Patents

Literature

260results about How to "Improve laying quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

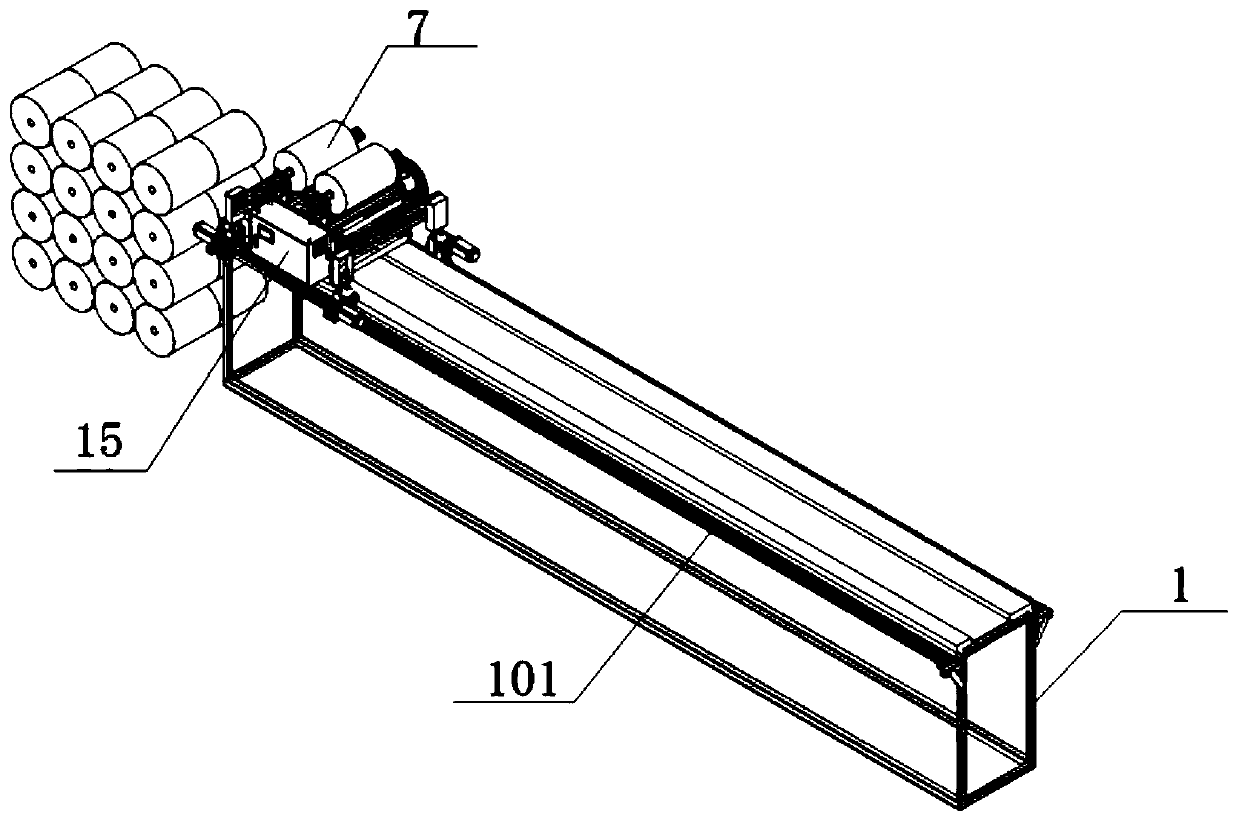

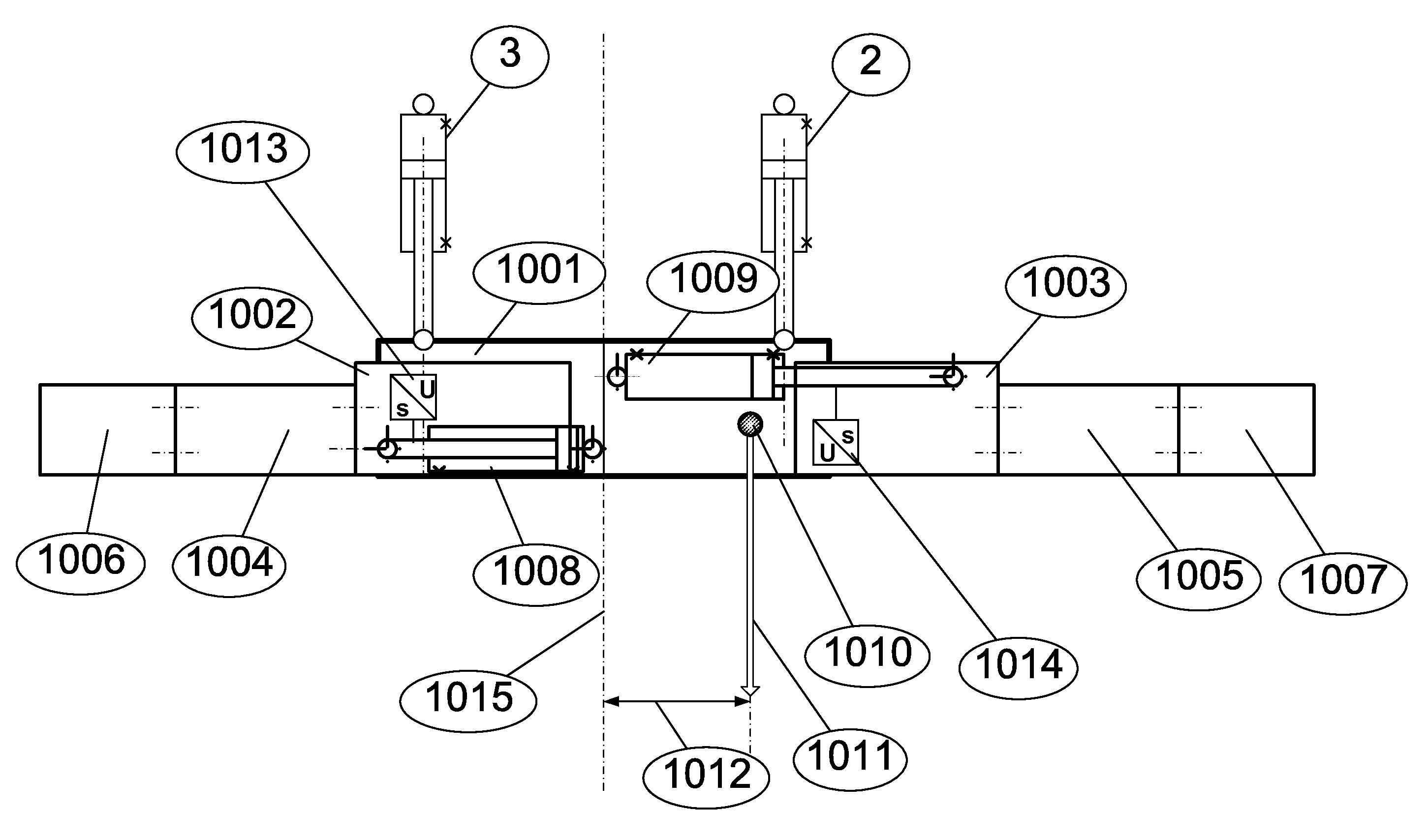

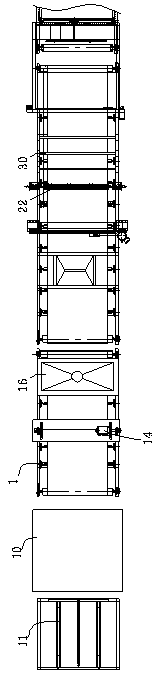

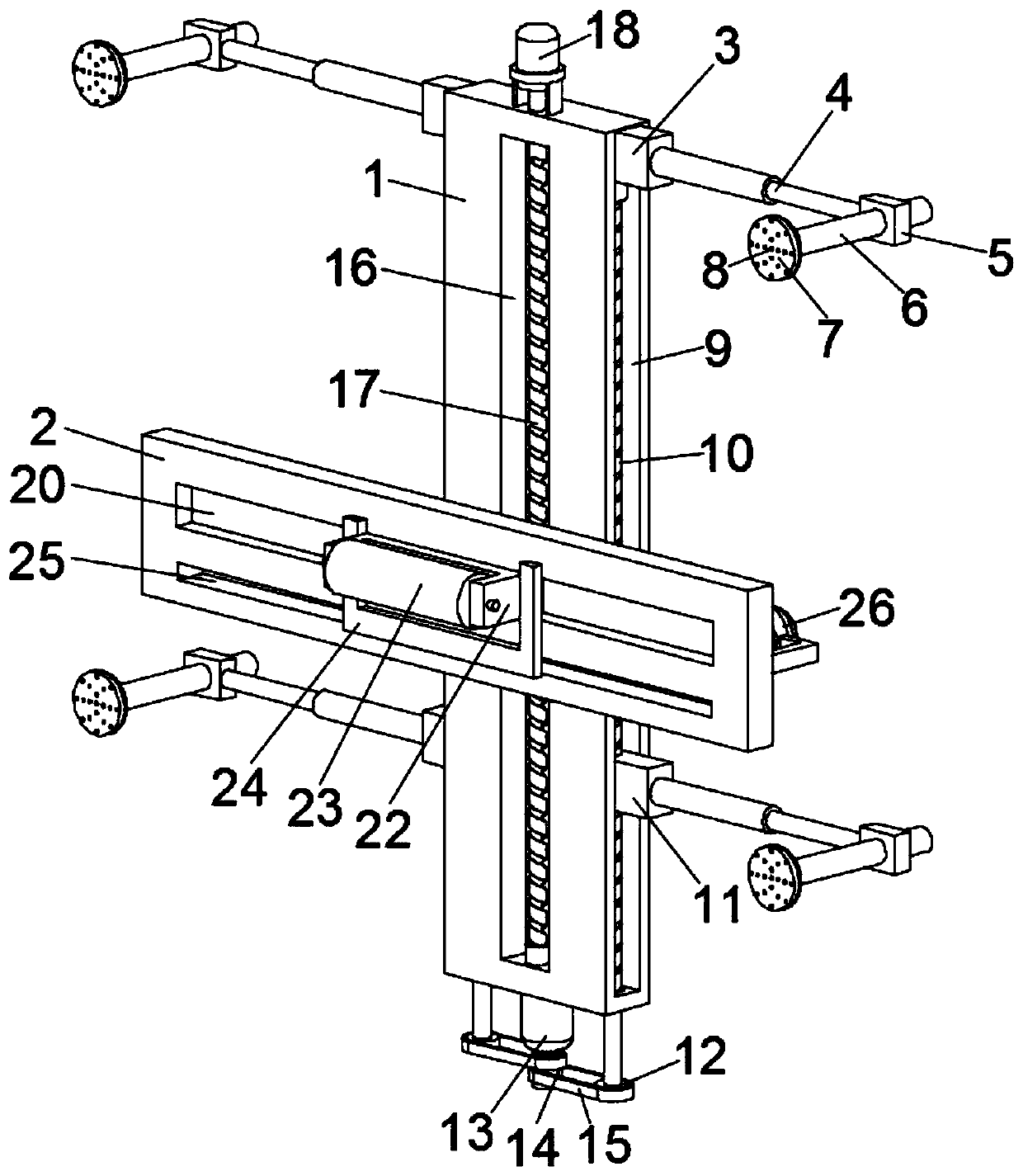

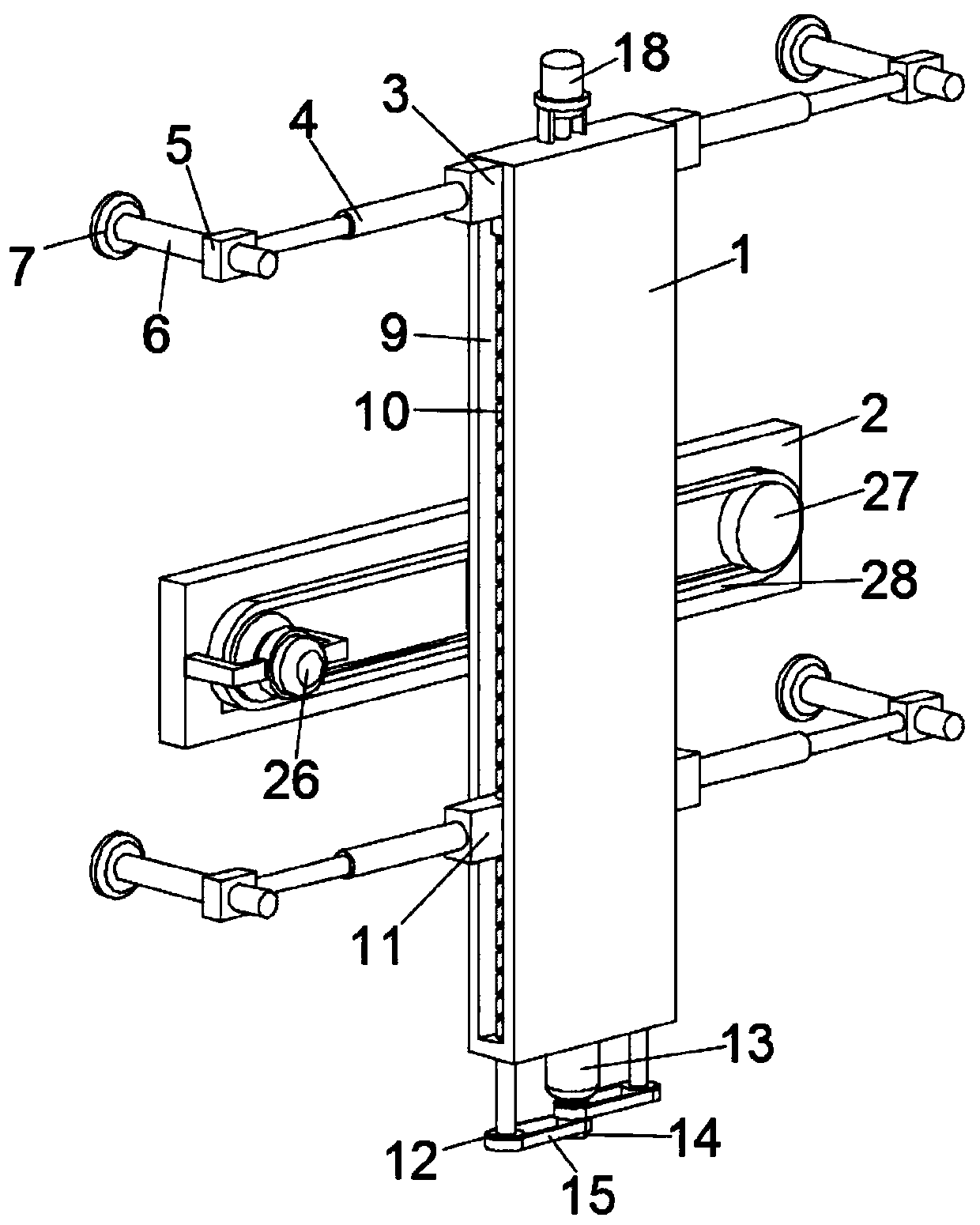

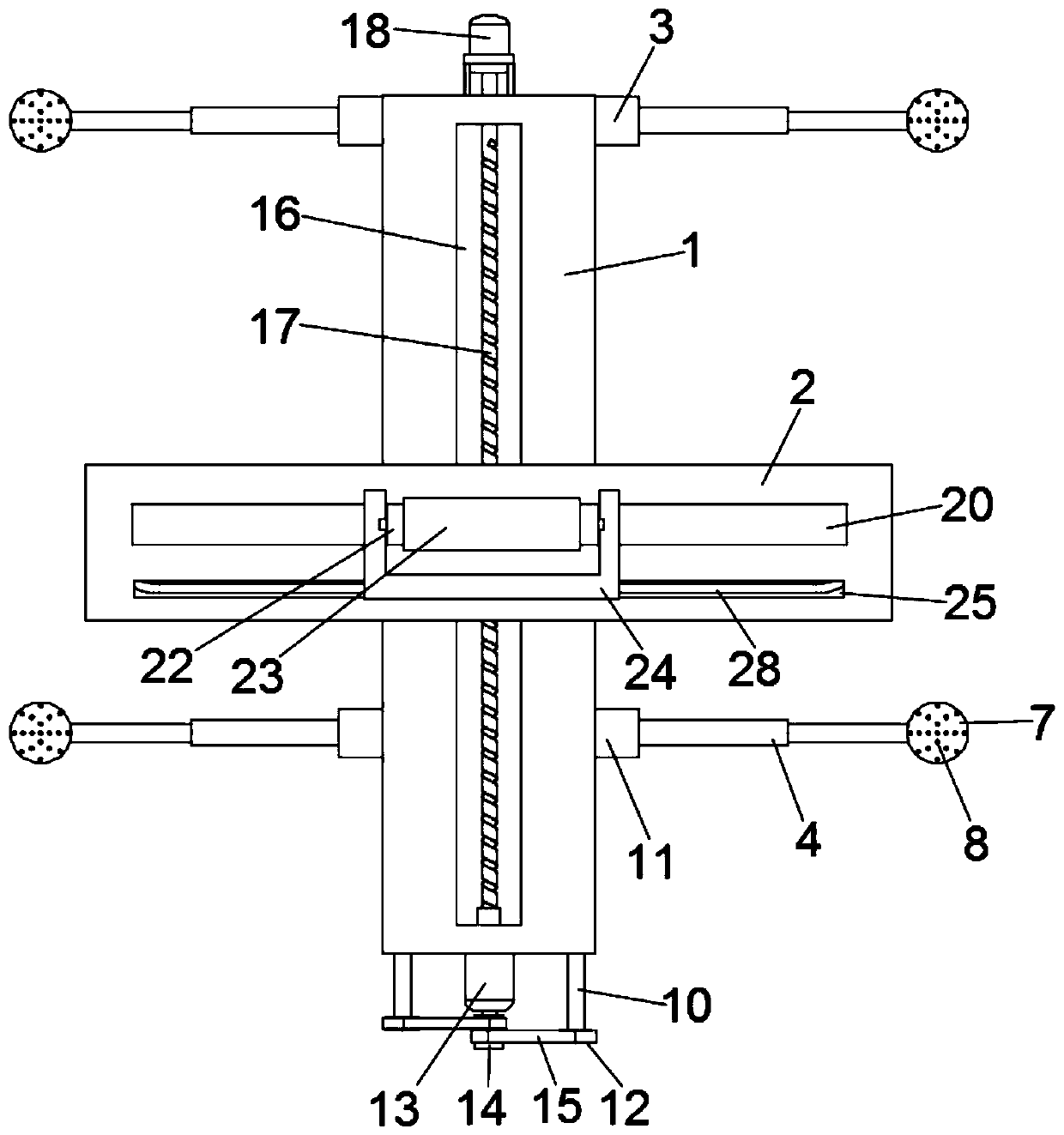

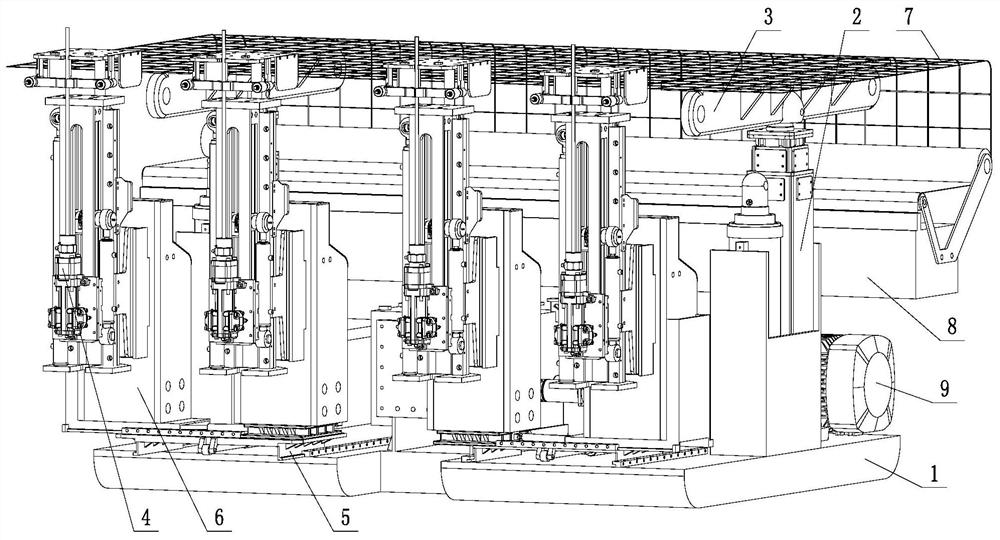

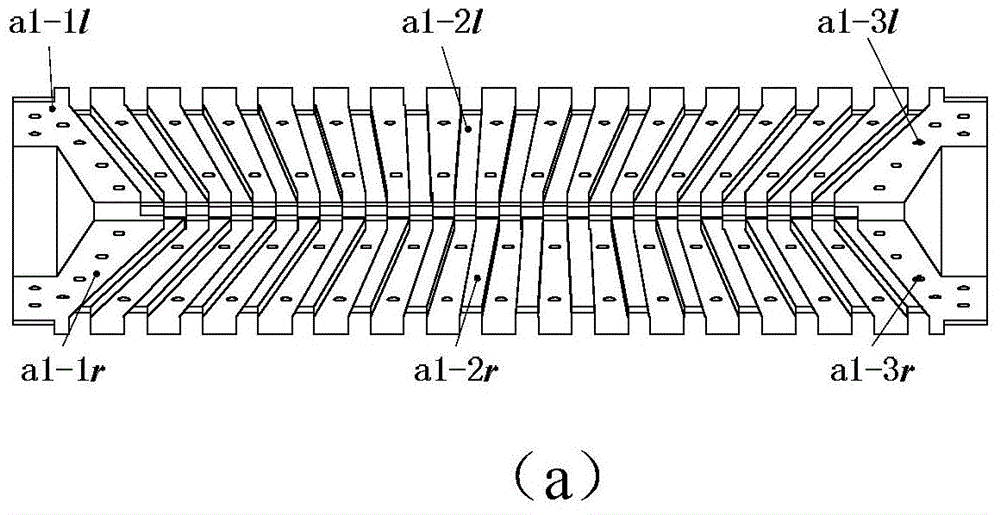

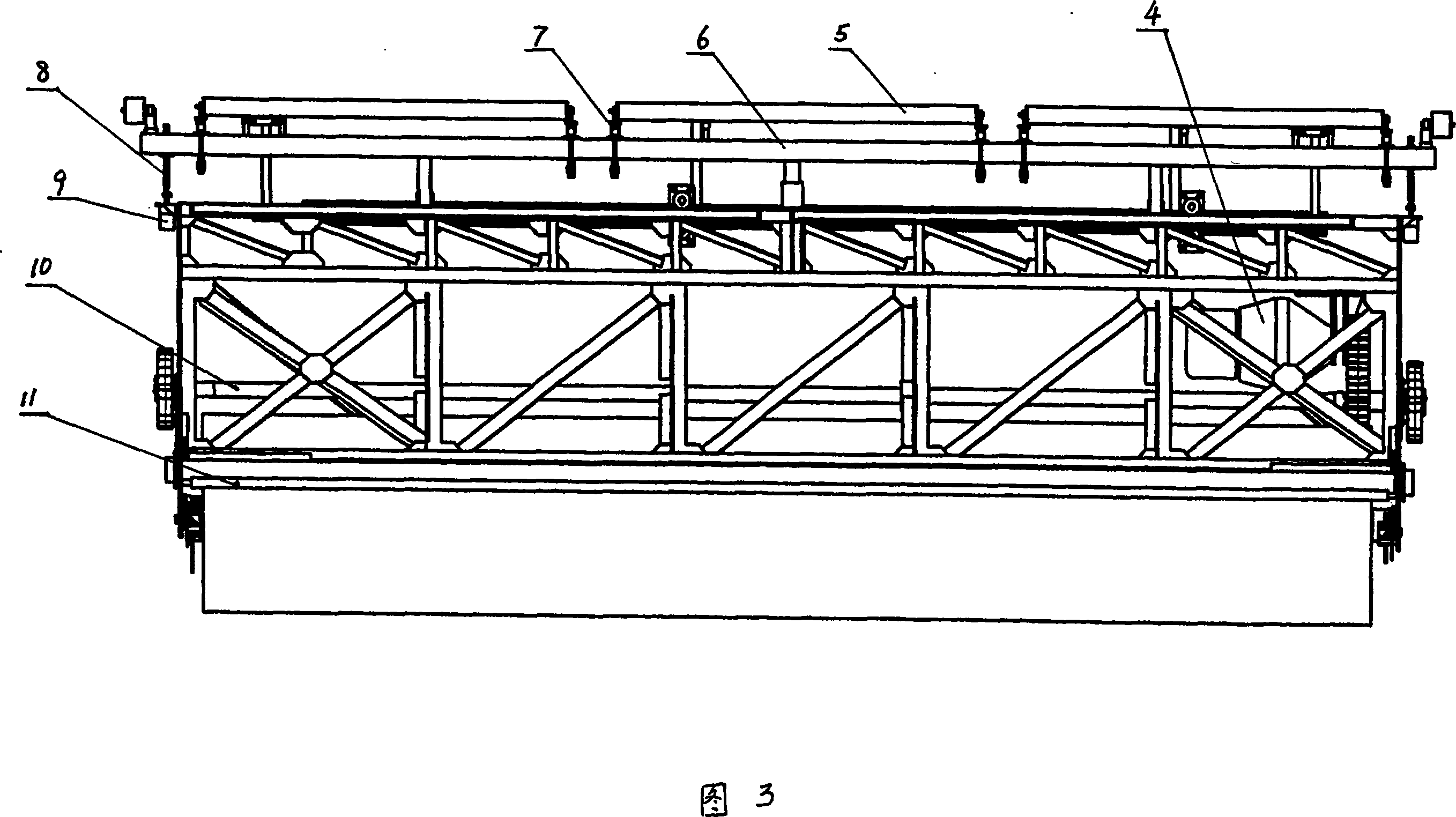

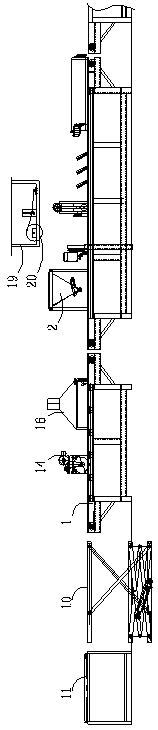

Wind power blade main beam cloth laying device

PendingCN111497286AImprove laying qualityReduce manual labor intensityDomestic articlesStructural engineeringMechanical engineering

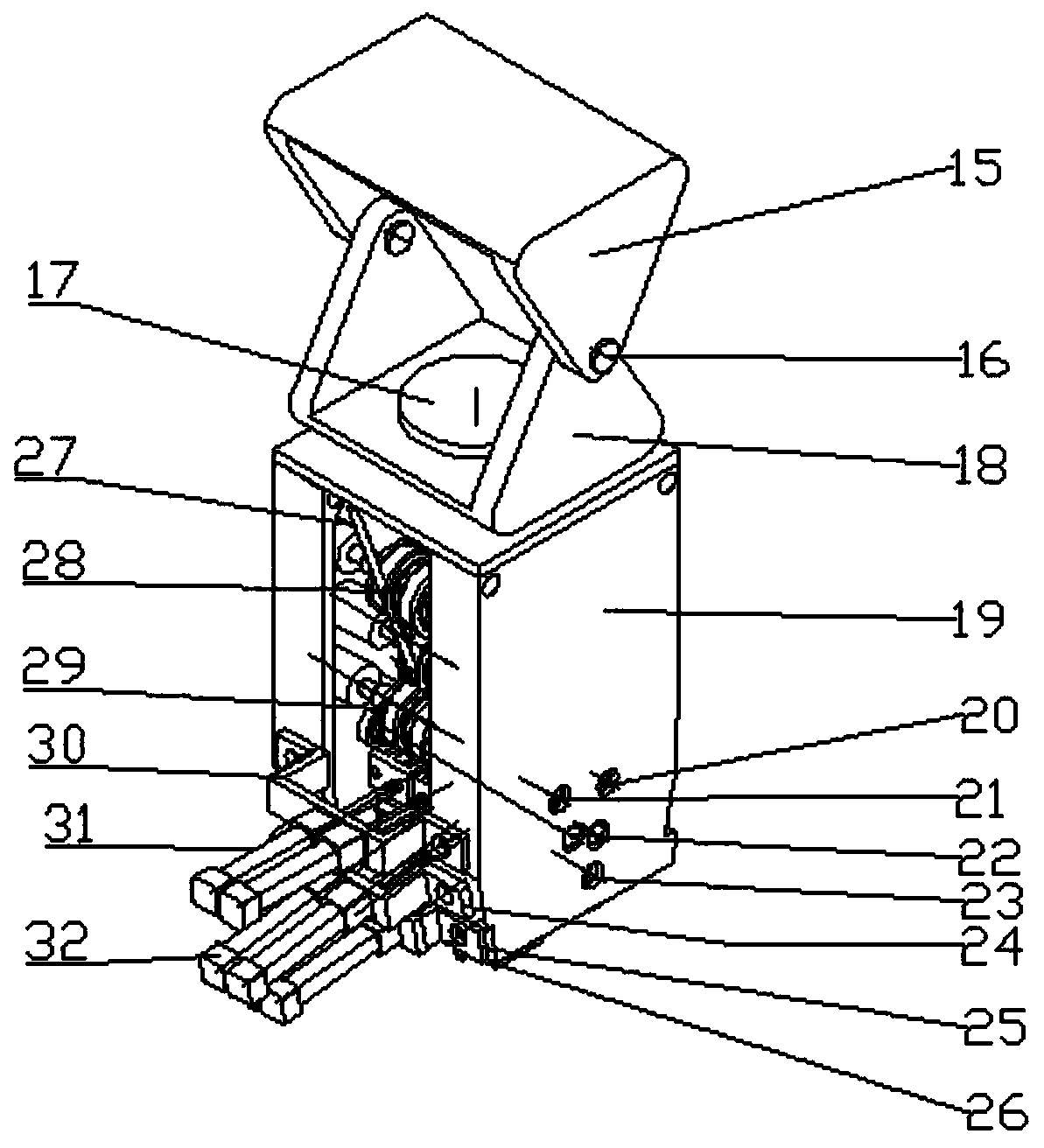

The invention discloses a wind power blade main beam cloth laying device. The wind power blade main beam cloth laying device comprises a cloth laying moving frame, a rotary transverse moving mechanismis arranged on the cloth laying moving frame, an unwinding frame is arranged on the rotary transverse moving mechanism, two cloth rolls which are parallel front and back are erected on the unwindingframe, the rotary transverse moving mechanism comprises a transverse moving assembly and a rotating assembly, the transverse moving assembly is used for controlling the unwinding frame to transverselymove in the chordwise direction of a blade main beam mold, and the rotating assembly is used for controlling the unwinding frame to rotate. The wind power blade main beam cloth laying device has theadvantages that the labor intensity of workers is reduced, the laying quality is improved, the blade forming period is shortened, and the laying efficiency is improved.

