Patents

Literature

115 results about "Mean time between failures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mean time between failures (MTBF) is the predicted elapsed time between inherent failures of a mechanical or electronic system, during normal system operation. MTBF can be calculated as the arithmetic mean (average) time between failures of a system. The term is used for repairable systems, while mean time to failure (MTTF) denotes the expected time to failure for a non-repairable system.

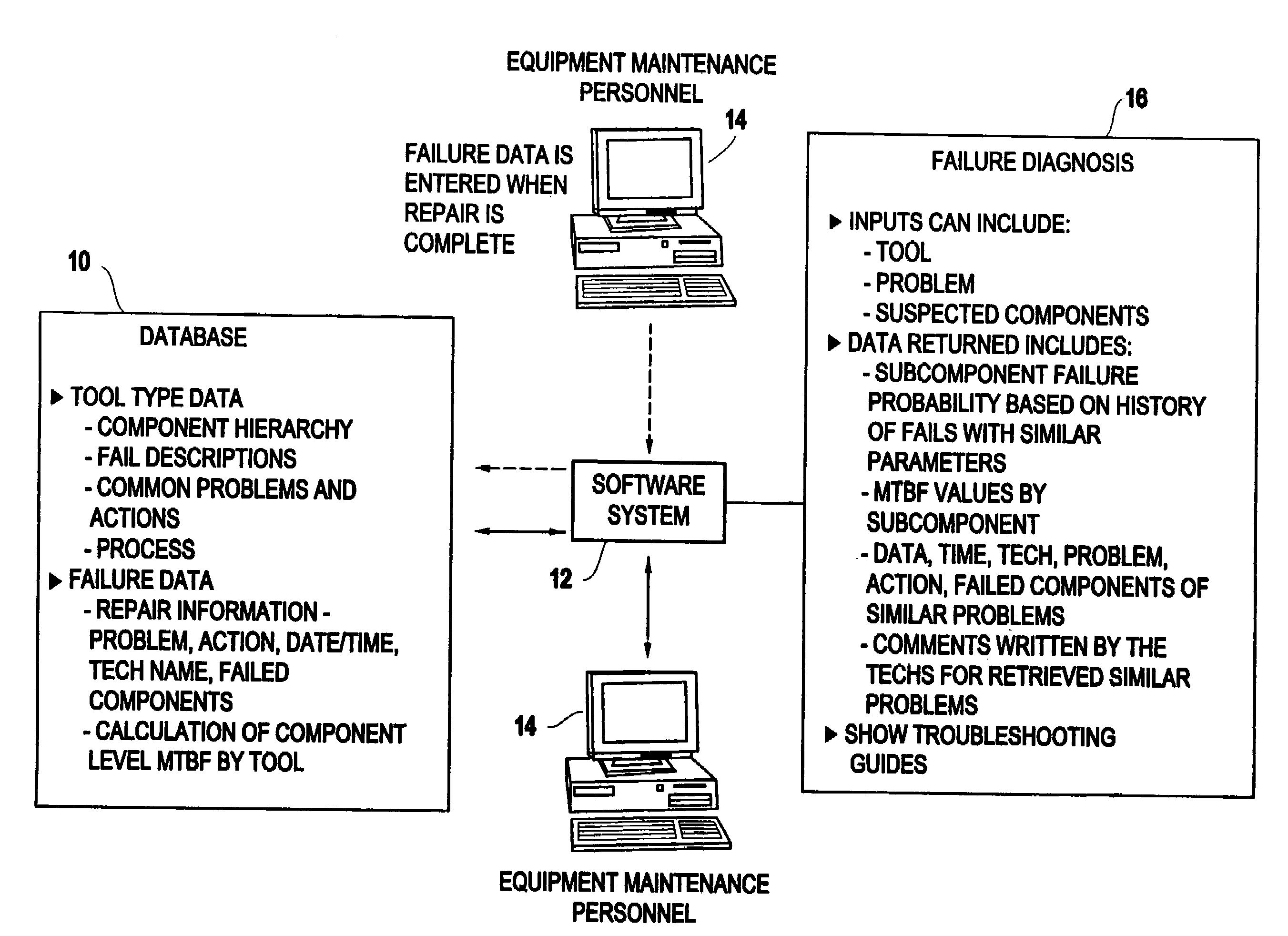

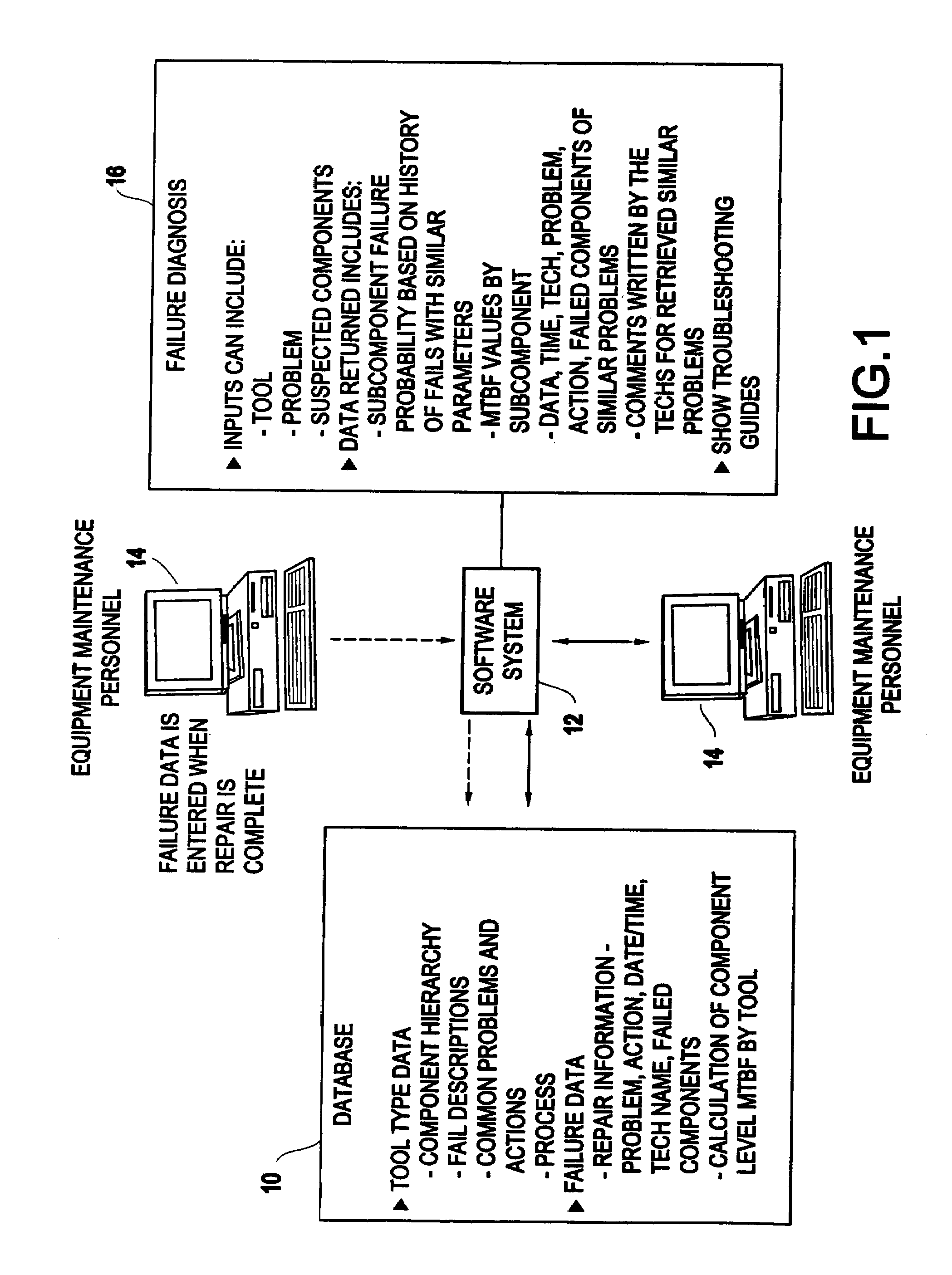

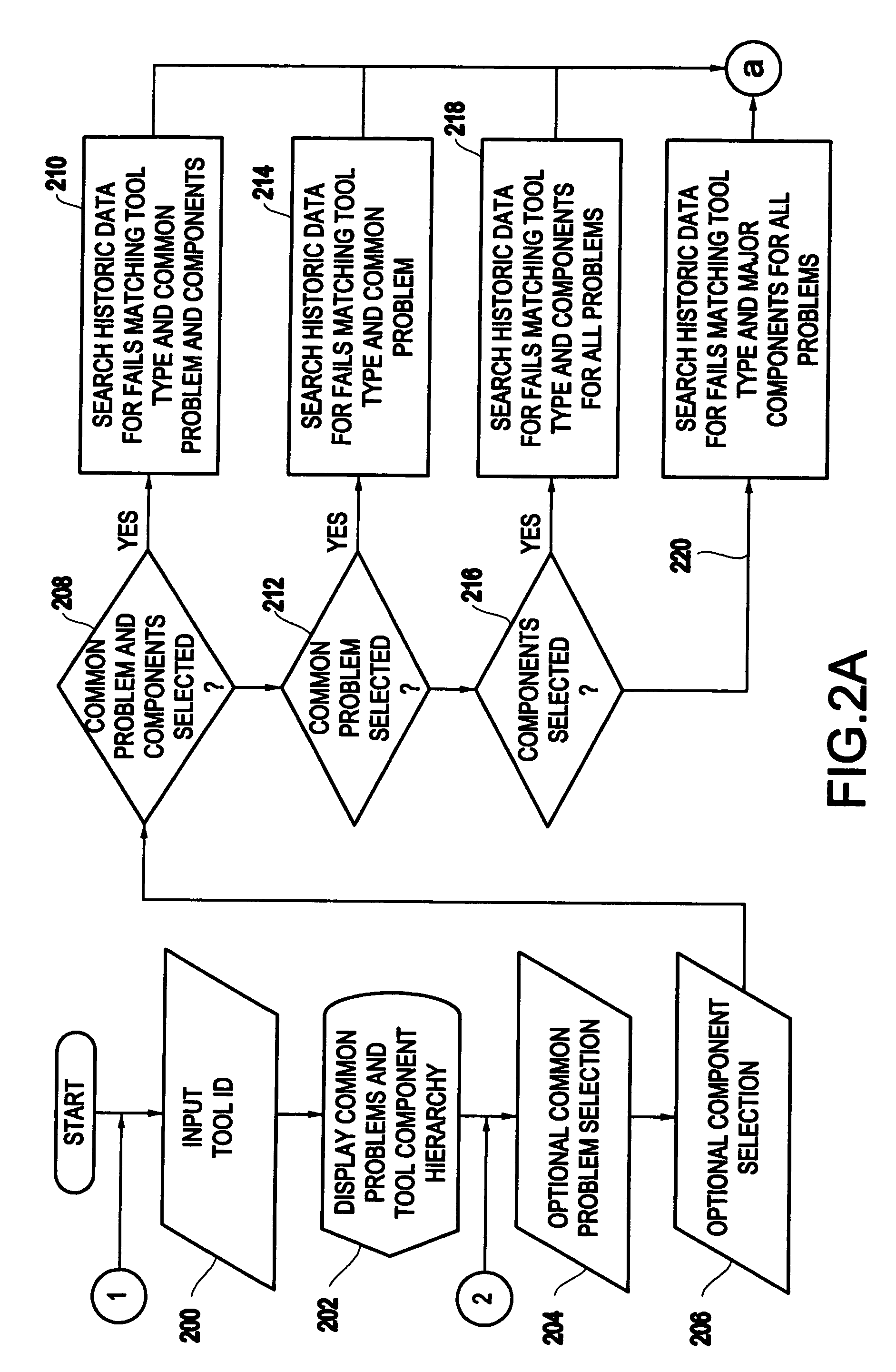

Automated knowledge system for equipment repair based on component failure history

InactiveUS7206771B2Accurate first time diagnosisVehicle testingRegistering/indicating working of vehiclesGraphicsGraphical user interface

The invention presents a computerized method for tracking equipment repair that begins by receiving an equipment identification of an item of equipment to be repaired from a user through a graphic user interface. The invention provides the user with a list of common problems for that item of equipment (and similar equipment) and a component hierarchy for the item of equipment. The invention allows the user to browse through multiple levels of the component hierarchy and select a major component, a minor component, or a subcomponent from the component hierarchy. The invention receives diagnosis input from the user optionally selecting one of the problems and / or a component from the component hierarchy and, in response, provides the user with detailed information regarding the problem or component selected by the user. Such detailed information comprises, for each direct subcomponent of the selected component (highest level if none selected), the number of failures, the probability of failure, the mean time between failures, the occurrence of the most recent failure for each component and the next expected failure, etc. Successful prior repairs for the same problem / component are presented including tool, date, time, technician, components involved and action taken. These successful repairs are linked to textual comments regarding the repair. Comments made for what is later determined to be an ineffectual repair are linked to the subsequent successful repair information.

Owner:IBM CORP

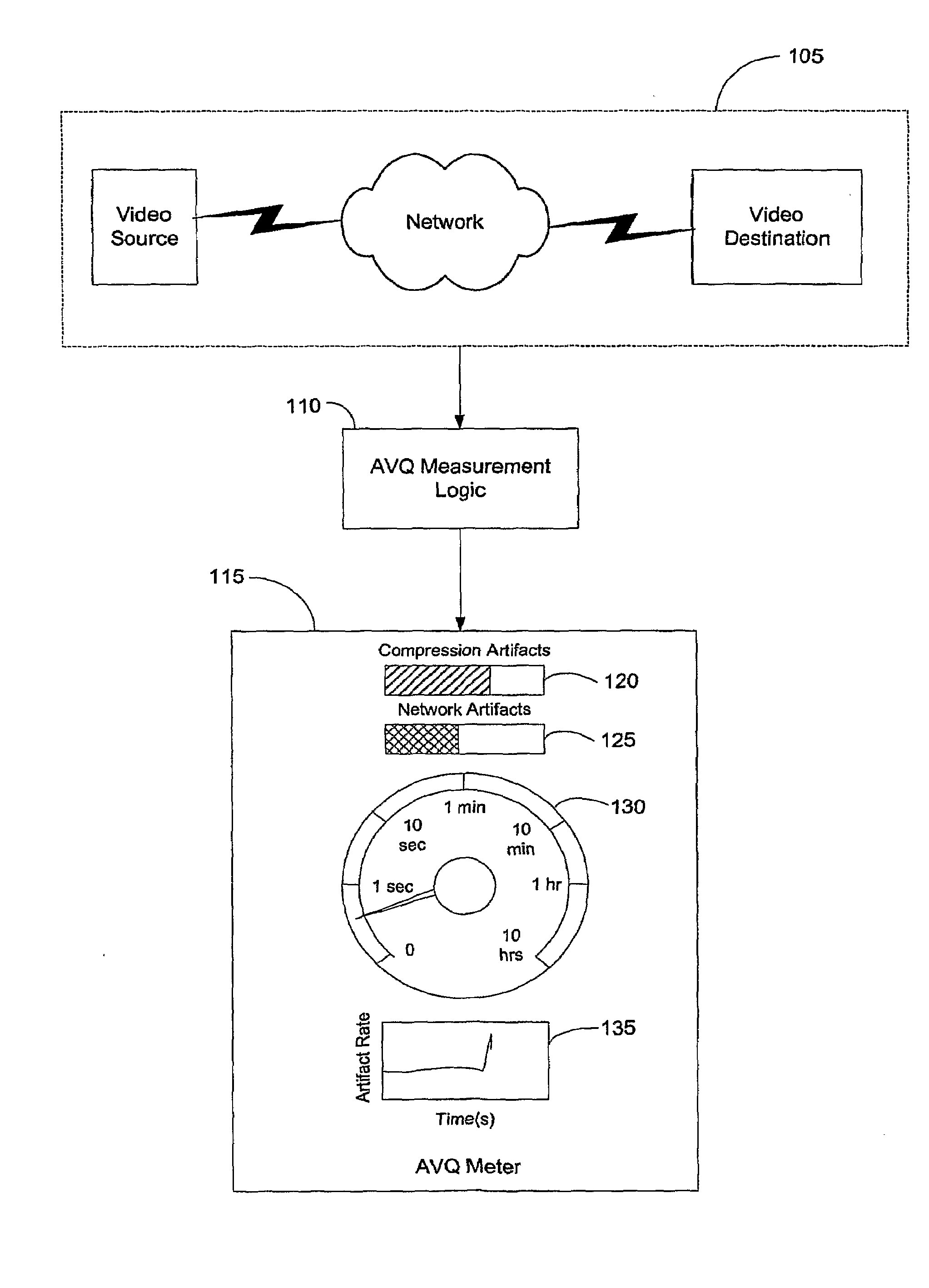

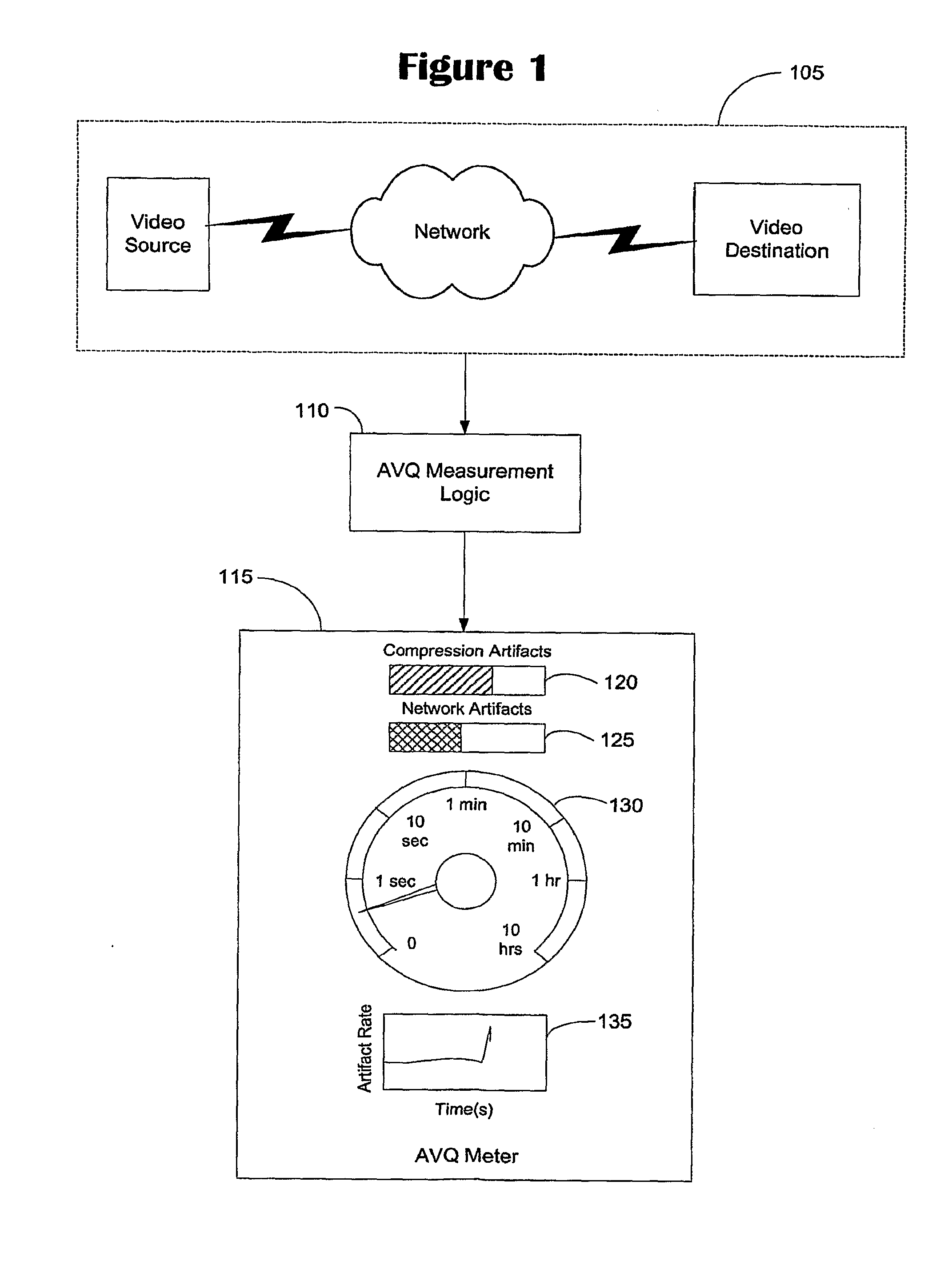

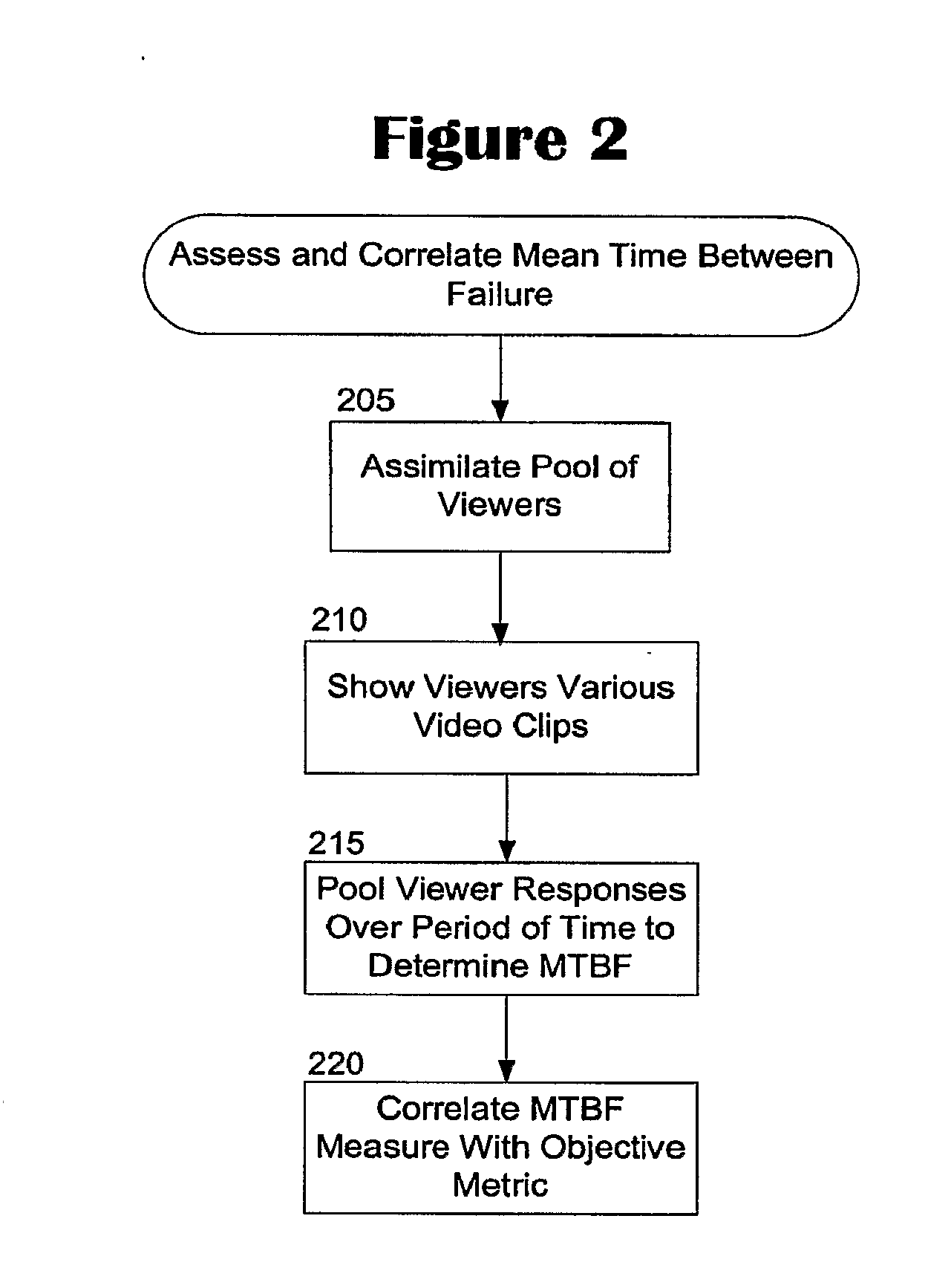

Automatic Video Quality Measurement System and Method Based on Spatial-Temporal Coherence Metrics

InactiveUS20090208140A1Abundant resourcesImage analysisPicture reproducers using cathode ray tubesPattern recognitionCompression artifact

An automatic video quality (AVQ) metric system for evaluating the quality of processed video and deriving an estimate of a subjectively determined function called Mean Time Between Failures (MTBF). The AVQ system has a blockiness metric, a streakiness metric, and a blurriness metric. The blockiness metric can be used to measure compression artifacts in processed video. The streakiness metric can be used to measure network artifacts in the processed video. The blurriness metric can measure the degradation (i.e., blurriness) of the images in the processed video to detect compression artifacts.

Owner:GEORGIA TECH RES CORP

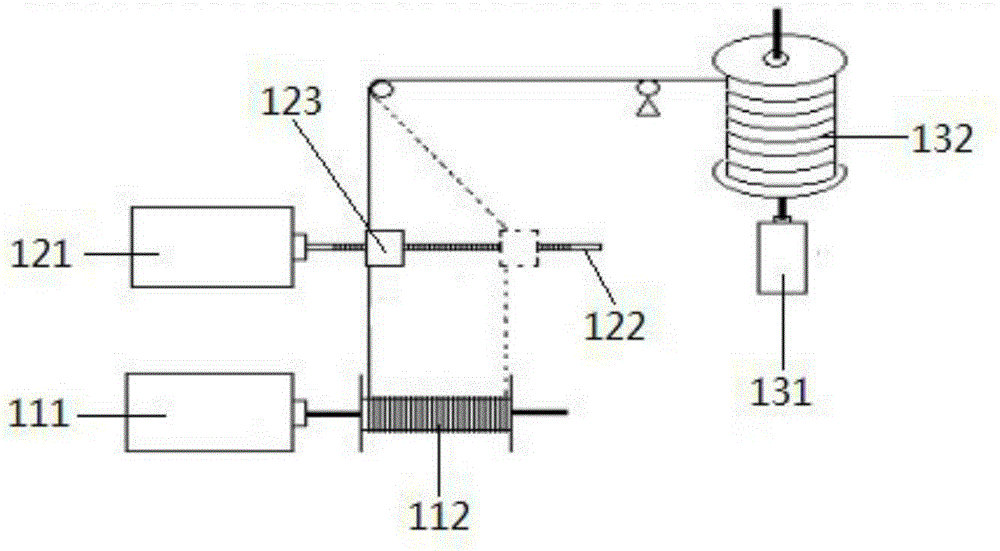

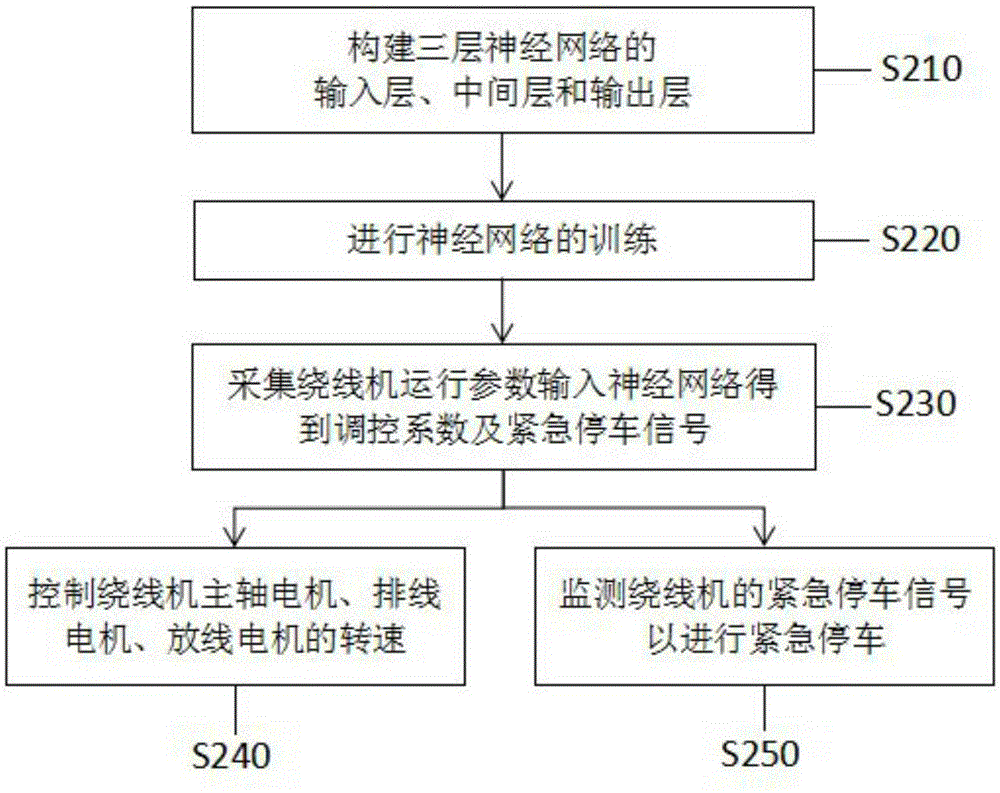

Coil winding machine control method based on BP nerve network, and coil winding machine

InactiveCN105404153AReduce disconnection frequencyAutomatic speed adjustmentCoils manufactureAdaptive controlWinding machineNerve network

The invention discloses a coil winding machine control method based on a BP nerve network. The method comprises the following steps: step one, determining an input-layer vector, an intermediate-layer vector and an output-layer vector of a three-layer nerve network; step two, according to historical data, obtaining a training sample, and training the nerve network; step three, according to a certain sampling period, measuring an internal temperature T, a vibration rate U, stress F between a wire arrangement device and a coiling frame, a main shaft motor rotating speed omega a, a wire arrangement motor rotating speed omega b and a wire laying motor rotating speed omega c of a coil winding machine by use of a sensor, and normalizing the parameters to obtain the input-layer vector and the output-layer vector; step four, controlling the main shaft motor rotating speed, the wire arrangement motor rotating speed and the wire laying motor rotating speed; and step five, according to emergency shutdown signals in the intermediate-layer vector, determining an operation state of the coil winding machine. According to the invention, the coiling line breaking frequency can be reduced, the product quality is improved, the machine mean time between failures is increased, and the realistic significance is great.

Owner:JILIN UNIV

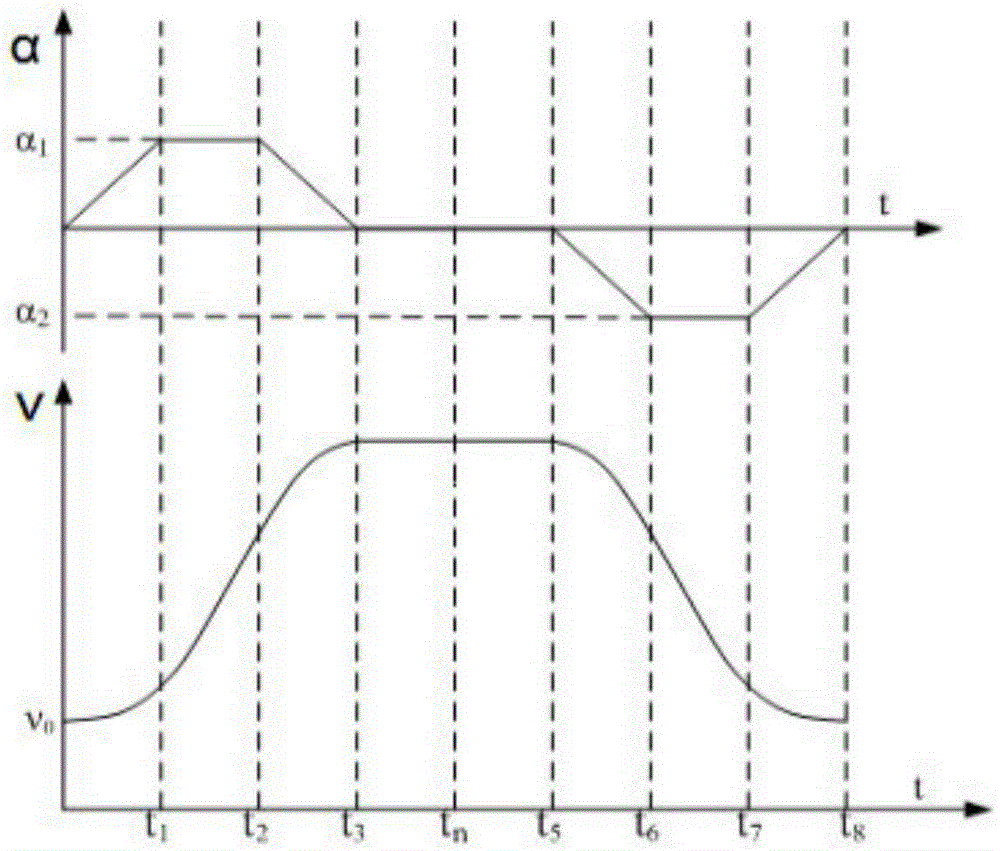

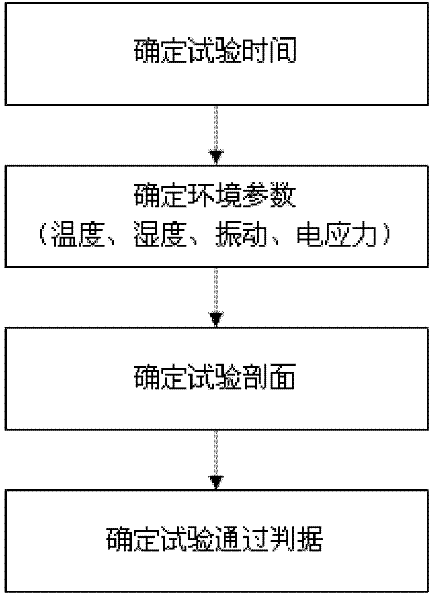

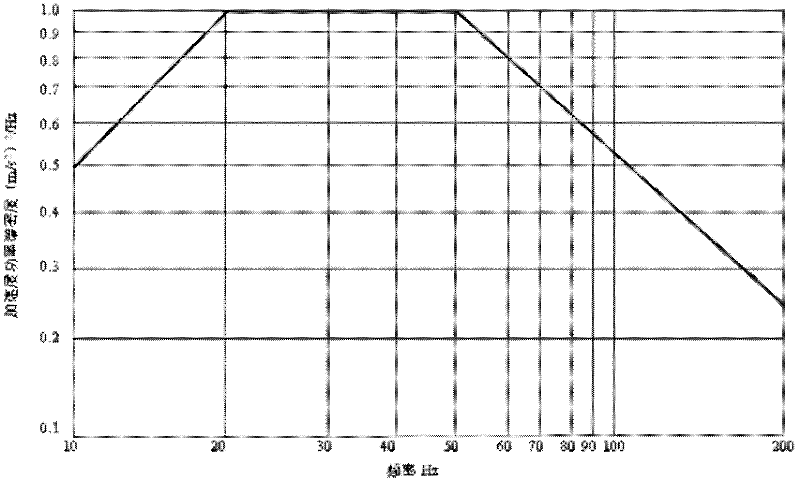

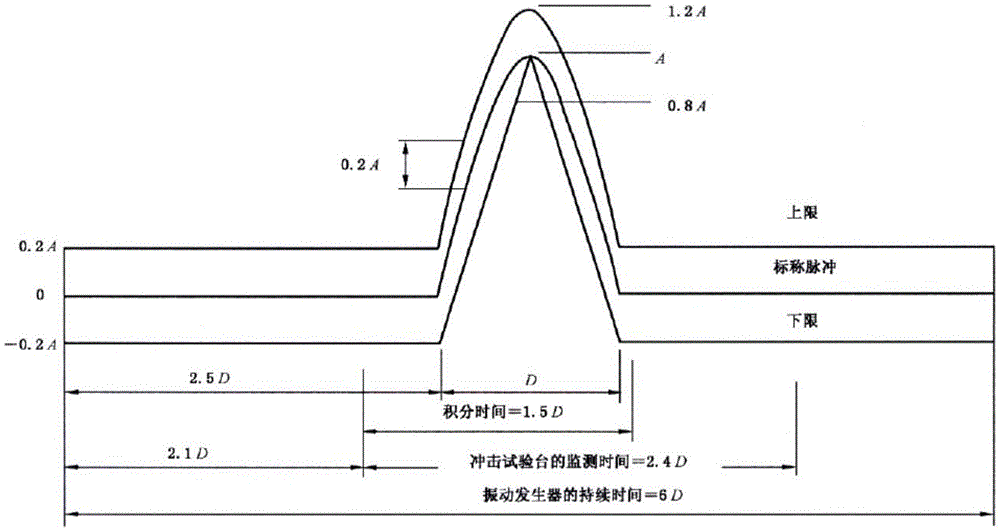

High-efficiency MTBF (Mean Time Between Failures) proof test method applied to ship navigation product

The invention relates to a high-efficiency MTBF (Mean Time Between Failures) proof test method applied to a ship navigation product, which comprises the following steps of: (1), determining test time; (2) determining environmental parameters; (3) determining a test section; and (4) determining test passing criterion. The method disclosed by the invention is a reliable acceptance test method, which is particularly applied to being used by the navigation product; a test program can be simplified by adopting the test method disclosed by the invention; the test time is shortened to r=(0.148-0.212)M from r=(1.1-45)M; the test time is greatly reduced; furthermore, the test section is greatly simplified; the development cycle can be greatly shortened; and a lot of test funds and resources, such as manpower, material and the like, can be saved.

