Patents

Literature

47results about How to "No prolapse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

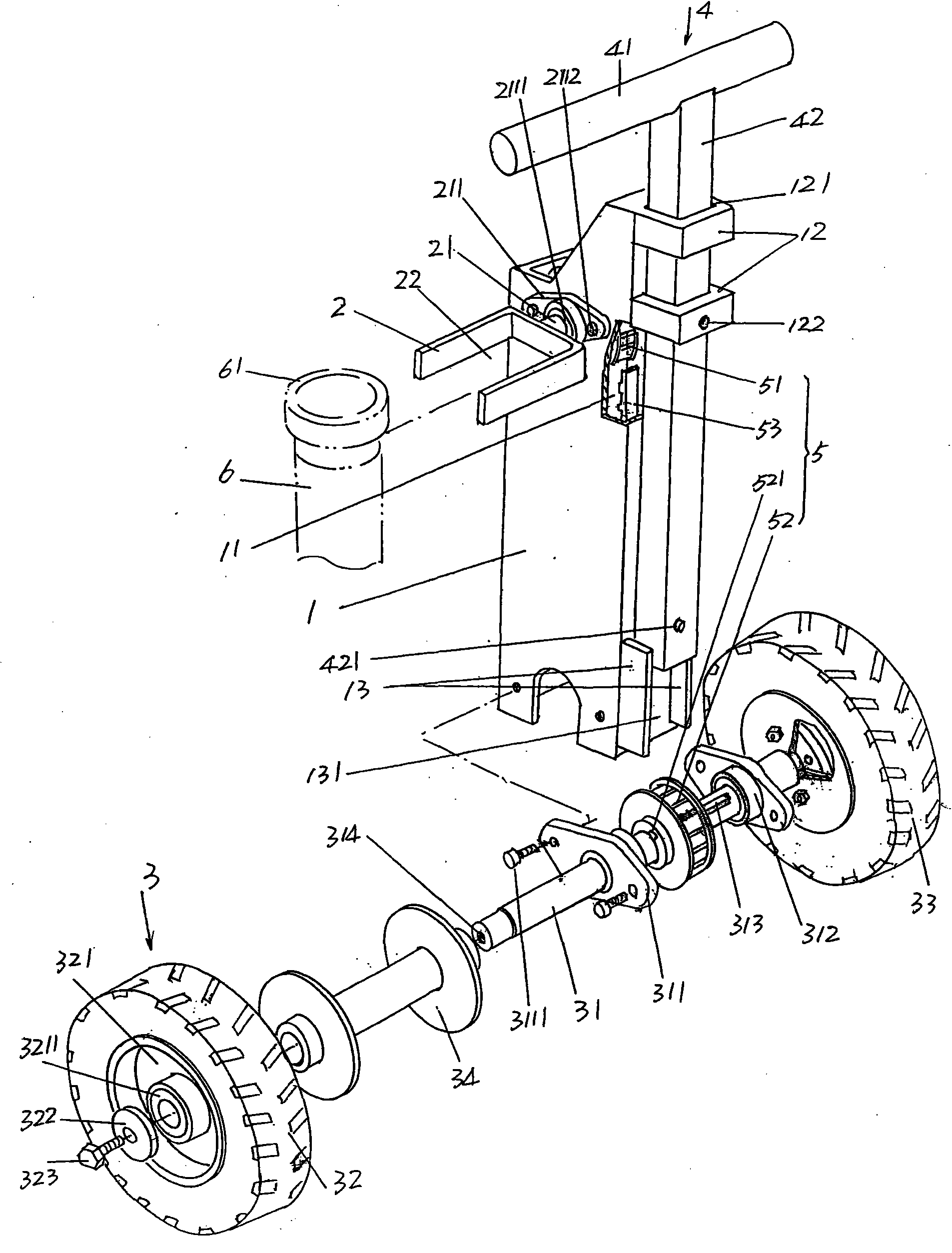

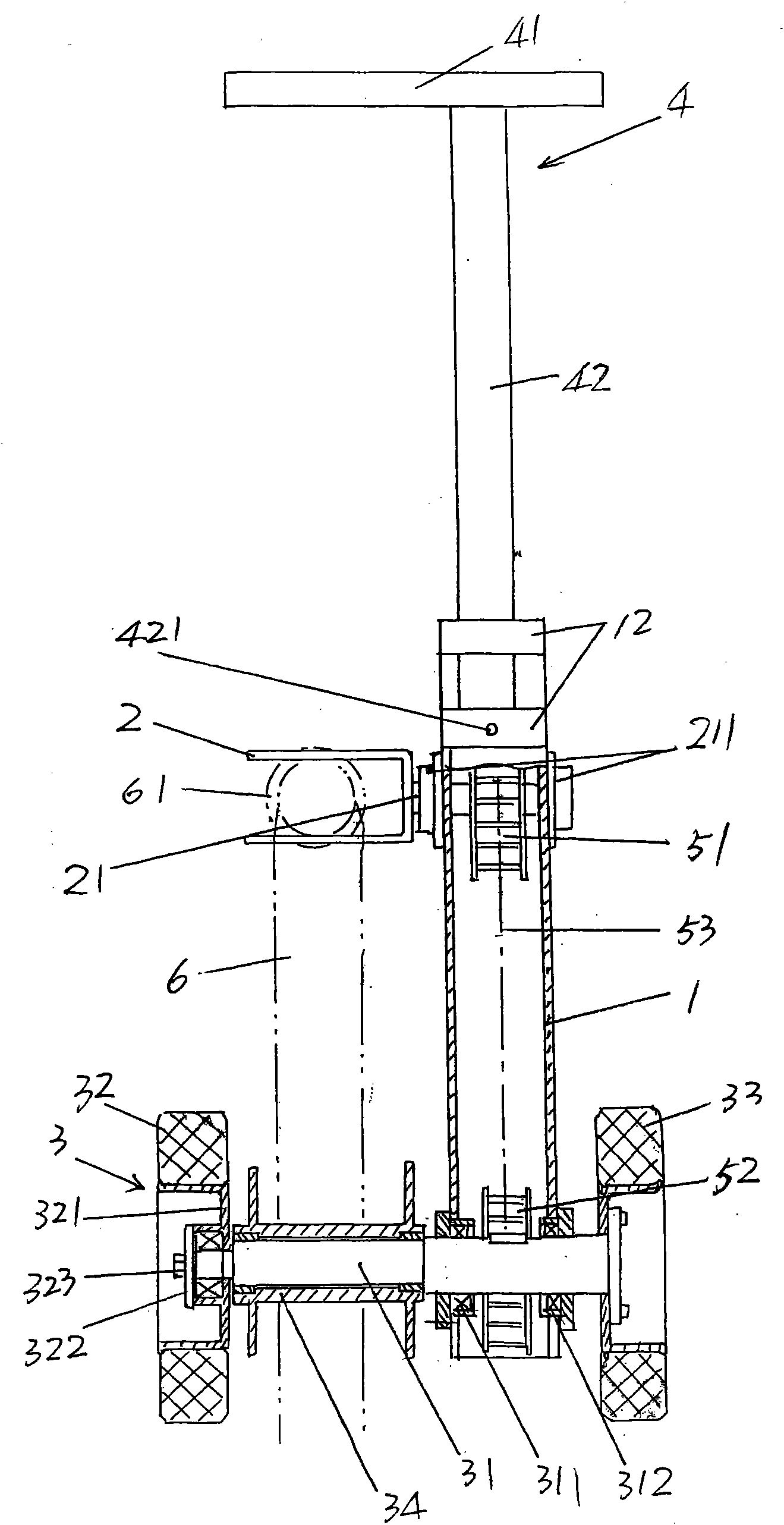

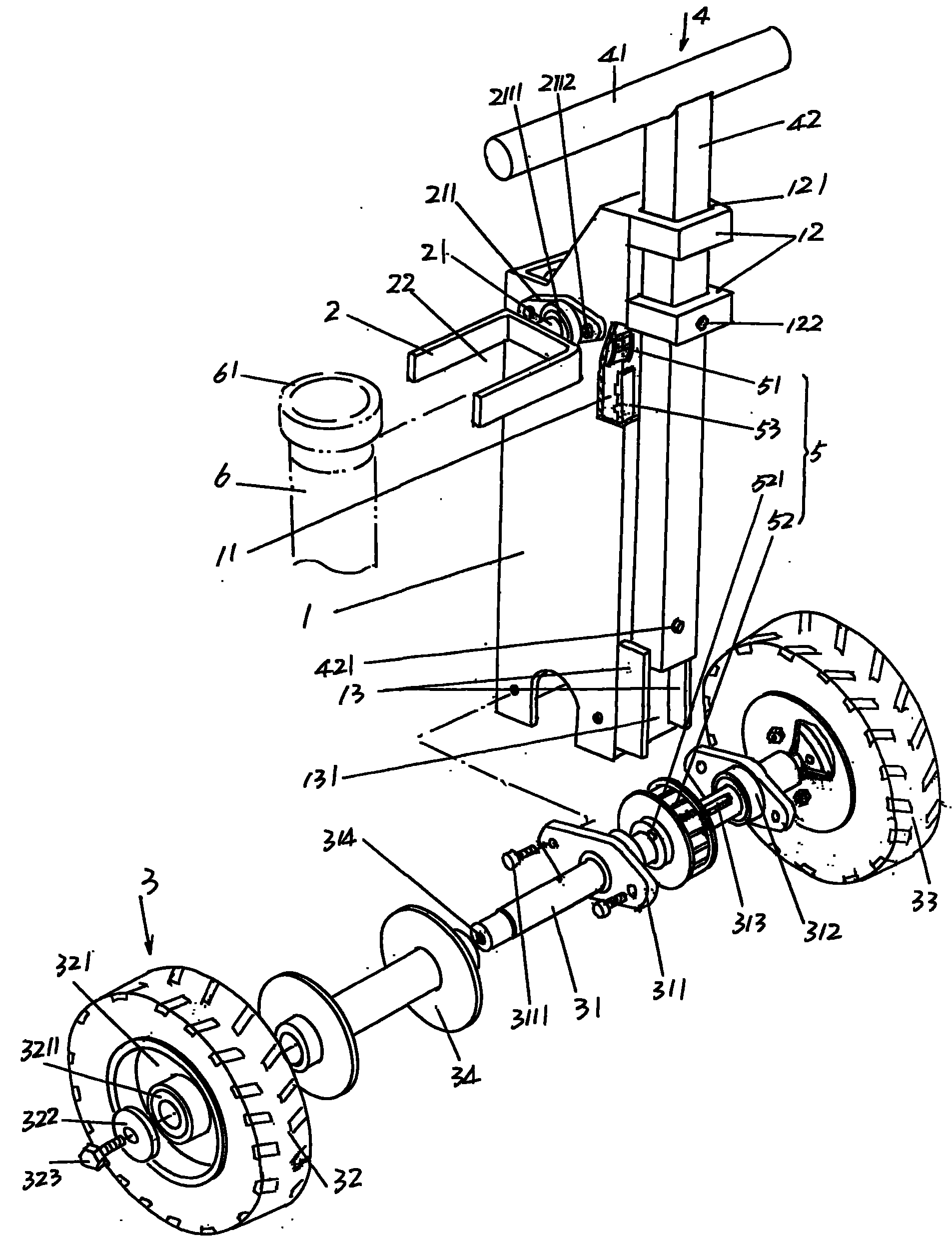

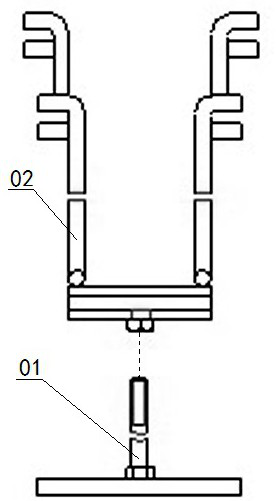

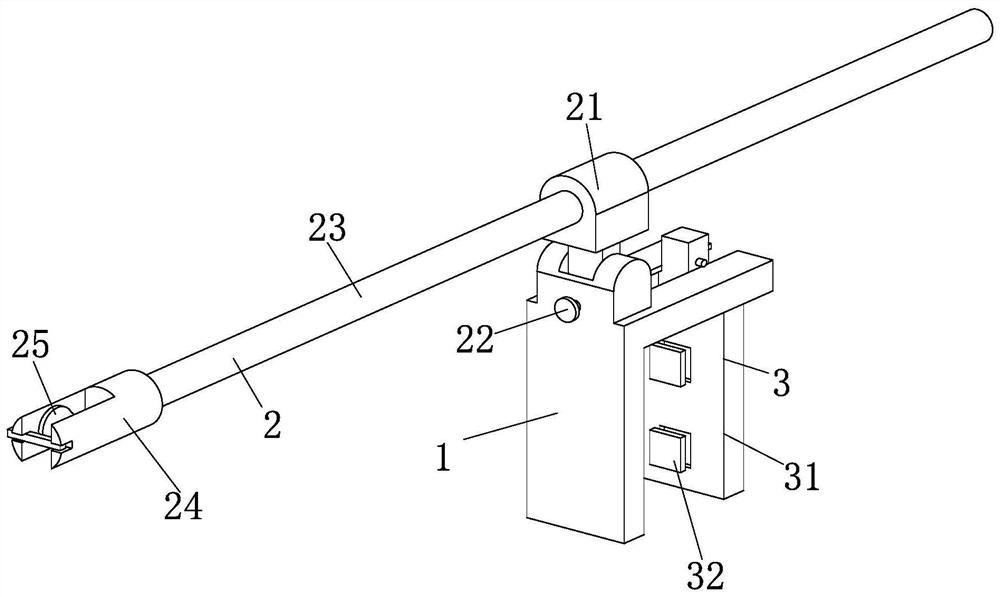

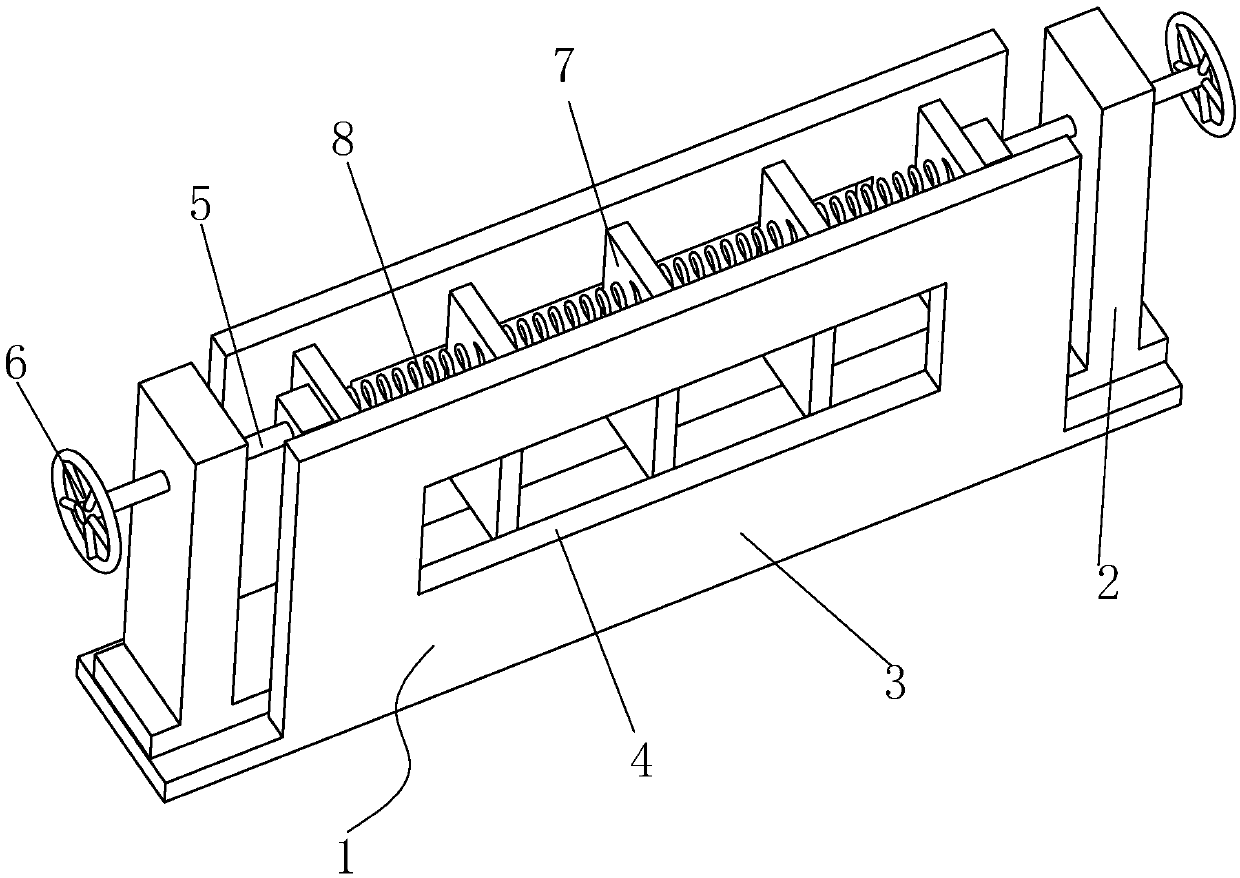

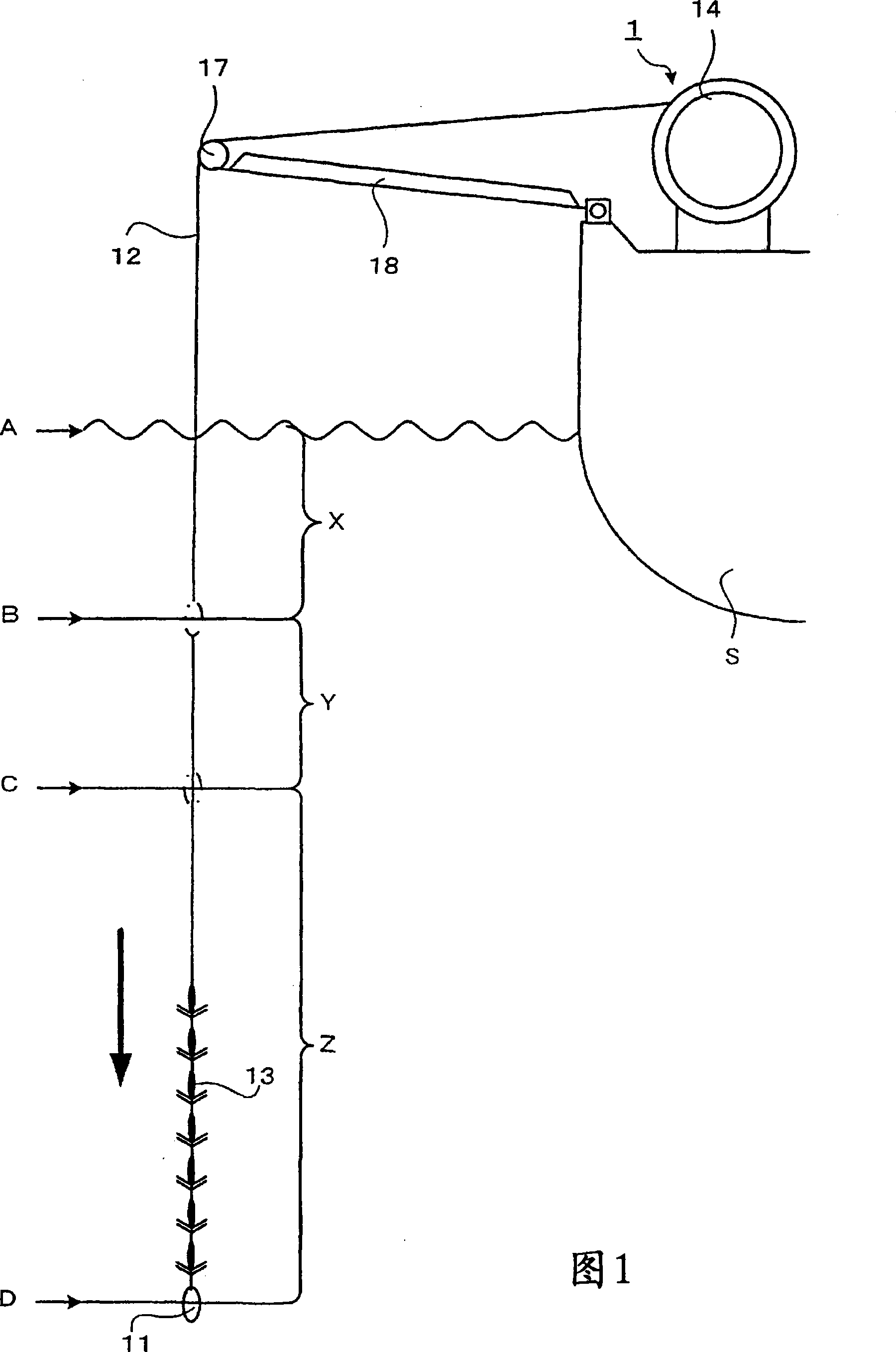

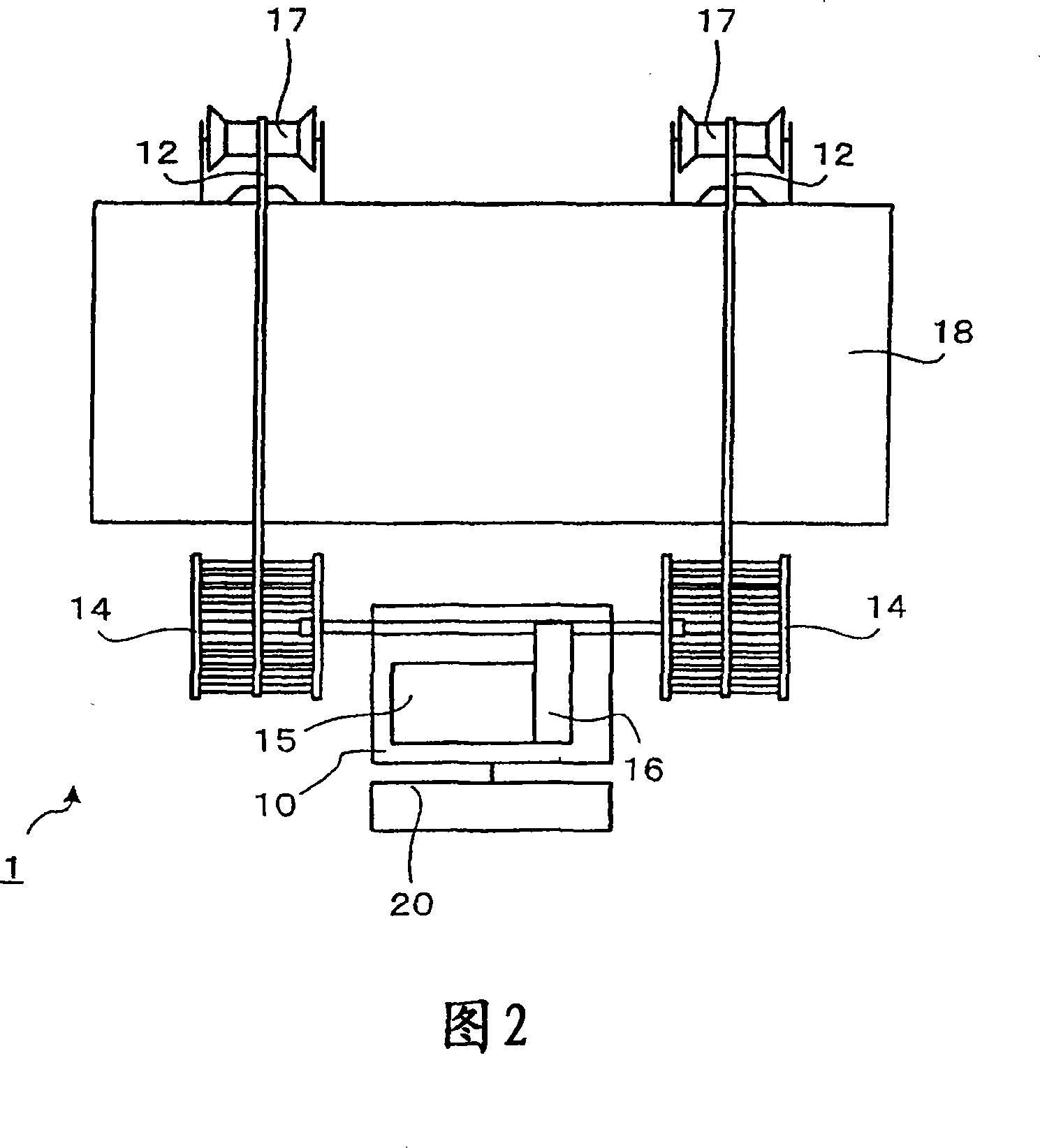

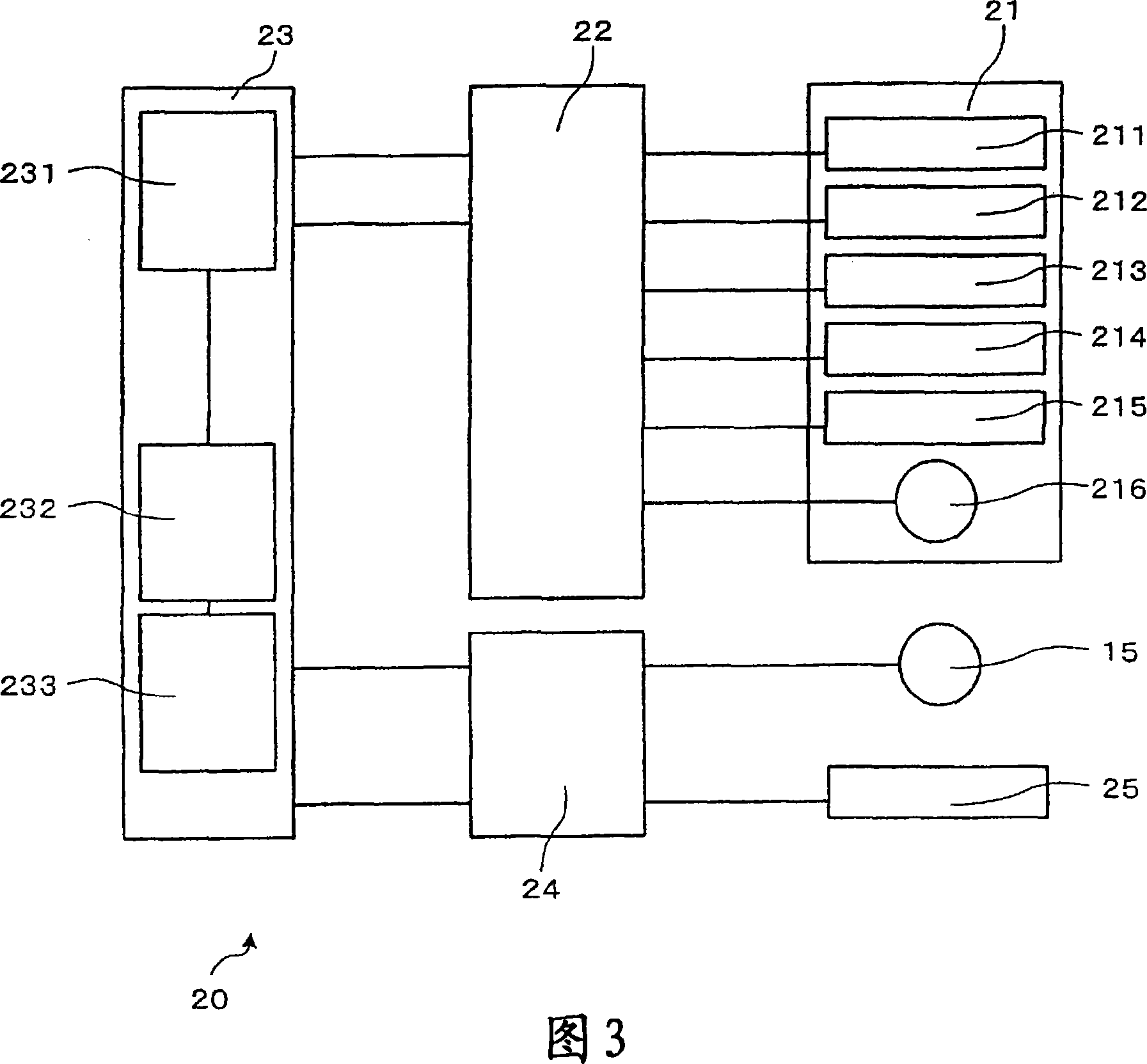

Handcart type fire hose recovery device

The invention relates to a handcart type fire hose recovery device, belonging to the technical field of fire-fighting equipment and comprising a base, a water hose joint fork, a travelling mechanism, a manual traction mechanism and a transmission mechanism, wherein the water hose joint fork is provided with a joint fork shaft, is rotatably arranged on the base by the joint fork shaft and is positioned on one side of the upper end of the base; the travelling mechanism is fixedly connected with the bottom of the base; the manual traction mechanism is equipped on the base; the transmission mechanism consists of a first transmission wheel, a second transmission wheel and a transmission belt and is used for driving the water hose joint fork to rotate; the first transmission wheel is fixed on the joint fork shaft; the second transmission wheel is fixedly arranged on the travelling mechanism; and one end of the transmission belt is sheathed on the first transmission wheel, and the other end of the transmission belt is sheathed on the second transmission wheel. The handcart type fire hose recovery device has the advantages of being capable of reducing the working intensity of fire fighters, avoiding the loosing or spinning phenomenon, and having simple whole structure, labor-saving movement and no condition that the water hose generates resistance to water in the hose reeling process.