Owner:江阴市科诚技术有限公司

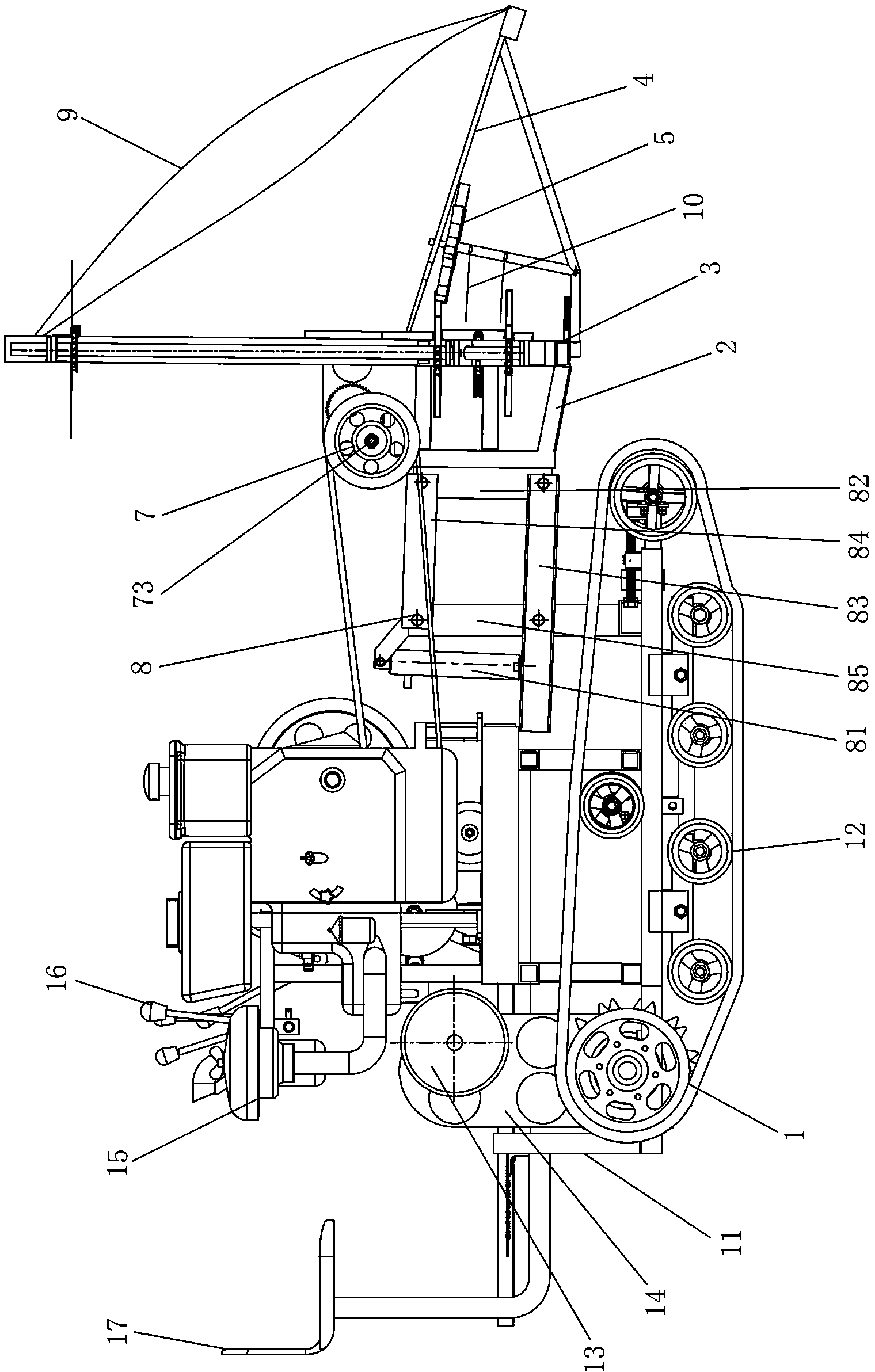

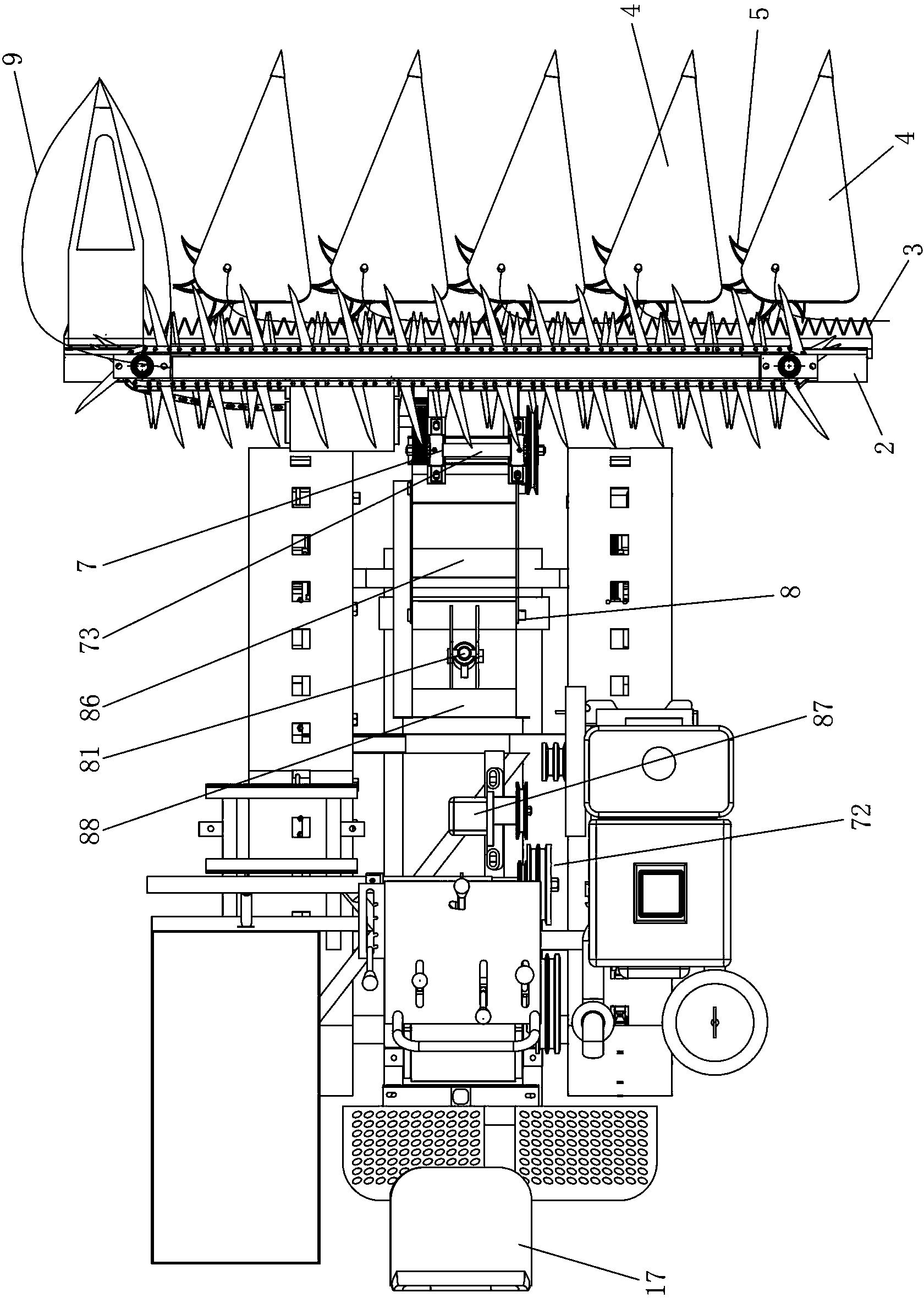

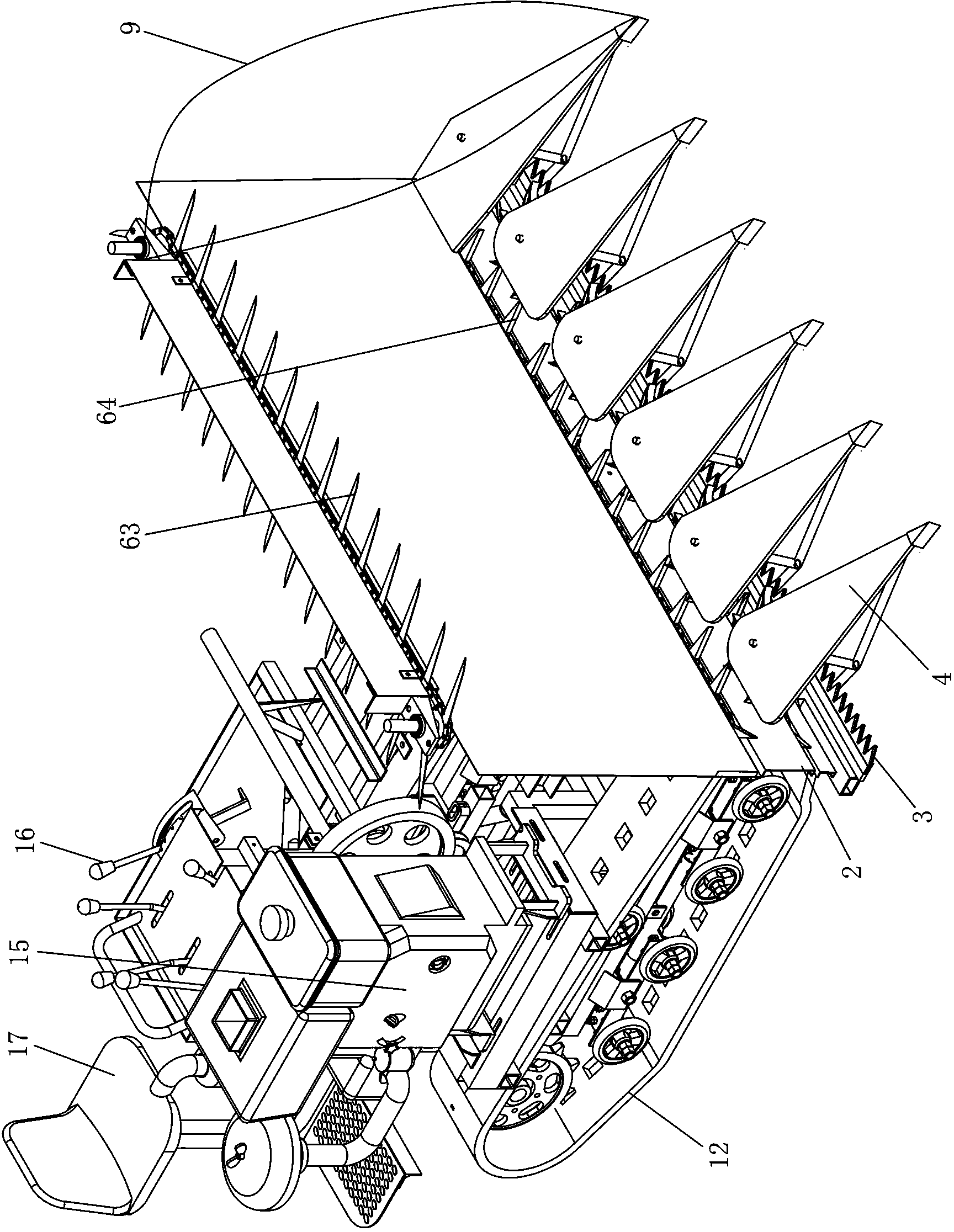

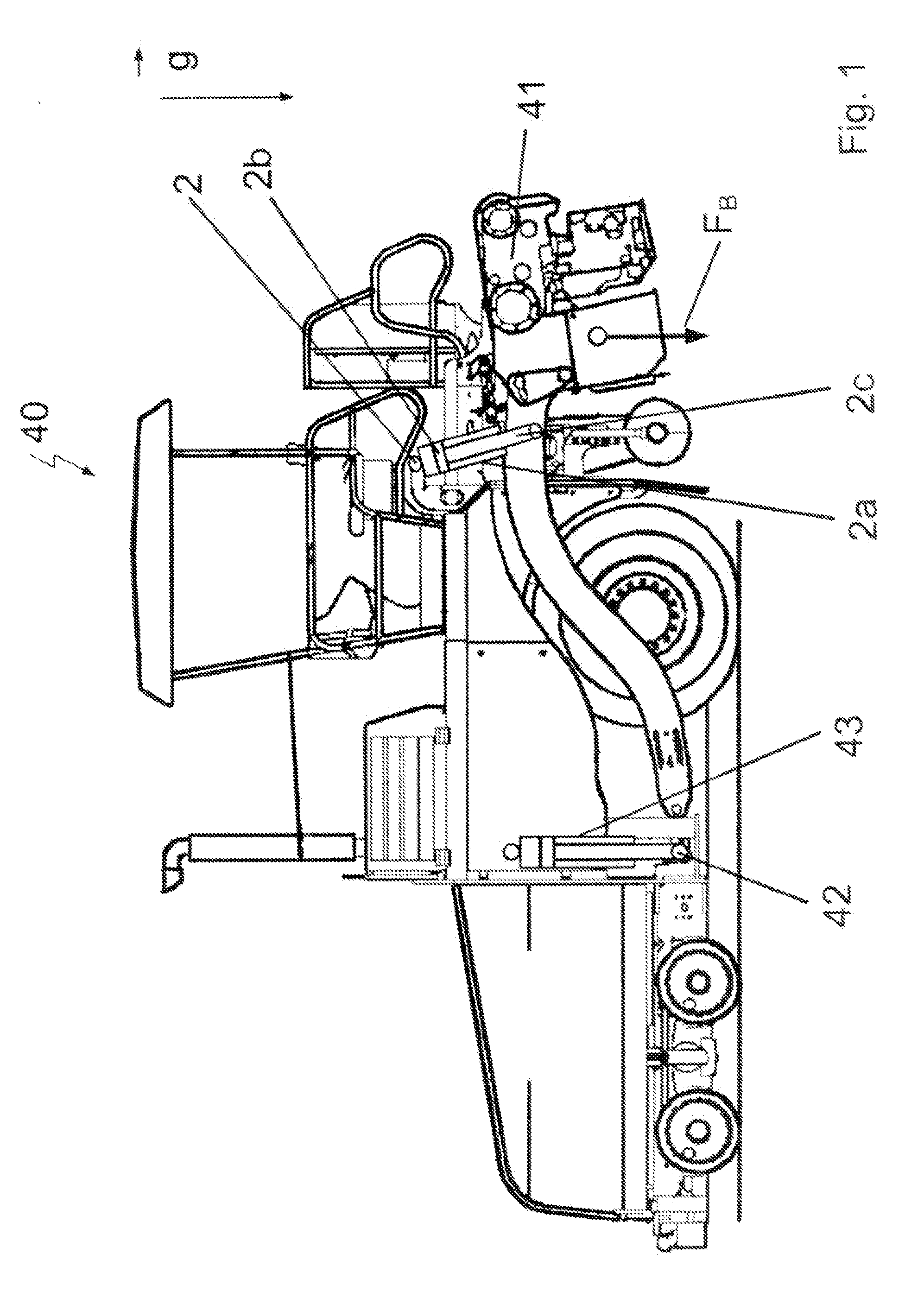

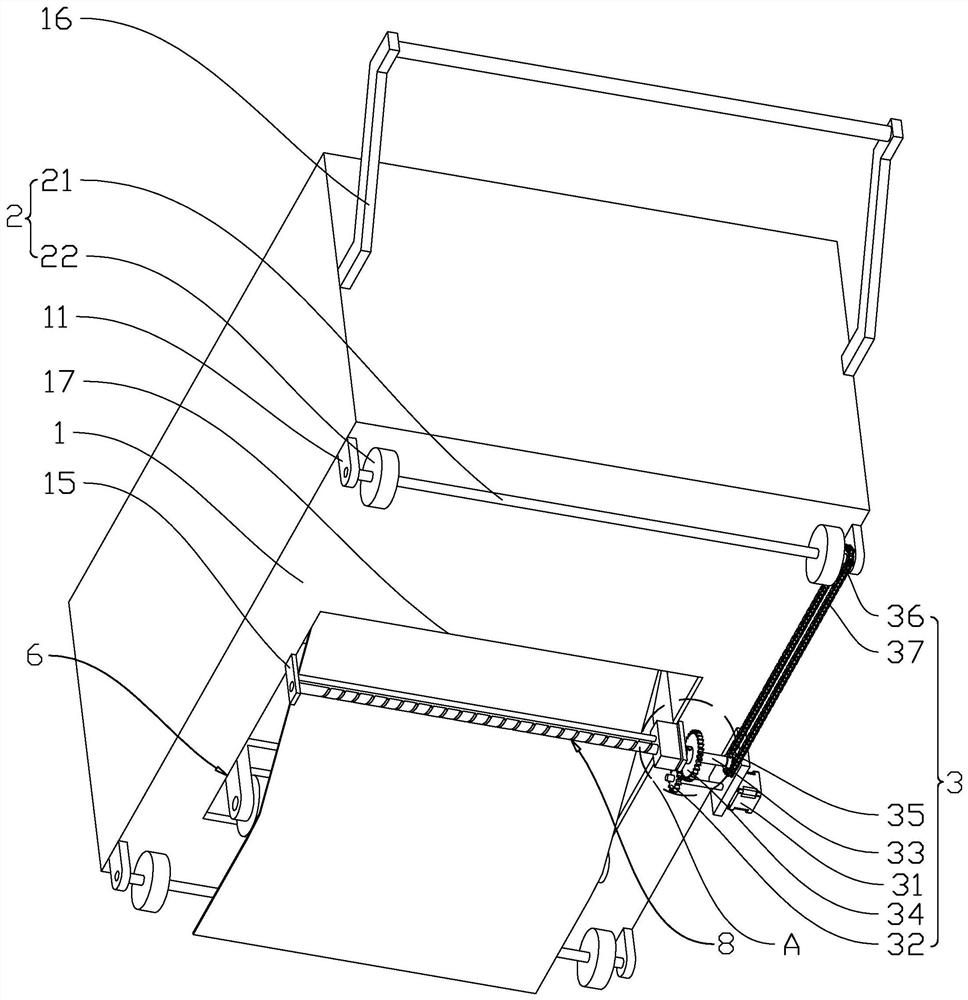

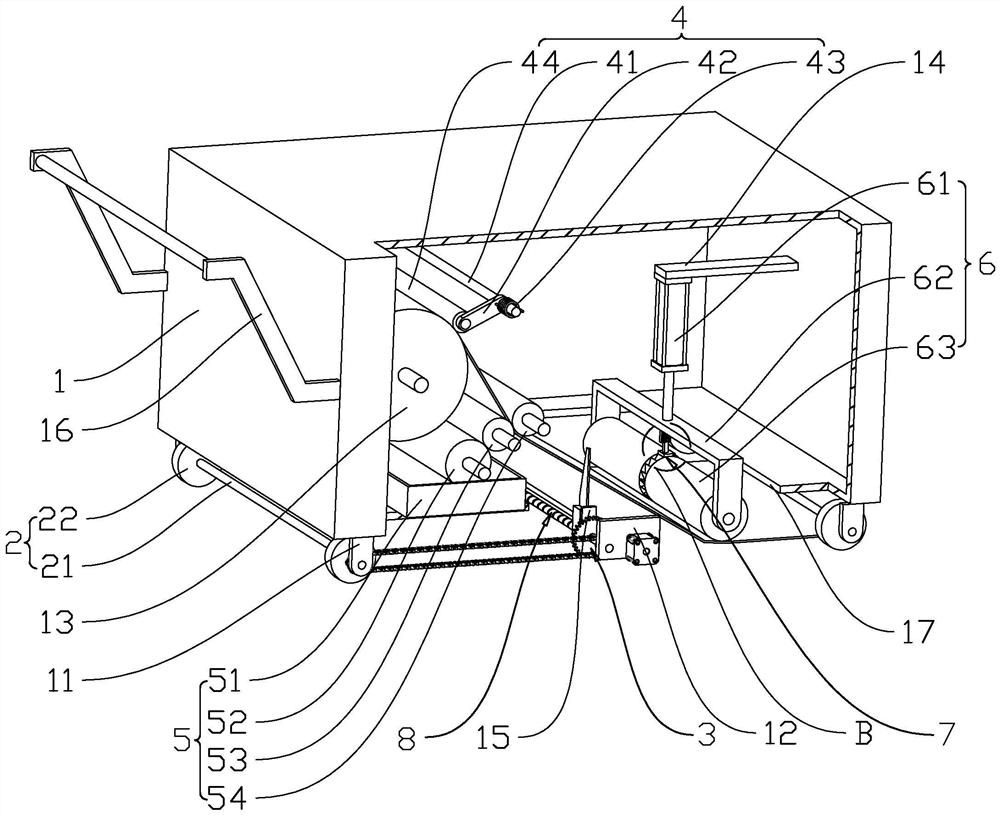

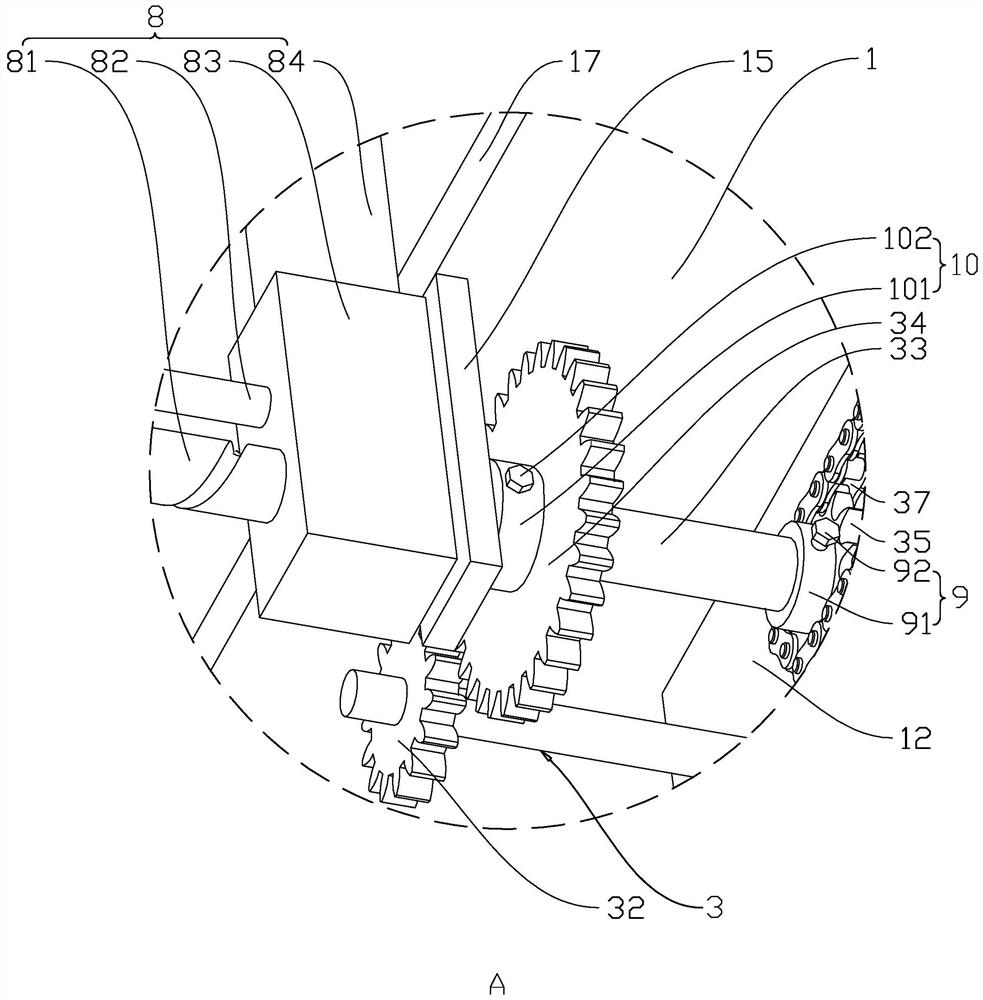

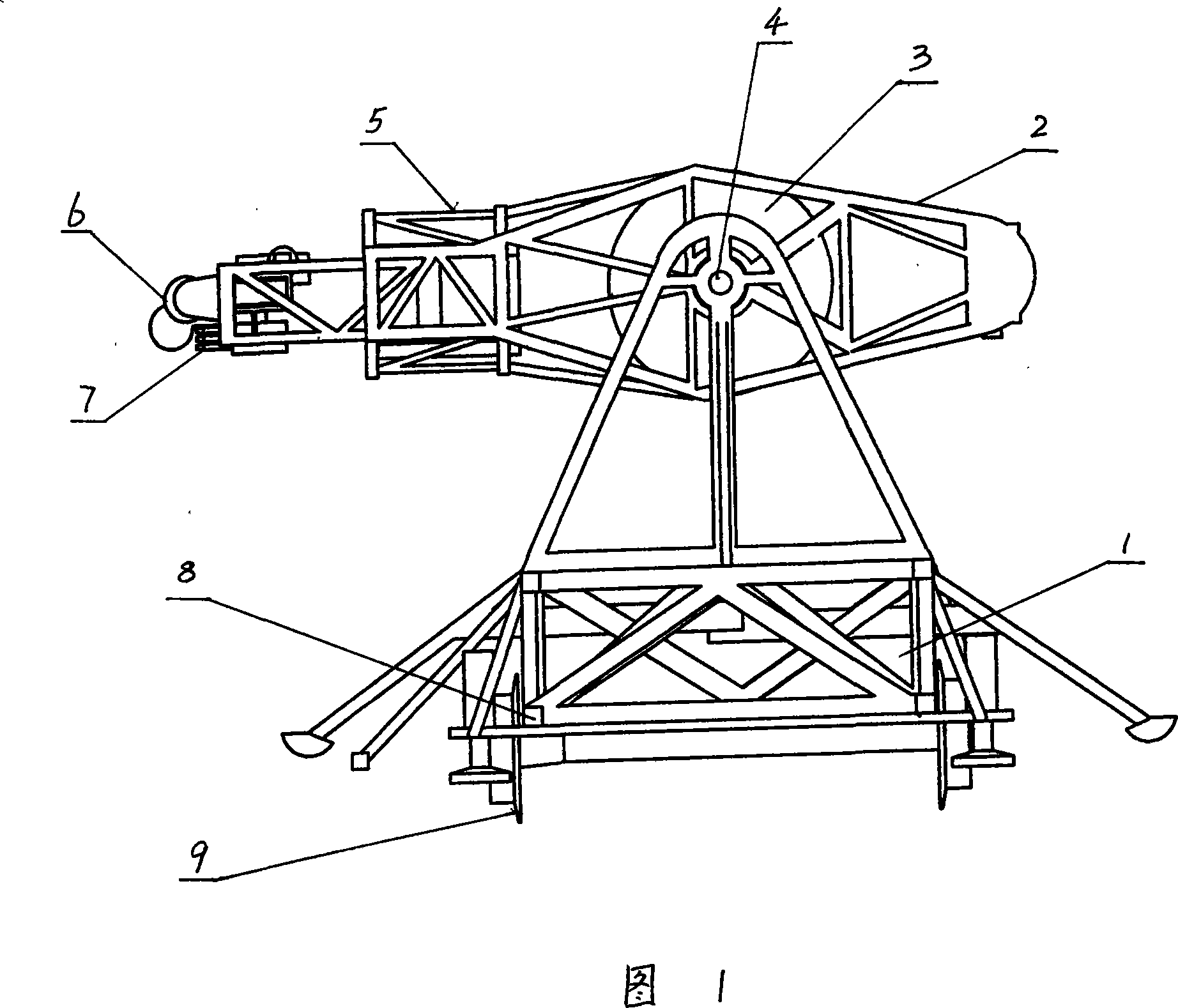

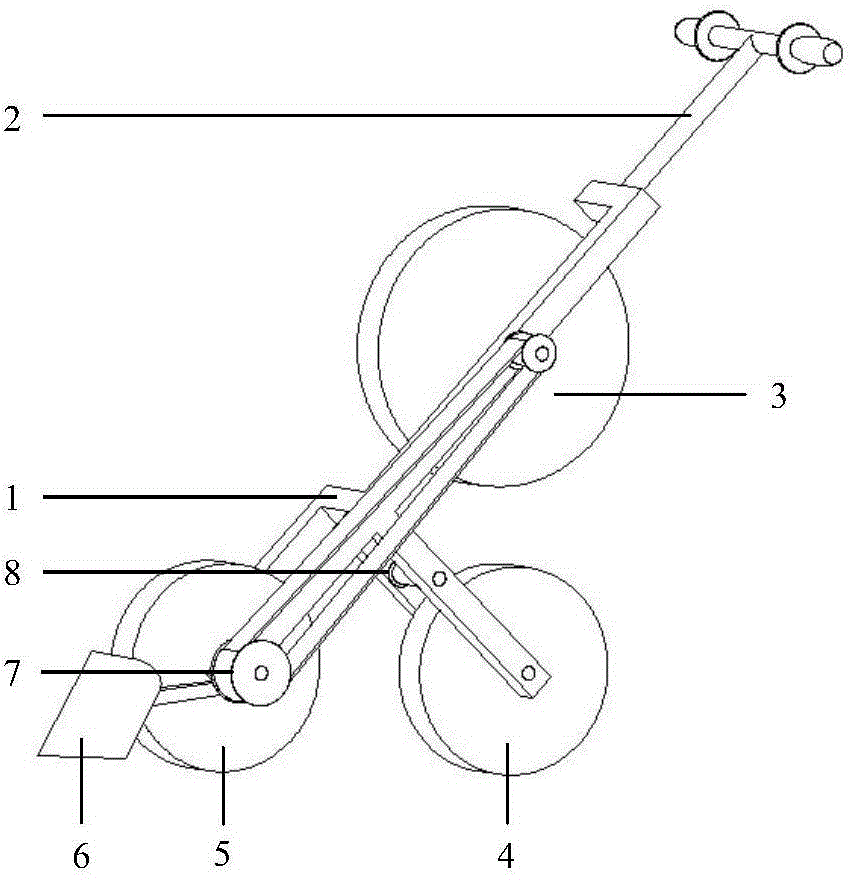

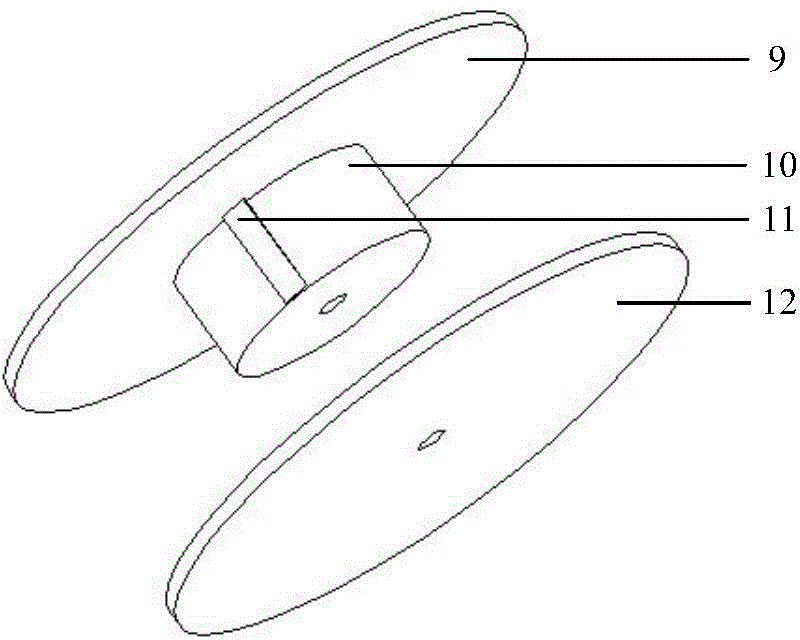

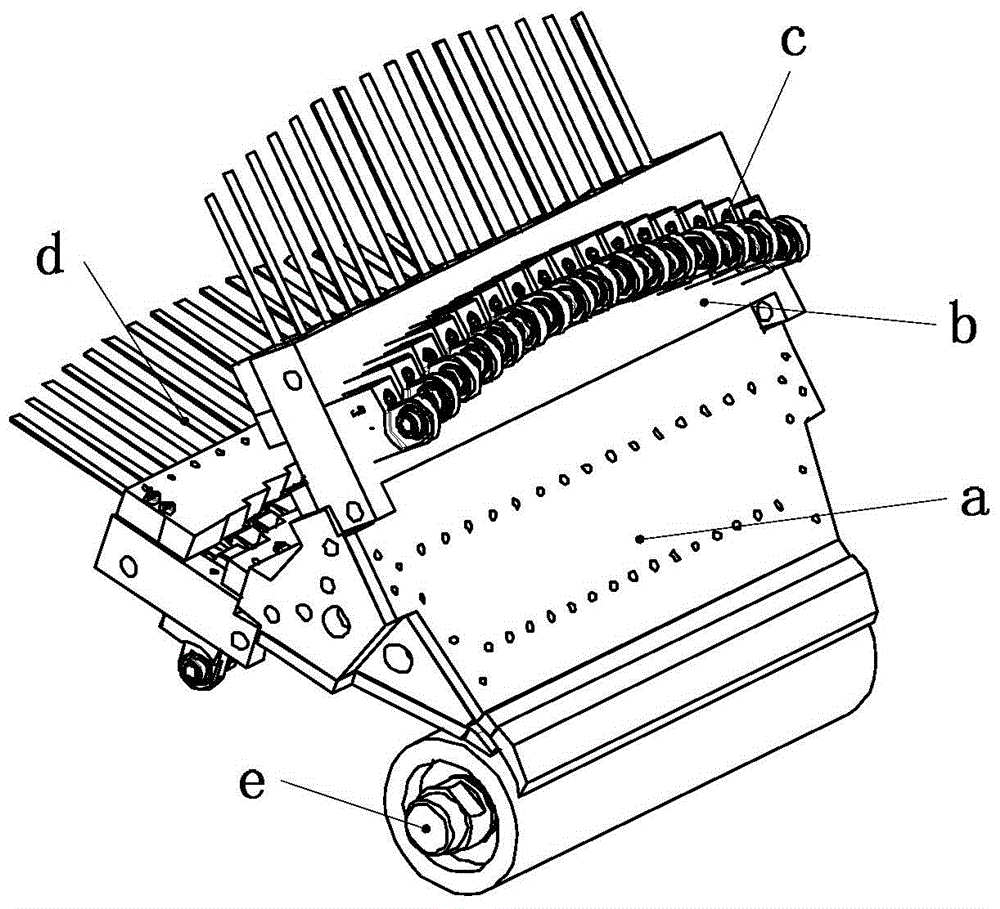

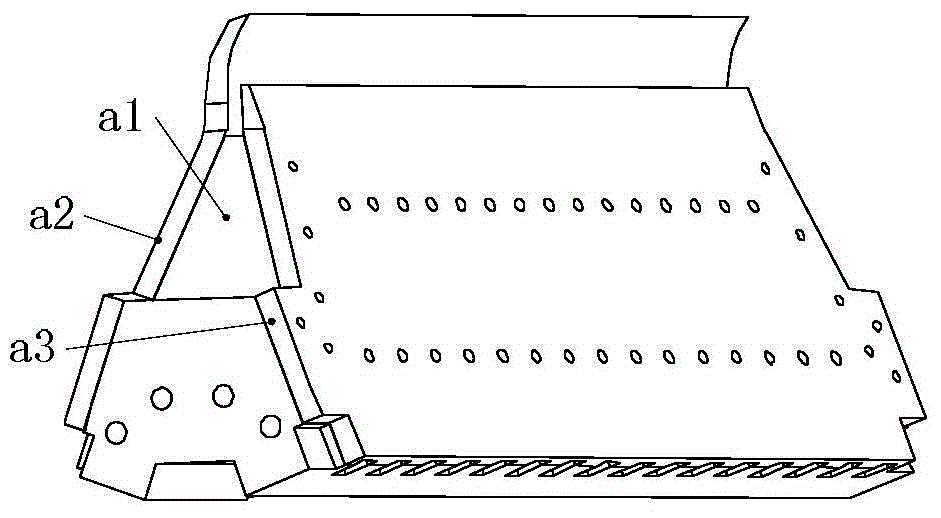

Small crawler-type oilseed rape windrower

ActiveCN104255185AFlexible walkingWalking smoothlyEndless track vehiclesHeadersTerrainPower consumption

The invention discloses a small crawler-type oilseed rape windrower comprising a small crawler-type walking chassis and a cutting table frame. The cutting table frame is provided with a cutter assembly, a grain lifter, a star wheel and a conveying chain component; the cutter assembly and the conveying chain component are connected to a power system of the small crawler-type walking chassis through a transmission mechanism; the cutting table frame is mounted on the small crawler-type walking chassis through a lifting adjusting device and is capable of moving horizontally and lifting vertically. The small crawler-type oilseed rape windrower has fine operation performance and maneuvering characteristics, working efficiency of oilseed rape cutting and windrowing operation can be improved, work intensity can be reduced, the angle is free of changing when the height of a cutting table is adjusted vertically, cutter incline is omitted, the stubble height is consistent during operation, the small crawler-type oilseed rape windrower is adaptive to different stubble height requirements and terrain conditions, the power consumption is even, cutting omission is avoided, and the cutting and windrowing quality is high.

