Patents

Literature

277 results about "Design improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

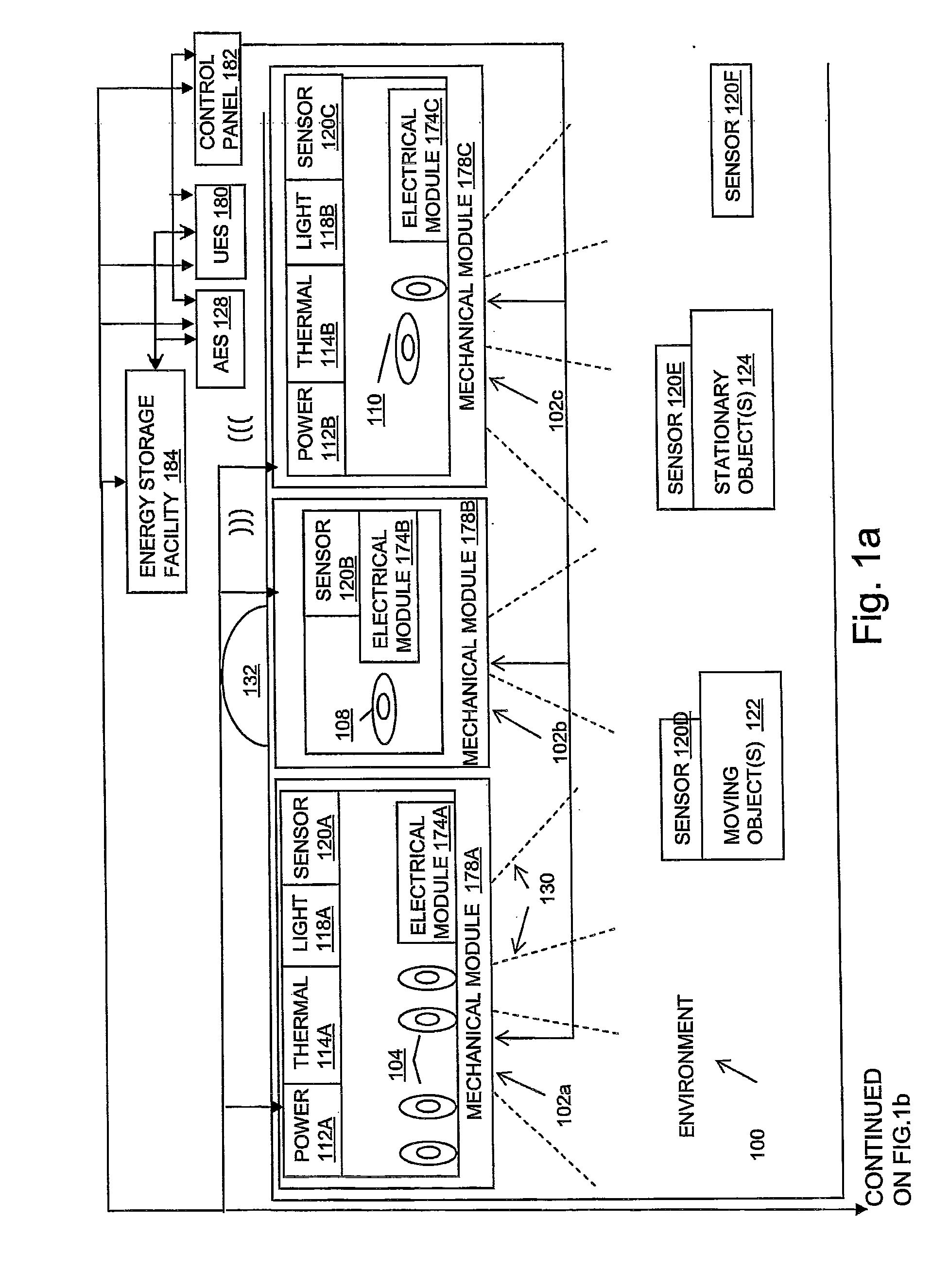

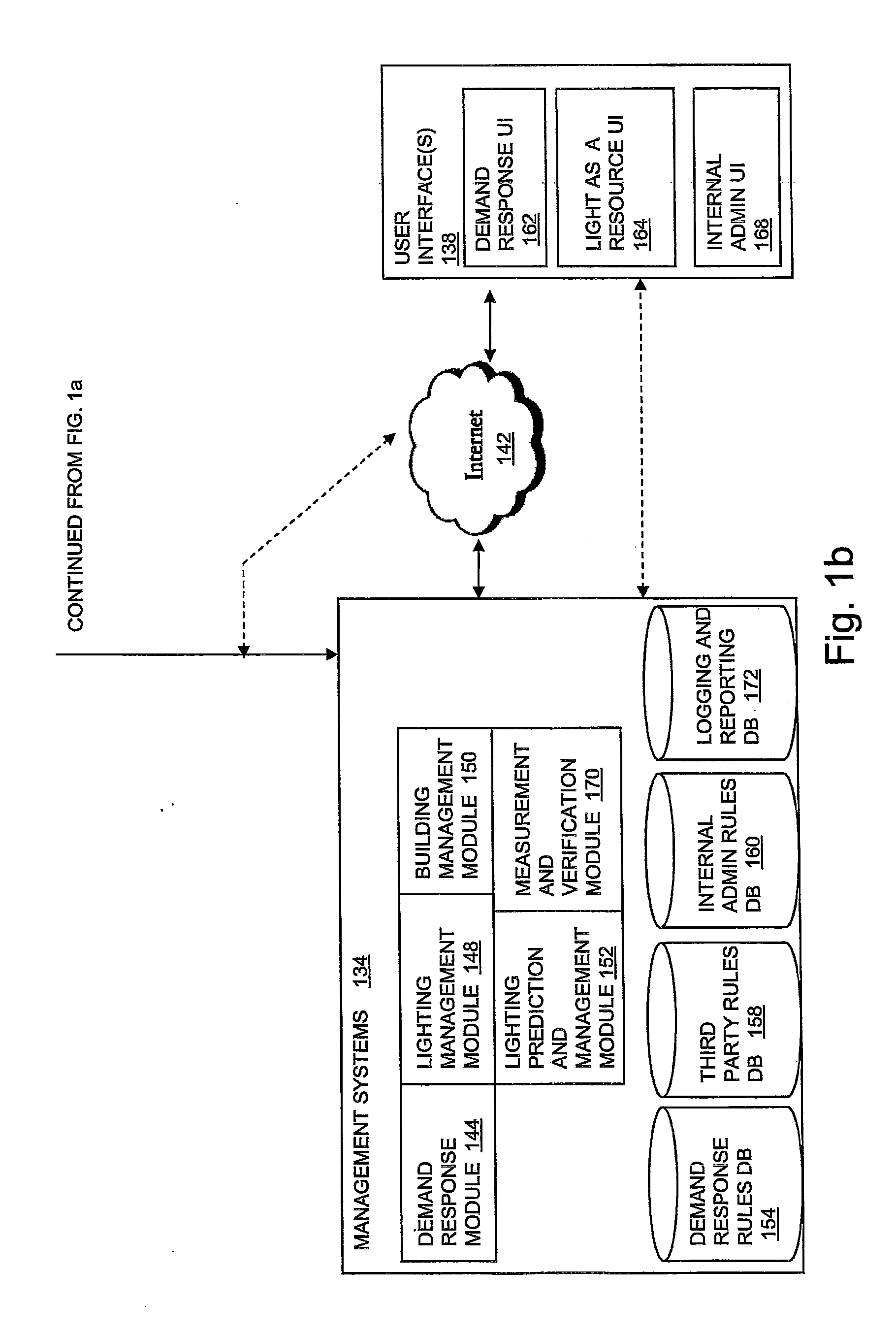

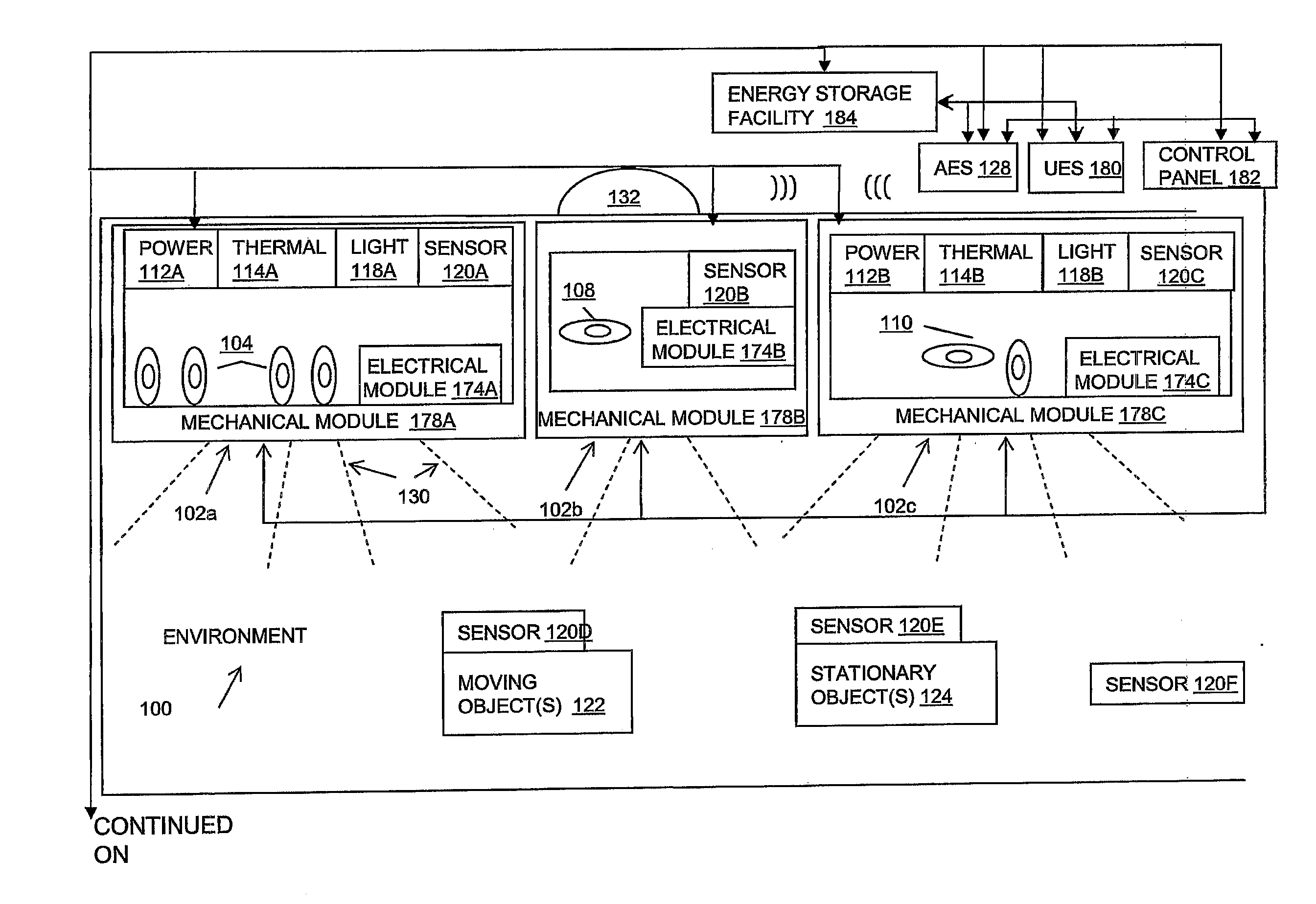

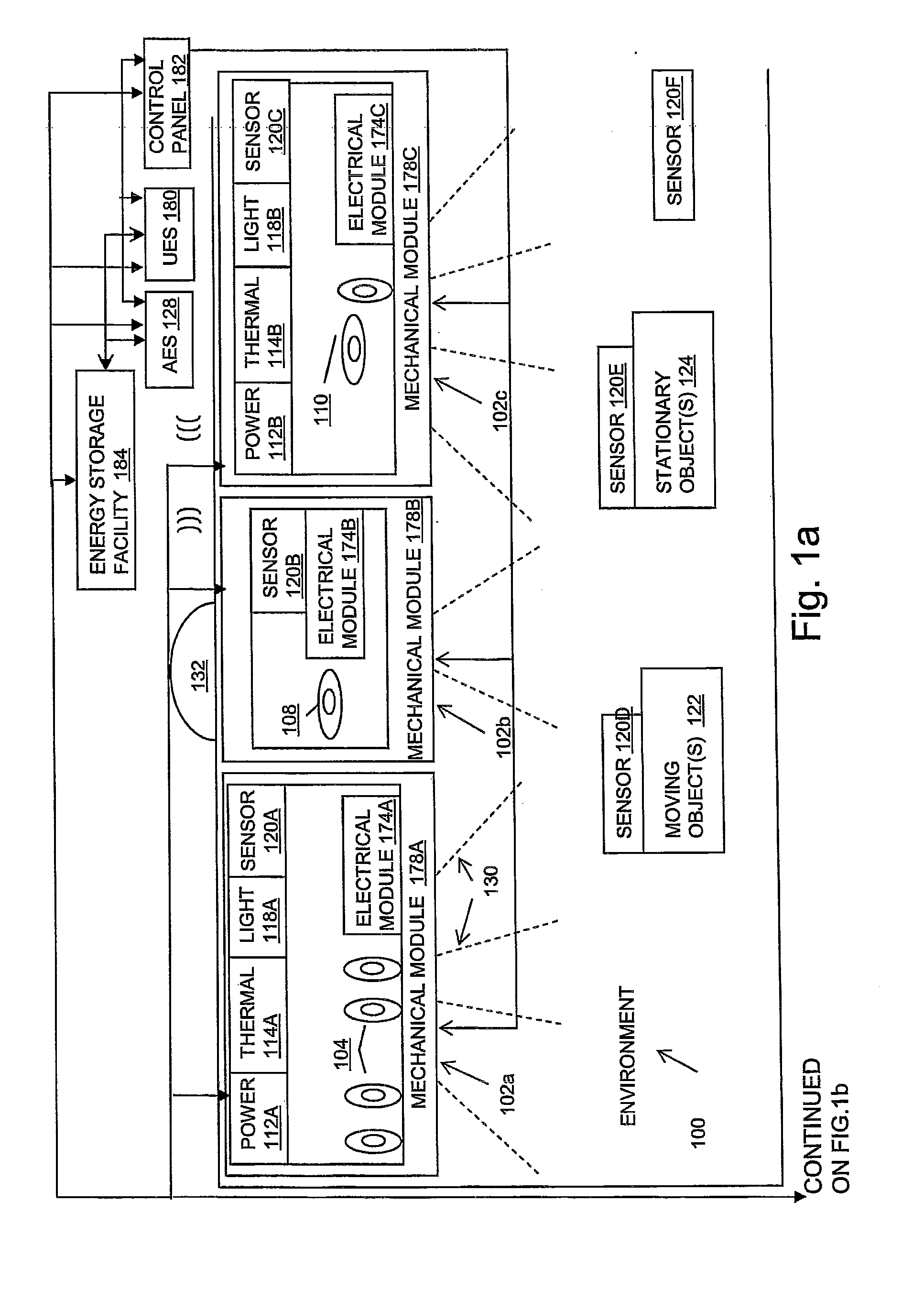

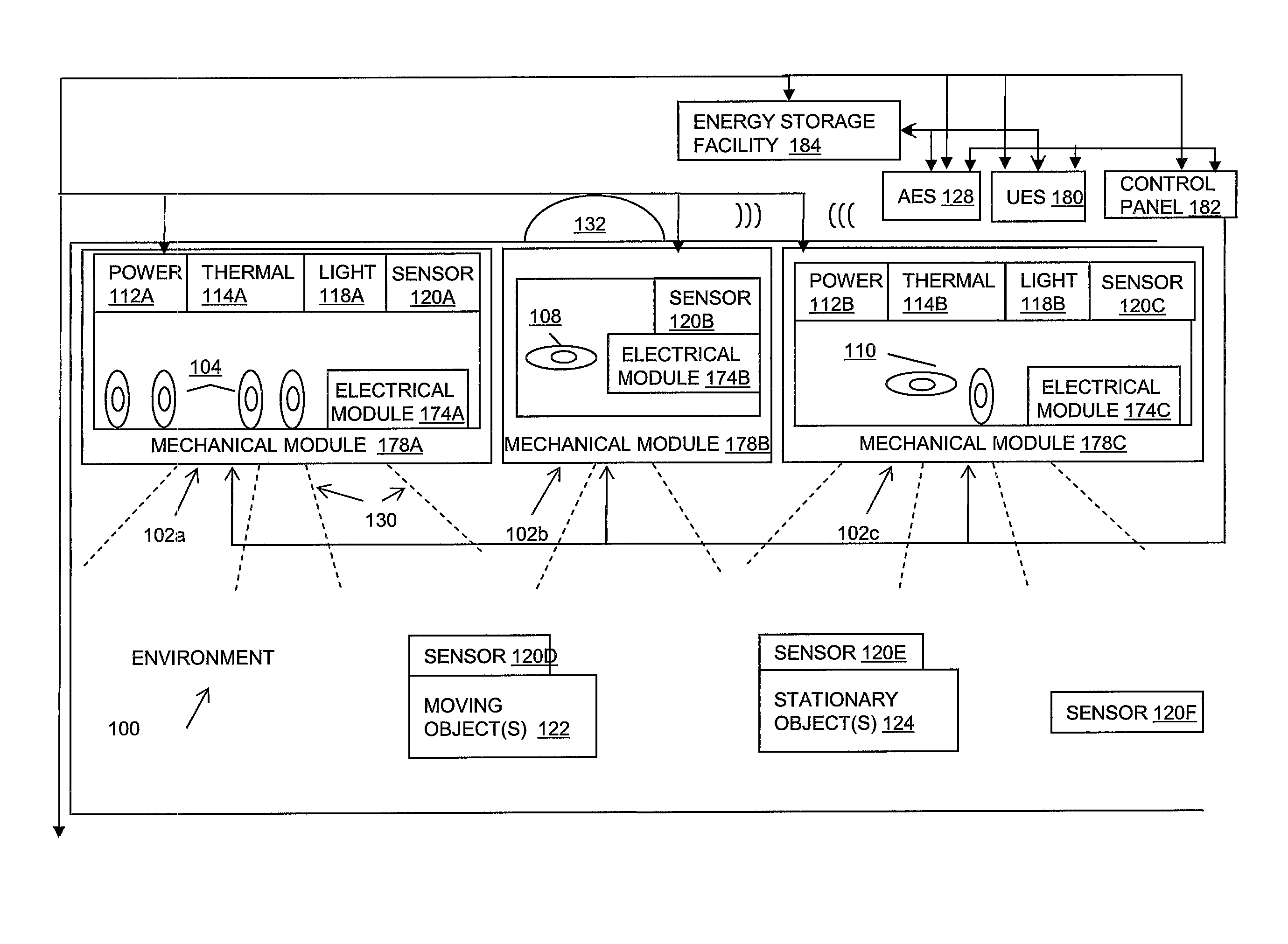

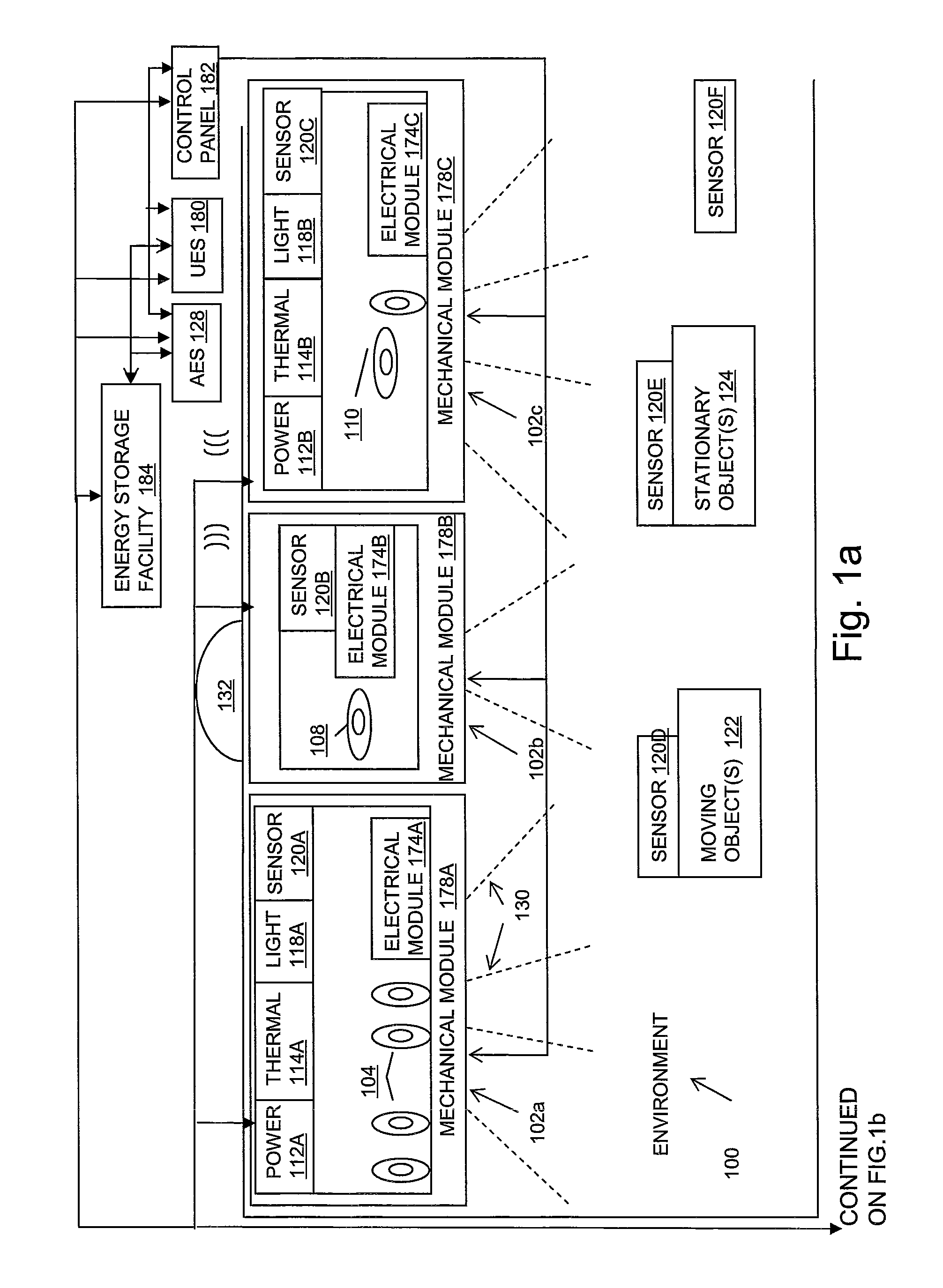

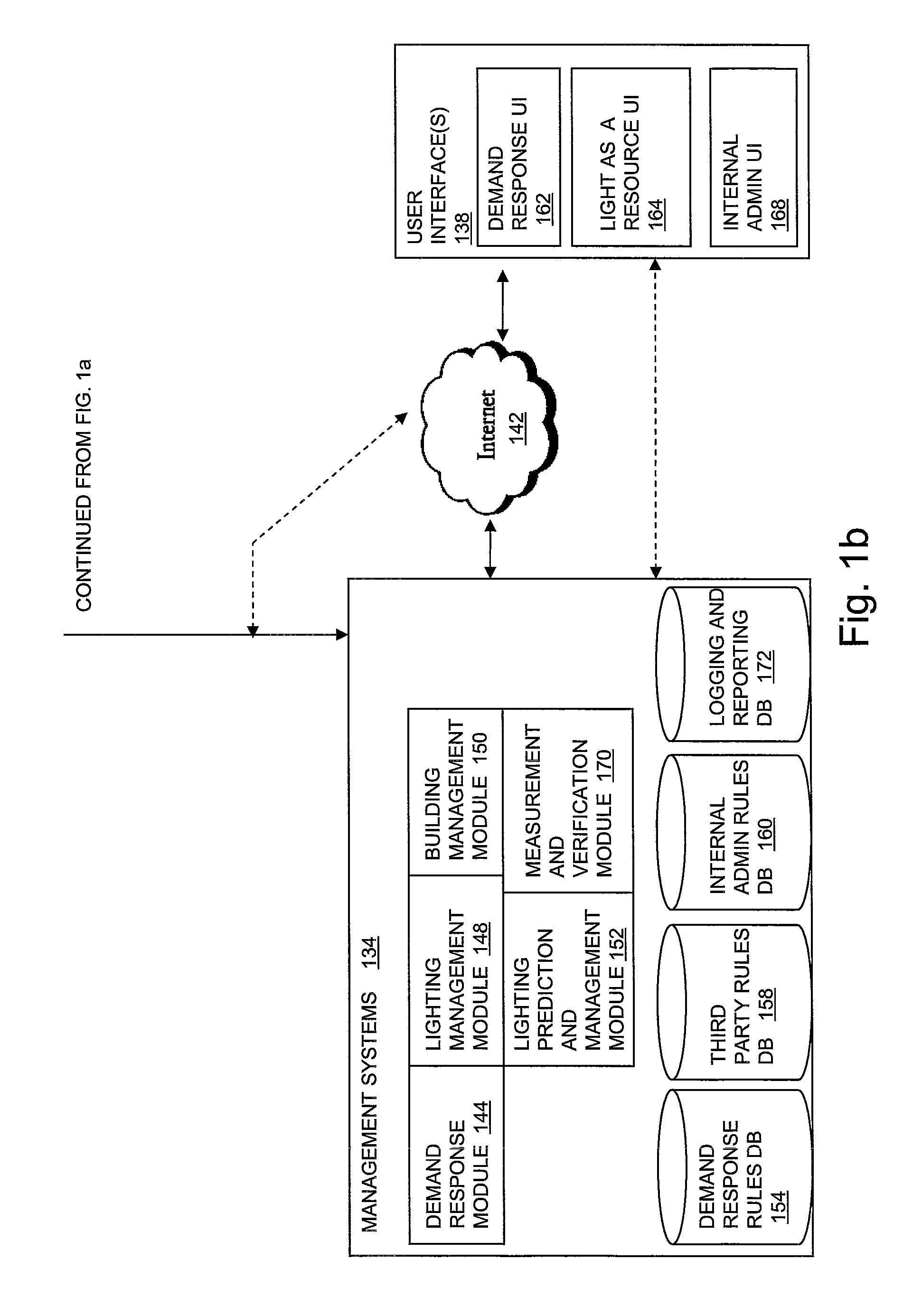

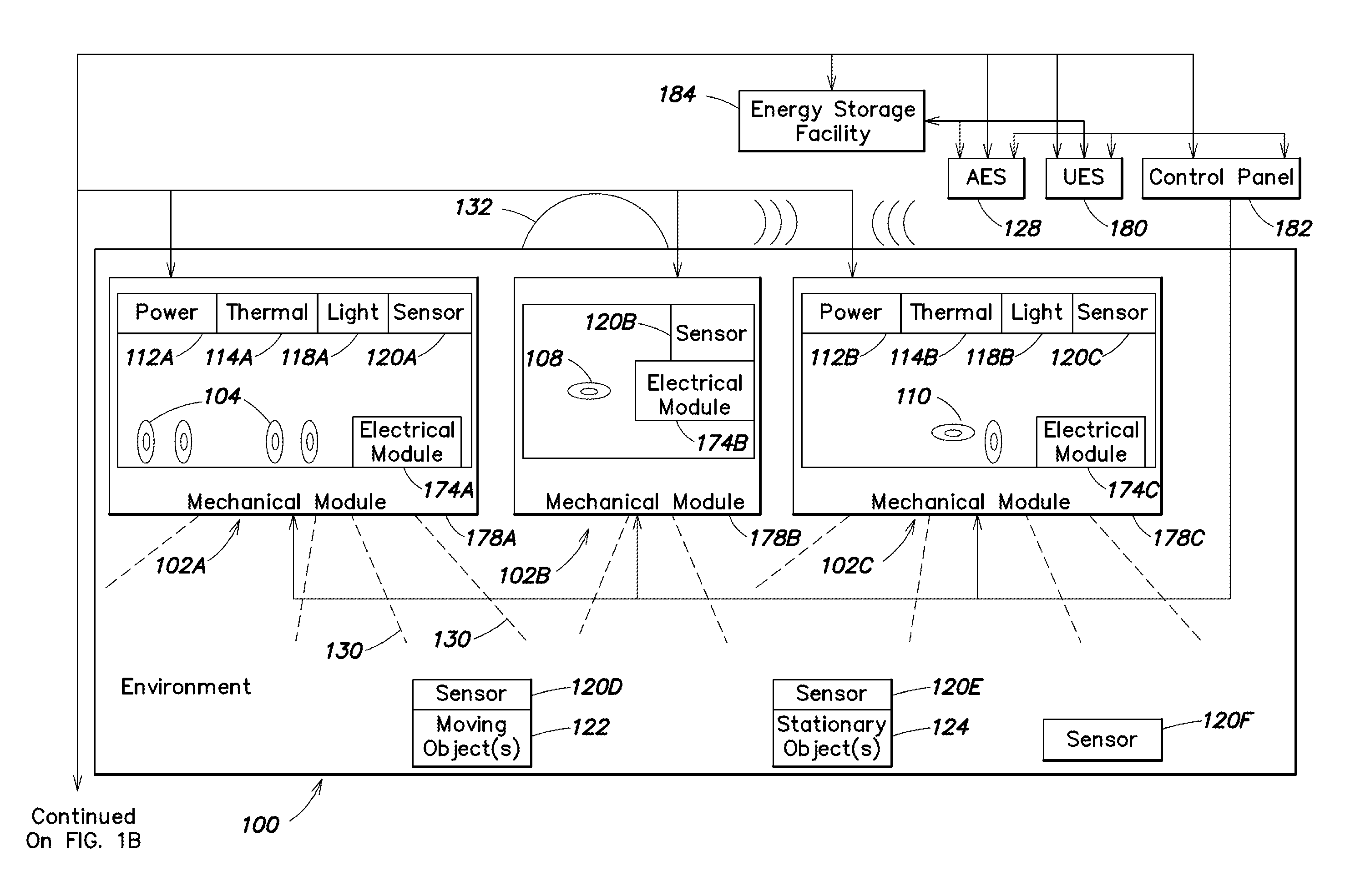

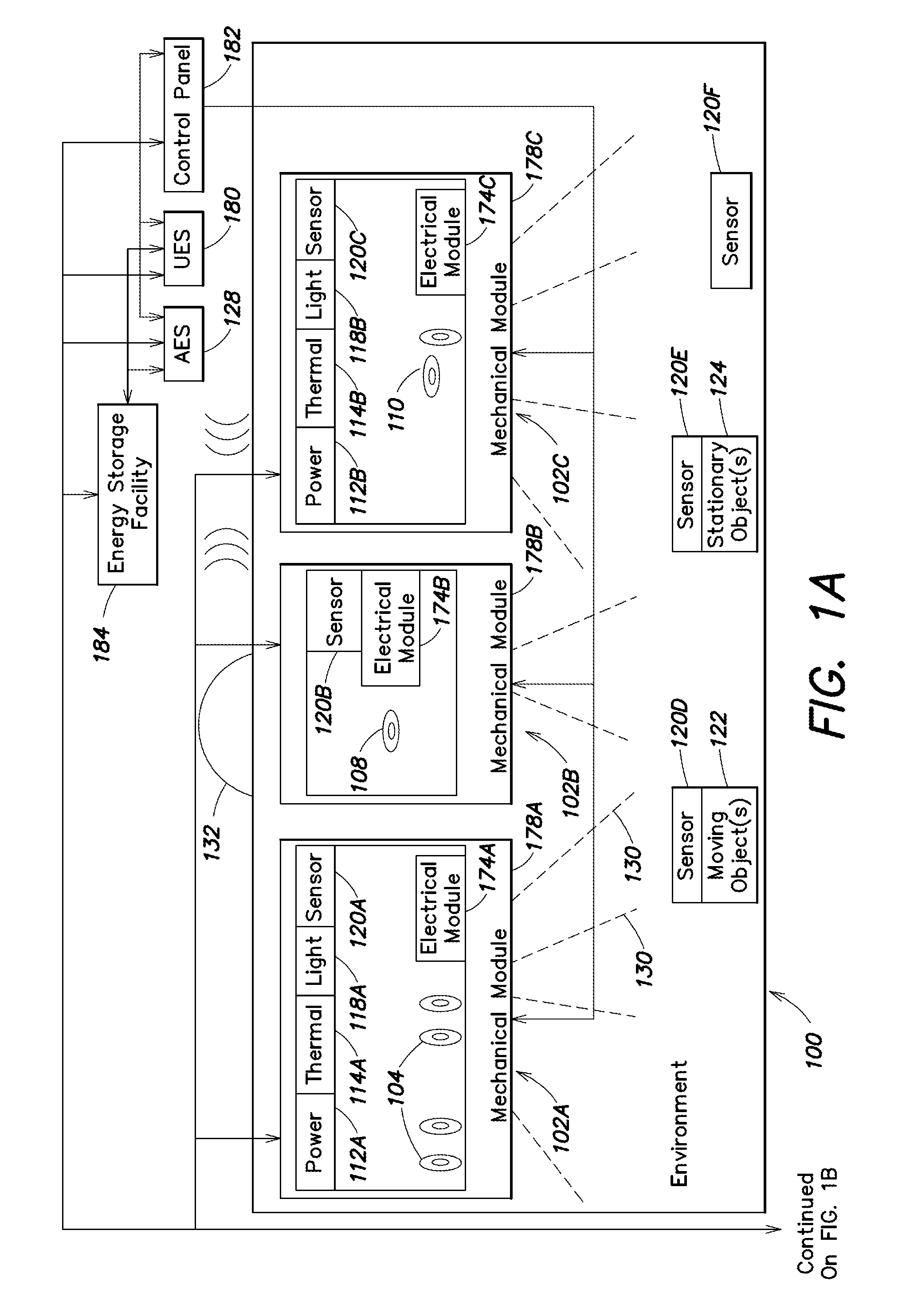

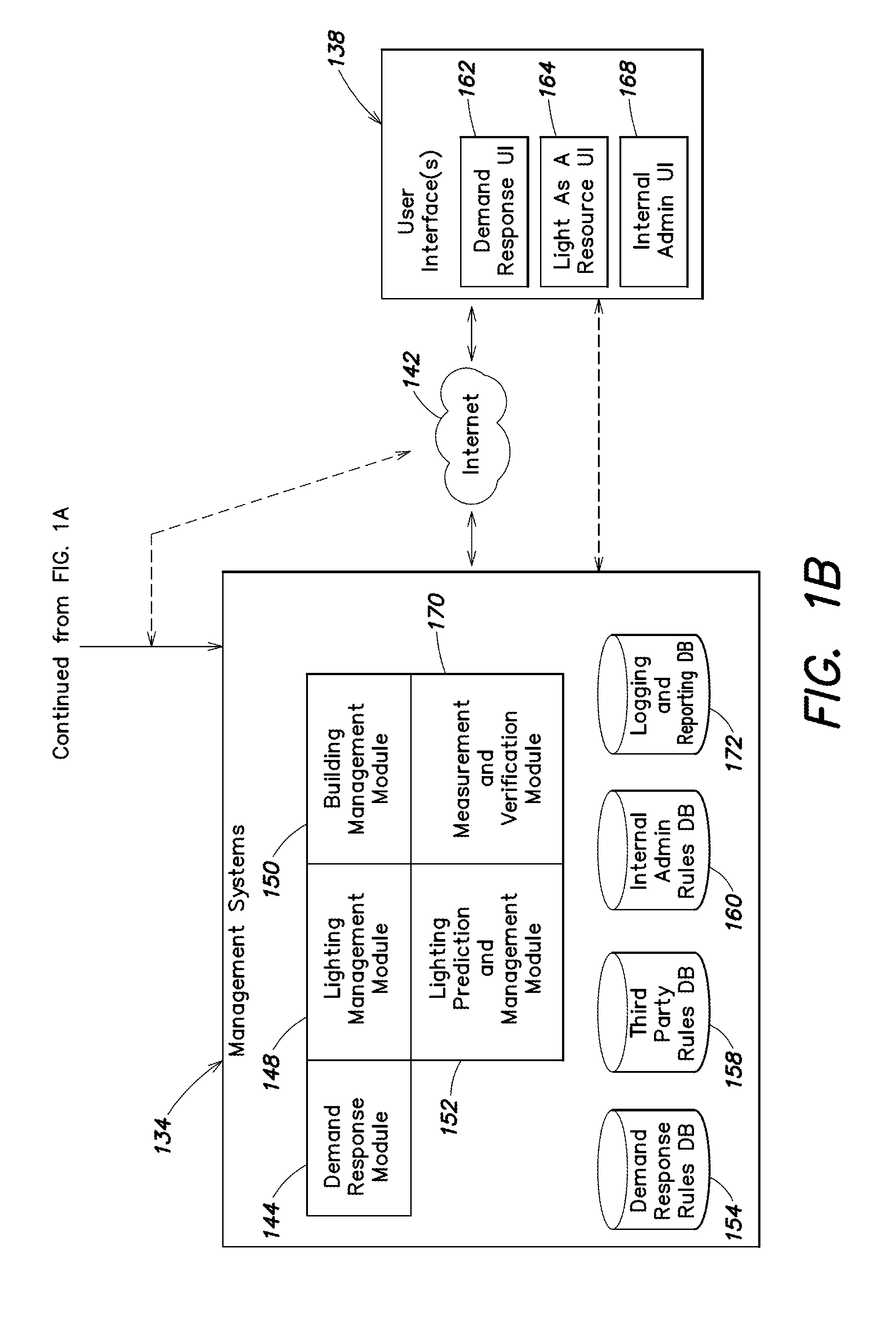

Fixture with Intelligent Light Modules

ActiveUS20100259931A1Mechanical apparatusPoint-like light sourceIntelligent lightingDesign improvement

