Patents

Literature

148results about How to "Reliable loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

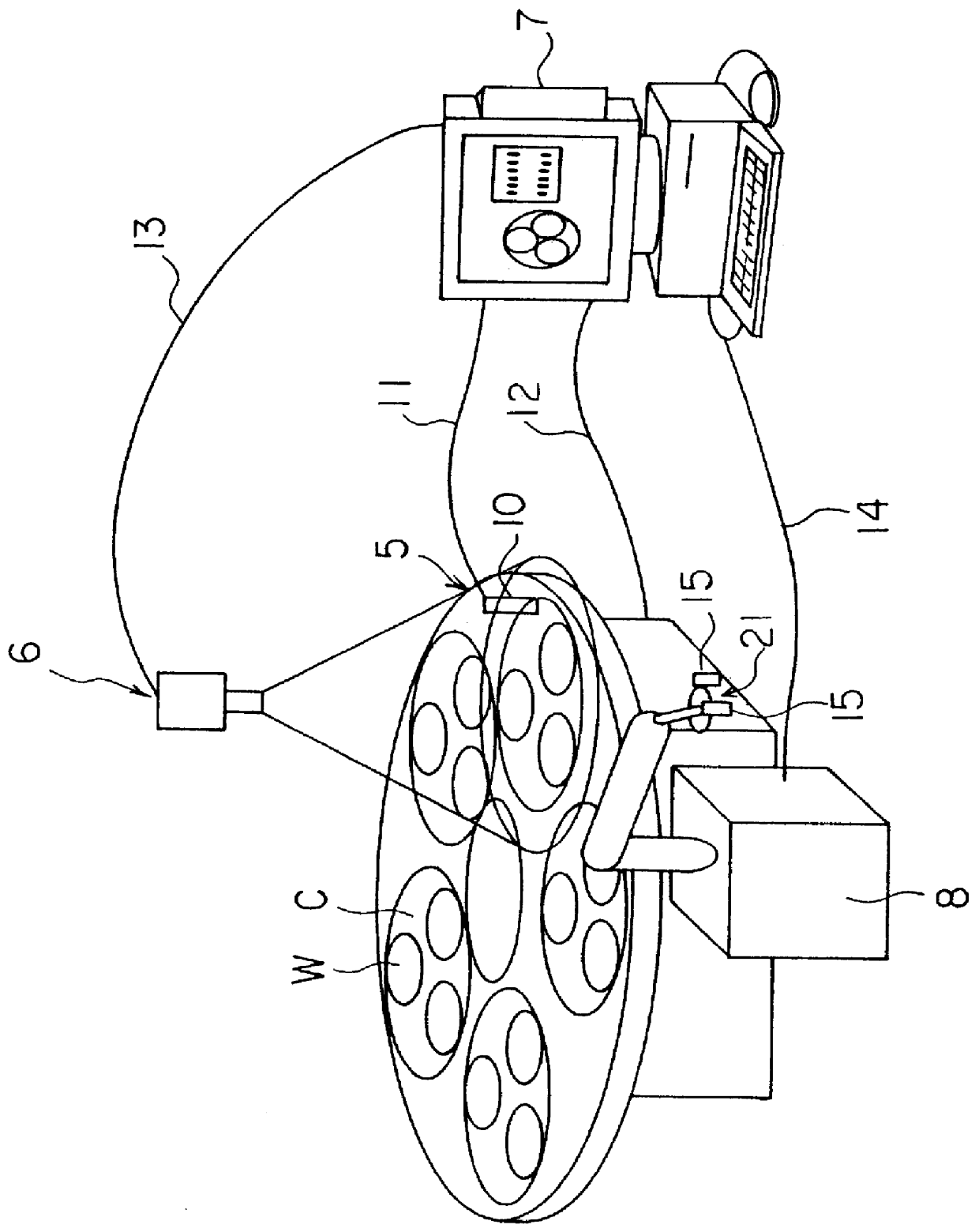

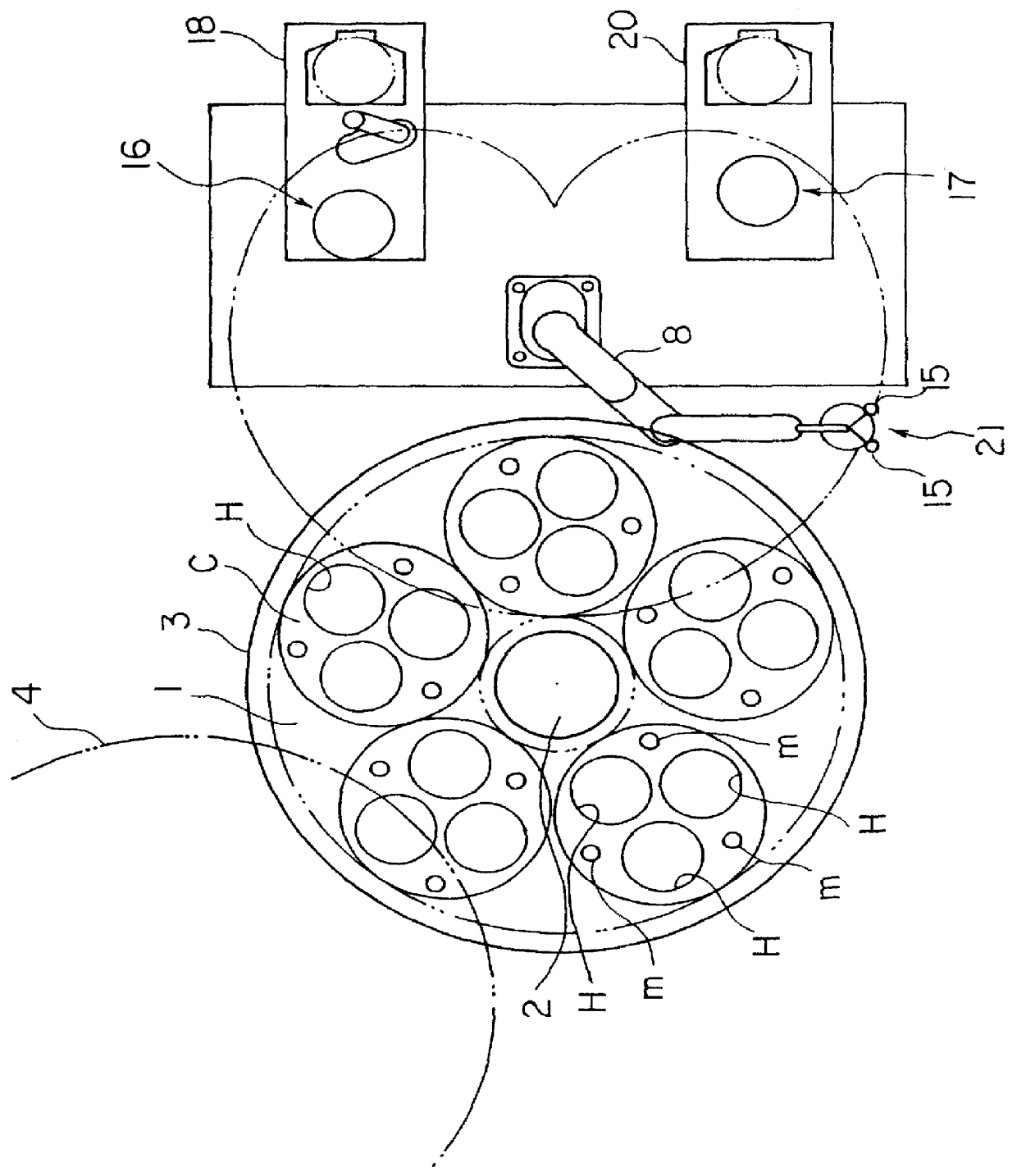

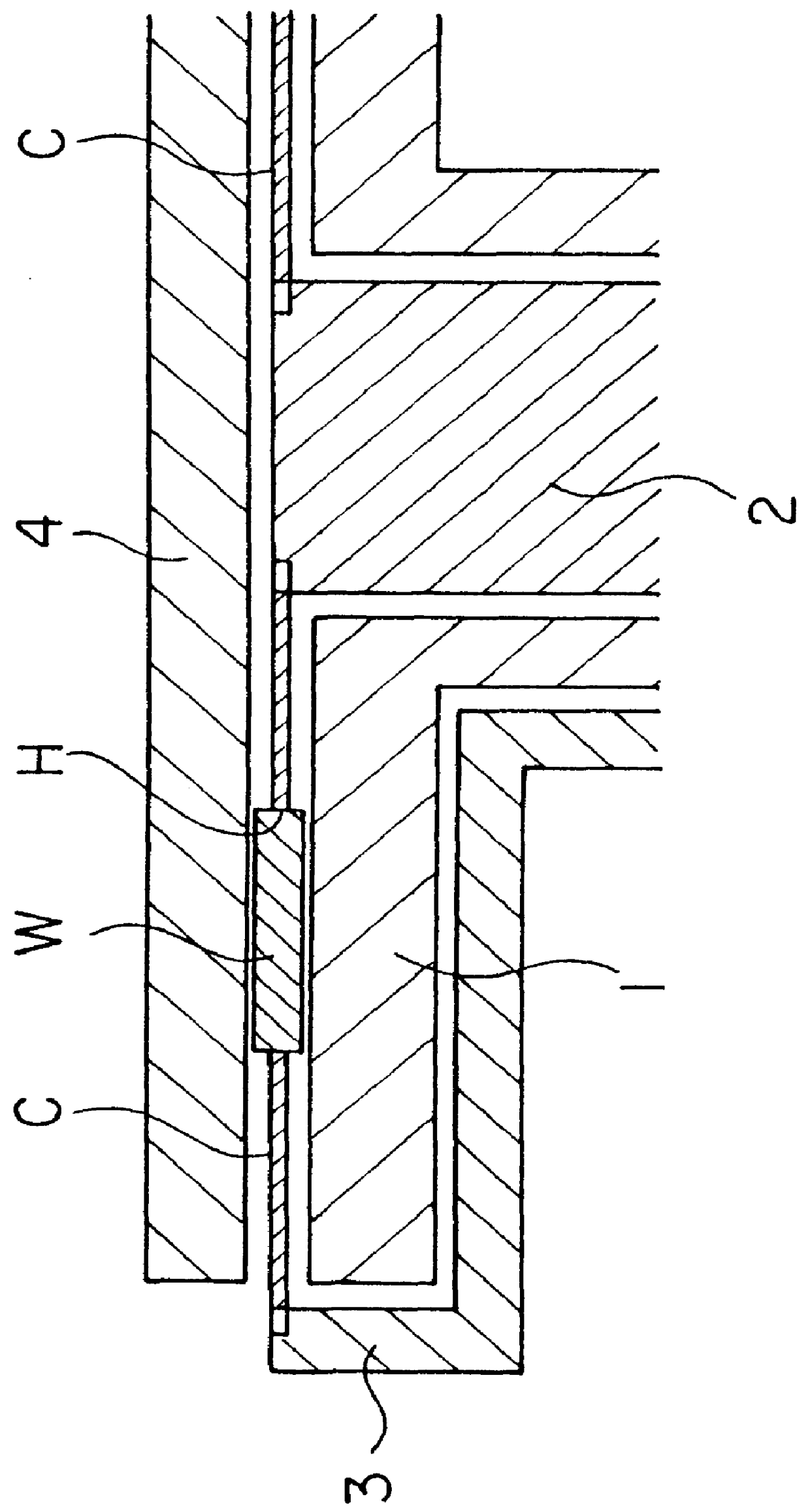

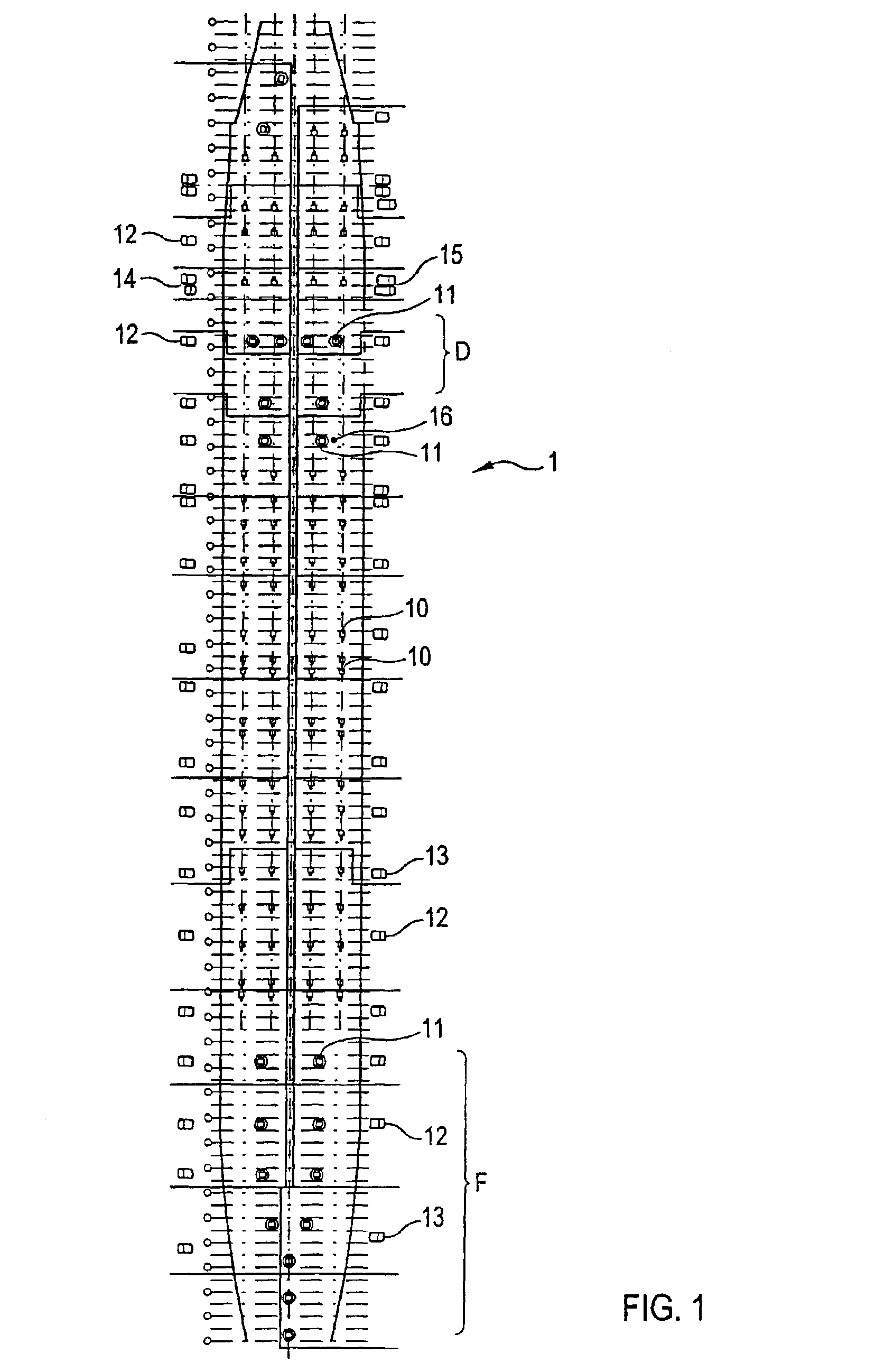

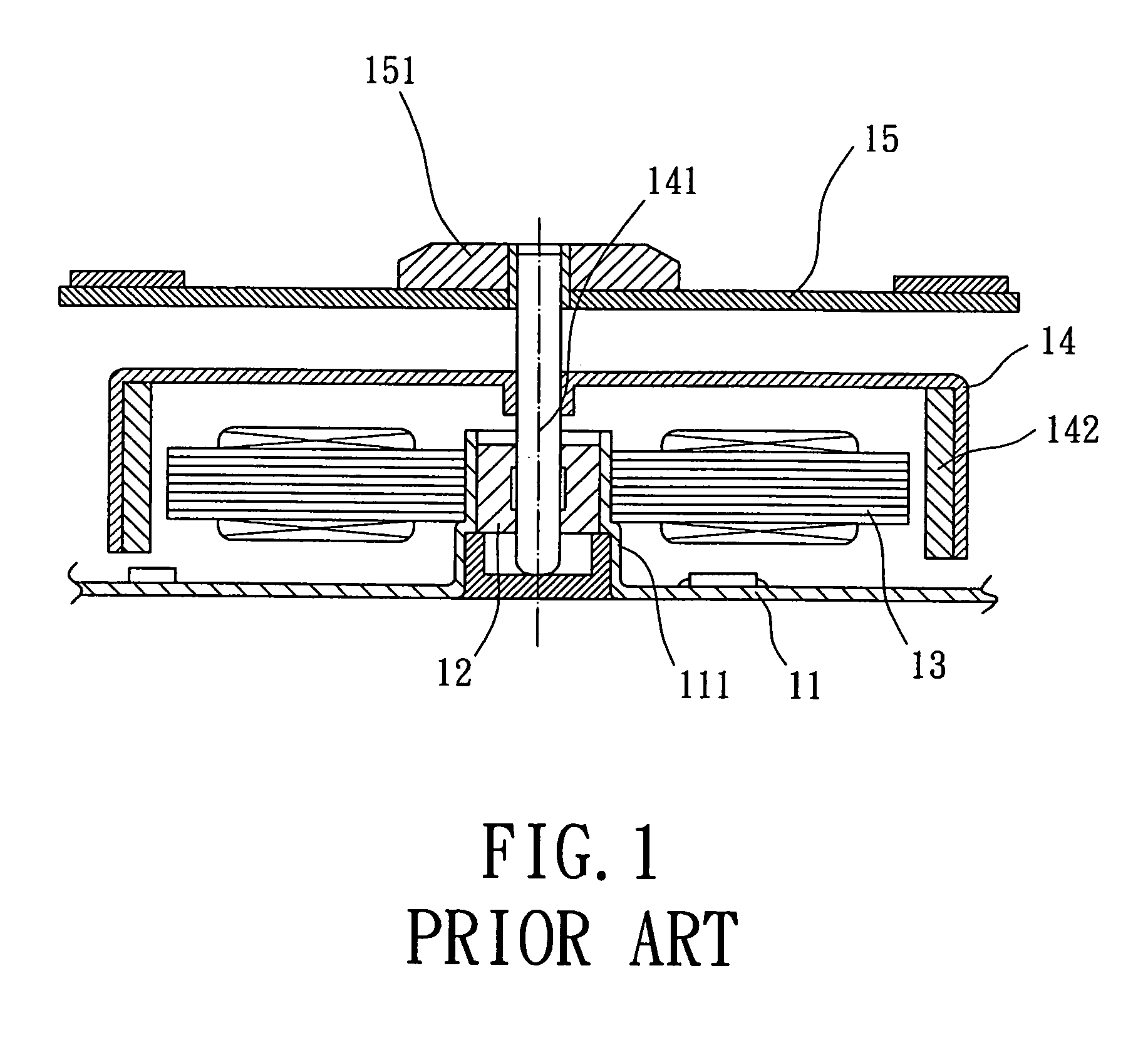

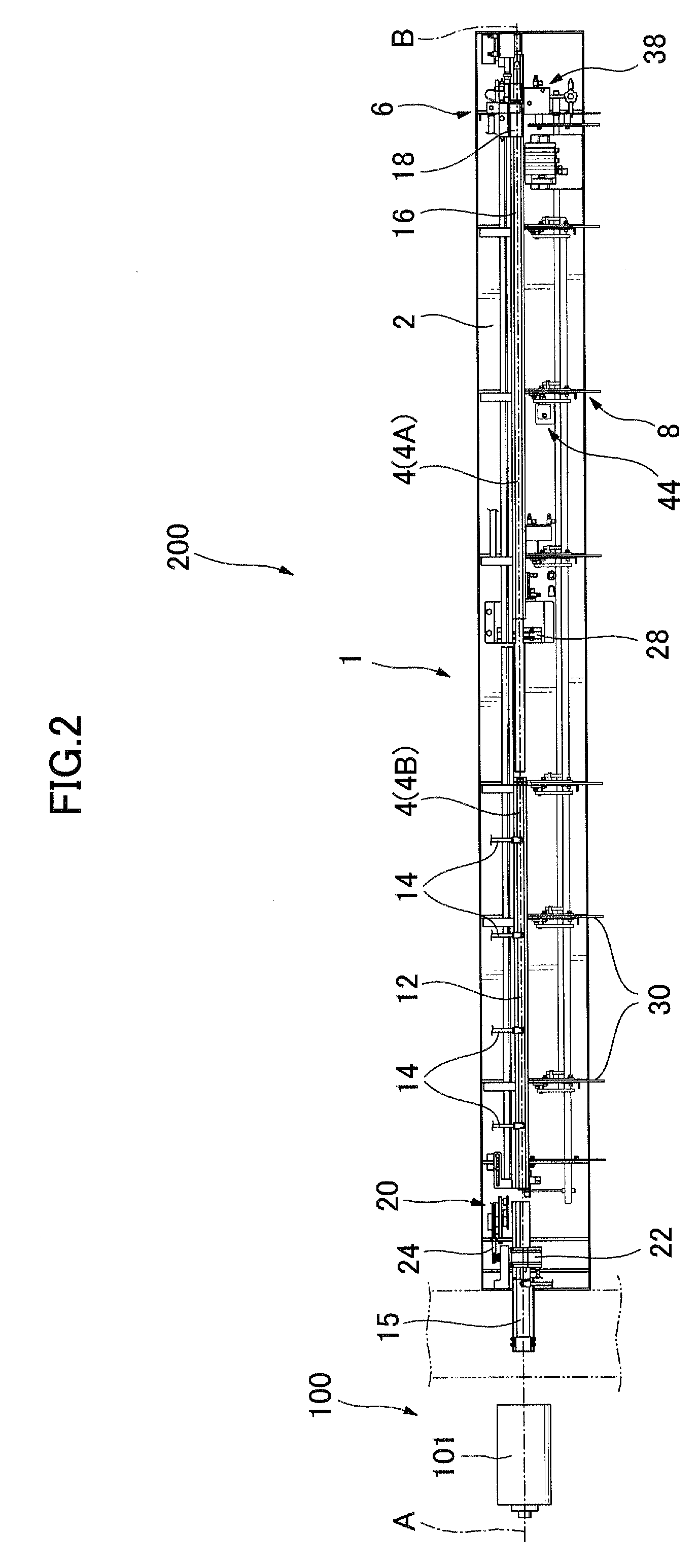

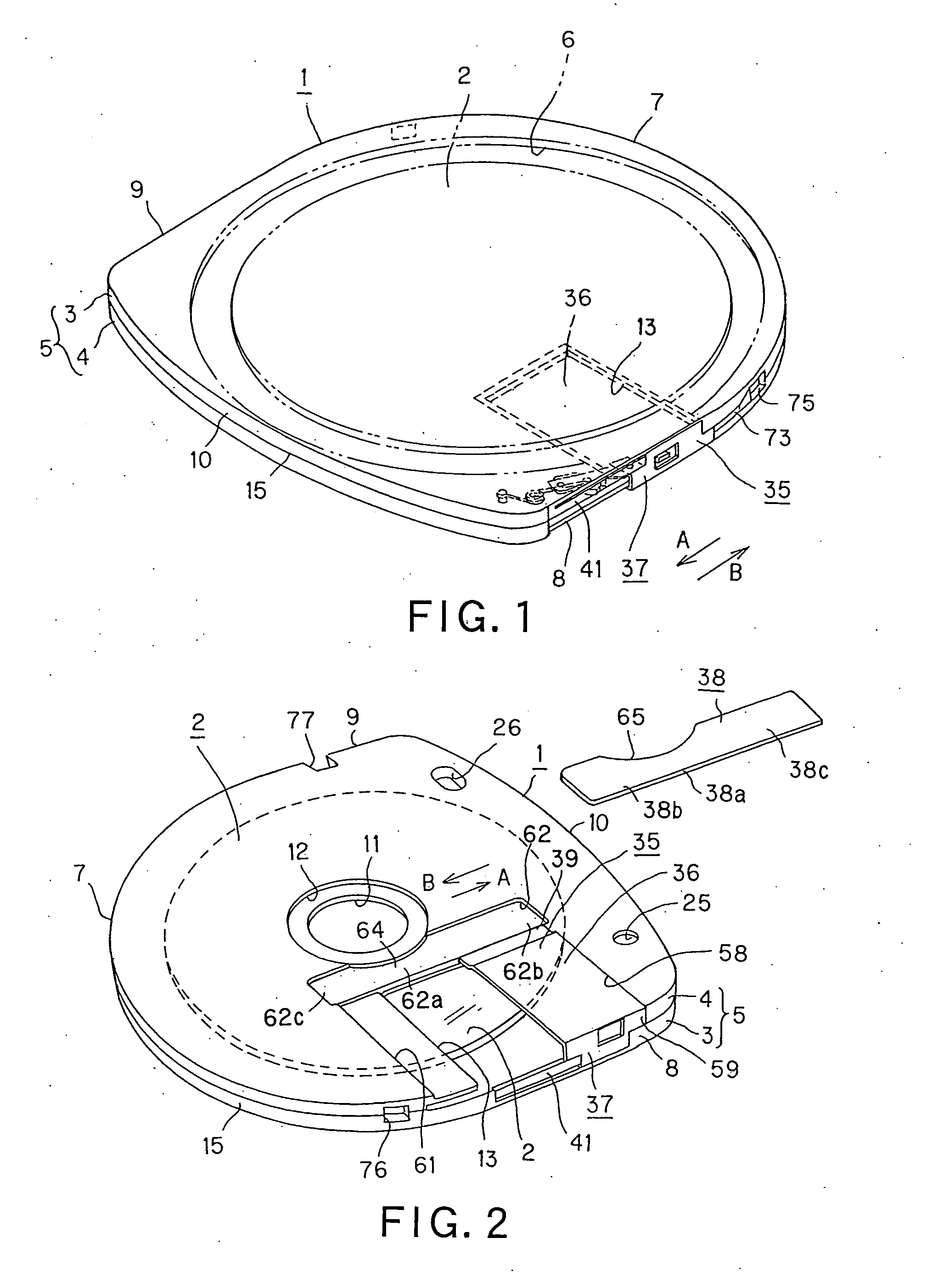

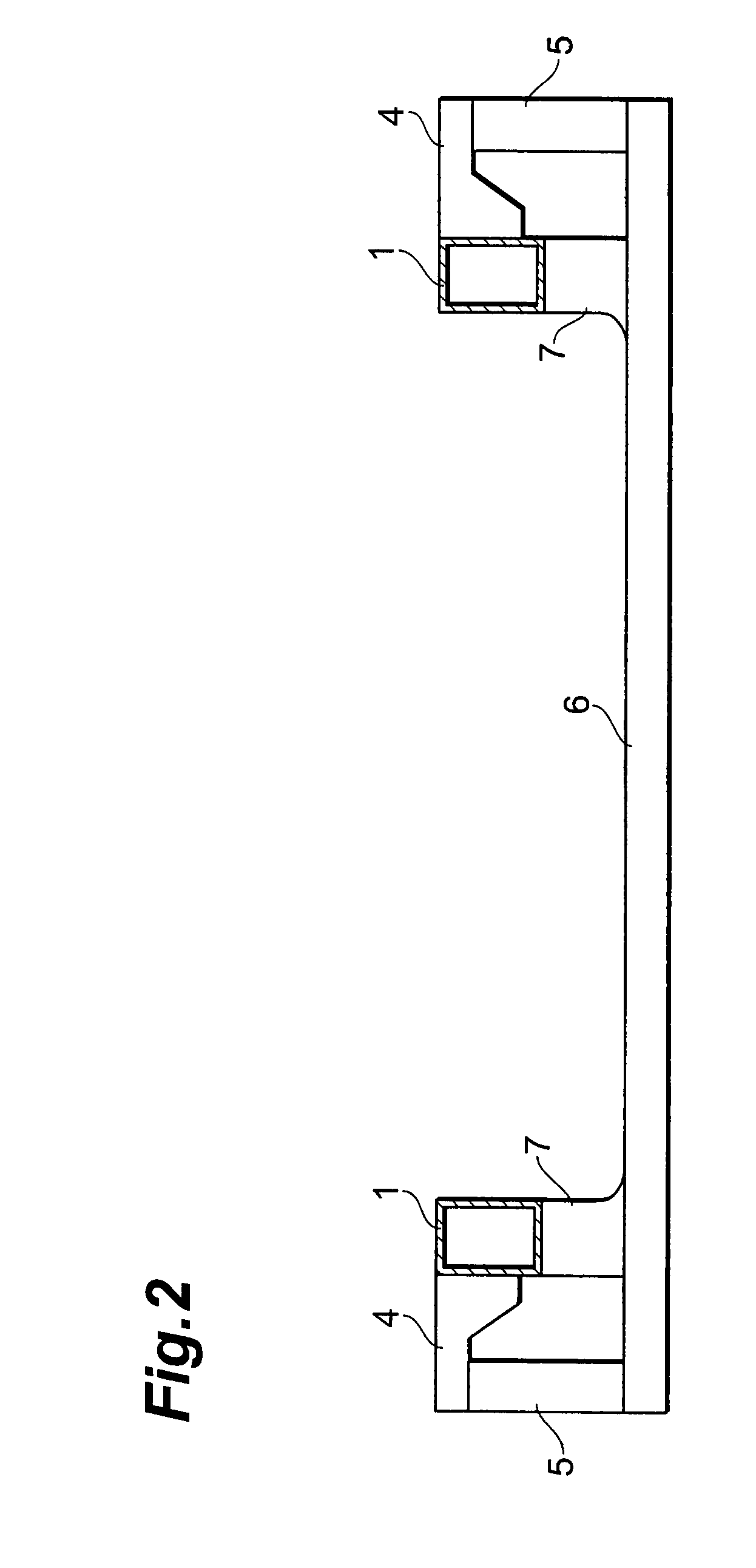

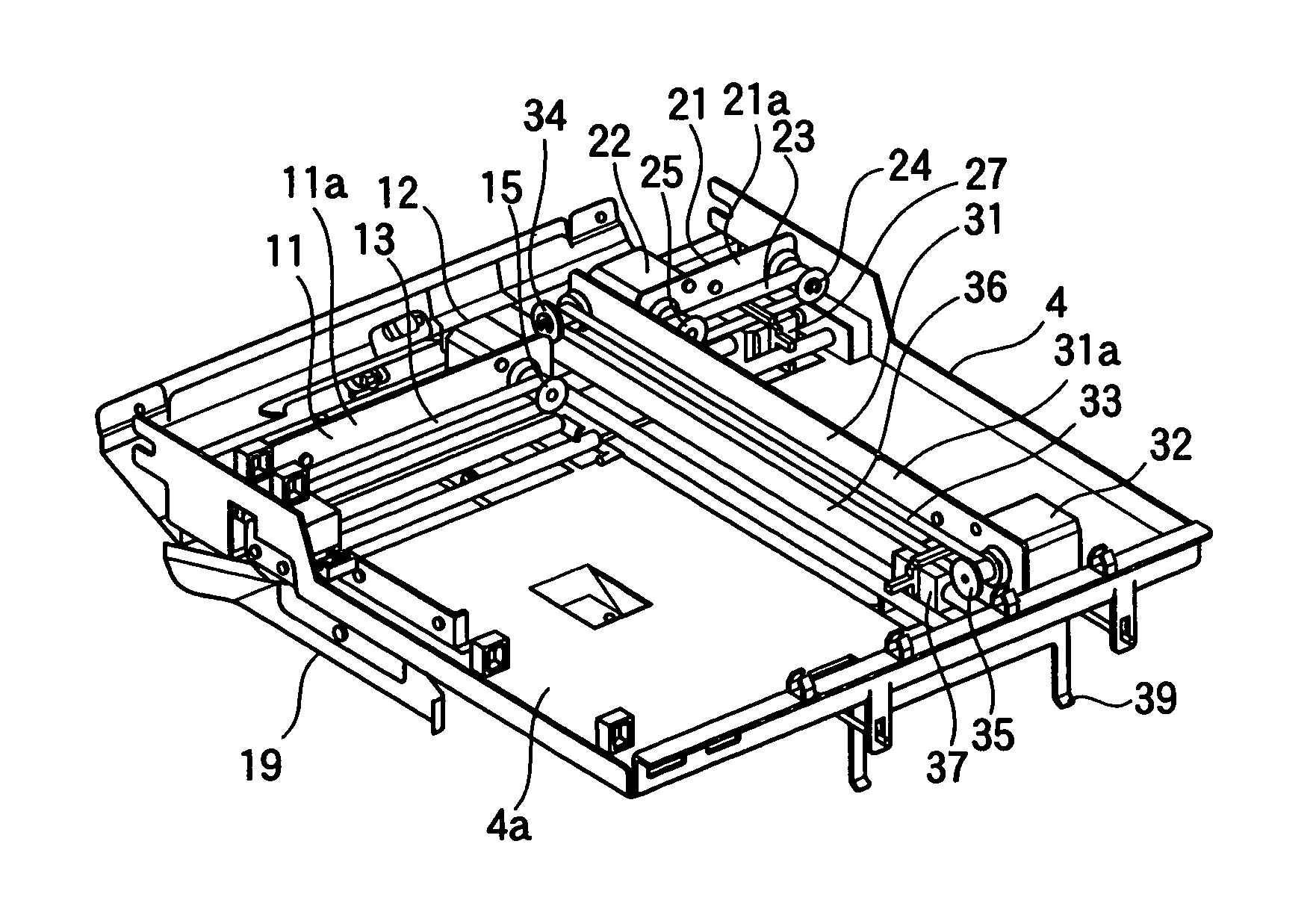

Automatic workpiece transport apparatus for double-side polishing machine

InactiveUS6135854AReliable loadingAccurate detectionRevolution surface grinding machinesGrinding drivesImaging processingEngineering

An automatic workpiece transport apparatus for a double-side polishing machine is disclosed. A carrier is positioned at a predetermined position by a positioning unit, and an image of the top surface of the carrier is captured by use of a visual sensor. A computer performs image processing to obtain the center coordinates of the wafers or the workpiece holders while reference marks or the like provided on the carrier are used as references. The transport robot is moved and controlled based on the thus-detected coordinate data in order to load the wafers into the workpiece holders or to unload the wafers from the workpiece holders. Further, two visual sensors are provided at the tip end of the arm of the transport robot. These visual sensors send to the computer an image of the peripheral portion of the held wafer. Thus, the computer performs fine adjustment in positioning the wafer and the workpiece. The automatic workpiece transport apparatus can reliably load and unload semiconductor wafers to and from the carrier that holds semiconductor substrates.

