Rolling straight-line guide rail pair reliability tester

A technology of linear guide pair and testing machine, which is applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems of not reflecting the technical performance and the true reliability of the guide rail pair, and achieve accurate testing. , Simple structure, convenient installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

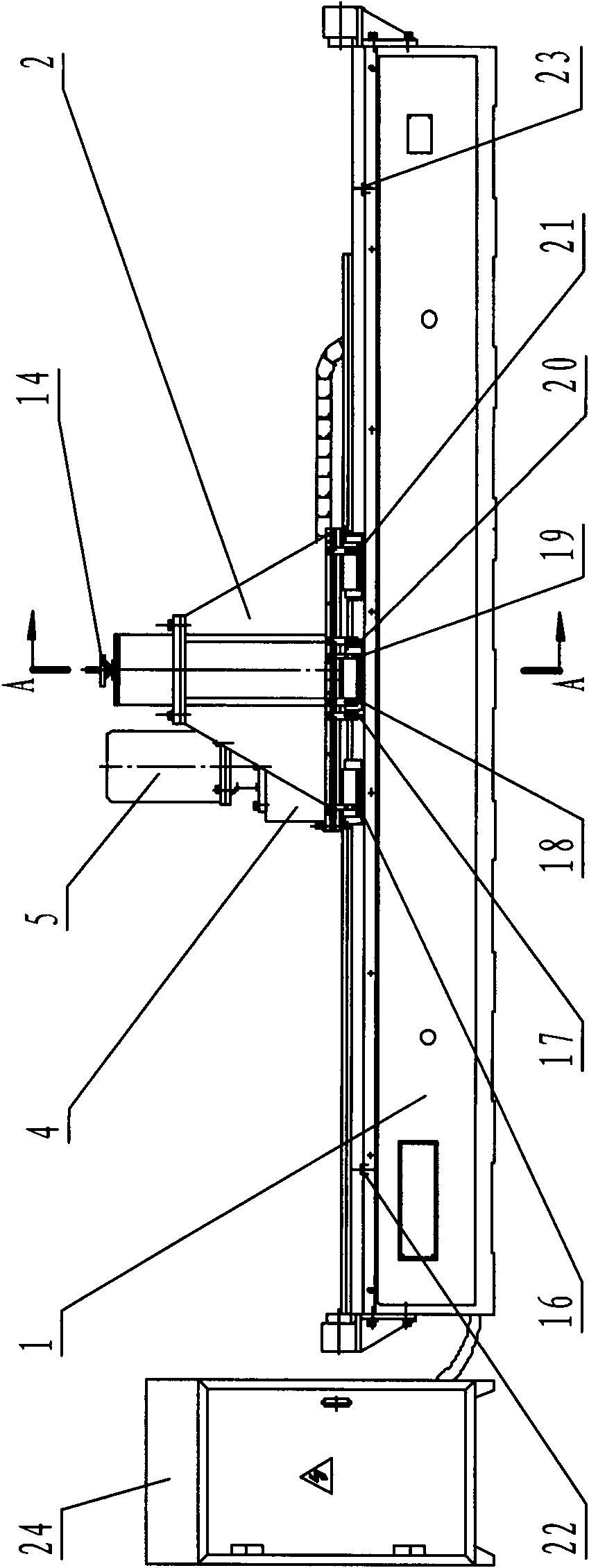

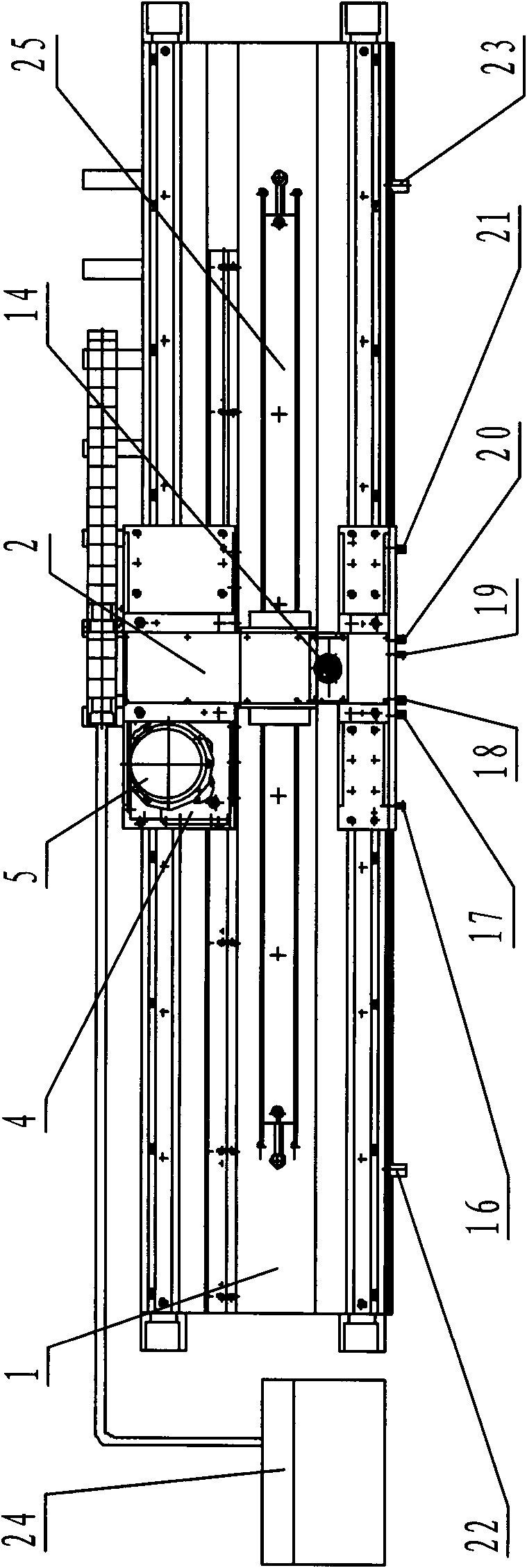

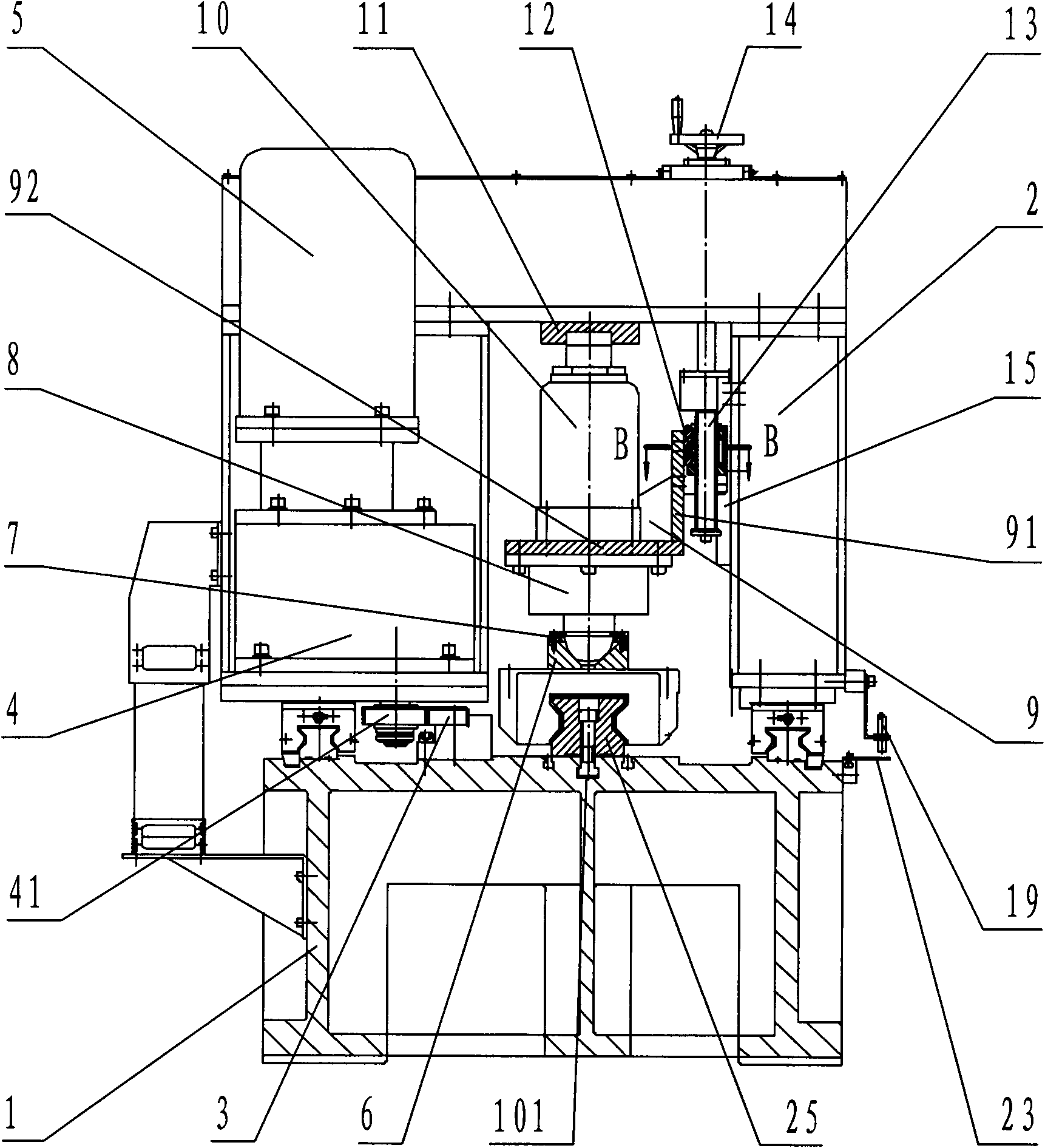

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as Figure 1 to Figure 4 As shown, the rolling linear guide pair reliability testing machine of the present invention includes a bed 1 and a gantry 2 that moves laterally on the bed. There is a T-shaped groove 101 parallel to the running guide rail of the gantry 2 in the middle of the table of the bed 1. The rolling linear guide rail pair 25 is fixed on the T-shaped slot 101 by a fastener, and a rack 3 is fixedly installed on the bed table between the T-shaped slot 101 and the rear guide rail of the gantry 2, and the rack 3 is connected to the T-shaped slot. The shaped groove 101 is parallel to the length of the bed 1; the rear column side of the gantry 2 is provided with a speed change mechanism, which is composed of a gearbox 4 and a variable frequency motor 5, and the output shaft end gear 41 of the gearbox 4 is connected to the rack 3 meshing; the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com