Patents

Literature

272results about How to "Avoid insufficient clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

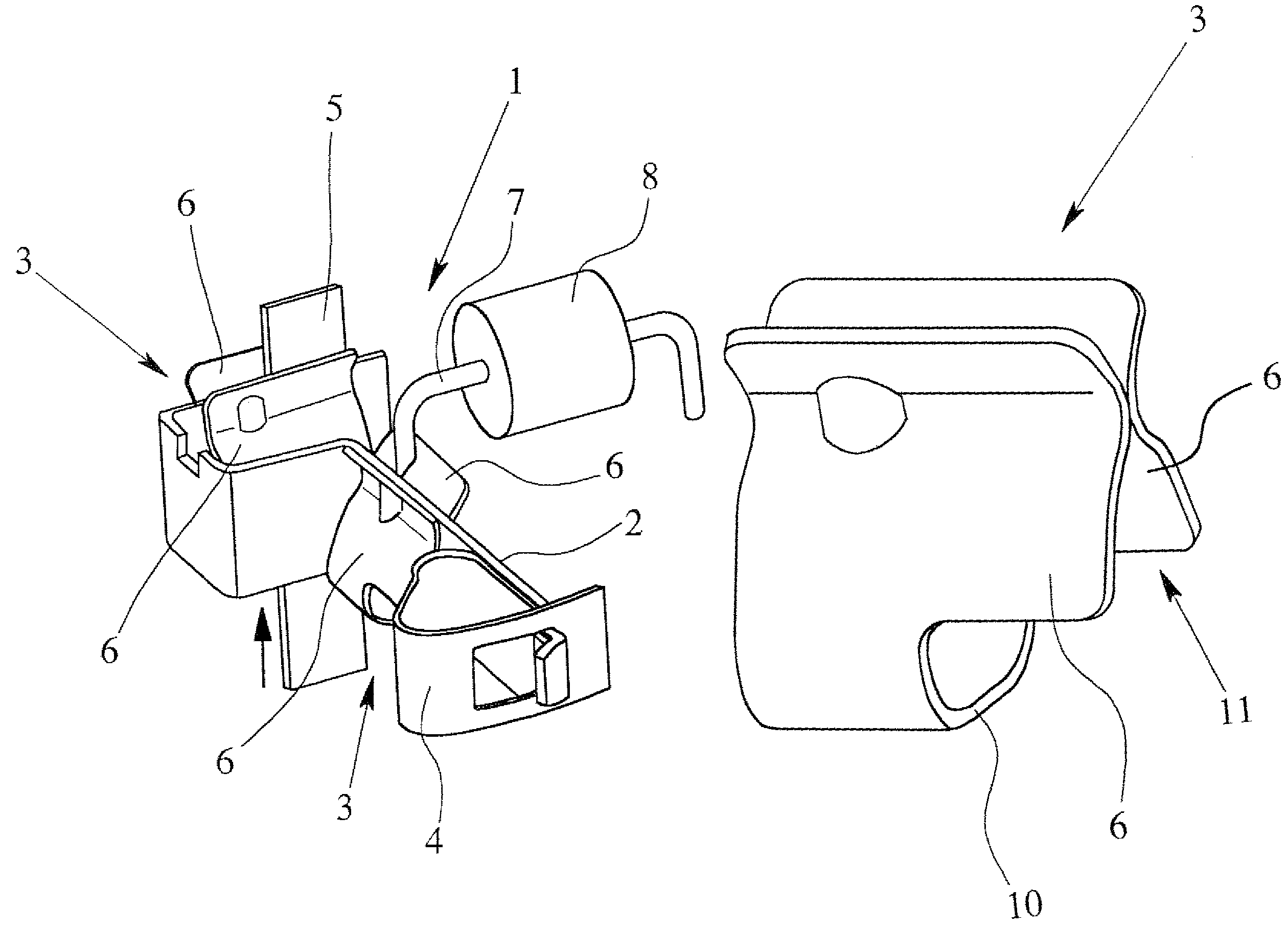

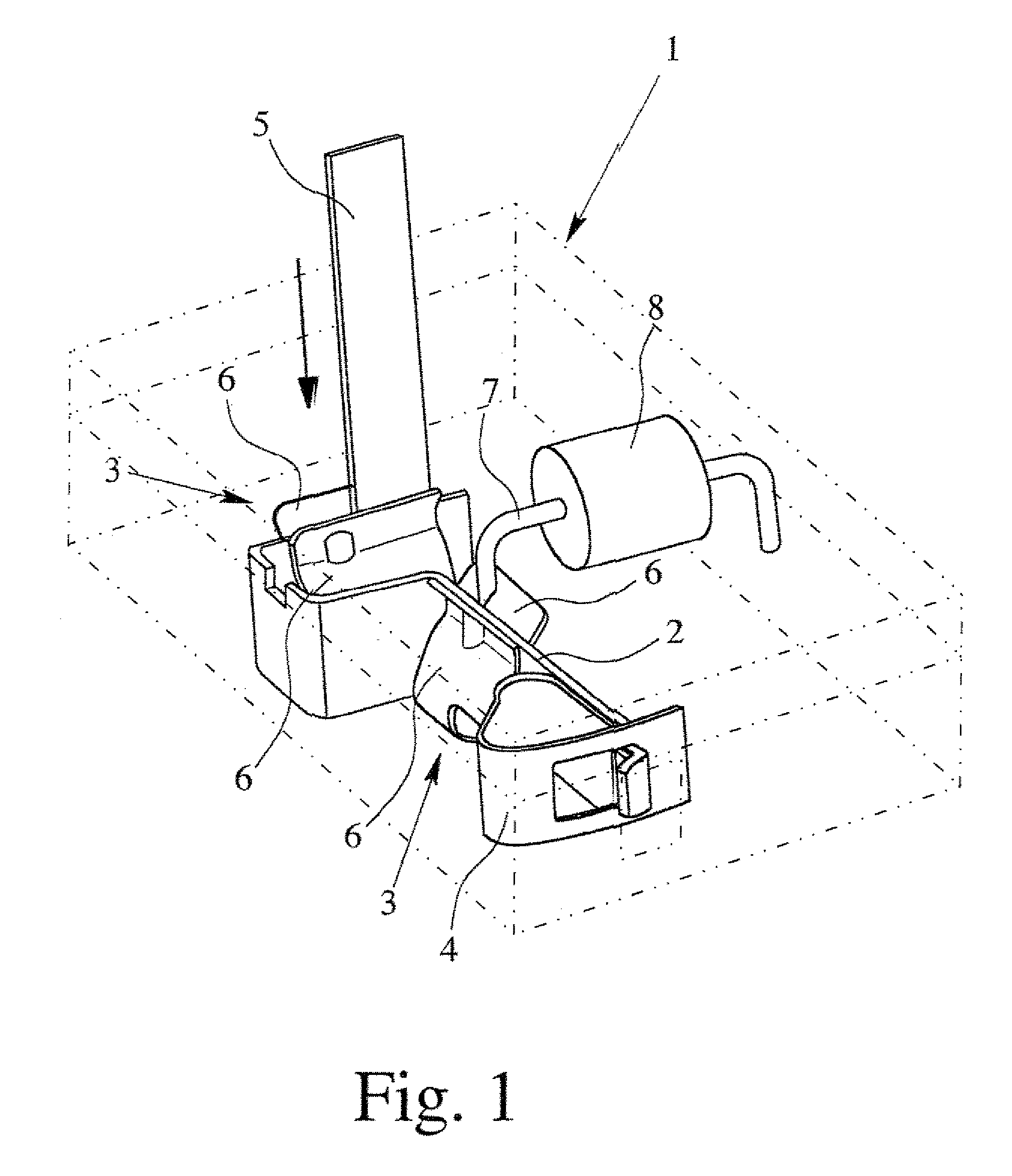

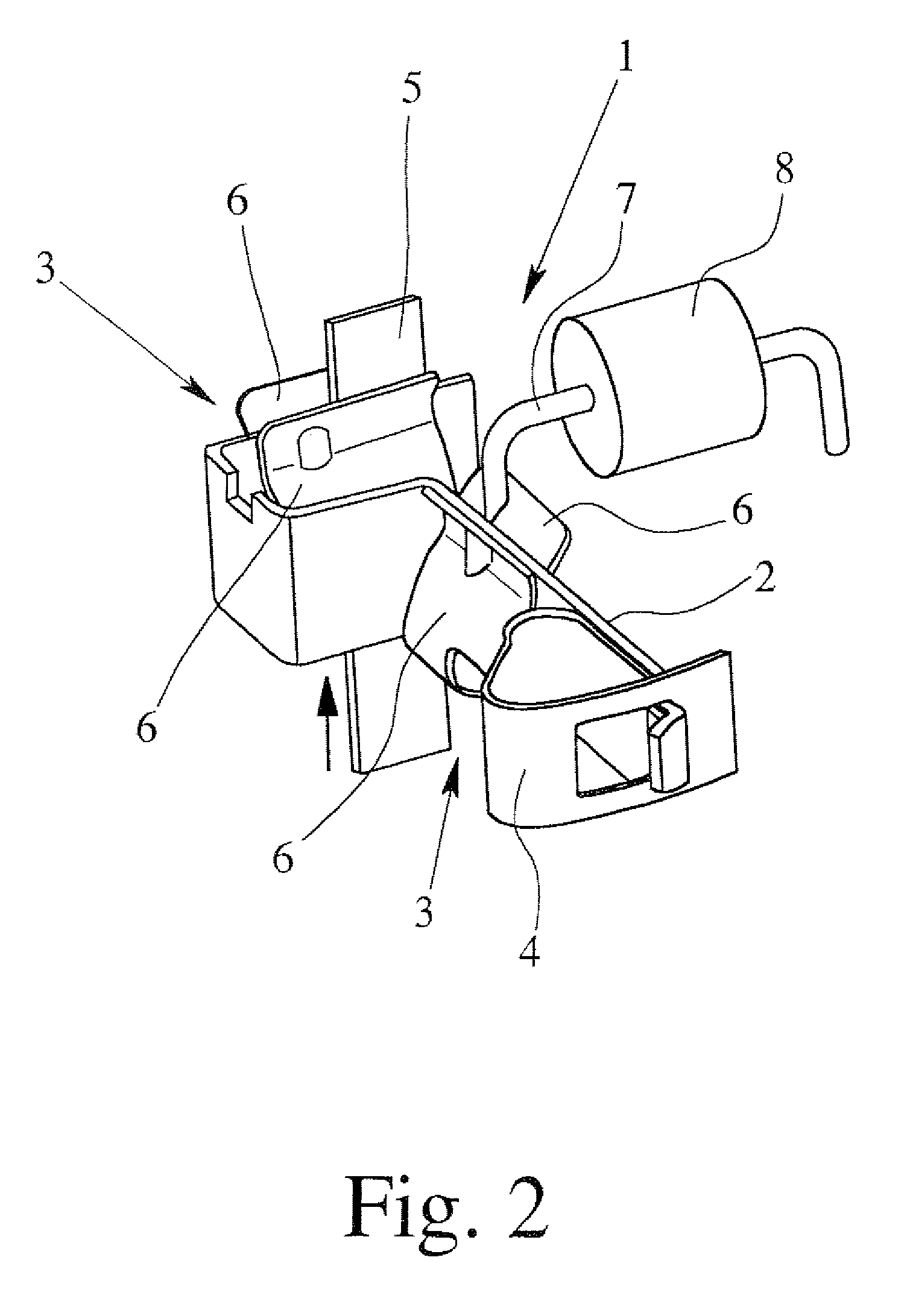

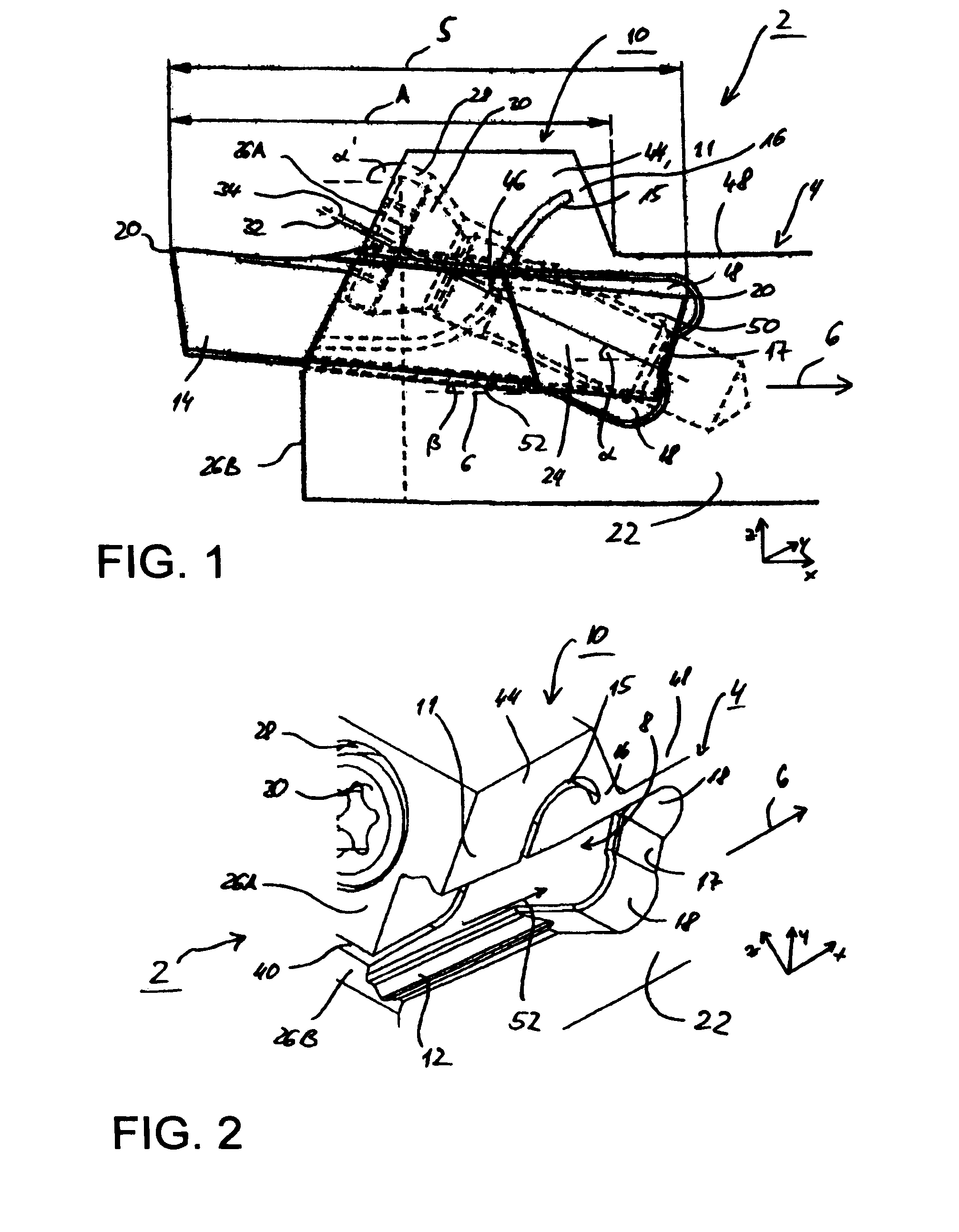

Electrical junction box for a solar cell module

InactiveUS20060289053A1Simple and reliable connectionReduce effortElectrically conductive connectionsPV power plantsElectrical junctionElectricity

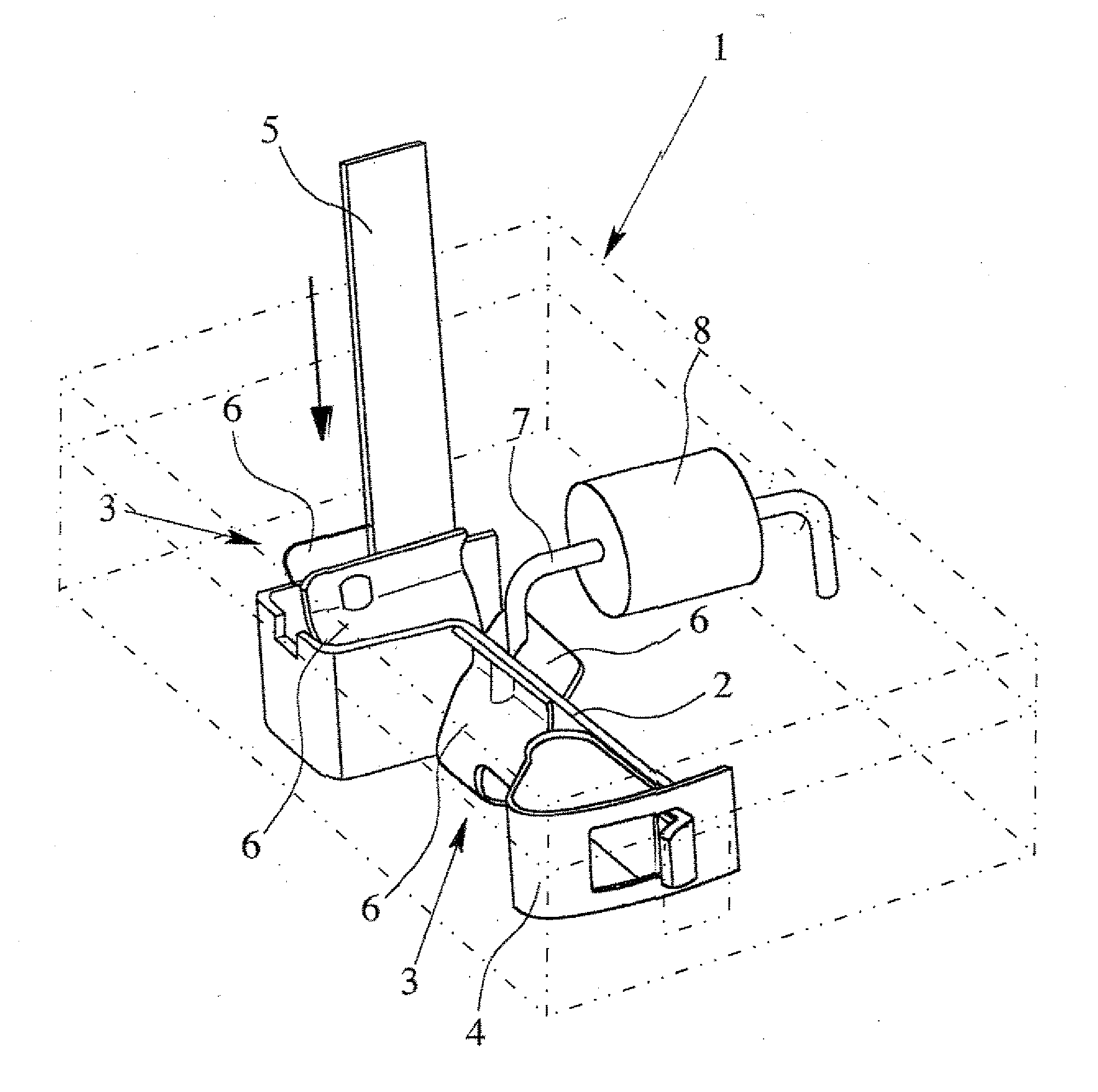

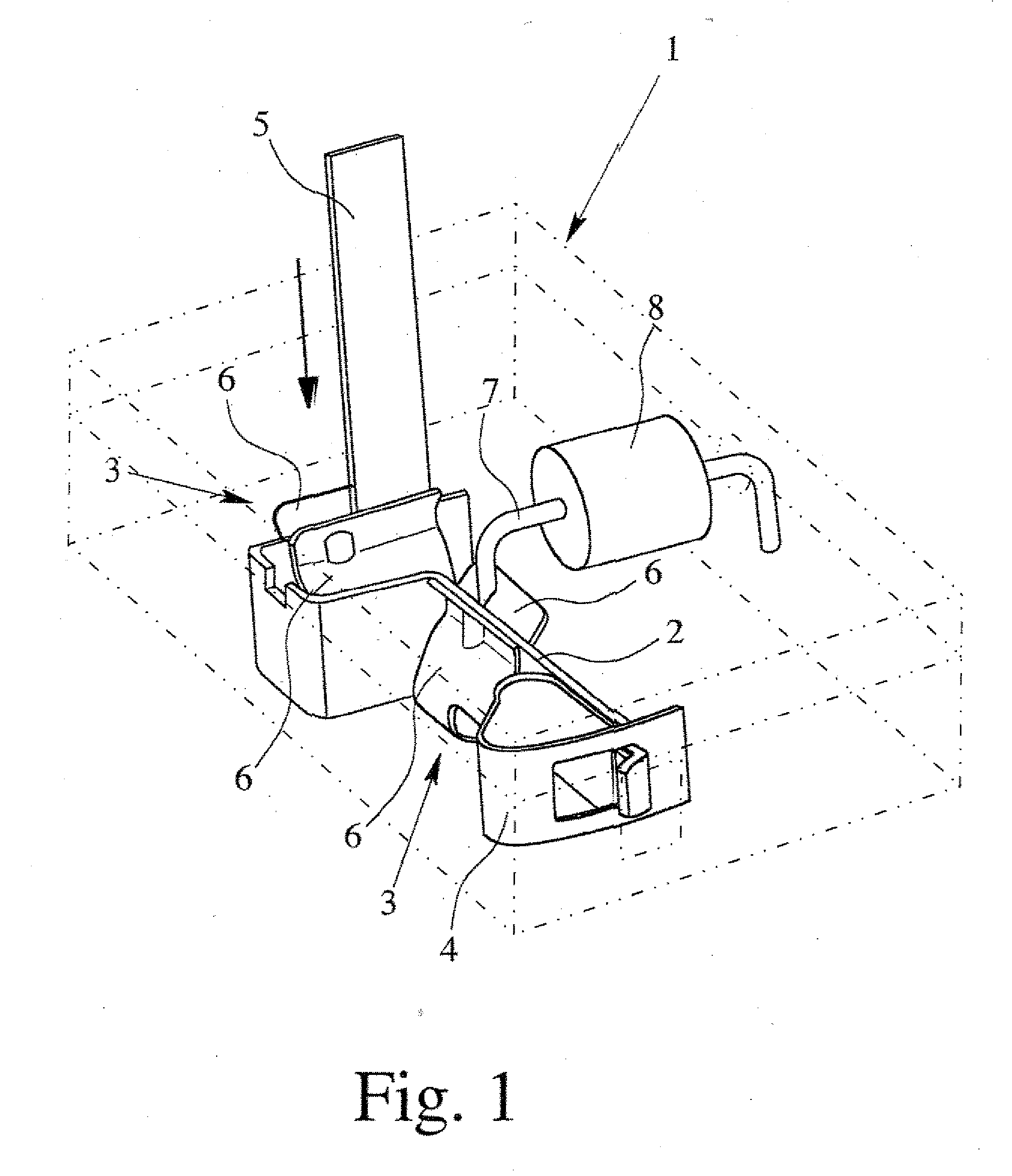

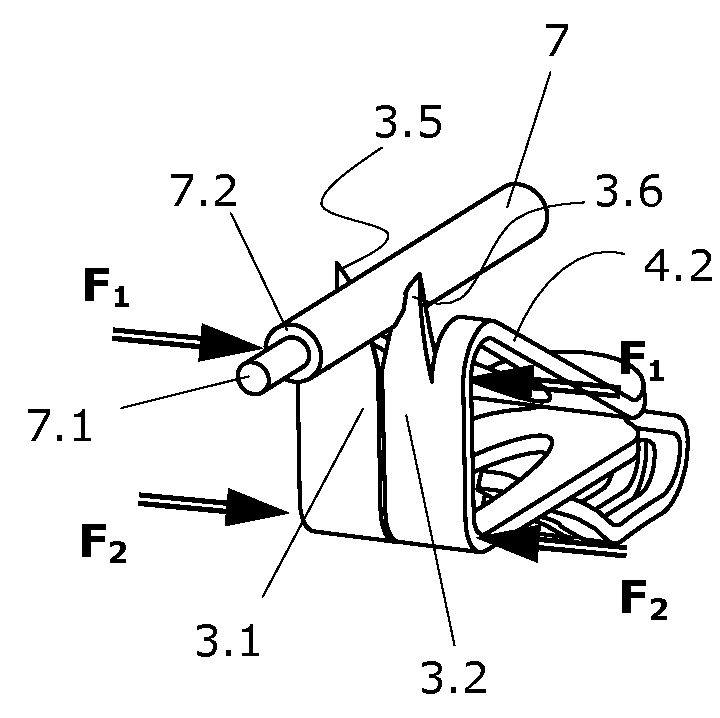

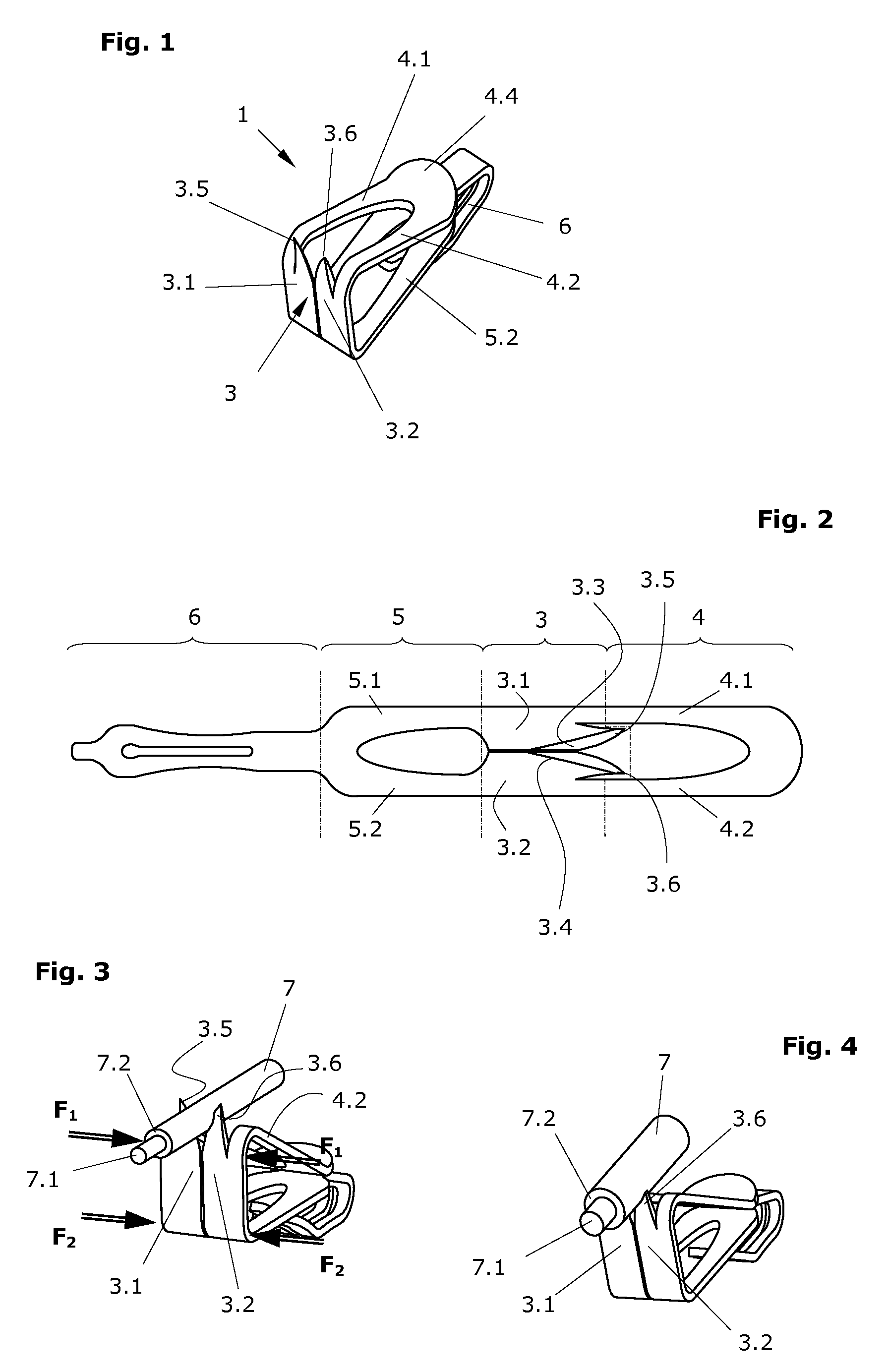

An electrical junction box for a solar cell module of solar cells which are connected with thin conductor strips, with a housing and electrical and / or electronic devices provided in the housing, and at least one electrical connection device (1) which has at least one terminal (3) and which is provided in the housing. The clamping mechanism (3) for producing clamping contact is made and arranged such that at least one thin conductor strip (5) routed out of the solar cell module can be inserted into the clamping mechanism in two different opposing entry directions. Thus, simple and reliable connection of thin conductor strips (5) routed out of the solar cell module can be guaranteed.