Owner:SHIN-ETSU HANDOTAI CO LTD

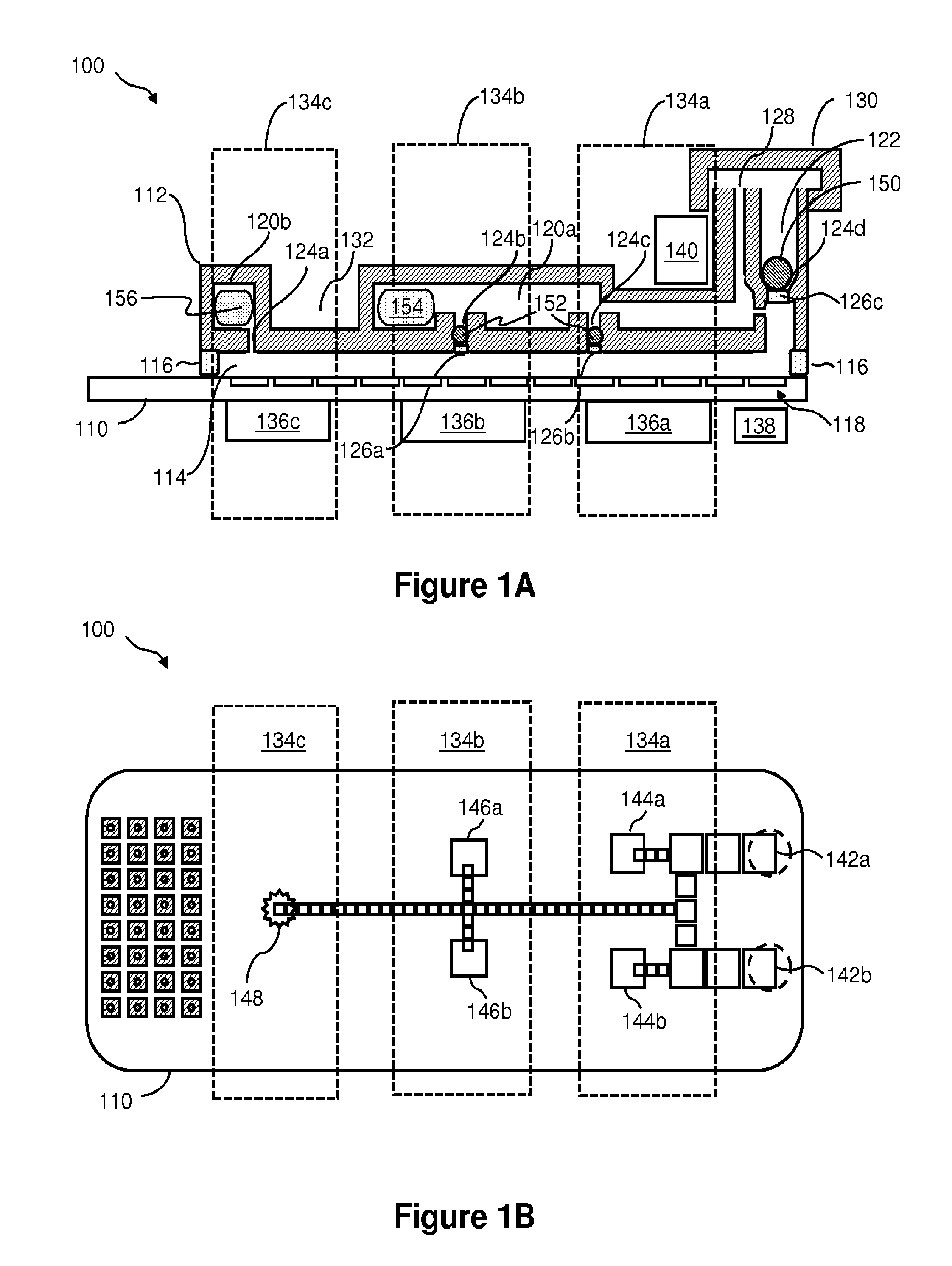

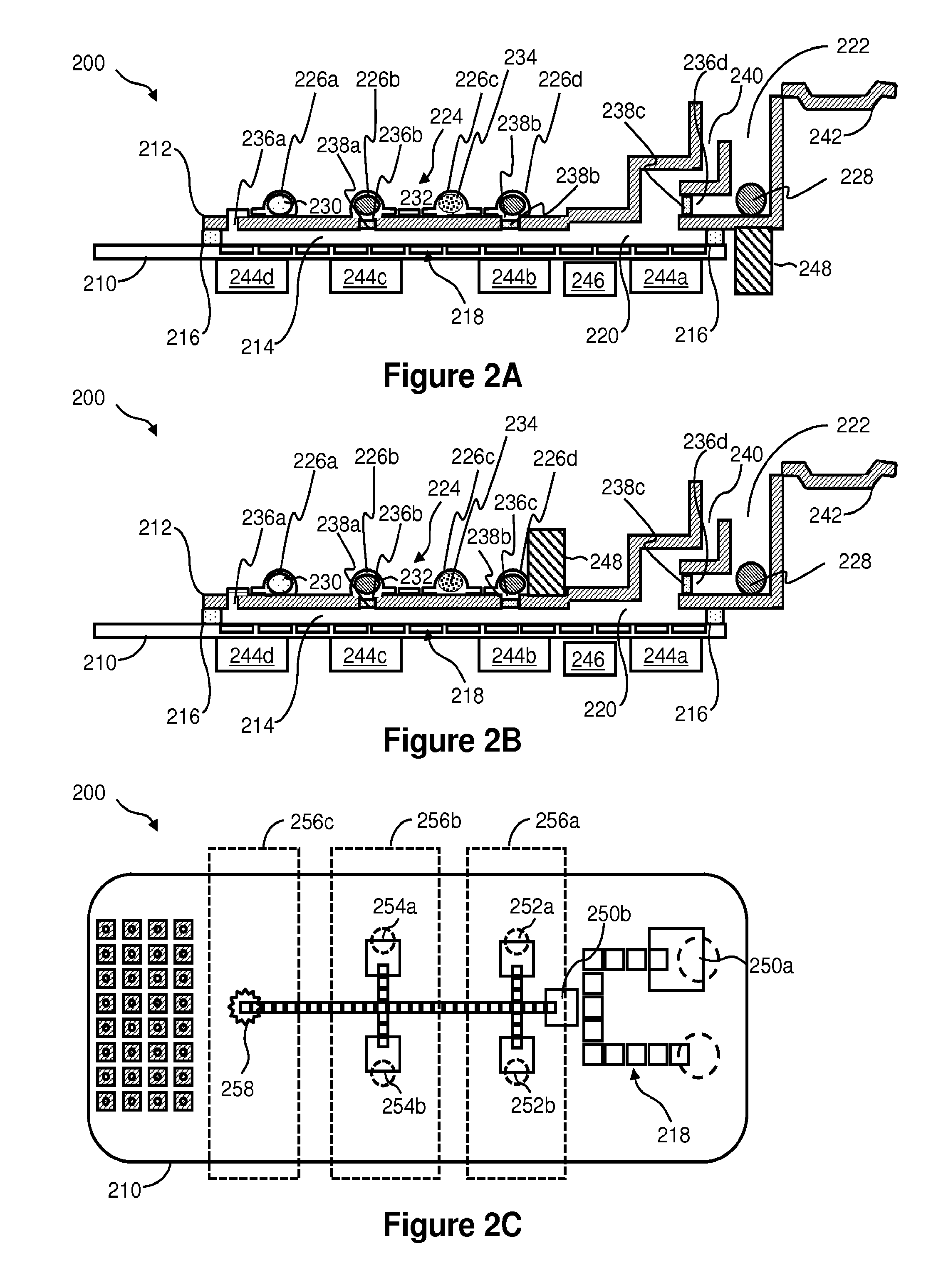

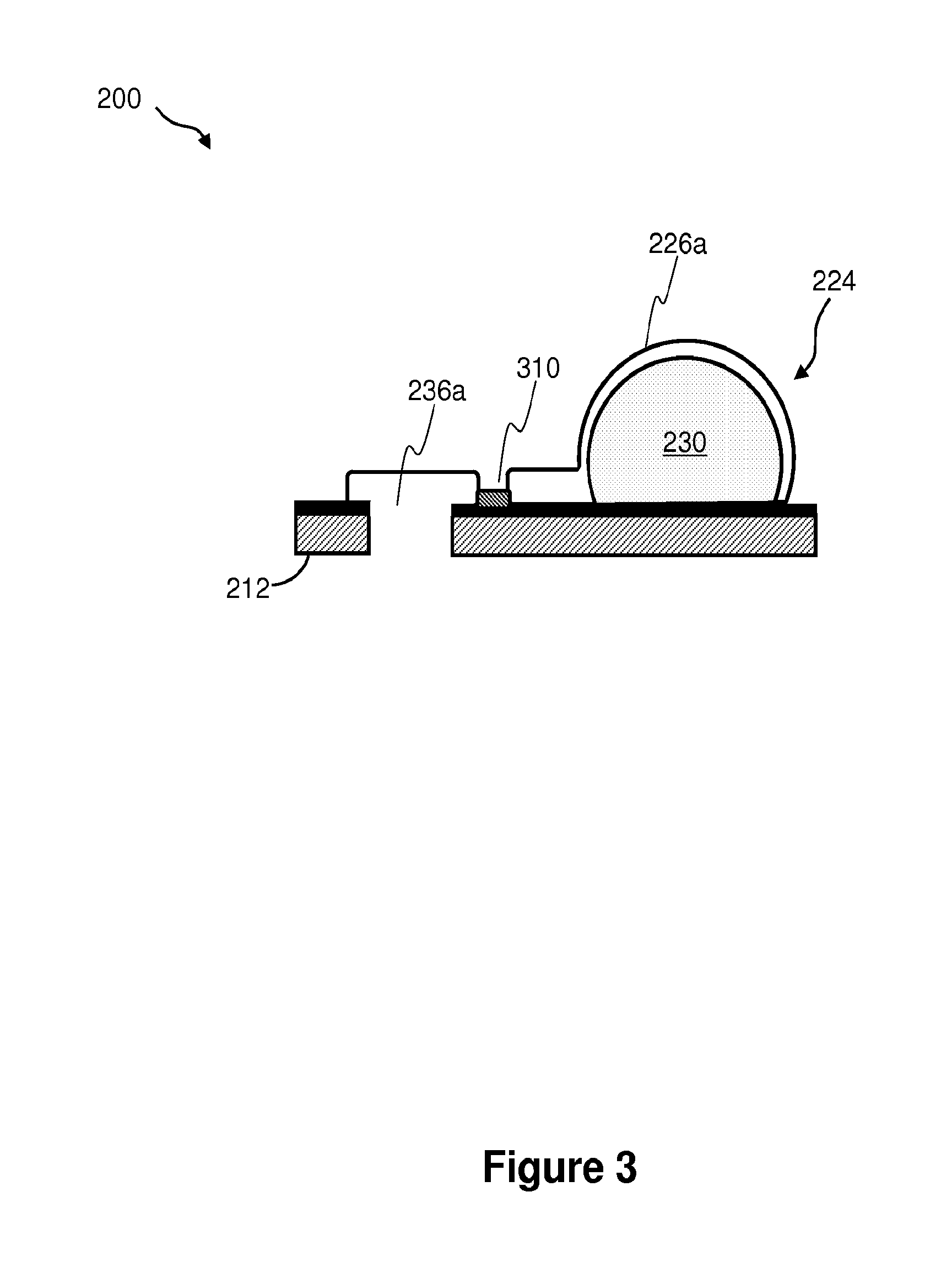

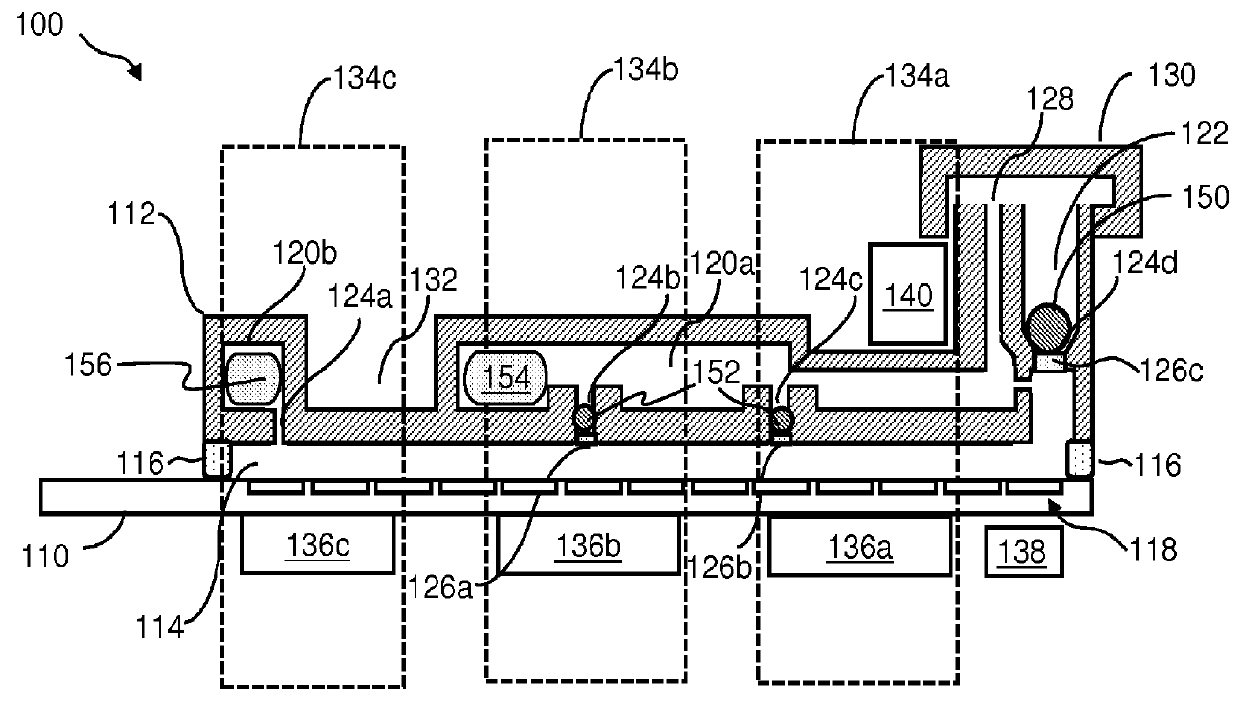

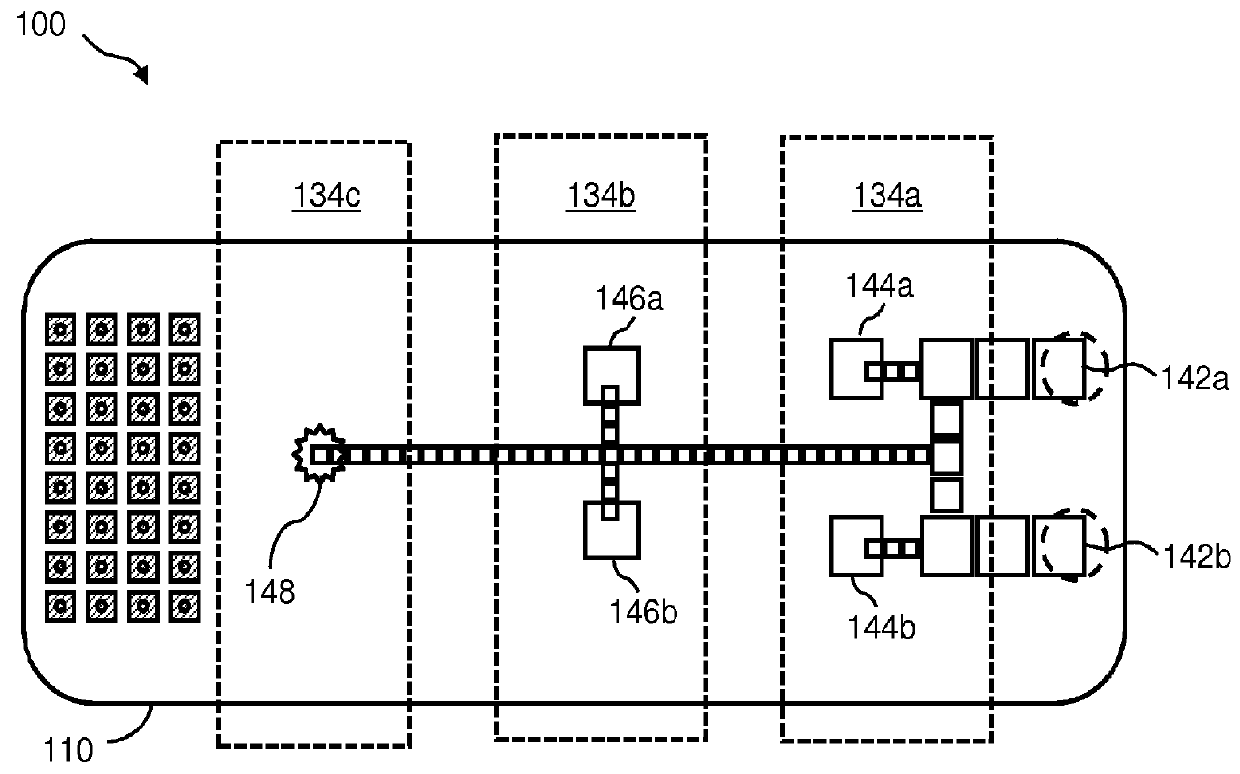

Droplet Operations Platform

ActiveUS20130217103A1Quick captureFast concentrationBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringActuator

The invention relates to a droplet actuator device and methods for integrated sample preparation and analysis of a biological sample. A droplet actuator device is provided for conducting droplet operations. The droplet actuator device may include a bottom substrate and a top substrate separated from each other to form a gap therebetween; an arrangement of droplet operations electrodes arranged on one or both of the bottom and / or top substrates for conducting droplet operations thereon; a reagent storage layer comprising one or more compartments bound to the top substrate; and one or more openings arranged to provide a fluidic path from the one or more compartments into the gap, upon breach of a breachable seal separating the one or more compartments and openings.

Owner:ADVANCED LIQUID LOGIC

Method for producing diol derivatives

InactiveUS20040138409A1Easy to getReliable loadingOrganic compound preparationCarboxylic acid esters preparationPrimary alcoholDiol

A method of producing a diol derivative efficiently and to high purity is provided. Specifically, the present invention relates to a method of producing a diol derivative having, as a fundamental step, a step of obtaining an alpha-hydroxycarboxylic acid ester by reacting (i) one or more 1,2-diols or (ii) a 1,2-diol and a primary alcohol as starting material(s) with oxygen in the presence of a catalyst comprising metal loaded on a carrier.

Owner:NIPPON SHOKUBAI CO LTD

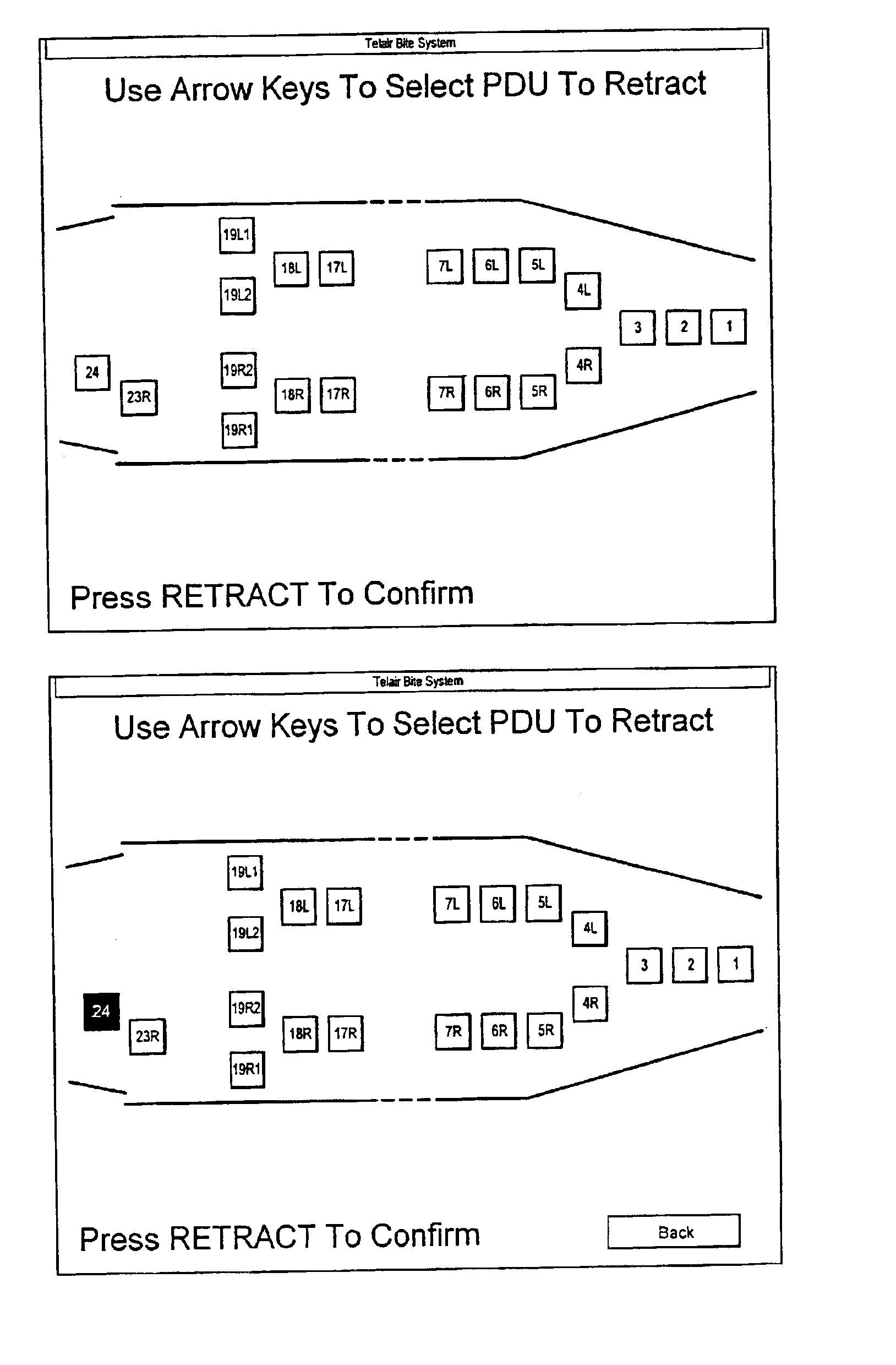

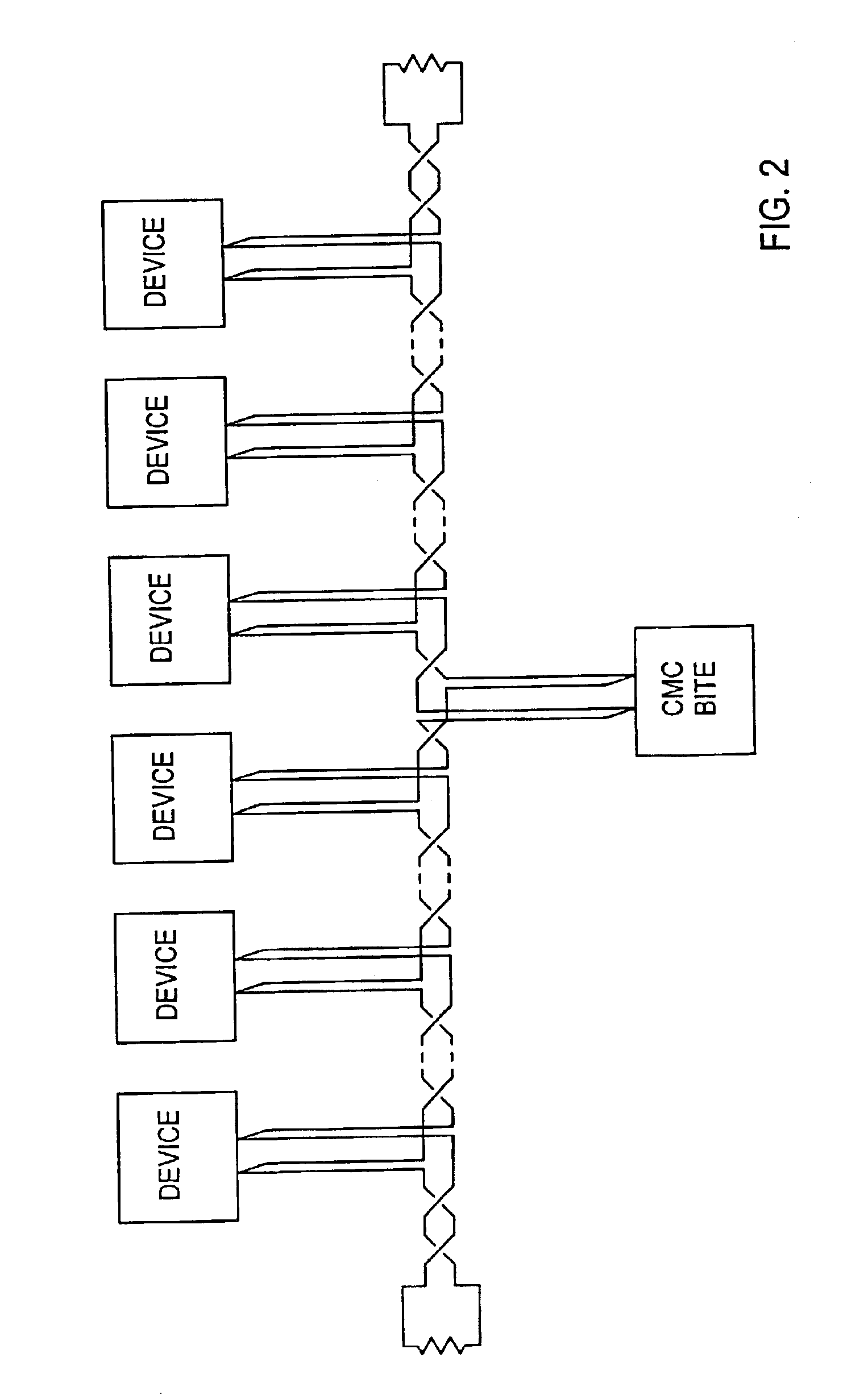

Freight-loading system for an aircraft

InactiveUS6867702B2Reliable unloadingReliable loading and unloadingData processing applicationsControl devices for conveyorsControl signalEngineering

A freight-loading system in a cargo hold of an aircraft is provided that offers enhanced operating safety. The freight-loading system comprises a plurality of power drive units (PDUs), which can be actuated by control signals in such a way that items of freight can be maneuvered into or out of the cargo hold as well as within it. The power drive units (PDUs) are connected by control leads to control panels for actuation by personnel. A control maintenance computer (CMC) is provided and connected to the power drive units (PDUs) and the control panels, and is so designed that status information from the power drive units (PDUs) and the control panels can be read out, and that the power drive units (PDUs) and / or the control panels are controllable by the control maintenance computer (CMC).

Owner:TELAIR INTERNATIONAL GMBH

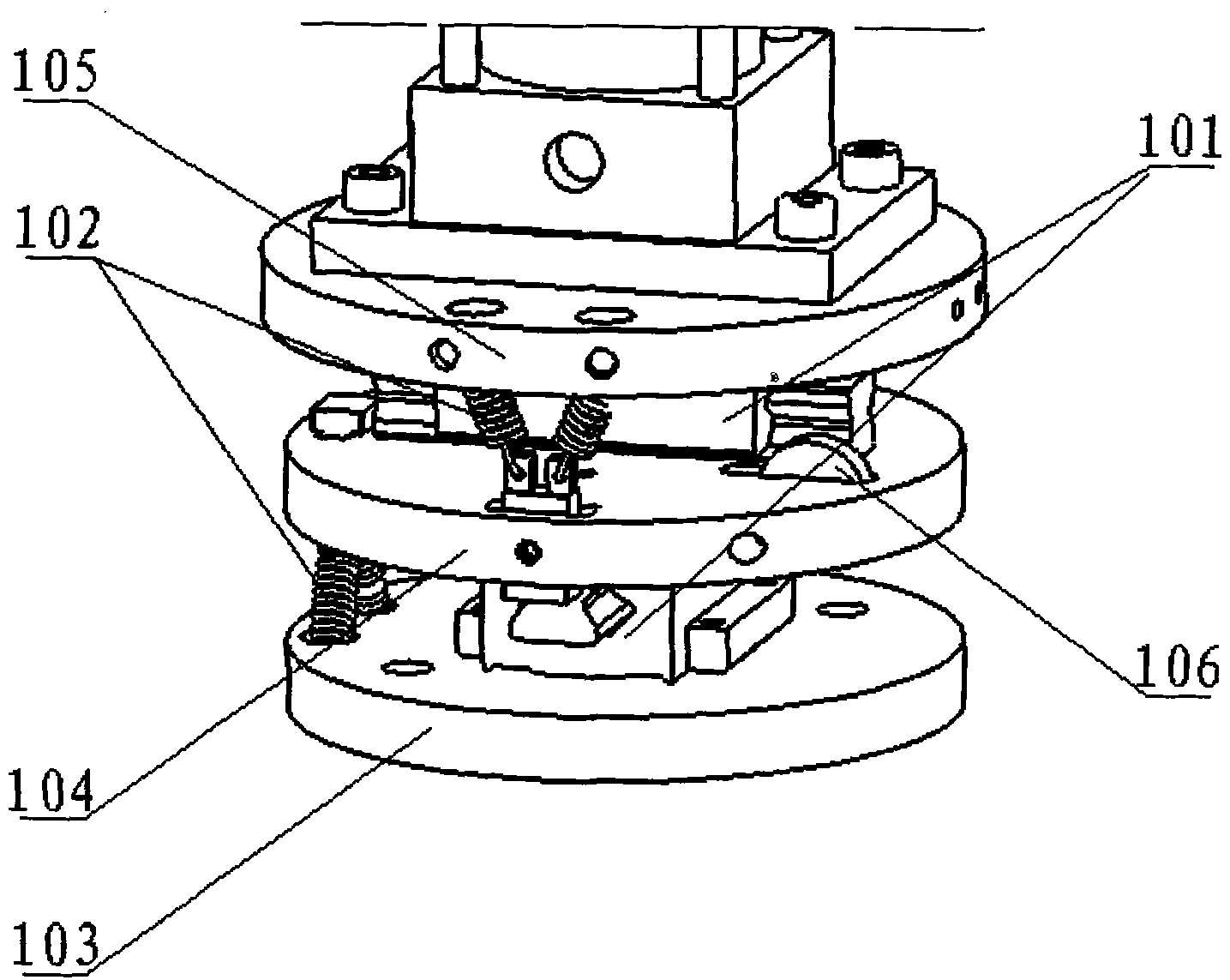

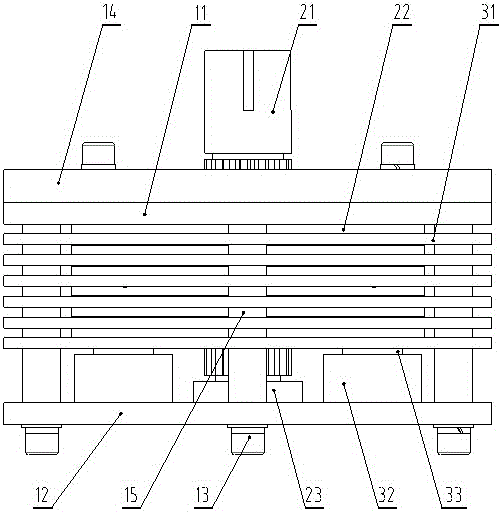

Elastic element creep testing method and tester thereof

InactiveCN1553162AReliable loadingHigh loading accuracyMaterial strength using tensile/compressive forcesHinge angleTest sample

In the present invention, a hinging point of lever is set on framework, one end of lever crossbeam is connected to hinging point and its loading crossbeam can be swung upwards and downwards around framework hinge, another end of lever is hinged with loading weight which is hinged on lever crossbeam through a movable block set and wirerope, movable block set can be two set, another loading application point between hinging point and weight hinged point is on lever crossbeam, adjustable guide bar is connected to loading application point and loading force from weight loading is applied to test sample through adjustable guide bar.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

