Second lining integrated complete set tool construction equipment and application method

A technology of construction equipment and application method, which is applied in the direction of mining equipment, shaft equipment, shaft lining, etc., can solve problems such as difficulty in ensuring smooth fit between waterproof board and inner wall of tunnel, difficulty in ensuring laying quality, and slowing down construction progress. Improve the quality of laying, improve the efficiency of height adjustment, the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

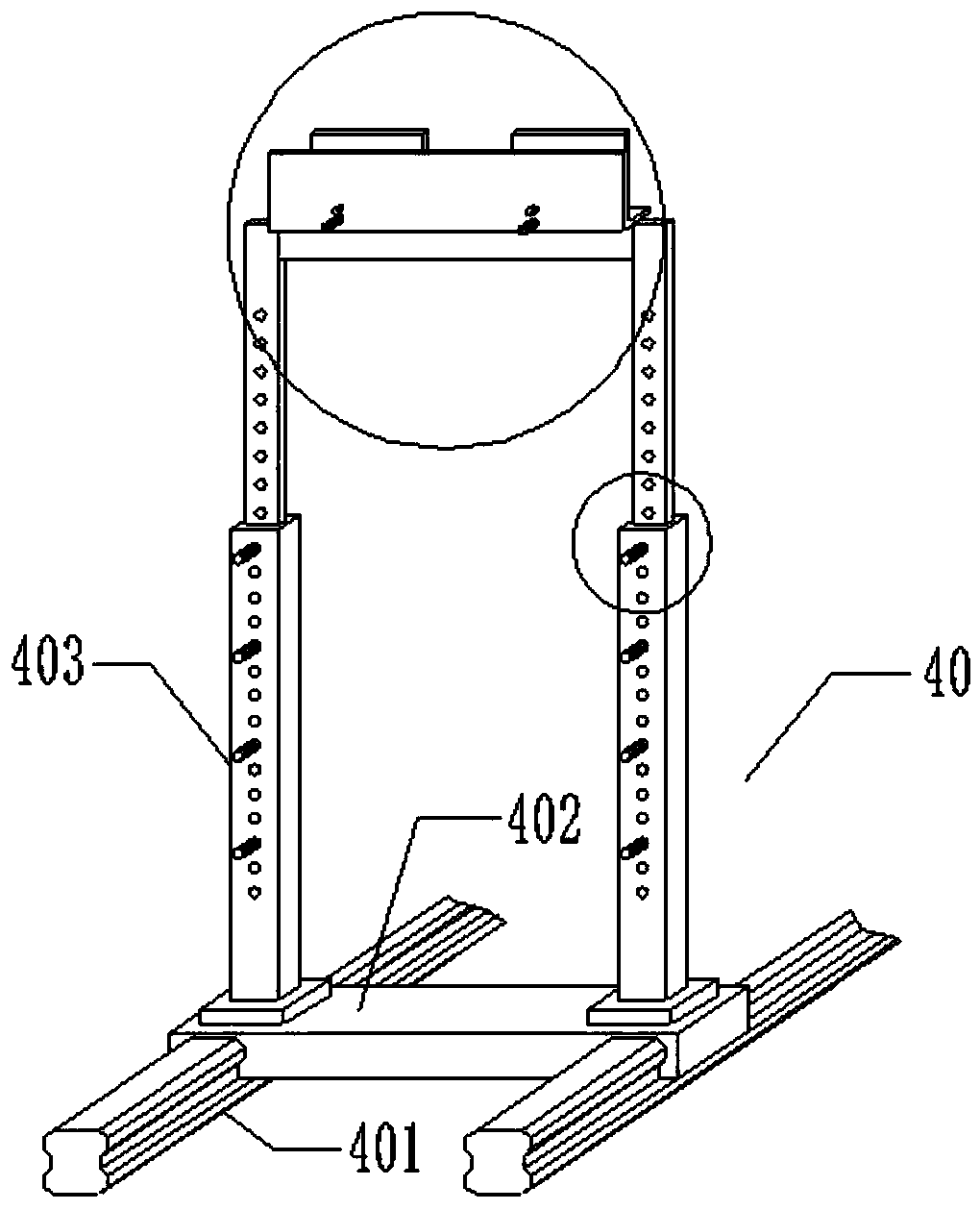

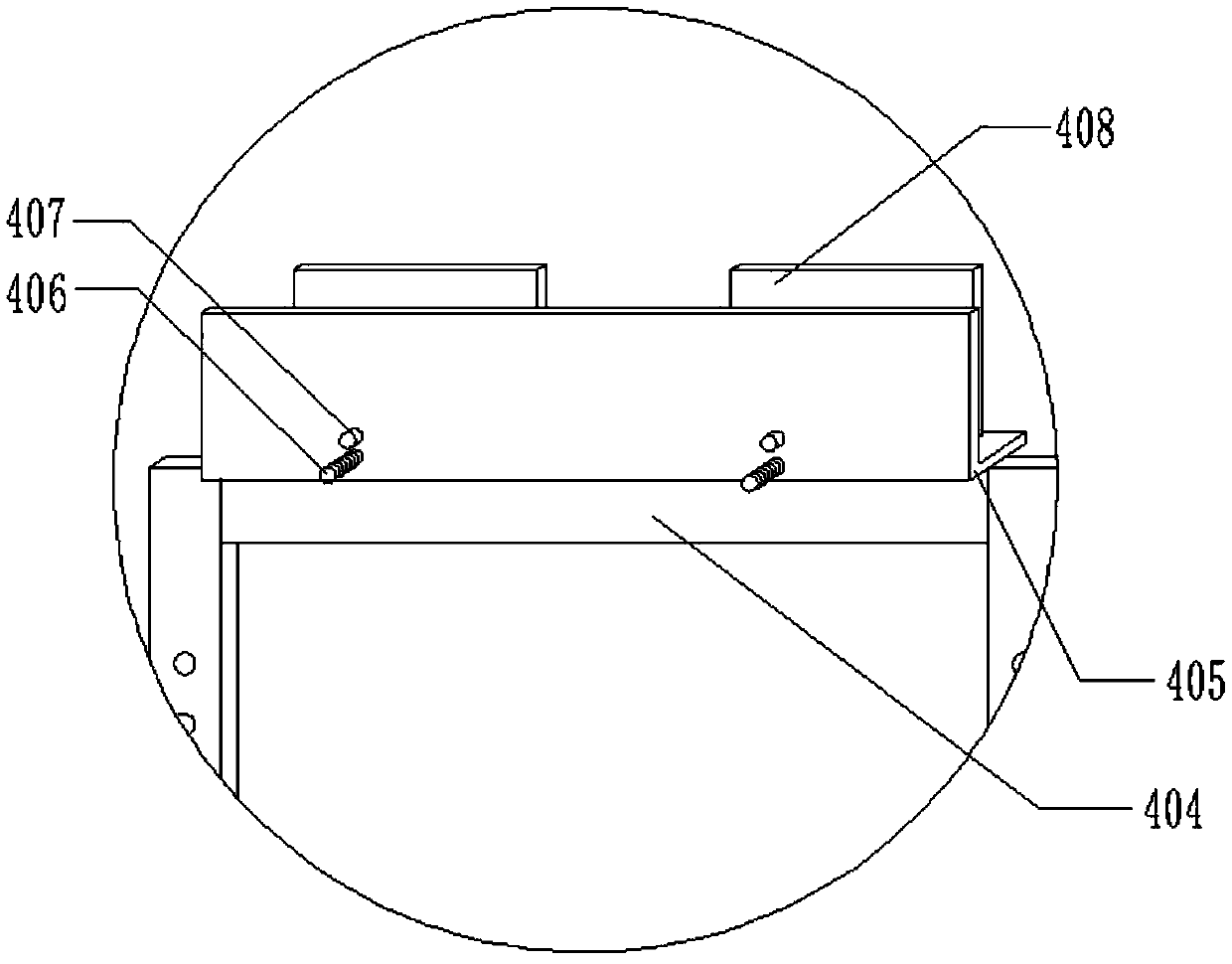

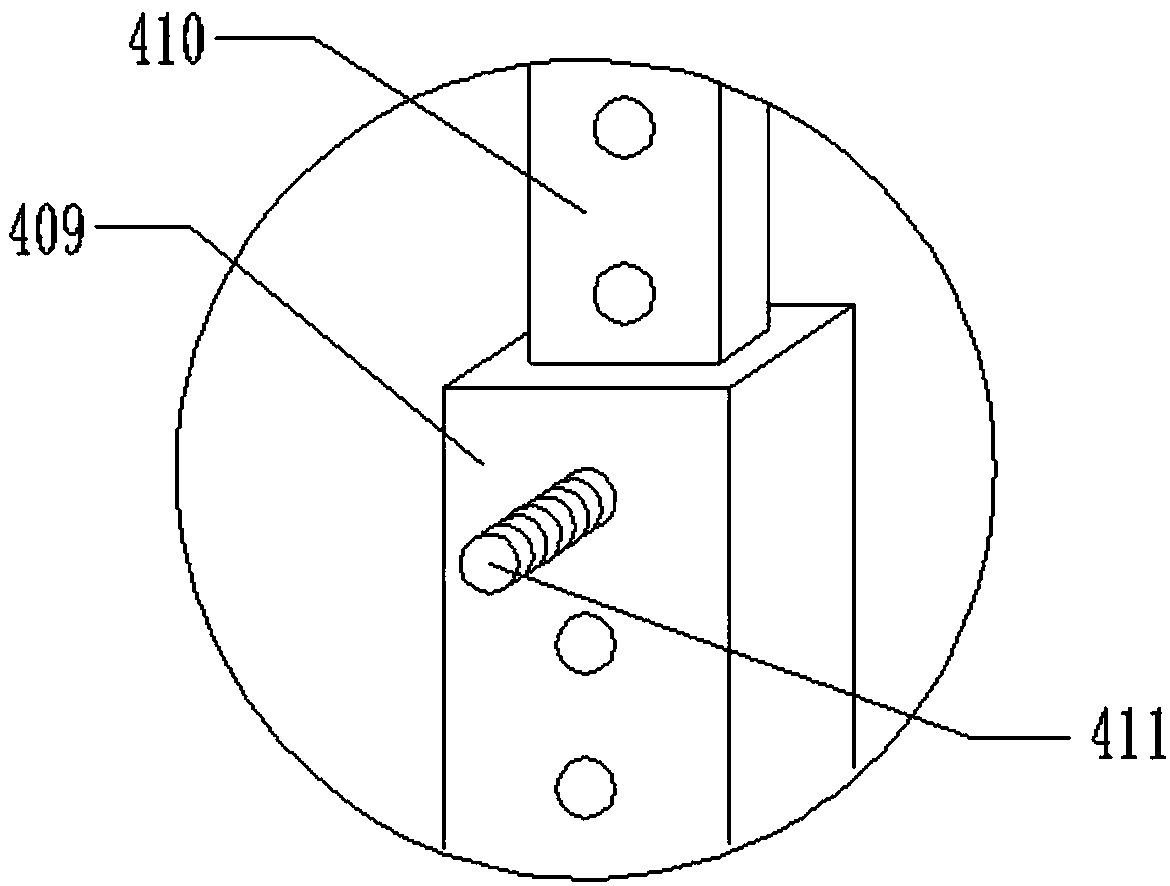

[0047] Such as Figure 1-Figure 9 As shown, a complete set of tooling construction equipment integrated with two linings, wherein the complete set of tooling construction equipment integrated with two linings includes a waterproof and drainage construction part 10, a window-by-window pouring part 20 for the second lining chute, and a molded grouting construction part for the vault 30 and the auxiliary moving part 40, the auxiliary moving part 40 is set along the direction parallel to the central axis of the bottom surface of the tunnel to be lined, and the auxiliary moving part 40 is provided with the waterproof and drainage construction part 10 from the inside to the outside, and the second lining chute is poured into the mold window by window The part 20 and the arch roof molded grouting constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com