Owner:张建明

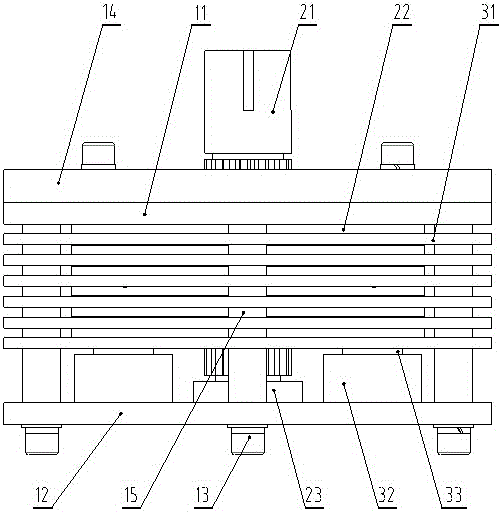

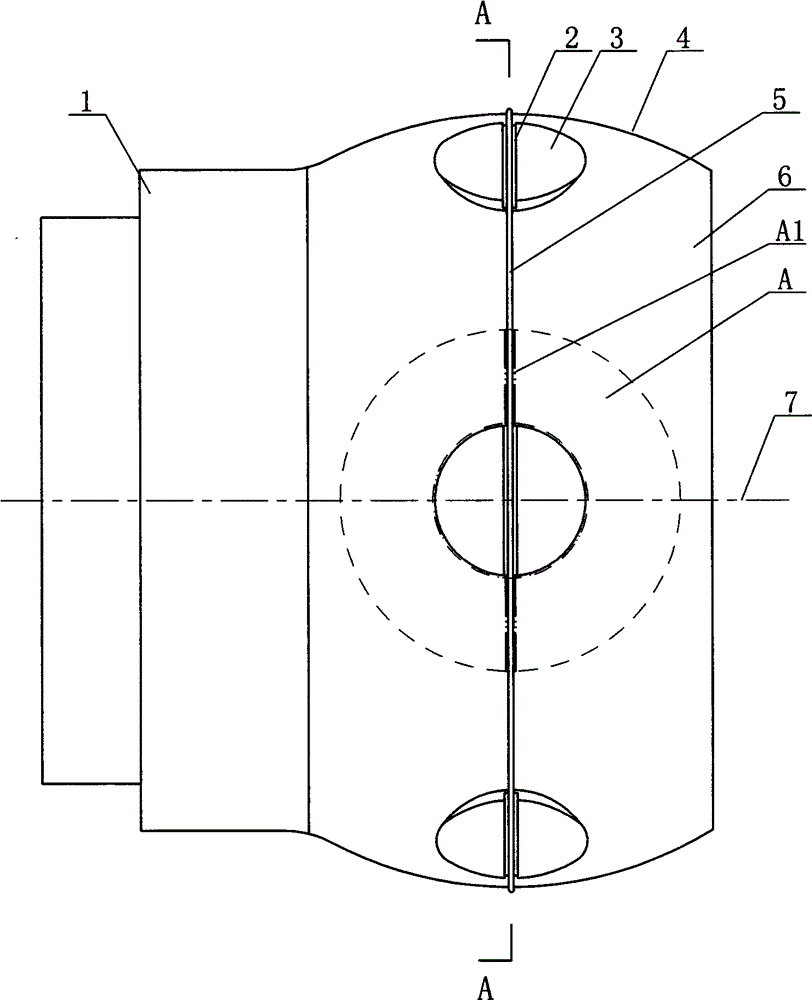

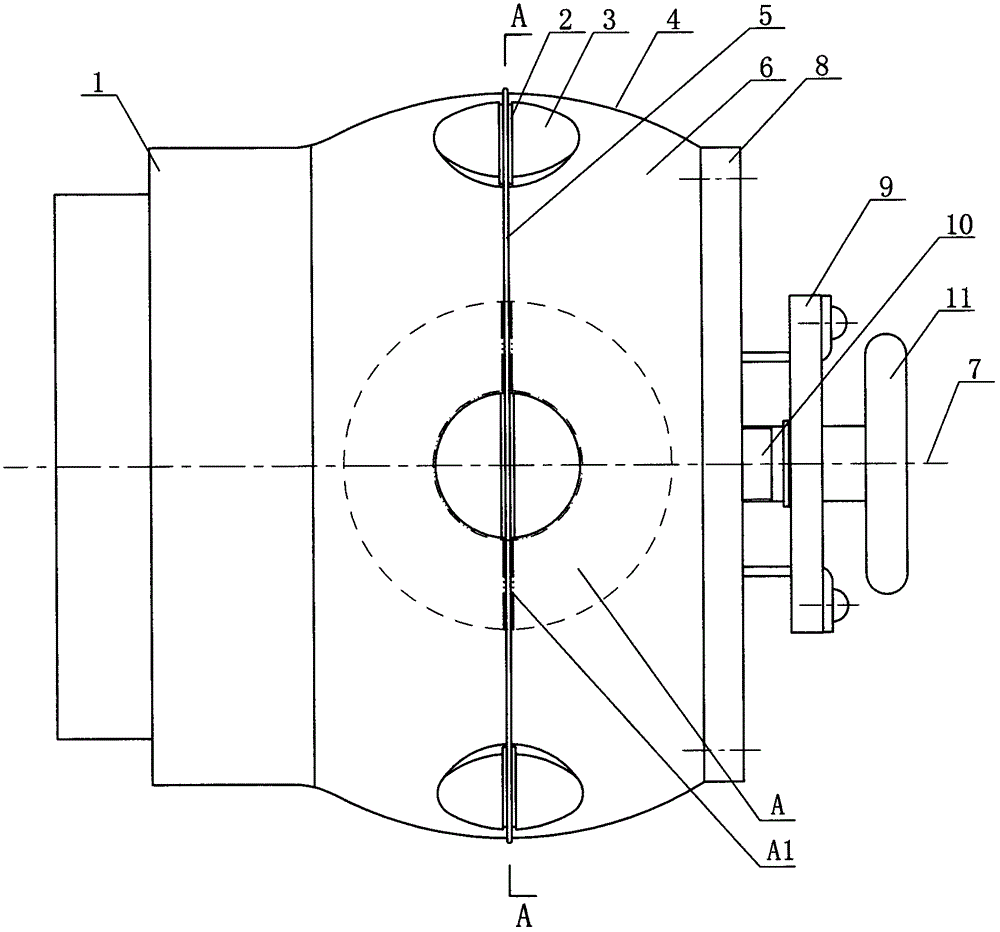

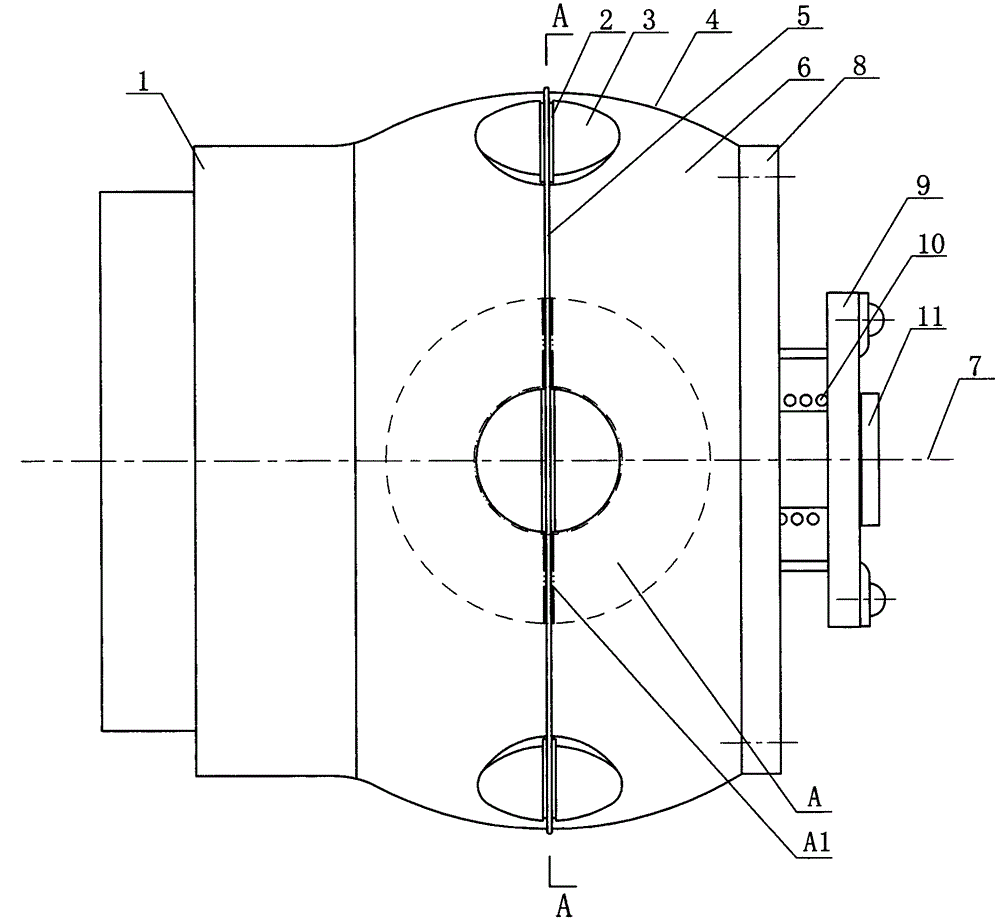

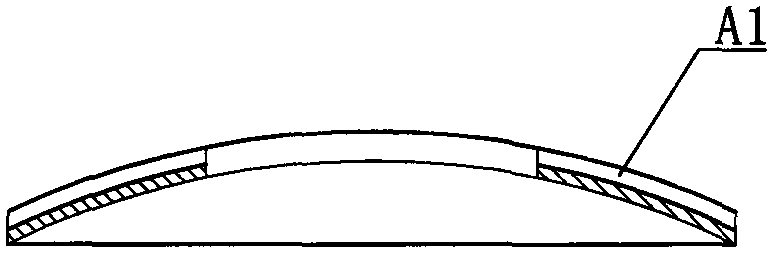

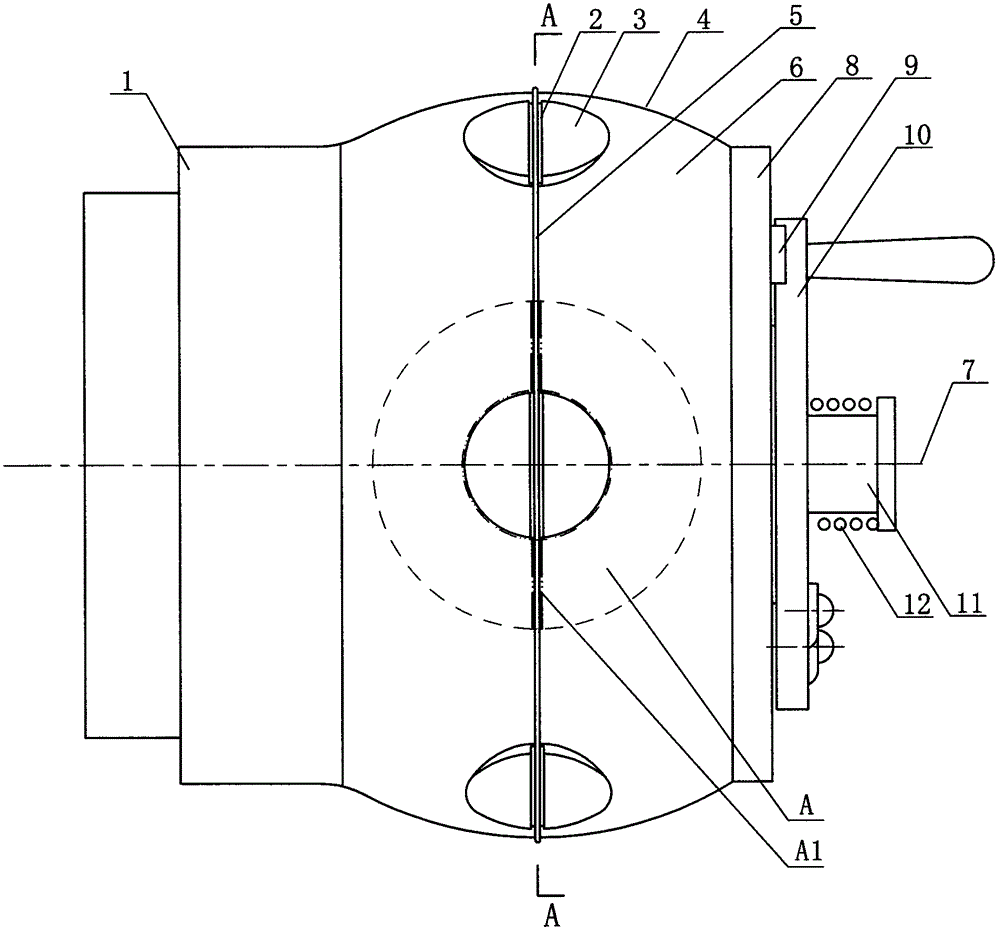

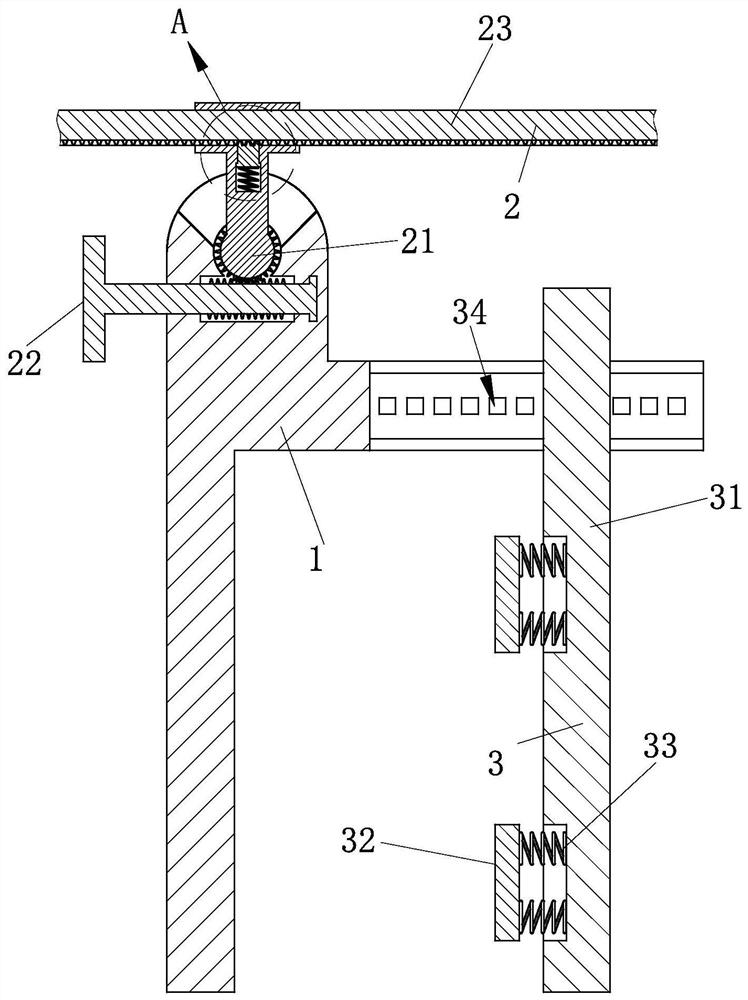

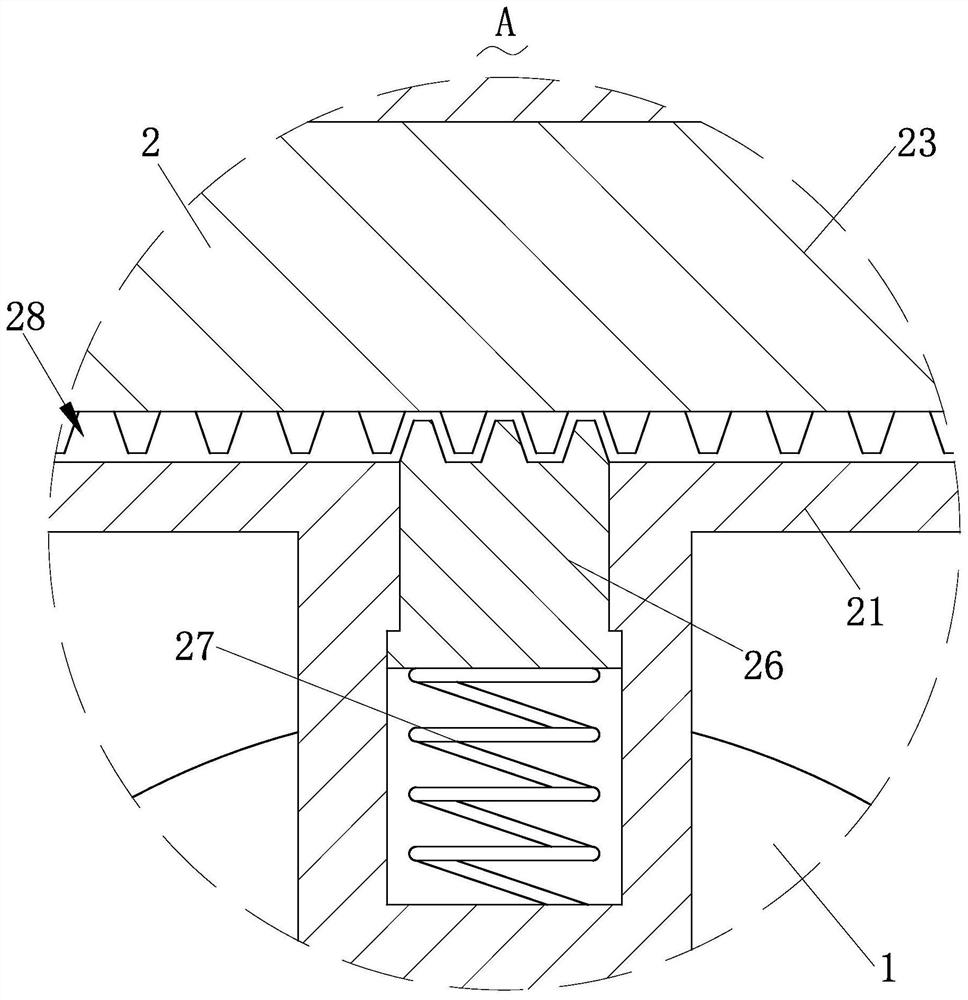

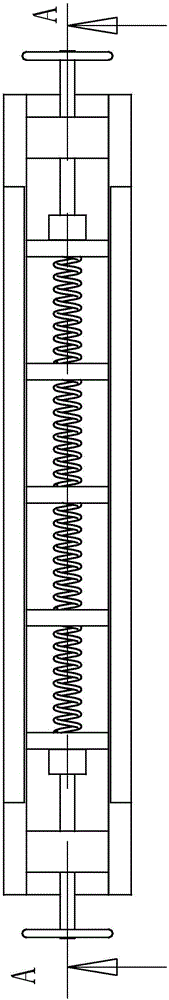

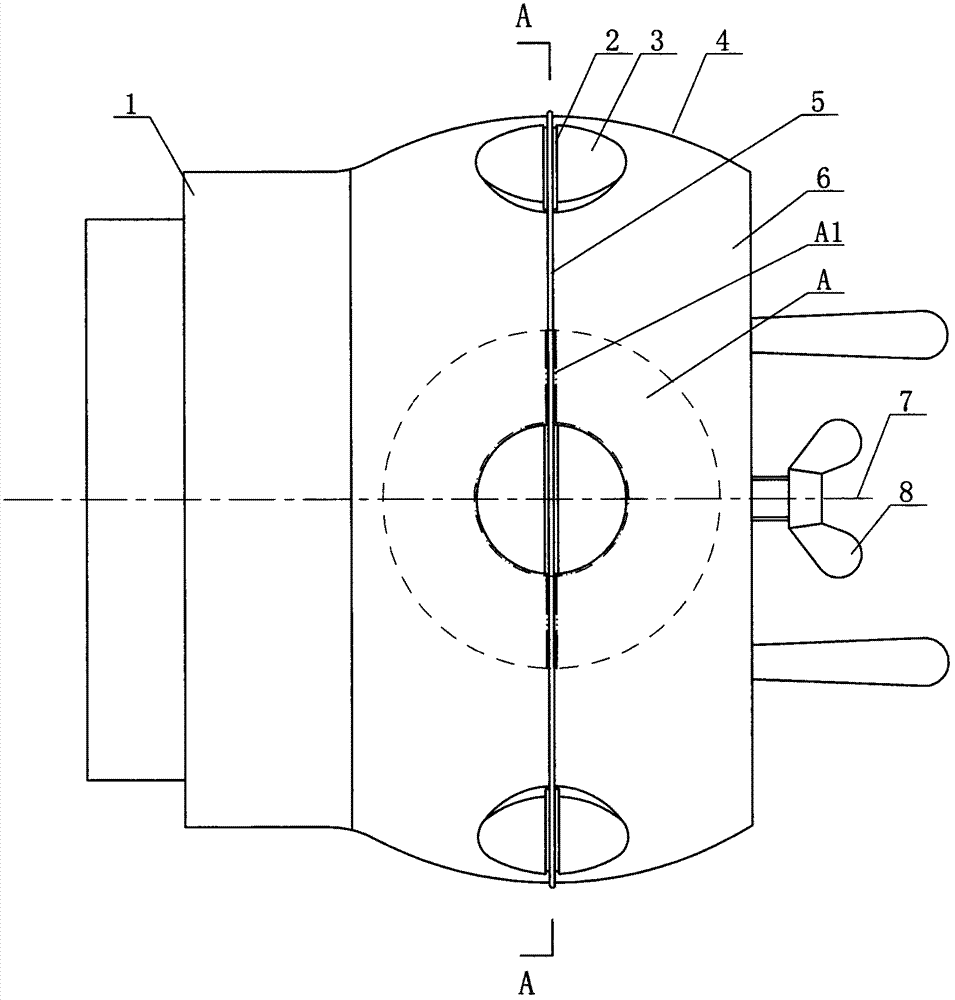

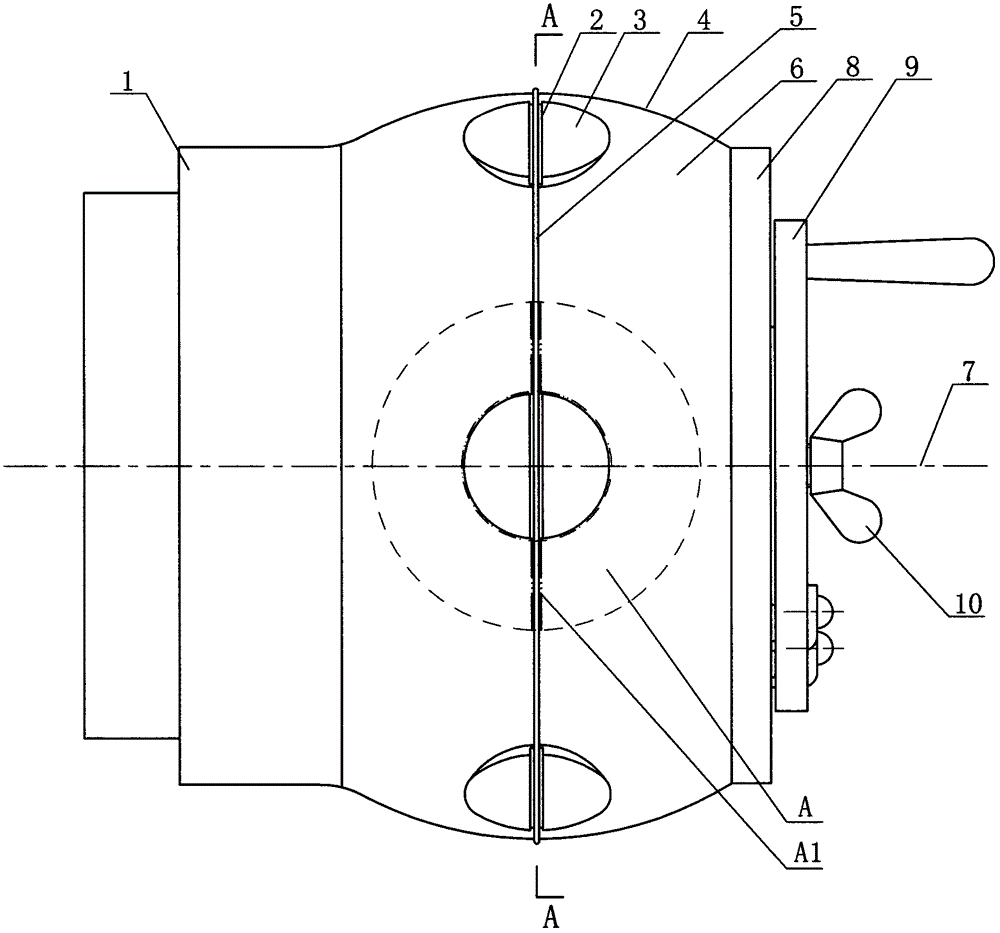

Testing apparatus for service life of load of valve execution mechanism and using method thereof