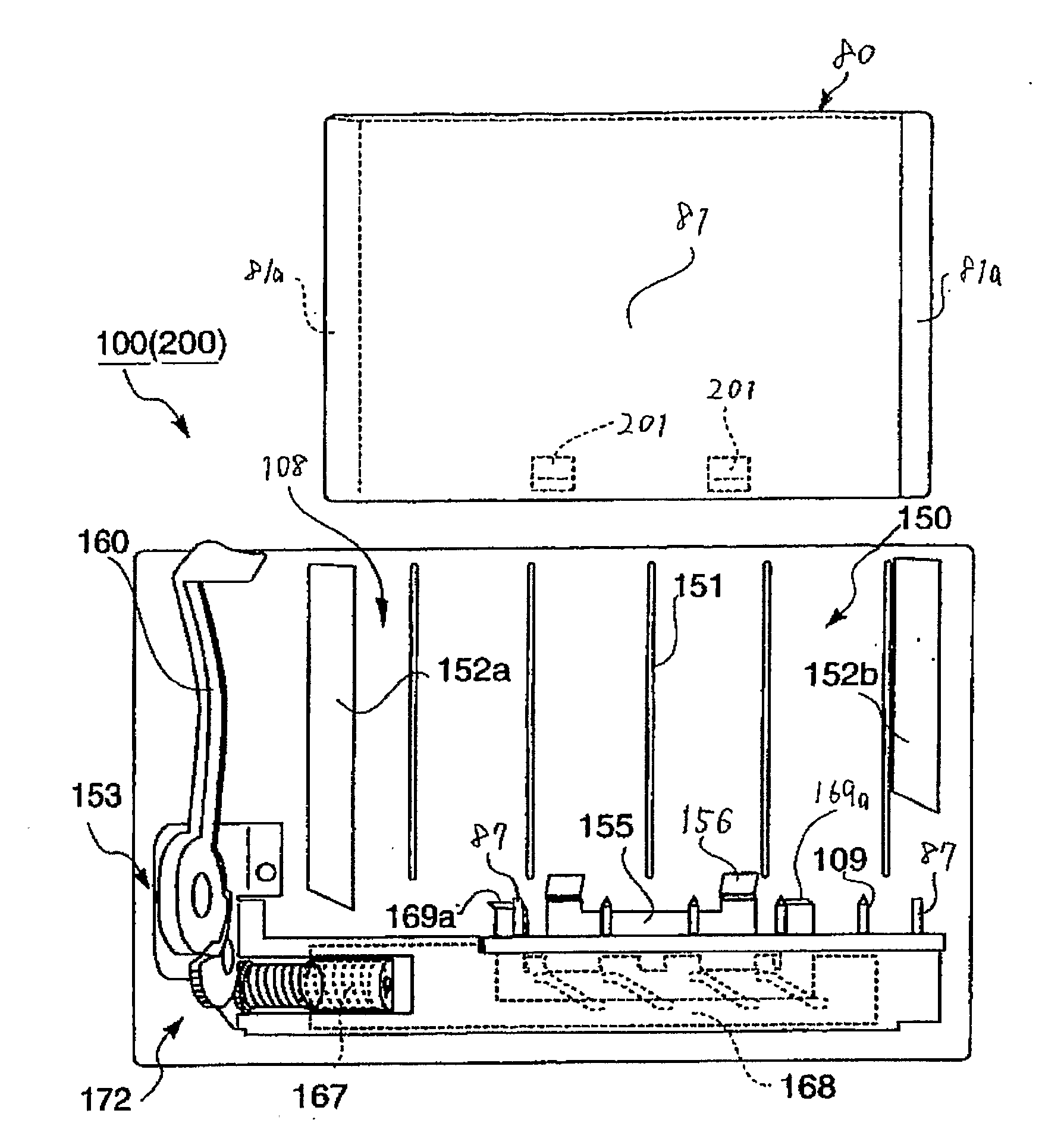

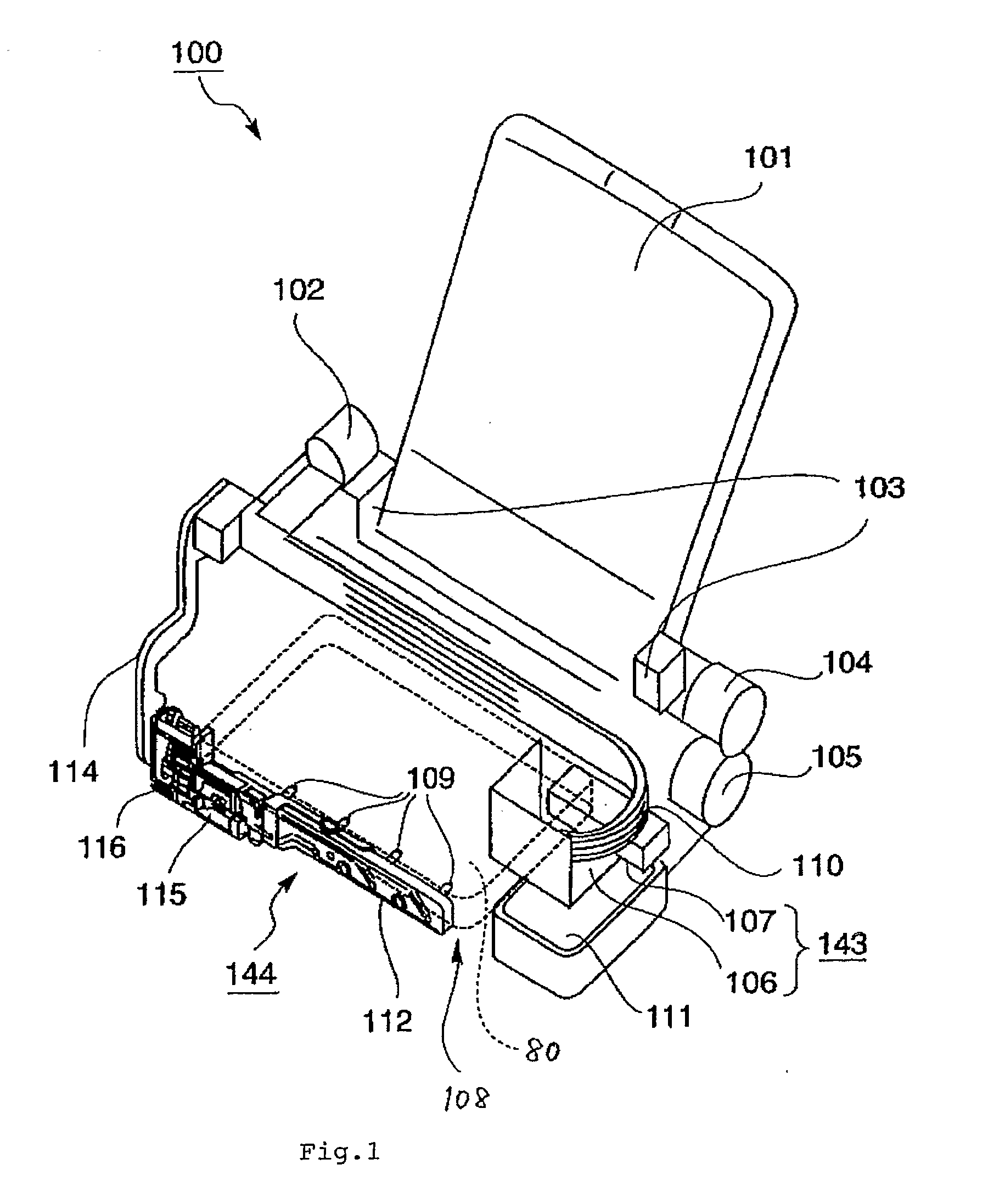

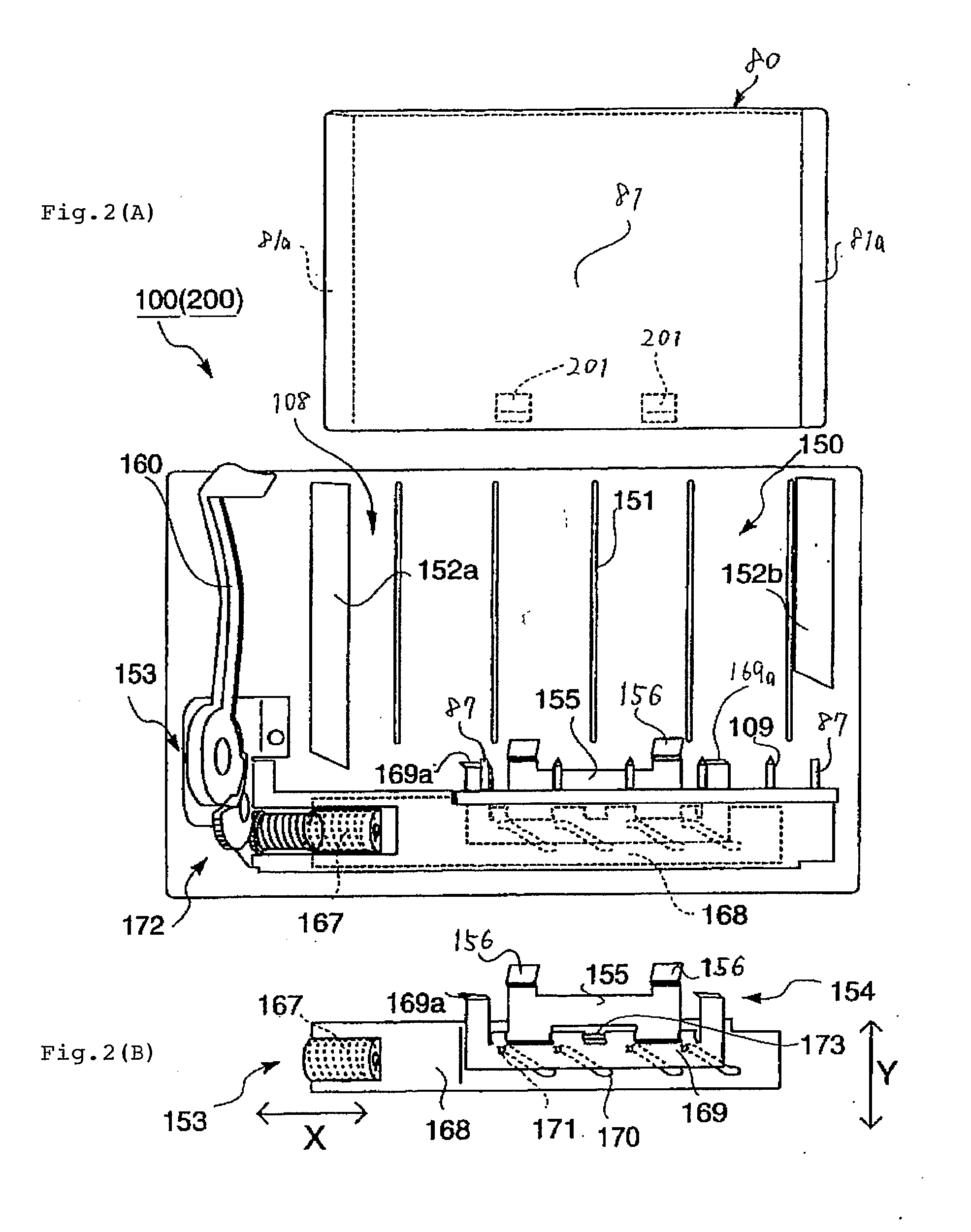

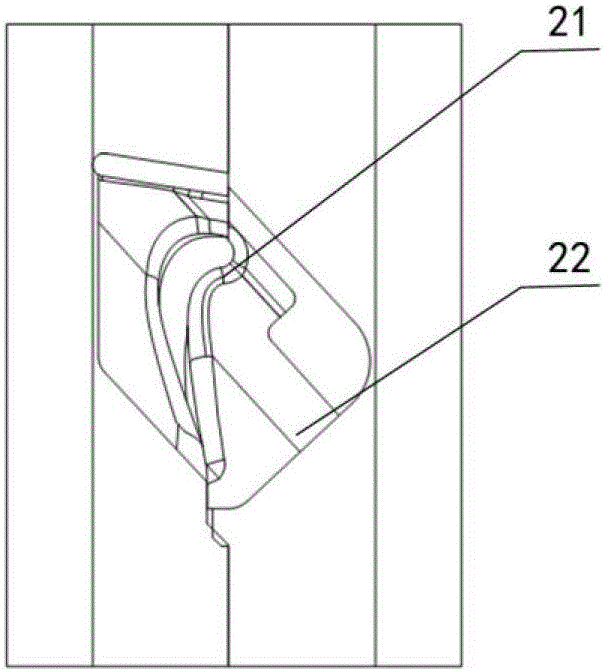

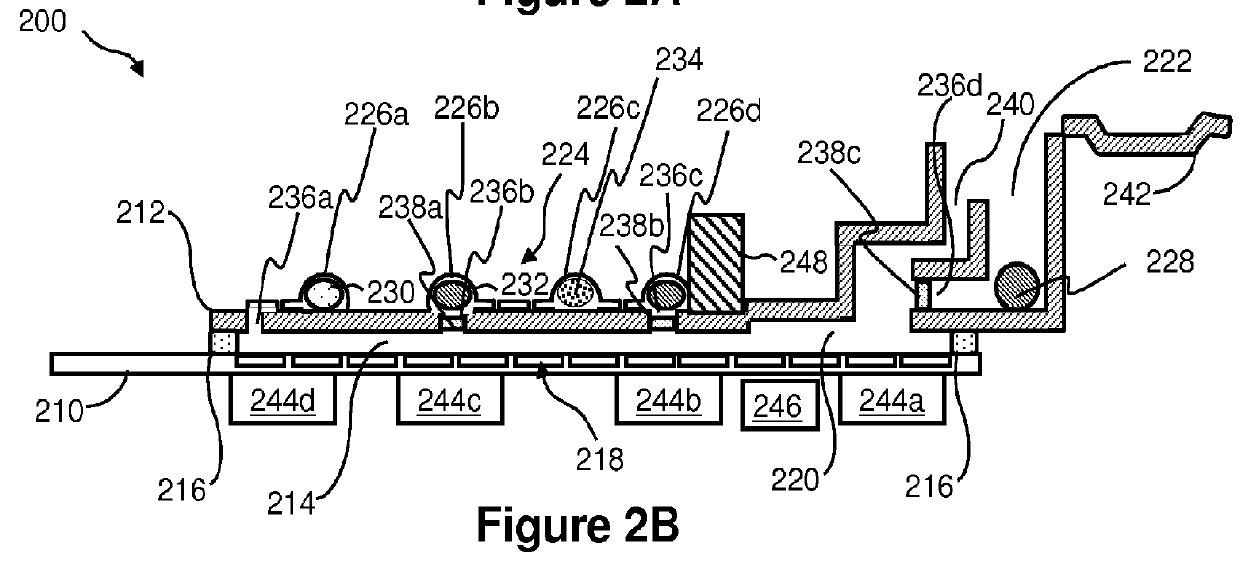

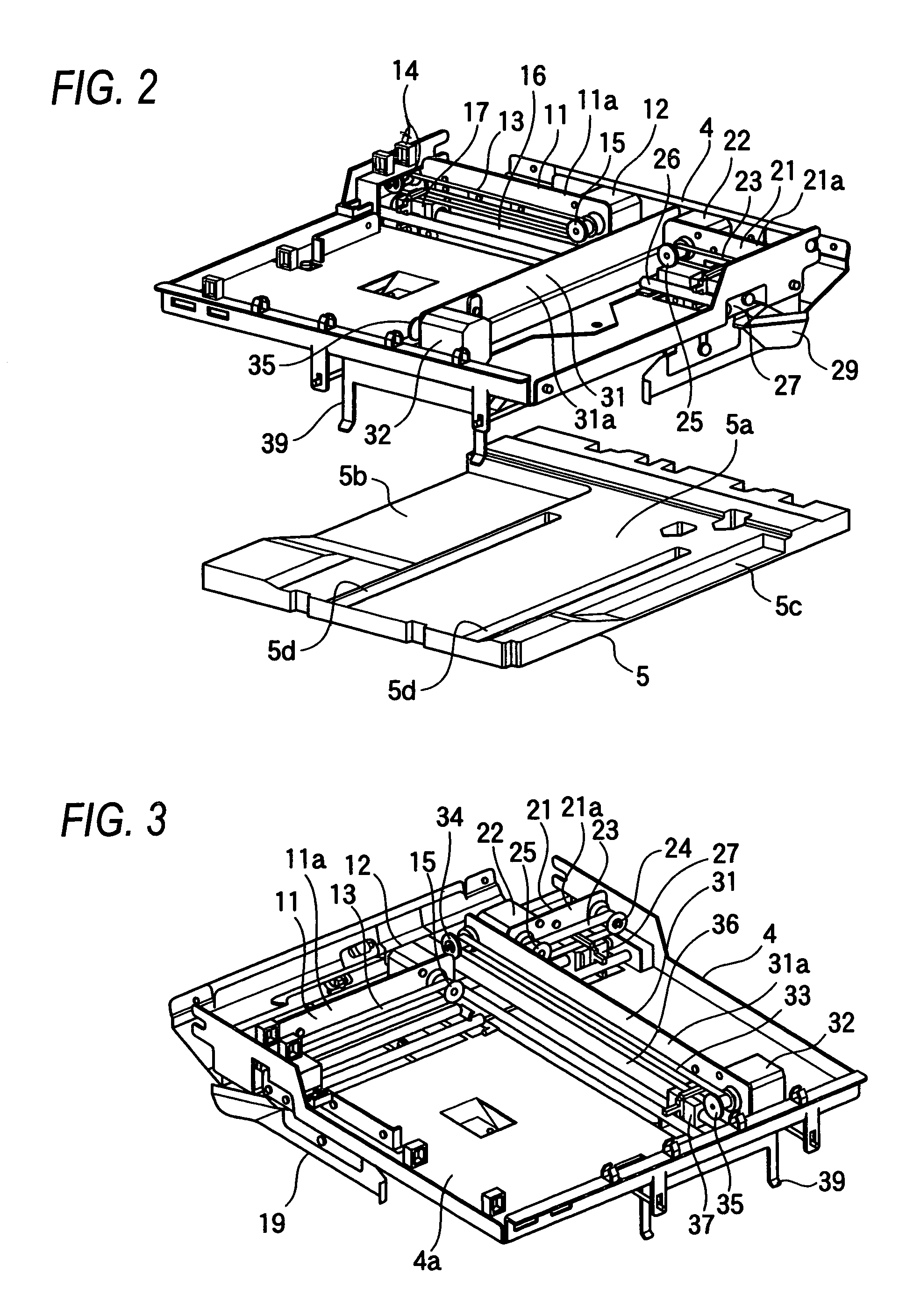

Liquid cartridge, loading/unloading device of liquid cartridge, recording apparatus, and liquid ejection apparatus

ActiveUS20090251512A1Reliable loadingPrevent insertionCoupling light guidesPrintingLiquid jetMagnetic tape

A cartridge loading / unloading device includes a cartridge holding mechanism 154 which holds a liquid cartridge 80 when a liquid cartridge 80 is inserted by a first predetermined stroke, and a power transmission converting mechanism 153 which ensures a push-in force required for loading of the ink cartridge 80 using the principle of the lever by the rotational motion of a lever arm 160, and which converts the rotational motion of the lever arm 160 into a second predetermined stroke S of movement required for loading of the ink cartridge 80 in a state in which it is held by the cartridge holding mechanism 154. The cartridge holding mechanism 154 includes an integral engaging member 155 which is engaged with the front side of one surface of the ink cartridge 80 in its loading direction across the center of the one surface.

Owner:SEIKO EPSON CORP

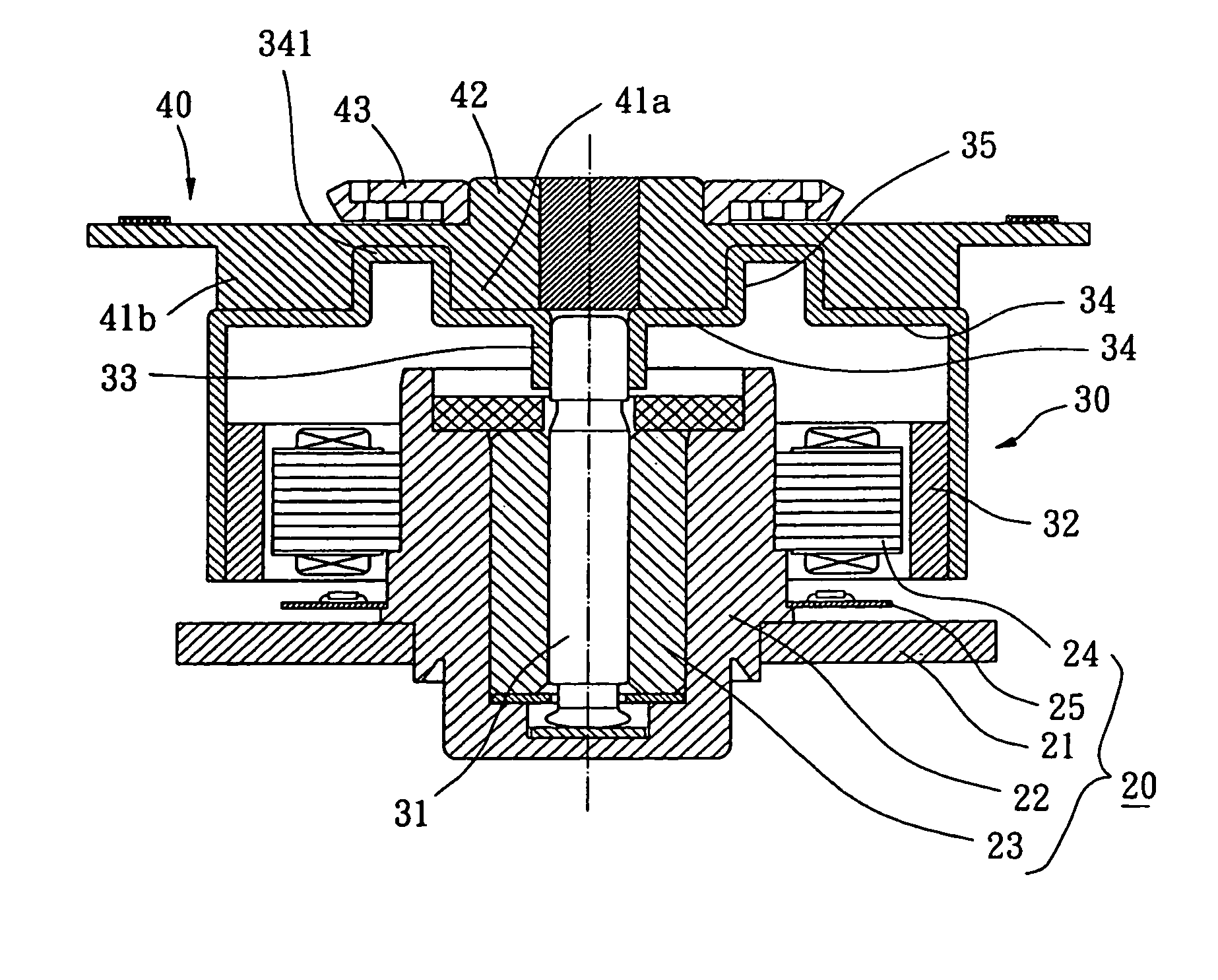

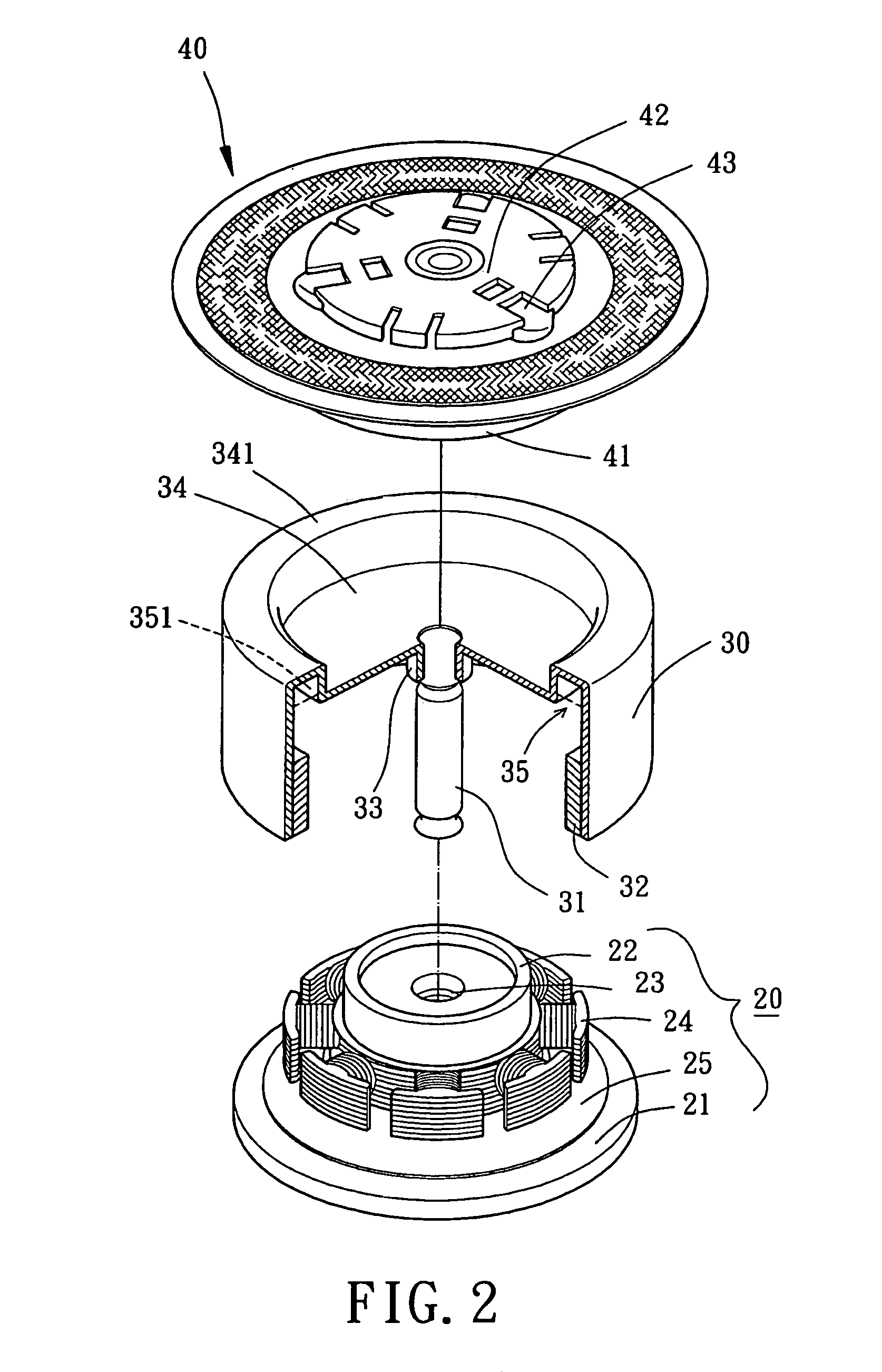

Brushless DC motor with tray coupling structure

InactiveUS7019423B1Flexible adjustmentReliable loadingMagnetic circuitRecord information storageCouplingEngineering

A brushless DC motor includes a fixed portion and a rotor. The rotor includes a shaft and a top engaging face. The shaft is rotatably held by the fixed portion. The top engaging face is located on a top side of the rotor. The rotor further includes at least one protruded engaging portion on the top engaging face. A carrier such as a tray or the like is fixedly coupled with the at least one protruded engaging portion. A compartment is defined in the rotor by the at least one protruded engaging portion. A filling material may be filled into the compartment for adjusting rotational balance of the rotor.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

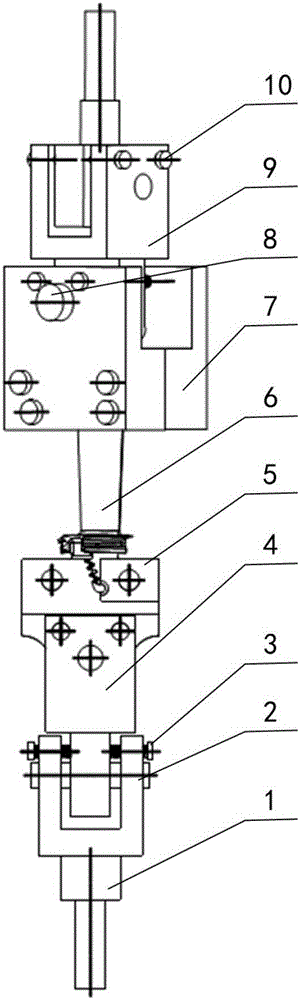

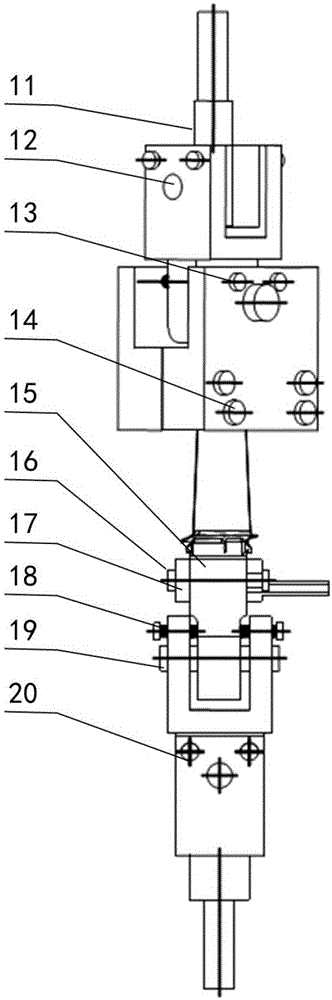

High-temperature fatigue test clamp and method capable of continuously adjusting blade check section stress distribution

ActiveCN106644702AReliable loadingAdjust angleStrength propertiesElasticity measurementStress distributionTurbine blade

The invention relates to a high-temperature fatigue test clamp and method capable of continuously adjusting check section stress distribution of a blade. According to the high-temperature fatigue test clamp, upper and lower chucks are arranged on a fatigue testing machine, and the blade is fixed on the testing machine through a fork, a wheel disc similar part and a blade combined clamp. The test clamp comprises four joints; bolts at two sides of each joint are adjusted and an included angle between the blade and a main axis of the testing machine can be continuously adjusted, so that eccentric stretching of the blade is realized. In combination of adjustment of a stretching load of the fatigue testing machine, simulation of a check section working stress field of a turbine blade can be realized. Furthermore, each adjusting bolt sleeves a pressing spring and the fastening length of each bolt keeps constant through the restoring force of the springs after detachment, so that repeated adjustment is avoided.

Owner:BEIHANG UNIV

Droplet operations platform

ActiveUS9248450B2Rapid capture and concentrationImprove throughputBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringActuator

Owner:ADVANCED LIQUID LOGIC

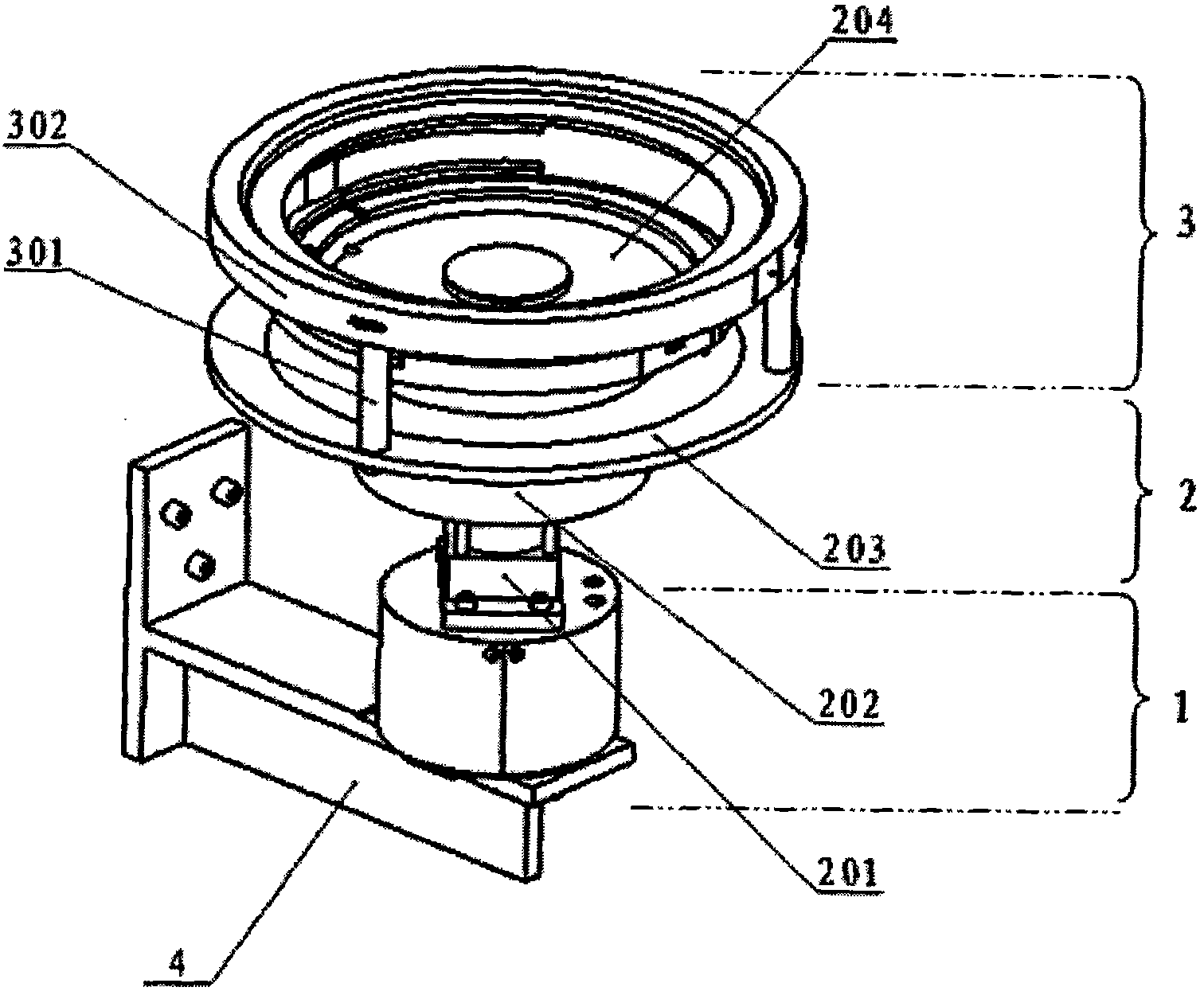

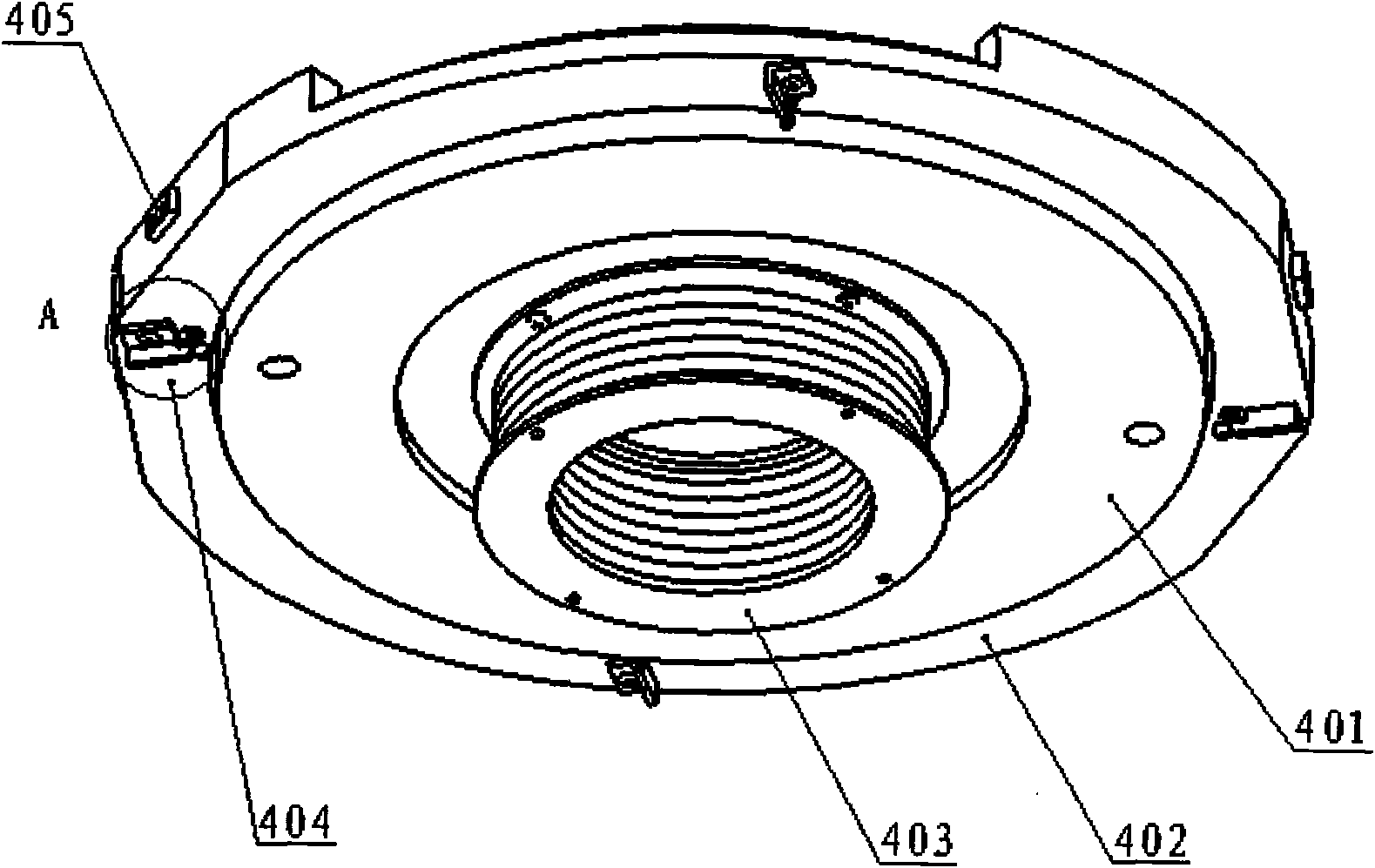

Silicon wafer positioning and loading device applied to chemical mechanical polishing equipment

ActiveCN102371535AFacilitate automatic loadingImprove loading efficiencySemiconductor/solid-state device manufacturingLapping machinesButt jointEngineering

The invention provides a silicon wafer positioning and loading device applied to chemical mechanical polishing equipment and relates to the technical field of silicon-wafer chemical mechanical polishing equipment. A base plate of the positioning and loading device is connected to a loading guide ring on the base plate through a supporting rod; a stretching part on a lifting driving mechanism is fixedly connected to a silicon wafer fixture thereon; the silicon wafer fixture is connected to a silicon wafer guide ring outside the silicon wafer fixture; a butt-joint guiding mechanism of a silicon wafer loading device and a silicon wafer resisting-joint guiding mechanism are arranged on the loading guide ring; and an automatic displacement adjusting mechanism and an automatic resetting mechanism are arranged on the base plate or the lower part of the lifting driving mechanism. The positioning and loading device can accurately position a silicon wafer and convey the silicon wafer to a loader for processing. The positioning and loading device has the advantages of simple structure, accurate positioning, loading safety, reliable property and operation convenience, and is beneficial to realizing the automatic loading of the silicon wafer and promoting the efficiencies for positioning, loading and processing the silicon wafer. The positioning and loading device is especially suitable for the loading of the silicon wafer in the chemical mechanical polishing equipment and also can be used for loading wafers during production processes of a transistor and an integrated circuit.