Owner:GUNTHER SPELSBERG GMBH CO

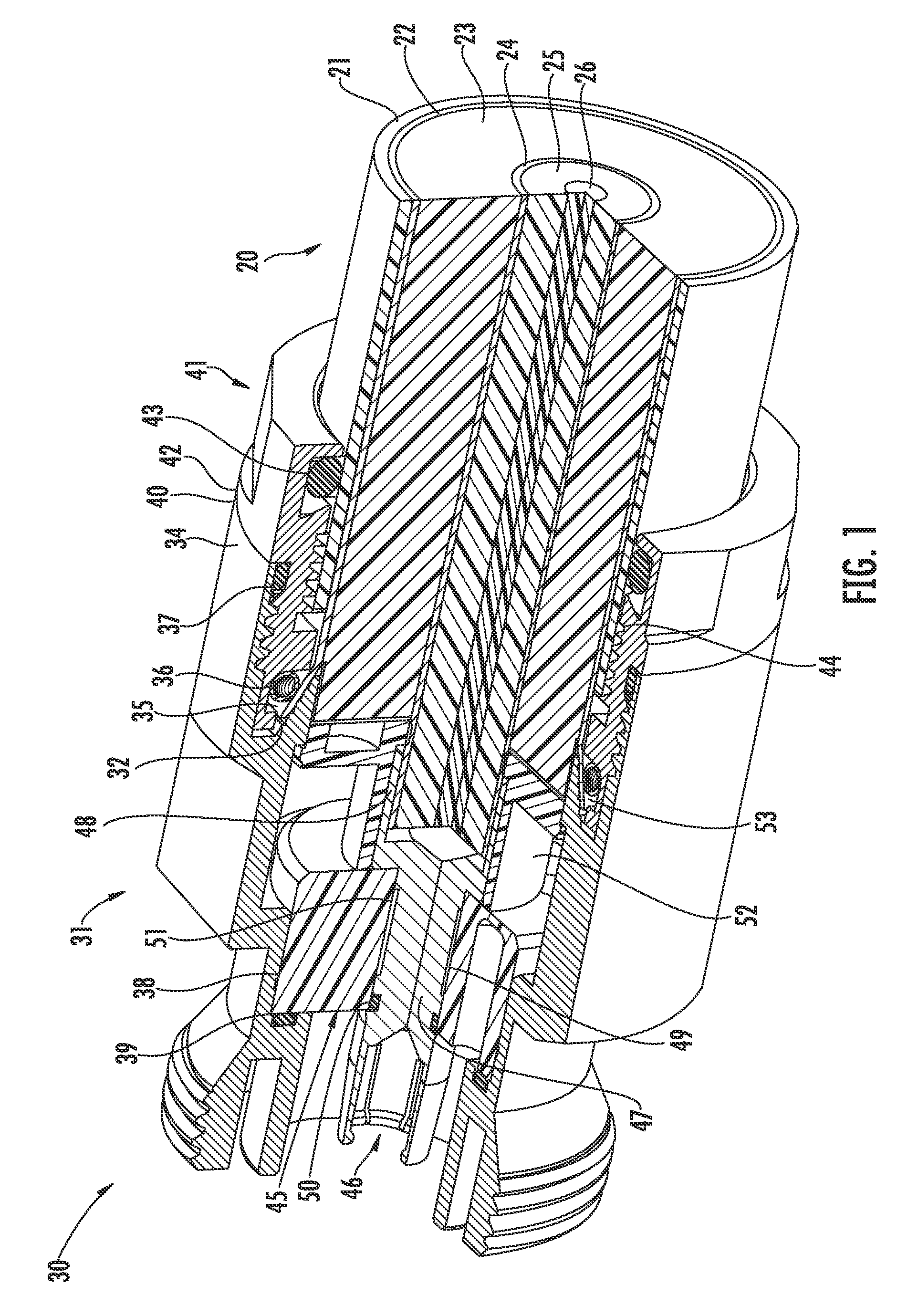

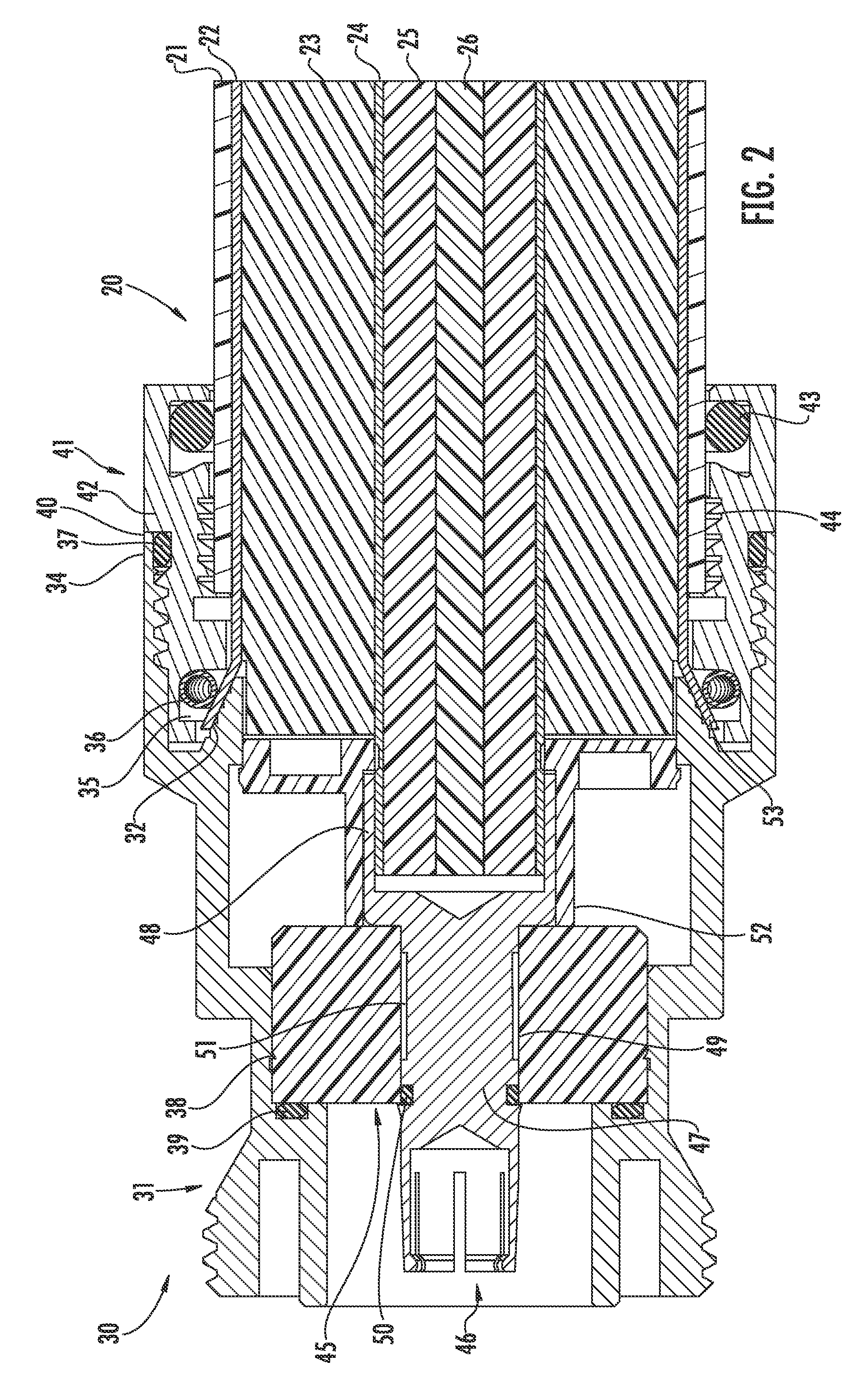

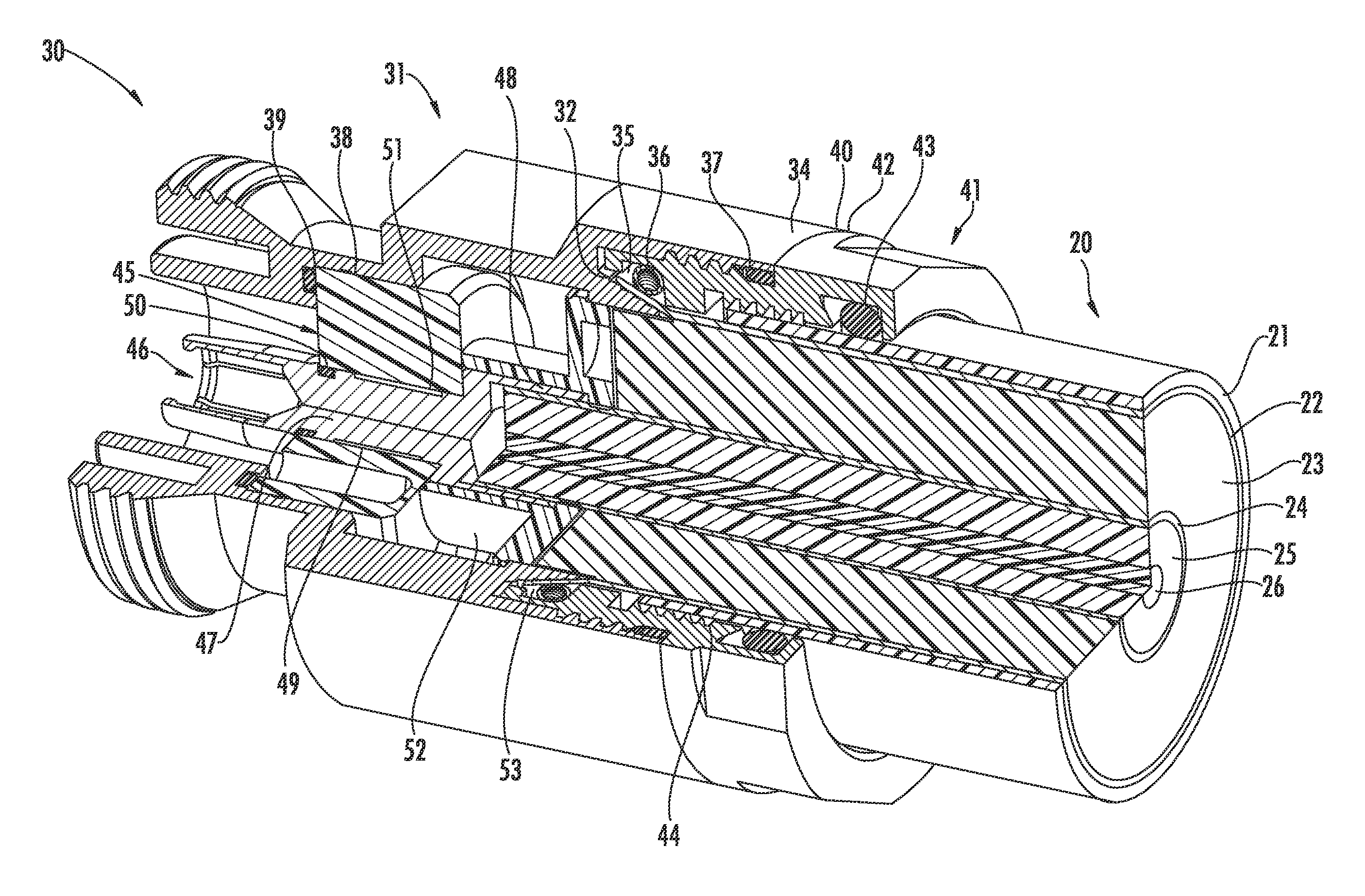

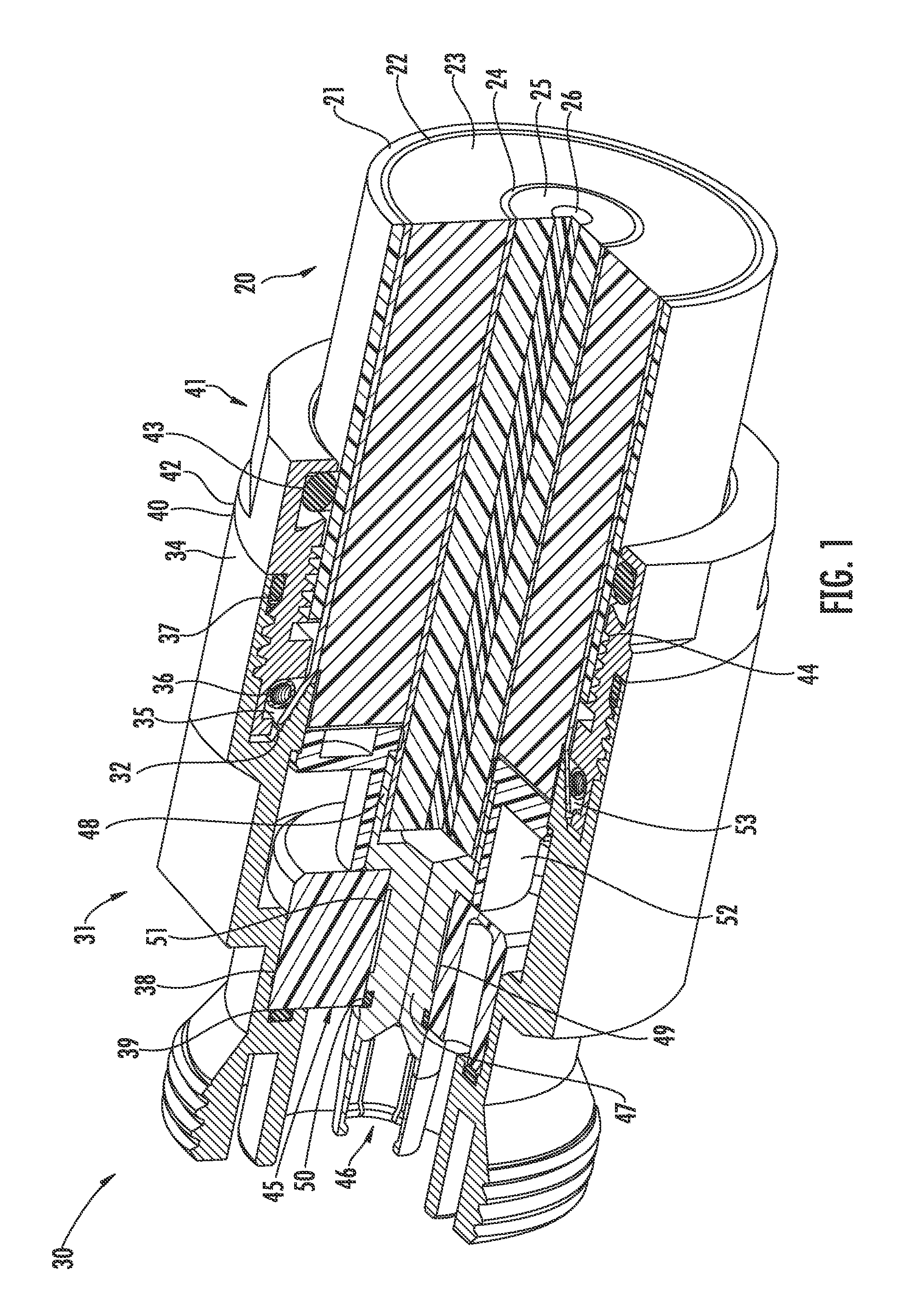

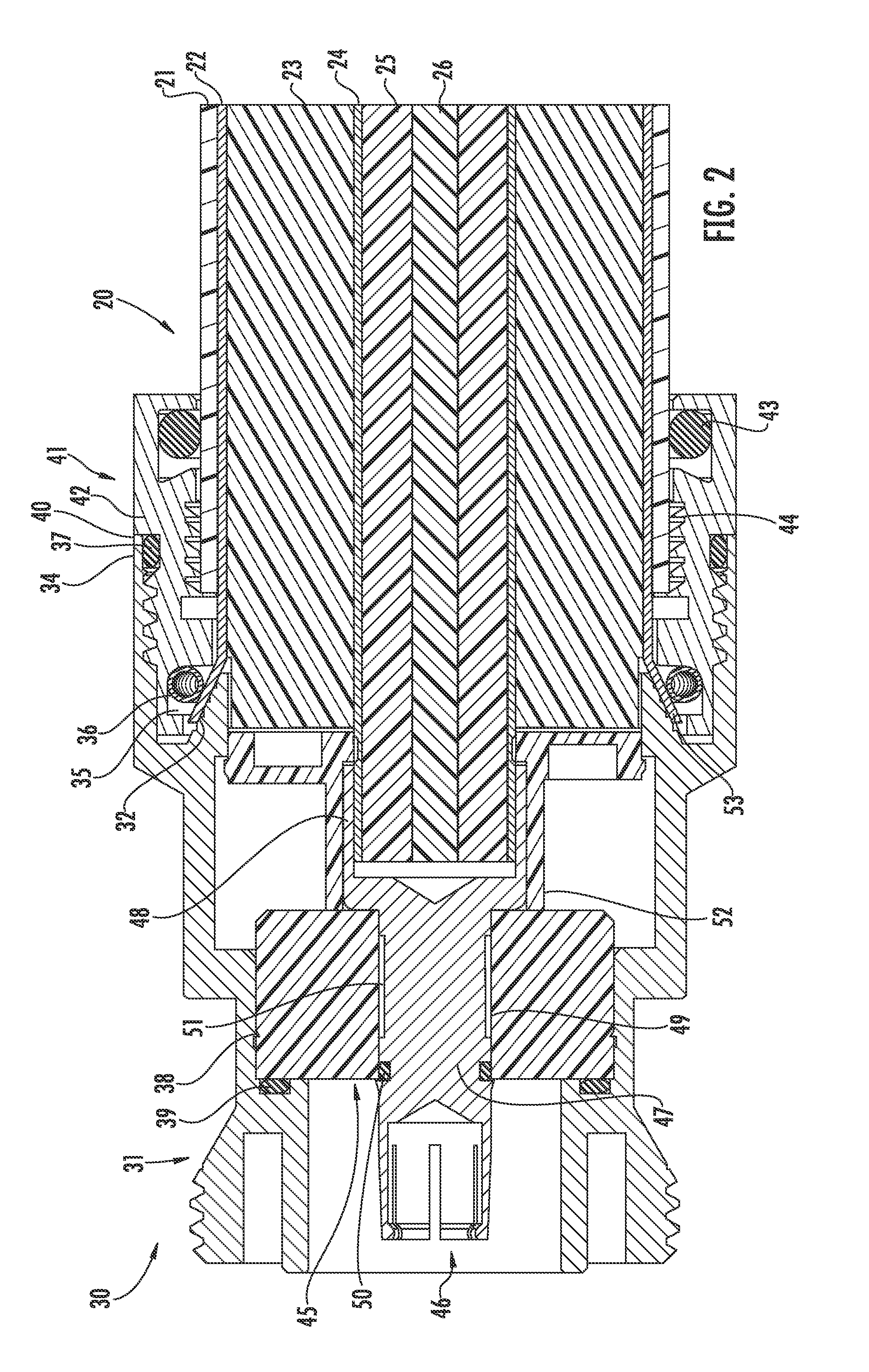

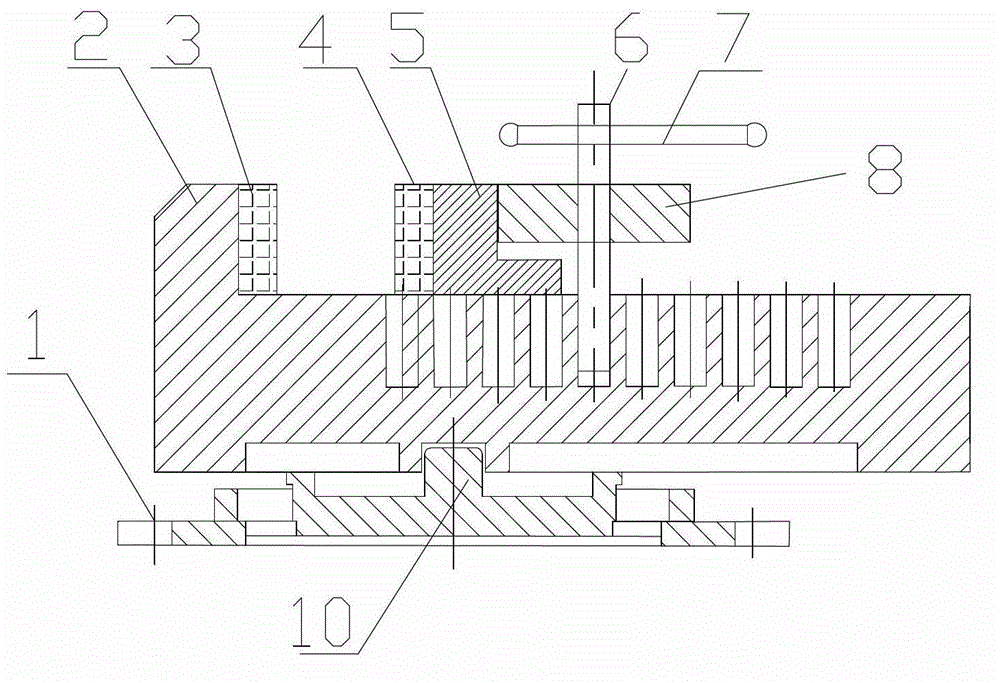

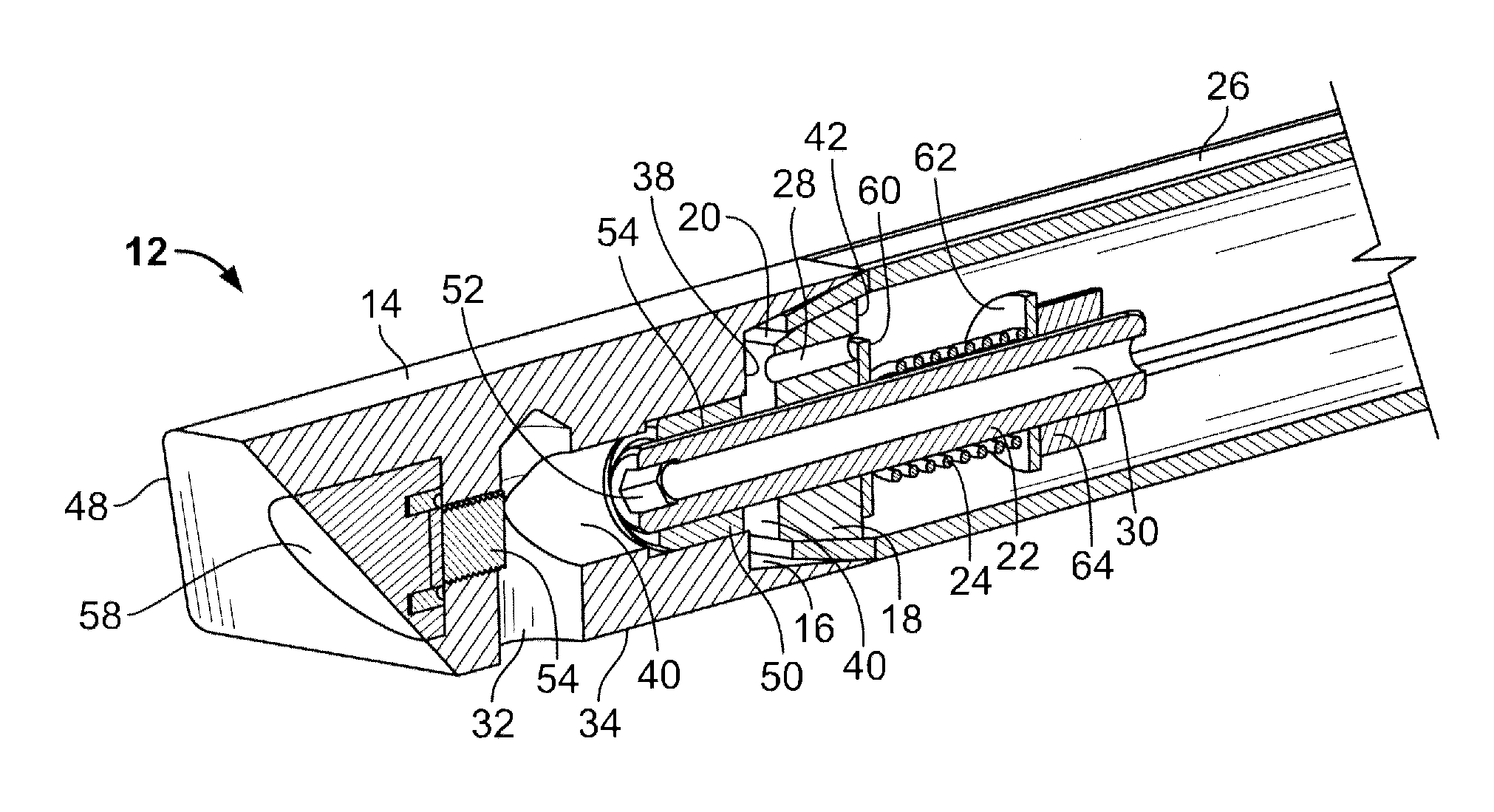

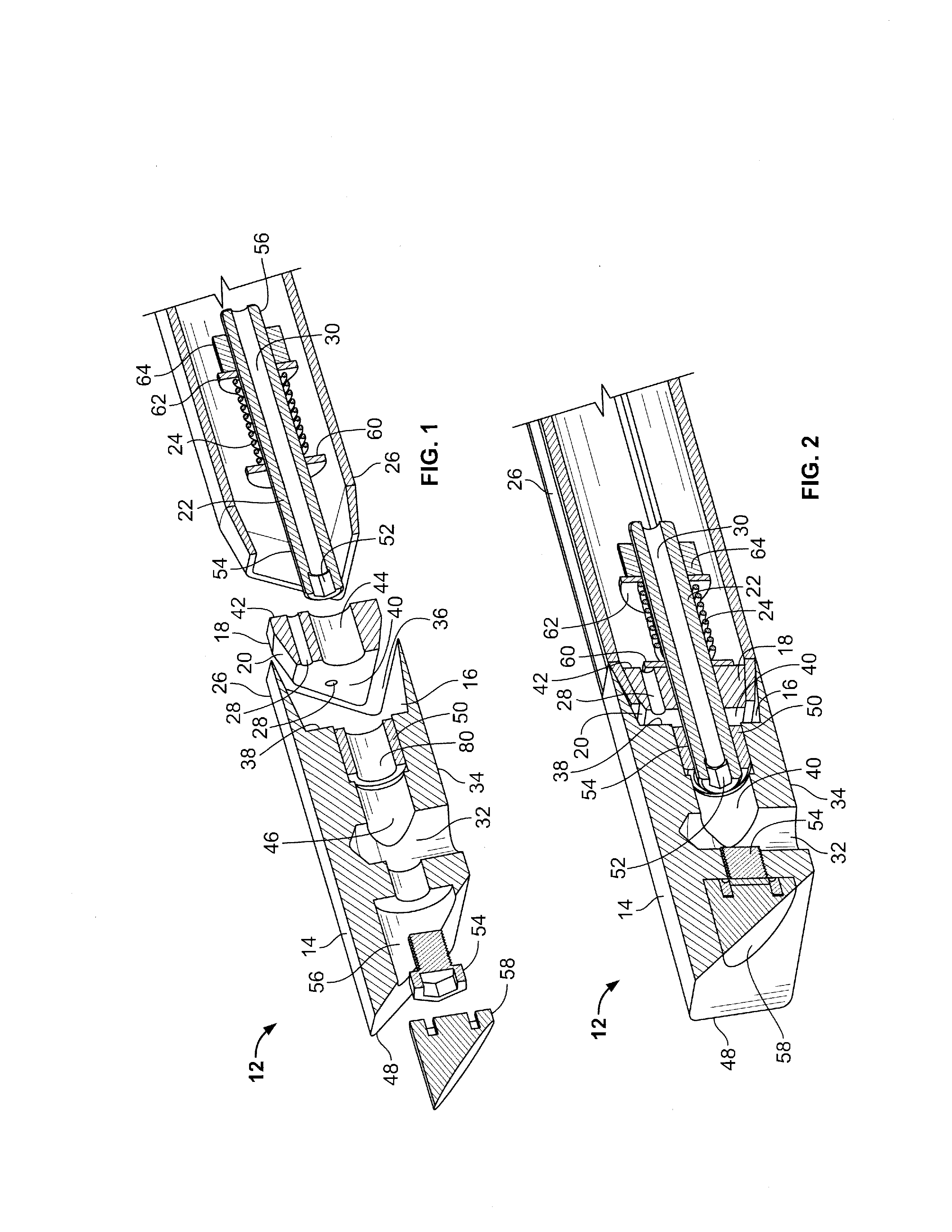

Connector for coaxial cable having rotational joint between insulator member and connector housing and associated methods

ActiveUS8206176B2Reduce and eliminate rotationReduce harmTwo pole connectionsContact member assembly/disassemblyElectrical conductorCoaxial cable

Owner:COMMSCOPE TECH LLC

Connector for coaxial cable having rotational joint between insulator member and center contact and associated methods

InactiveUS20110201232A1Easy to installCost-effectiveContact member manufacturingElectrically conductive connectionsElectrical conductorCoaxial cable

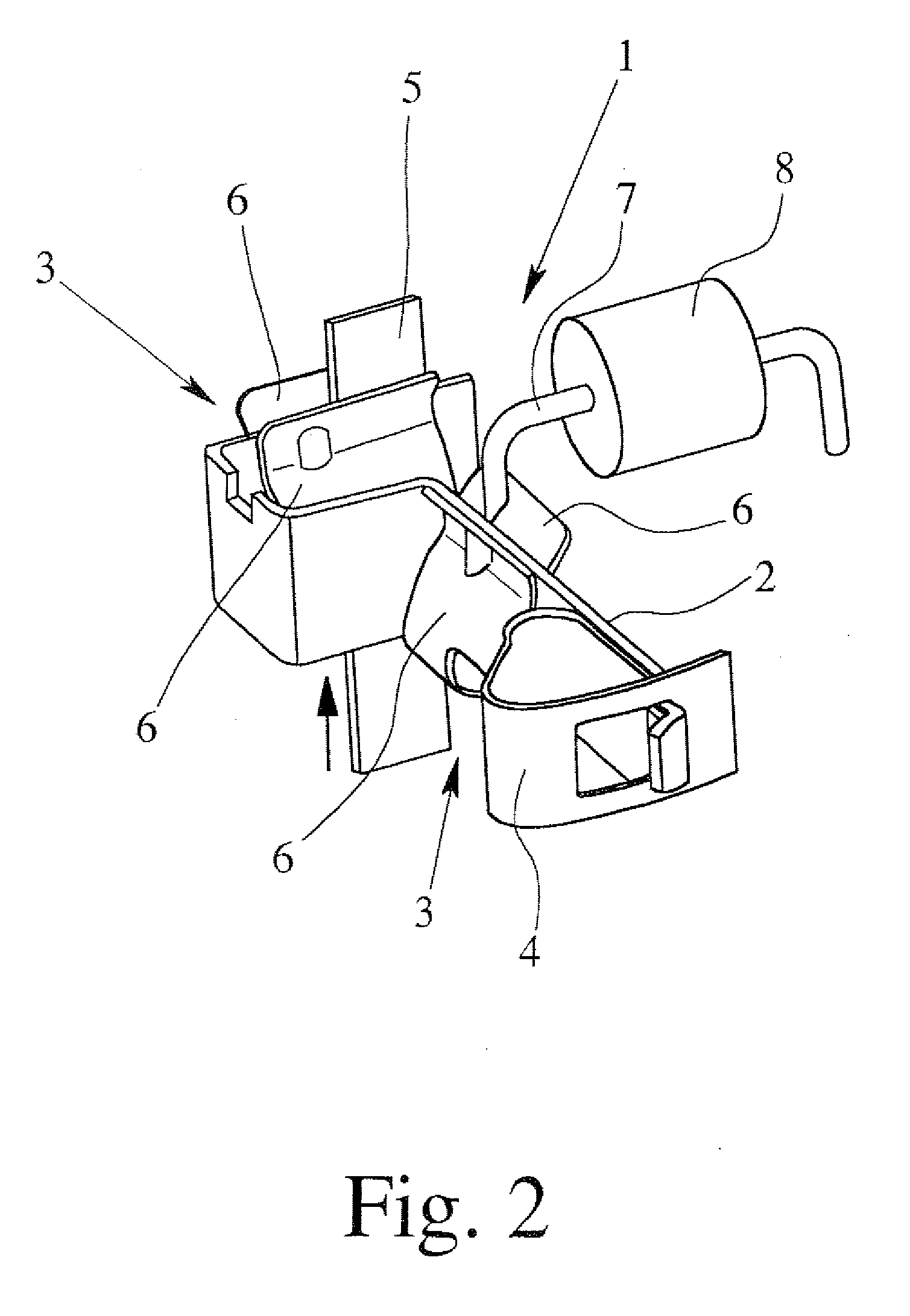

A connector is to be attached to a coaxial cable and includes a connector housing having a cylindrical shape to be coupled to an outer conductor of the coaxial cable. An insulator member has a central opening therein and is rotatably received within the connector housing to define a rotational joint therewith. A center contact has a shaft portion securely received within the central opening of the insulator member and an open end portion extending rearwardly from the shaft portion to securely receive the inner conductor therein.

Owner:ANDREW LLC

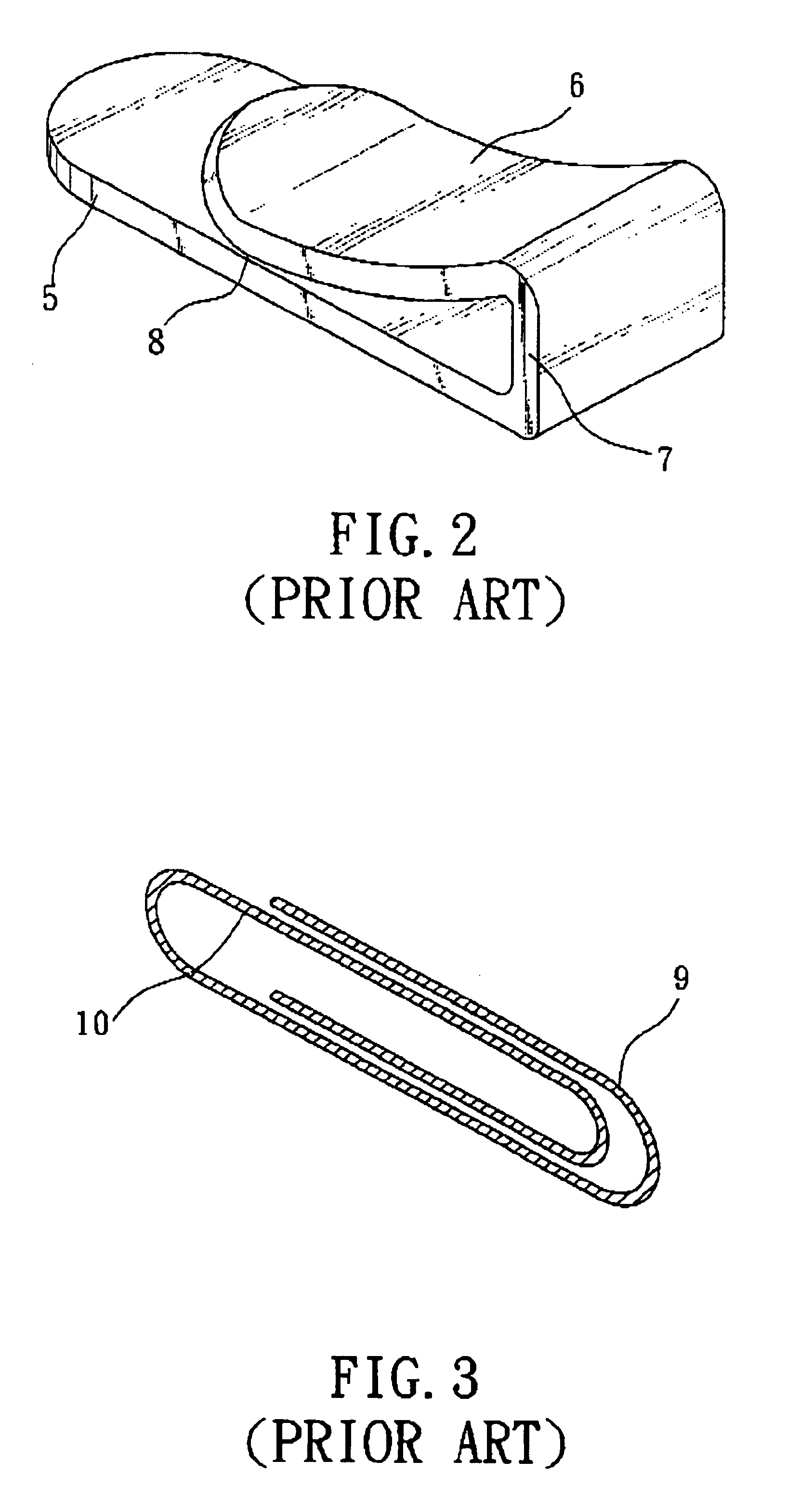

Electrical junction box for a solar cell module

InactiveUS7530837B2Simple and reliable connectionReduce effortCoupling device detailsPhotovoltaicsElectrical junctionElectrical conductor

An electrical junction box for a solar cell module of solar cells which are connected with thin conductor strips, with a housing and electrical and / or electronic devices provided in the housing, and at least one electrical connection device (1) which has at least one terminal (3) and which is provided in the housing. The clamping mechanism (3) for producing clamping contact is made and arranged such that at least one thin conductor strip (5) routed out of the solar cell module can be inserted into the clamping mechanism in two different opposing entry directions. Thus, simple and reliable connection of thin conductor strips (5) routed out of the solar cell module can be guaranteed.

Owner:GUNTHER SPELSBERG GMBH CO

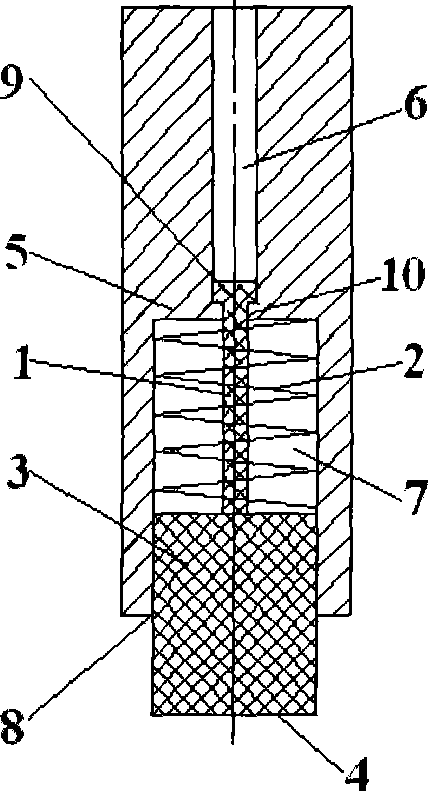

Clamping structure for fastening motion self-compensation

InactiveCN101367171AGuaranteed sizeEliminate misalignmentWelding/cutting auxillary devicesAuxillary welding devicesSelf compensationEngineering

The invention discloses a clamp structure for clamping and autocompensation; a clamping block (3) is arranged on a clamp; the surface of the clamping block (3) for clamping a workpiece is a clamping surface (4); and the clamping block (3) is made of an elastic material. With the technical proposal adopted, abrasion occurring in a clamping part and the change of the surface of the clamped workpiece are subjected to compensation by a simple elastic structure so as to ensure that a gripping jaw has enough clamping force in clamping and to guarantee the dimension of the workpiece after various machining processes (such as welding).