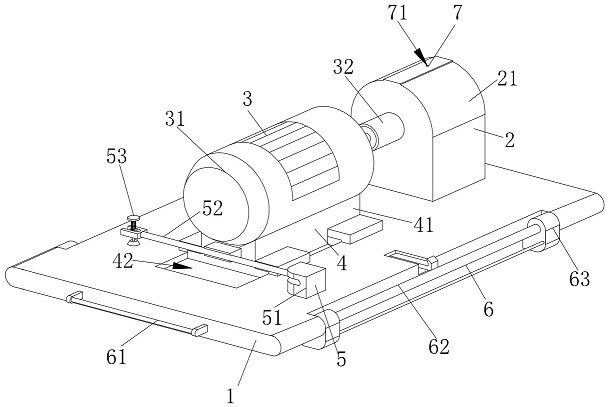

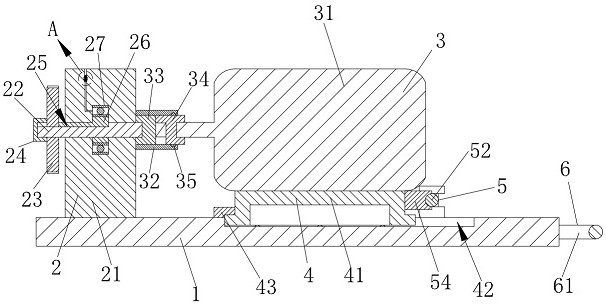

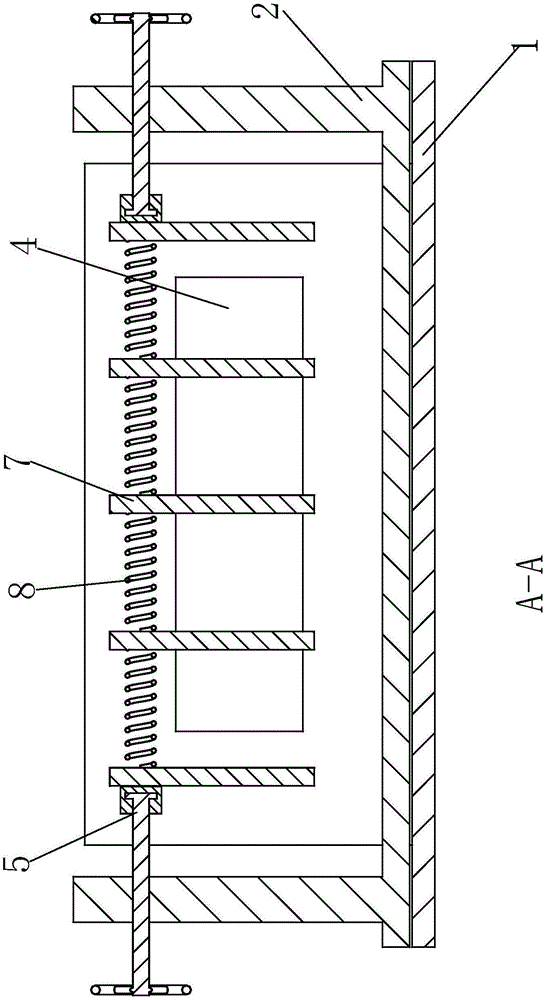

The invention provides a testing apparatus for a service life of a load of a valve execution mechanism and a using method thereof. The testing apparatus comprises a rack, a rotating mechanism and a loading mechanism. The rack is supported between a top plate and a bottom plate by support posts. A testing plate covers the top plate. Rotating shafts are installed in bearings between the top plate and the bottom plate and the upper ends of the rotating shafts pass out of the top plate and a mounting plate. More than one rotating plate is installed on the rotating shafts horizontally and rotates with the rotating shafts. The loading mechanism includes friction plates and hydraulic systems; through holes are formed in the friction plates and the friction plates sleeve the support posts through the through holes. One friction plate is arranged below each rotating plate; and the friction plates are separated by sleeving rings arranged on the support posts. The hydraulic systems are installed on the bottom plate and mandrils of the hydraulic systems support the bottom friction plates; under pushing of the mandrils, upward contact with the rotating plates is realized and the last friction plate is pushed upwardly by the sleeving ring and is in contact with the rotating plate arranged on the friction plate; and the rotating plates and the friction plates in close contact with the rotating plates respectively generate friction and the friction forces are transformed into torques by the rotating shafts, thereby realizing testing of the service life of the load of the valve execution mechanism.

Owner:TEFULONG SHANGHAI TECH CO LTD

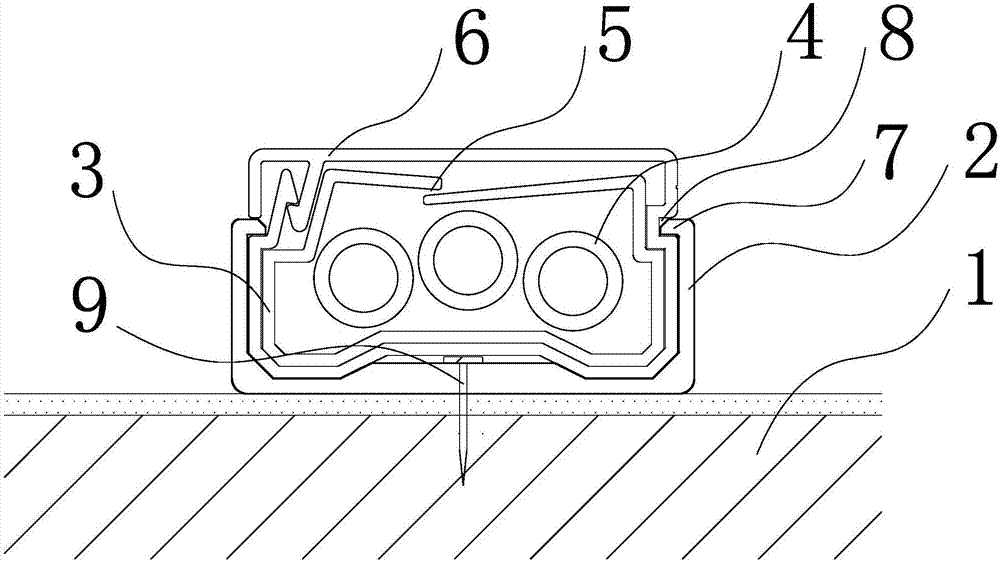

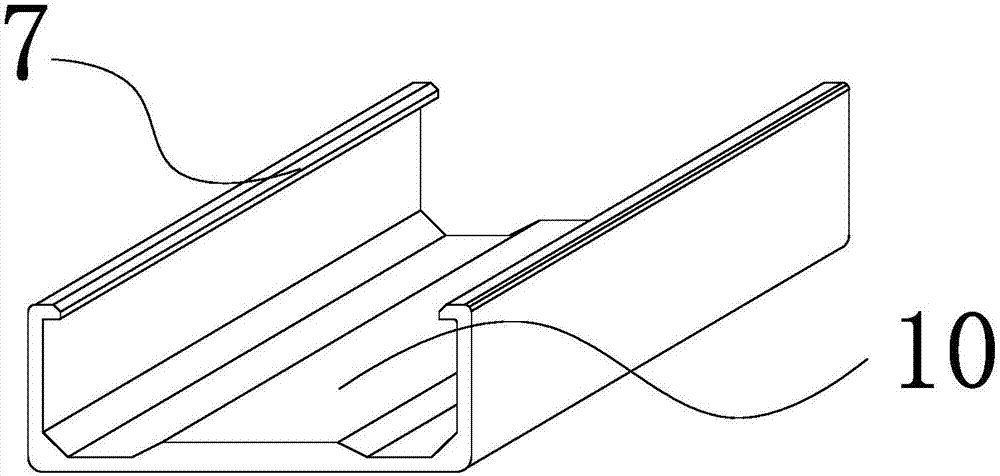

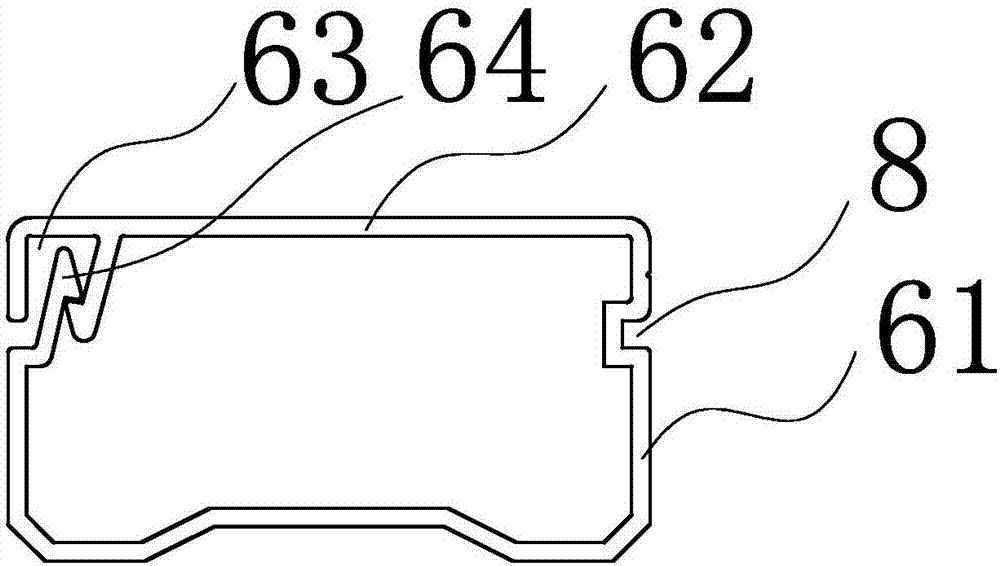

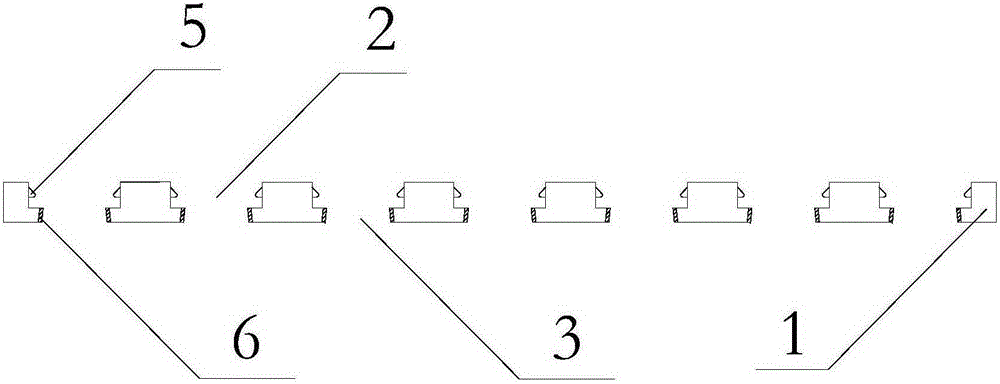

Integrated quickly-mounted wire groove and wiring method adopting same

InactiveCN107404097ANo prolapseInstallation saves time and effortApparatus for laying cablesEngineeringBuilding construction

The invention relates to the field of architectural decoration, and provides a simple structure, convenient and fast wiring installation, time-saving and labor-saving, neat and consistent pavement, good quality integrated quick-installation wire slot and a method for wiring by using the quick-install wire slot to solve the problem of The cable laying process in the prior art is cumbersome, time-consuming and labor-intensive, and the cables are easy to come out and affect the normal construction. It includes the wall and the U-shaped slot base fixed on the wall surface. The U-shaped The opening of the U-shaped card slot base faces outward, and the elastic cable management ring is elastically clamped in the opening of the U-shaped card slot base. The cable is pressed into the notch, and the edge of the elastic cable management ring corresponding to one side of the cable press-in notch extends inward and elastically abuts against the corresponding elastic cable management ring on the other side of the cable press-in notch.