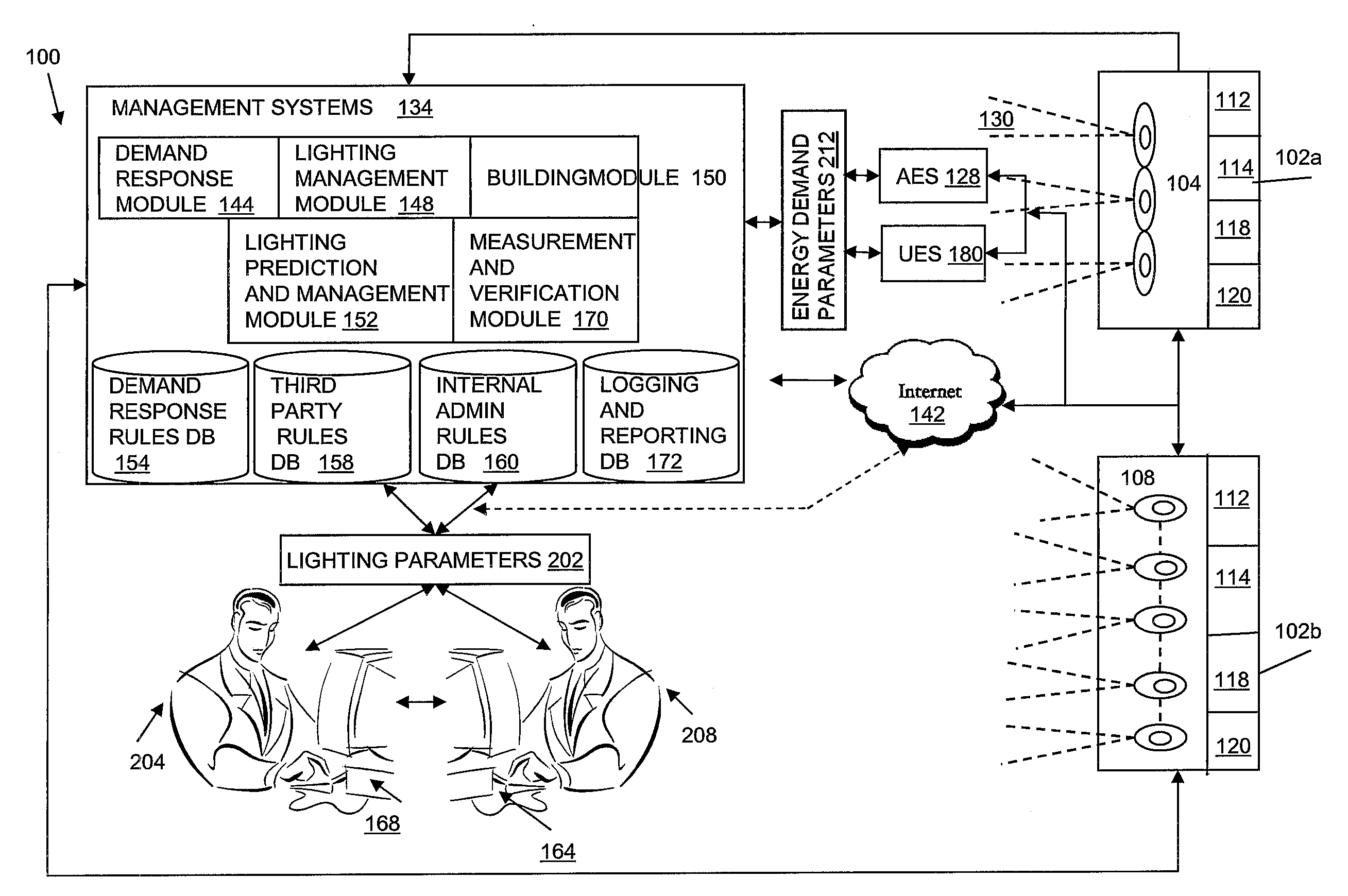

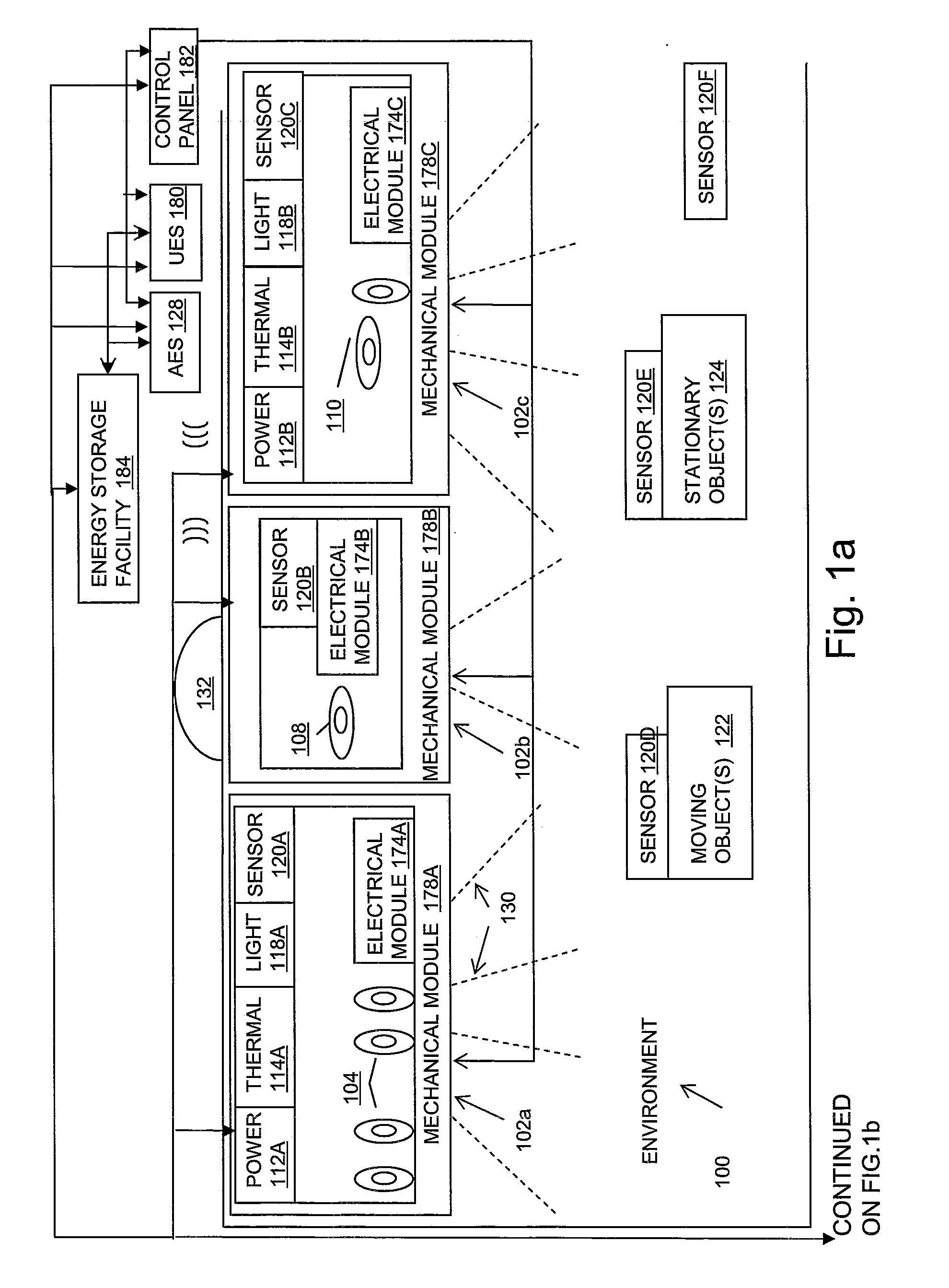

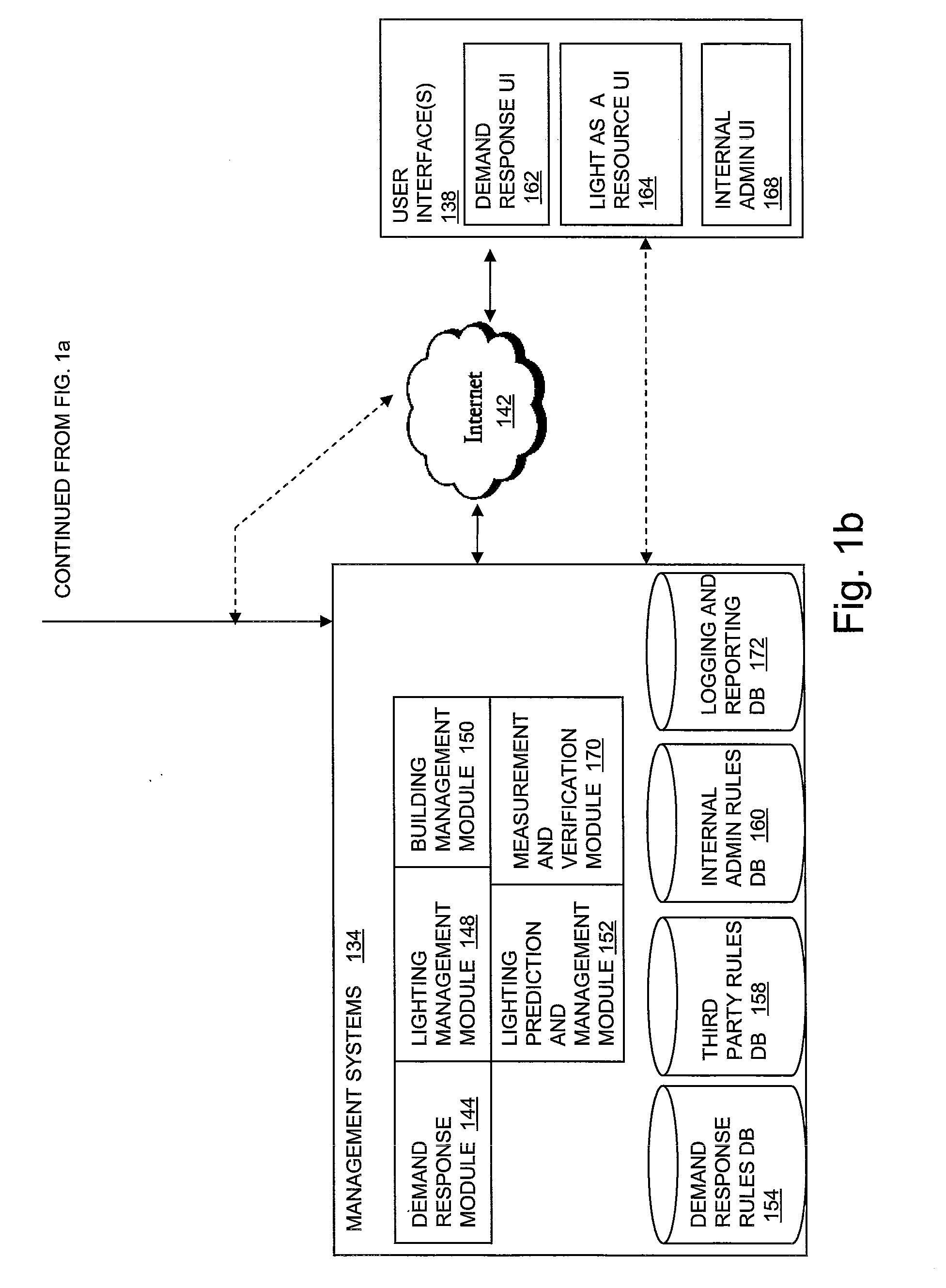

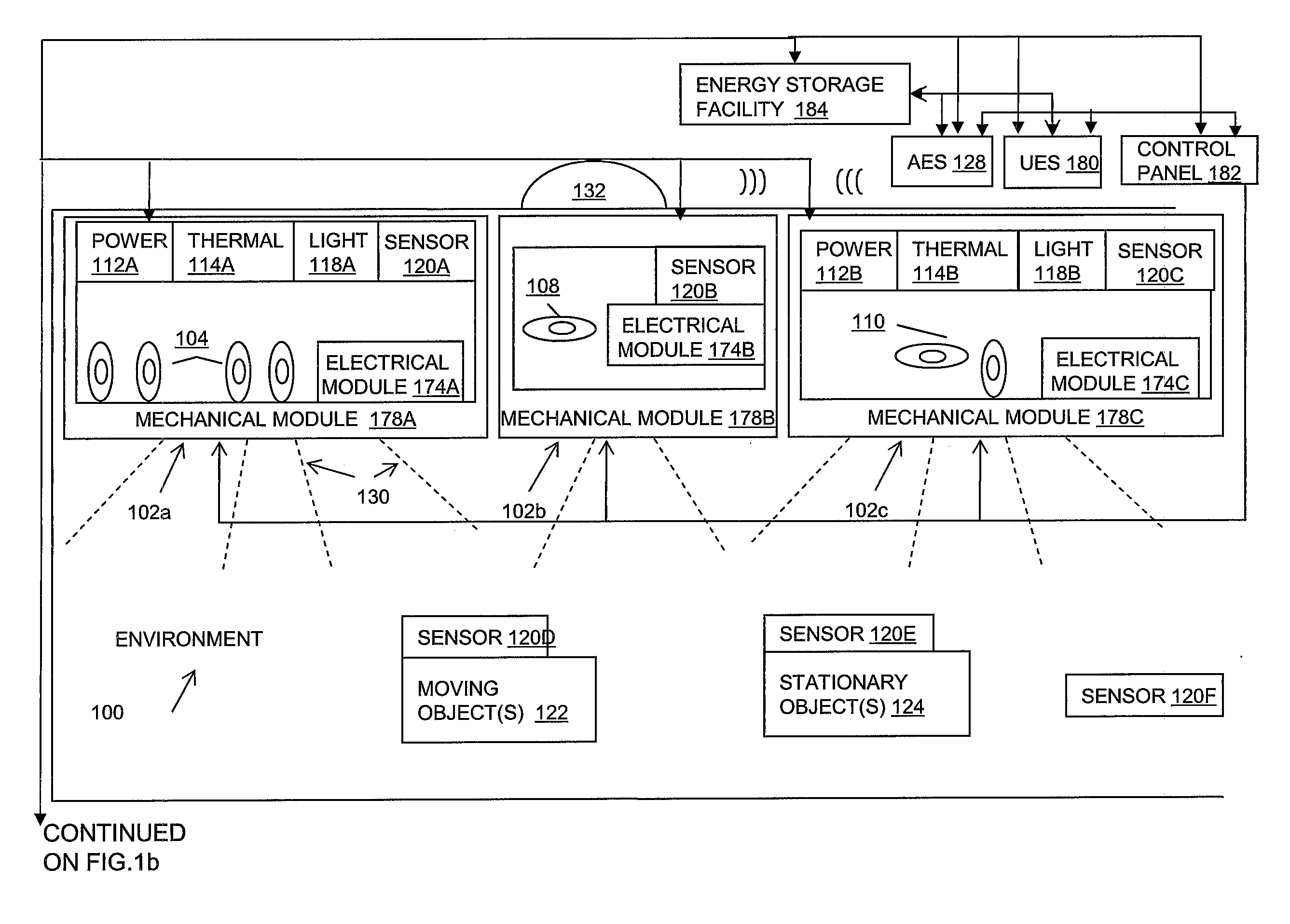

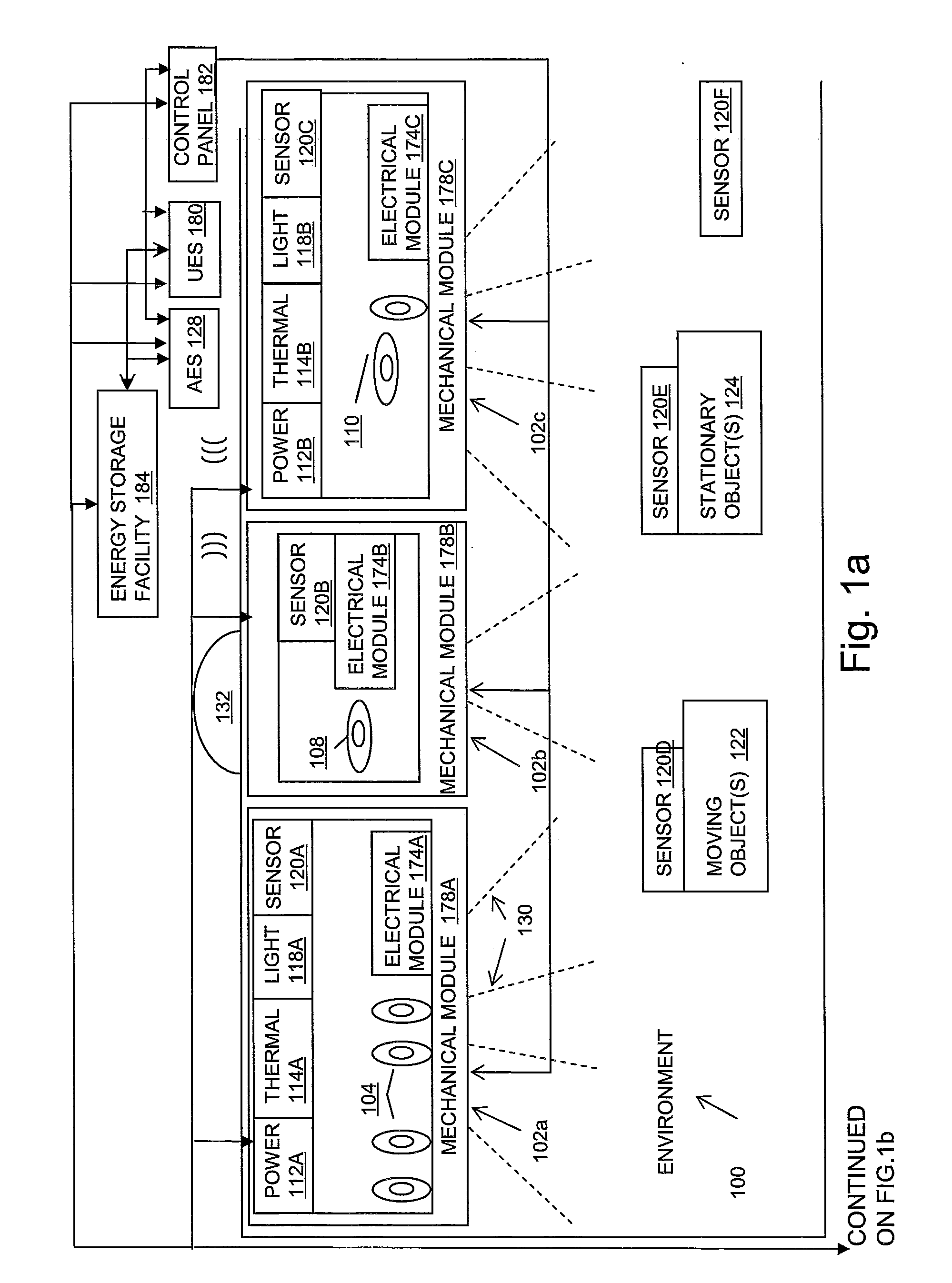

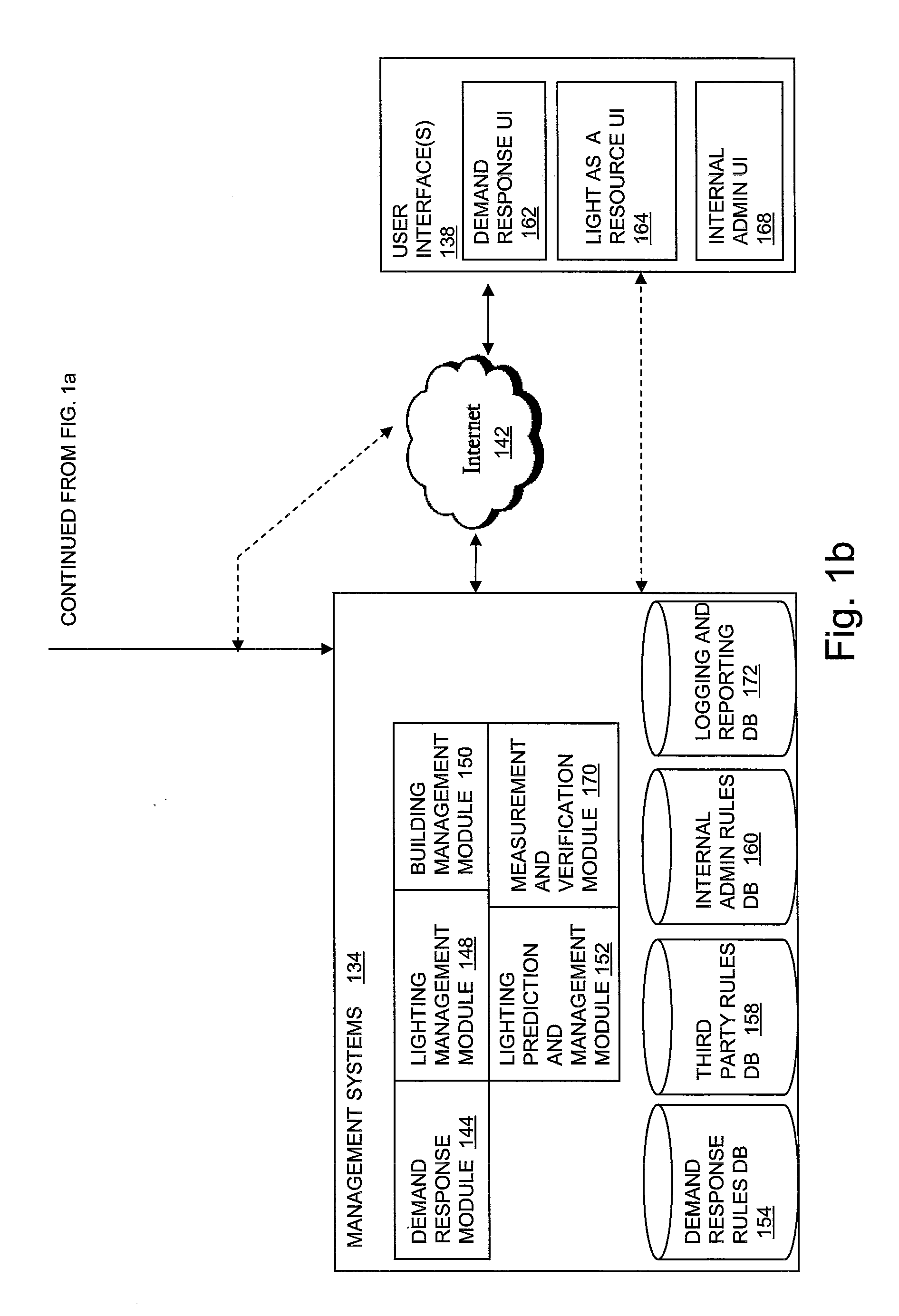

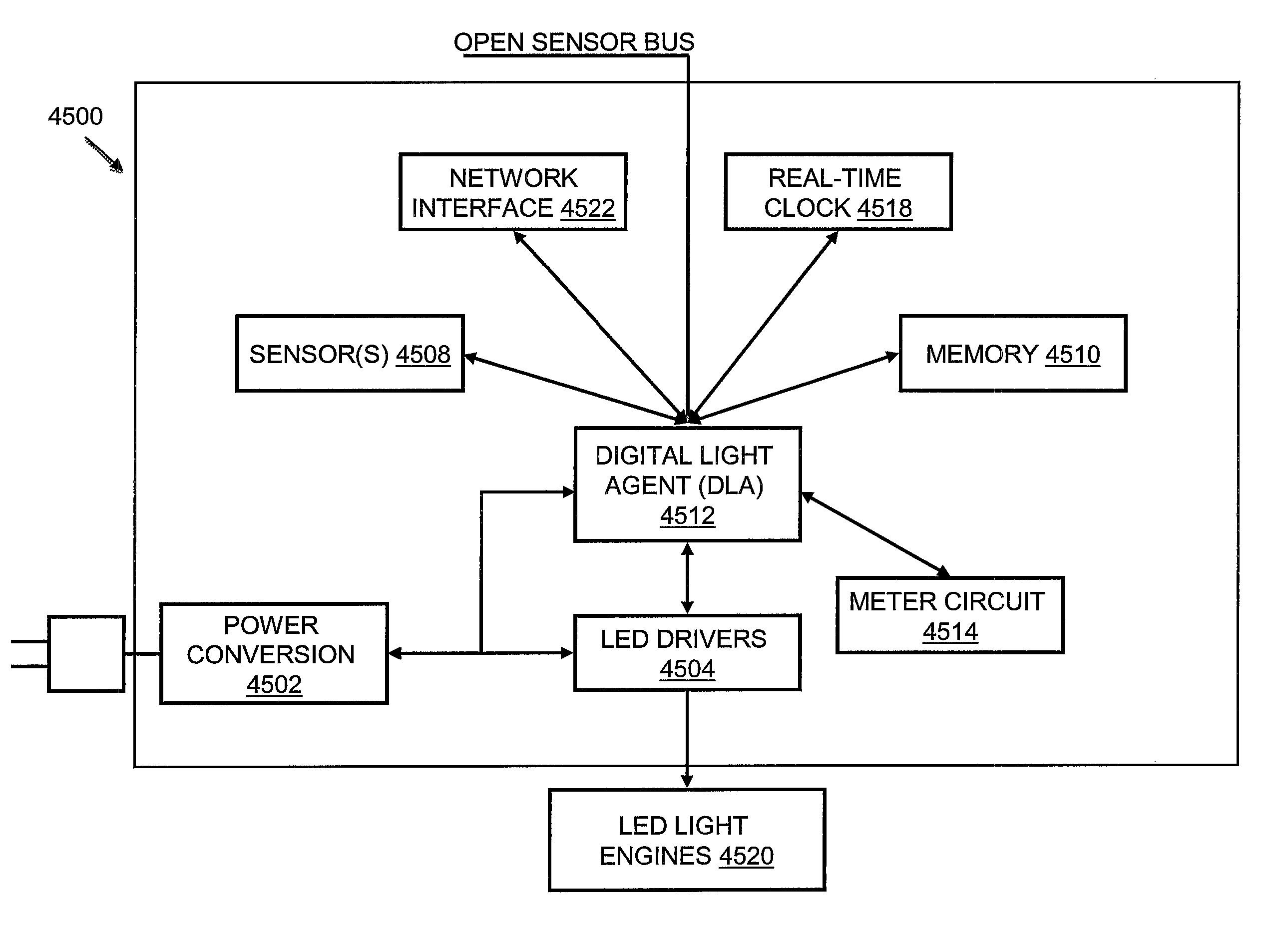

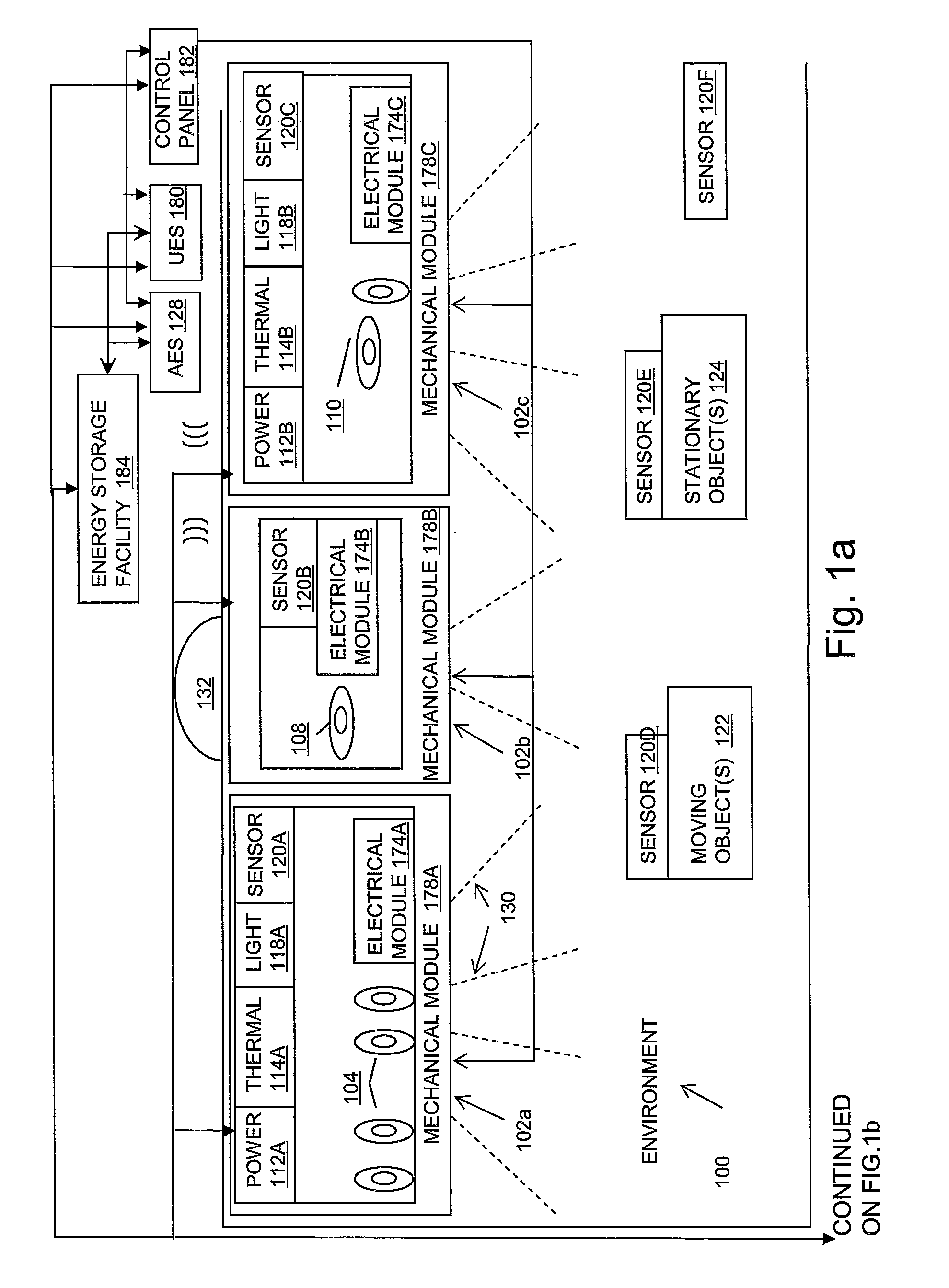

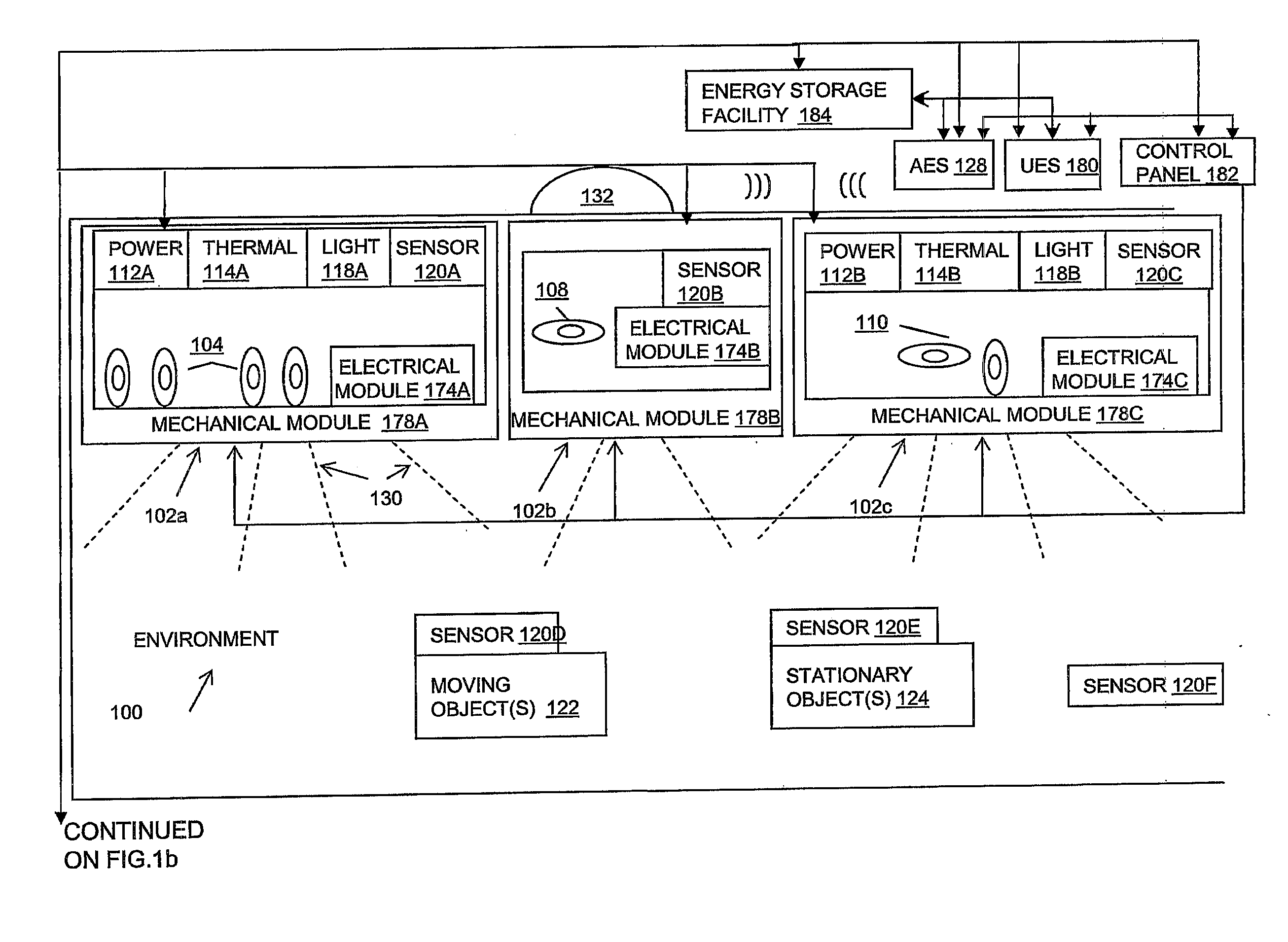

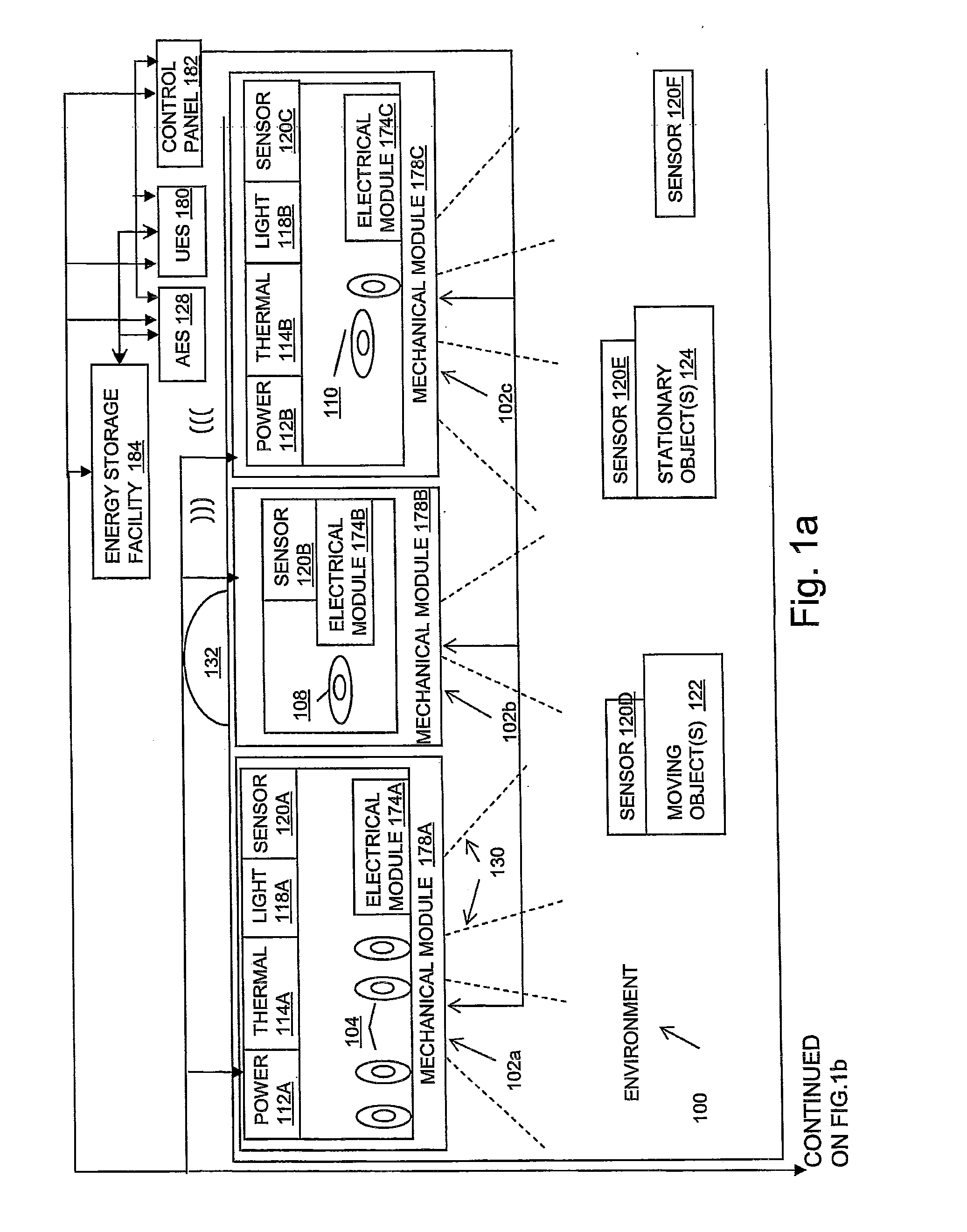

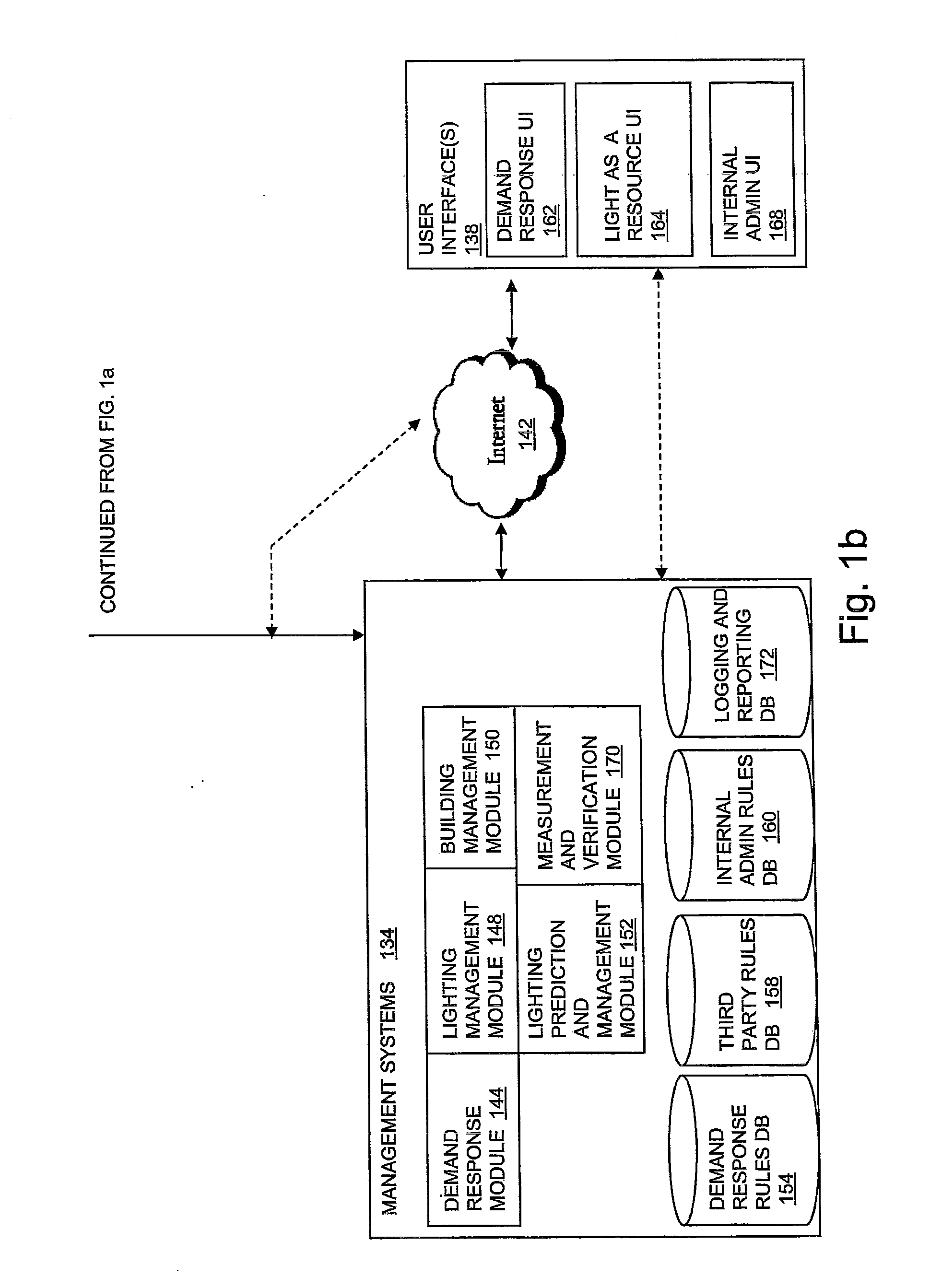