Owner:CHERY AUTOMOBILE CO LTD

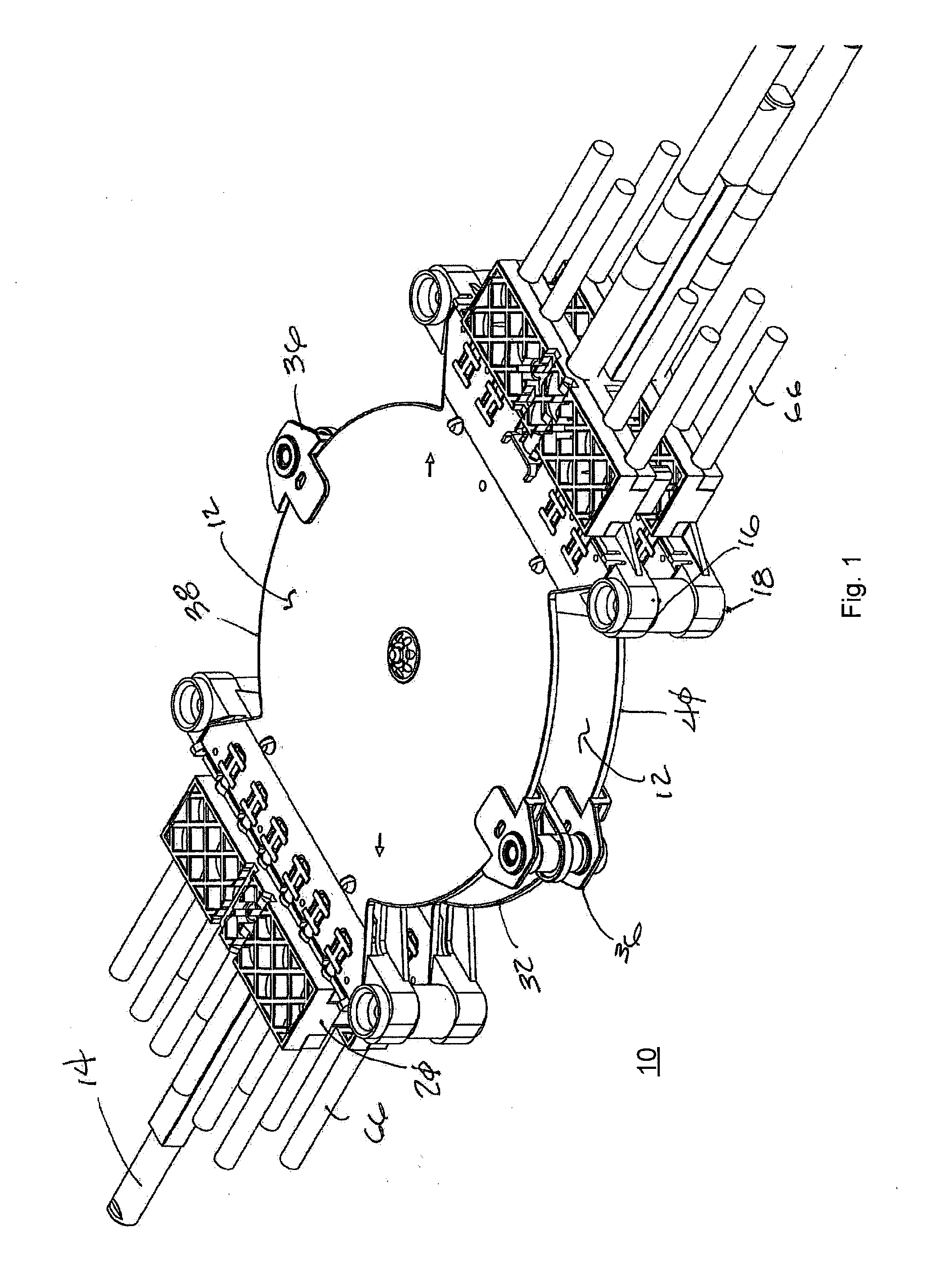

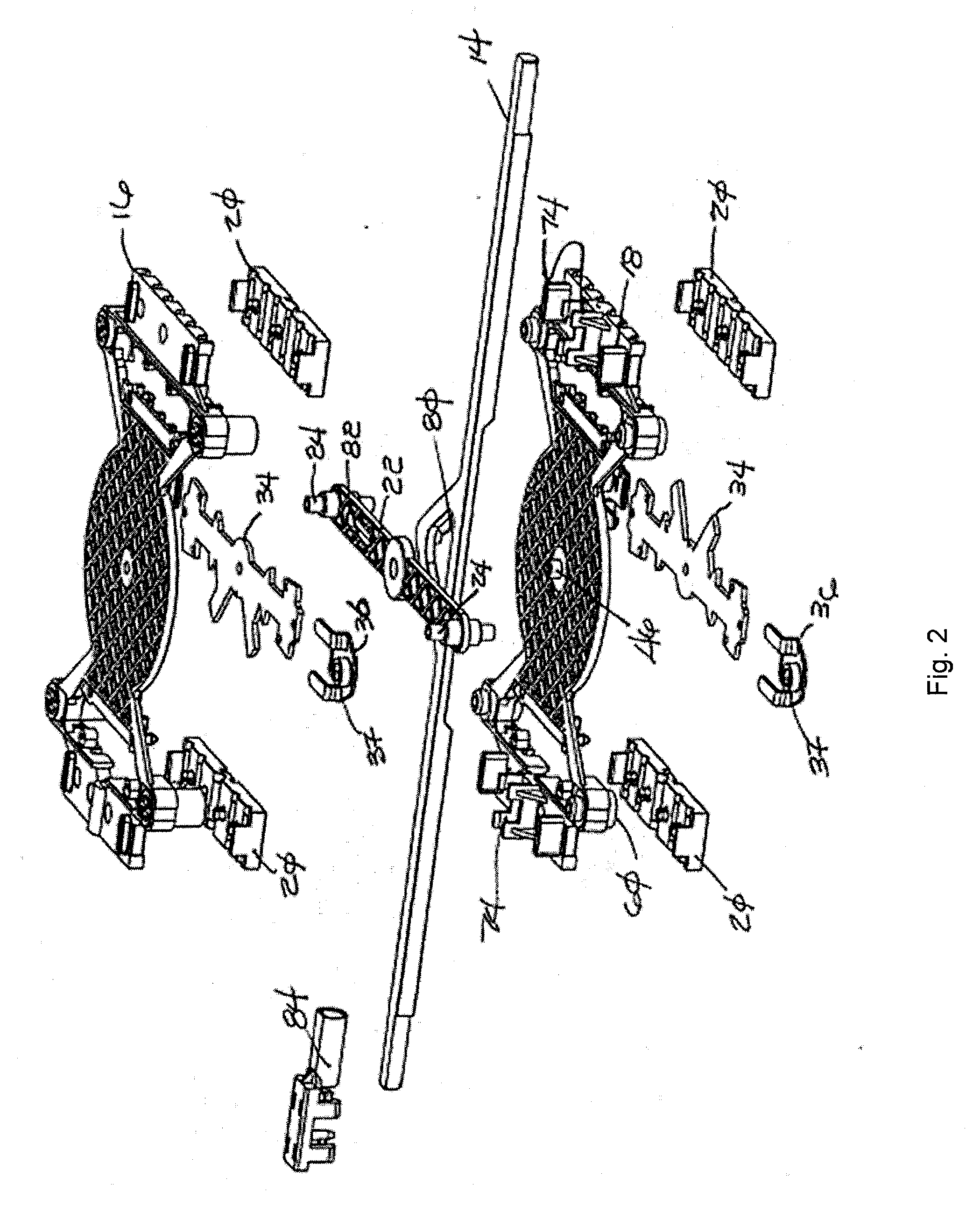

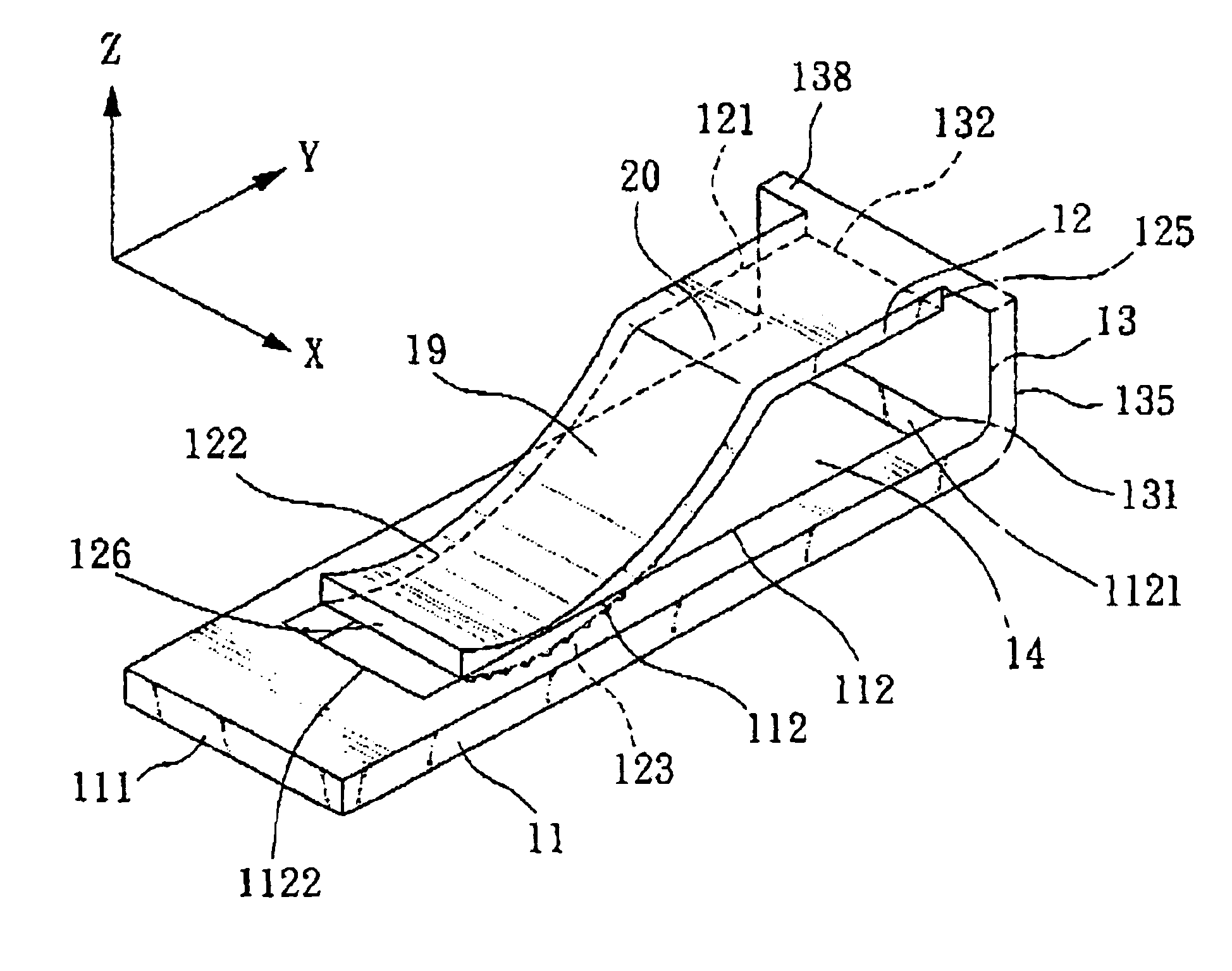

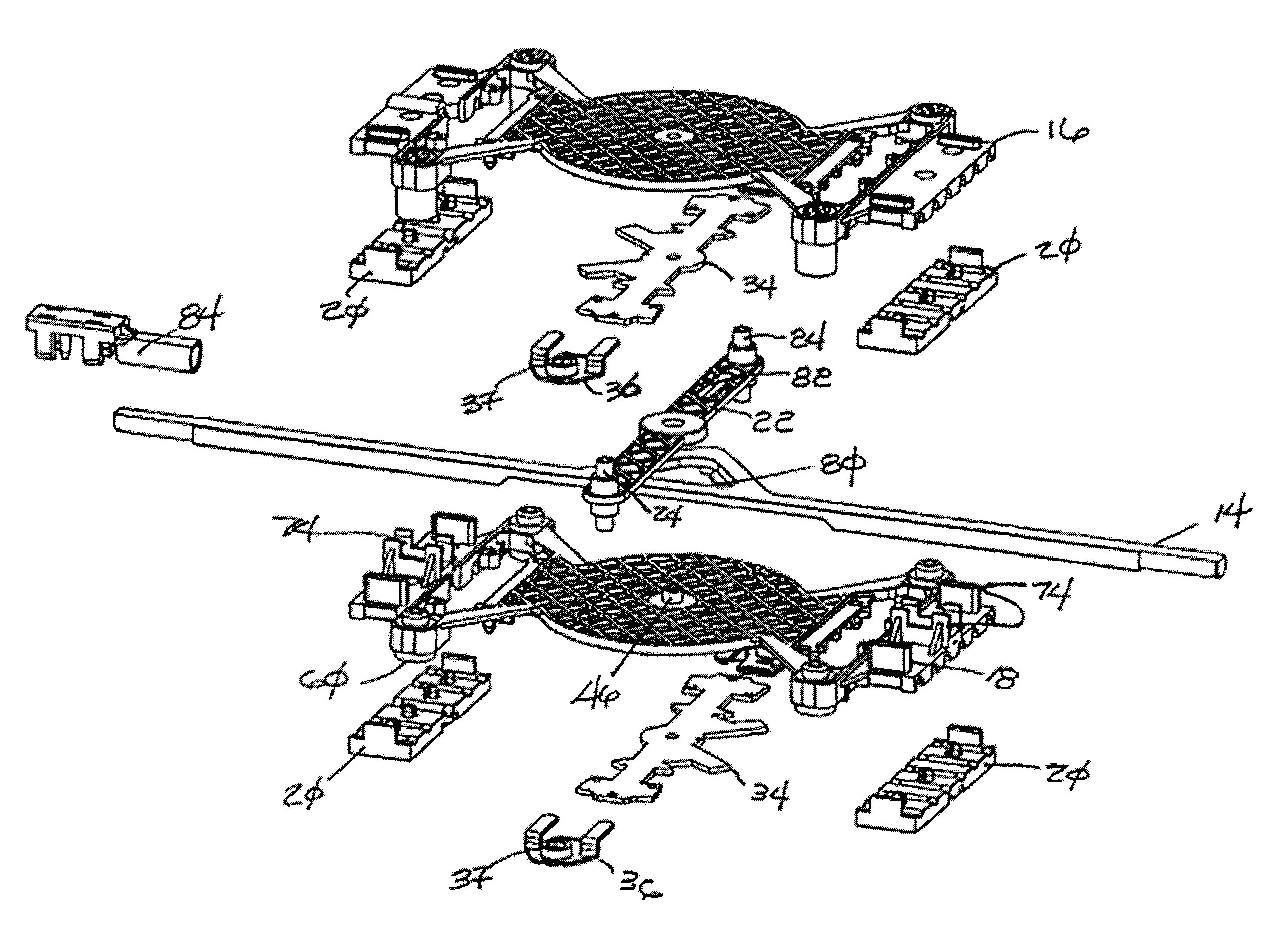

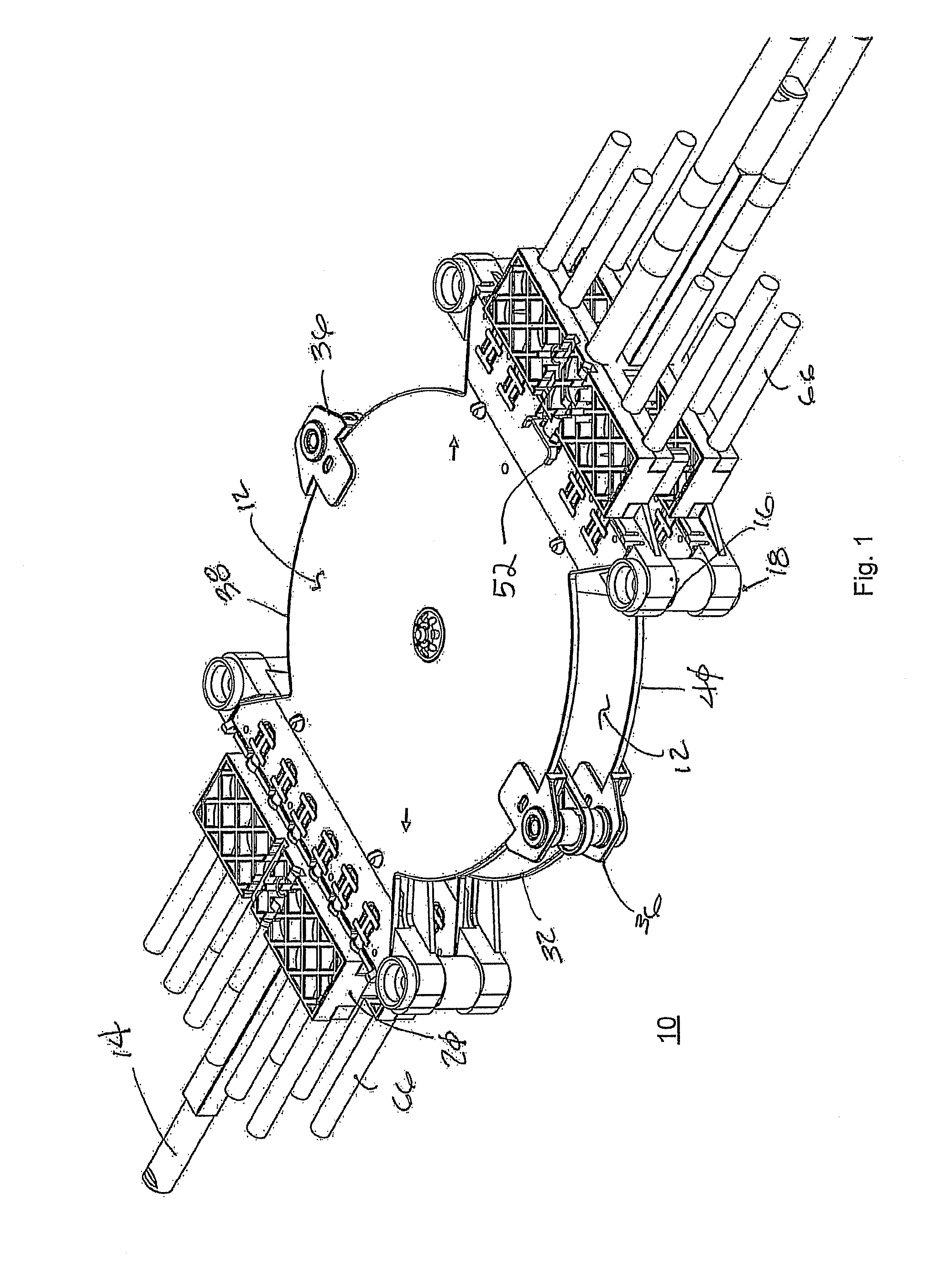

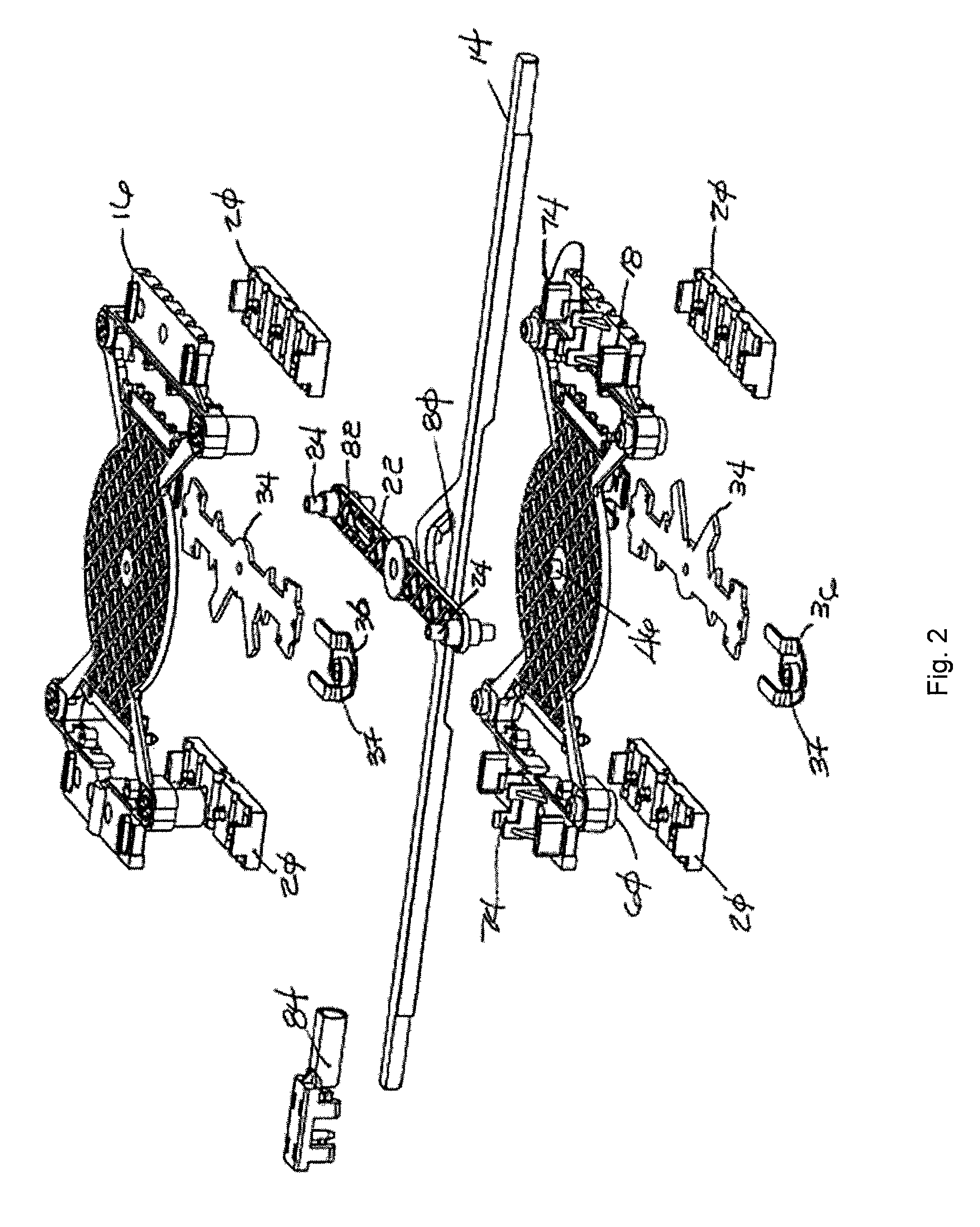

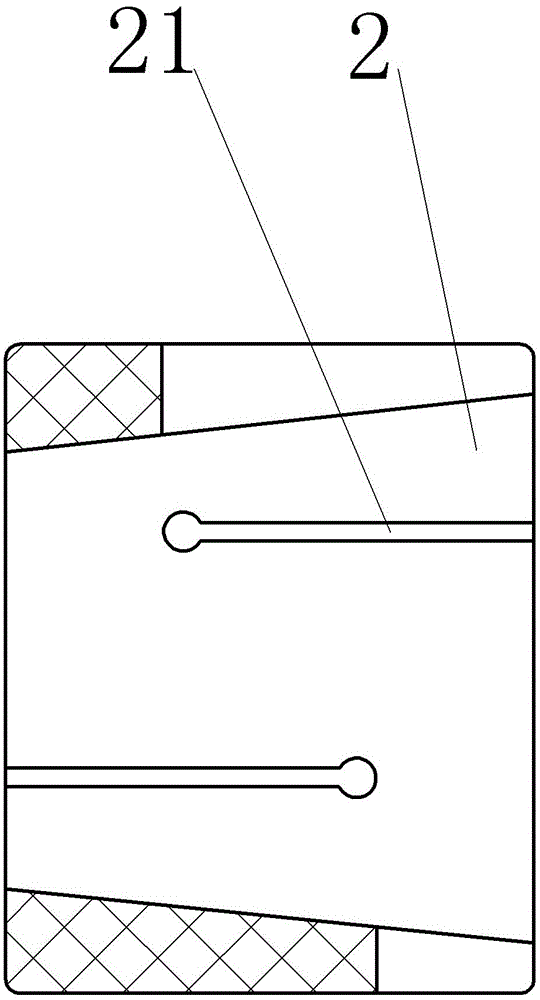

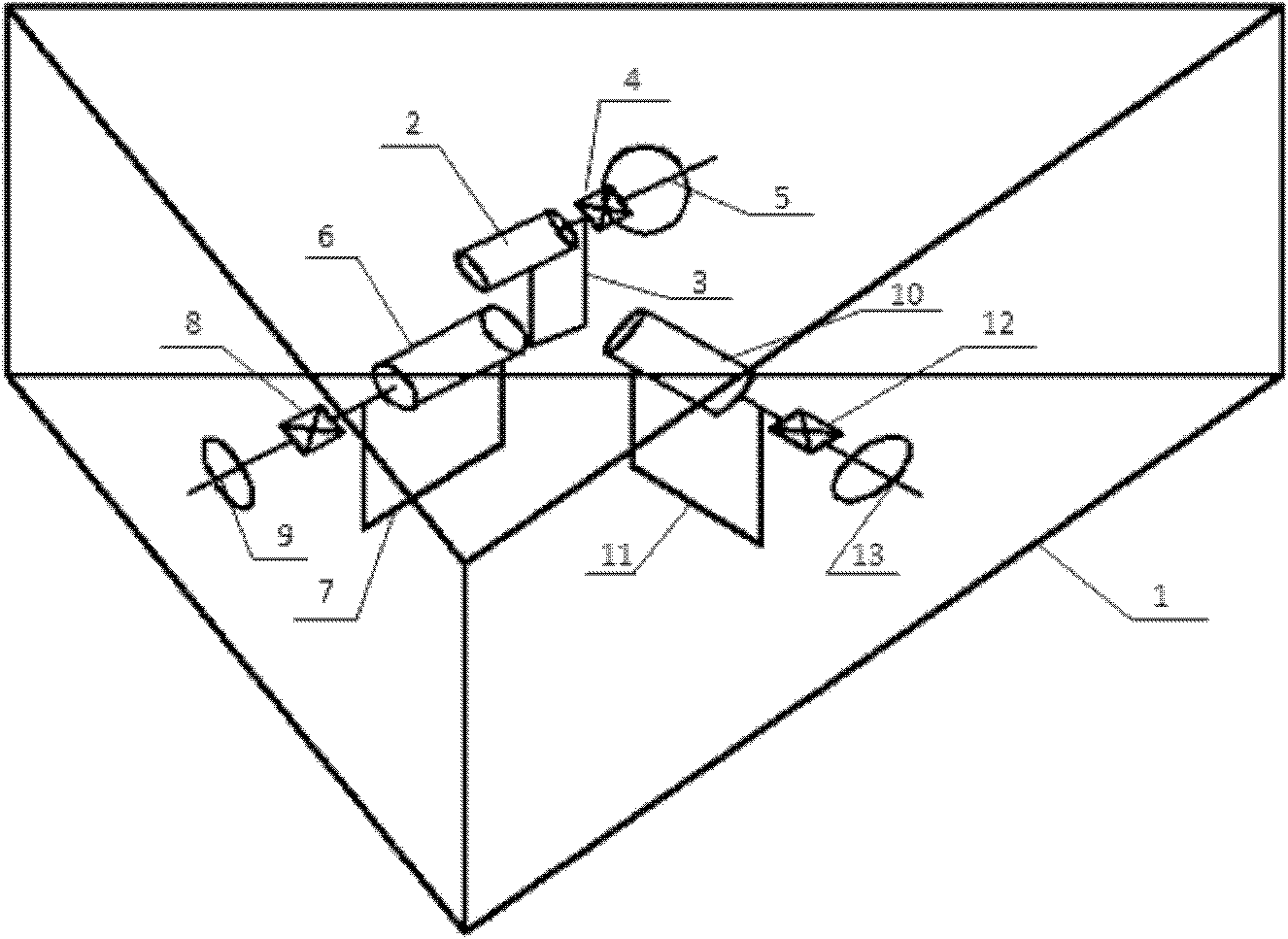

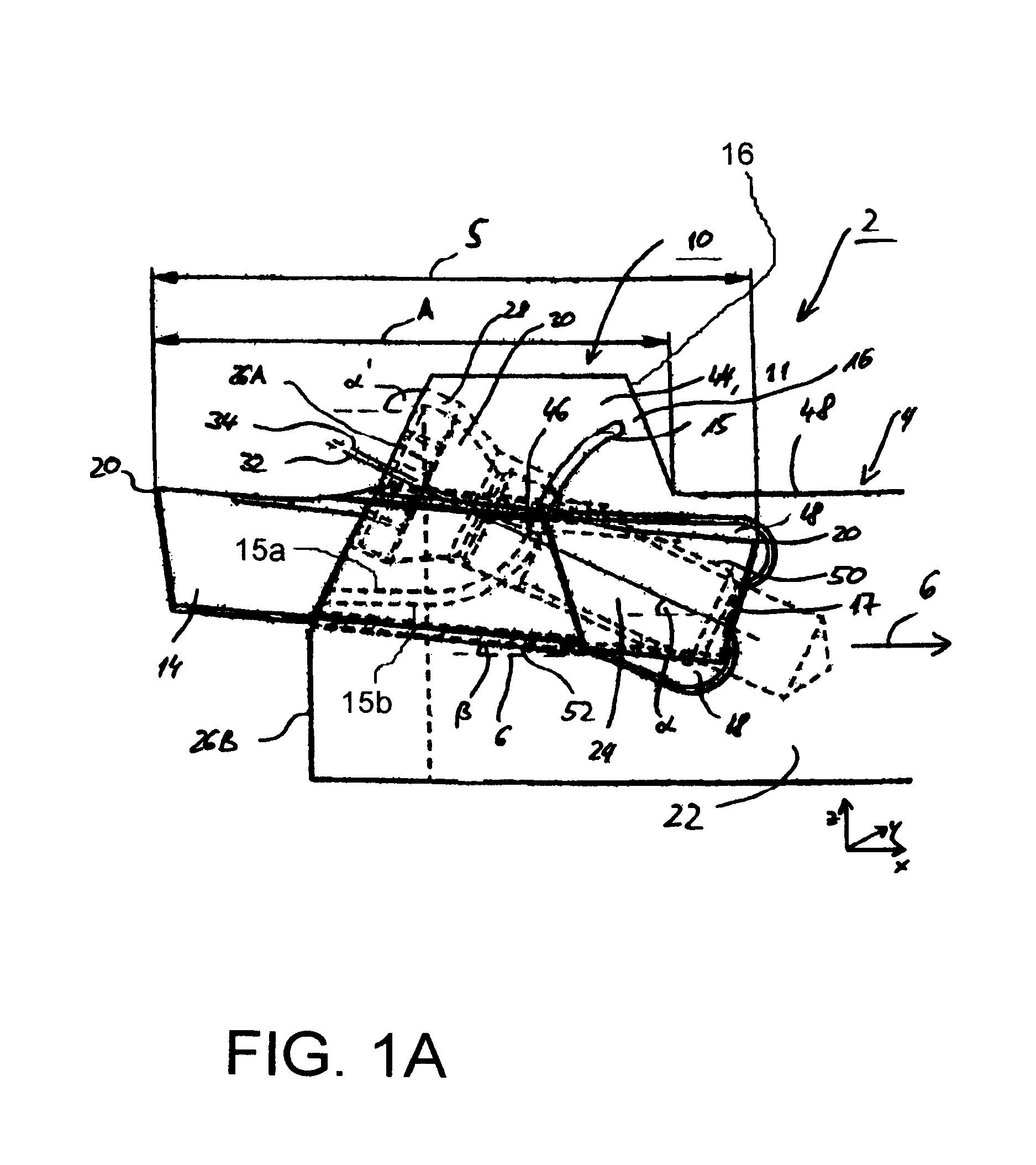

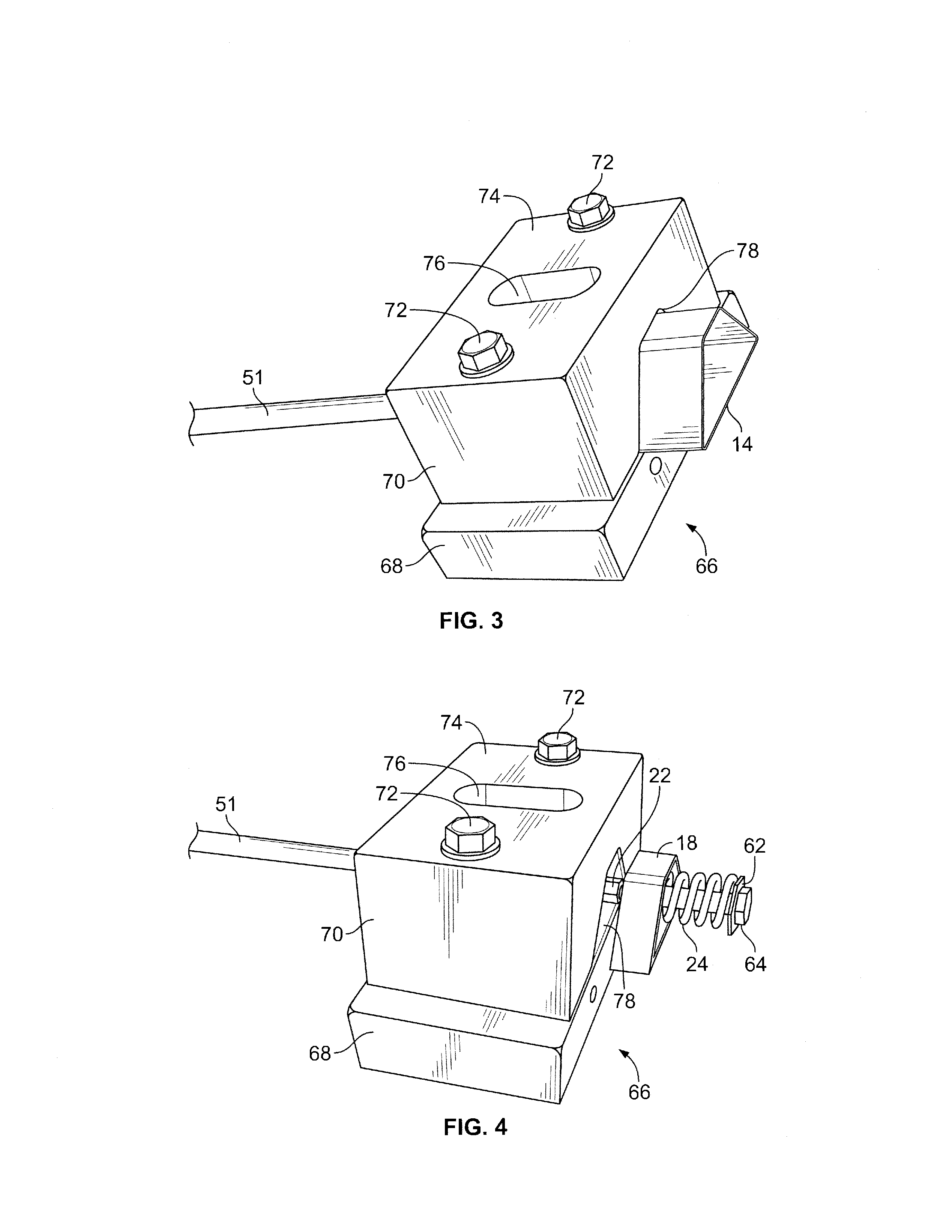

Phase Shifter Design Improvements

InactiveUS20110063049A1Zero compressionAvoid insufficient clamping forceCoupling device detailsDelay linesDesign improvementPrinted circuit board

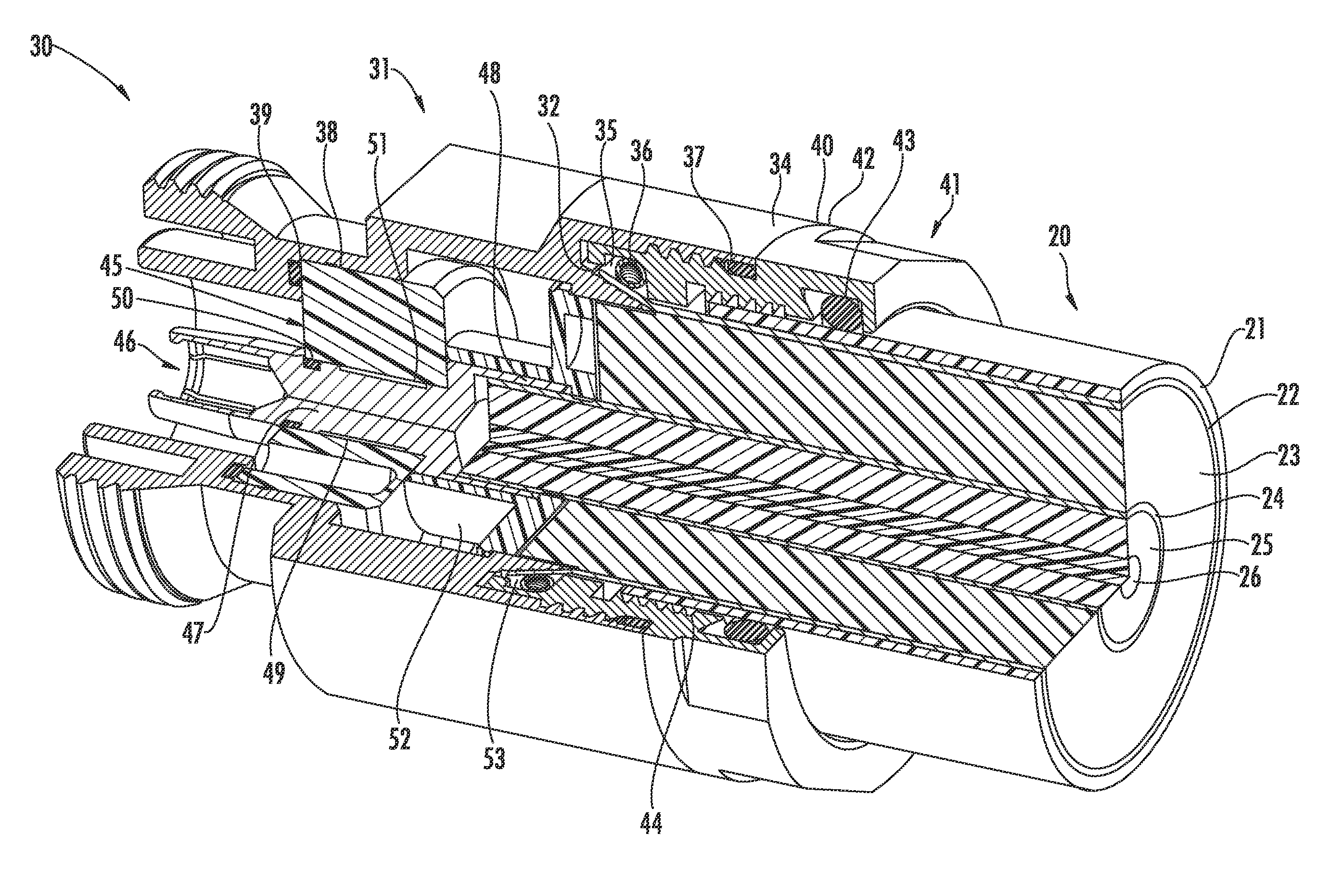

An improved phase shifter assembly is provided. The phase shifter assembly may comprise first and second sub-assemblies with certain common actuating elements. In one example, a first phase shifter sub-assembly is provided, the first phase shifter sub-assembly including a first phase shifter carrier, a first phase shifter printed circuit board mounted on the first phase shifter carrier, a first wiper printed circuit board coupled to an input of the first phase shifter printed circuit board and having at least a first end coupled to transmission lines on the first phase shifter printed circuit board, and at least one wiper support mechanically coupling the first wiper printed circuit board to the first phase shifter printed circuit board. A second phase shifter is similarly provided. Common actuating elements may include a pivot arm and a throw arm. The pivot arm may be rotatably mounted in the phase shifter assembly and be configured to engage a wiper support of at least one of the first and second phase shifter sub-assemblies. The throw arm may be mounted such that when the throw arm is moved linearly, the pivot arm rotates around a pivot.