Owner:HUNAN AGRICULTURAL UNIV

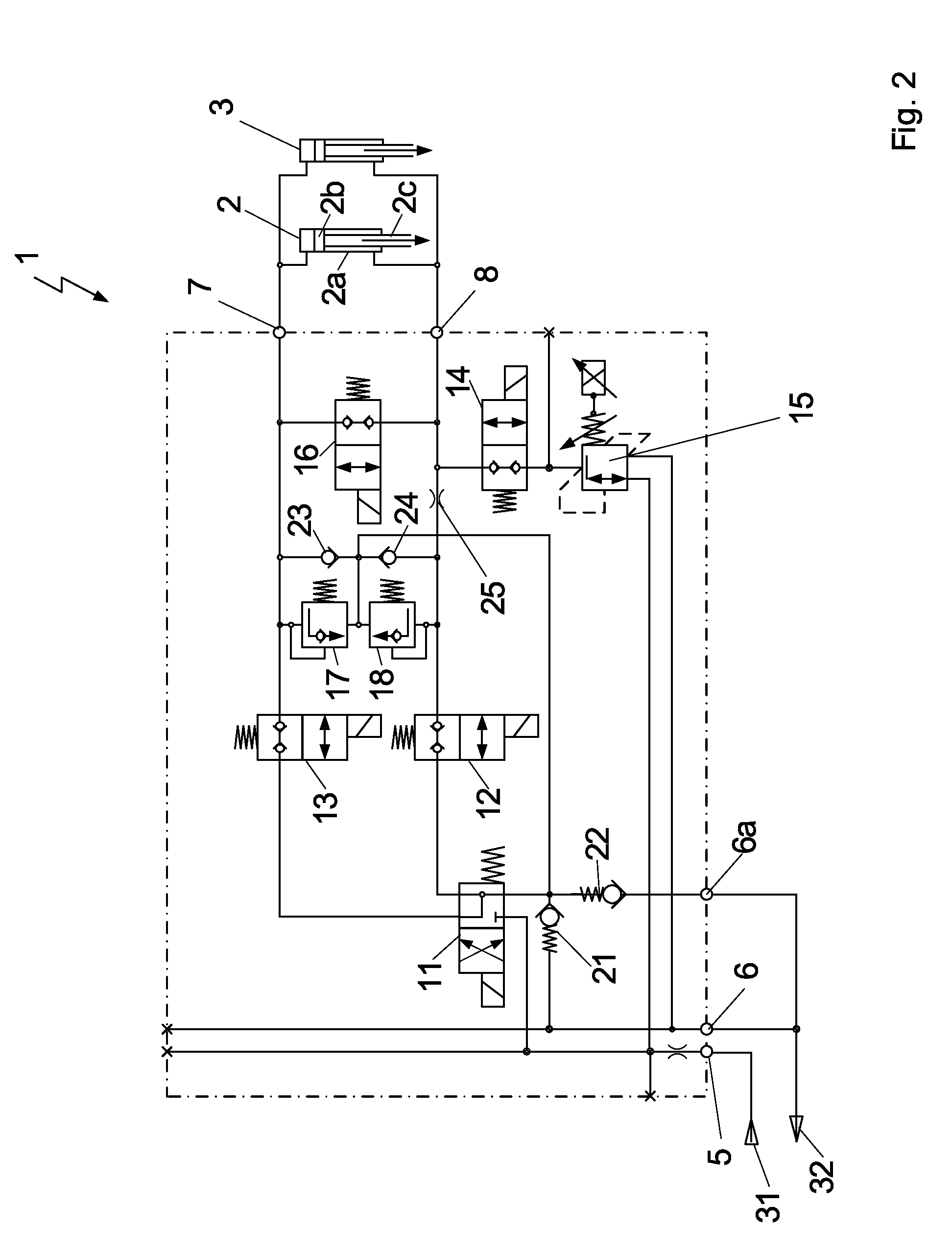

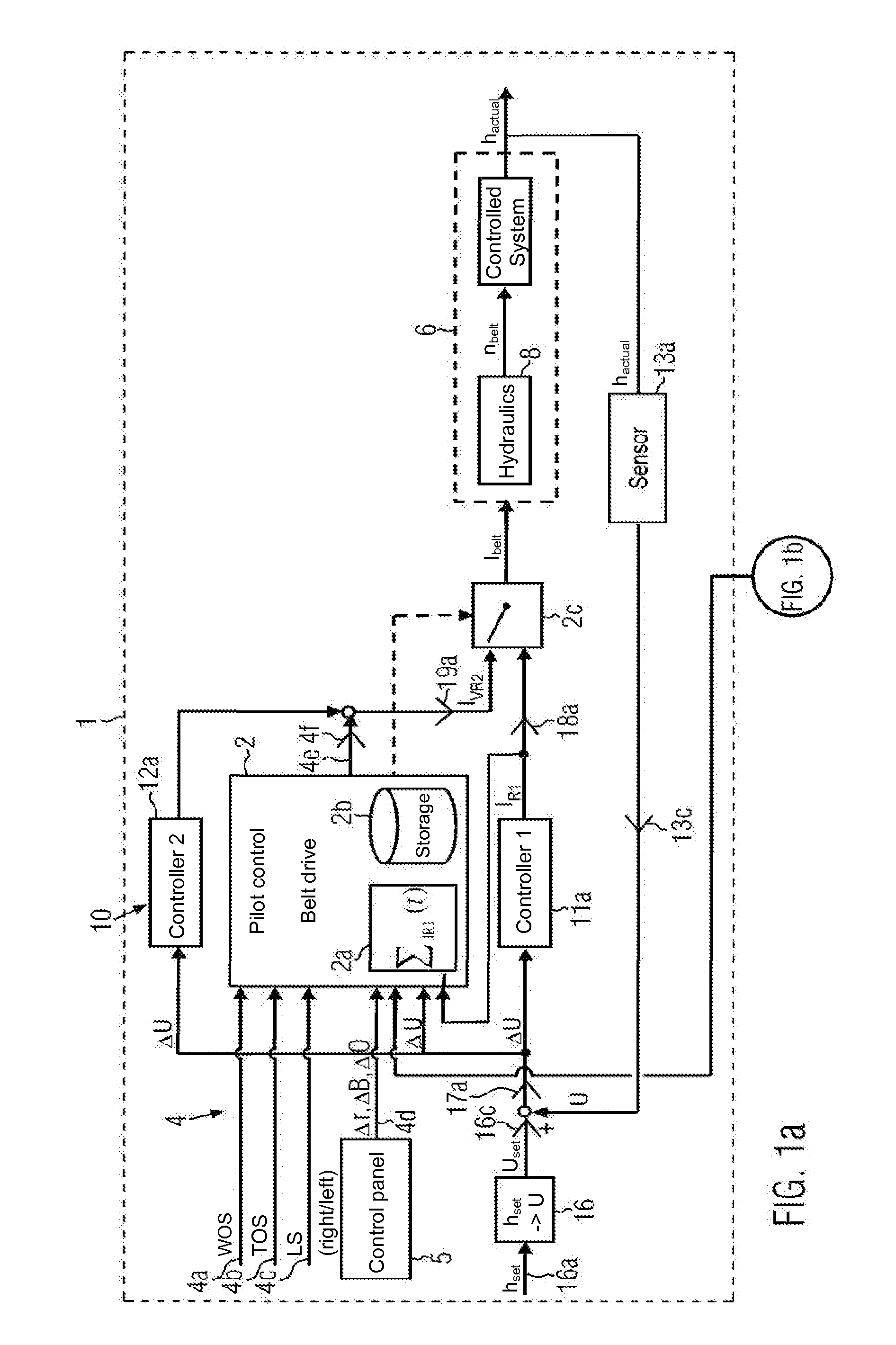

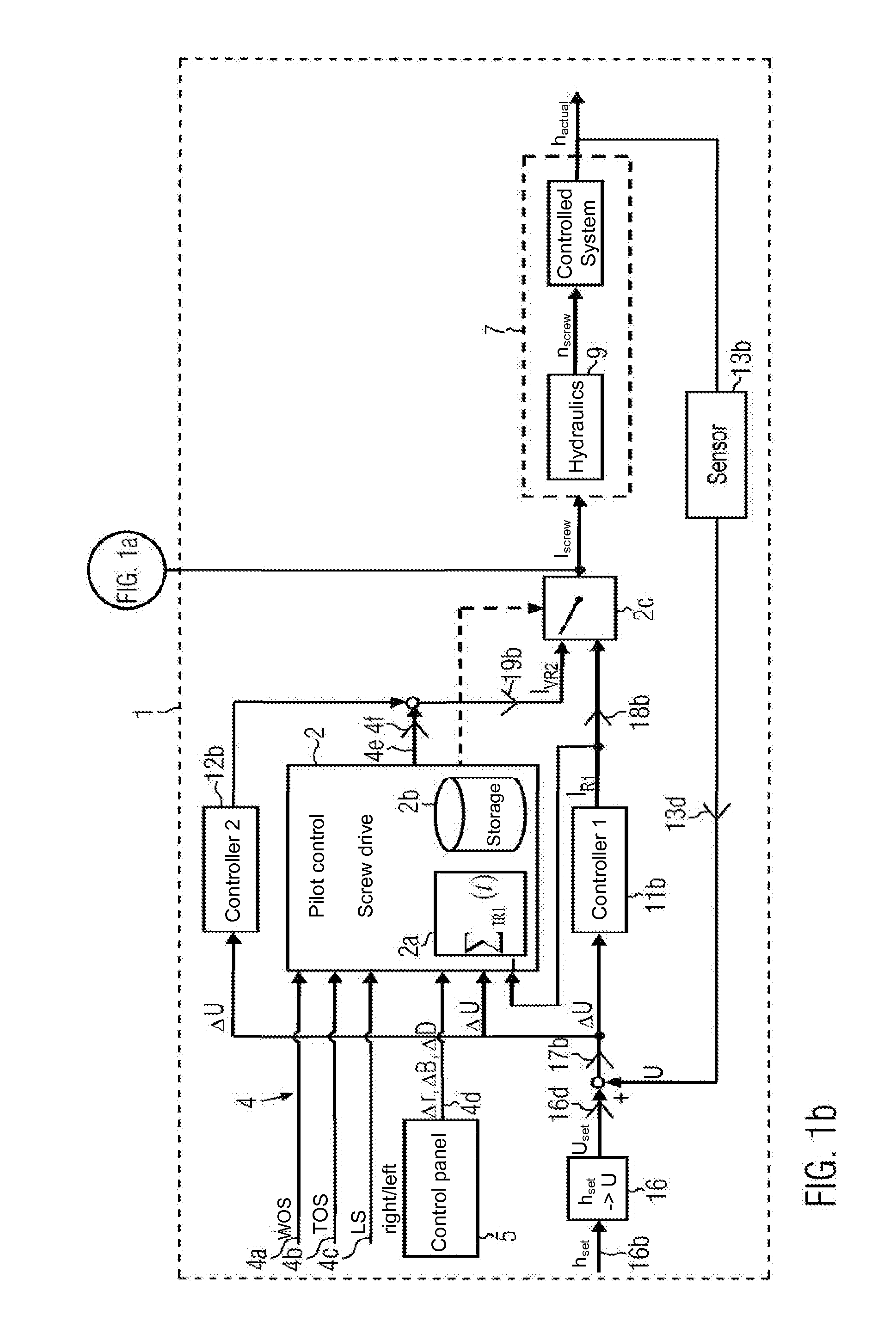

Hydraulic Control Arrangement for the Screed of a Road Finisher

ActiveUS20100284742A1Improve laying qualitySmall lossFluid couplingsRoads maintainenceProportional controlFuel tank

A hydraulic control arrangement for activating a double-acting actuating cylinder, which is connected on the piston side to a road finisher and on the piston-rod side to a screed of the road finisher, is provided. The hydraulic control arrangement includes a supply connection, a tank connection and two consumer connections, in which a loading pressure or a relief pressure is applied to the piston of the actuating cylinder via the consumer connections. The loading pressure or relief pressure is controlled as a function of a defined operating state, and, in a controlling-the-screed-load operating state, the relief pressure supplied to the actuating cylinder on the piston-rod side is controlled via a proportional pressure control valve.

Owner:BOMAG

Cable laying device

InactiveCN102738739AReduce or avoid harmReduce labor intensityApparatus for laying cablesEngineeringIdler-wheel

Owner:杨春

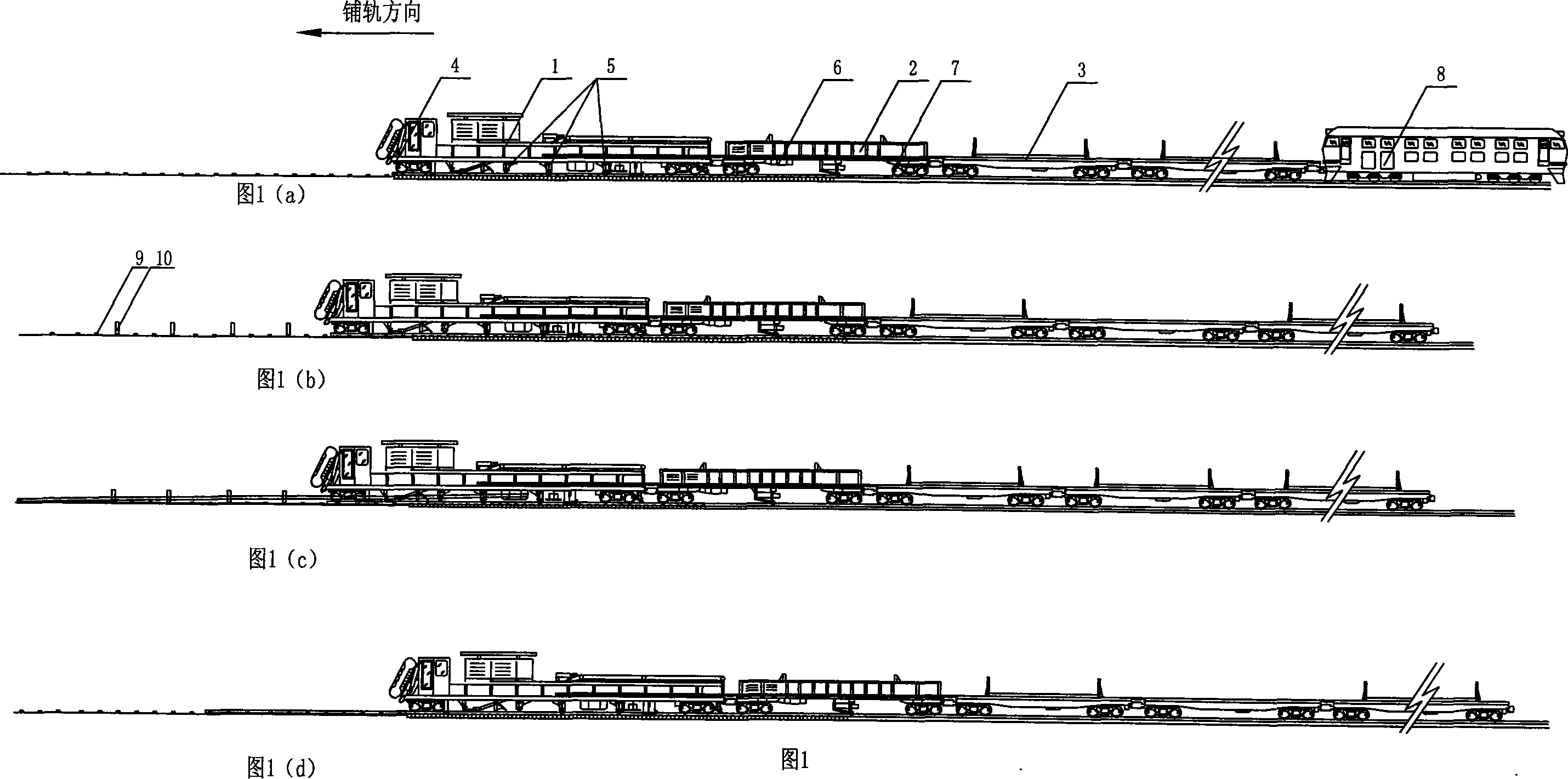

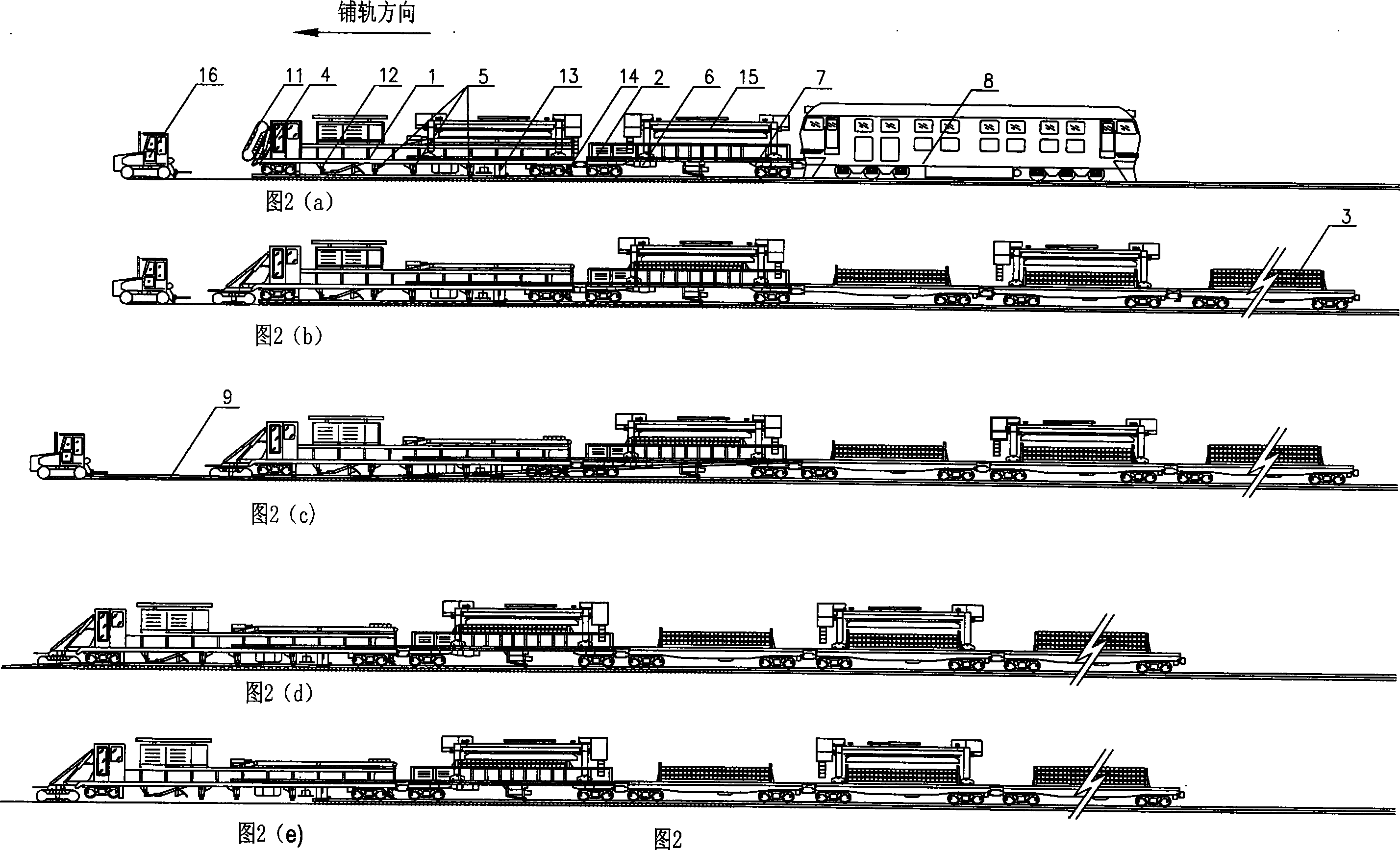

Constructing method for laying seamless line track of CPG 500 type seamless line long rail laying machine set

ActiveCN101050615AOne-time laying is smoothFast layingRailway track constructionIndustrial engineeringBuilding construction

The present invention relates to a construction method for laying seamless line rail track by using CPG 500 seamless line long rail string track-laying machine unit. It is characterized by that it utilizes CPG 500 model seamless line long rail string track-laying machine unit to lay long rail track with 500 m by means of one-step operation, and has no need of other equipment, and its working efficiency is high and laying quality is good.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