Owner:ZHEJIANG YASHA DECORATION

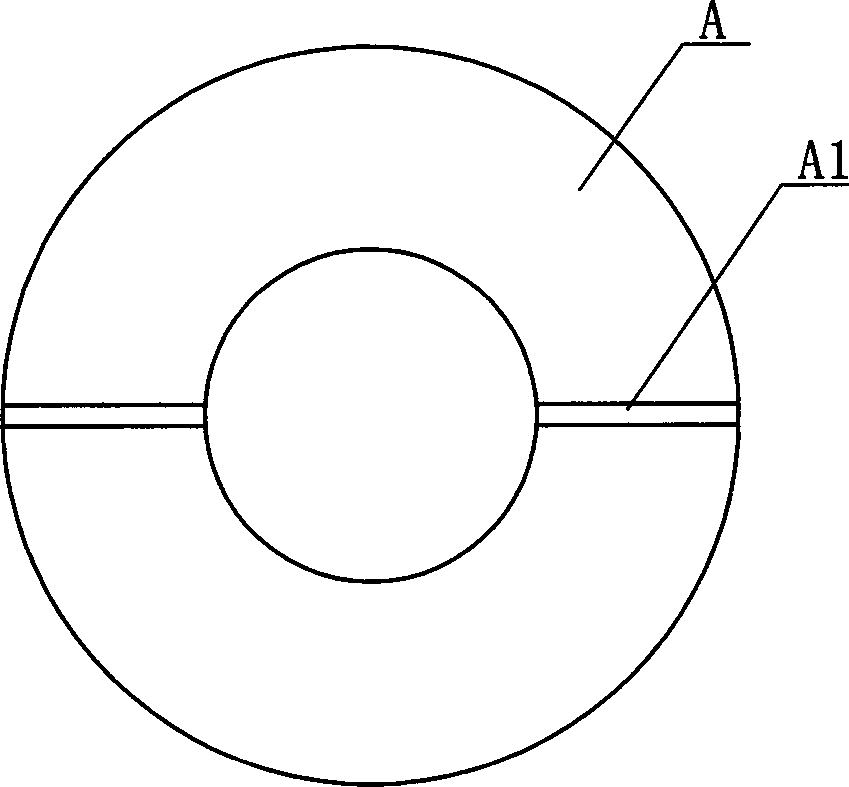

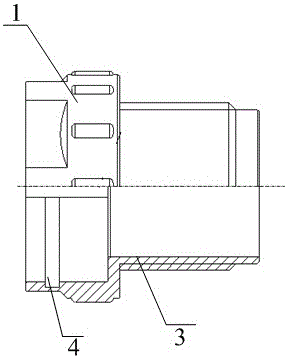

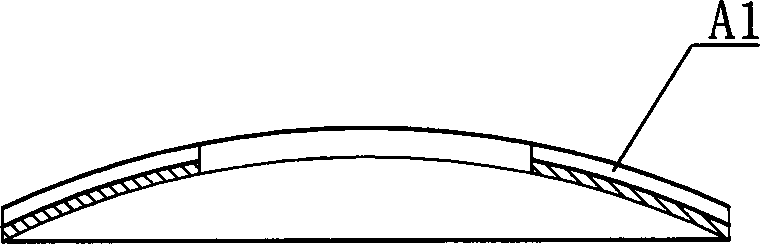

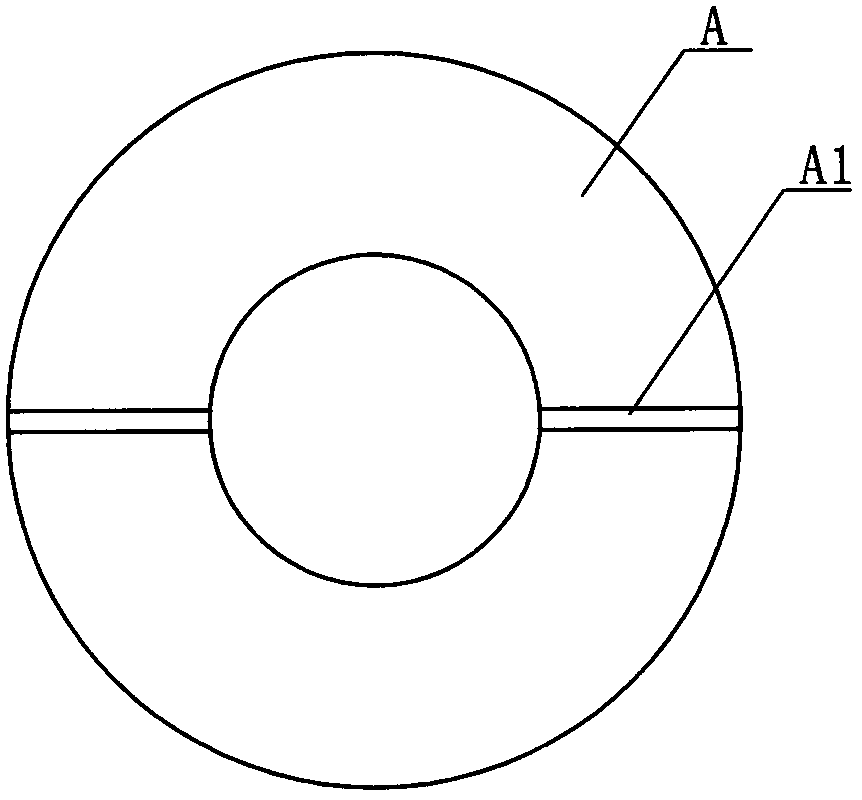

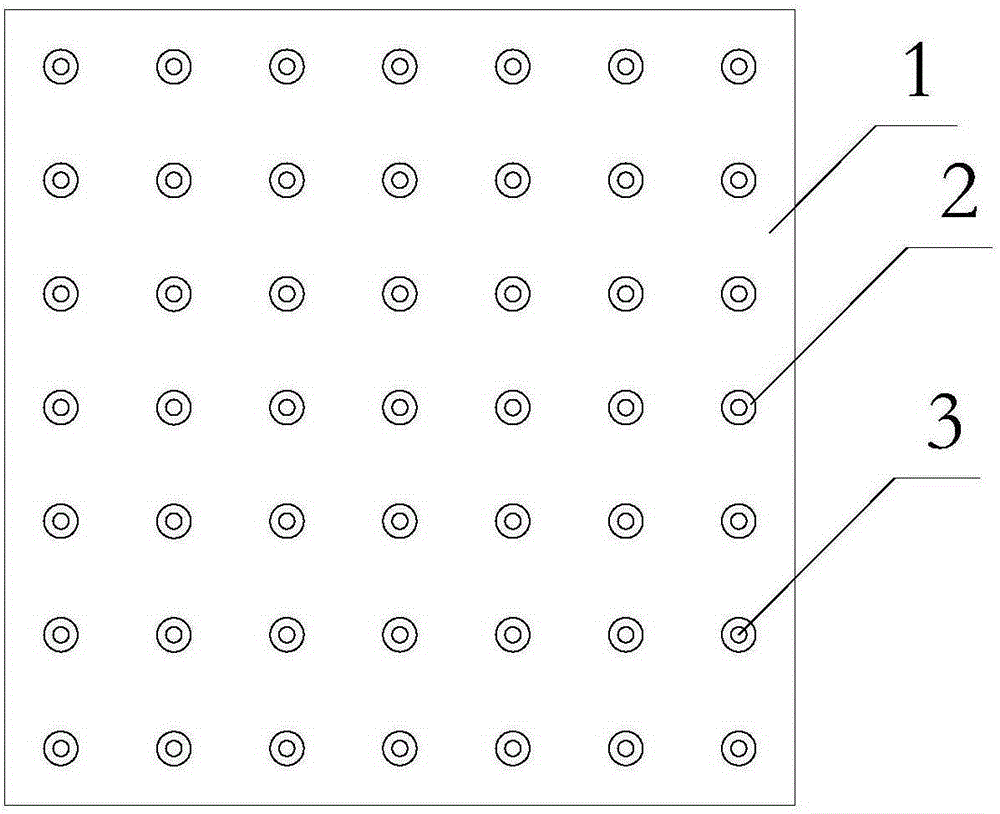

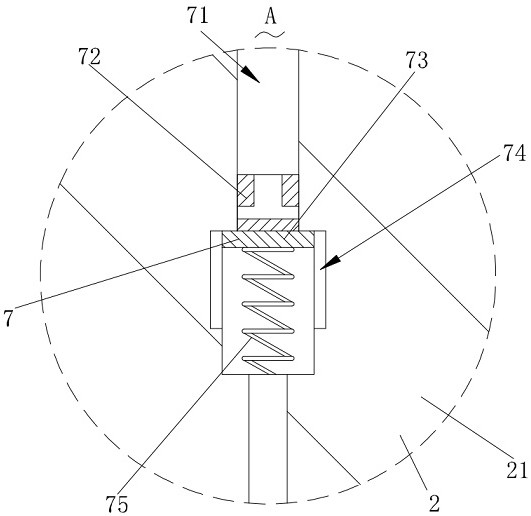

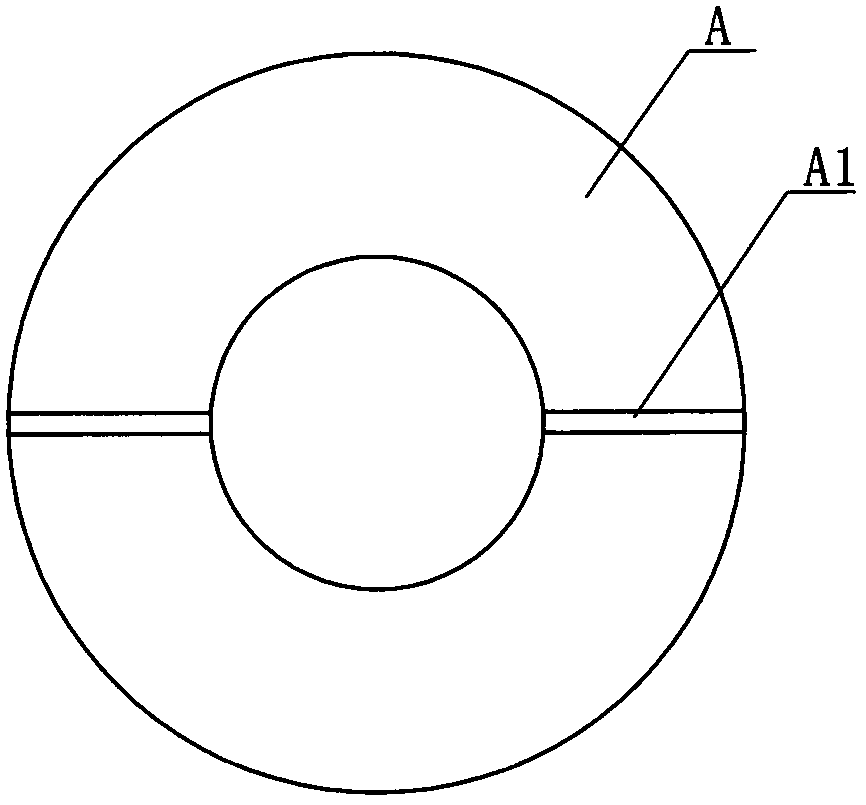

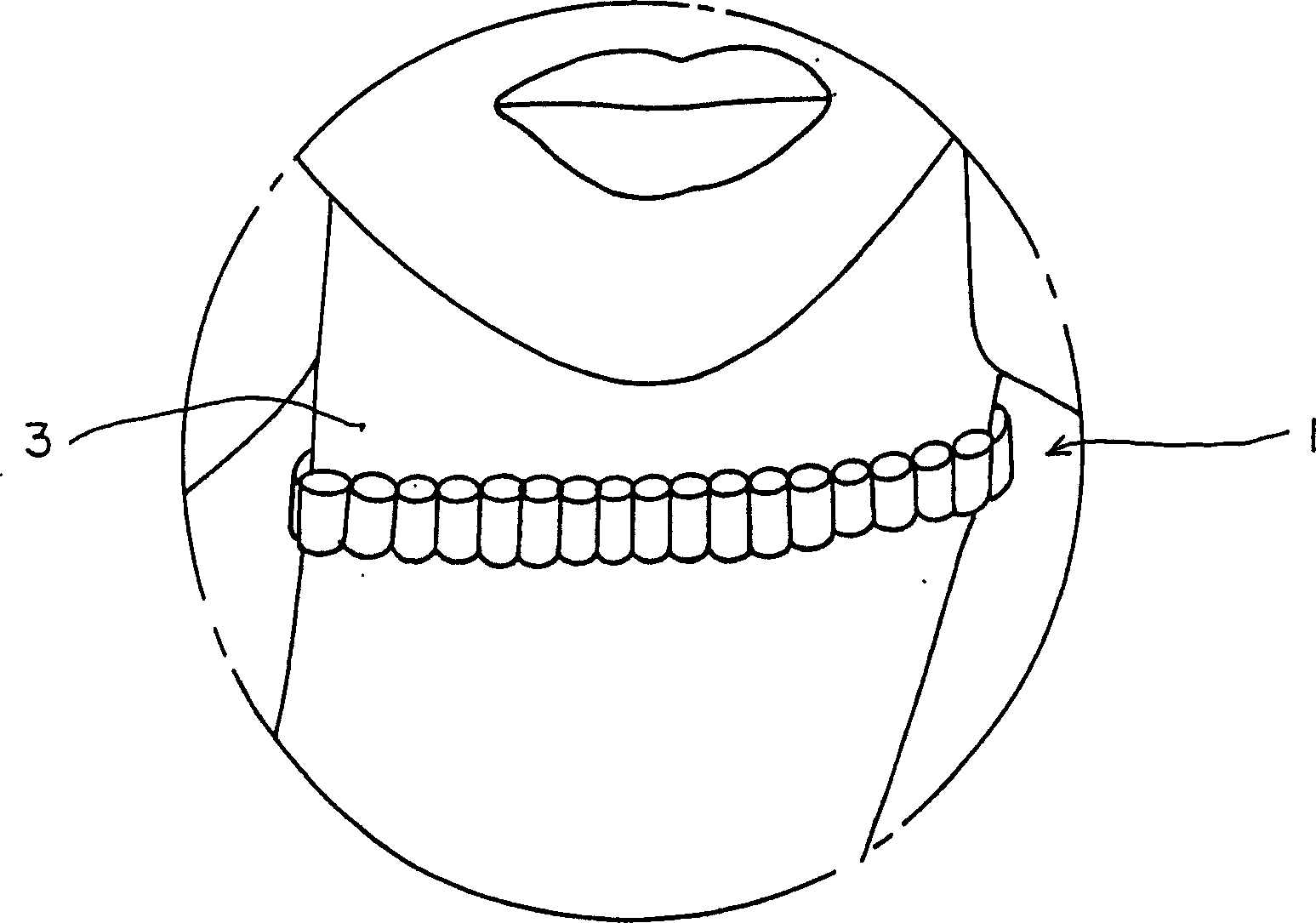

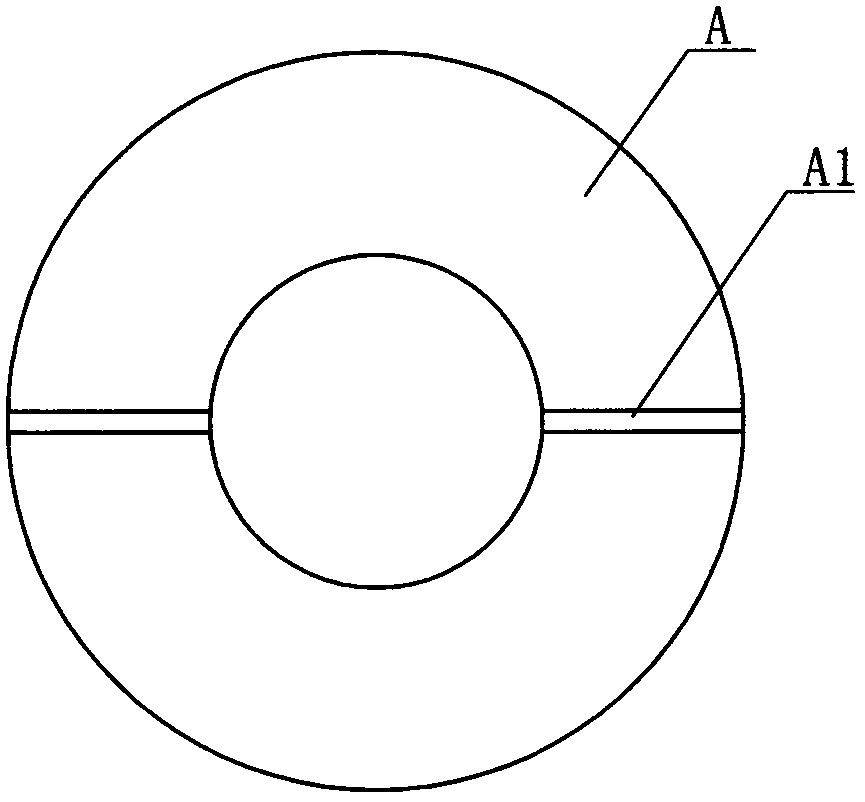

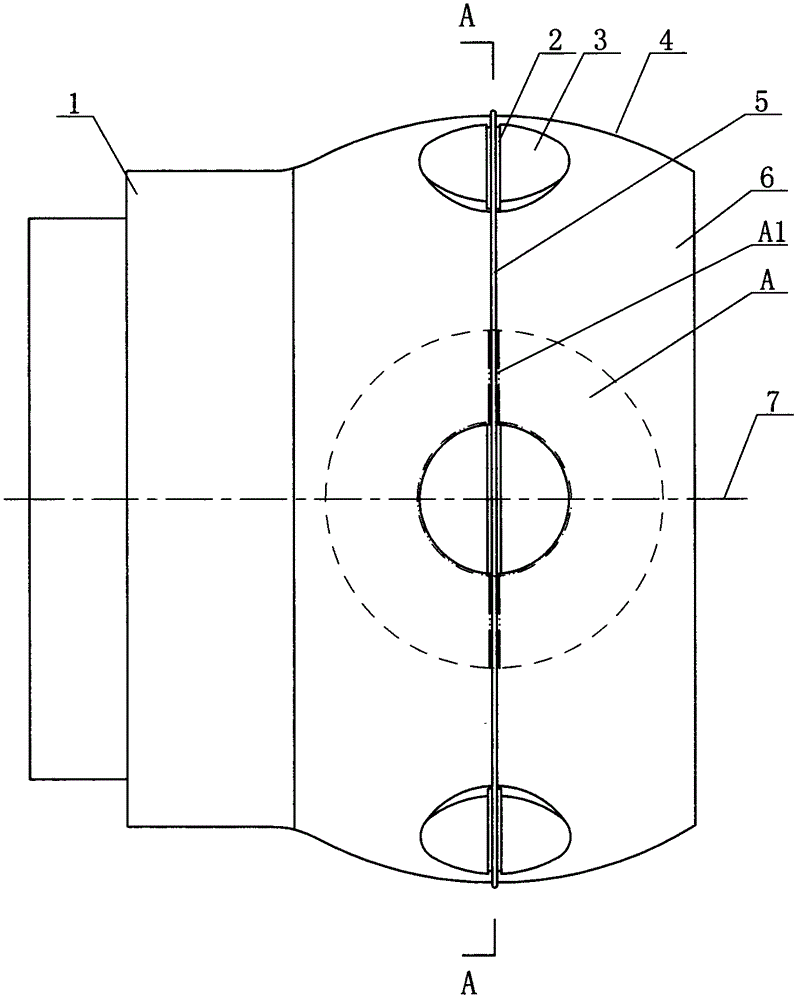

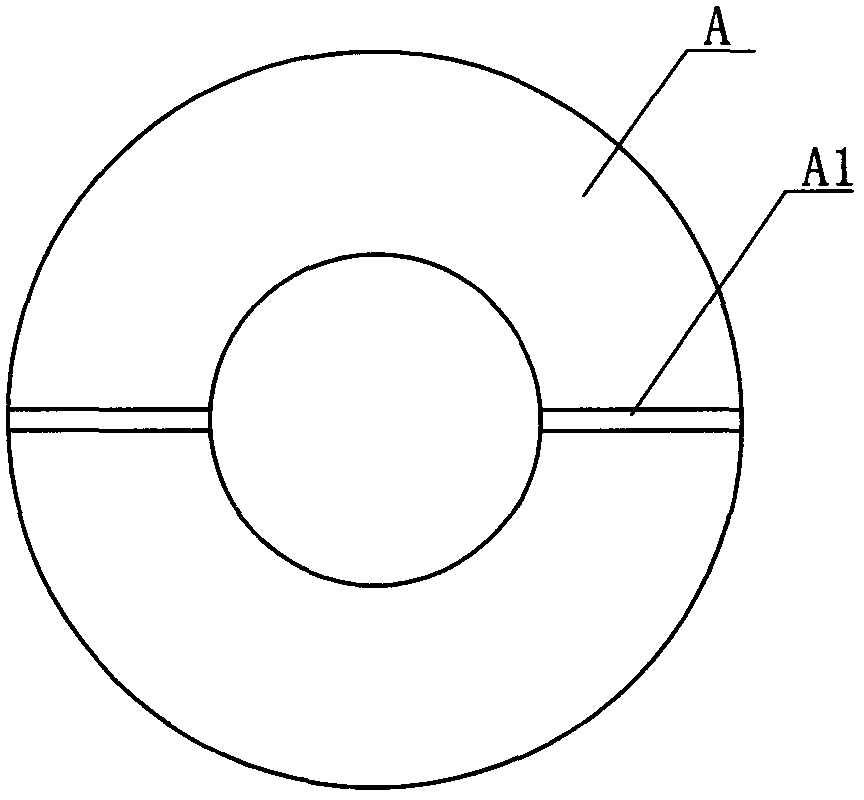

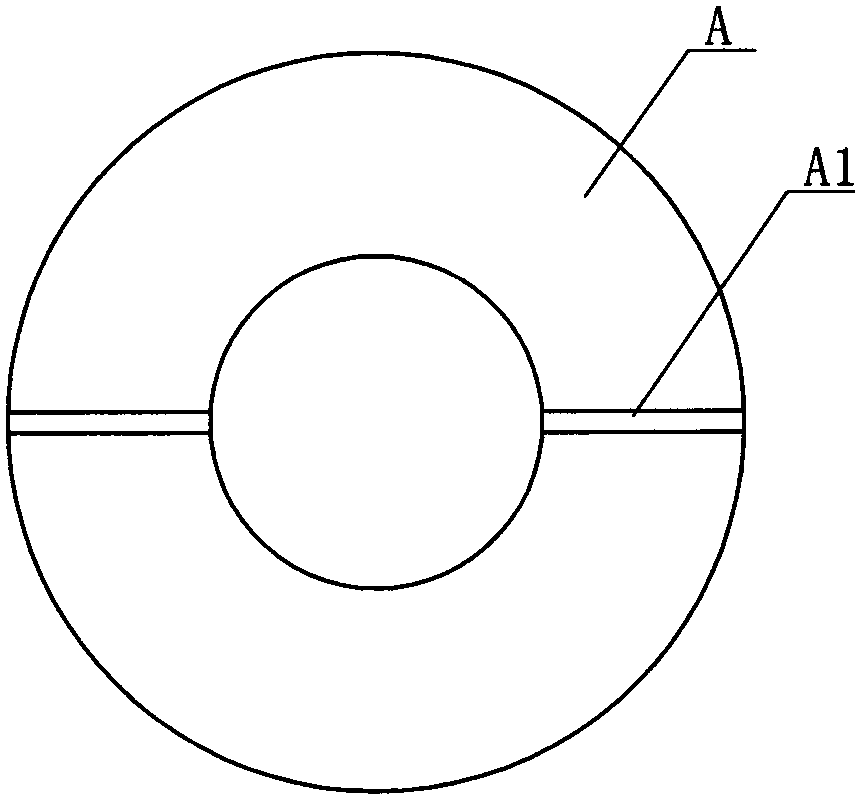

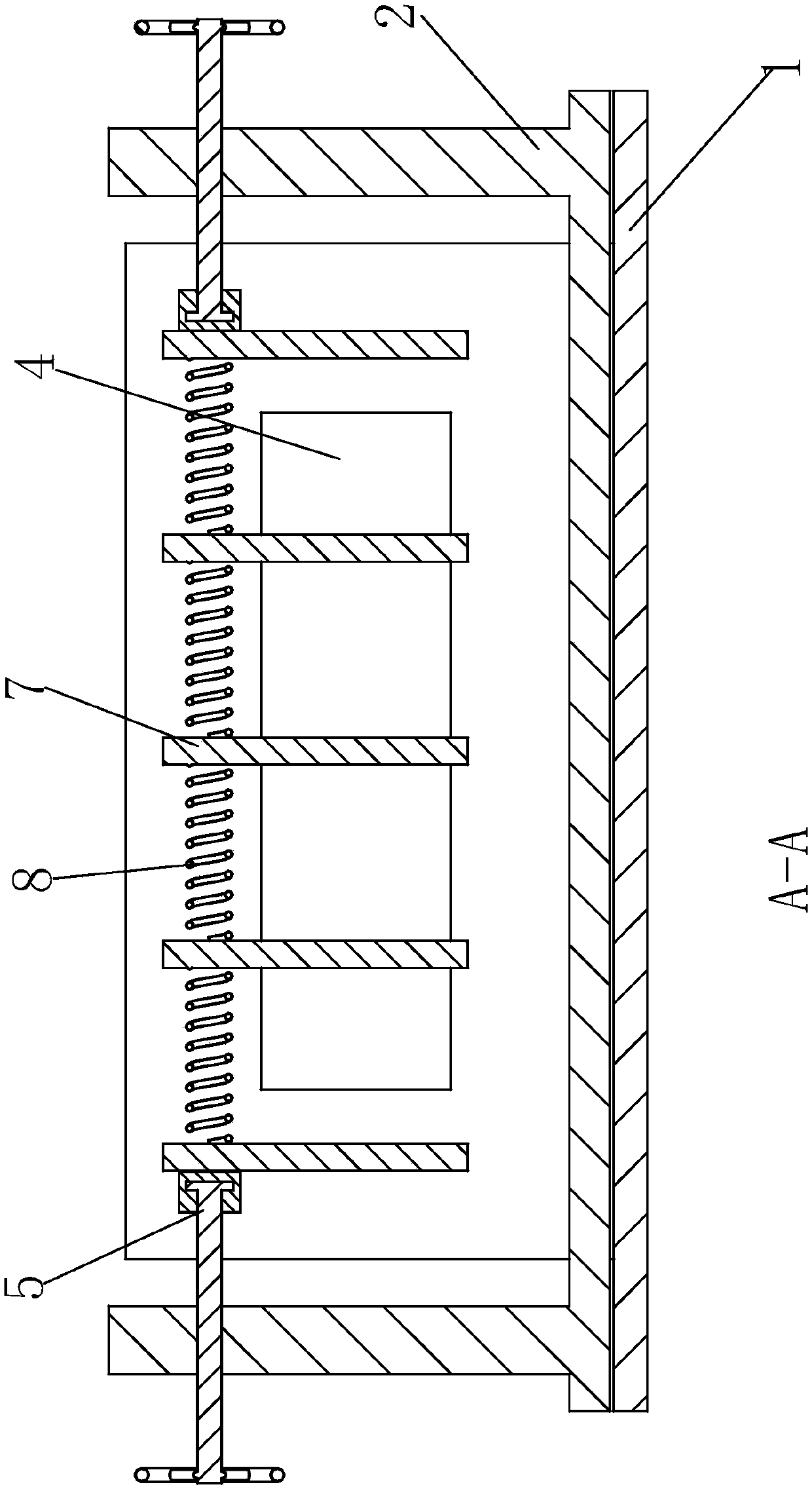

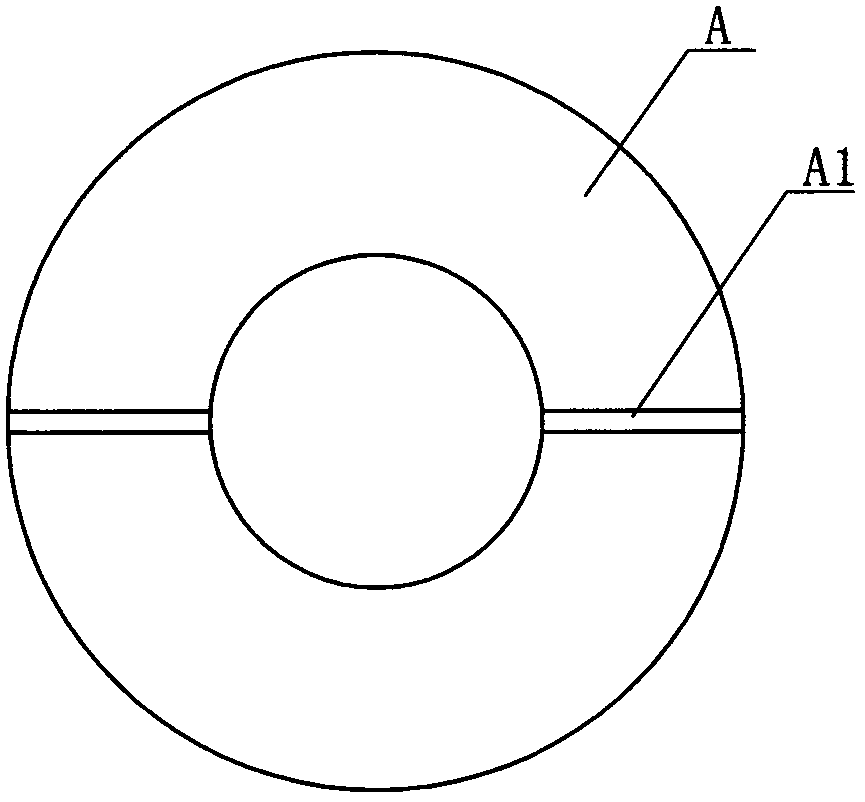

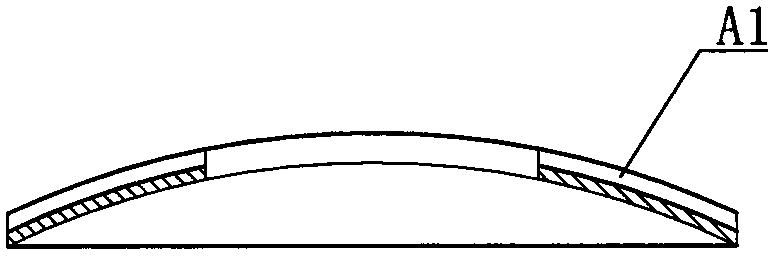

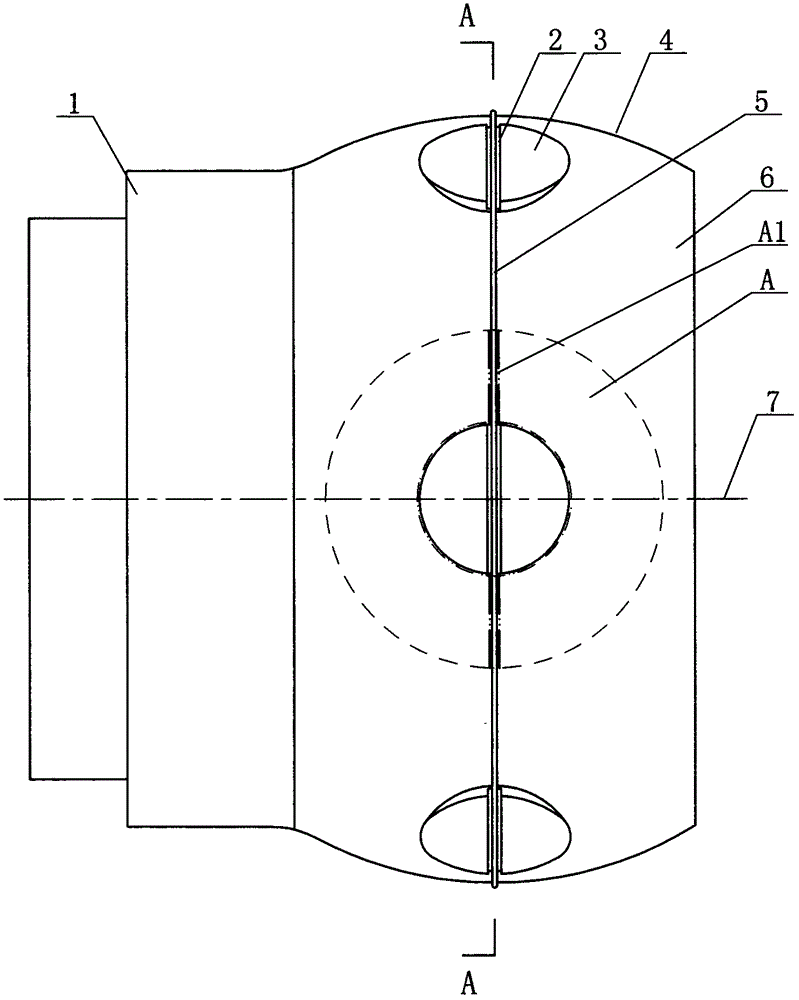

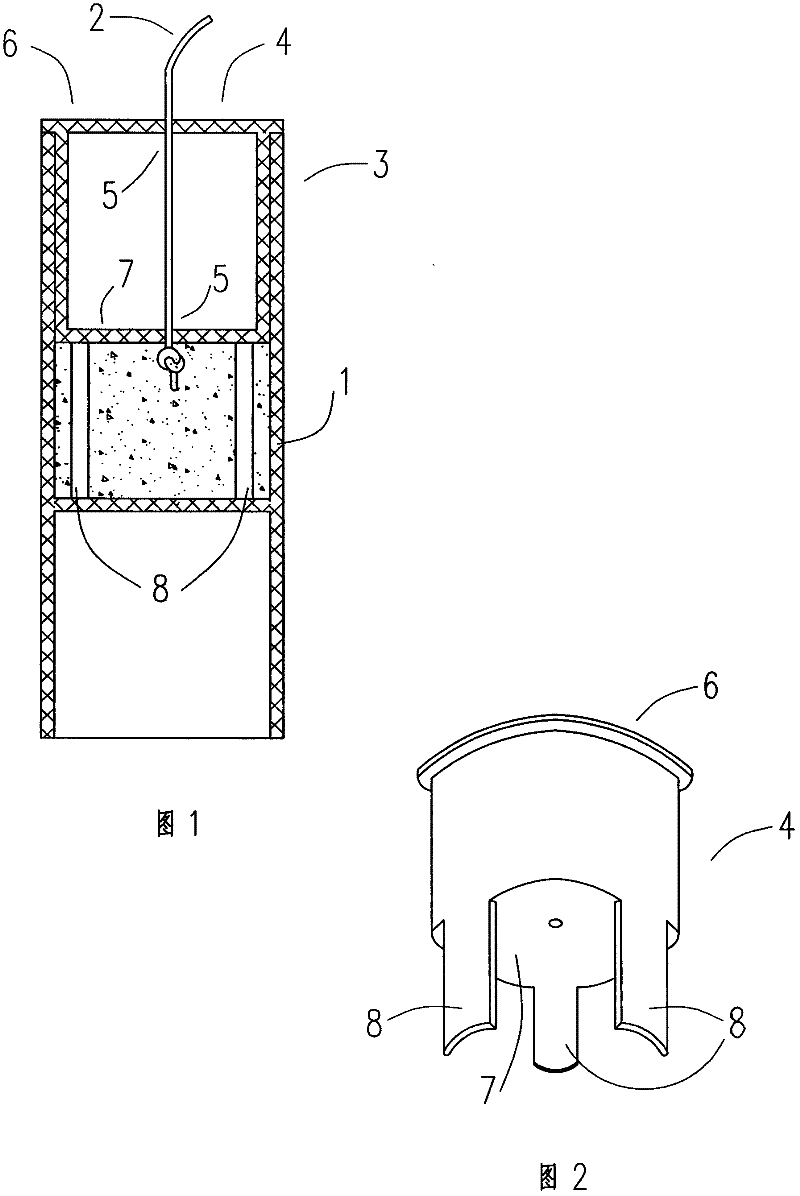

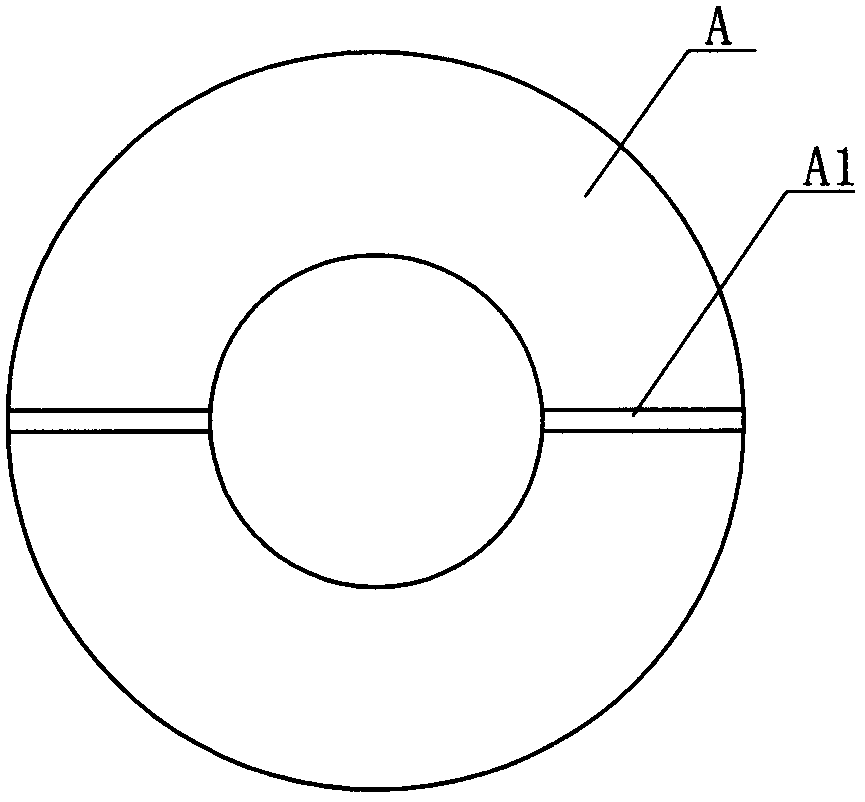

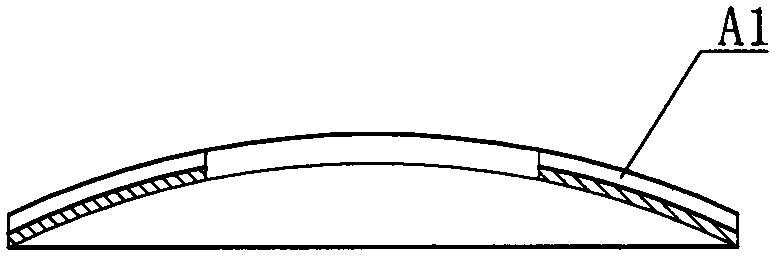

Spherical washer and fixture for grinding spherical washers

ActiveCN104832525ANo prolapseSimple structureWashersGrinding work supportsTransverse grooveEngineering

The invention discloses a spherical washer and a fixture for grinding spherical washers. An outer spherical surface of the spherical washer is provided with a narrow groove along the diameter direction; the fixture comprises a fixture body with an outer spherical surface, and a plurality of positioning pins are circumferentially and evenly distributed on the top of the outer spherical surface of the fixture body. The fixture is characterized in that the top of each positioning pin is provided with a transverse groove, and the transverse grooves are arranged in the top circumferential direction of the outer spherical surface. During grinding operation, the spherical washers arranged on the outer spherical surface of the fixture body are bound by a rope, the rope surrounds the outer spherical surface of the fixture body for a circle, the rope passes through the narrow grooves and the transverse grooves, one end of the rope is fixed on the fixture body, the other end of the rope is connected with the outer circle of a rotating ring, the rotating ring is screwed on a screw, a locknut is arranged on the outer end surface of the rotating ring, and the locknut is also screwed on the screw. The spherical washer provided by the invention can be rapidly clamped and reliably fixed on the fixture disclosed by the invention, consequently, the spherical washers can be conveniently ground by machining equipment, and working efficiency is increased.