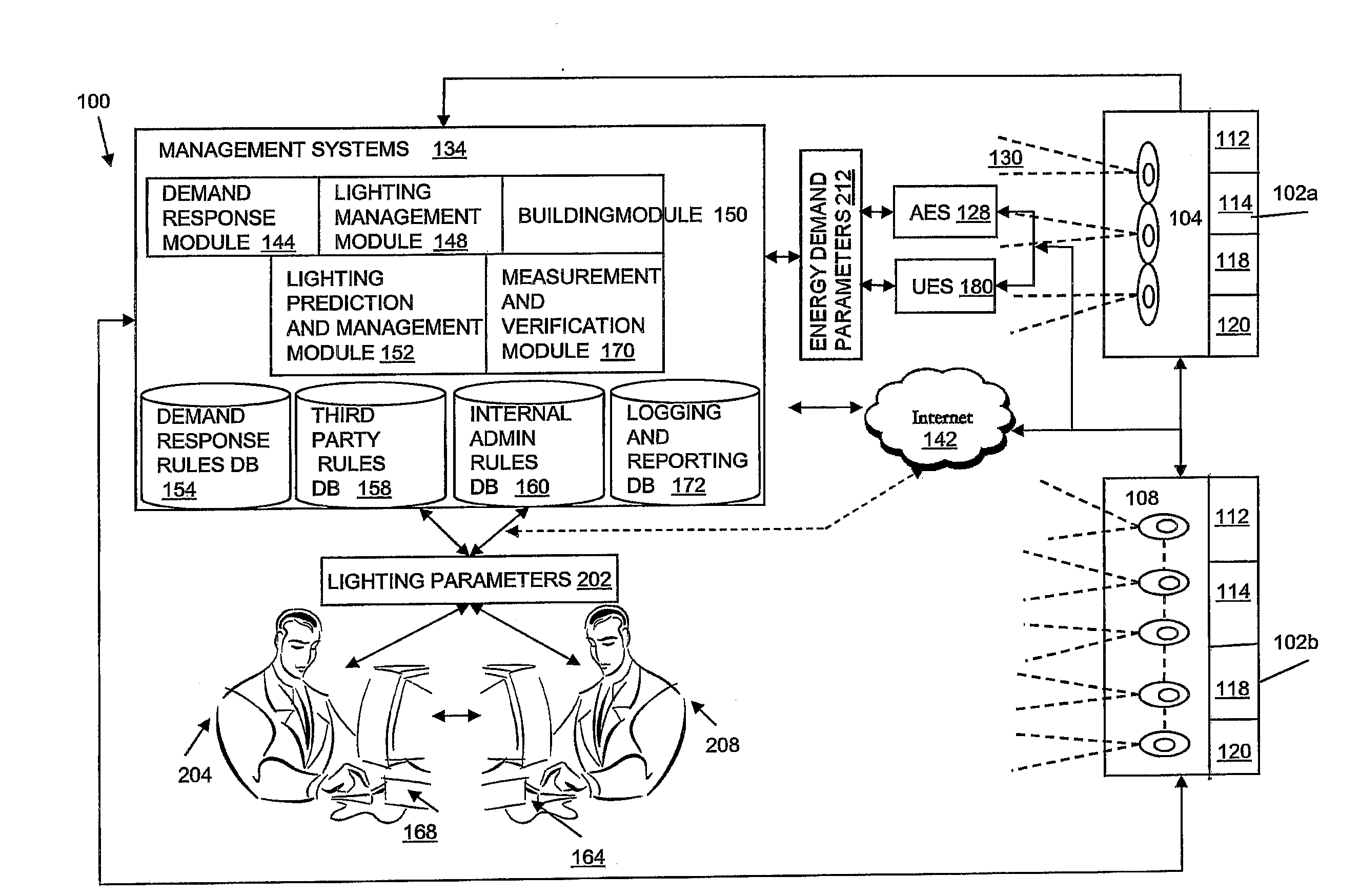

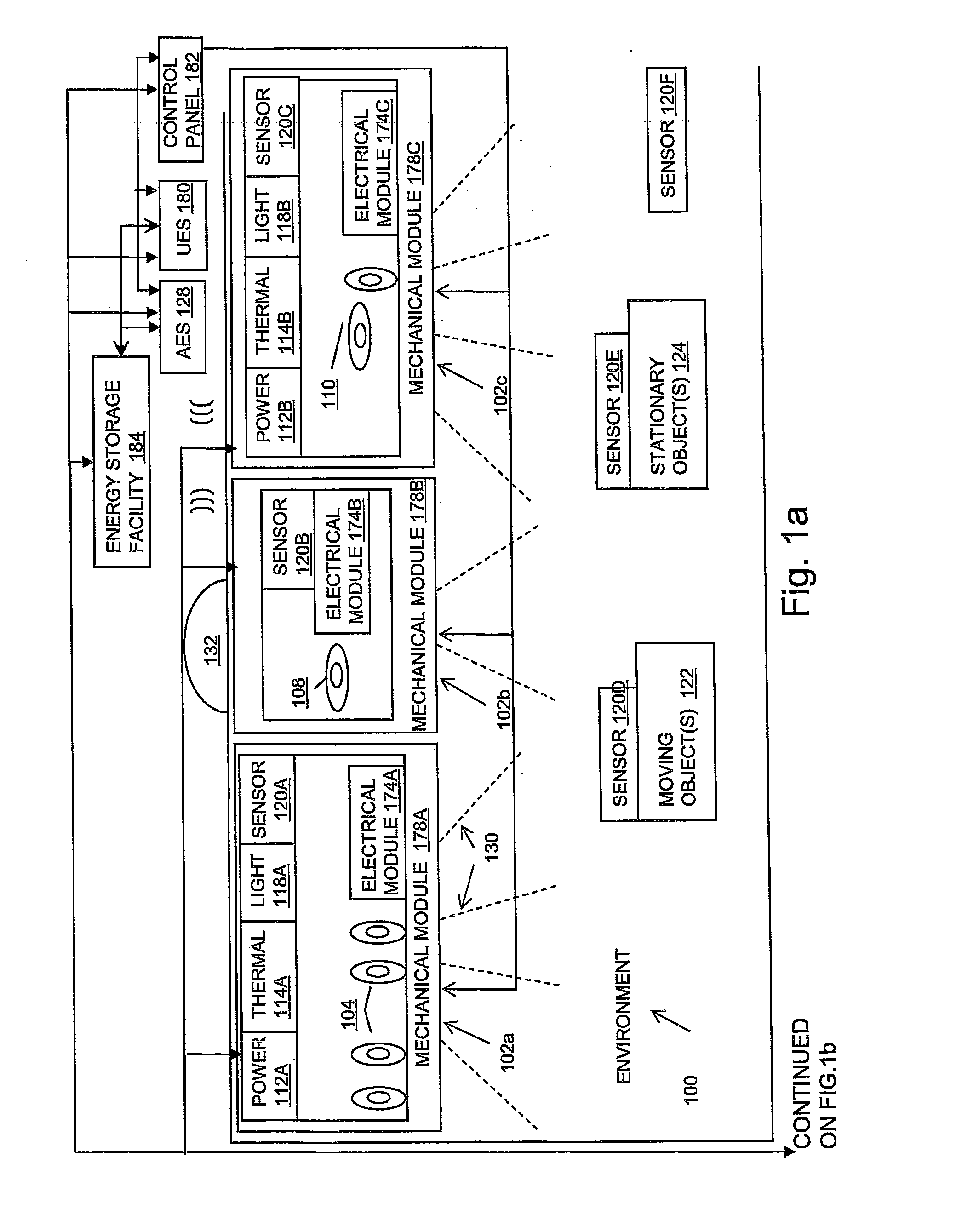

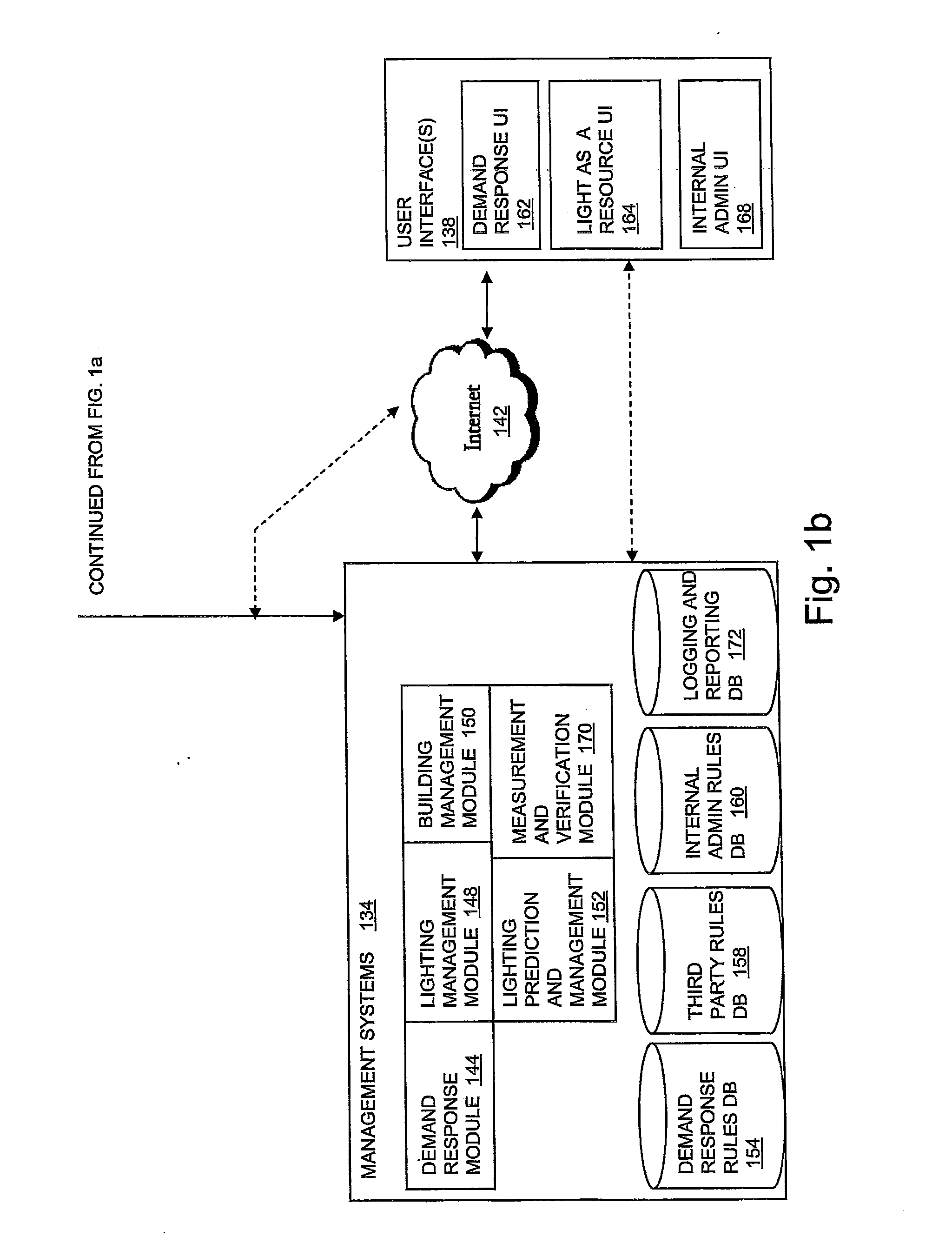

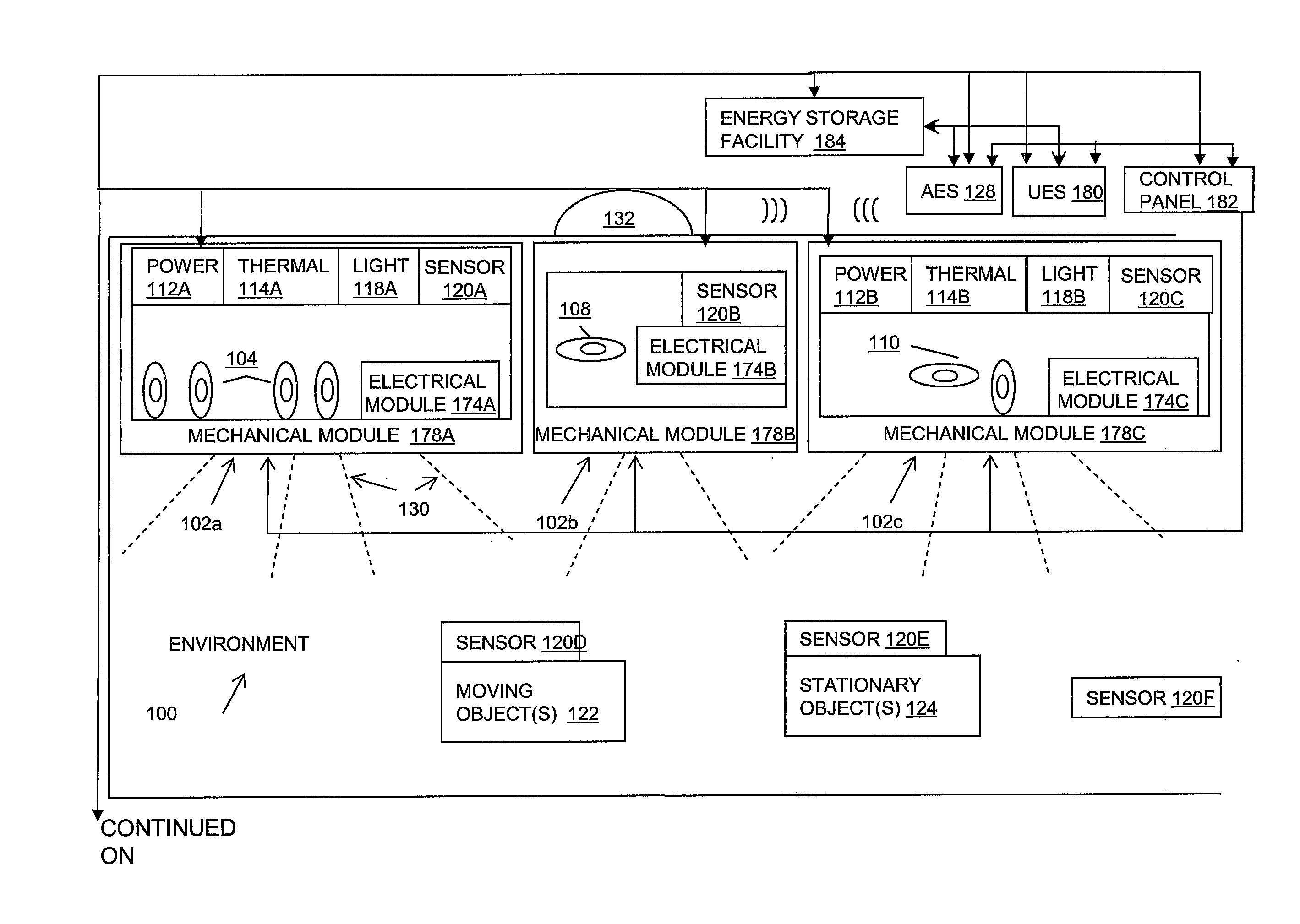

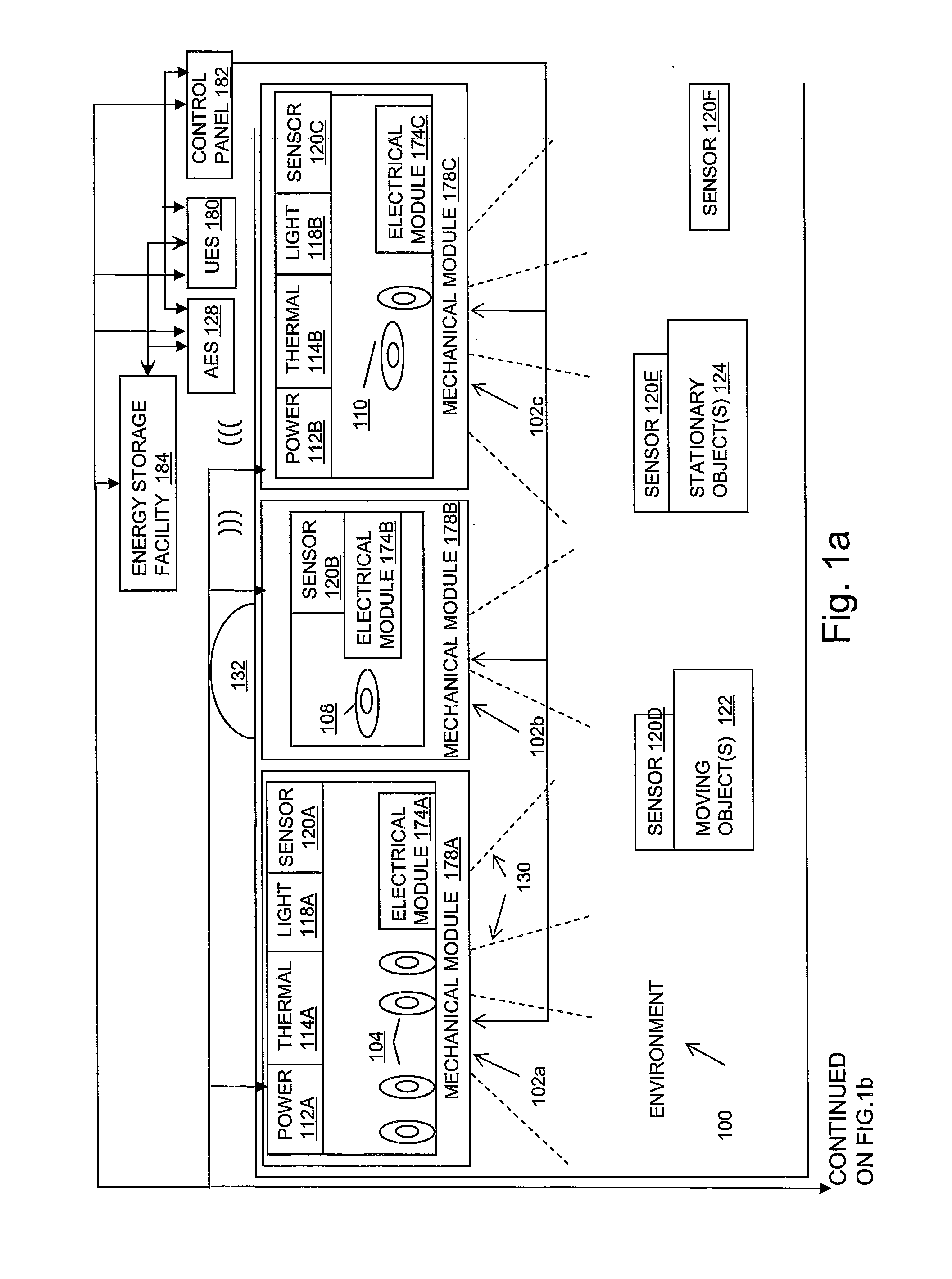

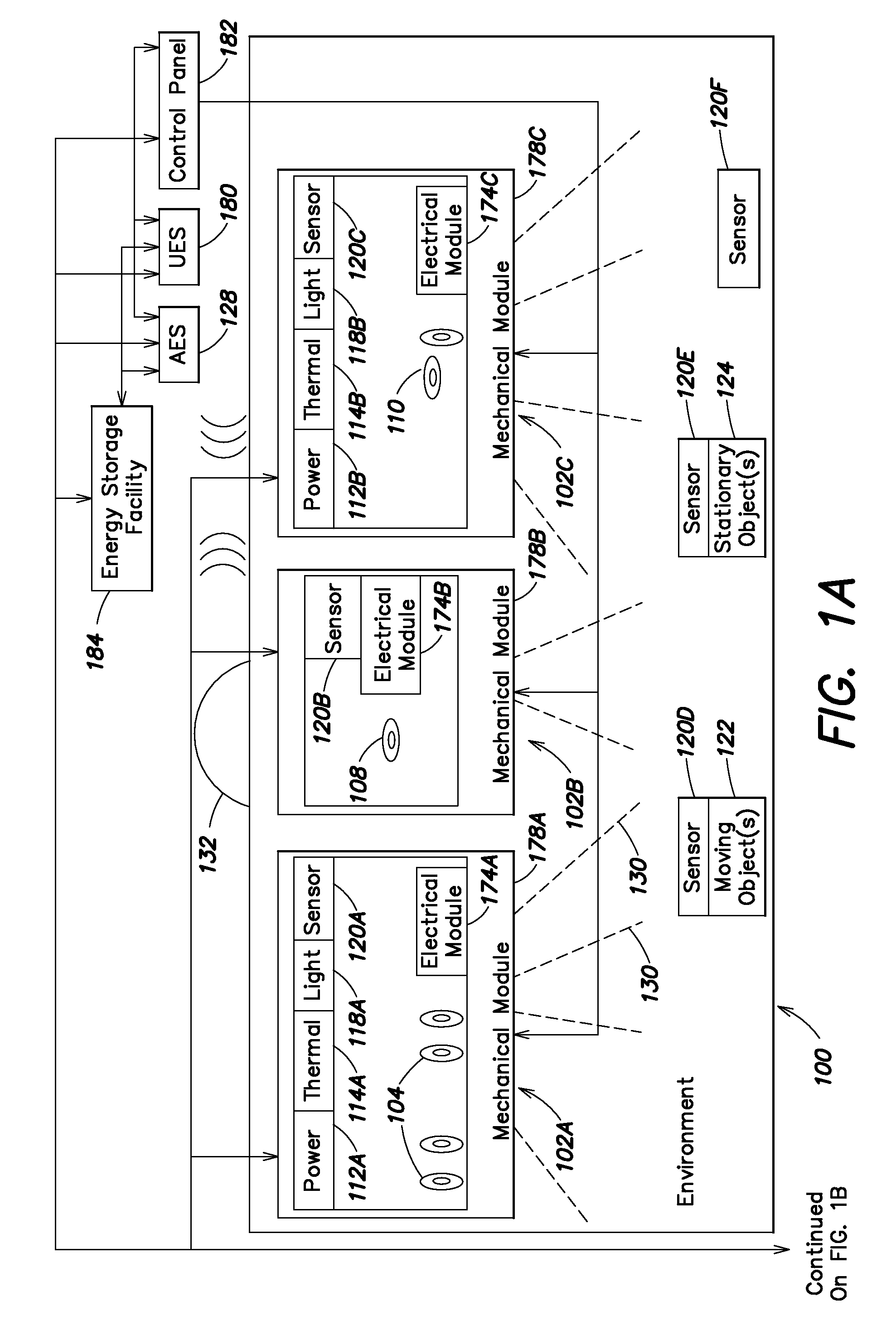

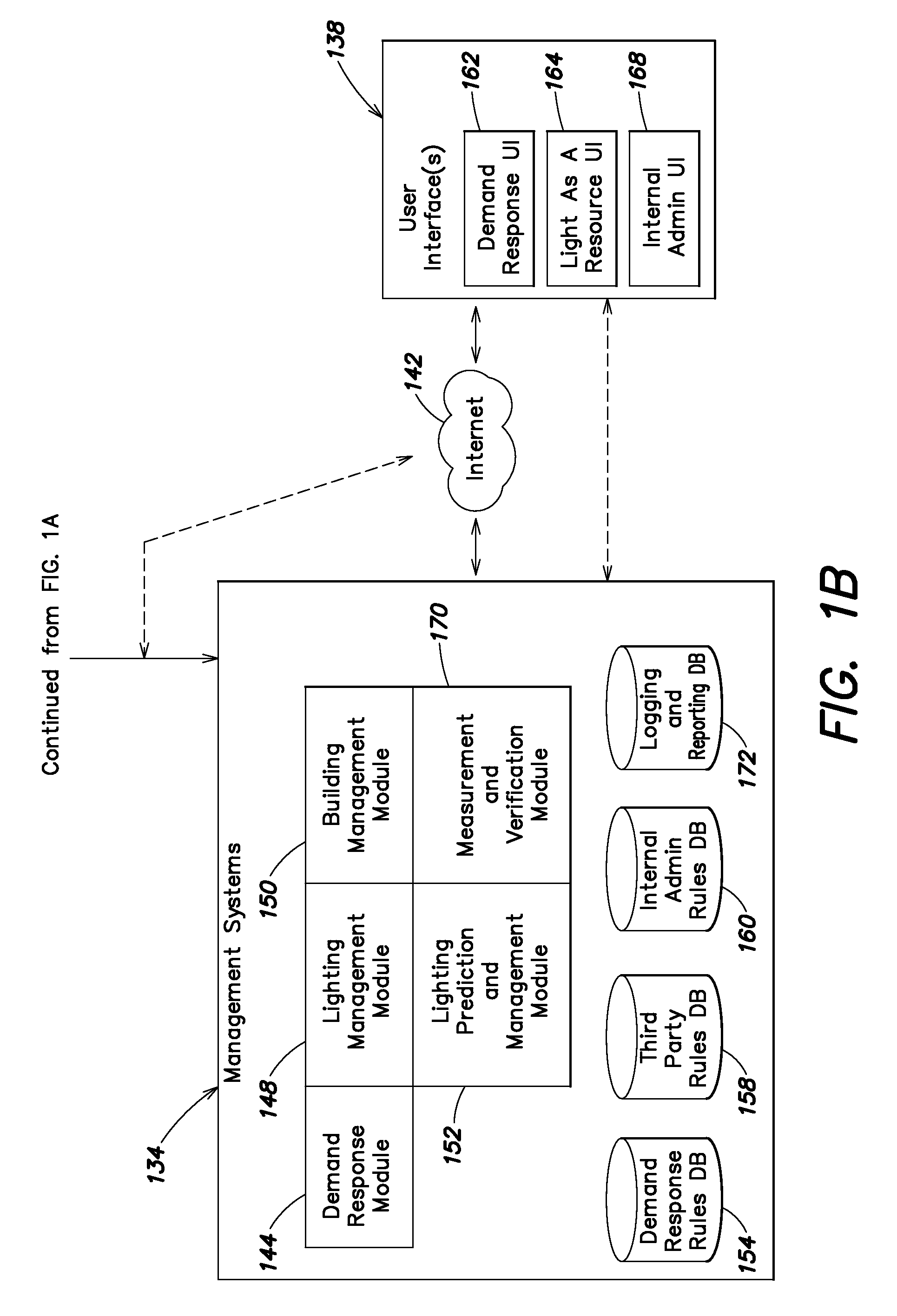

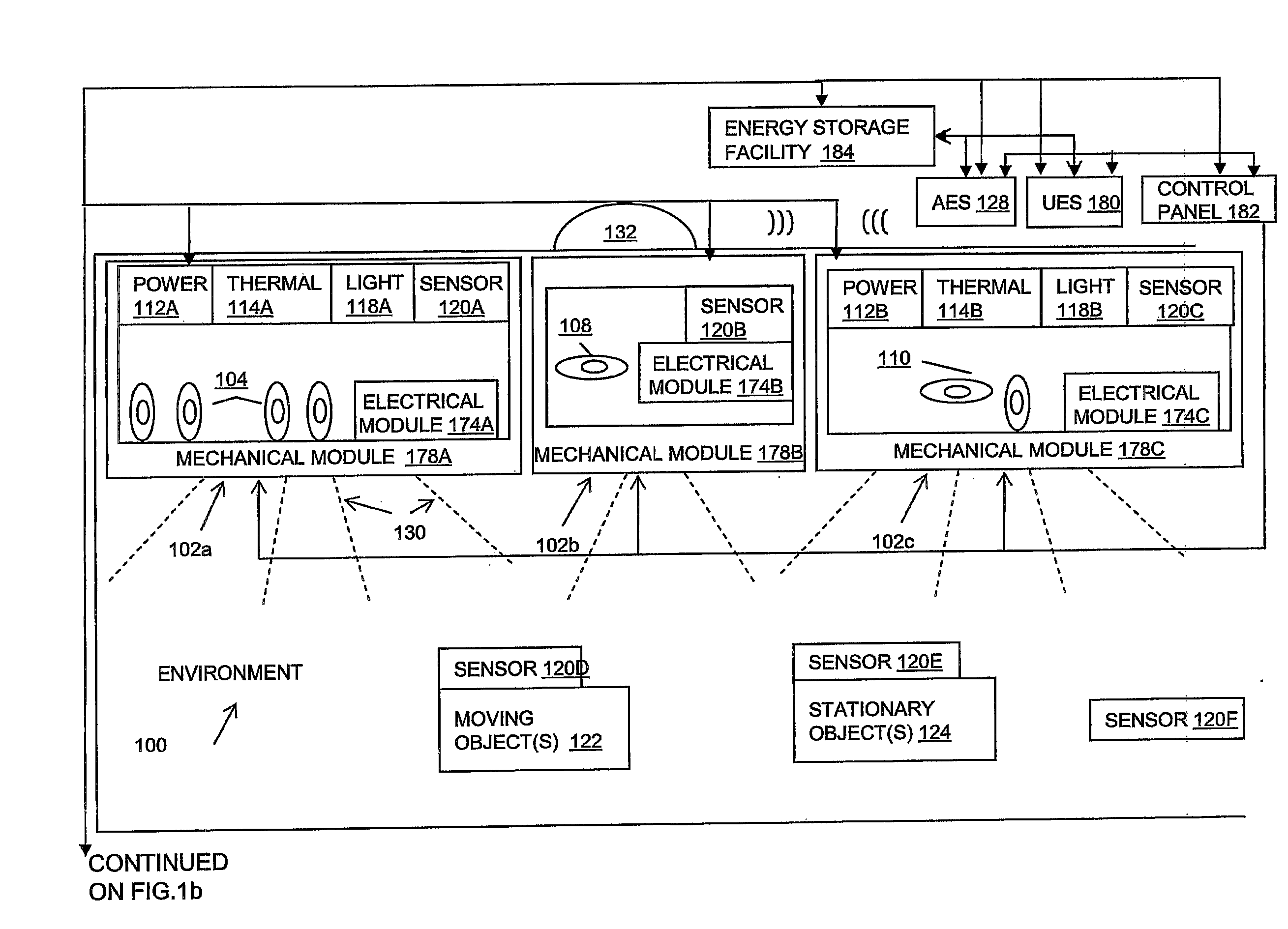

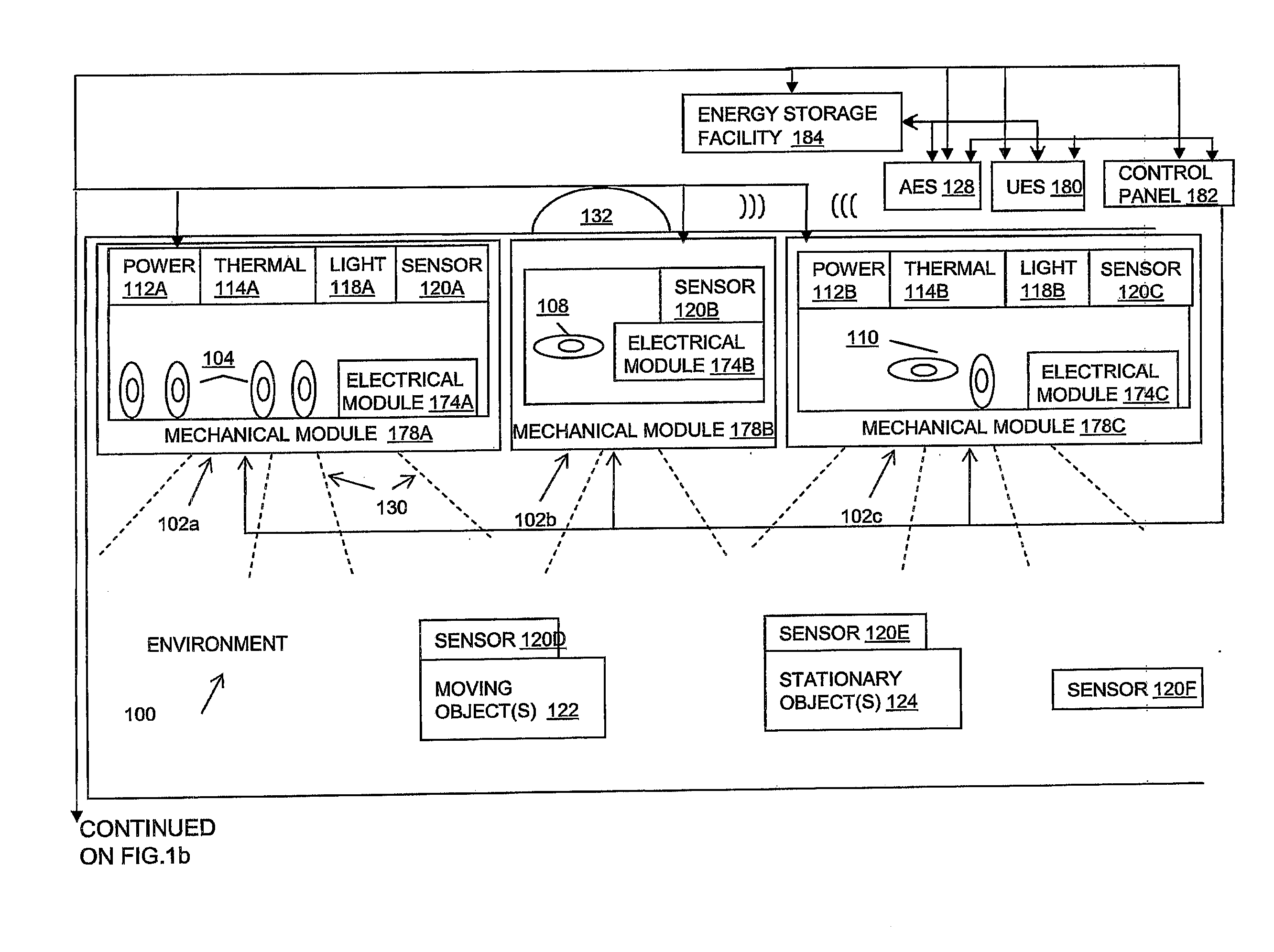

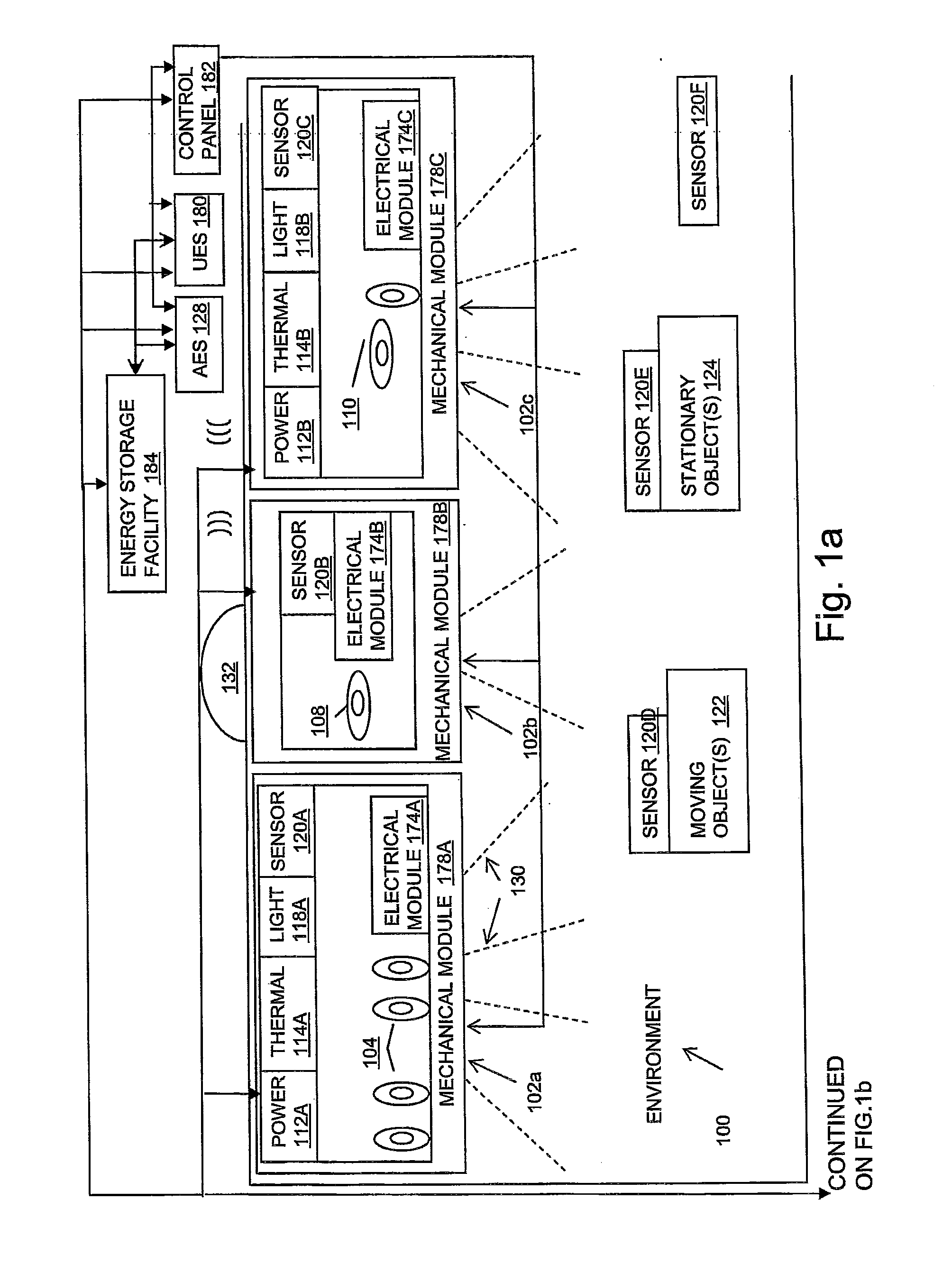

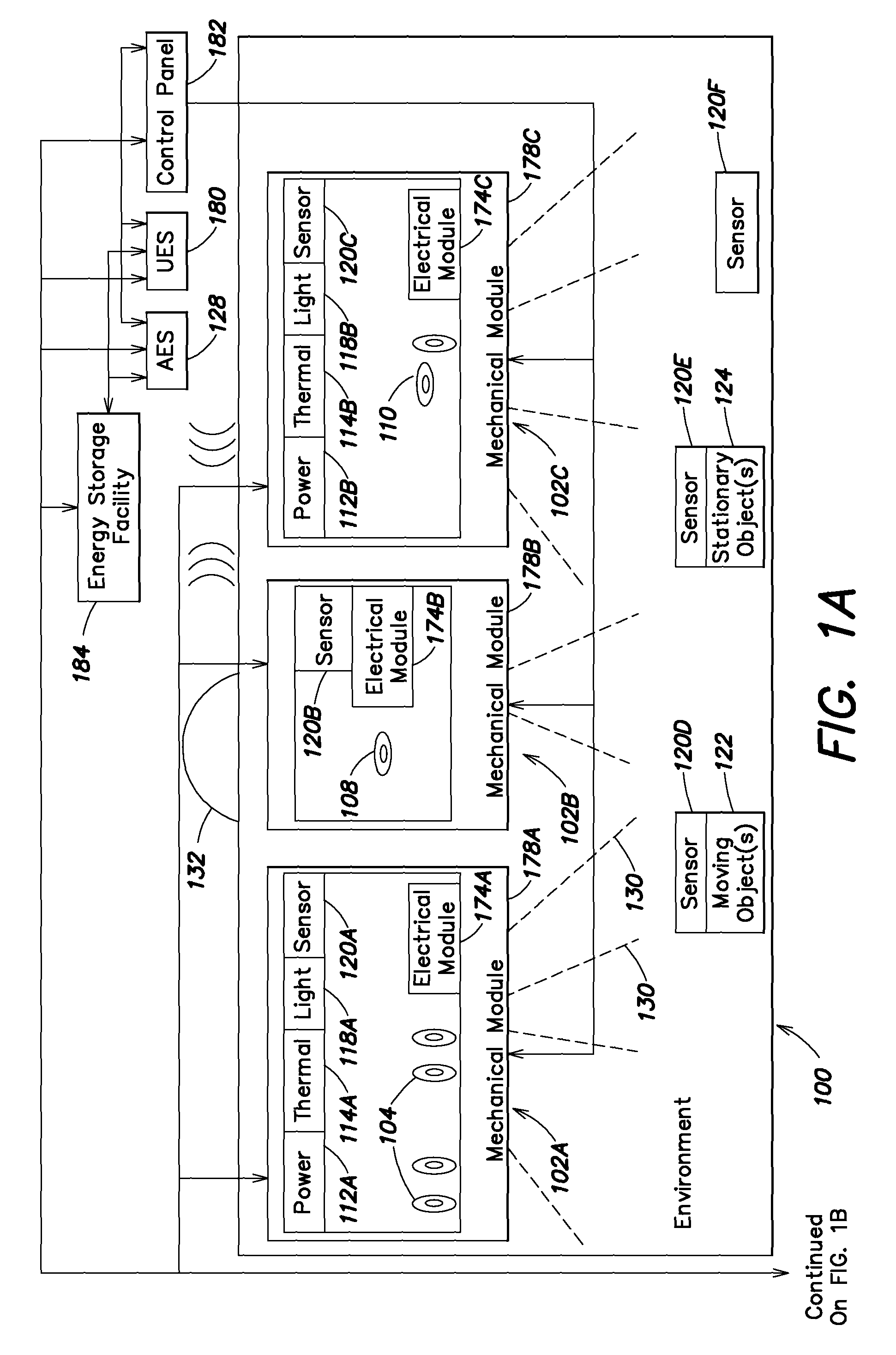