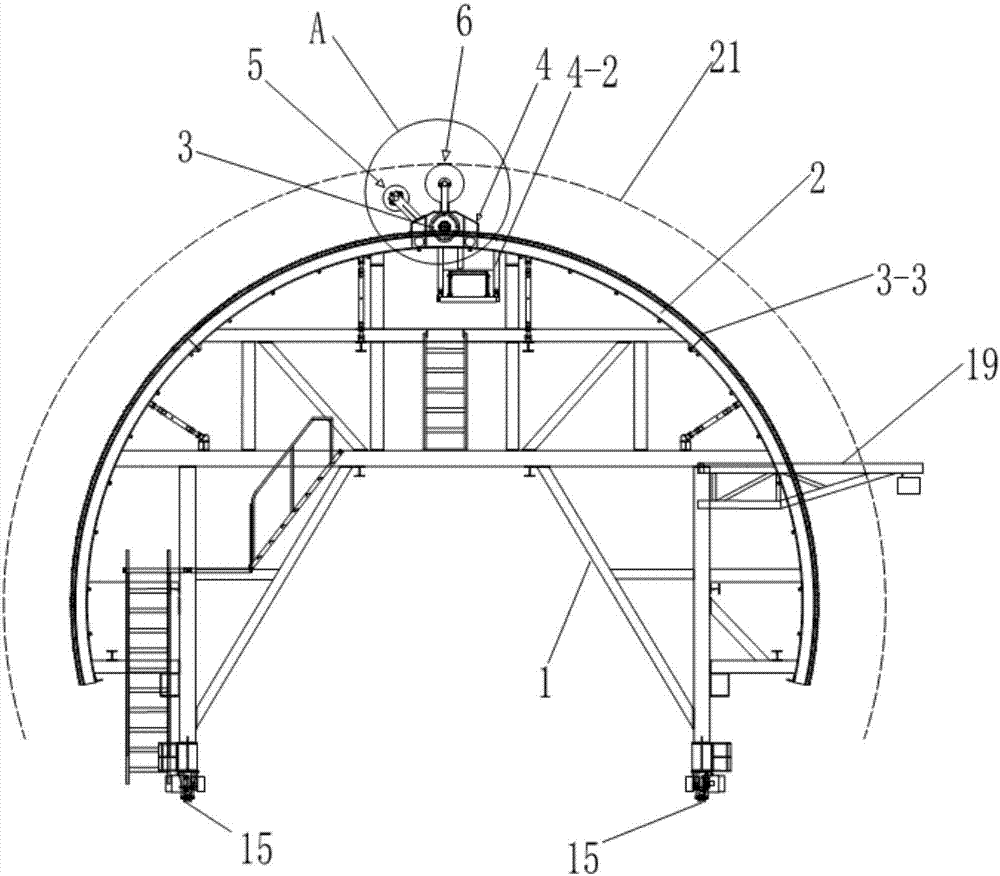

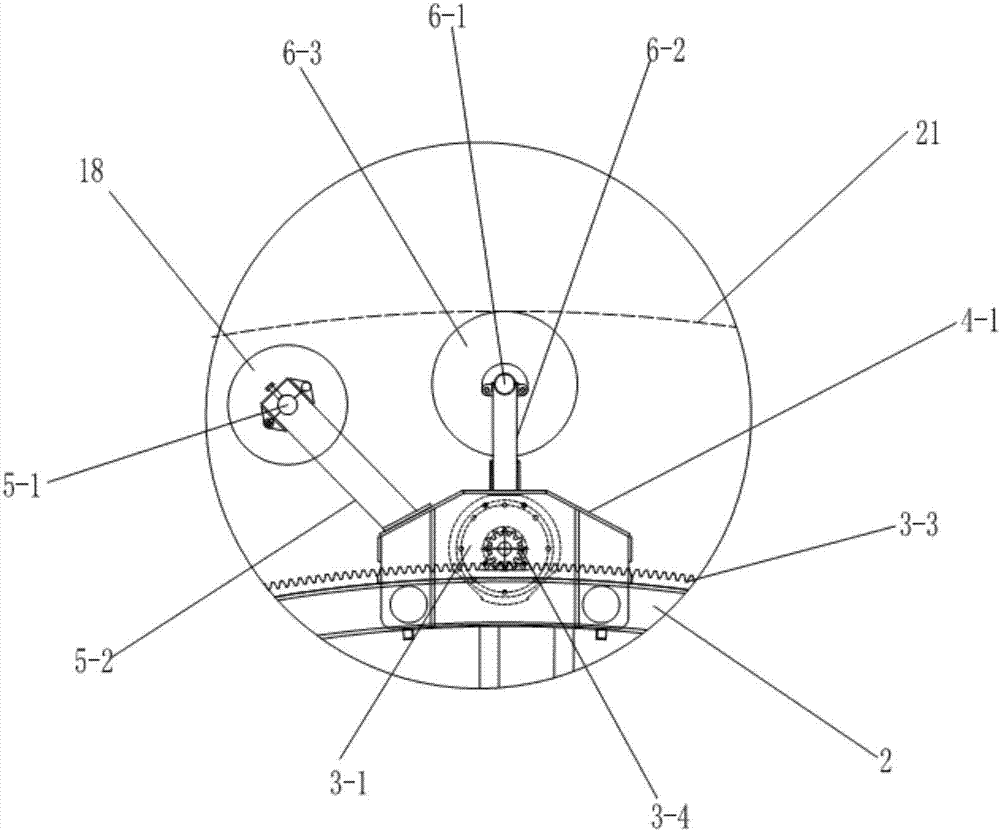

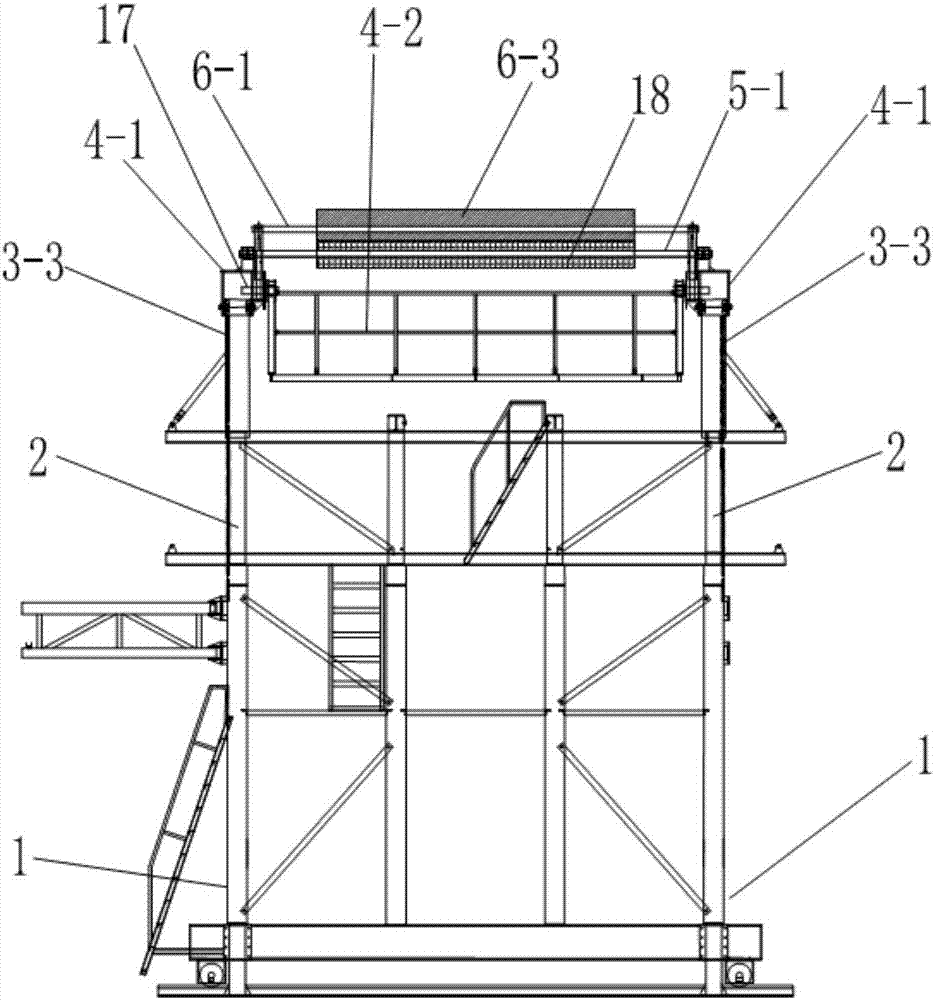

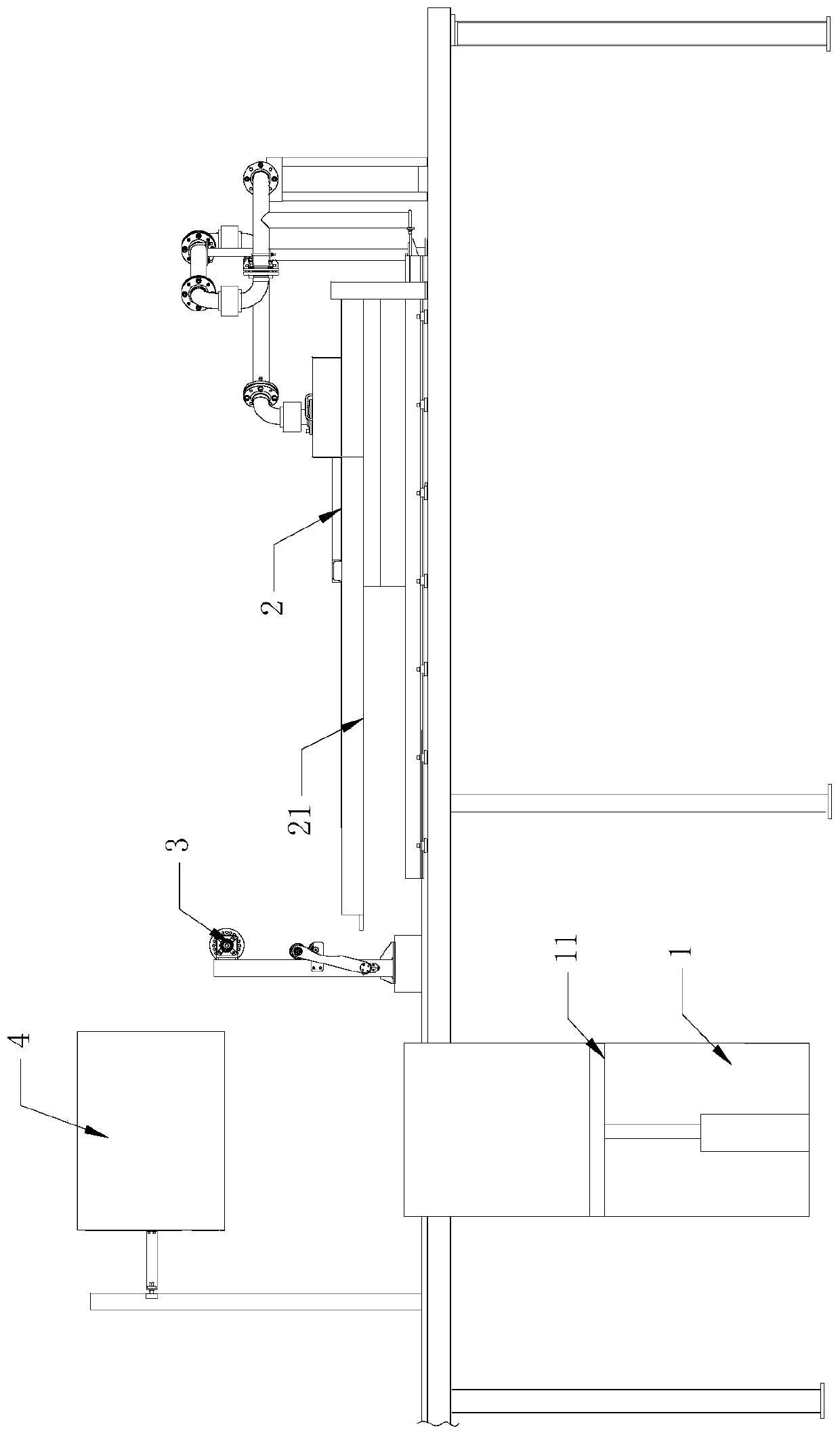

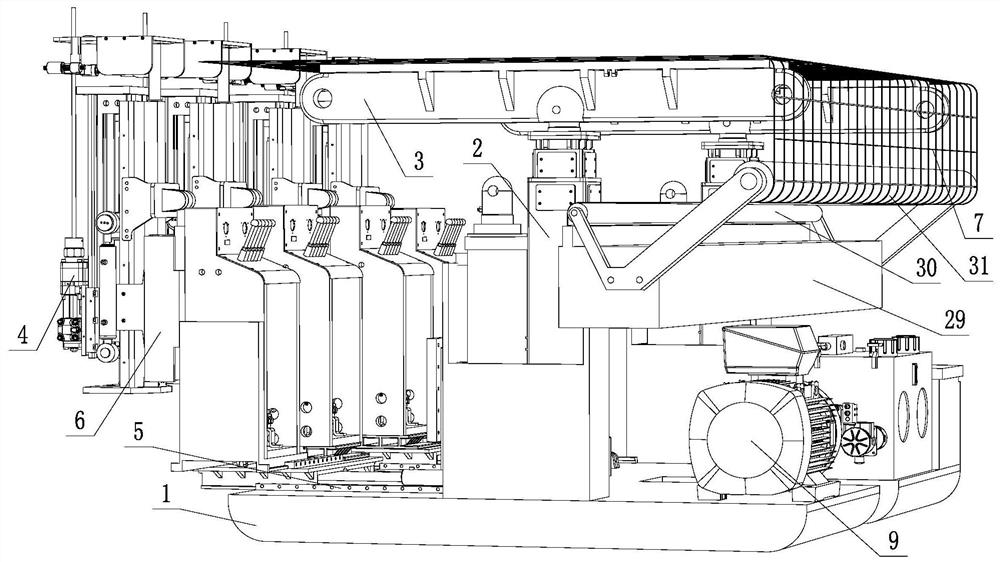

Tunnel waterproof plate laying trolley

ActiveCN107327309AGuarantee laying qualityFit tightlyUnderground chambersTunnel liningThrough transmissionEngineering

The invention discloses a tunnel waterproof plate laying trolley which comprises a plurality of trolley portals which are distributed in parallel. The trolley portals are provided with arch rings matched with the inner wall of a tunnel. A climbing mechanism is arranged on every two adjacent arch rings. The climbing mechanisms are installed on the arch rings in a transmission mode through transmission assemblies. A laying assembly and a leveling assembly are arranged on each climbing mechanism. Each climbing mechanism comprises two climbing boxes which are connected to the two corresponding adjacent arch rings in a transmission mode respectively, and a climbing trolley installed between the two climbing boxes, wherein the climbing trolley is installed on the climbing boxes through rotating shafts in a rotating mode. The climbing mechanisms can move in the circumferential direction of the arch rings, in this way, the laying assemblies can be driven to lay waterproof plates along the inner wall of the tunnel, meanwhile the leveling assemblies can level up the waterproof plates laid on the inner wall of the tunnel, it is guaranteed that the waterproof plates laid on the inner wall of the tunnel are closely attached to the inner wall of the tunnel, the laying efficiency of the waterproof plates is improved, and the laying quality of the waterproof plates is effectively guaranteed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

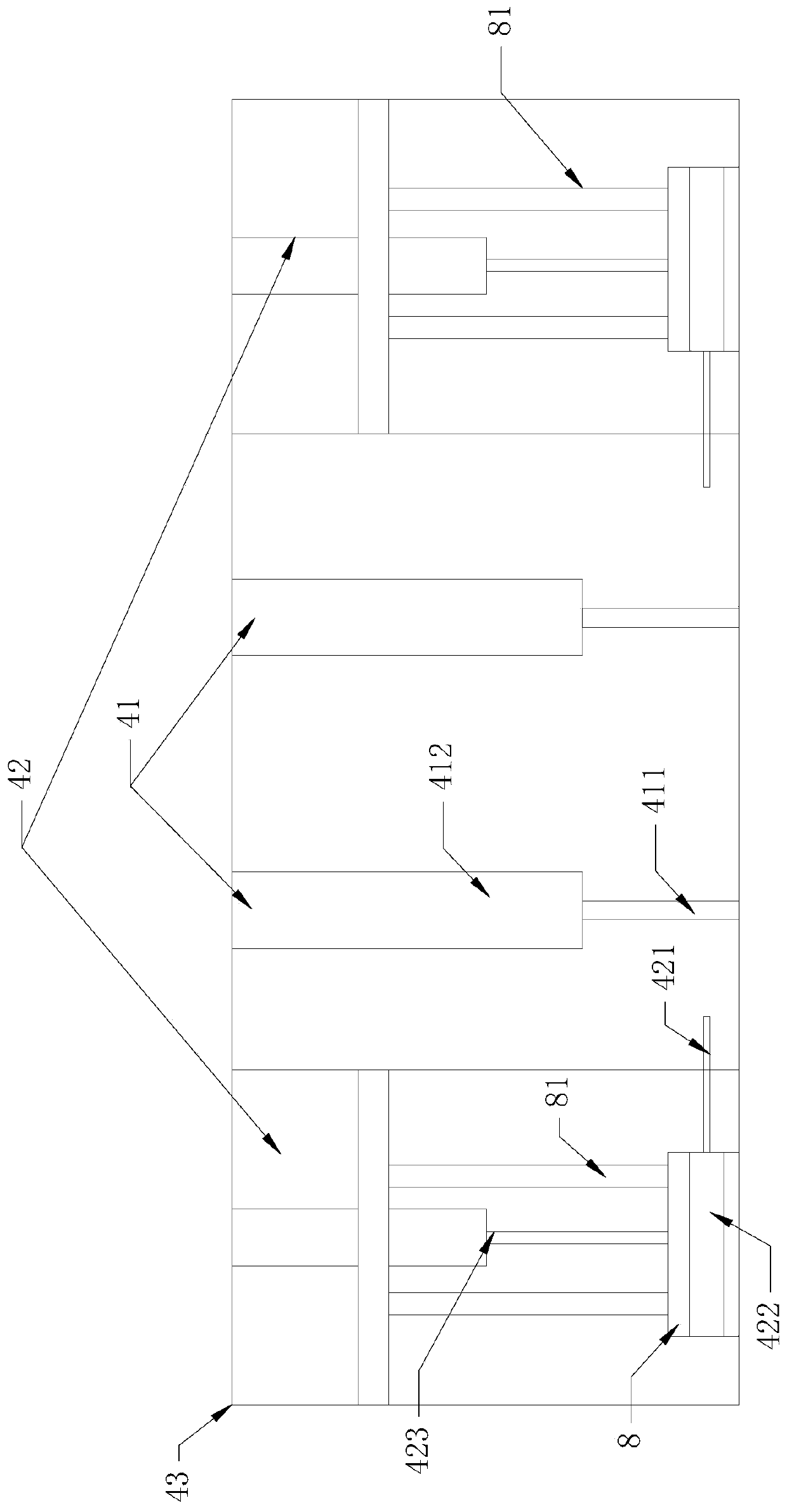

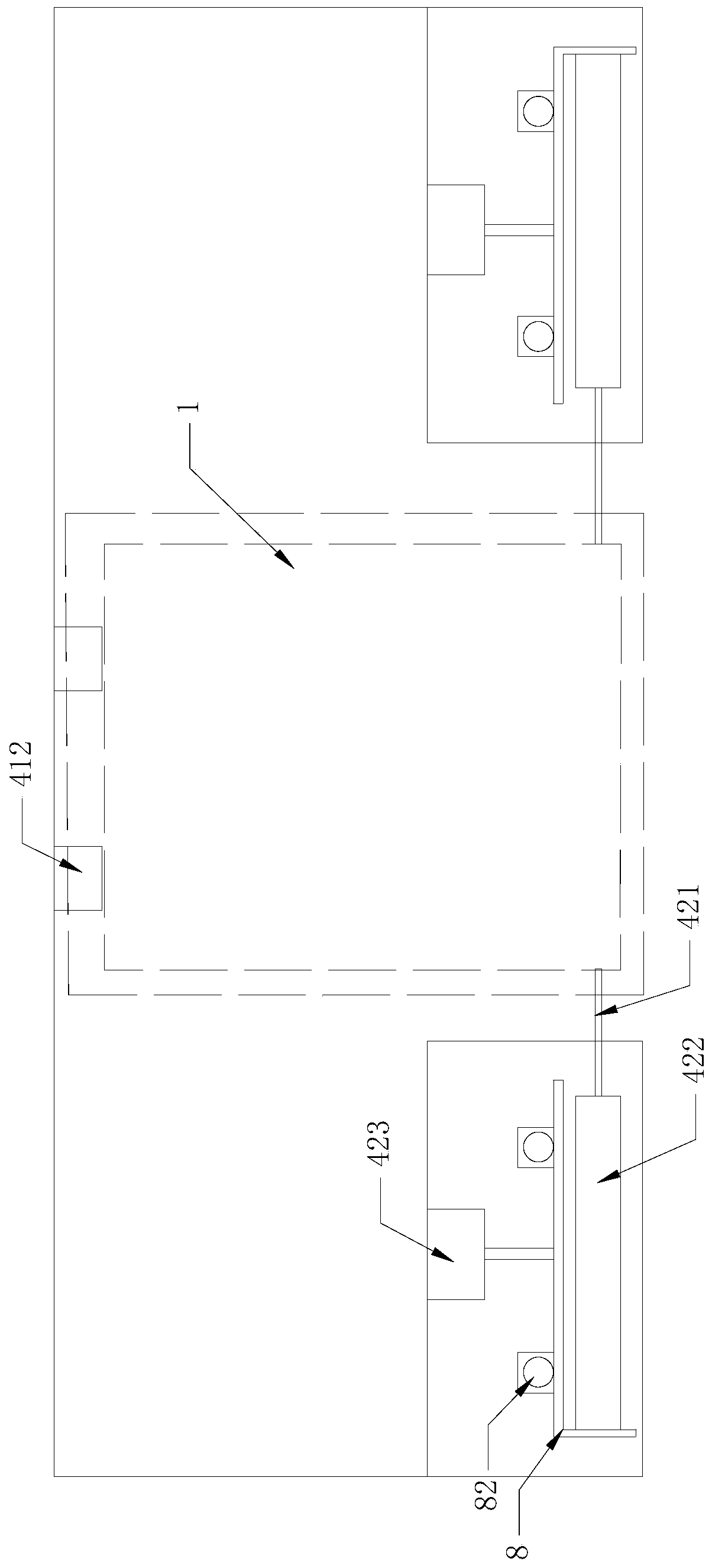

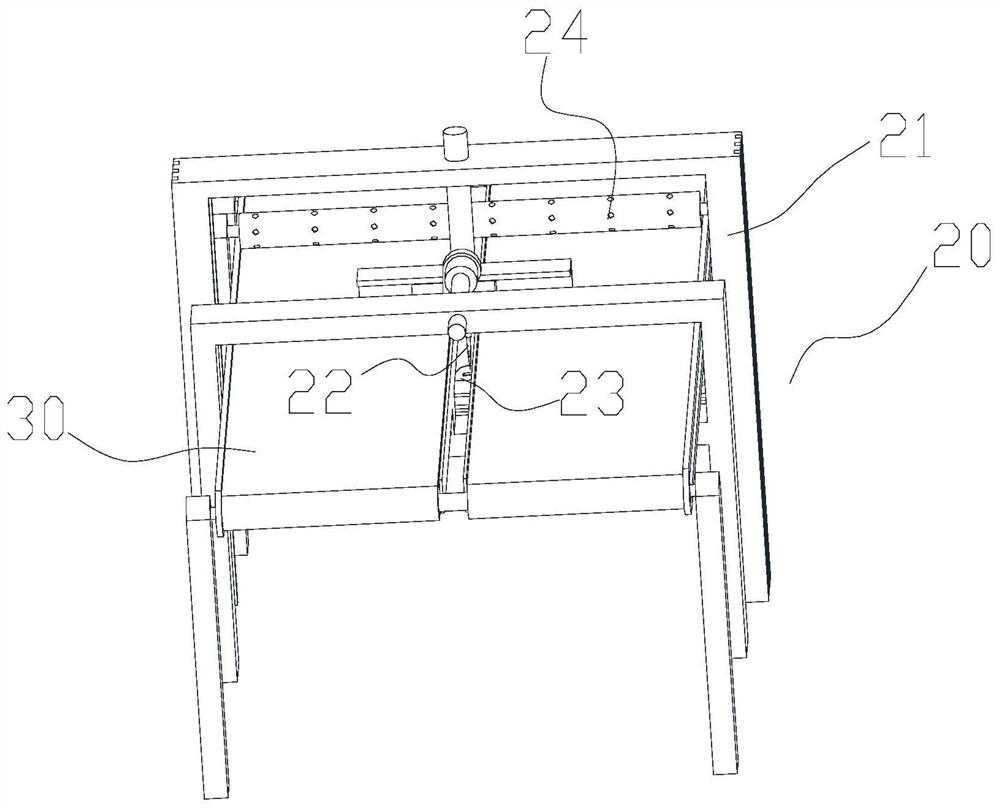

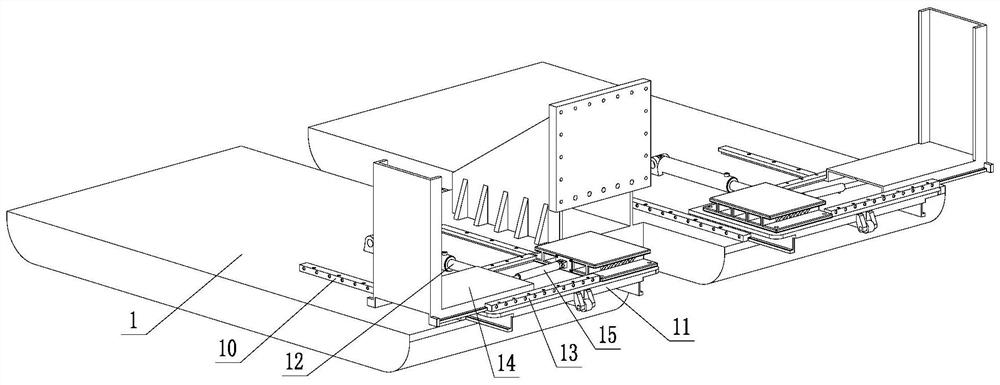

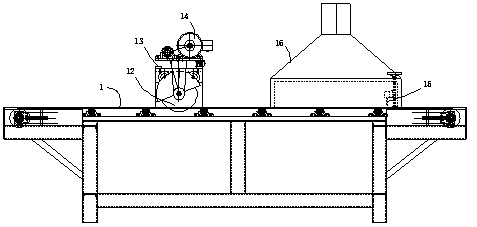

Spreading mechanism and spreading method for organic matter solid waste treatment device

PendingCN110803847AImprove laying qualityImprove laying efficiencySludge treatmentPressesProcess engineeringOrganic matter

The invention provides a spreading mechanism and a spreading method for an organic matter solid waste treatment device. The spreading mechanism comprises a filter cloth filter pressing chamber, a spreading bed and a cloth rolling frame used for providing a filter cloth, a tray capable of moving up and down is arranged in the filter cloth filter pressing chamber, the spreading bed comprises a spreading part capable of moving back and forth, and the cloth rolling frame is arranged between the spreading bed and the filter cloth filter pressing chamber; and the moving direction towards the filtercloth filter pressing chamber is taken as the advancing direction, the spreading part is in a filter cloth spreading state when advancing, and the spreading part is in a material spreading state whenretreating. The single-layer filter cloth is folded and then laid in the filter cloth filter pressing chamber layer by layer when moving back and forth, and material laying is conducted between the two folded layers of the filter cloth, so that the filter cloth spreading quality and the dehydration efficiency are effectively improved.

Owner:中合清源(济南)生态科技有限公司

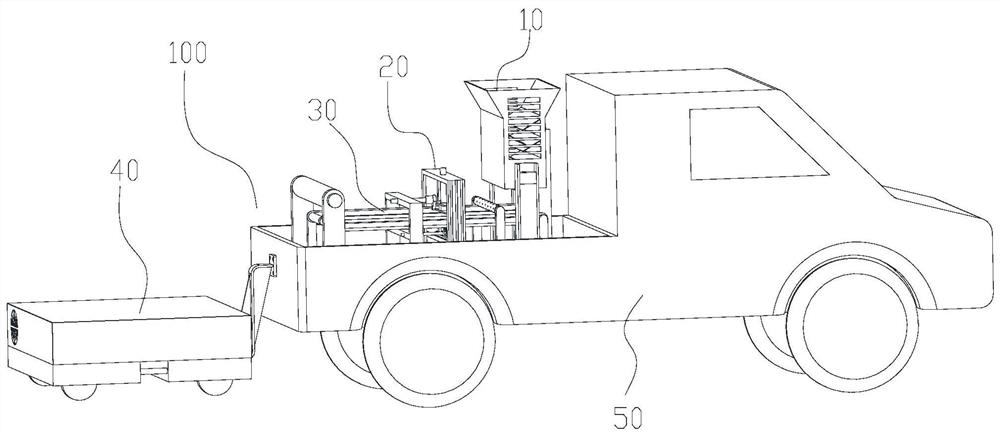

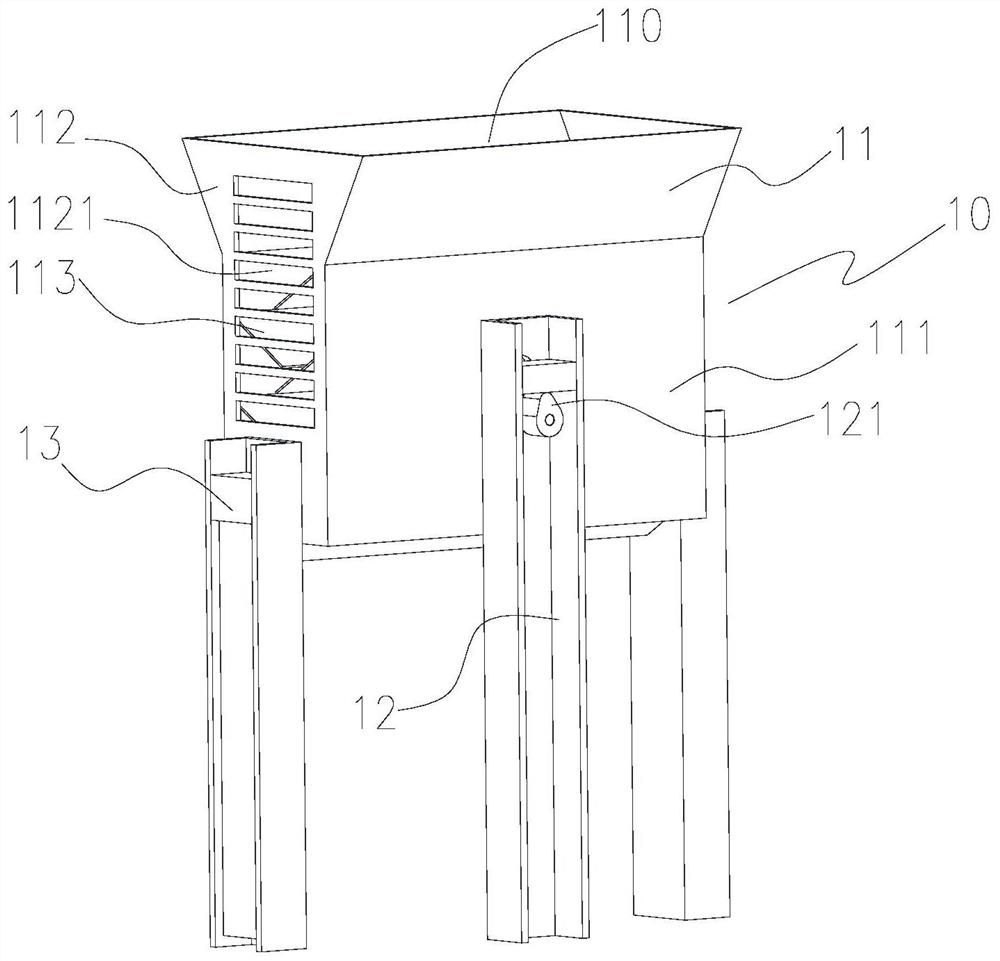

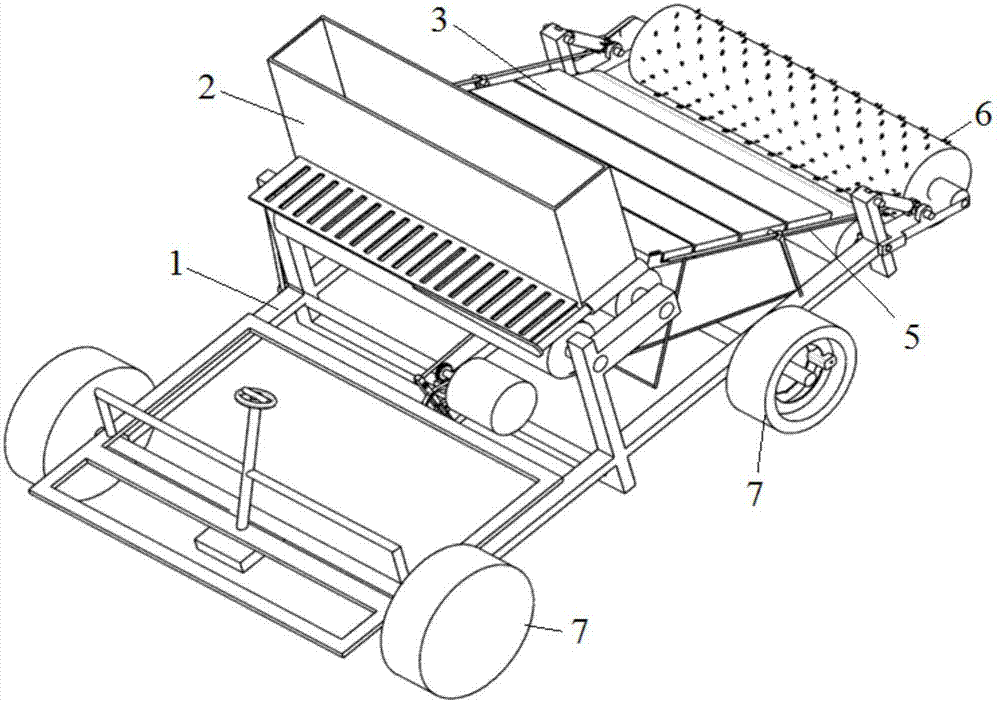

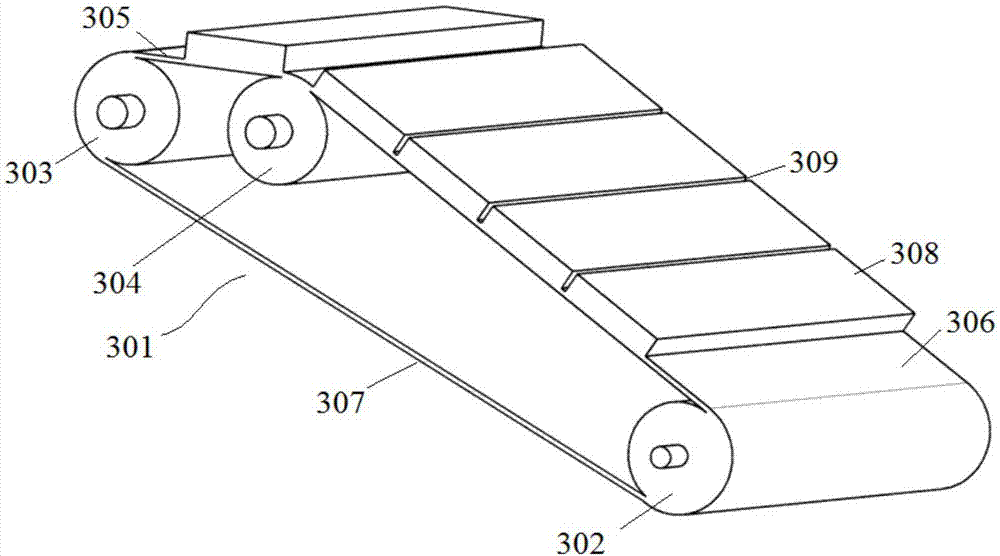

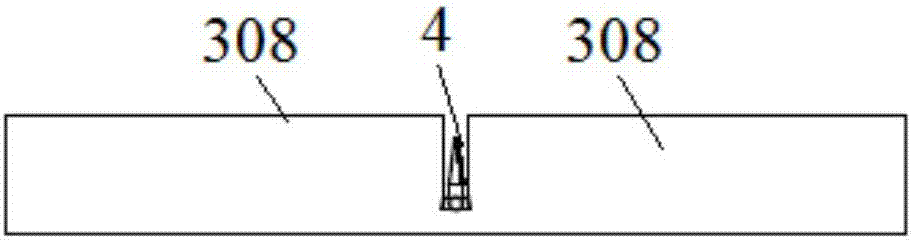

Full-automatic grass checker laying machine and full-automatic grass checker grass laying method

InactiveCN113774890AImprove efficiencyImprove laying qualitySievingScreeningAgricultural scienceAgricultural engineering

The invention discloses a full-automatic grass checker laying machine and a grass laying method implemented thereof. The full-automatic grass checker laying machine comprises a forage screening machine, a grass mat manufacturing machine, a conveying belt, a grass mat laying machine and a tractor, and the forage screening machine is used for screening out qualified forage from standby forage; the conveying belt is arranged between the forage screening machine and the grass mat manufacturing machine and conveys the qualified forage to the grass mat manufacturing machine, the grass mat manufacturing machine is used for weaving the qualified forage into a grass mat, and the grass mat laying machine is used for cutting the grass mat and pressing the cut grass mat into sandy soil. The tractor is connected with the grass mat laying machine and used for dragging the grass mat laying machine to move. According to the full-automatic grass checker laying machine and the grass laying method implemented thereof, target functions of arranging wheat straws, manufacturing grass mats and continuously laying grass checks are realized by utilizing an ingenious mechanical structure. If the full-automatic grass checker laying machine is put into use, the cost can be reduced, the manpower is saved, the laying efficiency is improved, and the laying quality of the grass checks can be ensured.