Owner:COMMSCOPE TECH LLC

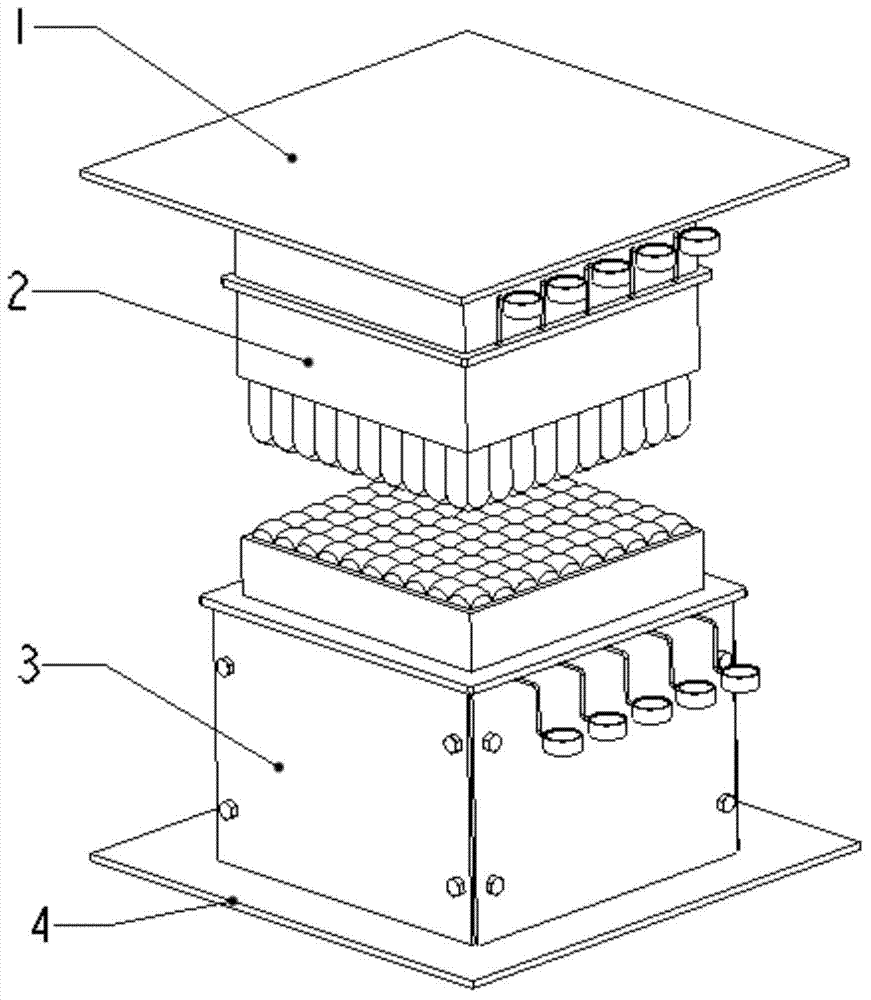

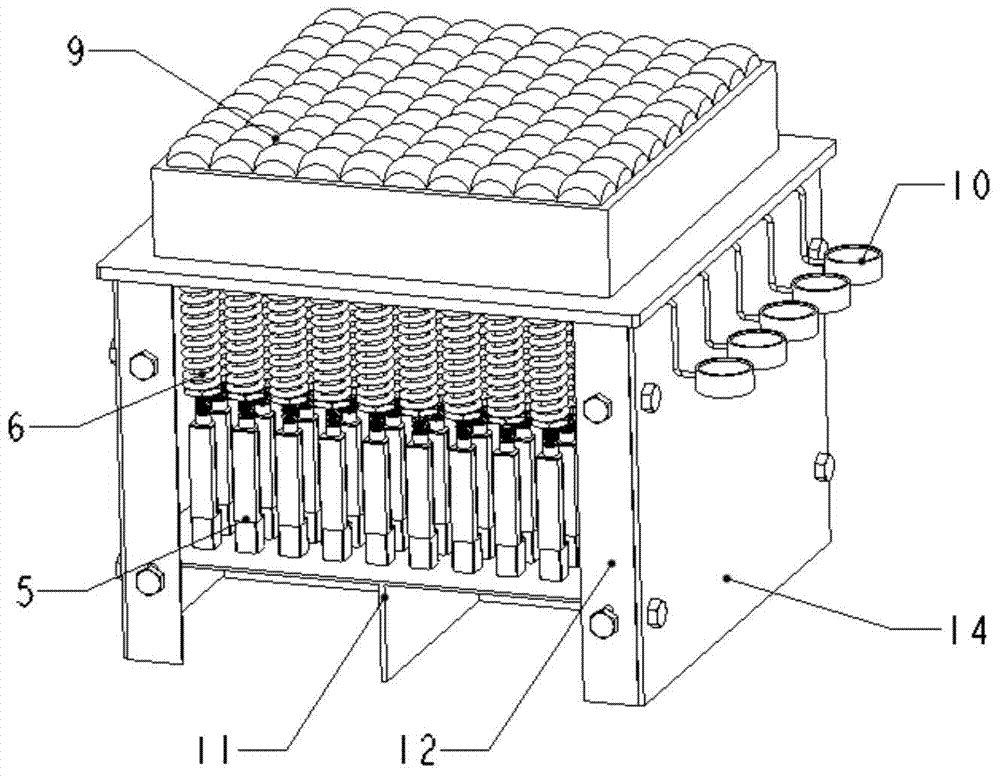

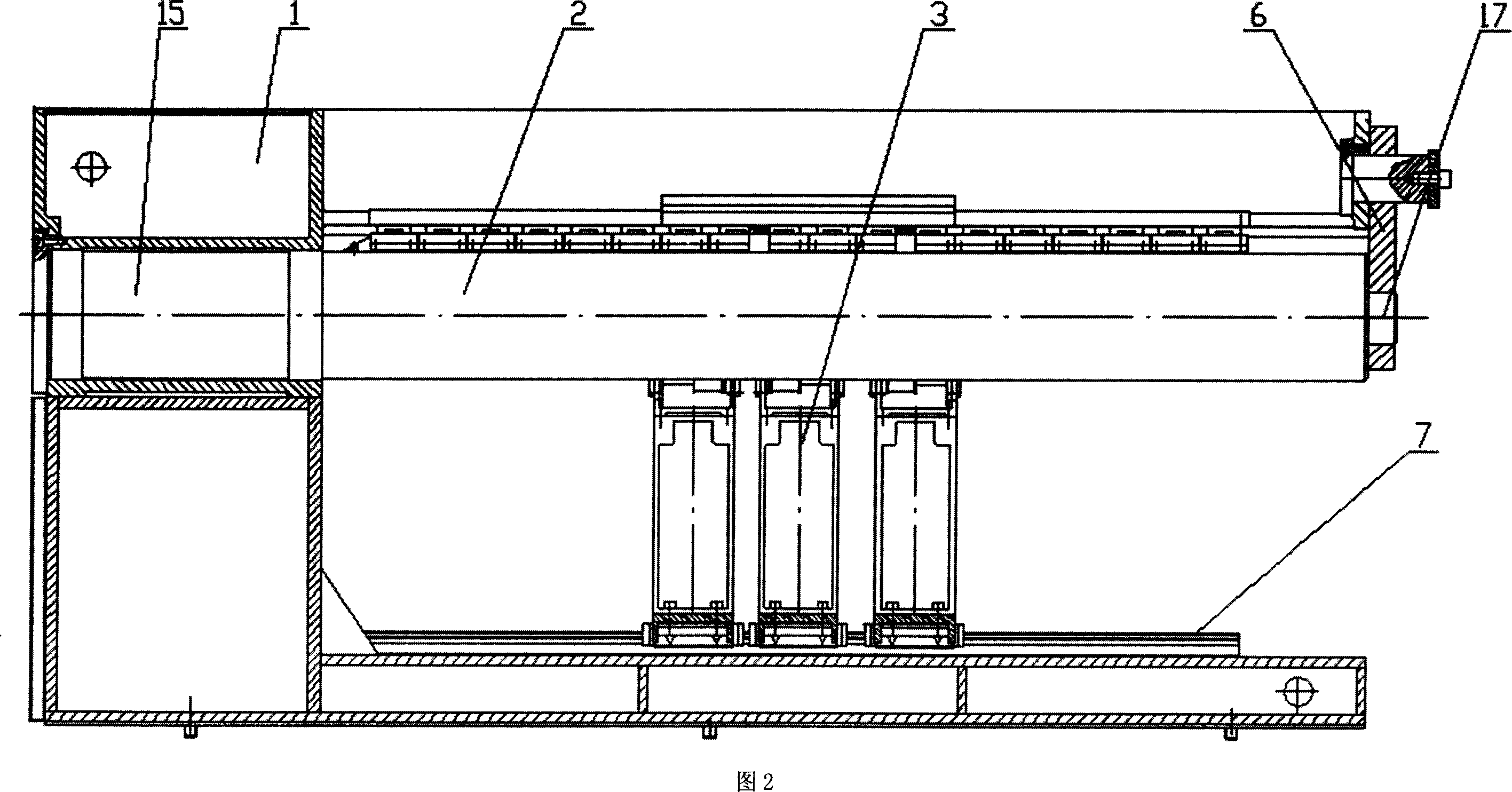

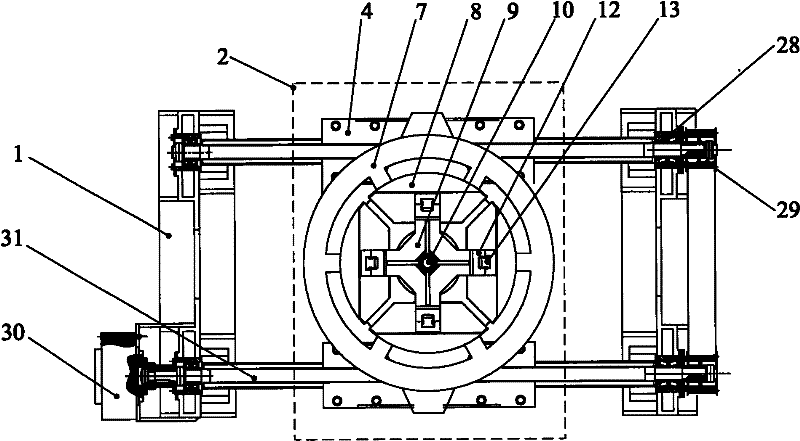

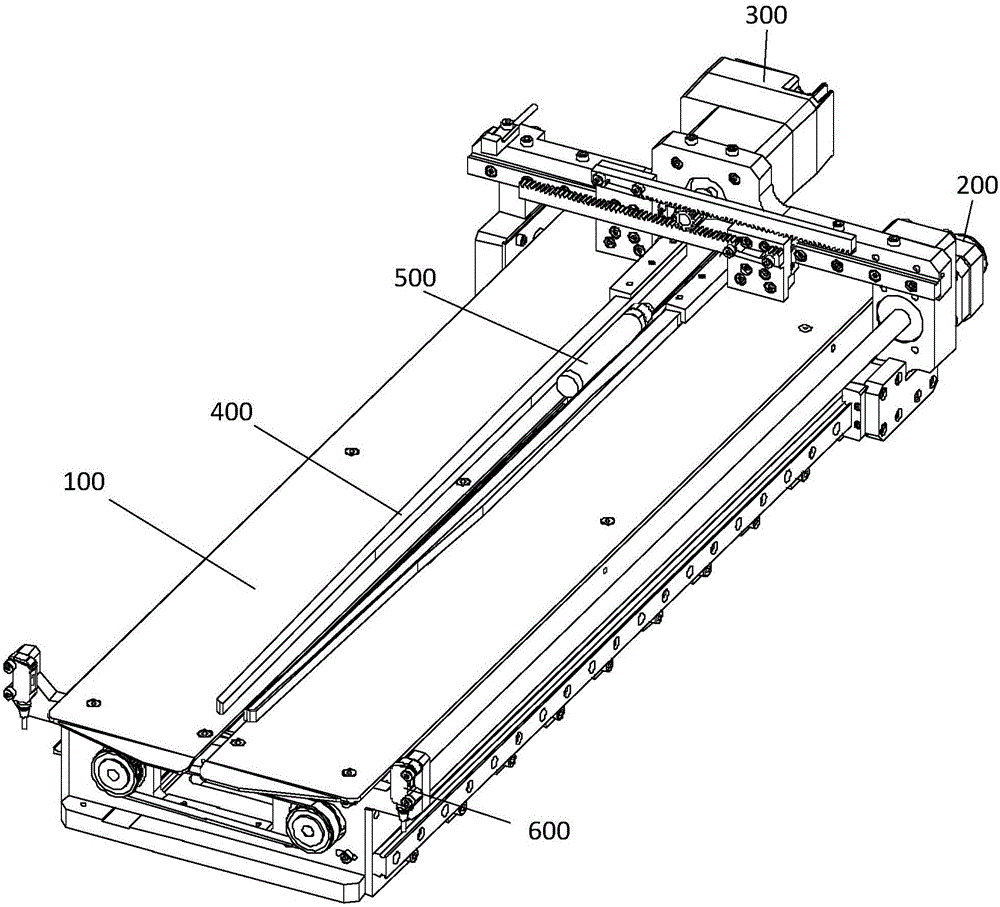

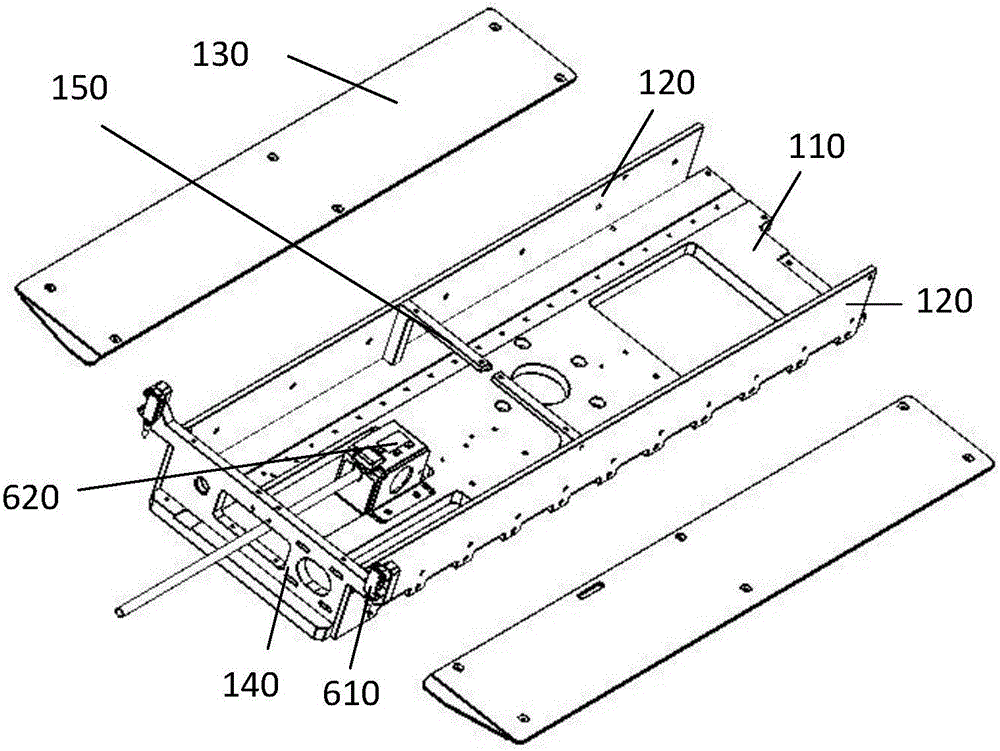

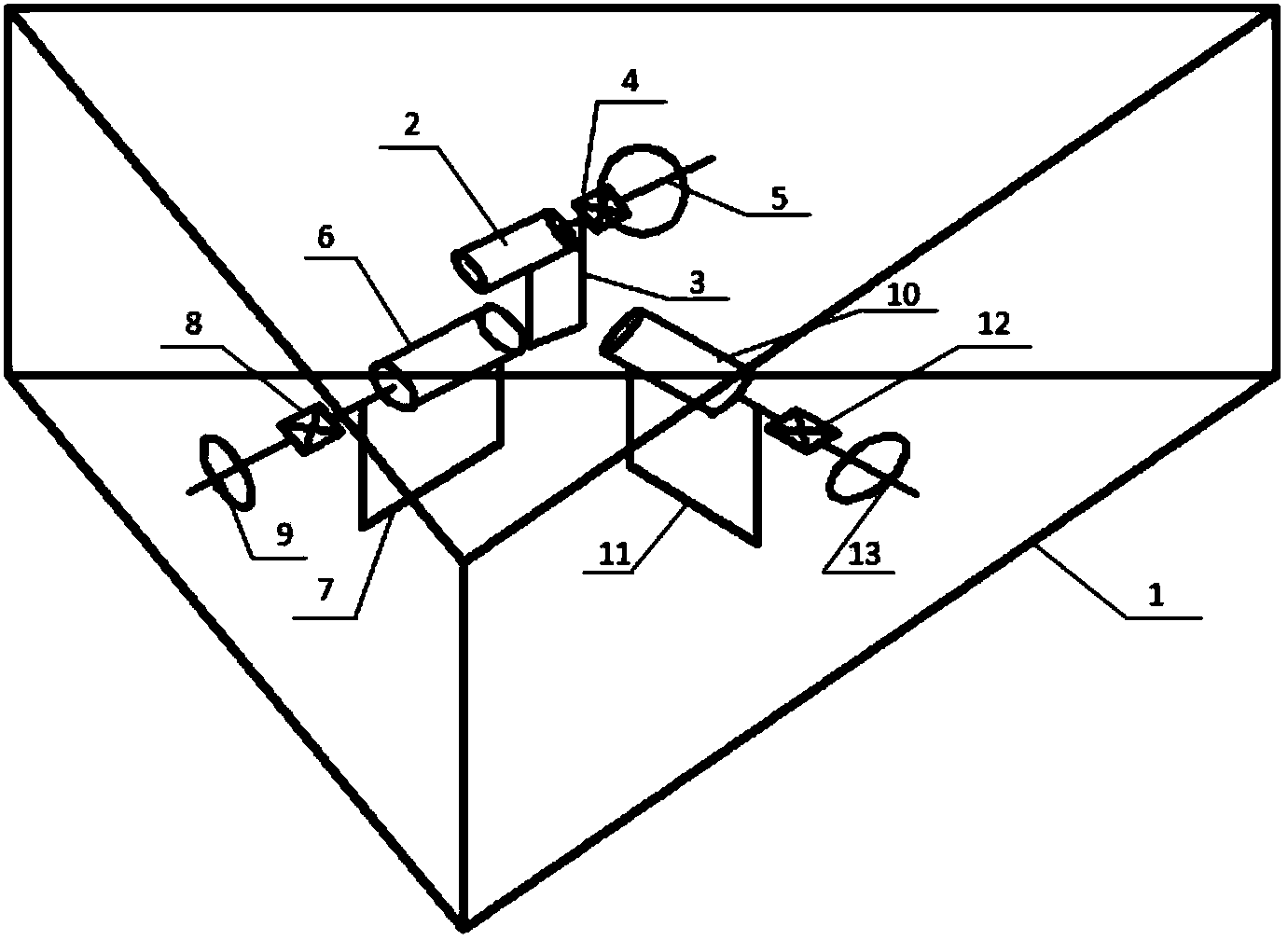

Discrete flexible die

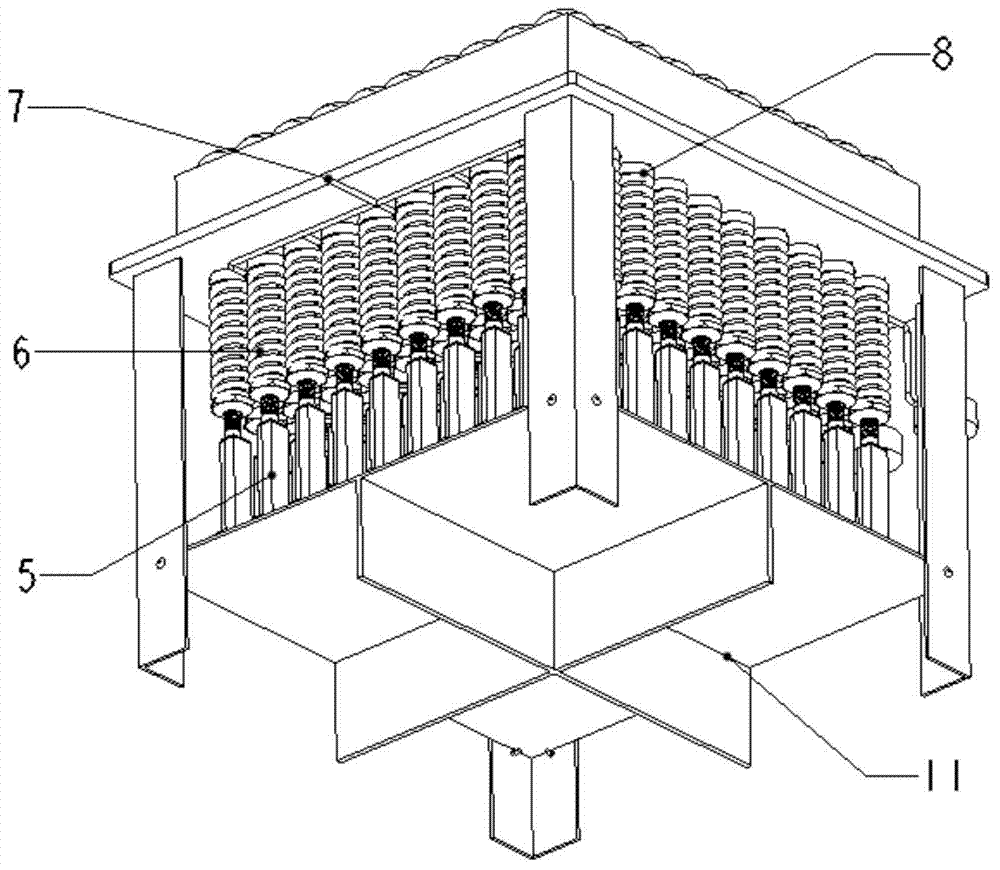

ActiveCN103752691AHigh shape adjustment accuracyFast shape adjustmentShaping toolsMachine pressPiezometer

Disclosed is a discrete flexible die. An upper discrete die is connected with an upper sider of a press, a lower discrete die is combined with a base of the press and comprises a lower die support, a top supporting plate of the lower die support is assembled with hydraulic tensioning sleeves, oil supply of each hydraulic tensioning sleeves is realized through an oil pipe, a piezometer is mounted at the tail end of each row of the oil pipes, a punch is inserted into a middle round hole of each hydraulic tensioning sleeve, and an electric push rod is mounted below each punch; the upper discrete die comprises an upper die support, hydraulic tensioning sleeves are mounted on a middle supporting plate of the upper die support, oil supply of each hydraulic tensioning sleeve is realized through an oil pipe, and a piezometer is mounted at the tail end of each row of the oil pipes. Shape adjusting is realized by adopting the electric push rods controlled by a circuit, and the die punches are locked through the hydraulic tensioning sleeves after shape adjusting is completed; the punches is high in bearing capacity, thereby being capable of used for plate forming and part supporting; the whole discrete flexible die is simple in structure and low in manufacturing cost; two implementable schemes are provided for curved surface continuation after forming, and the discrete flexible die is high in efficiency, low in cost and free of environmental pollution.

Owner:XI AN JIAOTONG UNIV

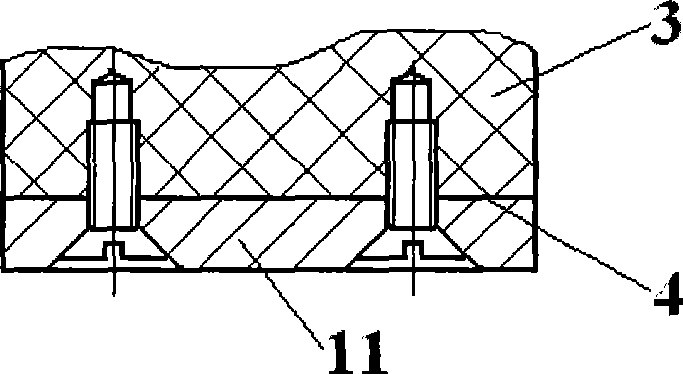

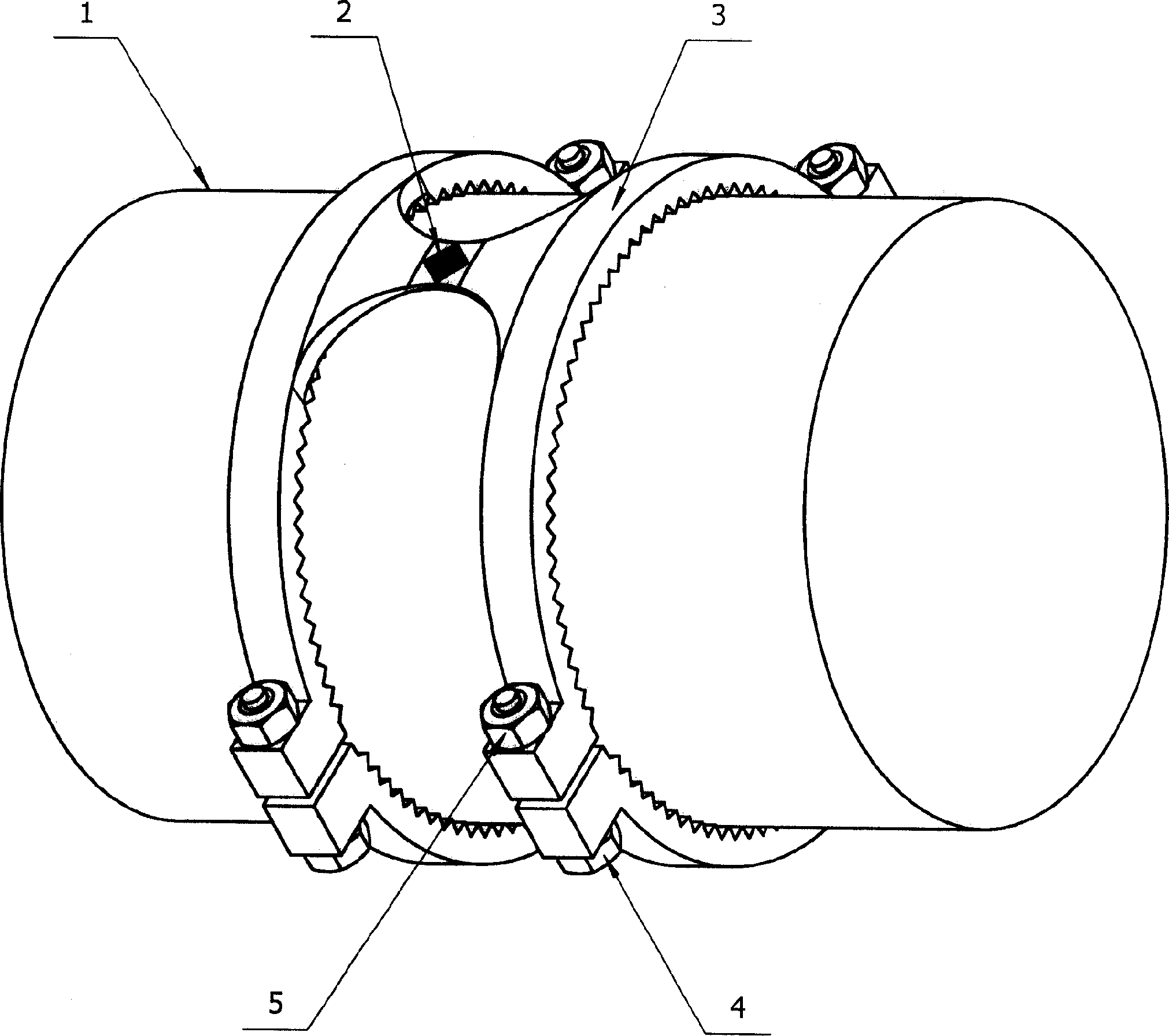

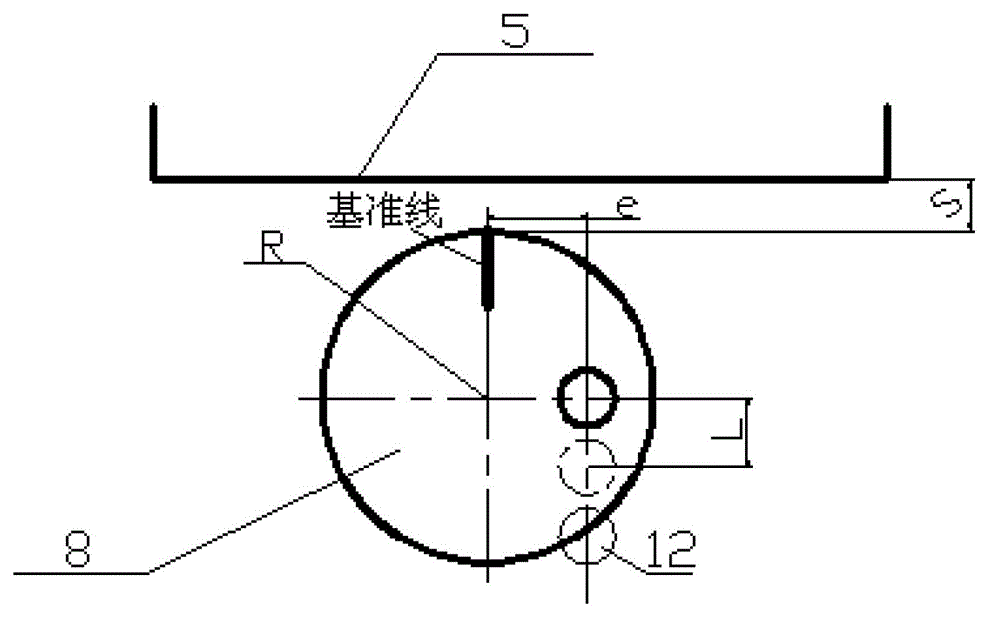

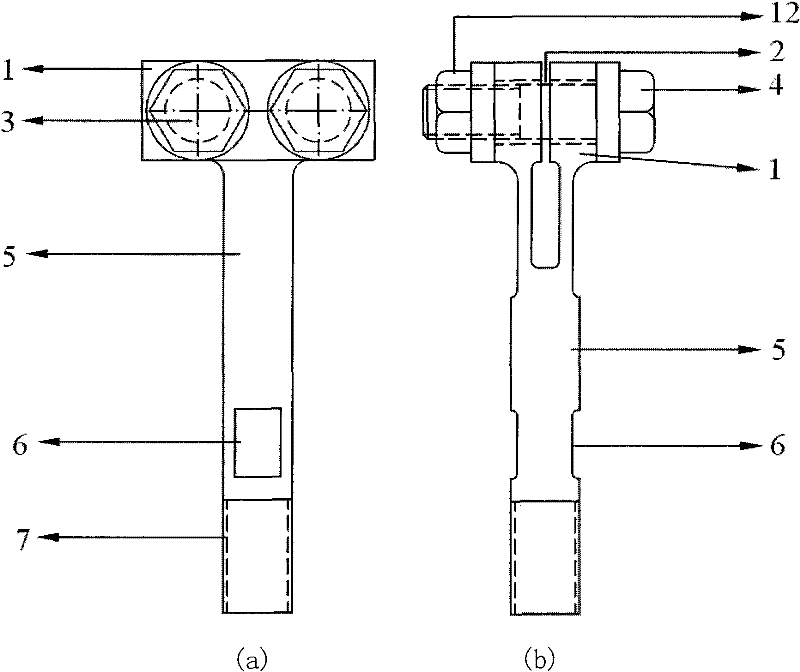

Clamp ring type torque sensor

InactiveCN1752725AEasy to detectAvoid insufficient clamping forceWork measurementTorque measurementElastomerDrive shaft

The present invention relates to a clamp ring type torque sensor for obtaining drive shaft torque. Said sensor adopts semi-ring design, and said sensor can be quickly clamp-mounted on the drive shaft only by utilizing holt and nut. When the torque is received by drive shaft, the shearing deformation which is directly proportional to the torque on the drive shaft can be transferred to the sensor elastic body on which a strain foil is stuck so as to obtain the torque signal of said drive shaft. Said invention also provides the design method of said sensor elastic body.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

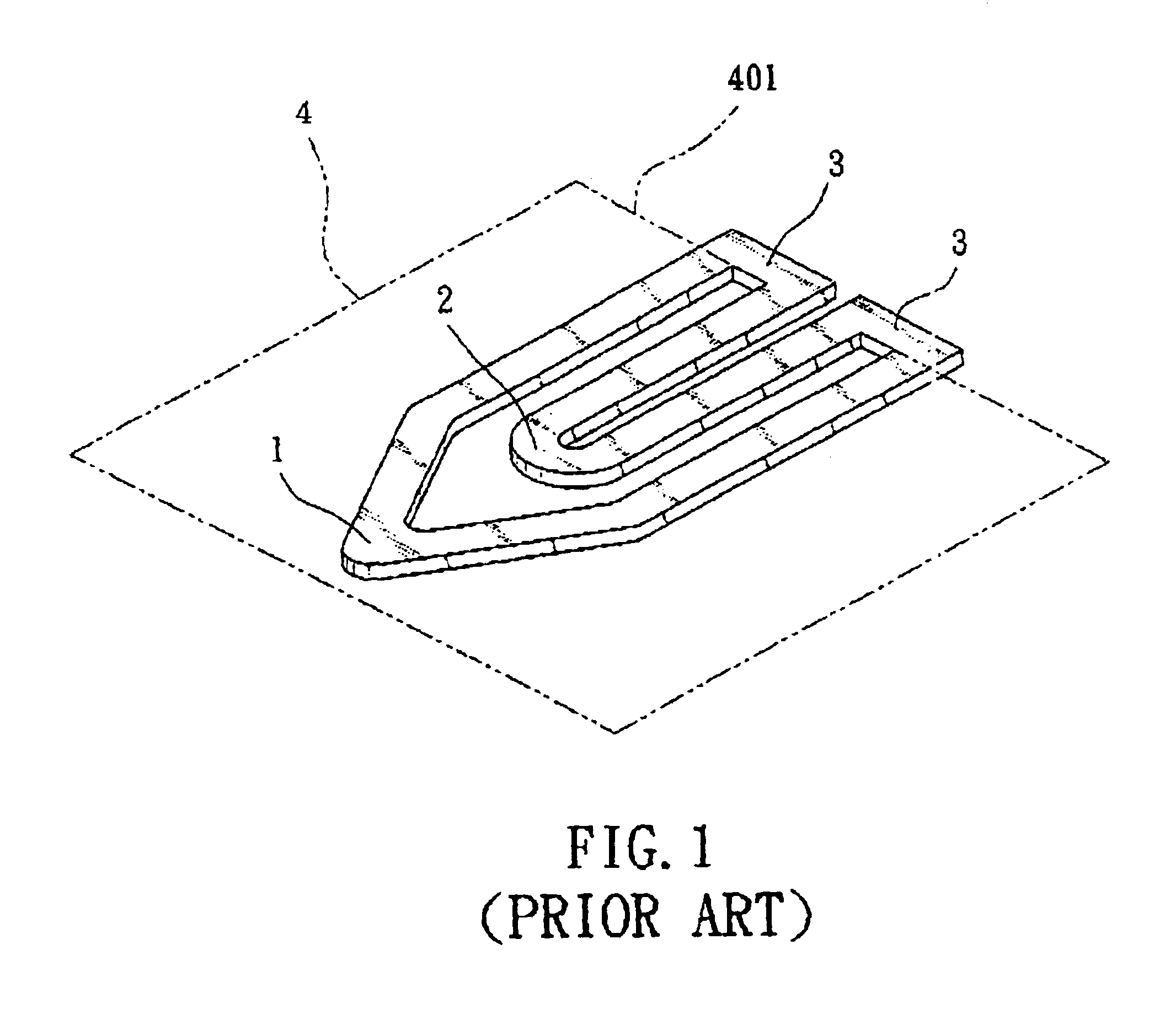

Paper clip

InactiveUS6973700B2Variable thicknessWide applicationSnap fastenersClothes buttonsRough surfaceEngineering

The present invention relates to an improved paper clip which is suitable for holding documents of different thicknesses. The improved paper clip includes three elements, which are a first clipping piece, a second clipping piece and a support beam. The first clipping piece is formed with a sunken slot therethrough and is connected to a bottom side of the support beam. The second clipping piece has a bending curve part and is connected to a top side of the support beam. The bending curve part is partially protruding into the sunken slot and is roughened to become a rough surface for increasing friction to tightly clamp documents. The inner surface of the support beam is a flat plane so as to provide a guiding function when the document is received between the first and second clipping pieces. The first and second clipping pieces are both adjoined to the inner surface of the support beam, such that the outer surface of the support beam substantially forms part of the outer contour of the paper clip.

Owner:HSIAO RAY LING

Integrated clamp for dovetail tenon turbine blade vibration fatigue test and test method

The invention discloses an integrated clamp for a dovetail tenon turbine blade vibration fatigue test and a test method. The integrated clamp comprises an integrated clamp body dovetail tenon turbine blade, wherein one end of the integrated clamp body dovetail tenon turbine blade is provided with a groove clamp port dovetail tenon turbine blade, an outer side surface of the groove clamp port dovetail tenon turbine blade is provided with a groove which is identical to a dovetail tenon in shape and can accommodate the dovetail tenon, and the top portion of the integrated clamp body dovetail tenon turbine blade is provided with an adjusting fastening bolt. The integrated clamp is advantaged in that the blade is prevented from breaking at an R portion of a throat portion of the tenon, the test can be smoothly accomplished, a test target is realized, the quantity of test parts is reduced, and test cost is reduced.