Owner:高邮市驿都小微企业服务管理有限公司

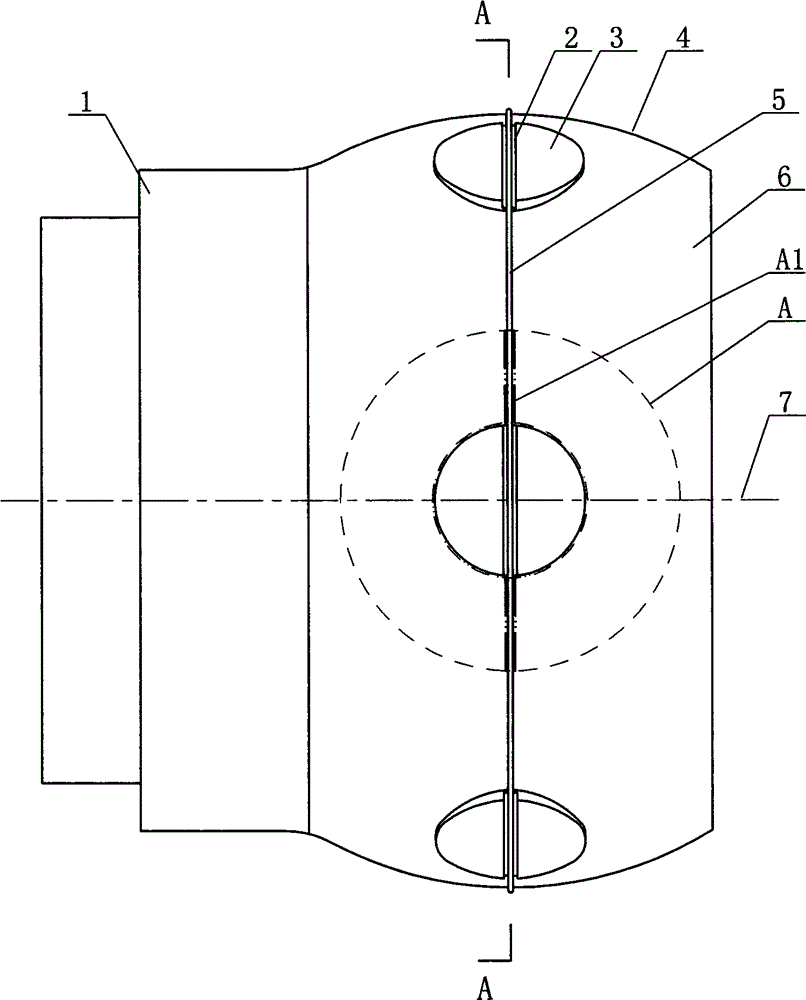

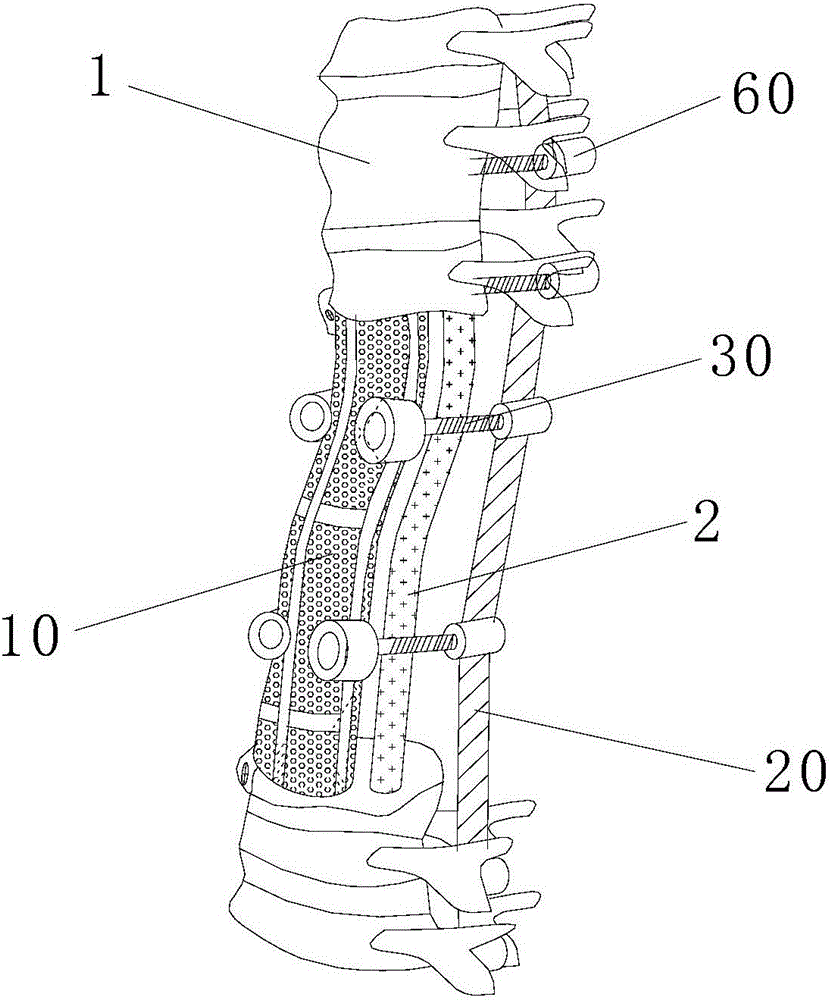

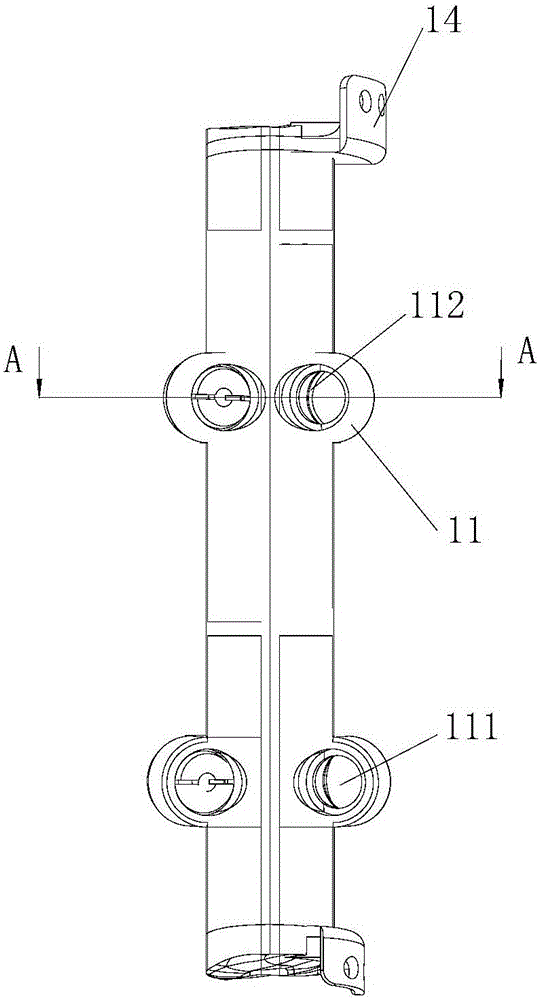

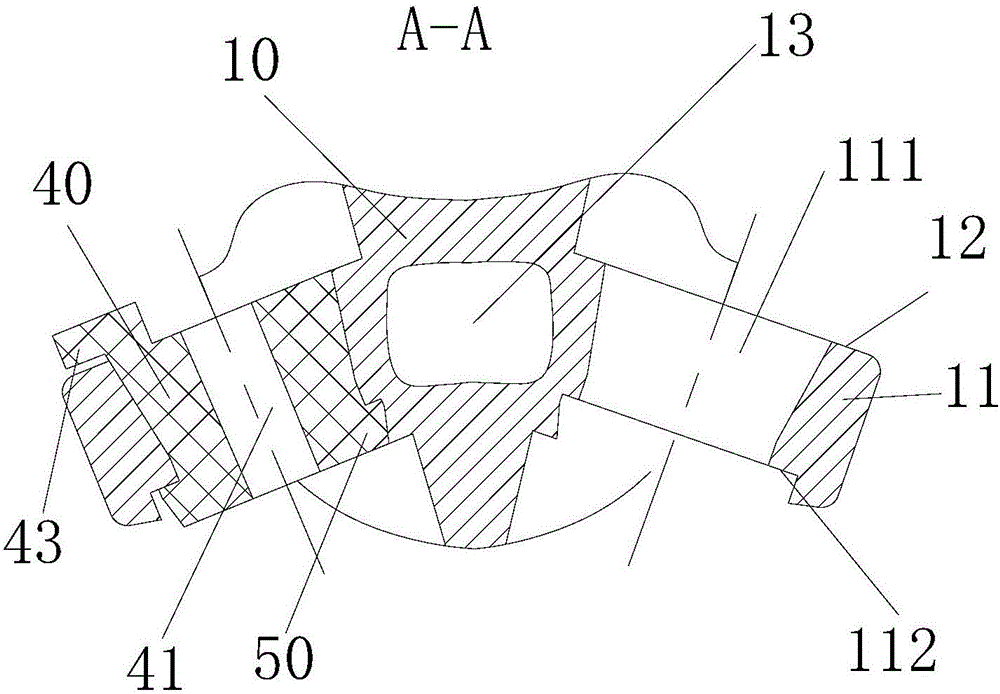

Artificial vertebral body fixing system

ActiveCN106308916AImprove stabilityNo displacementInternal osteosythesisState of artCross connection

The invention provides an artificial vertebral body fixing system, which comprises an artificial vertebral body main body arranged between adjacent human physiology vertebral bodies; two longitudinal connecting rods respectively arranged on two sides of spines of the human physiology vertebral bodies; cross connection nails connected between the artificial vertebral body main body and the longitudinal connecting rods; a connecting part connected onto the artificial vertebral body main body, and is provided with self-tapping through holes or threaded holes. When the connecting part is provided with the self-tapping through holes, the cross connection nails are screwed in the self-tapping through holes so as to be self-taped to form thread structures; when the connecting part is provided with the threaded holes, the cross connection nails are matched with the threaded holes. The technical scheme provided by the invention effectively solves the problem of poor artificial vertebral body stability in the prior art.

Owner:BEIJING AKEC MEDICAL

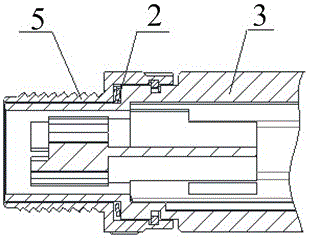

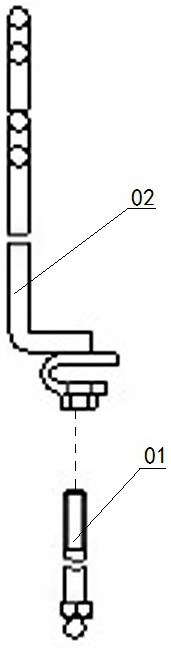

Anti-loosening structure of M12 connector

ActiveCN106129717AEliminate or reduce external forceNo connectivityEngagement/disengagement of coupling partsElastic componentStraight tube

The invention discloses an anti-loosening structure of an M12 connector. With the anti-loosening structure, a problem of connector loosening or even shedding in a continuous vibration state because of lack of an anti-loosening structure of the existing M12 connector can be solved. The anti-loosening structure comprises a connecting nut and a shell with a straight tube and a screwed tube; and the straight tube and the screwed tube are connected. A connecting front end of the shell is a threaded end; connecting threads are formed at one end of the inner side wall of the connecting nut; and the connecting nut sleeves the threaded tube by the connecting threads. Besides, a mounting groove is formed in the other end of the inner side wall of the connecting nut and an elastic component is installed in the mounting groove. On the basis of the structure, a loosening or even shedding phenomenon of a connector can be avoided; and thus the continuity and reliability of the M12 connector function are guaranteed.

Owner:SICHUAN YONGGUI SCI & TECH CO LTD

Fixture for grinding spherical surface gasket

The invention discloses a fixture for a grinding spherical surface gasket. The outer spherical surface of a grinded spherical surface gasket is provided with a narrow groove along a diameter direction. The fixture is characterized in that the fixture comprises a fixture body, wherein the top circumstance of the outer spherical surface of the fixture body is evenly provided with a plurality of locating pins; the top of each locating pin is provided with a lateral groove; during grinding work, the spherical surface gaskets arranged on the outer spherical surface of the fixture body are tightened by a belt rope; the belt rope passes through the narrow groove and the lateral grooves; one end of the belt rope is fixedly arranged on the fixture body, and the other end of the belt rope is connected with the outer circle of a rotation ring; the rotation ring is rotatably arranged on a shaft lever; the shaft lever is fixedly connected with a flange plate; the outer side of the rotation ring is provided with a fixed ring; the fixed ring is fixedly arranged on the shaft lever; a torsion spring is arranged between the rotation ring and the fixed ring; one end of the torsion spring is inserted into the rotation ring, and the other end of the torsion spring is inserted into the fixed ring. The fixture is used for the grinding processing of the outer spherical surface of the spherical surface gasket, the quick clamping and the reliable fixing of the spherical surface gasket can be realized, and working efficiency is improved.

Owner:山东格新精工有限公司

Outer spherical clamp for grinding spherical gaskets

The invention discloses an outer spherical clamp for grinding spherical gaskets. A narrow groove is formed in an outer spherical surface of each ground spherical gasket along the diameter direction; the clamp is characterized by comprising a clamp body, wherein a plurality of positioning pins are uniformly arranged on the circumference of the outer spherical surface of the clamp body; transverse grooves are formed in the tops of the positioning pins; in a grinding work process, the spherical gaskets arrayed on the outer spherical surface of the clamp body are tightened by a belt rope; the belt rope passes through the narrow grooves and the transverse grooves; the outer side end face of the clamp body is fixedly connected with an end cover; a movable plate and an adjusting screw rod are arranged on the outer side end face of the end cover; the adjusting screw rod is in threaded connection with the end cover; a rod end of the adjusting screw rod is provided with a hand wheel; the movable plate is rotationally arranged on the adjusting screw rod to do axial movement along with the adjusting screw rod; the two ends of the belt rope penetrate through the outer spherical surface of the clamp body to enter an inner hole of the clam body, and then penetrate through the end cover to be connected with the two centrally symmetric ends of the movable plate. The outer spherical clamp for grinding the spherical gaskets is used for grinding and machining the outer spherical surfaces of the spherical gaskets so that the rapid clamping and reliable fixation of the spherical gaskets can be realized and the working efficiency is improved.

Owner:TIANJIN JINHANG COMP TECH RES INST

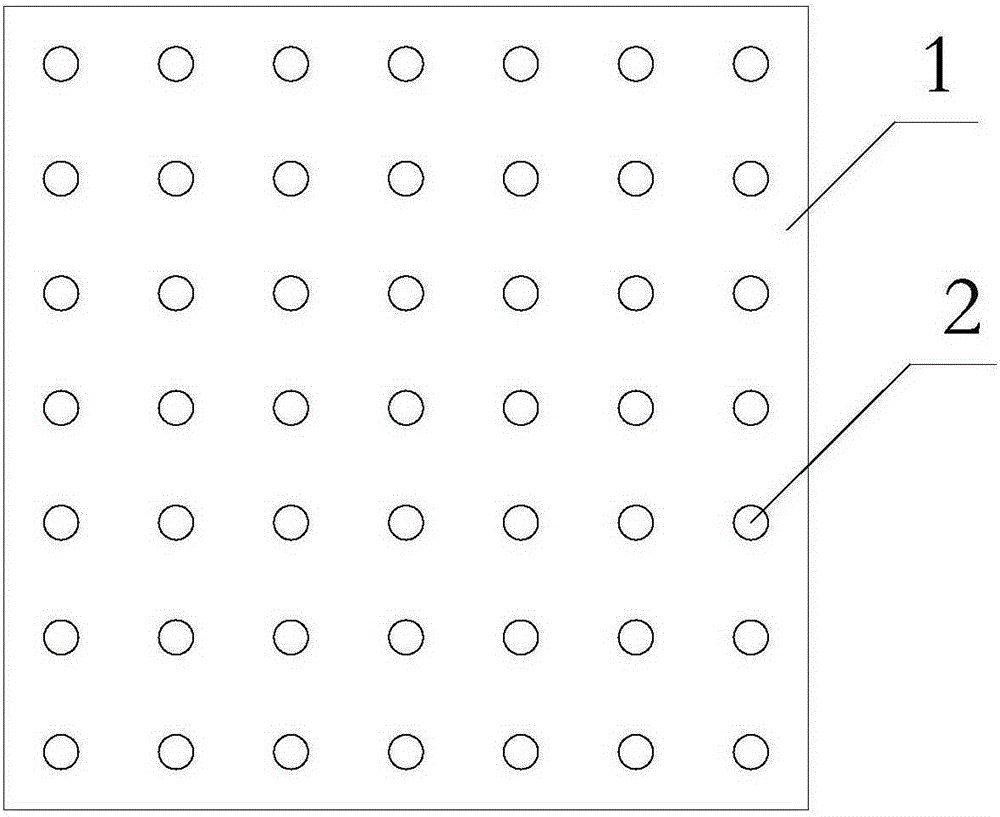

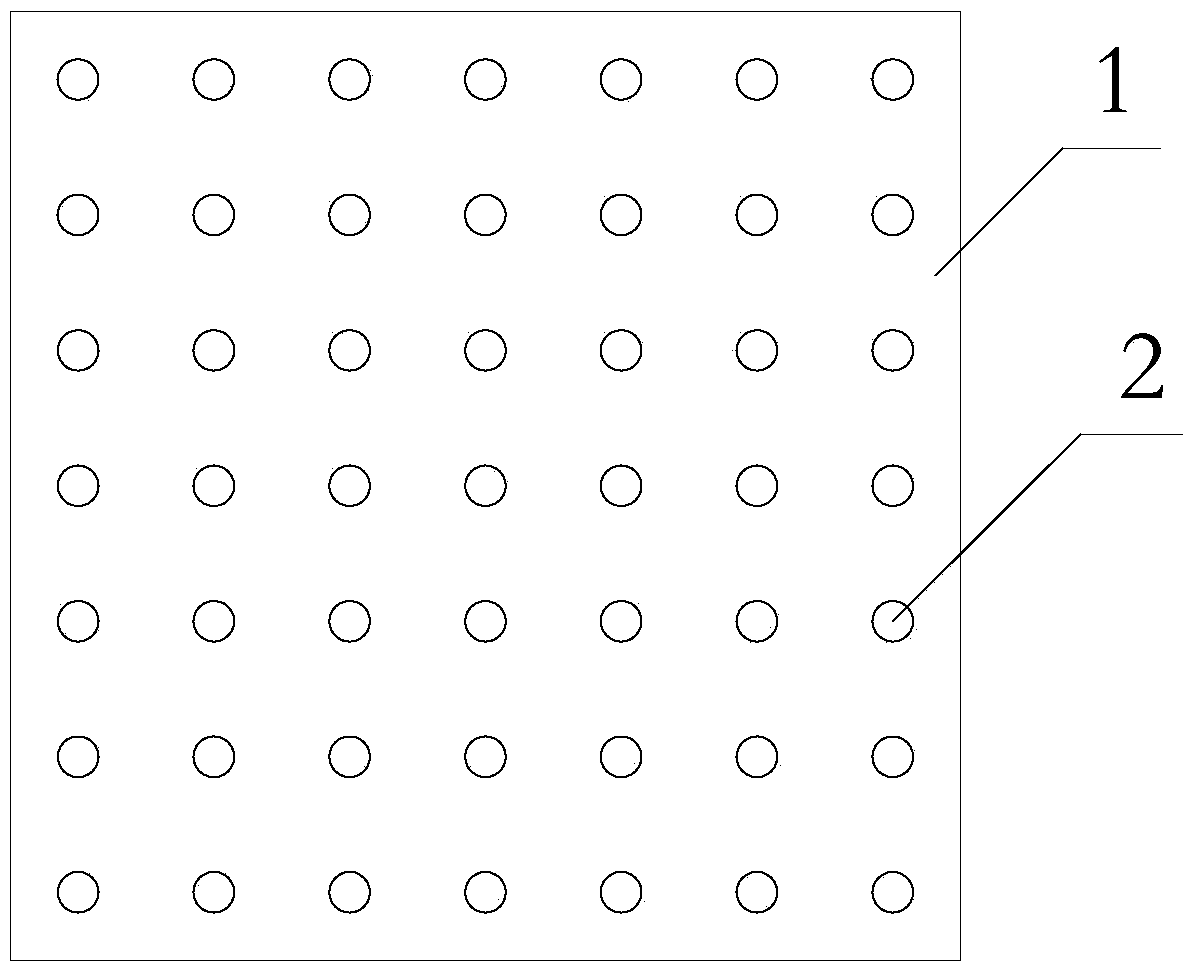

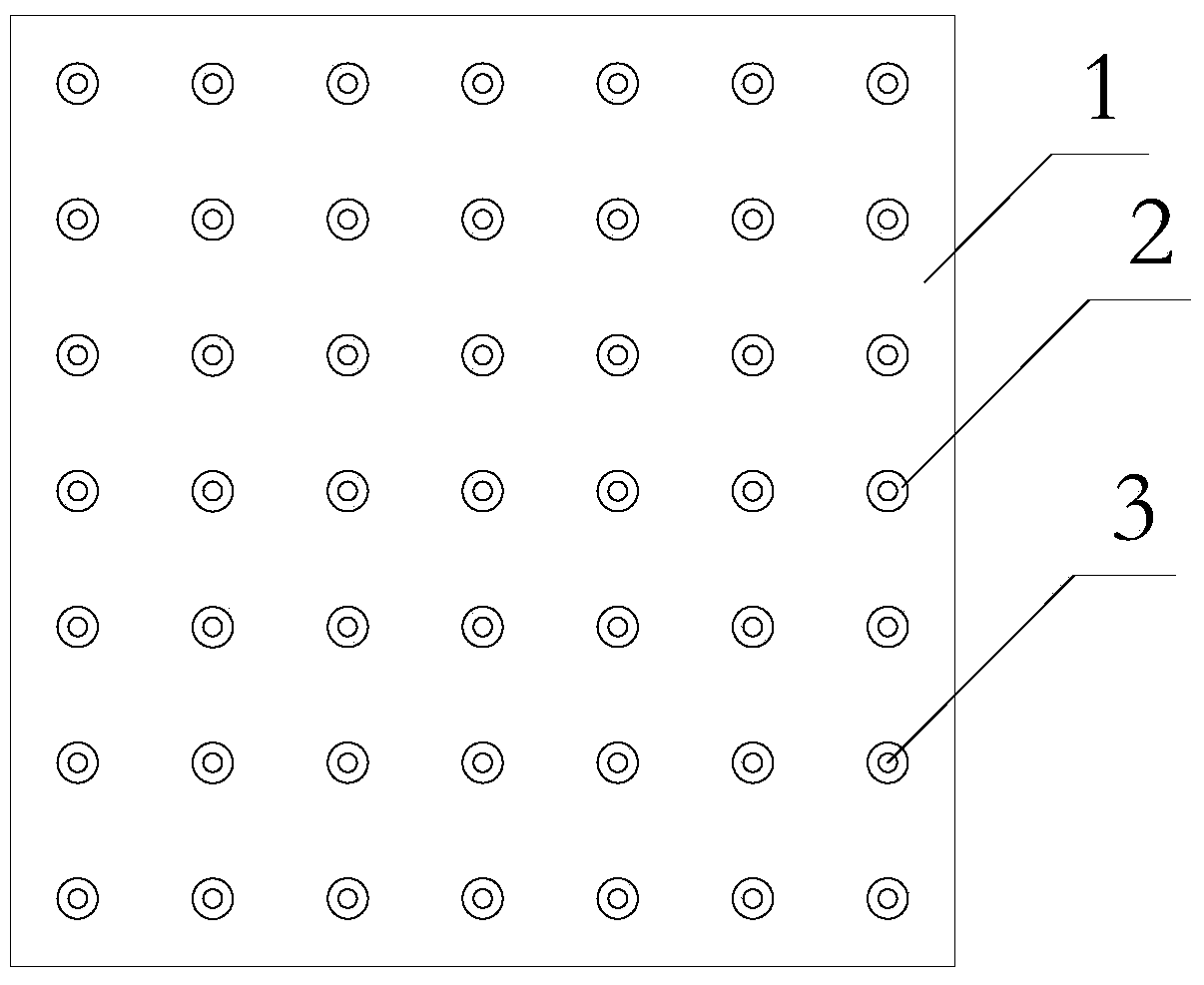

Yarn bobbin package

ActiveCN105314261APlace stableImprove drum transport efficiencyRigid containersContainers with multiple articlesYarnBobbin

The invention relates to a yarn bobbin package which comprises a plurality of lining plates. The upper surface of each lining plate is provided with a plurality of first grooves, and the lower surface of each lining plate is provided with second grooves which are identical with the first grooves in number and in one-to-one correspondence with the first grooves. The first grooves are communicated with the second grooves in a one-to-one vertical alignment mode. Each lining plate is provided with through holes identical with the first grooves in number. The lining plates are overlapped in sequence, yarn bobbins to be packaged are fixed between every two adjacent lining plates, the upper ends of the yarn bobbins to be packaged are embedded into the second grooves of the upper lining plates, and the lower ends of the yarn bobbins to be packaged are embedded into the first grooves of the lower lining plates, so that the whole package is formed. According to the yarn bobbin package, the defect that in a traditional mode, yarn bobbins collide with one another and consequently the yarn quality is affected due to the fact that the yarn bobbins deviate from positions in the transporting process is overcome; it is ensured that the yarn bobbins are firmly stored in the whole package, the packaging efficiency and the yarn bobbin transporting efficiency are improved, transportation losses are lowered, and the transportation cost is reduced; the yarn bobbin package is simple in structure and low in cost.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

Motor capable of preventing gear from falling off

ActiveCN113241874AEasy to replaceGuaranteed stabilityLubricant transferMechanical energy handlingDrive motorElectric machine

Owner:JIANGSU HENGKANG ELECTRICAL

Fixture for grinding outer spherical surface of spherical surface gasket

The invention discloses a fixture for grinding the outer spherical surface of a spherical surface gasket. The spherical surface of a spherical surface gasket is provided with a narrow groove along a diameter direction. The fixture is characterized in that the fixture comprises a fixture body, wherein the top circumstance of the outer spherical surface of the fixture body is evenly provided with a plurality of locating pins; the top of each locating pin is provided with a lateral groove; during grinding work, the spherical surface gaskets arranged on the outer spherical surface of the fixture body are tightened by a belt rope; the belt rope passes through the narrow groove and the lateral grooves; the outer side end surface of the fixture body is fixedly connected with an end cover; the outer side end surface of the end cover is provided with a movable plate; the movable plate and the end cover are connected by a hinge pin; the hinge pin movably passes through the center hole of the movable plate to be fixedly connected to the end cover; compression springs are arranged between the movable plate and the end cover; two ends of the belt rope pass through the outer spherical surface of the fixture body to enter the inner hole of the fixture body and then pass through the end cover to be connected to two central symmetry ends of the movable plate. The fixture for the outer spherical surface is used for the grinding processing of the outer spherical surface of the spherical surface gasket, the quick clamping and the reliable fixing of the spherical surface gasket can be realized, and working efficiency is improved.