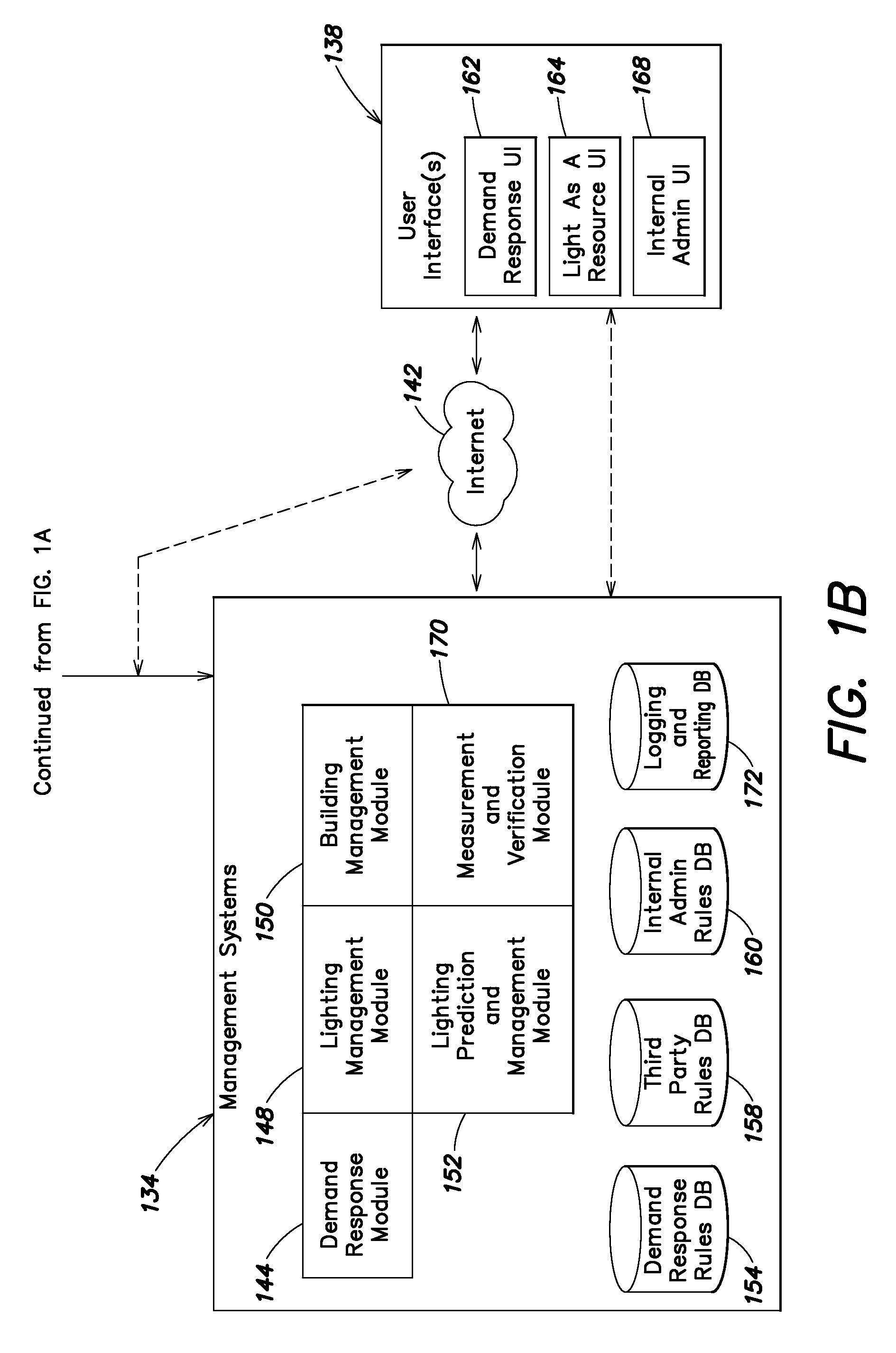

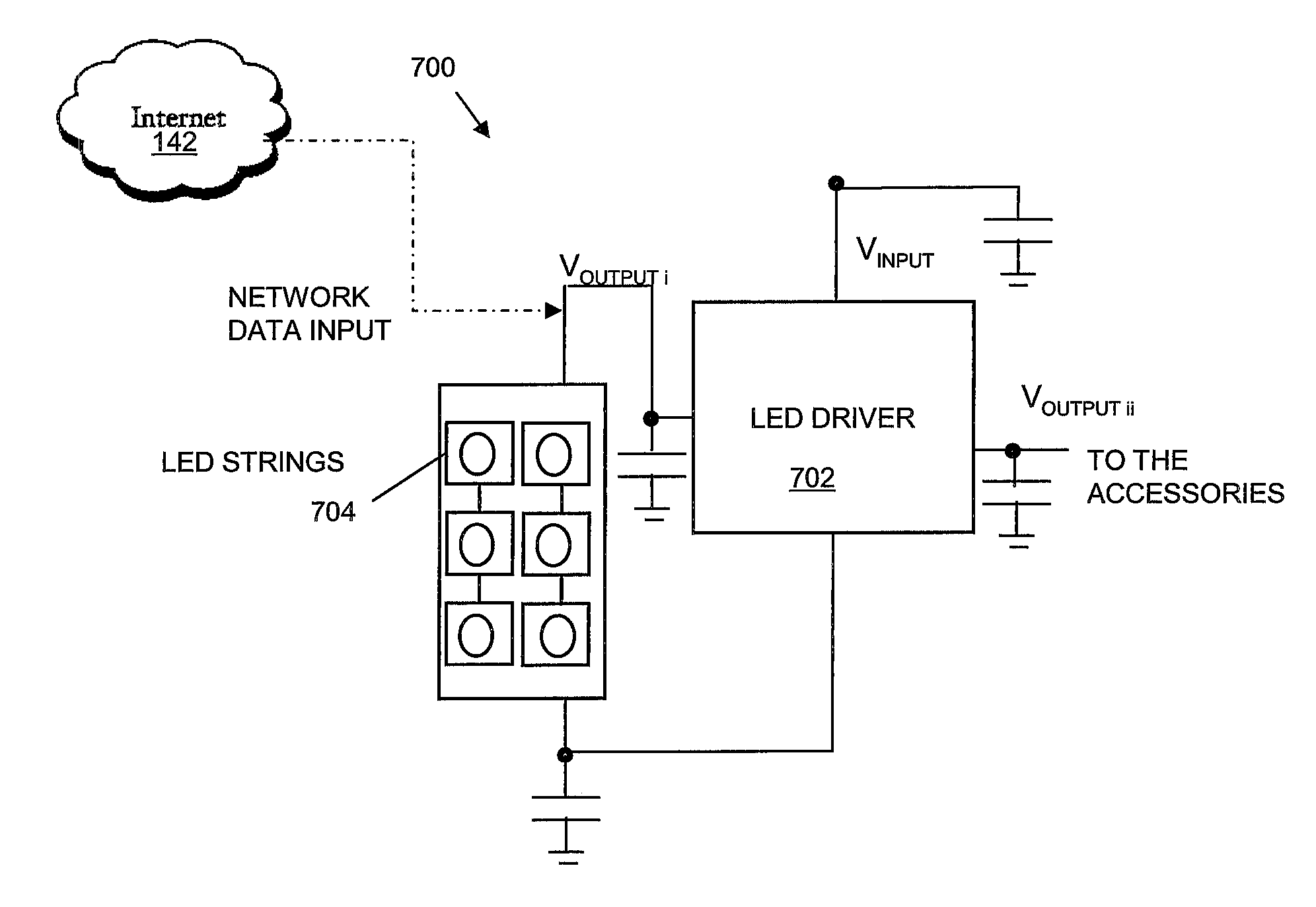

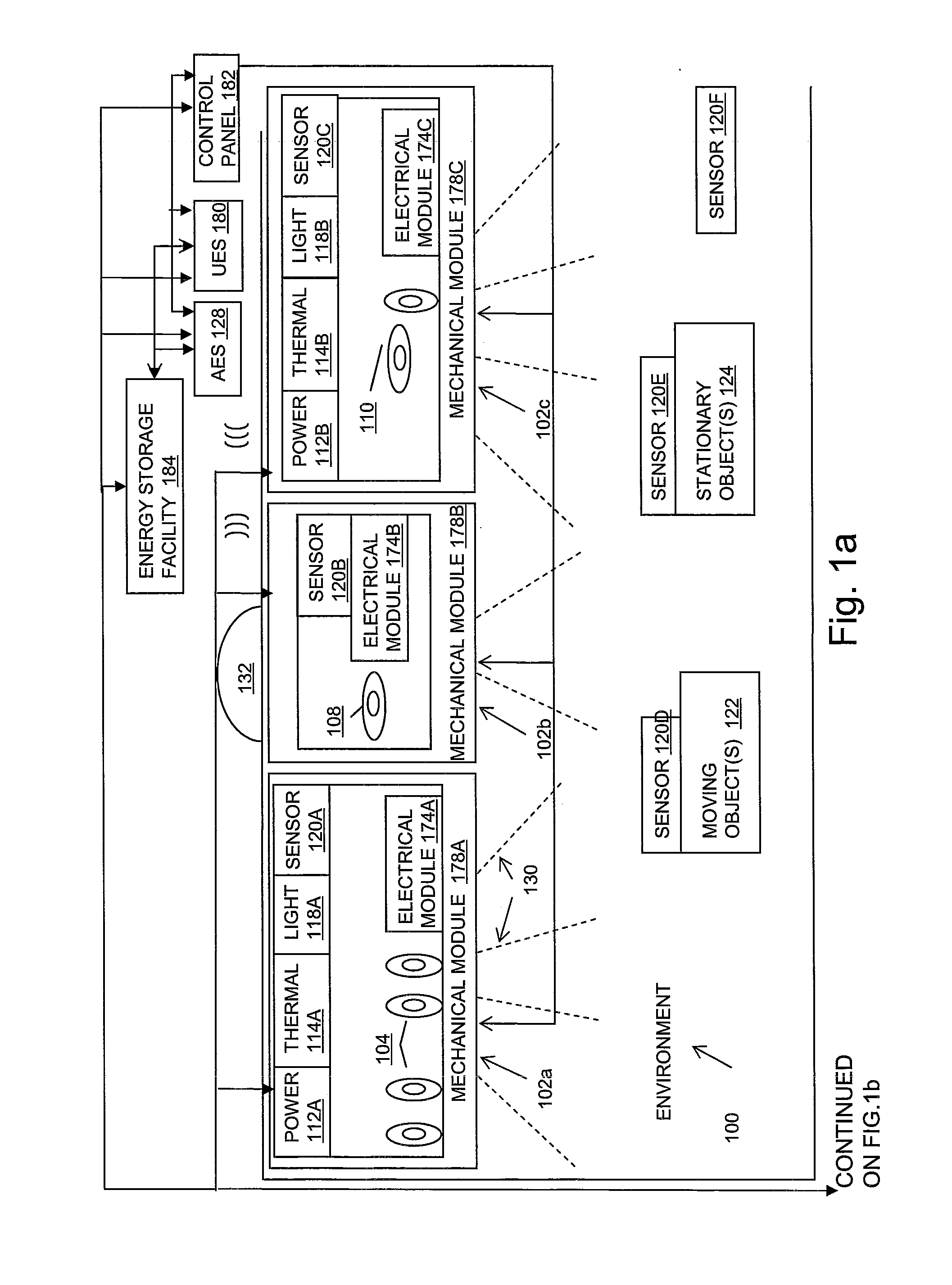

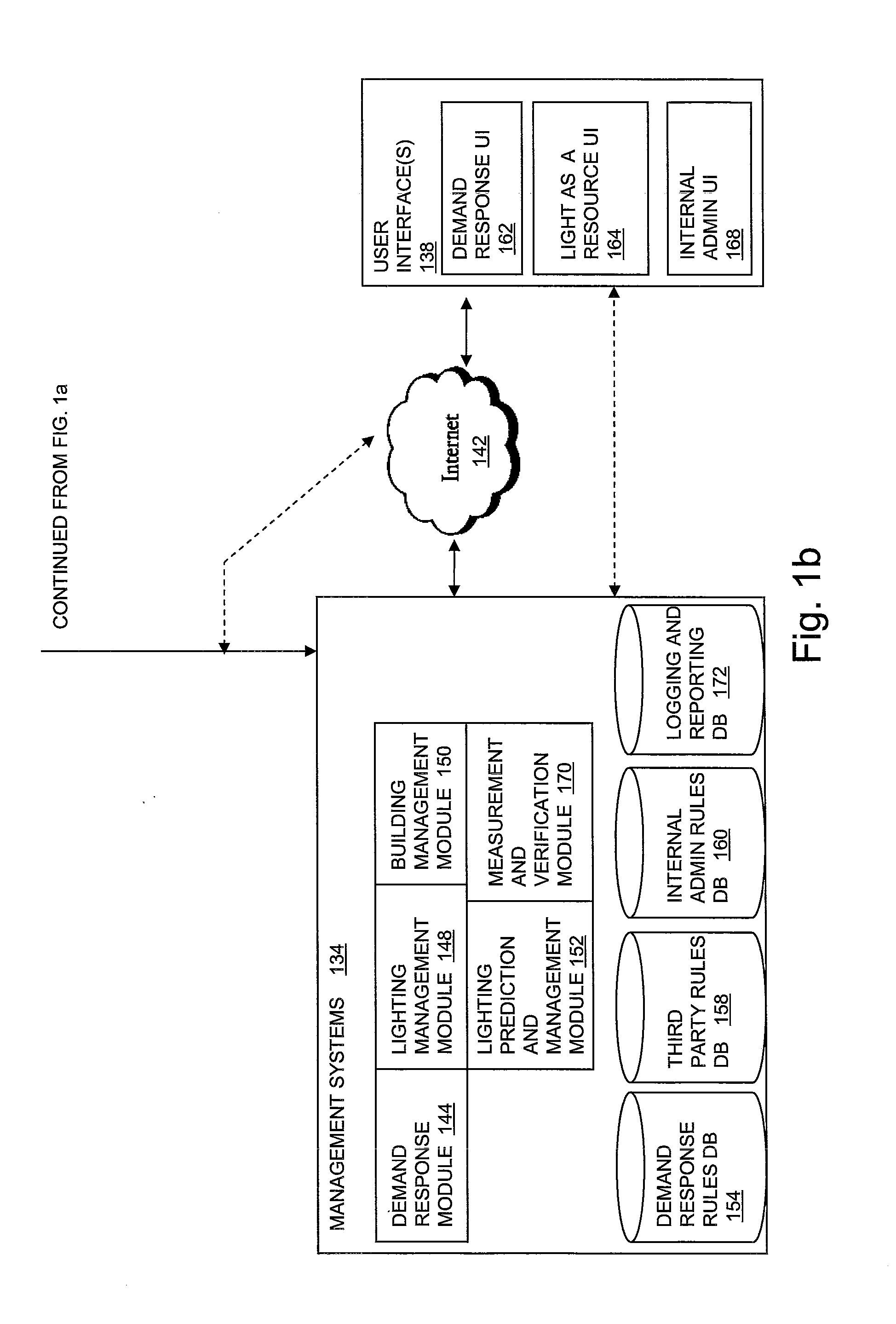

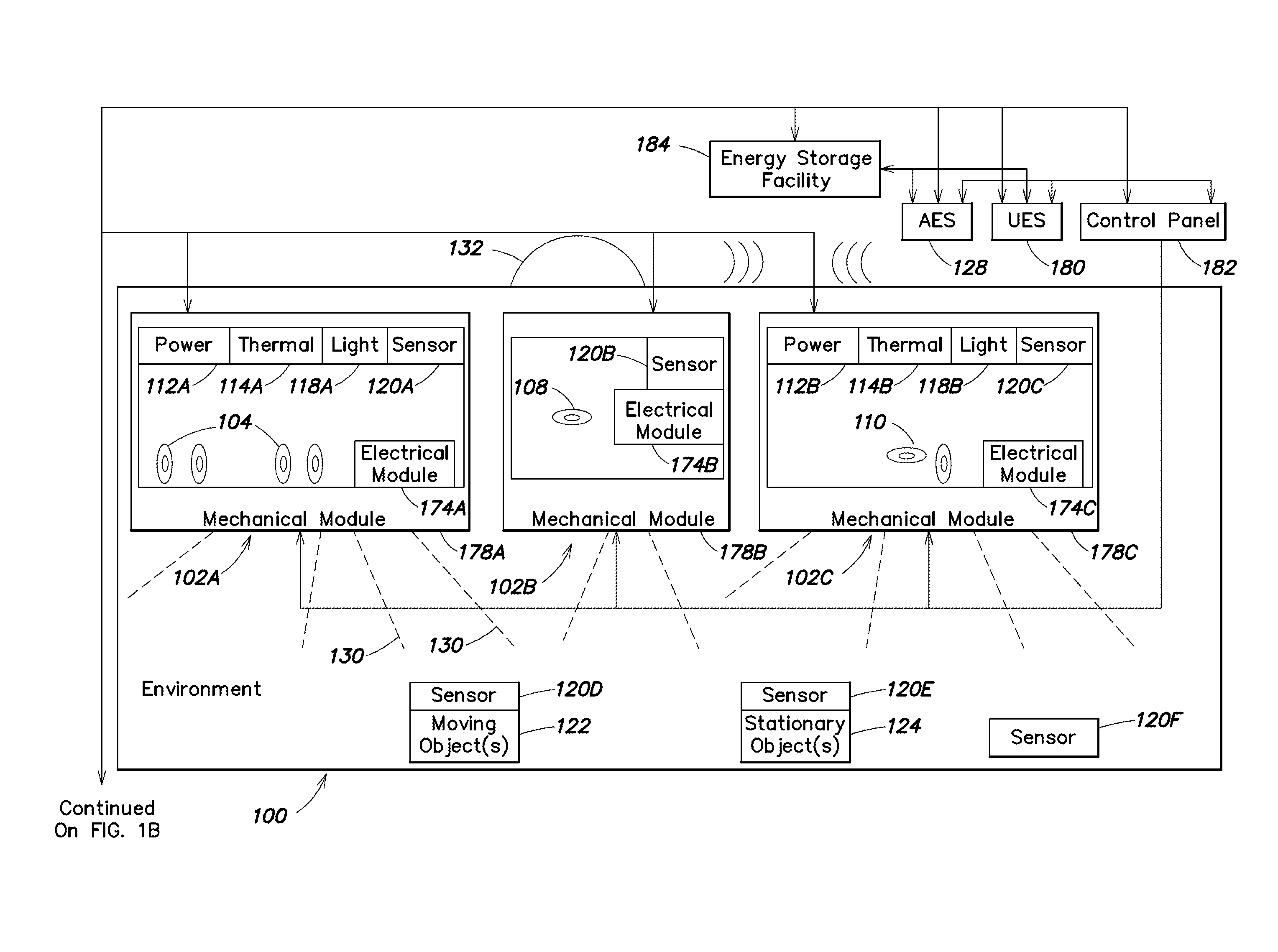

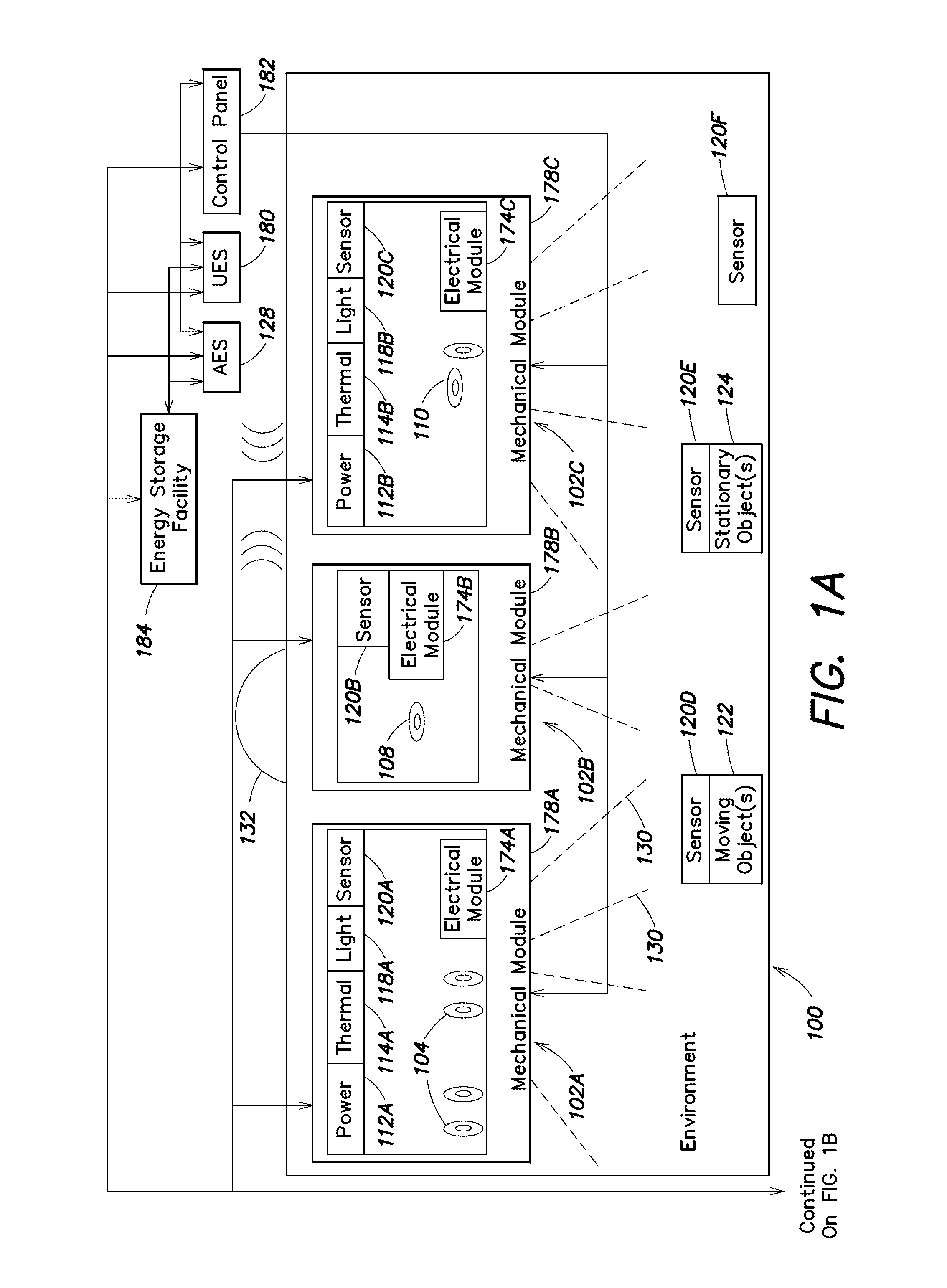

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Adaptive Dimming

ActiveUS20100264846A1Failure to compensateMaintain lightElectrical apparatusElectric light circuit arrangementSmart lightingDesign improvement