Owner:THE 45TH RES INST OF CETC

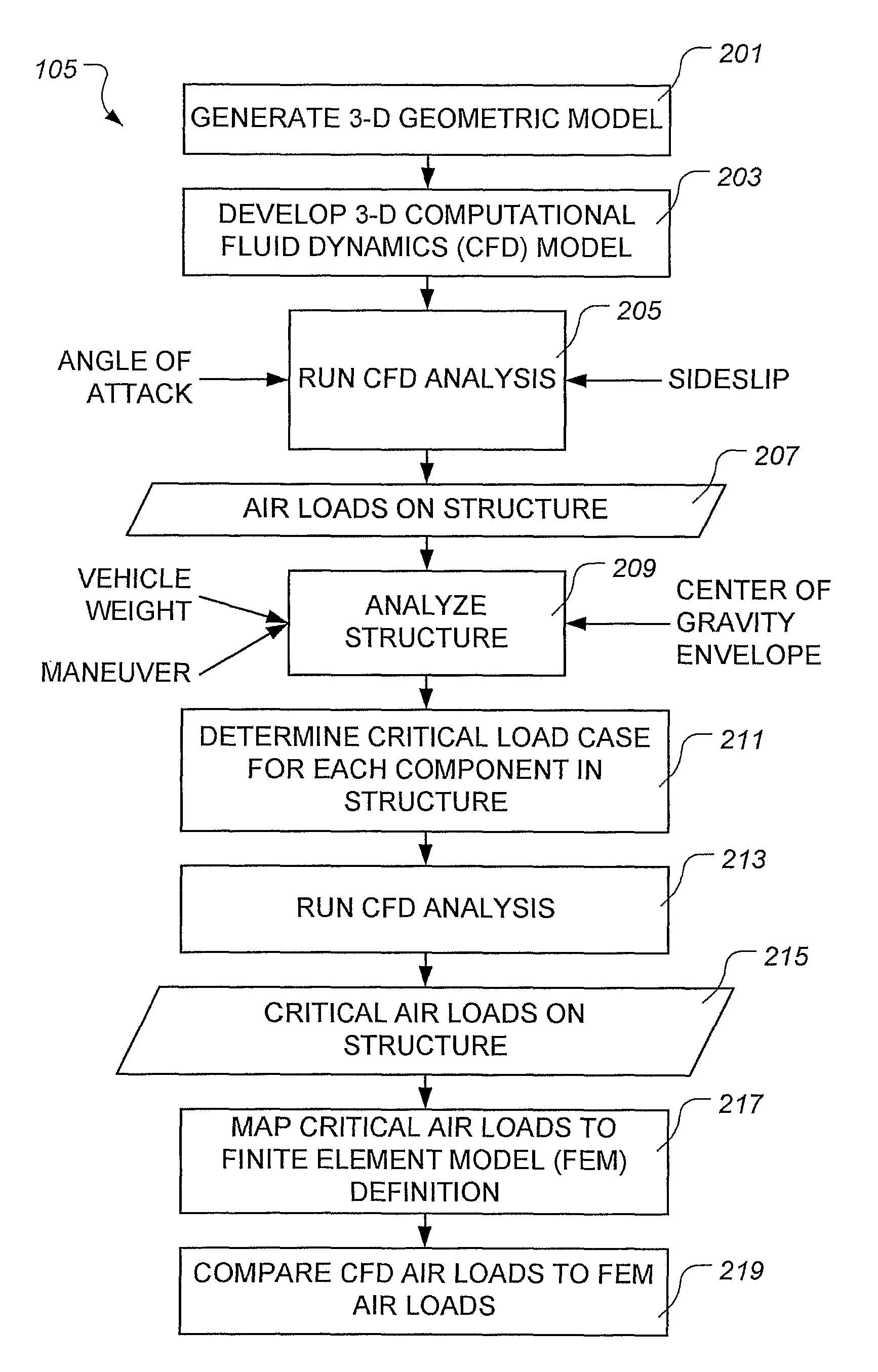

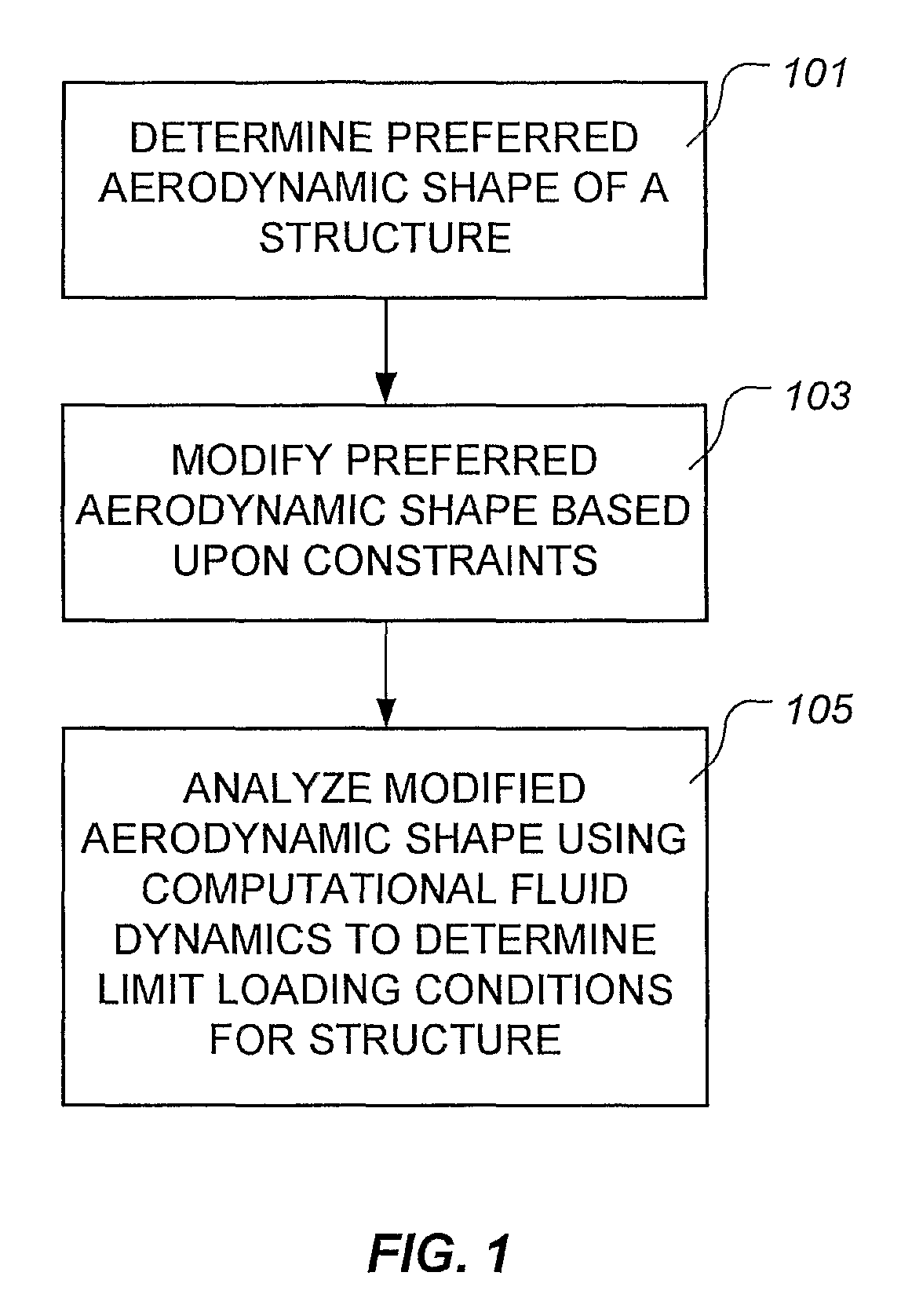

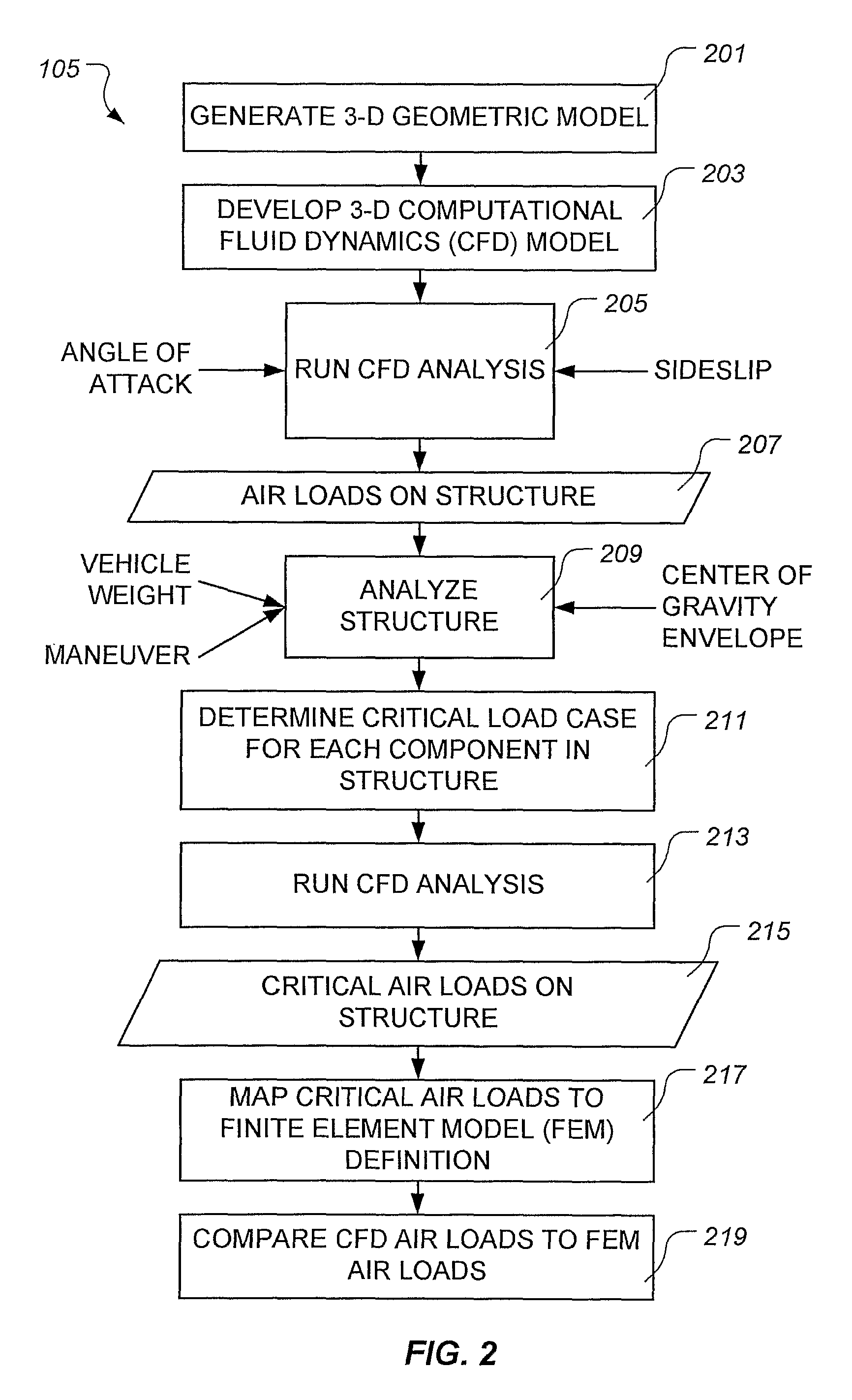

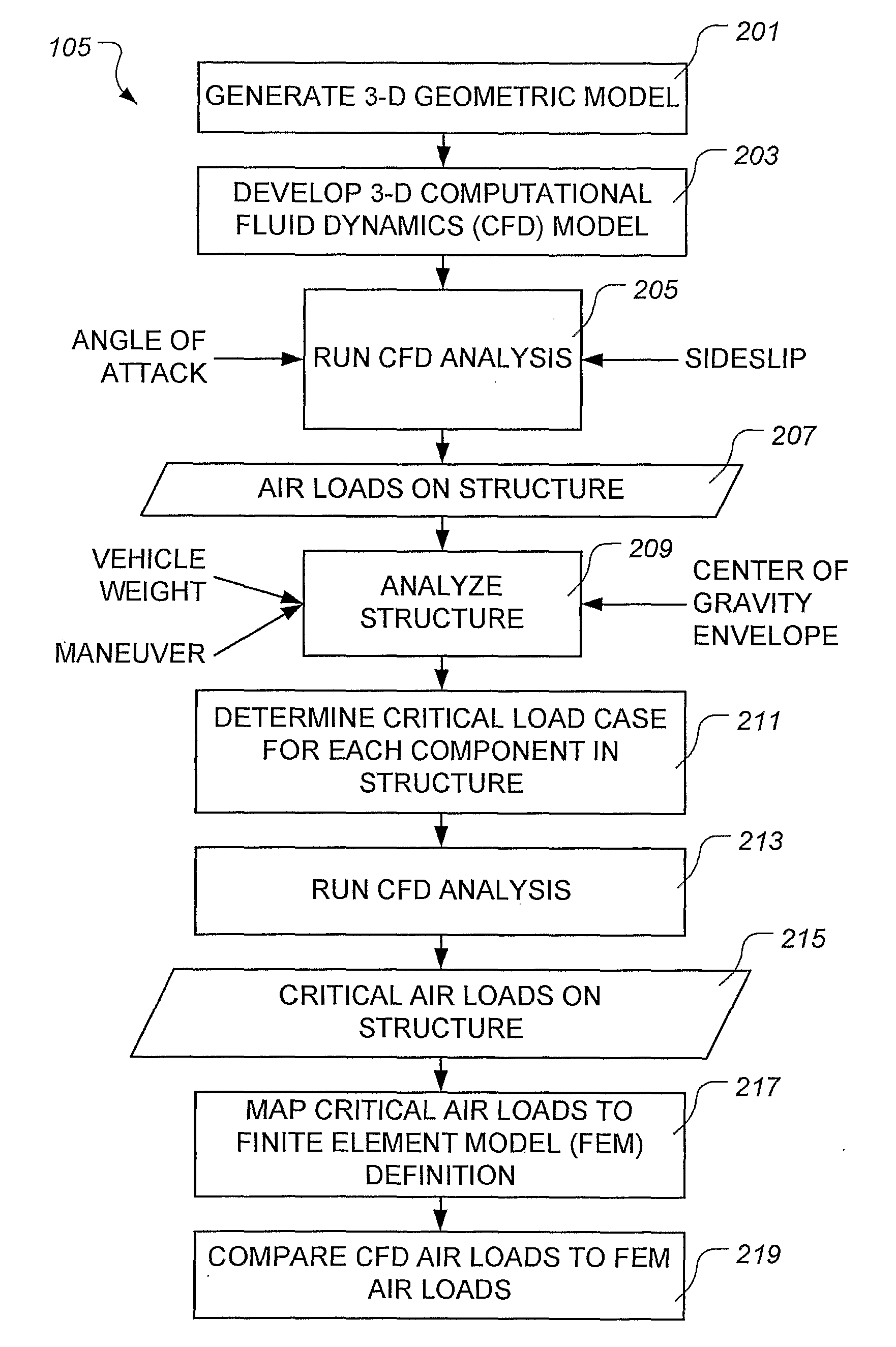

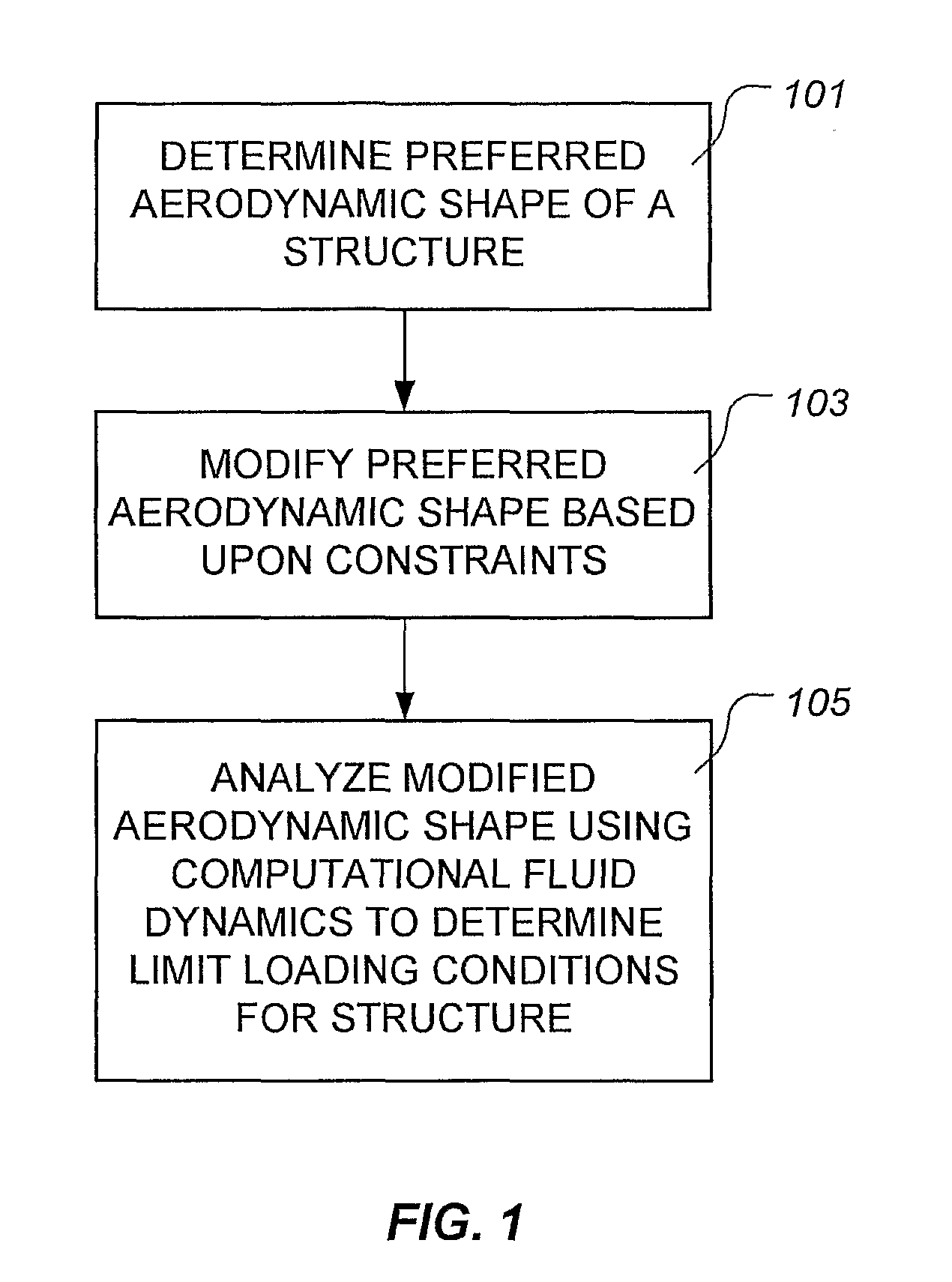

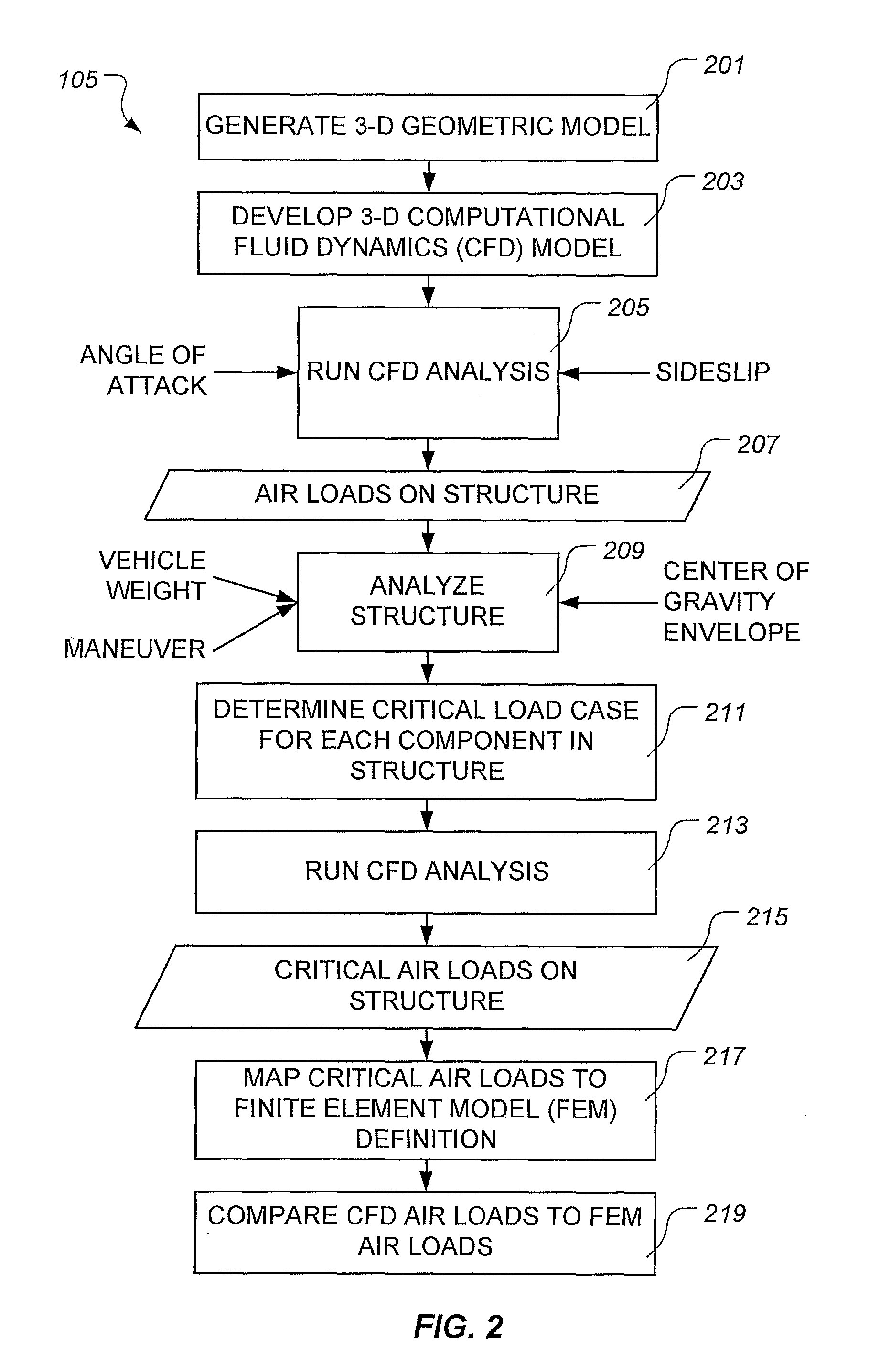

Method for designing a flight vehicle

InactiveUS7912681B2Simple designReliable loadingGeometric CADCosmonautic condition simulationsFlight vehicleEngineering

A method for designing a flight vehicle includes determining a preferred aerodynamic shape of a structure of the vehicle; modifying the preferred aerodynamic shape based upon constraints; and determining, using aerodynamic computational fluid dynamics, limit loading conditions for the modified aerodynamic shape. A computer-implemented system for designing a flight vehicle includes at least one computer operable to determine a preferred aerodynamic shape of a structure of the vehicle; modify the preferred aerodynamic shape based upon constraints; and determine, using aerodynamic computational fluid dynamics, limit loading conditions for the modified aerodynamic shape. Software for designing a flight vehicle, embodied in a computer-readable medium, is operable to, when executed, determine a preferred aerodynamic shape of a structure of the vehicle; modify the preferred aerodynamic shape based upon constraints; and determine, using aerodynamic computational fluid dynamics, limit loading conditions for the modified aerodynamic shape.

Owner:TEXTRON INNOVATIONS

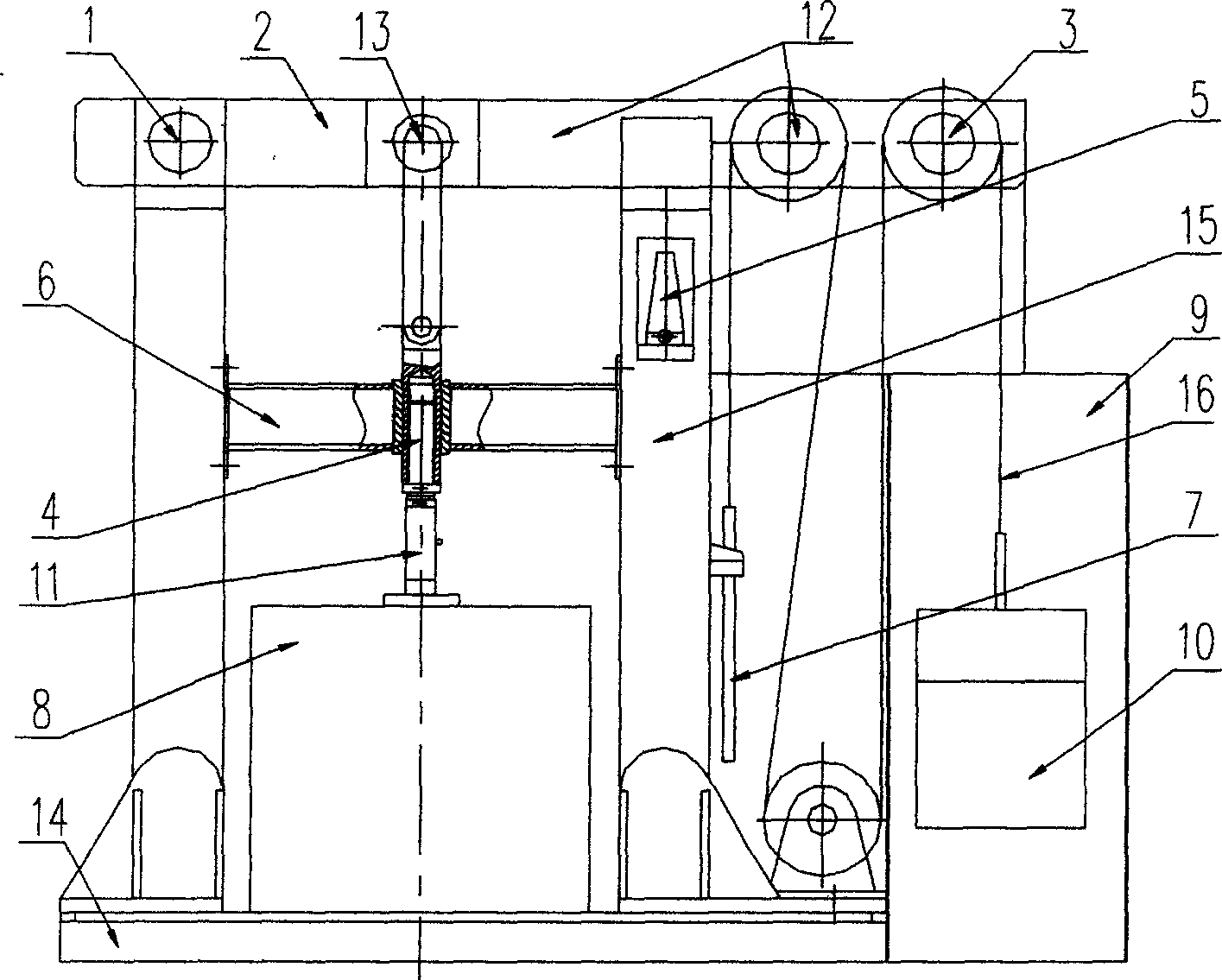

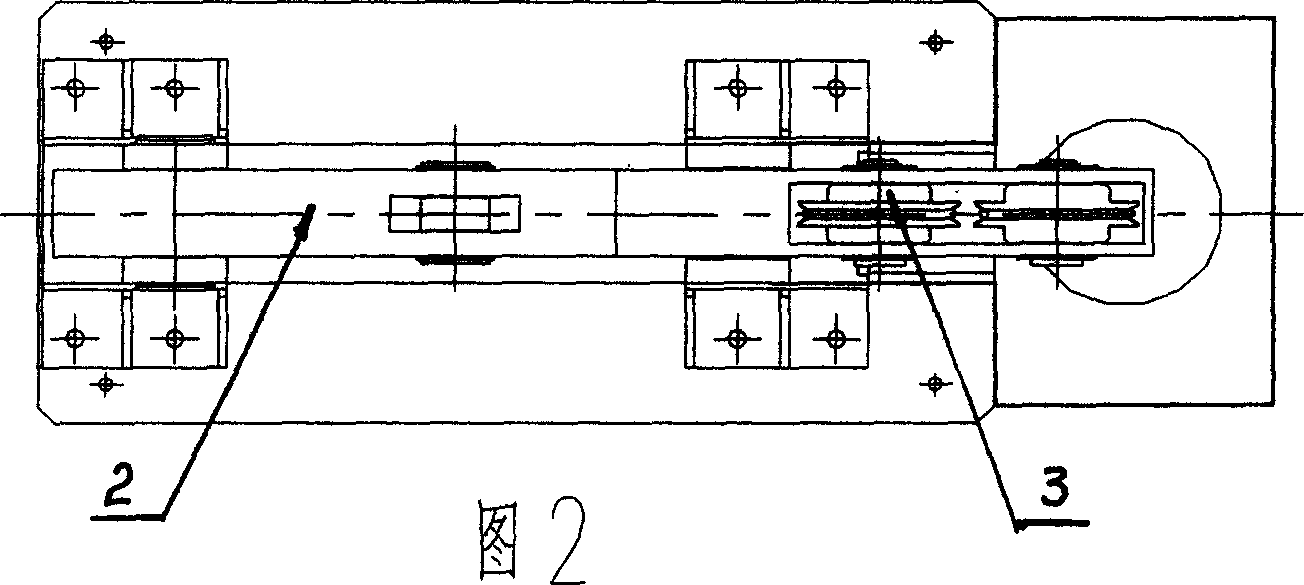

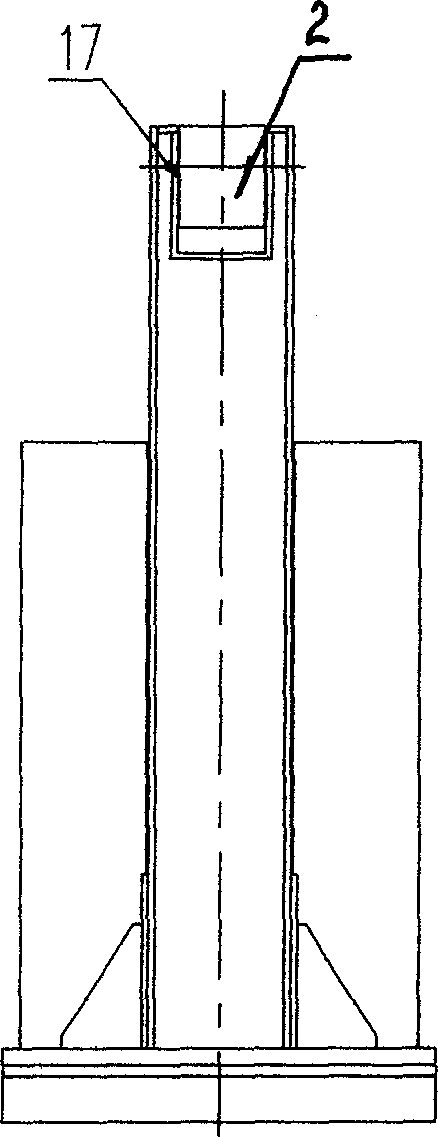

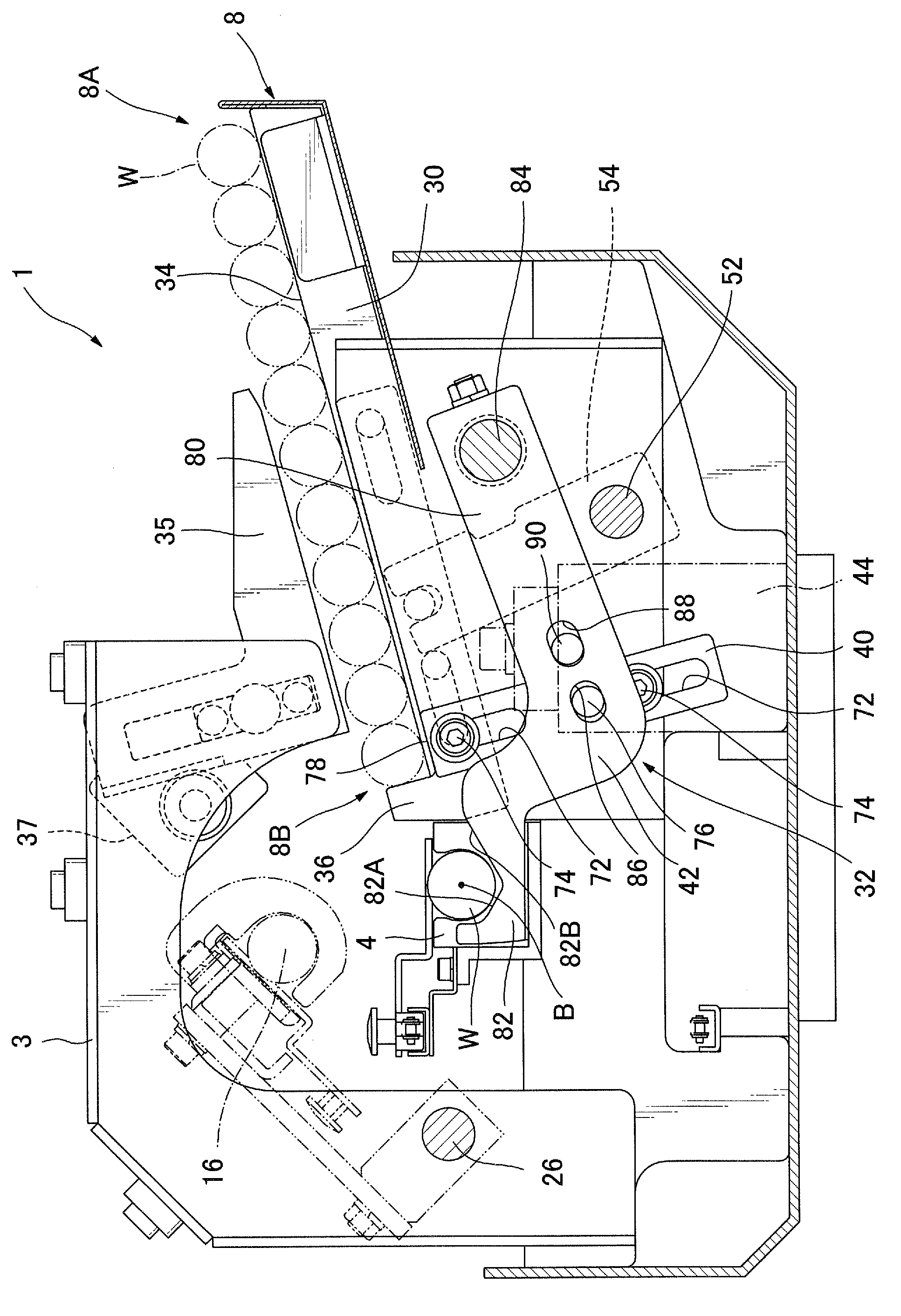

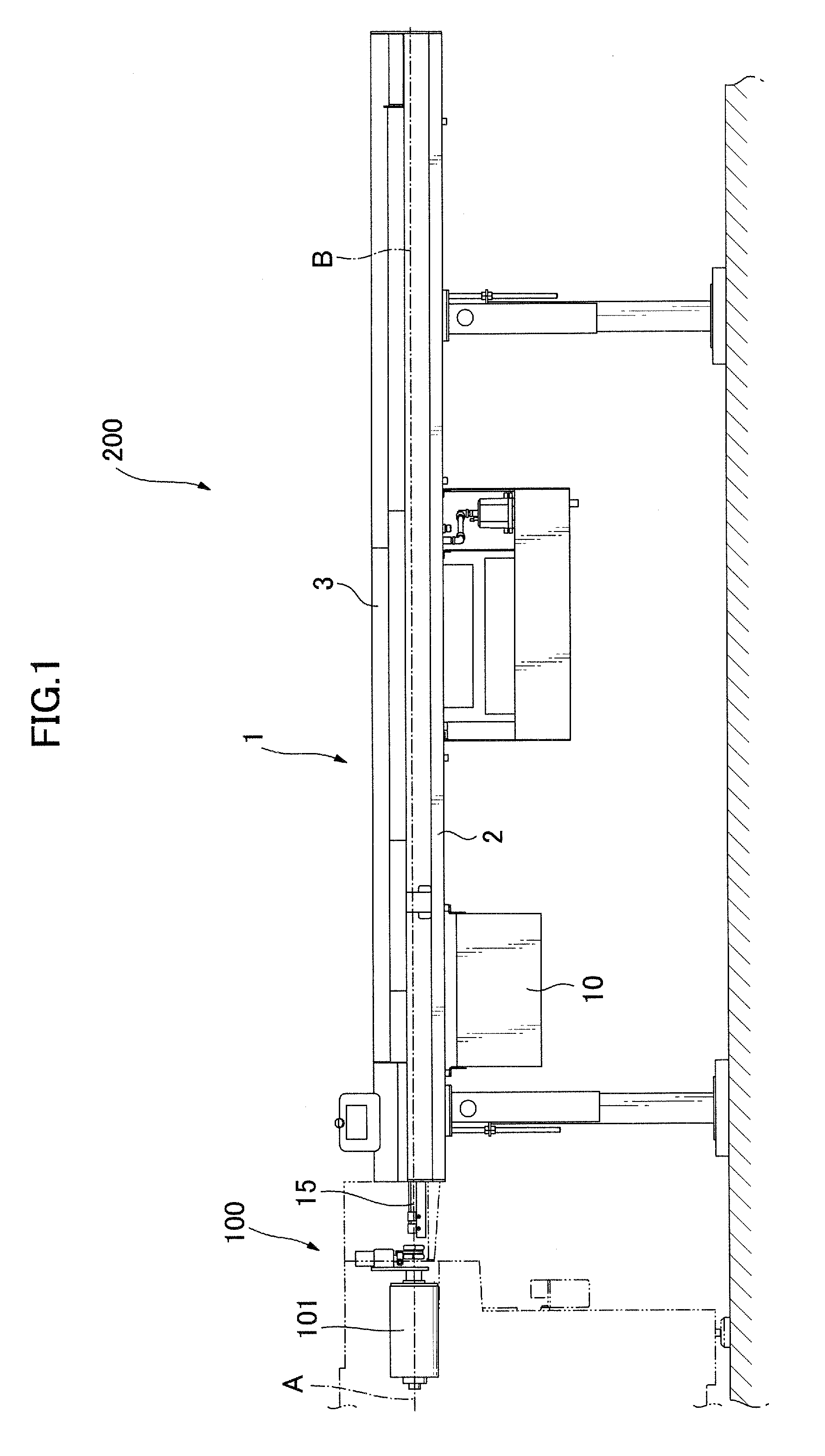

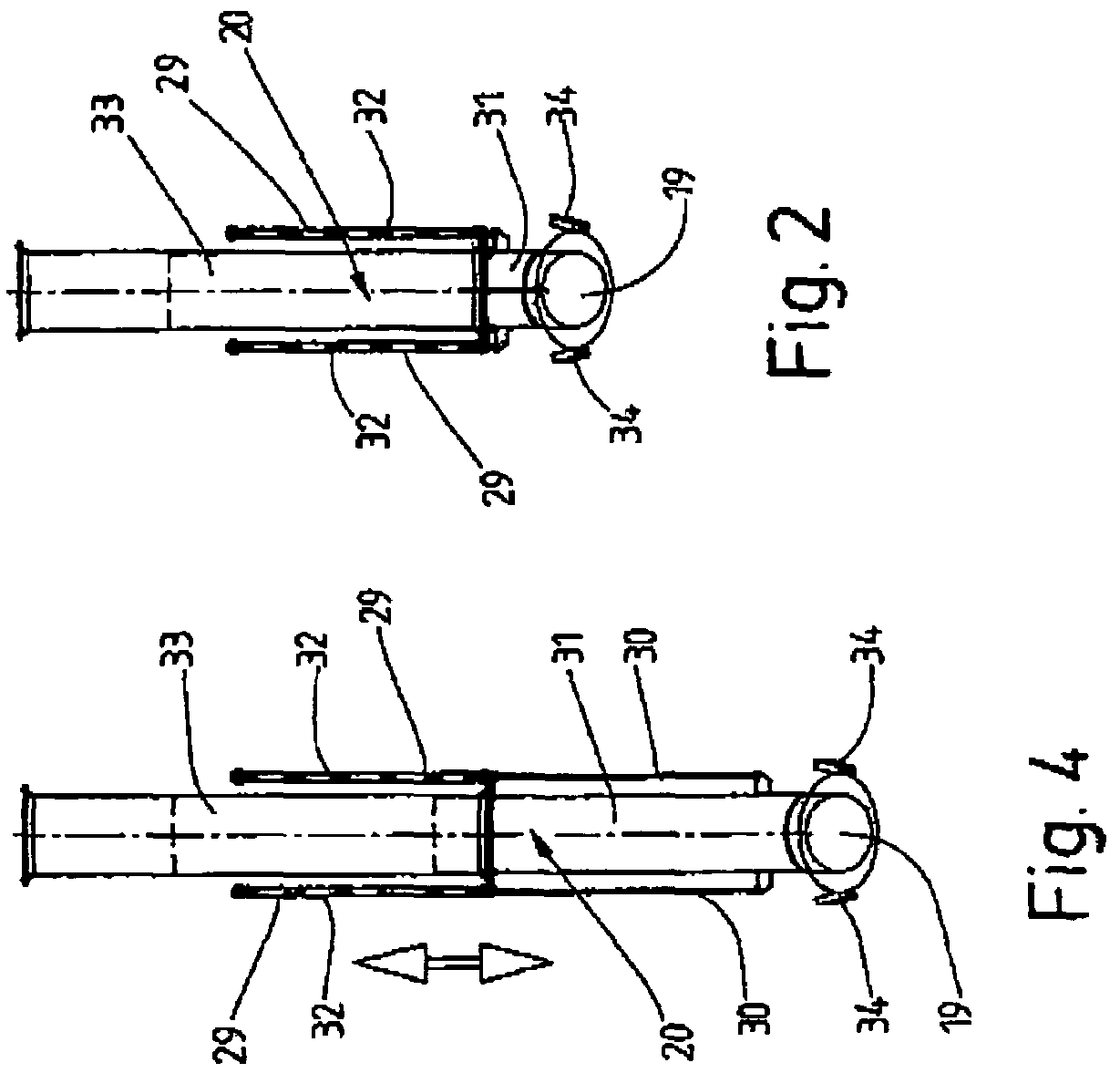

Bar feeder

ActiveUS20090180856A1Short timeReliable loadingAutomatic conveying/guiding stockLifting devicesEngineeringMechanical engineering

Disclosed is a bar feeder, which is capable of reliably loading a bar onto a guide rail with a simplified structure. The bar feeder 1 comprises a stock rack 8, a guide rail 4 for guiding a bar to a bar machining apparatus, and a bar supply mechanism 32 for taking bars W one by one out of the stock rack 8 and supplying the taken-out bar W onto the guide rail 4. The bar supply mechanism 32 includes a lifting member 40 adapted to lift a downstreammost one of the bar W on the stack rack 8, a bar receiving member 42 adapted to receive thereon the lifted bar W and supply the bar W onto the guide rail 4, and a stopper member 36 adapted to holds a second-downstreammost one of the bar W to be subsequently supplied. The lifting member 40 and the bar receiving member 42 are adapted to be driven by a common moving device 44, in such a manner that the lifting member 40 is linearly moved in an upward-downward direction in conjunction with a swing movement of the bar receiving member 42. The structure designed to drive the lifting member 40 and the bar receiving member 42 by the common moving device 44 makes it possible to reduce the number of components for a driving section, and achieve structural simplification.