Owner:TIANJIN NAVIGATION INSTR RES INST

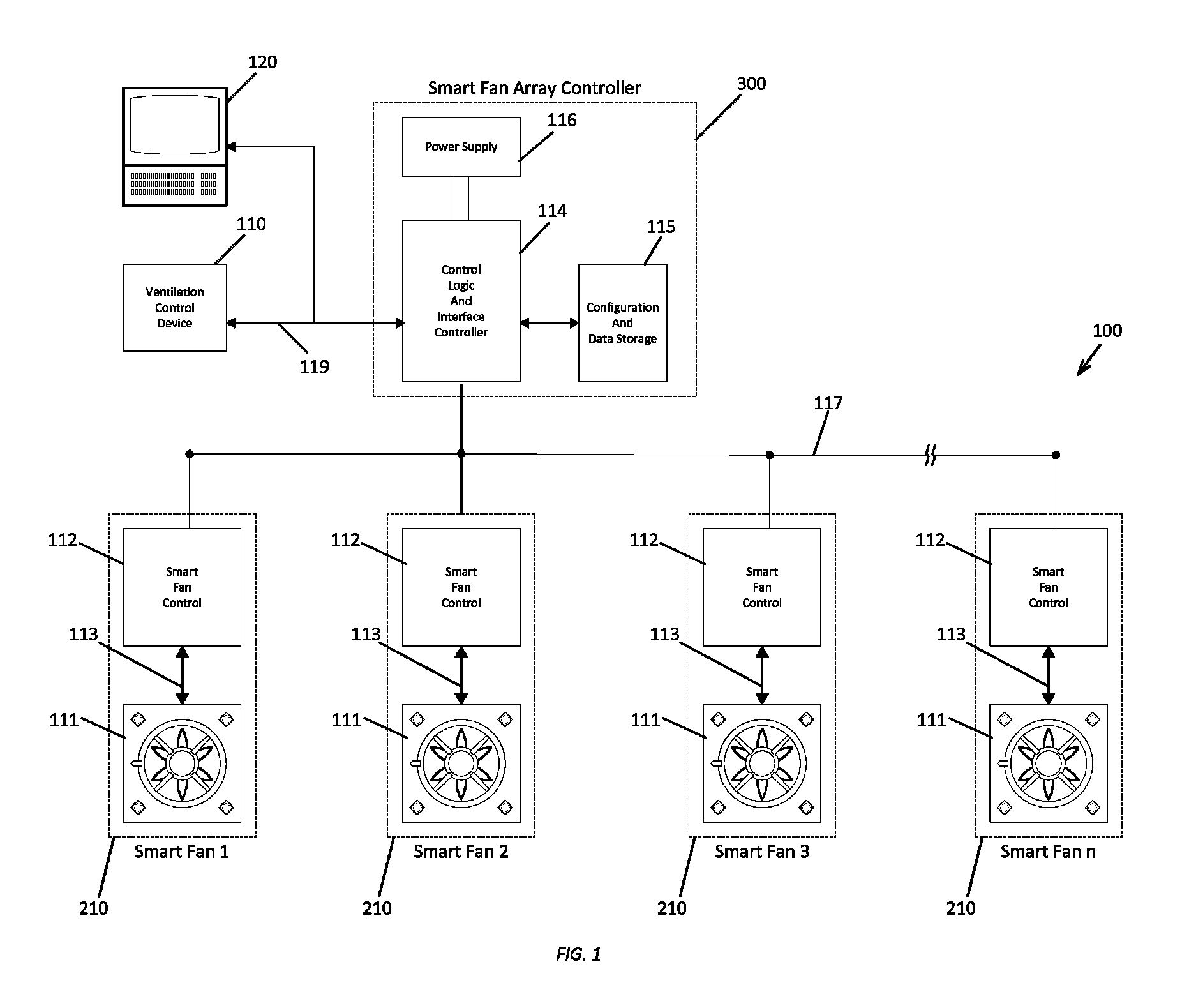

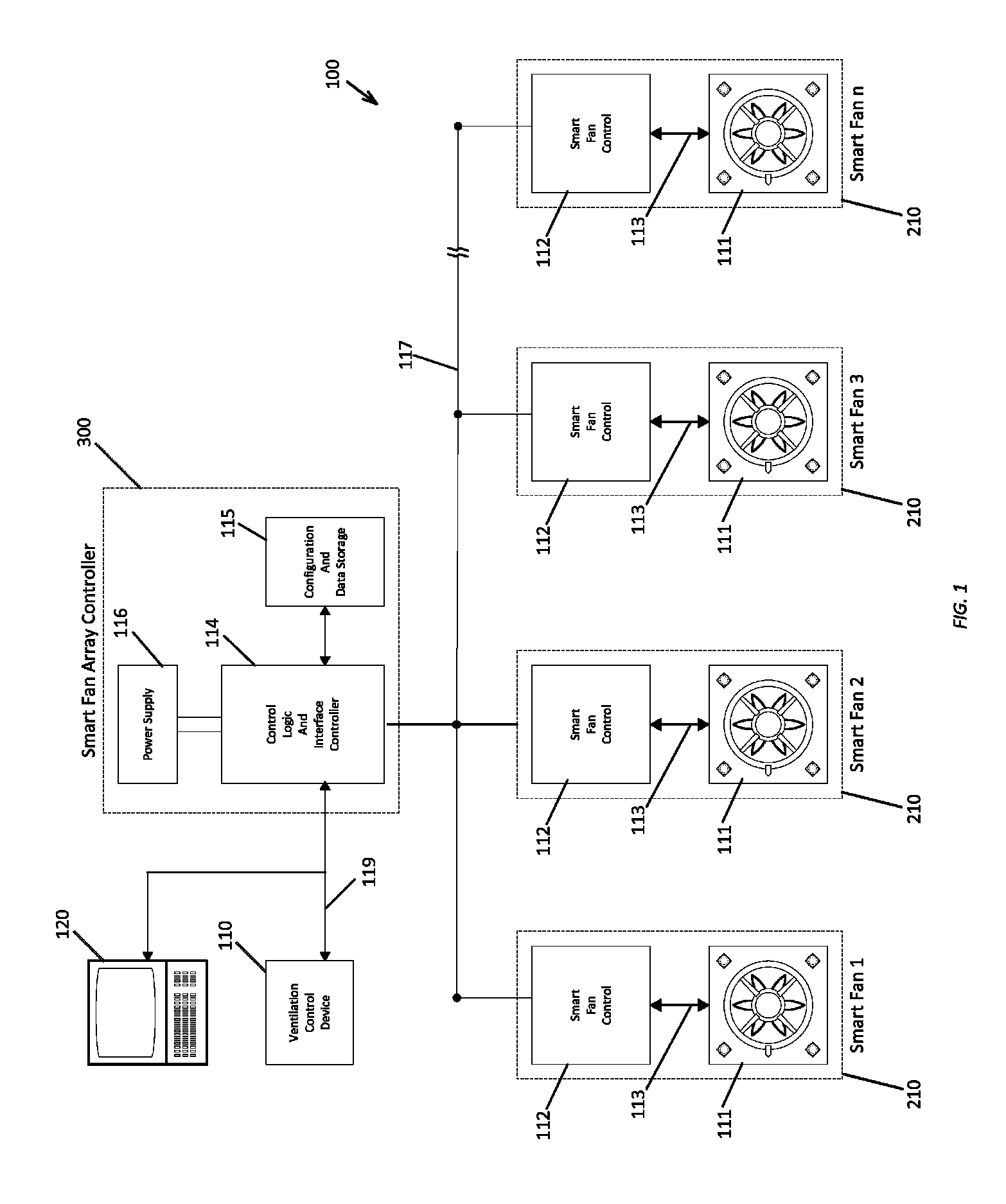

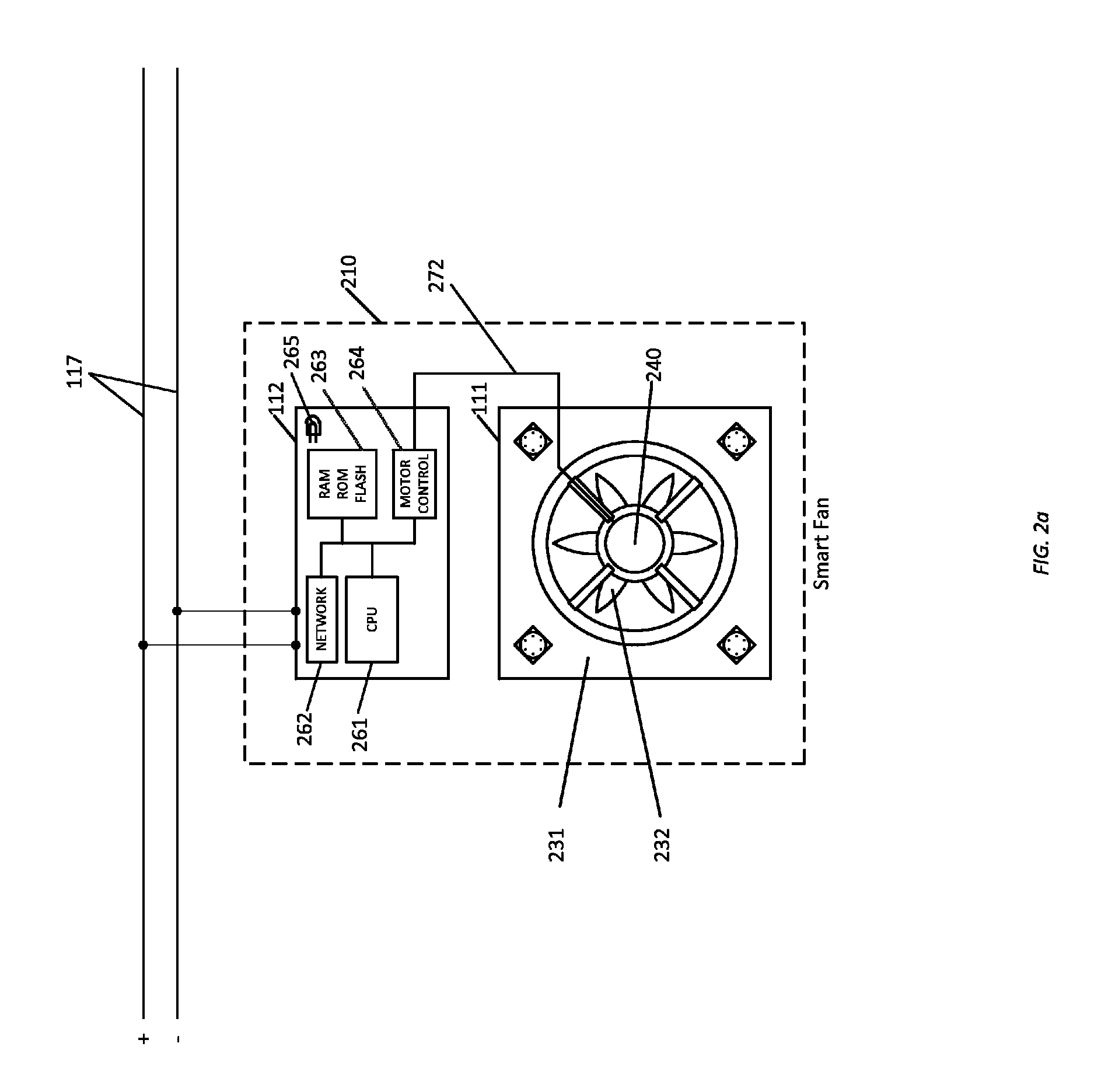

Fan array control system

ActiveUS9188355B1Extended service lifeIncrease fan life of systemMechanical apparatusSpace heating and ventilation safety systemsControl electronicsControl signal

A system and method for intelligent management of an array of fans. The system uses mean-time-between-failure, fan usage and other data in add ventilation, subtract ventilation and recycle array routines to maximize the life of the fans and the array. The system comprises a primary embodiment making use of smart fans in the array, each smart fan including a fan and appropriate control electronics capable of processing commands received from a smart fan array controller. Fan control signals are multiplexed over a local operating network power line using carrier communication protocols, command messages and data values, all to accomplish a goal of the system to maximize fan life. In an alternate embodiment, fan and array control electronics are integrated onto the fan array controller itself and power is provided to conventional fans using a conventional wiring harness.

Owner:DIGITAL CONTROL SYST

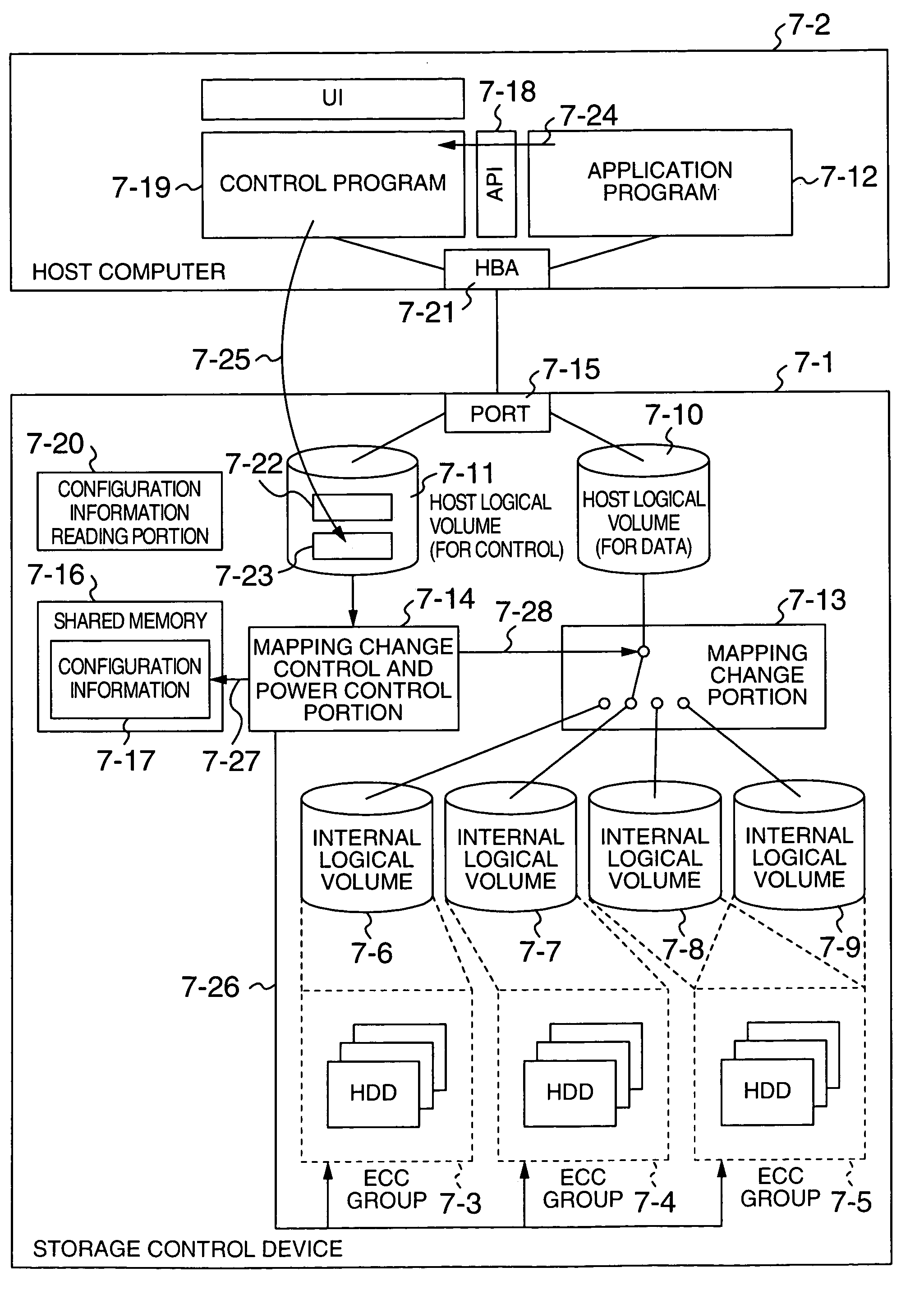

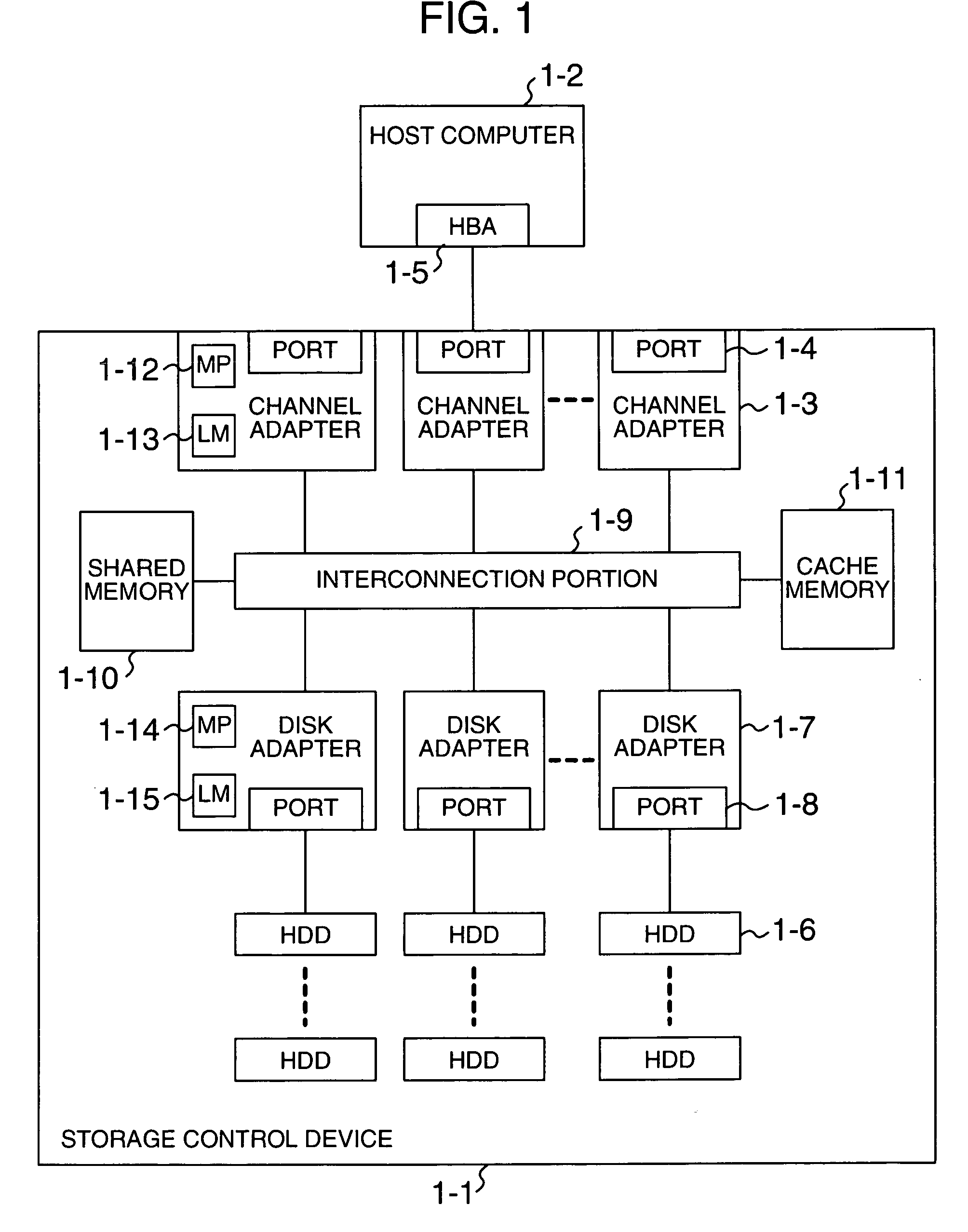

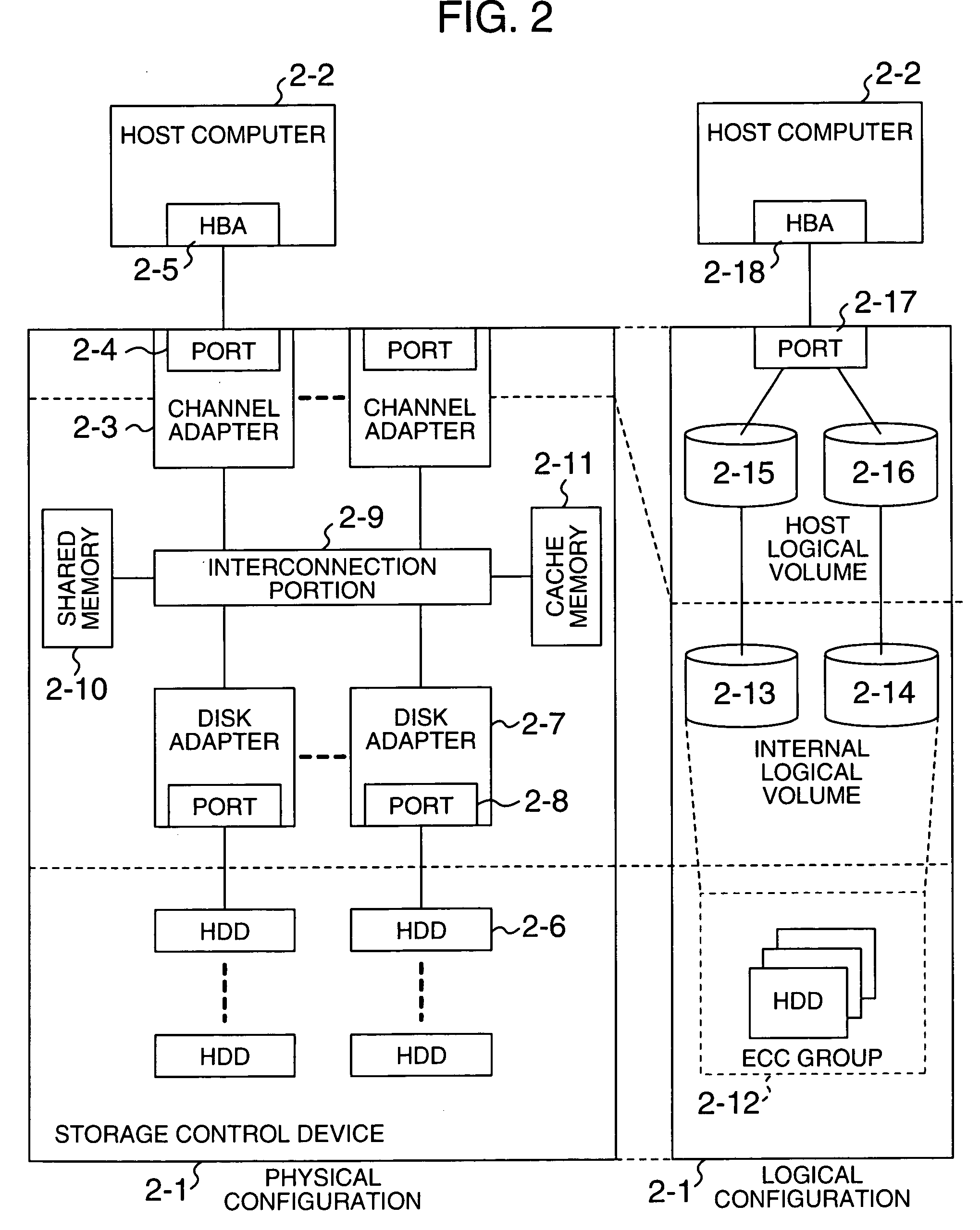

Memory control device and method for controlling the same

InactiveUS20050144383A1Increase capacityLarge capacityEnergy efficient ICTInput/output to record carriersTime extensionElectric machinery

The present invention provides a storage control device which enables the time between failures to prolong as much as possible, though it uses HDD's whose mean time between failures is relatively short. The storage control device controls spindle motors in a manner that a spindle motor is rotated regarding the HDD of data which can access from a host computer and a spindle motor is stopped regarding the HDD of data which are clearly judged that a host computer does not access the data. Whether the host computers can access the HDD or not is judged by the fact that whether the memory region (internal logical volume) provided by the HDD is in mapped to the host logical volume or not which is recognized by the host computer and is able to access thereby.

Owner:HITACHI LTD

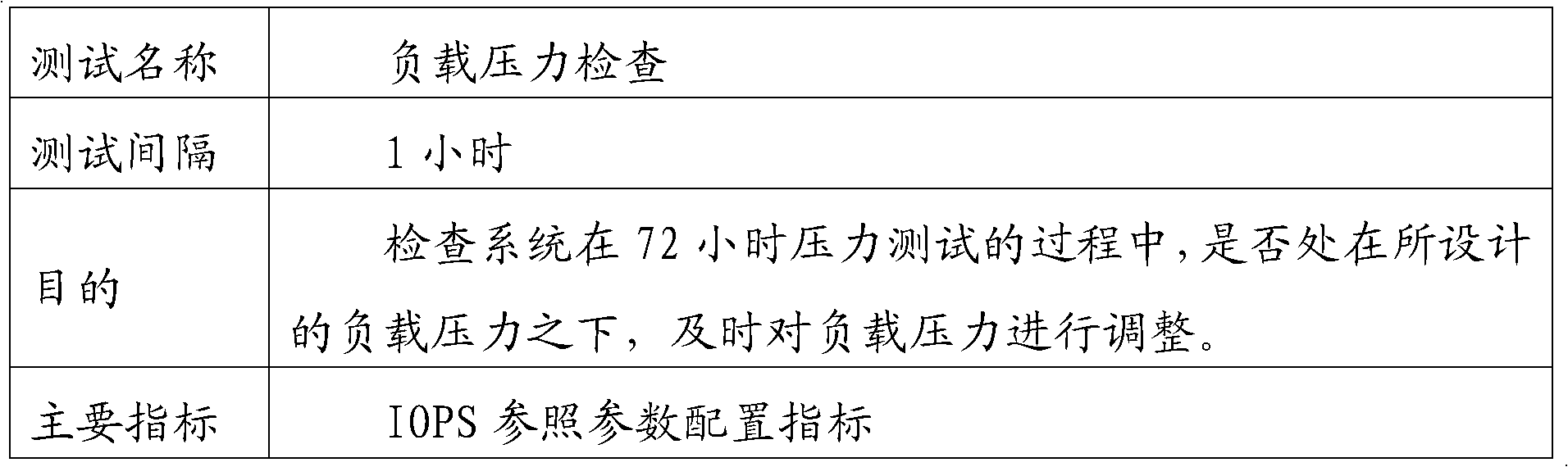

System and method for testing reliability of mass storage system

InactiveCN102097133AImprove developmentPromote progressStatic storageData acquisitionPerformance index

The invention discloses a system and a method for testing reliability of a mass storage system. The system comprises a data acquisition unit and a data analysis unit, wherein the data acquisition unit comprises a static test module, a 72-hour reliability test module, a recovery time test module, a bit error rate (BER) test module and a mean time between failures (MTBF) reference data acquisition module; the data analysis unit comprises a static test assessment module, a 72-hour reliability test result analysis module, a Markov analysis module, a Monte Carlo analysis module and a mean time to data loss (MTTDL) analysis module; and various performance indexes for reflecting a tested system are acquired by performing data acquisition and data analysis, performing comprehensive test on the aspects of static test, 72-hour reliability test, fault injection-based reliability test and the like and performing analysis by adopting the Markov module, the Monte Carlo module and a disk array MTTDL, so the technical problem that the reliability evaluation system in the prior art cannot comprehensively reflect the reliability of the mass storage system. The system and the method are particularly suitable for reliability test of the mass storage system.