Owner:BEIJING INST OF TECH ZHUHAI CAMPUS

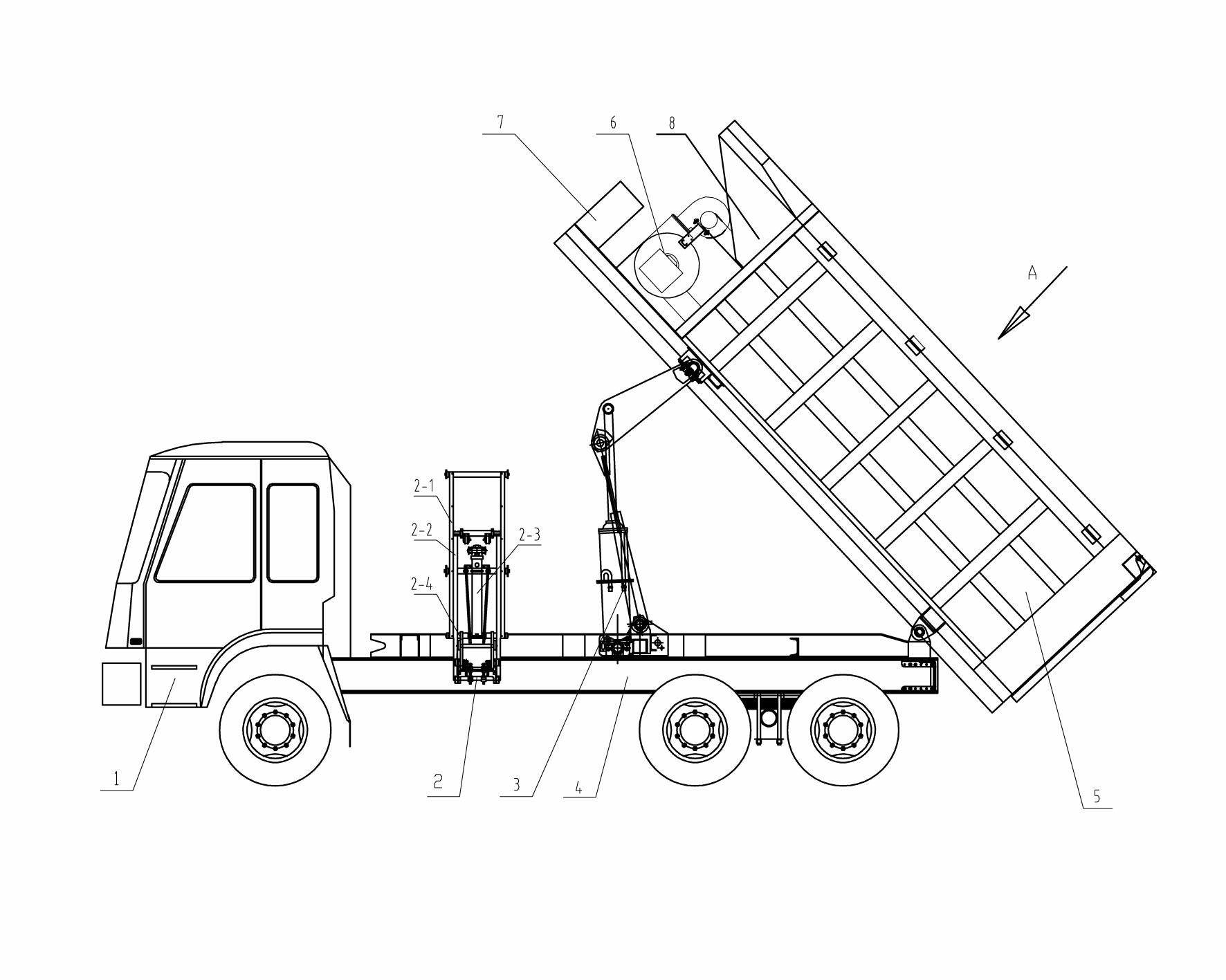

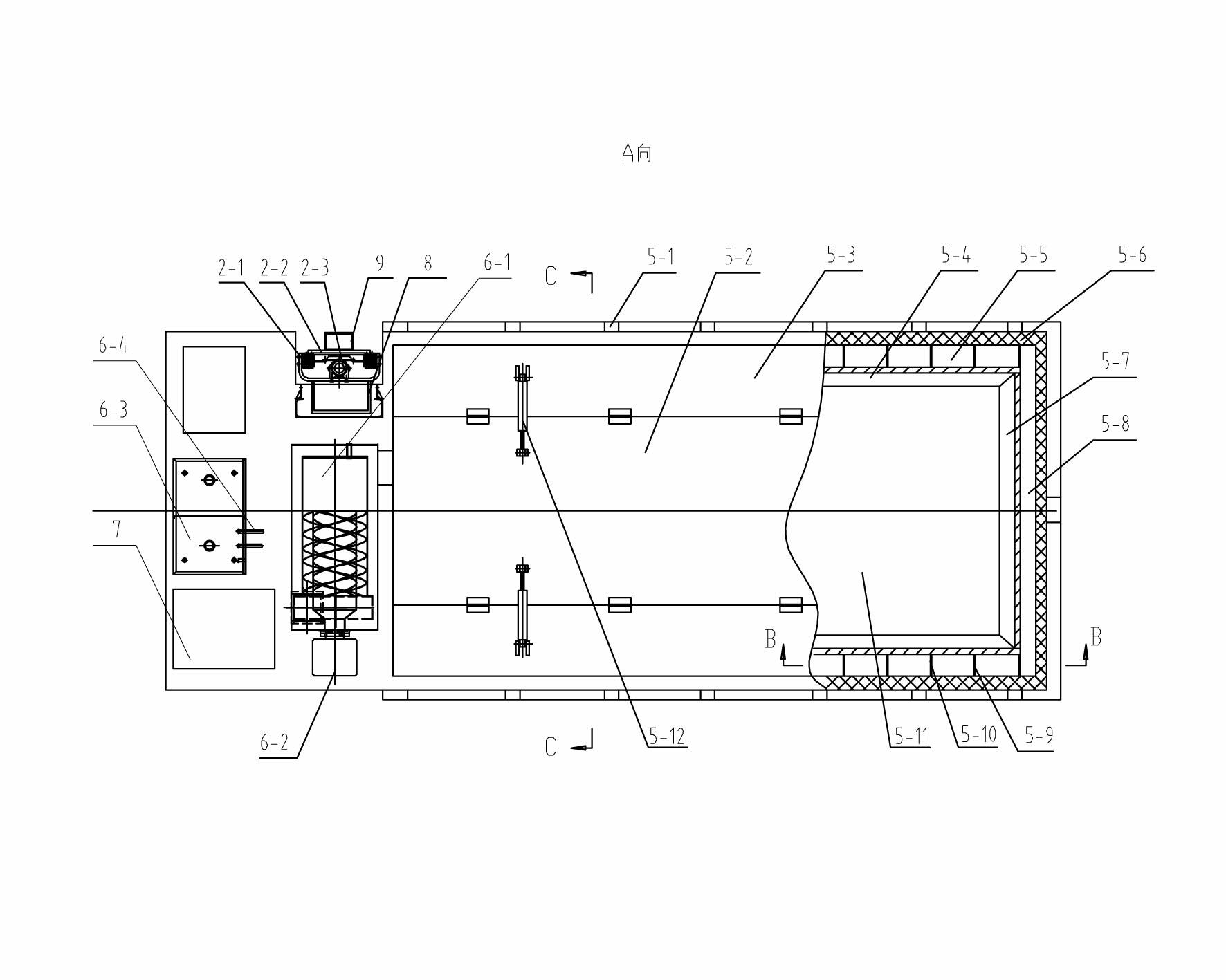

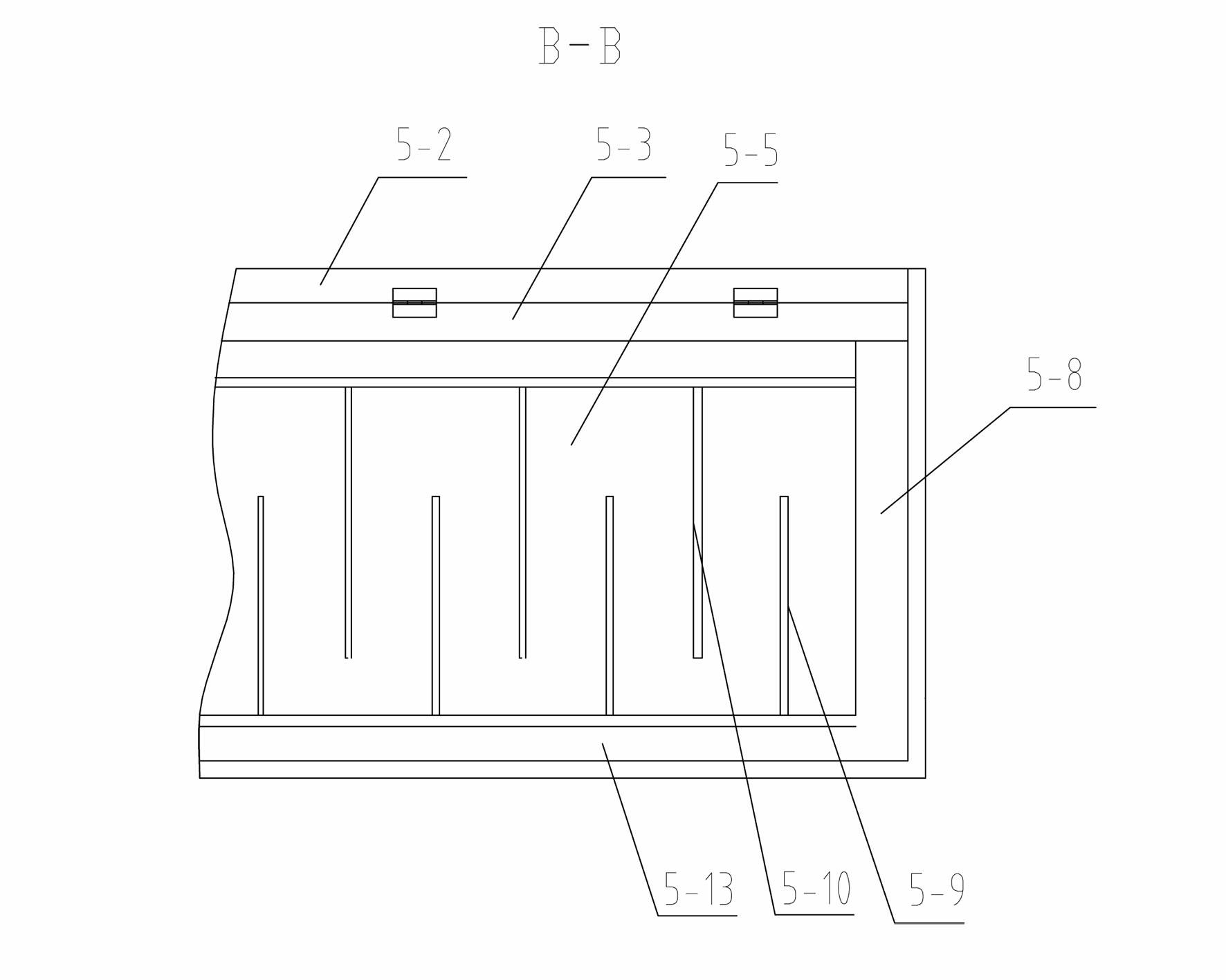

Heat insulation recycling transport vehicle for hot air circulation asphalt mixture

InactiveCN102660917AIncrease the heating areaReduce lossesConcrete transportationRoads maintainenceHeat conservationElectric control

A heat insulation recycling transport vehicle for hot air circulation asphalt mixture comprises a vehicle chassis, an asphalt mixture bin, a bin lifting mechanism, an excess material recycling transport mechanism, a follow charging hopper and an electric control device. The asphalt mixture bin is a tipper-hopper discharge type hot air circulation heating heat insulation bin mechanism, the heat insulation bin mechanism comprises a flipping frame, a heat insulation bin, a hot air circulation furnace device and a generator set, a feeding hopper is arranged on the heat insulation bin and is in butt joint with the follow charging hopper, the heat insulation bin comprises a heat insulation box, a bottom hot air channel, a tail hot air channel, two side wall hot air channels, two groups of spoilers and an inner bin, and the hot air circulation furnace device comprises a diesel tank, a diesel supply device, a hot air furnace and a high-temperature circulation fan. The heat insulation recycling transport vehicle has the advantages that heating is quick and uniform, the heat efficiency is high, hot air with waste heat can be recycled, loading transport heat insulation effects are fine, and the best laying temperature and quality of the asphalt mixture are constantly ensured.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

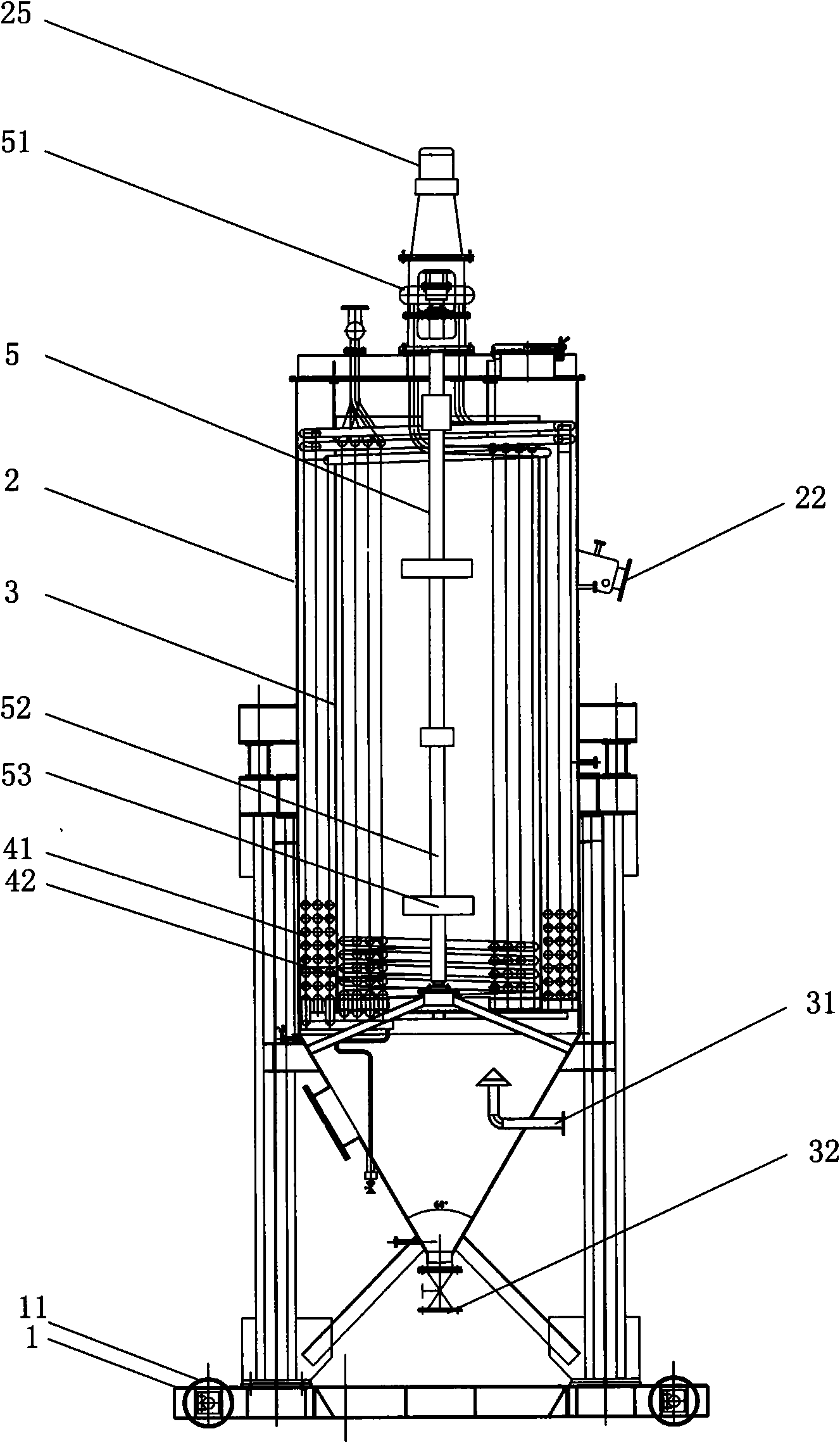

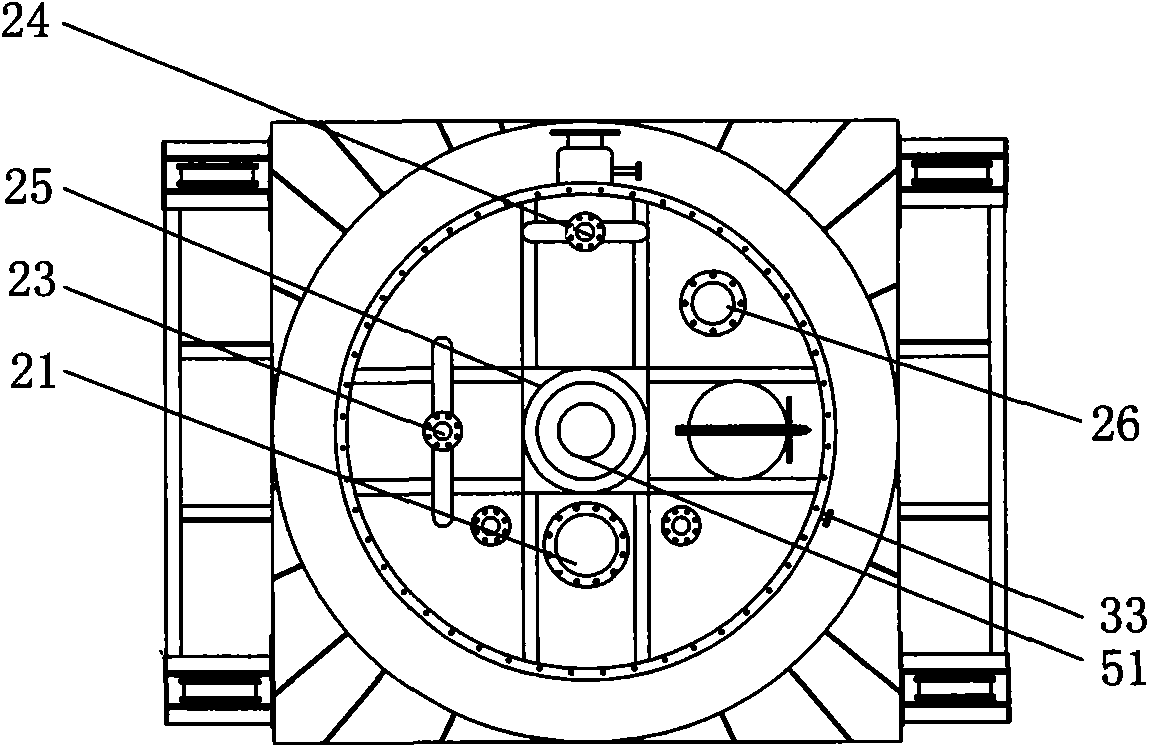

Stirring type asphalt melting tank

The invention relates to a stirring type asphalt melting tank which adopts a vertical structure and comprises five parts i.e. a heating coil, an internal cylinder, an external cylinder, a stirring device and a stand. Solid asphalt is transported to a feeding port of the asphalt melting tank through a conveying appliance, enters the asphalt melting tank, and is melted by absorbing heat to become liquid. The invention is also integrated with the stirring device to fully stir the melted asphalt, thereby the heat exchange efficiency is increased, and the heat exchange speed and the yield are enhanced.

Owner:常州能源设备总厂有限公司

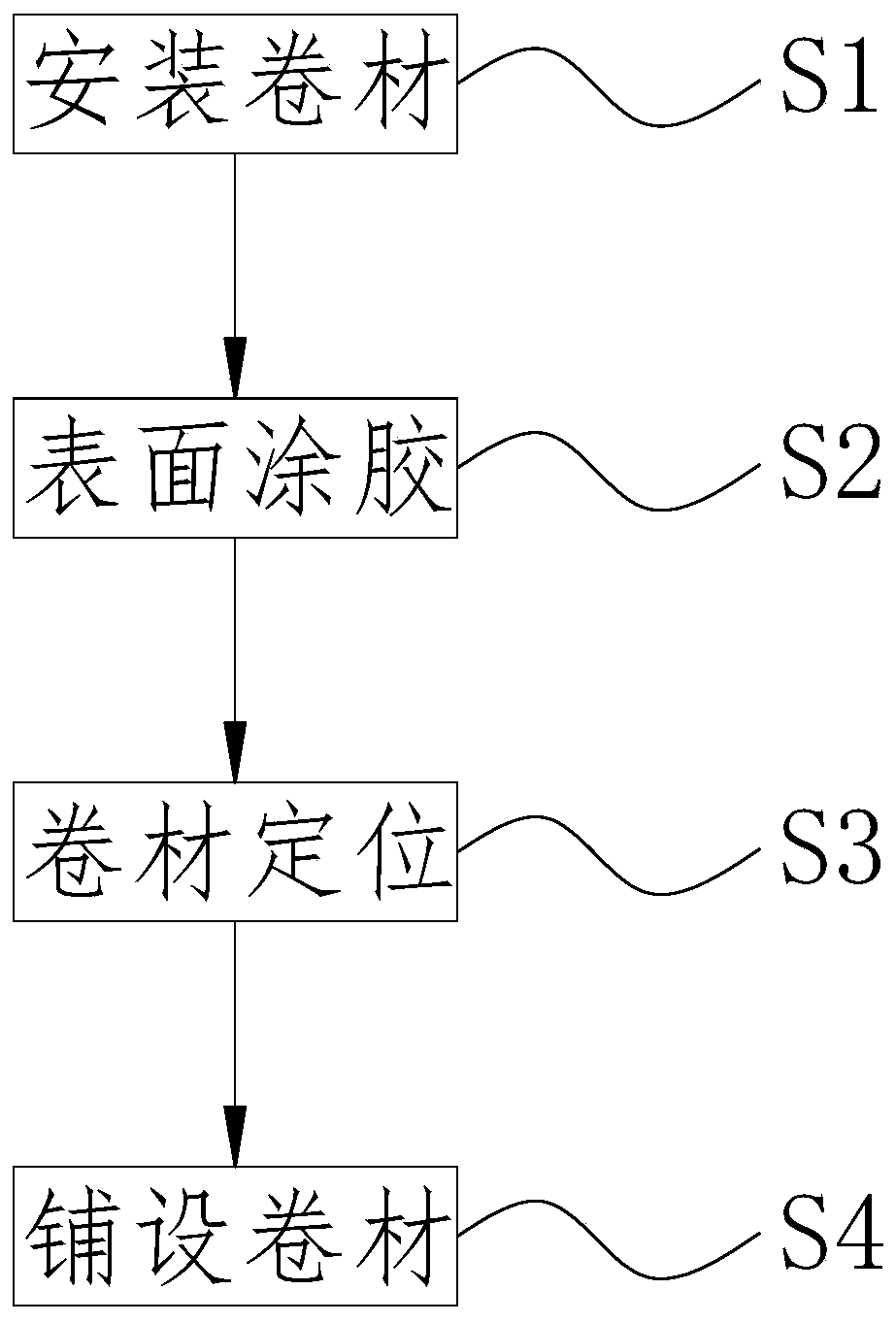

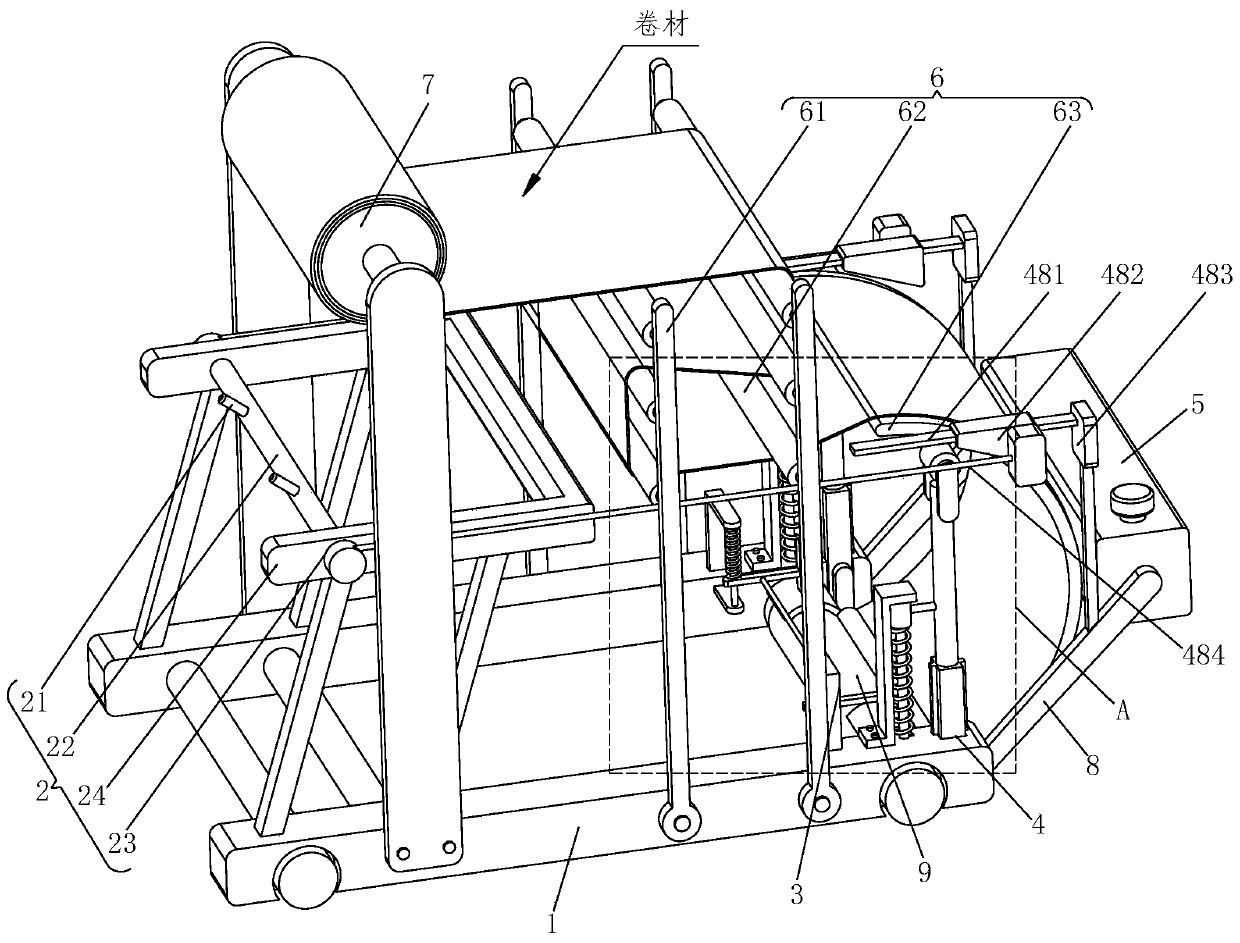

Waterproof coiled material laying construction method

The invention relates to a waterproof coiled material laying construction method. The waterproof coiled material laying construction method comprises a fixed base, a supporting assembly, a clamping mechanism, a positioning mechanism, a gluing mechanism, a bearing mechanism, a mounting roller, fixed plates and a fixed roller, the mounting roller is mounted above the fixed base through a first supporting plate, and the bearing mechanism is arranged above the fixed base and located on the right side of the mounting roller, the supporting assembly is arranged on the lower left portion of the mounting roller, the fixed roller is mounted on the inner side wall of the right end of the fixed base, the clamping mechanism is arranged over the fixed roller, the positioning mechanism is arranged on the right side of the clamping mechanism, the fixed plates are welded to the outer wall of the right end of the fixed base, the gluing mechanism is arranged at the upper end of the fixed plates, and thetwo side walls of a gluing shell are installed on the top side walls of the two fixed plates correspondingly. According to the waterproof coiled material laying construction method, the uniformity ofglue coating is effectively guaranteed, waste of glue is avoided, and meanwhile the tightness between a waterproof coiled material and a laid road surface is effectively guaranteed in the laying process.

Owner:盘达建设工程集团有限公司

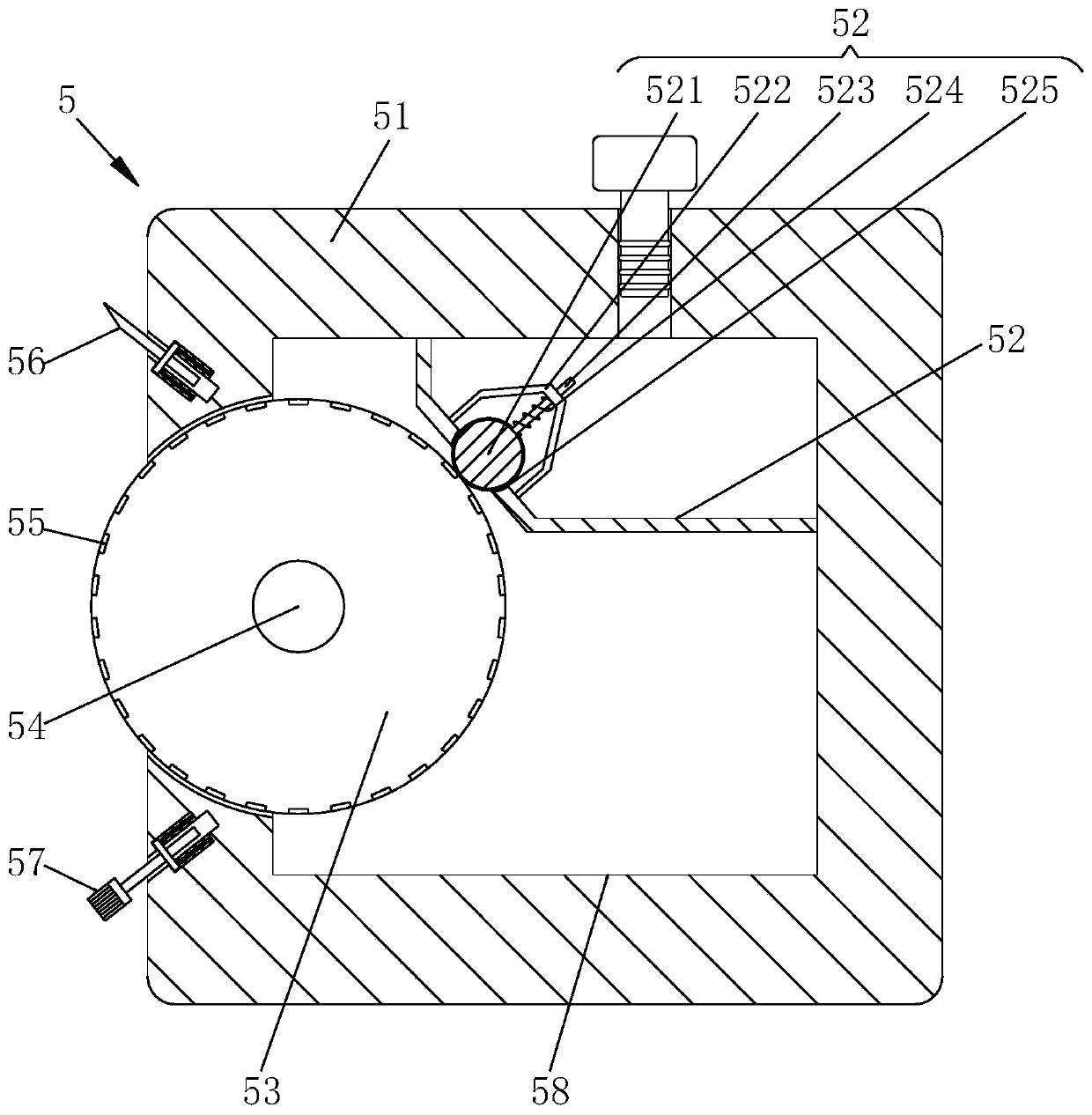

Turf planter

ActiveCN107409779AImprove laying efficiencyImprove laying qualityHops/wine cultivationTurf growingEngineeringMechanical engineering

The invention discloses a turf planter which comprises a frame, a storage device, a laying device, a turf retainer, a lifting control device and a rolling device. The storage device is used for storing a blocky turf to be planted, the laying device is used for receiving the blocky turf released from the storage device, conveying the blocky turf to the ground and laying the blocky turf, the turf retainer is arranged on the laying device and inserted into the blocky turf, the lifting control device is used for controlling the turf retainer to move and to be inserted into the blocky turf, the rolling device is used for rolling the blocky turf laid on the ground, and the storage device, the laying device and the rolling device are arranged on the frame. By the aid of the turf planter, turf laying efficiency and turf laying quality can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Building waterproof construction equipment and construction method thereof

ActiveCN112726976AIncrease resistanceReduce the probability of warpingLiquid surface applicatorsProtective foundationArchitectural engineeringStructural engineering

The invention relates to building waterproof construction equipment and a construction method thereof. The building waterproof construction equipment comprises a shell, a supporting plate, a moving assembly, an unwinding roller rotationally installed on the inner wall of the shell and a gluing assembly installed in the shell. A laying through hole is formed in the bottom wall of the shell in a penetrating mode, a fixing plate is fixed to the bottom wall of the shell, and a compaction assembly is installed on the fixing plate. The compaction assembly comprises an air cylinder fixed to the fixing plate, a U-shaped plate body fixed to the lower end of a piston rod of the air cylinder and a compaction roller rotationally installed between the two side walls of the U-shaped plate body, and a limiting assembly for preventing the compaction roller from rotating reversely is installed on the U-shaped plate body. According to the building waterproof construction equipment, the limiting assembly plays a good role in limiting reverse rotation of the compaction roller, the resistance of the shell moving in the direction opposite to the waterproof roll laying direction is increased, the probability that the laid waterproof roll tilts due to the fact that the shell is subjected to acting force in the reverse direction is reduced, and the laying quality of the waterproof coiled material and the waterproof effect of a building site are improved.