Owner:AECC AVIATION POWER CO LTD

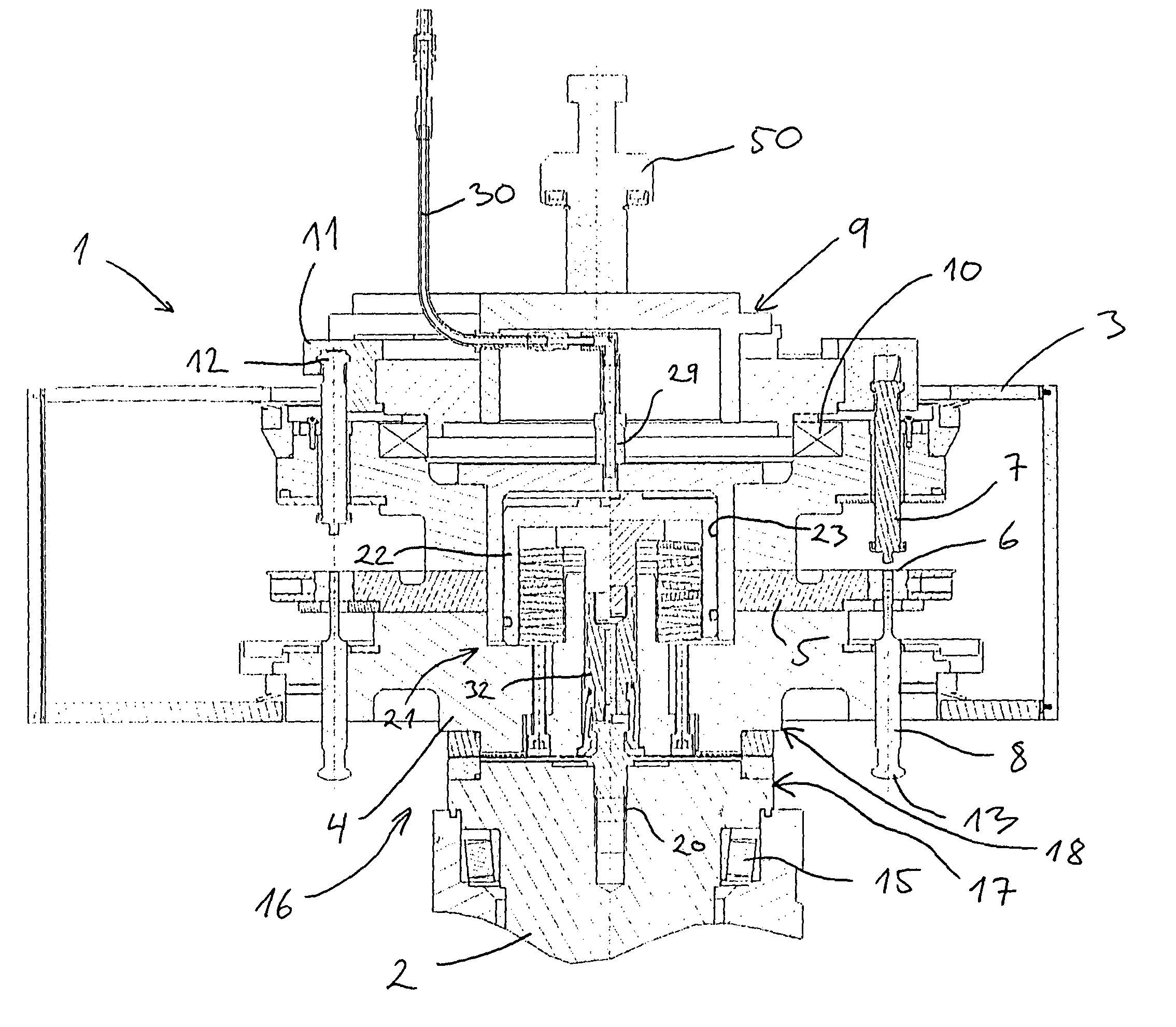

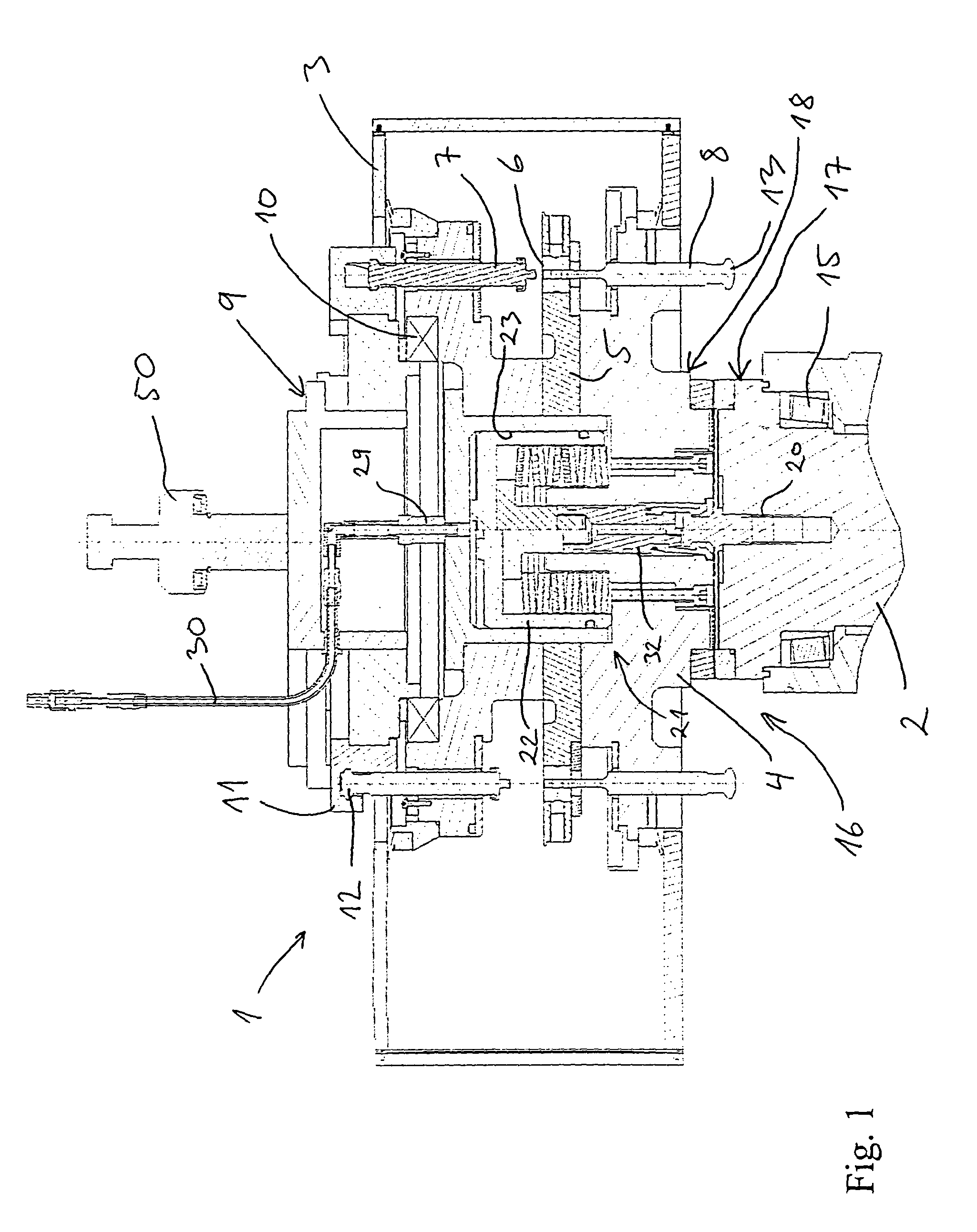

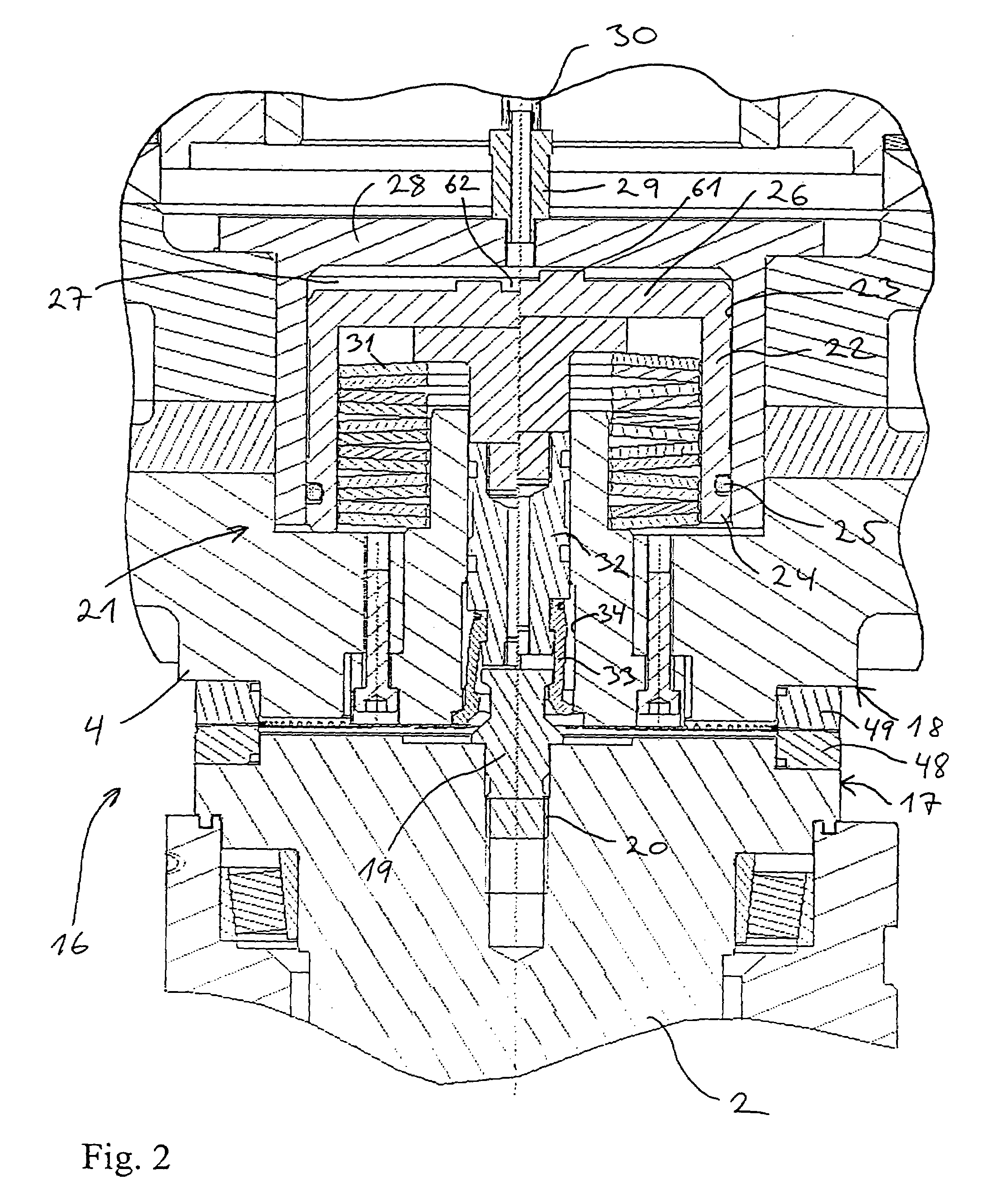

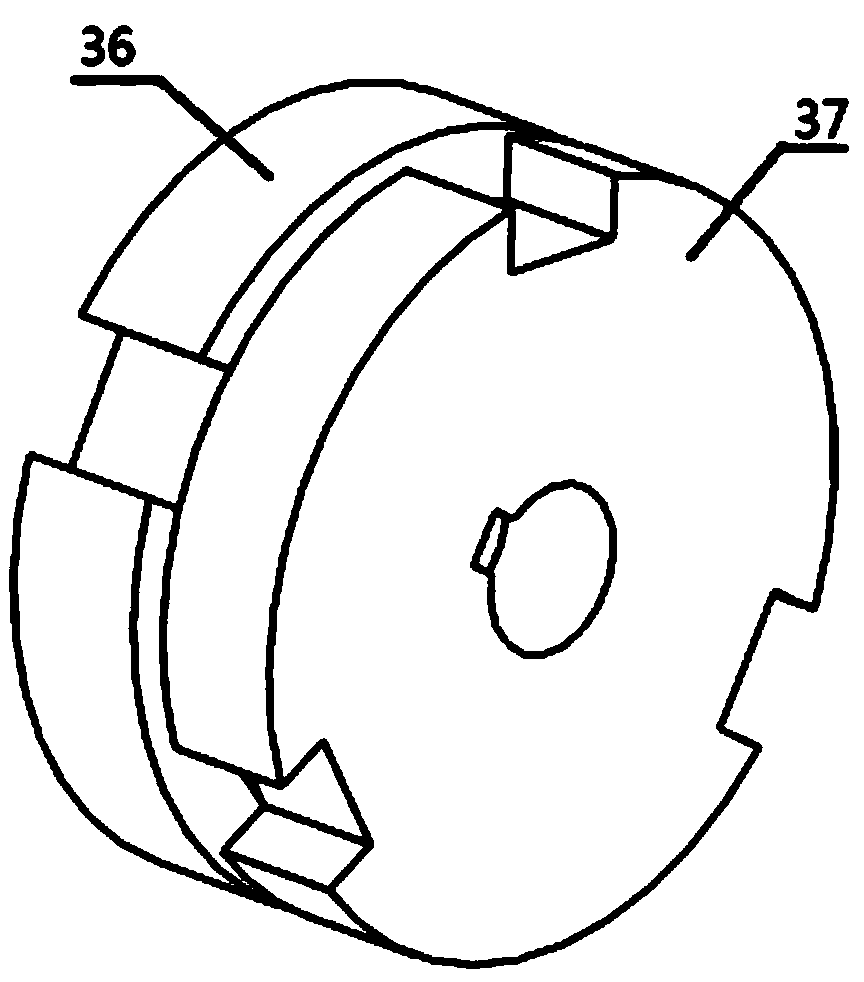

Rotary tablet press

InactiveUS6972105B2Directly appliedAvoid insufficient clamping forceConfectioneryWood working apparatusCouplingDrive shaft

A rotary tablet press comprises a rotary system constituted by a turret and a drive shaft arranged in a housing for rotation of the turret. The turret includes a die table and a number of punches are guided in the turret. The turret is connectable to the drive shaft by a coupling including a first coupling part and a second coupling part which are interconnectable by clamping elements engageable between the coupling parts by at least one pneumatic actuator situated in the rotary system.

Owner:COURTOY

Eccentric-wheel-type rapid clamping vice

Owner:SUZHOU VOCATIONAL UNIV

Welding jig for welding cylinder

InactiveCN1966200APrecise positioningEasy and reliable clampingWelding/cutting auxillary devicesAuxillary welding devicesReduction functionEngineering

The invention relates to a welding clamper which uses steel band to pack, with installment space reduction function, and longitudinally weld the coiled plate into cylinder, wherein said clamper comprises that: frame, spindle, positioning block for welding and positioning sheet which will be detached when the steel band is positioned; the steel band coiling device is mounted on the track of clamper, formed by steel band, worm device, and tension wheel; said steel band can be coiled to move longitudinally, to apply different work pieces; the clamper is formed by compressing plate, wedge block and cylinder, to clamp two opens of cylinder on the spindle. The invention has high efficiency and accuracy position.

Owner:HUAZHONG UNIV OF SCI & TECH

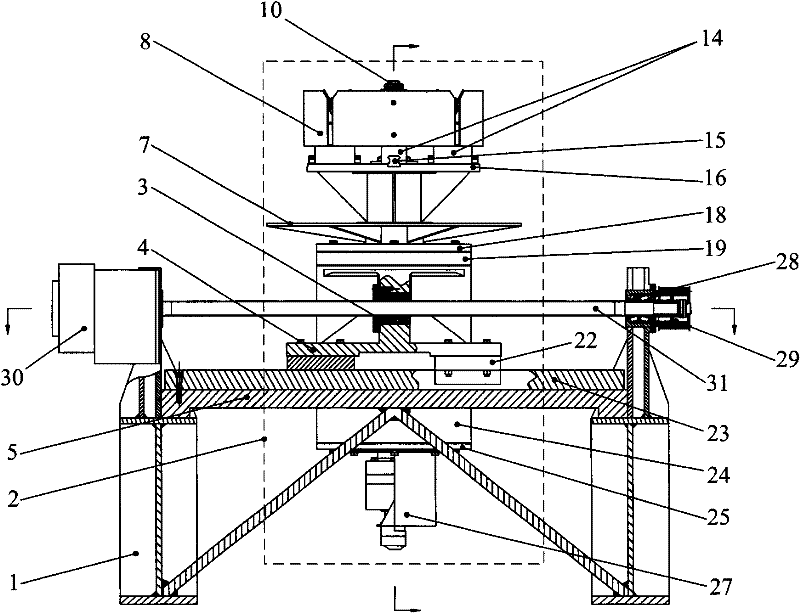

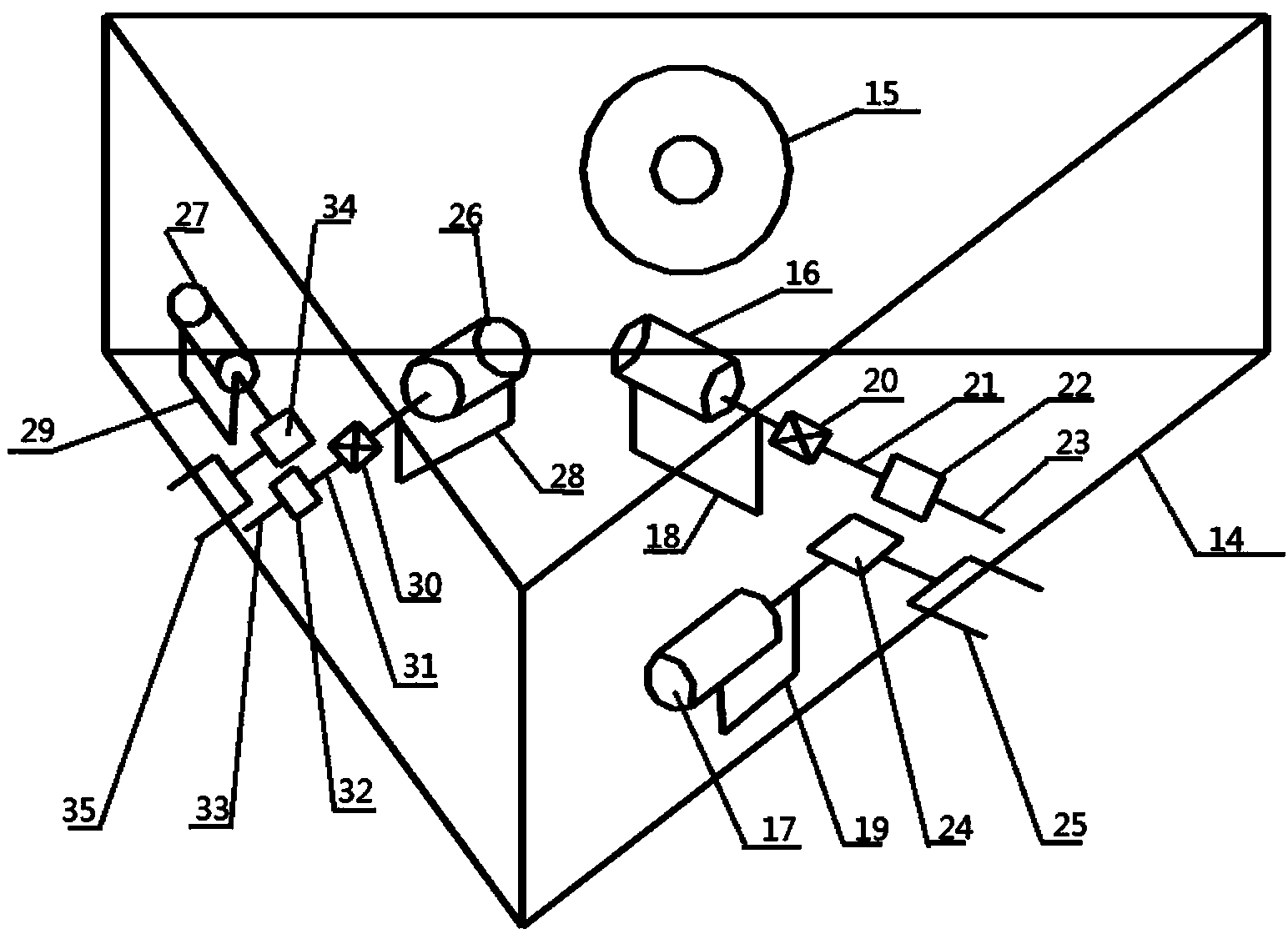

Outer-supporting expansion work piece clamping device used for spin forming of large rotating body section piece

InactiveCN102218482ALarge clamping strokeLow priceMetal-working feeding devicesPositioning devicesSelf lockingEngineering

The invention relates to an outer-supporting expansion work piece clamping device used for spin forming of a large rotating body section piece. The clamping device comprises a main body of the clamping device, wherein the hydraulic cylinder on the main body is connected with a wedge through a tension rod, the slider on the wedge is matched with the guide rail for the wedge; the slider under a chuck plate is matched with the guide rail for the chuck plate; a positioning plate and a hydraulic rotating cylinder are arranged on a hollow main shaft; horizontal lead screws are installed on the nut seat of a bearing for the main shaft; the lower end surface of the nut seat is fixedly provided with a slider matched with the guide rail on the nut seat; one end of each of the horizontal lead screwsis connected with a synchronous belt pulley; the other end of one horizontal lead screw is connected with a hydraulic motor; the hydraulic cylinder drives the tension rod to push the wedge, and the wedge moves up and down along the guide rail for the wedge through the slider on the wedge; the chuck plate radially moves along the guide rail for the chuck plate through the slider under the chuck plate; the positioning plate positions height; the hydraulic rotating cylinder drives the hollow main shaft to rotate; and the hydraulic motor drives the horizontal lead screws to move synchronously, sothat the main body of the clamping device can move horizontally. The invention has the advantages of good self-locking function and high clamping efficiency and is convenient for operation.

Owner:XI AN JIAOTONG UNIV

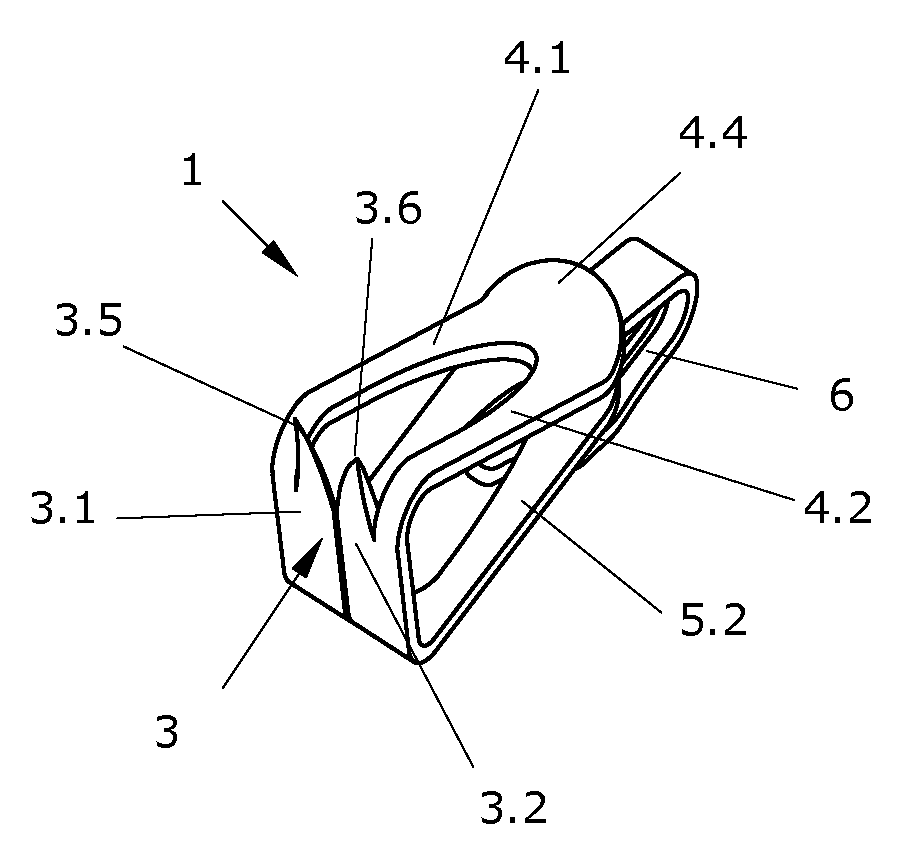

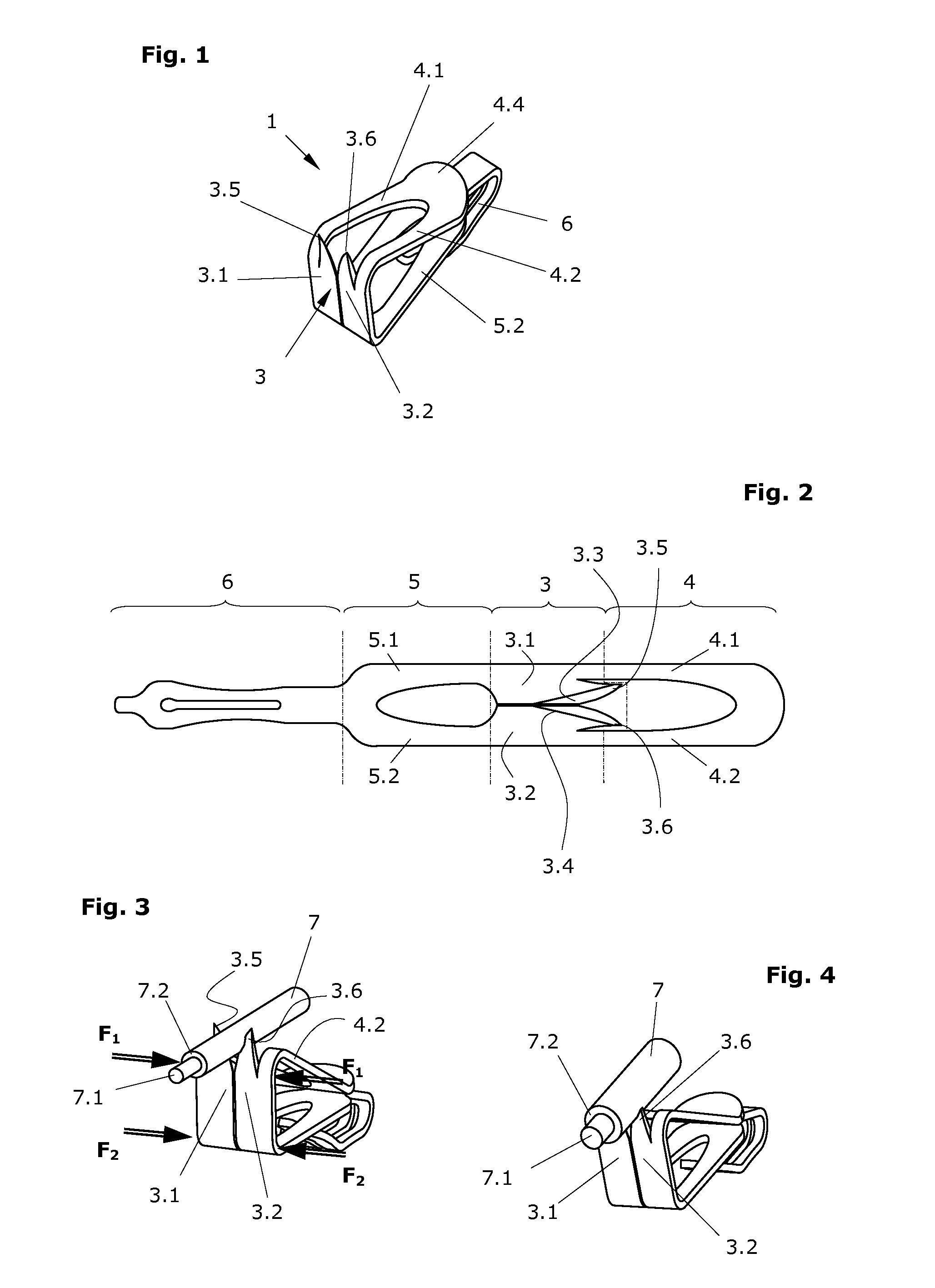

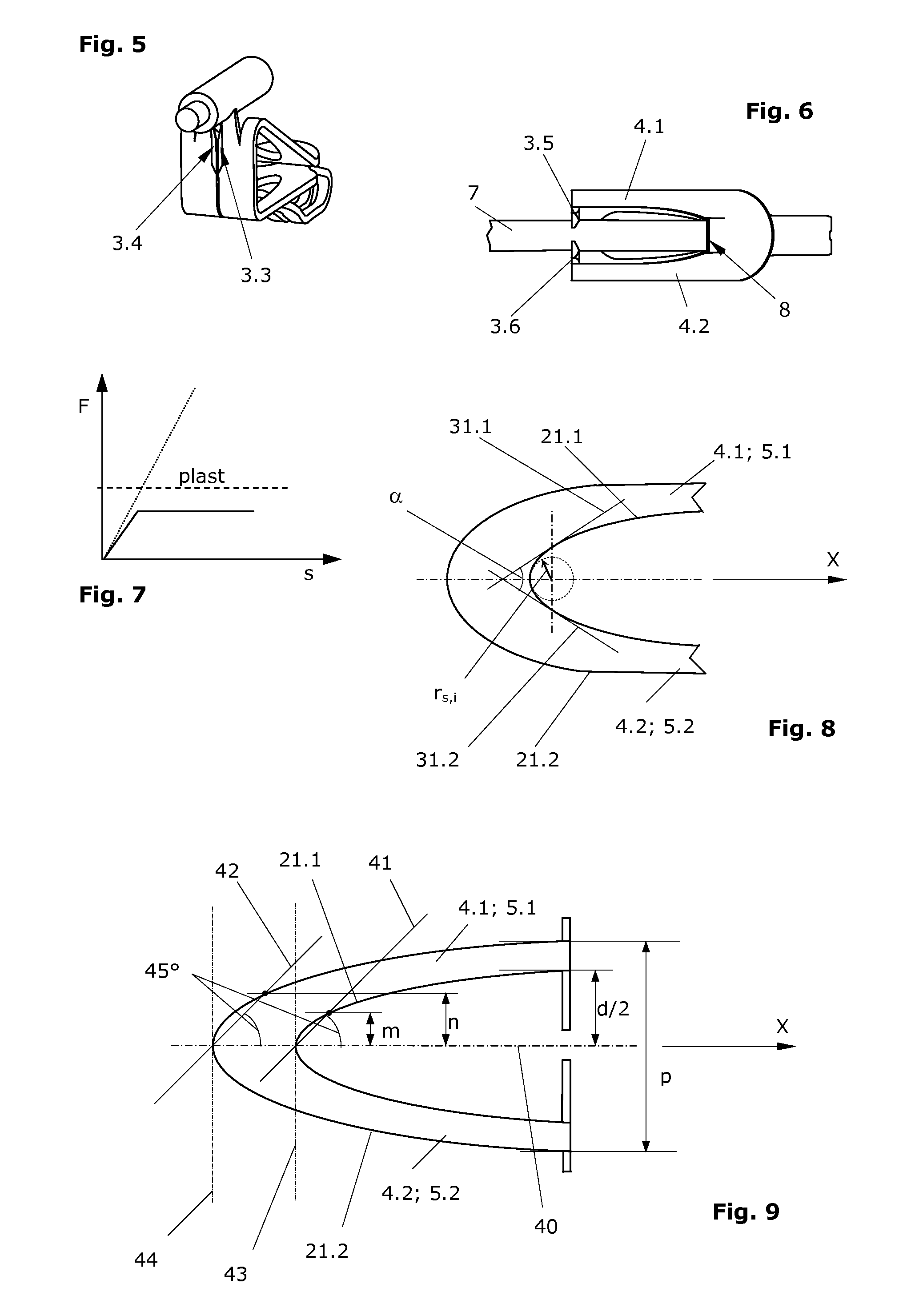

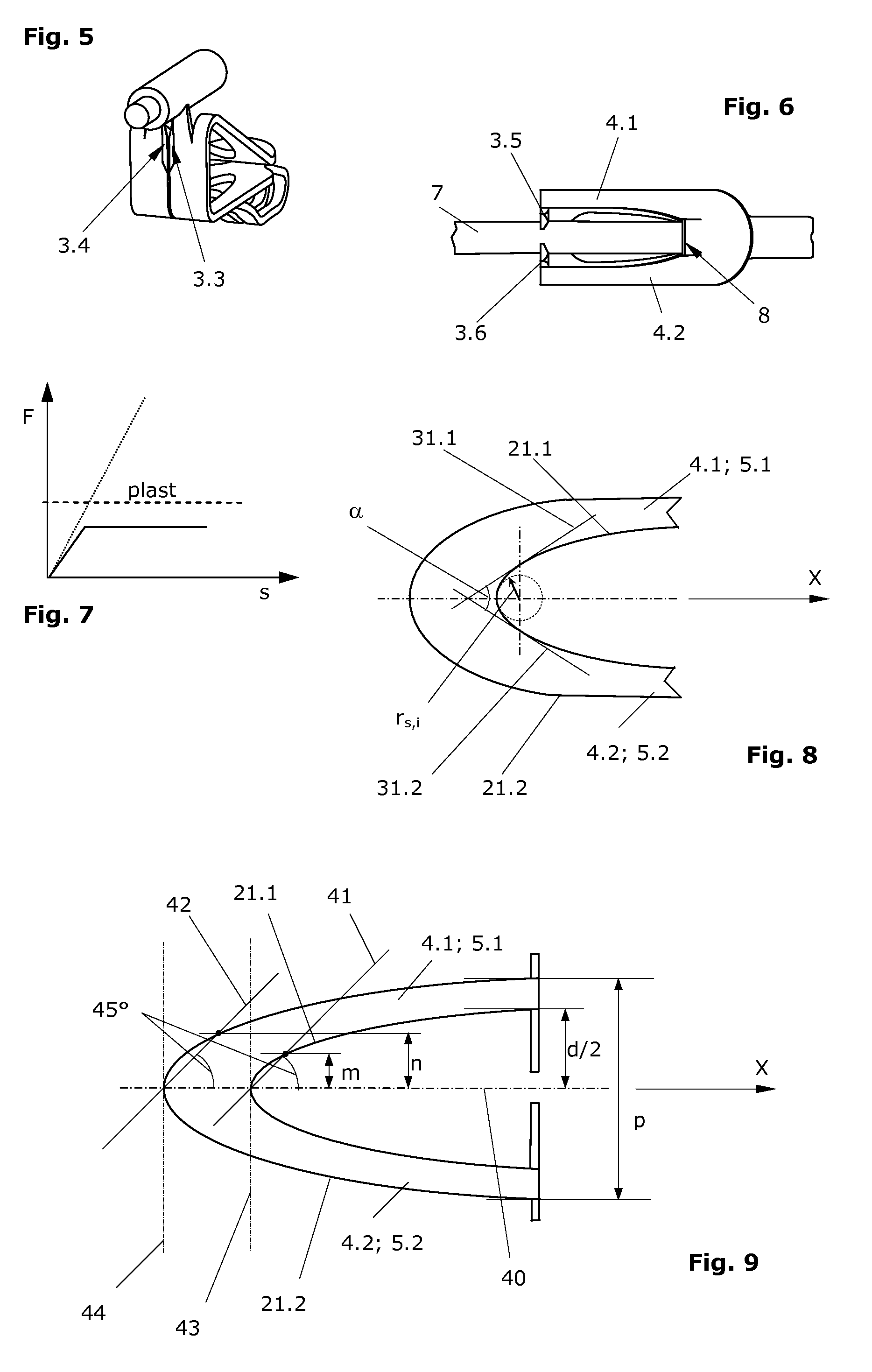

Insulation displacement contact and contacting device

InactiveUS20100009567A1Simple structureImprove the forceContact members penetrating/cutting insulation/cable strandsFastening/insulating connecting partsElectrical conductorMechanical engineering

Owner:REICHLE & DE-MASSARI

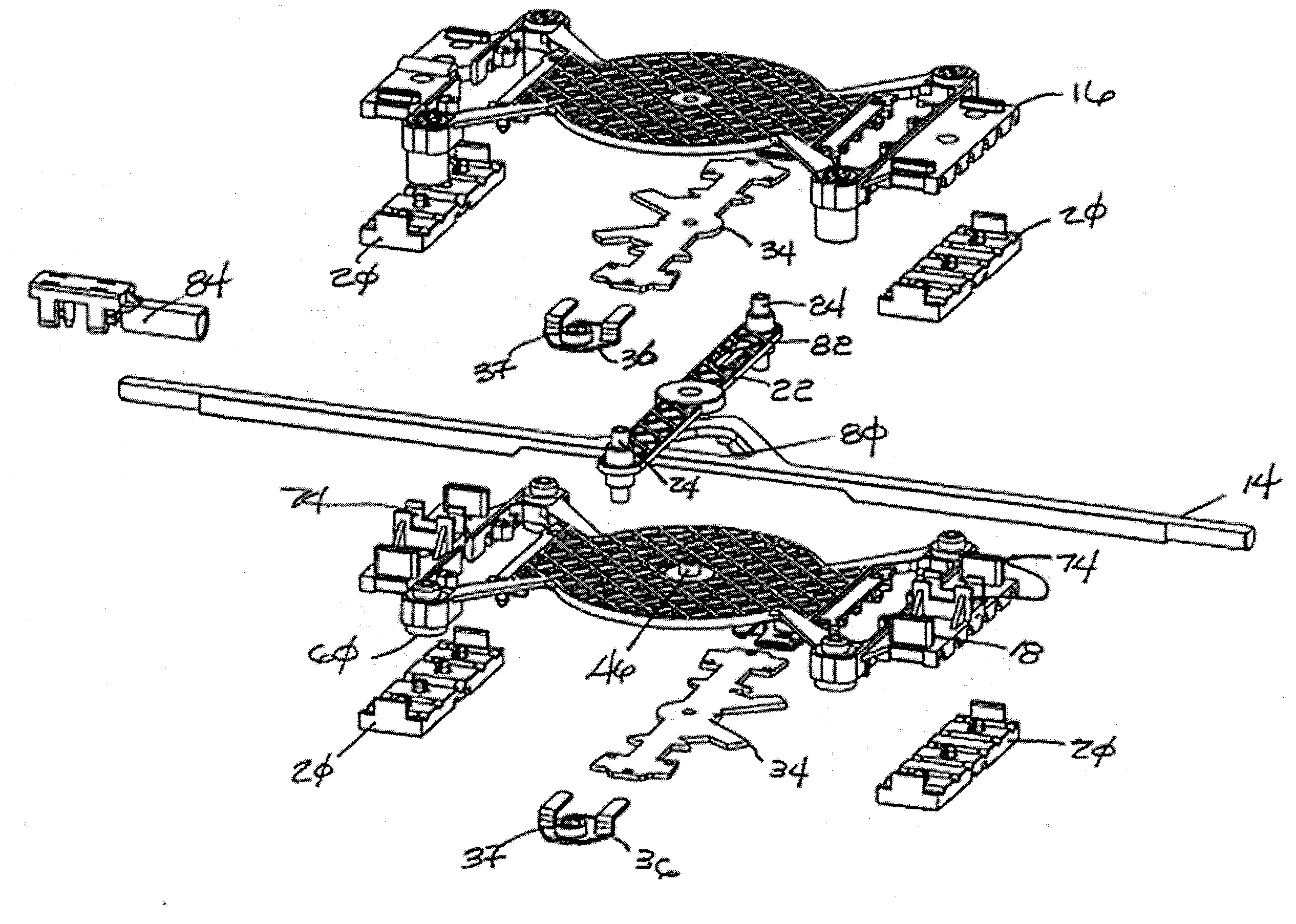

Plural phase shifter assembly having wiper PCBs movable by a pivot arm/throw arm assembly

InactiveUS8674787B2Improve protectionZero compressionElectrically conductive connectionsRelieving strain on wire connectionPrinted circuit boardTransmission line

An improved phase shifter assembly is provided. The phase shifter assembly may comprise first and second sub-assemblies with certain common actuating elements. In one example, a first phase shifter sub-assembly is provided, the first phase shifter sub-assembly including a first phase shifter carrier, a first phase shifter printed circuit board mounted on the first phase shifter carrier, a first wiper printed circuit board coupled to an input of the first phase shifter printed circuit board and having at least a first end coupled to transmission lines on the first phase shifter printed circuit board, and at least one wiper support mechanically coupling the first wiper printed circuit board to the first phase shifter printed circuit board. A second phase shifter is similarly provided. Common actuating elements may include a pivot arm and a throw arm. The pivot arm may be rotatably mounted in the phase shifter assembly and be configured to engage a wiper support of at least one of the first and second phase shifter sub-assemblies. The throw arm may be mounted such that when the throw arm is moved linearly, the pivot arm rotates around a pivot.