Owner:中国人民解放军装备指挥技术学院

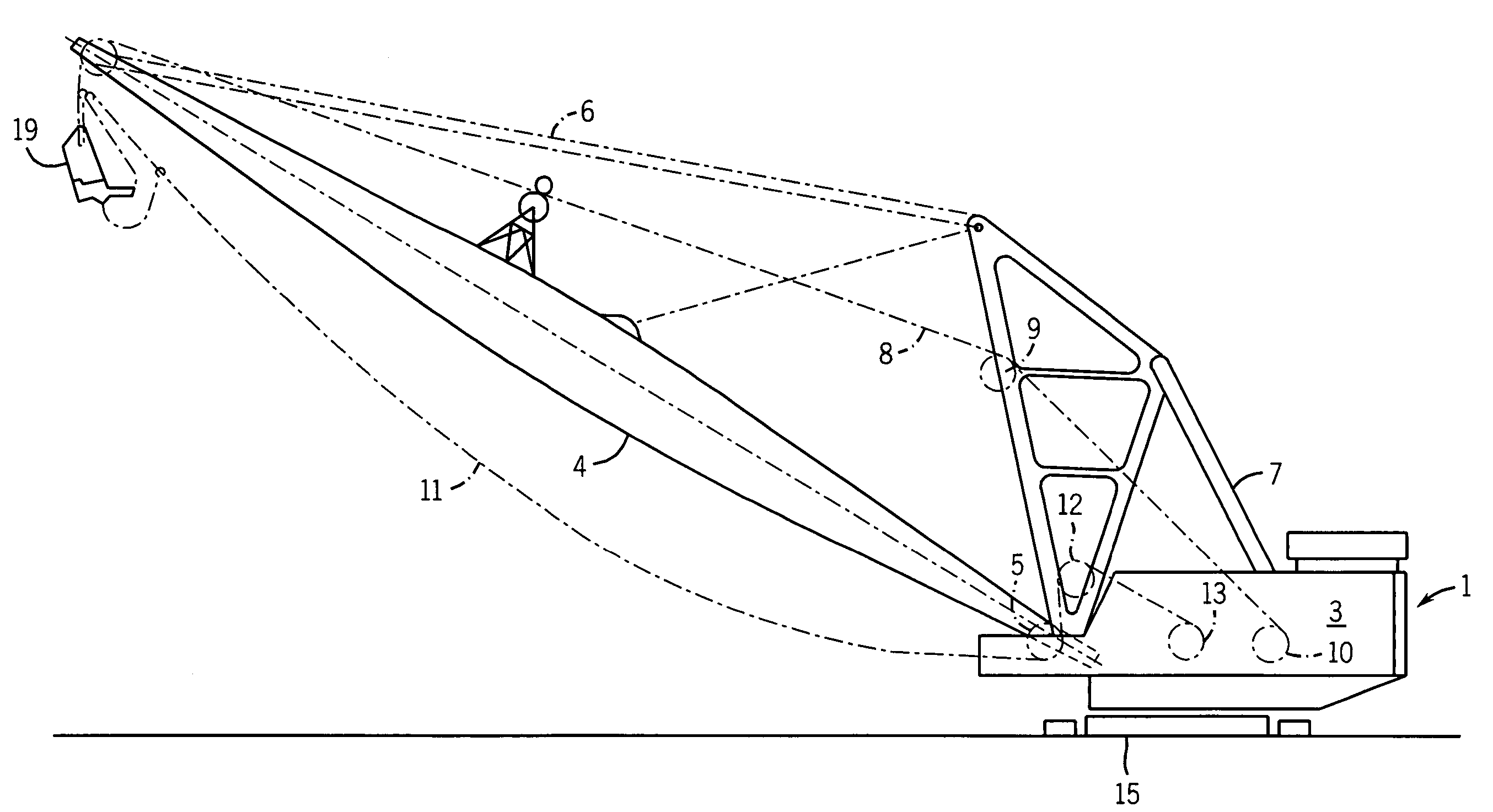

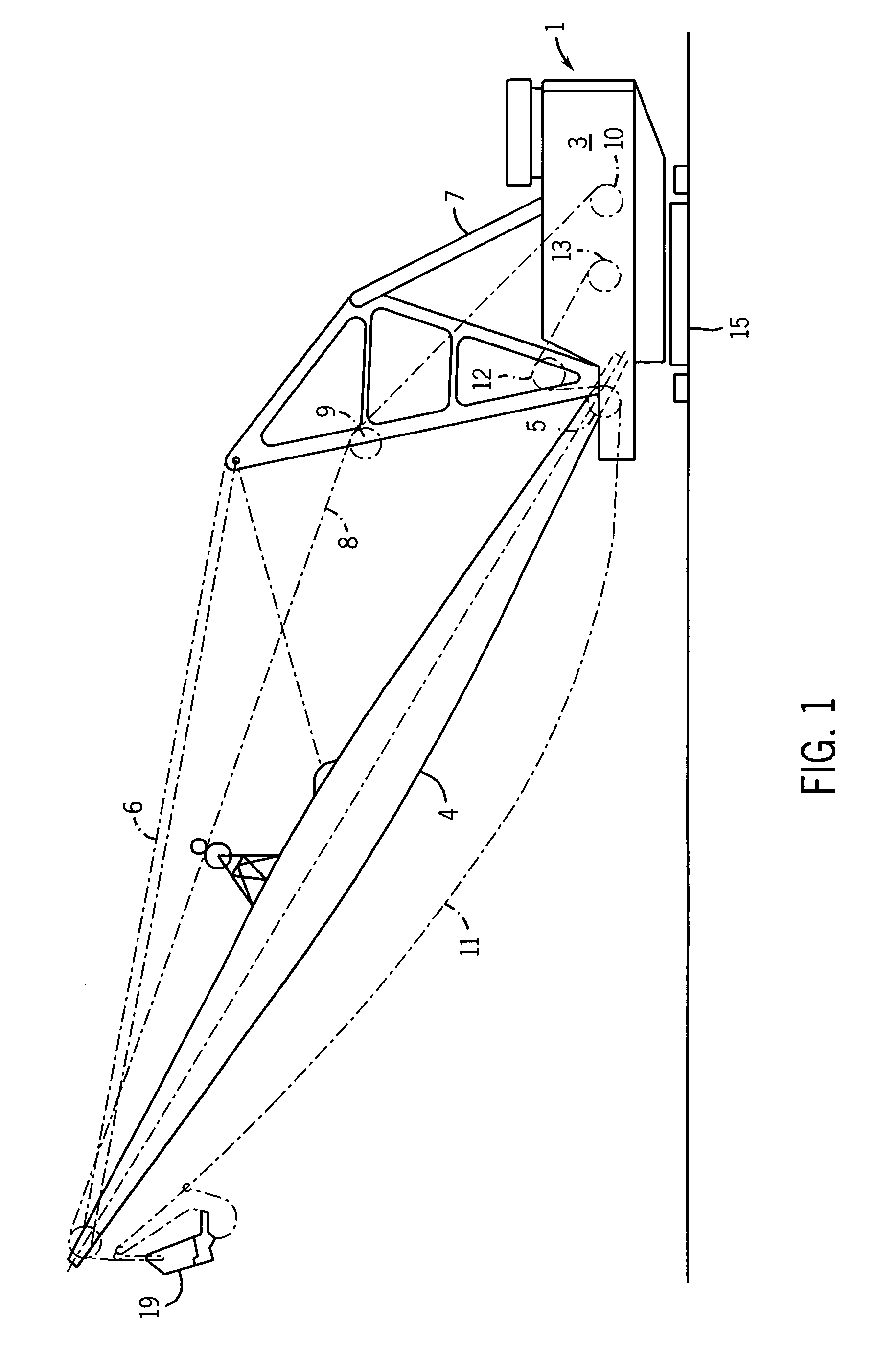

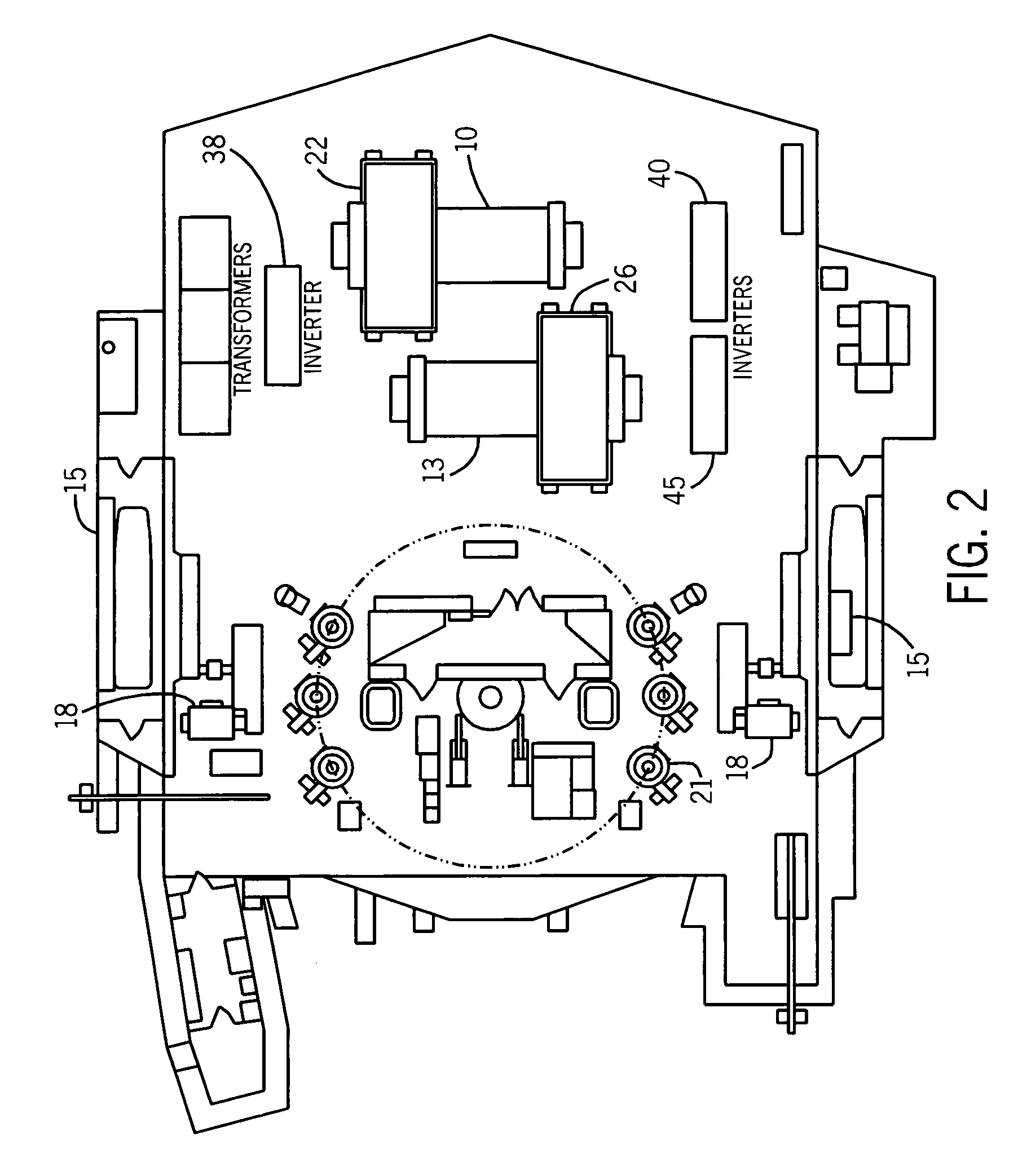

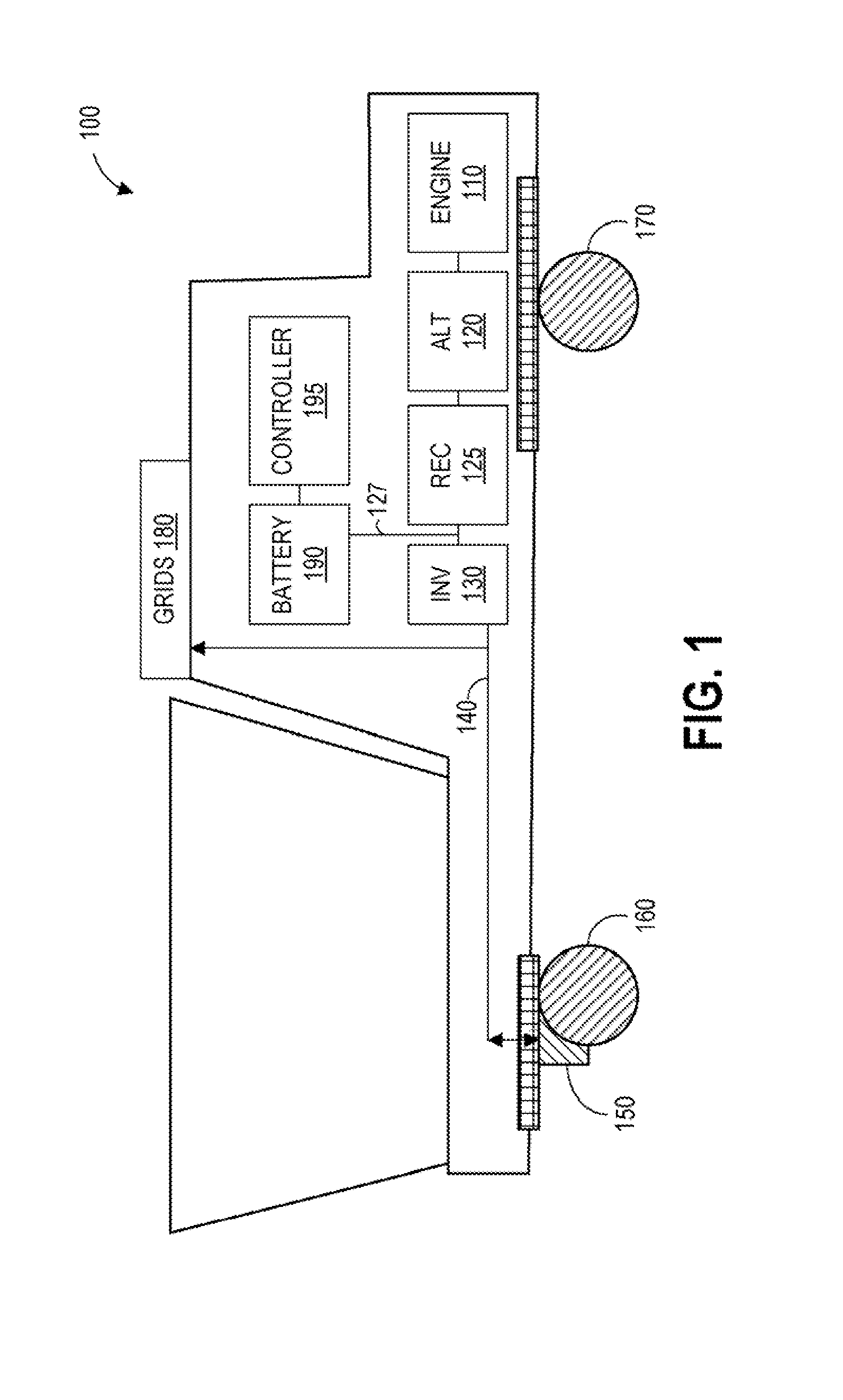

Dragline excavating machine with direct drive hoist and drag drums

A dragline excavating machine includes a gearless direct drive AC drive motor for driving each of the hoist and the drag drums in the system. The gearless AC motor is driven using a digital system which receives AC power from the utility system rectifies the power using active front end circuits, and converts the resultant DC to a frequency controlled AC using an inverter circuit. The resultant AC signal is employed to drive the gearless AC motor, resulting in reduced harmonic distortion, unity or leading power factor, and increased efficiency, reduced operating costs, and reduced mean time between failure.

Owner:SIEMENS ENERGY & AUTOMATION INC +1

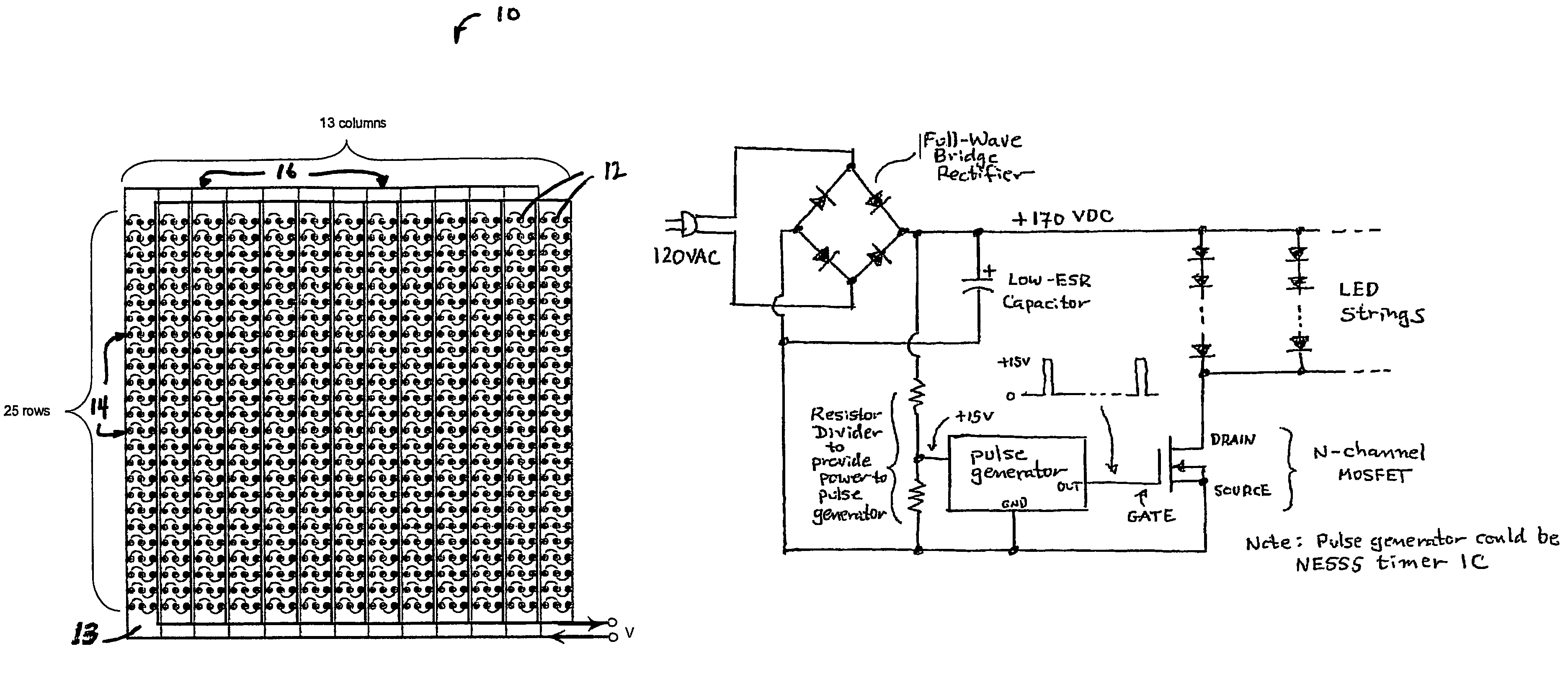

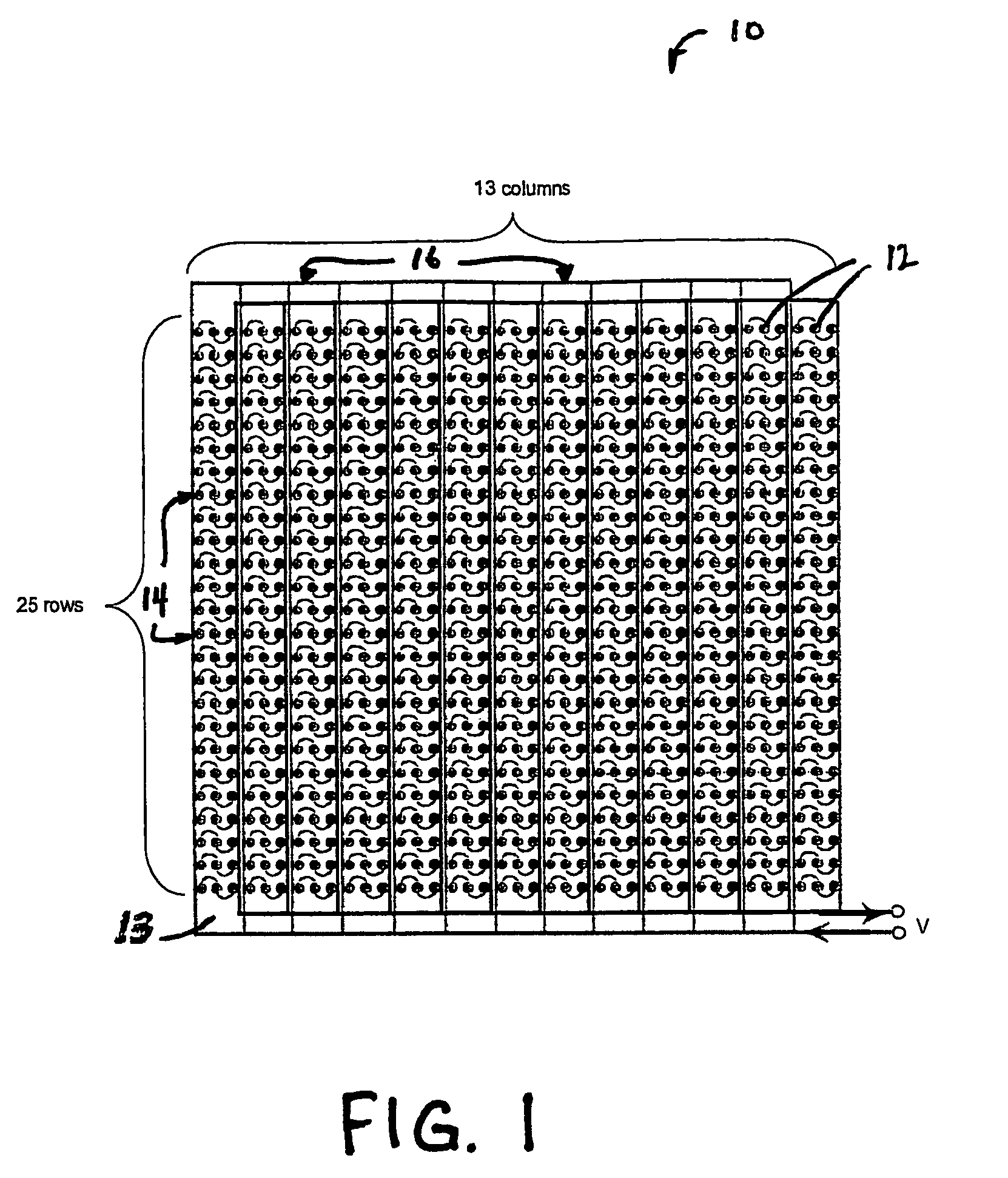

Series wiring of highly reliable light sources

ActiveUS7524085B2Same brightnessImprove the level ofLighting support devicesElectrical apparatusFailure rateLed array

The light array of this invention includes a number of columns and rows of LED's connected in a series / parallel combination. The series parallel combinations effectively optimize the impedance, accommodate failure rate, facilitate light mixing, provide a means of imbedding redundancy, and common cathodes or anodes. This arrangement provides a superior light source for consumer, industrial and specialty markets in respect to mean time between failure, process control, radiant intensity, wavelength mixing, power requirements and other characteristics of the light source. Each column includes a number of rows of plural LED's. The LED's in each row are wired in series and each column is wired in parallel so that if one LED fails only the LED's connected in series with the failed LED will also fail. There is redundancy in the circuit as well as the arrays so that if there are failures different current carrying elements or different series LEDS will automatically by powered on. The array may be connected in series with one or more LED arrays to form a module. Multiple modules may be connected in series with other multiple modules.

Owner:SILICON VALLEY BANK

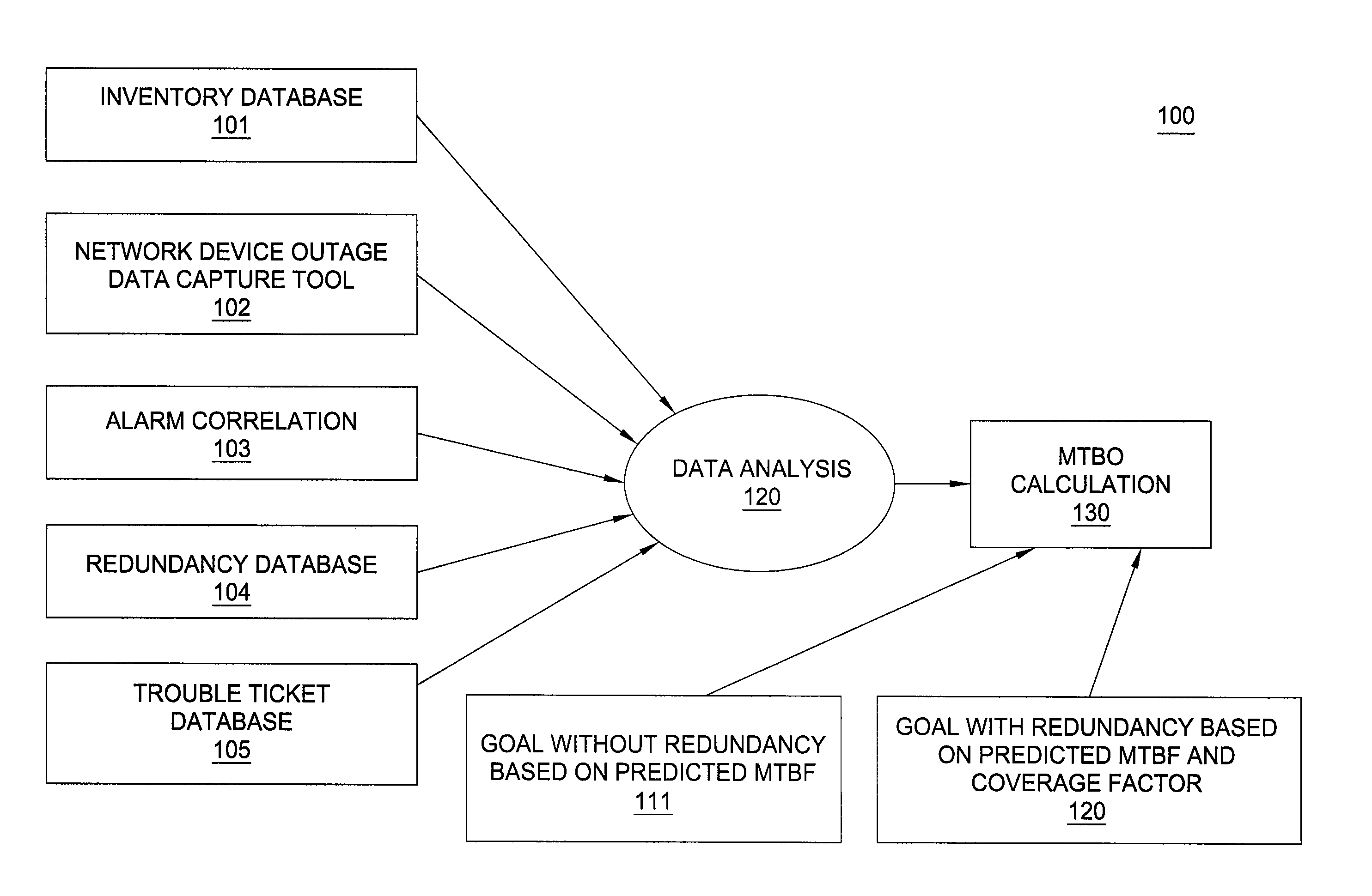

Method and apparatus for measuring customer impacting failure rate in communication networks

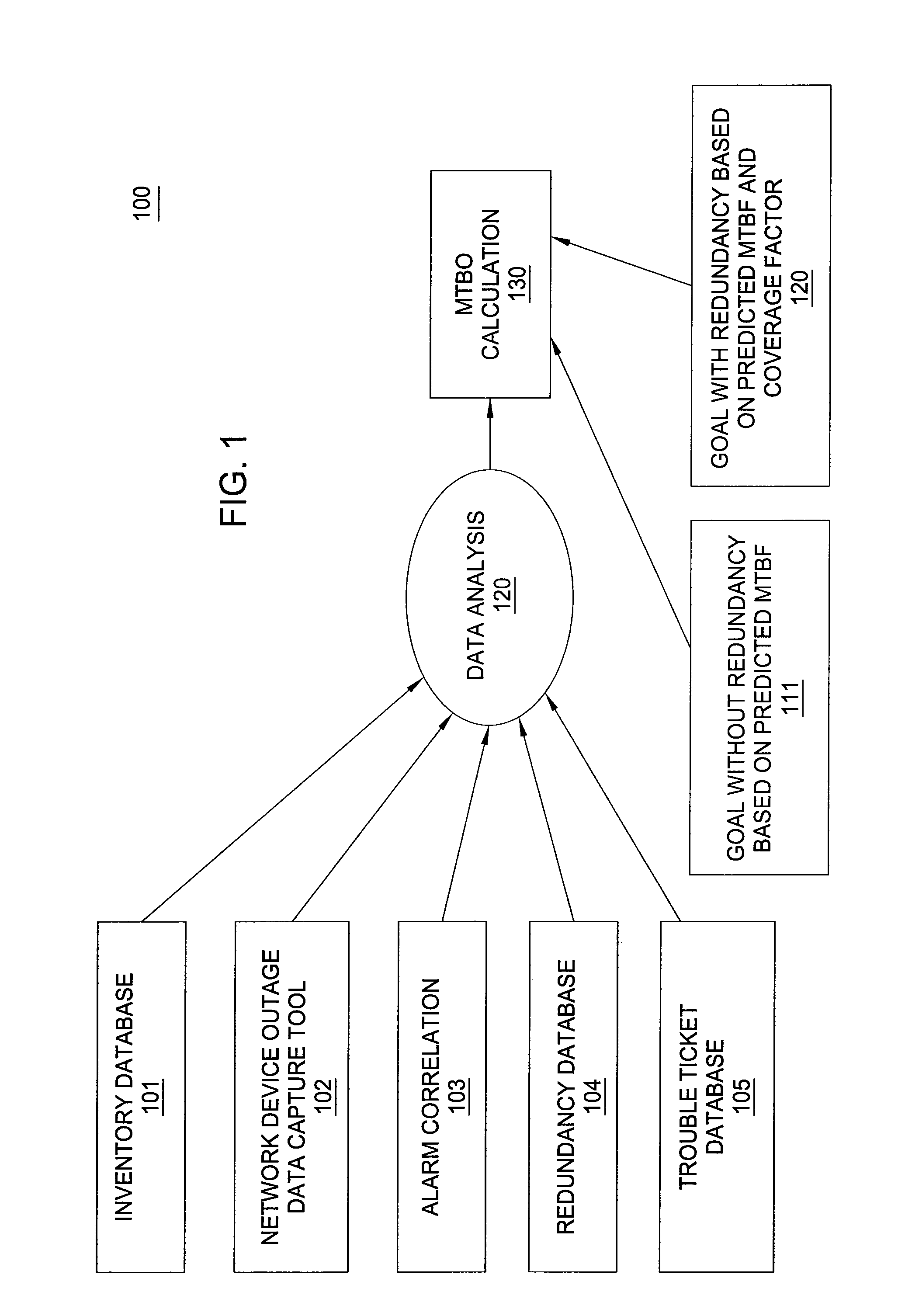

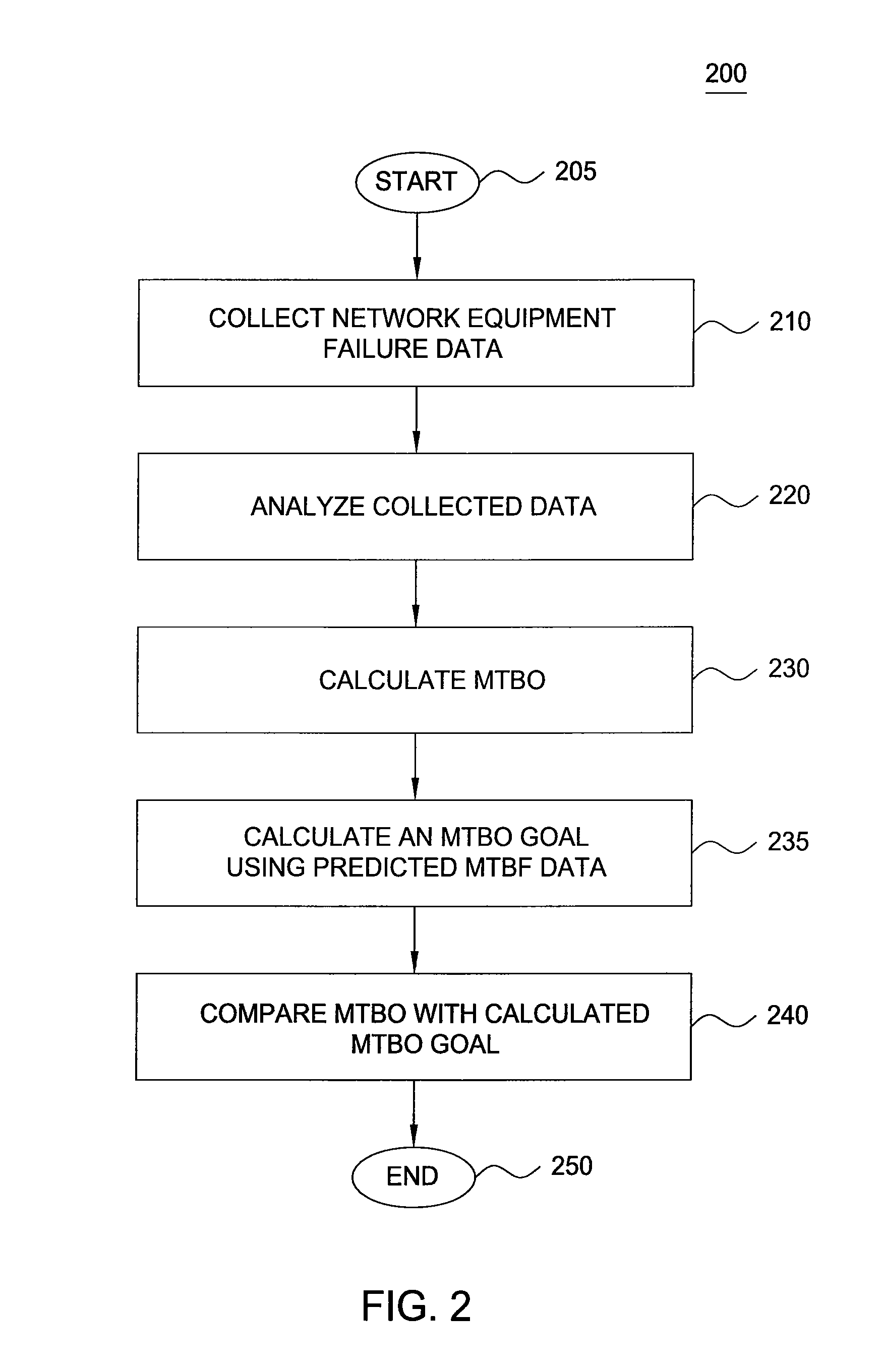

ActiveUS20100125745A1Reliability/availability analysisTransmissionFailure rateMean time between outages

A method and system for measuring a customer impacting failure rate in a communication network are disclosed. For example, the method collects a plurality of customer impacting network failure events, where the plurality of customer impacting network failure events comprises both hardware failure events and software failure events associated with a particular type of router or switch, or a particular type of component of the router or the switch. The method computes a Mean Time Between Outage (MTBO) metric from the plurality of customer impacting network failure events and compares the MTBO metric with a MTBO goal metric, wherein the MTBO goal metric is calculated in accordance with a predicted Mean Time Between Failure (MTBF) metric.