Owner:合肥国泓建设工程有限公司

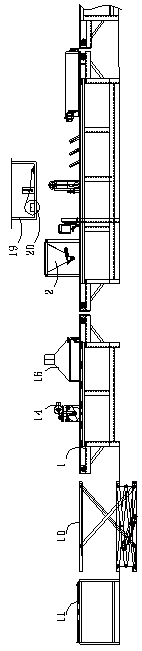

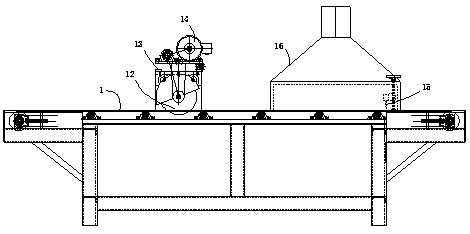

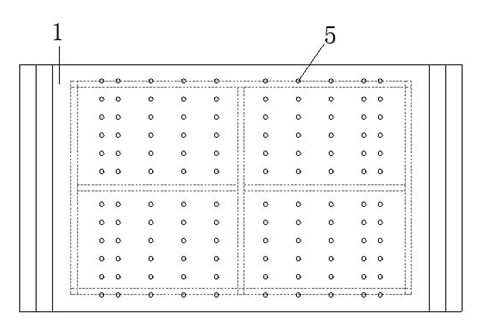

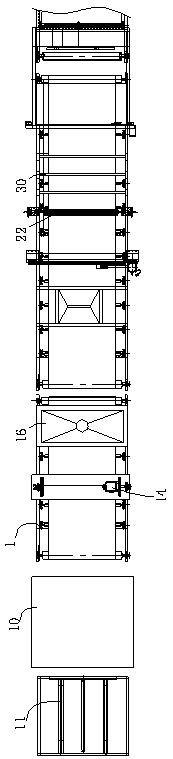

Fiber reinforced cement-based foam heat retaining board production line

ActiveCN107901207AEasy and quick slurry layingReliable laying qualityCeramic shaping plantsFeeding arrangmentsEngineeringFiber reinforcement

The invention discloses a fiber reinforced cement-based foam heat retaining board production line. The fiber reinforced cement-based foam heat retaining board production line comprises a conveying platform, and a dust absorbing device, a material laying device, a net laying device and a cutting off device are forwards arranged sequentially on the conveying platform from the starting end to the ending end. The fiber reinforced cement-based foam heat retaining board production line is characterized in that the material laying device comprises a material storing hopper, the material storing hopper is located above the conveying platform, and a discharging port at the lower end rightly faces the conveying working face. The material laying device further comprises an initial scraping mechanismlocated at the position, above the conveying platform, at the front end of the material storing hopper. The fiber reinforced cement-based foam heat retaining board production line can achieve composite laying of a screen cloth of a cement-based foam heat retaining plate and a mortar reinforcing layer, and has the advantages that mortar can be laid more easily, rapidly, conveniently, the productionline is reliable, the laying quality is good, the mortar layer is thin and rich, the technology is simple, the efficiency is high, and the product quality is good.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV

Marine wind power blade carbon fiber automatic forming equipment and laying process method

InactiveCN110789155AReal-time adjustmentReal-time detection of temperature changesFiberCarbon fibers

The invention relates to the technical field of wind power generation equipment, in particular to marine wind power blade carbon fiber automatic forming equipment and a laying process method. A horizontal three-degree-of-freedom parallel mechanism is used, and the horizontal three-degree-of-freedom parallel mechanism comprises a laying component used for laying fibers and a three-axis adjustable control mechanism used for realizing coordinate conversion of a filament laying mechanism and realizing multi-axis motion. A conveying device of the filament laying mechanism adopts a speed sensor anda plurality of compression rollers to control a filament bundle to be conveyed to a filament bundle tension control device, the high surface roughness is adjusted to ensure that the filament bundle does not slip, the filament bundle respectively passes through a re-transmission mechanism and a cutting device with cylinder cover, the filament bundle is melted under the action of an infrared radiation lamp tube heating device, and finally carbon fibers are laid through the pressurization cooling treatment of a cooling device. According to the marine wind power blade carbon fiber automatic forming equipment and the laying process method, through a motion platform capable of realizing multi-axis motion, a fiber laying head is driven to complete the laying work of the carbon fibers, the layingprocess is completed, the stable and uniform laying can be guaranteed, the filament laying process can be fed back and monitored in real time through a self-provided monitoring device, and the filament laying quality is improved.

Owner:JIANGSU UNIV OF SCI & TECH

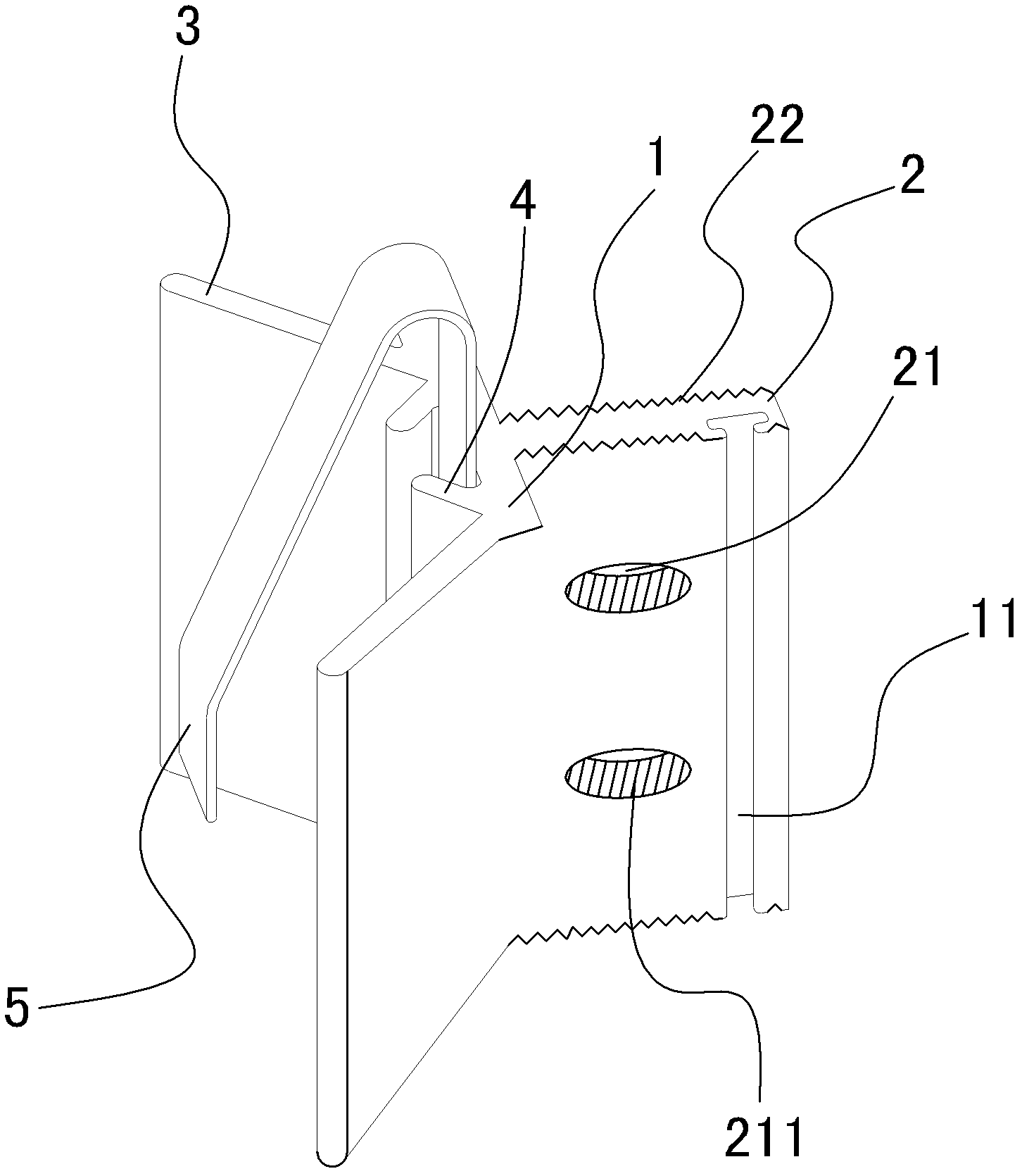

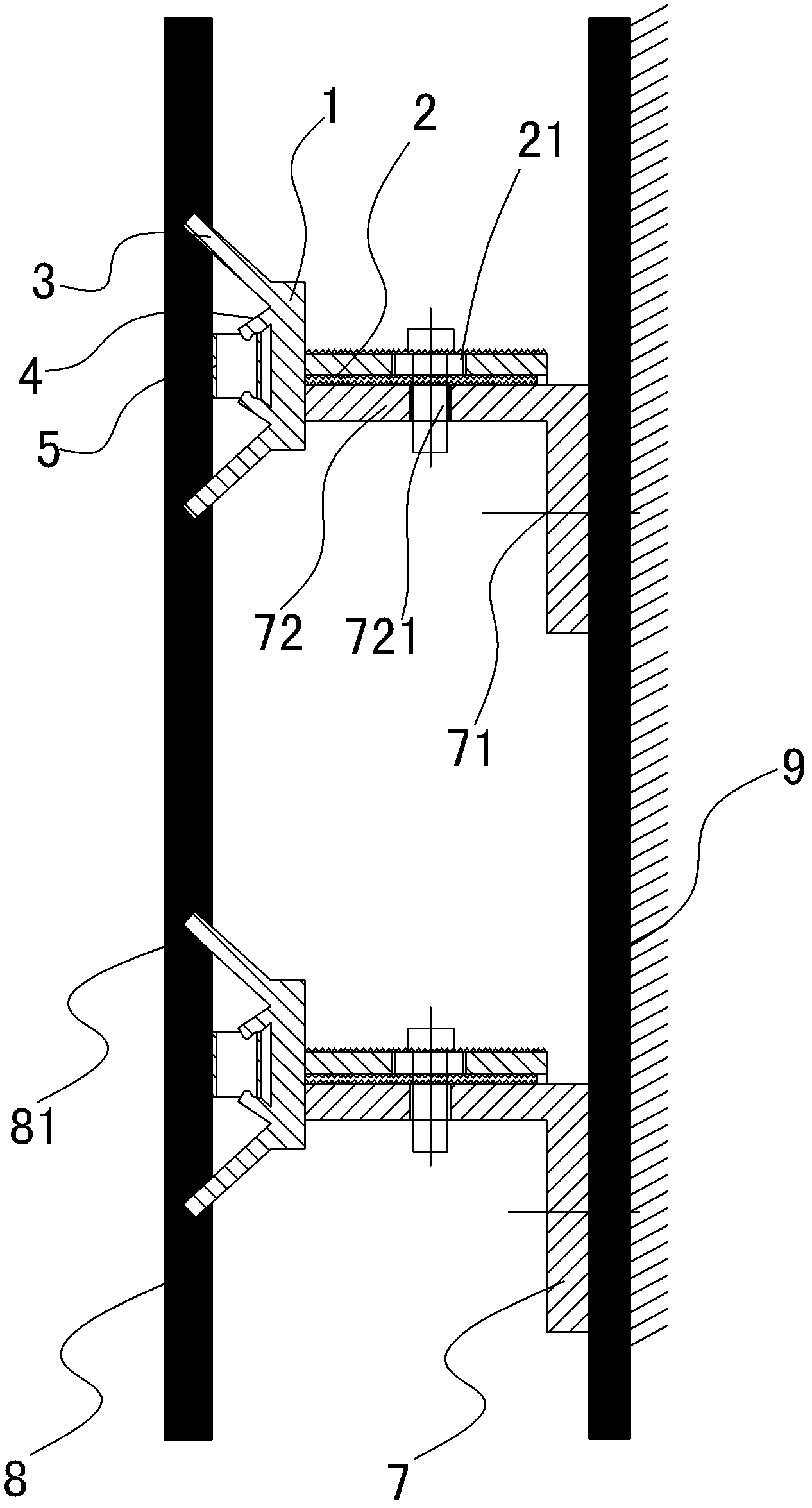

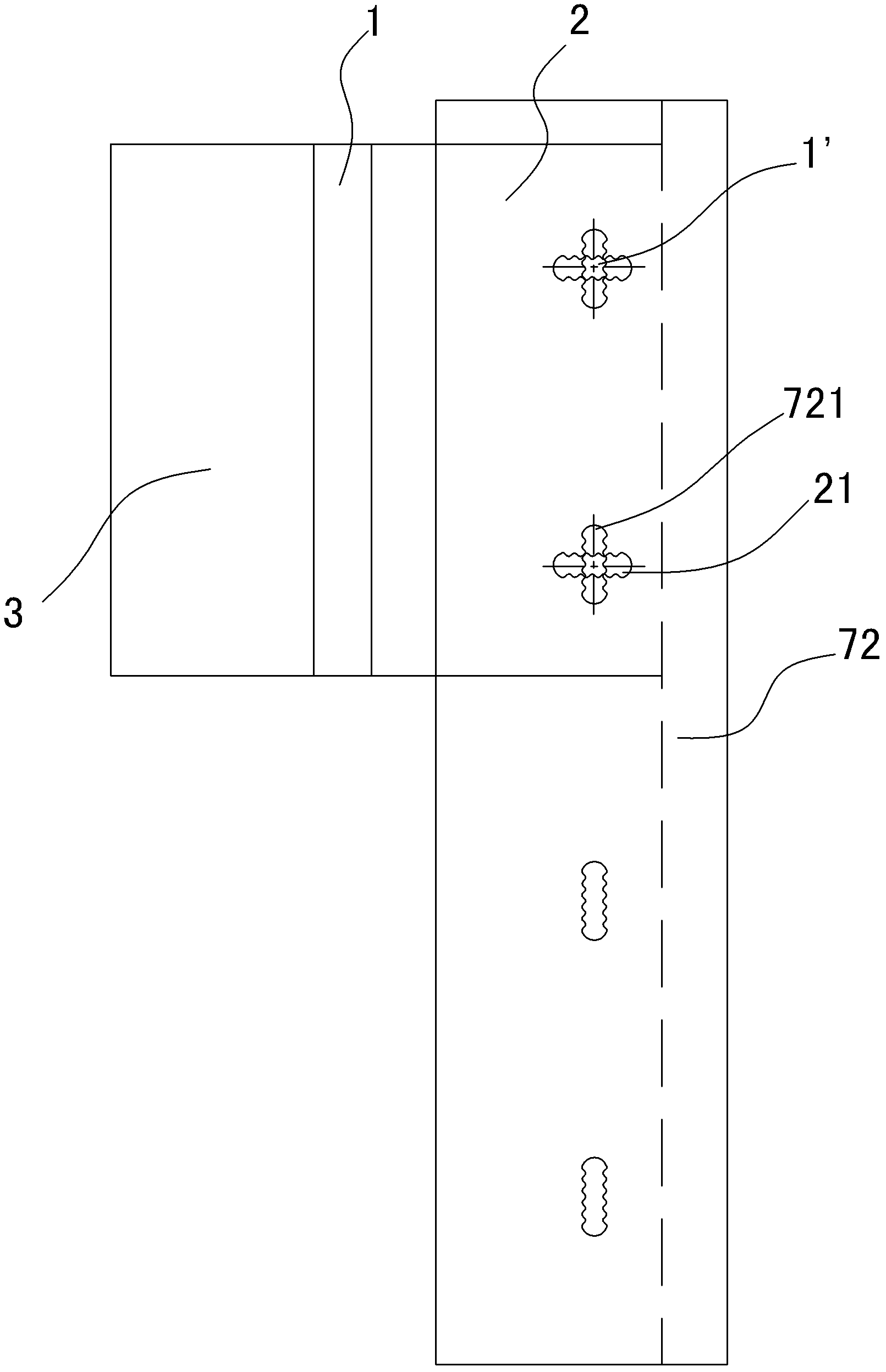

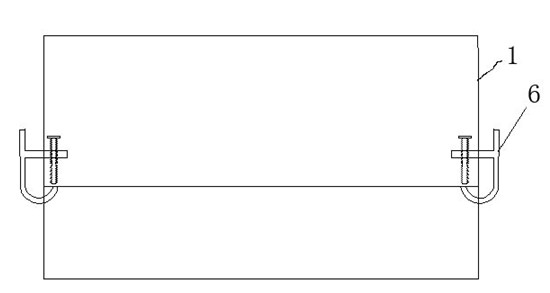

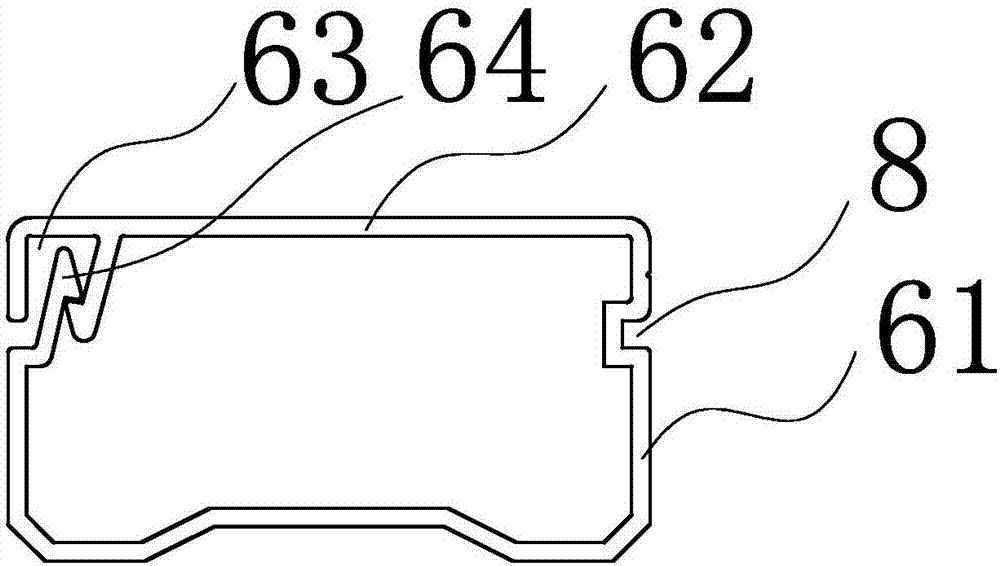

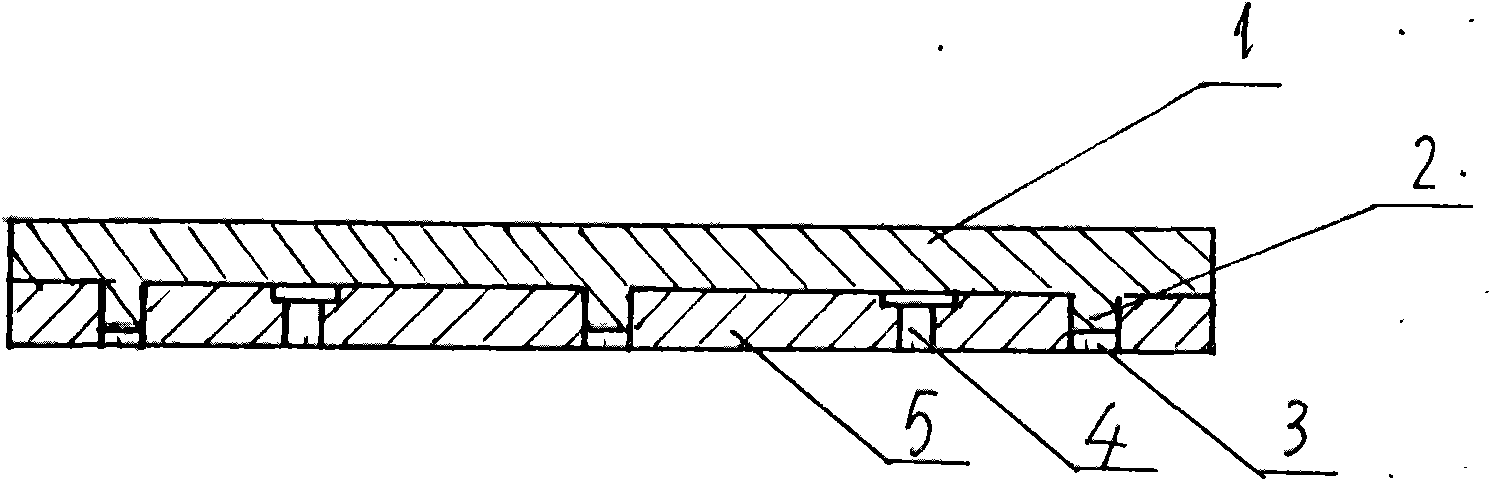

Installation fastener for building

InactiveCN102518280ASimple structureEasy to manufactureCovering/liningsEngineeringUltimate tensile strength

The invention discloses an installation device for a movable tile and stone building, and provides an installation fastener for a building. When the installation fastener is used, the installation procedure is simple, the labor intensity is low, the construction speed is high, the quality of laid tiles or stones is high, the removal and the replacement are convenient, tiles can be firmly laid on walls, and the fastener is also attractive and environmentally friendly. The installation fastener comprises a fastener body, a connecting plate extends horizontally from one side of the fastener body and is provided with a mounting hole, the other side of the fastener body is provided with two clamping strips with spacing, and the two clamping strips respectively extend to opposite directions.

Owner:王钦旭

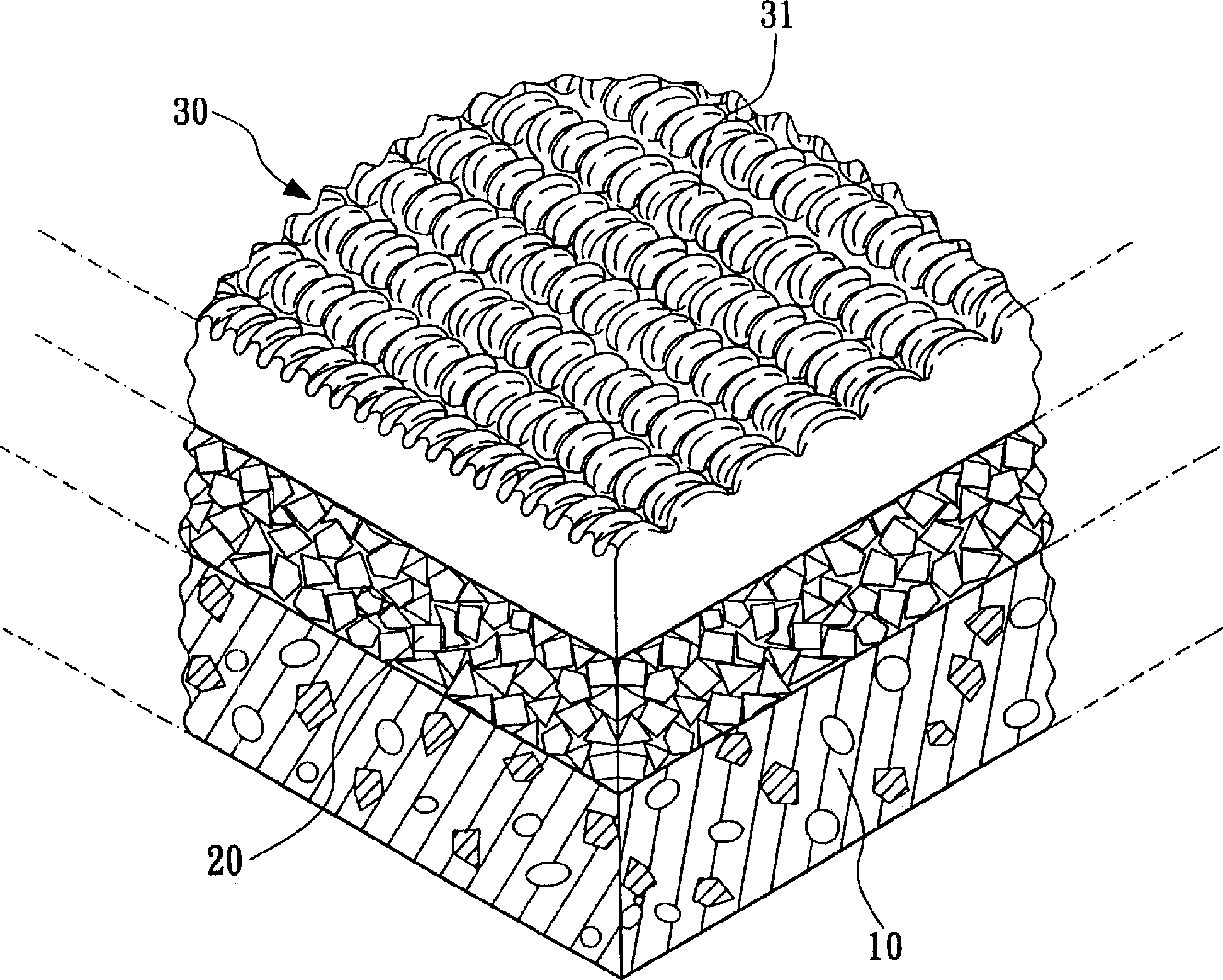

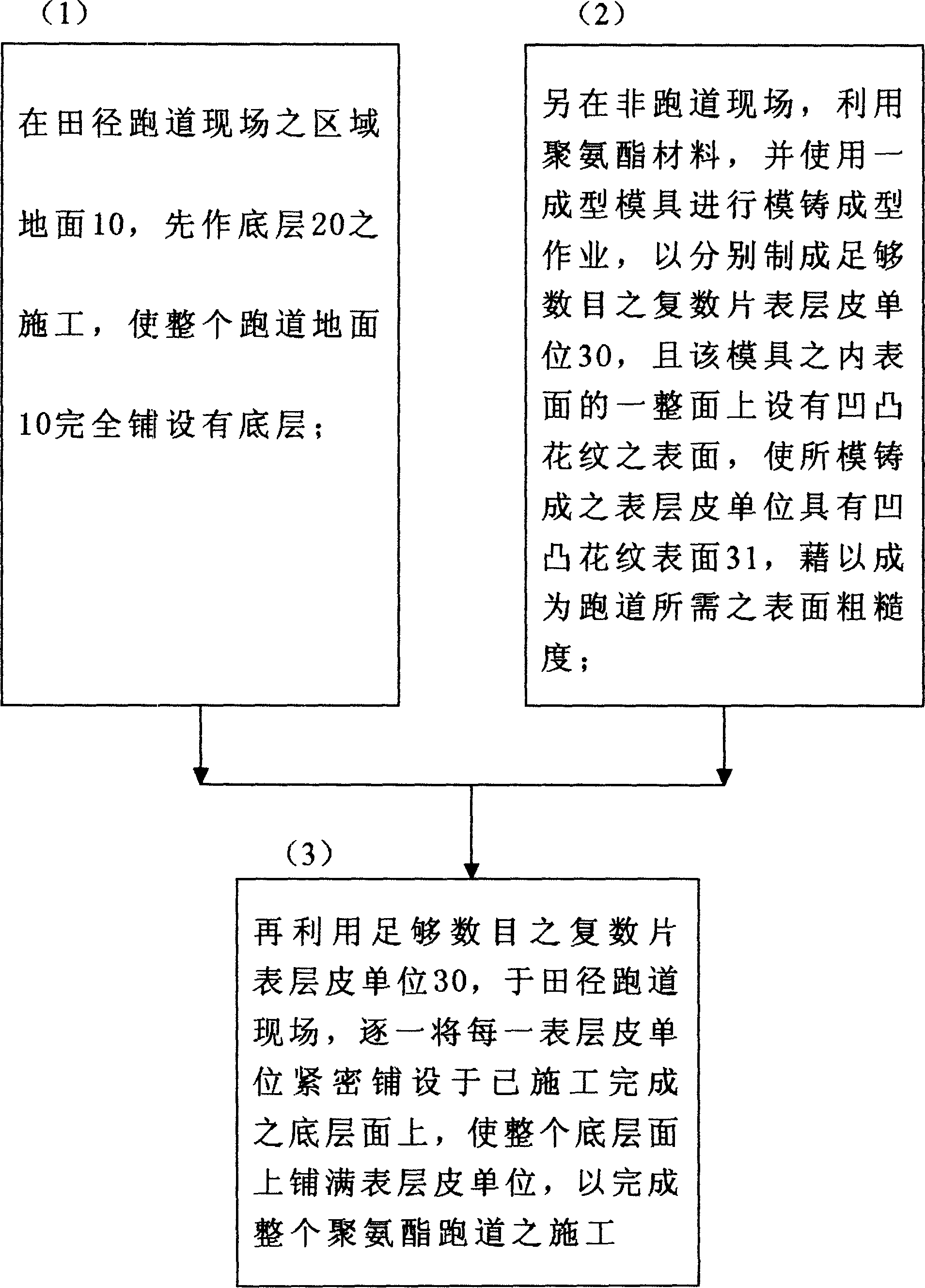

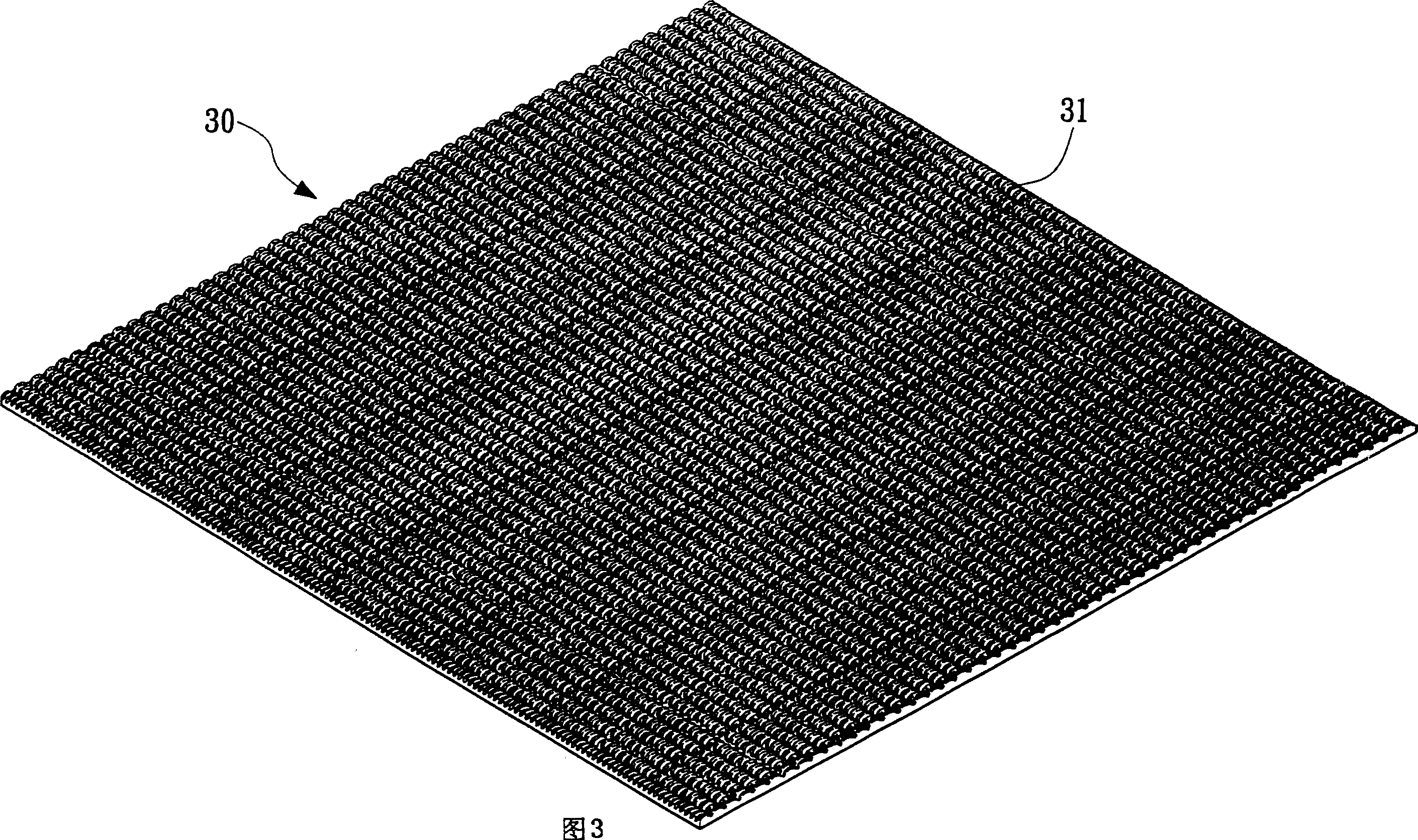

Method for construction of polyurethane track of sports field

InactiveCN1401401AFulfil requirementsFast constructionSki bindingsGround pavingsHigh surfaceEngineering

A method for constructing the polyurethane race track on sports ground includes preparing the base layer on the sports ground, prefabricating the standard polyurethane sheets (1.25mX5-25m) by mould, and tightly adhering the sheets on the base layer. Its advantages are high thickness uniformity and flatness, high weatherability, and high surface firmness.