Owner:薛瑞华

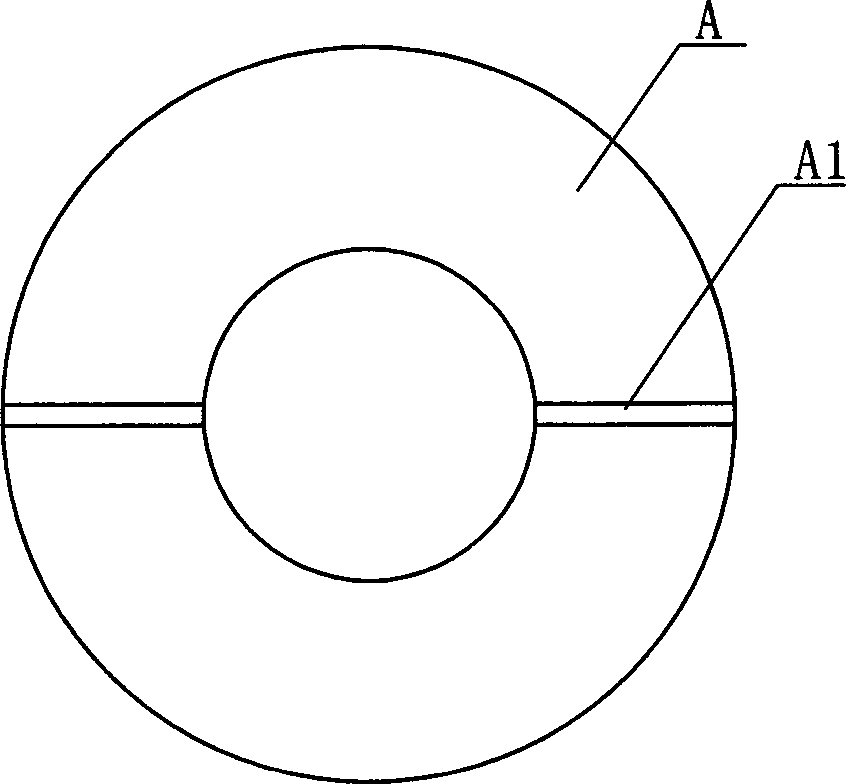

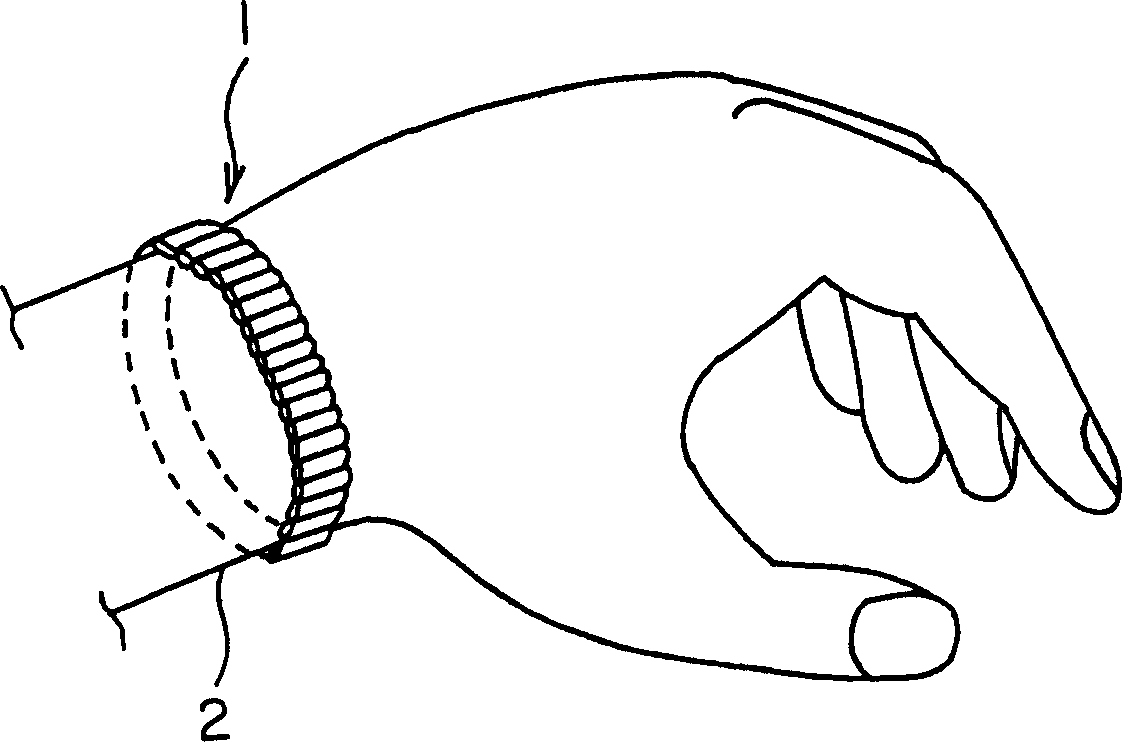

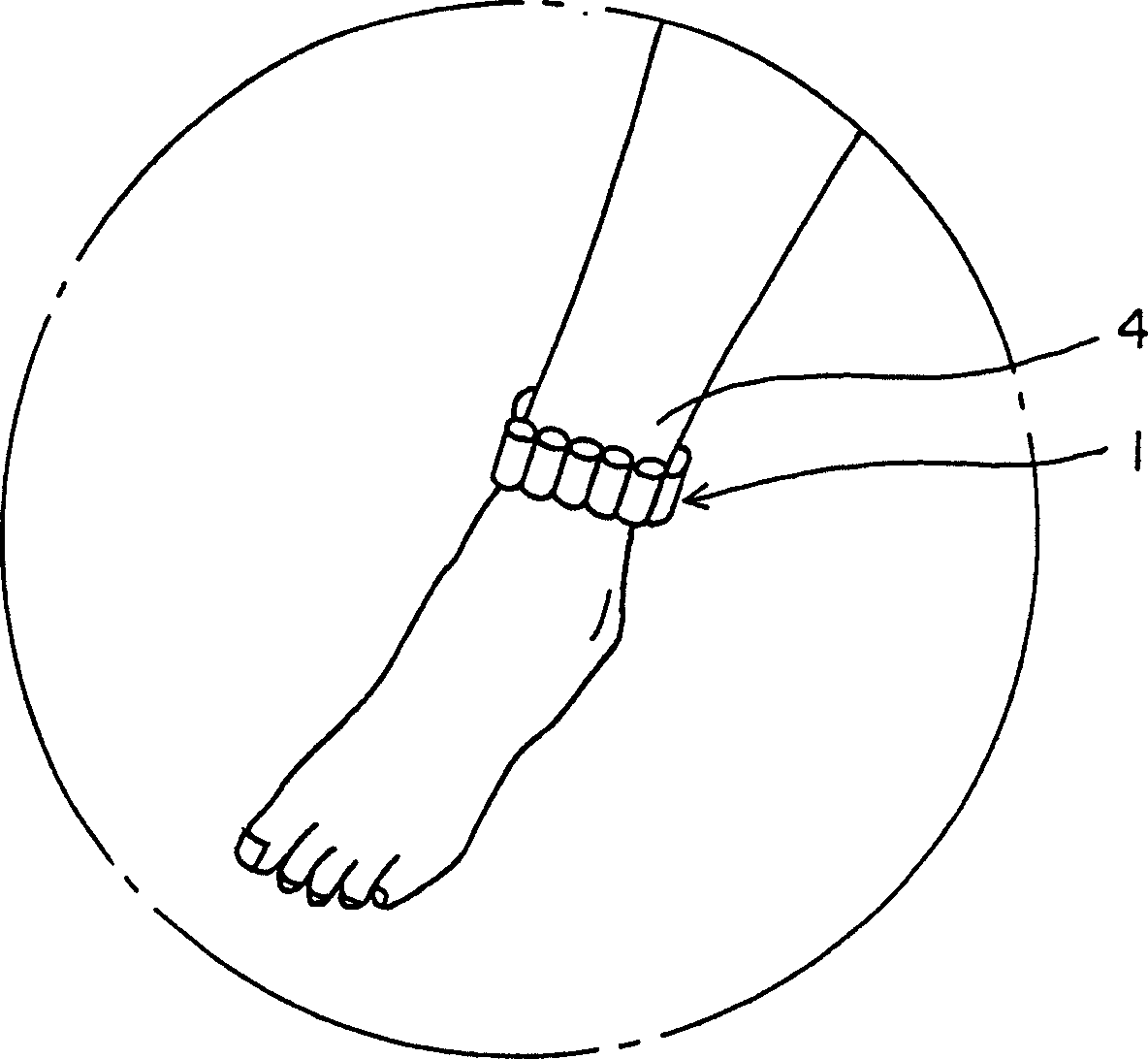

Permanent magnet rings

InactiveCN1509776ADenseImprove wearing effectElectrotherapyPermanent magnetsForce linesCircular dichroism

In a permanent magnet ring (1) formed by arranging a plurality of unit permanent magnets (21a, 21b, 21c . . . ), each of a plurality of the unit permanent magnets (21a, 21b, 21c . . . ) is formed in a circular cylindrical shape having a circular cross section, and a predetermined number of the unit permanent magnets are magnetically attracted each other so as to form a ring shape having a predetermined size, so that it is possible for the user to easily structure the permanent magnet ring (1) having a desired size, and it is possible to attach as many the unit permanent magnets as possible so as to be able to apply proper magnetic force lines to each part of the body.

Owner:SAGAMI CHEM METAL

Clamp for grinding spherical gaskets

The invention discloses a clamp for grinding spherical gaskets. A narrow groove is formed in an outer spherical surface of each ground spherical gasket along the diameter direction; the clamp is characterized by comprising a clamp body, wherein a plurality of positioning pins are uniformly arranged on the circumference of the outer spherical surface of the clamp body; transverse grooves are formed in the tops of the positioning pins; in a grinding work process, the spherical gaskets arrayed on the outer spherical surface of the clamp body are tightened by a belt rope; the belt rope passes through the narrow grooves and the transverse grooves; one end of the belt rope is fixed on the clamp body and the other end of the belt rope penetrates through the outer spherical surface of the clamp body to enter an inner hole of the clamp body, and then is connected with a lower swinging end of a swinging crank; the swinging crank is rotationally arranged on a shaft rod and the shaft rod is fixedly connected with a flange plate; an upper swinging end of the swinging crank is connected with one end of a tension spring and the other end of the tension spring is connected with an inner hole wall of the clamp body. The clamp for grinding the spherical gaskets is used for grinding and machining the outer spherical surfaces of the spherical gaskets so that the rapid clamping and reliable fixation of the spherical gaskets can be realized and the working efficiency is improved.

Owner:江苏广大瑞康农业发展有限公司

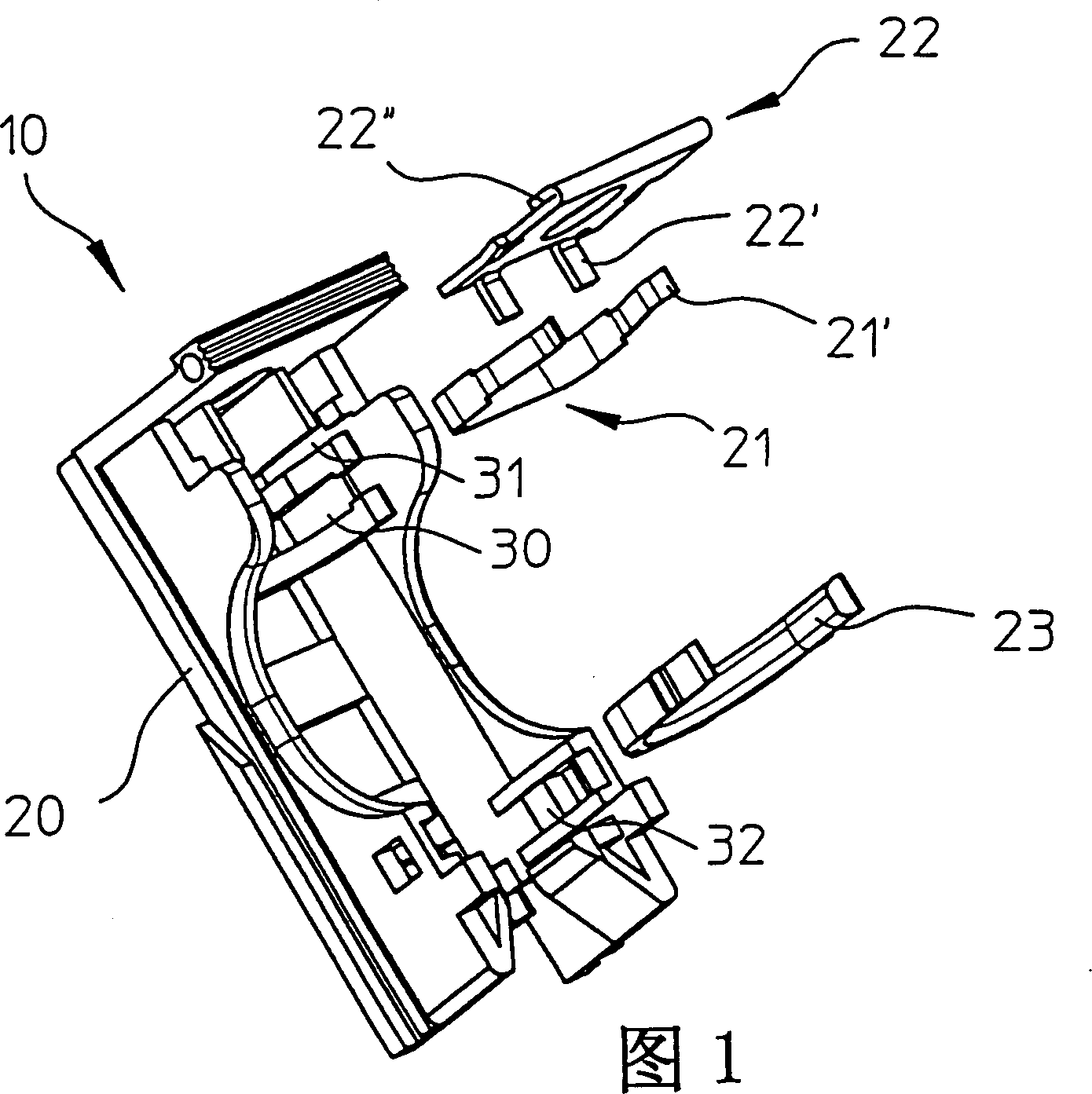

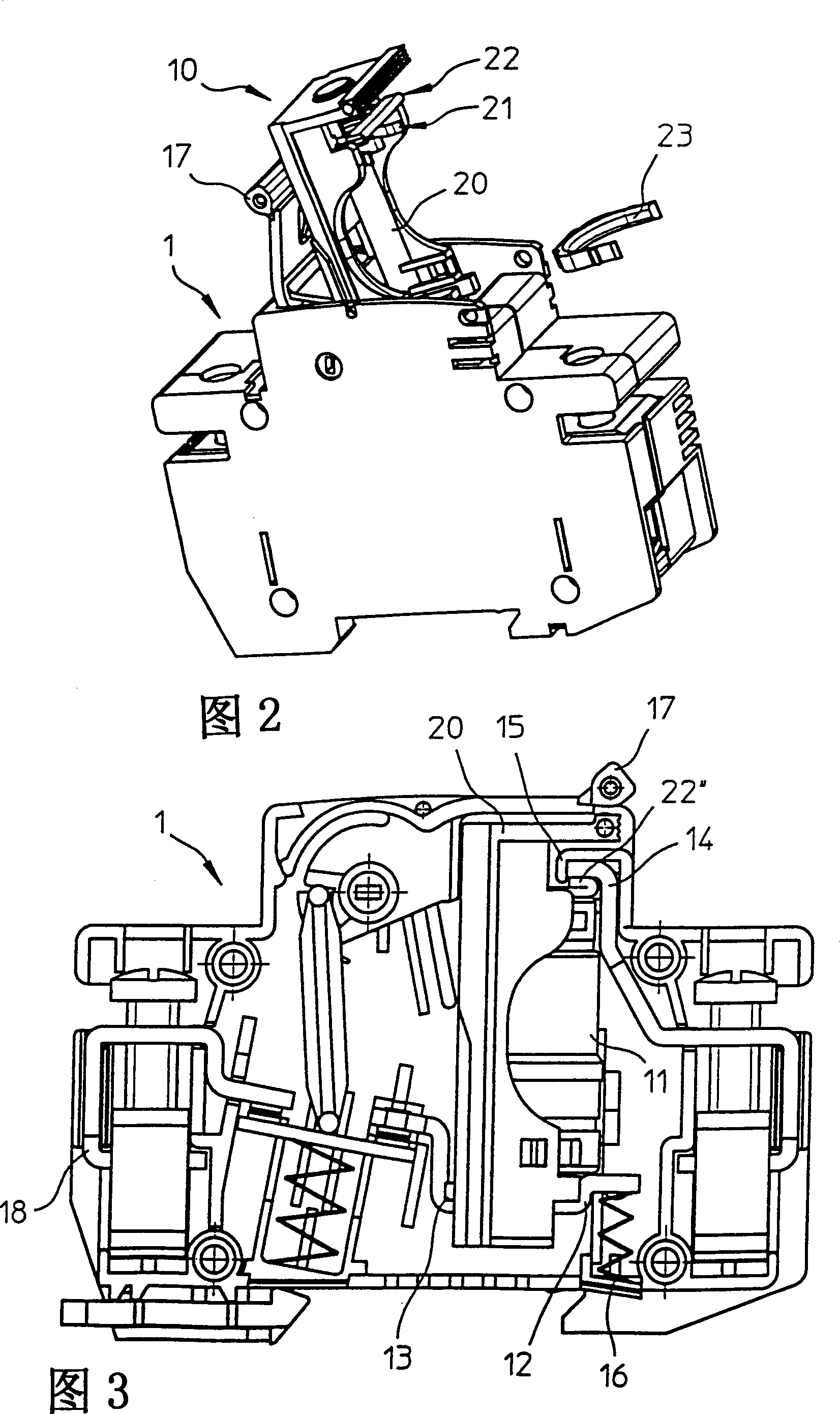

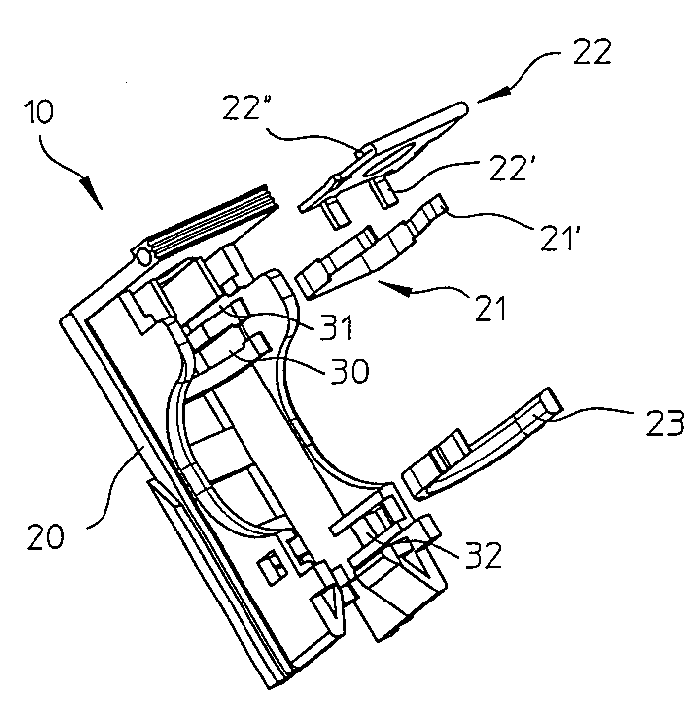

Electric appliance switch comprising a fuse seat

InactiveCN1178246CEasy to replaceNo prolapseProtective switch detailsContact engagementsElectrical conductorEngineering

A wall of a seat (10) surrounding a fuse (11) is provided with a first and second guiding slot (31, 30), adjacent to each other at a first end of the seat (10), and a third guiding slot (32) at a second end of the seat (10), all transversal to the seat axis. In the first guiding slot (31) an electrically conducting intermediate plate (22) and in the second guiding slot (30) a bow spring (21) and in the third guiding slot (32) a size controlling bow insert (23) are engagably inserted. In the state of closed contacts, the intermediate plate (22) electrically contacts the down conductor contact (14), which is, through an insulating partition (15), completely electrically insulated from the surroundings. The bow spring (21) is elastically spreadable on both ends. The improved fuse seat makes possible a simple replacement of fuses of various dimensions and prevents a dropping of the fuses out of a magazine, the down conductor contact, however, is completely protected against being touched.

Owner:ETI电元件股份公司 +1

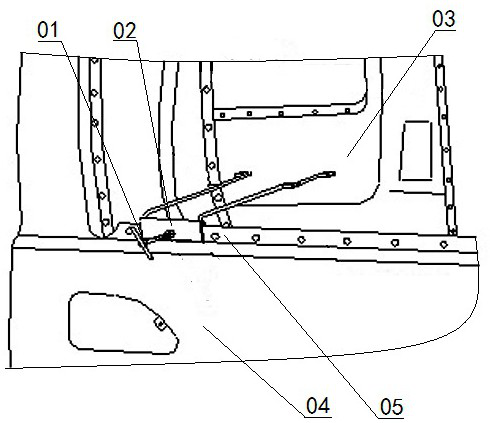

Electrophoretic painting device for car door

ActiveCN111235621BPromote prolapseEasy to installElectrophoretic coatingsElectrophoresesRotating drum

The invention discloses an electrophoretic painting device for car doors, which comprises a support rod. The support rod has a vertical bar section with a limit block at one end and a horizontal bar section connected to the other end of the vertical bar section. The other end of the horizontal bar section is connected with a The lower folding rod section inclined to one side of the limit block, the lower folding rod segment is connected with the upper folding rod segment; the angle between the upper folding rod segment and the lower folding rod segment and the angle between the lower folding rod segment and the cross bar segment The included angles are all obtuse angles; there is a drum mounted on the vertical rod section, and the drum has a drum body, a limit rod and a weight limit rod arranged on the upper part of the drum body; the axis line of the drum body The angle between the axis line of the weight limit rod and the axis line of the limit rod is obtuse, and the axis line of the weight limit rod and the axis line of the limit rod are set at 180°. The quality of the hammer limit rod is greater than the quality of the limit rod. Compared with the prior art, the present invention can solve the problems that the electrophoretic painting tooling of the existing car door has low versatility and the car door is easy to come out.