Owner:COMMSCOPE TECH LLC

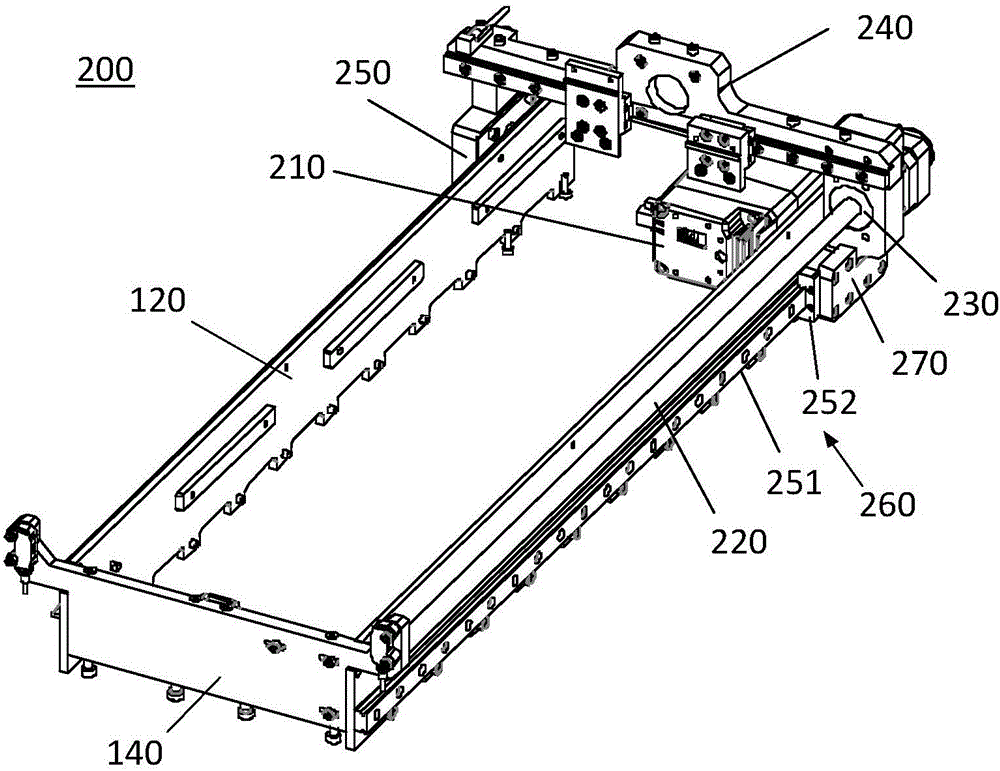

Box taking and placing mechanical arm

ActiveCN105858192ASolve installation difficultiesEasy to installConveyorsConveyor partsContact typeManipulator

The invention discloses a box taking and placing mechanical arm. The mechanical arm comprises a supporting frame, a mechanical claw device mounted on the supporting frame and an offset drive device driving the mechanical claw device to move; the mechanical claw device comprises a clamping mechanism fixedly connected with the offset drive device and two symmetrically-arranged clamping plates; one end of each clamping plate serves as a connecting part, and the other end of each clamping plate serves as a clamping part; the connecting parts are fixedly connected with the clamping mechanism, and the clamping parts incline towards the inner side relative to the connecting parts; and the box taking and placing mechanical arm can replace manpower, and take and place packaging boxes like a medicine box on a goods shelf, manpower is saved, meanwhile, work efficiency is improved, the clamping parts incline towards the inner side, fixed-point clamping of the boxes can be achieved, and compared with a full-contact type mechanical claw in the prior art, the box taking and placing mechanical arm has the beneficial effects that positioning and clamping are easier, and clamping missing cannot appear.

Owner:SUZHOU GICHEN S&T CO LTD

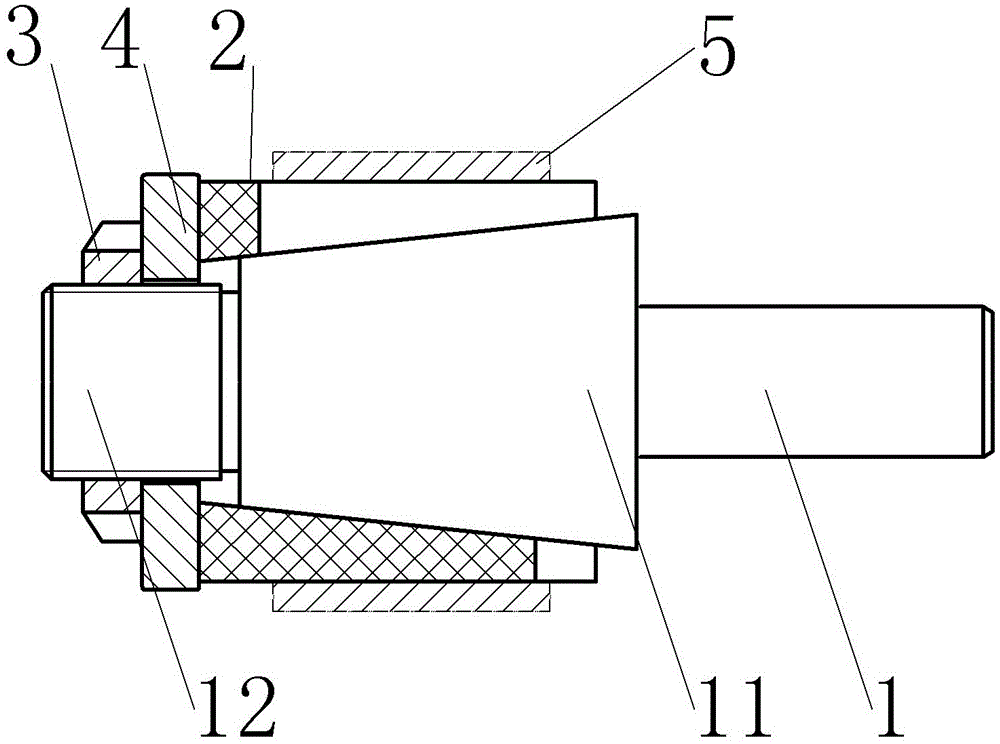

Outer circle turning clamp for thin-walled parts for motor

InactiveCN105014112AAvoid high dimensional accuracy requirementsAvoid assembly difficultiesExpansion mandrelsEngineeringScrew thread

The invention discloses an outer circle turning clamp for thin-walled parts for a motor. The outer circle turning clamp comprises a central spindle, an expansion sleeve, a pressing plate and a compression nut. The central spindle is provided with a threaded section and a conical section. The end, with a smaller diameter, of the conical section is close to the threaded section. The compression nut is in threaded connection with the threaded section. The expansion sleeve is a polyurethane expansion sleeve. The inner work face of the expansion sleeve is provided with a conical hole, and the taper of the conical hole is matched with that of the conical section of the central spindle. The pressing plate is located between the compression nut and the expansion sleeve and is annular. The inner diameter of the pressing plate is smaller than the inner diameter of the expansion sleeve and larger than the large diameter of the threaded section, and the outer diameter of the pressing plate is larger than the outer diameter of the expansion sleeve. The outer circle turning clamp is easy to design and manufacture and suitable for small-batch production or single part production.

Owner:CHONGQING SHANGZE ELECTROMECHANICAL

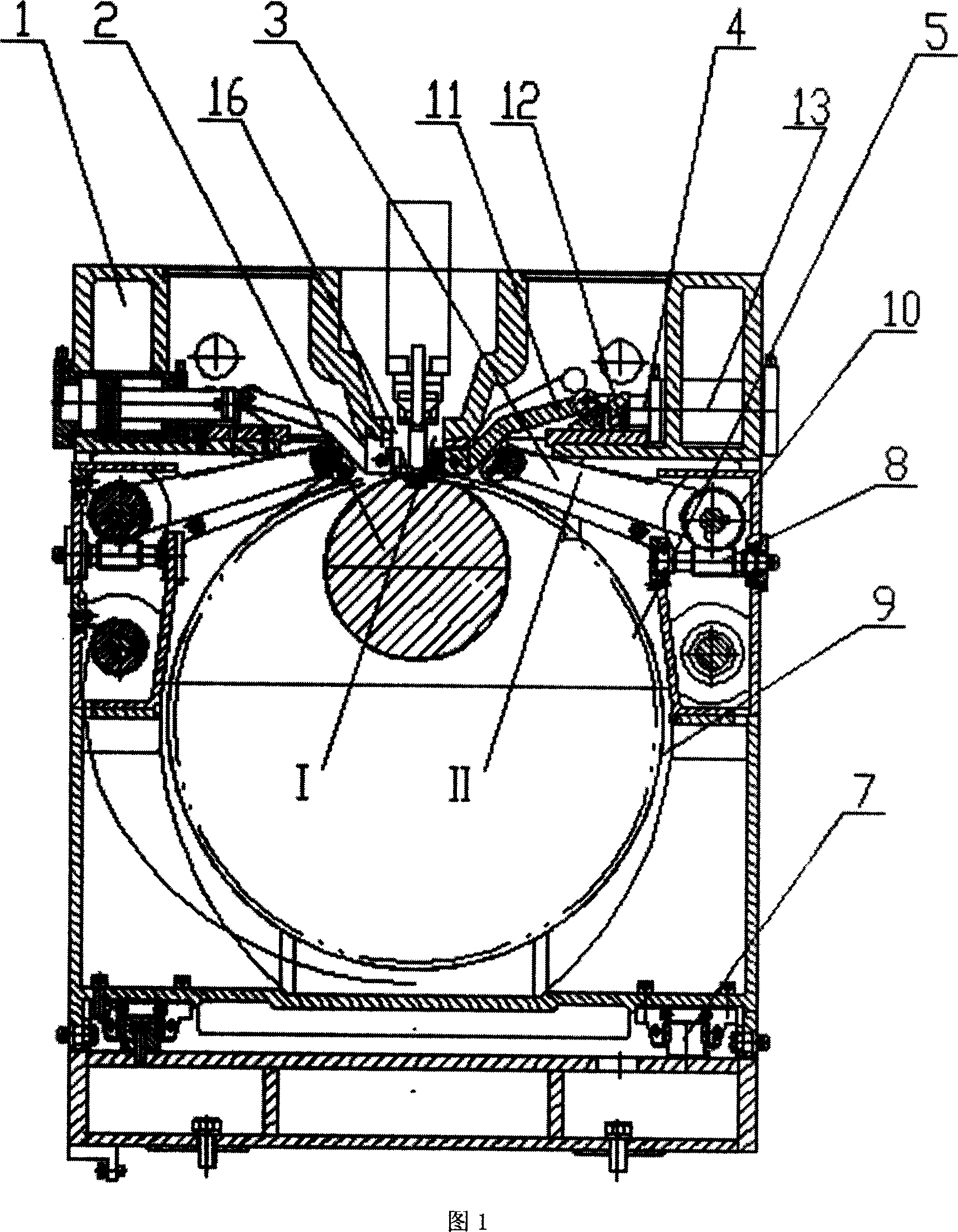

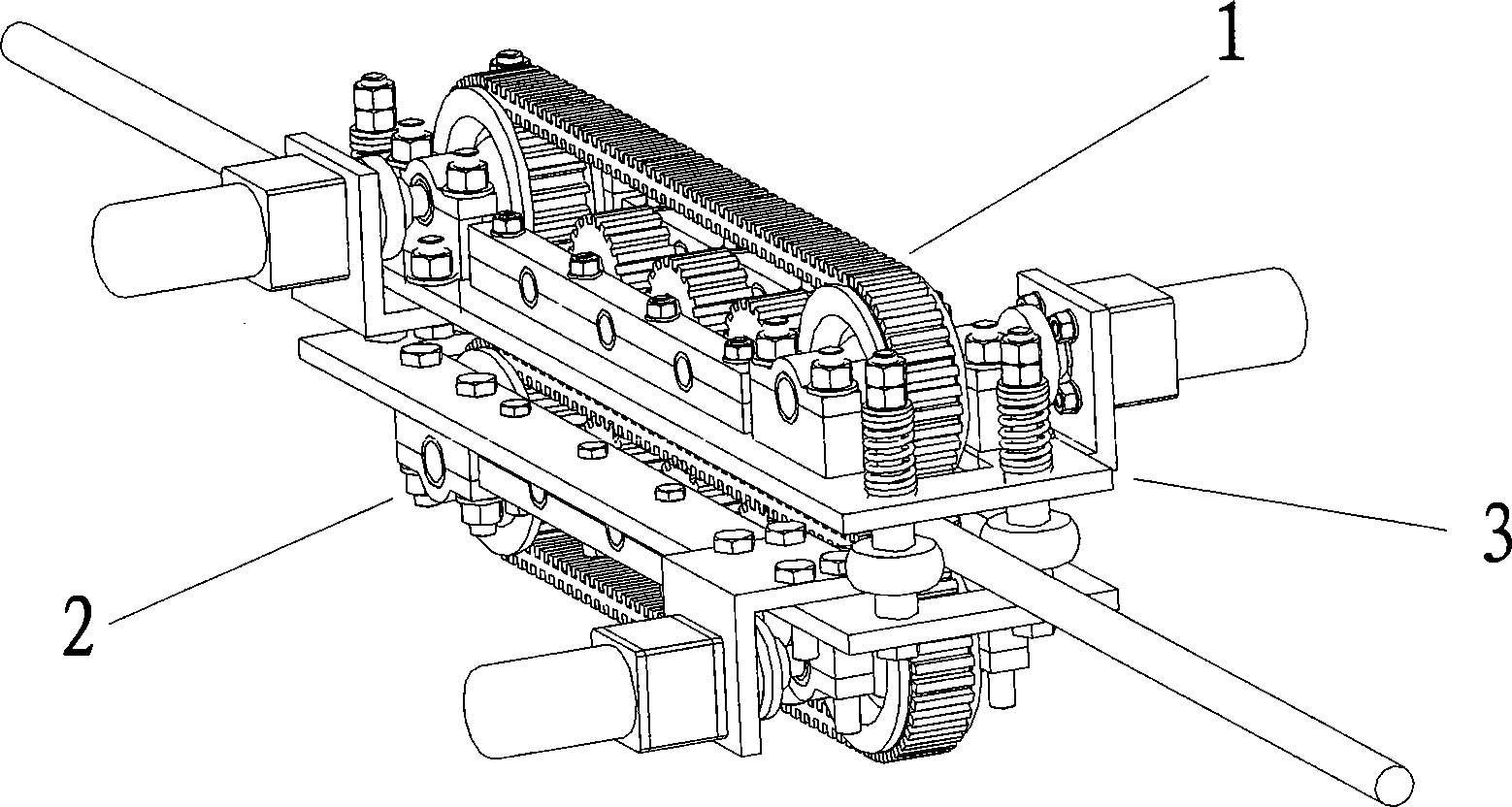

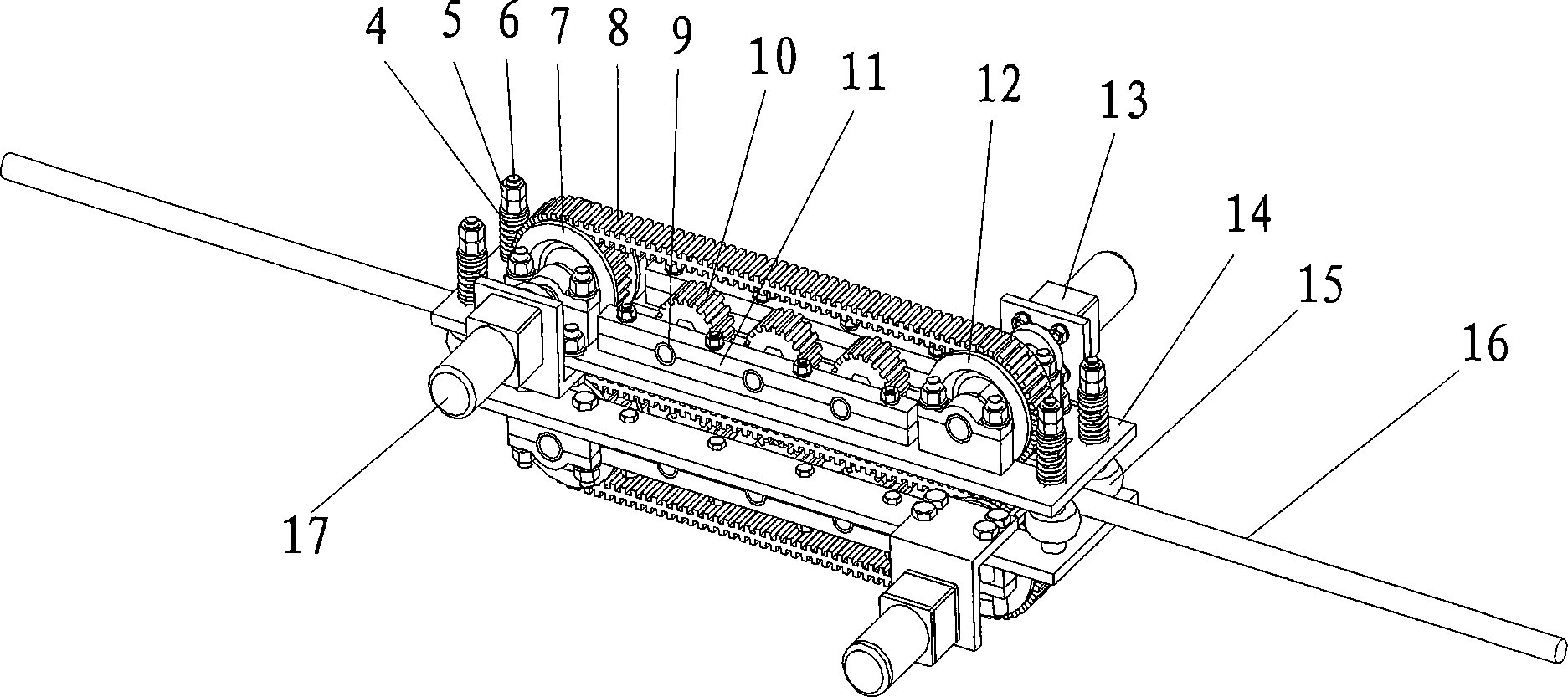

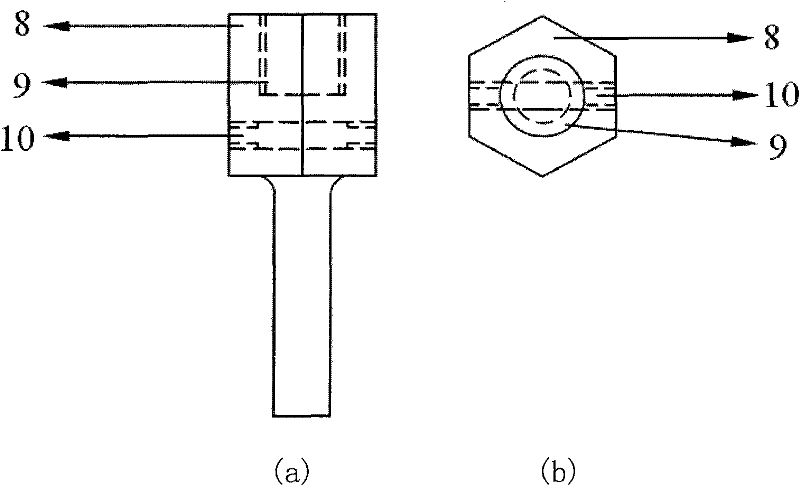

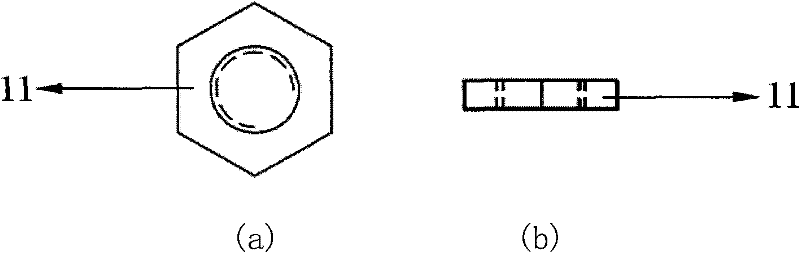

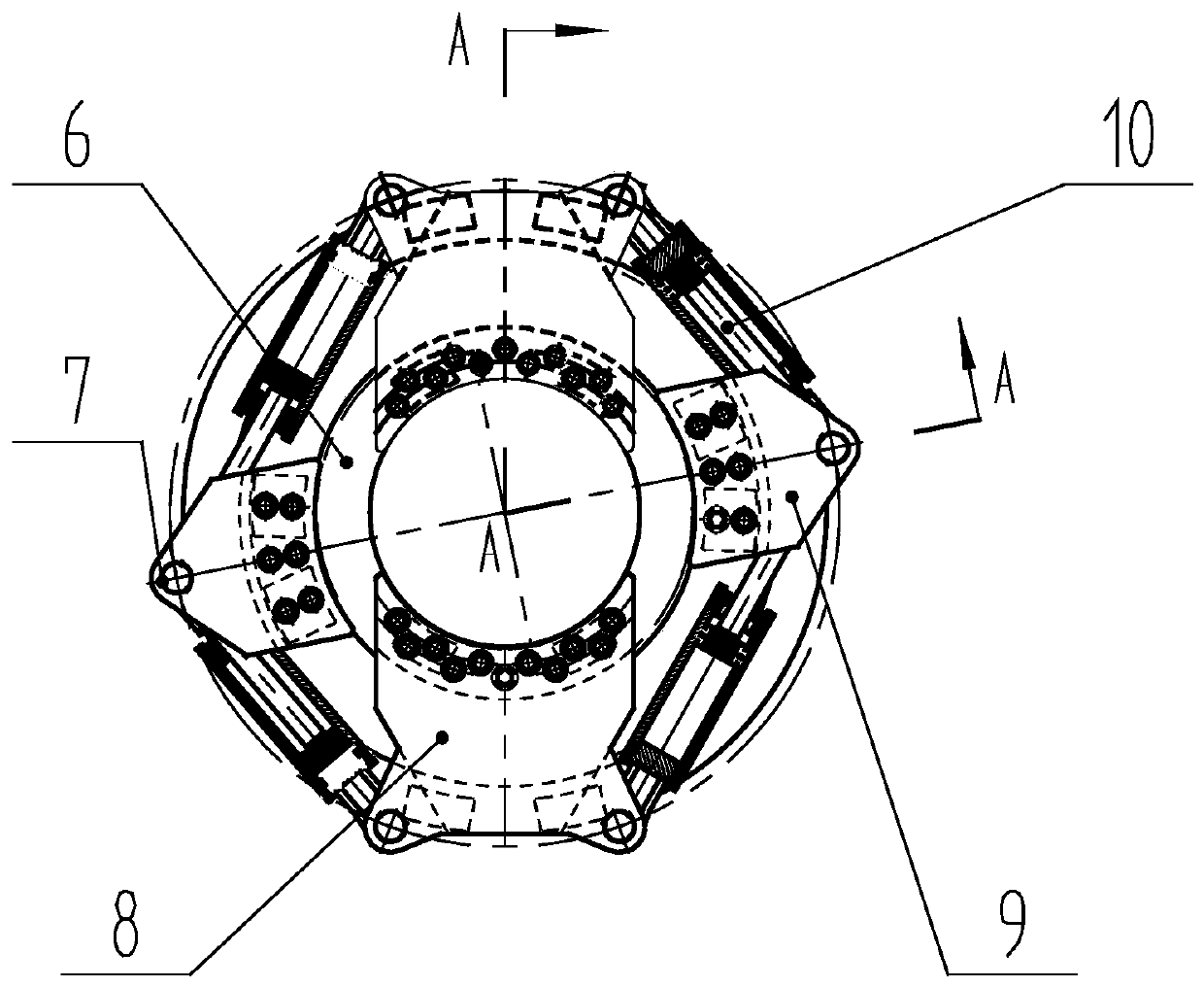

Robot main body mechanism for climb cable

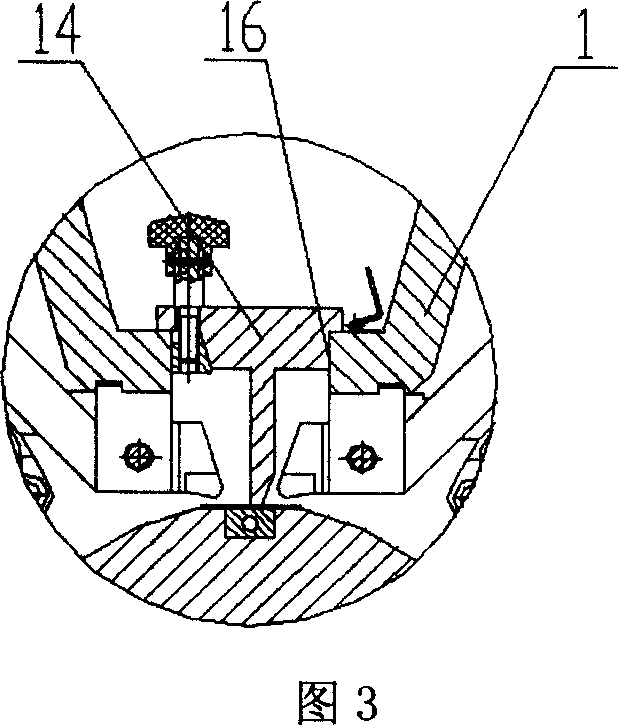

InactiveCN101244562AUniform pressureAvoid insufficient clamping forceManipulatorEngineeringPre and post

The invention relates to a robot body apparatus of climbing rope, belonging to the robot technical field. The robot body apparatus comprises the following: two track apparatuses (1,2) of upper and lower which are symmetry distributed along a cable (16) direction, wherein, the track apparatus (1,2) comprises a floor (14), a pre track wheel and a post track wheel (7,12) which are arranged on the floor (14) through a bearing support, a motor (17,13) for driving the pre and post track wheels (7, 12) and a track (8); the two track apparatuses (1,2) of upper and lower is clamped on the cable through the floor (14) by a clamping device (3); the anterior and the posterior of the floor (14) are respectively provided with guide mechanisms. The robot body apparatus of climbing rope has the advantages of simple structure, convenient assembly and disassembly, stationary clamping and shifting on the cable, high functional reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

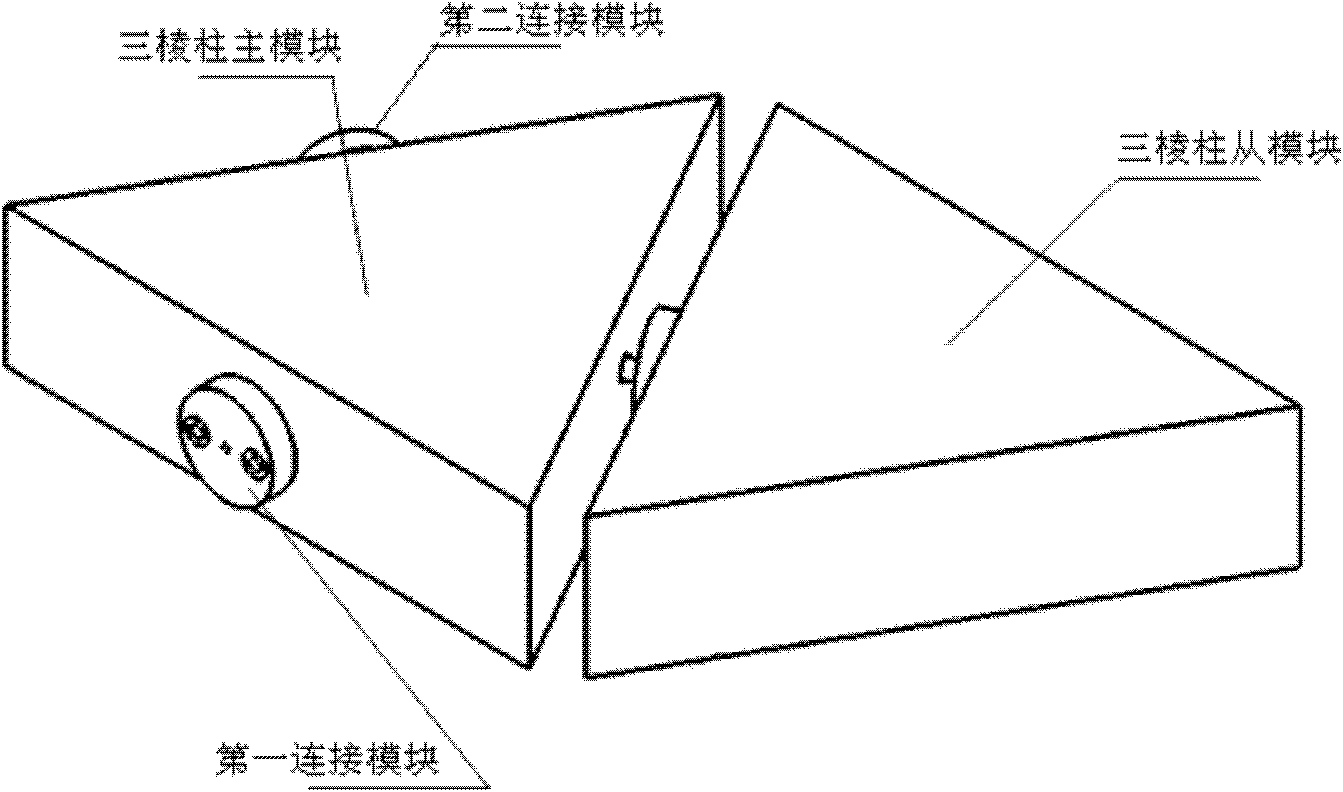

Master-slave modular robot

The invention provides a master-slave modular robot in the technical field of electromechanical engineering, which comprises a plurality of robot units. Each robot unit is connected with four adjacent robot units respectively and comprises a triangular-prism master module, a triangular-prism slave module and two connecting modules, wherein one side face of the triangular-prism master module is fixedly connected with one side face of the triangular-prism slave module; the other side faces of the triangular-prism master module are connected with a connecting module; and the other two side faces of the triangular-prism slave module are connected with the connecting modules of adjacent robot units. The connecting modules used in the invention can rapidly realize reliable connection of the modules; and rapid assembly, replacement, maintenance and functional expansion of different robot modules can be realized by modularizing the robot modules, so the manufacturing cost is remarkably lowered.