Owner:IKURA SEIKI

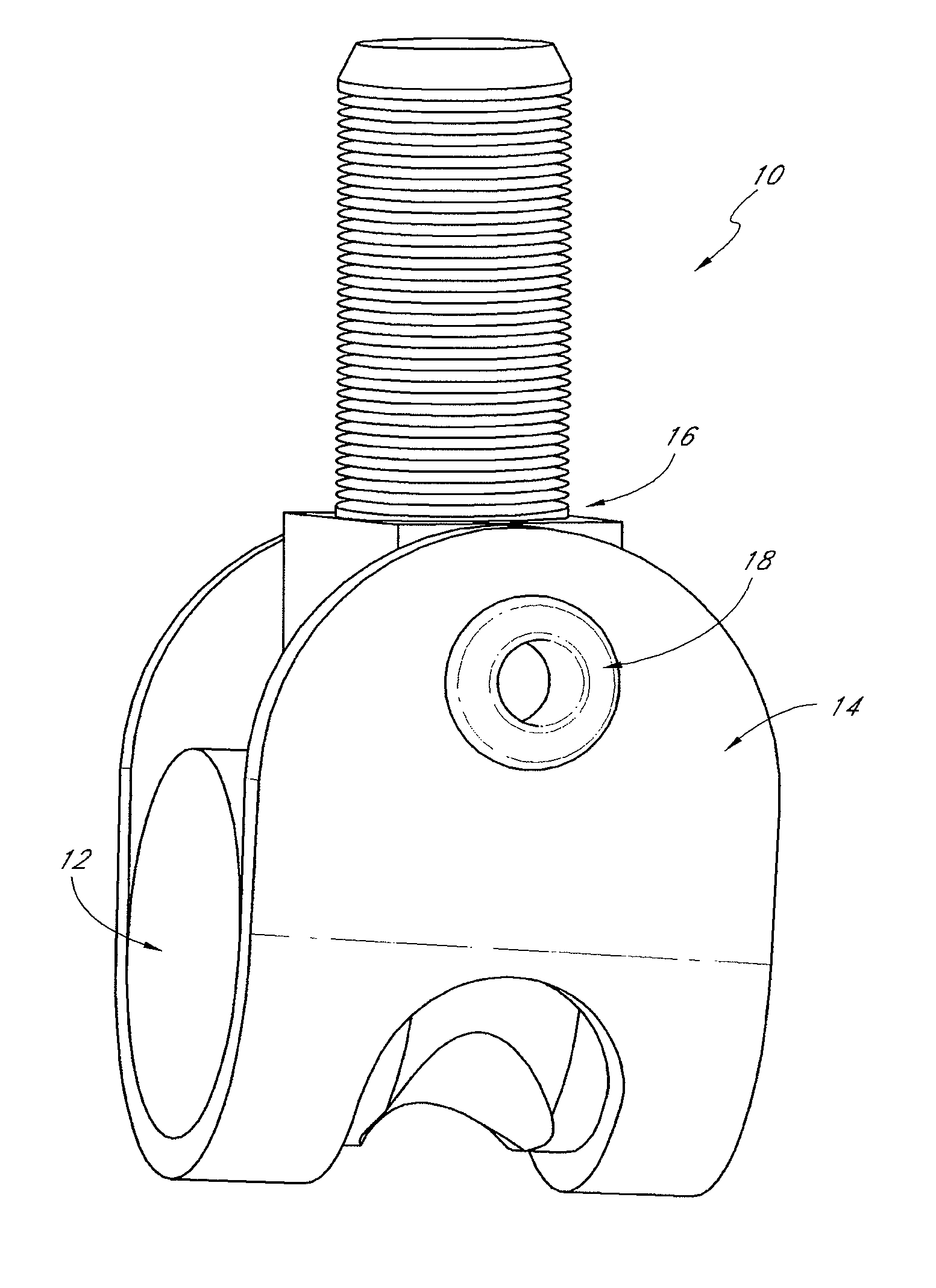

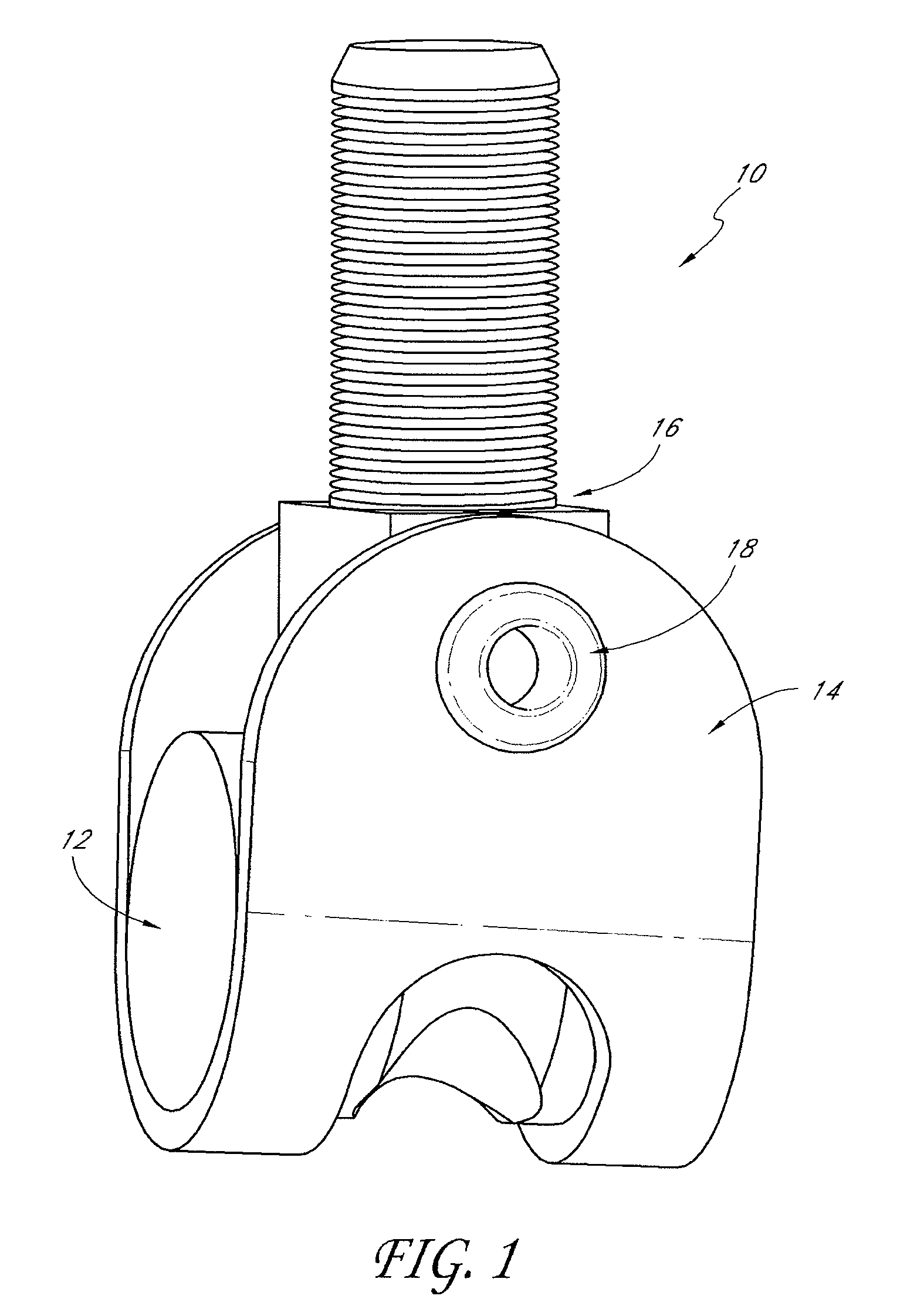

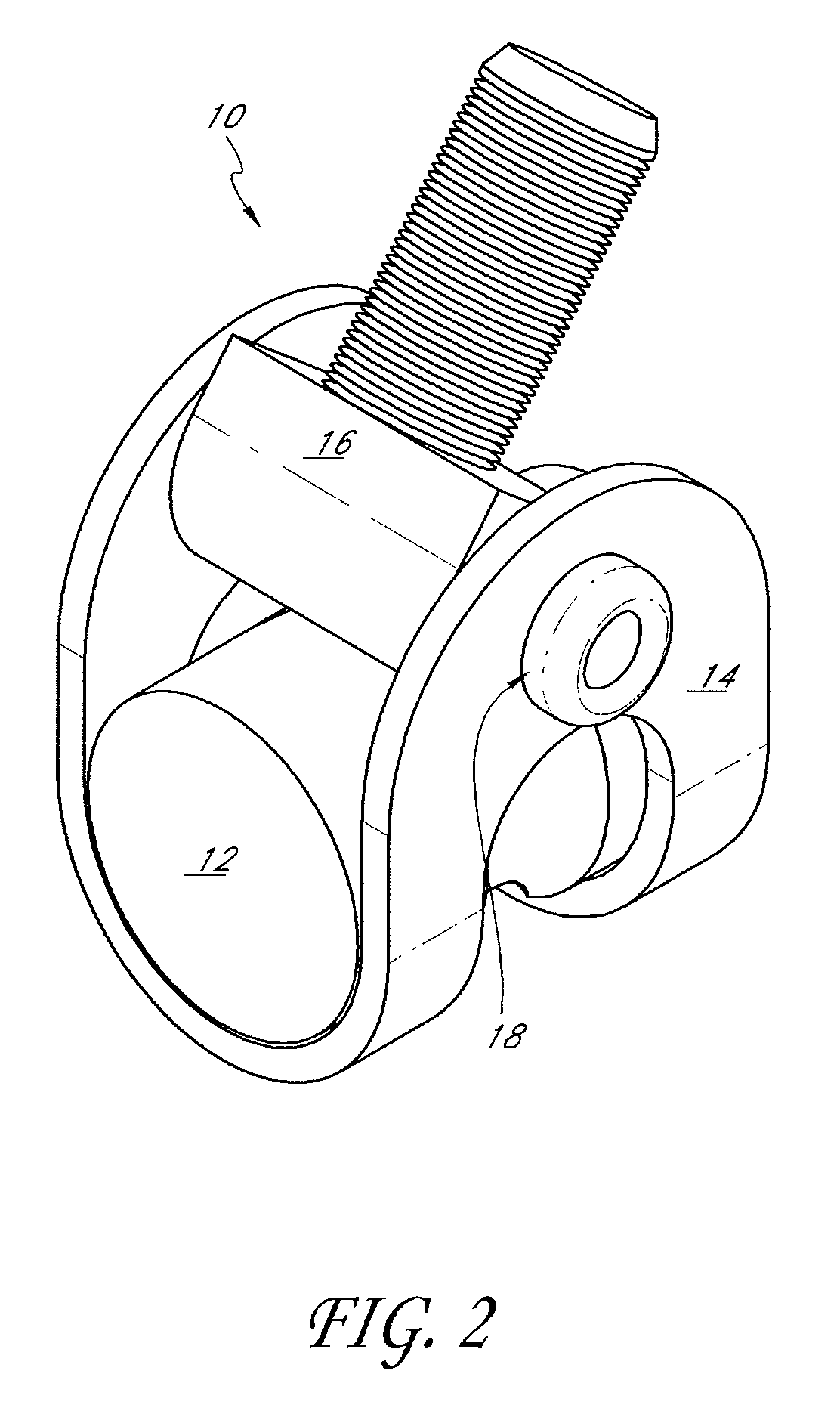

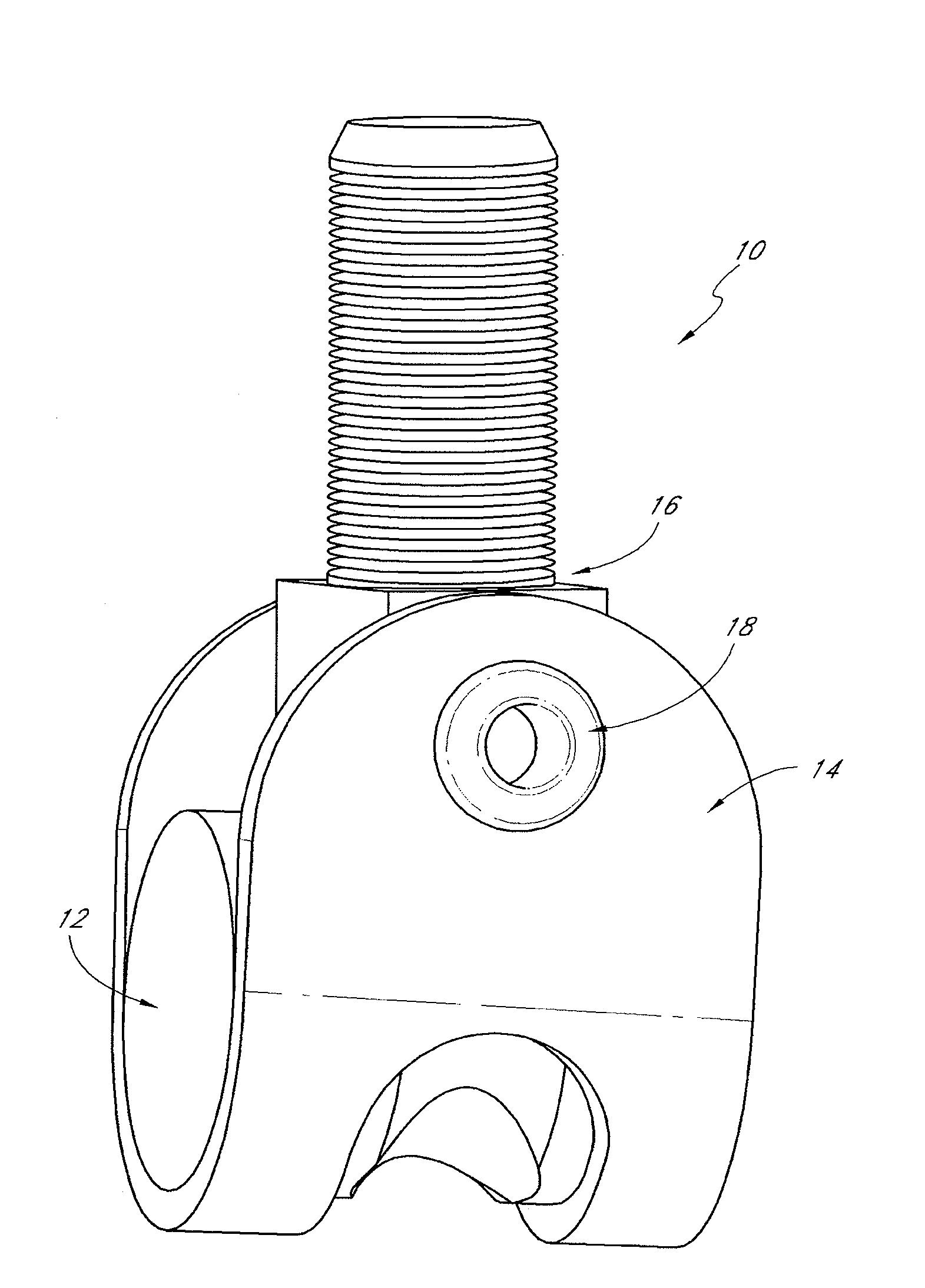

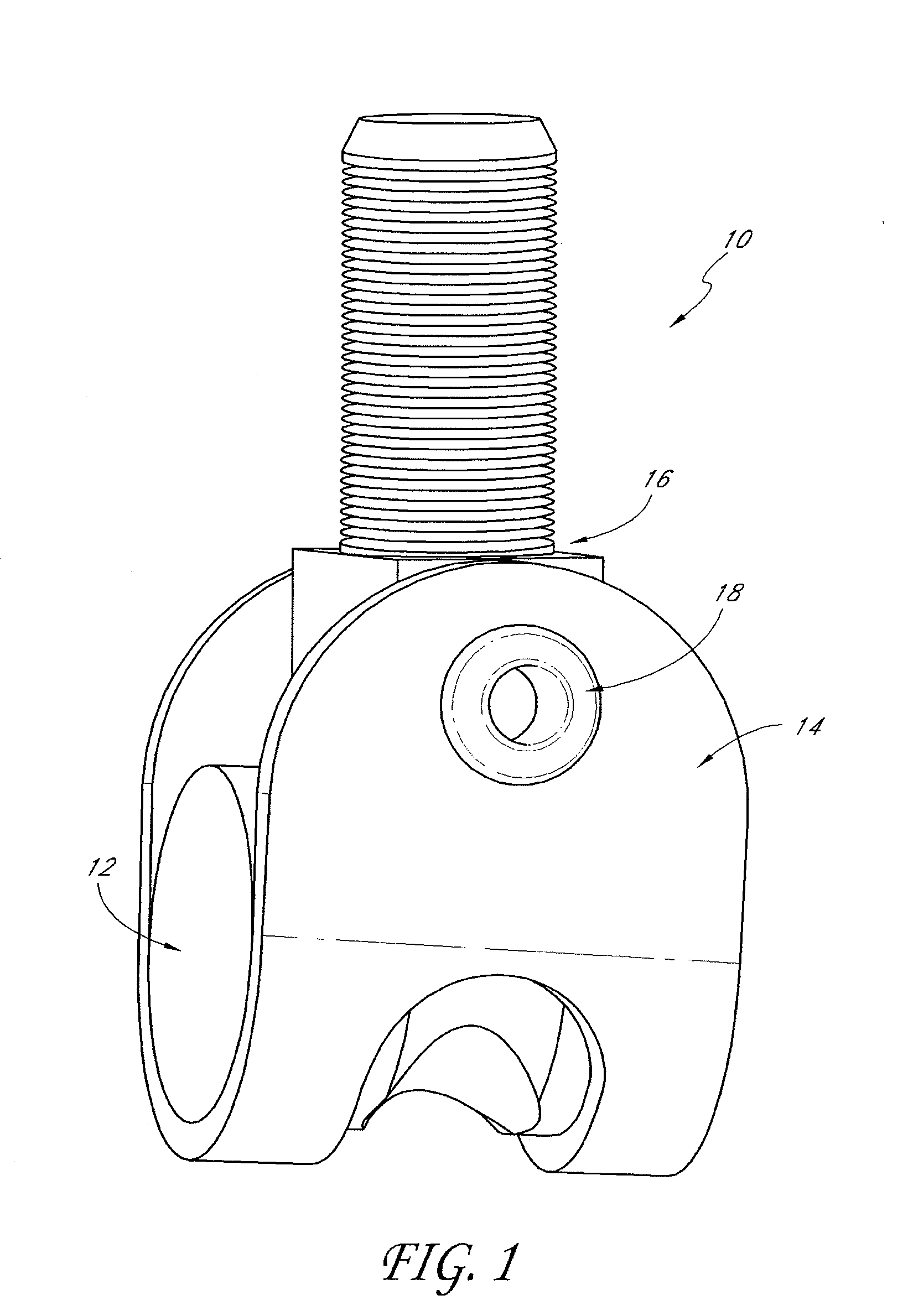

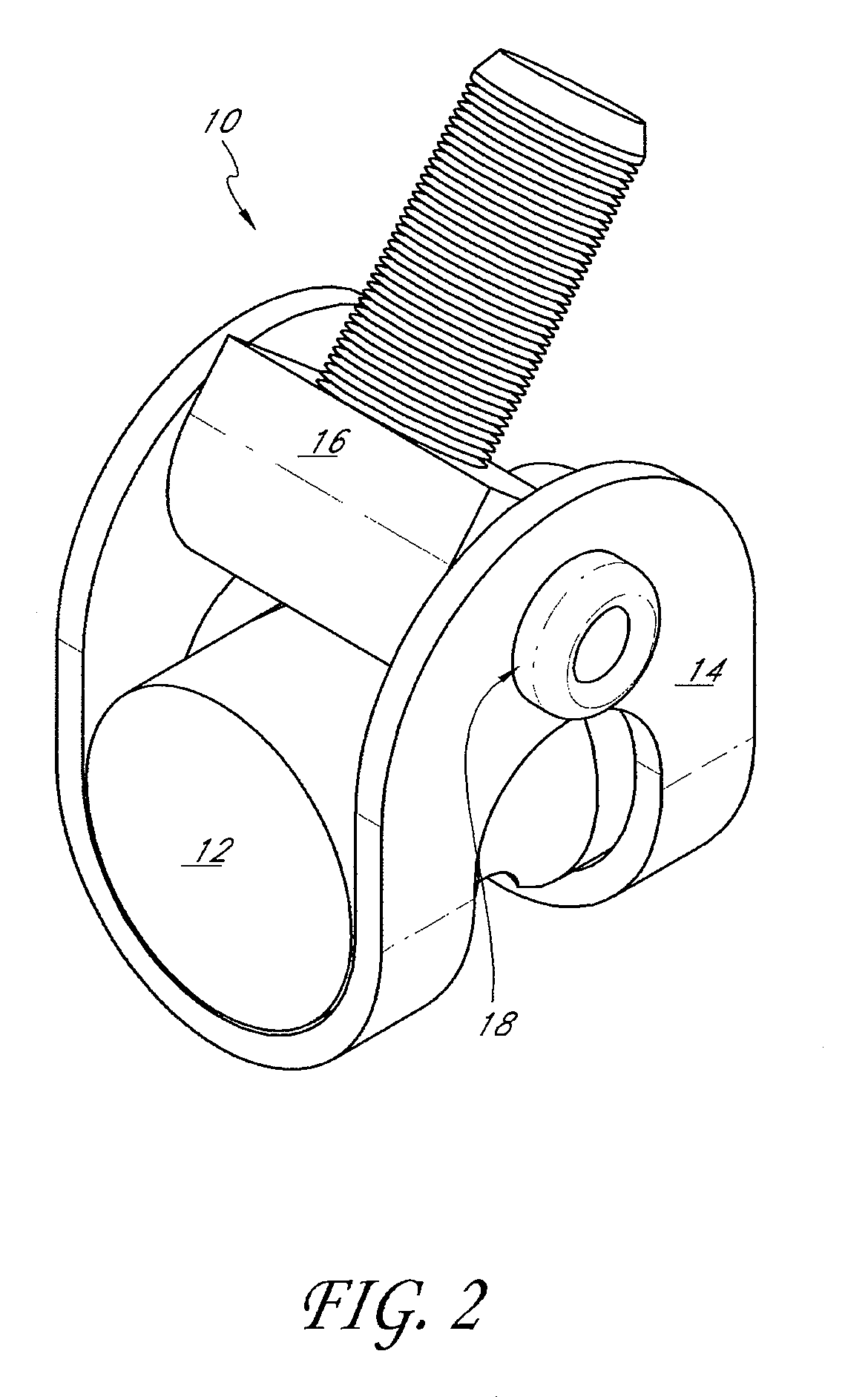

Swivel attachment and branch line restraint

ActiveUS7887248B2Improve utilizationImprove versatilityStands/trestlesKitchen equipmentDegrees of freedomEngineering

A swivel attachment and / or branch line restraint device with angular versatility and mobility for facilitating connection of installation components to support a pipe or other load relative to a support surface is provided. Advantageously, embodiments of the device provide a plurality of rotational or swivel degrees of freedom, which are substantially independently controllable, for its mating portions, which respectively engage corresponding mating portions of other installation components. The device embodiments can desirably be configured in male-female, male-male or female-female arrangements to enhance device utility and / or versatility, thereby advantageously allowing for use in a myriad of applications and installations, such as construction, utilities and the like, among others, to reliably support loads.