Owner:AT&T INTPROP I L P +1

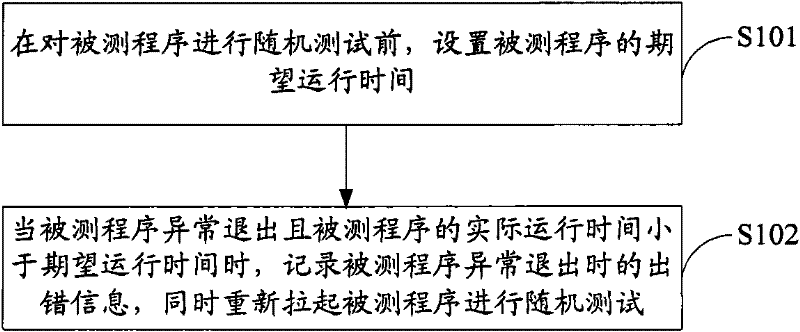

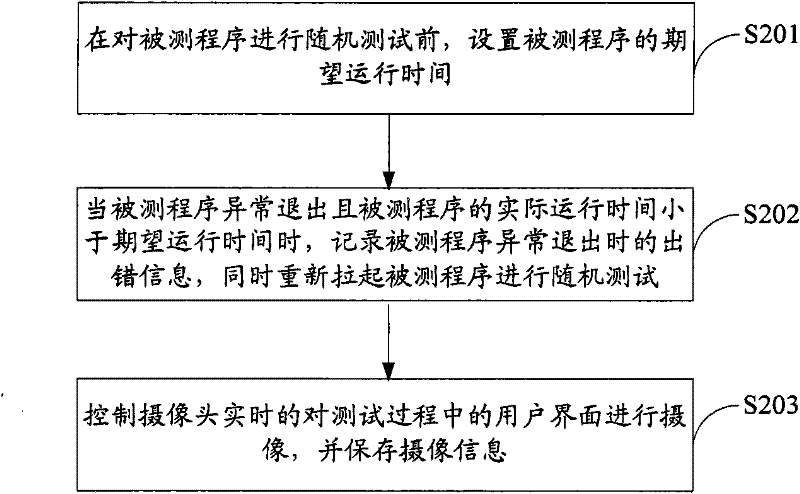

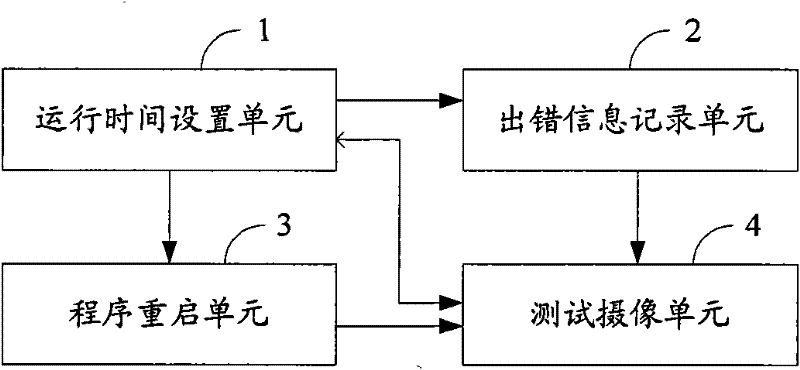

A test method and device for mean time between failures

ActiveCN102279787AEasy to debugRapid positioningSoftware testing/debuggingPresent methodRunning time

The invention is suitable for the field of software testing and provides a method and device for testing average fault-free time. The method comprises the following steps of: setting desired running time of a tested program before random testing of the tested program; and when the tested program exits abnormally and the practical running time of the tested program is shorter than the desired running time, recording error information when the tested program exits abnormally and randomly testing the tested program once again simultaneously. In the embodiment of the invention, the error information during abnormal exit of the tested program is recorded when the tested program exits abnormally and the practical execution time of the tested program is shorter than the desired execution time, so that the error information of the tested program can be positioned quickly, accurately and efficiently.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

Predictive Automated Maintenance System (PAMS)

InactiveUS20160005242A1Vehicle testingRegistering/indicating working of vehiclesHardware implementationsComputer science

A method of performing preventative, routine and repair maintenance on a plurality of geographically remote units includes the step of establishing a Common Core System (CCS), or portion of a unit under test (UUT) component that has a common configuration for each unit. The CCS can be established at manufacture, or it can be back fitted by hardware implementation on legacy UUT's. Each CCS is networked to an Advanced Automated Test System (AATS), which is further networked to a central knowledge database and to a plurality of remote users. The remote users can access the AATS through the network to conduct remote tests of the UUT through the CCS, and to troubleshoot the UUT in response to a UUT test fault. The central knowledge database can further store configuration and operation history for the UUT, to maintain configuration control and to predict a Mean Time Between Failures (MTBF) for the UUT.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

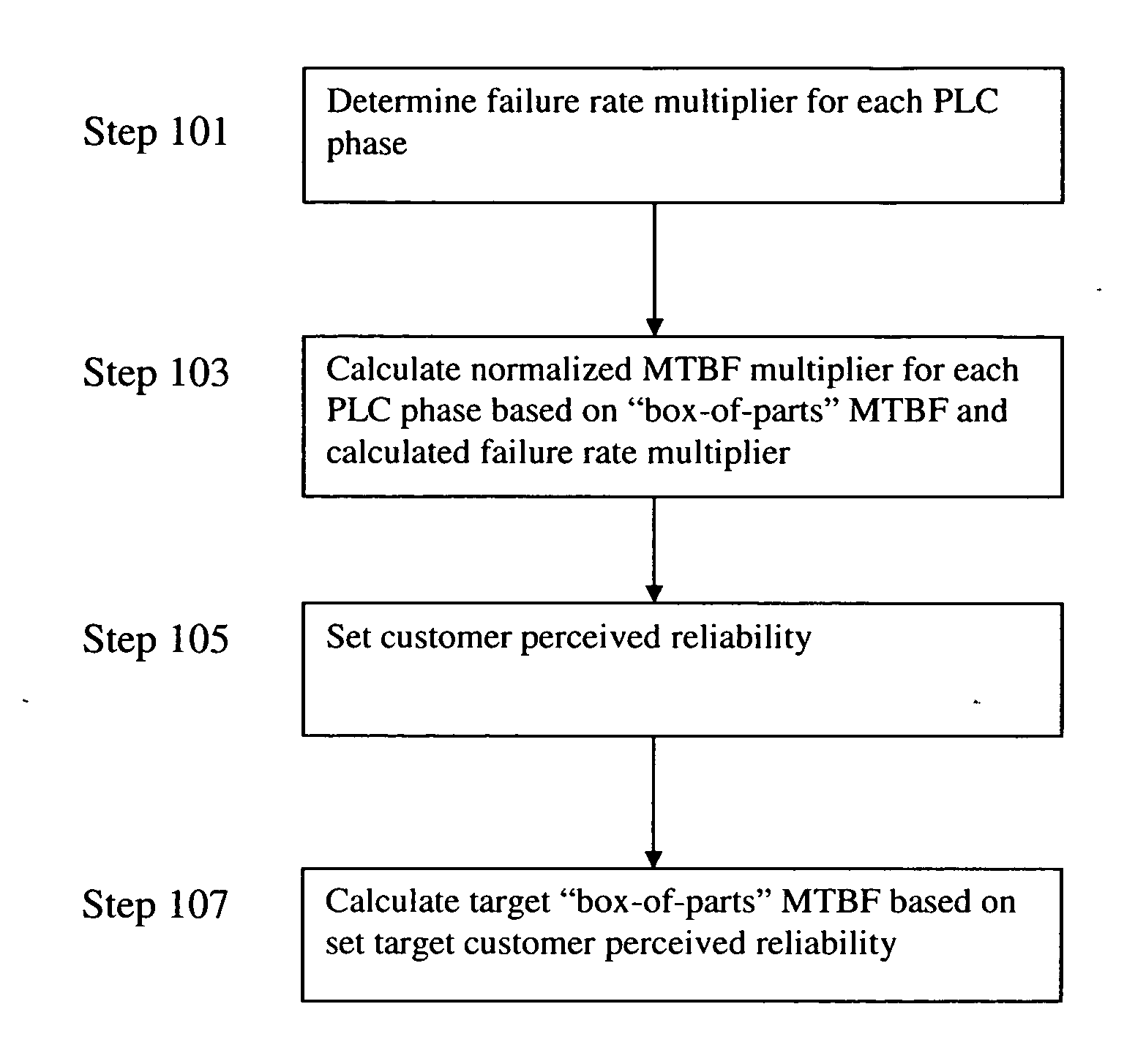

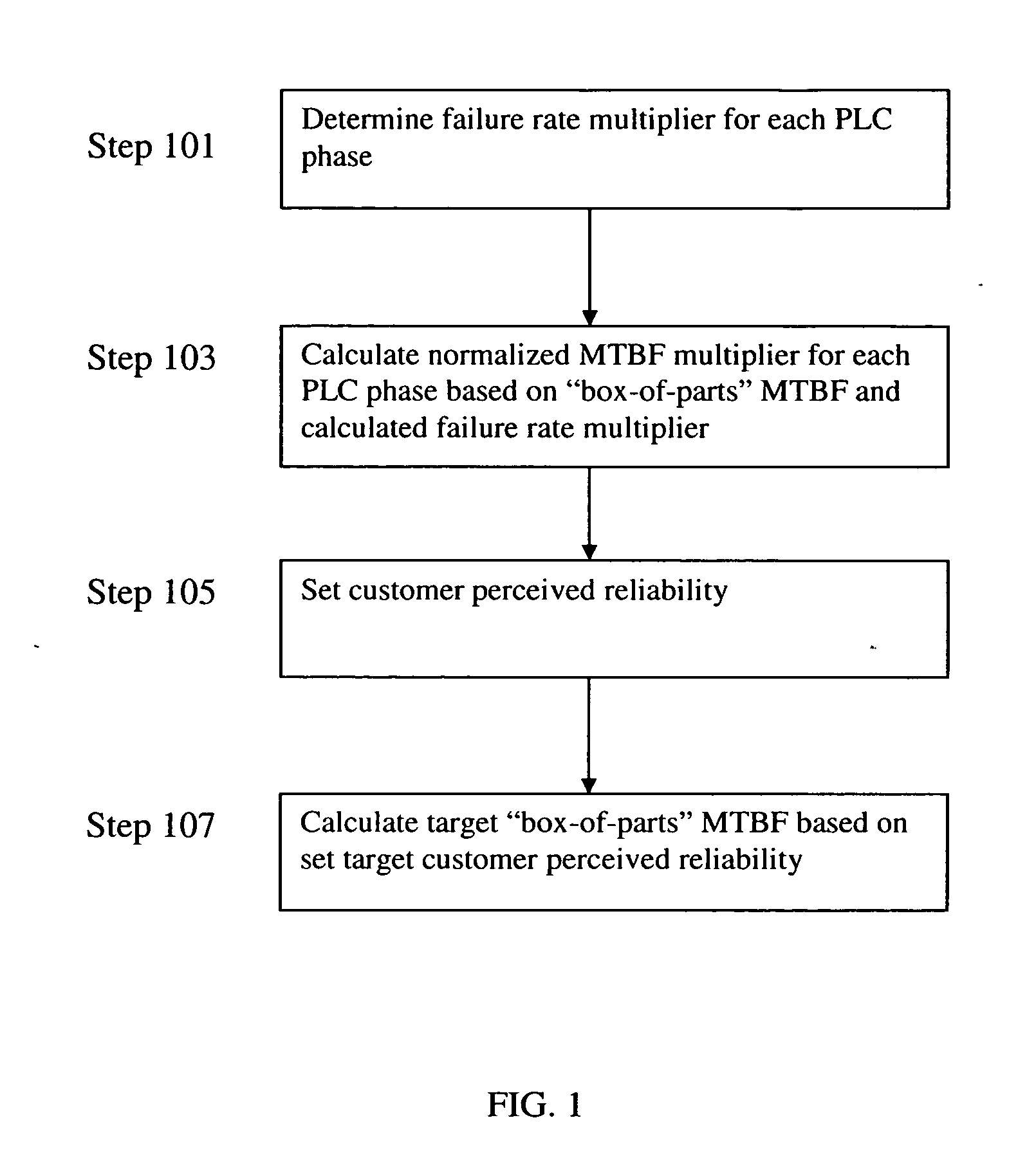

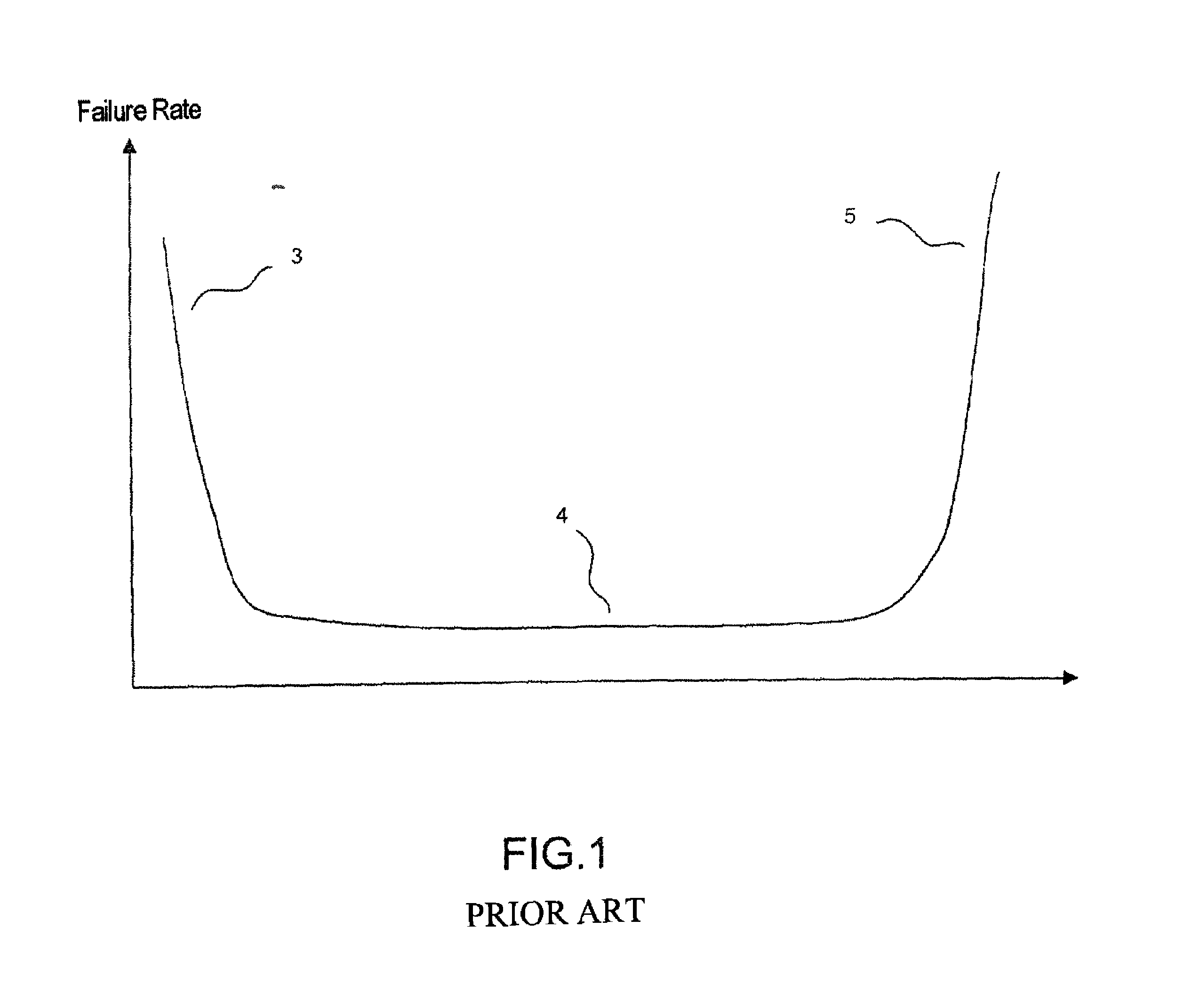

Achieving perceived reliability for repairable systems

A method to achieve perceived reliability for repairable systems including goal setting of different phases of the product life cycle. The method includes consideration of a plurality of product life cycle phases to determine a plurality of failure rate multipliers which are transformed to mean time between failures multipliers and normalized. Using these computed mean times between failures multipliers and a chosen level of customer use, the box-of-parts required mean time between failures level can be calculated. Also, the required mean time between failures for design, manufacturing, infant mortality, and service phase of product life cycle can be computed.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

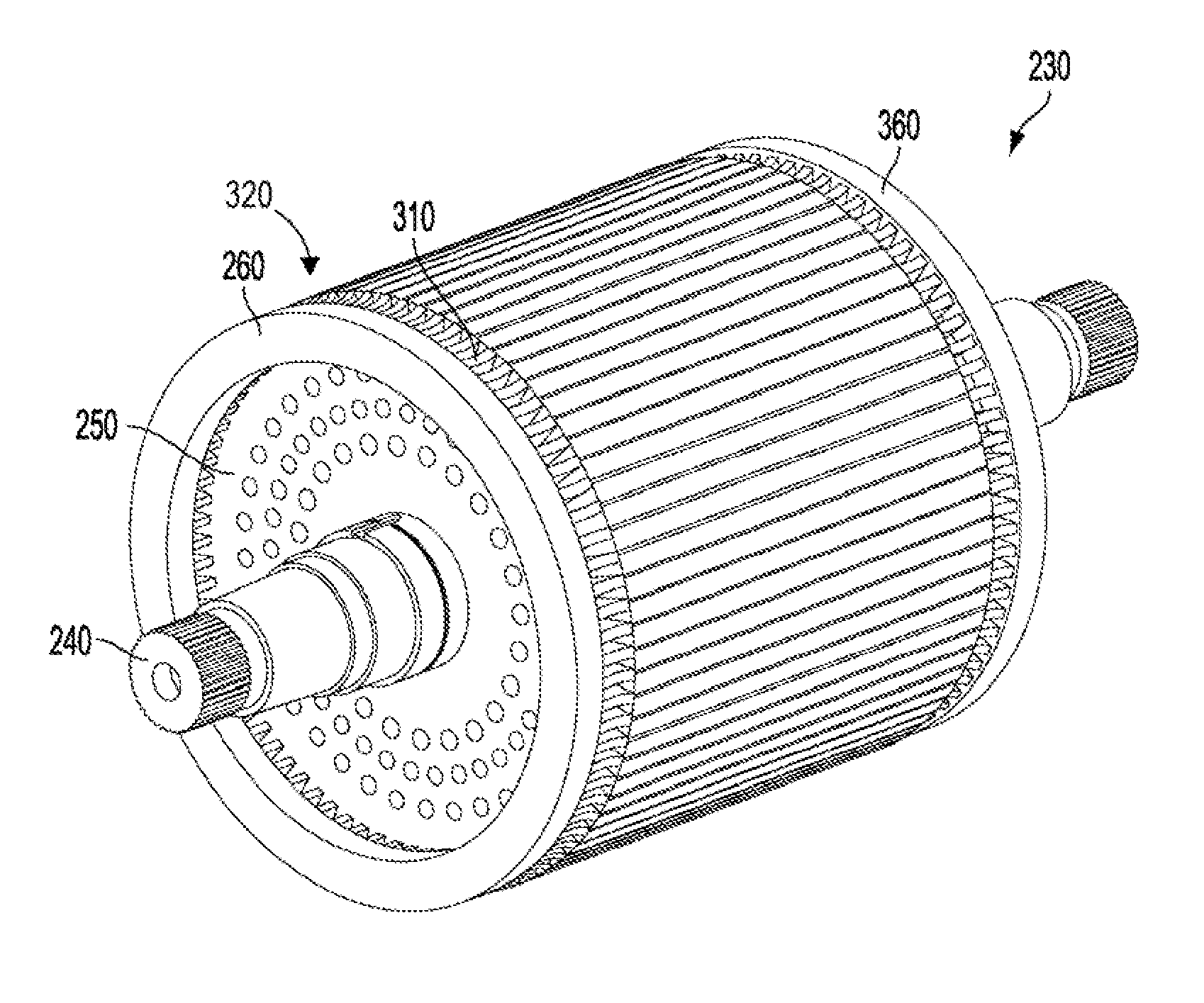

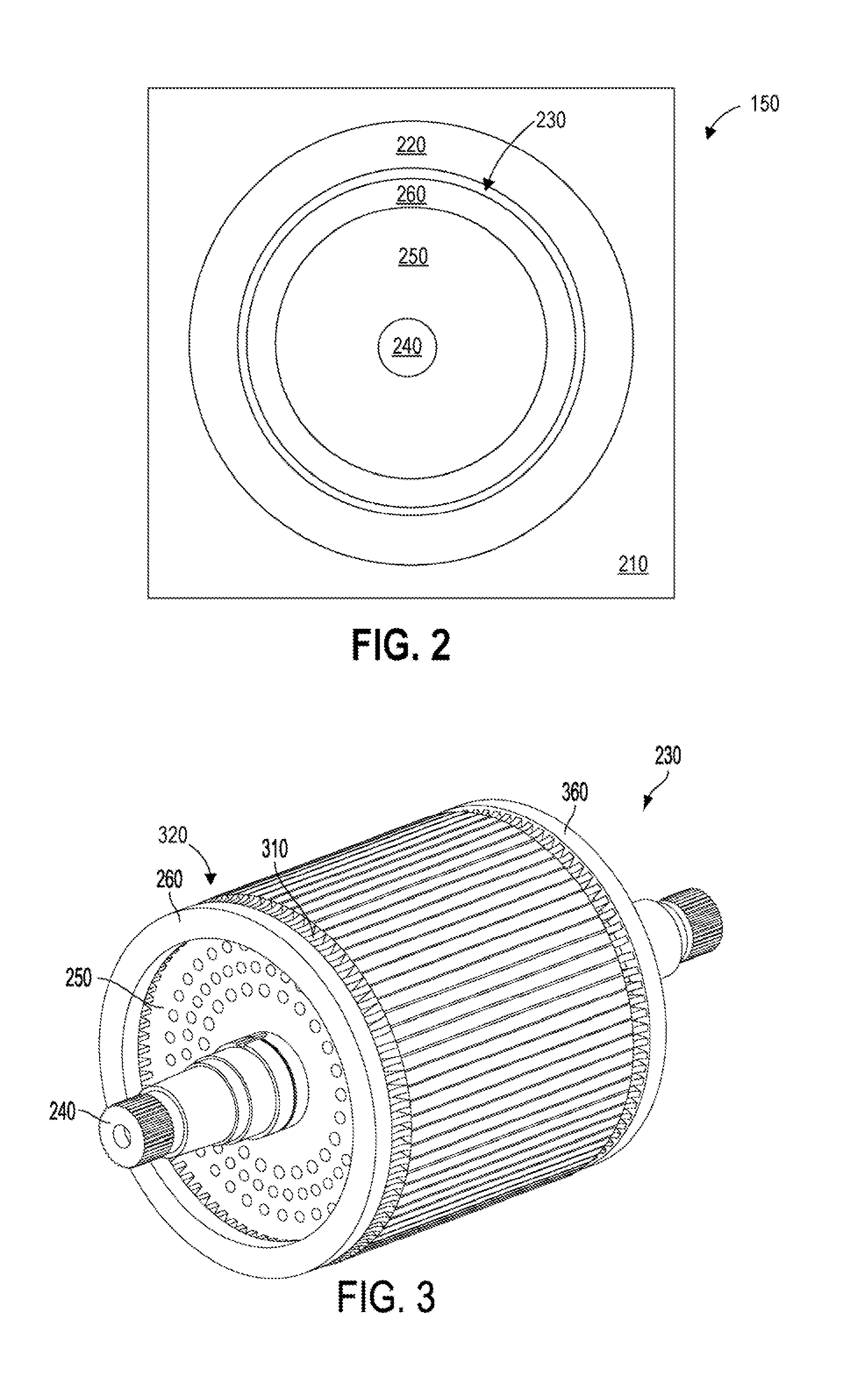

Traction motor

ActiveUS20110254400A1Ring stress can be reducedMean timeMagnetic circuit rotating partsSynchronous motorsPunchingInduction motor

In one embodiment, a rotor for an induction motor comprises a punching assembly, a plurality of conductive bars, and an end-ring. The plurality of conductive bars may be substantially parallel to an axis of the rotor and connected to the punching assembly at a periphery of the punching assembly. Each conductive bar includes an end connected to the end-ring. The end-ring comprises a punching side having a surface facing the punching assembly and a housing side having a surface opposite the punching surface. The end-ring may be thicker on the punching side than the housing side. In this manner, the peak end ring stresses may be reduced at higher speeds and the mean time between failures of the rotor may be increased. Alternatively, the threshold speed may be increased and the top-speed of the off-highway vehicle may be increased for a given expected mean time between failures of the rotor.

Owner:GE GLOBAL SOURCING LLC

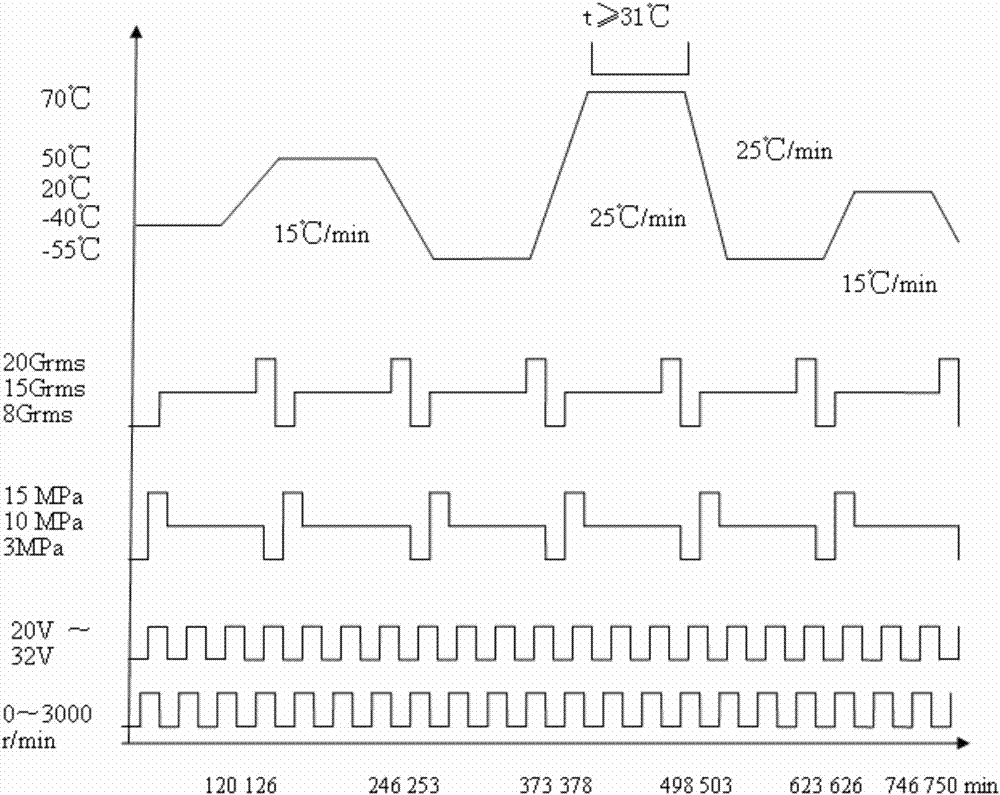

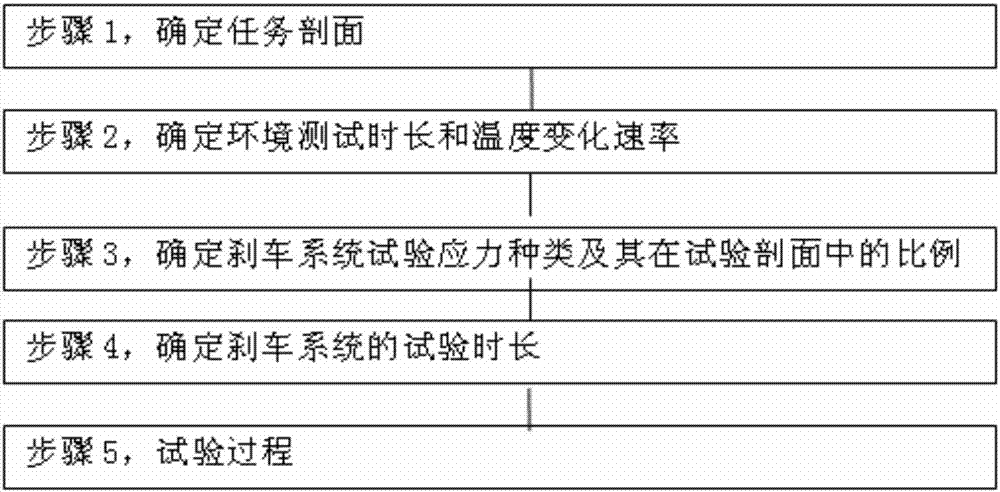

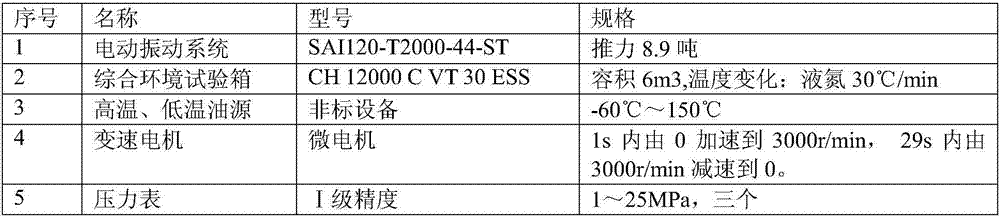

Testing method for combined stress of airplane brake system

InactiveCN107226218AImprove the effect of stimulating failureSolve the problem of applying comprehensive stressAircraft components testingStress conditionsBraking system

The invention provides a testing method for combined stress of an airplane brake system. The combined stress test section is incorporated into an extreme value environment condition in use to stimulate a using failure. According to the testing method for the combined stress of the airplane brake system, the overlaying effect is generated by simultaneously applying temperature and temperature changes, power supply voltage fluctuation, hydraulic stress and vibratory stress which exist simultaneously during using of the brake system, wherein the power supply voltage fluctuation is the power supply character, so that the failure stimulating effect is enhanced. A test for the brake system is completed under the combined stress condition within 90,000 min / 1,500 h, seven verifications such as the service life indicator for 2000 times of taking off and landing of the braking system, average failure interval time with 2000h of MTBF, high temperature, low temperature, vibrating, temperature impact and the power supply character are completed in one test, and the problem that the service life and reliability indicator of the brake system in the prior art cannot be comprehensively verified is solved. According to the combined stress testing method for the airplane brake system, testing cost is reduced, failures during using of civil airplane products are reduced, the flight attendance rate is improved, and reliability of a civil airplane is improved.

Owner:XIAN AVIATION BRAKE TECH

Method for evaluating availability of cloud computing system

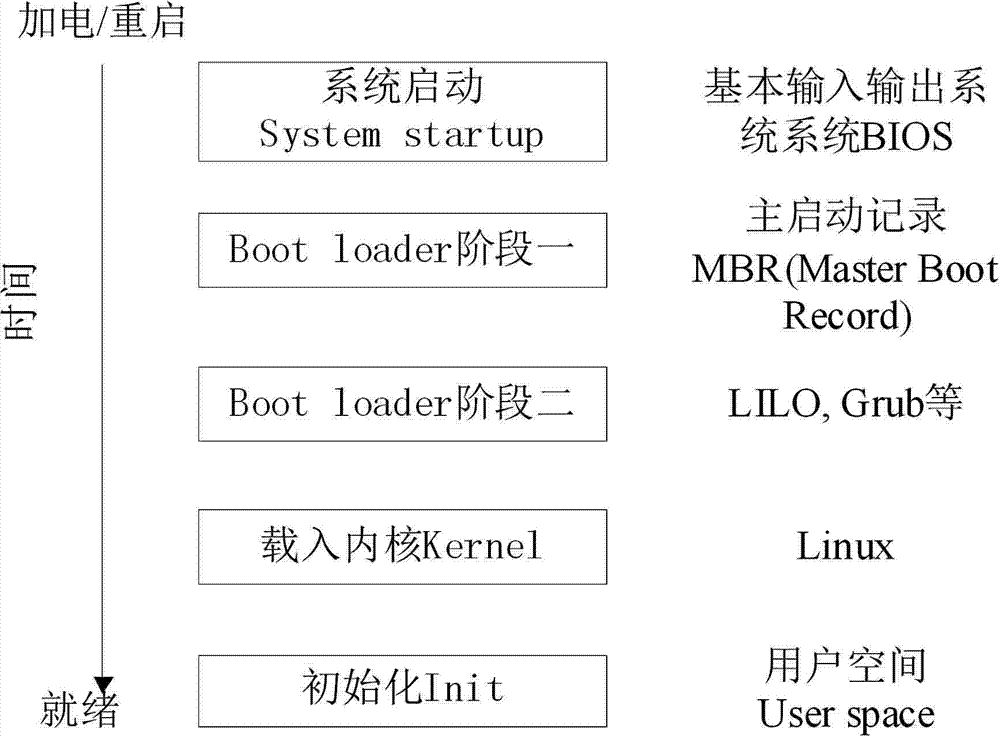

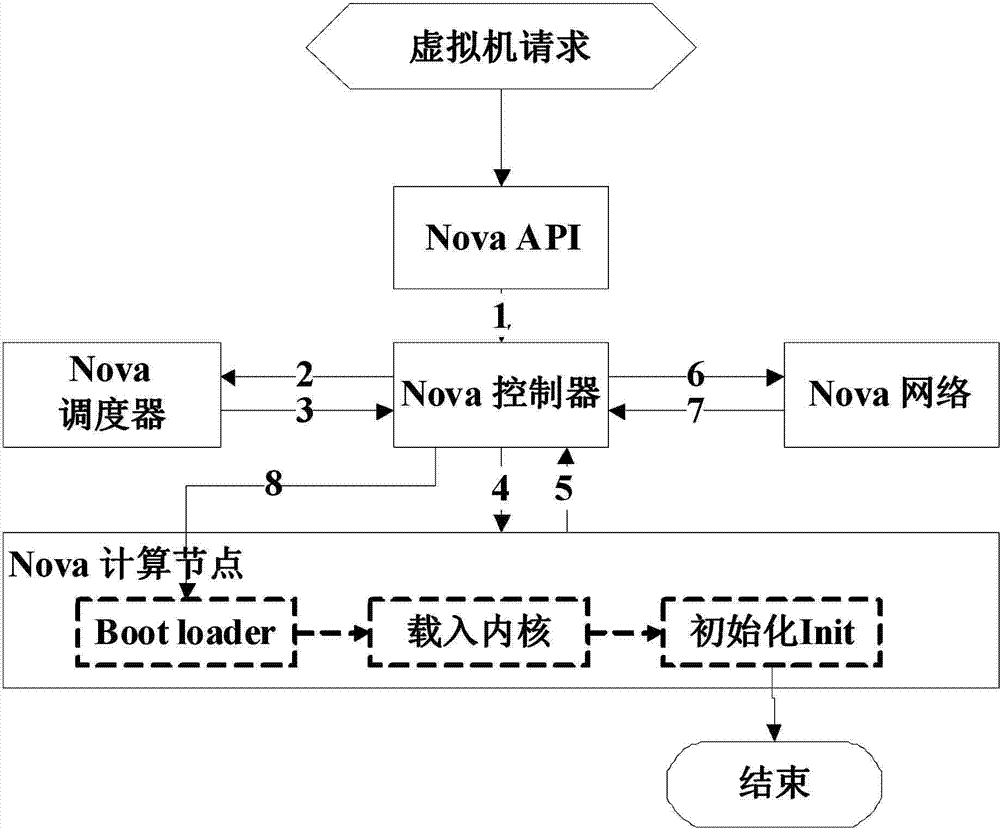

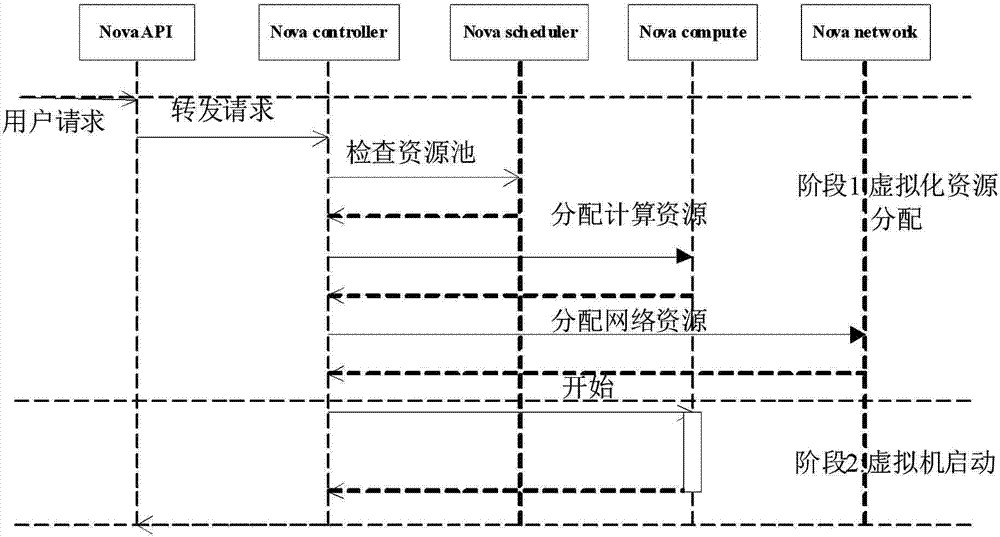

The invention discloses a method for evaluating availability of a cloud computing system. The method specifically comprises the steps of evaluating the start-up time of a virtual machine in a cloud computing service firstly; then roughly evaluating the availability of the cloud computing service according to the start-up time of the virtual machine; evaluating the mean down time of the virtual machine, and roughly evaluating the availability of a single virtual machine; after a service provider offers a part of parameters, accurately evaluating the availability of the cloud computing service; and evaluating the mean time between failures of a single physical machine, the mean time between failures of a physical machine cluster, the mean time between failures of a virtual machine cluster, and the availability of the virtual machine. Compared with the prior art, the method for evaluating availability of the cloud computing system can be used for deciding whether to migrate important applications to a cloud platform, and evaluating the availability of various applications based on a cloud computing platform, thereby having strong practicability.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD +1