Owner:SHANGHAI JIAO TONG UNIV

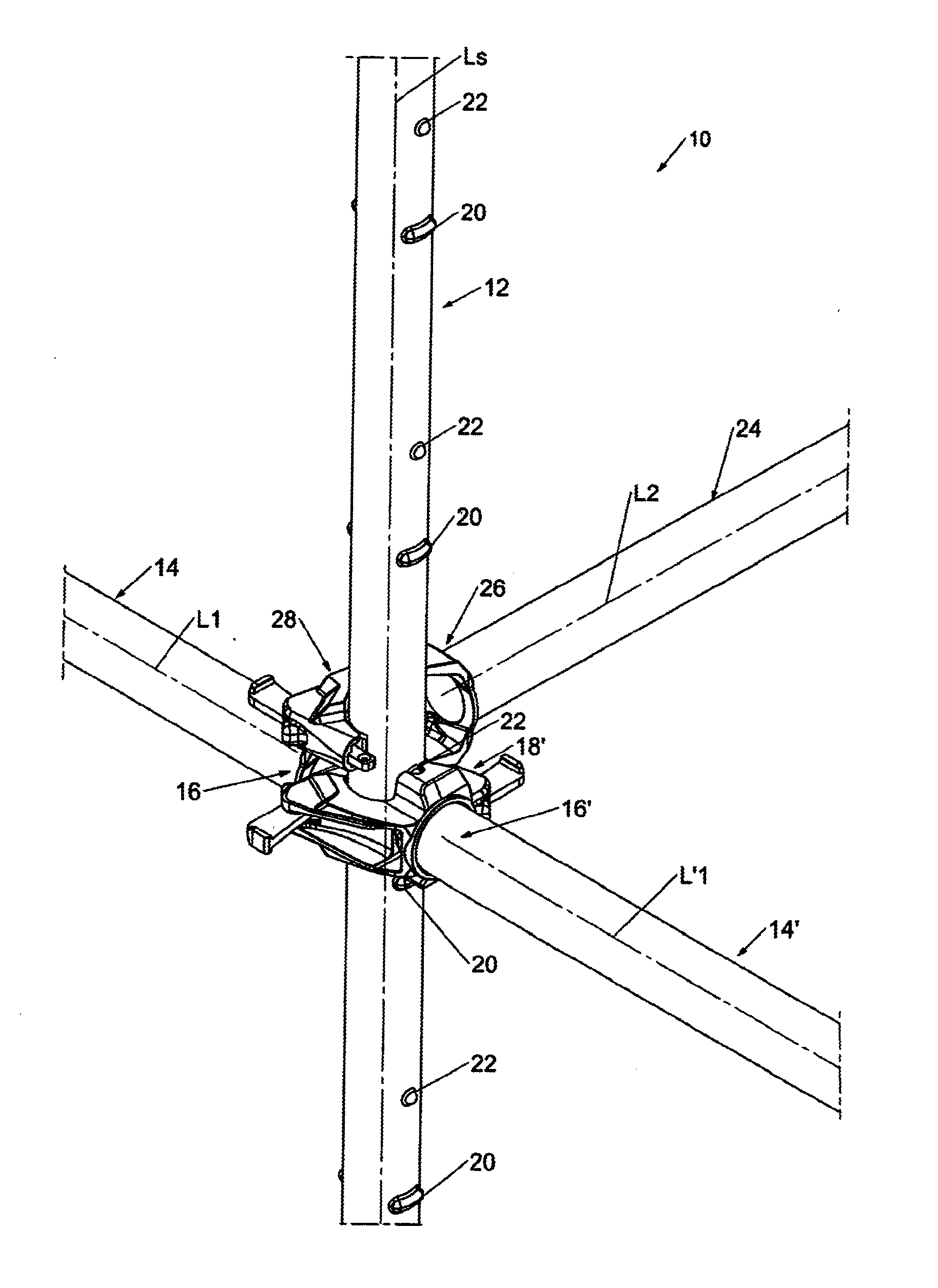

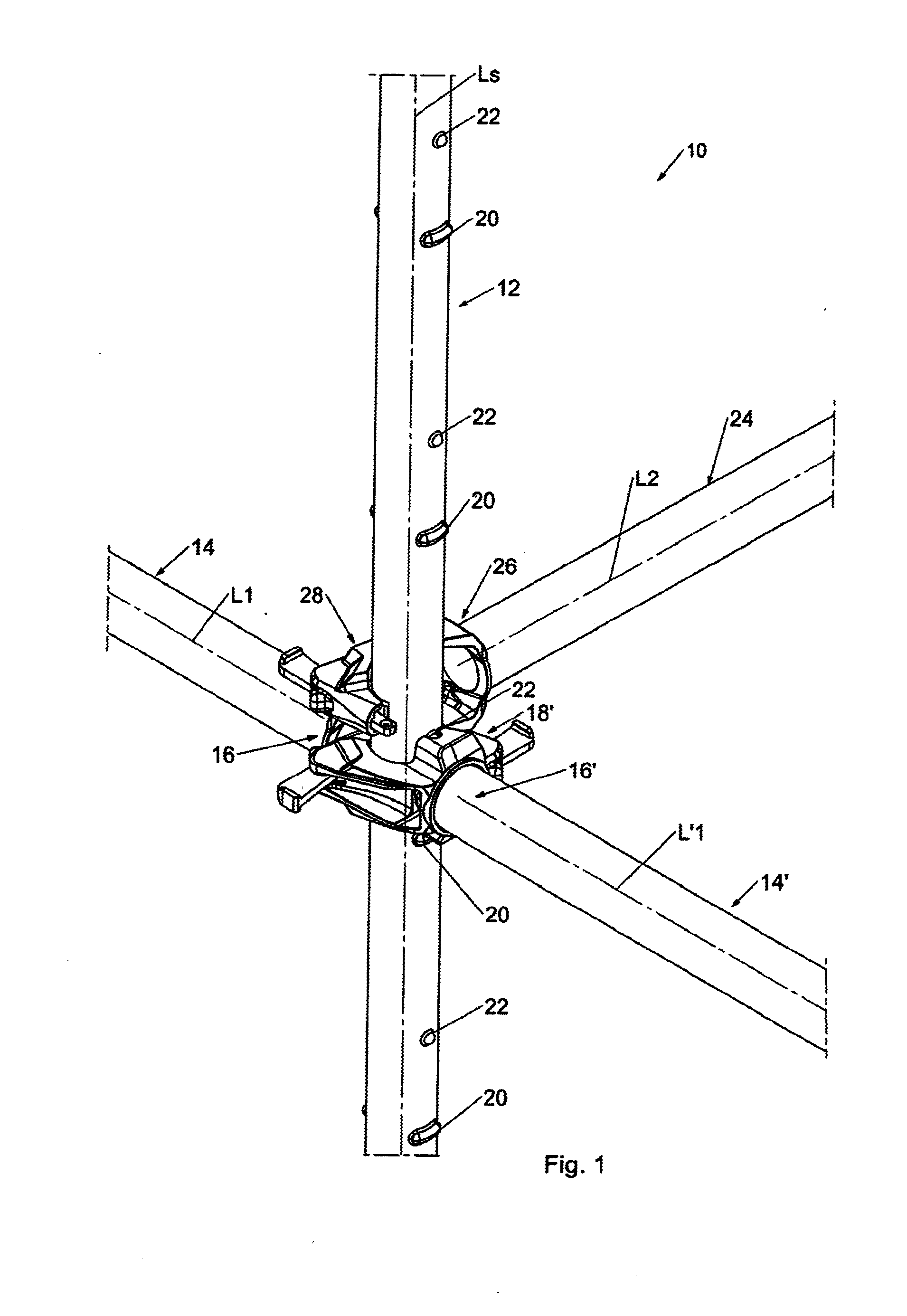

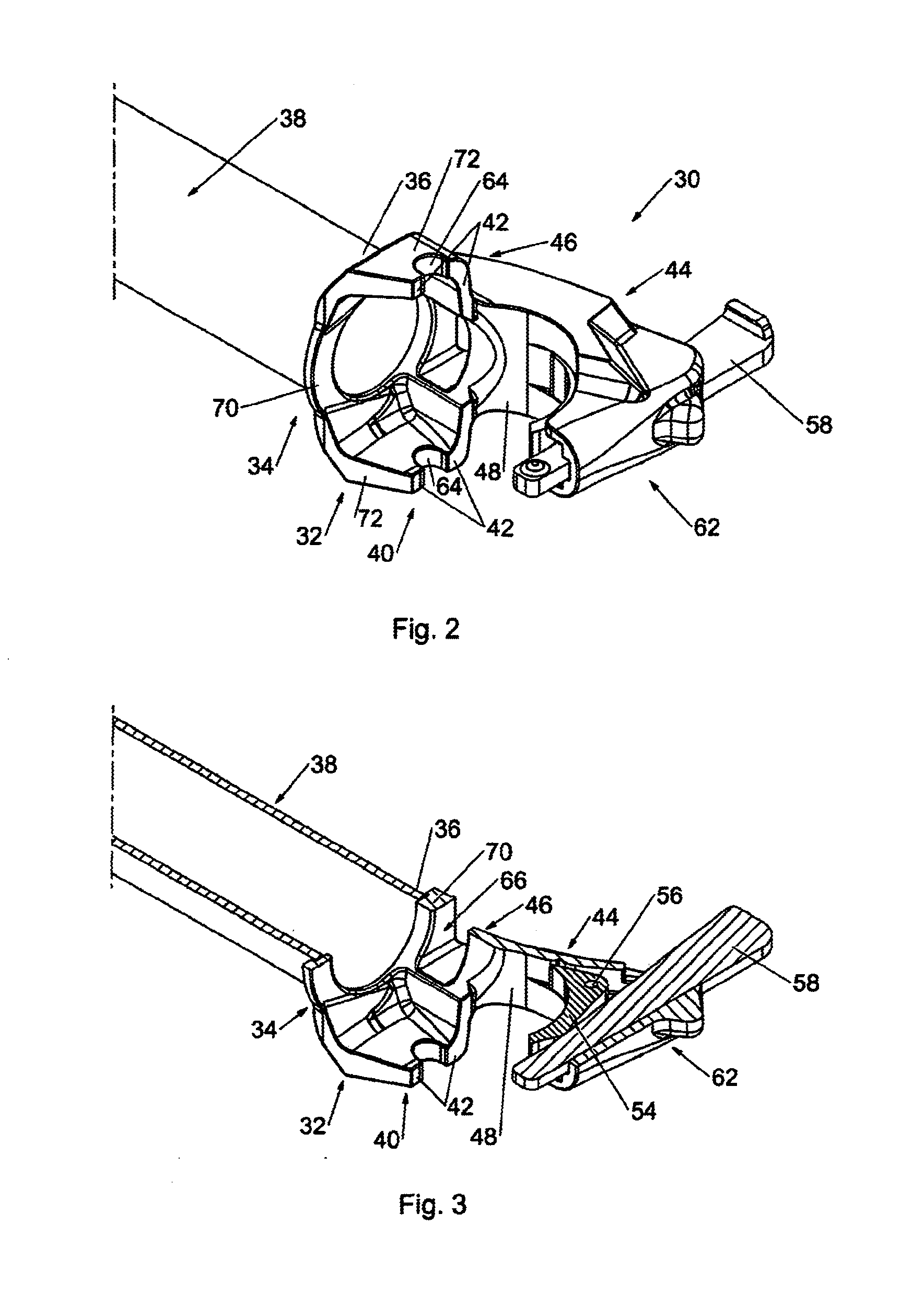

Scaffolding System, as Well as a Coupling, a Ledger and a Standard

A scaffolding system provided with standards each with an imaginary standard longitudinal central axis, first ledgers each with two extremities, first ledger couplings each connected at the extremity of a first ledger to the first ledger and which are configured for connecting the extremity of the first ledger to a standard, supporting projections which, viewed in the direction of the standard longitudinal central axis, are provided at regular distances on the outer surface of a said standard, wherein with a first ledger in a condition coupled to a standard, the first ledger coupling of the respective first ledger rests on a said supporting projection. Also, a coupling, a ledger and a standard intended for such a scaffolding system are disclosed.

Owner:SCAFOM INT

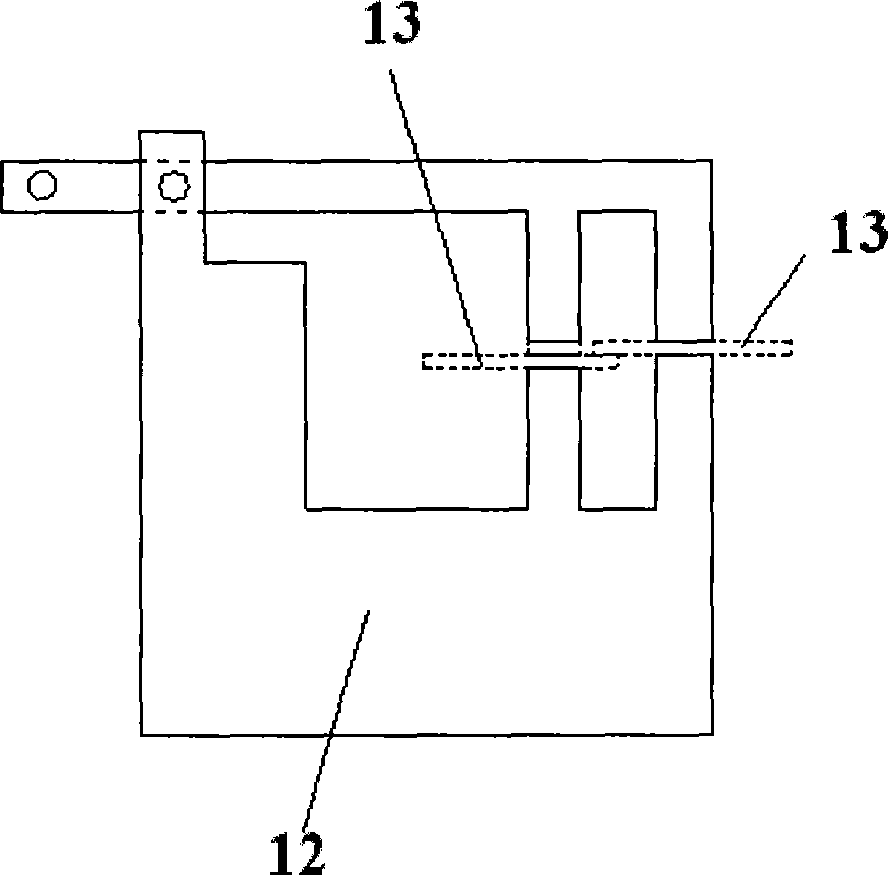

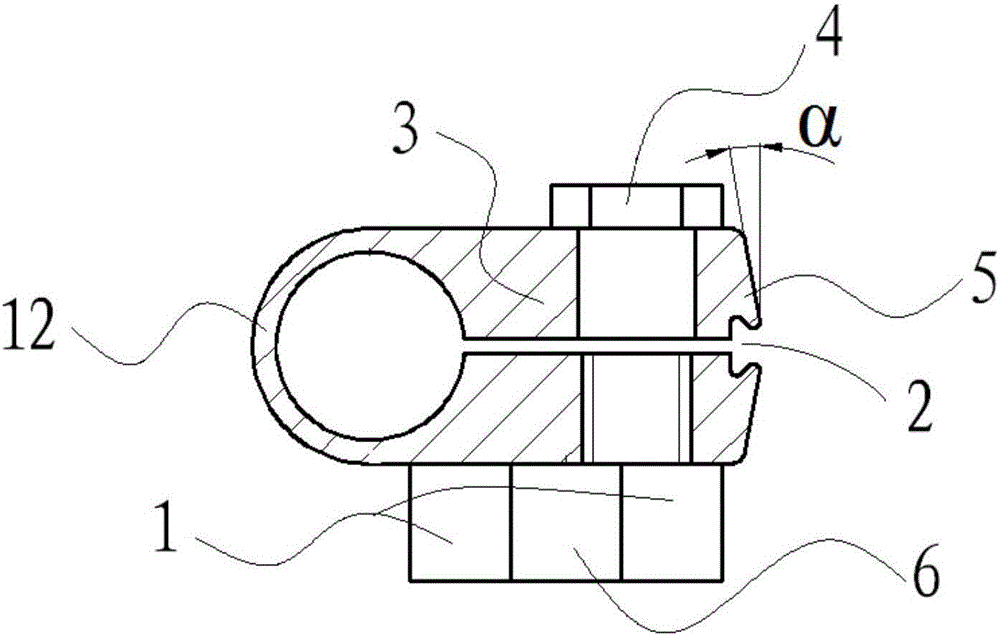

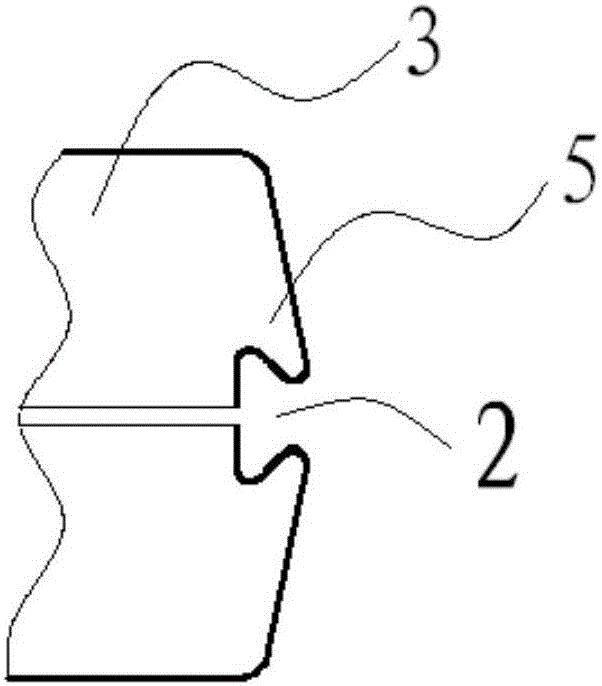

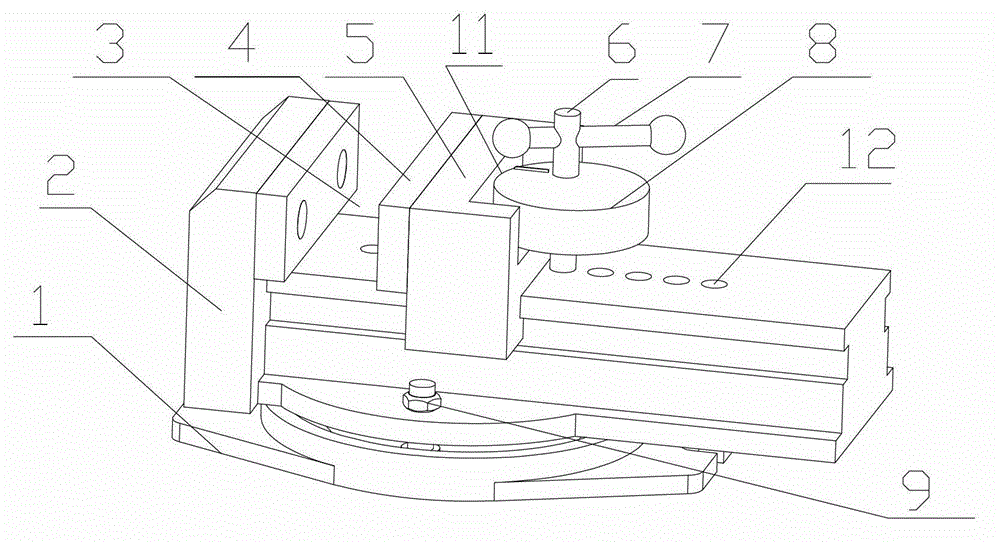

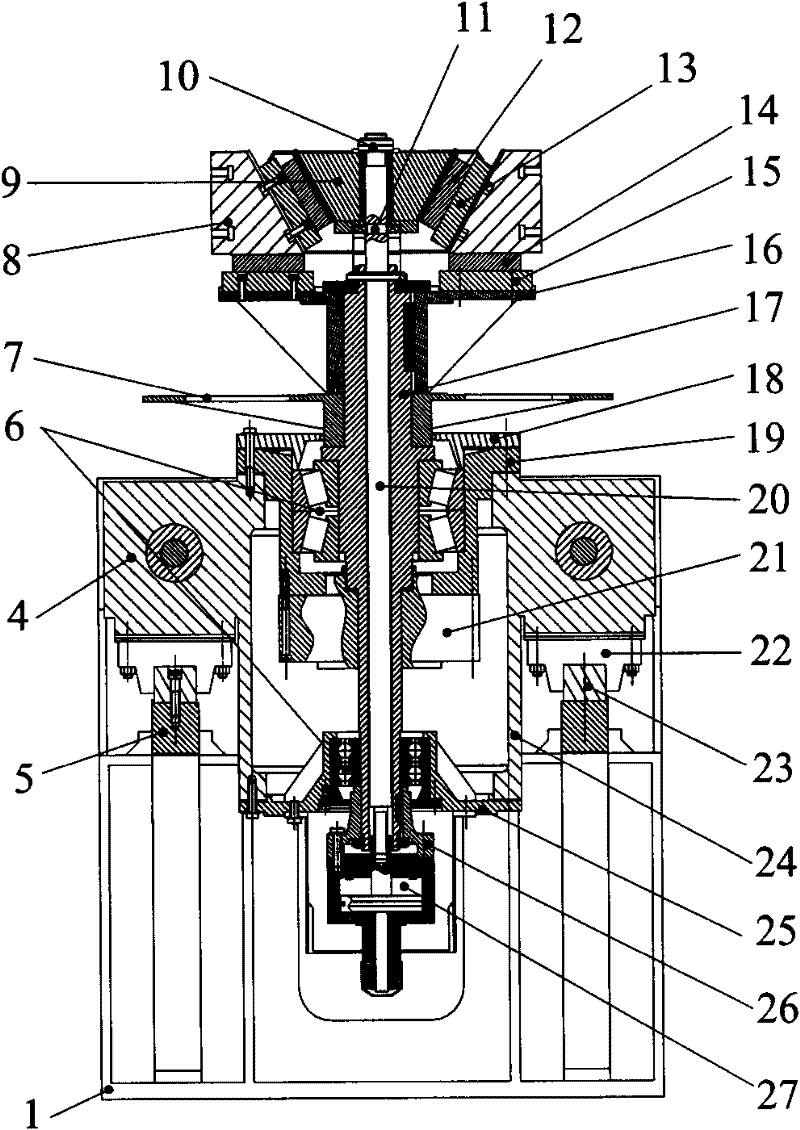

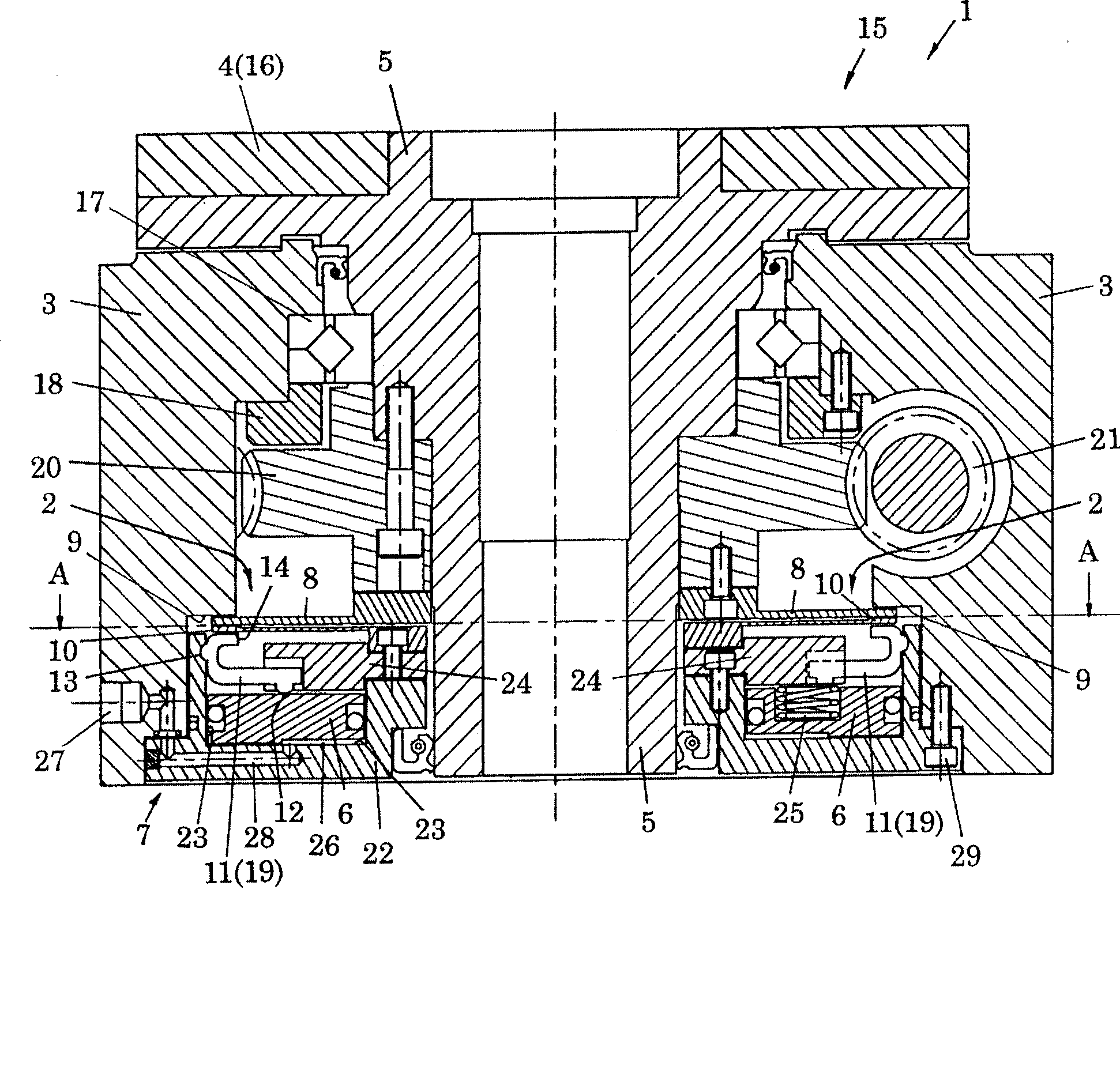

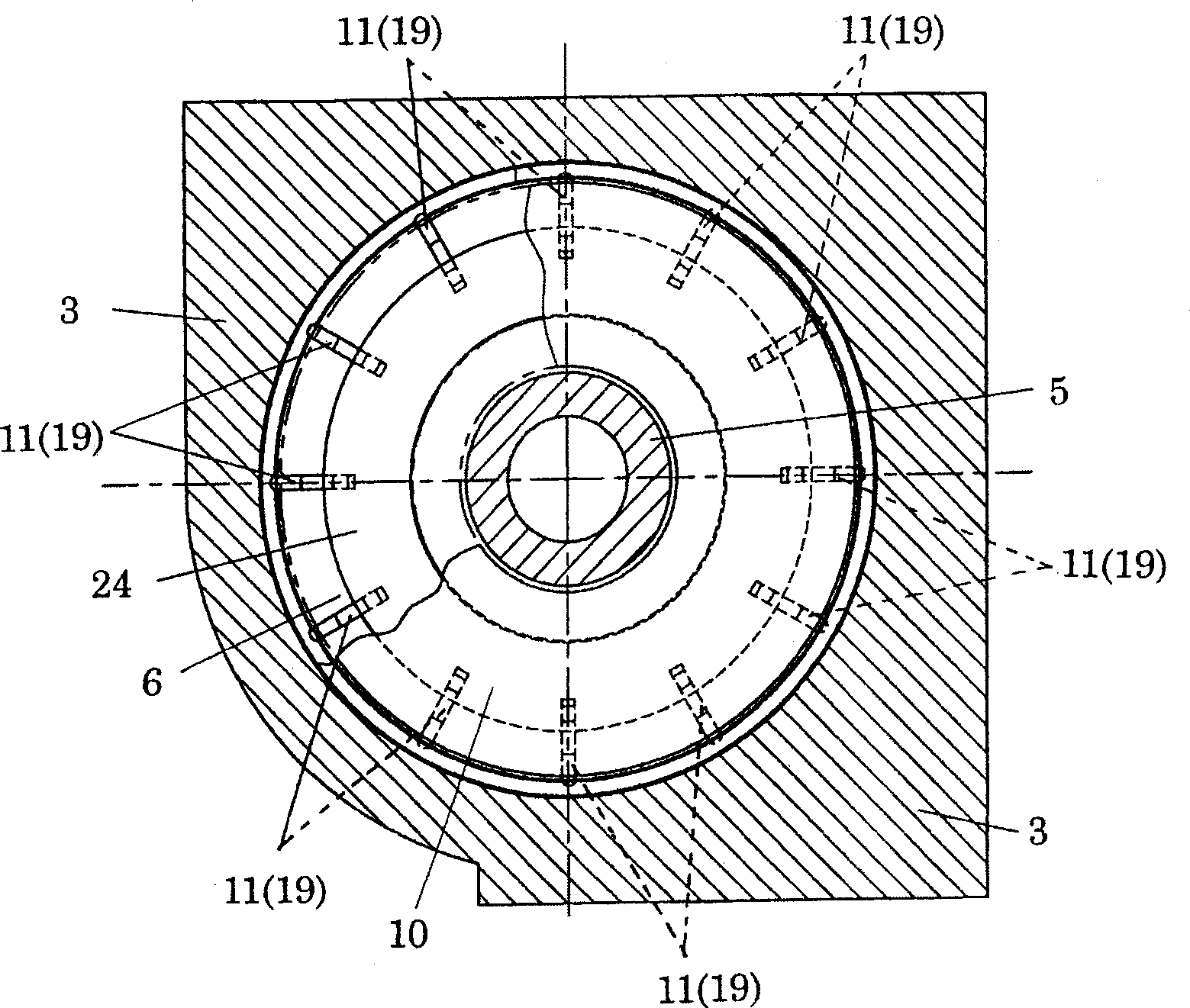

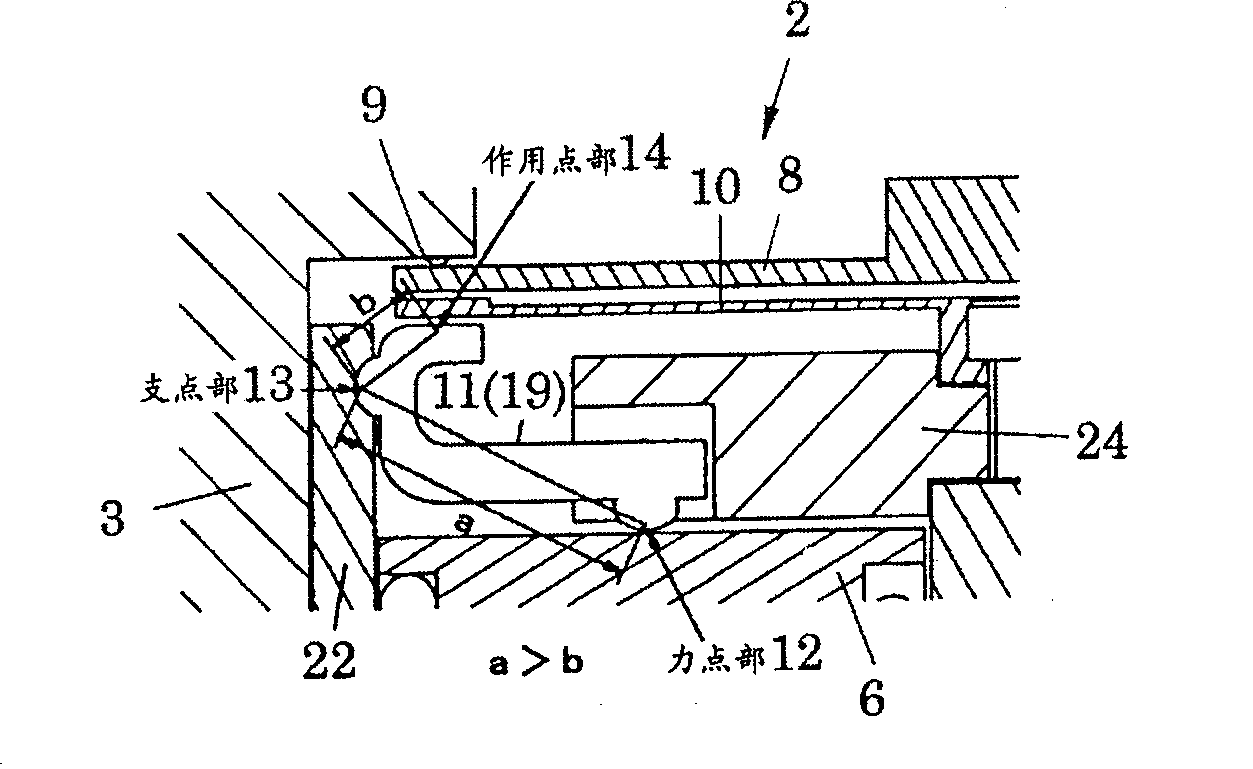

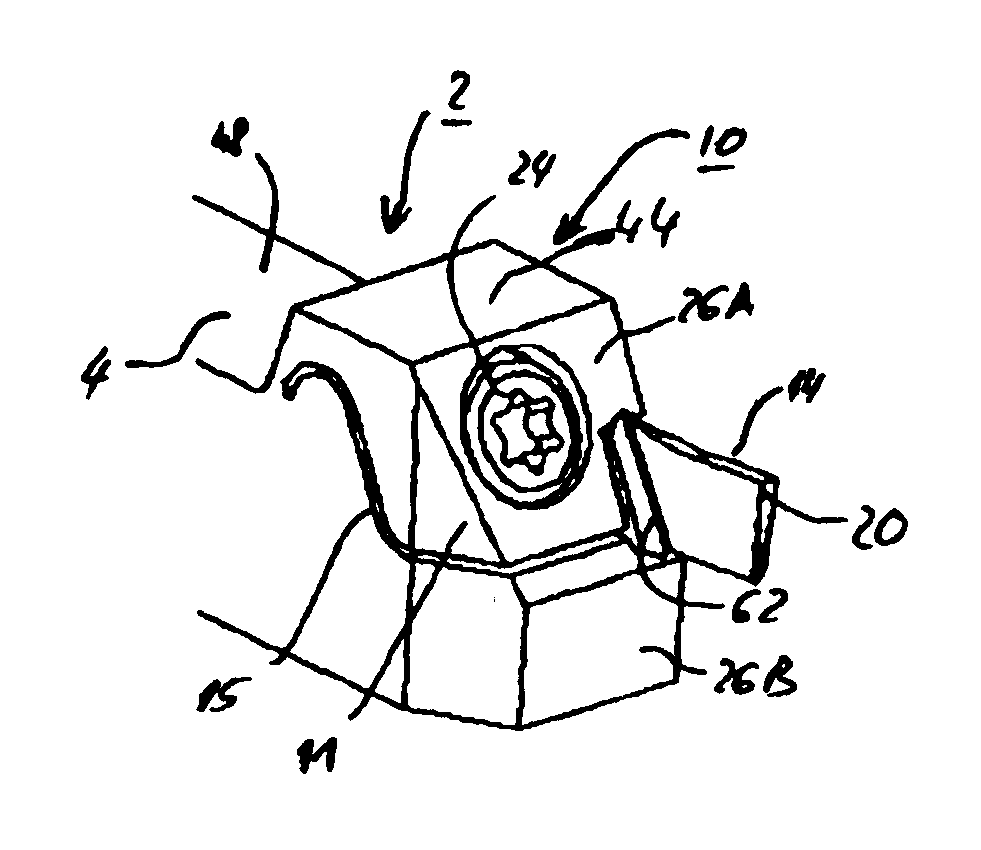

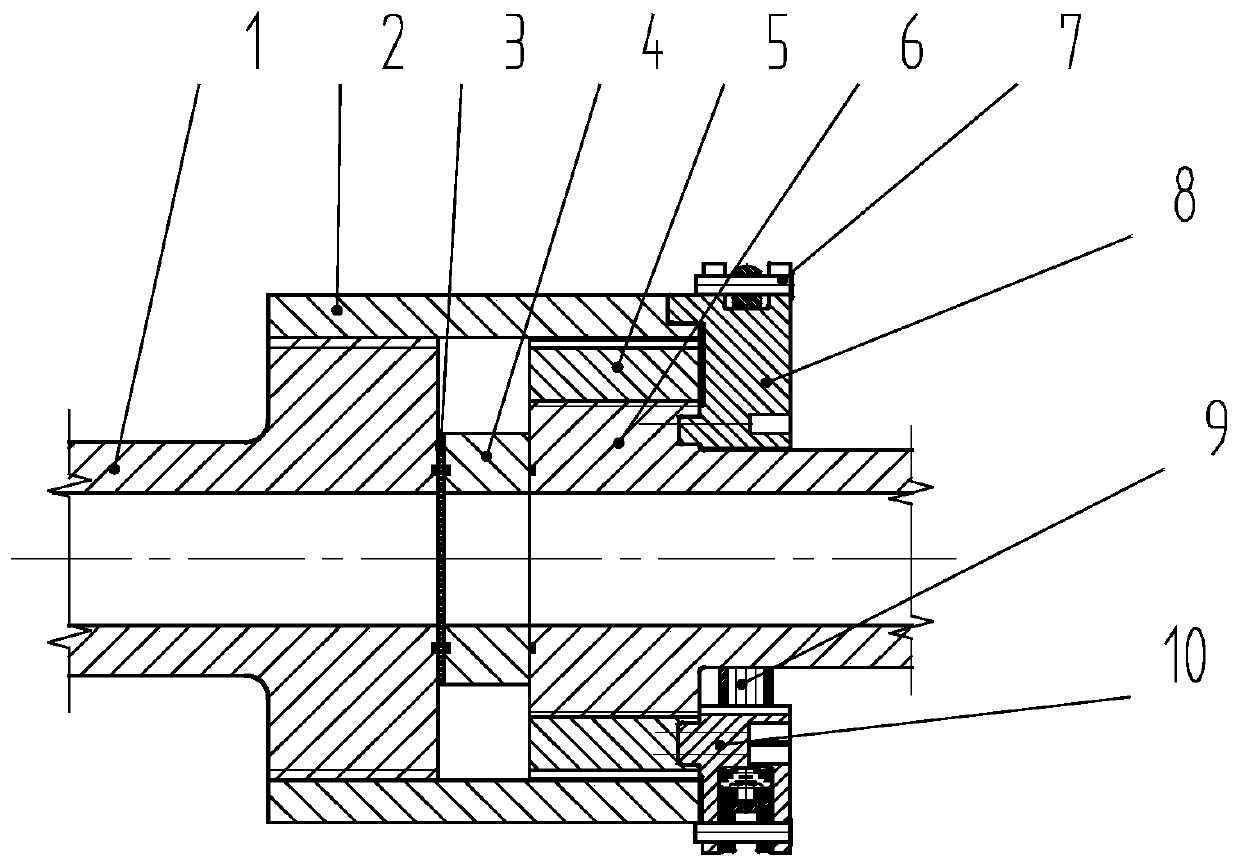

Clamping device for rotation dividing device for machine tool

InactiveCN101396797APrevents reduction in machining accuracyMiniaturizationPrecision positioning equipmentMachine tool componentsPistonRotational axis

The present invention relates to a clamping device of a rotation indexing device used by a machine tool. The invention provides a clamping mechanism which can endure high-load procession and generates enough clamping force in the clamping device of a rotation indexing device used by a machine tool. The clamping device (2) is provided with a clamping mechanism which is set with a mode of extending along a radius direction of rotation axis (5) and is composed of more than three lever components (11) between a clamping disc (8) and a piston component (6). The pulling force of the piston component (6) is increased through a lever principle and is acted on the clamping disc (8).