Owner:ISOTECH PRODS

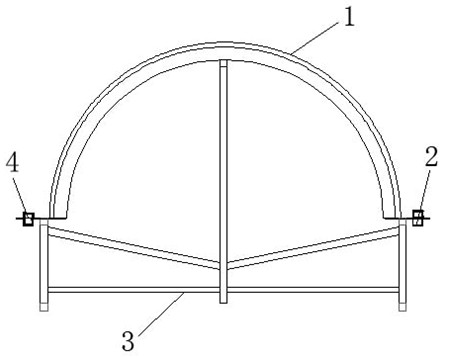

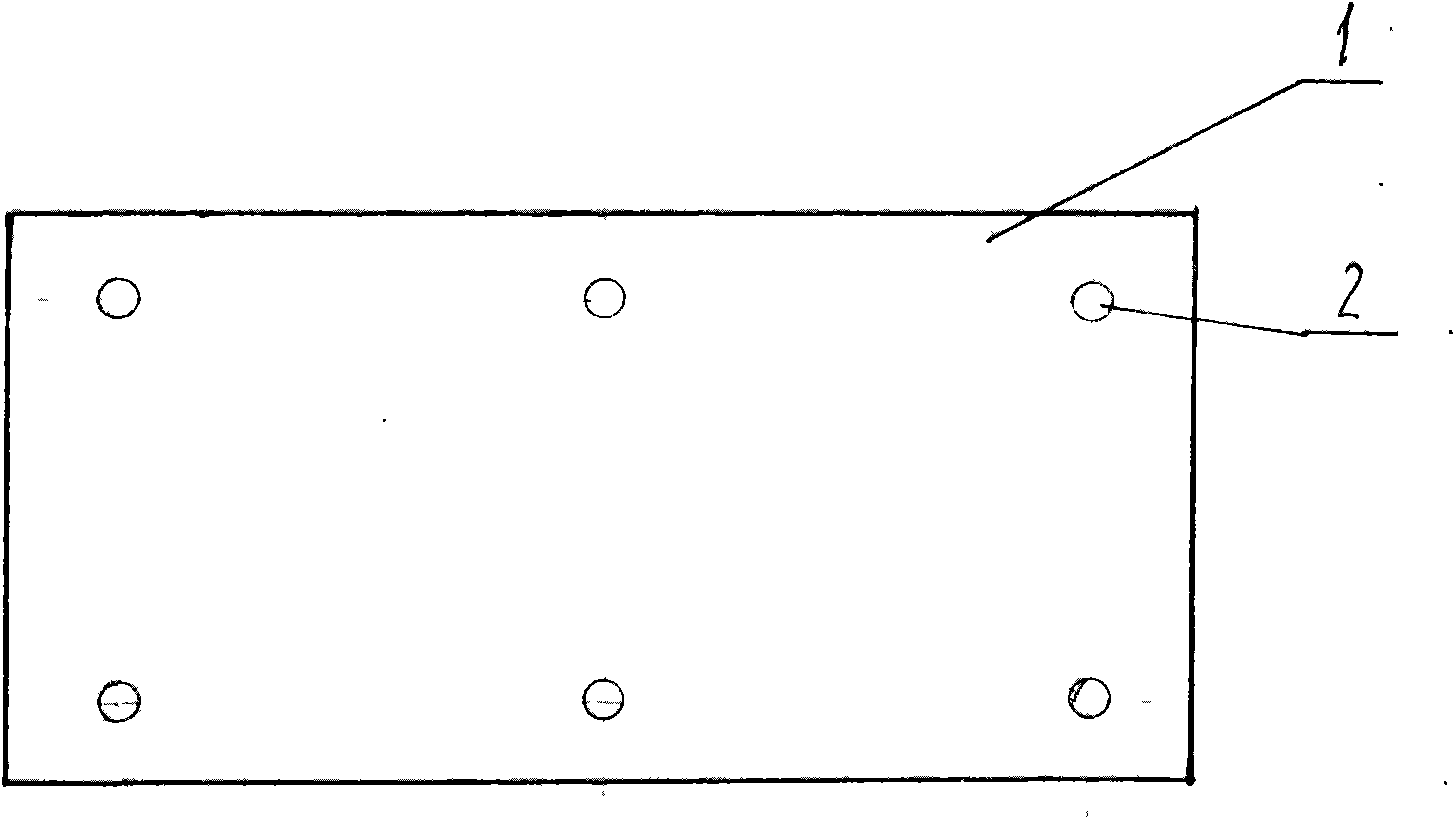

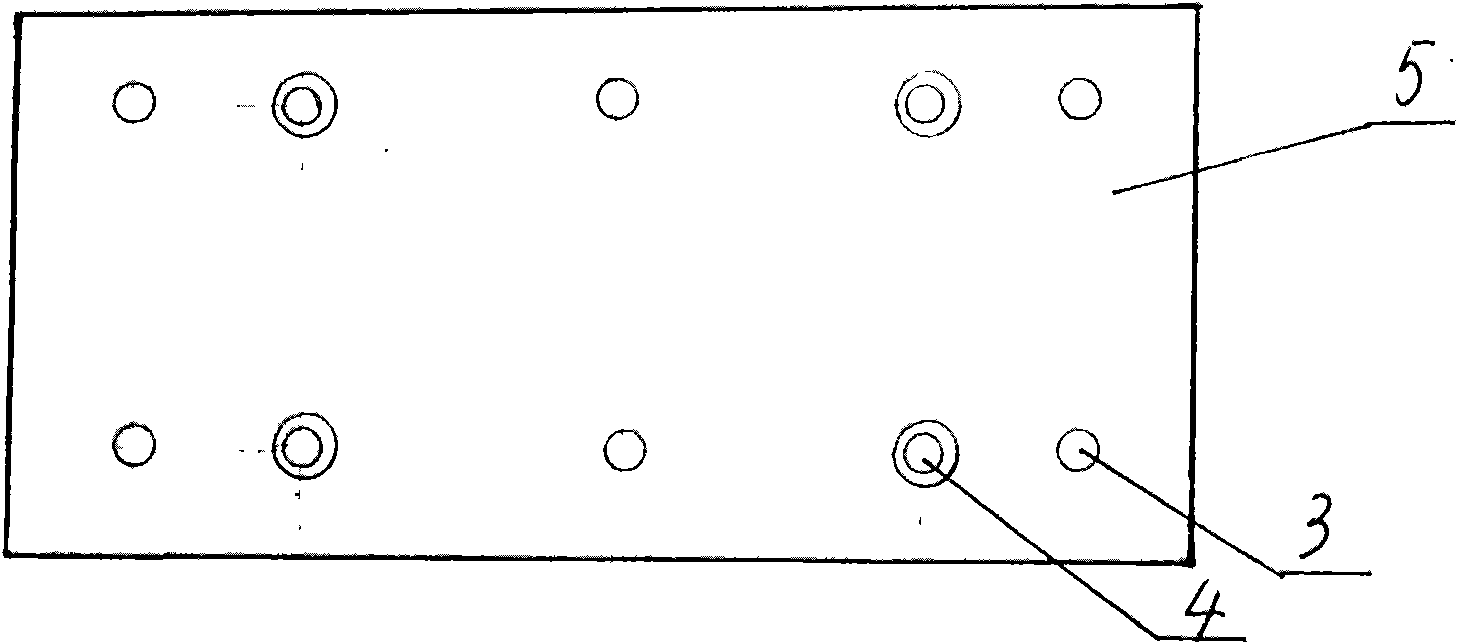

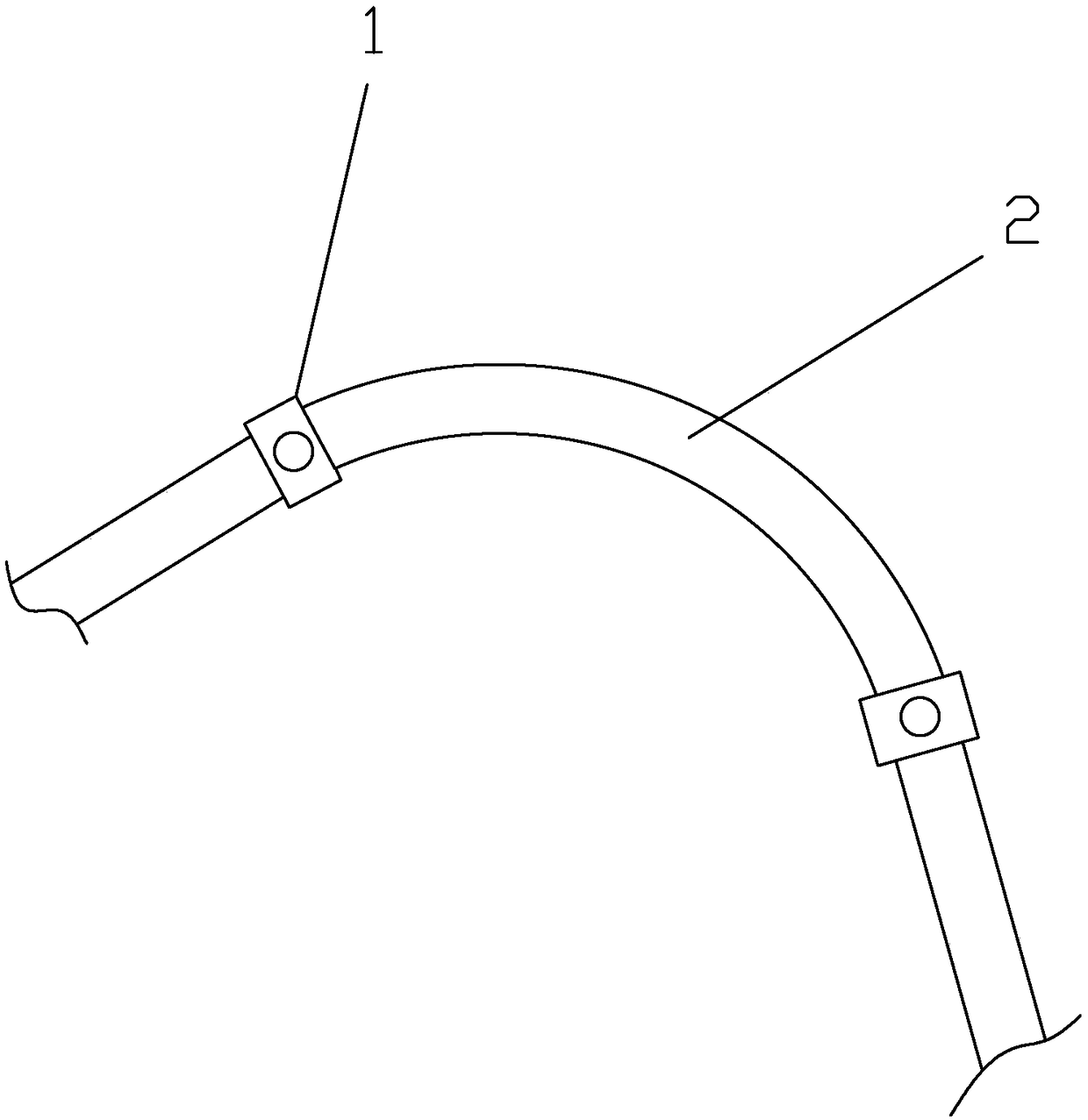

A laying method and auxiliary device for laying glass fiber cloth at the root of wind power blades

The invention provides a laying method and auxiliary device for laying glass fiber cloth at the root of wind power blades. Above, the two ends of the semi-circular steel plate are fixed grooves for glass fiber cloth, and the fixed grooves for glass fiber cloth are equipped with fixed square steel, and there are process holes on the semi-circular steel plate. Then lay glass fiber cloth on the device according to the order of leaf root laying, and fix it after laying a certain number of layers of glass fiber cloth. After all the glass fiber cloth is laid, directly lift the device and put it in the shell. The steel frame can still be used for the laying of the next set of glass fibers. The device is simple in use, convenient in process operation, good in laying quality of glass fiber cloth, and fast in hoisting time; simple in manufacture, convenient in assembly, low in cost, and long in service life.

Owner:TIANJIN CRRC WIND POWER BLADE ENG CO LTD

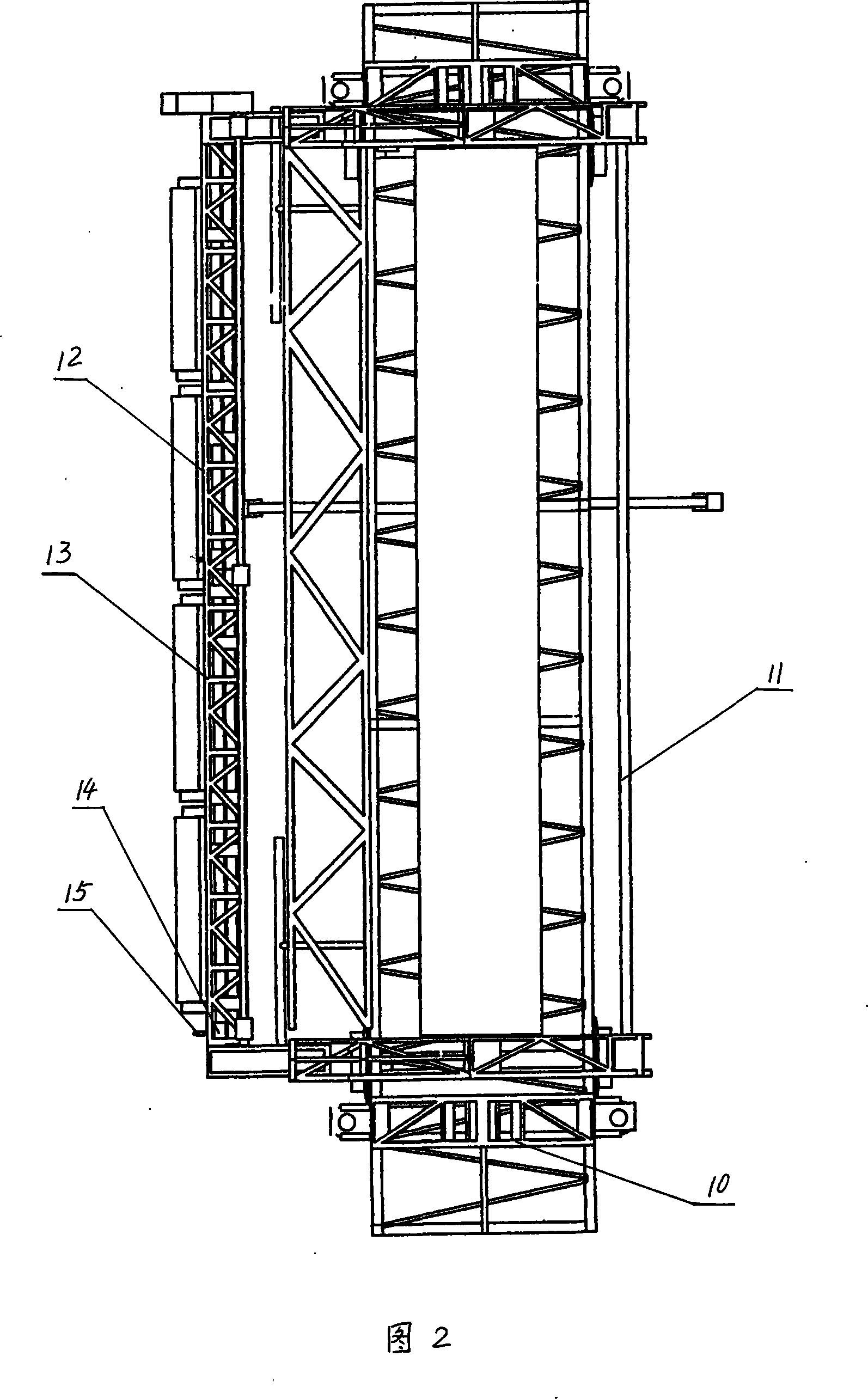

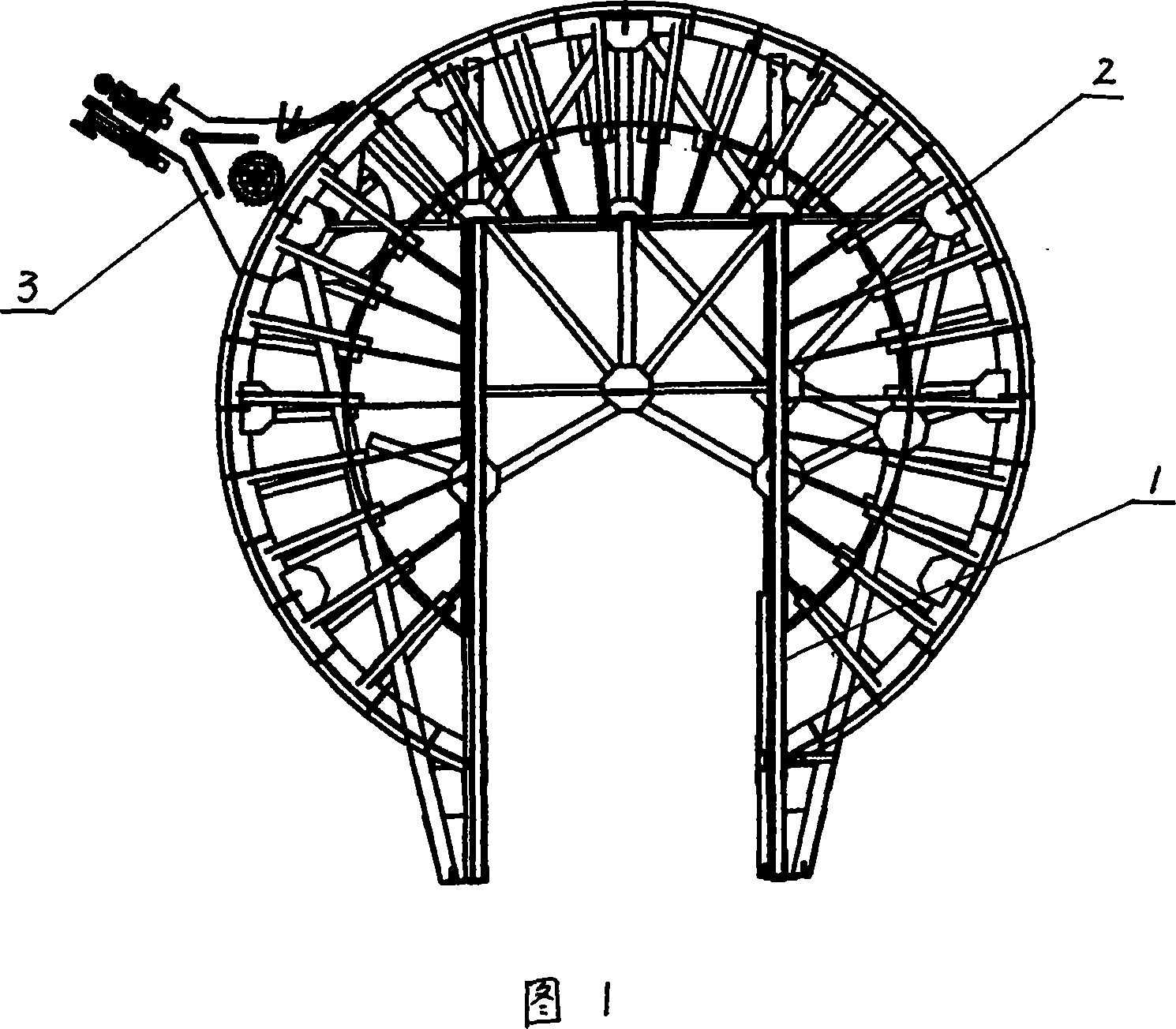

Radial type tunnel anti-seepage geotextile cloth laying machine

ActiveCN101182775AEasy to operateReduce workloadUnderground chambersTunnel liningReduction driveDrive shaft

A radiating tunnel earth-prevention work cloth distributor consists of a base, a rotary arm, a work cloth roller, a drive shaft, a floating bracket, a distributing cylinder, a glue spreader, a walk drive motor, a walk wheel and a main motor. The two walk wheels of a dolly are arranged below the base; the main motor is connected with the drive shaft through a reducer; the two ends of the rotary arm are respectively provided with another motor; the motor is connected with one end of a drive screw and the other end of the drive screw is connected with the support beam of the distributing cylinder; the distributing cylinder is arranged on the support beam; the glue spreader is arranged on the right of the distributing cylinder; the surface of the distributing cylinder is coated with a rubber layer. The structure adopts the mechanical operation for distributing the work cloth in the portal of round cross-section tunnel, thus facilitating the large-area work cloth distribution. The floating bracket presses the work cloth on the tunnel wall; the coordinated rotation of the distributing cylinder and the rotary arm completes the work cloth distribution on the tunnel wall; the distributing cylinder supported by the spring can adjust to the unevenness of the local wall surface.

Owner:CHINA GEZHOUBA GROUP CO LTD +1

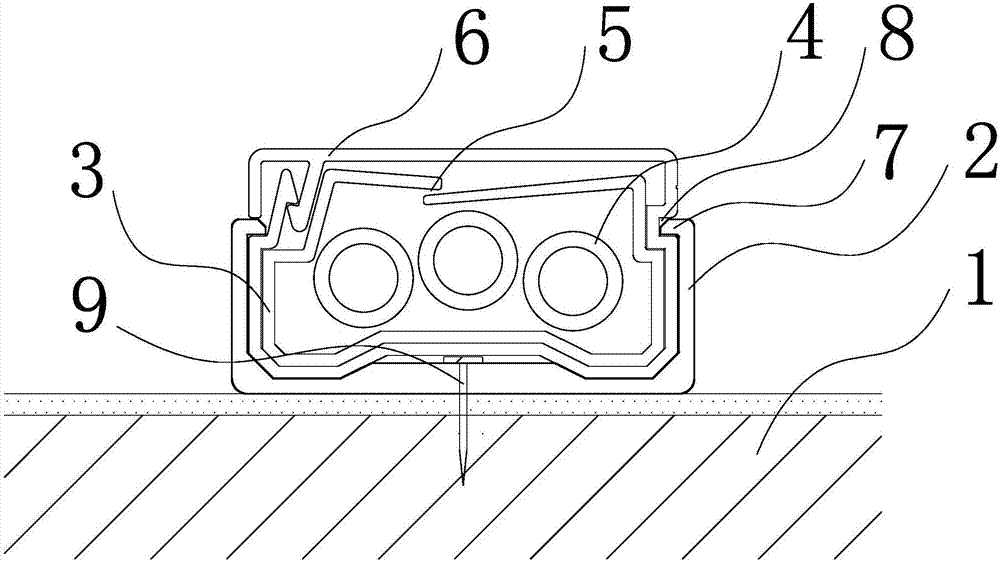

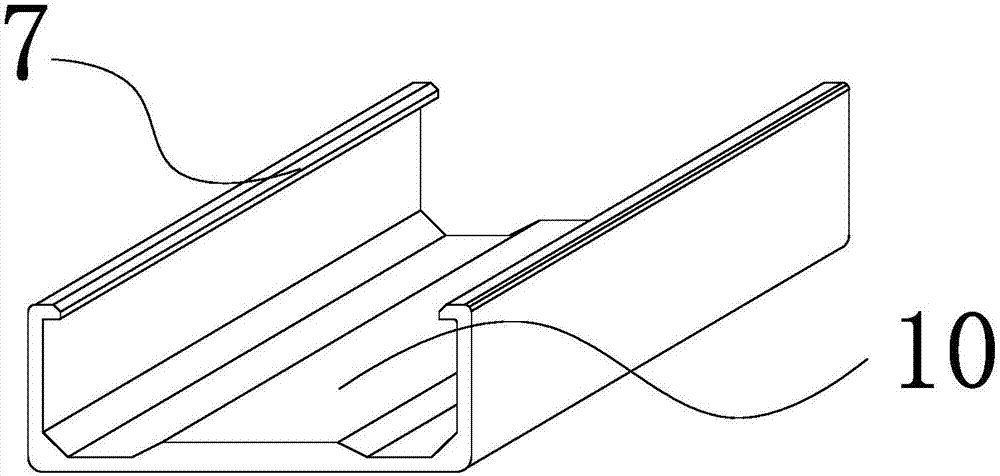

Integrated quickly-mounted wire groove and wiring method adopting same

InactiveCN107404097ANo prolapseInstallation saves time and effortApparatus for laying cablesEngineeringBuilding construction

The invention relates to the field of architectural decoration, and provides a simple structure, convenient and fast wiring installation, time-saving and labor-saving, neat and consistent pavement, good quality integrated quick-installation wire slot and a method for wiring by using the quick-install wire slot to solve the problem of The cable laying process in the prior art is cumbersome, time-consuming and labor-intensive, and the cables are easy to come out and affect the normal construction. It includes the wall and the U-shaped slot base fixed on the wall surface. The U-shaped The opening of the U-shaped card slot base faces outward, and the elastic cable management ring is elastically clamped in the opening of the U-shaped card slot base. The cable is pressed into the notch, and the edge of the elastic cable management ring corresponding to one side of the cable press-in notch extends inward and elastically abuts against the corresponding elastic cable management ring on the other side of the cable press-in notch.

Owner:ZHEJIANG YASHA DECORATION

Wallpaper paving device for architectural decoration

InactiveCN110843404AGuaranteed fixed effectAvoid wrinklesPaperhangingSuction forceConstruction engineering

The invention discloses a wallpaper paving device for architectural decoration. The wallpaper paving device comprises a vertical plate and a transverse plate, wherein adjustable fixing mechanisms aresymmetrically arranged on two side walls of the vertical plate; a second lifting assembly for driving the transverse plate to move up and down is arranged on the end surface, facing the transverse plate, of the vertical plate; and an adjustable rolling mechanism is mounted on the transverse plate. According to the wallpaper paving device for architectural decoration, the position adjustment of suckers on the periphery of the vertical plate is realized through the cooperation of a first lifting assembly and a telescopic rod, so that the wallpaper paving device is suitable for fixing wallpapersof different specifications; meanwhile, a plurality of air suction holes are formed in the suckers, suction force is dispersed, the suction process is more stable, the fixing effect of the wallpapersis ensured, and the wallpaper is prevented from being wrinkled; the rolling range of a roller is adjusted through the second lifting assembly and a horizontal moving assembly, so that the whole wall surface is completely covered, and the rolling paving efficiency is high; and the roller is wrapped with a soft cushion, so that bubbles are prevented from being generated between the wallpaper and thewall surface during rolling, and the paving quality and the attractiveness of the wallpaper are improved.

Owner:北京艺轩吉装饰工程有限公司

Micro-sprinkling belt spreading and rolling dual-purpose machine

The invention relates to a micro-sprinkling belt spreading and rolling dual-purpose machine. The micro-sprinkling belt spreading and rolling dual-purpose machine comprises a rack, a steering handle, a tape feed roller, a crawler wheel, a press wheel, a soil scraper, a transmission device and a guide wheel, wherein the rack consists of an upper beam, a long arm and two forked structures which are connected into an integer from top to bottom in sequence; the forked structures are respectively fixed at front and rear sides of the long arm through a lower beam vertical to the long arm; the two forked structures are respectively used for fixing the crawler wheel and the press wheel; the steering handle is T-shaped; the lower end of the steering handle is connected on the upper beam; the tape feed roller is fixed on the long arm between the lower beam and the upper beam through a wheel shaft; the crawler wheel and the press wheel are mounted on the rack through the wheel shaft; the soil scraper plate is movably connected to the front end of the press wheel through a connecting rod; the guide wheel is arranged behind the rack. The micro-sprinkling belt spreading and rolling dual-purpose machine can realize multiple purposes, is simple in structure, strong in function and good in stability, not only can be used for spreading micro-sprinkling belt, but also can be used for rolling the micro-sprinkling belt, so that the abrasion to the micro-sprinkling belt is reduced, and the service life of the micro-sprinkling belt is prolonged.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

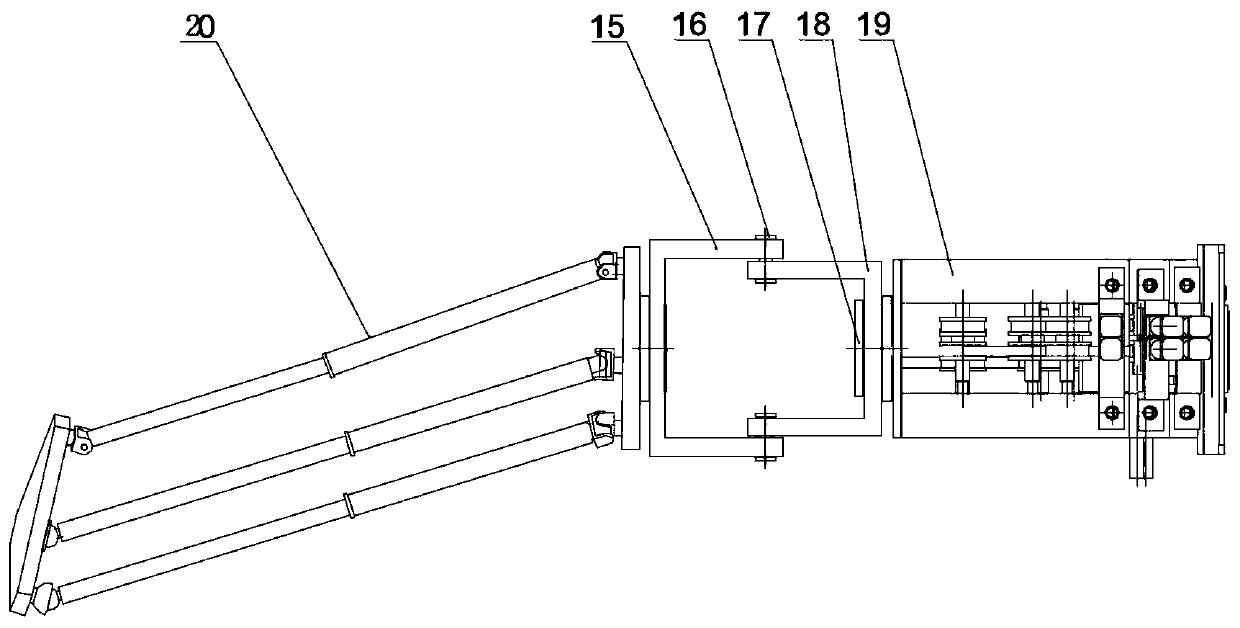

Excavating, supporting and anchoring combined unit drilling rig attitude adjusting and anchor net laying device and method

PendingCN111810150AImprove laying qualityReduce labor intensityDerricks/mastsMine roof supportsRock boltMechanical engineering

The invention provides an excavating, supporting and anchoring combined unit drilling rig attitude adjusting and anchor net laying device and method. The excavating, supporting and anchoring combinedunit drilling rig attitude adjusting and anchor net laying device comprises a base sliding shoe, a supporting upright, a supporting longitudinal beam, an anchor drilling rig, a drilling rig horizontalattitude adjustment component, a drilling rig height and angle attitude adjustment component, an anchor net and an anchor net laying component; the base sliding shoe is positioned behind a tunnelingmachine of an excavating, supporting and anchoring combined unit; the base sliding shoe follows the tunneling machine; the drilling rig horizontal attitude adjustment component is arranged on the upper surface of the base sliding shoe behind the supporting upright; the drilling rig height and angle attitude adjustment component is arranged on the drilling rig horizontal attitude adjustment component; the anchor drilling rig is arranged on the drilling rig height and angle attitude adjustment component; the anchor net laying component is arranged in front of the supporting upright; and the anchor net is positioned on the anchor net laying component. The excavating, supporting and anchoring combined unit drilling rig attitude adjusting and anchor net laying method comprises the steps of pulling the anchor net to a position above the anchor drilling rig, supporting the anchor net by using the supporting upright, adjusting the horizontal position and the swinging angle of the anchor drilling rig, enabling a push plate to extend out, drilling an anchor hole, mounting an anchor rod, fixing the anchor net, enabling the excavating, supporting and anchoring combined unit to integrally moveforwards, automatically releasing the anchor net and supplementing the anchor net to a tunnel roof.

