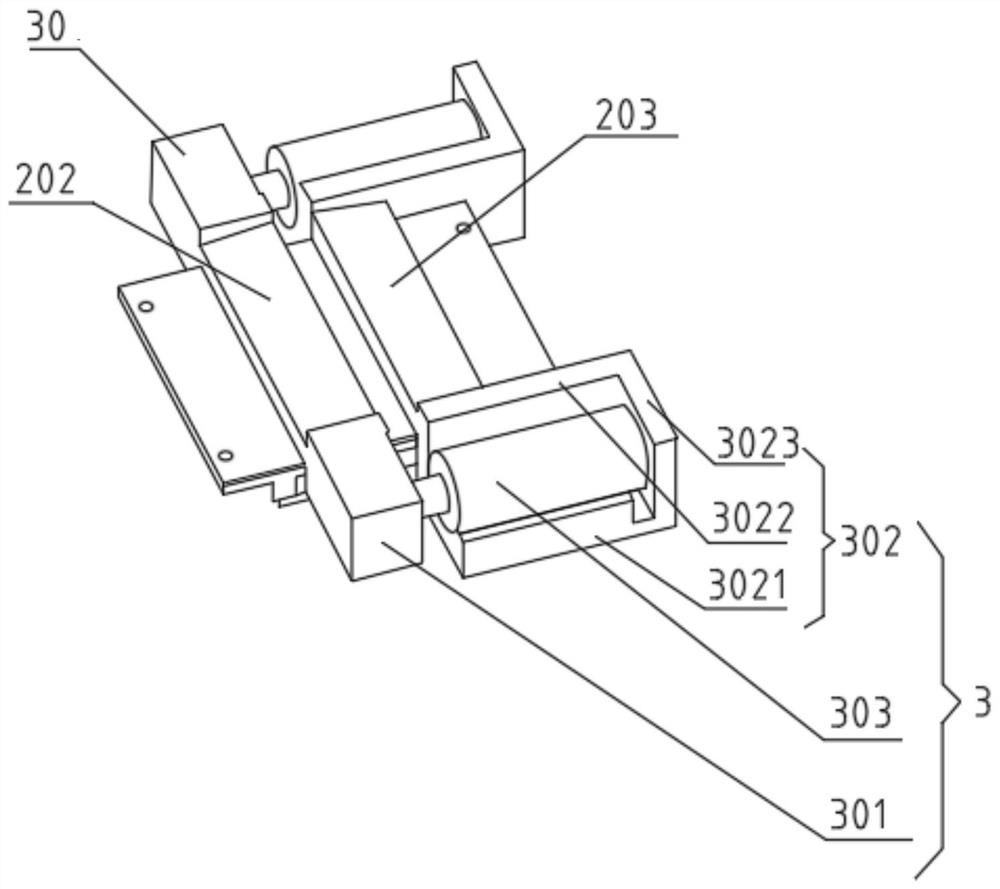

[0029] Such as image 3 As shown, the modular power device 3 includes a first base 301 and a second base 302, the connecting parts of the two ends of the first adjusting block 202 and the second adjusting block 203 are pins or holes, and the first base 301 Corresponding holes or pins are provided on the side of the second base 302, the first base 301 is connected with the pin hole at the end of the first adjusting block 202, and the second base 302 is connected with the pin hole at the end of the second adjusting block 203, In this way, the modular connection of the module power unit 3 is realized. According to the actual use of the support, the module power unit 3 and the two adjustment blocks can also be fixedly connected by casting, welding, bolting, etc., and the module can also be adjusted when the height needs to be adjusted. The power unit 3 is docked with the two adjustment blocks, so that the modular power unit 3 can be used flexibly and can be produced in a modular m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com