Owner:NIBCO INC

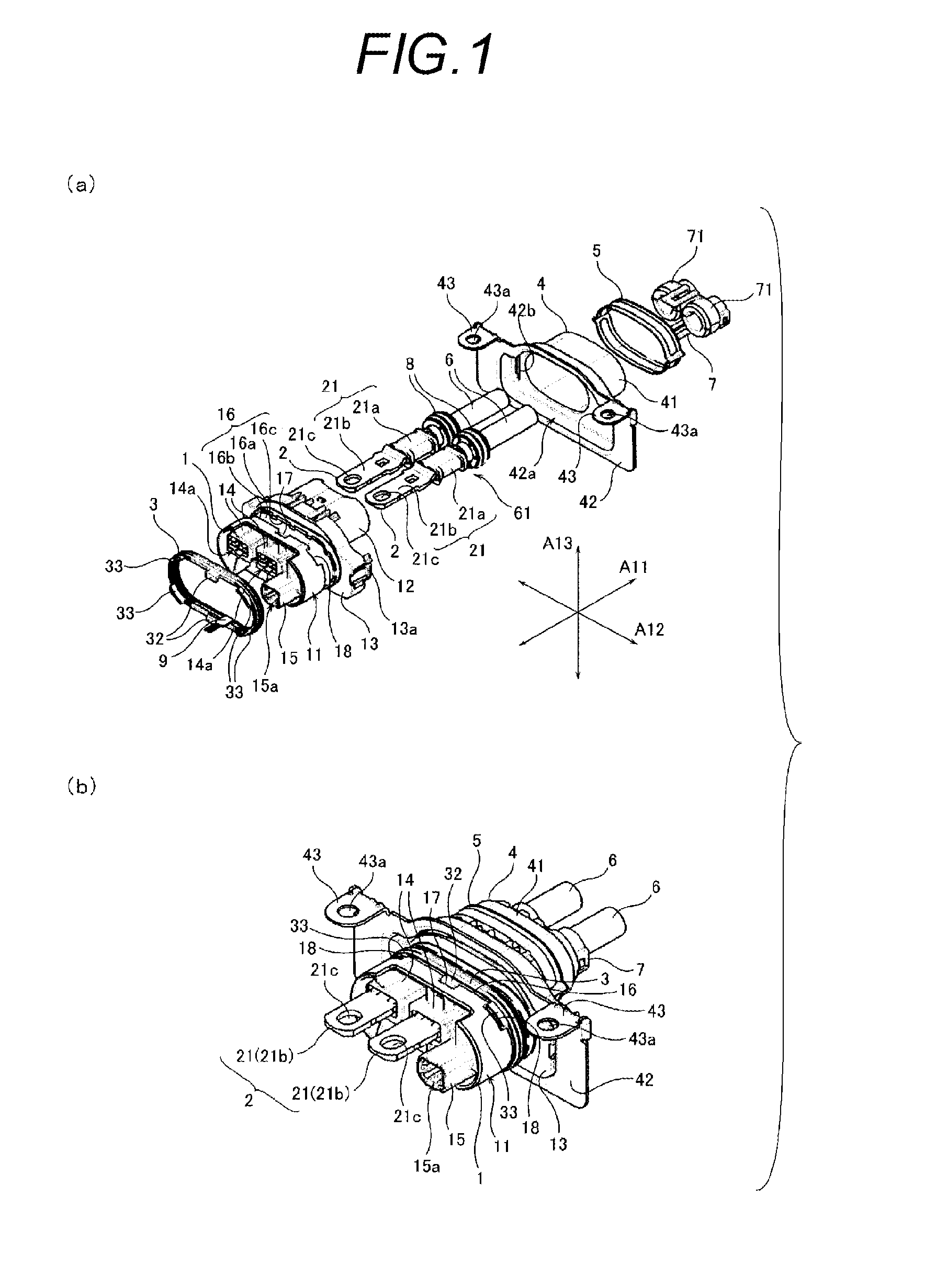

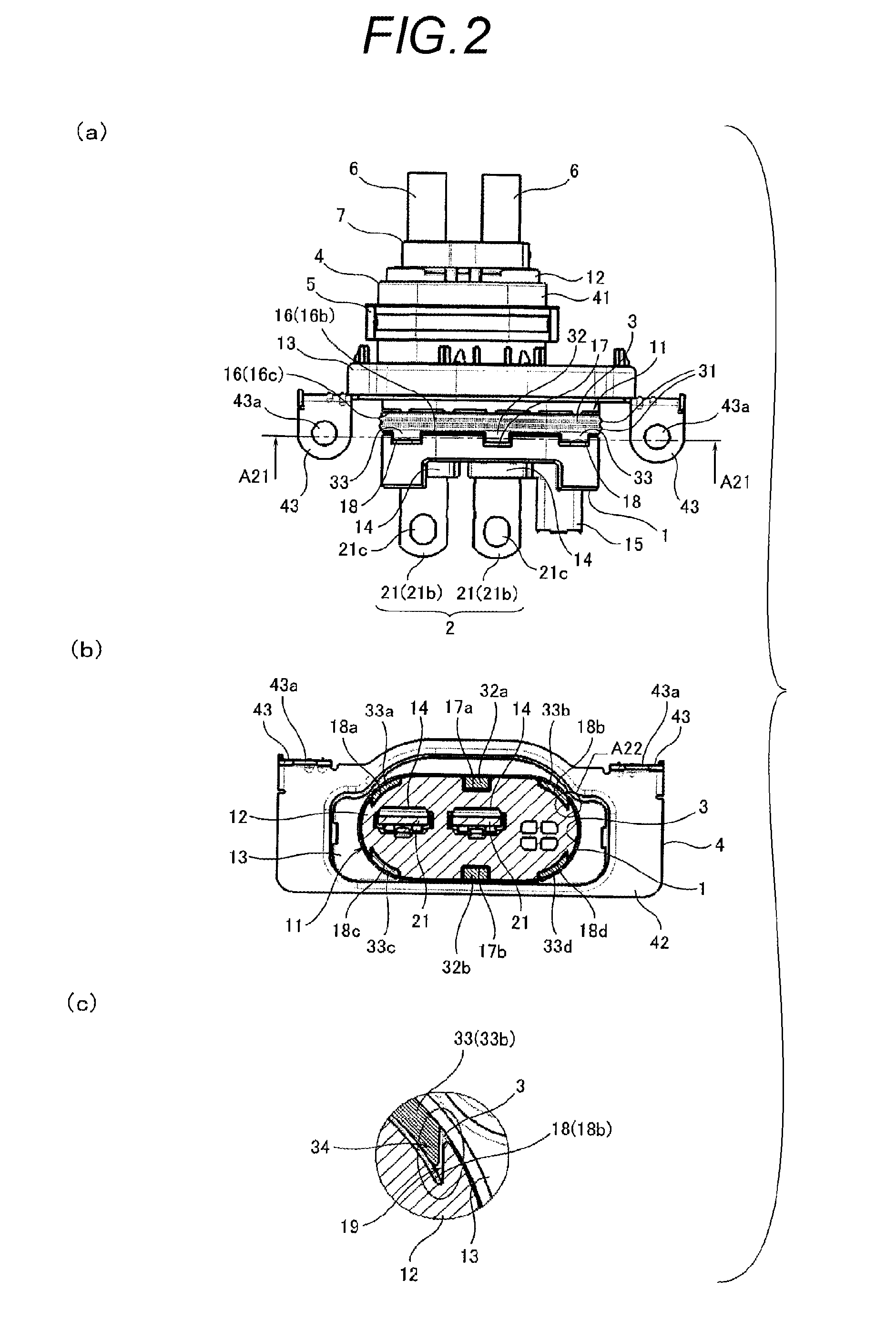

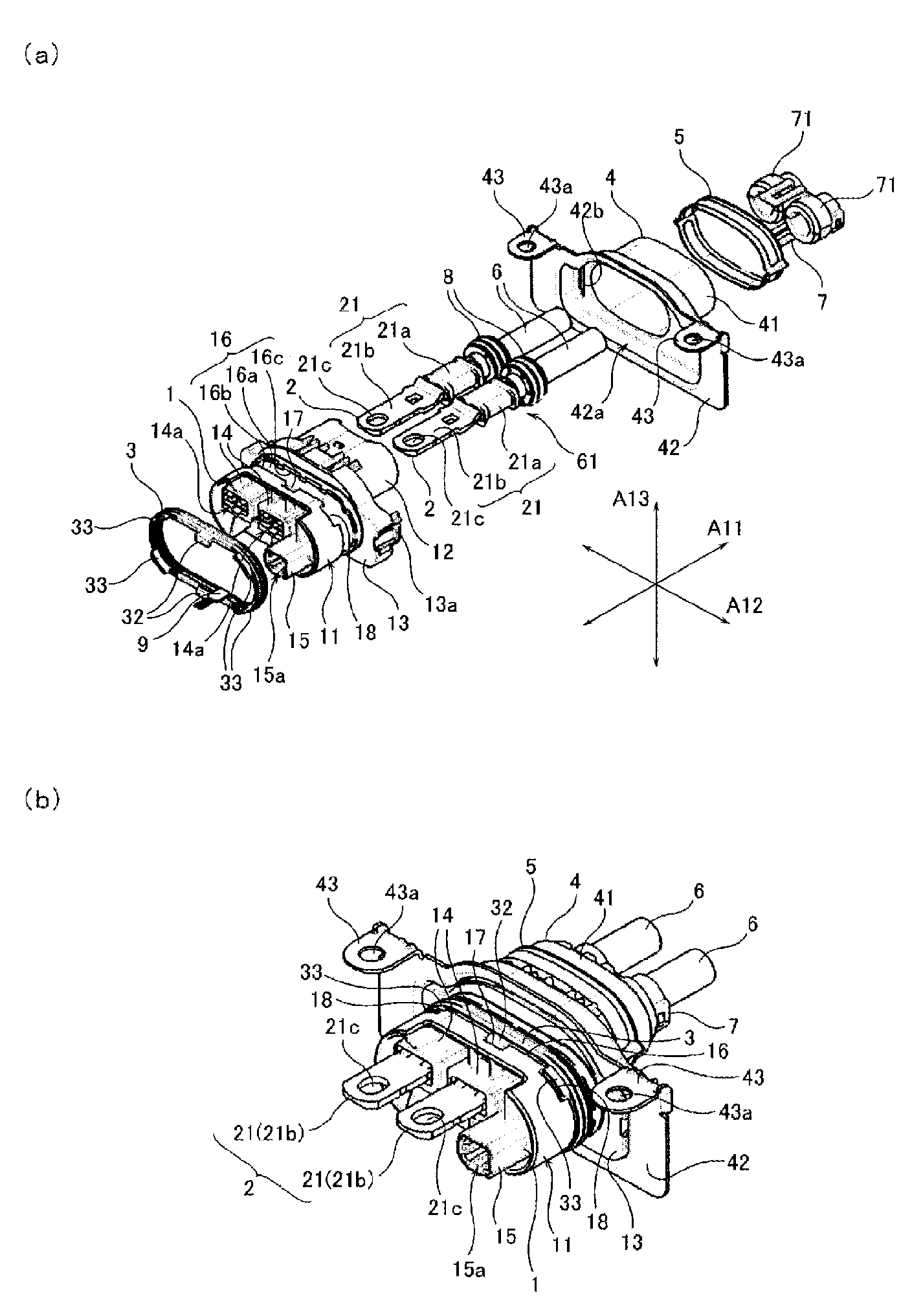

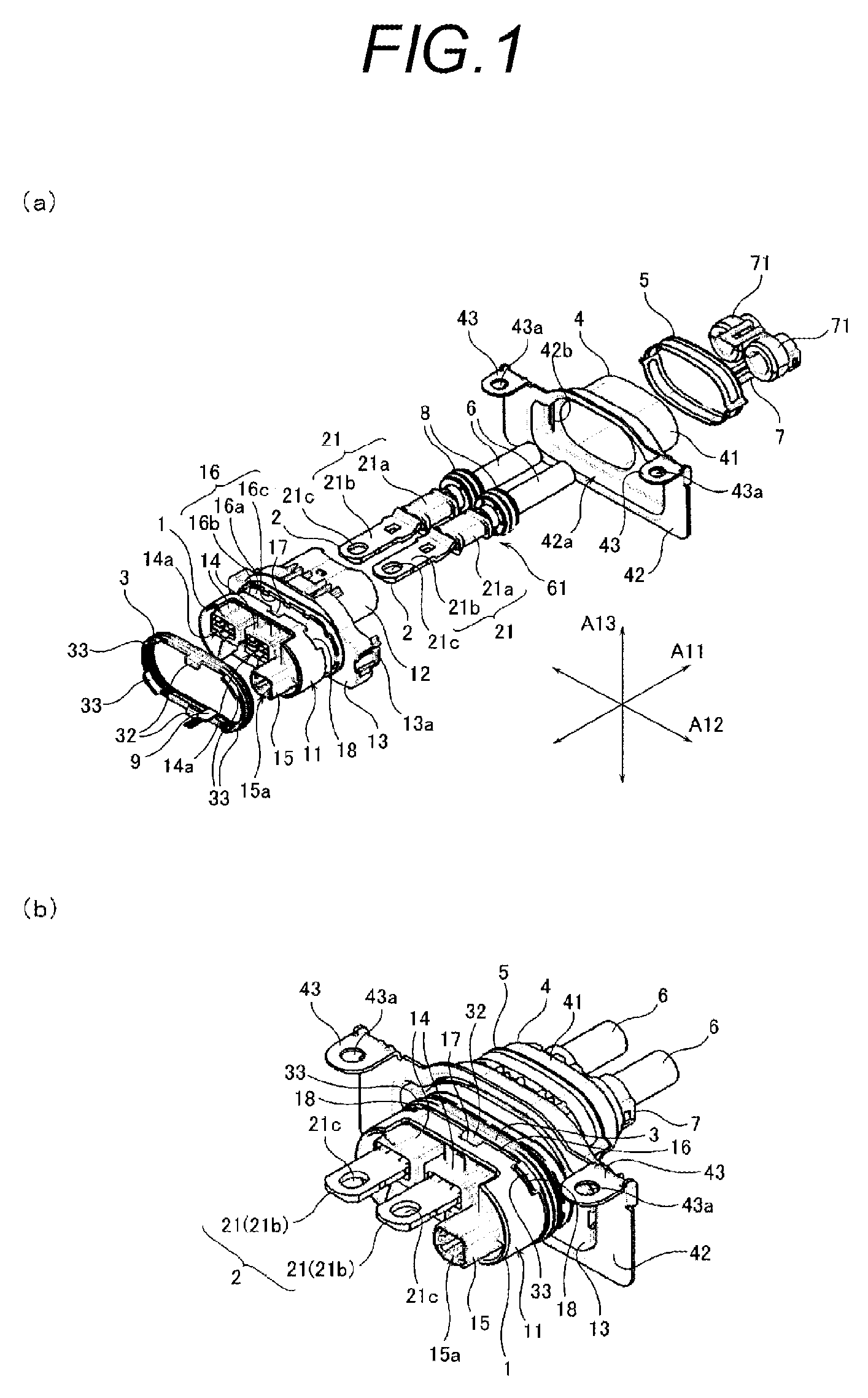

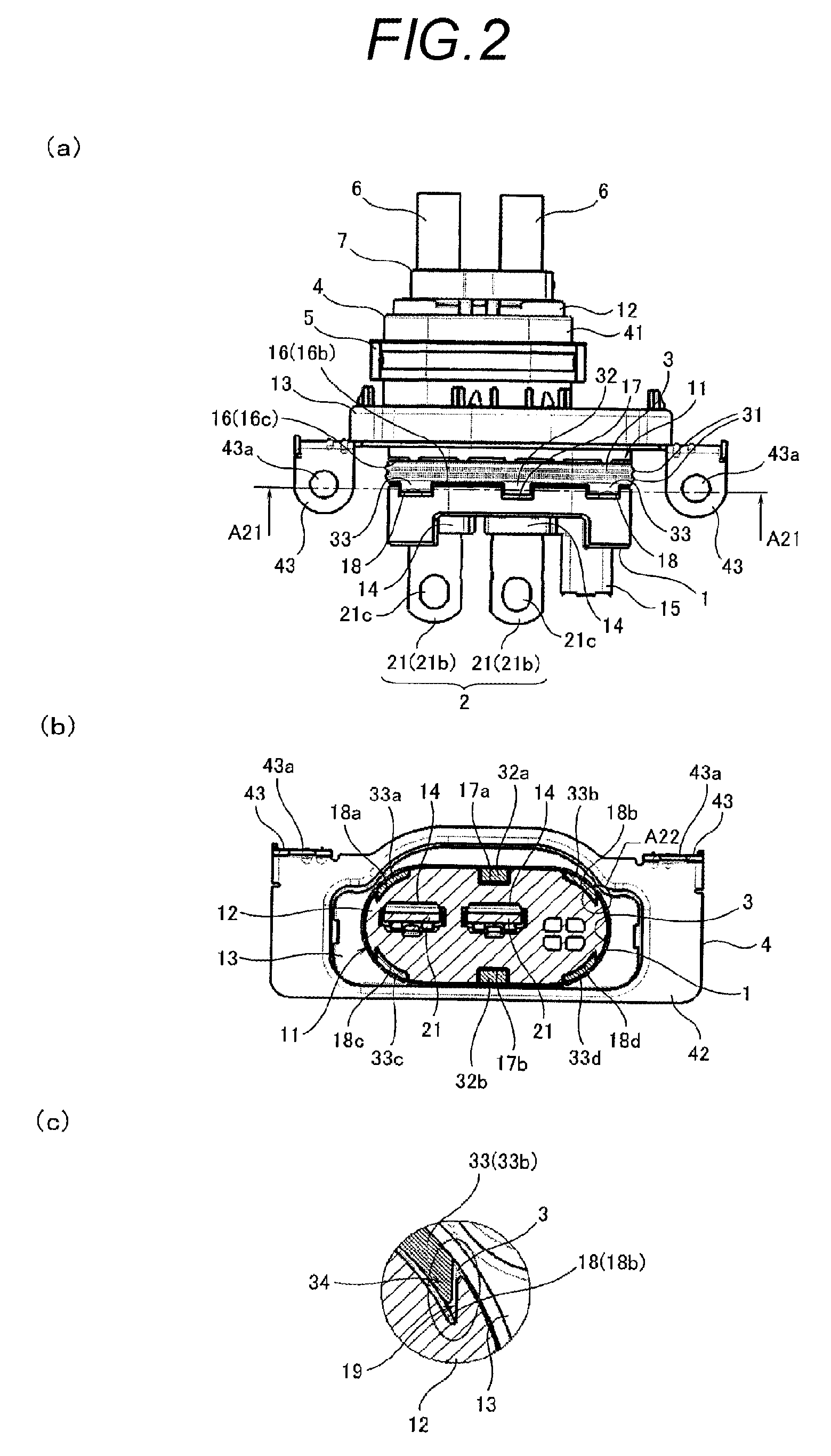

Connector assembly

ActiveUS20150288090A1Smoothly reliably engageReliable loadingVehicle connectorsSecuring/insulating coupling contact membersEngineeringElectric wire

A connector assembly includes a housing (1) in which a wire-side terminal (2) is held, and which is fitted to a mounting hole formed in a casing of a mating device to be connected, and a sealing member (3) which is attached to a groove part (16) formed in an outer peripheral part (11) of the housing thereby to keep an interior of the casing liquid tight. The sealing member (3) includes a convex part (33) formed in a curved part thereof, by protruding in a width direction from its peripheral edge part in a shape of an annularly continued band. The groove part (16) includes a concave part (18) formed by denting a groove wall (16b), corresponding to the convex part (33). The convex part (33) and the concave part (18) are engaged with each other.

Owner:YAZAKI CORP

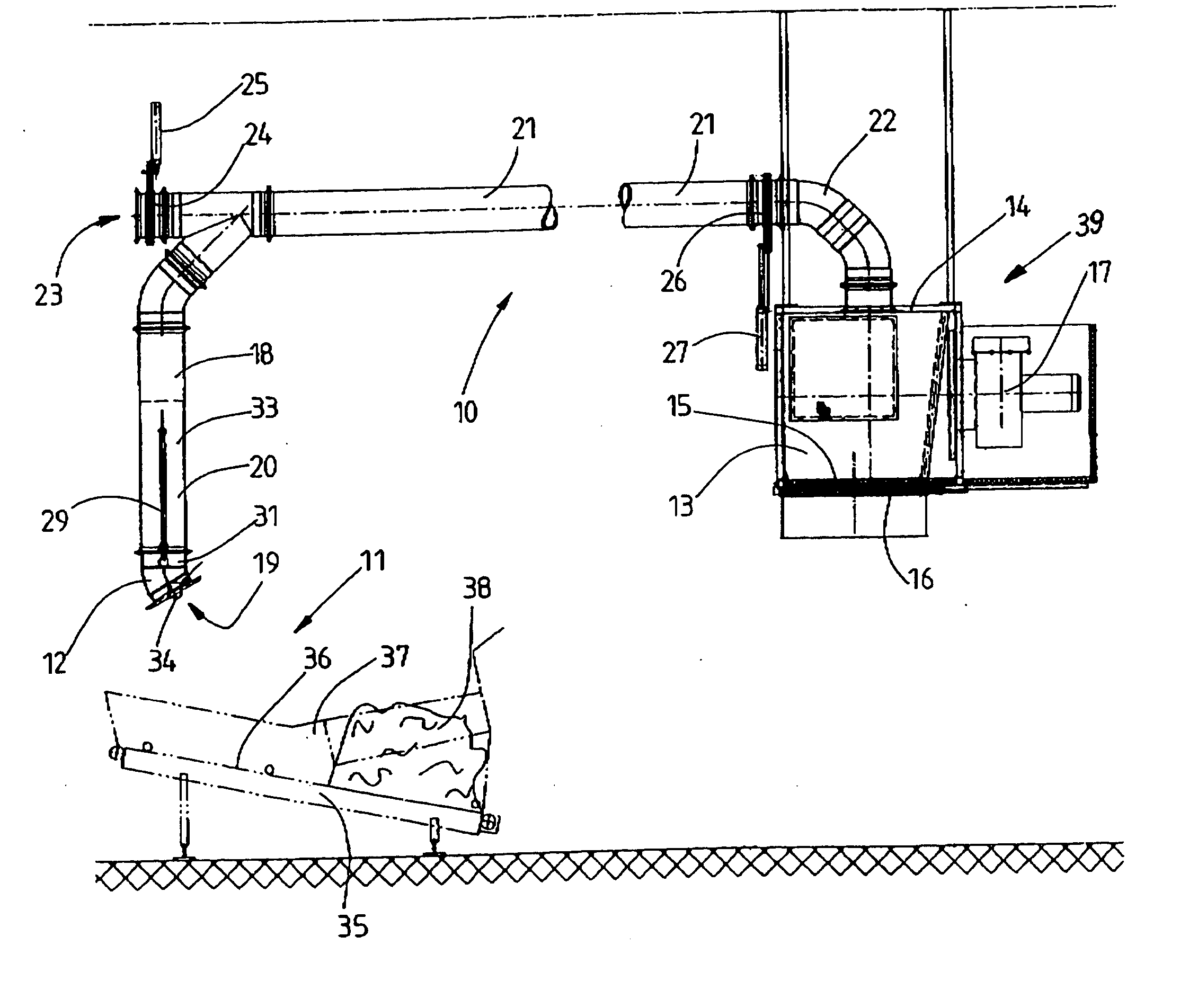

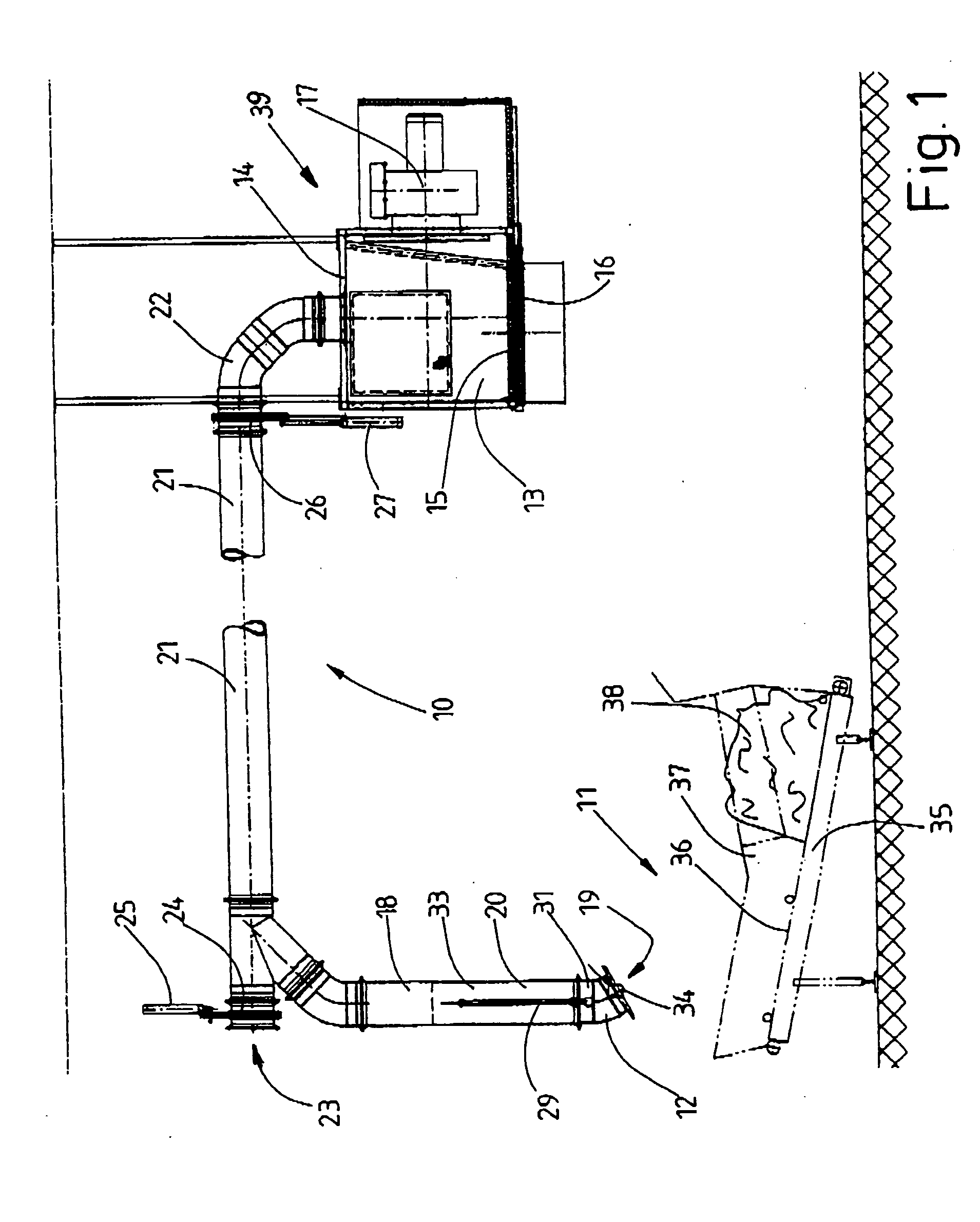

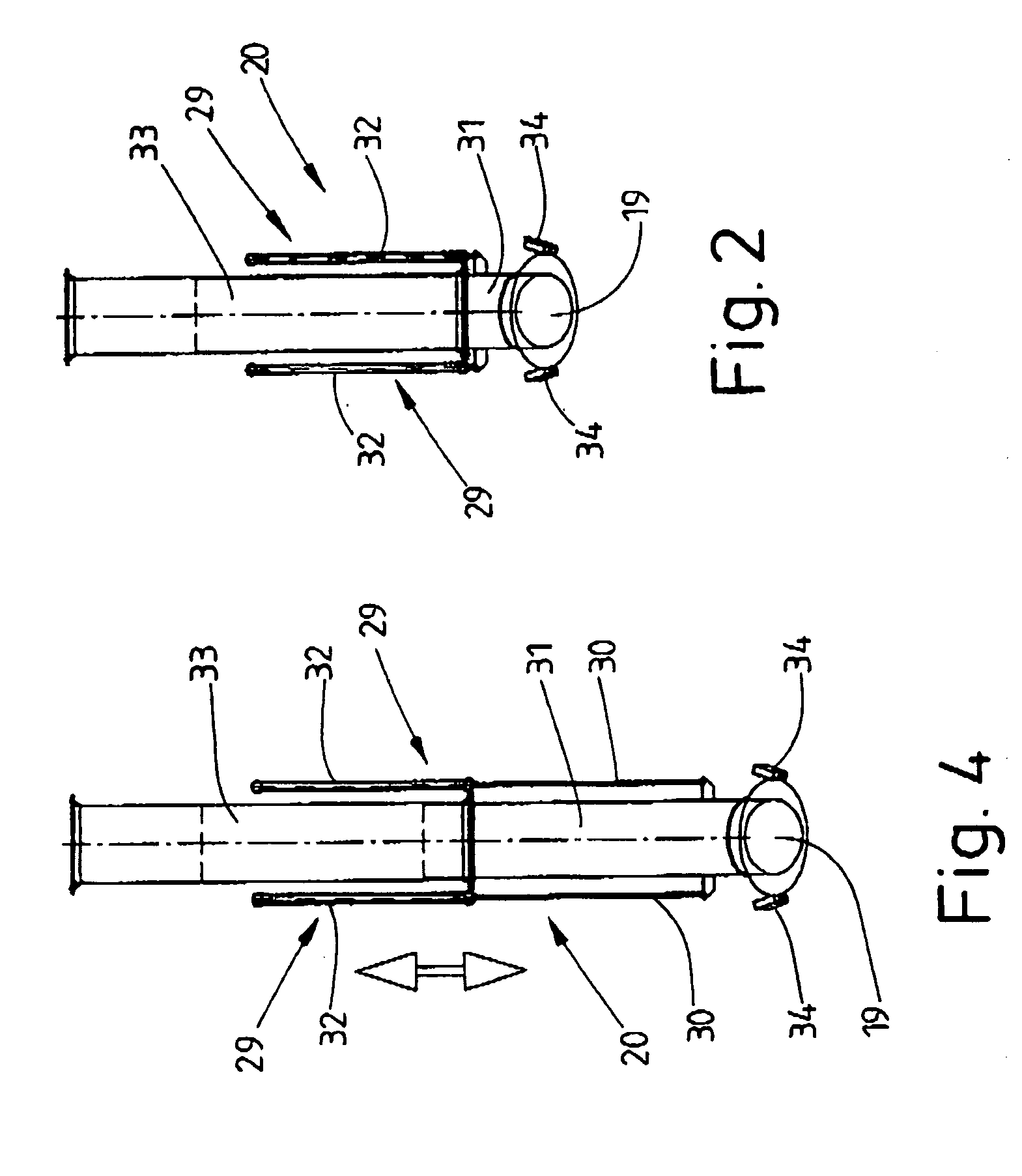

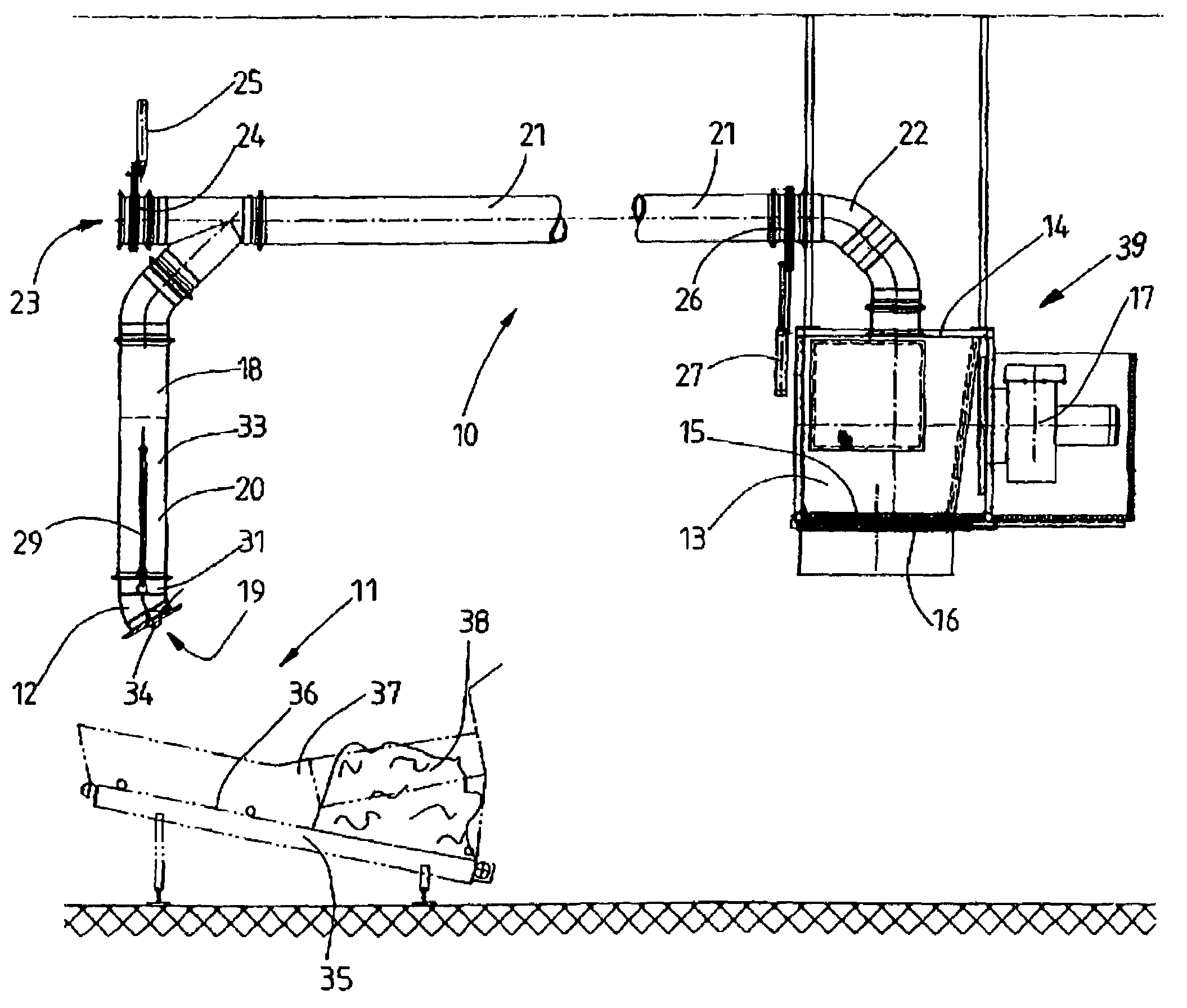

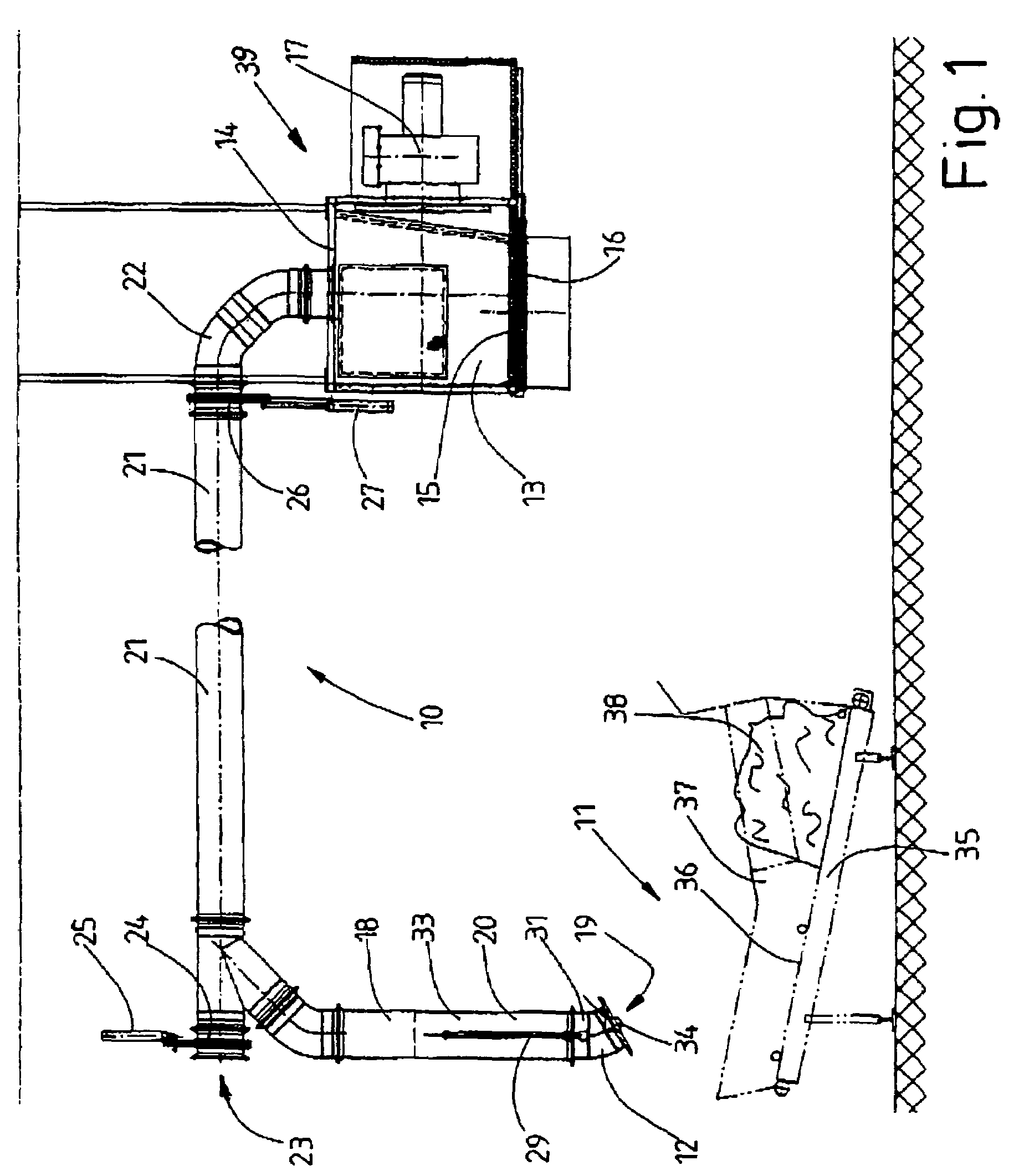

Method and device for the pneumatic transport of preferably linen

InactiveUS20050175420A1Reliable loadingReliable separationIroning apparatusBulk conveyorsMechanical engineeringTextile

A process and apparatus for separating or disentangling plugs of laundry by raising them after being picked up by the suction head (12) and briefly interrupting the suction operation. Venting of the suction head (12) which takes place in the process results in the plug of laundry (28) falling back onto the pile of laundry (38). This gives rise to the plug of laundry being automatically “forced apart”, whereupon the pneumatic conveyor can be automatically loaded with laundry by the suction head (12).

Owner:KANNEGIESSER GMBH CO HERBERT

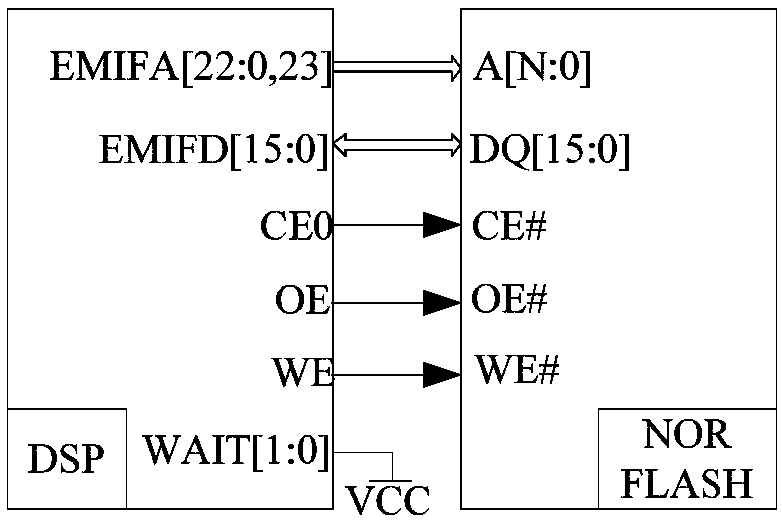

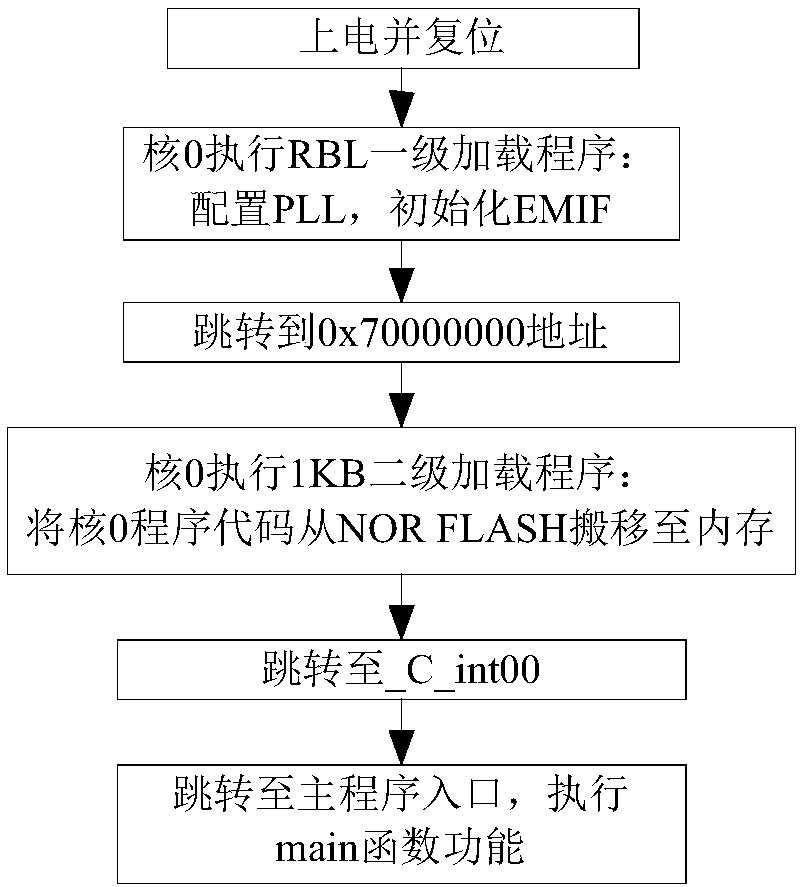

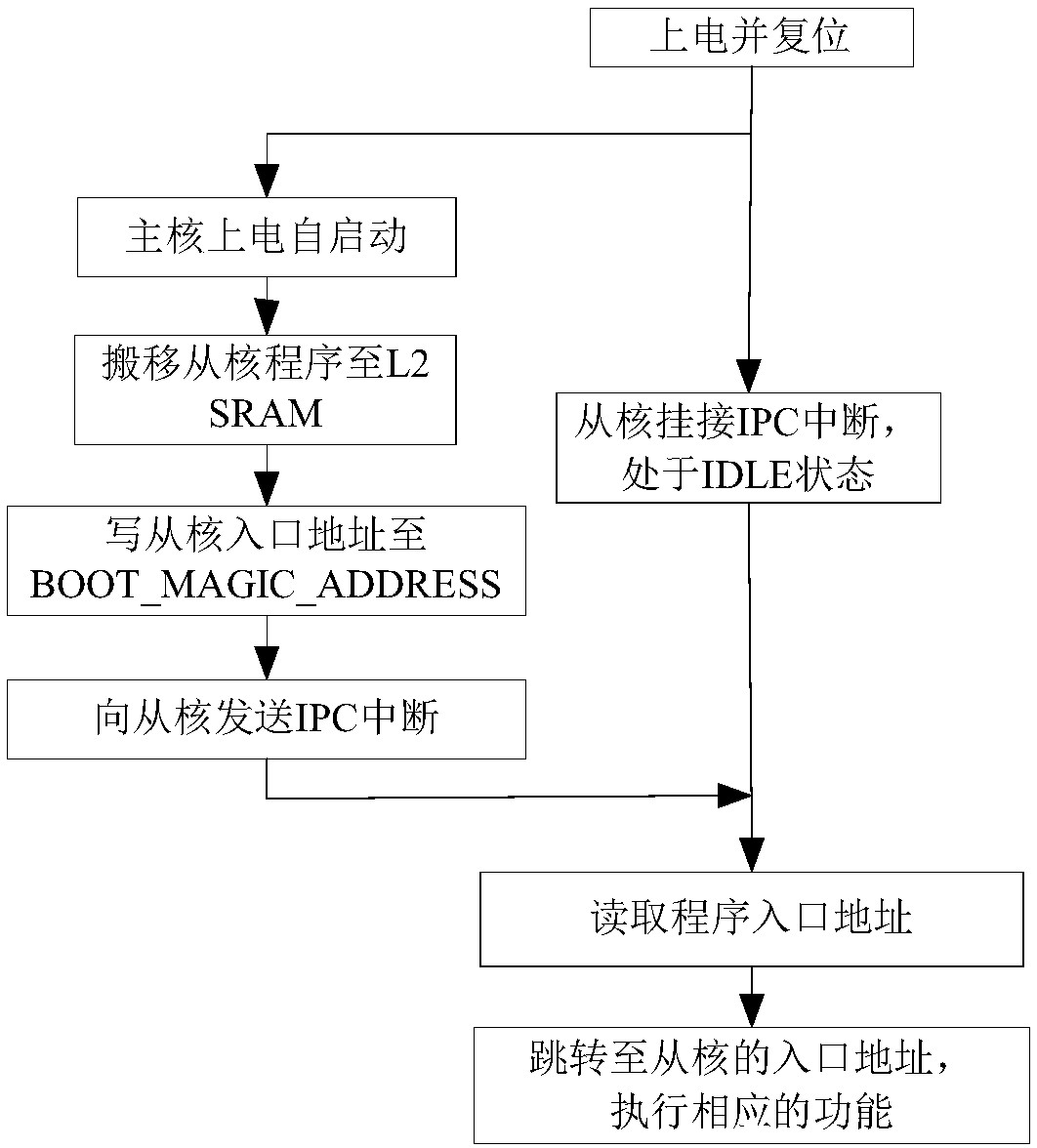

A simplified implementation of multi-core DSP power-on self-startup based on EMIF16

InactiveCN109213531AImprove loading efficiencyEasy to writeBootstrappingSoftware deploymentElectricitySoftware engineering

The invention relates to a simplified implementation method of multi-core DSP power-on self-start based on EMIF16, belonging to the field of embedded device power-on self-boot technology. Through thethree-stage loading process, the invention modifies the CMD file, stores the multi-core program in sections, and writes the program burning-writing function and the two-stage boot program, so that thecompiling and burning-writing process of the multi-core program can be completed under the same CCS project, and finally correctly realizes the power-on self-startup of the multi-core DSP program. The method disclosed by the invention discards the tedious processing process of the current multi-core DSP power-on self-startup, does not need to compile the multi-core programs separately, omits thestep of manually synthesizing a plurality of image files, and improves the loading efficiency of the multi-core programs. The method of writing burn-write function in engineering is adopted, which makes multi-core program burn-write convenient. The power-on loading process is simple, the program is more readable, the debugging cycle is greatly shortened, and the correct and reliable loading and running of multi-core DSP software can be realized.

Owner:HARBIN ENG UNIV

Method and device for the pneumatic transport of preferably linen

InactiveUS7524145B2Reliable loadingReliable separationIroning apparatusBulk conveyorsEngineeringMechanical engineering

A process and apparatus for separating or disentangling plugs of laundry by raising them after being picked up by the suction head (12) and briefly interrupting the suction operation. Venting of the suction head (12) which takes place in the process results in the plug of laundry (28) falling back onto the pile of laundry (38). This gives rise to the plug of laundry being automatically “forced apart”, whereupon the pneumatic conveyor can be automatically loaded with laundry by the suction head (12).