Owner:TSUDAKOMA KOGYO KK

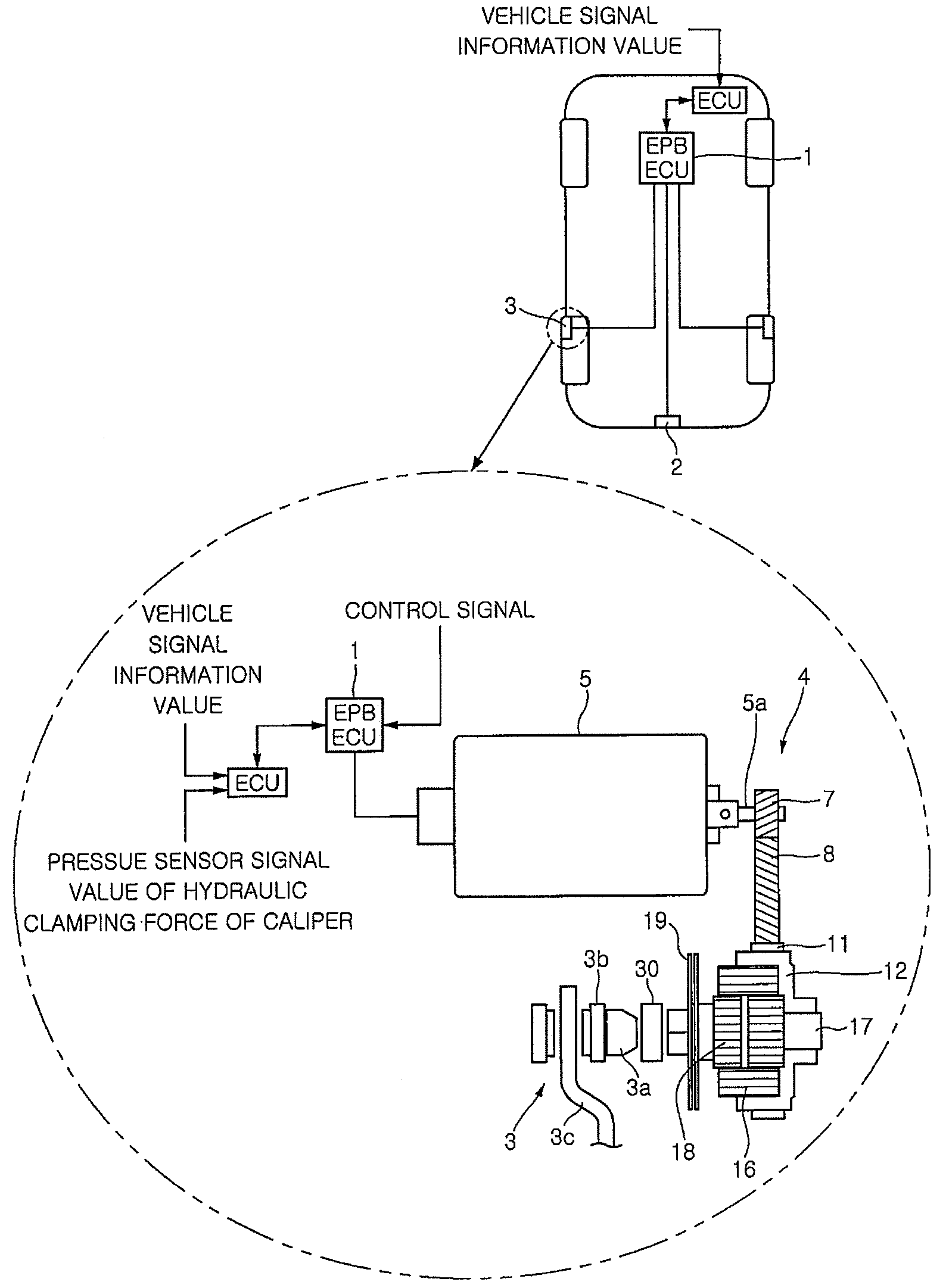

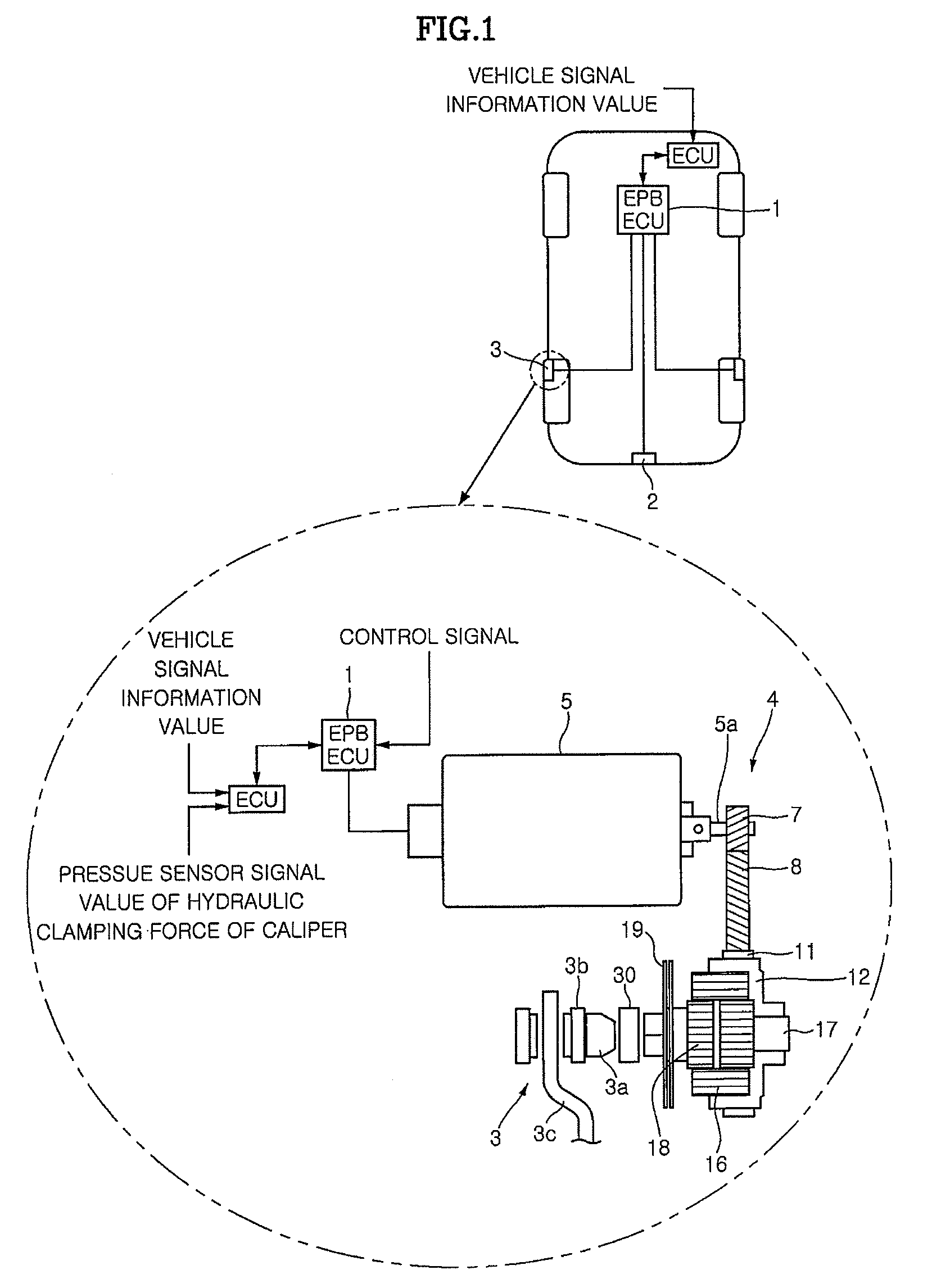

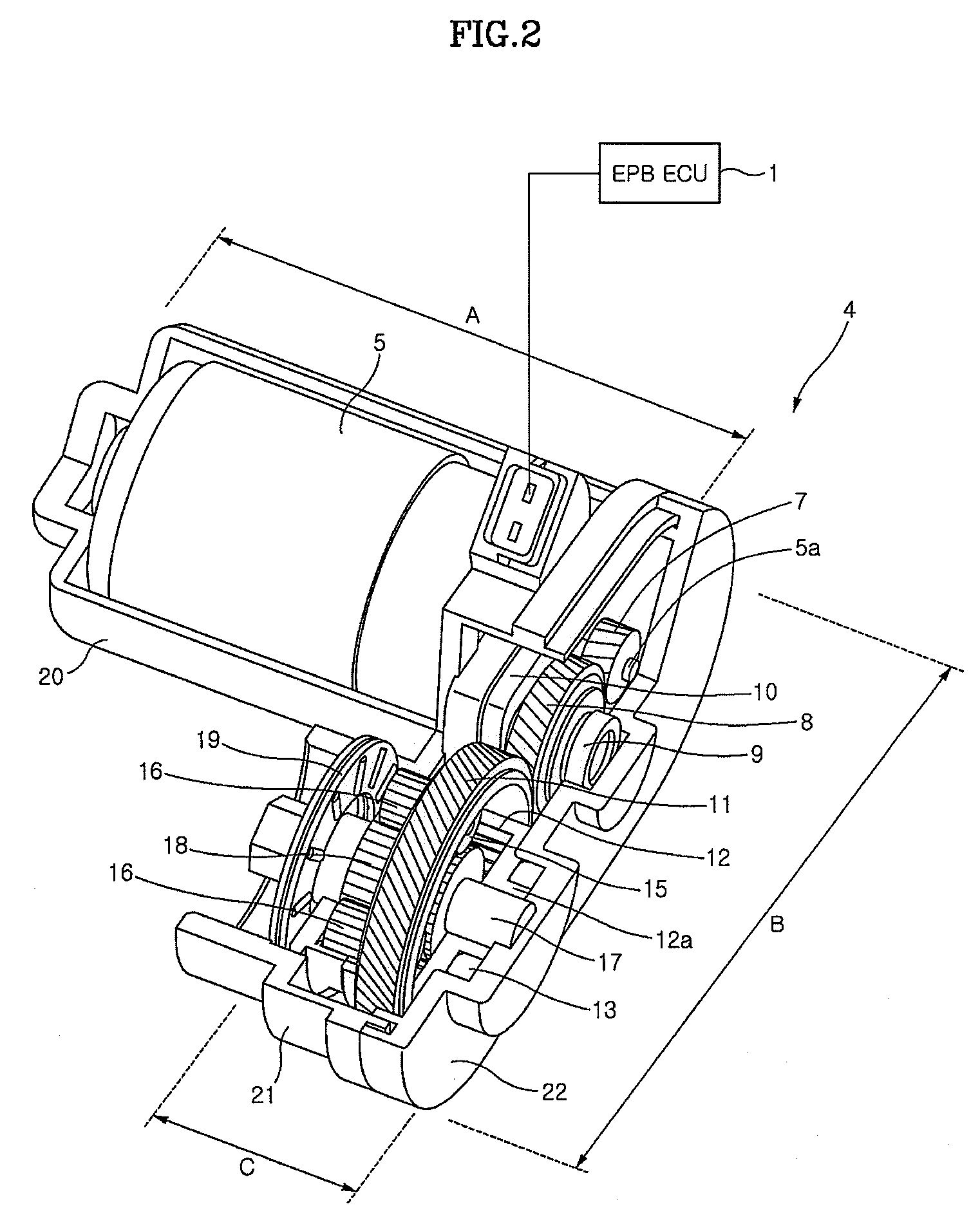

Caliper attaching type electrical parking brake in vehicle

ActiveUS20090308698A1Avoid insufficient clamping forceImprove installabilityBraking element arrangementsMechanically actuated brakesMotor driveGear wheel

According to an embodiment of the present invention, there is provided an EPB serving as an electrical parking brake in which a gear wheel and an external ring gear are arranged parallel to a driving gear rotating through a motor serving as the power source on a side surface, and fixed and output sun gears generating output torque are arranged to penetrate the external ring gear in a shaft direction via an internal ring gear and a planetary gear being in inner contact with the external ring gear, an overall length of a single body type housing with the motor is determined only by diameters of the driving gear, the gear wheel, and the external ring gear. Therefore, a power assembly converting the power of the motor driven by an ECU into the output torque is downsized so that a caliper mounted on a wheel presses a wheel disk.

Owner:HYUNDAI MOBIS CO LTD

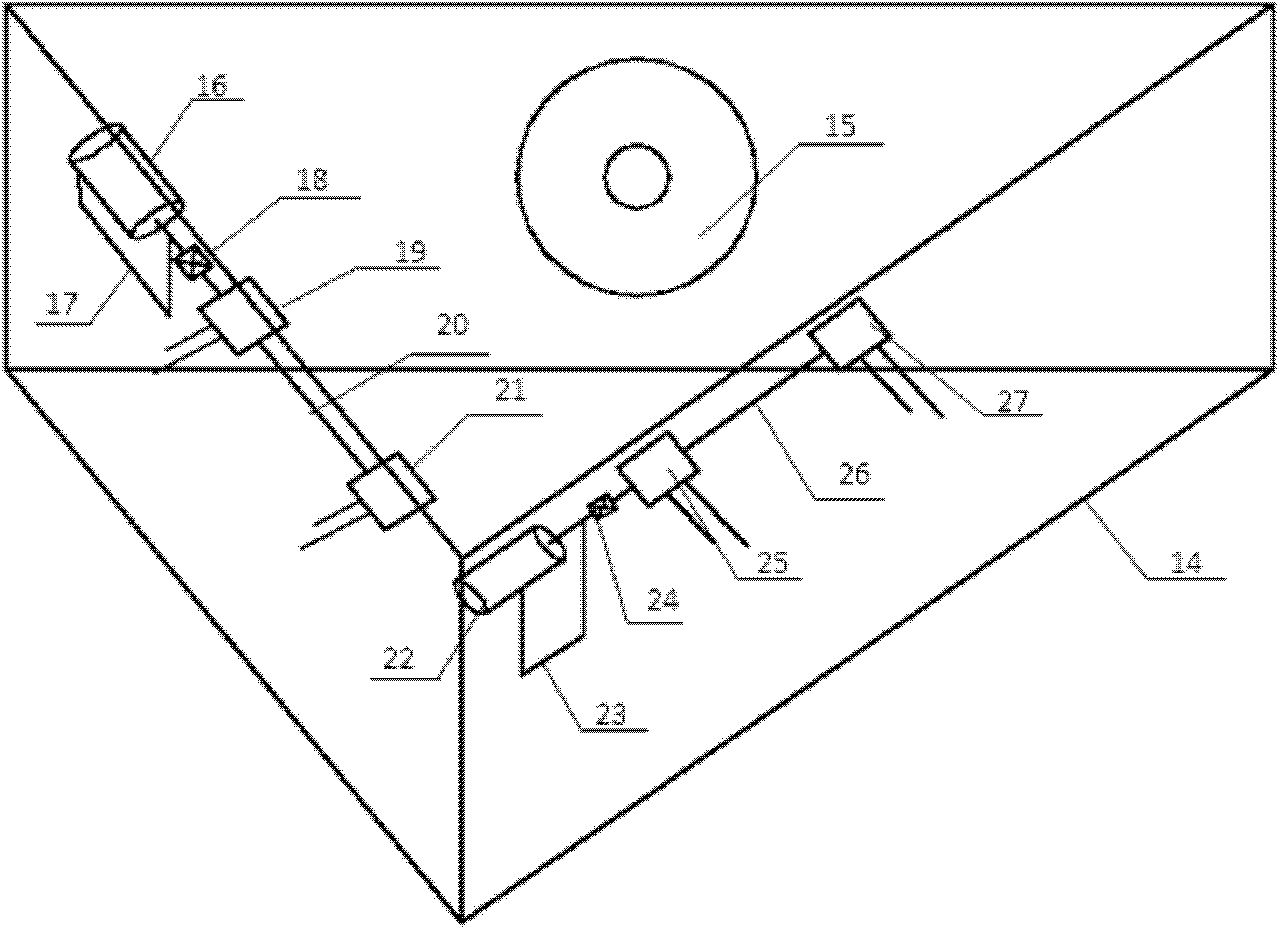

A water-cooled fixture for high temperature fatigue test of metal plate samples

InactiveCN102297804AAxial fatigue test implementationGood clamping forceMaterial strength using tensile/compressive forcesMaterials testingCooling effect

The invention relates to material testing equipment, in particular to a water-cooled jig for high-temperature fatigue testing of metal plate samples. The fixture is equipped with a chuck, an extension shaft and a water cooling device. There is a groove in the center of the chuck for placing a plate sample. The bolts pass through the holes on the chuck and clamped with the nuts; the extension shaft is connected with the water cooling device through threads, and the water cooling device is provided with a water hole for cooling water. The invention solves the problems of clamping ability and cooling effect of existing fixtures, not only can realize the axial fatigue test of metal plate samples under high temperature environment, but also can ensure the clamping force under high temperature and has good water cooling effect .

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Insulation displacement contact and contacting device

InactiveUS7857655B2Avoid insufficient clamping forceReliable methodContact members penetrating/cutting insulation/cable strandsFastening/insulating connecting partsElectrical conductorEngineering

Owner:REICHLE & DE-MASSARI

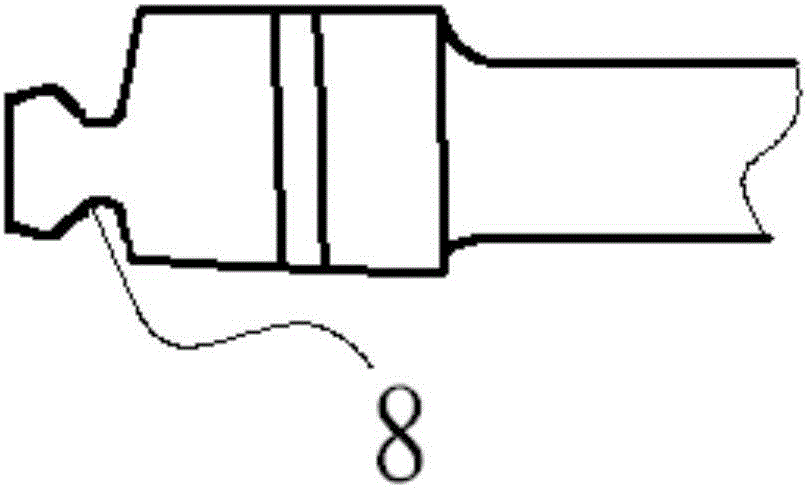

Grooving tool for cutting grooves in workpieces and a grooving tool tool holder for permitting replacement of inserts and permitting inserts to be replaced without moving the tool holder with respect to the grooving tool in which the tool holder is installed

ActiveUS20100158622A1Promote exchangeImprove accessibilityCutting insertsTurning toolsTrademarkKnife blades

A grooving tool for cutting grooves in workpieces and a grooving tool tool holder for permitting replacement of inserts and permitting inserts to be replaced without moving the tool holder with respect to the grooving tool in which the tool holder is installed. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KENNAMETAL INC

Composite fabrication vent assembly and method

ActiveUS20130175749A1Avoid insufficient clamping forceMaintain pressureSleeve/socket jointsPipe supportsControl mannerEngineering

A composite fabrication vent assembly for connection to an inflatable bladder, the combination of a vent assembly and an inflatable bladder, and a method of mechanically connecting a vent assembly and a bladder. The vent assembly comprises a body member having a first clamping surface, a clamping member having a second clamping surface, and a carriage member interconnecting the body member and the clamping member, with the first and second clamping surfaces in opposing relationship. With the open end of an inflatable bladder inserted between the opposed clamping surfaces, the carriage member is adapted to translate the body member and clamping member toward one another to form an airtight seal with the inflatable bladder. A controlled source of pressurized gas, connected to a gas inlet of the vent assembly, can then inflate and deflate the bladder in a controlled manner through one or more passageways in the vent assembly.

Owner:RUBBERCRAFT OF CALIFORNIA

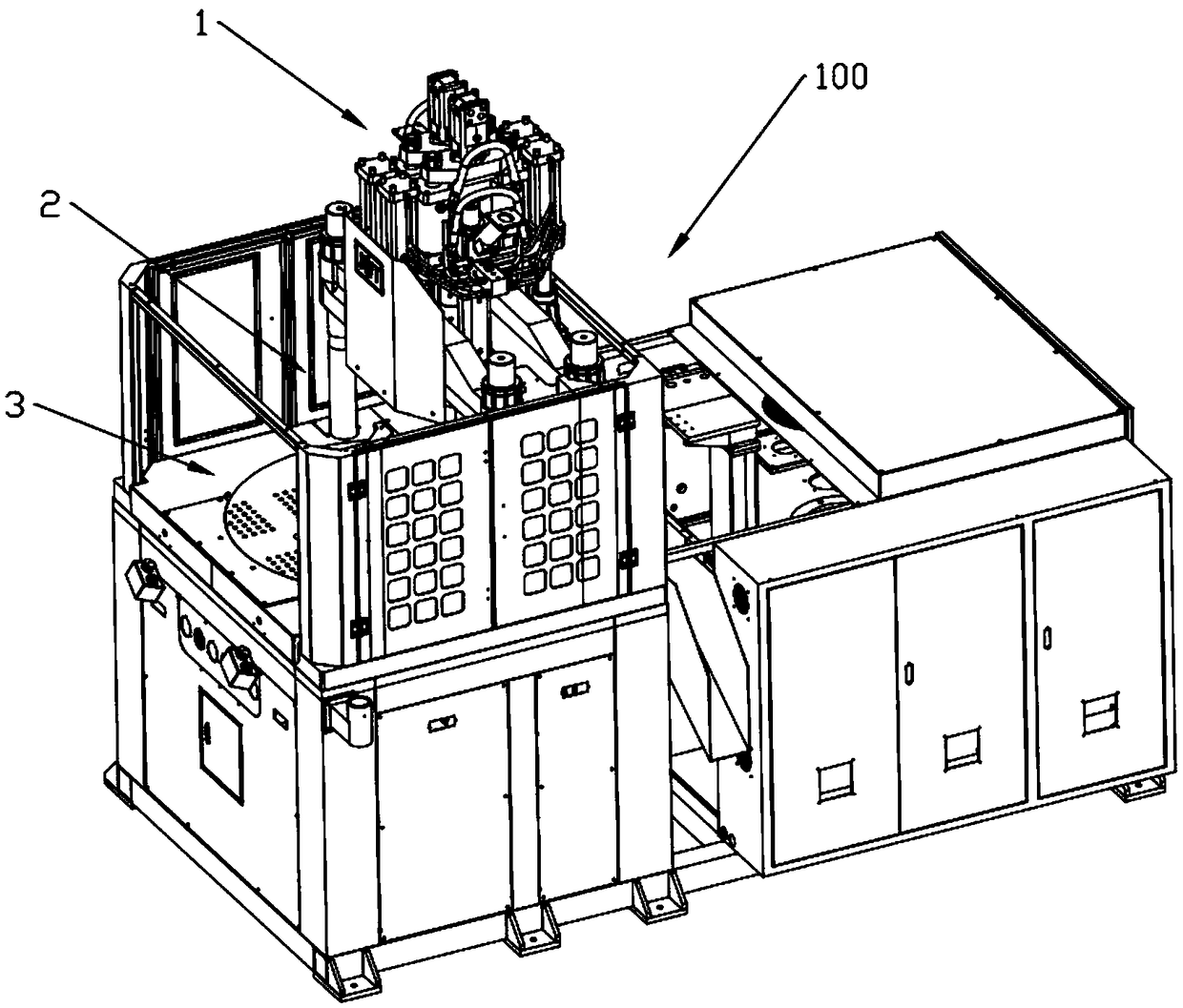

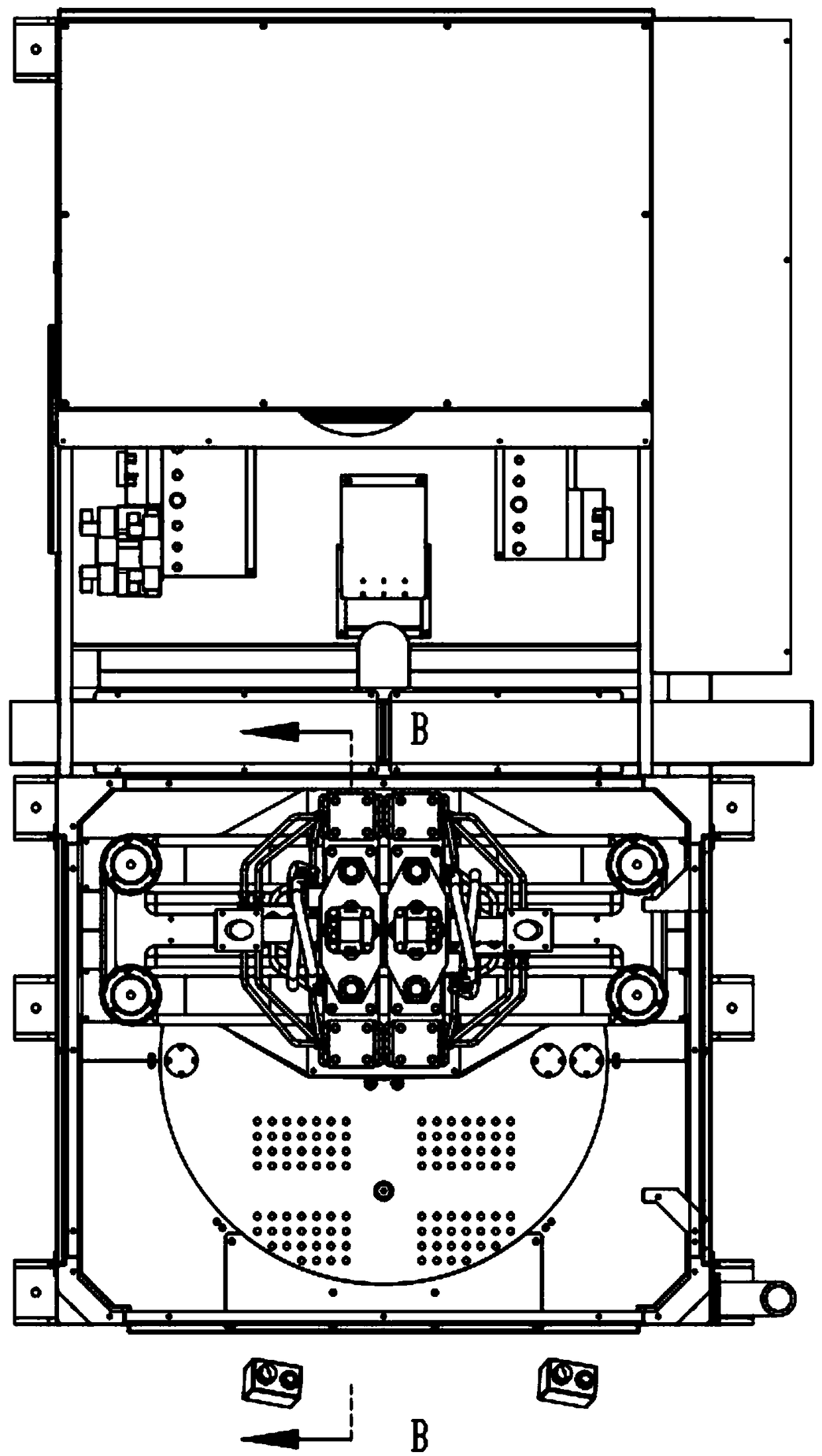

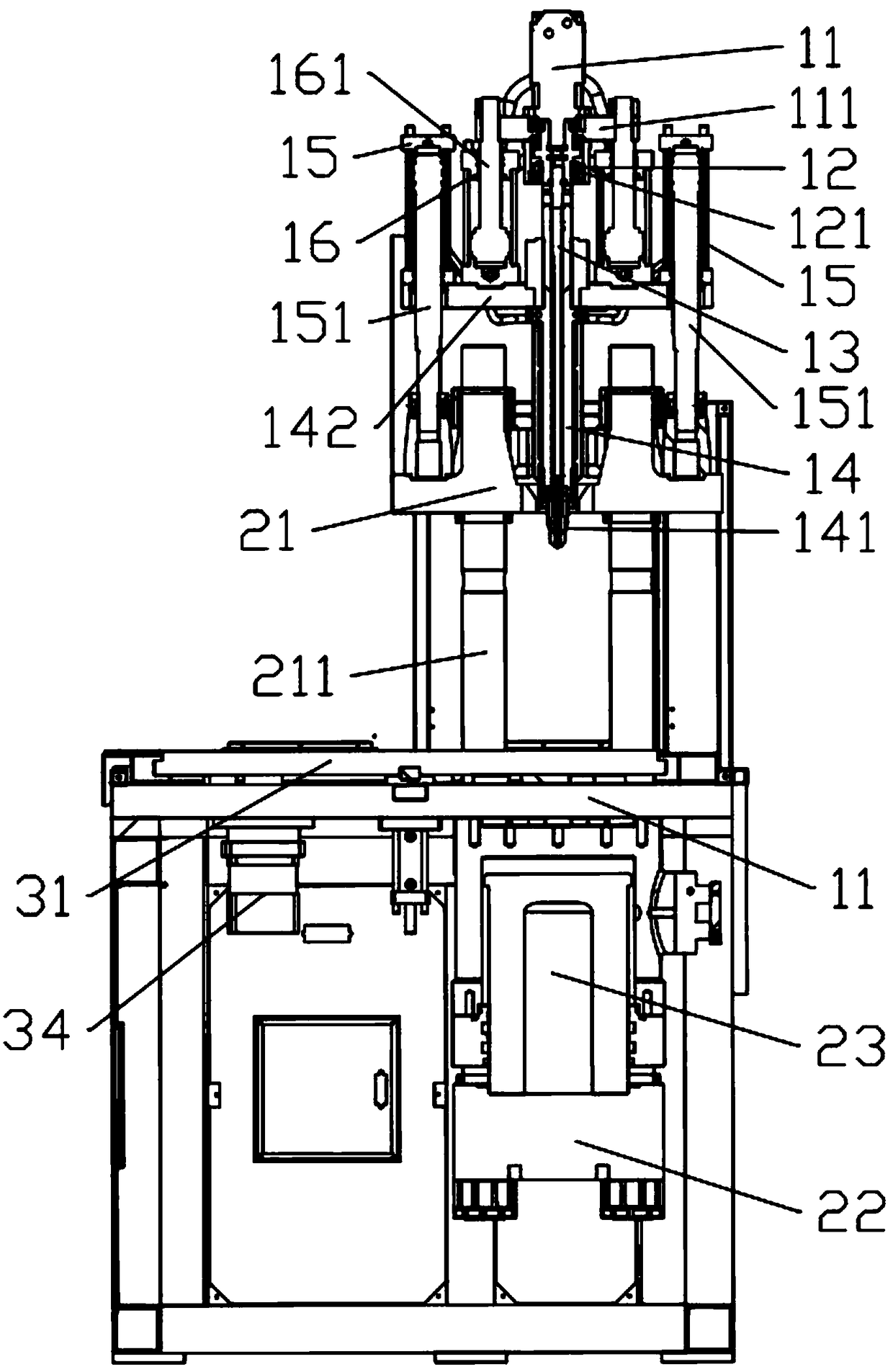

Vertical type double-color injection molding machine

InactiveCN109228136AStable structureNot easy to shiftMechanical engineeringInjection molding machine

The invention relates to a vertical type double-color injection molding machine. The vertical type double-color injection molding machine comprises a machine frame, wherein the machine frame comprisesat least two injection molding devices, a mold closing device and a rotary disc device; the mold closing device and the rotary disc device are matched with the injection molding devices; the mold closing device comprises an upper mold plate and a guide column, and the guide column is used for supporting the upper mold plate; the machine frame comprises an operation table, the operation table is penetrated into the guide column, and the rotary disc device is rotationally arranged on the operation table; the mold closing device is positioned at the lower end of the operation table; a mold is positioned between the rotary disc device and the upper mold plate. The vertical type double-color injection molding machine has the advantages that the mold can be rotated by the rotary disc device, and the rotary disc is rotated by using the support seat as the center of circle; the structure is stable, and the easiness in deflection is avoided; a motor is used for controlling, so as to avoid deflection in the mold closing process; the mold closing device can supply enough mold locking force for the mold, so as to prevent the flash and other poor conditions of the product because of existenceof the gap between the upper mold assembly and the lower mold assembly due to unenough mold locking force.

Owner:周芳

End surface driving film clamping device

The invention discloses an end surface driving film clamping device. A driving section and a rotary nut of the film clamping device are integrated into a whole and serve as a left side section; a filmclamping ring, a transition nut, a driven section, a trunnion, a double-lug support, a single-lug support and an oil cylinder are integrated into a whole and serve as a right side section; a cuttinggroove, with uniform cutting internal threads, of the rotary nut corresponds to a part, in which threads are not removed, of the transition nut with the uniform cutting external threads; and the oil cylinder drives the transition nut to rotate relative to the driven section and the rotary nut, the driven section is driven to move close to the driving section, so that a film and the film clamping ring are clamped. The film clamping ring comprises the trunnion, the double-lug support, the single-lug support and the driving device of the oil cylinder which are all installed in the end surface ofthe rotary nut, and the occupied radial space is reduced. The end surface driving film clamping device can provide enough clamping force for the film of shock tunnel type ground test equipment, and isparticularly suitable for the conditions that the caliber of a shock tube is large, requirement for the clamping force is high, and the space in the circumferential direction is limited.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Double-column self-reconfigurable modular robot

ActiveCN104249368AQuick assemblyFor quick replacementManipulatorAgricultural engineeringSelf-reconfiguring modular robot

The invention provides a double-column self-reconfigurable modular robot which comprises a plurality of robot units. Each robot unit comprises a prism main module, a prism slave module, a first claw type connecting module and a second claw type connecting module, a first side surface of each prism main module is fixedly connected with a first side surface of the corresponding prism slave module, a second side surface of each prism main module is connected with an end of the corresponding first claw type connecting module, and a third side surface of each prism main module is connected with an end of the corresponding second claw type connecting module; the other end of each first claw type connecting module is connected with the prism slave module of the corresponding adjacent first robot unit; the other end of each second claw type connecting module is connected with the prism slave module of the corresponding adjacent second robot unit; a second side surface of each prism slave module is connected with the corresponding claw type connecting module of the corresponding adjacent third robot unit, and a third side surface of each prism slave module is connected with the corresponding claw type connecting module of the corresponding adjacent fourth robot unit.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com