Yarn bobbin package

A yarn tube and coaxial technology is applied in the field of yarn tube packaging to achieve the effects of improving packaging efficiency and yarn tube transportation efficiency, low cost and saving transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

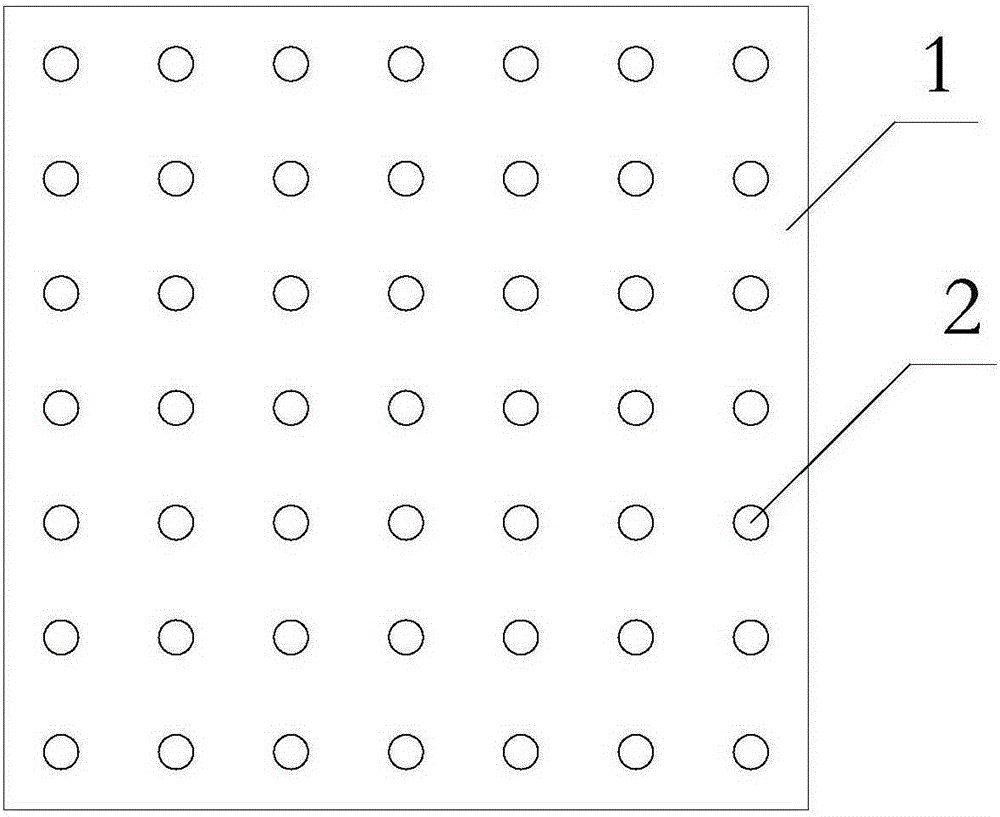

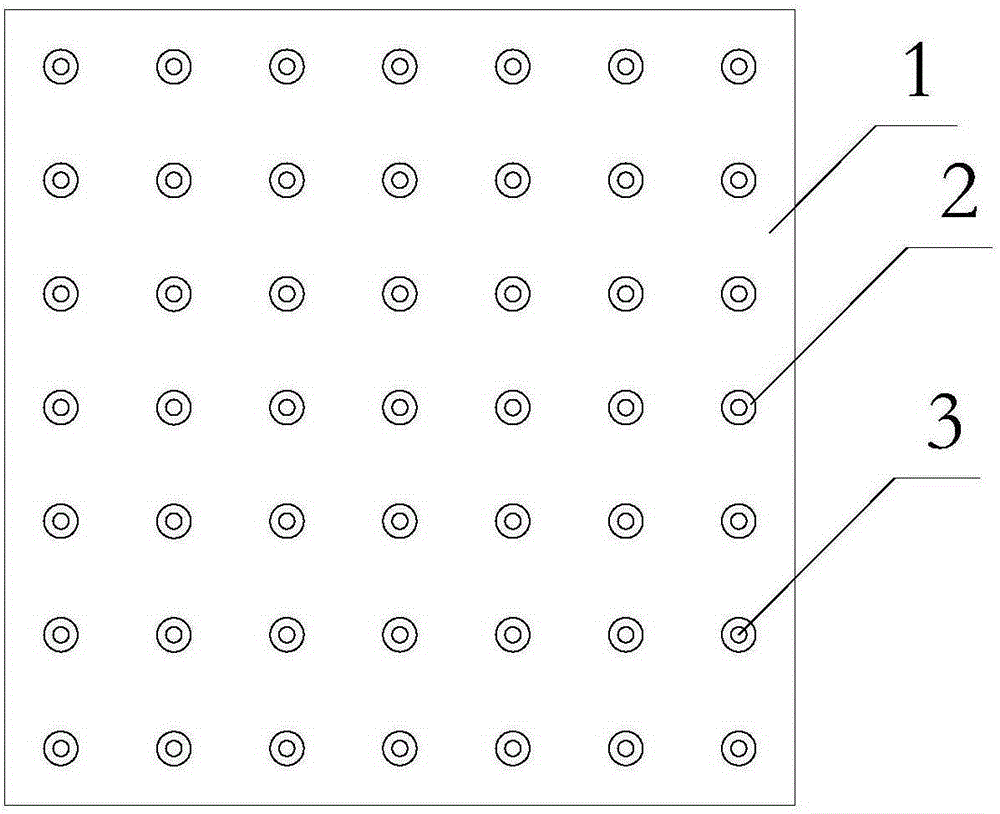

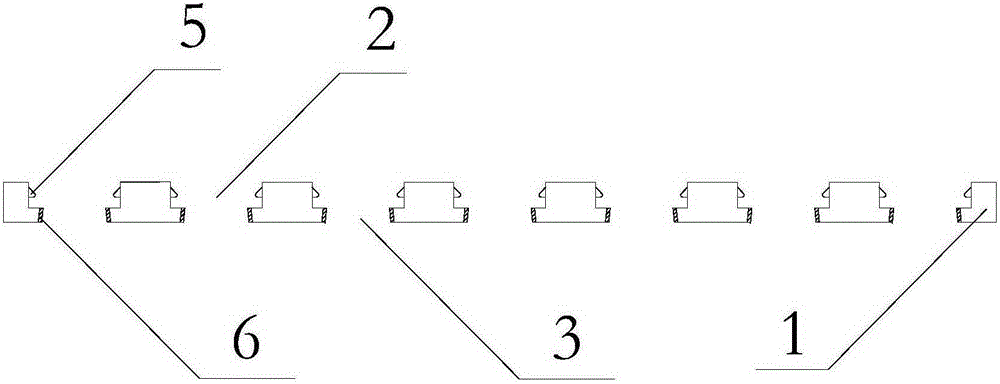

[0032] Such as figure 1 , 2 As shown in , 3 and 4, a yarn drum package includes a plurality of backing boards 1, the upper surface of each of the backing boards 1 is provided with several first grooves 2, and the lower surface of each of the backing boards 1 The surface is provided with second grooves 3 which have the same number as the first grooves 2 and correspond one by one. The same number of through holes as the number of the first grooves 2 is formed on the board 1, and a plurality of the lining boards 1 are stacked in sequence, and the yarn bobbin 8 to be packaged is fixed in two adjacent lining boards 1 between, and the upper end of the yarn bobbin 8 to be packaged is embedded in the second groove 3 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com