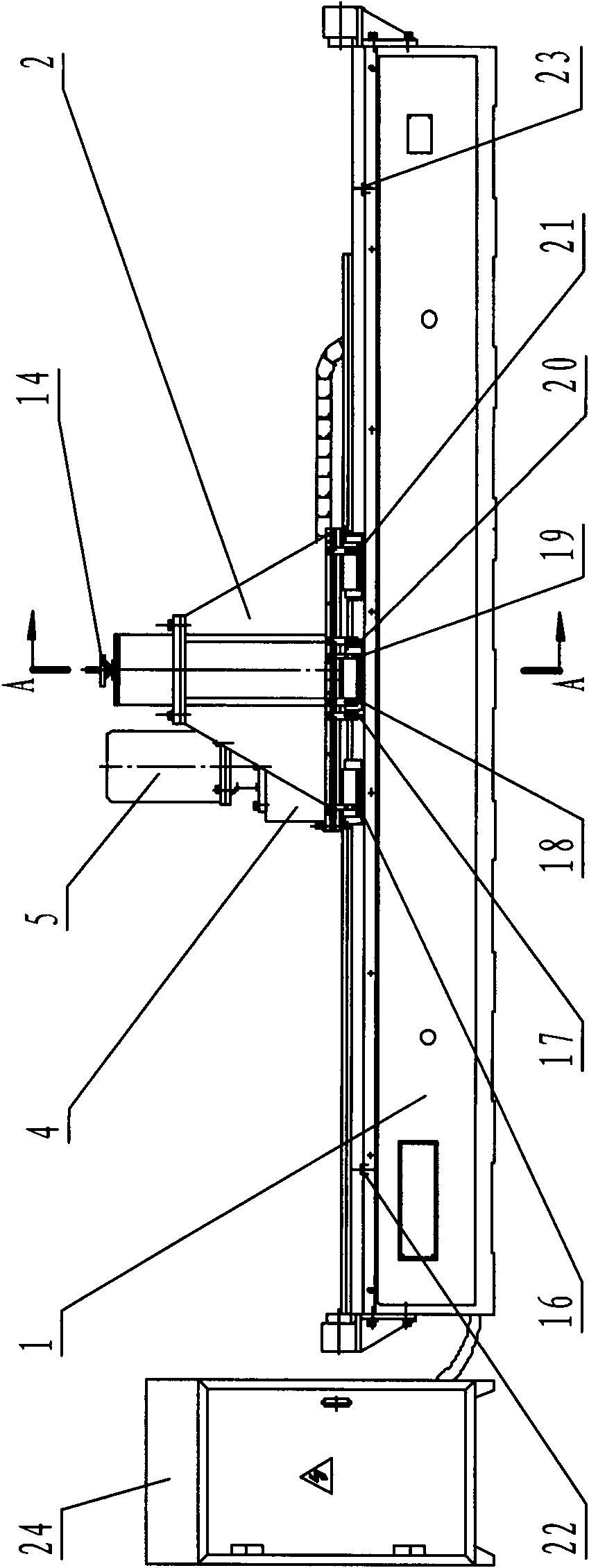

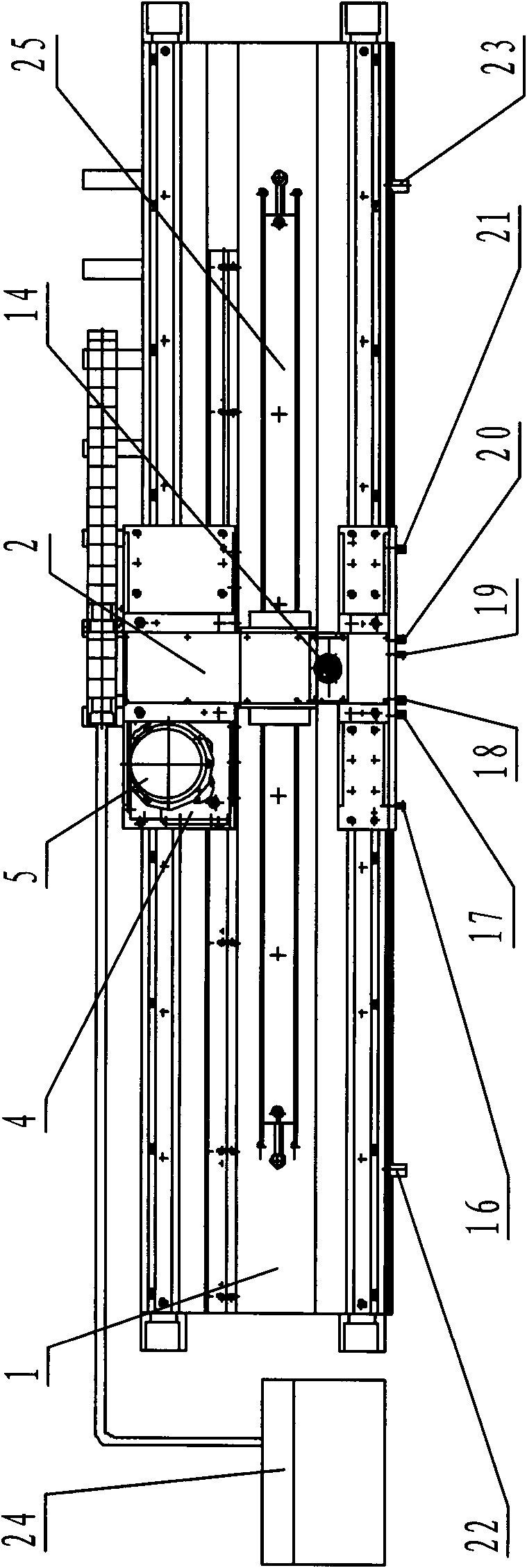

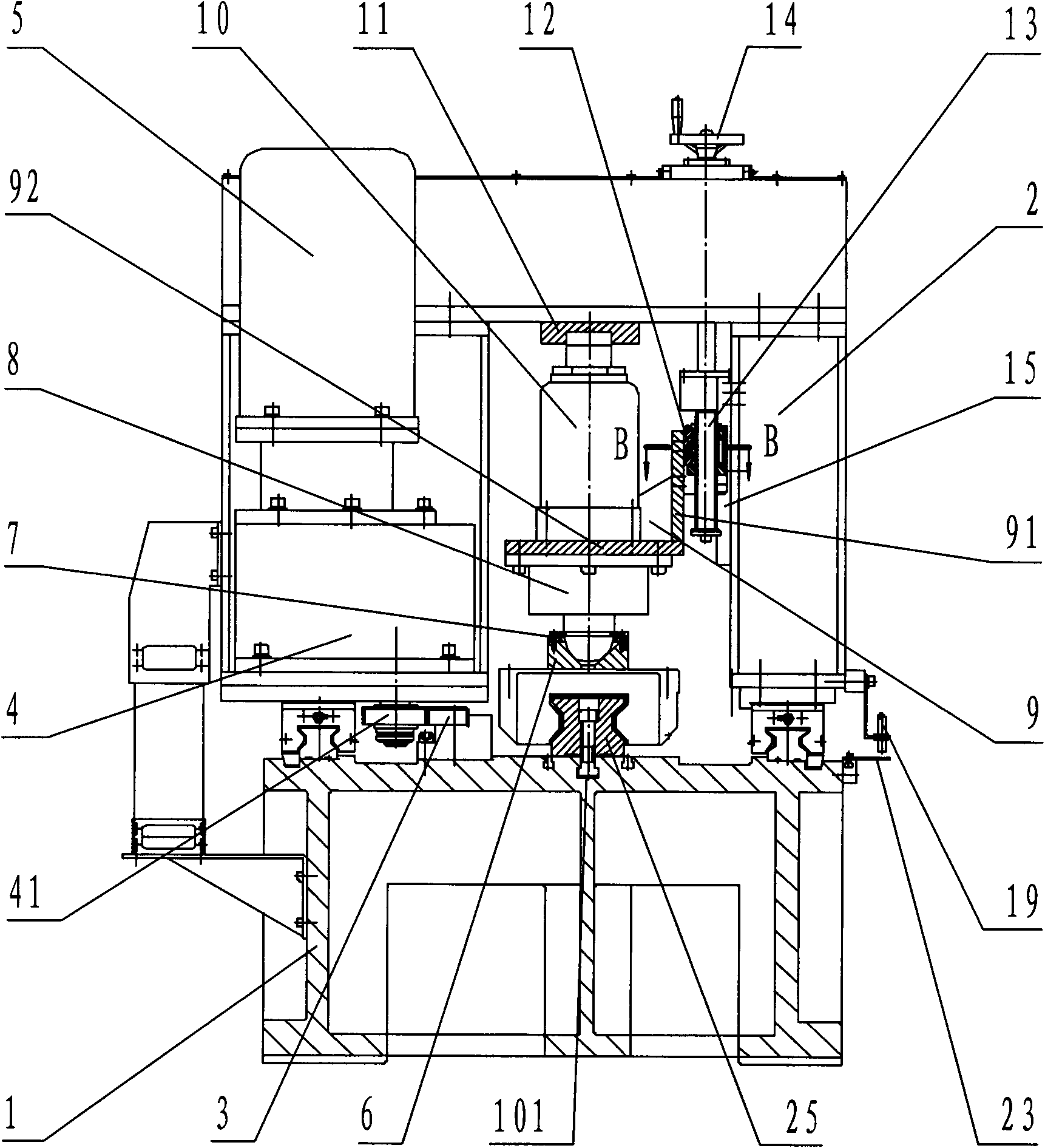

Rolling straight-line guide rail pair reliability tester

The invention discloses a rolling straight-line guide rail pair reliability tester, which comprises a lathe bed and a horizontal moving portal frame located on the lathe bed. A rack parallel to a portal frame moving guide rail is fixedly installed at the position slightly at the back on the table surface of the lathe bed, and the length of the rack is approximately equal to that of the lathe bed. A gear shift mechanism is disposed on one side of a rear column of the portal frame, and a gear at the output shaft end of the gear shift mechanism is meshed with the rack. A loading mechanism capable of going up and down is arranged on a front column of the portal frame and used for applying load to a detected rolling straight-line guide rail pair. The gear shift mechanism and electric appliance parts in the loading mechanism are connected with a control cabinet circuit with a digital display instrument. The rolling straight-line guide rail pair reliability tester is capable of measuring the number of times of running-in of the rolling straight-line guide rail pair on the conditions of high speed and heavy load and also capable of measuring indexes of linear speed, rated dynamic load, static load, mean cycles between failures and the like, simple in structure, convenient to install, reliable in loading and accurate in testing.

Owner:陕西汉江机床有限公司

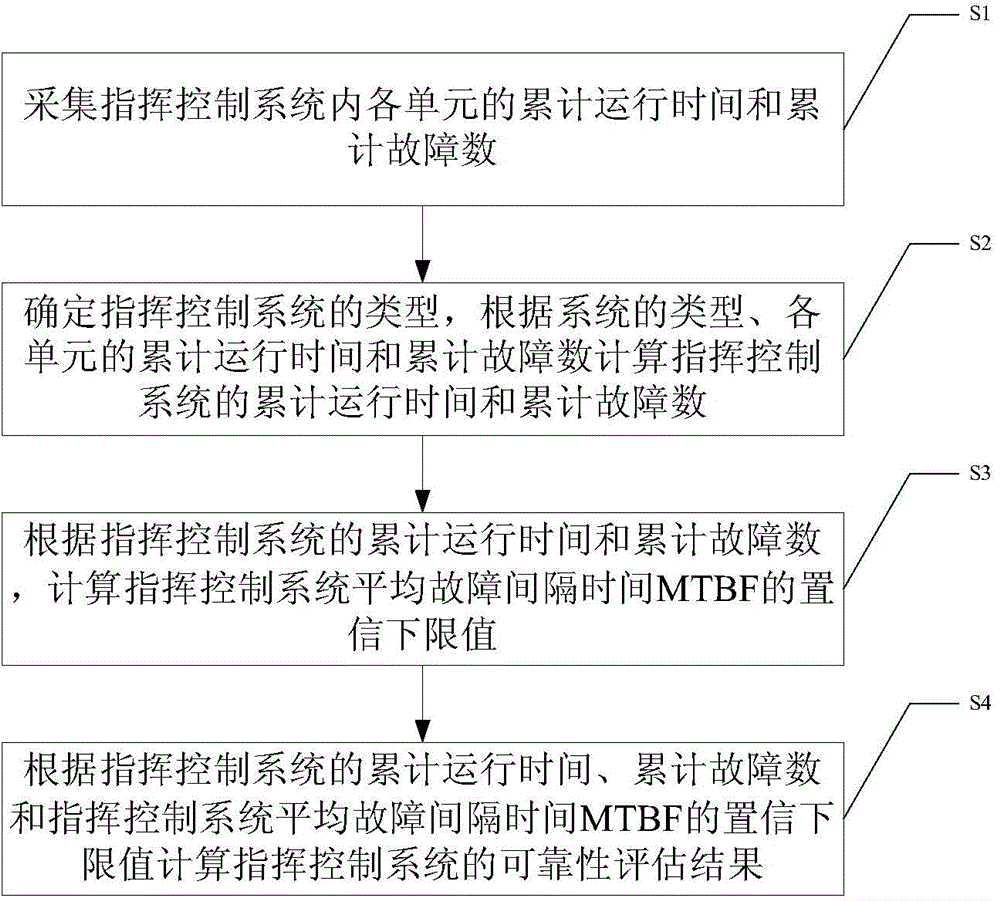

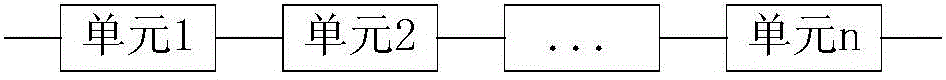

Method for evaluating reliability of command and control system

InactiveCN105787247AShorten assessment timeImprove evaluation efficiencySpecial data processing applicationsLower limitControl system

The invention discloses a method for evaluating the reliability of a command and control system. The method comprises the following steps of: acquiring the accumulated operation time and the accumulated failure number of various units in the command and control system; determining the type of the command and control system, and calculating the accumulated operation time and the accumulated failure number of the command and control system according to the type of the system and the accumulated operation time and the accumulated failure number of various units; calculating a lower confidence limit of the mean time between failures MTBF of the command and control system according to the accumulated operation time and the accumulated failure number of the command and control system; and calculating a reliability evaluation result of the command and control system according to the accumulated operation time and the accumulated failure number of the command and control system and the lower confidence limit of the mean time between failures MTBF of the command and control system. Compared with the before evaluation method, the technical scheme provided in the invention has the advantages that: the evaluation time is shortened; the evaluation efficiency is increased; and furthermore, by means of the reliability evaluation result, objective basis is provided for determining whether the reliability of the command and control system satisfies requirements or not.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

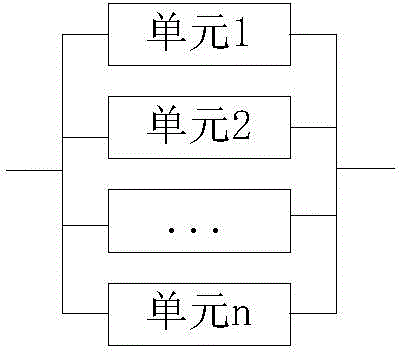

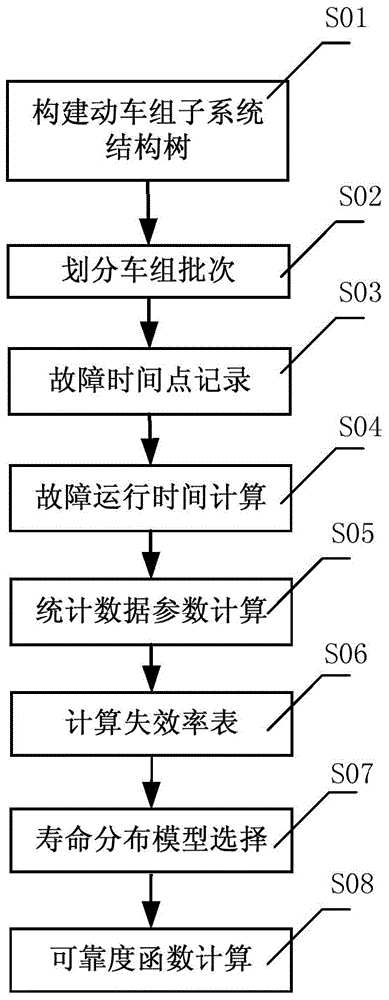

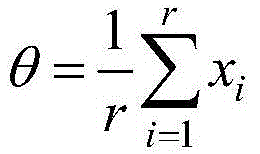

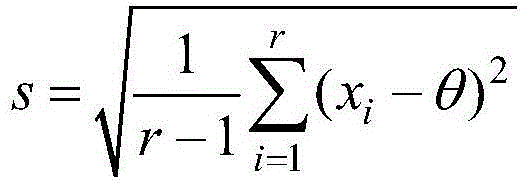

Application reliability assessment method of key component of multiple units subsystem

ActiveCN104899423ASolve the problem of lack of reliability analysis for online applicationsImprove accuracySpecial data processing applicationsFailure rateSecond order moments

The invention relates to the railway vehicle security field, and specifically relates to an application reliability assessment method of a key component of a multiple units subsystem. The method mainly comprises: establishing a multiple units subsystem structure tree and preprocessing field data to obtain failure interval mileage data; calculating the mean value, the variance, the second-order moment, the third-order moment, the fourth-order moment, the skewness Cs, the kurtosis Ce, and the average failure rate of acquired samples, and the skewness Cs' and the kurtosis Ce' of log-transformed samples; determining a component life distribution and a parameter estimation algorithm; and calculating the mean time between failures and the reliability. According to the invention, actual operation data of multiple units is effectively processed, and operation reliability estimation is performed on components of the multiple units, thus solving the problem of the lack of online application reliability analysis of multiple units. Meanwhile, the multiple units key component operation reliability assessment method based on field data of the invention is also applicable to operation reliability analysis of other railway vehicle components.

Owner:TONGJI UNIV

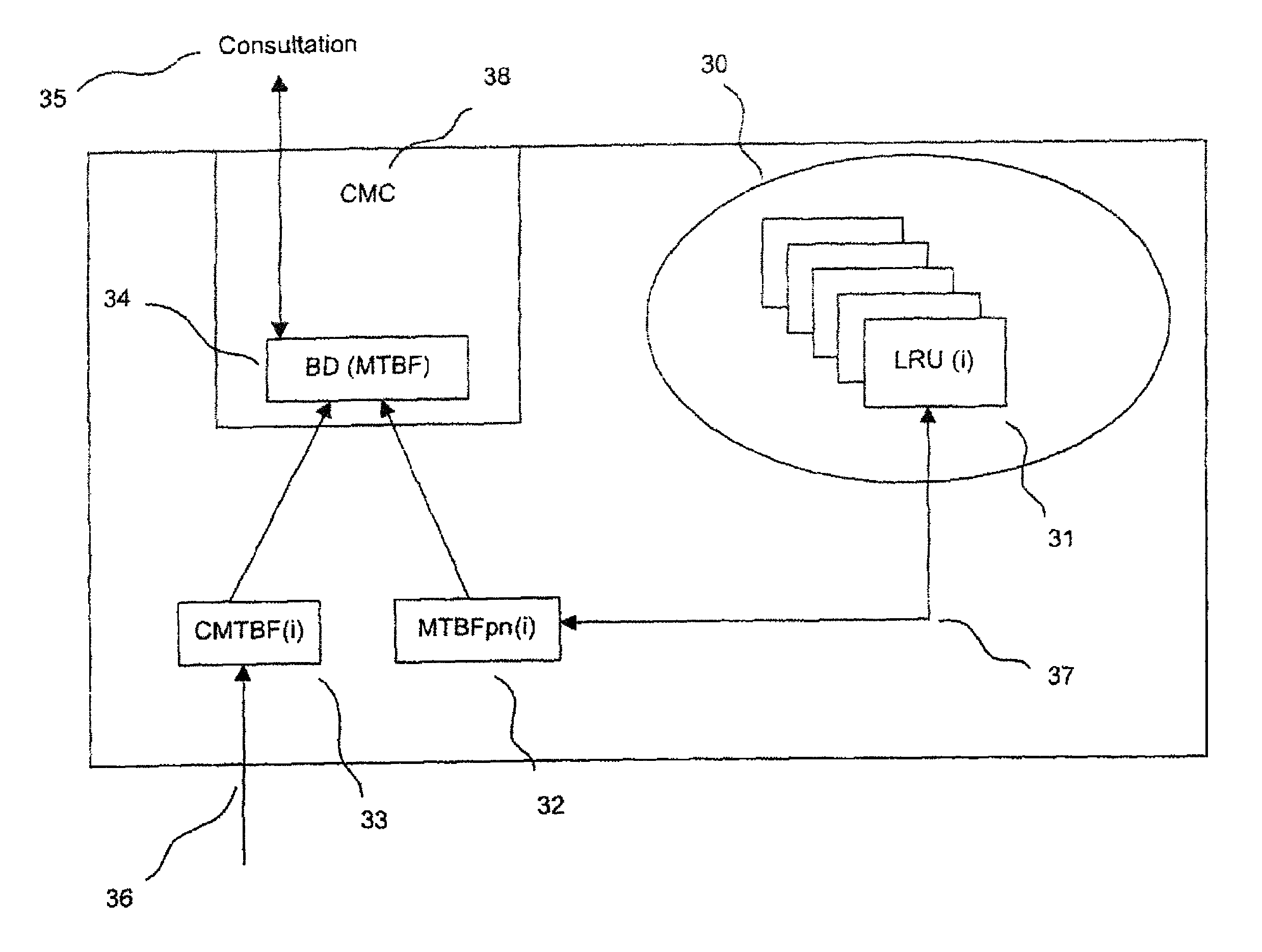

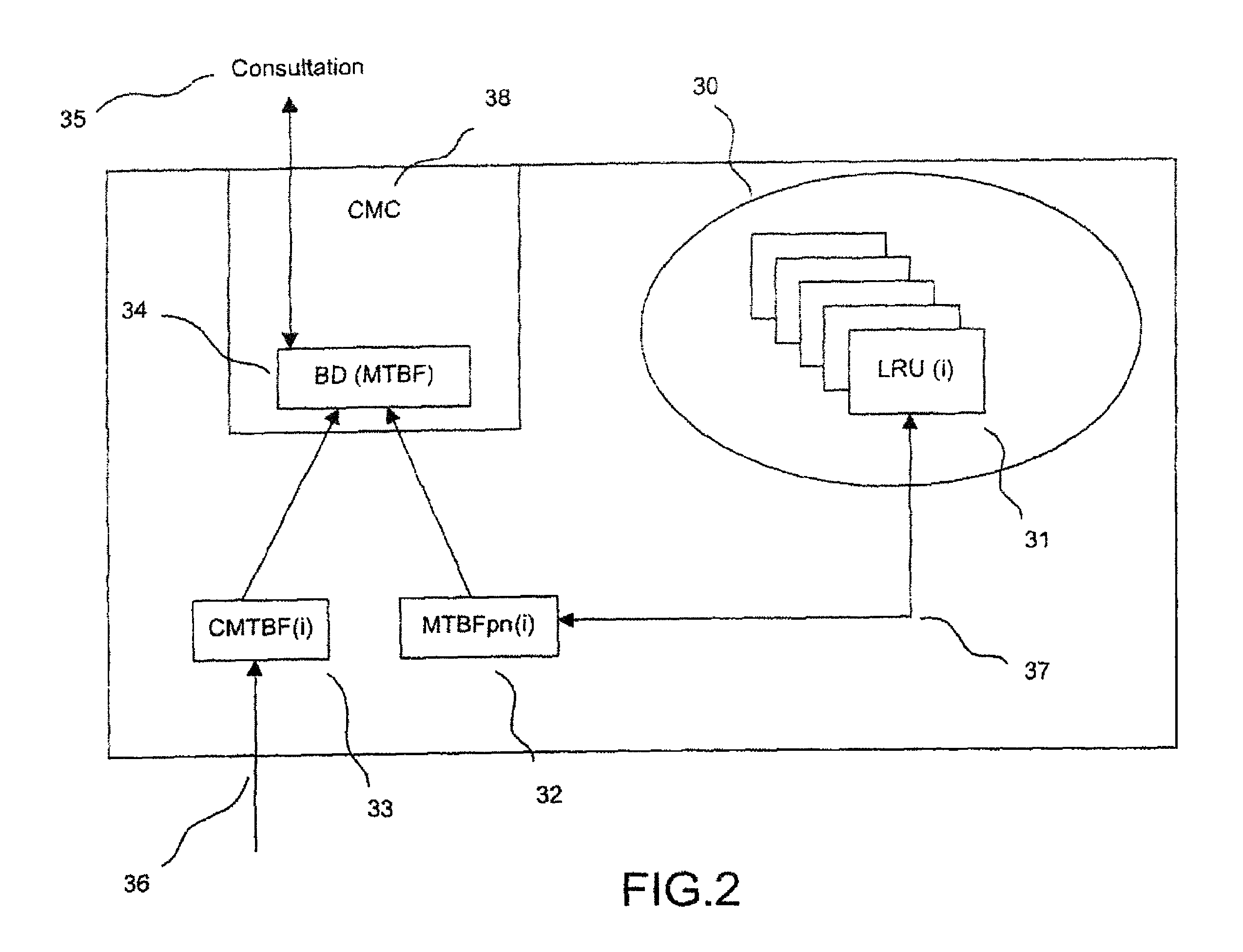

System for centralized maintenance of onboard electronic equipment

InactiveUS7809527B2Registering/indicating working of vehiclesDigital computer detailsDigital dataComputer science

A centralized maintenance system for aircraft which includes line replacement units (LRUs). The system includes at least one digital database whose data are information relating to the LRUs; and a device for updating the data of the database. The lifetime information for the LRUs is known and contained in the digital database. The database includes a mean time between failure (MTBF) data of each LRU. The MTBF data is able to be modified and updated, according to at least one event modifying the failure probabilities for at least one LRU.

Owner:THALES SA

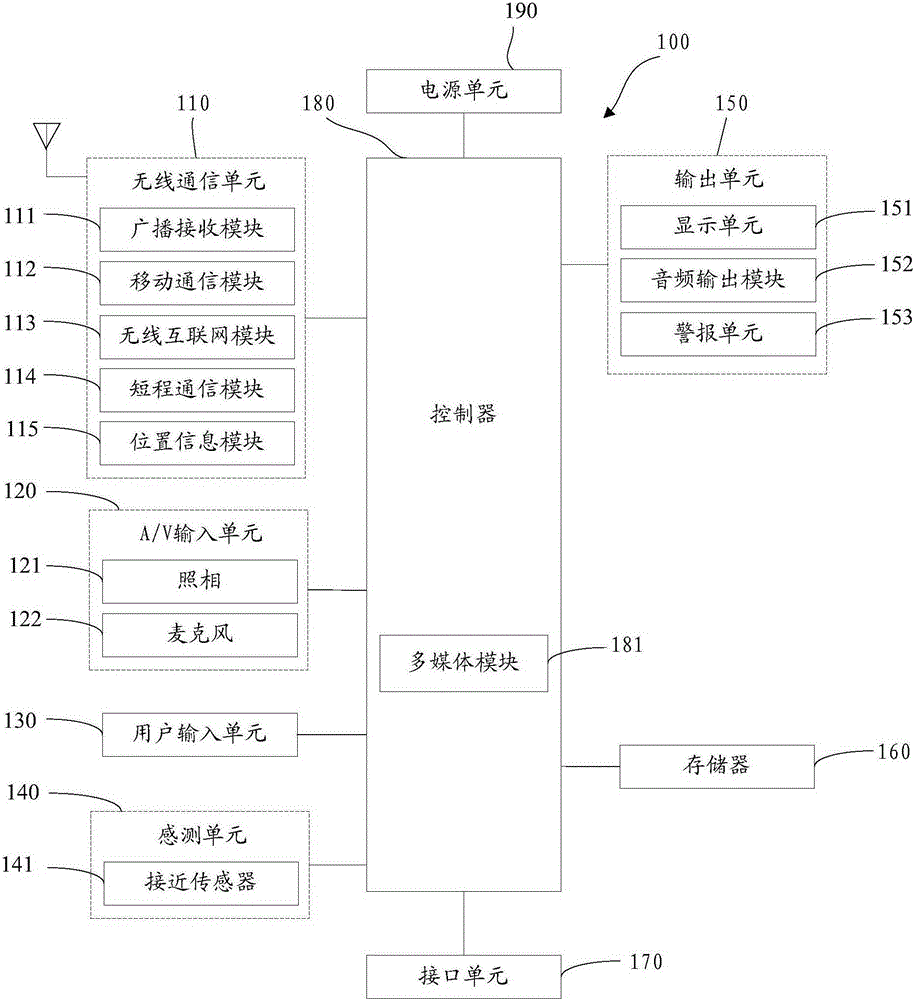

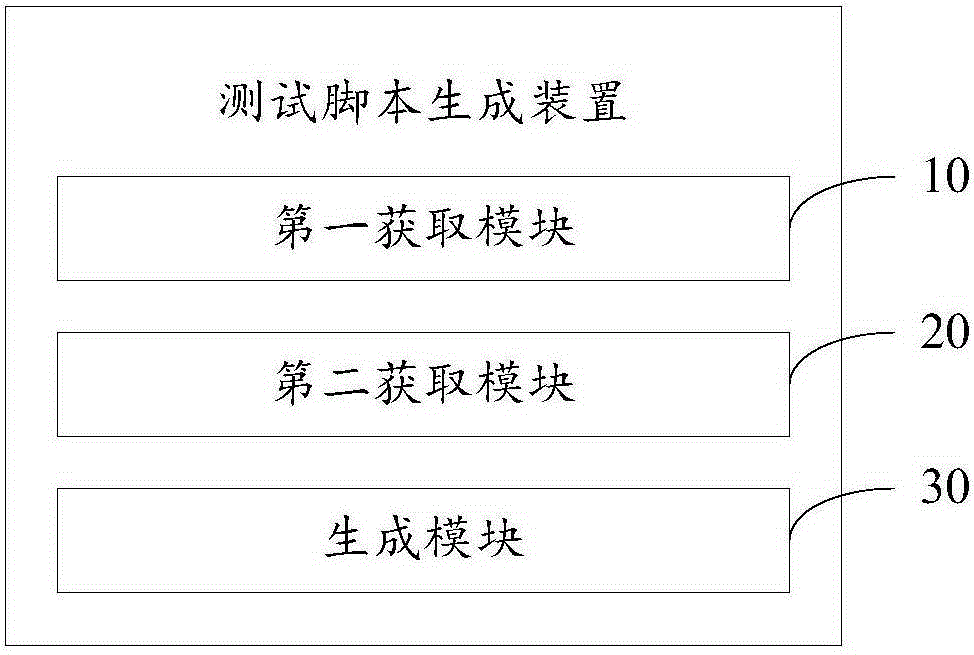

Test script generating device and method

InactiveCN105204992AImprove writing efficiencyRealize artificial motion simulationSoftware testing/debuggingTest scriptSoftware engineering

The invention discloses a test script generating device. The test script generating device comprises a first acquisition module, a second acquisition module and a generation module, wherein the first acquisition module is used for acquiring control instructions corresponding to all test steps in a preset MTBF (mean time between failure) test process; the second acquisition module is used for acquiring identification information of executive controls of the control instructions on the basis of a Uiautomator frame; the generation module is used for generating a test script of the preset MTBF test process according to the control instructions of the preset MTBF test process and the identification information of the executive controls of the control instructions. The invention further discloses a test script generating method. The writing efficiency of the test script can be improved.

