Fast and automatic compressing device for waste

A compression device and fast technology, applied in the field of compression devices, can solve the problem of slow compression of waste materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

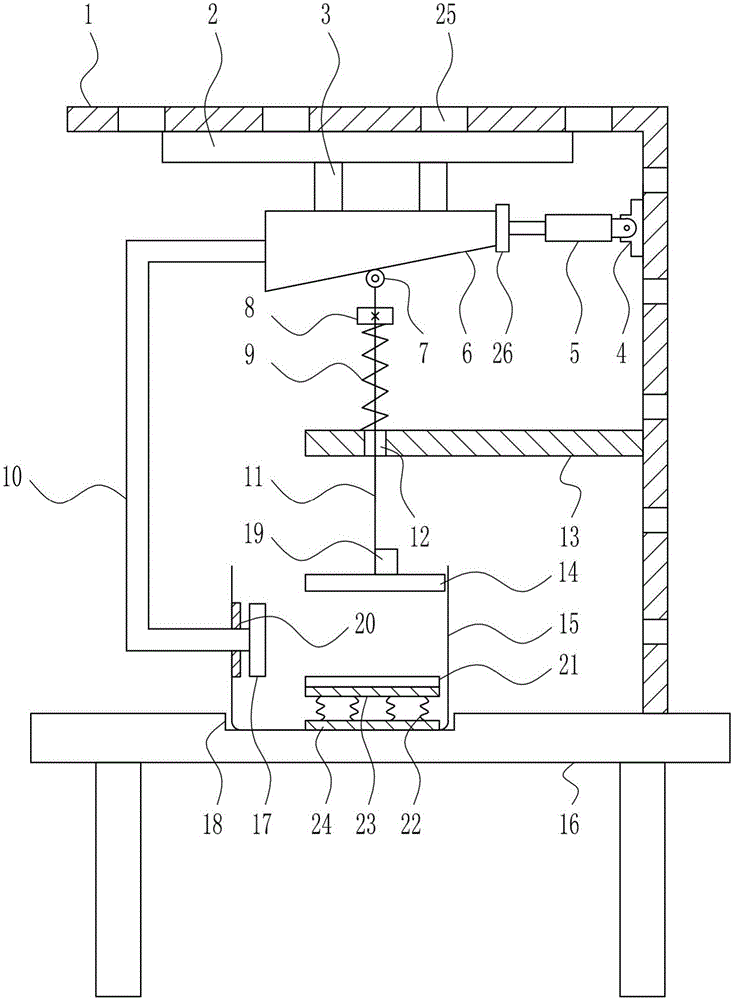

[0022] A rapid automatic compression device for waste materials, such as figure 1 As shown, it includes a first bracket 1, a slide rail 2, a slider 3, a fixed seat 4, an electric push rod 5, a wedge block 6, a contact wheel 7, a fixed stop 8, a first spring 9, a second bracket 10, Lifting rod 11, guide plate 13, first pressing plate 14, collecting frame 15, storage table 16 and second pressing plate 17; On the left side, a slide rail 2 is provided in the middle of the top of the first bracket 1, a slide rail 2 is provided with a slide block 3, a wedge block 6 is provided at the lower end of the slide block 3, and a second support 10 is provided in the middle of the left end of the wedge block 6. The right end of the support 10 passes through the collection frame 15, the second support 10 right end is provided with a second pressing plate 17, the inner right wall of the first support 1 is provided with a fixed seat 4 and a guide plate 13, and the fixed seat 4 is positioned abov...

Embodiment 2

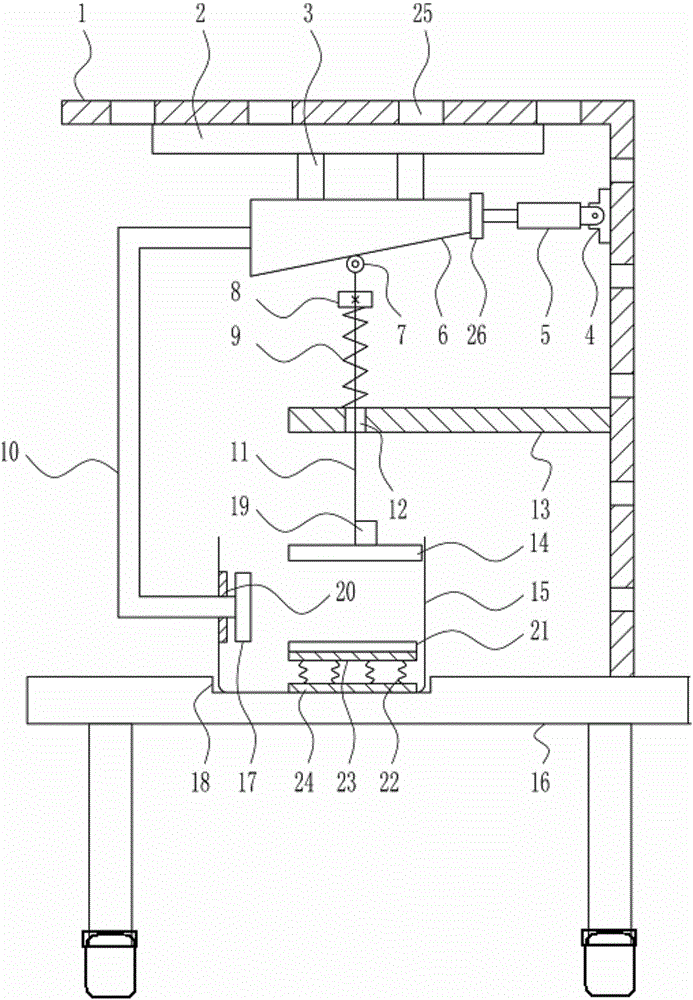

[0039] A rapid automatic compression device for waste materials, such as figure 2 As shown, on the basis of Embodiment 1, a universal wheel and a locking mechanism are added to facilitate the rapid and flexible movement of the compression device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com