Owner:KANNEGIESSER GMBH CO HERBERT

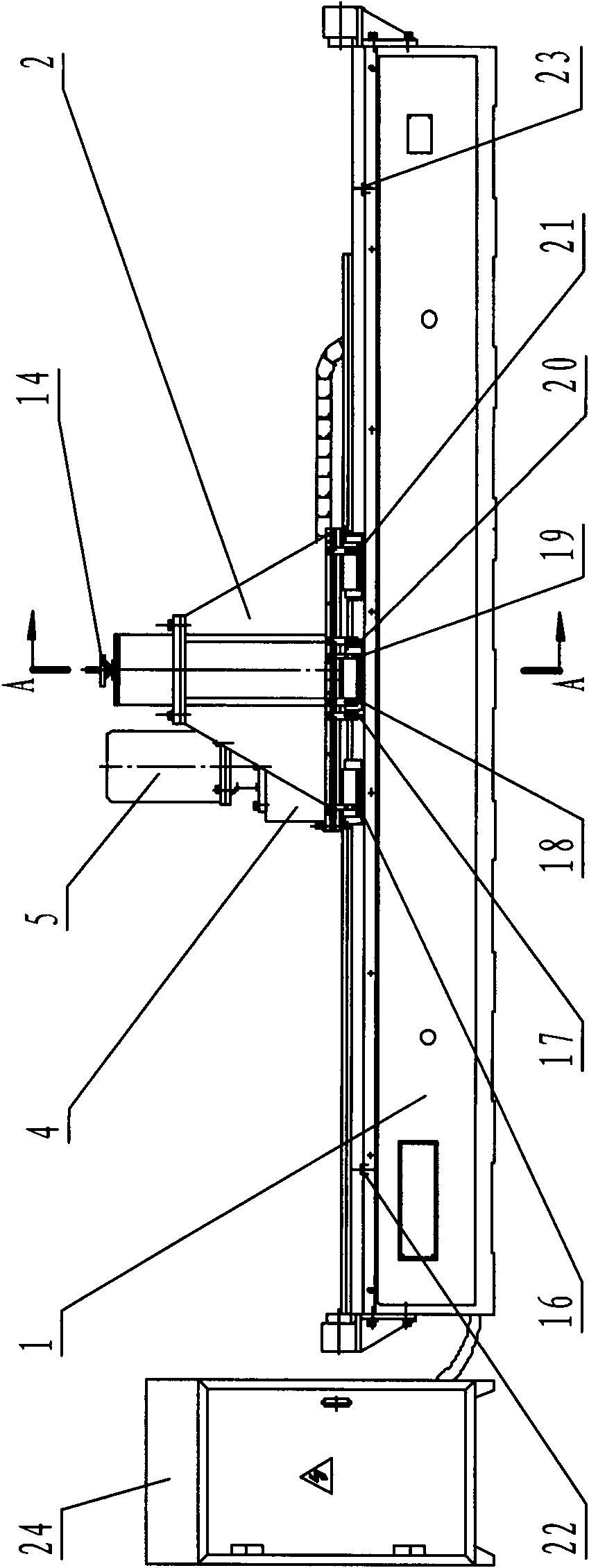

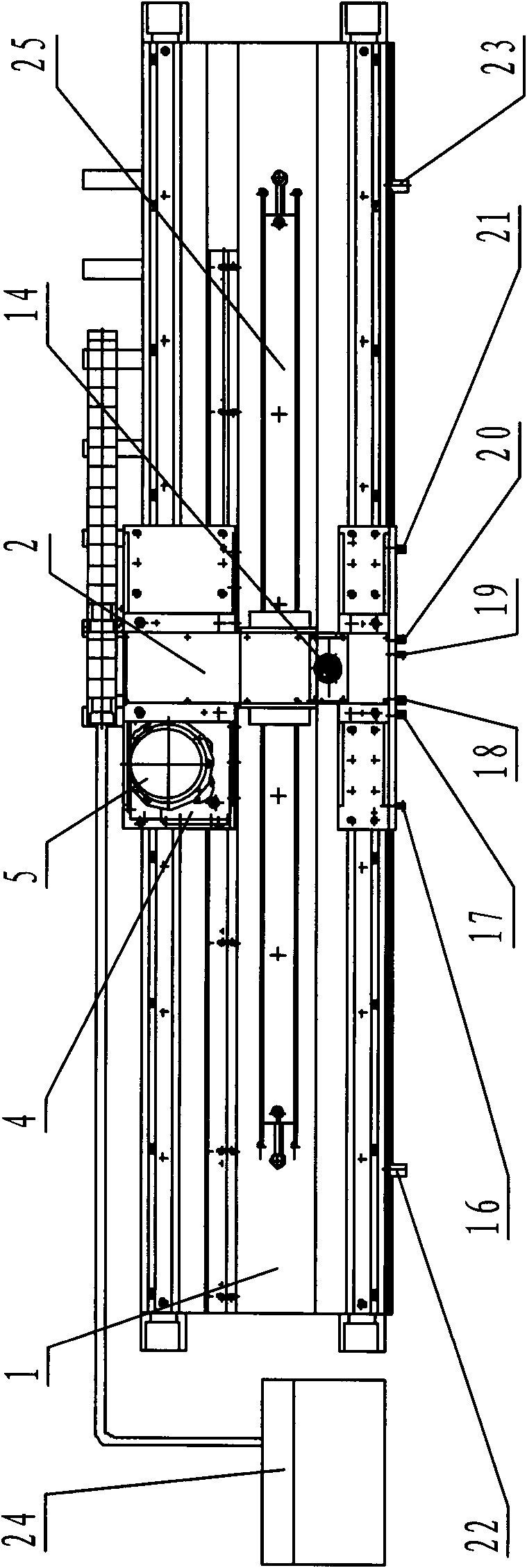

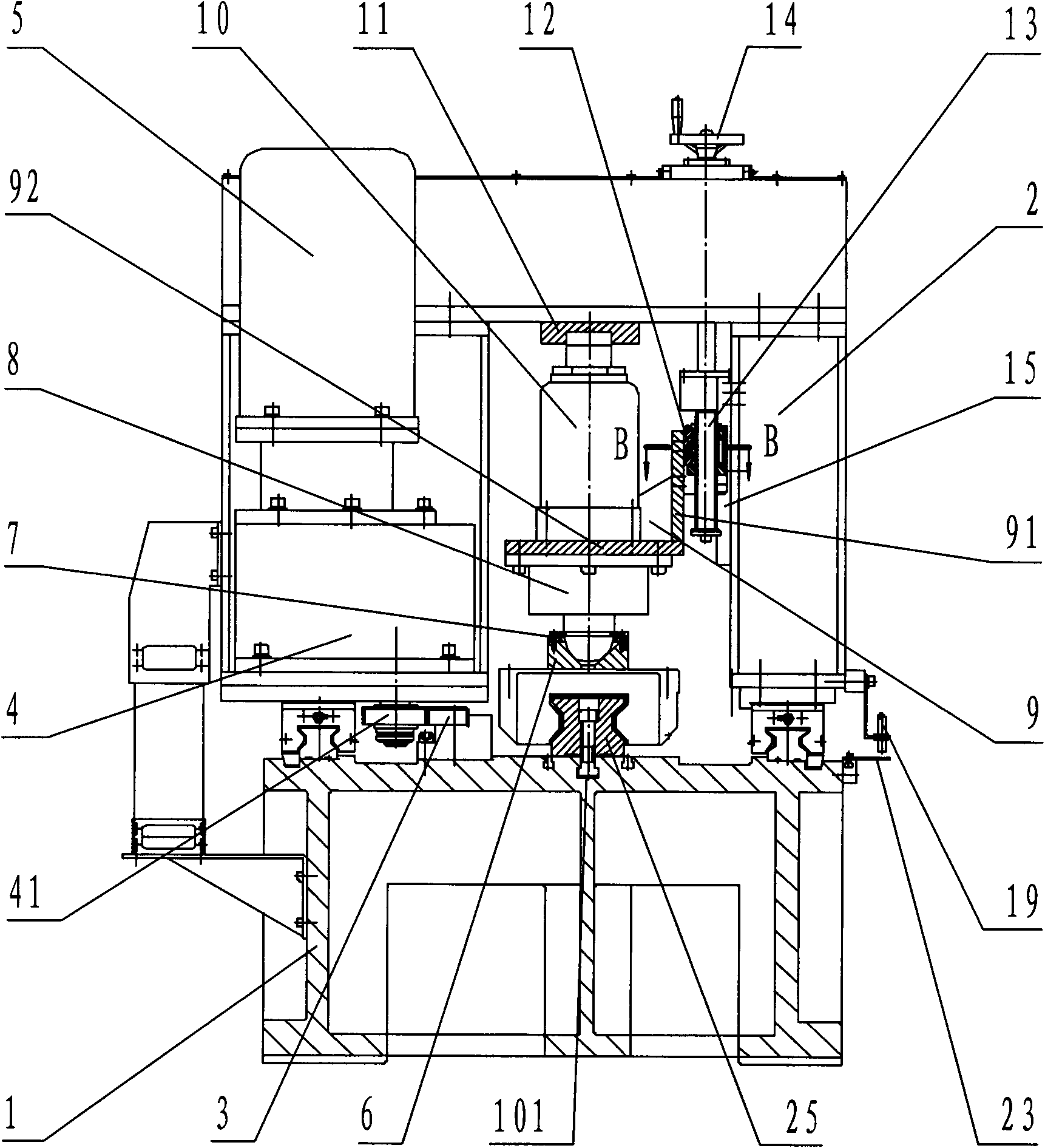

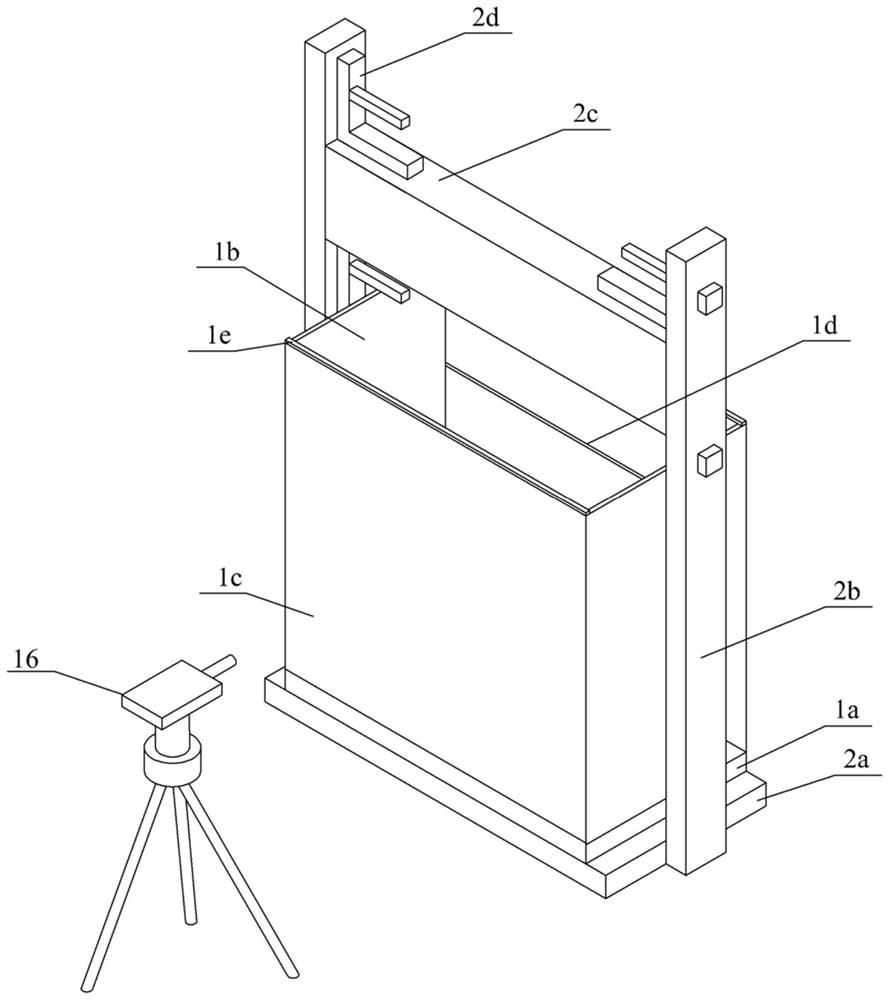

Rolling straight-line guide rail pair reliability tester

The invention discloses a rolling straight-line guide rail pair reliability tester, which comprises a lathe bed and a horizontal moving portal frame located on the lathe bed. A rack parallel to a portal frame moving guide rail is fixedly installed at the position slightly at the back on the table surface of the lathe bed, and the length of the rack is approximately equal to that of the lathe bed. A gear shift mechanism is disposed on one side of a rear column of the portal frame, and a gear at the output shaft end of the gear shift mechanism is meshed with the rack. A loading mechanism capable of going up and down is arranged on a front column of the portal frame and used for applying load to a detected rolling straight-line guide rail pair. The gear shift mechanism and electric appliance parts in the loading mechanism are connected with a control cabinet circuit with a digital display instrument. The rolling straight-line guide rail pair reliability tester is capable of measuring the number of times of running-in of the rolling straight-line guide rail pair on the conditions of high speed and heavy load and also capable of measuring indexes of linear speed, rated dynamic load, static load, mean cycles between failures and the like, simple in structure, convenient to install, reliable in loading and accurate in testing.

Owner:陕西汉江机床有限公司

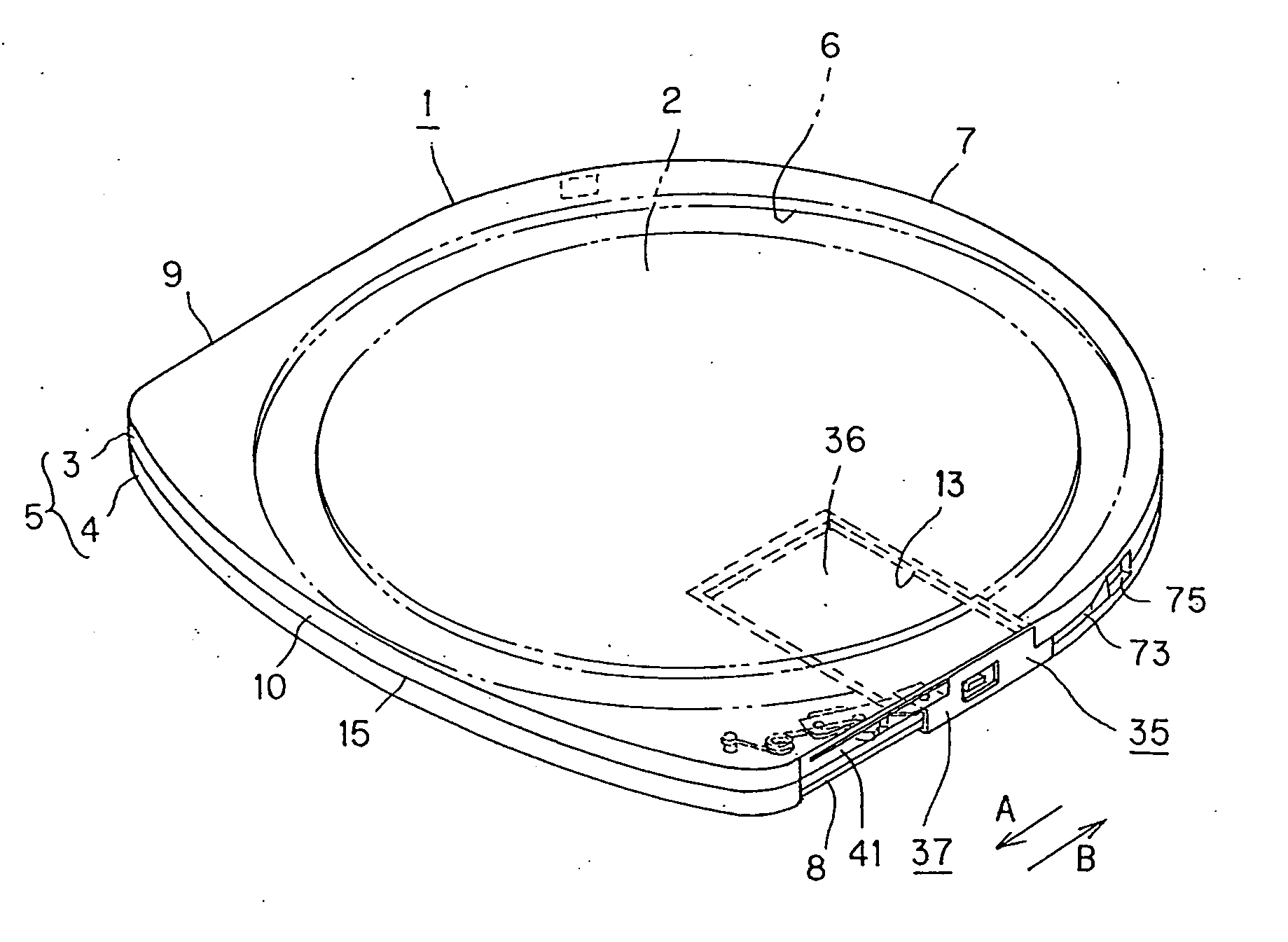

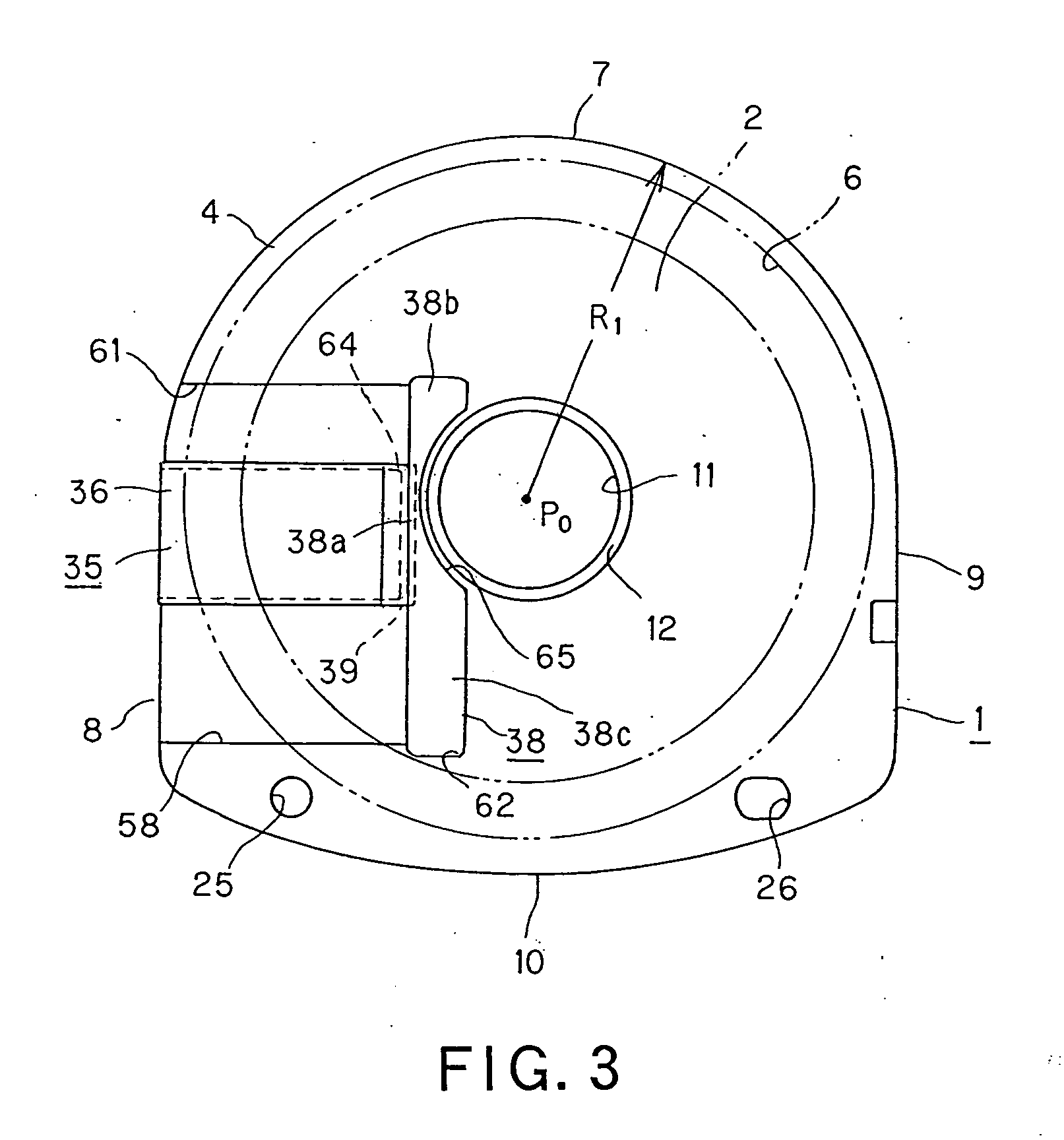

Disc cartridge

InactiveUS20050160445A1Easy to moveLarge recording and/or reproduction apertureRecord information storageFlat record carrier containersBiomedical engineeringOptical disc

A cartridge main body formed by aligning and bonding a pair of an upper half and a lower half rotatably contains an optical disc. The cartridge main body is provided on one of the opposite surfaces thereof with a central aperture, which is a drive aperture for receiving a drive means for driving the optical disc to turn, and a head receiving aperture, which is a recording and / or reproduction aperture for receiving a recording and / or reproduction means. A shutter member is fitted to the cartridge main body. The shutter member has a shutter section for exposing and closing the heard receiving aperture and is adapted to move to expose and close the head receiving aperture while it is supported at the base thereof within a range of one of the lateral sides thereof that is perpendicular to the above mentioned surface of the cartridge main body. The shutter section of the shutter member is supported at the front end thereof by a shutter guide member arranged between the central aperture and the head receiving aperture.

Owner:SONY CORP

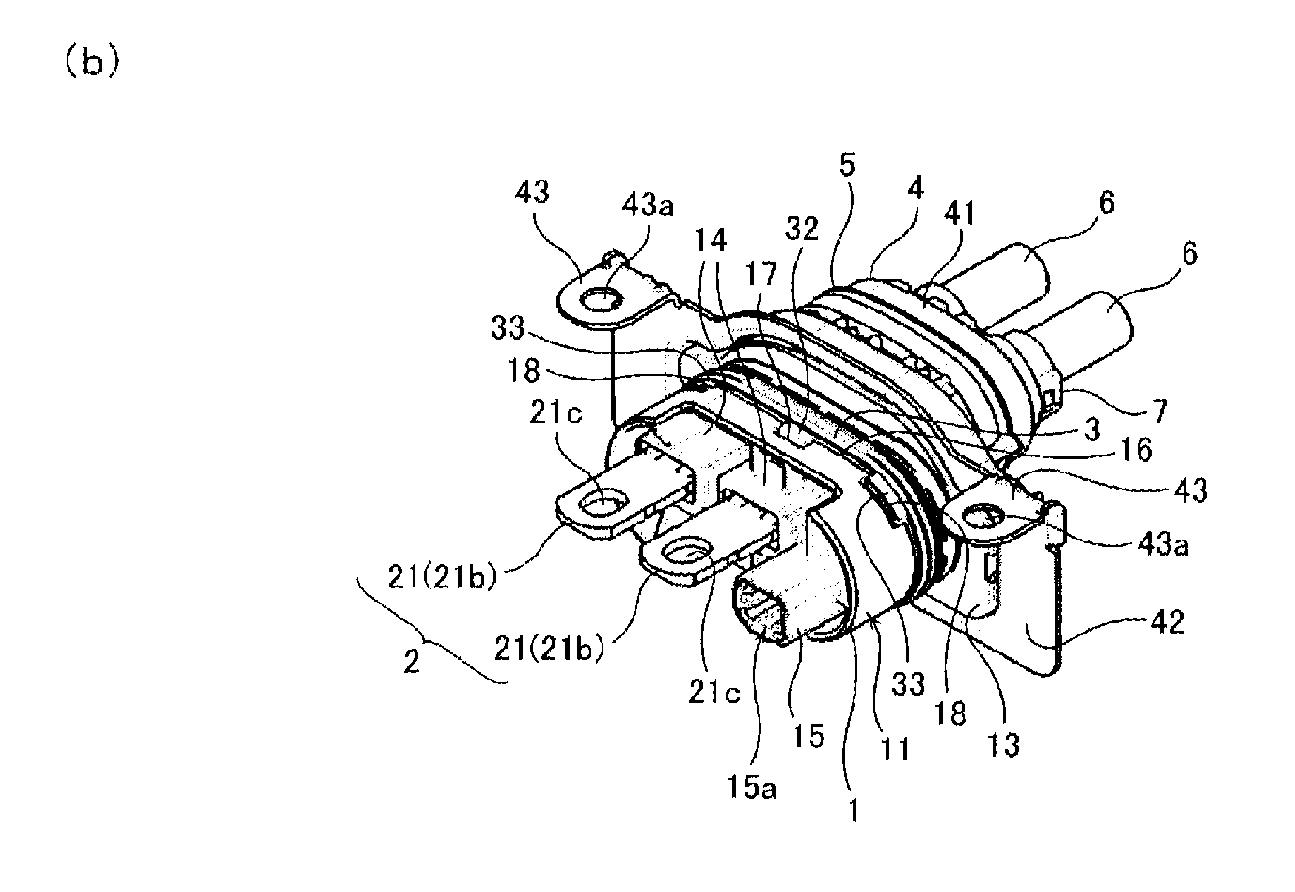

Connector assembly

ActiveUS9293856B2Reliable loadingPrevent rotationVehicle connectorsSecuring/insulating coupling contact membersEngineeringElectric wire

A connector assembly includes a housing (1) in which a wire-side terminal (2) is held, and which is fitted to a mounting hole formed in a casing 5 of a mating device to be connected, and a sealing member (3) which is attached to a groove part (16) formed in an outer peripheral part (11) of the housing thereby to keep an interior of the casing liquid tight. The sealing member (3) includes a convex part (33) formed in a curved part thereof, by protruding in a width direction from its peripheral edge part in a shape of an 10 annularly continued band. The groove part (16) includes a concave part (18) formed by denting a groove wall (16b), corresponding to the convex part (33). The convex part (33) and the concave part (18) are engaged with each other.

Owner:YAZAKI CORP

Swivel attachment and branch line restraint

ActiveUS20080258461A1Improve utilizationImprove versatilityStands/trestlesKitchen equipmentDegrees of freedomRotational degrees of freedom

A swivel attachment and / or branch line restraint device with angular versatility and mobility for facilitating connection of installation components to support a pipe or other load relative to a support surface is provided. Advantageously, embodiments of the device provide a plurality of rotational or swivel degrees of freedom, which are substantially independently controllable, for its mating portions, which respectively engage corresponding mating portions of other installation components. The device embodiments can desirably be configured in male-female, male-male or female-female arrangements to enhance device utility and / or versatility, thereby advantageously allowing for use in a myriad of applications and installations, such as construction, utilities and the like, among others, to reliably support loads.

Owner:NIBCO INC

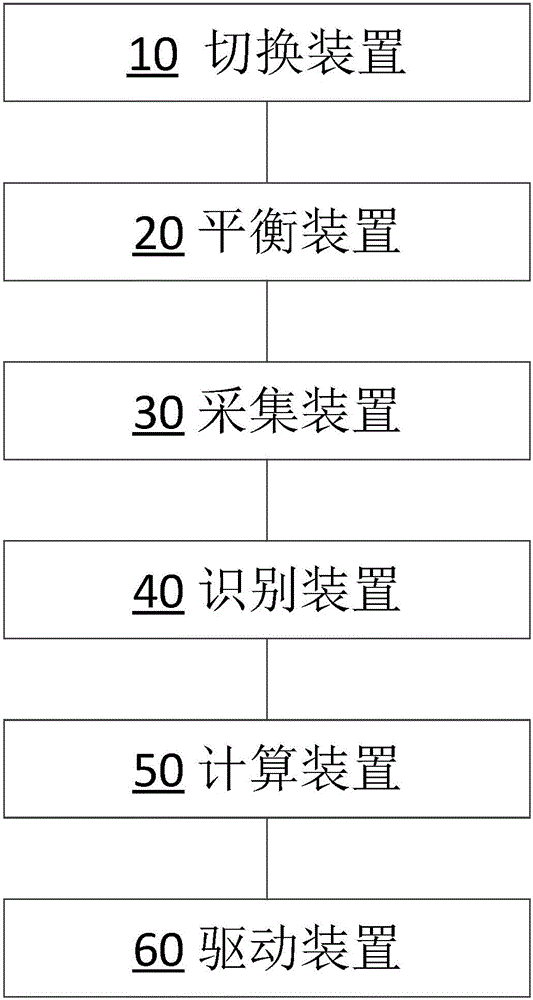

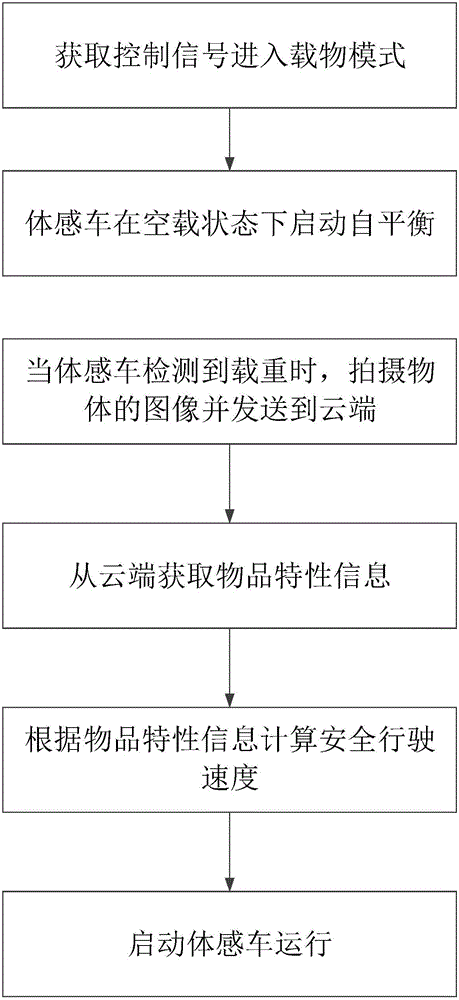

Method for somatosensory vehicle to carry object, and somatosensory vehicle

ActiveCN106020198AImprove operational reliabilityHeavy computationPosition/course control in two dimensionsSomatosensory systemControl signal

The invention discloses a method for a somatosensory vehicle to carry an object, and a somatosensory vehicle. The method for the somatosensory vehicle to carry the object comprises the following steps: obtaining control signals, and entering an object carrying mode; the somatosensory vehicle starting self-balance at a zero-load state; when the somatosensory vehicle detects a load, shooting an image of the object and sensing the image to a cloud end; obtaining object feature information from the cloud end; according to the object feature information, calculating a safe driving speed; and starting operation of the somatosensory vehicle. By use of the method provided by the invention, the somatosensory vehicle can safely and reliably carry the object without changing the circuit and the structure of a conventional somatosensory vehicle.

Owner:深圳市骜途智能科技有限公司

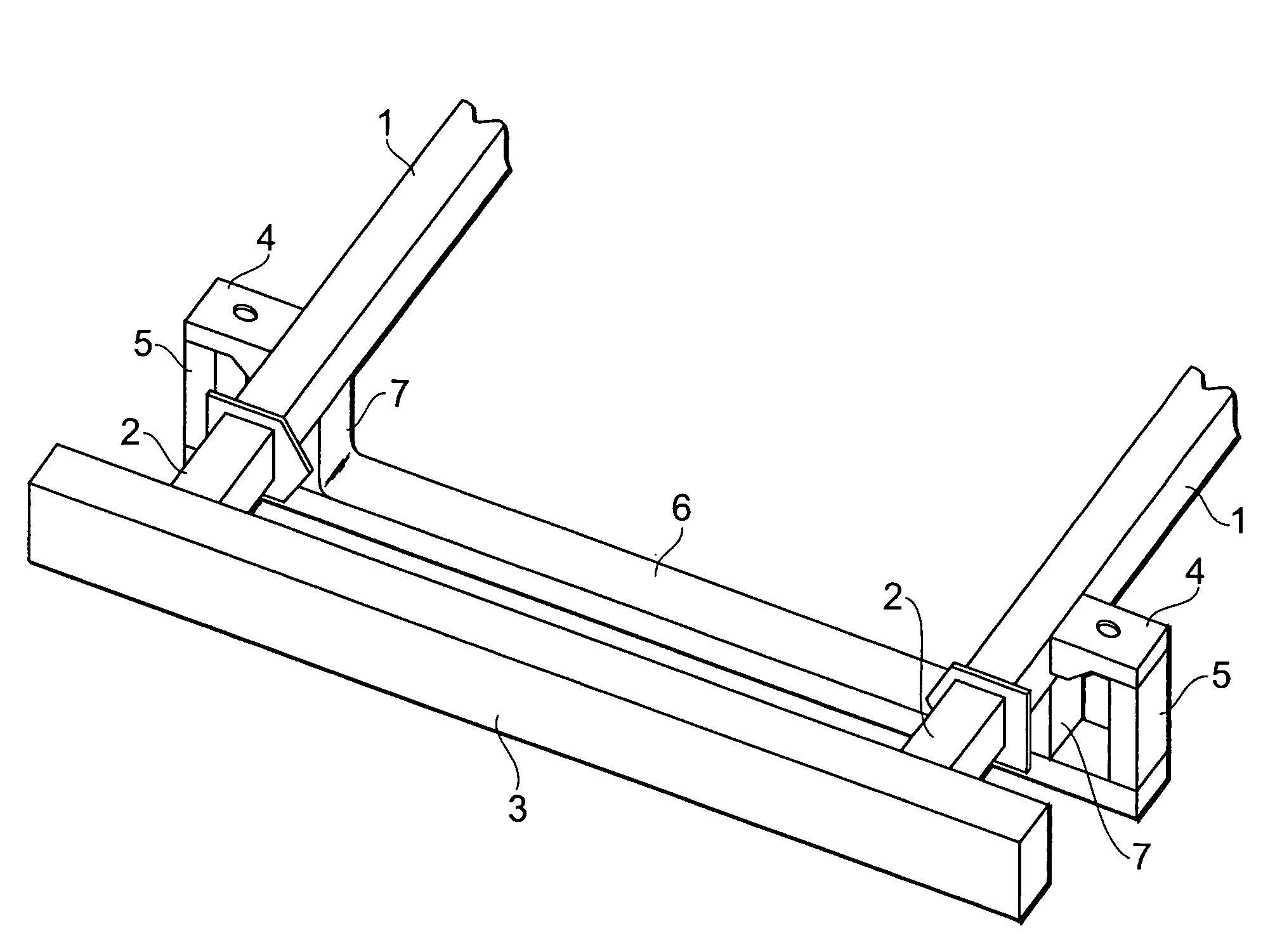

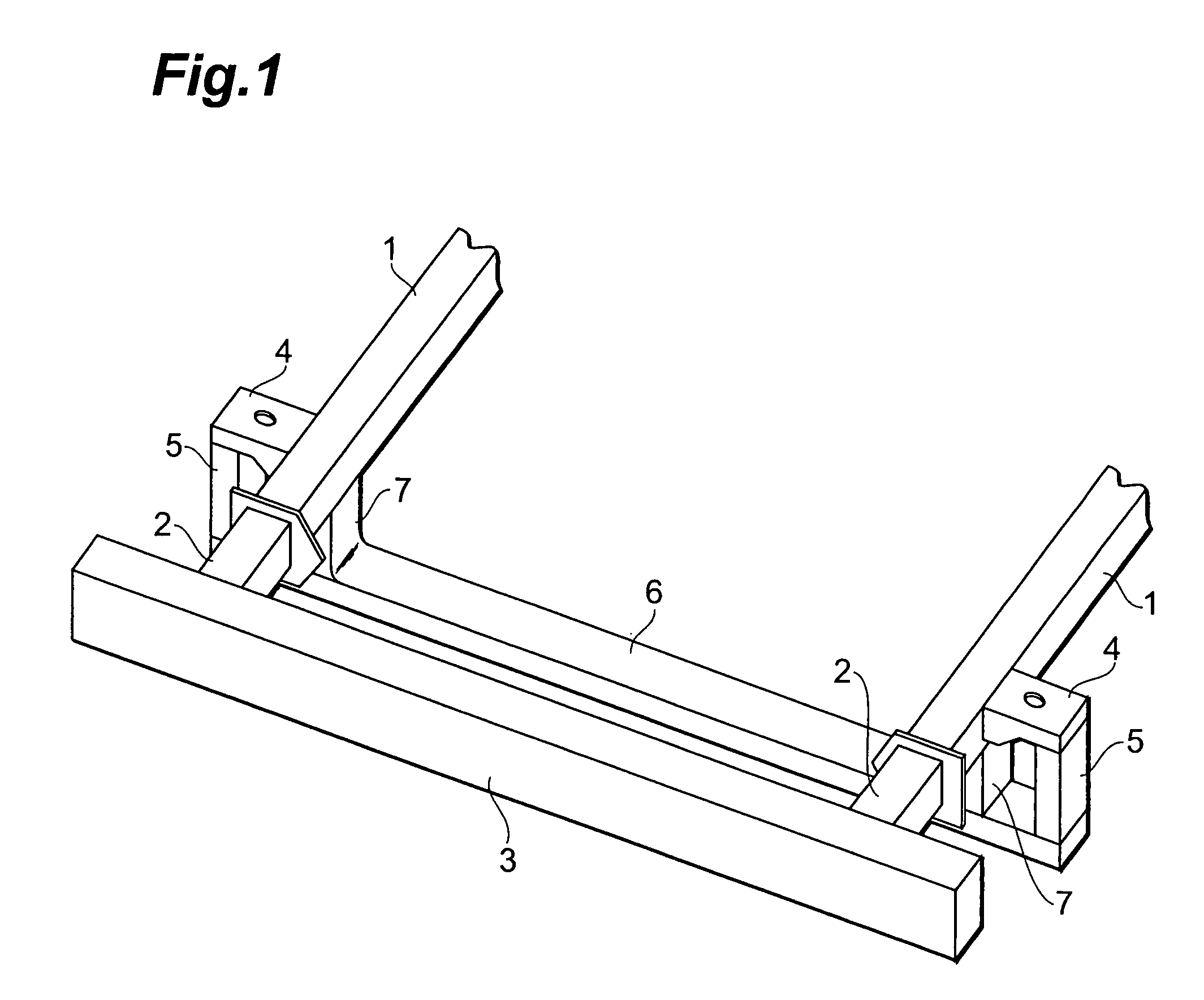

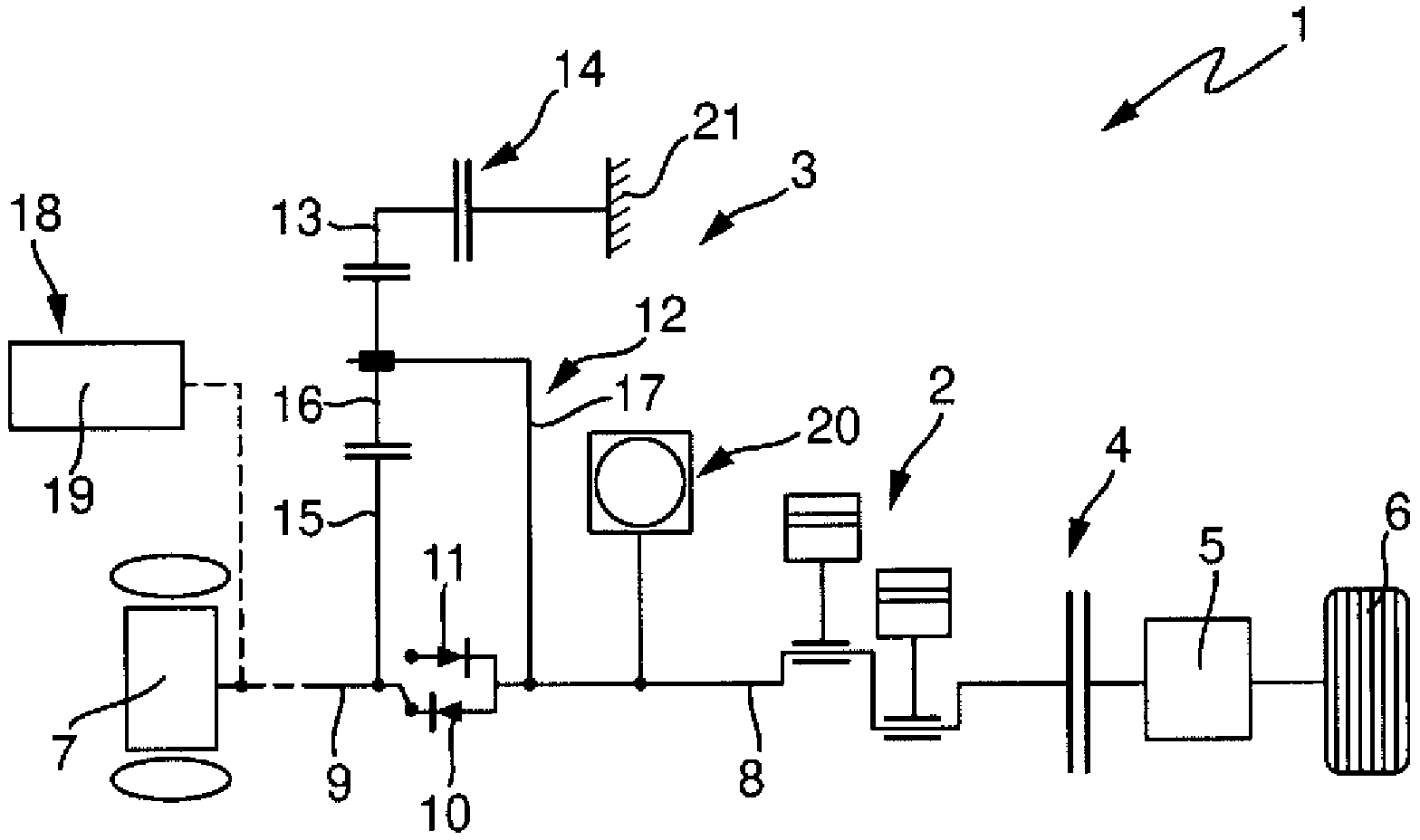

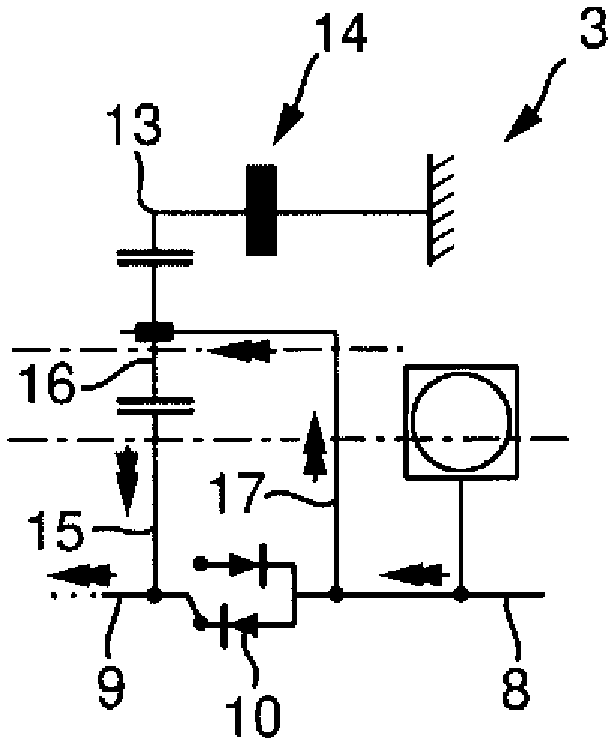

Structure of vehicle end section

InactiveUS7954884B2Easy to bendReliable loadingVehicle seatsPedestrian/occupant safety arrangementEngineeringExtremity Part

An object of the present invention is to provide a vehicle end structure capable of more reliably receiving a load upon a collision in a vehicle body of the frame construction. The vehicle end structure of the present invention is one constructed near a front end (or rear end) of a framework of a vehicle and is characterized by comprising a pair of body frame members 1 extending in an anteroposterior direction of the vehicle body; a bumper reinforce 3 hung at ends of the pair of frame members 1; a pair of brackets 4 located on the center side of the vehicle with respect to the ends of the pair of frame members 1 and projecting outwardly and laterally from the respective frame members; a pair of outer pillar members 5 extending downward from the respective brackets 4; a cross member 6 hung between the pair of outer pillar members 5; and a pair of inner pillar members 7 joining an upper surface of the cross member 6 to the respective frame members 1.