Owner:LIAONING TECHNICAL UNIVERSITY

Combined adhesive-free wall body surface decorative brick

A combined adhesive-free wall body surface decorative brick belongs to a building wall body decorative product. A base brick is provided with a mounting and connecting fixed hole and a countersunk head screw hole; a mounting and connecting fixed column matched with the mounting and connecting fixed hole is arranged on the inner side surface of a surface brick and is inserted and configured in the mounting and connecting fixed hole; and the surface brick is fixedly arranged on the outer surface of the base brick to form a whole. The brick adopts a surface brick and base brick combined structure, is free from using any adhesive during pavement on the wall surface and has the characteristics of novel and reasonable design, easy pavement, favorable pavement quality, easy operation, low labor intensity, high operation efficiency and long service life.

Owner:姚福才

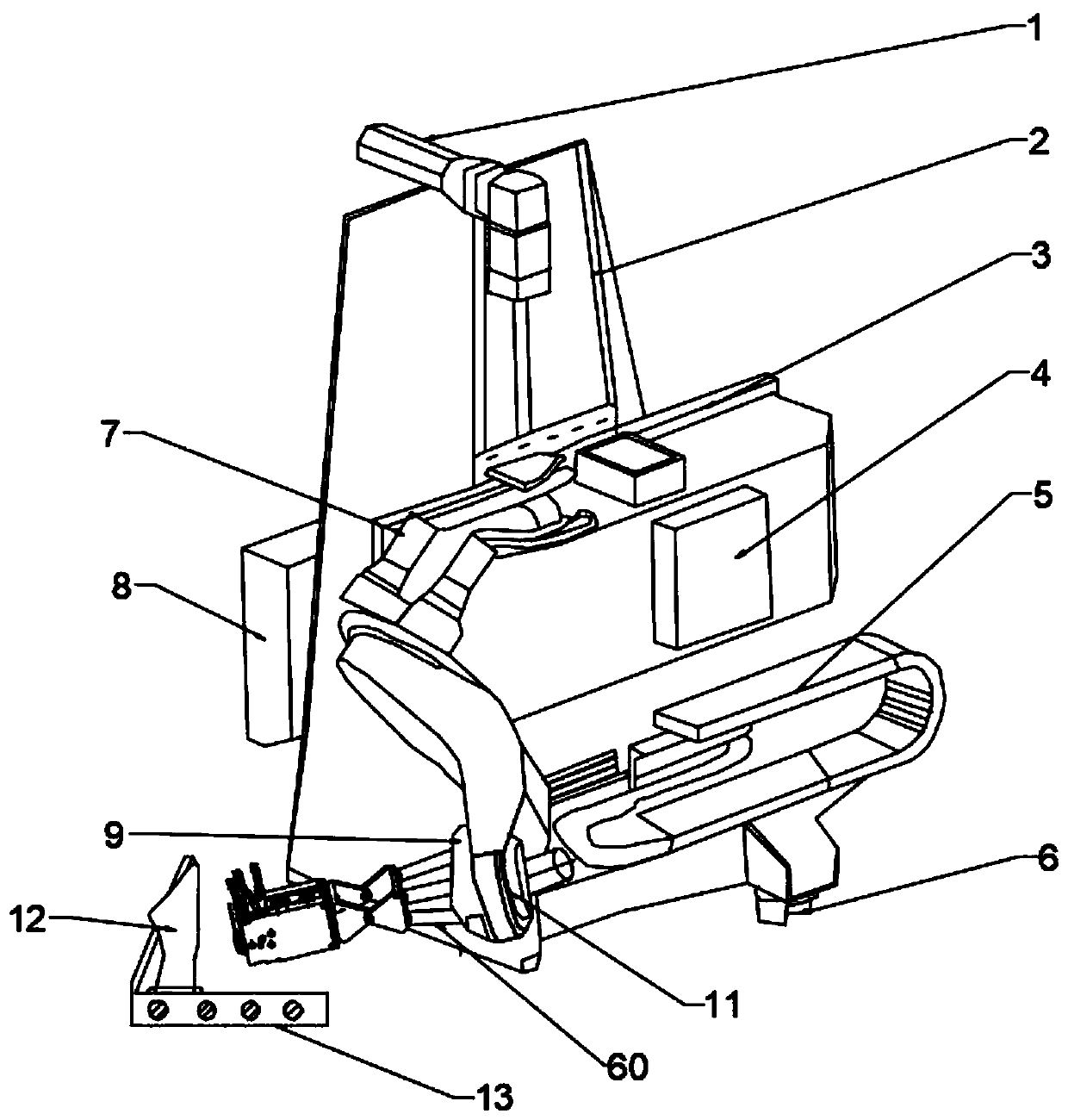

Multi-filament bundle equally-spaced filament-discharge compensation device of composite material filament paving head

The invention discloses a multi-filament bundle equally-spaced filament-discharge compensation device of a composite material filament paving head. The device comprises a guiding bundle combiner, an equally-spaced compensation cutter, multiple guiding cutting cutter heads, fiber filament bundles and a paving roller. The equally-spaced compensation cutter is provided with the multiple guiding cutting cutter heads and is used for compensation of difference of filament bundle channel paths of the guiding bundle combiner. The guiding bundle combiner is fixedly connected to the equally-spaced compensation cutter seat and is used for combining fiber filament bundles subjected to path compensation from different directions to form a uniformly-arranged fiber cloth and transmitting the uniformly-arranged fiber cloth into the paving roller for fiber filament bundle bi-directional paving arrangement. The paving roller is arranged oppositely to the guiding bundle combiner in a positional relationship fixation way and is used for paving and compacting the fiber cloth transmitted by the guiding bundle combiner on the surface of a mold so that a compact fiber paved layer is formed. The device realizes equally-spaced filament-discharge arrangement, provides and paves fibers with required length according to requirements, improves fiber paved product quality, reduces filament bundle waste and reduces control system complexity.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

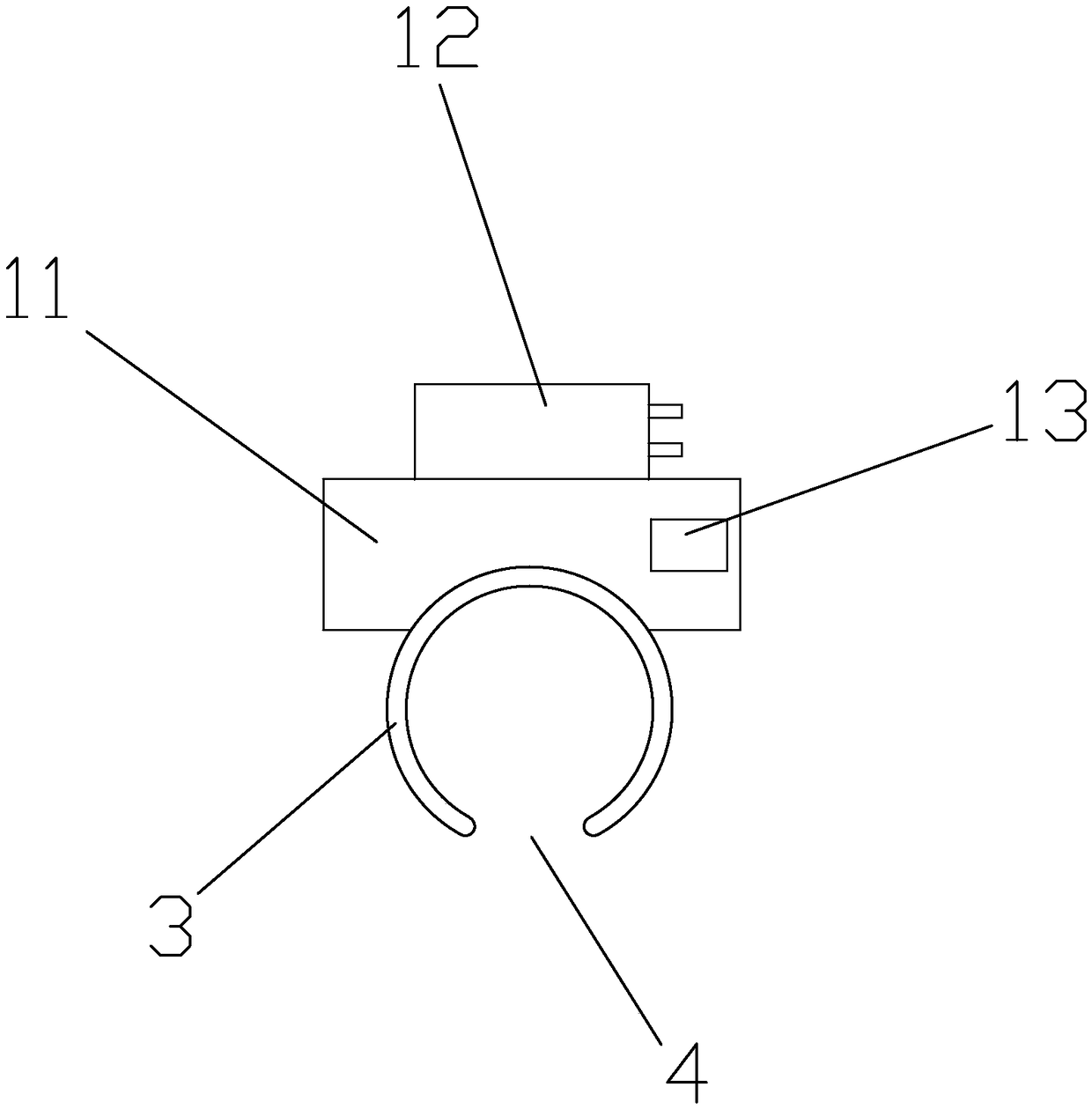

Device used for controlling bending radius of cable and use method thereof

InactiveCN109470174AAccurately grasp the degree of bendingImprove laying qualityUsing optical meansBend radiusElectric power

The invention relates to the field of electric power construction, in particular to a device used for controlling the bending radius of a cable and a use method thereof. The device includes two distance measurers, wherein one is used for emitting a distance measuring signal and the other is used for receiving the distance measuring signal, and the two distance measurers are arranged at the two ends of a to-be-measured arc cable respectively. When the straight-line distance, measured by the distance measurers, between the two ends of the to-be-measured arc cable is smaller than a threshold value, and an alarm sends alarm voice to warn that the optical cable needs reconstruction. The device can accurately control the cable bending radius to prevent the cable from over bending.

Owner:STATE GRID ZHEJIANG TONGXIANG POWER SUPPLY

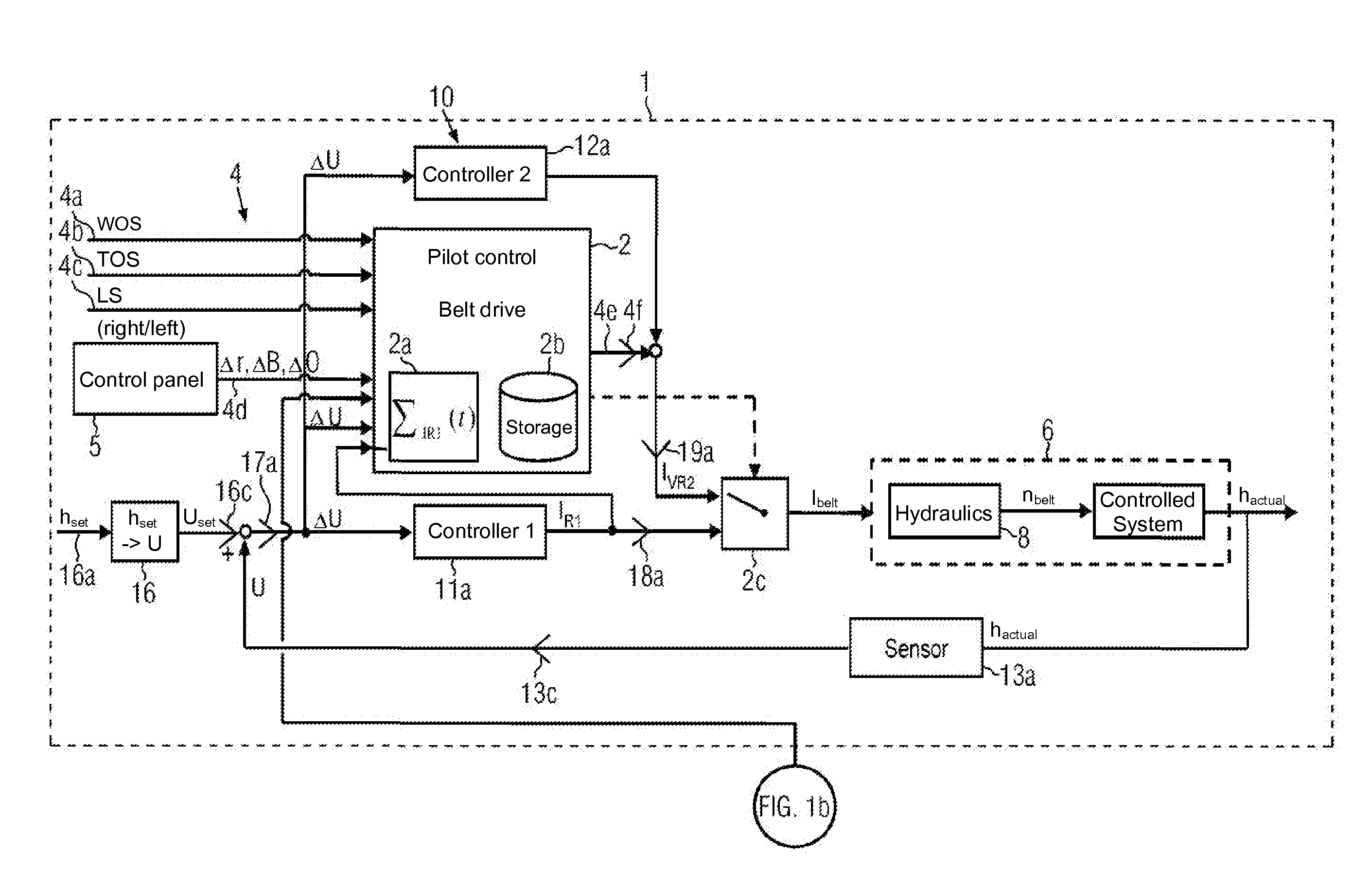

Road finishing machine with controllable conveyor devices

The invention relates to a road finishing machine with a controllable longitudinal conveyor device and a transverse conveyor device for mixed laying material disposed in the rear in the direction of motion. The road finishing machine furthermore comprises a control unit for adjusting a delivery rate of the longitudinal conveyor device and / or the transverse conveyor device. The control unit is connected with a sensory mechanism for determining a mixed laying material quantity or rate and adjusts the delivery rate in response to a signal from the sensory mechanism representing the mixed laying material quantity or rate. The control unit can be pilot controlled in response to laying parameters by a pilot control unit.

Owner:JOSEPH VOEGELE AG

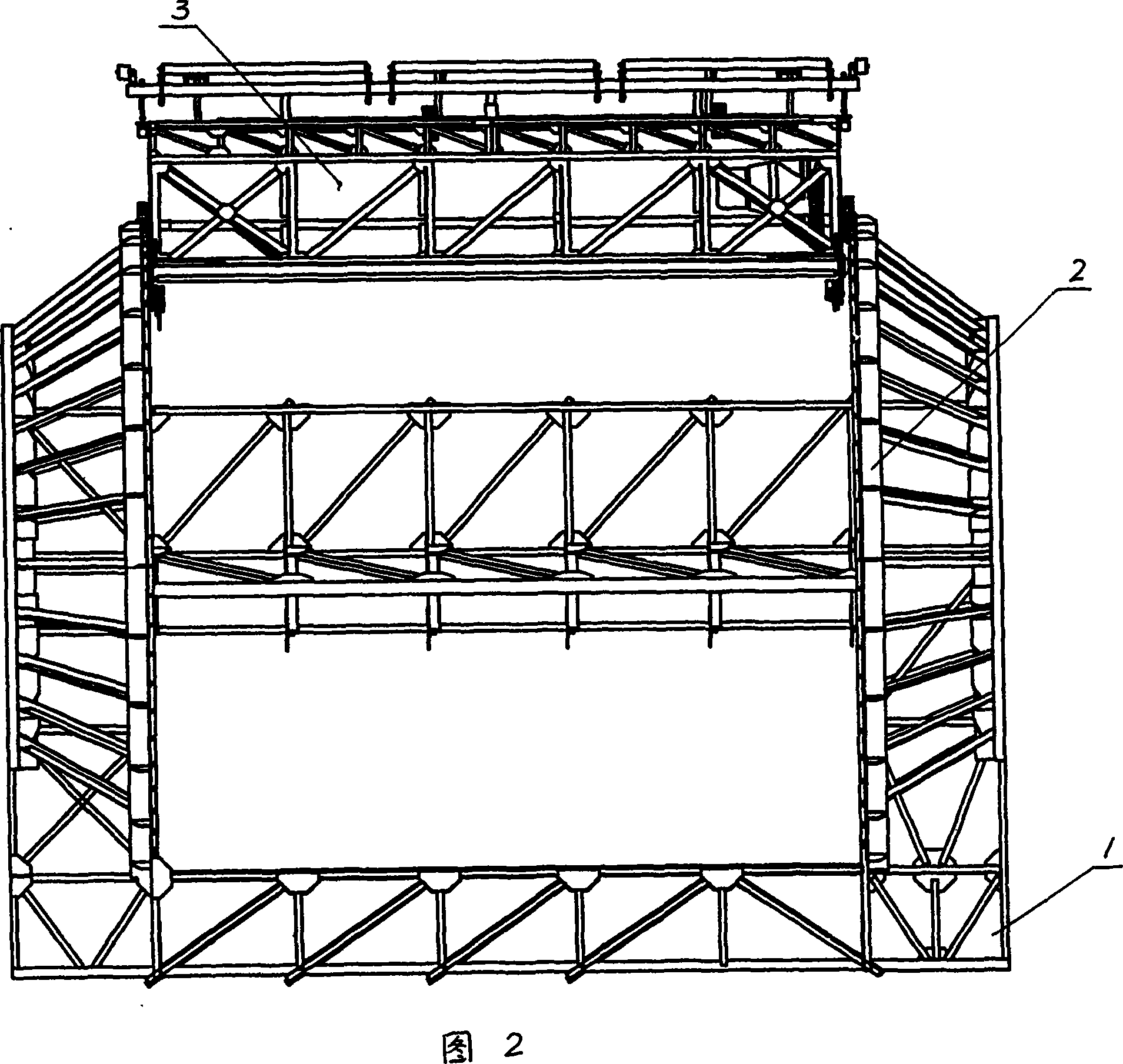

Door frame type seepage-proof earthwork cloth spreading machine for tunnel

InactiveCN101187309AEasy to operateReduce workloadUnderground chambersTunnel liningDrive shaftEngineering

The invention relates to a door frame type tunnel seepage control earthwork cloth paving machine, comprising a chassis, guide rails, and a cloth-paving trolley, wherein the cloth-paving trolley is constituted by a master motor, a cloth-paving cylinder, an earthwork cloth roll, a walking wheel, and a glue-spraying device. The cloth-paving trolley is stepped across between the two circular guide rails, and walks along a rail which is similar with the shape of tunnel section, the master motor is installed on a driving shaft, the earthwork cloth roll is positioned on the lower portion of the driving shaft, the master motor is connected with one end of a driving bolt, the other end of the driving bolt is connected with a strut beam of the cloth-paving cylinder, the cloth-paving cylinder is arranged on the strut beam on the top end of the trolley, and the cloth-paving cylinder is supported by a spring, and is coated with a rubber layer on the surface. With the structure, the invention can proceed earthwork cloth mechanical paving for tunnels with various form of section, and can pave earthwork cloth at a large scale, and the earthwork cloth is pressed on the tunnel walls by a strut beam, the working of paving is finished through the co-operating of the cloth-paving cylinder and the master motor, and the spring can be suitable to the unevenness of partial adjusting wall surface.

Owner:CHINA THREE GORGES UNIV +1

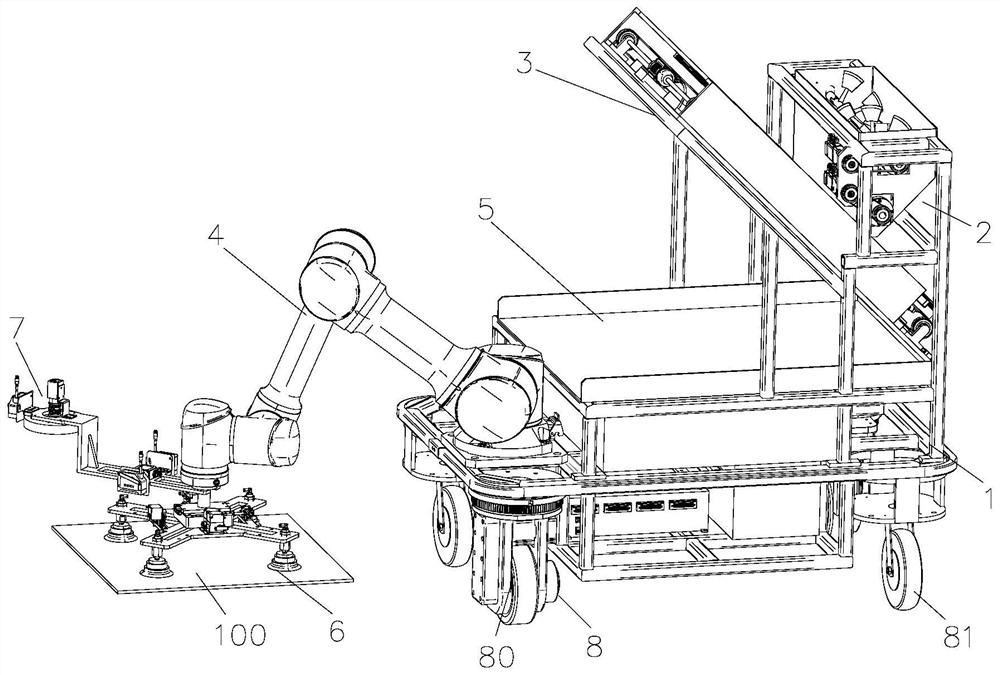

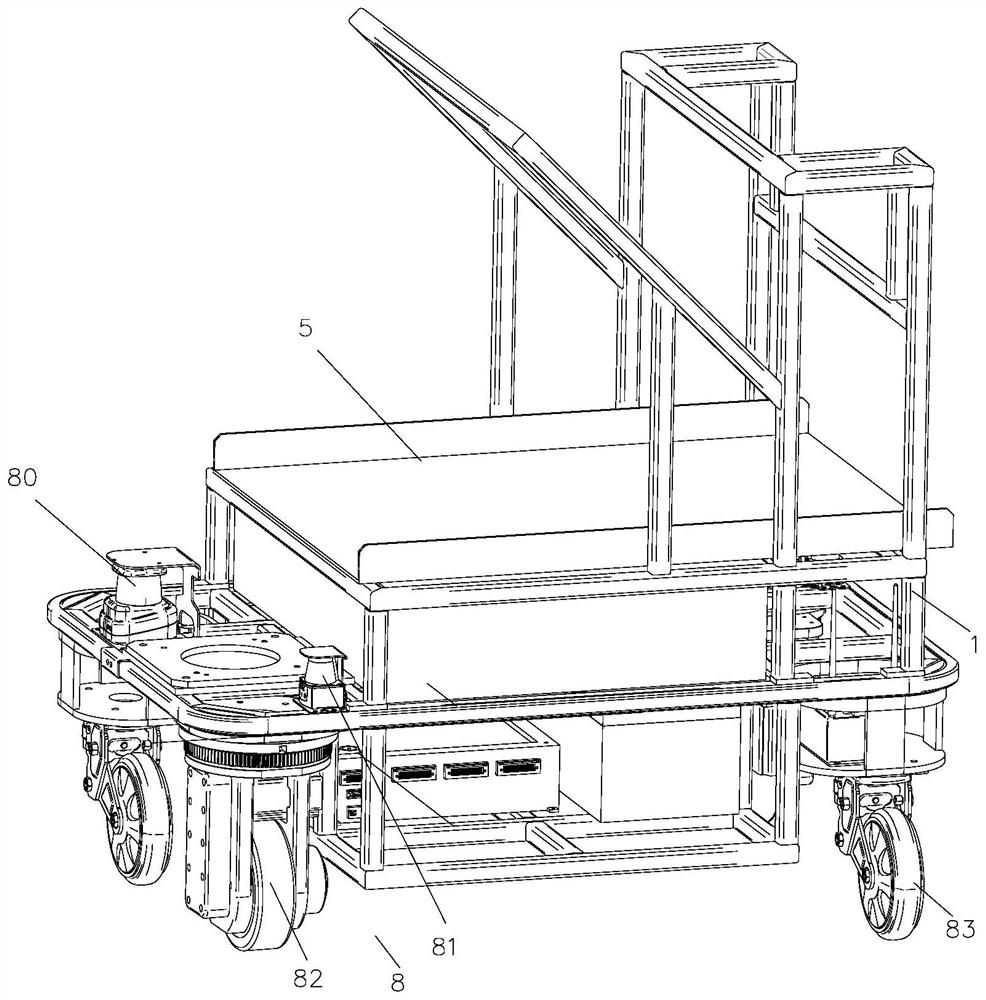

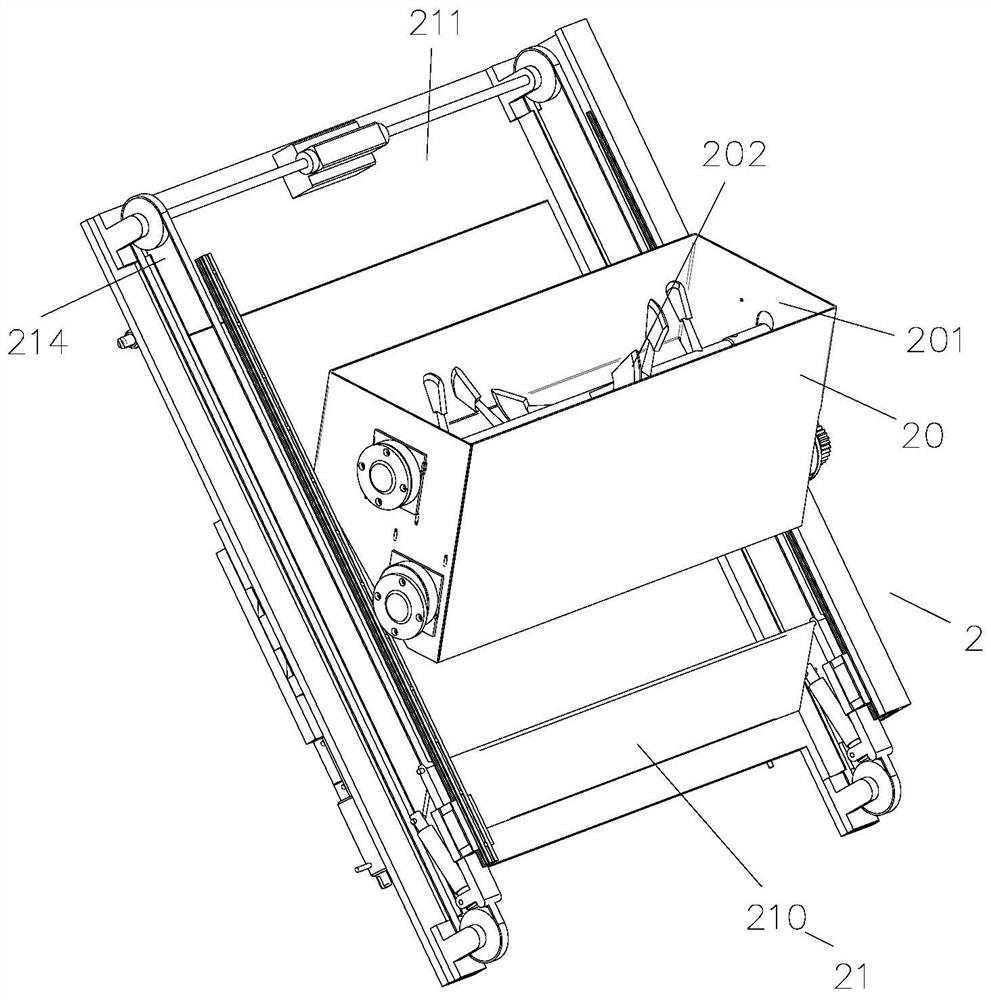

Paving device and paving robot

ActiveCN113494167AReduce hollowingImprove laying qualityClimate change adaptationBuilding constructionsBrickStructural engineering

The invention provides a paving device and a paving robot. The paving device is used for paving brick bodies; the paving device comprises a machine body, a glue scraping mechanism, a clamping mechanism, and a transferring mechanism; the glue scraping mechanism is installed on the machine body; at least part of the glue scraping mechanism makes contact with the surface of the to-be-laid brick bodies so as to be used for coating the to-be-laid brick bodies with a glue solution; at least part of the clamping mechanism is installed on the machine body, and at least part of the clamping mechanism corresponds to the glue scraping mechanism so as to be used for clamping the to-be-laid brick bodies; and at least part of the transferring mechanism is arranged on the machine body, the transferring mechanism is movably arranged along a preset track, and the to-be-laid brick bodies are installed at the free end of the transferring mechanism, so that the to-be-laid brick bodies are driven to move through the transferring mechanism, and the problem that in the prior art, the quality of floor tile laying is low is solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Technical method for manufacturing fiber reinforced cement based foam insulation board

ActiveCN107756617AEasy and quick to layLaying firmCeramic shaping plantsProduction lineMaterials science

The invention discloses a technical method for manufacturing a fiber reinforced cement based foam insulation board. The method comprises the following step: charging, namely, placing a prefabricated cement based foam insulation base board which is cut to reach thickness as requirement on a conveying platform of a flow production line; forwards conveying along with the conveying platform, wherein the surface of the base board is sequentially treated by dedusting, mortar spreading, mesh spreading and pressing, mortar coating and scraping, and synchronous cutting when the base board on the conveying platform is forwards conveyed. The method is characterized in that the mortar is directly input to the surface of the base board through a discharging control device during mortar spreading, and the mesh is pressed into the mortar spread on the surface of the base board; then a scraping plate which is transversely arranged along the conveying platform is operated to automatically scrape and level the passing mortar. According to the method, the mesh of the cement based foam insulation board can be combined and spread; in addition, the method has the advantages of being simple and quick tospread the mortar, reliable, high in spreading quality, thin and full in a mortar layer, simple in processes, high in efficiency, and high in product quality.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com