Testing apparatus for service life of load of valve execution mechanism and using method thereof

A valve execution, load life technology, applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc., can solve problems such as inability to provide constant load, easy deformation of disc springs, uncontrollable torque, etc. The load life test data is real, the torque adjustment is convenient, and the torque is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

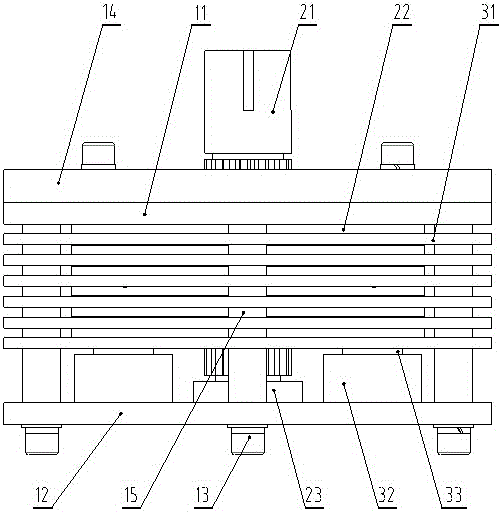

[0038] Such as figure 1 A structural schematic diagram of a valve actuator load life testing device provided by the present invention is as follows:

[0039] A valve actuator load life testing device, including a frame, a rotating mechanism and a loading mechanism;

[0040] The frame includes a top plate 11, a bottom plate 12 and more than three pillars 13; the pillars 13 are supported between the top plate 11 and the bottom plate 13 to form a machine cavity, and the top plate 11 is also covered with a test board 14 for placing the actuator;

[0041] The rotating mechanism includes a rotating shaft 21, a rotating disk 22 and a bearing 23; bearings 23 are respectively installed in the center of the top plate 11 and the bottom plate 12, the rotating shaft 21 is installed in the two bearings 23 and the upper end passes through the top plate 11 and the mounting plate 14, more than one The rotating disc 22 is installed horizontally on the rotating shaft 21 in the machine cavity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com