Testing method for combined stress of airplane brake system

A brake system and comprehensive stress technology, applied in the field of civil aircraft product development, can solve problems such as single verification and limitations, no verification of life and reliability, waste of time and resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

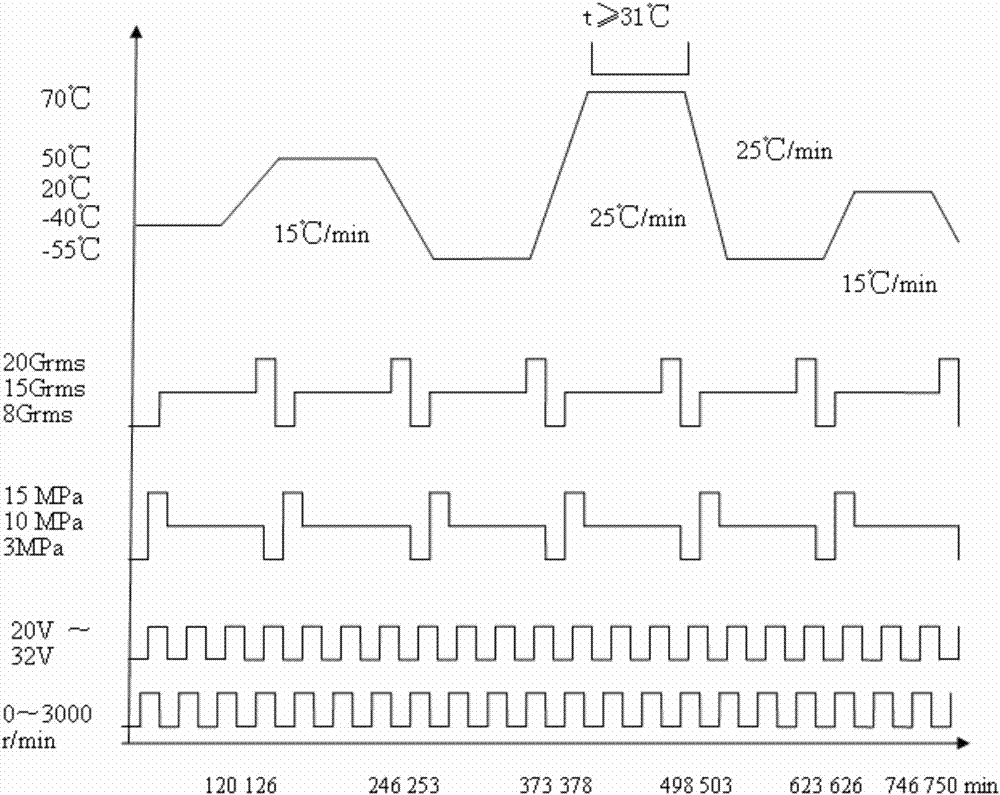

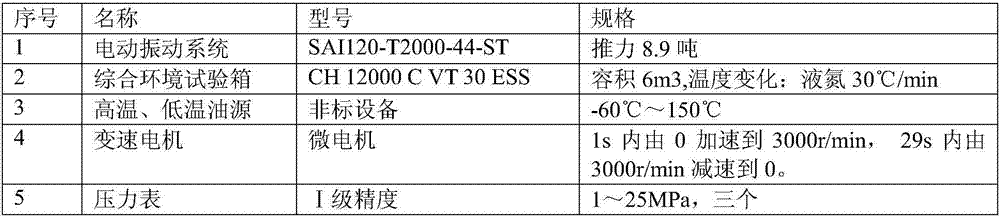

[0123] In this embodiment, a comprehensive stress test is carried out on a brake system of a civil aircraft. Include high temperature, low temperature, temperature shock, vibration, power supply specific, and rotational speed test contents in the test profile, and these tests will not be carried out after the test is completed. The development requires that the life of the braking system is 2000 lifts and the mean time between failures MTBF = 2000h. 1 landing time is 2h. Before the test, the failure mode analysis was carried out according to GJB899A 4.7, and the design improvement of the servo valve and the anti-skid brake control box was completed, and the service life and reliability indicators of the improved brake system were verified.

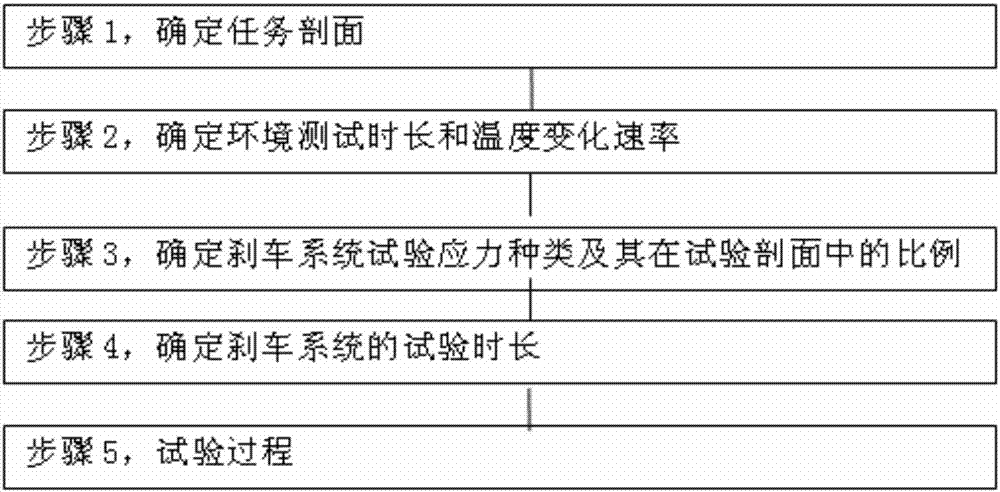

[0124] The concrete process of this embodiment is:

[0125] Step 1, Determine the Mission Profile

[0126] The first step is to determine the environmental quantities in the task profile of the braking system

[0127] Clause 2.1.6.5 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com