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

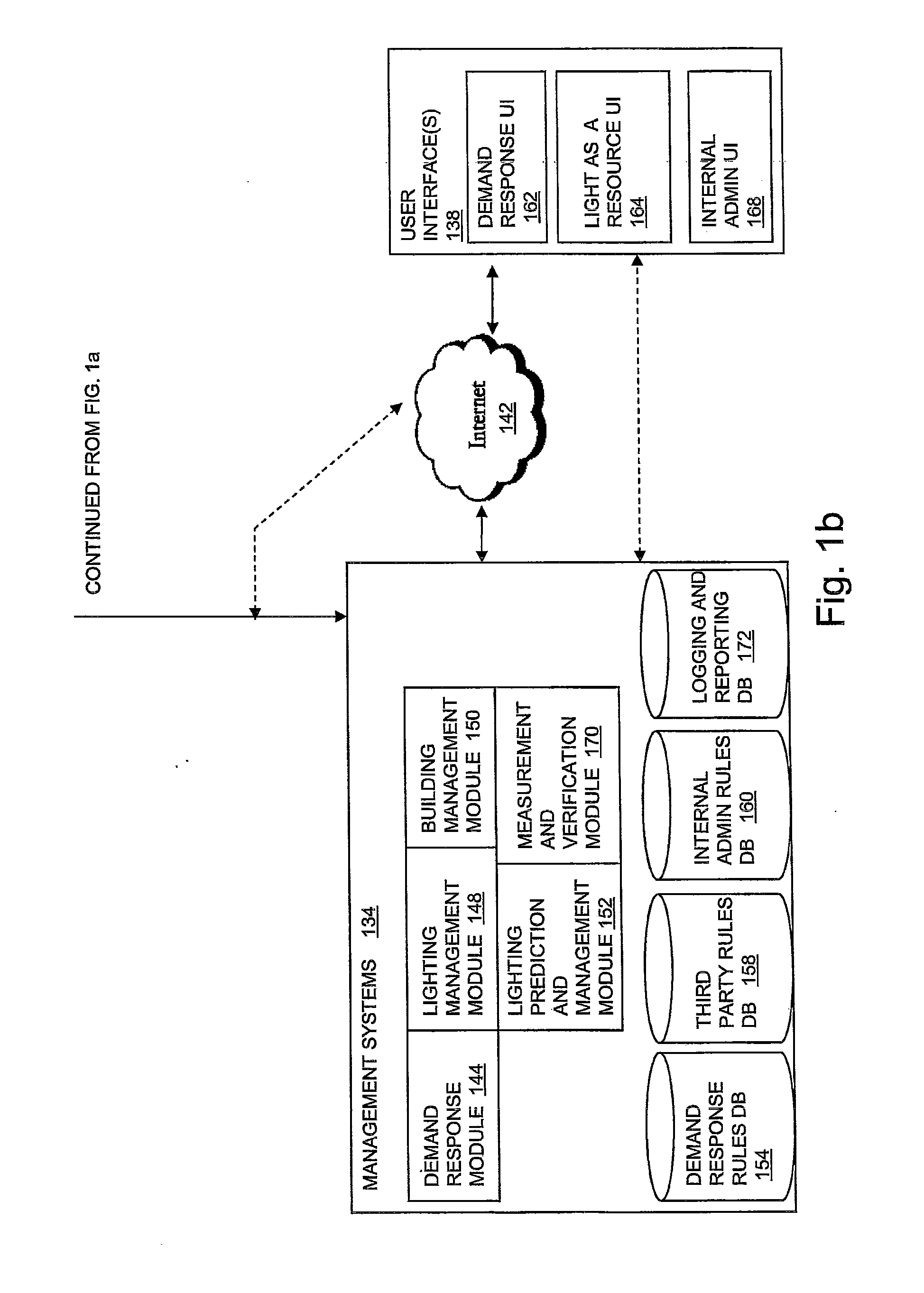

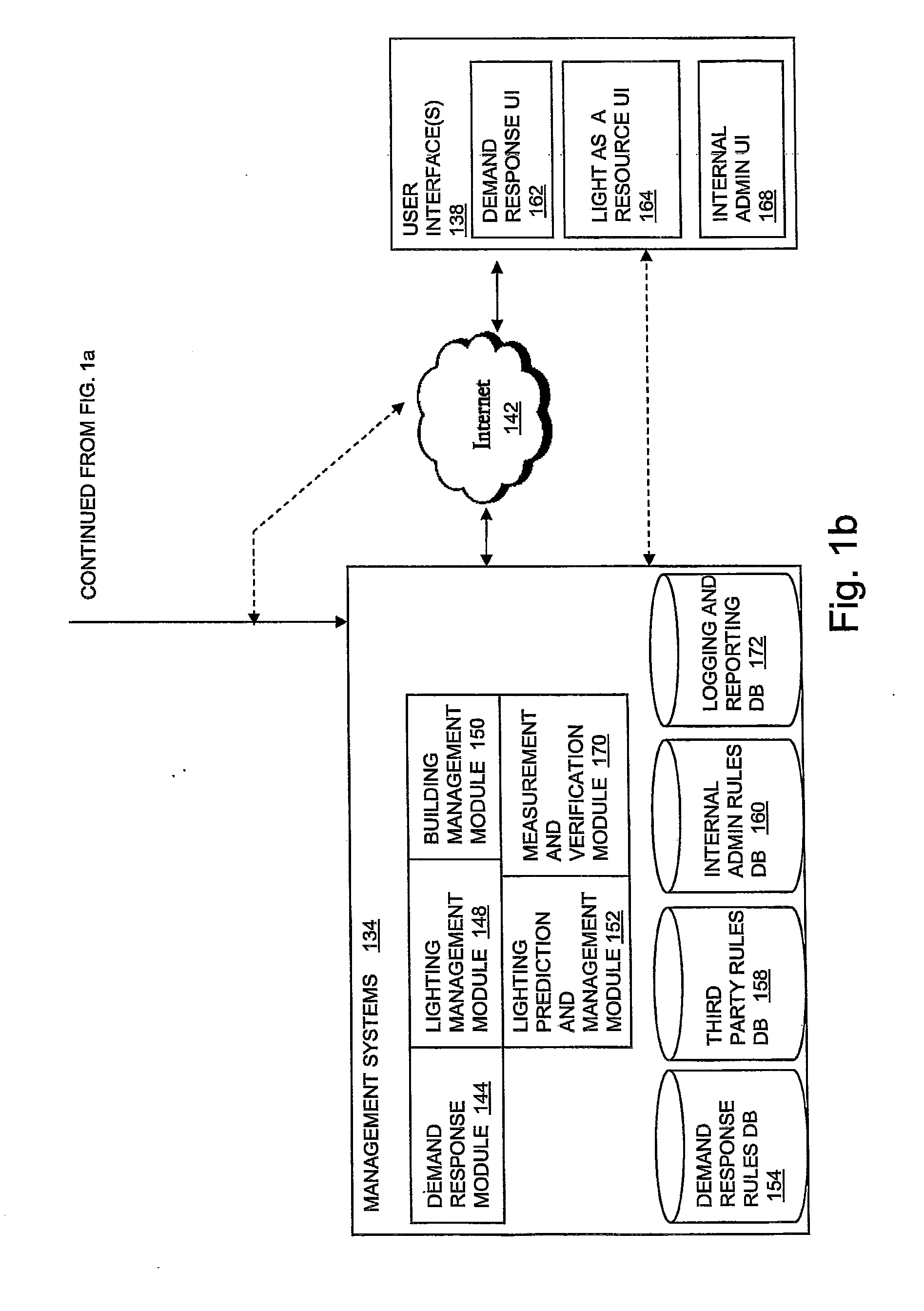

LED-based lighting methods, apparatus, and systems employing LED light bars, occupancy sensing, local state machine, and meter circuit

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Power Metering

ActiveUS20100270933A1Failure to compensateMaintain lightDischarge tube incandescent screensPlanar light sourcesDesign improvementSmart lighting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

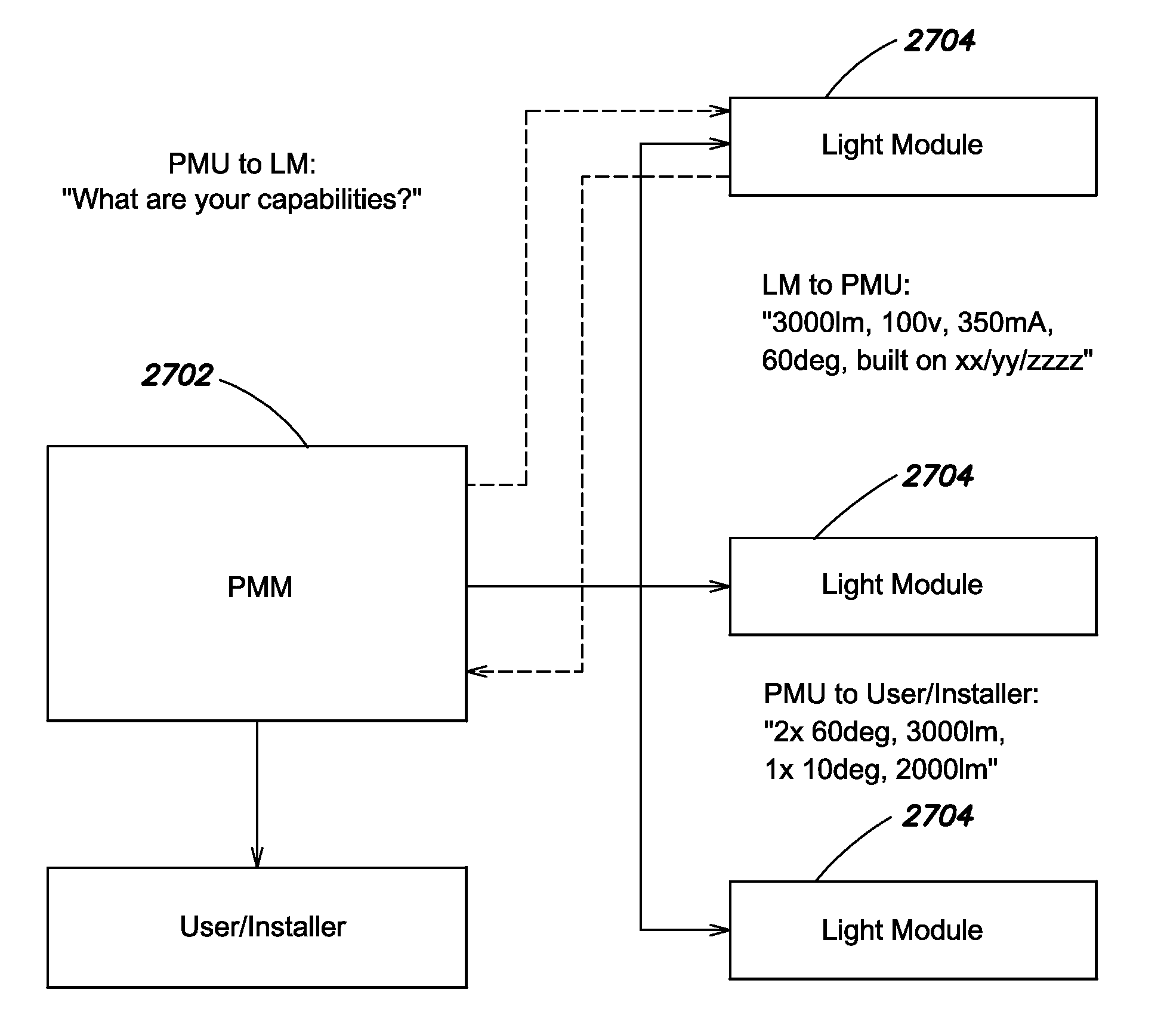

Power Management Unit with Light Module Identification

ActiveUS20110001436A1Failure to compensateMaintain lightElectrical apparatusElectric light circuit arrangementDesign improvementSmart lighting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Multi-Input Arbitration

ActiveUS20100295482A1Failure to compensateMaintain lightElectrical apparatusElectric light circuit arrangementMulti inputDesign improvement

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Remote Reporting

ActiveUS20100301769A1Failure to compensateMaintain lightPlanar light sourcesMechanical apparatusSmart lightingDesign improvement

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

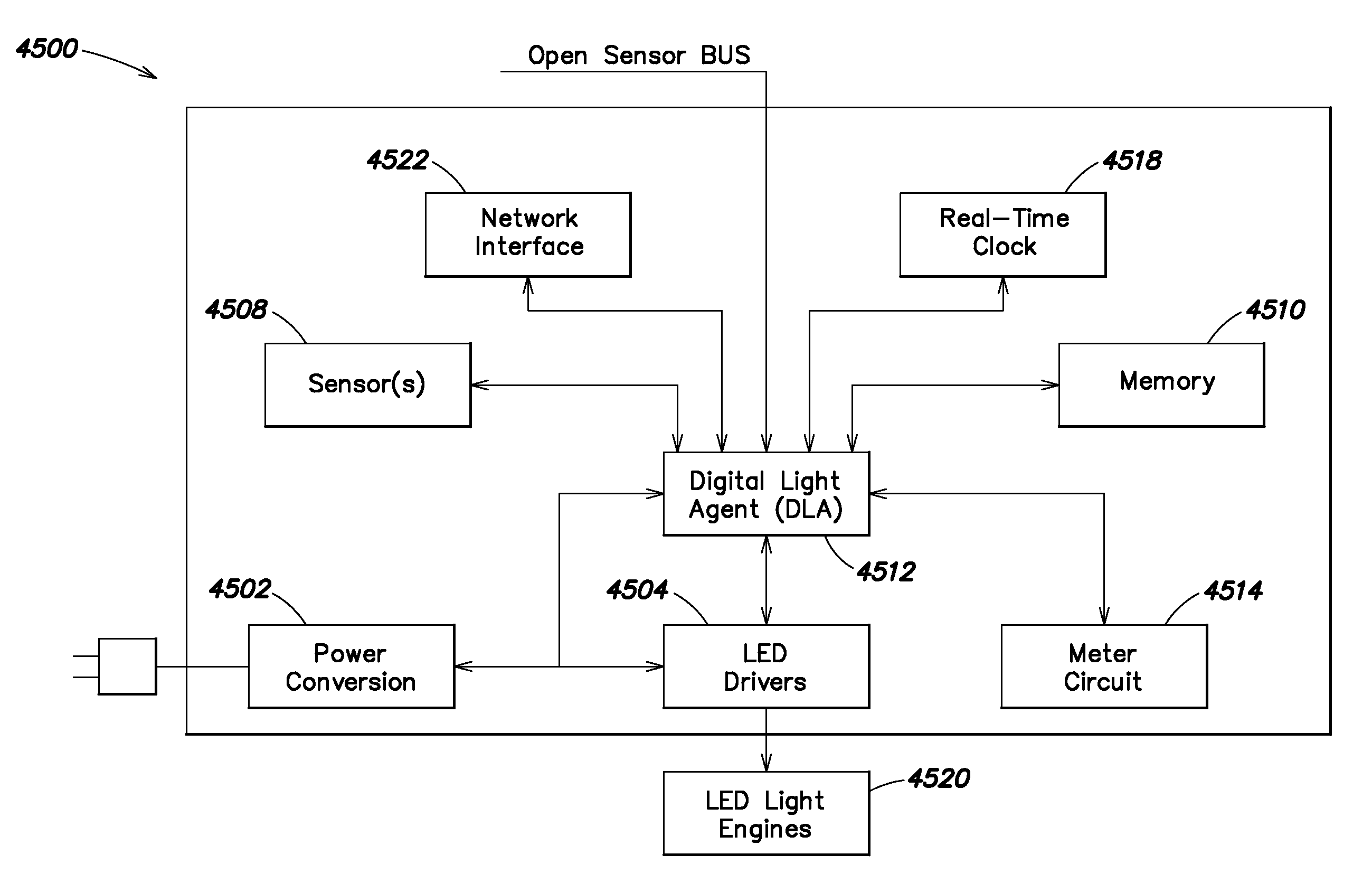

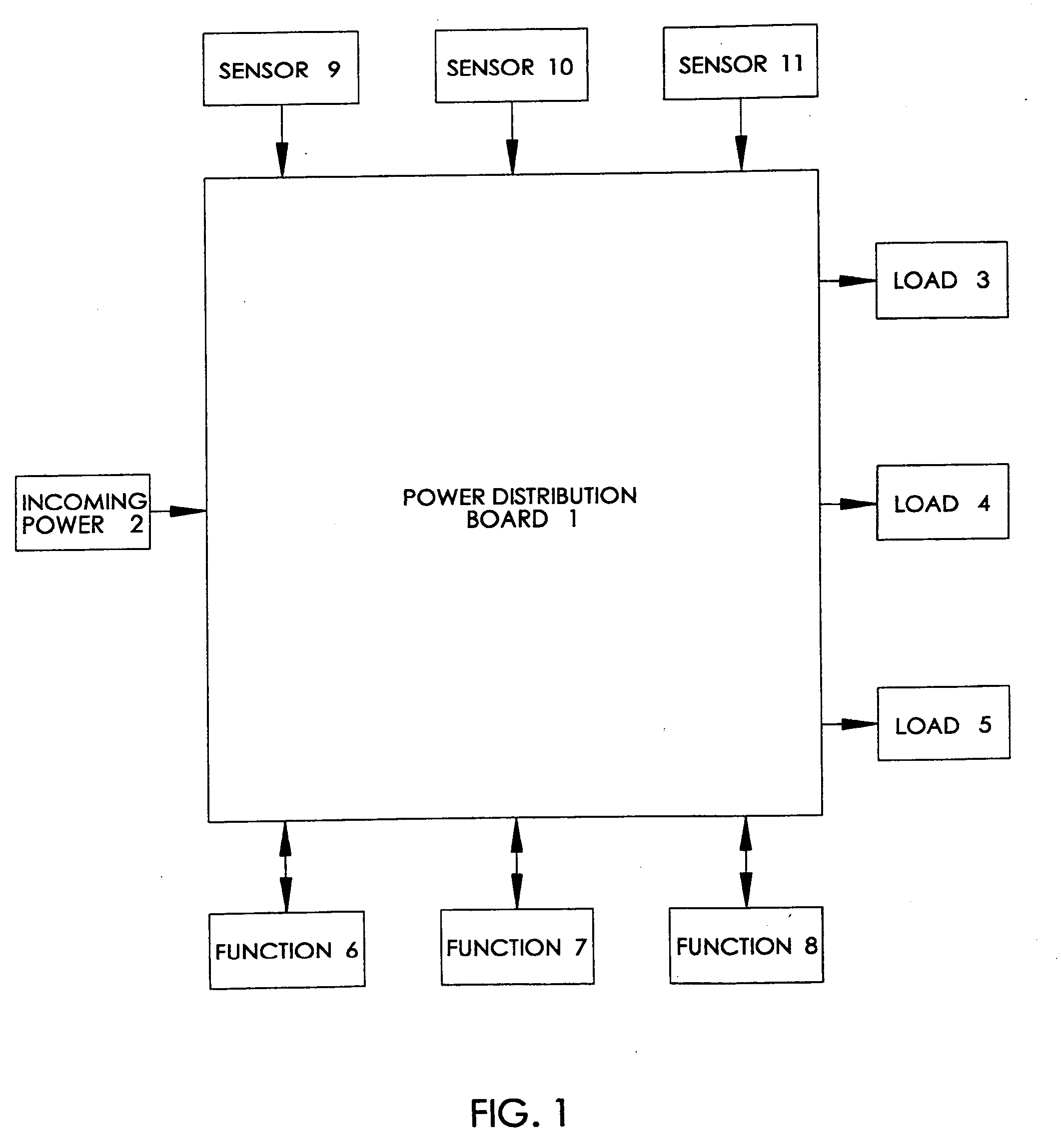

Power Management Unit with Modular Sensor Bus

ActiveUS20100295474A1Failure to compensateMaintain lightMechanical power/torque controlLevel controlDesign improvementSmart lighting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Methods, systems, and apparatus for commissioning an LED lighting fixture with remote reporting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Real Time Clock

ActiveUS20100301768A1Failure to compensateMaintain lightElectrical apparatusElectric light circuit arrangementReal-time clockSmart lighting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Power Source Arbitration

ActiveUS20100301771A1Failure to compensateMaintain lightElectrical apparatusElectric light circuit arrangementDesign improvementSmart lighting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Power Management Unit with Sensor Logging

ActiveUS20100295473A1Failure to compensateMaintain lightElectrical apparatusElectric light circuit arrangementSmart lightingDesign improvement

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC +1

Power management unit with power metering

ActiveUS8339069B2Discharge tube incandescent screensPlanar light sourcesDesign improvementSmart lighting

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

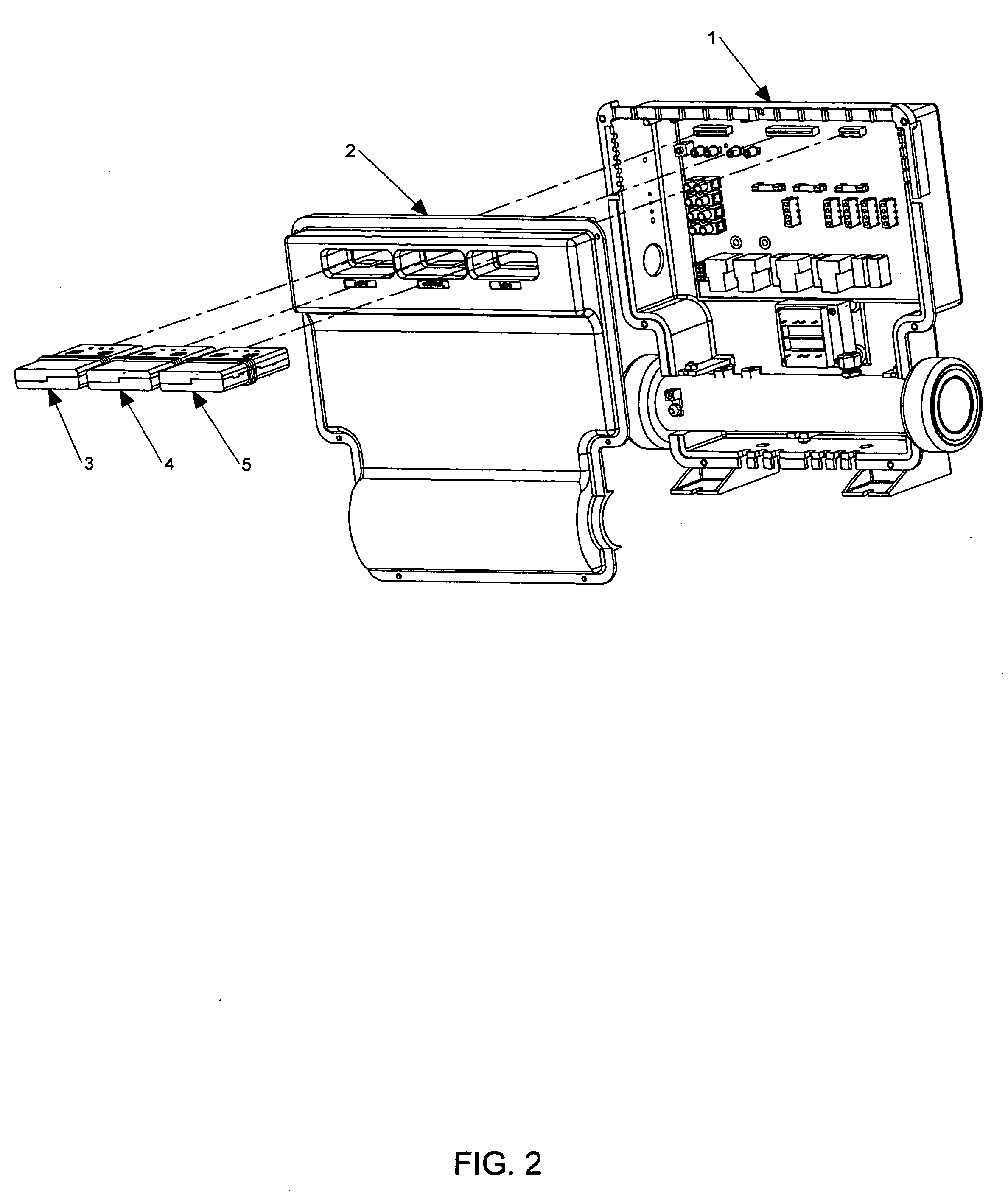

Fixture with Replaceable Light Bars

ActiveUS20100302779A1Failure to compensateMaintain lightMechanical apparatusLighting support devicesIntelligent lightingDesign improvement

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

LED lighting methods, apparatus, and systems including historic sensor data logging

ActiveUS8610376B2Electrical apparatusElectric light circuit arrangementDesign improvementSmart lighting

Owner:OSRAM SYLVANIA INC

Power management unit with multi-input arbitration

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

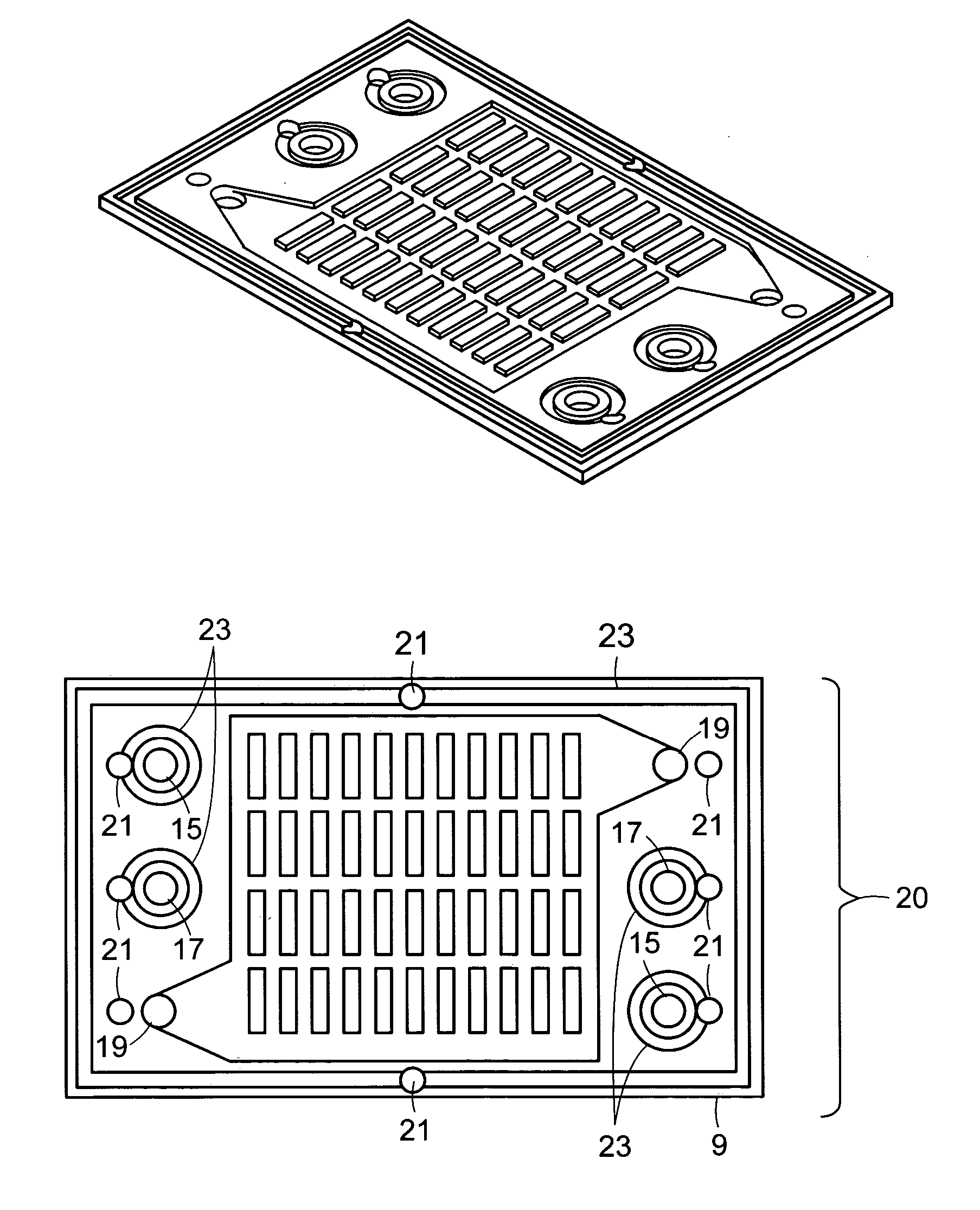

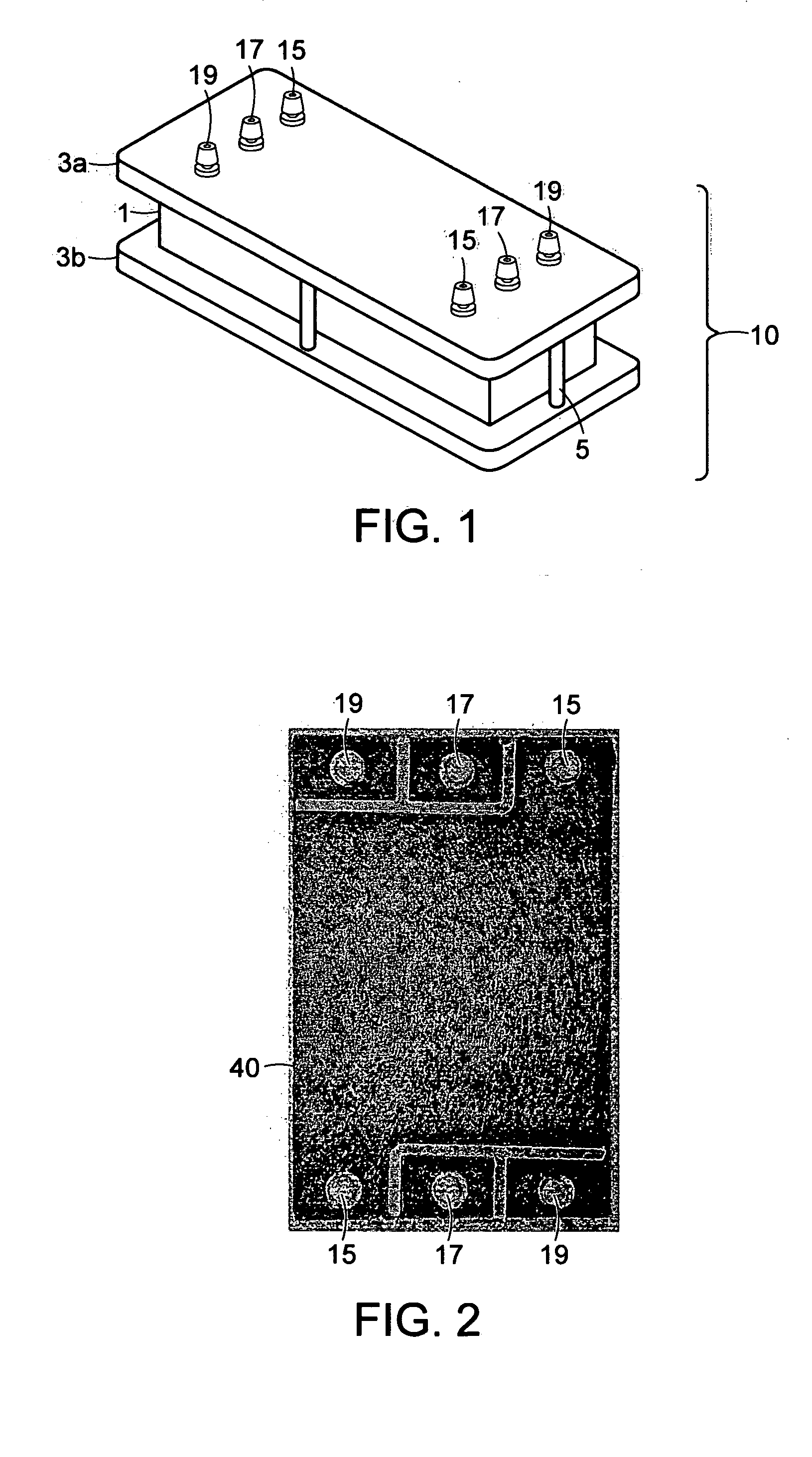

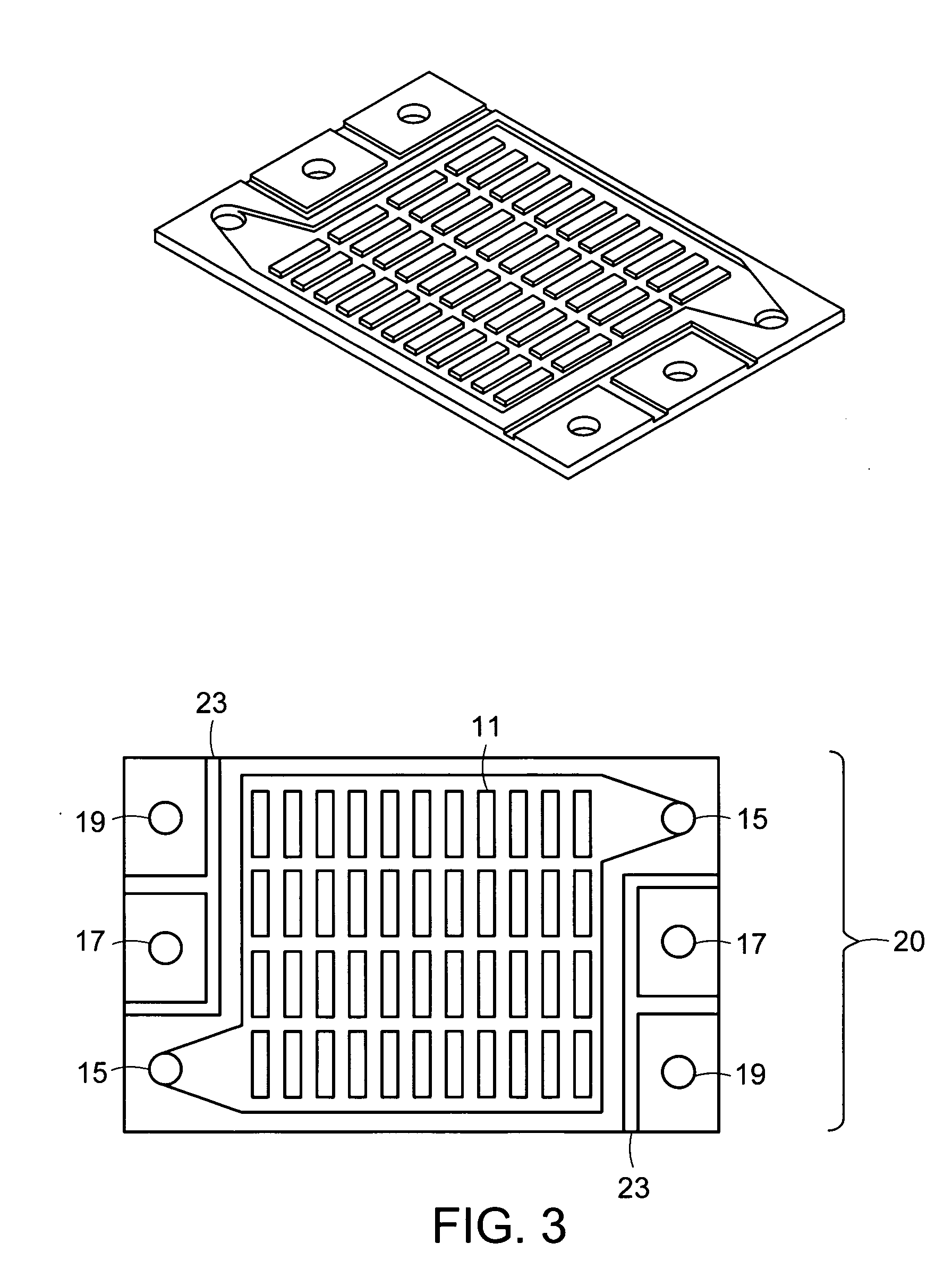

Membrane based electrochemical cell stacks

ActiveUS20050244703A1Eliminate needImprove the ease of assemblyFuel cell heat exchangeReactant parameters controlFuel cellsDesign improvement

The present invention provides membrane cassettes and stacks thereof which are suitable for a use in a variety of electrochemical applications. The invention further provides membrane cassettes which comprise one or more bipolar plates which have one or two reactant or coolant flow fields consisting of at least one groove in opposing surfaces of the bipolar plate. In certain preferred embodiments, the invention provides cassettes and stacks which are suitable for use in fuel cell applications. Particularly preferred embodiments of the invention include design improvements which enhance the performance and reliability of certain components of the fuel cell stack.