Owner:NUBIA TECHNOLOGY CO LTD

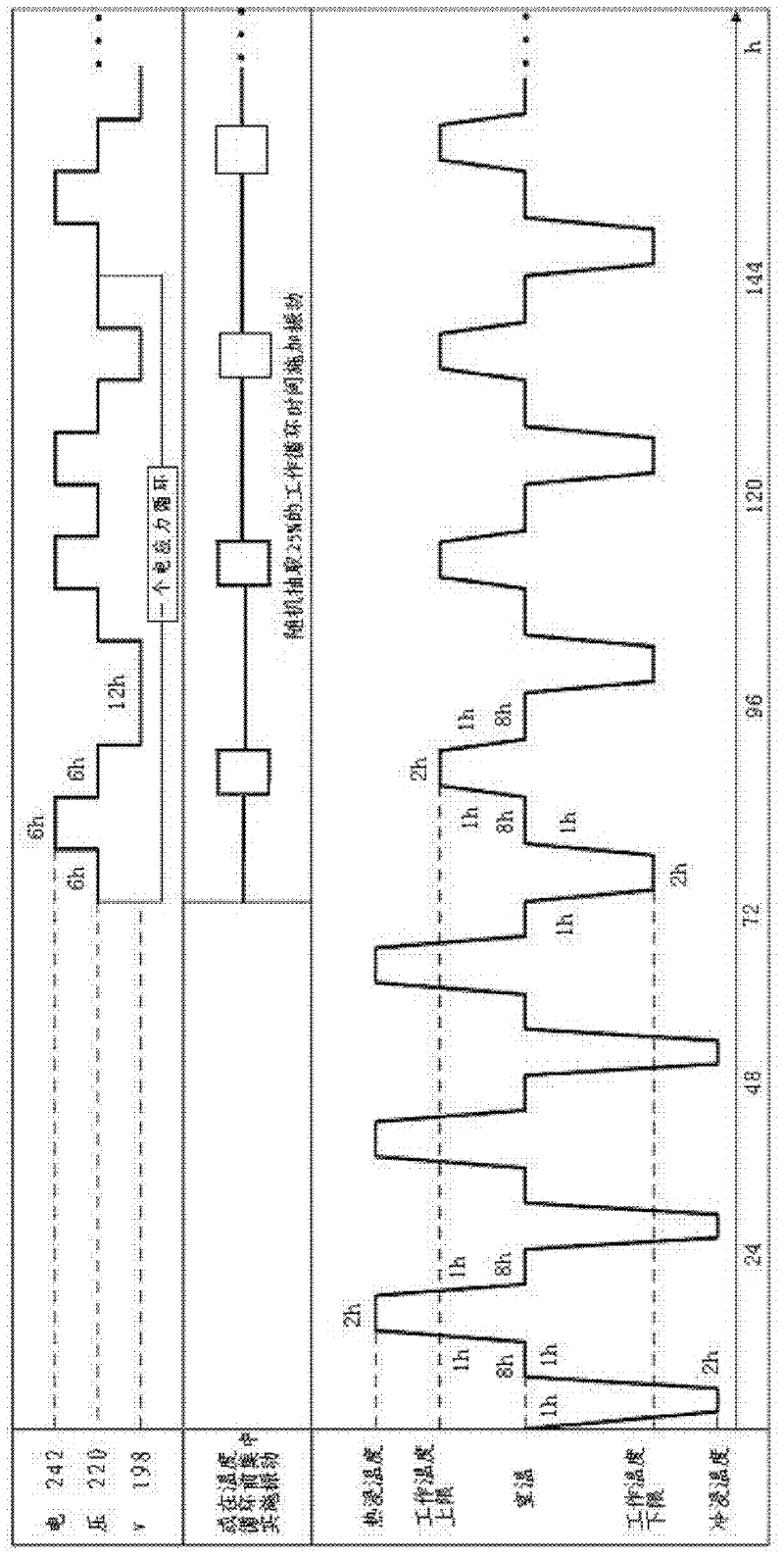

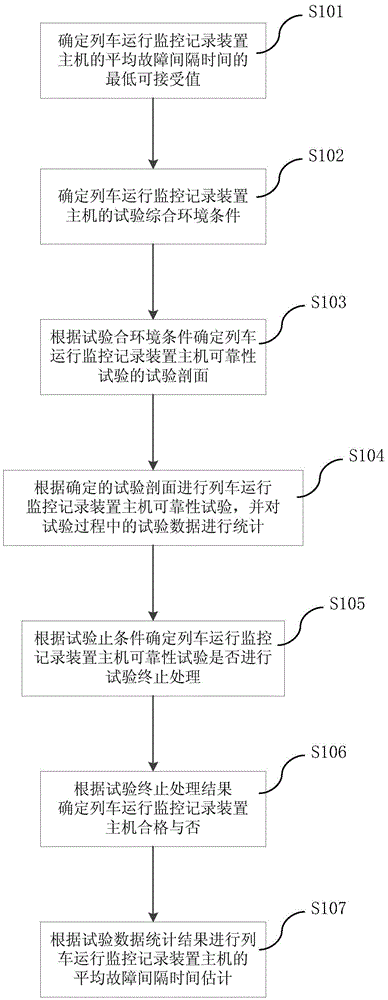

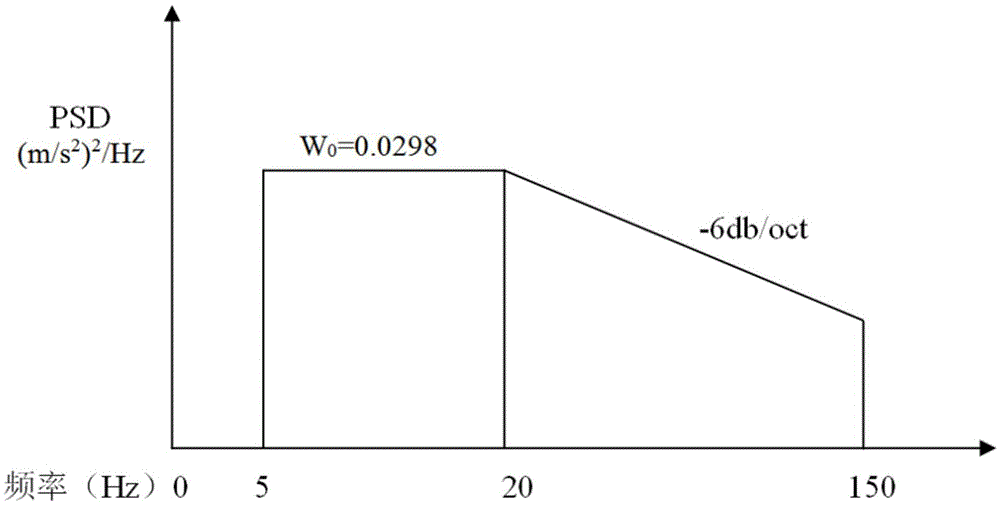

Train running monitoring record device host reliability test method

ActiveCN106681296AIdentification solutionMTBF value is accurateRegistering/indicating working of vehiclesElectric testing/monitoringDependabilityMean time between failures

The invention discloses a train running monitoring record device host reliability test method. The method comprises the following steps: determining the minimum acceptable value of mean time between failures of a train running monitoring record device host; determining the test comprehensive environment conditions of the host; determining a test profile according to the test comprehensive environment conditions; testing the reliability of the host according to the test profile, and doing statistics of test data; determining whether the test is terminated according to test termination conditions, and determining whether the host is qualified or not according to the test termination processing result; and finally, estimating the mean time between failures of the train running monitoring record device host according to the test data statistics result. The technical problem on how to identify the reliability index of a train running monitoring record device host quickly and effectively can be solved.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

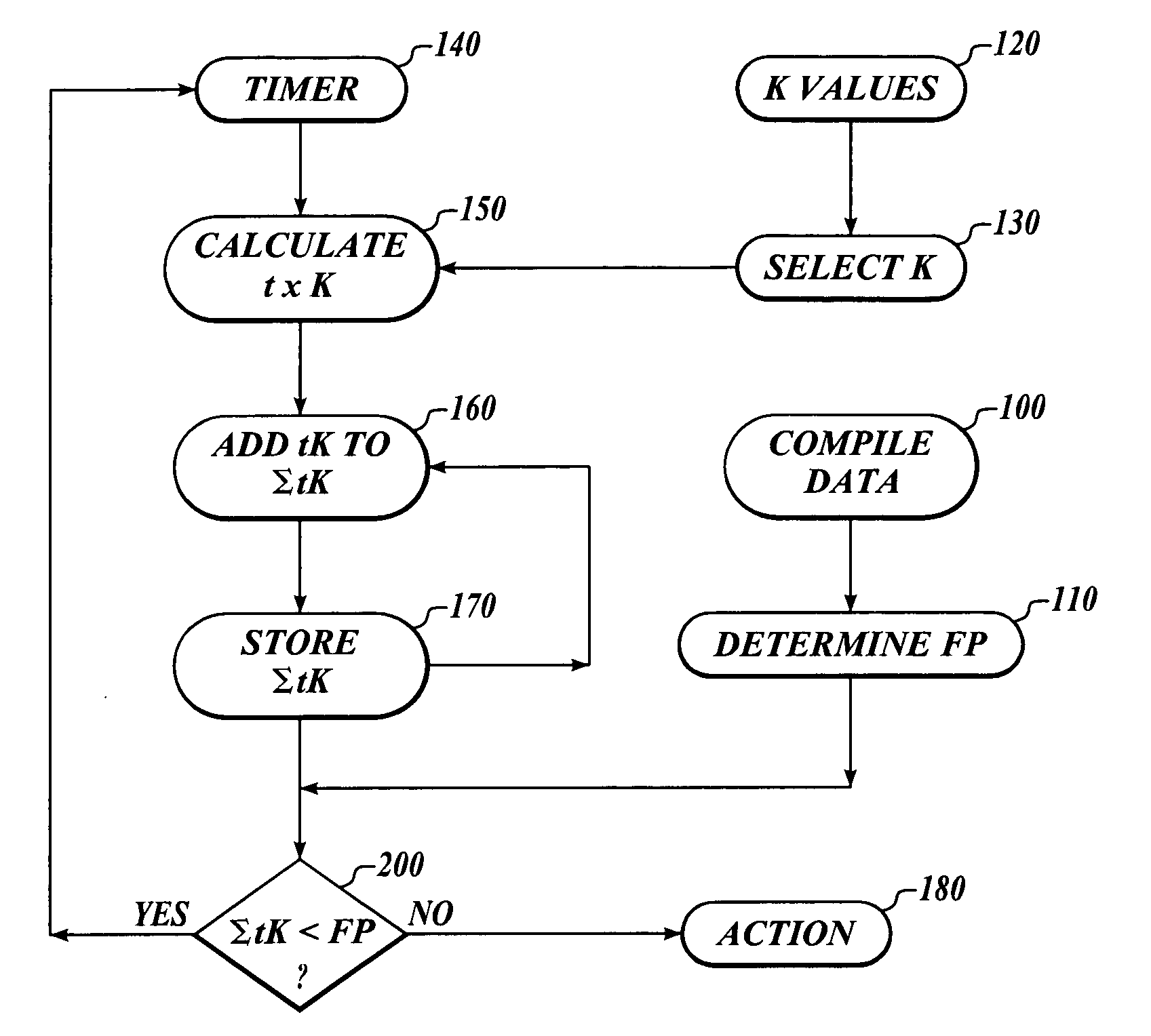

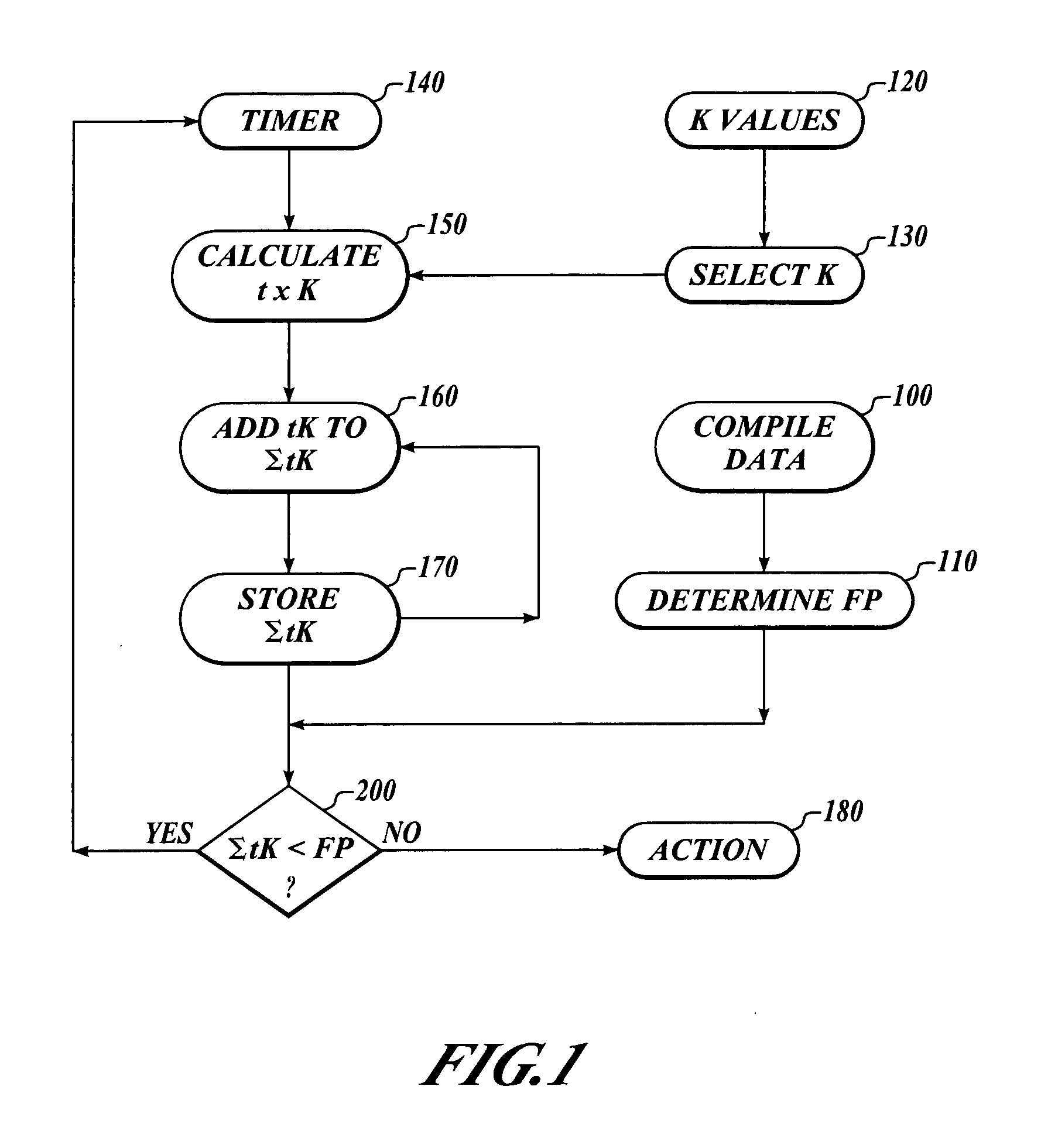

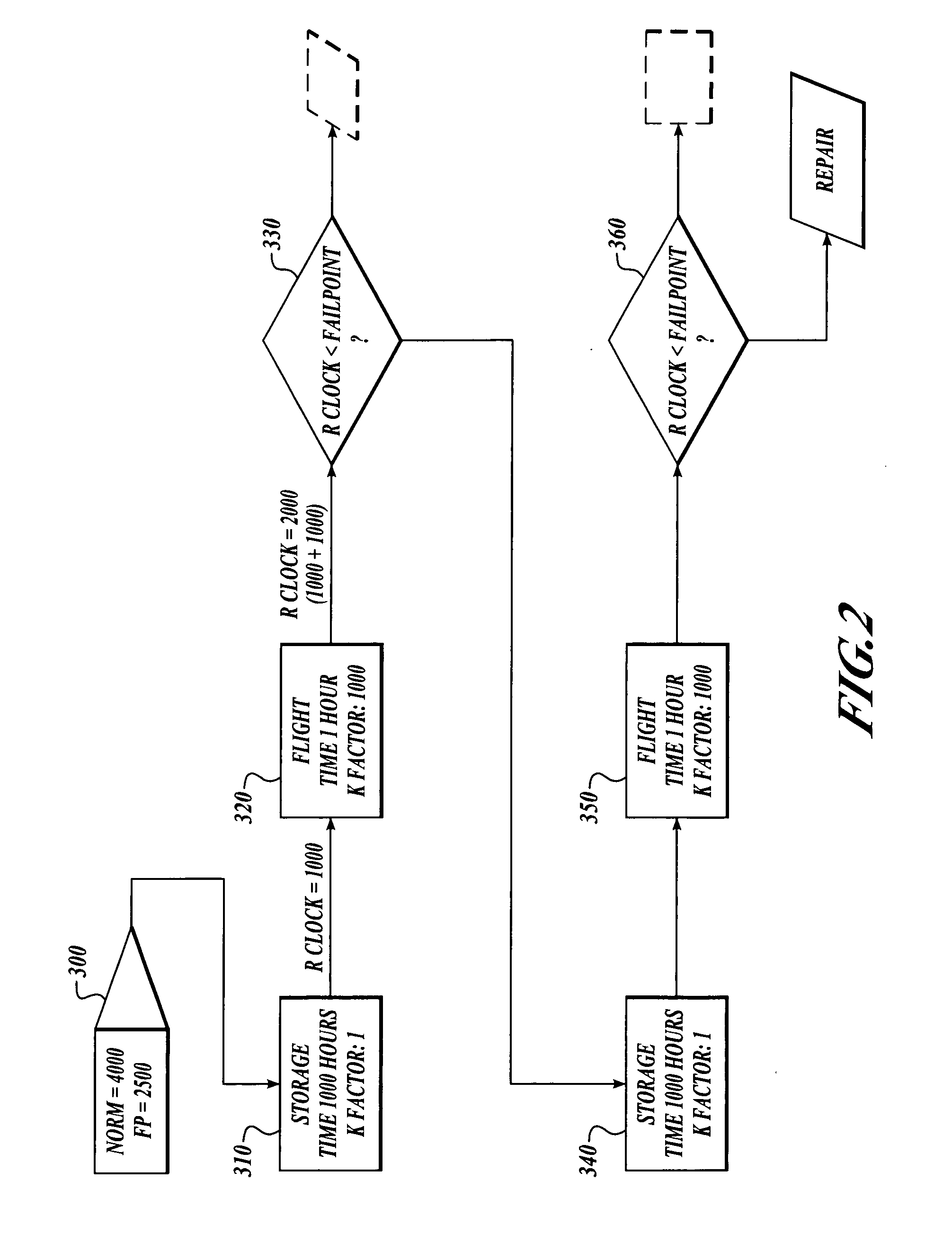

Lifecycle support software tool

InactiveUS20050171732A1Reduce supporting costsCostNuclear monitoringDigital computer detailsFailure rateComputer science

The invention provides a simulation process and method of utilizing it to time to better estimate when a component of a product is about to fail by tracking varying “environmental factors” related to the severity of conditions to which product is exposed over a period of time. The invention includes the steps of: (a) determining a distribution of mean times between failures or failure rate for each component of the product; (b) using statistical techniques to select a fail point for each component; (c) applying an aging factor for each component for conditions to which the product is subjected; and (d) calculating an estimated time for failure for a component using information comprising time periods the component was subjected to conditions, and aging factors relating to the conditions.

Owner:THE BOEING CO

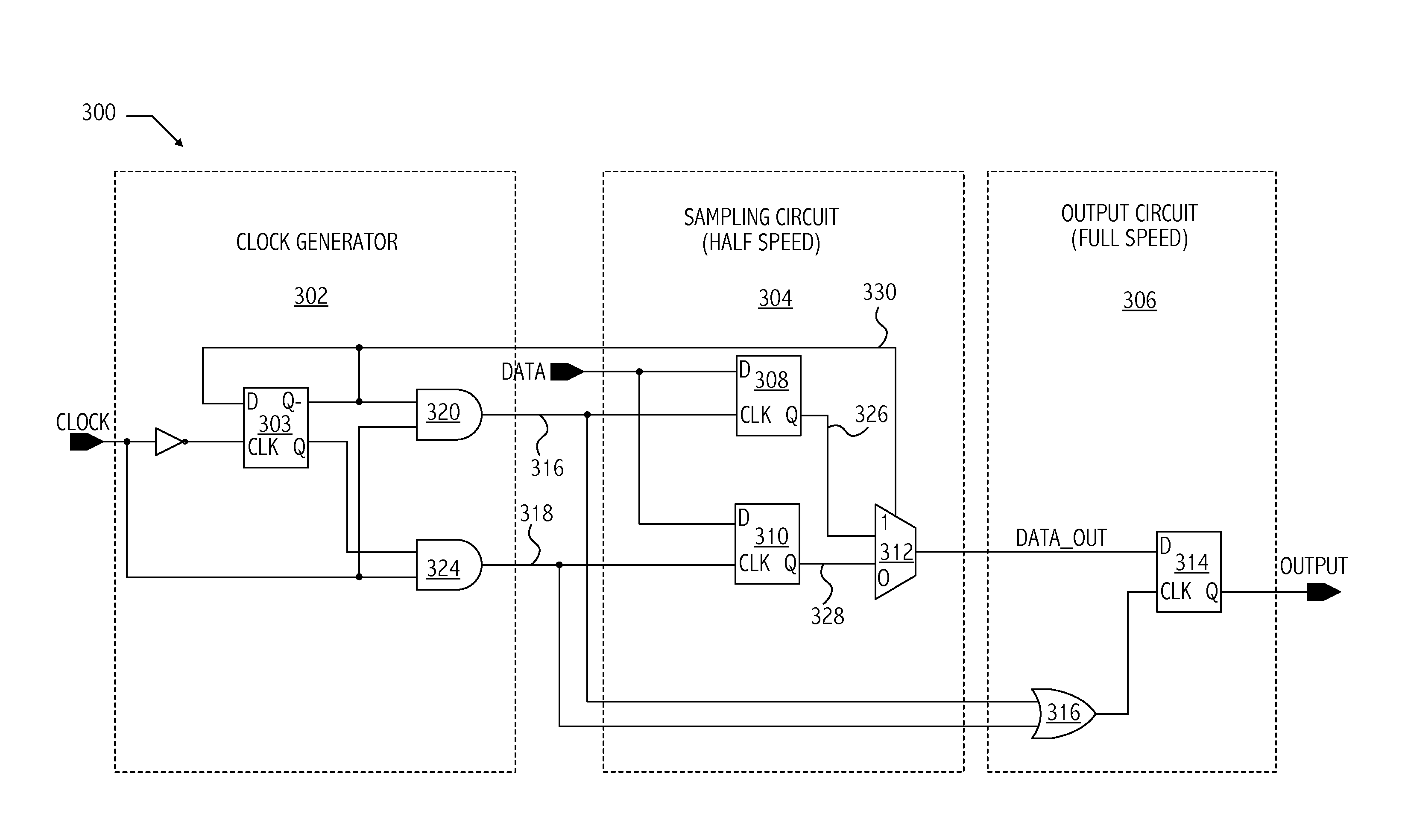

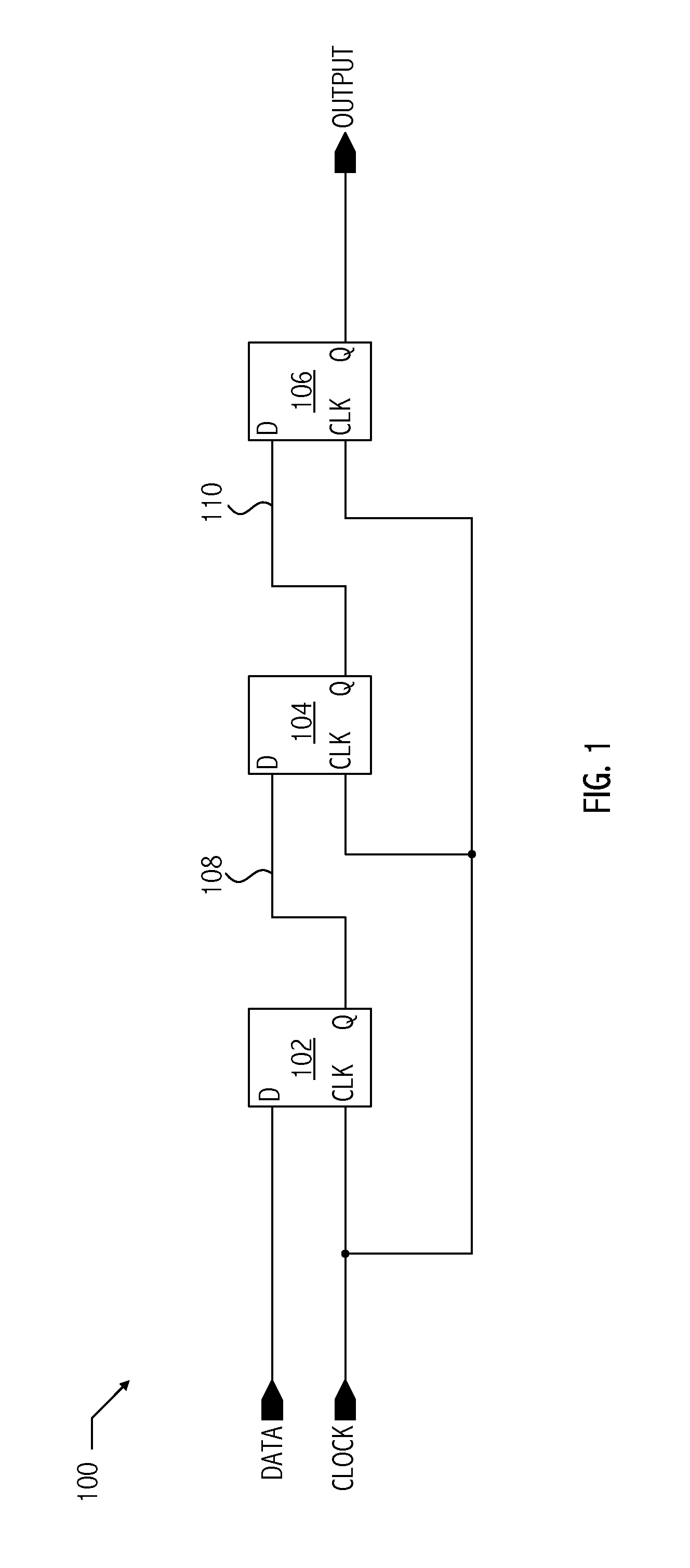

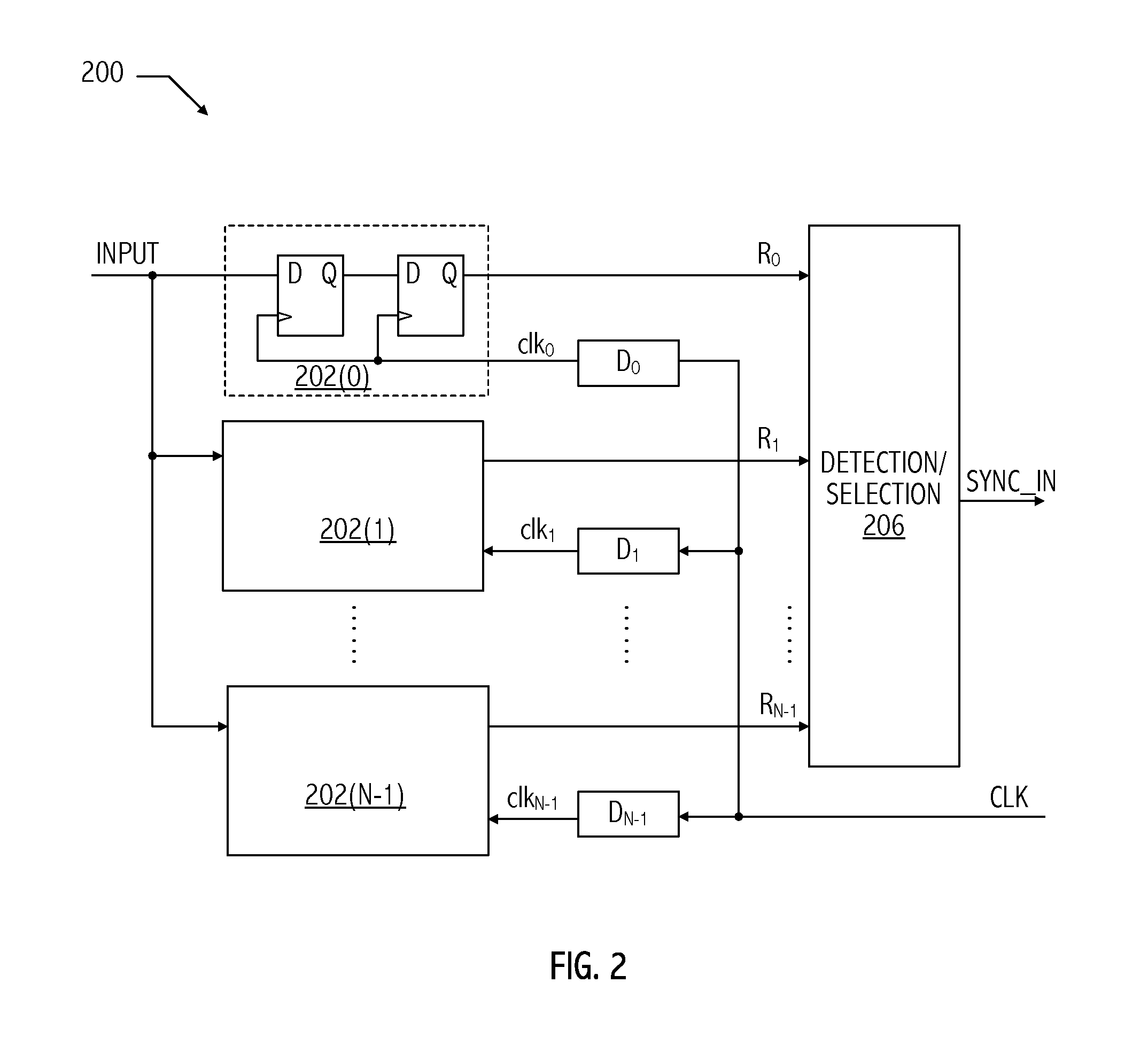

Parallel synchronizing cell with improved mean time between failures

In some embodiments, a synchronizing circuit includes at least one synchronization device that operates at a lower clock frequency than another synchronization device in the synchronization circuit. In at least one embodiment of the invention, a method includes sampling a first signal at a first frequency to thereby generate a plurality of sampled versions of the first signal. The first frequency is a frequency of a clock signal divided by N. N is a number greater than one. The method includes sampling a second signal at the frequency of the clock signal. The second signal is based on sequentially selected ones of the plurality of sampled versions of the first signal to thereby generate an output version of the first signal.

Owner:ATI TECH INC

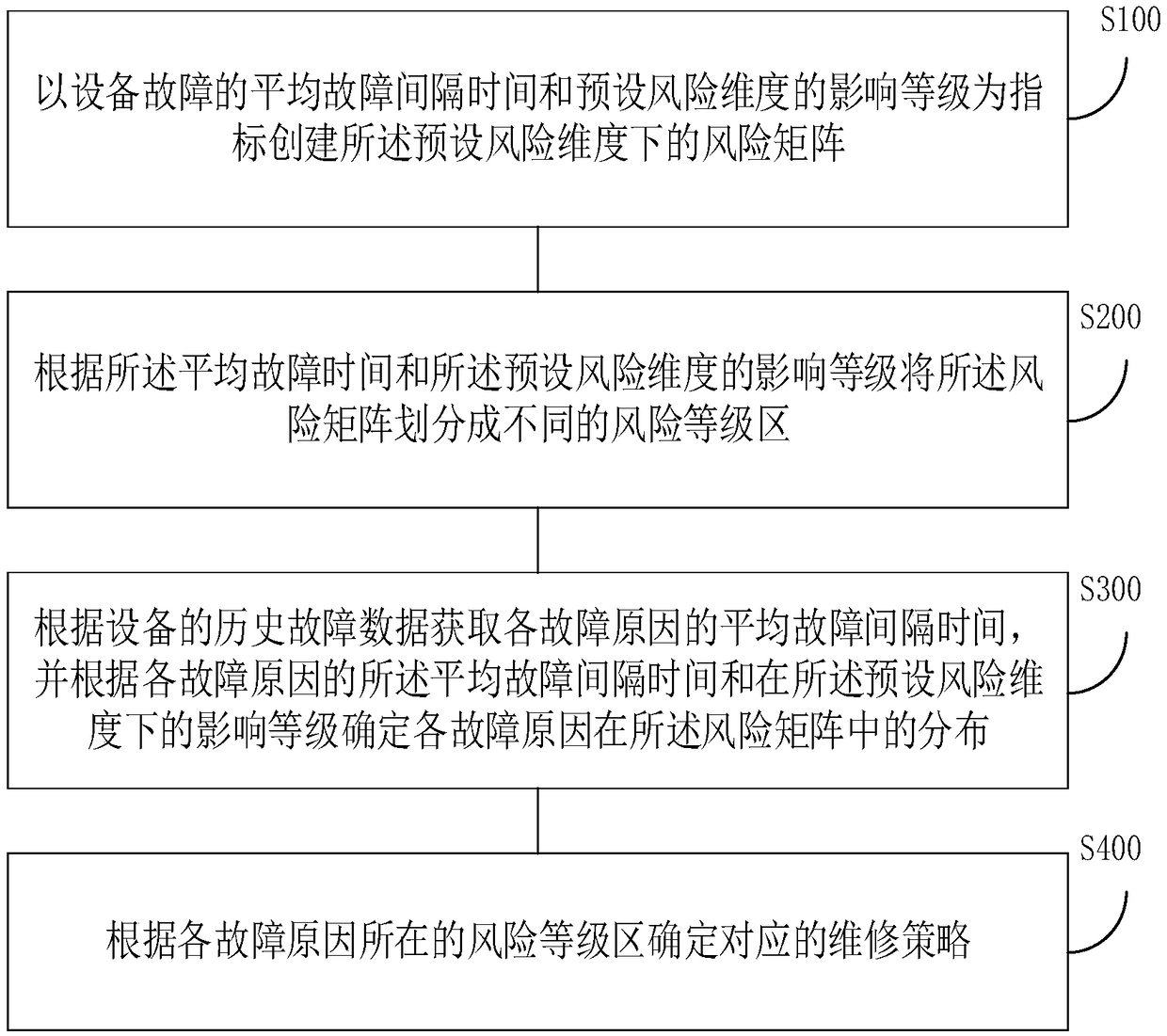

Maintenance policy formulation method, terminal and computer storage medium

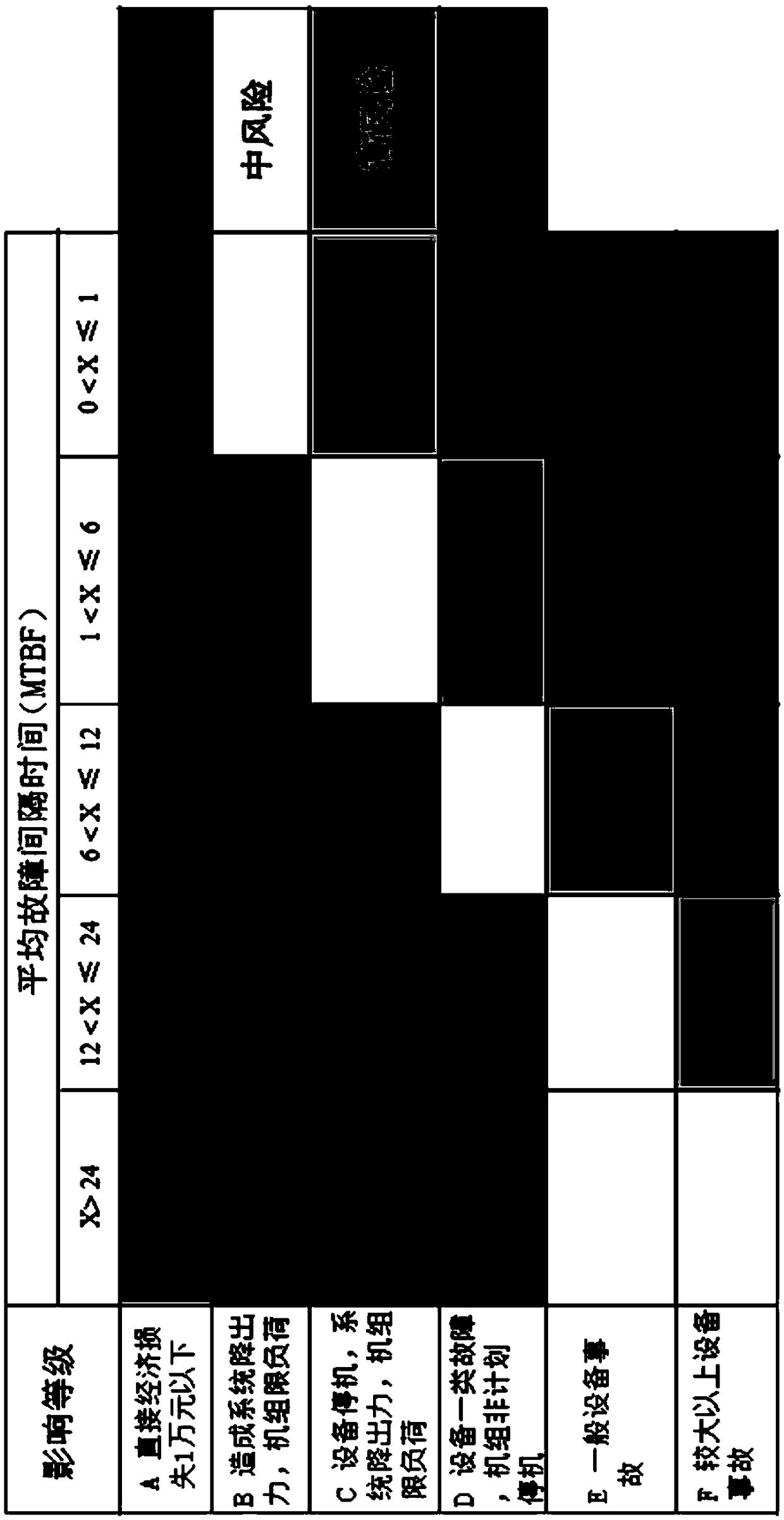

InactiveCN109376882AReduce the risk of failureOptimization StrategyResourcesMaintenance strategyComputer terminal

The invention discloses a maintenance strategy formulation method, a terminal and a computer storage medium. The method comprises the following steps: a risk matrix under a preset risk dimension is created by taking an average failure interval time of equipment failure and an influence grade of a preset risk dimension as indexes; The risk matrix is divided into different risk grade areas accordingto the mean failure time and the impact grade. According to the historical fault data of the equipment, the average fault interval time of each fault cause is obtained, and its distribution is determined according to the average fault interval time of each fault cause and the influence grade. According to the technical scheme of the invention, By establishing a risk matrix to visually display thecorresponding relationship between equipment risk and each fault cause, the risk sequence of each fault cause can be made clear and the corresponding maintenance strategy can be formulated, and whether the maintenance strategy of each fault cause is overhauled or not can be evaluated, so that the maintenance strategy can be optimized accordingly, and the limited maintenance resources can be reasonably allocated, and so on.