Owner:DONGFENG LIUZHOU MOTOR

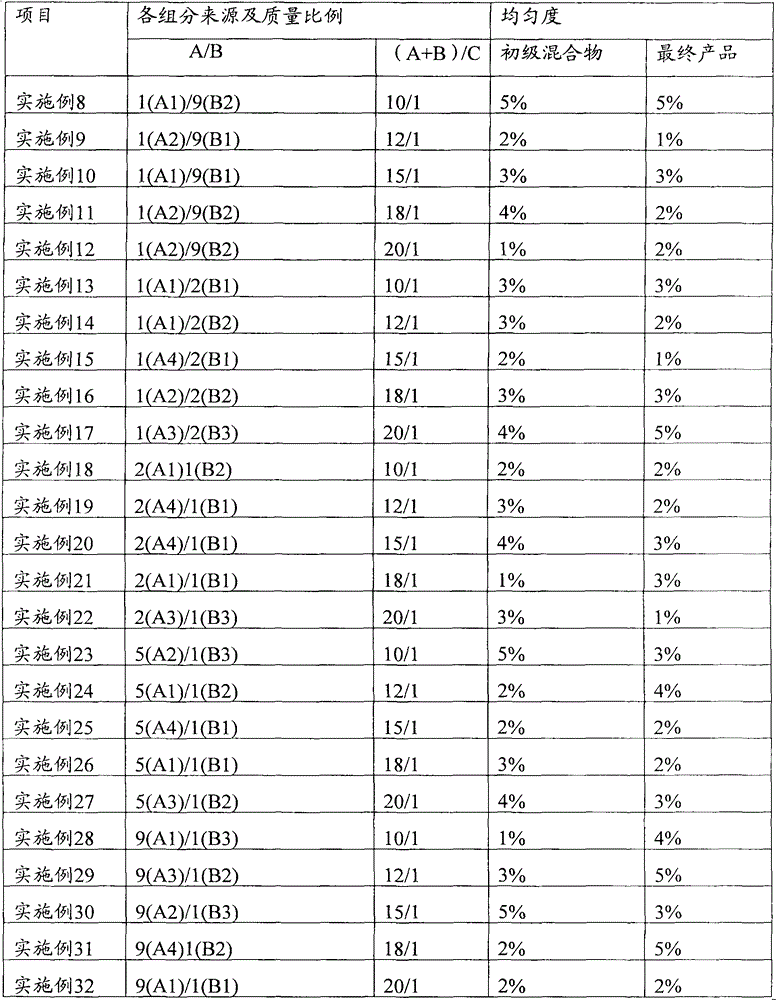

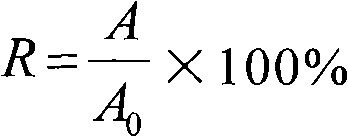

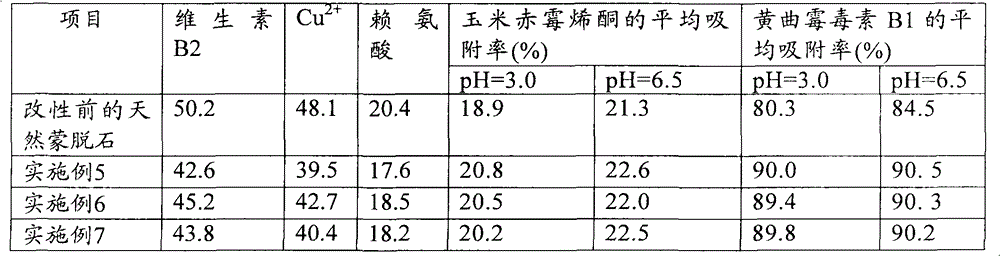

Yeast cell wall and its preparation method, feed additive and its preparation method and feed

ActiveCN103243028BSolve pollutionImprove reproductive performanceMicroorganism lysisAnimal feeding stuffBiotechnologyManno-oligosaccharide

The invention relates to a yeast cell wall, comprising 20%-70% by mass of beta-yeast glucan and 20%-70% by mass of mannan oligosaccharide. The invention also relates to a forage additive, comprising the yeast cell wall, sodium modified montmorillonite and selenium yeast, and by mass, a ratio of the yeast cell wall to the sodium modified montmorillonite is 1 : 9-9 : 1; and a ratio of a total of the yeast cell wall and the sodium modified montmorillonite to the selenium yeast is 10 : 1-20 : 1. The invention also relates to a preparation method for the yeast cell wall. The preparation method comprises the steps of breaking the cell wall of live yeast through self-dissolution, degrading the yeast with a compound enzyme, separating, purifying, drying and deactivating the enzyme to obtain the yeast cell wall, wherein the compound enzyme comprises papain, nuclease and bacteria protease, and by mass, the addition amount of the papain, nuclease and bacteria protease is 0.1-0.3%, 0.05-0.2% and 0.01-0.03% that of the dry material of the yeast. The invention also relates to forage, an addition level of the additive in the forage is 1.5-2.5 g / kg.

Owner:ANGELYEAST CO LTD

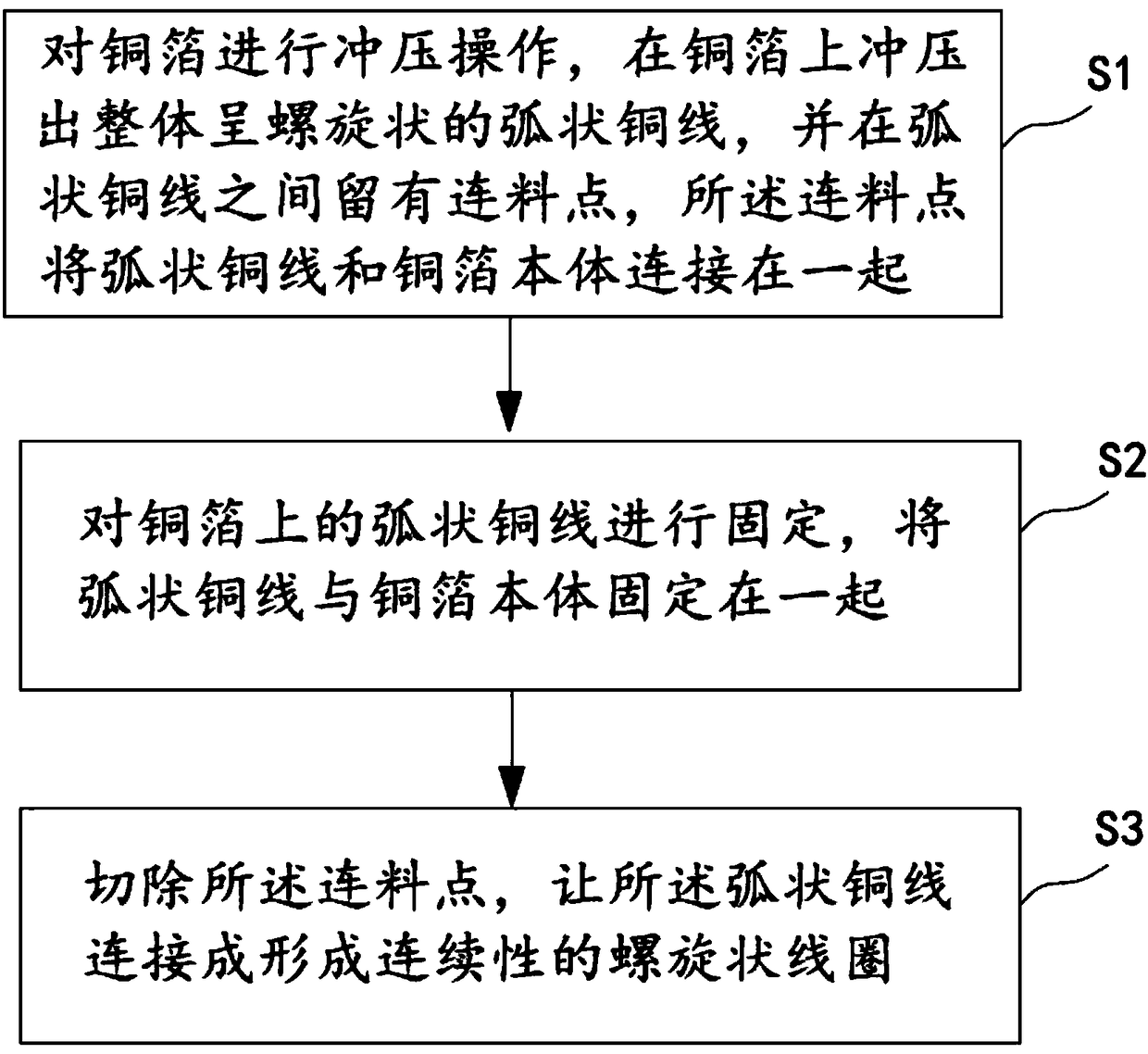

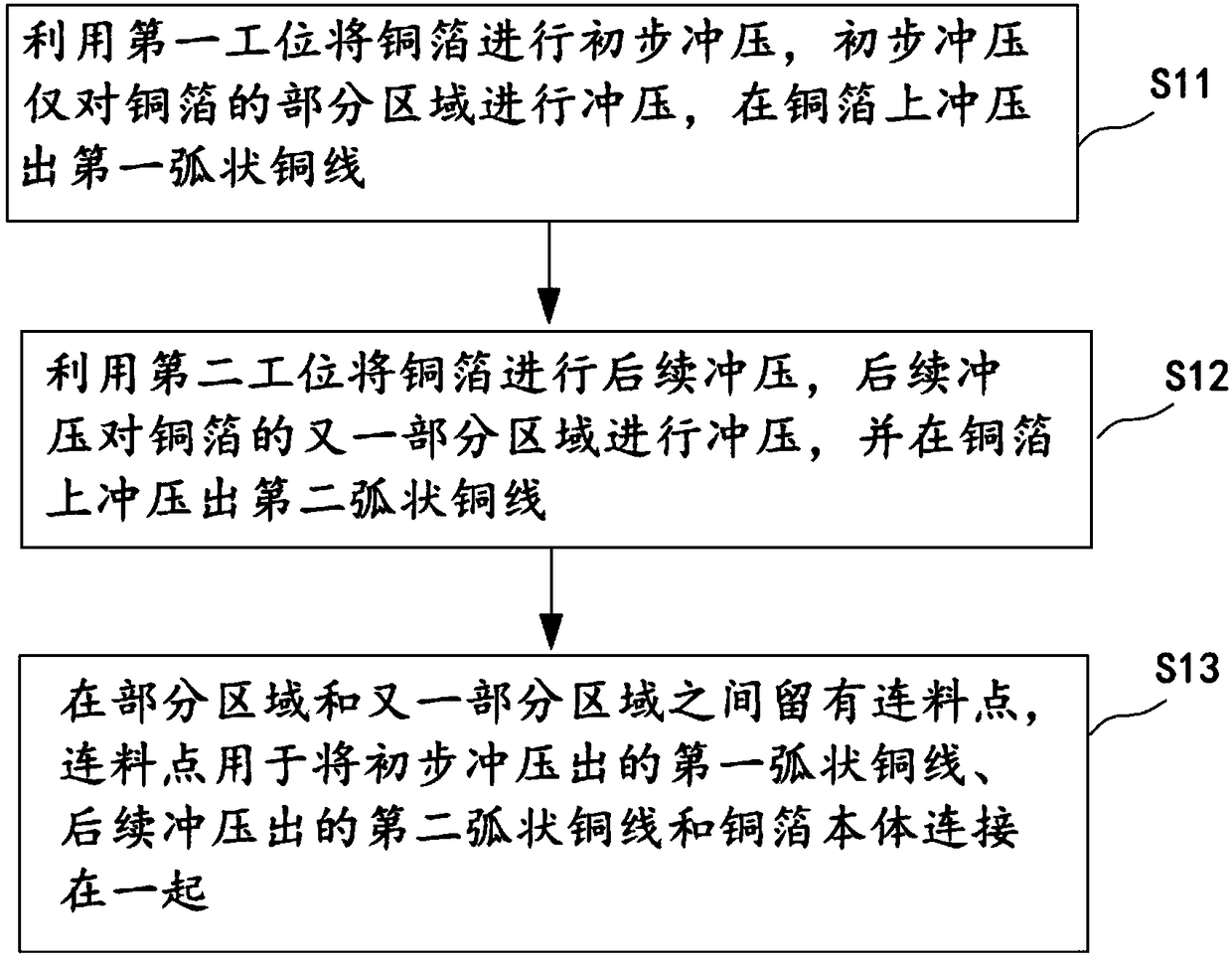

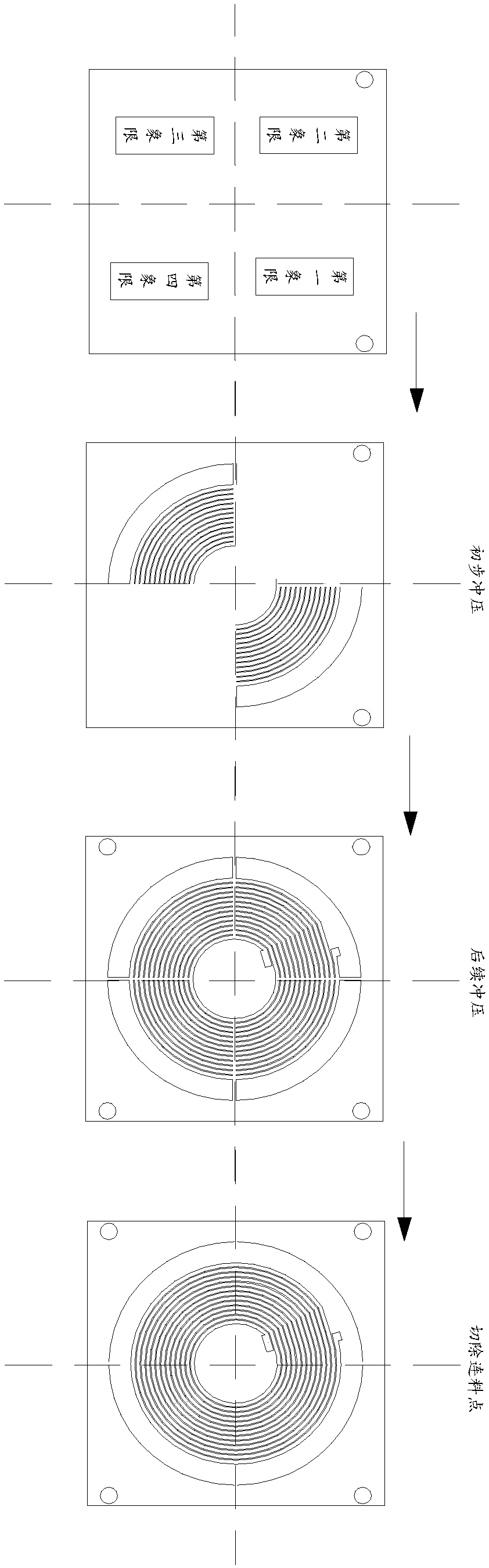

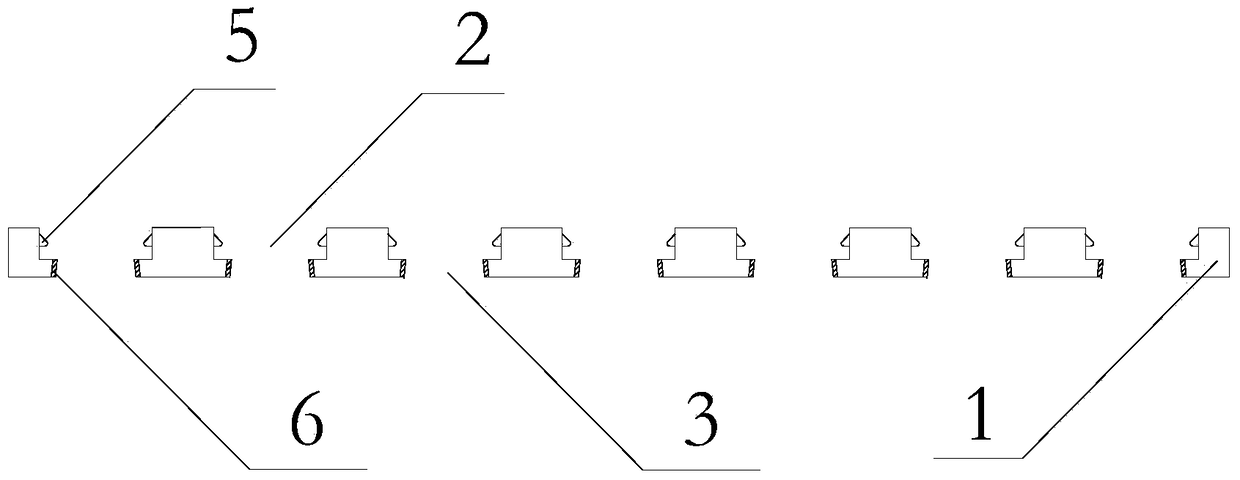

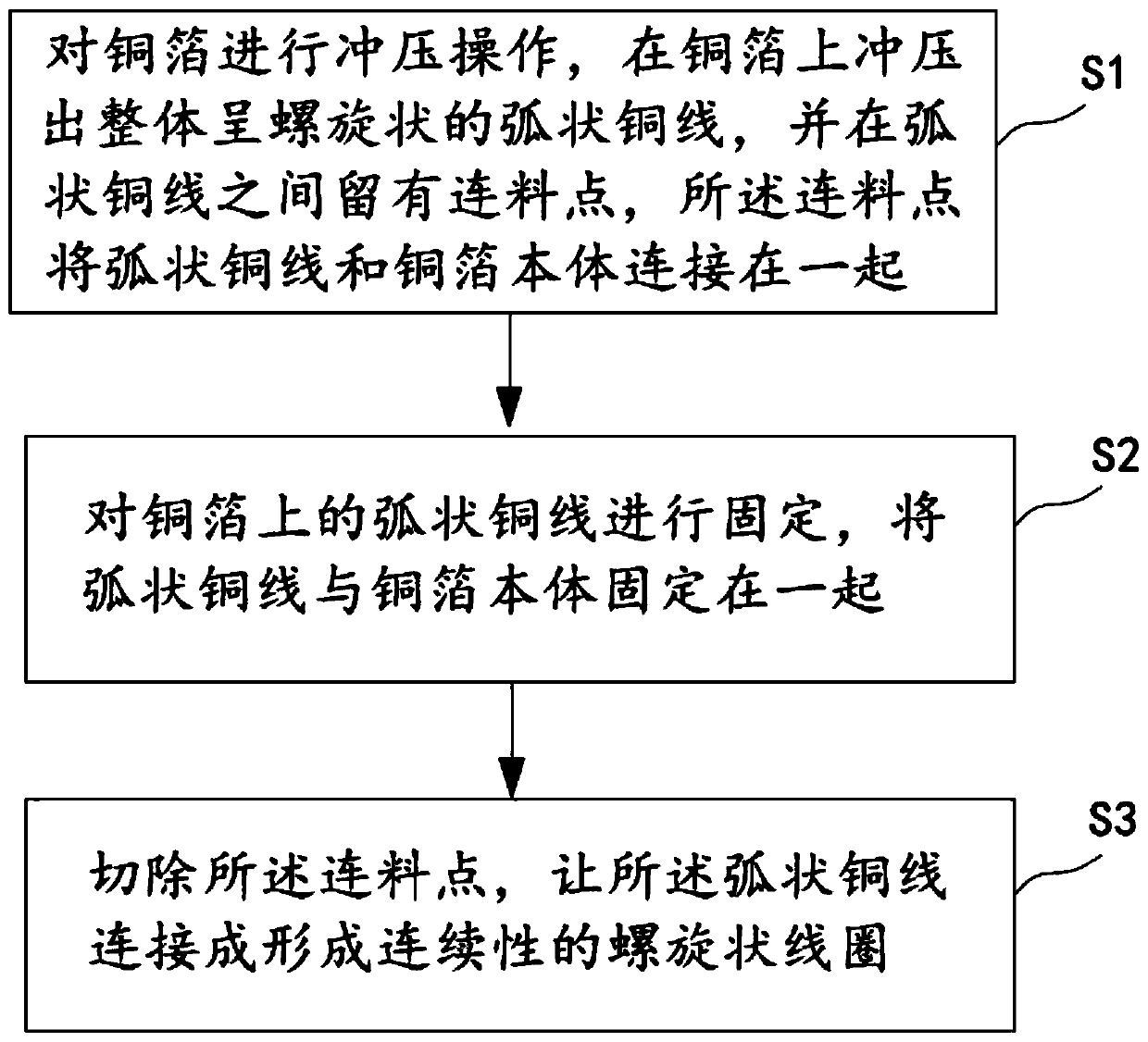

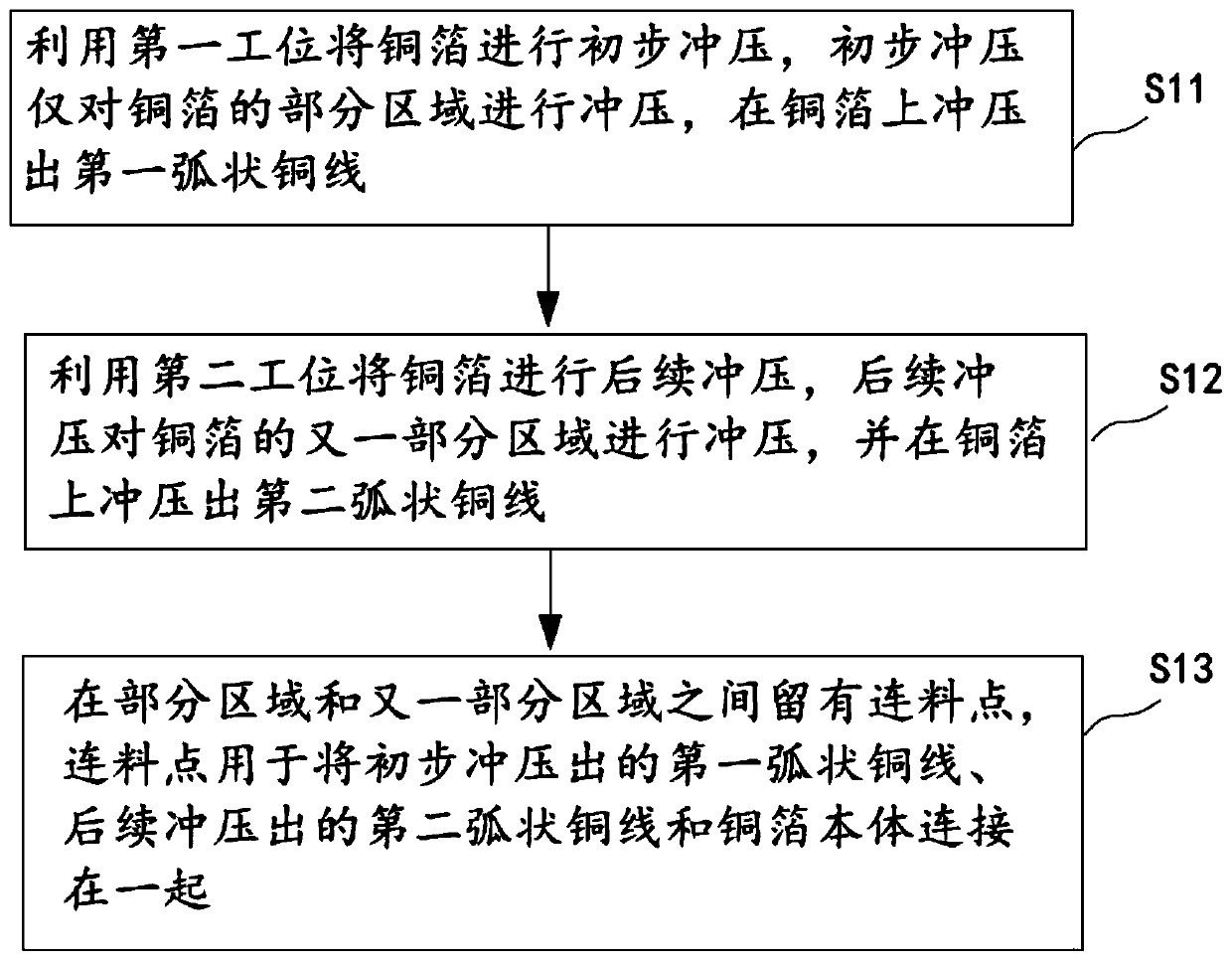

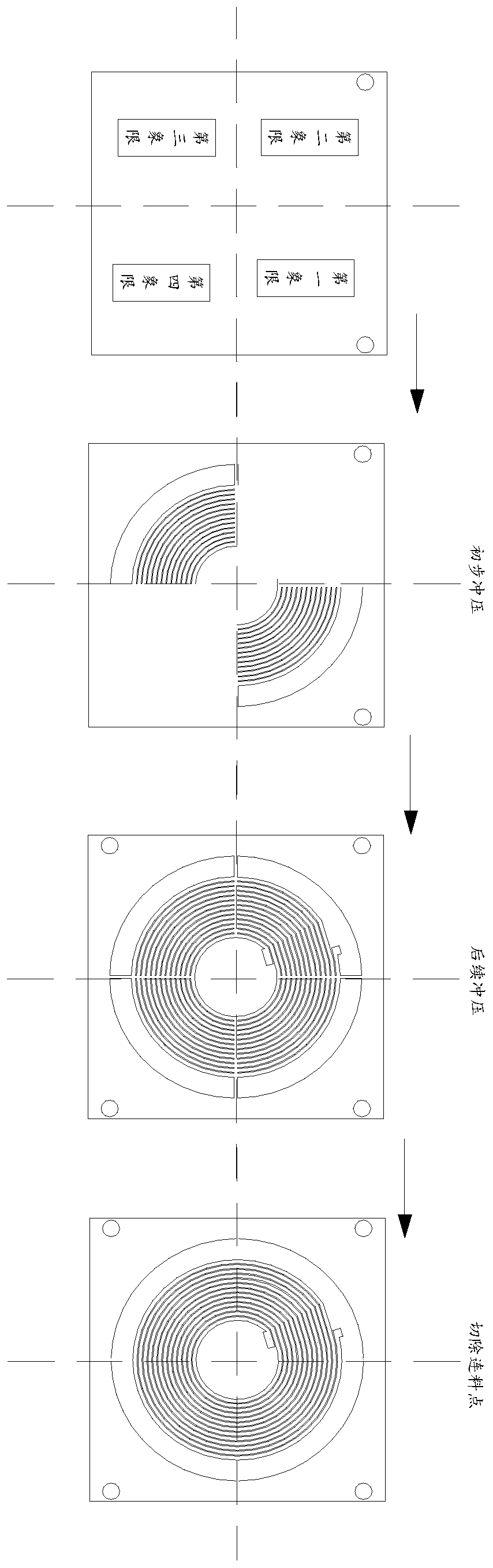

Method for manufacturing charging coil

ActiveCN108417381ASmooth rotationEasy to transportTransformers/inductances coils/windings/connectionsCoils manufacturePunchingCopper wire

The invention discloses a method for manufacturing a charging coil. The method comprises the following steps of: carrying out stamping operation on a copper foil, punching an arc-shaped copper wire with a spiral shape on the copper foil, and reserving a connecting material point between the arc-shaped copper wires, and connecting the arc-shaped copper wire and the copper foil body together; fixingthe arc-shaped copper wire on the copper foil, and fixing the arc-shaped copper wire and the copper foil body together; and cutting the connecting material points so that the arc-shaped copper wiresare connected to form a continuous spiral coil. The beneficial effect is that after the punching operation, the connecting point is left between the curved copper wires, and the connecting point is used to connect the arc-shaped copper wire with the copper foil body, thereby preventing the arc-shaped copper wire from prolapsed in a state in which the copper foil is suspended. Before the connectingpoint is cut off, the arc-shaped copper wire on the copper foil is fixed without prolapse. After the connecting point is cut off, the arc-shaped copper wire can be completely connected to form a continuous spiral coil, thereby manufacturing the charging coil.