Owner:SILICON VALLEY BANK

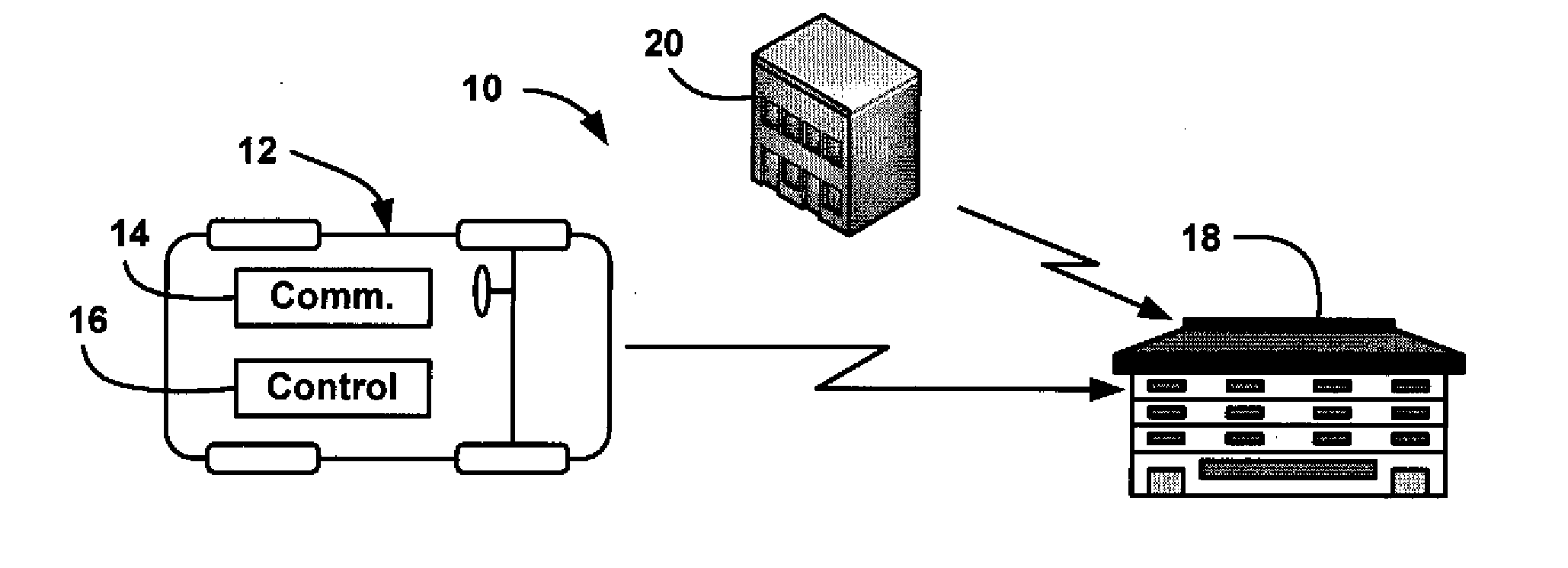

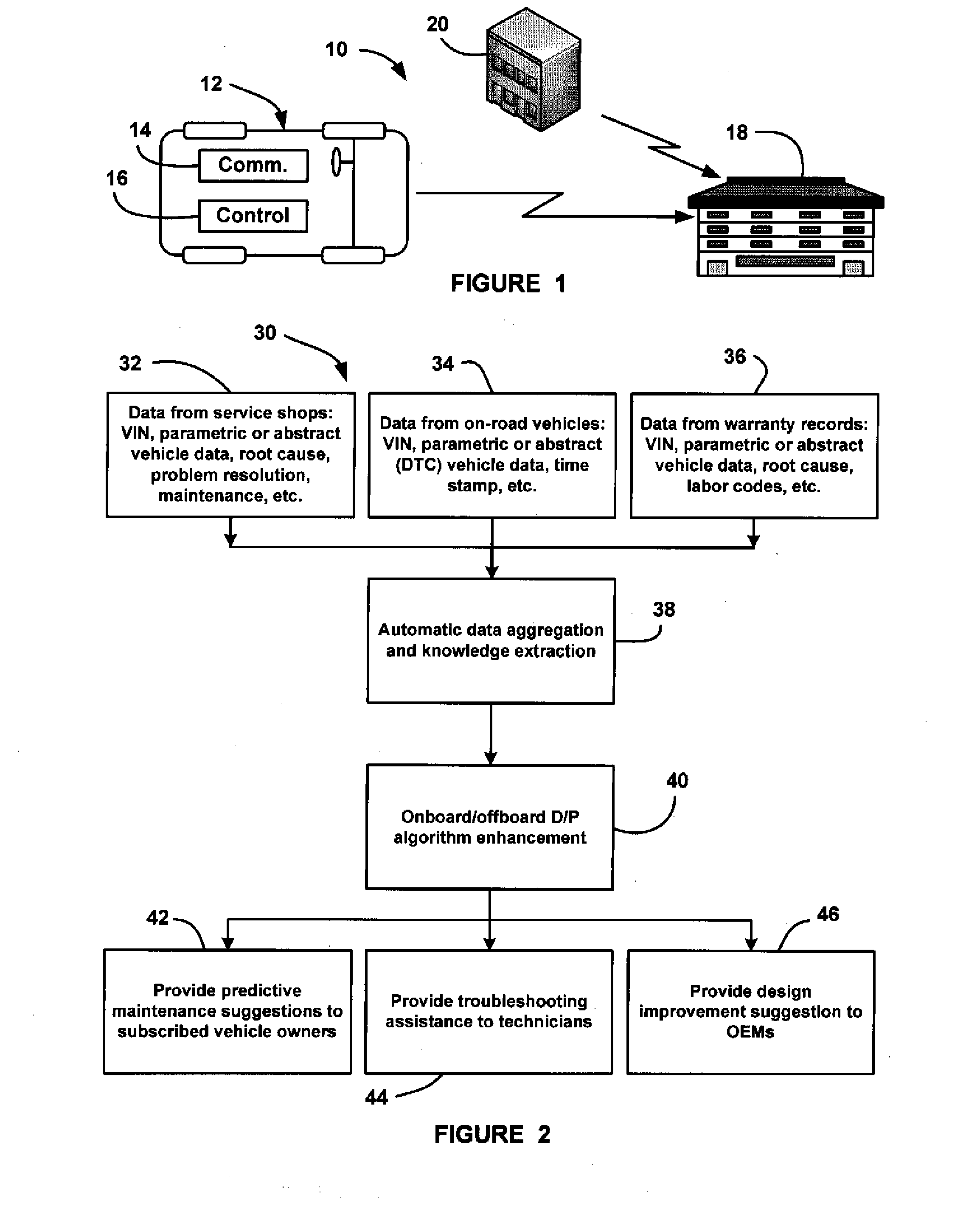

Telematics-enabled aggregated vehicle diagnosis and prognosis

ActiveUS20100063668A1OptimizationBetter identify vehicle faultsVehicle testingRegistering/indicating working of vehiclesInformation processingDiagnostic data

A system and method for telemetrically collecting on-road vehicle diagnostic data. In one embodiment, the method includes collecting vehicle diagnostic data from service shops, on-road vehicles and warranty records, aggregating the collected data and extracting knowledge therefrom. The extracted knowledge can be used to enhance algorithms on-board vehicles or at service centers so as to better identify vehicle faults and provide enhanced diagnostics and prognostics. The enhanced algorithms can then be used to provide predictive maintenance suggestions, provide trouble shooting assistance or provide vehicle design improvements.

Owner:GENERA MOTORS LLC +1

LED-based lighting methods, apparatus, and systems employing LED light bars, occupancy sensing, and local state machine

ActiveUS8536802B2Electrical apparatusElectric light circuit arrangementSmart lightingDesign improvement

In embodiments of the present invention, a method and system is provided for designing improved intelligent, LED-based lighting systems. The LED based lighting systems may include fixtures with one or more of rotatable LED light bars, integrated sensors, onboard intelligence to receive signals from the LED light bars and control the LED light bars, and a mesh network connectivity to other fixtures.

Owner:OSRAM SYLVANIA INC

Methods, systems, and apparatus for mapping a network of lighting fixtures with light module identification

ActiveUS8823277B2Electrical apparatusElectric light circuit arrangementIntelligent lightingDesign improvement

Owner:OSRAM SYLVANIA INC

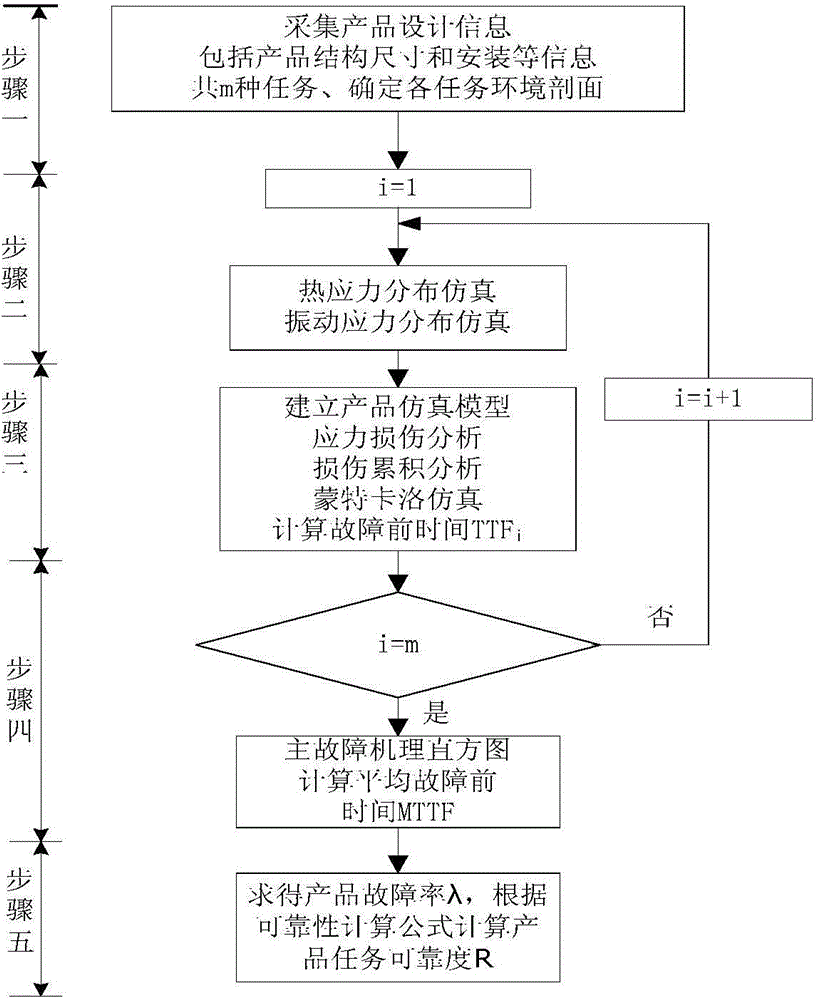

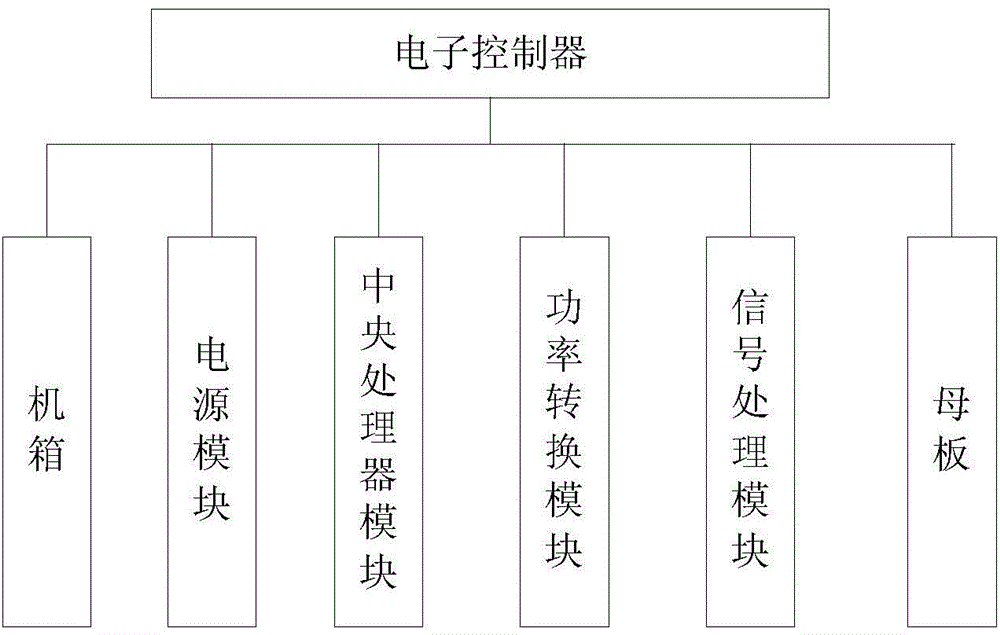

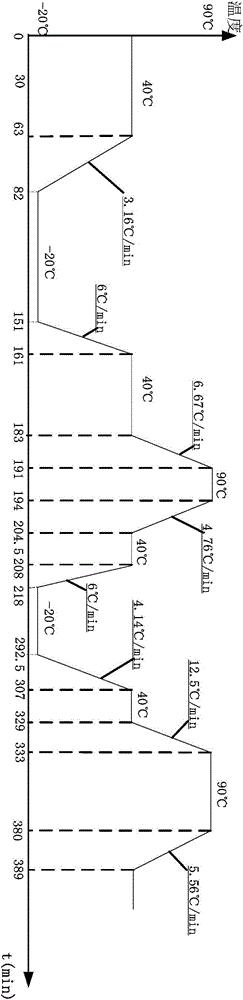

PoF (physics of failure) based method for calculating mission reliability of electronic product

ActiveCN103559418AIn line with the real situationReflect the stress situationSustainable transportationSoftware simulation/interpretation/emulationComputing MethodologiesDesign improvement

A PoF based method for calculating mission reliability of an electronic product comprises steps as follows: step one, information of all mission profiles of the product is collected, and an environment profile of each mission is determined; step two, thermal simulation and vibration simulation of environmental stress of each mission are performed, and a local response of the product to an environmental load is obtained; step three, a product simulation model is established; step four, simulation calculation of the product in all the mission profiles is completed, and the mean time to failure and a main failure mechanism of the product are obtained; and step five, the mission reliability of the product is calculated according to the mean time to failure. According to the PoF based method for calculating the mission reliability of the electronic product, all missions of the product during lifetime use are considered, the environmental stress of each mission is simulated, and the mean time to failure and the mission reliability of the product are comprehensively calculated. By means of a PoF model, the direction relation between parameters of a product material, structure, process and the like and the reliability can be obtained, and a design improvement direction is clearly and directly provided for the product.

Owner:BEIHANG UNIV

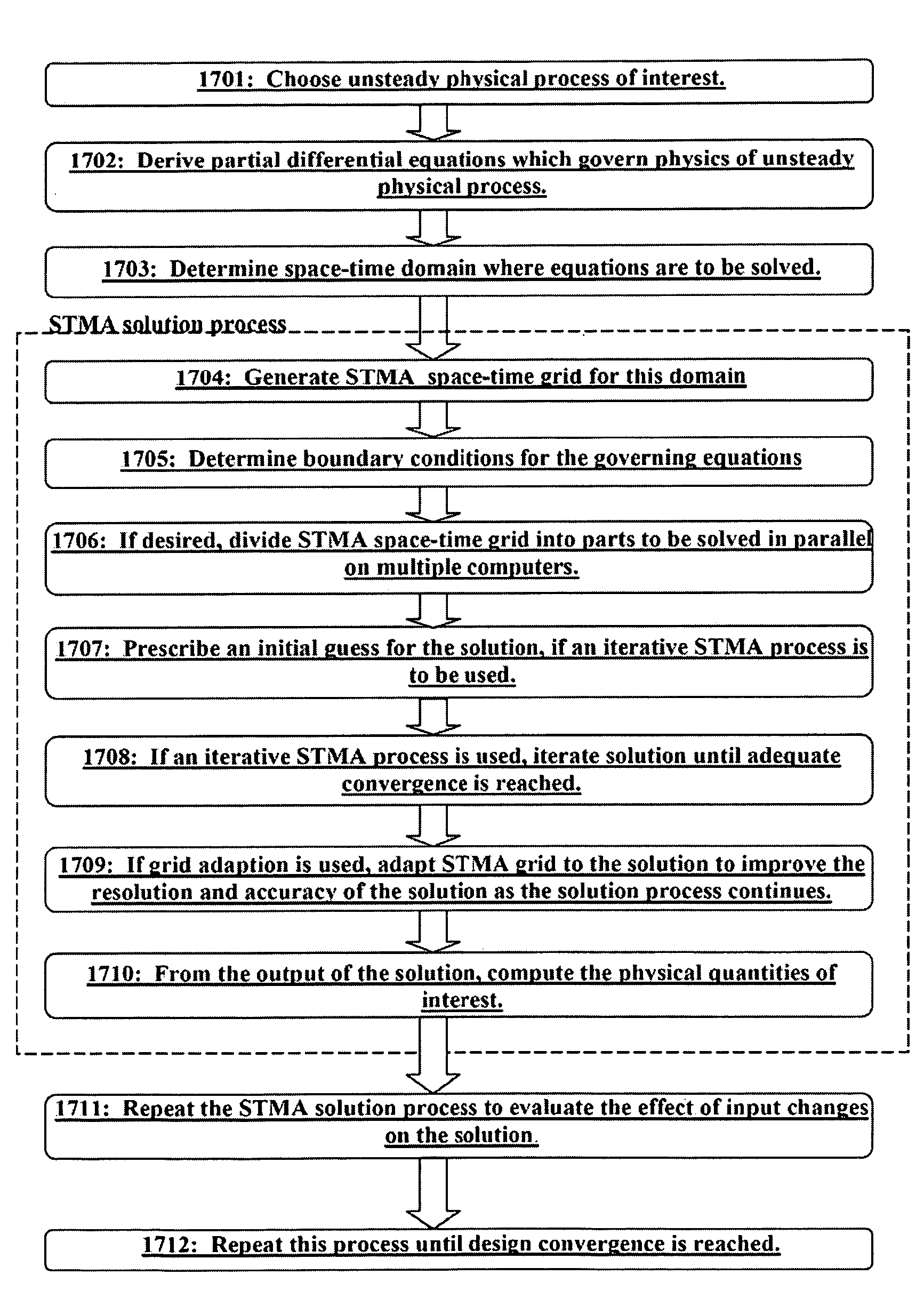

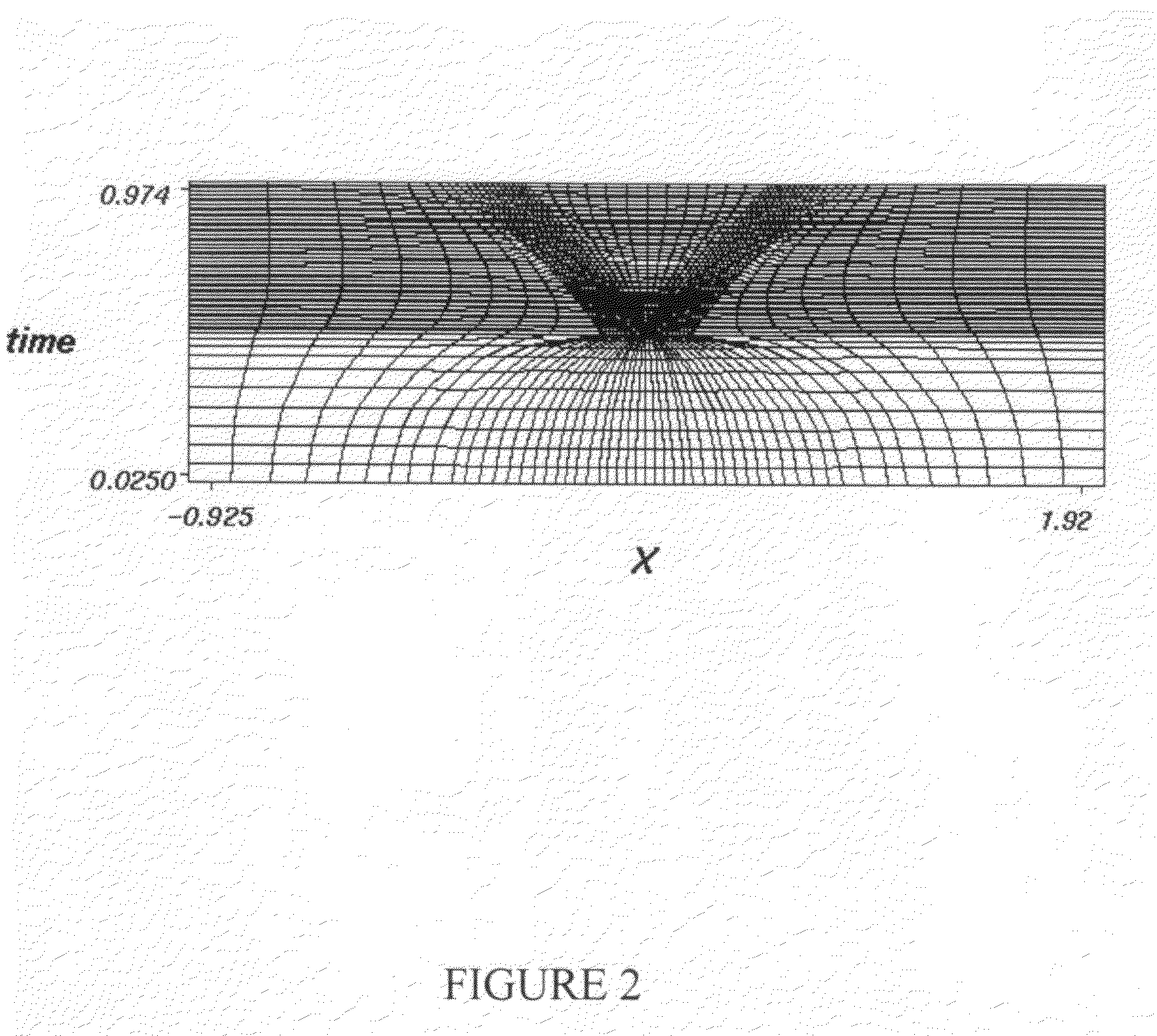

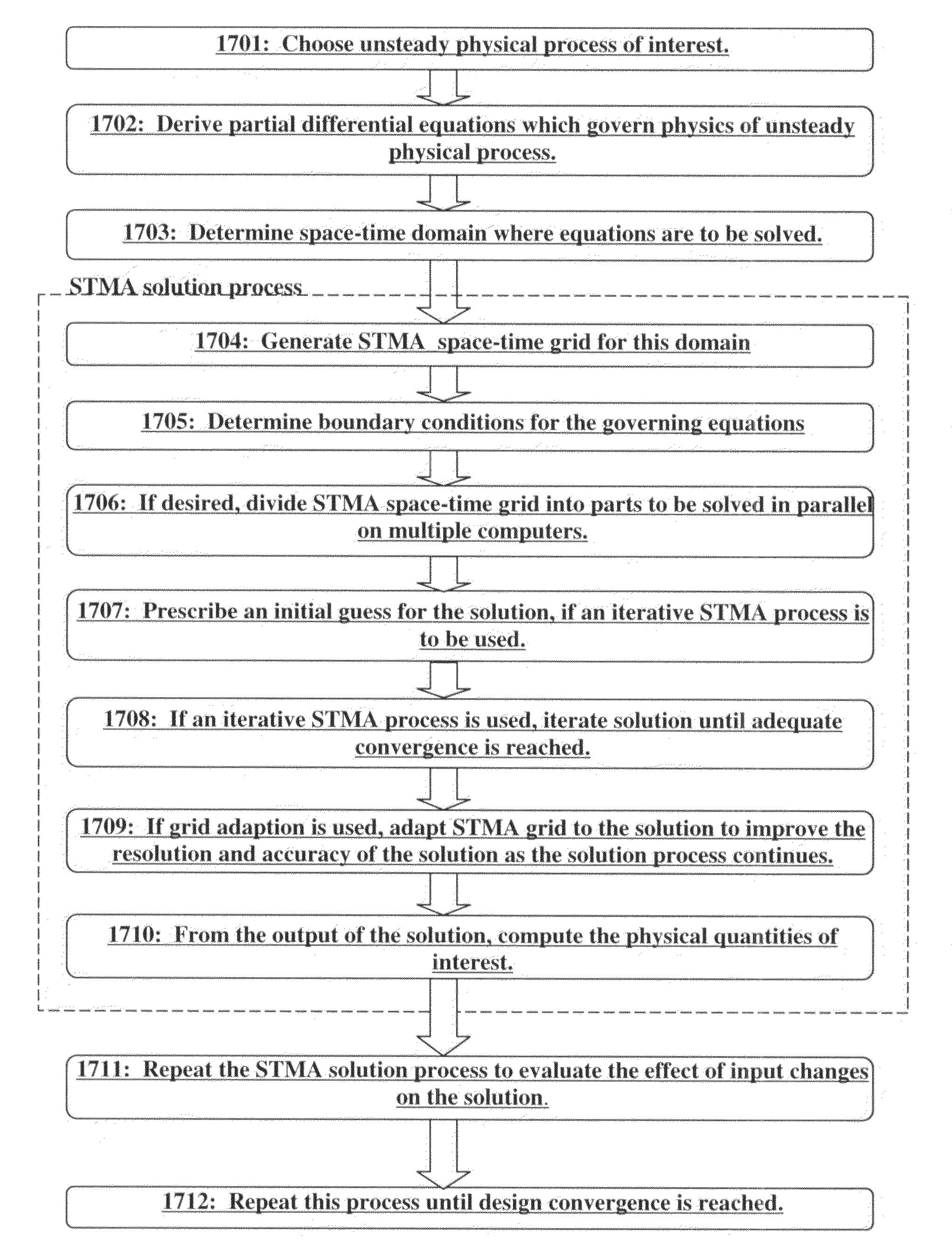

Method and system for the efficient calculation of unsteady processes on arbitrary space-time domains

InactiveUS20080300835A1Computation using non-denominational number representationDesign optimisation/simulationTime domainDesign improvement

Owner:HIXON TECH

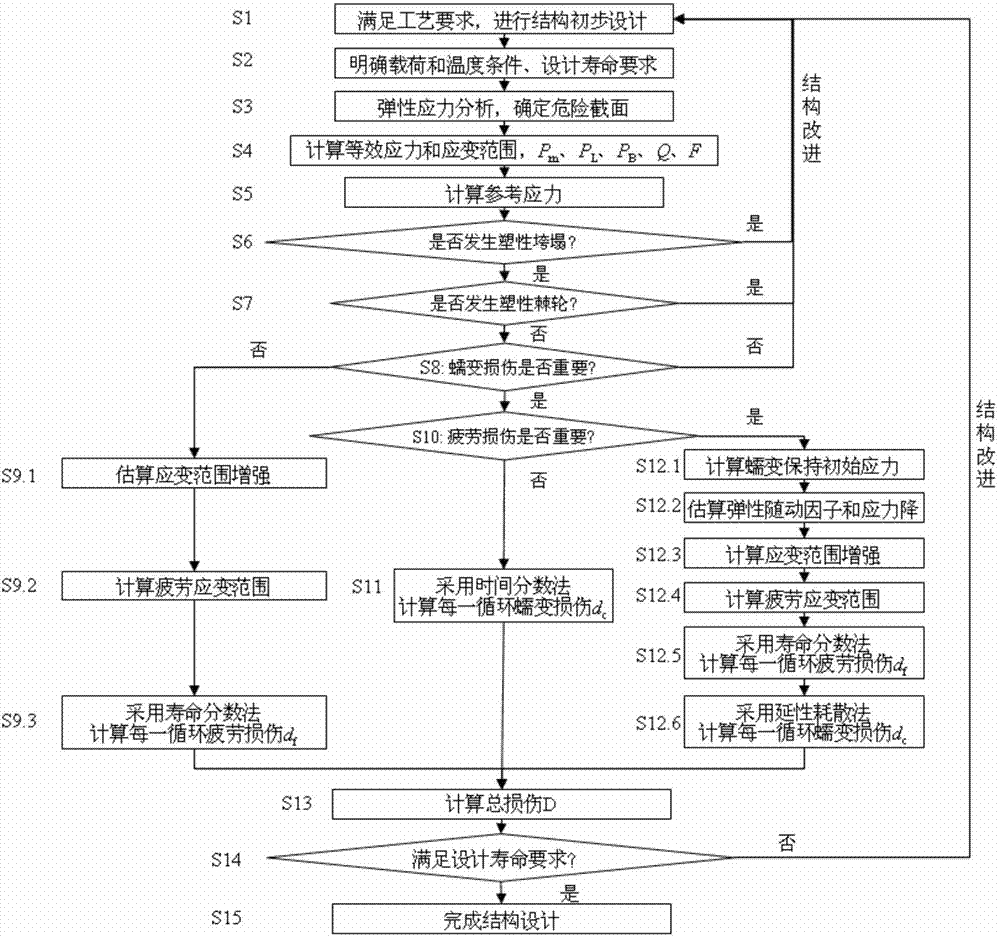

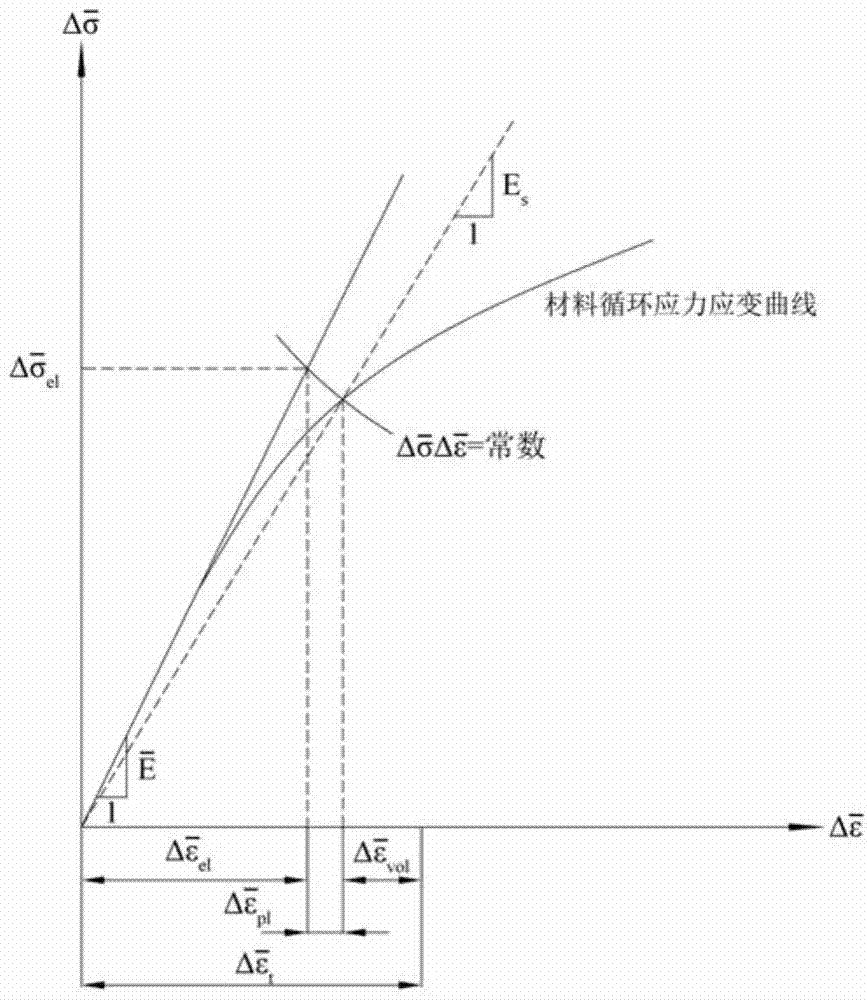

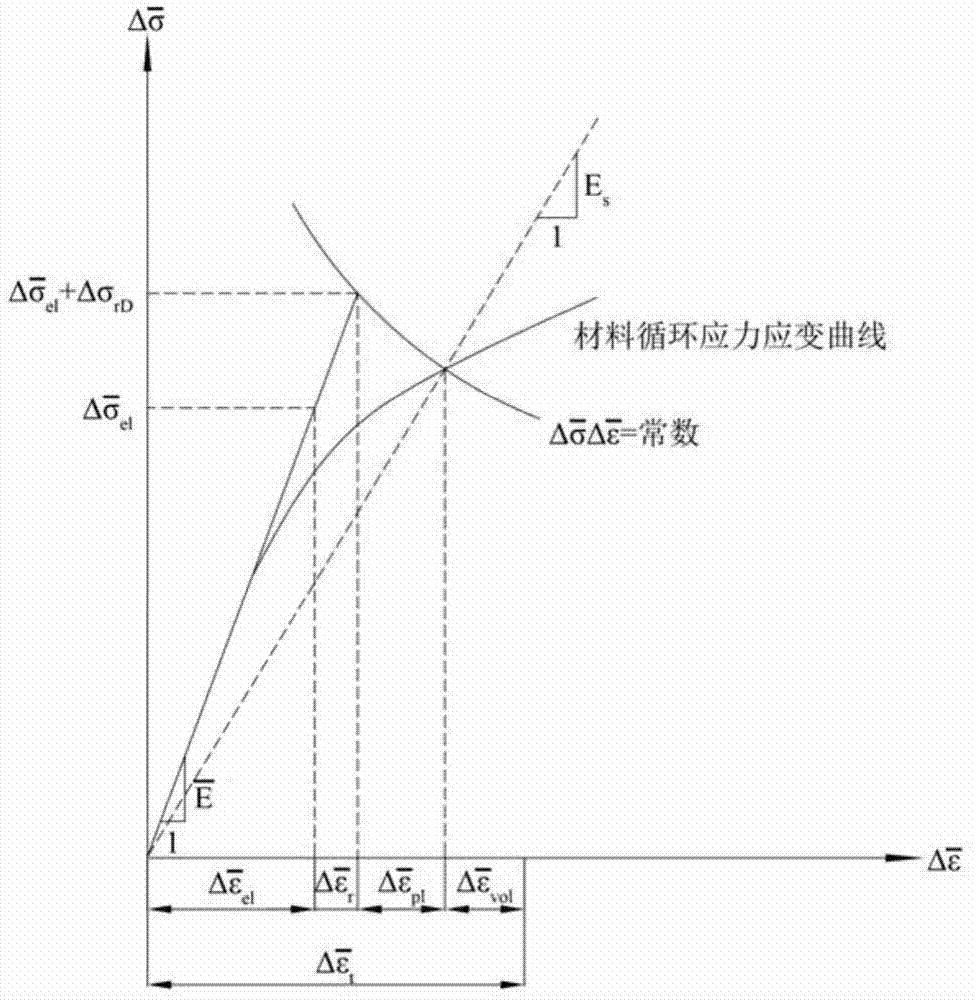

Service life based high-temperature container creep fatigue strength design method

The invention discloses a service life based high-temperature container creep fatigue strength design method. The method comprises the steps of 1, performing structure preliminary design; 2 determining load and temperature conditions and the design service life requirement; 3, determining dangerous sections; 4, calculating the equivalent stress and strain range; 5, calculating reference stress; 6, determining whether plastic collapse occurs; 7 determining whether the plastic ratchet occur; 8, determining whether creep damage is important; 9, estimating fatigue damage of each cycle when the creep damage is not important; 10, determining whether the fatigue damage is important; 11, estimating the creep damage when the fatigue damage is not important; 12, estimating damage of each cycle when the creep damage and the fatigue damage are non-ignorable; 13, estimating creep-fatigue total damage; 14, performing result analysis and structural design improvement; 15, completing structural design. According to the method, the foundation is laid for national establishing of creep and fatigue failure mode based high-temperature pressure container design standards and achieving design and manufacture of high-temperature pressure containers according to the service life.