Owner:华润电力技术研究院有限公司

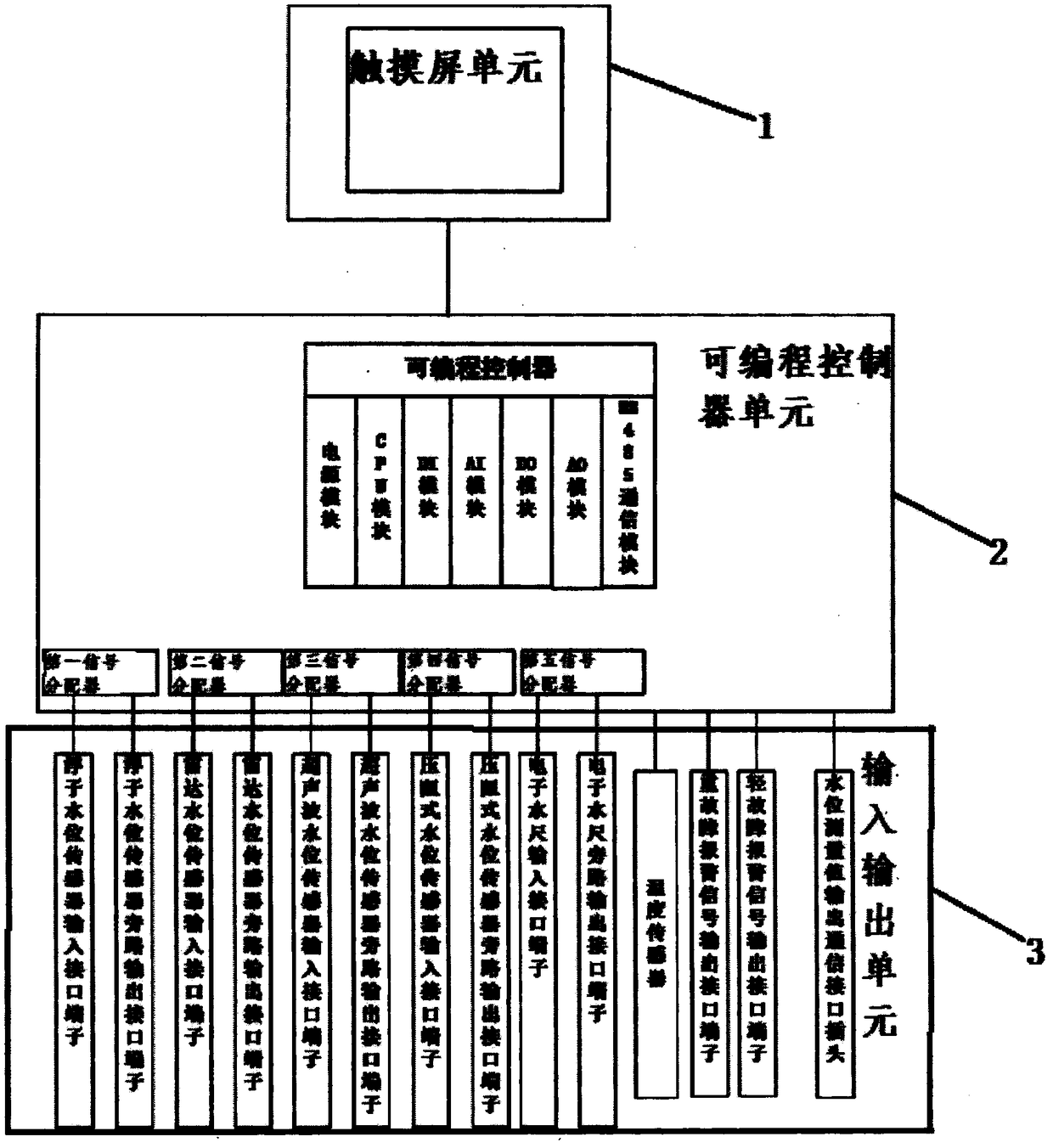

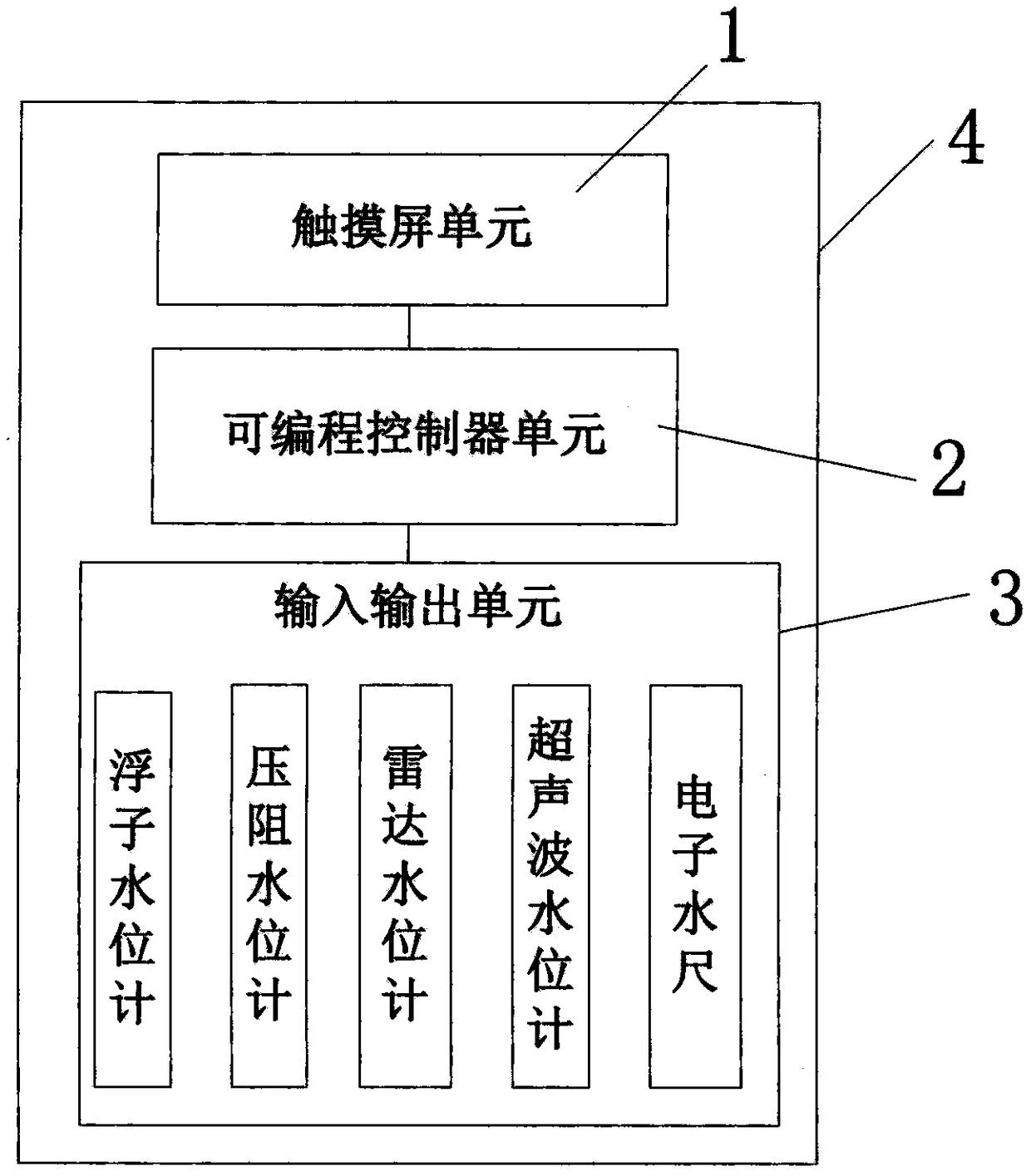

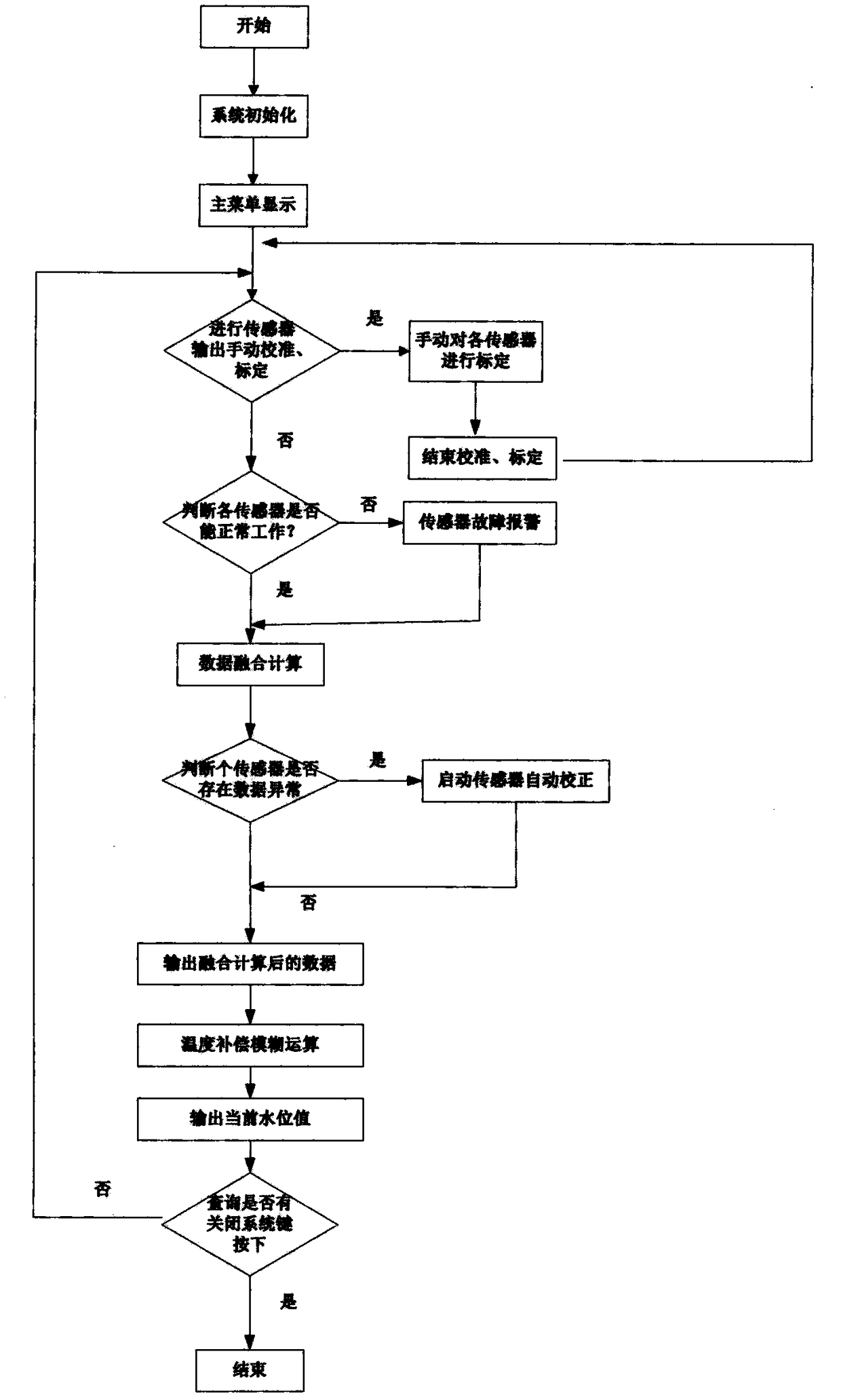

Intelligent water level monitor based on data fusion technology

ActiveCN108287007AHigh measurement accuracyDoes not affect collection workMachines/enginesLubrication indication devicesProgrammable logic controllerMultiple sensor

The invention discloses an intelligent water level monitor based on a data fusion technology. The monitor comprises a touchscreen unit for manually correcting and setting the altitude, upper and lowerlimits of water level, proportion and correcting parameters of an input and output unit and performing warning prompts, a programmable controller unit used for conducting comparison and analysis on the water level monitoring data transmitted by the input and output unit, and the input and output unit used for monitoring water level data. According to the monitor, measurement is sensed simultaneously by using multiple sensor units, the output of the monitor is the calculation value obtained through a data fusion algorithm, and according to an error theory, the measuring accuracy of the water level is significantly improved; a temperature compensation mechanism is introduced, which can reduce measuring errors brought by temperature variations; by means of the monitor, a malfunctioned waterlevel sensor can be intelligently recognized, and automatic calibration and correction can be conducted on the water level sensor, so that mean time between failures of water level monitoring equipment is increased and operation and maintenance workloads are reduced.

Owner:山东省水利勘测设计院有限公司

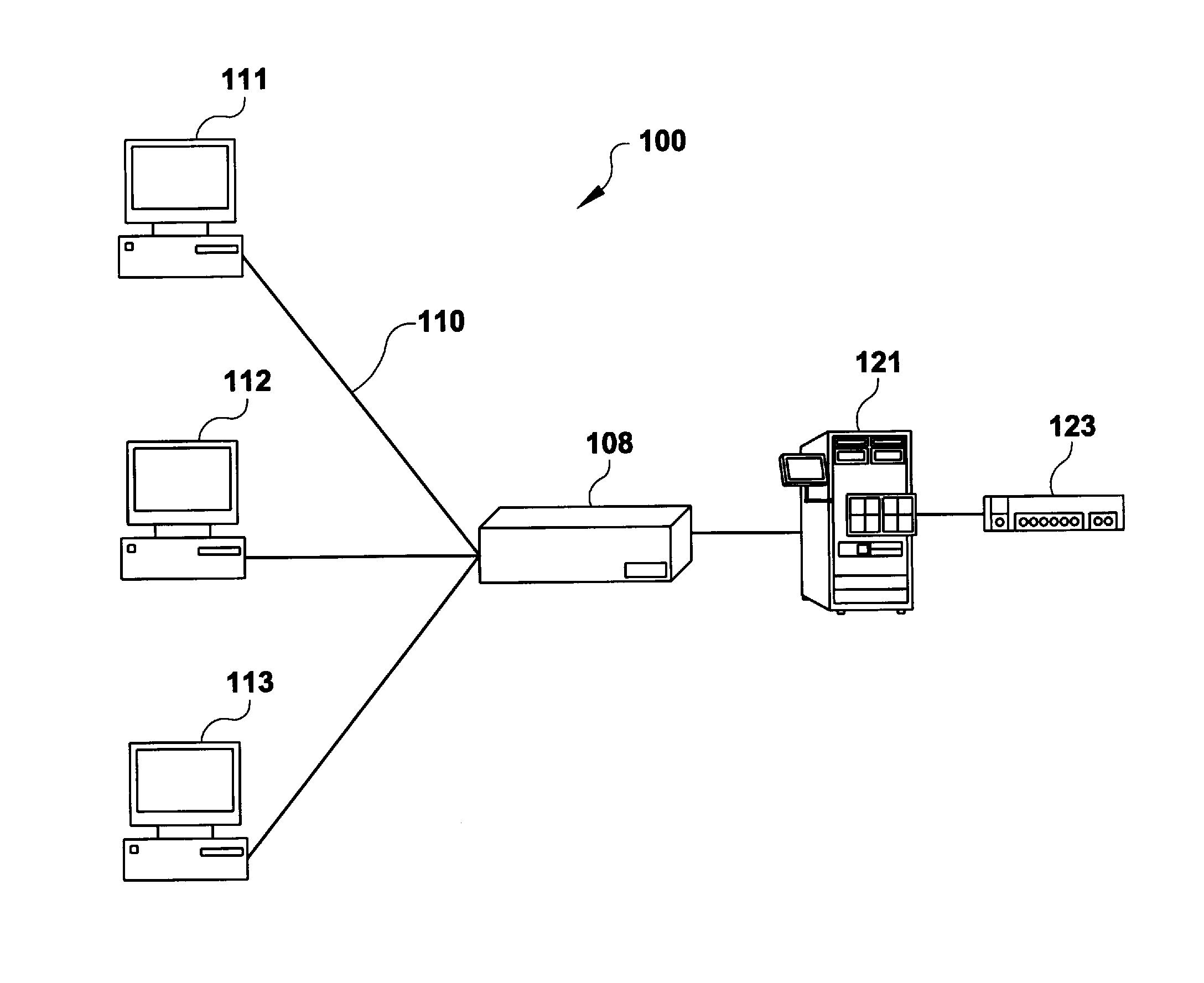

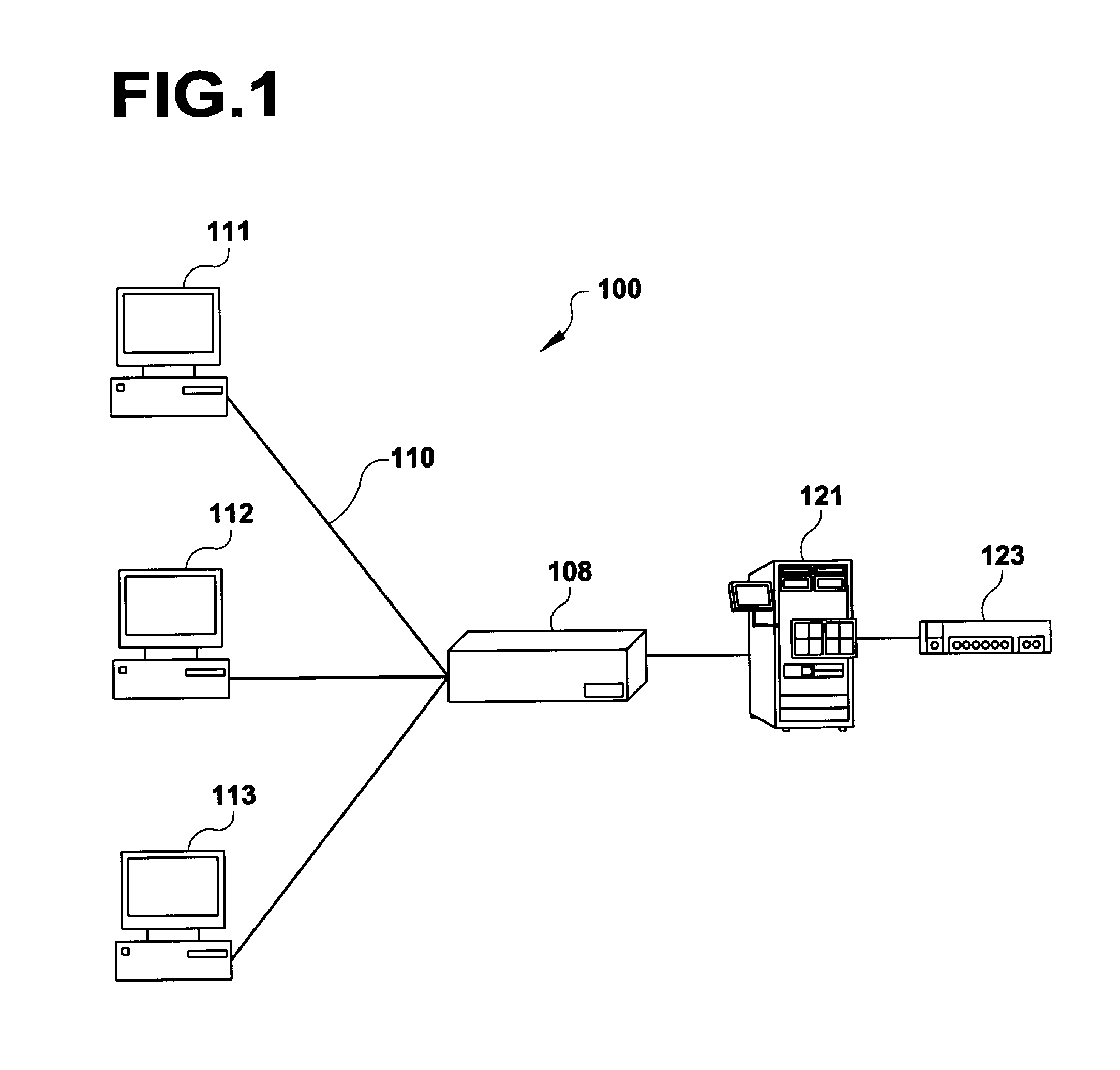

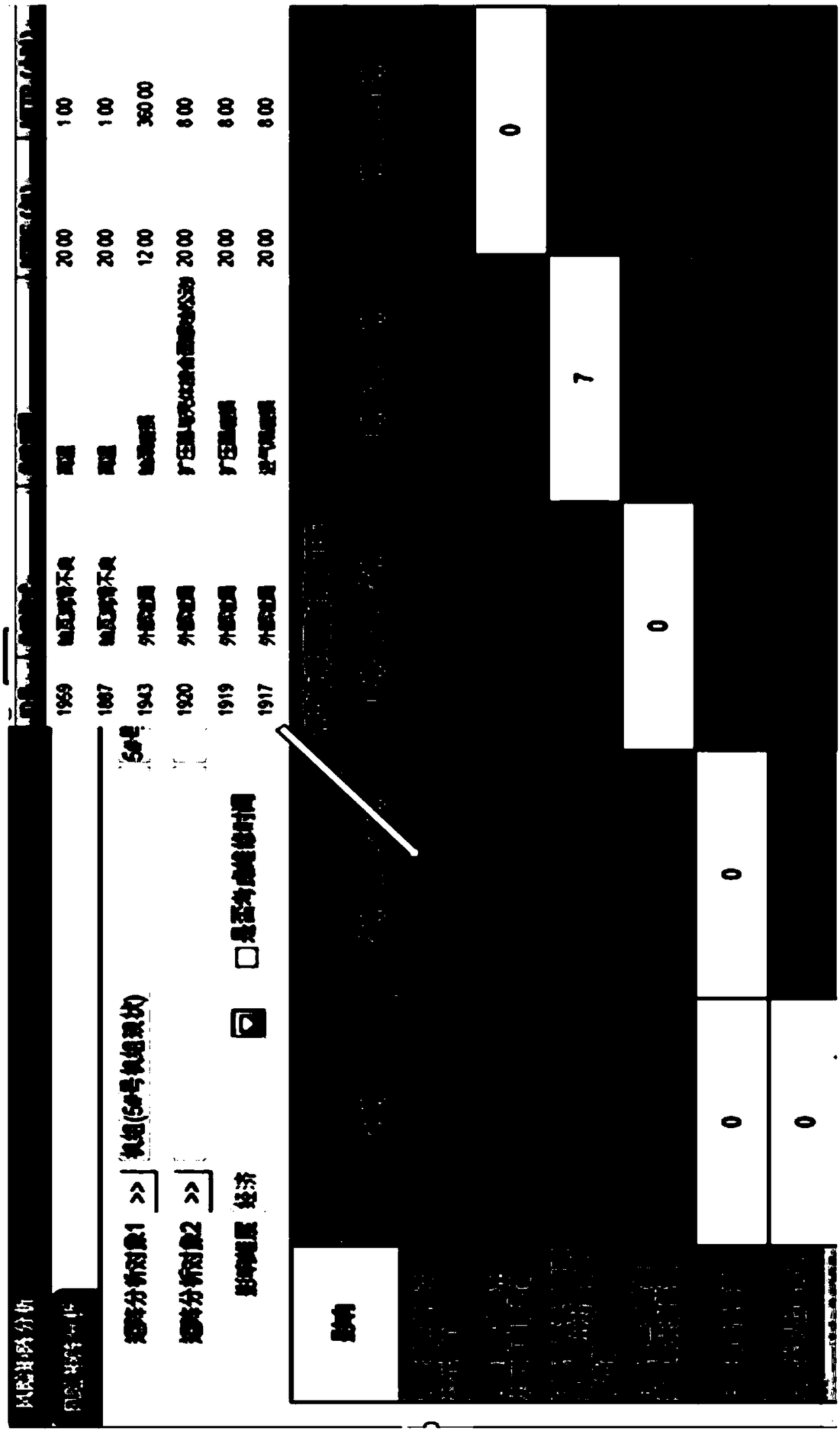

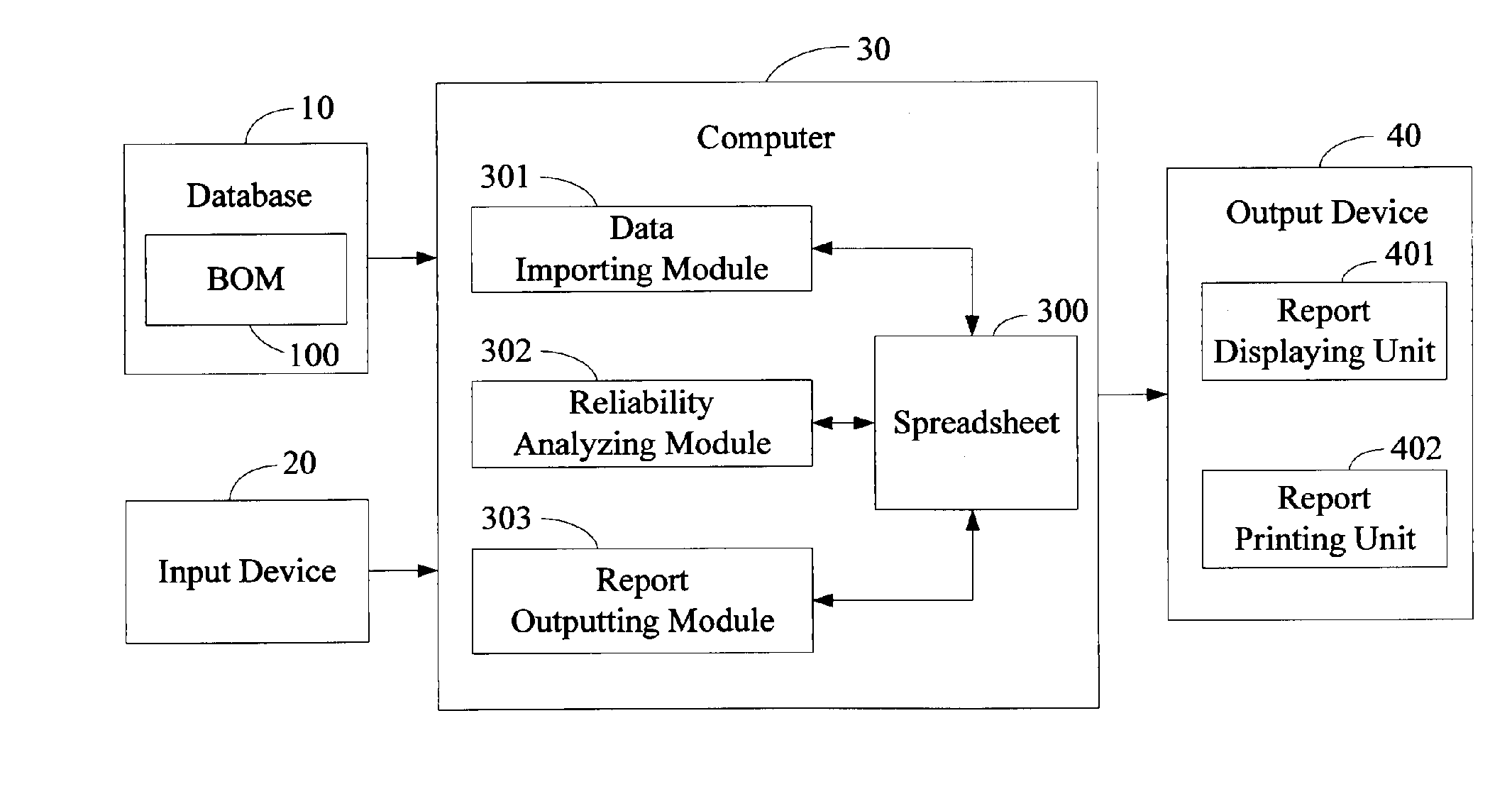

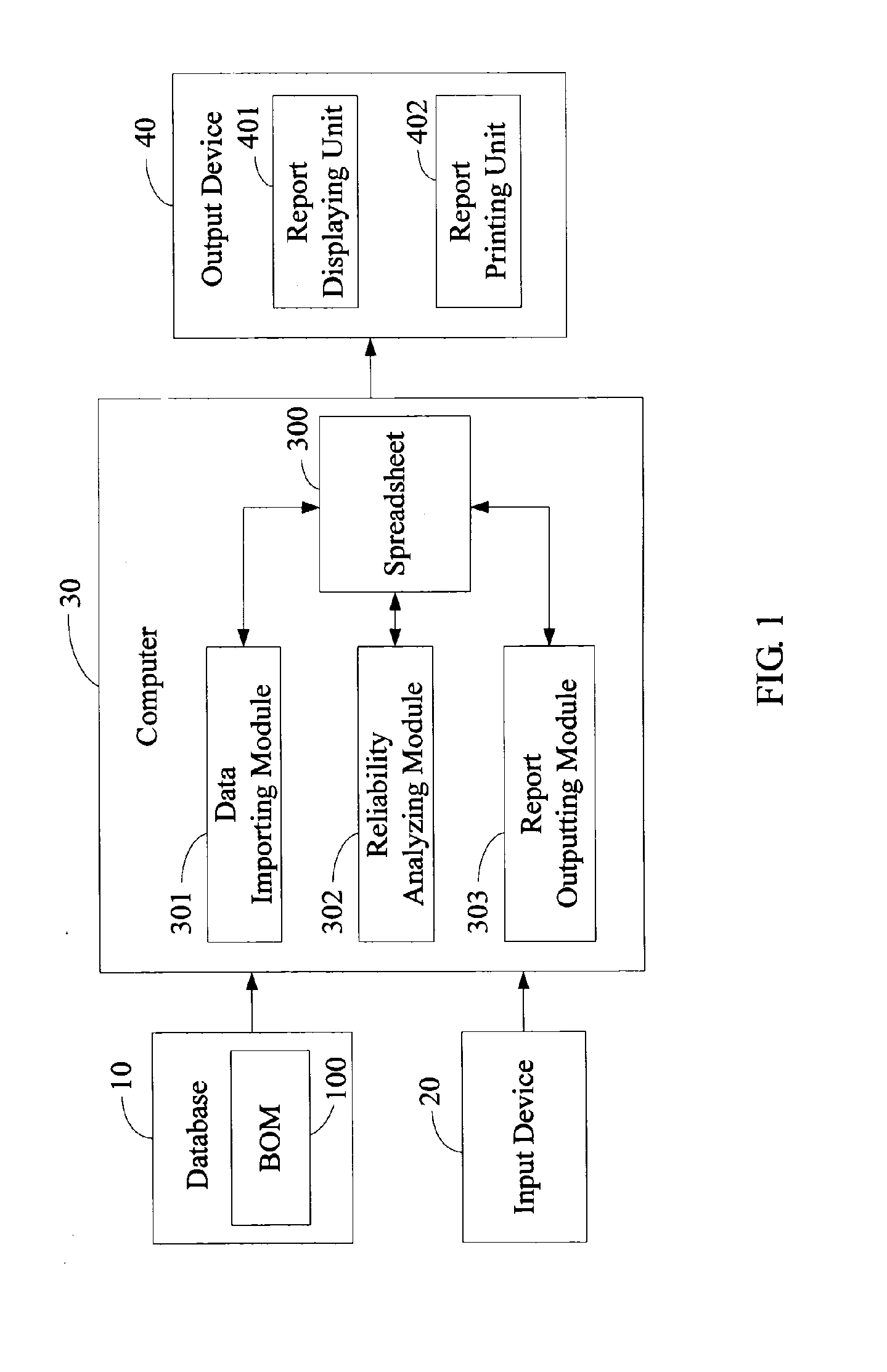

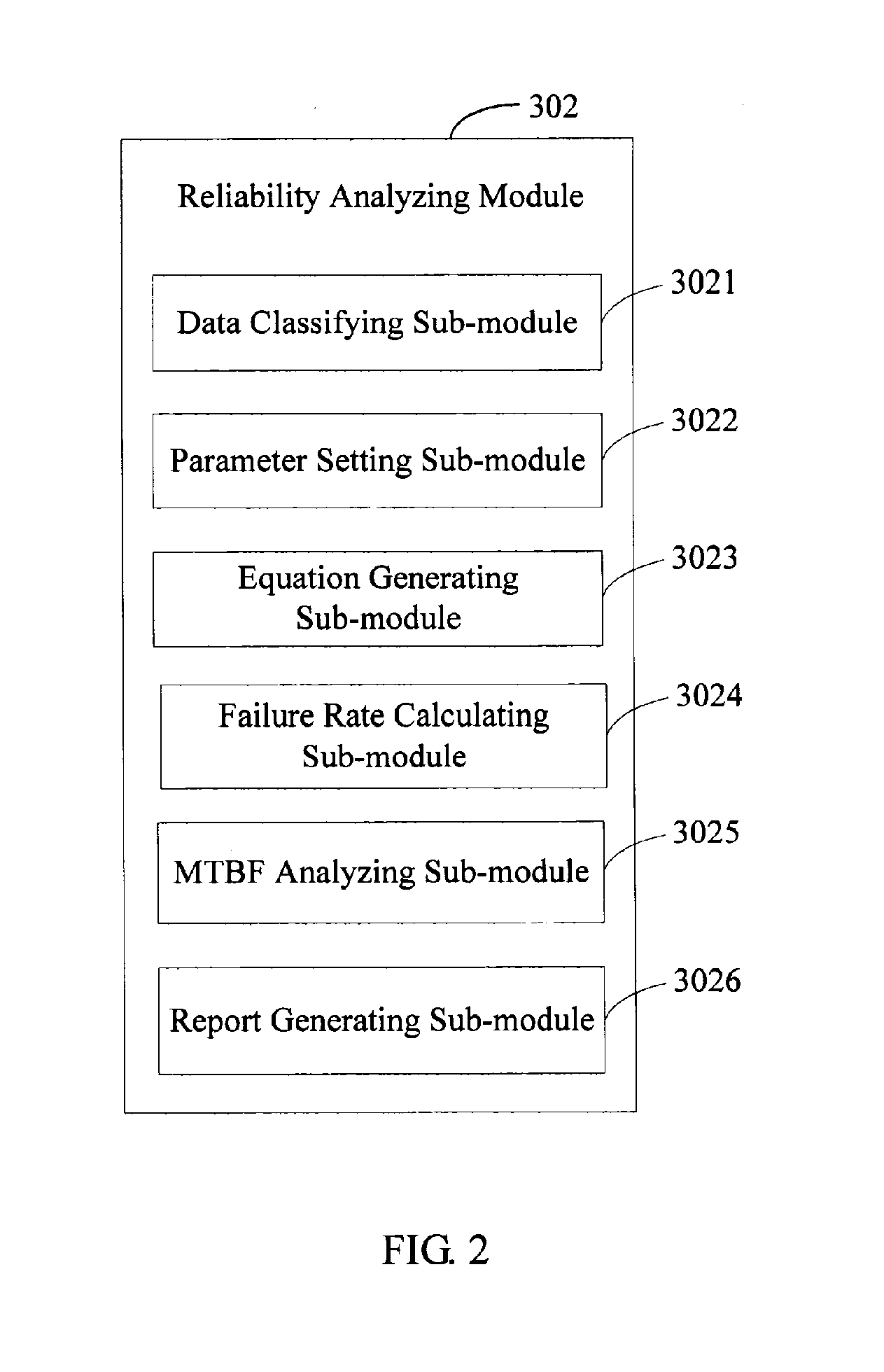

System and method for analyzing an mtbf of an electronic product

InactiveUS20070165381A1Reliability/availability analysisCooling/ventilation/heating modificationsBill of materialsElectronic form

A system for analyzing a mean time between failures (MTBF) of an electronic product is disclosed. The system includes a database (10) comprising a plurality of bill of material (BOM) tables (100) that stores data on components of the electronic product; and a computer (3) installed with a spreadsheet (300) for analyzing the MTBF of the electronic product. The computer includes: a data importing module (301) for importing the data stored in the BOM tables to the spreadsheet; a reliability analyzing module (302) for classifying the data in the spreadsheet, analyzing the reliability of the electronic product by calculating the MTBF of the electronic product in the spreadsheet, and for generating a reliability prediction report; and a report outputting module (303) for outputting the reliability prediction report to an output device (40). A related method is also disclosed.