Owner:DONGGUAN LINGYI PRECISION MFG TECH CO LTD

Outer spherical surface grinding fixture for spherical gasket

The invention discloses an outer spherical surface grinding fixture for a spherical gasket. The outer spherical surface of the spherical surface gasket is provided with a narrow groove. The outer spherical surface grinding fixture is characterized by comprising a fixture body, wherein a plurality of positioning pins are uniformly distributed on the top circumference of the outer spherical surface of the fixture body; the tops of the positioning pins are provided with transverse grooves. During grinding work, the spherical gasket distributed on the outer spherical surface of the fixture body is tied with a rope, and the rope passes through the narrow groove and the transverse grooves; the outer side end face of the fixture body is fixedly connected with an end cover; the outer side end face of the end cover is provided with a rotary plate and a check block; the rotary plate and the end cover are connected with each other through a pin shaft; the pin shaft movably passes through a center hole of the rotary plate, and is fixedly connected to the end cover; the outer side end face of the rotary plate is provided with a spring; the check block is fixed on the end cover; the two ends of the rope pass through the outer spherical surface of the fixture body to enter the inner hole of the fixture body, and pass through the end cover to be connected to the rotary plate. The outer spherical surface grinding fixture is applied to grinding of the outer spherical surface of the spherical gasket, rapid clamping and reliable fixing of the spherical gasket can be realized, and the working efficiency is increased.

Owner:瑞安市天裕机械有限公司

Auxiliary installation device of high-rise fire life saving machine for fire life saving

The invention discloses an auxiliary installation device of a high-rise fire life saving machine for fire life saving. The auxiliary installation device comprises an installation seat, a supporting structure, an installation sleeve, a supporting rod, a connecting sleeve, a guide wheel, a limiting rod, a fixing structure and clamping and fixing plates. The auxiliary installation device of the high-rise fire life saving machine for fire life saving has the beneficial effects that the clamping and fixing plates are arranged on the bottom side of the installation seat in parallel, fixing can be quickly carried out on a wall body in a use area through a descent control device, and meanwhile, the supporting rod located in the interior of the installation sleeve can slide relative to the installation sleeve so that a user can carry out adjustment on the extension length of the supporting rod according to the form of a building, and and the situation that a rope is directly contacted with thewall surface to cause rope jamming is avoided; the guide wheel located at the end of the supporting rod can greatly reduce frictional resistance generated in the sliding process of the rope, the sideface of the guide wheel is of an arc-shaped structure, and therefore the phenomenon that the rope can disengage when sliding on the side face of the guide wheel does not occur, and the safety of the lifesaving descent control device in the using process is improved.

Owner:任小平

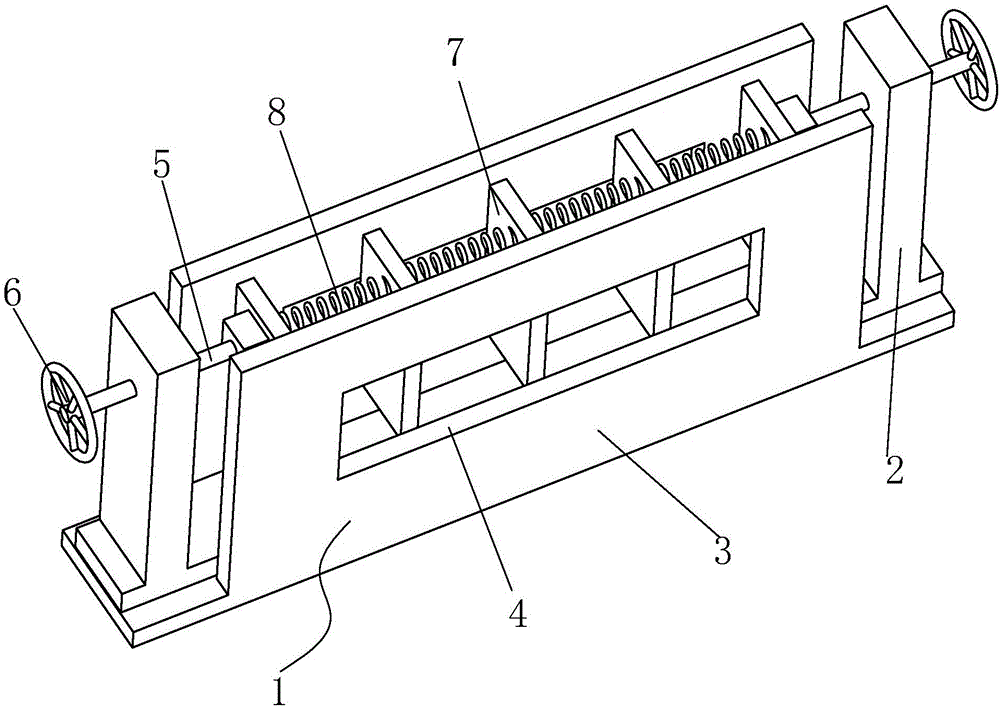

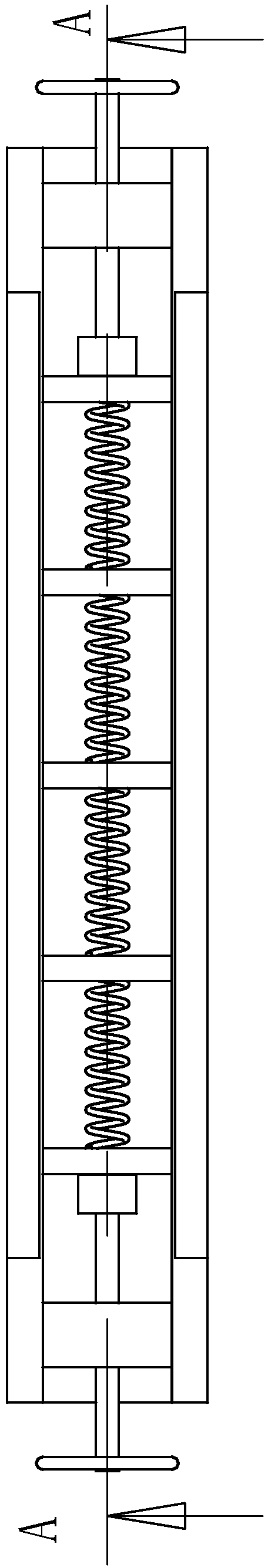

Tooth-shaped paper strip carding frame

ActiveCN106671562ANo prolapseImprove adjustment flexibilityMechanical working/deformationLamination ancillary operationsPulp and paper industry

The invention relates to a tooth-shaped paper strip carding frame. The tooth-shaped paper strip carding frame comprises a main frame body, wherein a supporting plate is arranged on each of the left side and the right side of the main frame body; a baffle plate is fixed on each of the front side and the rear side of the main frame body; a rectangular through hole is formed in the middle of each baffle plate; a screw is transversely arranged in each supporting plate in a matched manner; a rotary disc is fixed at the outer end of each screw; a plurality of limiting plates are uniformly and vertically arranged in the main frame body; a spring is fixedly mounted between upper parts of every two adjacent limiting plates; the lower parts of the limiting plates extend to the positions below the rectangular through holes; the left end surface of the limiting plate on the left-most side is movably connected with the right end of the screw on the left side, and the right end surface of the limiting plate on the right-most side is movably connected with the left end of the screw on the right side. According to the tooth-shaped paper strip carding frame, the multiple springs with the same elastic coefficient are taken as distance control parts for the limiting plates, so that the distance between any two adjacent limiting plates can keep identical effectively, and compared with a conventional tooth-shaped paper strip carding mode adopting metal columns, the tooth-shaped paper strip carding frame has the advantage that the adjustment flexibility can be greatly improved.

Owner:重庆南变机电有限公司

Spherical Gasket Grinding Fixture

ActiveCN104827393BNo prolapseAvoid reverse rotationGrinding work supportsTransverse grooveEngineering

The invention discloses a spherical washer grinding fixture. An outer spherical surface of each ground spherical washer is provided with a narrow groove along the diameter direction. The spherical washer grinding fixture is characterized in that the spherical washer grinding fixture comprises a fixture body, a plurality of positioning pins are circumferentially and evenly distributed on the top of an outer spherical surface of the fixture body, and the top of each positioning pin is provided with a transverse groove. During grinding operation, the spherical washers arranged on the outer spherical surface of the fixture body are bound by a rope, the rope passes through the narrow grooves and the transverse grooves, one end of the rope is fixed on the fixture body, the other end of the rope is connected with the outer circle of a rotating ring, the rotating ring is screwed on a screw, and the screw is fixedly connected with a flange plate; when the rotating ring is rotated in a forward direction, while tensioning the rope, the rotating ring moves in a direction away from the screw; the outer end surface of the rotating ring is fixedly connected with a handwheel, and the screw head of a locking screw on the handwheel aims at the head end of the screw. The spherical washer grinding fixture which is used for the grinding of the outer spherical surfaces of the spherical washers can rapidly clamp and reliably fix the spherical washers, and increases working efficiency.

Owner:HAIAN KEHAO TEXTILE CO LTD

A toothed carding rack for paper strips

ActiveCN106671562BNo prolapseImprove adjustment flexibilityMechanical working/deformationLamination ancillary operationsPulp and paper industry

The invention relates to a tooth-shaped paper strip carding frame. The tooth-shaped paper strip carding frame comprises a main frame body, wherein a supporting plate is arranged on each of the left side and the right side of the main frame body; a baffle plate is fixed on each of the front side and the rear side of the main frame body; a rectangular through hole is formed in the middle of each baffle plate; a screw is transversely arranged in each supporting plate in a matched manner; a rotary disc is fixed at the outer end of each screw; a plurality of limiting plates are uniformly and vertically arranged in the main frame body; a spring is fixedly mounted between upper parts of every two adjacent limiting plates; the lower parts of the limiting plates extend to the positions below the rectangular through holes; the left end surface of the limiting plate on the left-most side is movably connected with the right end of the screw on the left side, and the right end surface of the limiting plate on the right-most side is movably connected with the left end of the screw on the right side. According to the tooth-shaped paper strip carding frame, the multiple springs with the same elastic coefficient are taken as distance control parts for the limiting plates, so that the distance between any two adjacent limiting plates can keep identical effectively, and compared with a conventional tooth-shaped paper strip carding mode adopting metal columns, the tooth-shaped paper strip carding frame has the advantage that the adjustment flexibility can be greatly improved.

Owner:重庆南变机电有限公司

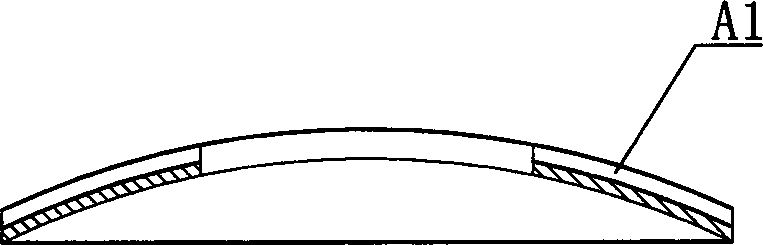

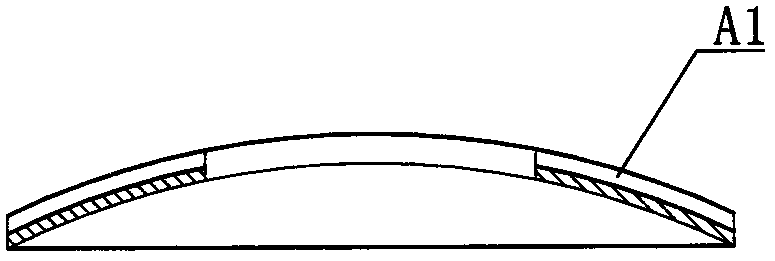

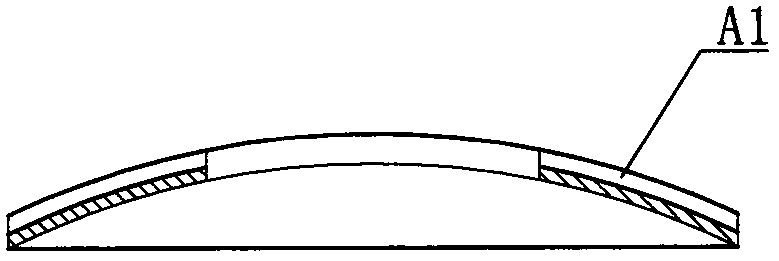

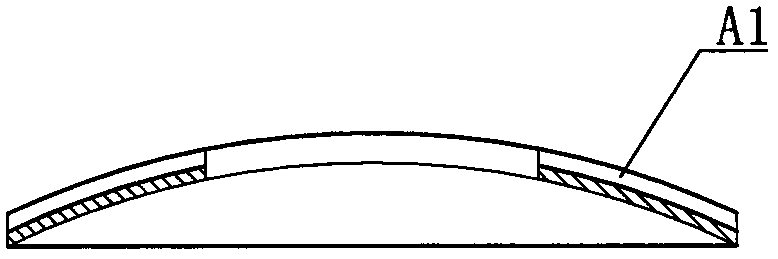

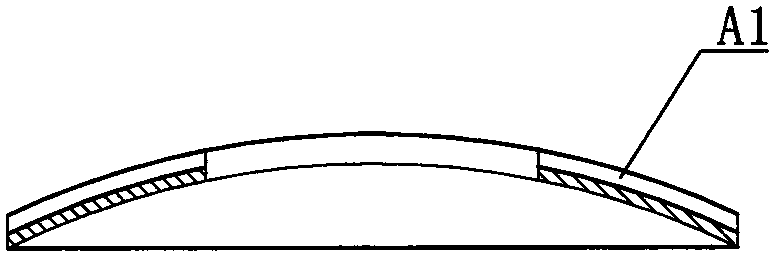

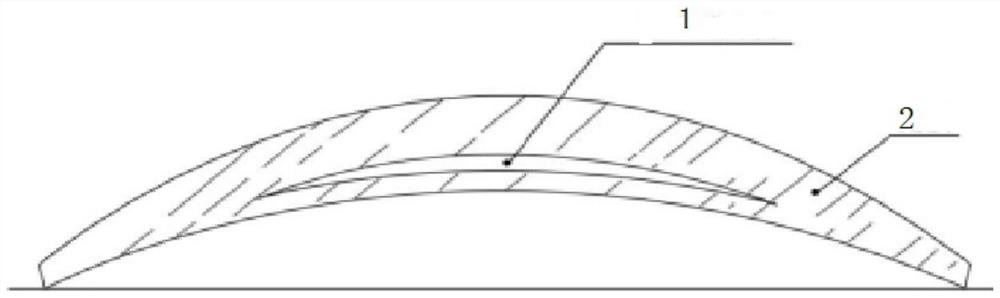

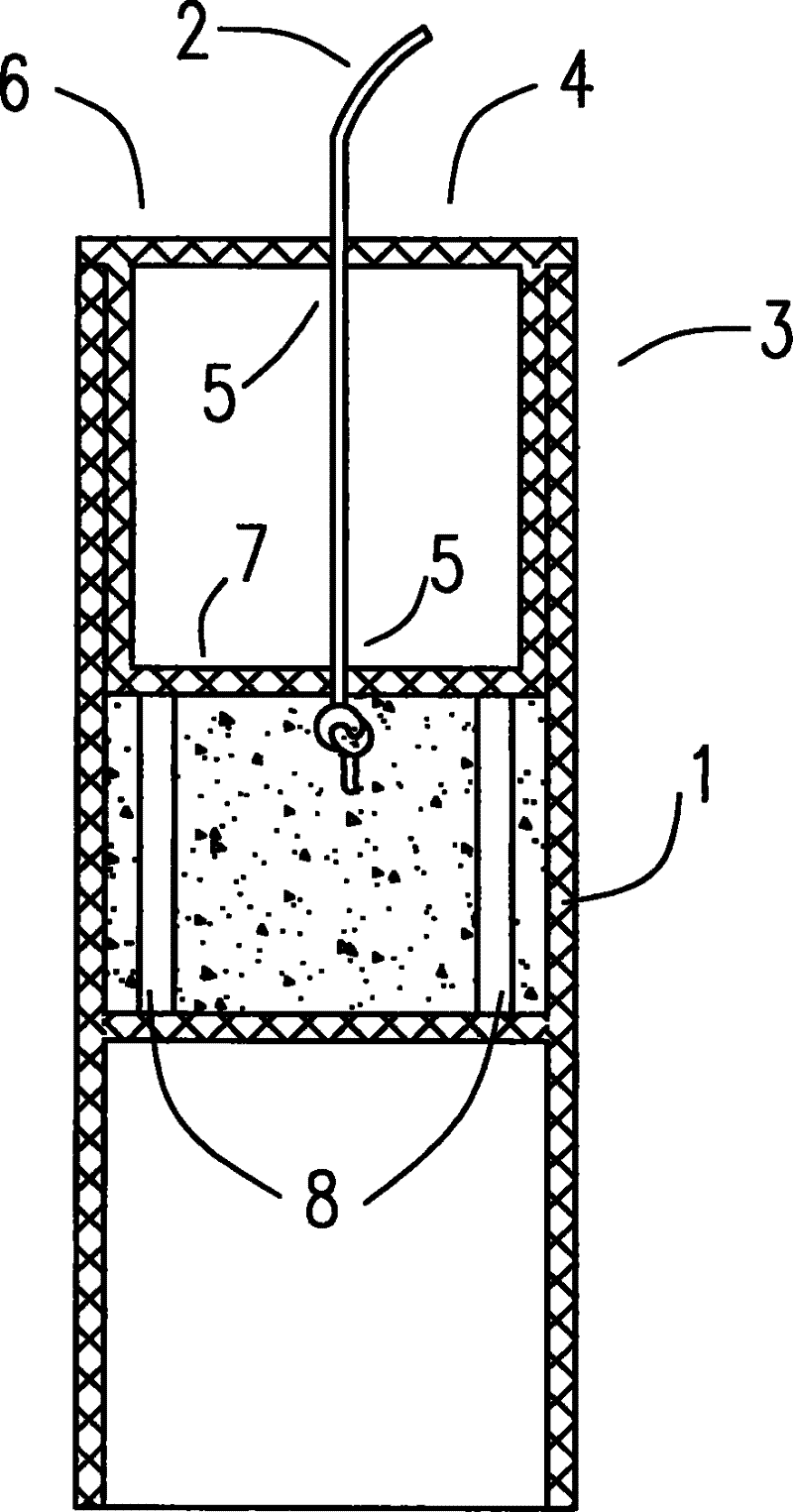

Artificial corneal endothelium in corneal stroma and preparation method thereof

PendingCN113101411ANo prolapseMedium water contentTissue regenerationProsthesisOphthalmologyBiomedical engineering

The invention discloses an artificial corneal endothelium in corneal stroma and a preparation method thereof. The preparation method comprises the following steps: preparing a dry-state silicon hydrogel mold blank: polymerizing a silicon hydrogel monomer into the dry-state silicon hydrogel mold blank; turning processing: fixing the dry silicone hydrogel mold base to a numerical control lathe, and turning artificial corneal endothelium, wherein the curvature radius of the front surface of the artificial corneal endothelium is consistent with that of the front surface of the cornea, and the curvature radius of the rear surface of the artificial corneal endothelium is close to that of the rear surface of the cornea; and polishing and hydration: polishing and trimming the front and rear surfaces of the artificial corneal endothelium, and fully hydrating in normal saline to form the colloidal corneal endothelium. The bottleneck that corneal endothelium transplantation must depend on the cornea of a high-quality donor is broken through, and the artificial corneal endothelium is implanted between corneal stroma layers of a patient, so that the artificial cornea does not take off, the intraocular interference is avoided, and the product is very safe.

Owner:广州宏达医疗设备有限公司

Method and device for controlling weight

A method and a device for controlling a weight capable of rapidly lowering the weight without producing problems with line slack and others. In the method of controlling the lowering speed of the weight when the weight attached to a fishline is lowered from a sea level to a specified depth, the weight comprises a deceleration means for decelerating the lowering speed of the weight according to the reduction in speed when the weight is positioned at a depth corresponding to a speed reducing area when a change in the speed of the weight when the weight is lowered by its own weight is classifiedinto a speed increasing area where the weight is thrown into the sea level, accelerated, and reaches the maximum speed, the speed reducing area where the speed of the weight is changed to be reduced after the speed increasing area, and a constant speed area where the speed of the weight is converged to an approximately specified value after the speed reducing area.

Owner:TOWA ELECTRIC SEISAKUSHO +1

A jig for grinding spherical gaskets

Owner:江苏广大瑞康农业发展有限公司

Environmental protection and safety firecrackers

An environmentally friendly and safe firecracker, comprising a shell and a lead wire, the shell is a U-shaped plastic molded part with an open end and a closed end, the inner cavity of the closed end is provided with a gunpowder part, and it is characterized in that: the shell It is a thin-walled shell, and also includes an end cover, the end cover is a plastic molded part, and the end cover is provided with lead through holes. One improvement is that the end cap is provided with a downwardly extending limiting foot. The invention has a simple structure, the shell and the end cover can be molded at one time, which is convenient for industrial production, has high safety factor in the production process, low cost of raw materials and processing, and the overall cost is reduced by more than 30%; the shell is closed, the moisture resistance is good, and the product reliability is high; Crisp, with echo effect, good burst loudness; burst rate of more than 95%, good safety performance; no paper scraps in discharge, discharge waste can be recycled, and the environmental protection benefits are remarkable.

Owner:祝阳

A kind of organosilicon dipping paint and its preparation method and application

The invention relates to the field of paint chemical industry, in particular to an organosilicon impregnating paint and its preparation method and application. The tensile strength of the cured product of the organosilicon impregnating varnish is above 15MPa, preferably in the range of 15-20MPa, and the bending strength of the cured product of the organosilicon impregnating varnish is above 25MPa, preferably in the range of 25-35MPa. The mechanical strength of the organosilicon impregnating paint of the invention has been greatly improved.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

A kind of yarn package

ActiveCN105314261BPlace stableImprove drum transport efficiencyRigid containersContainers with multiple articlesYarnBobbin

The invention relates to a yarn bobbin package which comprises a plurality of lining plates. The upper surface of each lining plate is provided with a plurality of first grooves, and the lower surface of each lining plate is provided with second grooves which are identical with the first grooves in number and in one-to-one correspondence with the first grooves. The first grooves are communicated with the second grooves in a one-to-one vertical alignment mode. Each lining plate is provided with through holes identical with the first grooves in number. The lining plates are overlapped in sequence, yarn bobbins to be packaged are fixed between every two adjacent lining plates, the upper ends of the yarn bobbins to be packaged are embedded into the second grooves of the upper lining plates, and the lower ends of the yarn bobbins to be packaged are embedded into the first grooves of the lower lining plates, so that the whole package is formed. According to the yarn bobbin package, the defect that in a traditional mode, yarn bobbins collide with one another and consequently the yarn quality is affected due to the fact that the yarn bobbins deviate from positions in the transporting process is overcome; it is ensured that the yarn bobbins are firmly stored in the whole package, the packaging efficiency and the yarn bobbin transporting efficiency are improved, transportation losses are lowered, and the transportation cost is reduced; the yarn bobbin package is simple in structure and low in cost.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD

Manufacturing method of charging coil stamping

ActiveCN108417381BPrevent prolapseSmooth rotationTransformers/inductances coils/windings/connectionsCoils manufacturePunchingCopper wire

The invention discloses a method for manufacturing a charging coil. The method comprises the following steps of: carrying out stamping operation on a copper foil, punching an arc-shaped copper wire with a spiral shape on the copper foil, and reserving a connecting material point between the arc-shaped copper wires, and connecting the arc-shaped copper wire and the copper foil body together; fixingthe arc-shaped copper wire on the copper foil, and fixing the arc-shaped copper wire and the copper foil body together; and cutting the connecting material points so that the arc-shaped copper wiresare connected to form a continuous spiral coil. The beneficial effect is that after the punching operation, the connecting point is left between the curved copper wires, and the connecting point is used to connect the arc-shaped copper wire with the copper foil body, thereby preventing the arc-shaped copper wire from prolapsed in a state in which the copper foil is suspended. Before the connectingpoint is cut off, the arc-shaped copper wire on the copper foil is fixed without prolapse. After the connecting point is cut off, the arc-shaped copper wire can be completely connected to form a continuous spiral coil, thereby manufacturing the charging coil.

Owner:DONGGUAN LINGYI PRECISION MFG TECH CO LTD

Fixture for grinding outer spherical surfaces of spherical washers

ActiveCN104827389ANo prolapseSimple structureGrinding work supportsMechanical engineeringTransverse groove

The invention discloses a fixture for grinding outer spherical surfaces of spherical washers. The outer spherical surface of each ground spherical washer is provided with a narrow groove along the diameter direction. The fixture is characterized in that the fixture comprises a fixture body, a plurality of positioning pins are circumferentially and evenly distributed on the top of an outer spherical surface of the fixture body, and the top of each positioning pin is provided with a transverse groove. During grinding operation, the spherical washers arranged on the outer spherical surface of the fixture body are bound by a rope, the rope passes through the narrow grooves and the transverse grooves, the outer end surface of the fixture body is fixedly connected with an end cover, a rotating plate is arranged on the outer end surface of the end cover, the rotating plate is connected with the end cover through a locking screw, the locking screw movably passes through the central hole of the rotating plate and is then screwed in the end cover, and both ends of the rope pass through the outer spherical surface of the fixture to enter the hole of the fixture body, and then pass through the end cover to connect with the rotating plate. The fixture which is used for the grinding of the outer spherical surfaces of the spherical washers can rapidly clamp and reliably fix the spherical washers, and increases working efficiency.

Owner:TIANJIN JINHANG COMP TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com