Owner:HEFEI GENERAL MACHINERY RES INST

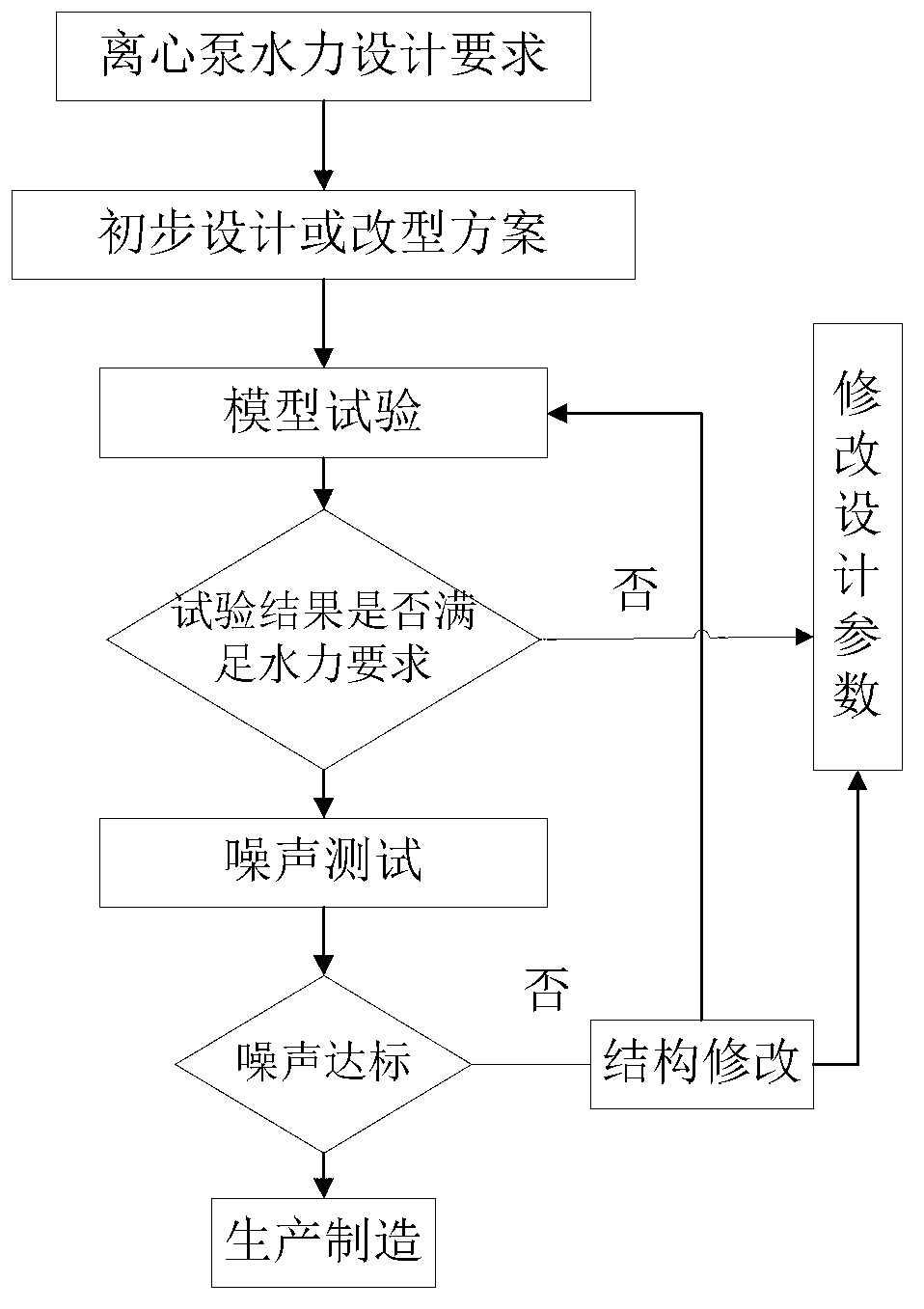

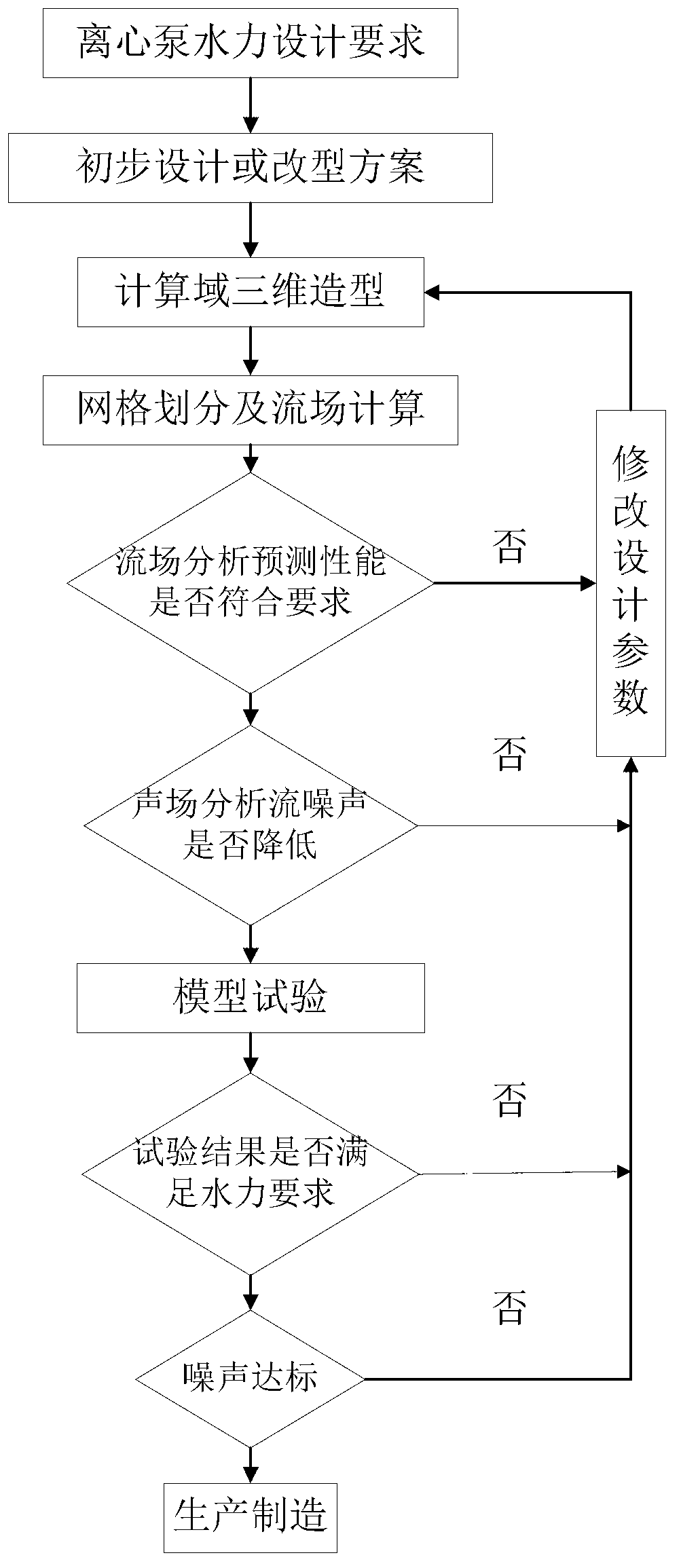

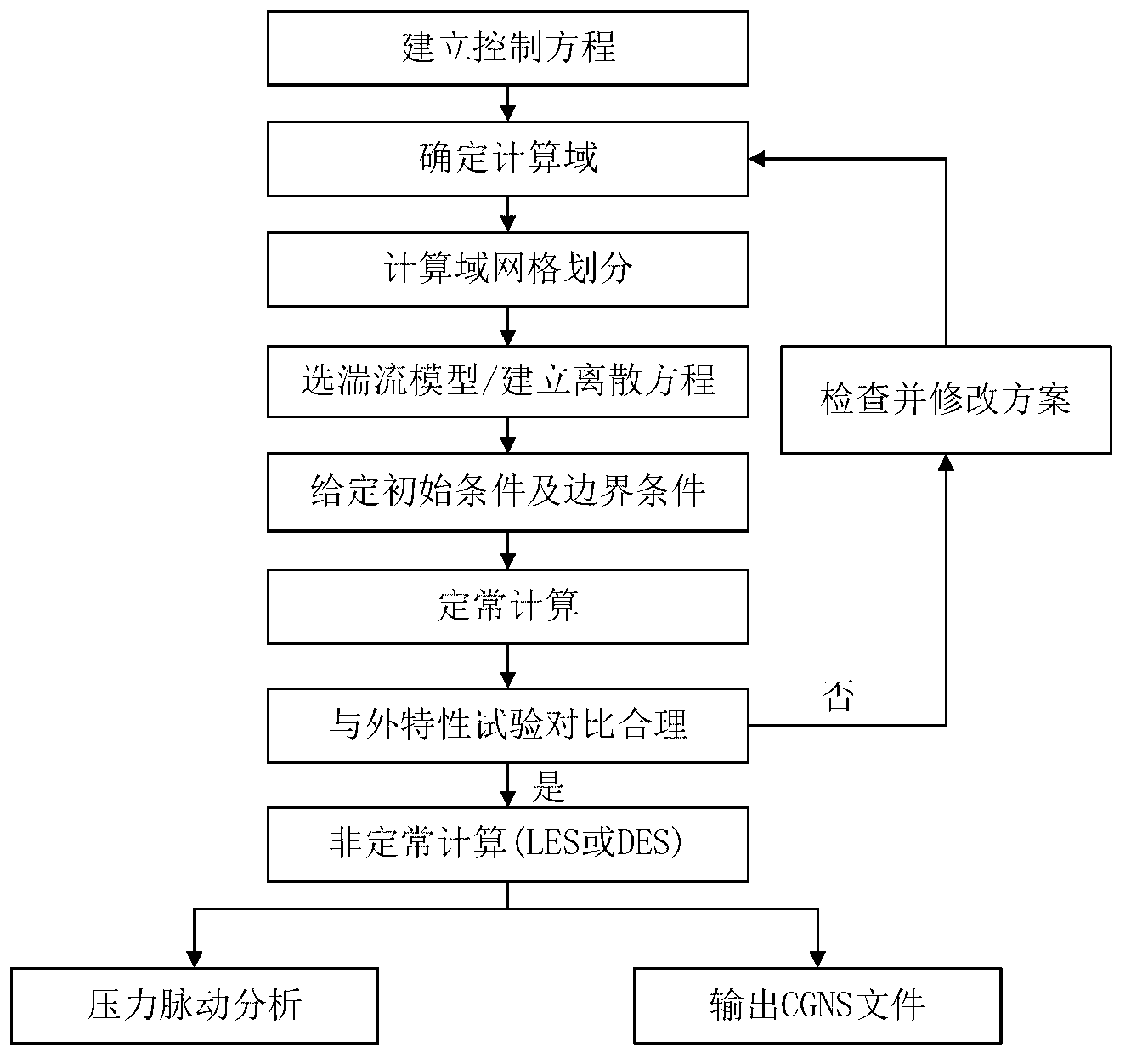

Low-noise hydraulic design method of centrifugal pump with low specific speed

ActiveCN103306985AImprove design qualityImprove machine performancePump componentsSpecial data processing applicationsLow noiseComputational acoustics

The invention discloses a low-noise design method of a centrifugal pump with low specific speed, and relates to an active control method of flow noise of turbomachinery. The design method comprises the steps that firstly, main structural dimensions of a centrifugal pump impeller and a helical pumping chamber (volute) are obtained by the traditional low-specific-speed pump design method; secondly, an internal flow field of the pump is computed by a computational fluid mechanics method; the performance of the pump is predicted whether to meet a design requirement; an optimum design improvement is performed by analyzing a stationary flow field; thirdly, flow induction noise of the pump with low specific speed is predicted by a computational acoustics method; if a flow noise index is qualified, the design is accomplished; if the flow noise index is disqualified, subsequent steps are performed; fourthly, the diameter of the impeller basically meeting a performance requirement in the design is adjusted to allow a gap between the impeller and a volute tongue to be increased continuously to 20%; splitter blades are added in the middles of blades to increase the lift, control the flow situation, and ensure the efficiency; and finally, the pump subjected to the impeller improvement design is subjected to noise prediction; if the flow noise index is qualified, the design is accomplished; and if the flow noise index is disqualified, the beginning step is repeated. The design method shortens the research and development period, saves the development cost, effectively improves the design quality of the centrifugal pump, can simultaneously meet low-noise requirements of the lift and the efficiency, and realizes optimization of the performance of the complete centrifugal pump with low specific speed.

Owner:JIANGSU UNIV

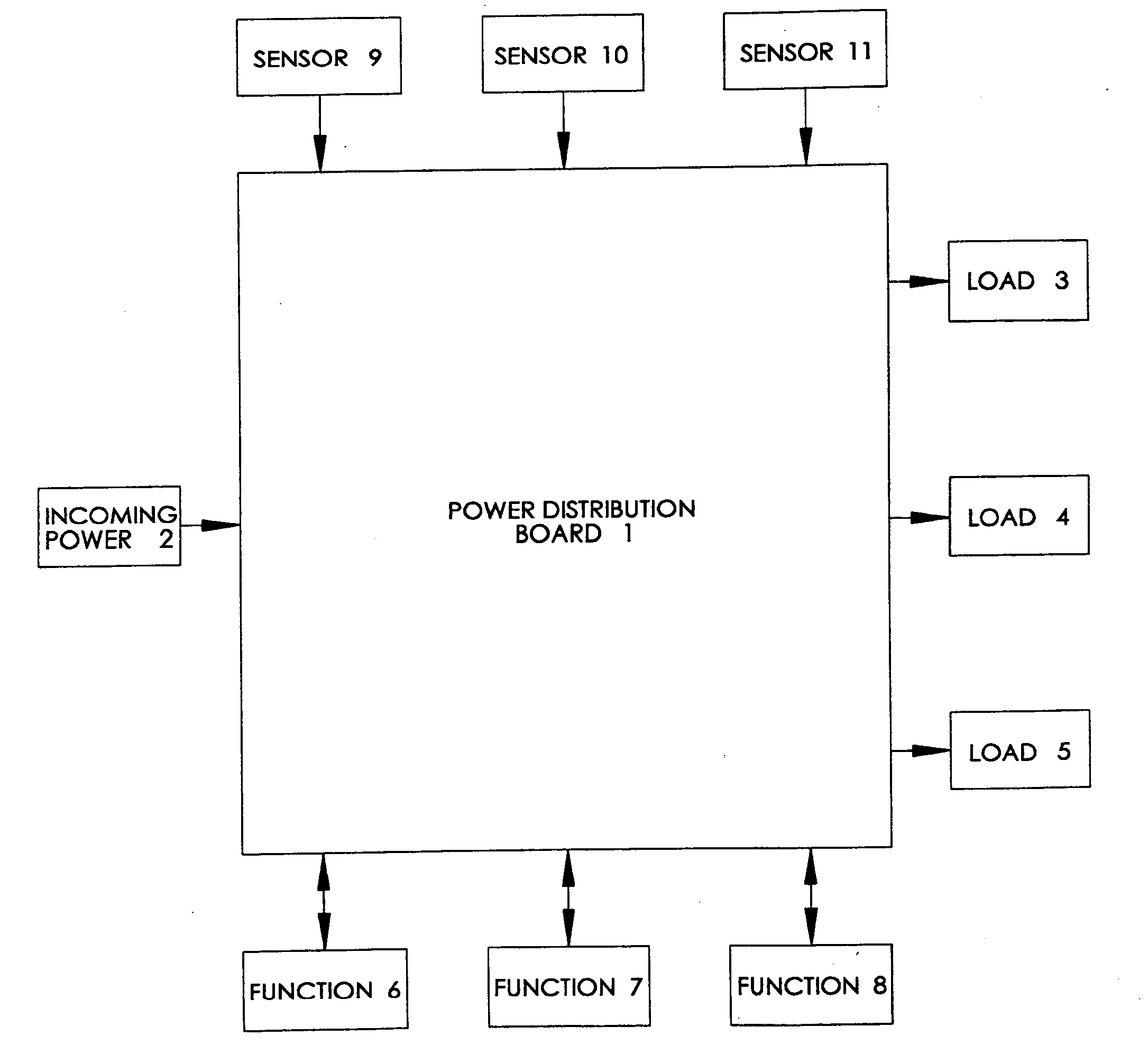

Low maintenance spa control system

ActiveUS20090132066A1Improve reliabilityImprove maintainabilityMechanical power/torque controlFluid heatersAs DirectedDesign improvement

A spa control system designed to reduce maintenance cost by providing modular construction for major control functions, with built-in diagnostic capabilities for isolating defective spa components. Multi-colored LEDs on the spaside panel constantly report the status of each component of the spa as well as the status of the functional modules themselves. Each time a component is activated, measurements of operational parameters, such as load currents, are instantly made and evaluated so that the proper LED color can be presented at the spaside. Since major functions such as audio, LED control, wireless, and spa logic are separated into removable modules, repair of the control system requires less time and less skilled personnel. Other design improvements, such as direct monitoring of heater element temperature and the purging of pumps on an as required-basis, enhance the spa's overall reliability and thus reduce the need for maintenance.

Owner:BALBOA WATER GRP LLC

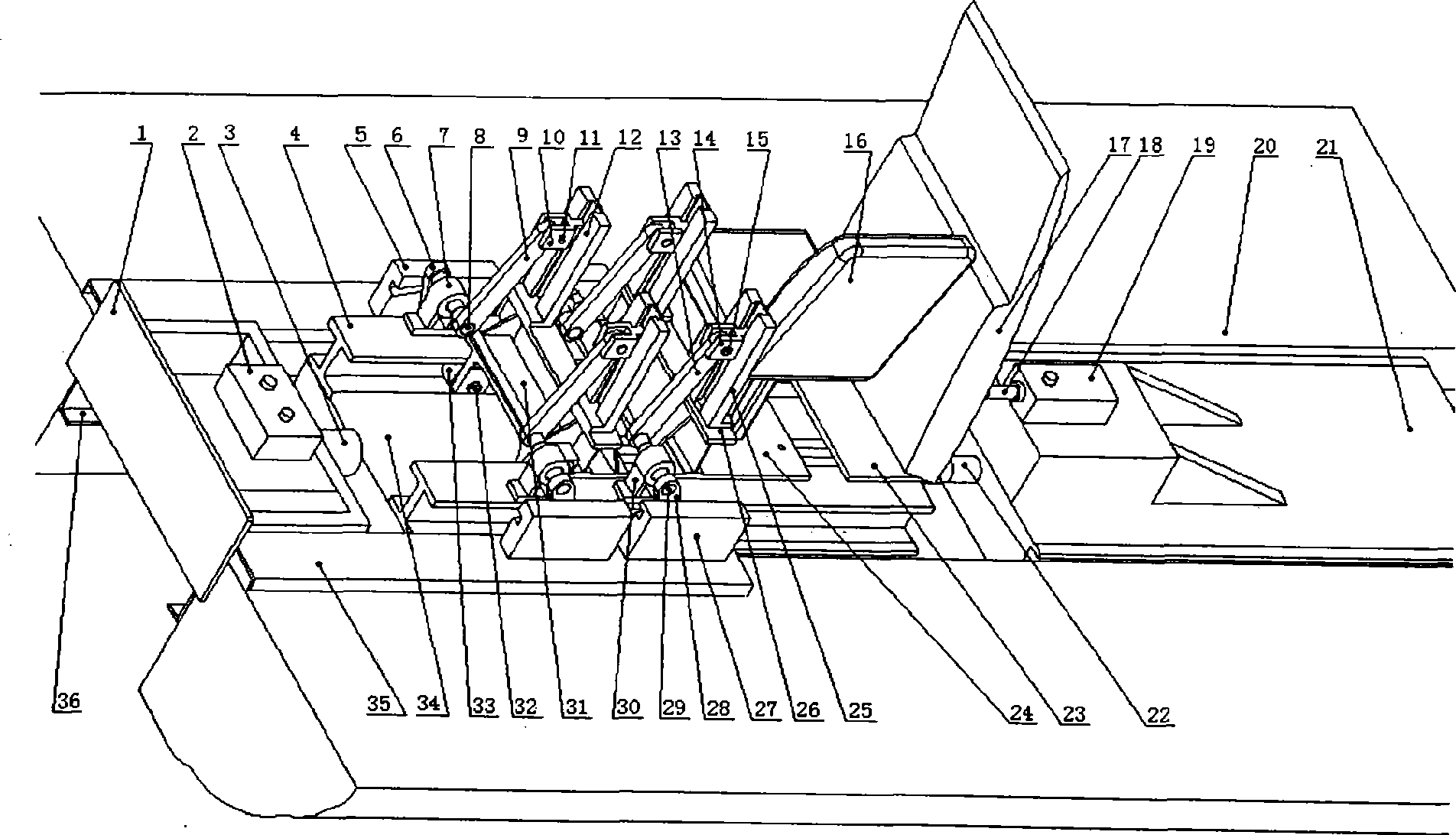

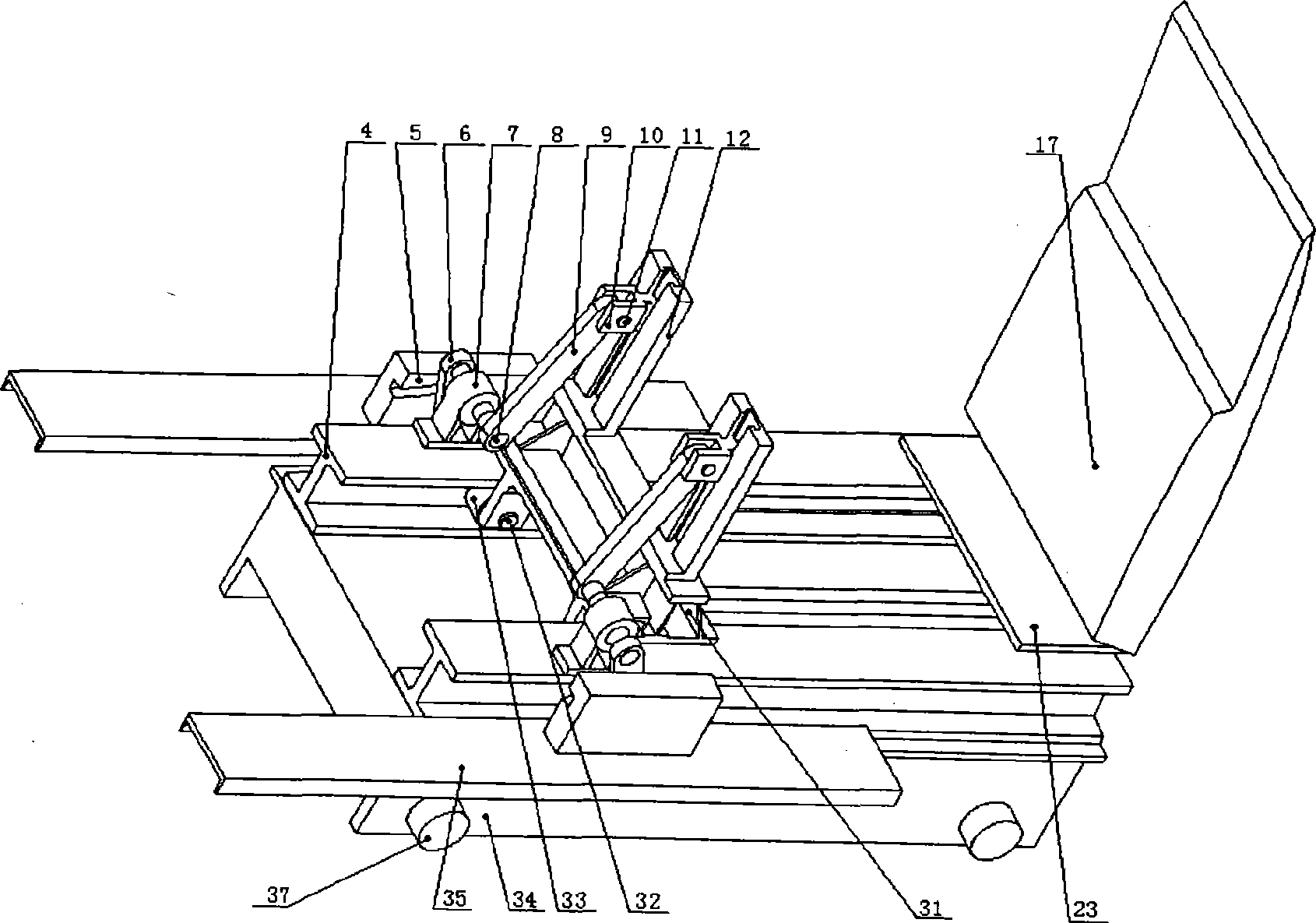

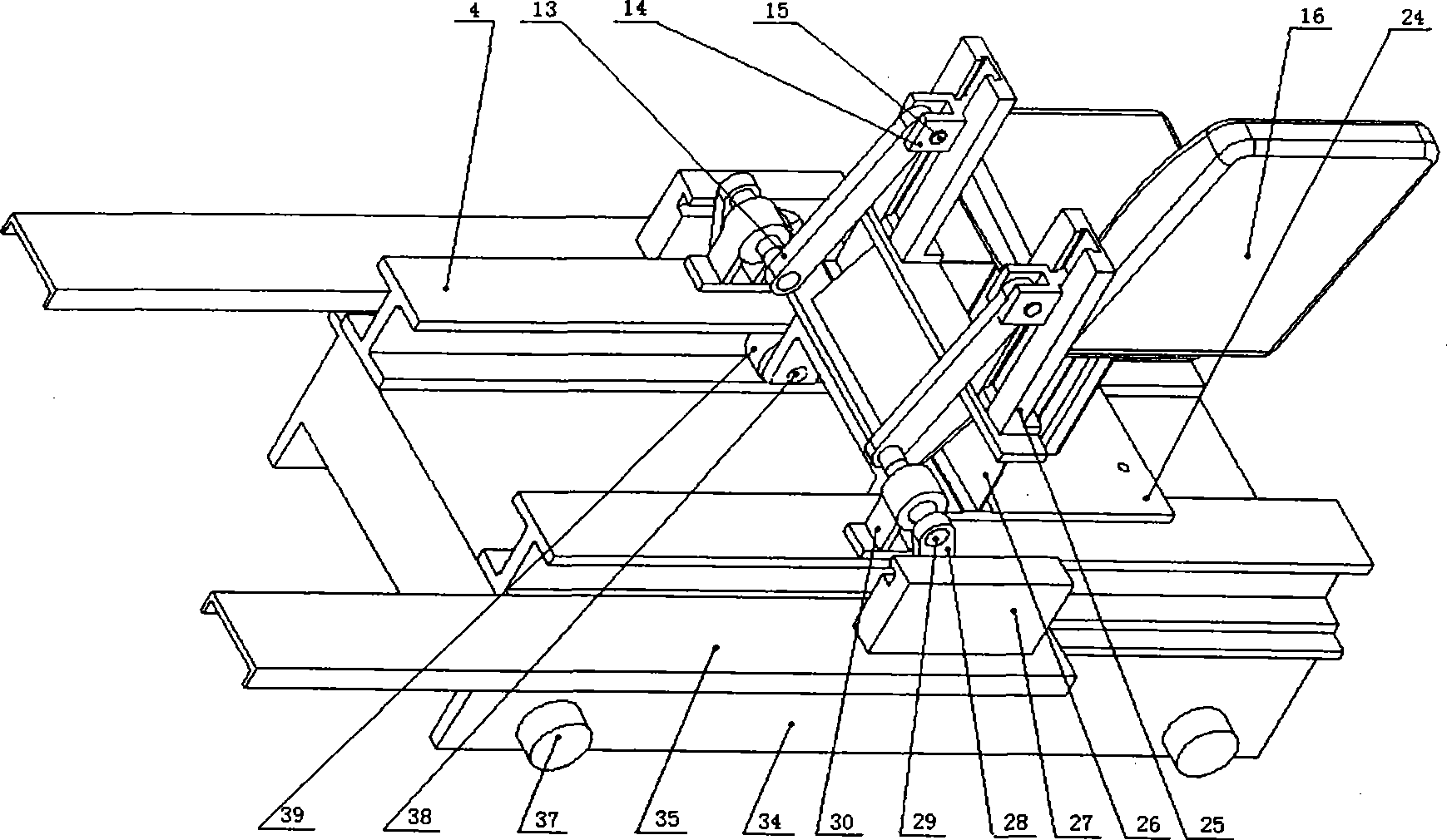

Simulation test device for automobile side collision

The invention provides an automobile side surface collision simulation testing device, belonging to the technical field of automobile collision simulation; the device can re-show the real mechanic environment of the side collision of the automobile, can be used for the detection and design improvement of driving safety products and driven safety products such as automobile doors, safety belt, safety lock, safety seat, safety airbag, automobile interior and the like, and can provide a mean for human biomechanics research under collision environment; the automobile side surface collision simulation testing device forms an automobile collision simulation system by a hydraulic automobile door energy absorber, a trolley energy absorber and a brake energy absorber which are arranged on a simulation movable obstacle vehicle; and the trolley is provided with a vehicle door motion control mechanism and a seat motion control mechanism. The automobile side surface collision simulation testing device has the beneficial effects that the automobile side surface collision simulation testing device can clearly reflect the motion relationship of the automobile door, the seat and the automobile door during the side surface collision of the automobile, can simulate the working environment of the driving and driven safety products during the side surface collision process of the automobile and has the advantages of high simulation precision, simple design procedure, compact structure of the device, small volume, easy operation and the like.

Owner:ZHONGBEI UNIV

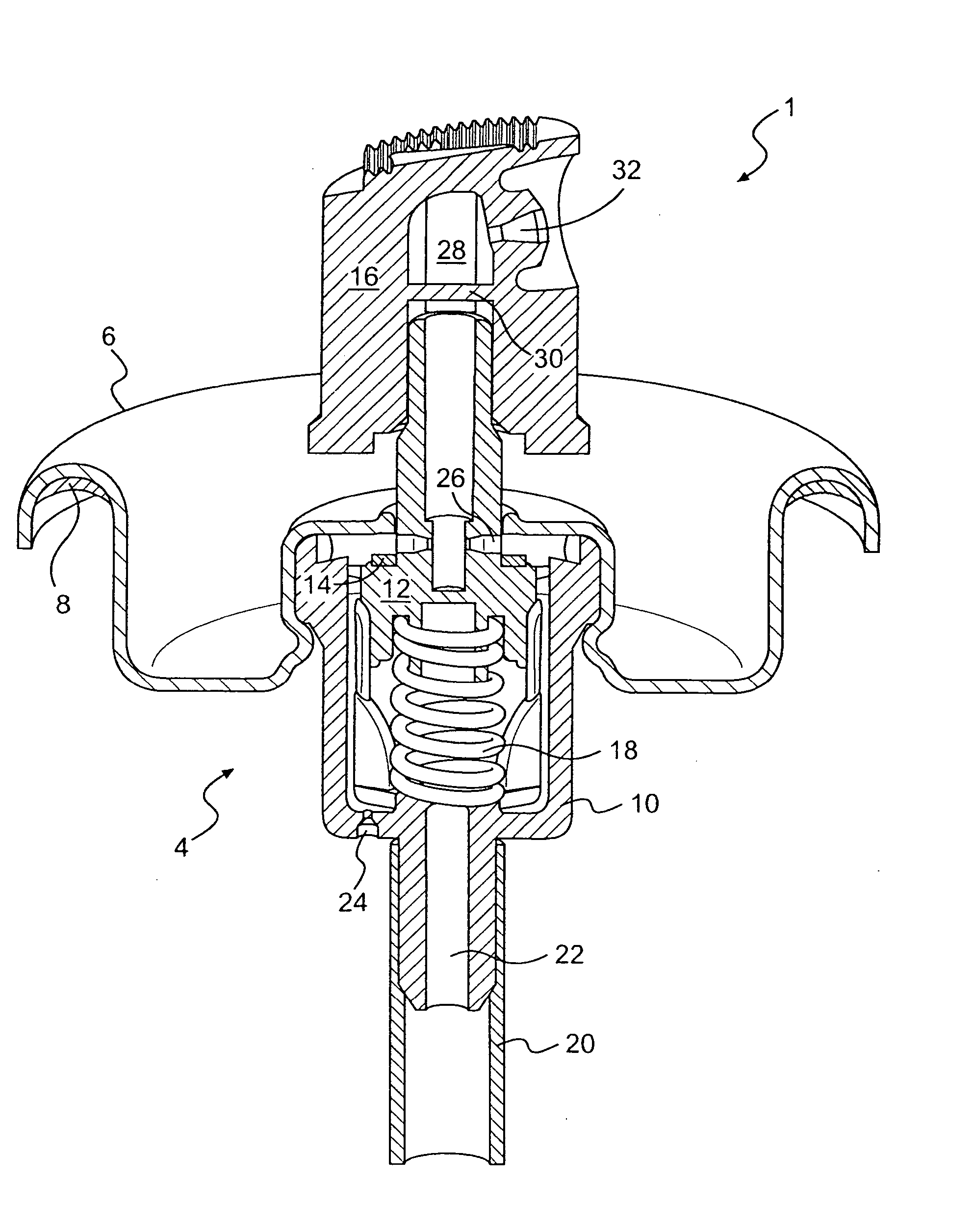

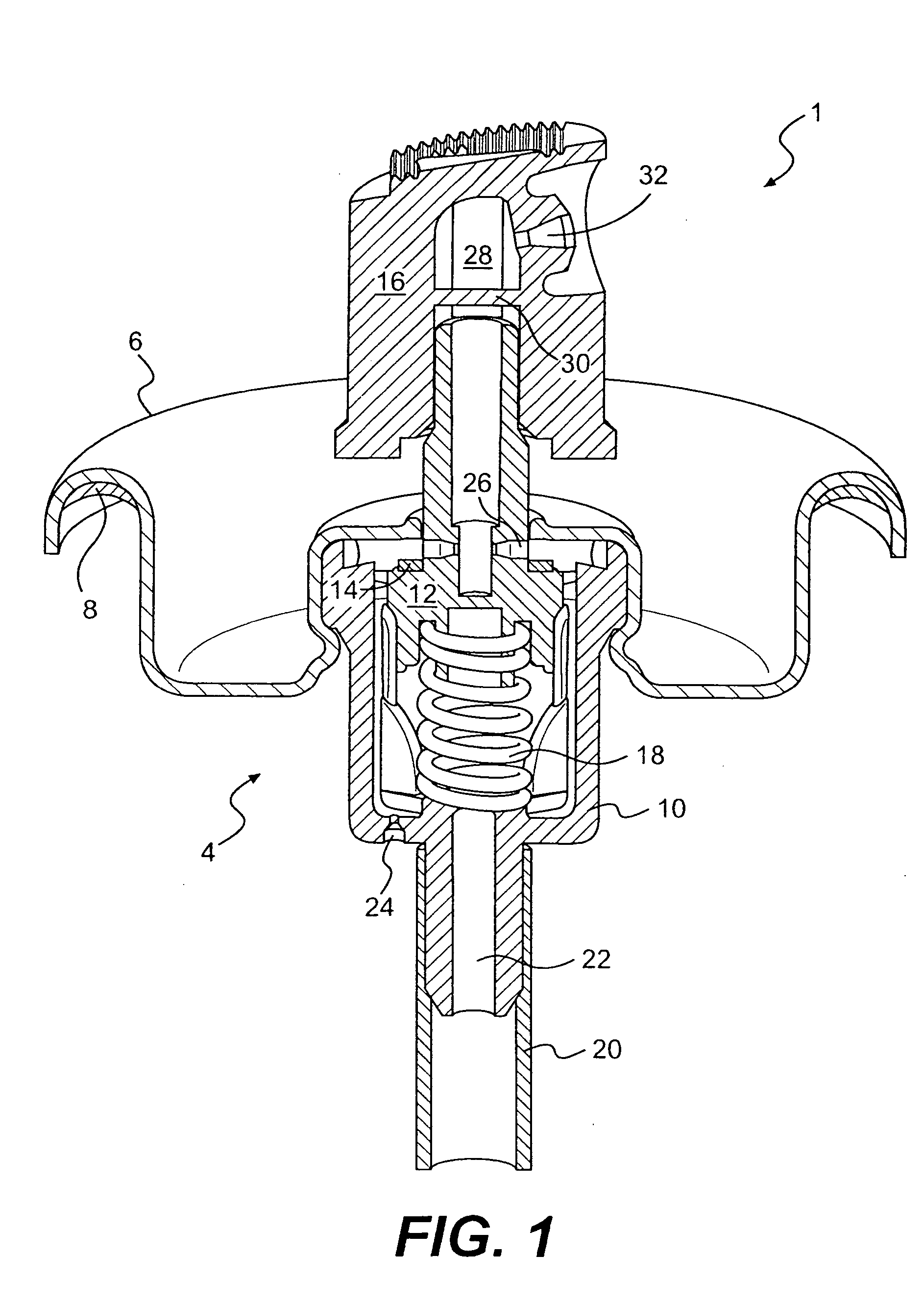

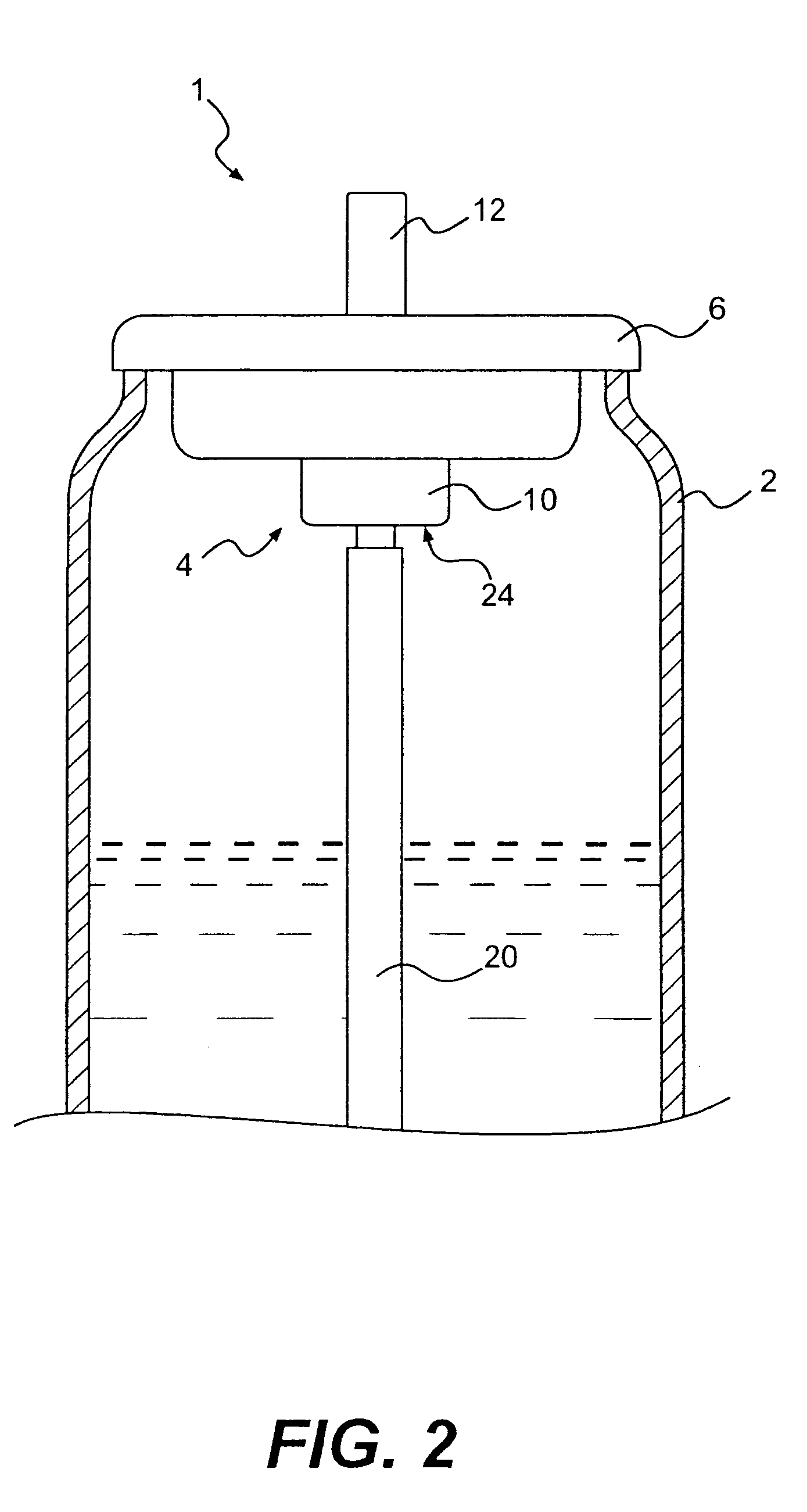

Method of designing improved spray dispenser assemblies

InactiveUS20050023368A1Reduces product retentionLiquid surface applicatorsWatering devicesDesign improvementEngineering

A method of determining design parameters for a design of a spray dispenser assembly for dispensing a mist. The method includes identifying one or more preferred performance characteristics of the spray dispenser to be designed and identifying design variables of structures of a spray dispenser assembly that affect those performance characteristics. The method also includes obtaining test data indicative of performance characteristics of spray dispensers at different combinations of values of the design variables. To achieve an improved dispenser design, design parameters are defined for the identified design variables based on the test data. The design parameters provide the preferred performance characteristics when embodied in a spray dispenser.