Owner:HON HAI PRECISION IND CO LTD

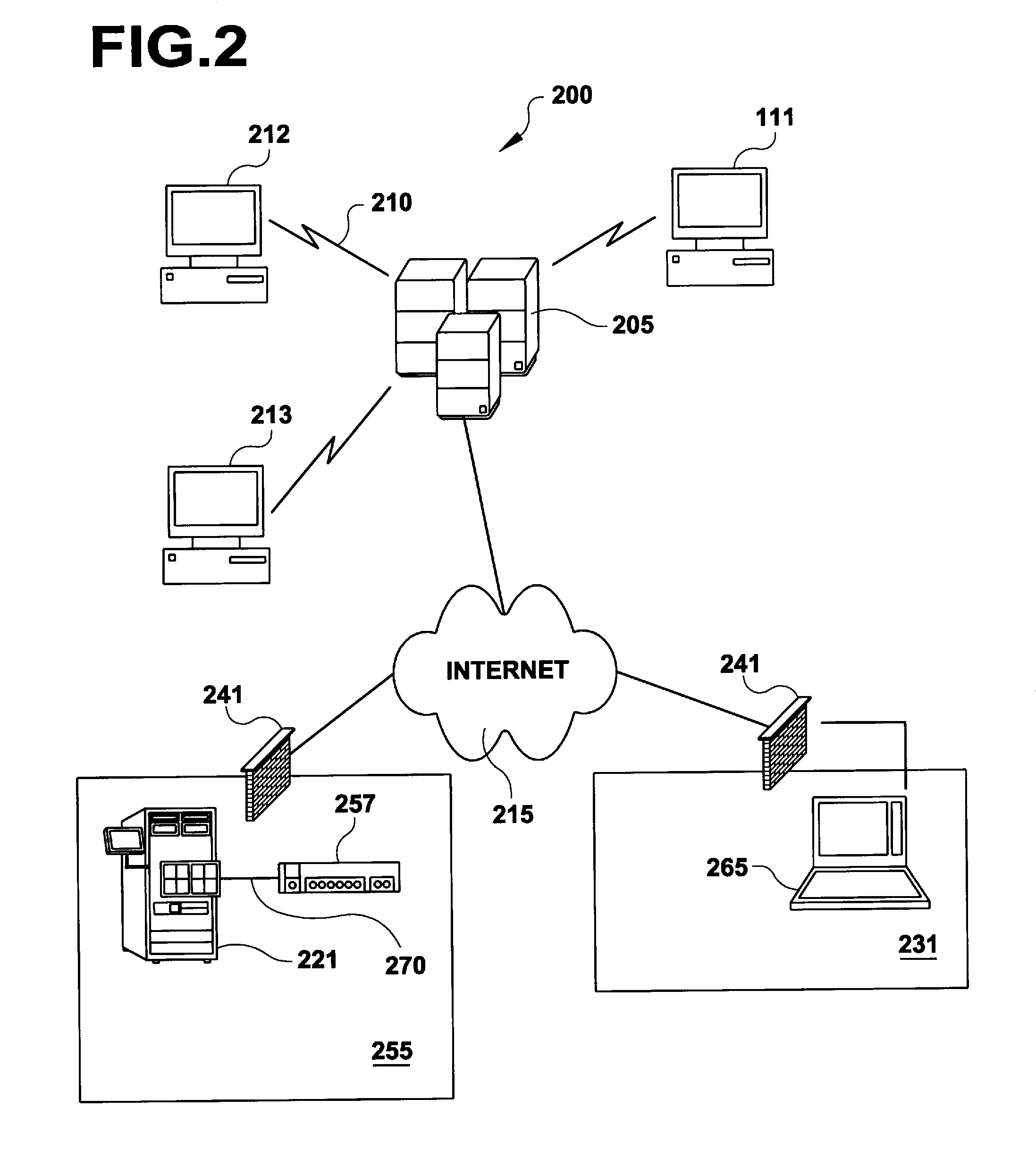

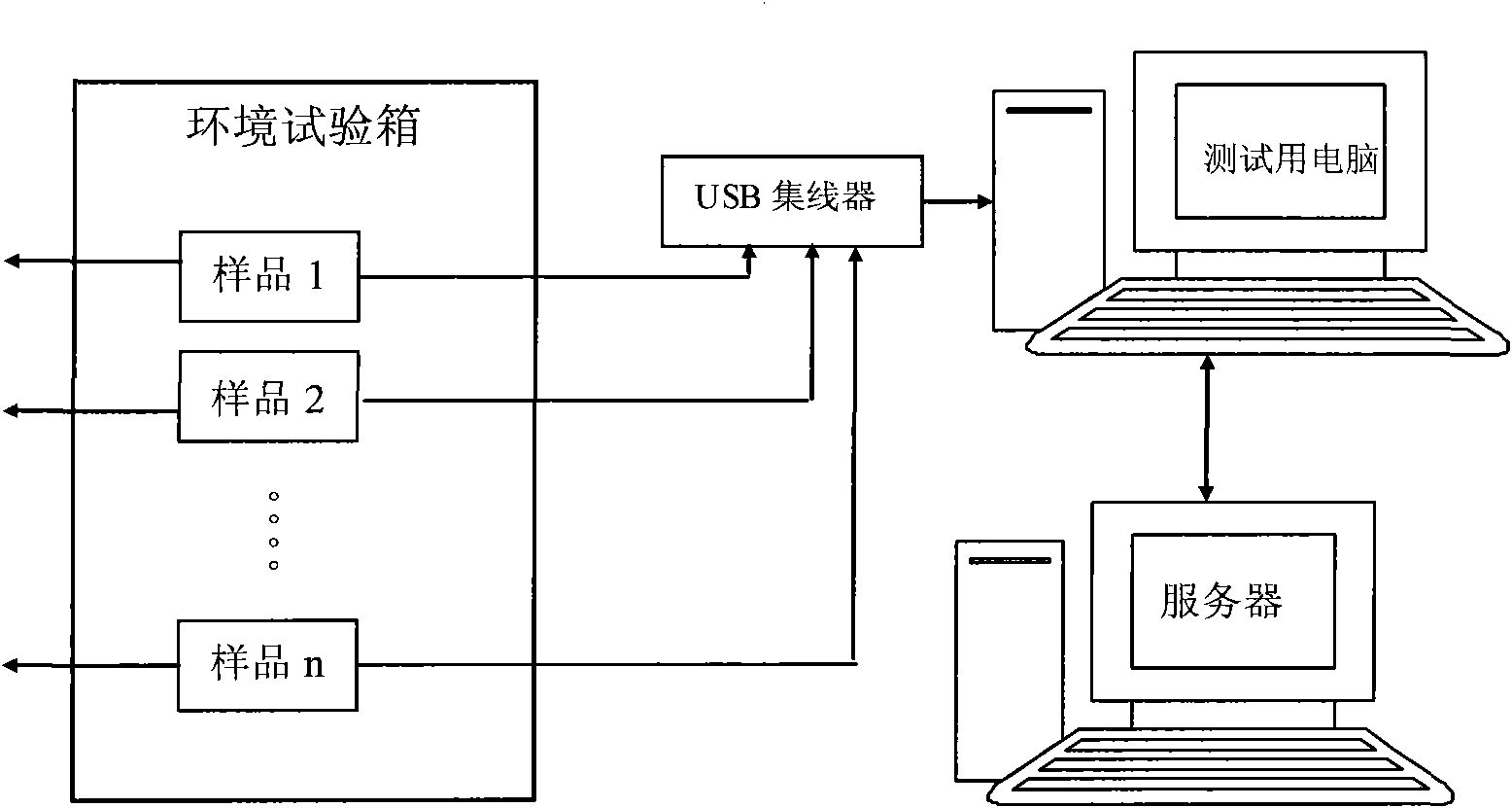

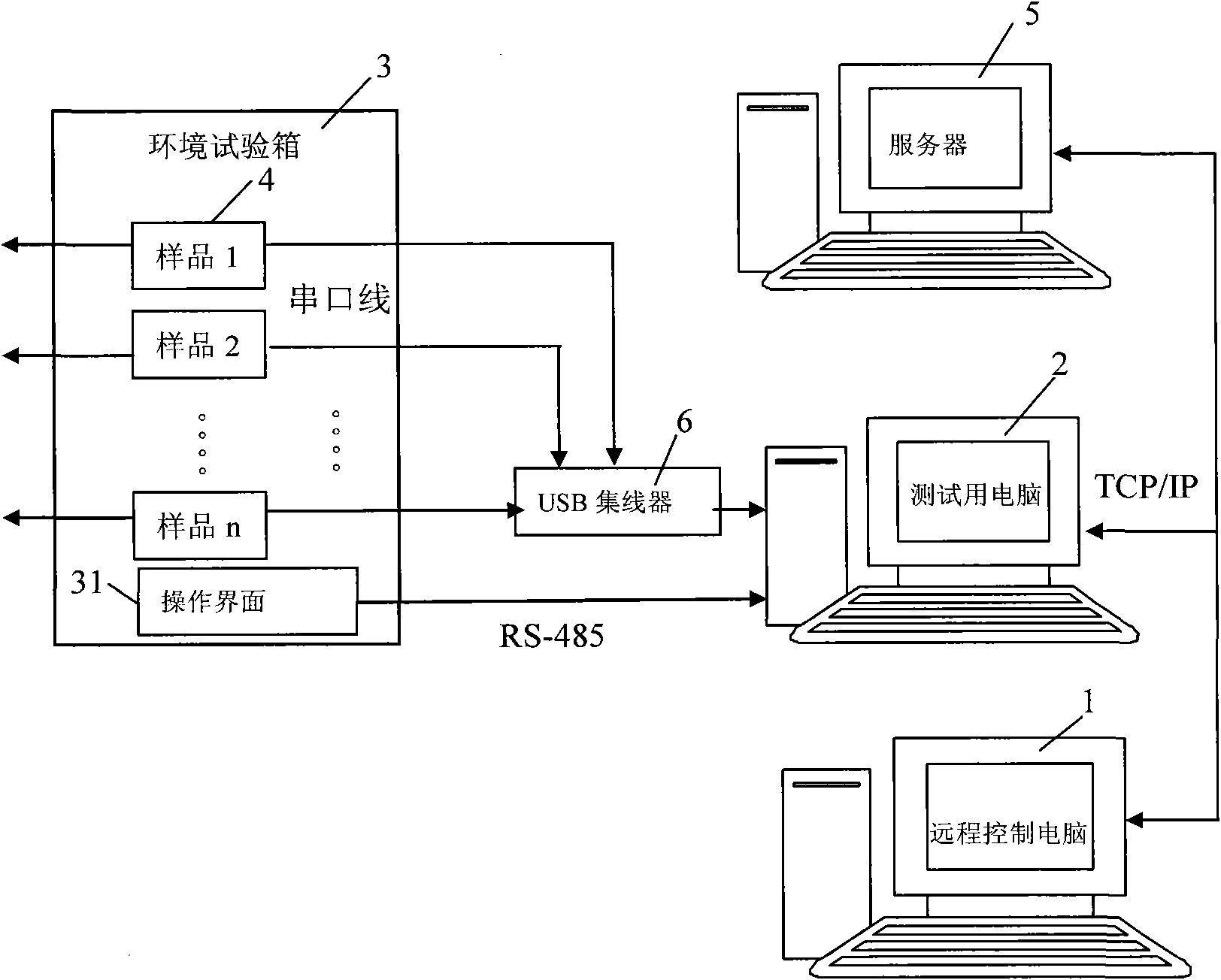

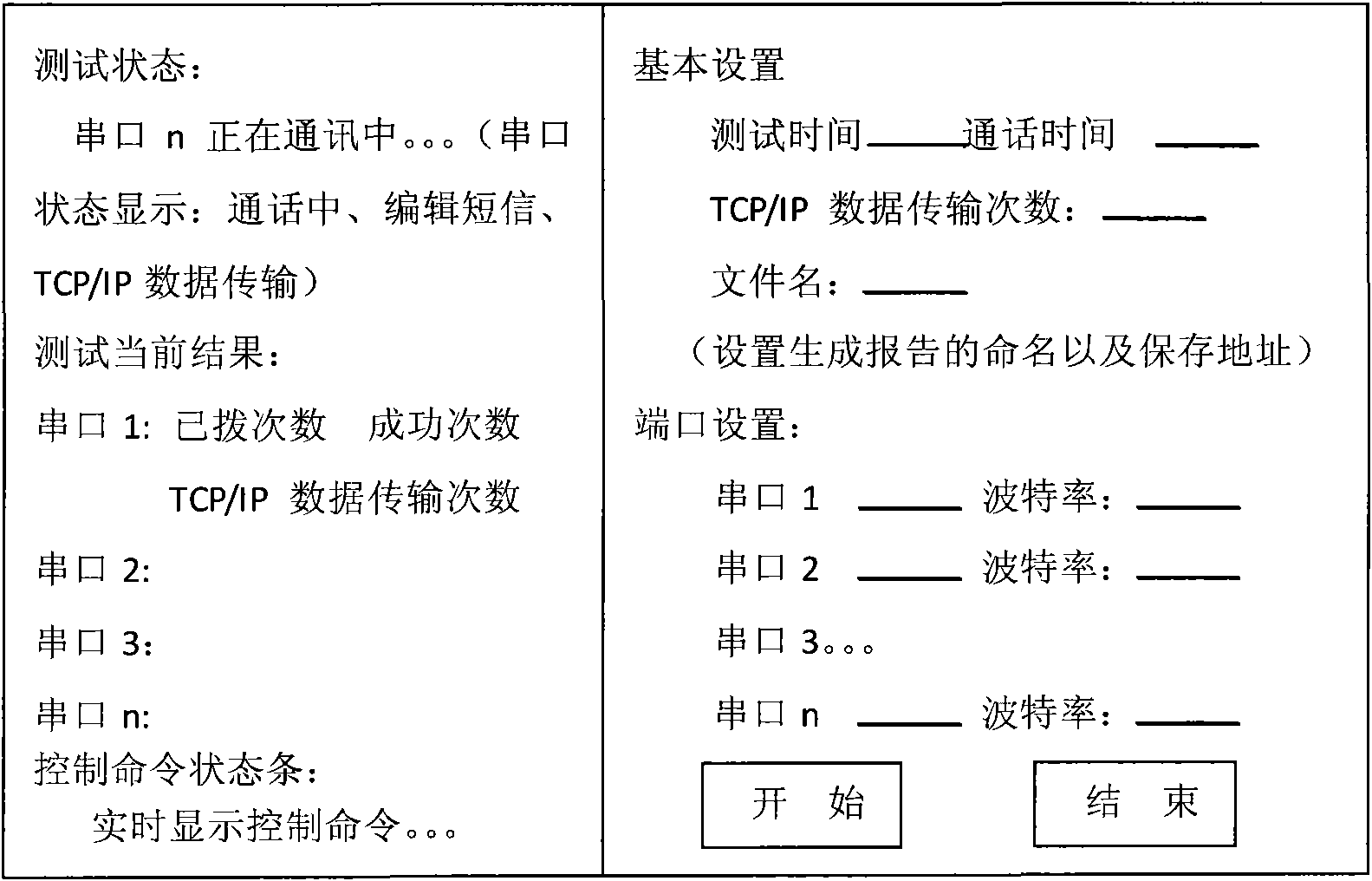

Remote reliability lifetime verification and test system, and method thereof

InactiveCN102739463AImplement automated testingReal-time monitoring of test statusData switching networksRemote controlTest sample

The invention discloses a remote reliability lifetime verification and test system, and a method thereof. The system comprises an environmental test chamber in which a plurality of test samples are arranged and a computer used for testing, wherein the environmental test chamber is connected with the computer used for testing through an USB concentrator, and the environmental test chamber comprises a controllable control interface. The test system further comprises a remote control computer for directly logging on to the computer used for testing to perform remote monitoring on the test samples. An environment operation control module and an automatic test module are arranged in the computer used for testing. An operational serial port is arranged in the environmental test chamber for receiving environmental condition operation control instructions sent from the computer used for testing. Based on the above-mentioned test system, the invention further provides a remote reliability lifetime verification and test method. By adopting the system and the method provided in the invention, automatic tests can be realized, test status is monitored in real time through remote control, troubleshooting is performed at any time, and mean time between failures of the test samples is accurately calculated.

Owner:SHANGHAI SIMCOM LTD

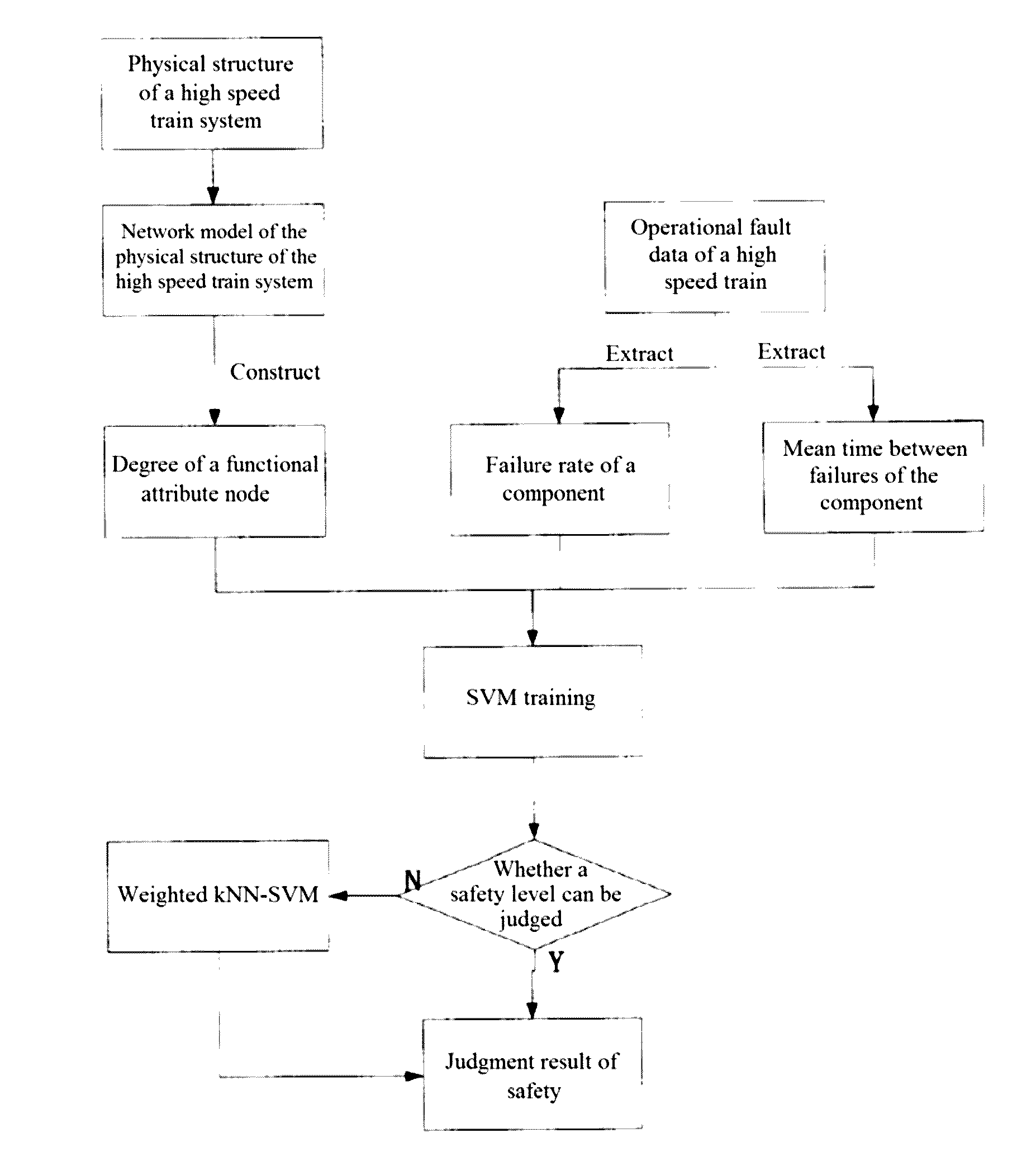

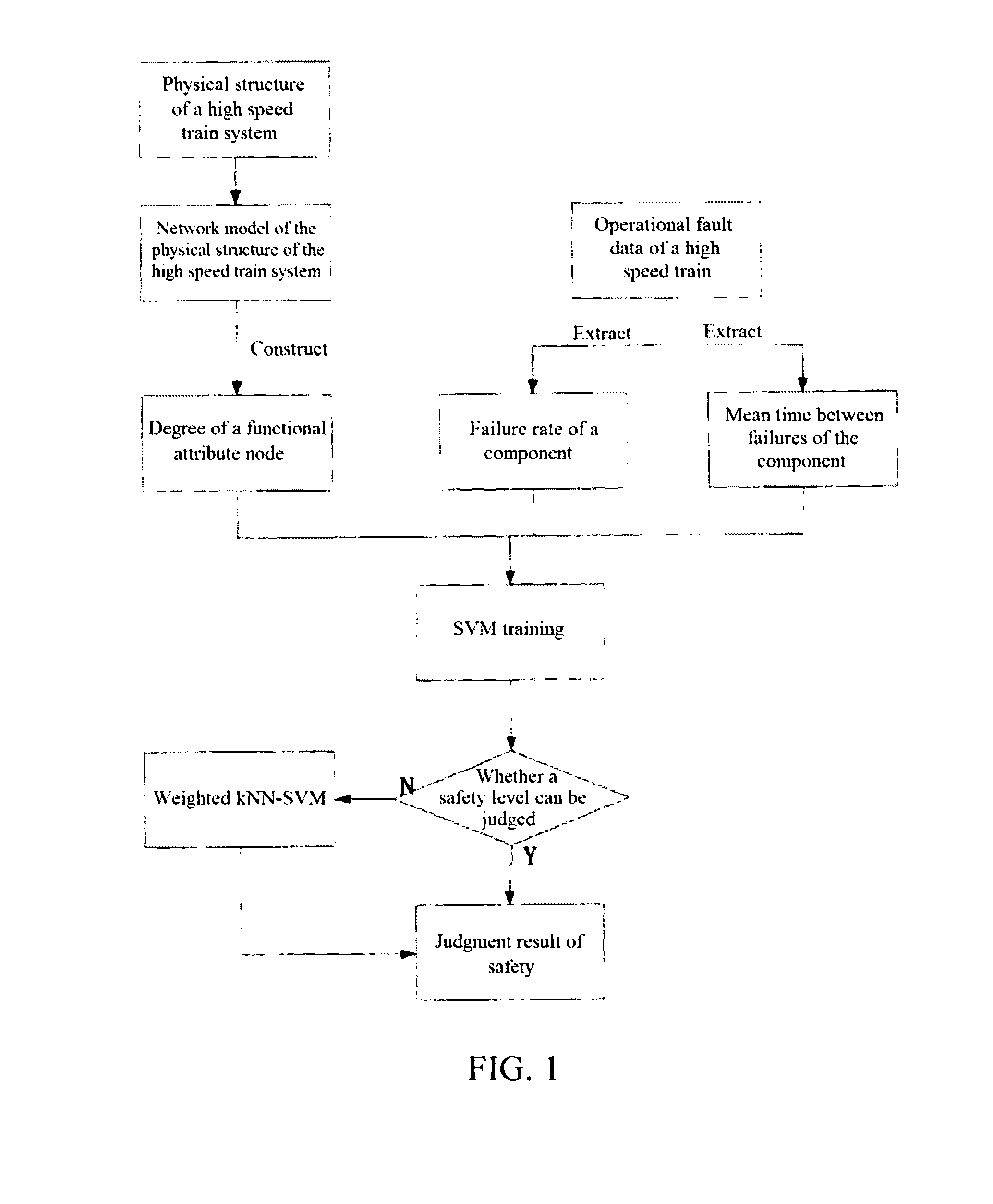

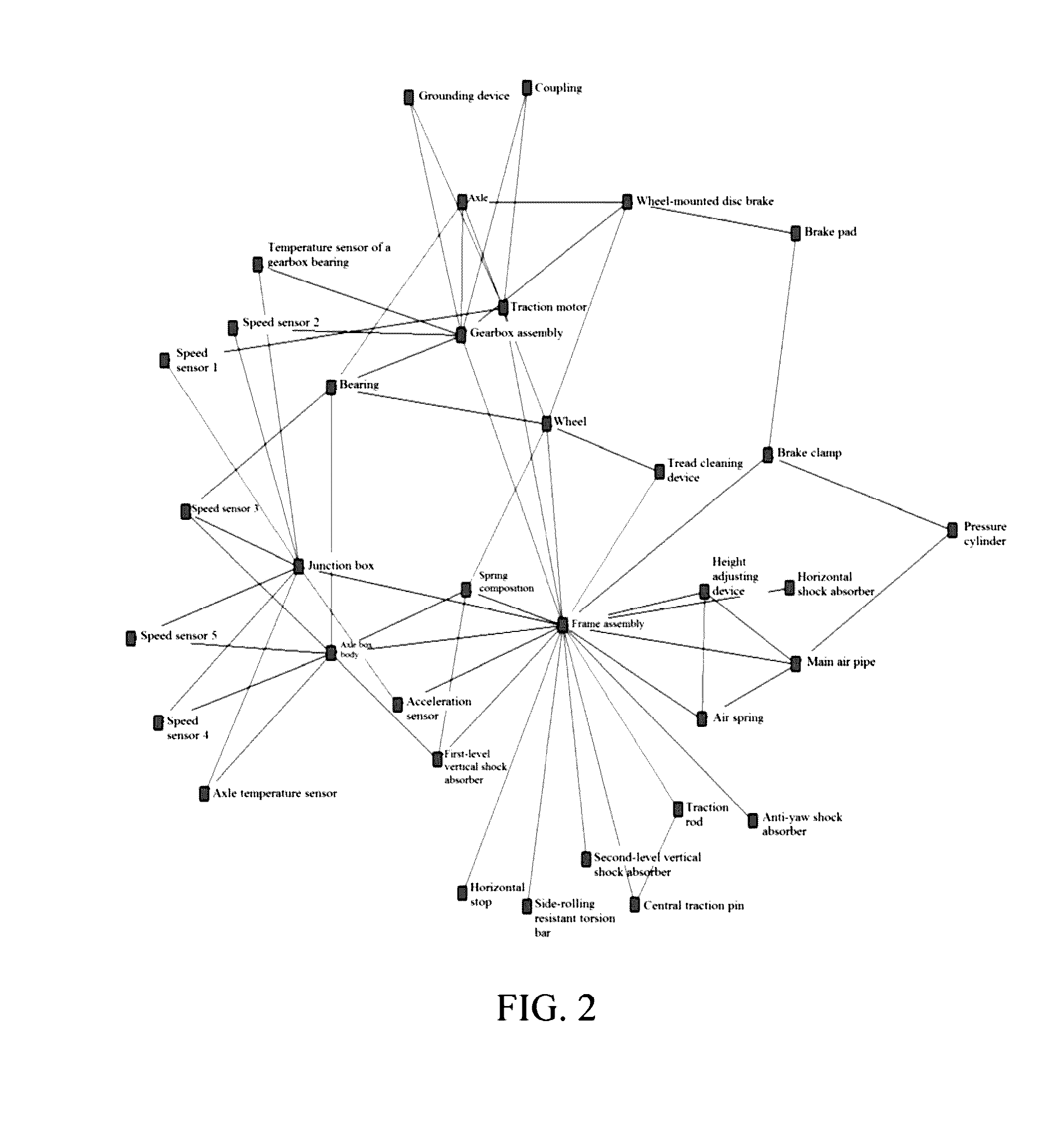

Complex network-based high speed train system safety evaluation method

ActiveUS20170015339A1The classification result is accurateIncrease speedKernel methodsRailway traffic control systemsFailure rateNetwork model

The invention discloses a complex network-based high speed train system safety evaluation method. The method includes steps as follows: (1) constructing a network model of a physical structure of a high speed train system, and constructing a functional attribute degree of a node based on the network model; (2) extracting a functional attribute degree, a failure rate and mean time between failures of a component as an input quantity, conducting an SVM training using LIBSVM software; (3) conducting a weighted kNN-SVM judgment: an unclassifiable sample point is judged so as to obtain a safety level of the high speed train system. For a high speed train system having a complicated physical structure and operation conditions, the method can evaluate the degree of influences on system safety when a state of a component in the system changes. The experimental result shows that the algorithm has high accuracy and good practicality.

Owner:BEIJING JIAOTONG UNIV

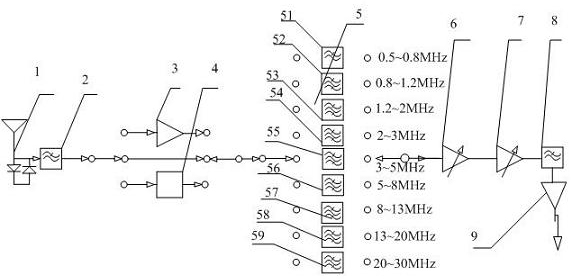

Short wave broadband receiver

The invention provides a short wave broadband receiver, which mainly comprises an analog output circuit and a digital output circuit connected with the analog output circuit, wherein the analog output circuit mainly comprises an amplitude limiting circuit, an input low pass filter, a mode selection assembly circuit, a band-pass filter assembly, an attenuator circuit, an output low pass filter and an output low noise amplifier which are connected sequentially; and the output low noise amplifier is connected with the digital output circuit. The short wave broadband receiver has beneficial effects of high scanning speed, no mirror image or intermediate frequency and no local oscillator phase noise, very suitability for broadband application, no interference signals generated by a local oscillator or frequency mixer, high linearity and low power consumption, less core parts and higher MTBF (Mean Time Between Failures).

Owner:CHENGDU ZHONGYA TONGMAO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com