Owner:TOYOTA JIDOSHA KK

Testing apparatus for service life of load of valve execution mechanism and using method thereof

The invention provides a testing apparatus for a service life of a load of a valve execution mechanism and a using method thereof. The testing apparatus comprises a rack, a rotating mechanism and a loading mechanism. The rack is supported between a top plate and a bottom plate by support posts. A testing plate covers the top plate. Rotating shafts are installed in bearings between the top plate and the bottom plate and the upper ends of the rotating shafts pass out of the top plate and a mounting plate. More than one rotating plate is installed on the rotating shafts horizontally and rotates with the rotating shafts. The loading mechanism includes friction plates and hydraulic systems; through holes are formed in the friction plates and the friction plates sleeve the support posts through the through holes. One friction plate is arranged below each rotating plate; and the friction plates are separated by sleeving rings arranged on the support posts. The hydraulic systems are installed on the bottom plate and mandrils of the hydraulic systems support the bottom friction plates; under pushing of the mandrils, upward contact with the rotating plates is realized and the last friction plate is pushed upwardly by the sleeving ring and is in contact with the rotating plate arranged on the friction plate; and the rotating plates and the friction plates in close contact with the rotating plates respectively generate friction and the friction forces are transformed into torques by the rotating shafts, thereby realizing testing of the service life of the load of the valve execution mechanism.

Owner:TEFULONG SHANGHAI TECH CO LTD

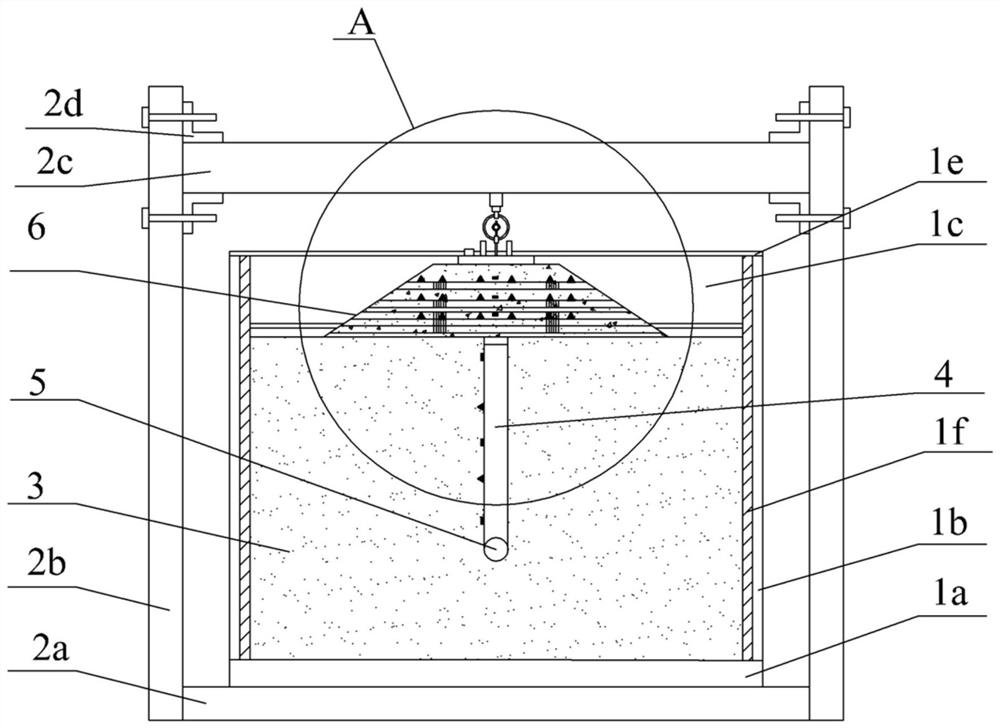

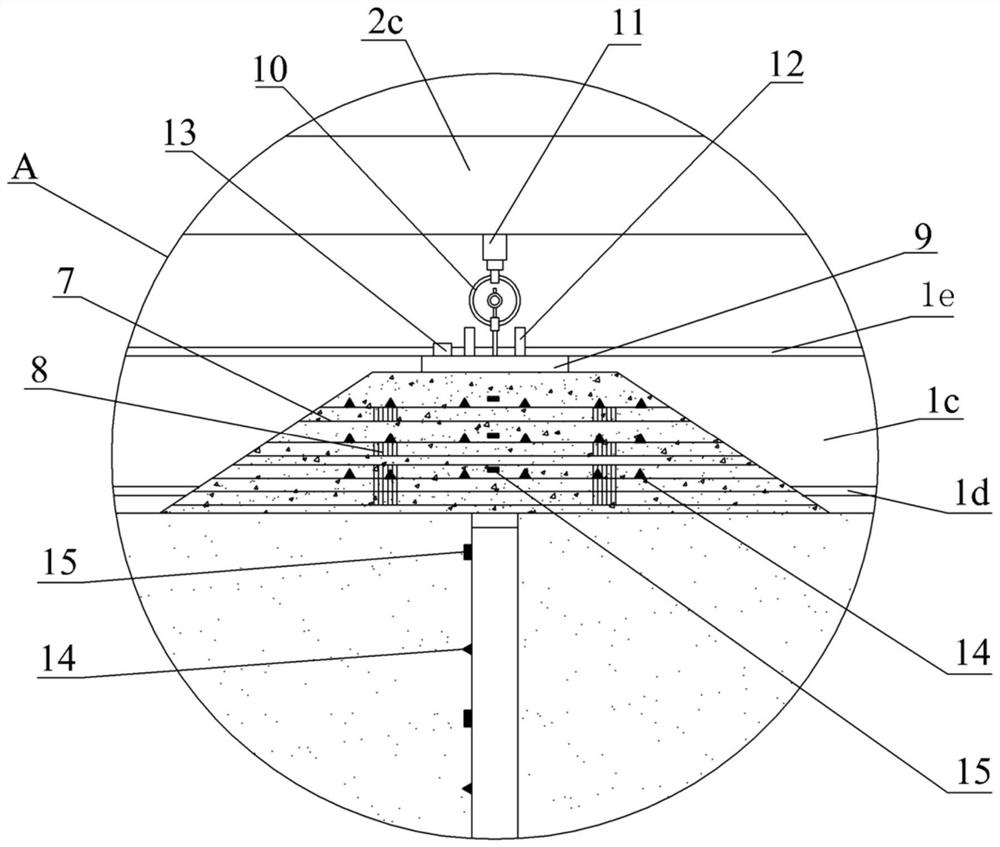

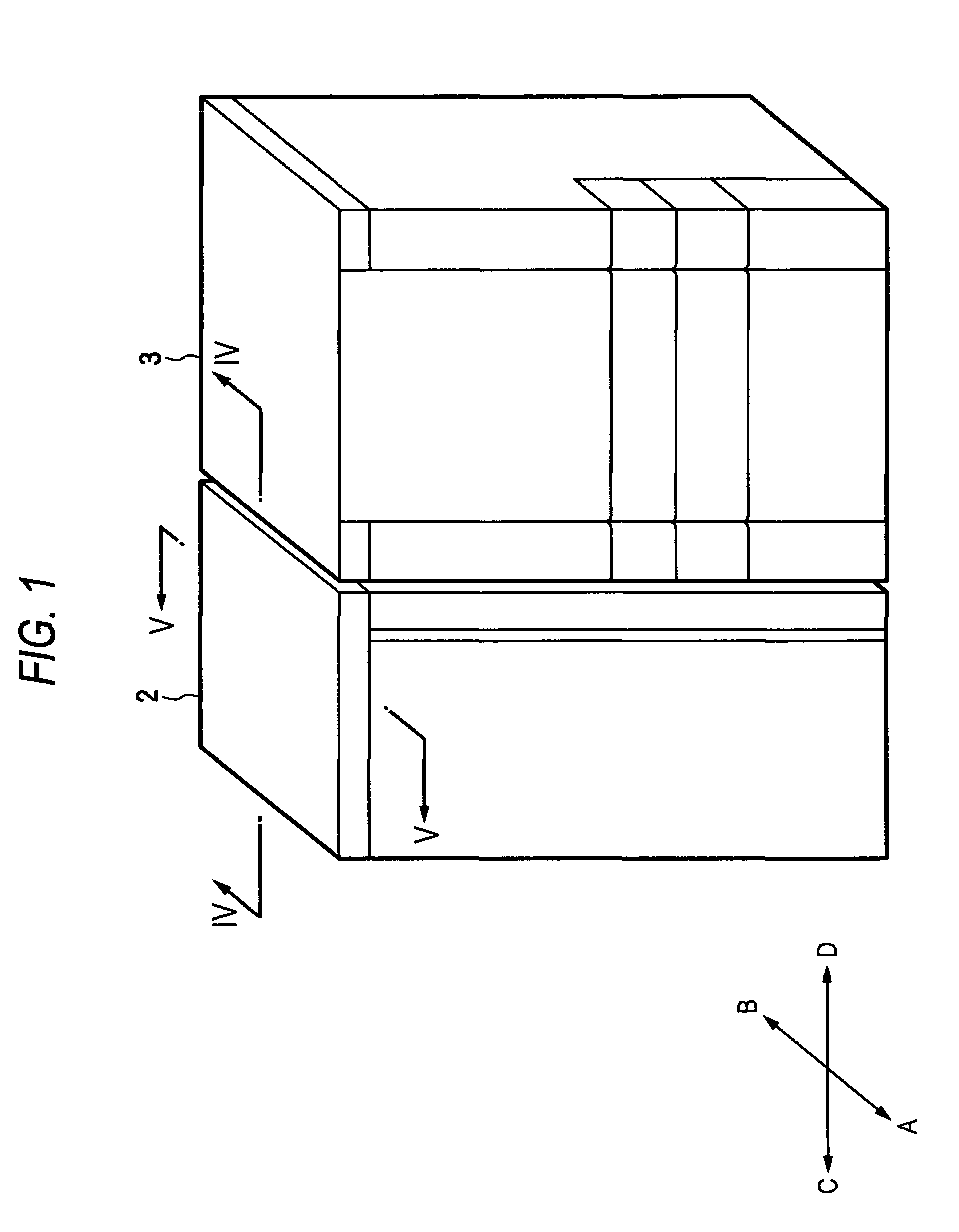

Model test device and test method for high-speed railway subgrade passing through karez

ActiveCN111610094ARich structural featuresRich flow characteristicsRailway tracksMaterial strength using tensile/compressive forcesSoil scienceTest chamber

The invention relates to a model test device for a high-speed railway subgrade passing through a karez. The device is mainly characterized in that a test box body is mounted below a cross beam of a reaction frame, and organic glass plates are arranged at the front part and the rear part of the test box body; the box body is filled with model soil in which tracer particles are buried; and a PVC vertical pipe and a PVC longitudinal pipe are arranged in the model soil; a railway subgrade is arranged on the top surface of the model soil; multiple layers of stiffened strips are arranged in the railway subgrade, a concrete base plate is laid on the upper portion of the railway subgrade, and a jack on the cross beam is arranged over a concrete plate; a vibration exciter and a displacement meter are arranged on the concrete base plate; three strain gauges are arranged on the model geogrids of the stiffened strips; three soil pressure boxes are vertically arranged on the railway subgrade, and three lateral soil pressure boxes and two strain gauges are arranged on the PVC vertical pipe; and a particle image velocimeter is arranged on the outer side of the test box body. According to the invention, the mechanical properties of the subgrade and the karez foundation under the train load can be obtained, so that a test basis is provided for reinforcement design and construction of the subgrade and the foundation of the high-speed railway in the karez region.

Owner:SOUTHWEST JIAOTONG UNIV

Paper treating unit and image forming system using the same

ActiveUS7017901B2Reliable loadingExcellently alignedRegistering devicesFunction indicatorsImage formationPulp and paper industry

Owner:RICOH PRINTING SYST

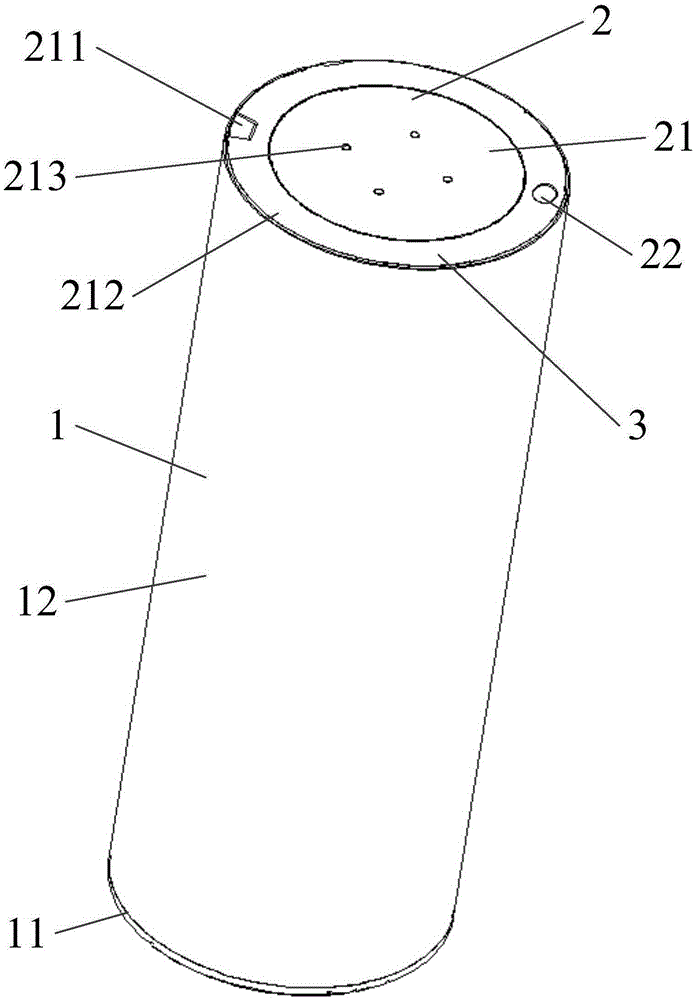

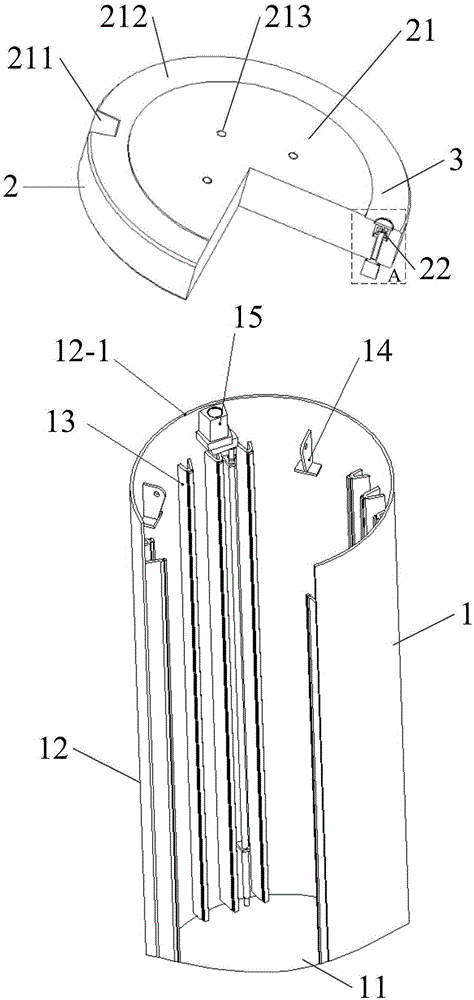

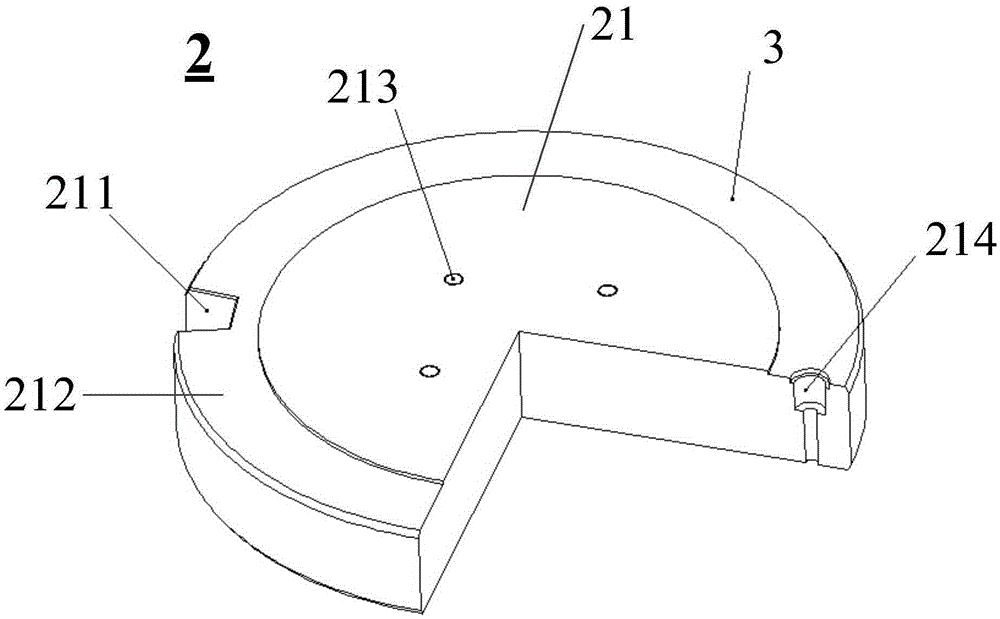

Fuel storage tank for dry type storage of spent fuel of nuclear power plant

ActiveCN105304151ASolve difficult technical problemsReduce the difficulty of operationNuclear energy generationReactor fuel elementsNuclear plantNuclear power

The invention discloses a fuel storage tank for dry type storage of spent fuel of a nuclear power plant, which aims at solving the technical problem of higher difficulty in the top cap covering process under water in the existing fuel storage tank structure. The fuel storage tank comprises an opening container, a top cap and a sealing ring, wherein the top cap comprises a shielding cap and an air intake assembly, the shielding cap is matched with an opening of the container, and the air intake assembly is arranged on the shielding cap; a water drainage notch and an annular groove are dug in the shielding cover, and the annular groove is used for placing the sealing ring; the container comprises a bottom plate, a cylinder body, a water drainage assembly, a support structure and hanging lugs, one end part of the cylinder body is in sealed welding with the bottom plate, the water drainage assembly is arranged at the inside wall of the cylinder body, the support structure is used for supporting a fuel basket, and the hanging lugs are used for supporting the shielding cap; when the shielding cap is hung at and covers the other end part of the cylinder body, the air intake assembly is used for providing an air intake passage for the cylinder body, and the water drainage assembly is butted with the water drainage notch, and is used for draining the liquid out of the container. The fuel storage tank has the advantages that the operation difficulty in covering the top cap under water is decreased, and the spent fuel assembly can be reliably loaded and stored.

Owner:中广核工程有限公司 +1

Method For Designing A Flight Vehicle

InactiveUS20080140359A1Simple designReliable loadingGeometric CADAnalogue computers for vehiclesFlight vehicleEngineering

A method for designing a flight vehicle includes determining a preferred aerodynamic shape of a structure of the vehicle; modifying the preferred aerodynamic shape based upon constraints; and determining, using aerodynamic computational fluid dynamics, limit loading conditions for the modified aerodynamic shape. A computer-implemented system for designing a flight vehicle includes at least one computer operable to determine a preferred aerodynamic shape of a structure of the vehicle; modify the preferred aerodynamic shape based upon constraints; and determine, using aerodynamic computational fluid dynamics, limit loading conditions for the modified aerodynamic shape. Software for designing a flight vehicle, embodied in a computer-readable medium, is operable to, when executed, determine a preferred aerodynamic shape of a structure of the vehicle; modify the preferred aerodynamic shape based upon constraints; and determine, using aerodynamic computational fluid dynamics, limit loading conditions for the modified aerodynamic shape.

Owner:TEXTRON INNOVATIONS

Method for controlling switchable planetary gear set in belt pulley plane of drive train

InactiveCN103261673AReliable loadingConfirmed favorableHybrid vehiclesPower operated startersStarter generatorFreewheel

The invention relates to a method for controlling a belt drive of a drive train of a motor vehicle. The belt drive is equipped with a planetary gear set which switches a transmission ratio between a starter-generator and an internal combustion engine, said planetary gear set having an internal gear which can be connected fixedly with respect to a housing by means of a brake;a web which is connected to a crankshaft of the internal combustion engine of the drive train and which has planet gears arranged over the circumference; a sun gear which is connected in a rotationally engaged manner to a rotor of the starter-generator and to at least one auxiliary unit; a first switchable freewheel which blocks in the torque direction from the rotor to the crankshaft; and a second switchable freewheel which blocks in the torque direction from the crankshaft to the rotor. In order to improve the switching accuracy of the brake and thereby avoid high torque loading during the closing of the brake, a characteristic curve of the torque that can be transmitted via the brake versus the actuating travel thereof is adapted.

Owner:SCHAEFFLER TECH AG & CO KG

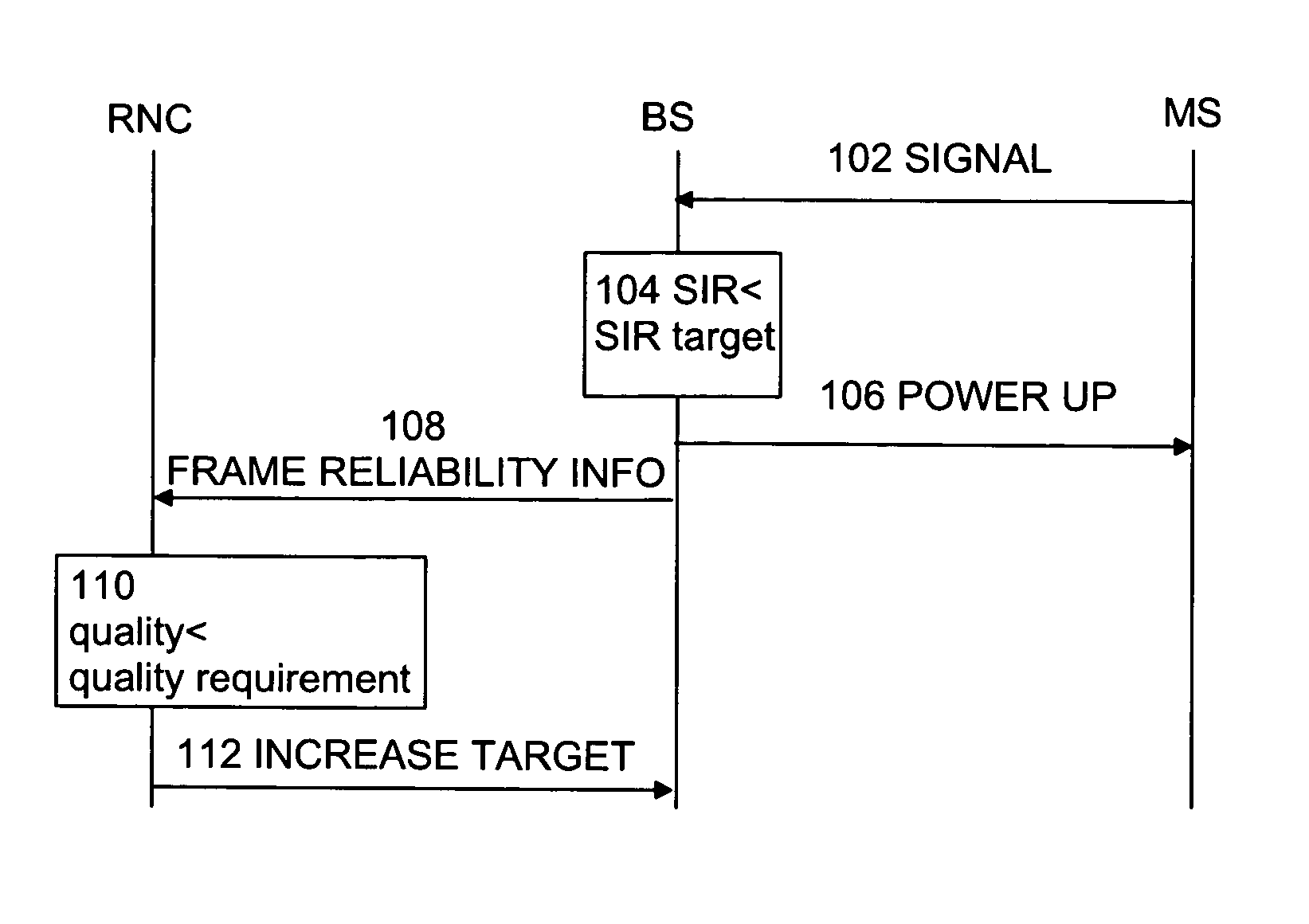

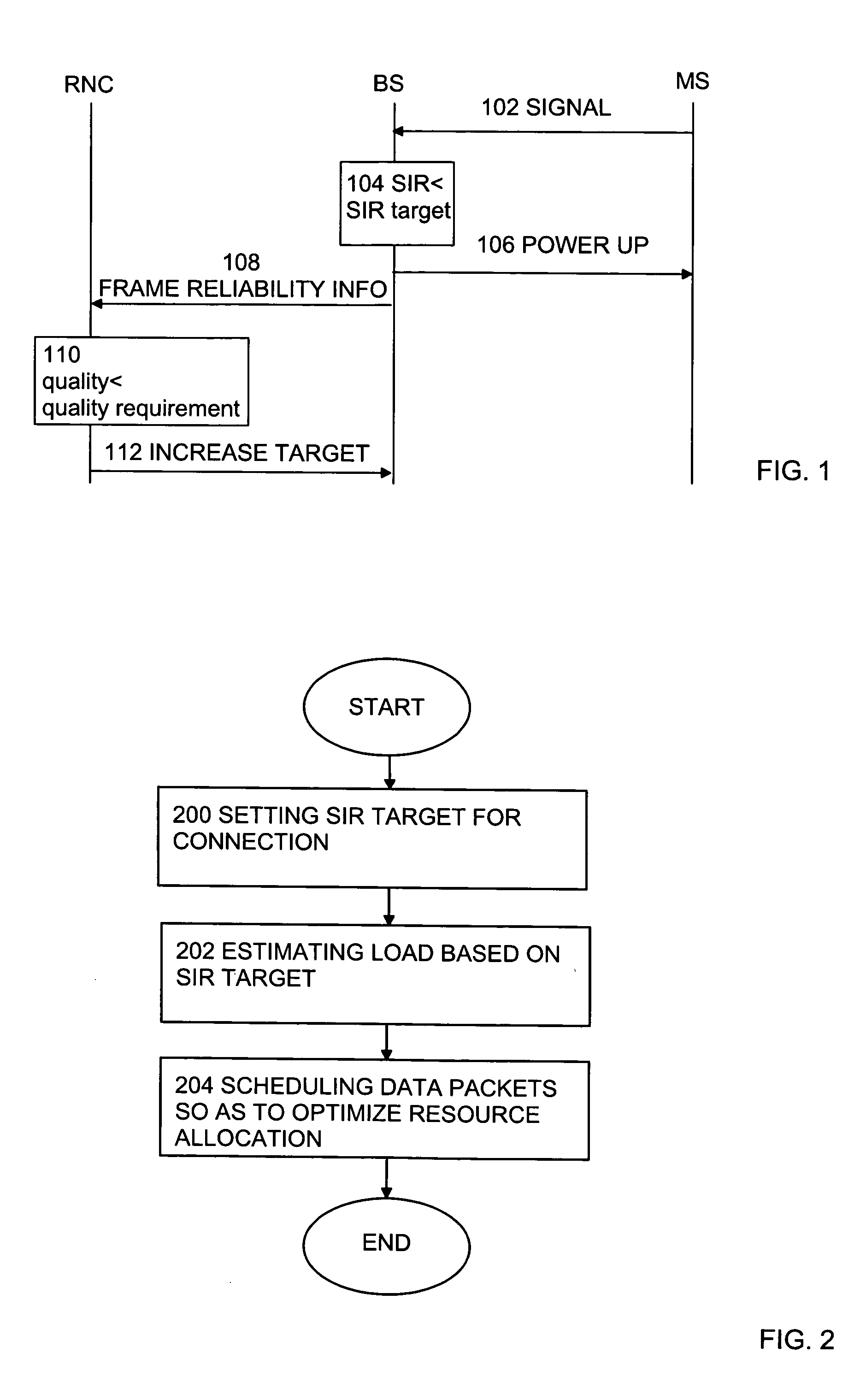

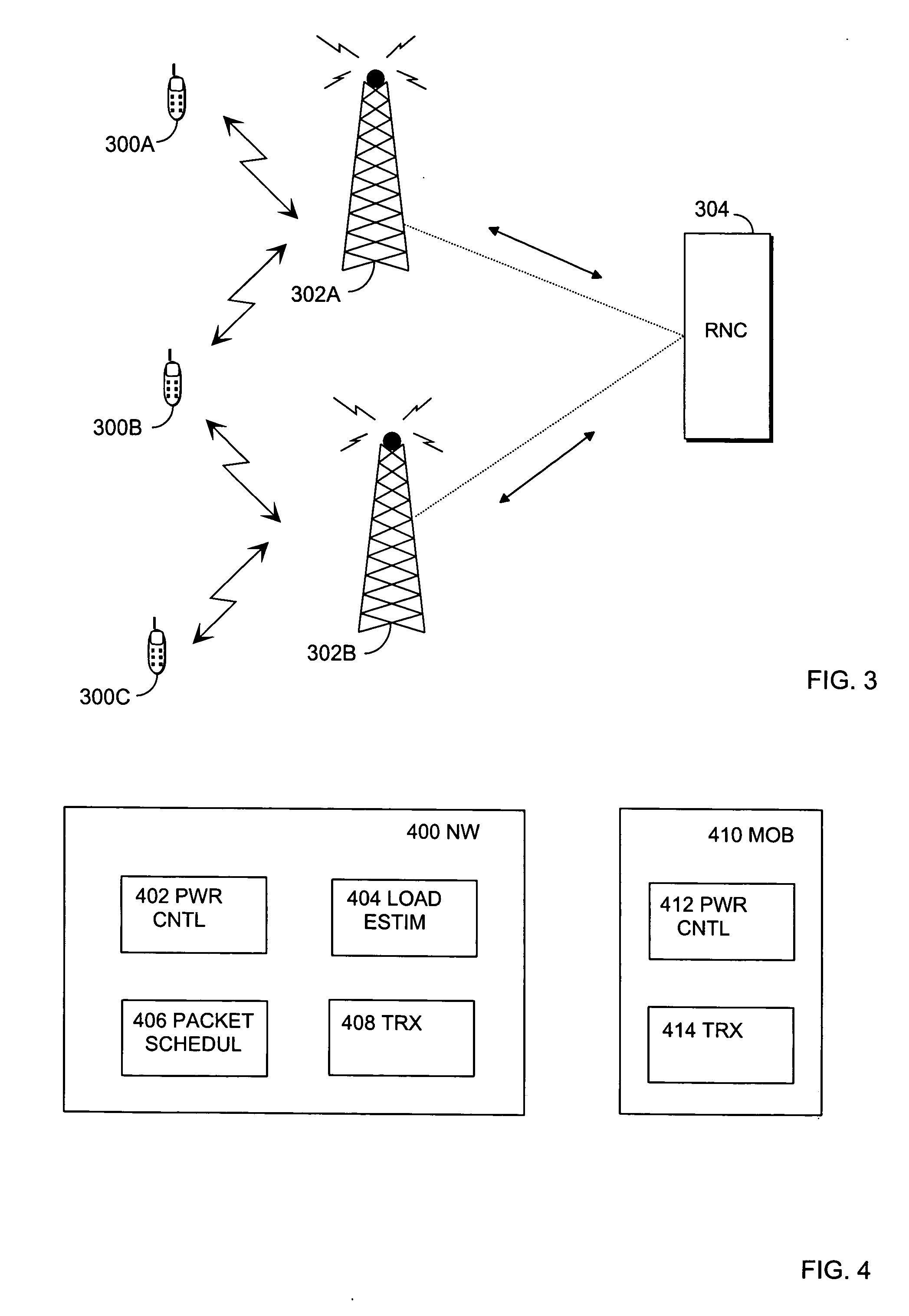

Method and arrangement for uplink scheduling

InactiveUS20050276258A1Increase transmit powerIncrease capacityTime-division multiplexData switching networksData connectionUplink scheduling

A mobile communication network including at least one base station for supporting at least one uplink data connection of at least one terminal that is in the audibility area of the base station, means for forming a quality target for the uplink connection of the terminal. The network comprises means for estimating load of a network element by applying the formed quality target, and means for scheduling uplink data packets to be sent by the at least one terminal by monitoring that the estimated load does not exceed a predetermined load threshold of the network element.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com