Owner:SC JOHNSON & SON INC

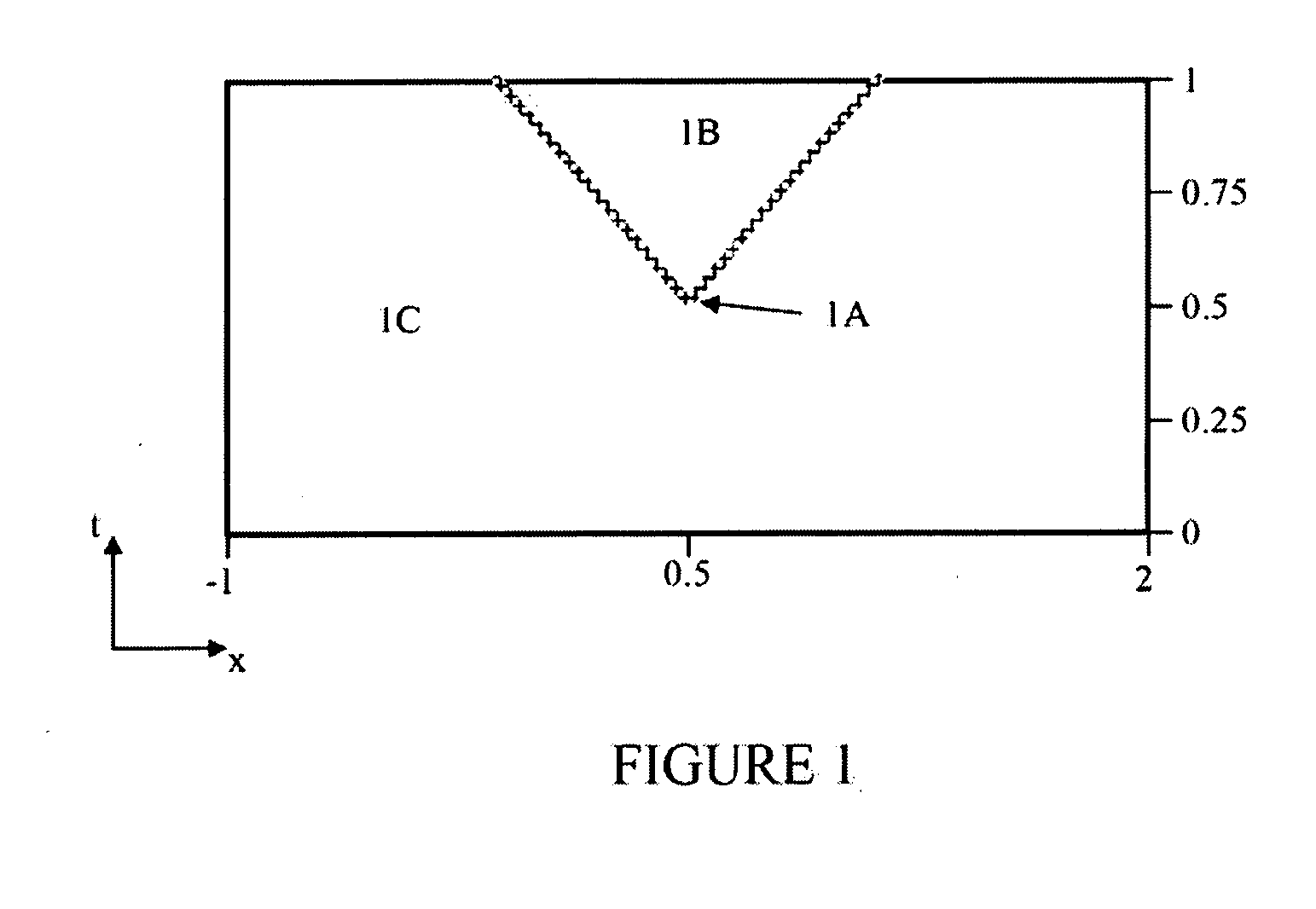

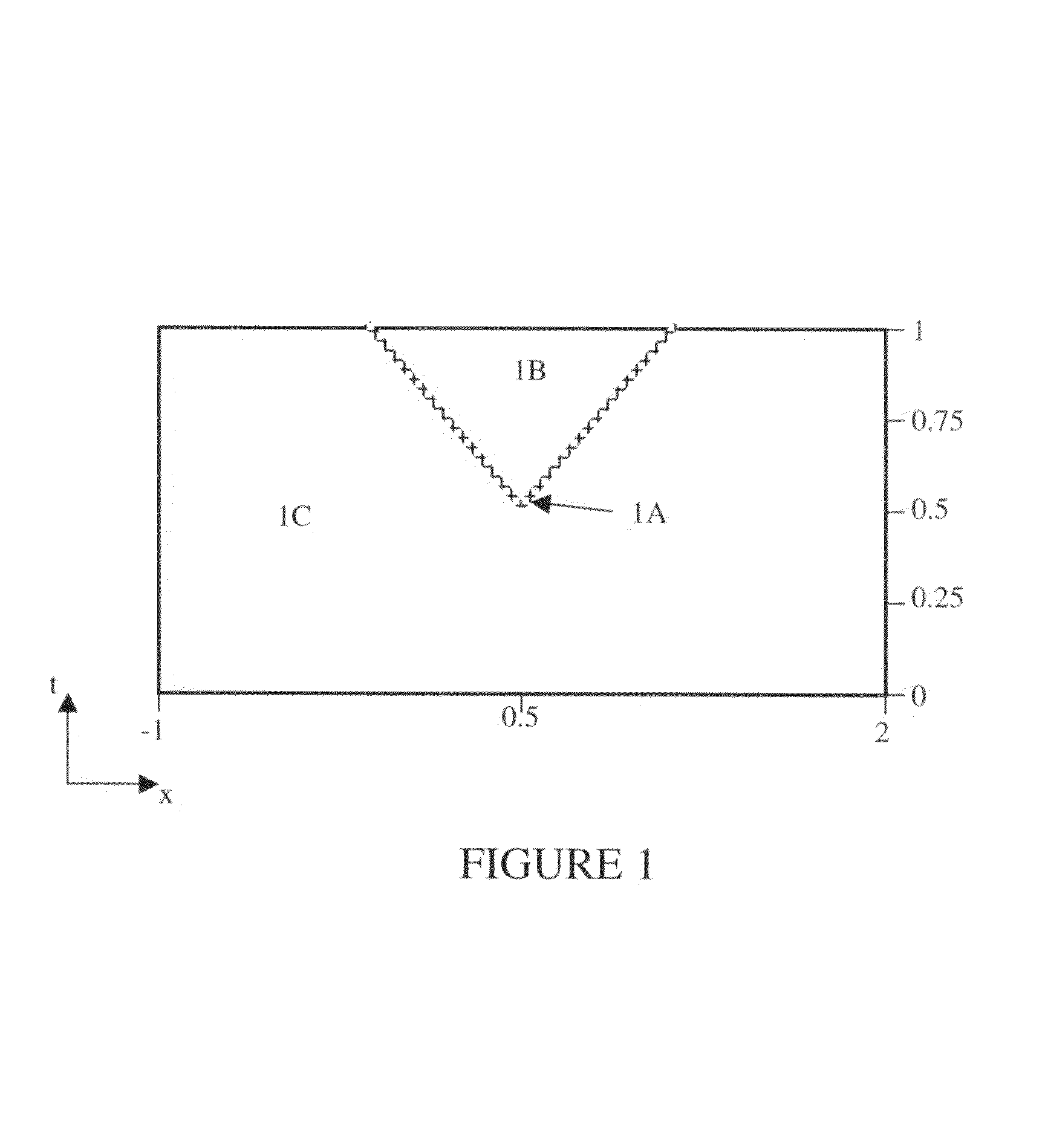

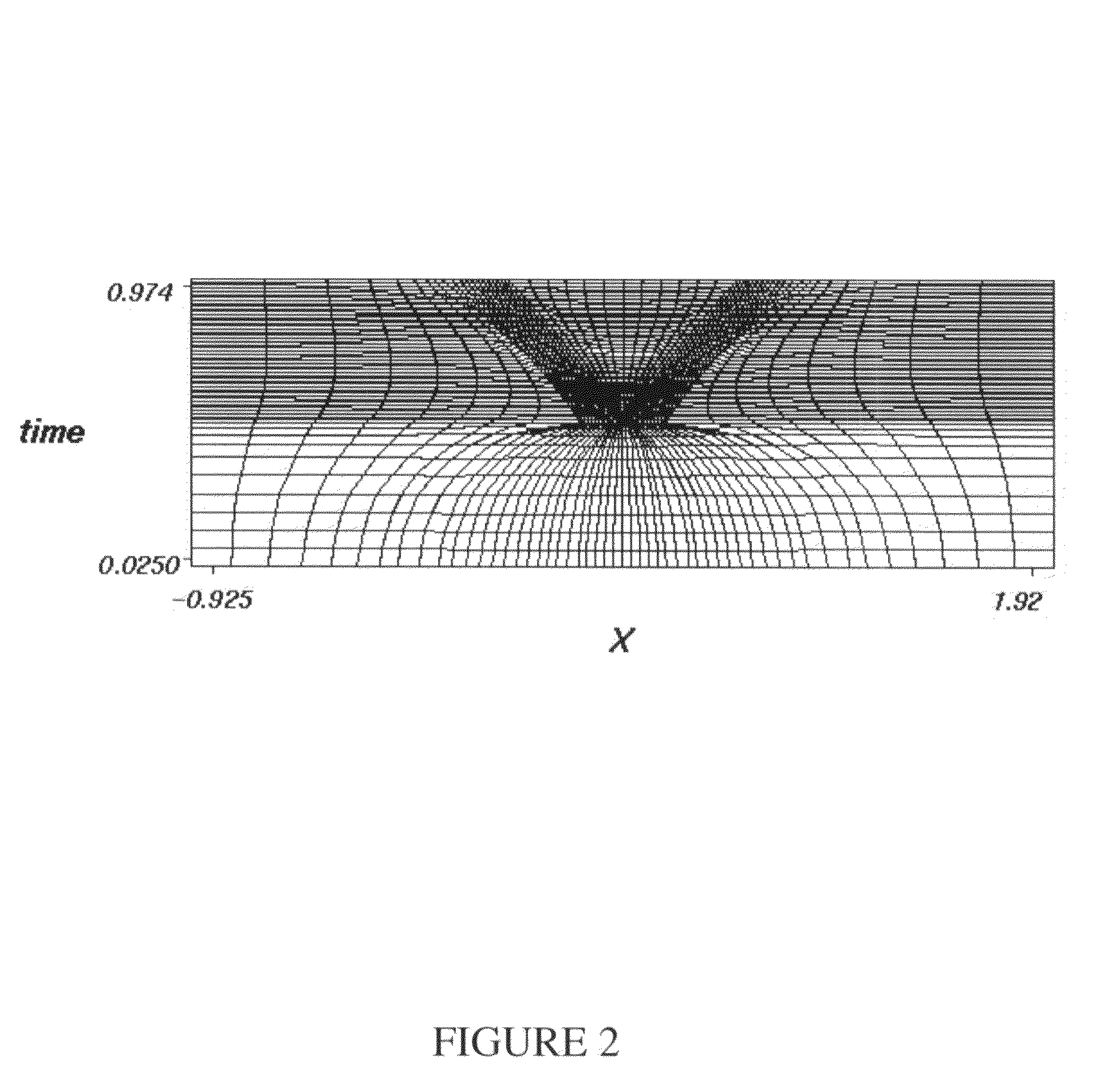

Method and system for the efficient calculation of unsteady processes on arbitrary space-time domains

ActiveUS7359841B1Well formedAnalogue computers for chemical processesComputation using non-denominational number representationTime domainSpace time domain

The Space-Time Mapping Analysis (STMA) method and system provides an engineering method and / or system for modeling and / or analyzing and / or designing and / or building and / or operating complex physical processes, components, devices, and phenomena. STMA can be used in a way for modifying and / or improving the design of many different products, components, processes, and devices, for example. Any physical system, whether existing or proposed, which exhibits, for example, unsteady flow phenomena, might be modeled by the STMA. Thus, STMA can be implemented as a part of an engineering system for design improvements and / or modifications and / or evaluations. The STMA system and / or method uses a space-time mapping technique wherein the space and time directions are treated in an equivalent way, such that, rather than solving a three-dimensional unsteady problem by sweeping in the time direction from an initial point in time to a final point in time, the problem is solved as a four-dimensional problem in space-time.

Owner:HIXON TECH

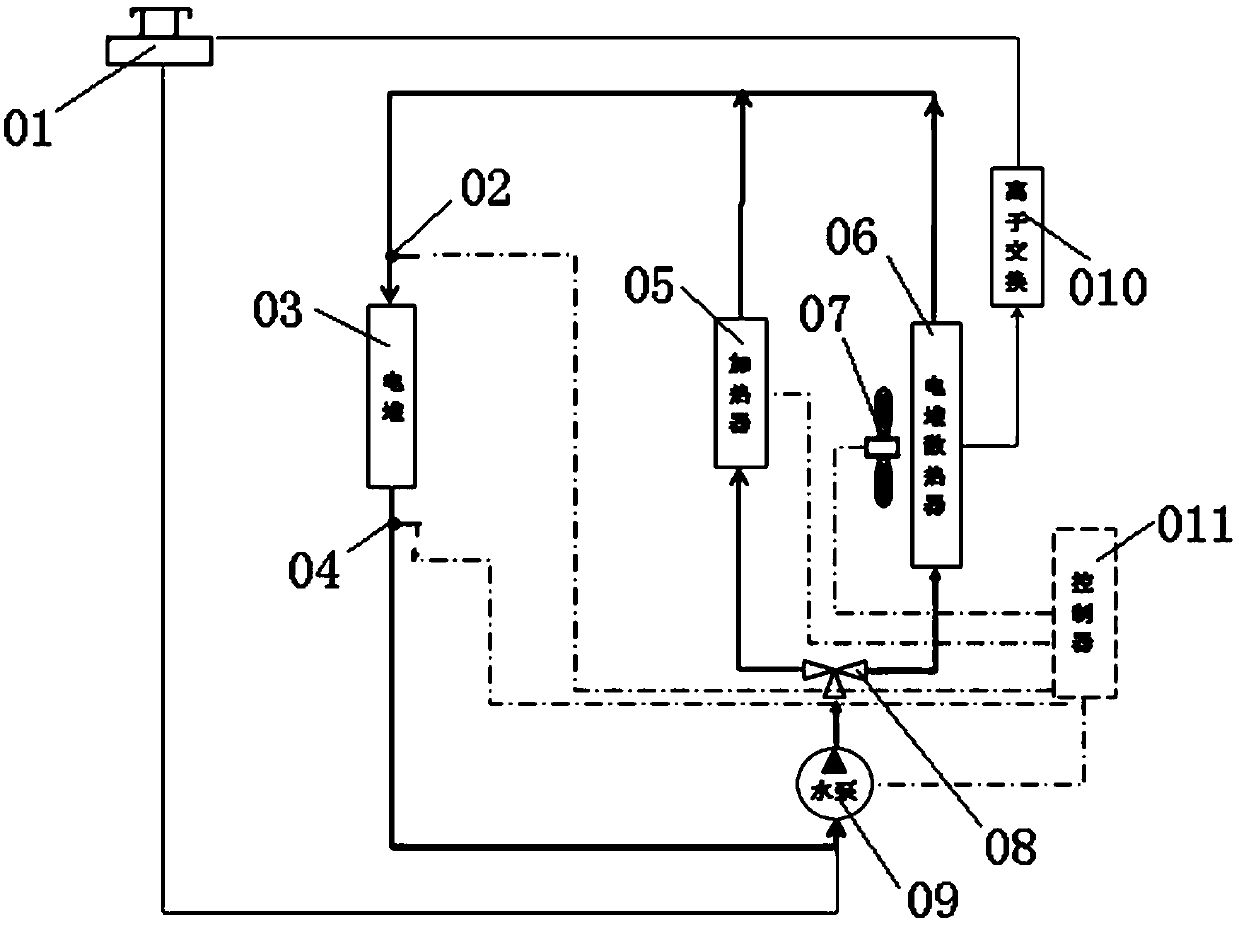

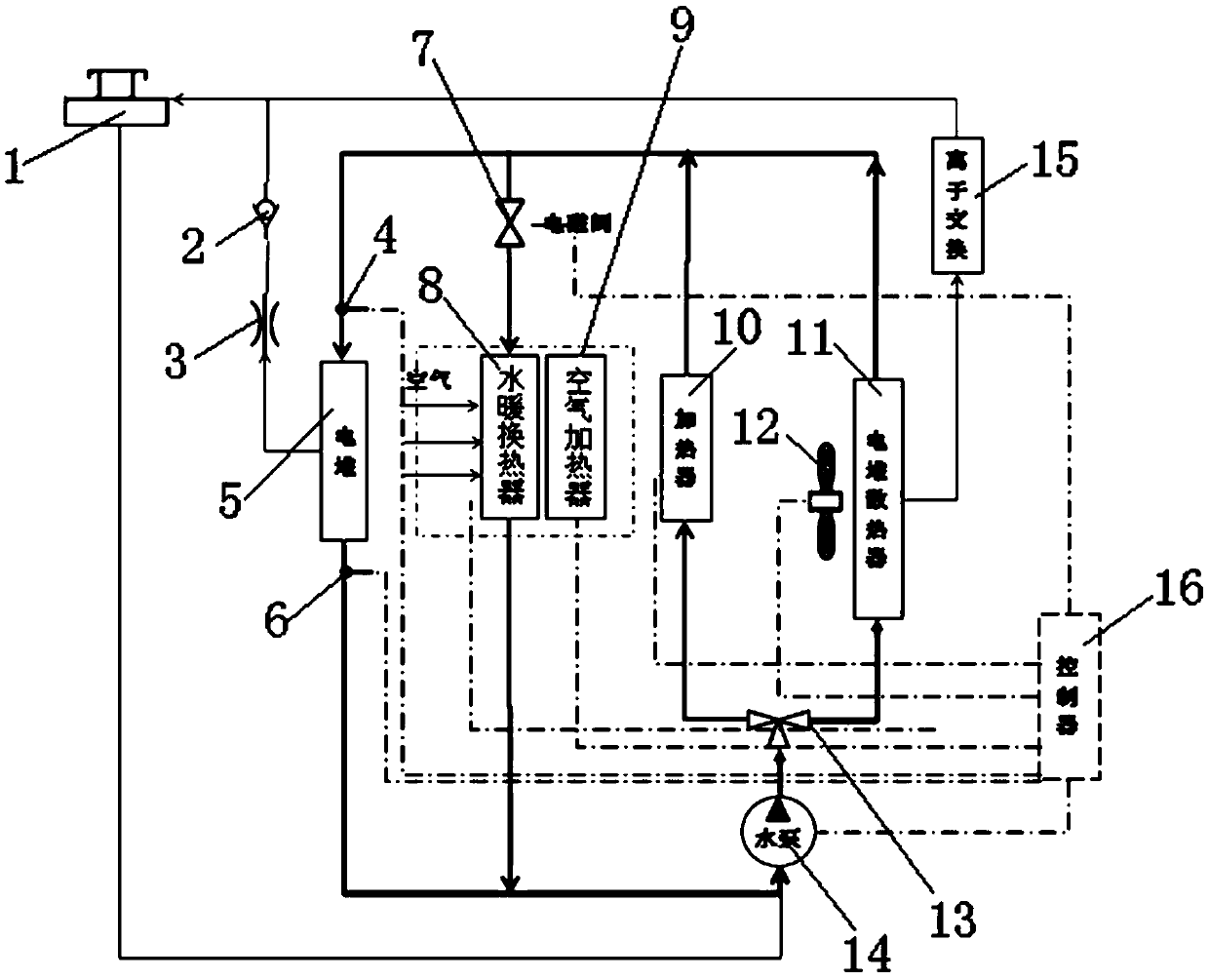

Thermal management system and control method for hydrogen fuel cell vehicle

ActiveCN109532565AStart fastImprove adaptabilityAir-treating devicesVehicle heating/cooling devicesSolenoid valveHydrogen fuel cell

The invention relates to a thermal management system and control method for a hydrogen fuel cell vehicle. The method includes an expansion kettle, a water pump, an electronic thermostat, a fuel cell radiator, a solenoid valve, a fuel cell stack and an ion exchanger. In order to overcome the restriction that an existing fuel cell stack can not be started under the condition of too low ambient temperature, an auxiliary water heating scheme is designed in a small circulation branch to achieve the fast start-up of the fuel cell stack at low temperature and improve the adaptability of the fuel cellstack to the low temperature environment. The waste heat recovery and utilization of the fuel cell stack can be achieved by adding an auxiliary air-conditioning water heating and heat exchange systemin a water system. The electricity demand of an air heater is reduced, the electric energy of the whole vehicle is saved, and the endurance range of vehicles in winter is increased. Through the design improvement of a degassing device for the fuel cell stack, the degassing problem of the fuel cell stack water system in the process of filling and operation is solved, and the reliability of the fuel cell heat management system is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

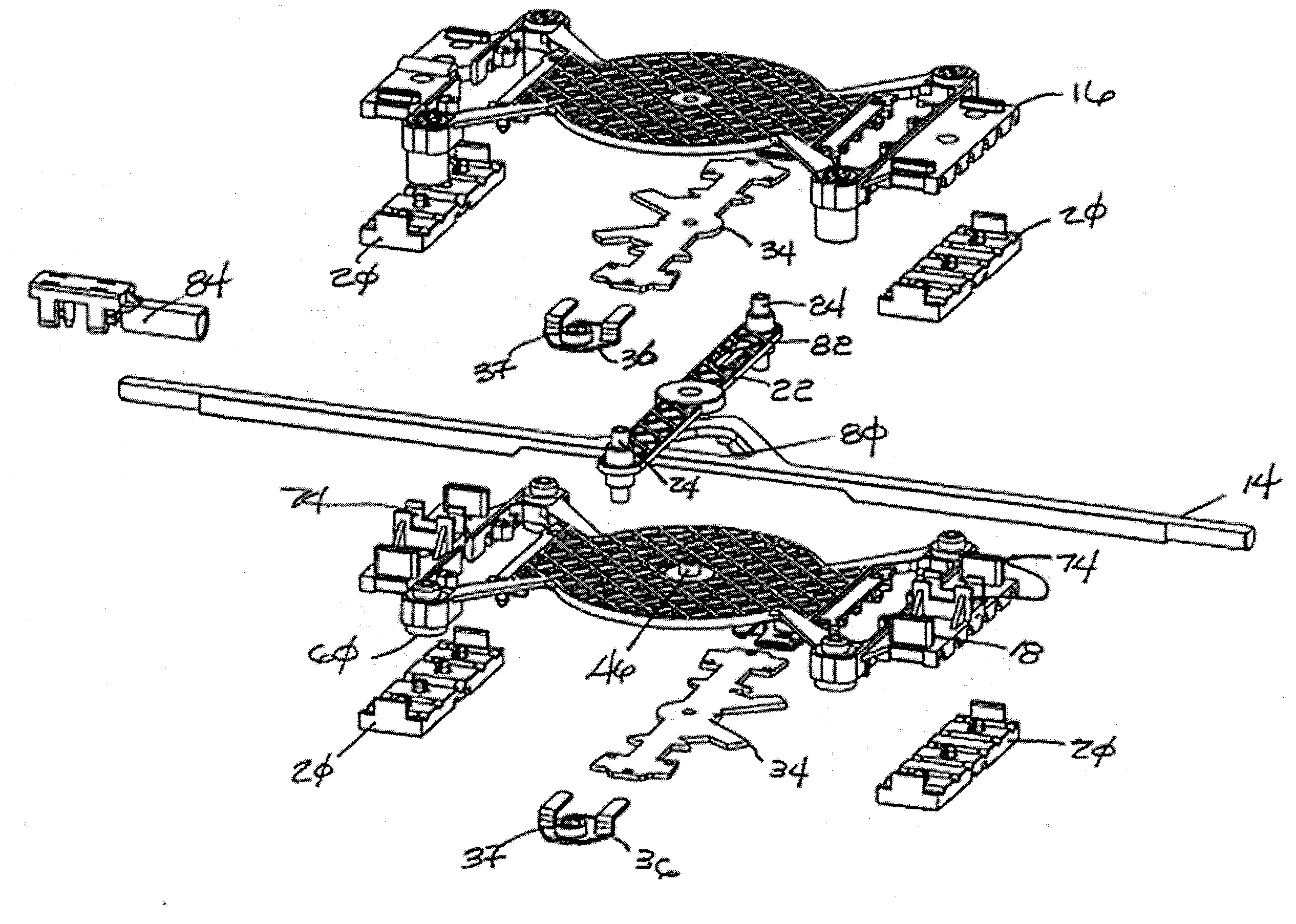

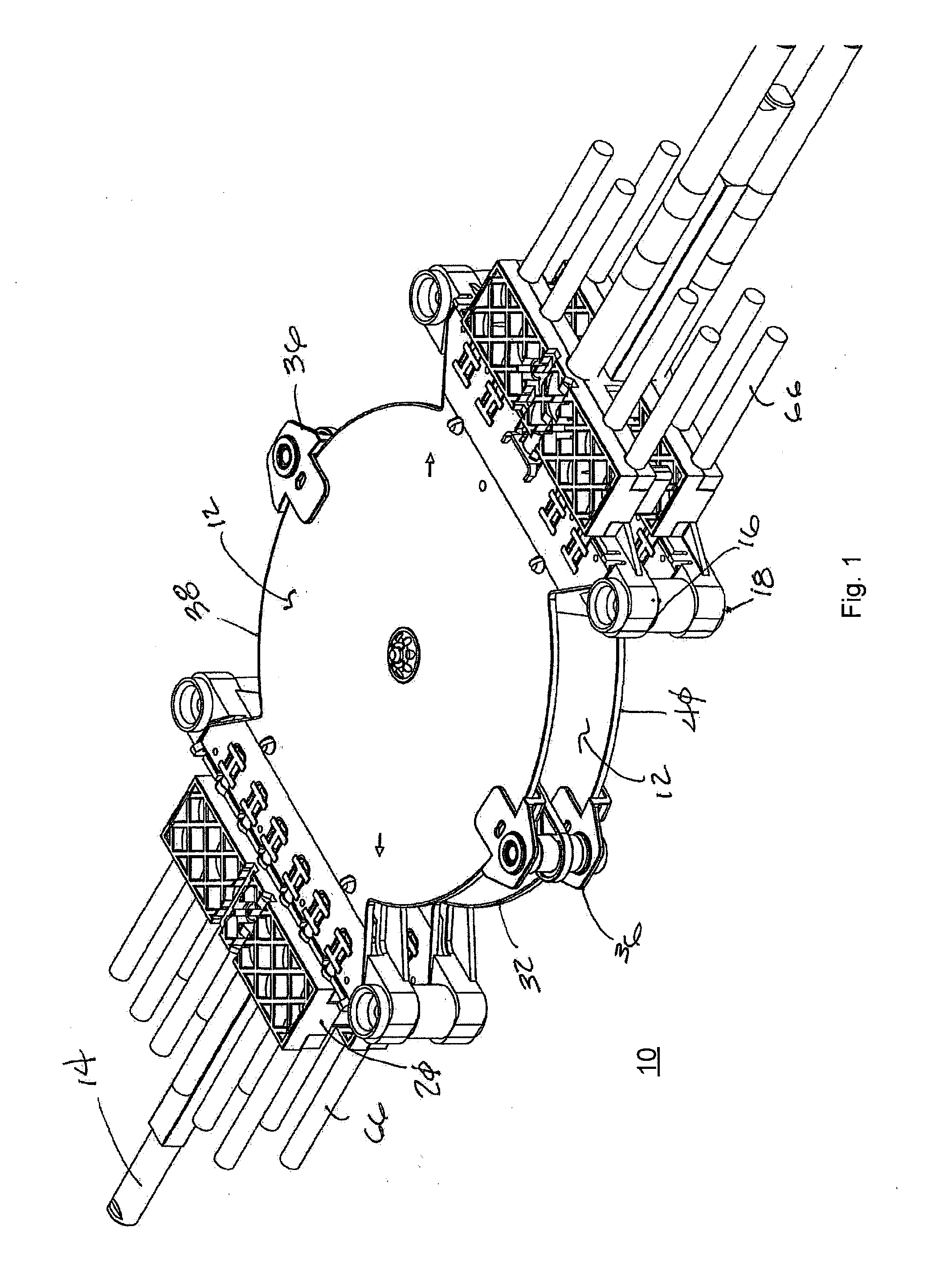

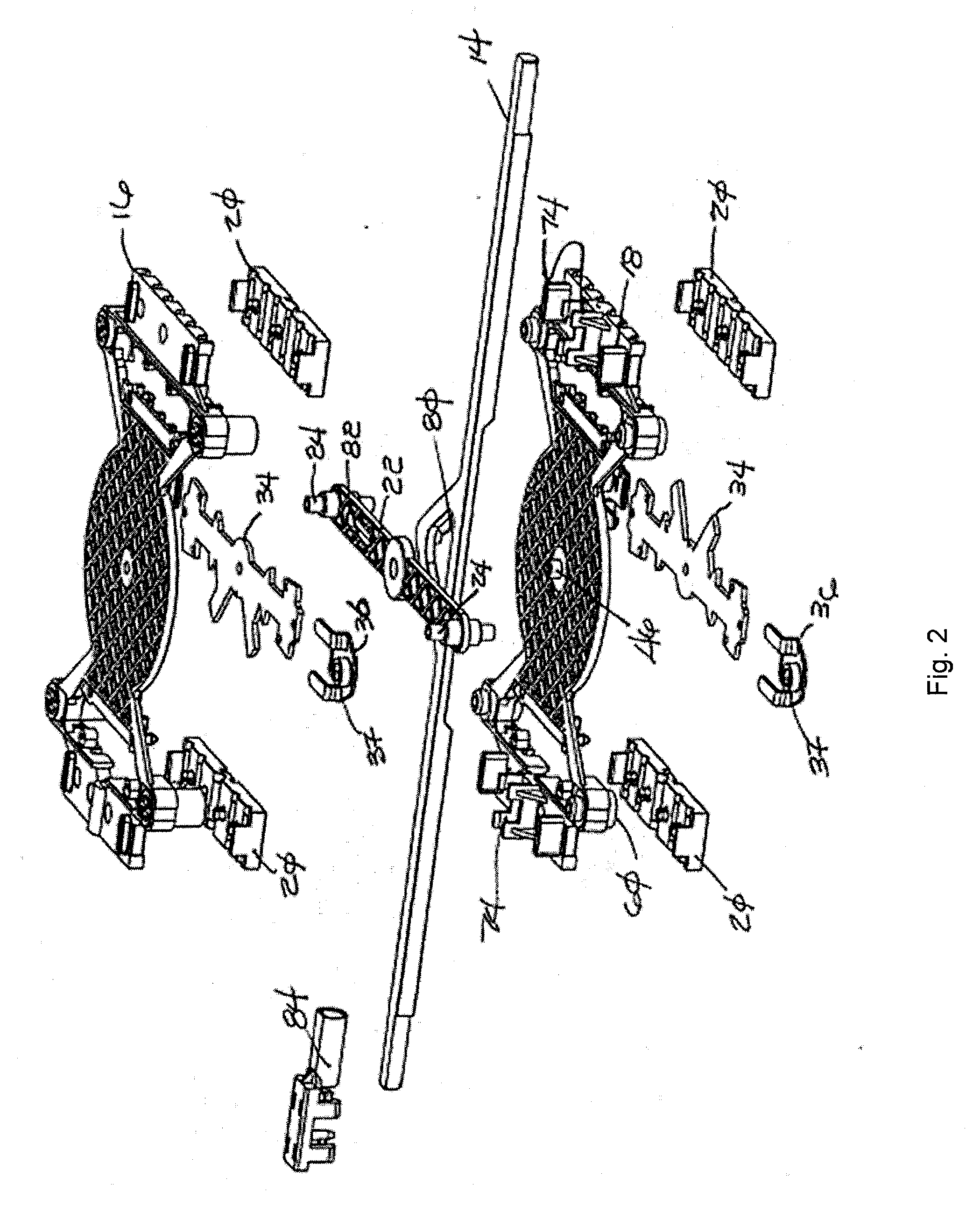

Phase Shifter Design Improvements

InactiveUS20110063049A1Zero compressionAvoid insufficient clamping forceCoupling device detailsDelay linesDesign improvementPrinted circuit board

An improved phase shifter assembly is provided. The phase shifter assembly may comprise first and second sub-assemblies with certain common actuating elements. In one example, a first phase shifter sub-assembly is provided, the first phase shifter sub-assembly including a first phase shifter carrier, a first phase shifter printed circuit board mounted on the first phase shifter carrier, a first wiper printed circuit board coupled to an input of the first phase shifter printed circuit board and having at least a first end coupled to transmission lines on the first phase shifter printed circuit board, and at least one wiper support mechanically coupling the first wiper printed circuit board to the first phase shifter printed circuit board. A second phase shifter is similarly provided. Common actuating elements may include a pivot arm and a throw arm. The pivot arm may be rotatably mounted in the phase shifter assembly and be configured to engage a wiper support of at least one of the first and second phase shifter sub-assemblies. The throw arm may be mounted such that when the throw arm is moved linearly, the pivot arm rotates around a pivot.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com